Page 1

• 80-ns Instruction Cycle Time

• 544 Words of On-Chip Data RAM

TMS320 SECOND-GENERATION

DIGITAL SIGNAL PROCESSORS

SPRS010B — MAY 1987 — REVISED NOVEMBER 1990

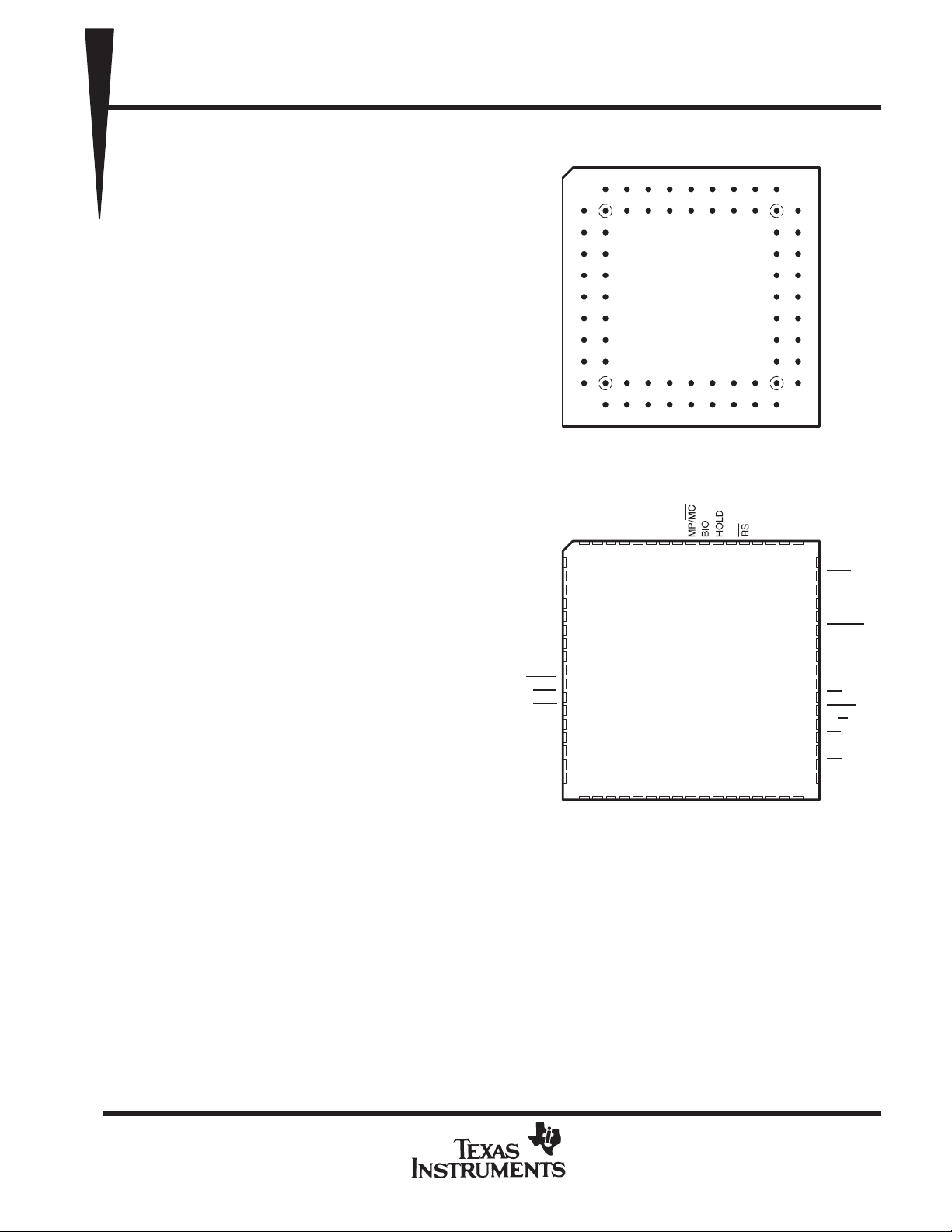

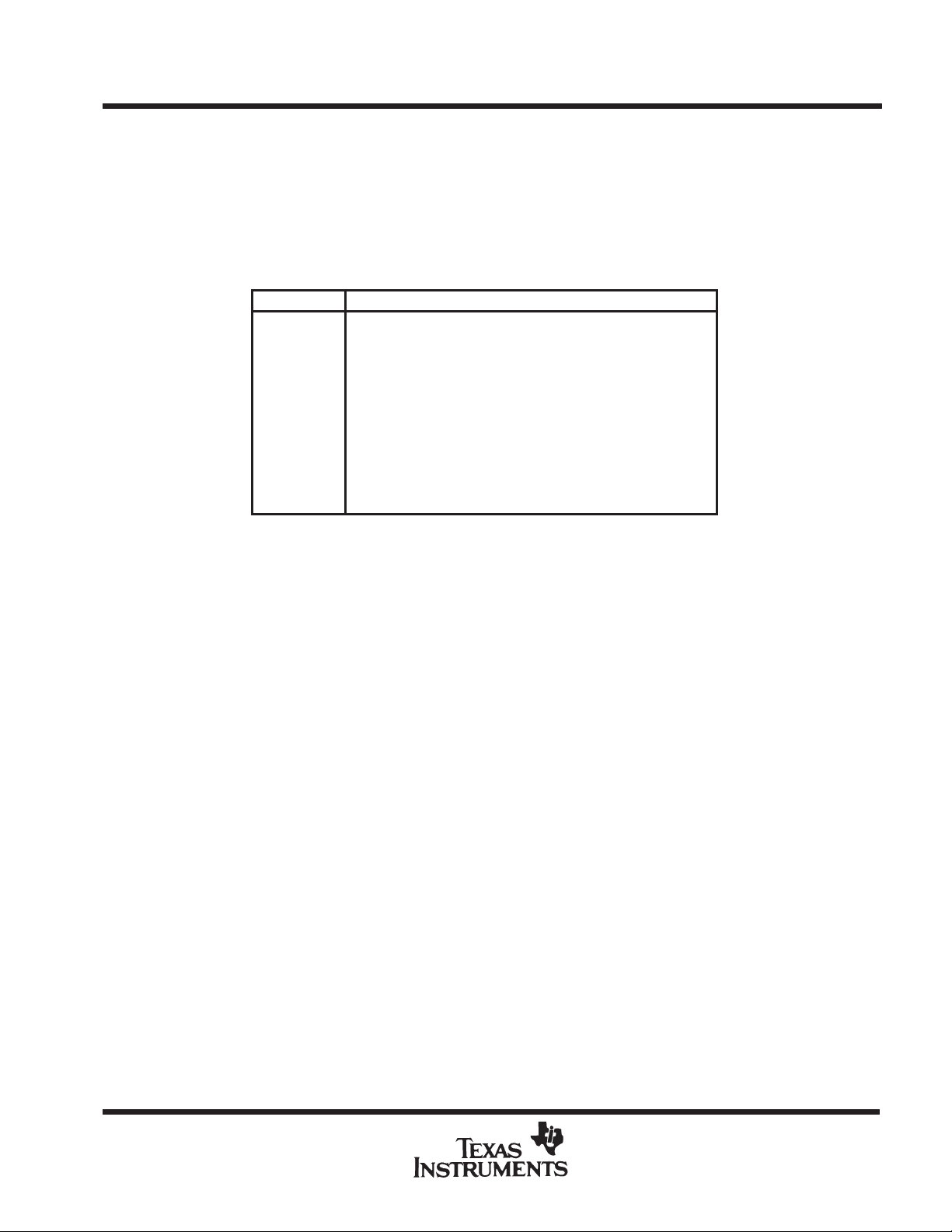

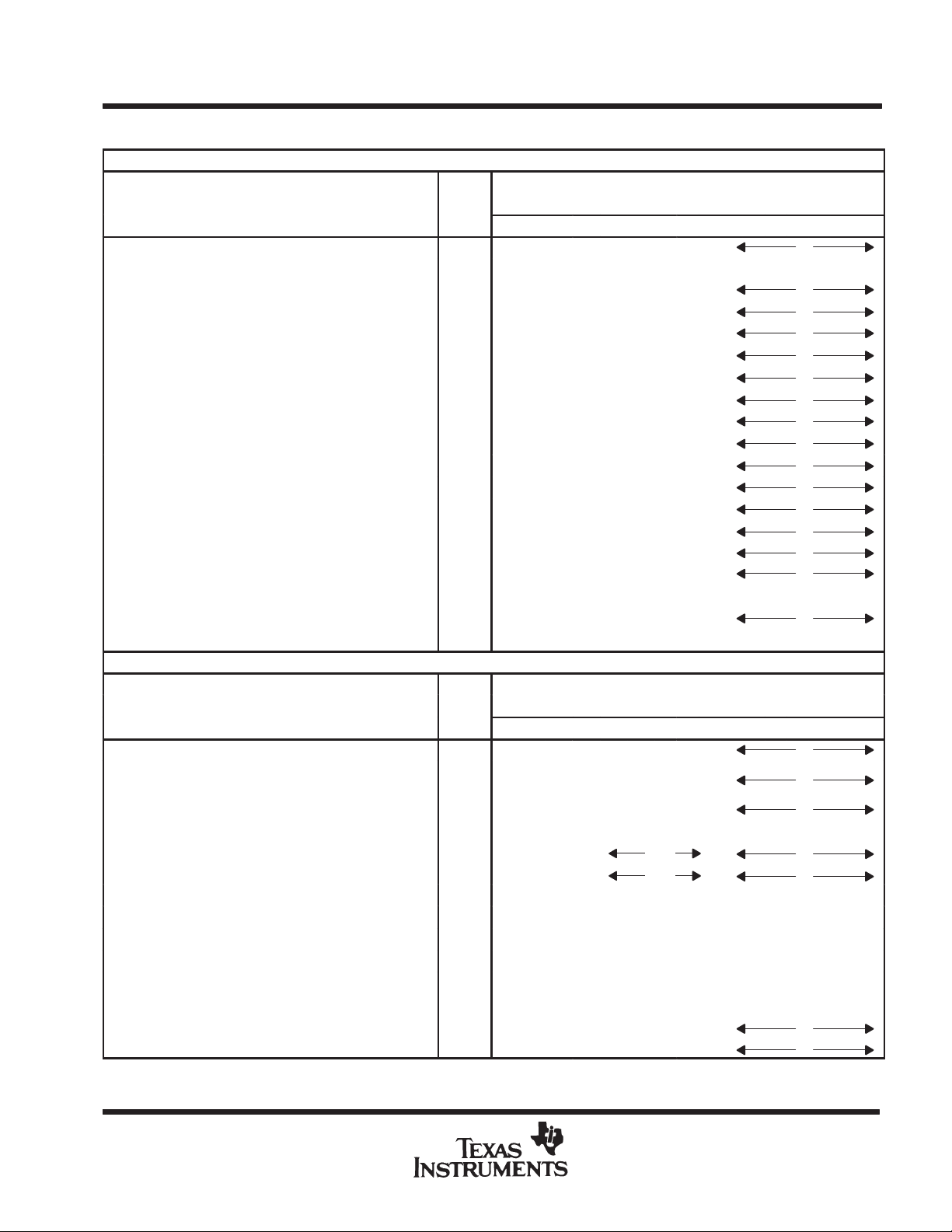

68-Pin GB Package

(Top View)

1234567891011

†

• 4K Words of On-Chip Secure Program

EPROM (TMS320E25)

• 4K Words of On-Chip Program ROM

(TMS320C25)

• 128K Words of Data/Program Space

• 32-Bit ALU/Accumulator

• 16 × 16-Bit Multiplier With a 32-Bit Product

• Block Moves for Data/Program

Management

• Repeat Instructions for Efficient Use of

Program Space

• Serial Port for Direct Codec Interface

• Synchronization Input for Synchronous

Multiprocessor Configurations

• Wait States for Communication to Slow

Off-Chip Memories/Peripherals

• On-Chip Timer for Control Operations

• Single 5-V Supply

• Packaging: 68-Pin PGA, PLCC, and

CER-QUAD

• 68-to-28 Pin Conversion Adapter Socket for

EPROM Programming

• Commercial and Military Versions Available

• NMOS Technology:

— TMS32020 200-ns cycle time. . . . . . . . .

• CMOS Technology:

— TMS320C25 100-ns cycle time. . . . . . . .

— TMS320E25 100-ns cycle time. . . . . . . .

— TMS320C25-50 80-ns cycle time. . . . . .

description

V

SS

D7

D6

D4

D3

D2

D1

D0

SYNC

INT0

INT1

INT2

V

CC

DR

FSR

A0

A

B

C

D

E

F

G

H

J

K

L

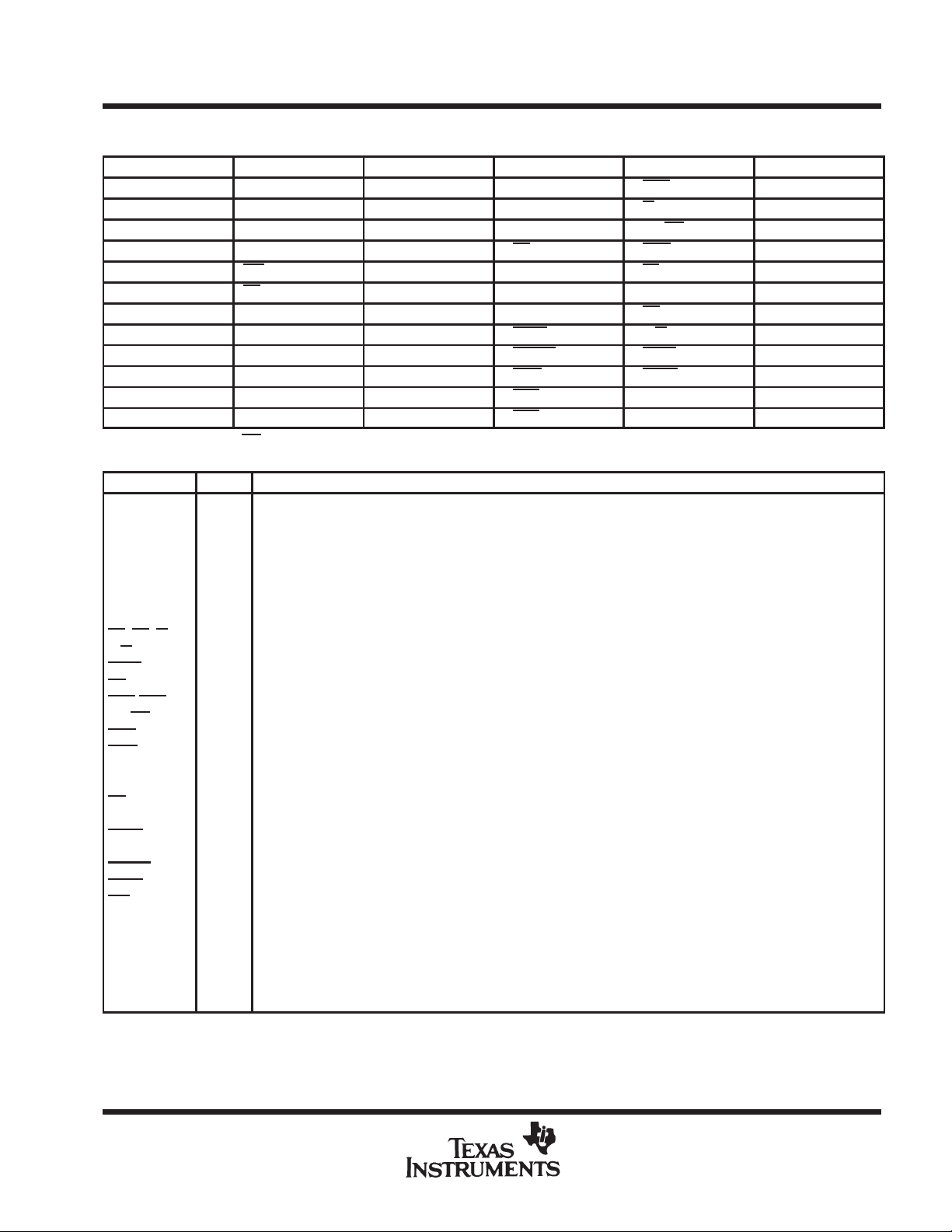

68-Pin FN and FZ Packages

D8D9D10

9 8 7 6 5 4 3 2 1 6867666564636261

10

11

12

D5

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43

A1A2A3A4A5A6A7A8A9

SS

V

D11

D12

(Top View)

D13

D14

D15

CC

V

READY

A11

A10

†

CLKR

CLKX

A12

A13

CC

A14

VCCV

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

A15

IACK

MSC

CLKOUT1

CLKOUT2

XF

HOLDA

DX

FSX

X2 CLKIN

X1

BR

STRB

R/W

PS

IS

DS

V

SS

ADVANCE INFORMATION

This data sheet provides complete design documentation for the second-generation devices of the TMS320

family . This facilitates the selection of the devices best suited for user applications by providing all specifications

and special features for each TMS320 member. This data sheet is divided into four major sections: architecture,

electrical specifications (NMOS and CMOS), timing diagrams, and mechanical data. In each of these sections,

generic information is presented first, followed by specific device information. An index is provided for quick

reference to specific information about a device.

ADVANCE INFORMATION concerns new products in the

sampling or preproduction phase of development.

Characteristic data and other specifications are subject to

change without notice.

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Copyright 1991, T exas Instruments Incorporated

1

Page 2

TMS320 SECOND-GENERATION

DEVICES

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

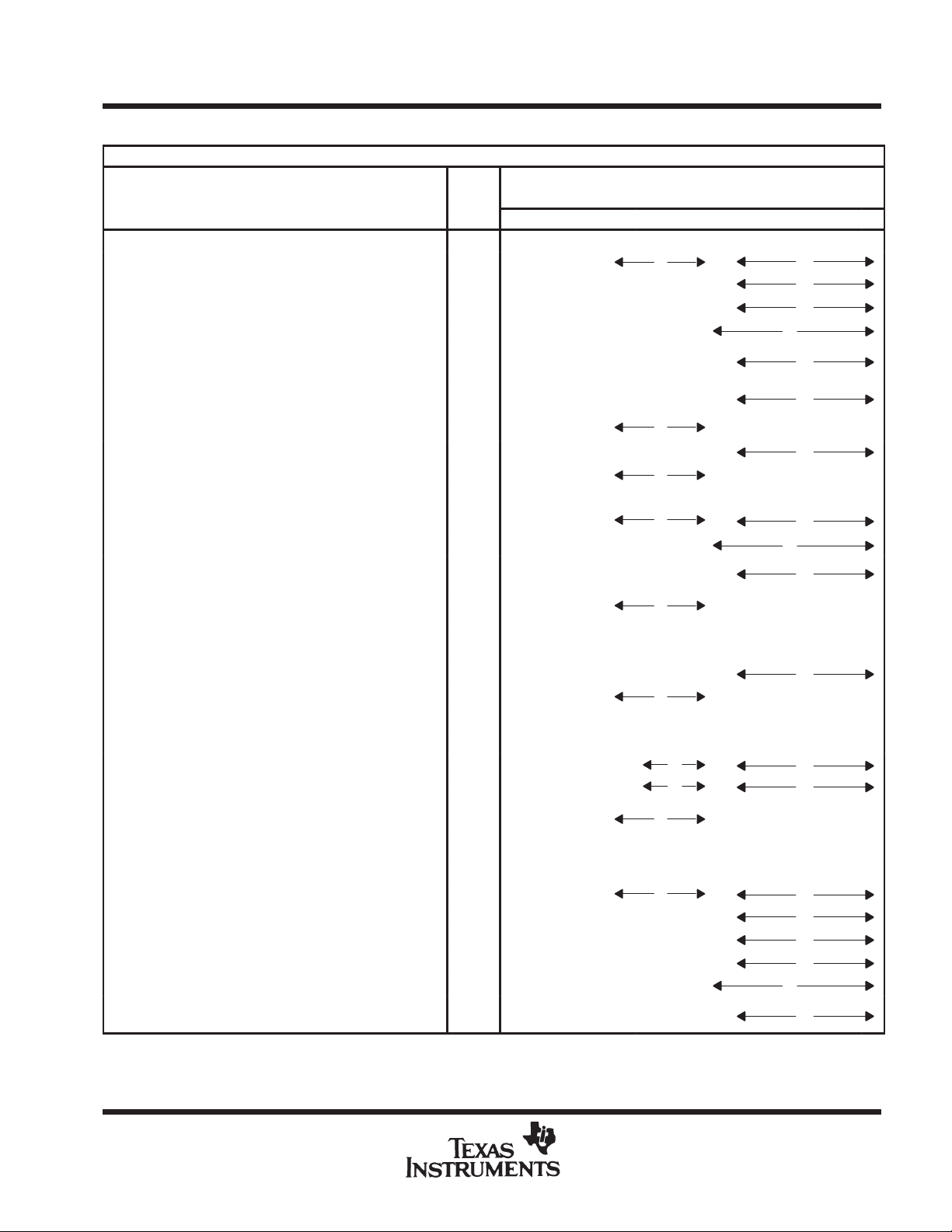

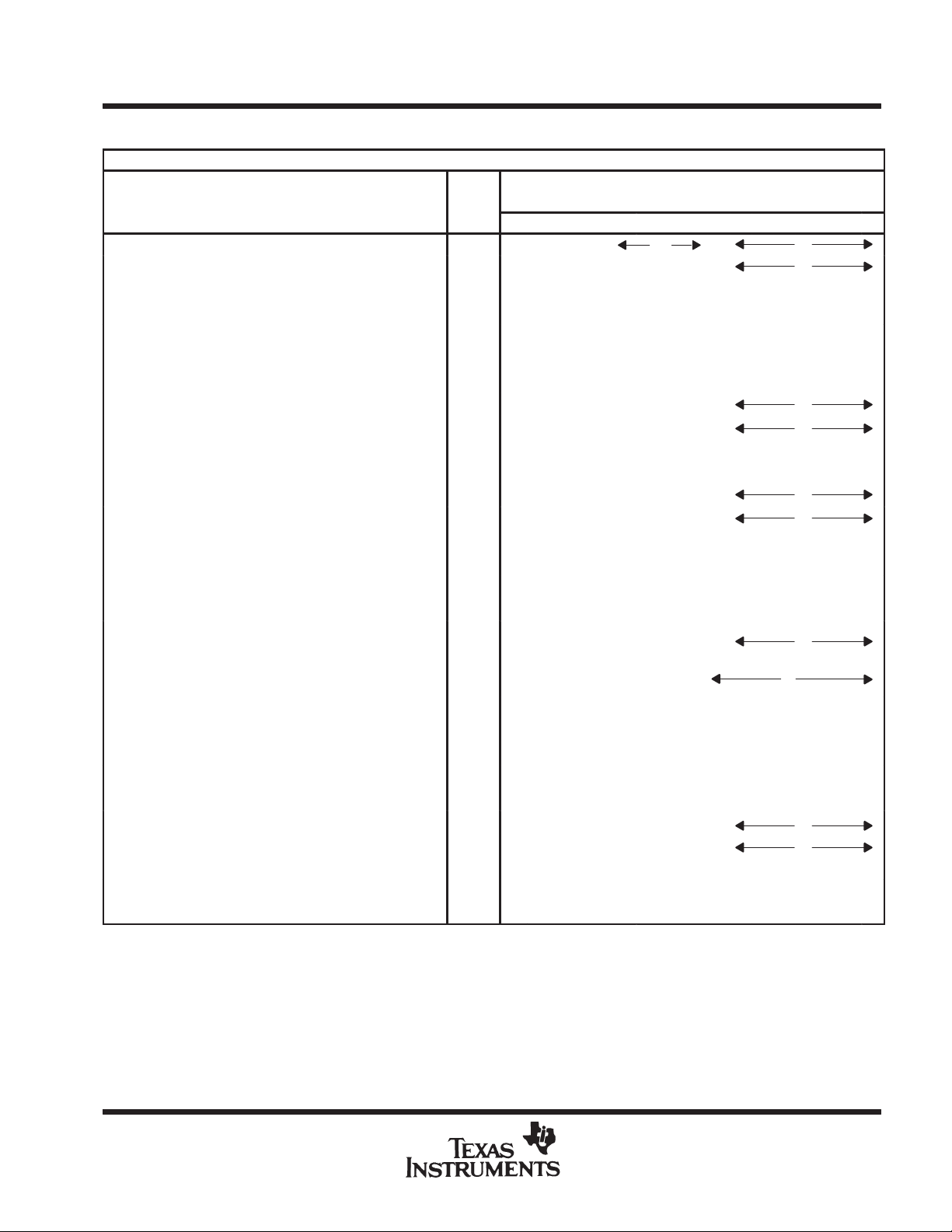

PGA AND PLCC/CER-QUAD PIN ASSIGNMENTS

FUNCTION PIN FUNCTION PIN FUNCTION PIN FUNCTION PIN FUNCTION PIN FUNCTION PIN

A0 K1/26 A12 K8/40 D2 E1/16 D14 A5/3 INT2 H1/22 V

A1 K2/28 A13 L9/41 D3 D2/15 D15 B6/2 IS J11/46 V

A2 L3/29 A14 K9/42 D4 D1/14 DR J1/24 MP/MC†A6/1 V

A3 K3/30 A15 L10/43 D5 C2/13 DS K10/45 MSC C10/59 V

A4 L4/31 BIO B7/68 D6 C1/12 DX E11/54 PS J10/47 V

A5 K4/32 BR G11/50 D7 B2/11 FSR J2/25 READY B8/66 XF D11/56

A6 L5/33 CLKOUT1 C11/58 D8 A2/9 FSX F10/53 RS A8/65 X1 G10/51

A7 K5/34 CLKOUT2 D10/57 D9 B3/8 HOLD A7/67 R/W H11/48 X2/CLKIN F11/52

A8 K6/36 CLKR B9/64 D10 A3/7 HOLDA E10/55 STRB H10/49

A9 L7/37 CLKX A9/63 D11 B4/6 IACK B11/60 SYNC F2/19

A10 K7/38 D0 F1/18 D12 A4/5 INT0 G1/20 V

A11 L8/39 D1 E2/17 D13 B5/4 INT1 G2/21 V

†

On the TMS32020, MP/MC must be connected to VCC.

‡

SIGNALS

V

CC

V

SS

X1

X2/CLKIN

CLKOUT1

CLKOUT2

D15-D0

A15-A0

, DS, IS

PS

R/W

STRB

RS

INT2-INT0

MP/MC

MSC

IACK

READY

BR

XF

HOLD

HOLDA

SYNC

BIO

DR

CLKR

FSR

DX

CLKX

FSX

‡

I/O/Z denotes input/output/high-impedance state.

I/O/Z

O

O

O

I/O/Z

O/Z

O/Z

O/Z

O/Z

O

O

O

O

O

O/Z

I/O/Z

I

5-V supply pins

I

Ground pins

Output from internal oscillator for crystal

I

Input to internal oscillator from crystal or external clock

Master clock output (crystal or CLKIN frequency/4)

A second clock output signal

16-bit data bus D15 (MSB) through D0 (LSB). Multiplexed between program, data, and I/O spaces.

16-bit address bus A15 (MSB) through A0 (LSB)

Program, data, and I/O space select signals

Read/write signal

Strobe signal

I

Reset input

I

External user interrupt inputs

I

Microprocessor/microcomputer mode select pin

Microstate complete signal

Interrupt acknowledge signal

I

Data ready input. Asserted by external logic when using slower devices to indicate that the current bus transaction

is complete.

Bus request signal. Asserted when the TMS320C2x requires access to an external global data memory space.

External flag output (latched software-programmable signal)

I

Hold input. When asserted, TMS320C2x goes into an idle mode and places the data, address, and control lines in

the high impedance state.

Hold acknowledge signal

I

Synchronization input

I

Branch control input. Polled by BIOZ instruction.

I

Serial data receive input

I

Clock for receive input for serial port

I

Frame synchronization pulse for receive input

Serial data transmit output

I

Clock for transmit output for serial port

Frame synchronization pulse for transmit. Configuration as either an input or an output.

DEFINITION

CC

CC

A10/61

B10/62

CC

CC

SS

SS

SS

H2/23

L6/35

B1/10

K11/44

L2/27

2

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Page 3

TMS320 SECOND-GENERATION

DEVICES

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

description

The TMS320 family of 16/32-bit single-chip digital signal processors combines the flexibility of a high-speed

controller with the numerical capability of an array processor, thereby offering an inexpensive alternative to

multichip bit-slice processors. The highly paralleled architecture and efficient instruction set provide speed and

flexibility to produce a MOS microprocessor family that is capable of executing more than 12.5 MIPS (million

instructions per section). The TMS320 family optimizes speed by implementing functions in hardware that other

processors implement through microcode or software. This hardware-intensive approach provides the design

engineer with processing power previously unavailable on a single chip.

The TMS320 family consists of three generations of digital signal processors. The first generation contains the

TMS32010 and its spinoffs. The second generation includes the TMS32020, TMS320C25, and TMS320E25,

which are described in this data sheet. The TMS320C30 is a floating-point DSP device designed for even higher

performance. Many features are common among the TMS320 processors. Specific features are added in each

processor to provide different cost/performance tradeoffs. Software compatibility is maintained throughout the

family to protect the user’s investment in architecture. Each processor has software and hardware tools to

facilitate rapid design.

introduction

The TMS32010, the first NMOS digital signal processor in the TMS320 family, was introduced in 1983. Its

powerful instruction set, inherent flexibility, high-speed number-crunching capabilities, and innovative

architecture have made this high-performance, cost-effective processor the ideal solution to many

telecommunications, computer, commercial, industrial, and military applications. Since that time, the

TMS320C10, a low-power CMOS version of the industry-standard TMS32010, and other spinoff devices have

been added to the first generation of the TMS320 family.

The second generation of the TMS320 family (referred to as TMS320C2x) includes four members, the

TMS32020, TMS320C25, TMS320C25-50, and TMS320E25. The architecture of these devices is based upon

that of the TMS32010.

The TMS32020, processed in NMOS technology, is source-code compatible with he TMS32010 and in many

applications is capable of two times the throughput of the first-generation devices. Its enhanced instruction set

(109 instructions), large on-chip data memory (544 words), large memory spaces, on-chip serial port, and

hardware timer make the TMS32020 a powerful addition to the TMS320 family.

The TMS320C25 is the second member of the TMS320 second generation. It is processed in CMOS technology,

is capable of an instruction cycle time of 100 ns, and is pin-for-pin and object-code compatible with the

TMS32020. The TMS320C25’s enhanced feature set greatly increases the functionality of the device over the

TMS32020. Enhancements included 24 additional instructions (133 total), eight auxiliary registers, an

eight-level hardware stack, 4K words of on-chip program ROM, a bit-reversed indexed-addressing mode, and

the low-power dissipation inherent to the CMOS process. An extended-temperature range version

(TMS320C25GBA) is also available.

The TMS320C25-50 is a high-speed version of the TMS320C25. It is capable of an instruction cycle time of less

than 80 ns. It is architecturally identical to the original 40-MHz version of the TMS320C25 and, thus, is pin-for-pin

and object-code compatible with the TMS320C25.

The TMS320E25 is identical to the TMS320C25, with the exception that the on-chip 4K-word program ROM is

replaced with a 4K-word on-chip program EPROM. On-chip EPROM allows realtime code development and

modification for immediate evaluation of system performance.

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

3

Page 4

TMS320 SECOND-GENERATION

DEVICES

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

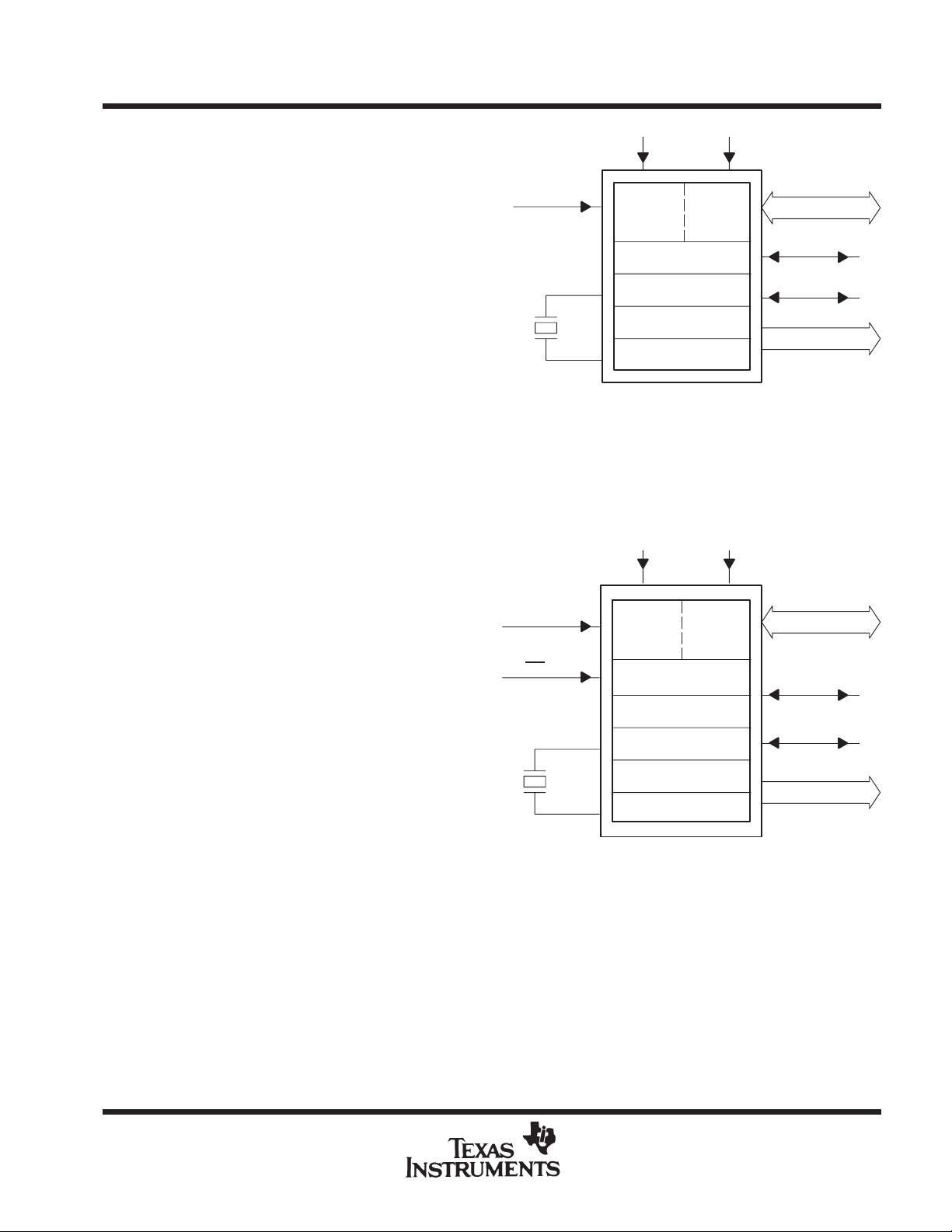

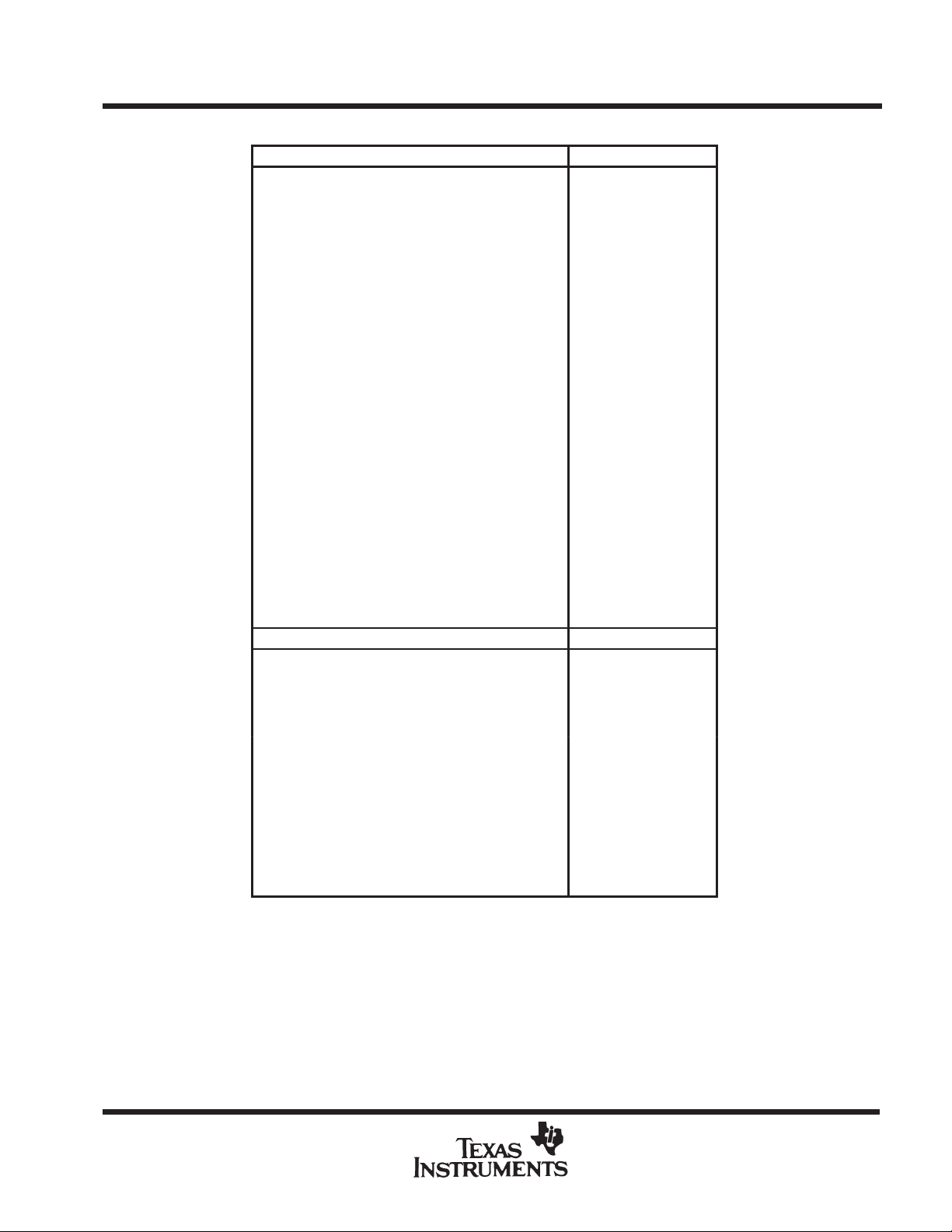

Key Features: TMS32020

• 200-ns Instruction Cycle Time

• 544 Words of On-Chip Data RAM

• 128K Words of Total Data/Program

Memory Space

• Wait States for Communication to Slower Off-Chip

Memories

• Source Code Compatible With the TMS320C1x

• Single-Cycle Multiply/Accumulate Instructions

• Repeat Instructions

• Global Data Memory Interface

• Block Moves for Data/Program Management

• Five Auxiliary Registers With Dedicated

Arithmetic Unit

• Serial Port for Multiprocessing or Interfacing

to Codecs, Serial Analog-to-Digital

Converters, etc.

Key Features: TMS320C25, TMS320C25-50, TMS320E25

• 80-ns Instruction Cycle Time (TMS320C25-50)

• 100-ns Instruction Cycle Time (TMS320C25)

• 4K Words of On-Chip Secure Program EPROM

(TMS320E25)

• 4K Words of On-Chip Program

ROM (TMS320C25)

• 544 Words of On-Chip RAM

• 128K Words of Total Program/Data

Memory Space

• Wait States for Communications to

Slower Off-Chip Memories

• Object-Code Compatible With the TMS32020

• Source-Code Compatible W ith TMS320C1x

• 24 Additional Instructions to Support

Adaptive Filtering, FFTs, and

Extended-Precision Arithmetic

• Block Moves for Data/Program Management

• Single-Cycle Multiply/Accumulate Instructions

• Eight Auxiliary Registers W ith Dedicated

Arithmetic Unit

• Bit-Reversed Indexed-Addressing Mode for

Radix-2 FFTS

• Double-Buffered Serial Port

+5 V GND

Interrupts

256-Word

Data/Prog

RAM

32-BIT ALU/ACC

288-Word

Multiplier

Shifters

Timer

Data

RAM

Data (16)

Multi-

Processor

Interface

Serial

Interface

Address (16)

• On-Chip Clock Generator

• Single 5-V Supply

• NMOS Technology

• 68-Pin Grid Array (PGA) Package

+5 V GND

Interrupts

MP/MC

256-Word

Data/Prog

RAM

32-Bit ALU/ACC

288-Word

Data

RAM

4K-Words

ROM/EPROM

Multiplier

Shifters

Timer

Data (16)

Multi-

Processor

Interface

Serial

Interface

Address (16)

• On-Chip Clock Generator

• Single 5-V Supply

• Internal Security Mechanism (TMS320E25)

• 68-to-28 Pin Conversion Adapter Socket

• CMOS Technology

• 68-Pin Grid Array (PGA) Package

(TMS320C25)

• 68-Lead Plastic Leaded Chip Carrier (PLCC)

Package (TMS320C25, TMS320C25-50)

• 68-Lead CER-QUAD Package (TMS320E25)

4

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Page 5

TMS320 SECOND-GENERATION

DEVICES

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

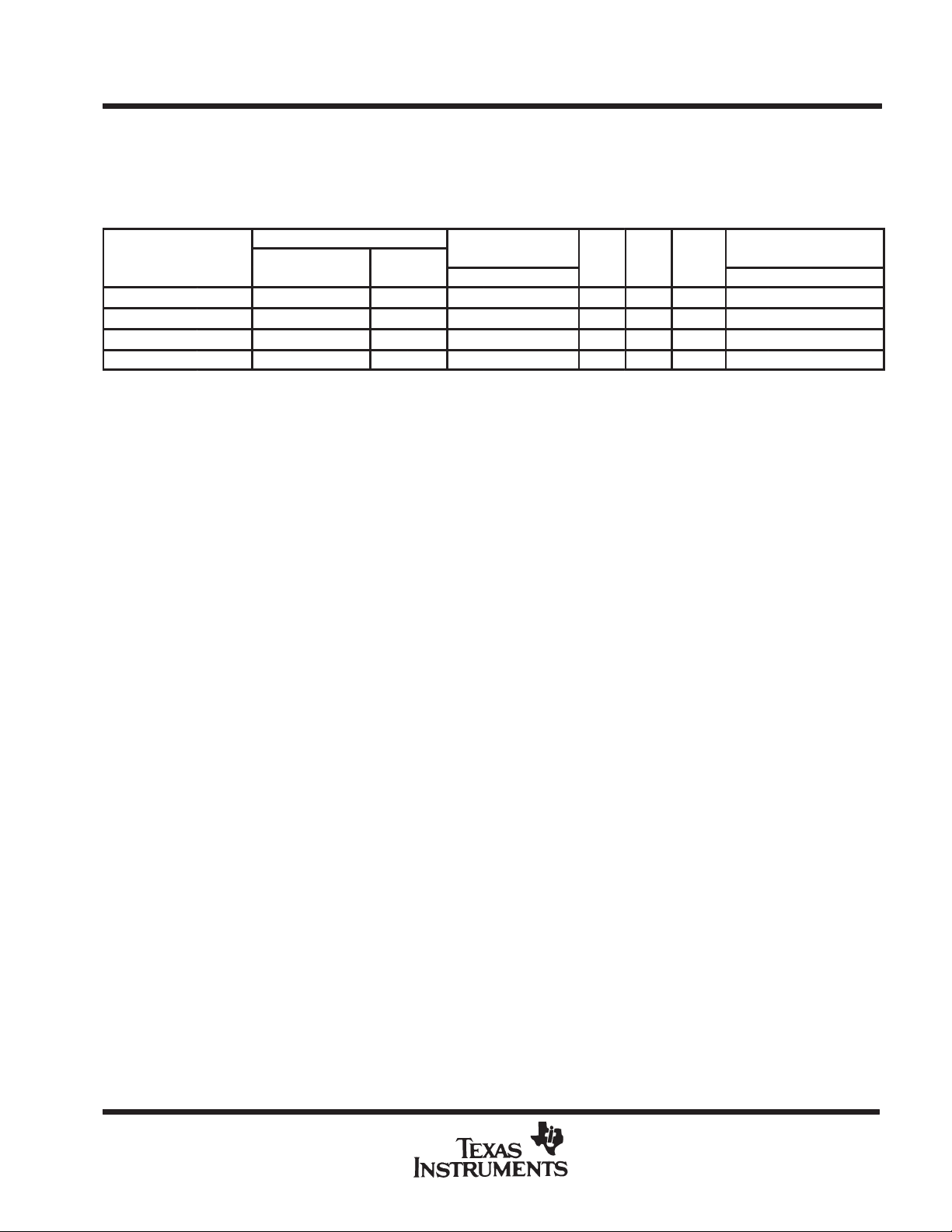

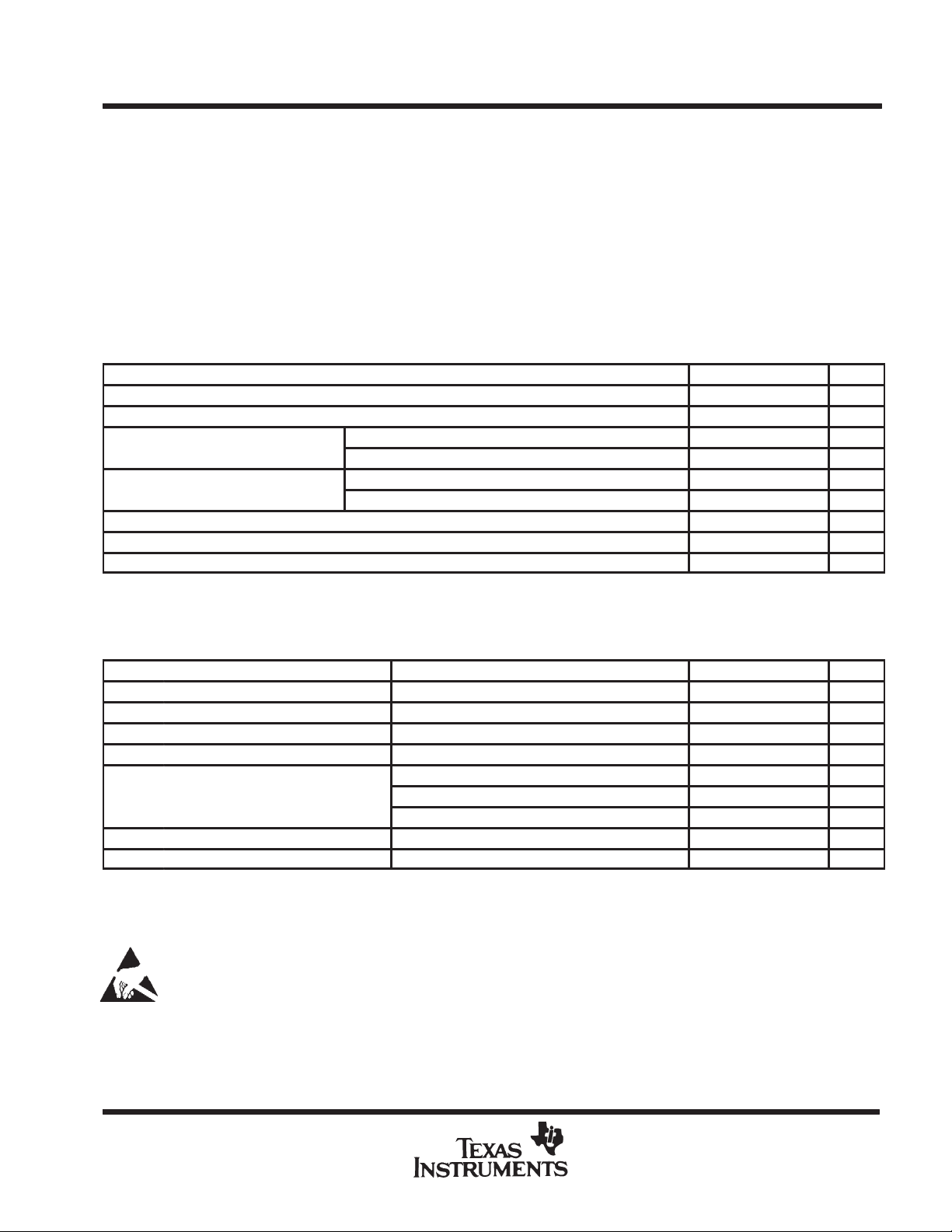

T able 1 provides an overview of the second-generation TMS320 processors with comparisons of memory, I/O,

cycle timing, power, package type, technology , and military support. For specific availability , contact the nearest

TI Field Sales Office.

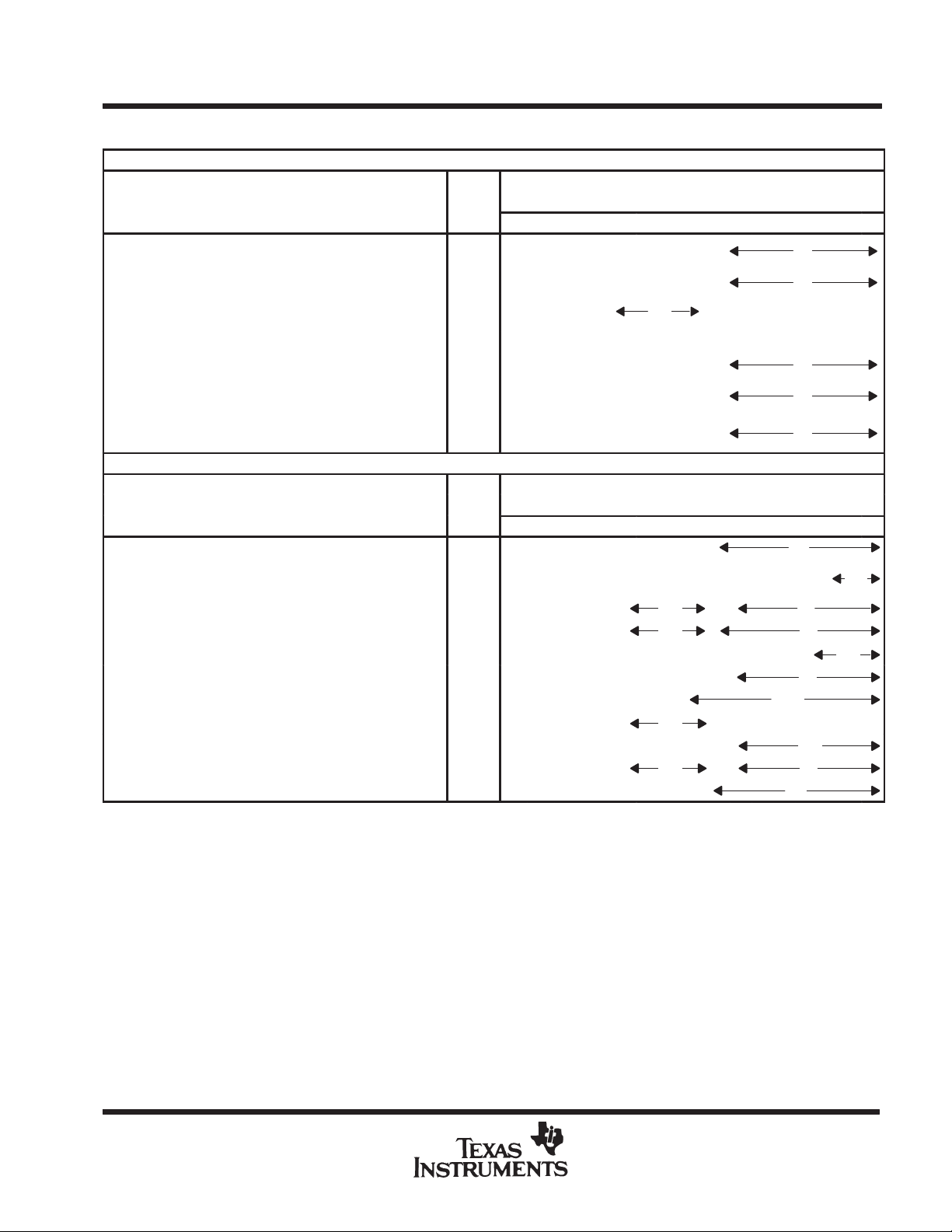

Table 1. TMS320 Second-Generation Device Overview

MEMORY

DEVICE

‡

TMS32020

TMS320C25

TMS320C25-50§(CMOS) 544 4K 64K 64K YES

TMS320E25

†

SER = serial; PAR = parallel; DMA = direct memory access; CON = concurrent DMA.

‡

Military version available; contact nearest TI Field Sales Office for availability .

§

Military version planned; contact nearest TI Field Sales Office for details.

(NMOS) 544 — 64K 64K YES

‡

(CMOS) 544 4K 64K 64K YES

§

(CMOS) 544 4K 64K 64K YES

ON-CHIP OFF-CHIP

RAM ROM/EPROM PROG DATA

SER PAR DMA PGA PLCC CER-QUAD

I/O

16 × 16

16 × 16

16 × 16

16 × 16

†

YES YES 200 1250 68 — —

CON YES 100 500 68 68 —

CON YES 80 500 — 68 —

CON YES 100 500 — — 68

TIMER

CYCLE

TIME

(ns)

TYP

POWER

(mW)

PACKAGE

TYPE

architecture

The TMS320 family utilizes a modified Harvard architecture for speed and flexibility. In a strict Harvard

architecture, program and data memory lie in two separate spaces, permitting a full overlap of instruction fetch

and execution. The TMS320 family’s modification of the Harvard architecture allows transfers between program

and data spaces, thereby increasing the flexibility of the device. This modification permits coefficients stored

in program memory to be read into the RAM, eliminating the need for a separate coefficient ROM. It also makes

available immediate instructions and subroutines based on computed values.

Increased throughput on the TMS320C2x devices for many DSP applications is accomplished by means of

single-cycle multiply/accumulate instructions with a data move option, up to eight auxiliary registers with a

dedicated arithmetic unit, and faster I/O necessary for data-intensive signal processing.

The architectural design of the TMS320C2x emphasizes overall speed, communication, and flexibility in

processor configuration. Control signals and instructions provide floating-point support, block-memory

transfers, communication to slower off-chip devices, and multiprocessing implementations.

32-bit ALU/accumulator

The 32-bit Arithmetic Logic Unit (ALU) and accumulator perform a wide range of arithmetic and logical

instructions, the majority of which execute in a single clock cycle. The ALU executes a variety of branch

instructions dependent on the status of the ALU or a single bit in a word. These instructions provide the following

capabilities:

• Branch to an address specified by the accumulator

• Normalize fixed-point numbers contained in the accumulator

• Test a specified bit of a word in data memory

One input to the ALU is always provided from the accumulator, and the other input may be provided from the

Product Register (PR) of the multiplier or the input scaling shifter which has fetched data from the RAM on the

data bus. After the ALU has performed the arithmetic or logical operations, the result is stored in the accumulator.

The 32-bit accumulator is split into two 16-bit segments for storage in data memory. Additional shifters at the

output of the accumulator perform shifts while the data is being transferred to the data bus for storage. The

contents of the accumulator remain unchanged.

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

5

Page 6

TMS320 SECOND-GENERATION

DEVICES

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

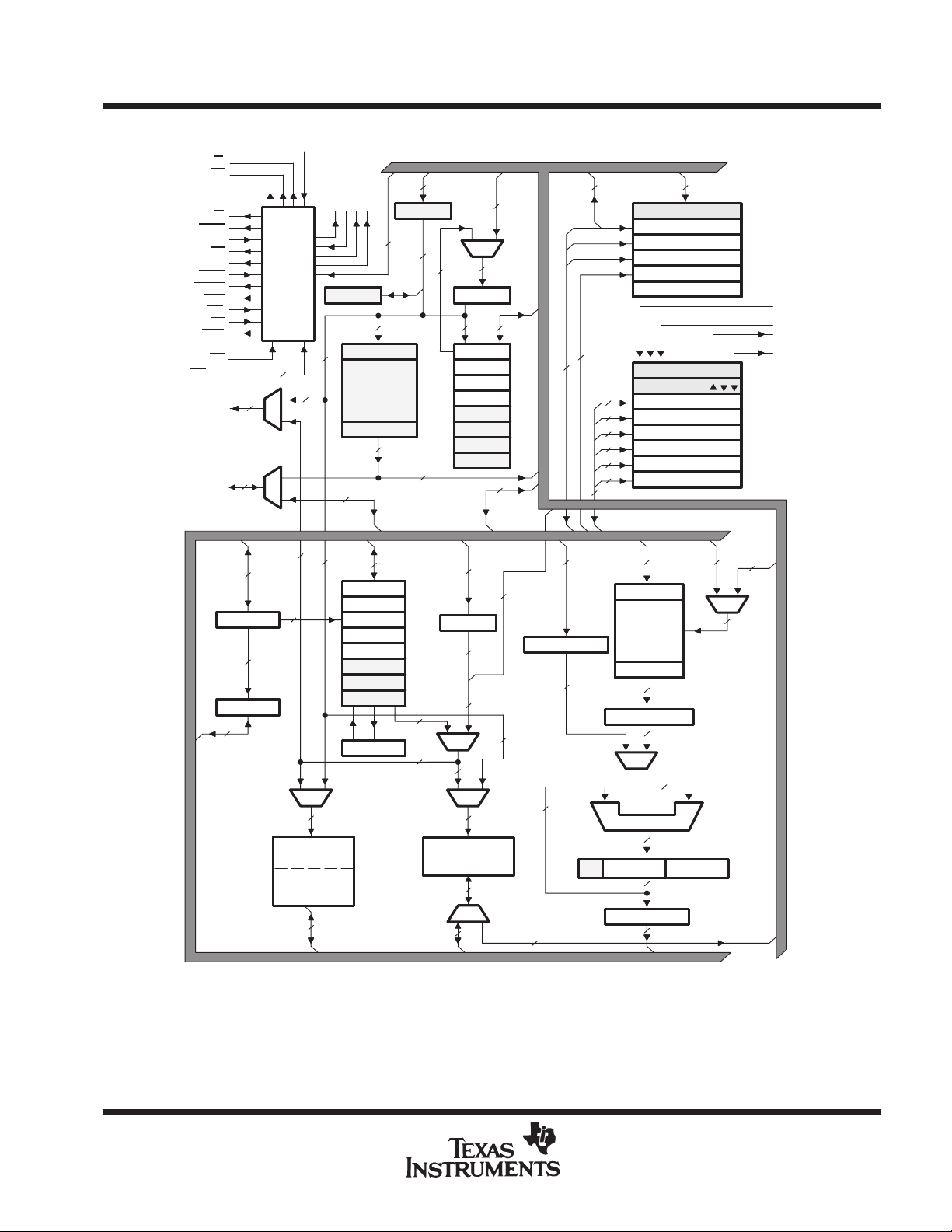

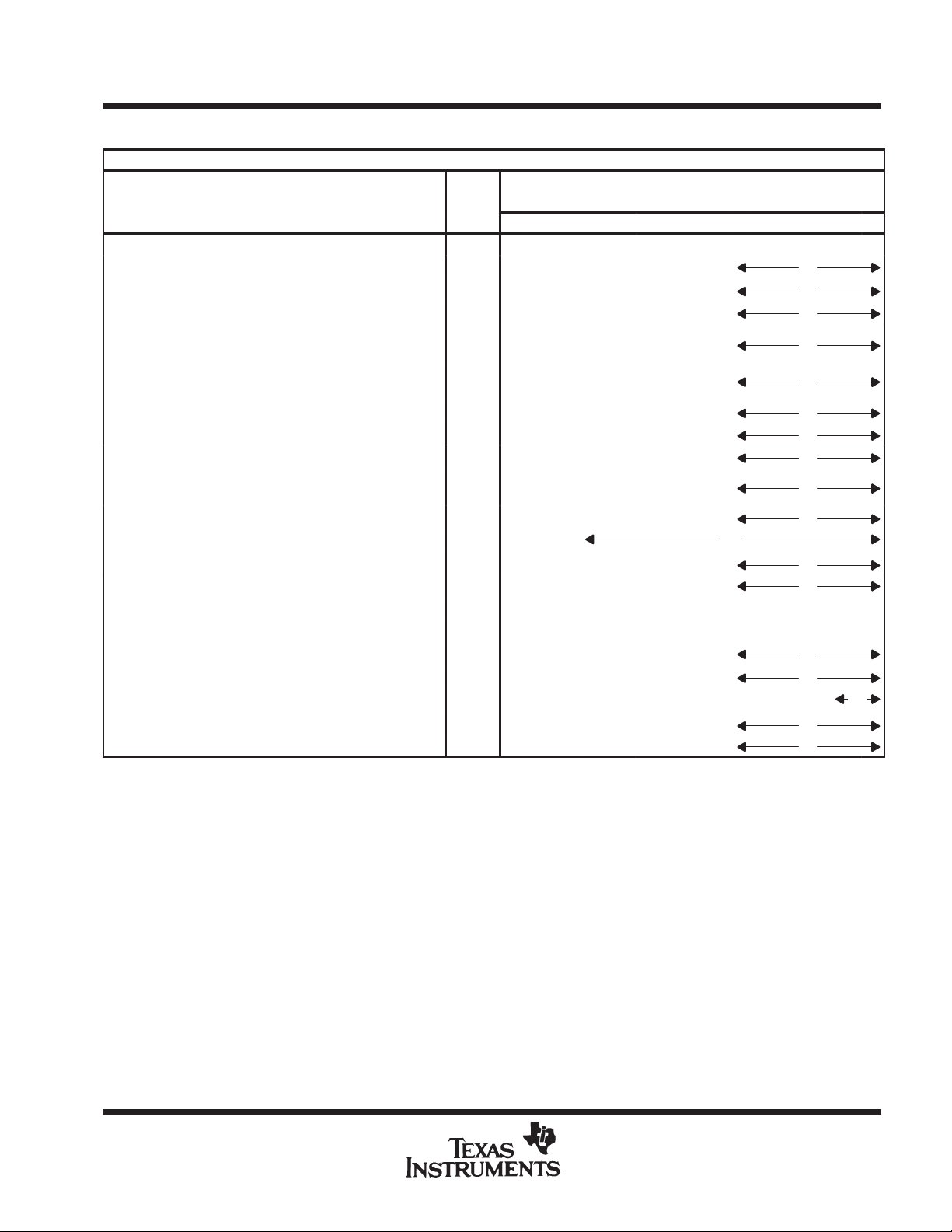

functional block diagram (TMS320C2x)

SYNC

IS

DS

PS

X1

X2/CLKIN

CLKOUT1

MCS(16)

(4096

Instruction

16

CLKOUT2

16

16

16 16 16

Address

Program

ROM/

EPROM

× 16)

16

Data Bus

R/W

STRB

READY

BR

XF

HOLD

HOLDA

MSC

BIO

RS

IACK

MP/MC

INT(2-0)

A15-A0

D15-D0

Controller

16

3

16

16

16

MUXMUX

16

PFC(16)

16

16

MUX

PC(16)

Stack

(8 x 16)

Program Bus

16

16

16 16

QIR(16)

IR(16)

STO(16)

ST1(16)

RPTC(8)

IFR(6)

RSR(16)

16

16

16

16

6

8

16

XSR(16)

DRR(16)

DXR(16)

TIM(16)

PRD(16)

IMR(6)

GREG(8)

Program Bus

DR

CLKR

FSR

DX

CLKX

FSX

16

16

16

16

3

MUX

Block B2

× 16)

(32

Data RAM

Block B1

(256

16

16

× 16)

16

3

ARP(3)

3

ARB(3)

3

LEGEND:

ACCH = Accumulator high IFR = Interrupt flag register PC = Program counter

ACCL = Accumulator low IMR = Interrupt mask register PFC = Prefetch counter

ALU = Arithmetic logic unit IR = Instruction register RPTC = Repeat instruction counter

ARAU = Auxiliary register arithmetic unitMCS = Microcall stack GREG = Global memory allocation register

ARB = Auxiliary register pointer buffer QIR = Queue instruction register RSR = Serial port receive shift register

ARP = Auxiliary register pointer PR = Product register XSR = Serial port transmit shift register

DP = Data memory page pointer PRD = Period register for timer AR0-AR7 = Auxiliary registers

DRR = Serial port data receive registerTIM = Timer ST0, ST1 = Status registers

DXR = Serial port data transmit register TR = Temporary register C = Carry bit

AR0(16)

AR1(16)

AR2(16)

AR3(16)

AR4(16)

AR5(16)

AR6(16)

AR7(16)

ARAU(16)

Data Bus

16

16

16

DP(9)

MUX

16

MUX

DATA/PROG

RAM (256

Block B0

MUX

16

9

9

16

16

× 16)

16

7 LSB

From IR

16

16

Shifter(0-16)

32

32

16

Shifter(-6, 0, 1, 4)

C

ACCH(16)

Shifters (0-7)

16

TR(16)

Multiplier

PR(32)

32

32

MUX

32

ALU(32)

32

ACCL(16)

32

†

16

16

MUX

16

16

6

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Page 7

TMS320 SECOND-GENERATION

DEVICES

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

scaling shifter

The TMS320C2x scaling shifter has 16-bit input connected to the data bus and a 32-bit output connected to the

ALU. The scaling shifter produces a left shift of 0 to 16 bits on the input data, as programmed in the instruction.

The LSBs of the output are filled with zeroes, and the MSBs may be either filled with zeroes or sign-extended,

depending upon the status programmed into the SXM (sign-extension mode) bit of status register ST1.

16 × 16-bit parallel multiplier

The 16 × 16-bit hardware multiplier is capable of computing a signed or unsigned 32-bit product in a single

machine cycle. The multiplier has the following two associated registers.

• A 16-bit Temporary Register (TR) that holds one of the operands for the multiplier, and

• A 32-bit Product Register (PR) that holds the product.

Incorporated into the instruction set are single-cycle multiply/accumulate instructions that allow both operands

to be processed simultaneously. The data for these operations may reside anywhere in internal or external

memory, and can be transferred to the multiplier each cycle via the program and data buses.

Four product shift modes are available at the Product Register (PR) output that are useful when performing

multiply/accumulate operations, fractional arithmetic, or justifying fractional products.

timer

The TMS320C2x provides a memory-mapped 16-bit timer for control operations. The on-chip timer (TIM)

register is a down counter that is continuously clocked by CLKOUT1 on the TMS320C25. The timer is clocked

by CLKOUT1/4 on the TMS32020. A timer interrupt (TINT) is generated every time the timer decrements to zero.

The timer is reloaded with the value contained in the period (PRD) register within the next cycle after it reaches

zero so that interrupts may be programmed to occur at regular intervals of PRD + 1 cycles of CLKOUT 1 on the

TMS320C25 or 4 × PRD × CLKOUT 1 cycles on the TMS32020.

memory control

The TMS320C2x provides a total of 544 16-bit words of on-chip data RAM, divided into three separate blocks

(B0, B1, and B2). Of the 544 words, 288 words (blocks B1 and B2) are always data memory, and 256 words

(block B0) are programmable as either data or program memory . A data memory size of 544 words allows the

TMS320C2x to handle a data array of 512 words (256 words if on-chip RAM is used for program memory), while

still leaving 32 locations for intermediate storage. When using block B0 as program memory, instructions can

be downloaded from external program memory into on-chip RAM and then executed.

When using on-chip program RAM, ROM, EPROM, or high-speed external program memory , the TMS320C2x

runs at full speed without wait states. However, the READY line can be used to interface the TMS320C2x to

slower, less-expensive external memory . Downloading programs from slow off-chip memory to on-chip program

RAM speeds processing while cutting system costs.

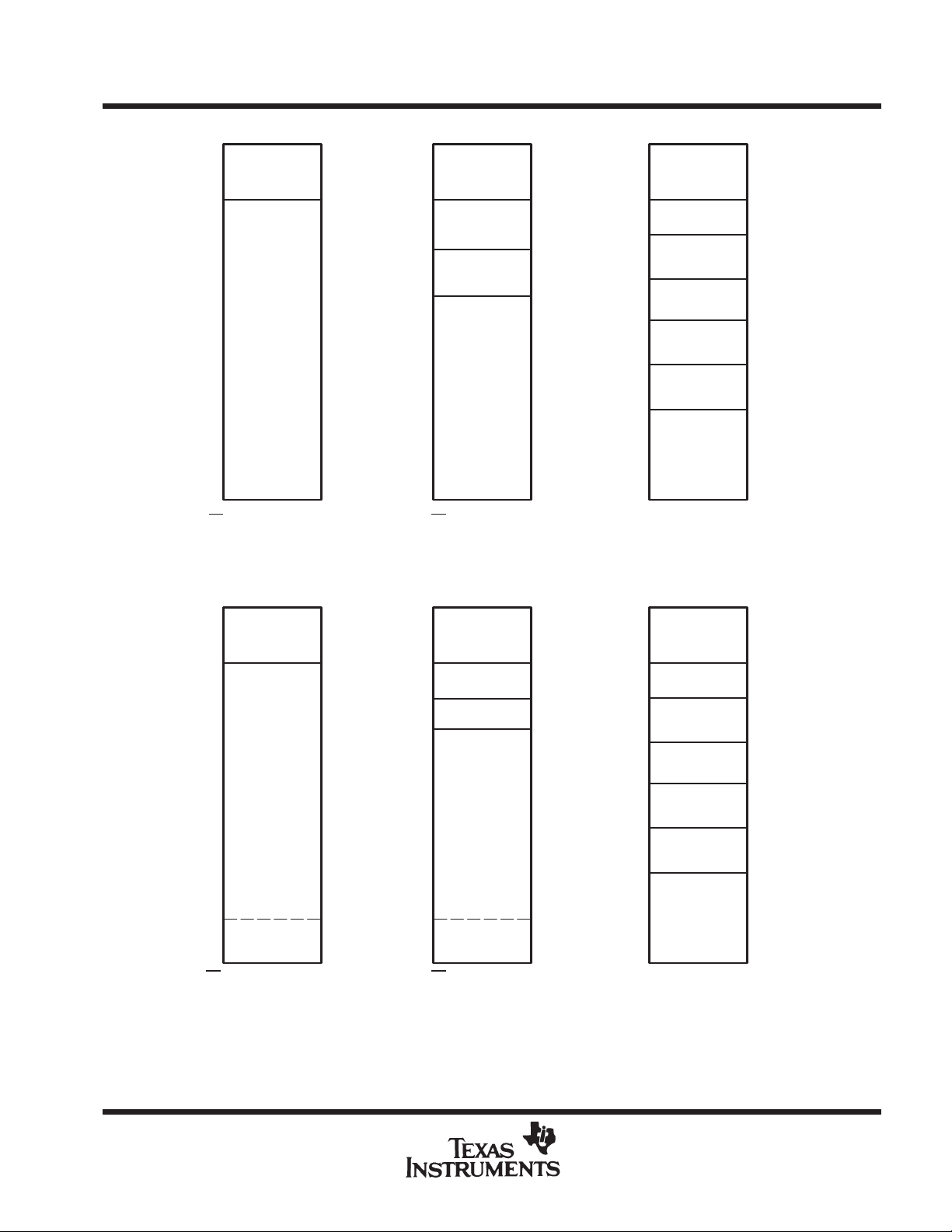

The TMS320C2x provides three separate address spaces for program memory, data memory, and I/O. The

on-chip memory is mapped into either the 64K-word data memory or program memory space, depending upon

the memory configuration (see Figure 1). The CNFD (configure block B0 as data memory) and CNFP (configure

block B0 as program memory) instructions allow dynamic configuration of the memory maps through software.

Regardless of the configuration, the user may still execute from external program memory.

The TMS320C2x has six registers that are mapped into the data memory space: a serial port data receive

register, serial port data transmit register, timer register, period register, interrupt mask register, and global

memory allocation register.

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

7

Page 8

TMS320 SECOND-GENERATION

DEVICES

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

0(0000h)

31(001Fh)

32(0020h)

65,535(FFFFh)

If MP/MC

(Microprocessor Mode)

Program Program Data

Interrupts

and Reserved

(External)

External

= 1

Interrupts

and Reserved

(On-Chip

31(001Fh)

32(0020h)

4015(0FAFh)

4016(0FB0h)

4095(0FFFh)

4096(1000h)

65,535(0FFFFh)

ROM/EPROM)

On-Chip

ROM/EPROM

Reserved

External

If MP/MC = 0

(Microcomputer Mode on TMS320C25)

0(0000h)0(0000h)

5(0005h)

6(0006h)

95(005Fh)

96(0060h)

127(007Fh)

128(0080h)

511(01FFh)

512(0200h)

767(02FFh)

768(0300h)

1023(03FFh)

1024(0400h)

65,535(0FFFFh)

(a) Memory Maps After a CNFD Instruction

On-Chip

Memory-Mapped

Registers

Reserved

On-Chip

Block B2

Reserved

On-Chip

Block B0

On-Chip

Block B1

External

Page 0

Pages 1-3

Pages 4-5

Pages 6 -7

Pages 8 -511

0(0000h)

31(001Fh)

32(0020h)

65,279(0FEFFh)

65,280(0FF00h)

65,535(0FFFFh)

If MP/MC

(Microprocessor Mode)

Program Program Data

Interrupts

and Reserved

(External)

Block B0

= 1

External

On-Chip

0(0000h)

31(001Fh)

32(0020h)

4015(0FAFh)

4016(0FB0h)

4095(0FFFh)

4096(1000h)

65,279(0FEFFh)

65,280(0FF00h)

65,535(0FFFFh)

If MP/MC

(Microcomputer Mode on TMS320C25)

Interrupts

and Reserved

(On-Chip

ROM/EPROM)

On-Chip

ROM/EPROM

Reserved

External

On-Chip

Block B0

= 0

0(0000h)

5(0005h)

6(0006h)

95(005Fh)

96(0060h)

127(007Fh)

128(0080h)

511(01FFh)

512(0200h)

767(02FFh)

768(0300h)

1023(03FFh)

1024(0400h)

65,535(0FFFFh)

(b) Memory Maps After a CNFP Instruction

On-Chip

Memory-Mapped

Registers

Reserved

On-Chip

Block B2

Reserved

Does Not

Exist

On-Chip

Block B1

External

Page 0

Pages 1-3

Pages 4-5

Pages 6 -7

Pages 8 -511

Figure 1. Memory Maps

8

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Page 9

TMS320 SECOND-GENERATION

DEVICES

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

interrupts and subroutines

The TMS320C2x has three external maskable user interrupts INT2-INT0, available for external devices that

interrupt the processor. Internal interrupts are generated by the serial port (RINT and XINT), by the timer (TINT),

and by the software interrupt (TRAP) instruction. Interrupts are prioritized with reset (RS

priority and the serial port transmit interrupt (XINT) having the lowest priority. All interrupt locations are on

two-word boundaries so that branch instructions can be accommodated in those locations if desired.

A built-in mechanism protects multicycle instructions from interrupts. If an interrupt occurs during a multicycle

instruction, the interrupt is not processed until the instruction is completed. This mechanism applies to

instructions that are repeated and to instructions that become multicycle due to the READY signal.

external interface

The TMS320C2x supports a wide range of system interfacing requirements. Program, data, and I/O address

spaces provide interface to memory and I/O, thus maximizing system throughput. I/O design is simplified by

having I/O treated the same way as memory. I/O devices are mapped into the I/O address space using the

processor’s external address and data buses in the same manner as memory-mapped devices. Interface to

memory and I/O devices of varying speeds is accomplished by using the READY line. When transactions are

made with slower devices, the TMS320C2x processor waits until the other device completes its function and

signals the processor via the READY line. Then, the TMS320C2x continues execution.

A full-duplex serial port provides communication with serial devices, such as codecs, serial A/D converters, and

other serial systems. The interface signals are compatible with codecs and many other serial devices with a

minimum of external hardware. The serial port may also be used for intercommunication between processors

in multiprocessing applications.

) having the highest

The serial port has two memory-mapped registers: the data transmit register (DXR) and the data receive register

(DRR). Both registers operate in either the byte mode or 16-bit word mode, and may be accessed in the same

manner as any other data memory location. Each register has an external clock, a framing synchronization

pulse, and associated shift registers. One method of multiprocessing may be implemented by programming one

device to transmit while the others are in the receive mode. The serial port on the TMS320C25 is double-buffered

and fully static.

multiprocessing

The flexibility of the TMS320C2x allows configurations to satisfy a wide range of system requirements and can

be used as follows:

• A standalone processor

• A multiprocessor with devices in parallel

• A slave/host multiprocessor with global memory space

• A peripheral processor interfaced via processor-controlled signals to another device.

For multiprocessing applications, the TMS320C2x has the capability of allocating global data memory space

and communicating with that space via the BR (bus request) and READY control signals. Global memory is data

memory shared by more than one processor. Global data memory access must be arbitrated. The 8-bit

memory-mapped GREG (global memory allocation register) specifies part of the TMS320C2x’s data memory

as global external memory . The contents of the register determine the size of the global memory space. If the

current instruction addresses an operand within that space, BR is asserted to request control of the bus. The

length of the memory cycle is controlled by the READY line.

The TMS320C2x supports DMA (direct memory access) to its external program/data memory using the HOLD

and HOLDA signals. Another processor can take complete control of the TMS320C2x’s external memory by

asserting HOLD

high-impedance state, and assert HOLDA. On the TMS320C2x, program execution from on-chip ROM may

proceed concurrently when the device is in the hold mode.

low. This causes the TMS320C2x to place its address data and control lines in a

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

9

Page 10

TMS320 SECOND-GENERATION

DEVICES

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

instruction set

The TMS320C2x microprocessor implements a comprehensive instruction set that supports both

numeric-intensive signal processing operations as well as general-purpose applications, such as

multiprocessing and high-speed control. The TMS32020 source code is upward-compatible with TMS320C25

source code. TMS32020 object code runs directly on the TMS320C25.

For maximum throughput, the next instruction is prefetched while the current one is being executed. Since the

same data lines are used to communicate to external data/program or I/O space, the number of cycles may vary

depending upon whether the next data operand fetch is from internal or external memory . Highest throughput

is achieved by maintaining data memory on-chip and using either internal or fast external program memory.

addressing modes

The TMS320C2x instruction set provides three memory addressing modes: direct, indirect, and immediate

addressing.

Both direct and indirect addressing can be used to access data memory . In direct addressing, seven bits of the

instruction word are concatenated with the nine bits of the data memory page pointer to form the 16-bit data

memory address. Indirect addressing accesses data memory through the auxiliary registers. In immediate

addressing, the data is based on a portion of the instruction word(s).

In direct memory addressing, the instruction word contains the lower seven bits of the data memory address.

This field is concatenated with the nine bits of the data memory page pointer to form the full 16-bit address. Thus,

memory is paged in the direct addressing mode with a total of 512 pages, each page containing 128 words.

Up to eight auxiliary registers (AR0-AR7) provide flexible and powerful indirect addressing (five on the

TMS32020, eight on the TMS320C25). To select a specific auxiliary register, the Auxiliary Register Pointer

(ARP) is loaded with a value from 0 to 7 for AR0 through AR7, respectively.

There are seven types of indirect addressing: auto-increment or auto-decrement, post-indexing by either adding

or subtracting the contents of AR0, single indirect addressing with no increment or decrement, and bit-reversal

addressing (used in FFT s on the TMS320C25 only) with increment or decrement. All operations are performed

on the current auxiliary register in the same cycle as the original instruction, following which the current auxiliary

register and ARP may be modified.

repeat feature

A repeat feature, used with instructions such as multiply/accumulates, block moves, I/O transfers, and table

read/writes, allows a single instruction to be performed up to 256 times. The repeat counter (RPTC) is loaded

with either a data memory value (RPT instruction) or an immediate value (RPTK instruction). The value of this

operand is one less than the number of times that the next instruction is executed. Those instructions that are

normally multicycle are pipelined when using the repeat feature, and effectively become single-cycle

instructions.

10

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Page 11

TMS320 SECOND-GENERATION

DEVICES

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

instruction set summary

Table 2 lists the symbols and abbreviations used in Table 3, the TMS320C25 instruction set summary. Table 3

consists primarily of single-cycle, single-word instructions. Infrequently used branch, I/O, and CALL instructions

are multicycle. The instruction set summary is arranged according to function and alphabetized within each

functional grouping. The symbol (

instruction set. The symbol (‡) indicates instructions that are not included in the TMS32020 instruction set.

SYMBOL DEFINITION

B

CM

D

FO

I

K

PA

PM

AR

S

X

†

) indicates those instructions that are not included in the TMS320C1x

Table 2. Instruction Symbols

4-bit field specifying a bit code

2-bit field specifying compare mode

Data memory address field

Format status bit

Addressing mode bit

Immediate operand field

Port address (PA0 through P A15 are predefined assembler symbols

equal to 0 through 15, respectively .)

2-bit field specifying P register output shift code

3-bit operand field specifying auxiliary register

4-bit left-shift code

3-bit accumulator left-shift field

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

11

Page 12

TMS320C25

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

Table 3. TMS320C25 Instruction Set Summary

ACCUMULATOR MEMORY REFERENCE INSTRUCTIONS

MNEMONIC

ABS Absolute value of accumulator 1 1 1 0 0 1 1 1 0 0 0 0 1 1 0 1 1

ADD Add to accumulator with shift 1 0 000 I

‡

ADDC

ADDH Add to high accumulator 1 0 1001000I

ADDK

ADDS

ADDT

ADLK

AND AND with accumulator 1 0 1001110I

ANDK

CMPL

LAC Load accumulator with shift 1 0 010 I

LACK Load accumulator immediate short 1 1 1001010

LACT

LALK

†

NEG

NORM

OR OR with accumulator 1 0 1001101I

†

ORK

‡

ROL

‡

ROR

SACH Store high accumulator with shift 1 0 1101 I

SACL Store low-order accumulator with shift 1 0 1100 I

SBLK†

†

SFL

†

SFR

SUB Subtract from accumulator with shift 1 0 001 I

SUBB

SUBC Conditional subtract 1 0 1000111I

SUBH Subtract from high accumulator 1 0 1000100I

SUBK

SUBS

†

These instructions are not included in the TMS320C1x instruction set.

‡

These instructions are not included in the TMS32020 instruction set.

Add to accumulator with carry 1 0 1000011I

‡

Add to accumulator short immediate 1 1 1001100

Add to low accumulator with sign

extension suppressed

Add to accumulator with shift specified by

T register

†

Add to accumulator long immediate with shift 2 1 1 0 1 00000010

†

AND immediate with accumulator with shift 2 1 1 0 1 00000100

†

Complement accumulator 1 1 100111000100111

Load accumulator with shift specified by

†

T register

†

Load accumulator long immediate with shift 2 1 1 0 1 00000001

Negate accumulator 1 1 100111000100011

†

Normalize contents of accumulator 1 1 10011101XXX0010

OR immediate with accumulator with shift 2 1 1 0 1 00000101

Rotate accumulator left 1 1 100111000110100

Rotate accumulator right 1 1 100111000110101

Subtract from accumulator long immediate

with shift

Shift accumulator left 1 1 100111000011000

Shift accumulator right 1 1 100111000011001

‡

Subtract from accumulator with borrow 1 0 1001111I

‡

Subtract from accumulator short immediate 1 1 1001101

Subtract from low accumulator with sign

extension suppressed

DESCRIPTION

NO.

WORDS

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1

0 1001001I

1

0 1001010I

1

0 1000010I

2

1 1 0 1 00000011

1 0 1 0 0 0 1 0 1 I

INSTRUCTION BIT CODE

S

S

S

S

S

S

X D

S

S D

D

D

D

K

D

D

D

D

K

D

D

DX

D

D

D

K

D

12

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Page 13

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

Table 3. TMS320C25 Instruction Set Summary (continued)

ACCUMULATOR MEMORY REFERENCE INSTRUCTIONS

TMS320C25

MNEMONIC

Subtract from accumulator with shift specified by

†

SUBT

XOR Exclusive-OR with accumulator 1 0 1001100I

XORK

ZAC Zero accumulator 1 1 100101000000000

ZALH Zero low accumulator and load high accumulator 1 0 1000000I

ZALR

ZALS

MNEMONIC

ADRK‡Add to auxiliary register short immediate 1 0 1 1 1 1 1 1 0

CMPR

LAR Load auxiliary register 1 0 0110 I

LARK Load auxilliary register short immediate 1 1 1000

LARP Load auxilliary register pointer 1 0 101010110001

LDP Load data memory page pointer 1 0 1010010I

LDPK Load data memory page pointer immediate 1 1 100100

LRLK†Load auxiliary register long immediate 2 1 1010 00000000

MAR Modify auxiliary register 1 0 1010101I

SAR Store auxiliary register 1 0 1110 I

SBRK‡Subtract from auxiliary register short immediate 1 0 1 1 1 1 1 1 1

†

These instructions are not included in the TMS320C1x instruction set.

‡

These instructions are not included in the TMS32020 instruction set.

T register

Exclusive-OR immediate with accumulator with

†

shift

Zero low accumulator and load high accumulator

‡

with rounding

Zero accumulator and load low accumulator with

sign extension suppressed

Compare auxiliary register with auxiliary

†

register AR0

DESCRIPTION

AUXILIARY REGISTERS AND DATA PAGE POINTER INSTRUCTIONS

DESCRIPTION

NO.

WORDS

WORDS

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1 0 1 0 0 0 1 1 0 I

1 1 0 1 00000110

2

0 1111011I

1

1

0 1000001I

NO.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1 1001110010100

1

INSTRUCTION BIT CODE

D

D

S

D

D

D

INSTRUCTION BIT CODE

K

CM

DR

KR

R

D

DP

R

D

DR

K

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

13

Page 14

TMS320C25

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

Table 3. TMS320C25 Instruction Set Summary (continued)

T REGISTER, P REGISTER, AND MULTIPLY INSTRUCTIONS

MNEMONIC

APAC Add P register to accumulator 1 1 1 0 0 1 1 1 0 0 0 0 1 0 1 0 1

†

LPH

LT Load T register 1 0 0111100I

LTA Load T register and accumulate previous product 1 0 0111101I

LTD

LTP

LTS

MAC†Multiply and accumulate 2 0 1011101I

MACD†Multiply and accumulate with data move 2 0 1011100I

MPY

MPYA‡Multiply and accumulate previous product 1 0 0111010I

MPYK Multiply immediate 1 1 01

MPYS‡

MPYU‡

PAC Load accumulator with P register 1 1 100111000010100

SPAC Subtract P register from accumulator 1 1 100111000010110

SPH

SPL

SPM

SQRA†Square and accumulate 1 0 0111001I

SQRS†Square and subtract previous product 1 0 1 0 1 1 0 1 0 I

†

These instructions are not included in the TMS320C1x instruction set.

‡

These instructions are not included in the TMS32020 instruction set.

Load high P register 1 0 1010011I

Load T register, accumulate previous product,

and move data

Load T register and store P register in

†

accumulator

†

Load T register and subtract previous product 1 0 1011011I

Multiply (with T register, store product in

P register)

Multiply and subtract previous product 1 0 0111011I

Multiply unsigned 1 1 1001111I

‡

Store high P register 1 0 1111101I

‡

Store low P register 1 0 1111100I

†

Set P register output shift mode 1 1 1001110000010

DESCRIPTION

NO.

WORDS

1

1

1

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 0111111I

0 0111110I

0 0111000I

INSTRUCTION BIT CODE

D

D

D

D

D

D

D

D

D

D

K

D

D

D

D

PM

D

D

14

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Page 15

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

Table 3. TMS320C25 Instruction Set Summary (continued)

BRANCH/CALL INSTRUCTIONS

TMS320C25

MNEMONIC

B Branch unconditionally 2 1 1 1 1 1 1 1 1 1

BACC†Branch to address specified by accumulator 1 1 100111000100101

BANZ Branch on auxiliary register not zero 2 1 11110111

BBNZ†Branch if TC bit ≠ 021 11110011

†

BBZ

BC

BGEZ Branch if accumulator ≥ 021 11101001

BGZ Branch if accumulator > 0 2 1 11100011

BIOZ Branch on I/O status = 0 2 1 11110101

BLEZ Branch if accumulator ≤ 021 11100101

BLZ Branch if accumulator < 0 2 1 11100111

BNC‡Branch on no carry 2 0 10111111

BNV†Branch if no overflow 2 1 11101111

BNZ Branch if accumulator ≠ 021 11101011

BV Branch on overflow 2 1 11100001

BZ Branch if accumulator = 0 2 1 11101101

CALA Call subroutine indirect 1 1 100111000100100

CALL Call subroutine 2 1 11111101

RET Return from subroutine 1 1 100111000100110

Branch if TC bit = 0 2 1 11110001

‡

Branch on carry 2 0 10111101

DESCRIPTION

I/O AND DATA MEMORY OPERATIONS

NO.

WORDS

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

INSTRUCTION BIT CODE

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

MNEMONIC

BLKD†Block move from data memory to data memory 2 1 1 1 0 1 1 0 1 I

Block move from program memory to data

†

BLKP

DMOV Data move in data memory 1 0 1010110I

FORT†Format serial port registers 1 1 10011100000111FO

IN Input data from port 1 1 000 I

OUT Output data to port 1 1 110 I

RFSM‡Reset serial port frame synchronization mode 1 1 100111000110110

RTXM†Reset serial port transmit mode 1 1 100111000100000

RXF†Reset external flag 1 1 100111000001100

SFSM‡Set serial port frame synchronization mode 1 1 100111000110111

STXM†Set serial port transmit mode 1 1 100111000100001

SXF

TBLR Table read 1 0 1011000I

TBLW Table write 1 0 1 0 1 1 0 0 1 I

†

These instructions are not included in the TMS320C1x instruction set.

‡

These instructions are not included in the TMS32020 instruction set.

memory

†

Set external flag 1 1 100111000001101

DESCRIPTION

NO.

WORDS

2

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

1 1111100I

INSTRUCTION BIT CODE

PA

PA

D

D

D

D

D

D

D

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

15

Page 16

TMS320C25

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

Table 3. TMS320C25 Instruction Set Summary (concluded)

CONTROL INSTRUCTIONS

MNEMONIC

†

BIT

†

BITT

CNFD

CNFP

DINT Disable interrupt 1 1 100111000000001

EINT Enable interrupt 1 1 100111000000000

†

IDLE

LST Load status register STO 1 0 1010000I

LST1

NOP No operation 1 0 101010100000000

POP Pop top of stack to low accumulator 1 1 100111000011101

POPD

PSHD

PUSH Push low accumulator onto stack 1 1 100111000011100

‡

RC

RHM

ROVM Reset overflow mode 1 1 100111000000010

†

RPT

RPTK

RSXM

‡

RTC

‡

SC

‡

SHM

SOVM Set overflow mode 1 1 100111000000011

SST Store status register ST0 1 0 1111000I

SST1

SSXM

‡

STC

TRAP

†

These instructions are not included in the TMS320C1x instruction set.

‡

These instructions are not included in the TMS32020 instruction set.

Test bit 1 1 0 0 1 I

Test bit specified by T register 1 0 1010111I

†

Configure block as data memory 1 1 100111000000100

†

Configure block as program memory 1 1 100111000000101

Idle until interrupt 1 1 100111000011111

†

Load status register ST1 1 0 1010001I

†

Pop top of stack to data memory 1 0 1111010I

†

Push data memory value onto stack 1 0 1010100I

Reset carry bit 1 1 100111000110000

‡

Reset hold mode 1 1 100111000111000

Repeat instruction as specified by data

memory value

Repeat instruction as specified by immediate

†

value

†

Reset sign-extension mode 1 1 100111000000110

Reset test/control flag 1 1 100111000110010

Set carry bit 1 1 100111000110001

Set hold mode 1 1 100111000111001

†

Store status register ST1 1 0 1111001I

†

Set sign-extension mode 1 1 100111000000111

Set test/control flag 1 1 100111000110011

†

Software interrupt 1 1 1 0 0 1 1 1 0 0 0 0 1 1 1 1 0

DESCRIPTION

NO.

WORDS

1

1

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0 1001011I

1 1001011

INSTRUCTION BIT CODE

B

D

D

D

D

D

D

D

K

D

D

16

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Page 17

TMS32020

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

TMS32020 PRODUCT NOTIFICATION

Texas Instruments has identified an unusual set of circumstances that will cause the BIT (Test Bit) instruction

on the TMS32020 to affect the contents of the accumulator; ideally, the BIT instruction should not affect the

accumulator. This set of conditions is:

1. The overflow mode is set (the OVM status register bit is set to one.)

2. And, the two LSBs of the BIT instruction opcode word are zero.

a. When direct memory addressing is used, every fourth data word is affected; all other locations are not

affected.

b. When indirect addressing is used, the two LSBs will be zero if a new ARP is not selected or if a new

ARP is selected and that ARP is 0 or 4.

3. And, adding the contents of the accumulator with the contents of the addressed data memory location,

shifted by 2

If all of these conditions are met, the contents of the accumulator will be replaced by the positive or negative

saturation value, depending on the polarity of the overflow.

Various methods for avoiding this phenomenon are available:

(bit code)

, causes an overflow of the accumulator.

• If the TMS32020 is not in the saturation mode when the BIT instruction is executed, the device operates

properly and the accumulator is not affected.

• Execute the Reset Overflow Mode (ROVM) instruction immediately prior to the BIT instruction and the Set

Overflow Mode (SOVM) instruction immediately following the BIT instruction.

• If direct memory addressing is being used during the BIT instructions, reorganize memory so that the page

relative locations 0, 4, 8, C, 10 . . . are not used.

• If indirect addressing is being used during the Bit instruction, select a new ARP which is not AR0 or AR4.

If necessary, follow the instruction with a LARP AR0 or LARP AR4 to restore the code.

• Use the T est Bit Specified by T Register (BITT) instruction instead of the BIT instruction. The BITT instruction

operates correctly and will not affect the accumulator under any circumstances.

• Replace TMS32020 with TMS320C25 for ideal pin-to-pIn and object-code compatibility . The BIT instruction

on the TMS320C25 executes properly and will not affect the accumulator under any circumstances.

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

17

Page 18

TMS320 SECOND-GENERATION

DEVICES

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

development support

Together, Texas Instruments and its authorized third-party suppliers offer an extensive line of development

support products to assist the user in all aspects of TMS320 second-generation-based design and

development. These products range from development and application software to complete hardware

development and evaluation systems. T able 4 lists the development support products for the second-generation

TMS320 devices.

System development may begin with the use of the simulator, Software Development System (SWDS), or

emulator (XDS) along with an assembler/linker. These tools give the TMS320 user various means of evaluation,

from software simulation of the second-generation TMS320s (simulator) to full-speed in-circuit emulation with

hardware and software breakpoint trace and timing capabilities (XDS).

Software and hardware can be developed simultaneously by using the macro assembler/linker, C compiler , and

simulator for software development, the XDS for hardware development, and the Software Development

System for both software development and limited hardware development.

Many third-party vendors offer additional development support for the second-generation TMS320s, including

assembler/linkers, simulators, high-level languages, applications software, algorithm development tools,

application boards, software development boards, and in-circuit emulators. Refer to the

Development Support Reference Guide

support products offered by both Texas Instruments and its third-party suppliers.

(SPRU011A) for further information about TMS320 development

TMS320 Family

Additional support for the TMS320 products consists of an extensive library or product and applications

documentation. Three-day DSP design workshops are offered by the TI Regional Technology Centers (RTCs).

These workshops provide insight into the architecture and the instruction set of the second-generation

TMS320s as well as hands-on training with the TMS320 development tools. When technical questions arise

regarding the TMS320 family, contact the Texas Instruments TMS320 Hotline at (713) 274-2320. Or, keep

informed on the latest TI and third-party development support tools by accessing the DSP Bulletin Board Service

(BBS) at (713) 274-2323. The BBS serves 2400-, 1200- and 300-bps modems. Also, TMS320 application

source code may be downloaded from the BBS.

18

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Page 19

TMS320 SECOND-GENERATION

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

Table 4. TMS320 Second-Generation Software and Hardware Support

SOFTWARE TOOLS PART NUMBER

Macro Assembler/Linker

IBM MS/PC-DOS TMDS3242850-02

VAX/VMS TMDS3242250-08

VAX ULTRIX TMDS3242260-08

SUN UNIX TMDS3242550-08

Simulator

IBM MS/PC-DOS TMDS3242851-02

VAX/VMS TMDS3242251-08

C Compiler

IBM MS/PC-DOS TMDX3242855-02

VAX/VMS TMDX3242255-08

VAX ULTRIX TMDX3242265-08

SUN UNIX TMDX3242555-08

DEVICES

Digital Filter Design Package (DFDP)

IBM PC-DOS DFDP-IBM002

DSP Software Library

IBM MS/PC-DOS TMDC3240812-12

VAX/VMS TMDC3204212-18

HARDWARE TOOLS PART NUMBER

Analog Interface Board 2 (AIB2) RTC/AIB320A-06

Analog Interface Board Adaptor RTC/ADP320A-06

EPROM Programmer Adaptor Socket

(68 to 28-pin)

Software Development System (SWDS) TMDX3268821

XDS/22 Emulator (see Note) TMDS3262221

XDS/22 Upgrade (TMS32020 to TMS320C2x) TMDX3282226

NOTE: Emulation support for the TMS320C25-50 is available from Macrochip

Research, Inc.; refer to the

(SPRU011A) for the mailing address.

Guide

TMS320 Family Development Support Reference

TMDX3270120

IBM is a trademark of International Business Machines Corporation.

PC-DOS is a trademark of International Business Machines Corporation.

VAX and VMS are trademarks of Digital Equipment Corporation.

XDS is a trademark of Texas Instruments Incorporated.

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

19

Page 20

TMS320 SECOND-GENERATION

DEVICES

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

documentation support

Extensive documentation supports the second-generation TMS320 devices from product announcement

through applications development. The types of documentation include data sheets with design specifications,

complete user’s guides, and 750 pages of application reports published in the book,

Applications with the TMS320 Family

TMS320C25

A series of DSP textbooks is being published by Prentice-Hall and John Wiley & Sons to support digital signal

processing research and education. The TMS320 newsletter,

quarterly and distributed to update TMS320 customers on product information. The TMS320 DSP bulletin board

service provides access to large amounts of information pertaining to the TMS320 family.

(SPRA014A), is available for that device.

(SPRA012A). An application report,

Details on Signal Processing

Digital Signal Processing

Hardware Interfacing to the

, is published

Refer to the

TMS320 documentation. To receive copies of second-generation TMS320 literature, call the Customer

Response Center at 1-800-232-3200.

TMS320 Family Development Support Reference Guide

(SPRU01 1A) for further information about

specification overview

The electrical specifications for the TMS32020, TMS320C25, TMS320E25, and TMS320C25-50 are given in

the following pages. Note that the electrical specifications for the TMS320E25 are identical to those for the

TMS320C25, with the addition of EPROM-related specifications. A summary of differences between

TMS320C25 and TMS320C25-50 specifications immediately follows the TMS320C25-50 specification.

20

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Page 21

TMS32020

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

absolute maximum ratings over specified temperature range (unless otherwise noted)†

Supply voltage range, V

Input voltage range – 0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output voltage range – 0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous power dissipation 2 W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range 0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range – 55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress rating only, and

functional operation of the device at these or any other conditions beyond those indicated in the “Recommended Operating Conditions” section of

this specification is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability .

‡

All voltage values are with respect to VSS.

recommended operating conditions

V

CC

V

SS

V

IH

IL

I

OH

I

OL

T

A

NOTES: 1. Case temperature (TC) must be maintained below 90°C.

Supply voltage 4.75 5 5.25 V

Supply voltage 0 V

High-level input voltage

Low-level input voltageV

High-level output current 300 µA

Low-level output current 2 mA

Operating free-air temperature (see Notes 1 and 2) 0 70 °C

2. R

= 36°C/Watt, R

θJA

‡

– 0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC

All inputs except CLKIN 2 VCC + 0.3 V

CLKIN 2.4 VCC + 0.3 V

All inputs except CLKIN – 0.3 0.8 V

CLKIN – 0.3 0.8 V

= 6°C/Watt.

θJC

MIN NOM MAX UNIT

electrical characteristics over specified free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP§MAX UNIT

V

OH

V

OL

I

Z

I

I

I

CC

C

I

C

O

§

All typical values for ICC are at VCC = 5 V, TA = 25°C.

should be placed in conductive foam. In a circuit, unused inputs should always be connected to an appropriated logic voltage level, preferably either

VCC or ground. Specific guidelines for handling devices of this type are contained in the publication

Electrostatic-Discharge-Sensitive (ESDS) Devices and Assemblies

High-level output voltage VCC = MIN, IOH = MAX 2.4 3 V

Low-level output voltage VCC = MIN, IOL = MAX 0.3 0.6 V

Three-state current VCC = MAX –20 20 µA

Input current VI = VSS to V

TA = 0°C, VCC = MAX, fx = MAX 360 mA

Supply current TA = 25°C, VCC = MAX, fx = MAX 250 mA

TC = 90°C, VCC = MAX, fx = MAX 285 mA

Input capacitance 15 pF

Output capacitance 15 pF

This device contains circuits to protect its inputs and outputs against damage due to high static voltages or electrostatic fields. These

circuits have been qualified to protect this device against electrostatic discharges (ESD) of up to 2 kV according to MIL-STD-883C,

Method 3015; however, it is advised that precautions should be taken to avoid application of any voltage higher than maximum-rated

voltages to these high-impedance circuits. During storage or handling, the device leads should be shorted together or the device

available from Texas Instruments.

CC

–10 10 µA

Guidelines for Handling

ADVANCE INFORMATION

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

21

Page 22

TMS32020

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

The TMS32020 can use either its internal oscillator or an external frequency source for a clock.

internal clock option

The internal oscillator is enabled by connecting a crystal across X1 and X2/CLKIN (see Figure 2). The frequency

of CLKOUT1

is one-fourth the crystal fundamental frequency. The crystal should be fundamental

mode, and parallel resonant, with an effective series resistance of 30

and be specified at a load capacitance of 20 pF.

PARAMETER TEST CONDITIONS MIN TYP†MAX UNIT

f

x

f

xs

C1, C2 TA = 0°C to 70°C 10 pF

†

Value derived from characterization data; minimum fsx at test = 825 kHz.

Input clock frequency TA = 0°C to 70°C 6.7 20.5 MHz

Serial port frequency TA = 0°C to 70°C 50

ADVANCE INFORMATION

CLOCK CHARACTERISTICS AND TIMING

Ω, a power dissipation of 1 mW,

†

2563 MHz

X1

X2/CLKIN

Crystal

C2C1

Figure 2. Internal Clock Option

external clock option

An external frequency source can be used by injecting the frequency directly into X2/CLKIN with X1 left

unconnected. The external frequency injected must conform to the specifications listed in the following table.

switching characteristics over recommended operating conditions (see Note 3)

PARAMETER MIN NOM MAX UNIT

t

c(C)

t

d(CIH-C)

t

f(C)

t

r(C)

t

w(CL)

t

w(CH)

td(C1-C2) CLKOUT1 high to CLKOUT2 low, CLKOUT2 high to CLKOUT1 high, etc. Q – 10 Q Q+10 ns

NOTE 3: Q = 1/4t

CLKOUT1/CLKOUT2 cycle time 195 597 ns

CLKIN high to CLKOUT1/CLKOUT2/STRB high/low 25 60 ns

CLKOUT1/CLKOUT2/STRB fall time 10 ns

CLKOUT1/CLKOUT2/STRB rise time 10 ns

CLKOUT1/CLKOUT2 low pulse duration 2Q – 15 2Q 2Q + 15 ns

CLKOUT1/CLKOUT2 high pulse duration 2Q – 15 2Q 2Q + 15 ns

.

c(C)

22

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Page 23

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

timing requirements over recommended operating conditions (see Note 3)

t

c(C)

t

f(CI)

t

r(CI)

t

w(CIL)

t

w(CIH)

t

su(S)

t

h(S)

†

Value derived from characterization data and not tested.

NOTES: 3. Q = 1/4t

CLKIN cycle time 195 597 ns

CLKIN fall time 10

CLKIN rise time 10

CLKIN low pulse duration, t

CLKIN high pulse duration, t

SYNC setup time before CLKIN low 10 Q – 10 ns

SYNC hold time from CLKIN low 15 ns

.

4. CLKIN duty cycle [t

c(C)

r(CI)

+ t

= 50 ns (see Note 4) 40 ns

c(CI)

= 50 ns (see Note 4) 40 ns

c(CI)

w(CIH)]/tc(CI)

must be within 40-60%.

2.15 V

RL = 825 Ω

TMS32020

MIN NOM MAX UNIT

†

ns

†

ns

2.0 V

1.88 V

0.92 V

0.80 V

2.4 V

2.2 V

0.8 V

0.6 V

From Output

Under Test

Figure 3. Test Load Circuit

0

(a) Input

0

Test

Point

CL = 100 pF

VIH (Min)

VIL (Max)

VOH (Min)

VOL (Max)

ADVANCE INFORMATION

(b) Output

Figure 4. Voltage Reference Levels

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

23

Page 24

TMS32020

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

MEMORY AND PERIPHERAL INTERFACE TIMING

switching characteristics over recommended operating conditions (see Note 3)

PARAMETER MIN TYP MAX UNIT

t

d(C1-S)

t

d(C2-S)

t

su(A)

t

h(A)

t

w(SL)

t

w(SH)

t

su(D)W

t

h(D)W

t

en(D)

t

ADVANCE INFORMATION

dis(D)

t

d(MSC)

†

Value derived from characterization data and not tested.

NOTES: 3. Q = 1/4t

STRB from CLKOUT1 (if STRB is present) Q – 15 Q Q + 15 ns

CLKOUT2 to STRB (if STRB is present) – 15 0 15 ns

Address setup hold time before STRB low (see Note 5) Q – 30 ns

Address hold time after STRB high (see Note 5) Q – 15 ns

STRB low pulse duration (no wait states, see Note 6) 2Q ns

STRB high pulse duration (between consecutive cycles, see Note 6) 2Q ns

Data write setup time before STRB high (no wait states) 2Q – 45 ns

Data write hold time from STRB high Q – 15 Q ns

Data bus starts being driven after STRB low (write cycle) 0

Data bus three-state after STRB high (write cycle) Q Q+30†ns

MSC valid from CLKOUT1 –25 0 25 ns

.

5. A15-A0, PS, DS, IS, R/W, and BR timings are all included in timings referenced as “address”.

6. Delays between CLKOUT1/CLKOUT2 edges and STRB

c(C)

edges track each other, resulting in t

no wait states.

†

w(SL)

and t

being 2Q with

w(SH)

ns

timing requirements over recommended operating conditions (see Note 3)

MIN NOM MAX UNIT

t

a(A)

t

su(D)R

t

h(D)R

t

d(SL-R)

t

d(C2H-R)

t

h(SL-R)

t

h(C2H-R)

t

d(M-R)

t

h(M-R)

†

Value derived from characterization data and not tested.

NOTES: 3. Q = 1/4t

Read data access time from address time (read cycle, see Notes 5 and 7) 3Q – 70

Data read setup time before STRB high 40 ns

Data read hold time from STRB high 0 ns

READY valid after STRB low (no wait states) Q – 40 ns

READY valid after CLKOUT2 high Q – 40 ns

READY hold time after STRB low (no wait states) Q – 5 ns

READY hold after CLKOUT2 high Q – 5 ns

READY valid after MSC valid 2Q – 50 ns

READY hold time after MSC valid 0 ns

.

5. A15-A0, PS, DS, IS, R/W, and BR timings are all included in timings referenced as “address”.

7. Read data access time is defined as t

c(C)

a(A)

= t

su(A)

+ t

w(SL)

– t

su(D)R

.

†

ns

24

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Page 25

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

RS, INT, BIO, AND XF TIMING

switching characteristics over recommended operating conditions (see Note 3 and 8)

PARAMETER MIN TYP MAX UNIT

t

d(RS)

t

d(IACK)

t

d(XF)

NOTES: 3. Q = 1/4t

CLKOUT1 low to reset state entered 45 ns

CLKOUT1 to IACK valid – 25 0 25 ns

XF valid before falling edge of STRB Q – 30 ns

.

c(C)

, INT , and BIO are asynchronous inputs and can occur at any time during a clock cycle. However , if the specified setup time is met,

8. RS

the exact sequence shown in the timing diagrams will occur.

timing requirements over recommended operating conditions (see Note 3 and 8)

MIN NOM MAX UNIT

t

su(IN)

t

h(IN)

t

f(IN)

t

w(IN)

t

w(RS)

†

Value derived from characterization data and not tested.

NOTES: 3. Q = 1/4t

INT/BIO/RS setup before CLKOUT1 high 50 ns

INT/BIO/RS hold after CLKOUT1 high 0 ns

INT/BIO fall time 15

INT/BIO low pulse duration t

RS low pulse duration 3t

.

8. RS

c(C)

, INT , and BIO are asynchronous inputs and can occur at any time during a clock cycle. However , if the specified setup time is met,

the exact sequence shown in the timing diagrams will occur.

c(C)

c(C)

TMS32020

†

ns

ns

ns

HOLD TIMING

switching characteristics over recommended operating conditions (see Note 3)

PARAMETER MIN TYP MAX UNIT

t

d(C1L-AL)

t

dis(AL-A)

t

dis(C1L-A)

t

d(HH-AH)

t

en(A-C1L)

†

Value derived from characterization data and not tested.

NOTES: 3. Q = 1/4t

HOLDA low after CLKOUT1 low –25

HOLDA low to address three-state 15

Address three-state after CLKOUT1 low (HOLD mode, see Note 9) 30

HOLD high to HOLDA high 50 ns

Address driven before CLKOUT1 low (HOLD mode, see Note 9) 10

.

9. A15-A0, PS, DS, IS, STRB, and R/W timings are all included in timings referenced as “address.”

c(C)

†

timing requirements over recommended operating conditions (see Note 3)

MIN NOM MAX UNIT

t

d(C2H-H)

NOTE 3: Q = 1/4t

HOLD valid after CLKOUT2 high Q – 45 ns

.

c(C)

†

25 ns

ns

†

ns

†

ns

ADVANCE INFORMATION

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

25

Page 26

TMS32020

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

SERIAL PORT TIMING

switching characteristics over recommended operating conditions (see Note 3)

PARAMETER MIN TYP MAX UNIT

t

d(CH-DX)

t

d(FL-DX)

t

d(CH-FS)

NOTES: 3. Q = 1/4t

timing requirements over recommended operating conditions (see Note 3)

t

c(SCK)

t

ADVANCE INFORMATION

f(SCK)

t

r(SCK)

t

w(SCK)

t

w(SCK)

t

su(FS)

t

h(FS)

t

su(DR)

t

h(DR)

†

Value derived from characterization data; minimum fsx at test = 825 kHz.

‡

Value derived from characterization data and not tested.

NOTES: 3. Q = 1/4t

DX valid after CLKX rising edge (see Note 10) 100 ns

DX valid after FSX falling edge (TXM = 0, see Note 10) 50 ns

FSX valid after CLKX rising edge (TXM = 1) 60 ns

.

10. The last occurrence of FSX falling and CLKX rising.

11. The duty cycle of the serial port clock must be within 40-60%.

c(C)

Serial port clock (CLKX/CLKR) cycle time 390 20 000

Serial port clock (CLKX/CLKR) fall time 50

Serial port clock (CLKX/CLKR) rise time 50

Serial port clock (CLKX/CLKR) low pulse duration (see Note 11) 150 12 000 ns

Serial port clock (CLKX/CLKR) high pulse duration (see Note 11) 150 12 000 ns

FSX/FSR setup time before CLKX/CLKR falling edge (TXM = 0) 20 ns

FSX/FSR hold time after CLKX/CLKR falling edge (TXM = 0) 20 ns

DR setup time before CLKR falling edge 20 ns

DR hold time after CLKR falling edge 20 ns

.

c(C)

MIN NOM MAX UNIT

†

ns

‡

ns

‡

ns

26

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

Page 27

TMS320C25, TMS320E25

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

absolute maximum ratings over specified temperature range (unless otherwise noted)

Supply voltage range, V

‡

– 0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC

†

Input voltage range: TMS320E25 pins 24 and 25 – 0.3 V to 15 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All other inputs – 0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output voltage range – 0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous power dissipation 1.5 W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range 0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range – 55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress rating only, and

functional operation of the device at these or any other conditions beyond those indicated in the “Recommended Operating Conditions” section of

this specification is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability .

‡

All voltage values are with respect to VSS.

recommended operating conditions

MIN NOM MAX UNIT

V

V

V

V

I

I

T

CC

SS

IH

IL

OH

OL

A

Supply voltage 4.75 5 5.25 V

Supply voltage 0 V

All inputs except CLKIN/CLKX/CLKR/INT (0-2) 2.35 VCC + 0.3 V

High-level input voltage INT (0-2) 2.5 VCC + 0.3 V

CLKIN/CLKX/CLKR 3.5 VCC + 0.3 V

Low-level input voltage

High-level output current 300 µA

Low-level output current 2 mA

Operating free-air temperature

All inputs except MP/MC – 0.3 0.8 V

MP/MC – 0.3 0.8 V

TMS320C25, TMS320E25 0 70 °C

TMS320C25GBA – 40 85 °C

electrical characteristics over specified free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP§MAX UNIT

V

OH

V

OL

I

Z

I

I

I

CC

C

I

C

O

§

All typical values are at VCC = 5 V, TA = 25°.

or the device should be placed in conductive foam. In a circuit, unused inputs should always be connected to an appropriate logic voltage level,

preferably either VCC or ground. Specific guidelines for handling devices of this type are contained in the publication “Guidelines for Handling

Electrostatic-Discharge Sensitive (ESDS) Devices and Assemblies” available from Texas Instruments

High-level output voltage VCC = MIN, IOH = MAX 2.4 3 V

Low-level output voltage VCC = MIN, IOL = MAX 0.3 0.6 V

Three-state current VCC = MAX –20 20 µA

Input current VI = VSS to V

Low-level input voltage TA = 0°C, VCC = MAX, fx = MAX

Input capacitance 15 pF

Output capacitance 15 pF

Caution. This device contains circuits to protect its inputs and outputs against damage due to high static voltages or electrostatic

fields. These circuits have been qualified to protect this device against electrostatic discharges (ESD) of up to 2 kV according to

MIL-STD-883C, Method 3015; however, it is advised that precautions to be taken to avoid application of any voltage higher than

maximum rated voltages to these high-impedance circuits. During storage or handling, the device leads should be shorted together

Normal 110 185

Idle/HOLD 50 100

CC

–10 10 µA

mA

ADVANCE INFORMATION

POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001

27

Page 28

TMS320C25, TMS320E25

SPRS010B — MA Y 1987—REVISED NOVEMBER 1990

The TMS32025 can use either its internal oscillator or an external frequency source for a clock.

internal clock option

The internal oscillator is enabled by connecting a crystal across X1 and X2/CLKIN (see Figure 2). The frequency

f

x

f

xs

C1, C2 TA = 0°C to 70°C 10 pF

†

ADVANCE INFORMATION

The serial port was tested at a minimum frequency of 1.25 MHz. However, the serial port was fully static but will properly function down

to fsx = 0 Hz.

of CLKOUT1

or overtone mode, and parallel resonant, with an effective series resistance of 30

of 1 mW, and be specified at a load capacitance of 20 pF. Note that overtone crystals require an additional tuned

LC circuit; see the application report,

Input clock frequency TA = 0°C to 70°C 6.7 40.96 MHz

Serial port frequency TA = 0°C to 70°C 0

is one-fourth the crystal fundamental frequency. The crystal should be either fundamental

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

CLOCK CHARACTERISTICS AND TIMING

Hardware Interfacing to the TMS320C25

Ω, a power dissipation

(SPRA014A).

†

5120 MHz

X1

X2/CLKIN

Crystal

C2C1

Figure 2. Internal Clock Option

external clock option

An external frequency source can be used by injecting the frequency directly into X2/CLKIN with X1 left

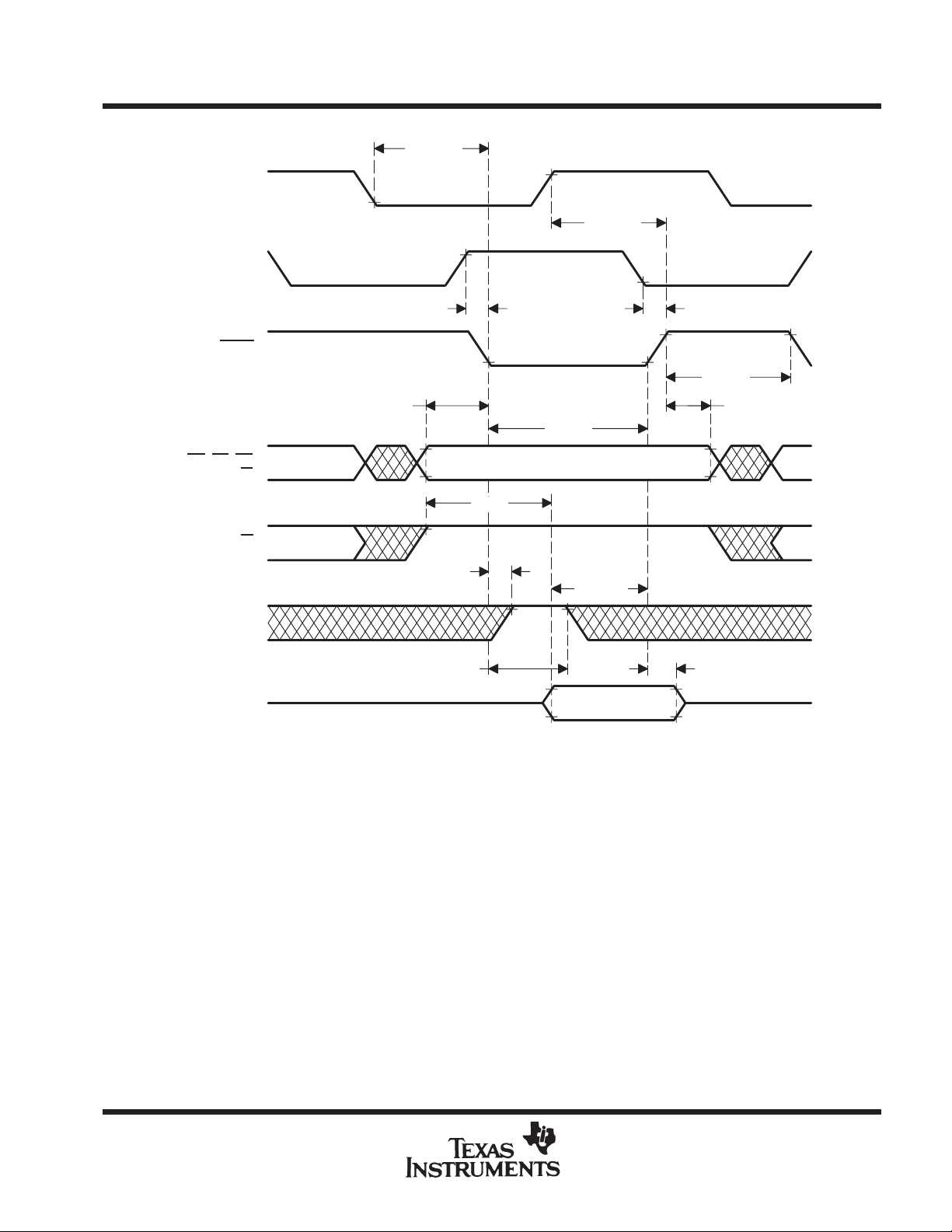

unconnected. The external frequency injected must conform to the specifications listed in the following table.