Page 1

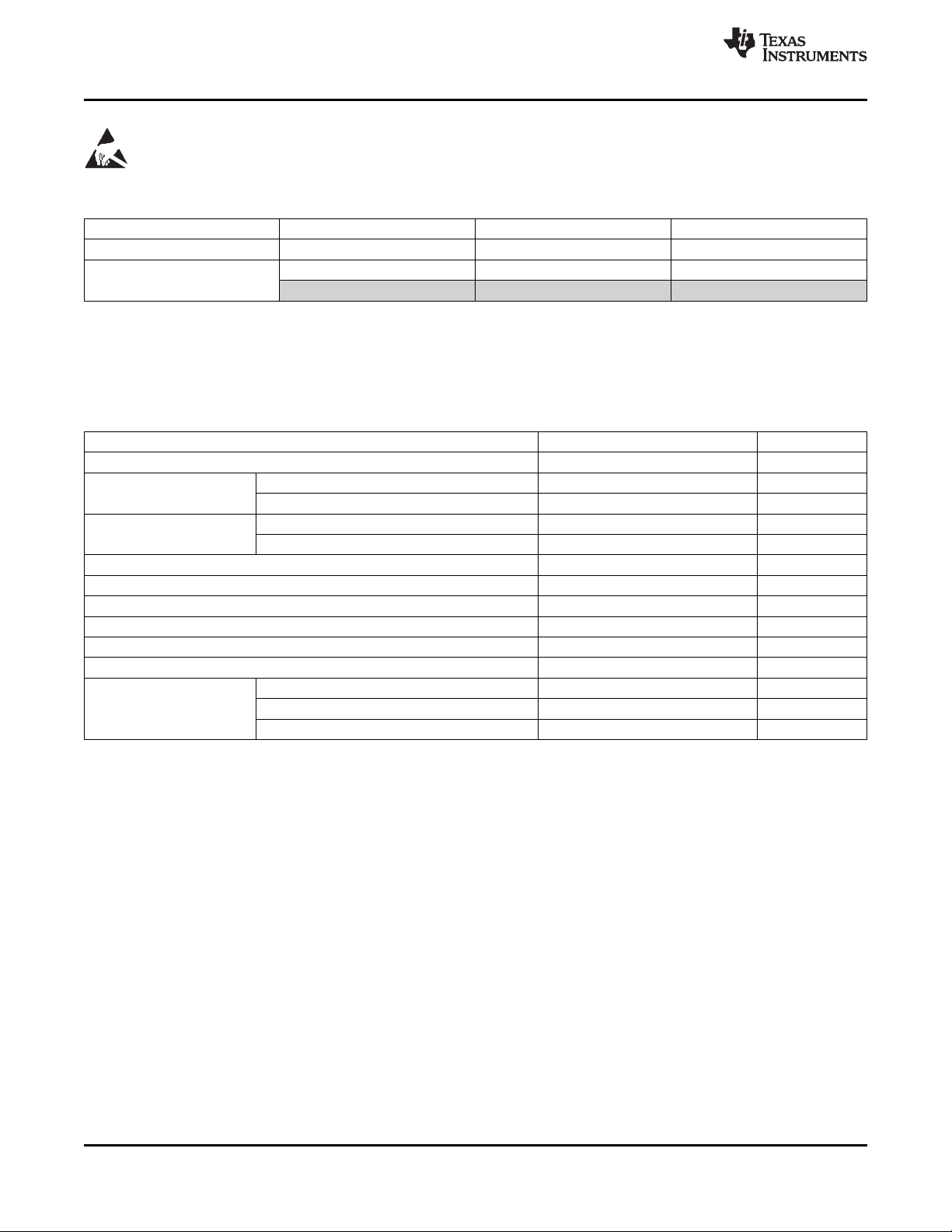

GND

GPIO

V

IN+

V

IN-

ALERT

SDA

SCL

ADC

TMP512

TMP513

DXP1

DXN1

DXP2

DXN2

Subregulator

3.3V

V+

Filter C

Two-Wire

Interface

Power Register

Current Register

Voltage Register

ADC

Low-Pass Filter

Internal

Diode

Temperature

Sensor

Mux

A0

DXP3

DXN3

TMP512

TMP513

www.ti.com

SBOS491 –JUNE 2010

Temperature and Power Supply System Monitors

Check for Samples: TMP512, TMP513

1

FEATURES

234

• ±1°C REMOTE DIODE SENSORS

• ±1°C LOCAL TEMPERATURE SENSOR

• SERIES RESISTANCE CANCELLATION

• n-FACTOR CORRECTION

• TEMPERATURE ALERT FUNCTION temperatures, on-chip temperatures, and system

• AVERAGING

• 12-BIT RESOLUTION

• DIODE FAULT DETECTION

• SENSES BUS VOLTAGES FROM 0V TO +26V

• REPORTS CURRENT IN AMPS, VOLTAGE IN Remote accuracy is ±1°C for multiple IC

VOLTS AND POWER IN WATTS

• HIGH ACCURACY: 1% MAX OVER TEMP

• WATCHDOG LIMITS:

– Upper Over-Limit

– Lower Under-Limit

APPLICATIONS

• DESKTOP AND NOTEBOOK COMPUTERS

• SERVERS

• INDUSTRIAL CONTROLLERS

• CENTRAL OFFICE TELECOM EQUIPMENT

• LCD/ DLP®/LCOS PROJECTORS

• STORAGE AREA NETWORKS (SAN)

DESCRIPTION

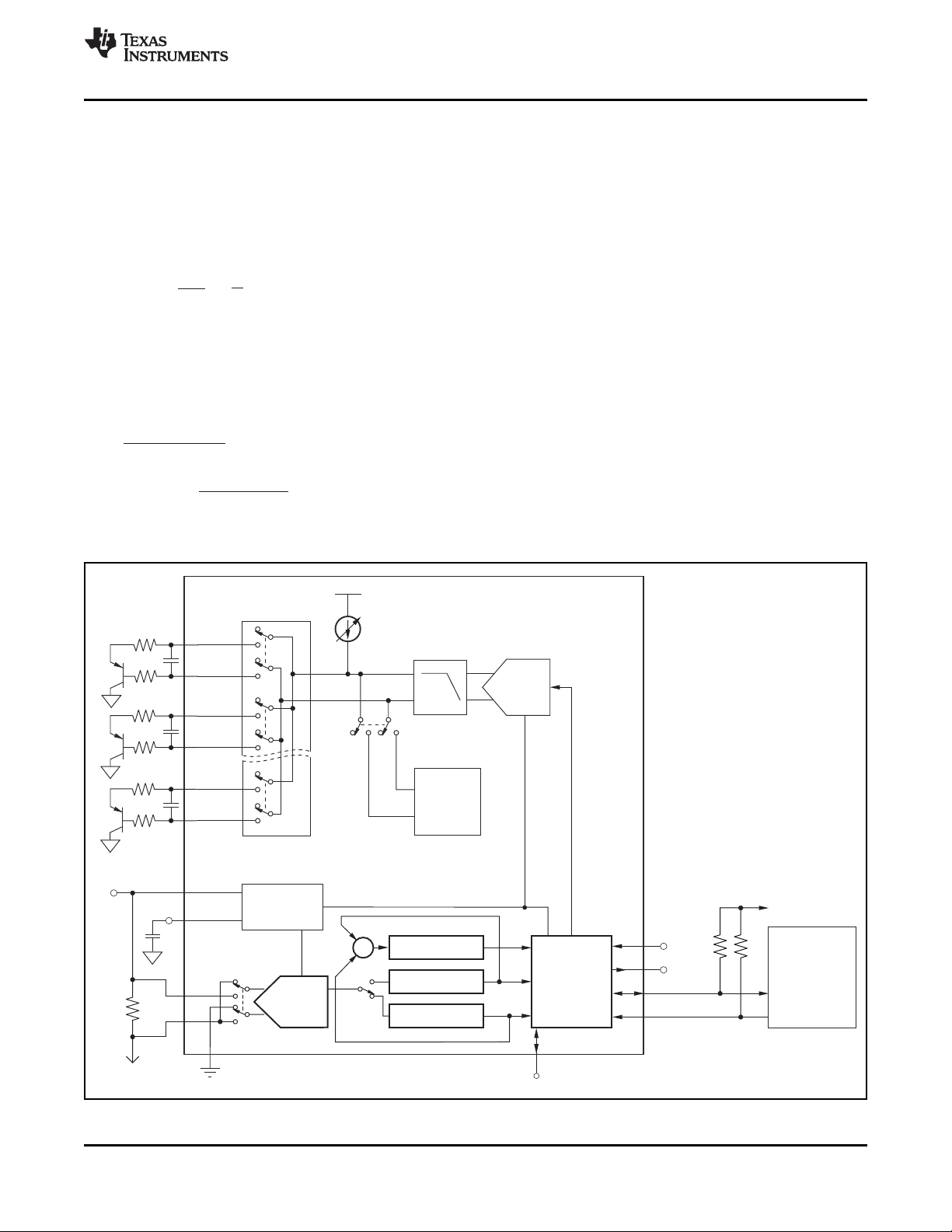

The TMP512 (dual-channel) and TMP513

(triple-channel) are system monitors that include

remote sensors, a local temperature sensor, and a

high-side current shunt monitor. These system

monitors have the capability of measuring remote

voltage/power/current consumption.

The remote temperature sensor diode-connected

transistors are typically low-cost, NPN- or PNP-type

transistors or diodes that are an integral part of

microcontrollers, microprocessors, or FPGAs.

manufacturers, with no calibration needed. The

two-wire serial interface accepts SMBus™ or

two-wire write and read commands.

The onboard current shunt monitor is a high-side

current shunt and power monitor. It monitors both the

shunt drop and supply voltage. A programmable

calibration value (along with the TMP512/TMP513

internal digital multiplier) enables direct readout in

amps; an additional multiplication calculates power in

watts. The TMP512 and TMP513 both feature two

separate onboard watchdog capabilities: an over-limit

comparator and a lower-limit comparator.

These devices use a single +3V to +26V supply,

drawing a maximum of 1.4mA of supply current, and

they are specified for operation from –40°C to

+125°C.

1

2DLP is a registered trademark of Texas Instruments.

3SMBus is a trademark of Intel Corporation.

4All other trademarks are the property of their respective owners.

UNLESS OTHERWISE NOTED this document contains

PRODUCTION DATA information current as of publication date.

Products conform to specifications per the terms of Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2010, Texas Instruments Incorporated

Page 2

TMP512

TMP513

SBOS491 –JUNE 2010

www.ti.com

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

PACKAGE INFORMATION

(1)

PRODUCT PACKAGE-LEAD PACKAGE DESIGNATOR PACKAGE MARKING

TMP512 SO-14 D TMP512A

TMP513

SO-16 D TMP513A

(2)

QFN-16

RSA TMP513A

(1) For the most current package and ordering information see the Package Option Addendum at the end of this document, or visit the

TMP512/TMP513 product folder at www.ti.com.

(2) Product preview device.

ABSOLUTE MAXIMUM RATINGS

(1)

Over operating free-air temperature range (unless otherwise noted).

TMP512, TMP513 UNIT

Supply Voltage, V+ 26 V

Filter C

Analog Inputs, V

IN+

, V

IN–

Open-Drain Digital Outputs GND – 0.3 to +6 V

GPIO, DXP, DXN GND – 0.3 to V+ + 0.3 V

Input Current Into Any Pin 5 mA

Open-Drain Digital Output Current 10 mA

Storage Temperature –65 to +150 °C

Junction Temperature +150 °C

ESD Ratings Charged-Device Model (CDM) 1000 V

(1) Stresses above these ratings may cause permanent damage. Exposure to absolute maximum conditions for extended periods may

degrade device reliability. These are stress ratings only, and functional operation of the device at these or any other conditions beyond

those specified is not implied.

(2) V

IN+

+26V.

and V

may have a differential voltage of –26V to +26V; however, the voltage at these pins must not exceed the range –0.3V to

IN–

Voltage GND – 0.3 to +6 V

Current 10 mA

Differential (V

IN+

) – (V

IN–

(2)

)

–26 to +26 V

Common-Mode –0.3 to +26 V

Human Body Model (HBM) 2000 V

Machine Model (MM) 150 V

2 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TMP512 TMP513

Page 3

TMP512

TMP513

www.ti.com

SBOS491 –JUNE 2010

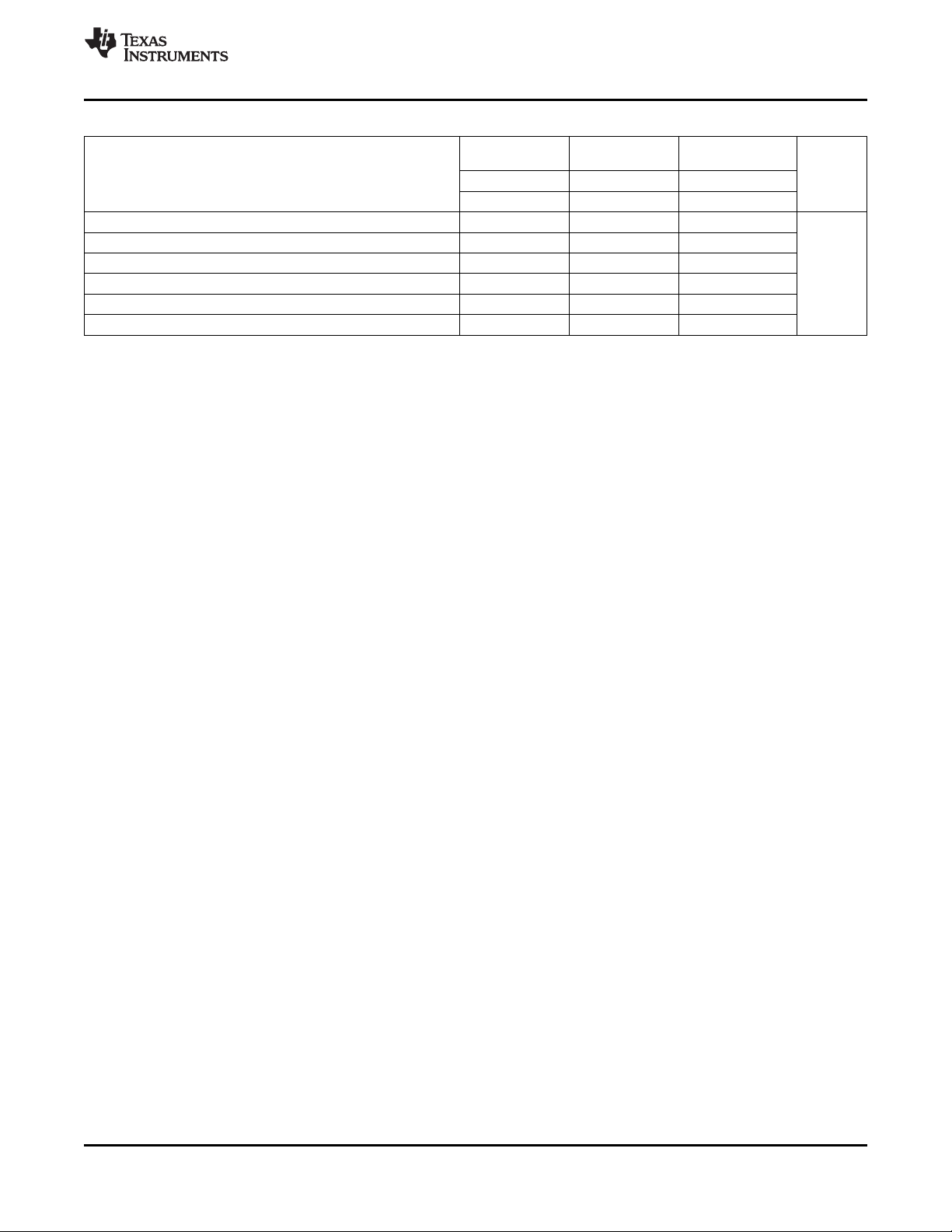

THERMAL INFORMATION

TMP512 TMP513AID

THERMAL METRIC

(1)

D (SOIC) D (SOIC) RSA

14 16 16

q

JA

q

JC(top)

q

JB

y

JT

y

JB

q

JC(bottom)

Junction-to-ambient thermal resistance

Junction-to-case(top) thermal resistance

Junction-to-board thermal resistance

Junction-to-top characterization parameter

Junction-to-board characterization parameter

Junction-to-case(bottom) thermal resistance

(2)

(3)

(4)

(5)

(6)

(7)

91.1 77.6 44.8

10.6 55.0 43.8

40.3 49.9 14.7

49.1 3.5 0.4

47.5 32.2 14.5

n/a n/a 2.6

(1) For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

(2) The junction-to-ambient thermal resistance under natural convection is obtained in a simulation on a JEDEC-standard, high-K board, as

specified in JESD51-7, in an environment described in JESD51-2a.

(3) The junction-to-case (top) thermal resistance is obtained by simulating a cold plate test on the package top. No specific

JEDEC-standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

(4) The junction-to-board thermal resistance is obtained by simulating in an environment with a ring cold plate fixture to control the PCB

temperature, as described in JESD51-8.

(5) The junction-to-top characterization parameter, yJT, estimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining qJA, using a procedure described in JESD51-2a (sections 6 and 7).

(6) The junction-to-board characterization parameter, yJB, estimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining qJA, using a procedure described in JESD51-2a (sections 6 and 7).

(7) The junction-to-case (bottom) thermal resistance is obtained by simulating a cold plate test on the exposed (power) pad. No specific

JEDEC standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

TMP513AIRSAR

TMP513AIRSAT

UNITS

°C/W

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): TMP512 TMP513

Page 4

TMP512

TMP513

SBOS491 –JUNE 2010

www.ti.com

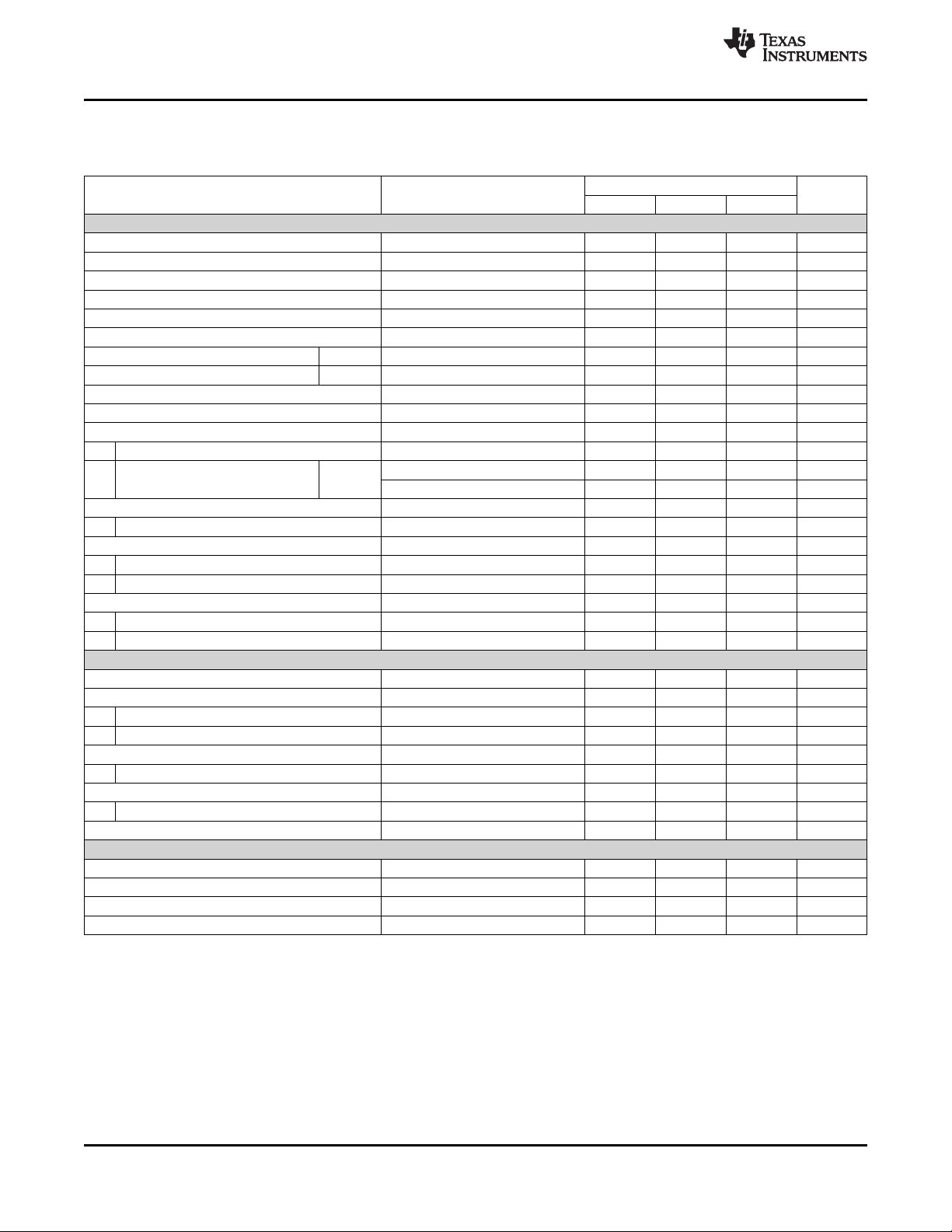

ELECTRICAL CHARACTERISTICS: V+ = +12V

Boldface limits apply over the specified temperature range, TA= –40°C to +125°C.

At TA= +25°C, V+ = 12V, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

INPUT

Current Sense (Input) Voltage Range PGA = ÷ 1 0 ±40 mV

Bus Voltage (Input Voltage) Range

Common-Mode Rejection CMRR V

Offset Voltage, RTI

vs Temperature 0.2 mV/°C

vs Power Supply PSRR

Current Sense Gain Error ±0.04 %

vs Temperature 0.0025 %

Input Impedance Active Mode

V

IN+

V

IN–

Input Leakage Power-Down Mode

V

IN+

V

IN–

DC ACCURACY

ADC Basic Resolution 12 Bits

1 LSB Step Size

Shunt Voltage 10 mV

Bus Voltage 4 mV

Current Measurement Error ±0.2 ±0.5 %

over Temperature ±1 %

Bus Voltage Measurement Error ±0.2 ±0.5 %

over Temperature ±1 %

Differential Nonlinearity ±0.1 LSB

ADC TIMING

ADC Conversion Time 12-Bit 665 733 ms

(1) BRNG is bit 13 of Configuration Register 1.

(2) This parameter only expresses the full-scale range of the ADC scaling. In no event should more than 26V be applied to this device.

(3) Referred-to-input (RTI).

(4) See Subregulator section.

(3)

Pin 20 mA

Pin 20 || 320 mA || kΩ

Pin 0.1 0.5 mA

Pin 0.1 0.5 mA

SENSE

(2)

= (V

IN+

– V

) = 32mV, PGA = ÷ 1, and BRNG

IN–

PGA = ÷ 2 0 ±80 mV

PGA = ÷ 4 0 ±160 mV

PGA = ÷ 8 0 ±320 mV

BRNG = 0 0 16 V

BRNG = 1 0 32 V

= 0V to 26V 100 120 dB

IN+

V

OS

V+ = 3V to 5.5V, Configuration 3

V+ = 4.5V to 26V, subregulator supply 0.1 mV/V

PGA = ÷ 1 ±10 ±100 mV

PGA = ÷ 2 ±20 ±125 mV

PGA = ÷ 4 ±30 ±150 mV

PGA = ÷ 8 ±40 ±200 mV

11-Bit 345 380 ms

10-Bit 185 204 ms

9-Bit 105 117 ms

(1)

= 1, unless otherwise noted.

TMP512, TMP513

(4)

10 mV/V

4 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TMP512 TMP513

Page 5

TMP512

TMP513

www.ti.com

SBOS491 –JUNE 2010

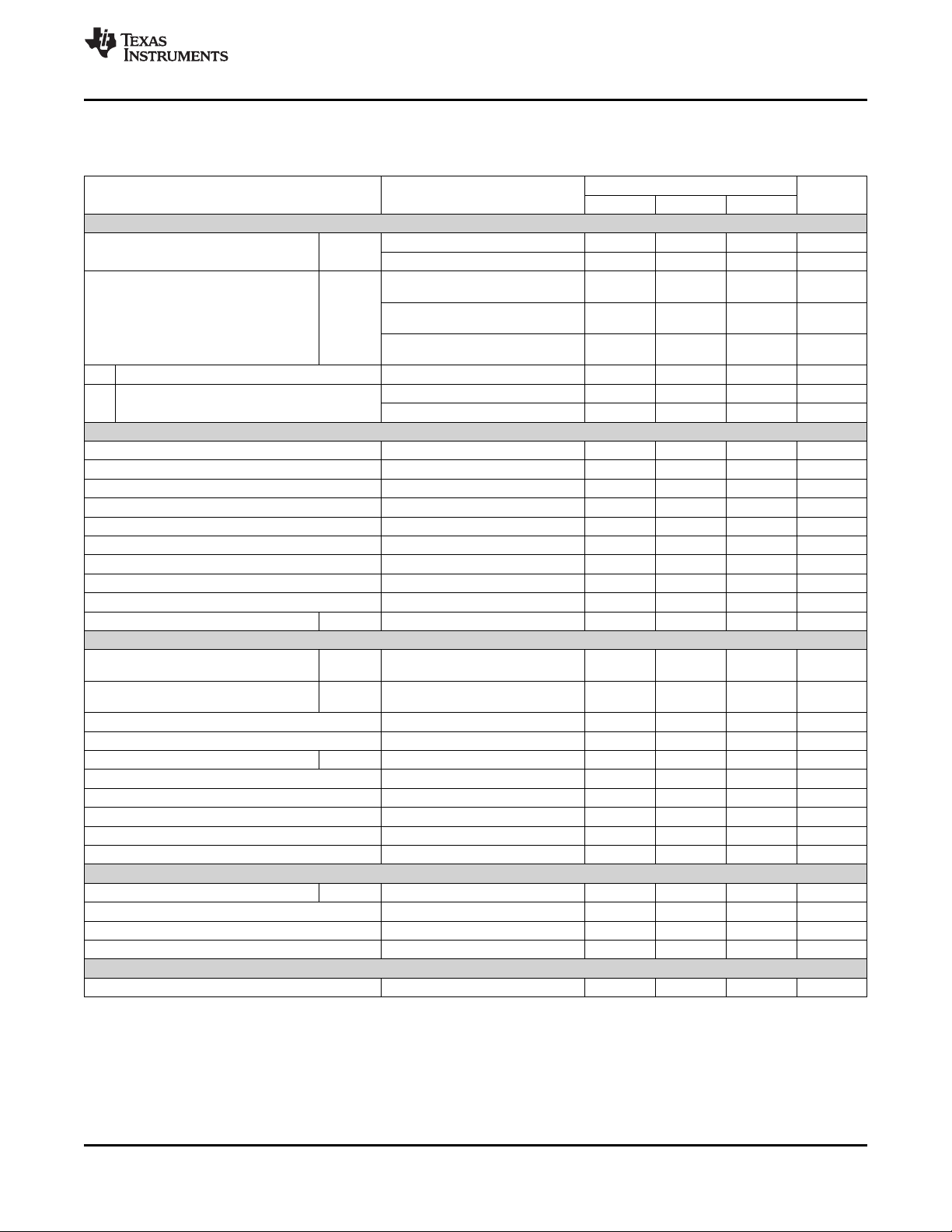

ELECTRICAL CHARACTERISTICS: V+ = +12V (continued)

Boldface limits apply over the specified temperature range, TA= –40°C to +125°C.

At TA= +25°C, V+ = 12V, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

TEMPERATURE ERROR

Local Temperature Sensor TE

Remote Temperature Sensor

vs Supply, Local V+ = 3V to 5.5V, Configuration 3

vs Supply, Remote

TEMPERATURE MEASUREMENT

Conversion Time (per channel) 100 115 130 ms

Resolution

Local Temperature Sensor 13 Bits

Remote Temperature Sensor 13 Bits

Remote Sensor Source Currents Series Resistance 3kΩ max

High 120 mA

Medium High 60 mA

Medium Low 12 mA

Low 6 mA

Default Non-Ideality Factor n TMP512/12 Optimized Ideality Factor 1.008

SMBus

Logic Input High Voltage (SCL, SDA, GPIO,

A0)

Logic Input Low Voltage (SCL, SDA, GPIO,

A0)

Hysteresis 500 mV

SMBus Output Low Sink Current 6 mA

SDA Output Low Voltage V

Logic Input Current 0 ≤ VIN≤ 6V –1 1 mA

SMBus Input Capacitance (SCL, SDA, GPIO, A0) 3 pF

SMBus Clock Frequency 3.4 MHz

SMBus Timeout

SCL Falling Edge to SDA Valid Time 1 ms

POWER SUPPLY

Specified Supply Range

Quiescent Current 1 1.4 mA

Quiescent Current, Power-Down Mode 55 100 mA

Power-On Reset Threshold 2 V

TEMPERATURE RANGE

Specified Temperature Range –40 +125 °C

(7)

(5) Tested with one-shot measurements, and with less than 5Ω effective series resistance, and with 100pF differential input capacitance.

(6) See Subregulator section.

(7) SMBus timeout in the TMP512/13 resets the interface any time SCL or SDA is low for over 28ms.

(5)

(6)

SENSE

= (V

– V

IN+

) = 32mV, PGA = ÷ 1, and BRNG

IN–

LOCAL

TE

REMOTE

V

IH

V

IL

OL

V+ +3 +26 V

TA= –40°C to +125°C ±1.25 ±2.5 °C

TA= +15°C to +85°C, V+ = 12V ±0.25 ±1 °C

TA= +15°C to +85°C, TD= –40°C to+

TA= –40°C to +100°C, TD= –40°C to

TA= –40°C to +125°C, TD= –40°C to

V+ = 4.5V to 26V, subregulator supply 0.01 0.05 °C/V

150°C, V+ = 12V

+150°C, V+ = 12V

+150°C

V+ = 3V to 5.5V, Configuration 3

I

= 6mA 0.15 0.4 V

OUT

(1)

= 1, unless otherwise noted.

TMP512, TMP513

±0.25 ±1 °C

(6)

(6)

2.1 V

25 30 35 ms

±1 ±3 °C

±3 ±5 °C

0.2 0.5 °C/V

0.2 0.5 °C/V

0.8 V

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): TMP512 TMP513

Page 6

1

2

3

4

5

6

7

V

IN-

SDA

SCL

A0

V

IN+

V+

Filter C

DXP2

DXN1

DXP1

GPIO

ALERT

GND

DXN2

14

13

12

11

10

9

8

TMP512

TMP512

TMP513

SBOS491 –JUNE 2010

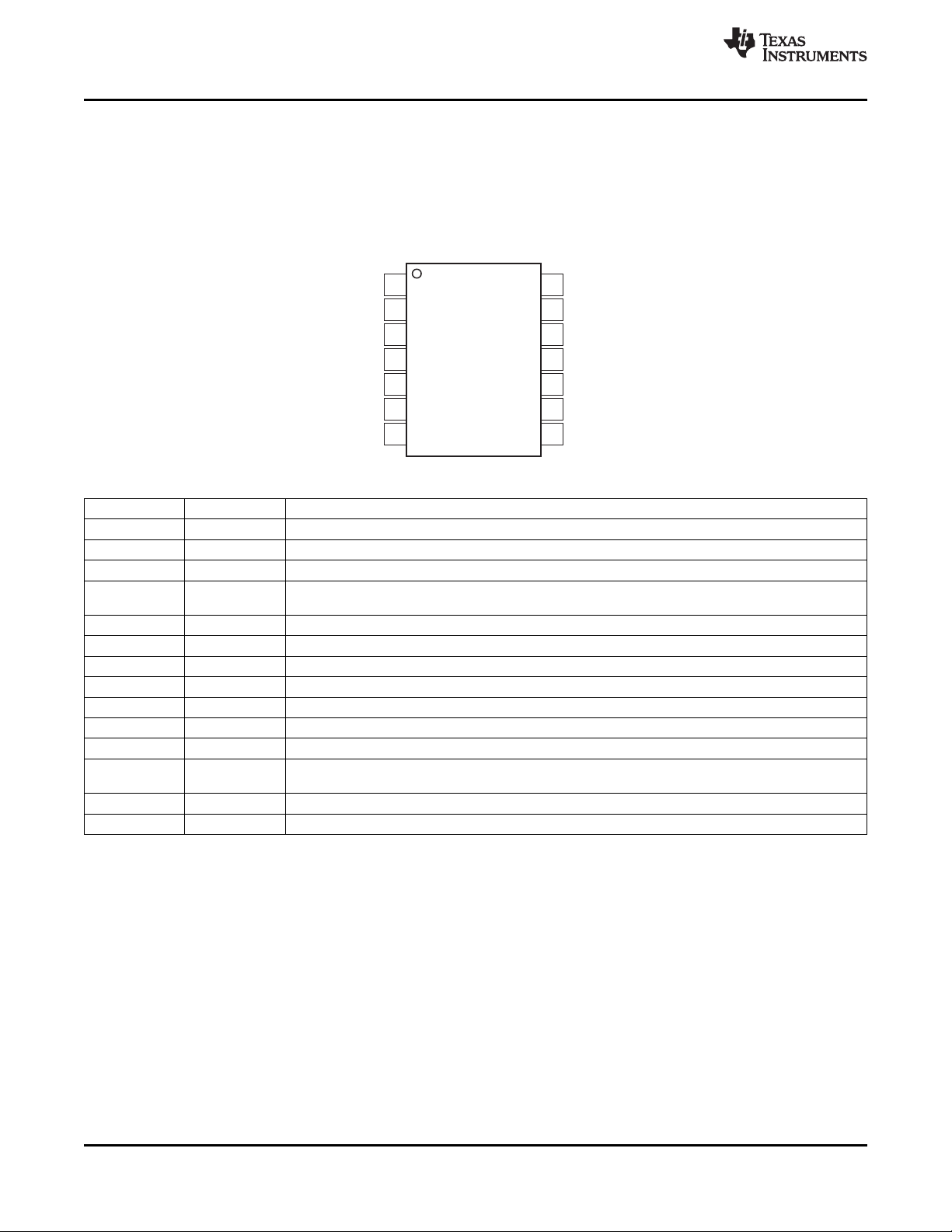

PIN CONFIGURATIONS

TMP512

space

D PACKAGE

SO-14

(TOP VIEW)

TMP512: PIN DESCRIPTIONS

PIN NO. NAME DESCRIPTION

1 Filter C Subregulator output and filter capacitor pin.

2 V+ Positive supply voltage (3V to 26V) See Figure 20.

3 V

4 V

IN+

IN-

5 SDA Serial bus data line for SMBus, open-drain; requires pull-up resistor.

6 SCL Serial bus clock line for SMBus, open-drain; requires pull-up resistor.

7 A0 Address pin

8 DXP1 Channel 1 positive connection to remote temperature sensor.

9 DXN1 Channel 1 negative connection to remote temperature sensor.

10 DXP2 Channel 2 positive connection to remote temperature sensor.

11 DXN2 Channel 2 negative connection to remote temperature sensor.

12 GPIO

13 ALERT Open-drain SMBus alert output. Controlled in SMBus Alert Mask Register. Default state is disabled.

14 GND Ground

Positive differential shunt voltage. Connect to positive side of shunt resistor.

Negative differential shunt voltage. Connect to negative side of shunt resistor. Bus voltage is measured

from this pin to ground.

General-purpose, user-programmable input/output. Totem-pole output. Connect to ground or supply

through a resistor if not used. Default state is as an input.

www.ti.com

6 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TMP512 TMP513

Page 7

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

Filter C

V+

V

IN+

V

IN-

SDA

SCL

A0

DXP1

GND

ALERT

GPIO

DXN3

DXP3

DXN2

DXP2

DXN1

TMP513

V

IN+

V

IN-

SDA

SCL

GPIO

DXN3

DXP3

DXN2

12

11

10

9

FilterC

1

2

3

4

5

6

7

8

13

14

15

16

A0

DXP1

DXN1

DXP2

ALERT

GND

V+

TMP513

TMP512

TMP513

www.ti.com

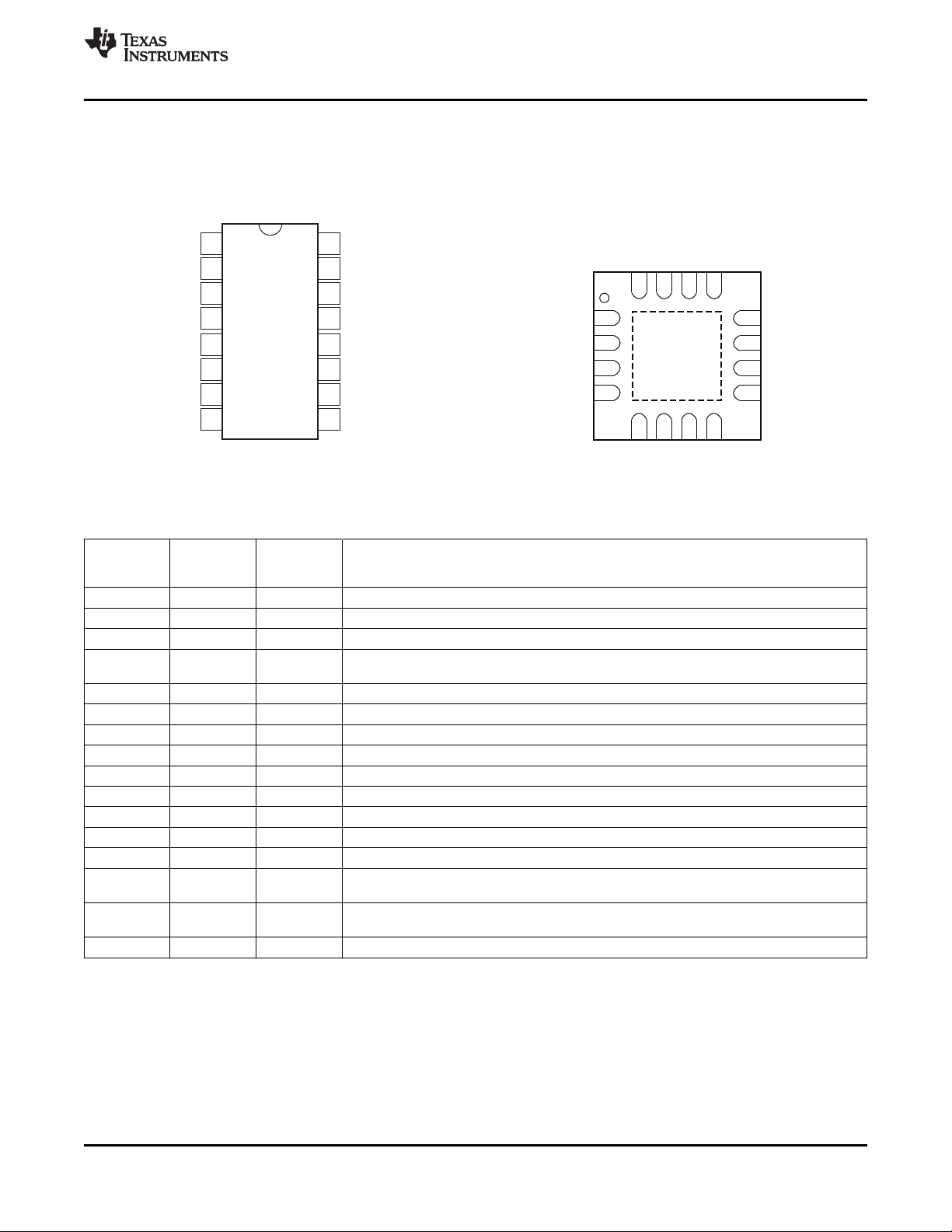

TMP513

space

D PACKAGE

SO-16

(TOP VIEW)

(1) Product preview device.

TMP513: PIN DESCRIPTIONS

D PACKAGE PACKAGE

SO-16 QFN-16 NAME DESCRIPTION

1 15 Filter C Subregulator output and filter capacitor pin.

2 16 V+ Positive supply voltage (3V to 26V) See Figure 20.

3 1 V

4 2 V

5 3 SDA Serial bus data line for SMBus, open-drain; requires pull-up resistor.

6 4 SCL Serial bus clock line for SMBus, open-drain; requires pull-up resistor.

7 5 A0 Address pin

8 6 DXP1 Channel 1 positive connection to remote temperature sensor.

9 7 DXN1 Channel 1 negative connection to remote temperature sensor.

10 8 DXP2 Channel 2 positive connection to remote temperature sensor.

11 9 DXN2 Channel 2 negative connection to remote temperature sensor.

12 10 DXP3 Channel 3 positive connection to remote temperature sensor.

13 11 DXN3 Channel 3 negative connection to remote temperature sensor.

14 12 GPIO

15 13 ALERT

16 14 GND Ground

RSA

IN+

IN-

Positive differential shunt voltage. Connect to positive side of shunt resistor.

Negative differential shunt voltage. Connect to negative side of shunt resistor. Bus voltage is

measured from this pin to ground.

General-purpose, user-programmable input/output. Totem-pole output. Connect to ground or

supply through a resistor if not used. Default state is as an input.

Open-drain SMBus alert output. Controlled in SMBus Alert Mask Register. Default state is

disabled.

RSA PACKAGE

SBOS491 –JUNE 2010

(1)

QFN-16

(TOP VIEW)

Product Folder Link(s): TMP512 TMP513

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 7

Page 8

-40 -25 0 25 50

75

100 125

6

5

4

3

2

1

0

1

2

3

4

5

6

-

-

-

-

-

-

Remote Temperature Error ( C)?

Ambient Temperature ( C)?

34 Units Shown

10

100

1k

10k 100k

1M

Gain(dB)

InputFrequency(Hz)

0

10

20

30

40

50

60

70

80

90

100

-

-

-

-

-

-

-

-

-

-

-40

-25

0

25 50

75 100

Local Temperature Error ( C)°

Ambient Temperature ( C)°

125

14 Units Shown

2.0

1.5

1.0

0.5

0

0.5

1.0

1.5

2.0

-

-

-

-

-40

-25

0

25 50

75 100

Offset( V)m

Temperature( C)°

125

15

10

5

0

5

10

15

-

-

-

40mVRange

80mVRange

160mVRange

320mVRange

-40

-25

0

25 50

75 100

GainError(m%)

Temperature( C)°

125

250

200

150

100

50

0

50

100--

320mVRange

160mVRange

80mVRange

40mVRange

-40

-25

0

25 50

75 100

Offset (mV)

Temperature ( C)°

125

32V Range

16V Range

35

30

25

20

15

10

5

0

5

10

15

-

-

-

TMP512

TMP513

SBOS491 –JUNE 2010

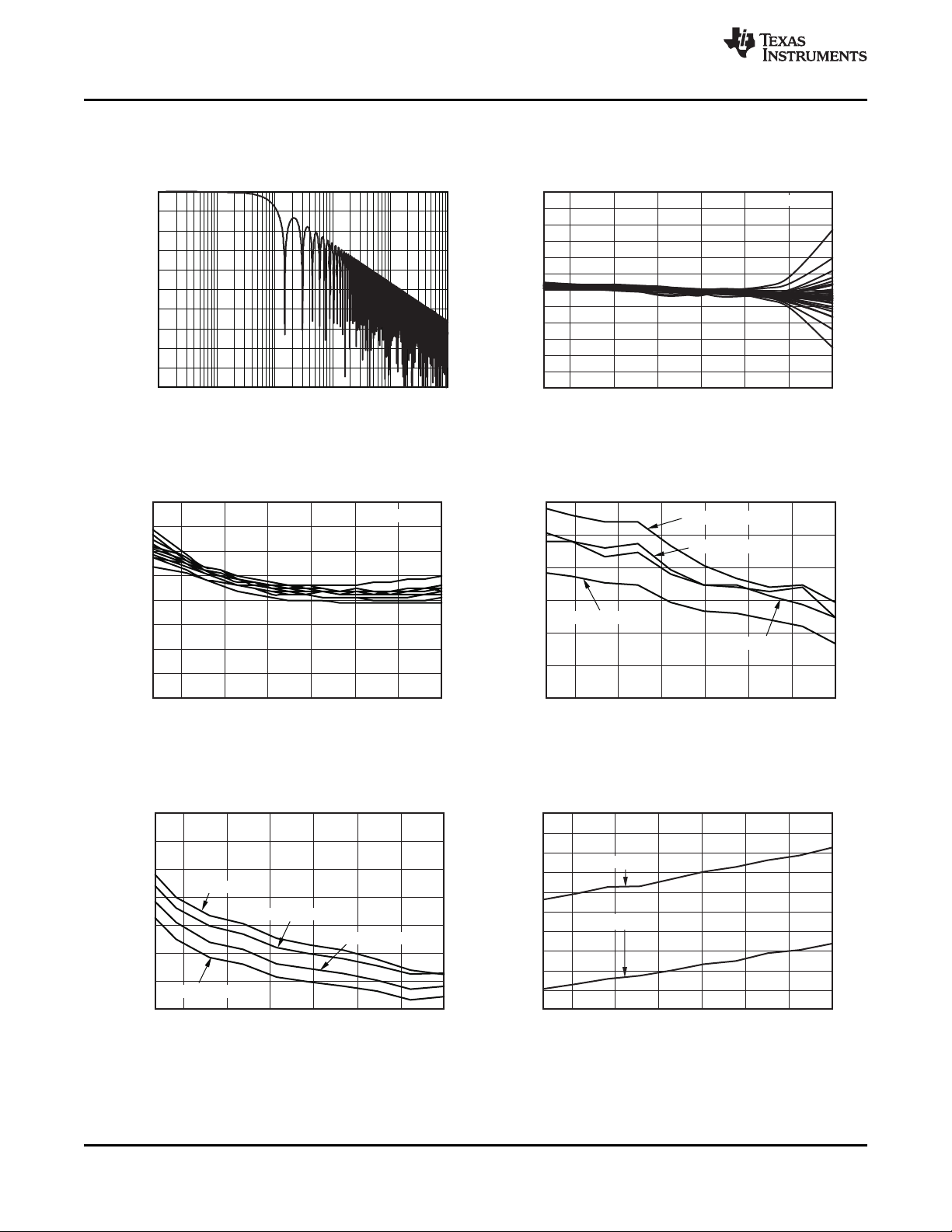

At TA= +25°C, V+ = 12V, V

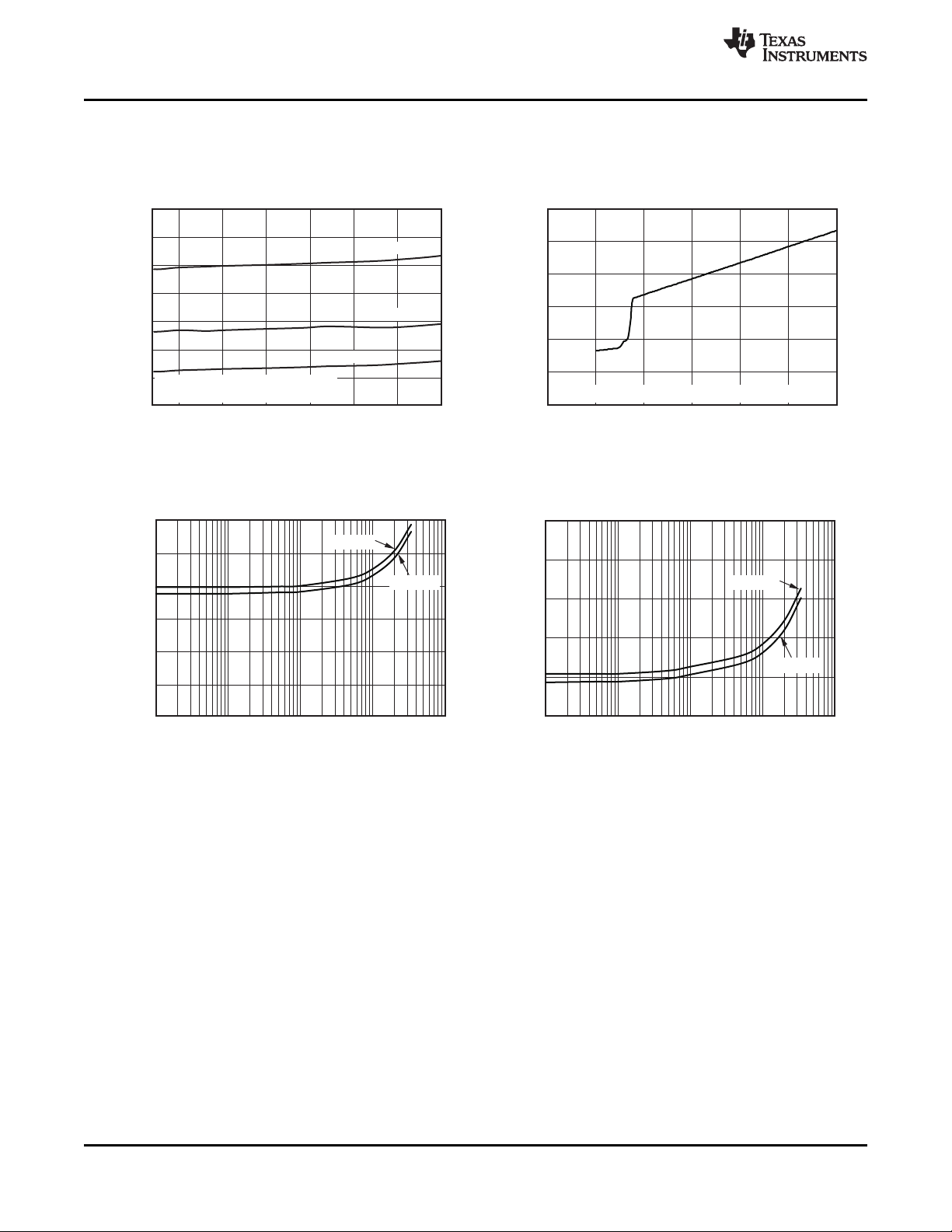

LOCAL TEMPERATURE ERROR vs TEMPERATURE SHUNT OFFSET vs TEMPERATURE

www.ti.com

TYPICAL CHARACTERISTICS: V+ = +12V

= (V

– V

SENSE

IN+

FREQUENCY RESPONSE REMOTE TEMPERATURE ERROR vs TEMPERATURE

Figure 1. Figure 2.

) = 32mV, PGA = ÷ 1, and BRNG = 1, unless otherwise noted.

IN–

8 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Figure 3. Figure 4.

SHUNT GAIN ERROR vs TEMPERATURE BUS VOLTAGE OFFSET vs TEMPERATURE

Figure 5. Figure 6.

Product Folder Link(s): TMP512 TMP513

Page 9

20

15

10

5

0

-5

-10

-15

-20

-0.4

-0.3

-0.2

-0.1 0

0.1 0.2 0.3

INL( V)m

InputVoltage(V)

0.4

-40

-25

0

25 50

75 100

Gain Error (m%)

Temperature ( C)°

125

250

200

150

100

50

0

50

100--

32V Range

16V Range

0

5

10

15 20

25

Input Currents (mA)

V Voltage (V)

IN-

30

2.0

1.5

1.0

0.5

0

0.5

1.0

1.5

-

-

-

V+ = 5.5V

V+ 5.5V=

V+ = 3V

V+ 3V=

Current into V

IN-

Current into V

IN+

-40

-25

0

25 50

75 100

I (mA)

Q

Temperature ( C)°

125

V+ = 5.5V

V+ = 12V

V+ = 3V

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

TMP512

TMP513

www.ti.com

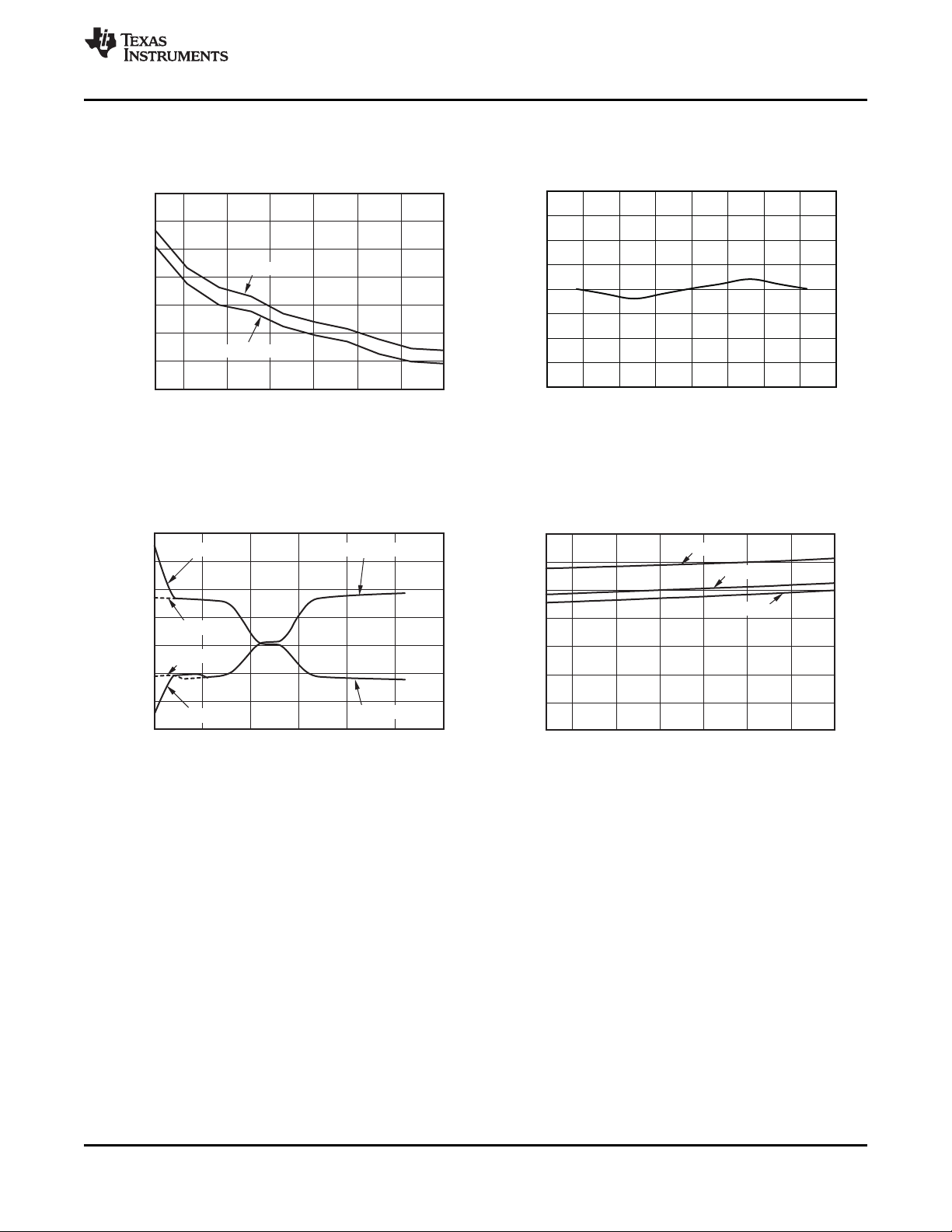

At TA= +25°C, V+ = 12V, V

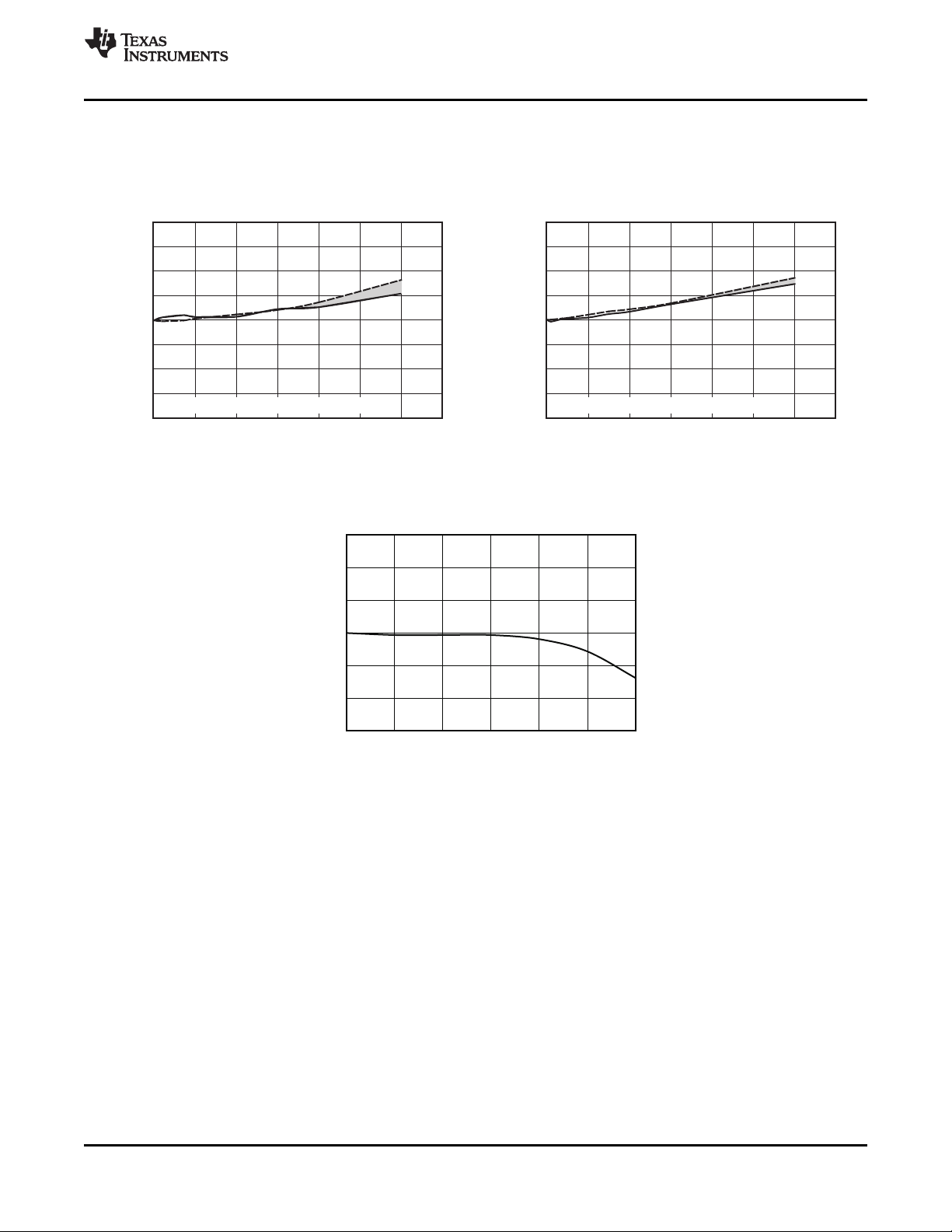

BUS GAIN ERROR vs TEMPERATURE INTEGRAL NONLINEARITY vs INPUT VOLTAGE

INPUT CURRENTS WITH LARGE DIFFERENTIAL

(V

IN+

TYPICAL CHARACTERISTICS: V+ = +12V (continued)

= (V

– V

SENSE

IN+

Figure 7. Figure 8.

VOLTAGES

at 12V, Sweep of V

) = 32mV, PGA = ÷ 1, and BRNG = 1, unless otherwise noted.

IN–

) ACTIVE IQvs TEMPERATURE

IN–

SBOS491 –JUNE 2010

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 9

Figure 9. Figure 10.

Product Folder Link(s): TMP512 TMP513

Page 10

I ( )

Q

mA

V (SV)

4.53.0 3.5 4.0 5.55.02.5

120

100

80

60

40

20

0

Note: Shutdown I vs V is for Subregulator Configuration 3

Q S

-40

-25

0

25

125

I ( A)m

Q

Temperature ( C)°

V+ = 5.5V

V+ = 12V

V+ = 3V

50 75 100

140

120

100

80

60

40

20

0

Note: Shutdown I vs Temperature is

for Subregulator Configurations 1 and 2

Q

1k

10k

100k

1M

10M

I ( A)m

Q

SCL Frequency (Hz)

V+ = 12V

V+ = 3.3V

1100

1050

1000

950

900

850

800

1k

10k

100k

1M

10M

I ( A)m

Q

SCL Frequency (Hz)

250

200

150

100

50

0

V+ = 12V

V+ = 3.3V

TMP512

TMP513

SBOS491 –JUNE 2010

At TA= +25°C, V+ = 12V, V

SHUTDOWN IQvs TEMPERATURE SUPPLY VOLTAGE

ACTIVE IQvs TWO-WIRE CLOCK FREQUENCY SHUTDOWN IQvs TWO-WIRE CLOCK FREQUENCY

TYPICAL CHARACTERISTICS: V+ = +12V (continued)

= (V

– V

SENSE

IN+

Figure 11. Figure 12.

) = 32mV, PGA = ÷ 1, and BRNG = 1, unless otherwise noted.

IN–

SHUTDOWN IQvs

www.ti.com

10 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Figure 13. Figure 14.

Product Folder Link(s): TMP512 TMP513

Page 11

Remote Temperature Error ( )°C

R ( W )

S

2.0

1.5

1.0

0.5

0

-0.5

-1.0

-1.5

-2.0

0 3500500 1000 1500 2000 2500 3000

Note: For all three subregulator configurations.

Remote Temperature Error ( )°C

R ( W )

S

2.0

1.5

1.0

0.5

0

-0.5

-1.0

-1.5

-2.0

0 3500500 1000 1500 2000 2500 3000

Note: For all three subregulator configurations.

3

2

1

0

-1

-2

-3

Capacitance(nF)

0 0.5 1.0 1.5 2.0 2.5 3.0

RemoteTemperatureError( C)°

TMP512

TMP513

www.ti.com

At TA= +25°C, V+ = 12V, V

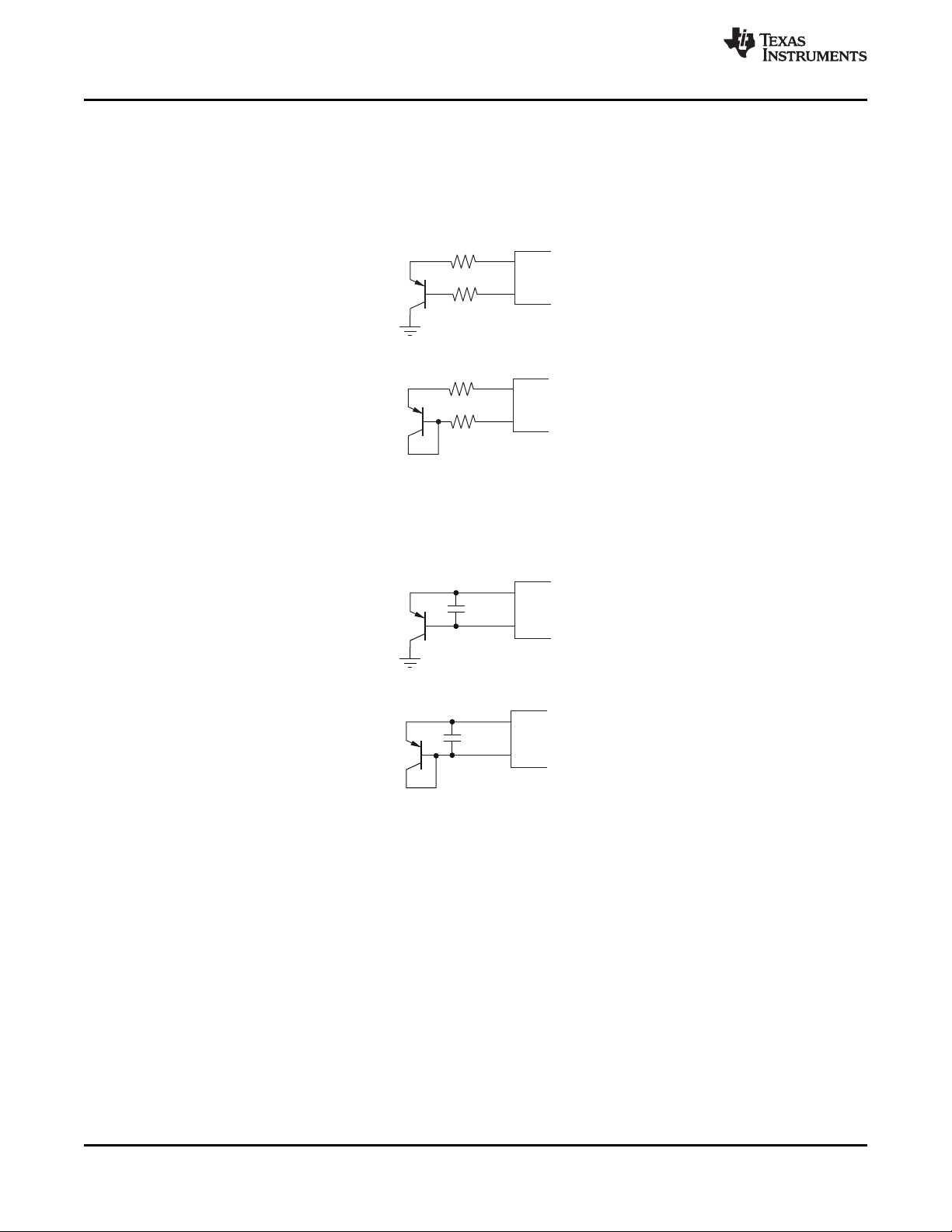

REMOTE TEMPERATURE ERROR vs SERIES REMOTE TEMPERATURE ERROR vs SERIES

(Diode-Connected Transistor, 2N3906 PNP) (GND Collector-Connected Transistor, 2N3906 PNP)

TYPICAL CHARACTERISTICS: V+ = +12V (continued)

= (V

– V

SENSE

IN+

RESISTANCE RESISTANCE

Figure 15. Figure 16.

) = 32mV, PGA = ÷ 1, and BRNG = 1, unless otherwise noted.

IN–

REMOTE TEMPERATURE ERROR

vs DIFFERENTIAL CAPACITANCE

SBOS491 –JUNE 2010

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 11

Figure 17.

Product Folder Link(s): TMP512 TMP513

Page 12

(b) Diode-Connected Transistor

(a) GND Collector-Connected Transistor

DXP

DXN

R

S1

(1)

R

S2

(1)

DXP

DXN

R

S1

(1)

R

S2

(1)

(b) Diode-ConnectedTransistor

(a) GNDCollector-ConnectedTransistor

DXP

DXN

C

DIFF

(1)

DXP

DXN

C

DIFF

(1)

TMP512

TMP513

SBOS491 –JUNE 2010

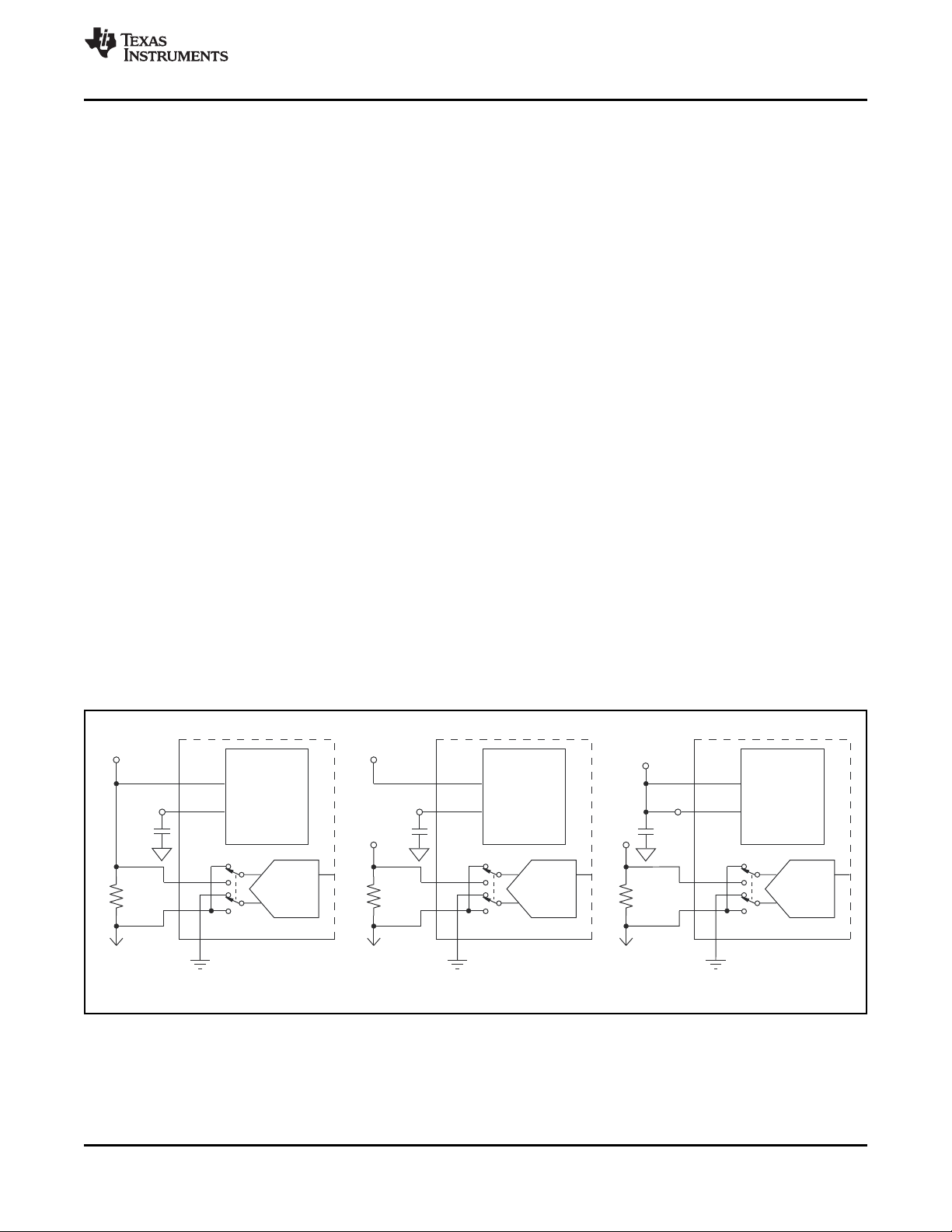

PARAMETRIC MEASUREMENT INFORMATION

TYPICAL CONNECTIONS

SERIES RESISTANCE CONFIGURATION

(1) RS1+ RS2should be less than 1kΩ; see Filtering section.

DIFFERENTIAL CAPACITANCE CONFIGURATION

www.ti.com

Figure 18.

(1) C

12 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

should be less than 2200pF; see Filtering section.

DIFF

Figure 19.

Product Folder Link(s): TMP512 TMP513

Page 13

Configuration 1 Configuration 2 Configuration 3

GND

ADC

Subregulator

3.3V

Subregulator

3.3V

V+ = 4.5V to 26V

Filter C

Load

470nF

Bus Voltage Range = 4.5V to 26V

Shunt

R

SHUNT

V

IN+

V

IN-

GND

ADC

V+ = 4.5V to 26V

Load

Filter C

470nF

Bus Voltage Range = 0V to 26V

Shunt

R

SHUNT

V

IN+

V

IN-

GND

ADC

Subregulator

3.3V

V+ = 3V to 5.5V

Load

Filter C

100nF

Bus Voltage Range = 0V to 26V

Shunt

R

SHUNT

V

IN+

V

IN-

TMP512

TMP513

www.ti.com

SBOS491 –JUNE 2010

APPLICATION INFORMATION

between the two systems is being addressed. Two

DESCRIPTION

The TMP512/13 are digital temperature sensors with

a digital current-shunt monitor that combine a local

die temperature measurement channel and remote

junction temperature measurement channels: two for

the TMP512 and three for the TMP513. The

TMP512/13 contain multiple registers for holding The subregulator can be configured to three different

configuration information, temperature, and voltage modes of operation. Each mode has its advantage

measurement results. These devices provide digital and limitation. Figure 20 shows the three

current, voltage, and power readings necessary for configuration arrangements. The minimum

accurate decision-making in precisely-controlled capacitance on the Filter C pin for Configurations 1

systems. Programmable registers allow flexible and 2 is 470nF. The minimum capacitance on the

configuration for setting warning limits, measurement Filter C pin for Configuration 3 is 100nF.

resolution, and continuous-versus-triggered

operation. Detailed register information appears at

the end of this data sheet, beginning with Table 3.

For proper remote temperature sensing operation, the V+ supply range of 4.5V to 26V connected to the

TMP512 requires transistors connected between shunt voltage, the bus voltage range cannot go to

DXP1 and DXN1 and between DXP2 and DXN2, and zero and is limited to 4.5V to 26V.

for the TMP513, between DXP3 and DXN3 as well.

Unused channels on the TMP512/13 must be

connected to GND.

The TMP512/13 offer compatibility with two-wire and is not limited to 4.5V as in Configuration 1.

SMBus interfaces. The two-wire and SMBus

protocols are essentially compatible with each other.

Two-wire is used throughout this data sheet, with

SMBus being specified only when a difference

bi-directional lines, SCL and SDA, connect the

TMP512/13 to the bus. SDA is an open-drain

connection. See Figure 21 for a typical application

circuit.

SUBREGULATOR

Configuration 1 has V+ and V

supplies the subregulator, which in turn supplies the

3.3V to the Filter C pin and the internal die. With the

Configuration 2 has V+ to the subregulator without

any other connections. Under this configuration, the

bus voltage range can go from 0V to 26V, because it

Configuration 3 has the subregulator V+ and Filter C

pins shorted together. V+ is limited to 3V to 5.5V

because the Filter C pin supplies the internal die; it

cannot exceed this voltage range. The bus voltage

range can go from 0V to 26V, because it is not limited

to 4.5V as in Configuration 1.

tied together. V+

IN+

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 13

Figure 20. Typical Subregulator Configurations

Product Folder Link(s): TMP512 TMP513

Page 14

TMP512

TMP513

SBOS491 –JUNE 2010

www.ti.com

SERIES RESISTANCE CANCELLATION Local Temperature Result Register and the Remote

Series resistance in an application circuit that typically

results from printed circuit board (PCB) trace

resistance and remote line length is automatically

cancelled by the TMP512/13, preventing what would

otherwise result in a temperature offset. A total of up

to 3kΩ of series line resistance is cancelled by the

TMP512/13, eliminating the need for additional

characterization and temperature offset correction.

See the Remote Temperature Error vs Series

Resistance typical characteristic curves (Figure 15 )

for details on the effects of series resistance and

power-supply voltage on sensed remote temperature

error.

Temperature Result Registers. Note that byte 1 is the

most significant byte, followed by byte 2, the least

significant byte. The first 13 bits are used to indicate

temperature. The least significant byte does not have

to be read if that information is not needed. The data

format for temperature is summarized in Table 10.

One LSB equals 0.0625°C. Negative numbers are

represented in binary twos complement format.

Following power-up or reset, the Temperature

Register will read 0°C until the first conversion is

complete. Unused bits in the Temperature Register

always read '0'.

REGISTER INFORMATION

DIFFERENTIAL INPUT CAPACITANCE The TMP512/13 contain multiple registers for holding

The TMP512/13 can tolerate differential input

capacitance of up to 2200pF with minimal change in

temperature error. The effect of capacitance on

sensed remote temperature error is illustrated in

Figure 16, Remote Temperature Error vs Differential

Capacitance. See the Filtering section for suggested

component values where filtering unwanted coupled

signals is needed.

configuration information, temperature and voltage

measurement results, and status information. These

registers are described in Table 3.

POINTER REGISTER

The 8-bit Pointer Register is used to address a given

data register. The Pointer Register identifies which of

the data registers should respond to a read or write

command on the two-wire bus. This register is set

TEMPERATURE MEASUREMENT DATA with every write command. A write command must be

Temperature measurement data may be taken over

an operating range of –40°C to +125°C for both local

and remote locations.

The Temperature Register of the TMP512/13 is

configured as a 13-bit, read-only register that stores

the output of the most recent conversion. Two bytes

must be read to obtain data, and are described in the

issued to set the proper value in the Pointer Register

before executing a read command. Table 3 describes

the pointer address of the TMP512/13 registers. The

power-on reset (POR) value of the Pointer Register is

00h (0000 0000b).

14 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TMP512 TMP513

Page 15

V V =-

BE2 BE1

nkT

q

I

I

2

1

(

(

In

n =

eff

1.008 300

(300 N )-

ADJUST

´

N 300

ADJUST

-=

300 1.008

n

eff

´

(

(

´

Power Register

Current Register

Two-Wire

Interface

Voltage Register

ADC

GND

GPIO

DXP1

DXN1

DXP2

DXN2

ADC

Low-Pass Filter

MUX

DXP3

DXN3

V

IN+

V

IN-

Current

Shunt

Load

Filter C

V+

Subregulator

3.3V

Internal

Diode

Temperature

Sensor

A0

ALERT

SDA

SCL

SMBus

Controller

3.3V Supply

TMP512

TMP513

TMP512

TMP513

www.ti.com

SBOS491 –JUNE 2010

n-FACTOR CORRECTION REGISTER twos-complement format, yielding an effective data

The TMP512/13 allow for a different n-factor value to

be used for converting remote channel

measurements to temperature. The remote channel

uses sequential current excitation to extract a

differential VBEvoltage measurement to determine

the temperature of the remote transistor. Equation 1

describes this voltage and temperature.

(1)

The value n in Equation 1 is a characteristic of the

particular transistor used for the remote channel. The

power-on reset value for the TMP512/13 is n = 1.008.

The value in the n-Factor Correction Register may be

used to adjust the effective n-factor according to

Equation 2 and Equation 3.

(2)

(3)

The n-factor value must be stored in Acknowledge and pulling SDA LOW.

range from –128 to +127. The n-factor value may be

written to and read from pointer address 16h for

remote channel 1, pointer address 17h for remote

channel 2, and pointer address 18h for remote

channel 3. The register power-on reset value is 00h,

thus having no effect unless the register is written to.

BUS OVERVIEW

The device that initiates the transfer is called a

master, and the devices controlled by the master are

slaves. The bus must be controlled by a master

device that generates the serial clock (SCL), controls

the bus access, and generates START and STOP

conditions.

To address a specific device, the master initiates a

START condition by pulling the data signal line (SDA)

from a HIGH to a LOW logic level while SCL is HIGH.

All slaves on the bus shift in the slave address byte

on the rising edge of SCL, with the last bit indicating

whether a read or write operation is intended. During

the ninth clock pulse, the slave being addressed

responds to the master by generating an

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 15

Figure 21. Typical Application Circuit

Product Folder Link(s): TMP512 TMP513

Page 16

TMP512

TMP513

SBOS491 –JUNE 2010

www.ti.com

Data transfer is then initiated and eight bits of data WRITING TO/READING FROM THE

are sent, followed by an Acknowledge bit. During TMP512/13

data transfer, SDA must remain stable while SCL is

HIGH. Any change in SDA while SCL is HIGH is

interpreted as a START or STOP condition.

Accessing a particular register on the TMP512/13 is

accomplished by writing the appropriate value to the

register pointer. Refer to Table 3 for a complete list of

Once all data have been transferred, the master registers and corresponding addresses. The value for

generates a STOP condition, indicated by pulling the register pointer as shown in Figure 24 is the first

SDA from LOW to HIGH while SCL is HIGH. The byte transferred after the slave address byte with the

TMP512/13 includes a 28ms timeout on its interface R/W bit LOW. Every write operation to the

to prevent locking up an SMBus. TMP512/13 requires a value for the register pointer.

SERIAL BUS ADDRESS

To communicate with the TMP512/13, the master

must first address slave devices via a slave address

byte. The slave address byte consists of seven

address bits, and a direction bit indicating the intent

of executing a read or write operation.

The TMP512/13 feature an address pin to allow up to

four devices to be addressed on a single bus. Table 1

describes the pin logic levels used to properly

connect up to four devices. The state of the A0 pin is

sampled on every bus communication and should be

set before any activity on the interface occurs. The

address pin is read at the start of each

communication event.

Writing to a register begins with the first byte

transmitted by the master. This byte is the slave

address, with the R/W bit LOW. The TMP512/13 then

acknowledge receipt of a valid address. The next

byte transmitted by the master is the address of the

register to which data will be written. This register

address value updates the register pointer to the

desired register. The next two bytes are written to the

register addressed by the register pointer. The

TMP512/13 acknowledge receipt of each data byte.

The master may terminate data transfer by

generating a START or STOP condition.

When reading from the TMP512/13, the last value

stored in the register pointer by a write operation

determines which register is read during a read

operation. To change the register pointer for a read

Table 1. TMP512/13 Address Pins and

operation, a new value must be written to the register

Slave Addresses pointer. This write is accomplished by issuing a slave

DEVICE TWO-WIRE

ADDRESS A0 PIN CONNECTION

1011100 Ground

1011101 V+

1011110 SDA

1011111 SCL

address byte with the R/W bit LOW, followed by the

register pointer byte. No additional data are required.

The master then generates a START condition and

sends the slave address byte with the R/W bit HIGH

to initiate the read command. The next byte is

transmitted by the slave and is the most significant

byte of the register indicated by the register pointer.

This byte is followed by an Acknowledge from the

SERIAL INTERFACE

master; then the slave transmits the least significant

byte. The master acknowledges receipt of the data

The TMP512/13 operate only as slave devices on the byte. The master may terminate data transfer by

two-wire bus and SMBus. SCL is an input only, and generating a Not-Acknowledge after receiving any

TMP512/13 cannot drive it. Connections to the bus data byte, or generating a START or STOP condition.

are made via the open-drain I/O lines SDA and SCL. If repeated reads from the same register are desired,

The SDA and SCL pins feature integrated spike it is not necessary to continually send the register

suppression filters and Schmitt triggers to minimize pointer bytes; the TMP512/13 retain the register

the effects of input spikes and bus noise. The pointer value until it is changed by the next write

TMP512/13 support the transmission protocol for fast operation.

(1kHz to 400kHz) and high-speed (1kHz to 3.4MHz)

modes. All data bytes are transmitted MSB first.

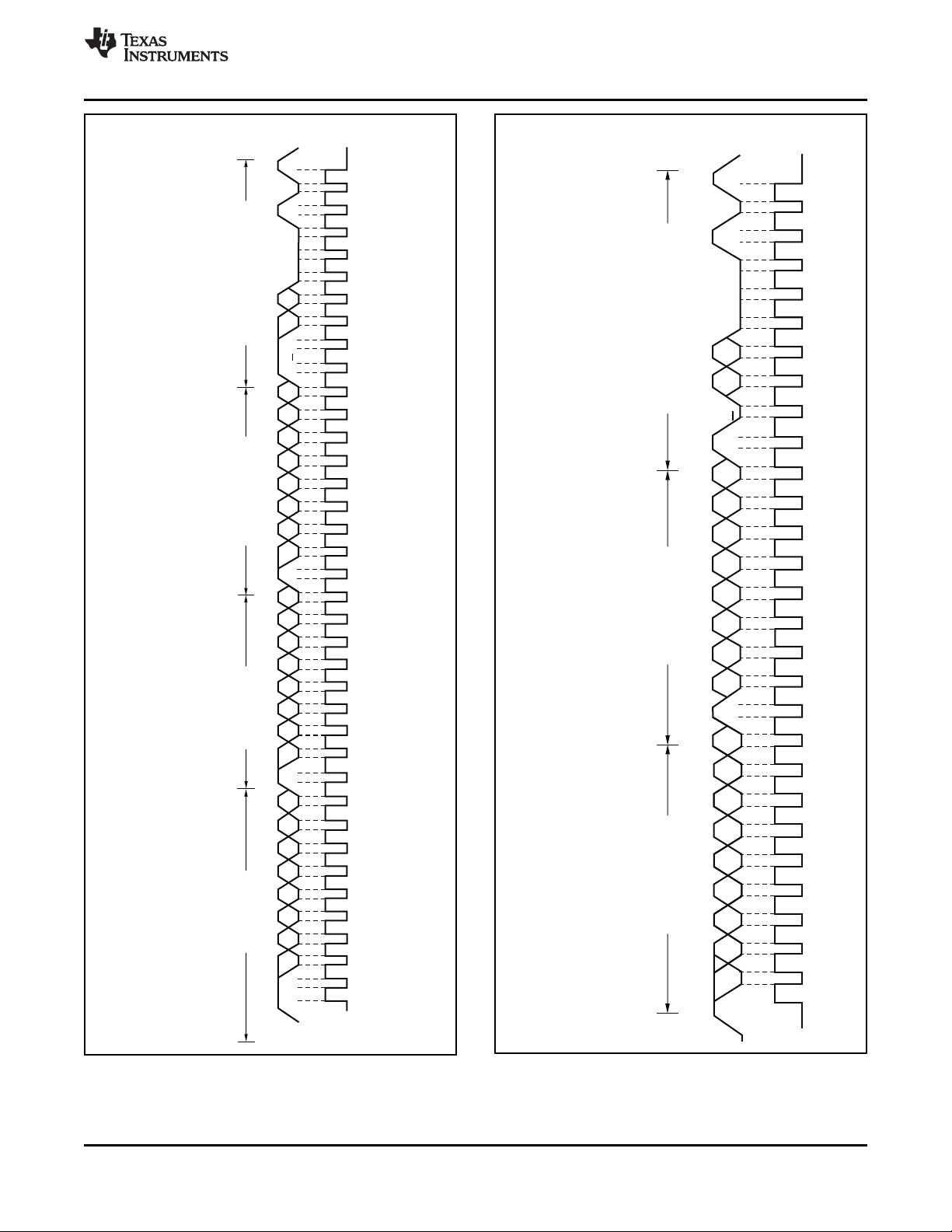

Figure 22 and Figure 23 show read and write

operation timing diagrams, respectively. Note that

register bytes are sent most-significant byte first,

followed by the least significant byte. See Figure 25

for an illustration of a typical register pointer

configuration.

16 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TMP512 TMP513

Page 17

Frame1Two-WireSlaveAddressByte

(1)

Frame2DataMSByte

(2)

1

StartBy

Master

ACKBy

TMP512/TMP513

ACKBy

Master

From

TMP512/TMP513

1 9 1

9

SDA

SCL

0 1 1 R/

W D15 D14 D13 D12 D11 D10 D9 D8

1 A1 A0

Frame3DataLSByte

(2)

StopNoACKBy

(3)

Master

From

TMP512/TMP513

1

9

D7 D6 D5 D4 D3 D2 D1 D0

NOTES:(1)ThevalueoftheSlaveAddressByteisdeterminedbythesettingsoftheA0pin.

RefertoTable1.

(2)Readdataisfromthelastregisterpointerlocation.Ifanewregisterisdesired,theregister

pointermustbeupdated.SeeFigure23.

(3)ACKbyMastercanalsobesent.

Frame1Two-WireSlaveAddressByte

(1)

Frame2RegisterPointerByte

StartBy

Master

ACKBy

TMP512/TMP513

ACKBy

TMP512/TMP513

1 9 1

ACKBy

TMP512/TMP513

1

D15 D14 D13 D12 D11 D10 D9 D8

9

9

SDA

SCL

1 0 1 1 1

A1 A0 R/W P7 P6 P5 P4 P3 P2 P1 P0

NOTE(1):ThevalueoftheSlaveAddressByteisdeterminedbythesettingsoftheA0pin.RefertoTable1.

Frame4DataLSByteFrame3DataMSByte

ACKBy

TMP512/TMP513

StopBy

Master

1

D7 D6 D5 D4 D3 D2 D1 D0

9

TMP512

TMP513

www.ti.com

SBOS491 –JUNE 2010

Figure 22. Timing Diagram for Write Word Format

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Link(s): TMP512 TMP513

Figure 23. Timing Diagram for Read Word Format

Page 18

Frame1SMBusALERTResponseAddressByte Frame2SlaveAddressByte

(1)

StartBy

Master

ACKBy

TMP512/TMP513

From

TMP512/TMP513

NACKBy

Master

StopBy

Master

1 9 1

9

SDA

SCL

ALERT

0 0 0 1 1 0 0 R/

W 1 0 1 1 1 A1 A0

0

NOTE(1):ThevalueoftheSlaveAddressByteisdeterminedbythesettingsoftheA0pin.RefertoTable1.

Frame1Two-WireSlaveAddressByte

(1)

Frame2RegisterPointerByte

1

StartBy

Master

ACKBy

TMP512/TMP513

ACKBy

TMP512/TMP513

1 9 1 9

SDA

SCL

0 1 1 1 A1 A0 R/W P7 P6 P5 P4 P3 P2 P1 P0 Stop

¼

NOTE(1):ThevalueoftheSlaveAddressByteisdeterminedbythesettingsoftheA0pin.RefertoTable1.

TMP512

TMP513

SBOS491 –JUNE 2010

www.ti.com

Figure 24. Timing Diagram for SMBus ALERT

Figure 25. Typical Register Pointer Set

18 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TMP512 TMP513

Page 19

SCL

SDA

t

(LOW)

t

R

t

F

t

(HDSTA)

t

(HDSTA)

t

(HDDAT)

t

(BUF)

t

(SUDAT)

t

(HIGH)

t

(SUSTA)

t

(SUSTO)

P S S P

TMP512

TMP513

www.ti.com

SBOS491 –JUNE 2010

TIMING DIAGRAMS Data Transfer: The number of data bytes transferred

Figure 26 describes the timing operations on the

TMP512/13. Parameters for Figure 26 are defined in

Table 2. Bus definitions are:

Bus Idle: Both SDA and SCL lines remain high.

Start Data Transfer: A change in the state of the

SDA line, from high to low, while the SCL line is high,

defines a START condition. Each data transfer

initiates with a START condition. Denoted as S in

Figure 26.

Stop Data Transfer: A change in the state of the

SDA line from low to high while the SCL line is high

defines a STOP condition. Each data transfer

terminates with a repeated START or STOP

condition. Denoted as P in Figure 26.

between a START and a STOP condition is not

limited and is determined by the master device. The

receiver acknowledges data transfer.

Acknowledge: Each receiving device, when

addressed, is obliged to generate an Acknowledge

bit. A device that acknowledges must pull down the

SDA line during the Acknowledge clock pulse in such

a way that the SDA line is stable low during the high

period of the Acknowledge clock pulse. Setup and

hold times must be taken into account. On a master

receive, data transfer termination can be signaled by

the master generating a Not-Acknowledge on the last

byte that has been transmitted by the slave.

Figure 26. Two-Wire Timing Diagram

Table 2. Timing Characteristics for Figure 26

FAST MODE HIGH-SPEED MODE

PARAMETER MIN MAX MIN MAX UNIT

SCL Operating Frequency f

Bus Free Time Between STOP and START Condition t

Hold time after repeated START condition. After this period, the first clock

is generated.

Repeated START Condition Setup Time t

STOP Condition Setup Time t

Data Hold Time t

Data Setup Time t

SCL Clock LOW Period t

SCL Clock HIGH Period t

Clock/Data Fall Time t

Clock/Data Rise Time t

for SCL ≤ 100kHz t

(SCL)

(BUF)

t

(HDSTA)

(SUSTA)

(SUSTO)

(HDDAT)

(SUDAT)

(LOW)

(HIGH)

(1) For cases with fall time of SCL less than 20ns and/or the rise or fall time of SDA less than 20ns, the hold time should be greater than

20ns.

(2) For cases with a fall time of SCL less than 10ns and/or the rise or fall time of SDA less than 10ns, the hold time should be greater than

10ns.

0.001 0.4 0.001 3.4 MHz

600 160 ns

100 100 ns

100 100 ns

100 100 ns

(1)

0

100 10 ns

1300 160 ns

600 60 ns

F

R

R

300 160 ns

300 160

1000

(2)

0

ns

ns

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Link(s): TMP512 TMP513

Page 20

TMP512

TMP513

SBOS491 –JUNE 2010

www.ti.com

HIGH-SPEED MODE SENSOR FAULT

In order for the two-wire bus to operate at frequencies The TMP512/13 can sense an open circuit.

above 400kHz, the master device must issue a Short-circuit conditions return a value of –256°C. The

High-Speed mode (Hs-mode) master code (0000 detection circuitry consists of a voltage comparator

1xxx) as the first byte after a START condition to that trips when the voltage at DXP exceeds (V+) –

switch the bus to high-speed operation. The 0.6V (typical). The comparator output is continuously

TMP512/13 do not acknowledge this byte, but switch checked during a conversion. If a fault is detected,

the input filters on SDA and SCL and the output filter the OPEN bit (bit 0) in the temperature result register

on SDA to operate in Hs-mode, allowing transfers at is set to '1' and the rest of the register bits should be

up to 3.4MHz. After the Hs-mode master code has ignored.

been issued, the master transmits a START condition

to a two-wire slave address that initiates a data

transfer operation. The bus continues to operate in

Hs-mode until a STOP condition occurs on the bus.

Upon receiving the STOP condition, the TMP512/13

switch the input and output filters back to Fast mode

operation.

POWER-UP CONDITIONS

Power-up conditions apply to a software reset via the

RST bit (bit 15) in the Configuration Register, or the

two-wire bus General Call Reset. At device power up,

all Status bits are masked, and the SMBus Alert

function is disabled. All watchdog outputs default to

active low and transparent (non-latched) modes.

SHUTDOWN MODE

The TMP512/13 shutdown mode of operation allows the user flexibility to shut down the shunt/bus voltage measurement and the temperature measurement functions individually. TEMPERATURE AVERAGING

When not using the remote sensor with the

TMP512/13, the DXP and DXN inputs must be

connected together to prevent meaningless fault

warnings.

UNDERVOLTAGE LOCKOUT

The TMP512/13 sense when the power-supply

voltage has reached a minimum voltage level for the

ADC to function. The detection circuitry consists of a

voltage comparator that enables the ADC after the

power supply (V+) exceeds 2.7V (typical). The

comparator output is continuously checked during a

conversion. The TMP512/13 do not perform a

temperature conversion if the power supply is not

valid. The PVLD bit (see Status Register; Local

Temperature Reset Register; Remote Temperature

Reset 1, 2 and 3 Registers) of the individual

Local/Remote Temperature Result Registers are set

to '1' and the temperature result may be incorrect.

To shut down the shunt/bus voltage measurement The TMP512/13 average the input diode voltages

function immediately, set bits 2 through 0 in that determine the remote temperature by sampling

Configuration Register 1 (00h) to '000' respectively. multiple times throughout a conversion. The

To shut down the shunt/bus voltage measurement temperature result can be extracted from four

after the end of the current conversion, set bits 2 different VBEreadings and is sampled 600 times in

through 0 in Configuration Resister 1 (00h) to '100' 130ms (max). Each VBEvoltage is sampled 150 times

respectively. through integration capacitors that average the

To shut down the temperature measurement function

immediately, set bits 15 through 11 in Configuration

Register 2 (01h) to '00000' respectively. To shut

down the temperature measurement after the end of

the current conversion, set bit 15 in Configuration

Register 2 (01h) to '0'.

ONE-SHOT COMMAND

For the TMP512/13, when the temperature core is in

shutdown and the voltage core is in triggered mode, a

single conversion is started on all enabled channels

by writing a '1' to the OS bit in Configuration Register

1. This write operation starts one conversion; the

TMP512/13 returns to shutdown mode when that

conversion completes. At the end of the conversion,

the Conversion Ready flags (bit 6 and bit 5) in the

Status Register are set to indicate end of conversion.

results throughout the conversion time. A delta-sigma

(ΔΣ) modulator and digital filter integrate the V

voltages and create a sync filter averaging system. In

addition, a low-pass filter is present at the input of the

converter with a cutoff frequency of 65kHz. This

integrating topology offers superior noise immunity.

BE

FILTERING

Remote junction temperature sensors are usually

implemented in a noisy environment. Noise is

frequently generated by fast digital signals and if not

filtered properly will induce errors that can corrupt

temperature measurements. The TMP512/13 have a

built-in 65kHz filter on the inputs of DXP and DXN to

minimize the effects of noise. However, a bypass

capacitor placed differentially across the inputs of the

remote temperature sensor is recommended to make

the application more robust against unwanted

20 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TMP512 TMP513

Page 21

T

ERR

=

1.004 1.008

1.008

-

(

(

´ °273.15+100 C

)

)

T =1.48 C

ERR

°

T

ERR

=

n 1.008

1.008

-

(

(

´ °273.15+T( C)

TMP512

TMP513

www.ti.com

coupled signals. The value of this capacitor should be Where:

between 100pF and 1nF. Some applications attain

better overall accuracy with additional series

resistance; however, this increased accuracy is

application-specific. When series resistance is added,

the total value should not be greater than 3kΩ. If

filtering is needed, suggested component values are

100pF and 50Ω on each input; exact values are

application-specific.

n = ideality factor of remote temperature sensor.

T(°C) = actual temperature.

T

Degree delta is the same for °C and K.

For n = 1.004 and T(°C) = 100°C:

GENERAL CALL RESET

The TMP512/13 support reset via the two-wire

General Call address 00h (0000 0000b). The

TMP512/13 acknowledge the General Call address

and respond to the second byte. If the second byte is

06h (0000 0110b), the TMP512/13 execute a

software reset state to all TMP512/13 registers, and

abort any conversion in progress. The TMP512/13

take no action in response to other values in the

second byte.

REMOTE SENSING

The TMP512/13 are designed to be used with either

discrete transistors or substrate transistors built into

processor chips and ASICs. Either NPN or PNP

transistors can be used, as long as the base-emitter

junction is used as the remote temperature sense.

NPN transistors must be diode-connected. PNP

transistors can either be transistor- or

diode-connected, as Figure 18 and Figure 19 show.

Errors in remote temperature sensor readings are

typically the consequence of the ideality factor and

current excitation used by the TMP512/13 versus the

manufacturer-specified operating current for a given

transistor. Some manufacturers specify a high-level

and low-level current for the temperature-sensing

substrate transistors. The TMP512/13 use 6mA for

I

and 120mA for I

LOW

The ideality factor (n) is a measured characteristic of

a remote temperature sensor diode as compared to

an ideal diode. The TMP512/13 allow for different

n-factor values; see the n-Factor Correction Register

section.

The ideality factor for the TMP512/13 is trimmed to

be 1.008. For transistors that have an ideality factor

that does not match the TMP512/13, Equation 4 can

be used to calculate the temperature error. Note that

for the equation to be used correctly, actual

temperature (°C) must be converted to kelvins (K).

space

HIGH

.

(4)

If a discrete transistor is used as the remote

temperature sensor with the TMP512/13, the best

accuracy can be achieved by selecting the transistor

according to the following criteria:

1. Base-emitter voltage > 0.25V at 6mA, at the

highest sensed temperature.

2. Base-emitter voltage < 0.95V at 120mA, at the

lowest sensed temperature.

3. Base resistance < 100Ω.

4. Tight control of VBEcharacteristics indicated by

small variations in hFE(that is, 50 to 150).

Based on these criteria, two recommended

small-signal transistors are the 2N3904 (NPN) or

2N3906 (PNP).

BASIC ADC FUNCTIONS

The two analog inputs to the TMP512/13, V

V

, connect to a shunt resistor in the bus of interest.

IN–

The TMP512/13 are powered by an internal

subregulator, which has a typical output of 3.3V. The

bus being sensed can vary from 0V to 26V. There are

no special considerations for power-supply

sequencing (for example, a bus voltage can be

present with the supply voltage off, and vice-versa).

The TMP512/13 sense the small drop across the

shunt for shunt voltage, and sense the voltage with

respect to ground from V

Figure 27 for an illustration of this operation.

When the TMP512/13 are in the normal operating

mode (that is, MODE bits of Configuration Register 1

are set to '111'), the devices continuously convert the

shunt voltage up to the number set in the shunt

voltage averaging function (Configuration Register 1,

SADC bits). The devices then convert the bus voltage

up to the number set in the bus voltage averaging

(Configuration Register 1, BADC bits). The Mode

control in Configuration Register 1 also permits

selecting modes to convert only voltage or current,

either continuously or in response to a two-wire

command.

SBOS491 –JUNE 2010

= error in TMP512/13 because n ≠ 1.008.

ERR

for the bus voltage. See

IN–

IN+

(5)

and

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Link(s): TMP512 TMP513

Page 22

´

Power Register

Current Register

Two-Wire

Interface

Voltage Register

ADC

GPIO

GND

DXP1

DXN1

DXP2

DXN2

ADC

Low-Pass Filter

MUX

DXP3

DXN3

V

IN+

V

IN-

Current

Shunt

Load

Filter C

V+

Subregulator

3.3V

Internal

Diode

Temperature

Sensor

A0

ALERT

SDA

SCL

SMBus

Controller

3.3V Supply

TMP512

TMP513

V = V -

SHUNT IN+VIN-

Typically < 50mV

V =

BUS

GND-V

IN-

Range of 0V to 26V

Typical Application: 12V

TMP512

TMP513

SBOS491 –JUNE 2010

www.ti.com

Figure 27. TMP512/13 Configured for Shunt and Bus Voltage Measurement

All current and power calculations are performed in

the background and do not contribute to conversion

time; conversion times shown in the Electrical

Characteristics table can be used to determine the

actual conversion time.

Power-Down mode reduces the quiescent current

and turns off current into the TMP512/13 inputs,

avoiding any supply drain. Full recovery from

Power-Down requires 40ms. ADC Off mode (set by

Configuration Register 1, MODE bits) stops all

conversions.

Although the TMP512/13 can be read at any time,

and the data from the last conversion remain

available, the Conversion Ready bit and the

Conversion Ready Temperature bit (Status Register,

CVR and CRT) are provided to help co-ordinate

one-shot or triggered conversions. The Conversion

Ready bit and the Conversion Ready Temperature bit

are set after all conversions, averaging, and

multiplication operations are complete.

The Conversion Ready bit and the Conversion Ready

Temperature bit clear when reading the Status

Register or triggering a single-shot conversion.

POWER MEASUREMENT

Current and bus voltage are converted at different

points in time, depending on the resolution and

averaging mode settings. For instance, when

configured for 12-bit and 128 sample averaging, up to

81ms in time between sampling these two values is

possible. Again, these calculations are performed in

the background and do not add to the overall

conversion time.

PGA FUNCTION

If larger full-scale shunt voltages are desired, the

TMP512/13 provide a PGA function that increases

the full-scale range up to 2, 4, or 8 times (320mV).

Additionally, the bus voltage measurement has two

full-scale ranges: 16V or 32V.

22 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TMP512 TMP513

Page 23

´

Power Register

Current Register

Two-Wire

Interface

Voltage Register

ADC

GND GPIO

DXP1

DXN1

DXP2

DXN2

ADC

Low-Pass Filter

MUX

DXP3

DXN3

V

IN+

V

IN-

Current

Shunt

Load

Filter C

V+

Subregulator

3.3V

Internal

Diode

Temperature

Sensor

A0

ALERT

SDA

SCL

SMBus

Controller

3.3V Supply

TMP512

TMP513

0.1 F to 1 F

Ceramic Capacitor

m m

10W

10W

TMP512

TMP513

www.ti.com

SBOS491 –JUNE 2010

COMPATIBILITY WITH TI HOT-SWAP This architecture has good inherent noise rejection;

CONTROLLERS however, transients that occur at or very close to the

The TMP512/13 are designed for compatibility with

hot-swap controllers such the TI TPS2490. The

TPS2490 uses a high-side shunt with a limit at 50mV;

the TMP512/13 full-scale range of 40mV enables the

use of the same shunt for current sensing below this

limit. When sensing is required at (or through) the

50mV sense point of the TPS2490, the PGA of the

TMP512/13 can be set to ÷2 to provide an 80mV

full-scale range. Overload conditions are another consideration for the

FILTERING AND INPUT CONSIDERATIONS

Measuring current is often noisy, and such noise can

be difficult to define. The TMP512/13 offer several

options for filtering by choosing resolution and

averaging in Configuration Register 1. These filtering

options can be set independently for either voltage or

current measurement.

The internal ADC is based on a delta-sigma (ΔΣ)

front-end with a 500kHz (±10%) typical sampling rate.

sampling rate harmonics can cause problems.

Because these signals are at 1MHz and higher, they

can be dealt with by incorporating filtering at the input

of the TMP512/13. The high frequency enables the

use of low-value series resistors on the filter for

negligible effects on measurement accuracy.

Figure 28 shows the TMP512/13 with an additional

filter added at the input.

TMP512/13 inputs. The TMP512/13 inputs are

specified to tolerate 26V across the inputs. A large

differential scenario might be a short to ground on the

load side of the shunt. This type of event can result in

full power-supply voltage across the shunt (as long

the power supply or energy storage capacitors

support it). It must be remembered that removing a

short to ground can result in inductive kickbacks that

could exceed the 26V differential and common-mode

rating of the TMP512/13. Inductive kickback voltages

are best dealt with by zener-type transient-absorbing

devices (commonly called transzorbs) combined with

sufficient energy storage capacitance.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 23

Figure 28. TMP512/13 with Input Filtering

Product Folder Link(s): TMP512 TMP513

Page 24

TMP512

TMP513

SBOS491 –JUNE 2010

www.ti.com

In applications that do not have large energy storage not generate an Acknowledge and continues to hold

electrolytics on one or both sides of the shunt, an the ALERT line low until the interrupt is cleared.

input overstress condition may result from an Successful completion of the read alert response

excessive dV/dt of the voltage applied to the input. A protocol clears the SMBus ALERT pin, provided that

hard physical short is the most likely cause of this the condition causing the alert no longer exists. The

event, particularly in applications with no large SMBus Alert flag is cleared separately by either

electrolytics present. This problem occurs because an reading the Status Register or by disabling the

excessive dV/dt can activate the ESD protection in SMBus Alert function.

the TMP512/13 in systems where large currents are

available. Testing has demonstrated that the addition

of 10Ω resistors in series with each input of the

TMP512/13 sufficiently protects the inputs against

dV/dt failure up to the 26V rating of the TMP512/13.

These resistors have no significant effect on

accuracy.

SMBus ALERT RESPONSE

The SMBus alert response functions only when the

Alert pin is active and in latch mode (03h, bit 0 = 1);

see Figure 24. The ALERT interrupt output signal is

latched and can be cleared only by either reading the

Status Register or by successfully responding to an

alert response address. If the fault is still present, the

ALERT pin re-asserts. Asserting the ALERT pin does

not halt automatic conversions that are already in

progress. The ALERT output pin is open-drain,

allowing multiple devices to share a common interrupt

line.

The TMP512/13 respond to the SMBus alert

response address, an interrupt pointer return-address

feature. The SMBus alert response interrupt pointer

provides quick fault identification for simple slave

devices. When an ALERT occurs, the master can

broadcast the alert response slave address (0001

100). Following this alert response, any slave devices

that generated interrupts identify themselves by

putting the respective addresses on the bus.

The alert response can activate several different

The Status Register flags indicate which (if any) of

the watchdogs have been activated. After power-on

reset (POR), the normal state of all flag bits is '0',

assuming that no alarm conditions exist.

EXTERNAL CIRCUITRY FOR ADDITIONAL

V

INPUT

BUS

The TMP512/13 GPIO can be used to control an

external circuit to switch the V

alternate location. Switching is most often done to

perform bus voltage measurements on the opposite

side of a MOSFET switch in series with the shunt

resistor.

Consideration must be given to the typical 20mA input

current of each TMP512/13 input, along with the

320kΩ impedance present at the V

bus voltage is measured. These effects can create

errors through the resistance of any external

switching method used. The easiest way to avoid

these errors is by reducing this resistance to a

minimum; select switching MOSFETs with the lowest

possible R

DS(on)

values.

The circuit shown in Figure 29 uses MOSFET pairs to

reduce package count. Back-to-back MOSFETs must

be used in each leg because of the built-in back

diodes from source-to-drain. In this circuit, the normal

connection for V

is at the shunt, with the optional

IN–

voltage measurement at the output of the control

FET.

measurement to an

BUS

input where the

IN–

slave devices simultaneously, similar to the two-wire

General Call. If more than one slave attempts to

respond, bus arbitration rules apply; the device with

the lower address code wins. The losing device does

24 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TMP512 TMP513

Page 25

´

Power Register

Current Register

Two-Wire

Interface

Voltage Register

ADC

GND

DXP1

DXN1

DXP2

DXN2

ADC

Low-Pass Filter

MUX

DXP3

DXN3

V

IN+

V

IN-

Load

Filter C

V+

Subregulator

3.3V

Internal

Diode

Temperature

Sensor

A0

ALERT

SDA

SCL

SMBus

Controller

3.3V Supply

TMP512

TMP513

Shunt

R

SHUNT

10kW

10kW

From

Hot-Swap

Controller

Control

FET

GPIO

N-Channel MOSFETs

Dual pairs such as Vishay SI1034

N-Channel MOSFETs

Dual pairs such as Vishay SI1034

P-Channel MOSFETs

Dual pairs such as

Vishay SI3991DV

TMP512

TMP513

www.ti.com

SBOS491 –JUNE 2010

Figure 29. External Circuitry for Additional V

BUS

Input

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Link(s): TMP512 TMP513

Page 26

MaxPossible_I=

V

R

SHUNT_MAX

SHUNT

MaxPossible_I=0.64

Minimum_LSB=

Max_Expected_I

32767

Minimum_LSB=18.311 10´

-6

Maximum_LSB =

Max_Expected_I

4095

Maximum_LSB = 146.520 10´

-6

Cal=trunc

0.04096

Current_LSB R´

SHUNT

Cal=4096

TMP512

TMP513

SBOS491 –JUNE 2010

www.ti.com

PROGRAMMING THE TMP512/13 POWER MEASUREMENT ENGINE

Calibration Register and Scaling

The Calibration Register makes it possible to set the scaling of the Current and Power Registers to whatever

values are most useful for a given application. One strategy may be to set the Calibration Register such that the

largest possible number is generated in the Current Register or Power Register at the expected full-scale point;

this approach yields the highest resolution. The Calibration Register can also be selected to provide values in the

Current and Power Registers that either provide direct decimal equivalents of the values being measured, or

yield a round LSB number. After these choices have been made, the Calibration Register also offers possibilities

for end user system-level calibration, where the value is adjusted slightly to cancel total system error.

This section presents two examples for configuring the TMP512/13 calibration. Both examples are written so the

information relates directly to the calibration setup found in the TMP512/13EVM software.

Calibration Example 1: Calibrating the TMP512/13 with no possibility for overflow.

NOTE

The numbers used in this example are the same used with the TMP512/13EVM software

as shown in Figure 30.

1. Establish the following parameters:

V

BUS_MAX

V

SHUNT_MAX

R

SHUNT

2. Use Equation 6 to determine the maximum possible current .

= 32

= 0.32

= 0.5

(6)

3. Choose the desired maximum current value. This value is selected based on system expectations.

Max_Expected_I = 0.6

4. Calculate the possible range of current LSBs. To calculate this range, first compute a range of LSBs that is

appropriate for the design. Next, select an LSB within this range. Note that the results will have the most

resolution when the minimum LSB is selected. Typically, an LSB is selected to be the nearest round number

to the minimum LSB value.

(7)

(8)

Choose an LSB in the range: Minimum_LSB < Selected_LSB < Maximum_LSB

Current_LSB = 20 × 10

–6

Note:

This value was selected to be a round number near the Minimum_LSB. This selection allows for

good resolution with a rounded LSB.

5. Compute the Calibration Register value using Equation 9:

26 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

(9)

Product Folder Link(s): TMP512 TMP513

Page 27

Power_LSB=20Current_LSB

Power_LSB=400 10´

-6

Max_Current=Current_LSB 32767´

Max_Current=0.65534

Max_ShuntVoltage=Max_Current_Before_Overflow R´

SHUNT

Max_ShuntVoltage=0.32

MaximumPower=Max_Current_Before_Overflow V´

BUS_MAX

MaximumPower=20.48

Corrected_Full_Scale_Cal=trunc

Cal MeasShuntCurrent

TMP513_Current

´

Corrected_Full_Scale_Cal=3548

TMP512

TMP513

www.ti.com

SBOS491 –JUNE 2010

6. Calculate the Power LSB with Equation 10. Equation 10 shows a general formula; because the bus voltage

measurement LSB is always 4mV, the power formula reduces to the calculated result.

(10)

7. Compute the maximum current and shunt voltage values (before overflow), as shown by Equation 11 and

Equation 12. Note that both Equation 11 and Equation 12 involve an If - then condition:

(11)

If Max_Current ≥ MaxPossible_I then

Max_Current_Before_Overflow = MaxPossible_I

Else

Max_Current_Before_Overflow = Max_Current

End If

(Note that Max_Current is greater than MaxPossible_I in this example.)

Max_Current_Before_Overflow = 0.64

(12)

If Max_ShuntVoltage ≥ V

Max_ShuntVoltage_Before_Overflow = V

SHUNT_MAX

SHUNT_MAX

Else

Max_ShuntVoltage_Before_Overflow= Max_ShuntVoltage

End If

(Note that Max_ShuntVoltage is greater than V

SHUNT_MAX

in this example.)

Max_ShuntVoltage_Before_Overflow = 0.32

8. Compute the maximum power with Equation 13.

9. (Optional second Calibration step.) Compute corrected full-scale calibration value based on measured

current.

TMP513_Current = 0.63484

MeaShuntCurrent = 0.55

Figure 30 illustrates how to perform the same procedure discussed in this example using the automated

TMP512/13EVM software. Note that the same numbers used in this nine-step example are used in the software

example. Note also that Figure 30 illustrates which results correspond to which step (for example, the information

entered in Step 1 is enclosed in a box in Figure 30 and labeled).

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Link(s): TMP512 TMP513

(13)

(14)

Page 28

TMP512

TMP513

SBOS491 –JUNE 2010

www.ti.com

Figure 30. TMP512/513EVM Calibration Software Automatically Computes Calibration Steps 1-9

28 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TMP512 TMP513

Page 29

MaxPossible_I=

V

R

SHUNT_MAX

SHUNT

MaxPossible_I=0.064

Minimum_LSB=

Max_Expected_I

32767

Minimum_LSB=1.831 10´

-6

Maximum_LSB =

Max_Expected_I

4095

Maximum_LSB = 14.652 10´

-6

Cal=trunc

0.04096

Current_LSB R´

SHUNT

Cal=4311

Power_LSB=20Current_LSB

Power_LSB=38 10´

-6

TMP512

TMP513

www.ti.com

SBOS491 –JUNE 2010

Calibration Example 2 (Overflow Possible)

This design example uses the nine-step procedure for calibrating the TMP512/13 where overflow is possible.

Figure 31 illustrates how the same procedure is performed using the automated TMP512/13EVN software. The

same numbers used in the nine-step example are used in the software example shown in Figure 31. Note also

that Figure 31 illustrates which results correspond to which step (for example, the information entered in Step 1

is circled in Figure 31 and labeled).

1. Establish the following parameters:

V

BUS_MAX

V

SHUNT_MAX

R

SHUNT

2. Determine the maximum possible current using Equation 15:

3. Choose the desired maximum current value: Max_Expected_I, ≤ MaxPossible_I. This value is selected

based on system expectations.

Max_Expected_I = 0.06

4. Calculate the possible range of current LSBs. This calculation is done by first computing a range of LSB's

that is appropriate for the design. Next, select an LSB withing this range. Note that the results will have the

most resolution when the minimum LSB is selected. Typically, an LSB is selected to be the nearest round

number to the minimum LSB.

= 32

= 0.32

= 5

(15)

(16)

(17)

Choose an LSB in the range: Minimum_LSB < Selected_LSB < Maximum_LSB

Current_LSB = 1.9 × 10

–6

Note:

This value was selected to be a round number near the Minimum_LSB. This section allows for good

resolution with a rounded LSB.

5. Compute the calibration register using Equation 18:

(18)

6. Calculate the Power LSB using Equation 19. Equation 19 shows a general formula; because the bus voltage

measurement LSB is always 4mV, the power formula reduces to calculate the result.

(19)

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 29

Product Folder Link(s): TMP512 TMP513

Page 30

Max_Current=Current_LSB 32767´

Max_Current=0.06226

Max_ShuntVoltage=Max_Current_Before_Overflow R´

SHUNT

Max_ShuntVoltage=0.3113

MaximumPower=Max_Current_Before_Overflow V´

BUS_MAX

MaximumPower=1.992

Corrected_Full_Scale_Cal=trunc

Cal MeasShuntCurrent

TMP513_Current

´

Corrected_Full_Scale_Cal=3462

TMP512

TMP513

SBOS491 –JUNE 2010

www.ti.com

7. Compute the maximum current and shunt voltage values (before overflow), as shown by Equation 20 and

Equation 21. Note that both Equation 20 and Equation 21 involve an If - then condition.

(20)

If Max_Current ≥ MaxPossible_I then

Max_Current_Before_Overflow = MaxPossible_I

Else

Max_Current_Before_Overflow = Max_Current

End If

(Note that Max_Current is less than MaxPossible_I in this example.)

Max_Current_Before_Overflow = 0.06226

(21)

If Max_ShuntVoltage ≥ V

Max_ShuntVoltage_Before_Overflow = V

SHUNT_MAX

SHUNT_MAX

Else

Max_ShuntVoltage_Before_Overflow= Max_ShuntVoltage

End If