Page 1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments

查询TMP141供应商

TMP141

SBAS347 − MARCH 2005

Digital Out Temperature Sensor with

Single-Wire SensorPath Bus

FEATURES

D SensorPath INTERFACE

D FOUR ADDRESSES

D RESOLUTION: +0.25°C (10-bit)

D WIDE TEMPERATURE RANGE:

−40°C to +125°C

D LOW QUIESCENT CURRENT: 110µA (typ)

D TEMPERATURE ACCURACY: ±2°C (max)

D EXTENDED SUPPLY RANGE: +2.7V to +5.5V

D MICRO-SIZE PACKAGES:

SOT23-6 or MSOP-8

APPLICATIONS

D MOTHERBOARDS

D VIDEO CARDS

D BASE STATIONS

D ROUTERS

Temperature

DESCRIPTION

The TMP141 is a digital output temperature sensor that

utilizes the single-wire SensorPath interface. The TMP141

is capable of measuring temperatures within 2°C of

accuracy over a temperature range of −25°C to +85°C and

3°C of accuracy over −40°C to +125°C. Low supply

current, and a supply range from 2.7V to 5.5V, make the

TMP141 an excellent candidate for a wide range of

low-power applications. The TMP141 is available in

SOT23-6 and MSOP-8 packages.

The TMP141 provides a simple, low-cost way to do

temperature measurement/monitoring and is ideal as a

part of an overall hardware health monitoring system. Up

to four TMP141s can be attached to a SensorPath bus. A

master configures the TMP141s and reads the

temperature output from all devices. No external sensing

components are needed for the TMP141 to measure and

report temperature.

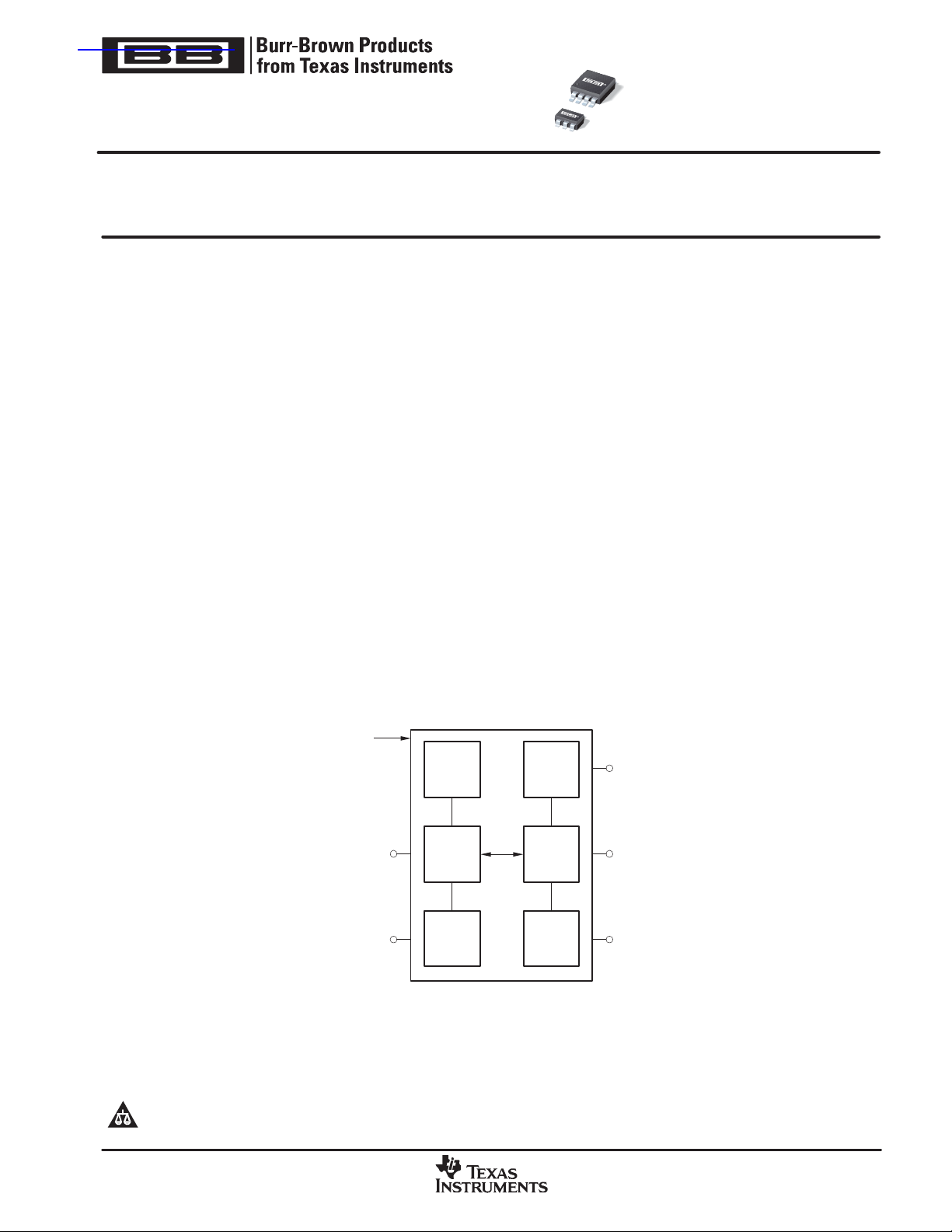

Diode

Temp.

Sensor

V+

GND

semiconductor products and disclaimers thereto appears at the end of this data sheet.

SensorPath is a trademark of National Semiconductor. All other trademarks are the property of their respective owners.

! !

∆Σ

A/D

Converter

OSC

TMP141

www.ti.com

Control

Logic

Serial

Interface

Config.

and Temp.

Register

ADD0

ADD1

SWD

Copyright 2005, Texas Instruments Incorporated

Page 2

"#$#

TMP141

SOT23-6

DBV

−40°C to +125°C

T141

TMP141

MSOP-8

DGK

−40°C to +125°C

T14G

SBAS347 − MARCH 2005

www.ti.com

ABSOLUTE MAXIMUM RATINGS

(1)

Supply Voltage +7V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Input Terminals, Voltage

Signal Input Terminals, Current

(2)

(V−) −0.5V to (V+) + 0.5V. . . .

(2)

10mA. . . . . . . . . . . . . . . . . . . . .

Maximum Output Current (SWD low) 10mA. . . . . . . . . . . . . . . . . . .

Operating Temperature −55°C to +127°C. . . . . . . . . . . . . . . . . . . . .

Storage Temperature −60°C to +150°C. . . . . . . . . . . . . . . . . . . . . . .

proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to

complete device failure. Precision integrated circuits may be more

susceptible t o damage because very small parametric changes could

cause the device not to meet its published specifications.

This integrated circuit can be damaged by ESD. Texas

Instruments recommends that all integrated circuits be

handled with appropriate precautions. Failure to observe

Junction Temperature +150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead Temperature (infrared 15s, vapor 60s) +300°C. . . . . . . . . . . .

ESD Rating:

Human Body Model (HBM) 4000V. . . . . . . . . . . . . . . . . . . . . . .

Charged-Device Model 1000V. . . . . . . . . . . . . . . . . . . . . . . . . .

(1)

Stresses above these ratings may cause permanent damage.

Exposure to absolute maximum conditions for extended periods

may degrade device reliability. These are stress ratings only , an d

functional operation of the device at these or any other conditions

beyond those specified is not supported.

(2)

Input terminals should not be driven beyond the power-supply

rails. Input signals that can swing more than 0.5V beyond the

supply rails should be current-limited to 10mA or less.

ORDERING INFORMATION

PRODUCT PACKAGE-LEAD

(1)

PACKAGE

DESIGNATOR

SPECIFIED

TEMPERATURE

RANGE

PACKAGE

MARKING

ORDERING

NUMBER

TRANSPORT

MEDIA, QUANTITY

TMP141AIDBVT Tape and Reel, 250

TMP141AIDBVR Tape and Reel, 3000

TMP141AIDGKT Tape and Reel, 250

TMP141AIDGKR Tape and Reel, 3000

(1)

For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI web site

at www .ti.com.

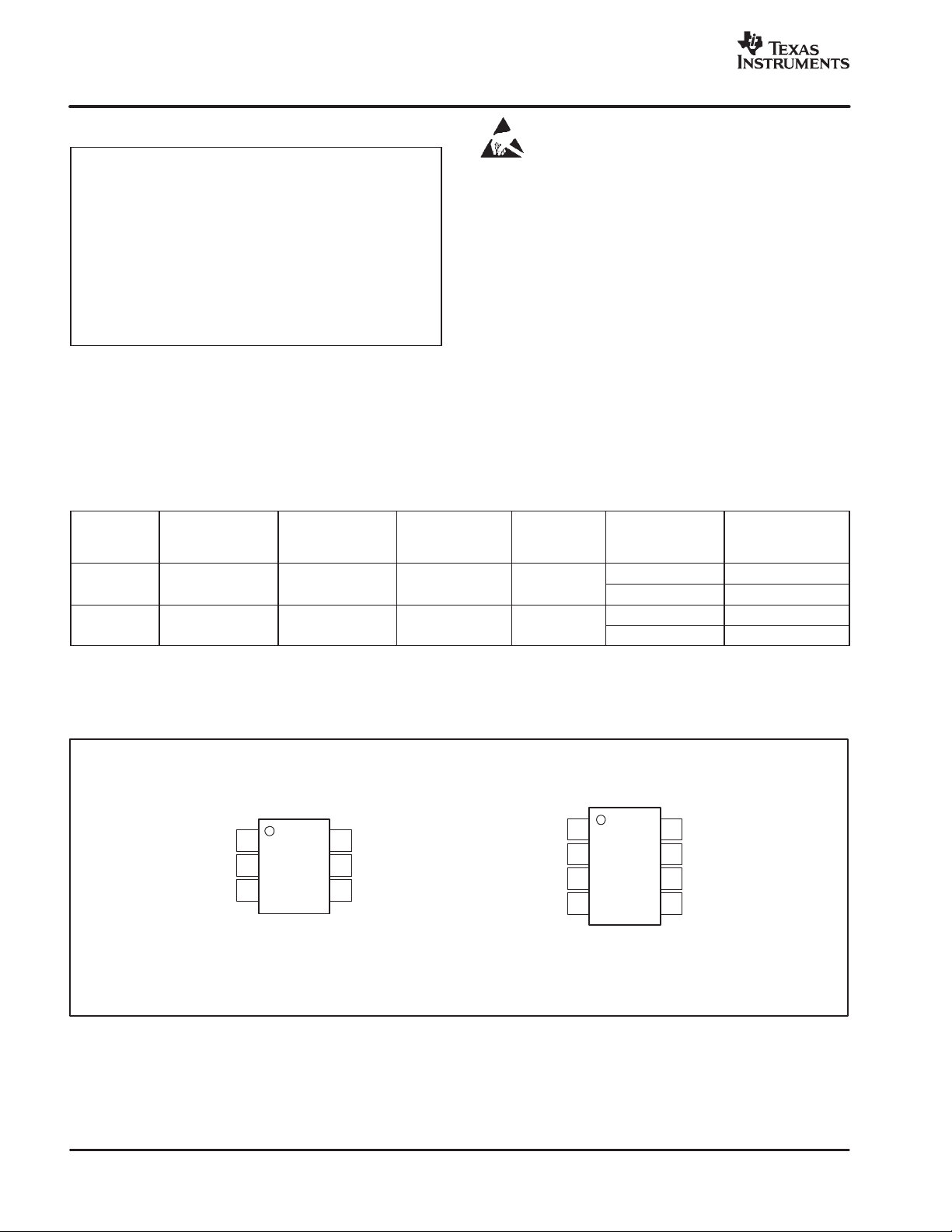

PIN CONFIGURATIONS

Top View

1

ADD0

2

GND

(1)

3

NC

NOTE: Pin 1 is determined by orienting the package marking as indicated in the diagram.

(1) NC = no connection. NC pins must be tied to ground.

2

T141

SOT23−6

1

6

ADD1

5

SWD

4

V+

NC

NC

NC

V+

(1)

(1)

(1)

T14G

2

3

4

MSOP−8

8

SWD

7

ADD1

6

ADD0

5

GND

Page 3

"#$#

www.ti.com

SBAS347 − MARCH 2005

ELECTRICAL CHARACTERISTICS

At TA = −40°C to +125°C and VS = +3.0V to +3.6V , unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNIT

TEMPERATURE INPUT

Range −40 +125 °C

Error T

ERROR

T = −25°C to +85°C ±0.2 ±2 °C

T = −40°C to +125°C ±3 °C

vs Supply ±0.2 ±0.5 °C/V

Resolution 10 Bits

Default Conversion Time t

CONV

See Table 4 for conversion time settings. 162 190 218 ms

DIGIT AL INPUT/OUTPUT PINS (SWD and ADD pins)

Input/Output Capacitance C

IN/OUT

SWD PIN

Input Leakage Current I

Input Logic Level Voltage (High) V

L

I

L

IH

GND < VIN < 5.5V and VS = GND/OPEN 0.005 µA

VS = 2.7V to 5.5V 0.6 × V

Input Logic Level Voltage (Low) V

IL

VS = 2.7V to 5.5V −0.5 0.25 × V

Input Hysteresis V

Output Logic Level Voltage (Low) V

Output OFF Current I

HYST

OL

OH

ADD0 and ADD1 PINS

Input Leakage Current I

Input Logic Level Voltage (High) V

Input Logic Level Voltage (Low) V

L

IH

IL

SensorPath CHARACTERISTICS

SWD Fall Time t

SWD Rise Time t

Min. Inactive Time Between SWD Signals t

Master or TMP141 Reset Drive Time t

TMP141 Detects Bus Activity t

f

r

INACT

RST

SFEdet

R

PULL-UP

R

PULL-UP

= 1.25kΩ ± 30%, CL = 400pF 300 ns

= 1.25kΩ ± 30%, CL = 400pF 1000 ns

Bus at High Level 11 µs

Master Drive Time

Data Bit 0 Write, Data Bit 0 Read t

Data Bit 1 Write t

Start Bit t

Mtr0

Mtr1

MtrS

TMP141 Drive Time

Data Bit 0−1 Read t

Attention Request t

Reset t

SLout1

SLoutA

RST_MA X

After VS is Above 2.6V 95 500 ms

POWER SUPPLY

Specified Voltage Range 3.0 3.6 V

Operating Voltage Range 2.7 5.5 V

Quiescent Current I

Q

While Converting

Power-On Reset Voltage 1.5 2.6 V

TEMPERATURE RANGE

Specified Range −40 +125 °C

Operating Range −55 +127 °C

Storage Range −60 +150 °C

Thermal Resistance q

JA

MSOP-8 150 °C/W

SOT23-6 200 °C/W

(1)

SensorPath activity only has a slight effect on quiescent current.

TMP141

0.25 °C

3 pF

GND < VIN < V

S

0.005 10 µA

2.1 VS + 0.5 V

S

VS + 0.5 V

−0.5 0.8 V

300 mV

S

IOL = 4mA 0.4 V

IOL = 50µA 0.2 V

0.005 10 µA

GND < VIN < V

S

0.9 × V

−0.5 0.1 × V

0.005 10 µA

S

VS + 0.5 V

S

354 µs

9.6 µs

11.8 17 µs

35.4 48.9 µs

80 109 µs

28.3 38.3 µs

165 228 µs

Standby 80 120 µA

(1)

110 170 µA

V

V

3

Page 4

"#$#

SBAS347 − MARCH 2005

TYPICAL CHARACTERISTICS

At TA = −40°C to +125°C and VS = +3.0V to +3.6V , unless otherwise noted.

200

180

160

140

A)

µ

120

(

Q

I

100

80

60

40

QUIESCENT CURRENT vsTEMPERATURE

5.5V

3.3V

2.7V

−55−35−

155 25456585105125

Temperature (_C)

200

180

160

140

A)

µ

(

120

STBY

I

100

80

60

40

2.7V

−55−35−

www.ti.com

I

vs TEMPERATURE

STBY

5.5V

3.3V

155 25456585105125

Temperature (_C)

1.0

0.8

0.6

0.4

C)

_

0.2

Error (

0

−

0.2

−

0.4

−

0.6

TYPICAL PERFORMANCE FOR THREE UNITS

−55−35−

155 25456585105125

Temperature (_C)

120

110

100

A)

µ

90

(

Q

I

80

220

210

200

190

180

170

Conversion Time −Default Setting (ms)

160

QUIESCENT CURRENT vs CONVERSION TIME

Peak Current

Average Current

TYPICAL CONVERSION TIME vs TEMPERATURE

−55−35−

3.3V

155 25456585105125

Temperature (_C)

2.7V

5.5V

70

60

0 200 400 600 800 1000 1200 1400 1600

Conversion Time (ms)

4

Page 5

www.ti.com

"#$#

SBAS347 − MARCH 2005

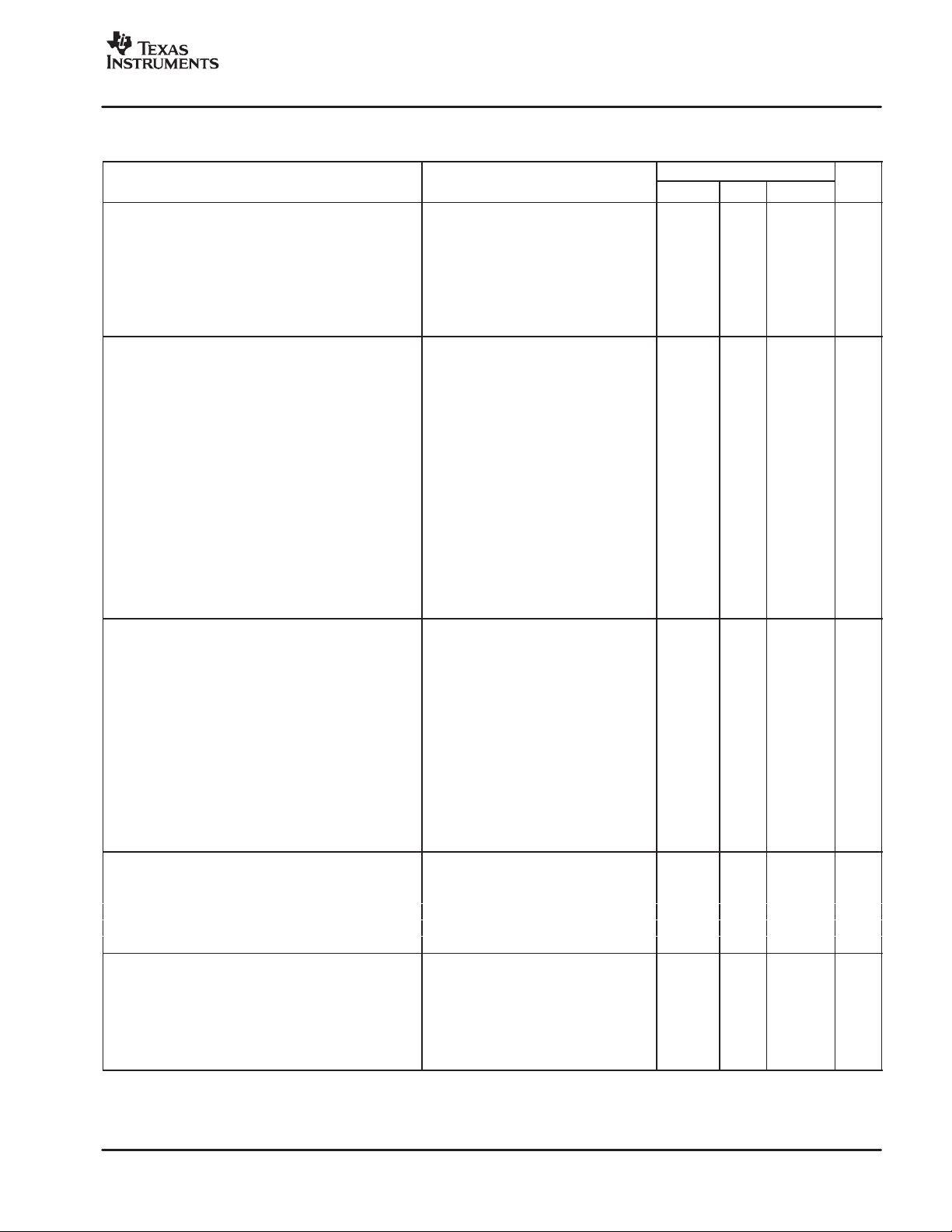

0µs50

t

INACT

t

INACT

t

Mtr0

µ

s 100µs

DetectStart

t

MtrS

Master Write Start

Master Write 0

t

INACT

t

Mtr1

SlvDetectData1

Master Write 1

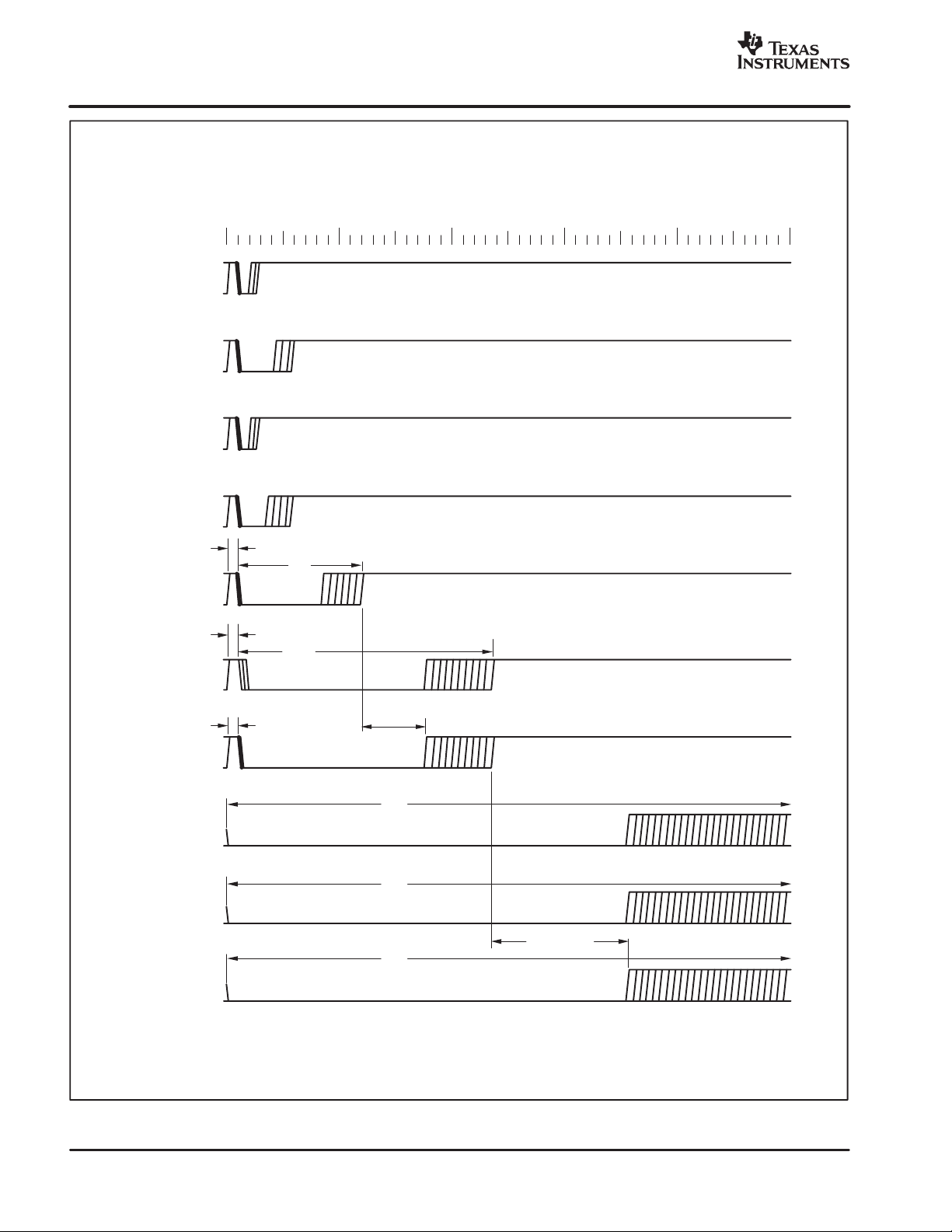

1a: Master Write timing and slave detection of the data placed on the SWD bus by the master .

t

INACT

t

Mtr0

Masterstartsa bit

SlvDetect_st

(1)

Slave detects bus activity and

doesnothing,leaving the bit a 0.

t

SFEdet

Master Read 0

1b: To place a ‘0’ on the bus, the slave does not drive the bus.

t

INACT

t

Mtr0

Master starts a bit

SlvDetect_st

(1)

Slave pulls Bus low to send back a 1

t

SFEdet

MstDetect_1

Master Read 1

1c: To place a ‘1’ on the bus, the slave holds the bus low after detecting that the master has started a data bit.

NOTE: (1) Margin from t

SFEdet

to t

Mtr0

is 2.2µs.

Figure 1. TMP141 Read and Write Signal Timing

5

Page 6

"#$#

SBAS347 − MARCH 2005

www.ti.com

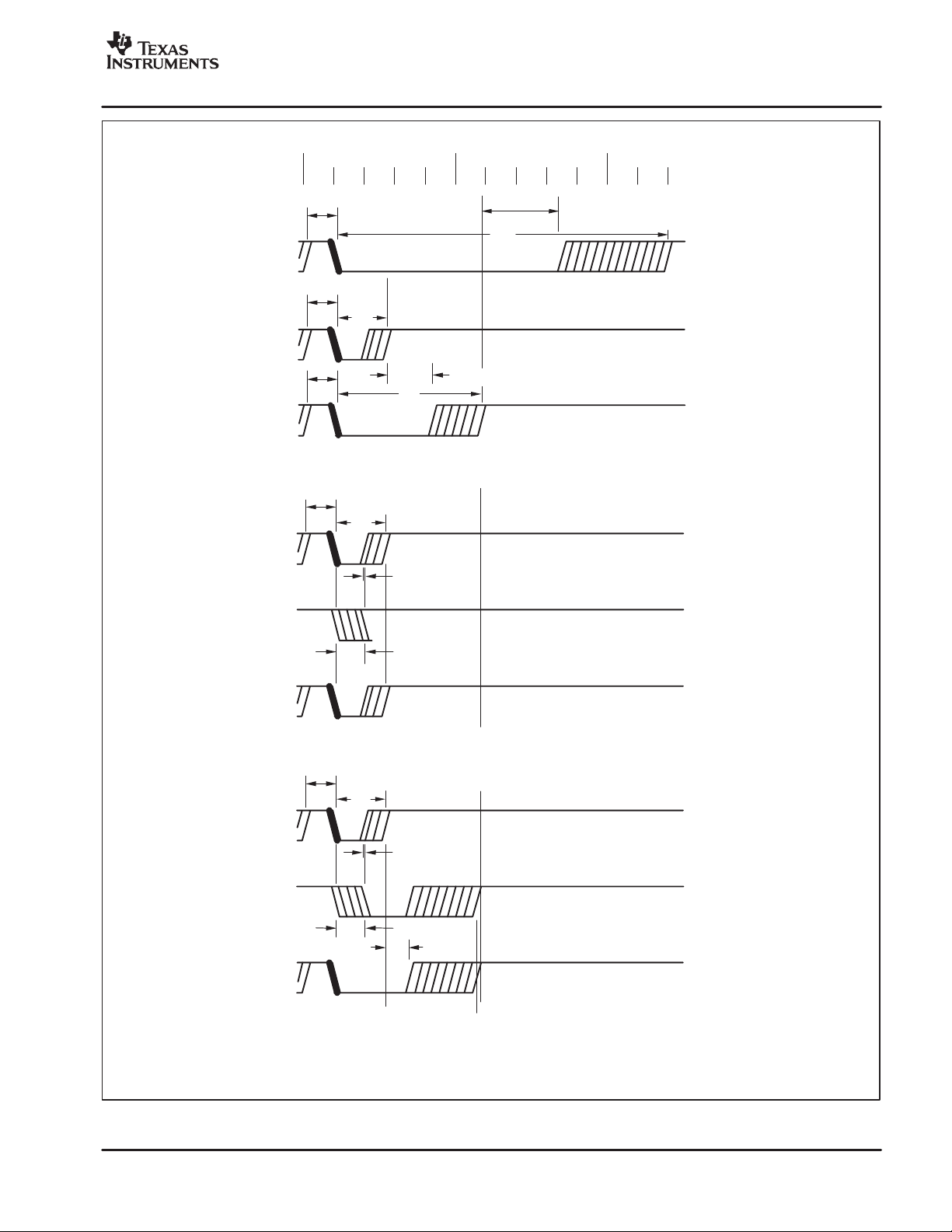

Master Write 0

Master Write 1

Master Read 0

Master Read 1

Master Write Start

Sout_Attention

0µs50

µ

s 100µs150µs 200µs250µs300µs 350µs 400µs450µs

t

INACT

t

MtrS

t

INACT

t

SLoutA

Attention

Mout_Reset

Sout_Reset

Reset

Attention

t

INACT

Detect

t

RST

t

RST

Reset Detect

t

RST

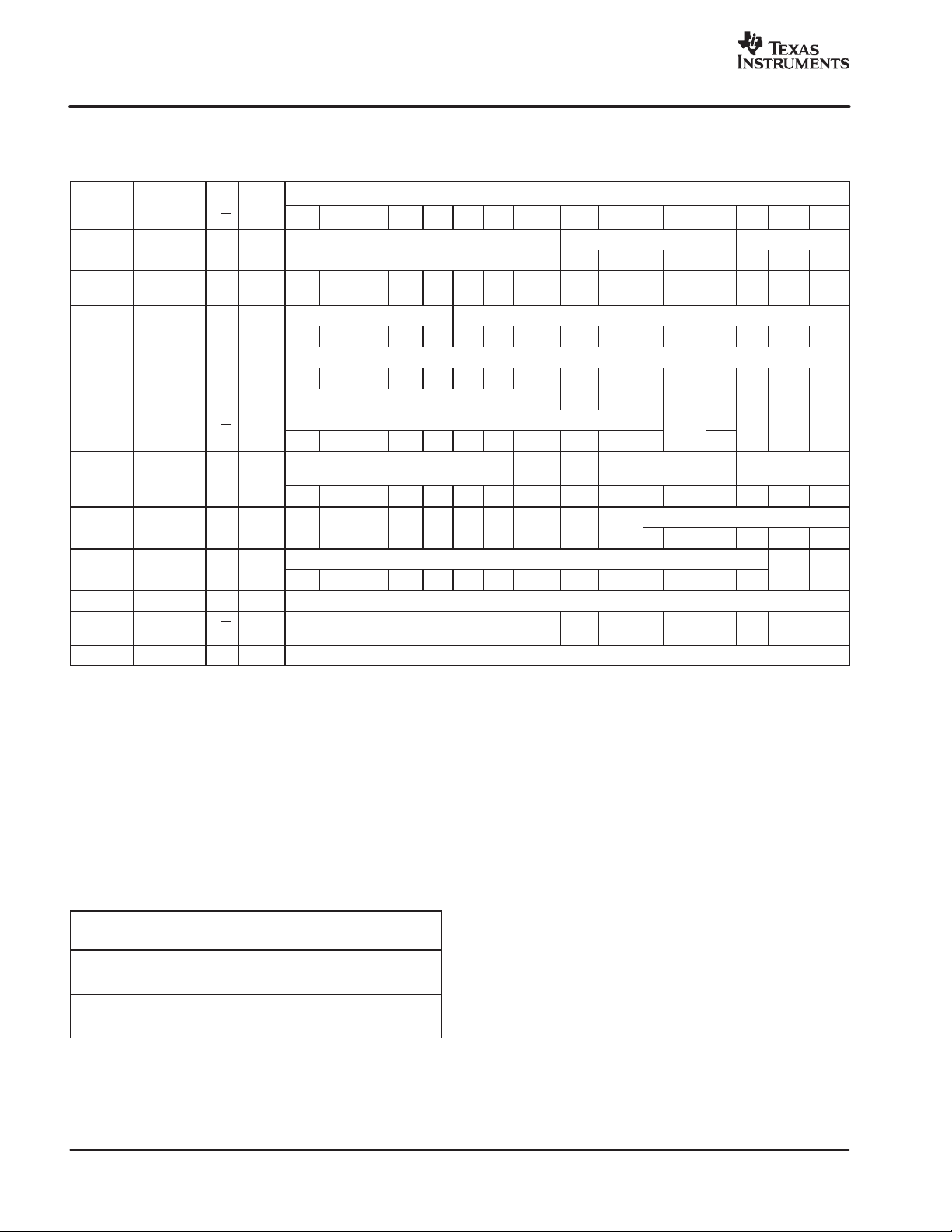

Figure 2. Relationship of the Five Types of Signals on SWD

6

Page 7

www.ti.com

"#$#

SBAS347 − MARCH 2005

OVERVIEW

The TMP141 is a digital output temperature sensor that

uses the single-wire SensorPath interface protocol. It does

not require any external sensing components for

measuring temperature. In order to minimize circuit board

space, the TMP141 is offered in the MSOP-8 and

SOT23-6 packages.

The primary usage of SensorPath-based systems is for

systems that monitor hardware health. The predefined

SensorPath functions are: temperature measurement,

voltage measurement, and non-volatile memory. The

specification allows for expansion by defining new

functions or enlarging upon the predefined functions. The

TMP141 implements the temperature measurement

function with a resolution of 0.25°C.

The SensorPath interface allows a master to read up to

seven slave devices on a bus, four of which can be

TMP141s. The master interrogates devices on the bus to

determine what they are, their capabilities, and how they

can be used. Devices on the Single-Wire Data (SWD) bus

are open drain. Therefore, the SWD bus requires a 1.25kΩ

pull-up resistor on the bus. This resistor may be provided

by the master. If the pull-up resistor is not included within

the master, an external resistor must be attached to the

bus. A 0.1µF capacitor is recommended for power-supply

bypassing, as shown in Figure 3. Registers inside each

device include information that identifies the device

capabilities, manufacturer, part ID, and even device

revision number.

VS=3.3V

TEMPERATURE SENSING AND

CONVERSION

The TMP141 senses the absolute temperature by utilizing

a diode which is part of the IC. Therefore, the sensing

device of the TMP141 is the chip itself. Thermal paths run

through the package leads as well as the plastic package,

and the lower thermal resistance of metal causes the leads

to provide the primary thermal path.

To maintain accuracy in applications that require air or

surface temperature measurement, care should be taken

that the package and leads thermally connect with the

surface where the temperature measurement is desired.

For example, a thermally-conductive adhesive assists in

achieving accurate surface temperature measurements.

Even without special precautions, because of the very low

power consumption of the TMP141, self-heating will

normally be well below 1LSB (0.25°C).

TYPICAL APPLICATION

The TMP141 is normally used with the address pins wired

high or low to select one of four possible addresses. The

value read from the hardware pins plus one is stored in

register 0 as the device number. When the master

transmits a matching device number, the TMP141 will

respond. In the example shown in Figure 3, ADD1:ADD0

are wired to 2h. In this example, 3h will be stored in register

0. When the master addresses device number 3, the

TMP141 in Figure 3 will respond. The TMP141 will also

work well in applications where ADD0:ADD1 are driven by

logic levels since it reads these pins every time it does a

conversion or bus transaction (see Table 2).

0.1µF

ADD1

TMP141 Master

ADD0

V

SS

Optional

Ω

R = 1.25k

SWD

The resistor R may be

integratedinto the master.

Figure 3. Typical Connections of the TMP141

7

Page 8

"#$#

SBAS347 − MARCH 2005

www.ti.com

DIGITAL INTERFACE

Up to four TMP141 devices can be connected to a single

signaling line, which is called Single-Wire Data (SWD).

This line is similar to the data line (SMBDAT) of the

industry-standard SMBus. The SensorPath bus uses a

power supply of 3.3V; therefore, the signaling levels are

approximately 3.3V and 0V.

Data is encoded in a pulse width encoding scheme. All

signaling is done by pulling the bus low for varying lengths

of time. With the exception of Reset and Attention

Request, the master starts all bits. Thus, when sending

data, the TMP141 does not pull the bus low. Rather, when

the TMP141 needs to send a ‘1’, it first detects that the line

has been pulled low by the master, and then holds the line

low long enough to signal a ‘1’. To send a ‘0’, the TMP141

simply leaves the bus alone; the master has already

placed a ‘0’ on the bus.

The SWD interface used on the TMP141 has five types of

signals that are identified by the length of time that the line

is held low. Conceptually, this device operates as a

five-state signaling system. The more common signals

have shorter durations in order to speed overall

transmission. The five signals and their approximate times

are:

D Data 0: Transmit a ‘0’ bit (15µs)

D Data 1: Transmit a ‘1’ bit (42µs)

D Start: Used by the master at the beginning of a

transaction (95µs)

D Attention Request: May be used by the TMP141 to

request service (196µs)

D Reset: Must be asserted by both the master and

slave(s) after power up. It may be asserted at other

times as needed (at least 348µs).

The bus must be inactive for at least 11µs before any

signal.

Attention Request

Any slave device may signal an Attention Request. Before

sending an Attention Request, the slave monitors the bus

to ensure that it is inactive. If an Attention Request

coincides with a data bit from another device or a Start Bit

from the master, the Attention Request will take

precedence since the Attention Request signal holds the

bus low longer. The master and all communicating slaves

will monitor the bus to detect an Attention Request. The

master monitors the bus in order to allow resending, in

case the Attention Request started simultaneously with a

Start Bit or a data bit. If the master was in the midst of a

transaction when the Attention Request was asserted, the

master can either continue with the transaction by

repeating the bit that was extended by the Attention

Request, initiating the next bit if a bit was not extended, or

it can service the Attention Request by issuing a new start

command for a new transaction.

Power-On Reset

All devices on the SWD bus, including the TMP141, are

required to generate a Reset signal at power up. Reset

aborts any operation in progress, and sets all registers to

the default values. The device that holds SWD low the

longest will define how long the Reset lasts. After a Reset,

a slave device may not send an Attention Request until the

master has sent at least 14 bits of data on the SWD bus.

Device Reset

The TMP141 will also Reset when the Reset bit is written

to the Device Control Register (bit 0). All registers are set

to the default value. The two least significant bits of the

Device Control Register are the only locations that

respond to a broadcast write command from the master.

A software-programmed reset of a device by writing to its

Device Control Register will not cause a Reset signal on

the bus.

Start

All devices on the bus continuously monitor the bus. The

master also monitors the bus to verify that it is inactive

before issuing a Start Bit. During the Start Bit, both the

master and slave(s) monitor the bus to detect an Attention

Request or a Reset. If there is an Attention Request, or a

Reset, the current signal is not treated as a Start Bit. The

master may reissue the Start Bit at a later time, but is not

required to.

8

BUS RESET

A Bus Reset occurs when the TMP141 detects a Reset

signal on the SWD bus. Upon Bus Reset, the TMP141 will

abandon any communication in progress. Internal

registers are not reset to their power-up values; thus, any

error flags such as BER or ORUN will remain unaffected.

If a conversion was in progress, it will continue to

completion.

Page 9

"#$#

www.ti.com

SBAS347 − MARCH 2005

Read and Write Transactions

A complete Read transmission consists of a Start Bit, the device number, the Register Number, R/W = 1, the data bits, an

even parity bit, and an Acknowledge bit. The most significant bit is sent first.

Read Transaction

START DEVICE NUMBER REGISTER NUMBER R/W 8 or 16 DATA BITS EP ACK

M M M M M M M M M M M S … S S M

A complete Write transmission consists of a Start Bit, the device number, the Register Number, R/W = 0, the data bits, an

even parity bit, and an Acknowledge bit.

Write Transaction

START DEVICE NUMBER REGISTER NUMBER R/W 8 or 16 DATA BITS EP ACK

M M M M M M M M M M M M … M M S

M indicates that the bit is initiated and controlled by the master. S indicates that the bit is initiated by the master but controlled

by the slave; if the data is a ‘1’, the slave lengthens the time that the bus is held low to signal a ‘1’.

The device number is three bits long. Device number 0 is reserved for a broadcast to all devices, leaving address space

for seven slaves.

The Register Number is six bits long.

The R/W

All data bits are started by the master pulling the bus low. The TMP141 will detect the bus being low within time t

If it is a read transaction and the TMP141 needs to send a ‘1’ for that bit period, it will hold the bus low for time t

is a ‘1’ for a read operation. The R/W bit is a ‘0’ for a write operation.

SFEdet

SLout1

.

In a Write operation, the data bits and parity are sent by the master . In a Read operation, the data bits and parity are sent

by the TMP141. Data length is eight bits for registers 0, 4, and 20h. All other registers are 16 bits long. The number of bits

transmitted or received depends on the length of the register: 8 bits for an 8-bit register and 16 bits for a 16-bit register.

Even parity (EP) is used on the SensorPath. The parity calculation includes all bits after the Start Bit, up to and including

the parity bit. Thus, the parity calculation includes the device number, the Register Number, R/W

, the data bits, and the

parity bit. In a Write operation, the TMP141 checks the parity sent by the master before generating the Acknowledge bit.

The Acknowledge bit is sent by the receiving unit. In a Write operation, the Acknowledge bit will come from the TMP141.

In a Read operation, the master generates the Acknowledge bit.

ACKNOWLEDGE Bit Definition:

1: A complete data transmission was completed without a parity error.

0: An error was detected. (BER in the Status Register will be set. An Attention Request will be generated.)

.

9

Page 10

"#$#

ADDRESS

VALUE

0

Device

R

1

(1)

Not Available (this register is 8 bits long)

2

Device ID

R

8D

3

Capabilities

R

1

5

Device

R/W

0

ENAB

Low

Shut

Reset

8

Capabilities

R

014A

9

Temperature

R0Sign

64°C

32°C

16°C

8°C

4°C

2°C

1°C

0.5°C

0.25°C

A

Temperature

R/W

0

EN_S

AT_E

www.ti.com

SBAS347 − MARCH 2005

APPLICATIONS INFORMATION

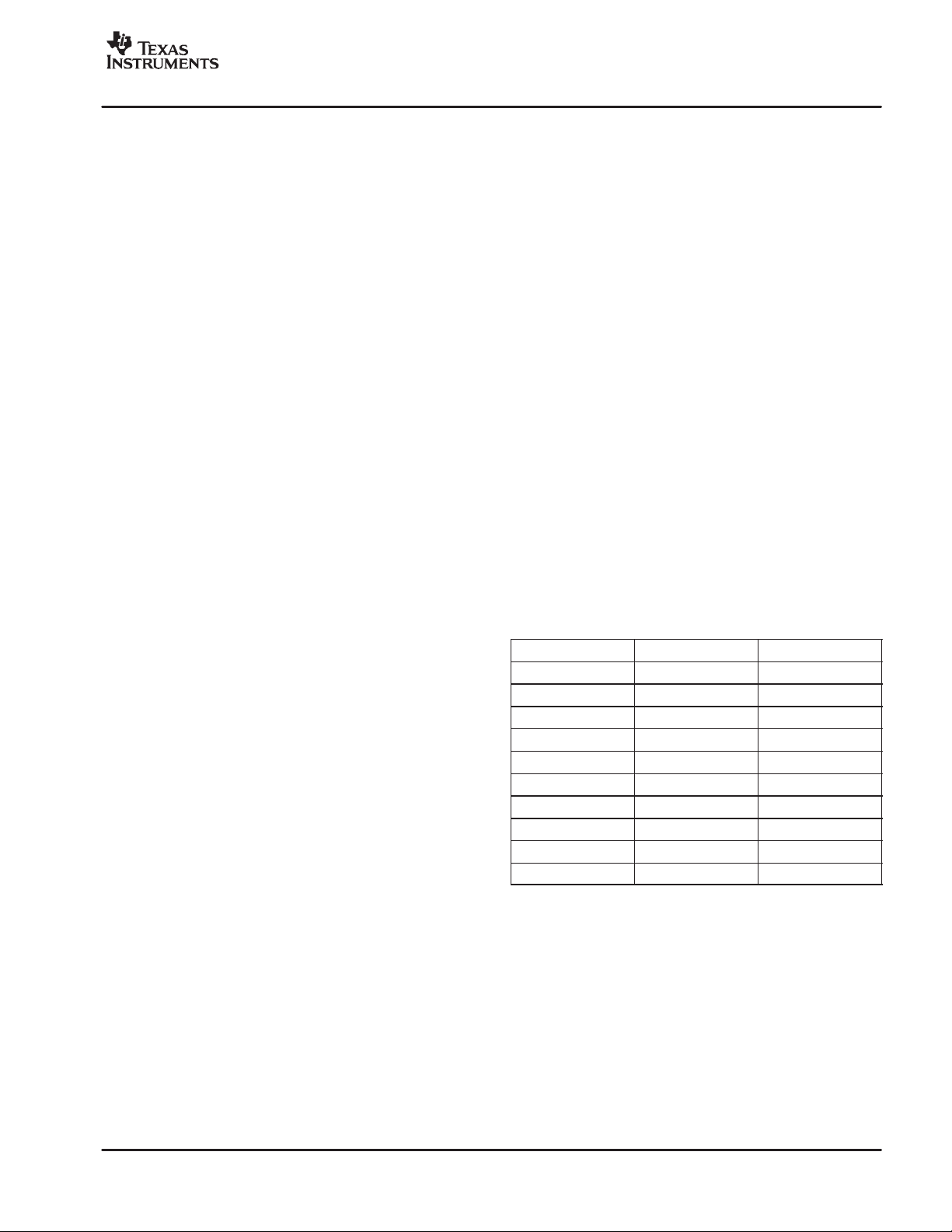

Table 1. Register Set Summary

RESET

(hex)

1

4 Status R 0 Not Available (this register is 8 bits long) BER 0 0 ORUN 0 0 0 SF1

8

B−1F Reserved R Undefined

20

21−3F Undefined Undefined

NAME R/W

Device

Number

Manufacturer

ID

Device

Control

Temperature

Temperature

Readout

Temperature

Control

Conversion

Rate

R 104C 0 0 0 1 0 0 0 0 0 1 0 0 1 1 0 0

R 014A

R/W 2

(hex)

(2)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Revision ID Device ID

0 0 0 0 0 0 0 0 1 0 0 0 1 1 0 1

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 1 0 1 0 0 1 0 1 0

°

0 0 0 0 0 0 0 0 0 0 0 0 0 0

Not Available (this register is 8 bits long) 0 0 0 0 0 0

BIT POSITION (MSB to the left. In a transmission, the MSB is sent first.)

Reserved See Table 2

0 0 0 0 0 AS2 AS1 AS0

Reserved Function 1

Reserved

Reserved

°

Internal

°

°

°

°

Sense

°

R

OUT

Sign Result is10 Bits Resolution Is 0.25°C

Size

°

°

0 0 0 0 0 0

Res

0

Reserved

Low

Pwr

Shut

Down

Conversion

Rate

(1)

See Table 2 for the value of register 0 at Reset.

(2)

See Table 4 for the conversion rate settings.

REGISTER DETAILS

Register 0: Device Number (Read-Only)

Register 0 is an 8-bit register. The device number is

created from the inputs at the address pins. The result is

placed in Register 0 according to Table 2.

Table 2. Device Number—Assignments

ADD1:ADD0 AS2:AS0

BITS 2:0

00 001

01 010

10 011

11 100

ADD1 and ADD0 are the physical pins used to define the

address to which the TMP141 responds to—they are not

the actual addresses. AS2:AS0 is the address to which the

device responds.

Device number 000b is the broadcast address reserved for

communicating with all devices, and can be responded to

by all slave devices. The TMP141 ignores a broadcast

Read transaction. A broadcast Write message may be

used to write to the Device Control Register, which is the

only register which responds to broadcast messages (see

the Device Control Register description).

Register 1: Manufacturer ID (Read-Only)

The Manufacturer ID for Texas Instruments is 104Ch.

Register 2: Device ID (Read-Only)

The device ID is unique for each device produced by TI.

Bits 10:0 contain 8Dh, which is the identifier for the

TMP141. Bits 15:11 identify the revision of the die and will

be incremented upon device revision.

Register 3: Capabilities (Read-Only)

Function 1 for the TMP141 is temperature measurement;

this is the only function defined for the TMP141. This

register has the value of 1h.

10

Page 11

www.ti.com

"#$#

SBAS347 − MARCH 2005

Register 4: Device Status (Read-Only)

This is an 8-bit register with the following bits defined:

Bit 7, Bus Error (BER): This bit is set whenever there is

an error indication in the Acknowledge bit of either

received or transmitted data. A bus error is cleared when

the master reads the Device Status Register or sends

Device Reset.

Bits 6−5: Reserved. These bits read as ‘0’.

Bit 4, Overrun (ORUN): This flag is set when another

temperature conversion is completed before the previous

conversion has been read by the master. This error is

cleared by Device Reset, or by reading the temperature

result from the Temperature Readout register.

Bits 3−1: Reserved. These bits read as ‘0’.

Bit 0, Status Function 1 (SF1): This flag is set when a

temperature conversion is completed, and the data is

stored in the Readout register. It is reset either when the

master reads the temperature conversion, or when the

TMP141 is reset.

Register 5: Device Control (Read/Write)

Bits 15−5: Reserved. These bits read as ‘0’.

Bit 4, Enable Function 1 (ENAB): This bit enables

temperature measurement; the default setting is disabled.

To begin temperature measurement, a ‘1’ must be written

to this bit. The enable sensor bit (EN_S) in the

Temperature Control register must also be set to enable

the sensor. (Bits cannot be written individually; a Write

operation affects the entire register.)

Bit 3: Reserved. This bit reads as ‘0’.

Bit 2, Low-Power Mode: When this bit is set, the

operation of all functions slow down in order to conserve

power. Default is ‘0’ for normal speed operation. (See

Table 4.)

Bit 1, Shutdown: When this bit is set, all functions are

disabled, placing the TMP141 in the lowest possible power

consumption mode. Default is ‘0’; this is normal operation.

To exit shutdown, write a ‘0’ to this location.

Bit 0, Reset: When this bit is set, the TMP141 performs a

Device Reset. During Reset, any operation is progress is

aborted, and all registers are set to their default values.

This bit self-clears when the Reset operation is completed.

It is not necessary to do a Device Reset after power-up.

Bits 1−0: These bits are the only location in the TMP141

that accepts a broadcast Write message.

Register 8: Temperature Capabilities (Read-Only)

Bits 15−9: Reserved. These bits read as ‘0’.

Bit 8: This bit is set, indicating that the internal temperature

sensing is the only option available.

Bit 7: This bit is ‘0’; it indicates that the TMP141 Tempera-

ture Readout register is 16 bits.

Bit 6: This bit is set to indicate that signed two’s

complement is the format of the temperature data.

Bits 5−3: These bits are 001b; they indicate that the

temperature data is 10 bits long.

Bits 2−0: These bits are 010b, and indicate that the

temperature data resolution is 0.25°C.

Register 9: Temperature Readout (Read-Only)

The TMP141 outputs 10 bits of precision to a resolution of

0.25°C. This 10-bit format covers a range from +127.75°C

to −128°C. Negative numbers are in two’s complement.

Table 3 shows some examples of the Temperature Data

format.

Data is left-justified, meaning that the ten bits of data are

in the most significant bits of this register. The temperature

data is contained in Bits 15:6. Bits 5:0 always read as ‘0’.

Table 3. Data Format Example

TEMPERATURE BINARY HEX

+127.75°C

+125.00°C 01 1111 0100 1F4h

+100.0°C 01 1001 0000 190h

−128°C

(1)

Both −128°C and +127.75 °C are beyond the specified operating

range of − 4 0 °C to +125°C. This table only illustrates the format

of the data.

(1)

+1.0°C 00 0000 0100 004h

+0.25°C 00 0000 0001 001h

0°C 00 0000 0000 000h

−0.25°C 11 1111 1111 3FFh

−1.0°C 11 1111 1100 3FCh

−100°C 10 011 1 0000 270h

(1)

01 1111 1111 1FFh

10 0000 0000 200h

11

Page 12

"#$#

SBAS347 − MARCH 2005

www.ti.com

Register Ah: Temperature Control (Read/Write)

Bits 15−2: Reserved. These bits read as ‘0’.

Bit 1, Enable Sensor (EN_S): Default is ‘0’, which is the

disabled state. In addition to setting this bit, the enable bit

in register 5 must also be set in order to measure

temperature.

Bit 0, Attention Enable (AT_E): Default is disabled.

When this bit is set, and the sensor is enabled (bit 1), the

TMP141 will generate Attention Requests. If enabled, an

Attention Request will be generated when a bit is set in the

Device Status register (register 4). See Figure 5 for the

details on the conditions for generating an Attention

Request.

Note: A bus error always attempts to generate an Attention

Request.

(For more information on the Attention Request

conditions, see the flowcharts in Figure 4 and Figure 5,

and the information on Exception Handling on page 14.)

The rules for generating an Attention Request are

different, depending on whether it was caused by a bus

error or a temperature conversion. A bus error always

attempts to generate an Attention Request, whereas a

conversion or a conversion overrun has several conditions

that may prevent the assertion of Attention Request.

These differences are illustrated in Figure 4 and Figure 5.

Register 20h: Conversion Rate (Read/Write)

The conversion rate is controlled by both the low-power bit

in the Device Control register, and the Conversion Rate

setting in the Conversion Rate register. This register is

device-specific, and therefore not defined by the

SensorPath specification. The conversion rate for a given

application is chosen based on system requirements and

limitations, such as the thermal response time of the

system (including the TMP141).

Table 4. Conversion Time Settings

LOW-POWER

MODE

(register 5, bit 2)

0 00 64

1 00 96

0 01 96

1 01 382

0 10 190 (default)

1 10 766

0 11 382

1 11 1532

CONVERSION

RATE SETTING

(register 20h, bits

1−0 binary)

TYPICAL

CONVERSION

TIME

(ms)

12

Page 13

www.ti.com

"#$#

SBAS347 − MARCH 2005

Attention

Request

Flow for

Conversion

Complete

Attention Request

Flow fo rBus Error

No

Bus Error?

Yes

SetBER = 1

Bus Reset?

No

Device Reset?

No

Yes

Yes

Set BER = 0

Yes

Conversion

Ready?

Yes

SF = 1?

Yes

Set ORUN = 1

Attention

Request

Enabled

(AT_E)?

Yes

Attention

Request

Service

Pending?

No

No

Set SF = 1

No

No

Bus Free?

Yes

Generate

Attention

Request

Figure 4. Attention Request Generated by a Bus

Error

No

Bus Free?

Yes

Generate

Attention

Request

No

Figure 5. Attention Request Generated by a

Conversion Complete

13

Page 14

"#$#

SBAS347 − MARCH 2005

www.ti.com

EXCEPTION HANDLING

ATTENTION REQUEST

Two conditions can cause the TM141 to generate an

Attention Request: a conversion completion and a bus

error.

Upon completion of a conversion, an Attention Request

may be asserted if an Attention Request is enabled (bit 0

in the Temperature Control register), if the bus is inactive,

and if there has not been an Attention Request on the bus

since the Device Status register was last read or the last

bus reset.

A slave generates an Attention Request by holding the bus

low for time t

signal (except Reset), it takes priority over the other bus

signals (Start, Data 1, and Data 0).

ATTENTION REQUEST SERVICE

The master is required to read the status register of all

slaves after an Attention Request to determine which

slave sent the request. While an Attention Request service

is pending, no slave can generate another Attention

Request to request a read of its Temperature Readout

register. However, Attention Requests caused by bus

errors will continue to be generated.

ACKNOWLEDGE (ACK)

During a Read transaction, the master sends the ACK bit

to indicate that the even parity (EP) bit was received, found

to be correct when compared to the data preceding it, and

no conflict was detected on the bus. During a Write

transaction, the slave sends the ACK bit with the same

meaning as when the master sends it. A transaction is

considered complete only when the ACK bit is received. If

. Because it is longer than any other

SLoutA

an ACK bit of ‘1’ is not received during a Write transaction,

the TMP141 will not perform any internal operations based

on that transaction. A transaction with an Acknowledge bit

of 0 is not considered complete by the TMP141, and the

following actions are performed:

1. The bus error bit in the TMP141 Device Status register

is set.

2. The TMP141 generates an Attention Request before

(or together with) the Start Bit of the next transaction.

A transaction that was not positively acknowledged is also

not considered complete by the master (that is, the master

will not use data that it received from a transaction that was

not acknowledged). The transaction may be repeated by

the master after detecting the source of the Attention

Request (the TMP141 or other slave that has a set BER bit

in the Device Status Register). Note that the SensorPath

protocol neither forces, nor automates re-execution of, the

transaction by the master.

Incomplete Transactions:

If the TMP141 receives a Start Bit during a transaction, it

aborts the current transaction, and begins a new one. This

process is not recommended, but is a legal operation. No

error will be generated.

If excess bits are received, the extra bits are ignored. The

TMP141 expects the parity (EP) and acknowledge (ACK)

bits in the usual places. However, in such cases, there is

usually a parity error, and the transaction is not

acknowledged. Error handling proceeds as described in

the Acknowledge section.

If insufficient bits are received, the TMP141 will wait

indefinitely for the missing bits. If the master starts a new

transaction before those bits are received, the TMP141

abandons the current transaction, and begins the new

transaction. No error is generated.

14

Page 15

"#$#

www.ti.com

SBAS347 − MARCH 2005

GLOSSARY

ACK (Acknowledge Bit): The bit that concludes a transmission indicating whether any errors were detected in the

transmission. A ‘1’ indicates that no errors were found; a ‘0’ indicates an error. An acknowledge error causes BER to be

set. BER will be set regardless of whether the device or the master generates the acknowledge error.

AT_E (Attention Enable): This is the LSB in the Temperature Control register (bit 0, register Ah). When set, the TMP141

will generate Attention Requests. If enabled, an Attention Request will be generated when a conversion is complete.

BER (Bus Error): A flag that is set when the TMP141 either generates or receives an Acknowledge error (bit 7 in the Status

register).

EN_S: (Sensor Enable Bit): This is bit 1 in the Temperature Control register. When set, temperature measurement is

enabled. Default setting is disabled. To report temperature, ENAB must also be set.

ENAB (Enable Temperature Sensing): This is a bit in the Device Control register. In the case of the TMP141, function

1 is temperature measurement. Setting this bit will enable temperature measurement (bit 4 in the Device Control register).

The sensor should also be turned on by the Sensor Enable flag (bit 1) in the Temperature Control register.

Even Parity: The number of bits in a transmission that are ‘1’ is even. The SensorPath uses even parity. All bits after the

start bit (up to and including the parity bit) are included in this calculation, but the ACK bit is not.

ORUN (Overrun Error): This flag is set when a temperature conversion is completed before the previous conversion has

been read by the master (bit 4 in the Device Status register). If other conditions are met, overrun will generate an Attention

Request.

PCI SIG (assigned identifiers): The ID for Texas Instruments is 104Ch. This number is programmed into the Manufacturer

ID register. Other IDs can be fond at http://www.pcisig.com/membership/vid_search/. This number enables identification

of the device manufacturer (which can be useful in determining the features of a device) and to perform

manufacturer-specific operations. There are no vendor-specific operations for the TMP141—all of the operations conform

to industry standards.

Pulse Width Encoding: A signaling scheme whereby the information is differentiated by the width of the pulse. In the case

of SensorPath, the pulses are created by pulling the bus low. The length of time that it is low determines the meaning of

that pulse. See the Digital Interface section on page 8.

SF1 (Status Function One): This flag is set when a temperature conversion is completed, and the data is stored in the

Readout register. It is reset when the master reads the temperature conversion, or when the TMP141 is reset.

Shutdown Mode: A very low-power state entered when the master writes to the shutdown bit (bit 1) in the Device Control

register. In the shutdown state, temperature conversions are stopped. The TMP141 consumes the lowest possible power

in this state (see also Low-Power Mode on page 11).

SWCLK: Single-Wire Clock, an optional signal used only when the SensorPath is used in synchronous mode. The TMP141

does not use and does not support this option. Systems that use SWCLK are using a two-wire SensorPath bus.

SWD (Single-Wire Data): The line used to communicate between master and slave devices as required by the specified

SensorPath. Five types of signals go over this line (Zero, One, Start, Attention Request, and Reset). Signals are

differentiated by the length of time that they hold the bus low. This is the only line used to communicate between the slaves,

such as the TMP141, and the master. A 1.25kΩ pull-up resistor may be integrated into the master, or it may be external.

Synchronous Mode: An optional mode used with SensorPath devices that do not meet the ±15% clock timing accuracy

requirement. The TMP141 clock meets the clock accuracy requirement, and therefore does not support the synchronous

mode (see SWCLK).

15

Page 16

PACKAGE OPTION ADDENDUM

www.ti.com

19-May-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

TMP141AIDBVR ACTIVE SOT-23 DBV 6 3000 Green (RoHS &

no Sb/Br)

TMP141AIDBVRG4 ACTIVE SOT-23 DBV 6 3000 Green (RoHS &

no Sb/Br)

TMP141AIDBVT ACTIVE SOT-23 DBV 6 250 Green (RoHS &

no Sb/Br)

TMP141AIDBVTG4 ACTIVE SOT-23 DBV 6 250 Green (RoHS &

no Sb/Br)

TMP141AIDGKR ACTIVE MSOP DGK 8 2500 Green (RoHS &

no Sb/Br)

TMP141AIDGKRG4 ACTIVE MSOP DGK 8 2500 Green (RoHS &

no Sb/Br)

TMP141AIDGKT ACTIVE MSOP DGK 8 250 Green (RoHS &

no Sb/Br)

TMP141AIDGKTG4 ACTIVE MSOP DGK 8 250 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS) or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 17

Page 18

Page 19

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power .ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Loading...

Loading...