Page 1

User's Guide

SLOU512–October 2018

TLV9001DPW-EVM

This user's guide contains support documentation for the TLV9001DPW evaluation module (EVM).

Included in this document is a description of how to set up and configure the EVM, printed circuit board

(PCB) layout, schematic, and bill of materials (BOM) of the TLV9001DPW EVM.

Contents

1 Introduction ................................................................................................................... 2

2 TLV9001DPW EVM Kit Contents.......................................................................................... 2

3 Circuit Configurations ....................................................................................................... 2

4 Schematic and PCB Layout................................................................................................ 3

5 Connections .................................................................................................................. 8

6 Bill of Materials and References........................................................................................... 8

List of Figures

1 TLV9001DPW EVM Schematic............................................................................................ 3

2 Silkscreen Schematic ....................................................................................................... 3

3 Difference Amplifier Schematic ............................................................................................ 4

4 Difference Amplifier Configured on TLV9001DPW EVM ............................................................... 4

5 Non-Inverting Amplifier Schematic ........................................................................................ 5

6 Non-Inverting Amplifier Configured on TLV9001DPW EVM ........................................................... 5

7 Inverting Amplifier Schematic.............................................................................................. 6

8 Inverting Amplifier Configured on TLV9001DPW EVM ................................................................. 6

9 Top Layer PCB Layout...................................................................................................... 7

10 Bottom Layer PCB Layout.................................................................................................. 7

List of Tables

1 TLV9001DPW EVM Kit Contents.......................................................................................... 2

SLOU512–October 2018

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

TLV9001DPW-EVM

1

Page 2

Introduction

1 Introduction

The TLV9001 is a high-performance, low cost, low power operational amplifier. For a full list of electrical

characteristics of the TLV9001, please refer to the TLV9001 product datasheet (SBOS833). This EVM is

developed to give users the ability to easily evaluate their design concepts using the TLV9001. The EVM

can be configured into three circuit configurations: difference amplifier, non-inverting amplifier and

inverting amplifier by populating different components on board.

2 TLV9001DPW EVM Kit Contents

Table 1 details the contents included in the TLV9001DPW EVM kit.

Table 1. TLV9001DPW EVM Kit Contents

Item Description Quantity

TLV9001DPW EVM PCB 1

Header Strip

3 Circuit Configurations

By populating different components on the PCB, the TLV9001DPW EVM can be configured into three

different circuits:

• Difference Amplifier

• Non-Inverting Amplifier

• Inverting Amplifier

100-mil (2.54-mm) spacing, 32 position,

through hole

www.ti.com

2

2

TLV9001DPW-EVM

Copyright © 2018, Texas Instruments Incorporated

SLOU512–October 2018

Submit Documentation Feedback

Page 3

-

+

V+

C2

C1

R1

C3

C4

R4

R2

R3

VOUT

VREF

V-

1

234

5

1

2

3

5

4

1

234

5

1

234

5

1

234

5

www.ti.com

4 Schematic and PCB Layout

This section provides the schematic and PCB layout of the TLV9001DPW EVM. Also included are the

schematics for the three TLV9001DPW EVM circuit configuration options.

4.1 Schematic

Figure 1 displays the circuit schematic of the TLV9001DPW EVM.

Schematic and PCB Layout

Figure 1. TLV9001DPW EVM Schematic

The schematic of the EVM is provided in silk screen located on the back of the PCB for easy reference.

Figure 2 displays the schematic provided on the back of the PCB.

Figure 2. Silkscreen Schematic

SLOU512–October 2018

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

TLV9001DPW-EVM

3

Page 4

-

+

V+

C2

C1

R1

C3

C4

R4

R2

R3

IN+

VOUT

VREF

V-

Schematic and PCB Layout

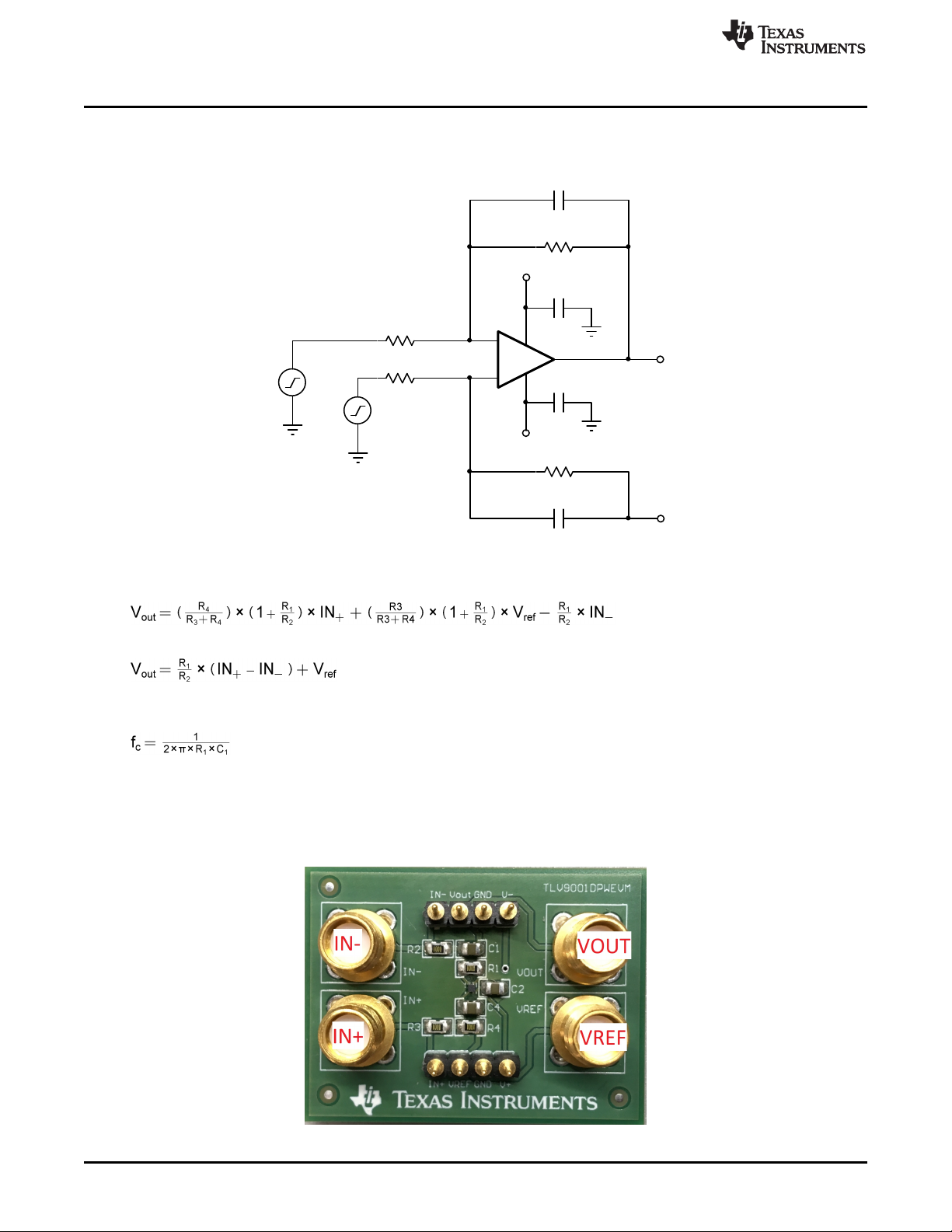

4.2 Difference Amplifier

Figure 3 displays the schematic for the difference amplifier circuit configuration.

www.ti.com

Figure 3. Difference Amplifier Schematic

Equation 1 displays the transfer function of the difference amplifier circuit configuration.

If R1 = R4 and R2 = R3, Equation 1 can simplify to Equation 2.

Capacitors C1 and C4 provide the option to filter the output of the amplifier. Equation 3 calculates the

cutoff frequency, fc, of the filter.

Where

• R1 = R4, R2 = R3, and C1 = C4

Figure 4 displays the TLV9001DPW EVM populated with the required components to be configured as a

difference amplifier.

(1)

(2)

(3)

4

TLV9001DPW-EVM

Figure 4. Difference Amplifier Configured on TLV9001DPW EVM

Copyright © 2018, Texas Instruments Incorporated

SLOU512–October 2018

Submit Documentation Feedback

Page 5

-

+

V+

C2

C1

R1

C3

R2

IN+

VOUT

V-

www.ti.com

4.3 Non-Inverting Amplifier

Figure 5 displays the schematic for the non-inverting amplifier circuit configuration. To configure the EVM

in a non-inverting configuration short R3 using a 0-Ω resistor or solder bridge, leave R4 and C4

unpopulated, and ground the input connection IN–. The input signal is applied directly to the high

impedance non-inverting input terminal using the IN+ connection on the EVM.

Schematic and PCB Layout

Figure 5. Non-Inverting Amplifier Schematic

Equation 4 displays the DC transfer function of the non-inverting amplifier circuit configuration shown in

Figure 5.

Capacitor C1 provides the option to filter the output. The cutoff frequency, fc, of the filter can be calculated

using Equation 5.

Figure 6 displays the TLV9001DPW EVM populated with the required components to be configured as a

non-inverting amplifier.

Figure 6. Non-Inverting Amplifier Configured on TLV9001DPW EVM

(4)

(5)

SLOU512–October 2018

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

TLV9001DPW-EVM

5

Page 6

-

+

V+

C2

C1

R1

C3

R2

VOUT

V-

Vcm

Schematic and PCB Layout

4.4 Inverting Amplifier

Figure 7 shows the schematic for the inverting amplifier circuit configuration. To configure the EVM in an

inverting configuration short R3 using a 0-Ω resistor or solder bridge, leave R4 and C4 unpopulated, and

apply the desired common mode voltage to the input connection, IN+. The input signal is applied using the

input connection IN–.

www.ti.com

Figure 7. Inverting Amplifier Schematic

Equation 6 displays the DC transfer function of the inverting amplifier circuit configuration.

Capacitor C1 provides the option to filter the output. The cutoff frequency, fc, of the filter can be calculated

using Equation 7.

Figure 8 shows the TLV9001DPW EVM populated with the required components to be configured as an

inverting amplifier.

Figure 8. Inverting Amplifier Configured on TLV9001DPW EVM

(6)

(7)

6

TLV9001DPW-EVM

Copyright © 2018, Texas Instruments Incorporated

SLOU512–October 2018

Submit Documentation Feedback

Page 7

www.ti.com

4.5 PCB Layout

The TLV9001DPW EVM is a two layer board. The PCB layout of the top layer is displayed in Figure 9.

Schematic and PCB Layout

Figure 9. Top Layer PCB Layout

The PCB layout of the bottom layer is displayed in Figure 10.

Figure 10. Bottom Layer PCB Layout

SLOU512–October 2018

Submit Documentation Feedback

Copyright © 2018, Texas Instruments Incorporated

TLV9001DPW-EVM

7

Page 8

Connections

5 Connections

This section provides a description for each connection available on the EVM.

5.1 Power

The power supply connections for the TLV9001DPW EVM can only be applied using the header strips

located at the top and bottom of the PCB. The positive power supply connection is labeled V+, the

negative power supply connection is labeled V–, and the ground connection is labeled GND. For the

minimum and maximum supply voltages of the TLV9001DPW EVM, please refer to the TLV9001 product

datasheet (SBOS833).

5.2 Input Connections

Signals for the input can be applied to the TLV9001DPW EVM through the use of SMA connectors or the

header pins. The input connections are labeled as IN+ and IN–.

5.3 Output Connections

Output connections are provided through the use of SMA connectors or the header pin labeled as VOUT.

5.4 Reference Voltage Connections

Signals or DC voltages for the reference voltage is applied to the TLV9001DPW EVM through the use of

the SMA connector or header pin labeled VREF.

www.ti.com

6 Bill of Materials and References

6.1 Bill of Materials

Designator QTY Description Part Number

PCB 1 Printed-Circuit-Board TLV9001DPW EVM

Header Strips 2 Header, 100 mil, 4x1, Gold, TH TS-104-G-AA

6.2 References

1. DIYAMP-EVM

2. DUAL-DIYAMP-EVM

3. TI Precision Labs Training

8

TLV9001DPW-EVM

Copyright © 2018, Texas Instruments Incorporated

SLOU512–October 2018

Submit Documentation Feedback

Page 9

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2018, Texas Instruments Incorporated

Loading...

Loading...