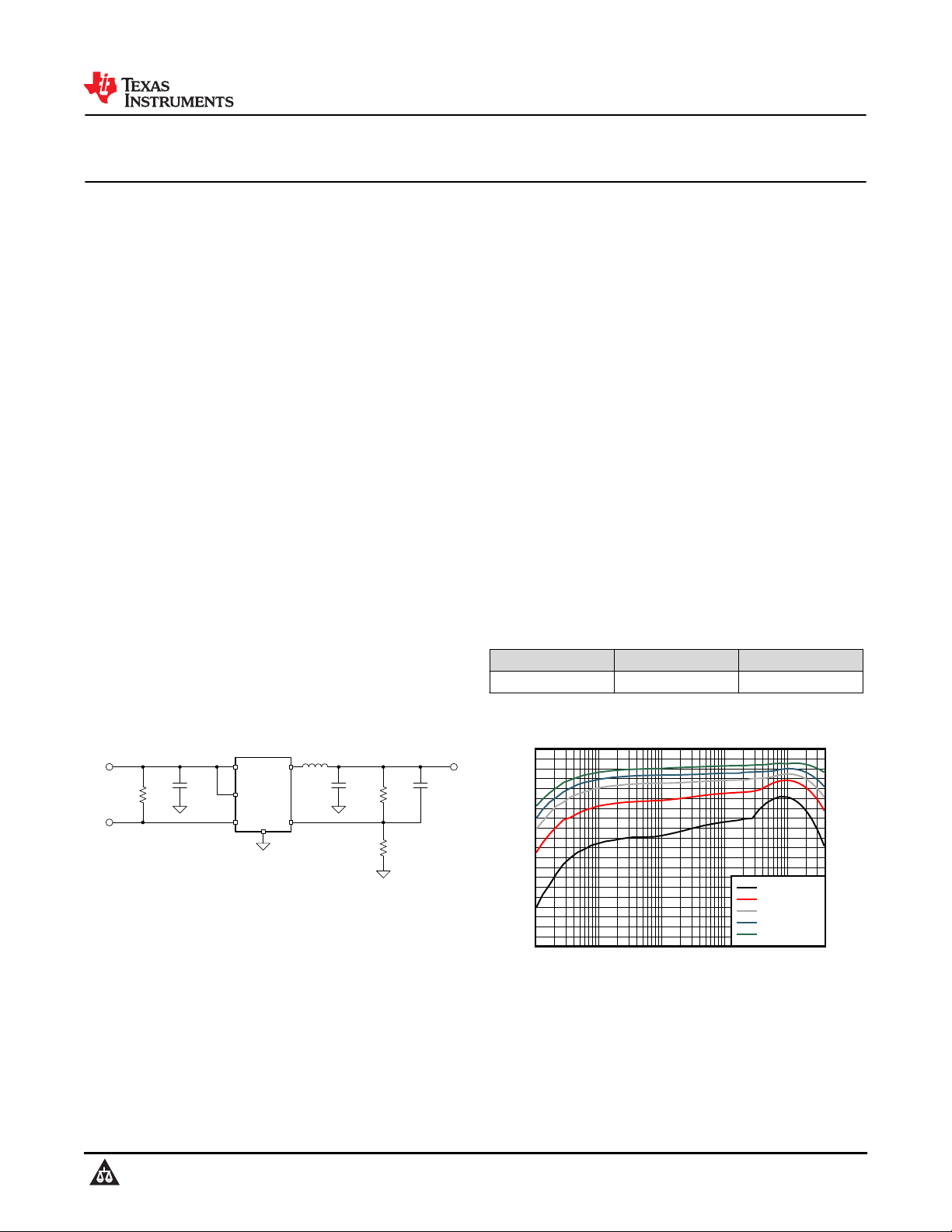

R1

200 k

R2

100 k

SW

GND FB

EN

PG

VIN

C2

3x10 µF

R3

100 k

C1

4.7 µF

V

IN

2.5 V to 5.5 V

V

PG

V

OUT

1.8 V

L1

0.47 µH

TLV62595

C3

120 pF

Load (A)

Efficiency (%)

50

55

60

65

70

75

80

85

90

95

100

100P 1m 10m 100m 1 4

D007

V

OUT

= 0.6V

V

OUT

= 1.2V

V

OUT

= 1.8V

V

OUT

= 2.5V

V

OUT

= 3.3V

TLV62595

www.ti.com

SLUSDR2 – DECEMBER 2020

SLUSDR2 – DECEMBER 2020

TLV62595

TLV62595, 2.5-V to 5.5-V Input, 4-A Step-Down Converter with 1% Output Accuracy in

1.5-mm × 1.5-mm QFN Package

1 Features

• Up to 97% efficiency

• Low R

power switches 26 mΩ / 25 mΩ

DS(ON)

• 2.5-V to 5.5-V input voltage range

• Adjustable output voltage from 0.6 V to 4 V

• 1% feedback voltage accuracy (full temperature

range)

• DCS-control topology

• Power save mode for light load efficiency

• 100% duty cycle for lowest dropout

• 10-μA operating quiescent current

• 2.2-MHz typical switching frequency

• Short circuit protection (HICCUP)

• Active output discharge

• Power good output

• Thermal shutdown protection

• Create a custom design using the TLV62595 with

the WEBENCH® Power Designer

2 Applications

• Solid state drive

• Portable electronics

• IP network camera

• Industrial PC

• Multifunction printers

3 Description

The TLV62595 is a high-frequency synchronous stepdown converter optimized for compact solution size

and high efficiency. The device integrates switches

capable of delivering an output current up to 4 A. At

medium to heavy loads, the converter operates in

pulse width modulation (PWM) mode with typical 2.2MHz switching frequency. At light load, the device

automatically enters Power Save Mode (PSM) to

maintain high efficiency over the entire load current

range with a quiescent current as low as 10-µA.

Based on the DCS Control topology, it provides a fast

transient response. The internal reference regulates

the output voltage down to 0.6 V with a high feedback

voltage accuracy of 1% over the junction temperature

range of –40°C to 125°C. The entire solution requires

a small 470-nH inductor, a single 4.7-μF input

capacitor and three 10-μF or single 47-μF output

capacitor.

The device is available in a 6-pin 1.5-mm x 1.5-mm

QFN package, offering a high power density solution.

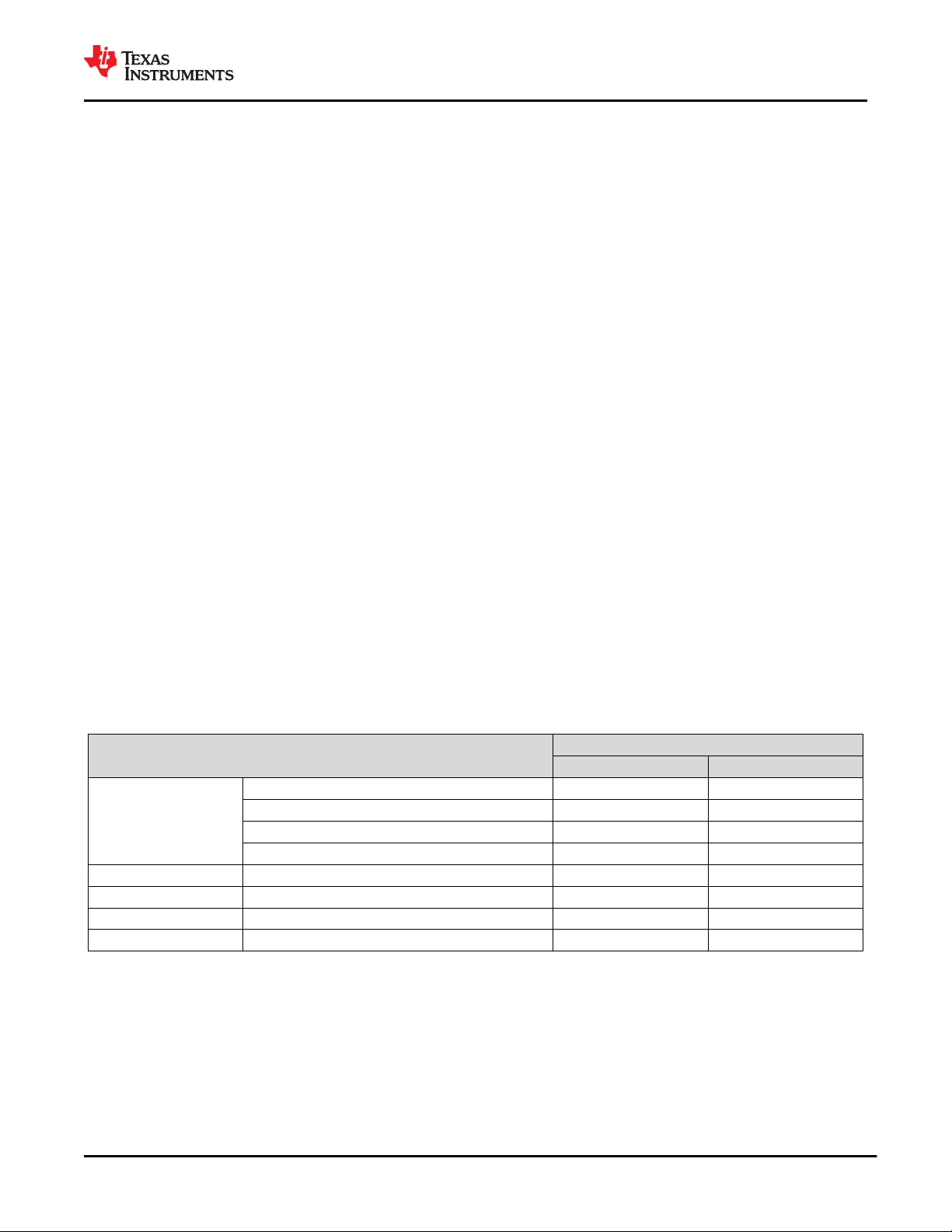

Device Information

PART NUMBER PACKAGE

TLV62595 6-Pin VSON-HR 1.5 mm x 1.5 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

(1)

BODY SIZE (NOM)

Typical Application Schematic

Copyright © 2020 Texas Instruments Incorporated

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Efficiency at VIN = 5 V

Product Folder Links: TLV62595

Submit Document Feedback

1

TLV62595

SLUSDR2 – DECEMBER 2020

www.ti.com

Table of Contents

1 Features............................................................................1

2 Applications.....................................................................1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Pin Configuration and Functions...................................3

6 Specifications.................................................................. 4

6.1 Absolute Maximum Ratings........................................ 4

6.2 ESD Ratings............................................................... 4

6.3 Recommended Operating Conditions.........................4

6.4 Thermal Information....................................................4

6.5 Electrical Characteristics.............................................5

6.6 Typical Characteristics................................................6

7 Detailed Description........................................................7

7.1 Overview.....................................................................7

7.2 Functional Block Diagram...........................................7

7.3 Feature Description.....................................................8

7.4 Device Functional Modes............................................9

4 Revision History

DATE REVISION NOTES

December 2020 * Initial release

8 Application and Implementation..................................10

8.1 Application Information............................................. 10

8.2 Typical Application....................................................10

9 Power Supply Recommendations................................18

10 Layout...........................................................................19

10.1 Layout Guidelines................................................... 19

10.2 Layout Example...................................................... 19

11 Device and Documentation Support..........................20

11.1 Device Support........................................................20

11.2 Documentation Support.......................................... 20

11.3 Receiving Notification of Documentation Updates..20

11.4 Support Resources................................................. 20

11.5 Trademarks............................................................. 20

11.6 Electrostatic Discharge Caution..............................21

11.7 Glossary..................................................................21

12 Mechanical, Packaging, and Orderable

Information.................................................................... 21

2 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TLV62595

SW

VIN

GND

PG

EN

FB

1

2

3

6

5

4

www.ti.com

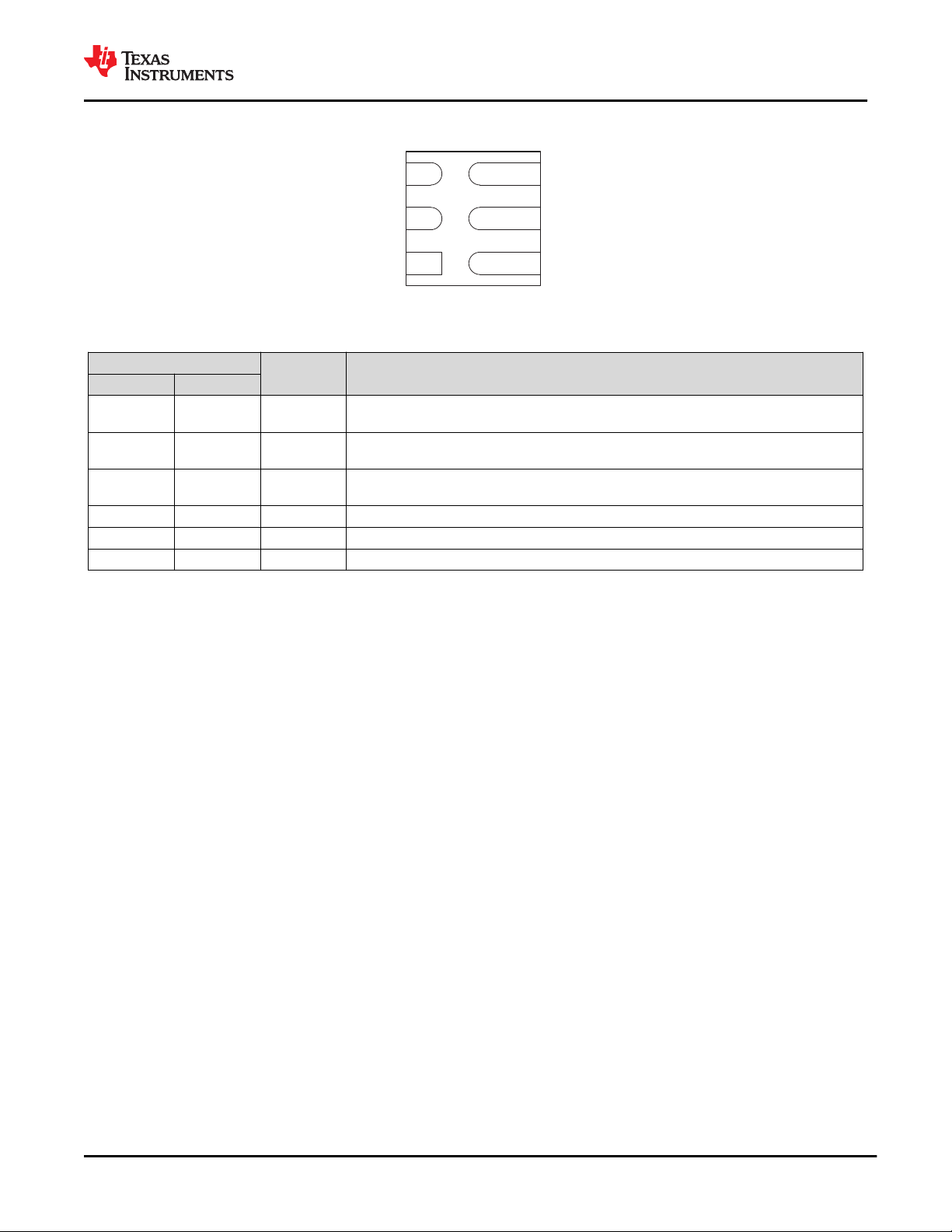

5 Pin Configuration and Functions

Figure 5-1. 6-Pin VSON-HR DMQ Package (Bottom View)

Table 5-1. Pin Functions

PIN

NAME NO.

EN 1 I

PG 2 O

FB 3 I

GND 4 Ground pin

SW 5 PWR Switch pin of the power stage

VIN 6 PWR Input voltage pin

I/O DESCRIPTION

Device enable pin. To enable the device, this pin needs to be pulled high. Pulling this pin low

disables the device. Do not leave floating.

Power-good open-drain output pin. The pullup resistor can be connected to voltages up to

5.5 V. If unused, leave it floating.

Feedback pin. For the fixed output voltage versions, this pin must be connected to the

output.

SLUSDR2 – DECEMBER 2020

TLV62595

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TLV62595

Submit Document Feedback

3

TLV62595

SLUSDR2 – DECEMBER 2020

www.ti.com

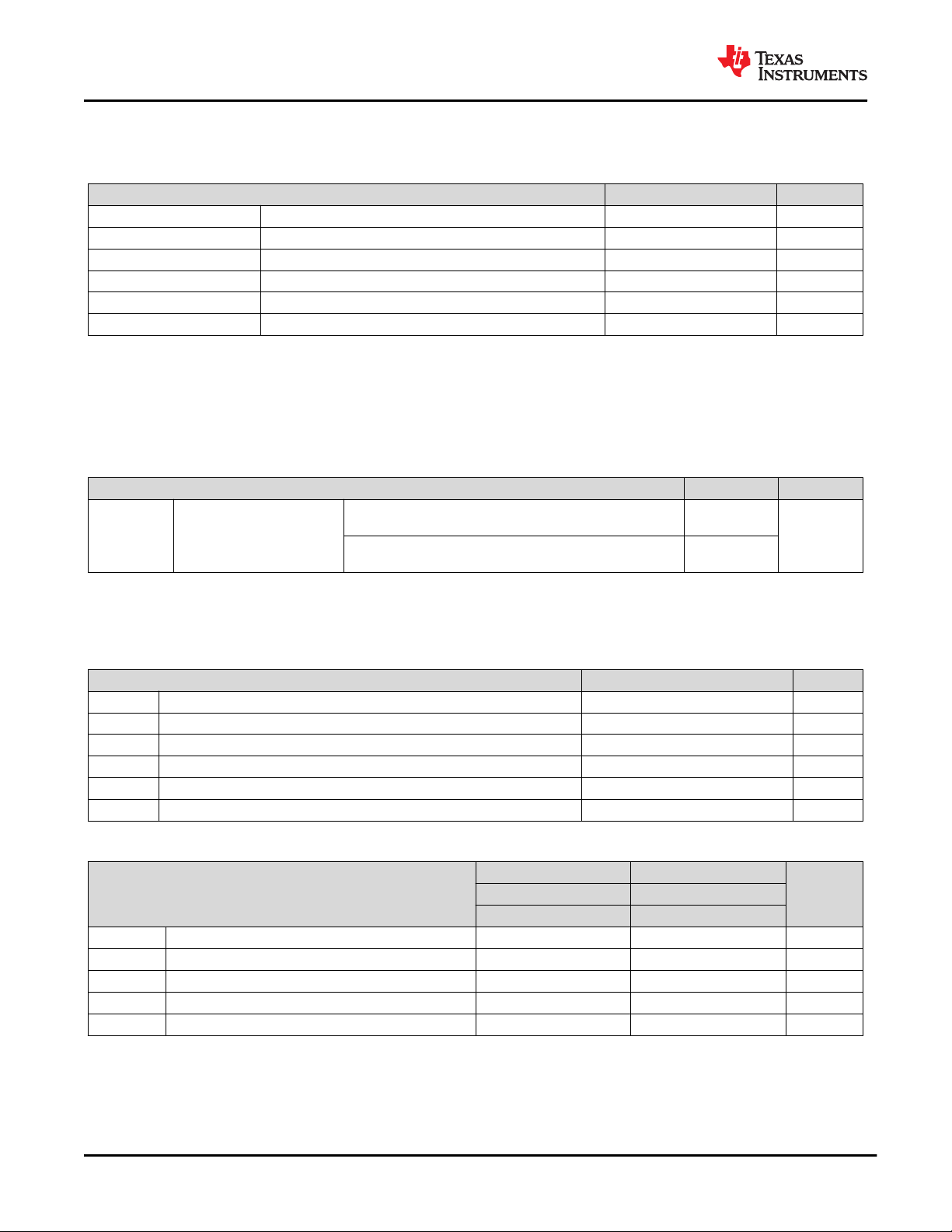

6 Specifications

6.1 Absolute Maximum Ratings

over operating temperature range (unless otherwise noted)

Pin voltage

Pin voltage

Pin voltage

Pin voltage

Temperature Operating Junction, T

Temperature Storage, T

(1) Stresses beyond those listed under Absolute Maximum Rating may cause permanent damage to the device. These are stress ratings

(2) All voltage values are with respect to the network ground terminal

(3) While switching

(2)

(2)

(2)

(2)

VIN, FB, EN, PG – 0.3 6 V

SW (DC) – 0.3 VIN + 0.3 V

SW (DC, in current limit) – 1 VIN + 0.3

SW (AC, less than 10ns)

STG

(3)

J

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under

Recommended Operating Condition. Exposure to absolute-maximum-rated conditions for extended periods may affect device

reliability.

6.2 ESD Ratings

Human body model (HBM), per ANSI/ESDA/JEDEC

(1)

V

(ESD)

Electrostatic discharge

JS-001

Charged device model (CDM), per JEDEC

specificationJESD22-C101

(1)

MIN MAX UNIT

– 2.5 10 V

–40 150 °C

–65 150 °C

VALUE UNIT

±2000

V

(2)

±500

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.3 Recommended Operating Conditions

Over operating temperature range (unless otherwise noted)

MIN NOM MAX UNIT

V

IN

V

OUT

I

OUT

V

PG

I

SINK_PG

T

J

Input voltage range 2.5 5.5 V

Output voltage range 0.6 4.0 V

Output curent range 0 4 A

Pull-up resistor voltage 5.5 V

Sink current at PG pin 1 mA

Operating junction temperature –40 125 °C

6.4 Thermal Information

TLV62595 TLV62595EVM-794

(1)

6 PINS 6 PINS

R

θJA

R

θJC(top)

R

θJB

Ψ

JT

Y

JB

THERMAL METRIC

Junction-to-ambient thermal resistance 129.5 71.4 °C/W

Junction-to-case (top) thermal resistance 103.9 n/a °C/W

Junction-to-board thermal resistance 33.1 n/a °C/W

Junction-to-top characterization parameter 3.8 3.9 °C/W

Junction-to-board characterization parameter 33.1 38.6 °C/W

UNITDMQ (JEDEC) DMQ (EVM)

(1) For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

4 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TLV62595

www.ti.com

6.5 Electrical Characteristics

TJ = 25 °C and VIN = 5 V, unless otherwise noted.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SUPPLY

I

Q

I

SD

V

UVLO

T

JSD

LOGIC INTERFACE EN

V

IH

V

IL

SOFT START, POWER GOOD

t

SS

V

PG

V

PG,OL

I

PG,LKG

t

PG,DLY

OUTPUT

V

FB

I

FB,LKG

I

DIS

POWER SWITCH

R

DS(on)

I

LIM

f

SW

Quiescent current EN = High, no load, device not switching 10 µA

Shutdown current EN = Low, TJ = -40℃ to 85℃ 0.05 µA

Undervoltage lock out threshold VIN falling 2.1 2.2 2.3 V

Undervoltage lock out hysteresis VIN rising 160 mV

Thermal shutdown threshold TJ rising 150 °C

Thermal shutdown hysteresis TJ falling 20 °C

High-level threshold voltage VIN = 2.5 V to 5.5 V 1.0 V

Low-level threshold voltage VIN = 2.5 V to 5.5 V 0.4 V

Soft start time Time from EN high to 95% of V

Power good lower threshold

Power good upper threshold

Low-level output voltage I

Input leakage current into PG pin VPG = 5.0 V 0.01 µA

Power good deglitch delay

Feedback regulation voltage

Feedback input leakage current for

adjustable output voltage

Output discharge current VSW = 0.4V; EN = LOW 400 mA

Load regulation I

High-side FET on-resistance 26 mΩ

Low-side FET on-resistance 25 mΩ

High-side FET switch current limit, DC 4.8 5.6 A

PWM switching frequency I

SLUSDR2 – DECEMBER 2020

TLV62595

nominal 1.75 ms

OUT

VPG rising, VFB referenced to VFB nominal 96 %

VPG falling, VFB referenced to VFB nominal 92 %

VPG rising, VFB referenced to VFB nominal 105 %

VPG falling, VFB referenced to VFB nominal 110 %

= 1 mA 0.4 V

sink

PG rising edge 100

PG falling edge 20

PWM mode, 2.5 V ≤ VIN ≤ 5.5 V, TJ = -40°C to

125°C

594 600 606 mV

VFB = 0.6 V 0.01 µA

= 0.5 A to 3 A, V

OUT

= 1 A, V

OUT

OUT

= 1.8 V 0.1 %/A

OUT

= 1.8 V 2.2 MHz

µs

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TLV62595

Submit Document Feedback

5

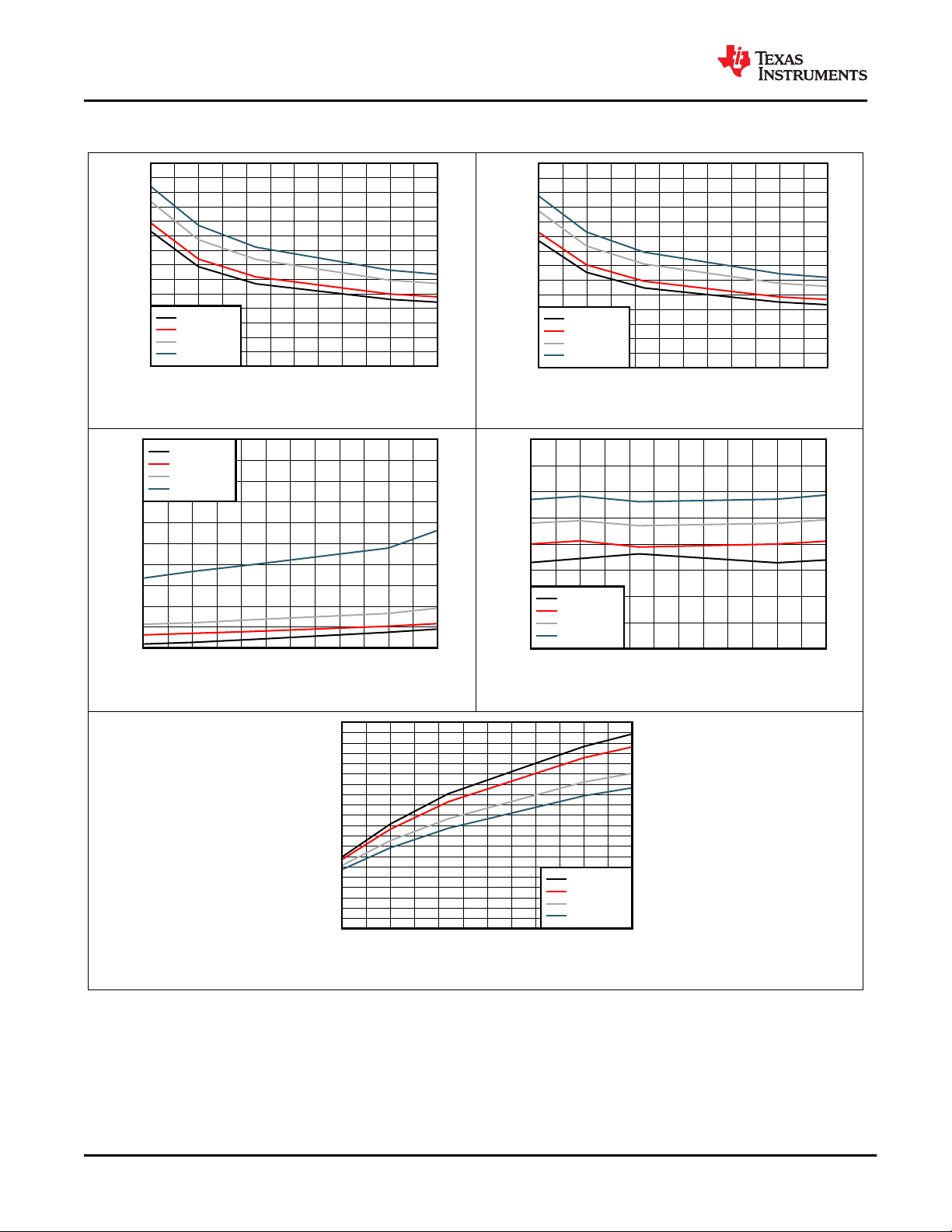

Input Voltage (V)

R

DS(on)

(mOhm)

2.5 3.0 3.5 4.0 4.5 5.0 5.5

0.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

D010

TJ = 0 °C

TJ = 25 °C

TJ = 85 °C

TJ = 125 °C

Input Voltage (V)

R

DS(on)

(mOhm)

2.5 3.0 3.5 4.0 4.5 5.0 5.5

0.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

D011

TJ = 0 °C

TJ = 25 °C

TJ = 85 °C

TJ = 125 °C

Input Voltage (V)

6KXWGRZQ&XUUHQW$

2.5 3.0 3.5 4.0 4.5 5.0 5.5

0.0

0.1

0.2

0.3

0.4

0.5

D000

TJ = -40 °C

TJ = 25 °C

TJ = 85 °C

TJ = 125 °C

Input Voltage (V)

4XLHVFHQW&XUUHQW$

2.5 3.0 3.5 4.0 4.5 5.0 5.5

0.0

2.0

4.0

6.0

8.0

D001

TJ = -40 °C

TJ = 25 °C

TJ = 85 °C

TJ = 125 °C

Input Voltage (V)

Output Discharge Current (mA)

2.5 3.0 3.5 4.0 4.5 5.0 5.5

0

50

100

150

200

250

300

350

400

450

500

D012

TJ = 0 °C

TJ = 25 °C

TJ = 85 °C

TJ = 125 °C

TLV62595

SLUSDR2 – DECEMBER 2020

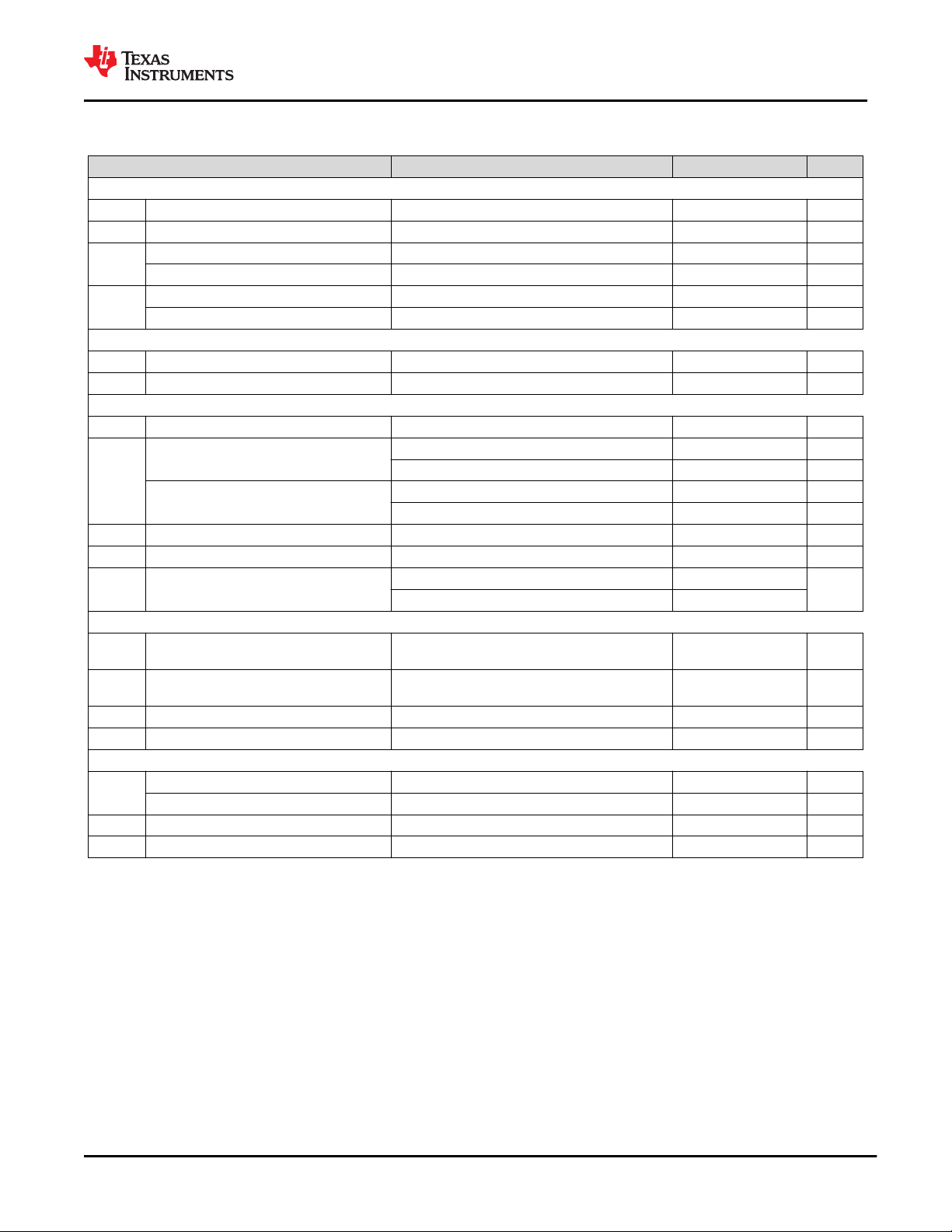

6.6 Typical Characteristics

www.ti.com

Figure 6-1. High-Side FET On-Resistance

Figure 6-3. Shutdown Current

Figure 6-2. Low-Side FET On-Resistance

Figure 6-4. Quiescent Current

6 Submit Document Feedback

Figure 6-5. Output Discharge Current

Product Folder Links: TLV62595

Copyright © 2020 Texas Instruments Incorporated

UVLO

Control Logic

Soft-Start

Thermal

Shutdown

Gate Drive

Peak Current Detect

Zero Current Detect

HICCUP

Modulator

Ton

Ramp

EA

V

SW

V

SW

V

REF

V

FB

V

REF

V

IN

V

SW

V

FB

V

REF

Comp

V

IN

FB

EN

0.6 V

Or

Fixed Output Voltages

PG

VIN

SW

GND

Output

Discharge

www.ti.com

SLUSDR2 – DECEMBER 2020

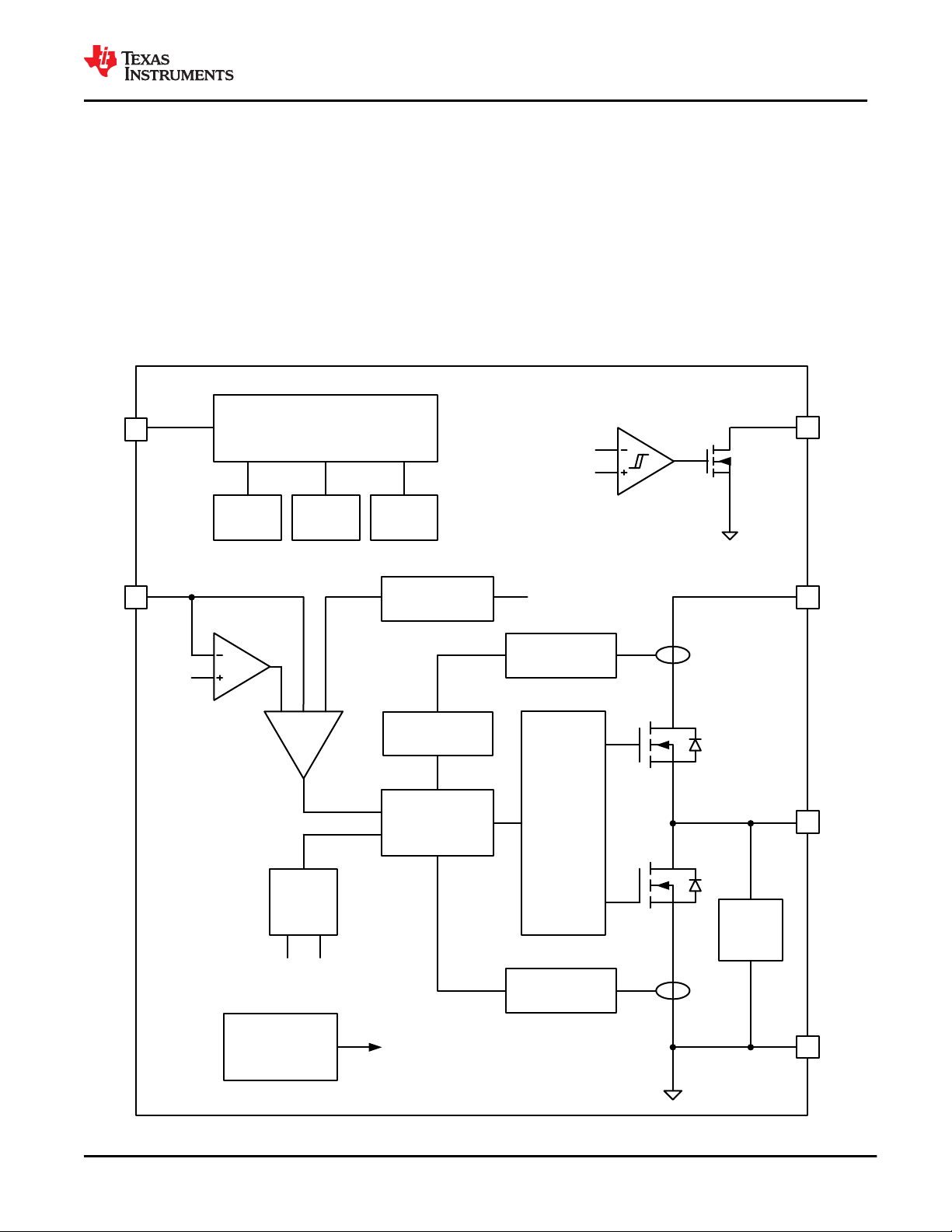

7 Detailed Description

7.1 Overview

The TLV62595 are synchronous step-down converters based on the DCS-Control topology with an adaptive

constant on-time control and a stabilized switching frequency. It operates in PWM (pulse width modulation) mode

for medium to heavy loads and in PSM (power save mode) at light load conditions, keeping the output voltage

ripple small. The nominal switching frequency is about 2.2 MHz with a small and controlled variation over the

input voltage range. As the load current decreases, the converter enters PSM, reducing the switching frequency

to keep efficiency high over the entire load current range. Since combining both PWM and PSM within a single

building block, the transition between modes is seamless and without effect on the output voltage. The devices

offer both excellent dc voltage and fast load transient regulation, combined with a very low output voltage ripple.

7.2 Functional Block Diagram

TLV62595

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TLV62595

Submit Document Feedback

7

ns

V

V

OUT

ON

450×=

×

=

-

é ù

×

ê ú

ë û

2

2

OUT

PSM

IN OUT

IN

ON

OUT

I

f

V V

V

T

V L

IN,MIN OUT OUT,MAX DS(on) L

V V I (R + R )= + ´

TLV62595

SLUSDR2 – DECEMBER 2020

www.ti.com

7.3 Feature Description

7.3.1 Pulse Width Modulation (PWM) Operation

At load currents larger than half the inductor ripple current, the device operates in pulse width modulation in

continuous conduction mode (CCM). The PWM operation is based on an adaptive constant on-time control with

stabilized switching frequency. To achieve a stable switching frequency in a steady state condition, the on-time is

calculated as:

(1)

7.3.2 Power Save Mode (PSM) Operation

To maintain high efficiency at light loads, the device enters power save mode (PSM) at the boundary to

discontinuous conduction mode (DCM). This happens when the output current becomes smaller than half of the

ripple current of the inductor. The device operates now with a fixed on-time and the switching frequency further

decreases proportionally to the load current. It can be calculated as:

(2)

In PSM, the output voltage rises slightly above the nominal target, which can be minimized using larger output

capacitance. At duty cycles larger than 90%, the device may not enter PSM. The device maintains output

regulation in PWM mode.

7.3.3 Minimum Duty Cycle and 100% Mode Operation

There is no limitation for small duty cycles, since even at very low duty cycles, the switching frequency is

reduced as needed to always ensure a proper regulation.

If the output voltage level comes close to the input voltage, the device enters 100% mode. While the high-side

switch is constantly turned on, the low-side switch is switched off. The difference between VIN and VOUT is

determined by the voltage drop across the high-side FET and the dc resistance of the inductor. The minimum

VIN that is needed to maintain a specific VOUT value is estimated as:

(3)

where

• V

• I

• R

= Minimum input voltage to maintain an output voltage

IN,MIN

OUT,MAX

= Maximum output current

= High-side FET ON-resistance

DS(on)

• RL = Inductor ohmic resistance (DCR)

7.3.4 Soft Start

About 250 μs after EN goes high, the internal soft-start circuitry controls the output voltage during start-up. This

avoids excessive inrush current and ensures a controlled output voltage ramp. It also prevents unwanted voltage

drops from high-impedance power sources or batteries. The TLV62595 can start into a pre-biased output.

7.3.5 Switch Current Limit and HICCUP Short-Circuit Protection

The switch current limit prevents the device from drawing excessive current in case of externally-caused

overcurrent or short circuit condition. Due to an internal propagation delay (typically 60 ns), the actual ac peak

current can exceed the static current limit during that time.

8 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TLV62595

www.ti.com

SLUSDR2 – DECEMBER 2020

TLV62595

If the current limit threshold is reached, the device delivers its maximum output current. Detecting this condition

for 32 switching cycles (about 13 μs), the device turns off the high-side MOSFET for about 100 μs which allows

the inductor current to decrease through the low-side MOSFET's body diode and then restart again with a soft

start cycle. As long as the overload condition is present, the device hiccups that way, limiting the output power.

7.3.6 Undervoltage Lockout

The undervoltage lockout (UVLO) function prevents misoperation of the device, if the input voltage drops below

the UVLO threshold. It is set to about 2.2 V with a hysteresis of typically 160 mV.

7.3.7 Thermal Shutdown

The junction temperature (TJ) of the device is monitored by an internal temperature sensor. If TJ exceeds 150°C

(typ.), the device goes in thermal shutdown with a hysteresis of typically 20°C. Once the TJ has decreased

enough, the device resumes normal operation.

7.4 Device Functional Modes

7.4.1 Enable, Disable and Output Discharge

The device starts operation, when Enable (EN) is set High. The input threshold levels are typically 0.9 V for

rising and 0.7 V for falling signals. Do not leave EN floating. Shutdown is forced if EN is pulled low with a

shutdown current of typically 50 nA. During shutdown, the internal power MOSFETs as well as the entire control

circuitry, are turned off and the output voltage is actively discharged through the SW pin by a current sink.

Therefore VIN must remain present for the discharge to function.

7.4.2 Power Good

The TLV62595 has a built-in power good (PG) function. The PG pin goes high impedance, when the output

voltage has reached its nominal value. Otherwise, including when disabled, in UVLO or in thermal shutdown, PG

is low (see Table 7-1). The PG function is formed with a window comparator, which has an upper and lower

voltage threshold. The PG pin is an open-drain output and is specified to sink up to 1 mA. The power good

output requires a pullup resistor connecting to any voltage rail less than 5.5 V.

The PG signal can be used for sequencing of multiple rails by connecting it to the EN pin of other converters.

Leave the PG pin unconnected when not used. The PG rising edge has a 100-µs blanking time and the PG

falling edge has a deglitch delay of 20 µs.

Table 7-1. PG Pin Logic

DEVICE CONDITIONS

EN = High, VFB ≥ 0.576 V √

Enable

Shutdown EN = Low √

Thermal Shutdown TJ > T

UVLO 0.7 V < VIN < V

Power Supply Removal VIN < 0.7 V √

EN = High, VFB ≤ 0.552 V √

EN = High, VFB ≤ 0.63 V √

EN = High, VFB ≥ 0.66 V √

JSD

UVLO

HIGH Z LOW

LOGIC STATUS

√

√

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TLV62595

Submit Document Feedback

9

R1

200 k

R2

100 k

SW

GND FB

EN

PG

VIN

C2

3x10 µF

R3

100 k

C1

4.7 µF

V

IN

2.5 V to 5.5 V

V

PG

V

OUT

1.8 V

L1

0.47 µH

TLV62595

C3

120 pF

TLV62595

SLUSDR2 – DECEMBER 2020

www.ti.com

8 Application and Implementation

Note

Information in the following applications sections is not part of the TI component specification, and TI

does not warrant its accuracy or completeness. TI’s customers are responsible for determining

suitability of components for their purposes, as well as validating and testing their design

implementation to confirm system functionality.

8.1 Application Information

The following section discusses the design of the external components to complete the power supply design for

several input and output voltage options by using typical applications as a reference.

8.2 Typical Application

Figure 8-1. Typical Application of TLV62595

8.2.1 Design Requirements

For this design example, use the parameters listed in Table 8-1 as the input parameters.

Table 8-1. Design Parameters

DESIGN PARAMETER EXAMPLE VALUE

Input voltage, TLV62595 2.5 V to 5.5 V

Output voltage 1.8 V

Output ripple voltage <20 mV

Maximum output current, TLV62595 4 A

Table 8-2 lists the components used for the example.

Table 8-2. List of Components

REFERENCE DESCRIPTION MANUFACTURER

C1 4.7 µF, Ceramic capacitor, 6.3 V, X7R, size 0603, JMK107BB7475MA Taiyo Yuden

C2 3 x 10 µF, Ceramic capacitor, 10 V, X7R, size 0603, GRM188Z71A106MA73D Murata

C3 120 pF, Ceramic capacitor, 50 V, size 0402 Std

L1 0.47 µH, Power Inductor, XFL4015-471MEB Coilcraft

R1 Depending on the output voltage, 1%, size 0402 Std

R2 100 kΩ, Chip resistor, 1/16 W, 1%, size 0402 Std

R3 100 kΩ, Chip resistor, 1/16 W, 1%, size 0402 Std

1. See the Third-Party Products Disclaimer.

10 Submit Document Feedback

Product Folder Links: TLV62595

Copyright © 2020 Texas Instruments Incorporated

OUT OUT

FB

V V

R1 R2 1 R2 1

V 0.6V

§ ·

§ ·

u u

¨ ¸

¨ ¸

© ¹

© ¹

µ12

3C

www.ti.com

SLUSDR2 – DECEMBER 2020

8.2.2 Detailed Design Procedure

8.2.2.1 Custom Design With WEBENCH® Tools

Click here to create a custom design using the TLV62595 device with the WEBENCH® Power Designer.

TLV62595

1. Start by entering the input voltage (VIN), output voltage (V

), and output current (I

OUT

) requirements.

OUT

2. Optimize the design for key parameters such as efficiency, footprint, and cost using the optimizer dial.

3. Compare the generated design with other possible solutions from Texas Instruments.

The WEBENCH Power Designer provides a customized schematic along with a list of materials with real-time

pricing and component availability.

In most cases, these actions are available:

• Run electrical simulations to see important waveforms and circuit performance

• Run thermal simulations to understand board thermal performance

• Export customized schematic and layout into popular CAD formats

• Print PDF reports for the design, and share the design with colleagues

Get more information about WEBENCH tools at www.ti.com/WEBENCH.

8.2.2.2 Setting The Output Voltage

The output voltage is set by an external resistor divider according to Equation 4:

(4)

R2 must not be higher than 100 kΩ to achieve high efficiency at light load while providing acceptable noise

sensitivity. Equation 5 shows how to compute the value of the feedforward capacitor for a given R2 value. For

the recommended 100 k value for R2, a 120-pF feedforward capacitor is used.

(5)

For the fixed output voltage versions, connect the FB pin to the output. R1, R2, and C3 are not needed. The

fixed output voltage devices have an internal feedforward capacitor.

8.2.2.3 Output Filter Design

The inductor and the output capacitor together provide a low-pass filter. To simplify this process, Table 8-3

outlines possible inductor and capacitor value combinations for most applications. Checked cells represent

combinations that are proven for stability by simulation and lab test. Further combinations should be checked for

each individual application.

Table 8-3. Matrix of Output Capacitor and Inductor Combinations, TLV62595

NOMINAL L [µH]

0.33

0.47 + +

1.0

(1) This LC combination is the standard value and recommended for most applications.

(2) Inductor tolerance and current derating is anticipated. The effective inductance can vary by 20% and –30%.

(3) Capacitance tolerance and bias voltage derating is anticipated. The effective capacitance can vary by 20% and –35%.

(2)

10 2 x 10 or 22 47 100

NOMINAL C

(1)

OUT

[µF]

(3)

+

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TLV62595

Submit Document Feedback

11

SW

IN

OUT

OUTL

L

MAX,OUTMAX,L

fL

V

V

1

VI

2

I

II

´

-

´=D

D

+=

TLV62595

SLUSDR2 – DECEMBER 2020

www.ti.com

Table 8-4. Matrix of Output Capacitor and Inductor Combinations, TLV62595

NOMINAL L [µH]

0.33

0.47 +

1.0

(2)

22 3 x 10 47 100

NOMINAL C

(1)

OUT

(3)

[µF]

+ +

8.2.2.4 Inductor Selection

The main parameter for the inductor selection is the inductor value and then the saturation current of the

inductor. To calculate the maximum inductor current under static load conditions, Equation 6 is given.

(6)

where

• I

OUT,MAX

= Maximum output current

• ΔIL = Inductor current ripple

• fSW = Switching frequency

• L = Inductor value

It is recommended to choose a saturation current for the inductor that is approximately 20% to 30% higher than

I

. In addition, DC resistance and size should also be taken into account when selecting an appropriate

L,MAX

inductor. Table 8-5 lists recommended inductors.

Table 8-5. List of Recommended Inductors

INDUCTANCE

[µH]

0.47

(1) See Third-party Products Disclaimer.

CURRENT RATING

[A]

4.8 2.0 x 1.6 x 1.0 32 HTEN20161T-R47MDR, Cyntec

4.6 2.0 x 1.2 x 1.0 25 HTEH20121T-R47MSR, Cyntec

4.8 2.0 x 1.6 x 1.0 32 DFE201610E - R47M, MuRata

4.8 2.0 x 1.6 x 1.0 32 DFE201210S - R47M, MuRata

5.1 2.0 x 1.6 x 1.0 34 TFM201610ALM-R47MTAA, TDK

5.2 2.0 x 1.6 x 1.0 25 TFM201610ALC-R47MTAA, TDK

6.6 4.0 x 4.0 x 1.6 8.36 XFL4015-471ME, Coilcraft

8.0 3.5 x 3.2 x 2.0 10.85 XEL3520-471ME, Coilcraft

6.8 4.5 x 4 x 1.8 11.2 WE-LHMI-744373240047, Würth

DIMENSIONS [L x W x

H mm]

MAX. DC

RESISTANCE [mΩ]

MFR PART NUMBER

(1)

8.2.2.5 Capacitor Selection

The input capacitor is the low-impedance energy source for the converters which helps to provide stable

operation. A low-ESR multilayer ceramic capacitor is recommended for best filtering and must be placed

between VIN and GND as close as possible to those pins. For most applications, a minimum effective input

capacitance of 3 µF should be present, though a larger value reduces input current ripple.

The architecture of the device allows the use of tiny ceramic output capacitors with low equivalent series

resistance (ESR). These capacitors provide low output voltage ripple and are recommended. To keep its low

resistance up to high frequencies and to get narrow capacitance variation with temperature, TI recommends

12 Submit Document Feedback

Product Folder Links: TLV62595

Copyright © 2020 Texas Instruments Incorporated

www.ti.com

SLUSDR2 – DECEMBER 2020

using X7R or X5R dielectrics. Considering the DC-bias derating the capacitance, the minimum effective output

capacitance is 20 µF for TLV62595.

A feedforward capacitor is required for the adjustable version, as described in Section 8.2.2.2. This capacitor is

not required for the fixed output voltage versions.

TLV62595

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TLV62595

Submit Document Feedback

13

Load (A)

Efficiency (%)

45

50

55

60

65

70

75

80

85

90

95

100P 1m 10m 100m 1 4

D002

VIN = 2.5V

VIN = 3.3V

VIN = 4.2V

VIN = 5.0V

Load (A)

Vout (V)

0.588

0.591

0.594

0.597

0.6

0.603

0.606

0.609

0.612

100P 1m 10m 100m 1 4

D021

VIN = 2.5 V

VIN = 3.3 V

VIN = 4.2 V

VIN = 5.0 V

Load (A)

Efficiency (%)

55

60

65

70

75

80

85

90

95

100

100P 1m 10m 100m 1 4

D003

VIN = 2.5V

VIN = 3.3V

VIN = 4.2V

VIN = 5.0V

Load (A)

Vout (V)

1.188

1.191

1.194

1.197

1.2

1.203

1.206

1.209

1.212

100P 1m 10m 100m 1 4

D031

VIN = 2.4 V

VIN = 3.3 V

VIN = 4.5 V

VIN = 5.0 V

Load (A)

Efficiency (%)

60

65

70

75

80

85

90

95

100

100P 1m 10m 100m 1 4

D004

VIN = 2.5V

VIN = 3.3V

VIN = 4.2V

VIN = 5.0V

Load (A)

Vout (V)

1.782

1.788

1.794

1.8

1.806

1.812

1.818

100P 1m 10m 100m 1 4

D041

VIN = 2.5 V

VIN = 3.3 V

VIN = 4.2 V

VIN = 5.0 V

TLV62595

SLUSDR2 – DECEMBER 2020

8.2.3 Application Curves

www.ti.com

VIN = 5.0 V, V

= 1.8 V, TA = 25°C, BOM = Table 8-2, unless otherwise noted.

OUT

V

= 0.6 V

OUT

Figure 8-2. Efficiency

V

= 0.6 V

OUT

Figure 8-3. Load Regulation

V

= 1.2 V

OUT

Figure 8-4. Efficiency

14 Submit Document Feedback

Figure 8-6. Efficiency

V

OUT

= 1.8 V

Product Folder Links: TLV62595

V

= 1.2 V

OUT

Figure 8-5. Load Regulation

V

= 1.8 V

OUT

Figure 8-7. Load Regulation

Copyright © 2020 Texas Instruments Incorporated

Load (A)

Efficiency (%)

60

65

70

75

80

85

90

95

100

100P 1m 10m 100m 1 4

D006

VIN = 3.3V

VIN = 4.2V

VIN = 5.0V

Load (A)

Vout (V)

2.475

2.485

2.495

2.505

2.515

2.525

100P 1m 10m 100m 1 4

D061

VIN = 3.3 V

VIN = 4.2 V

VIN = 5.0 V

Load (A)

Efficiency (%)

70

75

80

85

90

95

100

100P 1m 10m 100m 1 4

D005

VIN = 4.2V

VIN = 5.0V

Load (A)

Vout (V)

3.260

3.280

3.300

3.320

3.340

100P 1m 10m 100m 1 4

D051

VIN = 4.2V

VIN = 5.0V

Load (A)

Switching Frequency (kHz)

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

0

250

500

750

1000

1250

1500

1750

2000

2250

2500

2750

3000

D013

V

OUT

= 0.6V

V

OUT

= 1.2V

V

OUT

= 1.8V

V

OUT

= 2.5V

Input Voltage (V)

Switching Frequency (kHz)

2.5 3.0 3.5 4.0 4.5 5.0 5.5

0

250

500

750

1000

1250

1500

1750

2000

2250

2500

2750

3000

D014

V

OUT

= 0.6V

V

OUT

= 1.2V

V

OUT

= 1.8V

V

OUT

= 2.5V

V

OUT

= 3.3V

www.ti.com

V

OUT

= 2.5 V

V

OUT

SLUSDR2 – DECEMBER 2020

TLV62595

= 2.5 V

Figure 8-8. Efficiency

V

= 3.3 V

OUT

Figure 8-10. Efficiency

Figure 8-9. Load Regulation

V

= 3.3 V

OUT

Figure 8-11. Load Regulation

VIN = 3.3 V

Copyright © 2020 Texas Instruments Incorporated

Figure 8-12. Switching Frequency

Figure 8-13. Switching Frequency

Product Folder Links: TLV62595

I

OUT

= 1.0 A

Submit Document Feedback

15

Ambient Temperature (°C)

Output Current (A)

45 55 65 75 85 95 105 115 125

0

1

2

3

4

5

D020

VIN = 2.5 V

VIN = 3.3 V

VIN = 5.0 V

Ambient Temperature (°C)

Output Current (A)

45 55 65 75 85 95 105 115 125

0

1

2

3

4

5

D015

VIN = 2.5 V

VIN = 3.3 V

VIN = 5.0 V

Ambient Temperature (°C)

Output Current (A)

45 55 65 75 85 95 105 115 125

0

1

2

3

4

5

D017

VIN = 3.3 V

VIN = 5.0 V

Ambient Temperature (°C)

Output Current (A)

45 55 65 75 85 95 105 115 125

0

1

2

3

4

5

D016

VIN = 5.0 V

TLV62595

SLUSDR2 – DECEMBER 2020

V

= 1.2 V θJA= 71.4 °C/W

OUT

V

= 1.8 V θJA= 71.4 °C/W

OUT

www.ti.com

Figure 8-14. Thermal Derating

V

= 2.5 V θJA= 71.4 °C/W

OUT

Figure 8-16. Thermal Derating

Figure 8-15. Thermal Derating

V

= 3.3 V θJA= 71.4 °C/W

OUT

Figure 8-17. Thermal Derating

I

= 1.0 A

16 Submit Document Feedback

Figure 8-18. PWM Operation

OUT

Product Folder Links: TLV62595

I

= 0.1 A

OUT

Figure 8-19. PSM Operation

Copyright © 2020 Texas Instruments Incorporated

www.ti.com

SLUSDR2 – DECEMBER 2020

TLV62595

Load = 0.6 Ω

Figure 8-20. Start-up with Load

Load = 1.8 Ω

Figure 8-22. Disable, Active Output Discharge

Figure 8-21. Startup with No Load

Figure 8-23. Disable, Active Output Discharge at

No Load

I

= 0.05 A to 1A

OUT

Figure 8-24. Load Transient

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TLV62595

I

= 1 A to 2 A

OUT

Figure 8-25. Load Transient

Submit Document Feedback

17

7LPHV',9

D018

V

OUT

1V/DIV

I

COIL

2A/DIV

V

PG

5V/DIV

7LPHV',9

D019

V

OUT

1V/DIV

I

COIL

2A/DIV

V

PG

5V/DIV

TLV62595

SLUSDR2 – DECEMBER 2020

I

OUT

= 1 A

I

OUT

www.ti.com

= 1 A

Figure 8-26. HICCUP Short Circuit Protection

Figure 8-27. HICCUP Short Circuit Protection

(Zoom In)

9 Power Supply Recommendations

The device is designed to operate from an input voltage supply range from 2.4 V to 5.5 V. Ensure that the input

power supply has a sufficient current rating for the application.

18 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TLV62595

L1

VIN

GND

VOUT

C2

C1

C3

R1

R2

L1

C1

G

N

D

E

N

P

G

F

B

S

W

V

I

N

Solution size = 31mm

2

www.ti.com

SLUSDR2 – DECEMBER 2020

TLV62595

10 Layout

10.1 Layout Guidelines

The printed-circuit-board (PCB) layout is an important step to maintain the high performance of the device. See

Figure 10-1 for the recommended PCB layout.

• The input/output capacitors and the inductor should be placed as close as possible to the IC. This keeps the

power traces short. Routing these power traces direct and wide results in low trace resistance and low

parasitic inductance.

• The low side of the input and output capacitors must be connected properly to the GND pin to avoid a ground

potential shift.

• The sense traces connected to FB is a signal trace. Special care should be taken to avoid noise being

induced. Keep these traces away from SW nodes. The connection of the output voltage trace for the FB

resistors should be made at the output capacitor.

• Refer to Figure 10-1 for an example of component placement, routing and thermal design.

10.2 Layout Example

10.2.1 Thermal Considerations

Implementation of integrated circuits in low-profile and fine-pitch surface-mount packages typically requires

special attention to power dissipation. Many system-dependent issues such as thermal coupling, airflow, added

heat sinks and convection surfaces, and the presence of other heat-generating components affect the power

dissipation limits of a given component.

Two basic approaches for enhancing thermal performance are:

• Improving the power dissipation capability of the PCB design

• Introducing airflow in the system

Section 6.4 provides the thermal metric of the device on the EVM after considering the PCB design of real

applications. The big copper planes connecting to the pads of the IC on the PCB improve the thermal

performance of the device. For more details on how to use the thermal parameters, see the Thermal

Characteristics Application Notes, SZZA017 and SPRA953.

Figure 10-1. PCB Layout Recommendation

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TLV62595

Submit Document Feedback

19

TLV62595

SLUSDR2 – DECEMBER 2020

www.ti.com

11 Device and Documentation Support

11.1 Device Support

11.1.1 Third-Party Products Disclaimer

TI'S PUBLICATION OF INFORMATION REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT

CONSTITUTE AN ENDORSEMENT REGARDING THE SUITABILITY OF SUCH PRODUCTS OR SERVICES

OR A WARRANTY, REPRESENTATION OR ENDORSEMENT OF SUCH PRODUCTS OR SERVICES, EITHER

ALONE OR IN COMBINATION WITH ANY TI PRODUCT OR SERVICE.

11.1.2 Development Support

11.1.2.1 Custom Design With WEBENCH® Tools

Click here to create a custom design using the TLV62595 device with the WEBENCH® Power Designer.

1. Start by entering the input voltage (VIN), output voltage (V

), and output current (I

OUT

) requirements.

OUT

2. Optimize the design for key parameters such as efficiency, footprint, and cost using the optimizer dial.

3. Compare the generated design with other possible solutions from Texas Instruments.

The WEBENCH Power Designer provides a customized schematic along with a list of materials with real-time

pricing and component availability.

In most cases, these actions are available:

• Run electrical simulations to see important waveforms and circuit performance

• Run thermal simulations to understand board thermal performance

• Export customized schematic and layout into popular CAD formats

• Print PDF reports for the design, and share the design with colleagues

Get more information about WEBENCH tools at www.ti.com/WEBENCH.

11.2 Documentation Support

11.2.1 Related Documentation

For related documentation, see the following:

• Texas Instruments, Thermal Characteristics Application Note, SZZA017

• Texas Instruments, Thermal Characteristics Application Note, SPRA953

11.3 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. Click on

Subscribe to updates to register and receive a weekly digest of any product information that has changed. For

change details, review the revision history included in any revised document.

11.4 Support Resources

TI E2E™ support forums are an engineer's go-to source for fast, verified answers and design help — straight

from the experts. Search existing answers or ask your own question to get the quick design help you need.

Linked content is provided "AS IS" by the respective contributors. They do not constitute TI specifications and do

not necessarily reflect TI's views; see TI's Terms of Use.

11.5 Trademarks

TI E2E™ is a trademark of Texas Instruments.

WEBENCH® is a registered trademark of Texas Instruments.

All trademarks are the property of their respective owners.

20 Submit Document Feedback

Product Folder Links: TLV62595

Copyright © 2020 Texas Instruments Incorporated

www.ti.com

SLUSDR2 – DECEMBER 2020

11.6 Electrostatic Discharge Caution

TLV62595

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled

with appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may

be more susceptible to damage because very small parametric changes could cause the device not to meet its published

specifications.

11.7 Glossary

TI Glossary This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most

current data available for the designated devices. This data is subject to change without notice and revision of

this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: TLV62595

Submit Document Feedback

21

PACKAGE OPTION ADDENDUM

www.ti.com

PACKAGING INFORMATION

Orderable Device Status

TLV62595DMQR ACTIVE VSON-HR DMQ 6 3000 RoHS & Green NIPDAU Level-1-260C-UNLIM -40 to 125 IM

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead finish/

Ball material

(6)

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

(2)

RoHS: TI defines "RoHS" to mean semiconductor products that are compliant with the current EU RoHS requirements for all 10 RoHS substances, including the requirement that RoHS substance

do not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, "RoHS" products are suitable for use in specified lead-free processes. TI may

reference these types of products as "Pb-Free".

RoHS Exempt: TI defines "RoHS Exempt" to mean products that contain lead but are compliant with EU RoHS pursuant to a specific EU RoHS exemption.

Green: TI defines "Green" to mean the content of Chlorine (Cl) and Bromine (Br) based flame retardants meet JS709B low halogen requirements of <=1000ppm threshold. Antimony trioxide based

flame retardants must also meet the <=1000ppm threshold requirement.

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead finish/Ball material - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead finish/Ball material values may wrap to two

lines if the finish value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

6-Jan-2021

Samples

Addendum-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com 6-Jan-2021

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

TLV62595DMQR VSON-HRDMQ 6 3000 180.0 8.4 1.75 1.75 1.0 4.0 8.0 Q2

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com 6-Jan-2021

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TLV62595DMQR VSON-HR DMQ 6 3000 210.0 185.0 35.0

Pack Materials-Page 2

PACKAGE OUTLINE

PIN 1 INDEX AREA

1 MAX

SCALE 6.000

B

1.55

1.45

A

1.55

1.45

C

VSON - 1 mm max heightDMQ0006A

PLASTIC SMALL OUTLINE - NO LEAD

SEATING PLANE

0.08 C

0.5

3X

0.3

4X 0.5

2X

1

0.3

3X

0.2

0.1 C A B

0.05

C

(0.2) MIN

3

1

0.9

3X

0.7

4

6

0.25

3X

0.15

0.1 C A B

0.05

0.05

0.00

C

(0.2) TYP

4222645/C 10/2020

NOTES:

1. All linear dimensions are in millimeters. Any dimensions in parenthesis are for reference only. Dimensioning and tolerancing

per ASME Y14.5M.

2. This drawing is subject to change without notice.

www.ti.com

EXAMPLE BOARD LAYOUT

VSON - 1 mm max heightDMQ0006A

PLASTIC SMALL OUTLINE - NO LEAD

3X (0.25)

4X (0.5)

(R0.05) TYP

3X (0.6)

1

3

LAND PATTERN EXAMPLE

0.05 MAX

ALL AROUND

(0.65)

SCALE:30X

3X (1)

3X (0.2)

6

SYMM

4

(0.45)

PKG

0.05 MIN

ALL AROUND

SOLDER MASK

OPENING

NON SOLDER MASK

METAL

PADS 4-6

DEFINED

METAL UNDER

SOLDER MASK

SOLDER MASK

SOLDER MASK DETAILS

NOTES: (continued)

3. For more information, see Texas Instruments literature number SLUA271 (www.ti.com/lit/slua271).

www.ti.com

SOLDER MASK

OPENING

PADS 1-3

DEFINED

4222645/C 10/2020

EXAMPLE STENCIL DESIGN

VSON - 1 mm max heightDMQ0006A

PLASTIC SMALL OUTLINE - NO LEAD

EXPOSED METAL

3X (0.25)

4X (0.5)

(R0.05) TYP

METAL UNDER

SOLDER MASK

TYP

1

3

3X

3X (0.6)

(0.65)

3X (0.85)

(0.525)

PKG

SOLDER PASTE EXAMPLE

BASED ON 0.125 mm THICK STENCIL

81% PRINTED SOLDER COVERAGE BY AREA UNDER PACKAGE

PADS 4, 5 & 6:

SCALE:30X

3X (0.2)

6

SYMM

4

SOLDER MASK

OPENING

TYP

4222645/C 10/2020

NOTES: (continued)

4. Laser cutting apertures with trapezoidal walls and rounded corners may offer better paste release. IPC-7525 may have alternate

design recommendations.

www.ti.com

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party

intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages,

costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (https:www.ti.com/legal/termsofsale.html) or other applicable terms available either

on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s

applicable warranties or warranty disclaimers for TI products.IMPORTANT NOTICE

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2021, Texas Instruments Incorporated

Loading...

Loading...