Datasheet TLV571EVM, TLV571IPW, TLV571IPWR, TLV571IDWR, TLV571IDW Datasheet (Texas Instruments)

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

features

D

Fast Throughput Rate: 1.25 MSPS at 5 V,

625 KSPS at 3 V

D

Wide Analog Input: 0 V to AV

DD

D

Differential Nonlinearity Error: < ± 0.5 LSB

D

Integral Nonlinearity Error: < ± 0.5 LSB

D

Single 2.7-V to 5.5-V Supply Operation

D

Low Power: 12 mW at 3 V and 35 mW at 5 V

D

Auto Power Down of 1 mA Max

D

Software Power Down: 10 µA Max

D

Internal OSC

D

Hardware Configurable

D

DSP and Microcontroller Compatible

Parallel Interface

D

Binary/Twos Complement Output

D

Hardware Controlled Extended Sampling

D

Hardware or Software Start of Conversion

applications

D

Mass Storage and HDD

D

Automotive

D

Digital Servos

D

Process Control

D

General-Purpose DSP

D

Image Sensor Processing

description

The TLV571 is an 8-bit data acquisition system

that combines a high-speed 8-bit ADC and a

parallel interface. The device contains two on-chip control registers allowing control of software conversion start

and power down via the bidirectional parallel port. The control registers can be set to a default mode using a

dummy RD

while WR is tied low allowing the registers to be hardware configurable.

The TL V571 operates from a single 2.7-V to 5.5-V power supply. It accepts an analog input range from 0 V to

AVDD and digitizes the input at a maximum 1.25 MSPS throughput rate at 5 V . The power dissipations are only

12 mW with a 3-V supply or 35 mW with a 5-V supply. The device features an auto power-down mode that

automatically powers down to 1 mA 50 ns after conversion is performed. In software power-down mode, the

ADC is further powered down to only 10 µA.

Very high throughput rate, simple parallel interface, and low power consumption make the TLV571 an ideal

choice for high-speed digital signal processing.

AVAILABLE OPTIONS

PACKAGE

T

A

24 TSSOP

(PW)

24 SOIC

(DW)

–40°C to 85°C TLV571IPW TLV571IDW

Copyright 2000, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

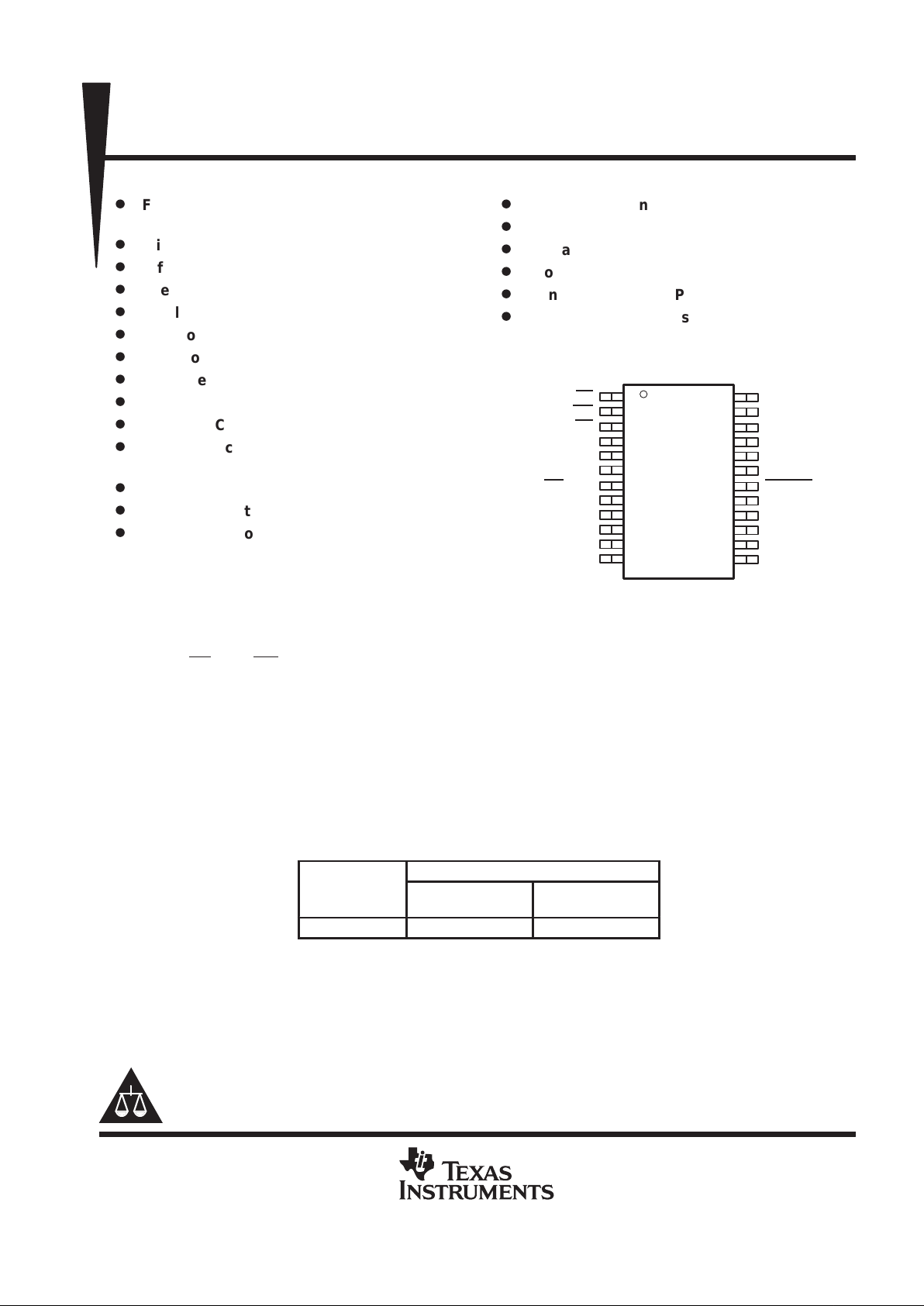

NC – No internal connection

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

CS

WR

RD

CLK

DGND

DV

DD

INT/EOC

DGND

DGND

D0

D1

D2

NC

AIN

AV

DD

AGND

REFM

REFP

CSTART

A1/D7

A0/D6

D5

D4

D3

DW OR PW PACKAGE

(TOP VIEW)

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

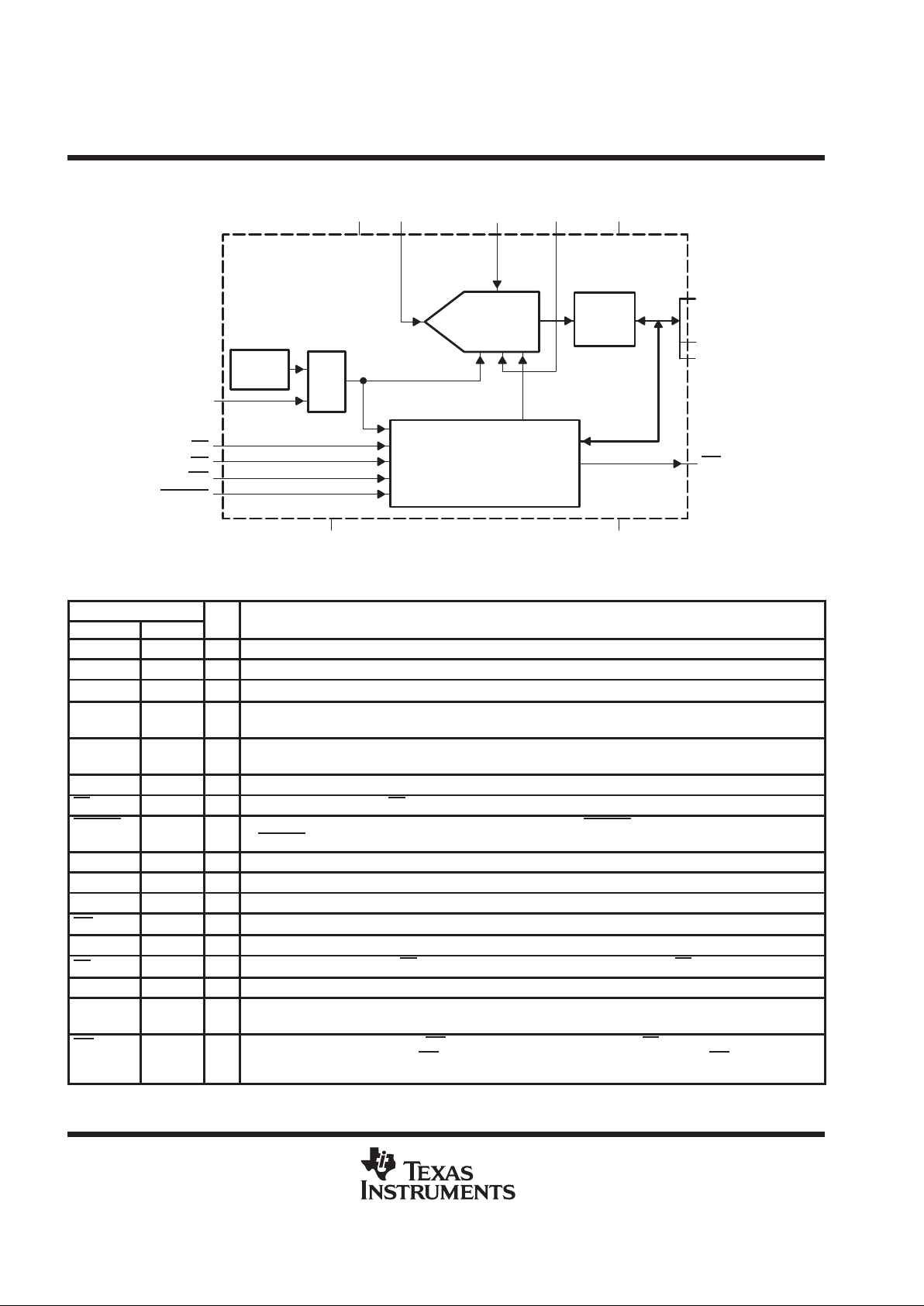

functional block diagram

Internal

Clock

CLK

CS

RD

INT/EOC

MUX

8-BIT

SAR ADC

Input Registers

and Control Logic

WR

CSTART

REFP

Three

State

Latch

AV

DD

D0 – D5

D6/A0

D7/A1

REFM DV

DD

DGNDAGND

AIN

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

AGND 21 Analog ground

AIN 23 I ADC analog input

AV

DD

22 Analog supply voltage, 2.7 V to 5.5 V

A0/D6 16 I/O Bidirectional 3-state data bus. D6/A0 along with D7/A1 is used as address lines to access CR0 and CR1 for

initialization.

A1/D7 17 I/O Bidirectional 3-state data bus. D7/A1 along with D6/A0 is used as address lines to access CR0 and CR1 for

initialization.

CLK 4 I External clock input

CS 1 I Chip select. A logic low on CS enables the TLV571.

CSTAR T 18 I Hardware sample and conversion start input. The falling edge of CST AR T starts sampling and the rising edge

of CSTART

starts conversion.

DGND 5, 8, 9 Digital ground

DV

DD

6 Digital supply voltage, 2.7 V to 5.5 V

D0 – D5 10–15 I/O Bidirectional 3-state data bus

INT/EOC

7 O End-of-conversion/interrupt

NC 24 Not connected

RD

3 I Read data. A falling edge on RD enables a read operation on the data bus when CS is low.

REFM 20 I Lower reference voltage (nominally ground). REFM must be supplied or REFM pin must be grounded.

REFP 19 I Upper reference voltage (nominally AVDD). The maximum input voltage range is determined by the difference

between the voltage applied to REFP and REFM.

WR

2 I Write data. A rising edge on the WR latches in configuration data when CS is low. When using software

conversion start, a rising edge on WR

also initiates an internal sampling start pulse. When WR is tied to ground,

the ADC in nonprogrammable (hardware configuration mode).

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

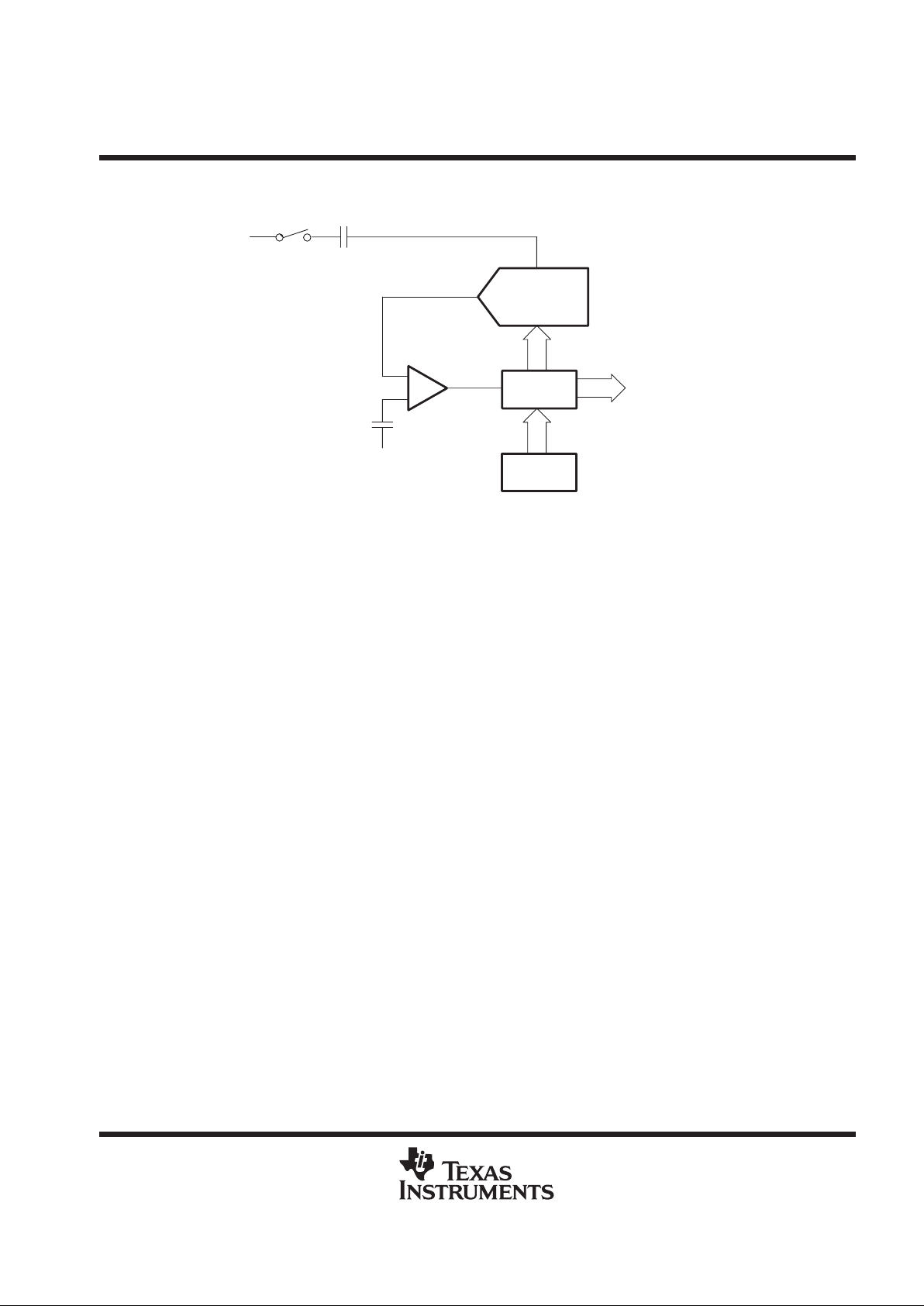

detailed description

analog-to-digital SAR converter

_

+

Charge

Redistribution

DAC

SAR

Register

REFM

ADC Code

Control

Logic

Ain

Figure 1

The TLV571 is a successive-approximation ADC utilizing a charge redistribution DAC. Figure 1 shows a

simplified version of the ADC.

The sampling capacitor acquires the signal on Ain during the sampling period. When the conversion process

starts, the SAR control logic and charge redistribution DAC are used to add and subtract fixed amounts of charge

from the sampling capacitor to bring the comparator into a balanced condition. When the comparator is

balanced, the conversion is complete and the ADC output code is generated.

sampling frequency, f

s

The TLV571 requires 16 CLKs for each conversion, therefore the equivalent maximum sampling frequency

achievable with a given CLK frequency is:

f

s(max)

= (1/16) f

CLK

The TL V571 is software configurable. The first two MSB bits, D(7,6) are used to address which register to set.

The remaining six bits are used as control data bits. There are two control registers, CR0 and CR1, that are user

configurable. All of the register bits are written to the control register during write cycles. A description of the

control registers is shown in Figure 2.

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

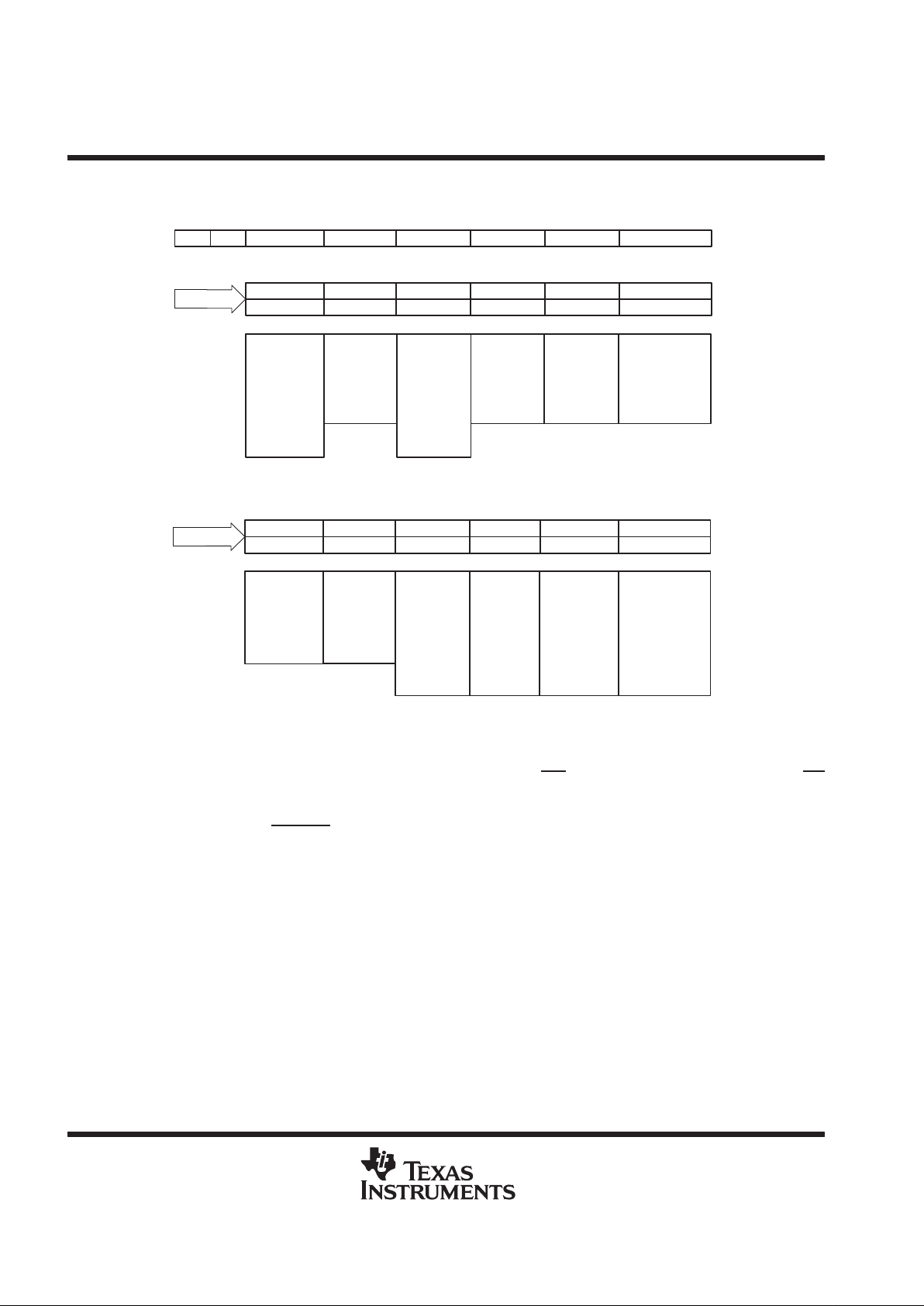

detailed description (continued)

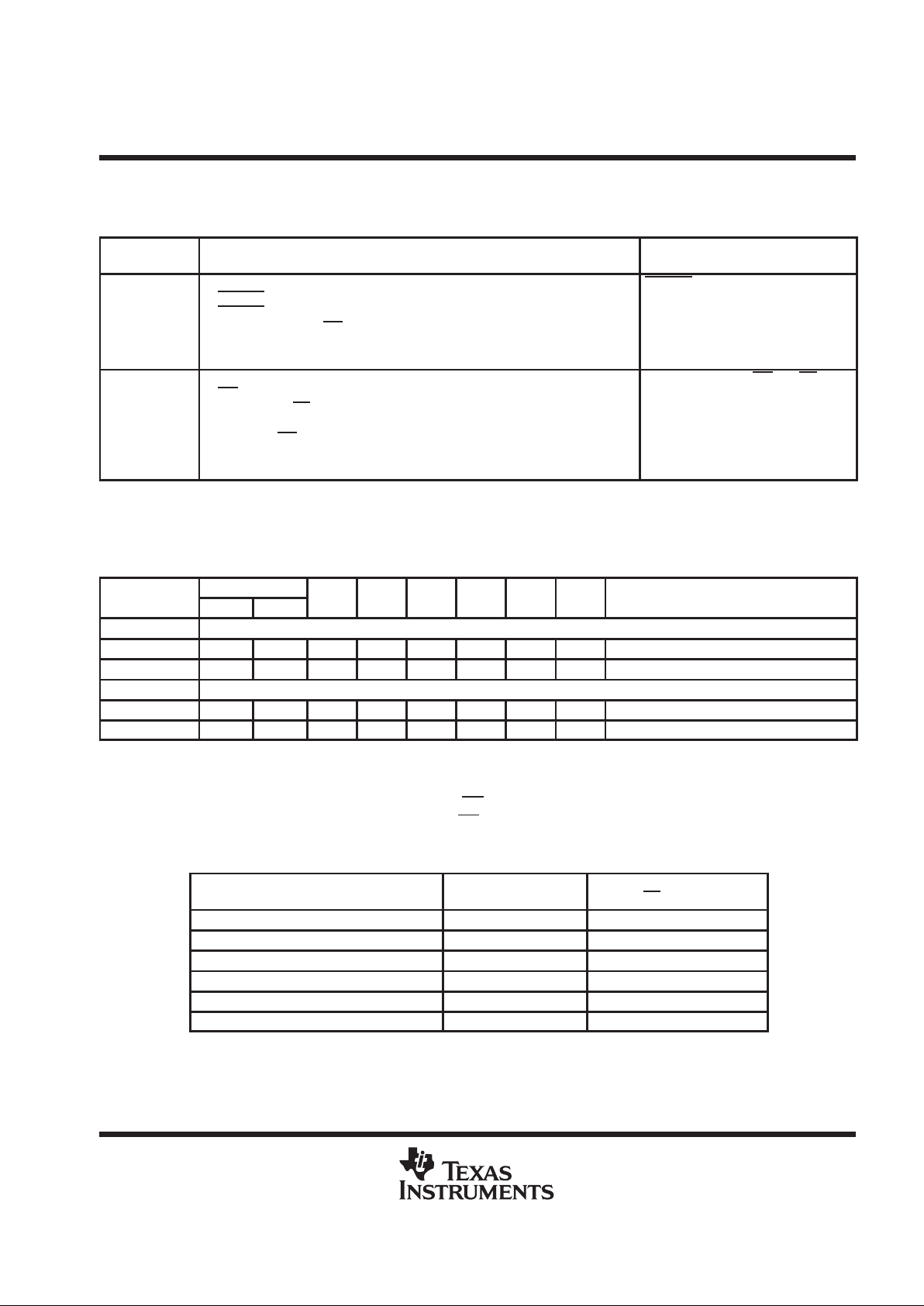

control registers

0:

Binary

1:

2’s

Complement

0:

Reserved

Bit,

Always

Write 0

0:

INT. OSC.

SLOW

1:

INT. OSC.

FAST

STARTSEL

A1 A0 D4 D3 D2 D1 D0D5

Control Register Zero (CR0)

D4D5 D3 D2 D1 D0

PROGEOC

CLKSEL SWPWDN Don’t Care

0:

HARDWARE

START

(CSTART)

A(1:0)=00

1:

SOFTWARE

START

0:

INT

1:

EOC

0:

Internal

Clock

1:

External

Clock

0:

NORMAL

1:

Powerdown

Reserved

Control Register One (CR1)

D4D5 D1 D0

OSCSPD 0 Reserved 0 Reserved OUTCODE Reserved

0:

Reserved

Bit

Always

Write 0

A(1:0)=01

0:

Reserved

Bit

Always

Write 0

D3 D2

Don’t Care

Don’t Care

Don’t Care

0:

Reserved

Bit,

Always

Write 0

Figure 2. Input Data Format

hardware configuration option

The TLV571 can configure itself. This option is enabled when the WR

pin is tied to ground and a dummy RD

signal is applied. The ADC is now fully configured. Zeros or default values are applied to both control registers.

The ADC is configured ideally for 3-V operation, which means the internal OSC is set at 10 MHz and hardware

start of conversion using CSTART.

ADC conversion modes

The TLV571 provides two start of conversion modes. Table 1 explains these modes in more detail.

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

detailed description (continued)

Table 1. Conversion Modes

START OF

CONVERSION

OPERATION COMMENTS – FOR INPUT

Hardware start

(CSTAR T)

CR0.D5 = 0

• Repeated conversions from AIN

• CSTART

falling edge to start sampling

• CSTART

rising edge to start conversion

• If in INT mode, one INT

pulse generated after each conversion

• If in EOC mode, EOC will go high to low at start of conversion, and return high

at end of conversion.

CSTAR T rising edge must be applied

a minimum of 5 ns before or after CLK

rising edge.

Software start

CR0.D5 = 1

• Repeated conversions from AIN

• WR

rising edge to start sampling initially. Thereafter, sampling occurs at the

rising edge of RD

.

• Conversion begins after 6 clocks after sampling has begun. Thereafter, if in INT

mode, one INT

pulse generated after each conversion

• If in EOC mode, EOC will go high to low at start of conversion and return high at

end of conversion.

With external clock, WR and RD rising

edge must be a minimum 5 ns before

or after CLK rising edge.

configure the device

The device can be configured by writing to control registers CR0 and CR1.

Table 2. TLV571 Programming Examples

INDEX

REGISTER

D7 D6

D5D4D3D2D1

D0

COMMENT

EXAMPLE1

CR0 0 0 0 0 0 0 0 0 Normal, INT OSC

CR1 0 1 0 0 0 0 0 0 Binary

EXAMPLE2

CR0 0 0 0 1 1 1 0 0 Power down, EXT OSC

CR1 0 1 0 0 0 0 1 0 2’s complement output

power down

The TLV571 offers two power down modes, auto power down and software power down. This device will

automatically proceed to auto power down mode if RD is not present one clock after conversion. Software power

down is controlled directly by the user by pulling CS to DVDD.

Table 3. Power Down Modes

PARAMETERS/MODES AUTO POWER DOWN

SOFTWARE POWER DOWN

(CS

= DVDD)

Maximum power down dissipation current 1 mA 10 µA

Comparator Power down Power down

Clock buffer Power down Power down

Control registers Saved Saved

Minimum power down time 1 CLK 2 CLK

Minimum resume time 1 CLK 2 CLK

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

detailed description (continued)

reference voltage input

The TL V571 has two reference input pins: REFP and REFM. The voltage levels applied to these pins establish

the upper and lower limits of the analog inputs to produce a full-scale and zero-scale reading respectively . The

values of REFP, REFM, and the analog input should not exceed the positive supply or be less than GND

consistent with the specified absolute maximum ratings. The digital output is at full scale when the input signal

is equal to or higher than REFP and is at zero when the input signal is equal to or lower than REFM.

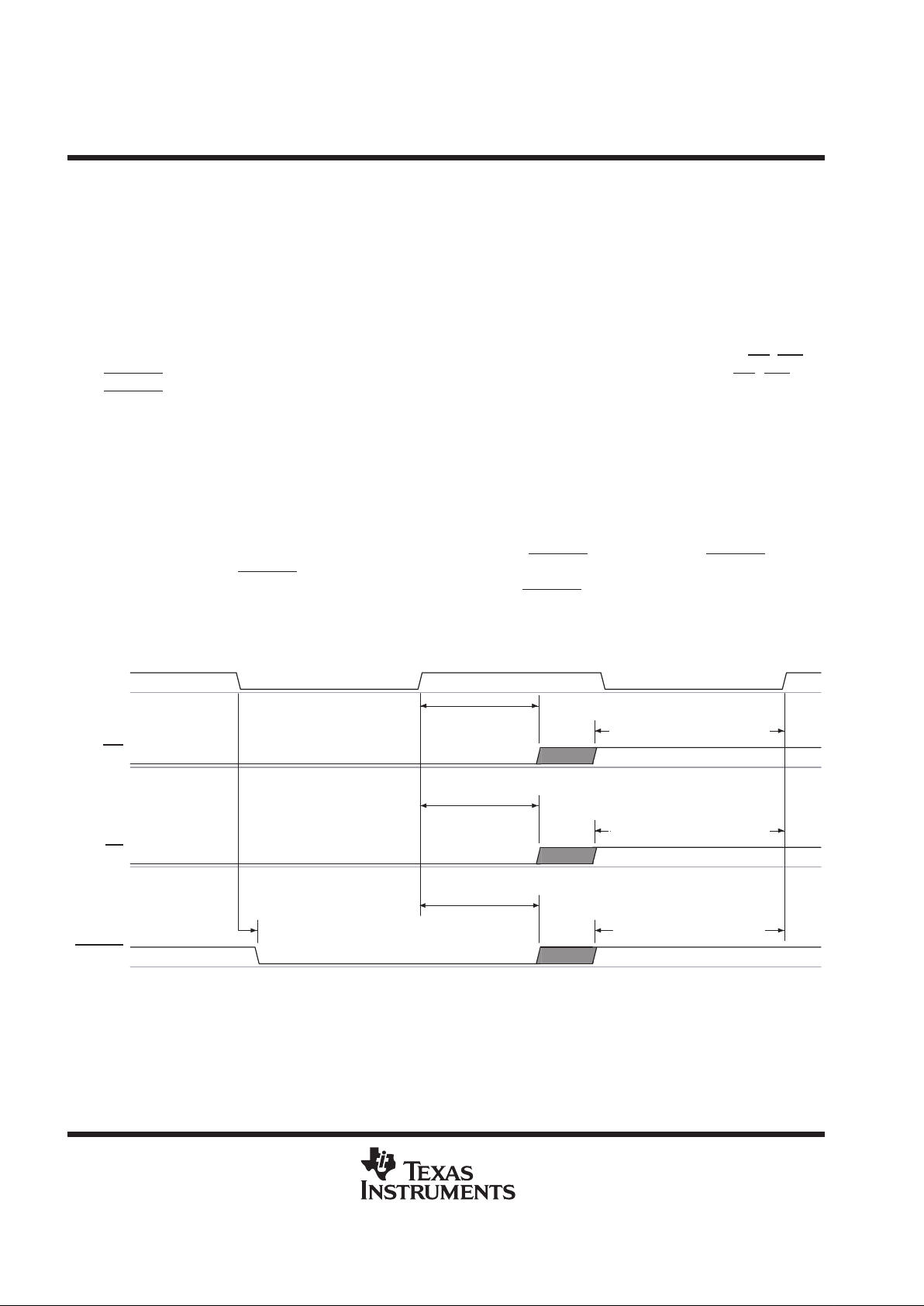

sampling/conversion

All sampling, conversion, and data output in the device are started by a trigger. This could be the RD, WR, or

CST ART signal depending on the mode of conversion and configuration. The rising edge of RD, WR, and

CSTART signal are extremely important, since they are used to start the conversion. These edges need to stay

close to the rising edge of the external clock (if it is used as CLK). The minimum setup and hold time with respect

to the rising edge of the external clock should be 5 ns minimum. When the internal clock is used, this is not an

issue since these two edges will start the internal clock automatically . Therefore, the setup time is always met.

Software controlled sampling lasts 6 clock cycles. This is done via the CLK input or the internal oscillator if

enabled. The input clock frequency can be 1 MHz to 20 MHz, translating into a sampling time from 0.6 µs to

0.3 µs. The internal oscillator frequency is 9 MHz minimum (ocillator frequency is between 9 MHz to 22 MHz),

translating into a sampling time from 0.6 µs to 0.3 µs. Conversion begins immediately after sampling and lasts

10 clock cycles. This is again done using the external clock input (1 MHz–20 MHz) or the internal oscillator

(9 MHz minimum) if enabled. Hardware controlled sampling, via CST AR T

, begins on falling CST AR T lasts the

length of the active CSTART

signal. This allows more control over the sampling time, which is useful when

sampling sources with large output impedances. On rising CSTART, conversion begins. Conversion in

hardware controlled mode also lasts 10 clock cycles. This is done using the external clock input (1 MHz–20 MHz)

or the internal oscillator (9 MHz minimum) as is the case in software controlled mode.

NOTE: tsu = setup time, th = hold time

ExtClk

WR

RD

CSTART

t

su(WRH_EXTCLKH)

≥5 ns

t

h(WRL_EXTCLKH)

≥5 ns

t

h(RDL_EXTCLKH)

≥5 ns

t

d(EXTCLK_CSTARTL)

≥5 ns

t

h(CSTARTL_EXTCLKH)

≥5 ns

t

su(CSTARTH_EXTCLKH)

≥5 ns

OR

OR

t

su(RDH_EXTCLKH)

≥5 ns

Figure 3. Trigger Timing – Software Start Mode Using External Clock

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

start of conversion mechanism

There are two ways to convert data: hardware and software. In the hardware conversion mode the ADC begins

sampling at the falling edge of CSTART and begins conversion at the rising edge of CSTART. Software start

mode ADC samples for 6 clocks, then conversion occurs for ten clocks. The total sampling and conversion

process lasts only 16 clocks in this case. If RD

is not detected during the next clock cycle, the ADC automatically

proceeds to a power-down state. Data is valid on the rising edge of INT in both conversion modes.

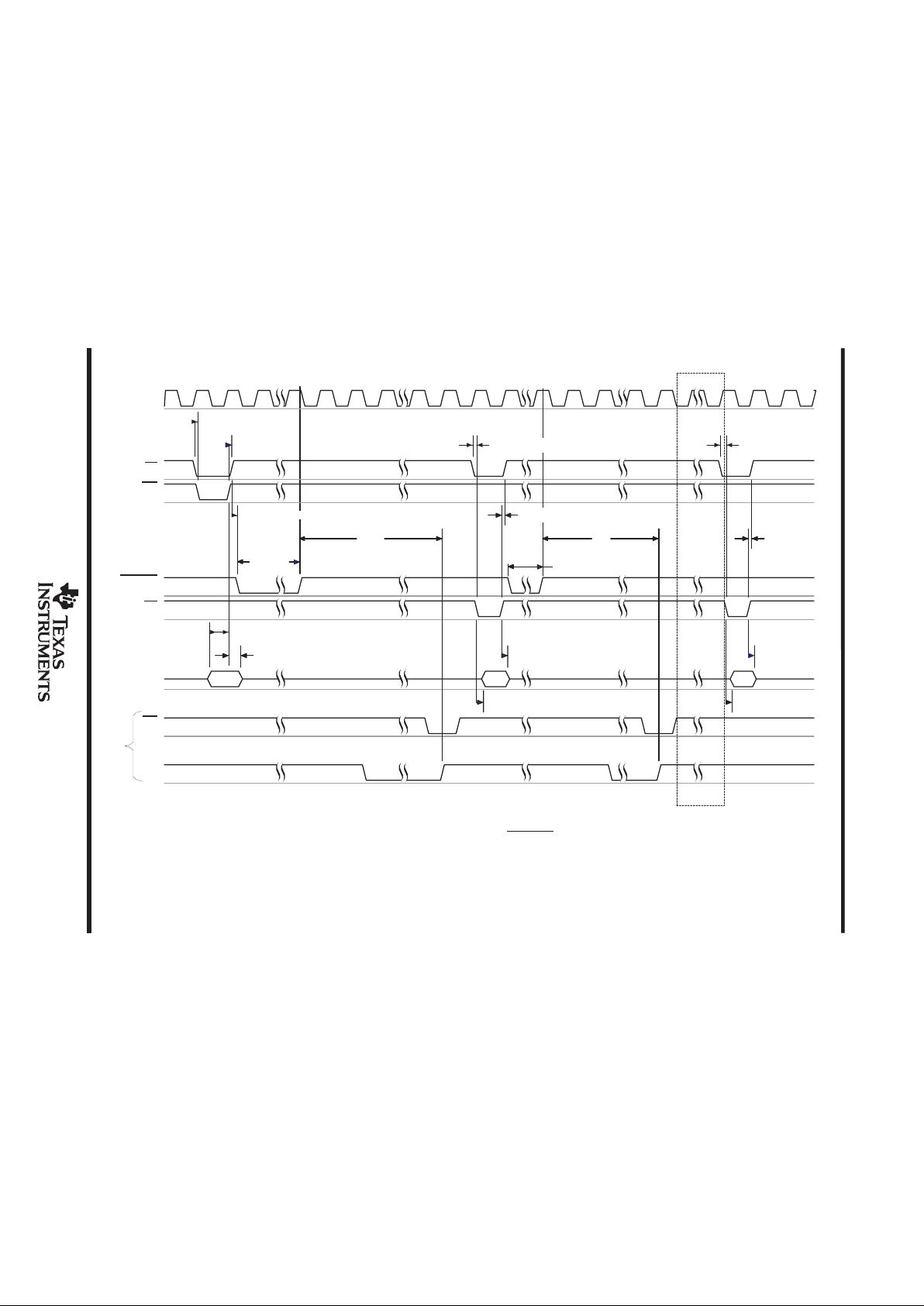

hardware CST ART conversion

external clock

With CS low and WR low, data is written into the ADC. The sampling begins at the falling edge of CSTART and

conversion begins at the rising edge of CST AR T. At the end of conversion, EOC goes from low to high, telling

the host that conversion is ready to be read out. The external clock is active and is used as the reference at all

times. With this mode, it is required that CST ART is not applied at the rising edge of the clock (see Figure 4).

TLV571

2.7 V to 5.5 V, 1-CHANNEL, 8-BIT

RARALLEL ANALOG-TO-DIGIT AL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

8

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

•

start of conversion mechanism (continued)

CLK

D[0:7]

EOC

t

su(CSL_WRL)

t

h(WRH_CSH)

t

d(CSH_CSTARTL)

t

(sample)

t

su(DAV_WRH)

t

h(WRH_DAV)

t

c

(10 CLKs)

t

en(RDL_DAV)

t

dis(RDH_DAV)

t

c

t

su(CSL_RDL)

t

en(RDL_DAV)

OR

Auto Powerdown

ADC ADC

Config

Data

t

(sample)

su(CSL_RDL)

t

h(RDH_CSH)

t

CS

WR

CSTART

RD

INT

Figure 4. Input Conversion – Hardware CSTART, External Clock

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

• 9

internal clock

With CS low and WR low, data is written into the ADC. The sampling begins at the falling edge of CST ART, and conversion begins at the rising

edge of CSTART. The internal clock turns on at the rising edge of CSTART. The internal clock is disabled after each conversion.

OR

Auto Powerdown

CS

WR

CSTART

INTCLK

RD

D[0:7]

INT

EOC

Config

Data

ADC

Data

ADC

Data

t

su(CSL_WRL)

t

h(WRH_CSH)

t

d(CSH_CSTARTL)

t

(sample)

t

su(DAV_WRH)

t

h(WRH_DAV)

t

c

t

su(CSL_RDL)

t

h(RDH_CSH)

t

en(RDL_DAV)

t

dis(RDH_DAV)

t

c

t

su(CSL_RDL)

t

en(RDL_DAV)

t

(STARTOSC)

t

(STARTOSC)

9

10

10

Auto Powerdown

Figure 5. Input Conversion – Hardware CSTART, Internal Clock

TLV571

2.7 V to 5.5 V, 1-CHANNEL, 8-BIT

RARALLEL ANALOG-TO-DIGIT AL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

10

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

•

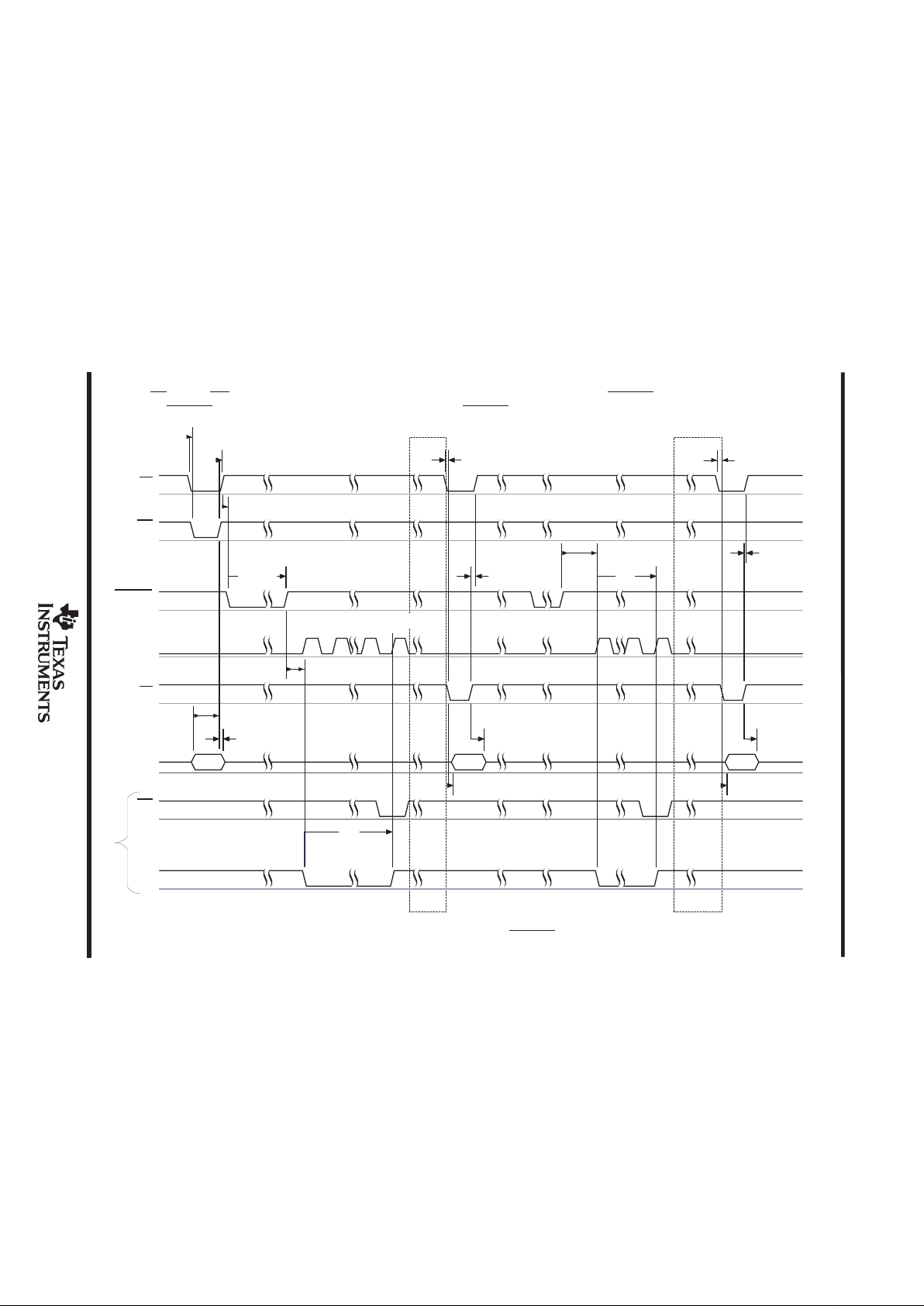

software START conversion

external clock

With CS low and WR low, data is written into the ADC. Sampling begins at the rising edge of WR. The conversion process begins 6 clocks

after sampling begins. At the end of conversion, the INT goes low telling the host that conversion is ready to be read out. EOC B low during

the conversion. The external clock is active and used as the reference at all times. With this mode, WR and RD should not be applied at the

rising edge of the clock (see Figure 3).

Auto Powerdown

CLK

CS

WR

RD

D[0:7]

INT

EOC

Config

Data

ADC Data ADC Data

t

su(CSL_WRL)

t

h(WRH_CSH)

t

su(DAV_WRH)

t

h(WRH_DAV)

t

c

t

su(CSL_RDL)

t

h(RDH_CSH)

t

en(RDL_DAV)

t

dis(RDH_DAV)

t

c

t

t

en(RDL_DAV)

015671516

OR

su(CSL_RDL)

t

(sample)

t

(sample)

04515

Figure 6. Input Conversion – Software Start, External Clock

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

• 11

software START conversion (continued)

internal clock

With CS low and WR low, data is written into the ADC. Sampling begins at the rising edge of WR. Conversion begins 6 clocks after sampling

begins. The internal clock begins at the rising edge of WR. The internal clock is disabled after each conversion. Subsequent sampling begins

at the rising edge of RD.

OR

Auto Powerdown

ADC

CS

WR

RD

INTCLK

D[0:7]

INT

EOC

Config

Data

ADC

Data

t

su(CSL_WRL)

t

h(WRH_CSH)

t

(sample)

t

su(DAV_WRH)

t

h(WRH_DAV)

t

c

t

su(CSL_RDL)

t

h(RDH_CSH)

t

en(RDL_DAV)

t

dis(RDH_DAV)

t

c

t

(STARTOSC)

t

(STARTOSC)

t

(sample)

456 045015 15

Auto Powerdown

Figure 7. Input Conversion – Software Start, Internal Clock

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

software START conversion (continued)

system clock source

The TLV571 internally derives multiple clocks from the SYSCLK for different tasks. SYSCLK is used for most

conversion subtasks. The source of SYSCLK is programmable via control register zero, bit 3. The source of

SYSCLK is changed at the rising edge of WR

of the cycle when CR0.D3 is programmed.

internal clock (CR0.D3 = 0, SYSCLK = internal OSC)

The TLV571 has a built-in 10 MHz OSC. When the internal OSC is selected as the source of SYSCLK, the

internal clock starts with a delay (one half of the OSC period max) after the falling edge of the conversion trigger

(either WR, RD, or CST ART). The OSC speed can be set to 10 ± 1 MHz or 20 ± 2 MHz by setting register bit

CR1.D4.

external clock (CR0.D3 = 1, SYSCLK = external clock)

The TLV571 is designed to accept an external clock input (CMOS/TTL logic) with frequencies from 1 MHz to

20 MHz.

host processor interface

The TLV571 provides a generic high-speed parallel interface that is compatible with high-performance DSPs

and general-purpose microprocessors. The interface includes D(0–7), INT/EOC, RD, and WR.

output format

The data output format is unipolar (code 0 to 255). The output code format can be either binary or twos

complement by setting register bit CR1.D1.

power up and initialization

After power up, CS

must be low to begin an I/O cycle. INT/EOC is initially high. The TL V571 requires two write

cycles to configure the two control registers. The first conversion after the device has returned from the power

down state may be invalid and should be disregarded.

definitions of specifications and terminology

integral nonlinearity

Integral nonlinearity refers to the deviation of each individual code from a line drawn from zero through full scale.

The point used as zero occurs 1/2 LSB before the first code transition. The full-scale point is defined as level

1/2 LSB beyond the last code transition. The deviation is measured from the center of each particular code to

the true straight line between these two points.

differential nonlinearity

An ideal ADC exhibits code transitions that are exactly 1 LSB apart. DNL is the deviation from this ideal value.

A differential nonlinearity error of less than ±1 LSB ensures no missing codes.

zero offset

The major carry transition should occur when the analog input is at zero volts. Zero error is defined as the

deviation of the actual transition from that point.

gain error

The first code transition should occur at an analog value 1/2 LSB above negative full scale. The last transition

should occur at an analog value 1 1/2 LSB below the nominal full scale. Gain error is the deviation of the actual

difference between first and last code transitions and the ideal difference between first and last code transitions.

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

software START conversion (continued)

signal-to-noise ratio + distortion (SINAD)

Signal-to-noise ratio + disortion is the ratio of the rms value of the measured input signal to the rms sum of all

other spectral components below the Nyquist frequency, including harmonics but excluding dc. The value for

SINAD is expressed in decibels.

effective number of bits (ENOB)

For a sine wave, SINAD can be expressed in terms of the number of bits. Using the following formula,

N = (SINAD – 1.76)/6.02

it is possible to get a measure of performance expressed as N, the effective number of bits. Thus, the effective

number of bits for a device for sine wave inputs at a given input frequency can be calculated directly from its

measured SINAD.

total harmonic distortion (THD)

T otal harmonic distortion is the ratio of the rms sum of the first six harmonic components to the rms value of the

measured input signal and is expressed as a percentage or in decibels.

spurious free dynamic range (SFDR)

Spurious free dynamic range is the difference in dB between the rms amplitude of the input signal and the peak

spurious signal.

DSP interface

The TL V571 is a 8-bit single input channel analog-to-digital converter with throughput up to 1.25 MSPS at 5 V

and up to 625 KSPS at 3 V . To achieve 1.25 MSPS throughput, the ADC must be clocked at 20 MHz. Likewise

to achieve 625 KSPS throughout, the ADC must be clocked at 10 MHz. The TL V571 can be easily interfaced

to microcontrollers, ASICs, and DSPs. Figure 8 shows the pin connections to interface the TLV571 to the

TMS320C6x DSP.

Address

Decoder

EN

A0–A15

TMS320C6X

HW

HR

INTx

D0–D15

D0–D7

CS

WR

RD

EOC

TLV571

REF

AIN

REFP

REFM

Figure 8. TMS320C6x DSP Interface

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

grounding and decoupling considerations

General practices should apply to the PCB design to limit high frequency transients and noise that are fed back

into the supply and reference lines. This requires that the supply and reference pins be sufficiently bypassed.

In most cases 0.1-µF ceramic chip capacitors are adequate to keep the impedance low over a wide frequency

range. Since their effectiveness depends largely on the proximity to the individual supply pin, they should be

placed as close to the supply pins as possible.

To reduce high frequency and noise coupling, it is highly recommended that digital and analog grounds be

shorted immediately outside the package. This can be accomplished by running a low impedance line between

DGND and AGND under the package.

TLV571

100 nF

DGND

DV

DD

AV

DD

AGND

REFP

REFM

100 nF

100 nF

V

REFP

V

REFM

AV

DD

DV

DD

Figure 9. Placement for Decoupling Capacitors

power supply ground layout

Printed-circuit boards that use separate analog and digital ground planes offer the best system performance.

Wire-wrap boards do not perform well and should not be used. The two ground planes should be connected

together at the low-impedance power-supply source. The best ground connection may be achieved by

connecting the ADC AGND terminal to the system analog ground plane making sure that analog ground

currents are well managed.

R

s

V

S

V

C

15 pF

Driving Source

†

TLV571

C

i

V

I

VI= Input Voltage at AIN

VS= External Driving Source Voltage

Rs= Source Resistance

R

i(ADC)

= Input Resistance of ADC

Ci= Input Capacitance

VC= Capacitance Charging Voltage

†

Driving source requirements:

• Noise and distortion for the source must be equivalent to the resolution of the converter.

• Rs must be real at the input frequency.

R

i(ADC)

AIN

Figure 10. Equivalent Input Circuit Including the Driving Source

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

simplified analog input analysis

Using the equivalent circuit in Figure 10, the time required to charge the analog input capacitance from 0 to V

S

within 1/2 LSB, tch(1/2 LSB), can be derived as follows.

The capacitance charging voltage is given by:

Where

R

t

= Rs + R

i

Ri = R

i(ADC)

tch = Charge time

V

C(t)

+

V

S

ǒ

1–e

–tchń

RtC

i

Ǔ

The input impedance Ri is 718 Ω at 5 V , and is higher (~ 1.25 kΩ) at 2.7 V. The final voltage to 1/2 LSB is given

by:

VC (1/2 LSB) = VS – (VS/512)

Equating equation 1 to equation 2 and solving for cycle time tc gives:

and time to change to 1/2 LSB (minimum sampling time) is:

t

ch

(1/2 LSB) = Rt × Ci × ln(512)

VS*

ǒ

VSń

512Ǔ+

V

S

ǒ

1–e

–tchń

RtC

i

Ǔ

Where

ln(512) = 6.238

Therefore, with the values given, the time for the analog input signal to settle is:

tch (1/2 LSB) = (Rs + 718 Ω) × 15 pF × ln(512)

This time must be less than the converter sample time shown in the timing diagrams. Which is 6x SCLK.

tch (1/2 LSB) ≤ 6x 1/f

(SCLK)

Therefore the maximum SCLK frequency is:

Max(f

(SCLK)

) = 6/tch (1/2 LSB) = 6/(ln(512) × Rt × Ci)

(1)

(2)

(3)

(4)

(5)

(6)

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

†

Supply voltage, GND to VCC –0.3 V to 6.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog input voltage range –0.3 V to AVDD + 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference input voltage range AVDD + 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital input voltage range –0.3 V to DV

DD

+ 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating virtual junction temperature range, TJ –40°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, TA, –40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

recommended operating conditions

power supplies

MIN MAX UNIT

Analog supply voltage, A V

DD

2.7 5.5 V

Digital supply voltage, DV

DD

2.7 5.5 V

NOTE 1: Abs (AVDD – DVDD) < 0.5 V

analog inputs

MIN MAX UNIT

Analog input voltage, AIN AGND VREFP V

digital inputs

MIN NOM MAX UNIT

High-level input voltage, V

IH

DVDD = 2.7 V to 5.5 V 2.1 2.4 V

Low level input voltage, V

IL

DVDD = 2.7 V to 5.5 V 0.8 V

p

DVDD = 4.5 V to 5.5 V 20 MHz

Input CLK frequenc

y

DVDD = 2.7 V to 3.3 V 10 MHz

DVDD = 4.5 V to 5.5 V, f

CLK

= 20 MHz 23 ns

Pulse duration, CLK high, t

w(CLKH)

DVDD = 2.7 V to 3.3 V, f

CLK

= 10 MHz 46 ns

DVDD = 4.5 V to 5.5 V, f

CLK

= 20 MHz 23 ns

Pulse duration, CLK low, t

w

(CLKL)

DVDD = 2.7 V to 3.3 V, f

CLK

= 10 MHz 46 ns

Rise time, I/O and control, CLK, CS 50 pF output load 4

Fall time, I/O and control, CLK, CS 50 pF output load 4

ns

reference specifications

MIN NOM MAX UNIT

AVDD = 3 V 2 AV

DD

V

VREFP

AVDD = 5 V 2.5 AV

DD

V

External reference voltage

AVDD = 3 V AGND 1 V

VREFM

AVDD = 5 V AGND 2 V

VREFP – VREFM 2 AVDD–AGND V

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating free-air temperature range, supply

voltages, and reference voltages (unless otherwise noted)

digital specifications

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Logic inputs

I

IH

High-level input current DVDD = 5 V, DVDD = 3 V, Input = DV

DD

–1 1 µA

I

IL

Low-level input current DVDD = 5 V, DVDD = 3 V, Input = 0 V –1 1 µA

C

i

Input capacitance 10 15 pF

Logic outputs

V

OH

High-level output voltage IOH = 50 µA to 0.5 mA DVDD–0.4 V

V

OL

Low-level output voltage IOL = 50 µA to 0.5 mA 0.4 V

I

OZ

High-impedance-state output current DVDD = 5 V, DVDD = 3 V, Input = DV

DD

1 µA

I

OL

Low-impedance-state output current DVDD = 5 V, DVDD = 3 V, Input = 0 V –1 µA

C

o

Output capacitance 5 pF

3 V, AVDD = DV

DD

9 10 11

Internal clock

5 V, AVDD = DV

DD

18 20 22

MHz

dc specifications

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Resolution 8 Bits

Accuracy

Integral nonlinearity, INL Best fit ±0.3 ±0.5 LSB

Differential nonlinearity , DNL ±0.3 ±0.5 LSB

Missing codes 0

E

O

Offset error ±0.15% ±0.3% FSR

E

G

Gain error ±0.2% ±0.4% FSR

Analog input

p

p

AIN, AVDD = 3 V, AVDD = 5 V 15 pF

CiInput capacitance

MUX input, AVDD = 3 V, AVDD = 5 V 25 pF

I

lkg

Input leakage current V

AIN

= 0 to AV

DD

±1 µA

Voltage reference input

r

i

Input resistance 2 kΩ

C

i

Input capacitance 300 pF

Power supply

p

pp

AVDD = DVDD = 3 V, f

CLK

= 10 MHz 4 5.5 mA

Operating supply current, I

DD

+

I

REF

AVDD = DVDD = 5 V, f

CLK

= 20 MHz

7 8.5 mA

p

AVDD+DVDD = 3 V 12 17 mW

PD

Power dissipation

AVDD+DVDD = 5 V 35 43 mW

AVDD = 3 V 1 8 µA

pp

p

Software

I

DD

+

I

REF

AVDD = 5 V 2 10 µA

IPDSupply current in power-down mode

AVDD = 3 V 0.5 1 mA

Auto

I

DD

+

I

REF

AVDD = 5 V 0.5 1 mA

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating free-air temperature range, supply

voltages, and reference voltages (unless otherwise noted) (continued)

ac specifications, AVDD = DVDD = 5 V (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f

= 100 kHz,

fs = 1.25 MSPS, AVDD = 5 V 47 49 dB

Signal-to-noise ratio, SNR

I

,

80% of FS

fs = 625 KSPS, AVDD = 3 V 47 49 dB

f

= 100 kHz,

fs = 1.25 MSPS, AVDD = 5 V 47 49 dB

Signal-to-noise ratio

+

distortion, SINAD

I

,

80% of FS

fs = 625 KSPS, AVDD = 3 V 47 49 dB

f

= 100 kHz,

fs = 1.25 MSPS, AVDD = 5 V –64 –52 dB

Total harmonic distortion, THD

I

,

80% of FS

fs = 625 KSPS, AVDD = 3 V –62 –52 dB

f

= 100 kHz,

fs = 1.25 MSPS, AVDD = 5 V 7.5 7.9 Bits

Effective number of bits, ENOB

I

,

80% of FS

fs = 625 KSPS, AVDD = 3 V 7.5 7.9 Bits

p

f

= 100 kHz,

fs = 1.25 MSPS, AVDD = 5 V –65 –51 dB

Spurious free dynamic range, SFDR

I

,

80% of FS

fs = 625 KSPS, AVDD = 3 V –64 –51 dB

Analog input

p

–1 dB Full-scale 0 dB input sine wave 12 18 MHz

Full-power bandwidth

–3 dB Full-scale 0 dB input sine wave 30 MHz

–1 dB –20 dB input sine wave 15 20 MHz

Small-signal bandwidth

–3 dB –20 dB input sine wave 35 MHz

p

AVDD = 4.5 V to 5.5 V 0.0625 1.25 MSPS

Sam ling rate, f

s

AVDD = 2.7 V to 3.3 V 0.0625 0.625 MSPS

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

19

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

timing requirements, AVDD = DVDD = 5 V (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

p

DVDD = 4.5 V to 5.5 V 50 ns

t

c

(CLK)

In ut clock Cycle time

DVDD = 2.7 V to 3.3 V 100 ns

t

(sample)

Reset and sampling time 6

SYSCLK

Cycles

t

c

Total conversion time 10

SYSCLK

Cycles

t

wL(EOC)

Pulse width, end of conversion, EOC 10

SYSCLK

Cycles

t

wL(INT)

Pulse width, interrupt 1

SYSCLK

Cycles

t

(STARTOSC)

Start-up time, internal oscillator 100 ns

t

d(CSH_CSTARTL)

Delay time, CS high to CSTAR T low 10 ns

DVDD = 5 V at 50 pF 20 ns

t

en

(RDL_DAV)

Enable time, data out

DVDD = 3 V at 50 pF 40 ns

DVDD = 5 V at 50 pF 5 ns

t

dis(RDH_DAV)

Disable time, data out

DVDD = 3 V at 50 pF 10 ns

t

su(CSL_WRL)

Setup time, CS to WR 5 ns

t

h(WRH_CSH)

Hold time, CS to WR 5 ns

t

w(WR)

Pulse width, write 1

Clock

Period

t

w(RD)

Pulse width, read 1

Clock

Period

t

su(DAV_WRH)

Setup time, data valid to WR 10 ns

t

h(WRH_DAV)

Hold time, data valid to WR 5 ns

t

su(CSL_RDL)

Setup time, CS to RD 5 ns

t

h(RDH_CSH)

Hold time, CS to RD 5 ns

t

h(WRL_EXTXLKH)

Hold time WR to clock high 5 ns

t

h(RDL_EXTCLKH)

Hold time RD to clock high 5 ns

t

h(CSTARTL_EXTCLKH)

Hold time CSTAR T to clock high 5 ns

t

su(WRH_EXTCLKH)

Setup time WR high to clock high 5 ns

t

su(RDH_EXTCLKH)

Setup time RD high to clock high 5 ns

t

su(CSTARTH_EXTCLKH)

Setup time CSTAR T high to clock high 5 ns

t

d(EXTCLK_CSTARTL)

Delay time clock low to CSTART low 5 ns

NOTE: Specifications subject to change without notice.

Data valid is denoted as DAV.

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 11

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

8.0

–40 –30 –20 –10 0 10 20 30 40 50 60 70 80

SUPPLY CURRENT

vs

FREE AIR TEMPERATURE

AVDD = DVDD = 5 V, 20 MHz

TA – Free Air Temperature – °C

AVDD = DVDD = 3 V, 10 MHz

I

CC

– Supply Current – mA

Figure 12

0

1

2

3

4

5

6

7

0 2 4 6 8 101214161820

SUPPLY CURRENT

vs

CLOCK FREQUENCY

f

clock

– Clock Frequency – MHz

AVDD = DVDD = 5 V

AVDD = DVDD = 3 V

I

CC

– Supply Current – mA

Figure 13

ANALOG INPUT BANDWIDTH

vs

FREQUENCY

AVDD = DVDD = 5 V,

AIN = 90% of FS,

REF = 5 V,

TA = 25°C

f – Frequency – MHz

Analog Input Bandwidth – dB

–2

–3

–4

–6

0.1 1

–1

0

1

10 100

–5

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

21

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 14

–0.15

–0.10

–0.05

–0.00

0.05

0.10

0.15

0 64 128 192 256

DNL – Differential Nonlinearity – LSB

Digital Output Code

DIFFERENTIAL NONLINEARITY

vs

DIGITAL OUTPUT CODE

AVDD = DVDD = 3 V,

External Ref = 3 V,

CLK = 10 MHz,

TA = 25°C

Figure 15

–0.06

–0.04

–0.02

0.00

0.02

0.04

0.06

0.08

0.10

0.12

0.14

0 64 128 192 256

INL – Integral Nonlinearity – LSB

Digital Output Code

INTEGRAL NONLINEARITY

vs

DIGITAL OUTPUT CODE

AVDD = DVDD = 3 V,

External Ref = 3 V,

CLK = 10 MHz,

TA = 25°C

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 16

–0.08

–0.06

–0.04

–0.02

0.00

0.02

0.04

0.06

0.08

0.10

0.12

0 64 128 192 256

DNL – Differential Nonlinearity – LSB

Digital Output Code

DIFFERENTIAL NONLINEARITY

vs

DIGITAL OUTPUT CODE

AVDD = DVDD = 5 V,

External Ref = 5 V,

CLK = 20 MHz,

TA = 25

°C

Figure 17

–0.08

–0.06

–0.04

–0.02

0.00

0.02

0.04

0.06

0.08

0.10

0.12

0.14

0 64 128 192 256

INL – Integral Nonlinearity – LSB

Digital Output Code

INTEGRAL NONLINEARITY

vs

DIGITAL OUTPUT CODE

AVDD = DVDD = 5 V,

External Ref = 5 V,

CLK = 20 MHz,

TA = 25°C

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

23

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 18

5

6

7

8

9

10

0 100 200 300

ENOB – Effective Number of Bits – BITS

f – Frequency – kHz

EFFECTIVE NUMBER OF BITS

vs

FREQUENCY

AVDD = DVDD = 3 V,

External Ref = 3 V

Figure 19

5

6

7

8

9

10

0 200 400 600

ENOB – Effective Number of Bits – BITS

f – Frequency – kHz

EFFECTIVE NUMBER OF BITS

vs

FREQUENCY

AVDD = DVDD = 5 V,

External Ref = 5 V

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 20

–140

–120

–100

–80

–60

–40

–20

0

20

0 100000 200000 300000

Magnitude – dB

f – Frequency – Hz

FAST FOURIER TRANSFORM

vs

FREQUENCY

AIN = 200 KHz

CLK = 10 MHz

AVDD = DVDD = 3 V

External Ref = 3 V

Figure 21

–140

–120

–100

–80

–60

–40

–20

0

20

0 200000 400000 600000

Magnitude – dB

f – Frequency – Hz

FAST FOURIER TRANSFORM

vs

FREQUENCY

AIN = 200 KHz

CLK = 20 MHz

AVDD = DVDD = 5 V

External Ref = 5 V

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

25

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

DW (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

16 PINS SHOWN

4040000/C 07/96

Seating Plane

0.400 (10,15)

0.419 (10,65)

0.104 (2,65) MAX

1

0.012 (0,30)

0.004 (0,10)

A

8

16

0.020 (0,51)

0.014 (0,35)

0.293 (7,45)

0.299 (7,59)

9

0.010 (0,25)

0.050 (1,27)

0.016 (0,40)

(15,24)

(15,49)

PINS **

0.010 (0,25) NOM

A MAX

DIM

A MIN

Gage Plane

20

0.500

(12,70)

(12,95)

0.510

(10,16)

(10,41)

0.400

0.410

16

0.600

24

0.610

(17,78)

28

0.700

(18,03)

0.710

0.004 (0,10)

M

0.010 (0,25)

0.050 (1,27)

0°–8°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0.006 (0,15).

D. Falls within JEDEC MS-013

TLV571

2.7 V TO 5.5 V, 1-CHANNEL, 8-BIT,

PARALLEL ANALOG-TO-DIGITAL CONVERTER

SLAS239A – SEPTEMBER 1999 – REVISED FEBRUARY 2000

26

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

PW (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PINS SHOWN

0,65

M

0,10

0,10

0,25

0,50

0,75

0,15 NOM

Gage Plane

28

9,80

9,60

24

7,90

7,70

2016

6,60

6,40

4040064/F 01/97

0,30

6,60

6,20

8

0,19

4,30

4,50

7

0,15

14

A

1

1,20 MAX

14

5,10

4,90

8

3,10

2,90

A MAX

A MIN

DIM

PINS **

0,05

4,90

5,10

Seating Plane

0°–8°

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. Falls within JEDEC MO-153

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Loading...

Loading...