Page 1

T

VIOmax AT 25°C

SYMBOL

TLV2211Y

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

D

Output Swing Includes Both Supply Rails

D

Low Noise...21 nV/√Hz Typ at f = 1 kHz

D

Low Input Bias Current...1 pA Typ

D

Very Low Power...13 µA Per Channel Typ

D

Common-Mode Input Voltage Range

V

DD–

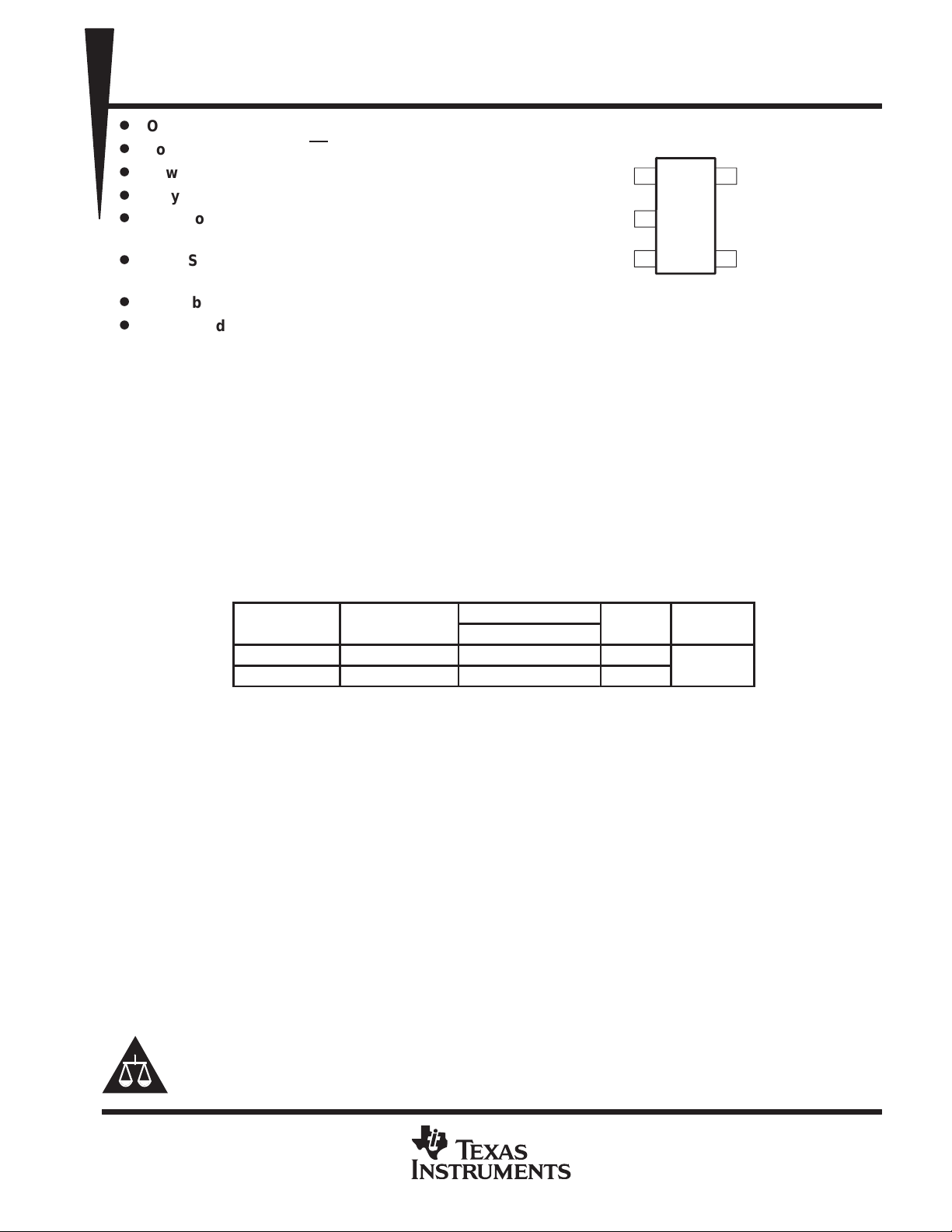

DBV PACKAGE

(TOP VIEW)

IN+ V

/GND

1

5

2

DD+

Includes Negative Rail

D

Wide Supply Voltage Range

IN–

OUT

43

2.7 V to 10 V

D

Available in the SOT-23 Package

D

Macromodel Included

description

The TL V2211 is a single operational amplifier manufactured using the T exas Instruments Advanced LinCMOS

process. These devices are optimized and fully specified for single-supply 3-V and 5-V operation. For this

low-voltage operation combined with micropower dissipation levels, the input noise voltage performance has

been dramatically improved using optimized design techniques for CMOS-type amplifiers. Another added

benefit is that these amplifiers exhibit rail-to-rail output swing. The output dynamic range can be extended using

the TL V221 1 with loads referenced midway between the rails. The common-mode input voltage range is wider

than typical standard CMOS-type amplifiers. To take advantage of this improvement in performance and to

make this device available for a wider range of applications, V

voltage test limit of ± 5 mV , allowing a minimum of 0 to 2-V common-mode input voltage range for a 3-V power

supply .

is specified with a larger maximum input offset

ICR

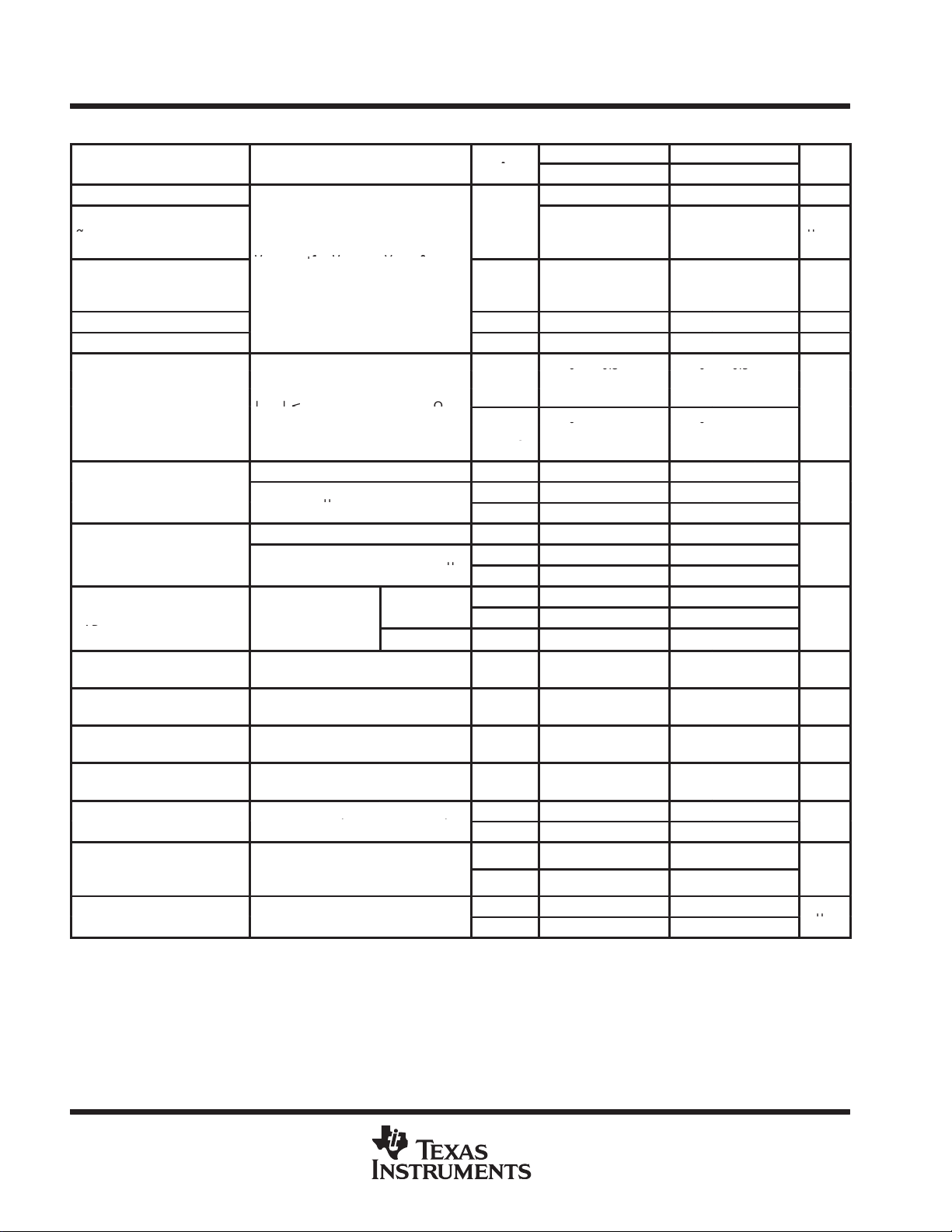

AVAILABLE OPTIONS

PACKAGED DEVICES

A

0°C to 70°C 3 mV TLV2211CDBV VACC

–40°C to 85°C 3 mV TLV2211IDBV VACI

†

The DBV package available in tape and reel only.

°

SOT-23 (DBV)

†

CHIP FORM

(Y)

The Advanced LinCMOS process uses a silicon-gate technology to obtain input offset voltage stability with

temperature and time that far exceeds that obtainable using metal-gate technology . This technology also makes

possible input-impedance levels that meet or exceed levels offered by top-gate JFET and expensive

dielectric-isolated devices.

The TLV2211, exhibiting high input impedance and low noise, is excellent for small-signal conditioning for

high-impedance sources such as piezoelectric transducers. Because of the low power dissipation levels

combined with 3-V operation, these devices work well in hand-held monitoring and remote-sensing

applications. In addition, the rail-to-rail output feature with single or split supplies makes these devices excellent

choices when interfacing directly to analog-to-digital converters (ADCs). All of these features combined with its

temperature performance make the TLV2211 ideal for remote pressure sensors, temperature control, active

voltage-resistive (VR) sensors, accelerometers, hand-held metering, and many other applications.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Advanced LinCMOS is a trademark of Texas Instruments Incorporated.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Copyright 1997, Texas Instruments Incorporated

1

Page 2

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

description (continued)

The device inputs and outputs are designed to withstand a 100-mA surge current without sustaining latch-up.

In addition, internal ESD-protection circuits prevent functional failures up to 2000 V as tested under

MIL-PRF-38535; however, care should be exercised when handling these devices as exposure to ESD may

result in degradation of the device parametric performance. Additional care should be exercised to prevent

V

supply-line transients under powered conditions. Transients of greater than 20 V can trigger the

DD +

ESD-protection structure, inducing a low-impedance path to V

sustained current supplied to the device must be limited to 100 mA or less. Failure to do so could result in a

latched condition and device failure.

/GND. Should this condition occur, the

DD –

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 3

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

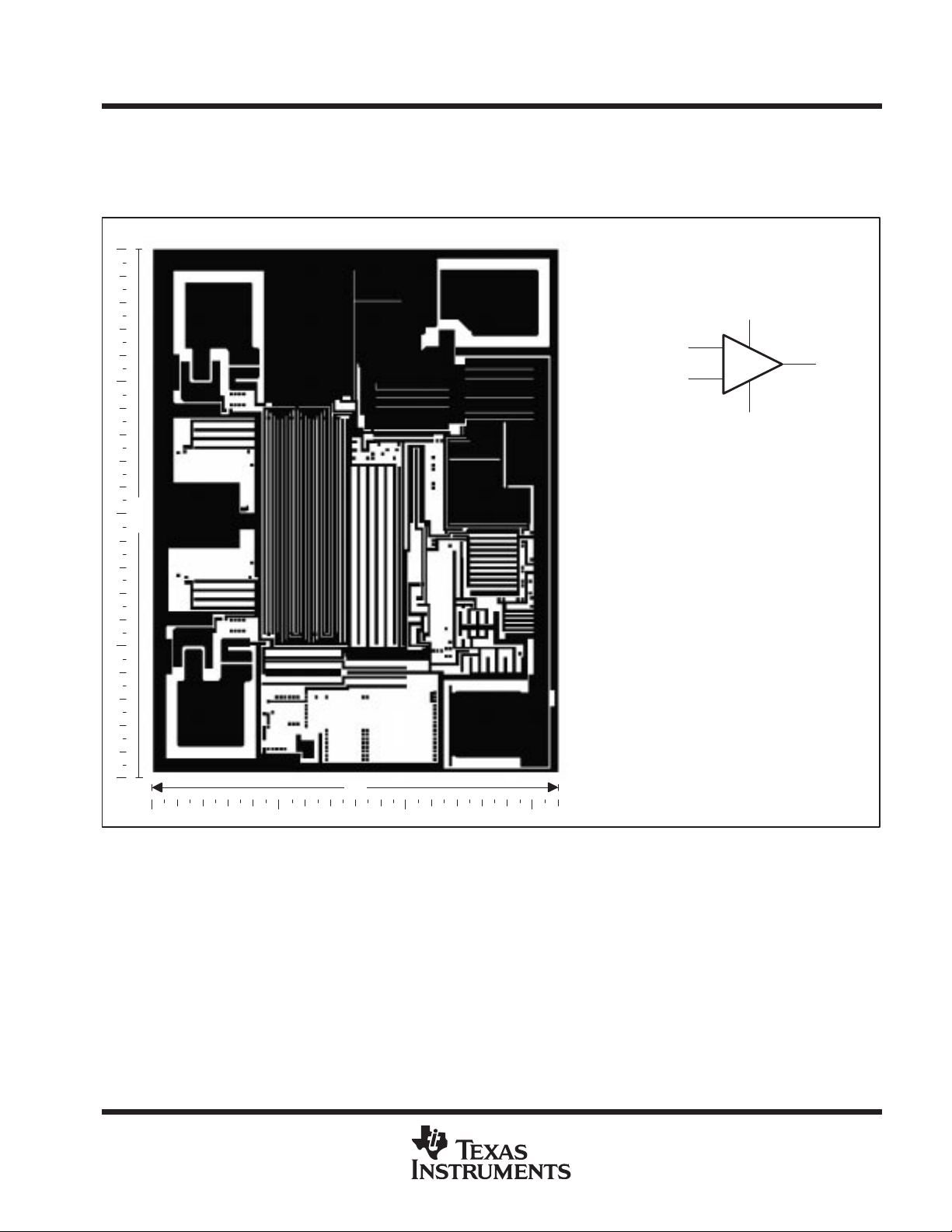

TLV2211Y chip information

This chip, when properly assembled, displays characteristics similar to the TLV2211C. Thermal compression

or ultrasonic bonding may be used on the doped-aluminum bonding pads. This chip may be mounted with

conductive epoxy or a gold-silicon preform.

BONDING PAD ASSIGNMENTS

40

(2)

(1)

(3)

(5)

(4)

V

DD+

V

+

–

DD–

(5)

(2)

/GND

(4)

OUT

(1)

IN+

(3)

IN–

CHIP THICKNESS: 10 MILS TYPICAL

BONDING PADS: 4 × 4 MILS MINIMUM

TJmax = 150°C

TOLERANCES ARE ±10%.

ALL DIMENSIONS ARE IN MILS.

PIN (2) IS INTERNALLY CONNECTED

TO BACKSIDE OF CHIP.

32

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

Page 4

T

l

R

l

D

7

11

94

4

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

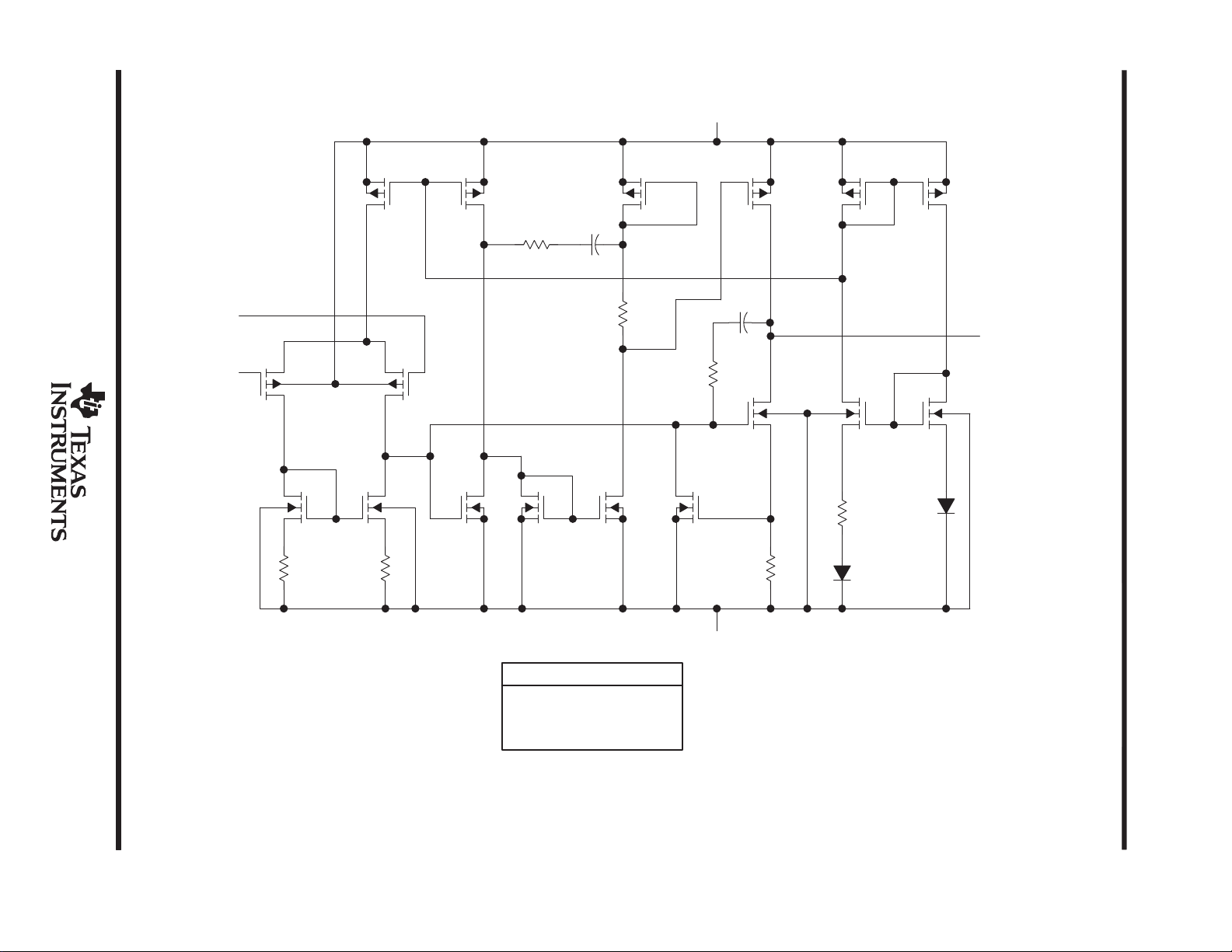

equivalent schematic

IN+

V

DD+

Q3 Q6 Q9 Q12 Q14 Q16

R7

C2

R6

C1

OUT

TLV2211, TLV2211Y

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUARY 1997

Advanced LinCMOSRAIL-TO-RAIL

emp

ate

e

ease

ate:

–

–

IN–

Q4Q1

•

Q2 Q5 Q7 Q8 Q10 Q11

R3

R4

COMPONENT COUNT

Transistors

Diodes

Resistors

Capacitors

†

Includes both amplifiers and all

ESD, bias, and trim circuitry

23

6

11

2

†

R5

V

DD–/GND

R1

R2

Q17Q15Q13

D1

D2

Page 5

PACKAGE

A

UNIT

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

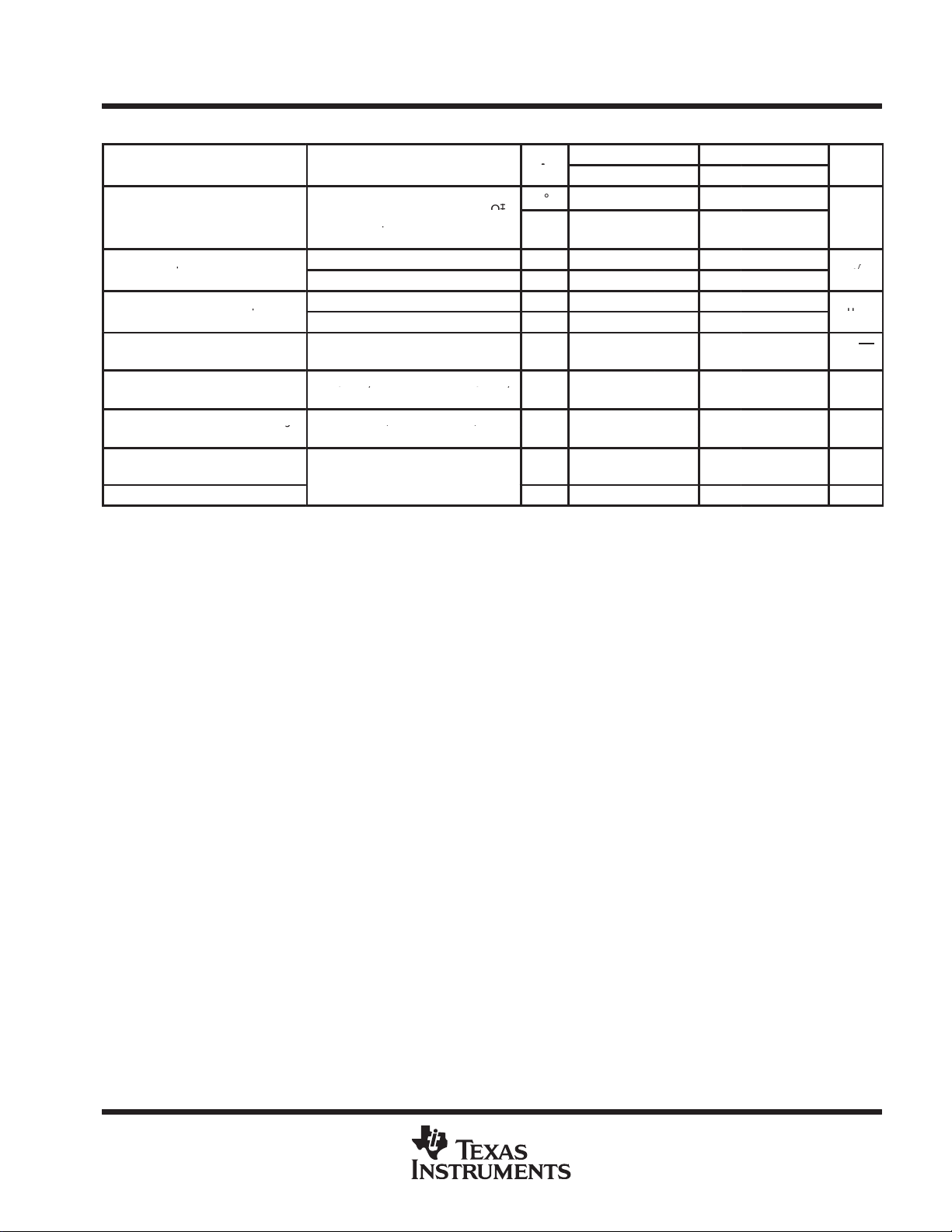

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

Supply voltage, V

Differential input voltage, V

Input voltage range, V

Input current, I

Output current, I

Total current into V

Total current out of V

Duration of short-circuit current (at or below) 25°C (see Note 3) unlimited. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

Storage temperature range, T

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds: DBV package 260°C. . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltage values, except differential voltages, are with respect to V

2. Differential voltages are at the noninverting input with respect to the inverting input. Excessive current flows when input is brought

below V

3. The output may be shorted to either supply. Temperature and /or supply voltages must be limited to ensure that the maximum

DD–

dissipation rating is not exceeded.

DBV 150 mW 1.2 mW/°C 96 mW 78 mW

(see Note 1) 12 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DD

I

(each input) ±5 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

±50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O

DD+

DD–

(see Note 2) ±V

ID

(any input, see Note 1) –0.3 V to V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

±50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

±50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

: TLV2211C 0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

TLV2211I –40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

.

DD –

– 0.3 V.

DISSIPATION RATING T ABLE

T

≤ 25°C DERATING FACTOR T

POWER RATING ABOVE TA = 25°CAPOWER RATINGAPOWER RATING

= 70°C T

= 85°C

†

DD

DD

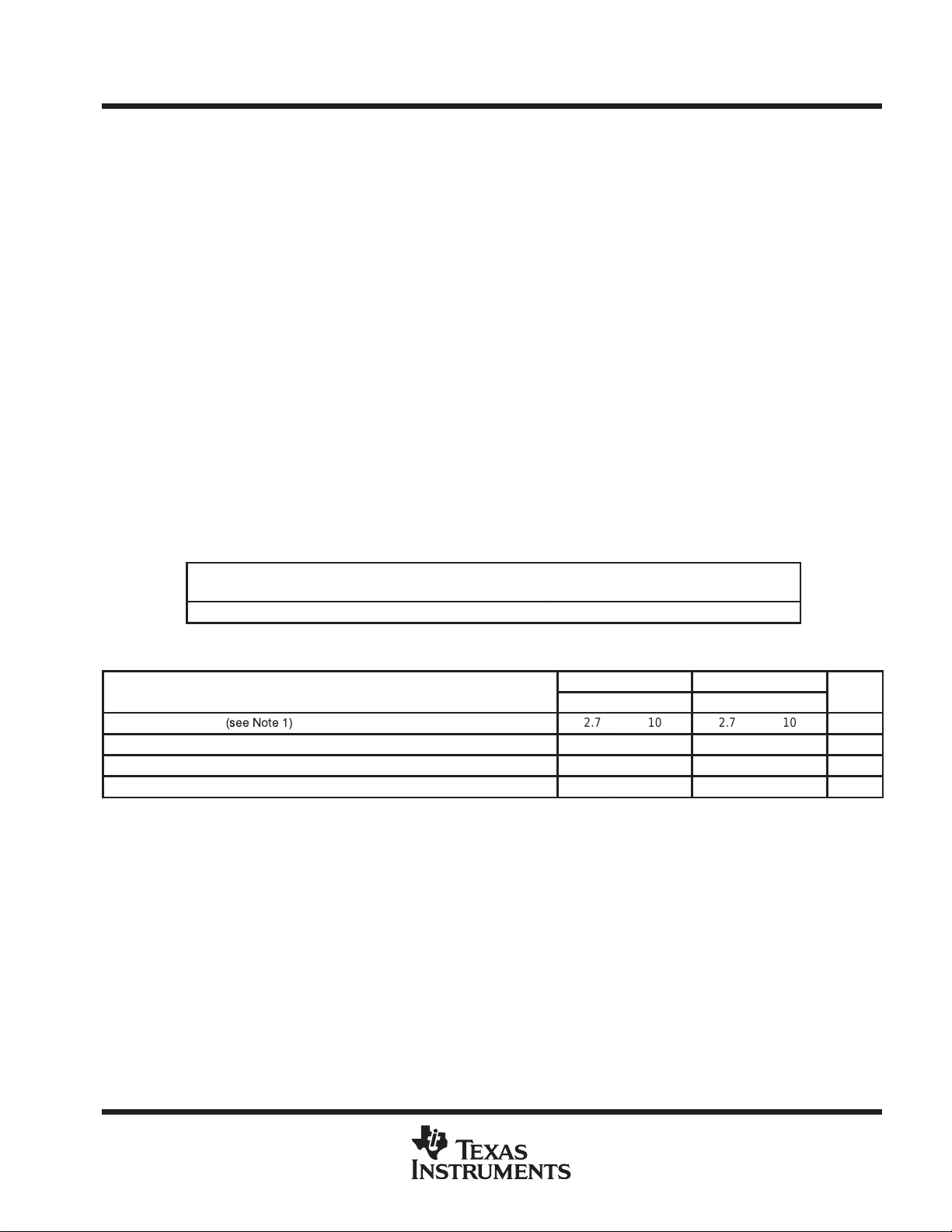

recommended operating conditions

Supply voltage, VDD(see Note 1)

Input voltage range, V

Common-mode input voltage, V

Operating free-air temperature, T

NOTE 1: All voltage values, except differential voltages, are with respect to V

I

IC

A

DD –

TLV2211C TLV2211I

MIN MAX MIN MAX

2.7 10 2.7 10 V

V

DD–VDD+

V

DD–VDD+

0 70 –40 85 °C

.

–1.3 V

–1.3 V

DD–VDD+

DD–VDD+

–1.3 V

–1.3 V

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

Page 6

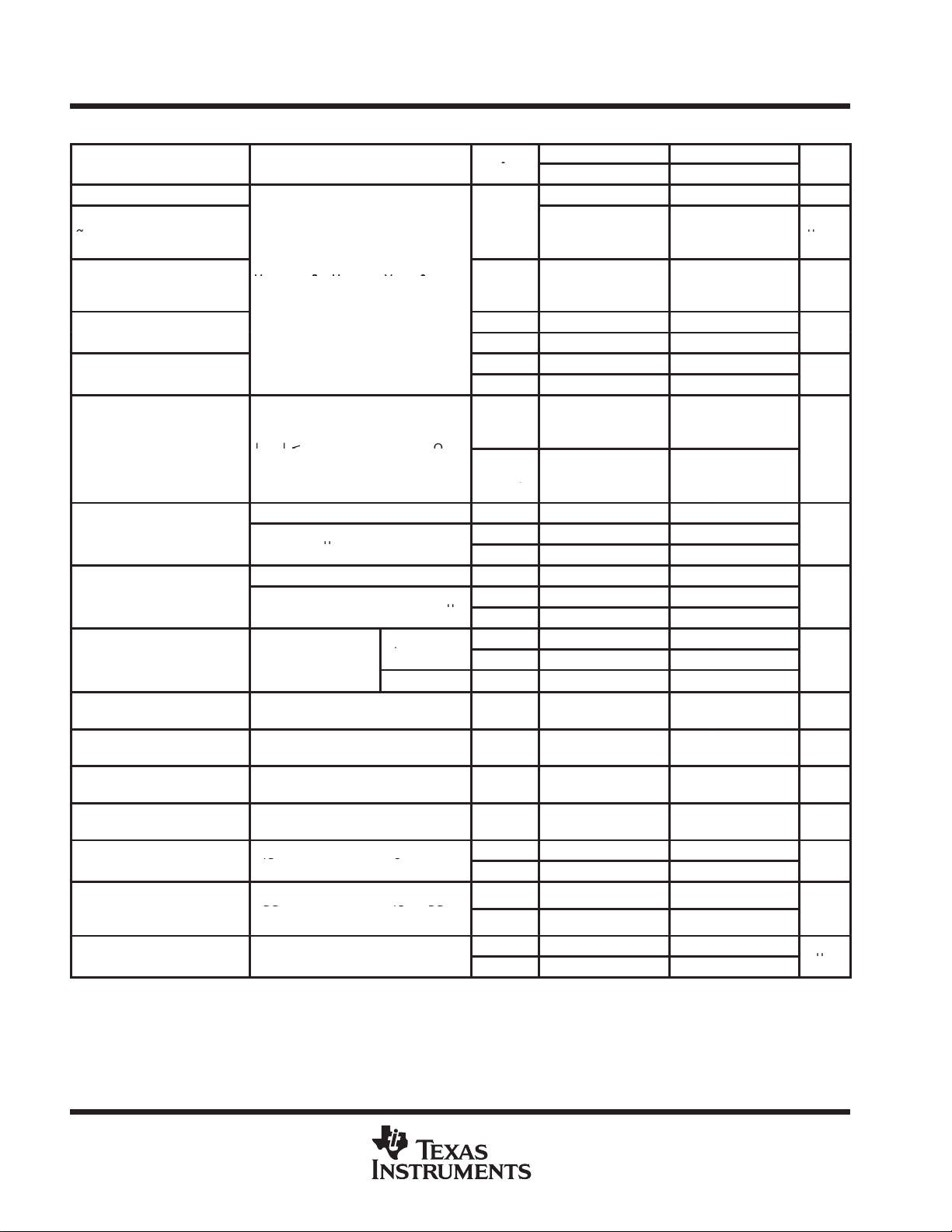

TLV2211, TLV2211Y

PARAMETER

TEST CONDITIONS

T

†

UNIT

fficient of i

t

1

1µV/°C

V

V

0to0.3to0to0.3

V

|V

R

Ω

V

0to0

g

voltage

I

250 µA

voltage

V

I

500 µA

Large signal

R

kΩ

‡

VD

V

O

V

V

CMRR

IC

,

O

,

dB

k

DD

,

IC DD

dB

IDDSupply current

V

No load

A

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

electrical characteristics at specified free-air temperature, VDD = 3 V (unless otherwise noted)

A

V

α

I

I

V

V

A

r

r

c

z

†

‡

NOTE 4: T ypical values are based on the input of fset voltage shift observed through 500 hours of operating life test at TA = 150°C extrapolated

Input offset voltage

IO

Temperature

coe

VIO

offset voltage

Input offset voltage

long-term drift

(see Note 4)

Input offset current Full range 0.5 150 0.5 150 pA

IO

Input bias current Full range 1 150 1 150 pA

IB

Common-mode input

ICR

voltage range

High-level output

OH

Low-level output

OL

-

differential voltage

VD

amplification

Differential input

i(d)

resistance

Common-mode

i(c)

input resistance

Common-mode

i(c)

input capacitance

Closed-loop

o

output impedance

Common-mode V

rejection ratio

Supply voltage

rejection ratio

SVR

(∆VDD /∆VIO)

pp

Full range for the TLV2211C is 0°C to 70°C. Full range for the TLV221 1I is – 40 °C to 85° C.

Referenced to 1.5 V

to TA = 25°C using the Arrhenius equation and assuming an activation energy of 0.96 eV.

p

npu

= ±1.5 V,

DD±

VO = 0,

| ≤5 mV,

IO

IOH = –100 µA 25°C 2.94 2.94

= –

OH

VIC = 1.5 V, IOL = 50 µA 25°C 15 15

= 1.5 V,

IC

VIC = 1.5 V,

= 1 V to 2

f = 10 kHz, 25°C 5 5 pF

f = 7 kHz, AV = 1 25°C 200 200

= 0 to 1.7 V,

RS = 50 Ω

V

= 2.7 V to 8 V, V

No load

= 1.5 V,

O

= 0,

IC

RS = 50 Ω

= 50

S

=

OL

= 10

L

RL = 1 MΩ

= 1.5 V,

= V

,

Full range

25°C 0.003 0.003 µV/mo

25°C

Full range

25°C 2.85 2.85

Full range 2.5 2.5

25°C 150 150

Full range 500 500

25°C 3 7 3 7

Full range 1 1

‡

25°C 600 600

25°C 10

25°C 10

25°C 65 83 65 83

Full range 60 60

25°C 80 95 80 95

/2

Full range

25°C 11 25 11 25

Full range 30 30

TLV2211C TLV2211I

MIN TYP MAX MIN TYP MAX

0.47 3 0.47 3000 mV

0 –0.3 0 –0.3

2 2.2 2 2.2

0 0

1.7 1.7

12

12

80 80

to

to

12

10

12

10

°

V

mV

V/mV

Ω

Ω

Ω

µ

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 7

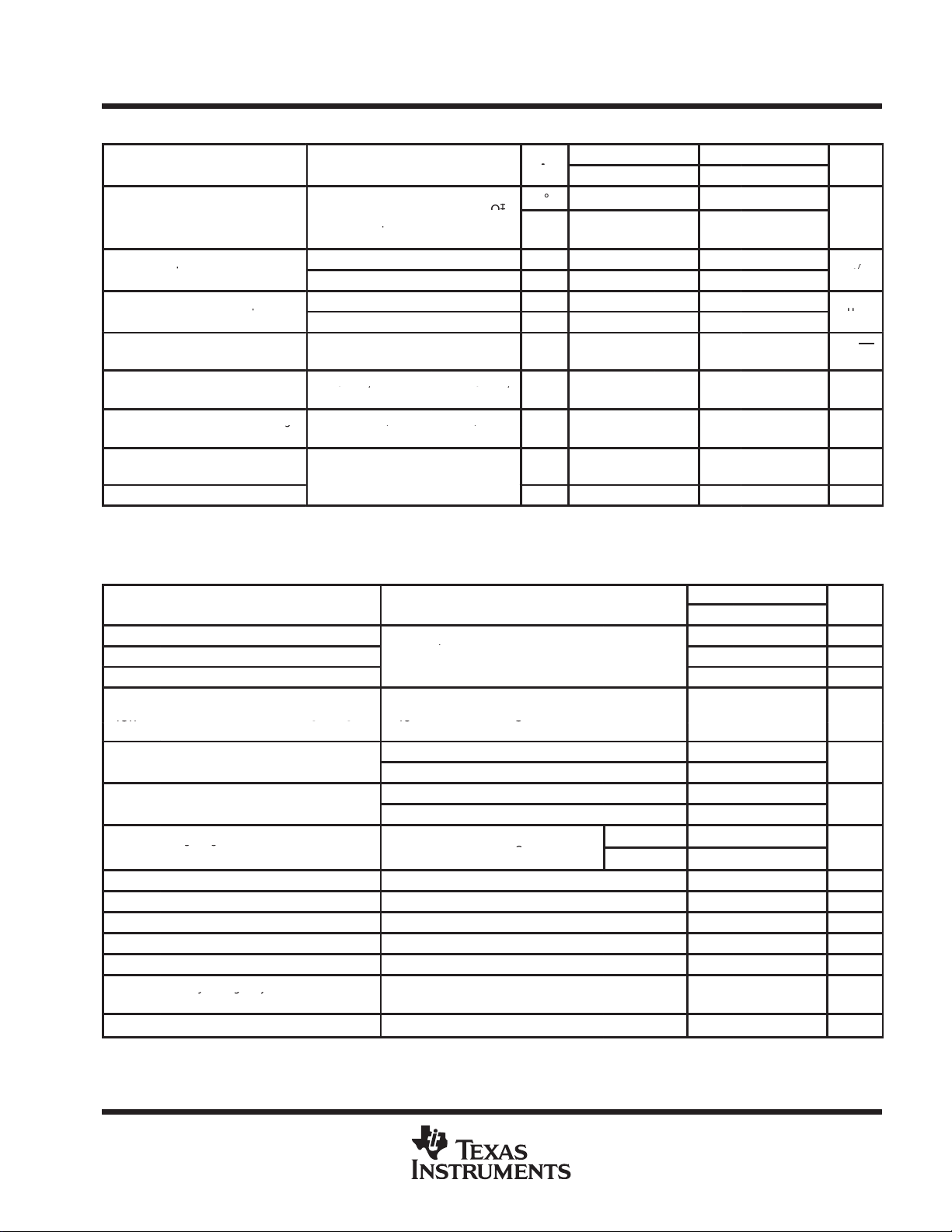

PARAMETER

TEST CONDITIONS

T

†

UNIT

25°C

0.01

0.025

0.01

0.025

V

1.1 V to 1.9 V

R

10 kΩ

‡

C

L

100 F

‡

0.005

0.005

V

q

V/√H

V

q

V

‡

,

Gain-bandwidth product

f 10 kHz,

R

L

kΩ,

25°C5656

kH

B

g

O(PP)

,

V

,

25°C77

kH

‡

L,L

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

operating characteristics at specified free-air temperature, VDD = 3 V (unless otherwise noted)

A

TLV2211C TLV2211I

MIN TYP MAX MIN TYP MAX

SR Slew rate at unity gain

Equivalent input noise

n

voltage

Peak-to-peak equivalent

N(PP)

input noise voltage

I

n

φ

m

†

Full range is –40°C to 85°C.

‡

Referenced to 1.5 V

Equivalent input noise

current

Maximum output-swing V

OM

bandwidth

Phase margin at

unity gain

Gain margin

p

=

O

=

=

p

f = 10 Hz 25°C 80 80

f = 1 kHz

f = 0.1 Hz to 1 Hz 25°C 660 660

f = 0.1 Hz to 10 Hz

f = 10 kHz, R

CL = 100 pF

= 1 V, A

RL = 10 kه,

R

= 10 kه, C

,

=

‡

‡

L

= 10 kΩ

10

= 1,

CL = 100 pF

= 100 pF

,

Full

range

25°C 22 22

25°C 880 880

25°C 0.6 0.6

°

°

‡

25°C 56° 56°

25°C 20 20 dB

V/µs

n

µ

fA/√Hz

z

z

z

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

Page 8

TLV2211, TLV2211Y

PARAMETER

TEST CONDITIONS

T

†

UNIT

coefficient of in ut

0.5

0.5µV/°C

V

V

IIOInput offset current

pA

IIBInput bias current

pA

V

|V

mV

R

Ω

V

g

High-l

t

voltage

I

250 µA

L

t

voltage

V

2.5 V

I

500 µA

Large signal

R

kΩ

‡

V

O

V

V

CMRR

IC

O

dB

k

rejection ratio

DD

IC DD

dB

IDDSupply current

V

No load

A

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

electrical characteristics at specified free-air temperature, VDD = 5 V (unless otherwise noted)

A

V

α

V

V

A

r

r

c

z

†

‡

NOTE 5: T ypical values are based on the input of fset voltage shift observed through 500 hours of operating life test at TA = 150°C extrapolated

Input offset voltage

IO

Temperature

VIO

offset voltage

Input offset voltage

long-term drift

(see Note 4)

p

p

Common-mode input

ICR

voltage range

OH

OL

VD

i(d)

i(c)

i(c)

o

SVR

Full range for the TLV2211C is 0°C to 70°C. Full range for the TLV221 1I is – 40 °C to 85° C.

Referenced to 1.5 V

evel outpu

ow-level outpu

differential

voltage amplification

Differential input

resistance

Common-mode

input resistance

Common-mode

input capacitance

Closed-loop

output impedance

Common-mode VIC = 0 to 2.7 V,

rejection ratio

Supply voltage

(∆VDD /∆VIO)

pp

to TA = 25°C using the Arrhenius equation and assuming an activation energy of 0.96 eV.

p

= ±2.5 V,

DD±

VO = 0,

| ≤5

IO

IOH = –100 µA 25°C 4.95 4.95

= –

OH

VIC = 2.5 V, IOL = 50 µA 25°C 12 12

,

=

IC

VIC = 2.5 V,

= 1 V to 4

f = 10 kHz, 25°C 5 5 pF

f = 7 kHz, AV = 1 25°C 200 200

RS = 50 Ω

VDD = 4.4 V to 8 V, VIC = VDD/2,

No load

= 2.5 V,

O

= 0,

IC

RS = 50 Ω

= 50

S

=

OL

= 10

L

RL = 1 MΩ

= 2.5 V,

O

Full range

25°C

25°C 0.5 0.5

Full range 150 150

25°C 1 1

Full range 150 150

25°C

Full range

25°C 4.875 4.875

Full range 4.5 4.5

25°C 120 120

Full range 500 500

25°C 6 12 6 12

Full range 3 3

‡

25°C 800 800

25°C 10

25°C 10

25°C 70 83 70 83

Full range 70 70

25°C 80 95 80 95

Full range 80 80

25°C 13 25 13 25

Full range 30 30

TLV2211C TLV2211I

MIN TYP MAX MIN TYP MAX

0.45 3 0.45 3 mV

0.003 0.003 µV/mo

0 –0.3 0 –0.3

to to to to

4 4.2 4 4.2

0 0

to to

3.5 3.5

12

12

10

10

12

12

°

p

p

V

mV

V/mV

Ω

Ω

Ω

µ

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 9

PARAMETER

TEST CONDITIONS

T

†

UNIT

25°C

0.01

0.025

0.01

0.025

V

1.5 V to 3.5 V

R

10 kΩ

‡

C

L

100 F

‡

0.005

0.005

V

q

V/√H

V

q

V

‡

,

Gain-bandwidth product

f 10 kHz,

R

L

kΩ,

25°C6565

kH

B

g

O(PP)

,

V

,

25°C77

kH

‡

L,L

PARAMETER

TEST CONDITIONS

UNIT

R

S

Ω

ICR

gg

IO

S

VOHHigh-level output voltage

V

VOLLow-level output voltage

mV

A

gg

V

V

V

V/mV

k

ygj

V

V

VDD/2

No load95dB

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

operating characteristics at specified free-air temperature, VDD = 5 V (unless otherwise noted)

A

TLV2211C TLV2211I

MIN TYP MAX MIN TYP MAX

SR Slew rate at unity gain

Equivalent input noise

n

voltage

Peak-to-peak equivalent

N(PP)

input noise voltage

I

n

φ

m

†

Full range is –40°C to 85°C.

‡

Referenced to 1.5 V

Equivalent input noise

current

Maximum output-swing V

OM

bandwidth

Phase margin at

unity gain

Gain margin

p

=

O

=

=

p

f = 10 Hz 25°C 72 72

f = 1 kHz

f = 0.1 Hz to 1 Hz 25°C 600 600

f = 0.1 Hz to 10 Hz

f = 10 kHz, R

CL = 100 pF

= 2 V, A

RL = 10 kه,

R

= 10 kه, C

,

=

‡

‡

L

= 10 kΩ

10

= 1,

CL = 100 pF

= 100 pF

,

Full

range

25°C 21 21

25°C 800 800

25°C 0.6 0.6

°

°

‡

25°C 56° 56°

25°C 22 22 dB

n

fA/√Hz

electrical characteristics at VDD = 3 V, TA = 25°C (unless otherwise noted)

TLV2211Y

MIN TYP MAX

V

IO

I

IO

I

IB

V

ICR

VD

r

i(d)

r

i(c)

c

i(c)

z

o

CMRR Common-mode rejection ratio VIC = 0 to 1.7 V, VO = 1.5 V, RS = 50 Ω 83 dB

SVR

I

DD

†

Referenced to 1.5 V

Input offset voltage

Input offset current

Input bias current

Common-mode input voltage range | VIO | ≤5 mV, RS = 50 Ω

p

p

Large-signal differential

voltage amplification

Differential input resistance 10

Common-mode input resistance 10

Common-mode input capacitance f = 10 kHz 5 pF

Closed-loop output impedance f = 7 kHz, AV = 1 200 Ω

Supply voltage rejection ratio

(∆VDD/∆VIO)

Supply current VO = 1.5 V, No load 11 µA

V

= ±1.5 V ,

DD±

= 50

IOH = –100 µA 2.94

IOH = –200 µA 2.85

VIC = 0, IOL = 50 µA 15

VIC = 0, IOL = 500 µA 150

= 1.5 V,

IC

= 2.7 V to 8 V,

DD

VO = 0, VIC = 0,

= 1 V to 2

O

=

IC

RL = 10 kΩ

RL = 1 MΩ

,

†

†

0.47 mV

0.5 pA

1 pA

–0.3

to

2.2

7

600

12

12

V/µs

z

µ

z

z

V

Ω

Ω

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

Page 10

TLV2211, TLV2211Y

PARAMETER

TEST CONDITIONS

UNIT

R

S

Ω

ICR

gg

IO

S

VOHHigh-level output voltage

V

VOLLow-level output voltage

mV

A

gg

V

V

V

V/mV

k

ygj

V

V

VDD/2

No load95dB

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

electrical characteristics at VDD = 5 V, TA = 25°C (unless otherwise noted)

TLV2211Y

MIN TYP MAX

V

I

IO

I

IB

V

VD

r

i(d)

r

i(c)

c

i(c)

z

o

CMRR Common-mode rejection ratio VIC = 0 to 2.7 V, VO = 2.5 V, RS = 50 Ω 83 dB

SVR

I

DD

†

Referenced to 1.5 V

Input offset voltage

IO

Input offset current

Input bias current

Common-mode input voltage range | VIO | ≤5 mV, RS = 50 Ω

ICR

p

p

Large-signal differential

voltage amplification

Differential input resistance 10

Common-mode input resistance 10

Common-mode input capacitance f = 10 kHz 5 pF

Closed-loop output impedance f = 7 kHz, AV = 1 200 Ω

Supply voltage rejection ratio

(∆VDD/∆VIO)

Supply current VO = 2.5 V, No load 13 µA

VDD± = ±2.5 V,

= 50

IOH = –100 µA 4.95

IOH = –250 µA 4.875

VIC = 2.5 V, IOL = 50 µA 12

VIC = 2.5 V, IOL = 500 µA 120

= 2.5 V,

IC

= 4.4 V to 8 V,

DD

VIC = 0, VO = 0,

= 1 V to 4

O

=

IC

RL = 10 kΩ

RL = 1 MΩ

,

†

†

0.45 mV

–0.3

800

0.5 pA

1 pA

to

4.2

12

12

12

V

Ω

Ω

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 11

VIOInput offset voltage

,

VIInput voltage

yg

IOSShort-circuit output current

yg

VD

g

CMRR

Common-mode rejection ratio

qy

k

Suppl

oltage rejection ratio

qy

,

SR

Slew rate

Gain-bandwidth product

φmPhase margin

qy

,

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

Table of Graphs

FIGURE

p

α

VIO

IIB/I

IO

V

OH

V

OL

V

O(PP)

V

O

A

VD

z

o

SVR

I

DD

V

O

V

O

V

n

THD + N Total harmonic distortion plus noise vs Frequency 46

B

1

Input offset voltage temperature coefficient Distribution 5, 6

Input bias and input offset currents vs Free-air temperature 7

p

High-level output voltage vs High-level output current 10, 13

Low-level output voltage vs Low-level output current 11, 12, 14

Maximum peak-to-peak output voltage vs Frequency 15

p

Output voltage vs Differential input voltage 18, 19

Differential voltage amplification

Output impedance vs Frequency 25, 26

pp

y-v

Supply current vs Supply voltage 32

Large-signal pulse response vs Time 35, 36, 37, 38

Small-signal pulse response vs Time 39, 40, 41, 42

Equivalent input noise voltage vs Frequency 43, 44

Noise voltage (referred to input) Over a 10-second period 45

p

Gain margin vs Load capacitance 50

Unity-gain bandwidth vs Load capacitance 51

Distribution 1, 2

vs Common-mode input voltage

vs Supply voltage 8

vs Free-air temperature 9

vs Supply voltage 16

vs Free-air temperature 17

vs Load resistance 20

vs Frequency

vs Free-air temperature 23, 24

vs Frequency 27

vs Free-air temperature 28

vs Frequency 29, 30

vs Free-air temperature

vs Load capacitance 33

vs Free-air temperature 34

vs Free-air temperature 47

vs Supply voltage 48

vs Frequency 21, 22

vs Load capacitance

3, 4

21, 22

31

49

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

11

Page 12

TLV2211, TLV2211Y

†

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

DISTRIBUTION OF TLV2211

INPUT OFFSET VOLTAGE

30

376 Amplifiers From 1 Wafer Lot

VDD = ±1.5 V

TA = 25°C

25

20

15

10

Precentage of Amplifiers – %

5

0

–1.5 –1 –0.5 0 0.5 1 1.5

VIO – Input Offset Voltage – mV

Figure 1

INPUT OFFSET VOLTAGE

vs

COMMON-MODE INPUT VOLTAGE

1

VDD = 3 V

0.8

RS = 50 Ω

TA = 25°C

0.6

DISTRIBUTION OF TLV2211

INPUT OFFSET VOLTAGE

30

376 Amplifiers From 1 Wafer Lot

VDD = ±2.5 V

TA = 25°C

25

20

15

10

Precentage of Amplifiers – %

5

0

–1.5 –1 –0.5 0 0.5 1 1.5

VIO – Input Offset Voltage – mV

Figure 2

INPUT OFFSET VOLTAGE

vs

COMMON-MODE INPUT VOLTAGE

1

VDD = 5 V

0.8

RS = 50 Ω

TA = 25°C

0.6

†

0.4

0.2

0

–0.2

–0.4

– Input Offset Voltage – mV

IO

–0.6

V

–0.8

–1

–1 0 1 2

VIC – Common-Mode Input Voltage – V

3

Figure 3

†

For all curves where VDD = 5 V, all loads are referenced to 2.5 V. For all curves where VDD = 3 V, all loads are referenced to 1.5 V.

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

0.4

0.2

0

–0.2

–0.4

– Input Offset Voltage – mV

IO

–0.6

V

–0.8

–1

–1012345

VIC – Common-Mode Input Voltage – V

Figure 4

Page 13

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

DISTRIBUTION OF TLV2211 INPUT OFFSET

VOLTAGE TEMPERATURE COEFFICIENT

50

32 Amplifiers From 1 Wafer Lot

VDD = ±1.5 V

P Package

40

TA = 25°C

30

20

Percentage of Amplifiers – %

10

0

–3 –2 –1 0 1 2 3

α

– Temperature Coefficient – µV/°C

VIO

Figure 5

INPUT BIAS AND INPUT OFFSET CURRENTS

vs

FREE-AIR TEMPERATURE

100

V

= ±2.5 V

DD±

90

VIC = 0

VO = 0

80

RS = 50 Ω

70

60

50

40

30

20

IO

I

10

DISTRIBUTION OF TLV2211 INPUT OFFSET

VOLTAGE TEMPERATURE COEFFICIENT

50

32 Amplifiers From 1 Wafer Lot

VDD = ±2.5 V

P Package

40

TA = 25°C

30

20

Percentage of Amplifiers – %

10

0

–3 –2 –1 0 1 2 3

α

– Temperature Coefficient – µV/°C

VIO

Figure 6

†

5

RS = 50 Ω

4

TA = 25°C

3

2

1

0

–1

– Input Voltage – V

–2

I

I

IB

I

IO

V

–3

–4

INPUT VOLTAGE

vs

SUPPLY VOLTAGE

| VIO | ≤5 mV

0

IB

IIB and IIO – Input Bias and Input Offset Currents – pA

I

25 45 65 85

TA – Free-Air Temperature – ° C

105 125

Figure 7

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

–5

1 1.5 2 2.5

| V

| – Supply Voltage – V

DD±

Figure 8

3 3.5 4

13

Page 14

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

INPUT VOLTAGE

vs

FREE-AIR TEMPERATURE

5

VDD = 5 V

4

3

2

1

– Input Voltage – V

I

V

0

–1

–55 –35 –15 5 25 45 65 85

TA – Free-Air Temperature – ° C

| VIO | ≤5 mV

Figure 9

LOW-LEVEL OUTPUT VOLTAGE

vs

LOW-LEVEL OUTPUT CURRENT

1.2

V

= 3 V

DD

TA = 25°C

1

VIC = 0

0.8

0.6

0.4

– Low-Level Output Voltage – V

0.2

OL

V

†‡

VIC = 0.75 V

VIC = 1.5 V

105 125

‡

3

2.5

2

1.5

1

– High-Level Output Voltage – V

0.5

OH

V

0

1.4

1.2

1

0.8

0.6

0.4

– Low-Level Output Voltage – V

OL

V

0.2

HIGH-LEVEL OUTPUT VOLTAGE

vs

HIGH-LEVEL OUTPUT CURRENT

TA = –40°C

TA = 25°C

TA = 85°C

TA = 125°C

0 200 400

| IOH | – High-Level Output Current – µA

Figure 10

LOW-LEVEL OUTPUT VOLTAGE

vs

LOW-LEVEL OUTPUT CURRENT

VDD = 3 V

VIC = 1.5 V

TA = 125°C

T

= 85°C

A

TA = 25°C

TA = – 40°C

†‡

VDD = 3 V

600 800

†‡

0

0123

IOL – Low-Level Output Current – mA

45

Figure 11

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

‡

For all curves where VDD = 5 V, all loads are referenced to 2.5 V. For all curves where VDD = 3 V, all loads are referenced to 1.5 V.

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

0

012 3

IOL – Low-Level Output Current – mA

Figure 12

45

Page 15

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

HIGH-LEVEL OUTPUT VOLTAGE

vs

HIGH-LEVEL OUTPUT CURRENT

5

4

TA = 85°C

TA = 25°C

3

TA = –40°C

2

– High-Level Output Voltage – V

1

V

OH

VDD = 5 V

VIC = 2.5 V

0

0 200 400 600

| IOH | – High-Level Output Current – µA

Figure 13

MAXIMUM PEAK-TO-PEAK OUTPUT VOLTAGE

vs

FREQUENCY

5

VDD = 5 V

4

†‡

TA = 125°C

800 1000

LOW-LEVEL OUTPUT VOLTAGE

†‡

vs

LOW-LEVEL OUTPUT CURRENT

1.4

VDD = 5 V

VIC = 2.5 V

1.2

TA = 125°C

1

TA = 85°C

0.8

TA = 25°C

0.6

0.4

– Low-Level Output Voltage – V

0.2

OL

V

0

01 2 3

IOL – Low-Level Output Current – mA

TA = –40°C

456

Figure 14

‡

SHORT-CIRCUIT OUTPUT CURRENT

vs

SUPPLY VOLTAGE

16

VO = VDD/2

VIC = VDD/2

14

TA = 25°C

12

VID = –100 mV

10

3

VDD = 3 V

2

1

– Maximum Peak-to-Peak Output Voltage – V

O(PP)

V

RI = 10 kΩ

TA = 25°C

0

2

10

3

10

f – Frequency – Hz

10

4

Figure 15

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

‡

For all curves where VDD = 5 V, all loads are referenced to 2.5 V. For all curves where VDD = 3 V, all loads are referenced to 1.5 V.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

8

6

4

2

– Short-Circuit Output Current – mA

OS

0

I

–2

2345

VDD – Supply Voltage – V

Figure 16

VID = 100 mV

678

15

Page 16

TLV2211, TLV2211Y

‡

‡

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

SHORT-CIRCUIT OUTPUT CURRENT

vs

FREE-AIR TEMPERATURE

14

12

10

8

6

4

2

– Short-Circuit Output Current – mA

OS

0

I

–2

–50 –25 0 25 50 75 100–75 125

TA – Free-Air Temperature – ° C

VID = 100 mV

Figure 17

VDD = 5 V

VIC = 2.5 V

VO = 2.5 V

VID = –100 mV

†‡

OUTPUT VOLTAGE

vs

DIFFERENTIAL INPUT VOLTAGE

3

VDD = 3 V

2.5

2

1.5

– Output Voltage – VV

1

O

0.5

0

–250–500–750–1000 250 500 750 10000

VID – Differential Input Voltage – µV

RI = 10 kΩ

VIC = 1.5 V

TA = 25°C

Figure 18

5

4

3

2

– Output Voltage – V

O

V

1

0

OUTPUT VOLTAGE

vs

DIFFERENTIAL INPUT VOLTAGE

VDD = 5 V

VIC = 2.5 V

RL = 10 kΩ

TA = 25°C

–250–500–750–1000 250 500 750 10000

VID – Differential Input Voltage – µV

Figure 19

DIFFERENTIAL VOLTAGE AMPLIFICATION

vs

LOAD RESISTANCE

3

10

10

10

– Differential Voltage Amplification – V/mV

VD

A

V

= 2 V

O(PP)

TA = 25°C

2

1

1

0.1 1 10

RL – Load Resistance – kΩ

VDD = 5 V

1

Figure 20

VDD = 3 V

2

10

10

‡

3

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

‡

For all curves where VDD = 5 V, all loads are referenced to 2.5 V. For all curves where VDD = 3 V, all loads are referenced to 1.5 V.

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 17

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

LARGE-SIGNAL DIFFERENTIAL VOLTAGE

AMPLIFICATION AND PHASE MARGIN

40

30

20

10

0

–10

Voltage Amplification – dB

–20

VD

AVD – Large-Signal Differential

A

–30

–40

3

10

10

f – Frequency – Hz

LARGE-SIGNAL DIFFERENTIAL VOLTAGE

AMPLIFICATION AND PHASE MARGIN

40

30

20

10

vs

FREQUENCY

Gain

4

Figure 21

vs

FREQUENCY

VDD = 3 V

RL = 10 kΩ

CL= 100 pF

TA = 25°C

Phase Margin

5

10

VDD = 5 V

RL= 10 kΩ

CL= 100 pF

TA = 25°C

Phase Margin

†

90°

45°

0°

m

om – Phase Margin

φ

–45°

–90°

6

10

†

90°

45°

10

0°

–45°

–90°

6

m

om – Phase Margin

φ

0

–10

Voltage Amplification – dB

–20

VD

AVD – Large-Signal Differential

A

–30

–40

3

10

10

f – Frequency – Hz

Gain

4

10

5

Figure 22

†

For all curves where VDD = 5 V, all loads are referenced to 2.5 V. For all curves where VDD = 3 V, all loads are referenced to 1.5 V.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

17

Page 18

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

LARGE-SIGNAL DIFFERENTIAL

VOLTAGE AMPLIFICATION

vs

FREE-AIR TEMPERATURE

3

10

RL = 1 MΩ

2

10

1

10

Amplification – V/mV

– Large-Signal Differential Voltage

VD

A

VDD = 3 V

VIC = 1.5 V

VO = 0.5 V to 2.5 V

1

–75 125

–50 –25 0 25 50 75 100

TA – Free-Air Temperature – ° C

RL = 10 kΩ

Figure 23

†‡

LARGE-SIGNAL DIFFERENTIAL

VOLTAGE AMPLIFICATION

vs

FREE-AIR TEMPERATURE

4

10

3

10

RL = 1 MΩ

2

10

1

10

Amplification – V/mV

– Large-Signal Differential Voltage A

VD

1

–75 –50 –25 0 25 50 75 100 125

RL = 10 kΩ

TA – Free-Air Temperature – ° C

VDD = 5 V

VIC = 2.5 V

VO = 1 V to 4 V

Figure 24

†‡

10

‡

3

OUTPUT IMPEDANCE

‡

vs

FREQUENCY

3

10

VDD = 3 V

TA = 25°C

Ω

2

10

1

1

10

AV = 100

AV = 10

AV = 1

1

10

– Output Impedance –

o

z

2

10

f– Frequency – Hz

10

3

10

4

3

10

VDD = 5 V

TA = 25°C

Ω

– Output Impedance –

o

z

10

10

2

1

1

10

AV = 100

AV = 10

AV = 1

1

Figure 25

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

‡

For all curves where VDD = 5 V, all loads are referenced to 2.5 V. For all curves where VDD = 3 V, all loads are referenced to 1.5 V.

OUTPUT IMPEDANCE

vs

FREQUENCY

2

10

f– Frequency – Hz

Figure 26

10

4

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 19

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

COMMON-MODE REJECTION RATIO

vs

FREQUENCY

100

VDD = 5 V

VO = 2.5 V

80

VDD = 3 V

60

VO = 1.5 V

40

20

CMRR – Common-Mode Rejection Ratio – dB

0

10

1

2

10

f – Frequency – Hz

10

3

Figure 27

SUPPLY-VOLTAGE REJECTION RATIO

vs

FREQUENCY

100

80

TA = 25°C

4

10

VDD = 3 V

TA = 25°C

†

COMMON-MODE REJECTION RATIO

†‡

vs

FREE-AIR TEMPERATURE

88

86

VDD = 5 V

10

84

VDD = 3 V

82

80

CMMR – Common-Mode Rejection Ratio – dB

5

78

– 50 – 25 0 25 50 75 100

– 75 125

TA – Free-Air Temperature – ° C

Figure 28

†

SUPPLY-VOLTAGE REJECTION RATIO

vs

FREQUENCY

100

80

k

SVR+

VDD = 5 V

TA = 25°C

†

k

60

40

k

SVR–

20

– Supply-Voltage Rejection Ratio – dB

0

SVR

k

–20

10

1

2

10

10

f – Frequency – Hz

Figure 29

†

For all curves where VDD = 5 V, all loads are referenced to 2.5 V. For all curves where VDD = 3 V, all loads are referenced to 1.5 V.

‡

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

SVR+

3

10

4

10

5

10

6

60

k

SVR–

40

20

– Supply-Voltage Rejection Ratio – dB

0

SVR

k

–20

10

1

2

10

f – Frequency – Hz

10

3

10

4

10

Figure 30

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

10

6

19

Page 20

TLV2211, TLV2211Y

Á

Á

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

SUPPLY-VOLTAGE REJECTION RATIO

FREE-AIR TEMPERATURE

100

VDD = 2.7 V to 8 V

VIC = VO = VDD /2

98

96

94

92

– Supply-Voltage Rejection Ratio – dB

SVR

k

90

–50 –25 0 25 50 75 100

TA – Free-Air Temperature – ° C

Figure 31

LOAD CAPACITANCE

0.040

0.035

0.030

sµ

V/

0.025

0.020

0.015

SR – Slew Rate –

0.010

VDD = 5 V

AV = –1

TA = 25°C

0.05

vs

SLEW RATE

vs

†

SUPPLY CURRENT

†

vs

SUPPLY VOLTAGE

30

VO = V

DD/2

VIC = V

No Load

25

Aµ

20

15

– Supply Current –

10

DD

I

5

125–75

0

0246

DD/2

TA = –40°C

VDD – Supply Voltage – V

TA = 25°C

TA = 85°C

810

Figure 32

‡

SLEW RATE

FREE-AIR TEMPERATURE

SR+

SR–

0.050

0.040

sµ

V/

0.030

0.020

SR – Slew Rate –

0.010

VDD = 5 V

RL = 10 kΩ

CL = 100 pF

AV = 1

†‡

vs

SR–

SR+

0

10

1

2

10

CL – Load Capacitance – pF

10

3

10

4

10

5

Figure 33

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

‡

For all curves where VDD = 5 V, all loads are referenced to 2.5 V. For all curves where VDD = 3 V, all loads are referenced to 1.5 V.

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

0

–75 125

–50 –25 0 25 50 75 100

TA – Free-Air Temperature – ° C

Figure 34

Page 21

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

INVERTING LARGE-SIGNAL PULSE

3

2.5

2

1.5

1

– Output Voltage – V

O

V

0.5

0

0 50 100 150 200 250 300

VOLTAGE-FOLLOWER LARGE-SIGNAL

PULSE RESPONSE

5

VDD = 5 V

RL = 10 kΩ

CL = 100 pF

4

AV = 1

TA = 25°C

RESPONSE

t – Time – µs

Figure 35

†

VDD = 3 V

RL = 10 kΩ

CL = 100 pF

AV = –1

TA = 25°C

350 400 450 500

†

INVERTING LARGE-SIGNAL PULSE

5

VDD = 5 V

RL = 10 kΩ

CL = 100 pF

4

AV = –1

TA = 25°C

3

2

– Output Voltage – V

O

V

1

0

0 50 100 150 200 250 300

Figure 36

VOLTAGE-FOLLOWER LARGE-SIGNAL

PULSE RESPONSE

5

VDD = 5 V

CL = 100 pF

AV = 1

4

TA = 25°C

RESPONSE

t – Time – µs

RL = 100 kΩ

Tied to 2.5 V

†

350 400 450 500

†

3

2

– Output Voltage – V

O

V

1

0

0 100 200 300 400 500 600

t – Time – µs

700 800 900 1000

Figure 37

†

For all curves where VDD = 5 V, all loads are referenced to 2.5 V. For all curves where VDD = 3 V, all loads are referenced to 1.5 V.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

2

– Output Voltage – V

O

V

RL = 10 kΩ

1

Tied to 2.5 V

0

0 100 200 300 400 500

t – Time – µs

Figure 38

RL = 10 kΩ

Tied to 0 V

21

Page 22

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

INVERTING SMALL-SIGNAL

PULSE RESPONSE

0.76

VDD = 3 V

RL = 10 kΩ

CL = 100 pF

074

AV = –1

TA = 25°C

0.72

0.7

– Output Voltage – V

0.68

O

V

0.66

0.64

0102030

t – Time – µs

Figure 39

VOLTAGE-FOLLOWER SMALL-SIGNAL

PULSE RESPONSE

0.76

VDD = 3 V

RL = 10 kΩ

0.74

0.72

CL = 100 pF

AV = 1

TA = 25°C

†

40 50

†

INVERTING SMALL-SIGNAL

PULSE RESPONSE

2.58

VDD = 5 V

RL = 10 kΩ

2.56

CL = 100 pF

AV = –1

TA = 25°C

2.54

2.52

2.5

O

2.48

V

VO – Output Voltage – V

2.46

2.44

0102030

t – Time – µs

Figure 40

VOLTAGE-FOLLOWER SMALL-SIGNAL

PULSE RESPONSE

2.58

2.56

2.54

VDD = 5 V

RL = 10 kΩ

CL = 100 pF

AV = 1

TA = 25°C

†

40 50

†

2.52

0.7

2.5

0.68

O

V

VO – Output Voltage – V

0.66

0.64

01020304050

t – Time – µs

Figure 41

†

For all curves where VDD = 5 V, all loads are referenced to 2.5 V. For all curves where VDD = 3 V, all loads are referenced to 1.5 V.

22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

O

2.48

V

VO – Output Voltage – V

2.46

2.44

01020304050

t – Time – µs

Figure 42

Page 23

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

80

Hz

70

nV/

60

50

40

30

20

10

– Equivalent Input Noise Voltage –

n

V

1000

750

500

250

EQUIVALENT INPUT NOISE VOLTAGE

vs

FREQUENCY

0

10

1

2

10

f – Frequency – Hz

10

Figure 43

INPUT NOISE VOLTAGE OVER

A 10-SECOND PERIOD

VDD = 5 V

f = 0.1 Hz to 10 Hz

TA = 25°C

VDD = 3 V

RS = 20 Ω

TA = 25°C

3

†

†

EQUIVALENT INPUT NOISE VOLTAGE

†

vs

FREQUENCY

80

10

70

nV/ Hz

60

50

40

30

20

10

– Equivalent Input Noise Voltage –

n

V

0

4

10

1

2

10

f – Frequency – Hz

10

3

VDD = 5 V

RS = 20 Ω

TA = 25°C

10

4

Figure 44

TOTAL HARMONIC DISTORTION PLUS NOISE

vs

FREQUENCY

10

VDD = 10 V

VIC = 2.5 V

RL = 10 kΩ

TA = 25°C

AV = 100

1

†

0

AV = 10

–250

Noise Voltage – nV

–500

–750

–1000

0246

t – Time – s

810

Figure 45

†

For all curves where VDD = 5 V, all loads are referenced to 2.5 V. For all curves where VDD = 3 V, all loads are referenced to 1.5 V.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

0.1

AV = 1

0.01

THD + N – Total Harmonic Distortion Plus Noise – %

10

1

2

10

f – Frequency – Hz

Figure 46

10

3

10

4

23

Page 24

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

GAIN-BANDWIDTH PRODUCT

FREE-AIR TEMPERATURE

80

VDD = 5 V

f = 10 kHz

RL = 10 kΩ

75

CL = 100 pF

70

65

60

Gain-Bandwidth Product – kHz

55

50

–50 – 25 0 25 50 10075

TA – Free-Air Temperature – ° C

Figure 47

PHASE MARGIN

LOAD CAPACITANCE

75°

TA = 25°C

vs

vs

†‡

GAIN-BANDWIDTH PRODUCT

vs

SUPPLY VOLTAGE

80

RL = 10 kΩ

CL = 100 pF

TA 25°C

75

70

65

60

Gain-Bandwidth Product – kHz

55

50

125–75

123 4 5 76

VDD – Supply Voltage – V

80

Figure 48

GAIN MARGIN

vs

LOAD CAPACITANCE

25

R

= 1000 Ω

null

60°

R

= 1000 Ω

null

45°

30°

m

om – Phase Margin

φ

15°

0

10

10 kΩ

V

10 kΩ

V

I

1

DD+

R

null

–

+

V

DD–

2

10

CL – Load Capacitance – pF

C

10

L

3

R

null

R

null

= 0

10

= 500 Ω

4

10

5

Figure 49

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

‡

For all curves where VDD = 5 V, all loads are referenced to 2.5 V. For all curves where VDD = 3 V, all loads are referenced to 1.5 V.

20

15

10

Gain Margin – dB

5

TA = 25°C

0

1

10

R

null

R

= 0

null

2

10

CL – Load Capacitance – pF

10

3

10

Figure 50

= 500 Ω

4

10

5

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 25

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

TYPICAL CHARACTERISTICS

UNITY-GAIN BANDWIDTH

vs

LOAD CAPACITANCE

80

TA = 25°C

70

60

50

40

30

20

– Unity-Gain Bandwidth – kHz

1

B

10

0

10

1

2

10

CL – Load Capacitance – pF

10

3

10

4

10

5

10

6

Figure 51

APPLICATION INFORMATION

driving large capacitive loads

The TLV2211 is designed to drive larger capacitive loads than most CMOS operational amplifiers. Figure 49

and Figure 50 illustrate its ability to drive loads up to 600 pF while maintaining good gain and phase margins

(R

= 0).

null

A smaller series resistor (R

when driving large capacitive loads. Figure 49 and Figure 50 show the effects of adding series resistances of

500 Ω and 1000 Ω. The addition of this series resistor has two effects: the first is that it adds a zero to the transfer

function and the second is that it reduces the frequency of the pole associated with the output load in the transfer

function.

The zero introduced to the transfer function is equal to the series resistance times the load capacitance. To

calculate the improvement in phase margin, equation (1) can be used.

–1

∆φ

m1

+

tan

ǒ

2 × π × UGBW × R

where :

∆φm1+

UGBW

R

null

C

improvement in phase margin

+

unity-gain bandwidth frequency

+

output series resistance

+

load capacitance

L

) at the output of the device (see Figure 52) improves the gain and phase margins

null

Ǔ

× C

null

L

(1)

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

25

Page 26

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

APPLICATION INFORMATION

driving large capacitive loads (continued)

The unity-gain bandwidth (UGBW) frequency decreases as the capacitive load increases (see Figure 51). To

use equation (1), UGBW must be approximated from Figure 51.

10 kΩ

V

DD+

driving heavy dc loads

10 kΩ

V

I

–

+

V

DD–

Figure 52. Series-Resistance Circuit

/GND

R

null

C

L

The TL V2211 is designed to provide better sinking and sourcing output currents than earlier CMOS rail-to-rail

output devices. This device is specified to sink 500 µA and source 250 µA at V

maximum quiescent I

of 25 µA. This provides a greater than 90% power efficiency.

DD

= 3 V and VDD = 5 V at a

DD

When driving heavy dc loads, such as 10 kΩ, the positive edge under slewing conditions can experience some

distortion. This condition can be seen in Figure 37. This condition is affected by three factors.

D

Where the load is referenced. When the load is referenced to either rail, this condition does not occur. The

distortion occurs only when the output signal swings through the point where the load is referenced.

Figure 38 illustrates two 10-kΩ load conditions. The first load condition shows the distortion seen for a 10-kΩ

load tied to 2.5 V. The third load condition shows no distortion for a 10-kΩ load tied to 0 V.

D

Load resistance. As the load resistance increases, the distortion seen on the output decreases. Figure 38

illustrates the difference seen on the output for a 10-kΩ load and a 100-kΩ load with both tied to 2.5 V.

D

Input signal edge rate. Faster input edge rates for a step input result in more distortion than with slower input

edge rates.

26

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 27

macromodel information

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

APPLICATION INFORMATION

Macromodel information provided was derived using Microsim

with Microsim

PSpice

. The Boyle macromodel (see Note 6) and subcircuit in Figure 53 are generated using

the TLV2211 typical electrical and operating characteristics at T

Parts

, the model generation software used

= 25°C. Using this information, output

A

simulations of the following key parameters can be generated to a tolerance of 20% (in most cases):

D

Maximum positive output voltage swing

D

Maximum negative output voltage swing

D

Slew rate

D

Quiescent power dissipation

D

Input bias current

D

Open-loop voltage amplification

NOTE 6: G. R. Boyle, B. M. Cohn, D. O. Pederson, and J. E. Solomon, “Macromodeling of Integrated Circuit Operational Amplifiers”,

of Solid-State Circuits,

V

DD+

RSS ISS

RP

2

IN –

DP

IN+

1

V

DD–

.SUBCKT TLV2211 1 2 3 4 5

C1 11 12 8.86E–12

C2 6 7 50.00E–12

DC 5 53 DX

DE 54 5 DX

DLP 90 91 DX

DLN 92 90 DX

DP 43DX

EGND 99 0 POLY (2) (3,0) (4,0) 0 .5 .5

FB 7 99 POLY (5) VB VC VE VLP

+ VLN 0 4.29E6 –6E6 6E6 6E6 –6E6

GA 6 0 1 1 12 9.425E–6

GCM 0 6 10 99 1320.2E–12

ISS 3 10 DC 1.250E–6

HLIM 90 0 VLIM 1K

J1 11 2 10 JX

J2 12 1 10 JX

R2 6 9 100.0E3

11

RD1

VAD

SC-9, 353 (1974).

3

10

J1 J2

12

C1

RD2

+

–

60

4

VE

+

VC

DC

DE

54

+–

R2

–

53

6

9

GCM

D

Unity-gain frequency

D

Common-mode rejection ratio

D

Phase margin

D

DC output resistance

D

AC output resistance

D

Short-circuit output current limit

99

EGND

+

–

+

FB

–

VB

C2

GA

RD1 60 11 106.1E3

RD2 60 12 106.1E3

R01 8 5 50

R02 7 99 150

RP 3 4 419.2E3

RSS 10 99 160.0E6

VAD 60 4 –.5

VB 9 0 DC 0

VC 3 53 DC .55

VE 54 4 DC .55

VLIM 7 8 DC 0

VLP 91 0 DC 0.1

VLN 0 92 DC 2.6

.MODEL DX D (IS=800.0E–18)

.MODEL JX PJF (IS=500.0E–15 BETA=166E–6

+ VTO=–.004)

.ENDS

7

VLIM

RO2

HLIM

8

5

OUT

+

–

90

RO1

+

DLP

–

DLN

91

+

–

IEEE Journal

92

–

VLNVLP

+

PSpice

and

Figure 53. Boyle Macromodel and Subcircuit

Parts

are trademark of MicroSim Corporation.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

27

Page 28

TLV2211, TLV2211Y

Advanced LinCMOS RAIL-TO-RAIL

MICROPOWER SINGLE OPERATIONAL AMPLIFIERS

SLOS156B – MAY 1996 – REVISED JANUAR Y 1997

MECHANICAL INFORMATION

DBV (R-PDSO-G5) PLASTIC SMALL-OUTLINE PACKAGE

0,95

1,30

1,00

0,40

0,20

45

1,80

1,50

2

1

3,10

2,70

3

0,05 MIN

M

0,25

3,00

2,50

Seating Plane

0,15 NOM

Gage Plane

0,25

0°–8°

0,10

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions include mold flash or protrusion.

4073253-3/A 09/95

28

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 29

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...