Page 1

CHIP FORM

40°C to 105°C

µ

查询TLV1393供应商

TLV1393, TLV1393Y, TLV2393, TLV2393Y

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

D

Low-Voltage and Single-Supply Operation

V

= 2 V to 7 V

CC

D

Common-Mode Voltage Range Includes

Ground

D

Fast Response Time

450 ns Typ (TLV2393)

D

Low Supply Current

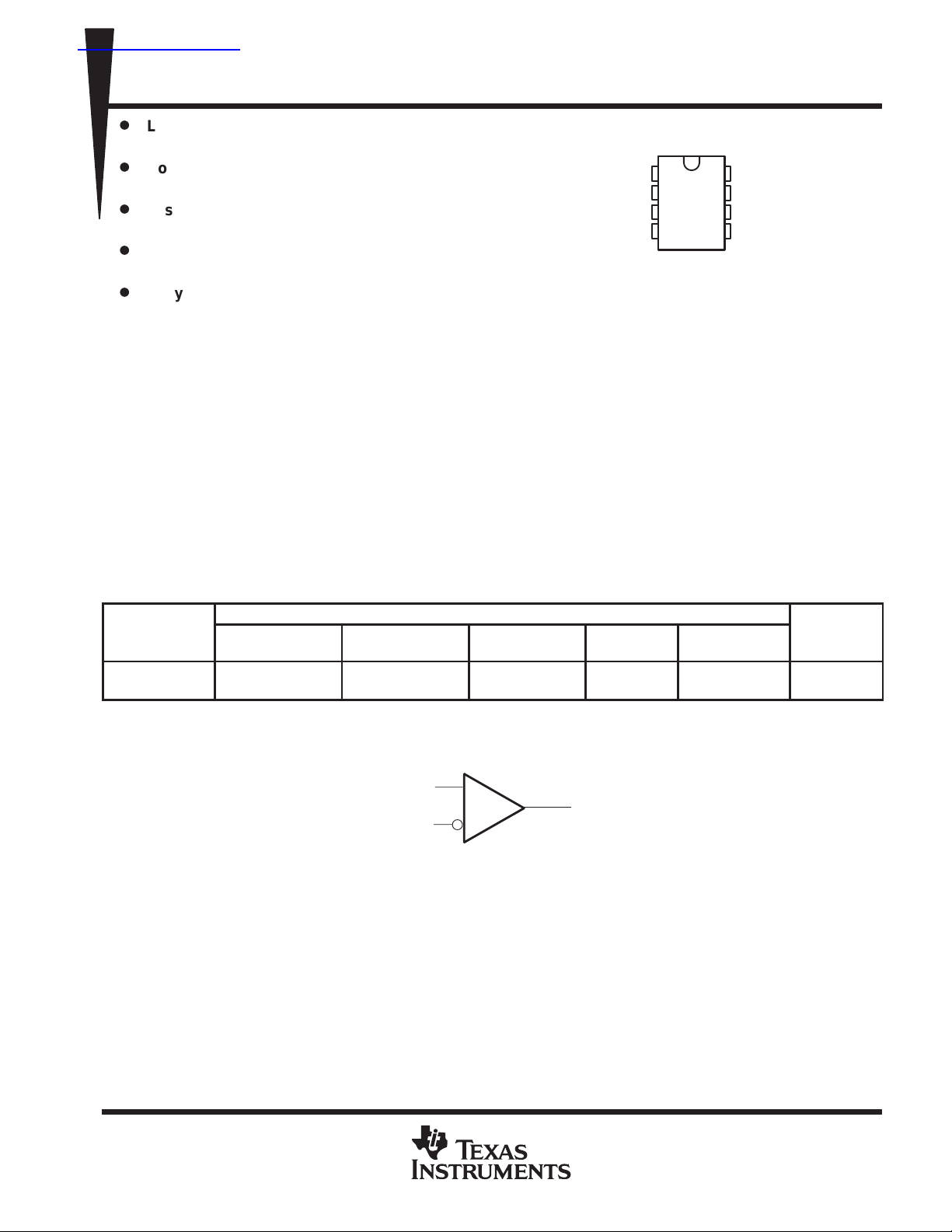

D, P, OR PW PACKAGE

(TOP VIEW)

1OUT

1IN–

GND

1IN+

1

8

2

7

3

6

4

5

V

CC

2OUT

2IN–

2IN+

0.16 mA Typ (TLV1393)

D

Fully Specified at 3-V and 5-V Supply

Voltages

description

The TLV1393 and the TLV2393 are dual differential comparators built using a new Texas Instruments

low-voltage, high-speed bipolar process. These devices have been specifically developed for low-voltage,

single-supply applications. Their enhanced performance makes them excellent replacements for the LM393 in

today’s improved 3-V and 5-V system designs.

The TLV1393, with its typical supply current of only 0.16 mA, is ideal for low-power systems. Response time

has also been improved to 0.7 µs. For higher-speed applications, the TLV2393 features excellent ac

performance with a response time of just 0.45 µs, three times that of the LM393.

Package availability for these devices includes the TSSOP (thin-shrink small-outline package). With a

maximum thickness of 1.1 mm and a package area that is 25% smaller than the standard surface-mount

package, the TSSOP is ideal for high-density circuits, particularly in hand-held and portable equipment.

AVAILABLE OPTIONS

PACKAGED DEVICES

T

A

°

–

†

The PW packages are only available left-ended taped and reeled (e.g., TLV1393IPWLE).

SUPPLY CURRENT

°

0.16 mA 0.7 µs TLV1393ID TLV1393IP TLV1393IPWLE TLV1393Y

(TYP)

1.1 mA

RESPONSE TIME

(TYP)

0.45 µs TLV2393ID TLV2393IP TLV2393IPWLE TLV2393Y

SMALL OUTLINE

(D)

symbol (each comparator)

IN+

IN–

PLASTIC DIP

(P)

OUT

TSSOP

(PW)

†

(Y)

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Copyright 1994, Texas Instruments Incorporated

1

Page 2

TLV1393, TLV1393Y, TLV2393, TLV2393Y

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

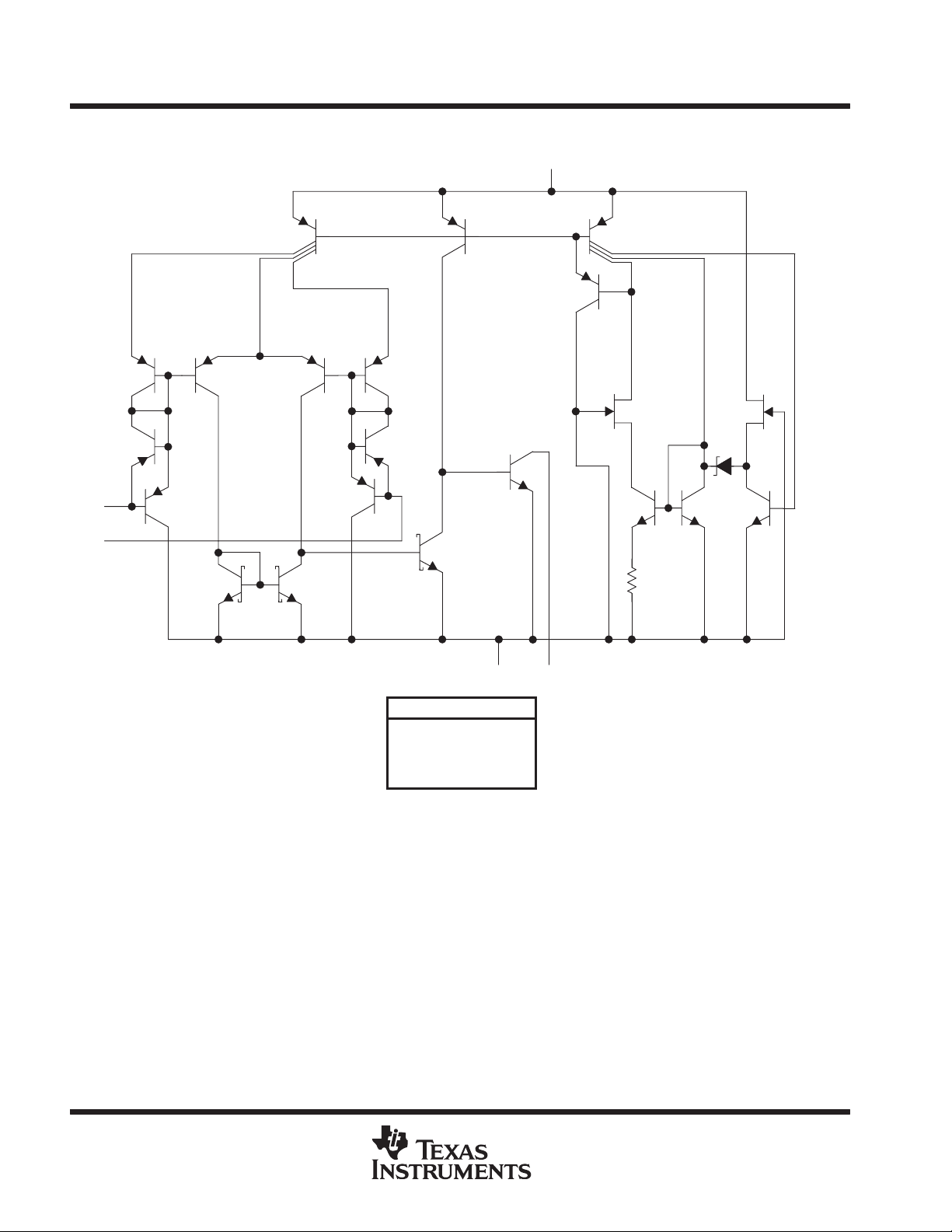

TLV1393, TLV1393Y equivalent schematic (each comparator)

V

CC

IN +

IN –

GND OUT

COMPONENT COUNT

Transistors 44

Resistors 1

Diodes

Epi-FET 2

7

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 3

TLV1393, TLV1393Y, TLV2393, TLV2393Y

DUAL DIFFERENTIAL COMPARATORS

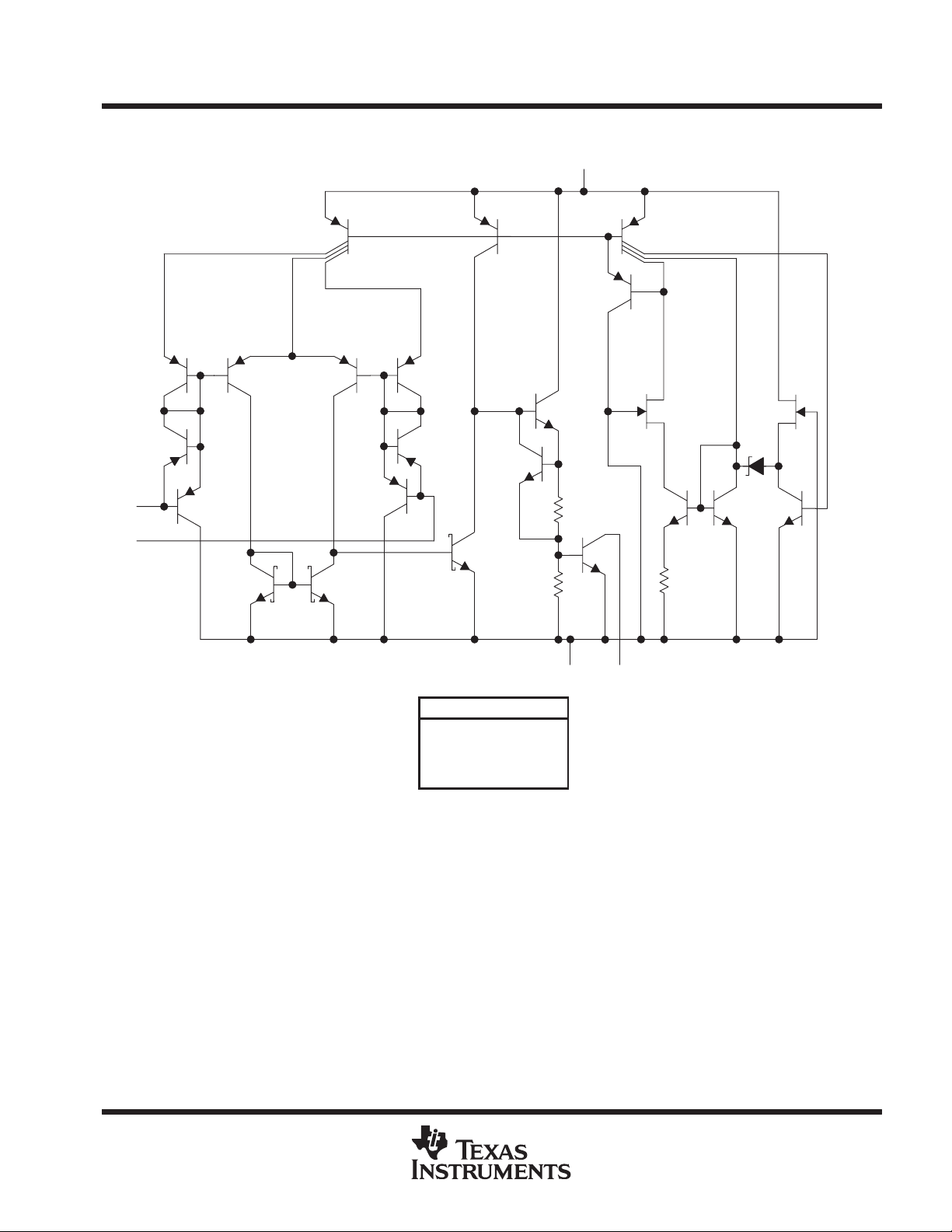

TLV2393, TLV2393Y equivalent schematic (each comparator)

V

CC

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

IN +

IN –

COMPONENT COUNT

Transistors 44

Resistors 1

Diodes

Epi-FET 2

GND OUT

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

Page 4

TLV1393, TLV1393Y, TLV2393, TLV2393Y

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

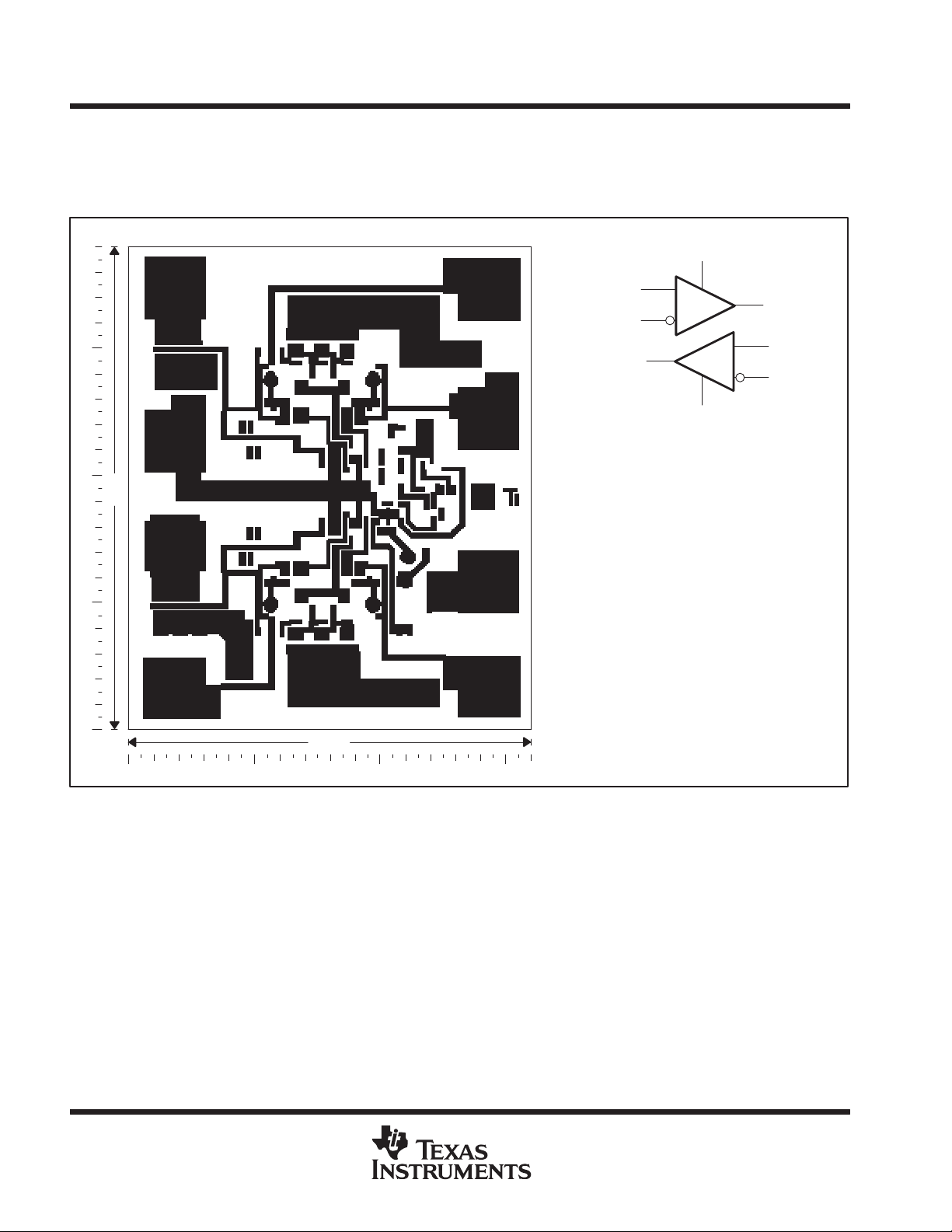

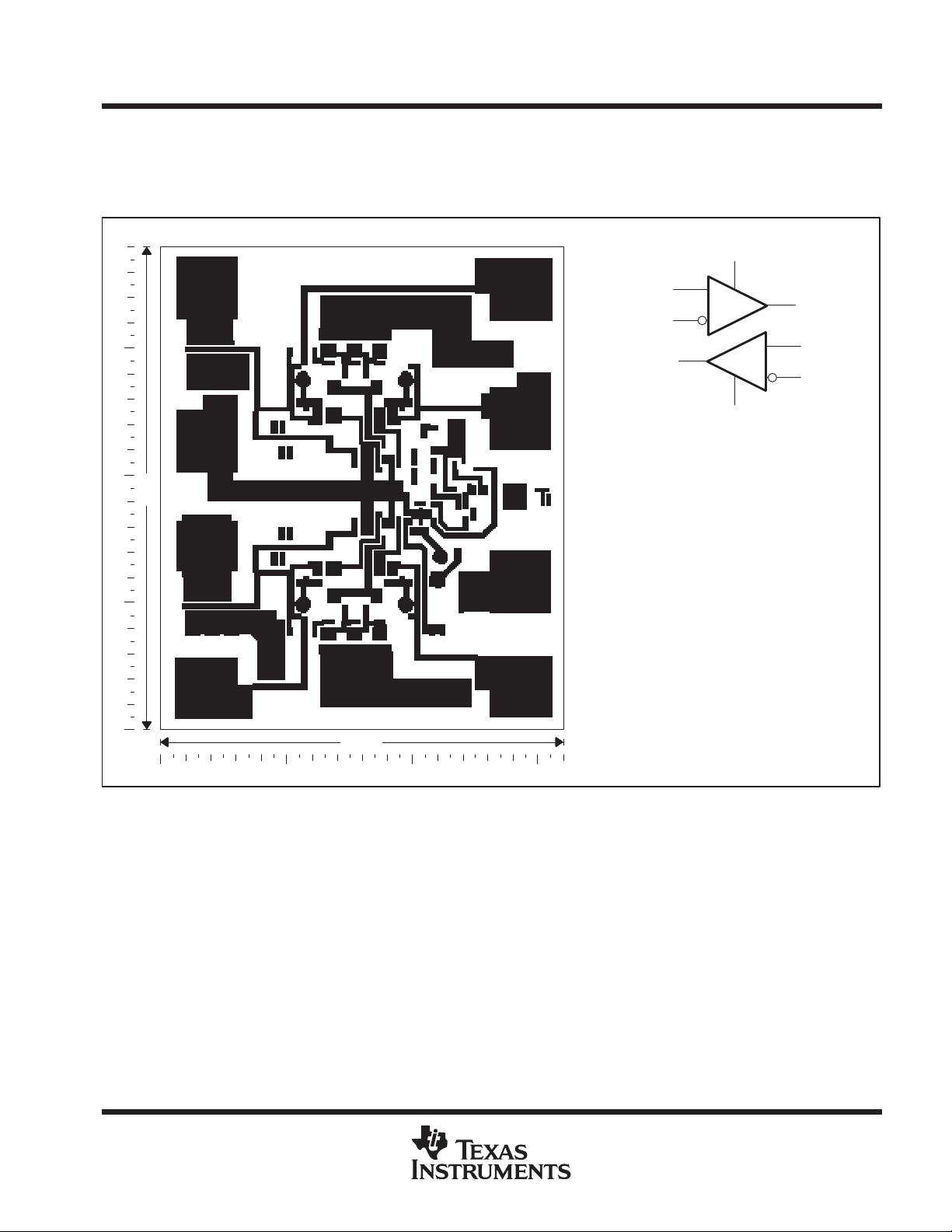

TLV1393Y chip information

This chip, when properly assembled, displays characteristics similar to the TL V1393. Thermal compression or

ultrasonic bonding may be used on the doped-aluminum bonding pads. Chips may be mounted with conductive

epoxy or a gold-silicon preform.

BONDING PAD ASSIGNMENTS

V

CC

+

–

GND

(8)

(4)

(1)

(5)

+

(6)

–

38

(8)

(6)(7)

(5)

1IN+

1IN–

2OUT

(3)

(2)

(7)

1OUT

2IN+

2IN–

(1)

(2)

32

(4)

(3)

CHIP THICKNESS: 13 TYPICAL

BONDING PADS: 3.54 × 3.54 MINIMUM

TJmax = 150°C

TOLERANCES ARE ±10%.

ALL DIMENSIONS ARE IN MILS.

PIN (4) IS INTERNALLY CONNECTED

TO BACKSIDE OF CHIP.

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 5

TLV1393, TLV1393Y, TLV2393, TLV2393Y

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

TLV2393Y chip information

This chip, when properly assembled, displays characteristics similar to the TL V2393. Thermal compression or

ultrasonic bonding may be used on the doped-aluminum bonding pads. Chips may be mounted with conductive

epoxy or a gold-silicon preform.

BONDING PAD ASSIGNMENTS

V

CC

+

–

GND

(8)

(4)

(1)

(5)

+

(6)

–

38

(8)

(6)(7)

(5)

1IN+

1IN–

2OUT

(3)

(2)

(7)

1OUT

2IN+

2IN–

(1)

(2)

32

(4)

(3)

CHIP THICKNESS: 15 TYPICAL

BONDING PADS: 3.6 × 3.6 MINIMUM

TJmax = 150°C

TOLERANCES ARE ±10%.

ALL DIMENSIONS ARE IN MILS.

PIN (4) IS INTERNALLY CONNECTED

TO BACKSIDE OF CHIP.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

Page 6

TLV1393, TLV1393Y, TLV2393, TLV2393Y

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

Supply voltage, V

Differential input voltage, V

Input voltage, V

Output voltage, V

Output current, I

Duration of short-circuit current to GND (see Note 3) unlimited. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

Storage temperature range –65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltage values, except differential voltages, are with respect to the network GND.

2. Differential voltages are at the noninverting input with respect to the inverting input.

3. Short circuits from the outputs to VCC can cause excessive heating and eventual destruction of the chip.

PACKAGE

(see Note 1) 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC

(any input) 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O

(each output) 20 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O

D 725 mW 5.8 mW/°C 464 mW 377 mW

P 1000 mW 8.0 mW/°C 640 mW 520 mW

PW 525 mW 4.2 mW/°C 336 mW 273 mW

(see Note 2) 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ID

–40°C to 105°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

DISSIPATION RATING T ABLE

TA ≤ 25°C

POWER RATING

DERATING FACTOR

ABOVE TA = 25°C

TA = 70°C

POWER RATING

TA = 85°C

POWER RATING

†

recommended operating conditions

Supply voltage, V

Operating free-air temperature, T

CC

A

MIN MAX

2 7 V

–40 105 °C

UNIT

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 7

PARAMETER

TEST CONDITIONS

T

†

UNIT

VIOInput offset voltage

V

V

V

min

mV

V

Common-mode input voltage range

V

IIOInput offset current

V

1.4 V

nA

IIBInput bias current

V

V

nA

IOHHigh-level output current

nA

I

High-level supply current

V

V

A

I

Low-level supply current

V

V

PARAMETER

TEST CONDITIONS

UNIT

electrical characteristics, VCC = 3 V

p

ICR

V

OL

I

OL

CCH

CCL

†

Full range is –40°C to 105°C.

Low-level output voltage VID = –1 V, IOL = 500 µA Full range 120 300 mV

p

p

Low-level output current VID = –1 V, VOL = 1.5 V 25°C 500 µA

p

p

pp

pp

TLV1393, TLV1393Y, TLV2393, TLV2393Y

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

A

= 1.4 V,

O

=

O

= 1.4

O

VID = 1 V, VOH = 3 V 25°C 0.1

VID = 1 V, VOH = 5 V Full range 100

=

O

OH

=

O

OL

=

IC

ICR

25°C 1.5 5

Full range 120 9

25°C

Full range

25°C 5 50

Full range 150

25°C –40 –250

Full range –400

25°C 160 250

Full range 300

25°C 160 250

Full range 300

VCC – 1.5

VCC –2

TLV1393

MIN TYP MAX

0 to

0 to

0 to

VCC –1.2

µ

switching characteristics, VCC = 3 V, CL = 15 pF, T

Response time

100-mV input step with 5-mV overdrive, RL connected to 5 V through 5.1 kΩ

= 25°C

A

TLV1393

MIN TYP MAX

0.7 µs

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

Page 8

TLV1393, TLV1393Y, TLV2393, TLV2393Y

PARAMETER

TEST CONDITIONS

T

†

UNIT

VIOInput offset voltage

V

V

V

min

mV

V

Common-mode input voltage range

V

IIOInput offset current

V

1.4 V

nA

IIBInput bias current

V

V

nA

IOHHigh-level output current

nA

I

High-level supply current

V

V

A

I

Low-level supply current

V

V

PARAMETER

TEST CONDITIONS

UNIT

Response time

s

PARAMETER

TEST CONDITIONS

UNIT

A

PARAMETER

TEST CONDITIONS

UNIT

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

electrical characteristics, VCC = 5 V

p

ICR

V

Low-level output voltage VID = –1 V, IOL = 500 µA Full range 120 300 mV

OL

p

p

p

I

Low-level output current VID = –1 V, VOL = 1.5 V 25°C 600 µA

OL

CCH

CCL

†

Full range is –40°C to 105°C.

pp

pp

p

= 1.4 V,

O

=

O

= 1.4

O

VID = 1 V, VOH = 3 V 25°C 0.1

VID = 1 V, VOH = 5 V Full range 100

=

O

OH

=

O

OL

A

=

IC

ICR

25°C 1.5 5

Full range 9

25°C

Full range

25°C 5 50

Full range 150

25°C –40 –250

Full range –400

25°C 200 300

Full range 350

25°C 200 300

Full range 350

VCC – 1.5

VCC –2

TLV1393

MIN TYP MAX

0 to

0 to

0 to

VCC –1.2

µ

switching characteristics, VCC = 5 V, CL = 15 pF, T

p

electrical characteristics, VCC = 3 V, T

V

Input offset voltage VO = 1.4 V, VIC = V

IO

V

Common-mode input voltage range

ICR

I

Input offset current VO = 1.4 V 5 50 nA

IO

I

Input bias current VO = 1.4 V –40 –250 nA

IB

I

High-level output current VID = 1 V, VOH = 3 V 0.1 nA

OH

I

Low-level output current VID = –1 V, VOL = 1.5 V 500 µA

OL

I

High-level supply current VO = V

CCH

I

Low-level supply current

CCL

100-mV input step with 5-mV overdrive, RL connected to 5 V through 5.1 kΩ 0.65

TTL-level input step, RL connected to 5 V through 5.1 kΩ

= 25°C

A

VO = V

switching characteristics, VCC = 3 V, CL = 15 pF, T

Response time 100-mV input step with 5-mV overdrive, RL connected to 5 V through 5.1 kΩ 0.7 µs

OH

OL

= 25°C

A

= 25°C

A

TLV1393

MIN TYP MAX

0.18

TLV1393Y

MIN TYP MAX

min 1.5 5 mV

ICR

0 to

VCC – 1.5

0 to

VCC –1.2

160 250

160 250

TLV1393Y

MIN TYP MAX

µ

V

µ

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 9

PARAMETER

TEST CONDITIONS

UNIT

A

PARAMETER

TEST CONDITIONS

UNIT

Response time

s

TLV1393, TLV1393Y, TLV2393, TLV2393Y

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

electrical characteristics, VCC = 5 V, T

V

IO

V

ICR

I

IO

I

IB

I

OH

I

OL

I

CCH

I

CCL

Input offset voltage VO = 1.4 V, VIC = V

Common-mode input voltage range

Input offset current VO = 1.4 V 5 50 nA

Input bias current VO = 1.4 V –40 –250 nA

High-level output current VID = 1 V, VOH = 3 V 0.1 nA

Low-level output current VID = –1 V, VOL = 1.5 V 600 µA

High-level supply current VO = V

Low-level supply current

= 25°C

A

VO = V

OH

OL

switching characteristics, VCC = 5 V, CL = 15 pF, T

p

100-mV input step with 5-mV overdrive, RL connected to 5 V through 5.1 kΩ 0.65

TTL-level input step, RL connected to 5 V through 5.1 kΩ

= 25°C

A

TLV1393Y

MIN TYP MAX

min 1.5 5 mV

ICR

0 to

VCC – 1.5

0 to

VCC –1.2

200 300

200 300

TLV1393Y

MIN TYP MAX

0.18

V

µ

µ

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

Page 10

TLV1393, TLV1393Y, TLV2393, TLV2393Y

PARAMETER

TEST CONDITIONS

T

†

UNIT

VIOInput offset voltage

V

V

V

min

mV

V

Common-mode input voltage range

V

VOLLow-level output voltage

mV

IIOInput offset current

V

1.4 V

nA

IIBInput bias current

V

V

nA

IOHHigh-level output current

nA

I

High-level supply current

V

V

A

I

Low-level supply current

V

V

mA

PARAMETER

TEST CONDITIONS

UNIT

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

electrical characteristics, VCC = 3 V

p

ICR

p

p

p

p

I

Low-level output current VID = –1 V, VOL = 1.5 V 25°C 4 mA

OL

CCH

CCL

†

Full range is –40°C to 105°C.

pp

pp

p

= 1.4 V,

O

VID = –1 V, IOL = 1 mA 25°C 80 300

VID = –1 V, IOL = 4 mA Full range 250 700

=

O

= 1.4

O

VID = 1 V, VOH = 3 V 25°C 0.1

VID = 1 V, VOH = 5 V Full range 100

=

O

OH

=

O

OL

0 to

0 to

TLV2393

0 to

VCC –1.2

µ

A

=

IC

ICR

25°C 1.5 5

Full range 9

25°C

Full range

25°C 5 50

Full range 150

25°C –100 –250

Full range –400

25°C 450 600

Full range 700

25°C 1.1 1.3

Full range 1.4

MIN TYP MAX

VCC – 1.5

VCC –2

switching characteristics, VCC = 3 V, CL = 15 pF, T

Response time

100-mV input step with 5-mV overdrive, RL connected to 5 V through 5.1 kΩ

= 25°C

A

TLV2393

MIN TYP MAX

0.45 1 µs

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 11

PARAMETER

TEST CONDITIONS

T

†

UNIT

VIOInput offset voltage

V

V

V

min

mV

V

Common-mode input voltage range

V

VOLLow-level output voltage

mV

IIOInput offset current

V

1.4 V

nA

IIBInput bias current

V

V

nA

IOHHigh-level output current

nA

I

High-level supply current

V

V

A

I

Low-level supply current

V

V

mA

PARAMETER

TEST CONDITIONS

UNIT

Response time

s

electrical characteristics, VCC = 5 V

p

pp

p

pp

p

VID = –1 V, IOL = 1 mA 25°C 70 300

VID = –1 V, IOL = 4 mA Full range 200 700

p

VID = 1 V, VOH = 3 V 25°C 0.1

VID = 1 V, VOH = 5 V Full range 100

ICR

p

p

I

OL

CCH

CCL

†

Full range is –40°C to 105°C.

Low-level output current VID = –1 V, VOL = 1.5 V 25°C 6 mA

= 1.4 V,

O

=

O

= 1.4

O

=

O

=

O

OH

OL

TLV1393, TLV1393Y, TLV2393, TLV2393Y

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

A

=

IC

ICR

25°C 1.5 5

Full range 9

25°C

Full range

25°C 5 50

Full range 150

25°C –100 –250

Full range –400

25°C 550 700

Full range 800

25°C 1.2 1.5

Full range 1.6

VCC – 1.5

VCC –2

TLV2393

MIN TYP MAX

0 to

0 to

0 to

VCC –1.2

µ

switching characteristics, VCC = 5 V, CL = 15 pF, T

p

100-mV input step with 5-mV overdrive, RL connected to 5 V through 5.1 kΩ 0.4 0.8

TTL-level input step, RL connected to 5 V through 5.1 kΩ

= 25°C

A

TLV2393

MIN TYP MAX

0.15 0.3

µ

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

11

Page 12

TLV1393, TLV1393Y, TLV2393, TLV2393Y

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

PARAMETER

TEST CONDITIONS

UNIT

Response time

s

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

electrical characteristics, VCC = 3 V, T

V

Input offset voltage VO = 1.4 V, VIC = V

IO

V

Common-mode input voltage range

ICR

V

Low-level output voltage VID = –1 V, IOL = 1 mA 80 300 mV

OL

I

Input offset current VO = 1.4 V 5 50 nA

IO

I

Input bias current VO = 1.4 V –100 –250 nA

IB

I

High-level output current VID = 1 V, VOH = 3 V 0.1 nA

OH

I

Low-level output current VID = –1 V, VOL = 1.5 V 4 mA

OL

I

High-level supply current VO = V

CCH

I

Low-level supply current

CCL

= 25°C

A

VO = V

OH

OL

switching characteristics, VCC = 3 V, CL = 15 pF, T

Response time

electrical characteristics, VCC = 5 V, T

V

IO

V

ICR

V

OL

I

IO

I

IB

I

OH

I

OL

I

CCH

I

CCL

Input offset voltage VO = 1.4 V, VIC = V

Common-mode input voltage range

Low-level output voltage VID = –1 V, IOL = 1 mA 70 300 mV

Input offset current VO = 1.4 V 5 50 nA

Input bias current VO = 1.4 V –100 –250 nA

High-level output current VID = 1 V, VOH = 3 V 0.1 nA

Low-level output current VID = –1 V, VOL = 1.5 V 6 mA

High-level supply current VO = V

Low-level supply current

100-mV input step with 5-mV overdrive, RL connected to 5 V through 5.1 kΩ

= 25°C

A

OH

VO = V

OL

= 25°C

A

TLV2393Y

MIN TYP MAX

min 1.5 5 mV

ICR

0 to

VCC – 1.5

MIN TYP MAX

min 1.5 5 mV

ICR

0 to

VCC – 1.5

0 to

VCC –1.2

450 600 µA

1.1 1.3 mA

TLV2393Y

MIN TYP MAX

0.45 1 µs

TLV2393Y

0 to

VCC –1.2

550 700 µA

1.2 1.5 mA

V

V

switching characteristics, VCC = 5 V, CL = 15 pF, T

12

p

100-mV input step with 5-mV overdrive, RL connected to 5 V through 5.1 kΩ 0.4 0.8

TTL-level input step, RL connected to 5 V through 5.1 kΩ

= 25°C

A

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TLV2393Y

MIN TYP MAX

0.15 0.3

µ

Page 13

Input overdrives for TLV1393

Input overdrives for TLV2393

TLV1393, TLV1393Y, TLV2393, TLV2393Y

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

TYPICAL CHARACTERISTICS

Table of Graphs

FIGURE

p

p

vs Low-to-high-level output response time 1, 3

vs High-to-low-level output response time 2, 4

vs Low-to-high-level output response time 5, 7

vs High-to-low-level output response time 6, 8

TLV1393 LOW-TO HIGH-LEVEL OUTPUT

RESPONSE FOR VARIOUS INPUT OVERDRIVES

3

40 mV

20 mV

10 mV

5 mV

– Output Voltage – VV

O

– Differential

ID

V

Input Voltage – mV

2 mV

0

100

0

0 0.5 1 1.5 2 2.5

Low-to High-Level Output Response Time – µs

Figure 1

VCC = 3 V

TA = 25° C

TLV1393 HIGH-TO LOW-LEVEL OUTPUT

RESPONSE FOR VARIOUS INPUT OVERDRIVES

3

40 mV

20 mV

10 mV

– Output Voltage – VV

O

0

100

0

– Differential

ID

V

Input Voltage – mV

5 mV

2 mV

VCC = 3 V

TA = 25° C

0 0.2 0.4 0.6 0.8

High-to Low-Level Output Response Time – µs

Figure 2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

13

Page 14

TLV1393, TLV1393Y, TLV2393, TLV2393Y

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

TYPICAL CHARACTERISTICS

TLV1393 LOW-TO HIGH-LEVEL OUTPUT

RESPONSE FOR VARIOUS INPUT OVERDRIVES

5

40 mV

20 mV

10 mV

5 mV

– Output Voltage – VV

O

– Differential

ID

V

Input Voltage – mV

2 mV

0

100

0

0 0.5 1 1.5 2 2.5

Low-to High-Level Output Response Time – µs

Figure 3

TLV2393 LOW-TO HIGH-LEVEL OUTPUT

RESPONSE FOR VARIOUS INPUT OVERDRIVES

VCC = 5 V

TA = 25° C

TLV1393 HIGH-TO LOW-LEVEL OUTPUT

RESPONSE FOR VARIOUS INPUT OVERDRIVES

5

40 mV

20 mV

10 mV

– Output Voltage – VV

O

0

100

0

– Differential

ID

V

Input Voltage – mV

5 mV

2 mV

VCC = 5 V

TA = 25° C

0 0.2 0.4 0.6 0.8

High-to Low-Level Output Response Time – µs

Figure 4

TLV2393 HIGH-TO LOW-LEVEL OUTPUT

RESPONSE FOR VARIOUS INPUT OVERDRIVES

3

– Output Voltage – VV

O

0

100

0

– Differential

ID

V

Input Voltage – mV

Low-to High-Level Output Response Time – µs

40 mV

20 mV

10 mV

5 mV

2 mV

VCC = 3 V

TA = 25° C

0 0.2 0.4 0.6 0.8 1

Figure 5

3

– Output Voltage – VV

O

0

100

0

– Differential

ID

V

Input Voltage – mV

High-to Low-Level Output Response Time – µs

40 mV

20 mV

10 mV

5 mV

2 mV

VCC = 3 V

TA = 25° C

0 0.1 0.2 0.3 0.4

Figure 6

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 15

TLV1393, TLV1393Y, TLV2393, TLV2393Y

DUAL DIFFERENTIAL COMPARATORS

SLCS121A – AUGUST 1993 – REVISED APRIL 1994

TYPICAL CHARACTERISTICS

TLV2393 LOW-TO HIGH-LEVEL OUTPUT

RESPONSE FOR VARIOUS INPUT OVERDRIVES

5

40 mV

20 mV

10 mV

5 mV

– Output Voltage – VV

O

0

100

0

– Differential

ID

V

Input Voltage – mV

2 mV

0 0.2 0.4 0.6 0.8 1

Low-to High-Level Output Response Time – µs

Figure 7

VCC = 5 V

TA = 25° C

TLV2393 HIGH-TO LOW-LEVEL OUTPUT

RESPONSE FOR VARIOUS INPUT OVERDRIVES

5

40 mV

20 mV

10 mV

– Output Voltage – VV

O

0

100

0

– Differential

ID

V

Input Voltage – mV

5 mV

2 mV

VCC = 5 V

TA = 25° C

0 0.1 0.2 0.3 0.4

High-to Low-Level Output Response Time – µs

Figure 8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

15

Page 16

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...