Page 1

User’s Guide Rev 0.1

SLLU104A - September 2007

September 2007

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate

Transceiver Evaluation Module (EVM) Users’ Guide

ABSTRACT

This User’s Guide describes the usage and construction of the TLK3134 evaluation module

(EVM). This document provides guidance on proper use by showing some de

and test modes. In addition, design, layout and schematic information is provided to the

customer. Information in this guide can be used to assist the customer in choosing the optimal

design methods and materials in designing a complete system.

vice configurations

This equipment is intended for use in a laboratory test environment only. It generates, uses, and can radiate radio frequency energy

and has not bee

designed to provide reasonable protection against radio frequency interference. Operation of this equipment in other environments

may cause interference with radio communications, in which case the user at own expense will be required to take whatever

measures may be required to correct this interference.

n tested for compliance with the limits of computing devices pursuant to subpart J of part 15 of FCC rules, which are

WARNING

1

Page 2

SLLU104A - September 2007

Contents

Introduction.................................................................................................................................................... 4

TLK3134 EVM Kit Contents........................................................................................................................... 5

Power .............................................................................................................................................................. 6

Power Monitoring LEDs ................................................................................................................................ 9

Control Signals ............................................................................................................................................ 12

MDIO ............................................................................................................................................................. 16

JTAG ............................................................................................................................................................. 17

Reset ............................................................................................................................................................. 18

Parallel Signals ............................................................................................................................................ 19

XAUI Mode (XGMII) Test and Setup Configuration ................................................................................... 21

Gigabit Ethernet Mode (RGMII) Test and Setup Configuration ............................................................... 24

Schematics................................................................................................................................................... 27

Board Layouts.............................................................................................................................................. 45

Figures

Figure 1. TLK3134 EVM Power Source Selection Example.....................................................................6

Figure 2. TLK3134 EVM VDDM Voltage Source Selection.......................................................................6

Figure 3. TLK3134 EVM VDDM Voltage Source Selection.......................................................................7

Figure 4. TLK3134 EVM Regulator Margin Selection...............................................................................7

Figure 5. TLK3134 EVM Voltage Monitor LED Enabled Example ...........................................................9

Figure 6. TLK3134 EVM Voltage Monitor LED Disabled Example ........................................................10

Figure 7. TLK3134 EVM Voltage Monitor LED Connected Directly to Plane Example........................10

Figure 8. Control Connectors (JMP13, JMP15, JMP20, JMP21, JMP25, JMP26).................................12

Figure 9. TLK3134 EVM MDIO Connector (JMP22) ................................................................................16

Figure 10. TLK3134 EVM JTAG Connector (JMP23).............................................................................17

Figure 11. RESET Switch (SW1, JMP10, or JMP11)..............................................................................18

Figure 12. Parallel Signal Header Block Example.................................................................................19

Figure 13. Parallel Signal Header Block Example.................................................................................19

Figure 14. Parallel Loop Back with Static Data Pattern Example........................................................20

Figure 15. Parallel Loop Back with Static Data Pattern Example........................................................20

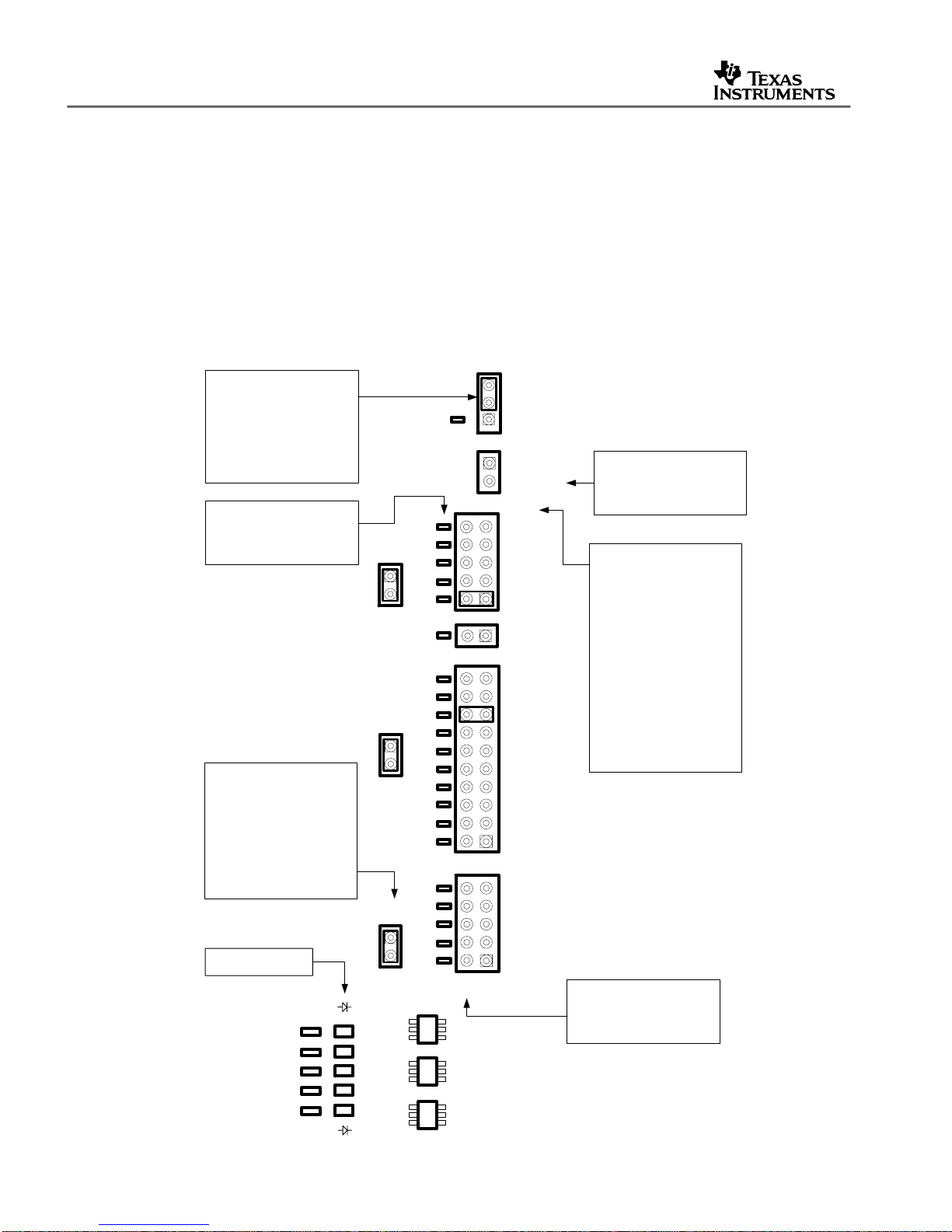

Figure 16. Example TLK3134 EVM Test Configuration – XAUI Mode (XGMII) Parallel Loopback ....23

Figure 17. Example TLK3134 EVM Test Configuration – Gigabit Ethernet Mode (RGMII) Serial

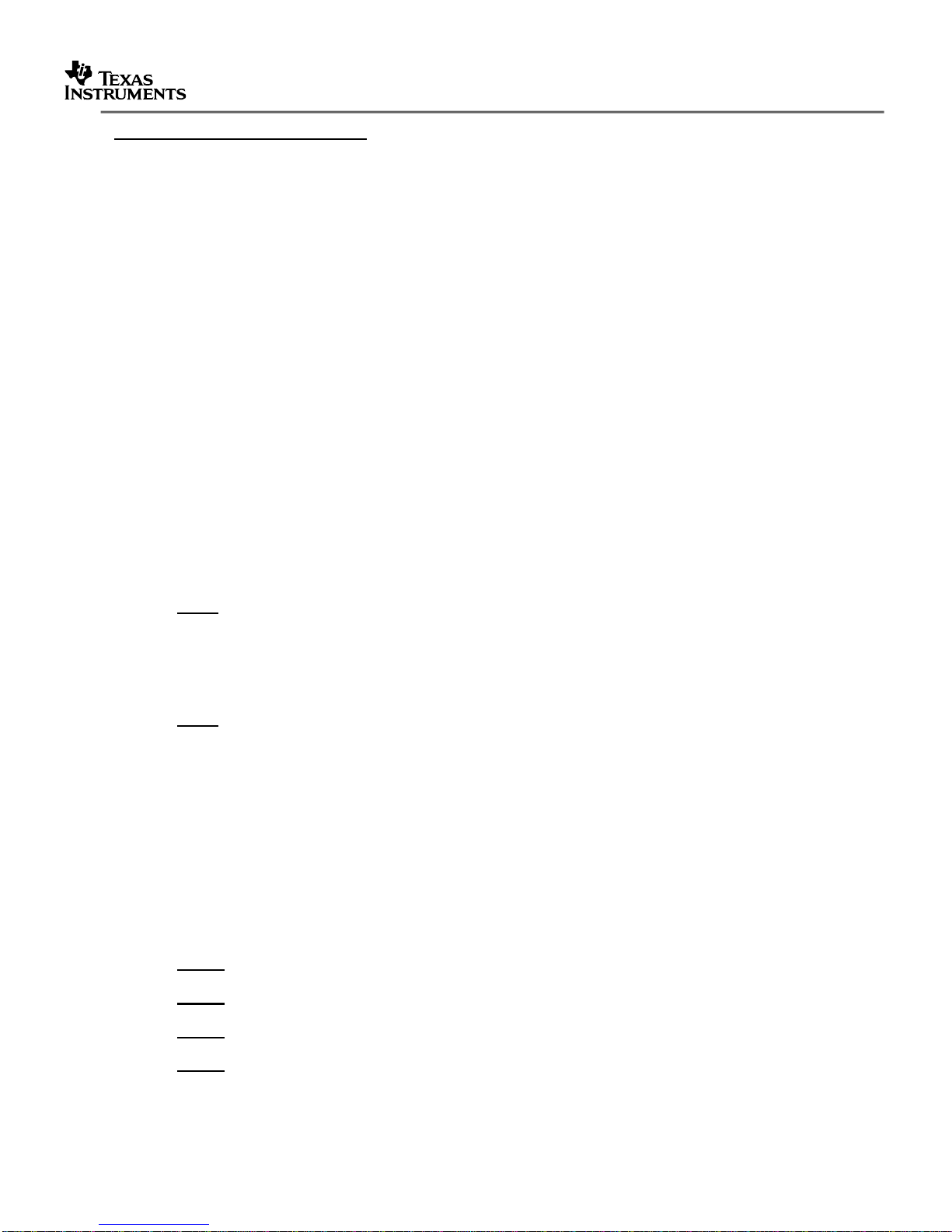

Loopback ................................................................................................................................................26

Figure 18. TLK3134 EVM Schematic, Sheet 1 Index .............................................................................27

Figure 19. TLK3134 EVM Schematic, Sheet 2 Device Power and Ground..........................................28

Figure 20. TLK3134 EVM Schematic, Sheet 3 Global Signals .............................................................29

Figure 21. TLK3134 EVM Schematic, Sheet 4 High Speed Differential...............................................30

Figure 22. TLK3134 EVM Schematic, Sheet 5 Jitter Cleaner Clock.....................................................31

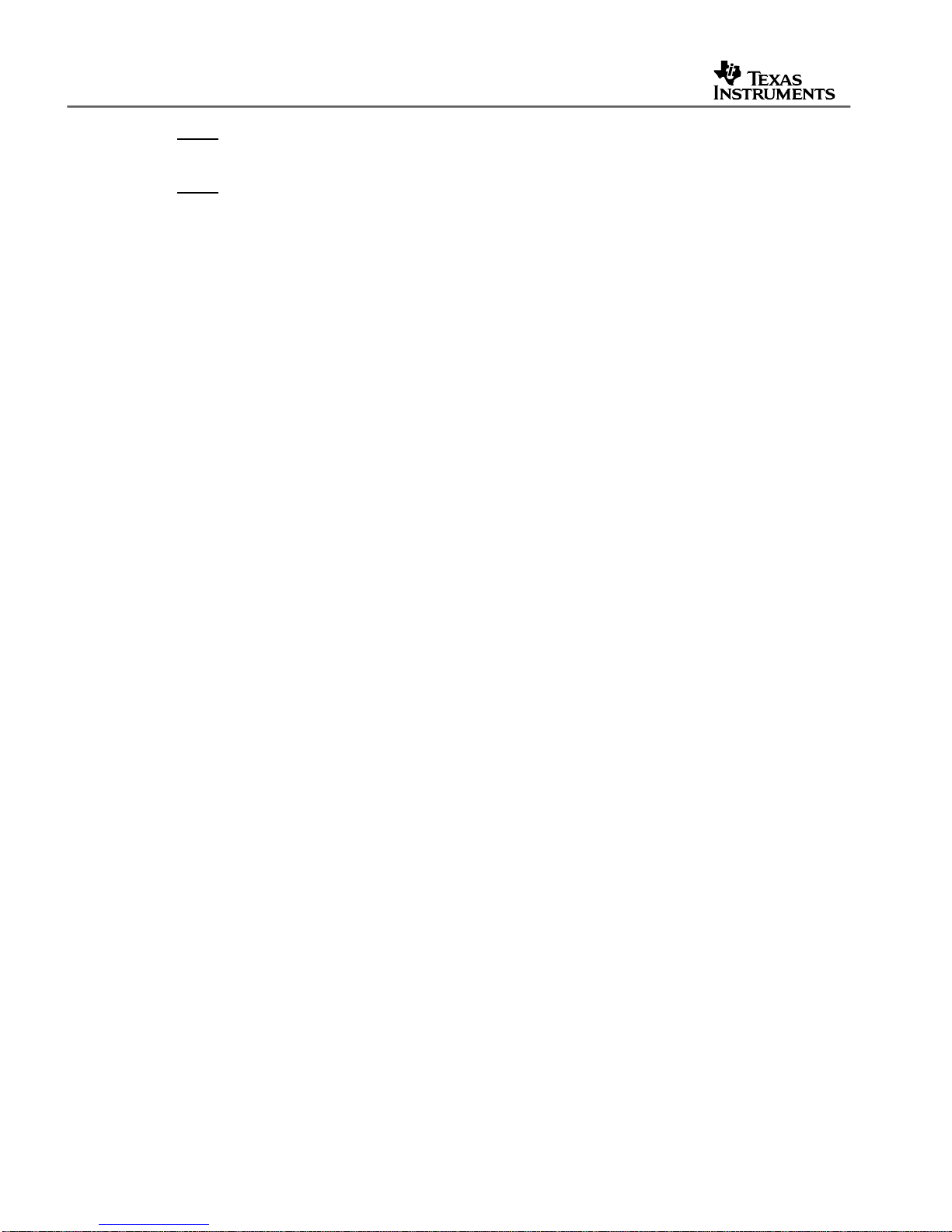

Figure 23. TLK3134 EVM Schematic, Sheet 6 JTAG and MDIO ...........................................................32

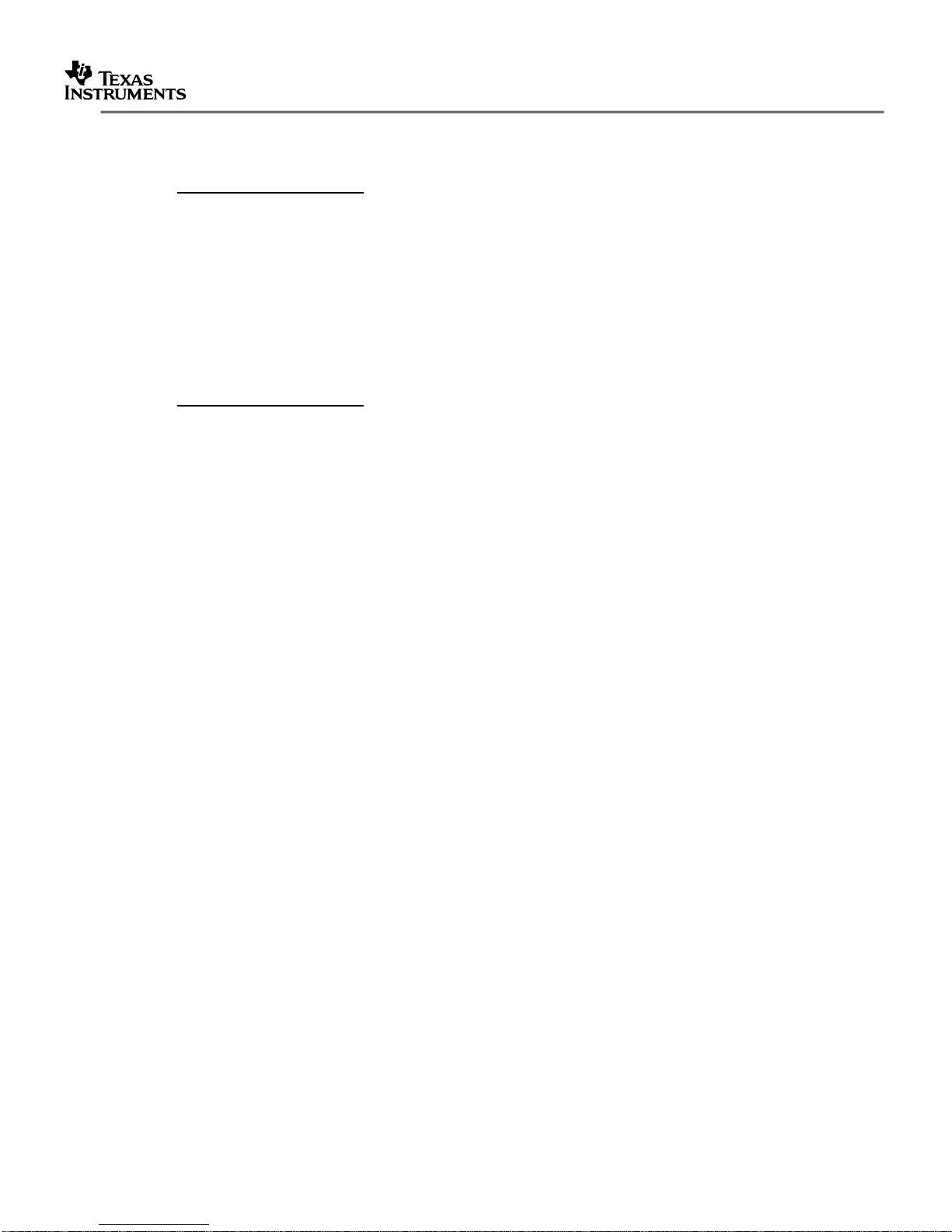

Figure 24. TLK3134 EVM Schematic, Sheet 7 TX and RX Data Lines .................................................33

Figure 25. TLK3134 EVM Schematic, Sheet 8 TX/RX Clocks and Control..........................................34

Figure 26. TLK3134 EVM Schematic, Sheet 9 Power Regulation ........................................................35

Figure 27. TLK3134 EVM Schematic, Sheet 10 Power Distribution ....................................................36

Figure 28. TLK3134 EVM Schematic, Sheet 11 1P2V and 2P5V Supply LEDs ...................................37

Figure 29. TLK3134 EVM Schematic, Sheet 12 1P5V, 1P8V, and 5V Supply LEDs............................38

Figure 30. TLK3134 EVM Schematic, Sheet 13 VDDM Supply LEDs...................................................39

Figure 31. TLK3134 EVM Schematic, Sheet 14 VDDR Supply LEDs ...................................................40

Figure 32. TLK3134 EVM Schematic, Sheet 15 VREF Supply LEDs....................................................41

Figure 33. TLK3134 EVM Schematic, Sheet 16 VJIT Supply LEDs......................................................42

Figure 34. TLK3134 EVM Layout, Top Signal (Layer 1) ........................................................................45

2 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 3

Figure 35. TLK3134 EVM Layout, Ground (Layers 2,4,6,8,10,11) .......................................................46

SLLU104A - September 2007

Figure 36. TLK3134 EVM Layout, Internal Signal (Layer 3).................................................................47

Figure 37. TLK3134 EVM Layout, Internal Signal (Layer 5).................................................................48

Figure 38. TLK3134 EVM Layout, Power (Layer 7)................................................................................49

Figure 39. TLK3134 EVM Layout, Power (Layer 9)................................................................................50

Figure 40. TLK3134 EVM Layout, Internal Signal (Layer 12)...............................................................51

Figure 41. TLK3134 EVM Layout, Ground (Layer 13) ...........................................................................52

Figure 42. TLK3134 EVM Layout, Internal Signal (Layer 14)................................................................53

Figure 43. TLK3134 EVM Layout, Ground (Layers 15) .........................................................................54

Figure 44. TLK3134 EVM Layout, Bottom Signal (Layers 16) ..............................................................55

TLK3134 EVM Layer Construction ..............................................................................................................56

Tables

Table 1. TLK3134 EVM Bill of Materials.................................................................................................43

.

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 3

Page 4

SLLU104A - September 2007

Introduction

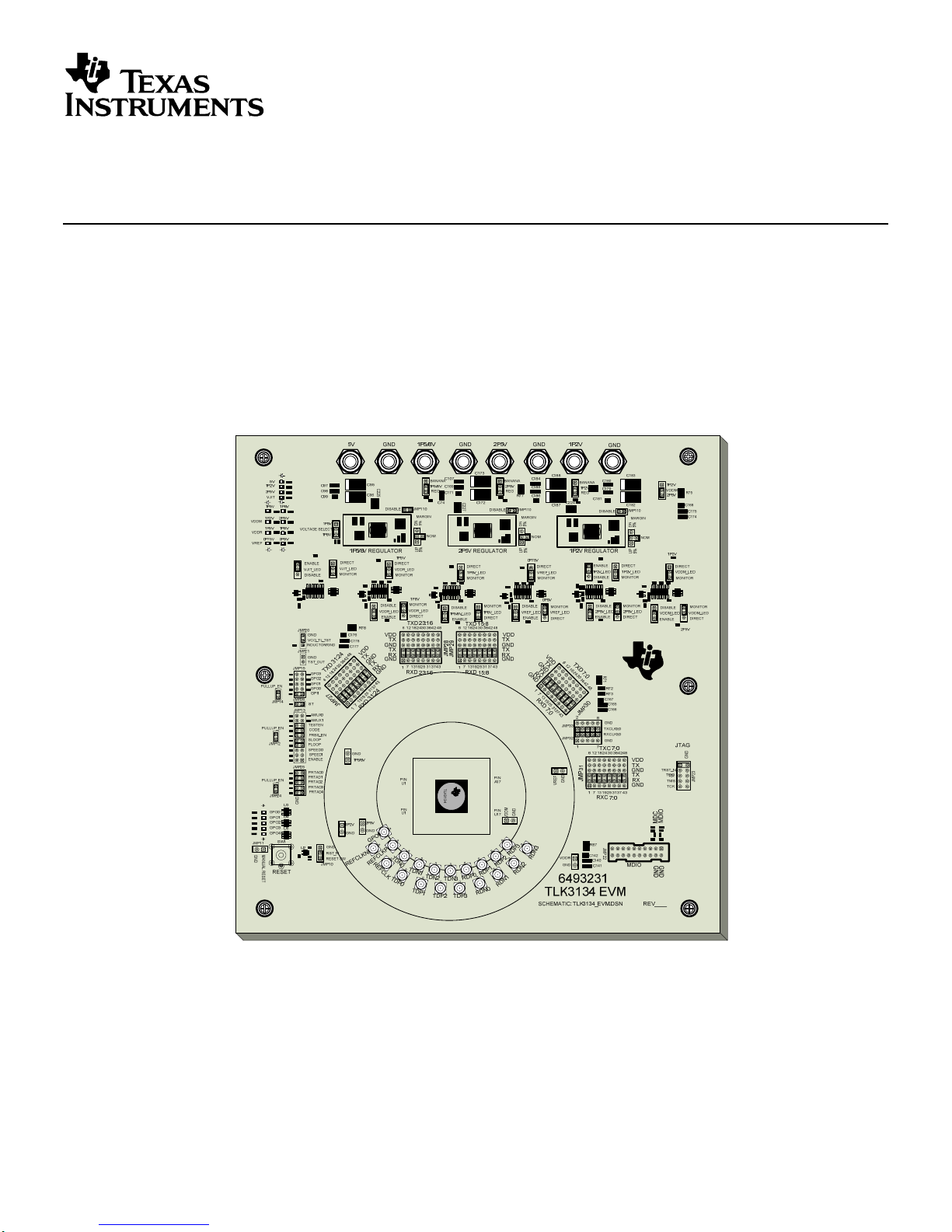

The Texas Instruments (TI™) TLK3134 SerDes evaluation module (EVM) board is used to

evaluate the functionality and the performance of TLK3134 XAUI Transceiver/4 Channel MultiRate Transceiver device (289-ball BGA). The TLK3134 is a flexible four channel independently

configurable serial transceiver that can be configured to be compliant with the 10Gbps Ethernet

XAUI Specification, the 1000Base-X 1Gbps Ethernet Specification and will also support

1X/2X/10X Fibre Channel (FC), CPRI (x1/x2/x3), OBSAI (x1/x2/x4) data rates. Many common

applications may be enabled by way of externally available control pins and detailed control of

the TLK3134 on a per channel basis is available by way of accessing a register space of control

bits available through a two-wire access port called the Management Data Input/Output (MDIO)

interface.

1

EVM PCB and High-speed Design Considerations

The board can be used to evaluate device parameters in addition to acting as a guide for highspeed board layout. As the frequency of op

special care to ensure that the highest signal integrity is maintained. To achieve this, the board's

impedance is controlled to 50 Ω for both the high-speed differential serial and low-speed parallel

data and clock connections. Vias are minimized and, when necessary, are designed to minimize

impedance discontinuities along the transmission line. Since the board contains both, serial and

parallel transmission lines, care was taken also to control trace length mismatch (board skew) to

less than +/- 1MIL.

Overall, the board layout is designed and optimized to support high-speed operation. Thus,

understanding impedance control and transmission line eff

speed boards. Some of the advanced features offered by this board include:

• PCB (printed circuit board) is designed for optimal high-speed signal integrity.

• SMP and parallel header fixtures are easily connected to test equipment.

• All input/output signals are accessible for rapid prototyping.

• The entire board can be powered from a single 5V power supply where the power planes

can be supplied through on-board regulators or t

• On-board capacitors provide AC coupling of high-speed receive signals.

• External parallel loop-back function can be achieved easily using simple 0.1 inch jumpers.

eration increases, the board designer must take

ects are crucial when designing high-

hrough separate banana jacks for isolation.

• Entire Board can operate from a single 5V power supply, or from individual power supplies.

•

Voltage Monitoring LED circuits provide quick indication that the voltage is within

specification.

1

The MDIO register map is located within the TLK3134 XAUI Transceiver/4 Channel Multi-Rate Transceiver datasheet.

4 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 5

SLLU104A - September 2007

TLK3134 EVM Kit Contents

The TLK3134 EVM kit contains the following:

• TLK3134 EVM board

• TLK3134 EVM User’s Guide (this document)

• TLK3134 XAUI Transceiver/4 Channel Multi-Rate Transceiver datasheet

• MDIO Interface EVM

• MDIO Interface EVM Documentation

• RS-232 Cable

• 20-conductor MDIO Ribbon Cable

• CD-ROM Containing MDIO Software

• 18 3-Foot SMA to SMP cables

.

• 8 1-Foot SMP to SMP cables

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 5

Page 6

SLLU104A - September 2007

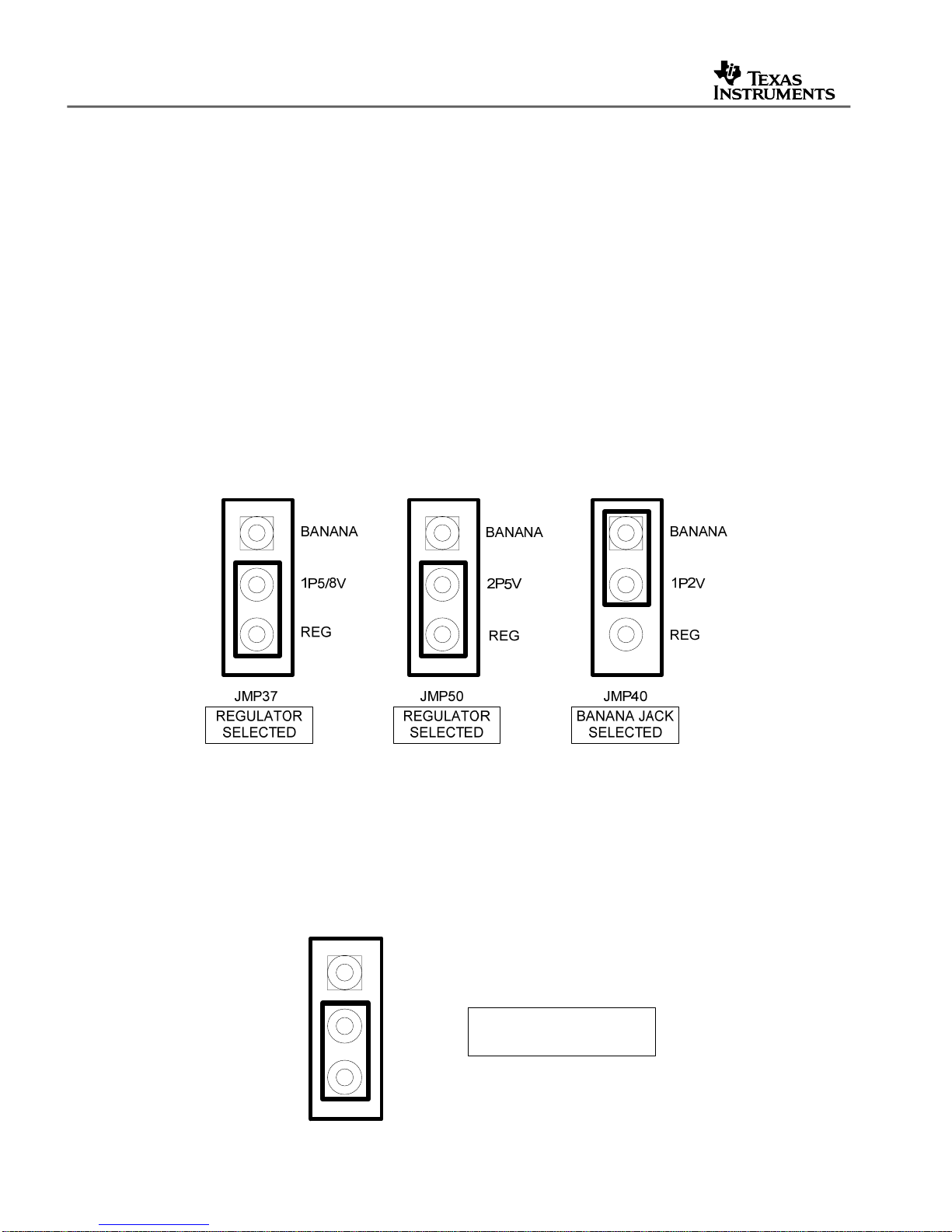

Power

The TLK3134 EVM can be operated off of a single 5V Power Supply utilizing the on-board

voltage regulators to generate the voltages required to correctly operate the TLK3134, off of

individual 1.2V, 1.5V or 1.8V, 2.5V, and 5V Power supplies, or a combination of both regulators

and separate individual supplies.

To modify your power supply configuration between either all Individual Supplies, all on-board

regulators, or a combinat

supply headers (JMP37, JMP40, and JMP50) selecting either the “BANANA” or the “REG” pin in

combination with the center pin. The following figure shows how to use the on-board regulators

for the 1.5V or 1.8V and 2.5V supply rails, and an individual power supply connected to the 1.2V

Banana Jack (P21). The 5V power supply is required for operation of the LEDs on this board

even if you are not using the on-board voltage regulators.

ion of both, simply change the jumper position on the appropriate power

Figure 1. TLK3134 EVM Power Source Selection Example

The MDIO power supply VDDM can be operated off of either 1.2V or 2.5V depending upon your

specific setup. If

you are using the supplied MDIO controller board that came with this

EVM kit, the 2.5V setting should be selected on the VDDM Power Select Header (JMP43).

Figure 2. TLK3134 EVM VDDM Voltage Source Selection

JMP43

1P2V

VDDM

2P5V

2.5V SELECTED AS

VDDM SUPPLY VOLTAGE

6 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 7

The PTH05010WAS voltage regulators included on the TLK3134 EVM are adjustable and are

SLLU104A - September 2007

set with a single external resistor. Separate regulators have been provided and set to output

1.2V and 2.5V because both voltages are required simultaneously. However, since 1.5V and

1.8V are not necessarily required simultaneously, a single regulator has been configured to

provide both of those voltages, although not at the same time depending upon the jumper

position on JMP115 shown in the following figure. JMP115 selects between the 1.5V set resistor

and the 1.8V set resistor and connects one or the other to the Voltage Adjust pin of the regulator.

Figure 3. TLK3134 EVM VDDM Voltage Source Selection

.

JMP115

1P8V

SELECTED

1P5V

VOLTAGE SELECT

1P8V

JMP115

1P5V

VOLTAGE SELECT

1P8V

1P5V

SELECTED

The PTH05010WAS voltage regulators are also equipped with a +/- 5% selectable Margin

Control allowing easy t

esting of the device near the

min/max voltage limits specified in the

datasheet. Place the jumper position to either the “UP 5%”, “DN 5%”, or “NOM” positions

keeping the center pin in common as demonstrated in the following figure.

Figure 4. TLK3134 EVM Regulator Margin Selection

DN

5%

UP

5%

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 7

DN

UP

5%

5%

DN

UP

5%

5%

Page 8

SLLU104A - September 2007

When the on-board regulators are not being used and independent power supplies are being

used instead, i.e. the case of a voltage tolerance test, the on-board regulators should be disabled

to prevent the regulator’s voltage sense line from trying to regulate the voltage supplied through

the banana jack and not from its own output. This is accomplished by placing a short on the

headers (JMP108, JMP110, and JMP114) labeled “DISABLE”. The remote sense feature is not

designed to compensate for the forward drop of non-linear or frequency dependent components

that may be placed in series with the converter output. Examples include OR-ing diodes, filter

inductors, ferrite beads, and fuses. When these components are enclosed by the remote sense

connection they are effectively placed inside the regulation control loop, which can adversely

affect the stability of the regulator. A large 0 ohm resistor has been installed at the voltage

entrance point of each power plane and can be replaced with a ferrite bead of desired. In this

situation, the 0 ohm resistors on the sense lines can be interchanged to connect the sense line

directly to its output and eliminate the additional components that could otherwise create

instability on the regulator’s output. For the 1.2V regulator, the R223 0 ohm resistor should be

removed and the R222 populated with a 0 ohm resistor. For the 1.5V or 1.8V regulator, R221

should be removed and placed on R220, and similarly R223 should be moved to R222 for the

2.5V regulator.

The VREF plane is sourced through a Voltage Divider providing half of the voltage on the 1P5/8V

plane. The VDDQ and VDDR power

pins of the TLK3134 can both be operated off of either 1.5V

or 1.8V with VREF being half of whatever voltage is on the VDDQ pins. The VREF plane can be

powered through the plane monitoring header (JMP3) and removing the 0 ohm resistor (R71)

although this is not recommended. A separate VDDR plane has been added as there is no

relationship between the VDDR pin and the VDDQ pins, however, the VDDR plane is sourced

through a 0 ohm resistor (R67) from the voltage on the 1P5/8V plane that provides power the

VDDQ pins. This resistor can be replaced with a ferrite bead or removed completely and an

external supply can be connected to the VDDR Header (JMP5) in the case different voltages are

desired on the two planes.

Furthermore, for more accurate current readings the PULLUP_EN Jumpers on all control pin

headers can be removed quickly disconnecting the pullu

p resistors from the voltage plane.

However, the removal of the PULLUP_EN jumpers will also require manual high/low control of

the control pins.

Better Performance can be achieved when the Jitter Cleaner is enabled by using an external

power supply on the 1.2

V Banana Jack. A dedicated LDO 1.2V Regulator powering the Jitter

Cleaner Power Plane should be considered for the end application.

8 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 9

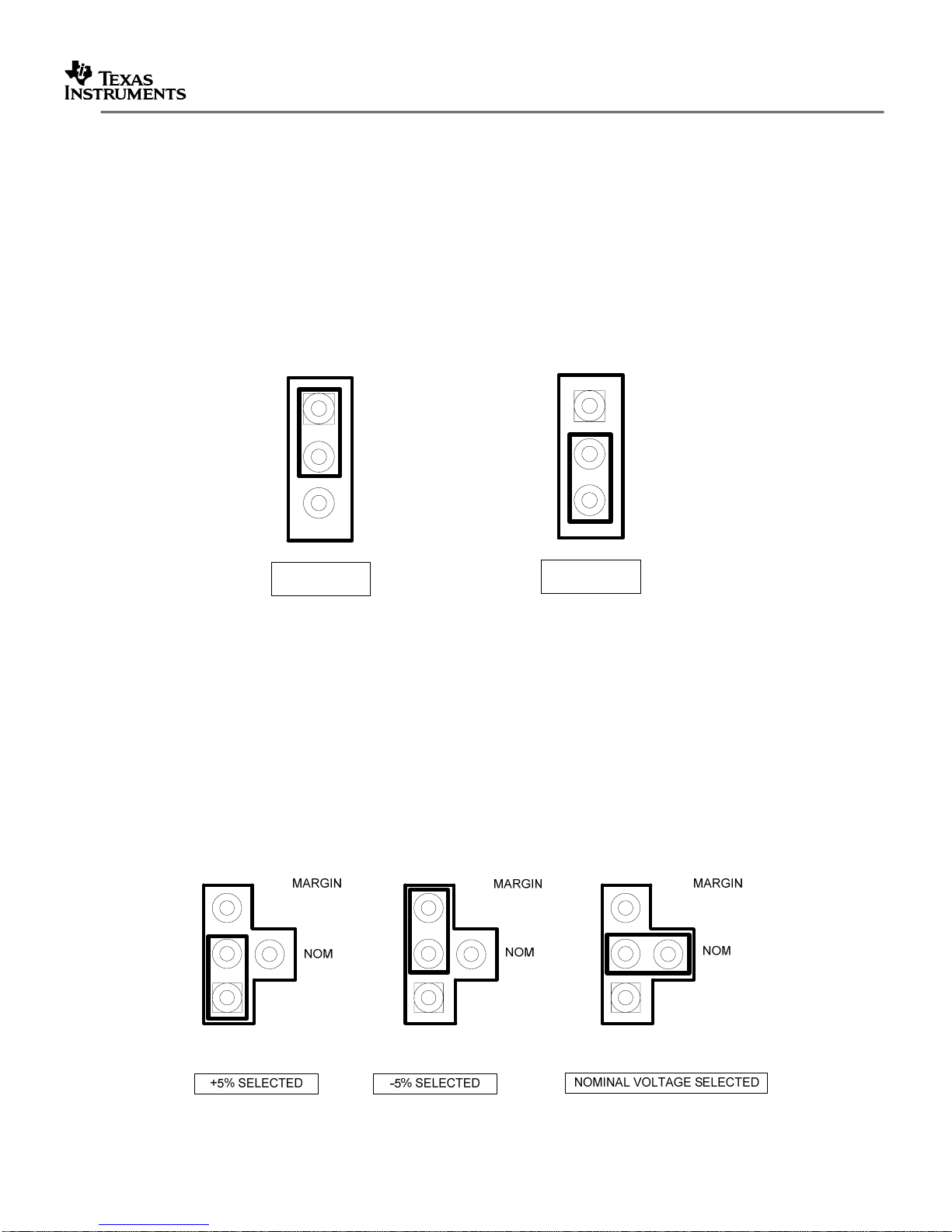

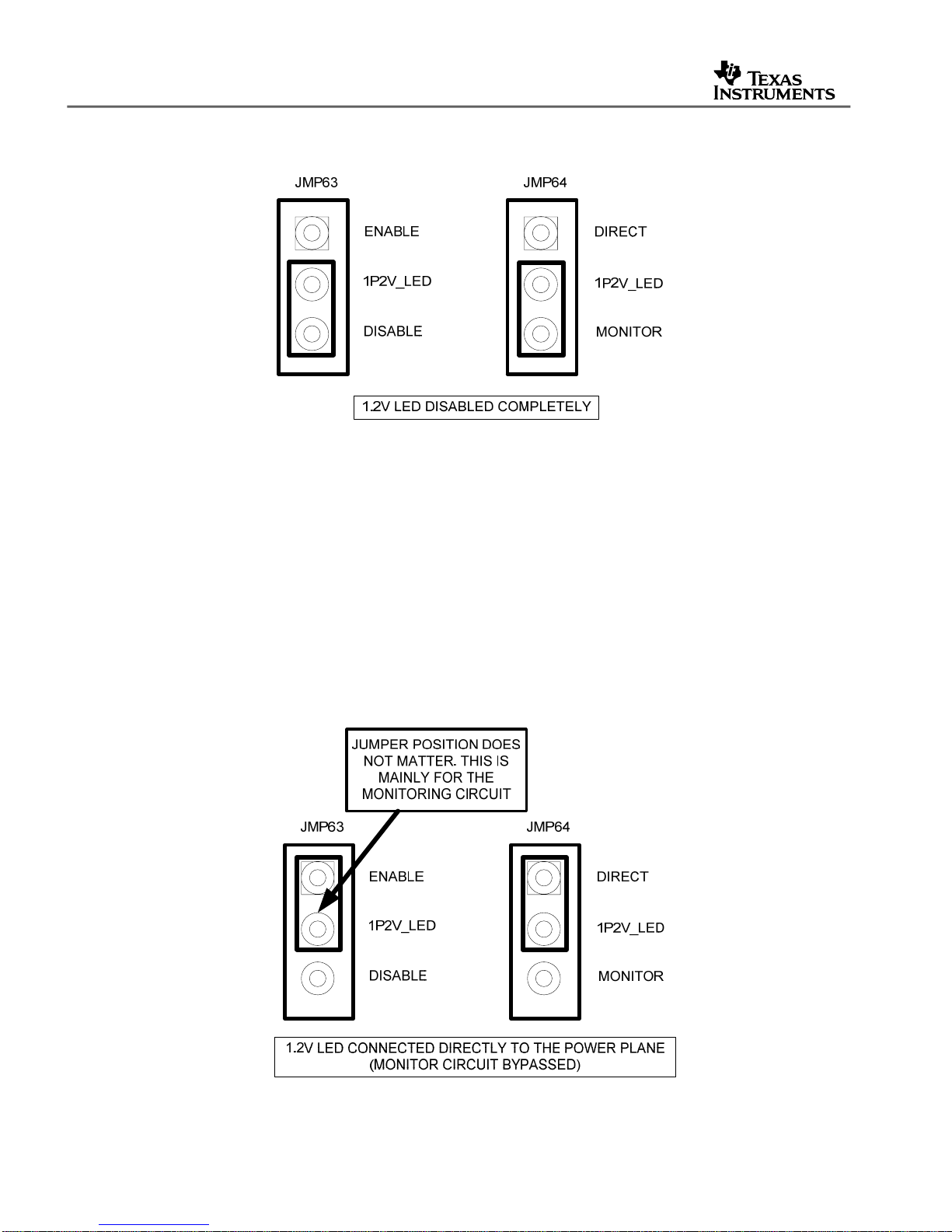

Power Monitoring LEDs

SLLU104A - September 2007

Each plane of the TLK3134 EVM has been equipped with a Voltage Monitoring circuit that will

monitor the voltage on the plane and light the LEDs when the voltage is within the min/max

datasheet limits for that power supply. A precision TI Voltage Reference chip is used along with

0.1% precision resistors setting min and max reference levels providing a detection circuit that is

accurate to approximately +/- 10mV. The LEDs should be used as a basic indication of the

status of power on the board being within the acceptable min/max limits given in the datasheet,

and not as a precise measurement tool as some LED circuits may turn off at slightly different

voltages when approaching the limits due to the manufacturing tolerances and available

component values.

The voltage monitor circuits can also be bypassed and the LEDs driven directly from the voltage

on the individual planes such as when performing voltage tolerance tests. Inste

only when the voltage on the plane is within the min/max range, the LED will be lit when the

voltage is greater than the voltage needed to turn on the LED drive circuit’s NPN transistor,

allowing current to flow, and the LED to be lit from the 5V source. In the Direct Connect mode,

the base resistors has been given extra margin to allow the LEDs to light when the voltage on

the plane is a little below the minimum limit of that supply in order to provide a LED indicator of

power on the plane during voltage tolerance tests near the lower supply limits.

.

ad of being lit

Figure 5. TLK3134 EVM Voltage Monitor LED Enabled Example

Placing the jumper on the ENABLE side of the Voltage Monitor Enable/Disable header connects

the power plane to the input of the voltage moni

toring circuit. This input is high impedance and

will not load down the power source providing the voltage to the plane.

Placing the header on the MONITOR side of the LED Monitor/Direct Connect selection header

connects the LED drive circui

t to the output of the Voltage Monitor circuit causing the LED to be

lit only when the voltage is within the acceptable range.

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 9

Page 10

SLLU104A - September 2007

Figure 6. TLK3134 EVM Voltage Monitor LED Disabled Example

Placing the jumper on the DISABLE side of the Voltage Monitor Enable/Disable header

disconnects the power plane to the input of the voltage monitoring cir

cuit and instead ties the

input to GND. This prevents the output of the Voltage Monitoring Circuit from floating and

possibly causing the LED to flicker during contact with the board.

Placing the jumper on the MONITOR side of the LED Monitor/Direct Connect selection header

connects the LED drive circui

t to the output of the Voltage Monitor circuit causing the LED to be

off since the voltage monitor circuit will sense that the plane voltage is GND which is less than

the acceptable plane voltage.

Figure 7. TLK3134 EVM Voltage Monitor LED Connected Directly to Plane Example

10 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 11

Placing the jumper on the DIRECT side of the LED Monitor/Direct Connect selection header

SLLU104A - September 2007

connects the LED drive circuit to the power plane itself causing the LED to be lit when the

voltage is great enough to cause current to flow through the LED drive circuit. This LED

configuration has been designed to be used when pushing the lower limits of the acceptable

voltage range to continue to provide an indicator that power is on the plane, however without

regards to what that voltage may actually be.

The jumper on the Voltage Monitor Enable/Disable header does not matter as this is only the

input to the voltage monitor circuit which has been bypassed when the LED dri

ve circuit is

connected directly to the power plane itself.

.

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 11

Page 12

SLLU104A - September 2007

Control Signals

All of the external control pins on the TLK3134 EVM have been consolidated to a single location

on the board and broken out into several header blocks for easier reference. LEDs have been

added to the GPO[4:0] lines in addition to the headers for scope probes, to allow easy monitoring

of the High/Low value on the line. The LED will be ON when the line is a Logic High, and the

LED will be OFF when the line is a Logic Low.

Figure 8. Control Connectors (JMP13, JMP15, JMP20, JMP21, JMP25, JMP26)

THE VCO_TL_TST PIN

GND. A LOCATION FOR

A SERIES INDUCTOR TO

GND HAS BEEN ADDED

HEADER BLOCKS ARE

PULLUP_EN HEADERS

WILL DISCONNECT THE

ACCURATE CURRENT

GPO[4:0] LEDS

SHOULD BE TIED TO

SHOULD IT BECOME

NEEDED.

THE RESISTORS ON

THIS SIDE OF ALL

PULL UP RESISTORS

REMOVING THE

JUMPER ON THE

PULL UP RESISTORS

FROM THE VOLTAGE

PLANE FOR MORE

MEASUREMENTS

R4

R15

R16

R17

R24

PULLUP_EN

PULLUP_EN

PULLUP_EN

D1

GPO0

D2

GPO1

D3

GPO2

D4

GPO3

D5

GPO4

JMP14

JMP12

JMP24

JMP20

GND

JMP21

JMP26

JMP13

GND

VCO_TL_TST

INDUCTOR/GND

GND

TST_OUT

GPO3

GPO2

GPO1

GPO0

GPI1

ST

AMUX0

AMUX1

TESTEN

CODE

PRBS_EN

SLOOP

PLOOP

SPEED0

SPEED1

ENABLE

PRTAD0

PRTAD1

PRTAD2

PRTAD3

PRTAD4

THE PINS ON THIS SIDE

THE TST_OUT PIN

SHOULD BE LEFT OPEN

IN THE APPLICATION

GPO4 HAS NOT BEEN

CONNECTED TO THIS

HEADER BLOCK BUT

RATHER TO A SMP

CONNECTOR LOCATED

ON THE BOTTOM OF

THE BOARD WITH THE

HIGH SPEED LINES.

LEDS HAVE BEEN

CONNECTED TO EACH

OF THE GP0[4:0] PINS

AND ARE LOCATED

BELOW JMP24 AND

JMP25

OF ALL HEADER

BLOCKS ARE GND

L1

JMP15

R39

R38

R37

R36

R35

R55

R14

R13

R12

R11

R10

R9

R8

R7

R6

R5

JMP25

R50

R51

R52

R53

R54

U3

U4

U5

12 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 13

Control Signal Pin Description:

SLLU104A - September 2007

.

VCO_TL_TST: This pin is the VCO Testability Input and should be grounded in the

application.

TST_OUT: This is the Jitter Cleaner Testability Pin. This signal should be left open

(unconnected) in the System Application.

GPO[4:0]:

These are General Purpose Outputs and must be left open (unconnected) in the

System Application.

GPI1: This is the General Purpose I

ST: This is the MDIO

Select pin and used to select Clause 22 (ST =1) or Clause 45 (ST=0)

nput and must be Grounded in the System Application.

operation.

AMU

X0: This is the SERDES Analog Mux 0 TX pin and must be open (unconnected) in the

System Application.

AMUX1:

This is the SERDES Analog Mux 1 RX pin and must be open (unconnected) in the

System Application.

TESTEN:

This is the Test Mode Enable Input pin and must be Grounded in the System

Application.

CODE

: This is the Code Enable pin. Th

is signal selects different functionality based on the

setting of the ST primary chip input pin.

: This signal is logically OR’d with the XAUI_ORDER register bit (Register

ST=0

Bit 32809.15). XAUI applications can either tie this input signal high (preferred)

or tie this signal low (must program the XAUI_ORDER register bit after device

reset to high if CODE is tied off low). 10GFC applications MUST tie this signal

low.

ST=1

: This signal is logically OR’d with the PCS_EN register bit (Register Bit

17.3). RGMII/GMII applications can either tie this input signal high (preferred) or

tie this signal low (must program the PCS_EN 17.3 register bit after device reset

to high if CODE is tied off low). Nom RGMII/GMII applications MUST tie this

input signal low.

PRBS_EN: This is th

e PRBS Enable Pin. When this pin is asserted HIGH, the internal PRBS

generator and comparator circuits are enabled on the transmit and receive data paths of all

channels. The PRBS results for each channel can be read through MDIO counters. Primary

chip output signals GPO3/GPO2/GPO2/GPO0 remain low during PRBS testing when the input

serial stream PRBS pattern is correct, and pulse high when PRBS errors are detected on the

input serial stream on a per channel basis.

GPO3

GPO2

GPO1

GPO0

: Contains the Channel 3 PRBS currently passing (when low) indication.

: Contains the Channel 2 PRBS currently passing (when low) indication.

: Contains the Channel 1 PRBS currently passing (when low) indication.

: Contains the Channel 0 PRBS currently passing (when low) indication.

An external loopback connection (via external cables) is required during PRBS

testing.

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 13

Page 14

SLLU104A - September 2007

ST=0: PRBS 223-1 is transmitted on each transmit channel serial output, and

compared on each receive channel serial input.

: PRBS 27-1 is transmitted on each transmit channel serial output, and

ST=1

compared on each receive channel serial input.

SLOOP: This pin is the Serial Loop Enable pin. When SLOOP is asserted HIGH, the serial

input from each channel is internally looped back to that

channel’s serial output, making that

channel a serial repeater. In device configurations where clock tolerance compensation is not

performed in the transmit direction, there are two options for error free serial loopback operation:

1) Frequency lock (0 ppm) the incoming serial data rate to the local reference

clock device

input.

2) Provision the TX SERDES REFCLK to run from

a jitter cleaned version of the

RX SERDES RXBCLK (Receive Byte Clock).

PLOOP: This pin is the Parallel Loop Enable pin. When PLOOP is asserted HIGH, the serial

output for each channel is internally looped back to its serial input so t

hat the transmit parallel

interface input data is output onto the receive parallel interface.

SPEED[1:0]: These are the Speed Selection Pins and put all four channels of the TLK3134 into

one of the three supported (full/half/

quarter) channel operation speeds.

00 – All Four Channels in Full Rate mode

01 – All Four Channels in Half Rate mode

10 – All Four Channels in Quarter Rate mode

11 – Software Selectable Rate

In the Software selectable rate mode, the rate for each channel may be

configured independently by the

The SPEED[1:0] inputs

control both RX and TX directions for all four channels

(Including XAUI and 10GFC

MDIO interface.

modes).

Please see Appendix A of the TLK3134 Datasheet for further information on

speed selection (full/half/quarter) for proper settings as a function

of the

application mode and reference clock frequency.

Please note that if these pins are not configured on the application board to

select “Software Selectable Rate”, then th

cannot be used to control the rate settings, and the full/half/quarter rate

selection is fixed.

ENABLE: This is the Device Enable pin. When ENABLE is held low, the device is in a low

power state. When ENABLE is high the device operates normally. A hard or soft reset muc

be applied after a change of state occurs on this input signal.

14 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

e internal speed register bits

h

Page 15

PRTAD[4:0]: These are the Port Address Assignment Pins and are used to select the Device

SLLU104A - September 2007

ID/Port ID in Clause 22/Clause 45 MDIO modes.

.

ST=0 (Clause 45 Mode)

:

If PRTAD[0] is a 0, then a PHY device is selected for XAUI/10GFC register

accesses (4.x

xxxx.x).

If PRTAD[0] is a 1, then a DTE device is selected for XAUI/10GFC register

accesses (5.x

xxxx.x).

PRTAD[4:1] selects the Clause 45 port address (TLK3134 must be located on

even boundaries since the lowest port address bit determines DTE/PHY, and is

used as a d

ST=1 (Clause 22 Mode)

evice address instead of port address).

:

PRTAD[4:2] selects a block of four sequential Clause 22 port addresses. Each

channel is implemented as a different port address, and can be accessed by

setting the a

ppropriate port address field within the Clause 22 MDIO transaction.

PRTAD[1:0] pins are not used in Clause 22 mode.

Channel 0 responds to port address 0 within the block of four port addresses.

Channel 1 responds to port address 1 within the block of four port addresses.

Channel 2 responds to port address 2 within the block of four port addresses.

Channel 3 responds to port address 3 within the block of four port addresses.

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 15

Page 16

SLLU104A - September 2007

MDIO

The TLK3134 supports the Management Data Input/Output (MDIO) Interface as defined in Clauses 22

and 45 of the IEEE 802.3ae Ethernet Specification. The MDIO allows register-based management and

control of the serial links. Normal operation of the TLK3134 is possible without the use of this interface,

however, some additional features are accessible only through this interface.

The MDIO Management Interface consists of a bi-directional data path (MDI

O) and a clock reference

(MDC). The device ID and port address are determined by control pins PRTAD[4:0]. The ST pin

controls whether the device responds as a Clause 22 or Clause 45 device.

In Clause 45 (ST=0), the top 4 control pins PRTAD[4:1] determine the device port address. In Clause

45 mode the TLK3134 can be accessed only through even port addresses. In th

is mode, the TLK3134

will respond if the PHY address field on the MDIO protocol (PA[4:0]) matches {PRTAD[4:1], 1’b0}. The

PRTAD[0] pin acts as a device ID pin where it determines whether the TLK3134 is a DTE or PHY

device and is required to be either 4 (PHY) or 5 (DTE), so only one bit is required to differentiate. If

PRTAD[0] is a 0, then a PHY device is selected for the XGXS. If PRTAD[0] is a 1, then a DTE device is

selected for the XGXS. In this mode, TLK3134 will respond as PHY if the Device address field

(DA[4:0]) on the MDIO protocol is 5’b00100 and as DTE if it is 5’b00101. Note, each register is

accessed as either DTE or PHY devices in the TLK3134, although physically there is only one register

accessed two different ways.

In Clause 22 (ST=1), the top 3 control pins PRTAD[4:2] determine the device port address. In this

mode the 4 individual channels in TLK3134 are classif

ied as 4 different ports. So for any PRTAD[4:2]

value there will be 4 ports per TLK3134. The TLK3134 will respond if the 3 MSB’s of PHY address field

on MDIO protocol (PA[4:2]) matches PRTAD[4:2]. The 2 LSB’s of PHY address field (PA[1:0]) will

determine which channel/port within the TLK3134 to respond.

If PA[1:0] = 2’b00, TLK3134’s Channel 0 will respond.

If PA[1:0] = 2’b01, TLK3134’s Channel 1 will respond.

If PA[1:0] = 2’b10, TLK3134’s Channel 2 will respond.

If PA[1:0] = 2’b11, TLK3134’s Channel 3 will respond.

Write transactions to invalid registers or read only registers will be ignored. Read transactions of invalid

registers will return a “0”.

The bi-directional MDIO pin is pulled up to 1.2V or 2.5V (VDDM) with a 1.5k Ω re

sistor as per the MDI

O

Standard.

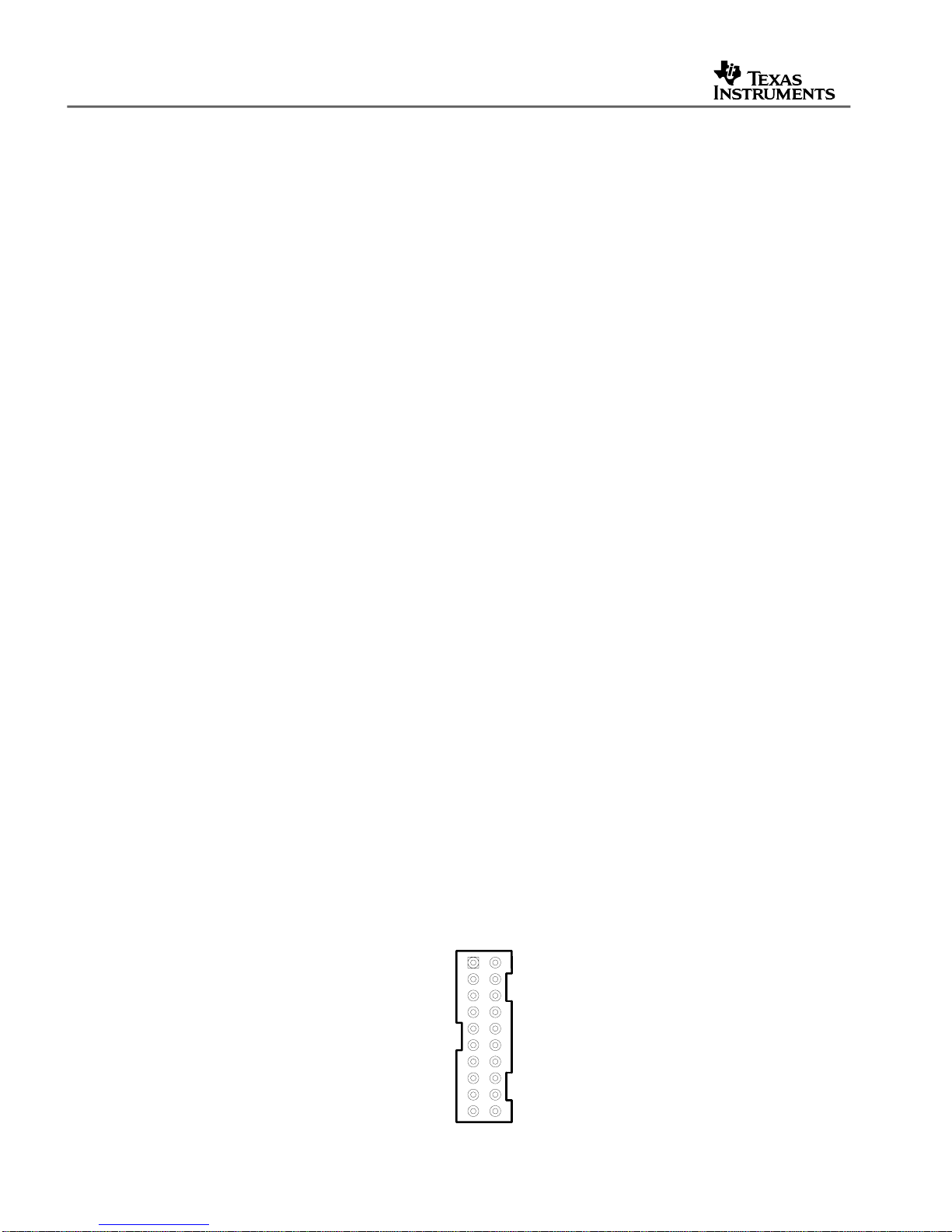

Figure 9. TLK3134 EVM MDIO Connector (JMP22)

MDIO

MDC

NC

NC

NC

NC

NC

NC

NC

NC

JMP22

16 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

GND

GND

NC

NC

NC

NC

NC

NC

NC

NC

Page 17

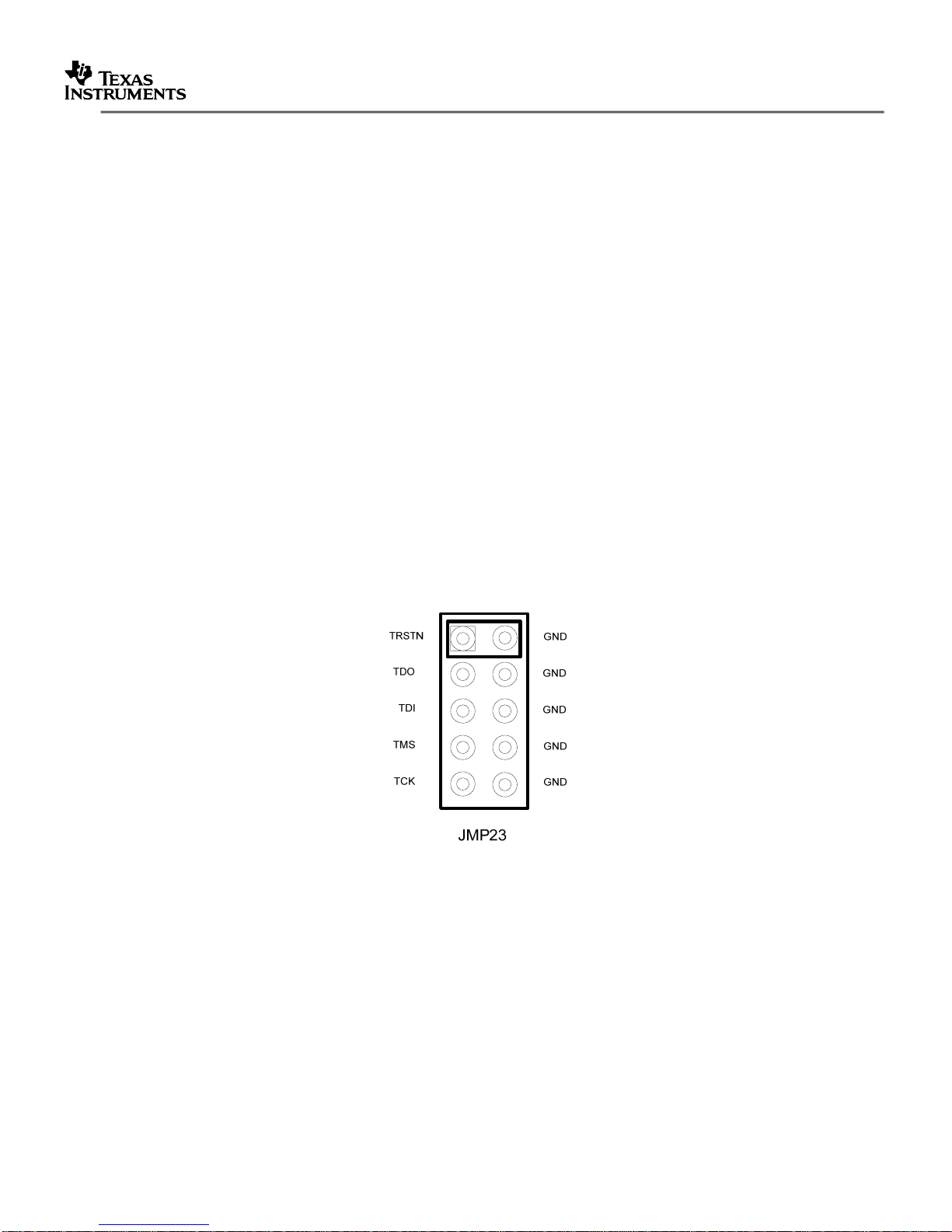

JTAG

SLLU104A - September 2007

The EVM also provides a separate connector to support the full five-pin JTAG interface of the TLK3134

as defined in IEEE 1149.1 for manufacturing tests.

.

TDI: This pin is the JTAG Input Data pin and is used

to serially shift test data and test

instructions into the device during the operation of the test port.

TDO: This pin is the JTAG Outp

ut Data pin and is used to serially shift test data and test

instructions out of the device during operation of the test port. When JTAG port is not in use,

TDO is in a high impedance state.

TMS: This pin is the JTAG Mode Select pin and is used to control the state of the internal testport controller.

TCK: This is the JTAG Clock pin and is used to clock stat

e information and test data into and

out of the device during the operation of the test port.

TRST_N: This is the JTAG Test Reset pin and is used to reset the JTAG logic into system

operational mode. NOTE

: TRST_N should be tied low when the JTAG port is not in use and

during normal operation of the port as shown in the following figure.

Figure 10. TLK3134 EVM JTAG Connector (JMP23)

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 17

Page 18

SLLU104A - September 2007

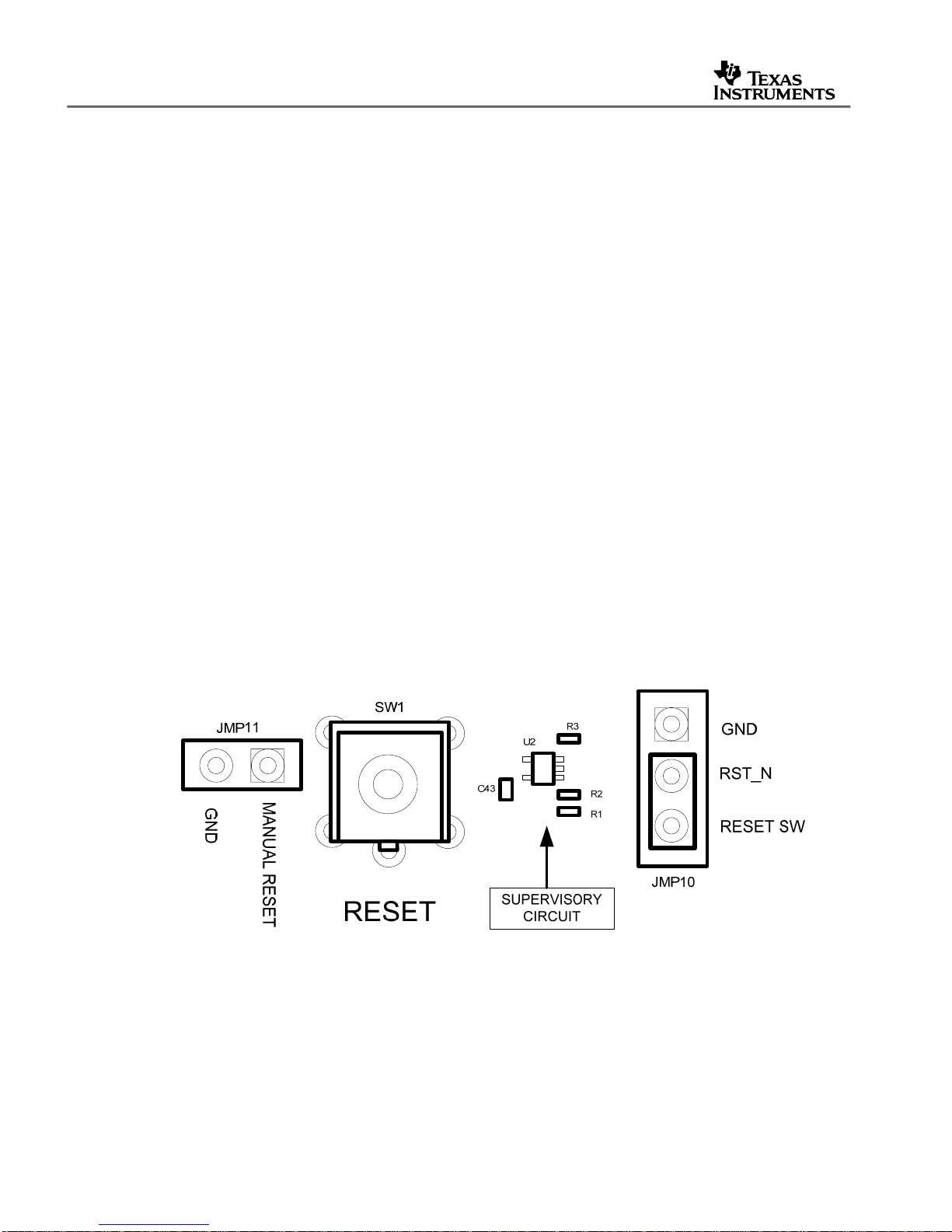

Reset

The TLK3134 EVM comes configured for Manual Reset operations involving the Pushbutton

Reset Switch (SW1). When switch SW1 is pressed, the TLK3134 device RESET pin (RST_N)

goes LOW and the entire TLK3134 device is reinitialized. A TI TPS3125J18 Ultra Low Voltage

Processor Supervisory Circuit is used to control the Reset line. During power-on, /RESET pin of

U2 is asserted when the supply voltage becomes higher than 0.75V. Thereafter, the supply

voltage supervisor monitors the voltage and keeps /RESET output active as long as the Voltage

remains below the threshold voltage (V

inactive state (high) to ensure proper system reset. The delay time, t

voltage has risen above the threshold voltage (V

There is also a manual reset input to the supervisory circuit, /MR, which accepts the input from

the pushbutton switch SW

the TLK3134 device whenever the pushbutton RESET is pressed. By placing a jumper on

JMP11, the Manual Reset (/MR) is tied hard to ground causing the TLK3134 to be held in a

constant state of Reset without the need to continually hold the Reset Pushbutton SW1. The

Supervisory circuit will release the Reset line to a HIGH 180mS (t

becomes greater than the threshold voltage (V

By removing the jumper from JMP10, the Supervised Reset Circuit is disconnected from the

RST_N line. Reset control from an external controller or piec

directly to pin 2 (RST_N) of JMP10 and a ground pin GND has been added to the JMP10 header

next to the RST_N pin to allow easy access for the return current on that cable.

). An internal timer delays the return of the output to the

IT

=180ms, starts after the

d

).

IT

1. A low level at /MR causes /RESET to become active, thus resetting

) from the time the /MR line

d

).

IT

e of equipment can be connected

Figure 11. RESET Switch (SW1, JMP10, or JMP11)

NOTE: The Jumper on JMP10 connecting RESET SW to RST_N must be connected as shown

in order to cause the TLK3134 to be reset and reinitialized If switch

SW1 is pressed, the device

RESET pin (RST_N) goes LOW, the entire TLK3134 device is reinitialized.

18 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 19

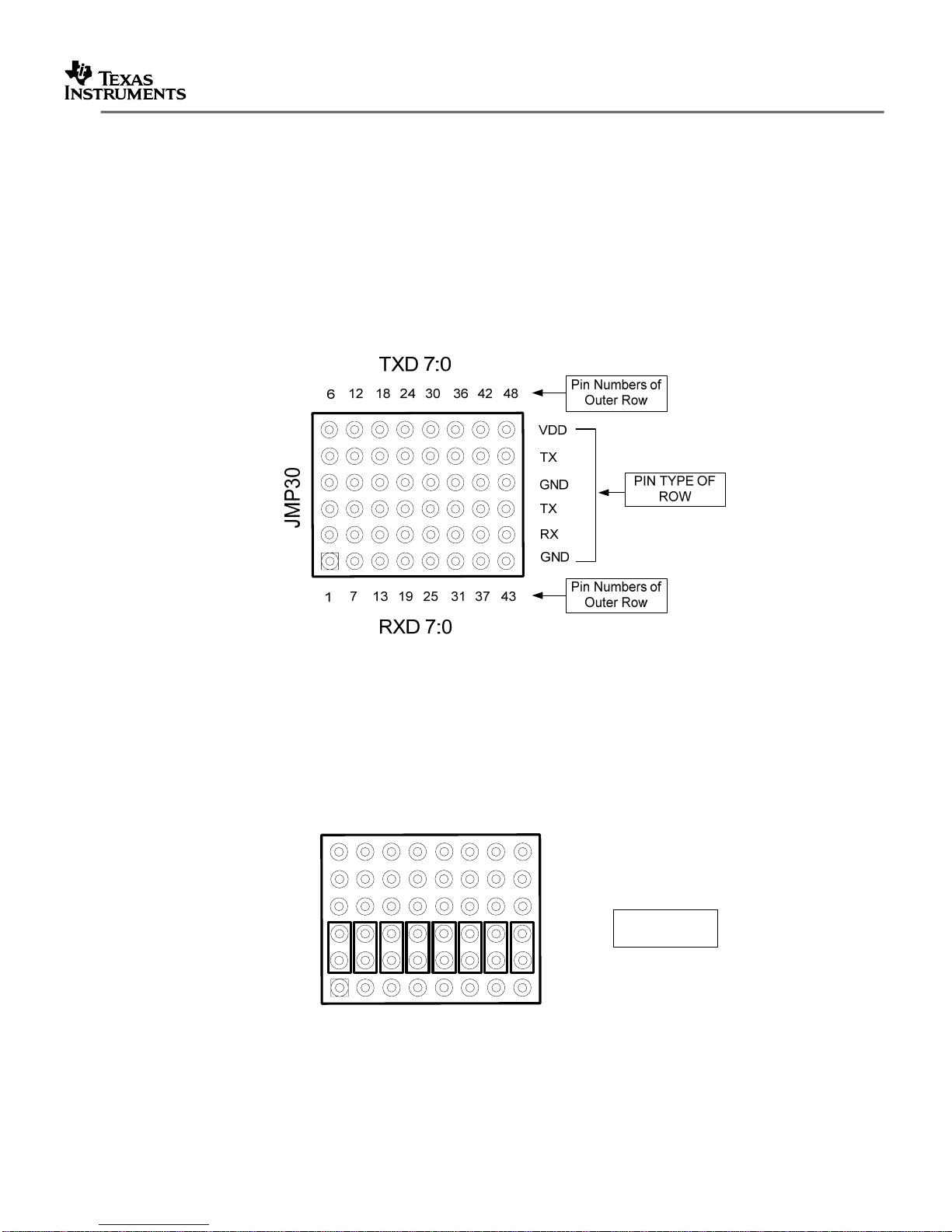

Parallel Signals

SLLU104A - September 2007

The parallel signals have on the TLK3134 EVM have been routed to a 0.1” header block that is

configured like the following figure. All RXD pins on all 4 header blocks (RXD[7:0], RXD[15:8],

RXD[23:16], RXD[31:24]), as well as all TXD pins on all 4 header blocks (TXD[7:0], TXD[15:8],

TXD[23:16], TXD[31:24]), have matched trace lengths to themselves +/- 1MIL. Due to routing

constraints RXD[31:0] and TXD[31:0] trace lengths are not matched to each other, but only to

themselves.

.

Figure 12. Parallel Signal Header Block Example

Parallel Loop back, shown in the following figure, can be easily implemented by placing Jumper

s

on the RX/TX pins of the header. For example, placing a jumper on pins 2 and 3 of JMP30 will

loop back TXD7 to RXD7.

Figure 13. Parallel Signal Header Block Example

TXD 7:0

JMP30

12

6

7

1

RXD 7:0

484218 24 30 36

VDD

TX

GND

TX

RX

GND

433713 19 25 31

PARALLEL

LOOPBACK

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 19

Page 20

SLLU104A - September 2007

Additional GND and VDD pins have been added into the header block for several reasons. The

GND pins next to the RXD and TXD pins provide a convenient ground reference for a scope

probe or coax cables. The additional TXD row and VDD pins allow a static pattern to be driven

into the TXD bus by placing jumpers across either the TXD and VDD pins for a HIGH, or TXD

and GND pins for a LOW eliminating the need for cables during quick tests. The extra row of

TXD can also be used to monitor the signals on the TXD pins while simultaneously looping back

into the RXD pins. The following figure shows a clock pattern (01010101) on TXD[7:0] being

looped back onto the RXD[7:0] pins.

Figure 14. Parallel Loop Back with Static Data Pattern Example

TXD 7:0

12

6

JMP30

7

1

RXD 7:0

484218 24 30 36

VDD

TX

GND

TX

RX

GND

433713 19 25 31

PARALLEL

LOOPBACK

The Transmit Data Clocks and Receive Data Clocks (XGMII) are located in header blocks

JMP32 and JMP33 with the clock pins next to

each other. These four signals are the parallel

(XGMII) side input and output clocks per channel. In XAUI/10GFC mode, TXCLK_1 and

RXCLK_1 are used. During Parallel Loopback, the clocks can be jumpered together as shown in

the following diagram.

Figure 15. Parallel Loop Back with Static Data Pattern Example

20 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 21

XAUI Mode (XGMII) Test and Setup Configuration

SLLU104A - September 2007

The device reset requirements and setup procedure to configure the TLK3134 for XAUII Mode

(XGMII) is as follows:

REFCLK frequency = 156.25 MHz, Serdes Data Rate = Full Rate, Mode = Transceiver,

Edge Mode = Source Centered, RX_CLK out = TXBCLK, Jitter Cleaner PLL Multiplier Ratio = 1X or Off

• Device Pin Setting(s) – Pin settings allow for maximum software configurability.

Ensure ST input pin is Low.

o

o Ensure CODE input pin is Low.

o Ensure PLOOP input pin is Low.

o Ensure SLOOP input pin is Low.

o Ensure SPEED [1:0] input pins are both High.

o Ensure ENABLE input pin is High.

o Ensure PRBS_EN input pin is Low.

• Reset Device

Issue a hard or soft reset (RST_N asserted for at least 10 us -or- Write 1’b1 to 4/5.0.15)

o

• Clock Configuration

If using JCPLL (JCPLL 1X)

o

JCPLL Mux Settings (Figure 3

Select REFCLK input (Default = Differential)

• If Single Ended REFCLK used – Write 2’b01 to 4/5.37120.15:14

• If Differential REFCLK used – Write 2’b00 to 4/5.37120.15:14

Write 2’b11 to 4/5.37120.13:12 to select differential REFCLKP/N as RXBYTECLK

Write 4’b0000 to 4/5.37120.11:8 to select jitter clean

Write 2’b00 to 4/5.37120.5:4 to select jitter clean

Write 2’b00 to 4/5.32810.15:14 to select SERDES TX clock as RX_CLK output

Write 16’h0081 to 4/5.37126 to set Charge pump control

Write 16’h0080 to 4/5.37128 to set TXRX output divider

Clock Divid

If using clock bypass mode (JCPLL Off)

o

JCPLL Mux Settings (Figure 3

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 21

e Settings (Table 211

Write 7’b1000000 to 4/5.37124.14:8 to set REF_DIV to value of 1

Write 1’b1 to 4/5.37124.15 REFDIV_EN to enable reference clock divider

Write 7’h14 to 4/5.37124.6:0 to set FB

Write 1’b1 to 4/5.37124.7 FBDIV_EN to enable feedback divider

Write 7’h14 to 4/5.37125.6:0 to set RXTX_DIV to value of 20

Write 1’b1 to 4/5.37125.7 OUTDIV_EN to enable output divider

Write 7’h0D to 4/5.37121.14:8 to set HSTL_DIV to value of 13

Write 7’h06 to 4/5.37121.6:0 to set HSTL_DIV2 to value

Write 15’h1515 to 4/5.36864.14:0 SERDES_PLL_CONFIG to set MPY RX/T

Write 16’h0000 to 4/5.36865 SERDES_RATE_CONFIG_TX_RX to set Full Rate

Write 1’b1 to 4/5.37127.15 to enable Jitter Cleaner

Wait 2 ms in order for JCPLL to lock

Select REFCLK input (Default = Differential)

• If Single Ended REFCLK used – Write 2’b01 to 4/5.37120.15:14

• If Differential REFCLK used – Write 2’b00 to 4/5.37120.15:14

Select RXBYTE_CLK (Default = Differential)

• If Single Ended REFCLK used – Write 2’b10 to 4/5.37120.13:12

• If Differential REFCLK used – Write 2’b11 to 4/5.37120.13:12

Select SERDES TX Reference Clock Input (Default = Differential)

• If Single Ended REFCLK used – Write 2’b10 to 4/5.37120.11:10

• If Differential REFCLK used – Write 2’b11 to 4/5.37120.11:10

Select SERDES RX Reference Clock Input (Default = Differential)

• If Single Ended REFCLK used – Write 2’b10 to 4/5.37120.9:8

• If Differential REFCLK used – W

Select HSTL_2X_CLK (Default = Differential)

• If Single Ended REFCLK used – Write 2’b10 to 4/5.37120.5:4

• If Differential REFCLK used – W

of the TLK3134 Datasheet)

of the TLK3134 Datasheet)

_DIV to value of 20

of the TLK3134 Datasheet)

ite 2’b11 to 4/5.37120.9:8

r

ite 2’b11 to 4/5.37120.5:4

r

ed clock

ed clock for HSTL VTP 2x

for SERDES TX/RX.

of 6

.

X multiplier factor to 10

Page 22

SLLU104A - September 2007

Write 2’b00 to 4/5.32810.15:14 to select SERDES TX clock as RX_CLK output

Write 6’h04 to 4/5.37121.6:0 to set HSTL_DIV2 to value of 4.

Write 16’h0000 to 4/5.36865 SERDES_RATE_CONFIG_TX_RX to set Full Rate

• Mode Control (Table 2

o Write 1’b1 to 4/5.32809.15

o Write 1’b0 to 4/5.32808.15 to set source centered data for TX side

o Write 1’b0 to 4/5.32808.11 to set source centered data for RX side

o Write 1’b0 to 4/5.32792.1 to disable XAUI data loop back

o Write 1’b0 to 4/5.32792.0 to disable XGMII data loop back

o Write 1’b0 to 4/5.0.14 to disable loop back mode

o Write 3’b110 to 4/5.36874.11:9 to set lane 0 TX swing setting amplitude to 1250 mVdfpp

o Write 3’b110 to 4/5.36876.11:9 to set lane 1 TX

o Write 3’b110 to 4/5.36878.11:9 to set lane 2 TX

o Write 3’b110 to 4/5.36880.11:9 to set lane 3 TX

• Poll Serdes PLL Status for Locked State

o Read 4/5.36891.4,0 SERDES_PLL_STAT

o Keep polling until both bits are high.

•

Issue Data path Reset

Write 1’b1 to 4/5.32800.15

o

• Clear Latched Registers

o

Read 4/5.1 XS_STATUS_1 to clear

o Read 4/5.8 XS_STATUS_2 to clear

o Read 4/5.32770 TX_FIFO_STATUS to clear

o Read 4/5.32771 TX_FIFO_DROP_COUNT to clear

o Read 4/5.32772 TX_FIFO_INSERT_COUNT to clear

o Read 4/5.32773 TX_CODEGEN_STATUS to clear

o Read 4/5.(32780,1,2,3) LANE_0~3_EOP_E

o Read 4/5.(32784,5,6,7) LANE_0~3_CODE_ERROR

o Read 4/5.32789 RX_LANE_ALIGN_STATUS to clear

o Read 4/5.32790 RX_CHANNEL_SYNC_STATUS to clear

o Read 4/5.32794 RX_CTC_STATUS to clear

o Read 4/5.32795 RX_CTC_INSERT_COUNT to clear

o Read 4/5.32796 RX_CTC_DELETE_COUNT to clear

o Read 4/5.32797 DATA_DOWN to clear

o Read 4/5.32799 CLOCK_DOWN_STATUS to clear

o Read 4/5.36891 SERDES_PLL_STATUS to clear

• Operational Mode Status

o Read Verify 4/5.1.7 XS_STATUS_1 – Fault (1’b0)

o Read Verify 4/5.1.2 XS_STATUS_1 – XS Transmit Link Status (1’b1)

o Read Verify 4/5.8.11 XS_STATUS_2 – Transmit fault (1’b0)

o Read Verify 4/5.8.10 XS_STATUS_2 – Receive fault (1’b0)

o Read Verify 4/5.24.12 XS_LANE_STAT

o Read Verify 4/5.24.3:0 XS_LANE_STAT

o Read Verify 4/5.32773.6:0 TX_CODEGEN_STATUS (6’b000000)

o Read Verify 4/5.36891.4 SERDES_PLL_STATUS – PLL_LOCK_RX (1’b1)

o Read Verify 4/5.36891.0 SERDES_PLL_STATUS – PLL_LOCK_TX (1’b1)

of the TLK3134 Datasheet)

XAUI_ORDER

swing setting amplitude to 1250 mVdfpp

swing setting amplitude to 1250 mVdfpp

swing setting amplitude to 1250 mVdfpp

US – PLL_LOCK_TX/RX

RROR_COUNT to clear

_COUNT to clear

US – Align status (1’b1)

US – Lane (3-0) sync (4’b1111)

22 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 23

Figure 16. Example TLK3134 EVM Test Configuration – XAUI Mode (XGMII) Parallel Loopback

SLLU104A - September 2007

D

D

8

4

V

4

2

X

2

:

4

T

D

1

6

N

3

3

G

0

D

X

T

1

2

1

6

7

X

3

T

X

4

2

8

2

P

M

J

D

R

N

G

3

4

7

3

1

3

4

5

2

2

:

9

1

1

3

3

D

1

X

7

R

1

V

D

D

T

6

G

X

1

T

N

2

X

D

1

T

R

G

X

N

D

1

7

R

D

8

X

1

X

7

2

:

4

0

3

0

3

6

4

2

4

3

1

9

2

5

D

7

:

0

8

0

3

P

3

1

M

3

J

7

4

3

.

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 23

Page 24

SLLU104A - September 2007

Gigabit Ethernet Mode (RGMII) Test and Setup Configuration

The device reset requirements and setup procedure to configure the TLK3134 for Gigabit

Ethernet Mode (RGMII) is as follows:

*Note: All global registers must be accessed indirectly through Clause 22.

REFCLK frequency = 125 MHz, Serdes Data Rate = Half Rate, Mode = Tr

RX_CLK[n] out = TXBCLK[n], Jitter Cleaner PLL Multiplier Ratio = 1X or Off

• Device Pin Setting(s) – Pin settings allow for maximum software configurability.

o Ensure ST input pin is high.

o Ensure CODE input pin is Low.

o Ensure PLOOP input pin is Low.

o Ensure SLOOP input pin is Low.

o Ensure SPEED [1:0] input pins are both High.

o Ensure ENABLE input pin is High.

o Ensure PRBS_EN input pin is Low.

• Reset Device

Issue a hard or soft reset (RST_N asserted for at least 10 us -or- W

o

• Clock Configuration

o If using JCPLL (JCPLL 1X)

JCPLL Mux Settings (

Select REFCLK input (Default = Differential)

• If Single Ended REFCLK used – Write 2’b01 to 4/5.37120.15:14

• If Differential REFCLK used – Write 2’b00 to 4/5.37120.15:14

Write 2’b11 to 4/5.37120.13:12 to select differential REFCLKP/N as RXBYTECLK

Write 4’b0000 to 4/5.37120.11:8 to select jitter cleaned clock

Write 2’b11 to 4/5.37120.7:6 to select differential REFC

Write 2’b00 to 4/5.37120.5:4 to select jitter clean

Write 2’b00 to 16.10:9 to select SERDES TX clock as RX_CLK output (per channel)

Write 16’h0081 to 4/5.37126 to set Charge pump control

Write 16’h0080 to 4/5.37128 to set TXRX output divider

Clock Divid

Write 7’b1000000 to 4/5.37124.14:8 to set REF_DIV to value of 1

Write 1’b1 to 4/5.37124.15 REFDIV_EN to enable reference clock divider

Write 7’h18 to 4/5.37124.6:0 to set FB_DIV to value of 24

Write 1’b1 to 4/5.37124.7 FBDIV_EN to enable feedback divider

Write 7’h18 to 4/5.37125.6:0 to set RXTX_DIV to value of 24

Write 1’b1 to 4/5.37125.7 OUTDIV_EN to enable RXTX_DIV output divider

Write 7’h0D to 4/5.37121.14:8 to set HSTL_DIV to value of 13

Write 7’h06 to 4/5.37121.6:0 to set HSTL_DIV2 to value

Write 15’h1515 to 4/5.36864.14:0 SERDES_PLL_CONFIG to set MPY RX/T

Write 16’h5555 to 4/5.36865 SERDES_RATE_CONFIG_TX_RX to set Half Rate

Write 1’b1 to 4/5.37127.15 to enable Jitter Cleaner

Wait 2 ms in order for JCPLL to lock

Else if using clock bypass mode (JCPLL Off)

o

JCPLL Mux Settings (

Select REFCLK input (Default = Differential)

• If Single Ended REFCLK used – Write 2’b01 to 4/5.37120.15:14

• If Differential REFCLK used – Write 2’b00 to 4/5.37120.15:14

Select RXBYTE_CLK (Default = Differential)

• If Single Ended REFCLK used – Write 2’b10 to 4/5.37120.13:12

• If Differential REFCLK used – Write 2’b11 to 4/5.37120.13:12

Select SERDES TX Reference Clock Input (Default = Differential)

• If Single Ended REFCLK used – Write 2’b10 to 4/5.37120.11:10

Figure 3 of the TLK3134 Datasheet)

e Settings (Table 211 of the TLK3134 Datasheet)

Figure 3 of the TLK3134 Datasheet)

• If Differential REFCLK used – Write 2’b11 to 4/5.37120.11:10

Select SERDES RX Reference Clock Input (Default = Differential)

ansceiver, Edge Mode = Source Centered Mode,

rite 1’b1 to 0.15)

for SERDES TX/RX.

LKP/N as Delay Stopwatch clock input

ed clock for HSTL VTP 2x

of 6

X multiplier factor to 10

24 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 25

• If Single Ended REFCLK used – Write 2’b10 to 4/5.37120.9:8

SLLU104A - September 2007

• If Differential REFCLK used – Write 2’b11 to 4/5.37120.9:8

Select DELAY_CLK (Default = Differential)

• If Single Ended REFCLK used – Write 2’b10 to 4/5.37120.7:6

• If Differential REFCLK used – Write 2’b11 to 4/5.37120.7:6

Select HSTL_2X_CLK (Default = Differential)

• If Single Ended REFCLK used – Write 2’b10 to 4/5.37120.5:4

• If Differential REFCLK used – W

Write 2’b00 to 16.10:9 to select SERDES TX clock as RX_CLK output (per channel)

Write 6’h04 to 4/5.37121.6:0 to set HSTL_DIV2 to value of 4.

Write 15’h1515 to 4/5.36864.14:0 SERDES_PLL_CONFIG to set MPY RX/T

Write 16’h5555 to 4/5.36865 SERDES_RATE_CONFIG_TX_RX to set Half Rate

• Mode Control (Table 2

o Write 1’b0 to 17.0 for RX source centered mode (per channel)

o Write 1’b0 to 17.1 for TX source centered mode (per channel)

o Write 1’b1 to 17.2 to enable 8B/10B encode decode functions (per channel)

o Write 1’b1 to 17.3 to enable 1000Base-X PCS TX & PCS RX functions (per channel)

o Write 1’b1 to 17.4 to set nibble order, LSB on rising edge, MSB on falling edge (per channel)

o Write 1’b1 to 17.5 to enable DDR data on TX/RX directions (per channel)

o Write 1’b0 to 17.6 to disable FC_PH overlay detection (per channel)

o Write 1’b1 to 17.7 to enable comma detection (per channel)

o Write 1’b0 to 17.9 to disable full DDR mode (per channel)

o Write 1’b0 to 16.8 to disable Farend Loop back (per channel)

o Write 1’b0 to 0.14 to disable loop back mode (per channel)

o Write 3’b111 to 4/5.36874.11:9 to set channel 0 TX swing setting amplitude to 1375 mVdfpp

o Write 3’b111 to 4/5.36876.11:9 to set channel 1 TX s

o Write 3’b111 to 4/5.36878.11:9 to set channel 2 TX s

o Write 3’b111 to 4/5.36880.11:9 to set channel 3 TX s

• Poll Serdes PLL Status for Locked State

o

Read 4/5.36891.4,0 SERDES_PLL_STAT

o Keep polling until both bits are high.

• Issue Data path Reset

Write 1’b1 to 16.11 (per channel)

o

• Clear Latched Registers

Read 1 PHY_STATUS_1 to clear (per channel)

o

o Read 18 PHY_RX_CTC_FIFO_STATUS to clear (per channel)

o Read 19 PHY_TX_CTC_FIFO_STATUS to clear (per channel)

o Read 28 PHY_CHANNEL_STATUS to clear (per channel)

o Read 4/5.36891 SERDES_PLL_STATUS to clear

• Operational Mode Status

o

Read Verify 1.2 PHY_STATUS_1 – Link Status (1’b1) (per channel)

o Read Verify 18.15 PHY_RX_CTC_FIFO_STATUS – RX_CTC_Reset (1’b0) (per channel)

o Read Verify 19.15 PHY_TX_CTC_FIFO_STATUS – TX_FIFO_Reset_1Gx (1’b0) (per channel)

o Read Verify 28.13:12 PHY_CHANNEL_STATUS – Enc/Dec Invalid Code Word (2’b00) (per channel)

o Read Verify 4/5.36891.4 SERDES_PLL_STATUS – PLL_LOCK_RX (1’b1)

of the TLK3134 Datasheet)

o Read Verify 4/5.36891.0 SERDES_PLL_STATUS – PLL_LOCK_TX (1’b1)

ite 2’b11 to 4/5.37120.5:4

r

wing setting amplitude to 1375 mVdfpp

wing setting amplitude to 1375 mVdfpp

wing setting amplitude to 1375 mVdfpp

US – PLL_LOCK_TX/RX

.

X multiplier factor to 10

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 25

Page 26

SLLU104A - September 2007

Figure 17. Example TLK3134 EVM Test Configuration – Gigabit Ethernet Mode (RGMII) Serial Loopback

D

D

84

V

4

2

TX

D

6

N

31:24

3

G

TX

TXD

182430

12

6

X

D

R

N

G

43

71

3

31

4

5

2

2

:

9

1

1

3

3

D

JMP27

X

7

R

1

V

D

D

TX

6

G

1

TXD 7:0

N

2

D

TX

R

GND

X

1

7

131925

R

X

D 7:0

4

2182430 36

48

0

3

3

1

JMP

7

4

33

4

O

P

G

P

K

N

T

L

K

D

C

L

C

F

E

R

N

F

R

E

0

E

R

FC

T

DN1

LK

T

D

P

0

3

P

D

R

2

P

D

2

R

1

N

P

D

D

R

R

1

N

D

R

26 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 27

Schematics

SLLU104A - September 2007

.

Figure 18. TLK3134 EVM Schematic, Sheet 1 Index

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 27

Page 28

SLLU104A - September 2007

Figure 19. TLK3134 EVM Schematic, Sheet 2 Device Power and Ground

28 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 29

Figure 20. TLK3134 EVM Schematic, Sheet 3 Global Signals

SLLU104A - September 2007

.

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 29

Page 30

SLLU104A - September 2007

Figure 21. TLK3134 EVM Schematic, Sheet 4 High Speed Differential

30 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 31

Figure 22. TLK3134 EVM Schematic, Sheet 5 Jitter Cleaner Clock

SLLU104A - September 2007

.

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 31

Page 32

SLLU104A - September 2007

Figure 23. TLK3134 EVM Schematic, Sheet 6 JTAG and MDIO

of

616

REV PAGEDOCUMENT NUMBERSIZE

1

1

TEXAS INSTURMENTS

6493231

2 Pin Berg Jumper

JMP24

1

MDIO KEYED CONNECTOR

PRTAD4

PRTAD3

PRTAD2

PRTAD4N5PRTAD3N4PRTAD2N3PRTAD1N2PRTAD0

2

2P5V

PRTAD_PULLUP_EN

PRTAD1

PRTAD0

M5

T1

M2

ST

REFCLK

JMP22

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

C94

NP

MDIO_CON

MDC_CON

C93

NP

2

R45 0

R46 0

R48

NP

R44

NP

R47

VDDM

R43

1.5K

3

NP

MDC

MDIO

U16

T16

MDC

MDIO

U1C

246810

JMP25

Header 5x2

13579

R54 4.99K

R53 4.99K

R52 4.99K

R51 4.99K

R50 4.99K

2P5V

R49

49.9

TLK3134

NOTE: PLACE THIS

TERMINATION RESISTOR

AS CLOSE TO THE

DEVICE PIN AS

POSSIBLE.

1

2

JMP26

R55 4.99K

ST

J20

REFCLK

2 Pin Berg Jumper

REFCLK

B

JTAG AND MDIO

PAGE TITLE

2

3

4

5

D D

32 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

246810

13579

TDI

TRST_N

TDO

N13

R15

N15

TDO

TRST_N

Header 5x2

TCK

TMS

P15

P17

TDI

TMS

TCK

TLK3134

B B

A A

4

5

JMP23

U1B

C C

Page 33

Figure 24. TLK3134 EVM Schematic, Sheet 7 TX and RX Data Lines

SLLU104A - September 2007

47

47

48

41

42

35

36

29

30

23

24

17

18

11

12

5

6

47

48

41

42

35

36

29

30

23

24

17

18

11

12

5

6

48

41

42

35

36

29

30

23

24

17

18

11

12

5

6

47

48

41

42

35

36

29

30

23

24

17

18

11

12

5

6

.

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 33

Page 34

SLLU104A - September 2007

Figure 25. TLK3134 EVM Schematic, Sheet 8 TX/RX Clocks and Control

34 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 35

Figure 26. TLK3134 EVM Schematic, Sheet 9 Power Regulation

SLLU104A - September 2007

3

2

1P8V_VADJ

1

1P5V_VADJ

.

12

12

12

12

12

C99 .01uf

C98 0.1uf

C97 1.0uf

C96 10uf

C95 68uf

12

12

12

12

12

12

12

12

12

12

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 35

Page 36

SLLU104A - September 2007

Figure 27. TLK3134 EVM Schematic, Sheet 10 Power Distribution

C142 .01uf

C141 0.1uf

C140 1.0uf

C170 0.1uf

C169 1.0uf

C173 10uf

C167 .01uf

C166 0.1uf

C165 1.0uf

R73 100

C181 .01uf

C180 0.1uf

C179 1.0uf

C183 10uf

C182 68uf

C176 .01uf

C178 0.1uf

C177 100uf

C168 .01uf

C175 0.1uf

C174 1.0uf

C186 .01uf C171 .01uf

C185 0.1uf

C184 1.0uf

C188 10uf

C187 68uf C172 68uf

1

36 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

1

1

Page 37

Figure 28. TLK3134 EVM Schematic, Sheet 11 1P2V and 2P5V Supply LEDs

SLLU104A - September 2007

.

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 37

Page 38

SLLU104A - September 2007

Figure 29. TLK3134 EVM Schematic, Sheet 12 1P5V, 1P8V, and 5V Supply LEDs

of

12 16

REV PAGEDOCUMENT NUMBERSIZE

1

2

3

R94 49 .9

5V 5V

R93 49 .9

5V

1P5V_LED_WINDOW_OUT

R96

105K

1

1 OUT

LM339AU14B

-

+

1 IN_P71 IN_N

6

1P8V_LED_VF

1P5V_LED_VF

LM339AU14C

21

21

2

2 OUT

-

+

2 IN_N42 IN_P

5

D9

D8

HSMB-C170

HSMB-C170

1P5V_LED_COL

C11E12C2

U16

JMP68

TEXAS INSTURMENTS

1P8V_LED_COL

3

5

E2

B2

B1

6

1P5V_LED_BASE

LED SELECT

123

JMP69

1P5V_LED_PLANE_OUT

R99 18.7K

R100 26.7K

1P5/8V

1P5/8V

123

1P8V_LED_PLANE_OUT

4

1P8V_LED_BASE

ZXTD09N50DE6

LED SELECT

5V

1P8V_LED_WINDOW_OUT

R102

105K

14

LM339AU14D

+

9

13

3 OUT

4 OUT

LM339AU14E

-

3 IN_N83 IN_P

+

4 IN_P114 IN_N

-

10

12

GND

LM339AU14A

VCC

3

5V

1

6493231

B

1P5V, 1P8V, AND 5V SUPPLY LEDS

PAGE TITLE

2

3

4

4P096V_REF2

5

NOTE: VOLTAGE WINDOW DETECTOR CIRCUITS MONITOR THE VOLTAGE O N THE PLANE AND LIGHTS THE

APPROPRIATE LED IF IT IS WITHIN THE ALLOWABLE DATASHEET RANGE.

USE 0.1% PRECISION RESISTORS FOR THE MOST

ACCURATE VOLTAGE DIVIDER REFERENCE LEVELS ON THE INPUT TO THE VOLTAGE WINDOW DETECTOR CIRCUIT

D D

38 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

1P5/8V_LED_N

1P5V_VREF_HIGH

JMP67

123

1P5V_VREF_LOW

R95

17.4K

R97

1.4K

C214

0.47uF

5V

1

VIN

U15

R98

9.76K

2

VOUT

GND

REF2940

3

C C

LED ENABLE

1P5/8V

1P8V_VREF_HIGH

R101

13.0K

B B

1P8V_VREF_LOW

R103

1.2K

5V

R104

10.2K

HSMB-C170

21

5V_LED_VF

R114 49.9

D12

A A

4

5

Page 39

Figure 30. TLK3134 EVM Schematic, Sheet 13 VDDM Supply LEDs

SLLU104A - September 2007

.

of

13 16

REV PAGEDOCUMENT NUMBERSIZE

1

5V 5V

1

TEXAS INSTURMENTS

6493231

2P5V_VDDM_LED_COL

1P2V_VDDM_LED_COL

3

C11E12C2

B1

U34

6

2

1P2V_VDDM_LED_BASE

JMP91

3

5V

1P2V_VDDM_LED_WINDOW_OUT

R169

105K

1

1 OUT

LM339AU32B

+

1 IN_P71 IN_N

2

2 OUT

LM339AU32C

-

+

5

6

R172 11.0K

VDDM

-

2 IN_N42 IN_P

5

E2

B2

ZXTD09N50DE6

4

2P5V_VDDM_LED_BASE

LED SELECT

LED SELECT

123

123

JMP93

1P2V_VDDM_LED_PLANE_OUT

2P5V_VDDM_LED_PLANE_OUT

2P5V_VDDM_LED_WINDOW_OUT

R173 41.2K

5V

R175

105K

14

LM339AU32D

+

9

13

3 OUT

4 OUT

LM339AU32E

+

4 IN_P114 IN_N

-

10

-

3 IN_N83 IN_P

12

GND

LM339AU32A

VCC

3

5V

B

VDDM SUPPLY LEDS

PAGE TITLE

2

3

4

4P096V_REF3

5

NOTE: VOLTAGE WINDOW DETECTOR CIRCUITS MONITOR THE VOLTAGE ON THE PLANE AND LIGHTS THE

APPROPRIATE LED IF IT IS WITHIN THE ALLOWABLE DATASHEET RANGE.

USE 0.1% PRECISION RESISTORS FOR THE MOST

ACCURATE VOLTAGE DIVIDER REFERENCE LEVELS ON THE INPUT TO THE V OLTAGE WINDOW DETECTOR CIRCUIT

D D

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 39

4

1P2V_VDDM_VREF_HIGH

1P2V_VDDM_VREF_LOW

R168

24.9K

R170

1.05K

C220

0.47uF

5V

2

1

VIN

VOUT

U33

GND

3

JMP92

123

LED ENABLE

VDDM

R171

10.0K

REF2940

C C

2P5V_VDDM_VREF_HIGH

R174

6.19K

B B

2P5V_VDDM_VREF_LOW

R176

1.1K

R177

10.0K

5

A A

Page 40

SLLU104A - September 2007

Figure 31. TLK3134 EVM Schematic, Sheet 14 VDDR Supply LEDs

HSMB-C170

21

1P8V_VDDR_LED_VF

1P5V_VDDR_LED_VF

D26

21

D25

HSMB-C170

R191 49.9

R190 49.9

40 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

VDDR_LED_IN

Page 41

Figure 32. TLK3134 EVM Schematic, Sheet 15 VREF Supply LEDs

SLLU104A - September 2007

.

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 41

Page 42

SLLU104A - September 2007

Figure 33. TLK3134 EVM Schematic, Sheet 16 VJIT Supply LEDs

42 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 43

Table 1. TLK3134 EVM Bill of Materials

SLLU104A - September 2007

Item Qty Reference Value Part Part_Number Manufacturer

1 4 C1,C2,C17,C31 2.2uF 0402 CAP GRM155R60J225ME15D Murata Electronics

2 5 C3,C4,C18,C25,C32 1uF 0402 CAP C0402X5R6R3-105KNE Venkel

3 6 C5,C6,C19,C26,C33,C39 0.47uF 0402 CAP GRM155R61A474KE15D Murata Electronics

4 30 C7,C8,C9,C10,C11,C12,C20,C21,C22,C27,

C28,C34,C35,C36,C40,C41,C44,C53,C54,

C63,C64,C73,C74,C83,C84,C85,C86,C87,

C88,C89

5 6 C13,C14,C23,C29,C37,C42 100pF 0402 CAP C0402COG500-101JNE Venkel

6 5 C15,C16,C24,C30,C38 10pF 0402 CAP C0402COG500-100JNE Venkel

7 1 C43 0.1uF 0603 CAP C1206C104J5RACTU Kemet

8 1 C90 1.5nF 0402 CAP C0402C152K5RACTU Kemet

9 1 C91 1.8nF 0402 CAP C0402C182K5RACTU Kemet

10 1 C92 3.3uF 0603 CAP C0603C335K9PACTU Kemet

11 2 C93,C94 UNINSTALLED 0603 CAP

12 4 C95,C172,C182,C187 68uF 7343 CAP TA025TCM106KDR Kemet

13 4 C96,C173,C183,C188 10uF 7343 CAP 293D106X0035D2W Venkel

14 8 C97,C140,C165,C169,C174,C177,C179,C1

84

15 8 C98,C141,C166,C170,C175,C178,C180,C1

85

16 8 C99,C142,C167,C168,C171,C176,C181,C1

86

17 6 C213,C214,C215,C220,C222,C223 0.47uF 0603 CAP GRM188R71E474KA12D Murata Electronics

18 3 C224,C225,C227 100uF 1812 CAP GRM43SR60J107ME20L Murata Electronics

19 9 C512,C513,C515,C517,C519,C520,C522,

C524,C525

20 3 C514,C518,C523 0.47uF 0402 CAP GRM188R71E474KA12D Murata Electronics

21 3 C516,C521,C526 10uF 3216 CAP

22 17 D1,D2,D3,D4,D5,D6,D7,D8,D9,D10,D12,D

21, D22,D25,D26,D27,D28

23 15 JMP1,JMP2,JMP3,JMP5,JMP7,JMP9,JMP11,

JMP12,JMP14,JMP21,JMP24,JMP26,JMP108,

JMP110,JMP114

24 25 JMP10,JMP20,JMP37,JMP40,JMP43,JMP50,

JMP63,JMP66,JMP67,JMP73,JMP92,JMP98,

JMP101,JMP64,JMP65,JMP68,JMP69,JMP72,

JMP91,JMP93,JMP97,JMP99,JMP100,JMP102

,JMP115

25 1 JMP13 Header

26 3 JMP15,JMP23,JMP25 Header

27 5 JMP27,JMP28,JMP29,JMP30,JMP31 Header

28 2 JMP32,JMP33 Header

29 3 JMP107,JMP109,JMP113 Header T

30 1 JMP22 20 Pin

31 20 J1,J2,J3,J4,J5,J6,J7,J8,J9,J10,J11,J12,J13,

J14,J15,J16,J17,J18,J19,J20

32 1 L1 INDUCTOR TBD 0603 IND UNINSTALLED

33 8 P1,P2,P3,P4,P11,P19,P20,P21 Banana

34 20 R1,R5,R6,R7,R8,R9,R10,R11,R12,R35,R3

6,

R37,R38,R39,R50,R51,R52,R53,R54,R55

35 6 R2,R4,R15,R16,R17,R24 49.9 0603 RES RG1608P-49R9-B-T1 Susumu Co

0.01uF 0402 CAP GRM21BR72A103KA01L Murata Electronics

1.0uF 1206 CAP C1206X7R250-105KNE Venkel

0.1uF 1206 CAP C1206C104J5RACTU Kemet

0.01uF 0805 CAP GRM21BR72A103KA01L Murata Electronics

220uF 7343 CAP

Blue Diffused 0805 LED HSMB-C170 Agilent

2 Pin

Header

3 Pin

Header

10x2

5x2

8x6

4x2

4pin

Ribbon

Connector

SMP

Connector

Jack

4.99K 0603 RES RG1608P-4991-B-T5 Susumu Co

HTSW-150-07-G-S Samtec

HTSW-150-07-G-S Samtec

HTSW-150-07-G-D Samtec

HTSW-150-07-G-D Samtec

HTSW-150-07-G-T Samtec

HTSW-150-07-G-D Samtec

HTSW-150-07-G-S Samtec

5103308-5 Tyco

19S101-40ME4 Rosenberger

108-0740-001 Emerson Network

Technologies

Electronics/Amp

Power Co

.

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 43

Page 44

SLLU104A - September 2007

36 1 R3 100K 0603 RES TNPW06031003BT9 Vishay/Dale

37 10 R13,R14,R20,R21,R44,R47,R48,R220,R22

2, R224

38 4 R18,R19,R25,R26 UNINSTALLED 0402 RES

39 3 R22,R23 0 0402 RES ERJ-2GE0R00X Panasonic - Ecg

40 2 R27,R28 150 0402 RES RG1005P-151-B-T5 Susumu Co

41 3 R29,R30,R49 49.9 0402 RES RG1005P-49R9-B-T5 Susumu Co

42 5 R31,R32,R33,R34,R40 40.2K 0402 RES RG1005P-4022-B-T5 Susumu Co

43 1 R42 100 0402 RES

44 1 R43 1.5K 0603 RES RG1608P-152-B-T5 Susumu Co

45 2 R45,R46 0 0603 RES ERJ-3GEY0R00V Panasonic - Ecg

46 10 R67,R71,R74,R75,R76,R77,R78,R221,R22

3, R225

47 2 R72,R73 100 0805 RES RG2012P-101-B-T5 Susumu Co.

48 12 R81,R82,R93,R94,R113,R114,R166,R167,

R190,R191,R202,R203

49 3 R83,R112,R168 24.9K 0603 RES RG1608P-2492-B-T5 Susumu Co.

50 11 R84,R90,R96,R102,R108,R169,R175,R193

, R199,R205,R211

51 3 R85,R105,R170 1.05K 0603 RES RR0816P-1051-B-T5-03H Susumu Co.

52 6 R86,R92,R106,R171,R177,R207 10.0K 0603 RES ERA-3AEB103V Panasonic - Ecg

53 3 R87,R110,R172 11.0K 0603 RES RG1608P-113-B-T5 Susumu Co.

54 2 R88,R173 41.2K 0603 RES RG1608P-4122-B-T5 Susumu Co.

55 2 R89,R174 6.19K 0603 RES RR0816P-6191-B-T5-77H Susumu Co.

56 2 R91,R176 1.1K 0603 RES RG1608P-112-B-T5 Susumu Co.

57 2 R95,R192 17.4K 0603 RES RR0816P-1742-B-T5-24C Susumu Co.

58 3 R97,R194,R206 1.4K 0603 RES RG1608P-1401-B-T5 Susumu Co.

59 3 R98,R195,R213 9.76K 0603 RES RR0816P-9761-B-T5-96H Susumu Co.

60 2 R99,R196 18.7K 0603 RES RG1608P-1872-B-T5 Susumu Co.

61 2 R100,R197 26.7K 0603 RES RR0816P-2672-B-T5-42C Susumu Co.

62 2 R101,R198 13.0K 0603 RES RG1608P-133-B-T5 Susumu Co.

63 2 R103,R200 1.2K 0603 RES RG1608P-122-B-T5 Susumu Co.

64 2 R104,R201 10.2K 0603 RES RG1608P-1022-B-T5 Susumu Co.

65 1 R204 47.0K 0603 RES RG1608P-473-B-T5 Susumu Co.

66 1 R208 1.0K 0603 RES RR0816P-102-B-T5 Susumu Co.

67 1 R209 3.9K 0603 RES RG1608P-392-B-T5 Susumu Co.

68 1 R210 36.0K 0603 RES RR0816P-363-B-T5 Susumu Co.

69 1 R212 1.15K 0603 RES RG1608P-1151-B-T5 Susumu Co.

70 1 R214 17.5K 0603 RES

71 1 R215 8.94K 0603 RES

72 1 R216 5.51K 0603 RES

73 1 R217 2.22K 0603 RES

74 1 SW1 Light Touch Switch EVQ-PBE05R Panasonic - Ecg

75 1 U1 TLK3134 IC TLK3134-ZEL TI

76 1 U2 TPS3125J18 IC TPS3125J18DBVR TI

77 9 U3,U4,U5,U13,U16,U18,U34,U40,U43 ZXTD09N50DE6 IC ZXTD09N50DE6TA Zetek

78 6 U11,U14,U32,U38,U41,U48 LM339A IC LM339AD TI

79 6 U12,U15,U17,U33,U39,U42 REF2940 IC REF2940AIDBZT TI

80 3 U44,U45,U47 PTH05010W IC PTH05010WAS TI

81 93 Shunts 2 pin Shunt 382811-6 Tyco

82 1 R78 (Ferrite Bead) 915 Ohm 100mA 1206 RES LF1206A302R-10 Steward

83 1 R41 1.21K 0402 RES

84 1 C177 100uF 1206 CAP

UNINSTALLED 0603 RES

0 1210 RES RK73Z2ETTE Koa Speer

49.9 0603 RES RG1608P-49R9-B-T1 Susumu Co.

105K 0603 RES RR0816P-1053-B-T5-03D Susumu Co.

Electronics/Amp

44 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 45

Board Layouts

SLLU104A - September 2007

.

Figure 34. TLK3134 EVM Layout, Top Signal (Layer 1)

J

M

P

2

7

0

3

P

M

J

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 45

Page 46

SLLU104A - September 2007

Figure 35. TLK3134 EVM Layout, Ground (Layers 2,4,6,8,10,11)

46 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 47

Figure 36. TLK3134 EVM Layout, Internal Signal (Layer 3)

SLLU104A - September 2007

.

TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide 47

Page 48

SLLU104A - September 2007

Figure 37. TLK3134 EVM Layout, Internal Signal (Layer 5)

48 TLK3134 XAUI Transceiver / 4 Channel Multi-Rate Transceiver Evaluation Module (EVM) Users’ Guide

Page 49

Figure 38. TLK3134 EVM Layout, Power (Layer 7)

SLLU104A - September 2007

.