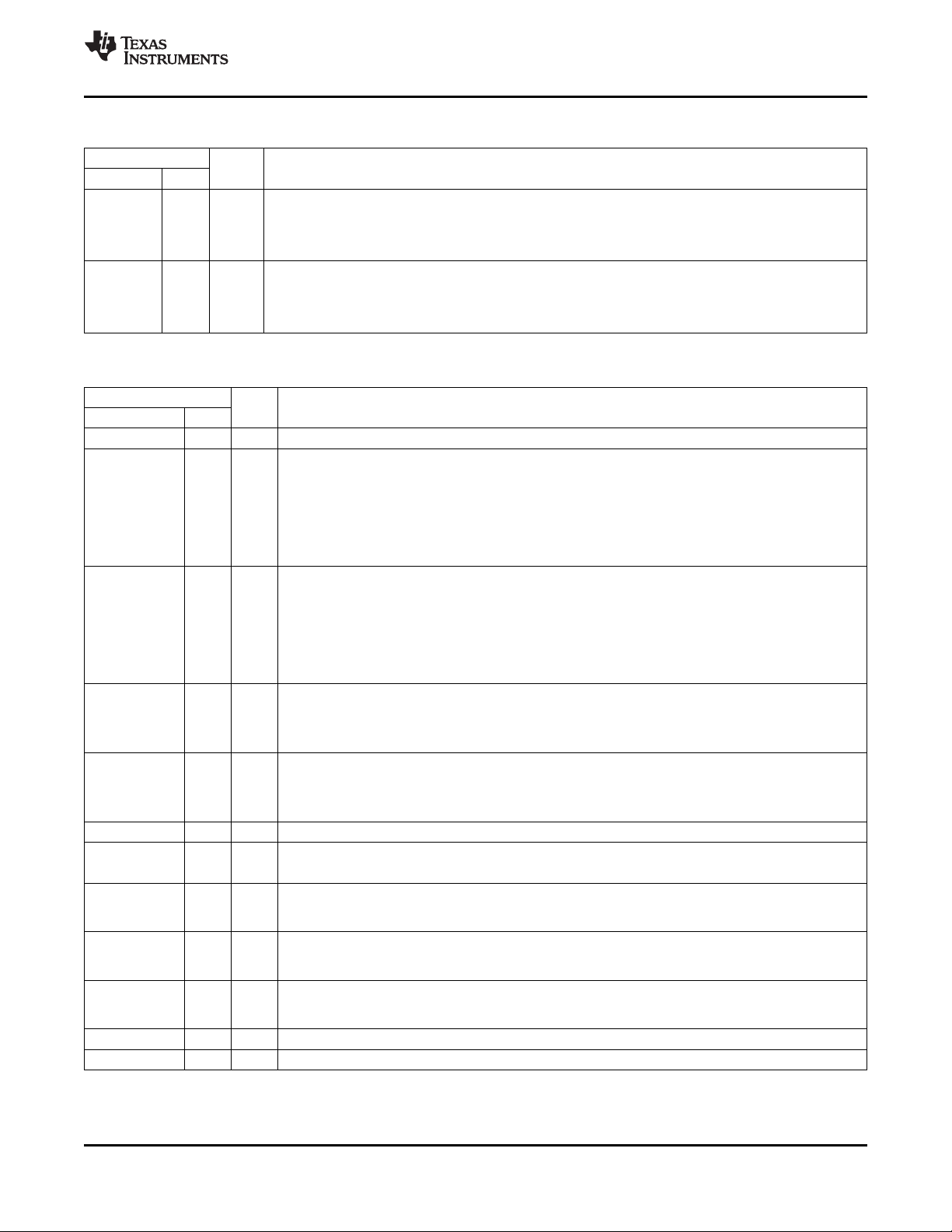

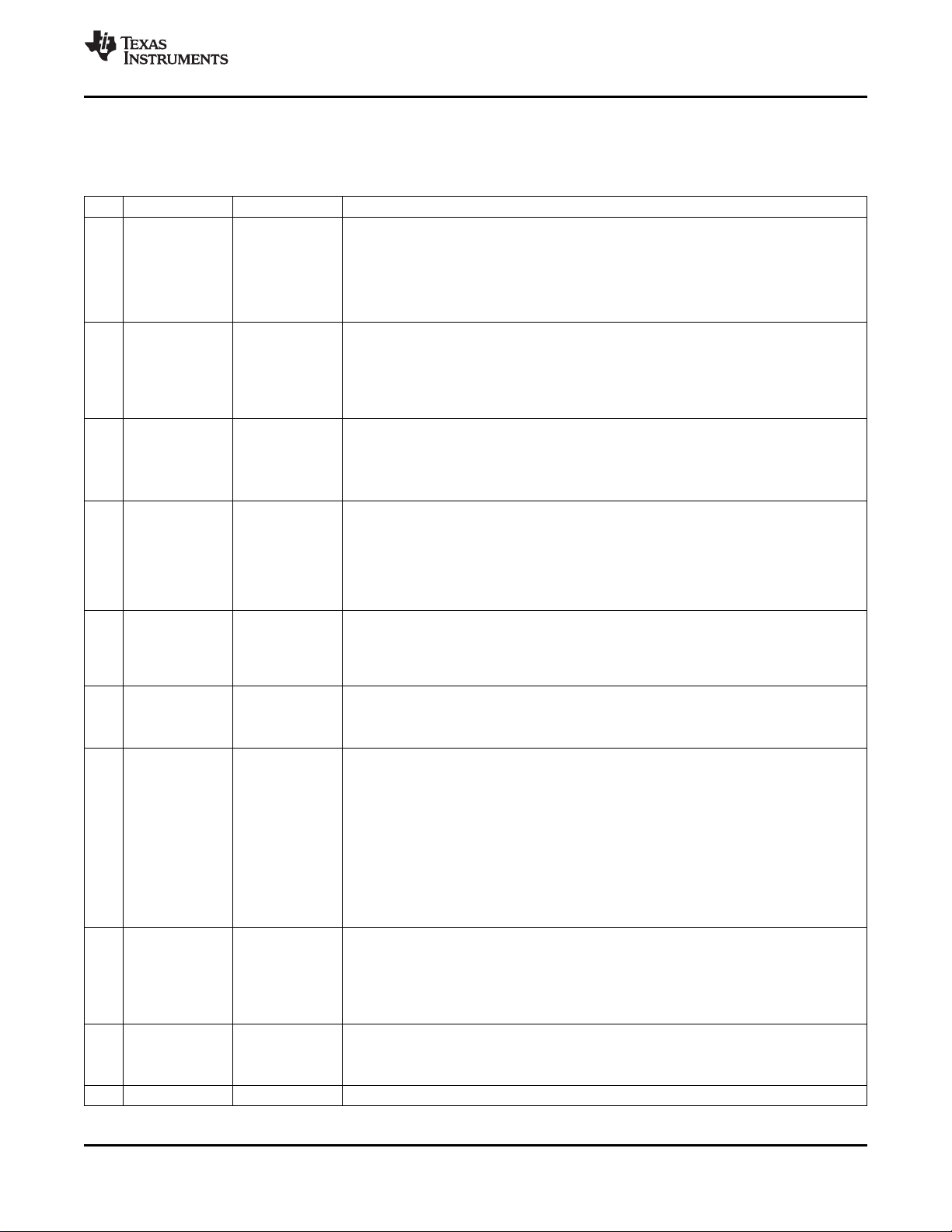

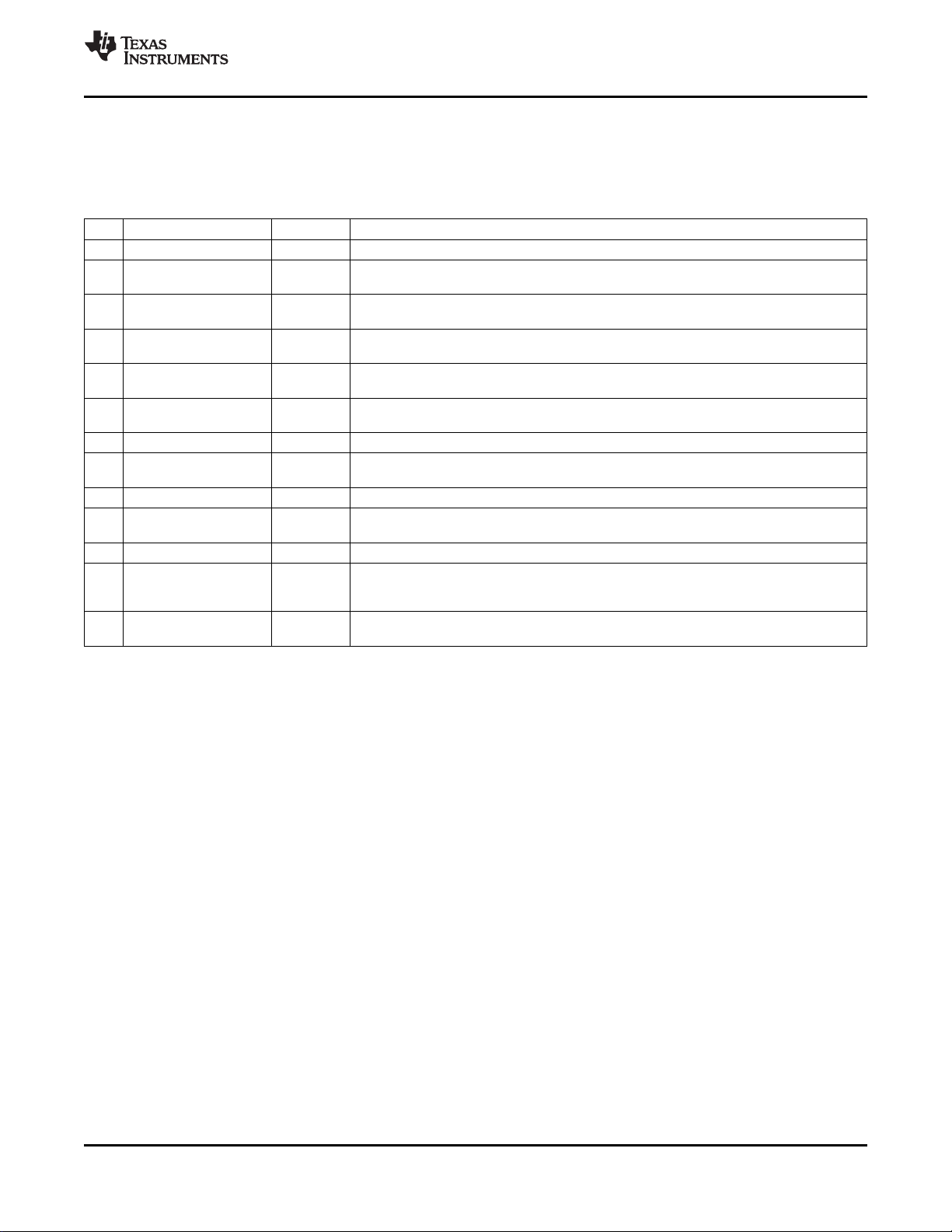

Magnetics

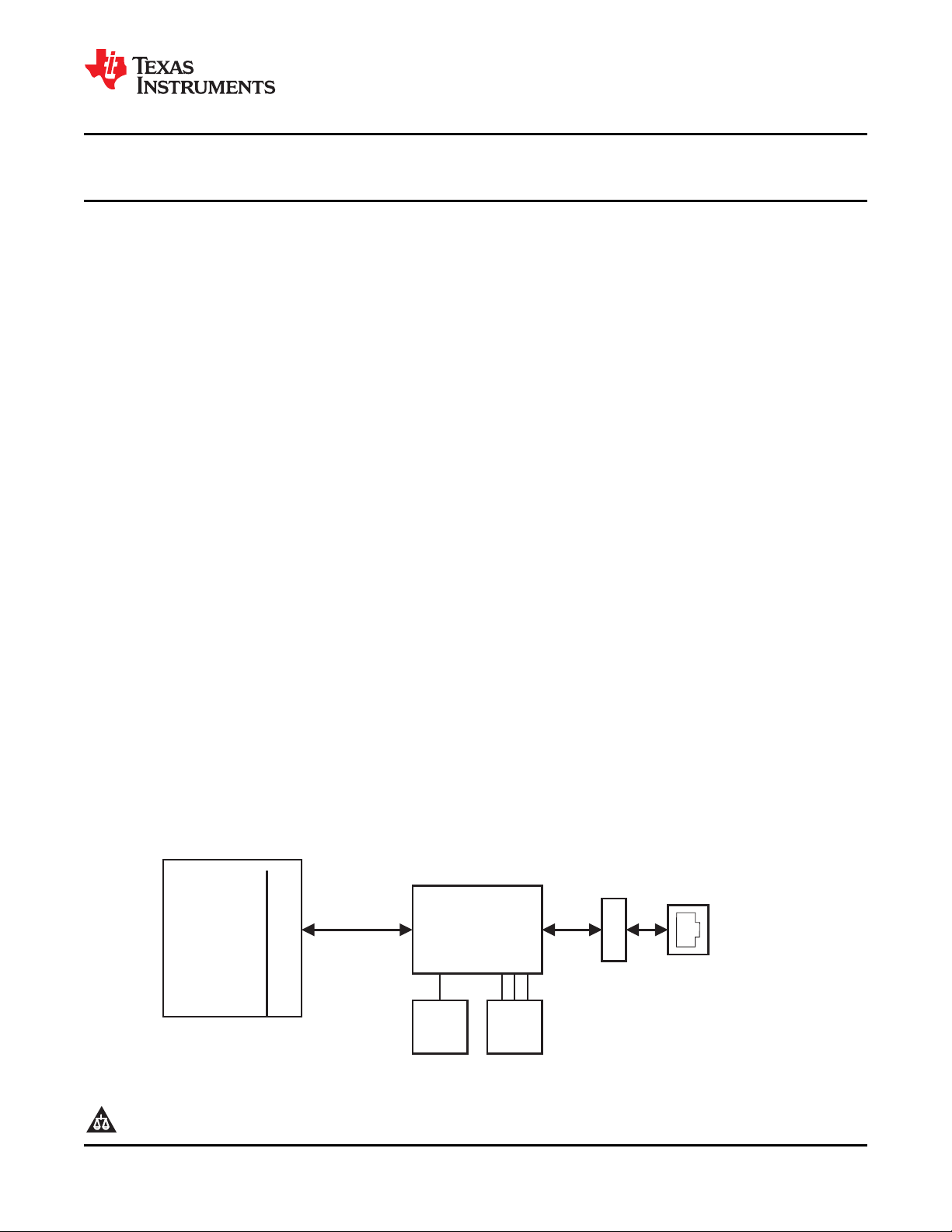

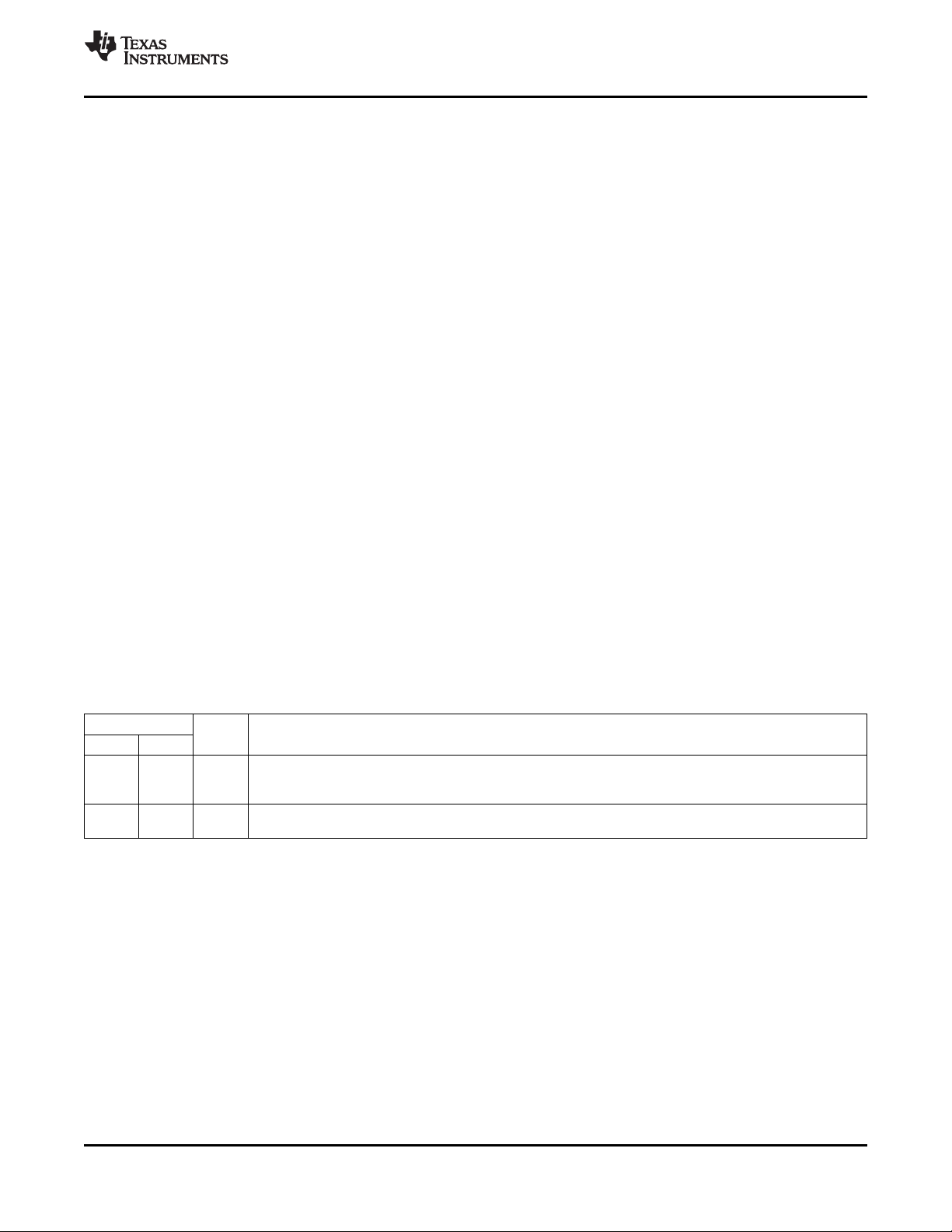

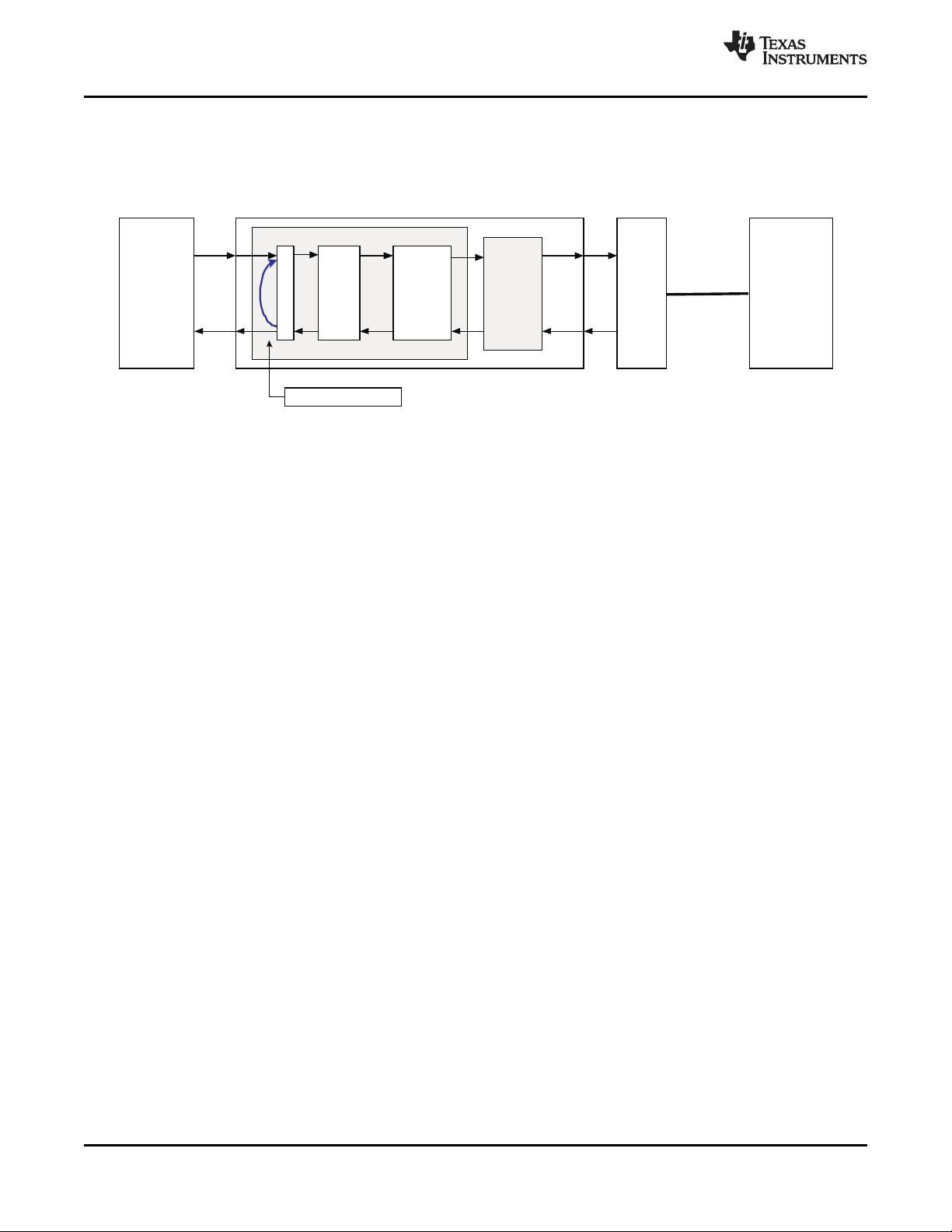

MPU/CPU

Media AccessController

MII

10/100Mb/s

TLK100

25-MHz

Clock

Source

Status

LEDs

RJ-45

10BASE-T

or

100BASE-TX

B0312-01

TLK100

www.ti.com

SLLS931–AUGUST 2009

Industrial Temp, Single Port 10/100 Mb/s Ethernet Physical Layer Transceiver

Check for Samples: TLK100

1 Introduction

1.1 Features

1

• Temperature From –40°C to 85°C

• Low Power Consumption, < 200mW Typical

• Cable Diagnostics

• Error-free Operation up to 200 meters under

typical conditions • Integrated ANSI X3.263 Compliant TP-PMD

• 3.3V MAC Interface

• Auto-MDIX for 10/100 Mb/s

• Energy Detection Mode

• 25 MHz Clock Out

• MII Serial Management Interface (MDC and

MDIO)

• IEEE 802.3u MII

• IEEE 802.3u Auto-Negotiation and Parallel

Detection

• IEEE 802.3u ENDEC, 10BASE-T

Transceivers and Filters

• Bus I/O Protection - ±16kV JEDEC HBM

• IEEE 802.3u PCS, 100BASE-TX Transceivers

• IEEE 1149.1 JTAG

Physical Sublayer with Adaptive Equalization

and Baseline Wander Compensation

• Programmable LED Support Link, 10/100 Mb/s

Mode, Activity, and Collision Detect

• 10/100 Mb/s Packet BIST (Built in Self Test)

• 48-pin TQFP Package (7mm) × (7mm)

1.2 Applications

• Industrial Controls and Factory Automation

• General Embedded Applications

1.3 General Description

The TLK100 is a single-port Ethernet PHY for 10BaseT and 100Base TX signaling. It integrates all the

physical-layer functions needed to transmit and receive data on standard twisted-pair cables. This device

supports the standard Media Independent Interface (MII) for direct connection to a Media Access

Controller (MAC).

The TLK100 is designed for power-supply flexibility, and can operate with a single 3.3V power supply or

with combinations of 3.3V, 1.8V, and 1.1V power supplies for reduced power operation.

The TLK100 uses mixed-signal processing to perform equalization, data recovery, and error correction to

achieve robust operation over CAT 5 twisted-pair wiring. It not only meets the requirements of IEEE 802.3,

but maintains high margins in terms of cross-talk and alien noise.

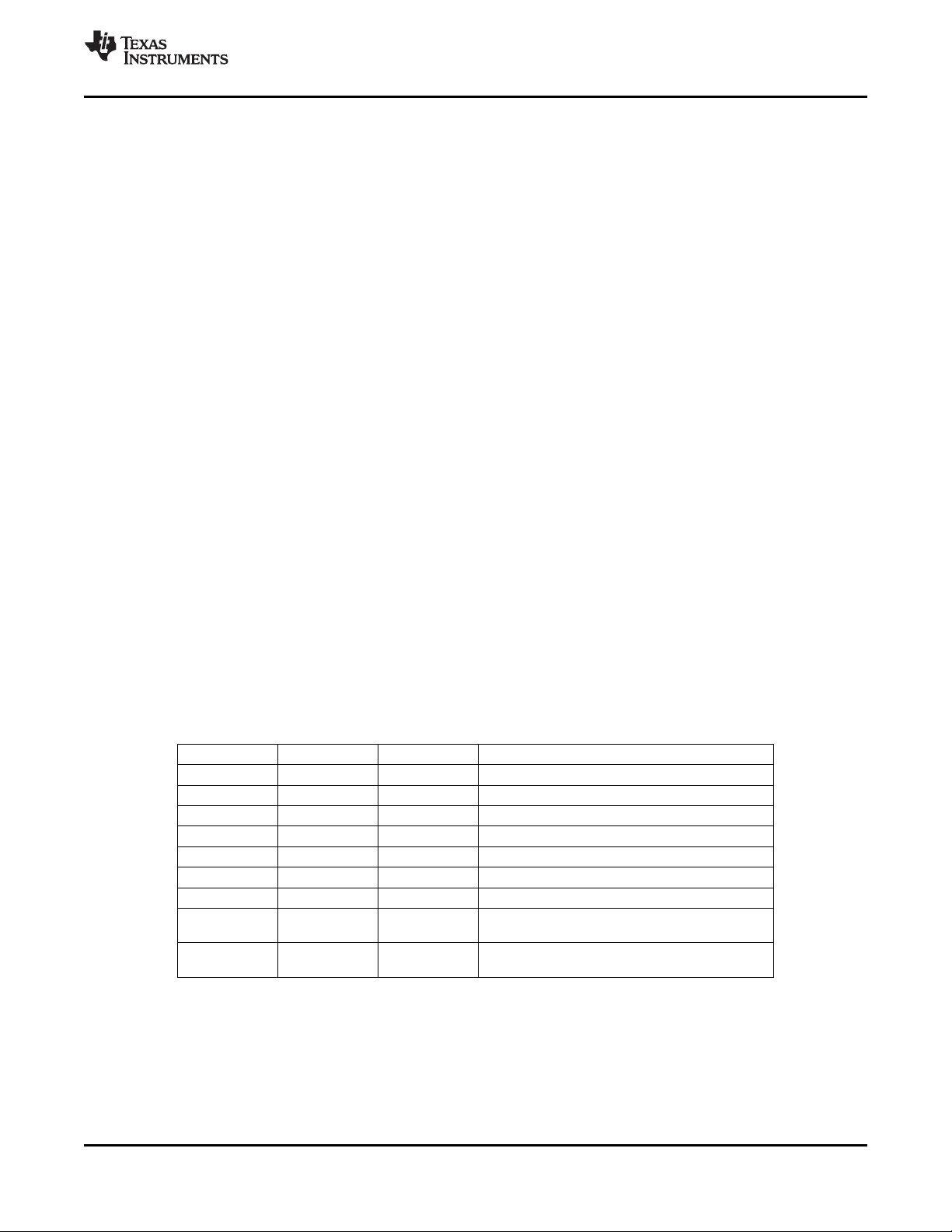

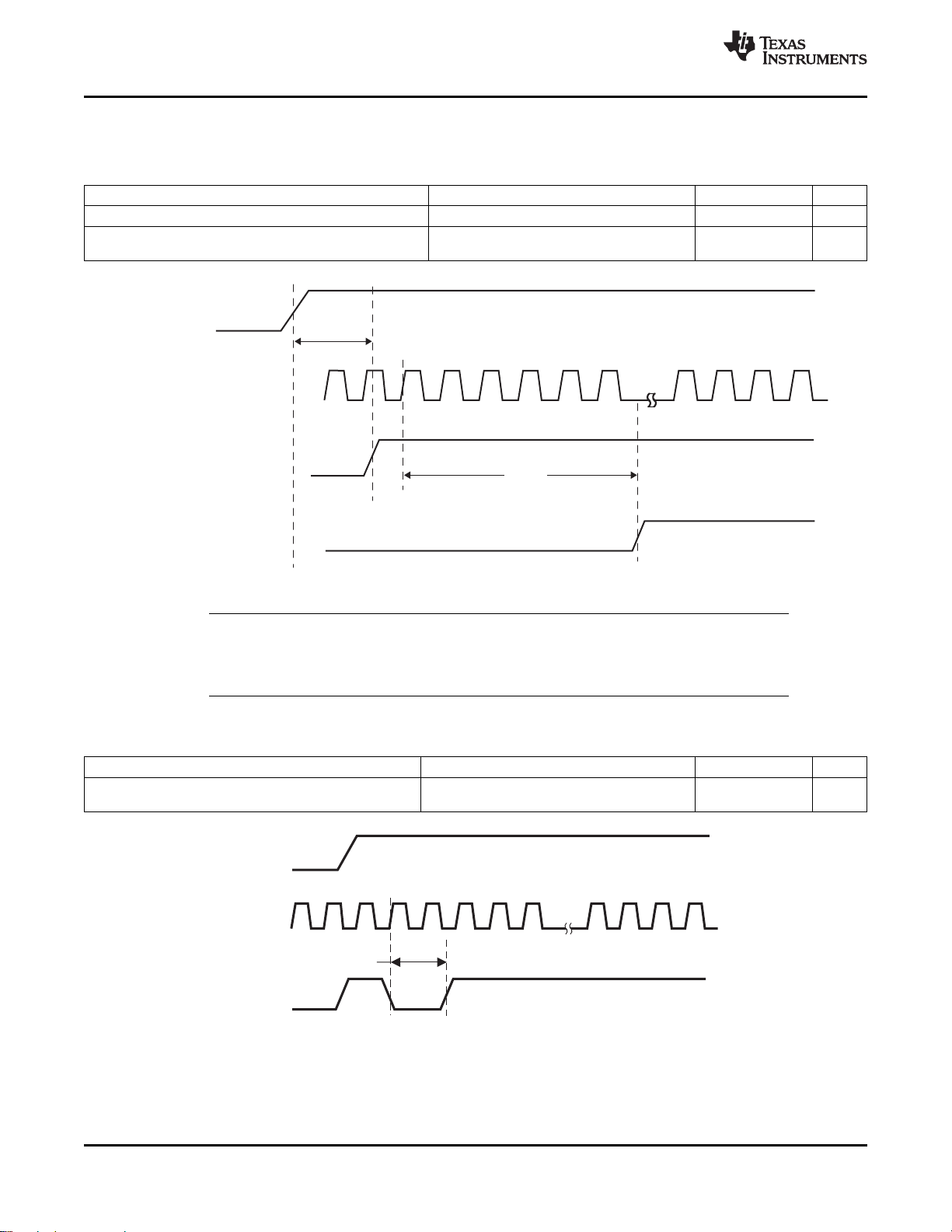

1.4 System Diagram

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testingof all parameters.

Copyright © 2009, Texas Instruments Incorporated

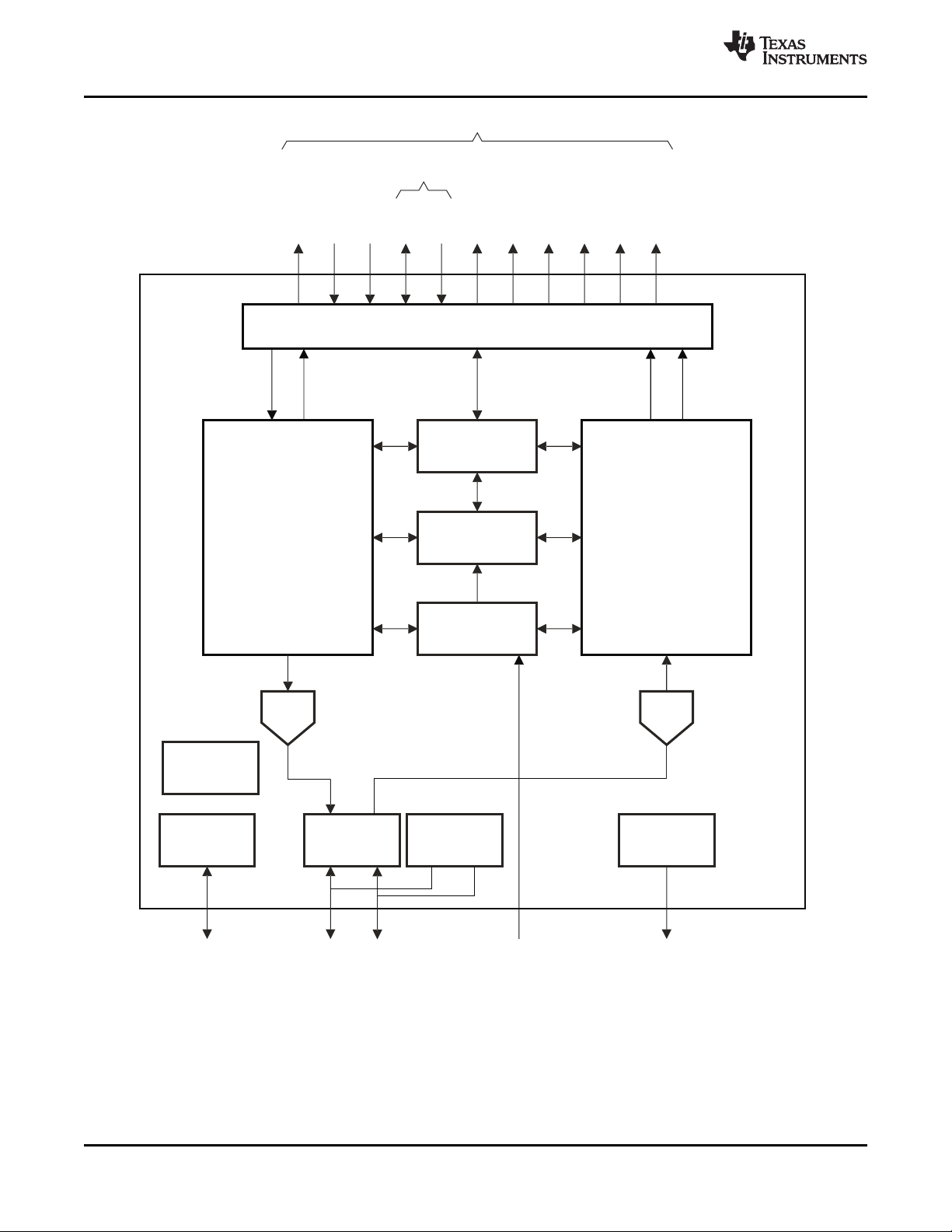

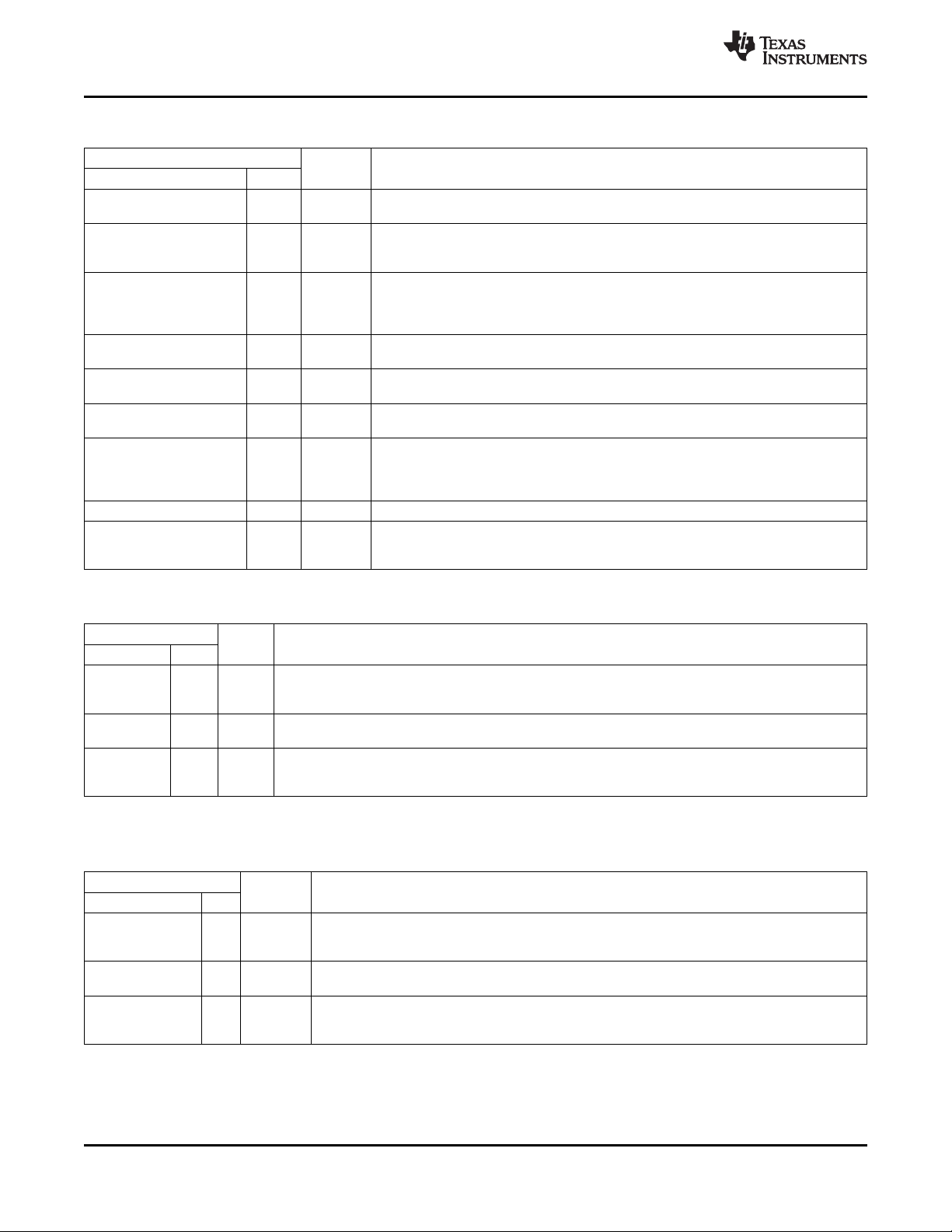

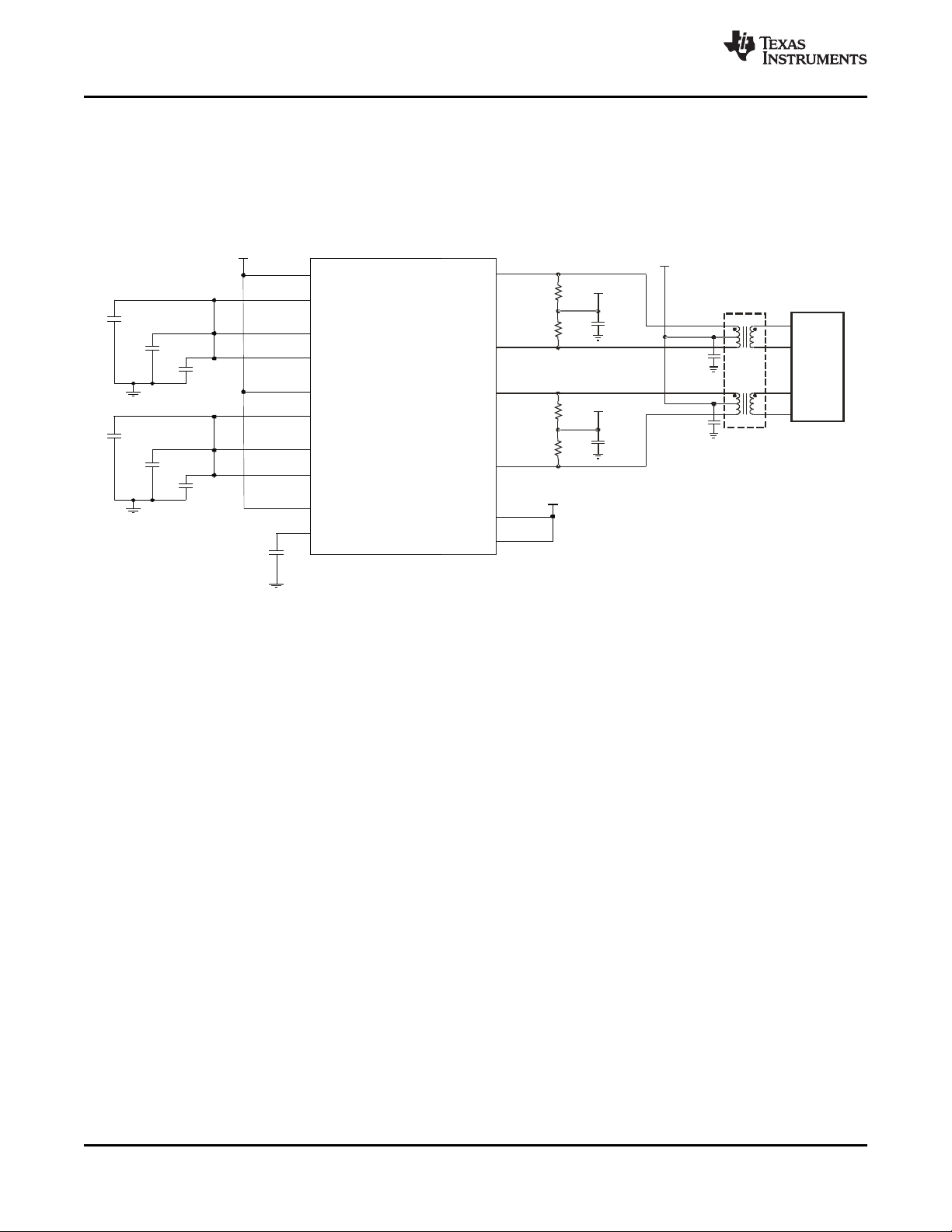

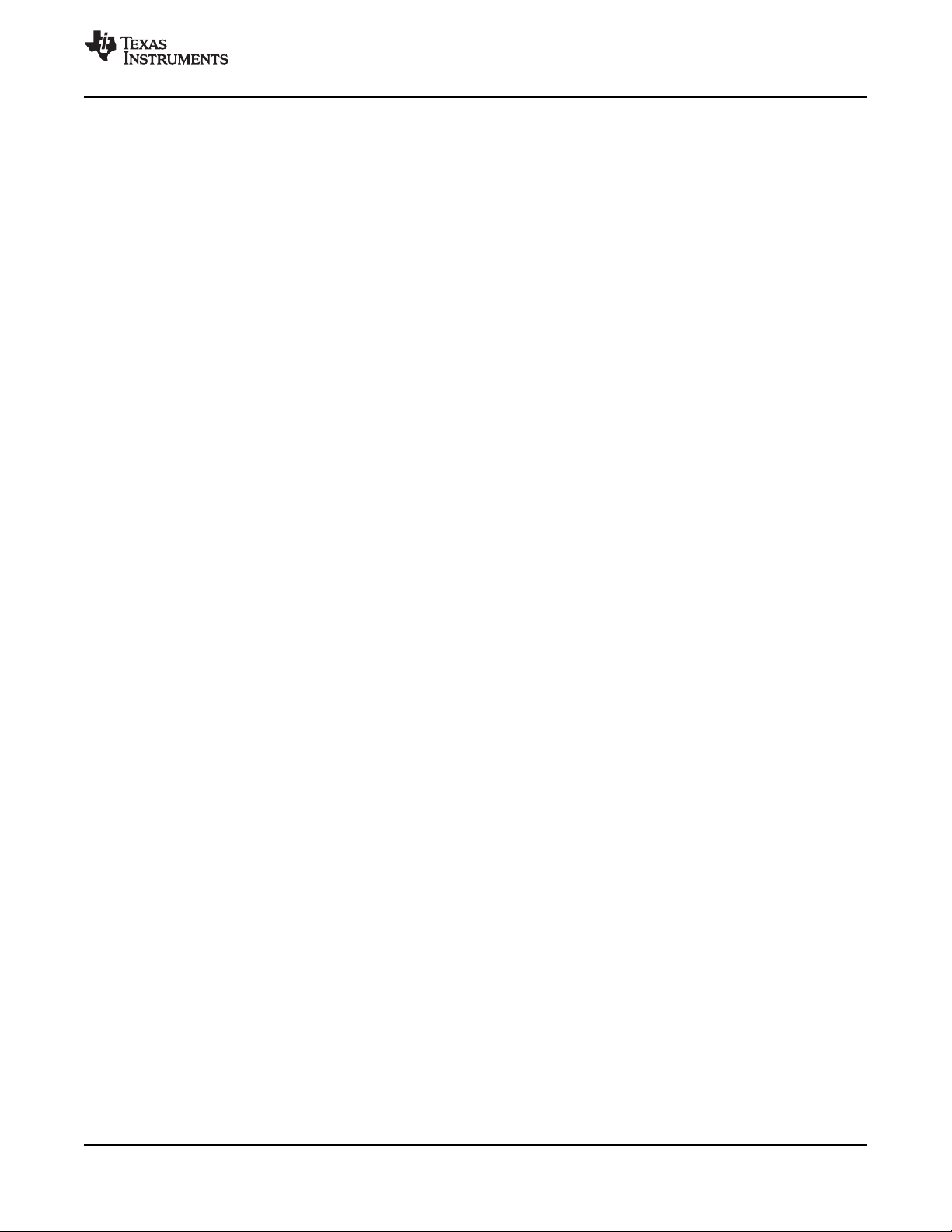

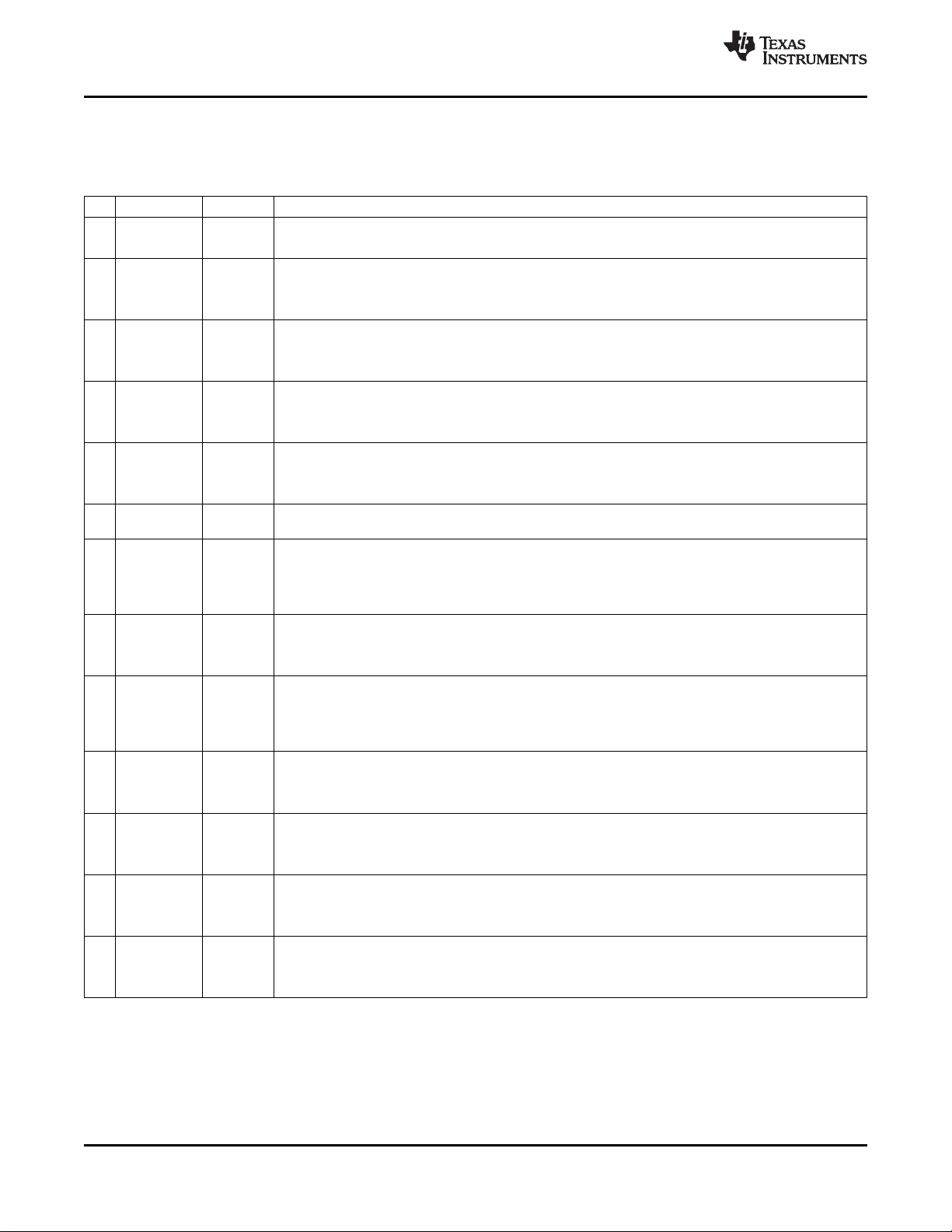

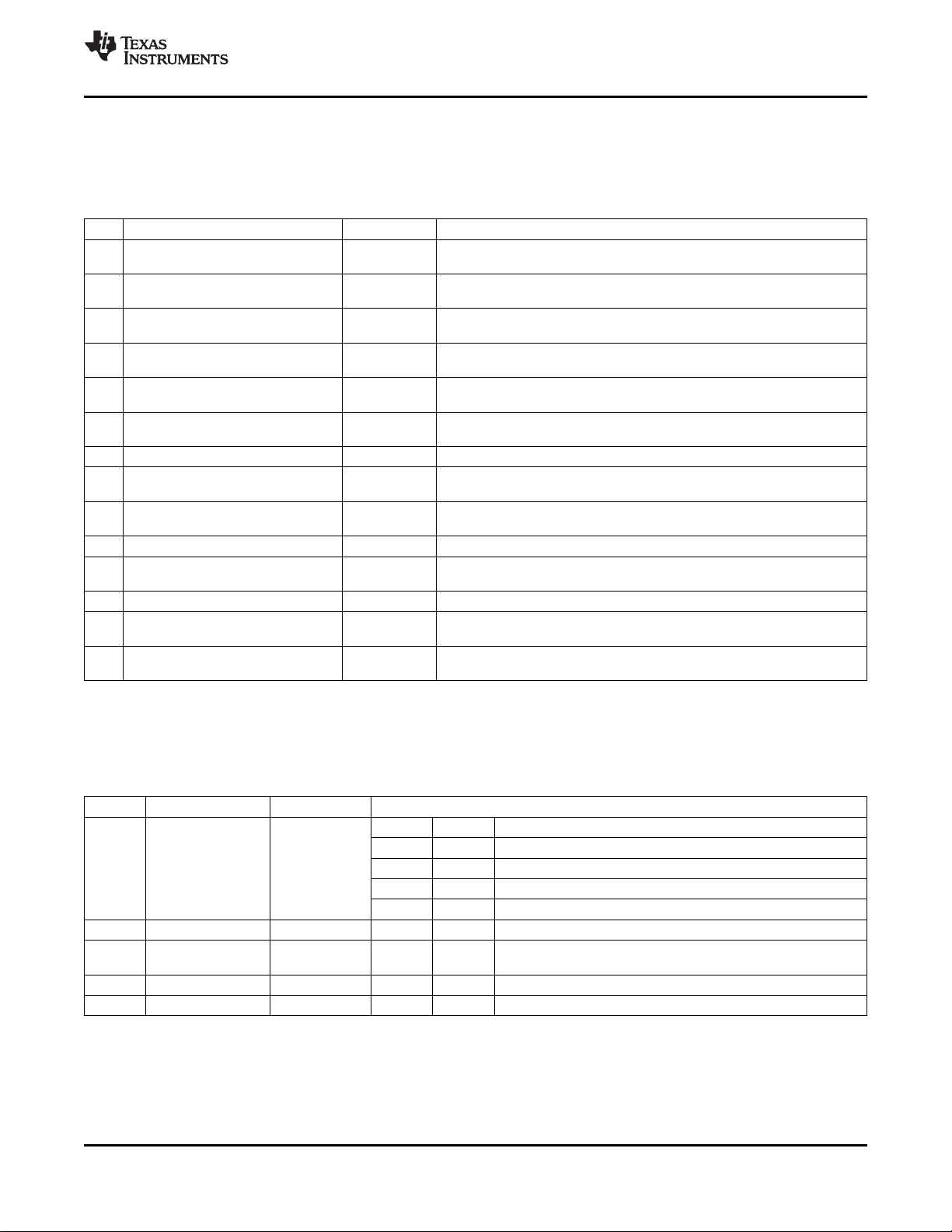

TX_CLK

TXD[3:0]

TX_EN

MDIO

MDC

COL

CRS/CRS_DV

RX_ER

RX_DV

RXD[3:0]

RX_CLK

TX_DATA RX_CLK

Reference Clock

TD± RD± LEDs

MII Interface

Auto-MDIX

DAC ADC

JTAG

MII

Serial

Management

TX_CLK RX_DATA

10BASE-T

and

100BASE-TX

10BASE-T

and

100BASE-TX

Transmit

Block

Receive

Block

MII

Registers

Auto-Negotiation

StateMachine

Clock

Generation

Boundary

Scan

LED

Drivers

B0313-01

Cable

Diagnostics

BIST

TLK100

SLLS931–AUGUST 2009

www.ti.com

Figure 1-1. TLK100 Functional Block Diagram

2 Introduction Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

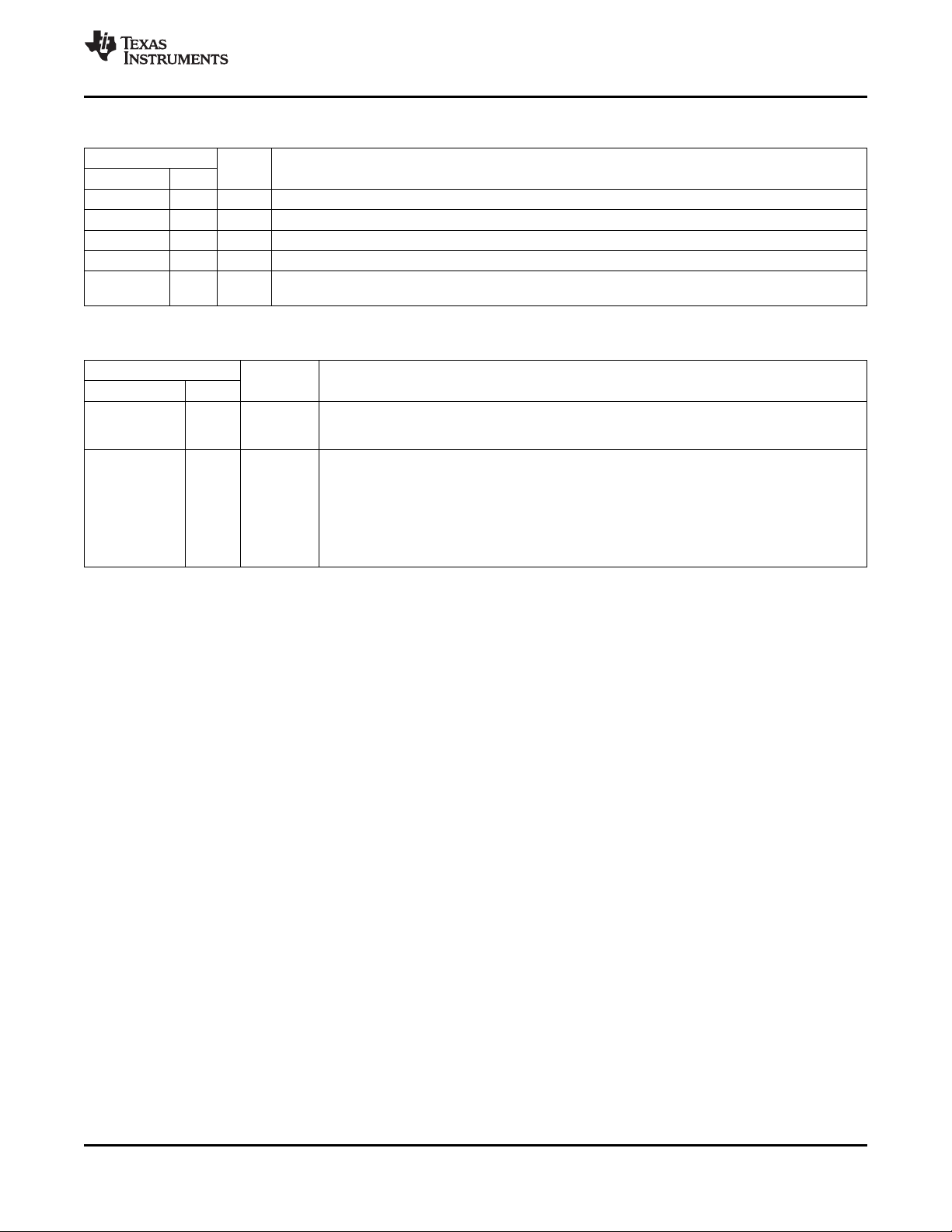

VSS

4

8

4

7

4

6

4

5

4

4

4

3

4

2

4

1

4

0

3

9

3

8

3

7

1

2

1

1

109

8

7

6

5

4

3

2

1

1

3

1

4

1

5

1

6

1

7

1

8

1

9

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

3

0

3

1

3

2

3

3

3

4

3

5

3

6

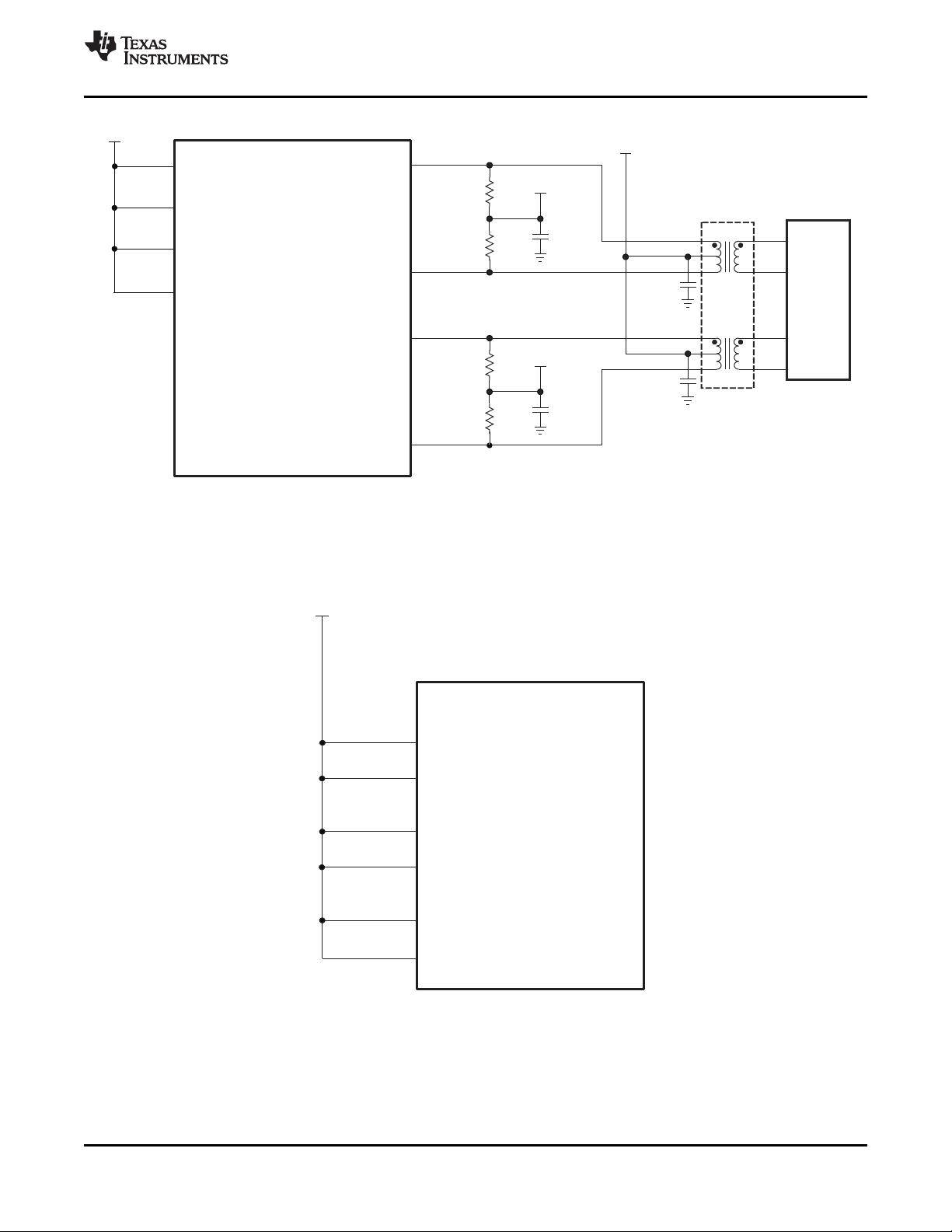

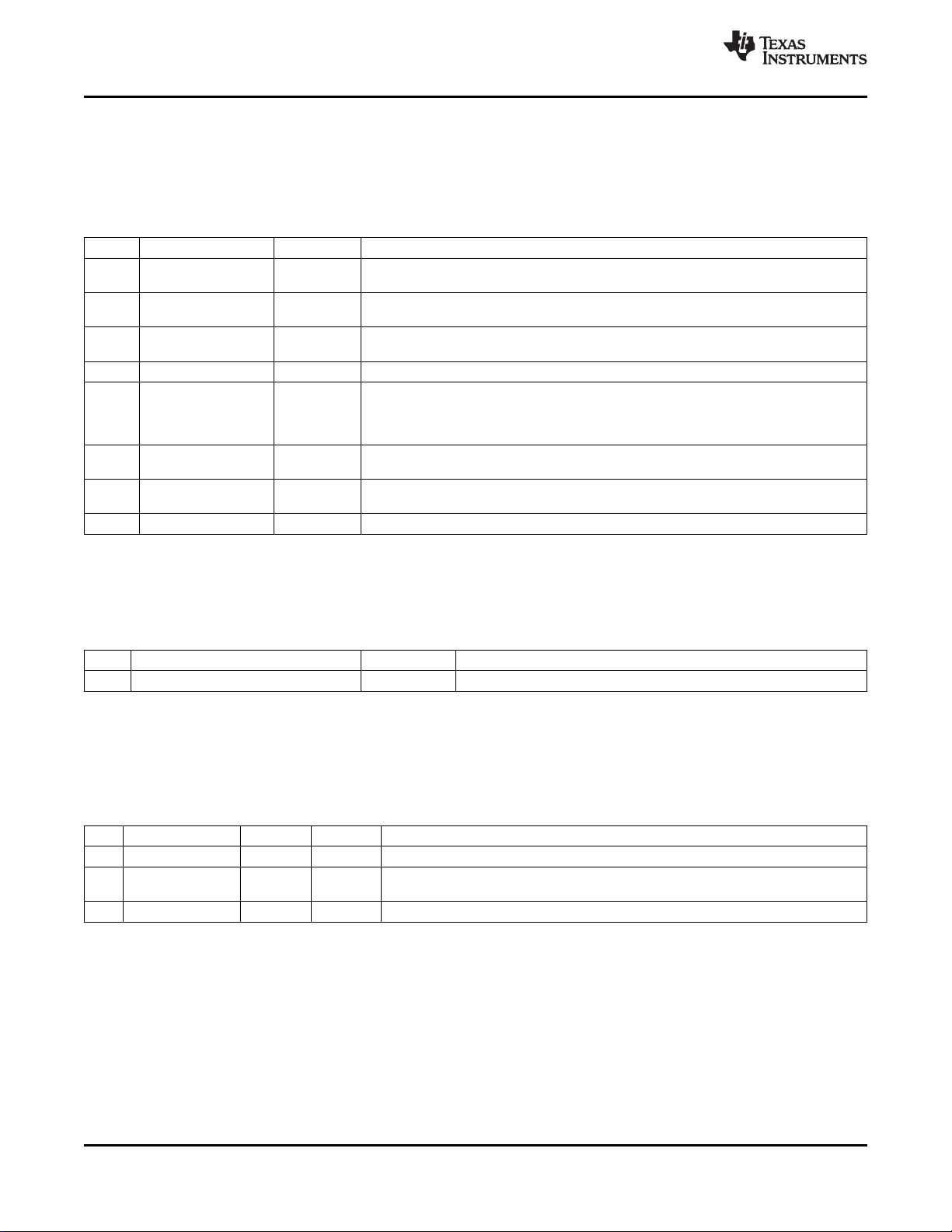

TLK100

RBIAS

CLK25OUT

MII_TXD_0

MII_TXD_1

MII_TXD_2

MII_TXD_3

MII_RX_CLK

MII_CRS / LED_CFG

MII_TX_EN

MII_TX_CLK

MII_COL / PHYAD0

MII_RX_DV

MII_RXD_0 / PHYAD1

MII_RXD_1 / PHYAD2

MII_RXD_2 / PHYAD3

MII_RXD_3 / PHYAD4

MDC

MDIO

LED_ACT / AN_EN

LED_SPEED/ AN_1

LED_LINK / AN_0

PWRDNN/INT

RESETN

JTAG_TCK

JTAG_TDI

JTAG_TMS

JTAG_TDO

JTAG_TRSTN

XO

MII_RX_ERR / MDIX_EN

TD-

TD+

RD-

RD+

VA11_PFBOUT

V18_PFBOUT

VA11_PFBIN1

VA11_PFBIN2

V18_PFBIN1

V18_PFBIN2

VDD33_ VA11

VDD11

VDD33_IO

VDD33_IO

VDD33_V18

VDD33_VD11

XI

TLK100

www.ti.com

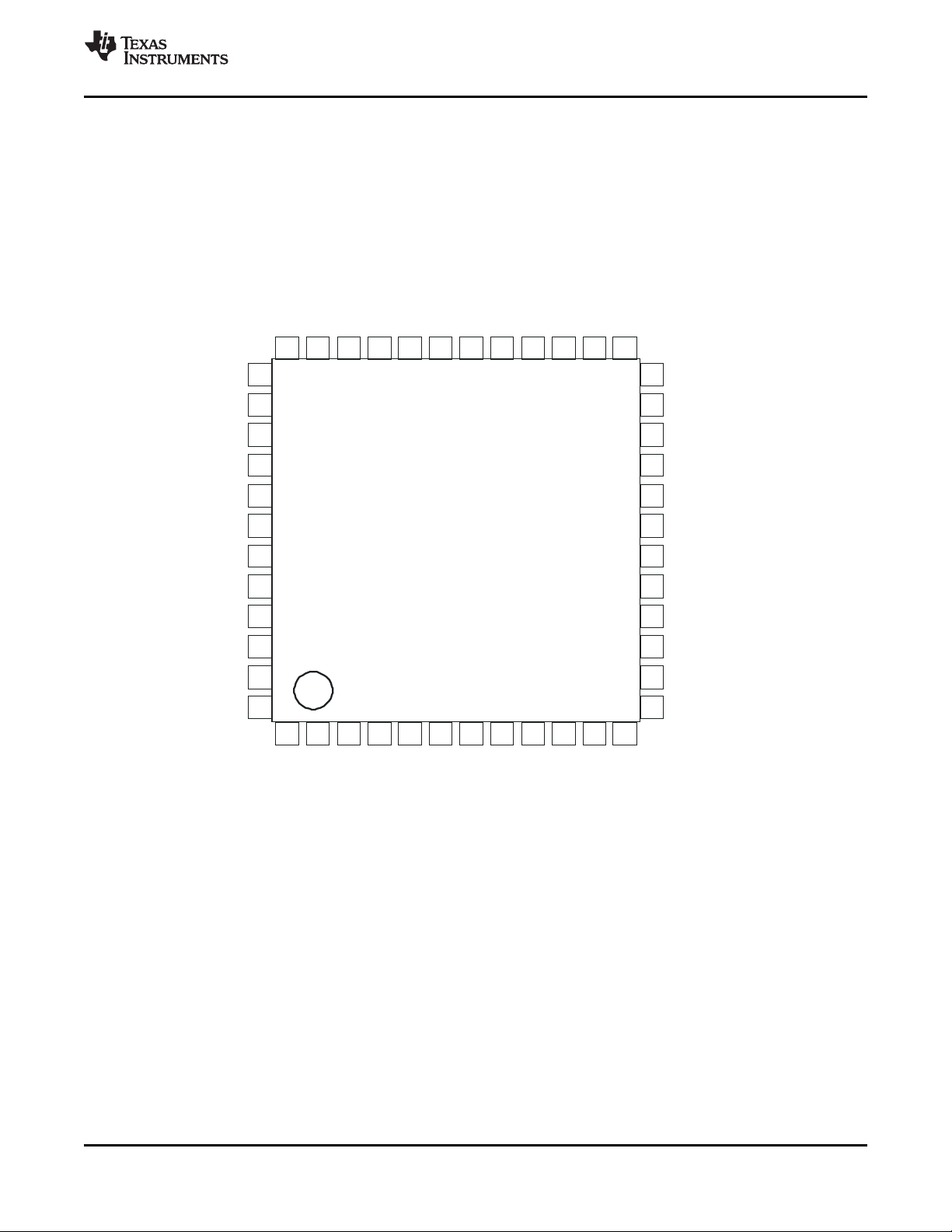

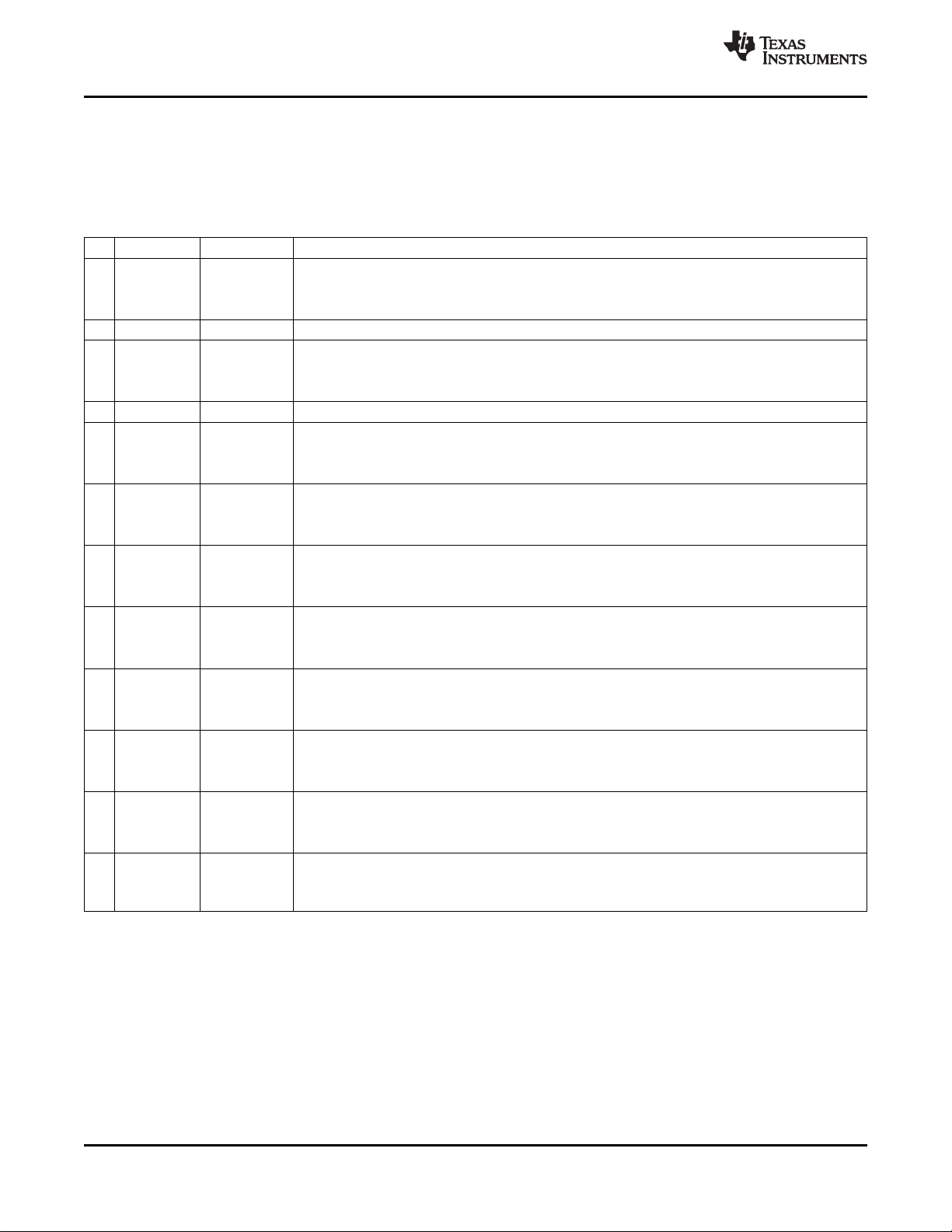

1.5 Pin Layout

SLLS931–AUGUST 2009

Figure 1-2. TLK100 PIN DIAGRAM, TOP VIEW

Copyright © 2009, Texas Instruments Incorporated Introduction 3

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

SLLS931–AUGUST 2009

www.ti.com

Contents

1 Introduction .............................................. 1 3.7 Cable Diagnostics .................................. 19

1.1 Features .............................................. 1

1.2 Applications .......................................... 1

1.3 General Description .................................. 1

1.4 System Diagram ..................................... 1

1.5 Pin Layout ............................................ 3

2 Pin Descriptions ......................................... 5

2.1 Serial Management Interface ........................ 5

2.2 MAC Data Interface .................................. 6

2.3 Clock Interface ....................................... 6

2.4 LED Interface ........................................ 6

2.5 JTAG Interface ....................................... 7

2.6 Reset and Power Down .............................. 7

2.7 Jumper Options ...................................... 8

2.8 10 Mb/s and 100 Mb/s PMD Interface ............... 9

2.9 Power and Bias Connections ........................ 9

2.10 Power Supply Configuration ........................ 10

3 Configuration ........................................... 13

3.1 Auto-Negotiation .................................... 13

3.2 Auto-MDIX .......................................... 14

3.3 PHY Address ....................................... 15

3.4 LED Interface ....................................... 16

3.5 Loopback Functionality ............................. 17

3.6 BIST ................................................ 18

4 Reset and Power Down Operation ................. 21

4.1 Hardware Reset .................................... 21

4.2 Software Reset ..................................... 21

4.3 Power Down/Interrupt .............................. 21

4.4 Power Down Modes ................................ 22

5 Design Guidelines ..................................... 23

5.1 TPI Network Circuit ................................. 23

5.2 Clock In (XI) Requirements ......................... 23

5.3 Thermal Vias Recommendation .................... 25

6 Register Block ......................................... 26

6.1 Register Definition .................................. 30

6.2 Register Control Register (REGCR) ................ 39

6.3 Address or Data Register (ADDAR) ................ 39

6.4 Extended Registers ................................. 40

6.5 Cable Diagnostic Registers ......................... 47

7 Electrical Specifications ............................. 56

7.1 ABSOLUTE MAXIMUM RATINGS ................. 56

7.2 THERMAL CHARACTERISTICS ................... 56

7.3 RECOMMENDED OPERATING CONDITIONS .... 56

7.4 DC CHARACTERISTICS ........................... 57

7.5 POWER SUPPLY CHARACTERISTICS ........... 57

7.6 AC Specifications ................................... 58

8 Appendix A: Digital Spectrum Analyzer (DSA)

Output .................................................... 70

4 Introduction Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

www.ti.com

2 Pin Descriptions

The TLK100 pins are classified into the following interface categories (each interface is described in the

sections that follow):

• Serial Management Interface

• MAC Data Interface

• Clock Interface

• LED Interface

• JTAG Interface

• Reset and Power Down

• Configuration (Jumper) Options

• 10/100 Mb/s PMD Interface

• Special Connect Pins

• Power and Ground pins

Note: Configuration pin option. See Section 2.7 for Jumper Definitions.

The definitions below define the functionality of each pin.

Type: I Input

Type: O Output

Type: I/O Input/Output

Type: OD Open Drain

Type: PD, PU Internal Pulldown/Pullup

Type: S Configuration Pin (All configuration pins have weak internal pullups or pulldowns. If

SLLS931–AUGUST 2009

a different default value is needed, then use an external 2.2kΩ resistor. See

Section 2.7 for details.)

2.1 Serial Management Interface

PIN

NAME NO.

MDC 32 I maximum MDC rate is 25 MHz; there is no minimum MDC rate. MDC is not required to be synchronous to the

MDIO 33 I/O

TYPE DESCRIPTION

MANAGEMENT DATA CLOCK: Clock signal for the management data input/output (MDIO) interface. The

MII_TX_CLK or the MII_RX_CLK.

MANAGEMENT DATA I/O: Bidirectional command / data signal synchronized to MDC. Either the local

controller or the TLK100 may drive the MDIO signal. This pin requires a pull-up resistor with value 1.5 kΩ.

Copyright © 2009, Texas Instruments Incorporated Pin Descriptions 5

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

SLLS931–AUGUST 2009

www.ti.com

2.2 MAC Data Interface

PIN

NAME NO.

MII_TX_CLK 19 O, PD

MII_TX_EN 18 I, PD MII_TX_CLK . It indicates the presence of valid data inputs on MII_TXD[3:0]. It is an

MII_TXD_0 13

MII_TXD_1 14 MII TRANSMIT DATA: The transmit data nibble received from the MAC that is

MII_TXD_2 15 synchronous to the rising edge of the MII_TX_CLK.

MII_TXD_3 16

MII_RX_CLK 23 O

MII_RX_DV 30 S, O, PD

MII_RX_ERR/MDIX_EN 31 S, O, PU

MII_RXD_0/PHYAD1 25

MII_RXD_1/PHYAD2 26

MII_RXD_2/PHYAD3 27

MII_RXD_3/PHYAD4 28

MII_CRS/LED_CFG 22 S, O, PU MII CARRIER SENSE: This pin is asserted high when the receive medium is non-idle.

MII_COL/PHYAD0 24 S, O, PU 10BASE-T/100BASE-TX half-duplex modes, this pin is asserted HIGH only when both

TYPE DESCRIPTION

MII TRANSMIT CLOCK: : MII Transmit Clock provides 25MHz or 2.5MHz reference

clock depending on the speed.

MII TRANSMIT ENABLE: MII_TX_EN is presented on the rising edge of the

active high signal.

IS, I, PD

MII RECEIVE CLOCK: MII receive clock provides a 25MHz or 2.5MHz reference clock,

depending on the speed, that is derived from the received data stream.

MII RECEIVE DATA VALID: This pin indicates valid data is present on the

corresponding MII_RXD[3:0].

MII RECEIVE ERROR: This pin indicates that an error symbol has been detected within

a received packet.

MII RECEIVE DATA: Symbols received on the cable are decoded and presented on

S, O, PD these pins synchronous to MII_RX_CLK. They contain valid data when MII_RX_DV is

asserted.

MII COLLISION DETECT: In Full Duplex Mode this pin is always low. In

the transmit and receive media are non-idle.

2.3 Clock Interface

PIN

NAME NO.

XI 39 I oscillator input. The TLK100 supports either an external crystal resonator connected across pins XI and

XO 37 O

CLK25OUT 12 O allows other devices to use the reference clock from the TLK100 without requiring additional clock

TYPE DESCRIPTION

CRYSTAL/OSCILLATOR INPUT: Reference clock. 25MHz ±50 ppm tolerance crystal reference or

XO, or an external CMOS-level oscillator source connected to pin XI only.

CRYSTAL OUTPUT: Reference Clock output. XO pin is used for crystal only. This pin should be left

floating when an oscillator input is connected to XI.

25 MHz CLOCK OUTPUT: In MII mode, this pin provides a 25 MHz clock output to the system. This

sources.

2.4 LED Interface

(See Table 3-3 for LED Mode Selection)

PIN

NAME NO.

LED_LINK/AN_0 36 S, O, PU Mode 2 and Mode 3, this pin indicates transmit and receive activity in addition to the status of the

LED_SPEED/AN_1 35 S, O, PU

LED_ACT/AN_EN 34 S, O, PU present on either Transmit or Receive channel. In Mode 3, this LED output may be programmed to

TYPE DESCRIPTION

This pin indicates the status of the link in Mode 1. When the link is good the LED will be ON. In

Link. The LED is ON when Link is good. It will blink when the transmitter or receiver is active.

This pin indicates the speed of the link. It is ON when the link speed is 100 Mb/s and OFF when it

is 10 Mb/s.

In mode 1 this pin indicates if there is any activity on the link. It is ON (pulse) when activity is

indicate Full-duplex status.

6 Pin Descriptions Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

www.ti.com

SLLS931–AUGUST 2009

2.5 JTAG Interface

PIN

NAME NO.

JTAG_TCK 44 I, PU This pin is the test clock.This pin has a weak internal pullup.

JTAG_TDI 45 I, PU This pin is the test data input.This pin has a weak internal pullup.

JTAG_TDO 47 O This pin is the test data output.

JTAG_TMS 46 I, PU This pin selects the test mode. This pin has a weak internal pullup.

JTAG_TRST This pin is an active low asynchronous test reset. This pin has a weak internal pullup.

N

TYPE DESCRIPTION

48 I, PU

2.6 Reset and Power Down

PIN

NAME NO.

RESETN 43 I, PU TLK100. Asserting this pin low for at least 1 μs will force a reset process to occur. All jumper

PWRDNN/INT 42 I, OD, PU device is power down mode.

TYPE DESCRIPTION

This pin is an active Low reset input that initializes or re-initializes all the internal registers of the

options are reinitialized as well.

Register access is required for this pin to be configured either as power down or as an interrupt.

The default function of this pin is power down.

When this pin is configured for a power down function, an active low signal on this pin will put the

When this pin is configured as an interrupt pin then this pin is asserted low when an interrupt

condition occurs. The pin has an open-drain output with a weak internal pull-up. Some

applications may require an external pull-up resistor.

Copyright © 2009, Texas Instruments Incorporated Pin Descriptions 7

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

SLLS931–AUGUST 2009

2.7 Jumper Options

Jumper option is an elegant way to configure the TLK100 into specific modes of operation. Some of the

functional pins are used as jumper options. The logic states of these pins are sampled during reset and

are used to configure the device into specific modes of operation. Below table shows the pins used for the

jumper option and its description. The functional pin name is indicated in parentheses.

A 2.2 kΩ resistor should be used for pull-down or pull-up to change the default jumper option. If the default

option is required, then there is no need for external pull-up or pull down resistors. Since these pins may

have alternate functions after reset is deasserted, they should not be connected directly to VCC or GND.

PIN TYPE

NAME NO. DESCRIPTION

PHYAD0 (MII_COL) 24

PHYAD1 (MII_RXD_0) 25

PHYAD2 (MII_RXD_1) 26 S, O, PD

PHYAD3 (MII_RXD_2) 27

PHYAD4 (MII_RXD_3) 28

www.ti.com

The TLK100 provides five PHY address pins, the states of which are latched into an

internal register at system hardware reset. The TLK100 supports PHY Address jumpering

values 0 (<00000>) through 31 (<11111>). All PHYAD[4:0] pins have weak internal

pull-down resistors.

AN_EN: When high, this puts the part into advertised Auto-Negotiation mode with the

capability set by AN_0 and AN_1 pins. When low, this puts the part into Forced Mode with

the capability set by AN_0 and AN_1 pins.

AN_0 / AN_1: These input pins control the forced or advertised operating mode of the

TLK100 according to the following table. The value on these pins is set by connecting the

input pins to GND (0) or VCC (1) through 2.2 kΩ resistors. These pins should NEVER be

connected directly to GND or VCC.

The status of these pins are latched into the Basic Mode Control Register and the

Auto_Negotiation Advertisement Register during Hardware-Reset.

The default is 111 since these pins have internal pull-ups.

AN_EN (LED_ACT) 34

AN_1 (LED_SPEED) 35 S, O, PU

AN_0 (LED_LINK) 36

LED_CFG (MII_CRS) 22 S, O, PU the LED pins. Default is Mode 1. All modes are also configurable via register access. See

MDIX_EN (MII_RX_ERR) 31 S, O, PU

AN_EN AN_1 AN_0 Forced Mode

0 0 0 10BASE-T, Half-Duplex

0 0 1 10BASE-T, Full-Duplex

0 1 0 100BASE-TX, Half-Duplex

0 1 1 100BASE-TX, Full-Duplex

AN_EN AN_1 AN_0 Advertised Mode

1 0 0 10BASE-T, Half/Full-Duplex

1 0 1 10BASE-TX, Half/Full-Duplex

1 1 0

1 1 1

This jumpering option along with LEDCR register bit determines the mode of operation of

the table in the LED Interface Section.

This jumpering option sets the Auto-MDIX mode. By default it enables MDIX. An external

pull-down will disable Auto-MDIX mode.

10BASE-T, Half-Duplex

100BASE-TX, Half-Duplex

10BASE-T, Half/Full-Duplex

100BASE-TX, Half/Full-Duplex

8 Pin Descriptions Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

www.ti.com

SLLS931–AUGUST 2009

2.8 10 Mb/s and 100 Mb/s PMD Interface

PIN

NAME NO.

TD–, TD+ 8, 9 I/O

RD–, RD+ 5, 6 I/O

TYPE DESCRIPTION

Differential common driver transmit output (PMD Output Pair). These differential outputs are automatically

configured to either 10BASE-T or 100BASE-TX signaling.

In Auto-MDIX mode of operation, this pair can be used as the Receive Input pair. These pins require 1.8V

or 3.3V bias for operation.

Differential receive input (PMD Input Pair). These differential inputs are automatically configured to accept

either 100BASE-TX or 10BASE-T signaling.

In Auto-MDIX mode of operation, this pair can be used as the Transmit Output pair. These pins require

1.8V or 3.3V bias for operation.

2.9 Power and Bias Connections

PIN

NAME NO.

RBIAS 3 I Bias Resistor Connection. Use a 4.99kΩ 1% resistor connected from RBIAS to GND.

V18_PFBOUT 40 O

VA11_PFBOUT 10 O

V18_PFBIN1 2

V18_PFBIN2 4

VA11_PFBIN1 1

VA11_PFBIN2 7

VDD11 20 O 1.1V Core Power Output. A capacitor of 1μF (Ceramic preferred) , should be placed close to the VDD11

VDD33_IO P I/O 3.3V Supply

VDD33_VA11 11 P This pin should be connected to 3.3V or 2.5V external supply, in single supply operation.

VDD33_V18 41 P In single supply operation, this pin should be connected to a 3.3V or 2.5V external supply. In multiple

VDD33_VD11 21 P This pin should be connected to 3.3V or 2.5V external supply, in single supply operation.

VSS 38 P Ground pin for Oscillator

GNDPAD 49 P Ground Pad

TYPE DESCRIPTION

1.8V Power Feedback Output. A 1μF capacitor (ceramic preferred), should be placed close to the

V18_PFBOUT.

In single supply operation, connect this pin should be connected to V18_PFBIN1 and V18_PFBIN2 (pin

2 and pin 4). See Figure 2-1 for proper placement pin.

In multiple supply operation, when supplying 1.8V from external supply, this pin should be connected

together with VDD33_V18 (pin 41), V18_PFBIN1 and V18_PFBIN2 (pin 2 and pin 4) to the 1.8V external

supply source. See Figure 2-2 for proper placement pin.

1.1V Analog Power Feedback Output. A 1 μF capacitor (Ceramic preferred), should be placed close to

the VA11_PFBOUT.

In single supply operation this pin should be connected to VA11_PFBIN1 and V11_PFBIN2 (pin 1 and

pin 7). See Figure 2-1 for proper placement pin.

In multiple supply operation, when supplying 1.1V from external supply, this pin should be connected

together with VDD33_VA11 (pin 11), V11_PFBIN1 and V11_PFBIN2 (pin 1 and pin 7) to 1.1V external

supply source. See Figure 2-3 for proper placement pin.

1.8V Power Feedback Input. These pins are fed with power from V18_PFBOUT (pin 40) in single supply

operation.

I

1.8V from external source in multiple supply operation. A small 1μF capacitor should be connected close

to each pin.

1.1V Analog Power Feedback Input. These pins are fed with power from: VA11_PFBOUT (pin 10) in

single supply operation.

I

1.1V from external source in multiple supply operation. A small capacitor of 0.1 μF should be connected

close to each pin.

17

29

External supply input to 1.1V analog regulator

In multiple supply operation this pin should be connected to external 1.1V supply source.

External supply input to 1.8V regulator

supply operation this pin should be connected to an external 1.8V supply source.

External supply input to 1.1V Core regulator

In multiple supply operation this pin should be connected to external 1.1V supply source.

Copyright © 2009, Texas Instruments Incorporated Pin Descriptions 9

Submit Documentation Feedback

Product Folder Link(s): TLK100

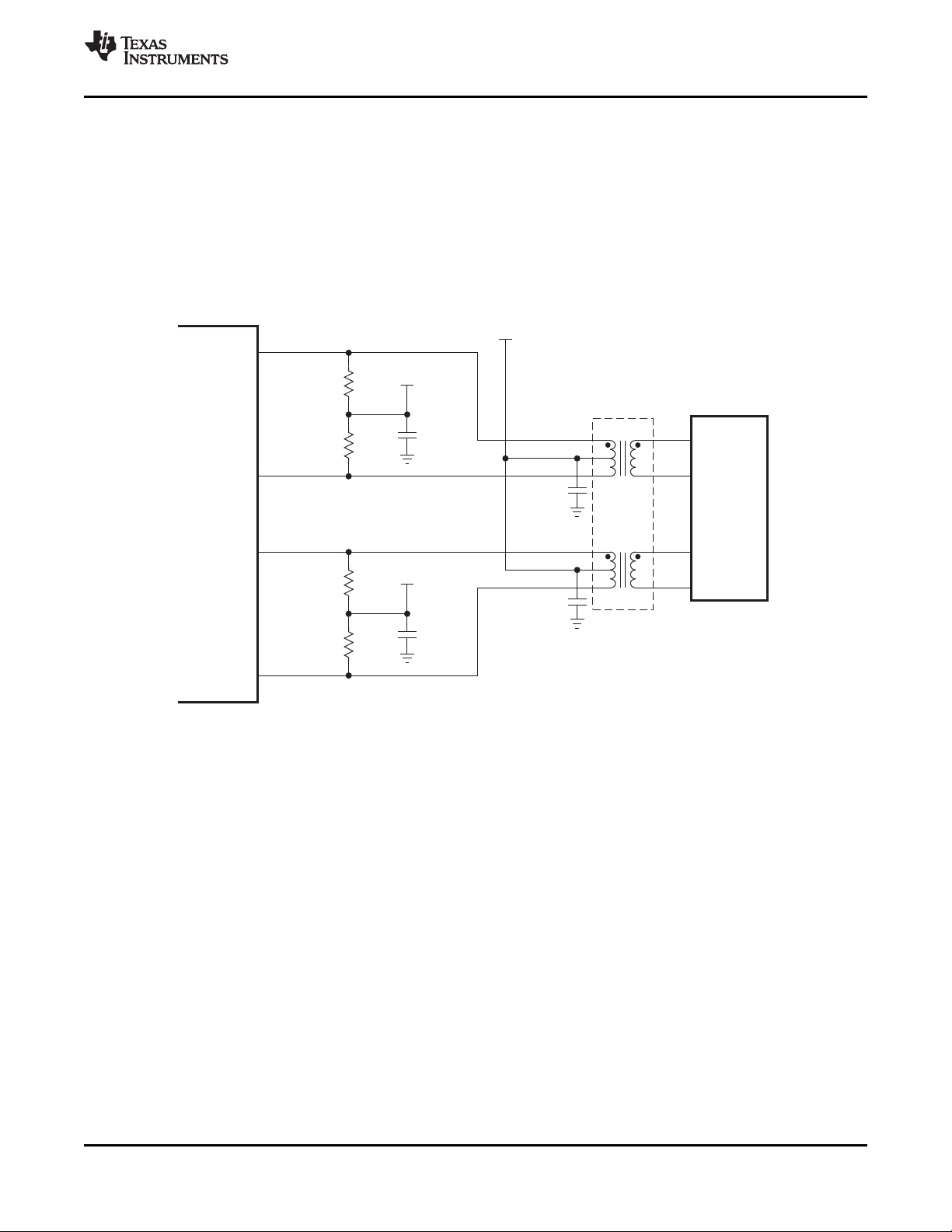

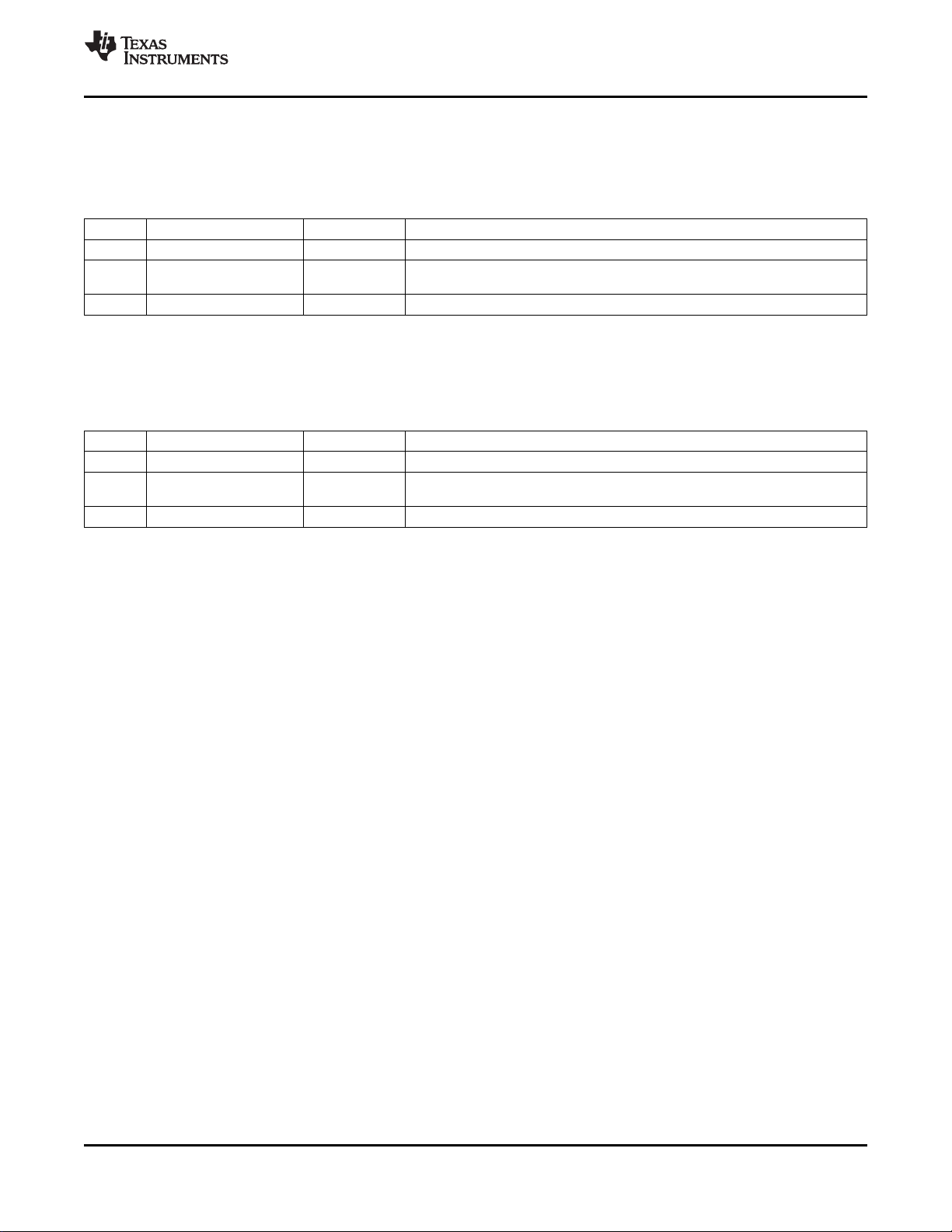

Vdd

Vdd

1 :1

1 :1

T1

RJ 45

3.3V

Supply

TLK100

11

VDD33_VA11

10

VA11_PFBOUT

1

VA11_PFBIN1

7

VA11_PFBIN2

21

VDD33_VD11

20

VDD11

.

17

VDD33_IO

29

VDD33_IO

5

RD–

RD–

6

RD+

RD+

49.9W

1.0 Fm

*

8

TD–

TD–

9

TD+

TD+

*

41

VDD33_V18

40

V18_PFBOUT

2

V18_PFBIN1

4

V18_PFBIN2

49.9W

49.9W

49.9W

0.1 Fm

0.1 Fm

0.1 Fm

0.1 Fm

0.1 Fm

0.1 Fm

0.1 Fm

3.3V

Supply

3.3V

Supply

0.1 Fm

1.0 Fm

1.0 Fm

TLK100

SLLS931–AUGUST 2009

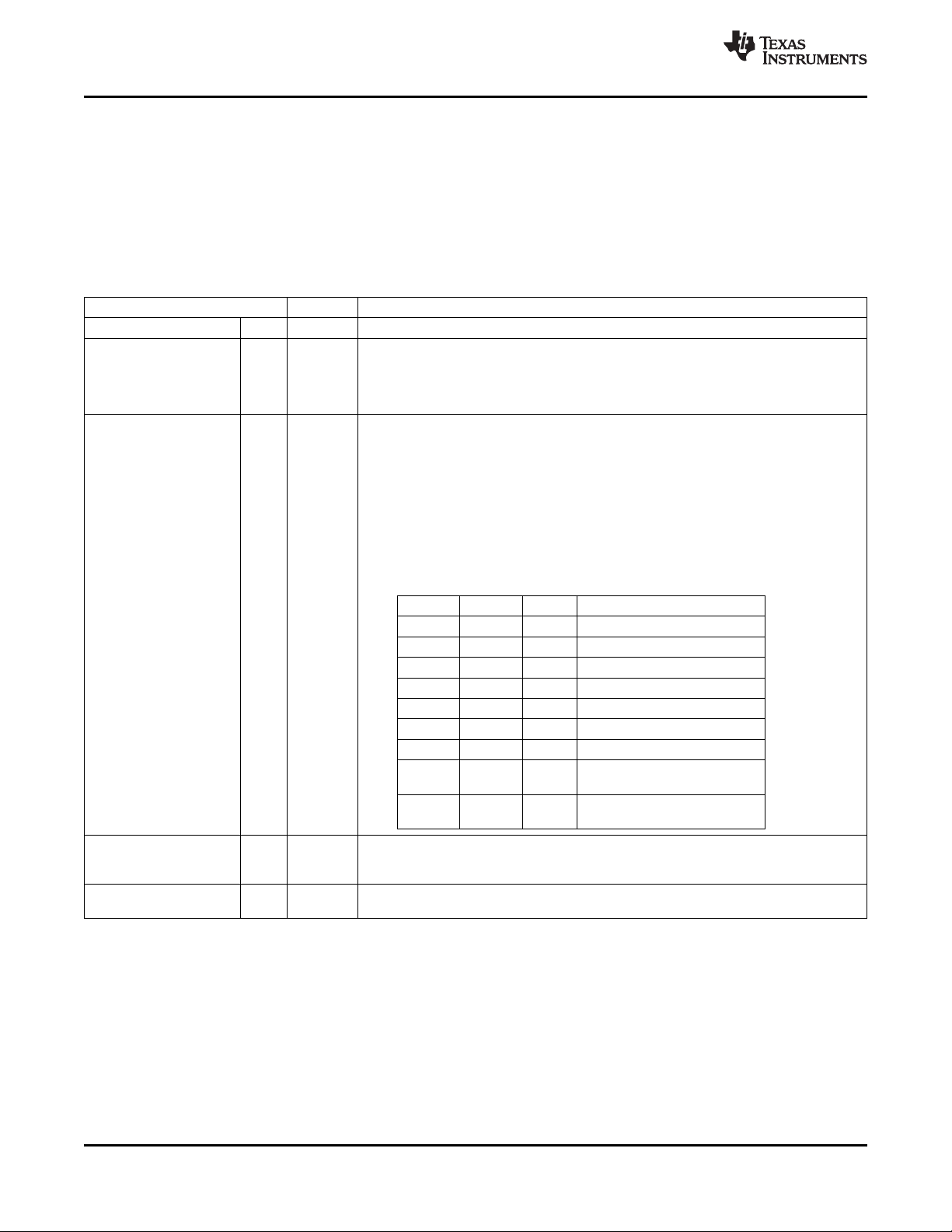

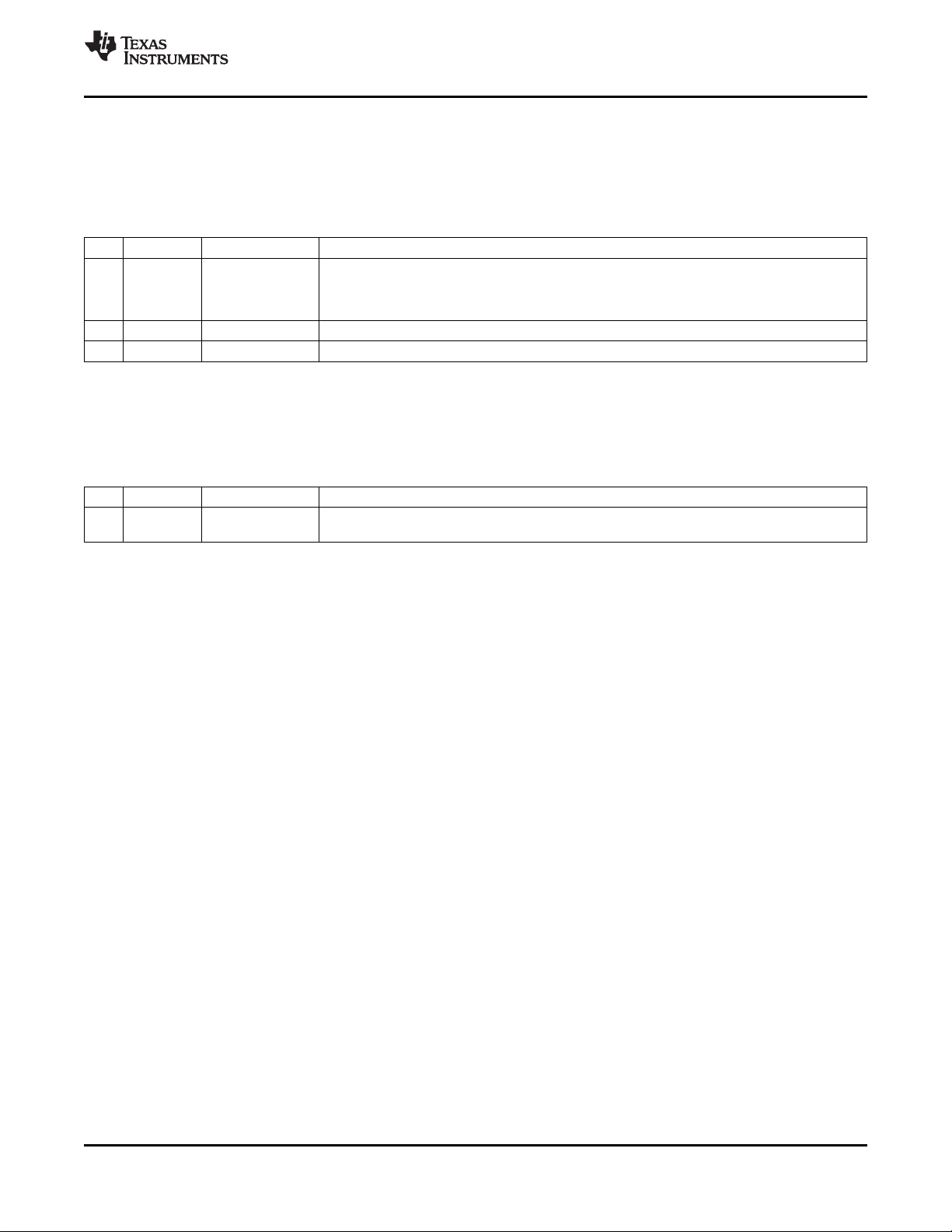

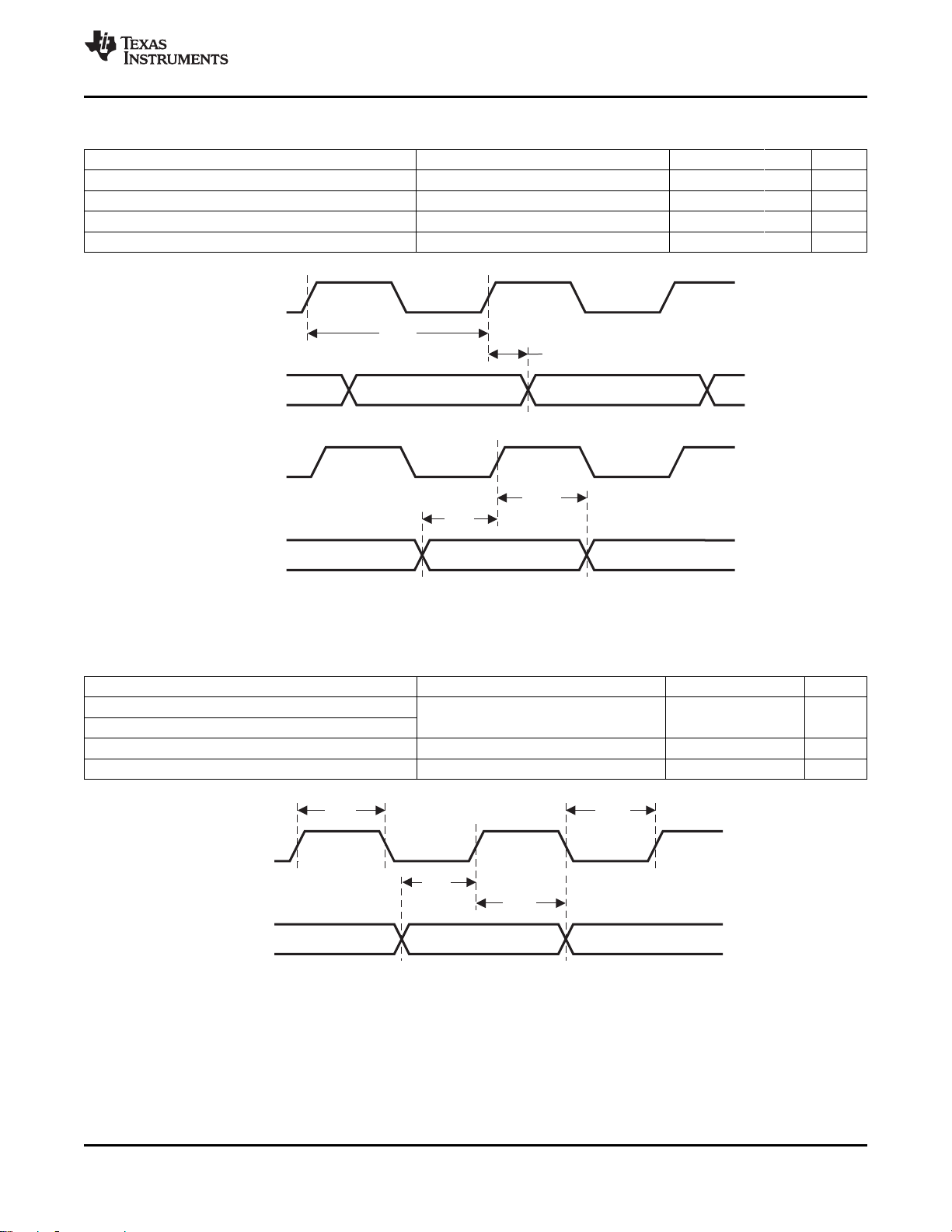

2.10 Power Supply Configuration

The TLK100 provides best-in-class flexibility of power supplies.

• Single supply operation – If a single 3.3V power supply is desired, the TLK100 will sense the presence

of the supply and configure the internal voltage regulators to provide all necessary supply voltages. To

operate in this mode, connect the TLK100 supply pins according to the following scheme:

www.ti.com

Figure 2-1. Power Scheme for Single Supply Operation

• Multiple Supply operation – When additional 1.8V and/or 1.1V external power rails are available, the

TLK100 can be configured in various ways as given in Table 2-1. This gives the highest flexibility for

the user and enables significant reduction in power consumption. When using multiple external

supplies, the internal regulators must be disabled by appropriate device connections.

– When an external 1.8V rail is available – Connect the external 1.8V to all following TLK100 pins to

enable proper operation: V18_PFBOUT (pin 40), V18_PFBIN1 (pin 2), V18_PFBIN2 (pin 4) and

VDD33_V18 (pin 41). In addition, connect the 1.8V rail to the transformer center tap to further

reduce the transmission power, as shown in Figure 2-2:

10 Pin Descriptions Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

Pin 5

(RD–)

RD–

Pin 6

(RD+)

RD+

Vdd

1.8 V

Supply

Pin 8

(TD–)

TD–

Pin 9

(TD+)

TD+

Vdd

1:1

1:1

T1

RJ45

Pin 41

(VDD33_V18)

Pin 40

(V18_PFBOUT)

Pin 2

(V18_PFBIN)

Pin 4

(V18_PFBIN2)

1.8 V

Supply

TLK100

499 W

499 W

499 W

499 W

0.1 Fm

0.1 Fm

0.1 F*m

0.1 F*m

1.1 V

Supply

TLK100

Pin11

(VDD33_VA11)

Pin10

(VA11_PFBOUT)

Pin1

(VA11_PFBIN1)

Pin7

(VA11_PFBIN2)

Pin21

(VDD33_VA11)

Pin20

(VDD11)

TLK100

www.ti.com

SLLS931–AUGUST 2009

Figure 2-2. Power Scheme for Operation With External 1.8V Supply

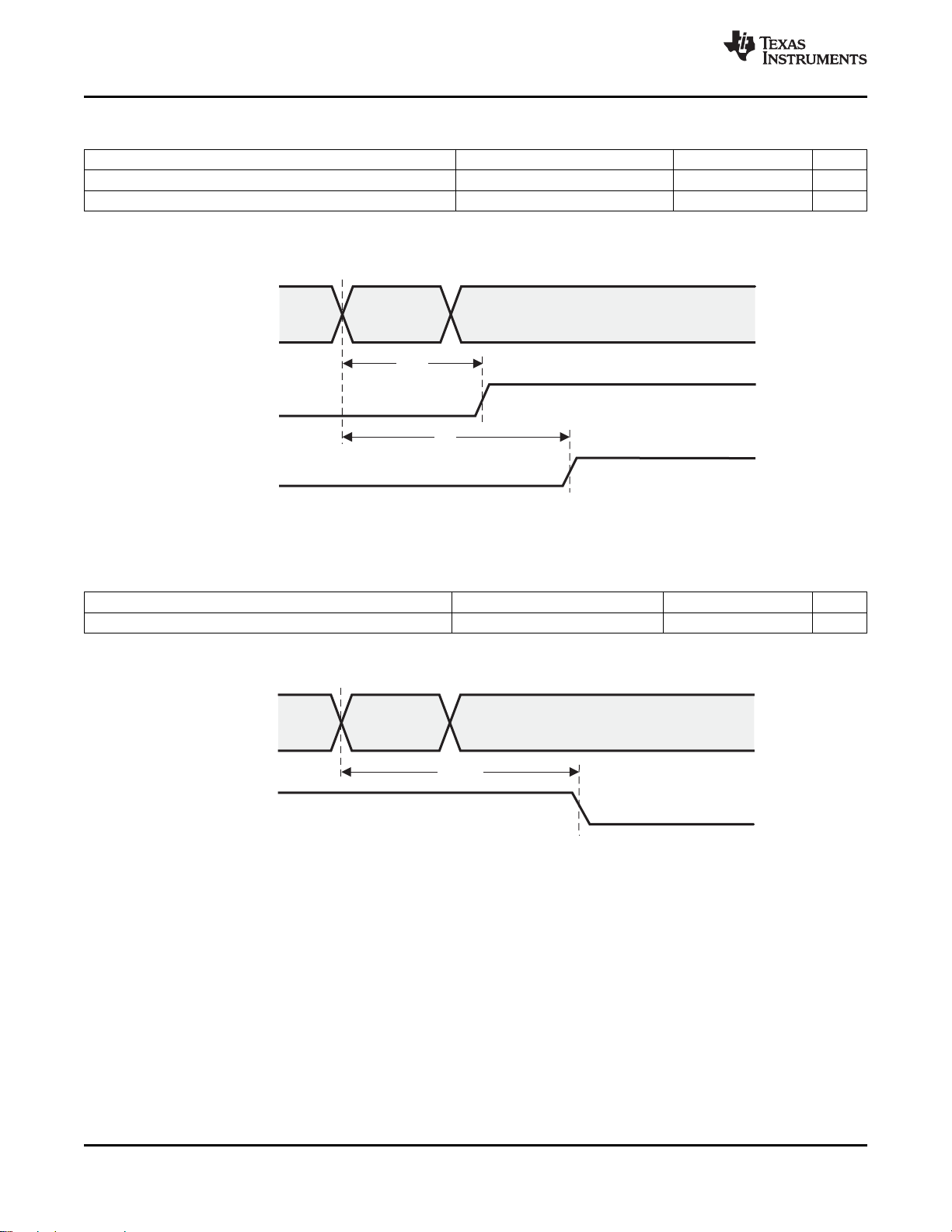

– External 1.1V rail – When external 1.1V rail is available – Connect the external 1.1V to the following

pins: VA11_PFBOUT (pin 10), VDD11 (pin 20), VA11_PFBIN1 (pin 1), VA11_PFBIN2 (pin 7),

VDD33_VA11 (pin 11) and VDD33_VD11 (pin 21) as shown in Figure 2-3:

• Lowest-power operation – When 1.1V and 1.8V supplies are already available in addition to 3.3V,

designers can take advantage of the lowest-power configuration of the TLK100. By supplying external

1.8 and 1.1V as explained above, all the internal regulators are powered down and the device is fully

driven by the external supplies giving the lowest power operation.

Copyright © 2009, Texas Instruments Incorporated Pin Descriptions 11

Figure 2-3. Power Scheme for Operation With External 1.1V Supply

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

SLLS931–AUGUST 2009

Other power supply options – Because the TLK100 incorporates independent voltage regulators,

designers may take advantage of several optional configurations, depending on available power supplies.

See Table 2-1 for these options.

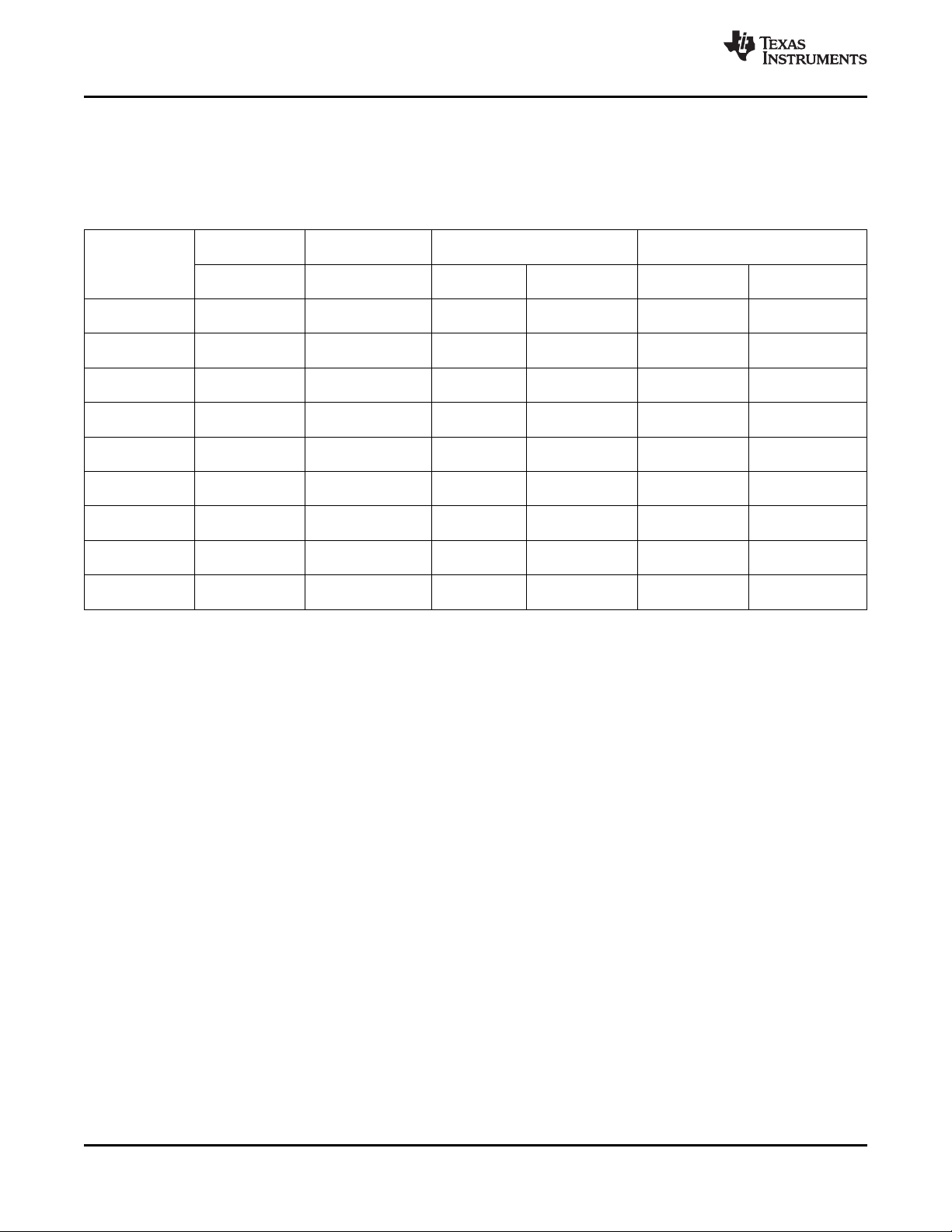

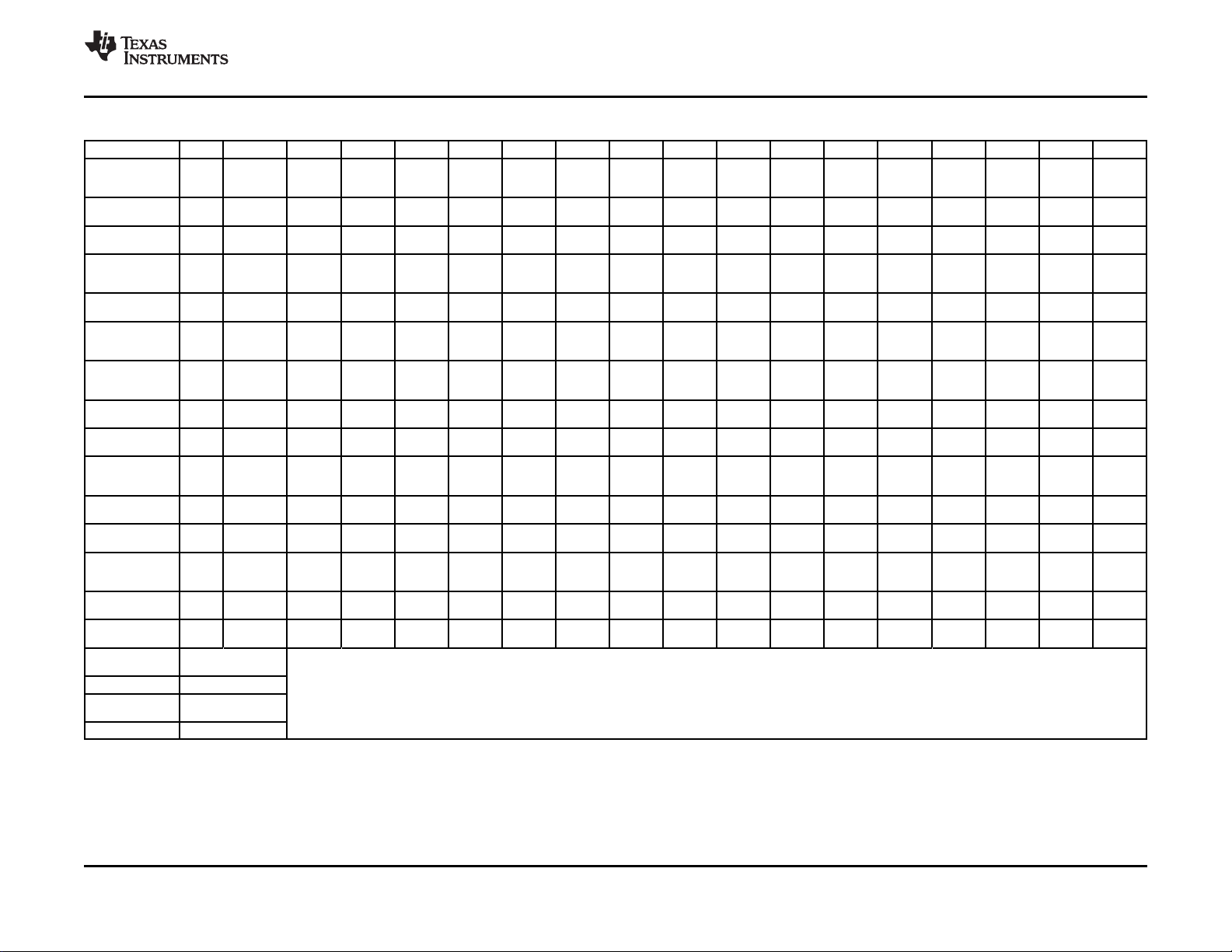

Table 2-1. Power Supply Options

MAC I/F Transformer CT

Mode

Single Supply 3.3V from 3.3V from 3.3V from 3.3V from

Operation external supply external supply external supply external supply

Lowest Power 3.3V from 1.8V from 1.8V from 1.1V from

Consumption external supply external supply external supply external supply

(3.3V) (3.3V or 1.8V)

Voltage Source Voltage Source Voltage Source Voltage Source

3.3V from 3.3V from 3.3V from 2.5V from

external supply external supply external supply external supply

3.3V from 3.3V from 3.3V from 1.1V from

external supply external supply external supply external supply

3.3V from 3.3V from 2.5V from 3.3V from

external supply external supply external supply external supply

3.3V from 3.3V from 2.5V from 2.5V from

external supply external supply external supply external supply

3.3V from 3.3V from 2.5V from 1.1V from

external supply external supply external supply external supply

3.3V from 1.8V from 1.8V from 3.3V from

external supply external supply external supply external supply

3.3V from 1.8V from 1.8V from 2.5V from

external supply external supply external supply external supply

Regulator Regulators

(ON/OFF) (ON/OFF)

ON ON

ON ON

ON OFF

ON ON

ON ON

ON OFF

OFF ON

OFF ON

OFF OFF

(1.8V) (1.1V)

www.ti.com

12 Pin Descriptions Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

www.ti.com

3 Configuration

This section includes information on the various configuration options available with the TLK100. The

configuration options described below include:

• Auto-Negotiation

• Auto-MDIX

• PHY Address

• LED Interface

• Loopback Functionality

• BIST

• Cable Diagnostics

3.1 Auto-Negotiation

The TLK100 device can auto-negotiate to operate in 10BASE-T or 100BASE-TX. If Auto-Negotiation is

enabled, then the TLK100 device negotiates with the link partner to determine the speed and duplex with

which to operate. If the link partner is unable to Auto-Negotiate, the TLK100 device would go into the

parallel detect mode to determine the speed of the link partner. Under parallel detect mode, the duplex

mode is fixed at half-duplex.

The TLK100 supports four different Ethernet protocols (10 Mb/s Half Duplex, 10 Mb/s Full Duplex, 100

Mb/s Half Duplex, and 100 Mb/s Full Duplex), so the inclusion of Auto-Negotiation ensures that the

highest performance protocol will be selected based on the advertised ability of the Link Partner. The

Auto-Negotiation function within the TLK100 can be controlled either by internal register access or by the

use of the AN_EN, AN_1 and AN_0 pins.

SLLS931–AUGUST 2009

The state of AN_EN, AN_0 and AN_1 pins determines whether the TLK100 is forced into a specific mode

or Auto-Negotiation will advertise a specific ability (or set of abilities) as given in Table 2-1. These pins

allow configuration options to be selected without requiring internal register access. The state of AN_EN,

AN_0 and AN_1, upon power-up/reset, determines the state of bits [8:5] of the ANAR register (0x04h).

Table 3-1. Auto-Negotiation Modes

AN_EN AN_1 AN_0 Forced Mode

0 0 0 10BASE-T, Half-Duplex

0 0 1 10BASE-T, Full-Duplex

0 1 0 100BASE-TX, Half-Duplex

0 1 1 100BASE-TX, Full-Duplex

AN_EN AN_1 AN_0 Advertised Mode

1 0 0 10BASE-T, Half/Full-Duplex

1 0 1 10BASE-TX, Half/Full-Duplex

1 1 0 10BASE-T, Half Duplex

1 1 1 10BASE-T, Half/Full-Duplex

100BASE-TX, Half Duplex

100BASE-TX, Half/Full-Duplex

Copyright © 2009, Texas Instruments Incorporated Configuration 13

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

SLLS931–AUGUST 2009

The Auto-Negotiation function can also be controlled by internal register access using registers as defined

by the IEEE 802.3u specification. For further detail regarding Auto-Negotiation, see Clause 28 of the IEEE

802.3u specification.

3.2 Auto-MDIX

The TLK100 device automatically determines whether or not it needs to cross over between pairs so that

an external crossover cable is not required. If the TLK100 device interoperates with a device that

implements MDI/MDIX crossover, a random algorithm as described in IEEE 802.3 determines which

device performs the crossover.

Auto-MDIX is enabled by default and can be configured via jumper or via PHYCR (0x10h) register, bits

[6:5].

The crossover can be manually forced through bit 5 of PHYCR (0x10h) register. Neither Auto-Negotiation

nor Auto-MDIX is required to be enabled in forcing crossover of the MDI pairs.

Auto-MDIX can be used in the forced 100BT mode but not in the forced MDIX mode. As in modern

networks all the nodes are 100BT, having the Auto-MDIX working in the forced 100BT mode will resolve

the link faster without the need for the long Auto-Negotiation.

www.ti.com

14 Configuration Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

MII_COL

MII_RXD_0

MII_RXD_1

MII_RXD_2

MII_RXD_3

2.2kW

VCC

PHYAD4=0 PHYAD3=0 PHYAD2=0 PHYAD1=1 PHYAD0=1

B0314-01

TLK100

www.ti.com

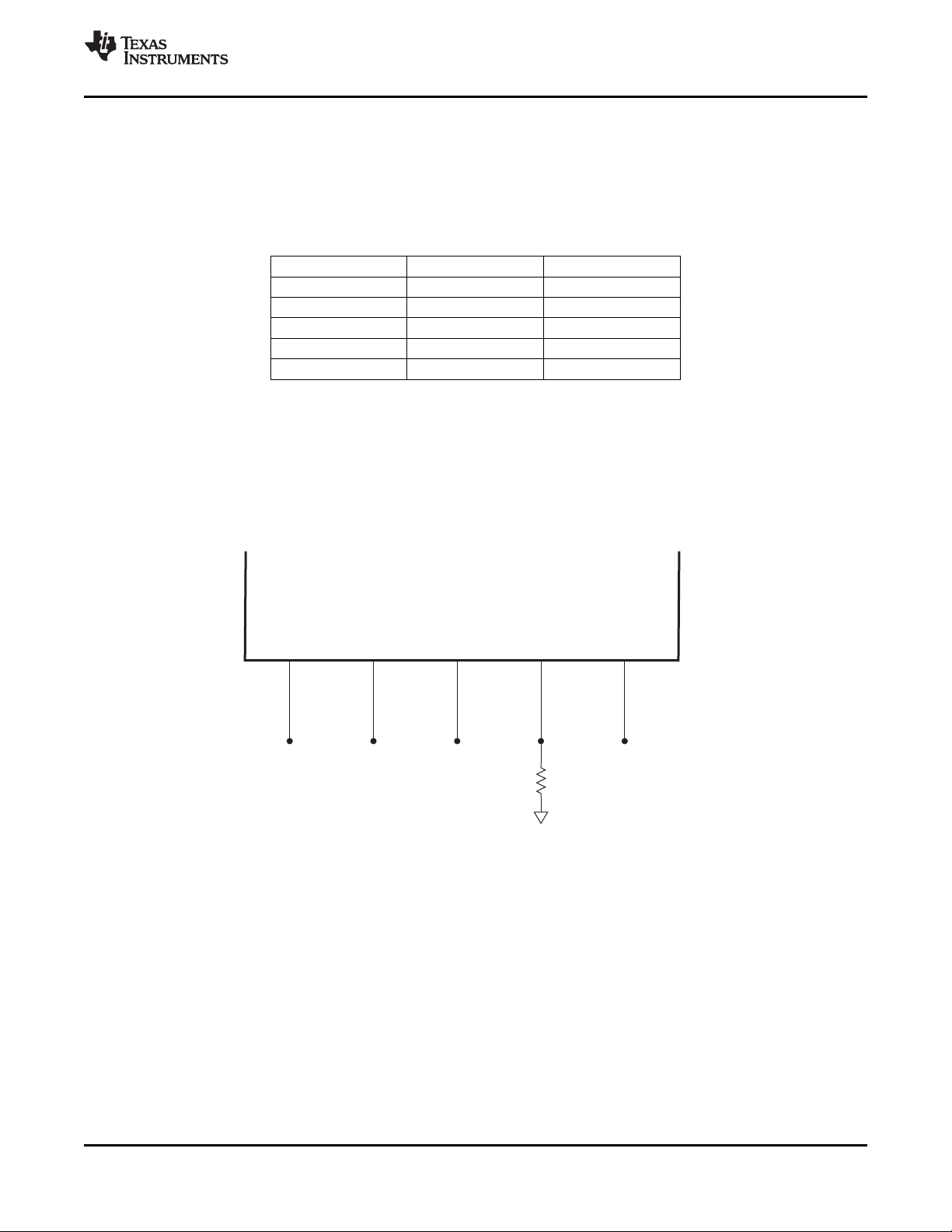

3.3 PHY Address

The 5 PHY address inputs pins are shared with the MII_RXD[3:0] pins and COL pin as shown in

Table 3-2.

Each TLK100 or port sharing an MDIO bus in a system must have a unique physical address. With 5

address input pins, the TLK100 can support PHY Address values 0 (<00000>) through 31 (<11111>). The

address-pin states are latched into an internal register at device power-up and hardware reset. Because

all the PHYAD[4:0] pins have weak internal pull-down resistors, the default setting for the PHY address is

00000 (0x00h).

See Figure 3-1 for an example of a PHYAD connection to external components. In this example, the

PHYAD configuration results in address 00010 (0x02h).

SLLS931–AUGUST 2009

Table 3-2. PHY Address Mapping

PIN # PHYAD FUNCTION RXD FUNCTION

24 PHYAD0 MII_COL

25 PHYAD1 MII_RXD_0

26 PHYAD2 MII_RXD_1

27 PHYAD3 MII_RXD_2

28 PHYAD4 MII_RXD_3

Figure 3-1. PHYAD Configuration Example

Copyright © 2009, Texas Instruments Incorporated Configuration 15

Submit Documentation Feedback

Product Folder Link(s): TLK100

LED_LINK

LED_SPEED

LED_ACT/COL

110 W 110 W110 W

2.2kW 2.2kW2.2kW

VCC

AN_EN=1 AN1=1 AN0=1

B0315-01

TLK100

SLLS931–AUGUST 2009

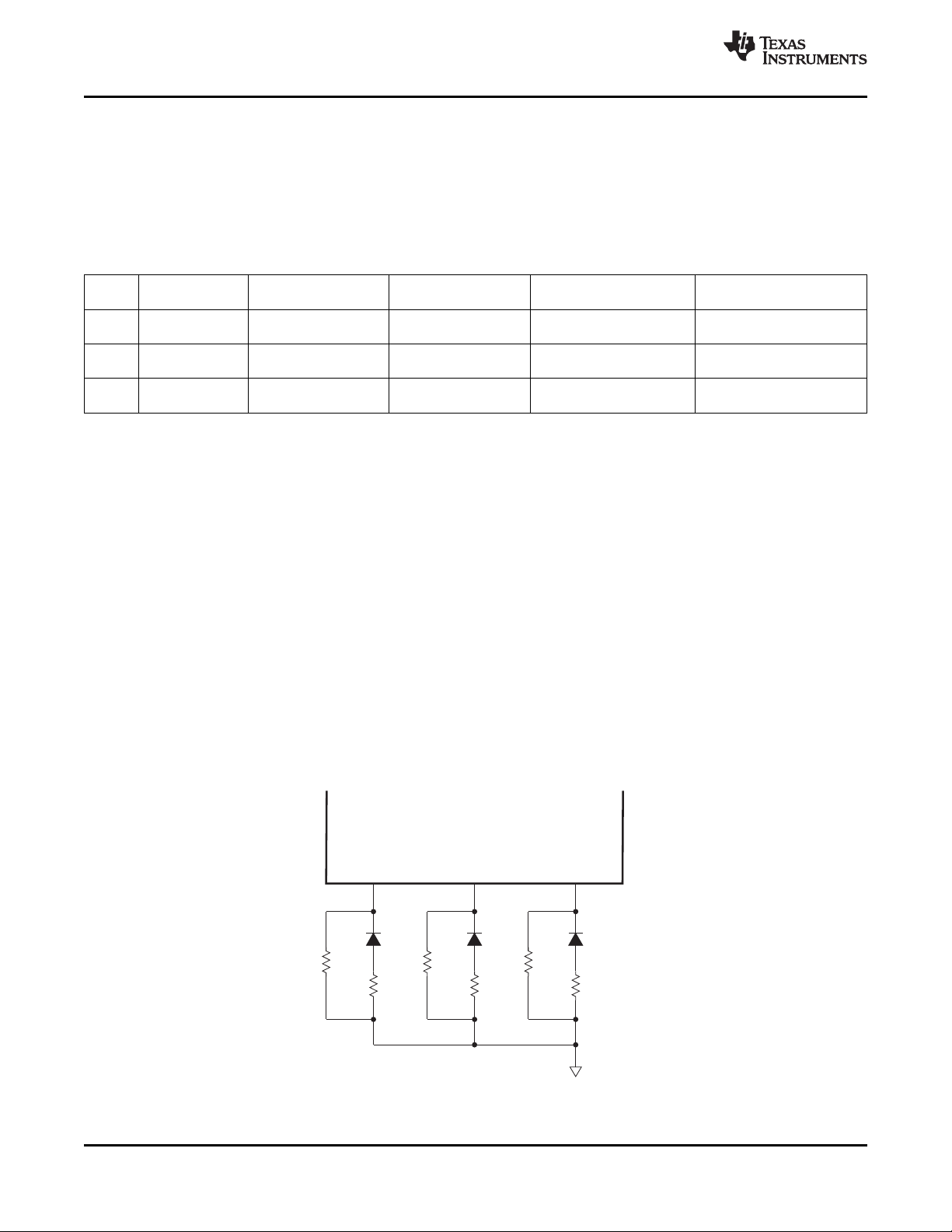

3.4 LED Interface

The TLK100 supports three configurable Light Emitting Diode (LED) pins. The device supports three LED

configurations: Link, Speed, and Activity. Functions are multiplexed among the LEDs into three modes.

The LEDs can be controlled by configuration pin and/or internal register bits. Bits 6:5 of the LED Direct

Control register (LEDCR) selects the LED mode as described in Table 3-3.

Table 3-3. LED Mode Select

Mode LED_LINK LED_SPEED LED_ACT

1 don't care 1

2 0 0

3 1 0

LED_CFG[1] LED_CFG[0]

(bit 6) (bit 5) or (pin 22)

ON for Good Link ON in 100 Mb/s ON Pulse for Activity

OFF for No Link OFF in 10 Mb/s OFF for No Activity

ON for Good Link ON in 100 Mb/s None

BLINK for Activity OFF in 10 Mb/s

ON for Good Link ON in 100 Mb/s ON for Full Duplex

BLINK for Activity OFF in 10 Mb/s OFF for Half Duplex

The LED_LINK pin in Mode 1 indicates the link status of the port. It is OFF when no LINK is present. In

Mode 2 and Mode 3 it is ON to indicate Link is good and BLINK to indicate activity is present on either

transmit or receive channel. The blink rate is decided by the bits 9:8 of the LEDCR register (0x18). The

default blink rate is 5Hz.

The LED_SPEED pin indicates 10 or 100 Mb/s data rate of the port. This LED is ON when the device is

operating in 100 Mb/s operation. The functionality of this LED is independent of mode selected.

www.ti.com

The LED_ACT pin in Mode 1 indicates the presence of either transmit or receive activity. The LED is ON

(Pulse) for Activity and OFF for No Activity. The width of the pulse is determined by the bits 14:13 of the

LEDCR register (0x18). The default pulse width is 200ms. In mode 3 this pin indicates the Duplex status

of operation. The LED is ON for Full Duplex and OFF for Half Duplex.

Bits 2:0 of the LEDCR register defines the polarity of the signals on the LED pins.

Since the Auto-Negotiation (AN) configuration options share the LED output pins, the external components

required for configuration-pin programming and those for LED usage must be considered in order to avoid

contention.

See Figure 3-2 for an example of AN connections to external components. In this example, the AN

programming results in Auto-Negotiation with 10/100 Half/Full-Duplex advertised.

16 Configuration Copyright © 2009, Texas Instruments Incorporated

Figure 3-2. AN Pin Configuration and LED Loading Example

Submit Documentation Feedback

Product Folder Link(s): TLK100

MAC/

Switch

PCS

Signal

Process

PHY

AFE

DigitalLoopback

PHY Digital

ExternalLoopback

AnalogLoopbackPCSLoopback

XFMR

RJ45

1

2

3

4

5

6

7

8

M

I

I

MIILoopback

TLK100

www.ti.com

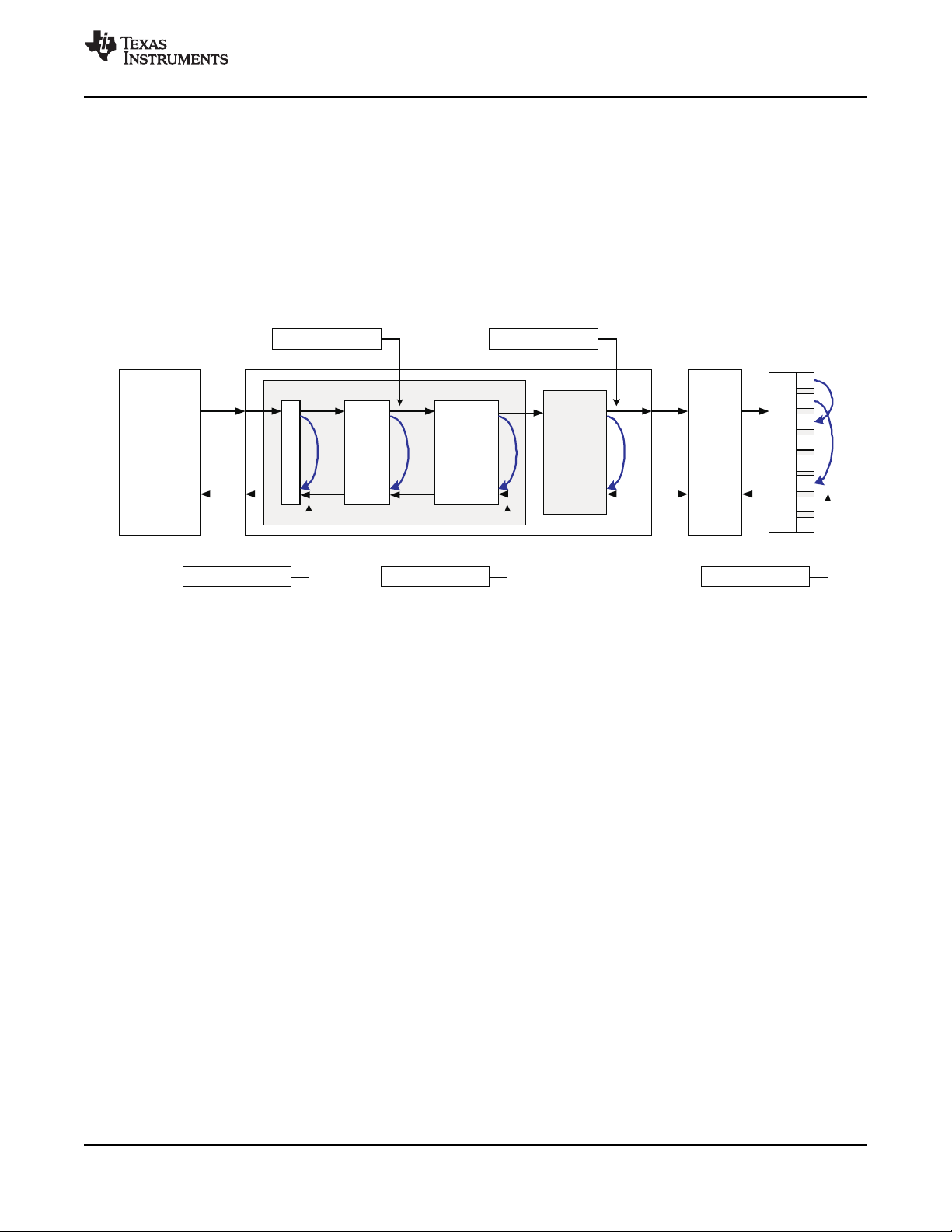

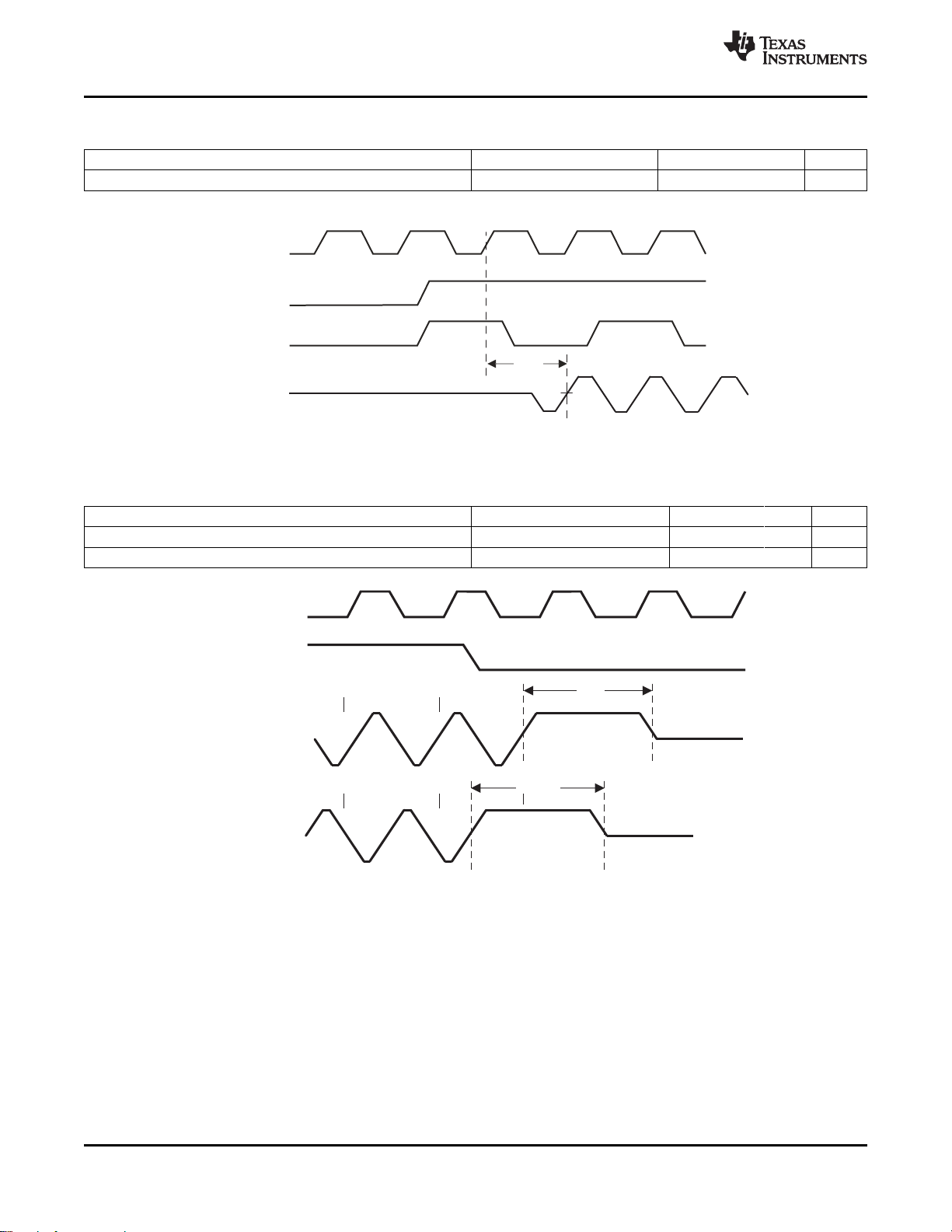

3.5 Loopback Functionality

The TLK100 provides several options for Loopback that test and verify various functional blocks within the

PHY. Enabling loopback mode allows in-circuit testing of the TLK100 digital and analog data path.

Generally, the TLK100 may be configured to one of the Near-end loopback modes or to the Far-end

(reverse) loopback.

3.5.1 Near-End Loopback

Near-end loopback provides the ability to loop the transmitted data back to the receiver via the digital or

analog circuitry. The point at which the signal is looped back is selected using loopback control bits with

several options being provided. Figure 3-3 shows the PHY near-end loopback functionality.

SLLS931–AUGUST 2009

Figure 3-3. Block Diagram, Near-End Loopback Mode

The Near-end Loopback mode is selected by setting the respective bit in the BIST Control Register

(BISCR), MII register address 0x16. Bits 3:0 of the BISCR register are used to set the loopback mode

according to the following:

• Bit [0]: MII Loopback

• Bit [1]: PCS Loopback (in 100BaseTX only)

• Bit [2]: Digital Loopback

• Bit [3]: Analog Loopback

While in Loopback mode the data is looped back and also transmitted onto the media. To ensure proper

operation in Analog Loopback mode 100Ω terminations should be attached to the RJ45 connector.

External Loopback can be performed while working in normal mode (Bits 3:0 of the BISCR register are

assert to 0 and on RJ45 connector pin 1 is shorted to pin 3 and pin 2 is shorted to pin 6).

To maintain the desired operating mode, Auto-Negotiation should be disabled before selecting Loopback

mode. This is not relevant for external-loopback mode.

Copyright © 2009, Texas Instruments Incorporated Configuration 17

Submit Documentation Feedback

Product Folder Link(s): TLK100

MAC/

Switch

PCS

Signal

Process

PHY

AFE

PHY Digital

XFMR

&

RJ45

CAT5 Cable

LinkPartner

M

I

I

ReverseLoopback

TLK100

SLLS931–AUGUST 2009

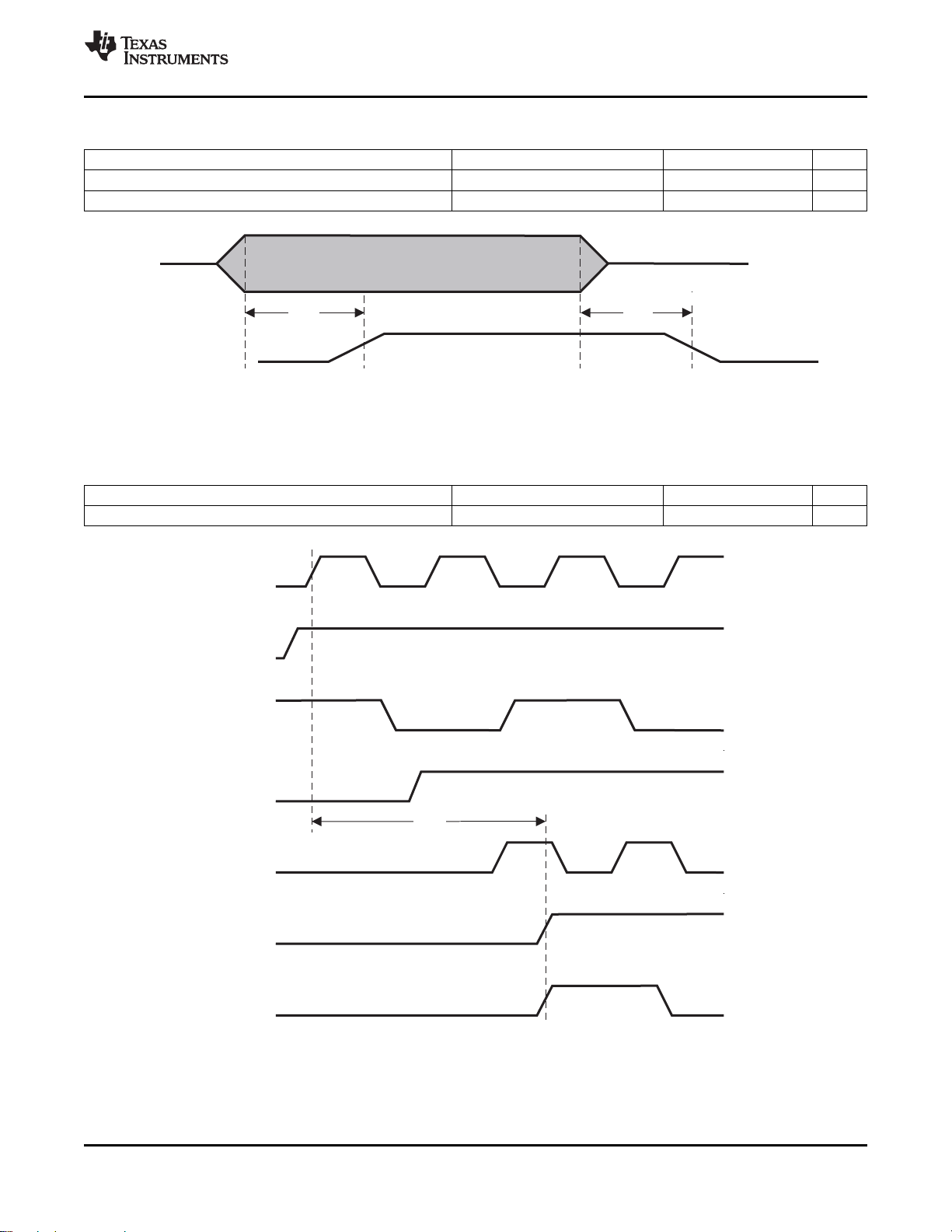

3.5.2 Far-End Loopback

Far-end (Reverse) loopback is a special test mode to allow testing the PHY from link partner side. In this

mode data that is received from the link partner pass through the PHY's receiver, looped back on the MII

and transmitted back to the link partner. Figure 3-4 shows Far-end loopback functionality.

The Reverse Loopback mode is selected by setting bit 4 in the BIST Control Register (BISCR), MII

register address 0x16.

While in Reverse Loopback mode the data is looped back and also transmitted onto the MAC Interface

and all data signals that come from the MAC are ignored.

www.ti.com

Figure 3-4. Block Diagram, Far-End Loopback Mode

3.6 BIST

The TLK100 incorporates an internal PRBS Built-in Self Test (BIST) circuit to accommodate in-circuit

testing or diagnostics. The BIST circuit can be utilized to test the integrity of the transmit and receive data

paths. The BIST testing can be performed using both internal loopback (digital or analog) or external loop

back using a cable fixture. The BIST simulates a real data transfer scenarios using real packets on the

lines. The BIST allows full control of the packets lengths and of the Inter Packet Gap (IPG)

The BIST is implemented with independent transmit and receive paths, with the transmit block generating

a continuous stream of a pseudo random sequence. The TLK100 generates a 23-bit pseudo random

sequence for doing the BIST test. The received data is compared to the generated pseudo-random data

by the BIST Linear Feedback Shift Register (LFSR) to determine the BIST pass/fail status. The number of

error bytes that the PRBS checker received is stored in the BISECR register (0x72h).The number of

transmitted bytes that the PRBS checker received is stored in the BISBCR register (0x71h). The status of

whether the PRBS checker is locked to the incoming receive bit stream, whether the PRBS is in sync or

not and whether the packet generator is busy or not can be found by reading the BISSR register (0x17h).

The PRBS test can be put in a continuous mode or single mode by using the bit 15 of the BISCR register

(0x16h). In the continuous mode, when one of the PRBS counter reaches the maximum value the counter

starts counting from zero again. In the single mode when the PRBS counter reaches its maximum value

the PRBS checker stops counting.

TLK100 allows the user to control the length of the PRBS packet. By programming the BISPLR register

(0x7Bh) register one can set the length of the PRBS packet. There is also an option to generate a single

packet transmission of two types 64 and 1518 bytes through register bit – bit13 of the BISCR register

(0x16h). The single generated packet is composed of a constant data.

18 Configuration Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

www.ti.com

3.7 Cable Diagnostics

With the vast deployment of Ethernet devices, the need for reliable, comprehensive and user-friendly

cable diagnostic tool is more important than ever. The wide variety of cables, topologies, and connectors

deployed results with the need to non-intrusively identify and report cable faults. TI cable diagnostic unit

provides extensive information about cable integrity.

The TLK100 offers the following capabilities in its Cable Diagnostic tools kit:

1. Time Domain Reflectometry (TDR).

2. Active Link Cable Diagnostic (ALCD).

3. Digital Spectrum Analyzer (DSA)

3.7.1 TDR

The TLK100 uses Time Domain Reflectometry (TDR) to determine the quality of the cables, connectors,

and terminations in addition to estimation of the cable length. Some of the possible problems that can be

diagnosed include opens, shorts, cable impedance mismatch, bad connectors, termination mismatches,

and any other discontinuities on the cable.

The TLK100 device transmits a test pulse of known amplitude (1V) down each of the two pairs of an

attached cable. The transmitted signal continues down the cable and reflects from each cable

imperfection, fault, bad connector and the end of the cable itself. After the pulse transmission the TLK100

measures the return time and amplitude of all these reflected pulses. This technique enables measuring

the distance and magnitude (impedance) of non-terminated cables (open or short), discontinuities (bad

connectors), and improperly-terminated cables with an accuracy of ±1m.

SLLS931–AUGUST 2009

To do this, the TLK100 uses a RAM with up to 256 samples to record all the input sampled data (Equals

to max possible measured cable length of over 200m). The TLK100 also uses soft data averaging to

reduce noise and improve accuracy. The TLK100 is capable of recording up to five reflections within the

tester pair. In case more than 5 reflections were recorded the TLK100 will save the last 5 of them.

For all TDR measurements, the transformation between time of arrival and physical distance is done by

the external host using minor computations (such as multiplication/addition and lookup tables). The host

must know the expected propagation delay of the cable, which depends, among other things, on the cable

category (e.g. CAT5/CAT5e/CAT6).

Copyright © 2009, Texas Instruments Incorporated Configuration 19

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

SLLS931–AUGUST 2009

3.7.2 ALCD

The TLK100 also supports Active Link Cable Diagnostic (ALCD). The ALCD offers a passive method to

estimate the cable length during active link. It uses passive digital signal processing based on adapted

data thus enabling measurement of cable length with an active link partner.

The ALCD also uses pre-defined parameters according to the cable properties (e.g. CAT5/CAT5e/CAT6)

in order to achieve higher accuracy in the estimated cable length. The ALCD Cable length measurement

accuracy is +/-5m for the pair used in the Rx path (due to the passive nature of the test we measure only

the pair on the Rx path).

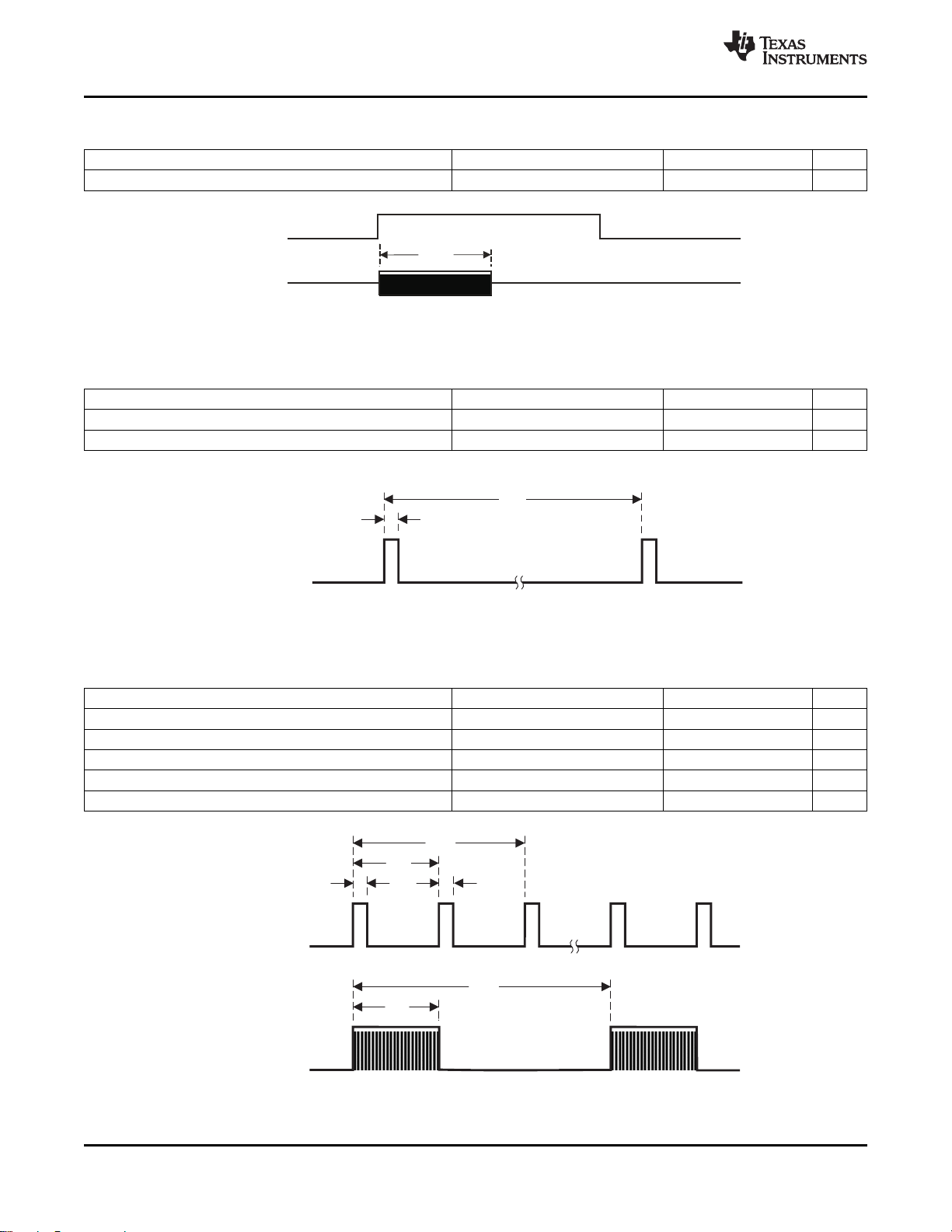

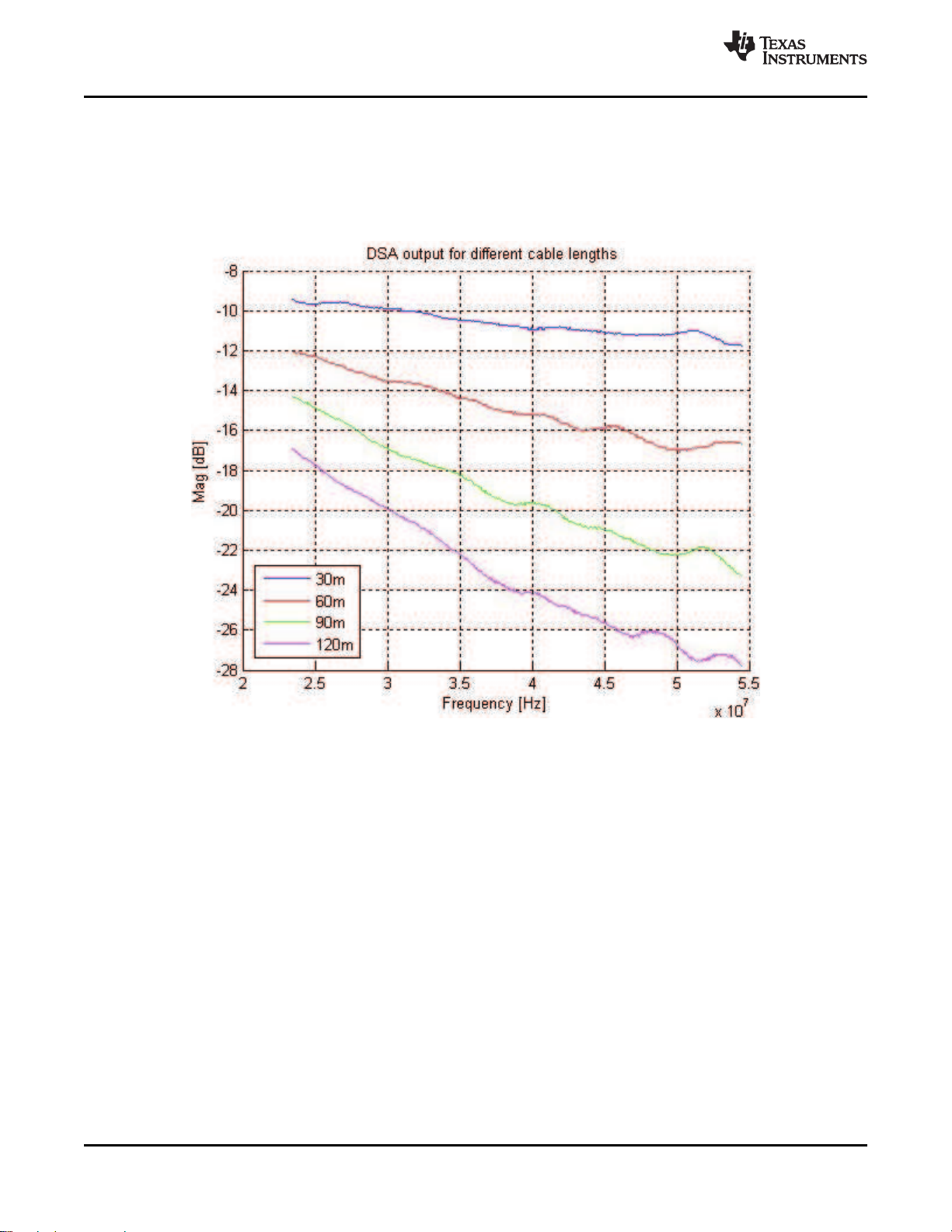

3.7.3 DSA

The TLK100 also offers a unique capability of Digital Spectrum Analyzer (DSA). The DSA enables a very

detailed analysis of the channel frequency response (Magnitude only). The DSA has the following

capabilities:

• Produce channel frequency response in resolution of 119.2Hz.

• Save up to 512 bins per DSA run.

• Full control in the analyzed frequency bins location and resolution.

• Programmable options for input data for the DSA:

– Use raw data taken directly from the channel

– Use adapted data that passed digital signal processing

• Use additional filtering for smoothing the total channel frequency response.

• Build in averaging for more accurate results

www.ti.com

NOTE: For an example of the DSA output please see appendix A

To reset the cable diagnostic registers, set bit 14 of RAMCR2 register (0x0D01) to '1'. Writing software

global reset 0x001F bit 15 does not reset the cable diagnostic registers.

20 Configuration Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

www.ti.com

4 Reset and Power Down Operation

At power up it is recommended to have the external reset pin (RESETN) active (low). The RESETN pin

should be de-asserted 200μs after the power is ramped up to allow the internal circuits to settle and for

the internal regulators to be stabilized. If required during normal operation, the device can be reset by a

hardware or software reset.

4.1 Hardware Reset

A hardware reset is accomplished by applying a low pulse (TTL level), with a duration of at least 1μs, to

the RESETN. This will reset the device such that all registers will be reinitialized to default values and the

hardware configuration values will be re-latched into the device (similar to the power-up/reset operation).

4.2 Software Reset

A software reset is accomplished by setting the reset bit (bit 15) of the BMCR register (0x00h). This bit

only resets the IEEE defined standard registers in the address space 0x00h to 0x07h. The software global

reset is accomplished by setting bit 15 of register PDN (0x001F) to ‘1’. This bit resets IEEE defined

registers (0x00h to 0x07h) and all the extended registers except for the cable-diagnostic registers and

RAM registers. For resetting the cable diagnostics and RAM registers, bit 14 of register RAMCR2

(0x0D01) should be set to ‘1’. The time from the point when the reset bit is set to the point the when

software reset has concluded is approximately 1.3 μs.

The software global reset resets the device such that all registers are reset to default values and the

hardware configuration values are maintained. Software driver code must wait 3 μs following a software

reset before allowing further serial MII operations with the TLK100.

SLLS931–AUGUST 2009

4.3 Power Down/Interrupt

The Power Down and Interrupt functions are multiplexed on pin 42 of the device. By default, this pin

functions as a power down input and the interrupt function is disabled. This pin can be configured as an

interrupt output pin by setting bit 15 (INTN_OE) to ‘1’ and bit 12 (INTN_OEN) to ‘0’ of the MINTCR (0x14h)

register. Bit 13 of the same MINTCR register is used to set the polarity of the interrupt.

4.3.1 Power Down Control Mode

The PWRDNN/INT pin can be asserted low to put the device in a Power Down mode. An external control

signal can be used to drive the pin low, overcoming the weak internal pull-up resistor. Alternatively, the

device can be configured to initialize into a Power Down state by use of an external pulldown resistor on

the PWRDNN/INT pin.

4.3.2 Interrupt Mechanisms

The interrupt function is controlled via register access. All interrupt sources are disabled by default. The

MINTMR register provides independent interrupt enable bits for the different interrupts supported by

TLK100. The PWRDNN/INT pin is asynchronously asserted low when an interrupt condition occurs. The

source of the interrupt can be determined by reading the interrupt status register MINTSR (0x13h). One or

more bits in the MINTSR will be set, denoting all currently pending interrupts. Reading of the MINTSR

clears ALL pending interrupts.

Copyright © 2009, Texas Instruments Incorporated Reset and Power Down Operation 21

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

SLLS931–AUGUST 2009

4.4 Power Down Modes

TLK100 supports four types of power saving modes. The lowest power consumption is in the "Extreme

Low Power" mode (ELP). To enter into the ELP mode the PWRDNN/INT pin is pulled LOW.

To enable the power-down modes described below, set bit 11 of register BMCR (0x00h) to '1'. In all

power-down modes, the entire PHY is powered down except for the SMI interface; the PHY stays in that

condition as long as the value of bit 11 of register BMCR (0x00h) remains '1'. When this bit is cleared, the

PHY powers up and returns to the last state it was in before it was powered down.

In General Power Down mode, bits 9 and 8 of the PHYCR register (0x10h) should be set to "01".

Additionally, bit 4 of the PHYCR register (0x10h) should be set to '1' so as to power down the internal PLL.

The SMI would operate on the reference clock.

In Active sleep mode, or Energy-Detect mode, every 1.4 seconds a Normal Link Pulse (NLP) is sent to

wake up the link-partner. To enter into the active sleep mode, bits 9 and 8 of register PHYCR (0x10h) is

set to "10". Automatic powerup is done when the link partner is detected.

In passive sleep mode, all core blocks are powered down. Automatic power-up is done when the link

partner is detected. To enter into the passive sleep mode, bits 9 and 8 of register PHYCR (0x10h) is set to

"11".

www.ti.com

22 Reset and Power Down Operation Copyright© 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

RD–

RD–

RD+ RD+

49.9 W

49.9 W

Vdd

Vdd

0.1 Fm

0.1 F*m

TD– TD–

TD+

TD+

49.9 W

49.9 W

Vdd

0.1 Fm

0.1 F*m

1:1

1:1

T1

RJ45

Placeresistorsandcapacitorsclosetothedevice.

Common-modechokes

mayberequired.

Note:CentertapisconnectedtoVdd

*Placecapacitorsclosetothe

transformercentertaps

Allvaluesaretypicalandare 1%±

S0339-01

TLK100

www.ti.com

5 Design Guidelines

5.1 TPI Network Circuit

Figure 5-1 shows the recommended circuit for a 10/100 Mb/s twisted pair interface. Below is a partial list

of recommended transformers. It is important that the user realize that variations with PCB and

component characteristics require that the application be tested to verify that the circuit meets the

requirements of the intended application.

• Pulse H1102

• Pulse HX1188

SLLS931–AUGUST 2009

Figure 5-1. 10/100 Mb/s Twisted Pair Interface

5.2 Clock In (XI) Requirements

The TLK100 supports an external CMOS-level oscillator source or an internal oscillator with an external

crystal.

5.2.1 Oscillator

If an external clock source is used, XI should be tied to the clock source and XO should be left floating.

The amplitude of the oscillator should be a nominal voltage of 1.8V.

Copyright © 2009, Texas Instruments Incorporated Design Guidelines 23

Submit Documentation Feedback

Product Folder Link(s): TLK100

S0340-01

XI XO

R

1

C

L2

C

L1

TLK100

SLLS931–AUGUST 2009

5.2.2 Crystal

The use of a 25MHz, parallel, 20pF-load crystal resonator is recommended if a crystal source is desired.

Figure 5-2 shows a typical connection for a crystal resonator circuit. The load capacitor values will vary

with the crystal vendors; check with the vendor for the recommended loads.

The oscillator circuit is designed to drive a parallel resonance AT-cut crystal with a minimum drive level of

100μW and a maximum of 500μW. If a crystal is specified for a lower drive level, a current limiting resistor

should be placed in series between XO and the crystal.

As a starting point for evaluating an oscillator circuit, if the requirements for the crystal are not known, set

the values for CL1and CL2at 33pF, and R1should be set at 0Ω.

Specification for 25MHz crystal are listed in Table 5-2.

www.ti.com

Figure 5-2. Crystal Oscillator Circuit

Table 5-1. 25 MHz Oscillator Specification

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Frequency 25 MHz

Frequency Tolerance Operational Temperature ±50 ppm

Frequency Stability 1 year aging ±50 ppm

Rise / Fall Time 10%–90% 8 nsec

Jitter (Short term) Cycle-to-cycle 50 psec

Jitter (Long term) Accumulative over 10 ms 1 nsec

Symmetry Duty Cycle 40% 60%

Load Capacitance 15 30 pF

Table 5-2. 25 MHz Crystal Specification

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Frequency 25 MHz

Frequency Tolerance Operational Temperature ±50 ppm

At 25°C ±50 ppm

Frequency Stability 1 year aging ±5 ppm

Load Capacitance 10 40 pF

24 Design Guidelines Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

M0117-01

TLK100

www.ti.com

5.3 Thermal Vias Recommendation

The following thermal via guidelines apply to GNDPAD, pin 49:

1. Thermal via size = 0.2 mm

2. Recommend 4 vias

3. Vias have a center to center separation of 2 mm.

Adherence to this guideline is required to achieve the intended operating temperature range of the device.

Figure 5-3 illustrates an example layout.

SLLS931–AUGUST 2009

Figure 5-3. Example Layout

Copyright © 2009, Texas Instruments Incorporated Design Guidelines 25

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

SLLS931–AUGUST 2009

6 Register Block

Table 6-1. Register Map

OFFSET HEX ACCESS TAG DESCRIPTION

00h RW BMCR Basic Mode Control Register

01h RO BMSR Basic Mode Status Register

02h RO PHYIDR1 PHY Identifier Register #1

03h RO PHYIDR2 PHY Identifier Register #2

04h RW ANAR Auto-Negotiation Advertisement Register

05h RO ANLPAR Auto-Negotiation Link Partner Ability Register

06h RO ANER Auto-Negotiation Expansion Register

07h RW ANNPTR Auto-Negotiation Next Page TX

08h RO ANLNPTR Auto-Negotiation Link Partner Ability Next Page Register

09h–0Ch RW RESERVED RESERVED

0Dh RW REGCR Register control register

0Eh RW ADDAR Address or Data register

0Fh RW RESERVED RESERVED

EXTENDED REGISTERS

10h RW PHYCR PHY Control Register

11h RO PHYSR PHY Status Register

12h RW MINTMR MII Interrupt Mask Register

13h RO MINTSR MII Interrupt Status Register

14h RW MINTCR MII Interrupt Control Register

15h RO RECR Receive Error Counter Register

16h RW BISCR BIST Control Register

17h RO BISSR BIST Status Register

18h RW LEDCR LED Direct Control Register

19h RW RESERVED RESERVED

1Ah RW CDCR Cable Diagnostic Control Register

1Bh RW CDSR Cable Diagnostic Status Register

1Ch RO CDRR Cable Diagnostic Results Register

1Dh-1Eh RW RESERVED RESERVED

1Fh RW PDR Power Down Register

42h RO FCSCR False Carrier Sense Counter Register

70h RW RXCCR RX Channel Control Register

71h RO BISBCR BIST Byte Count Register

72h RO BISECR BIST Error Count Register

7Bh RW BISPLR BIST Packet Length Register

7Ch RW BISIPGR BIST Inter Packet Gap Register

80h RW TDRSMR TDR State Machine Enable Register

90h RW TDRPAR TDR Pattern Amplitude Register

94h RW TDRMPR TDR Manual Pulse Register

0C00h–0C0Ch RW TDR Algorithm Registers

0C26h–0C2Ah RW ALCD/DSA Registers

0D00h, 0D01h, RAM registers

0D04h

0107h RW CD Pre Test Configuration 1 Register

010Fh RW CD Pre Test Configuration 2 Register

00AC RW LPF Bypass Register

RW

www.ti.com

26 Register Block Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

www.ti.com

SLLS931–AUGUST 2009

Copyright © 2009, Texas Instruments Incorporated Register Block 27

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

SLLS931–AUGUST 2009

www.ti.com

Table 6-2. Register Table

Register Name Addr Tag Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Basic Mode Control 00h BMCR Reset Loopback Speed Auto-Neg Power Isolate Restart Duplex Collision Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Register Selection Enable Down Auto-Neg Mode Test

Basic Mode Status 01h BMSR 100Base 100Base 100Base 10Base-T 10Base-T Reserved Reserved Reserved Reserved MF Auto-Neg Remote Auto-Neg Link Status Jabber Extended

Register -T4 -TX FDX -TX HDX FDX HDX Preamble Complete Fault Ability Detect Capability

PHY Identifier 02h PHYIDR 1 OUI MSB OUI MSB OUI MSB OUI MSB OUI MSB OUI MSB OUI MSB OUI MSB OUI MSB OUI MSB OUI MSB OUI MSB OUI MSB OUI MSB OUI MSB OUI MSB

Register 1

PHY Identifier 03h PHYIDR 2 OUI LSB OUI LSB OUI LSB OUI LSB OUI LSB OUI LSB VNDR_ VNDR_ VNDR_ VNDR_ VNDR_ VNDR_ MDL_ REV MDL_ REV MDL_ REV MDL_ REV

Register 2 MDL MDL MDL MDL MDL MDL

Auto-Negotiation 04h ANAR Next Page Reserved Remote Reserved ASM_DI R PAUSE T4 TX_FD TX 10_FD 10 Protocol Protocol Protocol Protocol Protocol

Advertisement Ind Fault Selection Selection Selection Selection Selection

Register

Auto-Negotiation Link 05h ANLPAR Next Page ACK Remote Reserved ASM_DI R PAUSE T4 TX_FD TX 10_FD 10 Protocol Protocol Protocol Protocol Protocol

Partner Ability Ind Fault Selection Selection Selection Selection Selection

Register (Base Page)

Auto-Negotiation 06h ANER Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved PDF LP_NP_ NP_ ABLE PAGE_ RX LP_AN_AB

Expansion Register ABLE LE

Auto-Negotiation Next 07h ANNPTR Next Page Reserved Message ACK2 TOG_TX CODE CODE CODE CODE CODE CODE CODE CODE CODE CODE CODE

Page TX Register Ind Page

Auto-Negotiate Link 08h ANLNPTR Next Page Reserved Message ACK2 TOG_TX CODE CODE CODE CODE CODE CODE CODE CODE CODE CODE CODE

Partner Ability Page Ind Page

Register

RESERVED 09-0Ch Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Register Control 0Dh REGCR Function Function Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved DEVICE DEVICE DEVICE DEVICE DEVICE

Register ADDRESS ADDRESS ADDRESS ADDRESS ADDRESS

Address or Data 0Eh ADDAR Addr/ Data Addr/ Data Addr /Data Addr /Data Addr/ Data Addr/ Data Addr /Data Addr /Data Addr/ Data Addr/ Data Addr /Data Addr /Data Addr/ Data Addr/ Data Addr /Data Addr /Data

Register

RESERVED 0Fh Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

EXTENDED REGISTERS

PHY Control Register 10h PHYCR TX FIFO TX FIFO Reserved Reserved Reserved Force Link Power Power Reserved Auto MDI-X Manual Disable Reserved Reserved Reserved Disable

PHY Status Register 11h PHYSR Reserved Speed Duplex Page AutoNego Link Status Reserved MDI Cross Reserved Sleep Reserved Reserved Reserved Reserved Polarity Jabber

MII Interrupt Mask 12h MINTMR Auto Nego Speed Duplex Page Auto Nego Link Status Reserved Reserved FIFO Over MDI cross Reserved Sleep Reserved Reserved Polarity Jabber

Register error Change Mode Received Complete Change Under flow over Mode Change Interrupt

MII Interrupt Status 13h MINTSR Auto Nego Speed Duplex Page Auto Nego Link Status Reserved Reserved FIFO Over MDI Reserved Sleep Reserved Reserved Polarity Jabber

Register Error Changed Mode Received Complete Changed Underflow Crossover Mode Changed

MII Interrupt Control 14h MINTCR Interrupt Reserved Interrupt Interrupt Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Register Pin Enable Polarity Pin Enable

Receive Error 15h RECR RXCERNT RXCERNT RXCERNT RXCERNT RXCERNT RXCERNT RXCERNT RXCERNT RXERCNT RXERCNT RXERCNT RXERCNT RXERCNT RXERCNT RXERCNT RXERCNT

Counter Register

BIST Control Register 16h BISCR PRBS Generate 64 bit mode Packet Reserved Reserved Reserved Reserved Reserved Reserved Reserved Loopback Loop back Loop back Loop back Loop back

Depth Depth Good Down Mode Down Mode Enable MDI-X PLL Jabber

Received Complete over Mode

Enable Enable Change Enable Enable Enable Enable change Change Enable Enable

Count PRBS Generation Mode Mode Mode Mode Mode

Mode Packets Enable

Enable Enable Enable

Changed Changed Changed

Suppress

Enable

28 Register Block Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

www.ti.com

SLLS931–AUGUST 2009

Table 6-2. Register Table (continued)

Register Name Addr Tag Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

BIST Status Register 17h BISSR Reserved Reserved Reserved Reserved PRBS PRBS Sync PRBS Core Power Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

BIST Byte Count 71h BISBCR PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS

Register Count Count Count Count Count Count Count Count Count Count Count Count Count Count Count Count

BIST Error Count 72h BISECR Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved PRBS Error PRBS Error PRBS Error PRBS Error PRBS Error PRBS Error PRBS Error PRBS Error

Register Count Count Count Count Count Count Count Count

BIST Packet Length 7Bh BISPLR PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS PRBS

register Packet Packet Packet Packet Packet Packet Packet Packet Packet Packet Packet Packet Packet Packet Packet Packet

BIST Inter Packet 7Ch BISIPGR PRBS IPG PRBS IPG PRBS IPG PRBS IPG PRBS IPG PRBS IPG PRBS IPG PRBS IPG PRBS IPG PRBS IPG PRBS IPG PRBS IPG PRBS IPG PRBS IPG PRBS IPG PRBS IPG

Gap Register Length Length Length Length Length Length Length Length Length Length Length Length Length Length Length Length

LED Control Register 18h LEDCR LED Pulse Width Pulse Width Force Reserved Reserved Blink Rate Blink Rate Reserved LED Mode LED Mode Reserved Reserved LED ACT LED LED LINK

Power Down Register 1Fh PDR Software Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

False Carrier Sense 42h FCSCR Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Idle_error_c Idle_error_c Idle_error_c Idle_error_c Idle_error_c Idle_error_c Idle_error_c Idle_error_c

Counter Register ount ount ount ount ount ount ount ount

RX Channel Control 70h RXCCR Rese-rved Rese-rved Rese-rved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Polarity Mdix Reserved Reserved

Register Inversion

Cable Diagnostic 1Ah CDCR Reserved Reserved ALCD/ DSA TDR test Reserved Cable Diag Cable Diag Cable Diag Reserved Reserved Reserved Reserved Reserved Reserved Reserved Channel

Register test start Start result result result Select

Cable Diagnostic 1Bh CDSR ALCD/ DSA TDR Fail TDR Done Reserved Reserved Reserved DSA Input DSA Input DSA Input DSA Input DSA ALCD/ DSA Reserved Reserved Reserved Reserved

Status Register Done Signal Signal Signal Signal Enalbe mode

Cable Diagnostic 1Ch CDRR Cable Diag Cable Diag Cable Diag Cable Diag Cable Diag Cable Diag Cable Diag Cable Diag Cable Diag Cable Diag Cable Diag Cable Diag Cable Diag Cable Diag Cable Diag Cable Diag

Results Register Results Results Results Results Results Results Results Results Results Results Results Results Results Results Results Results

TDR State Machine 80h TDRSMR Cmn_tdr_ Cmn_tdr Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Enable sm_mode _tx_sm_

TDR Pattern 90h TDRPAR Rese- rved Rese- rved Rese- rved Rese- rved Rese- rved Rese- rved Rese- rved Rese- rved Rese- rved Rese- rved Rese- rved TDR TDR TDR TDR TDR

Amplitude Register pattern pattern pattern pattern pattern

TDR Manual Pulse 94h TDRMPR Rese-rved Rese-rved Rese-rved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved TDR_TX Reserved

Register _START

TDR Algorithm

Registers

ALCD/DSA Registers 0C26h – 0C2Ah

CD Pre test 0107h, 010Fh

Configuration

LPF Bypass Register 00ACh

0C00h – 0C0Ch

Length Length Length Length Length Length Length Length Length Length Length Length Length Length Length Length

Enable Interrupt Polarity SPEED Polarity

Global

Reset

mode

Cable Diagnostic algorithmrelated registers

Locked Loss Generator Mode

Select Select Select

busy Status

Polarity

Copyright © 2009, Texas Instruments Incorporated Register Block 29

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

SLLS931–AUGUST 2009

6.1 Register Definition

In the register definitions under the ‘Default’ heading, the following definitions hold true:

• RW = Read Write access

• SC = Register sets on event occurrence and Self-Clears when event ends

• RW/SC = Read Write Access/Self Clearing bit

• RO = Read Only access

• COR = Clear on Read

• RO/COR = Read Only, Clear on Read

• RO/P = Read Only, Permanently set to a default value

• LL = Latched Low and held until read, based upon the occurrence of the corresponding event

• LH = Latched High and held until read, based upon the occurrence of the corresponding event

www.ti.com

30 Register Block Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

www.ti.com

6.1.1 Basic Mode Control Register (BMCR)

Table 6-3. Basic Mode Control Register (BMCR), address 0x0000

BIT BIT NAME DEFAULT DESCRIPTION

15 Reset 0, RW/SC PHY Software Reset:

1 = Initiate software Reset / Reset in Process.

0 = Normal operation.

Writing a 1 to this bit causes the PHY to be reset. When the reset operation is done, this bit

is cleared to 0 automatically. The configuration is relatched.

14 Loopback 0, RW Loopback:

1 = Loopback enabled.

0 = Normal operation.

When loopback mode is activated, the transmitter data presented on TXD is looped back to

RXD internally

13 Speed Selection Jumper, RW Speed Select:

When auto-negotiation is disabled writing to this bit allows the port speed to be selected.

1 = 100 Mb/s

0 = 10 Mb/s

12 Auto-Negotiation Jumper, RW Auto-Negotiation Enable:

Enable

11 Power Down 0, RW Power Down:

10 Isolate 0, RW Isolate:

9 Restart Auto- 0, RW/SC Restart Auto-Negotiation:

Negotiation

8 Duplex Mode Jumper, RW Duplex Mode:

7 Collision Test 0, RW Collision Test:

6:0 RESERVED 0, RO RESERVED: Write ignored, read as 0.

Configuration pin (jumper) controls initial value at reset.

1 = Auto-Negotiation Enabled – bits 8 and 13 of this register are ignored when this bit is

set.

0 = Auto-Negotiation Disabled – bits 8 and 13 determine the port speed and duplex

mode.

1 = Enables Power Down Modes - General Power Down Mode, Active Sleep Mode and

Passive Sleep Mode (see register 0x10)

0 = Normal operation.

1 = Isolates the Port from the MII with the exception of the serial management.

0 = Normal operation.

1 = Restart Auto-Negotiation. Re-initiates the Auto-Negotiation process. If

Auto-Negotiation is disabled (bit 12 = 0), this bit is ignored. This bit is self-clearing

and will return a value of 1 until Auto-Negotiation is initiated, whereupon it will

self-clear. Operation of the Auto-Negotiation process is not affected by the

management entity clearing this bit.

0 = Normal operation.

Re-initiates the Auto-Negotiation process. If Auto-Negotiation is disabled (bit 12 = 0), this bit

is ignored. This bit is self-clearing and will return a value of 1 until Auto-Negotiation is

initiated, whereupon it self-clears. Operation of the Auto-Negotiation process is not affected

by the management entity clearing this bit.

When auto-negotiation is disabled writing to this bit allows the port Duplex capability to be

selected.

1 = Full Duplex operation.

0 = Half Duplex operation.

1 = Collision test enabled.

0 = Normal operation

SLLS931–AUGUST 2009

Copyright © 2009, Texas Instruments Incorporated Register Block 31

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

SLLS931–AUGUST 2009

6.1.2 Basic Mode Status Register (BMSR)

Table 6-4. Basic Mode Status Register (BMSR), address 0x0001

BIT BIT NAME DEFAULT DESCRIPTION

15 100BASE-T4 0, RO/P 100BASE-T4 Capable:

This protocol is not available. Always 0 = Device does not perform 100BASE-T4 mode.

14 100BASE-TX 1, RO/P 100BASE-TX Full Duplex Capable:

Full Duplex

13 100BASE-TX 1, RO/P 100BASE-TX Half Duplex Capable:

Half Duplex

12 10BASE-T 1, RO/P 10BASE-T Full Duplex Capable:

Full Duplex

11 10BASE-T 1, RO/P 10BASE-T Half Duplex Capable:

Half Duplex

10: RESERVED 0, RO RESERVED: Write as 0, read as 0.

7

6 MF Preamble 1, RO/P Preamble suppression Capable:

Suppression

5 Auto- 0, RO Auto-Negotiation Complete:

Negotiation

Complete

4 Remote Fault 0, RO/LH Remote Fault:

3 Auto- 1, RO/P Auto Negotiation Ability:

Negotiation

Ability

2 Link Status 0, RO/LL Link Status:

1 Jabber Detect 0, RO/LH Jabber Detect: This bit only has meaning in 10 Mb/s mode.

0 Extended 1, RO/P Extended Capability:

Capability

1 = Device able to perform 100BASE-TX in full duplex mode.

0 = Device not able to perform 100BASE-TX in full duplex mode.

1 = Device able to perform 100BASE-TX in half duplex mode.

0 = Device not able to perform 100BASE-TX in half duplex mode.

1 = Device able to perform 10BASE-T in full duplex mode.

0 = Device not able to perform 10BASE-T in full duplex mode.

1 = Device able to perform 10BASE-T in half duplex mode.

0 = Device not able to perform 10BASE-T in half duplex mode.

1 = Device able to perform management transaction with preamble suppressed, 32-bits of preamble

needed only once after reset, invalid opcode or invalid turnaround.

0 = Device will not perform management transaction with preambles suppressed.

1 = Auto-Negotiation process complete.

0 = Auto-Negotiation process not complete (either still in process, disabled, or reset)

1 = Remote Fault condition detected (cleared on read or by reset). Fault criteria: Far End Fault

Indication or notification from Link Partner of Remote Fault.

0 = No remote fault condition detected.

1 = Device is able to perform Auto-Negotiation.

0 = Device is not able to perform Auto-Negotiation.

1 = Valid link established (for either 10 or 100 Mb/s operation).

0 = Link not established.

1 = Jabber condition detected.

0 = No Jabber. condition detected.

1 = Extended register capabilities.

0 = Basic register set capabilities only.

www.ti.com

The PHY Identifier Registers #1 and #2 together form a unique identifier for the TLK100. The Identifier

consists of a concatenation of the Organizationally Unique Identifier (OUI), the vendor's model number

and the model revision number. A PHY may return a value of zero in each of the 32 bits of the PHY

Identifier if desired. The PHY Identifier is intended to support network management. The IEEE-assigned

OUI for Texas Instruments is 080028h.

32 Register Block Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

www.ti.com

SLLS931–AUGUST 2009

6.1.3 PHY Identifier Register #1 (PHYIDR1)

Table 6-5. PHY Identifier Register #1 (PHYIDR1), address 0x0002

BIT BIT NAME DEFAULT DESCRIPTION

15 OUI_MSB <0010 0000 0000 OUI Most Significant Bits: Bits 3 to 18 of the OUI (080028h) are stored in bits 15 to 0 of

0000>, this register. The most significant two bits of the OUI are ignored (the IEEE standard refers

RO/P to these as bits 1 and 2).

6.1.4 PHY Identifier Register #2 (PHYIDR2)

Table 6-6. PHY Identifier Register #2 (PHYIDR2), address 0x0003

BIT BIT NAME DEFAULT DESCRIPTION

15:10 OUI_LSB <101000>, OUI Least Significant Bits:

9:4 VNDR_MDL <100000>, Vendor Model Number:

3:0 MDL_REV <0001>, RO/P Model Revision Number:

RO/P

RO/P

Bits 19 to 24 of the OUI (080028h) are mapped from bits 15 to 10 of this register respectively.

The six bits of vendor model number are mapped from bits 9 to 4 (most significant bit to bit 9).

Four bits of the vendor model revision number are mapped from bits 3 to 0 (most significant bit to

bit 3). This field is incremented for all major device changes.

Copyright © 2009, Texas Instruments Incorporated Register Block 33

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

SLLS931–AUGUST 2009

6.1.5 Auto-Negotiation Advertisement Register (ANAR)

This register contains the advertised abilities of this device as they are transmitted to its link partner during

Auto- Negotiation.

Table 6-7. Auto Negotiation Advertisement Register (ANAR), address 0x0004

BIT BIT NAME DEFAULT DESCRIPTION

15 NP 0, RW Next Page Indication:

0 = Next Page Transfer not desired.

1 = Next Page Transfer desired.

14 RESERVED 0, RO/P RESERVED by IEEE: Writes ignored, Read as 0.

13 RF 0, RW Remote Fault:

1 = Advertises that this device has detected a Remote Fault.

0 = No Remote Fault detected.

12 RESERVED 0, RW RESERVED for Future IEEE use: Write as 0, Read as 0

11 ASM_DIR 0, RW Asymmetric PAUSE Support for Full Duplex Links:

1 = Asymmetric PAUSE implemented.

0 = Asymmetric PAUSE not implemented.

10 PAUSE 0, RW PAUSE Support for Full Duplex Links:

1 = MAC PAUSE implemented

0 = MAC PAUSE not implemented

9 T4 0, RO/P 100BASE-T4 Support:

1 = 100BASE-T4 is supported by the local device.

0 = 100BASE-T4 not supported.

8 TX_FD Jumper, RW 100BASE-TX Full Duplex Support:

1 = 100BASE-TX Full Duplex is supported by the local device.

0 = 100BASE-TX Full Duplex not supported.

7 TX Jumper, RW 100BASE-TX Support:

1 = 100BASE-TX is supported by the local device.

0 = 100BASE-TX not supported.

6 10_FD Jumper, RW 10BASE-T Full Duplex Support:

1 = 10BASE-T Full Duplex is supported by the local device.

0 = 10BASE-T Full Duplex not supported.

5 10 Jumper, RW 10BASE-T Support:

1 = 10BASE-T is supported by the local device.

0 = 10BASE-T not supported.

4:0 Selector <00001>, RW Protocol Selection Bits:

These bits contain the binary encoded protocol selector supported by this port. <00001> indicates that

this device supports IEEE 802.3u.

www.ti.com

34 Register Block Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): TLK100

TLK100

www.ti.com

SLLS931–AUGUST 2009

6.1.6 Auto-Negotiation Link Partner Ability Register (ANLPAR) (BASE Page)

This register contains the advertised abilities of the Link Partner as received during Auto-Negotiation. The

content changes after the successful auto-negotiation if Next-pages are supported.