Page 1

SLLS528 – MARCH 2002

FEATURES

0.2-mA to 40-mA (Constant-Current Sink)

D

Drive Capability x 12 Bits Output Count into

24-Pin HTSSOP Package

D 1024 Gray-Scale Display (PWM Control 1024

Steps) with Max 25-MHz Clock Frequency

D 3-Way Brightness Adjustment

– Plane Brightness Adjustment for 64 Steps

(40% to 100%)

– Frequency Division for 16 Steps

(6.3% to 100%)

– Dot Correction for 256 Steps (0% to 100%)

D DS–Link Data Input/Output (Data Rate Max

20 Mbps) with Packet Operation

D 5 Error Information Types and 2 Gray–Scale

Clock Modes

D 3.3-V V

and LVTTL Interface

CC

APPLICATION

Full- or Multi-Color LED Display

D

DESCRIPTION

The TLC5930 is a constant-current sink driver

with an adjustable current value, and 1024 gray

scale display that uses pulse width control. The

output current is 0.2 mA to 40 mA with 12 bits of

RGBx4. The maximum current value of the

constant-current output can be set by one external

resistor.

The TLC5930 includes three kinds of brightness

adjustment functions: one adjusts the plane

brightness between devices, changing the current

values of all outputs uniformly. The second adjusts

the frequency division to controls overall panel

brightness, and the third adjusts the dot correction

per LED, changing the current values of

independent output.

The TLC5930 also includes color–tone correction

function for correcting color per dot (pixel) and

OVM function for constant-current output

terminals used for LED failure detection.

Other features include the thermal error flag

(TEF). The active wire-check (AWC) to check the

communication between the controller and the

device. The LED leakage-detect (LKD) to detect

the reverse leakage on the LED. The GCLK error

flag (GEF) and the HSYNC error flag (HEF) by

monitoring the gray-scale clock count, and the

dual source gray-scale clock (DSG) function to

switch the gray-scale clock to the external input

clock or to switch the internally-generated clock.

PowerPAD is a trademark of Texas Instruments Incorporated.

www.ti.com

The TLC5930 requires three signals for standard

operation: data input and gray-scale clock. Only

three-signal line and 24-pin HTSSOP package

reduce board area and total cost.

Copyright 2002, Texas Instruments Incorporated

1

Page 2

SLLS528 – MARCH 2002

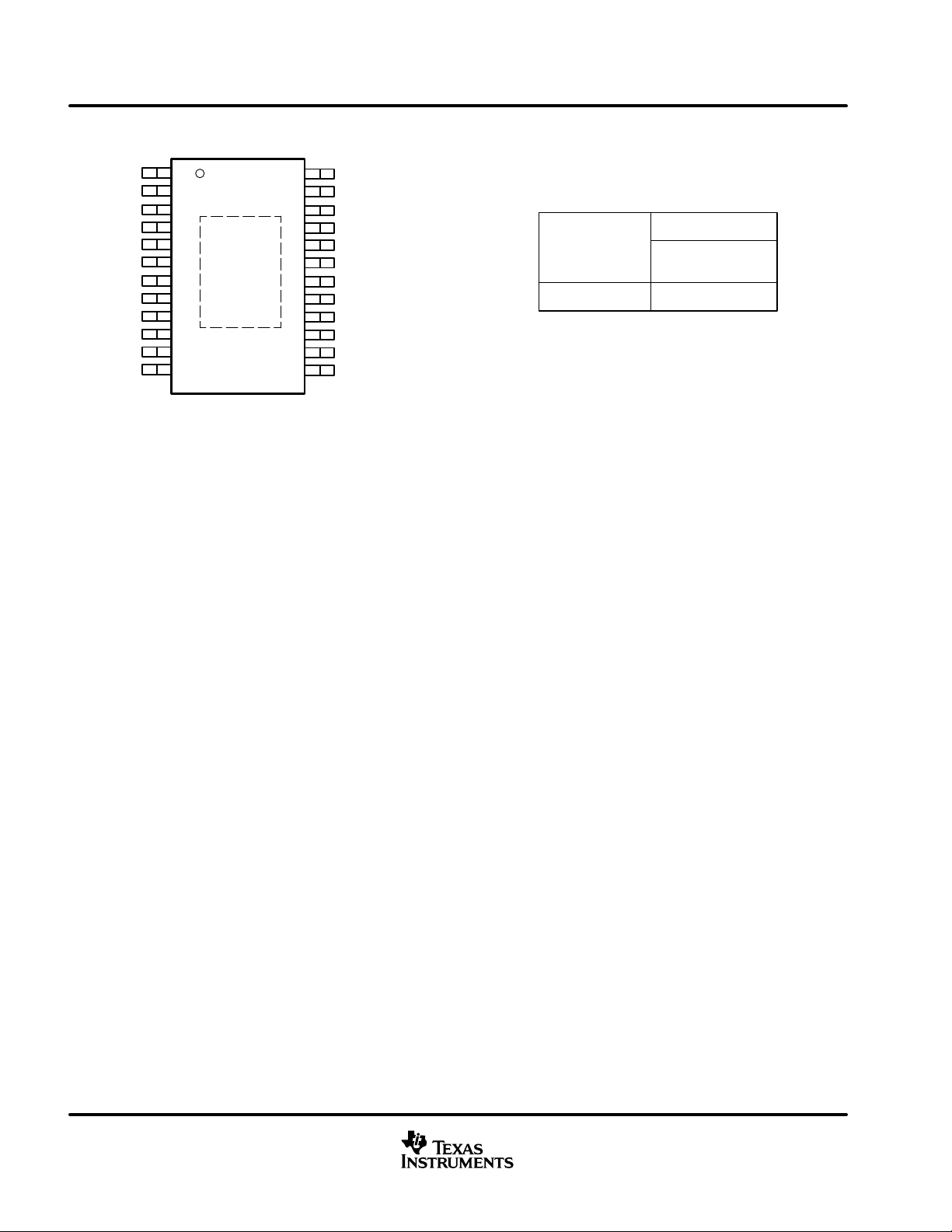

PWP PACKAGE

(TOP VIEW)

OUT0

OUT1

OUT2

GND

OUT3

OUT4

OUT5

GND

DTIN

STIN

GCLK

GND

1

2

3

4

5

6

7

8

9

10

11

12

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

24

23

22

21

20

19

18

17

16

15

14

13

OUT11

OUT10

OUT9

GND

OUT8

OUT7

OUT6

DTOUT

STOUT

XRST

IREF

VCC

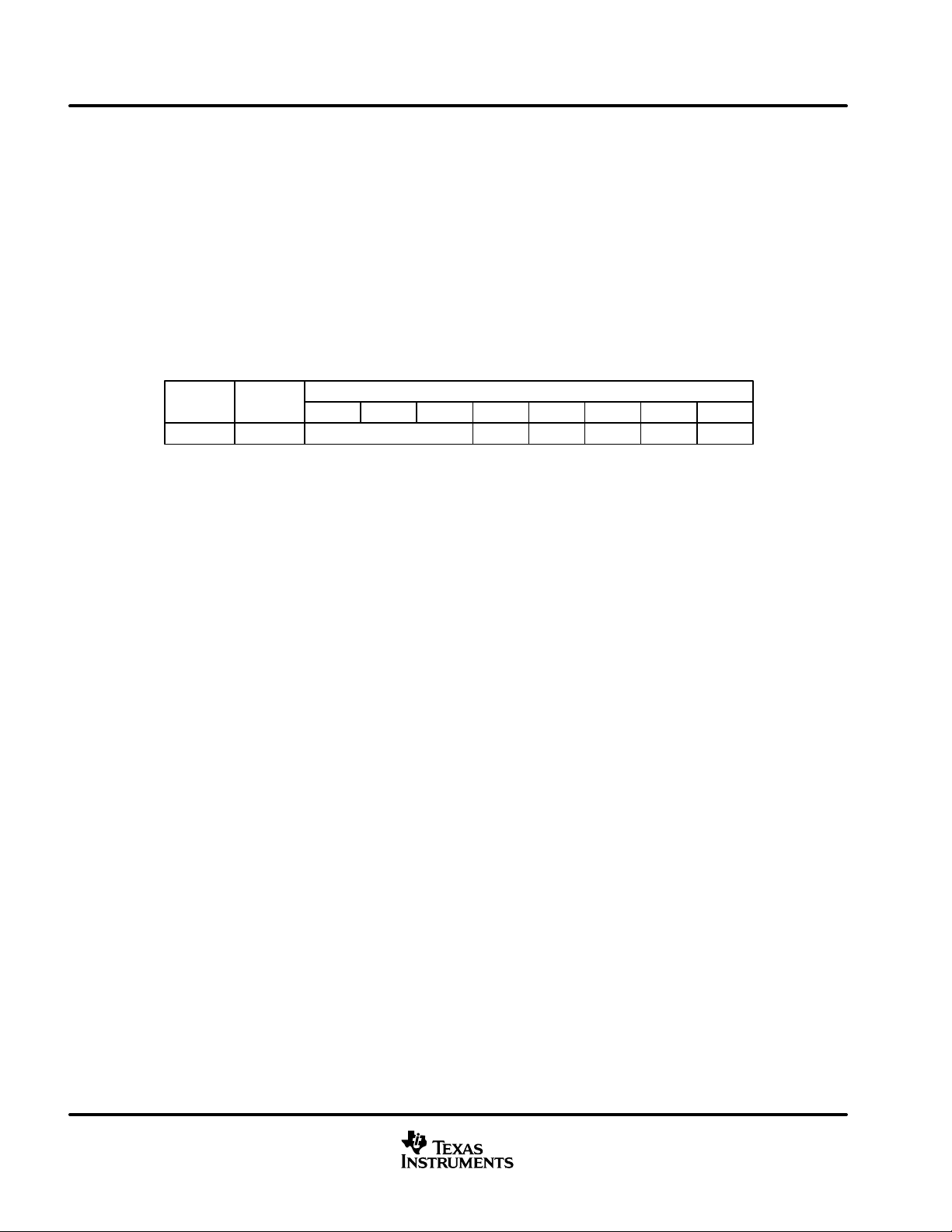

AVAILABLE OPTIONS

T

A

–20°C to 85°C

PACKAGE

PowerPad TSSOP

(PWP)

TLC5930PWP

†

Supply voltage, VCC –0.3 V to 4.0 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output current (dc), I

Input voltage range, V

Output voltage range, V

Storage temperature range, T

Power dissipation rating at (or above) T

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltages values are with respsect to GND terminal.

2. At operating temperature range over 25°C, dependent on derating factor of 41 mW/°C.

O(LC)

IN

DTOUT

V

OUT0 –

V

OUT0 –

stg

, V

V

V

STOUT

, (when off) –0.3 V to 17 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUT11

, (when on) –0.3 V to 10 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OUT11

= 25°C 3.7 W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

–0.3 V to (VCC – 0.2 V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–0.3 V to VCC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

–40°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

45 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

www.ti.com

Page 3

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

t

Á

P

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

SLLS528 – MARCH 2002

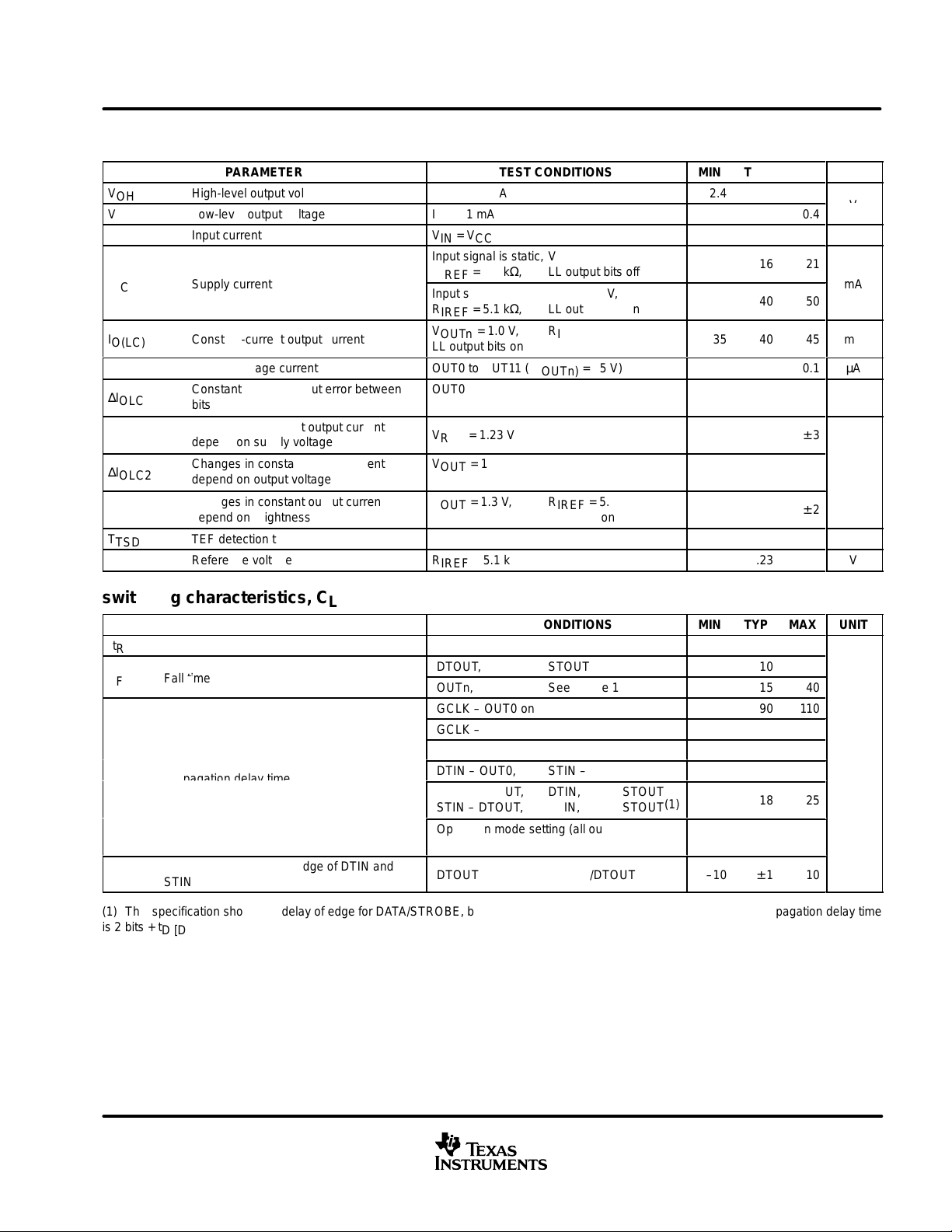

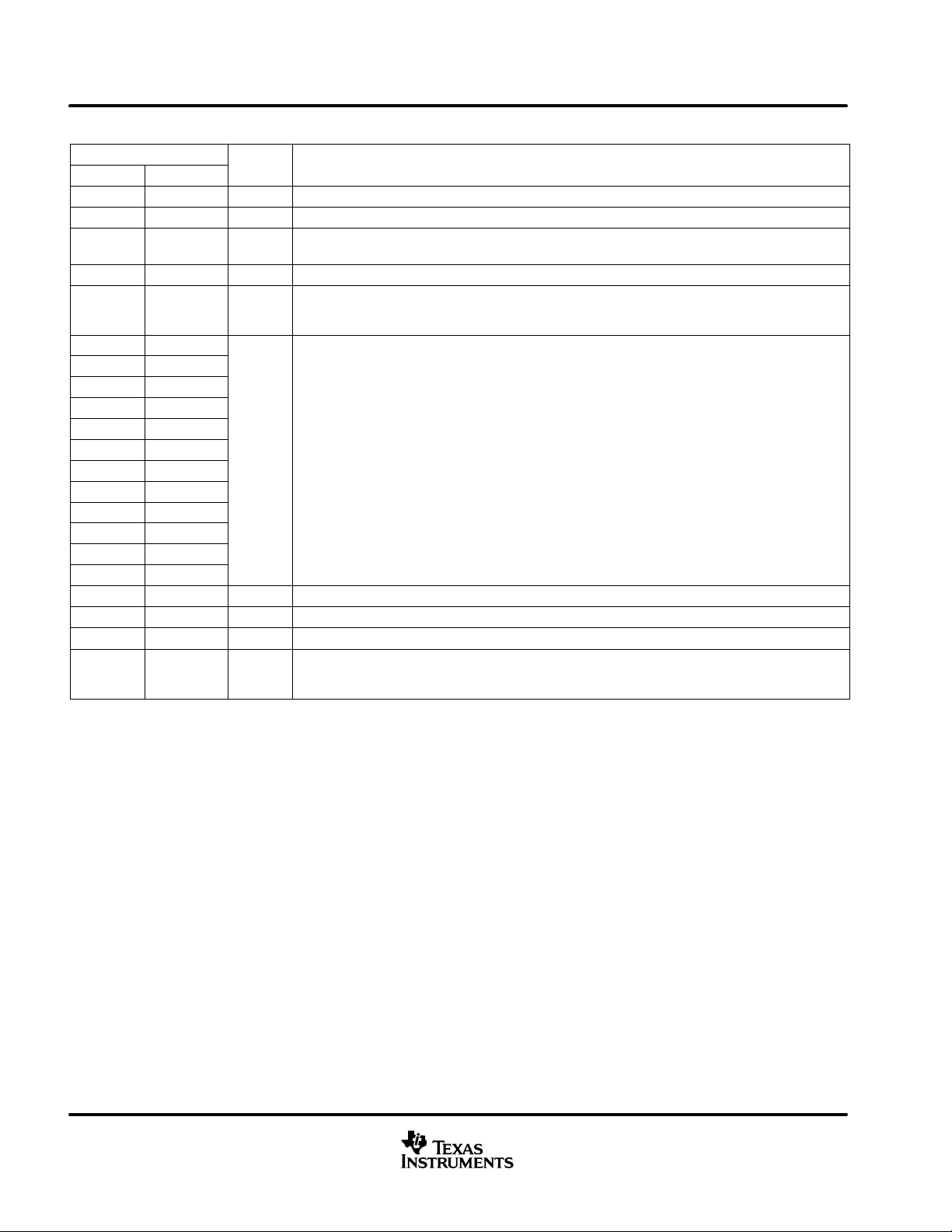

electrical characteristics, MIN/MAX: V

TA = 25°C (unless otherwise noted)

PARAMETER

V

OH

V

OL

I

I

I

CC

ÁÁ

I

O(LC)

I

LKG

∆I

OLC

ÁÁ

∆I

OLC1

∆I

ÁÁ

OLC2

∆I

OLC3

ÁÁ

T

TSD

V

IREF

High-level output voltage

Low-level output voltage

Input current

Supply current

БББББББББ

Constant-current output current

Output leakage current

Constant-current outout error between

БББББББББ

bits

Changes in constant output current

depend on supply voltage

Changes in constant output current

БББББББББ

depend on output voltage

Changes in constant output current

depend on brightness data

БББББББББ

TEF detection temperature

Reference voltage

= 3.0 V to 3.6 V, T

CC

= – 20°C to 85°C, TYP: V

A

TEST CONDITIONS

IOH = – 1 mA

IOL = 1 mA

VIN = VCC or GND

Input signal is static, V

R

= 5.1 kΩ, LL output bits off

IREF

Input signal is static, V

ББББББББББ

R

= 5.1 kΩ, LL output bits on

IREF

V

= 1.0 V, R

OUTn

LL output bits on

OUT0 to OUT11 (V

OUT0 to OUT11 (V

ББББББББББ

R

= 5.1 kΩ

IREF

V

= 1.23 V

REF

V

= 1 V to 3 V, R

OUT

ББББББББББ

V

= 1.23 V, 1 bit light on

IREF

V

= 1.3 V, R

OUT

V

= 1.23 V, 1 bit light on

IREF

ББББББББББ

OUT

OUT

IREF

(OUTn)

(OUTn)

IREF

IREF

= 1 V,

= 1 V,

= 5.1 kΩ,

= 15 V)

= 1 V),

= 5.1 kΩ,

= 5.1 kΩ,

Junction temperature

R

= 5.1 kΩ

IREF

CC

MIN

TYP

MAX

2.4

16

35

40

40

160

1.23

Á

± 4%

170

ÁÁÁ

ÁÁÁÁÁ

ÁÁÁÁÁ

ÁÁÁÁÁ

150

= 3.3 V,

0.4

± 1

21

50

45

0.1

± 3

± 1

± 2

UNIT

µA

mA

Á

mA

µA

Á

%/V

Á

Á

°C

V

V

switching characteristics, CL = 15 pF

PARAMETER

t

R

t

F

Rise time

Fall time

DTOUT, STOUT

DTOUT, STOUT

OUTn, See Figure 1

GCLK – OUT0 on

GCLK – OUT0 off

[(OUTn + 1) – OUTn]

PD

Á

p

ropagation delay time

ББББББББББ

DTIN – OUT0, STIN – OUT0

DTIN – DTOUT, DTIN, STOUT

ББББББББББ

STIN – DTOUT, STIN, STOUT

Operation mode setting (all output force off)

– OUT0 off

t

EDGE

Duty deviation between edge of DTIN and

Á

ББББББББББ

STIN

DTOUT/STOUT, STOUT/DTOUT

ББББББББББ

(1) This specification shows the delay of edge for DATA/STROBE, but data appears in the output with 2 bits delay. (Data propagation delay time

is 2 bits + tD

[D/STIN – D/STOUT]

)

TEST CONDITIONS

(1)

ÁÁÁ

Á

MIN

–10

TYP

Á

12

10

15

90

35

25

18

60

± 1

MAX

110

Á

Á

15

13

40

60

40

60

25

90

10

UNIT

ns

Á

Á

www.ti.com

3

Page 4

V

mA

SLLS528 – MARCH 2002

recommended operating conditions

dc characteristics

PARAMETER

Supply voltage, V

Voltage applied to constant-current output, V

High-level input voltage, V

Low-level input voltage, V

High-level output current, I

Low-level output current, I

Constant output current, I

Operating free-air temperature range, T

CC

O

IH

IL

OH

OL

O(LC)

A

CONDITIONS

OUT0 to OUT11 off

OUT0 to OUT11 on

VCC = 3.1 V @ DTOUT, STOUT

VCC = 3.1 V @ DTOUT, STOUT

OUT0 to OUT11

MIN

GND

3.0

2.0

– 20

MAX

VCC

– 1.0

3.6

15

10

0.8

1.0

40

85

UNIT

V

mA

°C

ac characteristics, V

PARAMETER

f

(GCLK)

t

(EDGE)

t

w(H)/tw(L)

t

w(L)

t

(DATA)

t

SU

(1) This is the frequency when any output is obtailed at two or more than gray-scale entered.

GCLK clock frequency

Time between edges

GCLK pulse duration

XRST reset pulse duration

Data transfer rate

Setup time

= 3.1 V to 3.5 V, T

CC

(1)

= –20°C to 85°C (unless otherwise noted)

A

CONDITIONS

2 gray scale inputs I

DTIN – STIN, STIN – DTIN

HSYNC – GCLK

O(LC)

= 40 mA

MIN

30

20

MAX

1

25

20

6.5

UNIT

MHz

ns

ms

Mb/s

ns

4

www.ti.com

Page 5

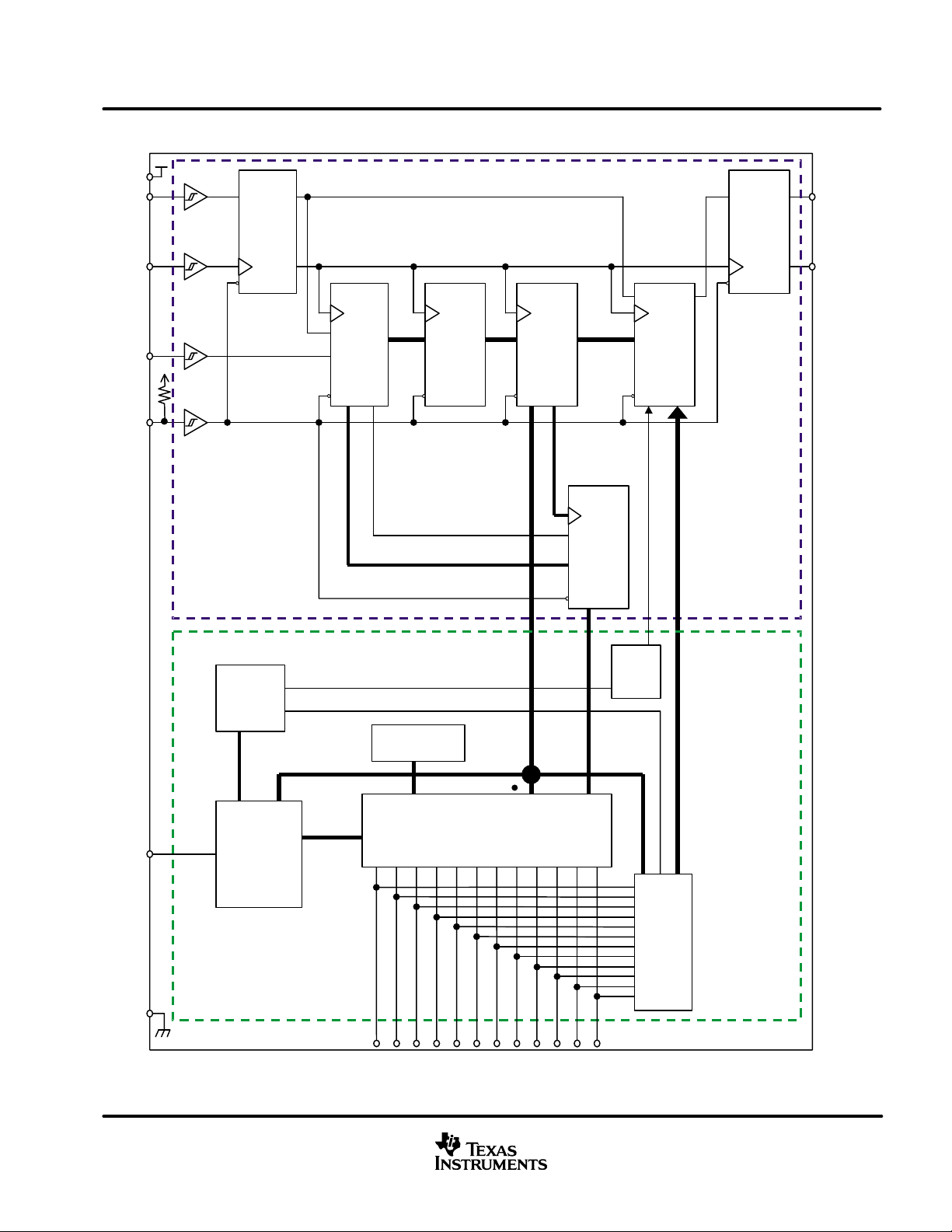

functional block diagram

SLLS528 – MARCH 2002

VCC

DTIN

STIN

GCLK

XRST

330 kΩ

D/S

Link

Decoder

CLR

Communication Logic

CLK

Packet

Interface

BLANK, FON, FOF, INHSW, INHCS

Packet

Shift

Register

GSCLK

Packet

Data

Latch

GS, BCP

PWM

Controller

Packet

Interface

DMDATA

D/S

Link

Decoder

DTOUT

STOUT

IREF

GND

Bandgap

Reference

Generator

BG, IBC

BG

Reference

Voltage

&

Bias Current

Generator

GND = DGND, AGND, LGND

ITEF

IOVM

BC

IDC,ICC

Analog Converter

Trimming

Circuit

Digital to Analog Converter

12-Bit Constant Current Driver

OUT2

OUT1

OUT0

OUT4

OUT3

&

OUT5

DC, CC

OUT6

OUT7

OUT9

OUT8

SW, CSW

OUT11

OUT10

Thermal

Error

Flag

Output

Voltage

Monitor

&

LED Leak

Detector

www.ti.com

5

Page 6

SLLS528 – MARCH 2002

Terminal Functions

TERMINAL

NAME NO.

DTIN 9 I DS–link data input

DTOUT 17 O DS–link data output

GCLK 11 I

GND 4, 8, 12, 21 – Ground

IREF 14 I/O

OUT0 1

OUT1 2

OUT2 3

OUT3 5

OUT4 6

OUT5 7

OUT6 18

OUT7 19

OUT8 20

OUT9 22

OUT10 23

OUT11 24

STIN 10 I DS–link strobe input

STOUT 16 O DS–link strobe output

VCC 13 I Power supply

XRST 15 I

I/O

Clock input for gray scale. The gray scale display is accomplished by lighting the LED until the

number of the gray-scale clock counted is equal to the data latched.

Constant-current value setting. LED current is set to the desired value by connecting an external

resistor between IREF and GND. The 168 times current compared to current across the external

resistor flows through the constant-current output terminals.

Constant-current output.

O

Reset signal. This signal is used to initialize the device reset is accomplished by pulling this pin low

(internally pulled up with a 330-kΩ resistor). If not used, this terminal should be left open or connect

to VCC.

DESCRIPTION

6

www.ti.com

Page 7

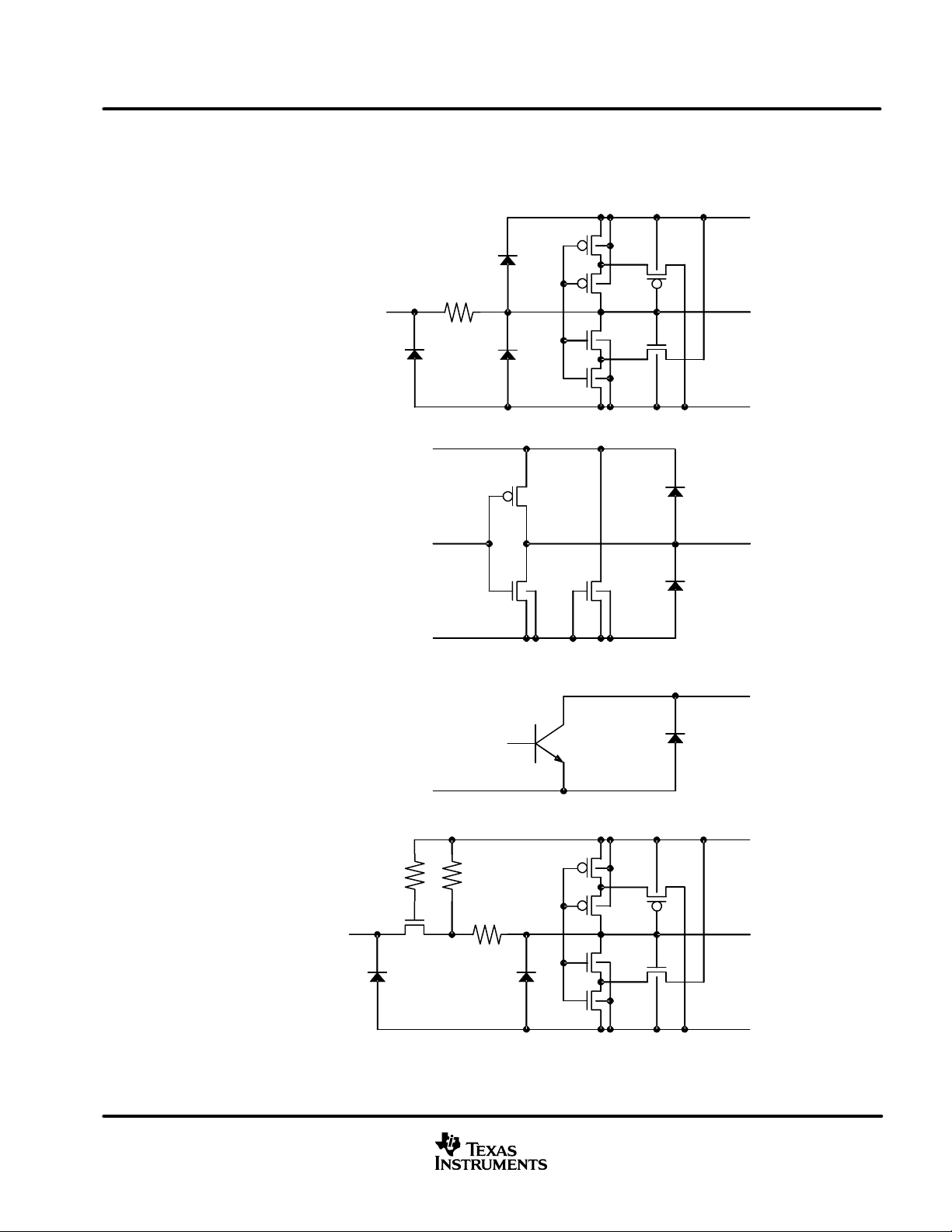

PIN EQUIVALENT INPUT AND OUTPUT SCHEMA TIC DIAGRAMS

DTIN, STIN, GCLK

PAD

SLLS528 – MARCH 2002

VCC

DTOUT, STOUT

OUTn

XRST

GND

VCC

PAD

GND

PAD

GND

VCC

PAD

330 k

www.ti.com

GND

7

Page 8

SLLS528 – MARCH 2002

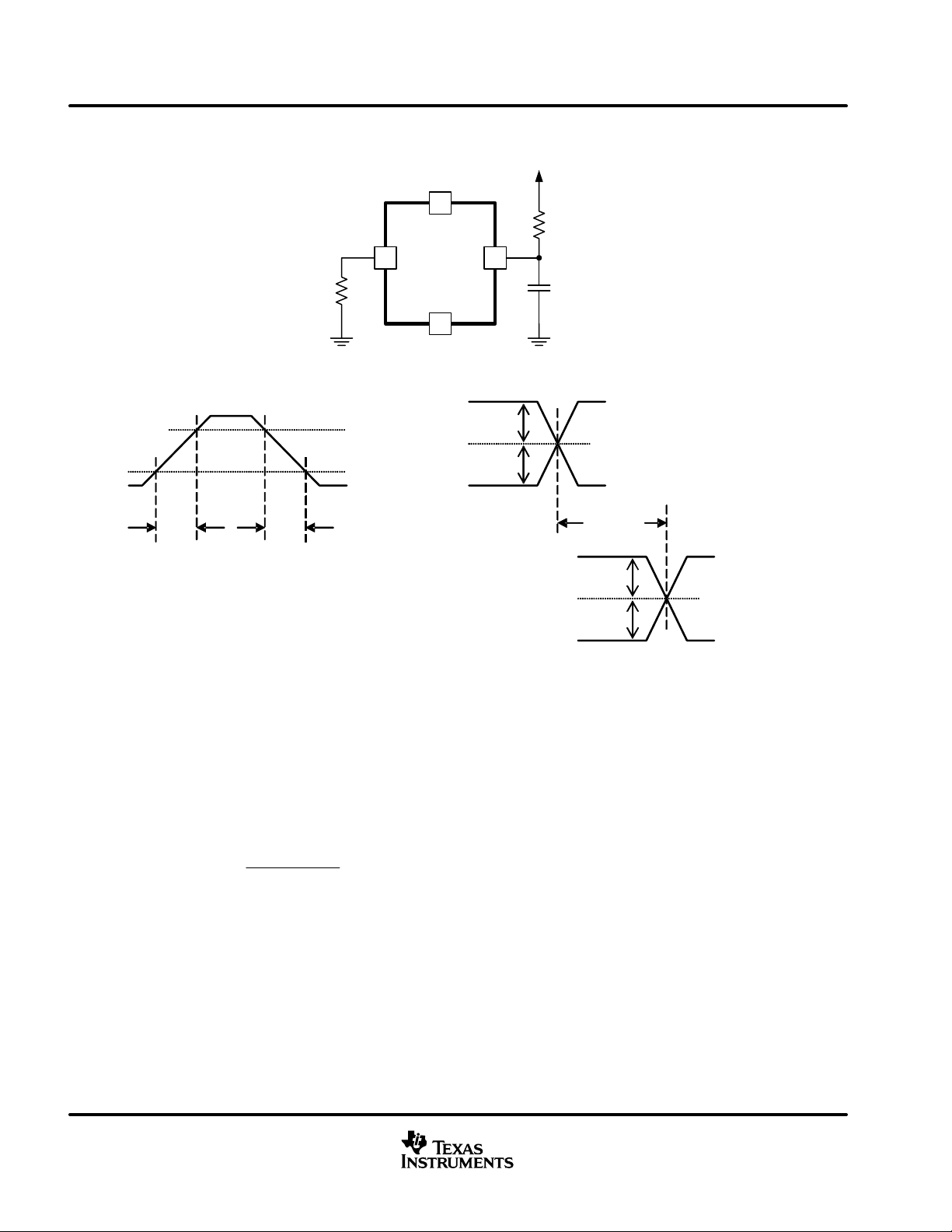

TIMING DIAGRAMS

VCC

VIL

Figure 1. Rise Time and Fall Time Test Circuit for OUTn

VIH

tR tF

5.1 kΩ

90%

10%

VCC

IREF OUTn

GND

56 Ω

15 pF

VIH or VOH

50%

50%

VIL or VOL

txxxx

VIH or VOH

50%

50%

VIL or VOL

Figure 2. Timing Requirements

PRINCIPLES OF OPERATION

setting for constant output current value

On the constanct current output terminals (OUT0 to OUT11), approximately 168 times the current that flows

through the external resistor, R

is calculated using the following equation:

R

where R

(IREF)

(IREF)

(W) +

168 1.23 V

I

O(LC)

should be ≤ 4.88 kΩ

Note that more current flows if IREF is connected directly to GND.

, (connected between IREF and GND) can flow. The external resistor value

IREF

(A)

(1)

8

www.ti.com

Page 9

NO. OF

NO. OF

SLLS528 – MARCH 2002

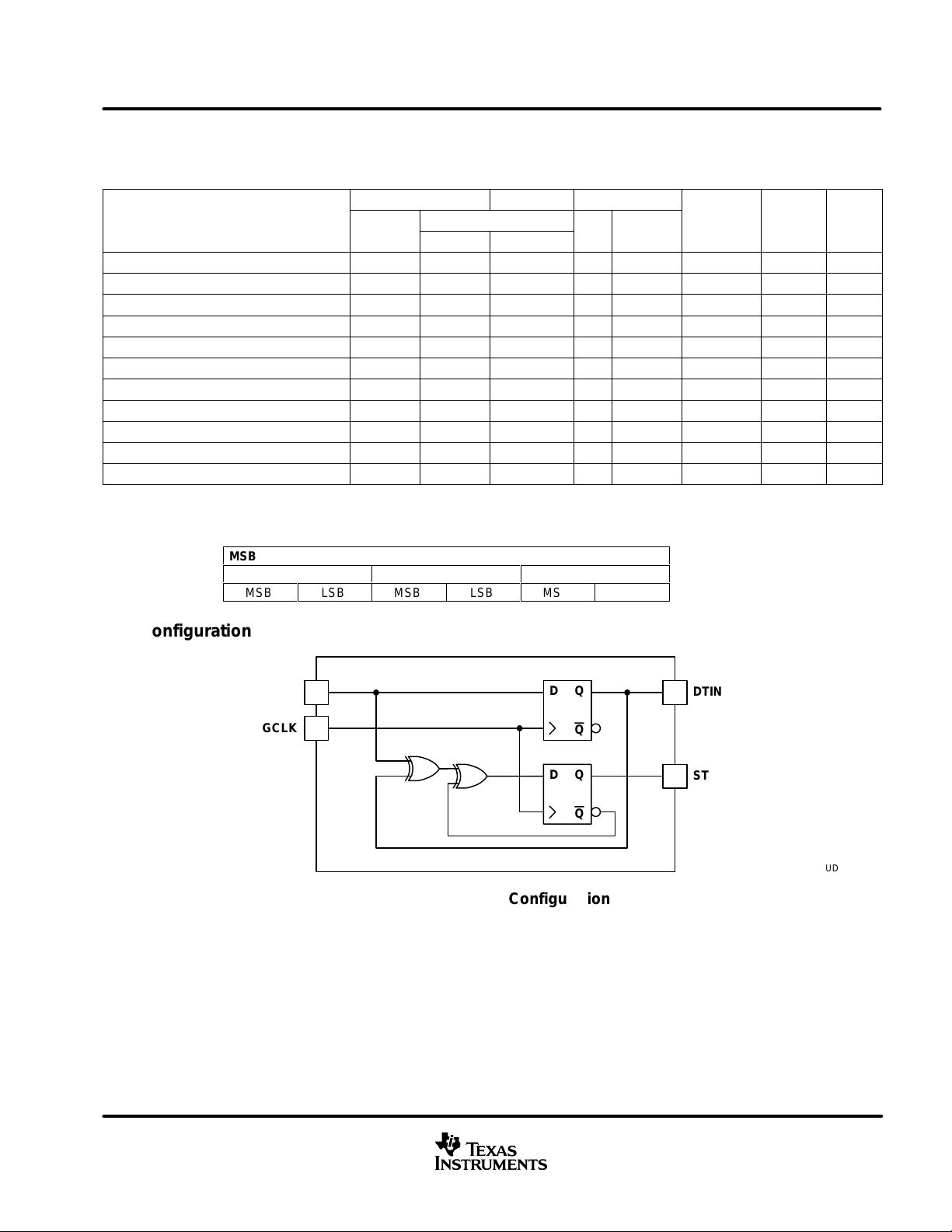

PRINCIPLES OF OPERATION

command packet list

ID COMMAND

FUNCTION

Internal reset 00 X 00 00000000 8(03h) 24 Write

Gray scale data setting 00or01.FF X X 02 00000010 10x12 output 136 Write

Dot correction data setting 00or01.FF X X 04 00000100 8x12 output 112 Write

Color tone correction data setting 00or01.FF X X 08 00001000 8x4set 48 Write

Plane brightness adjustment data setting 00or01.FF X X 10 00010000 16 32 Write

Color tone correction control setting 00or01.FF X X 20 00100000 8 24 Write

Operation mode setting 00or01.FF X X 40 01000000 16 32 Write

OVM information read 00or01.FF X X 50 01010000 16 32 Read

Failure monitor information read 00or01.FF X X 60 01100000 8 24 Read

Automatical ID setting 00 X 70 01110000 16(min) 32(min) Write

HSYNC synchronization 00 X 80 10000000 16 32 Wr/Rd

NOTE Common control is applied to all the devices connected. Indidual control is applied to the device specified by ID.

HEX

CONTROL

COMMON INDIVIDUAL

HEX BIN

DATA

BITS BITS

PACKET MODE

basic packet configuration

MSB LSB

ID (8 bit)

MSB

data configuration

DATA

GCLK

LSB

CMD (8 bit)

MSB

LSB

DATA (0 to 120 bit)

MSB

DQ

Q

DQ

Q

Figure 3. DS LINK Configuration

LSB

DTIN

STIN

UDG–02058

www.ti.com

9

Page 10

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

packet operation

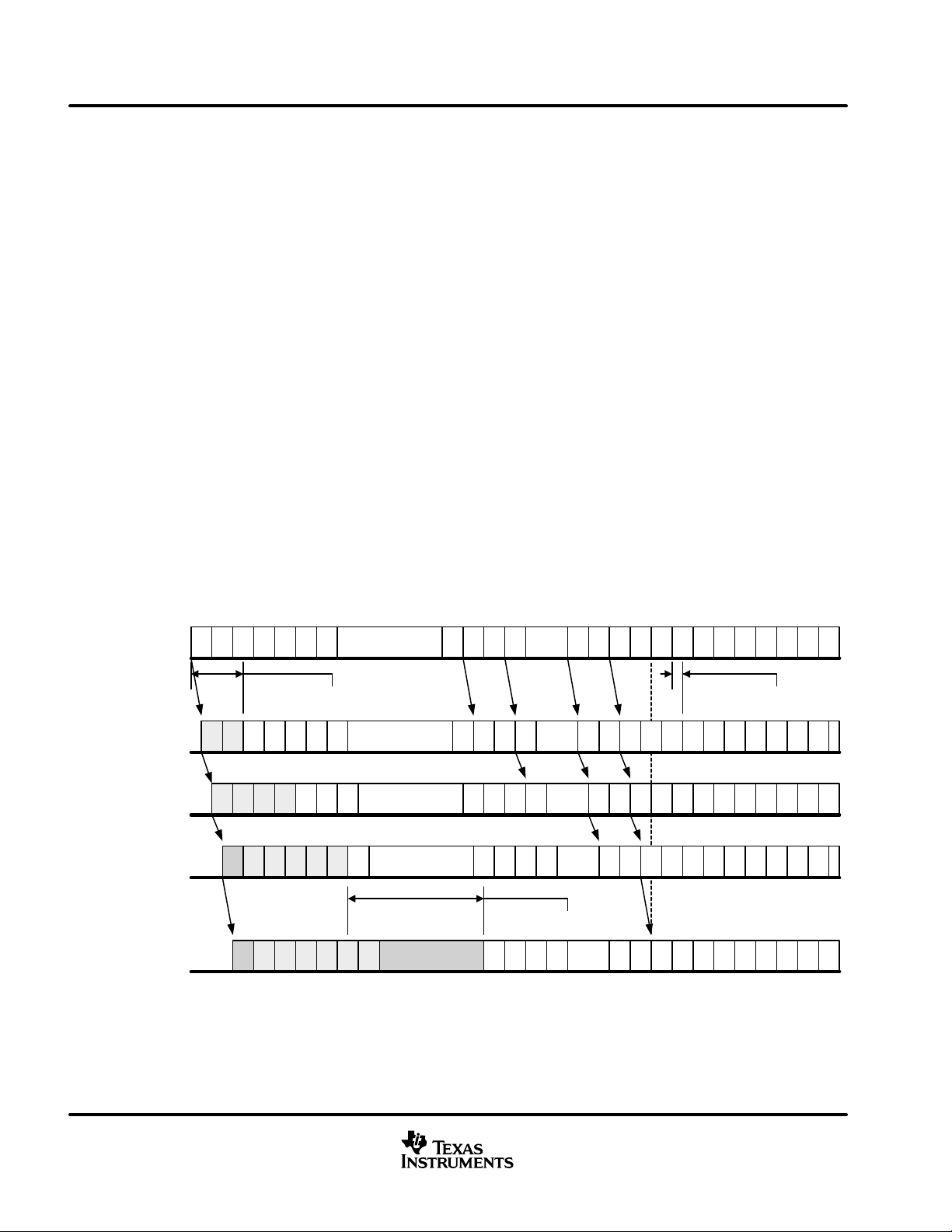

Data output is performed with delay of two bits from input. In other words, by using the edge of the input, data

before two b i t s appear in the output terminal. Figure 4 shows the concept for data transfer when some TLC5930s

are connected in a cascade, where data A–Z indicates valid data, and the asterisk (*) marks invalid data. Also,

data A is a first data input from controller, and there is assumed to be no data transition for DATA/STROBE

between [H and I] and [S and T] in the IC1 input data.

Invalid data is clocked out corresponding to the input edge to ensure that no data exists before data A. After

that, data A is clocked out with a time delay of two bits plus t

D(D/STIN–D/STOUT)

Once data output is started, data before two bits from current input is sequentially clocked out using the input

edge. It should be noted that data output stays during no transition of DATA/STROBE, since no input edge

makes the out p u t edge. Figure 4 shows that the output of IC1 remains in data F and does not go to data G until

the edge of input data I is entered (after IC1 clocked out data F , although the input data of IC1 is continued from

A to H.)

If data A to H are included in one packet, the data output for each output of the device in data H, (which indicates

the completion of packet operation), is performed out at the edge establishing data J for IC1, data L for IC2, data

O for IC3, and data Q for IC4 from the view of controller. In other words, in order to complete the packet operation

for all the devices connected in cascades, additional bit data equivalent to two times the number of devices

cascaded is needed to be clocked in.

using the input edge for data C.

Additionally , s i n c e e a c h d evice has the time delay, T

D(D/STIN–D/STOUT)

, from input to output, the controller views

that output having a time delay exceeding two bits against a virtual input to IC1. In this example, while, in

practice, the output data H for IC4 is established by the input edge of data Q, it appears to be synchronized with

data S for IC1.

A B C D E F G H I J K L M O P Q R S T U V W X Y Z

IC1 INPUT DATA

t

D(D/STIN–D/STOUT)

M O P Q R SI J K LGC DA B

M O P QI J K LGC DA B F

IC2 INPUT DATA

IC1 OUTPUT DATA

IC3 INPUT DATA

IC2 OUTPUT DATA

IC4 INPUT DATA

IC3 OUTPUT DATA

IC4 OUTPUT DATA

2 bit+t

D(D/STIN–D/STOUT)

A B C D E G H F I J L MK O P Q R S T U V W X

**

* * **

* * **

* * **

A B C D E G H F I J L MK O P Q R S T U V

F

**

* *

**

E

2-bit + tD

(D/STIN – D/STOUT)

H

E

H

UDG–02032

10

Figure 4. Data Transfer Concept in Cascade Connection

www.ti.com

Page 11

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

As shown in Figure 4, in order for all the cascade-connected devices to complete one packet operation,

additional bit data to input to the first stage equivalent to two times the number of devices cascaded is required

to be clocked in. But, in practice, sending just any data is not acceptable, and some packets with bits

corresponding to two times the number of devices connected are needed for synchronization to be successful.

For example, in the case that 16 ICs are connected in cascade, since 16 x 2 = 32 bits are needed to complete

the packet operation of sixteenth IC, OVM information reading packet as a dummy, which does not write any

data to the device, is desirable. Or, an alternative method to send any packet such as use of unused ID (e.g.

FFh) is available.

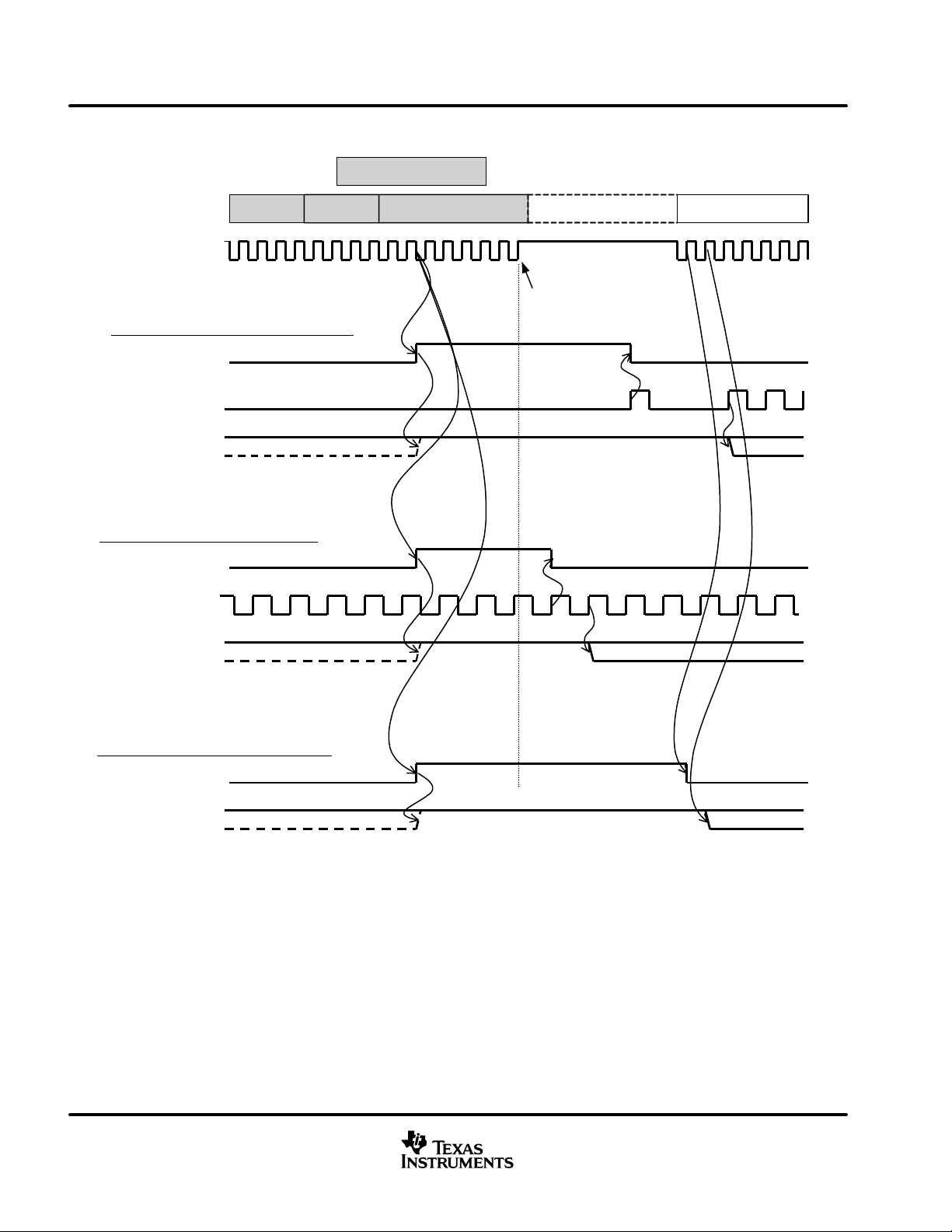

Figure 5 shows the concept for normal lighting-ON operation (based on pulse-width control method). Internal

BLANK goes high on the falling edge of the 21st bit in the HSYNC packet. If the constant-current output is ON

at that time, it is turned off (except for force on mode), and the data for which the latch flag is set in the HSYNC

packet is la t ched during internal BLANK high-level. Internal BLANK goes low on the rising edge of the gray-scale

clock (GCLK) after the edge of LSB (32nd bit) for HSYNC packet, and the TLC5930 goes into the status that

can be turned on by the constant-current output. The constant-current output is turned on by the next rising edge

of the gray-scale clock.

During power up, the initial value of BLANK is at a high level, therefore, operation for BLANK and

constant-current output when HSYNC packet is entered for the first time as a normal operation is dif ferent from

the example shown in Figure 5.

In addition, since BLANK and the gray-scale clock are ignored in the force-ON mode, the timing to be lighted

on is also different from the example shown in Figure 5.

www.ti.com

11

Page 12

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

HSYNC packet

DATA INPUT

1

INTERNAL CLOCK

When Gray Scale Clock is Not Sequential

INTERNAL BLANK

GCLK

CONSTANT

CURRENT OUTPUT

When Gray Scale Clock Is Sequential

INTERNAL BLANK

GCLK

CONSTANT

CURRENT OUTPUT

10

20

DATA

Next PacketID CMD

30

LSB of HSYNC Packet

Light ON

Light ON

When Internal Gray Scale Clock Is Used

INTERNAL BLANK

CONSTANT

CURRENT OUTPUT

12

Light ON

Figure 5. Normal Lighting-ON Operation

www.ti.com

Page 13

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

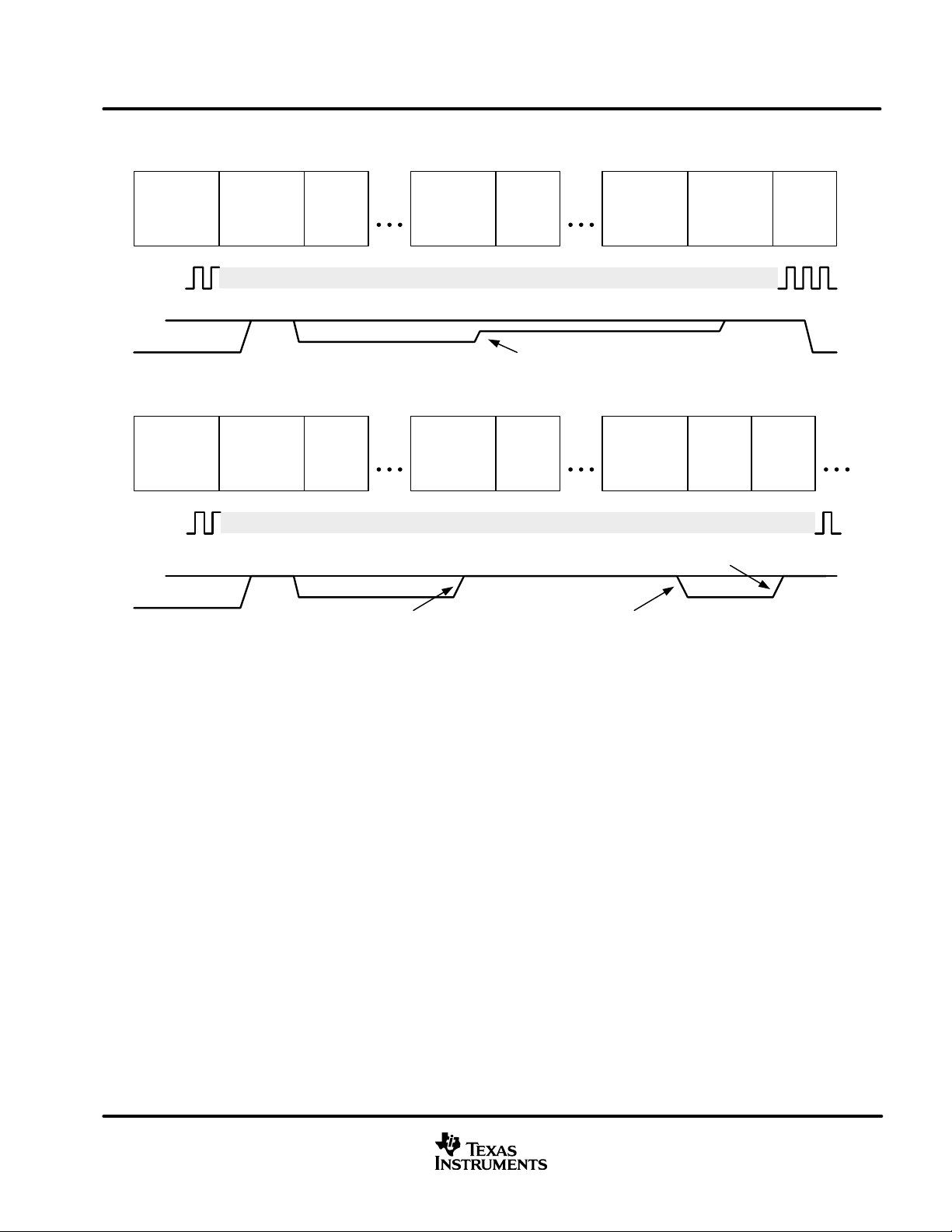

There are two different methods available as shown in Figure 6 for entering the gray-scale clock when in

light-ON mode. When the gray-scale clock is sequential, lighting-ON by the device is initiated after the HSYNC

packet operation for each device has been completed. When the external clock is used as gray-scale clock, all

the devices can be lighted-ON simultaneously by entering the gray scale clock after the HSYNC packet is

entered for the last device (in this example, just after OVM information reading packet has entered to IC1).

When Light-ON in a 4 Gray Scale With 16 ICs

When Gray Scale Clock Is Sequential (Including Use of Internally Generated Gray-Scale Clock)

GRAY SCALE

CLOCK

IC1 D/STIN

IC2 D/STIN

IC15 D/STIN

IC16 D/STIN

When Gray Scale Clock Is Not Sequential (External Input Only)

GRAY SCALE

CLOCK

IC1 D/STIN

HSYNC Packet 32 bits

IC1 Constant Current Output

HSYNC Packet 32 bits

IC2 Constant Current Output

Other Packet

IC15 Constant Current Output

Other Packet

IC16 Constant Current Output

HSYNC Packet 32 bits

IC1 Constant Current Output

OVM Information Reading Packet 32bits

OVM Information Reading Packet 32bits

ON

OVM Information Reading Packet 32bits

ON

HSYNC Packet 32 bits

ON

HSYNC Packet 32 bits

ON

ON

IC2 D/STIN

IC15 D/STIN

IC16 D/STIN

HSYNC Packet 32 bits

IC2 Constant Current Output

Other Packet

IC15 Constant Current Output

Other Packet

IC16 Constant Current Output

Figure 6. Lighting-ON Operation With 16 Devices

OVM Information Reading Packet 32bits

HSYNC Packet 32 bits

HSYNC Packet 32 bits

www.ti.com

ON

ON

ON

13

Page 14

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

command packet and operation

internal reset

By sending this packet once, the internal register within all the devices connected is set to the default value and

synchronized with the controller. Note that individual reset for the device is not available.

packet configuration

ID (bin)

00000000

default value

REGISTER DEFAULT VALUE COMMENTS

ID xxxxxxxx Indeterminate (no write) Automatic ID setting

Plane brightness 111111 (bin) 100%

Frequency division ratio 0000 (bin) 1/1 (no frequency division)

Dot correction 11111111 (bin) × 12 (output) 100% Dot correction data setting

Color tone correction 00000000 (bin) × 4 0% Color tone correction setting

Gray scale 0000000000 (bin) × 12 (output) 0 Gray scale data setting

CCEN–2

(color tone correction ON/OFF)

FORCE OFF 0 Normal operation Operation mode setting

FORCE ON 0 Normal operation Operation mode setting

DCEN 0 Dot correction disable Operation mode setting

BCEN 0 Brightness control disable Operation mode setting

LKDEN 0 LKD disable Operation mode setting

DSGSL 0 Use GCLK terminal Operation mode setting

OVM comparator voltage 0000 (bin) 0.3 V Operation mode setting

OVMF, OVMFA, GEF, HEF,

TEF

000 (bin) Color tone correction disable Color tone correction control

1

CMD (bin)

00000000

CMD (bin)

00000011

Plane brightness adjustment

data setting

Plane brightness correction

data setting

HSYNC, fault information

reading

initialization

During power up, the device is in an indeterminate condition. To fully reset the device after power up, it is

necessary to send an internal reset packet after entering the reset pulse to the XRST terminal or after sending

a 0 to each device 256 times as a dummy and then 03h.

Table 1. Input Configuration After Power-Up When Using XRST (reset pulse + 24 bit)

XRST

RESET (NEGATIVE PULSE)

(03000003h)

Note: Both DTIN and STIN should be 0 during XRST 0.

INTERNAL RESET PACKET

00000000

00000000

00000011

Table 2. Input Configuration After Power-Up When Not Using XRST (256 bit × devices + 24 bit)

14

DUMMY (bin)

0 (256 × devices)

(00h [256 bits × n] + 03000003h)

DATA (bin)

00000011

00000000

www.ti.com

INTERNAL RESET PACKET

00000000

00000011

Page 15

CMD

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

Á

Á

ÁÁÁ

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

ÁÁÁ

ÁÁÁ

ÁÁÁ

Á

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

gray scale data

Using this packet, the same gray-scale data can be written to all the connected devices simultaneously or

different gray-scale data can be written to each device.

The constant-current output is turned on (constant-current flows), except that gray-scale data entered to

gray-scale data latch is 0, synchronizing with the next rising edge of the gray-scale clock after the rising edge

of the gray-scale clock with the time delay of t

the 10-bit gray-scale counter counts the number of rising edge of the gray-scale clock and outputs is matched

to gray-scale data is turned off (constant-current flow stops).

The user can select either the gray scale clock using GCLK terminal input or the internally generated clock using

DTIN/STIN terminal input. (See DSG function section for more detail)

Table 3. Packet Configuration (136-bit)

from the edge of DTIN/STIN of HSYNC packet LSB. Thereafter ,

su

ID

(bin)

xxxxxxxx

CMD

(bin)

00000010

DATA

OUT0

10 bit

OUT1

10 bit

OUT2

10 bit

OUT3

10 bit

OUT4

10 bit

OUT5

10 bit

OUT6

10 bit

OUT7

10 bit

OUT8

10 bit

OUT9

10 bit

OUT10

10 bit

OUTn

dt [9]

Á

ББББББББББББББББББББББÁÁÁÁÁ

dt [8]

ÁÁ

0

0

1

1

dt [7]

0

0

1

1

Á

0

0

1

1

dt [6]

Á

dt [5]

ÁÁ

0

0

1

1

0

0

1

1

dt [4]

Á

0

0

1

1

dt [3]

Á

dt [2]

ÁÁ

0

0

1

1

0

0

1

1

dt [1]

Á

0

0

1

1

dt [0]

Á

0

1

0

1

GRAY SCALE

DATA

ÁÁÁÁ

0

1

.

.

.

1023

1024

(xx02xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxh) After ID and CMD, 10 bit data continues 12 output

OUT11

10 bit

www.ti.com

15

Page 16

CMD

ÁÁÁ

ÁÁÁ

Á

Á

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

Á

ÁÁÁ

ÁÁÁ

Á

Á

ÁÁÁ

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

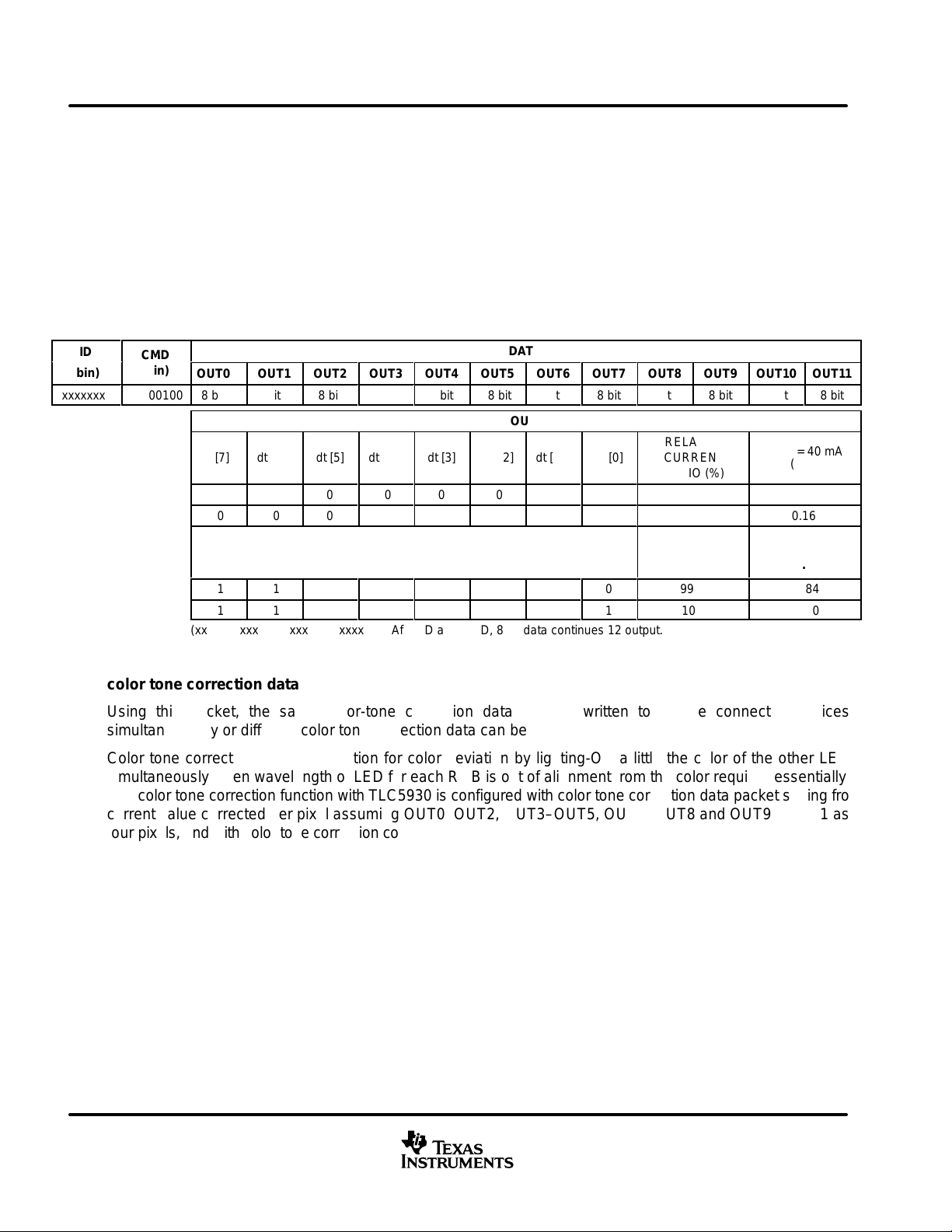

dot correction data

Using this packet, the same dot correction data can be written to all connected devices simultaneously, or

different dot correction data can be written to each device.

The dot correction register latch is configured with 12 output x 8 bit; the current value on each constant output

current can be adjusted in 256 steps as 1 step of 0.4% of current ratio between 100% and 0% when output

current is set to 100% by adjusting external resistor and brightness adjustment data. By using this function,

brightness deviation due to brightness variation of LED can be reduced.

Table 4. Packet Configuration (112-bit)

OUT5

8 bit

DATA

OUT6

8 bit

OUT7

8 bit

OUT8

8 bit

OUT9

8 bit

ID

(bin)

xxxxxxxx

CMD

(bin)

00000100

OUT0

8 bit

OUT1

8 bit

OUT2

8 bit

OUT3

8 bit

OUT4

8 bit

OUTn

RELATIVE

dt [7]

ÁÁ

0

0

dt [6]

Á

dt [5]

Á

0

0

0

0

dt [4]

ÁÁ

0

0

dt [3]

Á

0

0

dt [2]

ÁÁ

0

0

dt [1]

Á

dt [0]

Á

0

0

0

1

CURRENT

ÁÁÁÁ

RATIO (%)

0.0

0.4

.

.

ББББББББББББББББББÁÁÁÁÁ

1

1

1

1

1

1

1

1

1

1

1

1

1

1

0

1

.

99.6

100

(xx04xxxxxxxxxxxxxxxxxxxxxxx xh) After ID and CMD, 8 bit data continues 12 output.

color tone correction data

Using this packet, the same color-tone correction data can be written to all the connected devices

simultanoeously or different color tone correction data can be written to each device.

Color tone correction makes correction for color deviation by lighting-ON a little the color of the other LED

simultaneously when wavelength of LED for each RGB is out of alignment from the color required essentially.

The color tone correction function with TLC5930 is configured with color tone correction data packet setting fro

current value corrected per pixel assuming OUT0–OUT2, OUT3–OUT5, OUT6–OUT8 and OUT9–OUT11 as

four pixels, and with color tone correction control packet which controls ON/OFF by OUT0, OUT3, OUT6, OUT9,

and OUT1, OUT4, OUT7, OUT10, and OUT2, OUT5, OUT8, and OUT11 assuming that same color is assigned

for OUT0, OUT3, OUT6, OUT9 and OUT1, OUT4, OUT7, OUT10 and OUT2, OUT5, OUT8, and OUT11

respectively.

OUT10

8 bit

I

ÁÁÁÁ

OLC

OUT11

8 bit

= 40 mA

(mA)

0.0

0.16

.

.

.

ÁÁÁÁ

39.84

40.00

The current value for color tone correction set by this packet is set per pixel for OUT0–OUT2, OUT3–OUT5,

OUT6–OUT8, and OUT9–OUT11. In other words, the current value for color tone correction is same in

OUT0–OUT2, OUT3–OUT5, OUT6–OUT8, and OUT9–OUT11.

16

www.ti.com

Page 17

Á

БББББББББББББББ

Á

Á

ÁÁÁ

ÁÁÁ

БББББ

Á

Á

ÁÁÁ

Á

Á

Á

Á

ÁÁÁ

Á

Á

Á

Á

БББББ

Á

Á

Á

ÁÁÁ

ÁÁÁ

БББББ

ÁÁÁ

ÁÁÁ

БББББ

Á

Á

БББББББББББББББ

Á

Á

БББББ

Á

Á

Á

ÁÁÁ

ÁÁÁ

БББББ

ÁÁÁ

ÁÁÁ

БББББ

ÁÁÁ

БББББББББББББББ

БББББББББББББББ

БББББББББББББББ

БББББББББББББББ

БББББББББББББББ

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

The color tone correction register latch is configured with a 4 pixel × 8 bit, and the current value for color tone

correction by pixel can be adjusted between 50% and 0% when output current is set to 100% by adjusting

external resistor and brightness adjustment data. The color tone correction is divided into the coarse adjustment

with 2 bit / 4 steps and the fine adjustment with 6 bit / 64 steps. The current value for the coarse adjustment can

be set to 6.25%, 12.5%, 25% or 50% when current is set to 100% by adjusting external resistor and brightness

adjustment data. The current value for the fine adjustment can be adjusted in 64 steps as 1 step of 1.6% of

current ratio between 100% and 0% when current set at the coarse adjustment is 100%. By using this function,

color tone deviation for RGB can be individually corrected.

This packet sets the current value for color tone correction only, thus setting color tone correction control packet

to ON/OFF is required for effective color tone correction.

Table 5. Packet Configuration (48-bit)

ID

(bin)

xxxxxxxx

CMD

(bin)

00001000

PIXEL1

(OUT0, OUT1, OUT2)

8 bit

PIXEL2

(OUT3, OUT4, OUT5)

Pixel n

MSB LSB

COARSE ADJ

(2 bit)

ÁÁÁÁ

dt [7]

Á

Á

dt [6]

ÁÁ

1

1

.

.

.

1

1

0

1

1

1

1

1

.

.

ÁÁ

.

1

1

0

1

0

1

CURRENT VALUE SET BY COARSE TO 0%

БББББББББББББ

dt [5]

Á

0

0

БББББББББББББ

1

1

CURRENT VALUE AFTER PLANE BRIGHTNESS

FINE ADJUSTMENT (6 bit)

dt [4]

Á

dt [3]

ÁÁ

0

0

1

1

ADJUSTMENT (%)

(xx08xxxxxxxxh) After ID and CMD 8 bit data continues 4 set.

8 bit

0

0

1

1

6.25%

12.5%

25.0%

50.0%

dt [2]

Á

0

0

1

1

DATA

(OUT6, OUT7, OUT8)

dt [1]

Á

0

0

1

1

PIXEL3

8 bit

dt [0]

ÁÁ

0

1

0

1

(OUT9, OUT10, OUT11)

RELATIVE

CURRENT

ÁÁÁ

RATIO (%)

0.0

1.6

.

.

ÁÁÁ

.

98.4

100.0

PIXEL4

8 bit

I

= 40 mA

OLC

COARSE

ADJUSTMENT

ÁÁÁÁ

(3h) (mA)

0.0

0.3

.

ÁÁÁÁ

.

.

19.7

20.0

www.ti.com

17

Page 18

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

plane brightness adjustment data

Using this packet, the same brightness adjustment data and frequency division data can be written to all

connected devices simultaneously , o r different brightness adjustment data and frequency division data can be

written to each device.

The brightness adjustment data latch is configured with 1 x 16 bit, and the current value on each constant output

current can be adjusted in 64 steps as 1 step of 0.94% of current ratio between 100% and 40% when output

current is set to 100% by adjusting external resistor. By using this function, brightness adjustment between

devices can be accomplished by sending required the data from external even though these are mounted on

printed circuit board.

The frequency division ratio register latch is configured with 1 x 4 bit, and the frequency division ratio can be

adjusted in 16 steps between 1:1 and 1:16. This function means that brightness can be adjusted in 16 steps

only by selecting the frequency division ratio, if gray scale clock is set to 16 times the clock (1024x16=16384)

during horizontal scanning time. By using this function, the total panel brightness can be adjusted

simultaneously, and applied to the brightness of day or night.

Table 6. Packet Configuration (32 bit)

ID (Bin)

xxxxxxxx 00010000

(xx100xxxh)

FREQUENCY

CMD

(Bin)

DIVISION

RATIO

.

.

.

RESERVED

RELATIVE

BRIGHTNESS

RATIO (%)

.

.

.

RELATIVE CURRENT

MSB

dt [3]

RATIO (%)

40.00

40.94

.

.

.

99.06

100.00

DATA

FREQUENCY

DIVISION DATA

dt [2] dt [1] dt [0]

0 0 0 06.31:1

0 0 0 112.61:2

.

.

.

1 1 1 093.81:15

1 1 1 1100.01:16

LSB MSB LSB

RESERVED BRIGHTNESS CONTROL DATA

dt [3] dt [2] dt [1] dt [0]dt [5] dt [4]40 (mA)20 (mA)

8.00

8.18

.

.

.

19.82

20.00

16.00

16.38

.

.

.

39.62

40.00

00000000000

.

.

.

11111111110

1

1

UDG–02036

18

www.ti.com

Page 19

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

color tone correction control

Using this packet, the same color tone correction control data can be written to all the connected devices

simultaneously or different color tone correction control data can be written to each device.

The current value set to OUT0–OUT2, OUT3–OUT5, OUT6–OUT8, and OUT9–OUT11 respectively by color

tone correction data packet can be turned on and off per OUT0, OUT3, OUT6, OUT9 and OUT1, OUT4, OUT7,

OUT10 and OUT2, OUT5, OUT8, OUT11 by this color tone correction control packet.

The color tone correction control register latch is configured with 1 × 3 bit, and can be selected from the following

status.

1. To correct the LED color connected to OUT0, OUT3, OUT6, OUT9 (ROUT0, ROUT1, ROUT2, ROUT3)

using small lighting-ON of LED connected to OUT1, OUT4, OUT7, OUT10 (GOUT0, GOUT1, GOUT2,

GOUT3).

2. To correct the LED color connected to OUT0, OUT3, OUT6, OUT9 (ROUT0, ROUT1, ROUT2, ROUT3)

using small lighting-ON of LED connected to OUT2, OUT5, OUT8, OUT11 (BOUT0, BOUT1, BOUT2,

BOUT3).

3. To correct the LED color connected to OUT1, OUT4, OUT7, OUT10 (GOUT0, GOUT1, GOUT2, GOUT3)

using small lighting-ON of LED connected to OUT0, OUT3, OUT6, OUT9 (ROUT0, ROUT1, ROUT2,

ROUT3).

4. To correct the LED color connected to OUT1, OUT4, OUT7, OUT10 (GOUT0, GOUT1, GOUT2, GOUT3)

using small lighting–ON of LED connected to OUT2, OUT5, OUT8, OUT11 (BOUT0, BOUT1, BOUT2,

BOUT3).

5. To correct the LED color connected to OUT2, OUT5, OUT8, OUT11 (BOUT0, BOUT1, BOUT2, BOUT3)

using small lighting-ON of LED connected to OUT0, OUT3, OUT6, OUT9 (ROUT0, ROUT1, ROUT2,

ROUT3).

6. To correct the LED color connected to OUT2, OUT5, OUT8, OUT11 (BOUT0, BOUT1, BOUT2, BOUT3)

using small lighting-ON of LED connected to OUT1, OUT4, OUT7, OUT10 GOUT0, GOUT1, GOUT2,

GOUT3).

7. Does not perform color tone correction.

The constant-current output selected by this packet is lighted-ON with the current value set by the color tone

data packet as many as gray-scale data set to constant-current output for target corrected in addition to gray

scale data and current value set by itself. The current value in this status for lighing-ON equals the sum of the

original display and the color tone correction value.

www.ti.com

19

Page 20

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

Table 7. Packet Configuration (24 bit)

ID (Bin) CMD (Bin)

DATA

MSB LSB

CCEN2 CCEN1 CCEN0RESERVEDxxxxxxxx 00100000

CONSTANT CURRENT OUTPUT

FOR COLOR TONE CORRECTION

TARGETEDTURN ON

COLOR TONE CORRECTION OFF

OUT1 (GOUT0) OUT0 (ROUT0)

OUT4 (GOUT1) OUT3 (ROUT1)

OUT7 (GOUT2) OUT6 (ROUT2)

OUT10 (GOUT3) OUT9 (ROUT3)

OUT2 (BOUT0) OUT0 (ROUT0)

OUT5 (BOUT1) OUT3 (ROUT1)

OUT8 (BOUT2) OUT6 (ROUT2)

OUT11 (BOUT3) OUT9 (ROUT3)

OUT0 (ROUT0)

OUT3 (ROUT1)

OUT6 (ROUT2)

OUT9 (ROUT3)

OUT2 (BOUT0)

OUT5 (BOUT1)

OUT8 (BOUT2)

OUT11 (BOUT3)

OUT0 (ROUT0)

OUT3 (ROUT1)

OUT6 (ROUT2)

OUT9 (ROUT3)

OUT1 (GOUT0)

OUT4 (GOUT1)

OUT7 (GOUT2)

OUT10 (GOUT3)

COLOR TONE CORRECTION OFF

OUT1 (GOUT0)

OUT4 (GOUT1)

OUT7 (GOUT2)

OUT10 (GOUT3)

OUT1 (GOUT0)

OUT4 (GOUT1)

OUT7 (GOUT2)

OUT10 (GOUT3)

OUT2 (BOUT0)

OUT5 (BOUT1)

OUT8 (BOUT2)

OUT11 (BOUT3)

OUT2 (BOUT0)

OUT5 (BOUT1)

OUT8 (BOUT2)

OUT11 (BOUT3)

0 0 0

0 0 1

0 1 0

0 1 1

1 0 0

1 0 1

1 1 0

1 1 1

UDG–02035

Only one combination is allowed to turn the color tone correction on or off in 1 HSYNC cycle. In other words,

when multiple combinations of correction is required, repeated color tone correction with required number of

gray scale display at one time is necessary. The following is example when all combinations for color tone

correction are needed. Since the current value of the constant-current output for basic display is determined

by the brightness adjustment data plus the dot correction data, the current value for color tone correction is

determined per pixel by the color tone correction data packet based on the current value excluding the dot

correction data after brightness adjustment, although it is different by the constant-current output depending

on dot correction data. Accordingly, the current value for color tone correction is shown as follows.

OUT0 (ROUT0) = OUT1 (GOUT0) = OUT2 (BOUT0), OUT3 (ROUT1) = OUT4 (GOUT1) = OUT5 (BOUT1)

OUT6 (ROUT2) = OUT7 (GOUT2) = OUT8 (BOUT2), OUT9 (ROUT3) = OUT10 (GOUT3) = OUT11 (BOUT3)

20

www.ti.com

Page 21

PRINCIPLES OF OPERATION

The following example shows all the combinations of color tone correction control with 8 gray scale.

SLLS528 – MARCH 2002

Figure 7. Color Tone Correction Control Combinations With 8–Bit Gray Scale

The timing of lighting-ON for the basic display to be turned on is delayed by t

The lighting-ON for color tone correction is turned on based on ON/OFF timing of output for color tone corrected.

www.ti.com

D(OUTn+1–OUTn)

until OUT1–OUT11.

21

Page 22

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

operation mode setting

Using this packet, the same operation mode can be set to all the connected devices simultanoeously or different

operation modes can be set to each device.

Table 8. Packet Configuration (32-bit)

ID (Bin) CMD (Bin)

xxxxxxxx 01000000

MSB

RESERVED

DATA

LSB

F

R

D

L

S

G

S

L

D

K

C

D

E

E

N

N

E

B

S

C

E

E

R

N

V

E

D

F

O

O

R

R

C

C

E

E

O

O

F

N

F

OVM

DETECTION

VOLTAGE

SETTING

00 00

10 00

00 10

10 10

00 01

10 01

00 11

10 11

01 00

11 00

01 10

11 10

01 01

11 01

01 11

11 11

0.3 V

0.1 V

0.2 V

0.3 V

0.4 V

0.5 V

0.6 V

0.7 V

0.8 V

0.9 V

1.0 V

1.1 V

1.2 V

1/2 VCC

2/3 VCC

NO UPDATE

UDG–02037

22

00

NORMAL OPERATION

10

FORCE ALL OUTPUT ON

01

FORCE ALL OUTPUT OFF

11

INHIBIT

01SET BRIGHTNESS ADJUSTMENT TO 111111 (100%)

COMPLY WITH VALUE SET BY LATCH

01SET DOT CORRECTION TO 11111111 (100%)

COMPLY WITH VALUE SET BY LATCH

01LKD FUNCTION OFF

LKD FUNCTION ON

01USE INPUT CLOCK TO GCLK AS GRAY SCALE

USE INTERNAL CLOCK WITH INPUT CLOCK TO DTIN/STIN

www.ti.com

Page 23

Á

Á

Á

Á

Á

Á

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

This packet allows DSG function, LKD function, dot correction function, brightness adjustment function, flag

setting for enable/disable to turn all the output on/off, and data setting for detection voltage set in the OVM

function.

DSG function (dual source gray scale clock)

The DSG function selects gray-scale clock from the input clock to GCLK terminal or internally-generated clock

using input to the DTIN/STIN terminals. By using the DSGSL flag in this packet, the signal used for the gray scale

clock is switched as below from next HSYNC packet. By using this function, the number of signal lines for gray

scale clock can be reduced, and display can be continued if DATA/STROBE lines are alive, even though the

gray scale clock has stopped due to any failures such as disconnection when using GCLK terminal.

The GEF/HEF function informs of any failures that may occur on the gray scale clock.

DSGSL=0: input clock to GCLK terminal (maximum operating frequency: 20 MHz)

DSGSL=1: internally generated clock using data input to DTIN/STIN terminals (maximum operating

frequency: 10 MHz)

LKD function

The LKD function supplies a constant-current of approximately 0.6 µA to the output terminal. When the power

supply voltage for the LED is 0 V (GND), writing a 1 to the LKDEN flag allows current flow through LED

subtracted leakage current of the device output transistor (below 0.1 µA) from 0.6 µA, and at this time the voltage

on output terminal decreases if the reverse leakage current occurs on LED. In this function, since maximum

applied voltage is 2.7 V, occurrence of reverse leakage current across LED can be found by reading the OVM

detection result through OVM information reading packet by setting the OVM detection voltage to 2/3 VCC. This

function should be used in combination with the FORCE OFF function to turn off all the constant-current outputs

off. The example for this function is shown in Table 9 below.

Table 9. LKD Function Sequence Example

1

Set LED power supply to 0 V (GND)

2

Set operation mode setting packet to force ON=0, force

Á

Á

ББББББББББББББ

OFF = 1 and LKDEN = 1

3

Wait at least 1 µs

4

Read OVM result through OVM information reading packet

5

Set operation mode setting paclet to force ON = 0, force

ББББББББББББББ

OFF = 0 and LKDEN = 0

Set OVM detection voltage and force all outputs OFF and

БББББББББББББ

LKD functions ON

Demand detection result

LKD function OFF and return to normal operation

БББББББББББББ

DCEN/BCEN

By writing 0 to the flag, the corresponding data (plane brightness data or dot correction data) is set to 100%

default value. By writing 1 to the flag, corresponding data is complied with the value set by data setting packet.

When both DCEN and BCEN are 0, the current value will be 100% of the value set by R

IREF

.

The function by flag setting becomes effective from next HSYNC packet after this packet, and in addition, when

both BCEN and DCEN flags are 1, the value set by respective data setting packets does not become effective

unless BCL and DCL flags in HSYNC packet are set to 1.

Setting bot h BCEN and DCEN flags to 0, doesn’t a f fect the latch flags in the HSYNC packet. This function writes

the default 1 to internal latch and the shift register is not updated. Therefore, unless the value for shift register

is updated in respective data setting packet, when plane brightness and dot correction functions are used next,

the previous status can be returned by latching the value of shift register into internal latch by setting BCL/DCL

flag in HSYNC packet after setting this packet.

www.ti.com

23

Page 24

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

all output force off

By writing 0 to force-ON flag and 1 to force-OFF flag in this packet, all the outputs can be turned off

simultaneaously. Also, in this mode, by writing 0 to force-ON flag and 0 to force-OFF flag, it returns to the normal

operation.

all output force on

By writing 1 to force-ON flag and 0 to force-OFF flag in this packet, all the output are turned on independent

of the gray scale data from next HSYNC packet after this packet. At this time, the current value depends on the

plane brightness adjustment data and dot correction data. However, when both DCEN and BCEN are 0, it is

100% of the current value set by R

it returns to the normal operation after sending the HSYNC packet.

Table 10. All Outputs Forced ON Sequence Example

1

Plane brightness, dot corection data setting packet

2

Operation mode setting packet: force ON = 1 and force OFF = 0

3

HSYNC synchronization packet

4

Operation mode setting packet: force ON = 0 and force OFF = 0

5

HSYNC synchronization packet

. Also, in this mode, by writing 0 to force-ON flag and 0 to force-OFF flag,

IREF

Set desired value for output current.

Demand all output force ON.

Al outputs force ON.

Demand return to normal operation

Return to normal operation

Figure 8 shows the operation concept for this mode. All the constant-current outputs are turned on with the

current value set independent of the gray-scale data by HSYNC packet after writing 1 to force-ON flag and 0

to force-OFF flag in operation mode setting packet (these are not turned on if the dot correction value is 0). It

remains in that state independent of gray scale clock until all output force off mode in the packet is sent or

HSYNC packet is sent after writing 0 to force-ON flag and 0 to force-OFF flag in the packet.

24

www.ti.com

Page 25

PRINCIPLES OF OPERATION

ALL OUTPUT FORCE ON OPERATION

OPERATION

MODE SETTING

PACKET

FORCE ON = 1

FORCE OFF = 0

GRAY

SCALE

CLOCK

CONSTANT

CURRENT

OUTPUT

RELATION TO ALL OUTPUT FORCE OFF

NORMAL

LIGHT ON

OPERATION

MODE SETTING

PACKET

FORCE ON = 1

FORCE OFF = 0

HSYNC

PACKET

HSYNC

PACKET

OTHER

PACKET

OTHER

PACKET

FORCE ON

HSYNC

PACKET

DON’T CARE

OPERATION

MODE SETTING

PACKET

FORCE ON = 0

FORCE OFF = 1

OPERATION

OTHER

PACKET

IF DIFFERENT CURRENT VALUE IS SET

OTHER

PACKET

A

MODE SETTING

PACKET

FORCE ON = 0

FORCE OFF = 0

OPERATION

MODE SETTING

PACKET

FORCE ON = 0

FORCE OFF = 0

HSYNC

PACKET

OTHER

PACKET

A

SLLS528 – MARCH 2002

OTHER

PACKET

NORMAL

LIGHT ON

HSYNC

PACKET

GRAY

SCALE

CLOCK

CONSTANT

CURRENT

OUTPUT

NORMAL

LIGHT ON

LIGHT ON BY ALL

OUTPUT FORCE OFF

DON’T CARE

LIGHT OFF BY RELEASE OF ALL OUTPUT

FORCE ON (LATCHED BY HSYNC)

RE–LIGHT ON BY RELEASE OF

ALL OUTPUT FORCE OFF

FORCE ONFORCE ON

Figure 8. All Output Force ON Operation

Note that, in relation to all output force off shown in Figure 8, when the HSYNC packet is between the other

packet and operation mode setting packet with force-ON = 0 / force-OFF = 0, no re-light-ON happens by release

of all the output force-OFF.

OVM function

The OVM function is to compare the voltage across the constant-current output terminals (OUT0 to OUT11) with

the detection voltage set by this packet, and to output 0 as a comparison result if voltage across terminal is higher

than detection voltage and 1 if lower. The TLC5930 has one comparator per output as shown in Figure 9.

The comparison result input ORed with all the output appears in OVMFA of failure monitor information reading,

and result per output appears in OVM information reading data OVMF[0:1 1]. By using this function, where LED

disconnection (the voltage across output falls below 0.3 V) or LED short (the voltage across output goes

extremely high) has occurred can be detected. Also, the voltage across the constant-current output terminals

can be known when it is being turned on by changing the setting value of detection voltage, and heat-up from

the device can be minimized by controlling the voltage applied to the anode of the LED to minimize the voltage

across constant-current output (approximately 0.4 V at I

= 40 mA) based on the resulting voltage.

O

UDG–0203

www.ti.com

25

Page 26

Á

Á

Á

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

OUT0

INTERNAL OUT0

LIGHT ON SIGNAL

INTERNAL OUT1

LIGHT ON SIGNAL

OUT1

.

.

.

OUT10

INTERNAL OUT10

LIGHT ON SIGNAL

+

OVMFA

+

.

.

.

.

.

.

.

.

.

+

OVMF[0]

OVMF[1]

.

.

.

OVMF[10]

INTERNAL OUT11

LIGHT ON SIGNAL

+

OVMF[11]

OUT11

+

COMPARISON

VOLTAGE

UDG–02039

Figure 9. OVM Function

The comparator works so that if a flag is set when read in its operation, voltage across the constant-current

output terminals is lower than the comparison voltage. However, the constant-current output is needed to be

turned on approximately 1 µs continuously until the comparator starts working. For this reason, the following

sequence is recommended to ensure the proper result.

Table 11. OVM Function Sequence Example

1

Gray-scale data, dot correction data setting packet

2

Operation mode setting packet: force ON = 1 and force

OFF = 0

3

HSYNC synchronization packet

4

Wait at least 1 µs

5

OVM information reading packet or failure monitor information

reading packet

6

Operation mode setting packet; force ON = 0 and force

Á

БББББББББББББ

OFF = 0

7

HSYNC synchronization packet

Set the desired value for output current.

Set OVM detection voltage and demand all output force ON.

Al outputs force ON.

Read OVM comparison result.

Demand return to normal operation.

ББББББББББББББ

Return to normal operation

26

www.ti.com

Page 27

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

OVM information read

Using this packet, the comparison results between OVM detection voltage set by operation mode setting packet

and the each voltage across constant-current output terminal can be read by the individual constant-current

output terminals.

For individual IDs, each flag is information for each constant-current output for each specified device ID.

However for common ID devices, the ORed information for constant-current output terminals of devices is

connected in series. Data sent from the controller should be 0 as a dummy data except for ID and CMD. If the

flag is 1, it is passed through.

Table 12. Packet Configuration (32-bit)

ID (Bin) CMD (Bin)

xxxxxxxx 01010000 RESERVED

(xx500000h. PACKET SENT FROM CONTROLLER)

MSB

OVMF

[11]

OUT11 RESULT

OUT10 RESULT

OUT9 RESULT

OVMF

OVMF

[10]

[9]

OUT8 RESULT

OUT7 RESULT

DATA

OVMF

OVMF

[8]

[7]

OUT6 RESULT

OUT5 RESULT

OVMF

OVMF

[6]

[5]

OUT4 RESULT

OUT3 RESULT

OVMF

OVMF

[4]

[3]

OUT2 RESULT

OUT1 RESULT

OVMF

OVMF

[2]

[1]

OUT0 RESULT

LSB

OVMF

[0]

UDG–02040

www.ti.com

27

Page 28

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

failure monitor information read

Using this packet, information is ORed when all outputs for OVM detection results, error flags for HEF, GEF,

TEF, and AWC flag can be read out. For individual IDs, each flag is information for each device, and for common

IDs, the information is ORed for devices connected in series. Although defective devices cannot be detected,

problems can be detected only by sending this packet periodically. Data other than AWC sent from controller

should be 0 as a dummy except ID and CMD. When the failure monitor information is 0, the input data (except

AWC) passes through. OVMFA and TEF are sent when this packet is sent. However , HEF and GEF are sent

when the HSYNC packet before this packet has been sent.

Table 13. Packet Configuration (24-bit)

ID (Bin) CMD (Bin)

xxxxxxxx 01100000 RESERVED OVMFA

(xx6000h.PACKET SENT FROM CONTROLLER)

DATA

LSBMSB

HEF GEF TEF AWC

UDG–02041

The default value for all the information is 1, so, note that 1 may be read out until normal lighting-ON starts after

the reset packet is sent.

OVMFA

The information ORed with detection results for all constant-current output in OVM function appears in this flag.

Although defective constant-current output cannot be identified by reading this flag, the OVM function detects

output errors.

HEF function (HSYNC Error Flag)

This function is to set 0 to HEF flag if the input number of gray-scale clock per 1 HSYNC cycle is more than 1024,

and 1 if less than 1025, at the time when the next HSYNC packet is sent. For example, when, despite the normal

gray-scale clock, the sending period of the HSYNC packet is shortened for any reason and the number of

gray-scale clock in 1 HSYNC cycle is less than 1025, that is, when the HSYNC packet is entered with the number

of gray-scale clock than 1025, HEF is set to 1. In other words, by using this function, one can know failure in

the HSYNC cycle. This function is assumed to use the TLC5930 for 1024 gray scale, and if use it less than 1025

such as 256 gray scale, this flag should be neglected even though it is always set to 1.

Regarding the number of the gray-scale clock needed for lighting-ON, a gray-scale clock total of 1025,

equivalent to 1024 plus 1, is needed to complete lighting on with 1024 gray-scale clock, since lighting on starts

with second rising edge of gray-scale clock after LSB input of the HSYNC packet.

GEF function (GCLK Error Flag)

This function is to set 0 to GEF flag if the number of gray-scale clock meet the requied number of gray-scale

per 1 HSYNC cycle, and 1 if not, at the time when the next HSYNC packet is sent. For example, when the

gray-scale data f o r g i ven constant-current output is 100, and the gray-scale clock is entered between 2 and 100

for each HSYNC cycle, the correcponding constant-current output remains in an on–state until the next HSYNC

packet is sent. When the clock is less than 2, the output is not turned on. In this case, if lighting-ON for the number

of gray-scale clock is not done, GEF is set to 1 assumed as failure. In other words, by using this function, one

can know whether the gray scale clock is normally sent or 1 HSYNC cycle meet the lighting-ON time desired.

Notes that this flag is set to 1 independent of the status of the gray-scale clock during one HSYNC cycle after

all outputs are forced on.

28

www.ti.com

Page 29

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

failure monitor information read (continued)

TEF function (thermal error flag)

This function, is used to determine when the junction temperature of the device exceeds its limit. This function

sets 0 to the TEF flag if the junction temperature is less than 160_C, and set it to 1 if the temperature is greater

than 160_C.

AWC function (active wire check)

This function is used to check that the communication between controller and driver is performing normally. The

TLC5930 clocks out the inverted data from written data into bits when this packet is entered. For individual IDs,

the inverted data from the controller output returns to the controller. For common IDs, the same data as the

controller output returns to the controller if the number of devices connected in series is even, but returns to the

inverted data if it is odd.

read information output

For failure monitor information reading (including OVM information reading, failure monitor information flags in

the HSYNC packet), for individual IDs or common IDs, it is set to 1 if an error is indicated. Input data is passed

through if there is no error detected. For A WC, for both individual and common IDs, the inverted data from input

data is clocked out. When the ID is neither common nor matched, the data including AWC is passed through.

Table 16 shows four connected device. Bold bits indicates the reading information output from the device.

Table 14. Read Information Output

DEVICE NUMBER

IC1 INPUT (CONTROLLER OUTPUT)

IC1 OUTPUT (IC2 INPUT)

IC2OUTPUT (IC3 INPUT)

IC3 OUTPUT (IC4 INPUT)

IC4 OUTPUT (CONTROLLER INPUT)

DEVICE

NUMBER

IC1 INPUT

IC1 OUTPUT

IC2 OUTPUT

IC3 OUTPUT

IC4 OUTPUT

DEVICE

NUMBER

IC1 INPUT

IC1 OUTPUT

IC2 OUTPUT

IC3 OUTPUT

IC4 OUTPUT

ID

NO.

1

ID

NO.

3

DATA BIT 111111111122222222223333

.123456789012345678901234567890123

x000000010110000000000000xxxxxxxxx

xxx000000010110000000010001xxxxxxx

xxxxx000000010110000000010001xxxxx

xxxxxxx000000010110000000010001xxx

xxxxxxxxx000000010110000000010001x

DATA BIT 111111111122222222223333

.123456789012345678901234567890123

x000000110110000000000000xxxxxxxxx

xxx000000110110000000000000xxxxxxx

xxxxx000000110110000000000000xxxxx

xxxxxxx000000110110000000001101xxx

xxxxxxxxx000000110110000000001101x

CONDITION

IC1: OVM fail

IC2: ALL PASS

IC3: HEF, GEF fail

IC4: ALL PASS

ID

NO.

COMM

ON

ID

NO.

2

ID

NO.

4

DATA BIT 111111111122222222223333

.123456789012345678901234567890123

x000000000110000000000000xxxxxxxxx

xxx000000000110000000010001xxxxxxx

xxxxx000000000110000000010000xxxxx

xxxxxxx000000000110000000011101xxx

xxxxxxxxx000000000110000000011100x

DATA BIT 111111111122222222223333

.123456789012345678901234567890123

x000000100110000000000000xxxxxxxxx

xxx000000100110000000000000xxxxxxx

xxxxx000000100110000000000001xxxxx

xxxxxxx000000100110000000000001xxx

xxxxxxxxx000000100110000000000001x

DATA BIT 111111111122222222223333

.123456789012345678901234567890123

x000001000110000000000000xxxxxxxxx

xxx000001000110000000000000xxxxxxx

xxxxx000001000110000000000000xxxxx

xxxxxxx000001000110000000000000xxx

xxxxxxxxx000001000110000000000001x

www.ti.com

29

Page 30

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

automatic ID setting

The device that receives this packet stops DTOUT and STOUT for 8 bits (ID portion in below packet

configuration) after CMD, and recognizes the 8 bits as its own ID. Next, 8 bits data with recognized ID plus 1

bit is clocked out, and dummy data sent is passed through until 03h data is entered. When the device receives

03h data, it recognizes the ID setting completion and is ready to receive the next command. During reception

of the next 8 bits each device receives, DATA/STROBE output is inhibited, so the controller must send dummy

data (0) with bit counts of at least minimum device number times 8 bit after ID/CMD/DATA(ID) until this packet

operation is completed including DTOUT/STOUT output.

Table 15. Packet Configuration (32-bit + 8-bit (IC–1))

ID (Bin) CMD (Bin)

00000000 01110000 xxxxxxxx

(0070xxh + 00h × IC NUMBER + 03h)

ID DUMMY END

DATA (BIN)

00000000 × IC NUMBER

00000011

UDG–02043

The following is a sequence example for automatic ID setting (in the case of one device and four devices). In

this example, IC1 input indicates output from the controller, while the last device output indicates the input for

the controller. Since the blank portion in the example does not recognize the input in DS-LINK, input to controller

is continuous ID/CMD/DATA(DATA=number of devices + 1). There are two different methods to send

DATA(END) 03h;

D Calculate and send the number of dummy data as the number of devices times 8 bits.

D Stop the dummy data output synchronizing with receiving the ID/CMD/DATA(DATA=number of devices +

1) at the controller input and send DATA 03h.

The latter case is useful when the number of connected devices is unknown (for automatic recognition). The

number of devices connected that can be known from that DATA(ID) received by the controller shows the

number of devices plus 1. In any case, dummy data should be an 8-bit base.

Table 16. One IC (No Dummy Data)

IC NUMBER DATA BIT

IC1 INPUT

IC1 OUTPUT

..............1111111111222222222233333333334444

.....1234567890123456789012345678901234567890123.....

xxxxx0000000001110000000000010000001100000011xxxxx

xxxxxxx0000000001110000........0000001000000011xxx

30

IC NUMBER DATA BIT

IC1 INPUT

IC1 OUTPUT (IC2 INPUT)

IC2 OUTPUT (IC3 INPUT)

IC3 OUTPUT (IC4 INPUT)

IC4 OUTPUT

Table 17. Four ICs (24-bit Dummy Data)

..............11111111112222222222333333333344444444445555555555666666666677

.....12345678901234567890123456789012345678901234567890123456789012345678901..

xxxxx0000000001110000000000010000000000000000000000000000000000000011xxxxxxxxx

xxxxxxx0000000001110000........0000001000000000000000000000000000000011xxxxxxx

xxxxxxxxx00000000011100........00........00000011000000000000000000000011xxxxx

xxxxxxxxxxx000000000111........00........00........000001000000000000000011xxx

xxxxxxxxxxxxx0000000001........11........00........00........0000010100000011x

www.ti.com

Page 31

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

HSYNC synchronization

The constant-current output is turned on, synchronizing with this packet. In addition, for common IDs, the failure

monitor information flag is read out through the 5 LSB of DA TA within the packet (see failure monitor information

read section), and data written in the internal register within gray scale data setting packet, plane brightness

adjustment data setting packet, dot correction data setting packet, color tone correction setting packet, and color

tone correction control setting packet are latched, depending on the status of the register latch flag of 5 MSB

of DATA. Since each flag in the register latch flag is independent, writing a 1 allows the respective packet data

to be latched. Writing a 0 to the flag allows no latch. By using this function, gray scale data, plane brightness

adjustemnt data , dot correction data, color–tone correction, and correction control setting packets can be sent

asynchronously with the HSYNC cycle.

Note that no lighting-ON occurs when the gray-scale clock is entered before this HSYNC packet of normal

lighting-ON operation (including use of internally generated clock) during the first normal lighting-ON operation

(PWM operation) after power up. Normal operation occurs after the second operation.

Table 18. Packet Configuration (32-bit)

ID (Bin) CMD (Bin)

00000000 10000000

(0080xxh.PACKET SENT FORM CONTROLLER)

REGISTER LATCH FLAG DATA FAILURE MONITOR FLAG

MSB LSB

OVMFA

REFER FAILURE MONITOR READ

1

1

1

LATCH COLOR TONE CORRECTION DATA

LATCH PLANE BRIGHTNESS ADJUSTMENT DATA1

CORRECTION CONTROL DATA

LATCH DOT CORRECTION DATA

LATCH COLOR TONE

LATCH GRAY SCALE DATA1

NO LATCH0 0 0 0 0

HEF GEF TEF AWCRESERVEDGSL BCL DCL CCL CSL

Table 21 shows the relationship between failure monitor information reading packet, HSYNC packet, and other

various error flags.

Table 19. Error Flag Relationships

TIME

HSYNC

PACKET

1

1

1

1

FAIL

RELEASE

FAILURE

PACKET

0

1

1

0

HSYNC

PACKET

0

0

0

0

FAIL

OCCUR

HSYNC

PACKET

1

1

1

1

FAILURE

PACKET

1

1

1

1

FAIL

RELEASE

HSYNC

PACKET

0

0

0

0

OVMFA

HEF

GEF

TEF

FAIL

OCCUR

FAILURE

PACKET

1

0

0

1

UDG–02044

FAILURE

PACKET

0

0

0

0

www.ti.com

31

Page 32

Á

Á

S

{

Á

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

calculating constant-current output

The current value of constant-current output can be calculated using the following expression.

I

OLC (n)

Where IDC is main current (except color tone correction), ICC is color tone correction current. Both currents are

referenced with reference current, I

I

from color tone correction data and color tone correction control data. n is output terminal number, 0 to 11.

CC

reference current

The reference current I

brightness data, r

I

IREF

VȀ

IREF

+ 42ǒI

+ 4

+

) I

DC (n)

can be calculated with external resistor, R

IREF

, using the following expression.

BC

VȀ

IREF

ǒ

ȱ

0.4 )

ȧ

R

Ǔ

IREF

0.6ǒrBC) 1

ǒ

Ȳ

main current

The main current, I

scale data, and reference current, I

+

I

DC (n)

, can be calculated with dot correction data, rDC, logic signal, S

DC

ǒ

r

DC (n)

256

Ǔ

S

MAIN (n)

CC (n)

64

Ǔ

(IREF)

Ǔ

Ǔ

, and I

ȳ

V

ȧ

is established by dot correction data and gray scale data.

(DC)

IREF

ȴ

, using the following expression.

IREF

I

IREF

, voltage reference, V

IREF

IREF

, established by gray

MAIN

(2)

, and plane

(3)

(4)

(5)

Where S

ÁÁÁÁÁБББББ

MAIN (n) =

ÁÁÁÁ

, is set to following value depending on gray scale data, rGC.

MAIN

1: r

0: r

БББББ

GC (n)

GC (n)

> 0

= 0

32

www.ti.com

Page 33

Á

S

{

Á

S

{

Á

S

{

Á

Á

S

{

Á

Á

S

{

Á

Á

S

{

Á

PRINCIPLES OF OPERATION

color tone correction current

SLLS528 – MARCH 2002

The color tone correction current, I

logic signal, S

, for color tone correction current switch established by the combination of color tone correction

CC

, can be calculated with I′CC established by color tone correction data, and

CC

control data with logic signal for main current switch, using the following expression.

is expressed depending on color tone correction data r

I′

CC

r

IȀ

IȀ

IȀ

IȀ

CC(9)

CC(0)

CC(3)

CC(6)

+ IȀ

+ IȀ

+ IȀ

+ IȀ

CC(1)

CC(4)

CC(7)

CC(10)

+ IȀ

+ IȀ

+ IȀ

+ IȀ

CC(2)

CC(5)

CC(8)

CC(11)

+

2

+

2

+

2

+

ǒ

4 * r

ǒ

4 * r

ǒ

4 * r

ǒ

2

1

1

1

4 * r

CC1[7:6]

CC2[7:6]

CC3[7:6]

1

CC4[7:6]

SCC is set up by color tone correction control switch, S

r

and S

CCEN

БББББÁББББББББББББ

CCEN1 =

MAIN

. S

is expressed as follows:

CCEN

1: r

CCEN

=0 0 1 (bin)

Ǔ

Ǔ

Ǔ

Ǔ

CCEN

CC1[5:0]

r

CC2[5:0]

r

CC3[5:0]

r

CC1

64

64

64

CC4[5:0]

64

through r

I

IREF

I

IREF

I

IREF

I

IREF

as follows.

CC4

, established by color tone correction control data

0: except the above

(6)

(7)

(8)

(9)

БББББÁББББББББББББ

CCEN2 =

1: r

CCEN

=0 1 0 (bin)

0: except the above

БББББÁББББББББББББ

CCEN3 =

1: r

CCEN

=0 1 1 (bin)

0: except the above

БББББÁББББББББББББ

CCEN4 =

1: r

CCEN

=1 0 0 (bin)

0: except the above

БББББ

CCEN5 =

БББББ

CCEN6 =

БББББ

ББББББББББББ

1: r

0: except the above

ББББББББББББ

1: r

0: except the above

ББББББББББББ

CCEN

CCEN

=1 0 1 (bin)

=1 1 0 (bin)

www.ti.com

33

Page 34

Á

S

{

Á

Á

S

{

Á

Á

S

{

Á

Á

S

{

Á

S

{

Á

S

{

Á

Á

S

{

Á

Á

S

{

Á

Á

S

{

Á

Á

S

{

Á

Á

S

{

Á

Á

S

{

SLLS528 – MARCH 2002

PRINCIPLES OF OPERATION

1: (S

CC[0] =

ÁÁÁÁ

CC[1] =

ÁÁÁÁ

CC[2] =

ÁÁÁÁ

ÁÁÁÁÁББББББББББББББББББББ

CC[3] =

CCEN3

0: except the above

ББББББББББББББББББББ

1: (S

CCEN1

0: except the above

ББББББББББББББББББББ

1: (S

CCEN2

0: except the above

ББББББББББББББББББББ

1: (S

CCEN3

and S

and S

and S

and S

MAIN[1]

MAIN[0]

MAIN[0]

MAIN[4]

) or (S

) or (S

) or (S

) or (S

CCEN5

CCEN6

CCEN4

CCEN5

and S

and S

and S

and S

MAIN[2]

MAIN[2]

MAIN[1]

MAIN[5]

) = TRUE

) = TRUE

) = TRUE

) = TRUE

0: except the above

ÁÁÁÁÁББББББББББББББББББББ

CC[4] =

1: (S

CCEN1

and S

MAIN[3]

) or (S

CCEN6

and S

MAIN[5]

) = TRUE

0: except the above

ÁÁÁÁÁББББББББББББББББББББ

CC[5] =

1: (S

CCEN2

and S

MAIN[3]

) or (S

CCEN4

and S

MAIN[4]

) = TRUE

0: except the above

ÁÁÁÁÁББББББББББББББББББББ

CC[6] =

1: (S

CCEN3

and S

MAIN[7]

) or (S

CCEN5

and S

MAIN[8]

) = TRUE

0: except the above

ÁÁÁÁ

ББББББББББББББББББББ

1: (S

CC[7] =

ÁÁÁÁ

CC[8] =

ÁÁÁÁ

CC[9] =

ÁÁÁÁ

CC[10] =

ÁÁÁÁ

ÁÁÁÁÁББББББББББББББББББББ

CC[11] =

CCEN1

0: except the above

ББББББББББББББББББББ

1: (S

CCEN2

0: except the above

ББББББББББББББББББББ

1: (S

CCEN3

0: except the above

ББББББББББББББББББББ

1: (S

CCEN1

0: except the above

ББББББББББББББББББББ

1: (S

CCEN2

and S

and S

and S

and S

and S

MAIN[6]

MAIN[6]

MAIN[10]

MAIN[9]

MAIN[9]

) or (S

) or (S

) or (S

) or (S

) or (S

CCEN6

CCEN4

CCEN5

CCEN6

CCEN4

and S

and S

and S

and S

and S

MAIN[8]

MAIN[7]

MAIN[11]

MAIN[10]

MAIN[11]

) = TRUE

) = TRUE

) = TRUE

) = TRUE

) = TRUE

0: except the above

34

www.ti.com