TLC5920

16x8 BIT LED DRIVER/CONTROLLER

SLAS264 – MARCH 2000

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

Drive Capability:

– Segment . . . 30 mA × 16 Bits

– Common . . . 640 mA

D

Constant Current Output ...3 mA to 30 mA

(Current Value Setting for All Channels

Using External Resistor)

D

Constant Current Accuracy ±6% (Maximum

Error Between Bits)

D

Data Input: Clock Synchronized Serial Input

D

LED Type Applied Cathode Common

D

Logic Power Supply Voltage 4.5 V to 5.5 V

D

LED Power Supply Voltage 4.5 V to 5.5 V

D

Operating Frequency . . . 10 MHz

D

Operating Free-Air Temperature Range

–20°C to 85°C

D

48-Pin SSOL Package

description

The TLC5920 is an LED driver incorporating a

16-channel shift register, data latch, and constant

current circuitry with current value control and

8-channel common driver into a single chip. The

constant output current is capable of 30 mA for 16

bits simultaneously , and the current value can be

set by one external register. This device also

includes a 16-bit segment driver and 8-bit

common driver; therefore, the monocolor LED

array with 16 × 8 dots can be driven by only one

TLC5920, and a two-color LED array with 16 x 16

dots can be driven by two TLC5920s.

Copyright 2000, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

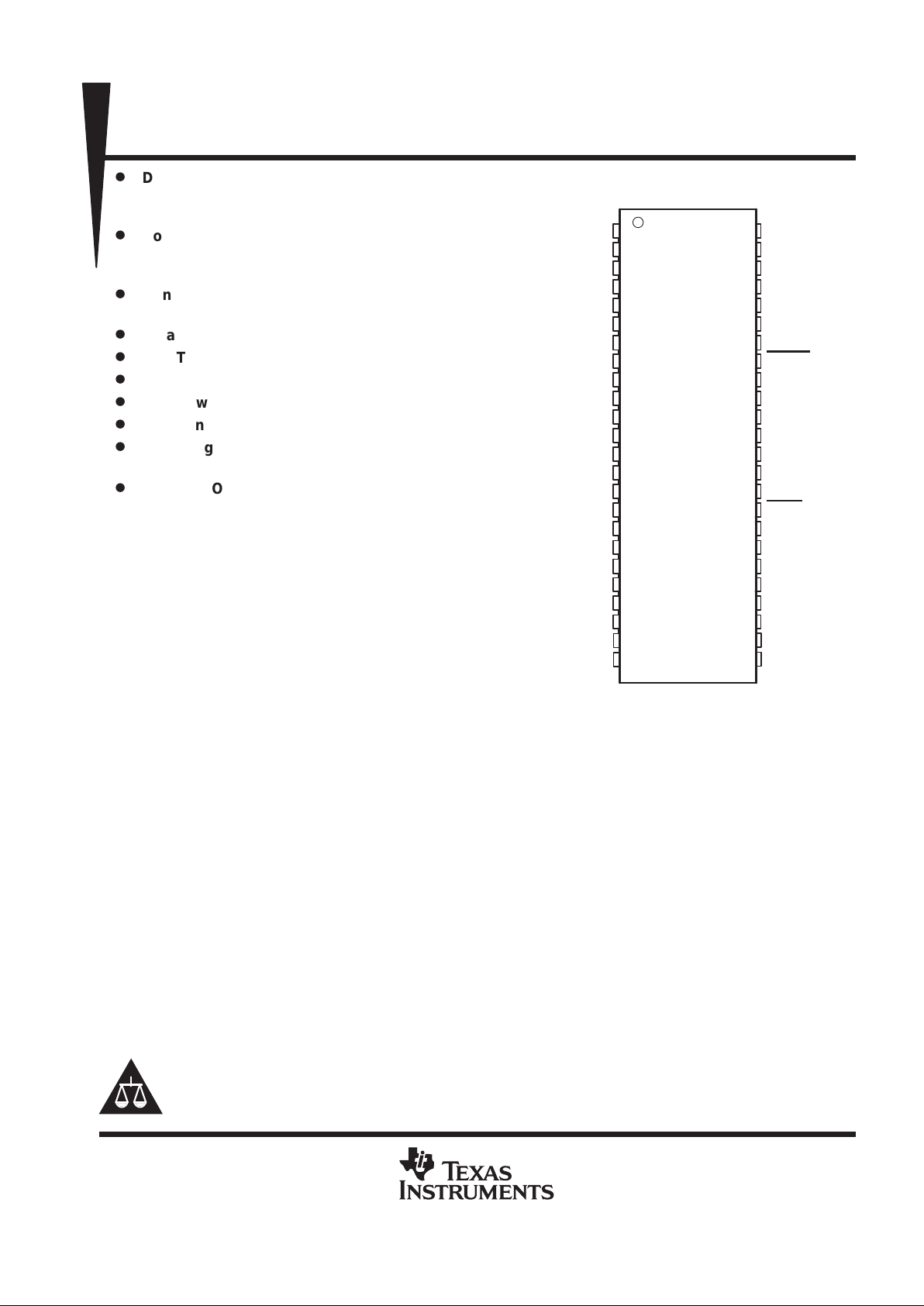

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

COM3

COM2

COM1

COM0

GNDLED

NC

NC

VLED

S0

S1

S2

S3

S4

S5

S6

S7

IREF

VLED

VANA

NC

GNDANA

S8

S9

S10

GNDLED

COM4

COM5

COM6

COM7

GNDLED

SIN

LATCH

SCLK

BLANK

CSEL0

GNDLOG

CSEL1

CSEL2

VLOG

DSEL

SOUT

VLED

DSEL

S15

S14

S13

S12

S11

DL PACKAGE

(TOP VIEW)

TLC5920

16x8 BIT LED DRIVER/CONTROLLER

SLAS264 – MARCH 2000

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

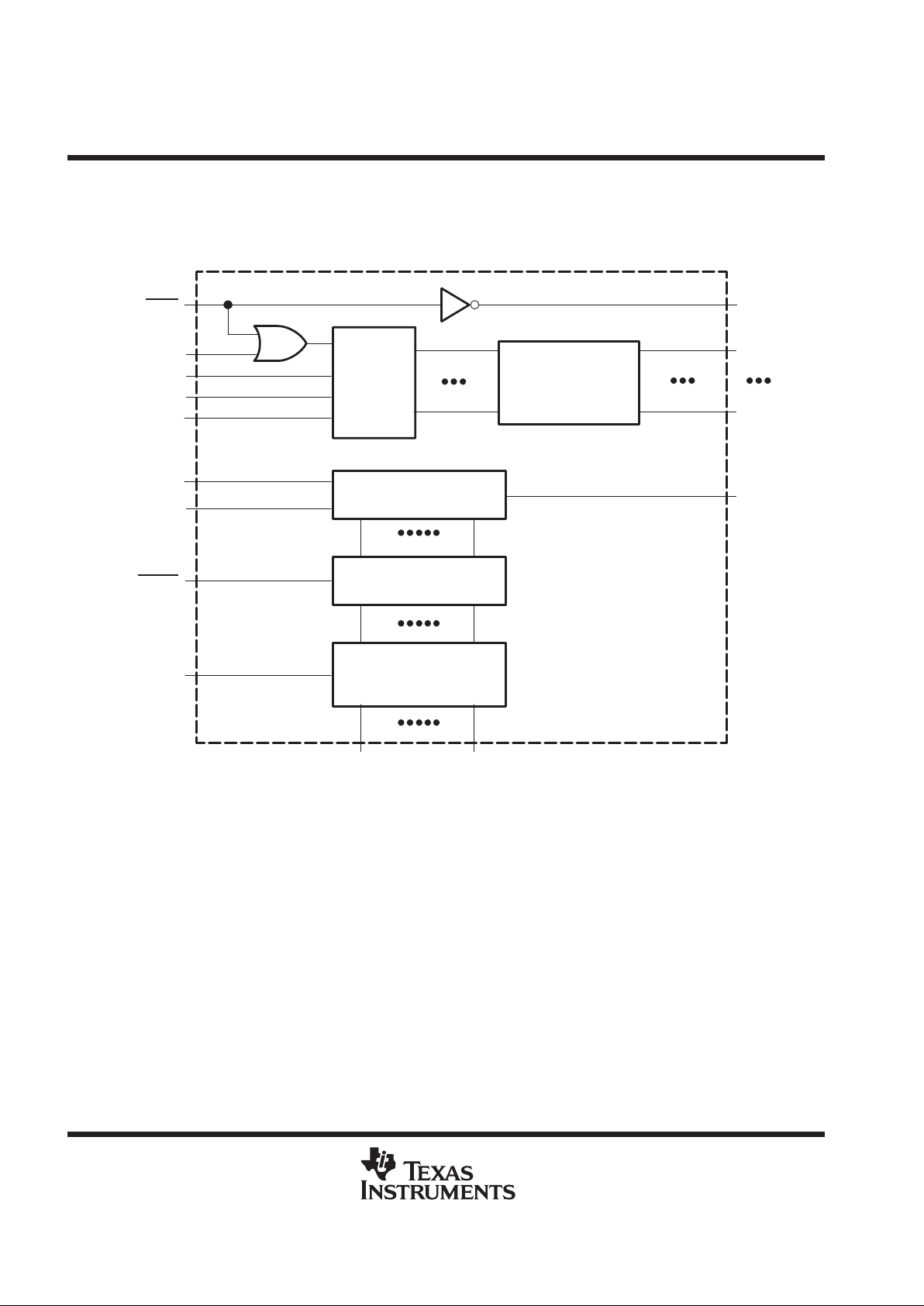

functional block diagram

S15

Common

Driver

3 TO 8

Decoder

S0

16 bits

Shift Register

16 bits

Data Latch

Segment Driver

and

Current Control

DSEL

BLANK

CSEL0

CSEL1

CSEL2

SIN

SCLK

LATCH

IREF

DSEL

COM0

COM7

SOUT

TLC5920

16x8 BIT LED DRIVER/CONTROLLER

SLAS264 – MARCH 2000

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

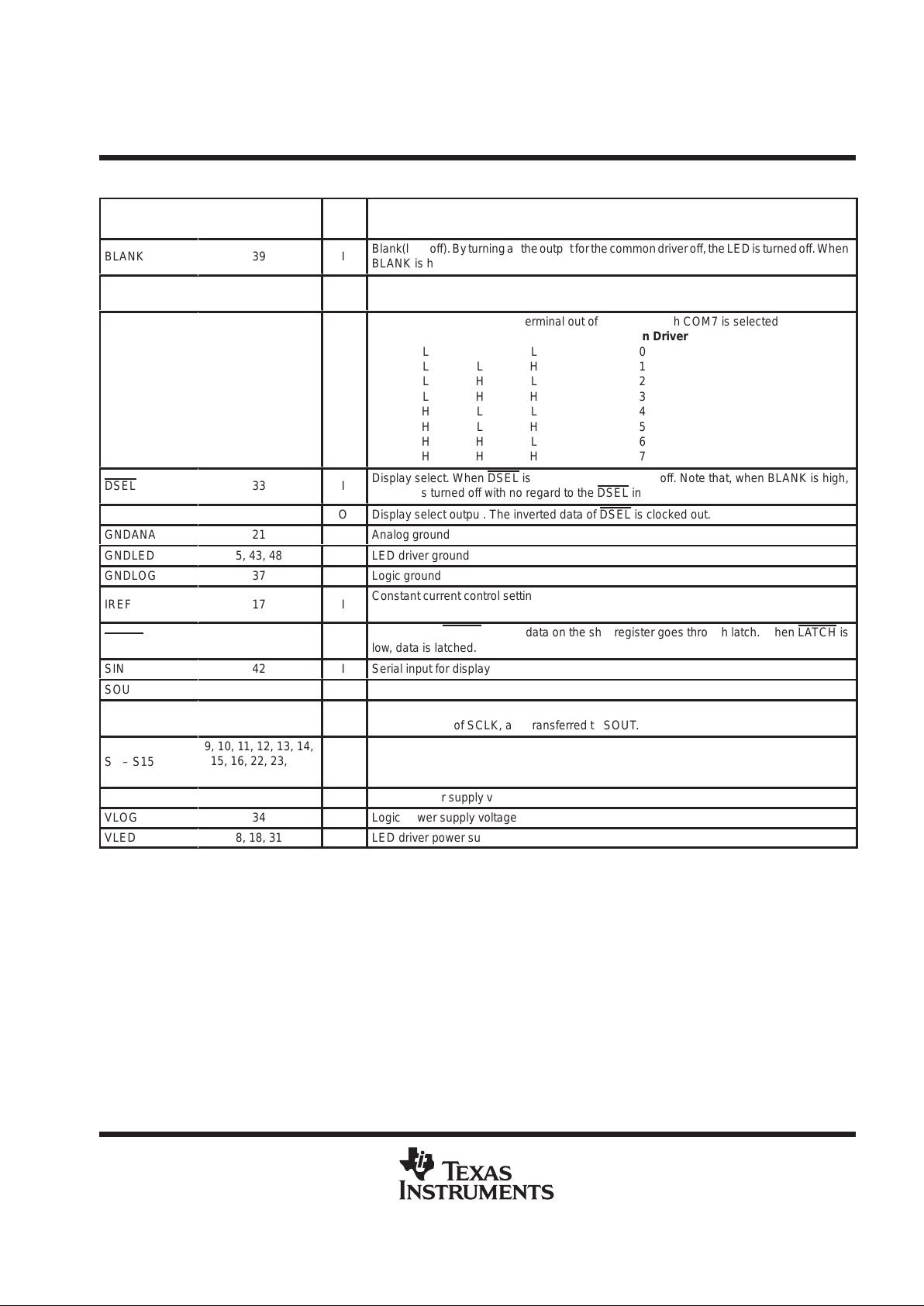

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

ÁÁÁ

Á

BLANK

ÁÁÁÁ

Á

39

Á

Á

I

ББББББББББББББББББББ

Á

Blank(light off). By turning all the output for the common driver off, the LED is turned off. When

BLANK is high, the LED is turned off.

ÁÁÁ

Á

COM0 – COM7

ÁÁÁÁ

Á

4, 3, 2, 1, 47, 46,

45, 44

Á

Á

O

ББББББББББББББББББББ

Á

LED common driver output

ÁÁÁ

Á

ÁÁÁ

Á

ÁÁÁ

Á

ÁÁÁ

Á

ÁÁÁ

Á

CSEL0 – 2

ÁÁÁÁ

Á

ÁÁÁÁ

Á

ÁÁÁÁ

Á

ÁÁÁÁ

Á

ÁÁÁÁ

Á

38, 36, 35

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

I

ББББББББББББББББББББ

Á

ББББББББББББББББББББ

Á

ББББББББББББББББББББ

Á

ББББББББББББББББББББ

Á

ББББББББББББББББББББ

Á

Common driver select. One terminal out of COM0 through COM7 is selected.

2 1 0 Common Driver

LLL 0

LLH 1

LHL 2

LHH 3

HLL 4

HLH 5

HHL 6

HHH 7

ÁÁÁ

Á

DSEL

ÁÁÁÁ

Á

33

Á

Á

I

ББББББББББББББББББББ

Á

Display select. When DSEL is high, the LED is turned off. Note that, when BLANK is high,

the LED is turned off with no regard to the DSEL

input.

DSEL

30

O

Display select output. The inverted data of DSEL is clocked out.

GNDANA

21

Analog ground

GNDLED

5, 43, 48

LED driver ground

GNDLOG

37

Logic ground

ÁÁÁ

Á

IREF

ÁÁÁÁ

Á

17

Á

Á

I

ББББББББББББББББББББ

Á

Constant current control setting. The LED current is set to the desired value by connecting

an external resistor between IREF and GND.

ÁÁÁ

Á

LATCH

ÁÁÁÁ

Á

41

Á

Á

I

ББББББББББББББББББББ

Á

Latch. When LATCH is high, data on the shift register goes through latch. When LATCH is

low, data is latched.

SIN

42

I

Serial input for display

SOUT

32

O

Serial output for display

ÁÁÁ

Á

SCLK

ÁÁÁÁ

Á

40

Á

Á

I

ББББББББББББББББББББ

Á

Synchronous clock input for serial data transfer. The input data of SIN is synchronized to

the rising edge of SCLK, and transferred to SOUT.

ÁÁÁ

Á

S0 – S15

ÁÁÁÁ

Á

9, 10, 11, 12, 13, 14,

15, 16, 22, 23, 24,

25, 26, 27, 28, 29

Á

Á

O

ББББББББББББББББББББ

Á

LED segment driver output

VANA

19

Analog power supply voltage

VLOG

34

Logic power supply voltage

VLED

8, 18, 31

LED driver power supply voltage

TLC5920

16x8 BIT LED DRIVER/CONTROLLER

SLAS264 – MARCH 2000

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

absolute maximum ratings† (see Note 1)

Logic supply voltage, V

(LOG)

– 0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED supply voltage, V

(LED)

– 0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog supply voltage, V

(ANA)

– 0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output current, I

OH(S)

– 32 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output current, I

OL(C)

650 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage range, VI – 0.3 V to V

(LOG)

+ 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output voltage range, VO – 0.3 V to V

(LOG)

+ 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation 1500 mW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermal resistance 83°C/W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range (see Note 2), T

A

– 20 to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–40°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltage values are with respect to GND terminal.

2. TJ ≤ 150°C (refer to appendix thermal condition).

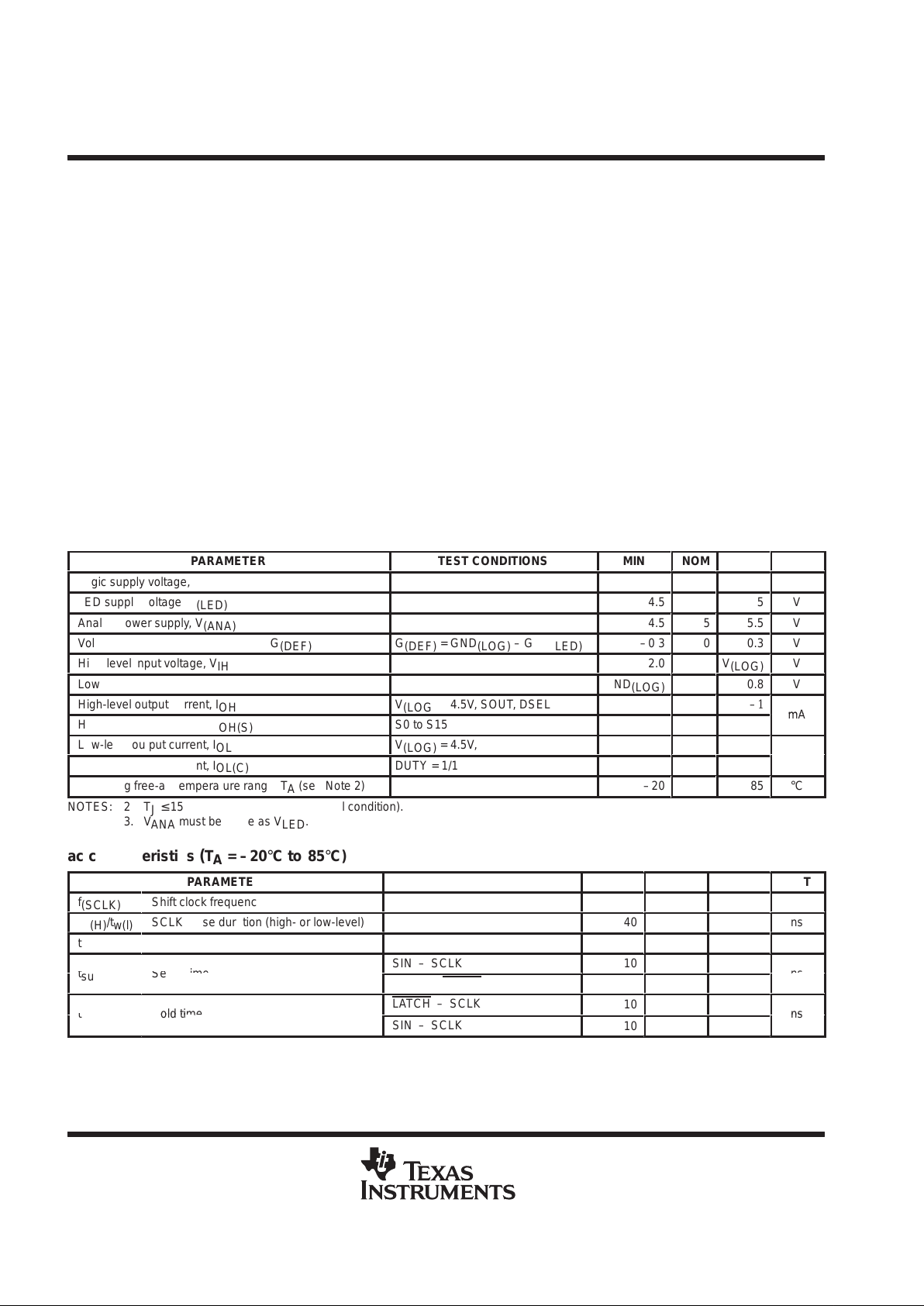

recommended operating conditions

dc characteristics (see Note 3)

PARAMETER

TEST CONDITIONS

MIN

NOM

MAX

UNIT

Logic supply voltage, V

(LOG)

4.5

5

5.5

V

LED supply voltage, V

(LED)

4.5

5

5.5

V

Analog power supply, V

(ANA)

4.5

5

5.5

V

Voltage between GND and V

(DEF), G(DEF)

G

(DEF)

= GND

(LOG)

– GND

(LED)

–0.3

0

0.3

V

High-level input voltage, V

IH

2.0

V

(LOG)

V

Low-level input voltage, V

IL

GND

(LOG)

0.8

V

High-level output current, I

OH

V

(LOG)

= 4.5V, SOUT, DSEL

–1

High-level output current, I

OH(S)

S0 to S15

–30

mA

Low-level output current, I

OL

V

(LOG)

= 4.5V, SOUT, DSEL

1.6

Low-level output current, I

OL(C)

DUTY = 1/16, COM0 to COM7

640

mA

Operating free-air temperature range, TA (see Note 2)

–20

85

°C

NOTES: 2 TJ ≤ 150°C (refer to appendix thermal condition).

3. V

ANA

must be same as V

LED

.

ac characteristics (TA = –20°C to 85°C)

PARAMETER

TEST CONDITIONS

MIN

NOM

MAX

UNIT

f

(SCLK)

Shift clock frequency

10

MHz

t

w(H)/tw(l)

SCLK pulse duration (high- or low-level)

40

ns

tr/t

f

Rise/fall time

100

ns

p

SIN – SCLK

10

tsuSetup time

SCLK – LATCH

10

ns

LATCH – SCLK

10

thHold time

SIN – SCLK

10

ns

TLC5920

16x8 BIT LED DRIVER/CONTROLLER

SLAS264 – MARCH 2000

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

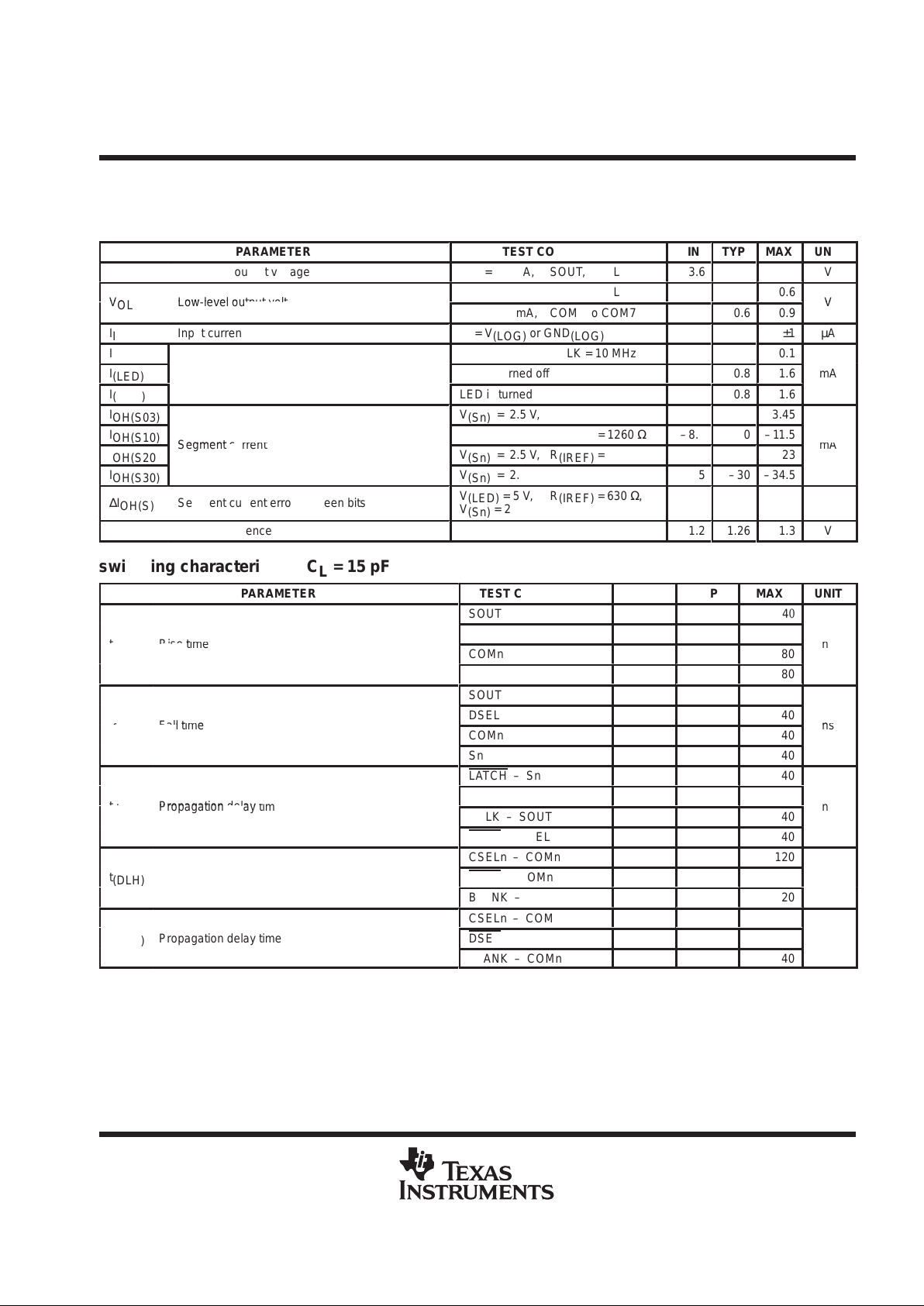

electrical characteristics (unless otherwise noted),

MIN/MAX: V

(LOG)

= V

(ANA)

= V

(LED)

= 4.5 V to 5.5 V, T

A

= –20°C to 85°C

TYP: V

(LOG)

= V

(ANA)

= V

(LED)

= 5 V, T

A

= 25°C

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

V

OH

High-level output voltage

IOH = –1 mA, SOUT, DSEL

3.6

V

p

IOL = 1.6 mA, SOUT , DSEL

0.6

VOLLow-level output voltage

IOL = 640 mA, COM0 to COM7

0.6

0.9

V

I

I

Input current

VI = V

(LOG)

or GND

(LOG)

±1

µA

I

(LOG)

Data transfer, SCLK = 10 MHz

0.1

I

(LED)

Supply current

LED is turned off

0.8

1.6

mA

I

(ANA)

LED is turned off

0.8

1.6

I

OH(S03)

V

(Sn)

= 2.5 V , R

(IREF)

= 4200 Ω

–2.45

–3

–3.45

I

OH(S10)

V

(Sn)

= 2.5 V , R

(IREF)

= 1260 Ω

–8.5

–10

–11.5

I

OH(S20)

Segment current

V

(Sn)

= 2.5 V , R

(IREF)

= 630 Ω

–17

–20

–23

mA

I

OH(S30)

V

(Sn)

= 2.5 V , R

(IREF)

= 420 Ω

–25.5

–30

–34.5

ÁÁ

Á

∆I

OH(S)

БББББББББББ

Á

Segment current error between bits

ББББББББ

Á

V

(LED)

= 5 V, R

(IREF)

= 630 Ω,

V

(Sn)

= 2.5 V

ÁÁÁ

Á

±3%

Á

Á

±6%

Á

Á

V

REF

Voltage reference

1.2

1.26

1.3

V

switching characteristics, CL = 15 pF

PARAMETER

TEST CONDITIONS

MIN

TYP

MAX

UNIT

SOUT

40

DSEL

40

trRise time

COMn

80

ns

Sn

80

SOUT

40

DSEL

40

tfFall time

COMn

40

ns

Sn

40

LATCH –Sn

40

p

SCLK – Sn

40

tdPropagation delay time

SCLK – SOUT

40

ns

DSEL – DSEL

40

CSELn – COMn

120

t

(DLH)

Propagation delay time

DSEL – COMn

120

ns

()

BLANK – COMn

120

CSELn – COMn

40

t

(DHL)

Propagation delay time

DSEL – COMn

40

ns

()

BLANK – COMn

40

TLC5920

16x8 BIT LED DRIVER/CONTROLLER

SLAS264 – MARCH 2000

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

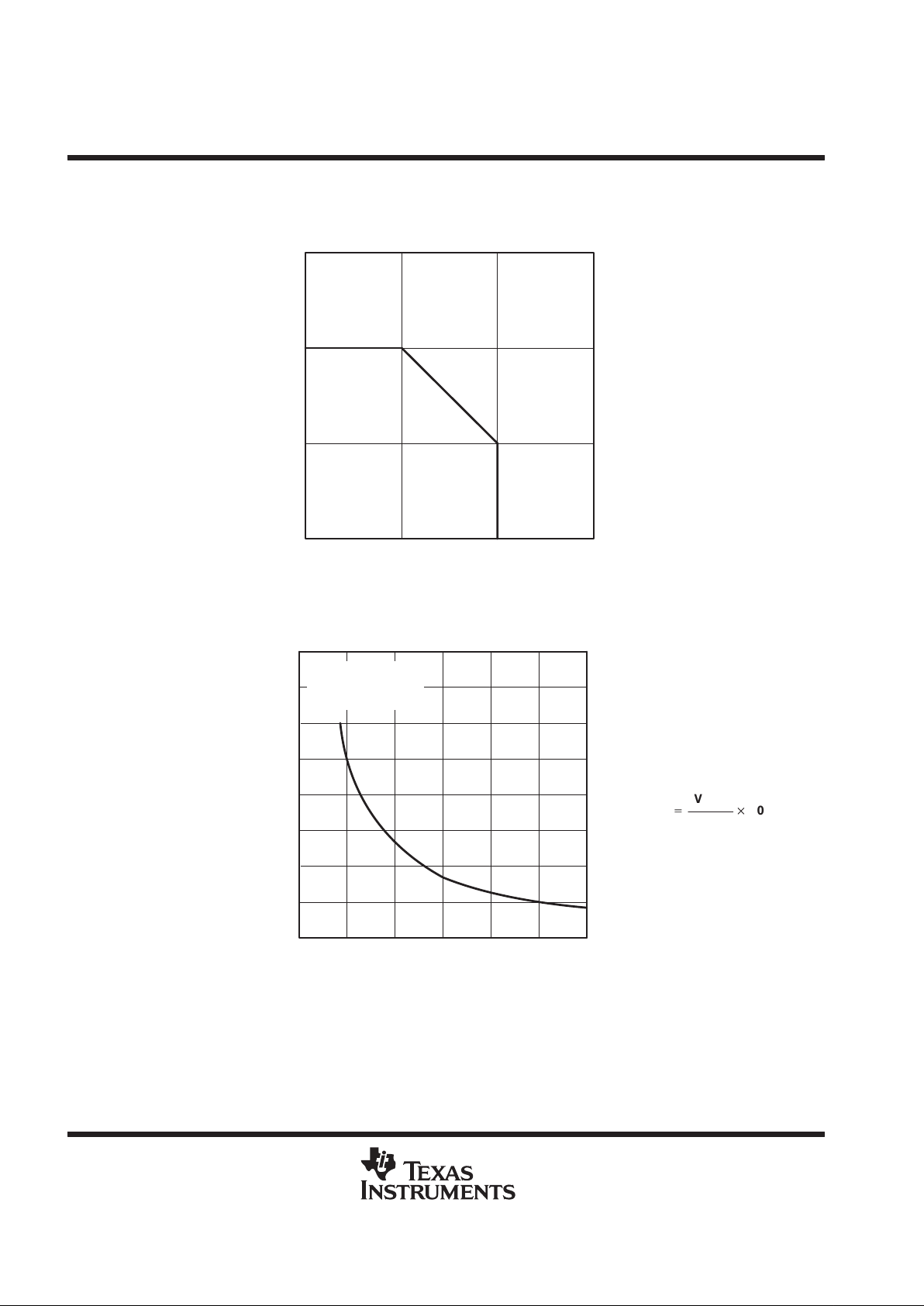

PARAMETER MEASUREMENT INFORMATION

0.78

1.5

TA – Free-Air Temperature – °C

0 25 85–20

POWER RATING

vs

FREE-AIR TEMPERATURE

–

I

Power Rating

– mAI

OH(S)

I

OH(S)

+

V

REF

R

(IREF)

10

0

R

(IREF)

– kΩ

2.50.5

10

20

30

40

1 1.5 2 30

VCC = 5 V,

V

(Sn)

= 2.5 V,

TA = 25°C

SEGMENT CURRENT – I

OHS

Segment Current –

TLC5920

16x8 BIT LED DRIVER/CONTROLLER

SLAS264 – MARCH 2000

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

• 7

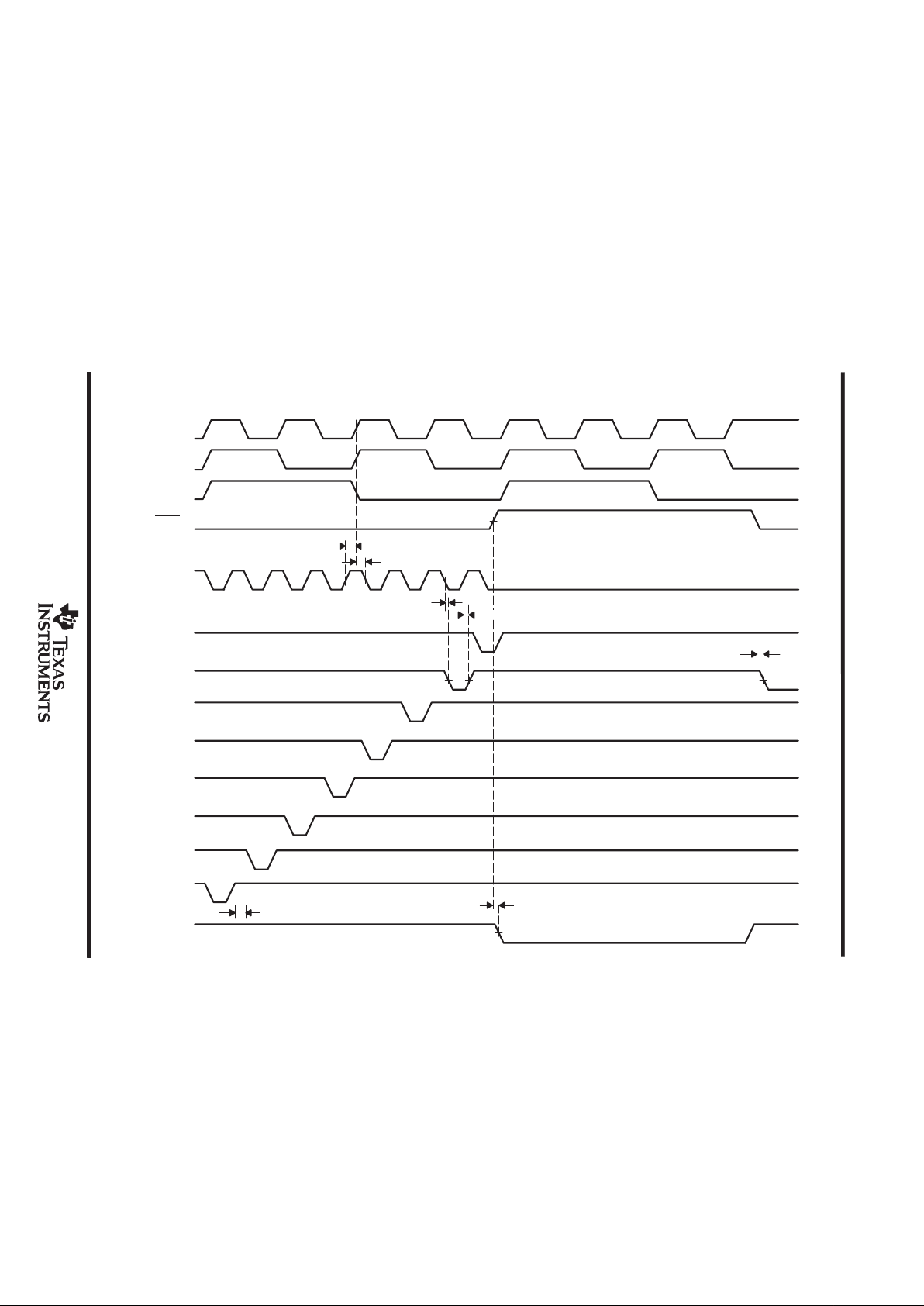

timing diagram (common driver)

CSEL0

tsu BLK–CSEL

th BLK–CSEL

td DSEL

CSEL1

CSEL2

DSEL

BLANK

COM0

COM1

COM2

COM3

COM4

COM5

COM6

COM7

DSEL

td BLK–COMMON

td BLK–COMMON

td DSEL–COMMON

Segment Data Write Timing

TLC5920

16x8 BIT LED DRIVER/CONTROLLER

SLAS264 – MARCH 2000

Template Release Date: 7–11–94

8

POST OFFICE BOX 655303 DALLAS, TEXAS 75265

•

timing diagram (segment driver)

D0A D14AD1A D2A D0B D01B D2BD15A

D0B D1B D2B

D1B D2B D3B

D14B D15B D0C

D15B D0C D1C

D14B

D15BD14BD14A D15A

SCLK

tsu D–CLK

D0A D1A D2A D0B D1B D2B D0C D1C D2C

D15A D15A

D13BD14A D14A

D0BD1A D1A

SIN

LATCH

S14

S15

D15AD0A D0A

th(LAT–SCLK)

tsu(LAT–SCLK)

th D–CLK

t

clk

t

wl

t

wh

t

r

td LAT–SO

td SCLK–SO

td SCLK–SOUT

S0

S1

SOUT

t

f

tw LAT

TLC5920

16x8 BIT LED DRIVER/CONTROLLER

SLAS264 – MARCH 2000

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

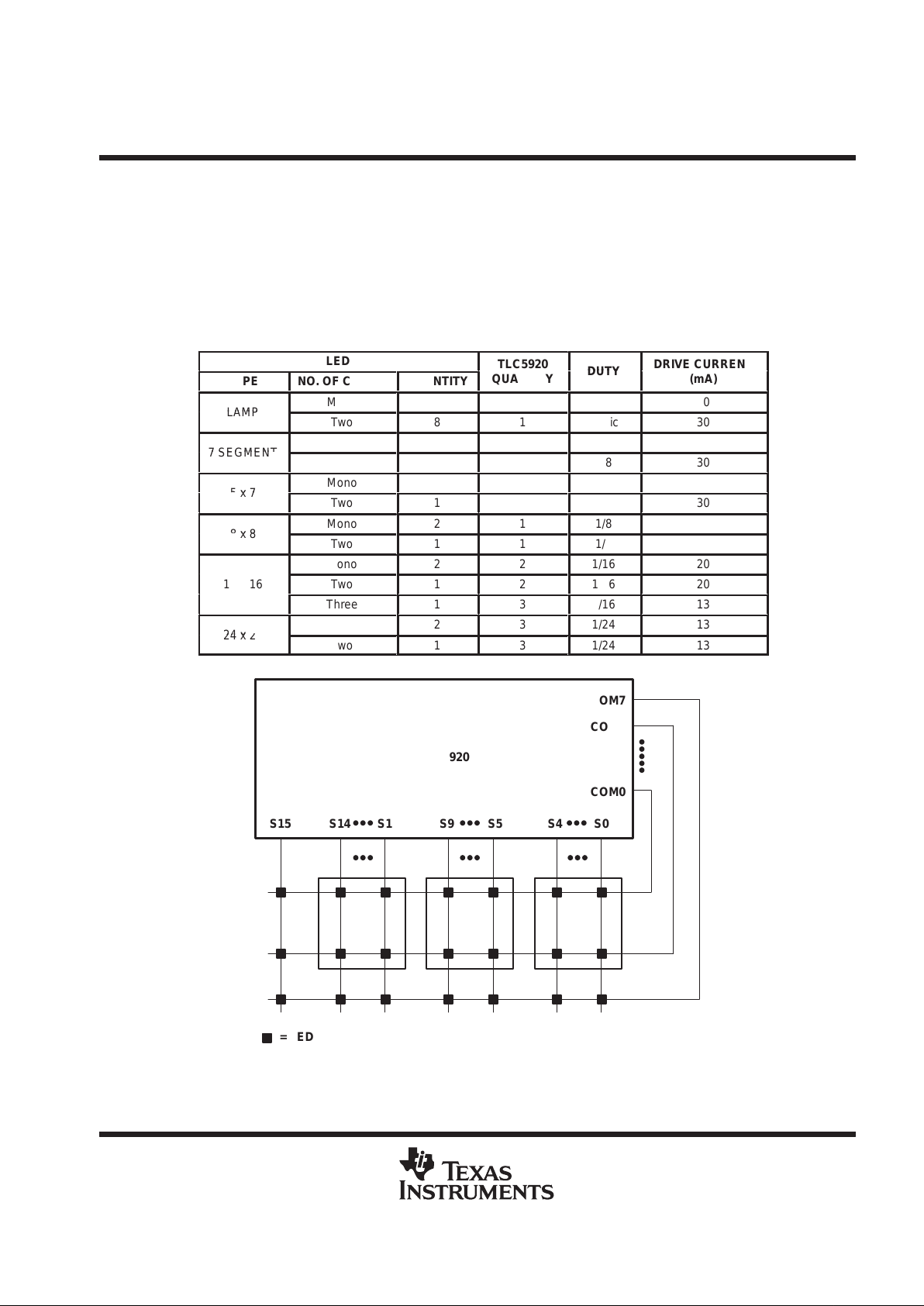

APPLICATION INFORMATION

example 1

The other remaining terminals used for dot matrix LED drive can be utilized for LED lamp drive and other

displays.

LEDs driven by TLC5920

cathode common type

LED

TLC5920

DRIVE CURRENT

TYPE

NO. OF COLOR

QUANTITY

QUANTITY

DUTY

(mA)

Mono

16

1

Static

30

LAMP

Two

8

1

Static

30

Mono

16

1

1/8

30

7 SEGMENT

Two

8

1

1/8

30

Mono

3

1

1/8

30

5

x

7

Two

1

1

1/8

30

Mono

2

1

1/8

30

8

x

8

Two

1

1

1/8

30

Mono

2

2

1/16

20

16 x 16

Two

1

2

1/16

20

Three

1

3

1/16

13

Mono

2

3

1/24

13

24

x

24

Two

1

3

1/24

13

TLC5920

S15

COM0

COM6

COM7

S14 S10 S9 S5 S4 S0

= LED

TLC5920

16x8 BIT LED DRIVER/CONTROLLER

SLAS264 – MARCH 2000

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

example 2

Using two TLC5920s, an LED with two colors and 16 x 16 dots can be driven. The number of LED arrays can

also be increased by making a cascade connection in the application circuit.

COM7

IREF

IC2

TLC5920

DSEL

SCLKSCLK

DSEL

SIN

DSEL

COM0

COM7

IC1

TLC5920

2SOUT

Red

SIN

SOUT

2DSEL

2IREF

SOUT

DSEL

IREF

COM0

1SOUT

Green

1IREF

1SIN

Green

2SIN

Red

1DSEL

SCLK

LATCH

BLANK

CSEL2

CSEL0

CSEL1

S15

S0

16 x 16 Dots

Two–Colors LED Array

S15

S0

CSEL0

CSEL1

CSEL2

BLANK

LATCH

CSEL0

CSEL1

CSEL2

BLANK

LATCH

= LED

TLC5920

16x8 BIT LED DRIVER/CONTROLLER

SLAS264 – MARCH 2000

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

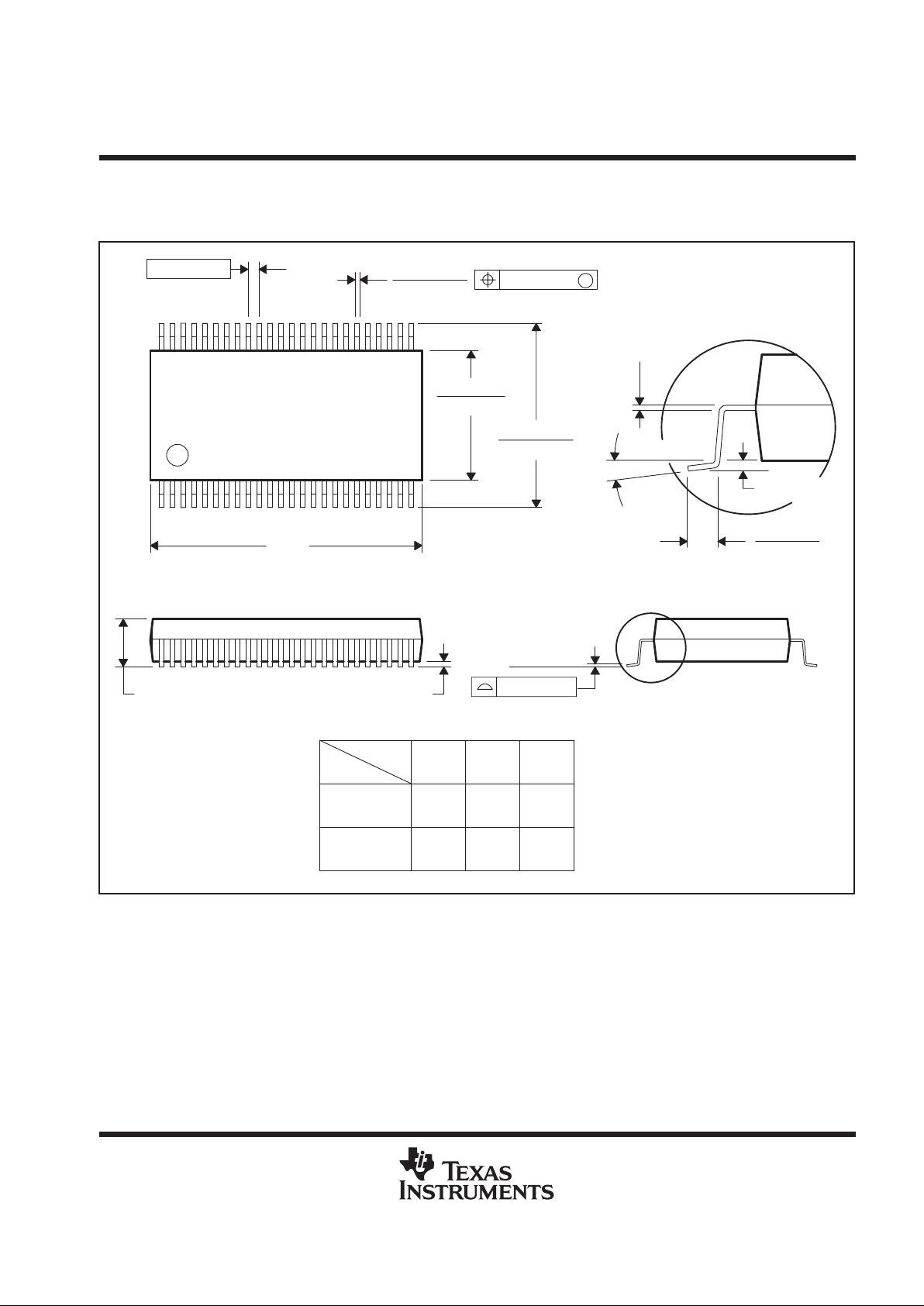

MECHANICAL DATA

DL (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

4040048/D 08/97

48 PINS SHOWN

56

0.730

(18,54)

0.720

(18,29)

4828

0.370

(9,40)

(9,65)

0.380

Gage Plane

DIM

0.420 (10,67)

0.395 (10,03)

A MIN

A MAX

0.006 (0,15) NOM

PINS **

0.630

(16,00)

(15,75)

0.620

0.010 (0,25)

Seating Plane

0.020 (0,51)

0.040 (1,02)

25

24

0.008 (0,203)

0.012 (0,305)

48

1

0.008 (0,20) MIN

A

0.110 (2,79) MAX

0.299 (7,59)

0.291 (7,39)

0.004 (0,10)

M

0.005 (0,13)

0.025 (0,635)

0°–8°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0.006 (0,15).

D. Falls within JEDEC MO-118

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Loading...

Loading...