Datasheet TLC5618AQDR, TLC5618AQD, TLC5618AMJGB, TLC5618AMJG, TLC5618AMFKB Datasheet (Texas Instruments)

...

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

Programmable Settling Time to 0.5 LSB

2.5 µs or 12.5 µs Typ

D

Two 12-Bit CMOS Voltage Output DACs in

an 8-Pin Package

D

Simultaneous Updates for DAC A and

DAC B

D

Single Supply Operation

D

3-Wire Serial Interface

D

High-Impedance Reference Inputs

D

Voltage Output Range ... 2 Times the

Reference Input Voltage

D

Software Powerdown Mode

D

Internal Power-On Reset

D

TMS320 and SPI Compatible

D

Low Power Consumption:

3 mW Typ in Slow Mode,

8 mW Typ in Fast Mode

D

Input Data Update Rate of 1.21 MHz

D

Monotonic Over Temperature

D

Available in Q-Temp Automotive

HighRel Automotive Applications

Configuration Control / Print Support

Qualification to Automotive Standards

applications

D

Battery Powered Test Instruments

D

Digital Offset and Gain Adjustment

D

Battery Operated/Remote Industrial

Controls

D

Machine and Motion Control Devices

D

Cellular Telephones

description

The TLC5618 is a dual 12-bit voltage output

digital-to-analog converter (DAC) with buffered

reference inputs (high impedance). The DACs

have an output voltage range that is two times the

reference voltage, and the DACs are monotonic.

The device is simple to use, running from a single

supply of 5 V. A power-on reset function is

incorporated in the device to ensure repeatable

start-up conditions.

Digital control of the TLC5618 is over a 3-wire

CMOS-compatible serial bus. The device receives a 16-bit word for programming and

producing the analog output. The digital inputs

feature Schmitt triggers for high noise immunity.

Digital communication protocols include the

SPI, QSPI, and Microwire standards.

Two versions of the device are available. The

TLC5618 does not have an internal state machine

and is dependent on all external timing signals. The TLC5618A has an internal state machine that counts the

number of clocks from the falling edge of CS

and then updates and disables the device from accepting further

data inputs. The TLC5618A is recommended for TMS320 and SPI processors, and the TLC5618 is

recommended only for SPI or 3-wire serial port processors. The TLC5618A is backward-compatible and

designed to work in TLC5618 designed systems.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

SPI and QSPI are trademarks of Motorola, Inc.

Microwire is a trademark of National Semiconductor Corporation.

Copyright 1999, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

1

2

3

4

8

7

6

5

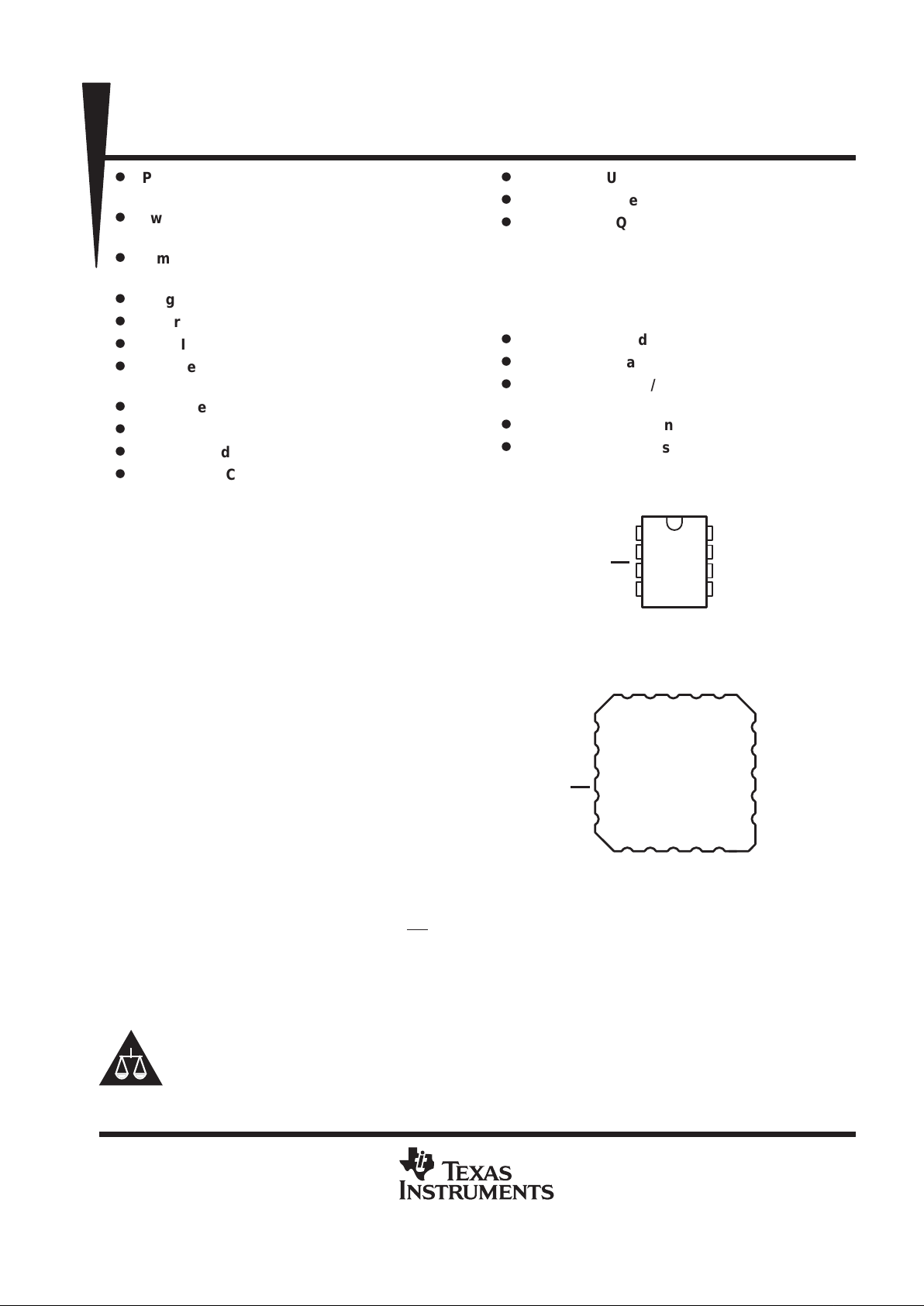

DIN

SCLK

CS

OUT A

V

DD

OUT B

REFIN

AGND

D, P, OR JG PACKAGE

(TOP VIEW)

1920132

17

18

16

15

14

1312119 10

5

4

6

7

8

NC

OUTB

NC

REFIN

NC

NC

SCLK

NC

CS

NC

NC

DINNCV

NC

OUTA

NC

AGND

NC

NC

FK PACKAGE

(TOP VIEW)

DD

On products compliant to MIL-PRF-38535, all parameters are tested

unless otherwise noted. On all other products, production

processing does not necessarily include testing of all parameters.

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

description (continued)

The 8-terminal small-outline D package allows digital control of analog functions in space-critical applications.

The TLC5618C is characterized for operation from 0°C to 70°C. The TLC5618I is characterized for operation

from –40°C to 85°C. The TLC5618Q is characterized for operation from –40°C to 125°C. The TLC5618M is

characterized for operation from –55°C to 125°C.

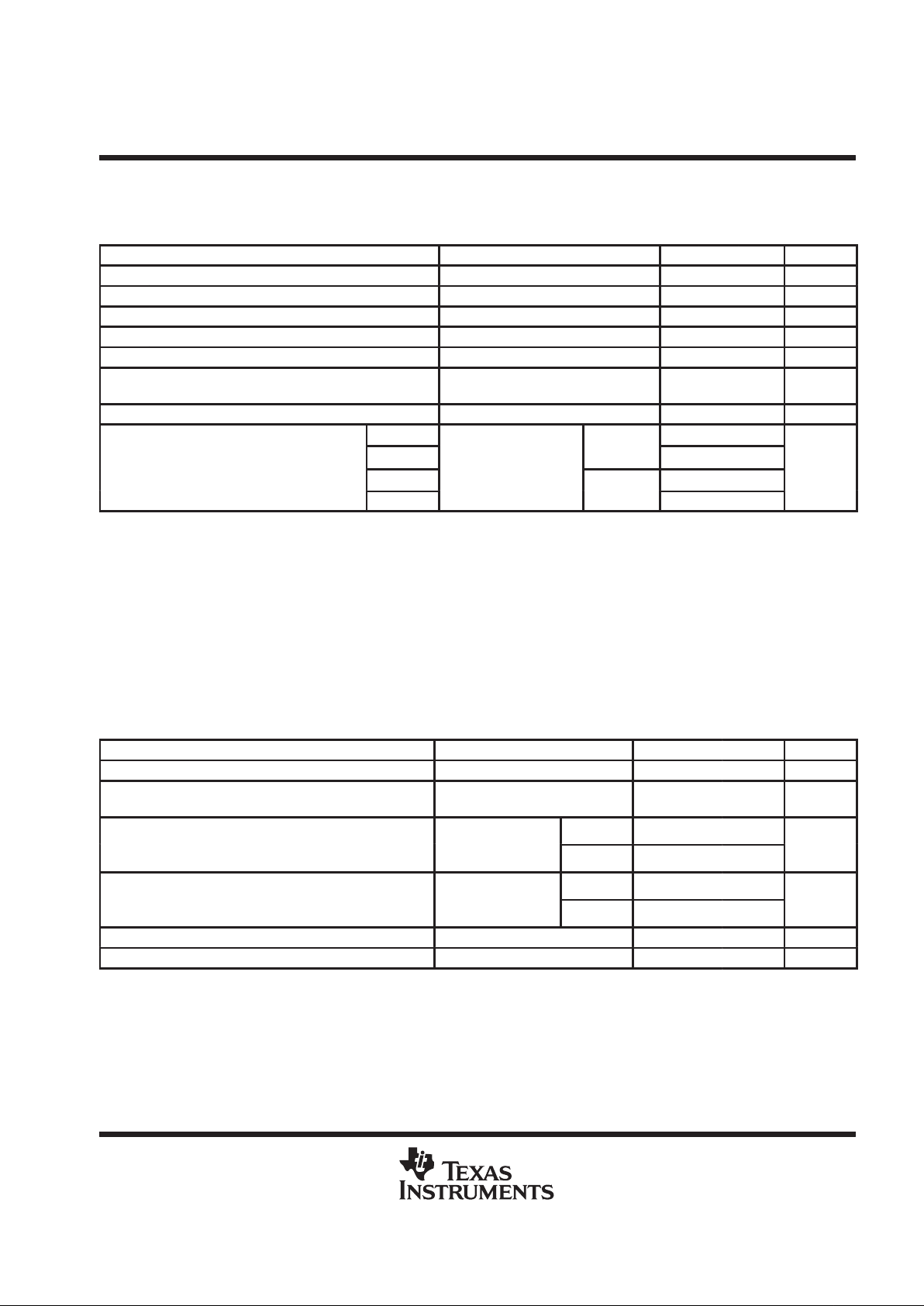

AVAILABLE OPTIONS

PACKAGE

T

A

SMALL OUTLINE

†

(D)

PLASTIC DIP

(P)

CERAMIC DIP

(JG)

20 PAD LCC

(FK)

0°C to 70°C

TLC5618CD

TLC5618ACD

TLC5618CP

TLC5618ACP

—

—

—

—

–40°C to 85°C

TLC5618ID

TLC5618AID

TLC5618IP

TLC5618AIP

—

—

—

—

–40°C to 125°C TLC5618AQD — — —

–55°C to 125°C — — TLC5618AMJG TLC5618AMFK

†

The D package is available in tape and reel by adding R to the part number

(e.g., TLC5618CDR)

DEVICE

COMPATIBILITY

TLC5618 SPI, QSPI and Microwire

TLC5618A TMS320Cxx, SPI, QSPI, and Microwire

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

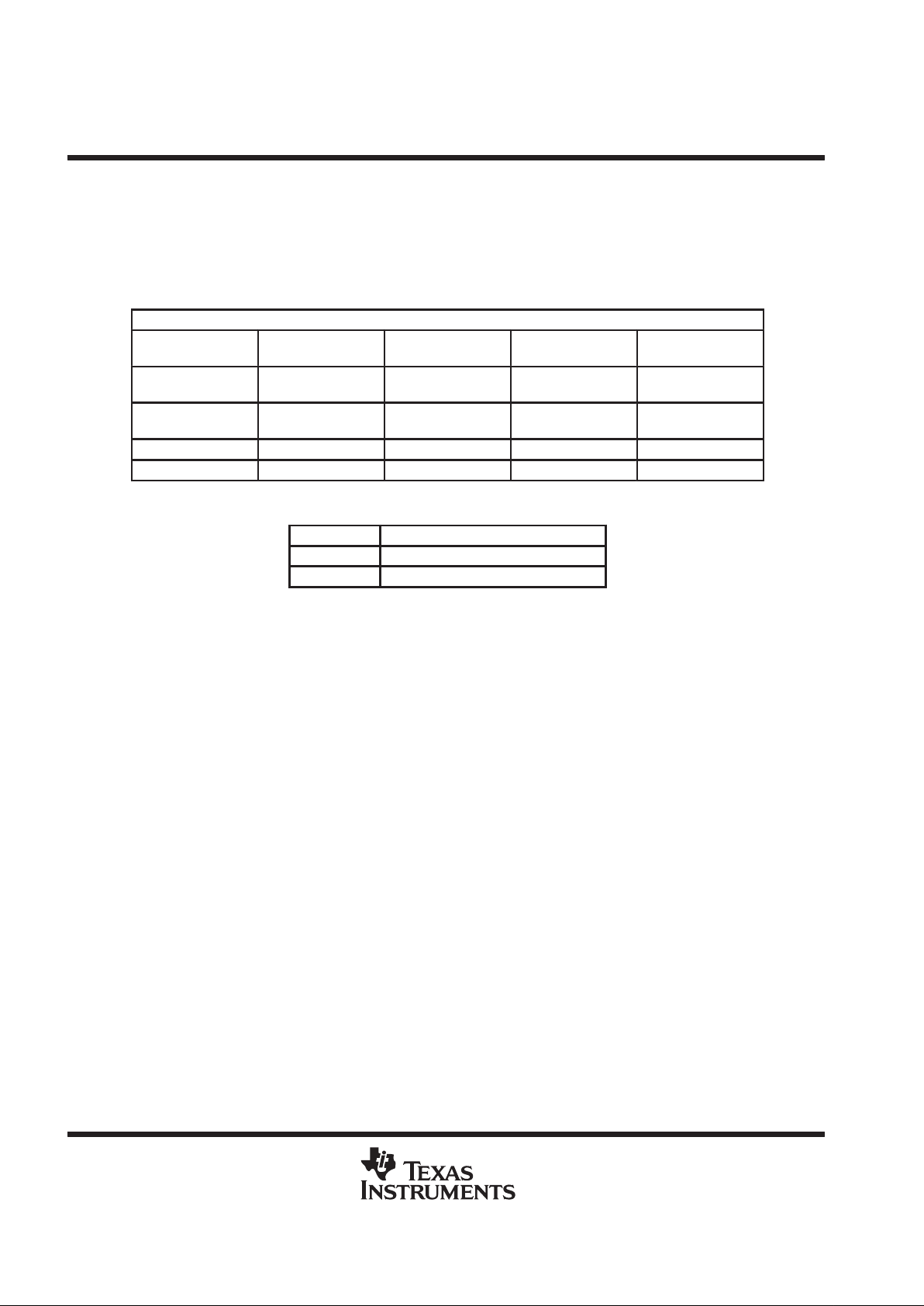

functional block diagram

_

+

DAC

12-Bit DAC Register Latch A

Power-Up

Reset

Control

Logic

16-Bit Shift Register

4

Program

Bits

12 Data Bits

(LSB) (MSB)

REFIN

AGND

CS

SCLK

DIN

OUT A

(Voltage Output)

_

+

RR

DAC A

×2

Double

Buffer

Latch

_

+

_

+

OUT B

(Voltage Output)

DAC B

DAC

R

×2

R

12-Bit DAC Register Latch B

7

4

6

5

3

2

1

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

AGND 5 Analog ground

CS 3 I Chip select, active low

DIN 1 I Serial data input

OUT A 4 O DAC A analog output

OUT B 7 O DAC B analog output

REFIN 6 I Reference voltage input

SCLK 2 I Serial clock input

V

DD

8 Positive power supply

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

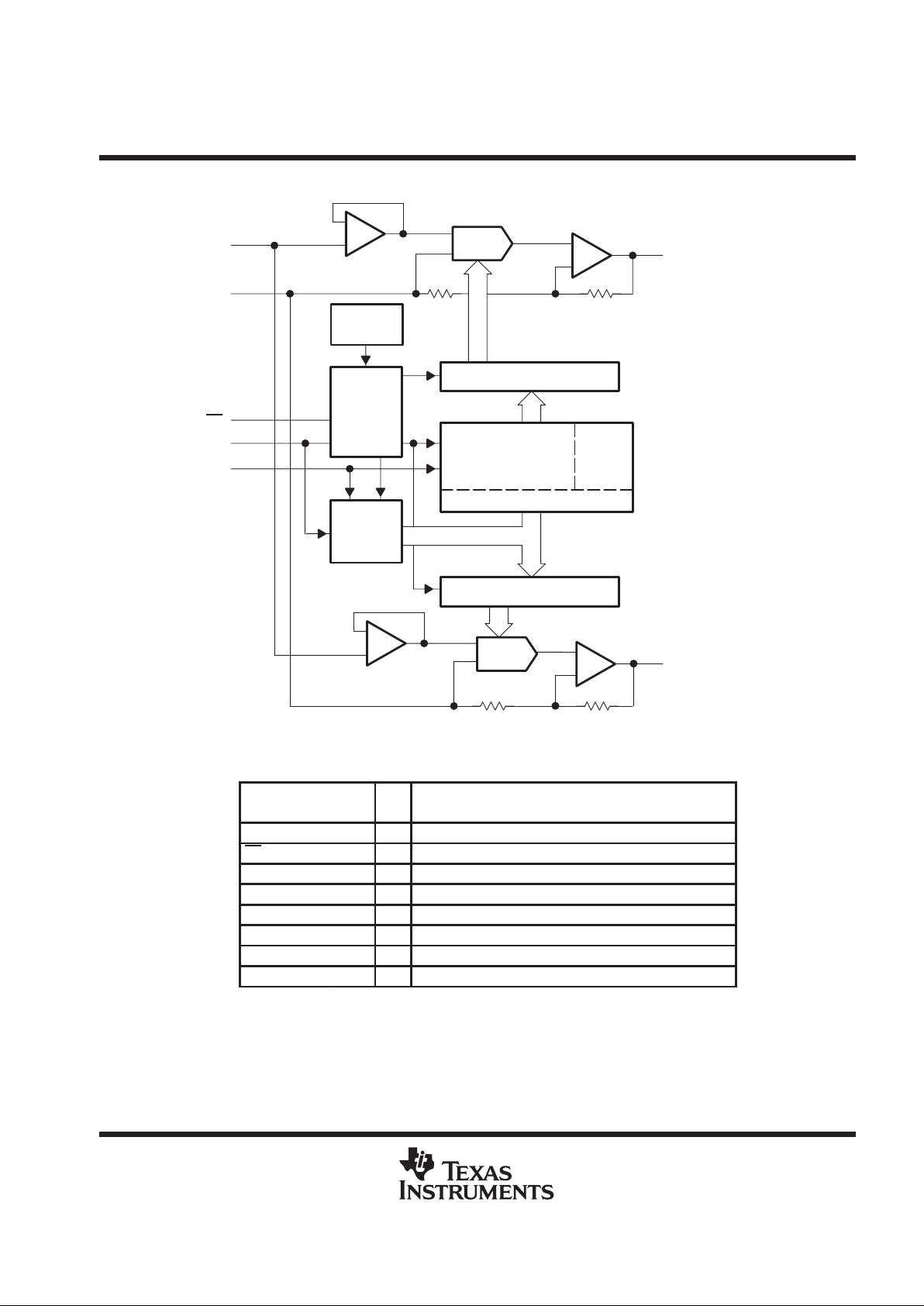

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

†

Supply voltage (VDD to AGND) 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital input voltage range to AGND – 0.3 V to VDD + 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference input voltage range to AGND – 0.3 V to V

DD

+ 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output voltage at OUT from external source V

DD

+ 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous current at any terminal ±20 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, TA: TLC5618C, TLC5618AC 0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . .

TLC5618I, TLC5618AI –40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . .

TLC5618AQ –40°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TLC5618AM –55°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

DISSIPATION RATING TABLE

T

≤ 25°C DERATING FACTOR T

= 70°C T

= 85°C T

= 125°C

PACKAGE

A

POWER RATING ABOVE TA = 25°C

‡

A

POWER RATINGAPOWER RATINGAPOWER RATING

D 635 mW 5.08 mW/°C 407 mW 330 mW —

FK 1375 mW 11.00 mW/°C 880 mW 715 mW 275 mW

JG 1050 mW 8.40 mW/°C 672 mW 546 mW 210 mW

P 1202 mW 9.61 mW/°C 769 mW 625 mW —

‡

This is the inverse of the traditional Junction-to-Ambient thermal Resistance (RΘJA). Thermal Resistances are not production tested and are for

informational purposes only.

recommended operating conditions

MIN NOM MAX UNIT

Supply voltage, V

DD

4.5 5 5.5 V

High-level digital input voltage, V

IH

VDD = 5 V 0.7 V

DD

V

Low-level digital input voltage, V

IL

VDD = 5 V 0.3 V

DD

V

Reference voltage, V

ref

to REFIN terminal 2 2.048 VDD–1.1 V

Load resistance, R

L

2 kΩ

TLC5618C, TLC5618AC 0 70

p

p

TLC5618I, TLC5618AI –40 85

°

Operating free-air temperature, T

A

TLC5618AQ –40 125

°C

TLC5618AM –55 125

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

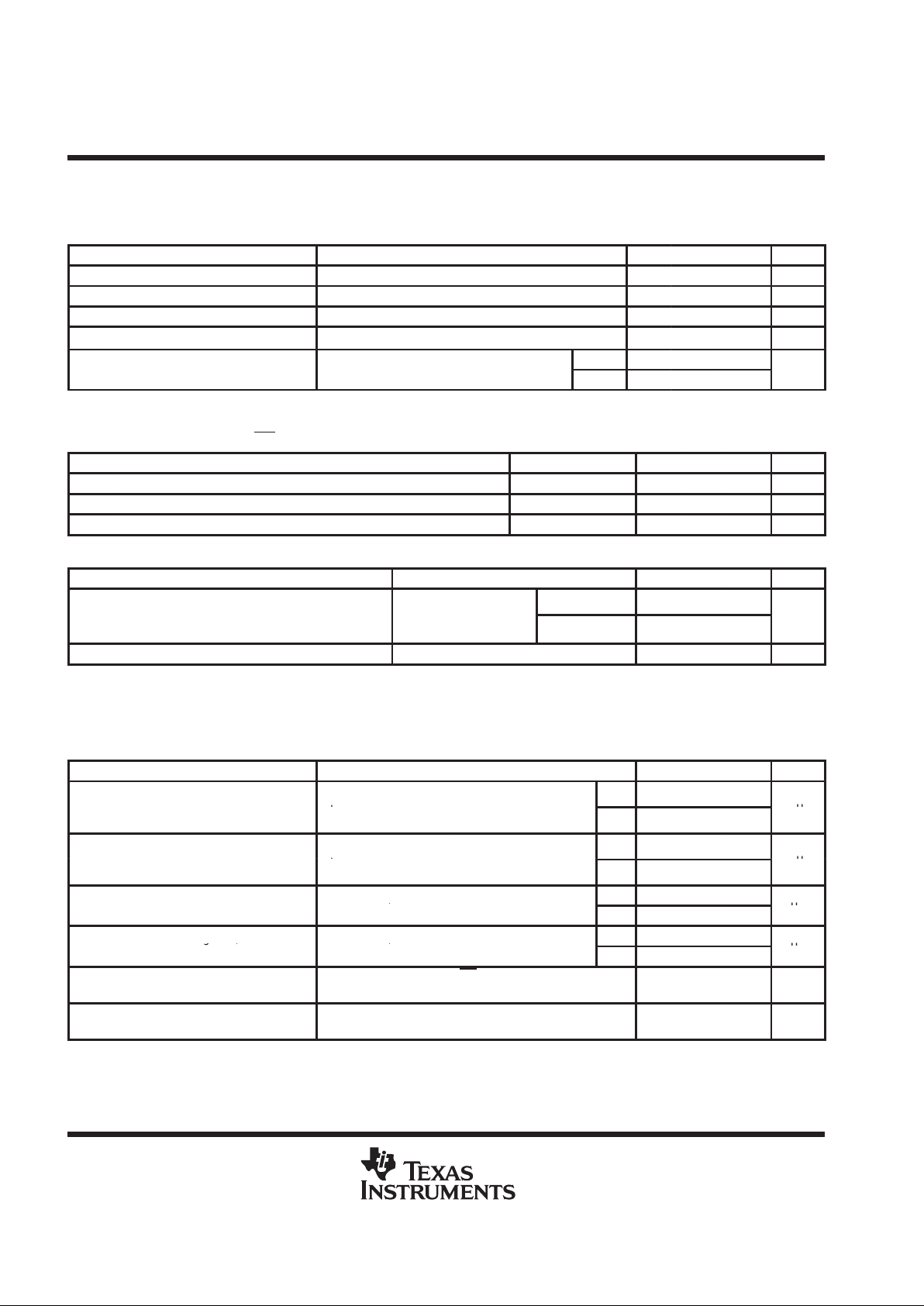

electrical characteristics over recommended operating free-air temperature range, VDD = 5 V ±5%,

V

ref(REFIN)

= 2.048 V (unless otherwise noted)

static DAC specifications

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Resolution 12 bits

Integral nonlinearity (INL), end point adjusted V

ref(REFIN)

= 2.048 V , See Note 1 ±4 LSB

Differential nonlinearity (DNL) V

ref(REFIN)

= 2.048 V , See Note 2 ±0.5 ± 1 LSB

E

ZS

Zero-scale error (offset error at zero scale) V

ref(REFIN)

= 2.048 V , See Note 3 ±12 mV

Zero-scale-error temperature coefficient V

ref(REFIN)

= 2.048 V , See Note 4 3 ppm/°C

E

G

Gain error V

ref(REFIN)

= 2.048 V , See Note 5 ±0.29

% of FS

voltage

Gain error temperature coefficient V

ref(REFIN)

= 2.048 V , See Note 6 1 ppm/°C

Zero scale

65

pp

Gain

Slo

w

65

PSRR

Power-su ly rejection ratio

Zero scale

See Notes 7 and 8

65

dB

Gain

Fast

65

NOTES: 1. The relative accuracy or integral nonlinearity (INL) sometimes referred to as linearity error, is the maximum deviation of the output

from the line between zero and full scale excluding the effects of zero code and full-scale errors.

2. The differential nonlinearity (DNL) sometimes referred to as differential error, is the difference between the measured and ideal 1

LSB amplitude change of any two adjacent codes. Monotonic means the output voltage changes in the same direction (or remains

constant) as a change in the digital input code.

3. Zero-scale error is the deviation from zero voltage output when the digital input code is zero.

4. Zero-scale-error temperature coefficient is given by: EZSTC = [EZS(T

max

) – EZS(T

min

)]/V

ref

× 106/(T

max

– T

min

).

5. Gain error is the deviation from the ideal output (V

ref

– 1 LSB) with an output load of 10 kΩ excluding the effects of the zero-error.

6. Gain temperature coefficient is given by: EGTC = [EG(T

max

) – EG (T

min

)]/V

ref

× 106/(T

max

– T

min

).

7. Zero-scale-error rejection ratio (EZS-RR) is measured by varying the VDD from 4.5 V to 5.5 V dc and measuring the proportion of

this signal imposed on the zero-code output voltage.

8. Gain-error rejection ratio (EG-RR) is measured by varying the VDD from 4.5 V to 5.5 V dc and measuring the proportion of this signal

imposed on the full-scale output voltage after subtracting the zero scale change.

OUT A and OUT B output specifications

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

O

Voltage output range RL = 10 kΩ 0 VDD–0.4 V

Output load regulation accuracy V

O(OUT)

= 4.096 V , RL = 2 kΩ ±0.29

% of FS

voltage

p

V

O(A OUT)

= VDD,

Fast 38

I

OSC(sink)

Out ut short circuit sink current

V

O(B OUT)

=

V

DD

,

Input code zero

Slow 23

mA

p

V

O(A OUT)

= 0 V,

Fast –54

I

OSC(

source

)

Out ut short circuit source current

V

O(B OUT)

= 0 V,

Full-scale code

Slow –29

mA

I

O(sink)

Output sink current V

O(OUT)

= 0.25 V 5 mA

I

O(source)

Output source current V

O(OUT)

= 4.2 V 5 mA

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating free-air temperature range, VDD = 5 V ±5%,

V

ref(REFIN)

= 2.048 V (unless otherwise noted) (continued)

reference input (REFIN)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VIInput voltage range 0 VDD–2 V

RiInput resistance 10 MΩ

CiInput capacitance 5 pF

Reference feedthrough REFIN = 1 Vpp at 1 kHz + 1.024 V dc (see Note 9) –60 dB

p

Slow 0.5

Reference input bandwidth (f

– 3

dB)

REFIN

= 0.2

V

pp

+ 1.

024 V dc

Fast 1

MH

z

NOTE 9: Reference feedthrough is measured at the DAC output with an input code = 000 hex and a V

ref(REFIN)

input = 1.024 V dc + 1 V

pp

at 1 kHz.

digital inputs (DIN, SCLK, CS)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

IH

High-level digital input current VI = V

DD

±1 µA

I

IL

Low-level digital input current VI = 0 V ±1 µA

C

i

Input capacitance 8 pF

power supply

PARAMETER TEST CONDITIONS MIN TYP MAX

UNIT

pp

VDD = 5.5 V,

Slow 0.6 1

IDDPower supply current

No load

,

All inputs = 0 V or V

DD

Fast 1.6 2.5

mA

Power down supply current D13 = 0 (see Table 2) 1 µA

operating characteristics over recommended operating free-air temperature range, VDD = 5 V ±5%,

V

ref(REFIN)

= 2.048 V (unless otherwise noted)

analog output dynamic performance

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

p

p

CL = 100 pF,

V

ref(REFIN)

= 2.048 V ,

°

Slow 0.3 0.5

SR+Output slew rate, positive

R

L

= 10 kΩ,

Code 32 to Code 4096,

T

A

=

25°C

,

VO from 10% to 90%

Fast

2.4 3

V/µs

p

CL = 100 pF,

V

ref(REFIN)

= 2.048 V ,

°

Slow 0.15 0.25

SR–Output slew rate, negative

R

L

= 10 kΩ,

Code 4096 to Code 32,

T

A

=

25°C

,

VO from 10% to 90%

Fast

1.2 1.5

V/µs

p

To ±0.5 LSB,

CL = 100 pF,

Slow 12.5

tsOutput settling time

,

RL = 10 kΩ,

See Note 10

Fast

2.5

µ

s

Output settling time, To ±0.5 LSB,

CL = 100 pF,

Slow 2

t

s(c)

g,

code-to-code

,

RL = 10 kΩ,

See Note 11

Fast

2

µ

s

Glitch energy

DIN = All 0s to all 1s,

f

(SCLK)

= 100 kHz

CS = VDD,

5 nV–s

S/(N+D) Signal to noise + distortion

V

ref(REFIN)

= 1 Vpp at 1 kHz and 10 kHz + 1.024 V dc,

Input code = 10 0000 0000

78 dB

NOTES: 10. Settling time is the time for the output signal to remain within ±0.5 LSB of the final measured value for a digital input code change

of 020 hex to 3FF hex or 3FF hex to 020 hex.

11. Settling time is the time for the output signal to remain within ±0.5 LSB of the final measured value for a digital input code change

of one count.

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

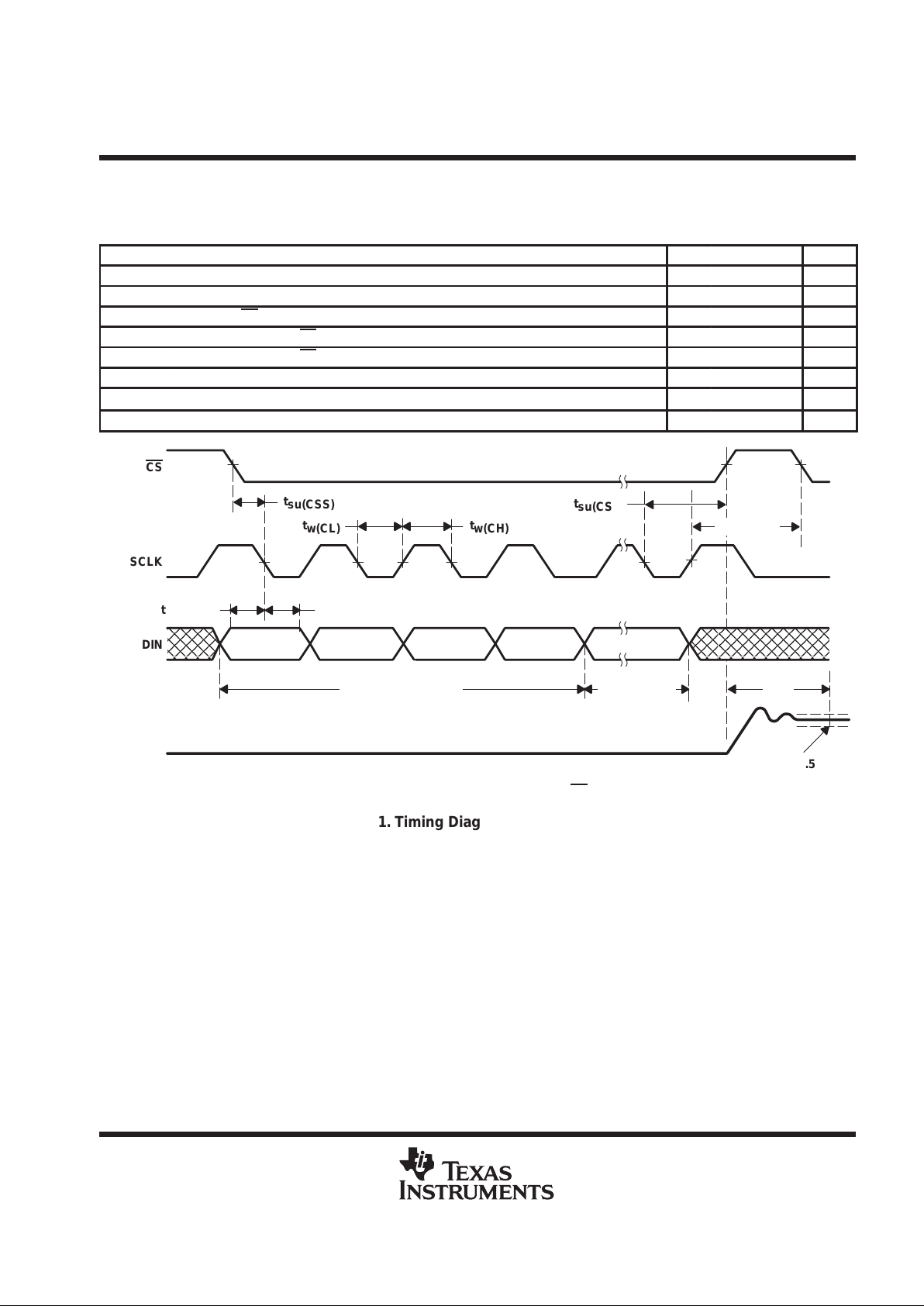

operating characteristics over recommended operating free-air temperature range, VDD = 5 V ±5%,

V

ref(REFIN)

= 2.048 V (unless otherwise noted) (continued)

digital input timing requirements

MIN NOM MAX UNIT

t

su(DS)

Setup time, DIN before SCLK low 5 ns

t

h(DH)

Hold time, DIN valid after SCLK low 5 ns

t

su(CSS)

Setup time, CS low to SCLK low 5 ns

t

su(CS1)

Setup time, SCLK ↓ to CS ↑, external end-of-write 10 ns

t

su(CS2)

Setup time, SCLK ↑ to CS ↓, start of next write cycle 5 ns

t

w(CL)

Pulse duration, SCLK low 25 ns

t

w(CH)

Pulse duration, SCLK high 25 ns

t

d(CS1)

Delay time, CLK↑ to data disable (TLC5618A only) 5 20 ns

NOTE A: The input clock, applied at the SCLK terminal, should be inhibited high when CS is high to minimize clock feedthrough.

t

su(CSS)

t

w(CL)

t

w(CH)

CS

SCLK

DIN

t

su(DS)

t

h(DH)

D15 D14 D13 D12 D11 D0

t

s

DAC A/B

OUT

≤ Final Value ±0.5 LSB

(see Note A)

Program Bits (4)

DAC Data

Bits (12)

t

su(CS1)

t

su(CS2)

Figure 1. Timing Diagram for the TLC5618

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

NOTE A: The input clock, applied at the SCLK terminal, should be inhibited high when CS is high to minimize clock feedthrough.

t

su(CSS)

t

w(CL)

t

w(CH)

CS

SCLK

DIN

t

su(DS)

t

h(DH)

D15 D14 D13 D12 D11 D0

t

s

DAC A/B

OUT

≤ Final Value ±0.5 LSB

(see Note A)

Program Bits (4)

DAC Data

Bits (12)

t

su(CS1)

t

su(CS2)

16th Falling Edge

t

d(CS1)

Internally Generated

Disable at This Time

Internal

Latch

Control

(see Note A)

Figure 2. Timing Diagram for TLC5618A Only

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 3

15

10

0

–5

012

Output Sink Current – mA

20

25

Output Load Voltage – V

OUTPUT SINK CURRENT (FAST MODE)

vs

OUTPUT LOAD VOLTAGE

30

3.5

5

35

40

1.50.5 2.5 3 4

4.5

VDD = 5 V,

Input Code = 0

Figure 4

–30

–20

–10

0

Output Source Current – mA

–40

–50

Output Load Voltage – V

OUTPUT SOURCE CURRENT (FAST MODE)

vs

OUTPUT LOAD VOLTAGE

–60

0 0.5 1

1.5 2

2.5 3 3.5 4 4.5

VDD = 5 V,

Input Code = 4095

Figure 5

10

5

0

–0

Output Sink Current – mA

15

20

Output Load Voltage – V

OUTPUT SINK CURRENT (SLOW MODE)

vs

OUTPUT LOAD VOLTAGE

25

0 0.5 1

1.5 2

2.5 3 3.5 4 4.5

VDD = 5 V,

Input Code = 0

Figure 6

–15

–10

–5

0

Output Source Current – mA

–20

–25

Output Load Voltage – V

OUTPUT SOURCE CURRENT (SLOW MODE)

vs

OUTPUT LOAD VOLTAGE

–30

0 0.5 1

1.5 2

2.5 3 3.5 4 4.5

VDD = 5 V,

Input Code = 4095

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 7

0.4

Supply Current – mA

1

1.4

SUPPLY CURRENT

vs

TEMPERATURE

1.2

0.8

0.6

0.2

0

–60 –40 –20 0 20 40 60 80 100 120 140

Temperature – °C

VDD = 5 V,

V

REFIN

= 2.048 V ,

TA = 25°C

Fast Mode

Slow Mode

1.6

Figure 8

–10

–15

–20

–30

100 1000

Relative Gain – dB

–5

0

f – Frequency – kHz

RELATIVE GAIN (FAST MODE)

vs

FREQUENCY

5

10 K

–25

VCC = 5 V,

V

REFIN

= 0.2 VPP + 2.048 Vdc,

TA = 25°C

Figure 9

–10

–15

–20

–30

100 1000

Relative Gain – dB

–5

0

f – Frequency – kHz

RELATIVE GAIN (SLOW MODE)

vs

FREQUENCY

5

10 K

–25

VCC = 5 V,

V

REFIN

= 0.2 VPP +2.048 Vdc,

TA = 25°C

–35

–40

Figure 10

80

75

70

65

110

THD – Total Harmonic Distortion – dB

85

90

f – Frequency – kHz

TOTAL HARMONIC DISTORTION (SLOW MODE)

vs

FREQUENCY

95

100

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 11

70

65

60

110

THD+N – Total Harmonic Distortion + Noise – dB

75

80

f – Frequency– kHz

TOTAL HARMONIC DISTORTION + NOISE (SLOW MODE)

vs

FREQUENCY

85

100

Figure 12

75

70

65

110

SNR – Signal-To-Noise Ratio – dB

80

f – Frequency– kHz

SIGNAL-TO-NOISE RATIO (SLOW MODE)

vs

FREQUENCY

85

100

Figure 13

85

80

75

110

THD – Total Harmonic Distortion – dB

90

f – Frequency – kHz

TOTAL HARMONIC DISTORTION (FAST MODE)

vs

FREQUENCY

95

100

Figure 14

75

70

65

110

THD+N – Total Harmonic Distortion + Noise – dB

80

f – Frequency – kHz

TOTAL HARMONIC DISTORTION + NOISE (FAST MODE)

vs

FREQUENCY

85

100

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

75

70

65

110

SNR – Signal-To-Noise Ratio – dB

80

f – Frequency – kHz

SIGNAL-TO-NOISE RATIO (FAST MODE)

vs

FREQUENCY

85

100

Figure 15

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

–0.6

1

0

–0.2

0.8

0.6

0.4

0.2

–0.4

–0.8

–1

Samples

500 2000 3000 40950 1000 1500 2500 3500

DNL – Differential Nonlinearity – LSB

Figure 16. Differential Nonlinearity With Input Code

–2

–1

–1.5

1

0.5

0

–0.5

–2.5

–3.0

Samples

500 2000 3000 40950 1000 1500 2500 3500

INL – Integral Nonlinearity – LSB

Figure 17. Integral Nonlinearity With Input Code

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

general function

The TLC5618 uses a resistor string network buffered with an op amp to convert 12-bit digital data to analog

voltage levels (see functional block diagram and Figure 18). The output is the same polarity as the reference

input (see Table 1).

The output code is given by: 2

ǒ

V

REFIN

Ǔ

CODE

4096

An internal circuit resets the DAC register to all 0s on power up.

_

+

Resistor

String

DAC

5 V

0.1 µF

AGND V

DD

OUT

REFIN

R

R

_

+

×2

DIN

CS

SCLK

Figure 18. TLC5618 Typical Circuit

Table 1. Binary Code Table (0 V to 2 V

REFIN

Output)

,

Gain = 2

INPUT OUTPUT

1111 1111 1111

2ǒV

REFIN

Ǔ

4095

4096

:

:

1000 0000 0001

2

ǒ

V

REFIN

Ǔ

2049

4096

1000 0000 0000

2ǒV

REFIN

Ǔ

2048

4096

+

V

REFIN

0111 1111 1111

2

ǒ

V

REFIN

Ǔ

2047

4096

:

:

0000 0000 0001

2

ǒ

V

REFIN

Ǔ

1

4096

0000 0000 0000

0 V

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

buffer amplifier

The output buffer has a rail-to-rail output with short circuit protection and can drive a 2-kΩ load with a 100-pF

load capacitance. Settling time is a software selectable 12.5 µs or 2.5 µs, typical to within ±0.5 LSB of final value.

external reference

The reference voltage input is buffered, which makes the DAC input resistance not code dependent. Therefore,

the REFIN input resistance is 10 MΩ and the REFIN input capacitance is typically 5 pF, independent of input

code. The reference voltage determines the DAC full-scale output.

logic interface

The logic inputs function with CMOS logic levels. Most of the standard high-speed CMOS logic families may

be used.

serial clock and update rate

Figure 1 shows the TLC5618 timing. The maximum serial clock rate is:

f

(SCLK)max

+

1

t

wǒCHǓmin

)

t

wǒCLǓmin

+

20 MHz

The digital update rate is limited by the chip-select period, which is:

t

p(CS)

+16 ǒt

wǒCH

Ǔ

)

t

wǒCL

Ǔ

Ǔ

)

t

suǒCS1

Ǔ

This equals an 810-ns or 1.23-MHz update rate. However, the DAC settling time to 12 bits limits the update rate

for full-scale input step transitions.

serial interface

When chip select (CS) is low, the input data is read into a 16-bit shift register with the input data clocked in, most

significant bit first. The falling edge of the SCLK input shifts the data into the input register.

The rising edge of CS then transfers the data to the DAC register. When CS is high, input data cannot be clocked

into the input register.

The 16 bits of data can be transferred with the sequence shown in Figure 19.

D15 D14 D13 D12 D11 12 Data Bits D0

Program Bits Data Bits

16 Bits

MSB (Input Word) MSB (Data) LSB (Data, Input Word)

Figure 19. Input Data Word Format

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

Table 2 shows the function of program bits D15 – D12.

Table 2. Program Bits D15 – D12 Function

PROGRAM BITS

D15 D14 D13 D12

DEVICE FUNCTION

1 X X X

Write to latch A with serial interface register data

and latch B updated with buffer latch data

0 X X 0 Write to latch B and double buffer latch

0 X X 1 Write to double buffer latch only

X 0 X X 12.5 µs settling time

X 1 X X 2.5 µs settling time

X X 0 X Powered-up operation

X X 1 X Power down mode

function of the latch control bits (D15 and D12)

Three data transfers are possible. All transfers occur immediately after CS goes high and are described in the

following sections.

latch A write, latch B update (D15 = high, D12 = X)

The serial interface register (SIR) data are written to latch A and the double buffer latch contents are written to

latch B. The double buffer contents are unaffected. This program bit condition allows simultaneous output

updates of both DACs.

Serial

Interface

Register

D12 = X

D15 = High

Latch A

Latch B

Double

Buffer Latch

To DAC A

To DAC B

Figure 20. Latch A Write, Latch B Update

latch B and double-buffer 1 write (D15 = low, D12 = low)

The SIR data are written to both latch B and the double buffer. Latch A is unaffected.

Serial

Interface

Register

D12 = Low

D15 = Low

Latch A

Latch B

Double

Buffer Latch

To DAC A

To DAC B

Figure 21. Latch B and Double-Buffer Write

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

double-buffer-only write (D15 = low, D12 = high)

The SIR data are written to the double buffer only. Latch A and B contents are unaffected.

Serial

Interface

Register

D12 = High

D15 = Low

Latch A

Latch B

Double

Buffer

To DAC A

To DAC B

Figure 22. Double-Buffer-Only Write

purpose and use of the double buffer

Normally only one DAC output can change after a write. The double buffer allows both DAC outputs to change

after a single write. This is achieved by the two following steps.

1. A double-buffer-only write is executed to store the new DAC B data without changing the DAC A and B

outputs.

2. Following the previous step, a write to latch A is executed. This writes the SIR data to latch A and also

writes the double-buffer contents to latch B. Thus both DACs receive their new data at the same time,

and so both DAC outputs begin to change at the same time.

Unless a double-buffer-only write is issued, the latch B and double-buffer contents are identical. Thus, following

a write to latch A or B with another write to latch A does not change the latch B contents.

operational examples

changing the latch A data from zero to full code

Assuming that latch A starts at zero code (e.g., after power-up), the latch can be filled with 1s by writing (bit D15

on the left, D0 on the right)

1X0X 1111 1111 1111

to the serial interface. Bit D14 can be zero to select slow mode or one to select fast mode. The other X can be

zero or one (don’t care).

The latch B contents and the DAC B output are not changed by this write unless the double-buffer contents are

different from the latch B contents. This can only be true if the last write was a double-buffer-only write.

changing the latch B data from zero to full code

Assuming that latch B starts at zero code (e.g., after power-up), the latch can be filled with 1s by writing (bit D15

on the left, D0 on the right).

0X00 1111 1111 1111

to the serial interface. Bit D14 can be zero to select slow mode or one to select fast mode. The data (bits D0

to D11) are written to both the double buffer and latch B.

The latch A contents and the DAC A output are not changed by this write.

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

double-buffered change of both DAC outputs

Assuming that DACs A and B start at zero code (e.g., after power-up), if DAC A is to be driven to mid-scale and

DAC B to full-scale, and if the outputs are to begin rising at the same time, this can be achieved as follows:

First,

0d01 1111 1111 1111

is written (bit D15 on the left, D0 on the right) to the serial interface. This loads the full-scale code into the double

buffer but does not change the latch B contents and the DAC B output voltage. The latch A contents and the

DAC A output are also unaffected by this write operation.

Changing from fast to slow or slow to fast mode changes the supply current which can glitch the outputs, and

so D14 (designated by d in the above data word) should be set to maintain the speed mode set by the previous

write.

Next,

1X0X 1000 0000 0000

is written (bit D15 on the left, D0 on the right) to the serial interface. Bit D14 can be zero to select slow mode

or one to select fast mode. The other X can be zero or one (don’t care). This writes the mid-scale code

(100000000000) to latch A and also copies the full-scale code from the double buffer to latch B. Both DAC

outputs thus begin to rise after the second write.

DSP serial interface

Utilizing a simple 3-wire serial interface shown in Figure 23, the TLC5618A can be interfaced to TMS320

compatible serial ports. The 5618A has an internal state machine that will count 16 clocks after receiving a falling

edge of CS

and then disable further clocking in of data until the next falling edge is received on CS. Therefore

CS can be connected directly to the FS pins of the serial port and only the leading falling edge of the DSP will

be used to start the write process. The TLC5618A is designed to be used with the TMS320Cxx DSP in burst

mode serial port transmit operation.

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

19

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

SCLK

DIN

CS

TLC5618A

CLKX

DX

FSX

TMS320C203

DSP

V

CC

OUT A

OUT B

GND

REFIN

2.5 V dc

FSR

To Source

Ground

Analog

Output

Analog

Output

CLKR

Figure 23. Interfacing The TLC5618A to the TMS320C203 DSP

general serial interface

Both the TLC5618 and TLC5618A are compatible with SPI, QSPI, or Microwire serial standards. The hardware

connections are shown in Figures 24 and 25. The TLC5618A has an internal state machine that will count 16

clocks after the falling edge of CS and then internally disable the device. The internal edge is ORed together

with CS so that the rising edge can be provided to CS prior to the occurrence of the internal edge to also disable

the device.

The SPI and Microwire interfaces transfer data in 8-bit bytes, therefore, two write cycles are required to input

data to the DAC. The QSPI interface, which has a variable input data length from 8 to 16 bits, can load the DAC

input register in one write cycle.

SCLK

DIN

CS

TLC5618,

TLC5618A

SK

SO

I/O

Microwire

Port

Figure 24. Microwire Connection

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

SCLK

DIN

CS

TLC5618,

TLC5618A

SCK

MOSI

I/O

SPI/QSPI

Port

CPOL = 1, CPHA = 0

Figure 25. SPI/QSPI Connection

linearity, offset, and gain error using single end supplies

When an amplifier is operated from a single supply , the voltage offset can still be either positive or negative. With

a positive offset, the output voltage changes on the first code change. With a negative offset the output voltage

may not change with the first code depending on the magnitude of the offset voltage.

The output amplifier attempts to drive the output to a negative voltage. However, because the most negative

supply rail is ground, the output cannot drive below ground and clamps the output at 0 V.

The output voltage then remains at zero until the input code value produces a sufficient positive output voltage

to overcome the negative offset voltage, resulting in the transfer function shown in Figure 26.

DAC Code

Output

Voltage

0 V

Negative

Offset

Figure 26. Effect of Negative Offset (Single Supply)

This offset error, not the linearity error , produces this breakpoint. The transfer function would have followed the

dotted line if the output buffer could drive below the ground rail.

For a DAC, linearity is measured between zero-input code (all inputs 0) and full-scale code (all inputs 1) after

offset and full scale are adjusted out or accounted for in some way . However , single supply operation does not

allow for adjustment when the offset is negative due to the breakpoint in the transfer function. So the linearity

is measured between full-scale code and the lowest code that produces a positive output voltage. The code is

calculated from the maximum specification for the negative offset.

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

21

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

power-supply bypassing and ground management

Printed-circuit boards that use separate analog and digital ground planes offer the best system performance.

Wire-wrap boards do not perform well and should not be used. The two ground planes should be connected

together at the low-impedance power-supply source. The best ground connection may be achieved by

connecting the DAC AGND terminal to the system analog ground plane making sure that analog ground

currents are well-managed.

A 0.1-µF ceramic bypass capacitor should be connected between V

DD

and AGND and mounted with short leads

as close as possible to the device. Use of ferrite beads may further isolate the system analog and digital power

supplies.

Figure 27 shows the ground plane layout and bypassing technique.

0.1 µF

Analog Ground Plane

1

2

3

4

8

7

6

5

Figure 27. Power-Supply Bypassing

saving power

Setting the DAC register to all 0s minimizes power consumption by the reference resistor array and the output

load when the system is not using the DAC.

ac considerations/analog feedthrough

Higher frequency analog input signals may couple to the output through internal stray capacitance. Analog

feedthrough is tested by holding CS high, setting the DAC code to all 0s, sweeping the frequency applied to

REFIN, and monitoring the DAC output.

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

D (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PIN SHOWN

4040047/D 10/96

0.228 (5,80)

0.244 (6,20)

0.069 (1,75) MAX

0.010 (0,25)

0.004 (0,10)

1

14

0.014 (0,35)

0.020 (0,51)

A

0.157 (4,00)

0.150 (3,81)

7

8

0.044 (1,12)

0.016 (0,40)

Seating Plane

0.010 (0,25)

PINS **

0.008 (0,20) NOM

A MIN

A MAX

DIM

Gage Plane

0.189

(4,80)

(5,00)

0.197

8

(8,55)

(8,75)

0.337

14

0.344

(9,80)

16

0.394

(10,00)

0.386

0.004 (0,10)

M

0.010 (0,25)

0.050 (1,27)

0°–8°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion, not to exceed 0.006 (0,15).

D. Falls within JEDEC MS-012

TLC5618, TLC5618A

PROGRAMMABLE DUAL 12-BIT DIGITAL-TO-ANALOG CONVERTERS

SLAS156E – JULY 1997 – REVISED SEPTEMBER 1999

23

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

FK (S-CQCC-N**) LEADLESS CERAMIC CHIP CARRIER

4040140/C 11/95

28 TERMINALS SHOWN

B

0.358

(9,09)

MAX

(11,63)

0.560

(14,22)

0.560

0.458

0.858

(21,8)

1.063

(27,0)

(14,22)

A

NO. OF

MINMAX

0.358

0.660

0.761

0.458

0.342

(8,69)

MIN

(11,23)

(16,26)

0.640

0.740

0.442

(9,09)

(11,63)

(16,76)

0.962

1.165

(23,83)

0.938

(28,99)

1.141

(24,43)

(29,59)

(19,32)(18,78)

**

20

28

52

44

68

84

0.020 (0,51)

TERMINALS

0.080 (2,03)

0.064 (1,63)

(7,80)

0.307

(10,31)

0.406

(12,58)

0.495

(12,58)

0.495

(21,6)

0.850

(26,6)

1.047

0.045 (1,14)

0.045 (1,14)

0.035 (0,89)

0.035 (0,89)

0.010 (0,25)

12

1314151618 17

11

10

8

9

7

5

432

0.020 (0,51)

0.010 (0,25)

6

12826 27

19

21

B SQ

A SQ

22

23

24

25

20

0.055 (1,40)

0.045 (1,14)

0.028 (0,71)

0.022 (0,54)

0.050 (1,27)

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. This package can be hermetically sealed with a metal lid.

D. The terminals are gold-plated.

E. Falls within JEDEC MS-004

MECHANICAL DATA

MCER001A – JANUARY 1995 – REVISED JANUARY 1997

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

JG (R-GDIP-T8) CERAMIC DUAL-IN-LINE

0.310 (7,87)

0.290 (7,37)

0.014 (0,36)

0.008 (0,20)

Seating Plane

4040107/C 08/96

5

4

0.065 (1,65)

0.045 (1,14)

8

1

0.020 (0,51) MIN

0.400 (10,16)

0.355 (9,00)

0.015 (0,38)

0.023 (0,58)

0.063 (1,60)

0.015 (0,38)

0.200 (5,08) MAX

0.130 (3,30) MIN

0.245 (6,22)

0.280 (7,11)

0.100 (2,54)

0°–15°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. This package can be hermetically sealed with a ceramic lid using glass frit.

D. Index point is provided on cap for terminal identification.

E. Falls within MIL STD 1835 GDIP1-T8

MECHANICAL DATA

MCER001A – JANUARY 1995 – REVISED JANUARY 1997

25

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

P (R-PDIP-T8) PLASTIC DUAL-IN-LINE PACKAGE

4040082/B 03/95

0.310 (7,87)

0.290 (7,37)

0.010 (0,25) NOM

0.400 (10,60)

0.355 (9,02)

58

41

0.020 (0,51) MIN

0.070 (1,78) MAX

0.240 (6,10)

0.260 (6,60)

0.200 (5,08) MAX

0.125 (3,18) MIN

0.015 (0,38)

0.021 (0,53)

Seating Plane

M

0.010 (0,25)

0.100 (2,54)

0°–15°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Falls within JEDEC MS-001

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...