Page 1

查询TLC272供应商

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

D

Trimmed Offset Voltage:

TLC277 . . . 500 µV Max at 25°C,

V

= 5 V

DD

D

Input Offset Voltage Drift...Typically

0.1 µV/Month, Including the First 30 Days

D

Wide Range of Supply Voltages Over

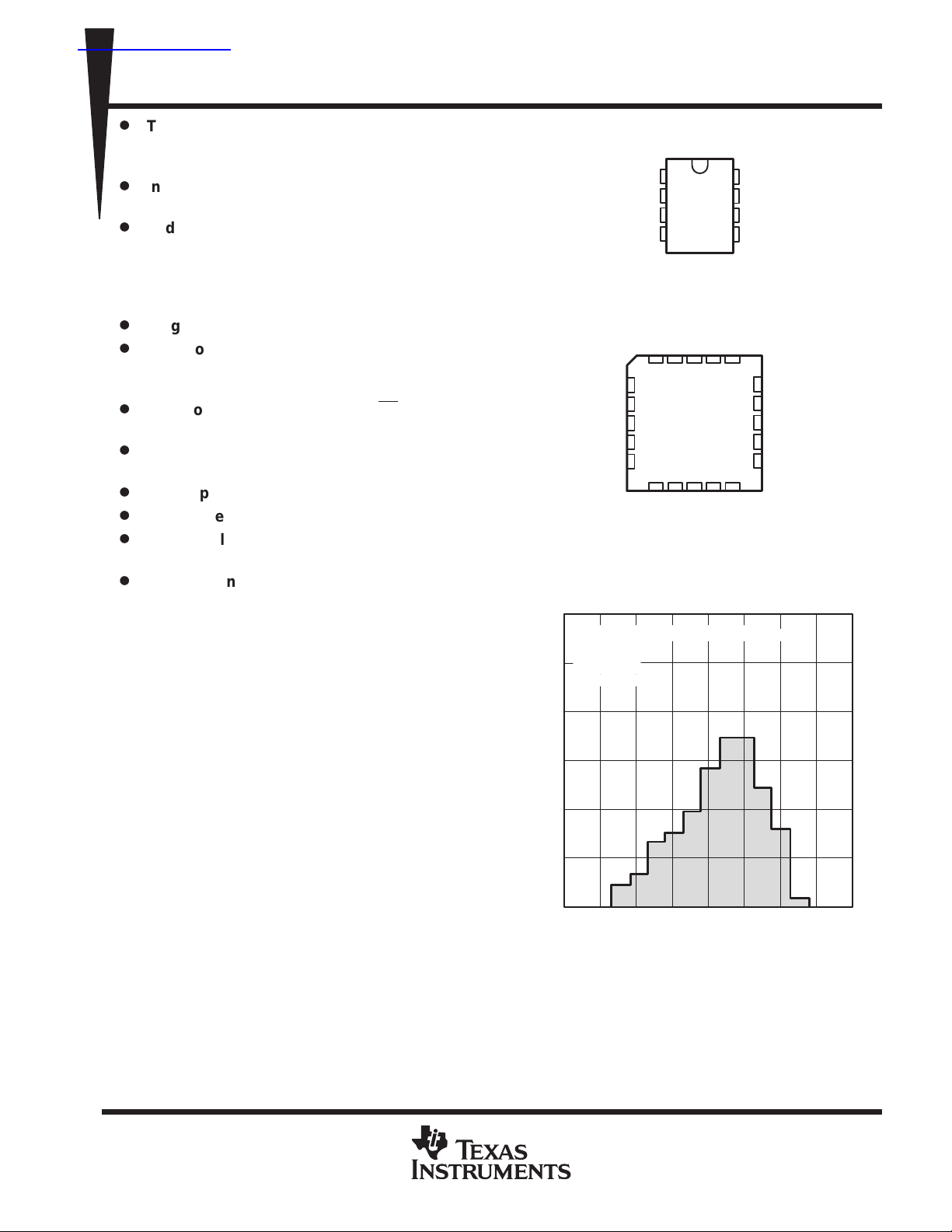

D, JG, P, OR PW PACKAGE

(TOP VIEW)

1OUT

1IN–

1IN+

GND

1

2

3

4

8

7

6

5

V

DD

2OUT

2IN–

2IN+

Specified Temperature Range:

0°C to 70°C...3 V to 16 V

–40°C to 85°C...4 V to 16 V

–55°C to 125°C...4 V to 16 V

D

Single-Supply Operation

D

Common-Mode Input Voltage Range

Extends Below the Negative Rail (C-Suffix,

I-Suffix types)

D

Low Noise...Typically 25 nV/√Hz at

f = 1 kHz

D

Output Voltage Range Includes Negative

Rail

D

High Input impedance...1012 Ω Typ

D

ESD-Protection Circuitry

D

Small-Outline Package Option Also

Available in Tape and Reel

D

Designed-in Latch-Up Immunity

description

The TLC272 and TLC277 precision dual

operational amplifiers combine a wide range of

input offset voltage grades with low offset voltage

drift, high input impedance, low noise, and speeds

approaching that of general-purpose BiFET

NC

1IN–

NC

1IN+

NC

NC – No internal connection

30

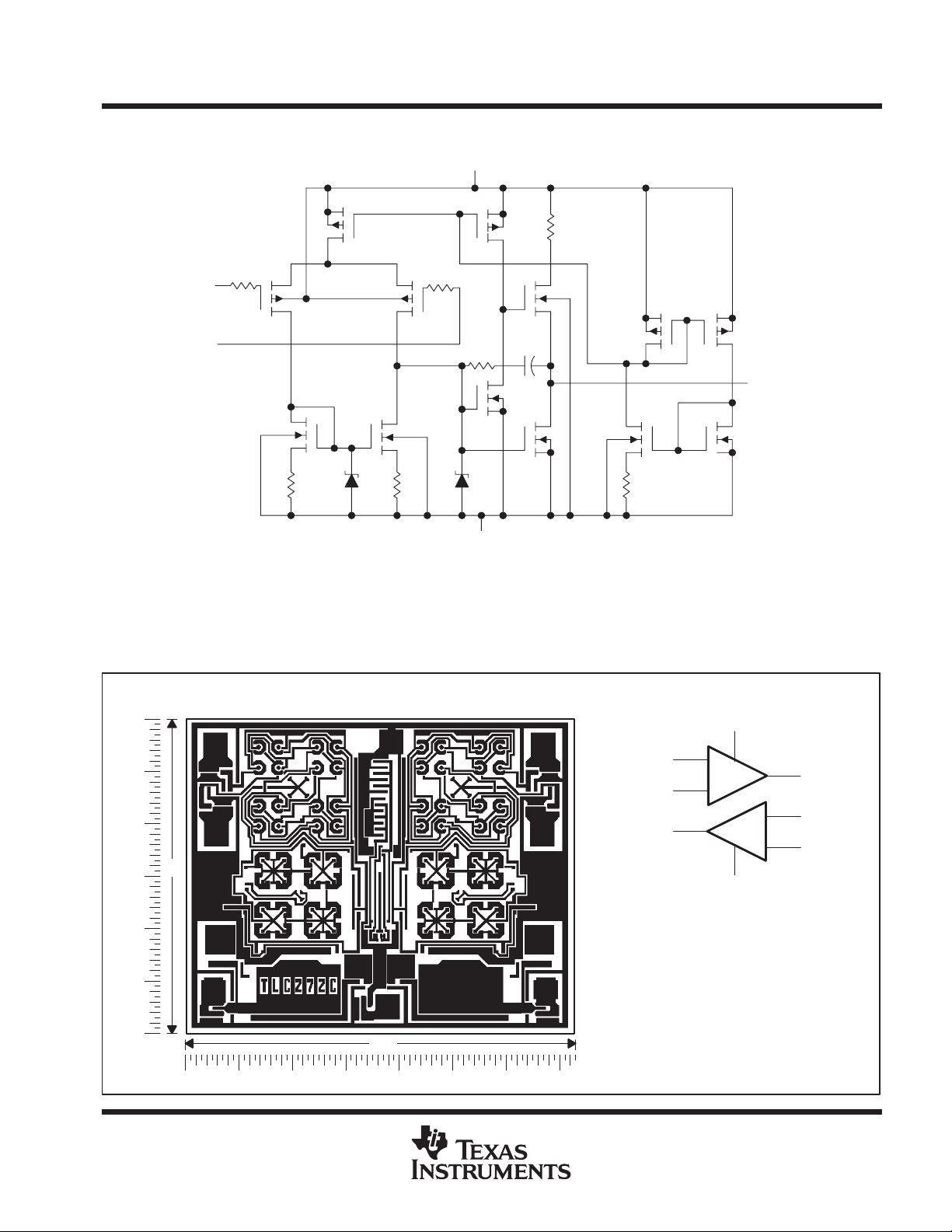

473 Units Tested From 2 Wafer Lots

VDD = 5 V

TA = 25°C

25

P Package

20

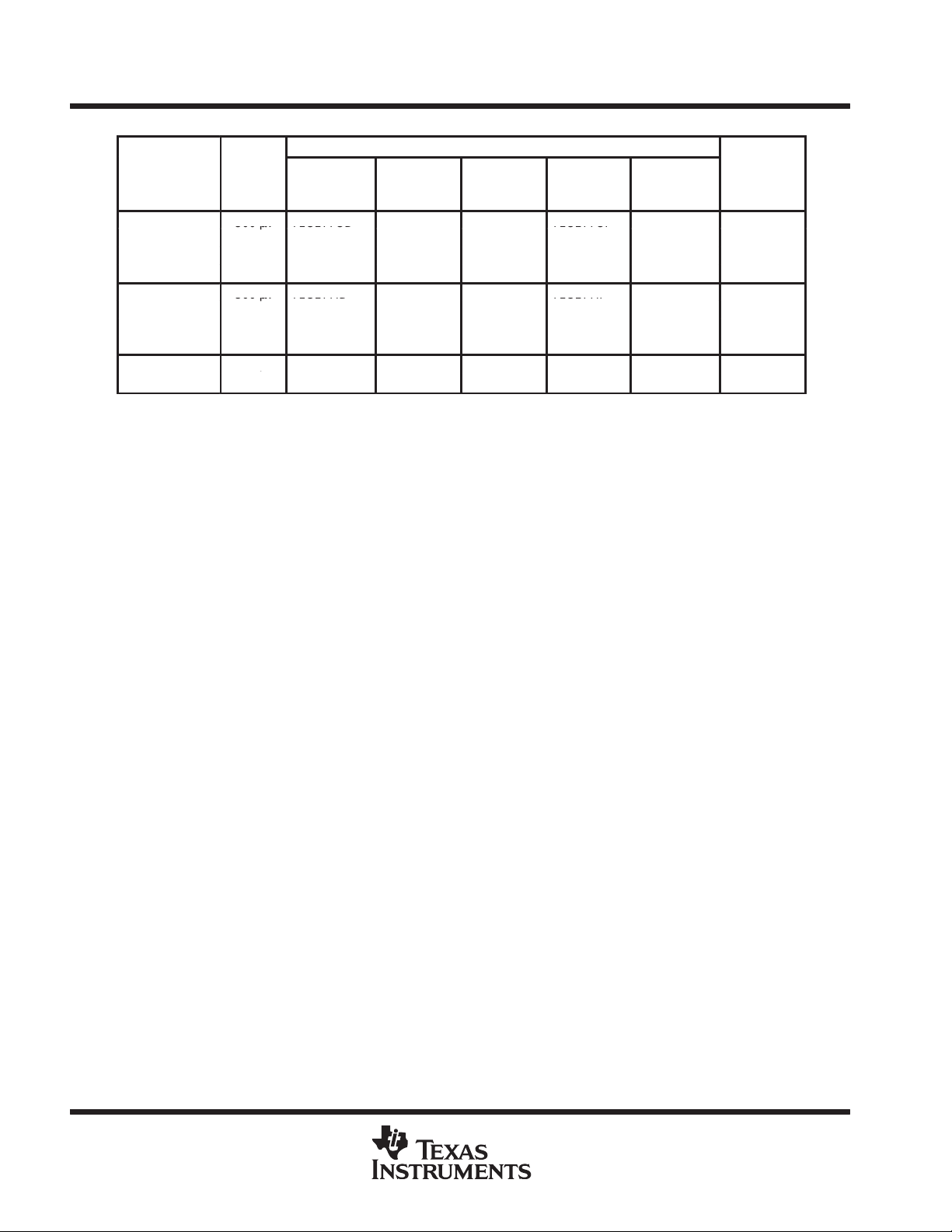

FK PACKAGE

(TOP VIEW)

DD

1OUT

NC

NC

GND

V

NC

18

17

16

15

14

NC

2IN +

NC

2OUT

NC

2IN–

NC

NC

3 2 1 20 19

4

5

6

7

8

910111213

NC

DISTRIBUTION OF TLC277

INPUT OFFSET VOLTAGE

devices.

These devices use T exas instruments silicon-gate

15

LinCMOS technology, which provides offset

voltage stability far exceeding the stability

available with conventional metal-gate pro-

10

Percentage of Units – %

cesses.

The extremely high input impedance, low bias

5

currents, and high slew rates make these costeffective devices ideal for applications which have

previously been reserved for BiFET and NFET

products. Four offset voltage grades are available

0

–800

4000–400

VIO – Input Offset Voltage – µV

(C-suffix and I-suffix types), ranging from the

low-cost TLC272 (10 mV) to the high-precision TLC277 (500 µV). These advantages, in combination with good

common-mode rejection and supply voltage rejection, make these devices a good choice for new

state-of-the-art designs as well as for upgrading existing designs.

800

LinCMOS is a trademark of Texas Instruments Incorporated.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Copyright 1994, Texas Instruments Incorporated

1

Page 2

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

CHIP

500 µV

TLC277CD

TLC277CP

0°C to 70°c

500 µV

TLC277ID

TLC277IP

40°C to 85°C

55°C to 125°C

µ

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

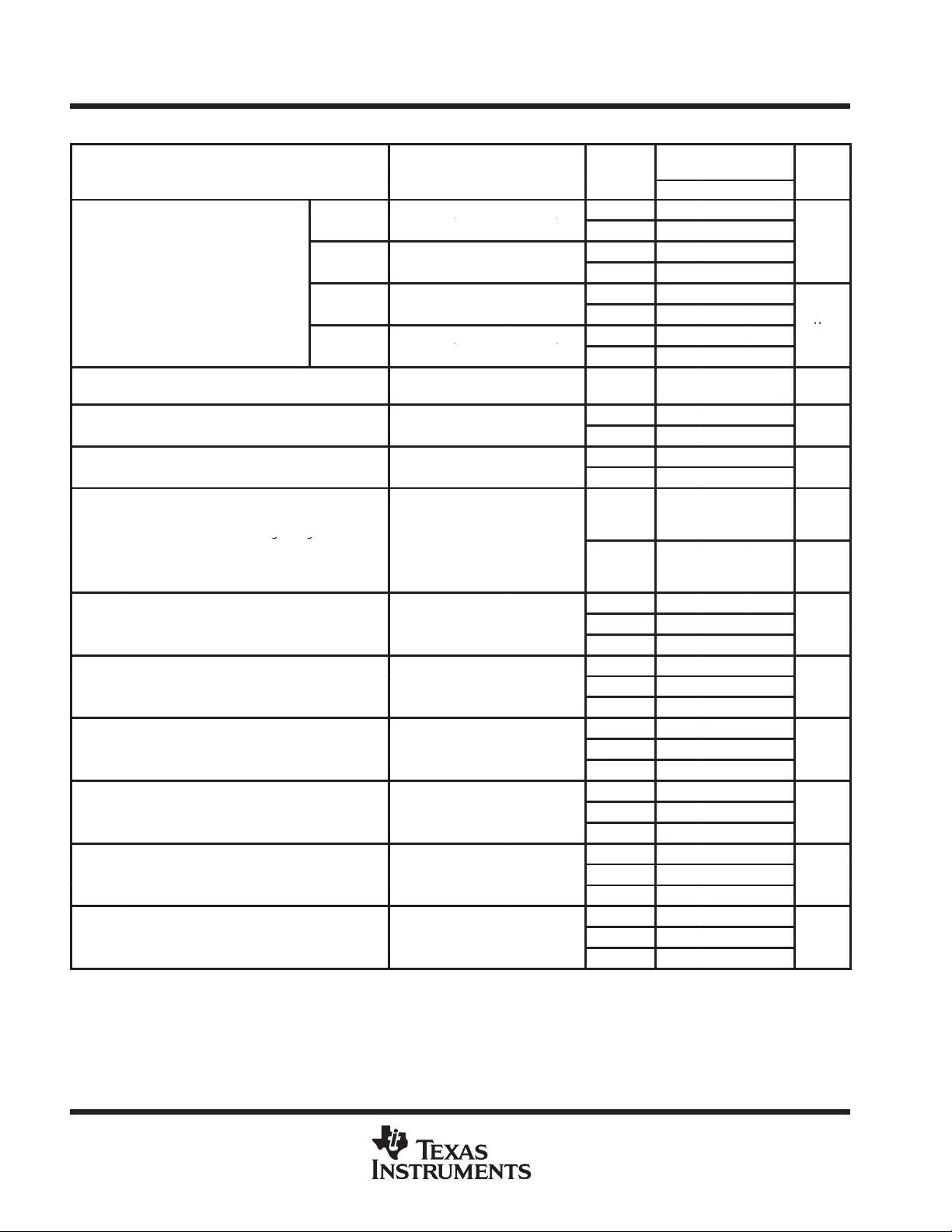

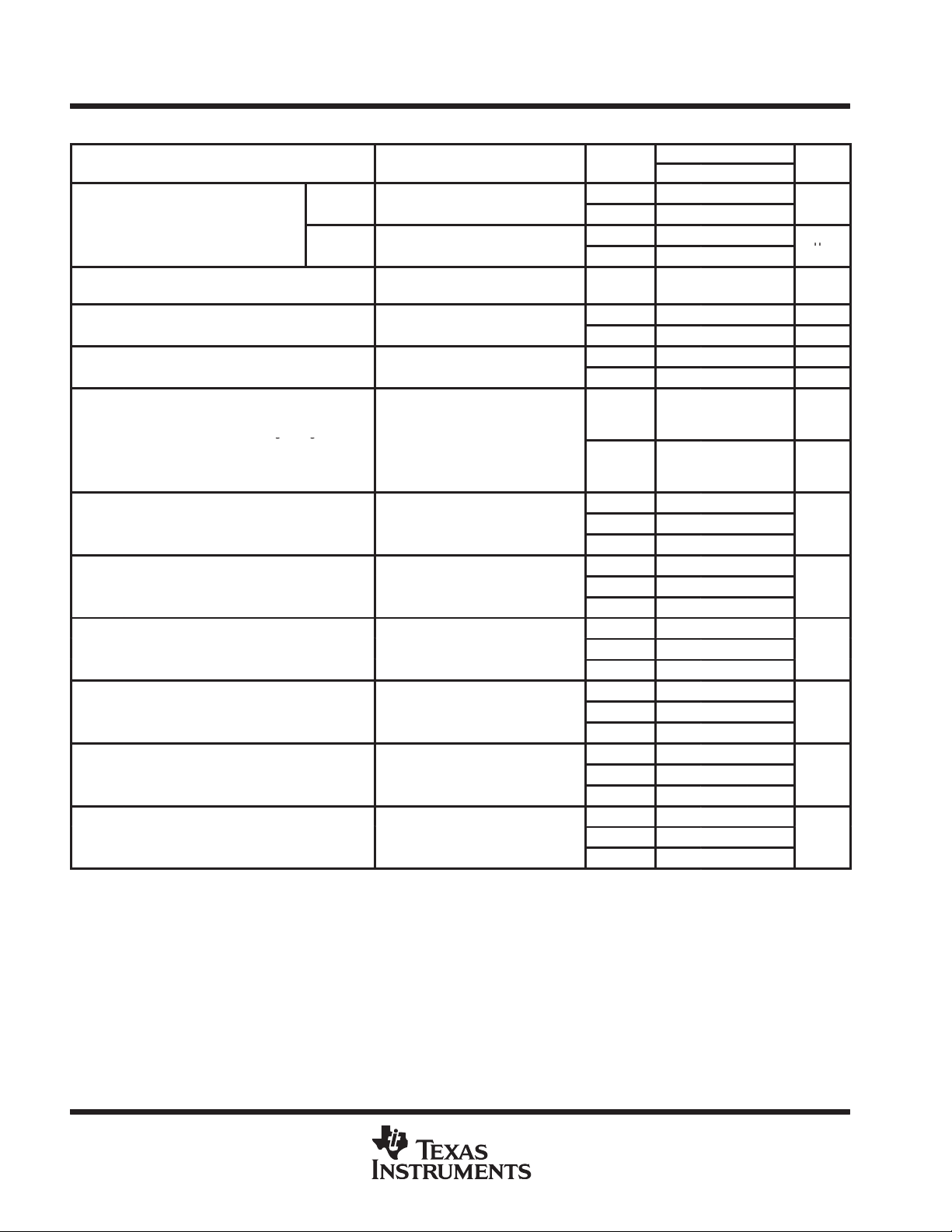

AVAILABLE OPTIONS

PACKAGED DEVICES

T

A

°

°

–

°

–

The D package is available taped and reeled. Add R suffix to the device type (e.g., TLC277CDR).

VIOmax

AT 25°C

500 µV TLC277CD — — TLC277CP — —

°

°

°

2 mV

5 mV TLC272ACD — — TLC272ACP — —

10mV TLC272CD — — TLC272CP TLC272CPW TLC272Y

500 µV TLC277ID — — TLC277IP — —

2 mV

5 mV TLC272AID — — TLC272AIP — —

10 mV TLC272ID — — TLC272IP — —

500 µV TLC277MD TLC277MFK TLC277MJG TLC277MP — —

10 mV TLC272MD TLC272MFK TLC272MJG TLC272MP — —

description (continued)

In general, many features associated with bipolar technology are available on LinCMOS operational amplifiers

without the power penalties of bipolar technology . General applications such as transducer interfacing, analog

calculations, amplifier blocks, active filters, and signal buffering are easily designed with the TLC272 and

TLC277. The devices also exhibit low voltage single-supply operation, making them ideally suited for remote

and inaccessible battery-powered applications. The common-mode input voltage range includes the negative

rail.

SMALL

OUTLINE

(D)

TLC272BCD — —

TLC272BID — —

CHIP

CARRIER

(FK)

CERAMIC

DIP

(JG)

PLASTIC

DIP

(P)

TLC272BCP — —

TLC272BIP — —

TSSOP

(PW)

FORM

(Y)

A wide range of packaging options is available, including small-outline and chip carrier versions for high-density

system applications.

The device inputs and outputs are designed to withstand –100-mA surge currents without sustaining latch-up.

The TLC272 and TLC277 incorporate internal ESD-protection circuits that prevent functional failures at voltages

up to 2000 V as tested under MIL-STD-883C, Method 3015.2; however, care should be exercised in handling

these devices as exposure to ESD may result in the degradation of the device parametric performance.

The C-suffix devices are characterized for operation from 0°C to 70°C. The I-suffix devices are characterized

for operation from – 40°C to 85°C. The M-suffix devices are characterized for operation over the full military

temperature range of –55°C to 125°C.

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 3

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

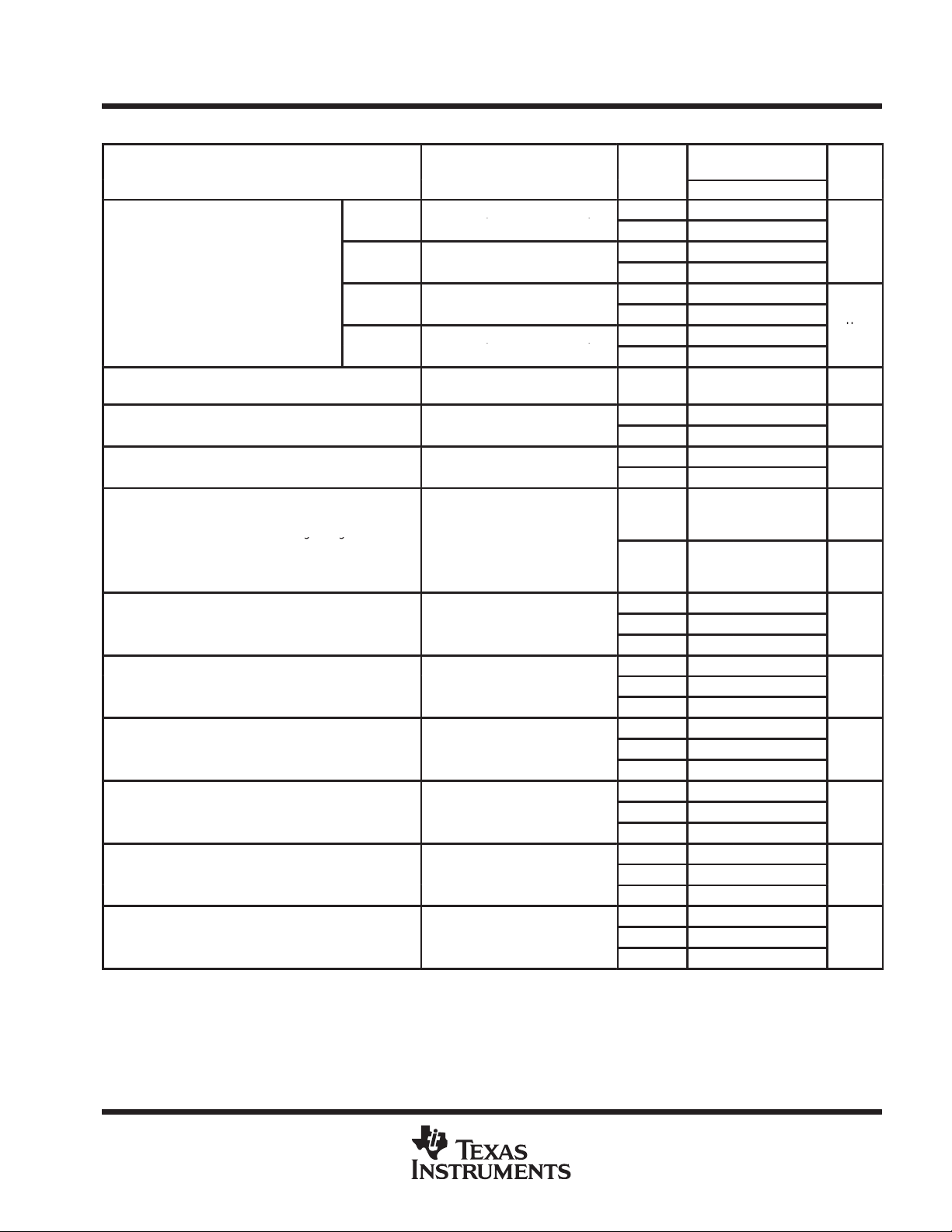

equivalent schematic (each amplifier)

P3 P4

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

V

DD

R6

N3

D2R4D1R3

N5

C1

N4

P5 P6

OUT

N7N6

R7

IN–

IN+

R1

P1

N1

R2

P2

R5

N2

GND

TLC272Y chip information

This chip, when properly assembled, displays characteristics similar to the TLC272C. Thermal compression or

ultrasonic bonding may be used on the doped-aluminum bonding pads. Chips may be mounted with conductive

epoxy or a gold-silicon preform.

BONDING PAD ASSIGNMENTS

V

DD

+

–

GND

(8)

(4)

(1)

(5)

+

(6)

–

60

1IN+

1IN–

2OUT

(3)

(2)

(7)

1OUT

2IN+

2IN–

73

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

CHIP THICKNESS: 15 TYPICAL

BONDING PADS: 4 × 4 MINIMUM

TJmax = 150°C

TOLERANCES ARE ±10%.

ALL DIMENSIONS ARE IN MILS.

PIN (4) IS INTERNALLY CONNECTED

TO BACKSIDE OF CHIP.

3

Page 4

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

UNIT

Common-mode input voltage, V

V

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

Supply voltage, V

Differential input voltage, V

Input voltage range, V

Input current, I

output current, I

Total current into V

Total current out of GND 45 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Duration of short-circuit current at (or below) 25°C (see Note 3) unlimited. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature, T

Storage temperature range –65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Case temperature for 60 seconds: FK package 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds: D, P, or PW package 260°C. . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 60 seconds: JG package 300°C. . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltage values, except differential voltages, are with respect to network ground.

2. Differential voltages are at IN+ with respect to IN–.

3. The output may be shorted to either supply. Temperature and/or supply voltages must be limited to ensure that the maximum

dissipation rating is not exceeded (see application section).

(see Note 1) 18 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DD

±5 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

I

(each output) ±30 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O

45 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DD

(see Note 2) ±V

ID

(any input) –0.3 V to V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

: C suffix 0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I suffix –40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

M suffix –55°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

DD

DD

PACKAGE

D 725 mW 5.8 mW/°C 464 mW 377 mW N/A

FK 1375 mW 11 mW/°C 880 mW 715 mW 275 mW

JG 1050 mW 8.4 mW/°C 672 mW 546 mW 210 mW

P 1000 mW 8.0 mW/°C 640 mW 520 mW N/A

PW 525 mW 4.2 mW/°C 336 mW N/A N/A

TA ≤ 25°C

POWER RATING

DERATING FACTOR

recommended operating conditions

Supply voltage, V

Operating free-air temperature, T

DD

p

IC

VDD = 5 V –0.2 3.5 –0.2 3.5 0 3.5

VDD = 10 V –0.2 8.5 –0.2 8.5 0 8.5

A

DISSIPATION RATING TABLE

ABOVE TA = 25°C

POWER RATING

TA = 70°C

C SUFFIX I SUFFIX M SUFFIX

MIN MAX MIN MAX MIN MAX

3 16 4 16 4 16 V

0 70 –40 85 –55 125

TA = 85°C

POWER RATING

TA = 125°C

POWER RATING

°C

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 5

†

A

TLC272C

O

,

IC

,

mV

TLC272AC

O

,

IC

,

VIOInput offset voltage

TLC272BC

O

,

IC

,

V

TLC277C

O

,

IC

,

IIOInput offset current (see Note 4)

V

V

V

pA

IIBInput bias current (see Note 4)

V

V

V

pA

V

gg

(∆VDD/∆VIO)

V

2.5 V

V

5 V

No load

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

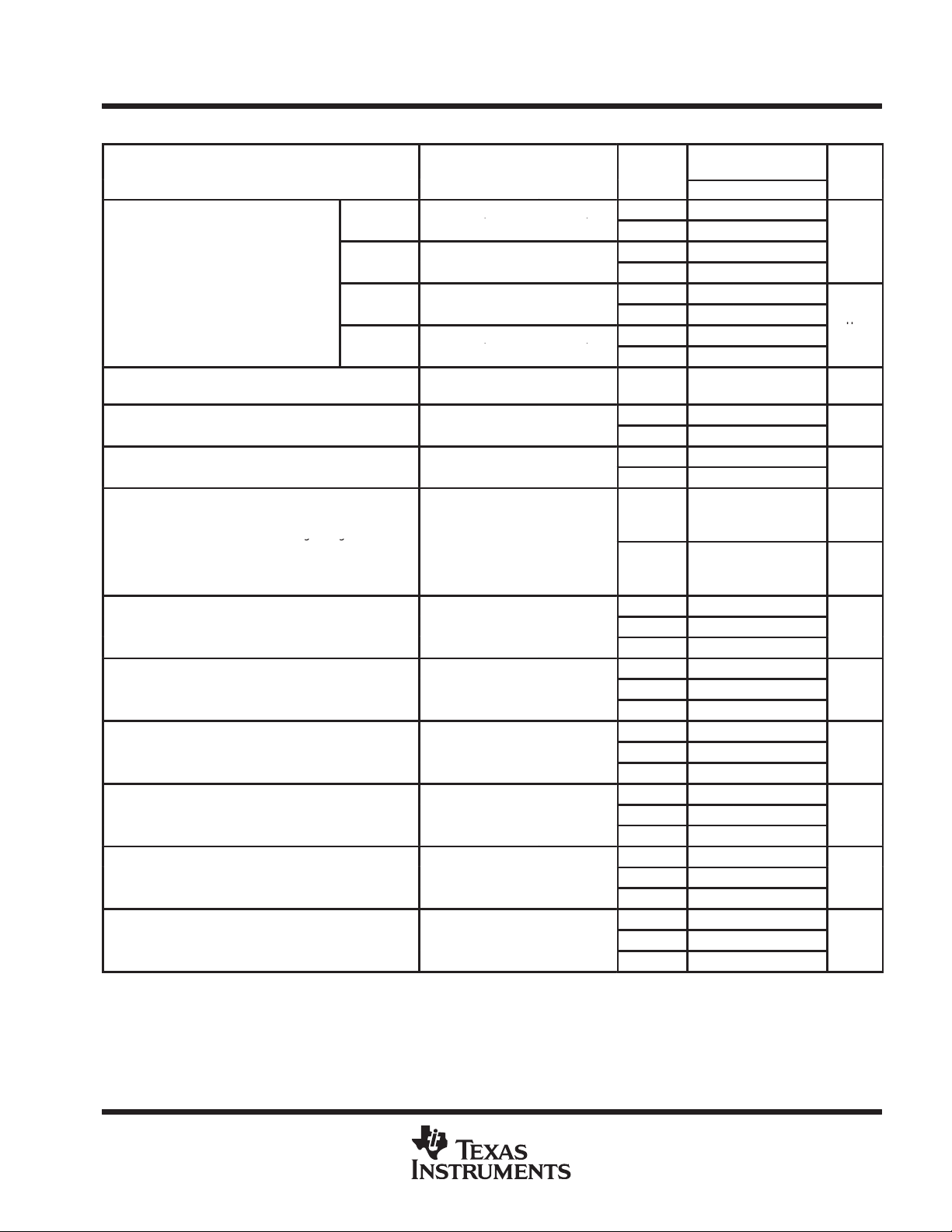

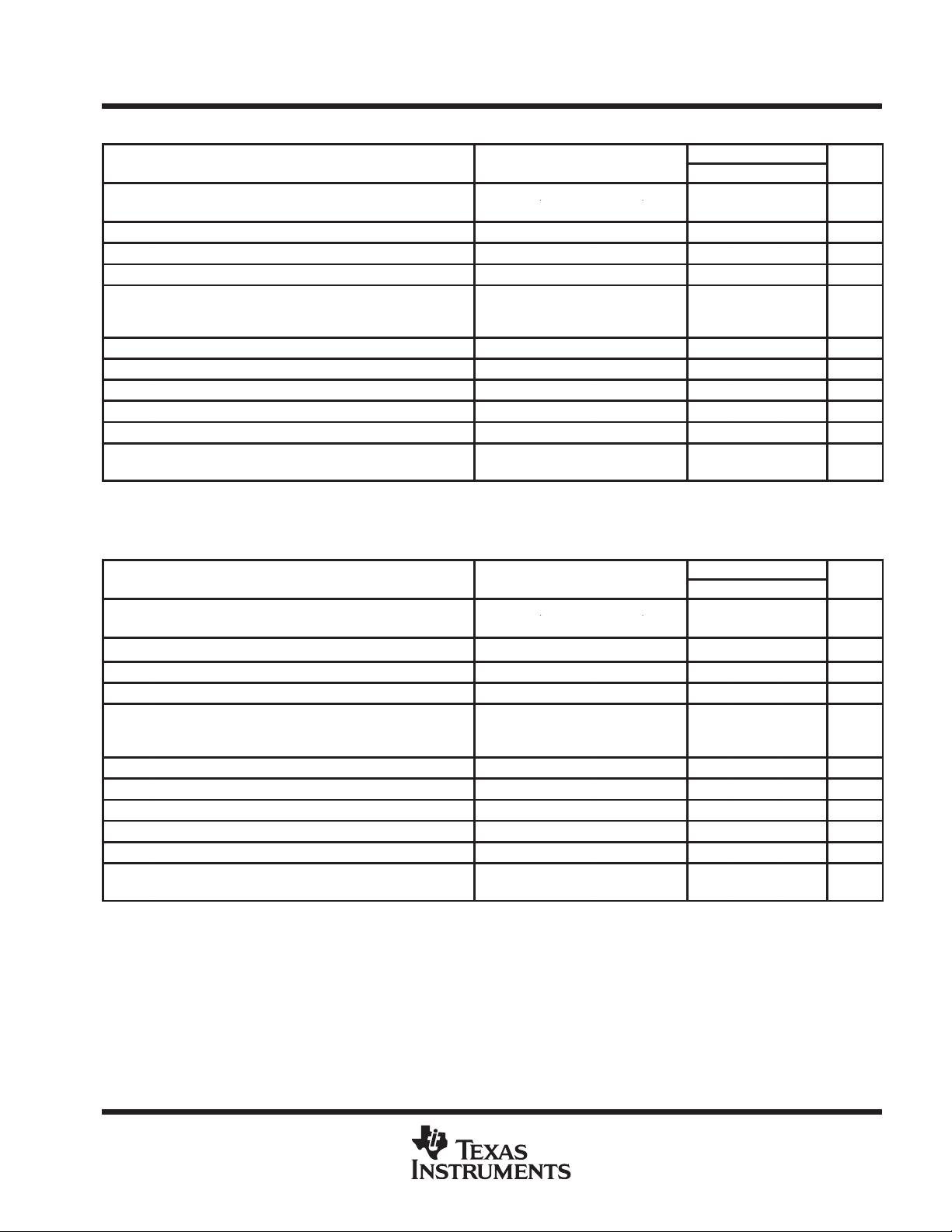

electrical characteristics at specified free-air temperature, VDD = 5 V (unless otherwise noted)

TLC272C, TLC272AC,

PARAMETER TEST CONDITIONS

V

= 1.4 V, V

RS = 50 Ω,

V

= 1.4 V, V

p

α

V

V

A

CMRR Common-mode rejection ratio VIC = V

k

I

DD

†

Full range is 0°C to 70°C.

NOTES: 4. The typical values of input bias current and input offset current below 5 pA were determined mathematically.

Temperature coefficient of input offset voltage

VIO

p

p

Common-mode input voltage range

ICR

(see Note 5)

High-level output voltage VID = 100 mV, RL = 10 kΩ

OH

Low-level output voltage VID = –100 mV, IOL = 0

OL

Large-signal differential voltage amplification VO = 0.25 V to 2 V, RL = 10 kΩ

VD

Supply-voltage rejection ratio

SVR

Supply current (two amplifiers)

5. This range also applies to each input individually.

RS = 50 Ω,

V

= 1.4 V, V

RS = 50 Ω,

V

= 1.4 V, V

RS = 50 Ω,

= 2.5 V,

O

= 2.5 V,

O

min

ICR

VDD = 5 V to 10 V, VO = 1.4 V

,

=

O

= 0,

RL = 10 kΩ

= 0,

RL = 10 kΩ

= 0,

RL = 10 kΩ

= 0,

RL = 10 kΩ

= 2.5

IC

= 2.5

IC

=

IC

T

A

25°C 1.1 10

Full range

25°C 0.9 5

Full range

25°C 230 2000

Full range

25°C 200 500

Full range

25°C to

70°C

25°C 0.1

70°C 7 300

25°C 0.6

70°C 40 600

25°C

Full range

25°C 3.2 3.8

0°C

70°C 3 3.8

25°C 0 50

0°C

70°C 0 50

25°C 5 23

0°C 4 27

70°C 4 20

25°C 65 80

0°C 60 84

70°C 60 85

25°C 65 95

0°C 60 94

70°C 60 96

25°C 1.4 3.2

,

0°C

70°C 1.2 2.6

TLC272BC, TLC277C

MIN TYP MAX

6.5

3000

1500

1.8 µV/°C

–0.2

–0.2

to

4

to

3.5

3 3.8

–0.3

to

4.2

0 50

1.6 3.6

UNIT

12

µ

p

p

V

V

V

mV

V/mV

dB

dB

mA

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

Page 6

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

†

A

TLC272C

O

,

IC

,

mV

TLC272AC

O

,

IC

,

VIOInput offset voltage

TLC272BC

O

,

IC

,

V

TLC277C

O

,

IC

,

IIOInput offset current (see Note 4)

V

V

V

pA

IIBInput bias current (see Note 4)

V

V

V

pA

V

gg

(∆VDD/∆VIO)

V

2.5 V

V

5 V

No load

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

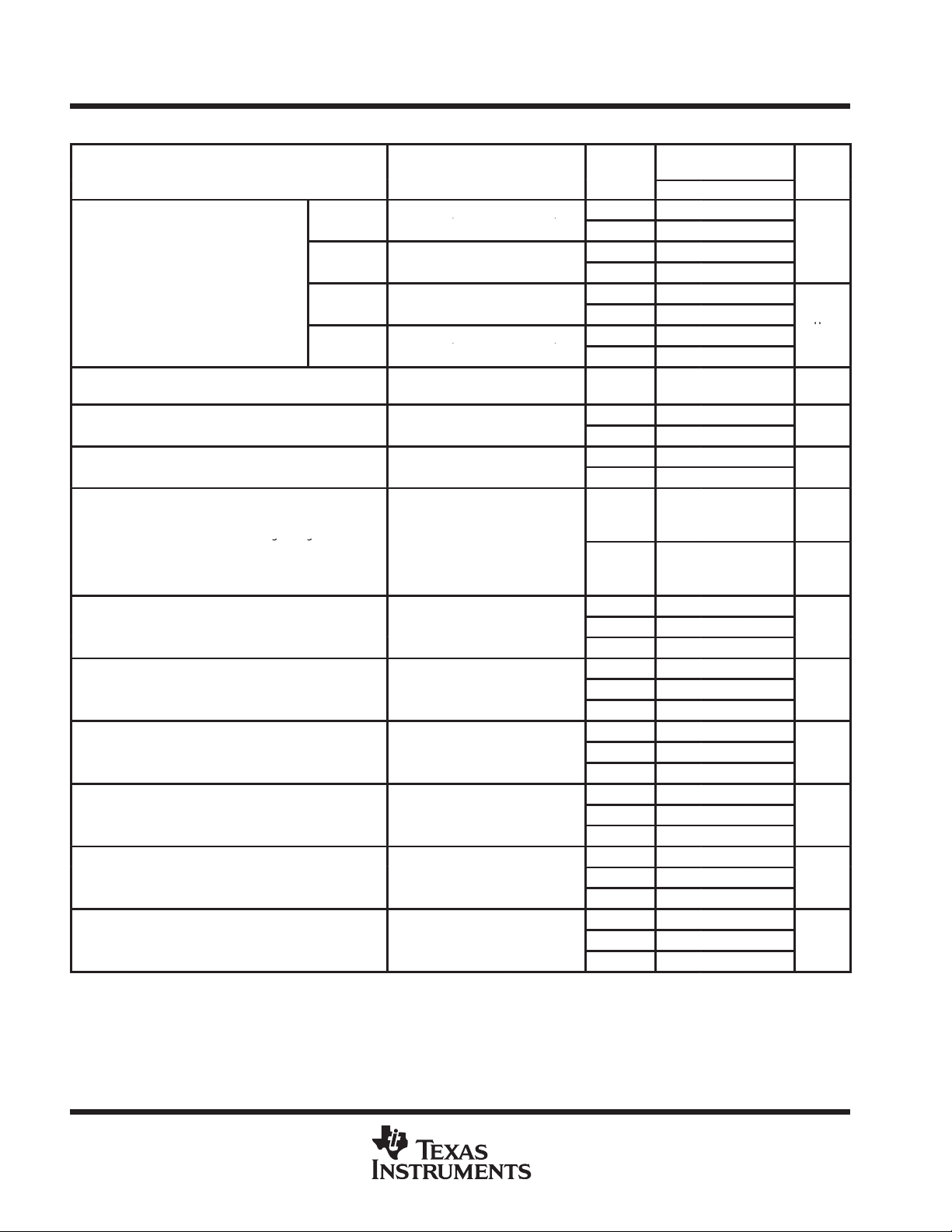

electrical characteristics at specified free-air temperature, VDD = 10 V (unless otherwise noted)

TLC272C, TLC272AC,

PARAMETER TEST CONDITIONS

V

= 1.4 V, V

RS = 50 Ω,

V

= 1.4 V, V

p

α

V

V

A

CMRR Common-mode rejection ratio VIC = V

k

I

DD

†

Full range is 0°C to 70°C.

NOTES: 4. The typical values of input bias current and input offset current below 5 pA were determined mathematically .

Temperature coefficient of input offset voltage

VIO

p

p

Common-mode input voltage range

ICR

(see Note 5)

High-level output voltage VID = 100 mV, RL = 10 kΩ

OH

Low-level output voltage VID = –100 mV, IOL = 0

OL

Large-signal differential voltage amplification VO = 1 V to 6 V, RL = 10 kΩ

VD

Supply-voltage rejection ratio

SVR

Supply current (two amplifiers)

5. This range also applies to each input individually.

RS = 50 Ω,

V

= 1.4 V, V

RS = 50 Ω,

V

= 1.4 V, V

RS = 50 Ω,

= 5 V,

O

= 5 V,

O

min

ICR

VDD = 5 V to 10 V, VO = 1.4 V

,

=

O

= 0,

RL = 10 kΩ

= 0,

RL = 10 kΩ

= 0,

RL = 10 kΩ

= 0,

RL = 10 kΩ

= 5

IC

= 5

IC

=

IC

T

A

25°C 1.1 10

Full range

25°C 0.9 5

Full range

25°C 290 2000

Full range

25°C 250 800

Full range

25°C to

70°C

25°C 0.1

70°C 7 300

25°C 0.7

70°C 50 600

25°C

Full range

25°C 8 8.5

0°C

70°C 7.8 8.4

25°C 0 50

0°C

70°C 0 50

25°C 10 36

0°C 7.5 42

70°C 7.5 32

25°C 65 85

0°C 60 88

70°C 60 88

25°C 65 95

0°C 60 94

70°C 60 96

25°C 1.9 4

,

0°C

70°C 1.6 3.4

TLC272BC, TLC277C

MIN TYP MAX

6.5

3000

1900

2 µV/°C

–0.2

–0.3

to

to

9

9.2

–0.2

to

8.5

7.8 8.5

0 50

2.3 4.4

UNIT

12

µ

p

p

V

V

V

mV

V/mV

dB

dB

mA

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 7

†

A

TLC272I

O

,

IC

,

mV

TLC272AI

O

,

IC

,

VIOInput offset voltage

TLC272BI

O

,

IC

,

V

TLC277I

O

,

IC

,

IIOInput offset current (see Note 4)

V

V

V

pA

IIBInput bias current (see Note 4)

V

V

V

pA

V

gg

(∆VDD/∆VIO)

V

V

No load

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

electrical characteristics at specified free-air temperature, VDD = 5 V (unless otherwise noted)

TLC272I, TLC272AI,

PARAMETER TEST CONDITIONS

V

= 1.4 V, V

RS = 50 Ω,

V

= 1.4 V, V

p

α

V

V

A

CMRR Common-mode rejection ratio VIC = V

k

I

DD

†

Full range is –40°C to 85°C.

NOTES: 4. The typical values of input bias current and input offset current below 5 pA were determined mathematically .

Temperature coefficient of input offset voltage

VIO

p

p

Common-mode input voltage range

ICR

(see Note 5)

High-level output voltage VID = 100 mV, RL = 10 kΩ

OH

Low-level output voltage VID = –100 mV, IOL = 0

OL

Large-signal differential voltage amplification

VD

Supply-voltage rejection ratio

SVR

Supply current (two amplifiers)

5. This range also applies to each input individually.

RS = 50 Ω,

V

= 1.4 V, V

RS = 50 Ω,

V

= 1.4 V, V

RS = 50 Ω,

= 2.5 V,

O

= 2.5 V,

O

VO = 1 V to 6 V,

min

ICR

VDD = 5 V to 10 V, VO = 1.4 V

= 5 V,

O

= 0,

RL = 10 kΩ

= 0,

RL = 10 kΩ

= 0,

RL = 10 kΩ

= 0,

RL = 10 kΩ

= 2.5

IC

= 2.5

IC

RL = 10 kΩ

= 5 V,

IC

T

A

25°C 1.1 10

Full range

25°C 0.9 5

Full range

25°C 230 2000

Full range

25°C 200 500

Full range

25°C to

85°C

25°C 0.1

85°C 24 15

25°C 0.6

85°C 200 35

25°C

Full range

25°C 3.2 3.8

–40°C

85°C 3 3.8

25°C 0 50

–40°C

85°C 0 50

25°C 5 23

–40°C

85°C 3.5 19

25°C 65 80

–40°C 60 81

85°C 60 86

25°C 65 95

–40°C

85°C 60 96

25°C 1.4 3.2

–40°C

85°C 1.1 2.4

TLC272BI, TLC277I

MIN TYP MAX

3500

2000

1.8 µV/°C

–0.2

–0.2

–0.3

to

4

4.2

to

3.5

3 3.8

3.5 32

60 92

1.9 4.4

to

0 50

UNIT

13

7

µ

p

p

V

V

V

mV

V/mV

dB

dB

mA

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

Page 8

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

†

A

TLC272I

O

,

IC

,

mV

TLC272AI

O

,

IC

,

VIOInput offset voltage

TLC272BI

O

,

IC

,

V

TLC277I

O

,

IC

,

IIOInput offset current (see Note 4)

V

V

V

pA

IIBInput bias current (see Note 4)

V

V

V

pA

V

gg

(∆VDD/∆VIO)

V

V

No load

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

electrical characteristics at specified free-air temperature, V

PARAMETER TEST CONDITIONS

V

= 1.4 V, V

RS = 50 Ω,

V

= 1.4 V, V

p

α

V

V

A

CMRR Common-mode rejection ratio VIC = V

k

I

DD

†

Full range is –40°C to 85°C.

NOTES: 4. The typical values of input bias current and input offset current below 5 pA were determined mathematically .

Temperature coefficient of input offset voltage

VIO

p

p

Common-mode input voltage range

ICR

(see Note 5)

High-level output voltage VID = 100 mV, RL = 10 kΩ

OH

Low-level output voltage VID = –100 mV, IOL = 0

OL

Large-signal differential voltage amplification VO = 1 V to 6 V, RL = 10 kΩ

VD

Supply-voltage rejection ratio

SVR

Supply current (two amplifiers)

5. This range also applies to each input individually.

RS = 50 Ω,

V

= 1.4 V, V

RS = 50 Ω,

V

= 1.4 V, V

RS = 50 Ω,

= 5 V,

O

= 5 V,

O

min

ICR

VDD = 5 V to 10 V, VO = 1.4 V

= 5 V,

O

= 0,

RL = 10 kΩ

= 0,

RL = 10 kΩ

= 0,

RL = 10 kΩ

= 0,

RL = 10 kΩ

= 5

IC

= 5

IC

= 5 V,

IC

= 10 V (unless otherwise noted)

DD

TLC272I, TLC272AI,

T

A

25°C 1.1 10

Full range

25°C 0.9 5

Full range

25°C 290 2000

Full range

25°C 250 800

Full range

25°C to

85°C

25°C 0.1

85°C 26 1000

25°C 0.7

85°C 220 2000

25°C

Full range

25°C 8 8.5

–40°C

85°C 7.8 8.5

25°C 0 50

–40°C

85°C 0 50

25°C 10 36

–40°C

85°C 7 31

25°C 65 85

–40°C 60 87

85°C 60 88

25°C 65 95

–40°C

85°C 60 96

25°C 1.4 4

–40°C

85°C 1.5 3.2

TLC272BI, TLC277I

MIN TYP MAX

–0.2

–0.3

to

9

9.2

–0.2

to

8.5

7.8 8.5

7 46

60 92

2.8 5

UNIT

13

7

3500

2900

2 µV/°C

to

0 50

µ

p

p

V

V

V

mV

V/mV

dB

dB

mA

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

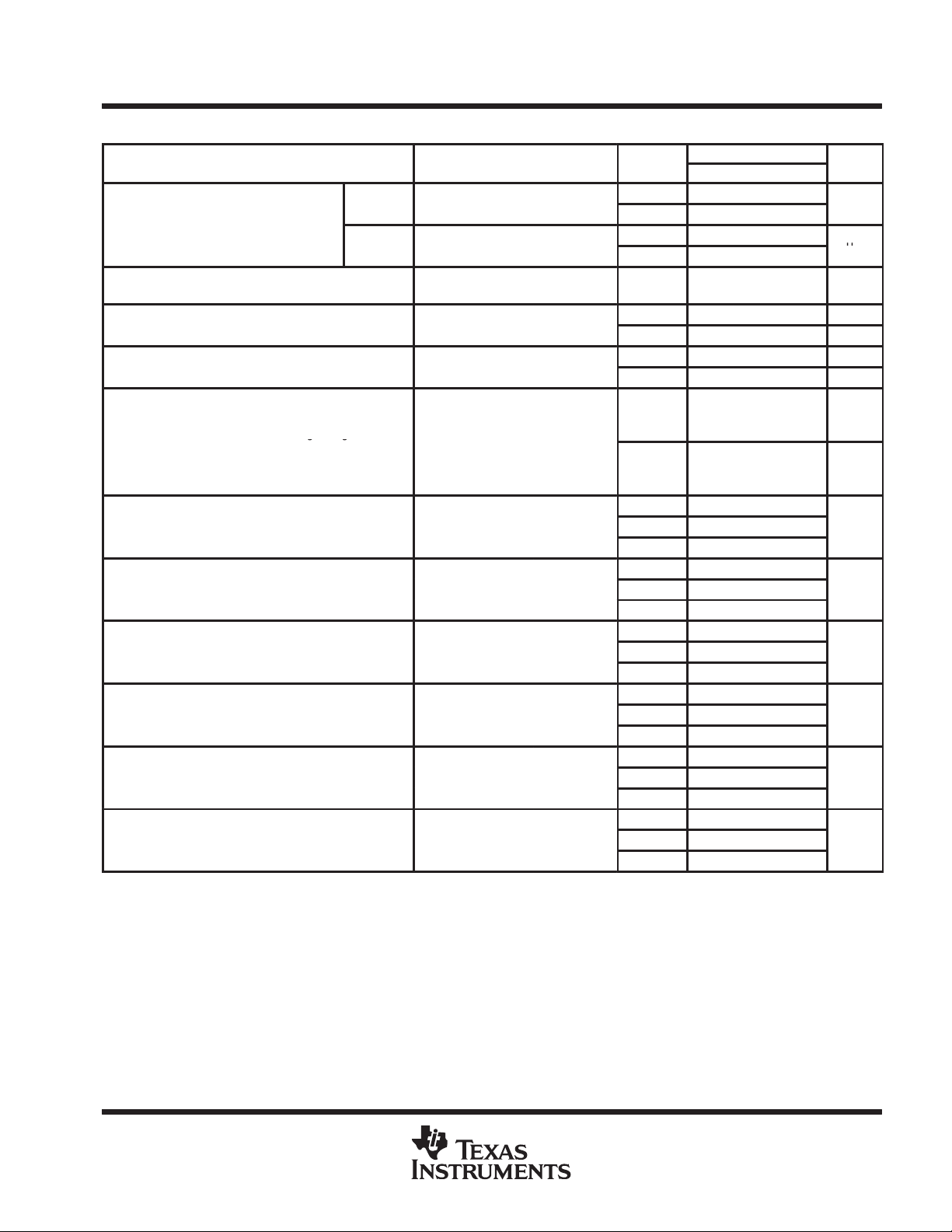

Page 9

PARAMETER

TEST CONDITIONS

T

†

UNIT

TLC272M

O

,

IC

,

mV

VIOInput offset voltage

TLC277M

O

,

IC

,

V

IIOInput offset current (see Note 4)

V

2.5 V

V

2.5 V

IIBInput bias current (see Note 4)

V

2.5 V

V

2.5 V

V

gg

(∆VDD/∆VIO)

V

2.5 V

V

2.5 V

No load

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

electrical characteristics at specified free-air temperature, VDD = 5 V (unless otherwise noted)

A

V

= 1.4 V, V

p

α

V

V

A

CMRR Common-mode rejection ratio VIC = V

k

SVR

I

DD

†

Full range is –55°C to 125°C.

NOTES: 4. The typical values of input bias current and input offset current below 5 pA were determined mathematically .

Temperature coefficient of input offset

VIO

voltage

p

p

Common-mode input voltage range

ICR

(see Note 5)

High-level output voltage VID = 100 mV, RL = 10 kΩ

OH

Low-level output voltage VID = –100 mV, IOL = 0

OL

Large-signal differential voltage amplification VO = 0.25 V to 2 V RL = 10 kΩ

VD

Supply-voltage rejection ratio

Supply current (two amplifiers)

5. This range also applies to each input individually.

RS = 50 Ω,

V

= 1.4 V, V

RS = 50 Ω,

=

O

=

O

min

ICR

VDD = 5 V to 10 V, VO = 1.4 V

,

=

O

= 0,

RL = 10 kΩ

= 0,

RL = 10 kΩ

=

IC

=

IC

=

IC

25°C 1.1 10

Full range

25°C 200 500

Full range

25°C to

125°C

25°C 0.1 pA

125°C 1.4 15 nA

25°C 0.6 pA

125°C 9 35 nA

25°C

Full range

25°C 3.2 3.8

–55°C

125°C 3 3.8

25°C 0 50

–55°C

125°C 0 50

25°C 5 23

–55°C

125°C 3.5 16

25°C 65 80

–55°C 60 81

125°C 60 84

25°C 65 95

–55°C

125°C 60 97

25°C 1.4 3.2

,

–55°C

125°C 1 2.2

TLC272M, TLC277M

MIN TYP MAX

3750

2.1 µV/°C

0

–0.3

to

to

4

4.2

0

to

3.5

3 3.8

0 50

3.5 35

60 90

2 5

12

µ

V

V

V

mV

V/mV

dB

dB

mA

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

Page 10

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

PARAMETER

TEST CONDITIONS

T

†

UNIT

TLC272M

mV

VIOInput offset voltage

TLC277M

V

IIOInput offset current (see Note 4)

V

5 V

V

5 V

IIBInput bias current (see Note 4)

V

5 V

V

5 V

V

gg

am lification

(∆VDD/∆VIO)

V

V

No load

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

electrical characteristics at specified free-air temperature, VDD = 10 V (unless otherwise noted)

A

VO = 1.4 V, VIC = 0, 25°C 1.1 10

p

α

V

V

A

CMRR Common-mode rejection ratio VIC = V

k

SVR

I

DD

†

Full range is –55°C to 125°C.

NOTES: 4. The typical values of input bias current and input offset current below 5 pA were determined mathematically .

Temperature coefficient of input offset

VIO

voltage

p

p

Common-mode input voltage range

ICR

(see Note 5)

High-level output voltage VID = 100 mV, RL = 10 kΩ

OH

Low-level output voltage VID = –100 mV, IOL = 0

OL

Large-signal differential voltage

VD

p

Supply-voltage rejection ratio

Supply current (two amplifiers)

5. This range also applies to each input individually.

RS = 50 Ω, RL = 10 kΩ Full range 12

VO = 1.4 V, VIC = 0, 25°C 250 800

RS = 50 Ω, RL = 10 kΩ Full range 4300

25°C to

125°C

,

=

O

,

=

O

VO = 1 V to 6 V, RL = 10 kΩ

min

ICR

VDD = 5 V to 10 V, VO = 1.4 V

= 5 V,

O

IC

IC

IC

=

=

= 5 V,

25°C 0.1 pA

125°C 1.8 15 nA

25°C 0.7 pA

125°C 10 35 nA

25°C

Full range

25°C 8 8.5

–55°C

125°C 7.8 8.4

25°C 0 50

–55°C 0 50

125°C 0 50

25°C 10 36

–55°C

125°C 7 27

25°C 65 85

–55°C 60 87

125°C 60 86

25°C 65 95

–55°C

125°C 60 97

25°C 1.9 4

–55°C

125°C 1.3 2.8

TLC272M, TLC277M

MIN TYP MAX

2.2 µV/°C

0

–0.3

to

to

9

9.2

0

to

8.5

7.8 8.5

7 50

60 90

3 6

µ

V

V

V

mV

V/mV

dB

dB

mA

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 11

PARAMETER

TEST CONDITIONS

UNIT

VIOInput offset voltage

O

,

IC

,

1.110mV

PARAMETER

TEST CONDITIONS

UNIT

VIOInput offset voltage

O

,

IC

,

1.110mV

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

electrical characteristics, VDD = 5 V, TA = 25°C (unless otherwise noted)

TLC272Y

MIN TYP MAX

V

p

α

I

IO

I

IB

V

V

V

A

CMRR Common-mode rejection ratio VIC = V

k

I

DD

NOTES: 4. The typical values of input bias current and input offset current below 5 pA were determined mathematically .

Temperature coefficient of input offset voltage 1.8 µV/°C

VIO

Input offset current (see Note 4) VO = 2.5 V, VIC = 2.5 V 0.1 pA

Input bias current (see Note 4) VO = 2.5 V, VIC = 2.5 V 0.6 pA

Common-mode input voltage range (see Note 5)

ICR

High-level output voltage VID = 100 mV, RL = 10 kΩ 3.2 3.8 V

OH

Low-level output voltage VID = –100 mV, IOL = 0 0 50 mV

OL

Large-signal differential voltage amplification VO = 0.25 V to 2 V RL = 10 kΩ 5 23 V/mV

VD

Supply-voltage rejection ratio (∆VDD/∆VIO) VDD = 5 V to 10 V, VO = 1.4 V 65 95 dB

SVR

Supply current (two amplifiers)

5. This range also applies to each input individually.

= 1.4 V, V

RS = 50 Ω,

min 65 80 dB

ICR

VO = 2.5 V,

No load

= 0,

RL = 10 kΩ

VIC = 2.5 V,

–0.2

–0.3

to

4

4.2

1.4 3.2 mA

to

V

electrical characteristics, VDD = 10 V, TA = 25°C (unless otherwise noted)

TLC272Y

MIN TYP MAX

V

p

α

I

IO

I

IB

V

V

V

A

CMRR Common-mode rejection ratio VIC = V

k

I

DD

NOTES: 4. The typical values of input bias current and input offset current below 5 pA were determined mathematically .

Temperature coefficient of input offset voltage 1.8 µV/°C

VIO

Input offset current (see Note 4) VO = 5 V, VIC = 5 V 0.1 pA

Input bias current (see Note 4) VO = 5 V, VIC = 5 V 0.7 pA

Common-mode input voltage range (see Note 5)

ICR

High-level output voltage VID = 100 mV, RL = 10 kΩ 8 8.5 V

OH

Low-level output voltage VID = –100 mV, IOL = 0 0 50 mV

OL

Large-signal differential voltage amplification VO = 1 V to 6 V, RL = 10 kΩ 10 36 V/mV

VD

Supply-voltage rejection ratio (∆VDD/∆VIO) VDD = 5 V to 10 V, VO = 1.4 V 65 95 dB

SVR

Supply current (two amplifiers)

5. This range also applies to each input individually.

= 1.4 V, V

RS = 50 Ω,

min 65 85 dB

ICR

VO = 5 V,

No load

= 0,

RL = 10 kΩ

VIC = 5 V,

–0.2

–0.3

to

9

9.2

1.9 4 mA

to

V

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

11

Page 12

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

A

SR

Slew rate at unity gain

C

g

V/µs

See Figure 1

R

L

See Figure 1

See Figure 3

V

10 mV

f

B

C

L

See Figure 3

A

SR

Slew rate at unity gain

C

g

V/µs

See Figure 1

R

L

See Figure 1

See Figure 3

V

f

B

C

L

See Figure 3

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

operating characteristics at specified free-air temperature, V

PARAMETER TEST CONDITIONS T

V

= 1 V

,

IPP

V

= 2.5 V

IPP

RS = 20 Ω,

CL = 20 pF,

CL = 20 pF,

=

,

1

RL = 10 kΩ,

= 20 pF,

p

L

ure 1

See Fi

V

B

B

φ

Equivalent input noise voltage

n

Maximum output-swing bandwidth

OM

Unity-gain bandwidth

1

Phase margin

m

f = 1 kHz,

See Figure 2

VO = VOH,

= 10 kΩ,

VI = 10 mV,

=

I

=

p

= 20 F,

= 5 V

DD

25°C 3.6

0°C 4

70°C 3

25°C 2.9

0°C 3.1

70°C 2.5

25°C 25

25°C 320

0°C 340

70°C 260

25°C 1.7

0°C

70°C 1.3

25°C 46°

0°C 47°

70°C 43°

TLC272C, TLC272AC,

TLC272BC, TLC277C

MIN TYP MAX

2

UNIT

nV/√Hz

kHz

MHz

operating characteristics at specified free-air temperature, VDD = 10 V

PARAMETER TEST CONDITIONS T

25°C 5.3

V

= 1 V

RL = 10 kΩ,

= 20 pF,

p

L

ure 1

See Fi

V

B

B

φ

Equivalent input noise voltage

n

Maximum output-swing bandwidth

OM

Unity-gain bandwidth

1

Phase margin

m

f = 1 kHz,

See Figure 2

VO = VOH,

= 10 kΩ,

VI = 10 mV,

= 10 mV,

I

= 20 F,

p

IPP

V

= 5.5 V

IPP

RS = 20 Ω,

CL = 20 pF,

CL = 20 pF,

=

,

1

0°C 5.9

70°C 4.3

25°C 4.6

0°C 5.1

70°C 3.8

25°C 25

25°C 200

0°C 220

70°C 140

25°C 2.2

0°C

70°C 1.8

25°C 49°

0°C 50°

70°C 46°

TLC272C, TLC272AC,

TLC272BC, TLC277C

MIN TYP MAX

2.5

UNIT

nV/√Hz

kHz

MHz

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 13

A

SR

Slew rate at unity gain

C

g

V/µs

See Figure 1

R

L

See Figure 1

See Figure 3

V

f

B

C

L

See Figure 3

A

SR

Slew rate at unity gain

C

g

V/µs

See Figure 1

R

L

See Figure 1

See Figure 3

V

f

B

C

L

See Figure 3

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

operating characteristics at specified free-air temperature, VDD = 5 V

PARAMETER TEST CONDITIONS T

25°C 3.6

V

V

B

B

φ

Equivalent input noise voltage

n

Maximum output-swing bandwidth

OM

Unity-gain bandwidth

1

Phase margin

m

RL = 10 kΩ,

= 20 pF,

p

L

ure 1

See Fi

f = 1 kHz,

See Figure 2

VO = VOH,

= 10 kΩ,

VI = 10 mV,

= 10 mV,

I

=

p

= 20 F,

= 1 V

IPP

V

= 2.5 V

IPP

RS = 20 Ω,

CL = 20 pF,

CL = 20 pF,

=

,

1

–40°C 4.5

85°C 2.8

25°C 2.9

–40°C 3.5

85°C 2.3

25°C 25

25°C 320

–40°C 380

85°C 250

25°C 1.7

–40°C

85°C 1.2

25°C 46°

–40°C 49°

85°C 43°

TLC272I, TLC272AI,

TLC272BI, TLC277I

MIN TYP MAX

2.6

UNIT

nV/√Hz

kHz

MHz

operating characteristics at specified free-air temperature, VDD = 10 V

PARAMETER TEST CONDITIONS T

25°C 5.3

V

V

B

B

φ

Equivalent input noise voltage

n

Maximum output-swing bandwidth

OM

Unity-gain bandwidth

1

Phase margin

m

RL = 10 kΩ,

= 20 pF,

p

L

ure 1

See Fi

f = 1 kHz,

See Figure 2

VO = VOH,

= 10 kΩ,

VI = 10 mV,

= 10 mV,

I

= 20 F,

p

= 1 V

IPP

V

= 5.5 V

IPP

RS = 20 Ω,

CL = 20 pF,

CL = 20 pF,

=

,

1

–40°C 6.8

85°C 4

25°C 4.6

–40°C 5.8

85°C 3.5

25°C 25

25°C 200

–40°C 260

85°C 130

25°C 2.2

–40°C

85°C 1.7

25°C 49°

–40°C 52°

85°C 46°

TLC272I, TLC272AI,

TLC272BI, TLC277I

MIN TYP MAX

3.1

UNIT

nV/√Hz

kHz

MHz

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

13

Page 14

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

PARAMETER

TEST CONDITIONS

T

UNIT

SR

Slew rate at unity gain

C

g

V/µs

See Figure 1

R

L

See Figure 1

See Figure 3

V

f

B

C

L

See Figure 3

PARAMETER

TEST CONDITIONS

T

UNIT

SR

Slew rate at unity gain

C

g

V/µs

See Figure 1

R

L

See Figure 1

See Figure 3

V

10 mV

f

B

C

L

See Figure 3

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

operating characteristics at specified free-air temperature, V

V

= 1 V

RL = 10 kΩ,

= 20 pF,

p

L

ure 1

See Fi

V

B

B

φ

Equivalent input noise voltage

n

Maximum output-swing bandwidth

OM

Unity-gain bandwidth

1

Phase margin

m

f = 1 kHz,

See Figure 2

VO = VOH,

= 10 kΩ,

VI = 10 mV,

= 10 mV,

I

= 20 F,

p

IPP

V

= 2.5 V

IPP

RS = 20 Ω,

CL = 20 pF,

CL = 20 pF,

=

,

1

= 5 V

DD

A

25°C 3.6

–55°C 4.7

125°C 2.3

25°C 2.9

–55°C 3.7

125°C 2

25°C 25

25°C 320

–55°C 400

125°C 230

25°C 1.7

–55°C

125°C 1.1

25°C 46°

–55°C 49°

125°C 41°

operating characteristics at specified free-air temperature, VDD = 10 V

A

25°C 5.3

V

= 1 V

,

IPP

V

= 5.5 V

IPP

RS = 20 Ω,

CL = 20 pF,

CL = 20 pF,

=

,

1

RL = 10 kΩ,

= 20 pF,

p

L

ure 1

See Fi

V

B

B

φ

Equivalent input noise voltage

n

Maximum output-swing bandwidth

OM

Unity-gain bandwidth

1

Phase margin

m

f = 1 kHz,

See Figure 2

VO = VOH,

= 10 kΩ,

VI = 10 mV,

=

I

= 20 F,

p

–55°C 7.1

125°C 3.1

25°C 4.6

–55°C 6.1

125°C 2.7

25°C 25 nV/√Hz

25°C 200

–55°C 280

125°C 110

25°C 2.2

–55°C

125°C 1.6

25°C 49°

–55°C 52°

125°C 44°

TLC272M, TLC277M

MIN TYP MAX

2.9

TLC272M, TLC277M

MIN TYP MAX

3.4

nV/√Hz

kHz

MHz

kHz

MHz

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 15

PARAMETER

TEST CONDITIONS

UNIT

SR

Slew rate at unity gain

L

,

L

,

V/µs

PARAMETER

TEST CONDITIONS

UNIT

SR

Slew rate at unity gain

L

,

L

,

V/µs

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

operating characteristics, V

V

B

B

φ

Equivalent input noise voltage f = 1 kHz, RS = 20 Ω, See Figure 2 25

n

Maximum output-swing bandwidth

OM

Unity-gain bandwidth VI = 10 mV, CL = 20 pF, See Figure 3 1.7 MHz

1

Phase margin

m

DD

= 5 V, T

operating characteristics, VDD = 10 V, T

V

B

B

φ

Equivalent input noise voltage f = 1 kHz, RS = 20 Ω, See Figure 2 25

n

Maximum output-swing bandwidth

OM

Unity-gain bandwidth VI = 10 mV, CL = 20 pF, See Figure 3 2.2 MHz

1

Phase margin

m

= 25°C

A

R

= 10 kΩ, C

See Figure 1

VO = VOH,

See Figure 1

VI = 10 mV,

See Figure 3

= 25°C

A

R

= 10 kΩ, C

See Figure 1

VO = VOH,

See Figure 1

VI = 10 mV,

See Figure 3

V

= 20 pF,

CL = 20 pF, RL = 10 kΩ,

f = B1, CL = 20 pF,

= 20 pF,

CL = 20 pF, RL = 10 kΩ,

f = B1, CL = 20 pF,

= 1 V 3.6

IPP

V

= 2.5 V 2.9

IPP

V

= 1 V 5.3

IPP

V

= 5.5 V 4.6

IPP

TLC272Y

MIN TYP MAX

nV/√Hz

320 kHz

46°

TLC272Y

MIN TYP MAX

nV/√Hz

200 kHz

49°

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

15

Page 16

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

PARAMETER MEASUREMENT INFORMATION

single-supply versus split-supply test circuits

Because the TLC272 and TLC277 are optimized for single-supply operation, circuit configurations used for the

various tests often present some inconvenience since the input signal, in many cases, must be offset from

ground. This inconvenience can be avoided by testing the device with split supplies and the output load tied to

the negative rail. A comparison of single-supply versus split-supply test circuits is shown below. The use of either

circuit gives the same result.

V

I

1/2 V

V

DD

–

V

+

C

L

(a) SINGLE SUPPLY (b) SPLIT SUPPLY

O

V

R

L

I

V

DD+

–

+

V

DD–

Figure 1. Unity-Gain Amplifier

DD

2 kΩ

V

20 Ω

20 Ω

(a) SINGLE SUPPLY

DD

–

+

V

O

2 kΩ

V

DD+

–

+

20 Ω20 Ω

V

(b) SPLIT SUPPLY

C

DD–

V

O

L

R

L

V

O

16

1/2 V

DD

Figure 2. Noise-Test Circuit

10 kΩ

V

100 Ω

V

I

DD

–

V

+

(a) SINGLE SUPPLY (b) SPLIT SUPPLY

O

C

L

100 Ω

V

I

10 kΩ

V

DD+

–

+

V

DD–

V

O

C

L

Figure 3. Gain-of-100 Inverting Amplifier

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 17

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

PARAMETER MEASUREMENT INFORMATION

input bias current

Because of the high input impedance of the TLC272 and TLC277 operational amplifiers, attempts to measure

the input bias current can result in erroneous readings. The bias current at normal room ambient temperature

is typically less than 1 pA, a value that is easily exceeded by leakages on the test socket. Two suggestions are

offered to avoid erroneous measurements:

1. Isolate the device from other potential leakage sources. Use a grounded shield around and between the

device inputs (see Figure 4). Leakages that would otherwise flow to the inputs are shunted away.

2. Compensate for the leakage of the test socket by actually performing an input bias current test (using

a picoammeter) with no device in the test socket. The actual input bias current can then be calculated

by subtracting the open-socket leakage readings from the readings obtained with a device in the test

socket.

One word of caution: many automatic testers as well as some bench-top operational amplifier testers use the

servo-loop technique with a resistor in series with the device input to measure the input bias current (the voltage

drop across the series resistor is measured and the bias current is calculated). This method requires that a

device be inserted into the test socket to obtain a correct reading; therefore, an open-socket reading is not

feasible using this method.

85

V = V

IC

14

Figure 4. Isolation Metal Around Device Inputs

(JG and P packages)

low-level output voltage

T o obtain low-supply-voltage operation, some compromise was necessary in the input stage. This compromise

results in the device low-level output being dependent on both the common-mode input voltage level as well

as the differential input voltage level. When attempting to correlate low-level output readings with those quoted

in the electrical specifications, these two conditions should be observed. If conditions other than these are to

be used, please refer to Figures 14 through 19 in the Typical Characteristics of this data sheet.

input offset voltage temperature coefficient

Erroneous readings often result from attempts to measure temperature coefficient of input offset voltage. This

parameter is actually a calculation using input offset voltage measurements obtained at two different

temperatures. When one (or both) of the temperatures is below freezing, moisture can collect on both the device

and the test socket. This moisture results in leakage and contact resistance, which can cause erroneous input

offset voltage readings. The isolation techniques previously mentioned have no effect on the leakage since the

moisture also covers the isolation metal itself, thereby rendering it useless. It is suggested that these

measurements be performed at temperatures above freezing to minimize error.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

17

Page 18

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

PARAMETER MEASUREMENT INFORMATION

full-power response

Full-power response, the frequency above which the operational amplifier slew rate limits the output voltage

swing, is often specified two ways: full-linear response and full-peak response. The full-linear response is

generally measured by monitoring the distortion level of the output while increasing the frequency of a sinusoidal

input signal until the maximum frequency is found above which the output contains significant distortion. The

full-peak response is defined as the maximum output frequency , without regard to distortion, above which full

peak-to-peak output swing cannot be maintained.

Because there is no industry-wide accepted value for significant distortion, the full-peak response is specified

in this data sheet and is measured using the circuit of Figure 1. The initial setup involves the use of a sinusoidal

input to determine the maximum peak-to-peak output of the device (the amplitude of the sinusoidal wave is

increased until clipping occurs). The sinusoidal wave is then replaced with a square wave of the same

amplitude. The frequency is then increased until the maximum peak-to-peak output can no longer be maintained

(Figure 5). A square wave is used to allow a more accurate determination of the point at which the maximum

peak-to-peak output is reached.

(b) BOM > f > 1 kHz(a) f = 1 kHz

Figure 5. Full-Power-Response Output Signal

(c) f = B

OM

test time

Inadequate test time is a frequent problem, especially when testing CMOS devices in a high-volume,

short-test-time environment. Internal capacitances are inherently higher in CMOS than in bipolar and BiFET

devices and require longer test times than their bipolar and BiFET counterparts. The problem becomes more

pronounced with reduced supply levels and lower temperatures.

(d) f > B

OM

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 19

vs High level out ut current

10, 11

OH

gg

yg

vs Common mode in ut voltage

14, 15

VOLLow-level output voltage

g

vs Su ly voltage

20

VD

gg g

IDDSupply current

yg

SR

Slew rate

yg

B1Unity-gain bandwidth

vs Su ly voltage

34

φ

m

g

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

Table of Graphs

FIGURE

V

IO

α

VIO

V

OH

A

VD

I

IB

I

IO

V

IC

V

O(PP)

φ

m

V

n

Input offset voltage Distribution 6, 7

Temperature coefficient of input offset voltage Distribution 8, 9

High-level output voltage

p

Large-signal differential voltage amplification

Input bias current vs Free-air temperature 22

Input offset current vs Free-air temperature 22

Common-mode input voltage vs Supply voltage 23

pp

Normalized slew rate vs Free-air temperature 28

Maximum peak-to-peak output voltage vs Frequency 29

Phase margin

Equivalent input noise voltage vs Frequency 37

Phase shift vs Frequency 32, 33

vs High-level output current 10, 11

vs Supply voltage

vs Free-air temperature 13

vs Differential input voltage

vs Free-air temperature 17

vs Low-level output current 18, 19

vs Supply voltage 20

vs Free-air temperature

vs Frequency 32, 33

vs Supply voltage 24

vs Free-air temperature 25

vs Supply voltage 26

vs Free-air temperature 27

vs Free-air temperature 30

vs Supply voltage 31

vs Supply voltage 34

vs Free-air temperature

vs Load capacitance 36

p

12

16

21

35

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

19

Page 20

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

DISTRIBUTION OF TLC272

INPUT OFFSET VOLTAGE

60

753 Amplifiers Tested From 6 Wafer Lots

VDD = 5 V

50

TA = 25°C

P Package

40

30

20

Percentage of Units – %

10

0

–5

–4 –3 –2 –1 0 1 2 34

VIO – Input Offset Voltage – mV

DISTRIBUTION OF TLC272 AND TLC277

INPUT OFFSET VOLTAGE

TEMPERATURE COEFFICIENT

60

324 Amplifiers Tested From 8 Wafer Lots

VDD = 5 V

50

TA = 25°C to 125°C

P Package

Outliers:

(1) 20.5 µV/°C

40

Figure 6

DISTRIBUTION OF TLC272

INPUT OFFSET VOLTAGE

60

753 Amplifiers Tested From 6 Wafer Lots

VDD = 10 V

50

TA = 25°C

P Package

40

30

20

Percentage of Units – %

10

0

5

–5

VIO – Input Offset Voltage – mV

5

43210–1–2–3–4

Figure 7

DISTRIBUTION OF TLC272 AND TLC277

INPUT OFFSET VOLTAGE

TEMPERATURE COEFFICIENT

60

324 Amplifiers Tested From 8 Wafer Lots

VDD = 5 V

50

TA = 25°C to 125°C

P Package

Outliers:

(1) 21.2 µV/°C

40

30

20

Percentage of Units – %

10

0

–10

αVIO – Temperature Coefficient – µV/°C

20

Figure 8

20–2–4–6–8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

10

864

30

20

Percentage of Units – %

10

0

–8 –6 –4 –2 0 2 4 6 8

–10

αVIO – Temperature Coefficient – µV/°C

10

Figure 9

Page 21

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

HIGH-LEVEL OUTPUT VOLTAGE

vs

5

4

3

2

1

OH

V

VOH – High-Level Output Voltage – V

0

NOTE A: The 3-V curve only applies to the C version.

HIGH-LEVEL OUTPUT CURRENT

VDD = 4 V

VDD = 3 V

0

IOH – High-Level Output Current – mA

Figure 10

VID = 100 mV

TA = 25°C

See Note A

VDD = 5 V

–8–6–4–2

–10

16

14

12

10

8

6

4

OH

VOH – High-Level Output Voltage – V

V

2

0

0

†

HIGH-LEVEL OUTPUT VOLTAGE

vs

HIGH-LEVEL OUTPUT CURRENT

VID = 100 mV

VDD = 16 V

VDD = 10 V

–5 –15 –20 –25 –35

IOH – High-Level Output Current – mA

TA = 25°C

–30–20–10

Figure 11

–40

16

14

12

10

8

6

4

OH

VOH – High-Level Output Voltage – V

V

2

0

0

HIGH-LEVEL OUTPUT VOLTAGE

vs

SUPPLY VOLTAGE

VID = 100 mV

RL = 10 kΩ

TA = 25°C

VDD – Supply Voltage – V

Figure 12

1412108642 16

VDD –1.6

VDD –1.7

VDD –1.8

VDD –1.9

VDD –2

VDD –2.1

VDD –2.2

OH

VOH – High-Level Output Voltage – V

V

VDD –2.3

VDD –2.4

HIGH-LEVEL OUTPUT VOLTAGE

vs

FREE-AIR TEMPERATURE

VDD = 5 V

VDD = 10 V

–75

–50 –25 0 20 50 75 100

TA – Free-Air Temperature – ° C

Figure 13

IOH = –5 mA

VID = 100 mA

125

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

21

Page 22

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

700

650

600

550

500

450

400

OL

VOL – Low-Level Output Voltage – mV

V

350

300

0

TYPICAL CHARACTERISTICS

LOW-LEVEL OUTPUT VOLTAGE

vs

COMMON-MODE INPUT VOLTAGE

VDD = 5 V

IOL = 5 mA

TA = 25°C

VID = –100 mV

VID = –1 V

0.5 1.5 2.5 3.5

VIC – Common-Mode Input Voltage – V

321

4

500

450

400

350

300

OL

VOL – Low-Level Output Voltage – mV

V

250

0

†

LOW-LEVEL OUTPUT VOLTAGE

vs

COMMON-MODE INPUT VOLTAGE

VDD = 10 V

IOL = 5 mA

TA = 25°C

VID = –100 mV

VID = –1 V

VID = –2.5 V

13579

VIC – Common-Mode Input Voltage – V

108642

800

700

600

500

400

300

200

OL

100

VOL – Low-Level Output Voltage – mV

V

0

0

Figure 14

LOW-LEVEL OUTPUT VOLTAGE

vs

DIFFERENTIAL INPUT VOLTAGE

IOL = 5 mA

VIC = |V

TA = 25°C

VDD = 5 V

VDD = 10 V

–1 –3 –5 –7 –9

VID – Differential Input Voltage – V

ID/

2|

–8–6–4–2 –10

900

800

700

600

500

400

300

200

OL

VOL – Low-Level Output Voltage – mV

V

100

0

–75

Figure 15

LOW-LEVEL OUTPUT VOLTAGE

vs

FREE-AIR TEMPERATURE

IOL = 5 mA

VID = –1 V

VIC = 0.5 V

VDD = 5 V

VDD = 10 V

TA – Free-Air Temperature – ° C

1007550250–25–50

125

Figure 16

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Figure 17

Page 23

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

LOW-LEVEL OUTPUT VOLTAGE

vs

LOW-LEVEL OUTPUT CURRENT

1.0

0

0

VID = –1 V

VIC = 0.5 V

TA = 25°C

See Note A

VDD = 4 V

VDD = 3 V

IOL – Low-Level Output Current – mA

VDD = 5 V

Figure 18

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

OL

VOL – Low-Level Output Voltage – V

V

0.1

NOTE A: The 3-V curve only applies to the C version.

†

LOW-LEVEL OUTPUT VOLTAGE

vs

LOW-LEVEL OUTPUT CURRENT

3.0

VID = –1 V

0

VIC = 0.5 V

TA = 25°C

0

VDD = 16 V

VDD = 10 V

252015105

IOL – Low-Level Output Current – mA

30

2.5

2.0

1.5

1.0

OL

0.5

VOL – Low-Level Output Voltage – V

V

7654321

8

Figure 19

LARGE-SIGNAL

DIFFERENTIAL VOLTAGE AMPLIFICATION

SUPPLY VOLTAGE

60

RL = 10 kΩ

50

40

30

20

Voltage Amplification – V/mV

VD

A

AVD – Large-Signal Differential

10

0

0

2 4 6 8 10 12 14

VDD – Supply Voltage – V

Figure 20

vs

TA = –55°C

TA = 0°C

TA = 25°C

TA = 85°C

TA = 125°C

16

LARGE-SIGNAL

DIFFERENTIAL VOLTAGE AMPLIFICATION

FREE-AIR TEMPERATURE

50

45

40

35

30

25

20

15

Voltage Amplification – V/mV

VD

AVD – Large-Signal Differential

A

10

5

0

–75

–50 –25 0 25 50 75 100

VDD = 5 V

TA – Free-Air Temperature – ° C

Figure 21

vs

RL = 10 kΩ

VDD = 10 V

125

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

23

Page 24

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

T

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

INPUT BIAS CURRENT AND INPUT OFFSET CURREN

vs

FREE-AIR TEMPERATURE

10000

1000

– Input Bias and Offset Currents – pA

IO

I

and

IB

I

NOTE A: The typical values of input bias current and input

offset current below 5 pA were determined mathematically .

100

10

0.1

VDD = 10 V

VIC = 5 V

See Note A

I

IB

1

25

35 55 75 95 115

45 65 85 105

TA – Free-Air Temperature – ° C

Figure 22

I

IO

125

16

14

12

10

8

6

4

IC

V – Common-Mode Input Voltage – V

2

0

0

†

COMMON-MODE

INPUT VOLTAGE POSITIVE LIMIT

vs

SUPPLY VOLTAGE

TA = 25°C

2 4 6 8 10 12 14

VDD – Supply Voltage – V

Figure 23

16

SUPPLY CURRENT

vs

SUPPLY VOLTAGE

– Supply Current – mAI

DD

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

VO = VDD/2

No Load

TA = 25°C

0

2 4 6 8 10 12 14

VDD – Supply Voltage – V

TA = –55°C

TA = 0°C

TA = 70°C

TA = 125°C

16

4

3

2

1

0

–75

VO = VDD/2

No Load

–50 –25

3.5

2.5

1.5

– Supply Current – mA

DD

I

0.5

Figure 24

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

SUPPLY CURRENT

vs

FREE-AIR TEMPERATURE

VDD = 10 V

VDD = 5 V

0 25 50 75 100

TA – Free-Air Temperature – ° C

Figure 25

125

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 25

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

8

AV = 1

V

= 1 V

IPP

7

RL = 10 kΩ

CL = 20 pF

6

µsSR – Slew Rate – V/

TA = 25°C

See Figure 1

5

4

3

2

1

0

0

SLEW RATE

vs

SUPPLY VOLTAGE

VDD – Supply Voltage – V

TYPICAL CHARACTERISTICS

8

7

6

µsSR – Slew Rate – V/

5

4

3

2

1

1412108642

16

0

–75

†

SLEW RATE

vs

FREE-AIR TEMPERATURE

AV = 1

VDD = 10 V

V

= 5.5 V

IPP

VDD = 5 V

V

= 1 V

IPP

TA – Free-Air Temperature – ° C

RL = 10 kΩ

CL = 20 pF

See Figure 1

VDD = 5 V

V

= 2.5 V

IPP

VDD = 10 V

V

= 1 V

IPP

1007550250–25–50 125

NORMALIZED SLEW RATE

FREE-AIR TEMPERATURE

1.5

1.4

1.3

1.2

1.1

1.0

0.9

Normalized Slew Rate

0.8

0.7

0.6

0.5

–75

VDD = 10 V

VDD = 5 V

TA – Free-Air Temperature – ° C

Figure 26

vs

AV = 1

V

= 1 V

IPP

RL = 10 kΩ

CL = 20 pF

1007550250–25–50 125

10

9

8

7

6

5

4

3

2

– Maximum Peak-to-Peak Output Voltage – V

1

O(PP)

V

0

10

Figure 27

MAXIMUM PEAK OUTPUT VOLTAGE

vs

FREQUENCY

VDD = 10 V

TA = 125°C

TA = 25°C

TA = –55°C

VDD = 5 V

RL = 10 kΩ

See Figure 1

1000100

f – Frequency – kHz

10000

Figure 28

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Figure 29

25

Page 26

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

Á

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

UNITY-GAIN BANDWIDTH

FREE-AIR TEMPERATURE

3.0

2.5

2.0

1.5

– Unity-Gain Bandwidth – MHz

1

B

1.0

–75

TA – Free-Air Temperature – ° C

vs

TYPICAL CHARACTERISTICS

2.5

2.0

1.5

1.0

VI = 10 mV

CL = 20 pF

TA = 25°C

See Figure 3

0

VDD = 5 V

VI = 10 mV

CL = 20 pF

See Figure 3

1007550250–25–50

125

– Unity-Gain Bandwidth – MHz

1

B

†

UNITY-GAIN BANDWIDTH

vs

SUPPLY VOLTAGE

VDD – Supply Voltage – V

1412108642

16

Figure 30

VD

A

AVD – Large-Signal Differential

LARGE-SIGNAL DIFFERENTIAL VOLTAGE

AMPLIFICATION AND PHASE SHIFT

7

10

VDD = 5 V

6

RL = 10 kΩ

10

TA = 25°C

5

10

4

10

3

10

2

10

Voltage Amplification

1

10

1

0.1

10

FREQUENCY

A

VD

Phase Shift

f – Frequency – Hz

vs

Figure 31

0°

30°

60°

90°

Phase Shift

120°

150°

180°

1 M100 k10 k1 k100

10 M

Figure 32

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

26

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 27

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

LARGE-SIGNAL DIFFERENTIAL VOLTAGE

AMPLIFICATION AND PHASE SHIFT

7

10

VDD = 10 V

6

10

10

10

10

10

Voltage Amplification

VD

10

AVD – Large-Signal Differential

A

RL = 10 kΩ

TA = 25°C

5

4

3

2

Phase Shift

1

1

0.1

10

vs

FREQUENCY

A

VD

f – Frequency – Hz

†

0°

30°

60°

Phase Shift

90°

120°

150°

180°

10 M

1 M100 k10 k1 k100

53°

52°

51°

50°

49°

48°

m – Phase Margin

m

φ

47°

46°

45°

0

PHASE MARGIN

vs

SUPPLY VOLTAGE

VI = 10 mV

CL = 20 pF

TA = 25°C

See Figure 3

VDD – Supply Voltage – V

1412108642 16

Figure 33

50°

48°

46°

44°

m – Phase Margin

m

φ

42°

40°

–75

PHASE MARGIN

vs

FREE-AIR TEMPERATURE

VDD = 5 V

VI = 10 mV

CL = 20 pF

See Figure 3

TA – Free-Air Temperature – ° C

1007550250–25–50

125

Figure 34

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Figure 35

27

Page 28

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

TYPICAL CHARACTERISTICS

50°

45°

40°

35°

m – Phase Margin

m

φ

30°

25°

10 30 50 70 90

0

PHASE MARGIN

vs

CAPACITIVE LOAD

VDD = 5 V

VI = 10 mV

TA = 25°C

See Figure 3

CL – Capacitive Load – pF

Figure 36

EQUIVALENT INPUT NOISE VOLTAGE

vs

FREQUENCY

400

VDD = 5 V

nV/ Hz

300

200

100

n

V

VN – Equivalent Input Noise Voltage –

80604020

100

0

1

f – Frequency – Hz

RS = 20 Ω

TA = 25°C

See Figure 2

10010

1000

Figure 37

28

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 29

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

APPLICATION INFORMATION

single-supply operation

While the TLC272 and TLC277 perform well using dual power supplies (also called balanced or split supplies),

the design is optimized for single-supply operation. This design includes an input common-mode voltage range

that encompasses ground as well as an output voltage range that pulls down to ground. The supply voltage

range extends down to 3 V (C-suffix types), thus allowing operation with supply levels commonly available for

TTL and HCMOS; however, for maximum dynamic range, 16-V single-supply operation is recommended.

Many single-supply applications require that a voltage be applied to one input to establish a reference level that

is above ground. A resistive voltage divider is usually sufficient to establish this reference level (see Figure 38).

The low input bias current of the TLC272 and TLC277 permits the use of very large resistive values to implement

the voltage divider, thus minimizing power consumption.

The TLC272 and TLC277 work well in conjunction with digital logic; however, when powering both linear devices

and digital logic from the same power supply, the following precautions are recommended:

1. Power the linear devices from separate bypassed supply lines (see Figure 39); otherwise, the linear

device supply rails can fluctuate due to voltage drops caused by high switching currents in the digital

logic.

2. Use proper bypass techniques to reduce the probability of noise-induced errors. Single capacitive

decoupling is often adequate; however, high-frequency applications may require RC decoupling.

V

DD

R4

–

+

V

V

+

O

REF

VO+

V

(V

REF

DD

R1)R3

*

VI)

R3

R4

R2

)

V

REF

V

V

REF

R1

R3

R2

C

0.01 µF

I

Figure 38. Inverting Amplifier With Voltage Reference

OUT

OUT

–

+

(a) COMMON SUPPLY RAILS

–

+

Logic Logic Logic

LogicLogicLogic

Power

Supply

Power

Supply

(b) SEPARATE BYPASSED SUPPLY RAILS (preferred)

Figure 39. Common vs Separate Supply Rails

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

29

Page 30

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

APPLICATION INFORMATION

input characteristics

The TLC272 and TLC277 are specified with a minimum and a maximum input voltage that, if exceeded at either

input, could cause the device to malfunction. Exceeding this specified range is a common problem, especially

in single-supply operation. Note that the lower range limit includes the negative rail, while the upper range limit

is specified at V

The use of the polysilicon-gate process and the careful input circuit design gives the TLC272 and TLC277 very

good input offset voltage drift characteristics relative to conventional metal-gate processes. Offset voltage drift

in CMOS devices is highly influenced by threshold voltage shifts caused by polarization of the phosphorus

dopant implanted in the oxide. Placing the phosphorus dopant in a conductor (such as a polysilicon gate)

alleviates the polarization problem, thus reducing threshold voltage shifts by more than an order of magnitude.

The offset voltage drift with time has been calculated to be typically 0.1 µV/month, including the first month of

operation.

Because of the extremely high input impedance and resulting low bias current requirements, the TLC272 and

TLC277 are well suited for low-level signal processing; however, leakage currents on printed-circuit boards and

sockets can easily exceed bias current requirements and cause a degradation in device performance. It is good

practice to include guard rings around inputs (similar to those of Figure 4 in the Parameter Measurement

Information section). These guards should be driven from a low-impedance source at the same voltage level

as the common-mode input (see Figure 40).

– 1 V at TA = 25°C and at VDD – 1.5 V at all other temperatures.

DD

Unused amplifiers should be connected as grounded unity-gain followers to avoid possible oscillation.

noise performance

The noise specifications in operational amplifier circuits are greatly dependent on the current in the first-stage

differential amplifier. The low input bias current requirements of the TLC272 and TLC277 result in a very low

noise current, which is insignificant in most applications. This feature makes the devices especially favorable

over bipolar devices when using values of circuit impedance greater than 50 kΩ, since bipolar devices exhibit

greater noise currents.

–

V

I

+

OUT OUT OUT

V

I

(b) INVERTING AMPLIFIER

–

+

V

I

(c) UNITY-GAIN AMPLIFIER(a) NONINVERTING AMPLIFIER

–

+

Figure 40. Guard-Ring Schemes

output characteristics

The output stage of the TLC272 and TLC277 is designed to sink and source relatively high amounts of current

(see typical characteristics). If the output is subjected to a short-circuit condition, this high current capability can

cause device damage under certain conditions. Output current capability increases with supply voltage.

All operating characteristics of the TLC272 and TLC277 are measured using a 20-pF load. The devices can

drive higher capacitive loads; however, as output load capacitance increases, the resulting response pole

occurs at lower frequencies, thereby causing ringing, peaking, or even oscillation (see Figure 41). In many

cases, adding a small amount of resistance in series with the load capacitance alleviates the problem.

30

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 31

output characteristics (continued)

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

APPLICATION INFORMATION

(a) CL = 20 pF, RL = NO LOAD

(c) CL = 150 pF, RL = NO LOAD

V

I

(b) CL = 130 pF, RL = NO LOAD

2.5 V

–

+

–2.5 V

(d) TEST CIRCUIT

V

C

L

O

TA = 25°C

f = 1 kHz

V

= 1 V

IPP

Figure 41. Effect of Capacitive Loads and Test Circuit

Although the TLC272 and TLC277 possess excellent high-level output voltage and current capability , methods

for boosting this capability are available, if needed. The simplest method involves the use of a pullup resistor

(R

) connected from the output to the positive supply rail (see Figure 42). There are two disadvantages to the

P

use of this circuit. First, the NMOS pulldown transistor N4 (see equivalent schematic) must sink a comparatively

large amount of current. In this circuit, N4 behaves like a linear resistor with an on resistance between

approximately 60 Ω and 180 Ω , depending on how hard the operational amplifier input is driven. With very low

values of R

, a voltage offset from 0 V at the output occurs. Second, pullup resistor R

P

acts as a drain load to

P

N4 and the gain of the operational amplifier is reduced at output voltage levels where N5 is not supplying the

output current.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

31

Page 32

TLC272, TLC272A, TLC272B, TLC272Y, TLC277

LinCMOS PRECISION DUAL OPERATIONAL AMPLIFIERS

SLOS091B – OCTOBER 1987 – REVISED AUGUST 1994

APPLICATION INFORMATION

output characteristics (continued)

V

DD

V

+

I

–

VDD – V

R2

O

P

R1

Rp =

IF + IL + I

Ip = Pullup current required by

the operational amplifier

(typically 500 µA)

Figure 42. Resistive Pullup to Increase V

R

I

I

I

P

P

V

O

F

R

L

L

OH

Figure 43. Compensation for Input Capacitance

C

–

V

+

O

feedback

Operational amplifier circuits almost always employ feedback, and since feedback is the first prerequisite for

oscillation, some caution is appropriate. Most oscillation problems result from driving capacitive loads

(discussed previously) and ignoring stray input capacitance. A small-value capacitor connected in parallel with

the feedback resistor is an effective remedy (see Figure 43). The value of this capacitor is optimized empirically .

electrostatic discharge protection

The TLC272 and TLC277 incorporate an internal electrostatic discharge (ESD) protection circuit that prevents

functional failures at voltages up to 2000 V as tested under MIL-STD-883C, Method 3015.2. Care should be

exercised, however, when handling these devices as exposure to ESD may result in the degradation of the

device parametric performance. The protection circuit also causes the input bias currents to be temperature

dependent and have the characteristics of a reverse-biased diode.

latch-up