Datasheet THS6012EVM, THS6012CDWP, THS6012CDWPR, THS6012IDWPR, THS6012IGQER Datasheet (Texas Instruments)

...

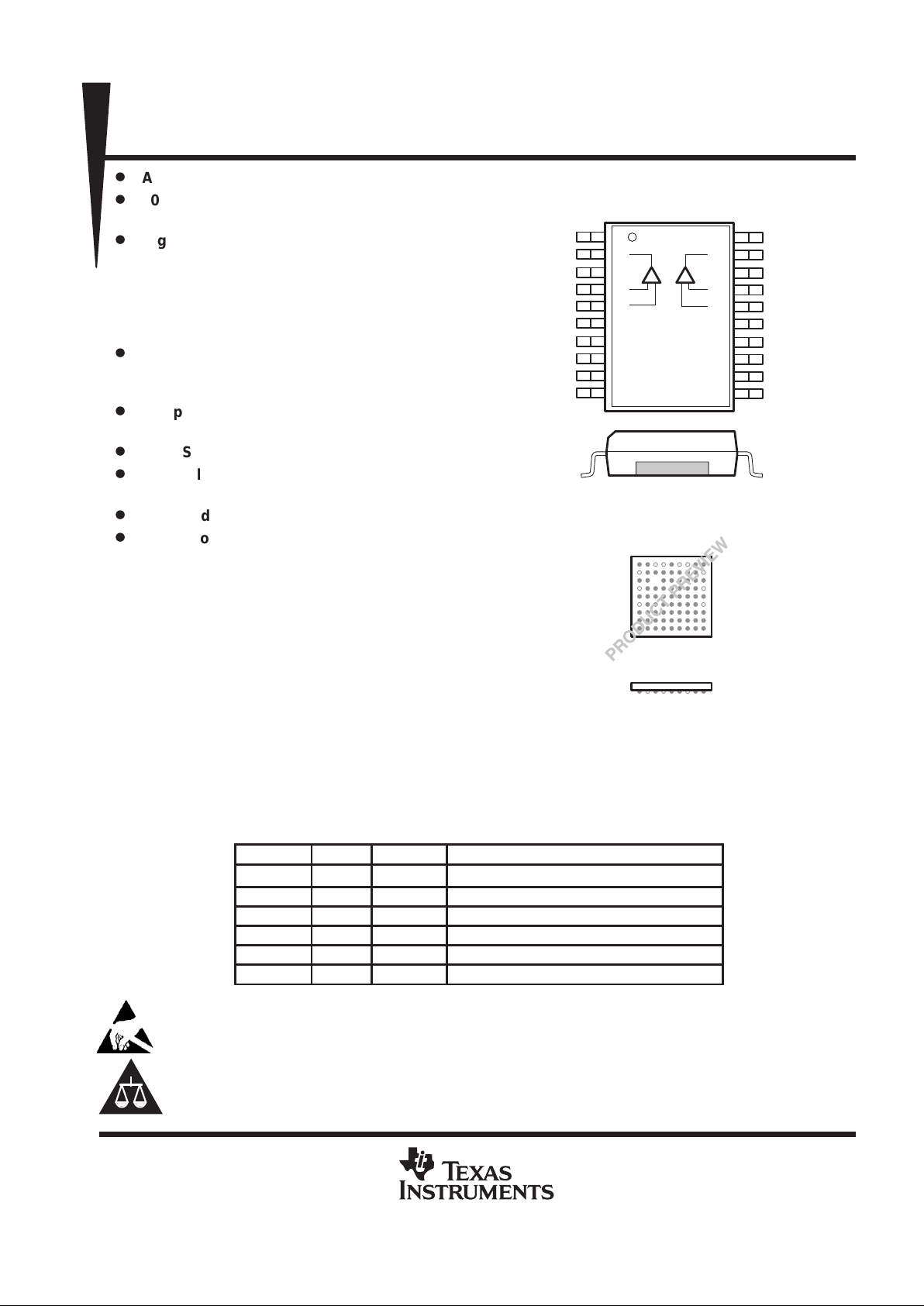

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

ADSL Differential Line Driver

D

400 mA Minimum Output Current Into 25-Ω

Load

D

High Speed

– 140 MHz Bandwidth (–3dB) With 25-Ω

Load

– 315 MHz Bandwidth (–3dB) With 100-Ω

Load

– 1300 V/µs Slew Rate, G = 5

D

Low Distortion

– –72 dB 3rd Order Harmonic Distortion at

f = 1 MHz, 25-Ω Load, and 20 V

PP

D

Independent Power Supplies for Low

Crosstalk

D

Wide Supply Range ±4.5 V to ±16 V

D

Thermal Shutdown and Short Circuit

Protection

D

Improved Replacement for AD815

D

Evaluation Module Available

description

The THS6012 contains two high-speed drivers

capable of providing 400 mA output current (min)

into a 25 Ω load. These drivers can be configured

differentially to drive a 50-Vp-p output signal over

low-impedance lines. The drivers are current

feedback amplifiers, designed for the high slew

rates necessary to support low total harmonic

distortion (THD) in xDSL applications. The THS6012 is ideally suited for asymmetrical digital subscriber line

(ADSL) applications at the central office, where it supports the high-peak voltage and current requirements of

this application.

Separate power supply connections for each driver are provided to minimize crosstalk. The THS6012 is

available in the small surface-mount, thermally enhanced 20-pin PowerPAD package.

HIGH-SPEED xDSL LINE DRIVER/RECEIVER FAMILY

DEVICE

DRIVER RECEIVER DESCRIPTION

THS6002

•

• Dual differential line drivers and receivers

THS6012 • 500-mA dual differential line driver

THS6022 • 250-mA dual differential line driver

THS6032 • Low-power ADSL central office line driver

THS6062 • Low-noise ADSL receiver

THS7002 • Low-noise programmable gain ADSL receiver

CAUTION: The THS6012 provides ESD protection circuitry. However, permanent damage can still occur if this device is subjected

to high-energy electrostatic discharges. Proper ESD precautions are recommended to avoid any performance degradation or loss

of functionality.

Copyright 2000, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PowerPAD is a trademark of Texas Instruments Incorporated.

VCC–

1OUT

V

CC+

1IN+

1IN–

NC

NC

NC

NC

NC

V

CC–

2OUT

V

CC+

2IN+

2IN–

NC

NC

NC

NC

NC

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

Cross Section View Showing PowerPAD

Thermally Enchanced SOIC (DWP)

PowerPAD Package

(TOP VIEW)

(SIDE VIEW)

MicroStar Junior (GQE) Package

(TOP VIEW)

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

AVAILABLE OPTIONS

PACKAGED DEVICE

T

A

PowerPAD PLASTIC

SMALL OUTLINE

†

(DWP)

MicroStar Junior

(GQE)

EVALUATION

MODULE

0°C to 70°C THS6012CDWP THS6012CGQE THS6012EVM

–40°C to 85°C THS6012IDWP THS6012IGQE —

†

The PWP packages are available taped and reeled. Add an R suffix to the device type (i.e.,

THS6012CPWPR)

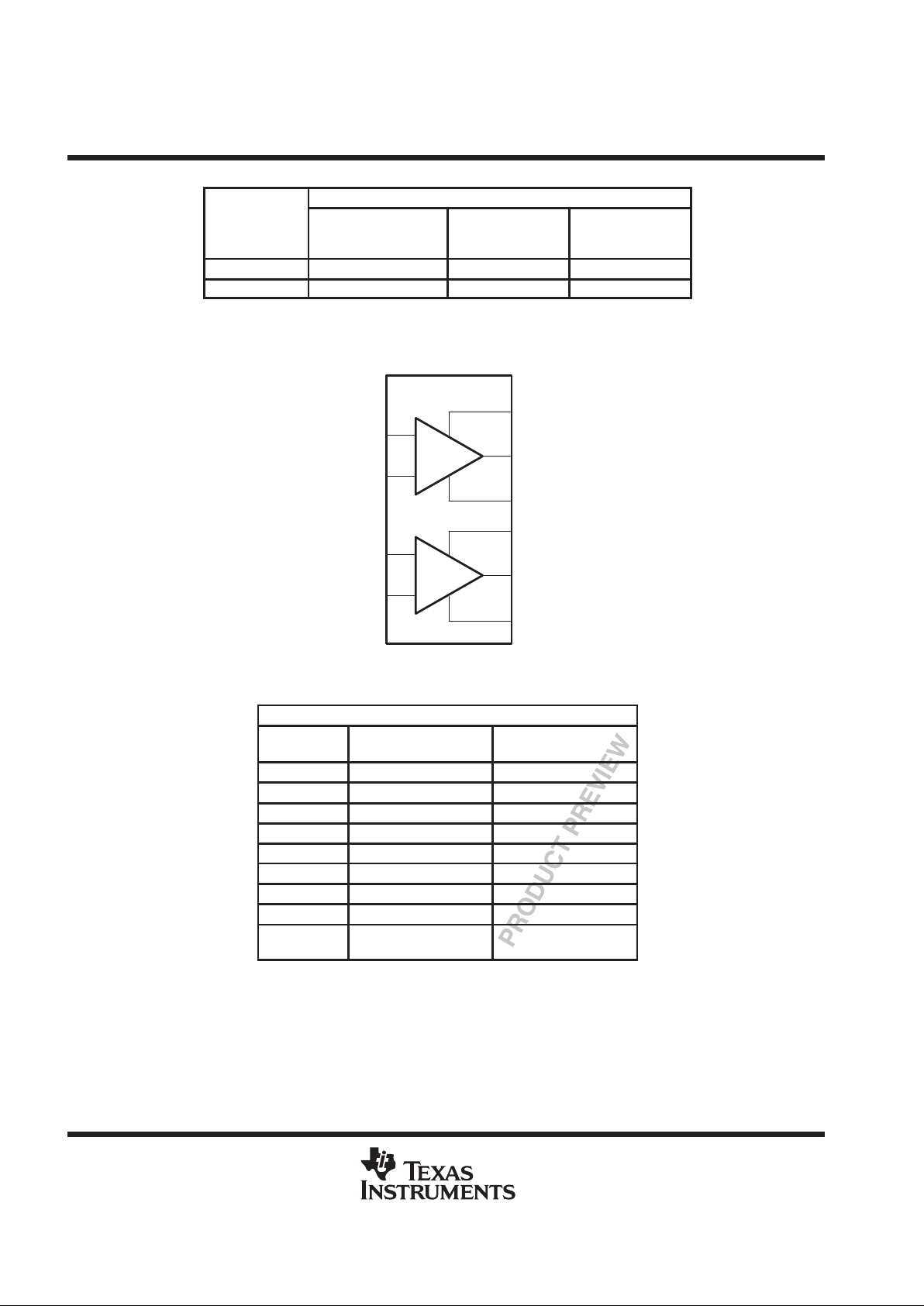

functional block diagram

_

+

Driver 1

Driver 2

_

+

3

4

5

17

16

2

1

18

19

20

VCC+

V

CC+

V

CC–

V

CC–

1OUT

2OUT

1IN+

1IN–

2IN+

2IN–

Terminal Functions

TERMINAL

NAME DWP PACKAGE

TERMINAL NO.

GQE PACKAGE

TERMINAL NO.

1OUT 2 A3

1IN– 5 F1

1IN+ 4 D1

2OUT 19 A7

2IN– 16 F9

2IN+ 17 D9

V

CC+

3, 18 B1, B9

V

CC–

1, 20 A4, A6

NC 6, 7, 8 ,9, 10, 11, 12, 13,

14, 15

NA

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

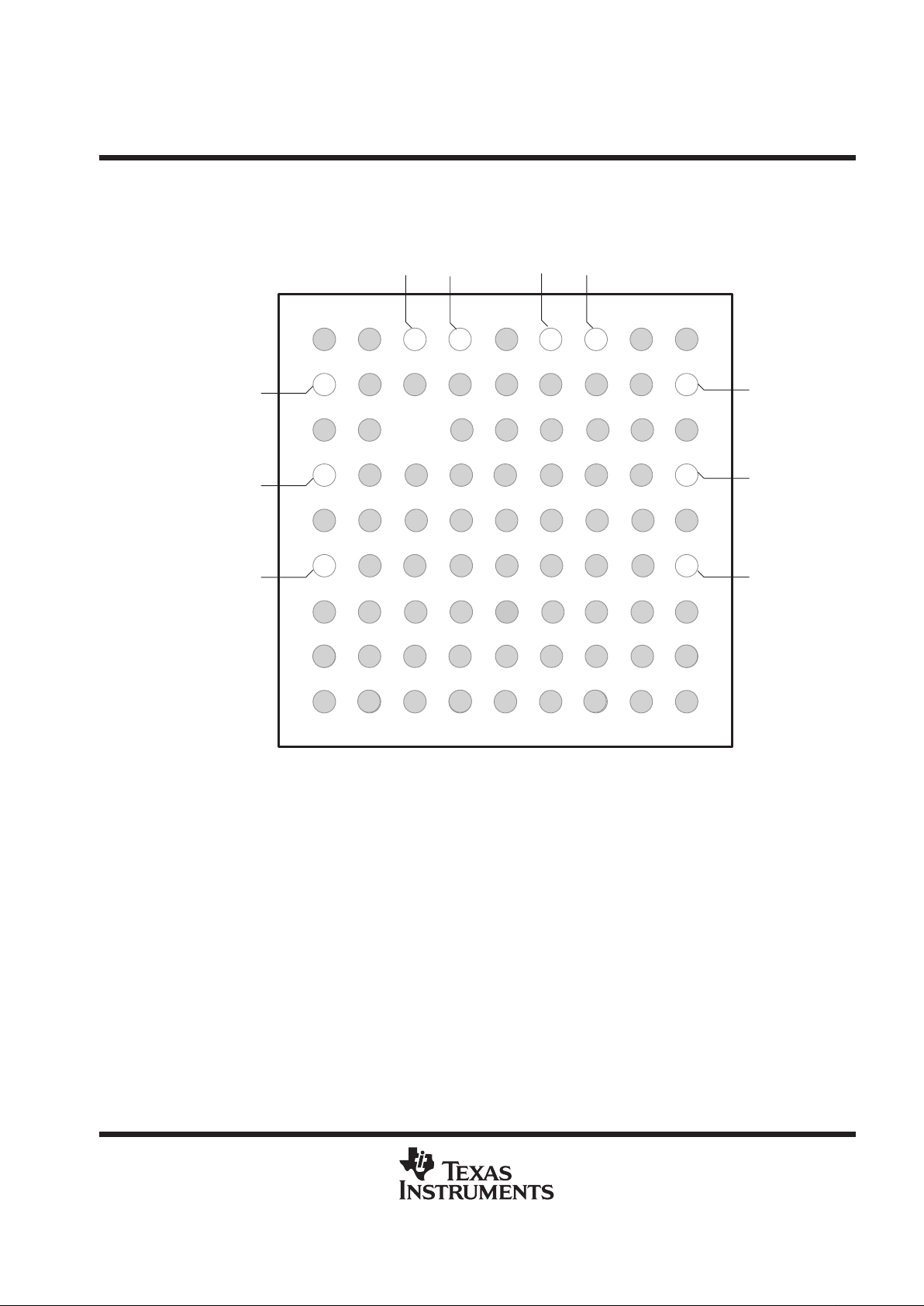

pin assignments

98765

A

B

C

D

E

F

321

G

H

J

4

2IN+

1N+

1IN–

NC

NC

NC

NC

NC

NCNC NC NC NC

NC NC NC

NC NC NC

NC NC NC

NC NC

NC NC NC

V

CC+

NCNC

NCNC

NC

NC

NCNC NC

NCNC NC

NC NC

NC NC

NC

NC

NC

NC

NC NC

NC

2OUT

NC

NC

NC NCNC NC

NC

NC NC NC

NC

NC

1OUT

NC NC

2IN–

NC

NCNC

NC

V

CC+

NOTE: Shaded terminals are used for thermal connection to the ground plane.

MicroStarJunior (GQE) Package

(TOP VIEW)

V

CC–

V

CC–

NC

NCNCNC

NC

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

†

Supply voltage, V

CC+

to V

CC–

33 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage, VI (driver and receiver) ±V

CC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output current, I

O

(driver) (see Note 1) 800 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential input voltage, VID 6 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation at (or below) TA = 25°C (see Note 1) 5.8 W. . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free air temperature, T

A

–40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature, T

stg

–65°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 300°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: The THS6012 incorporates a PowerPad on the underside of the chip. This acts as a heatsink and must be connected to a thermal

dissipation plane for proper power dissipation. Failure to do so can result in exceeding the maximum junction temperature, which could

permanently damage the device. See the

Thermal Information

section of this document for more information about PowerPad

technology.

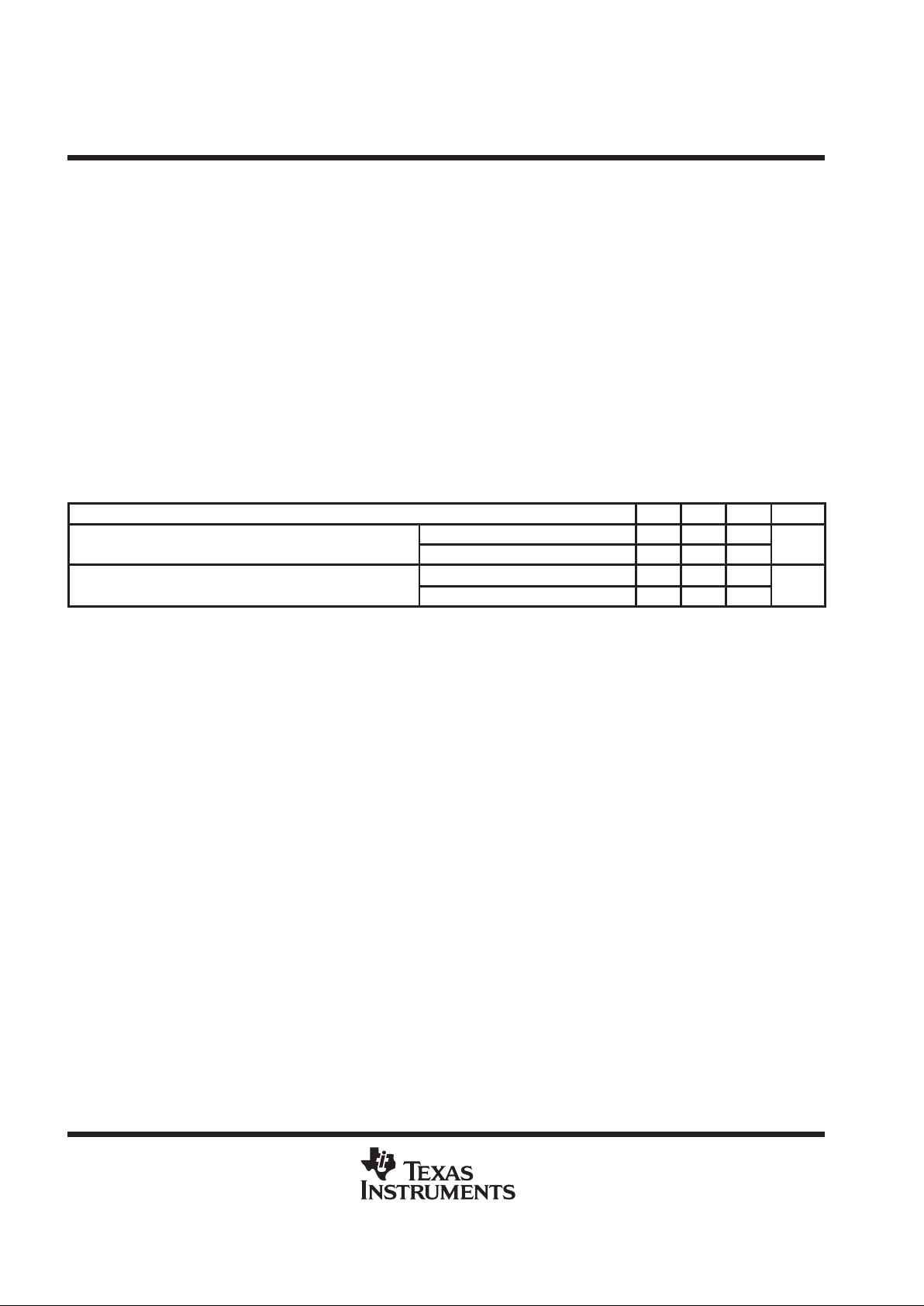

recommended operating conditions

MIN TYP MAX UNIT

pp

Split supply ±4.5 ±16

Suppl

y v

oltage, V

CC+

and V

CC–

Single supply 9 32

V

p

p

C suffix 0 70

°

O erating free-air tem erature, T

A

I suffix –40 85

°C

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

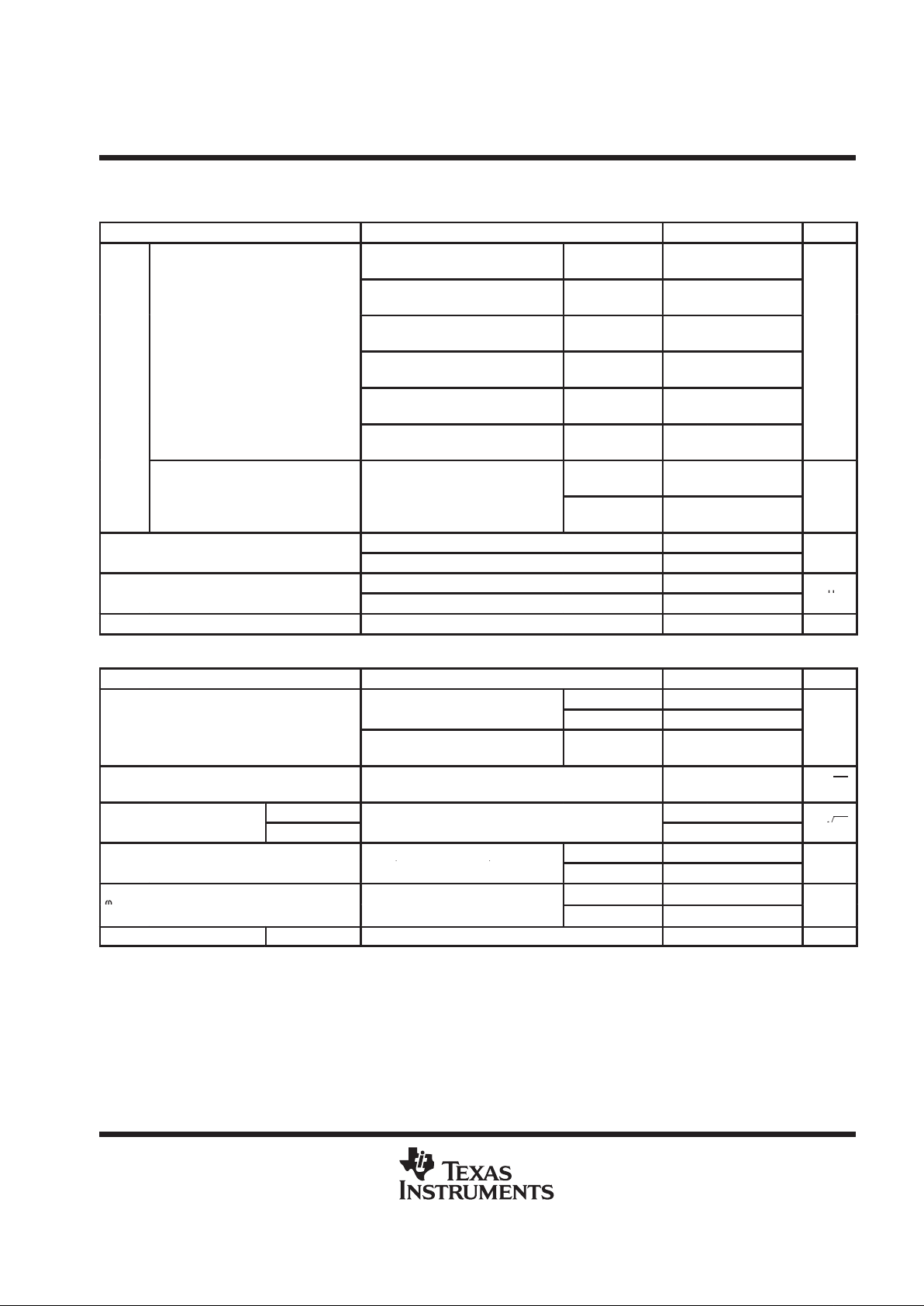

electrical characteristics, VCC = ±15 V, RL = 25 Ω, RF = 1 kΩ, TA = 25°C (unless otherwise noted)

dynamic performance

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VI = 200 mV , G = 1,

RF = 680 Ω,RL = 25 Ω

VCC = ±15 V 140

VI = 200 mV , G = 1,

RF = 1 kΩ,RL = 25 Ω

VCC = ±5 V 100

VI = 200 mV , G = 2,

RF = 620 Ω,RL = 25 Ω

VCC = ±15 V 120

Small-signal bandwidth (–3 dB)

VI = 200 mV , G = 2,

RL = 25 Ω,RF = 820 Ω

VCC = ±5 V 100

MH

z

BW

VI = 200 mV , G = 1,

RF = 820 Ω,RL = 100 Ω

VCC = ±15 V 315

VI = 200 mV , G = 2,

RF = 560 Ω,RL = 100 Ω

VCC = ±15 V 265

VCC = ±5 V,

RF = 820 Ω

30

Bandwidth for 0.1 dB flatness

V

I

=

200 mV,G

=

1

VCC = ±15 V,

RF = 680 Ω

40

MH

z

p

VCC = ±15 V, V

O(PP)

= 20 V 20

Full power bandwidth (see Note 3)

VCC = ±5 V, V

O(PP)

= 4 V 35

MH

z

VCC = ±15 V, VO = 20 V

(PP)

, G = 5 1300

SR

Slew rate

VCC = ±5 V, VO = 5 V

(PP)

, G = 2 900

V/µs

t

s

Settling time to 0.1% 0 V to 10 V Step, G = 2 70 ns

noise/distortion performance

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

= ±15 V, R

= 680 Ω,

V

O(PP)

= 20 V –65

CC

,

F

,

G = 2, f = 1 MHz

V

O(PP)

= 2 V –79

THD

Total harmonic distortion

VCC = ±5 V, RF = 680 Ω,

G = 2, f = 1 MHz

V

O(PP)

= 2 V –76

dBc

V

n

Input voltage noise

VCC = ±5 V or ±15 V, f = 10 kHz,

G = 2, Single-ended

1.7

nV/√Hz

p

Positive (IN+)

V

= ±5 V or ±15 V, f = 10 kHz,

11.5

InInput noise current

Negative (IN–)

CC

,

G = 2

,

16

p

A/√H

z

G = 2, NTSC,

VCC = ±5 V 0.04%

ADDifferential gain error

,,

RL = 150 Ω, 40 IRE Modulation

VCC = ±15 V 0.05%

p

G = 2, NTSC,

VCC = ±5 V 0.07°

φDDifferential hase error

RL = 150 Ω, 40 IRE Modulation

VCC = ±15 V 0.08°

Crosstalk Driver to driver VI = 200 mV, f = 1 MHz –62 dB

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

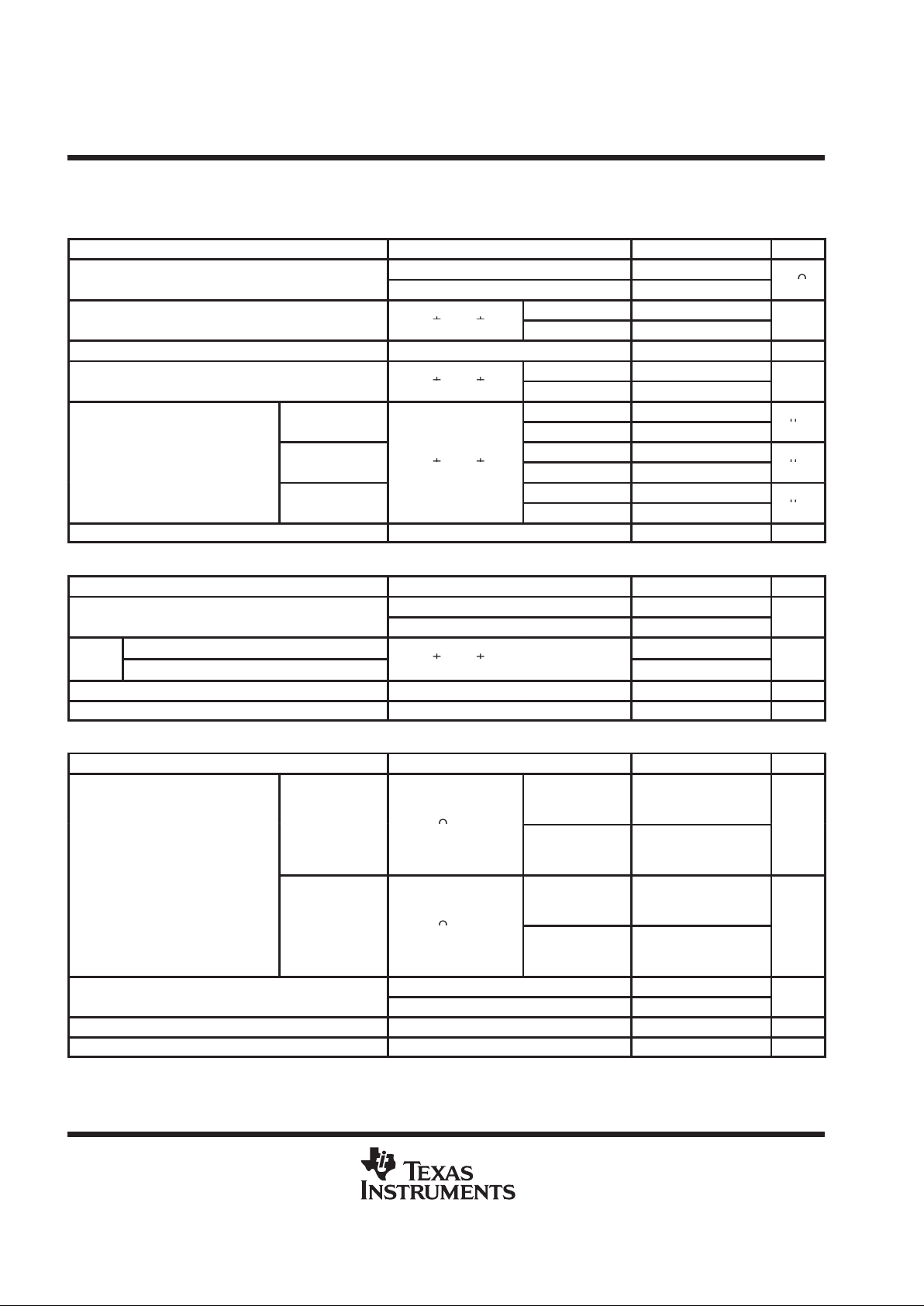

electrical characteristics, VCC = ±15 V, RL = 25 Ω, RF = 1 kΩ, TA = 25°C (unless otherwise noted)

(continued)

dc performance

PARAMETER TEST CONDITIONS

†

MIN TYP MAX UNIT

p

p

VCC = ±5 V 1.5

Open loop transresistance

VCC = ±15 V 5

MΩ

p

TA = 25°C 2 5

VIOInput offset voltage

V

CC

= ±5 V or

±15 V

TA = full range 7

mV

Input offset voltage drift VCC = ±5 V or ±15 V, TA = full range 20 µV/°C

p

TA = 25°C 1.5 4

Differential input offset voltage

V

CC

=

±5 V or ±15 V

TA = full range 5

mV

TA = 25°C 3 9

Negative

TA = full range 12

µ

A

p

TA = 25°C 4 10

IIBInput bias current

Positive

V

CC

= ±5 V or

±15 V

TA = full range 12

µ

A

TA = 25°C 1.5 8

Differential

TA = full range 11

µ

A

Differential input offset voltage drift VCC = ±5 V or ±15 V, TA = full range 10 µV/°C

input characteristics

PARAMETER TEST CONDITIONS

†

MIN TYP MAX UNIT

p

VCC = ±5 V ±3.6 ±3.7

V

ICR

Common-mode input voltage range

VCC = ±15 V ±13.4 ±13.5

V

Common-mode rejection ratio

62 70

CMRR

Differential common-mode rejection ratio

V

CC

= ±5 V or

±15 V

,

T

A

=

full range

100

dB

R

I

Input resistance 300 kΩ

C

I

Differential input capacitance 1.4 pF

output characteristics

PARAMETER TEST CONDITIONS

†

MIN TYP MAX UNIT

VCC = ±5 V

3

to

–2.8

3.2

to

–3

p

Single ended

R

L

= 25

Ω

VCC = ±15 V

11.8

to

–11.5

12.5

to

–12.2

V

VOOutput voltage swing

VCC = ±5 V

6

to

–5.6

6.4

to

–6

Differential

R

L

= 50

Ω

VCC = ±15 V

23.6

to

–23

25

to

–24.4

V

p

VCC = ±5 V, RL = 5 Ω 500

IOOutput current (see Note 2)

VCC = ±15 V, RL = 25 Ω 400 500

mA

I

OS

Short-circuit output current (see Note 2) 800 mA

R

O

Output resistance Open loop 13 Ω

NOTE 2: A heat sink is required to keep the junction temperature below absolute maximum when an output is heavily loaded or shorted. See

absolute maximum ratings and

Thermal Information

section.

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics, VCC = ±15 V, RL = 25 Ω, RF = 1 kΩ, TA = 25°C (unless otherwise noted)

power supply

PARAMETER TEST CONDITIONS

†

MIN TYP MAX UNIT

pp

p

Split supply ±4.5 ±16.5

VCCPower supply operating range

Single supply 9 33

V

VCC = ±5 V TA = full range 12

I

CC

Quiescent current (each driver)

TA = 25°C 11.5 13

mA

V

CC

=

±15 V

TA = full range 15

TA = 25°C –68 –74

pp

V

CC

=

±5 V

TA = full range –65

dB

PSRR

Power supply rejection ratio

TA = 25°C –64 –72

V

CC

=

±15 V

TA = full range –62

dB

†

Full range is 0°C to 70°C for the THS6012C and –40°C to 85°C for the THS6012I.

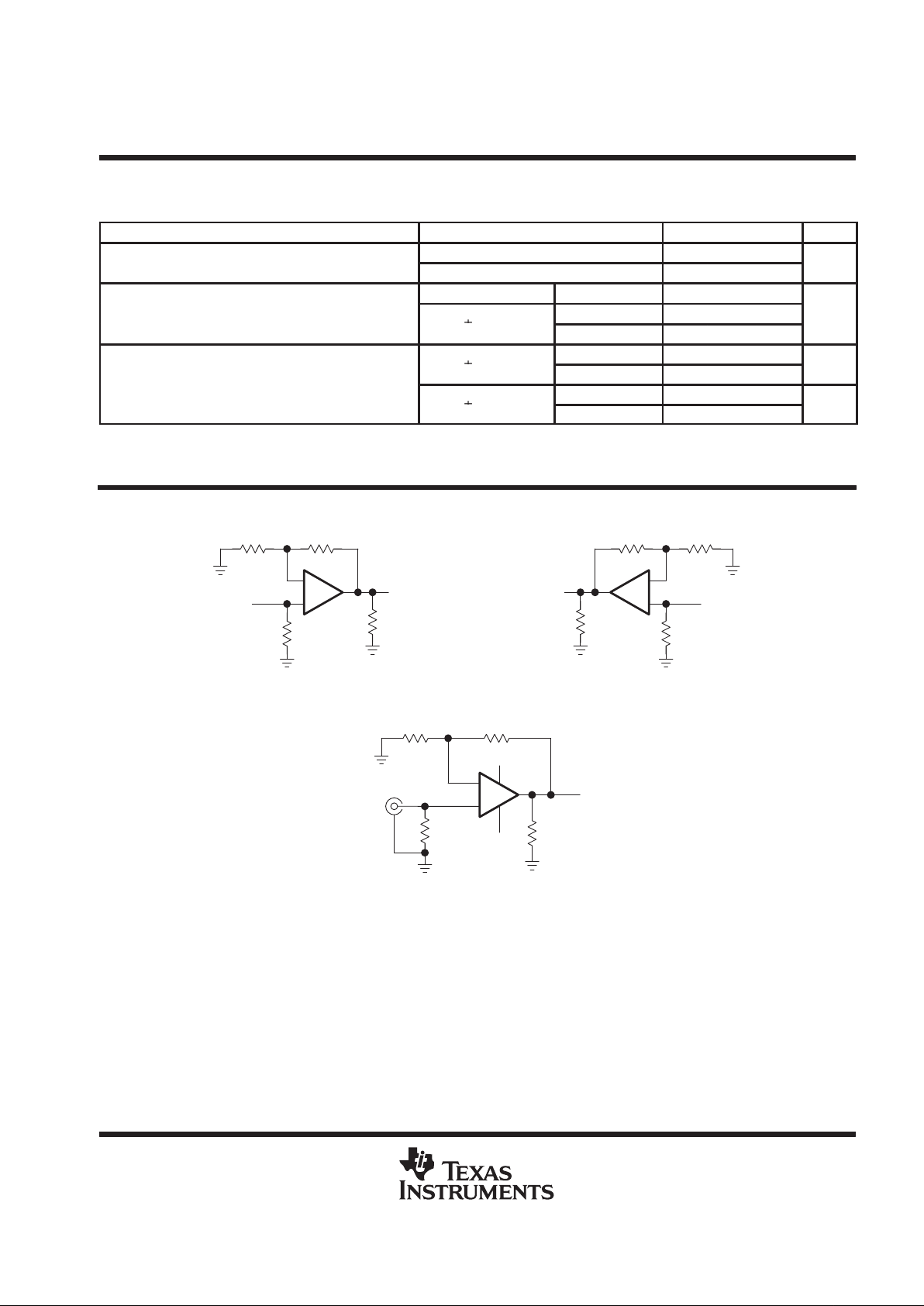

PARAMETER MEASUREMENT INFORMATION

+

–

1 kΩ

V

I

V

O

25 Ω

50 Ω

1 kΩ

Driver 1

+

–

1 kΩ

V

I

V

O

25 Ω

50 Ω

1 kΩ

Driver 2

Figure 1. Input-to-Output Crosstalk Test Circuit

V

I

V

O

+

–

R

G

R

F

R

L

25 Ω

50 Ω

–15 V

15 V

Figure 2. Test Circuit, Gain = 1 + (RF/RG)

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

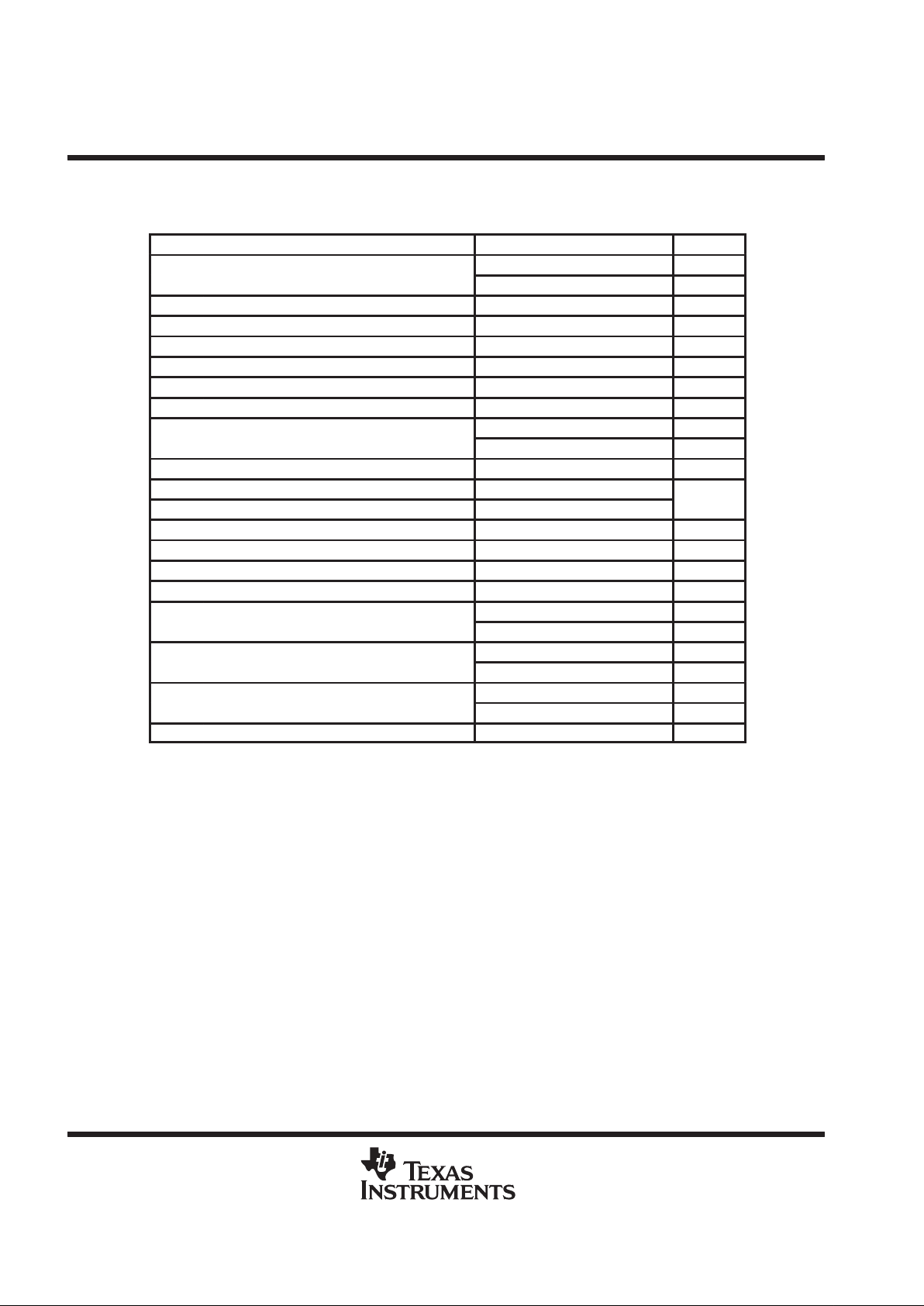

TYPICAL CHARACTERISTICS

Table of Graphs

FIGURE

p

p

vs Supply voltage 3

V

O(PP)

Peak-to-peak output voltage

vs Load resistance 4

V

IO

Input offset voltage vs Free-air temperature 5

I

IB

Input bias current vs Free-air temperature 6

CMRR Common-mode rejection ratio vs Free-air temperature 7

Input-to-output crosstalk vs Frequency 8

PSRR Power supply rejection ratio vs Free-air temperature 9

Closed-loop output impedance vs Frequency 10

pp

vs Supply voltage 11

ICCSupply current

vs Free-air temperature 12

SR Slew rate vs Output step 13, 14

V

n

Input voltage noise vs Frequency

I

n

Input current noise vs Frequency

15

Normalized frequency response vs Frequency 16, 17

Output amplitude vs Frequency 18–21

Normalized output response vs Frequency 22–25

Small and large frequency response 26, 27

vs Frequency 28, 29

Single-ended harmonic distortion

vs Output voltage 30, 31

DC input offset voltage 32, 33

Differential gain

Number of 150-Ω loads 34, 35

p

DC input offset voltage 32, 33

Differential phase

Number of 150-Ω loads 34, 35

Output step response 36–38

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

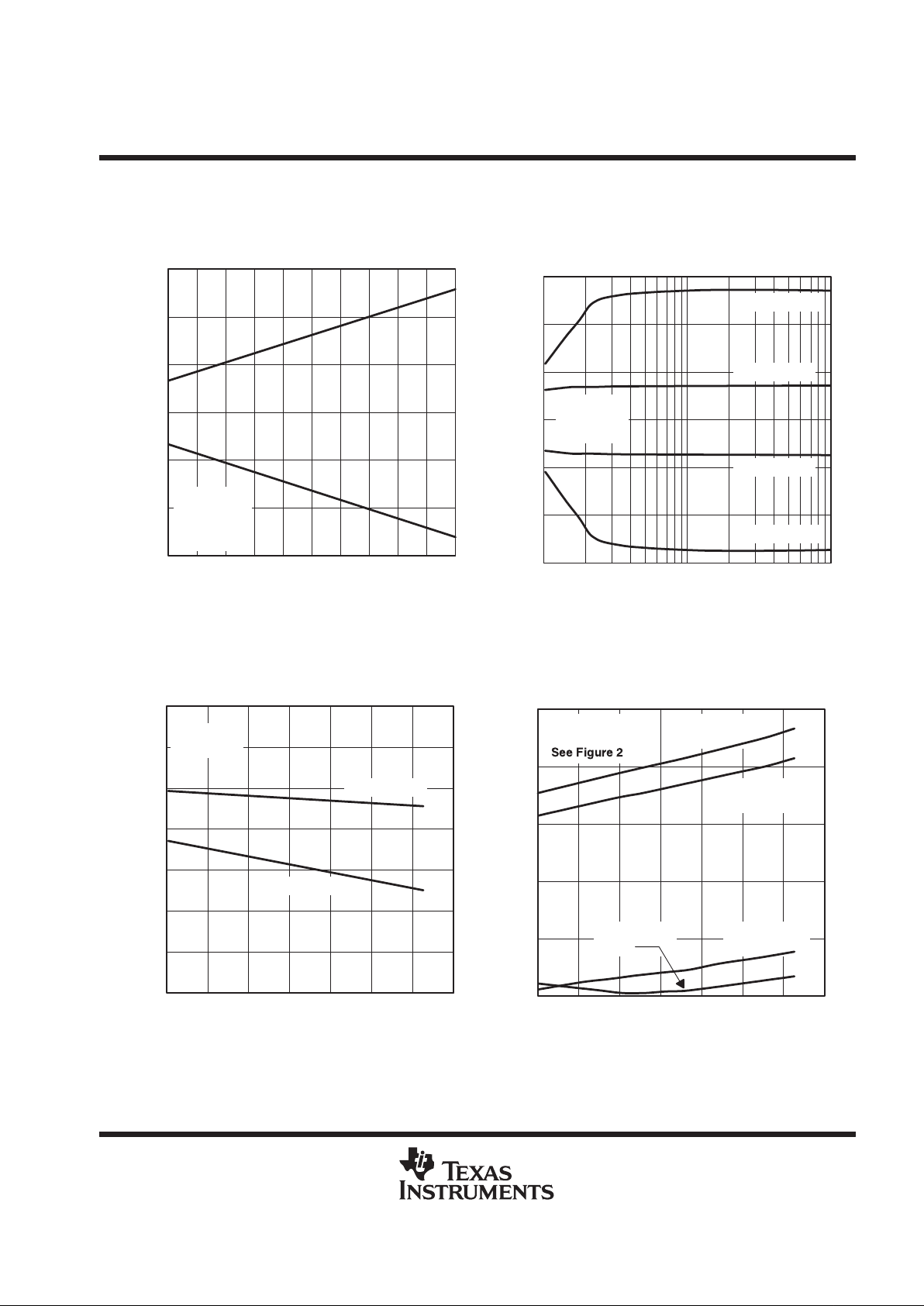

Figure 3

VCC – Supply Voltage – V

PEAK-TO-PEAK OUTPUT VOLTAGE

vs

SUPPLY VOLTAGE

5678 1112109

0

–5

–10

–15

10

5

TA = 25°C

RF = 1 kΩ

RL = 25 Ω

Gain = 1

14 1513

15

V

O(PP)

– Peak-to-Peak Output Voltage – V

Figure 4

10 100 1000

RL – Load Resistance – Ω

15

5

–5

–15

10

0

–10

VCC = ±15 V

VCC = ±5 V

PEAK-TO-PEAK OUTPUT VOLTAGE

vs

LOAD RESISTANCE

TA = 25°C

RF = 1 kΩ

Gain = 1

VCC = ±5 V

VCC = ±15 V

V

O(PP)

– Peak-to-Peak Output Voltage – V

Figure 5

TA – Free-Air Temperature – °C

–40 –20 0 20 80 1006040

VCC = ±5 V

INPUT OFFSET VOLTAGE

vs

FREE-AIR TEMPERATURE

VCC = ±15 V

V

IO

– Input Offset Voltage – mV

1

–1

–3

–5

0

–2

–4

2

G = 1

RF = 1 kΩ

Figure 6

TA – Free-Air Temperature – °C

–40 –20 0 20 80 1006040

INPUT BIAS CURRENT

vs

FREE-AIR TEMPERATURE

5

3

1

0

4

2

VCC = ±15 V

I

IB+

VCC = ±5 V

I

IB+

VCC = ±15 V

I

IB–

VCC = ±5 V

I

IB–

I

IB

– Input Bias Current – Aµ

G = 1

RF = 1 kΩ

See Figure 2

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

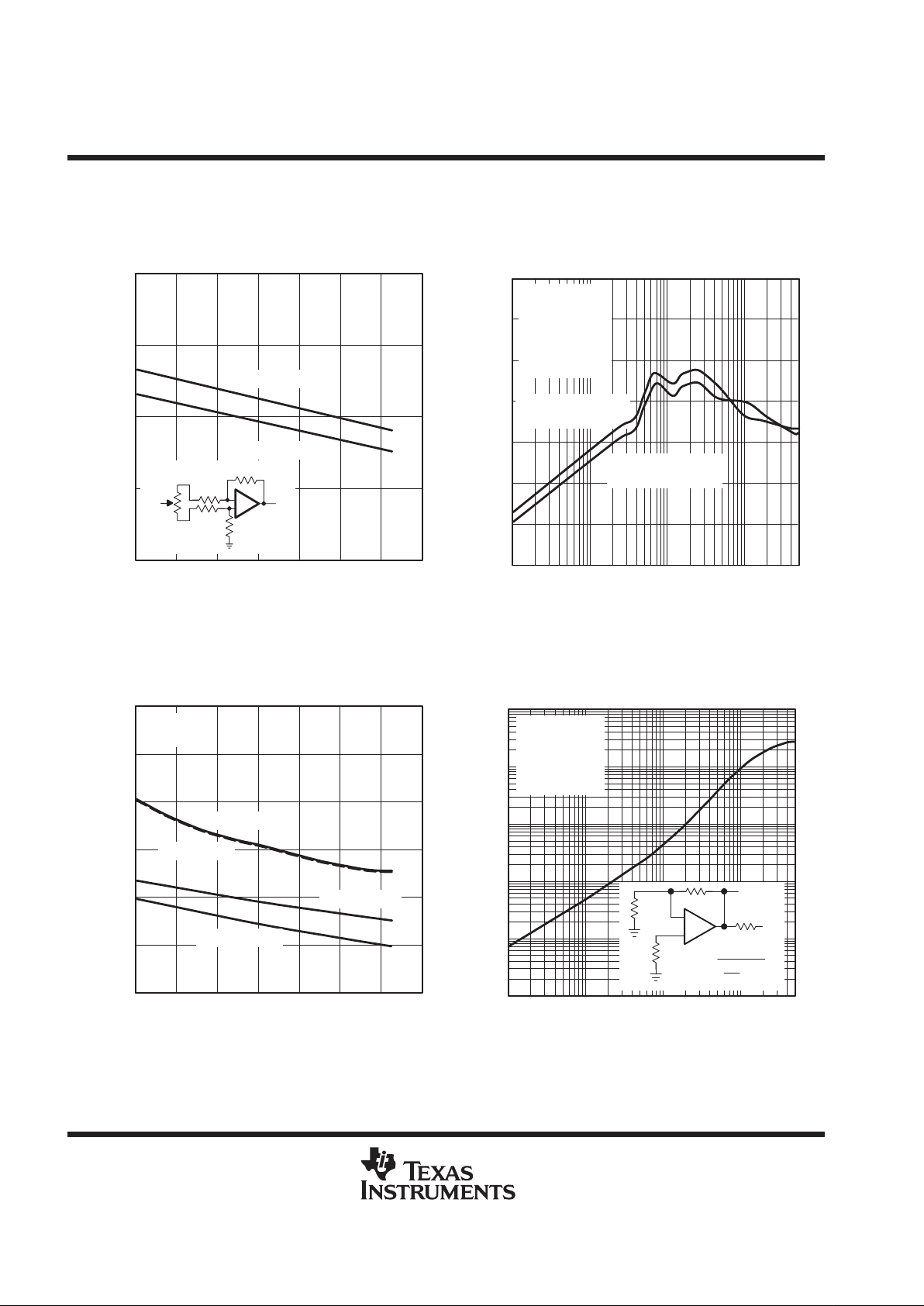

Figure 7

TA – Free-Air Temperature – °C

CMRR – Common-Mode Rejection Ratio – dB

–40 –20 0 20 806040

75

65

60

80

70

VCC = ±5 V

COMMON-MODE REJECTION RATIO

vs

FREE-AIR TEMPERATURE

VCC = ±15 V

1 kΩ

1 kΩ

V

I

+

–

V

O

1 kΩ

1 kΩ

Figure 8

f – Frequency – Hz

INPUT–TO–OUTPUT CROSSTALK

vs

FREQUENCY

–80

–90

10M100k

–70

–60

500M

Input–To–Output Crosstalk – dB

–50

–20

1M 100M

VCC = ± 15 V

RF = 1 Ω

RL = 25 Ω

Gain = 2

VI = 200 mV

See Figure 2

Driver 1 = Input

Driver 2 = Output

Driver 1 = Output

Driver 2 = Input

–40

–30

Figure 9

TA – Free-Air Temperature – °C

PSRR – Power Supply Rejection Ratio – dB

–40 –20 0 20 80 1006040

POWER SUPPLY REJECTION RATIO

vs

FREE-AIR TEMPERATURE

90

80

70

65

85

75

95

VCC = 15 V

VCC = 5 V

VCC =–5 V

VCC = –15 V

G = 1

RF = 1 kΩ

Figure 10

1

0.1

0.01

0.001

1M

f – Frequency – Hz

100k 10M 100M

10

100

Closed-Loop Output Impedance –

VCC = ±15 V

RF = 1 kΩ

Gain = 2

TA = 25°C

V

I(PP)

= 1 V

500M

Ω

V

O

+

–

50 Ω

1 kΩ

1 kΩ

V

I

THS6012

1 kΩ

(

V

I

V

O

=

1000

Z

o

)

– 1

CLOSED-LOOP OUTPUT IMPEDANCE

vs

FREQUENCY

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 11

±VCC – Supply Voltage – V

5678 1112109

6

5

10

8

9

7

I

CC

– Supply Current – mA

TA = 25°C

RF = 1 kΩ

Gain = +1

14 1513

12

11

SUPPLY CURRENT

vs

SUPPLY VOLTAGE

Figure 12

TA – Free-Air Temperature – °C

–40 –20 0 20 80 1006040

SUPPLY CURRENT

vs

FREE-AIR TEMPERATURE

10

6

2

0

8

4

12

VCC = ±15 V

VCC = ±5 V

I

CC

– Supply Current – mA

13

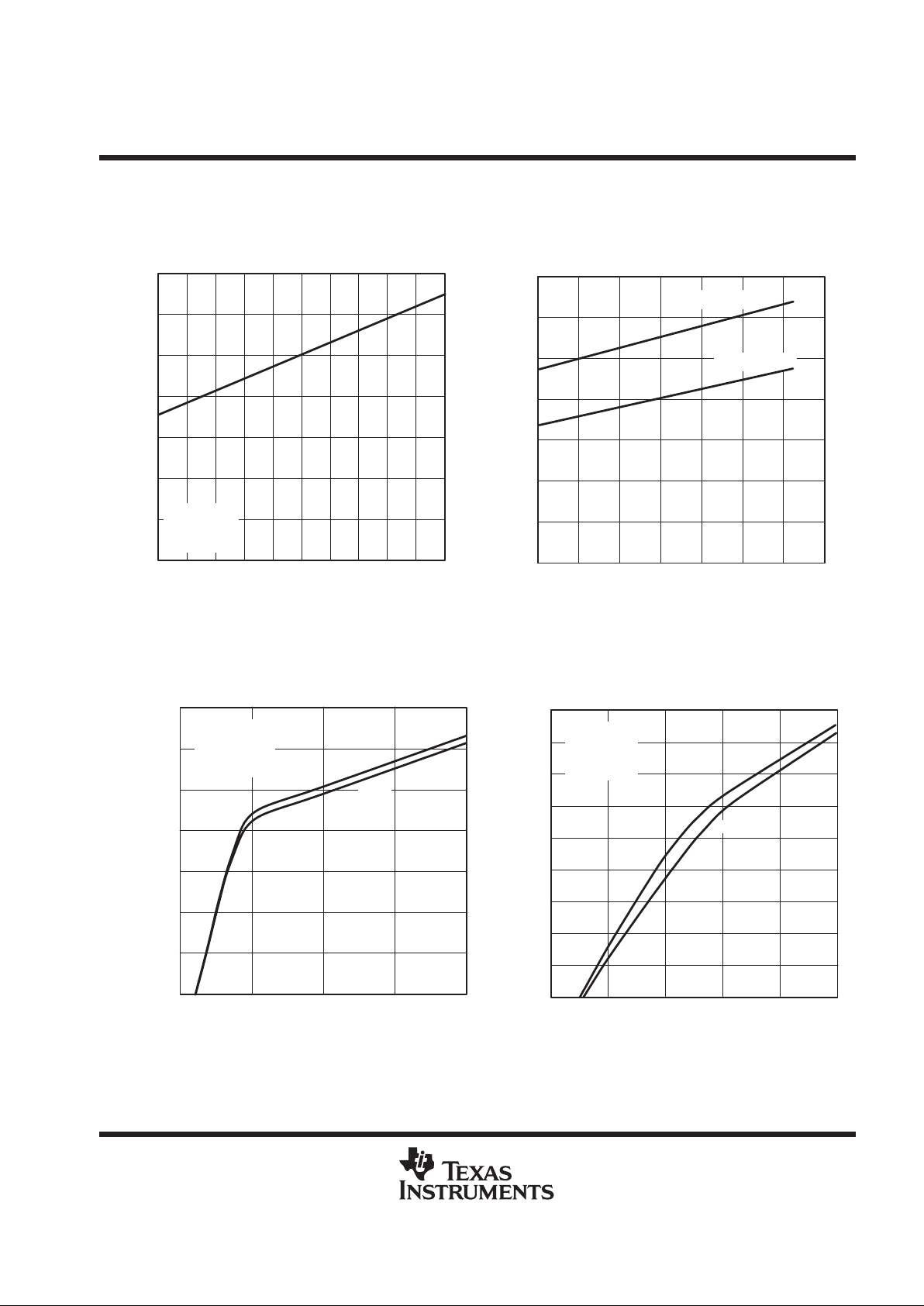

Figure 13

0

SLEW RATE

vs

OUTPUT STEP

Output Step (Peak–To–Peak) – V

1500

100

20

900

5

1100

700

10

1300

Slew Rate – V Sµ

500

300

VCC = ± 15V

Gain = 5

RF = 1 kΩ

RL = 25 Ω

15

+SR

–SR

Figure 14

0

SLEW RATE

vs

OUTPUT STEP

Output Step (Peak–To–Peak) – V

1000

100

5

700

1

800

600

23

900

Slew Rate – V Sµ

500

300

4

VCC = ± 5V

Gain = 2

RF = 1 kΩ

RL = 25 Ω

400

200

+SR

–SR

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

10

1

100

VCC = ±15 V

TA = 25°C

In+ Noise

f – Frequency – Hz

10 100 1k 10k 100k

nV/ Hz

Hz

– Voltage Noise –V

n

– Current Noise – pA/I

n

10

1

100

In– Noise

Vn Noise

INPUT VOLTAGE AND CURRENT NOISE

vs

FREQUENCY

Figure 15

Figure 16

f – Frequency – Hz

Normalized Frequency Response – dB

100 1M 10M 100M

–2

–4

–6

–8

–3

–5

–7

2

0

1

–1

NORMALIZED FREQUENCY RESPONSE

vs

FREQUENCY

VCC = ±15 V

VI = 200 mV

RL = 25 Ω

Gain = 1

TA = 25°C

RF = 510 Ω

RF = 300 Ω

RF = 750 Ω

RF = 1 kΩ

500M

Figure 17

NORMALIZED FREQUENCY RESPONSE

vs

FREQUENCY

f – Frequency – Hz

Normalized Frequency Response – dB

100K 1M 10M 100M

–1

–3

–5

–7

–2

–4

–6

1

2

0

VCC = ±15 V

Vin = 200 mV

RL = 25 Ω

Gain = 2

TA = 25°C

–8

–10

–9

500M

RF = 470 Ω

RF = 360 Ω

RF = 620 Ω

RF = 1 kΩ

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 18

f – Frequency – Hz

OUTPUT AMPLITUDE

vs

FREQUENCY

–5

–6

10M100k

–2

–1

500M

Output Amplitude – dB

0

3

1M 100M

1

2

–4

–3

VCC = ± 5 V

Gain = 1

RL = 25 Ω

VI = 200 mV

RF = 1 kΩ

RF = 1.5 kΩ

RF = 620 Ω

Figure 19

f – Frequency – Hz

OUTPUT AMPLITUDE

vs

FREQUENCY

1

0

10M100k

4

5

500M

Output Amplitude – dB

6

9

1M 100M

7

8

2

3

VCC = ± 5 V

Gain = 2

RL = 25 Ω

VI = 200 mV

RF = 820 Ω

RF = 1.2 kΩ

RF = 510 Ω

Figure 20

f – Frequency – Hz

OUTPUT AMPLITUDE

vs

FREQUENCY

–10

10M100k

20

30

500M

Output Level – dB

40

70

1M 100M

50

60

Gain = 1000

0

10

VCC = ± 5 V

RG =10 Ω

RL = 25 Ω

VO = 2 V

Gain = 100

Figure 21

f – Frequency – Hz

OUTPUT AMPLITUDE

vs

FREQUENCY

–10

10M100k

20

30

500M

Output Level – dB

40

70

1M 100M

50

60

Gain = 1000

0

10

VCC = ± 5 V

RG =10 Ω

RL = 25 Ω

VO = 2 V

Gain = 100

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 22

NORMALIZED OUTPUT RESPONSE

vs

FREQUENCY

1M

f – Frequency – Hz

100k 10M 100M

Normalized Output Response – dB

500M

–3

–5

–7

–9

–4

–6

–8

–1

0

–2

1

RL = 200 Ω

RL = 100 Ω

RL = 25 Ω

VCC = ±15 V

RF = 1 kΩ

Gain = 1

VI = 200 mV

RL = 50 Ω

Figure 23

NORMALIZED OUTPUT RESPONSE

vs

FREQUENCY

1M

f – Frequency – Hz

100k 10M 100M

Normalized Output Response – dB

VCC = ±15 V

RF = 1 kΩ

Gain = 2

VI = 200 mV

500M

–3

–5

–7

–9

–4

–6

–8

–1

0

–2

1

RL = 200 Ω

RL = 100 Ω

RL = 50 Ω

RL = 25 Ω

Figure 24

NORMALIZED OUTPUT RESPONSE

vs

FREQUENCY

1M

f – Frequency – Hz

100k 10M 100M

Normalized Output Response – dB

VCC = ±15 V

RL = 100 Ω

Gain = 1

VI = 200 mV

500M

–1

–3

–5

–7

–2

–4

–6

1

2

0

3

RF = 620 Ω

RF = 820 Ω

RF = 1 kΩ

Figure 25

NORMALIZED OUTPUT RESPONSE

vs

FREQUENCY

1M

f – Frequency – Hz

100k 10M 100M

Normalized Output Response – dB

VCC = ±15 V

RL = 100 Ω

Gain = 2

VI = 200 mV

500M

–1

–3

–5

–2

–4

–6

1

2

0

3

RF = 430 Ω

RF = 1 kΩ

RF = 620 Ω

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 26

f – Frequency – Hz

SMALL AND LARGE SIGNAL FREQUENCY RESPONSE

–27

–30

10M100k

–18

–15

500M

Output Level – dBV

–12

–3

1M 100M

–9

–6

VI = 500 mV

–24

–21

Gain = 1

VCC = ± 15 V

RF = 820 Ω

RL = 25 Ω

VI = 250 mV

VI = 125 mV

VI = 62.5 mV

Figure 27

f – Frequency – Hz

SMALL AND LARGE SIGNAL FREQUENCY RESPONSE

–21

–24

10M100k

–12

–9

500M

Output Level – dBV

–6

3

1M 100M

–3

0

VI = 500 mV

–18

–15

Gain = 2

VCC = ± 15 V

RF = 680 Ω

RL = 25 Ω

VI = 250 mV

VI = 125 mV

VI = 62.5 mV

Figure 28

f – Frequency – Hz

SINGLE–ENDED HARMONIC DISTORTION

vs

FREQUENCY

–90

–100

1M

–60

100k

–80

–70

10M

Single–Ended Harmonic Distortion (dBc)

–50

–40

2nd Harmonic

3rd Harmonic

VCC = ± 15 V

Gain = 2

RF = 680 Ω

RL = 25 Ω

V

O(PP)

= 2V

Figure 29

f – Frequency – Hz

SINGLE–ENDED HARMONIC DISTORTION

vs

FREQUENCY

–90

–100

1M

–60

100k

–80

–70

10M

Single–Ended Harmonic Distortion (dBc)

–50

–40

2nd Harmonic

3rd Harmonic

VCC = ± 5 V

Gain = 2

RF = 680 Ω

RL = 25 Ω

V

O(PP)

= 2V

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 30

V

O(PP)

– Output Voltage – V

SINGLE–ENDED HARMONIC DISTORTION

vs

OUTPUT VOLTAGE

–90

–100

10

0

–80

–70

20

Single–Ended Harmonic Distortion (dBc)

–60

–50

515

2nd Harmonic

3rd Harmonic

VCC = ± 15 V

Gain = 2

RF = 680 Ω

RL = 25 Ω

f = 1 MHz

Figure 31

V

O(PP)

– Output Voltage – V

SINGLE–ENDED HARMONIC DISTORTION

vs

OUTPUT VOLTAGE

–90

–100

2

0

–80

–70

4

Single–Ended Harmonic Distortion – dBc

–60

–50

13

2nd Harmonic

3rd Harmonic

VCC = ± 5 V

Gain = 2

RF = 680 Ω

RL = 25 Ω

f = 1 MHz

DC Input Offset Voltage – V

DIFFERENTIAL GAIN AND PHASE

vs

DC INPUT OFFSET VOLTAGE

0.03

0.02

0.01

0

–0.5 –0.1–0.3 0.1 0.7

0.05

–0.7

0.3 0.5

0.04

VCC = ±15 V

RL = 150 Ω

RF = 1 kΩ

f = 3.58 MHz

Gain = 2

40 IRE Modulation

0.02

0

0.04

Differential Phase –

°

0.06

0.08

0.10

Phase

Differential Gain – %

Gain

Figure 32

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

DC Input Offset Voltage – V

DIFFERENTIAL GAIN AND PHASE

vs

DC INPUT OFFSET VOLTAGE

0.03

0.02

0.01

0

–0.5 –0.1–0.3 0.1 0.7

0.05

–0.7

0.3 0.5

0.04

VCC = ±5 V

RL = 150 Ω

RF = 1 kΩ

f = 3.58 MHz

Gain = 2

40 IRE Modulation

0.02

0

0.04

Differential Phase –

°

0.06

0.08

0.10

Gain

Differential Gain – %

Phase

Figure 33

Number of 150-Ω Loads

DIFFERENTIAL GAIN AND PHASE

vs

NUMBER OF 150-Ω LOADS

0.09

0.06

0.03

0

28

0.15

1

4

Differential Gain – %

0.12

VCC = ±15 V

RF = 1 kΩ

Gain = 2

f = 3.58 MHz

40 IRE Modulation

100 IRE Ramp

0.05

0

0.10

Differential Phase –

°

0.15

0.20

0.25

Gain

Phase

3567

Figure 34

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Number of 150-Ω Loads

DIFFERENTIAL GAIN AND PHASE

vs

NUMBER OF 150-Ω LOADS

0.09

0.06

0.03

0

0.15

Differential Gain – %

0.12

0.05

0

0.10

Differential Phase –

°

0.15

0.20

0.25

VCC = ±5 V

RF = 1 kΩ

Gain = 2

f = 3.58 MHz

40 IRE Modulation

100 IRE Ramp

Gain

Phase

28143567

Figure 35

Figure 36

t – Time – ns

VCC = ±15 V

Gain = 2

RL = 25 Ω

RF = 1 kΩ

tr/tf= 300 ps

See Figure 3

400-mV STEP RESPONSE

100

–100

0

–200

V

O

– Output Voltage – mV

300

200

0 15010050 200 250 350300 400 450 500

400

–300

–400

Figure 37

t – Time – ns

10-V STEP RESPONSE

2

–2

0

–4

V

O

– Output Voltage – V

6

4

0 15010050 200 250 350300 400 450 500

8

–6

–8

VCC = ±15 V

Gain = 2

RL = 25 Ω

RF = 1 kΩ

tr/tf= 5 ns

See Figure 3

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

19

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

t – Time – ns

VCC = ±15 V

Gain = 5

RL = 25 Ω

RF = 2 kΩ

tr/tf= 5 ns

See Figure 3

20-V STEP RESPONSE

4

–4

0

–8

V

O

– Output Voltage – V

12

8

0 15010050 200 250 350300 400 450 500

16

–12

–16

Figure 38

APPLICATION INFORMATION

The THS6012 contains two independent operational amplifiers. These amplifiers are current feedback topology

amplifiers made for high-speed operation. They have been specifically designed to deliver the full power

requirements of ADSL and therefore can deliver output currents of at least 400 mA at full output voltage.

The THS6012 is fabricated using Texas Instruments 30-V complementary bipolar process, HVBiCOM. This

process provides excellent isolation and high slew rates that result in the device’s excellent crosstalk and

extremely low distortion.

independent power supplies

Each amplifier of the THS6012 has its own power supply pins. This was specifically done to solve a problem

that often occurs when multiple devices in the same package share common power pins. This problem is

crosstalk between the individual devices caused by currents flowing in common connections. Whenever the

current required by one device flows through a common connection shared with another device, this current,

in conjunction with the impedance in the shared line, produces an unwanted voltage on the power supply . Proper

power supply decoupling and good device power supply rejection helps to reduce this unwanted signal. What

is left is crosstalk.

However, with independent power supply pins for each device, the effects of crosstalk through common

impedance in the power supplies is more easily managed. This is because it is much easier to achieve low

common impedance on the PCB with copper etch than it is to achieve low impedance within the package with

either bond wires or metal traces on silicon.

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

power supply restrictions

Although the THS6012 is specified for operation from power supplies of ±5 V to ±15 V (or singled-ended power

supply operation from 10 V to 30 V), and each amplifier has its own power supply pins, several precautions must

be taken to assure proper operation.

1. The power supplies for each amplifier must be the same value. For example, if the driver 1 uses ±15 volts,

then the driver 2 must also use ±15 volts. Using ±15 volts for one amplifier and ±5 volts for another amplifier

is not allowed.

2. T o save power by powering down one of the amplifiers in the package, the following rules must be followed.

• The amplifier designated driver 1 must always receive power. This is because the internal startup

circuitry uses the power from the driver 1 device.

• The –V

CC

pins from both drivers must always be at the same potential.

• Driver 2 is powered down by simply opening the +V

CC

connection.

The THS6012 incorporates a standard Class A-B output stage. This means that some of the quiescent current

is directed to the load as the load current increases. So under heavy load conditions, accurate power dissipation

calculations are best achieved through actual measurements. For small loads, however, internal power

dissipation for each amplifier in the THS6012 can be approximated by the following formula:

PD≅ǒ2VCCI

CC

Ǔ)ǒ

VCC_V

O

Ǔ

ǒ

V

O

R

L

Ǔ

Where:

P

D

= Power dissipation for one amplifier

VCC= Split supply voltage

I

CC

= Supply current for that particular amplifier

VO= Output voltage of amplifier

RL= Load resistance

To find the total THS6012 power dissipation, we simply sum up both amplifier power dissipation results.

Generally , the worst case power dissipation occurs when the output voltage is one-half the V

CC

voltage. One

last note, which is often overlooked: the feedback resistor (RF) is also a load to the output of the amplifier and

should be taken into account for low value feedback resistors.

device protection features

The THS6012 has two built-in protection features that protect the device against improper operation. The first

protection mechanism is output current limiting. Should the output become shorted to ground the output current

is automatically limited to the value given in the data sheet. While this protects the output against excessive

current, the device internal power dissipation increases due to the high current and large voltage drop across

the output transistors. Continuous output shorts are not recommended and could damage the device.

Additionally , connection of the amplifier output to one of the supply rails (±V

CC

) can cause failure of the device

and is not recommended.

The second built-in protection feature is thermal shutdown. Should the internal junction temperature rise above

approximately 180_C, the device automatically shuts down. Such a condition could exist with improper heat

sinking or if the output is shorted to ground. When the abnormal condition is fixed, the internal thermal shutdown

circuit automatically turns the device back on.

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

21

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

thermal information

The THS6012 is packaged in a thermally-enhanced DWP package, which is a member of the PowerP AD family

of packages. This package is constructed using a downset leadframe upon which the die is mounted

[see Figure 39(a) and Figure 39(b)]. This arrangement results in the lead frame being exposed as a thermal pad

on the underside of the package [see Figure 39(c)]. Because this thermal pad has direct thermal contact with

the die, excellent thermal performance can be achieved by providing a good thermal path away from the thermal

pad.

The PowerP AD package allows for both assembly and thermal management in one manufacturing operation.

During the surface-mount solder operation (when the leads are being soldered), the thermal pad can also be

soldered to a copper area underneath the package. Through the use of thermal paths within this copper area,

heat can be conducted away from the package into either a ground plane or other heat dissipating device. This

is discussed in more detail in the

PCB design considerations

section of this document.

The PowerPAD package represents a breakthrough in combining the small area and ease of assembly of

surface mount with the, heretofore, awkward mechanical methods of heatsinking.

DIE

Side View (a)

End View (b)

Bottom View (c)

DIE

Thermal

Pad

NOTE A: The thermal pad is electrically isolated from all terminals in the package.

Figure 39. Views of Thermally Enhanced DWP Package

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

recommended feedback and gain resistor values

As with all current feedback amplifiers, the bandwidth of the THS6012 is an inversely proportional function of

the value of the feedback resistor. This can be seen from Figures 17 – 20. The recommended resistors with a

±15 V power supply for the optimum frequency response with a 25-Ω load system are 680-Ω for a gain = 1 and

620-Ω for a gain = 2 or –1. Additionally, using a ±5 V power supply, it is recommended that a 1-kΩ feedback

resistor be used for a gain of 1 and a 820-Ω feedback resistor be used for a gain of 2 or –1. These should be

used as a starting point and once optimum values are found, 1% tolerance resistors should be used to maintain

frequency response characteristics. Because there is a finite amount of output resistance of the operational

amplifier, load resistance can play a major part in frequency response. This is especially true with these drivers,

which tend to drive low-impedance loads. This can be seen in Figure 1 1, Figure 23, and Figure 24. As the load

resistance increases, the output resistance of the amplifier becomes less dominant at high frequencies. To

compensate for this, the feedback resistor should change. For 100-Ω loads, it is recommended that the

feedback resistor be changed to 820 Ω for a gain of 1 and 560 Ω for a gain of 2 or –1. Although, for most

applications, a feedback resistor value of 1 kΩ is recommended, which is a good compromise between

bandwidth and phase margin that yields a very stable amplifier.

Consistent with current feedback amplifiers, increasing the gain is best accomplished by changing the gain

resistor, not the feedback resistor . This is because the bandwidth of the amplifier is dominated by the feedback

resistor value and internal dominant-pole capacitor. The ability to control the amplifier gain independently of the

bandwidth constitutes a major advantage of current feedback amplifiers over conventional voltage feedback

amplifiers. Therefore, once a frequency response is found suitable to a particular application, adjust the value

of the gain resistor to increase or decrease the overall amplifier gain.

Finally, it is important to realize the effects of the feedback resistance on distortion. Increasing the resistance

decreases the loop gain and increases the distortion. It is also important to know that decreasing load

impedance increases total harmonic distortion (THD). Typically, the third order harmonic distortion increases

more than the second order harmonic distortion.

offset voltage

The output offset voltage, (VOO) is the sum of the input offset voltage (VIO) and both input bias currents (IIB) times

the corresponding gains. The following schematic and formula can be used to calculate the output offset

voltage:

VOO+

V

IO

ǒ

1

) ǒ

R

F

R

G

Ǔ

Ǔ

"

I

IB

)

R

S

ǒ

1

) ǒ

R

F

R

G

Ǔ

Ǔ

"

I

IB–RF

+

–

V

I

+

R

G

R

S

R

F

I

IB–

V

O

I

IB+

Figure 40. Output Offset Voltage Model

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

23

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

noise calculations and noise figure

Noise can cause errors on very small signals. This is especially true for the amplifying small signals. The noise

model for current feedback amplifiers (CFB) is the same as voltage feedback amplifiers (VFB). The only

difference between the two is that the CFB amplifiers generally specify different current noise parameters for

each input while VFB amplifiers usually only specify one noise current parameter. The noise model is shown

in Figure 42. This model includes all of the noise sources as follows:

• e

n

= Amplifier internal voltage noise (nV/√Hz)

• IN+ = Noninverting current noise (pA/√Hz)

• IN– = Inverting current noise (pA/√Hz)

• e

Rx

= Thermal voltage noise associated with each resistor (eRx = 4 kTRx)

_

+

R

F

R

S

R

G

e

Rg

e

Rf

e

Rs

e

n

IN+

Noiseless

IN–

e

ni

e

no

Figure 41. Noise Model

The total equivalent input noise density (eni) is calculated by using the following equation:

eni+

ǒ

e

n

Ǔ

2

)ǒIN

)

R

S

Ǔ

2

)ǒIN–

ǒRFø

R

G

Ǔ

Ǔ

2

)

4kTRs)

4kTǒRFø

R

G

Ǔ

Ǹ

Where:

k = Boltzmann’s constant = 1.380658 × 10

–23

T = Temperature in degrees Kelvin (273 +°C)

RF || RG = Parallel resistance of RF and R

G

To get the equivalent output noise of the amplifier, just multiply the equivalent input noise density (eni) by the

overall amplifier gain (AV).

eno+

eniAV+

e

ni

ǒ

1

)

R

F

R

G

Ǔ

(Noninverting Case)

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

noise calculations and noise figure (continued)

As the previous equations show, to keep noise at a minimum, small value resistors should be used. As the

closed-loop gain is increased (by reducing RG), the input noise is reduced considerably because of the parallel

resistance term. This leads to the general conclusion that the most dominant noise sources are the source

resistor (RS) and the internal amplifier noise voltage (en). Because noise is summed in a root-mean-squares

method, noise sources smaller than 25% of the largest noise source can be effectively ignored. This can greatly

simplify the formula and make noise calculations much easier to calculate.

This brings up another noise measurement usually preferred in RF applications, the noise figure (NF). Noise

figure is a measure of noise degradation caused by the amplifier. The value of the source resistance must be

defined and is typically 50 Ω in RF applications.

NF+10log

ȧ

ȧ

ȱ

Ȳ

e

2

ni

ǒ

e

Rs

Ǔ

2

ȧ

ȧ

ȳ

ȴ

Because the dominant noise components are generally the source resistance and the internal amplifier noise

voltage, we can approximate noise figure as:

NF+10log

ȧ

ȧ

ȧ

ȧ

ȧ

ȱ

Ȳ

1

)

ȧ

ȡ

Ȣ

ǒ

e

n

Ǔ

2

)ǒIN

)

R

S

Ǔ

2

ȧ

ȣ

Ȥ

4kTR

S

ȧ

ȧ

ȧ

ȧ

ȧ

ȳ

ȴ

Figure 42 shows the noise figure graph for the THS6012.

NOISE FIGURE

vs

SOURCE RESISTANCE

18

14

0

20

16

12

Noise Figure – dB

Rs – Source Resistance – Ω

10 100 1k 10k

TA = 25°C

8

4

10

6

2

Figure 42. Noise Figure vs Source Resistance

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

25

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

driving a capacitive load

Driving capacitive loads with high performance amplifiers is not a problem as long as certain precautions are

taken. The first is to realize that the THS6012 has been internally compensated to maximize its bandwidth and

slew rate performance. When the amplifier is compensated in this manner, capacitive loading directly on the

output will decrease the device’s phase margin leading to high frequency ringing or oscillations. Therefore, for

capacitive loads of greater than 10 pF, it is recommended that a resistor be placed in series with the output of

the amplifier, as shown in Figure 44. A minimum value of 10 Ω should work well for most applications. For

example, in 75-Ω transmission systems, setting the series resistor value to 75 Ω both isolates any capacitance

loading and provides the proper line impedance matching at the source end.

+

_

THS6012

C

LOAD

1 kΩ

Input

Output

1 kΩ

10 Ω

Figure 43. Driving a Capacitive Load

PCB design considerations

Proper PCB design techniques in two areas are important to assure proper operation of the THS6012. These

areas are high-speed layout techniques and thermal-management techniques. Because the THS6012 is a

high-speed part, the following guidelines are recommended.

D

Ground plane – It is essential that a ground plane be used on the board to provide all components with a

low inductive ground connection. Although a ground connection directly to a terminal of the THS6012 is not

necessarily required, it is recommended that the thermal pad of the package be tied to ground. This serves

two functions. It provides a low inductive ground to the device substrate to minimize internal crosstalk and

it provides the path for heat removal.

D

Input stray capacitance – To minimize potential problems with amplifier oscillation, the capacitance at the

inverting input of the amplifiers must be kept to a minimum. T o do this, PCB trace runs to the inverting input

must be as short as possible, the ground plane must be removed under any etch runs connected to the

inverting input, and external components should be placed as close as possible to the inverting input. This

is especially true in the noninverting configuration. An example of this can be seen in Figure 44, which shows

what happens when 1.8 pF is added to the inverting input terminal in the noninverting configuration. The

bandwidth increases dramatically at the expense of peaking. This is because some of the error current is

flowing through the stray capacitor instead of the inverting node of the amplifier. Although, in the inverting

mode, stray capacitance at the inverting input has little effect. This is because the inverting node is at a

virtual ground

and the voltage does not fluctuate nearly as much as in the noninverting configuration.

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

26

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

PCB design considerations (continued)

f – Frequency – Hz

Normalized Frequency Response – dB

100 1M 10M 100M 500M

–1

–3

–5

–7

–2

–4

–6

3

1

2

0

NORMALIZED FREQUENCY RESPONSE

vs

FREQUENCY

VCC = ±15 V

VI = 200 mV

RL = 25 Ω

RF = 1 kΩ

Gain = 1

CI = 0 pF

(Stray C Only)

CI = 1.8 pF

+

–

1 kΩ

50 Ω

RL =

25 Ω

C

in

V

in

V

out

Figure 44. Driver Normalized Frequency Response vs Frequency

D

Proper power supply decoupling – Use a minimum of a 6.8-µF tantalum capacitor in parallel with a 0.1-µF

ceramic capacitor on each supply terminal. It may be possible to share the tantalum among several

amplifiers depending on the application, but a 0.1-µF ceramic capacitor should always be used on the

supply terminal of every amplifier. In addition, the 0.1-µF capacitor should be placed as close as possible

to the supply terminal. As this distance increases, the inductance in the connecting etch makes the capacitor

less effective. The designer should strive for distances of less than 0.1 inches between the device power

terminal and the ceramic capacitors.

Because of its power dissipation, proper thermal management of the THS6012 is required. Although there are

many ways to properly heatsink this device, the following steps illustrate one recommended approach for a

multilayer PCB with an internal ground plane.

1. Prepare the PCB with a top side etch pattern as shown in Figure 45. There should be etch for the leads as

well as etch for the thermal pad.

2. Place 18 holes in the area of the thermal pad. These holes should be 13 mils in diameter. They are kept

small so that solder wicking through the holes is not a problem during reflow.

3. It is recommended, but not required, to place six more holes under the package, but outside the thermal

pad area. These holes are 25 mils in diameter. They may be larger because they are not in the area to be

soldered so that wicking is not a problem.

4. Connect all 24 holes, the 18 within the thermal pad area and the 6 outside the pad area, to the internal

ground plane.

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

27

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

PCB design considerations (continued)

5. When connecting these holes to the ground plane, do not use the typical web or spoke via connection

methodology . Web connections have a high thermal resistance connection that is useful for slowing the heat

transfer during soldering operations. This makes the soldering of vias that have plane connections easier.

However, in this application, low thermal resistance is desired for the most ef ficient heat transfer. Therefore,

the holes under the THS6012 package should make their connection to the internal ground plane with a

complete connection around the entire circumference of the plated through hole.

6. The top-side solder mask should leave exposed the terminals of the package and the thermal pad area with

its five holes. The four larger holes outside the thermal pad area, but still under the package, should be

covered with solder mask.

7. Apply solder paste to the exposed thermal pad area and all of the operational amplifier terminals.

8. With these preparatory steps in place, the THS6012 is simply placed in position and run through the solder

reflow operation as any standard surface-mount component. This results in a part that is properly installed.

Addition 6 vias outside of thermal pad area

but under the package

(Via diameter = 25 mils)

Thermal pad area (0.19 x 0.21) with 18 vias

(Via diameter = 13 mils)

Figure 45. PowerPAD PCB Etch and Via Pattern

The actual thermal performance achieved with the THS6012 in its PowerPAD package depends on the

application. In the previous example, if the size of the internal ground plane is approximately 3 inches × 3 inches,

then the expected thermal coefficient, θ

JA

, is about 21.5_C/W. For a given θJA, the maximum power dissipation

is shown in Figure 46 and is calculated by the following formula:

PD+

ǒ

T

MAX–TA

q

JA

Ǔ

Where:

P

D

= Maximum power dissipation of THS6012 (watts)

T

MAX

= Absolute maximum junction temperature (150°C)

T

A

= Free-ambient air temperature (°C)

θ

JA

= θJC + θ

CA

θJC = Thermal coefficient from junction to case (0.37°C/W)

θ

CA

= Thermal coefficient from case to ambient

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

28

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

PCB design considerations (continued)

More complete details of the PowerP AD installation process and thermal management techniques can be found

in the Texas Instruments Technical Brief,

PowerPAD Thermally Enhanced Package.

This document can be

found at the TI web site (www.ti.com) by searching on the key word PowerPAD. The document can also be

ordered through your local TI sales office. Refer to literature number SLMA002 when ordering.

TA – Free-Air Temperature – °C

–40 –20 0 20 80 1006040

MAXIMUM POWER DISSIPATION

vs

FREE-AIR TEMPERATURE

5

3

1

0

4

2

6

7

Maximum Power Dissipation – W

8

9

TJ = 150°C

PCB Size = 3” x 3”

No Air Flow

θJA = 21.5°C/W

2 oz Trace and

Copper Pad

with Solder

θJA = 43.9°C/W

2 oz Trace and Copper Pad

without Solder

Figure 46. Maximum Power Dissipation vs Free-Air Temperature

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

29

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

ADSL

The THS6012 was primarily designed as a line driver and line receiver for ADSL (asymmetrical digital subscriber

line). The driver output stage has been sized to provide full ADSL power levels of 20 dBm onto the telephone

lines. Although actual driver output peak voltages and currents vary with each particular ADSL application, the

THS6012 is specified for a minimum full output current of 400 mA at its full output voltage of approximately 12

V . This performance meets the demanding needs of ADSL at the central office end of the telephone line. A typical

ADSL schematic is shown in Figure 47.

_

+

6.8 µF0.1 µF

–15 V

6.8 µF0.1 µF

15 V

1 kΩ

1 kΩ

+

+

V

I+

_

+

6.8 µF0.1 µF

–15 V

6.8 µF0.1 µF

15 V

1 kΩ

1 kΩ

+

+

V

I–

+

–

1 kΩ

0.1 µF

1 kΩ

2 kΩ

12.5 Ω

+

–

1 kΩ

0.1 µF

1 kΩ

2 kΩ

1:2

Telephone Line

12.5 Ω

–15 V

15 V

15 V

–15 V

0.01 µF

THS6062

THS6062

V

O+

V

O–

THS6012

Driver 1

THS6012

Driver 2

100 Ω

Figure 47. THS6012 ADSL Application

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

30

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

ADSL (continued)

The ADSL transmit band consists of 255 separate carrier frequencies each with its own modulation and

amplitude level. With such an implementation, it is imperative that signals put onto the telephone line have as

low a distortion as possible. This is because any distortion either interferes directly with other ADSL carrier

frequencies or it creates intermodulation products that interfere with ADSL carrier frequencies.

The THS6012 has been specifically designed for ultra low distortion by careful circuit implementation and by

taking advantage of the superb characteristics of the complementary bipolar process. Driver single-ended

distortion measurements are shown in Figures 29 – 32. It is commonly known that in the differential driver

configuration, the second order harmonics tend to cancel out. Thus, the dominant total harmonic distortion

(THD) will be primarily due to the third order harmonics. For these tests the load was 25 Ω. Additionally , distortion

should be reduced as the feedback resistance drops. This is because the bandwidth of the amplifier increases,

which allows the amplifier to react faster to any nonlinearities in the closed-loop system.

Another significant point is the fact that distortion decreases as the impedance load increases. This is because

the output resistance of the amplifier becomes less significant as compared to the output load resistance.

general configurations

A common error for the first-time CFB user is to create a unity gain buffer amplifier by shorting the output directly

to the inverting input. A CFB amplifier in this configuration oscillates and is not recommended. The THS6012,

like all CFB amplifiers, must have a feedback resistor for stable operation. Additionally, placing capacitors

directly from the output to the inverting input is not recommended. This is because, at high frequencies, a

capacitor has a very low impedance. This results in an unstable amplifier and should not be considered when

using a current-feedback amplifier. Because of this, integrators and simple low-pass filters, which are easily

implemented on a VFB amplifier, have to be designed slightly dif ferently . If filtering is required, simply place an

RC-filter at the noninverting terminal of the operational-amplifier (see Figure 49).

V

I

V

O

C1

+

–

R

G

R

F

R1

f

–3dB

+

1

2pR1C1

V

O

V

I

+ ǒ

1

)

R

F

R

G

Ǔ

ǒ

1

1)sR1C1

Ǔ

Figure 48. Single-Pole Low-Pass Filter

If a multiple pole filter is required, the use of a Sallen-Key filter can work very well with CFB amplifiers. This is

because the filtering elements are not in the negative feedback loop and stability is not compromised. Because

of their high slew-rates and high bandwidths, CFB amplifiers can create very accurate signals and help minimize

distortion. An example is shown in Figure 50.

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

31

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

general configurations (continued)

V

I

C2

R2R1

C1

R

F

R

G

R1 = R2 = R

C1 = C2 = C

Q = Peaking Factor

(Butterworth Q = 0.707)

(

=

1

Q

2 –

)

R

G

R

F

_

+

f

–3dB

+

1

2pRC

Figure 49. 2-Pole Low-Pass Sallen-Key Filter

There are two simple ways to create an integrator with a CFB amplifier. The first one shown in Figure 51 adds

a resistor in series with the capacitor. This is acceptable because at high frequencies, the resistor is dominant

and the feedback impedance never drops below the resistor value. The second one shown in Figure 52 uses

positive feedback to create the integration. Caution is advised because oscillations can occur because of the

positive feedback.

+

–

C1

R

F

R

G

V

O

V

I

THS6012

V

O

V

I

+ ǒ

R

F

R

G

Ǔ

ȧ

ȡ

Ȣ

S

)

1

RFC1

S

ȧ

ȣ

Ȥ

Figure 50. Inverting CFB Integrator

+

–

R

F

V

O

R

G

R2R1

C1

R

A

V

I

THS6012

For Stable Operation:

R2

R1 || R

A

≥

R

F

R

G

sR1C1

(

)

R

F

R

G

1 +

VO

≅ V

I

Figure 51. Non-Inverting CFB Integrator

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

32

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

general configurations (continued)

Another good use for the THS6012 amplifiers is as very good video distribution amplifiers. One characteristic

of distribution amplifiers is the fact that the differential phase (DP) and the differential gain (DG) are

compromised as the number of lines increases and the closed-loop gain increases. Be sure to use termination

resistors throughout the distribution system to minimize reflections and capacitive loading.

+

–

620 Ω620 Ω

75 Ω

75 Ω

75 Ω

75 Ω

75 Ω

N Lines

V

O1

V

ON

THS6012

75 Ω Transmission Line

V

I

Figure 52. Video Distribution Amplifier Application

evaluation board

An evaluation board is available for the THS6012 (literature number SLOP132). This board has been configured

for proper thermal management of the THS6012. The circuitry has been designed for a typical ADSL application

as shown previously in this document. For more detailed information, refer to the

THS6012EVM User’s Manual

(literature number SLOU034). To order the evaluation board contact your local TI sales office or distributor.

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

33

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL INFORMATION

DWP (R-PDSO-G20) PowerPAD PLASTIC SMALL-OUTLINE PACKAGE

Gage Plane

0.411 (10,44)

0.430 (10,92)

0.010 (0,25) NOM

0.010 (0,25)

Seating Plane

0.050 (1,27)

0.016 (0,40)

4073226/B 01/96

11

10

0.500 (12,70)

0.510 (12,95)

20

1

0.004 (0,10)

0.000 (0,00)

0.096 (2,43) MAX

0.020 (0,51)

0.014 (0,35)

0.293 (7,45)

0.299 (7,59)

0.050 (1,27)

M

0.010 (0,25)

0.004 (0,10)

+2°–8°

Thermal Pad 0.150 (3,81) 0.170 (4,31) NOM

(see Note C)

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. The thermal performance may be enhanced by bonding the thermal pad to an external thermal plane.

PowerPAD is a trademark of Texas Instruments Incorporated.

THS6012

500-mA DUAL DIFFERENTIAL LINE DRIVER

SLOS226C– SEPTEMBER 1998 – REVISED FEBRUARY 2000

34

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

GQE (S-PLGA-N80) PLASTIC LAND GRID ARRAY

98765

J

H

G

F

E

D

321

C

B

A

4

4,00 TYP

Seating Plane

5,20

4,80

SQ

0,87

0,93

0,08 MAX

0,23

0,33

1,00 MAX

0,50

0,50

0,08

M

∅ 0,05

4200461/A 10/99

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. MicroStar Junior LGA configuration

MicroStar Junior LGA is a trademark of Texas Instruments Incorporated.

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Loading...

Loading...