Page 1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments

www.ti.com

−

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

FEATURES

D Fully Differential Architecture

D Bandwidth: 260 MHz

D Slew Rate: 1800 V/µs

D IMD

D OIP

: −73 dBc at 30 MHz

3

: 29 dBm at 30 MHz

3

D Output Common-Mode Control

D Wide Power Supply Voltage Range: 5 V, ±5 V,

12 V, 15 V

D Input Common-Mode Range Shifted to

Include the Negative Power Supply Rail

D Power-Down Capability (THS4504)

D Evaluation Module Available

DESCRIPTION

The THS4504 and THS4505 are high-performance fully

differential amplifiers from Texas Instruments. The

THS4504, featuring power-down capability, and the

THS4505, without power-down capability, set new

performance standards for fully differential amplifiers

with unsurpassed linearity, supporting 12-bit operation

through 40 MHz. Package options include the 8-pin

SOIC and the 8-pin MSOP with PowerPAD for a

smaller footprint, enhanced ac performance, and

improved thermal dissipation capability.

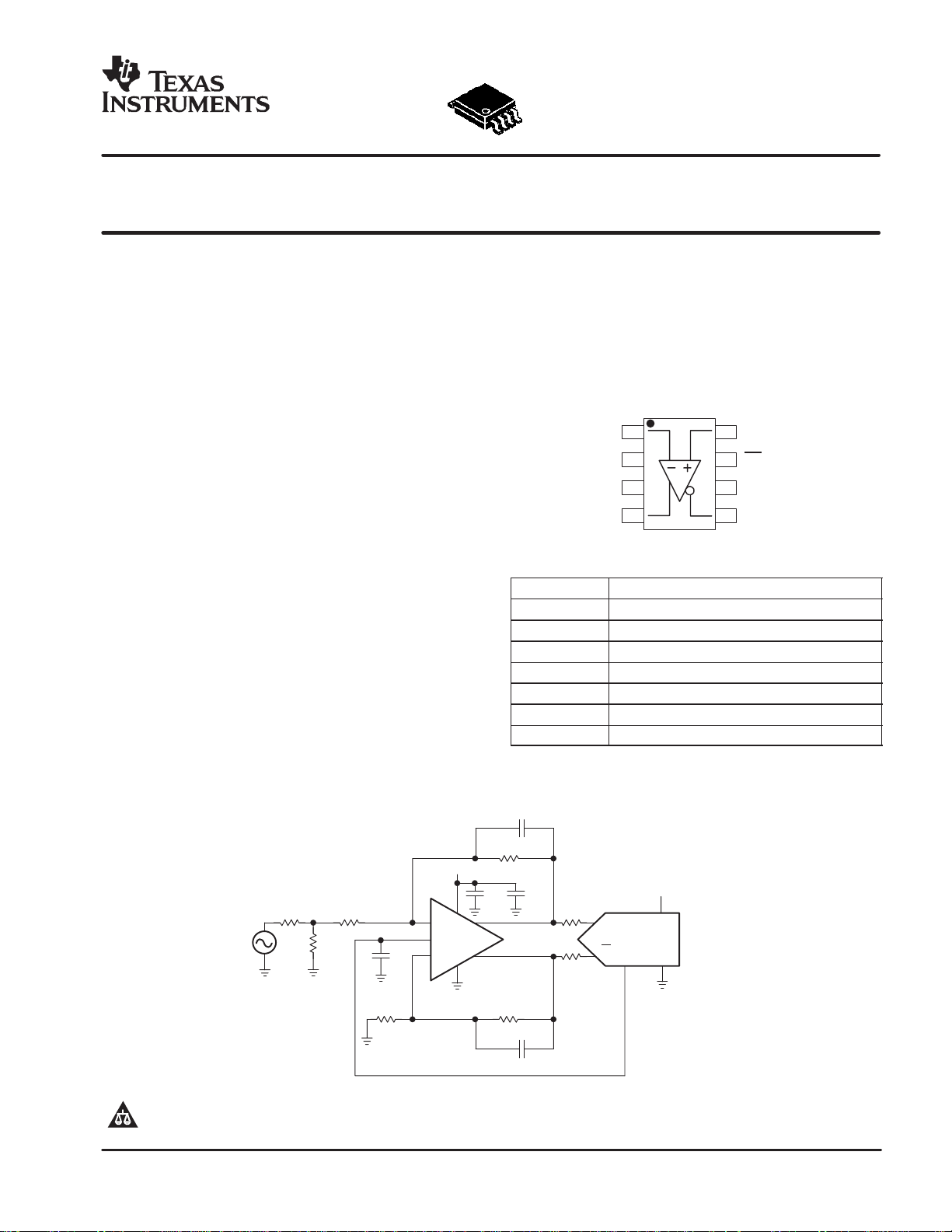

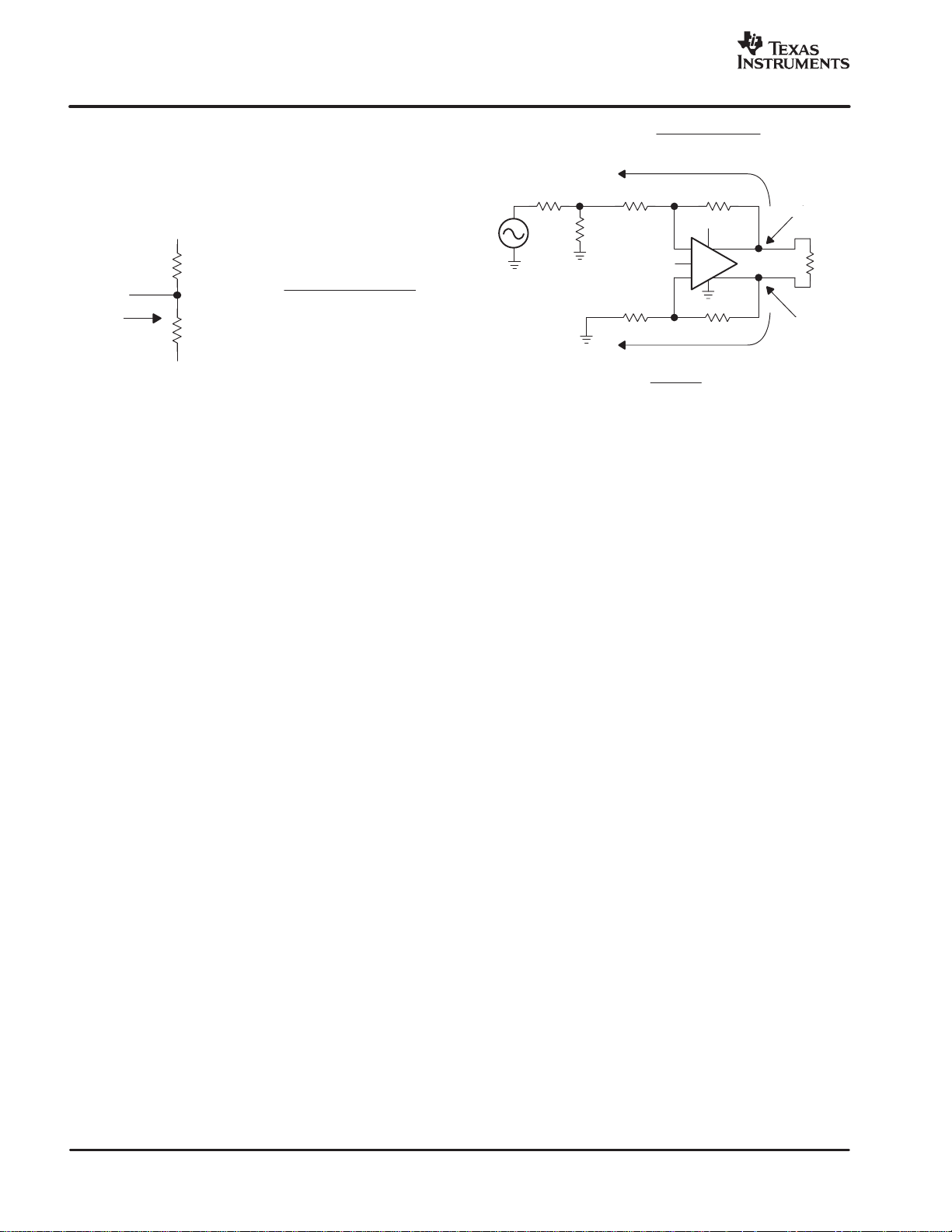

APPLICATION CIRCUIT DIAGRAM

APPLICATIONS

D High Linearity Analog-to-Digital Converter

Preamplifier

D Wireless Communication Receiver Chains

D Single-Ended to Differential Conversion

D Differential Line Driver

D Active Filtering of Differential Signals

1

V

IN−

OCM

V

S+

2

3

4

V

V

OUT+

RELATED DEVICES

DEVICE(1) DESCRIPTION

THS4504/5 260 MHz, 1800 V/µs, V

THS4500/1 370 MHz, 2800 V/µs, V

THS4502/3 370 MHz, 2800 V/µs, Centered V

THS4120/1 3.3 V , 100 MHz, 43 V/µs, 3.7 nV√Hz

THS4130/1 ±15 V, 150 MHz, 51 V/µs, 1.3 nV√Hz

THS4140/1 ±15 V, 160 MHz, 450 V/µs, 6.5 nV√Hz

THS4150/1 ±15 V, 150 MHz, 650 V/µs, 7.6 nV√Hz

(1)

Even numbered devices feature power-down capability

8.2 pF

8

7

6

5

V

IN+

PD

V

S−

V

OUT−

Includes V

ICR

Includes V

ICR

S−

S−

ICR

499 Ω

5 V

5 V

ADC

12 Bit/80 MSps

V

ref

Copyright 2002, Texas Instruments Incorporated

50 Ω

V

S

semiconductor products and disclaimers thereto appears at the end of this data sheet.

PowerPAD is a trademark of Texas Instruments.

!"# "#$" "%&$#" " '&# " &! #$" "! '$! %

!(!)'!"#* ! #$# % !$ !(! "$#! " #! '$+!,- '!%."+ #

!)!#&$) $&$#!&#*

487 Ω

53.6 Ω

1 µF

523 Ω

+

V

−

OCM

0.1 µF 10 µF

−

+

24.9 Ω

IN

IN

24.9 Ω

499 Ω

8.2 pF

Page 2

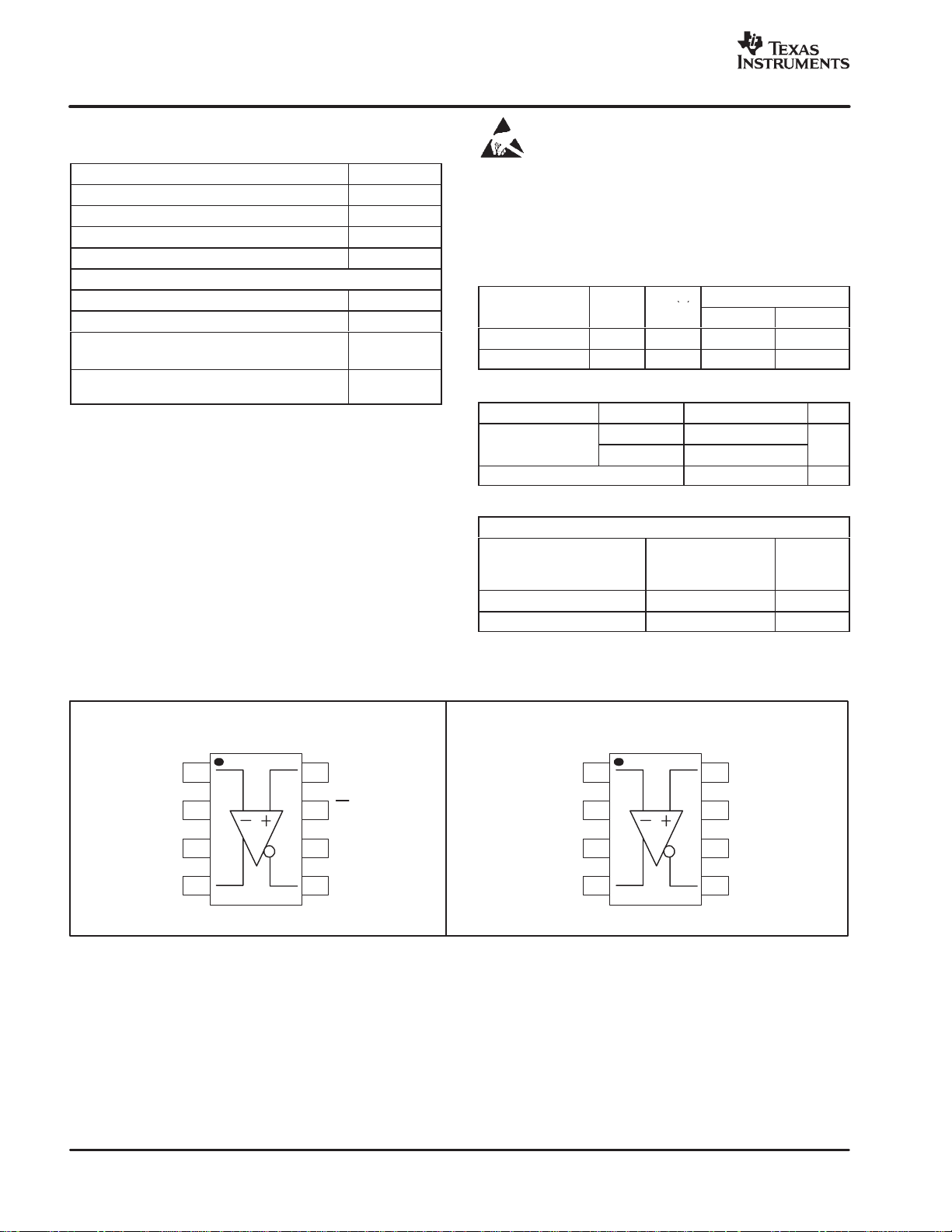

(1)

PACKAGE

θ

JC

θ

JA

(1)

Supply voltage

V

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

www.ti.com

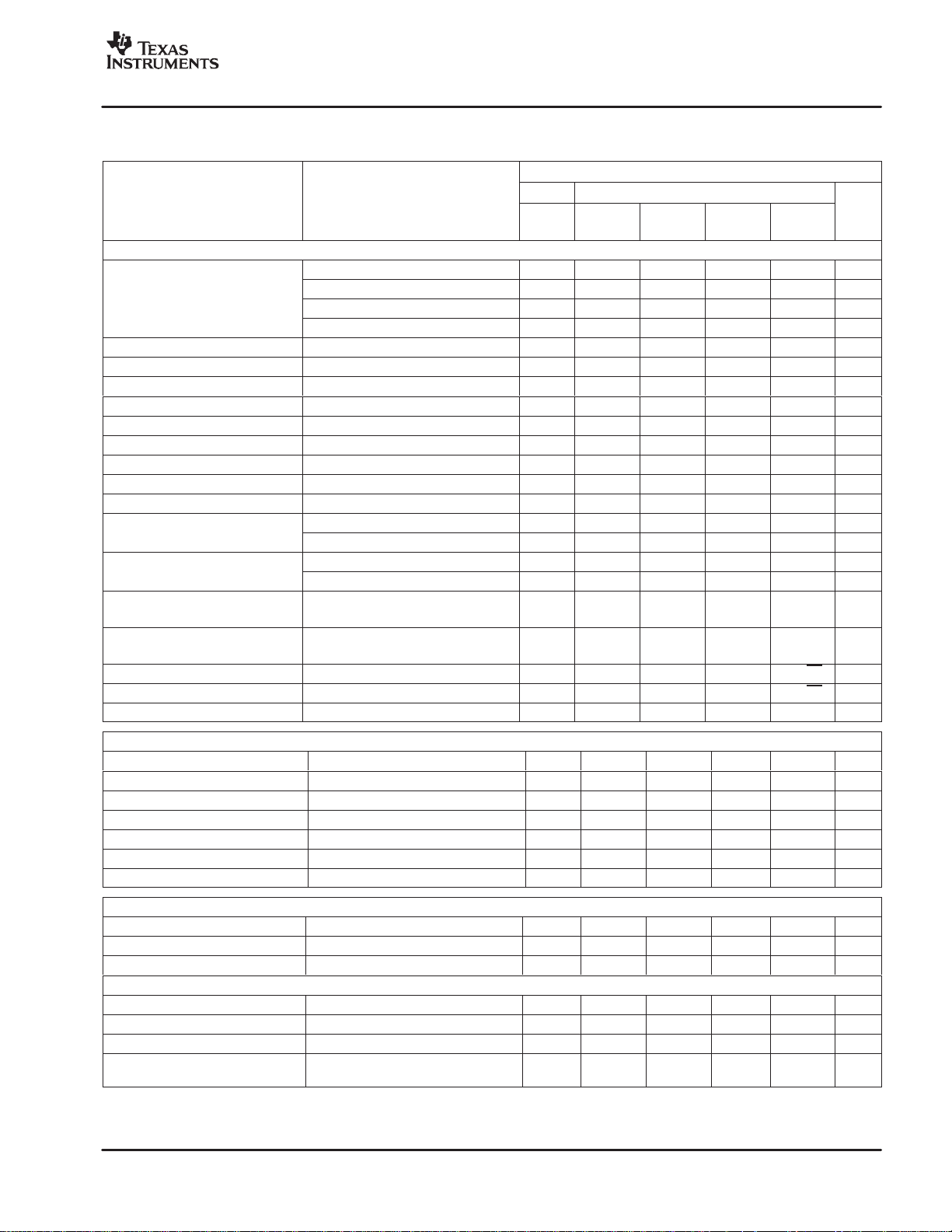

ABSOLUTE MAXIMUM RATINGS

over operat i n g f ree-air temperature range unless otherwise noted

UNIT

Supply voltage, V

Input voltage, V

Output current, IO

S

I

(2)

Differential input voltage, V

ID

16.5 V

±V

S

150 mA

4 V

Continuous power dissipation See Dissipation Rating Table

Maximum junction temperature, T

Operating free-air temperature range, T

Storage temperature range, T

J

A

stg

Lead temperature

1,6 mm (1/16 inch) from case for 10 seconds

(1)

Stresses above these ratings may cause permanent damage.

150°C

−40°C to 85°C

−65°C to

150°C

300°C

Exposure to absolute maximum conditions for extended periods

may degrade device reliability. These are stress ratings only, and

functional operation of the device at these or any other conditions

beyond those specified is not implied.

(2)

The THS450x may incorporate a PowerPAD on the underside of

the chip. This acts as a heatsink and must be connected to a

thermally dissipative plane for proper power dissipation. Failure

to do so may result in exceeding the maximum junction

temperature which could permanently damage the device. See TI

technical brief SLMA002 for more information about utilizing the

PowerPAD thermally enhanced package.

PIN ASSIGNMENTS

THS4504

(TOP VIEW)

D AND DGN

(1)

This integrated circuit can be damaged by ESD. Texas

Instruments recommends that all integrated circuits be

handled with appropriate precautions. Failure to observe

proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to

complete device failure. Precision integrated circuits may be more

susceptible t o damage because very small parametric changes could

cause the device not to meet its published specifications.

PACKAGE DISSIPATION RATINGS

θ

(°C/W)

θ

(°C/W)

D (8 pin) 38.3 167 740 mW 390 mW

DGN (8 pin) 4.7 58.4 2.14 W 1.11 W

POWER RATING

TA ≤ 25°C TA = 85°C

RECOMMENDED OPERATING CONDITIONS

MIN NOM MAX UNIT

Dual supply ±5 ±7.5

Single supply 4.5 5 15

Operating free-air temperature, TA−40 85 °C

PACKAGE/ORDERING INFORMATION

ORDERABLE PACKAGE AND NUMBER

PLASTIC

SMALL OUTLINE

(1)

(D)

THS4504D THS4504DGN BDB

THS4505D THS4505DGN BDC

(1)

This package is available taped and reeled. To order this

packaging option, add an R suffix to the part number (e.g.,

THS4504DR).

THS4505

(TOP VIEW)

PLASTIC MSOP

(DGN)

D AND DGN

PACKAGE

MARKING

V

1

IN−

V

2

OCM

V

3

S+

V

4

OUT+

V

8

IN+

7

PD

6

V

S−

V

5

OUT−

V

1

IN−

V

2

OCM

V

3

S+

V

4

OUT+

V

8

IN+

7

NC

6

V

S−

V

5

OUT−

2

Page 3

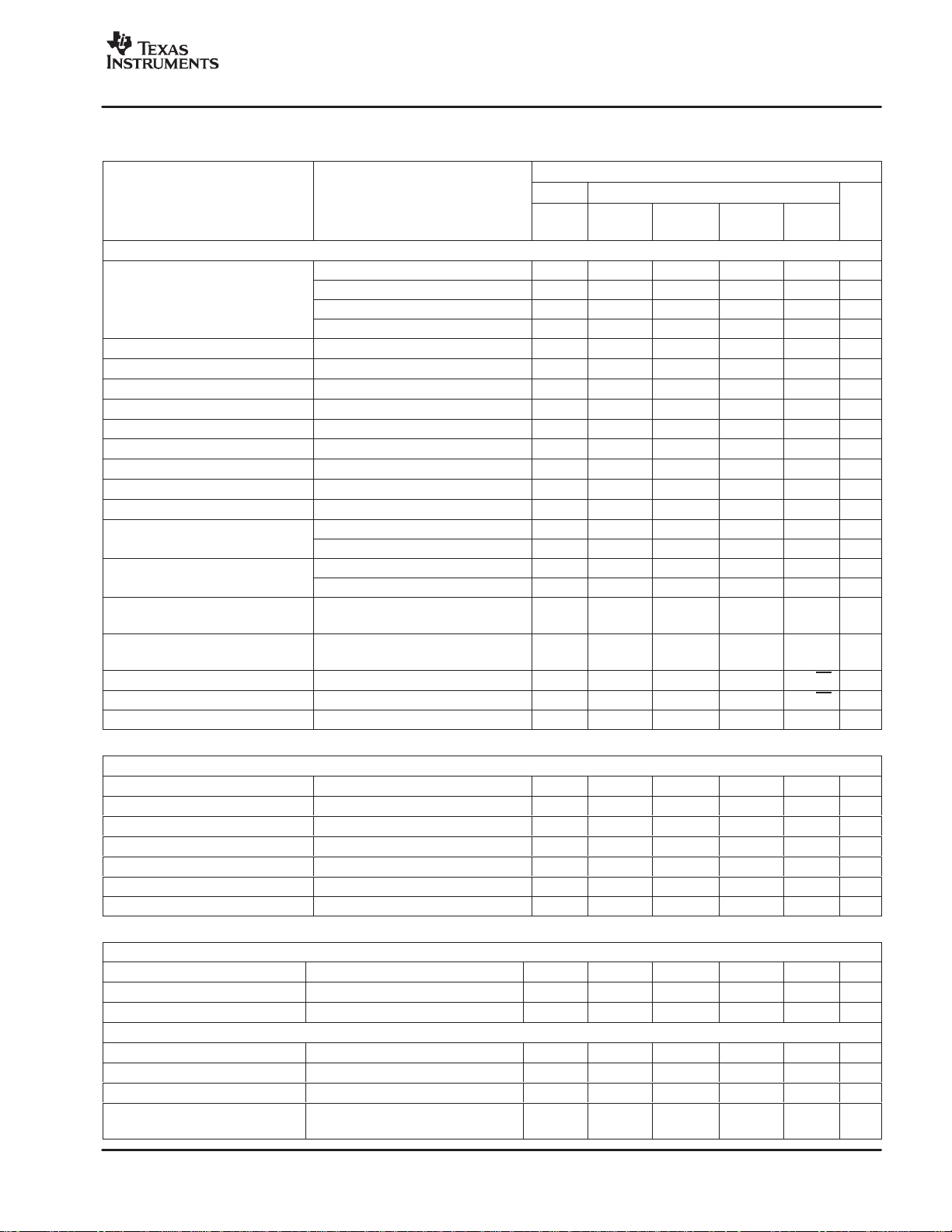

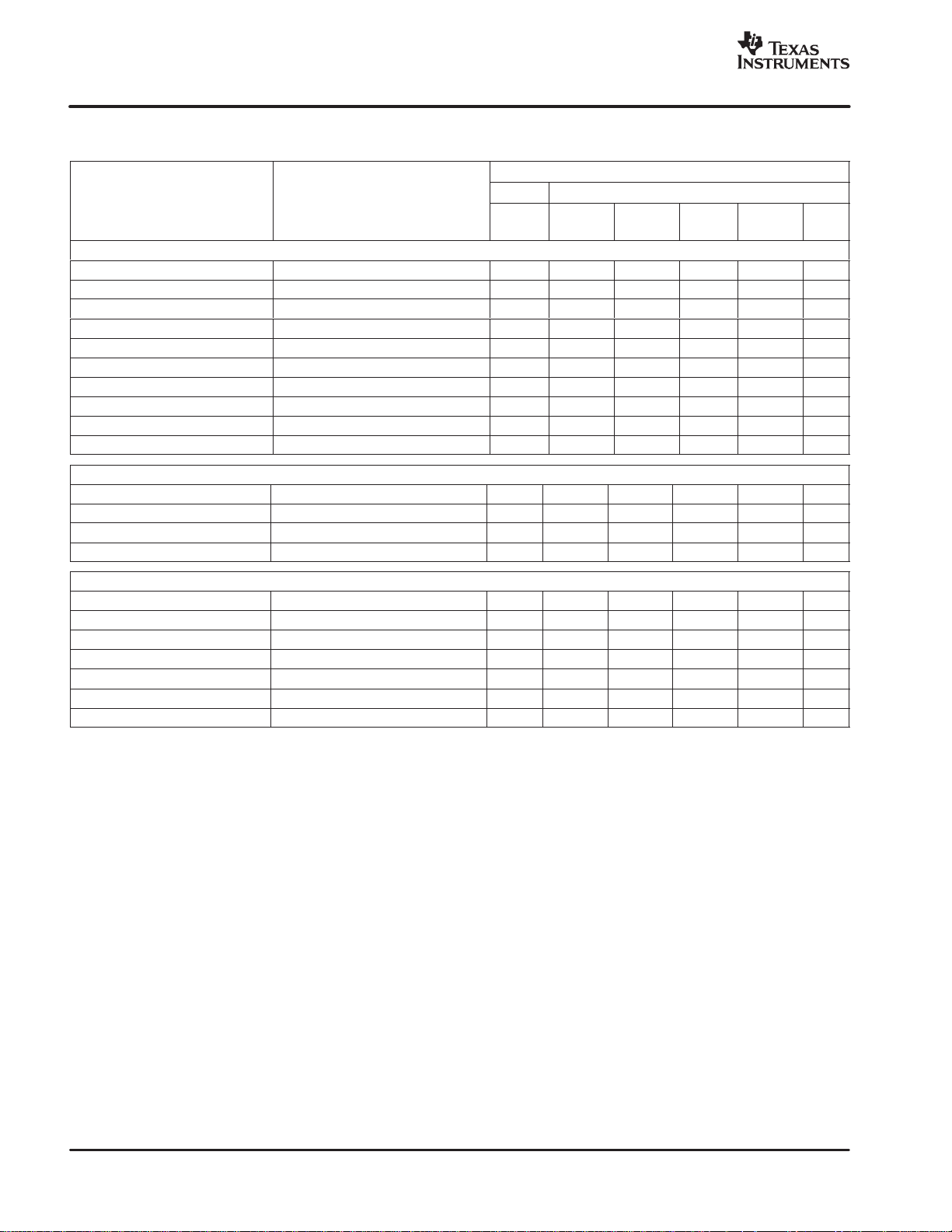

MIN/

PARAMETER

TEST CONDITIONS

MIN/

/

Small-signal bandwidth

2nd harmonic

3rd harmonic

www.ti.com

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

ELECTRICAL CHARACTERISTICS VS = ±5 V

Rf = Rg = 499 Ω, RL = 800 Ω, G = +1, Single-ended input unless otherwise noted.

THS4504 AND THS4505

TYP OVER TEMPE R ATURE

25°C 25°C

AC PERFORMANCE

G = 1, PIN= −20 dBm, Rf = 499 Ω 260 MHz Typ

G = 2, PIN= −20 dBm, Rf = 499 Ω 110 MHz Typ

G = 5, PIN= −20 dBm, Rf = 499 Ω 40 MHz Typ

G = 10, PIN = −20 dBm, Rf = 499 Ω 20 MHz Typ

Gain-bandwidth product G > +10 210 MHz Typ

Bandwidth for 0.1dB flatness PIN = −20 dBm 65 MHz Typ

Large-signal bandwidth G = 1, VP = 2 V 250 MHz Typ

Slew rate 4 VPP Step 1800 V/µs Typ

Rise time 2 VPP Step 0.8 ns Typ

Fall time 2 VPP Step 1 ns Typ

Settling time to 0.01% VO = 4 V

0.1% VO = 4 V

Harmonic distortion G = 1, VO = 2 V

Third-order intermodulation

distortion

Third-order output intercept point

Input voltage noise f > 1 MHz 8 nV/√Hz Typ

Input current noise f > 100 kHz 2 pA/√Hz Typ

Overdrive recovery time Overdrive = 5.5 V 60 ns Typ

VO = 2 VPP, fc = 30 MHz,

Rf = 499 Ω, 200 kHz tone spacing

fc = 30 MHz, Rf = 499 Ω,

Referenced to 50 Ω

PP

PP

PP

f = 8 MHz −79 dBc Typ

f = 30 MHz −66 dBc Typ

f = 8 MHz −93 dBc Typ

f = 30 MHz −65 dBc Typ

100 ns Typ

20 ns Typ

−73 dBc Typ

29 dBm Typ

0°C to

70°C

−40°C to

85°C

UNITS

TYP

MAX

Typ

DC PERFORMANCE

Open-loop voltage gain 55 52 50 50 dB Min

Input offset voltage −4 −7 / −1 −8 / 0 −9 / +1 mV Max

Average offset voltage drift ±10 ±10 µV/°C Typ

Input bias current 4 4.6 5 5.2 µA Max

Average bias current drift ±10 ±10 nA/°C Typ

Input offset current 0.5 1 2 2 µA Max

Average offset current drift ±40 ±40 nA/°C Typ

INPUT

Common-mode input range −5.7 / 2.6 −5.4 / 2.3 −5.1 / 2 −5.1 / 2 V Min

Common-mode rejection ratio 80 74 70 70 dB Min

Input impedance 107 || 1 Ω || pF Typ

OUTPUT

Differential output voltage swing RL = 1 kΩ ±8 ±7.6 ±7.4 ±7.4 V Min

Differential output current drive RL = 20 Ω 130 110 100 100 mA Min

Output balance error PIN = −20 dBm, f = 100 kHz −65 dB Typ

Closed-loop output impedance

(single-ended)

f = 1 MHz 0.1 Ω Typ

3

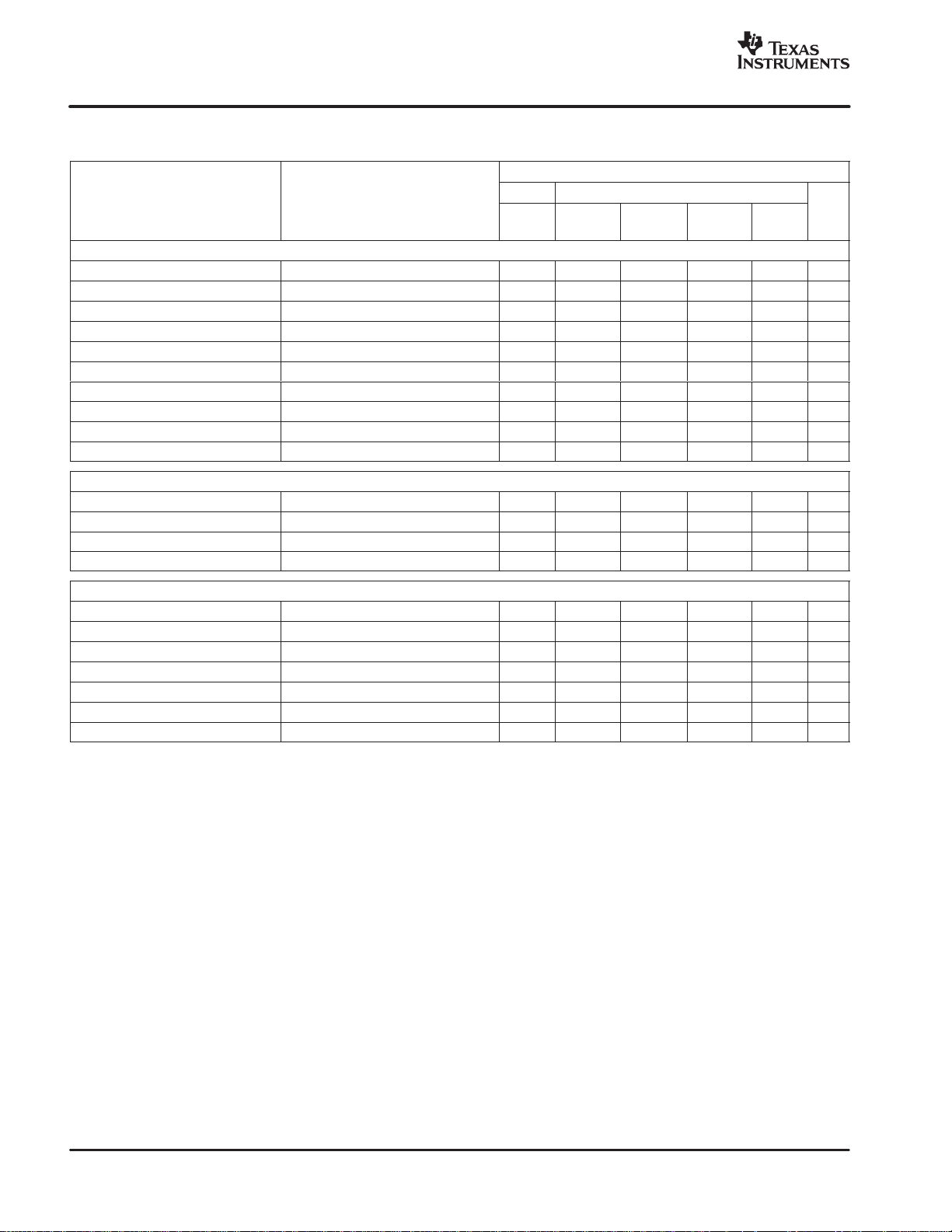

Page 4

MIN/

PARAMETER

TEST CONDITIONS

MIN/

/

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

ELECTRICAL CHARACTERISTICS VS = ±5 V (continued)

Rf = Rg = 499 Ω, RL = 800 Ω, G = +1, Single-ended input unless otherwise noted.

THS4504 AND THS4505

TYP OVER TEMPE R ATURE

25°C 25°C

OUTPUT COMMON-MODE VOLTAGE CONTROL

Small-signal bandwidth RL = 400 Ω 200 MHz Typ

Slew rate 2 VPP step 92 V/µs Typ

Minimum gain 1 0.98 0.98 0.98 V/V Min

Maximum gain 1 1.02 1.02 1.02 V/V Max

Common-mode offset voltage −0.4 −4.6/+3.8 −6.6/+5.8 −7.6/+6.8 mV Max

Input bias current V

Input voltage range ±4 ±3.7 ±3.4 ±3.4 V Min

Input impedance 25 || 1 kΩ || pF Typ

Maximum default voltage V

Minimum default voltage V

POWER SUPPLY

Specified operating voltage ±5 ±7.5 ±7.5 ±7.5 V Max

Maximum quiescent current 16 20 23 25 mA Max

Minimum quiescent current 16 13 11 9 mA Min

Power supply rejection (±PSRR) 80 76 73 70 dB Min

= 2.5 V 100 150 170 170 µA Max

OCM

left floating 0 0.05 0.10 0.10 V Max

OCM

left floating 0 −0.05 −0.10 −0.10 V Min

OCM

0°C to

70°C

−40°C to

85°C

www.ti.com

UNITS

TYP

MAX

POWER DOWN (THS4505 ONL Y)

Enable voltage threshold Device enabled ON above –2.9 V −2.9 V Min

Disable voltage threshold Device disabled OFF below –4.3 V −4.3 V Max

Power-down quiescent current 800 1000 1200 1200 µA Max

Input bias current 200 240 260 260 µA Max

Input impedance 50 || 1 kΩ || pF Typ

Turnon time delay 1000 ns Typ

Turnoff time delay 800 ns Typ

4

Page 5

MIN/

PARAMETER

TEST CONDITIONS

MIN/

/

Small-signal bandwidth

2nd harmonic

3rd harmonic

www.ti.com

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

ELECTRICAL CHARACTERISTICS VS = 5 V

Rf = Rg = 499 Ω, RL = 800 Ω, G = +1, Single-ended input unless otherwise noted.

THS4504 AND THS4505

TYP OVER TEMPERATURE

25°C 25°C

AC PERFORMANCE

G = 1, PIN = −20 dBm, Rf = 499 Ω 210 MHz Typ

G = 2, PIN = −20 dBm, Rf = 499 Ω 120 MHz Typ

G = 5, PIN = −20 dBm, Rf = 499 Ω 40 MHz Typ

G = 10, PIN = −20 dBm, Rf = 499 Ω 20 MHz Typ

Gain-bandwidth product G > +10 200 MHz Typ

Bandwidth for 0.1 dB flatness PIN = −20 dBm 100 MHz Typ

Large-signal bandwidth G = 1, VP = 1 V 200 MHz Typ

Slew rate 2 VPP Step 900 V/µs Typ

Rise time 2 VPP Step 1.1 ns Typ

Fall time 2 VPP Step 1 ns Typ

Settling time to 0.01% VO = 2 V Step 100 ns Typ

0.1% VO = 2 V Step 20 ns Typ

Harmonic distortion G = 1, VO = 2 V

f = 8 MHz, −77 dBc Typ

f = 30 MHz −56 dBc Typ

f = 8 MHz −74 dBc Typ

f = 30 MHz −57 dBc Typ

Third-order intermodulation

distortion

Third-order output intercept point

Input voltage noise f > 1 MHz 8 nV/√Hz Typ

Input current noise f > 100 kHz 2 pA/√Hz Typ

Overdrive recovery time Overdrive = 5.5 V 60 ns Typ

VO = 2 VPP, fc = 30 MHz,

Rf = 499 Ω, 200 kHz tone spacing

fc = 30 MHz, Rf = 499 Ω,

Referenced to 50 Ω

PP

−72 dBc Typ

28 dBm Typ

0°C to

70°C

−40°C to

85°C

UNITS

TYP

MAX

Typ

DC PERFORMANCE

Open-loop voltage gain 54 51 49 49 dB Min

Input offset voltage −4 −7 / −1 −8 / 0 −9 / +1 mV Max

Average offset voltage drift ±10 ±10 µV/°C Typ

Input bias current 4 4.6 5 5.2 µA Max

Average bias current drift ±10 ±10 nA/°C Typ

Input offset current 0.5 0.7 1.2 1.2 µA Max

Average offset current drift ±20 ±20 nA/°C Typ

INPUT

Common-mode input range −0.7/2.6 −0.4 / 2.3 −0.1 / 2 −0.1 / 2 V Min

Common-mode rejection ratio 80 74 70 70 dB Min

Input impedance 107 || 1 Ω || pF Typ

OUTPUT

Differential output voltage swing RL = 1 kΩ, Referenced to 2.5 V ±3.3 ±3 ±2.8 ±2.8 V Min

Output current drive RL = 20 Ω 110 90 80 80 mA Min

Output balance error PIN = −20 dBm, f = 100 kHz −38 dB Typ

Closed-loop output impedance

(single-ended)

f = 1 MHz 0.1 Ω Typ

5

Page 6

PARAMETER

TEST CONDITIONS

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

ELECTRICAL CHARACTERISTICS VS = 5 V (continued)

Rf = Rg = 499 Ω, RL = 800 Ω, G = +1, Single-ended input unless otherwise noted.

THS4504 AND THS4505

TYP OVER TEMPERATURE

25°C 25°C

OUTPUT COMMON-MODE VOLTAGE CONTROL

Small-signal bandwidth RL = 400 Ω 160 MHz Typ

Slew rate 2 VPP Step 80 V/µs Typ

Minimum gain 1 0.98 0.98 0.98 V/V Min

Maximum gain 1 1.02 1.02 1.02 V/V Max

Common-mode offset voltage 0.4 −2.6/3.4 −4.2/5.4 −5.6/6.4 mV Max

Input bias current V

Input voltage range 1 / 4 1.2 / 3.8 1.3 / 3.7 1.3 / 3.7 V Min

Input impedance 25 || 1 kΩ || pF Typ

Maximum default voltage V

Minimum default voltage V

POWER SUPPLY

Specified operating voltage 5 15 15 15 V Max

Maximum quiescent current 14 17 19 21 mA Max

Minimum quiescent current 14 11 10 8 mA Min

Power supply rejection (+PSRR) 75 72 69 66 dB Min

= 2.5 V 1 2 3 3 µA Max

OCM

left floating 2.5 2.55 2.6 2.6 V Max

OCM

left floating 2.5 2.45 2.4 2.4 V Min

OCM

0°C to

70°C

−40°C

to 85°C

www.ti.com

UNITS

MIN/

MAX

POWER DOWN (THS4505 ONL Y)

Enable voltage threshold Device enabled ON above 2.1 V 2.1 V Min

Disable voltage threshold Device disabled OFF below 0.7 V 0.7 V Max

Power-down quiescent current 600 800 1200 1200 µA Max

Input bias current 100 125 140 140 µA Max

Input impedance 50 || 1 kΩ || pF Typ

Turnon time delay 1000 ns Typ

Turnoff time delay 800 ns Typ

6

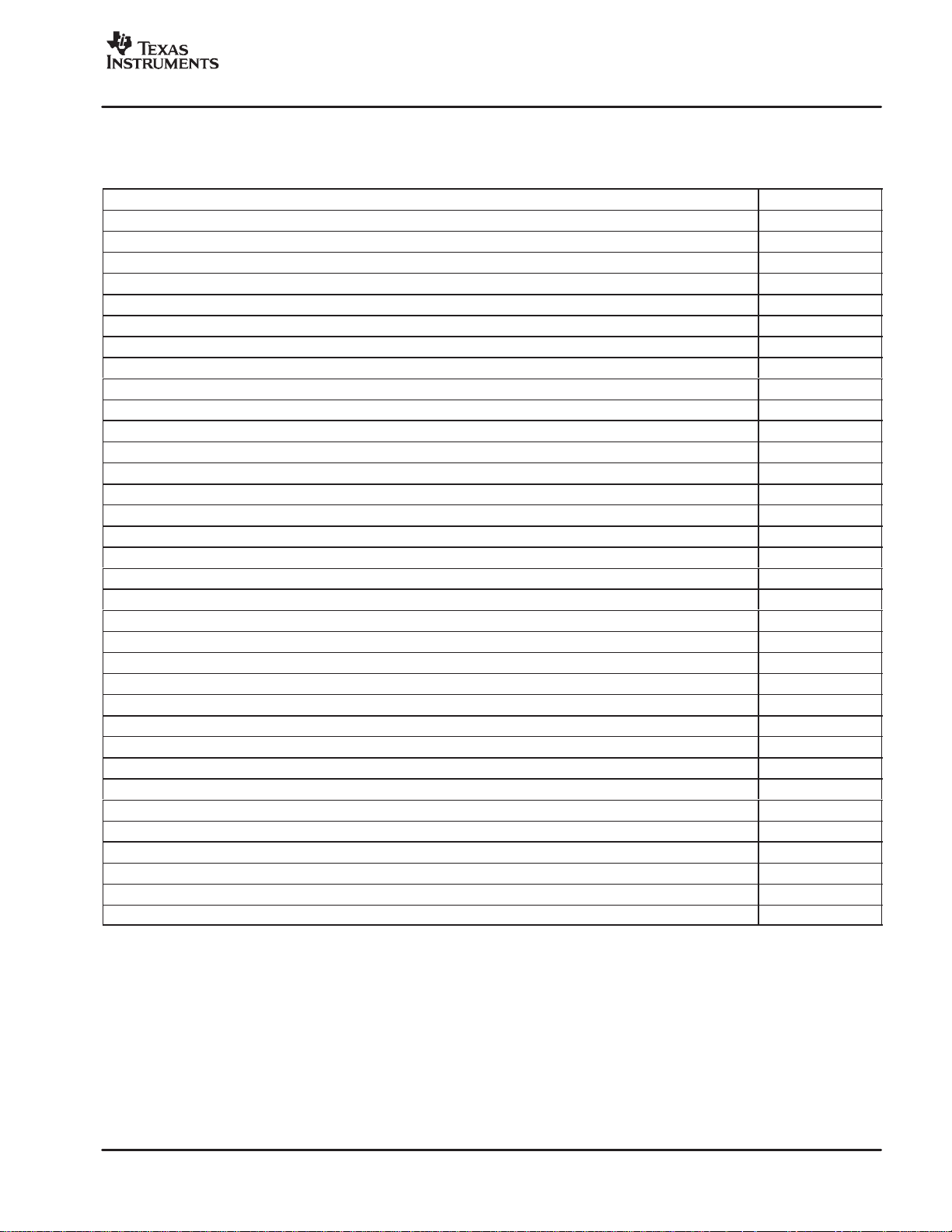

Page 7

www.ti.com

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

TYPICAL CHARACTERISTICS

Table of Graphs (±5 V)

Small signal unity gain frequency response 1

Small signal frequency response 2

0.1 dB gain flatness frequency response 3

Large signal frequency response 4

Harmonic distortion (single-ended input to differential output) vs Frequency 5

Harmonic distortion (single-ended input to differential output) vs Output voltage swing 6, 7

Harmonic distortion (single-ended input to differential output) vs Load resistance 8

Third order intermodulation distortion (single-ended input to differential output) vs Frequency 9

Third order output intercept point vs Frequency 10

Slew rate vs Differential output voltage step 11

Settling time 12, 13

Large signal transient response 14

Small signal transient response 15

Overdrive recovery 16, 17

Voltage and current noise vs Frequency 18

Rejection ratios vs Frequency 19

Rejection ratios vs Case temperature 20

Output balance error vs Frequency 21

Open-loop gain and phase vs Frequency 22

Open-loop gain vs Case temperature 23

Input bias offset current vs Case temperature 24

Quiescent current vs Supply voltage 25

Input offset voltage vs Case temperature 26

Common-mode rejection ratio vs Input common-mode range 27

Output voltage vs Load resistance 28

Closed-loop output impedance vs Frequency 29

Harmonic distortion (single-ended and differential input to differential output) vs Output common-mode voltage 30

Small signal frequency response at V

Output offset voltage at V

Quiescent current vs Power-down voltage 33

Turnon and turnoff delay times 34

Single-ended output impedance in power down vs Frequency 35

Power-down quiescent current vs Case temperature 36

Power-down quiescent current vs Supply voltage 37

OCM

OCM

vs Output common-mode voltage 32

FIGURE

31

7

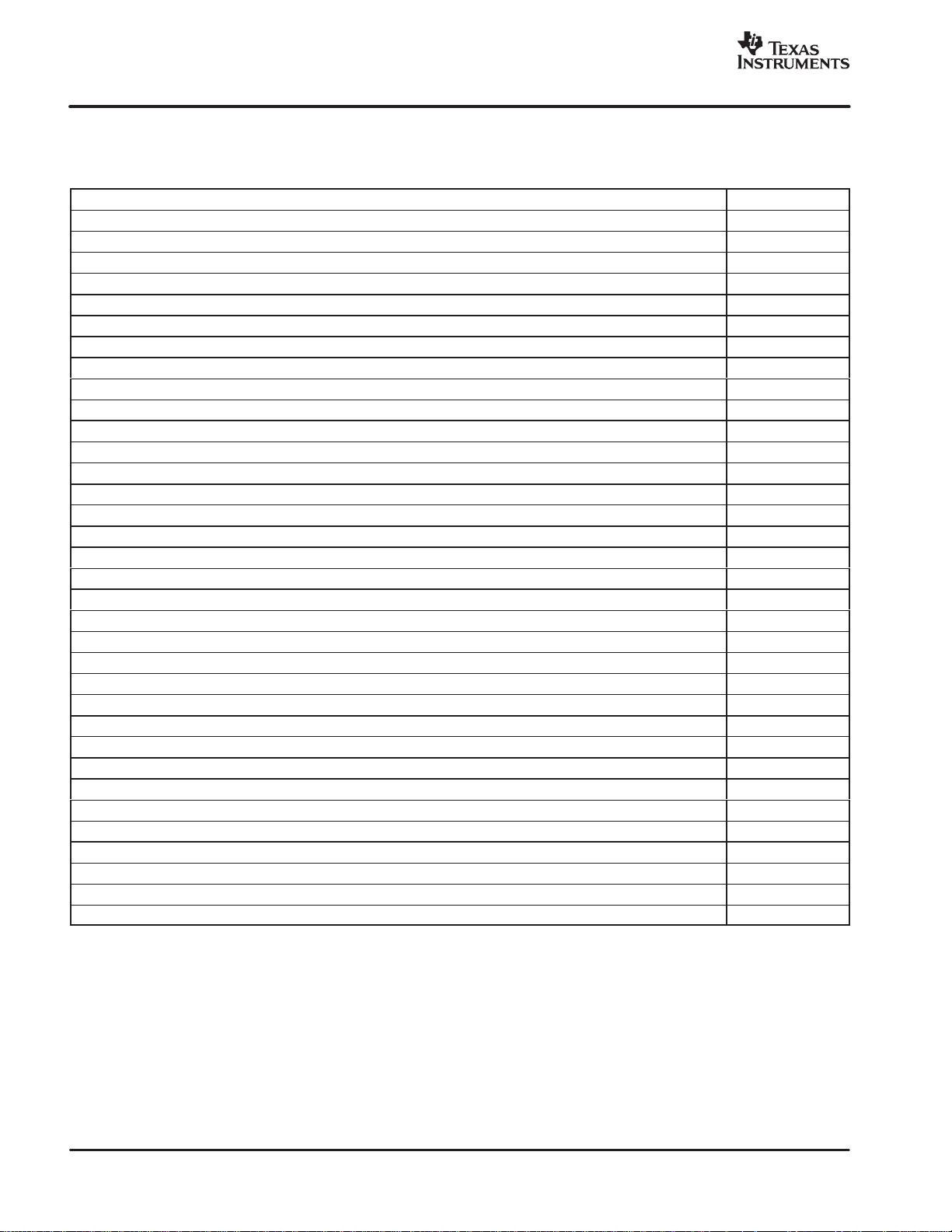

Page 8

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

TYPICAL CHARACTERISTICS

Table of Graphs (5 V)

Small signal unity gain frequency response 38

Small signal frequency response 39

0.1 dB gain flatness frequency response 40

Large signal frequency response 41

Harmonic distortion (single-ended input to differential output) vs Frequency 42

Harmonic distortion (single-ended input to differential output) vs Output voltage swing 43, 44

Harmonic distortion (single-ended input to differential output) vs Load resistance 45

Third-order intermodulation distortion vs Frequency 46

Third-order intercept point vs Frequency 47

Slew rate vs Differential output voltage step 48

Settling time 49, 50

Overdrive recovery 51, 52

Large-signal transient response 53

Small-signal transient response 54

Voltage and current noise vs Frequency 55

Rejection ratios vs Frequency 56

Rejection ratios vs Case temperature 57

Output balance error vs Frequency 58

Open-loop gain and phase vs Frequency 59

Open-loop gain vs Case temperature 60

Input bias offset current vs Case temperature 61

Quiescent current vs Supply voltage 62

Input offset voltage vs Case temperature 63

Common-mode rejection ratio vs Input common-mode range 64

Output voltage vs Load resistance 65

Closed-loop output impedance vs Frequency 66

Harmonic distortion (single-ended and differential input) vs Output common-mode voltage 67

Small signal frequency response at V

Output offset voltage vs Output common-mode voltage 69

Quiescent current vs Power-down voltage 70

Turnon and turnoff delay times 71

Single-ended output impedance in power down vs Frequency 72

Power-down quiescent current vs Case temperature 73

Power-down quiescent current vs Supply voltage 74

OCM

www.ti.com

FIGURE

68

8

Page 9

www.ti.com

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

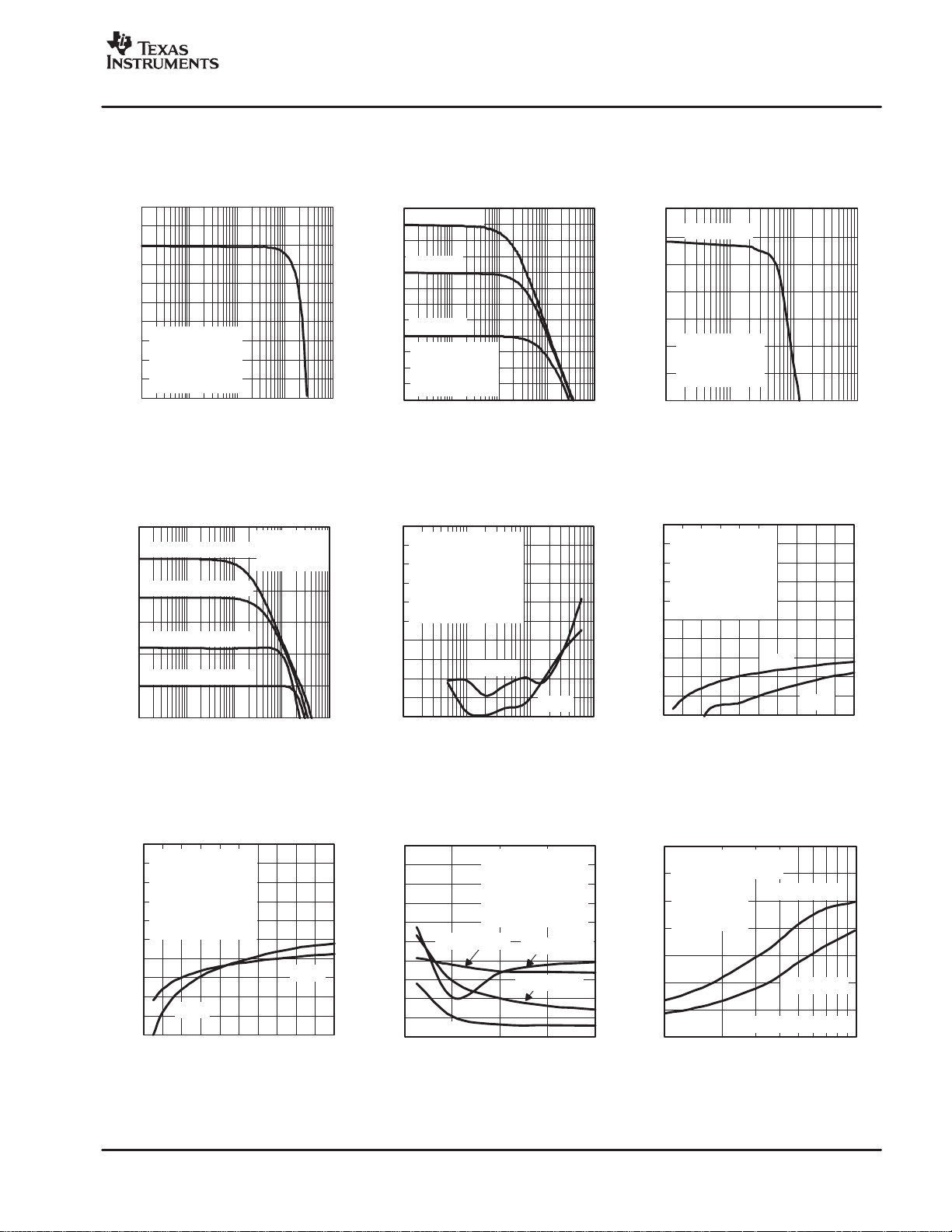

TYPICAL CHARACTERISTICS (±5 V Graphs)

SMALL SIGNAL UNITY GAIN FREQUENCY

RESPONSE

1

0.5

0

−0.5

−1

−1.5

−2

Gain = 1

−2.5

RL = 800 Ω

Rf = 499 Ω

−3

Small Signal Unity Gain − dB

PIN = −20 dBm

−3.5

VS = ±5 V

−4

0.1 1 10 100 1000

f − Frequency − MHz

Figure 1

LARGE SIGNAL FREQUENCY RESPONSE

25

Gain = 10, Rf = 1.8 kΩ

20

Gain = 5, Rf = 1.8 kΩ

15

10

Gain = 2, Rf = 1.8 kΩ

5

Large Signal Gain − dB

Gain = 1, Rf = 499 Ω

0

−5

0.1 1 10 100 1000

f − Frequency − MHz

RL = 800 Ω

VO = 2 V

VS = ±5 V

PP

Figure 4

SMALL SIGNAL FREQUENCY RESPONSE

22

Gain = 10

20

18

16

Gain = 5

14

12

10

8

Gain = 2

6

RL = 800 Ω

4

Small Signal Gain − dB

Rf =499 Ω

2

PIN = −20 dBm

0

VS = ±5 V

−2

0.1 1 10 100 1000

f − Frequency − MHz

Figure 2

HARMONIC DISTORTION

vs

FREQUENCY

0

Single-Ended Input to

−10

Differential Output

Gain = 1

−20

RL = 800 Ω

−30

Rf = 499 Ω

VO = 2 V

−40

−50

−60

−70

−80

Harmonic Distortion − dBc

−90

−100

0.1 1 10 100

VS = ±5 V

PP

HD2

HD3

f − Frequency − MHz

Figure 5

0.1 dB GAIN FLATNESS

FREQUENCY RESPONSE

0.05

Rf = 499 Ω

0

−0.05

−0.1

−0.15

Gain = 1

−0.2

−0.25

−0.3

RL = 800 Ω

PIN = −20 dBm

VS = ±5 V

1

10 100 1000

f − Frequency − MHz

0.1 dB Gain Flatness − dB

Figure 3

HARMONIC DISTORTION

vs

OUTPUT VOLTAGE SWING

0

Single-Ended Input to

−10

Differential Output

Gain = 1

−20

RL = 800 Ω

−30

Rf = 499 Ω

f= 8 MHz

−40

VS = ±5 V

−50

−60

−70

−80

Harmonic Distortion − dBc

−90

−100

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

VO − Output Voltage Swing − V

HD2

Figure 6

HD3

HARMONIC DISTORTION

vs

OUTPUT VOLTAGE SWING

0

Single Input to

−10

Differential Output

Gain = 1

−20

RL = 800 Ω

−30

Rf = 499 Ω

f= 30 MHz

−40

VS = ±5 V

−50

−60

−70

−80

Harmonic Distortion − dBc

−90

−100

HD3

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

VO − Output Voltage Swing − V

Figure 7

HD2

HARMONIC DISTORTION

vs

LOAD RESISTANCE

0

−10

−20

−30

−40

−50

−60

−70

Harmonic Distortion − dBc

−80

−90

HD3, 8 MHz

−100

0 400 800 1200 1600

RL − Load Resistance − Ω

HD3, 30 MHz

Single-Ended Input to

Differential Output

Gain = 1

VO = 2 V

PP

Rf = 499 Ω

VS = ±5 V

HD2, 30 MHz

HD2, 8 MHz

Figure 8

THIRD-ORDER INTERMODULATION

DISTORTION

vs

FREQUENCY

−30

Single-Ended Input to

Differential Output

−40

Gain = 1

RL = 800 Ω

−50

Rf = 499 Ω

VS = ±5 V

−60

−70

−80

−90

−100

Third-Order Intermodulation Distortion − dBc

10 100

f − Frequency − MHz

VO = 2 V

PP

VO = 1 V

200 kHz Tone Spacing

Figure 9

PP

9

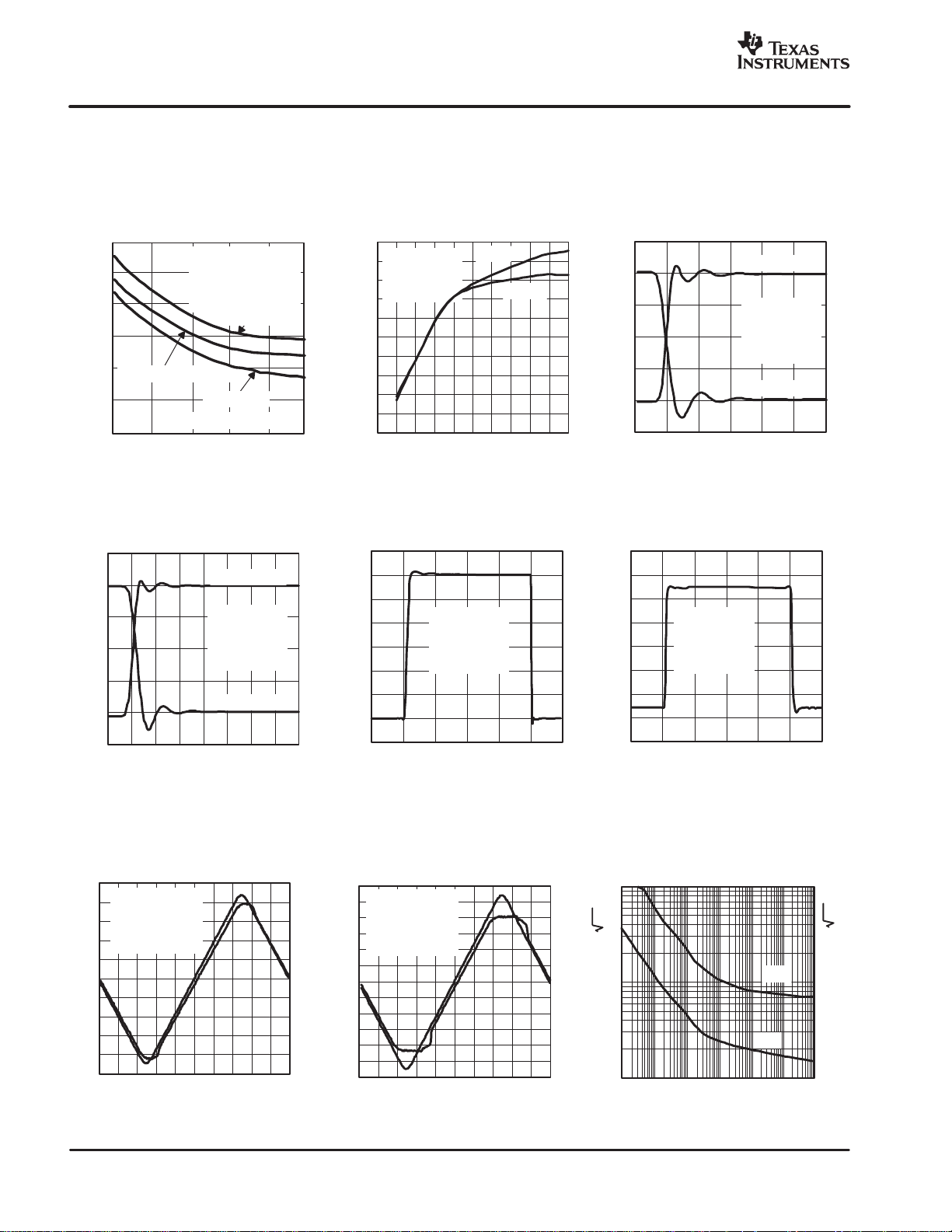

Page 10

E

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

TYPICAL CHARACTERISTICS (±5 V Graphs)

www.ti.com

THIRD-ORDER OUTPUT INTERCEPT

POINT

vs

60

50

40

30

20

10

3

0

OIP − Third-Order Output Intersept Point − dBm

0 20 40 60 80 100

FREQUENCY

Gain = 1

Rf = 499 Ω

VO = 2 V

VS = ± 5 V

200 kHz Tone Spacing

Normalized to 200 Ω

200 kHz Tone Spacing

f − Frequency − MHz

PP

Normalized to 50 Ω

RL = 800 Ω

Figure 10

SETTLING TIME

3

2

1

0

−1

− Output Voltage − V

O

V

−2

−3

0 5 10 15 20 25 30 35 40

Rising Edge

Gain = 1

RL = 800 Ω

Rf = 499 Ω

f= 1 MHz

VS = ±5 V

t − Time − ns

Falling Edge

SLEW RATE

vs

DIFFERENTIAL OUTPUT VOLTAGE STEP

2000

Gain = 1

1800

RL = 800 Ω

Rf = 499 Ω

1600

sµ

VS = ±5 V

1400

V/

1200

1000

800

600

SR − Slew Rate −

400

200

0

0.5 1 1.5 2 2.5 3 3.5 4 4.5 50

VO − Differential Output Voltage Step − V

Fall

Rise

Figure 11

LARGE-SIGNAL TRANSIENT RESPONSE

2

1.5

1

0.5

0

−0.5

− Output Voltage − V

O

−1

V

−1.5

−2

−100 0 100 200 300 400 500

Gain = 1

RL = 800 Ω

Rf = 499 Ω

tr/tf = 300 ps

VS = ±5 V

t − Time − ns

1.5

1

0.5

0

−0.5

− Output Voltage − V

O

V

−1

−1.5

0 50 100 150 200 250 300

SETTLING TIME

Rising Edge

Gain = 1

RL = 800 Ω

Rf = 499 Ω

f= 1 MHz

VS = ±5 V

Falling Edge

t − Time − ns

Figure 12

SMALL-SIGNAL TRANSIENT RESPONS

0.4

0.3

0.2

0.1

0

−0.1

− Output Voltage − V

O

−0.2

V

−0.3

−0.4

−100 0 100 200 300 400 500

Gain = 1

RL = 800 Ω

Rf = 499 Ω

tr/tf = 300 ps

VS = ±5 V

t − Time − ns

OVERDRIVE RECOVERY

5

Gain = 4

4

RL = 800 Ω

Rf = 499 Ω

3

Overdrive = 4.5 V

2

VS = ±5 V

1

0

−1

−2

−3

Single-Ended Output Voltage − V

−4

−5

0 0.1 0.2 0.3 0.4 0.5 0.6

10

Figure 13

t − Time − µs

Figure 16

0.7 0.8 0.9 1

2.5

2

1.5

1

0.5

0

−0.5

−1

−1.5

−2

−2.5

Figure 14

OVERDRIVE RECOVERY

6

Gain = 4

5

RL = 800 Ω

4

Rf = 499 Ω

Overdrive = 5.5 V

3

VS = ±5 V

2

1

0

−1

−2

− Input Voltage − VV

I

−3

−4

Single-Ended Output Voltage − V

−5

−6

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

t − Time − µs

Figure 17

3

2

1

0

−1

−2

−3

Figure 15

VOLTAGE AND CURRENT NOISE

vs

FREQUENCY

100

nV/ Hz

10

− Input Voltage − VV

I

− Voltage Noise −

n

V

1

0.01 0.1 1 10 100

f − Frequency − kHz

Figure 18

V

n

I

n

1000 10 k

pA/ Hz

− Current Noise −

n

I

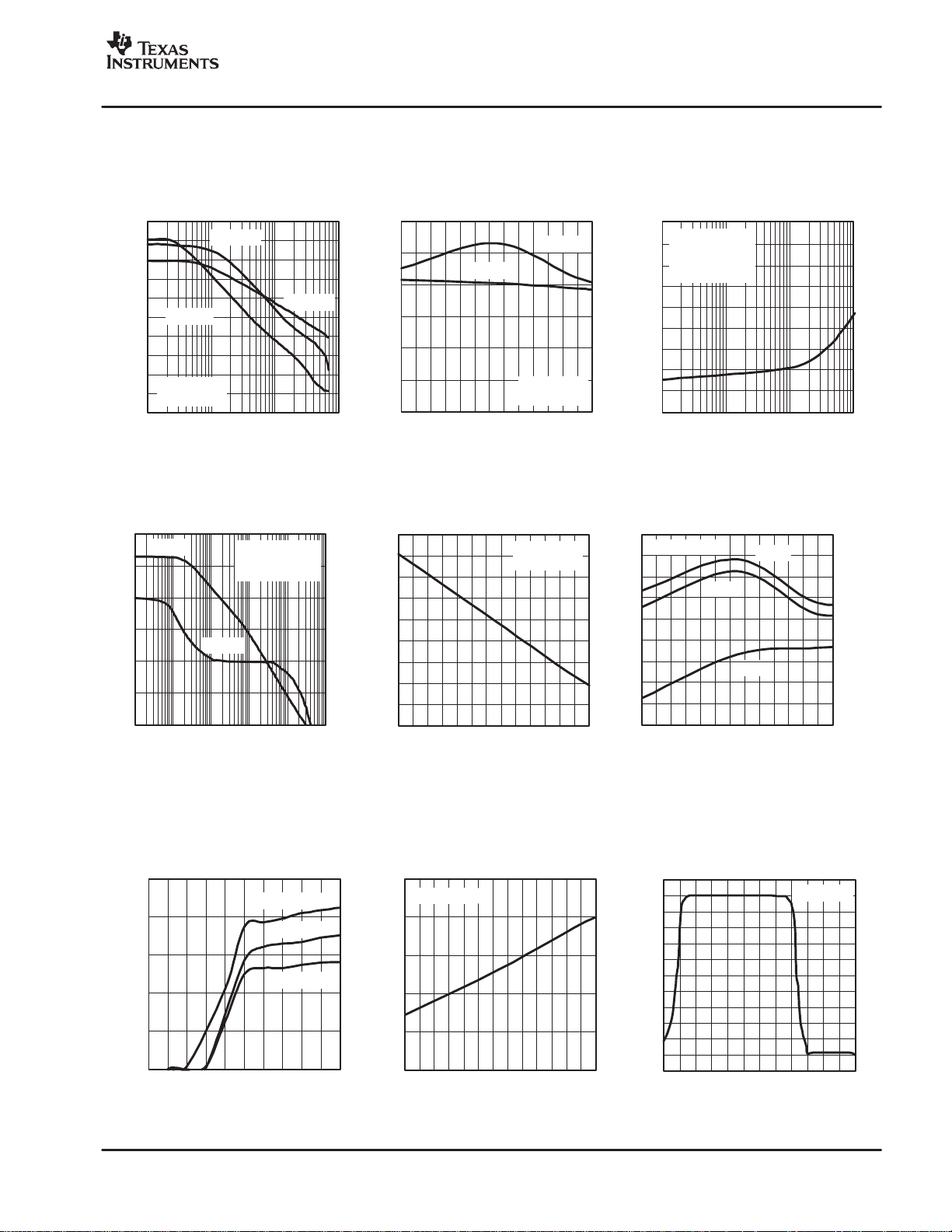

Page 11

www.ti.com

0

INPUT OFFSET VOLTAGE

COMMON-MODE REJECTION RATIO

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

TYPICAL CHARACTERISTICS (±5 V Graphs)

REJECTION RATIOS

vs

90

80

70

60

50

40

30

20

Rejection Ratios − dB

10

0

−10

0.1 1 10 100

FREQUENCY

PSRR−

RL = 800 Ω

VS = ±5 V

f − Frequency − MHz

PSRR+

CMMR

Figure 19

OPEN-LOOP GAIN AND PHASE

vs

60

50

40

30

20

Open-Loop Gain − dB

10

0

0.01 0.1 1 10 100 1000

FREQUENCY

Gain

Phase

f − Frequency − MHz

PIN = −30 dBm

RL = 800 Ω

VS = ±5 V

Figure 22

Rejection Ratios − dB

30

0

−30

°

−60

Phase −

−90

Open-Loop Gain − dB

−120

−150

REJECTION RATIOS

vs

120

100

CASE TEMPERATURE

CMMR

80

60

40

20

0

−40−30−20−10 0 10 20 30 40 50 60 70 80 90

PSRR+

RL = 800 Ω

VS = ±5 V

Case Temperature − °C

Figure 20

OPEN-LOOP GAIN

vs

CASE TEMPERATURE

58

57

56

55

54

53

52

51

50

49

−40−30−20−10 0 10 20 30 40 50 60 70 80 9

Case Temperature − °C

RL = 800 Ω

VS = ±5 V

Figure 23

OUTPUT BALANCE ERROR

vs

10

0

−10

−20

−30

−40

−50

−60

Output Balance Error − dB

−70

−80

0.1 1 10 100

FREQUENCY

PIN = 16 dBm

RL = 800 Ω

Rf = 499 Ω

VS = ±5 V

f − Frequency − MHz

Figure 21

INPUT BIAS AND OFFSET CURRENT

vs

CASE TEMPERATURE

3.4

VS = ±5 V

3.3

Aµ

3.2

3.1

3

2.9

2.8

− Input Bias Current −

2.7

IB

I

2.6

2.5

−40−30−20−100 10 20 30 40 50 60 70 80 90

I

Case Temperature − °C

IB+

I

IB−

I

OS

Figure 24

0

−0.01

Aµ

−0.02

−0.03

−0.04

−0.05

−0.06

− Input Offset Current −

−0.07

OS

I

−0.08

−0.09

QUIESCENT CURRENT

25

20

15

10

Quiescent Current − mA

5

0

SUPPLY VOLTAGE

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

VS − Supply Voltage − ±V

Figure 25

vs

TA = 85°C

TA = 25°C

TA = −40°C

CASE TEMPERATURE

5

VS = ±5 V

4

3

2

− Input Offset Voltage − mV

1

OS

V

0

−40−30−20−10 0 10 20 30 40 50 60 70 80 90

Case Temperature − °C

Figure 26

vs

INPUT COMMON-MODE RANGE

110

100

90

80

70

60

50

40

30

20

10

0

−10

CMRR − Common-Mode Rejection Ratio − dB

−6 −5 −4 −3 −2 −1 0 1 2 3 4 5 6

Input Common-Mode Voltage Range − V

VS = ±5 V

Figure 27

vs

11

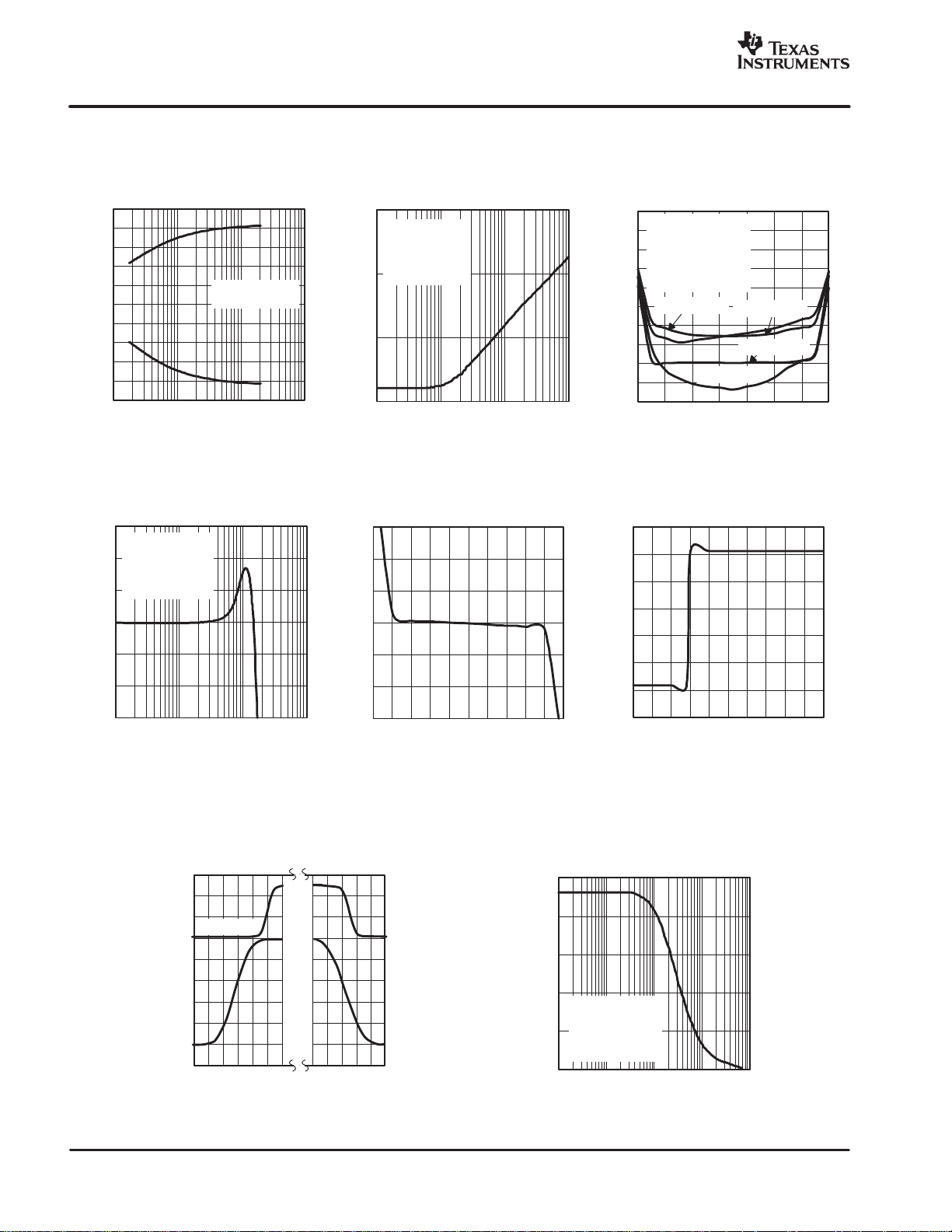

Page 12

E

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

TYPICAL CHARACTERISTICS (±5 V Graphs)

www.ti.com

OUTPUT VOLTAGE

vs

LOAD RESISTANCE

5

4

3

2

1

0

−1

− Output Voltage − VV

−2

O

−3

−4

−5

10 100 1000

RL − Load Resistance − Ω

VS = ±5 V

TA = −40 to 85°C

10000

Figure 28

SMALL SIGNAL FREQUENCY RESPONS

at V

3

− dB

Gain = 1

RL = 400 Ω

OCM

2

Rf = 499 Ω

PIN= −20 dBm

VS = ±5 V

1

0

−1

−2

−3

1 10 100 1000

Small Signal Frequency Response at V

OCM

f − Frequency − MHz

CLOSED-LOOP OUTPUT IMPEDANCE

vs

100

Ω

10

1

− Closed Loop Output Impedance −

O

0.1

Z

FREQUENCY

Gain = 1

RL = 400 Ω

Rf = 499 Ω

VI = −4 dBm

VS = ±5 V

0.1 1 10 100

f − Frequency − MHz

Figure 29

OUTPUT OFFSET VOLTAGE at V

OCM

vs

OUTPUT COMMON-MODE VOLTAGE

600

400

200

0

−200

− Output Offset Voltage − mV

−400

OS

V

−600

−5 −4 −3 −2 −1 0 1 2 3 4 5

VOC − Output Common-Mode Voltage − V

HARMONIC DISTORTION

vs

OUTPUT COMMON-MODE VOLTAGE

0

Single-Ended to

−10

Differential Output

Gain = 1

−20

VO = 2 V

−30

−40

−50

−60

−70

−80

Harmonic Distortion − dBc

−90

−100

−3.5 −2.5 −1.5 −0.5 0.5 1.5 2.5 3.5

V

OCM

PP

Rf = 499 Ω

VS = ±5 V

HD3, 30 MHz

− Output Common-Mode Voltage − V

HD2, 30 MHz

HD2, 8 MHz

HD2, 3 MHz

Figure 30

QUIESCENT CURRENT

vs

POWER-DOWN VOLTAGE

30

25

20

15

10

5

Quiescent Current − mA

0

−5

−5 −4.5 −4 −3.5 −3 −2.5 −2 −1.5 −1 −0.5 0

Power-Down Voltage − V

12

Figure 31

TURNON AND TURNOFF DELAY TIME

Current

0

−1

−2

−3

−4

Powerdown Voltage Signal − V

−5

−6

0 0.5 1 2

1.5 2.5 3

t − Time − ms

100.5101 102 103

Figure 34

Figure 32

0.03

0.02

0.01

0

Quiescent Current − mA

Figure 33

SINGLE-ENDED OUTPUT IMPEDANCE

IN POWER DOWN

vs

FREQUENCY

1500

1200

Ω

900

600

Gain = 1

in Powerdown −

RL = 800 Ω

Rf = 499 Ω

300

− Single-Ended Output Impedance

O

Z

VI = −1 dBm

VS = ±5 V

0

0.1 1 10 100 1000

f − Frequency − MHz

Figure 35

Page 13

www.ti.com

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

TYPICAL CHARACTERISTICS (±5 V Graphs)

POWER-DOWN QUIESCENT CURRENT

vs

1000

Aµ

Power-Down Quiescent Current −

CASE TEMPERATURE

RL = 800 Ω

900

VS = ±5 V

800

700

600

500

400

300

200

100

0

−40−30−20−10 0 10 20 30 40 50 60 70 80 90

Case Temperature − °C

Figure 36

POWER-DOWN QUIESCENT CURRENT

vs

1000

900

800

700

600

500

400

300

200

100

Power-Down Quiescent Current − Aµ

SUPPLY VOLTAGE

RL = 800 Ω

0

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

VS − Supply Voltage − ±V

Figure 37

13

Page 14

E

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

TYPICAL CHARACTERISTICS (5 V Graphs)

www.ti.com

SMALL SIGNAL UNITY GAIN FREQUENCY

RESPONSE

1

0

−1

−2

Gain = 1

RL = 800 Ω

Rf = 499 Ω

−3

Small Signal Unity Gain − dB

PIN = −20 dBm

VS = 5 V

−4

0.1 1 10 100 1000

f − Frequency − MHz

Figure 38

LARGE SIGNAL FREQUENCY RESPONSE

25

Gain = 10, Rf = 1.8 kΩ

20

Gain = 5, Rf = 1.8 kΩ

15

10

Gain = 2, Rf = 1.8 kΩ

5

Large Signal Gain − dB

Gain = 1, Rf = 1.8 kΩ

0

−5

0.1 1 10 100 1000

f − Frequency − MHz

RL = 800 Ω

VO = 2 V

VS = 5 V

PP

Figure 41

SMALL SIGNAL FREQUENCY RESPONS

22

Gain = 10

20

18

16

Gain = 5

14

12

10

8

Gain = 2

6

RL = 800 Ω

4

Small Signal Gain − dB

Rf = 499 Ω

2

PIN = −20 dBm

0

VS = 5 V

−2

0.1 1 10 100 1000

f − Frequency − MHz

Figure 39

HARMONIC DISTORTION

vs

FREQUENCY

0

Single-Ended Input to

−10

Differential Output

Gain = 1

−20

RL = 800 Ω

−30

Rf = 499 Ω

VO = 2 V

−40

−50

−60

−70

−80

Harmonic Distortion − dBc

−90

−100

0.1 1 10 100

VS = 5 V

PP

HD3

HD2

f − Frequency − MHz

Figure 42

0.1 dB GAIN FLATNESS

FREQUENCY RESPONSE

0.05

0

Gain = 1

RL = 800 Ω

PIN = −20 dBm

VS = 5 V

1

Rf = 499 Ω

10 100 1000

f − Frequency − MHz

−0.05

−0.1

−0.15

−0.2

0.1 dB Gain Flatness − dB

−0.25

−0.3

Figure 40

HARMONIC DISTORTION

vs

OUTPUT VOLTAGE SWING

0

Single-Ended Input to

−10

Differential Output

Gain = 1

−20

RL = 800 Ω

−30

Rf = 499 Ω

f= 8 MHz

−40

VS = 5 V

−50

−60

−70

−80

Harmonic Distortion − dBc

−90

−100

00 0.5 1 1.5 2 2.5 3 3.5 4

VO − Output Voltage Swing − V

HD3

HD2

Figure 43

HARMONIC DISTORTION

vs

OUTPUT VOLTAGE SWING

0

Single-Ended Input to

−10

Differential Output

Gain = 1

−20

RL = 800 Ω

−30

Rf = 499 Ω

f= 30 MHz

−40

VS = 5 V

−50

−60

−70

−80

Harmonic Distortion − dBc

−90

−100

HD3

0 0.5 1 1.5 2 2.5 3 3.5 4

VO − Output Voltage Swing − V

Figure 44

14

HARMONIC DISTORTION

vs

LOAD RESISTANCE

0

−10

−20

−30

HD2

−40

−50

−60

−70

Harmonic Distortion − dBc

−80

−90

−100

HD3, 30 MHz

HD3, 8 MHz

0 400 800 1200 1600

RL − Load Resistance − Ω

Single-Ended Input to

Differential Output

Gain = 1

VO = 2 V

PP

Rf = 499 Ω

VS = ±5 V

HD2, 30 MHz

HD2, 8 MHz

−30

−40

−50

−60

−70

−80

−90

−100

Third-Order Intermodulation Distortion − dBc

10 100

Figure 45

DISTORTION

vs

FREQUENCY

Single-Ended Input to

Differential Output

Gain = 1

RL = 800 Ω

Rf = 499 Ω

VS = 5 V

200 kHz Tone Spacing

f − Frequency − MHz

Figure 46

VO = 2 V

VO = 1 V

PP

PP

THIRD-ORDER INTERMODULATION

Page 15

www.ti.com

E

E

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

TYPICAL CHARACTERISTICS (5 V Graphs)

THIRD-ORDER OUTPUT INTERCEPT

POINT

vs

60

50

40

30

20

10

3

0

OIP − Third-Order Output Intersept Point − dBm

FREQUENCY

Gain = 1

Rf = 499 Ω

VO = 2 V

PP

VS = 5 V

200 kHz Tone Spacing

Normalized to 50 Ω

Normalized to 200 Ω

RL = 800 Ω

0 20 40 60 80 100

f − Frequency − MHz

Figure 47

SETTLING TIME

3

Rising Edge

2

t − Time − ns

Gain = 1

RL = 800 Ω

Rf = 499 Ω

f= 1 MHz

VS = 5 V

Falling Edge

1

0

−1

− Output Voltage − V

O

V

−2

−3

0 5 10 15 20 25 30 35 40

SLEW RATE

vs

DIFFERENTIAL OUTPUT VOLTAGE STEP

1200

Gain = 1

RL = 800 Ω

1000

Rf = 499 Ω

sµ

VS = 5 V

V/

800

600

400

SR − Slew Rate −

200

0

0.5 1 1.5 2 2.5 3 3.5 40

VO − Differential Output Voltage Step − V

Fall

Rise

Figure 48

OVERDRIVE RECOVERY

5

Gain = 4

4

RL = 800 Ω

Rf = 499 Ω

3

Overdrive = 4.5 V

2

VS = ±5 V

1

0

−1

−2

−3

Single-Ended Output Voltage − V

−4

−5

0 0.1 0.2 0.3 0.4 0.5 0.6

t − Time − µs

0.7 0.8 0.9 1

2.5

2

1.5

1

0.5

0

−0.5

−1

−1.5

−2

−2.5

1.5

1

0.5

0

−0.5

− Output Voltage − V

O

V

−1

−1.5

50 100 150 200 250 300

0

t − Time − ns

Figure 49

OVERDRIVE RECOVERY

6

Gain = 4

5

RL = 800 Ω

4

Rf = 499 Ω

Overdrive = 5.5 V

3

VS = ±5 V

2

1

0

−1

−2

− Input Voltage − VV

I

−3

−4

Single-Ended Output Voltage − V

−5

−6

SETTLING TIME

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

t − Time − µs

Rising Edge

Gain = 1

RL = 800 Ω

Rf = 499 Ω

f= 1 MHz

VS = 5 V

Falling Edge

3

2

1

0

−1

− Input Voltage − VV

I

−2

−3

Figure 50

LARGE-SIGNAL TRANSIENT RESPONS

2

1.5

1

0.5

0

−0.5

− Output Voltage − V

O

−1

V

−1.5

−2

−100 0 100 200 300 400 500

Gain = 1

RL = 800 Ω

Rf = 499 Ω

tr/tf = 300 ps

VS = ±5 V

t − Time − ns

Figure 53

Figure 51

SMALL-SIGNAL TRANSIENT RESPONS

0.4

0.3

0.2

0.1

0

−0.1

− Output Voltage − V

O

−0.2

V

−0.3

−0.4

−100 0 100 200 300 400 500

Gain = 1

RL = 800 Ω

Rf = 499 Ω

tr/tf = 300 ps

VS = ±5 V

t − Time − ns

Figure 54

Figure 52

VOLTAGE AND CURRENT NOISE

vs

FREQUENCY

100

nV/ Hz

10

− Voltage Noise −

n

V

1

0.01 0.1 1 10 100

f − Frequency − kHz

I

n

Figure 55

V

n

1000 10 k

− Current Noise − pA/ Hz

I

15

n

Page 16

0

0

0

Open-Loop Gain − dB

Phase −

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

TYPICAL CHARACTERISTICS (5 V Graphs)

www.ti.com

REJECTION RATIOS

vs

90

80

70

60

50

40

30

20

Rejection Ratios − dB

10

0

−10

0.1 1 10 100

FREQUENCY

PSRR−

RL = 800 Ω

VS = 5 V

f − Frequency − MHz

PSRR+

CMMR

Figure 56

OPEN-LOOP GAIN AND PHASE

vs

60

50

40

30

20

10

0

0.01 0.1 1 10 100 1000

FREQUENCY

Gain

Phase

f − Frequency − MHz

PIN = −30 dBm

RL = 800 Ω

VS = 5 V

Figure 59

30

0

−30

−60

−90

−12

−15

REJECTION RATIOS

CASE TEMPERATURE

120

100

PSRR−

80

60

40

Rejection Ratios − dB

20

0

−40−30−20−10 0 10 20 30 40 50 60 70 80 90

PSRR+

Case Temperature − °C

Figure 57

OPEN-LOOP GAIN

vs

CASE TEMPERATURE

57

56

55

54

°

53

52

51

50

49

Open-Loop Gain − dB

48

47

46

−40−30−20−100 10 20 30 40 50 60 70 80 90

Case Temperature − °C

Figure 60

vs

CMMR

RL = 800 Ω

VS = 5 V

RL = 800 Ω

VS = 5 V

OUTPUT BALANCE ERROR

vs

FREQUENCY

0

PIN = 16 dBm

−10

RL = 800 Ω

Rf = 499 Ω

−20

VS = 5 V

−30

−40

−50

−60

Output Balance Error − dB

−70

−80

0.1 1 10 10

f − Frequency − MHz

Figure 58

INPUT BIAS AND OFFSET CURRENT

vs

CASE TEMPERATURE

3.75

VS = 5 V

Aµ

3.5

3.25

3

2.75

2.5

2.25

− Input Bias Current −

2

IB

I

1.75

1.5

1.25

−40−30−20−10 0 10 20 30 40 50 60 70 80 90

Case Temperature − °C

I

IB+

I

IB−

I

OS

Figure 61

0

−0.01

Aµ

−0.02

−0.03

−0.04

−0.05

−0.06

−0.07

− Input Offset Current −

−0.08

OS

I

−0.09

−0.1

Quiescent Current − mA

16

QUIESCENT CURRENT

vs

25

20

15

10

5

0

SUPPLY VOLTAGE

TA = 85°C

TA = 25°C

TA = −40°C

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

VS − Supply Voltage − ±V

Figure 62

INPUT OFFSET VOLTAGE

vs

CASE TEMPERATURE

5

VS = 5 V

4

3

2

− Input Offset Voltage − mV

1

OS

V

0

−40−30−20−10 0 10 20 30 40 50 60 70 80 90

Case Temperature − °C

Figure 63

COMMON-MODE REJECTION RATIO

vs

INPUT COMMON-MODE RANGE

110

100

90

80

70

60

50

40

30

20

10

0

−10

CMRR − Common-Mode Rejection Ratio − dB

−1012345

Input Common-Mode Range − V

VS = 5 V

Figure 64

Page 17

www.ti.com

E

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

TYPICAL CHARACTERISTICS (5 V Graphs)

OUTPUT VOLTAGE

vs

LOAD RESISTANCE

5

4

3

2

1

0

−1

− Output Voltage − VV

−2

O

−3

−4

−5

10 100 1000

RL − Load Resistance − Ω

VS = ±5 V

TA = −40 to 85°C

10000

Figure 65

SMALL SIGNAL FREQUENCY RESPONSE

at V

3

− dB

Gain = 1

RL = 400 Ω

OCM

2

Rf = 499 Ω

PIN= −20 dBm

VS = 5 V

1

0

−1

−2

−3

1 10 100 1000

Small Signal Frequency Response at V

OCM

f − Frequency − MHz

Figure 68

CLOSED-LOOP OUTPUT IMPEDANCE

vs

100

Ω

10

1

− Closed Loop Output Impedance −

O

0.1

Z

0.1 1 10 100

FREQUENCY

Gain = 1

RL = 400 Ω

Rf = 499 Ω

VIN = −4 dBm

VS = 5 V

f − Frequency − MHz

Figure 66

OUTPUT OFFSET VOLTAGE

vs

OUTPUT COMMON-MODE VOLTAG

800

600

400

200

0

−200

−400

− Output Offset Voltage − mV

−600

OS

V

−800

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

VOC − Output Common-Mode Voltage − V

Figure 69

HARMONIC DISTORTION

vs

OUTPUT COMMON-MODE VOLTAGE

0

−10

−20

−30

−40

−50

−60

Harmonic Distortion − dBc

−70

−80

Single-Ended to

Differential Output

Gain = 1, VO = 2 V

Rf = 499 Ω, VS = 5 V

HD3, 30 MHz

1.5

HD3, 8 MHz

2

HD2,

8 MHz

1

VOC − Output Common-Mode Voltage − V

PP

HD2, 30 MHz

2.5

3

Figure 67

QUIESCENT CURRENT

vs

POWER-DOWN VOLTAGE

25

VS = 5 V

20

15

10

Quiescent Current − mA

5

0

0 0.25 0.5 0.75 1 1.25 1.5 1.75 2 2.25 2.5

Power-down Voltage − V

Figure 70

3.5

4

TURNON AND TURNOFF DELAY TIME

0.03

0.02

Current

0

−1

−2

−3

−4

Power-Down Voltage Signal − V

−5

−6

0 0.5 1 2

1.5 2.5 3

100.5101 102 103

t − Time − ms

0.01

0

Quiescent Current − mA

Figure 71

17

Page 18

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

TYPICAL CHARACTERISTICS (5 V Graphs)

www.ti.com

SINGLE-ENDED OUTPUT IMPEDANCE

IN POWER DOWN

vs

FREQUENCY

1500

1200

Ω

900

600

Gain = 1

in Power Down −

RL = 800 Ω

Rf = 499 Ω

300

− Single-Ended Output Impedance

O

Z

PIN = −1 dBm

VS = 5 V

0

0.1 1 10 100 1000

f − Frequency − MHz

Figure 72

POWER-DOWN QUIESCENT CURRENT

vs

CASE TEMPERATURE

800

RL = 800 Ω

700

VS = 5 V

600

500

400

300

200

100

Power-Down Quiescent Current − Aµ

0

−40−30−20−10 0 10 20 30 40 50 60 70 80 90

Case Temperature − °C

Figure 73

POWER-DOWN QUIESCENT CURRENT

vs

SUPPLY VOLTAGE

0

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

VS − Supply Voltage − V

Power-Down Quiescent Current − Aµ

1000

900

800

700

600

500

400

300

200

100

Figure 74

18

Page 19

www.ti.com

APPLICATION INFORMATION

FULLY DIFFERENTIAL AMPLIFIERS

Differential signaling offers a number of performance

advantages in high-speed analog signal processing

systems, including immunity to external common-mode

noise, suppression of even-order nonlinearities, and

increased dynamic range. Fully differential amplifiers not

only serve as the primary means of providing gain to a

differential signal chain, but also provide a monolithic

solution for converting single-ended signals into

differential signals for easier, higher performance

processing. The THS4500 family of amplifiers contains the

flagship products in Texas Instruments’ expanding line of

high-performance fully differential amplifiers. Information

on fully differential amplifier fundamentals, as well as

implementation specific information, is presented in the

applications section of this data sheet to provide a better

understanding of the operation of the THS4500 family of

devices, and to simplify the design process for designs

using these amplifiers.

The THS4504 and THS4505 are intended to be low-cost

alternatives to the THS4500/1/2/3 devices. From a

topology standpoint, the THS4504/5 have the same

architecture as the THS4500/1. Specifically, the input

common-mode range is designed to include the negative

power supply rail.

Applications Section

D Fully Differential Amplifier Terminal Functions

D Input Common-Mode Voltage Range and the

THS4500 Family

D Choosing the Proper Value for the Feedback and

Gain Resistors

D Application Circuits Using Fully Differential

Amplifiers

D Key Design Considerations for Interfacing to an

Analog-to-Digital Converter

D Setting the Output Common-Mode Voltage With the

V

Input

OCM

D Saving Power with Power-Down Functionality

D Linearity: Definitions, Terminology, Circuit

Techniques, and Design Tradeoffs

D An Abbreviated Analysis of Noise in Fully

Differential Amplifiers

D Printed-Circuit Board Layout Techniques for Optimal

Performance

D Power Dissipation and Thermal Considerations

D Power Supply Decoupling Techniques and

Recommendations

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

D Evaluation Fixtures, Spice Models, and Applications

Support

D Additional Reference Material

FULLY DIFFERENTIAL AMPLIFIER

TERMINAL FUNCTIONS

Fully differential amplifiers are typically packaged in

eight-pin packages as shown in the diagram. The device

pins include two inputs (V

V

), two power supplies (VS+, VS−), an output

OUT+

common-mode control pin (V

power-down pin (PD).

V

1

IN−

V

V

OCM

V

S+

OUT+

2

3

4

Fully Differential Amplifier Pin Diagram

A standard configuration for the device is shown in the

figure. The functionality of a fully differential amplifier can

be imagined as two inverting amplifiers that share a

common noninverting terminal (though the voltage is not

necessarily fixed). For more information on the basic

theory of operation for fully differential amplifiers, refer to

the Texas Instruments application note titled Fully

Differential Amplifiers, literature number SLOA054.

INPUT COMMON-MODE VOLTAGE RANGE

AND THE THS4500 FAMILY

The key difference between the THS4500/1 and the

THS4502/3 is the input common-mode range for the two

devices. The input common-mode range of the

THS4504/5 is the same as the THS4500/1. The THS4502

and THS4503 have an input common-mode range that is

centered around midrail, and the THS4500 and THS4501

have an input common-mode range that is shifted to

include the negative power supply rail. Selection of one or

the other is determined by the nature of the application.

Specifically, the THS4500 and THS4501 are designed for

use in single-supply applications where the input signal is

ground-referenced, as depicted in Figure 75. The

THS4502 and THS4503 are designed for use in

single-supply or split-supply applications where the input

signal is centered between the power supply voltages, as

depicted in Figure 76.

IN+

, V

), two outputs (V

IN−

), and an optional

OCM

OUT−

V

8

IN+

7

PD

6

V

S−

V

5

OUT−

,

19

Page 20

V

(1–β)–V

(1–β))2V

V

2β

)

)

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

www.ti.com

R

S

V

S

Application Circuit for the THS4500 and THS4501,

Featuring Single-Supply Operation With a

Ground-Referenced Input Signal

R

g1

R

T

V

OCM

R

g2

R

f1

+V

S

+

−

+

−

R

f2

Figure 75

R

S

V

S

Application Circuit for the THS4500 and THS4501,

Featuring Split-Supply Operation With an Input

Signal Referenced at the Midrail

R

g1

R

T

V

OCM

R

g2

+V

+

−

−V

R

f1

S

−

+

S

R

f2

Figure 76

Equations 1−5 allow for calculation of the required input

common-mode range for a given set of input conditions.

The equations allow calculation of the input commonmode range requirements given information about the

input signal, the output voltage swing, the gain, and the

output common-mode voltage. Calculating the maximum

and minimum voltage required for VN and VP (the

amplifier’s input nodes) determines whether or not the

input common-mode range is violated or not. Four

equations are required. Two calculate the output voltages

and two calculate the node voltages at VN and VP (note

that only one of these needs calculation, as the amplifier

forces a virtual short between the two nodes).

V

OUT)

OUT–

+

+

–V

VN+ V

Where: β +

VP+ V

IN)

(1–β) ) V

IN)

(1–β) ) V

IN–

RF) R

(1–β) ) V

IN)

IN–

2β

(1–β)) 2V

IN–

β

OUT)

R

G

G

β

OUT–

OCM

β

OCM

(1

β

(2

(3)

(4)

(5)

NOTE:

The equations denote the device inputs as VN and

V

, and the circuit inputs as V

P

20

IN+

and V

IN−

.

R

V

IN+

V

IN−

Diagram For Input Common-Mode Range Equations

g

V

p

V

OCM

V

n

R

g

R

f

+

−

+

−

R

f

V

OUT−

V

OUT+

Figure 77

The two tables below depict the input common-mode

range requirements for two different input scenarios, an

input referenced around the negative rail and an input

referenced around midrail. The tables highlight the

differing requirements on input common-mode range, and

illustrate reasoning for choosing either the THS4500/1 or

the THS4502/3. For signals referenced around the

negative power supply, the THS4500/1 should be chosen

since its input common-mode range includes the negative

supply rail. For all other situations, the THS4502/3 offers

slightly improved distortion and noise performance for

applications with input signals centered between the

power supply rails.

Table 1. Negative-Rail Referenced

Gain

V

(V/V)

−2.0 to

1

−1.0 to

2

−0.5 to

4

−0.25 to

8

NOTE: This table assumes a negative-rail referenced, single-ended

input signal on a single 5-V supply as shown in Figure 75.

V

(V)

IN+

2.0

1.0

0.5

0.25

NMIN

V

V

IN

(VPP)

and V

V

NMAX

IN−

(V)

0 4 2.5 4 0.75 1.75

0 2 2.5 4 0.5 1.167

0 1 2.5 4 0.3 0.7

0 0.5 2.5 4 0.167 0.389

= V

PMIN

OCM

(V)

= V

V

OD

(VPP)

PMAX

V

NMIN

(V)

.

V

NMAX

(V)

Table 2. Midrail Referenced

Gain

V

(V/V)

1

2

4

2.25 to

8

NOTE: This table assumes a midrail referenced, single-ended input

signal on a single 5-V supply.

V

IN+

0.5 to

4.5

1.5 to

3.5

2.0 to

3.0

2.75

NMIN

V

V

IN

(VPP)

and V

V

NMAX

IN−

(V)

(V)

2.5 4 2.5 4 2 3

2.5 2 2.5 4 2.16 2.83

2.5 1 2.5 4 2.3 2.7

2.5 0.5 2.5 4 2.389 2.61

= V

PMIN

OCM

(V)

= V

V

OD

(VPP)

PMAX

V

.

NMIN

(V)

V

NMAX

(V)

Page 21

www.ti.com

R

1

R2

T

6)

R3)RT|| R

)

)

)

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

CHOOSING THE PROPER VALUE FOR THE

FEEDBACK AND GAIN RESISTORS

The selection of feedback and gain resistors impacts

circuit performance in a number of ways. The values in this

section provide the optimum high frequency performance

(lowest distortion, flat frequency response). Since the

THS4500 family of amplifiers is developed with a voltage

feedback architecture, the choice of resistor values does

not have a dominant effect on bandwidth, unlike a current

feedback amplifier. However, resistor choices do have

second-order effects. For optimal performance, the

following feedback resistor values are recommended. In

higher gain configurations (gain greater than two), the

feedback resistor values have much less ef fect on the high

frequency performance. Example feedback and gain

resistor values are given in the section on basic design

considerations (Table 3).

Amplifier loading, noise, and the flatness of the frequency

response are three design parameters that should be

considered when selecting feedback resistors. Larger

resistor values contribute more noise and can induce

peaking in the ac response in low gain configurations, and

smaller resistor values can load the amplifier more heavily,

resulting in a reduction in distortion performance. In

addition, feedback resistor values, coupled with gain

requirements, determine the value of the gain resistors,

directly impacting the input impedance of the entire circuit.

While there are no strict rules about resistor selection,

these trends can provide qualitative design guidance.

Table 3. Resistor Values for Balanced Operation

in Various Gain Configurations

V

OD

ǒ

Gain

V

1 392 412 383 54.9

1 499 523 487 53.6

2 392 215 187 60.4

2 1.3k 665 634 52.3

5 1.3k 274 249 56.2

5 3.32k 681 649 52.3

10 1.3k 147 118 64.9

10 6.81k 698 681 52.3

NOTE: Values in the table above assume a 50 Ω source impedance.

V

R2 & R4 (Ω) R1 (Ω) R3 (Ω) RT (Ω)

Ǔ

IN

R1

R

S

S

R3

R

T

R2

V

n

−

+

−

+

V

P

R4

V

out+

V

out−

V

OCM

Figure 78

Equations for calculating fully differential amplifier resistor

values in order to obtain balanced operation in the

presence of a 50-Ω source impedance are given in

equations 6 through 9.

APPLICATION CIRCUITS USING FULLY

DIFFERENTIAL AMPLIFIERS

Fully differential amplifiers provide designers with a great

deal of flexibility in a wide variety of applications. This

section provides an overview of some common circuit

configurations and gives some design guidelines.

Designing the interface to an ADC, driving lines

differentially, and filtering with fully differential amplifiers

are a few of the circuits that are covered.

BASIC DESIGN CONSIDERATIONS

The circuits in Figures 75 through 78 are used to highlight

basic design considerations for fully differential amplifier

circuit designs.

T

β1+

V

V

V

V

+

1

R

S

R1 ) R2

OD

+ 2

S

OD

+ 2

IN

–

R1

ǒ

1–

2(1)K)

1–β

ǒ

β1) β

1–β

β1) β

R3

β2+

K

2

Ǔǒ

2

2

Ǔ

2

K +

R1

R2 + R4

R3 + R1 *ǒRs|| R

S

R3 ) RT|| RS) R4

R

T

RT) R

Ǔ

S

(

Ǔ

(7

(8

(9

For more detailed information about balance in fully

differential amplifiers, see Fully Differential Amplifiers,

referenced at the end of this data sheet.

21

Page 22

C

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

www.ti.com

INTERFACING TO AN ANALOG-TO-DIGITAL

CONVERTER

The THS4500 family of amplifiers are designed

specifically to interface to today’s highest-performance

analog-to-digital converters. This section highlights the

key concerns when interfacing to an ADC and provides

example ADC/fully differential amplifier interface circuits.

Key design concerns when interfacing to an

analog-to-digital converter:

D Terminate the input source properly . In high-frequency

receiver chains, the source feeding the fully

differential amplifier requires a specific load

impedance (e.g., 50 Ω).

D Design a symmetric printed-circuit board layout.

Even-order distortion products are heavily influenced

by layout, and careful attention to a symmetric layout

will minimize these distortion products.

D Minimize inductance in power supply decoupling

traces and components. Poor power supply

decoupling can have a dramatic effect on circuit

performance. Since the outputs are differential,

differential currents exist in the power supply pins.

Thus, decoupling capacitors should be placed in a

manner that minimizes the impedance of the current

loop.

D Use separate analog and digital power supplies and

grounds. Noise (bounce) in the power supplies

(created by digital switching currents) can couple

directly into the signal path, and power supply noise

can create higher distortion products as well.

D Use care when filtering. While an RC low-pass filter

may be desirable on the output of the amplifier to filter

broadband noise, the excess loading can negatively

impact the amplifier linearity. Filtering in the feedback

path does not have this effect.

D AC-coupling allows easier circuit design. If

dc-coupling is required, be aware of the excess power

dissipation that can occur due to level-shifting the

output through the output common-mode voltage

control.

D Do not terminate the output unless required. Many

open-loop, class-A amplifiers require 50-Ω

termination for proper operation, but closed-loop fully

differential amplifiers drive a specific output voltage

regardless of the load impedance present.

Terminating the output of a fully differential amplifier

with a heavy load adversely effects the amplifier’s

linearity.

D Comprehend the V

Determine if t h e ADC’s voltage reference can provide

input drive requirements.

OCM

the required amount of current to move V

OCM

to the

desired value. A buffer may be needed.

D Decouple the V

effect. V

is a high-impedance node that can act as

OCM

pin to eliminate the antenna

OCM

an antenna. A large decoupling capacitor on this node

eliminates this problem.

D Be cognizant of the input common-mode range. If the

input signal is referenced around the negative power

supply rail (e.g., around ground on a single 5 V

supply), then the THS4500/1 accommodates the

input signal. If the input signal is referenced around

midrail, choose the THS4502/3 for the best operation.

D Packaging makes a difference at higher frequencies.

If possible, choose the smaller, thermally enhanced

MSOP package for the best performance. As a rule,

lower junction temperatures provide better

performance. If possible, use a thermally enhanced

package, even if the power dissipation is relatively

small compared to the maximum power dissipation

rating to achieve the best results.

D Comprehend the effect of the load impedance seen by

the fully differential amplifier when performing

system-level intercept point calculations. Lighter

loads (such as those presented by an ADC) allow

smaller intercept points to support the same level of

intermodulation distortion performance.

EXAMPLE ANALOG-TO-DIGITAL

CONVERTER DRIVER CIRCUITS

The THS4500 family of devices is designed to drive

high-performance ADCs with extremely high linearity,

allowing for the maximum effective number of bits at the

output of the data converter. Two representative circuits

shown below highlight single-supply operation and split

supply operation. Specific feedback resistor , gain resistor,

and feedback capacitor values are not specified, as their

values depend on the frequency of interest. Information on

calculating these values can be found in the applications

material above.

F

R

R

g

S

V

S

Using the THS4503 With the ADS5410

R

T

+

V

−

1 µF

R

−5 V

g

R

5 V

10 µF 0.1 µF

−

OCM

+

THS4503

10 µF 0.1 µF

R

Figure 79

f

iso

iso

5 V

IN

ADS5410

12 Bit/80 MSps

IN

CM

0.1 µF

R

R

f

C

F

22

Page 23

www.ti.com

C

C

F

R

R

g

S

V

S

R

T

+

V

−

1 µF

R

g

5 V

OCM

−

+

R

f

10 µF 0.1 µF

THS4501

R

f

C

F

R

iso

R

iso

5 V

ADS5421

IN

14 Bit/40 MSps

IN

CM

0.1 µF

Using the THS4501 With the ADS5421

Figure 80

FULLY DIFFERENTIAL LINE DRIVERS

The THS4500 family of amplifiers can be used as

high-frequency, high-swing differential line drivers. Their

high power supply voltage rating (16.5 V absolute

maximum) allows operation on a single 12-V or a single

15-V supply. The high supply voltage, coupled with the

ability to provide differential outputs enables the ability to

drive 26 VPP into reasonably heavy loads (250 Ω or

greater). The circuit in Figure 81 illustrates the THS4500

family of devices used as high speed line drivers. For line

driver applications, close attention must be paid to thermal

design constraints due to the typically high level of power

dissipation.

C

G

R

T

0.1 µF

R

g

V

OCM

R

R

S

V

S

g

R

f

15 V

+

−

THS4504 V

+

−

R

f

C

G

DD

R

iso

R

iso

VOD = 26 V

C

S

R

C

S

PP

Fully Differential Line Driver With High Output Swing

Figure 81

FILTERING WITH FULLY DIFFERENTIAL

AMPLIFIERS

Similar to their single-ended counterparts, fully differential

amplifiers have the ability to couple filtering functionality

with voltage gain. Numerous filter topologies can be based

on fully differential amplifiers. Several of these are outlined

in A Differential Circuit Collection, (literature number

SLOA064) referenced at the end of this data sheet. The

circuit below depicts a simple two-pole low-pass filter

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

applicable to many different types of systems. The first

pole is set by the resistors and capacitors in the feedback

paths, and the second pole is set by the isolation resistors

and the capacitor across the outputs of the isolation

resistors.

F1

R

S

V

S

R

g1

R

T

R

g2

A Two-Pole, Low-Pass Filter Design Using a Fully

Differential Amplifier With Poles Located at:

P1 = (2πRfCF)−1 in Hz and P2 = (4πR

Figure 82

Often times, filters like these are used to eliminate

broadband noise and out-of-band distortion products in

signal acquisition systems. It should be noted that the

increased load placed on the output of the amplifier by the

second low-pass filter has a detrimental effect on the

distortion performance. The preferred method of filtering

is using the feedback network, as the typically smaller

capacitances required at these points in the circuit do not

load the amplifier nearly as heavily in the pass-band.

SETTING THE OUTPUT COMMON-MODE

VOLTAGE WITH THE V

L

The output common-mode voltage pin provides a critical

function to the fully dif ferential amplifier; it accepts an input

voltage and reproduces that input voltage as the output

common-mode voltage. In other words, the V

provides the ability to level-shift the outputs to any voltage

inside the output voltage swing of the amplifier.

A description of the input circuitry of the V

below to facilitate an easier understanding of the V

interface requirements. The V

resistors between the power supply rails to set the default

output common-mode voltage to midrail. A voltage

applied to the V

voltage as long as the source has the ability to provide

enough current to overdrive the two 50-kΩ resistors. This

phenomenon is depicted in the V

diagram. The table contains some representative

examples to aid in determining the current drive

requirement for the V

is especially important when using the reference voltage

pin alters the output common-mode

OCM

voltage source. This parameter

OCM

+

−

OCM

OCM

R

f1

R

iso

−

+

R

iso

R

f2

C

F2

C)−1 in Hz

iso

INPUT

OCM

pin is shown

OCM

pin has two 50-kΩ

equivalent circuit

OCM

C

V

O

input

OCM

23

Page 24

V

V

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

www.ti.com

of an analog-to-digital converter to drive V

OCM

. Output

current drive capabilities differ from part to part, so a

voltage buffer may be necessary in some applications.

V

S+

R = 50 kΩ

V

OCM

I

IN

Equivalent Input Circuit for V

R = 50 kΩ

V

S−

IIN =

OCM

2 V

OCM

− VS+ − V

R

S−

Figure 83

I1 =

R

T

V

OCM

R

g1

= 2.5 V

R

g2

I2 =

Rf2 + R

R

S

S

Depiction of DC Power Dissipation Caused By

Output Level-Shifting in a DC-Coupled Circuit

OCM

Rf1+ Rg1 + RS || R

DC Current Path to Ground

5 V

+

−

DC Current Path to Ground

V

OCM

g2

T

R

f1

−

+

R

f2

2.5-V DC

R

2.5-V DC

L

Figure 84

By design, the input signal applied to the V

propagates to the outputs as a common-mode signal. As

shown in the equivalent circuit diagram, the V

has a high impedance associated with it, dictated by the

two 50-kΩ resistors. While the high impedance allows for

relaxed drive requirements, it also allows the pin and any

associated printed-circuit board traces to act as an

antenna. For this reason, a decoupling capacitor is

recommended o n this node for the sole purpose of filtering

any high frequency noise that could couple into the signal

path through the V

circuitry. A 0.1-µF or 1-µF

OCM

capacitance is a reasonable value for eliminating a great

deal of broadband interference, but additional, tuned

decoupling capacitors should be considered if a specific

source of electromagnetic or radio frequency interference

is present elsewhere in the system. Information on the ac

performance (bandwidth, slew rate) of the V

OCM

is included in the specification table and graph section.

OCM

input

OCM

circuitry

pin

SAVING POWER WITH POWER-DOWN

FUNCTIONALITY

The THS4500 family of fully differential amplifiers contains

devices that come with and without the power-down

option. Even-numbered devices have power-down

capability, which is described in detail here.

The power-down pin of the amplifiers defaults to the

positive supply voltage in the absence of an applied

voltage (i.e. an internal pullup resistor is present), putting

the amplifier in the power-on mode of operation. To turn off

the amplifier in an effort to conserve power, the

power-down pin can be driven towards the negative rail.

The threshold voltages for power-on and power-down are

relative to the supply rails and given in the specification

tables. Above the enable threshold voltage, the device is

on. Below the disable threshold voltage, the device is off.

Behavior in between these threshold voltages is not

specified.

Since the V

common-mode voltage, the ability for increased power

dissipation exi s t s . W h i l e t h i s does not pose a performance

problem for the amplifier, it can cause additional power

dissipation of which the system designer should be aware.

The circuit shown in Figure 84 demonstrates an example

of this phenomenon. For a device operating on a single

5-V supply with an input signal referenced around ground

and an output common-mode voltage of 2.5 V, a dc

potential exists between the outputs and the inputs of the

device. The amplifier sources current into the feedback

network in order to provide the circuit with the proper

operating point. While there are no serious effects on the

circuit performance, the extra power dissipation may need

to be included in the system’s power budget.

pin provides the ability to set an output

OCM

Note that this power-down functionality is just that; the

amplifier consumes less power in power-down mode. The

power-down mode is not intended to provide a

high-impedance output. In other words, the power-down

functionality is not intended to allow use as a 3-state bus

driver. When in power-down mode, the impedance looking

back into the output of the amplifier is dominated by the

feedback and gain setting resistors.

The time delays associated with turning the device on and

off are specified as the time it takes for the amplifier to

reach 50% of the nominal quiescent current. The time

delays are on the order of microseconds because the

amplifier moves in and out of the linear mode of operation

in these transitions.

24

Page 25

www.ti.com

SLOS363A − AUGUST 2002 − REVISED AUGUST 2003

LINEARITY: DEFINITIONS, TERMINOLOGY,

CIRCUIT TECHNIQUES, AND DESIGN

TRADEOFFS

The THS4500 family of devices features unprecedented

distortion performance for monolithic fully differential

amplifiers. This section focuses on the fundamentals of

distortion, circuit techniques for reducing nonlinearity,

and methods for equating distortion of fully differential

amplifiers to desired linearity specifications in RF receiver

chains.

Amplifiers are generally thought of as linear devices. In

other words, the output of an amplifier is a linearly scaled

version of the input signal applied to it. In reality, however,

amplifier transfer functions are nonlinear. Minimizing

amplifier nonlinearity is a primary design goal in many

applications.

Intercept points are specifications that have long been

used as key design criteria in the RF communications

world as a metric for the intermodulation distortion

performance of a device in the signal chain (e.g.,

amplifiers, mixers, etc.). Use of the intercept point, rather

than strictly the intermodulation distortion, allows for

simpler system-level calculations. Intercept points, like

noise figures, can be easily cascaded back and forth

through a signal chain to determine the overall receiver

chain’s intermodulation distortion performance. The

relationship between intermodulation distortion and

intercept point is depicted in Figure 85 and Figure 86.

P

∆fc = fc − f1

∆fc = f2 − f

Power

P

c

P

S

O

O

P

S

IMD3 = PS − P

O

P

OUT

(dBm)

OIP

P

O

P

S

3

IMD

3

IIP

3X

1X

3

P

IN

(dBm)

Figure 86

Due to the intercept point’s ease of use in system level

calculations for receiver chains, it has become the

specification of choice for guiding distortion-related design