THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

DC Fan Drive Speed Control With No

External Power Drive Stage Required

D

11% to 100% PWM Range Adjustable Via

0–2.5 V DC Control Voltage – Suited for

Cooling Fan Applications Requiring

Variable RPM to Reduce Noise and/or

Increase MTBF

D

Speed Control Capability With Either DC or

PWM Input Signal for Greater System-Level

Flexibility

D

Sleep-State Mode to Eliminate External Fan

ON/OFF Power Device – Suited for Cooling

Fans

in Instantly Available

PCs

D

Thermal Shutdown Protection

D

High Impedance V

PWM

Input for Speed

Control of Multiple Fans With a Single

Signal

D

Locked Rotor Protection (THMC40,

THMC41) With Open-Drain Output

Indication (THMC41)

D

Open-Drain Tachometer Signal Valid Over

Entire RPM Range (THMC40)

D

Noise Immune Signal Conditioning to Allow

Use of Low-Cost Hall Effect Position

Sensor

D

Patented High Efficiency Drive Topology

With Integrated Low R

DS(ON)

LDMOS

Output Drivers

1

2

3

4

5

6

7

14

13

12

11

10

9

8

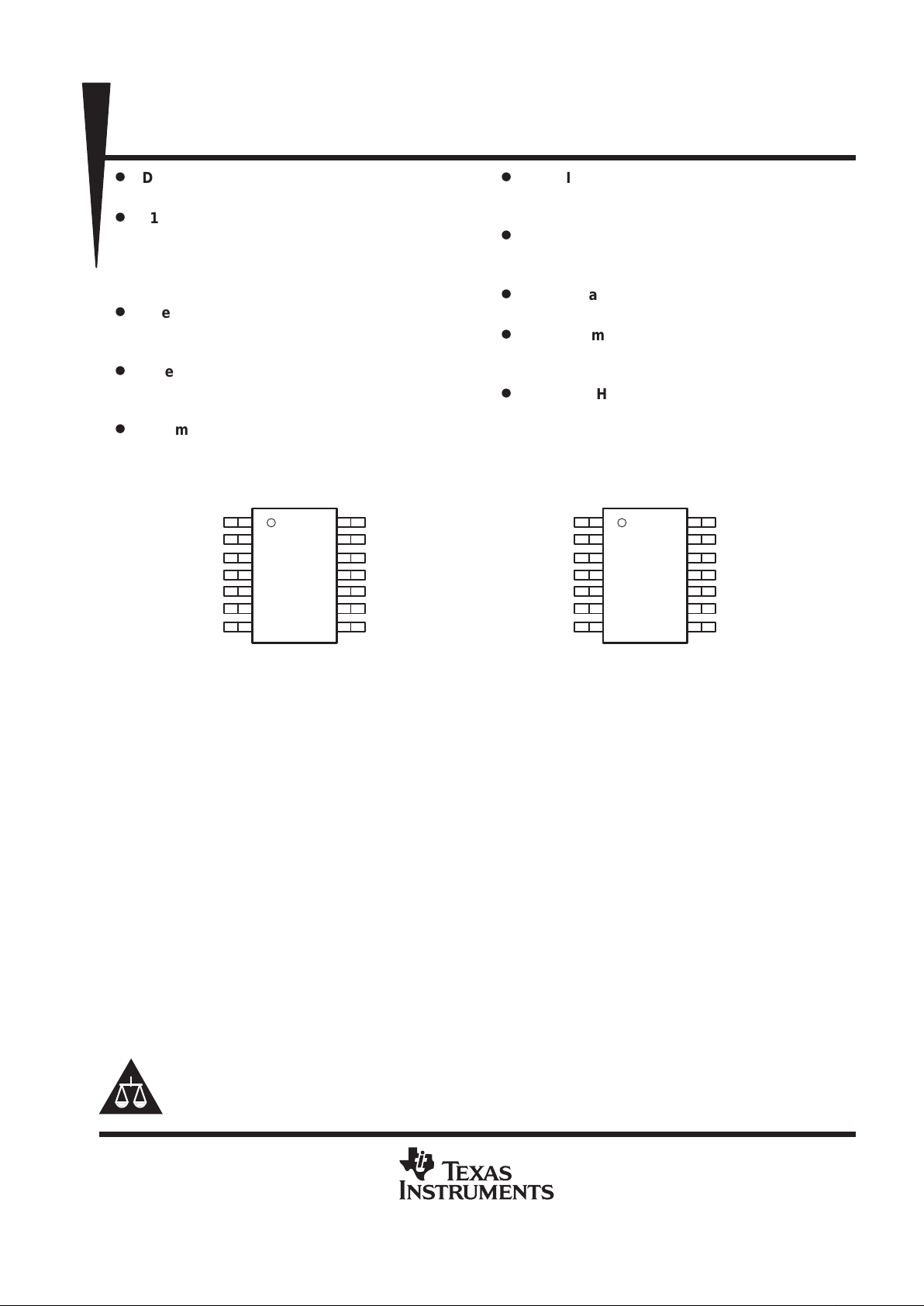

C

OSC

TACH

CP

V

PWR

V

OUT

NC

PGND

V

PWM

H+

H–

PHA

PHB

AGND

NC

THMC40 ...TACH OUTPUT

14-Pin SOP D Package

(TOP VIEW)

1

2

3

4

5

6

7

14

13

12

11

10

9

8

C

OSC

RD

CP

V

PWR

V

OUT

NC

PGND

V

PWM

H+

H–

PHA

PHB

AGND

NC

THMC41 . . . RD OUTPUT

14-Pin SOP D Package

(TOP VIEW)

description

The THMC40 and THMC41 are 2-phase, dc brushless motor (BLM) drive and control devices intended for use

with 12-Vdc cooling fans. Both devices include a high-efficiency PWM drive topology using integrated 0.5-Ω

(typical) LDMOS drivers, plus a speed control input stage to provide the industry’s first solution for efficient

speed control

inside

dc cooling fans. This patented solution eliminates the need for power drive components

on the main system board, thus reducing printed-circuit board (PCB) component count, PCB space, and

assembly time. This solution also offers other advantages over the two commonly used fan speed control

methods, adjustable external dc supply voltage, and adjustable external PWM drive duty cycle.

Unlike other methods which control speed external to the cooling fan, the THMC40 and THMC41 high-efficiency

PWM drive stage adjusts only the level of motor phase winding power. All other circuitry inside the fan obtains

power from the fixed dc voltage fan supply. This method eliminates the typical problem associated with an

external dc voltage regulation method causing loss of headroom to internal control circuitry at low fan supply

voltage and the resulting limitation of low-speed operation to ≈40%. The PWM drive method employed by the

THMC40 and THMC41 also reduces fan supply power consumption over the external linear regulation method,

which has V×I power loss due to the voltage drop across the regulator.

An external PWM drive method disrupts power to the motor and also to all internal fan circuitry . The THM40 and

THMC41 solution maintains all signal integrity with phase drive commutation and tachometer, while providing

reliable low speed fan operation down to 1 1% PWM. This method allows fan health monitoring over the full fan

speed range.

Copyright 2000, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

description (continued)

The V

OUT

duty cycle, and thus the motor speed, is proportional to the voltage present at the V

PWM

input terminal.

This terminal allows controlling the fan speed via a DAC output from an external control IC or an RC-filtered

PWM output from a PC Super I/O chip.

The THMC40 and THMC41 have an internal Hall sensor amplifier and signal conditioner, global thermal

shutdown, locked rotor protection, and automatic restart after a locked rotor condition. The THMC40 provides

an open-drain tachometer output signal, while the THMC41 provides an open-drain locked rotor detection

output signal. These devices also provide a sleep-state mode to eliminate the need for an external power

component to disconnect the fan from the supply during a system sleep state or

instantly available

power down.

The THMC40 and THMC41 are primarily intended for cooling fan applications that require RPM speed control

and the availability of a tachometer or locked rotor detection signal.

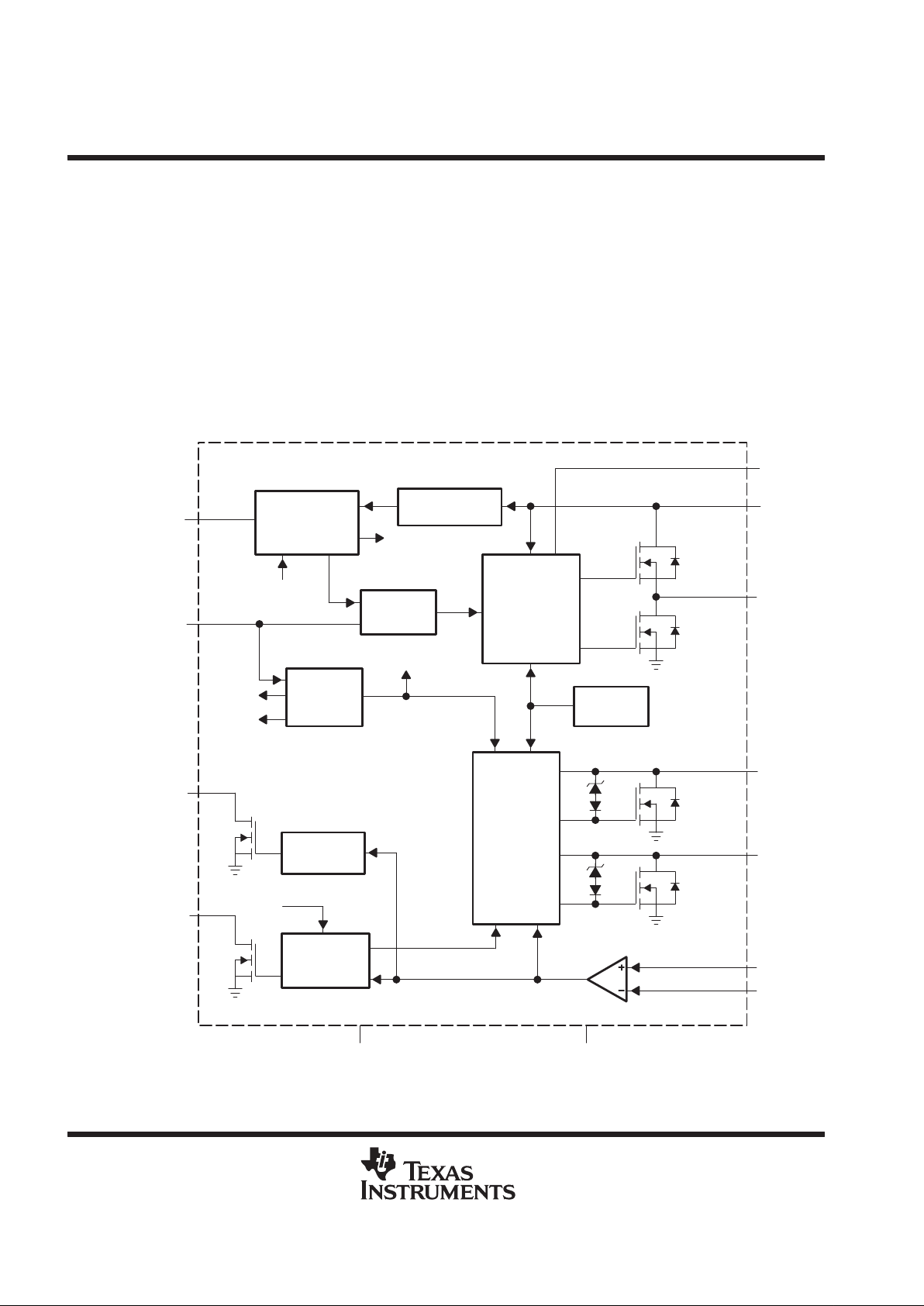

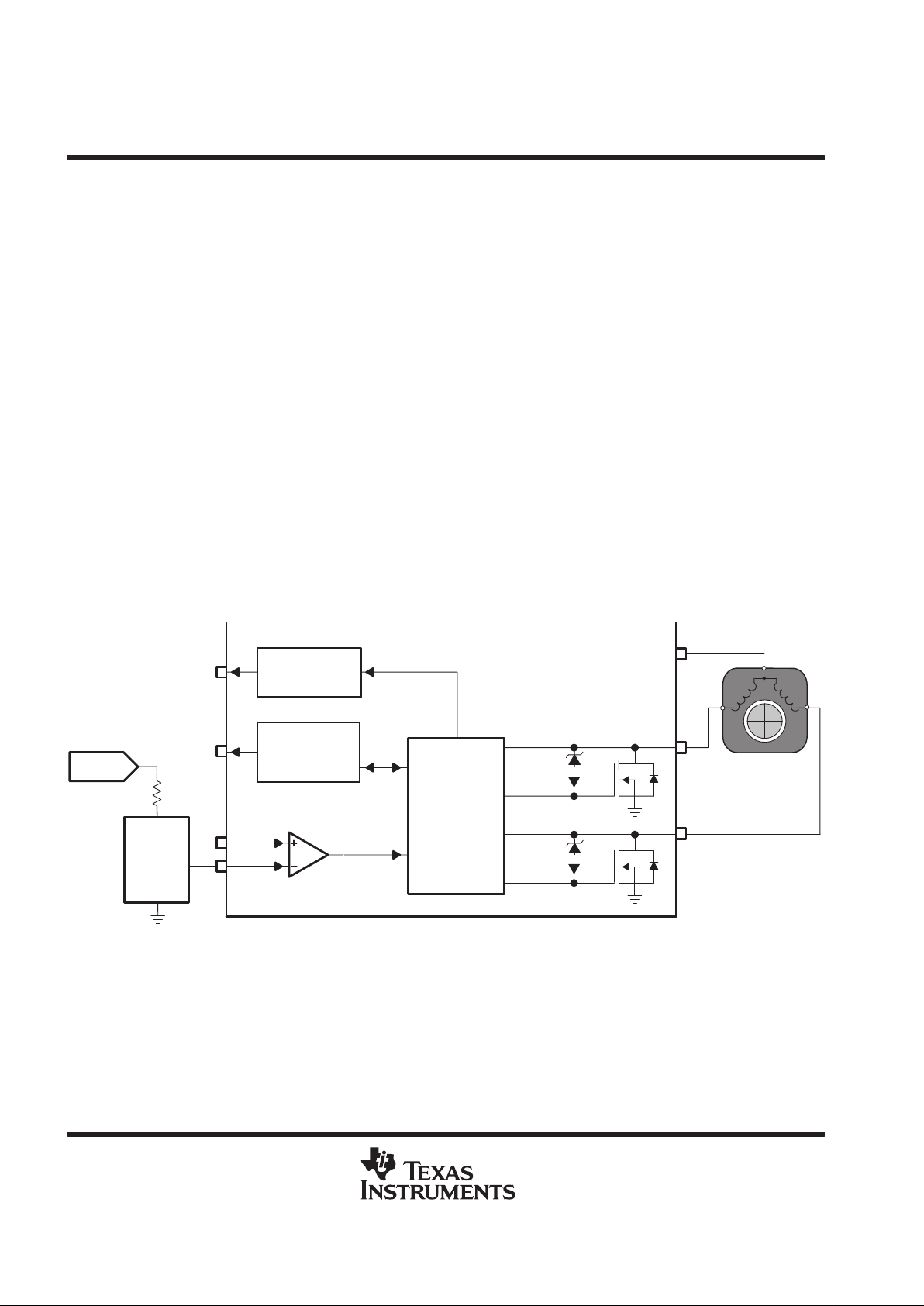

functional block diagram

Tachometer

Output

CP

V

PWM

Low-Side

Gate Drive

Control Logic

and Global

Thermal

Shutdown

High-Side Gate

Drive With

Synchronous

Rectification

Charge Pump

Locked Rotor

Detection and

Auto Restart

SLEEP

START and

SLEEP

Detection

PWM

Generator

PWM

Oscillator

23 kHz Nominal

PUC and V

REF

Thermal

Shutdown

OSC

V

START

V

SLEEP

OSC

PWM

SLEEP

C

OSC

TACH

(THMC40)

RD

(THMC41)

V

PWR

V

OUT

PHA

PHB

H+

H–

PGNDAGND

Hall Sensor

Comparator

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

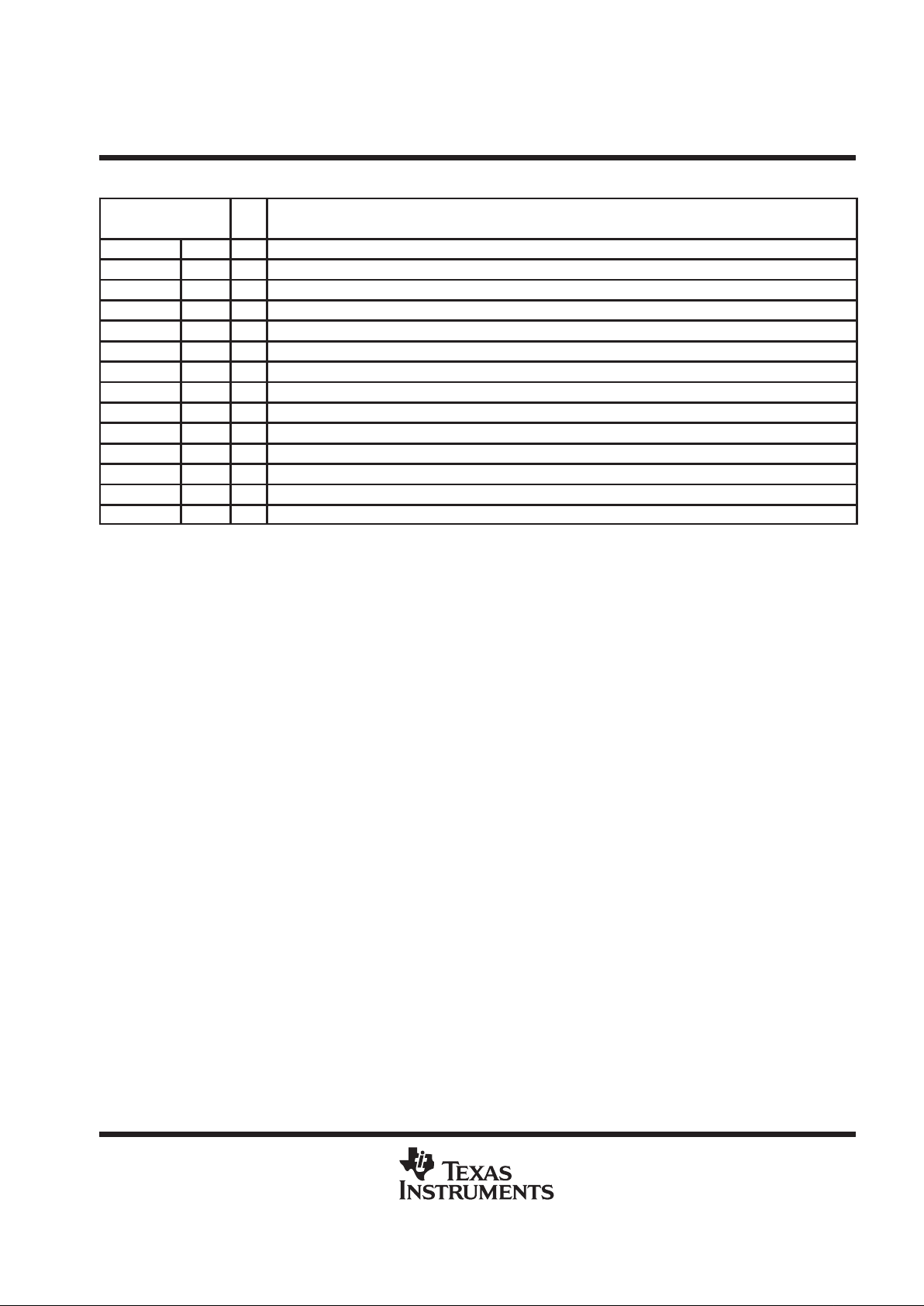

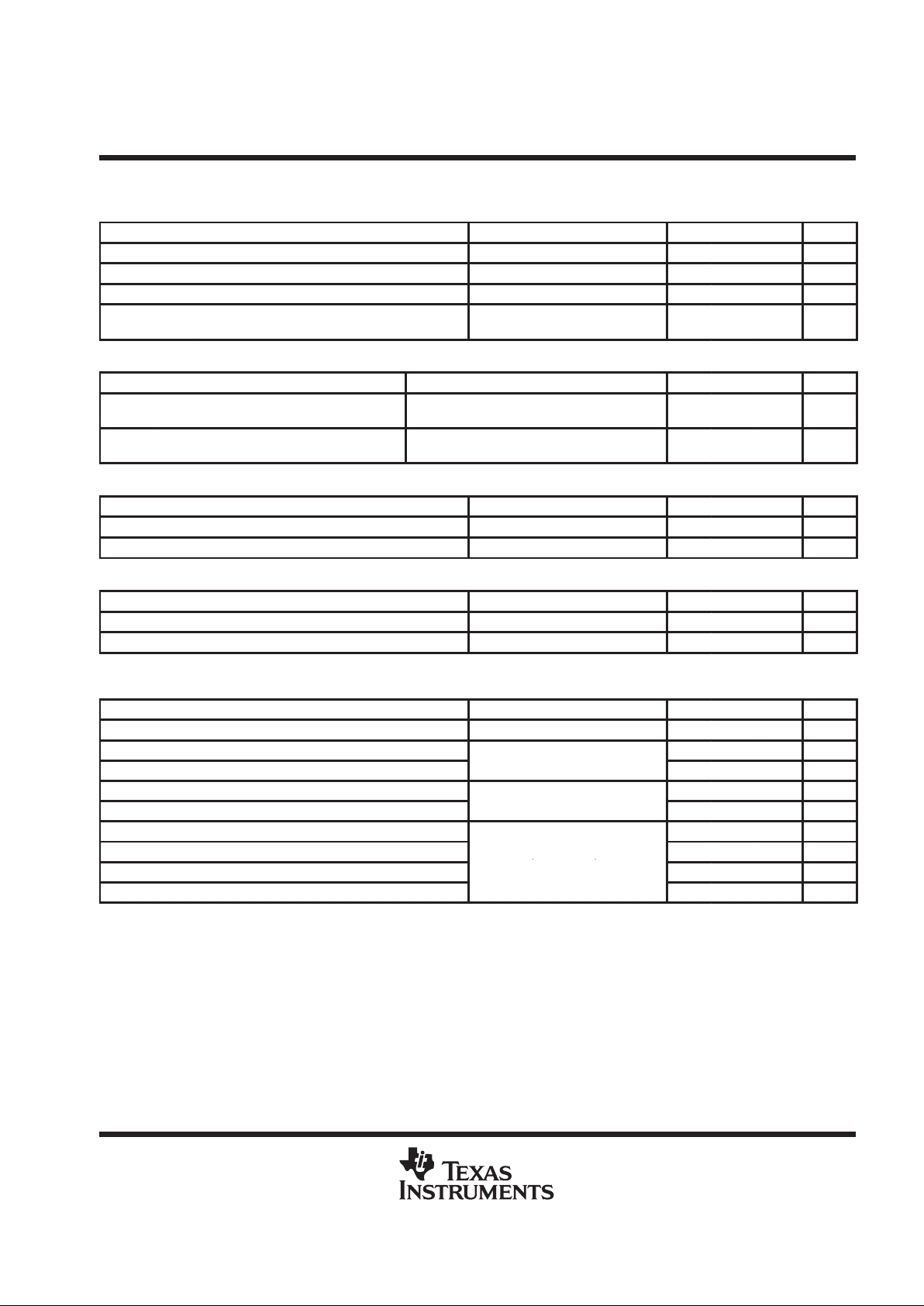

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

AGND 9 I IC analog ground and substrate connection

CP 3 I External charge pump capacitor

C

OSC

1 I/O External oscillator capacitor

H– 12 I Hall sensor negative input

H+ 13 I Hall sensor positive input

NC 6, 8 – No connection

PGND 7 I Power ground for high-side charge pump

PHA 11 O Low-side driver for phase A motor winding

PHB 10 O Low-side driver for phase B motor winding

RD 2 O Open-drain locked rotor detection output—THMC41 only

TACH 2 O Open-drain tachometer output signal—THMC40 only

V

OUT

5 O High-side PWM driver output for motor windings

V

PWR

4 I Supply voltage input

V

PWM

14 I PWM duty cycle control voltage input

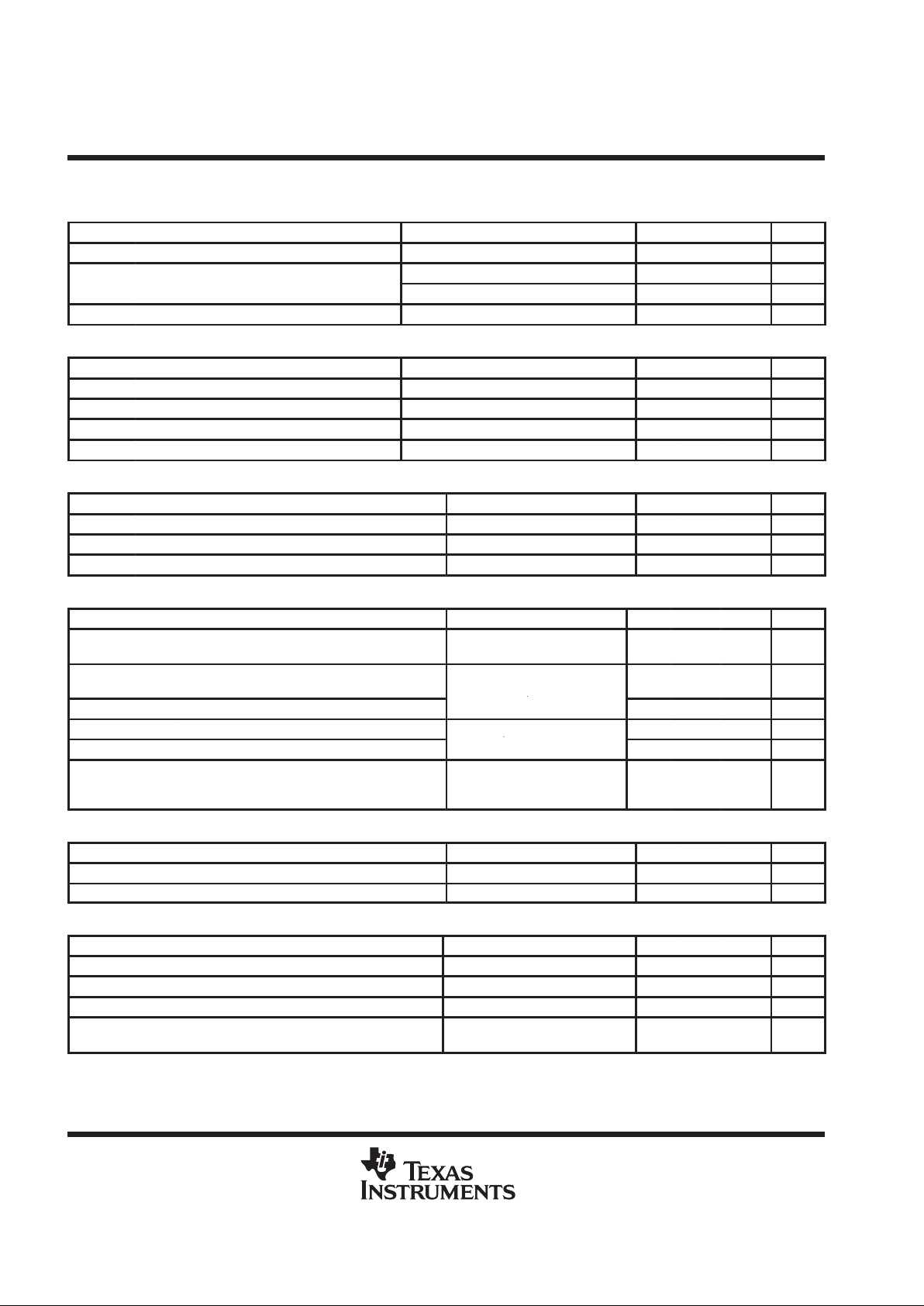

absolute maximum ratings over operating case temperature range (unless otherwise noted)

†

(see Note 1)

Supply voltage input, V

PWR

18 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High-side driver, PWM output voltage, V

OUT

18 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low-side drivers, phase A and B output, V

PHA

, V

PHB

40 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hall sensor amplifier input voltage, V

H+

, VH– 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PWM duty cycle control input voltage, V

PWM

7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open-drain tachometer output voltage (THMC40), V

TACH

, or open-drain RD output voltage

(THMC41), VRD 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oscillator capacitor voltage, V

COSC

7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charge pump capacitor voltage, VCP 30 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous high-side PWM output source/sink current, I

OUT

1.5 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous low-side PWM output sink current, I

PHA

, I

PHB

1.5 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Junction-to-case thermal resistance, R

θJC

26.9°C/W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Junction-to-ambient thermal resistance , R

θJA

(see Note 2) 122.3°C/W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous power dissipation at 25°C , P

D

(see Note 3) 1022 mW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power derating factor above 25°C ambient , P

DERA TING

(see Note 4) 8.18 mW/°C. . . . . . . . . . . . . . . . . . . . .

Operating case temperature range, TC –30°C to 80°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum junction temperature, T

J

150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature (soldering, 10 sec), T

LEAD

300°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltage values are with respect to GND.

2. JEDEC low-K board with 0 LFM airflow

3. 150°C maximum junction temperature, JEDEC low-K board with 0 LFM airflow

4. 80°C maximum ambient and 150°C maximum junction temperature

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

dc electrical characteristics, V

PWR

= 12 V, TA = – 30°C to 80°C (unless otherwise noted)

supply current

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

PWR

Supply voltage range 11 12 13 V

pp

Idle condition in locked rotor detect 2.5 5 mA

I

VPWR

V

PWR

su

pply current

I

LOAD

= –1 A, V

OUT

low, TA = 25°C 5 mA

I

SLEEP

Sleep-state current V

PWM

≤ 0.4 V 300 400 µA

PHA, PHB low-side phase winding driver outputs

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

LEAK

PHA,PHB output leakage current Output = OFF, V

PHx

= 12 V 0.1 10 µA

V

OL

PHA, PHB low-level output voltage Output = ON, I

PHx

= 1 A, TA = 25°C 0.5 0.6 V

R

DS(ON)

PHA, PHB output ON resistance Output = ON, I

PHx

= 1A, TA = 25°C 0.5 0.6 Ω

V

CLAMP

PHA, PHB output active clamp voltage Output = OFF, I

PHx

= 200 mA 32 38 V

Hall sensor signal conditioning

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

IB(HL)

Hall input bias current ±0.1 ±1 µA

V

ICR(HL)

ICR(HL) common-mode input voltage range 1 3.5 V

V

IO

Hall comparator input offset voltage Over V

ICR(HL)

= 1 V to 3.5 V –7 0 7 mV

V

OUT

high-side phase winding driver output

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

LEAK

V

OUT

output sleep-state leakage current

Sleep state engaged,

V

VOUT

= 0 V to V

PWR

±0.1 ±10 µA

V

OH

V

OUT

high-level output voltage

Run state, Output high

I

= –1 A, T

= 25°C

V

PWR

– 0.4

V

PWR

– 0.6

V

R

DS(ON)

V

OUT

output high-side resistance to V

PWR

VOUT

,

A

0.4 0.6 Ω

V

RECIR

V

OUT

output recirculation voltage

Run state, Output low

– 0.3 – 0.5 V

R

DS(ON)(SYNC)VOUT

synchronous switch resistance to PGND

,

I

VOUT

= –1 A, TA = 25°C

0.3 0.5 Ω

I

LIMIT

Pulsed V

OUT

synchronous rectification current

limit

Run state, V

OUT=VPWR

=12V,

V

COSC

> V

PWM,

t

PULSE

= 100 µs, See Note 5

2 2.6 A

CP high-side gate drive charge pump capacitor input

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

CP

Charge pump voltage I

VCP

= –60 µA, V

PWM

= 2.5 V 22 26 V

V

CP(UVLO)VCP

undervoltage lock-out 6.5 7.6 8.5 V

C

OSC

external oscillator capacitor

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

CHARGE

C

OSC

charge source current V

COSC

= 1.4 V, Charge mode –130 –180 –230 µA

I

DISCHARGECOSC

discharge sink current V

COSC

= 1.4 V, Discharge mode 130 180 230 µA

V

DISCHARGECOSC

upper threshold for switching to current sink 2 2.3 2.6 V

V

CHARGE

C

OSC

lower threshold for switching to current

source

0.43 0.5 0.57 V

NOTE 5: V

OUT

current limit, in conjunction with thermal shutdown function, provides device survivability under V

OUT

-to-V

PWR

short condition.

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

dc electrical characteristics, V

PWR

= 12 V , TA = –30°C to 80°C (unless otherwise noted) (continued)

V

PWM

high-side PWM duty cycle adjust input

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

IB(PWM)

V

PWM

input bias current V

PWM

= 0 V to 3 V ±1 µA

V

PWM

(100%) V

PWM

voltage equivalent to 100% duty cycle 2.3 V

V

SLEEP

V

PWM

voltage threshold to engage sleep mode 0.6 0.7 V

V

START

V

PWM

voltage threshold to disengage sleep

mode

0.8 0.9 V

thermal shutdown characteristics

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

T

TSD

V

OUT

, PHA, PHB global thermal shutdown

thresholds

Temperature increasing until outputs are off,

See Note 6

150 185 °C

T

HYST

Thermal shutdown hysteresis

After T

TSD

, temperature decreasing until out-

puts return to normal operation, See Note 6

15 °C

TACH Tachometer open-drain output (THMC40)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

TACHLEAK

TACH high-level output leakage current V

TACH

= 5 V 0.1 1 µA

V

OL

TACH low-level output voltage I

TACH

= 5 mA 0.1 0.3 V

RD locked rotor detection open-drain output (THMC41)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

RDLEAK

RD high-level output leakage current VRD = 5 V, Locked rotor condition 0.1 1 µA

V

OL

RD low-level output voltage IRD = 5 mA, No locked rotor 0.1 0.3 V

ac electrical characteristics, V

PWR

= 12 V, TA = –30°C to 80°C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

f

PWM

High-side gate drive PWM frequency C

OSC

= 2200 pF 22.7 kHz

t

RD

Locked rotor detect delay time

p

1 s

t

RETRY

Auto-restart delay time

C

OSC

=

2200 pF, See Figure 9

8 s

t

HALL

Hall zero-crossing deglitch time

25 µs

t

DEAD(PHx)

Dead time between phase commutations

See Figure 2

5 µs

t

f(OUT)

V

OUT

output fall time 25 ns

t

r(OUT)

V

OUT

output rise time

R

= 20 Ω , L

= 5 mH,

25 ns

t

f(PHx)

PHA or PHB fall time

L

,

L

,

See Note 6

1 µs

t

r(PHx)

PHA or PHB rise time 1 µs

NOTE 6: Design targets only. Not tested in production.

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

general overview

The THMC40 and THMC41 are 2-phase dc brushless fan motor drivers with PWM speed control intended

primarily for applications requiring a wide speed control range and an open-drain tachometer output signal

(THMC40), or a locked rotor detection output (THMC41). The V

OUT

drive duty cycle, and thus fan speed, is

proportional to the voltage level at the V

PWM

input terminal. Each device has an internal Hall sensor

comparator/signal conditioner, a low power sleep-state mode, locked rotor protection with automatic restart

after a locked rotor condition, and over-temperature protection. The tachometer signal (THMC40) can be used

to monitor the

health

of the fan or to close an external loop based on fan RPM. The THMC40 and THMC41

provide a more efficient drive solution to fan RPM control than external linear voltage control. This solution is

also considerably more efficient than controlling dc brushless fan RPM using external PWM drive.

low-side motor phase winding driver outputs (PHA, PHB)

The PHA and PHB outputs provide low-side drive of the motor’s two stator phase windings (see block diagram

and Figure 1). These outputs have a typical R

DS(ON)

of 400 mΩ at 25°C and a 1-A continuous current rating.

The PHA and PHB outputs have an active flyback clamp (V

ZCLAMP

in Figure 1) of 38 V (typical) to snub inductive

energy when a phase drive switches off. The outputs also have global thermal shutdown to prevent device

failure.

Drive commutation of PHA and PHB outputs is controlled according to rotor position monitored by a Hall-effect

position sensor. Discussion of this function is found in the following section, and the relationship between PHA

and PHB outputs to Hall input signal is shown in Figure 2.

Locked Rotor

Detection and

Auto-Restart

V

OUT

TACH

(THMC40)

NS

SN

Tachometer

Output Driver

V

ZCLAMP

V

ZCLAMP

Low-Side

Gate Drive

Control

Logic, and

Global

Thermal

Shutdown

Naked

Hall

Sensor

V

PWR

Hall Sensor

Comparator

RD

(THMC41)

H+

H–

PHA

PHB

Figure 1. Low-Side Gate Drive Block Diagram

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Hall sensor comparator and signal conditioning inputs (H+, H–)

Referring to Figure 1, the THMC40 and THMC41 have an internal Hall sensor comparator allowing the use of

low-cost naked Hall sense elements. The Hall signal conditioning block receives a low-level differential voltage

from the naked Hall position sensor element. The comparator then implements a zero differential voltage

crossing detection with a deglitch time of 25 µs (typical) to reject noise on the Hall signal inputs. Referring to

Figure 2, the PHx drive that was on (low) turns off after the 25-µs deglitch time is reached. Then the opposite

PHx drive turns on after another delay time. This 5-µs (typical)

dead time

is implemented to prevent both phases

from conducting simultaneously and to allow time for the inductive energy to be snubbed from the phase that

was just turned off. The Hall comparator circuit has an input offset voltage (V

IO

) which is not greater than ±7

mV. The common-mode input voltage range is 1 V to 3.5 V (see Figure 2).

t

DEAD(PHx)

V

CM

PHA Output

Voltage

PHB Output

Voltage

OFF

ON

OFF

ON

V

IO

5 µst

HALL

25 µs

t

DEAD(PHx)

t

HALL

25 µs

5 µs

Time

TACH Output

Voltage (THMC40)

OFF

ON

Hall Sensor

Waveform

(VH+ - VH–)

Figure 2. Hall Sensor Signal Conditioning Waveforms

Table 1 shows PHA and PHB commutation, and TACH output (THMC40) functionality:

Table 1. PHA and PHB Low-Side Drive Commutation and TACH Functionality

H+ H– PHA PHB

TACH

(THMC40)

+ – High (OFF) Low (ON) High (OFF)

– + Low (ON) High (OFF) Low (ON)

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

high-side PWM output driver (V

OUT

)

Referring to Figure 3, V

OUT

is a drive output to provide PWM controlled power to the common node of the motor

phase windings using an internally generated PWM signal. The PWM duty cycle controls the effective drive

power to the motor, and thus motor speed. The high-side V

OUT

DMOS output transistor has a typical R

DS(ON)

of 400 mΩ at 25°C and a 1-A continuous current.

PWM

CP

C

OSC

Charge Pump,

HS Gate Drive,

Synchronous

Rectification,

and

Global Thermal

Shutdown

Triangle W ave

Generator

0.5 V to 2.3 V

PUC

Synchronous

Low-Side

Switch

High-Side

Driver

0.1 µF

V

PWR

V

OUT

V

PWM

2200 pF

COMP

Figure 3. High-Side PWM Drive

The frequency of the PWM drive (typically 23 kHz) is such that the L/R time constant of the motor phase winding

filters the current. Referring to Figure 4, during the on-time (t

ON

) of a PWM period, V

OUT

is driven high forcing

voltage across a phase winding and increasing the current. During t

OFF,

PWM off-time, the V

OUT

high-side

DMOS is switched off, the phase winding inductive energy is recirculated, and the current decreases. To

minimize the voltage drop and the resulting energy loss during recirculation, a low-side DMOS synchronous

switch is provided, as shown in Figure 3. This low-side DMOS device has a 2-A minimum current limit to prevent

device failures should a solder bridge occur between the adjacent V

PWR

and V

OUT

terminals.

I

RECIRCULATE

I

MOTOR

t

ON

t

OFF

I

DRIVE

t

PWM

PWM

Time

Figure 4. Motor Current Waveform

The V

OUT

circuit is protected by the global thermal shutdown of the THMC40 and THMC41 by turning off both

the high-side and low-side DMOS drivers when an over-temperature condition is detected. V

OUT

is also held

off when the charge-pump voltage (V

CP

) is lower than its undervoltage lock-out threshold, V

CP(UVLO)

.

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

charge pump (CP)

THMC40 and THMC41 have an internal charge pump which utilizes an external reservoir capacitor (CP) to

generate the gate-drive voltage for the V

OUT

output high-side DMOS transistor (see Figure 3). The

recommended value for CP is 0.1 µF, with a minimum rating of 35 WVdc. The charge pump is disabled during

the sleep state (see the sleep/run state section) to minimize current consumption into V

PWR

. The charge pump

also incorporates internal undervoltage lockout detection used to disable V

OUT

when the charge pump voltage

does not have an adequate level above V

PWR

to fully drive the high-side DMOS gate. Thus, the VCP (UVLO),

in conjunction with the charge pump start-up time, delays the V

OUT

drive for a short time after the device has

transitioned from sleep to run state, until the charge pump voltage reaches the UVLO threshold.

PWM oscillator/triangle waveform generator (C

OSC

)

The PWM oscillator uses source and sink currents switched into an external capacitor (C

OSC

) to set the PWM

frequency and generate a triangle waveform. A PWM oscillator cycle consists of charging C

OSC

with a constant

current source (–180 µA typical) until the C

OSC

voltage ramps up to an upper threshold (2.3 V typical), and then

discharging C

OSC

with a constant current sink (180 µA typical) until the C

OSC

voltage ramps down to a lower

threshold (0.5 V typical). The charge/discharge cycle is repeated each time the 2.3-V or 0.5-V threshold is

reached (see Figure 5).

V

2.3 V

S

R

Q

Q

V

REF

V

PWR

C

OSC

V

PWM

2200 pF

PWM

–180 µA

2.3 V

0.5 V

180 µA

Time

0.5 V

0

Q

Q

V

COSC

Figure 5. PWM Triangle Waveform Generator

The following equation can be used to calculate the value of C

OSC

needed for a desired PWM frequency , f

PWM

:

C

OSC(max)

+

I

CHARGE(min)

2 f

PWM(min)

ǒV

DISCHARGE

*

V

CHARGE

Ǔ

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PWM duty cycle control voltage (V

PWM

) – dc control voltage input

The voltage at the V

PWM

terminal determines the PWM duty cycle of the output (V

OUT

) to control drive power

to the fan motor, and thus control fan speed (see Figures 3 and 6). The V

PWM

voltage is internally compared

against the 0.5-V to 2.3-V triangle waveform generated on the C

OSC

terminal. The PWM signal output from this

comparator has a duty cycle proportional to the voltage at V

PWM

, as shown in Figure 6. The output of this

comparator is used as the PWM input to the V

OUT

drive stage.

50

40

20

10

0

90

30

0 0.2 0.4 0.6 0.8 1 1.2

70

60

80

100

1.4 1.6 1.8 2.4

– Duty Cycle – %

V

OUT

2 2.2

V

PWM

– Input Voltage – V

RUN STATE

SLEEP

STATE

V

SLEEP

=0.7 V

V

START

= 0.8 V

Must be exceeded

to enter run state

V

OUT

Duty Cycle =

(V

PWM

- 0.5)/1.8 × 100

Figure 6. Relationship of V

OUT

Duty Cycle, V

START

, and V

SLEEP

vs V

PWM

Input Voltage

PWM duty cycle control voltage (V

PWM

) – digital PWM control input

To allow control of the THMC40 and THMC41 by either a PWM or a dc input control signal, it is recommended

that the fan manufacturer includes a 100-kΩ, 0.1-µF RC filter between the speed control wire and the V

PWM

terminal (see Figure 7). This method allows the end user to control the fan speed with either a PWM signal or

a dc control voltage. Many PC Super I/O ICs and hardware monitoring ICs provide one of the two fan speed

control outputs. Therefore, fans with THMC40 and THMC41 ICs can be used with a wide variety of control

schemes to provide variable fan speed without an external fan drive power stage.

C = 0.1 µF

V

PWM

PWM Generator

(Super I/O or

HW Monitor)

PC Motherboard

Inside Cooling Fan

R = 100 kΩ

THMC40

and

THMC41

Full Speed Option

V

FAN

Speed

Control

1 – 10 MΩ†

1 – 10 MΩ

†

Sleep State Option

†

Optional resistors control fan operation with open speed control input.

Figure 7. PWM Input Control With RC Filter Inside the Cooling Fan

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PWM duty cycle control voltage (V

PWM

) – digital PWM control input (continued)

Figure 8 illustrates the relationship between V

OUT

output duty-cycle and a 0–3.3-V digital PWM input control

signal.

– Duty Cycle – %

V

OUT

3.3-V Duty Cycle Input to RC Filter

50

40

20

10

0

90

30

0102030405060

70

60

80

100

70 80 90 100

RUN STATE

SLEEP

STATE

V

OUT

% =((3.3 V ×

(Input%÷100)-0.5)÷1.8) ×100

V

SLEEP=21%

V

START

= 24%

Must be exceeded to

enter run state

Figure 8. Relationship of V

OUT

Duty Cycle, V

SLEEP

, V

ST ART

vs 0–3.3 V PWM Input Duty Cycle

sleep/run state

Sleep-state and run-state modes are provided, as illustrated in Figures 6 and 8. The sleep state is intended to

minimize V

PWR

(fan) supply current requirements (300 µA typical) when cooling fan operation is not required.

This feature is especially beneficial for PC OEMs needing to meet the

instantly available

PC requirements

without the use of additional external circuitry.

The sleep state is engaged when the V

PWM

input voltage is below the V

SLEEP

threshold (0.7 V typical, 1 1.1%

duty cycle). During the sleep state, all output drivers are turned off and any unused circuits are powered down

to minimize current drain. Once sleep state is engaged, V

PWM

must exceed the V

ST ART

threshold (0.8 V typical,

17% duty cycle) to disable the sleep state and enter the run state, allowing the motor to be driven. Once the

run state is engaged, outputs V

OUT

, PHA, and PHB are active and the V

PWM

voltage can be decreased to obtain

minimum fan speed down to the V

SLEEP

threshold. This procedure allows the user to overcome initial motor

stiction with a PWM duty cycle of 17% to avoid the possibility of false locked rotor detection during initial start-up.

See Figure 6 for the V

PWM

input voltage relationship to sleep mode and V

OUT

duty cycle.

A control device with a voltage range of 0 V to 2.5 V is recommended to provide the adjustable V

PWM

reference

voltage to the THMC40 and THMC41. A 2.5-V DAC is an optimal choice as the controlling circuitry , whether as

a stand-alone device, or as an integrated function in a multiple-function device. Using a control device without

a minimum 0.5-V to 2.3-V range reduces the RPM control range of the fan motor and may not allow duty-cycle

settings of 0% and/or 100%.

thermal shutdown

The THMC40 and THMC41 provide protection against excessive device temperature with a thermal sensor that

monitors the die temperature. Should some operating or abnormal condition cause the die temperature to

exceed T

TSD

, the thermal shutdown threshold (165°C typical), all output drivers are turned off. Once T

TSD

has

been exceeded, the die temperature must fall below a hysteresis temperature (typical T

TSD

–15°C) before the

output drivers are re-enabled.

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

locked rotor protection

An internal digital timer monitors the output of the Hall sensor amplifier. When a change in commutation state

is not observed within one second (typical with 2200 pF C

OSC

), the V

OUT

, PHA, and PHB outputs are disabled

for eight seconds (typical with 2200 pF C

OSC

). After the outputs have been disabled for eight seconds (typical

with 2200 pF C

OSC

), the THMC40 and THMC41 re-enable the V

OUT

, PHA, and PHB outputs to automatically

restart the motor after a locked rotor condition. If the locked rotor condition still exists, the above process repeats

itself until the condition is removed, or the THMC40 and THMC41 are powered down (see Figure 9).

NOTE:

The locked rotor detection time and auto-retry time are proportional to the PWM frequency, and

therefore to the value of C

OSC

. With a C

OSC

value of 2200 pF, the PWM frequency is typically

22.7 kHz, locked rotor detection time is typically one second, and auto-retry time is typically

eight seconds.

1s

Hall Sensor

Comparator

Output

1s 8s8s

V

OUT

, PHA and

PHB Output

Enable

RD Output

(THMC41)

Tach Output

(THMC40)

Figure 9. Typical Locked Rotor Protection Timing Waveforms

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

open-drain tachometer output (TACH)—THMC40 Only

The THMC40 T ACH output is an open-drain output activated by the Hall sensor comparator output (see Figure

9). When the Hall sensor comparator output is high, the T ACH output floats high. When the Hall sensor amplifier

output is low, the TACH output is pulled low. The resulting output signal has two pulses per revolution on a

four-pole motor.

The T ACH output can be used to monitor and measure actual fan speed. This output can also be used as part

of a closed-loop speed control system.

NOTE:

It is recommended that the fan manufacturer not place a pullup resistor for this terminal on the fan

circuit board. Leaving the output as open-drain allows the end user to pull up this terminal with an

external resistor to the supply voltage of their choice (that is, 3.3 V or 5 V).

open-drain locked rotor detection output—THMC41 only

The THMC41 RD output is an open-drain output pulled low during normal fan operation and allowed to float

during a locked rotor condition (see Figure 9). This signal can be used to alert the system of a locked rotor

condition.

The RD output can also be used as a

fan present

or

fan OK

signal by using a general-purpose input terminal

on a PC Super I/O chip to detect the logic state of this terminal. When this input is high, the signal indicates that

the fan has been disconnected or is in a locked rotor condition.

NOTE:

It is recommended that the fan manufacturer not place a pullup resistor for this terminal on the fan

circuit board. Leaving the output as open-drain allows the end user to pull up this terminal with an

external resistor to the supply voltage of their choice (that is, 3.3V or 5V).

supply voltage input (V

PWR

)

The V

PWR

terminal serves as the voltage supply input to the THMC40 and THMC41. A 0.1-µF bypass capacitor

should be placed as close to this terminal as the layout permits. Additional bulk capacitance of 2.2 µF to 10 µF

on this terminal is highly recommended to reduce current spikes on the supply line during motor commutation,

thus reducing radiated emissions from the fan. See Application Information for further details.

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

C

OSC

TACH

CP

V

PWR

V

OUT

NC

PGND

V

PWM

H+

H–

PHA

PHB

AGND

NC

THMC40D

MOTOR

LO

R1

100 kΩ

L2

L1

HALL

SENSOR

1

2

3

4

5

6

7

14

12

13

11

10

9

8

0.1 µF

C5

10 µF

16 V

GND

Speed Control Input

2200 pF

24

3

1

0.1 µF

TACH

+12 V

CR1

1N4002

R2

3.01 kΩ

C4

0.1 µF

NOTE: Traces in bold handle highest current.

+

C3

C2

C1

Full Speed Option

Sleep State Option

†

Optional resistors control fan operation with open speed control input.

1 – 10 MΩ†

1 – 10 MΩ†

‡

‡

An analog ground trace should be connected close to the ground connection of C4 and C5.

Figure 10. THMC40 Application Schematic

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

C

OSC

RD

CP

V

PWR

V

OUT

NC

PGND

V

PWM

H+

H–

PHA

PHB

AGND

NC

THMC41D

MOTOR

LO

R1

100 kΩ

L2

L1

HALL

SENSOR

1

2

3

4

5

6

7

14

12

13

11

10

9

8

0.1 µF

C5

10 µF

16 V

GND

2200 pF

24

3

1

0.1 µF

RD+12 V

CR1

1N4002

R2

3.01 kΩ

C4

0.1 µF

+

C3

C2

C1

Speed Control Input

Full Speed Option

Sleep State Option

1 – 10 MΩ†

1 – 10 MΩ†

NOTE: Traces in bold handle highest current.

†

Optional resistors control fan operation with open speed control input.

‡

‡

An analog ground trace should be connected close to the ground connection of C4 and C5.

Figure 11. THMC41 Application Schematic

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

D (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PINS SHOWN

4040047/D 10/96

0.228 (5,80)

0.244 (6,20)

0.069 (1,75) MAX

0.010 (0,25)

0.004 (0,10)

1

14

0.014 (0,35)

0.020 (0,51)

A

0.157 (4,00)

0.150 (3,81)

7

8

0.044 (1,12)

0.016 (0,40)

Seating Plane

0.010 (0,25)

PINS **

0.008 (0,20) NOM

A MIN

A MAX

DIM

Gage Plane

0.189

(4,80)

(5,00)

0.197

8

(8,55)

(8,75)

0.337

14

0.344

(9,80)

16

0.394

(10,00)

0.386

0.004 (0,10)

M

0.010 (0,25)

0.050 (1,27)

0°–8°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion, not to exceed 0.006 (0,15).

D. Falls within JEDEC MS-012

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

Customers are responsible for their applications using TI components.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Loading...

Loading...