THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

T wo-Wire SMBus Serial Interface

D

On-Chip and External Diode-Connected

Transistor Temperature Monitoring

– ±2.5°C Accuracy for On-Die

– ±3°C Accuracy for External

D

Programmable Under/Overtemperature

Limits

D

Under/Overtemperature Interrupt Signal to

Host Controller

D

Low Operating Current ...35 µA (Average)

D

Low Standby Current ...3 µA

D

3-V to 3.6-V Supply Voltage Range

description

The THMC10 is a dual digital temperature monitor with under/overtemperature alerts intended for use in

personal computer systems or any other system requiring local as well as remote temperature monitoring and

management (e.g., servers and workstations). The device may be used in smart battery applications and

memory modules. The device is designed to measure the temperature on a microprocessor using a

diode-connected transistor on the microprocessor die, such as the one present on the Intel

Pentium II, III,

and the Sun UltraSP ARC. The device may also be used with a low-cost, diode-connected, discrete transistor,

such as a 2N3904 or 2N3906, for remote temperature sensing applications.

The THMC10 uses a two-current measurement technique on a single diode-connected transistor that cancels

the absolute value of the remote transistor’s VBE; therefore, no calibration is needed. The second channel

measures an on-chip temperature sensor which can be used to monitor the ambient temperature in the

THMC10’s operating environment.

The THMC10 uses a two-wire, SMBus interface to report temperature in an 8-bit, 2s complement format in °C.

Under/overtemperature limits for both the on-chip and remote temperature sensors are user programmable via

the SMBus interface. The ALERT

terminal can be used as an interrupt or SMBus alert function to indicate

under/overtemperature. The STBY terminal and the

start/stop

bit in the SMBus interface allow the device to

enter a low current standby mode (typically <10 µA).

The THMC10 also provides diagnostics via the ALERT terminal and the SMBus interface for an open remote

sensor connection or if the sensor connection is shorted to V

DD.

Copyright 1999, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Intel and Pentium are registered trademarks of Intel Corporation.

Sun is a registered trademark and UltraSPARC is a trademark of Sun Microsystems.

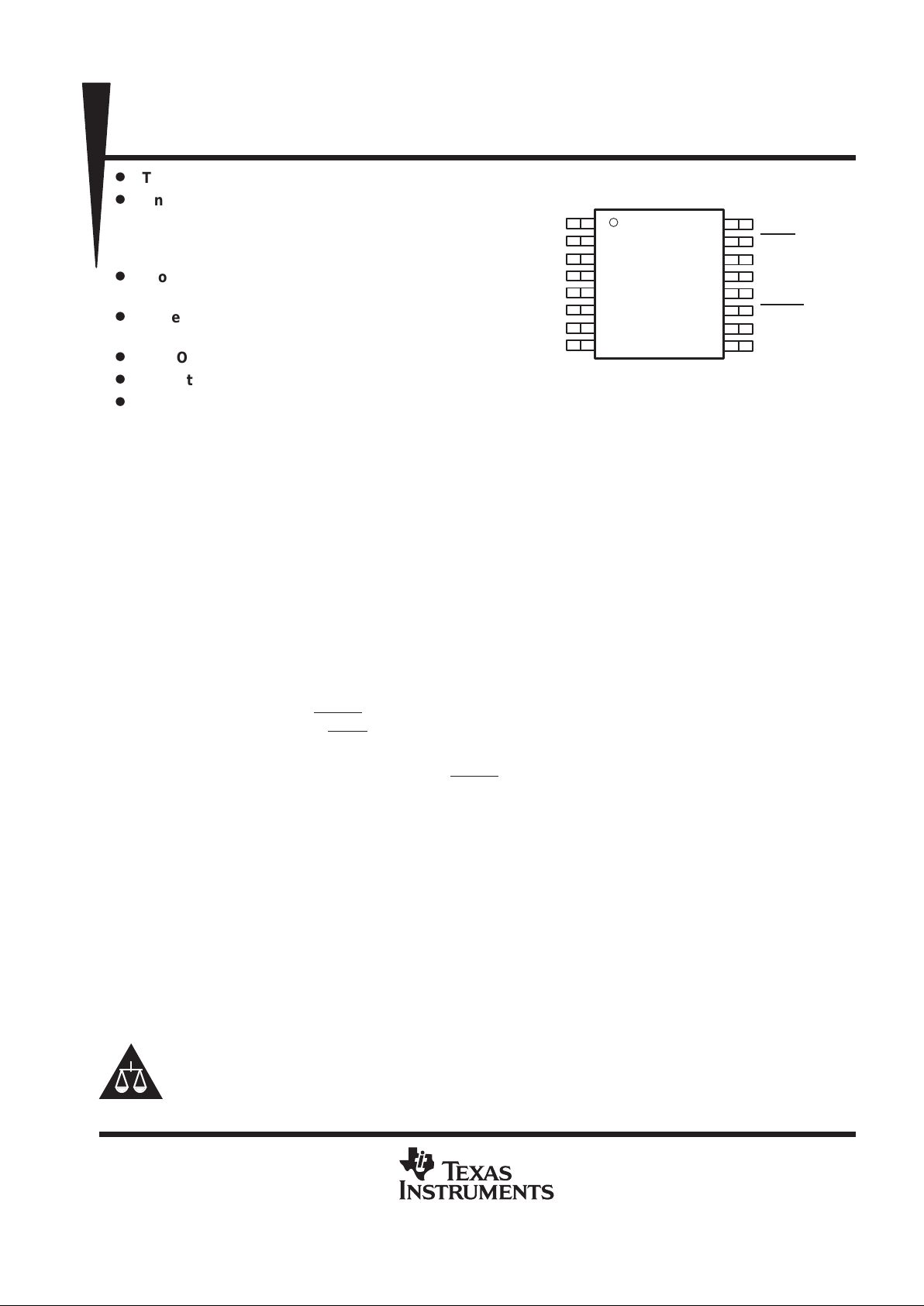

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

N/C

V

DD

DXP

DXN

N/C

ADD1

GND

GND

N/C

STBY

SCLK

N/C

SDATA

ALERT

ADD0

N/C

SSOP DBQ Package

(TOP VIEW)

THMC10

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

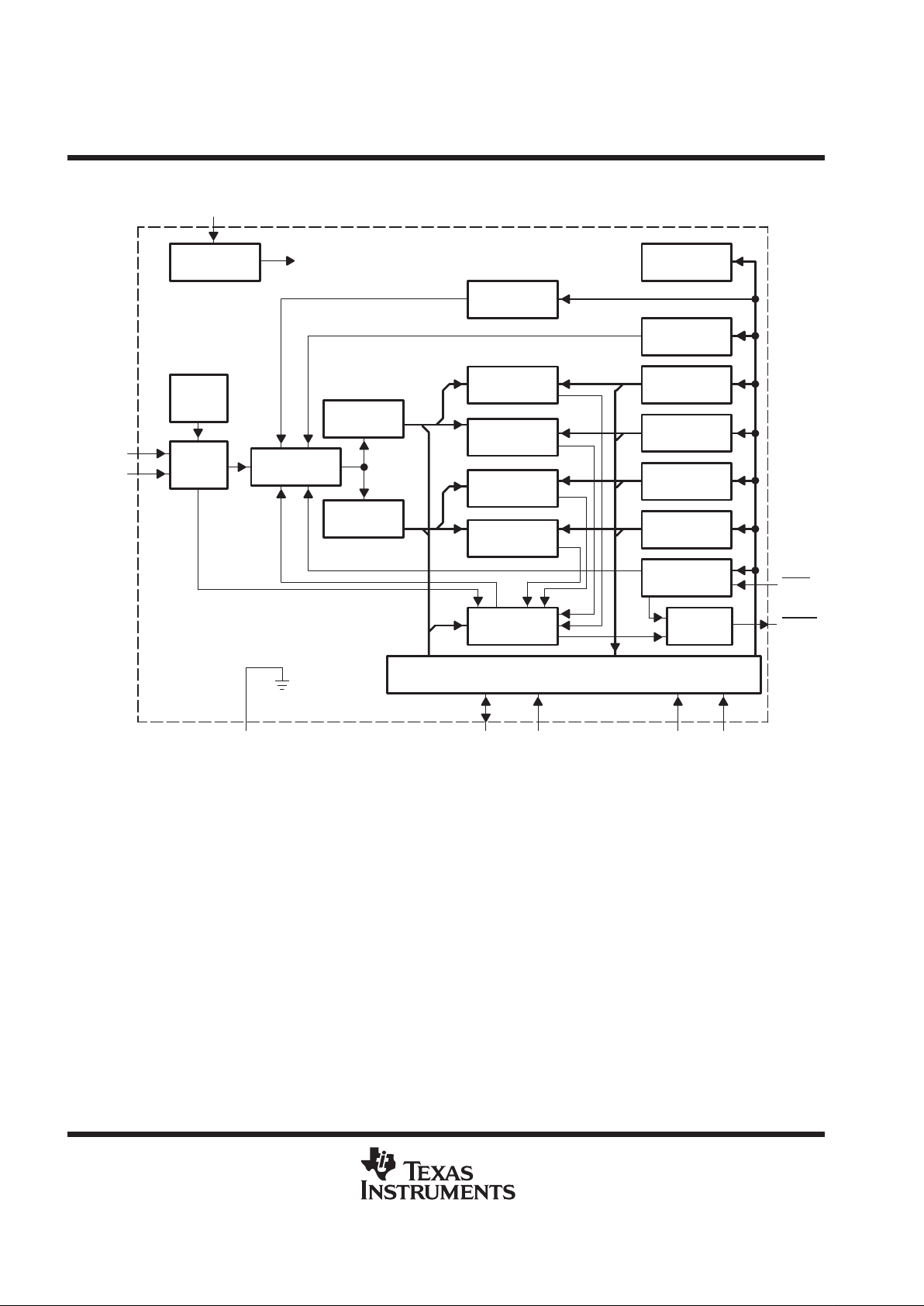

schematic/block diagram

Interrupt

Masking

GND

STBY

DXP

Configuration

Register

High Limit

Register

Low Limit

Register

High Limit

Register

Low Limit

Register

Auto-Acquire

Rate Register

ADDR Pointer

Register

One-Shot

Register

Low Limit

Comparator

High Limit

Comparator

Status

Register

8-Bit A/D

Converter

Power-up

Clear

On-Chip

Temp

Sensor

Analog

MUX

Local Temp

Register

Remote Temp

Register

Low Limit

Comparator

High Limit

Comparator

SDATA

SMBus Interface

DXN

ALERT

V

DD

To All Registers

SCLK ADD0 ADD1

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

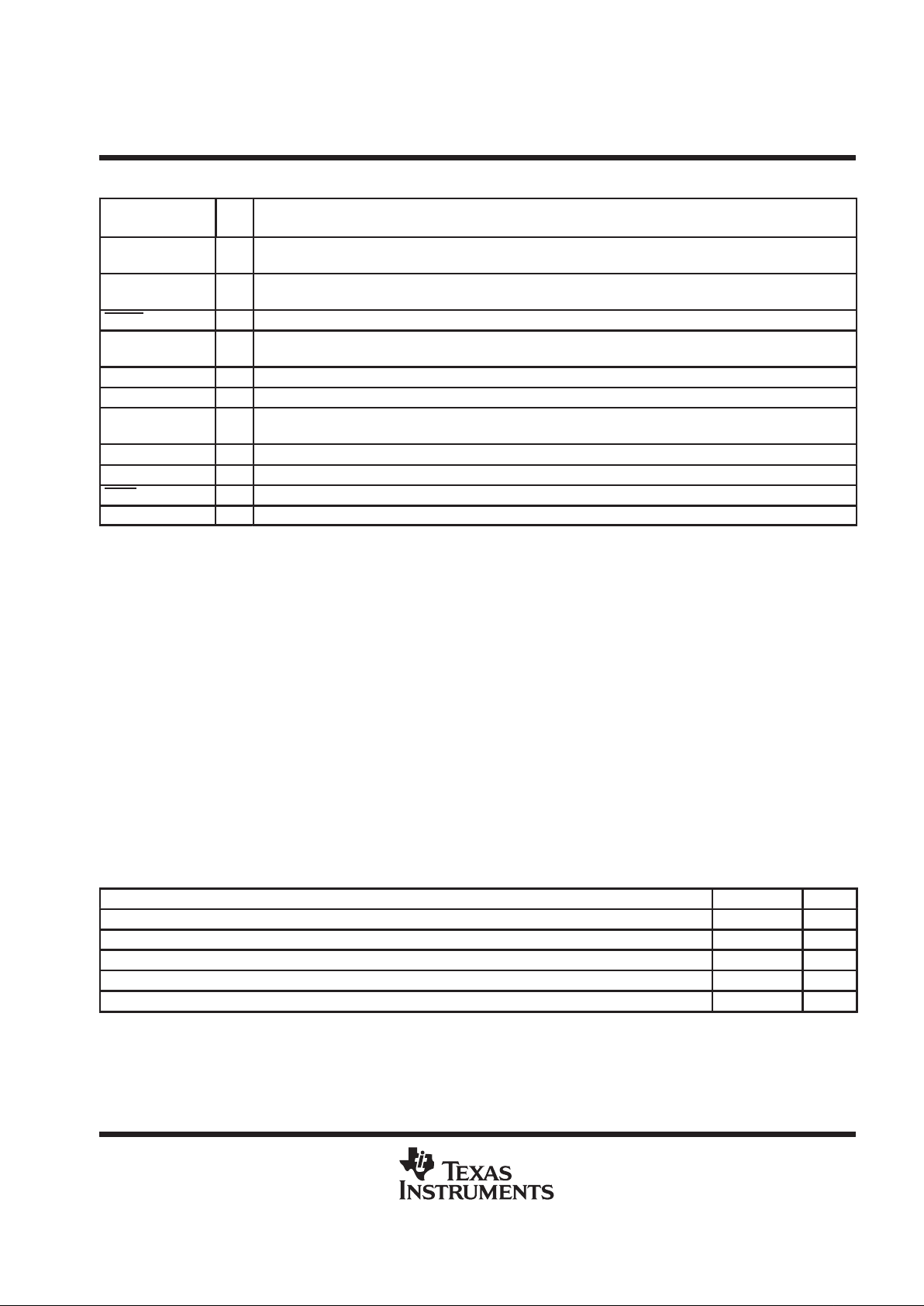

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

ADD0 10 I SMBus address select terminal 0 (Note: Excess capacitance on this terminal may cause SMBus address

recognition problems.)

ADD1 6 I SMBus address select terminal 1 (Note: Excess capacitance on this terminal may cause SMBus address

recognition problems.)

ALERT 11 O Active low temperature interrupt signal

DXN 4 I/O Current sink for external diode connected transistor and A/D negative input (Do not leave floating if no external

diode is used – should be tied to GND.)

DXP 3 I/O Current source for external diode connected transistor and A/D positive input

GND 7, 8 I IC ground

N/C 1, 5, 9,

13, 16

N/C No connection

SCLK 14 I SMBus serial clock input terminal – clock signal for SMBus serial data

SDATA 12 I/O SMBus serial data I/O terminal – serial data I/O for SMBus

STBY 15 I Active low standby mode input

V

DD

2 I IC supply voltage – should be decoupled with external 0.1 µF capacitor

absolute maximum ratings over operating case temperature (see Note 1) (unless otherwise noted)

†

Input voltage on: VDD supply terminal, V

(DDIN)

–0.3 V to 6 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O terminals, V

(IOIN)

–0.3 V to V

DD

+ 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SMBus terminals, V

(SMBIN)

–0.3 V to 6 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DXN terminal, V

(DXN)

–0.3 V to 0.8 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SMBus input/output current, I

(SMBIN)

–1 mA to 50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DXN input current, I

(DXN)

–1 mA to 1 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous power dissipation, P

D

330 mW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating case temperature range, TC –55°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature, T

stg

–65°C to 165°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Junction temperature, TJ 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature (soldering, 10 sec), T

(LEAD)

300°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: All voltage values are with respect to GND.

recommended operating conditions

MIN MAX UNITS

Supply voltage, V

DD

3 3.6 V

SMBus input high voltage, V

IH

2.2 V

SMBus input low voltage, V

IL

0.8 V

SMBus operating frequency, f

(SCLK)

10 100 kHz

Operating ambient temperature, T

A

0 85 °C

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

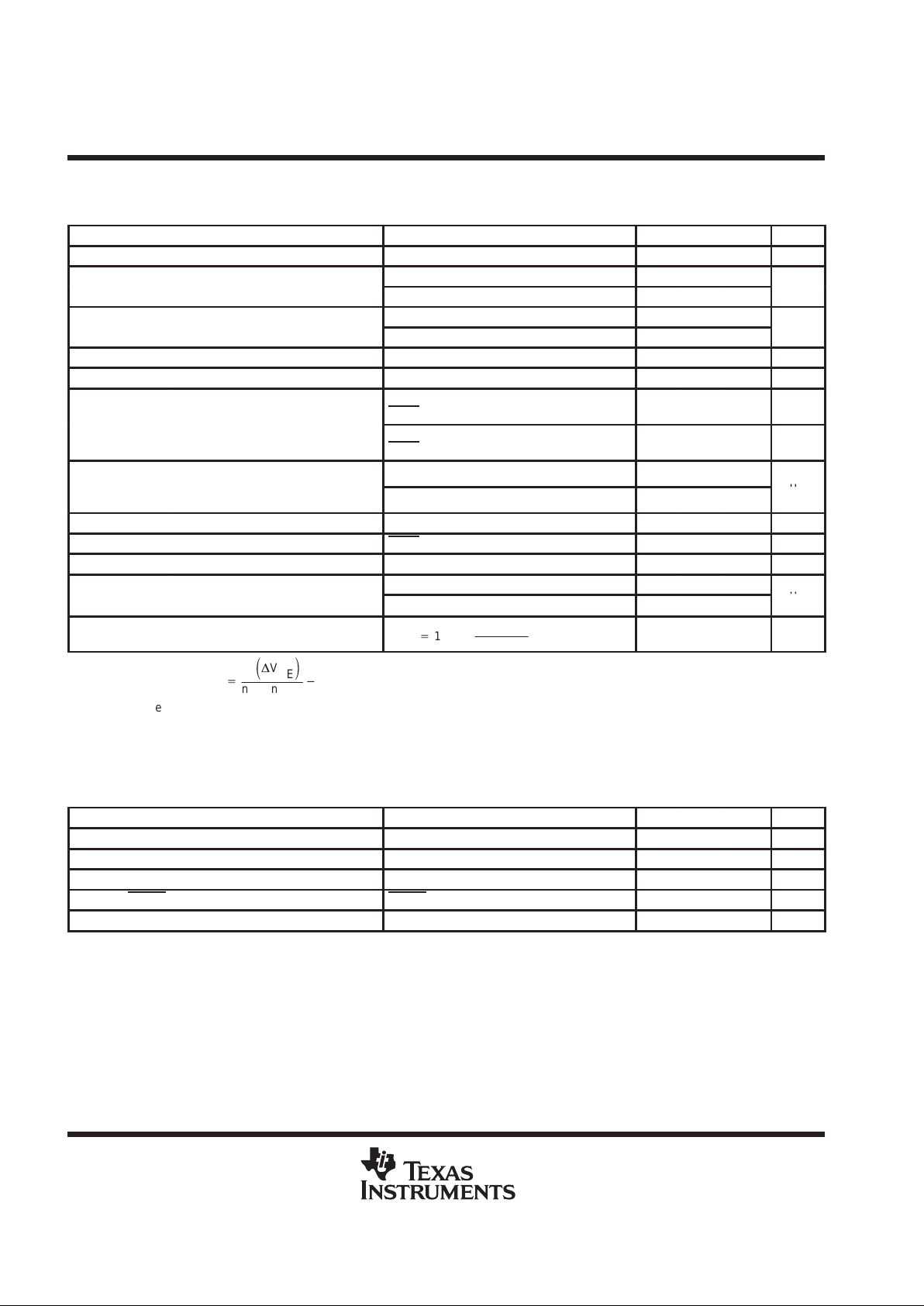

dc electrical characteristics, VDD = 3.3 V, TA = 25°C (unless otherwise noted)

A/D and supply

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

T

(RES)

T emperature resolution No missed codes 1 °C

Initial temperature error from internal

TA = 60°C to 100°C –2 2

°

T

(ERR1)

diode

TA = full range

–3 3

°C

Initial temperature error from external

TA = 60°C to 100°C –2.5 2.5

°

T

(ERR2)

diode (see Note 2)

TA = full range

–3.5 3.5

°C

V

(UVLOCK)

Under voltage lockout voltage VDD input, disables acquisition, rising edge 2.65 2.8 2.95 V

V

(POR)

Power-up reset threshold On VDD input, falling edge 1 2.25 2.5 V

pp

Logic inputs forced to VDD or GND,

STBY

mode, SMBus is static

3 10 µA

I

(DD,STANDBY)VDD

standby supply current

Logic inputs forced to VDD or GND,

STBY

mode, SCLK = 10 kHz

4 µA

VDD operating supply current (aver-

Slow auto-aquire rate (0.25 samples/sec) 40 70

I

DD

aged over 4 seconds in auto-acquire

mode)

Fast auto-aquire rate (2 samples/sec)

45 180

µ

A

V

(D,SOURCE)

DXN source voltage 0.7 V

I

(DLEAK)

DXP and DXN leakage current STBY = 0, DXP = DXN = 0 2 µA

I

(ADD,BIAS)

Add {0:1} bias current Momentary on power up 35 100 µA

DXP = 1.5 V, high level 100

I

(DIODE)

Diode source current

DXP = 1.5 V , low level 10

µ

A

I

(RATIO)

Diode source current ratio

DXP+1.5 V,

high level

low level

9.7 10 10.2

BasedonT(°C)

+

q

ǒ

D

V

BE

Ǔ

nk[ln(10

)]

*

273

Where

q = 1.6 × 10

–19

(charge)

n = 1.0085 (diode ideality factor)

k = 1.38 × 10

–23

(Boltzman’s constant)

NOTE 2:

SMBus

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

IH

Input high voltage 2.2 V

V

IL

Input low voltage 0.8 V

I

OL1

SMBus output low current SDATA = 0.6 V 6 mA

I

OL2

ALERT output low current ALERT = 0.4 V 1 mA

I

I

SMBus input current –1 1 µA

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

ac electrical characteristics, VDD = 3.3 V, TA = 25°C (unless otherwise noted)

A/D and supply

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

t

(CONV)

One-shot conversion time

One-shot mode from SMBus stop bit to temperature

conversion completed (both channels)

12 ms

Acquisition rate accuracy Auto-aquire mode –25% 25%

SMBus

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

f

(SCLK

) SCLK operating frequency See Figure 1 10 100 kHz

t

(BUF)

Bus free time between stop and start condition See Figure 1 4.7 µs

t

(HDSTA)

Hold time after (repeated) start condition. After this period, the

first clock is generated

See Figure 1 4 µs

t

(SUSTA)

Repeated start condition setup time See Figure 1 4.7 µs

t

(SUSTO)

Stop condition setup time See Figure 1 4 µs

t

(HDDAT)

Data hold time See Figure 1 300 ns

t

(SUDAT)

Data setup time See Figure 1 250 ns

t

(LOW)

SCLK clock low period See Figure 1 4.7 µs

t

(HIGH)

SCLK clock high period See Figure 1 4 50 µs

t

(LOWSEXT)

Cumulative clock low extend time (slave device) See Figure 1 25 ms

t

(LOWMEXT)

Cumulative clock low extend time (master device) See Figure 1 10 ms

t

F

Clock/data fall time See Figure 1 300 ns

t

R

Clock/data rise time See Figure 1 1000 ns

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

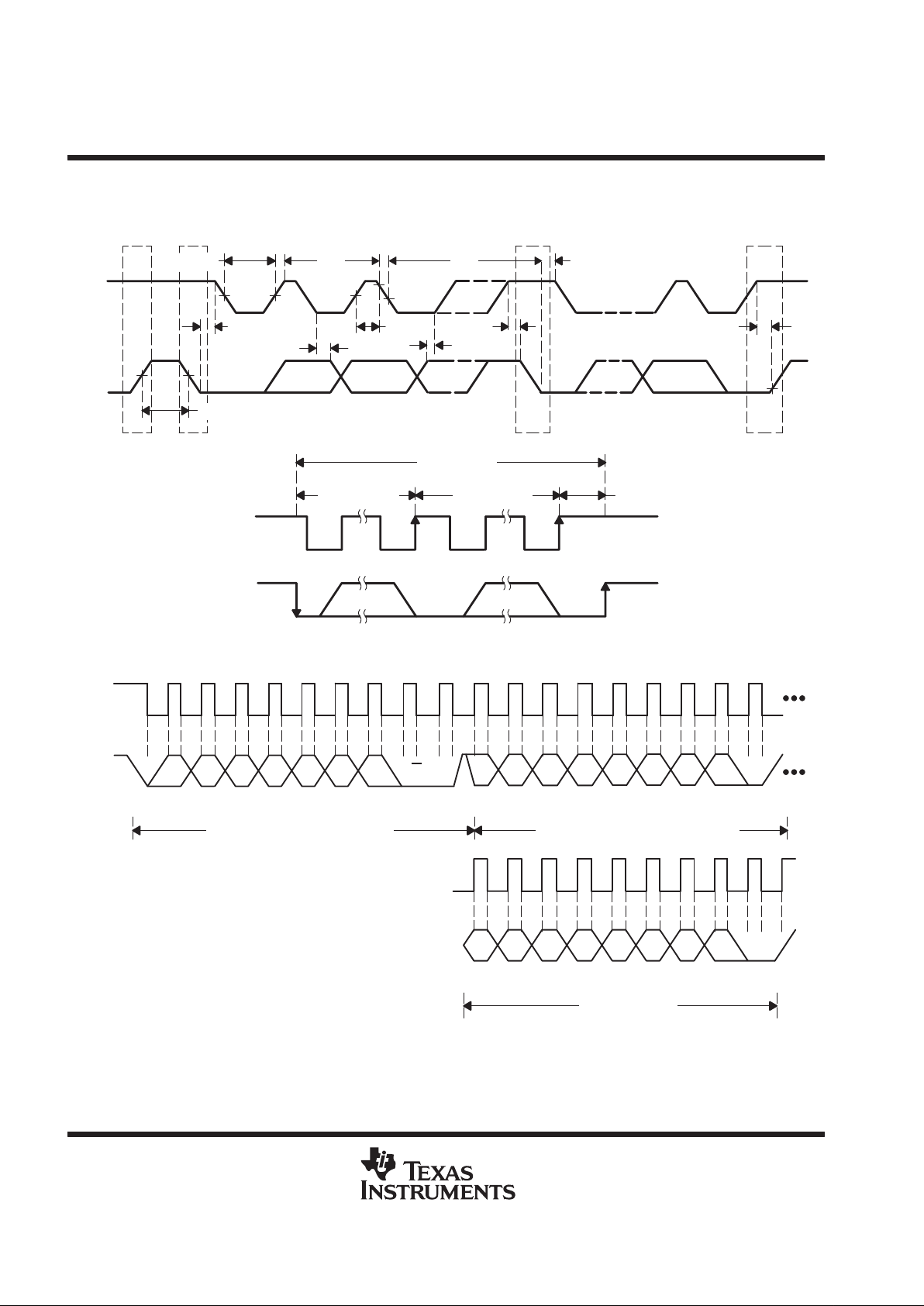

PARAMETER MEASUREMENT INFORMATION

SMBus timing diagrams

PS

t

(HDSTA)

t

(HDDAT)

t

(HIGH)

t

(SUDAT)

t

(SUSTA)

t

(HDSTA)

t

(SUSTO)

SP

SCLK

SDATA

Start

Stop

SCLK

ACK

SCLK

ACK

t

(LOWMEXT)

SCLK

SDATA

t

(LOW)

t

(LOWSEXT)

t

F

t

R

t

(BUF)

t

(LOWMEXT)

t

(LOWMEXT)

Figure 1. SMBus Timing Diagram

Frame 3 Data Byte

Frame 1 SMBus Slave Address Byte

Frame 2 Address Pointer Register Byte

A6 A5 A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0R/W

SCLK

SDATA

Start By

Master

ACK By

THMC10

ACK By

THMC10

D7 D6 D5 D4 D3 D2 D1 D0

ACK By

THMC10

SCLK

(Continued)

SDATA

(Continued)

1

91 9

1

9

Stop By

Master

Figure 2. SMBus Timing Diagram for Write Byte Format

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

SMBus timing diagrams (continued)

Frame 1 SMBus Slave Address Byte

Frame 2 Address Pointer Register Byte

A6 A5 A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0R/W

SCLK

SDATA

Start By

Master

ACK By

THMC10

ACK By

Master

SCLK

(Continued)

DATA

Continued)

1

91 9

Frame 3 SMBus Slave Address Byte

Frame 4 Data Byte Read From THMC10

A6 A5 A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0R/W

Start By

Master

ACK By

THMC10

NACK By

THMC10

1

91 9

Stop By

Master

Figure 3. SMBus Timing Diagram for Read Byte Format

Frame 1 SMBus Slave Address Byte

Frame 2 Address Pointer Register Byte

A6 A5 A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0R/W

SCLK

DATA

Start By

Master

ACK By

THMC10

ACK By

THMC10

1

91 9

Stop By

Master

Figure 4. SMBus Timing Diagram for Send Byte Format (Used for One-Shot Command)

Frame 1 SMBus Slave Address Byte

Frame 2 Data Byte From THMC10

A6 A5 A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0R/W

SCLK

DATA

Start By

Master

ACK By

THMC10

NACK

By Master

1

91 9

Stop By

Master

Figure 5. SMBus Timing Diagram for Recieve Byte Format

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

SMBus registers and addresses

T able 1. ADD{0:1} SMBus Slave Address Map

ADD0 ADD1 RESULTING THMC10 SMBus

SLAVE ADDRESS

0 0 0011 000

0 3-State 0011 001

0 1 0011 010

3-State 0 0101 001

3-State 3-State 0101 010

3-State 1 0101 01 1

1 0 1001 100

1 3-State 1001 101

1 1 1001 1 10

Table 2. SDATA Temperature Data Format (In 8-Bit, 2s Complement)

TEMPERATURE

(°C)

ROUNDED DIGITAL OUTPUT

130.00 127 0 111 1111

127.00 127 0 111 1111

126.60 127 0 111 1111

25.25 25 0 001 1001

0.50 1 0 000 0001

0.25 0 0 000 0000

0.00 0 0 000 0000

–0.25 0 0 000 0000

–0.50 0 0 000 0000

–0.75 –1 1 111 1111

–1.00 –1 1 111 1111

–25.00 –25 1 110 011 1

–25.25 –26 1 110 0110

–54.75 –55 1 100 1001

–55.00 –55 1 100 1001

–65.00 –65 1 011 1111

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

SMBus registers and addresses (continued)

Table 3. Address Pointer Register Map

REGISTER

ADDRESS

POINTER

POR STATE FUNCTION

RIT 00h 0000 0000†Read internal temperature

RET 01h 0000 0000†Read external temperature

RS 02h 0000 0000 Read status byte

RC 03h 0000 0000 Read configuration byte

RCR 04h 0000 0010 Read acquisition rate byte

RIHL 05h 0111 1111 Read internal high limit

RILL 06h 1100 1001 Read internal low limit

REHL 07h 0111 1111 Read external high limit

RELL 08h 1100 1001 Read external low limit

WC 09h N/A Write configuration byte

WCR 0Ah N/A Write acquisition rate byte

WIHL 0Bh N/A Write internal high threshold

WILL 0Ch N/A Write internal low threshold

WEHL 0Dh N/A Write external high threshold

WELL 0Eh N/A Write external low threshold

OSHT 0Fh N/A One-shot (uses send byte format)

MFG ID FEh 0100 1001 Read manufacturer ID (0×49 for TI)

REV ID FFh N/A Read silicon revision number

†

If the THMC10 is in standby

Table 4. Configuration Register Bit Assignments

BIT NAME POR STATE FUNCTION

7 (MSB) MASK 0 Masks ALERT interrupts if high.

6 Run/stop 0 Standby mode control bit, if high, standby mode is initiated. (Note: Does not disable SMBus Interface)

5 to 0 Reserved

Table 5. Status Register Bit Assignments

BIT NAME POR STATE FUNCTION

7 (MSB) BUSY 0 A/D is busy acquiring when high.

6 LHIGH

†

0 Internal high-temperature alarm has tripped when high, cleared by power-on reset (POR) or readout of

entire status byte.

5 LLOW

†

0 Internal low-temperature alarm has tripped when high, cleared by POR or readout of entire status byte.

4 RHIGH

†

0 External high-temperature alarm has tripped when high, cleared by POR or readout of entire status byte.

3 RLOW

†

0 External low-temperature alarm has tripped when high, cleared by POR or readout of entire status byte.

2 OPEN

†

0 A high indicates an external diode open.

1 to 0 0 Reserved

†

These flags stay high until cleared by POR or until the status byte register is read.

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

SMBus registers and addresses (continued)

Table 6. Acquistion Rate Register Bit Assignments

DATA

ACQUISITION RATE

(Hz)

AVERAGE SUPPLY CURRENT

(µA TYPICAL AT VDD=3.3V)

00h 0.0625 40

01h 0.125 40

02h 0.25 40

03h 0.5 40

04h 1 42

05h 2 45

06h 4 55

07h 8 65

08h to FFh Reserved N/A

Table 7. Alert Response Address Map

(Using Receive Byte Format in Figure 5)

THMC10 ALERT RESPONSE

SMBUS SLAVE ADDRESS

ADD1 ADD0

DATA IF

ALERT

LOW

0001 100 0 0 0011 000

0001 100 0 3-State 0011 001

0001 100 0 1 0011 010

0001 100 3-State 0 0101 001

0001 100 3-State 3-State 0101 010

0001 100 3-State 1 0101 011

0001 100 1 0 1001 100

0001 100 1 3-State 1001 101

0001 100 1 1 1001 110

functional description

standby input (STBY)

Standby mode disables the A/D and reduces the supply current drain to less than 10 µA.

Standby mode is engaged by forcing the STBY

terminal low or by setting the

start/stop

bit in the configuration

byte register to a 1.

Hardware and software standby modes behave almost identically . All data is retained in memory and the SMBus

interface is active and scanning for reads and writes. The only difference is that in hardware standby mode, the

one-shot command does not initiate an acquisition. The standby mode is not a shutdown mode. With activity

on the SMBus, extra supply current is drawn (see A/D and supply dc electrical characteristics). In the software

standby mode, the THMC10 can be forced to perform temperature acquisitions via the one-shot command,

despite the

start/stop

bit being high.

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

standby input (STBY) (continued)

Forcing the STBY terminal low activates the hardware standby mode. In a notebook computer, this line may

be connected to the system suspend-state signal. Pulling the STBY terminal low overrides any software

acquisition command. If a hardware or software standby command is received while an acquisition is in

progress, the acquisition cycle is truncated, and the data from that acquisition is not latched into either

temperature reading register. The previous data is not changed and remains available.

Peak supply current drain during an auto-aquire period is typically 300 µA. Slowing down the auto-acquire rate

minimizes the average supply current (see

A/D and supply dc electrical characteristics). In between

acquisitions, the instantaneous supply current is about 40 µA, due to the current consumed by the auto-aquire

rate timer. In standby mode, supply current drops to about 3 µA. At very low supply voltages (under the

power-on-reset threshold), the supply current is higher due to the address terminal bias currents. It can be as

high as 100 µA, depending on ADD0 and ADD1 settings.

under/overtemperature and remote diode diagnostics interrupt alert terminal (ALERT)

The THMC10 allows the user to program upper and lower temperature limits for both the on-chip and the remote

temperature sensor. If any of these limits are exceeded, or an open external diode is detected, the THMC10

asserts the ALERT to a logic low state to alert the user that an interrupt has occurred. This feature is useful in

applications where minimal SMBus traffic is desired by only interrogating the THMC10 for faults or temperature

when a fault has occurred.

It is recommended that the user always double-check the validity of an ALERT condition by reading the current

temperature values and comparing them with the programmed high and low temperature limits.

The ALERT function can also be masked by setting bit 6 in the configuration register to a logic 1. If this bit is

set, the ALERT

terminal is not asserted low, even if a trip point is reached.

The ALERT

signal and corresponding status register bits can only be cleared by reading from the alert response

address (0001 100) or by a power-on reset of the device (see alert response address section).

NOTE:

The ALERT

terminal is an open-drain output and requires an external pullup resistor.

alert response address (0001 100)

The SMBus alert response address allows the user to quickly check the status of the ALERT

terminal via the

SMBus receive byte protocol (see Figure 5). This is useful in applications where another device on the SMBus

needs to know the status of the THMC10 ALERT

terminal without requiring the complex logic needed to decode

the contents of the status register. If the ALER T has been asserted low, the data read from the alert response

address is the THMC10 slave address (determined by ADD0 and ADD1 – see Table 8). If the fault condition

which caused the ALERT to go low is no longer present when the alert response address is successfully read,

the ALERT

terminal returns to a logic high state and the corresponding bits in the THMC10 status register are

cleared. If the ALERT terminal has not been asserted low , the THMC10 responds to the alert response address

with a NACK signal after the alert response address is sent.

The alert response address can activate several different slave devices simultaneously. It is similar to the

general call address outlined in the I2C Bus specification. If more than one device attempts to respond to the

alert response address, SMBus arbitration rules apply , causing the device with the lowest slave address to win

control of the SMBus. The device that loses arbitration in this example does not generate an ACK signal and

continues to hold the ALERT terminal low until the device with the losing slave address is serviced. This

technique requires the SMBus host controller to use level-sensitive interrupt inputs in order to assure that each

device is serviced.

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

SMBus slave address select terminals (ADD0 and ADD1)

The ADD0 and ADD1 terminals allow the user to select between nine unique SMBus slave addresses to allow

up to nine THMC10 devices to be used by the same SMBus host controller. The following truth table shows how

the voltage at ADD0 and ADD1 determines the SMBus slave address of the THMC10.

Table 8. SMBus Slave Address Map (ADD0 and ADD1)

ADD0 ADD1 RESULTING SMBus ADDRESS

0 0 001 1 000

0 3-State 0011 001

0 1 001 1 010

3-State 0 0101 001

3-State 3-State 0101 010

3-State 1 0101 011

1 0 1001 100

1 3-State 1001 101

1 1 1001 1 10

SMBus serial clock input terminal (SCLK)

The SCLK terminal allows the host controller to send a clock signal that synchronizes the data coming into or

out of the SDA TA terminal of the THMC10. The frequency of this clock can be anywhere between 10 kHz and

100 kHz. Timing diagrams showing the relationship of SCLK to SDA T A are shown in Figure 1 through Figure 4.

SMBus serial data input/output terminal (SDATA)

The SDA TA terminal allows the host controller to program the THMC10 with set points and with configuration

data. The SDA TA terminal also allows the THMC10 to send data back to the host controller (remote and local

temperature, interrupt status, etc.). Data sent into or out of the SDA TA terminal is synchronous with the rising

edge of SCLK. Timing diagrams in Figure 1 through Figure 5 show the relationship between SDA T A and SCLK.

Table 1 through Table 5 show the THMC10 register maps that are used to configure and read the THMC10.

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

external temperature sensor connections (DXP and DXN)

The DXP and DXN terminals are used to sense the remote temperature of either a microprocessor die or a

simple diode-connected transistor. Referring to Figure 6, the THMC10 has an internal state machine controlling

an analog MUX, an 8-bit A/D converter, plus 10-µA and 90-µA nominal current sources. The analog MUX

switches between the THMC10’s internal temperature sensor and the external one connected to DXP and DXN.

This allows the use of only one 8-bit A/D converter, eliminating errors which would be present when using two

separate A/Ds. The THMC10 takes a V

BE

measurement at 100 µA, then takes a VBE measurement at 10 µA,

and subtracts the difference between the two sampled values. It then scales the resulting ∆VBE measurement

into a 2s complement, 8-bit binary format that is available over the SMBus interface (see T able 2). By using two

different current levels and a single diode-connected transistor to measure the ∆V

BE

, the absolute VBE is

canceled, and therefore no calibration is needed.

8–Bit A/D

Converter

DXP

Substrate

On-Chip Temp

Sensor

GND

V

DD

10 µ 90 µA

Control

State

Machine

Analog

MUX

Remote

Die

Substrate

DXN

Remote

Temp

Sensor

(CPU)

THMC10

Front End

A

Figure 6. Temperature Measurement Block Diagram

external temperature sensor diagnostics (DXP and DXN)

The THMC10 provides diagnostic capabilities to allow detection of either an open external sensor or a shorted

external sensor. When DXP is shorted to GND or VDD, the THMC10 reports 127°C for the external temperature.

If the interrupt mask bit is not set in the configuration register, it asserts the ALERT terminal low and sets bit two

in the status register. When DXP is shorted to DXN, the THMC10 reports 0°C for the external temperature and

no fault is reported. If any of the above conditions exceed a temperature limit, then a temperature limit error is

also indicated in the status register if the interrupt mask bit is not set.

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

PC board layout considerations

D

Place the THMC10 as close as practical to the remote diode. In a noisy environment, such as a computer

motherboard, this distance can be 4 inches to 8 inches (typical) or more, as long as the worst noise sources

(such as CRTs, clock generators, memory buses, and ISA/PCI buses) are avoided.

D

Route the DXP–DXN lines away from the deflection coils of a CRT. Also, avoid routing the traces across

a fast memory bus which can easily introduce 30°C error even with good filtering. Otherwise, most noise

sources are fairly benign.

D

Route the DXP and DXN traces in parallel and in close proximity to each other, away from any high-voltage

traces such as 12 Vdc. Leakage currents from PC board contamination must be be taken into consideration,

since a 20-MΩ leakage path from DXP to ground causes about 1°C error.

D

Connect guard traces to GND on either side of the DXP–DXN traces (Figure 7). With guard traces in place,

routing near high-voltage traces is not an issue.

D

Route through as few vias and crossunders as possible to minimize copper/solder thermocouple effects.

D

When introducing a thermocouple, insure that both the DXP and the DXN paths have matching

thermocouples. In general, PC board induced thermocouples are not a serious problem. A copper-solder

thermocouple exhibits 3 µV/°C, and it takes about 200 µV of voltage error at DXP–DXN to cause a 1°C

measurement error. Hence, most parasitic thermocouple errors are swamped out.

D

Use wide traces. Narrow traces are more inductive and tend to pick up radiated noise. The 10-mil widths

and spacings recommended in Figure 7 are not absolutely necessary as they offer only a minor

improvement in leakage and noise, but usage is recommended where practical.

D

Copper can not be used as an EMI shield and only ferrous materials such as steel work well. Placing a

copper ground plane between the DXP–DXN traces and traces carrying high-frequency noise signals does

not help reduce EMI.

PC board layout checklist

D

Place the THMC10 as close as possible to the remote diode.

D

Keep traces away from high voltages (12 V bus).

D

Keep traces away from fast data/memory buses and CRTs.

D

Use recommended trace widths and spacings.

D

Place a ground plane under the traces.

D

Use guard traces flanking DXP and DXN and connecting to GND.

D

Place the noise filter and the 0.1-µF VDD bypass capacitors close to the THMC10.

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

PC board layout checklist (continued)

10 MILS

DXN

DXP

GND

GND

10 MILS

MINIMUM

10 MILS

10 MILS

Figure 7. Recommended PC Board Layout for DXP/DXN Traces

uses of twisted pair and shielded cables

For remote-sensor distances longer than 8 inches or in particularly noisy environments, a twisted pair is

recommended. Its practical length is 6 feet to 12 feet (typical) before noise becomes a problem, as tested in

a noisy electronics laboratory. For longer distances, the best solution is a shielded twisted pair like that used

for audio microphones. For example, a Belden #8451 works well for distances up to 100 feet in a noisy

environment. Connect the twisted pair to DXP and DXN and the shield to GND, and leave the shield’s remote

end unterminated. Excess capacitance at DXN limits practical remote sensor distances (see A/D and supply

dc electrical characteristics). For very long cable runs, the cable’s parasitic capacitance often provides noise

filtering; hence, the 2200-pF capacitor can often be removed or reduced in value. Cable resistance also affects

remote-sensor accuracy. A 1-Ω series resistance introduces about 0.5°C error.

Belden is a registered trademark of Belden Corporation.

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

THMC10

SCLK

SDATA

ALERT

ADD1

ADD0

SCLK

V

DD

C2

2200 pF

Q1

2N3904

or

Equivalent

3

4

DXP

DXN

GNDGND

87

14

12

11

6

10

V

DD

STBY

15

2

SDATA

ALERT

ADD1

ADD0

STBY

C1

0.1 µF

R3

10 kΩ

R2

10 kΩ

R1

10 kΩ

To VDD,

GND, or

FLOAT

Figure 8. Typical Application Schematic

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PERFORMANCE DATA

temperature error vs power supply sinusoidal noise frequency

–2

–1

0

1

2

3

f – Frequency – Hz

10 100 1k 100k 100M1M10k 10M

62 mV

p-p

Remote

125 mV

p-p

Local

125 mV

p-p

Remote

62 mV

p-p

Local

250 mV

p-p

Local

250 mV

p-p

Remote

t – Temperature Error –

C

°

250 mV

p-p

Local

250 mV

p-p

Remote

Figure 9. Data Plot

STDBY V

DD

15 2

V

DD

SMBCLK

SMBDATA

ALERT

V

DD

GND

GND

ADD0 ADD1

Q1

2N3904

R4

50 Ω

HP8116A

Generator

To ICA93LV

I2C Controller

14

12

11

7

8

10 6

4

3

DXP

DXN

THMC10

R1

10 kΩ

R2

50 Ω

R3

1 kΩ

C1

20 pF

NOTE: No 0.1 µF VDD capacitor.

Figure 10. Test Circuit

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PERFORMANCE DATA

temperature error vs PNP collector square wave noise frequency

–1

0

1

f – Frequency – Hz

10 100 1k 100k 100M1M10k 10M

100 mV

p-p

Local

100 mV

p-p

Remote

t – Temperature Error –

C

°

Figure 11. Data Plot

STDBY V

DD

15 2

3.3 V

SMBCLK

SMBDATA

ALERT

3.3 V

GND

GND

ADD0 ADD1

Q1

2N3906

R2

50 Ω

HP8116A

Generator

To ICA93LV

I2C Controller

14

12

11

7

8

10 6

4

3

DXP

DXN

THMC10

R1

10 kΩ

NOTE: No 0.1 µF VDD capacitor.

No 2200 pF DXP-DXN filter capacitor.

Representative of

Processor On-Die

Sensing Diode

Figure 12. Test Circuit

THMC10

REMOTE/LOCAL TEMPERATURE MONITOR

WITH SMBus INTERFACE

SLIS089 – DECEMBER 1999

19

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

DBQ (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

Gage Plane

0.008 (0,20) NOM

0.010 (0,25)

0.016 (0,40)

0.035 (0,89)

2420

Seating Plane

(8,74)

(8,56)

0.3370.337

(8,56)

(8,74)

0.344 0.344

4073301/D 08/98

13

0.150 (3,81)

0.157 (3,99)

0.012 (0,30)

0.008 (0,20)

12

A

24–PIN SHOWN

1

24

16

DIM

PINS **

A MIN

A MAX

0.004 (0,10)

0.010 (0,25)

0.069 (1,75) MAX

0.244 (6,20)

0.228 (5,80)

0.197

(5,00)

(4,78)

0.188

0.004 (0,10)

M

0.005 (0,13)

0.025 (0,64)

0°–8°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0.006 (0,15).

D. Falls within JEDEC MO-137

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Loading...

Loading...