Page 1

www.ti.com

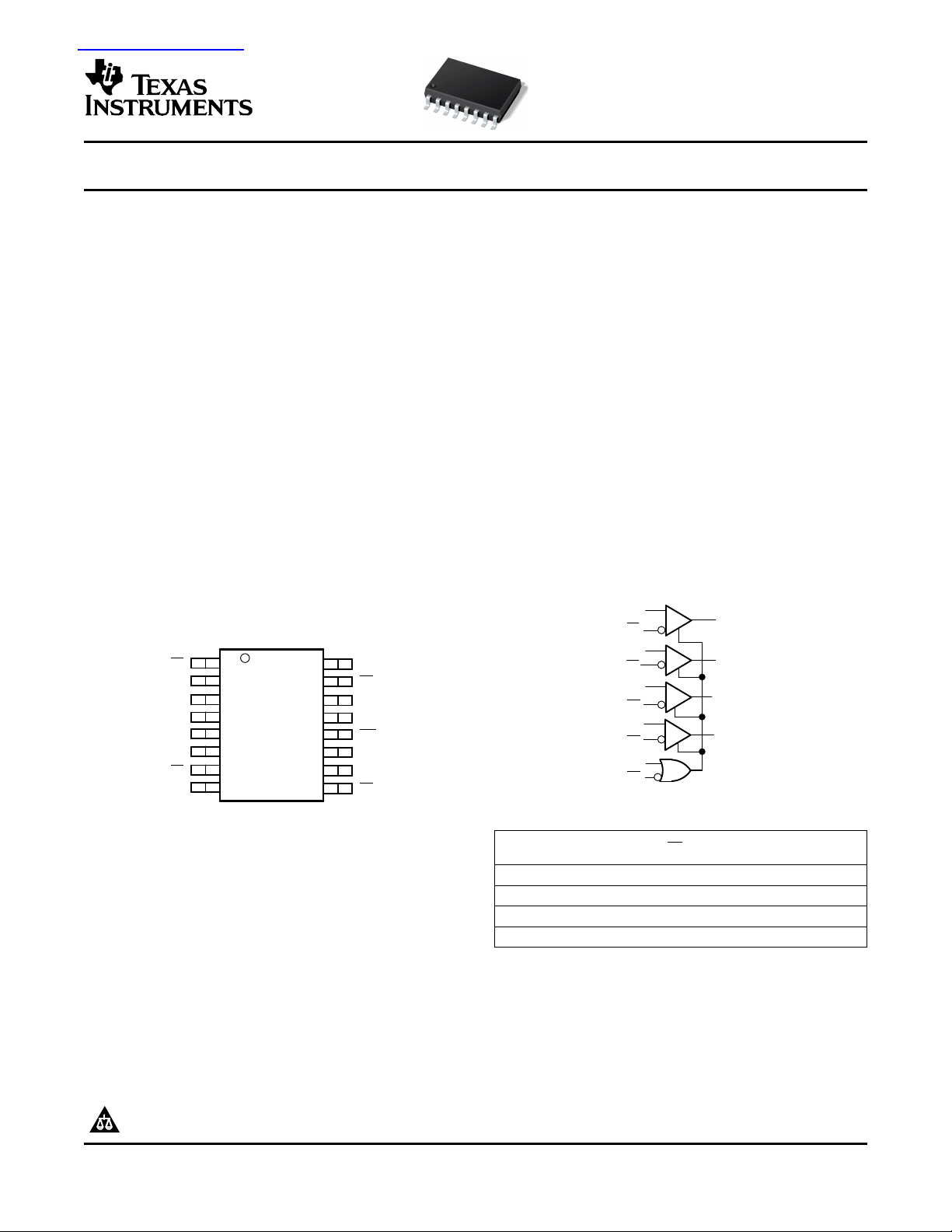

AI

AO

BO

CO

DO

AIAI

BI

BI

C1

C1

D1

D1D1

E2

E1

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

AI

AI

AO

E1

BO

BI

BI

GND

VCC

DI

DI

DO

E2

CO

CI

CI

SOIC PACKAGE

(TOP VIEW)

查询TAS5121I供应商

TB5R3

SLLS643 – SEPTEMBER 2005

QUAD DIFFERENTIAL PECL RECEIVERS

FEATURES DESCRIPTION

• Functional Replacement for the Agere BRF1A

• Pin Equivalent to General Trade 26LS32

• High Input Impedance Approximately 8 k Ω

• <2.6-ns Maximum Propagation Delay

• TB5R3 Provides 50-mV Hysteresis (Typical)

• -1.1-V to 7.1-V Common-Mode Input Voltage

Range

• Single 5-V ± 10% Supply

• ESD Protection HBM > 3 kV and CDM > 2 kV

• Operating Temperature Range: -40 ° C to 85 ° C

• Available in Gull-Wing SOIC (JEDEC MS-013, The packaging for this differential line receiver is a

DW) and SOIC (D) Package

APPLICATIONS

• Digital Data or Clock Transmission Over Bal-

anced Lines

These quad differential receivers accept digital data

over balanced transmission lines. They translate

differential input logic levels to TTL output logic

levels.

The TB5R3 is a pin- and function-compatible replacement for the Agere systems BRF1A; it includes 3-kV

HBM and 2-kV CDM ESD protection.

The power-down loading characteristics of the receiver input circuit are approximately 8 k Ω relative to

the power supplies; hence they do not load the

transmission line when the circuit is powered down.

16-pin gull wing SOIC (DW) or a 16 pin SOIC (D).

The enable inputs of this device include internal

pull-up resistors of approximately 40 k Ω that are

connected to V

to ensure a logical high level input

CC

if the inputs are open circuited.

PIN ASSIGNMENTS

FUNCTIONAL BLOCK DIAGRAM

Enable Truth Table

E1 E2

0 0 Active

1 0 Active

0 1 Disabled

1 1 Active

OUTPUT

CONDITION

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2005, Texas Instruments Incorporated

Page 2

www.ti.com

TB5R3

SLLS643 – SEPTEMBER 2005

These devices have limited built-in ESD protection. The leads should be shorted together or the device

placed in conductive foam during storage or handling to prevent electrostatic damage to the MOS gates.

ORDERING INFORMATION

PART NUMBER

TB5R3DW TB5R3 Gull-Wing SOIC NiPdAu Production

TB5R3LDW TB5R3L Gull-Wing SOIC SnPb Production

TB5R3D TB5R3 SOIC NiPdAu Production

TB5R3LD TB5R3L SOIC SnPb Production

(1) Add the R suffix for tape and reel carrier (i.e., TB5R3DR)

POWER DISSIPATION RATINGS

PACKAGE JUNCTION-TO-AMBIENT TOR

DW

D

(1) This is the inverse of the junction-to-ambient thermal resistance when board-mounted with no air flow.

(2) In accordance with the low-K thermal metric definitions of EIA/JESD51-3.

(3) In accordance with the high-K thermal metric definitions of EIA/JESD51-7.

(1)

CIRCUIT BOARD POWER RATING POWER RATING

MODEL TA≤ 25 ° C TA= 85 ° C

Low-K

High-K

Low-K

High-K

PART MARKING Package LEAD FINISH STATUS

THERMAL RESISTANCE, DERATING FAC-

WITH NO AIR FLOW TA≥ 25 ° C

(2)

(3)

(2)

(3)

831 mW 120.3 ° C/W 8.3 mW/ ° C 332 mW

1240 mW 80.8 ° C/W 12.4 mW/ ° C 494 mW

763 mW 131.1 ° C/W 7.6 mW/ ° C 305 mW

1190 mW 84.1 ° C/W 11.9 mW/ ° C 475 mW

(1)

THERMAL CHARACTERISTICS

PARAMETER PACKAGE VALUE UNIT

θ

JB

θ

JC

Junction-to-Board

Thermal Resistance

Junction-to-Case

Thermal Resistance

DW 53.7

D 47.5

DW 47.1

D 44.2

° C/W

° C/W

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range unless otherwise noted

Supply voltage, V

Magnitude of differential bus (input) voltage, |V

ESD

Continuous power dissipation See Dissipation Rating Table

Storage temperature, T

(1) Stresses beyond those listed under "absolute maximum ratings” may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions” is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) Tested in accordance with JEDEC Standard 22, Test Method A114-A.

(3) Tested in accordance with JEDEC Standard 22, Test Method C101.

CC

Human Body Model

Charged-Device Model

stg

- VAI|, |V

(2)

AI

All pins ± 3.5 kV

(3)

All pins ± 2 kV

- VBI|, |V

BI

(1)

UNIT

0 V to 6 V

- VCI|, |V

CI

- VDI| 8.4 V

DI

-65 ° C to 150 ° C

2

Page 3

www.ti.com

SLLS643 – SEPTEMBER 2005

RECOMMENDED OPERATING CONDITIONS

MIN NOM MAX UNIT

Supply voltage, V

CC

Bus pin input voltage, VAI, VAI, VBIVBI, VCI, or VCI, VDI, V

Magnitude of differential input voltage, |V

Low-level enable input voltage

High-level enable input voltage

Operating free-air temperature, T

(2)

, VIL(V

(2)

, VIH(V

A

- VAI|, |V

AI

= 5.5 V) 0.8 V

CC

= 5.5 V) 2 V

CC

DI

- VBI|, |V

BI

- VCI|, |V

CI

- VDI| 0.1 6 V

DI

4.5 5 5.5 V

(1)

-1.2

-40 85 ° C

(1) The algebraic convention, in which the least positive (most negative) limit is designated as minimum is used in this data sheet, unless

otherwise noted.

(2) The input levels and difference voltage provide no noise immunity and should be tested only in a static, noise-free environment.

DEVICE ELECTRICAL CHARACTERISTICS

over operating free-air temperature range unless otherwise noted

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

CC

Supply current

(1)

(1) Current is dc power draw as measured through GND pin and does not include power delivered to load.

Outputs disabled 50 mA

Outputs enabled 48 mA

TB5R3

7.2 V

RECEIVER ELECTRICAL CHARACTERISTICS

over operating free-air temperature range unless otherwise noted

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

V

V

V

V

V

I

I

I

I

I

I

I

R

(1) This parameter is listed using a magnitude and polarity/direction convention, rather than an algebraic convention, to match the original

(2) The input levels and difference voltage provide no noise immunity and should be tested only in a static, noise-free environment.

Output low voltage V

OL

Output high voltage V

OH

Enable input clamp voltage V

IK

Positive-going differential input threshold voltage

TH+

Negative-going differential input threshold voltage

TH-

Differential input threshold voltage hysteresis, (V

HYST

OZL

Output off-state current, (High-Z) V

OZH

Output short circuit current V

OS

Enable input low current V

IL

(2)

, (V

- VxI) x = A, B, C, or D 100 mV

xl

(2)

, (V

- VxI) x = A, B, C, or D mV

xl

- V

TH+

) 50 mV

TH_

Enable input high current VIN= 2.7 V 20 µA

IH

Enable input reverse current VIN= 5.5 V 100 µA

Differential input low current V

IL

Differential input high current VCC= 5.5V, VIN= 7.2 V 1 mA

IH

Small-signal output resistance Ω

O

= 4.5 V, IOL= 8 mA 0.4 V

CC

= 4.5 V, IOH= -400 µA 2.4 V

CC

= 4.5 V, II= -5 mA -1

CC

= 5.5 V

CC

= 5.5 V mA

CC

= 5.5 V, VIN= 0.4 V µA

CC

V

= 5.5 V

CC

= 5.5V, VIN= -1.2 V -2

CC

VO= 0.4 V -20

VO= 2.4 V 20 µA

Output High 50

Output Low 25

Agere data sheet.

(1)

V

-

(1)

100

(1)

µA

-

(1)

400

-

(1)

400

(1)

mA

3

Page 4

www.ti.com

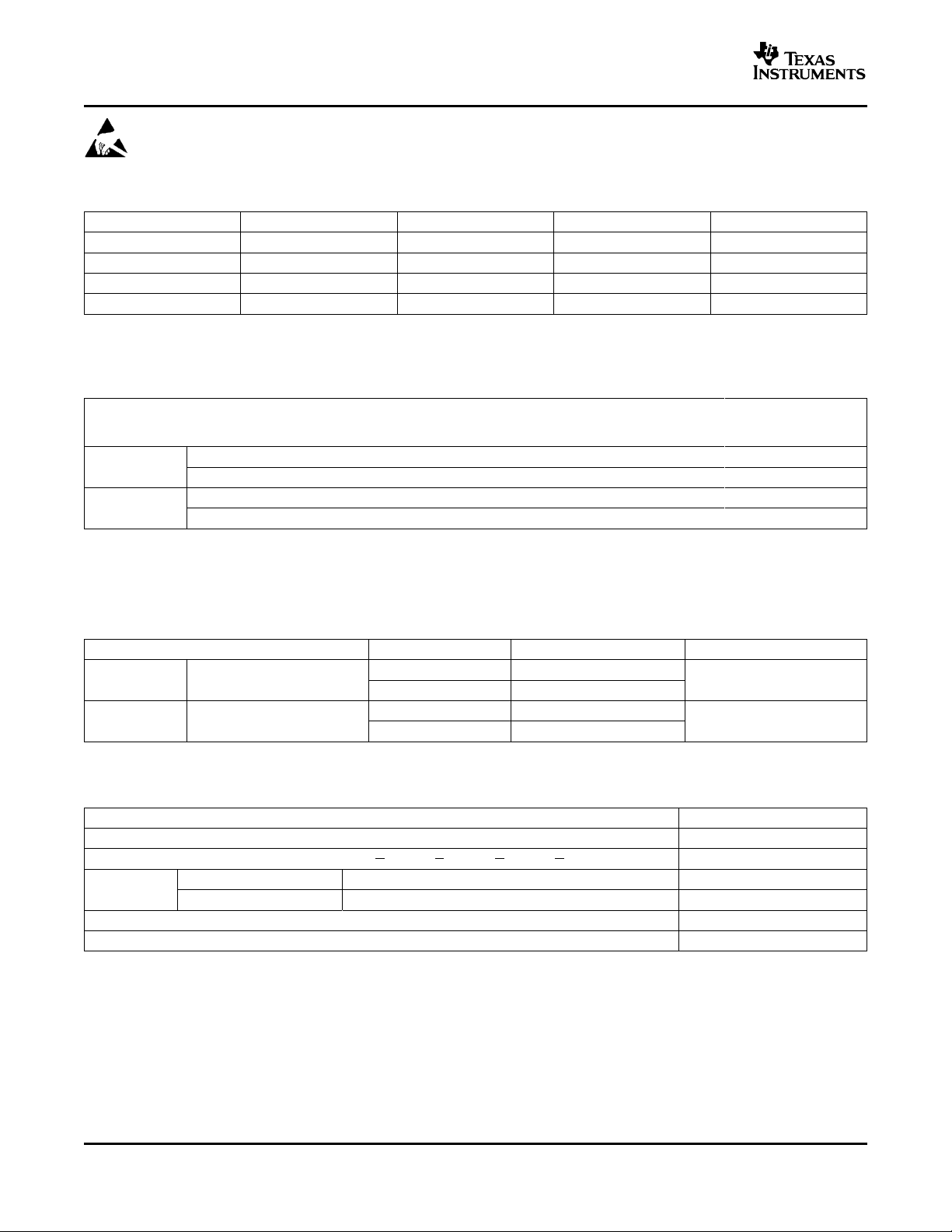

OUTPUT

3.7 V

2.7 V

3.2 V

V

OH

VOL

1.5 V

t

THL

t

PHL

t

PLH

t

TLH

20%

80%

20%

80%

INPUT

INPUT

See Note A See Note A

t

f

t

r

80% 80%

20% 20%

TB5R3

SLLS643 – SEPTEMBER 2005

SWITCHING CHARACTERISTICS

over operating free-air temperature range unless otherwise noted

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

PLH

t

PHL

t

PLH

t

PHL

t

PHZ

t

PLZ

t

skew1

∆ t

-p

∆ t

t

PZH

t

PZL

t

TLH

t

THL

Propagation delay time, low-to-high-level output 1.64 <2.6

Propagation delay time, high-to-low-level output 1.57 <2.6

Propagation delay time, low-to-high-level output 2.2 3.5

Propagation delay time, high-to-low-level output 2.1 3.5

Output disable time, high-level-to-high-impedance

(3)

output

Output disable time, low-level-to-high-impedance

(3)

output

Pulse-width distortion, |t

skew1p

Part-to-part output waveform skew

Same part output waveform skew CL= 10 pF, See Figure 2 and Figure 4 0.3 ns

skew

Output enable time, high-impedance-to-high-level

(3)

output

Output enable time, high-impedance-to-low-level

(3)

output

- t

PHL

|

PLH

Rise time (20%-80%) 1 ns

Fall time (80%-20%) 1 ns

CL= 0 pF

CL= 50 pF, See Figure 2 and Figure 4

(1)

, See Figure 2 and Figure 4 ns

(2)

7.7 12 ns

CL= 5 pF, See Figure 3 and Figure 5

5.2 12 ns

CL= 10 pF, See Figure 2 and Figure 4 0.7 ns

CL= 150 pF, See Figure 2 and Figure 4 4 ns

CL= 10 pF, TA= 75 ° C, See Figure 2 and

Figure 4

0.8 1.4 ns

CL= 10 pF, See Figure 2 and Figure 4 1.5 ns

6.9 12 ns

CL= 10 pF, See Figure 3 and Figure 4

6.3 12 ns

CL= 10 pF, See Figure 2 and Figure 4

ns

(1) The propagation delay values with a 0 pF load are based on design and simulation.

(2) tr/tf: 3 ns (20% - 80%)

(3) See Table 1.

A. tr/tf: 3 ns (20% - 80%)

Figure 1. Receiver Propagation Delay Times

4

Page 5

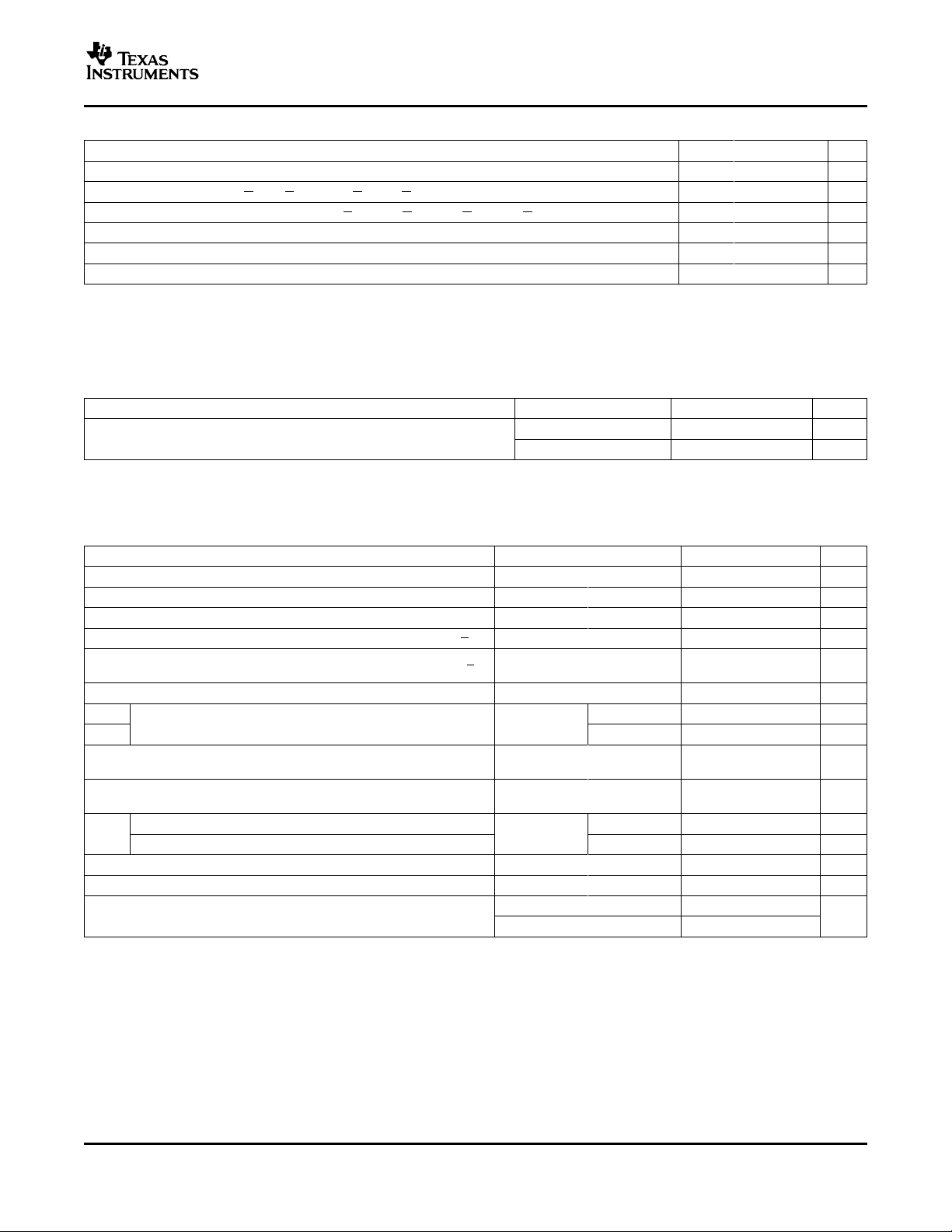

www.ti.com

OUTPUT

2.4 V

0.4 V

1.5 V

t

PHZ

t

PZH

t

PLZ

t

PZL

0.2 V

0.2 V

0.2 V

0.2 V

0.4 V

2.4 V

1.5 V

E2

See

Note A

E1

See

Note B

V

OH

V

OL

TO OUTPUT

OF DEVICE

UNDER TEST

5 V

5 k

DIODES TYPE

458E, 1N4148,

OR EQUIVALENT

2 k

C

L

CLincludes test-fixture and probe capacitance.

TO OUTPUT

OF DEVICE

UNDER TEST

C

L

500

1.5 V

CLincludes test-fixture and probe capacitance.

A. E2 = 1 while E1 changes states.

B. E1 = 0 while E2 changes states.

TB5R3

SLLS643 – SEPTEMBER 2005

Figure 2. Receiver Enable and Disable Timing

Parametric values specified under the Electrical Characteristics and Timing Characteristics sections for the data

transmission driver devices are measured with the following output load circuits.

Figure 3. Receiver Propagation Delay Time and Enable Time (t

Figure 4. Receiver Disable Time (t

, t

PHZ

) Test Circuit

PLZ

PZH

, t

) Test Circuit

PZL

5

Page 6

www.ti.com

0

2

4

3.5

3

2.5

0 50 100 150 200

t

pd

− Propagation Delay Time − ns

CL − Load Capacitance − pF

2251751257525

1.5

1

0.5

t

PLH

t

PHL

TB5R3

SLLS643 – SEPTEMBER 2005

TYPICAL CHARACTERISTICS

TYPICAL PROPAGATION DELAY

vs

LOAD CAPACITANCE

NOTE: This graph is included as an aid to the system designers. Total circuit delay varies with load capacitance. The total

delay is the sum of the delay due to external capacitance and the intrinsic delay of the device. Intrinsic delay is listed

in the table above as the 0 pF load condition. The incremental increase in delay between the 0 pF load condition and

the actual total load capacitance represents the extrinsic, or external delay contributed by the load.

Figure 5.

6

Page 7

www.ti.com

0

0.5

1

1.5

2.5

−50 0 50 100 150

− Low-to-High Propagation Delay − ns

t

PLH

T

J

− Junction Temperature − C

25−25 75 125 175

2

Max

Typ

Min

VCC = 5 V

Loaded per Figure 3

− High-to-Low Propagation Delay − ns

t

PHL

0

0.5

1

1.5

2.5

−50 0 50 100 150

T

J

− Junction Temperature − C

25−25 75 125 175

2

V

CC

= 5 V ,

Loaded per Figure 3

Typ

Min

Max

0

0.5

1

1.5

2.5

−50 0 50 100 150

T

J

− Junction Temperature − C

25−25 75 125 175

2

V

O

− Output Voltage − V

3.5

3

4

V

CC

= 4.5 V ,

Loaded per Figure 3

VOH, min

VOL, max

0

5

10

15

25

−50 0 50 100 150

T

J

− Junction Temperature − C

25−25 75 125 175

20

I

CC

− Supply Current − mA

35

30

50

V

CC

= 5.5 V

VOH, min

VOL, max

40

45

TYPICAL CHARACTERISTICS (continued)

TB5R3

SLLS643 – SEPTEMBER 2005

LOW-TO-HIGH PROPAGATION DELAY HIGH-TO-LOW PROPAGATION DELAY

vs vs

JUNCTION TEMPERATURE JUNCTION TEMPERATURE

Figure 6. Figure 7.

MINIMUM V

AND MAXIMUM V

OH

vs vs

OL

TYPICAL AND MAXIMUM I

JUNCTION TEMPERATURE JUNCTION TEMPERATURE

CC

Figure 8. Figure 9.

7

Page 8

www.ti.com

VSn I

Sn

(

VLn I

Ln

)

TJ T

A

P

D

JA

TJ T

A

P

D

JA(S)

JA(S)

JC

CA

JB

BA

JCCAJB

BA

40

60

80

100

120

140

0 100 200 300 400 500

Thermal Impedance − C/W

D, Low−K

DW, Low−K

DW, High−K

D, High−K

TB5R3

SLLS643 – SEPTEMBER 2005

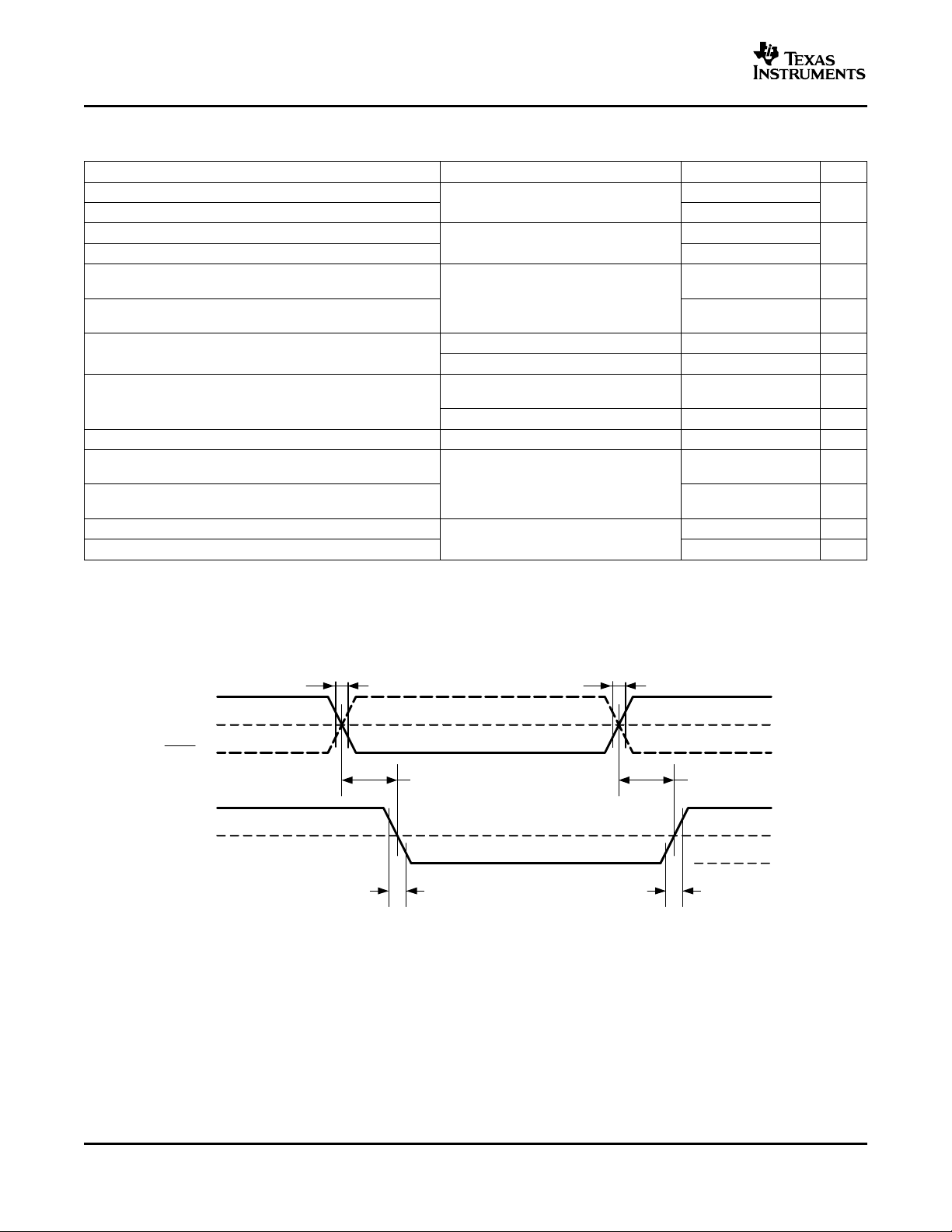

APPLICATION INFORMATION

Power Dissipation

The power dissipation rating, often listed as the

package dissipation rating, is a function of the ambient temperature, TA, and the airflow around the

device. This rating correlates with the device's maximum junction temperature, sometimes listed in the

absolute maximum ratings tables. The maximum

junction temperature accounts for the processes and

materials used to fabricate and package the device,

in addition to the desired life expectancy.

There are two common approaches to estimating the

internal die junction temperature, TJ. In both of these

methods, the device internal power dissipation P

needs to be calculated This is done by totaling the

supply power(s) to arrive at the system power dissipation:

and then subtracting the total power dissipation of the

external load(s):

The first T

and ambient temperature, along with one parameter:

θJA, the junction-to-ambient thermal resistance, in

degrees Celsius per watt.

The product of P

rise above the ambient temperature. Therefore:

calculation uses the power dissipation

J

and θ

D

JA

is the junction temperature

which the device is mounted and on the airflow over

the device and PCB. JEDEC/EIA has defined

standardized test conditions for measuring θJA. Two

commonly used conditions are the low-K and the

high-K boards, covered by EIA/JESD51-3 and

EIA/JESD51-7 respectively. Figure 10 shows the

low-K and high-K values of θ

versus air flow for this

JA

device and its package options.

The standardized θ

JA

values may not accurately

represent the conditions under which the device is

used. This can be due to adjacent devices acting as

heat sources or heat sinks, to nonuniform airflow, or

to the system PCB having significantly different thermal characteristics than the standardized test PCBs.

D

The second method of system thermal analysis is

more accurate. This calculation uses the power

dissipation and ambient temperature, along with two

device and two system-level parameters:

(1)

• θJC, the junction-to-case thermal resistance, in

degrees Celsius per watt

• θJB, the junction-to-board thermal resistance, in

degrees Celsius per watt

(2)

• θCA, the case-to-ambient thermal resistance, in

degrees Celsius per watt

• θBA, the board-to-ambient thermal resistance, in

degrees Celsius per watt.

In this analysis, there are two parallel paths, one

through the case (package) to the ambient, and

another through the device to the PCB to the ambient. The system-level junction-to-ambient thermal im-

(3)

pedance, θ

, is the equivalent parallel impedance

JA(S)

of the two parallel paths:

Figure 10. Thermal Impedance vs Air Flow

Note that θ

8

is highly dependent on the PCB on

JA

where

The device parameters θ

and θ

JC

account for the

JB

internal structure of the device. The system-level

parameters θ

and θ

CA

take into account details of

BA

the PCB construction, adjacent electrical and mechanical components, and the environmental conditions

including airflow. Finite element (FE), finite difference

(FD), or computational fluid dynamics (CFD) programs can determine θ

and θBA. Details on using

CA

these programs are beyond the scope of this data

sheet, but are available from the software manufacturers.

(4)

(5)

Page 9

Page 10

Page 11

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Loading...

Loading...