Page 1

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

20-W DIGITAL AUDIO-POWER AMPLIFIER WITH EQ, DRC, AND 2.1 MODE

Check for Samples: TAS5711

1

FEATURES

2

• Audio Input/Output

– 20-W Into an 8-Ω Load From an 18-V Supply – Up to 90% Efficient

– Wide PVDD Range, From 8 V to 26 V – AD and BD Filter Mode Support

– Efficient Class-D Operation Eliminates – SNR: 106 dB, A-Weighted

Need for Heatsinks

– One Serial Audio Input (Two Audio Performance

Channels)

– 2.1 Mode (2 SE + 1 BTL) Be Used As Power Limiter. Enables

– 2.0 Mode (2 BTL)

– Single-Filter PBTL Mode Support

– I2C Address Selection Pin (Chip Select)

– Supports 8-kHz to 48-kHz Sample Rate

(LJ/RJ/I2S)

• Audio/PWM Processing

– Independent Channel Volume Controls With

24-dB to Mute

– Separate Dynamic Range Control for

Satellite and Subchannels

– 21 Programmable Biquads for Speaker EQ

and Other Audio Processing Features

– Programmable Coefficients for DRC Filters APPLICATIONS – DC Blocking Filters – Support for 3D Effects

• General Features

– Serial Control Interface Operational Without

MCLK

– Factory-Trimmed Internal Oscillator for

Automatic Rate Detection

– Surface Mount, 48-Pin, 7-mm × 7-mm

HTQFP Package

– Thermal and Short-Circuit Protection

– Support for AD or BD Mode

• Benefits

– EQ: Speaker Equalization Improves Audio

– DRC: Dynamic Range Compression. Can

Speaker Protection, Easy Listening,

Night-Mode Listening.

– Separate DRC for Satellite and

Subchannels

– Autobank Switching: Preload Coefficients

for Different Sample Rates. No Need to

Write new Coefficients to the Part When

Sample Rate Changes.

– Autodetect: Automatically Detects

Sample-Rate Changes. No Need for

External Microprocessor Intervention

• Requires Only 3.3 V and PVDD

• Television

• iPod™ Dock

• Sound Bar

DESCRIPTION

The TAS5711 is a 20-W, efficient, digital audio power

amplifier for driving stereo bridge-tied speakers. One

serial data input allows processing of up to two

discrete audio channels and seamless integration to

most digital audio processors and MPEG decoders.

The device accepts a wide range of input data and

data rates. A fully programmable data path routes

these channels to the internal speaker drivers.

The TAS5711 is an I2S slave-only device receiving all

clocks from external sources. The TAS5711 operates

with a PWM carrier between 384-kHz switching rate

and 352-KHz switching rate depending on the input

sample rate. Oversampling combined with a

fourth-order noise shaper provides a flat noise floor

and excellent dynamic range from 20 Hz to 20 kHz.

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2iPod is a trademark of Apple Inc.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2009, Texas Instruments Incorporated

Page 2

SDIN

LRCLK

SCLK

MCLK

RESET

PDN

SDA

PLL_FLTM

PLL_FLTP

AVDD/DVDD

PVDD

OUT_A

OUT_C

OUT_B

OUT_D

BST_A

BST_C

BST_B

BST_D

3.3 V 8 V–26 V

SCL

Digital

Audio

Source

I C

Control

2

Control

Inputs

LC

SE

LC

BTL

B0264-09

Loop

Filter

(1)

LC

SE

PVDD

PVDD

A_SEL( )FAULT

TAS5711

SLOS600 –DECEMBER 2009

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

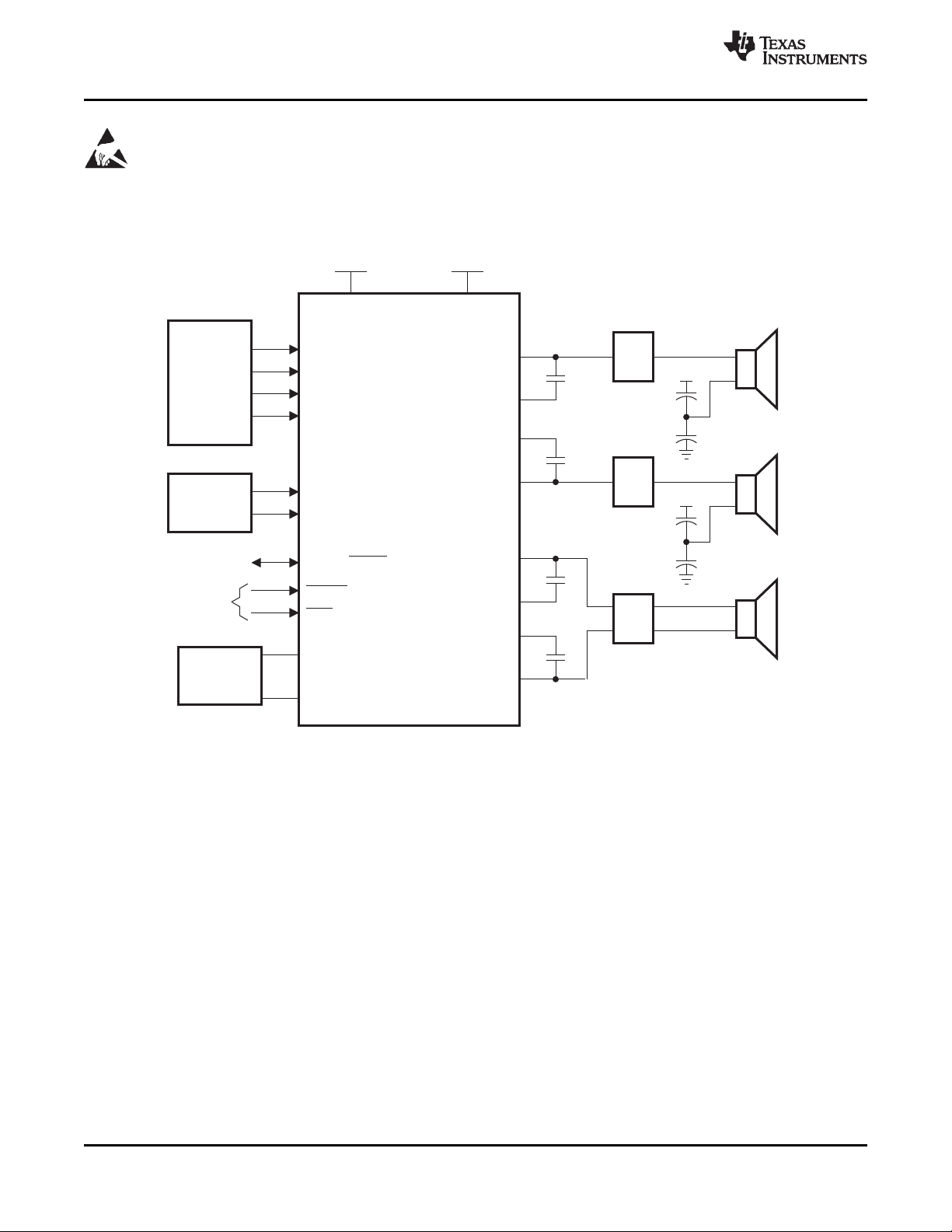

SIMPLIFIED APPLICATION DIAGRAM

www.ti.com

(1) See TAS5711 EVM User's Guide (SLOU280) for loop filter values.

2 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 3

SDIN

MCLK

SCLK

LRCLK

Serial

Audio

Port

Protection

Logic

ClickandPop

Control

Digital AudioProcessor

(DAP)

SDA

SCL

4

Order

th

Noise

Shaper

and

PWM

S

R

C

SampleRate

Autodetect

andPLL

Serial

Control

Microcontroller

Based

System

Control

TerminalControl

OUT_A

OUT_B

2 HB´

FET Out

OUT_C

OUT_D

2 HB´

FET Out

B0262-06

TAS5711

www.ti.com

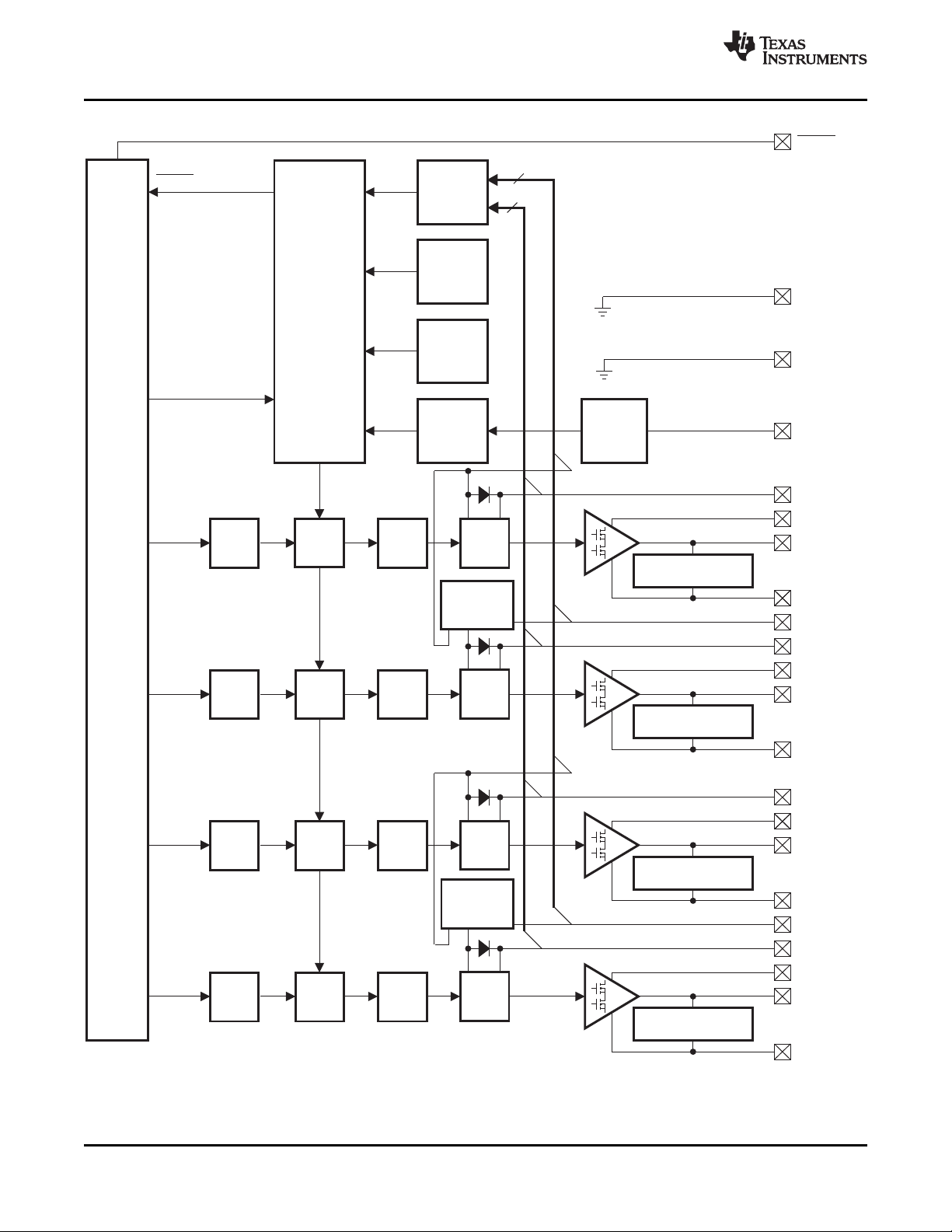

FUNCTIONAL VIEW

SLOS600 –DECEMBER 2009

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): TAS5711

Page 4

Temp.

Sense

VALID

FAULT

AGND

OC_ADJ

Power

On

Reset

Under-

voltage

Protection

GND

PWM_D

OUT_D

PGND_CD

PVDD_D

BST_D

Gate

Drive

PWM

Rcv

Overcurrent

Protection

4

Protection

and

I/OLogic

PWM_C

OUT_C

PGND_CD

PVDD_C

BST_C

Timing

Gate

Drive

Ctrl

PWM

Rcv

GVDD_CD

PWM_B

OUT_B

PGND_AB

PVDD_B

BST_B

Timing

Gate

Drive

Ctrl

PWM

Rcv

PWM_A

OUT_A

PGND_AB

PVDD_A

BST_A

Timing

Gate

Drive

Ctrl

PWM

Rcv

GVDD_AB

Ctrl

PulldownResistor

PulldownResistor

PulldownResistor

PulldownResistor

4

GVDD_CD

Regulator

GVDD_AB

Regulator

Timing

I

sense

B0034-05

PWMController

FAULT

TAS5711

SLOS600 –DECEMBER 2009

www.ti.com

Figure 1. Power Stage Functional Block Diagram

4 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 5

+

L

R

+

+

+

+

+

Vol1

Vol2

ealpha

1BQ

1BQ

1BQ

1BQ

6BQ

6BQ

1BQ

1BQ

1BQ

Input Muxing

Log

Math

Attack

Decay

1

Master ON/OFF

(0x46[0])

Energy

MAXMUX

ealpha

B0321-08

1

1

1

1

1

1

51 V1OM

52 V2OM

I2C:57

VDISTB

I2C:56

VDISTA

60 V6OM

55

2A

I2C:53 – V1IM

31

2B–2F, 58

32–36, 5C

59

I C Subaddress in Red

2

5D

5E

29

30

I2C:54 – V2IM

L

R

1BQ

1BQ

Vol1

5A

5B

21 (D8, D9)

½

½

61

+

+

+

–1

0

Auto-lp

(0x46 Bit 5)

Log

Math

Attack

Decay

1

Master ON/OFF

(0x46[1])

Energy

MAXMUX

ealpha

ealpha

ealpha

Vol2

+

+

3D

3D

3A

3A

TAS5711

www.ti.com

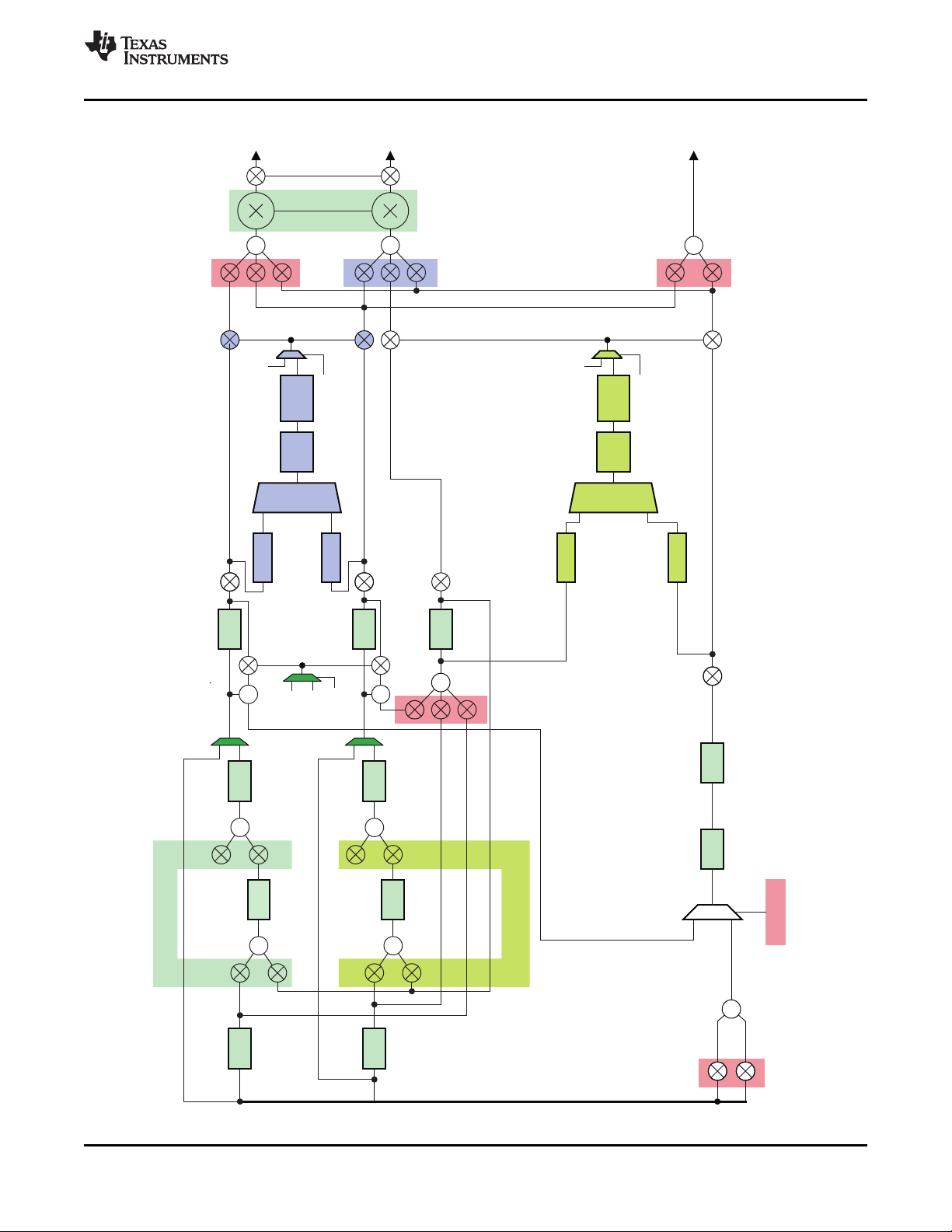

DAP Process Structure

SLOS600 –DECEMBER 2009

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): TAS5711

Page 6

SSTIMER

OC_ADJ

PLL_FLTP

VR_ANA

PBTL

AVSS

PLL_FLTM

BST_A

GVDD_OUT

PVDD_A

OUT_A

RESET

PVDD_A

STEST

PDN

VR_DIG

OSC_RES

DVSSO

DVDD

MCLK

A_SEL

SCLK

SDIN

LRCLK

AVDD

SDA

SCL

DVSS

GND

VREG

BST_B

PVDD_B

PVDD_C

OUT_C

PVDD_D

BST_D

PGND_AB

OUT_B

PGND_CD

OUT_D

AGND

PGND_AB

PVDD_B

PGND_CD

PVDD_D

BST_C

PVDD_C

GVDD_OUT

P0075-08

PHP Package

(TopView)

TAS5711

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15 161718 19 20

21 222324

25

26

27

28

29

30

31

32

484746

45 44

43 42 41 40 39 38 37

36

35

34

33

TAS5711

SLOS600 –DECEMBER 2009

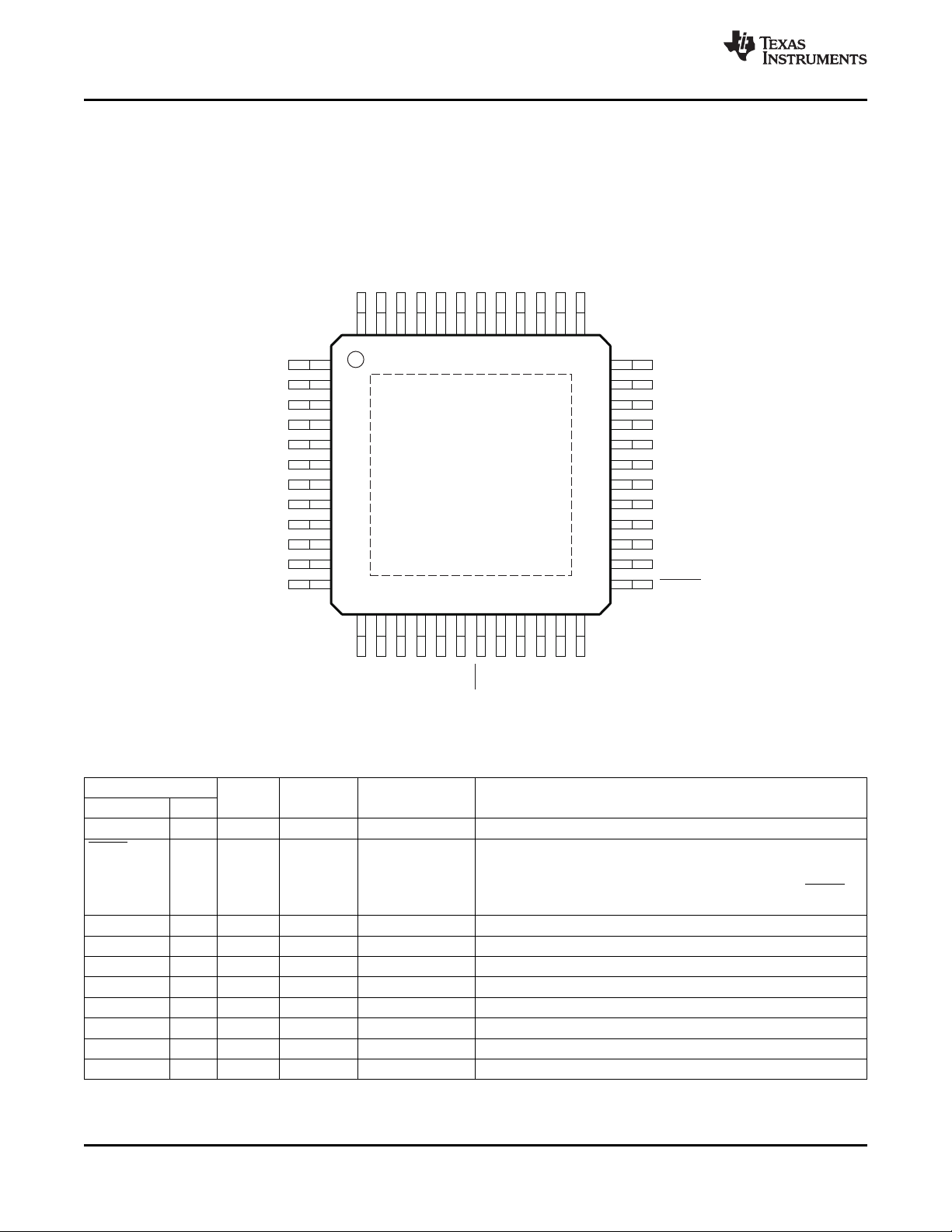

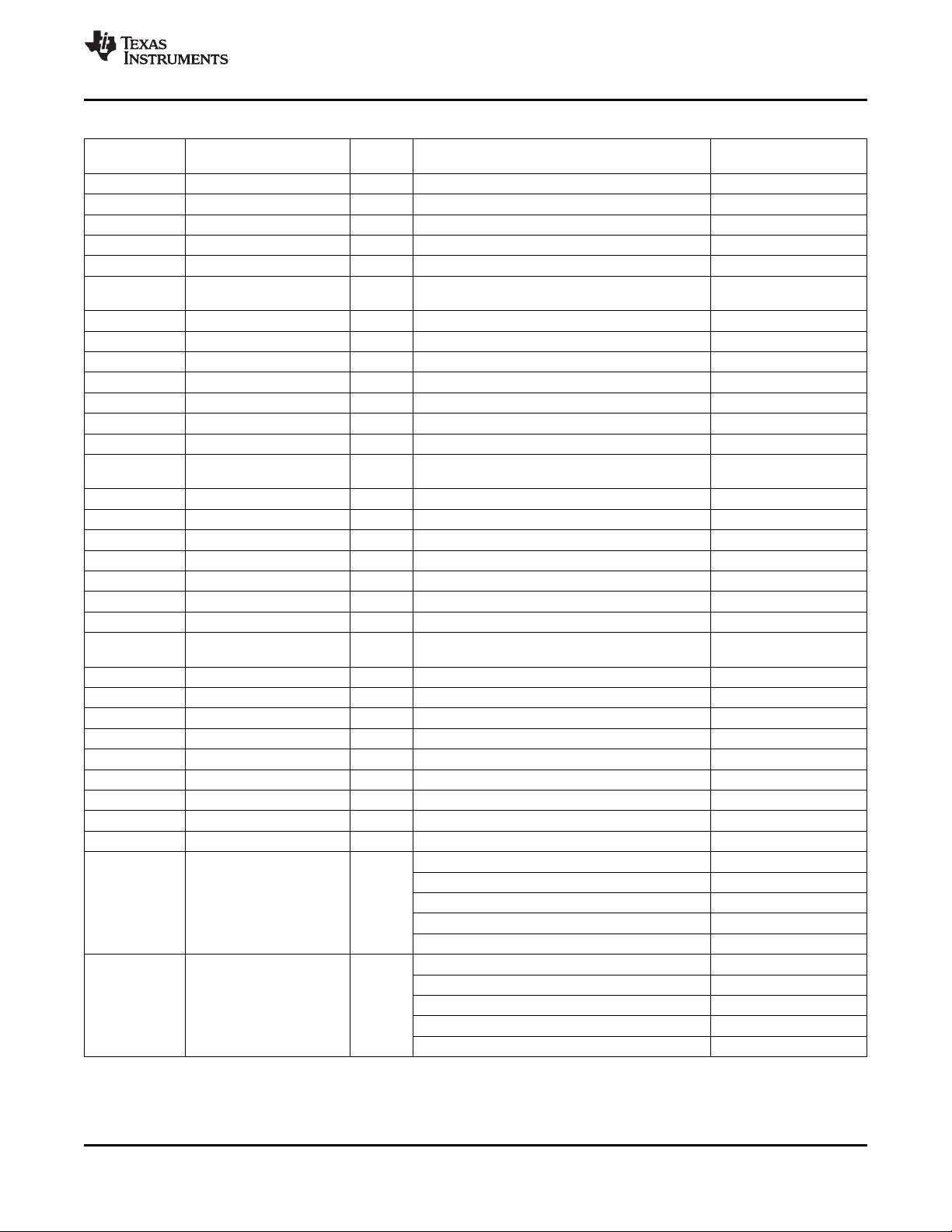

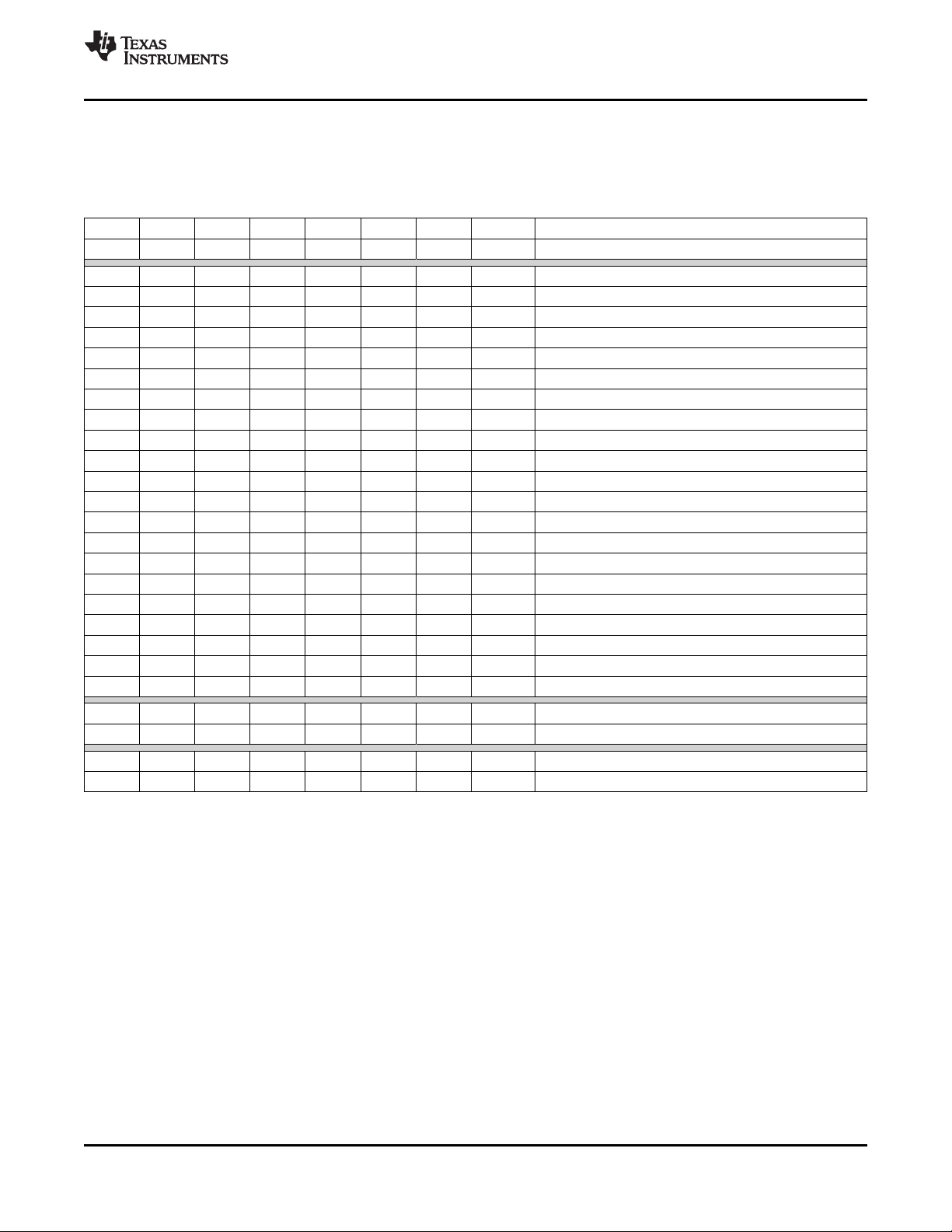

PIN ASSIGNMENT

www.ti.com

DEVICE INFORMATION

PIN

NAME NO.

AGND 30 P Analog ground for power stage

A_SEL 14 DIO A value of 0 (15-kΩ pulldown) makes the I2C device address 0x34,

AVDD 13 P 3.3-V analog power supply

AVSS 9 P Analog 3.3-V supply ground

BST_A 4 P High-side bootstrap supply for half-bridge A

BST_B 43 P High-side bootstrap supply for half-bridge B

BST_C 42 P High-side bootstrap supply for half-bridge C

BST_D 33 P High-side bootstrap supply for half-bridge D

DVDD 27 P 3.3-V digital power supply

DVSSO 17 P Oscillator ground

(1) TYPE: A = analog; D = 3.3-V digital; P = power/ground/decoupling; I = input; O = output

(2) All pullups are weak pullups and all pulldowns are weak pulldowns. The pullups and pulldowns are included to assure proper input logic

levels if the pins are left unconnected (pullups → logic 1 input; pulldowns → logic 0 input).

(1)

TYPE

5-V

TOLERANT

TERMINATION

PIN FUNCTIONS

(2)

and a value of 1 (15-kΩ pullup) makes it 0x36. This pin can be

programmed after RESET to be an output by writing 1 to bit 0 of I2C

register 0x05. In that mode, the A_SEL pin is redefined as FAULT

(see ERROR REPORTING for details).

DESCRIPTION

6 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 7

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

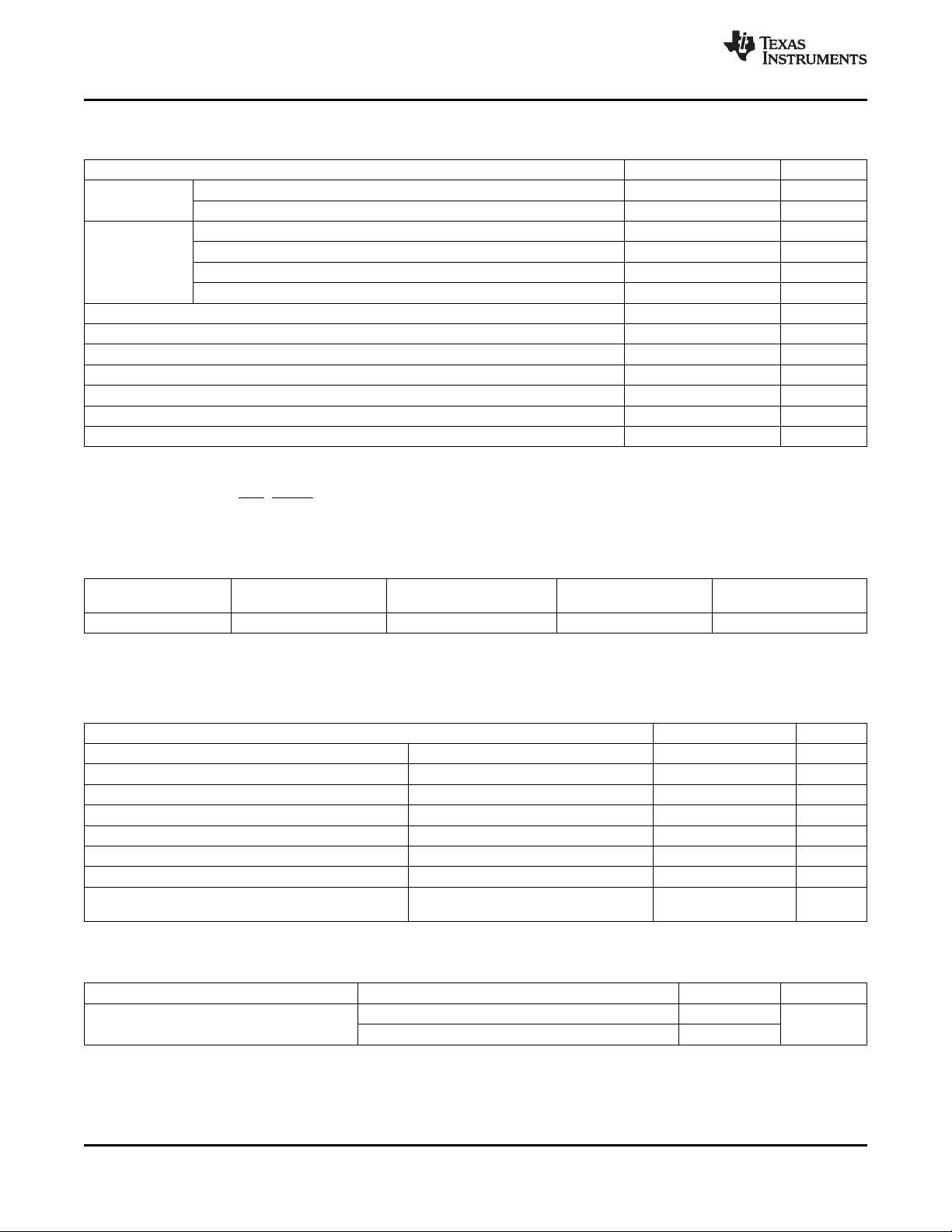

PIN FUNCTIONS (continued)

PIN

NAME NO.

DVSS 28 P Digital ground

GND 29 P Analog ground for power stage

GVDD_OUT 5, 32 P Gate drive internal regulator output. This pin must not be used to

LRCLK 20 DI 5-V Pulldown Input serial audio data left/right clock (sample rate clock)

MCLK 15 DI 5-V Pulldown Master clock input

OC_ADJ 7 AO Analog overcurrent programming. Requires resistor to ground.

OSC_RES 16 AO Oscillator trim resistor. Connect an 18.2-kΩ 1% resistor to DVSSO.

OUT_A 1 O Output, half-bridge A

OUT_B 46 O Output, half-bridge B

OUT_C 39 O Output, half-bridge C

OUT_D 36 O Output, half-bridge D

PBTL 8 DI Low means BTL or SE mode; high means PBTL mode. Information

PDN 19 DI 5-V Pullup Power down, active-low. PDN prepares the device for loss of power

PGND_AB 47, 48 P Power ground for half-bridges A and B

PGND_CD 37, 38 P Power ground for half-bridges C and D

PLL_FLTM 10 AO PLL negative loop filter terminal

PLL_FLTP 11 AO PLL positive loop filter terminal

PVDD_A 2, 3 P Power supply input for half-bridge output A

PVDD_B 44, 45 P Power supply input for half-bridge output B

PVDD_C 40, 41 P Power supply input for half-bridge output C

PVDD_D 34, 35 P Power supply input for half-bridge output D

RESET 25 DI 5-V Pullup Reset, active-low. A system reset is generated by applying a logic

SCL 24 DI 5-V I2C serial control clock input

SCLK 21 DI 5-V Pulldown Serial audio data clock (shift clock). SCLK is the serial audio port

SDA 23 DIO 5-V I2C serial control data interface input/output

SDIN 22 DI 5-V Pulldown Serial audio data input. SDIN supports three discrete (stereo) data

SSTIMER 6 AI Controls ramp time of OUT_x to minimize pop. Leave this pin

STEST 26 DI Factory test pin. Connect directly to DVSS.

VR_ANA 12 P Internally regulated 1.8-V analog supply voltage. This pin must not

VR_DIG 18 P Internally regulated 1.8-V digital supply voltage. This pin must not be

VREG 31 P Digital regulator output. Not to be used for powering external

TYPE

(1)

5-V

TOLERANT

TERMINATION

(2)

drive external devices.

goes directly to power stage.

supplies by shutting down the Noise Shaper and initiating PWM stop

sequence.

low to this pin. RESET is an asynchronous control signal that

restores the DAP to its default conditions, and places the PWM in

the hard mute state (tristated).

input data bit clock.

formats.

floating for BD mode. Requires capacitor of 2.2 nF to GND in AD

mode. The capacitor determines the ramp time.

be used to power external devices.

used to power external devices.

circuitry.

DESCRIPTION

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Link(s): TAS5711

Page 8

TAS5711

SLOS600 –DECEMBER 2009

www.ti.com

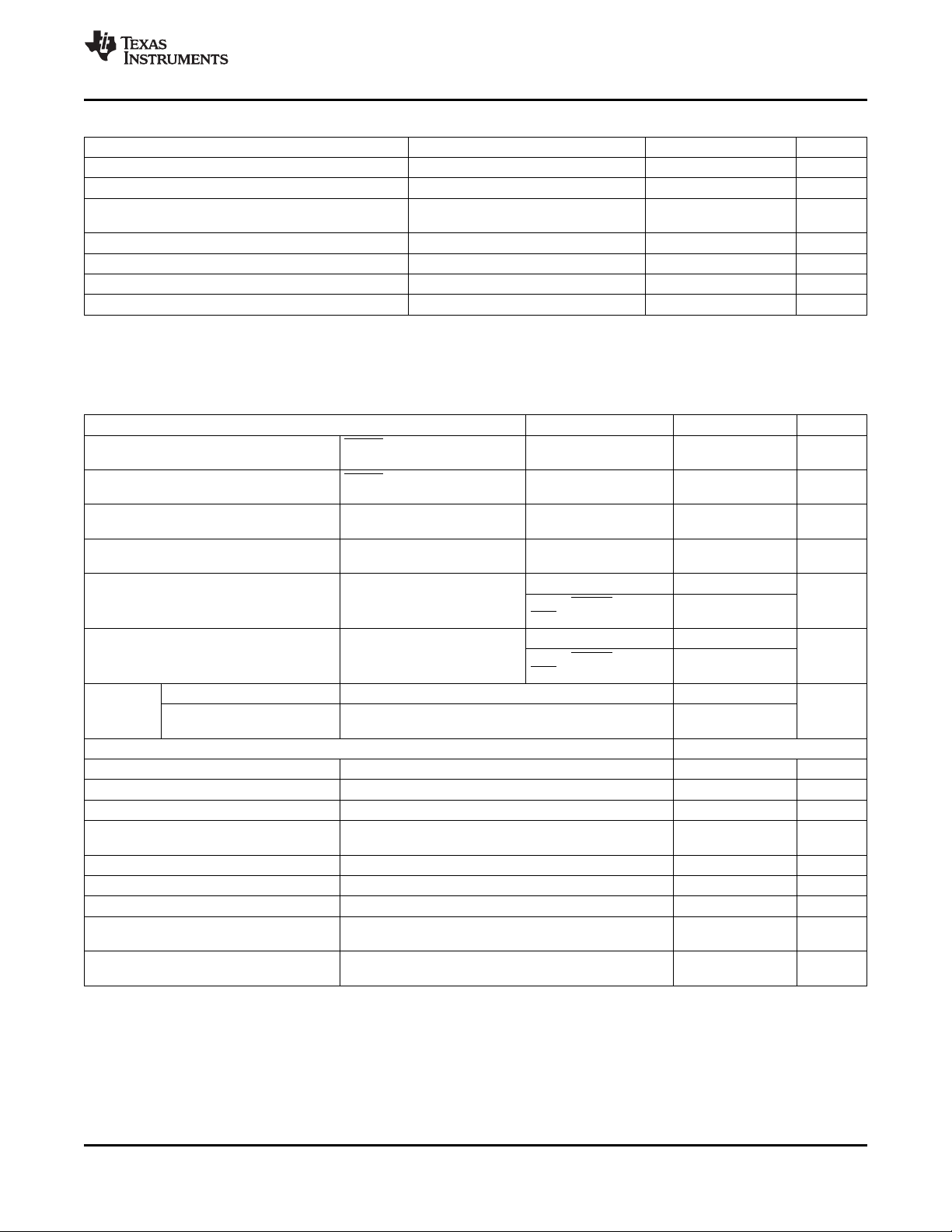

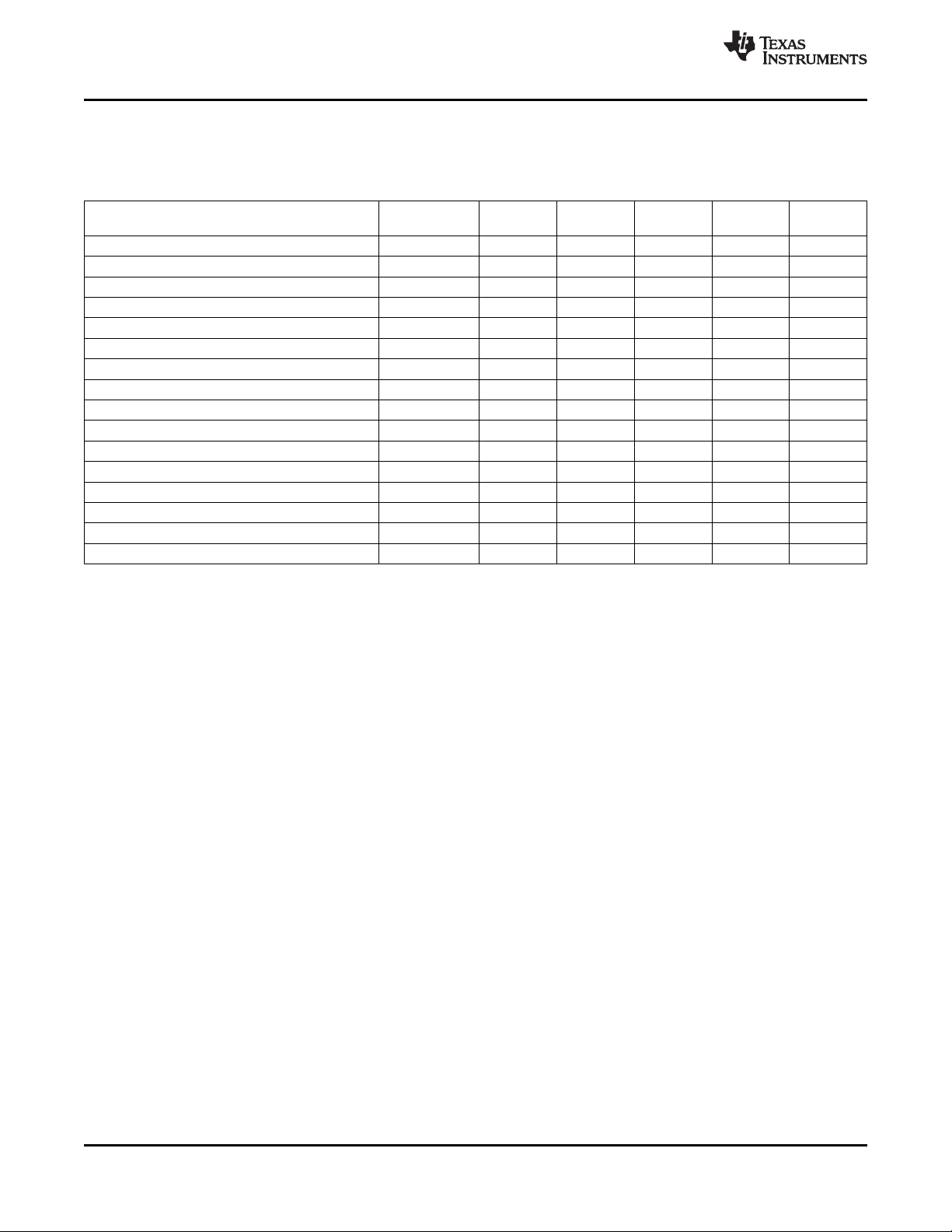

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

Supply voltage

Input voltage

OUT_x to PGND_x 32

BST_x to PGND_x 43

Input clamp current, I

Output clamp current, I

Operating free-air temperature 0 to 85 °C

Operating junction temperature range 0 to 150 °C

Storage temperature range, T

(1) Stresses beyond those listed under absolute ratings may cause permanent damage to the device. These are stress ratings only and

functional operation of the device at these or any other conditions beyond those indicated under recommended operation conditions are

not implied. Exposure to absolute-maximum conditions for extended periods may affect device reliability.

(2) 5-V tolerant inputs are PDN, RESET, SCLK, LRCLK, MCLK, SDIN, SDA, and SCL.

(3) Maximum pin voltage should not exceed 6.0V

(4) DC voltage + peak ac waveform measured at the pin should be below the allowed limit for all conditions.

DVDD, AVDD –0.3 to 3.6 V

PVDD_x –0.3 to 30 V

OC_ADJ –0.3 to 4.2 V

3.3-V digital input –0.5 to DVDD + 0.5 V

5-V tolerant

(2)

digital input (except MCLK) –0.5 to DVDD + 2.5

5-V tolerant MCLK input –0.5 to AVDD + 2.5

IK

OK

stg

(1)

VALUE UNIT

(3)

(3)

(4)

(4)

V

V

V

V

±20 mA

±20 mA

–40 to 125 °C

DISSIPATION RATINGS

PACKAGE

(1)

DERATING FACTOR TA≤ 25°C TA= 45°C TA= 70°C

ABOVE TA= 25°C POWER RATING POWER RATING POWER RATING

7-mm × 7-mm HTQFP 40 mW/°C 5 W 4.2 W 3.2 W

(1) This data was taken using 1 oz trace and copper pad that is soldered directly to a JEDEC standard high-k PCB. The thermal pad must

be soldered to a thermal land on the printed-circuit board. See TI Technical Briefs SLMA002 for more information about using the

HTQFP thermal pad

RECOMMENDED OPERATING CONDITIONS

MIN NOM MAX UNIT

Digital/analog supply voltage DVDD, AVDD 3 3.3 3.6 V

Half-bridge supply voltage PVDD_x 8 26 V

V

IH

V

IL

T

A

(1)

T

J

High-level input voltage 5-V tolerant 2 V

Low-level input voltage 5-V tolerant 0.8 V

Operating ambient temperature range 0 85 °C

Operating junction temperature range 0 125 °C

RL(BTL) Load impedance Output filter: L = 15 μH, C = 680 nF. 6 8 Ω

LO(BTL) Output-filter inductance μH

Minimum output inductance under 10

short-circuit condition

(1) Continuous operation above the recommended junction temperature may result in reduced reliability and/or lifetime of the device.

PWM OPERATION AT RECOMMENDED OPERATING CONDITIONS

PARAMETER TEST CONDITIONS VALUE UNIT

Output sample rate

11.025/22.05/44.1-kHz data rate ±2% 352.8 kHz

48/24/12/8/16/32-kHz data rate ±2% 384

8 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 9

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

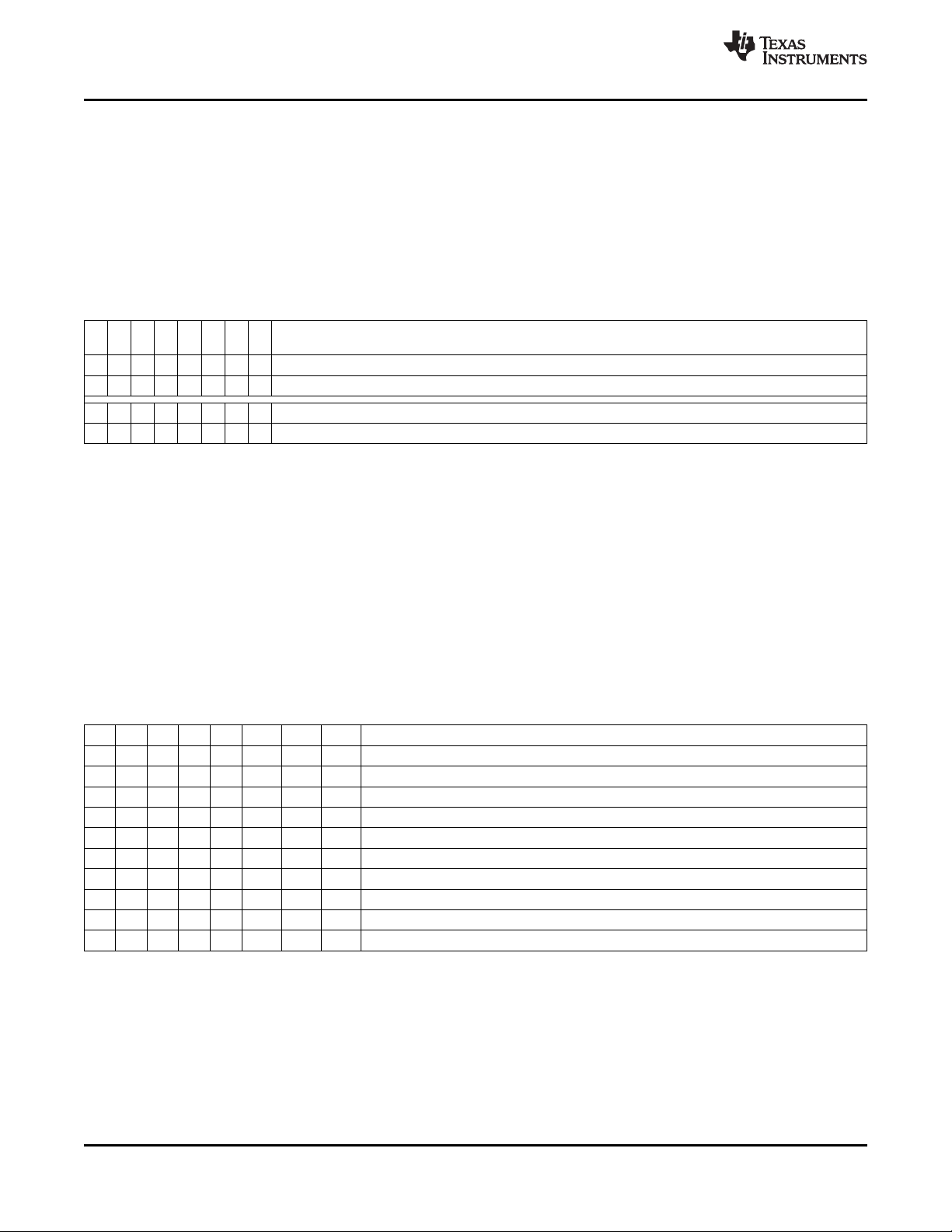

PLL INPUT PARAMETERS AND EXTERNAL FILTER COMPONENTS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

f

MCLKI

MCLK Frequency 2.8224 24.576 MHz

MCLK duty cycle 40% 50% 60%

tr /

tf

(MCLK)

Rise/fall time for MCLK 5 ns

LRCLK allowable drift before LRCLK reset 4 MCLKs

External PLL filter capacitor C1 SMD 0603 X7R 47 nF

External PLL filter capacitor C2 SMD 0603 X7R 4.7 nF

External PLL filter resistor R SMD 0603, metal film 470 Ω

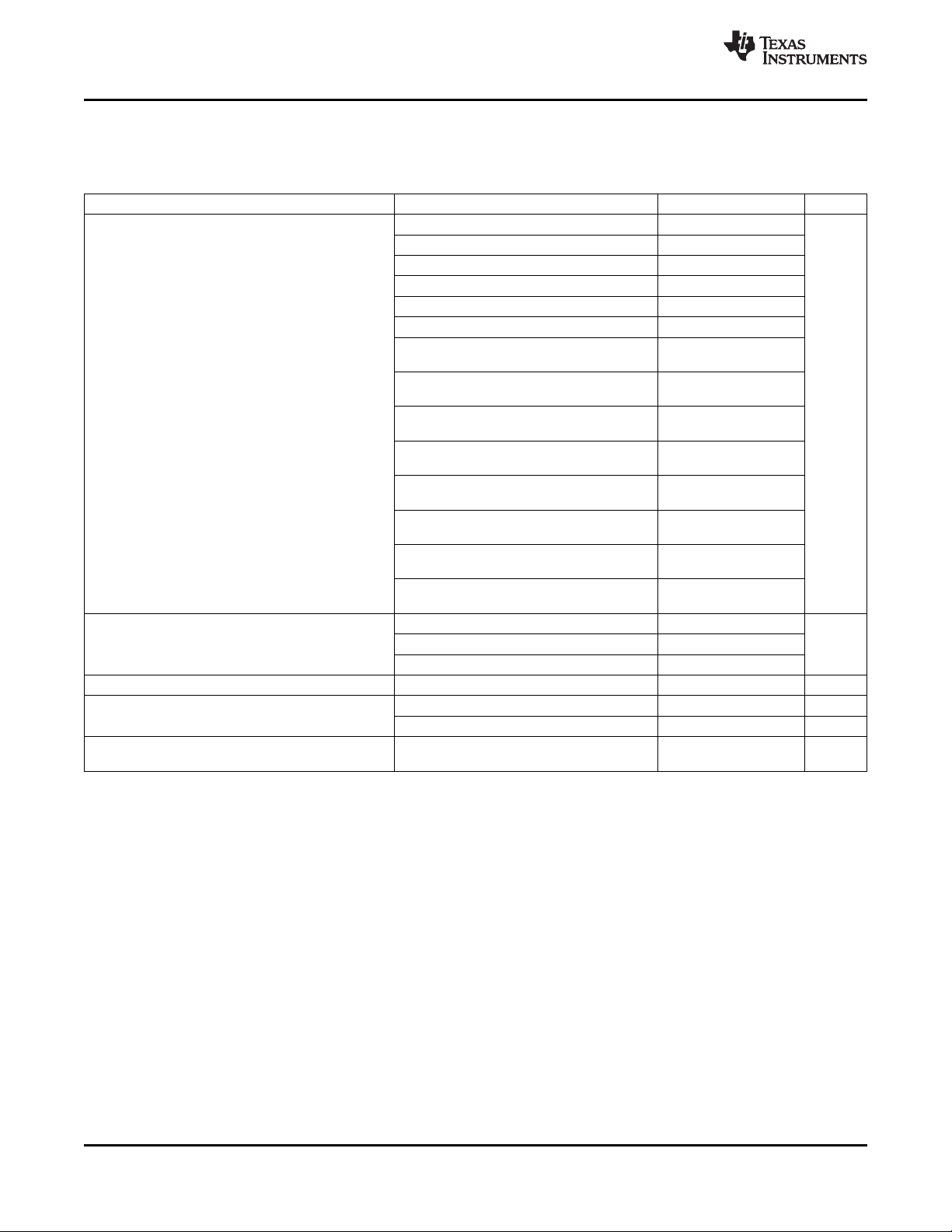

ELECTRICAL CHARACTERISTICS

DC Characteristics

TA = 25°, PVCC_x = 18V, DVDD = AVDD = 3.3V, RL= 8Ω, BTL AD Mode, FS = 48KHz (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

OH

V

OL

I

IL

I

IH

I

DD

I

PVDD

r

DS(on)

I/O Protection

V

uvp

V

uvp,hyst

(3)

OTE

OTE

HYST

OLPC Overload protection counter f

I

OC

I

OCT

R

OCP

R

PD

(1) IIHfor the PBTL pin has a maximum limit of 200 µA due to an intenal pulldown on the pin.

(2) This does not include bond-wire or pin resistance.

(3) Specified by design

High-level output voltage A_SEL and SDA IOH= –4 mA 2.4 V

DVDD = AVDD = 3 V

Low-level output voltage A_SEL and SDA IOL= 4 mA 0.5 V

DVDD = AVDD = 3 V

Low-level input current μA

High-level input current μA

3.3 V supply current mA

3.3 V supply voltage (DVDD,

AVDD)

VI< VIL; DVDD = AVDD 75

= 3.6V

VI> VIH; DVDD = 75

AVDD = 3.6V

Normal Mode 48 70

Reset (RESET = low, 24 32

PDN = high)

Normal Mode 30 55

Half-bridge supply current No load (PVDD_x) mA

Reset (RESET = low, 5 13

PDN = high)

Drain-to-source resistance, LS TJ= 25°C, includes metallization resistance 180

(2)

Drain-to-source resistance,

HS

TJ= 25°C, includes metallization resistance 180

Undervoltage protection limit PVDD falling 7.2 V

Undervoltage protection limit PVDD rising 7.6 V

Overtemperature error 150 °C

Extra temperature drop

(3)

required to recover from error

= 384 kHz 0.63 ms

PWM

Overcurrent limit protection Resistor—programmable, max. current, R

= 22 kΩ 4.5 A

OCP

30 °C

Overcurrent response time 150 ns

OC programming resistor Resistor tolerance = 5% for typical value; the minimum

range resistance should not be less than 20 kΩ.

Internal pulldown resistor at Connected when drivers are tristated to provide bootstrap

the output of each half-bridge capacitor charge.

20 22 kΩ

3 kΩ

(1)

mΩ

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): TAS5711

Page 10

TAS5711

SLOS600 –DECEMBER 2009

AC Characteristics (BTL)

PVDD_x = 18 V, BTL AD mode, FS = 48 KHz, RL= 8 Ω, R

f

= 384 kHz, TA= 25°C (unless otherwise specified). All performance is in accordance with recommended operating

PWM

conditions (unless otherwise specified).

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

PVDD = 18 V, 10% THD, 1-kHz input signal 21

PVDD = 18 V, 7% THD, 1-kHz input signal 20

PVDD = 12 V, 10% THD, 1-kHz input signal 9.5

PVDD = 12 V, 7% THD, 1-kHz input signal 9

PVDD = 8 V, 10% THD, 1-kHz input signal 4.1

PVDD = 8 V, 7% THD, 1-kHz input signal 3.9

PBTL mode, PVDD = 12 V, RL= 4 Ω,

10% THD, 1-kHz input signal

PBTL mode, PVDD = 12 V, RL= 4 Ω,

7% THD, 1-kHz input signal

P

O

THD+N Total harmonic distortion + noise PVDD = 12 V, PO= 1 W 0.08%

V

n

SNR Signal-to-noise ratio

(1) SNR is calculated relative to 0-dBFS input level.

Power output per channel W

Output integrated noise (rms) A-weighted 44 μV

Crosstalk

(1)

PBTL mode, PVDD = 18 V, RL= 4 Ω,

10% THD, 1-kHz input signal

PBTL mode, PVDD = 18 V, RL= 4 Ω,

7% THD, 1-kHz input signal

SE mode, PVDD = 12 V, RL= 4 Ω,

10% THD, 1-kHz input signal

SE mode, PVDD = 12 V, RL= 4 Ω,

7% THD, 1-kHz input signal

SE mode, PVDD = 24 V, RL= 4 Ω,

10% THD, 1-kHz input signal

SE mode, PVDD = 24 V, RL= 4 Ω,

7% THD, 1-kHz input signal

PVDD = 18 V, PO= 1 W 0.06%

PVDD = 8 V, PO= 1 W 0.2%

PO= 0.25 W, f = 1 kHz (BD Mode) –82 dB

PO= 0.25 W, f = 1 kHz (AD Mode) –69 dB

A-weighted, f = 1 kHz, maximum power at

THD < 1%

= 22 KΩ, C

OCP

= 33 nF, audio frequency = 1 kHz, AES17 filter,

BST

19.2

18

42.8

40

4.6

4.3

17.8

16

106 dB

www.ti.com

10 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 11

t

h1

t

su1

t

(edge)

t

su2

t

h2

SCLK

(Input)

LRCLK

(Input)

SDIN

T0026-04

t

r

t

f

TAS5711

www.ti.com

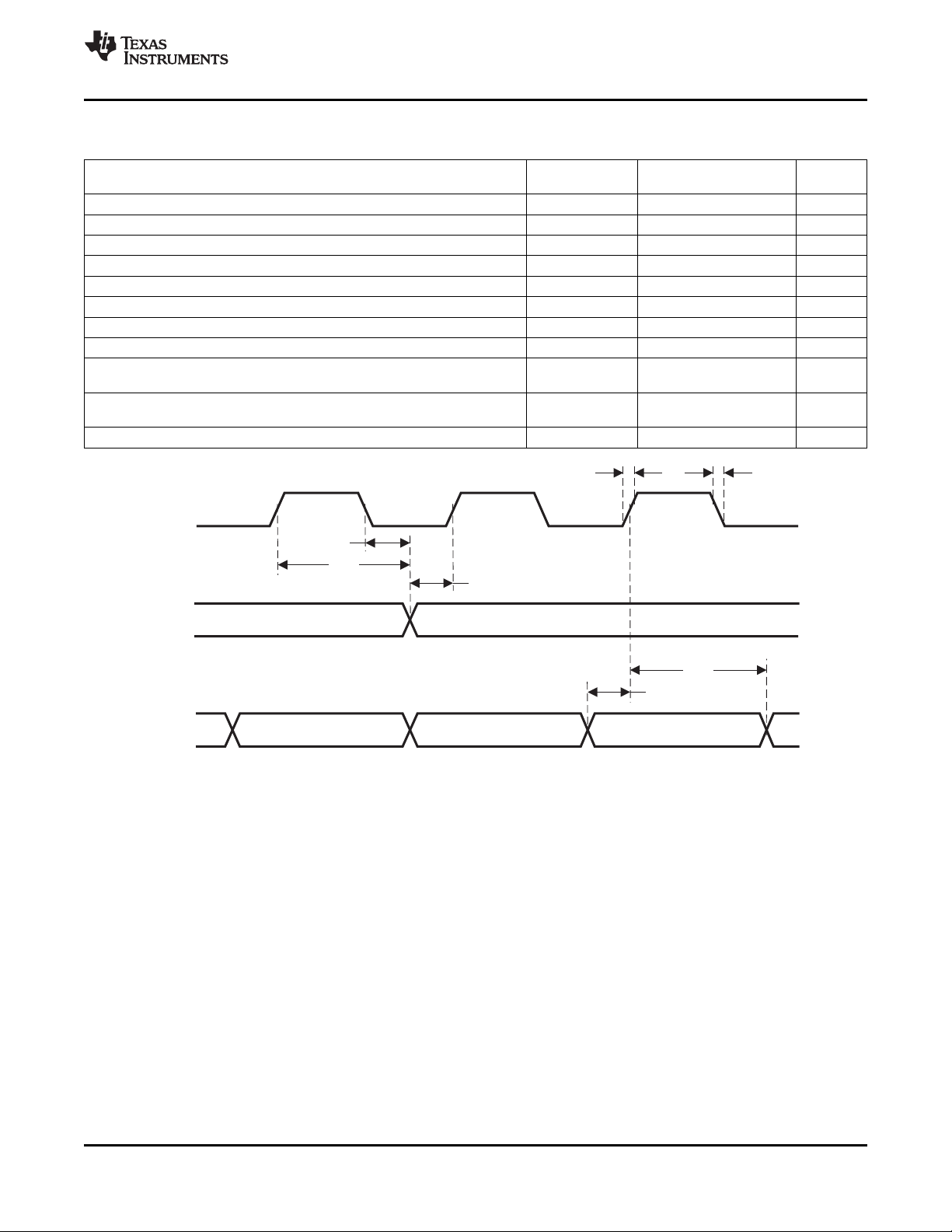

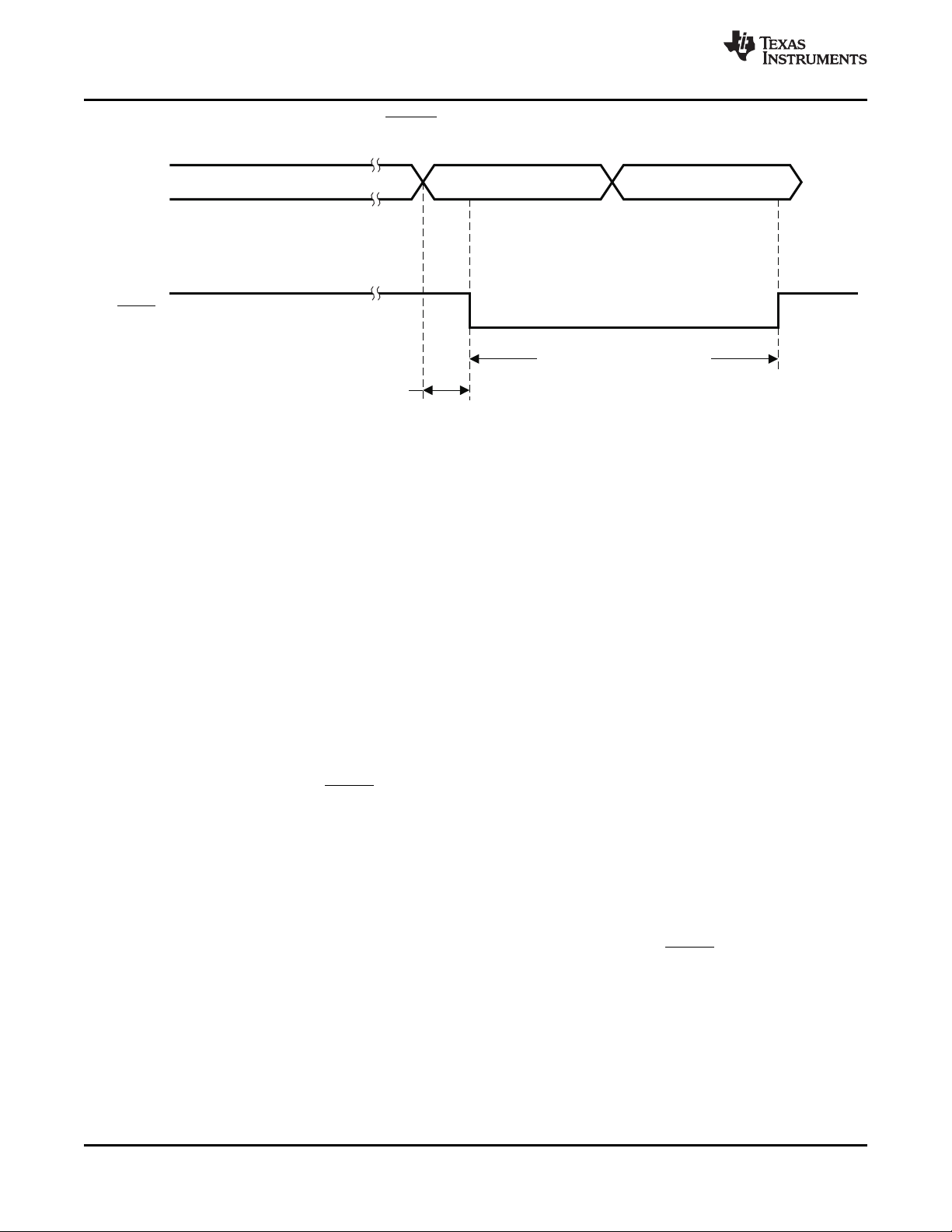

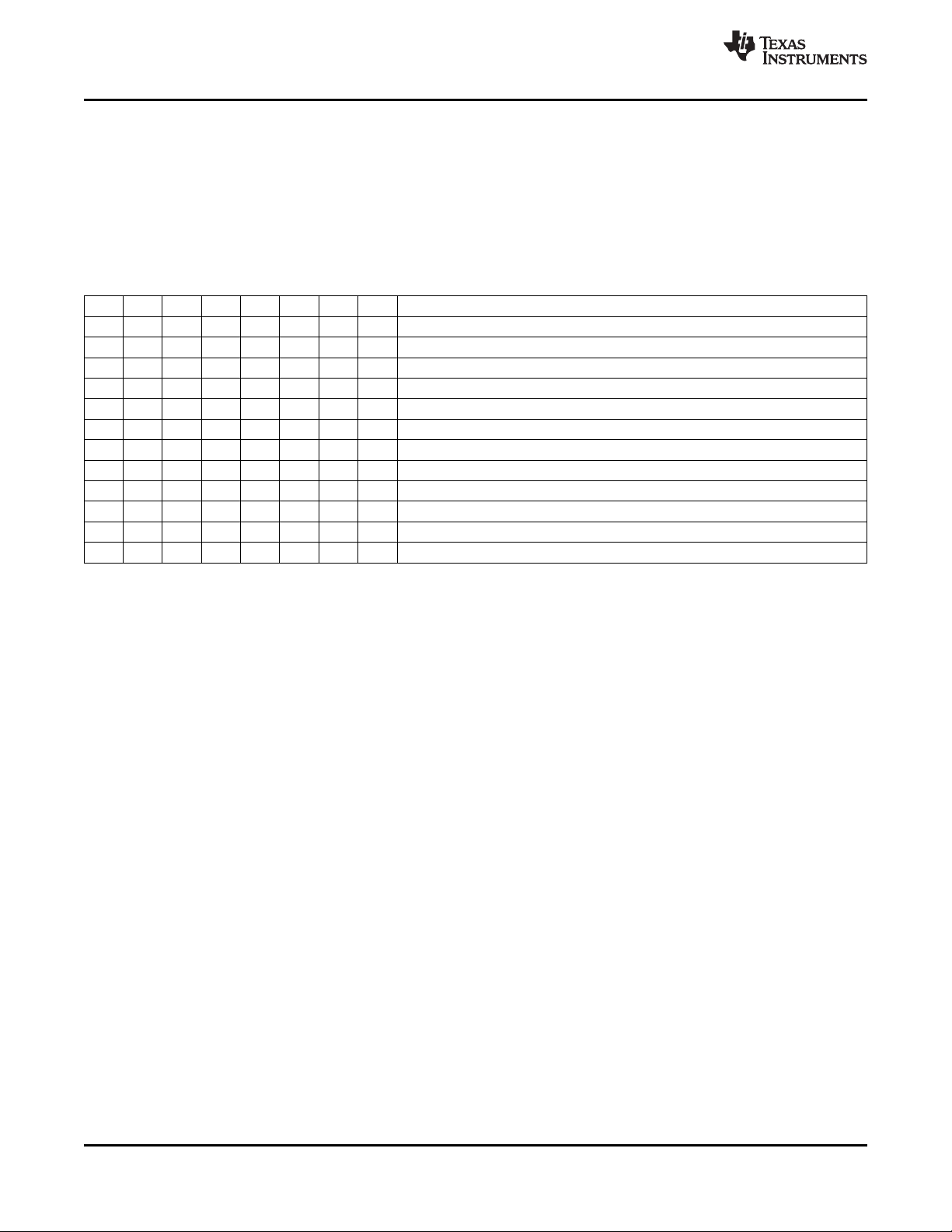

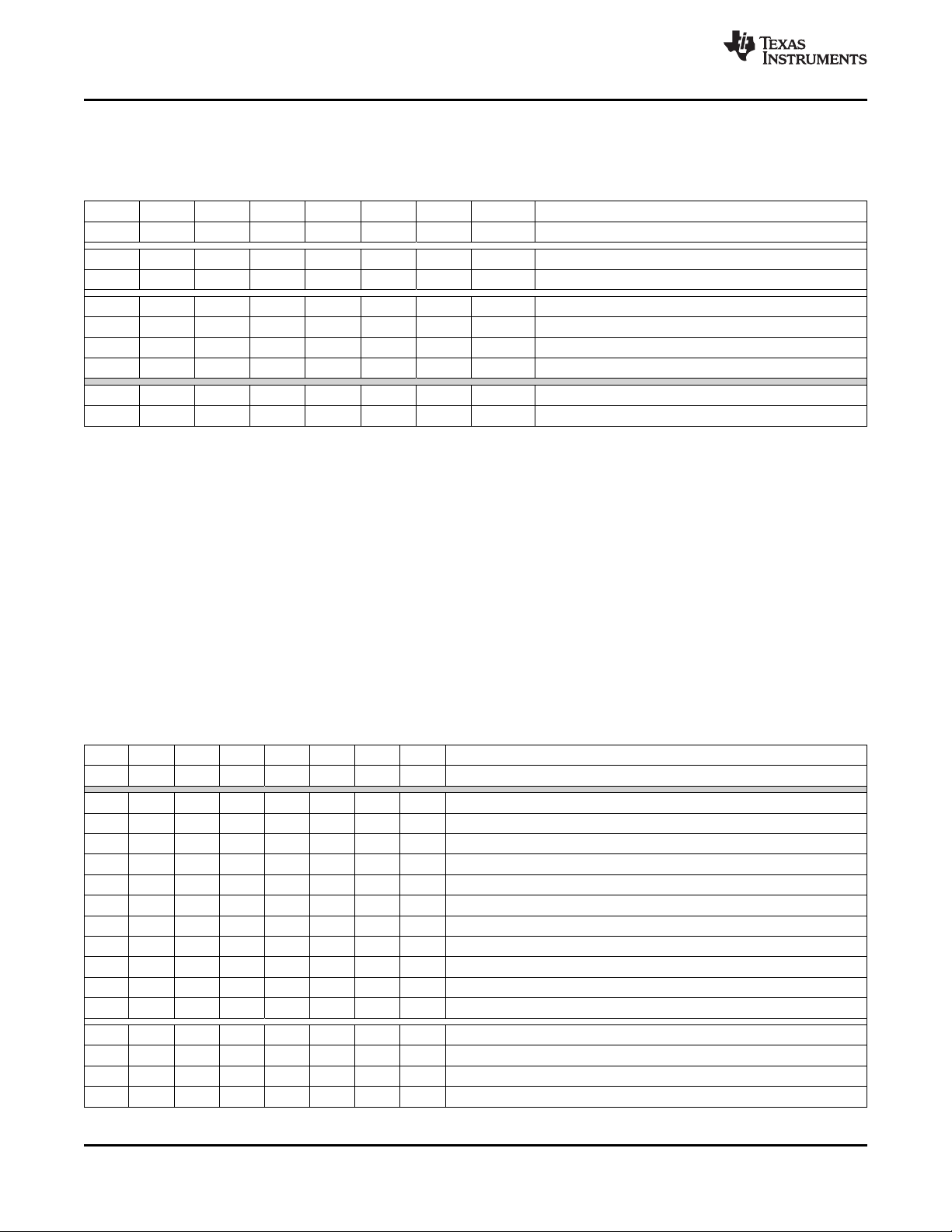

SERIAL AUDIO PORTS SLAVE MODE

over recommended operating conditions (unless otherwise noted)

PARAMETER MIN TYP MAX UNIT

f

SCLKIN

t

su1

t

h1

t

su2

t

h2

t

(edge)

tr/t

f

Frequency, SCLK 32 × fS, 48 × fS, 64 × f

S

Setup time, LRCLK to SCLK rising edge 10 ns

Hold time, LRCLK from SCLK rising edge 10 ns

Setup time, SDIN to SCLK rising edge 10 ns

Hold time, SDIN from SCLK rising edge 10 ns

LRCLK frequency 8 48 48 kHz

SCLK duty cycle 40% 50% 60%

LRCLK duty cycle 40% 50% 60%

SCLK rising edges between LRCLK rising edges 32 64

LRCLK clock edge with respect to the falling edge of SCLK –1/4 1/4

Rise/fall time for SCLK/LRCLK 8 ns

SLOS600 –DECEMBER 2009

TEST

CONDITIONS

CL= 30 pF 1.024 12.288 MHz

SCLK

edges

SCLK

period

Figure 2. Slave Mode Serial Data Interface Timing

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Link(s): TAS5711

Page 12

SCL

SDA

t

w(H)

t

w(L)

t

r

t

f

t

su1

t

h1

T0027-01

SCL

SDA

t

h2

t

(buf)

t

su2

t

su3

Start

Condition

Stop

Condition

T0028-01

TAS5711

SLOS600 –DECEMBER 2009

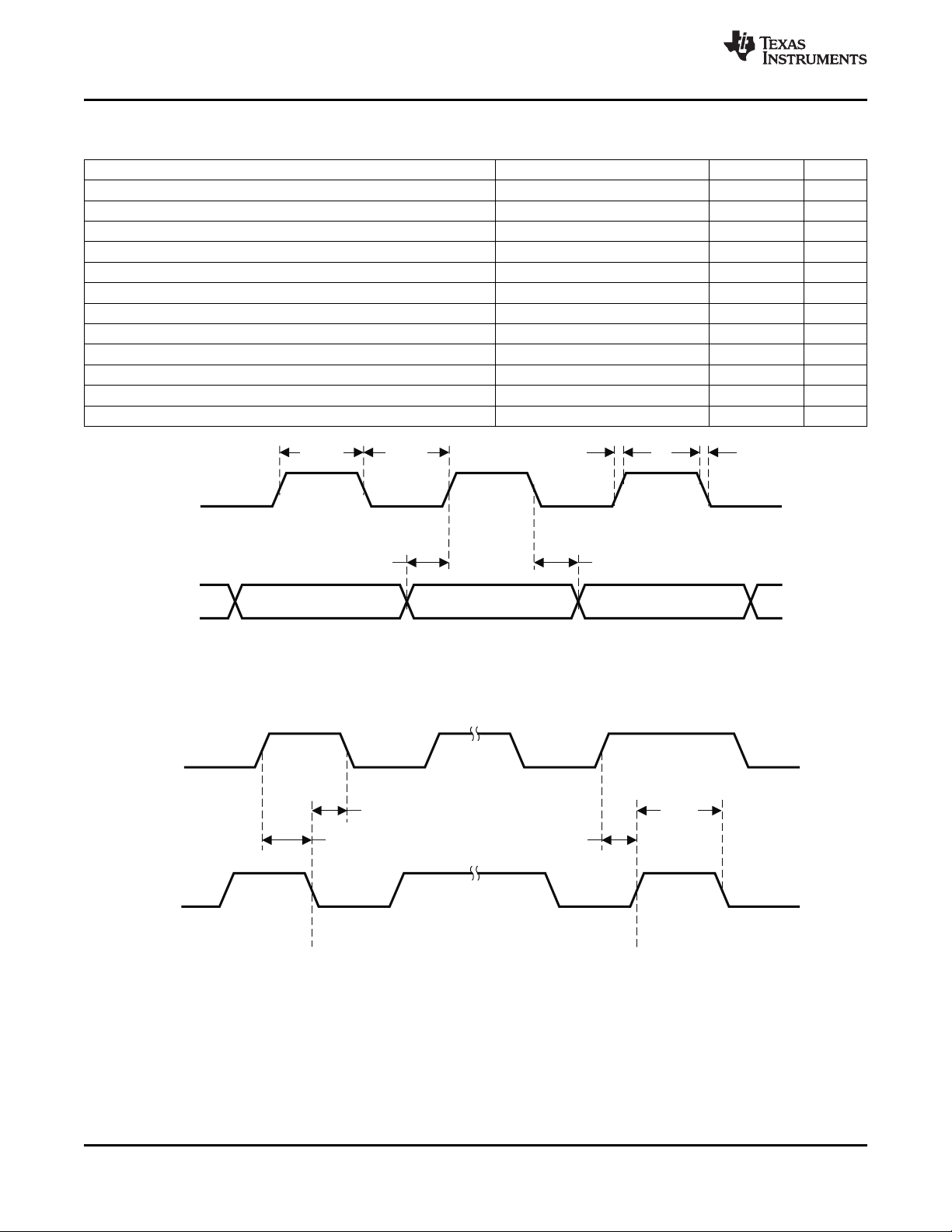

I2C SERIAL CONTROL PORT OPERATION

Timing characteristics for I2C Interface signals over recommended operating conditions (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN MAX UNIT

f

t

t

t

t

t

t

t

t

t

t

C

SCL

w(H)

w(L)

r

f

su1

h1

(buf)

su2

h2

su3

Frequency, SCL No wait states 400 kHz

Pulse duration, SCL high 0.6 μs

Pulse duration, SCL low 1.3 μs

Rise time, SCL and SDA 300 ns

Fall time, SCL and SDA 300 ns

Setup time, SDA to SCL 100 ns

Hold time, SCL to SDA 0 ns

Bus free time between stop and start condition 1.3 μs

Setup time, SCL to start condition 0.6 μs

Hold time, start condition to SCL 0.6 μs

Setup time, SCL to stop condition 0.6 μs

Load capacitance for each bus line 400 pF

L

www.ti.com

Figure 3. SCL and SDA Timing

Figure 4. Start and Stop Conditions Timing

12 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 13

t

w(RESET)

RESET

t

d(I2C_ready)

SystemInitialization.

EnableviaI C.

2

T0421-01

I C Active

2

I C Active

2

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

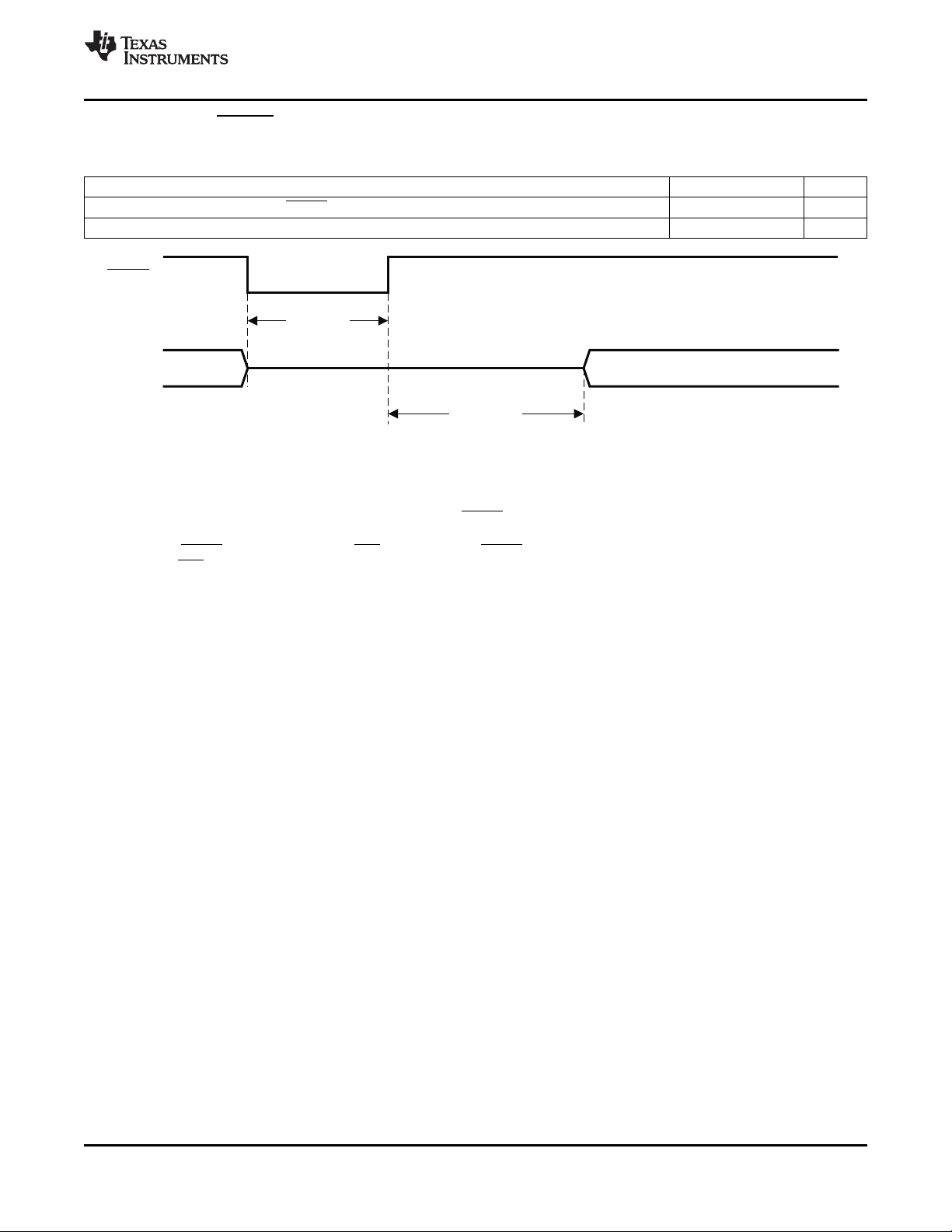

RESET TIMING (RESET)

Control signal parameters over recommended operating conditions (unless otherwise noted). Please refer to Recommended

Use Model section on usage of all terminals.

PARAMETER MIN TYP MAX UNIT

t

w(RESET)

t

d(I2C_ready)

NOTES: On power up, it is recommended that the TAS5711 RESET be held LOW for at least 100 μs after DVDD has

reached 3 V.

If the RESET is asserted LOW while PDN is LOW, then the RESET must continue to be held LOW for at least 100 μs

after PDN is deasserted (HIGH).

Pulse duration, RESET active 100 µs

Time to enable I2C 12.0 ms

Figure 5. Reset Timing

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Link(s): TAS5711

Page 14

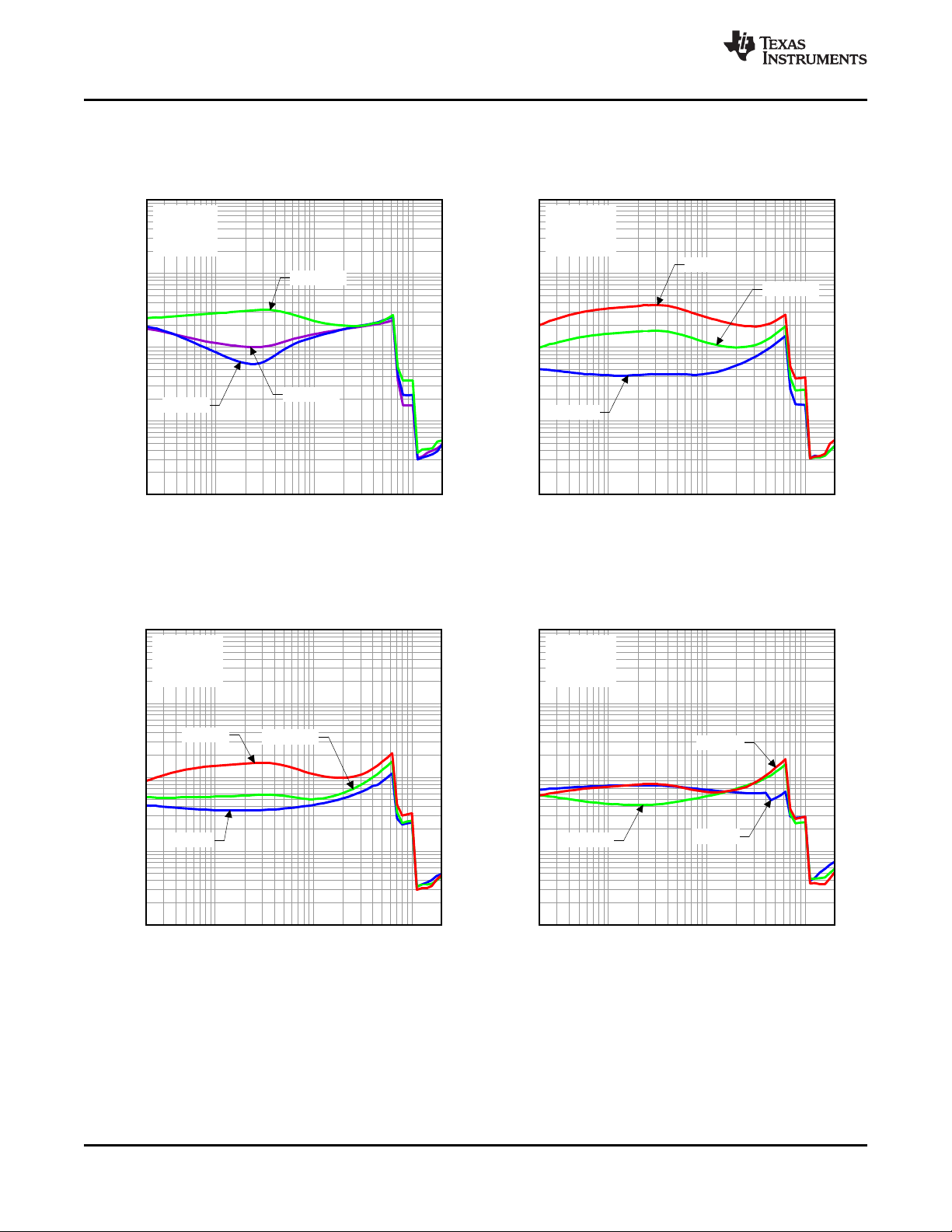

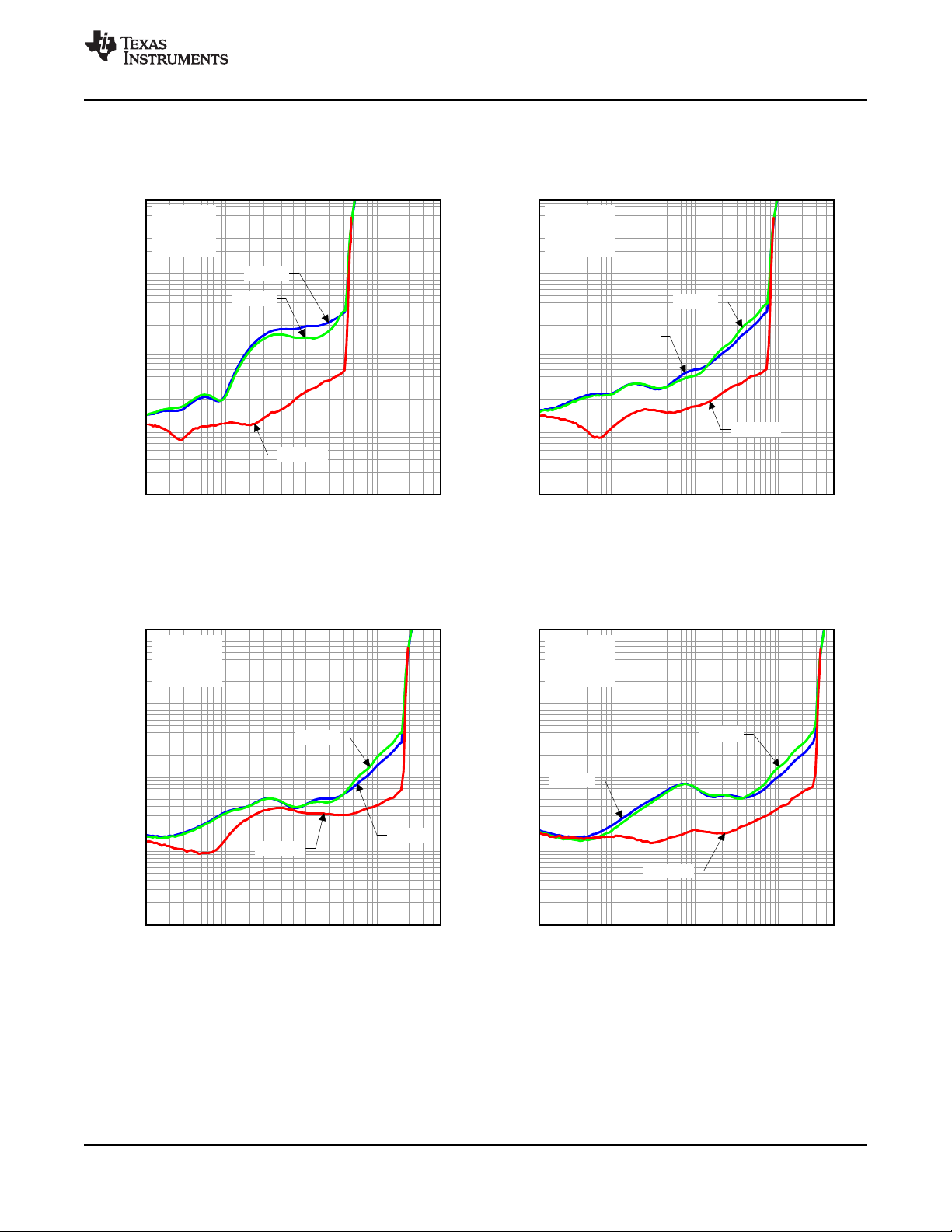

Frequency (Hz)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

FREQUENCY

0.001

0.01

0.1

1

10

20 100 1k 10k 20k

PO = 0.5W

PO = 1W

PO = 2.5W

G001

PVDD = 8V

RL = 8Ω

TA = 25°C

Frequency (Hz)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

FREQUENCY

0.001

0.01

0.1

1

10

20 100 1k 10k 20k

PO = 1W

PO = 2.5W

PO = 5W

G002

PVDD = 12V

RL = 8Ω

TA = 25°C

Frequency (Hz)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

FREQUENCY

0.001

0.01

0.1

1

10

20 100 1k 10k 20k

PO = 1W

PO = 2.5W

PO = 5W

G003

PVDD = 18V

RL = 8Ω

TA = 25°C

Frequency (Hz)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

FREQUENCY

0.001

0.01

0.1

1

10

20 100 1k 10k 20k

PO = 1W

PO = 2.5W

PO = 5W

G004

PVDD = 24V

RL = 8Ω

TA = 25°C

TAS5711

SLOS600 –DECEMBER 2009

www.ti.com

TYPICAL CHARACTERISTICS, BTL CONFIGURATION

Figure 6. Figure 7.

Figure 8. Figure 9.

14 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 15

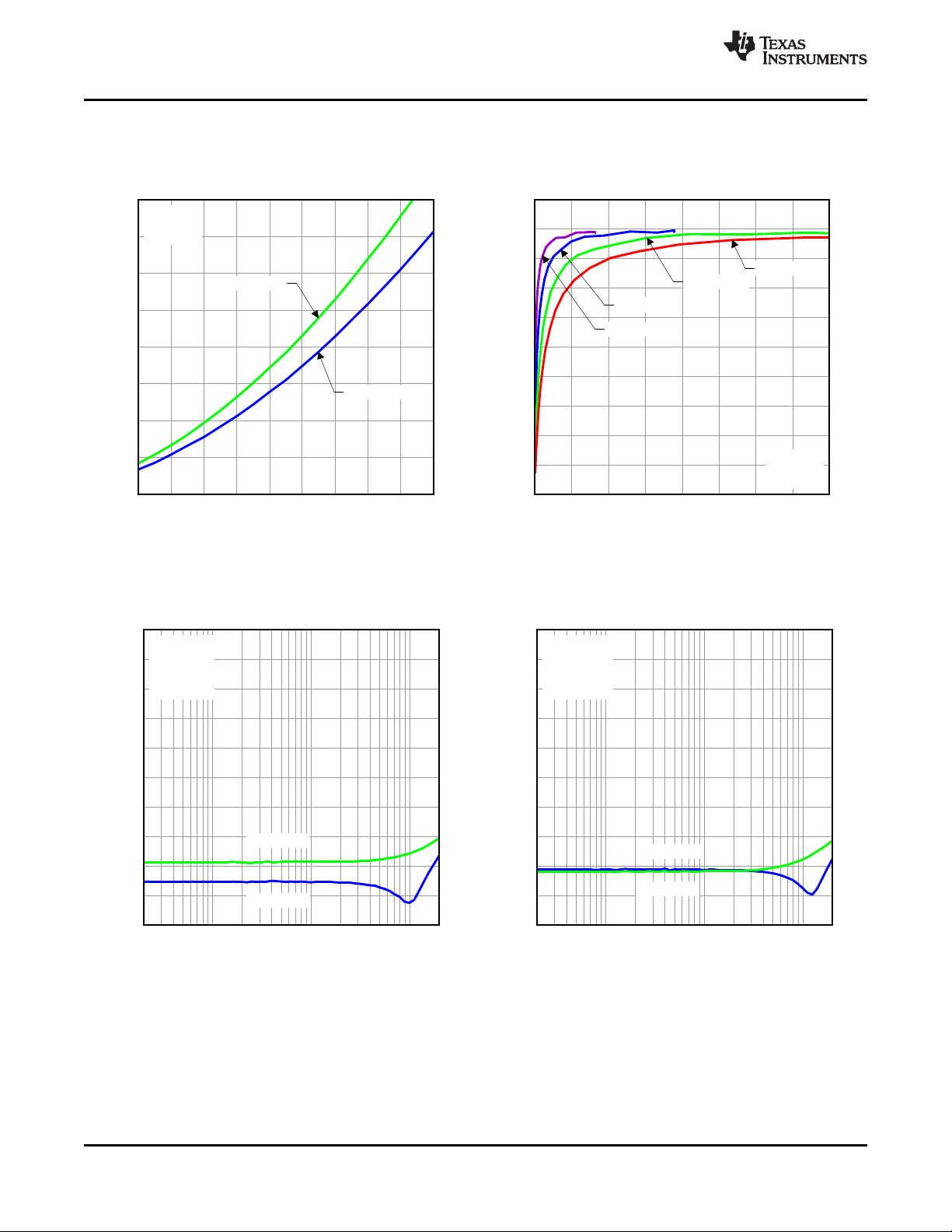

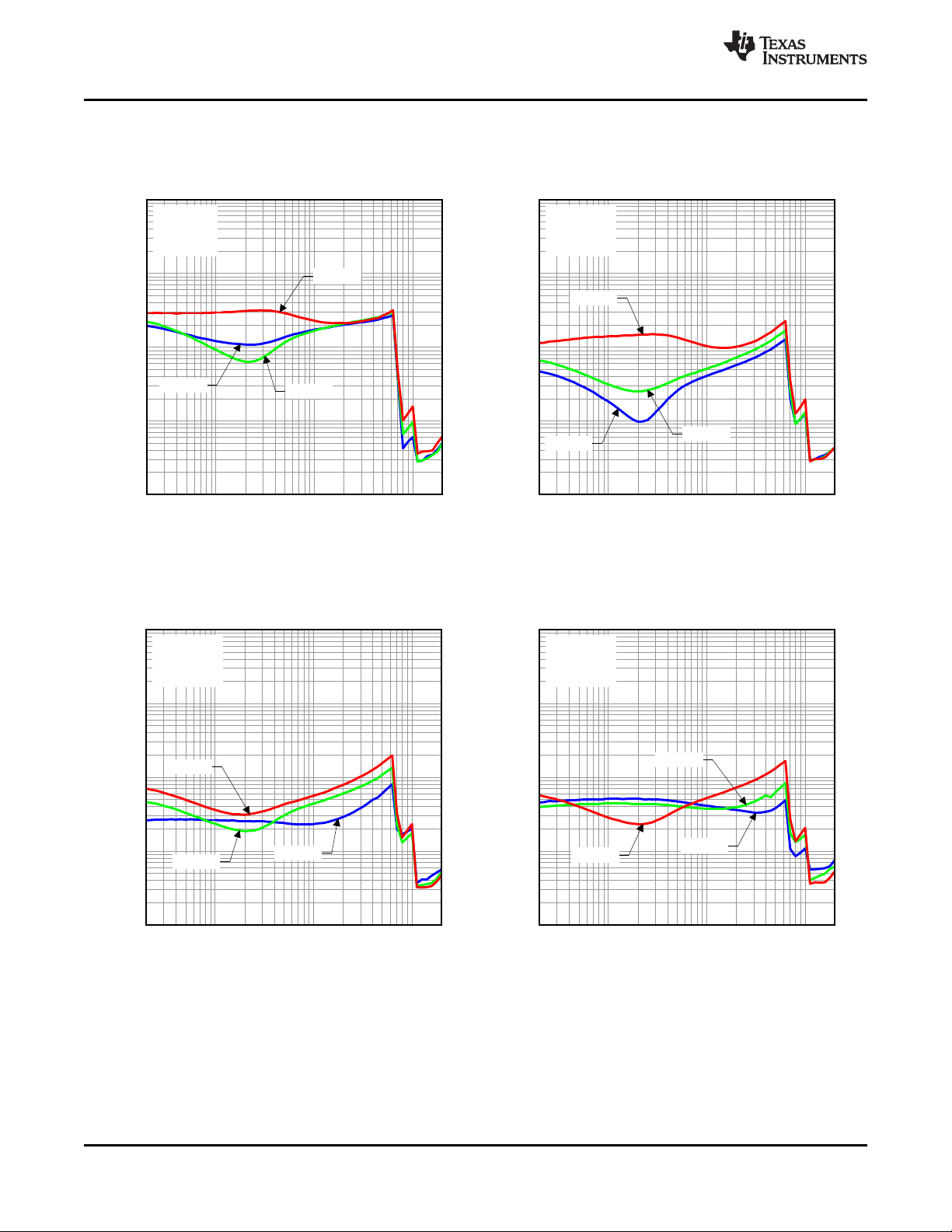

Output Power (W)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

OUTPUT POWER

0.01 0.1 1 10 50

0.001

0.01

0.1

1

10

f = 20Hz

f = 1kHz

f = 10kHz

G005

PVDD = 8V

RL = 8Ω

TA = 25°C

Output Power (W)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

OUTPUT POWER

0.01 0.1 1 10 50

0.001

0.01

0.1

1

10

f = 20Hz

f = 1kHz

f = 10kHz

G006

PVDD = 12V

RL = 8Ω

TA = 25°C

Output Power (W)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

OUTPUT POWER

0.01 0.1 1 10 50

0.001

0.01

0.1

1

10

f = 20Hz

f = 1kHz

f = 10kHz

G007

PVDD = 18V

RL = 8Ω

TA = 25°C

Output Power (W)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

OUTPUT POWER

0.01 0.1 1 10 50

0.001

0.01

0.1

1

10

f = 20Hz

f = 1kHz

f = 10kHz

G008

PVDD = 24V

RL = 8Ω

TA = 25°C

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

TYPICAL CHARACTERISTICS, BTL CONFIGURATION (continued)

Figure 10. Figure 11.

Figure 12. Figure 13.

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Link(s): TAS5711

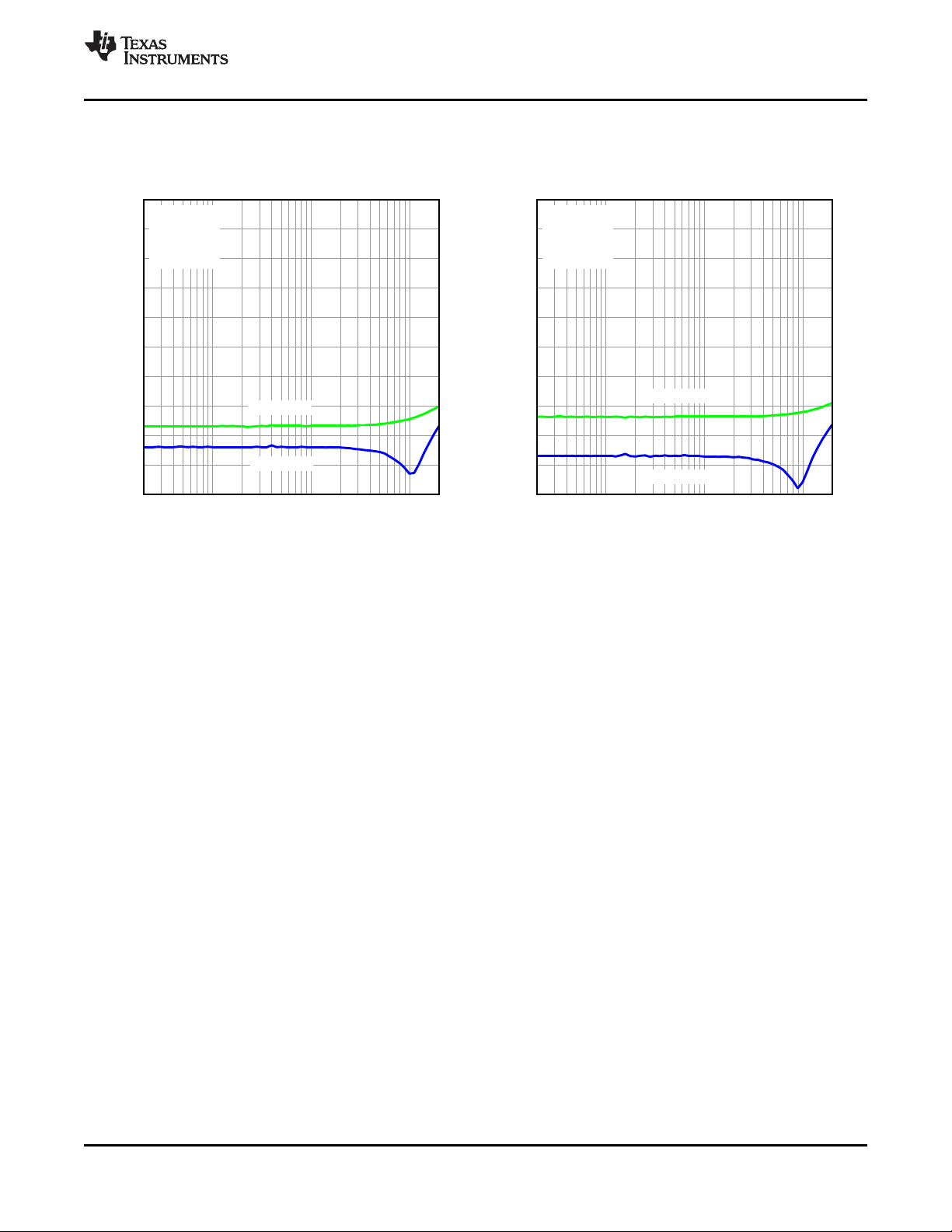

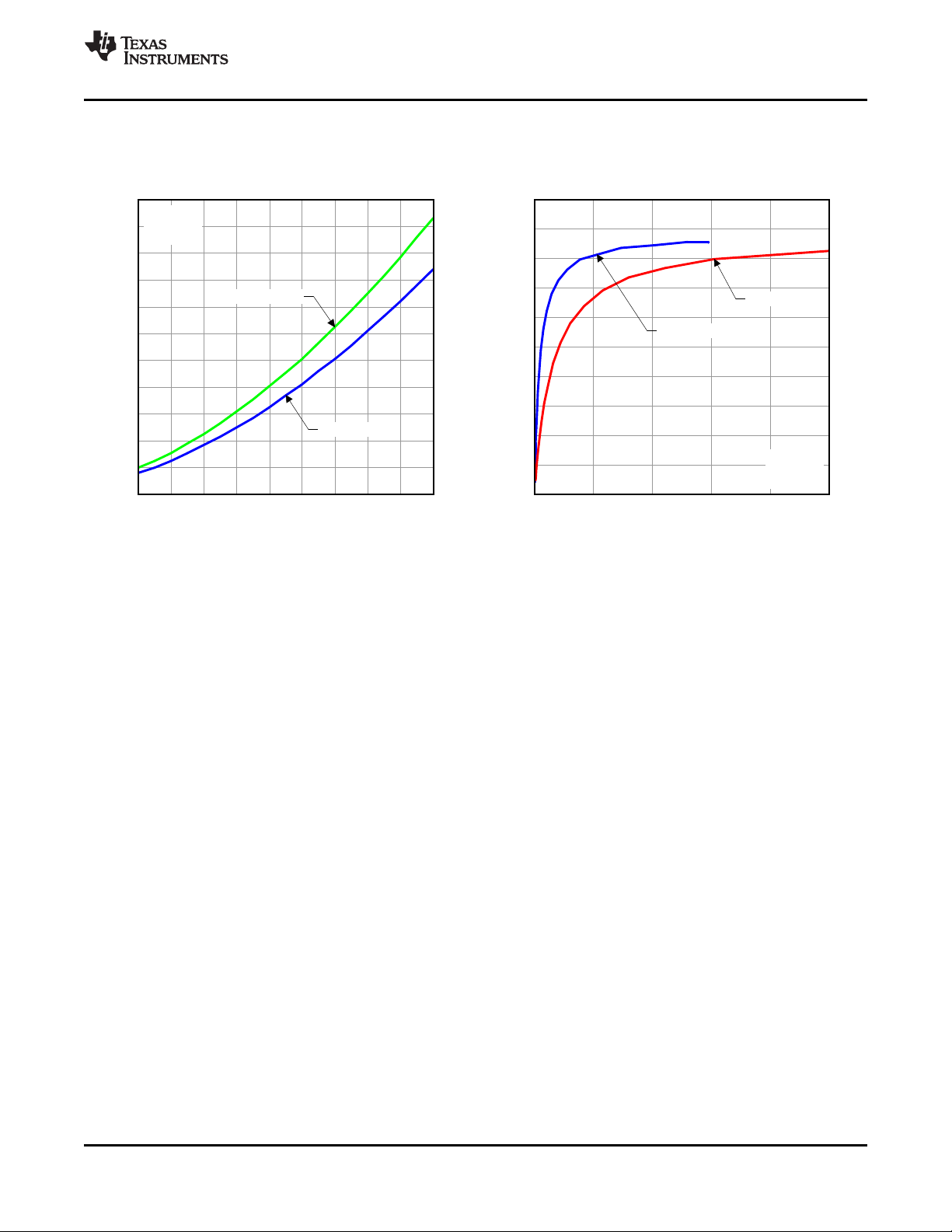

Page 16

Supply Voltage (V)

Output Power (W)

OUTPUT POWER

vs

SUPPLY VOLTAGE

8 10 12 14 16 18 20 22 24 26

0

5

10

15

20

25

30

35

40

THD+N = 1%

THD+N = 10%

G009

RL = 8Ω

TA = 25°C

Total Output Power (W)

Efficiency (%)

EFFICIENCY

vs

TOTAL OUTPUT POWER

0 5 10 15 20 25 30 35 40

0

10

20

30

40

50

60

70

80

90

100

PVDD = 8V

PVDD = 12V

PVDD = 18V

PVDD = 24V

G010

RL = 8Ω

TA = 25°C

Frequency (Hz)

Crosstalk (dB)

CROSSTALK

vs

FREQUENCY

-100

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

20 100 1k 10k 20k

Left to Right

Right to Left

G011

PO = 1W

PVDD = 8V

RL = 8Ω

TA = 25°C

Frequency (Hz)

Crosstalk (dB)

CROSSTALK

vs

FREQUENCY

-100

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

20 100 1k 10k 20k

Left to Right

Right to Left

G012

PO = 1W

PVDD = 12V

RL = 8Ω

TA = 25°C

TAS5711

SLOS600 –DECEMBER 2009

TYPICAL CHARACTERISTICS, BTL CONFIGURATION (continued)

www.ti.com

Figure 14. Figure 15.

Figure 16. Figure 17.

16 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 17

Frequency (Hz)

Crosstalk (dB)

CROSSTALK

vs

FREQUENCY

-100

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

20 100 1k 10k 20k

Left to Right

Right to Left

G013

PO = 1W

PVDD = 18V

RL = 8Ω

TA = 25°C

Frequency (Hz)

Crosstalk (dB)

CROSSTALK

vs

FREQUENCY

-100

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

20 100 1k 10k 20k

Left to Right

Right to Left

G014

PO = 1W

PVDD = 24V

RL = 8Ω

TA = 25°C

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

TYPICAL CHARACTERISTICS, BTL CONFIGURATION (continued)

Figure 18. Figure 19.

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Link(s): TAS5711

Page 18

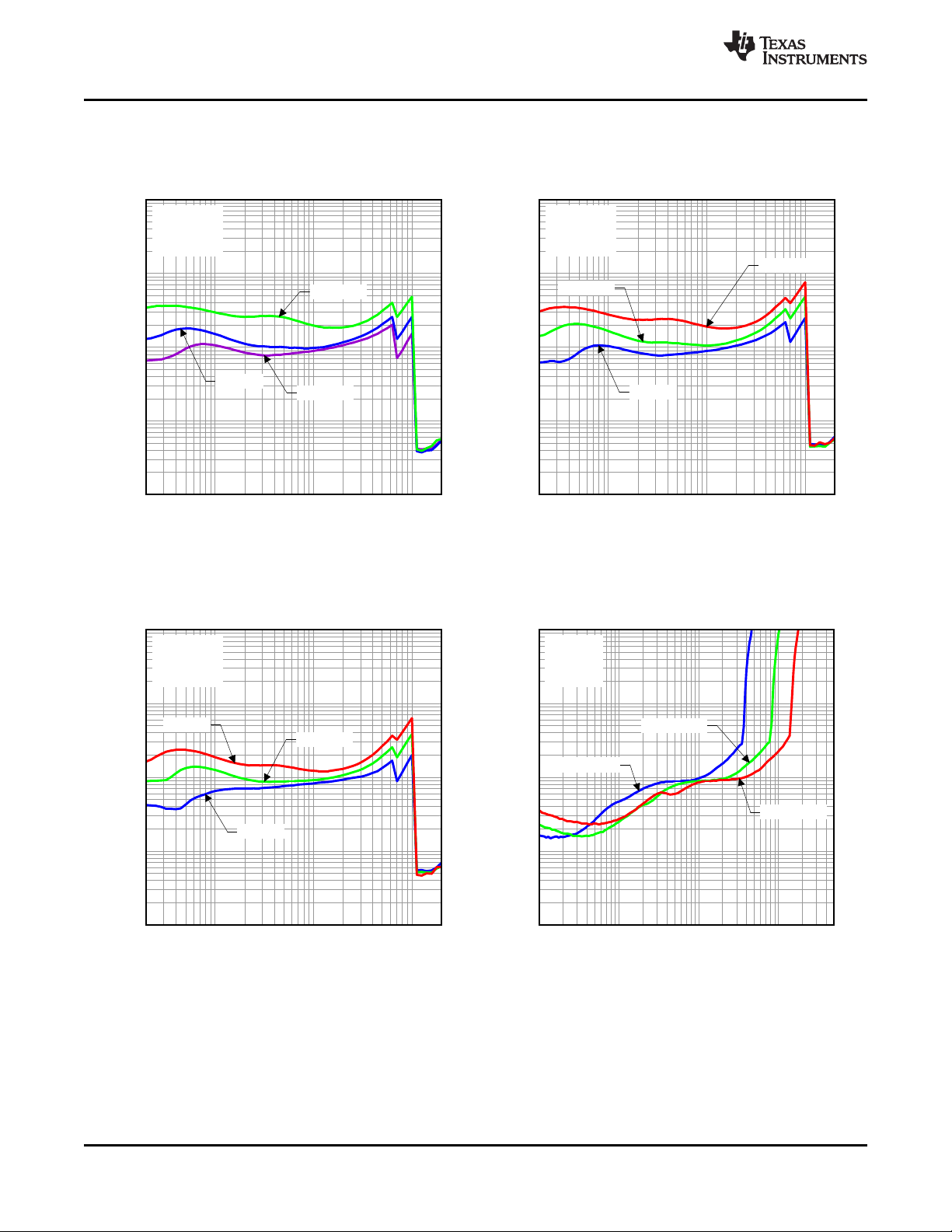

Frequency (Hz)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

FREQUENCY

0.001

0.01

0.1

1

10

20 100 1k 10k 20k

PO = 0.5W

PO = 1W

PO = 2.5W

G015

PVDD = 12V

RL = 4Ω

TA = 25°C

Frequency (Hz)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

FREQUENCY

0.001

0.01

0.1

1

10

20 100 1k 10k 20k

PO = 1W

PO = 2.5W

PO = 5W

G016

PVDD = 18V

RL = 4Ω

TA = 25°C

Frequency (Hz)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

FREQUENCY

0.001

0.01

0.1

1

10

20 100 1k 10k 20k

PO = 1W

PO = 2.5W

PO = 5W

G017

PVDD = 24V

RL = 4Ω

TA = 25°C

Output Power (W)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

OUTPUT POWER

0.01 0.1 1 10 50

0.001

0.01

0.1

1

10

PVDD = 12V

PVDD = 18V

PVDD = 24V

G018

f = 1kHz

RL = 4Ω

TA = 25°C

TAS5711

SLOS600 –DECEMBER 2009

www.ti.com

TYPICAL CHARACTERISTICS, SE CONFIGURATION

Figure 20. Figure 21.

Figure 22. Figure 23.

18 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 19

Supply Voltage (V)

Output Power (W)

OUTPUT POWER

vs

SUPPLY VOLTAGE

8 10 12 14 16 18 20 22 24 26

0

2

4

6

8

10

12

14

16

18

20

22

THD+N = 1%

THD+N = 10%

G019

RL = 4Ω

TA = 25°C

Total Output Power (W)

Efficiency (%)

EFFICIENCY

vs

TOTAL OUTPUT POWER

0 3 6 9 12 15

0

10

20

30

40

50

60

70

80

90

100

PVDD = 12V

PVDD = 24V

G020

RL = 4Ω

TA = 25°C

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

TYPICAL CHARACTERISTICS, SE CONFIGURATION (continued)

Figure 24. Figure 25.

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Link(s): TAS5711

Page 20

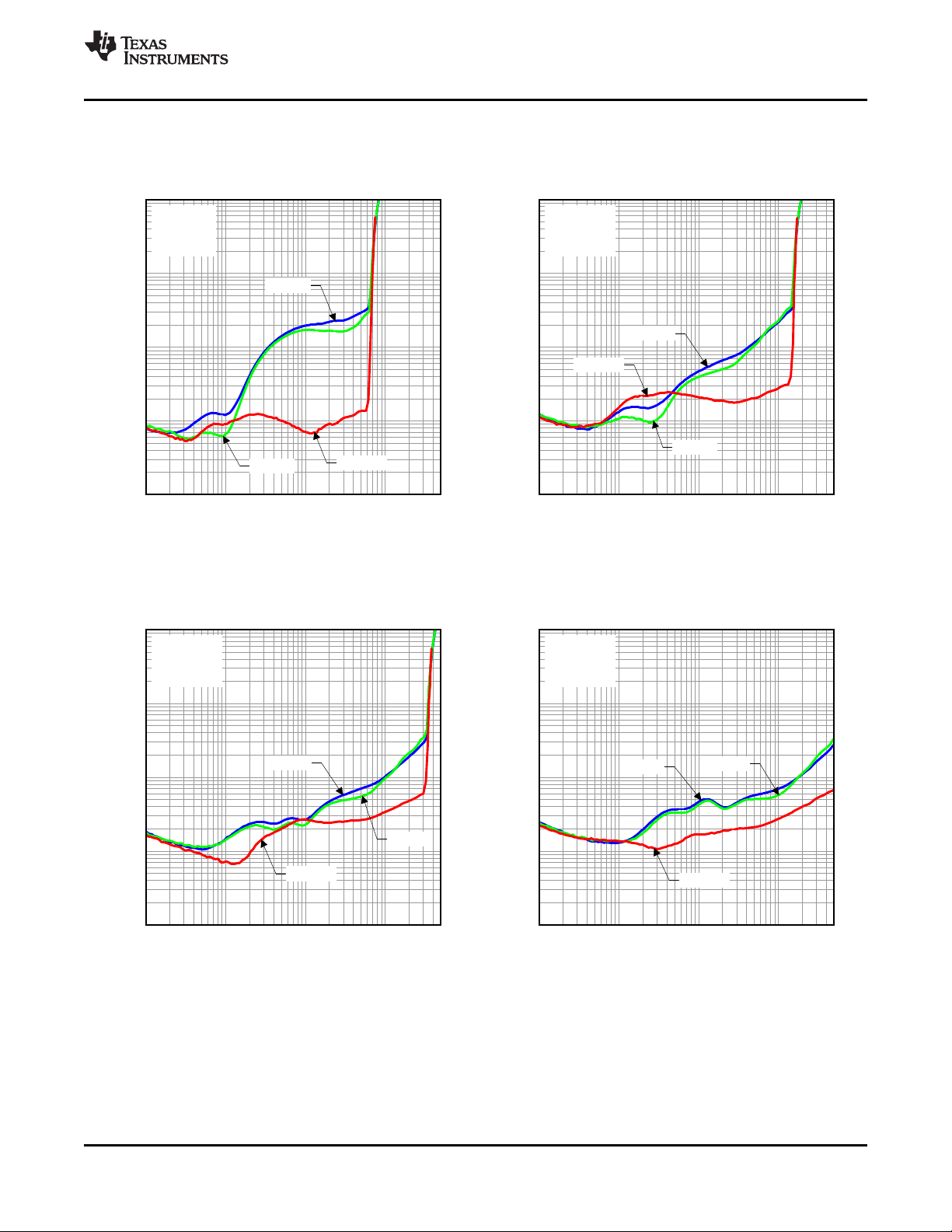

Frequency (Hz)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

FREQUENCY

0.001

0.01

0.1

1

10

20 100 1k 10k 20k

PO = 1W

PO = 2W

PO = 5W

G021

PVDD = 8V

RL = 4Ω

TA = 25°C

Frequency (Hz)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

FREQUENCY

0.001

0.01

0.1

1

10

20 100 1k 10k 20k

PO = 1W

PO = 2W

PO = 5W

G022

PVDD = 12V

RL = 4Ω

TA = 25°C

Frequency (Hz)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

FREQUENCY

0.001

0.01

0.1

1

10

20 100 1k 10k 20k

PO = 1W

PO = 2W

PO = 5W

G023

PVDD = 18V

RL = 4Ω

TA = 25°C

Frequency (Hz)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

FREQUENCY

0.001

0.01

0.1

1

10

20 100 1k 10k 20k

PO = 1W

PO = 2W

PO = 5W

G024

PVDD = 24V

RL = 4Ω

TA = 25°C

TAS5711

SLOS600 –DECEMBER 2009

www.ti.com

TYPICAL CHARACTERISTICS, PBTL CONFIGURATION

Figure 26. Figure 27.

Figure 28. Figure 29.

20 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 21

Output Power (W)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

OUTPUT POWER

0.01 0.1 1 10 50

0.001

0.01

0.1

1

10

f = 20Hz

f = 1kHz

f = 10kHz

G025

PVDD = 8V

RL = 4Ω

TA = 25°C

Output Power (W)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

OUTPUT POWER

0.01 0.1 1 10 50

0.001

0.01

0.1

1

10

f = 20Hz

f = 1kHz

f = 10kHz

G026

PVDD = 12V

RL = 4Ω

TA = 25°C

Output Power (W)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

OUTPUT POWER

0.01 0.1 1 10 50

0.001

0.01

0.1

1

10

f = 20Hz

f = 1kHz

f = 10kHz

G027

PVDD = 18V

RL = 4Ω

TA = 25°C

Output Power (W)

THD+N (%)

TOTAL HARMONIC DISTORTION + NOISE

vs

OUTPUT POWER

0.01 0.1 1 10 50

0.001

0.01

0.1

1

10

f = 20Hz

f = 1kHz

f = 10kHz

G028

PVDD = 24V

RL = 4Ω

TA = 25°C

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

TYPICAL CHARACTERISTICS, PBTL CONFIGURATION (continued)

Figure 30. Figure 31.

Figure 32. Figure 33.

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Link(s): TAS5711

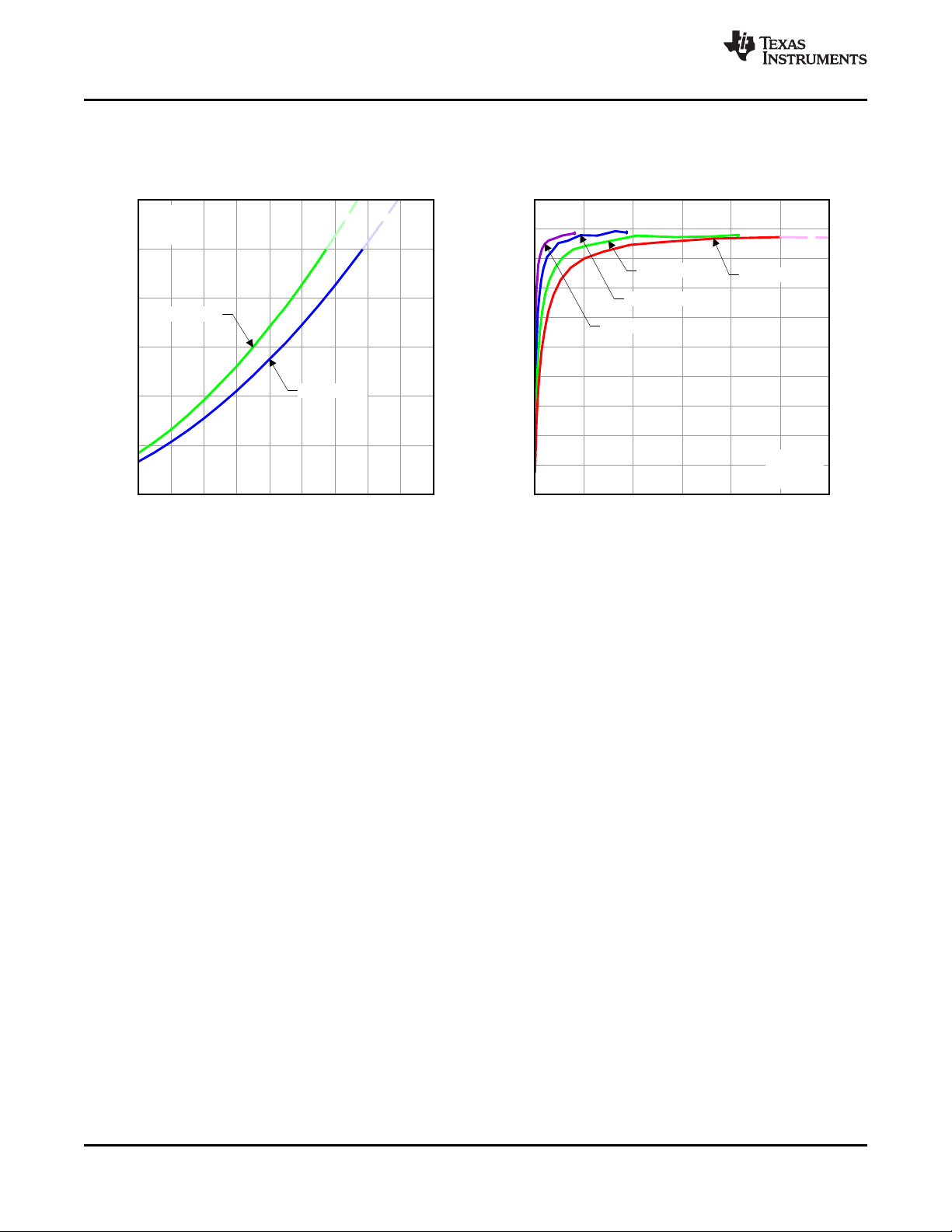

Page 22

Supply Voltage (V)

Output Power (W)

OUTPUT POWER

vs

SUPPLY VOLTAGE

8 10 12 14 16 18 20 22 24 26

0

10

20

30

40

50

60

THD+N = 1%

THD+N = 10%

G029

RL = 4Ω

TA = 25°C

Total Output Power (W)

Efficiency (%)

EFFICIENCY

vs

TOTAL OUTPUT POWER

0 10 20 30 40 50 60

0

10

20

30

40

50

60

70

80

90

100

PVDD = 8V

PVDD = 12V

PVDD = 18V

PVDD = 24V

G030

RL = 4Ω

TA = 25°C

TAS5711

SLOS600 –DECEMBER 2009

TYPICAL CHARACTERISTICS, PBTL CONFIGURATION (continued)

NOTE: Dashed lines represent thermally limited regions. NOTE: Dashed line represents thermally limited region.

Figure 34. Figure 35.

www.ti.com

22 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 23

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

DETAILED DESCRIPTION

POWER SUPPLY

To facilitate system design, the TAS5711 needs only a 3.3-V supply in addition to the (typical) 18-V power-stage

supply. An internal voltage regulator provides suitable voltage levels for the gate drive circuitry. Additionally, all

circuitry requiring a floating voltage supply, e.g., the high-side gate drive, is accommodated by built-in bootstrap

circuitry requiring only a few external capacitors.

In order to provide good electrical and acoustical characteristics, the PWM signal path for the output stage is

designed as identical, independent half-bridges. For this reason, each half-bridge has separate bootstrap pins

(BST_x), and power-stage supply pins (PVDD_x). The gate drive voltages (GVDD_AB and GVDD_CD) are

derived from the PVDD voltage. Special attention should be paid to placing all decoupling capacitors as close to

their associated pins as possible. In general, inductance between the power-supply pins and decoupling

capacitors must be avoided.

For a properly functioning bootstrap circuit, a small ceramic capacitor must be connected from each bootstrap pin

(BST_x) to the power-stage output pin (OUT_x). When the power-stage output is low, the bootstrap capacitor is

charged through an internal diode connected between the gate-drive regulator output pin (GVDD_x) and the

bootstrap pin. When the power-stage output is high, the bootstrap capacitor potential is shifted above the output

potential and thus provides a suitable voltage supply for the high-side gate driver. In an application with PWM

switching frequencies in the range from 352 kHz to 384 kHz, it is recommended to use 33-nF 50-V X7R

capacitors, size 0603 or 0805, for the bootstrap supply. These 33-nF capacitors ensure sufficient energy storage,

even during minimal PWM duty cycles, to keep the high-side power stage FET (LDMOS) fully turned on during

the remaining part of the PWM cycle.

Special attention should be paid to the power-stage power supply; this includes component selection, PCB

placement, and routing. As indicated, each half-bridge has independent power-stage supply pins (PVDD_x). For

optimal electrical performance, EMC compliance, and system reliability, it is important that each PVDD_x pin is

decoupled with a 100-nF ceramic capacitor placed as close as possible to each supply pin.

The TAS5711 is fully protected against erroneous power-stage turnon due to parasitic gate charging.

ERROR REPORTING

The A_SEL pin has two functions: I2C device-address select and fault indication. On RESET, this pin is an input

and defines the I2C address. But this pin can be programmed after RESET to be an output by writing 1 to bit 0 of

I2C register 0x05. In that mode, the A_SEL pin has the definition shown in Table 1.

Any fault resulting in device shutdown is signaled by the A_SEL pin going low (see Table 1). A latched version of

this pin is available on D1 of register 0x02. The bit can be cleared only by an I2C write.

Table 1. FAULT Output States

FAULT DESCRIPTION

0 Overcurrent (OC) or undervoltage (UVP) error or overtemperature error (OTE) or over

1 No faults (normal operation)

voltage ERROR

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Link(s): TAS5711

Page 24

FAULT

~300ns

ProgrammableRecovery Time

PowerStage

FaultState

FAULT

NO-FAULT NO-FAULT

T0450-01

TAS5711

SLOS600 –DECEMBER 2009

www.ti.com

Table 1. FAULT Output States (continued)

Figure 36. Fault Timing Diagram

DEVICE PROTECTION SYSTEM

Overcurrent (OC) Protection With Current Limiting

The device has independent, fast-reacting current detectors on all high-side and low-side power-stage FETs. The

detector outputs are closely monitored by two protection systems. The first protection system controls the power

stage in order to prevent the output current further increasing, i.e., it performs a cycle-by-cycle current-limiting

function, rather than prematurely shutting down during combinations of high-level music transients and extreme

speaker load impedance drops. If the high-current condition situation persists, i.e., the power stage is being

overloaded, a second protection system triggers a latching shutdown, resulting in the power stage being set in

the high-impedance (Hi-Z) state. The device returns to normal operation once the fault condition (i.e., a short

circuit on the output) is removed. Current limiting and overcurrent protection are not independent for half-bridges.

That is, if the bridge-tied load between half-bridges A and B causes an overcurrent fault, half-bridges A, B, C,

and D are shut down.

Overtemperature Protection

The TAS5711 has over temperature-protection system. If the device junction temperature exceeds 150°C

(nominal), the device is put into thermal shutdown, resulting in all half-bridge outputs being set in the

high-impedance (Hi-Z) state and FAULT being asserted low. The TAS5711 recovers automatically once the

temperature drops approximately 30°.

Undervoltage Protection (UVP) and Power-On Reset (POR)

The UVP and POR circuits of the TAS5711 fully protect the device in any power-up/down and brownout situation.

While powering up, the POR circuit resets the overload circuit and ensures that all circuits are fully operational

when the PVDD and AVDD supply voltages reach 7.6 V and 2.7 V, respectively. Although PVDD and AVDD are

independently monitored, a supply voltage drop below the UVP threshold on AVDD or either PVDD pin results in

all half-bridge outputs immediately being set in the high-impedance (Hi-Z) state and FAULT being asserted low.

24 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 25

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

SSTIMER FUNCTIONALITY

The SSTIMER pin uses a capacitor connected between this pin and ground to control the output duty cycle when

exiting all-channel shutdown. The capacitor on the SSTIMER pin is slowly charged through an internal current

source, and the charge time determines the rate at which the output transitions from a near zero duty cycle to the

desired duty cycle. This allows for a smooth transition that minimizes audible pops and clicks. When the part is

shutdown the drivers are tristated and transition slowly down through a 3K resistor, similarly minimizing pops and

clicks. The shutdown transition time is independent of SSTIMER pin capacitance. Larger capacitors will increase

the start-up time, while capacitors smaller than 2.2 nF will decrease the start-up time. The SSTIMER pin should

be left floating for BD modulation (BTL and PBTL modes) and in 2.1 mode.

CLOCK, AUTO DETECTION, AND PLL

The TAS5711 is a slave device. It accepts MCLK, SCLK, and LRCLK. The digital audio processor (DAP)

supports all the sample rates and MCLK rates that are defined in the clock control register .

The TAS5711 checks to verify that SCLK is a specific value of 32 fS, 48 fS, or 64 fS. The DAP only supports a 1 ×

fSLRCLK. The timing relationship of these clocks to SDIN is shown in subsequent sections. The clock section

uses MCLK or the internal oscillator clock (when MCLK is unstable, out of range, or absent) to produce the

internal clock (DCLK) running at 512 time the PWM switching frequency.

The DAP can autodetect and set the internal clock control logic to the appropriate settings for all supported clock

rates as defined in the clock control register.

TAS5711 has robust clock error handling that uses the bulit-in trimmed oscillator clock to quickly detect

changes/errors. Once the system detects a clock change/error, it will mute the audio (through a single step mute)

and then force PLL to limp using the internal oscillator as a reference clock. Once the clocks are stable, the

system will auto detect the new rate and revert to normal operation. During this process, the default volume will

be restored in a single step (also called hard unmute). The ramp process can be programmed to ramp back

slowly (also called soft unmute) as defined in volume register (0x0E).

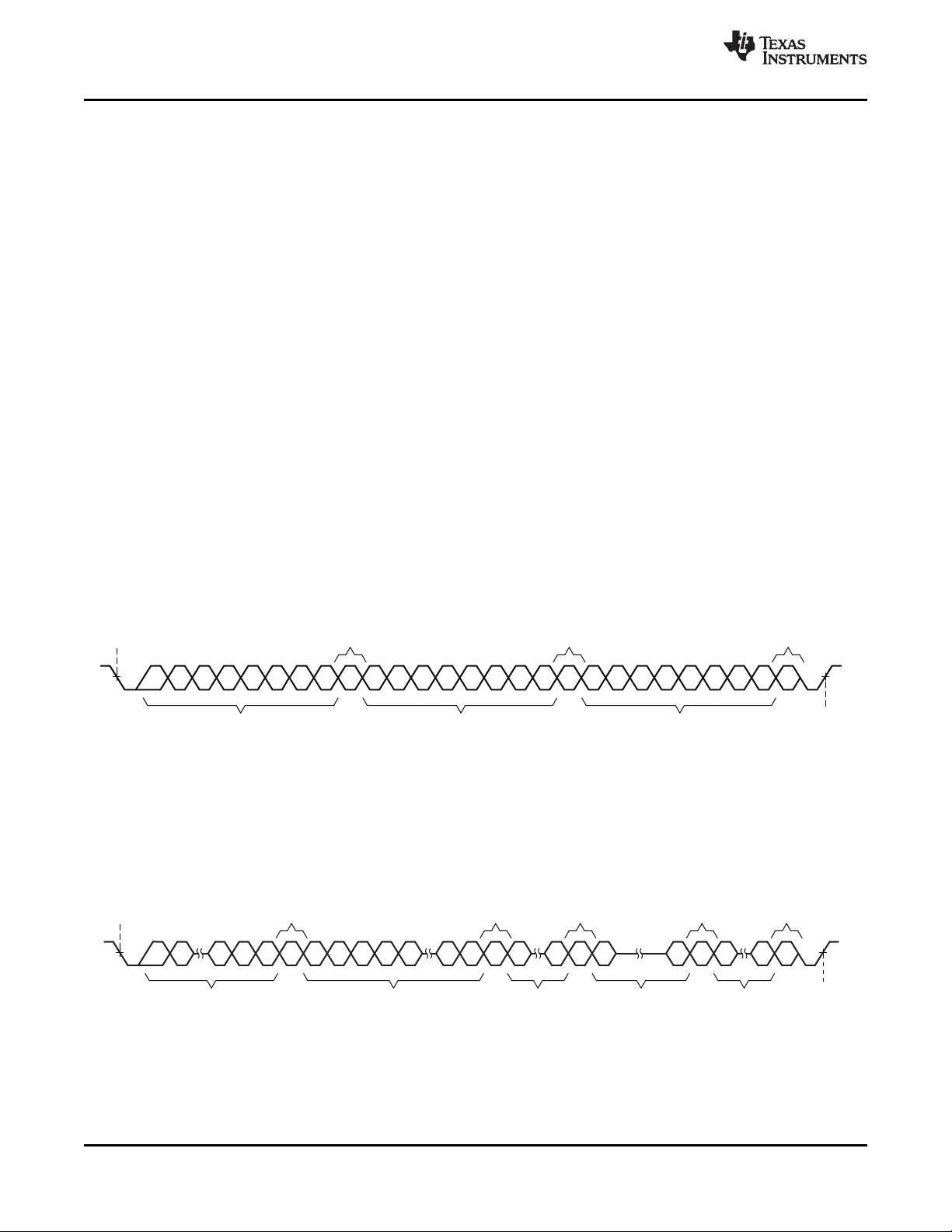

SERIAL DATA INTERFACE

Serial data is input on SDIN. The PWM outputs are derived from SDIN. The TAS5711 DAP accepts serial data in

16-, 20-, or 24-bit left-justified, right-justified, and I2S serial data formats.

PWM Section

The TAS5711 DAP device uses noise-shaping and sophisticated non-linear correction algorithms to achieve high

power efficiency and high-performance digital audio reproduction. The DAP uses a fourth-order noise shaper to

increase dynamic range and SNR in the audio band. The PWM section accepts 24-bit PCM data from the DAP

and outputs two BTL PWM audio output channels.

The PWM section has individual channel dc blocking filters that can be enabled and disabled. The filter cutoff

frequency is less than 1 Hz. Individual channel de-emphasis filters for 44.1- and 48-kHz are included and can be

enabled and disabled.

Finally, the PWM section has an adjustable maximum modulation limit of 93.8% to 99.2%.

For detailed description of using audio processing features like DRC, EQ, 3D, and Bass Boost, please refer to

User's Guide and TAS570X GDE software development tool documentation. Also refer to GDE software

development tool for device data path.

SERIAL INTERFACE CONTROL AND TIMING

The I2S mode is set by writing to register 0x04.

I2S Timing

I2S timing uses LRCLK to define when the data being transmitted is for the left channel and when it is for the

right channel. LRCLK is low for the left channel and high for the right channel. A bit clock running at 32, 48, or

64 × fSis used to clock in the data. There is a delay of one bit clock from the time the LRCLK signal changes

state to the first bit of data on the data lines. The data is written MSB first and is valid on the rising edge of bit

clock. The DAP masks unused trailing data bit positions.

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Link(s): TAS5711

Page 26

23

22

SCLK

32Clks

LRCLK(NoteReversedPhase)

LeftChannel

24-BitMode

1

19 18

20-BitMode

16-BitMode

15

14

MSB LSB

32Clks

RightChannel

2-ChannelI S(PhilipsFormat)StereoInput

2

T0034-01

5

4

9 8

1

0

0

4

5

1

0

23

22 1

19 18

15

14

MSB LSB

5

4

9 8

1

0

0

4

5

1

0

SCLK

23

22

SCLK

24Clks

LRCLK

LeftChannel

24-BitMode

1

19 18

20-BitMode

16-BitMode

15

14

MSB LSB

24Clks

RightChannel

2-ChannelI S(PhilipsFormat)StereoInput/Output(24-Bit TransferWordSize)

2

T0092-01

3

2

5

4

9 8

17

16

1

0

0

4

5

13

12

1

09 8

23

22

SCLK

1

19 18

15

14

MSB LSB

3

2

5

4

9 8

17

16

1

0

4

5

13

12

1

09 8

TAS5711

SLOS600 –DECEMBER 2009

www.ti.com

NOTE: All data presented in 2s-complement form with MSB first.

Figure 37. I2S 64-fSFormat

26 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

NOTE: All data presented in 2s-complement form with MSB first.

Figure 38. I2S 48-fSFormat

Product Folder Link(s): TAS5711

Page 27

SCLK

16Clks

LRCLK

LeftChannel

16-BitMode

1 1

15 15

14 14

MSB LSB

16Clks

RightChannel

2-ChannelI S(PhilipsFormat)StereoInput

2

T0266-01

3 3

2 2

5 5

4 4

9 98 80

13 13

10 10

11 1112 12

SCLK

MSB LSB

23

22

SCLK

32Clks

LRCLK

LeftChannel

24-BitMode

1

19 18

20-BitMode

16-BitMode

15

14

MSB LSB

32Clks

RightChannel

2-ChannelLeft-JustifiedStereoInput

T0034-02

4

5

9 8

1

4

5

1

0

0

0

23

22 1

19 18

15

14

MSB LSB

4

5

9 8

1

4

5

1

0

0

0

SCLK

TAS5711

www.ti.com

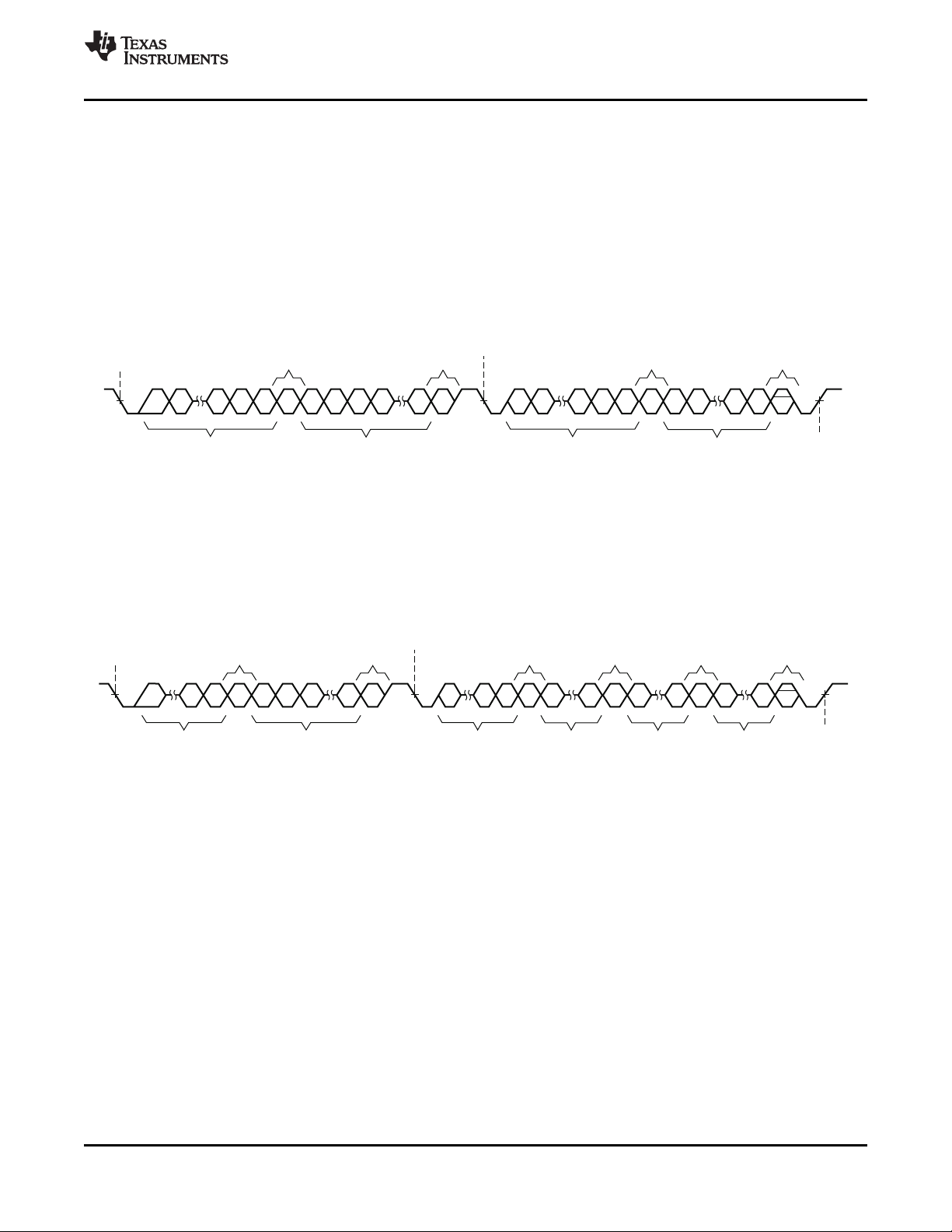

NOTE: All data presented in 2s-complement form with MSB first.

SLOS600 –DECEMBER 2009

Figure 39. I2S 32-fSFormat

Left-Justified

Left-justified (LJ) timing uses LRCLK to define when the data being transmitted is for the left channel and when it

is for the right channel. LRCLK is high for the left channel and low for the right channel. A bit clock running at 32,

48, or 64 × fSis used to clock in the data. The first bit of data appears on the data lines at the same time LRCLK

toggles. The data is written MSB first and is valid on the rising edge of the bit clock. The DAP masks unused

trailing data bit positions.

NOTE: All data presented in 2s-complement form with MSB first.

Figure 40. Left-Justified 64-fSFormat

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Link(s): TAS5711

Page 28

23

22

SCLK

24Clks

LRCLK

LeftChannel

24-BitMode

1

19 18

20-BitMode

16-BitMode

15

14

MSB LSB

24Clks

RightChannel

2-ChannelLeft-JustifiedStereoInput(24-Bit TransferWordSize)

T0092-02

4

5

9 8

17

16

1

4

5

13

12

1

9 8

0

0

0

21

17

13

23

22

SCLK

1

19 18

15

14

MSB LSB

4

5

9 8

17

16

1

4

5

13

12

1

9 8

0

0

0

21

17

13

SCLK

16Clks

LRCLK

LeftChannel

16-BitMode

1 1

15 15

14 14

MSB LSB

16Clks

RightChannel

2-ChannelLeft-JustifiedStereoInput

T0266-02

3 3

2 2

5 5

4 4

9 98 80 0

13 13

10 10

11 1112 12

SCLK

MSB LSB

TAS5711

SLOS600 –DECEMBER 2009

www.ti.com

NOTE: All data presented in 2s-complement form with MSB first.

Figure 41. Left-Justified 48-fSFormat

NOTE: All data presented in 2s-complement form with MSB first.

Right-Justified

Right-justified (RJ) timing uses LRCLK to define when the data being transmitted is for the left channel and when

Figure 42. Left-Justified 32-fSFormat

28 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 29

23

22

SCLK

32Clks

LRCLK

LeftChannel

24-BitMode

1

20-BitMode

16-BitMode

15

14

MSB LSB

SCLK

32Clks

RightChannel

2-ChannelRight-Justified(SonyFormat)StereoInput

T0034-03

19 18

1

19 18

1

0

0

0

15

14

15

14

23

22 1

15

14

MSB LSB

19 18

1

19 18

1

0

0

0

15

14

15

14

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

it is for the right channel. LRCLK is high for the left channel and low for the right channel. A bit clock running at

32, 48, or 64 × fSis used to clock in the data. The first bit of data appears on the data 8 bit-clock periods (for

24-bit data) after LRCLK toggles. In RJ mode the LSB of data is always clocked by the last bit clock before

LRCLK transitions. The data is written MSB first and is valid on the rising edge of bit clock. The DAP masks

unused leading data bit positions.

Figure 43. Right Justified 64-fSFormat

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 29

Product Folder Link(s): TAS5711

Page 30

23

22

SCLK

24Clks

LRCLK

LeftChannel

24-BitMode

1

20-BitMode

16-BitMode

15

14

MSB LSB

SCLK

24Clks

RightChannel

MSB

2-ChannelRight-JustifiedStereoInput(24-Bit TransferWordSize)

T0092-03

5

19 18

1

5

19 18

1

5

0

0

0

2

2

2

6

6

6

15

14

15

14

23

22 1

15

14

5

19 18

1

5

19 18

1

5

0

0

0

2

2

2

6

6

6

15

14

15

14

LSB

TAS5711

SLOS600 –DECEMBER 2009

www.ti.com

Figure 44. Right Justified 48-fSFormat

Figure 45. Right Justified 32-fSFormat

30 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 31

7-BitSlave Address

R/

W

8-BitRegister Address(N)

A

8-BitRegisterDataFor

Address(N)

Start Stop

SDA

SCL

7

6

5

4

3

2 1

0

7

6

5

4

3

2 1

0

7

6

5

4

3

2 1

0

7

6

5

4

3

2 1

0

A

8-BitRegisterDataFor

Address(N)

A A

T0035-01

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

I2C SERIAL CONTROL INTERFACE

The TAS5711 DAP has a bidirectional I2C interface that compatible with the I2C (Inter IC) bus protocol and

supports both 100-kHz and 400-kHz data transfer rates for single and multiple byte write and read operations.

This is a slave only device that does not support a multimaster bus environment or wait state insertion. The

control interface is used to program the registers of the device and to read device status.

The DAP supports the standard-mode I2C bus operation (100 kHz maximum) and the fast I2C bus operation

(400 kHz maximum). The DAP performs all I2C operations without I2C wait cycles.

General I2C Operation

The I2C bus employs two signals; SDA (data) and SCL (clock), to communicate between integrated circuits in a

system. Data is transferred on the bus serially one bit at a time. The address and data can be transferred in byte

(8-bit) format, with the most significant bit (MSB) transferred first. In addition, each byte transferred on the bus is

acknowledged by the receiving device with an acknowledge bit. Each transfer operation begins with the master

device driving a start condition on the bus and ends with the master device driving a stop condition on the bus.

The bus uses transitions on the data pin (SDA) while the clock is high to indicate a start and stop conditions. A

high-to-low transition on SDA indicates a start and a low-to-high transition indicates a stop. Normal data bit

transitions must occur within the low time of the clock period. These conditions are shown in Figure 46. The

master generates the 7-bit slave address and the read/write (R/W) bit to open communication with another

device and then waits for an acknowledge condition. The TAS5711 holds SDA low during the acknowledge clock

period to indicate an acknowledgment. When this occurs, the master transmits the next byte of the sequence.

Each device is addressed by a unique 7-bit slave address plus R/W bit (1 byte). All compatible devices share the

same signals via a bidirectional bus using a wired-AND connection. An external pullup resistor must be used for

the SDA and SCL signals to set the high level for the bus.

Figure 46. Typical I2C Sequence

There is no limit on the number of bytes that can be transmitted between start and stop conditions. When the last

word transfers, the master generates a stop condition to release the bus. A generic data transfer sequence is

shown in Figure 46.

Pin A_SEL defines the I2C device address. An external 15-kΩ pulldown on this pin gives a device address of

0x34 and a 15-kΩ pullup gives a device address of 0x36. The 7-bit address is 0011011 (0x36) or 0011010

(0x34).

I2C Device Address Change Procedure

• Write to device address change enable register, 0xF8 with a value of 0xF9 A5 A5 A5.

• Write to device register 0xF9 with a value of 0x0000 00XX, where XX is the new address.

• Any writes after that should use the new device address XX.

Single- and Multiple-Byte Transfers

The serial control interface supports both single-byte and multiple-byte read/write operations for subaddresses

0x00 to 0x1F. However, for the subaddresses 0x20 to 0xFF, the serial control interface supports only

multiple-byte read/write operations (in multiples of 4 bytes).

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 31

Product Folder Link(s): TAS5711

Page 32

A6 A5 A4 A3 A2 A1 A0

R/W

ACK A7 A6 A5 A4 A3 A2 A1 A0 ACK D7 D6 D5 D4 D3 D2 D1 D0 ACK

Start

Condition

Stop

Condition

Acknowledge Acknowledge Acknowledge

I CDevice Addressand

2

Read/WriteBit

Subaddress DataByte

T0036-01

D7 D0 ACK

Stop

Condition

Acknowledge

I CDevice Addressand

2

Read/WriteBit

Subaddress LastDataByte

A6 A5 A1 A0 R/W ACK A7 A5 A1 A0 ACK D7 ACK

Start

Condition

Acknowledge Acknowledge Acknowledge

FirstDataByte

A4 A3A6

OtherDataBytes

ACK

Acknowledge

D0 D7 D0

T0036-02

TAS5711

SLOS600 –DECEMBER 2009

www.ti.com

During multiple-byte read operations, the DAP responds with data, a byte at a time, starting at the subaddress

assigned, as long as the master device continues to respond with acknowledges. If a particular subaddress does

not contain 32 bits, the unused bits are read as logic 0.

During multiple-byte write operations, the DAP compares the number of bytes transmitted to the number of bytes

that are required for each specific subaddress. For example, if a write command is received for a biquad

subaddress, the DAP expects to receive five 32-bit words. If fewer than five 32-bit data words have been

received when a stop command (or another start command) is received, the data received is discarded.

Supplying a subaddress for each subaddress transaction is referred to as random I2C addressing. The TAS5711

also supports sequential I2C addressing. For write transactions, if a subaddress is issued followed by data for

that subaddress and the 15 subaddresses that follow, a sequential I2C write transaction has taken place, and the

data for all 16 subaddresses is successfully received by the TAS5711. For I2C sequential write transactions, the

subaddress then serves as the start address, and the amount of data subsequently transmitted, before a stop or

start is transmitted, determines how many subaddresses are written. As was true for random addressing,

sequential addressing requires that a complete set of data be transmitted. If only a partial set of data is written to

the last subaddress, the data for the last subaddress is discarded. However, all other data written is accepted;

only the incomplete data is discarded.

Single-Byte Write

As shown in Figure 47, a single-byte data write transfer begins with the master device transmitting a start

condition followed by the I2C device address and the read/write bit. The read/write bit determines the direction of

the data transfer. For a write data transfer, the read/write bit will be a 0. After receiving the correct I2C device

address and the read/write bit, the DAP responds with an acknowledge bit. Next, the master transmits the

address byte or bytes corresponding to the TAS5711 internal memory address being accessed. After receiving

the address byte, the TAS5711 again responds with an acknowledge bit. Next, the master device transmits the

data byte to be written to the memory address being accessed. After receiving the data byte, the TAS5711 again

responds with an acknowledge bit. Finally, the master device transmits a stop condition to complete the

single-byte data write transfer.

Figure 47. Single-Byte Write Transfer

Multiple-Byte Write

A multiple-byte data write transfer is identical to a single-byte data write transfer except that multiple data bytes

are transmitted by the master device to the DAP as shown in Figure 48. After receiving each data byte, the

TAS5711 responds with an acknowledge bit.

Figure 48. Multiple-Byte Write Transfer

32 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 33

A6 A5 A0 R/W ACK A7 A6 A5 A4 A0 ACK A6 A5 A0 ACK

Start

Condition

Stop

Condition

Acknowledge Acknowledge Acknowledge

I CDevice Addressand

2

Read/WriteBit

Subaddress DataByte

D7 D6 D1 D0 ACK

I CDevice Addressand

Read/WriteBit

2

Not

Acknowledge

R/WA1 A1

RepeatStart

Condition

T0036-03

A6 A0 ACK

Acknowledge

I CDevice Addressand

Read/WriteBit

2

R/WA6 A0 R/W ACK A0 ACK D7 D0 ACK

Start

Condition

Stop

Condition

Acknowledge Acknowledge Acknowledge

LastDataByte

ACK

FirstDataByte

RepeatStart

Condition

Not

Acknowledge

I CDevice Addressand

Read/WriteBit

2

Subaddress OtherDataBytes

A7 A6 A5 D7 D0 ACK

Acknowledge

D7 D0

T0036-04

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

Single-Byte Read

As shown in Figure 49, a single-byte data read transfer begins with the master device transmitting a start

condition followed by the I2C device address and the read/write bit. For the data read transfer, both a write

followed by a read are actually done. Initially, a write is done to transfer the address byte or bytes of the internal

memory address to be read. As a result, the read/write bit becomes a 0. After receiving the TAS5711 address

and the read/write bit, TAS5711 responds with an acknowledge bit. In addition, after sending the internal memory

address byte or bytes, the master device transmits another start condition followed by the TAS5711 address and

the read/write bit again. This time the read/write bit becomes a 1, indicating a read transfer. After receiving the

address and the read/write bit, the TAS5711 again responds with an acknowledge bit. Next, the TAS5711

transmits the data byte from the memory address being read. After receiving the data byte, the master device

transmits a not acknowledge followed by a stop condition to complete the single byte data read transfer.

Figure 49. Single-Byte Read Transfer

Multiple-Byte Read

A multiple-byte data read transfer is identical to a single-byte data read transfer except that multiple data bytes

are transmitted by the TAS5711 to the master device as shown in Figure 50. Except for the last data byte, the

master device responds with an acknowledge bit after receiving each data byte.

Figure 50. Multiple Byte Read Transfer

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 33

Product Folder Link(s): TAS5711

Page 34

CH1_audio

CH1_audio

CH1_audio

CH1_audio

CH2_audio

CH2_audio

CH3_audio

CH3_audio

CH2_audio

CH2_audio

PWM1

PWM1

PWM1

PWM1

PWM2

PWM2

PWM2

PWM2

PWM3

PWM3

PWM3

PWM3

PWM4

PWM4

PWM4

PWM4

2.0 BTL A D

0x20 (23) = 0

0x20 (19) = 0

0x05 (3) = X

0x05 (2) = 0

Reg set ti ng

2.0 BTL BD

0x20 (23) = 1

0x20 (19) = 1

0x05 (3) = X

0x05 (2) = 0

Reg set ti ng

2.1 SE, BTL- AD

0x20 (23) = 0

0x20 (19) = 0

0x05 (3) = 0

0x05 (2) = 1

Reg set ti ng

2.1 SE, BTL- BD

0x20 (23) = 0

0x20 (19) = 0

0x05 (3) = 1

0x05 (2) = 1

Reg set ti ng

A

A

A

A

B

B

B

B

C

C

C

C

D

D

D

D

B0378-01

TAS5711

SLOS600 –DECEMBER 2009

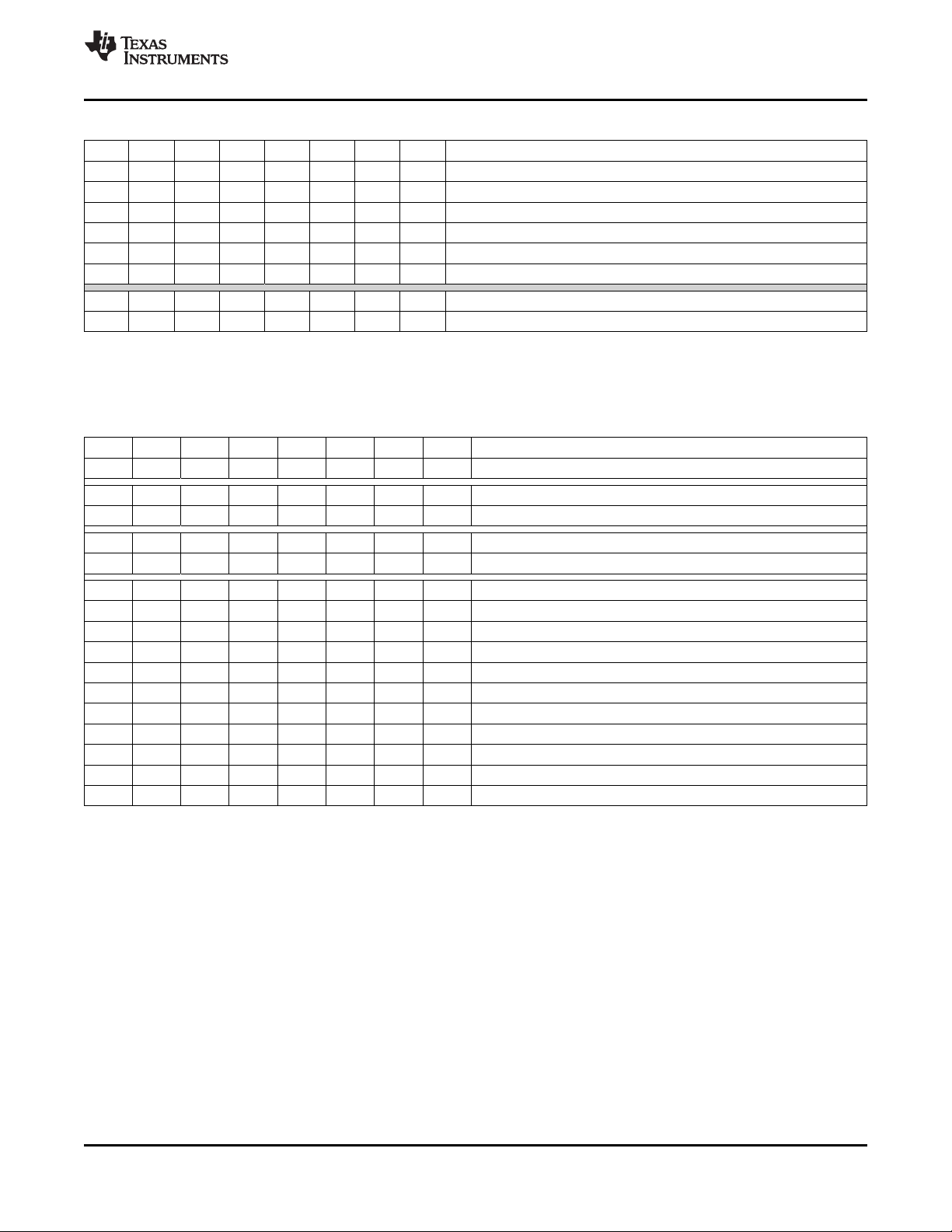

Output Mode and MUX Selection

www.ti.com

2.1-Mode Support

The TAS5711 uses a special mid-Z ramp sequence to reduce click and pop in SE-mode and 2.1-mode

operation.To enable the mid-Z ramp, register 0x05 bit D7 must be set to 1. To enable 2.1 mode, register 0x05 bit

D2 must be set to 1. The SSTIMER pin should be left floating in this mode.

Single-Filter PBTL-Mode Support

The TAS5711 supports parallel BTL (PBTL) mode with OUT_A/OUT_B (and OUT_C/OUT_D) connected before

the LC filter. In order to put the part in PBTL configuration, drive PBTL (pin 8) HIGH. This synchronizes the

turnoff of half-bridges A and B (and similarly C/D) if an overcurrent condition is detected in either half-bridge.

There is a pulldown resistor on the PBTL pin that configures the part in BTL mode if the pin is left floating.

PWM output multiplexers should be updated to set the device in PBTL mode. Output Mux Register (0x25) should

be written with a value of 0x01 10 32 45. Also, the PWM shutdown register (0x19) should be written with a value

of 0x3A.

Figure 51. Output Mode and MUX Selection

34 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 35

Output Level (dB)

Input Level (dB)

T

O

K

M0091-02

1:1 TransferFunction

Implemented TransferFunction

S

Z

–1

AlphaFilterStructure

w

a

B0265-01

Energy

Filter

a w,

T,K,O a wa,

a d d

/ ,a w

DRC1

DRC2

0x3A 0x40,0x41,0x42 0x3B/0x3C

0x3E/0x3F

0x43,0x44,0x45

0x3D

Compression

Control

Attack

and

Decay

Filters

AudioInput

DRCCoefficient

NOTE:

=1 –w α

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

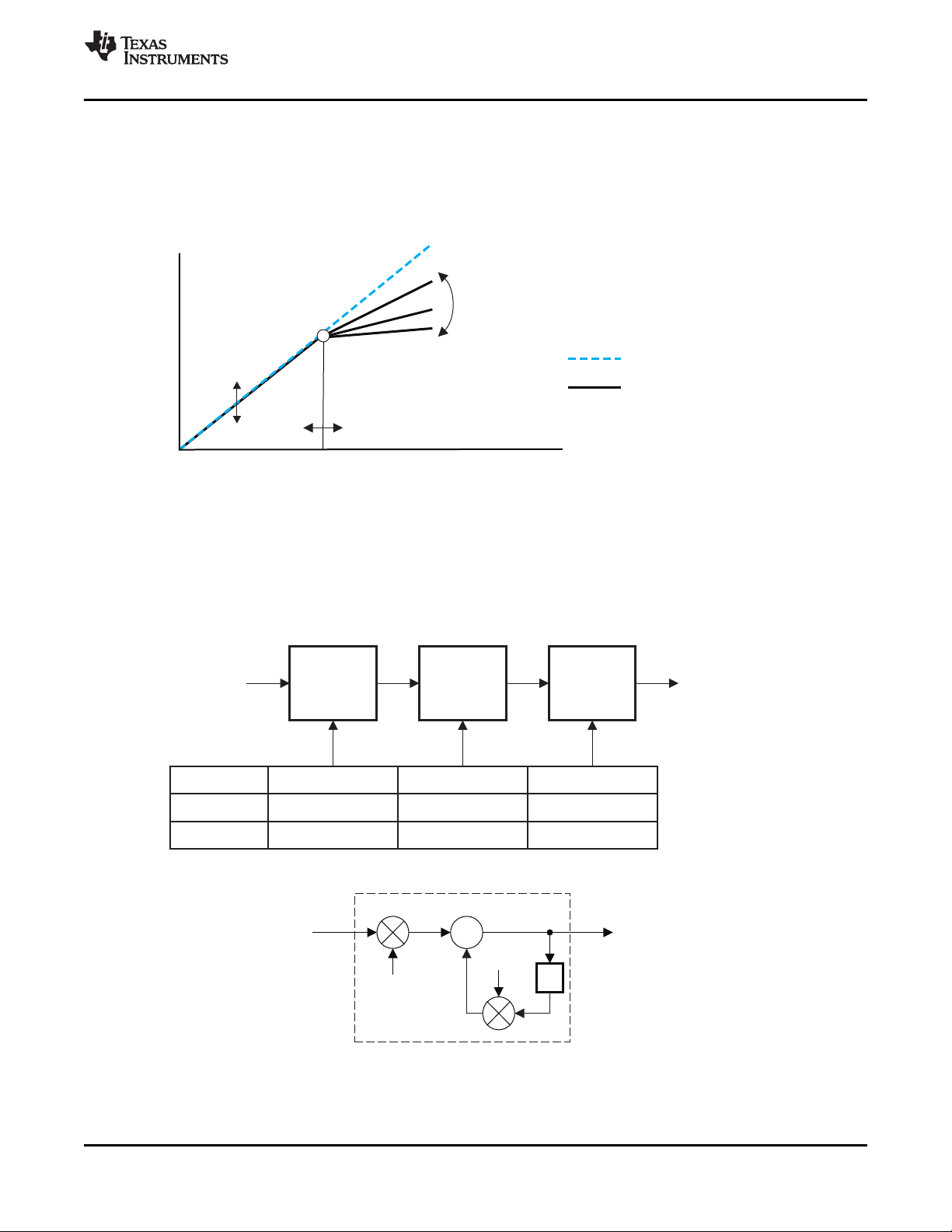

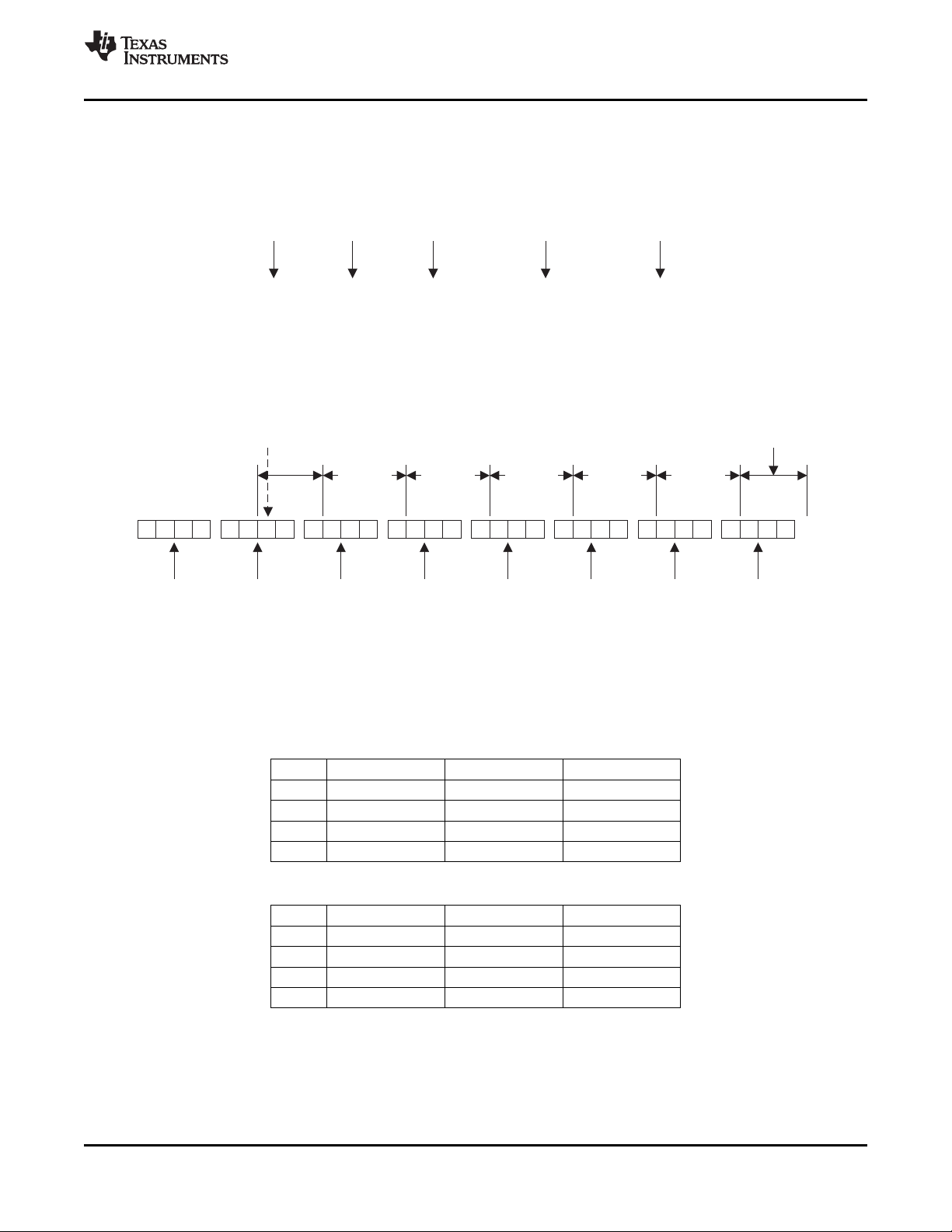

Dynamic Range Control (DRC)

The DRC scheme has a single threshold, offset, and slope (all programmable). There is one ganged DRC for the

left/right channels and one DRC for the subchannel.

The DRC input/output diagram is shown in Figure 52.

Refer to GDE software tool for more description on T, K, and O parameters.

Professional-quality dynamic range compression automatically adjusts volume to flatten volume level.

• Each DRC has adjustable threshold, offset, and compression levels

• Programmable energy, attack, and decay time constants

• Transparent compression: compressors can attack fast enough to avoid apparent clipping before engaging,

and decay times can be set slow enough to avoid pumping.

Figure 52. Dynamic Range Control

T = 9.23 format, all other DRC coefficients are 3.23 format

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 35

Figure 53. DRC Structure

Product Folder Link(s): TAS5711

Page 36

2 Bit

–23

S_xx.xxxx_xxxx_xxxx_xxxx_xxxx_xxx

2 Bit

–5

2 Bit

–1

2 Bit

0

SignBit

2 Bit

1

M0125-01

TAS5711

SLOS600 –DECEMBER 2009

www.ti.com

BANK SWITCHING

The TAS5711 uses an approach called bank switching together with automatic sample-rate detection. All

processing features that must be changed for different sample rates are stored internally in three banks. The

user can program which sample rates map to each bank. By default, bank 1 is used in 32kHz mode, bank 2 is

used in 44.1/48 kHz mode, and bank 3 is used for all other rates. Combined with the clock-rate autodetection

feature, bank switching allows the TAS5711 to detect automatically a change in the input sample rate and switch

to the appropriate bank without any MCU intervention.

An external controller configures bankable locations (0x29-0x36, 0x3A-0x3F, and 0x58-0x5F) for all three banks

during the initialization sequence.

If auto bank switching is enabled (register 0x50, bits 2:0) , then the TAS5711 automatically swaps the coefficients

for subsequent sample rate changes, avoiding the need for any external controller intervention for a sample rate

change.

By default, bits 2:0 have the value 000; indicating that bank switching is disabled. In that state, updates to

bankable locations take immediate effect. A write to register 0x50 with bits 2:0 being 001, 010, or 011 brings the

system into the coefficient-bank-update state update bank1, update bank2, or update bank3, respectively. Any

subsequent write to bankable locations updates the coefficient banks stored outside the DAP. After updating all

the three banks, the system controller should issue a write to register 0x50 with bits 2:0 being 100; this changes

the system state to automatic bank switching mode. In automatic bank switching mode, the TAS5711

automatically swaps banks based on the sample rate.

Command sequences for updating DAP coefficients can be summarized as follows:

1. Bank switching disabled (default): DAP coefficient writes take immediate effect and are not

influenced by subsequent sample rate changes.

OR

Bank switching enabled:

(a) Update bank-1 mode: Write "001" to bits 2:0 of reg 0x50. Load the 32 kHz coefficients.

(b) Update bank-2 mode: Write "010" to bits 2:0 of reg 0x50. Load the 48 kHz coefficients.

(c) Update bank-3 mode: Write "011" to bits 2:0 of reg 0x50. Load the other coefficients.

(d) Enable automatic bank switching by writing "100" to bits 2:0 of reg 0x50.

26-Bit 3.23 Number Format

All mixer gain coefficients are 26-bit coefficients using a 3.23 number format. Numbers formatted as 3.23

numbers means that there are 3 bits to the left of the decimal point and 23 bits to the right of the decimal point.

This is shown in Figure 54 .

Figure 54. 3.23 Format

36 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): TAS5711

Page 37

(1or0) 2 +´1(1or0) 2 +(1or0) 2 +.......(1or0) 2 +.......(1or0) 2´ ´ ´ ´

0 –1 –4 –23

2 Bit

1

2 Bit

0

2 Bit

–1

2 Bit

–4

2 Bit

–23

M0126-01

u

Coefficient

Digit8

u

u u u u

S

x

Coefficient

Digit7

x.

x x x

Coefficient

Digit6

x

x x x

Coefficient

Digit5

x

x x x

Coefficient

Digit4

x

x x x

Coefficient

Digit3

x

x x x

Coefficient

Digit2

x

x x x

Coefficient

Digit1

Fraction

Digit5

Fraction

Digit4

Fraction

Digit3

Fraction

Digit2

Fraction

Digit1

Integer

Digit1

Sign

Bit

Fraction

Digit6

u=unusedordon’tcarebits

Digit=hexadecimaldigit

M0127-01

0

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

The decimal value of a 3.23 format number can be found by following the weighting shown in Figure 54. If the

most significant bit is logic 0, the number is a positive number, and the weighting shown yields the correct

number. If the most significant bit is a logic 1, then the number is a negative number. In this case every bit must

be inverted, a 1 added to the result, and then the weighting shown in Figure 55 applied to obtain the magnitude

of the negative number.

Figure 55. Conversion Weighting Factors—3.23 Format to Floating Point

Gain coefficients, entered via the I2C bus, must be entered as 32-bit binary numbers. The format of the 32-bit

number (4-byte or 8-digit hexadecimal number) is shown in Figure 56

Figure 56. Alignment of 3.23 Coefficient in 32-Bit I2C Word

Table 2. Sample Calculation for 3.23 Format

dB Linear Decimal Hex (3.23 Format)

0 1 8,388,608 0080 0000

5 1.7782794 14,917,288 00E3 9EA8

–5 0.5623413 4,717,260 0047 FACC

X L = 10

(X/20)

Table 3. Sample Calculation for 9.17 Format

dB Linear Decimal Hex (9.17 Format)

0 1 131,072 2 0000

5 1.77 231,997 3 8A3D

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 37

–5 0.56 73,400 1 1EB8

X L = 10

(X/20)

Product Folder Link(s): TAS5711

D = 8,388,608 × L H = dec2hex (D, 8)

D = 131,072 × L H = dec2hex (D, 8)

Page 38

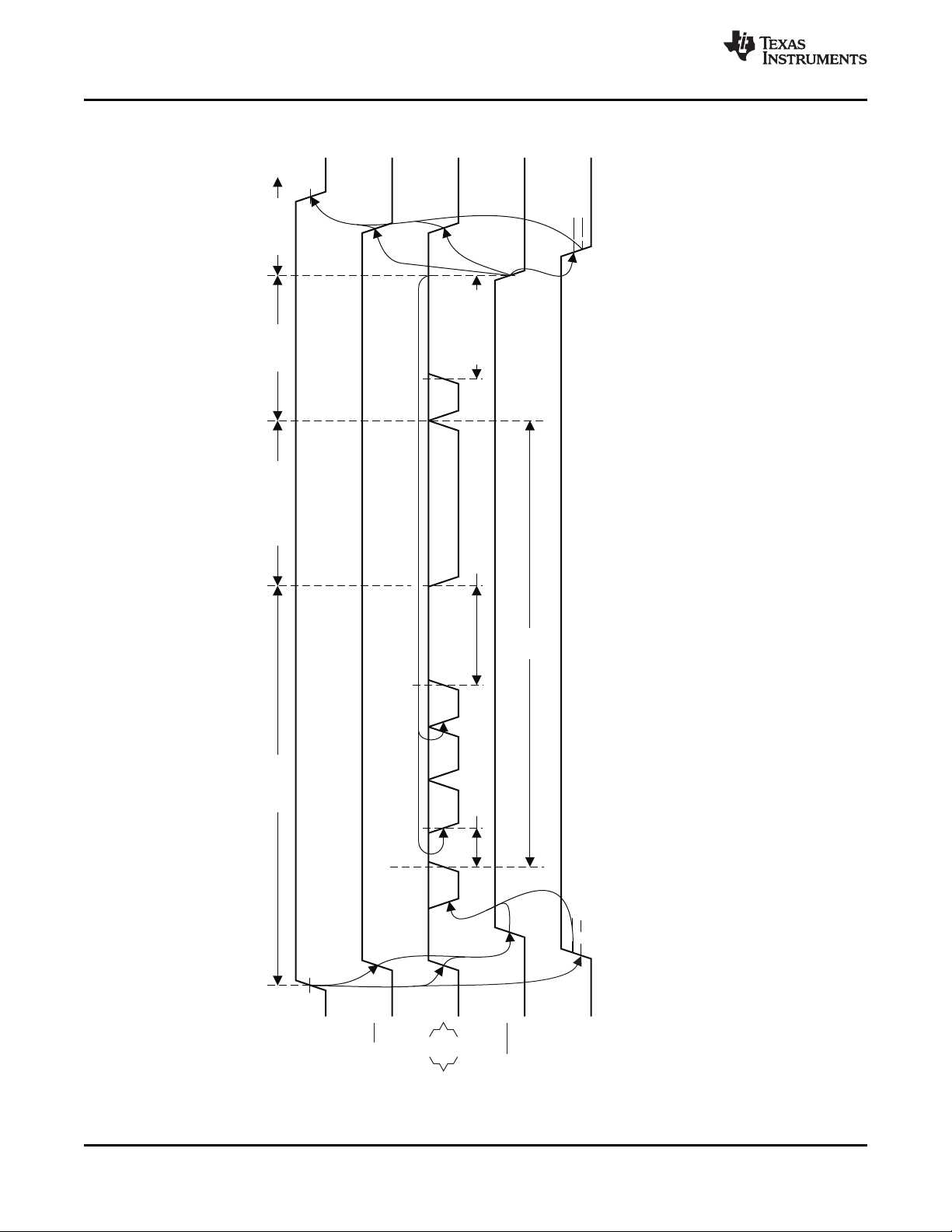

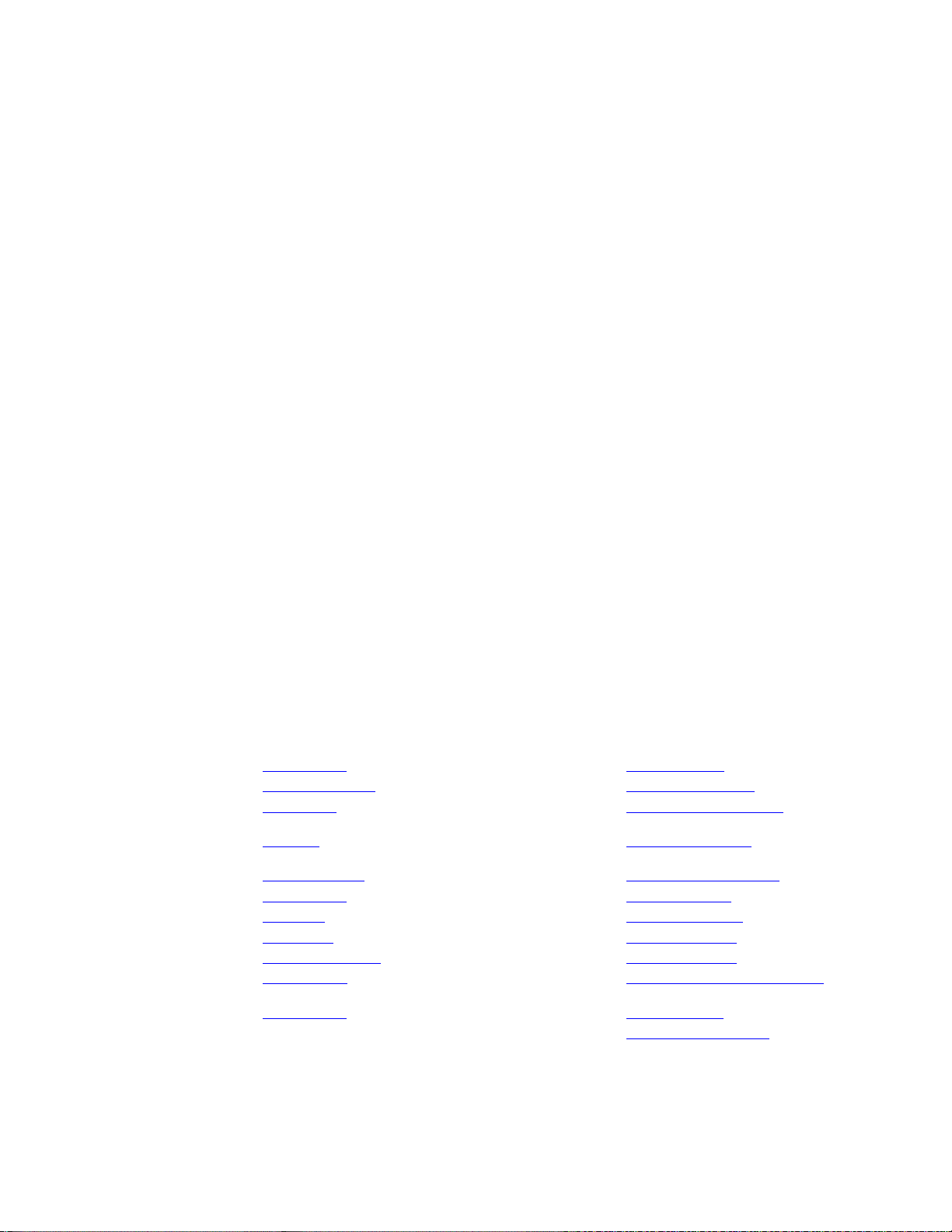

Initialization

50 ms

2 sm

2 sm

2 sm

AVDD/DVDD

PDN

PVDD

RESET

T0419-05

3 V

3 V

0 ns

0 ns

10 sm

100 sμ

13.5 ms

100 sm

6 V

6 V

8 V

8 V

I C

2

SCL

SDA

Trim

Volume and Mute Commands

Exit

SD

Enter

SD

DAP

Config

Other

Config

t

PLL

(1)

1 ms + 1.3 t

stop

(2)

0 ns

Normal Operation

Shutdown

Powerdown

(1) t has to be greater than 240 ms + 1.3 t .

This constraint only applies to the first trim command following AVDD/DVDD power-up.

It does not apply to trim commands following subsequent resets.

(2) t /t = PWM start/stop time as defined in register 0X1A

(3) When Mid-Z ramp is enabled (for 2.1 mode), t = 300 ms

PLL

start

start stop

start

1 ms + 1.3 t

start

(2)(3)

TAS5711

SLOS600 –DECEMBER 2009

Recommended Use Model

www.ti.com

38 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Figure 57. Recommended Command Sequence

Product Folder Link(s): TAS5711

Page 39

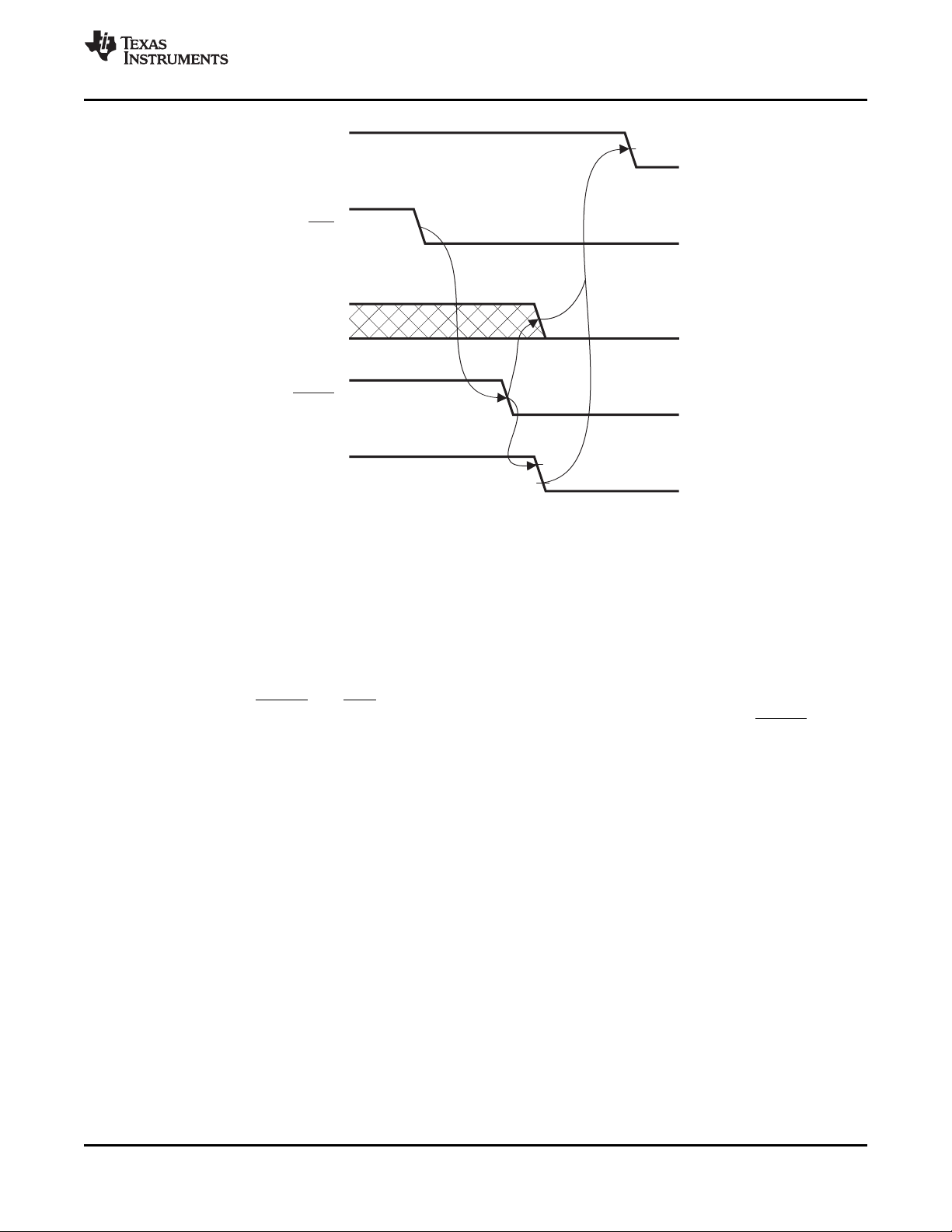

2 sm

2 sm

AVDD/DVDD

PDN

PVDD

RESET

T0420-05

3V

8V

6V

I C

2

2ms

0ns

0ns

0ns

TAS5711

www.ti.com

SLOS600 –DECEMBER 2009

Figure 58. Power Loss Sequence

Recommended Command Sequences

Initialization Sequence

Use the following sequence to power-up and initialize the device:

1. Hold all digital inputs low and ramp up AVDD/DVDD to at least 3 V.

2. Initialize digital inputs and PVDD supply as follows:

• Drive RESET = 0, PDN = 1, and other digital inputs to their desired state while ensuring that

all are never more than 2.5 V above AVDD/DVDD. Wait at least 100 µs, drive RESET = 1,

and wait at least another 13.5 ms.

• Ramp up PVDD to at least 8 V while ensuring that it remains below 6 V for at least 100 µs

after AVDD/DVDD reaches 3 V. Then wait at least another 10 µs.