Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments

查询TAS5122供应商

www.ti.com

FEATURES

D 2 × 30 W (BTL) Into 6 Ω at 1 kHz

D 95-dB Dynamic Range (in System With

TAS5026)

D < 0.2% THD+N (in System – 30 W RMS Into

6-Ω Resistive Load)

D Device Power Efficiency Typical >90% Into

6-Ω Load

D Self-Protection Design (Including

Undervoltage, Overtemperature, and Short

Conditions) With Error Reports

D Internal Gate Drive Supply Voltage Regulator

D EMI Compliant When Used With

Recommended System Design

SLES088D – AUGUST 2003 – REVISED MAY 2004

TM

APPLICATIONS

D DVD Receiver

D Home Theatre

D Mini/Micro Component Systems

D Internet Music Appliance

DESCRIPTION

The TAS5122 is a high-performance, integrated stereo

digital amplifier power stage designed to drive 6-Ω

speakers at up to 30 W per channel. The device

incorporates TI’s PurePath Digitalt technology and is

used with a digital audio PWM processor (TAS50XX) and

a simple passive demodulation filter to deliver high-quality,

high-efficiency, true-digital audio amplification.

The efficiency of this digital amplifier is typically greater

than 90%. Overcurrent protection, overtemperature

protection, and undervoltage protection are built into the

TAS5122, safeguarding the device and speakers against

fault conditions that could damage the system.

1

0.1

THD+N − Total Harmonic Distortion + Noise − %

0.01

40m 100m 10 40

THD + NOISE vs OUTPUT POWER

RL = 6 Ω

TC = 75°C

THD+N − Total Harmonic Distortion + Noise − %

1

PO − Output Power − W

semiconductor products and disclaimers thereto appears at the end of this data sheet.

1

0.1

0.01

20 100 1k 10k

THD + NOISE vs FREQUENCY

RL = 6 Ω

TC = 75°C

PO = 30 W

PO = 10 W

PO = 1 W

f − Frequency − Hz

20k

PurePath Digital and PowerPAD are trademarks of Texas Instruments.

Other trademarks are the property of their respective owners.

! "#$ ! %#&'" ($) (#"!

" !%$""! %$ *$ $! $+! !#$! !(( ,-)

(#" %"$!!. ($! $"$!!'- "'#($ $!. '' %$$!)

Copyright 2004, Texas Instruments Incorporated

D

R

A

A

B

B

C

C

D

D

DCA PACKAGE

SLES088D – AUGUST 2003 – REVISED MAY 2004

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam during

storage or handling to prevent electrostatic damage to the MOS gates.

www.ti.com

GENERAL INFORMATION

Terminal Assignment

The TAS5122 is offered in a thermally enhanced 56-pin

DCA package (thermal pad is on the bottom). Output of the

DCA package is highly dependent on thermal design. See

the Thermal Information section. Therefore, it is important

to design the heatsink carefully.

(TOP VIEW)

GND

GVDD

BST_A

PVDD_

PVDD_

OUT_A

OUT_A

GND

GND

OUT_B

OUT_B

PVDD_

PVDD_

BST_B

BST_C

PVDD_

PVDD_

OUT_C

OUT_C

GND

GND

OUT_D

OUT_D

PVDD_

PVDD_

BST_D

GVDD

GND

GND

GND

GREG

DVDD

GND

DGND

GND

PWM_AP

PWM_AM

RESET_AB

PWM_BM

PWM_BP

DREG

M1

M2

M3

REG_RTN

PWM_CP

PWM_CM

ESET_CD

PWM_DM

PWM_DP

SD_AB

SD_CD

OTW

GREG

GND

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range unless otherwise noted

TAS5122 UNITS

DVDD to DGND –0.3 V to 4.2 V

GVDD to GND 28 V

PVDD_X to GND (dc voltage) 28 V

OUT_X to GND (dc voltage) 28 V

BST_X to GND (dc voltage) 40 V

GREG to GND

PWM_XP, RESET, M1, M2, M3, SD,

OTW

Maximum operating junction

temperature, T

Storage temperature –40°C to 125°C

(1)

Stresses beyond those listed under “absolute maximum ratings”

may cause permanent damage to the device. These are stress

ratings only, and functional operation of the device at these or any

other conditions beyond those indicated under “recommended

operating conditions” is not implied. Exposure to absolutemaximum-rated conditions for extended periods may affect device

reliability.

(2)

GREG is treated as an input when the GREG pin is overdriven by

GVDD of 12 V .

(2)

–0.3 V to DVDD + 0.3 V

J

14.2 V

–40°C to 150°C

ORDERING INFORMATION

T

A

0°C to 70°C TAS5122DCA 56-pin small TSSOP

PACKAGE DESCRIPTION

PACKAGE DISSIPATION RATINGS

R

PACKAGE

56-pin DCA TSSOP 1.14 See Note 1

(1)

The TAS5122 package is thermally enhanced for conductive

cooling using an exposed metal pad area. It is impractical to use the

device with the pad exposed to ambient air as the only heat sinking

of the device.

For this reason, R

thermal treatment provided in the application. An example and

discussion of typical system R

Thermal Information section. This example provides additional

information regarding the power dissipation ratings. This example

should be used as a reference to calculate the heat dissipation

ratings for a specific application. TI application engineering

provides technical support to design heatsinks if needed.

a system parameter that characterizes the

θJA

θJC

(°C/W)

values are provided in the

θJA

R

θJA

(°C/W)

(1)

2

www.ti.com

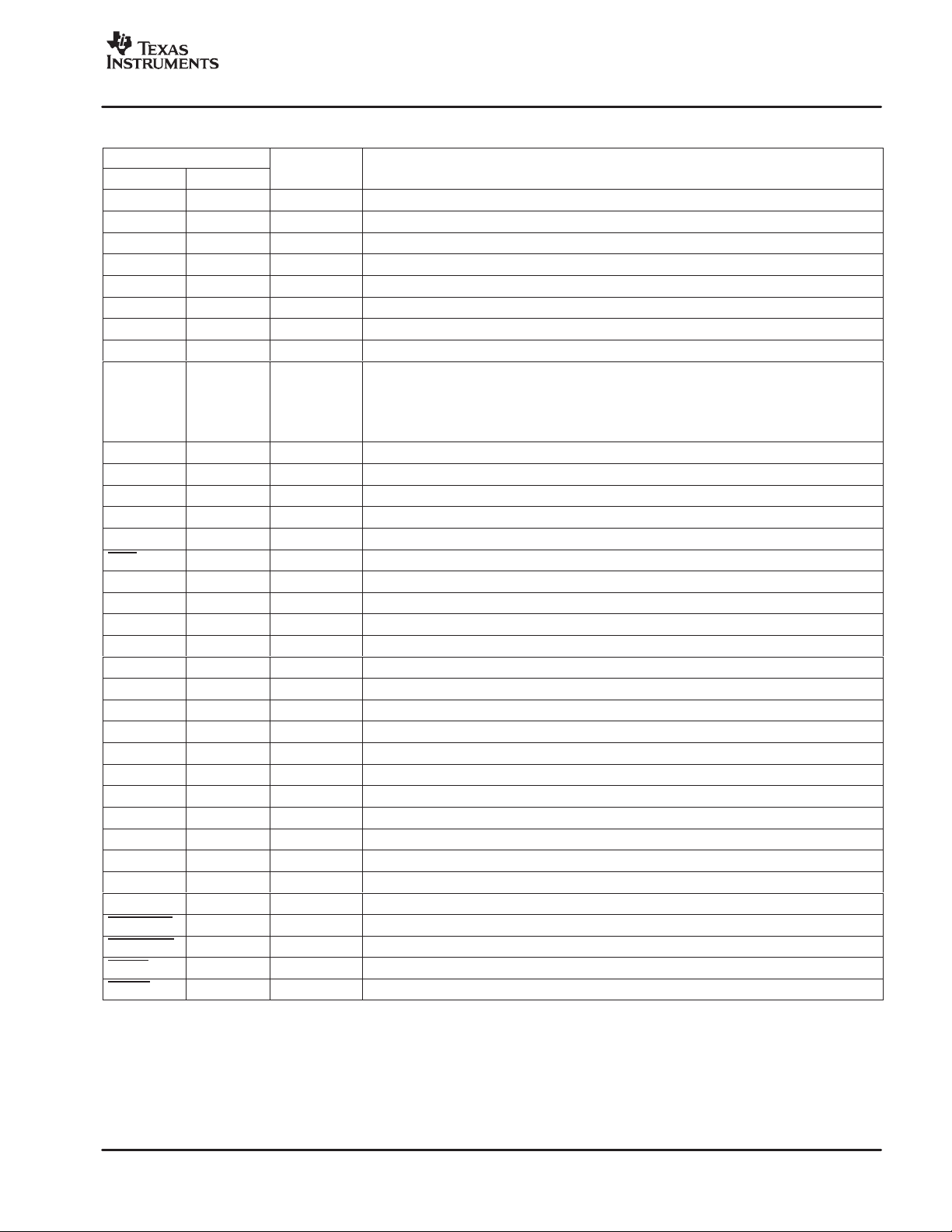

FUNCTION

(1)

DESCRIPTION

TERMINAL

NAME NO.

BST_A

BST_B

BST_C

BST_D

DGND

DREG

DREG_RTN

DVDD

GND

GREG

GVDD

M1

M2

M3

OTW

OUT_A

OUT_B

OUT_C

OUT_D

PVDD_A

PVDD_B

PVDD_C

PVDD_D

PWM_AM

PWM_AP

PWM_BM

PWM_BP

PWM_CM

PWM_CP

PWM_DM

PWM_DP

RESET_AB

RESET_CD

SD_AB

SD_CD

(1)

I = input, O = output, P = power

54 P

43 P

42 P

31 P

6 P

13 P

17 P

4 P

1, 2, 5,

7, 27, 28,

29, 36, 37,

48, 49, 56

3, 26 P

30, 55 P

14 I

15 I

16 I

25 O

50, 51 O

46, 47 O

38, 39 O

34, 35 O

52, 53 P

44, 45 P

40, 41 P

32, 33 P

9 I

8 I

11 I

12 I

19 I

18 I

21 I

22 I

10 I

20 I

23 O

24 O

SLES088D – AUGUST 2003 – REVISED MAY 2004

Terminal Functions

HS bootstrap supply (BST), external capacitor to OUT_A required

HS bootstrap supply (BST), external capacitor to OUT_B required

HS bootstrap supply (BST), external capacitor to OUT_C required

HS bootstrap supply (BST), external capacitor to OUT_D required

Digital I/O reference ground

Digital supply voltage regulator decoupling pin, capacitor connected to GND

Digital supply voltage regulator decoupling return pin

I/O reference supply input (3.3 V)

P

Power ground (I/O reference ground – pin 22)

Gate drive voltage regulator decoupling pin, capacitor to GND

Voltage supply to on−chip gate drive and digital supply voltage regulators

Mode selection pin

Mode selection pin

Mode selection pin

Overtemperature warning output, open drain with internal pullup

Output, half-bridge A

Output, half-bridge B

Output, half-bridge C

Output, half-bridge D

Power supply input for half-bridge A

Power supply input for half-bridge B

Power supply input for half-bridge C

Power supply input for half-bridge D

Input signal (negative), half-bridge A

Input signal (positive), half-bridge A

Input signal (negative), half-bridge B

Input signal (positive), half-bridge B

Input signal (negative), half-bridge C

Input signal (positive), half-bridge C

Input signal (negative), half-bridge D

Input signal (positive), half-bridge D

Reset signal, active low

Reset signal, active low

Shutdown signal for half-bridges A and B

Shutdown signal for half-bridges C and D

3

SLES088D – AUGUST 2003 – REVISED MAY 2004

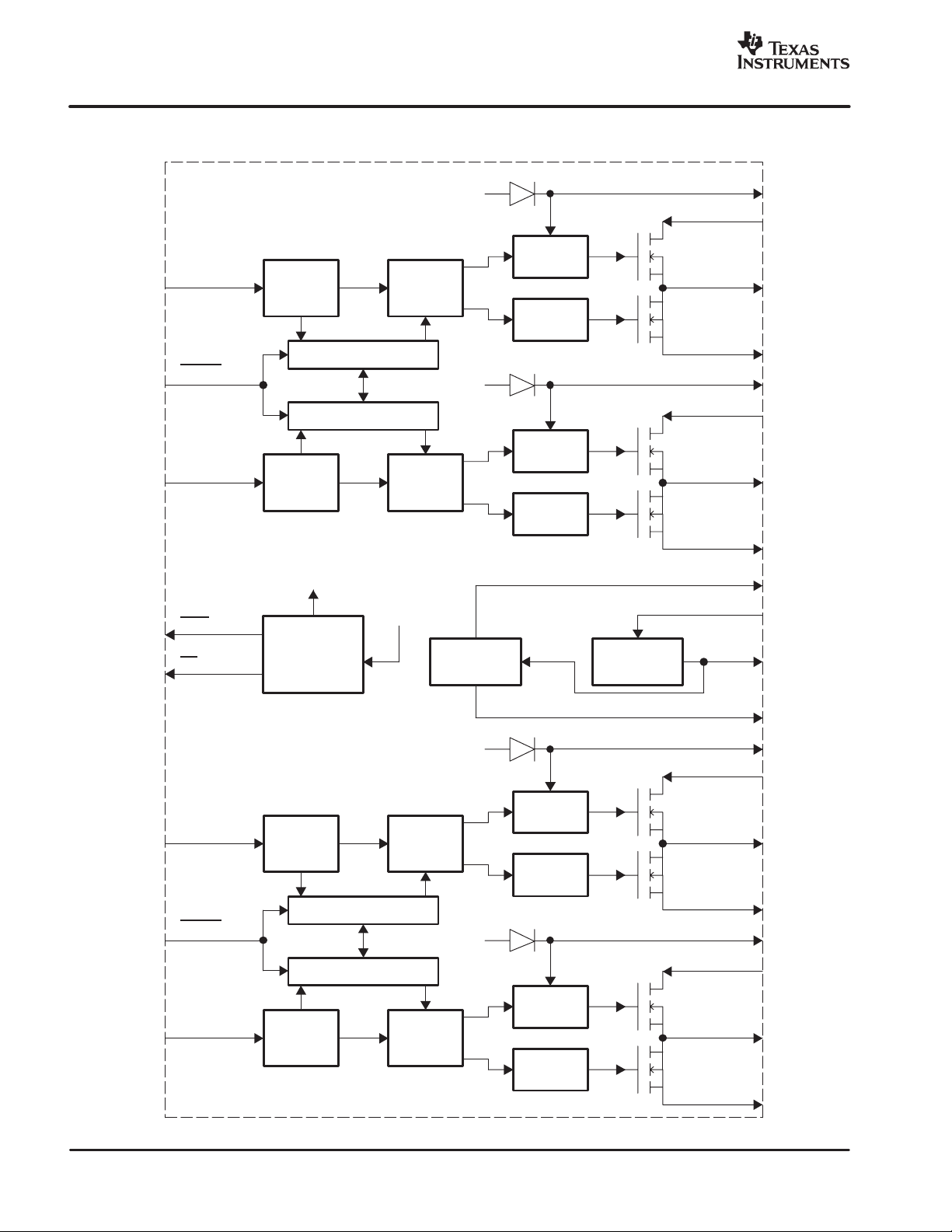

FUNCTIONAL BLOCK DIAGRAM

www.ti.com

GREG

Gate

PWM_AP OUT_A

RESET

PWM_BP OUT_B

OTW

SD

PWM

Receiver

PWM

Receiver

To

Protection

Blocks

OT

Protection

UVP

Protection A

Protection B

Timing

Control

GREG

Timing

Control

GREG

DREG

Drive

Gate

Drive

Gate

Drive

Gate

Drive

GREG

DREG_RTN

BST_A

PVDD_A

GND

BST_B

PVDD_B

GND

DREG

GVDD

GREG

DREG_RTN

GREG

Gate

PWM_CP OUT_C

RESET

PWM_DP OUT_D

4

PWM

Receiver

Protection C

Protection D

PWM

Receiver

Timing

Control

GREG

Timing

Control

Drive

Gate

Drive

Gate

Drive

Gate

Drive

BST_C

PVDD_C

GND

BST_D

PVDD_D

GND

www.ti.com

POOutput power

SLES088D – AUGUST 2003 – REVISED MAY 2004

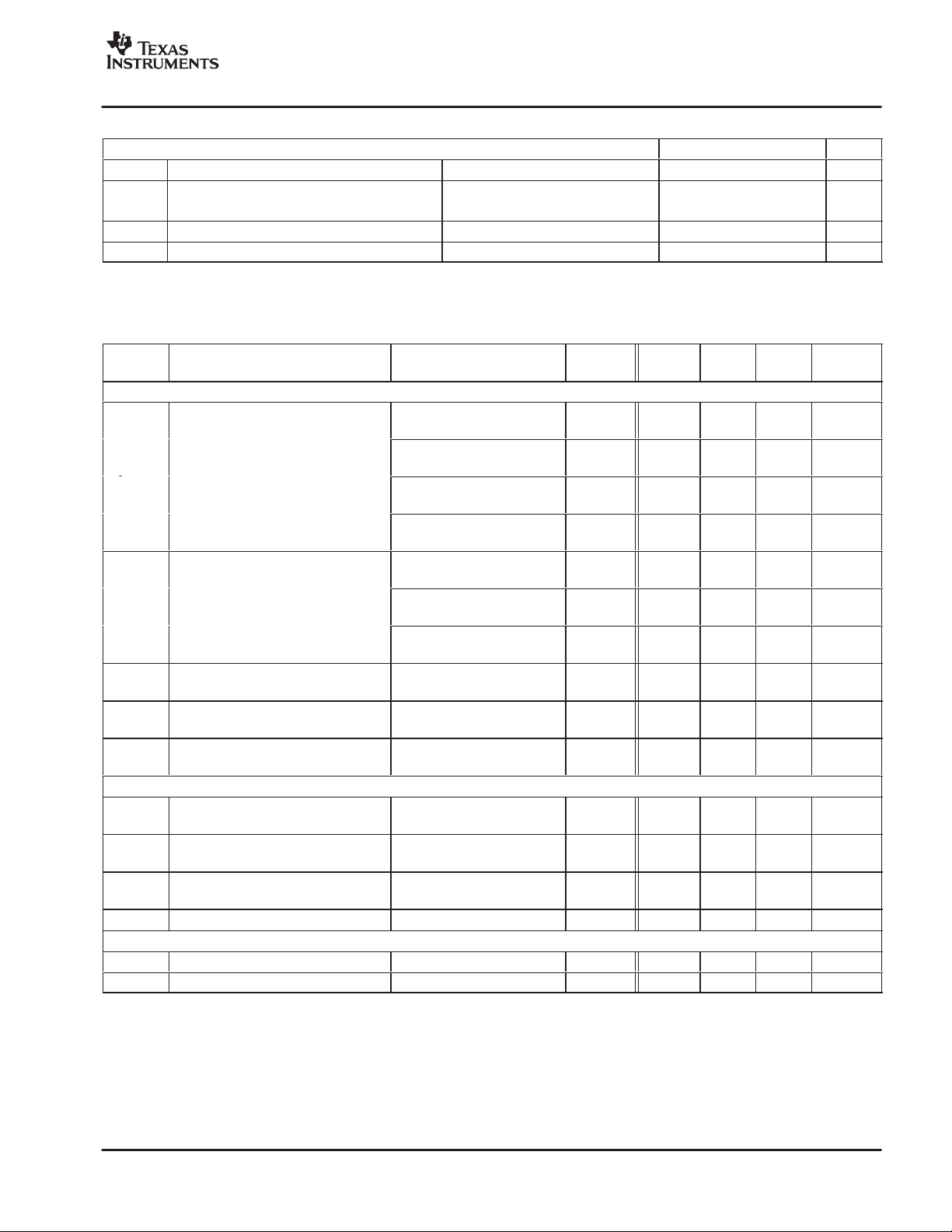

RECOMMENDED OPERATING CONDITIONS

MIN TYP MAX UNIT

DVDD Digital supply

GVDD

PVDD_x Half-bridge supply Relative to GND, RL= 6 Ω to 8 Ω 0 23 25.5 V

T

J

(1)

It is recommended for DVDD to be connected to DREG via a 100-Ω resistor.

Supply for internal gate drive and logic

regulators

Junction temperature 0 125 _C

(1)

Relative to DGND 3 3.3 3.6 V

Relative to GND 16 23 25.5 V

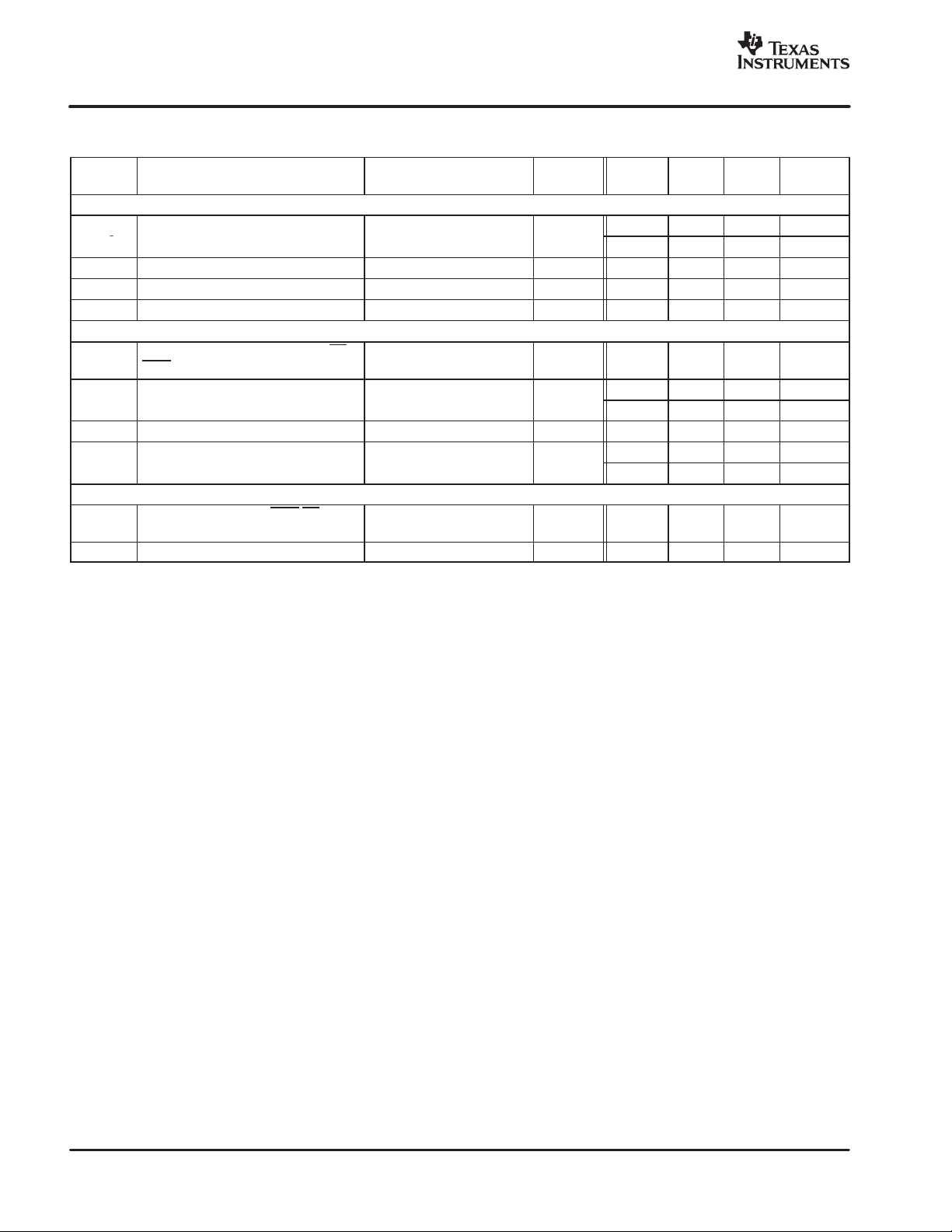

ELECTRICAL CHARACTERISTICS

PVDD_X = 23 V, GVDD = 23 V, DVDD = 3.3 V, DVDD connected to DREG via a 100-Ω resistor, RL = 6 Ω, 8X fs = 384 kHz, unless otherwise

noted. AC performance is recorded as a chipset with TAS5010 as the PWM processor and TAS5122 as the power stage.

SYMBOL PARAMETER TEST CONDITIONS

AC PERFORMANCE, BTL MODE, 1 kHz

RL = 8 Ω, unclipped,

AES17 filter

RL = 8 Ω, THD = 10%,

AES17 filter

RL = 6 Ω, THD = 0.4%,

AES17 filter

RL = 6 Ω, THD = 10%,

AES17 filter

Po = 1 W/ channel, RL = 6 Ω,

AES17 filter

THD+N Total harmonic distortion + noise

V

n

SNR Signal-to-noise ratio

DR Dynamic range

INTERNAL VOLTAGE REGULATOR

DREG Voltage regulator

GREG Voltage regulator

IVGDD GVDD supply current, operating

IDVDD DVDD supply current, operating fS = 384 kHz, no load 1 5 mA Max

OUTPUT STAGE MOSFETs

R

DSon,LS

R

DSon ,HS

Output RMS noise

Forward on-resistance, LS TJ = 25°C 155 mΩ Max

Forward on-resistance, HS TJ = 25°C 155 mΩ Max

Po = 10 W/channel, RL = 6 Ω,

AES17 filter

Po = 30 W/channel, RL = 6 Ω,

AES17 filter

A-weighted, mute, RL = 6 Ω,

20 Hz to 20 kHz, AES17 filter

f = 1 kHz, A-weighted,

RL = 6 Ω,, AES17 filter

f = 1 kHz, A-weighted,

RL = 6 Ω,, AES17 filter

Io = 1 mA,

PVDD = 18 V−30.5 V

Io = 1.2 mA,

PVDD = 18 V−30.5 V

fS = 384 kHz, no load, 50%

duty cycle

TYPICAL

TA=25°C

3.1 V Typ

13.4 V Typ

TA=25°C

T

=

Case

75°C

0.05% Typ

0.05% Typ

0.2% Typ

240 µV Max

24 mA Max

UNITS

24 W Typ

29 W Typ

30 W Typ

37 W Typ

95 dB Typ

95 dB Typ

MIN/TYP/

MAX

5

V

Undervoltage protection limit, GVDD

7.4

VIHHigh-level input voltage

Leakage

Input leakage current

SLES088D – AUGUST 2003 – REVISED MAY 2004

www.ti.com

ELECTRICAL CHARACTERISTICS

PVDD_x = 23 V, GVDD = 23 V, DVDD = 3.3 V, RL = 6 Ω, 8X fs = 384 kHz, unless otherwise noted

SYMBOL

INPUT/OUTPUT PROTECTION

uvp,G

OTW Overtemperature warning 125 °C Typ

OTE Overtemperature error 150 °C Typ

OC Overcurrent protection 5.0 A Min

STATIC DIGITAL SPECIFICATION

PWM_AP, PWM_BP, M1, M2, M3, SD,

OTW

V

IL

OTW/SHUTDOWN (SD)

V

OL

Low-level input voltage 0.8 V Max

Internally pullup R from OTW/SD to

DVDD

Low level output voltage IO = 4 mA 0.4 V Max

PARAMETER TEST CONDITIONS

TYPICAL

TA=25°C

30 22.5 kΩ Min

TA=25°C

6.9 V Min

7.9 V Max

DVDD V Max

−10 µA Min

T

=

Case

75°C

2 V Min

10 µA Max

UNITS

MIN/TYP/

MAX

6

www.ti.com

Gate-Drive

SLES088D – AUGUST 2003 – REVISED MAY 2004

SYSTEM CONFIGURATION USED FOR CHARACTERIZATION (BTL)

Power Supply

External Power Supply

H-Bridge

Power Supply

TAS5122

ERR_RCVY

PWM_AP_1

PWM_AM_1

VALID_1

PWM PROCESSOR

TAS50xx

PWM_AP_2

PWM_AM_2

VALID_2

1 µF

100 nF

100 Ω

100 nF

1 µF

1

GND

2

GND

3

GREG

4

OTW

5

SD_CD

6

SD_AB

7

PWM_DP

8

PWM_DM

9

RESET_CD

10

PWM_CM

11

PWM_CP

12

DREG_RTN

13

M3

14

M2

15

M1

16

DREG

17

PWM_BP

18

PWM_BM

19

RESET_AB

20

PWM_AM

21

PWM_AP

22

GND

23

DGND

24

GND

25

DVDD

26

GREG

27

GND

28

GND

BST_D

PVDD_D

PVDD_D

OUT_D

OUT_D

OUT_C

OUT_C

PVDD_C

PVDD_C

BST_C

BST_B

PVDD_B

PVDD_B

OUT_B

OUT_B

OUT_A

OUT_A

PVDD_A

PVDD_A

BST_A

GND

GVDD

GND

GND

GND

GND

GVDD

GND

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

1.5 Ω

1.5 Ω

1.5 Ω× 2

1.5 Ω

1.5 Ω

33 nF

100 nF

1.5 Ω

33 nF

33 nF

100 nF

1.5 Ω

33 nF

(1)

(1)

L

PCB

(1)

100 nF

L

PCB

L

PCB

(1)

100 nF

L

PCB

(2)

10 µH

470 nF

10 µH

(2)

(2)

10 µH

470 nF

10 µH

(2)

100 nF

100 nF

100 nF

100 nF

100 nF

100 nF

4.7 kΩ

4.7 kΩ

4.7 kΩ

4.7 kΩ

1000 µF

1000 µF

(1)

Voltage Clamp 30 V, PN SMAJ28A, MFG MICROSEMI

(2)

L

: Track in the PCB (1 mm wide and 50 mm long)

PCB

7

SLES088D – AUGUST 2003 – REVISED MAY 2004

www.ti.com

From

PWM

Processor

Figure 1. Typical Single-Ended Design With TAS5122 DCA

8

www.ti.com

THD+N − Total Harmonic Distortion + Noise − %

Noise Amplitude − dBr

SLES088D – AUGUST 2003 – REVISED MAY 2004

TYPICAL CHARACTERISTICS

TOTAL HARMONIC DISTORTION + NOISE

vs

OUTPUT POWER

10

RL = 6 Ω

TC = 75°C

TAS5122SE

1

0.1

0.01

500m 1 10

PO − Output Power − W

Figure 2

TAS5122BTL

50

TOTAL HARMONIC DISTORTION + NOISE

vs

FREQUENCY

1

RL = 6 Ω

TC = 75°C

PO = 30 W

0.1

PO = 10 W

PO = 1 W

THD+N − Total Harmonic Distortion + Noise − %

0.01

20 100 1k 10k

f − Frequency − Hz

Figure 3

20k

−100

−120

−140

−60 dBFS FFT

0

RL = 6 Ω

FFT = −60 dB

−20

TC = 75°C

TAS5010 PWM Processor Device

−40

−60

−80

0 2 4 6 8 10121416182022

f − Frequency − kHz

Figure 4

TOTAL HARMONIC DISTORTION + NOISE

vs

OUTPUT POWER

1

RL = 6 Ω

TC = 75°C

0.1

THD+N − Total Harmonic Distortion + Noise − %

0.01

40m 100m 10 40

PO − Output Power − W

1

Figure 5

9

P

− Output Power − W

P

− Power Loss − W

SLES088D – AUGUST 2003 – REVISED MAY 2004

www.ti.com

OUTPUT POWER

vs

H-BRIDGE VOLTAGE

55

TC = 75°C

50

45

40

35

30

25

20

O

15

10

5

0

0 2 4 6 8 101214161820222426

VDD − Supply Voltage − V

RL = 6 Ω

Figure 6

RL = 8 Ω

SYSTEM OUTPUT STAGE EFFICIENCY

vs

OUTPUT POWER

100

90

80

70

60

50

40

30

20

η − System Output Stage Efficiency − %

10

0

0 5 10 15 20 25 30

PO − Output Power − W

Figure 7

f = 1 kHz

RL = 6 Ω

TC = 75°C

5

4

3

2

tot

1

0

POWER LOSS

vs

OUTPUT POWER

f = 1 kHz

RL = 6 Ω

TC = 75°C

0 5 10 15 20 25 30

PO − Output Power − W

Figure 8

OUTPUT POWER

vs

CASE TEMPERATURE

40

PVDD = 23 V

38

RL = 6 Ω

36

34

32

Channel 1

30

28

− Output Power − W

O

26

P

24

22

20

0 10 20 30 40 50 60 70 80 90 100110 120130

TC − Case Temperature − °C

Channel 2

Figure 9

10

www.ti.com

Amplitude − dBr

SLES088D – AUGUST 2003 – REVISED MAY 2004

AMPLITUDE

vs

FREQUENCY

3.0

2.5

2.0

1.5

1.0

0.5

0.0

−0.5

−1.0

−1.5

−2.0

−2.5

−3.0

10 100 1k 50k10k

f − Frequency − Hz

Figure 10

RL = 8 Ω

RL = 6 Ω

ON-STATE RESISTANCE

vs

JUNCTION TEMPERATURE

200

190

180

170

160

150

− On-State Resistance − mΩ

140

on

r

130

120

0 102030405060708090100

TJ − Junction Temperature − °C

Figure 11

11

SLES088D – AUGUST 2003 – REVISED MAY 2004

www.ti.com

THEORY OF OPERATION

POWER SUPPLIES

The power device only requires two supply voltages,

GVDD and PVDD_x.

GVDD is the gate drive supply for the device, regulated

internally down to approximately 12 V, and decoupled with

regards to board GND on the GREG pins through an

external capacitor. GREG powers both the low side and

high side via a bootstrap step-up conversion. The

bootstrap supply is charged after the first low-side turnon

pulse. Internal digital core voltage DREG is also derived

from GVDD and regulated down by internal LDRs to 3.3 V.

The gate-driver LDR can be bypassed for reducing idle

loss in the device by shorting GREG to GVDD and directly

feeding in 12 V. This can be useful in an application where

thermal conduction of heat from the device is difficult.

Bypassing the LDR reduces power dissipation.

PVDD_x is the H-bridge power supply pin. T wo power pins

exist for each half-bridge to handle the current density. It

is important that the circuitry recommendations around

the PVDD_x pins are followed carefully both topology- and

layout-wise. For topology recommendations, see the

System Configuration Used for Characterization section.

Following these recommendations is important for

parameters like EMI, reliability, and performance.

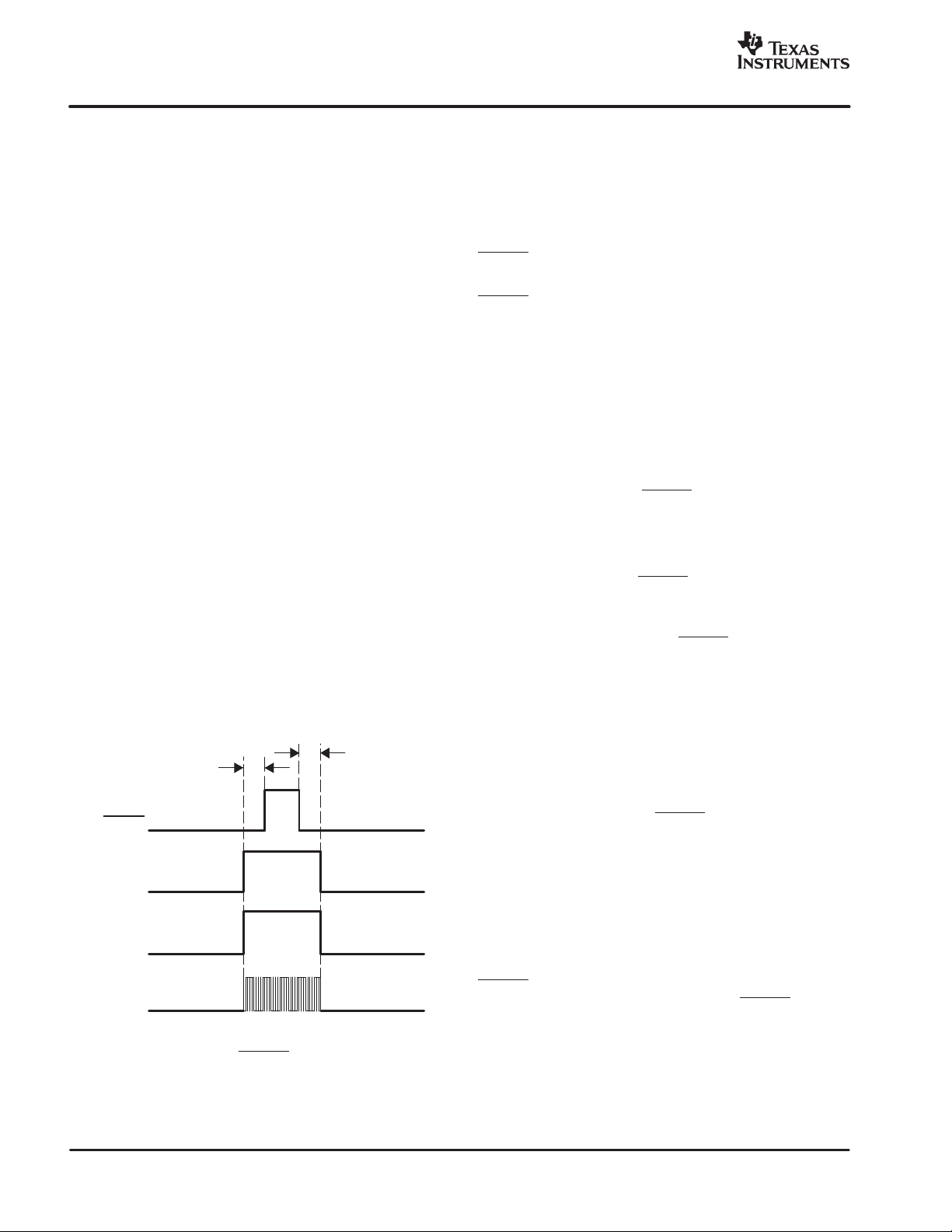

SYSTEM POWER-UP/POWER-DOWN

SEQUENCE

Powering Up

> 1 ms

> 1 ms

RESET

(1)

GVDD

PVDD_x

(1)

During power up when RESET is asserted LOW, all

MOSFETs are turned off and the two internal half-bridges

are in the high-impedance state (Hi-Z). The bootstrap

capacitors supplying high-side gate drive are at this point

not charged. To comply with the click and pop scheme and

(1)

PWM_xP

PVDD should not be powered up before GVDD.

use of non-TI PWM processors it is recommended to use

a 4-kΩ pulldown resistor on each PWM output node to

ground. This precharges the bootstrap supply capacitors

and discharges the output filter capacitor (see the System

Configuration Used for Characterization section).

After GVDD has been applied, it takes approximately 800

µs to fully charge the BST capacitor. Within this time,

RESET must be kept low. After approximately 1 ms, the

power stage bootstrap capacitor is charged.

RESET can now be released if the modulator is powered

up and streaming PWM signals to the power stage

PWM_xP.

A constant HIGH dc level on PWM_xP is not permitted,

because it would force the high-side MOSFET ON until it

eventually ran out of BST capacitor energy and might

damage the device.

An unknown state of the PWM output signals from the

processor is illegal and should be avoided, which in

practice means that the PWM processor must be powered

up and initialized before RESET is de-asserted HIGH to

the power stage.

Powering Down

For powering down the power stage, an opposite

approach is necessary. RESET must be asserted LOW

before the valid PWM signal is removed.

When TI PWM processors are used with TI power stages,

the correct timing control of RESET and PWM_xP is

performed by the modulator.

Precaution

The TAS5122 must always start up in the high-impedance

(Hi-Z) state. In this state, the bootstrap (BST) capacitor is

precharged by a resistor on each PWM output node to

ground. See System Configuration Used for

Characterization. This ensures that the power stage is

ready for receiving PWM pulses, indicating either HIGHor LOW-side turnon after RESET is deasserted to the

power stage.

With the following pulldown and BST capacitor size, the

charge time is:

C = 33 nF, R = 4.7 kΩ

R × C × 5 = 775.5 µs

After GVDD has been applied, it takes approximately

800 µs to fully charge the BST capacitor. During this time,

RESET must be kept low. After approximately 1 ms, the

power stage BST is charged and ready. RESET can now

be released if the PWM modulator is ready and is

streaming valid PWM signals to the power stage. Valid

PWM signals are switching PWM signals with a frequency

between 350−400 kHz. A constant HIGH level on the

PWM_xP forces the high side MOSFET ON until it

eventually runs out of BST capacitor energy. Putting the

device in this condition should be avoided.

12

www.ti.com

SLES088D – AUGUST 2003 – REVISED MAY 2004

In practice this means that the DVDD-to-PWM processor

should be stable and initialization should be completed

before RESET is deasserted to the power stage.

CONTROL I/O

Shutdown Pin: SD

The SD pin functions as an output pin and is intended for

protection-mode signaling to, for example, a controller or

other PWM processor device. The pin is open-drain with

an internal pullup to DVDD.

The logic output is, as shown in the following table, a

combination of the device state and RESET input:

SD RESET DESCRIPTION

0 0 Not used

0 1 Device in protection mode, i.e., UVP and/or OC

and/or OT error

(2)

1

1 1 Normal operation

Temperature Warning Pin: OTW

The OTW pin gives a temperature warning signal when

temperature exceeds the set limit. The pin is of the

open-drain type with an internal pullup to DVDD.

Overall Reporting

The SD pin, together with the OTW pin, gives chip state

information as described in Table 1.

0 Device set high-impedance (Hi-Z), SD forced high

(2)

SD is pulled high when RESET is asserted low independent

of chip state (i.e., protection mode). This is desirable to

maintain compatibility with some TI PWM processors.

OTW DESCRIPTION

0 Junction temperature higher than 125°C

1 Junction temperature lower than 125°C

The device can be recovered by toggling RESET low and

then high, after all errors are cleared.

Overcurrent (OC) Protection

The device has individual forward current protection on

both high-side and low-side power stage FETs. The OC

protection works only with the demodulation filter present

at the output. See Demodulation Filter Design in the

Application Information section of this data sheet for

design constraints.

Overtemperature (OT) Protection

A dual temperature protection system asserts a warning

signal when the device junction temperature exceeds

125°C. The OT protection circuit is shared by all

half-bridges.

Undervoltage (UV) Protection

Undervoltage lockout occurs when GVDD is insufficient

for proper device operation. The UV protection system

protects the device under power-up and power-down

situations. The UV protection circuits are shared by all

half-bridges.

Reset Functions

The functions of the reset input are:

D Reset is used for re-enabling operation after a

latching error event (PMODE1).

D Reset is used for disabling output stage

switching (mute function).

The error latch is cleared on the falling edge of reset and

normal operation is resumed when reset goes high.

PROTECTION MODE

Autorecovery (AR) After Errors (PMODE0)

Table 1. Error Signal Decoding

OTW SD DESCRIPTION

0 0 Overtemperature error (OTE)

0 1 Overtemperature warning (OTW)

1 0 Overcurrent (OC) or undervoltage (UVP) error

1 1 Normal operation, no errors/warnings

Chip Protection

The TAS5122 protection function is implemented in a

closed loop with, for example, a system controller or other

TI PWM processor device. The TAS5122 contains three

individual systems protecting the device against fault

conditions. All of the error events covered result in the

output stage being set in a high-impedance state (Hi-Z) for

maximum protection of the device and connected

equipment.

In autorecovery mode (PMODE0) the TAS5122 is

self-supported i n handling of error situations. All protection

systems are active, setting the output stage in the

high-impedance state to protect the output stage and

connected equipment. However, after a short time period

the device auto-recovers, i.e., operation is automatically

resumed provided that the system is fully operational.

The auto-recovery timing is set by counting PWM input

cycles, i.e., the timing is relative to the switching frequency.

The AR system is common to both half-bridges.

Timing and Function

The function of the autorecovery circuit is as follows:

1. An error event occurs and sets the

protection latch (output stage goes Hi-Z).

2. The counter is started.

13

A

SLES088D – AUGUST 2003 – REVISED MAY 2004

www.ti.com

3. After n/2 cycles, the protection latch is

cleared but the output stage remains Hi-Z

(identical to pulling RESET

low).

4. After n cycles, operation is resumed

(identical to pulling RESET high) (n = 512).

Error

Protection

Latch

Shutdown

SD

Autorecovery

PWM

Counter

R-RESET

Figure 12. Autorecovery Function

Latching Shutdown on All Errors (PMODE1)

In latching shutdown mode, all error situations result in a

permanent shutdown (output stage Hi-Z). Re-enabling can

be done by toggling the RESET pin.

All Protection Systems Disabled (PMODE2)

In PMODE2, all protection systems are disabled. This

mode is purely intended for testing and characterization

purposes and thus not recommended for normal device

operation.

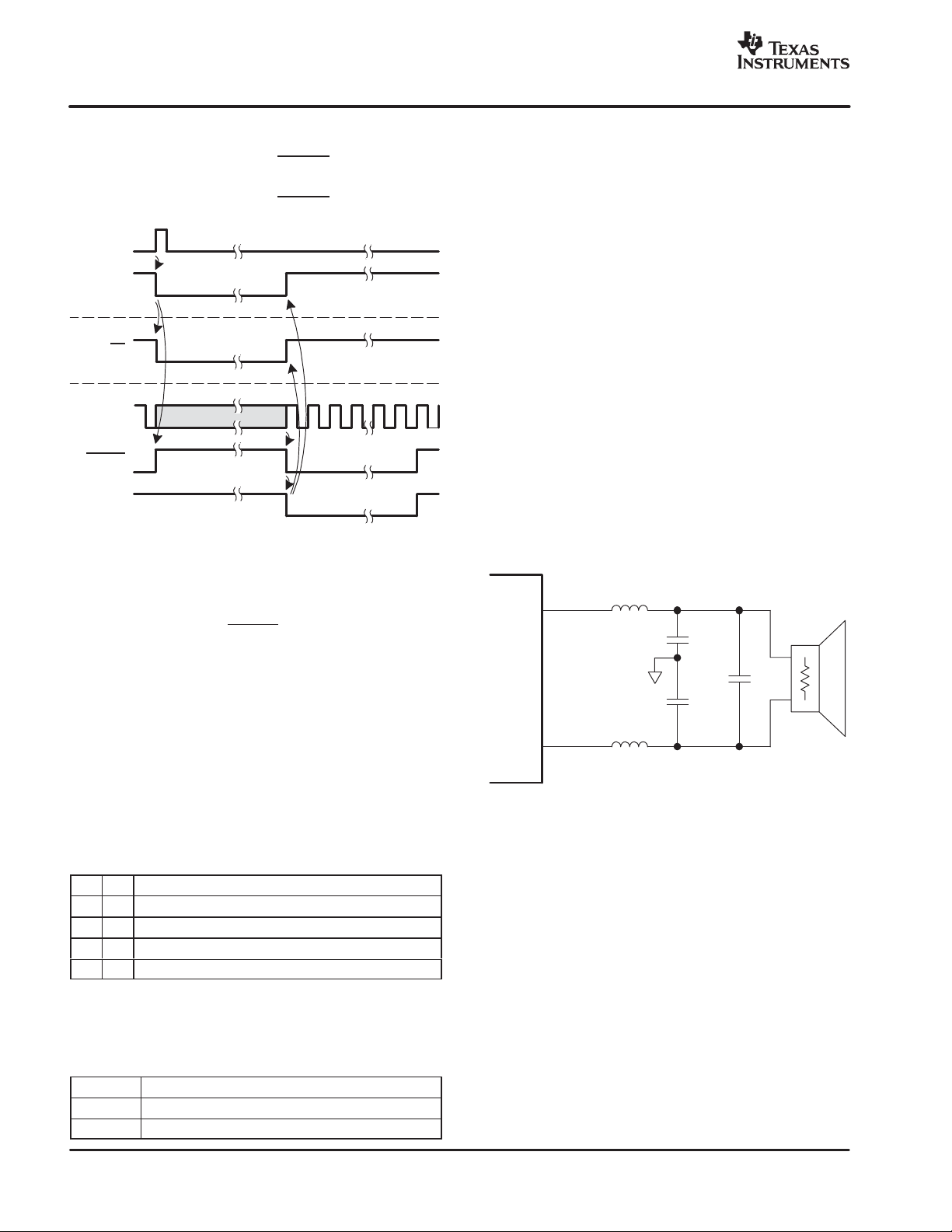

APPLICATION INFORMATION

DEMODULATION FILTER DESIGN AND

SPIKE CONSIDERATIONS

The output square wave is susceptible to overshoots

(voltage spikes). The spike characteristics depend on

many elements, including silicon design and application

design and layout. The device should be able to handle

narrow spike pulses, less than 65 ns, up to 65 volts peak.

For more detailed information, see TI application note

SLEA025.

The PurePath Digital amplifier outputs are driven by

heavy-duty DMOS transistors in an H-bridge

configuration. These transistors are either off or fully on,

which reduces the DMOS transistor on-state resistance,

R

, and the power dissipated in the device, thereby

DSon

increasing efficiency.

The result is a square-wave output signal with a duty cycle

that is proportional to the amplitude of the audio signal. It

is recommended that a second-order LC filter be used to

recover the audio signal. For this application, EMI is

considered important; therefore, the selected filter is the

full-output type shown in Figure 13.

TAS51xx

Output A

Output B

L

L

C1A

C1B

C2

R

(Load)

MODE Pins Selection

The protection mode is selected by shorting M1/M2 to

DREG or DGND according to Table 2.

Table 2. Protection Mode Selection

M1 M2 PROTECTION MODE

0 0 Reserved

0 1 Latching shutdown on all errors (PMODE1)

1 0 Reserved

1 1 Reserved

The output configuration mode is selected by shorting the

M3 pin to DREG or DGND according to Table 3.

Figure 13. Demodulation Filter (AD Mode)

The main purpose of the output filter is to attenuate the

high-frequency switching component of the PurePath

Digital amplifier while preserving the signals in the audio

band.

Design of the demodulation filter affects the performance

of the power amplifier significantly. As a result, to ensure

proper operation of the overcurrent (OC) protection circuit

and meet the device THD+N specifications, the selection

of the inductors used in the output filter must be considered

according to the following. The rule is that the inductance

should remain stable within the range of peak current seen

at maximum output power and deliver at least 5 µH of

Table 3. Output Mode Selection

M3 OUTPUT MODE

0 Bridge-tied load output stage (BTL)

1 Reserved

14

inductance at 15 A.

If this rule is observed, the TAS5122 does not have

distortion issues due to the output inductors, and

overcurrent conditions do not occur due to inductor

saturation in the output filter.

www.ti.com

L - Inductance -

H

SLES088D – AUGUST 2003 – REVISED MAY 2004

Another par a meter to be considered is the idle current loss

in the inductor. This can be measured or specified as

inductor dissipation (D). The target specification for

dissipation is less than 0.05.

In general, 10-µH inductors suffice for most applications.

The frequency response of the amplifier is slightly altered

by the change in output load resistance; however, unless

tight control of frequency response is necessary (better

than 0.5 dB), it is not necessary to deviate from 10 µH.

The graphs in Figure 14 display the inductance vs current

characteristics of two inductors that are recommended for

use with the TAS5122.

INDUCTANCE

vs

CURRENT

11

10

9

µ

8

7

6

5

4

0 5 10 15

DASL983XX-1023

I - Current - A

DFB1310A

Figure 14. Inductance Saturation

The selection of the capacitor that is placed across the

output of each inductor (C2 in Figure 13) is simple. To

complete the output filter, use a 0.47-µF capacitor with a

voltage rating at least twice the voltage applied to the

output stage (PVDD).

This capacitor should be a good quality polyester dielectric

such as a Wima MKS2-047ufd/100/10 or equivalent.

In order to minimize the EMI effect of unbalanced ripple

loss in the inductors, 0.1-µF 50-V SMD capacitors (X7R or

better) (C1A and C1B in Figure 13) should be added from

the output of each inductor to ground.

THERMAL INFORMATION

R

is a system thermal resistance from junction to

θ

JA

ambient ai r. As such, it is a system parameter with roughly

the following components:

D R

(the thermal resistance from junction to

θ

JC

case, or in this case the metal pad)

D Thermal grease thermal resistance

D Heatsink thermal resistance

R

has been provided in the Package Dissipation

θ

JC

Ratings section.

The thermal grease thermal resistance can be calculated

from the exposed pad area and the thermal grease

manufacturer’s area thermal resistance (expressed in

°C-in2/W). The area thermal resistance of the example

thermal grease with a 0.002-inch-thick layer is about 0.1

°C-in2/W. The approximate exposed pad area is as

follows:

56-pin HTSSOP 0.045 in

Dividing the example thermal grease area resistance by

the surface area gives the actual resistance through the

thermal grease for both ICs inside the package:

56-pin HTSSOP 2.27 °C/W

The thermal resistance of thermal pads is generally

considerably higher than a thin thermal grease layer.

Thermal tape has an even higher thermal resistance.

Neither pads nor tape should be used with either of these

two packages. A thin layer of thermal grease with careful

clamping of the heatsink is recommended. It may be

difficult to achieve a layer 0.001 inch thick or less, so the

modeling below is done with a 0.002-inch-thick layer,

which may be more representative of production thermal

grease thickness.

Heatsink thermal resistance is generally predicted by the

heatsink vendor, modeled using a continuous flow

dynamics (CFD) model, or measured.

Thus, for a single monaural IC, the system R

thermal grease resistance + heatsink resistance.

DCA THERMAL INFORMATION

The thermally enhanced DCA package is based on the

56-pin HTSSOP, but includes a thermal pad (see

Figure 15) to provide an effective thermal contact between

the IC and the PCB.

The PowerPAD package (thermally enhanced

HTSSOP) combines fine-pitch, surface-mount technology

with thermal performance comparable to much larger

power packages.

The PowerP AD package is designed to optimize the heat

transfer to the PWB. Because of the small size and limited

mass of an HTSSOP package, thermal enhancement is

2

= R

θ

JA

+

θ

JC

15

SLES088D – AUGUST 2003 – REVISED MAY 2004

www.ti.com

achieved by improving the thermal conduction paths that

remove heat from the component. The thermal pad is

formed using a patented lead-frame design and

manufacturing technique to provide a direct connection to

the heat-generating IC. When this pad is soldered or

otherwise thermally coupled to an external heat dissipater,

high power dissipation in the ultrathin, fine-pitch,

surface-mount package can be reliably achieved.

Thermal Methodology for the DCA 56-Pin,

2y15-W, 8-W Package

The thermal design for the DCA part (e.g., thermal pad

Copper Layer − Component Side

Solder

TAS5122DCA

soldered to the board) should be similar to the design in the

following figures. The cooling approach is to conduct the

dissipated heat into the via pads on the board, through the

vias in the board, and into a heatsink (aluminum bar) (if

necessary).

Figure 15 shows a recommended land pattern on the

PCB.

PowerPAD

5y1 1 Vias (f 0.3 mm)

4mm

Figure 15. Recommended Land Pattern

The lower via pad area, slightly larger than the IC pad itself,

is exposed with a window in the solder resist on the bottom

surface of the board. It is not coated with solder during the

board construction to maintain a flat surface. In production,

this can be accomplished with a peelable solder mask.

An aluminum bar is used to keep the through-hole leads

8 mm

from shorting to the chassis. The thermal compound

shown has a pad-to-aluminum bar thermal resistance of

about 3.2° C/W.

The chassis provides the only heatsink to air and is chosen

as representative of a typical production cooling approach.

16

www.ti.com

SLES088D – AUGUST 2003 – REVISED MAY 2004

Insulating

Front Panel

Stereo

Amplifier

Board

Wakefield T ype 126

Thermal Compound

Under Via Pads

(3.2°C/W)

PCB (3.65C/W)

Figure 16. 56-Pin DCA Package Cross-Sectional View (Side)

Plastic Top

56-Pin DCA Package

(1.145C/W)

Wakefield T ype 126

Thermal Compound

(0.1°C/W)

Insulating

Back Panel

1 mm

8-mm y 10-mm y 40 mm

Aluminum Bar

(0.09°C/W)

Aluminum Chassis 7.2 in. y 1 in. y 0.1 in. Thick

Sides of U-Shaped Chassis Are 1.25 in. High (3.9°C/W)

Plastic Top

PCB (3.6°C/W)

Stereo

Amplifier

Board

Wakefield T ype 126

Thermal Compound

Aluminum Chassis 7.2 in. y. 1 in y 0.1 in. Thick

Sides of U-Shaped Chassis Are 1.25 in. High (3.9°C/W)

56-Pin DCA Package

(1.14°C/W)

(2 Places)

(0.1°C/W)

Figure 17. Spatial Separation With Multiple Packages

The land pattern recommendation shown in Figure 15 is

for optimal performance with aluminum bar thermal

resistance of 0.09 ° C/W. The following table shows the

4-40 Machine Screw

With Star Washer

and Nut

(3 Places)

Wakefield T ype 126

Thermal Compound

Under Via Pads

(3.2°C/W)

8-mm y 10-mm y 40-mm

Aluminum Bar

(0.09°C/W)

decrease in thermal resistance through the PCB with a

corresponding increase in the land pattern size. Use the

table for thermal design tradeoffs.

17

SLES088D – AUGUST 2003 – REVISED MAY 2004

www.ti.com

LAND PATTERN

7×13 vias (5×10 mm) 2.2°C/W

5×11 vias (4×8 mm) 3.6°C/W

Thermal

Pad

3,90 mm

2,98 mm

PCB THERMAL

RESISTANCE

8,20 mm

7,20 mm

Figure 18. Thermal Pad Dimensions for DCA

Package

the output stage prior to operation is in the

high-impedance state, this is done by having a

passive pulldown resistor on each speaker

output to GND (see System Configuration Used

for Characterization).

Other things that can affect the audible click level:

D The spectrum of the click seems to follow the

speaker impedance vs frequency curve—the

higher the impedance, the higher the click

energy.

D Crossover filters used between woofer and

tweeter in a speaker can have high impedance

in the audio band, which should be avoided if

possible.

Another way to look at it is that the speaker impulse

response is a major contributor to how the click energy is

shaped in the audio band and how audible the click is.

The following mode transitions feature click and pop

reduction in Texas Instruments PWM processors.

STATE

(1)

Normal

Mute → Normal

(1)

Normal

Error recovery → Normal

(1)

Normal

Hard Reset → Normal

(1)

Normal = switching

→ Mute Yes

Error recovery

→

(ERRCVY)

→ Hard Reset No

(1)

(1)

(1)

CLICK AND

POP REDUCED

Yes

Yes

Yes

Yes

REFERENCES

CLICK AND POP REDUCTION

TI modulators feature a pop and click reduction system

that controls the timing when switching starts and stops.

Going from nonswitching to switching operation causes a

spectral energy burst to occur within the audio bandwidth,

which is heard in the speaker as an audible click, for

instance, after having asserted RESET LH during a

system start-up.

To make this system work properly, the following design

rules must be followed when using the TAS5122 power

stage:

D The relative timing between the PWM_AP/M_x

signals and their corresponding VALID_x signal

should not be skewed by inserting delays,

because this increases the audible amplitude

level of the click.

D The output stage must start switching from a

fully discharged output filter capacitor. Because

18

1. TAS5000 Digital Audio PWM Processor data

manual – TI (SLAS270)

2. True Digital Audio Amplifier TAS5001 Digital Audio

PWM Processor data sheet – TI (SLES009)

3. True Digital Audio Amplifier TAS5010 Digital Audio

PWM Processor data sheet – TI (SLAS328)

4. True Digital Audio Amplifier TAS5012 Digital Audio

PWM Processor data sheet – TI (SLES006)

5. TAS5026 Six-Channel Digital Audio PWM

Processor data manual – TI (SLES041)

6. TAS5036A Six-Channel Digital Audio PWM

Processor data manual – TI (SLES061)

7. TAS3103 Digital Audio Processor With 3D Effects

data manual – TI (SLES038)

8. Digital Audio Measurements application report – TI

(SLAA114)

9. System Design Considerations for True Digital

Audio Power Amplifiers application report – TI

(SLAA117)

MECHANICAL DATA

MPDS044 – JANUARY 1998

DCA (R-PDSO-G**) PowerPAD PLASTIC SMALL-OUTLINE PACKAGE

48 PINS SHOWN

0,50

48

1

1,20 MAX

0,27

0,17

25

24

A

0,15

0,05

0,08

M

6,20 8,30

6,00

7,90

Seating Plane

0,10

Thermal Pad

(See Note D)

0,15 NOM

Gage Plane

0°–8°

0,25

0,75

0,50

PINS **

DIM

A MAX

A MIN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. The package thermal performance may be enhanced by bonding the thermal pad to an external thermal plane.

This pad is electrically and thermally connected to the backside of the die and possibly selected leads.

E. Falls within JEDEC MO-153

PowerPAD is a trademark of Texas Instruments Incorporated.

48

12,60

12,40

56

14,10

64

17,10

16,9013,90

4073259/A 01/98

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

Loading...

Loading...