Page 1

查询TAS5110A供应商

www.ti.com

TAS5110A

SLES079A – APRIL 2003 – REVISED MAY 2003

PurePath Digital AMPLIFIER

TAS5110A 50-W DIGITAL AMPLIFIER POWER STAGE

FEATURES

D 50 W RMS Power Into 6 Ω at 10% THD

D 40 W RMS Power Into 6 Ω at 0.1% THD

D THD+N < 0.09% Typical (1-kHz Input Signal)

D 93-dB Dynamic Range (TDAA System)

D Power Efficiency > 90% Into 6-Ω and 8-Ω

Load

D Low Profile, SMD 32-Pin PowerPAD

Package

D Self-Protecting Design

D 3.3-V Digital Interface

D EMI Compliant When Used With

Recommended System Design

APPLICATIONS

D DVD Receiver

D Home Theater

D Mini/Micro Component Systems

D Internet Music Appliance

D Car Audio Amplifiers and Head Units

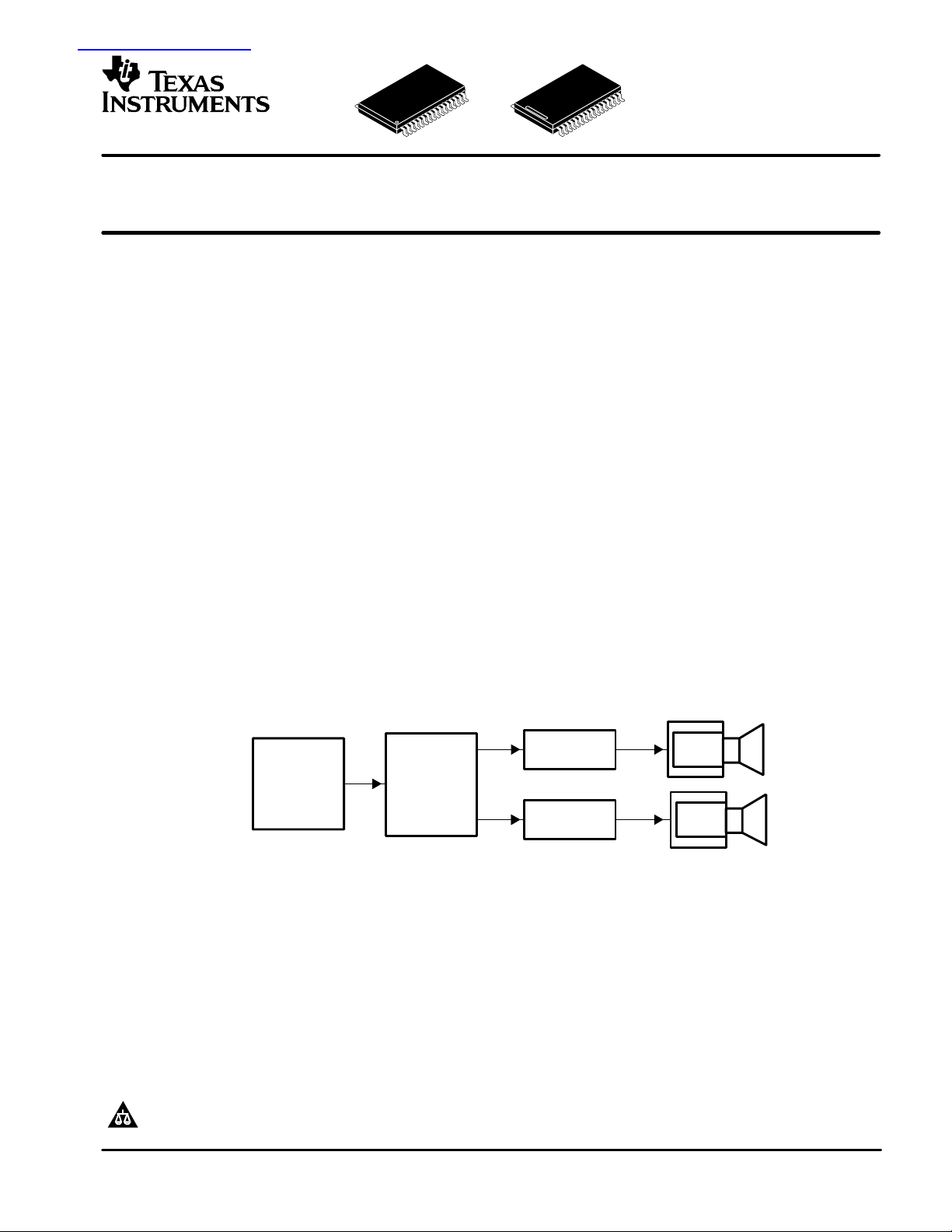

TYPICAL TDAA STEREO AUDIO SYSTEM

DESCRIPTION

The TAS5110A is a high-performance true-digital audio

amplifier (TDAA) power stage, designed to drive 50 W per

channel. The TAS5110A incorporates TI’s Equibit and

PurePath Digital technology and is used in conjunction

with a digital audio PWM processor (TAS50xx) to deliver

high-power , true-digital audio amplification. The efficiency

of this digital amplifier can be greater than 90%, reducing

the size of both the power supplies and heat sinks needed.

The TAS5110A accepts a mono PWM 3.3-V input and

controls the switching of an internal CMOS H-bridge.

When used with the TAS50xx PWM processor, system

performance of less than 0.09% THD is attainable.

Overcurrent protection, overtemperature, and

undervoltage protections are built into the TAS5110A,

safeguarding the H-bridge and speakers against output

shorts, overvoltage conditions, and other fault conditions

that could damage the system.

Left

Digital Audio

• TAS3001

• DSP

• S/PDIF

• 1394

• Volume

• EQ

• DRC

• Bass

• Treble

Please be aware that an important notice concerning availability , standard warranty, and use in critical applications of TexasInstruments

semiconductor products and disclaimers thereto appears at the end of this data sheet.

PowerP AD, PurePath Digital, and Equibit are trademarks of Texas Instruments.

PRODUCTION DATA information is current as of publication date. Products

conform to specifications per the terms of Texas Instruments standard warranty.

Production processing does not necessarily include testing of all parameters.

• Serial Audio Input Port

• Internal PLL

• PWM Processor

TAS50xx

Right

TAS5110A

TAS5110A

• Two H-Bridge Power Devices

Copyright 2003, Texas Instruments Incorporated

L-C

Filter

L-C

Filter

Page 2

TAS5110A

www.ti.com

SLES079A – APRIL 2003 – REVISED MA Y 2003

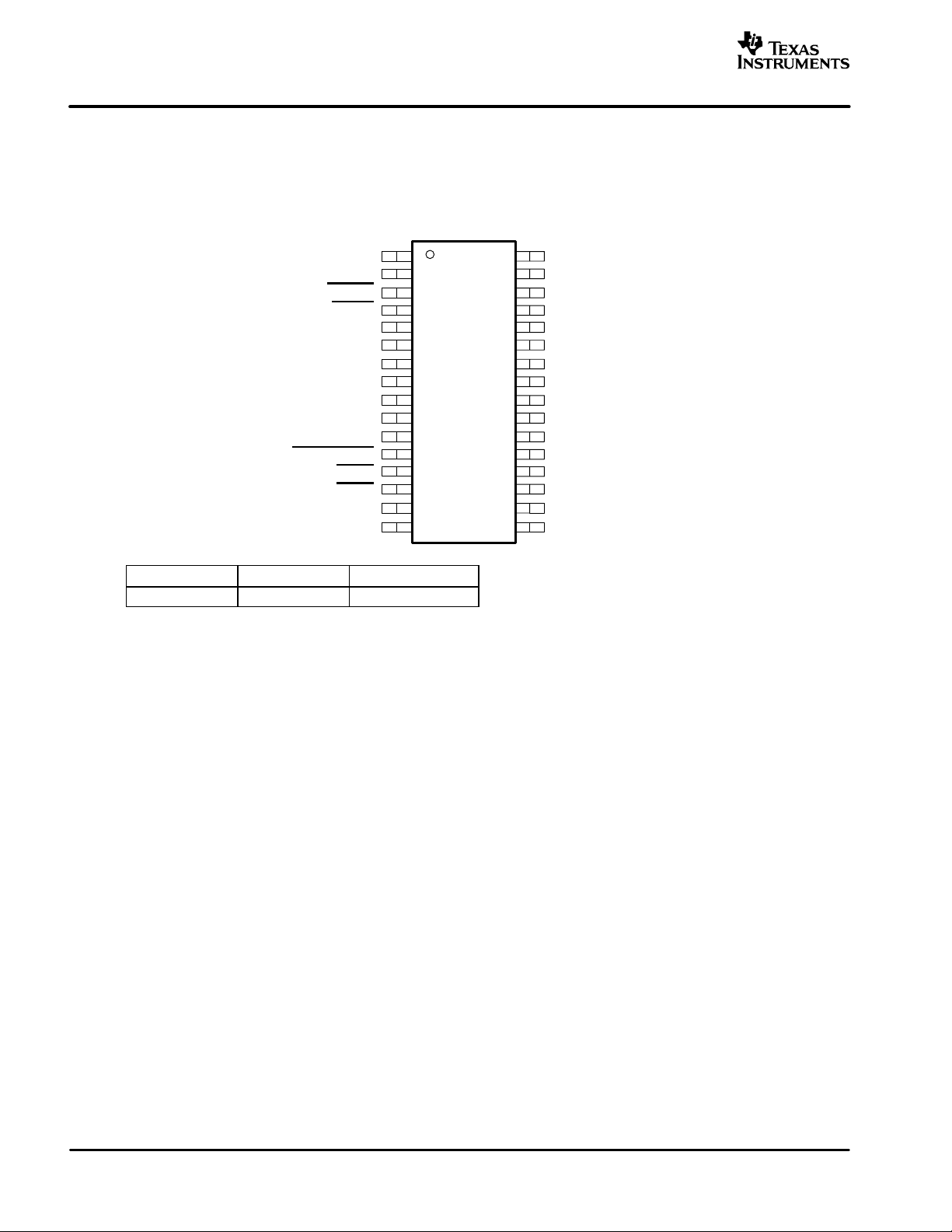

TERMINAL ASSIGNMENTS

The TAS51 10A is offered in a thermally enhanced 32-pin TSSOP surface-mount package (DAD). The DAD package

has the PowerPAD on top.

DAD PACKAGE

(TOP VIEW)

PWM_BP

PWM_BM

RESET

PWDN

BIAS_B

BIAS_A

VRFILT

DVSS

DVSS

DVSS

DVDD

SHUTDOWN

ERR0

ERR1

PWM_AM

PWM_AP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

PVDDB2

LDROUTB

BOOTSTRAPB

PVDDB1

PVDDB1

OUTPUTB

OUTPUTB

PVSS

PVSS

OUTPUTA

OUTPUTA

PVDDA1

PVDDA1

BOOTSTRAPA

LDROUTA

PVDDA2

ORDERING INFORMATION

T

C

0°C to 70°C TAS5110ADAD TAS5110ADADR

PACKAGE TAPE AND REEL

REFERENCES

1. TAS5000 Digital Audio PWM Processor data manual (SLAS270)

2. True Digital Audio Amplifier TAS5001 Digital Audio PWM Processor data sheet (SLES009)

3. True Digital Audio Amplifier TAS5010 Digital Audio PWM Processor data sheet (SLAS328)

4. True Digital Audio Amplifier TAS5012 Digital Audio PWM Processor data sheet (SLES006)

5. Digital Audio Measurements application report (SLAA114)

6. PowerPAD Thermally Enhanced Package technical brief (SLMA002)

2

Page 3

www.ti.com

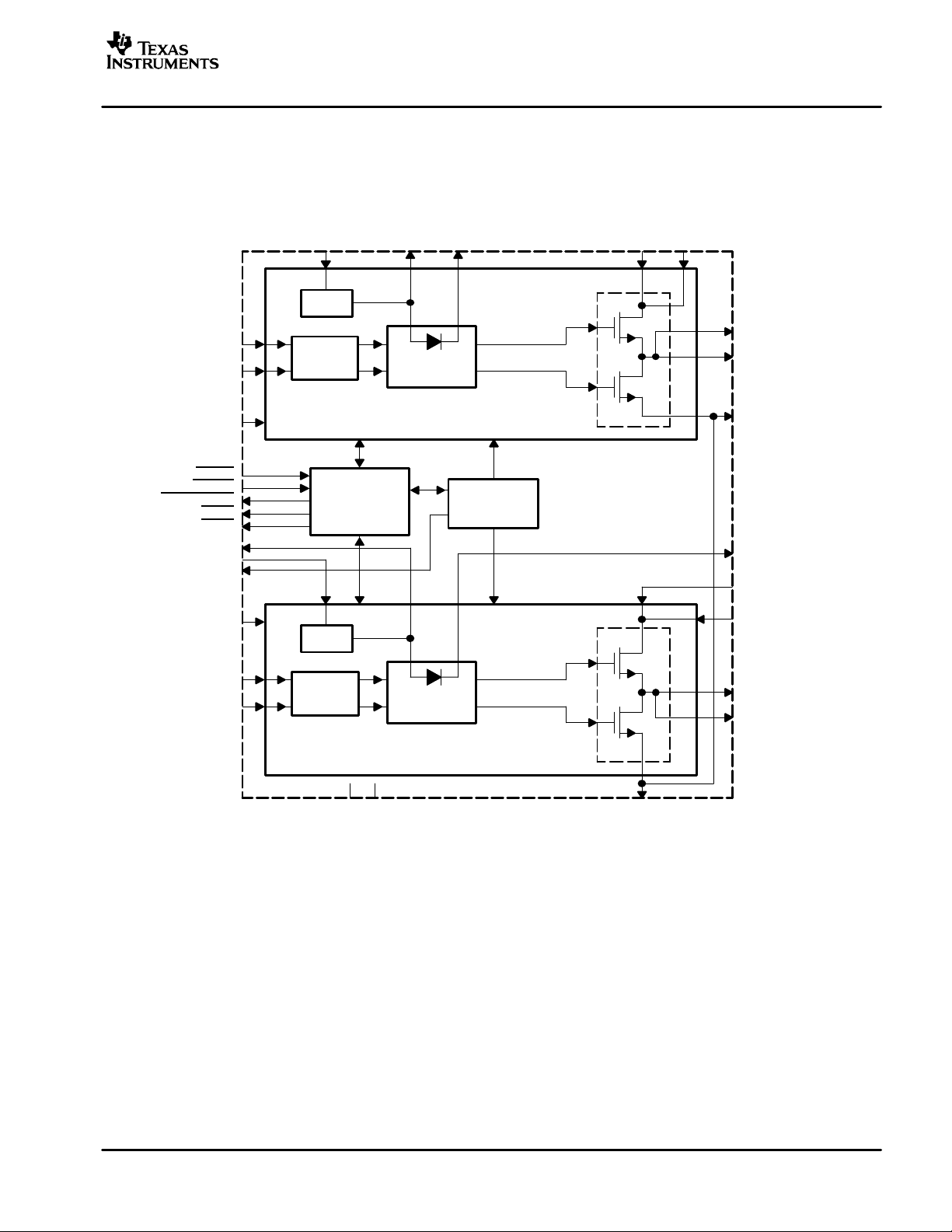

A

FUNCTIONAL BLOCK DIAGRAM

TAS5110A

SLES079A – APRIL 2003 – REVISED MAY 2003

PWM_AP

PWM_AM

BIAS_A

PWDN

RESET

SHUTDOWN

ERR1

ERR0

LDROUTB

PVDDB2

VRFILT

BIAS_B

PWM_BM

PWM_BP

PVDDA2

LDR

DIFF

RCVR

Control/Sense

Circuit

LDR

DIFF

RCVR

LDROUTA

Bootstrap

Gate Drive

Bootstrap

Gate Drive

BOOTSTRAP

1/2 H-Bridge

Band-Gap

Reference

1/2 H-Bridge

PVDDA1

PVDDA1

OUTPUTA

OUTPUTA

PVSS

BOOTSTRAPB

PVDDB1

PVDDB1

OUTPUTB

OUTPUTB

DVDD

DVSS

PVSS

3

Page 4

TAS5110A

SLES079A – APRIL 2003 – REVISED MAY 2003

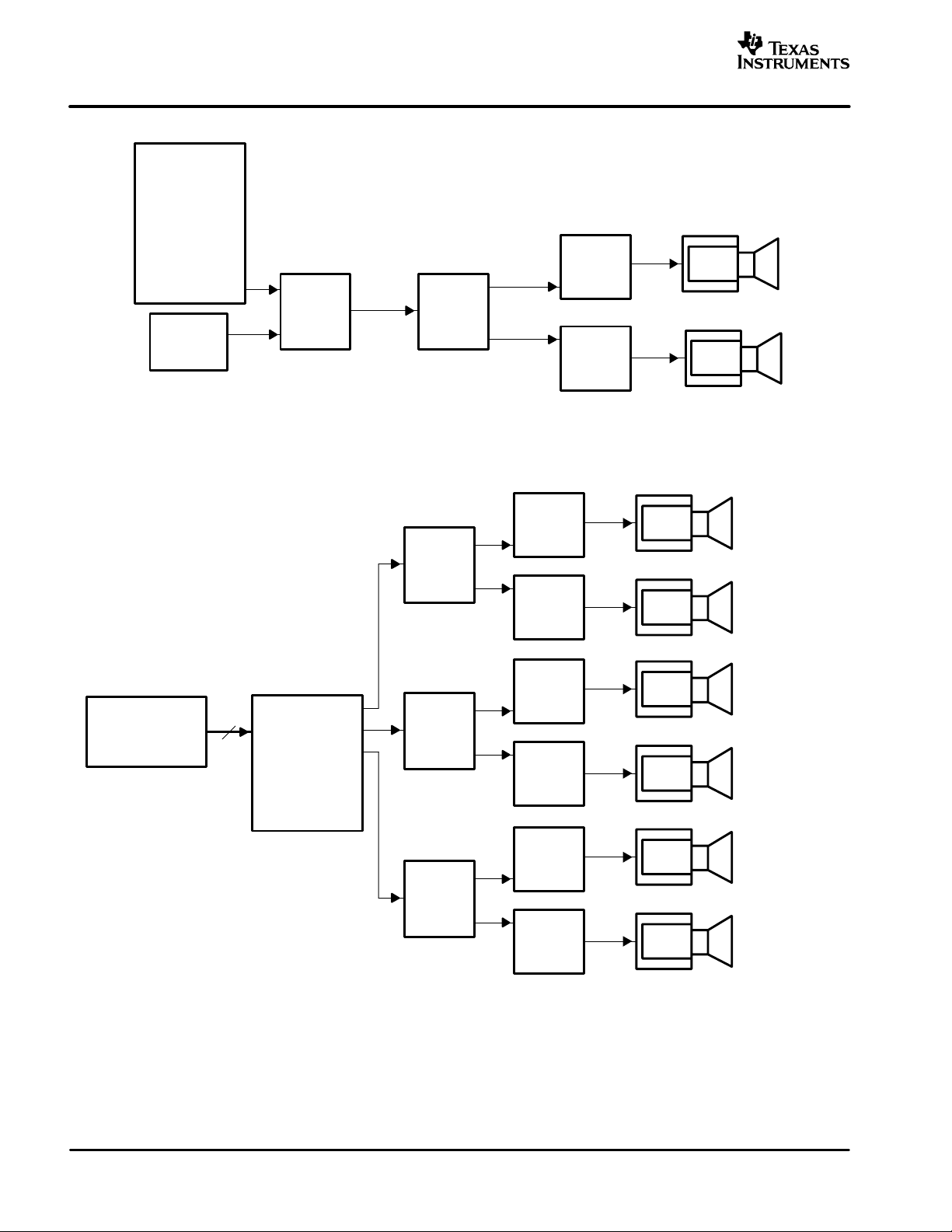

SUGGESTED SYSTEM BLOCK DIAGRAMS

Digital Audio

• USB

• IEEE 1394

• S/PDIF

• ADC

• Automotive

MOST

Network

I2C

Audio

Control

Figure 1. System #1: Stereo Configuration With a TAS3001 Digital Audio Processor

TAS30xx

• Digital Parametric EQ

• Volume

• DRC

• Bass

• Treble

• Serial Audio Input Port

• Internal PLL

TAS50xx

Left

Right

TAS5110A

TAS5110A

• Two H-Bridges

www.ti.com

L-C

Filter

L-C

Filter

Home Theater

DVD 6-Channel

Encoded Digital

Audio Source

6

TI DSP

• Dolby AC-3

• DTS

• Volume

• EQ

• DRC

• Bass

• Treble

TAS50xx

TAS50xx

TAS50xx

CH1

CH2

CH3

CH4

CH5

CH6

TAS5110A

TAS5110A

TAS5110A

TAS5110A

TAS5110A

TAS5110A

L-C

Filter

L-C

Filter

L-C

Filter

L-C

Filter

L-C

Filter

L-C

Filter

Left

Right

Surround Left

Surround Right

Center

Subwoofer

Figure 2. System #2: 6-Channel Audio Playback

4

Page 5

TAS5110A

www.ti.com

SLES079A – APRIL 2003 – REVISED MAY 2003

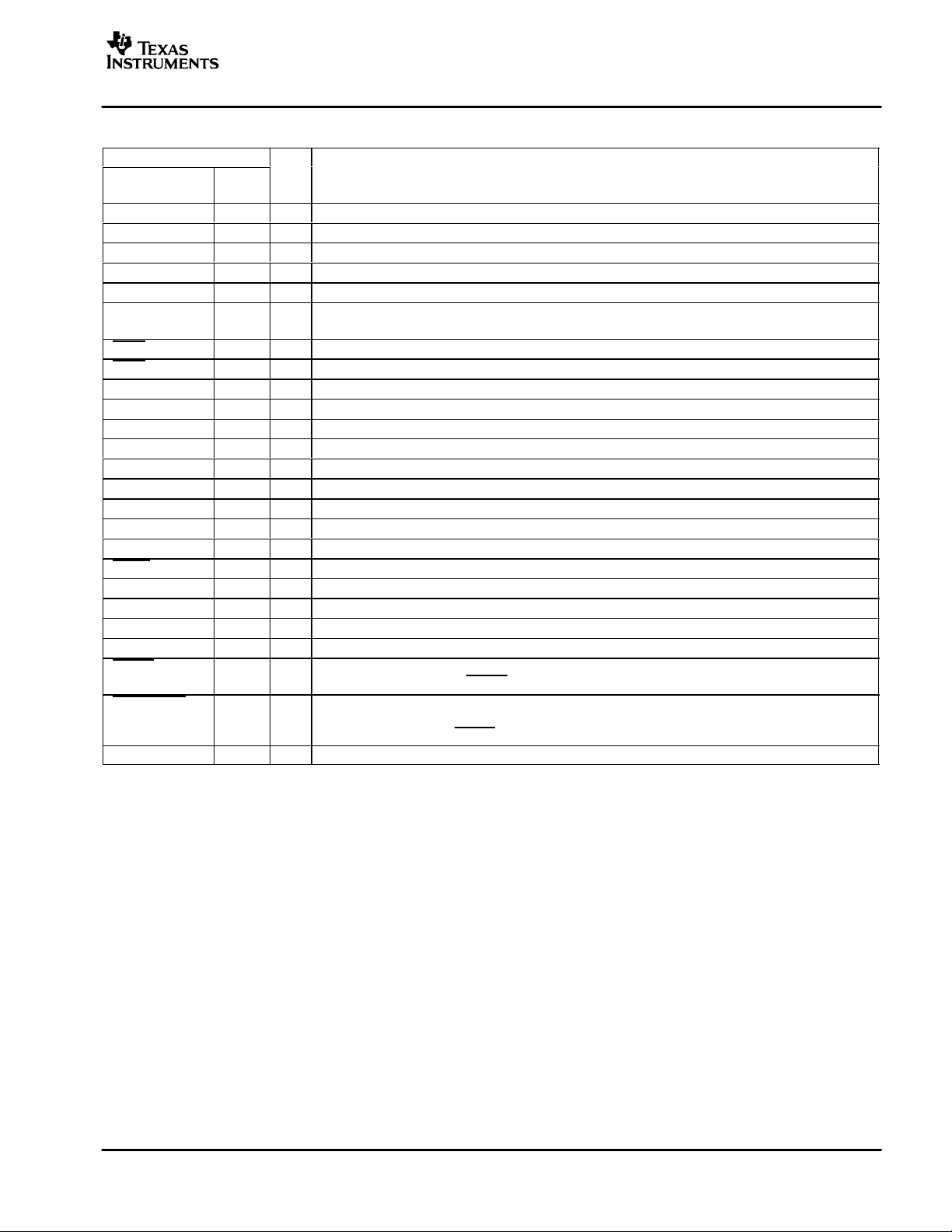

Terminal Functions

TERMINAL

NAME DAD

NO.

BIAS_A 6 I Connect external resistor to DVSS.

BIAS_B 5 I Connect external resistor to DVSS.

BOOTSTRAPA 19 O Bootstrap capacitor pin for H-bridge A

BOOTSTRAPB 30 O Bootstrap capacitor pin for H-bridge B

DVDD 11 — 3.3-V digital voltage supply for logic

DVSS 8, 9,10— Digital ground for logic is internally connected to PVSS. All three pins must be tied together but not

ERR1 14 O Error/warning report indicator . This output is open drain with internal pullup resistor .

ERR0 13 O Error/warning report indicator . This output is open drain with internal pullup resistor .

LDROUTA 18 O Low-voltage drop-out regulator output A (not to be used to supply current to external circuitry)

LDROUTB 31 O Low-voltage drop-out regulator output B (not to be used to supply current to external circuitry)

OUTPUTA 22, 23 O H-bridge output A

OUTPUTB 26, 27 O H-bridge output B

PVDDA1 20, 21 — High-voltage power supply, H-bridge A

PVDDA2 17 — High-voltage power supply for low-dropout voltage regulator A-side

PVDDB1 28, 29 — High-voltage power supply, H-bridge B

PVDDB2 32 — High-voltage power supply for low-dropout voltage regulator B-side

PVSS 24, 25 — High-voltage power supply ground

PWDN 4 I Power down = 0, normal mode = 1

PWM_AM 15 I PWM input A(–)

PWM_AP 16 I PWM input A(+)

PWM_BP 1 I PWM input B(+)

PWM_BM 2 I PWM input B(–)

RESET 3 I Reset and mute mode = 0, normal mode = 1; when in reset mode, H-bridge MOSFETs are in low-low

SHUTDOWN 12 O Device is in shutdown due to fault condition, normal mode = 1, shutdown = 0; when device is in

VRFILT 7 O A filter capacitor must be added between the VRFILT and DVSS pins.

NOTE:

The four PWM inputs: PWM_AP, PWM_AM, PWM_BP, and PWM_BM must always be connected to the TAS50xx output pins and never

left floating. Floating PWM input pins cause an illegal PWM input state signal to be asserted.

Dual pins: OUTPUTA, OUTPUTB, PVDDA1, and PVDDB1 must have both pins connected externally to the same point on the circuit board,

respectively . Both PVSS pins must also be connected together externally. These multiple pins are for the high-current DMOS output devices.

Failure to connect all the multiple pins to the same respective node results in excessive current flow in the internal bond wires and can cause

the device to fail. All electrical characteristics are specified and measured with all of the multiple pins of each type connected to a single node.

I/O DESCRIPTION

connected externally to PVSS. See Figure 5.

output state. Asserting the RESET signal low causes all fault conditions to be cleared.

shutdown mode the H-bridge MOSFETs are in low-low output state. The latched output can be

cleared by asserting the RESET signal. This output is open drain with internal pullup resistor.

5

Page 6

TAS5110A

www.ti.com

SLES079A – APRIL 2003 – REVISED MAY 2003

FUNCTIONAL DESCRIPTION

PWM H-Bridge State Control

The digital interface control signals consists of PWM_AP, PWM_AM, PWM_BP, and PWM_BM. These signals are

a complementary differential signal format for the A-side half-bridge and the B-side half-bridge.

Bootstrapped Gate Drive

The TAS5110A includes two dedicated bootstrapped power supplies. A bootstrap capacitor is connected between

the individual bootstrap pin and the associated output. For example, a capacitor is connected between the

BOOTSTRAPA pin and the OUTPUT A pin and another capacitor is connected between the BOOTSTRAPB pin and

the OUTPUTB pin. The bootstrap power supply minimizes the number of high voltage power supply levels externally

supplied to the system, while providing a low-noise supply level for driving the high-side N-channel DMOS transistors.

Low-Dropout Voltage Regulator

Two on-chip low-dropout voltage regulators (LDO) are provided to minimize the number of external power supplies

needed for the system. These voltage regulators are for internal circuits only and cannot be used for external circuitry .

Each LDO is dedicated to a half-bridge and its gate driver. An LDO output capacitor is connected between the

individual LDO output pin and the associated output return. For example, a capacitor is connected between the

LDROUTA pin and the PVSS pin and another capacitor is connected between the LDROUTB pin and the PVSS pin.

High-Current H-bridge Output Stage

The positive outputs of the H-bridge are the two OUTPUT A pins. The negative outputs of the H-bridge are the two

OUTPUTB pins. The logic for the input command to H-bridge outputs is described in the H-bridge output mapping

section immediately following. When the T AS5110A is in the normal mode, as seen in the H-bridge output mapping

tables, the outputs are decoded from the inputs. However, the TAS5110A is immediately shut down if any of the

following error conditions occur: overcurrent, overtemperature, low regulator output voltage, or an illegal PWM input

state is applied. For these conditions, the outputs are set to the appropriate disabled state as specified in the H-bridge

output mapping section, and the SHUTDOWN pin is set low.

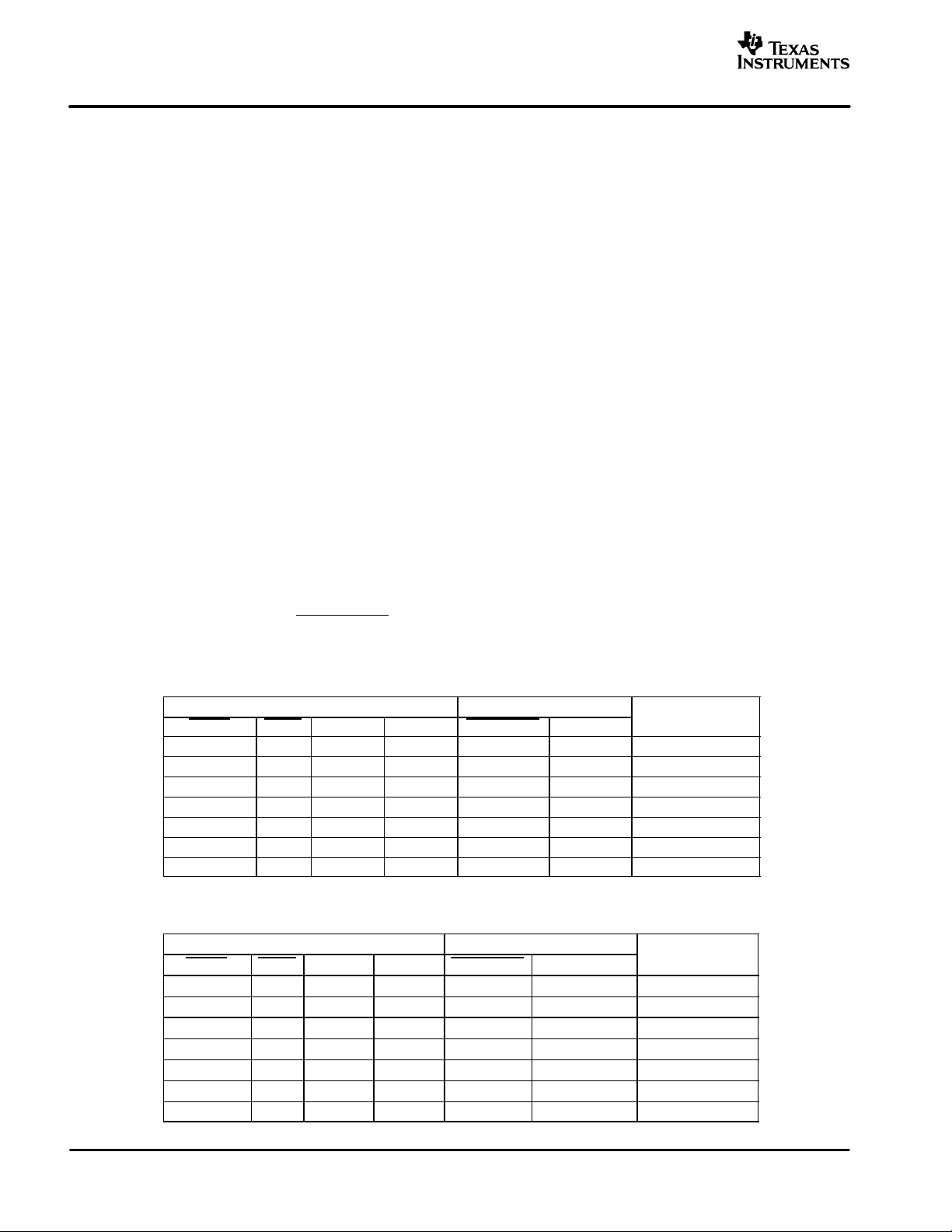

H-Bridge Output Mapping

The A-side half-bridge output is designed to the following truth table:

INPUTS OUTPUTS

RESET PWDN PWM_AP PWM_AM SHUTDOWN OUTPUTA

X X X X 0 0 or Hi-Z

X 0 X X 1 Hi-Z Power down

0 1 X X 1 0 Reset

1 1 0 0 0 0 Shutdown

1 1 0 1 1 0 Normal

1 1 1 0 1 1 Normal

1 1 1 1 0 0 Shutdown

(1)

Output is 0 for low voltage, overtemperature, and illegal input. Hi-Z is for overcurrent.

(1)

DESCRIPTION

Shutdown

The B-side half-bridge output is designed to the following truth table:

INPUTS OUTPUTS

RESET PWDN PWM_BP PWM_BM SHUTDOWN OUTPUTB

X X X X 0 0 or Hi-Z

X 0 X X 1 Hi-Z Power down

0 1 X X 1 0 Reset

1 1 0 0 0 0 Shutdown

1 1 0 1 1 0 Normal

1 1 1 0 1 1 Normal

1 1 1 1 0 0 Shutdown

(1)

Output is 0 for low voltage, overtemperature, or illegal input. Hi-Z is for overcurrent.

(1)

DESCRIPTION

Shutdown

6

Page 7

www.ti.com

Control/Sense Circuitry

TAS5110A

SLES079A – APRIL 2003 – REVISED MAY 2003

The control/sense circuitry consists of the following 3.3-V logic level pins: PWDN

, RESET, ERR0, ERR1, and

SHUTDOWN. The active-low PWDN input pin powers down all internal circuitry and forces the H-bridge outputs to

the Hi-Z state. When the PWDN pin is low, the open drain ERR0, ERR1, and SHUTDOWN pins are also disabled

so that their outputs can be pulled high. The active-low RESET input pin forces the H-bridge outputs to the low-low

state and resets the overcurrent shutdown latch. The PWDN pin overrides the RESET pin. The ERR0, ERR1, and

SHUTDOWN outputs indicate the following conditions in the TAS51 10A as shown in the following table. These three

outputs are open-drain connections with internal pullup resistors so that wire-ORed connections can be made by the

user with other external control devices. The short-circuit protect error condition latches the TAS5110A in this

shutdown state and forces the H-bridge outputs to the Hi-Z state until the device is reset by means of the RESET

pin. The illegal PWM input state, overtemperature, and low regulator voltage error conditions does not latch the

device in the shutdown condition. Instead the H-bridge outputs are forced to the low-low state and the TAS5110A

returns to normal operation as soon as the error condition ends. Loss of clocking PWM signal is also considered an

illegal PWM input state.

SHUTDOWN ERR1 ERR0 FUNCTION OUTPUTA OUTPUTB

0 0 0 Illegal PWM input state Low Low

0 0 1 Short circuit protect (latch) Hi-Z Hi-Z

0 1 0 Over temperature protect Low Low

0 1 1 Low regulator voltage protect Low Low

1 0 0 Reserved — —

1 0 1 Reserved — —

1 1 0 High temperature – warning Normal Normal

1 1 1 Normal operation Normal Normal

7

Page 8

TAS5110A

www.ti.com

SLES079A – APRIL 2003 – REVISED MAY 2003

DEVICE OPERATION

Power Sequences

System Power-up/Power-down Sequencing

The recommended power-up/power-down sequence is shown in Figure 3. For proper operation the RESET signal

should be kept low when both DVDD and output power (PVDDA1, PVDDA2, PVDDB1, and PVDDB2) are being

applied. The RESET signal should remain low for at least 1 ms after output power is applied.

(1)

DVDD

PWDN

≥ 1 ms

PVDDA2

PVDDB2

u 100 µs

PVDDA1

PVDDB1

u 100 µs

RESET

u 1 ms

(1)

For most applications, it is recommended that the PWDN pin be connected directly to the DVDD pin.

Figure 3. Power-Up/Power-Down Sequence

RESET Function

The device is put into a reset condition when the (active low) RESET signal is asserted. While in the reset state, the

input H-bridge control signals consisting of PWM_AP, PWM_AM, PWM_BP, and PWM_BM are ignored, and the

H-bridge MOSFET s are placed in a state where OUTPUT A and OUTPUTB are both low. Asserting the RESET signal

low also causes the short circuit protection latch to be reset. The RESET signal is normally connected to the V ALID

signal from the TAS50xx.

Reinitialization Sequence

Proper initial conditions for this device include asserting the RESET signal until the reset operation has completed

(1 ms). Additionally, when using this device with the TAS50xx controller, this function can be accomplished by

asserting the reset pin on the TAS50xx during the reset sequence (see Figure 3).

Audio Application Considerations

Optimal Power Transfer For H-Bridge

The TAS5110A is a power H-bridge that is designed to deliver a maximum of 50 W RMS into a 6-Ω load. In order

to achieve 50 W into 6 Ω, the system designer must provide an adequate thermal design. See the Thermal

Methodology for the 32-Pin DAD Package 50 W, 6-Ω Test section for a discussion of possible thermal solutions.

Careful attention must be given to the value of the high-voltage power supply level for a given load resistance. See

recommended operating conditions. See the Maximum Available Power at Common Load Impedances for DAD

Packages section.

reconstruction output filter

An output reconstruction filter is required between the H-bridge outputs and the loudspeaker load. This second-order

low-pass filter passes the audio information to the loudspeaker, while filtering out the high-frequency out-of-band

information contained in the H-bridge output PWM pulses. The values of the L and C components selected are

dependent on the loudspeaker load impedance.

8

Page 9

TAS5110A

DC su ly voltage range

www.ti.com

SLES079A – APRIL 2003 – REVISED MAY 2003

Fault Indicator Usage

The TAS5110A is a self-protecting device that provides device fault reporting, including overtemperature protect,

undervoltage lockout (low regulator voltage), and short-circuit protection. The short circuit protection protects against

short circuits that may occur at the loudspeaker load when configured. The T AS5110A is not recommended for driving

loads less than 6 Ω, because the internal current limit protection might be activated.

An undervoltage lockout signal occurs when an insufficient voltage level is present on the LDROUTA or LDROUTB

pins. During this condition, gate drive levels are not sufficient for driving the power MOSFET s. Normal operation is

resumed when the minimum proper LDROUT A or LDROUTB level is obtained and the low regulator voltage protect

signal is de-asserted. See the control/sense circuitry section for error and warning conditions.

A high-temperature warning signal is asserted on pin ERR0

when the device temperature exceeds 125°C typical.

If the internal device temperature exceeds 150°C typical, the overtemperature protect signal is asserted and the

TAS51 10A is shut down. The device re-enables once the temperature drops to 125 °C typical. See the control/sense

circuitry section for error and warning conditions.

Detection of an illegal PWM input state or the loss of a clocking PWM input signal causes an illegal PWM input state

signal to be asserted on the ERR1and ERR0 pins and sets the SHUTDOWN pin to the low state.

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range unless otherwise noted

DVDD to DVSS –0.3 V to 4.2 V

PWM_AP, PWM_AM, PWM_BP , PWM_BM –0.3 V to DVDD + 0.3 V

DC supply voltage range

Output DMOS drain-to-source breakdown voltage 28 V

Operating junction temperature range, T

Storage temperature range, T

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds) 260°C

(1)

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

RESET, PWDN –0.3 V to DVDD + 0.3 V

PVDDA1 to PVSS, PVDDB1 to PVSS –0.3 V to 28 V

PVDDA2 to PVSS, PVDDB2 to PVSS 0.3 V to 27 V

J

stg

(1)

UNIT

–40°C to 150°C

–65°C to 150°C

9

Page 10

TAS5110A

yg

LOAD IMPEDANCE

PVDAA1/PVDDB1

APPROXIMATE MAXIMUM

THD+N AT MAXIMUM POWER

SLES079A – APRIL 2003 – REVISED MAY 2003

RECOMMENDED OPERATING CONDITIONS

(maximum output power = 50 W (RMS), TJ = 25°C)

www.ti.com

Thermal Data

T

J(SD)

T

J(W)

T

C

(2)

R

θJC

(2)

R

θJA

(1)

One of the most influential components on the thermal performance of a package is board design. In order to take full advantage of the heat

dissipating abilities of the PowerPAD packages, a board must be used that acts similar to a heat sink and allows for the use of the exposed (and

solderable), deep downset pad. See Appendix A of the PowerP AD Thermally Enhanced Package technical brief, TI literature number SLMA002.

(2)

For the DAD package.

(1)

MIN NOM MAX UNIT

Shutdown junction temperature 150 °C

Warning junction temperature 125 °C

Operating temperature Commercial 0 25 70 °C

Thermal resistance junction-to-case

Thermal resistance junction-to-ambient

pp

2 oz. trace and copper pad without solder

p

1.6 °C/W

44.3 °C/W

RL = 6 Ω to 8 Ω

MIN NOM MAX UNIT

Digital DVDD to DVSS 3 3.3 3.6 V

PVDDA2 to PVSS 16.5 22 26.5

Supply voltage

(1)

Connect LDROUT A to PVDDA2 and connect LDROUTB to PVDDB2. Under this condition, the H-bridge forward on-state resistance is increased.

This increases internal power dissipation. Maximum output power may need to be reduced to meet thermal conditions.

Regulator

PVDDB2 to PVSS 16.5 22 26.5

PVDDA2 to PVSS

PVDDB2 to PVSS

(1)

(1)

10.5 16.5

10.5 16.5

V

Maximum Available Power at Common Load Impedances for the DAD Package Unclipped (0 dB) Level

(Ω)

6 27 50 < 10%

6 27 43 < 0.09%

8 27 34 < 0.09%

(1)

Dependent on board design and component selection

(2)

T est conditions are described in the Thermal Methodology for the 32-Pin DAD Package 50 W , 6-Ω Test.

(VDC)

OUTPUT POWER (W)

AND 1-kHz INPUT

(2)

STATIC DIGITAL SPECIFICATIONS

RESET, PWDN, PWM_AP, PWM_AM, PWM_BP, PWM_BM, TJ = 25°C, DVDD = 3.3 V

PARAMETERS MIN MAX UNIT

V

V

ERR0, ERR1, SHUTDOWN, (Open Drain With Internal Pullup Resistor) TJ = 25°C, DVDD = 3.3 V)

V

High-level input voltage 2 V

IH

Low-level input voltage 0.8 V

IL

Input leakage current –10 10 µA

PARAMETERS MIN MAX UNIT

Internal pullup resistors from SHUTDOWN, ERR0, ERR1 to DVDD 15 kΩ

Low-level output voltage (IO = 4 mA) 0.4 V

OL

(1)

10

Page 11

TAS5110A

www.ti.com

SLES079A – APRIL 2003 – REVISED MAY 2003

ELECTRICAL CHARACTERISTICS

Supply, TJ = 25°C (FS = 384 kHz, OUTPUTA and OUTPUTB not connected, DVDD = 3.3 V, PVDDA1 = 25 V,

PVDDB1 = 25 V, PVDDA2 = 22 V, PVDDB2 = 22 V, 50% input duty cycle)

PARAMETER TYP MAX UNIT

DVDD

Supply current PVDDA1, PVDDB1

PVDDA2, PVDDB2

(1)

13-kΩ resistor from BIAS_A (pin 1 1) to DVSS and 13-kΩ resistor from BIAS_B (pin 12) to DVSS.

H-Bridge Transistors, PVDDA2 = PVDDB2 = 22 V, DVDD = 3.3 V, TJ = 25°C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Drain-to-source breakdown voltage ID = 1 mA, PWDN = 0, Hi-Z state 28 V

Forward on-state resistance, low-side drivers

OUTPUT A and OUTPUTB to PVSS

Forward on-state resistance, high-side drivers

PVDDA1 to OUTPUT A, PVDDB1 to OUTPUTB

On-state resistance matching, low-side drivers 98%

On-state resistance matching, high-side drivers 98%

(1)

T est time should be < 1 ms to minimize temperature change

(2)

These parameters are measured with voltage-sensing contacts separate from the current-carrying contacts.

(3)

Connect PVDDA2 and PVDDB2 to a 22-V power supply with respect to PVSS. LDROUT A, LDROUTB, BOOTSTRAP A, and BOOTSTRAPB pins

open.

(4)

Connect PVDDA2 to 22-V power supply with respect to PVSS. LDROUTA, LDROUTB, BOOTSTRAPA, and BOOTSTRAPB capacitors are

connected, respectively. Clock PWM inputs to allow bootstrap capacitors to charge. 93–99% modulation must be used on PWM_AP , PWM_AM,

PWM_BP , and PWM_BM inputs to prevent the activity detector from shutting down the device during this measurement. Note that FS = 384 kHz.

Operating 2 mA

PWDN = 0 500 µA

Operating

PWDN = 0 25 µA

Operating 6.5 mA

PWDN = 0 250 µA

I

= 2.5 A,

SINK

See Notes 1, 2, and 3,

I

SOURCE

See Notes 1, 2, and 4,

(1)

= 2.5 A,

PWM_AP = PWM_BP = 0,

PWM_AM = PWM_BM = 1

PWM_AP = PWM_BP = 1,

PWM_AM = PWM_BM = 0

6.3 mA

0.2 0.24 Ω

0.2 0.24 Ω

Electrical Characteristics, Voltage Regulator, TJ = 25°C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output voltage (LDROUTA, LDROUTB)

(1)

These voltage regulators are for internal gate drive circuits only and are not to be used under any circumstances to supply current to external

circuity.

IO = 5 mA, PVDDA2=PVDDB2 =18 V to 27 V,

See Note 1, DVDD = 3.3 V

14.5 15.3 16 V

11

Page 12

TAS5110A

SLES079A – APRIL 2003 – REVISED MAY 2003

160

140

120

100

80

60

40

– Junction Temperature – °C

J

T

20

Figure 4. Temperature vs On-State Resistance

JUNCTION TEMPERATURE

vs

ON-STA TE RESISTANCE

0

0.15 0.20 0.25 0.30 0.35 0.40

r

– On-State Resistance – Ω

(on)

www.ti.com

TAS50xx

RESET

PWM_M_L

PWM_P_L

VALID

3.3 V

Error

Reporting

APPLICATION INFORMATION

TAS5110A (DAD Package)

16

C2

C7

R2

R1

PWM_AP

15

PWM_AM

14

ERR1

13

ERR0

12

SHUTDOWN

11

DVDD

10

DVSS

9

DVSS

8

DVSS

7

VRFILT

6

BIAS_A

5

BIAS_B

4

PWDN

3

RESET

2

PWM_BM

1

PWM_BP

PVDDA2

LDROUTA

BOOTSTRAPA

PVDDA1

PVDDA1

OUTPUTA

OUTPUTA

OUTPUTB

OUTPUTB

PVDDB1

PVDDB1

BOOTSTRAPB

LDROUTB

PVDDB2

PVSS

PVSS

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

C5

22 V

C3 C4

C6

22 V

L1

L2

Snubber

Circuit

C1

Snubber

Circuit

dc

+

_

12

Figure 5. Typical TAS5110A Application (One Channel Shown)

Page 13

TAS5110A

www.ti.com

SLES079A – APRIL 2003 – REVISED MAY 2003

THERMAL INFORMATION

Traditionally, surface mount and power have been mutually exclusive terms. A variety of scaled-down TO-220 type

packages have leads formed as gull wings to make them applicable for surface-mount applications. These packages,

however, have two shortcomings: they do not address the low profile requirements (<2 mm) of many of today’s

advanced systems, and they do not offer a terminal count that is high enough to accommodate increasing integration.

On the other hand, traditional low-power surface-mount packages require power-dissipation derating that severely

limits the usable range of many high-performance analog circuits.

The PowerP AD package (thermally enhanced HTSSOP) combines fine-pitch surface-mount technology with thermal

performance comparable to much larger power packages.

The PowerPAD package is designed to optimize the heat transfer to the PCB. Because of the very small size and

limited mass of a HTSSOP package, thermal enhancement is achieved by improving the thermal conduction paths

that remove heat from the component. The thermal pad is formed using a patented lead-frame design and

manufacturing technique to provide a direct connection to the heat-generating IC. When this pad is soldered or

otherwise thermally coupled to an external heat dissipater, high power dissipation in the ultrathin, fine-pitch,

surface-mount package can be reliably achieved. See the dissipation derating table.

DAD Package

Thermal

Pad

Top V iew DAD

DIE

End View DAD

Figure 6. View of Thermally Enhanced DAD Package

13

Page 14

TAS5110A

www.ti.com

SLES079A – APRIL 2003 – REVISED MAY 2003

Thermal Methodology for the 32-Pin DAD Package 50 W, 6-Ω Test

The thermal test for the DAD part (e.g., thermal pad oriented away from the board) was conducted as shown in

Figure 7 and Figure 8. The cooling approach was to attach a heat sink to the thermal pad and conduct the heat to

ambient air.

Since the approach was to use a chassis below the board, it was inverted and a spacer bar used to connect the pads

thermally to the heat sink. The bar was made high enough that the components on the board were clear of the chassis.

The pad-to-spacer thermal resistance was about 3.2°C/W with the thermal compound indicated.

The chassis provided the only heat sink to air and was chosen as representative of a possible cooling approach. A

closed plastic top and insulating front and back panels ensured that only the bottom and sides of the U shaped chassis

contributed to cooling. The chassis was spaced 0.25 inch from the table to simulate a normal chassis configuration.

The thermal pad does not need to be isolated from ground. (Any heat sink with a thermal resistance to air of 3.9°C/W

or lower also works.) In this test, the exposed chassis reached long-term equilibrium temperatures above 50°C, so

the approach would have to be modified for touch temperature consideration. The chassis temperature after 10

minutes of 50 W into 6 Ω was below 50°C.

The test ran for three hours with 2 × 50 W RMS at 1 kHz into a 6-Ω resistive load at an ambient lab temperature of

23°C. No audio or thermal problems were encountered during that time.

Plastic Top Cover

Insulating

Front Panel

32 DAD Package

Wakefield T ype 126

Thermal Compound

(3.2°C/W)

Aluminum Space Bar

(1/4 in. Thick)

(2.44°C/W)

Wakefield T ype 126

Thermal Compound

(0.169°C/W)

Stereo Amplifier Board

1.25 in.

Aluminum Chassis 7.2 in. × 1 in. × 0.1 in. Thick.

Sides of U-Shaped Chassis Are 1.25 in. High

(3.9°C/W).

Figure 7. 32-Pin DAD Package Cross-Sectional View (Side)

Insulating

Back Panel

14

Page 15

www.ti.com

TAS5110A

SLES079A – APRIL 2003 – REVISED MAY 2003

Plastic Top and Insulating

Front and Back Panels

Stereo Amplifier Board

1.25 in.

Aluminum Space Bar (1/4 in. Thick)

Aluminum Chassis 7.2 in. × 1 in. × 0.1 in. Thick. Sides of

U-Shaped Chassis Are 1.25 in. High (3.9°C/W).

Figure 8. 32-Pin DAD Package Cross-Sectional View (Front)

32 DAD Packages

(1.6°C/W)

Wakefield T ype 126

Thermal Compound

(3.2°C/W)

(2.44°C/W)

2.33 in.

4-40 Machine Screws With

Star Washers

1 mm

Wakefield T ype 126

Thermal Compound

(0.169°C/W)

15

Page 16

Page 17

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty . Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. T o minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party , or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2003, Texas Instruments Incorporated

Loading...

Loading...