Page 1

Stellaris® MDL-BDC24 Brushed DC Motor

Control Module

Getting Started Guide

MDL-BDC24-GSG-04 Copyright © 2009–2011 Texas Instruments

Page 2

Copyright

Copyright © 2009–2011 Texas Instruments, Inc. All rights reserved. Stellaris and StellarisWare are registered trademarks of Texas Instruments.

ARM and Thumb are registered trademarks, and Cortex is a trademark of ARM Limited. Other names and brands may be claimed as the property

of others.

Texas Instruments

108 Wild Basin, Suite 350

Austin, TX 78746

http://www.ti.com/stellaris

2 January 5, 2011

Page 3

Stellaris® Brushed DC Motor Control User’s Manual

Table of Contents

Chapter 1: Introduction to Jaguar................................................................................................................... 5

Features.............................................................................................................................................................. 7

Differences between the MDL-BDC and MDL-BDC24 ....................................................................................... 8

Warnings............................................................................................................................................................. 8

Chapter 2: General Operation.......................................................................................................................... 9

Operating Modes .............................................................................................................................................. 10

Fault Conditions ............................................................................................................................................ 10

Coast/Brake Jumper ..................................................................................................................................... 11

Power and Motor Wiring ............................................................................................................................... 11

Chapter 3: Servo/PWM-based Control.......................................................................................................... 13

Servo-style PWM Speed Control Input ............................................................................................................. 13

Calibrating the PWM Input ............................................................................................................................ 13

Chapter 4: Introduction to Network-Based Control.....................................................................................15

Network Security and System Safety ............................................................................................................... 15

Trusted Mode (FIRST Robotics Competition feature) ...................................................................................... 15

Chapter 5: Operation using the RS232 Interface.........................................................................................17

BDC-COMM Application Overview ................................................................................................................... 17

Chapter 6: Firmware Update Using BDC-COMM ......... ................................................................................19

Important Information........................................................................................................................................ 19

Step 1: Hardware Setup................................................................................................................................ 19

Step 2: Run BDC-COMM.............................................................................................................................. 20

Step 3: Assign Unique CAN ID ..................................................................................................................... 20

Step 4: Update Firmware .............................................................................................................................. 20

Chapter 7: Closed-Loop Control Options.....................................................................................................21

Wiring................................................................................................................................................................ 21

Constant Current Control.................................................................................................................................. 22

Position Control using an Encoder ................................................................................................................... 22

Position Control Using a Potentiometer............................................................................................................ 23

Speed Control................................................................................................................................................... 23

Chapter 8: Operation Using the CAN Interface............................................................................................ 25

CAN Overview .................................................................................................................................................. 25

CAN IDs............................................................................................................................................................ 25

CAN Network .................................................................................................................................................... 25

Control Options for Networked Jaguar Modules ............................................................................................... 26

Appendix A: Jaguar Communication Cables...............................................................................................29

CAN Terminator................................................................................................................................................ 29

CAN Cable........................................................................................................................................................ 29

CAN Cable Assembly ................................................................................................................................... 30

CAN Cable Pin Assignments ........................................................................................................................ 30

RS232 Cable .................................................................................................................................................... 30

RS232 Cable Assembly ................................................................................................................................ 30

RS232 Cable Pin Assignments..................................................................................................................... 31

External References ......................................................................................................................................... 31

January 5, 2011 3

Page 4

4 January 5, 2011

Page 5

CHAPTER 1

Introduction to Jaguar

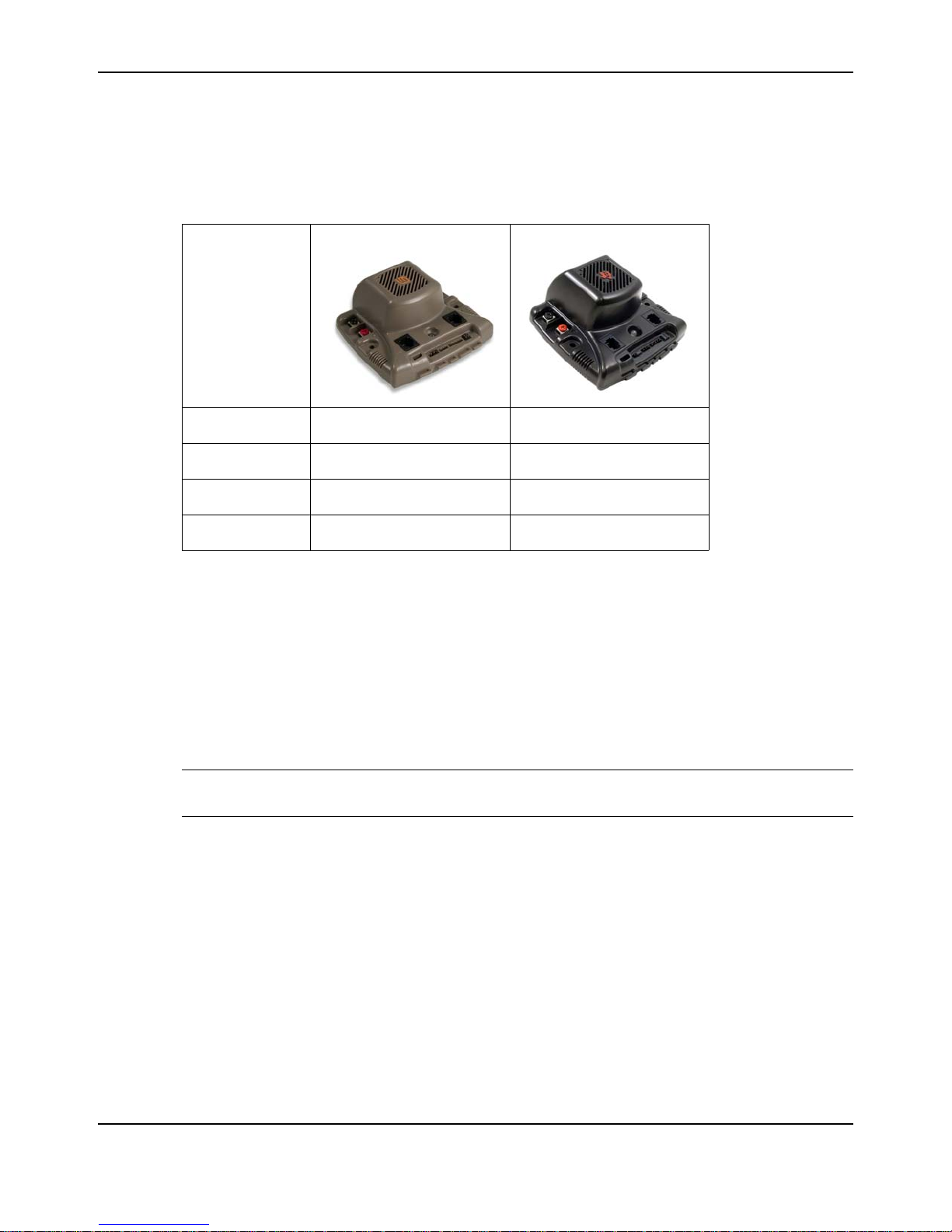

Texas Instruments presents the next generation FIRST Robotics Competition (FRC) motor

controller: the MDL-BDC24 brushed DC motor control (also known as Black Jaguar). The

MDL-BDC24 builds on the success of the first-generation MDL-BDC (Gray Jaguar) by adding an

RS232-to-CAN gateway and enhanced electrical performance. Designed specifically for the FRC

competition, the MDL-BDC and MDL-BDC24 modules facilitate the design of complex robots

within the short six-week FRC build period.

This document provides a complete description of how to use Jaguar in both Networked and Servo

control modes. Information applies to both the MDL-BDC and MDL-BDC24 models except where

noted. Additional information can be found in the MDL-BDC and MDL-BDC24 data sheets, as well

as in related application notes.

Figure 1-1. Next Generation Brushed DC Motor Control Module, MDL-BDC24

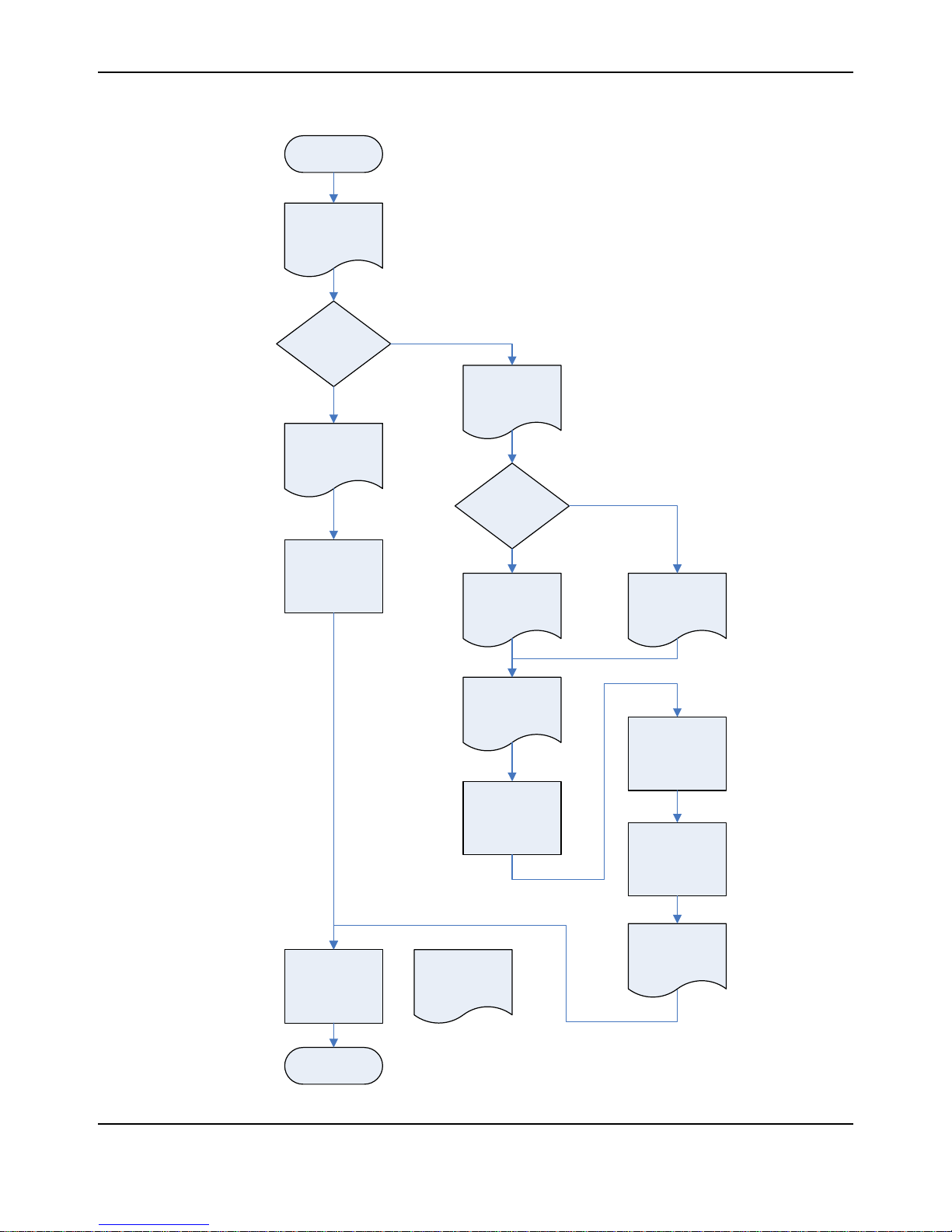

The flowchart in Figure 1-2 provides an overview of the process of developing with the MDL-BDC

and MDL-BDC24 modules. We suggest checking off each step as it is completed.

January 5, 2011 5

Page 6

Getting Started

with Jaguar

Connect:

- Servo cable

- Power cable

- Motor cable

Decision:

Control using

Servo/PWM or

Network?

Read Jaguar GSG

Introduction and

General Operation

Chapters

Servo/PWM

Read Jaguar GSG

Servo/PWM

Control

Chapter

Ready to Run!

Read Jaguar GSG

Introduction to

Network Control

Chapter

Decision :

CAN Interface

Method

Network

Read 3rd Party

CAN Bridge

documentation

3rd Party CAN Interface

Assemble and

connect cables:

- RS232/CAN

- Power

Read Jaguar GSG

Operation using

RS232 Chapter

Read Jaguar GSG

Firmware Update

using BDC-COMM

Chapter

Update firmware in

each Jaguar

Connect to cRIO-

based FRC control

system

Black Jaguar Bridge

Read Jaguar GSG

Operation using

the CAN Interfac e

Chapter

Appendix A

Jaguar Cable

Assemblie s

Assign CAN ID

(ID Value > 1)

Introduction to Jaguar

Figure 1-2. MDL-BDC24 Development Process

6 January 5, 2011

Page 7

Features

The Stellaris® Brushed DC Motor Control Module with CAN (MDL-BDC24) offers a variable speed

control for 12 V and 24 V brushed DC motors at up to 40 A continuous current. The motor control

module includes high performance Controller Area Network (CAN) connectivity and a rich set of

control options and sensor interfaces, including analog and quadrature encoder interfaces. The

high-frequency PWM on the MDL-BDC24 enables DC motors to run smoothly and quietly over a

wide speed range. The module uses highly optimized software and a powerful 32-bit Stellaris®

microcontroller to implement open-loop speed control as well as closed-loop control of speed,

position, or motor current.

The MDL-BDC24 provides the following features:

Quiet control of brushed DC motors

Three options for Speed control

CAN communication

Getting Started Guide

– 15 kHz PWM frequency

– Industry-standard R-C servo type (PWM) interface

– Controller Area Network (CAN) interface

– RS232 serial interface

– Multicast shared serial bus for connecting systems in electromagnetically noisy

environments

– 1M bits/s bit rate

– CAN protocol version 2.0 B

– Full configurability of module options

– Real-time monitoring of current, voltage, speed, and other parameters

– Firmware update

RS232 serial communication

– Bridges RS232 port to a CAN network

– Directly interfaces to a PC serial port or National Instruments cRIO

Status LED indicates Run, Direction, and Fault conditions

Motor brake/coast selector

Limit switch inputs for forward and reverse directions

Quadrature encoder input (QEI)

– Index input

– 5 V supply output to encoder

Analog input

– Accepts 10 kΩ potentiometer or 0-3 V input

Screw terminals for all power wiring

Headers (0.1 inch pitch) for all control signals

January 5, 2011 7

Page 8

Introduction to Jaguar

Differences between the MDL-BDC and MDL-BDC24

First generation Jaguar motor controls (MDL-BDC) have similar capabilities to the second

generation Jaguar (MDL-BDC24). Functional differences are summarized in Table 1-1.

Table 1-1. MDL-BDC and MDL-BDC24 Differences

MDL-BDC (Gray) MDL-BDC24 (Black)

Feature

Part Number

Voltage Range

RS232C Port

Terminal Screws

a. Captive terminal screws should not be removed because metal debris can be created.

b. Non-captive screws are safe to remove and are compatible with ring-terminal use.

Internally, the MDL-BDC24 is a completely new design that makes use of switching converters and

synchronous rectification to improve overall energy efficiency.

Software should be updated to the latest version to ensure that all capabilities of the MDL-BDC or

MDL-BDC24 module are enabled and functional.

Warnings

WARNING – Be aware of the following warnings. Failure to heed warnings can result in damage

to the module or invalidation of the module warranty.

Mount the Jaguar module so that the vents in the top and sides of the unit are not restricted in

any way. Maintain a clearance of at least ½ inch between modules.

MDL-BDC MDL-BDC24

6–13 V 6–30 V

No Yes

Captive – Do not remove

a

Loose – Okay to remove

b

Reverse wiring is unprotected; doing so voids the Jaguar module's warranty.

Do not exceed the absolute maximum supply voltage (30 V

MDL-BDC). Doing so causes permanent damage to the module.

Protect Jaguar from all situations where debris could enter through ventilation slots or

connector openings.

8 January 5, 2011

for MDL-BDC24, 13 V for

DC

Page 9

Motor

Out

(–) Motor

(+) Mo tor

(–) In

(+) In

From Power

Distributio n

Module

M ot or outpu t is not pr ot e ct e d

against short-circuits.

User Switch

Use hooks to prevent

wires shaking loose

Maintain 0.5" cl earance

around all vents

Stat us LE D

Mounting holes

3.50" centers

Motor coast/brake jumper

Ma in ta in 0. 5" cl e ar an ce

around all vents

For power wiring use

12 A W G W ire w it h #6 ri ng

or spade terminals

CAN P ort

RS232/CAN Port

Anal og input (0-3V)

Encoder Input

Limit switch inputs

CHAPTER 2

General Operation

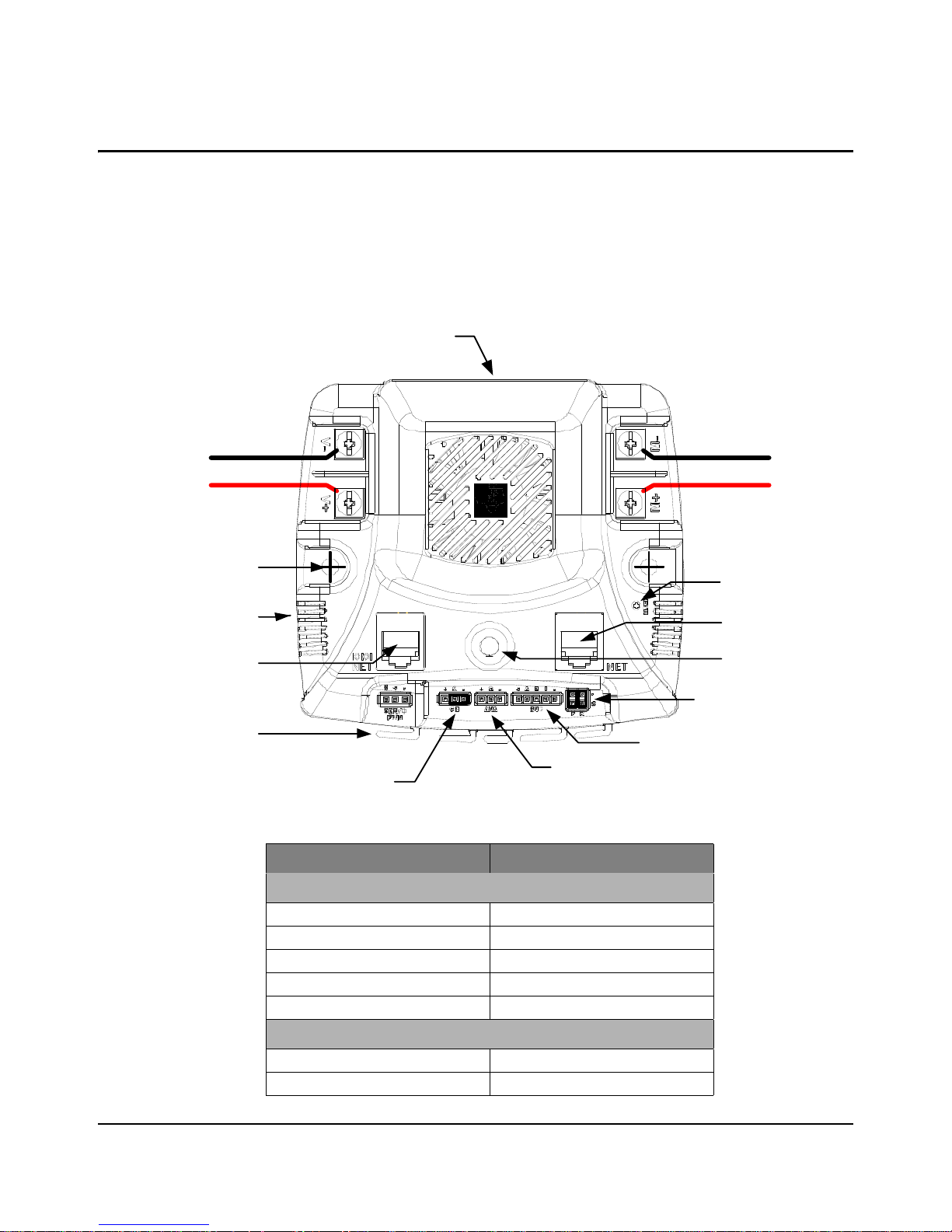

This chapter describes the general operation of the MDL-BDC24 motor control module. Figure 2-1

shows the key features of the MDL-BDC24 motor control. Table 2-1 provides a key to the status

LED.

Figure 2-1. MDL-BDC24 Key Features

January 5, 2011 9

Table 2-1.

Table 2-2. Status LED

Normal Operating Conditions

Solid Yellow Neutral (speed set to 0)

Fast Flashing Green Forward

Fast Flashing Red Reverse

Solid Green Full-speed forward

Solid Red Full-speed reverse

Fault Conditions

Slow Flashing Yellow Loss of servo or Network link

Fast Flashing Yellow Invalid CAN ID

LED State Module Status

Page 10

General Operation

Table 2-2. Status LED (Continued)

Slow Flashing Red Fault condition

Calibration Conditions

Fast Flashing Red and Green Calibration mode active

Fast Flashing Red and Yellow Calibration mode failure

Fast Flashing Green and Yellow Calibration mode success

Slow Flashing Red and Green

Operating Modes

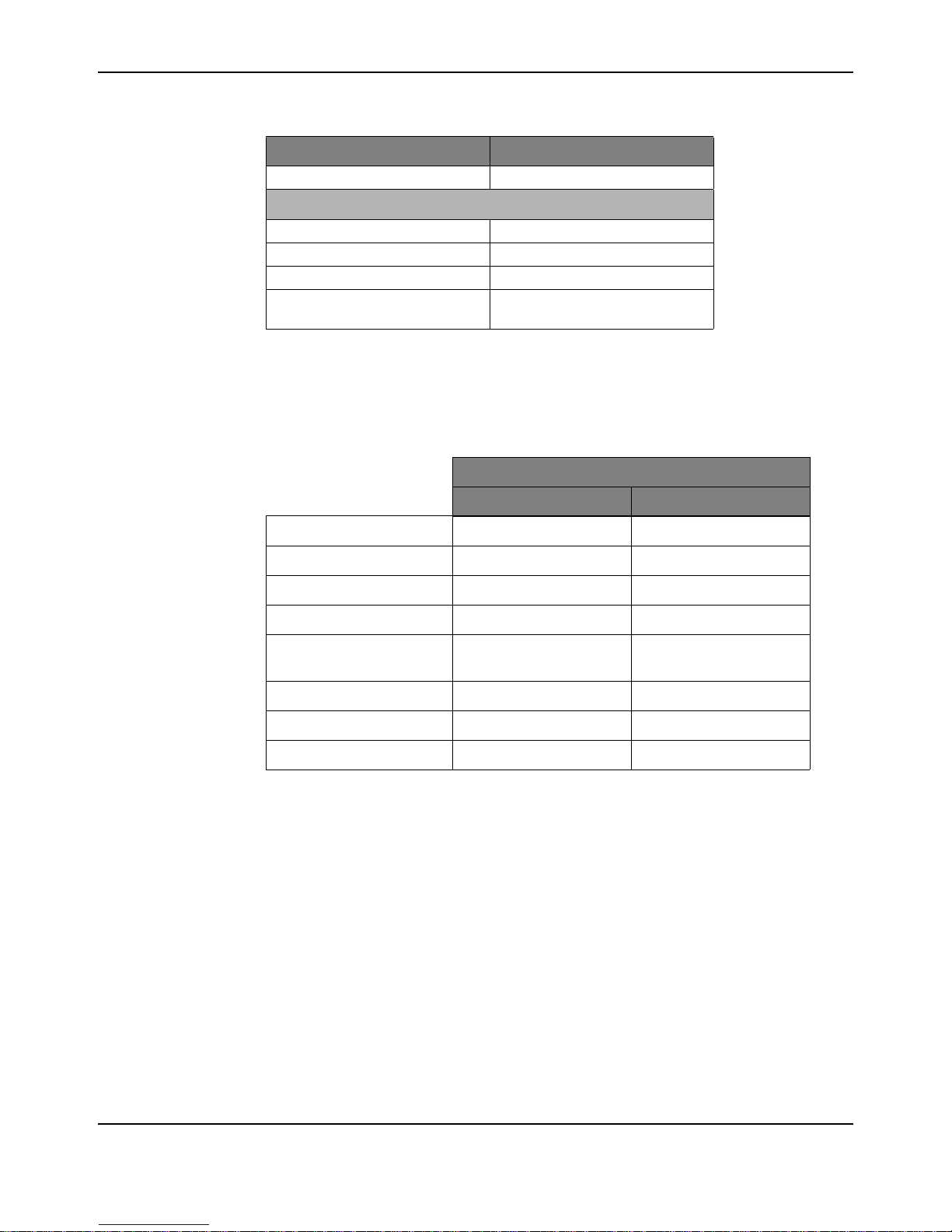

The MDL-BDC24 can be controlled using either the Servo-style PWM Input or the CAN interface.

Table 2-3 compares the capabilities of each control method.

Table 2-3.

Table 2-4. Control Method Comparison

LED State Module Status

Calibration mode reset to factory

default settings success

Control Method

Servo-Style PWM input CAN/RS232C Interface

Jaguar supports the simultaneous use of CAN for monitoring and the Servo-style input for speed.

Fault Conditions

A slow flashing Red LED indicates that the MDL-BDC24 detected one of the following fault

conditions:

Power supply under-voltage

Over temperature

Speed Control Yes Yes

Analog Position Control No Yes

Encoder Position Control No Yes

Configurable Parameters No Yes

Voltage, Current

Measurement

Limit Switches Yes Yes

Coast/Brake Feature Yes Yes

Firmware Update No Yes

a. By default, the jumper sets coast/brake. Network commands can over-ride the jumper

setting.

No Yes

a

Over current

Limit switch activated in the current direction of motion

When a fault condition occurs, the motor shuts down and the LED indicates a fault state during the

fault condition and for 3 seconds after the fault cause is cleared (except for the limit switch fault,

10 January 5, 2011

Page 11

which is cleared instantly). A slow flashing Yellow LED indicates that the MDL-BDC24 is not

receiving a valid control signal.

Coast/Brake Jumper

The coast/brake signal controls the dynamics of the drive signal to the motor. When set to brake,

the MDL-BDC24 is able to achieve greater deceleration and holding torque because it decays

regenerative current from the motor.

The coast/brake signal can be set with a jumper or controlled by a signal from a digital source. A

single wire connected to the center (S) pin, is recommended. Do not connect to the + pin (+3.3 V)

of this connector as any mis-wiring could damage the MDL-BDC24.

The coast/brake jumper setting can be overwritten when using the CAN/RS232 interface.

Power and Motor Wiring

The Overview diagram (Figure 1-2 on page 6) shows motor and power connections to the

MDL-BDC24. For power wiring, use 10-12 AWG wire terminated with #6 ring or spade terminals.

The control is not protected against reverse polarity or short-circuits.

Getting Started Guide

January 5, 2011 11

Page 12

General Operation

12 January 5, 2011

Page 13

Motor

Out

(–) Motor

(+) Motor

P W M speed

signal from

Di g it al Sid ecar

+5V

GN D

Reverse direction

switch(es)

Normally-closed

Li mi t switches

(–) In

(+) In

From Power

Distribution

Module

User Switch

PWM

+5V is o ptional (no internal connection)

Status LED

Forward direction

swi tch(e s)

Ins tall jumpers if

limit switc hes are

not used.

CHAPTER 3

Servo/PWM-based Control

The MDL-BDC and MDL-BDC24 both support speed and direction control through a servo-style

PWM input. Figure 3-1 shows the servo-wiring details.

Figure 3-1. Wiring for Servo-style PWM Control

Servo-style PWM Speed Control Input

Calibrating the PWM Input

January 5, 2011 13

The servo PWM input controls motor speed and direction. The digital signal must meet the timing

and voltage requirements listed in the MDL-BDC24 specifications. The center pin (+) has no

internal connection. Because the signal is optically isolated, both the signal (S) and GND (-) pins

must be connected to the signal source.

The servo-style PWM input is optically isolated. All other control inputs are non-isolated and are

referenced to the power supply (-).

To accommodate variation in the timing of the supplied signal, Jaguar has a calibrate feature that

sets new values for full-forward, full-reverse and points in between. Calibration is normally only

required in applications where the PWM source has uncertainties due to analog radio links or other

variables. Direct digital sources are unlikely to require calibration.

Page 14

Servo/PWM-based Control

To calibrate the servo-style PWM input for a specific range, connect a PWM source, then:

1. Hold down the USER switch with a straightened paperclip for 5 seconds.

2. The LED flashes Red and Green to indicate Calibration mode.

3. Instruct the controller to send a full-forward signal for one or more seconds.

4. Instruct the controller to send a full-reverse signal for one or more seconds.

5. The LED flashes Green and Yellow quickly to indicate a successful calibration.

The MDL-BDC24 samples these signals and centers the speed range and neutral position

between these limits. A calibration failure signals if an out-of-range signal is detected. This

condition is indicated by flashing the LED Red and Yellow.

14 January 5, 2011

Page 15

CHAPTER 4

Introduction to Network-Based Control

Both MDL-BDC and MDL-BDC24 support CAN-based control, configuration and firmware

updates. MDL-BDC24 also supports the same command set over RS232.

Network Security and System Safety

The factory default network protocol allows for very flexible control networks with all commands

being accepted and executed without restriction. However, a vulnerability is that faulty software

has the potential to send errant messages. To address the possibility that motors could run when

they are not supposed to, a special set of trusted commands have been added. This capability is

supported in an FRC-specific firmware update. All MDL-BDC and MDL-BDC24 modules must

have updated firmware if they are to be used with CAN or RS232 communication in an FRC

competition.

Trusted Mode (FIRST Robotics Competition feature)

Each MDL-BDC and MDL-BDC24 module expects to see a trusted message from the Host every

100 ms. If a trusted message is not received, the MDL-BDC and MDL-BDC24 module shut down

the motor output until trusted communication is restored.

Trusted communication relies on a proprietary protocol that defines a dynamic message token,

known only to the host driver and a specific MDL-BDC or MDL-BDC24 module.

Non-FIRST users should use the factory-default firmware (available in source form) which does

not implement trusted communication.

January 5, 2011 15

Page 16

Introduction to Network-Based Control

16 January 5, 2011

Page 17

Motor

Out

(–) Motor

(+) Motor

(–) In

(+) In

From Power

Distribution

Module

DB9 Adapter

Connect to

Host Controller

(PC, cRIO)

To other CAN

Devices

Black Jaguar bridges

RS232 to CAN

CHAPTER 5

Operation using the RS232 Interface

The MDL-BDC24 supports a full set of network control and configuration functions over a standard

RS232C serial interface. The command protocol is essentially the same as the protocol used on

the CAN interface allowing the MDL-BDC24 to automatically bridge all commands between the

RS232 and CAN interfaces.

RS232 signals are implemented on the left-side NET connector, which has a special IOIOI

annotation as shown in Figure 5-1.

Figure 5-1. MDL-BDC24 Bridges for RS232 to CAN

See Appendix A, “Jaguar Communication Cables,” on page 29 for details of the RS232 cable

assembly. The recommended DB9 adapter design contains an integrated CAN terminator.

BDC-COMM Application Overview

BDC-COMM is a Windows application for configuring and controlling a Jaguar network using a PC’s

RS232 serial port. It is also a convenient tool for performing firmware updates. BDC-COMM requires

the use of an

MDL-BDC24 to bridge RS232 to CAN. Figure 5-2 on page 18 shows the main GUI

window of the BDC-COMM application.

January 5, 2011 17

Page 18

Operation using the RS232 Interface

Figure 5-2. BDC-COMM GUI Main Window

18 January 5, 2011

Page 19

Connect to PC

Seri al Port

Connec t to PC

Serial Port

JaguarBlack Jaguar

Black Jaguar

Ter mi nator

Ter minator

Firmware Update

Update Firmware

on this Jaguar

RS232/CAN Bridge

Firmware Update

CHAPTER 6

Firmware Update Using BDC-COMM

Firmware update capability allows Texas Instruments to provide new software, in binary format,

that contains feature enhancements and bug fixes.

Special firmware releases have been created for FRC 2010. Both MDL-BDC and MDL-BDC24

have firmware updates available. This firmware update must be installed prior to using RS232 or

CAN-based control. Firmware update is optional for Servo/PWM control.

Firmware update requires RS232 and CAN cables, at least one MDL-BDC24, the binary file, a PC

with an RS232 port, and a 12 V power source.

The BDC-COMM Application User’s Guide contains additional detail on using the tool for firmware

update as well as other configuration and control functions.

Important Information

Observe the following precautions when updating firmware:

We strongly recommend connecting only one Jaguar to the network at a time. The exception is

when updating a single first generation (MDL-BDC) Jaguar. To update an MDL-BDC Jaguar,

add only theMDL-BDC24 that is being used as the RS232-to-CAN bridge.

Use the correct binary file. For first generation MDL-BDC modules, the file is named

QS-BDC.bin. For second generation MDL-BDC24 modules (black), the file is named

QS-BDC24.bin

Step 1: Hardware Setup

Connect an MDL-BDC24 (black) to a PC following the information in Chapter 5, “Operation

using the RS232 Interface” on page 17.

If a first-generation (MDL-BDC) Jaguar (gray) requires firmware update, then connect it to the

MDL-BDC24 (see Figure 6-1).

Apply power. The LED on the Jaguar(s) flash yellow indicating loss-of-link.

Figure 6-1. Valid Conf igurations for Firmware Update

January 5, 2011 19

Page 20

Firmware Update Using BDC-COMM

Step 2: Run BDC-COMM

Run BDC-COMM.EXE.

The LED on the Jaguar(s) should now be solid yellow indicating a valid network link. If the LED

is not solid yellow, check all network connections as well as the BDC-COMM Com Port setting.

A valid link must be established before proceeding to the next step.

Step 3: Assign Unique CAN ID

If two modules are connected, each must have a unique CAN ID. The factory default CAN ID

is 1.

Assign the Jaguar modules the ID > 1 so that new Jaguar modules from the factory do not

operate on your robot.

Using the BDC-COMM application, select the System tab and enter a new ID (a unique

number from 2..63).

Click “Assign.” The LED on the module(s) starts flashing green.

Press the USER button on the module that is to receive the new ID. This must be done within

5 seconds or the operation times out.

The module’s LED blinks the number of times that corresponds to the ID if assignment was

successful (for example, if you assign the unique ID number of 5, the LED blinks five times).

A fast-flashing yellow LED indicates an invalid CAN ID. This can occur if an attempt is made to

reassign an ID that is already in use.

Step 4: Update Firmware

A valid link must be established before proceeding. Ensure that the LED indicates solid yellow.

It might be necessary to reconnect to the CAN network to synchronize the trusted link.

Select the board ID that you want to update using the “Board ID” menu.

Select File > Update Firmware from the top menu bar.

Browse to locate the appropriate binary file:

– The MDL-BDC24 (black) uses the qs-bdc24.bin file.

– The MDL-BDC (gray) uses the qs-bdc.bin file.

Click OK and then click Update.

A progress bar displays the firmware update progress.

When the firmware update completes, reconnect bdc-comm to the network to re-establish a

link.

The System tab in BDC-COMM displays the firmware version.

20 January 5, 2011

Page 21

CHAPTER 7

Closed-Loop Control Options

A network-controlled Jaguar supports several types of closed-loop control through an internal PID

controller.

Constant-current control

Position control using an encoder

Position control using a potentiometer

Speed control

Only one mode can be used at a time.

For each control mode, refer to API, VI, or tool documentation for information on which commands

to use for configuration.

Wiring

All closed-loop mode, except for constant-current control, require an external sensor. Figure 7-1

shows an advanced wiring configuration using the CAN interface. The diagram shows wiring for

position sensing using both a position potentiometer and a quadrature encoder. Although two

sensor types are shown, the MDL-BDC software supports control and monitoring of only one

sensor at a time.

January 5, 2011 21

Page 22

Closed-Loop Control Options

(-) Supply / GND

(+) Supply

Power In

Motor Out

(-) Motor

(+) Motor

External coast/brake

control (optional)

H=Coast, L=Brake

Normally-closed

limit switches

10kΩ Potentiometer

position sensor (opt)

CAN cable to/from

other devices

CAN cable to/from

other devices

Encoder

(opt)

+3V Reference

0-3V signal

GND

+5V supply

A signal

B signal

Index signal

GND

GND

GND

GND

Forward Limit

Reverse Limit

User switch

sets CAN ID

Figure 7-1. Advanced Wiring Diagram

Constant Current Control

The MDL-BDC and MDL-BDC24 modules default to voltage control, but in some applications

current (ampere) control is a more useful parameter. In this mode, the MDL-BDC and

MDL-BDC24’s internal current sensor is used to complete a constant-current control loop. The

capabilities of this mode are a function of the motor’s parameters and the electrical specification

for the module as listed in the data sheet. A small DC motor might not be suitable for use with the

Jaguar’s constant-current mode.

No additional wiring is needed for constant current control.

Position Control using an Encoder

22 January 5, 2011

In position control mode, the MDL-BDC and MDL-BDC24 modules accept position commands

over the network, and then use an internal PID controller to autonomously move the motor to the

specified position.

The QEI software position count changes on each pulse of the Encoder A input. For example, a

360° movement of a 100 pulse-per-revolution (PPR) encoder results in a 100-count change in the

position value. PPR is sometimes referred to as the number of lines that an encoder has.

The relationship between the Encoder B input and the Encoder A input determines whether the

position counter increments or decrements.

Page 23

An edge on the Index (“I”) input resets the position counter to zero.

The MDL-BDC and MDL-BDC24 modules support a wide range of shaft encoders. Encoder

electrical parameters are detailed in the corresponding data sheets.

If the P, I and D parameters are positive (or zero), the MDL-BDC and MDL-BDC24 modules expect

that a forward condition (+ voltage on White terminal, - voltage on Green) generates increasing

counts on the encoder interface. Increasing counts occur when the rising (or falling) edge of the A

input leads the rising (or falling) edge of the B input.

If the P, I and D parameters are negative (or zero), the MDL-BDC and MDL-BDC24 modules

expect that a forward condition (+ voltage on White terminal, - voltage on Green) generates

decreasing counts on the encoder interface. Decreasing counts occur when the rising (or falling)

edge of the B input leads the rising (or falling) edge of the A input.

See Figure 7-1 on page 22 for wiring information. For reliable operation, keep encoder wiring short

and route it away from noise sources. The encoder inputs are not electrically isolated.

Position Control Using a Potentiometer

Position control can also be implemented with a single or multi-turn potentiometer. Potentiometers

with continuous rotation are not supported.

The MDL-BDC and MDL-BDC24 modules contain a built-in bias pin for use with 10 kΩ

potentiometers. If another potentiometer value or analog source is used, it must have a 0-3 V

range.

Getting Started Guide

If the P, I and D parameters are positive (or zero), Jaguar expects that a forward condition (+

voltage on White terminal, - voltage on Green) generates an increasing voltage on the analog

input.

If the P, I and D parameters are positive (or zero), Jaguar expects that a forward condition (+

voltage on White terminal, - voltage on Green) generates a decreasing voltage on the analog

input.

The analog input is not electrically isolated.

Speed Control

Speed control can be implemented with either an encoder or with a simple tachometer sensor. If a

tachometer sensor is used (such as a gear-tooth sensor), then the signal should be connected to

the Encoder ‘A’ input signal, with the ‘B’ and ‘I’ input left unconnected.

The speed set-point is defined in revolutions per second. Adjust the encoder-lines parameter if the

sensor generates more than one pulse per revolution.

January 5, 2011 23

Page 24

Closed-Loop Control Options

24 January 5, 2011

Page 25

CHAPTER 8

Operation Using the CAN Interface

CAN Overview

Controller Area Network (CAN) provides a powerful interface for controlling one or more Jaguar

modules. Jaguar has a 6P6C socket and a 6P4C socket for daisy-chaining modules using

standard cables. Each end of the CAN network should be terminated with a 100

The CAN protocol used by Jaguar includes the following capabilities:

Firmware update over CAN

Read supply voltage, motor voltage, temperature and current

Set and read motor voltage or target position

Set control mode to speed or position

Configure parameters

Enable features such as closed-loop speed and position control.

Trusted communication with keep-alive commands for fail-safe operation

CAN IDs

Each MDL-BDC24 module on the CAN bus is accessed using an assigned ID number. The ID

defaults to 1, but should be changed to a unique value from 2 to 63 by following the ID Assignment

procedure. The procedure is detailed in Step 3 of the firmware update procedure in Chapter 6,

“Firmware Update Using BDC-COMM”, page 19.

Ω resistor.

At the network protocol level, ID assignment involves the following:

1. The Host sends Assign ID + number command to all Jaguar modules.

2. Pressing the USER switch on an MDL-BDC24 informs that particular module to accept the

previously specified ID number and save it to non-volatile memory. The operation times out if a

switch is not pressed within 5 seconds.

3. The Jaguar with the new ID assignment sends out a message to let all Jaguar modules know

that the ID assignment is complete. Normal operation resumes.

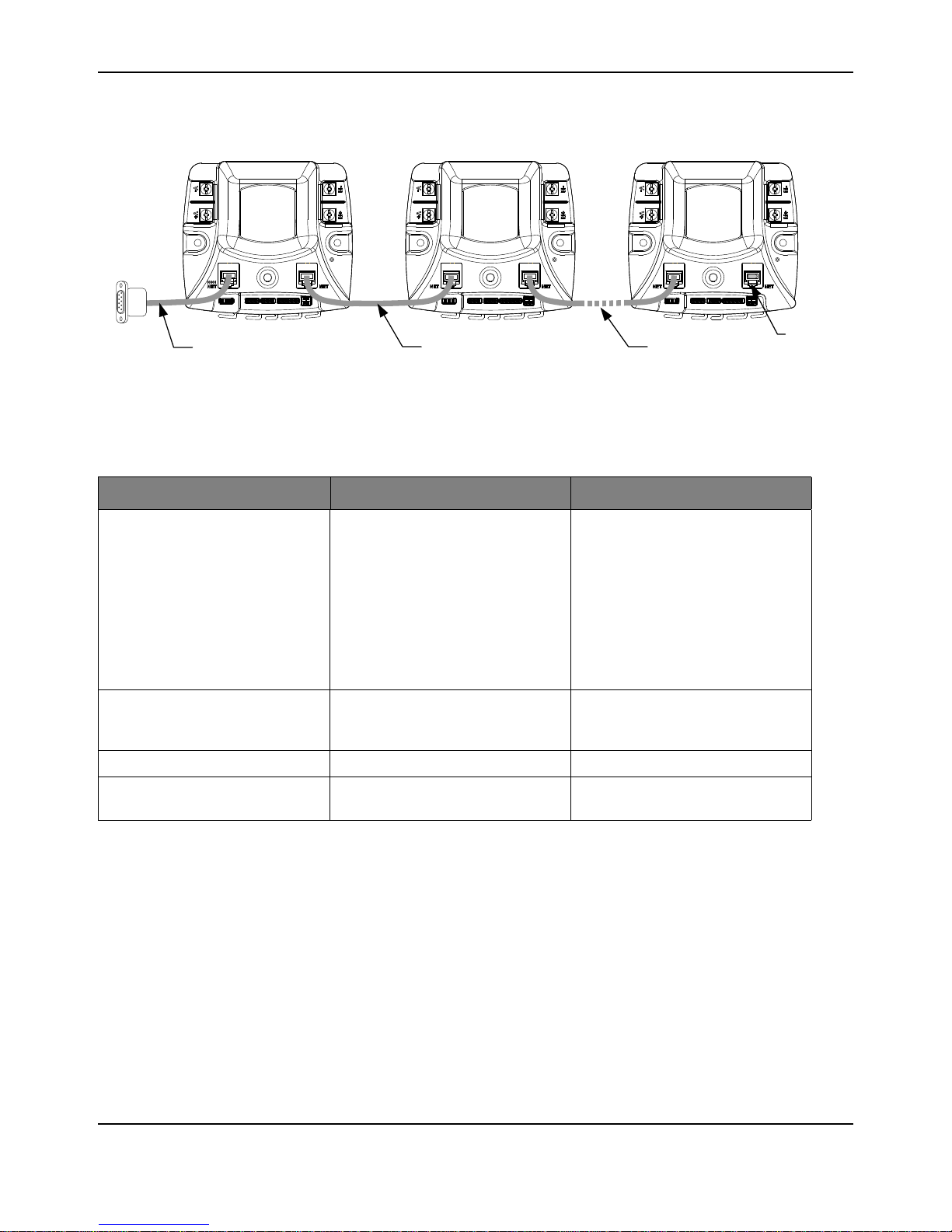

CAN Network

A CAN network consists of one or more Jaguar modules, an interface or bridge, and a host

controller. Figure 8-1 shows a typical configuration.

January 5, 2011 25

Page 26

Operation Using the CAN Interface

Connect to cRIO

Seri al Port

Jaguar or Black JaguarBlack Jaguar

Serial to 6P6C cable

Jaguar or Black Jaguar

Terminator

Plug

Additional Jaguars6P4C or 6P6C modular cable

Figure 8-1. CAN Network Topology

CAN cabling follows a daisy-chained topology using modular cable. Table 8-1 lists network

parameters.

Table 8-1. CAN Wiring Parameters

Parameter Value Notes

Maximum Nodes 16 A node is defined as a device on the

CAN network. This includes all

Jaguar modules and any device that

sends and receives CAN messages.

If you use the Black Jaguar as a

bridge, all Jaguar modules (gray or

black, including the Bridge) count as

nodes, but the computer (or CRIO)

does not since it is sending

messages over the serial port.

Total Cable Length (maximum) 20 ft / 6.1m Tip: Start with this length of bulk cable

and cut all segments from it to ensure

compliance.

Termination Resistance 100 At each end of the network.

Cable Type 4 or 6 conductor modular cable. 28 or

26 AWG.

See Appendix A, “Jaguar Communication Cables,” on page 29 for cable and terminator assembly

instructions.

Control Options for Networked Jaguar Modules

The Host controller on a Jaguar network requires a software driver to implement the CAN

communication protocol. Protocol details are available from the RDK-BDC24 pages at

www.luminarymicro.com/jaguar To simplify programming, National Instruments and Texas

Instruments have created a range of tools to simplify Jaguar control.

The following Host tools/APIs/Virtual Instruments are available:

BDC-COMM is a Windows application for configuring, testing, and performing firmware

upgrades.

26 January 5, 2011

Page 27

Getting Started Guide

LabView VI

Java API

C++ API

Example source code for a host-based on a Stellaris Microcontroller can be found in

StellarisWare® (\boards\rdk-bdc\bdc-ui) also available at www.luminarymicro.com/jaguar.

January 5, 2011 27

Page 28

Operation Using the CAN Interface

28 January 5, 2011

Page 29

100 ohm 1/6 W Resistor

Digikey 100EBK- ND or similar

6P6C Modular Plug

AMP 5- 556384- 3 or sim ilar

Crimp resistor lead s

to center contacts

Modular plug for stranded flat oval cable

AMP P/No. 5-641335

Digikey Stock No. A9092-ND

Modular cable – 4 conductor

Assmann Elect. AT-K-26-4-S/100-R

Digikey Stock No. A0043R-100-ND

2x

6P6C/6P4C Modular Plug Crimp Tool

APPENDIX A

Jaguar Communication Cables

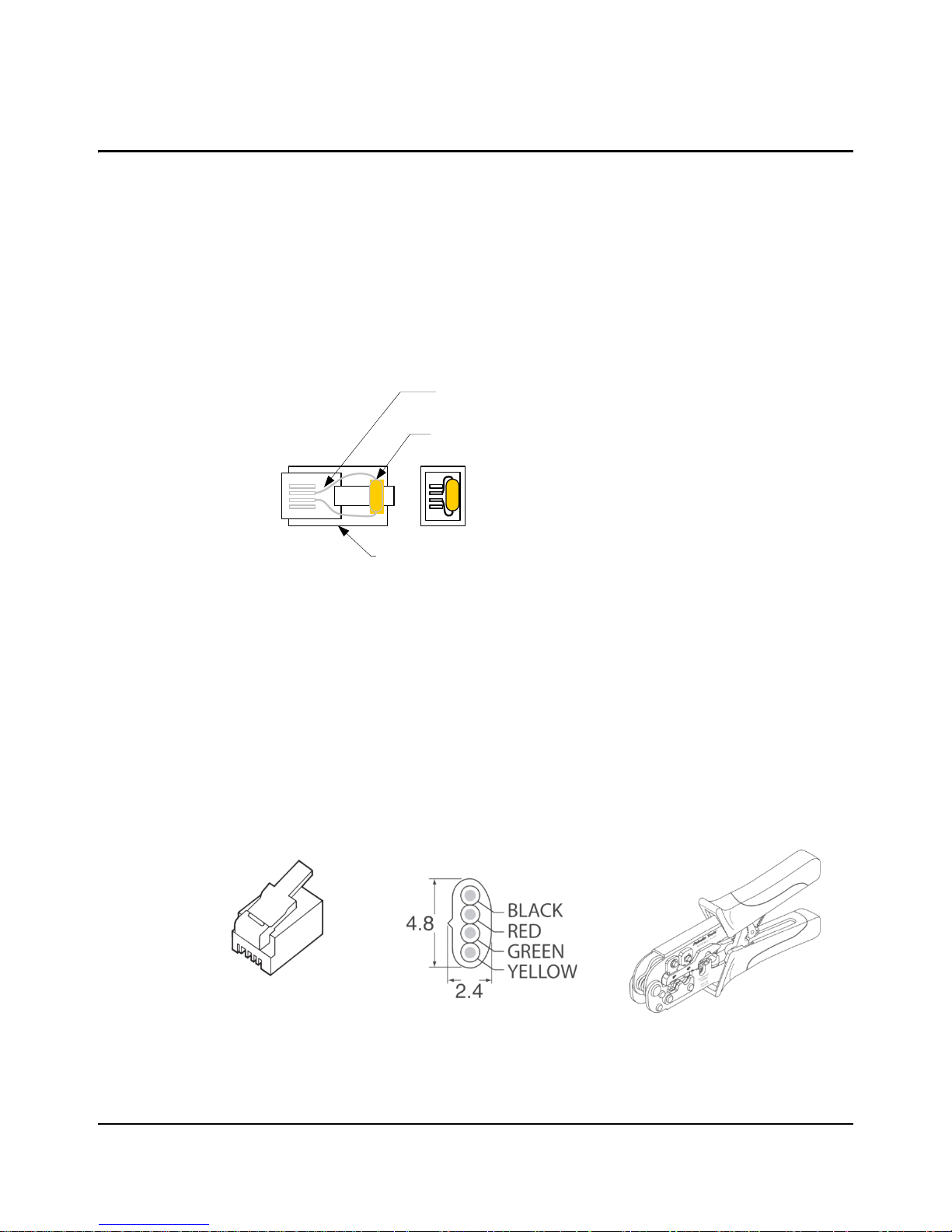

CAN Terminator

Because the CAN signals operate at high bit rates (1 MBPS), a terminator is required at each end

of the network. A simple network might work with a single terminator, but this is not recommended

for normal use. The termination resistor is also important for returning the CAN signaling levels to

the recessive state when no nodes are transmitting. Figure A-1 shows the recommended

terminator construction.

Figure A-1. CAN Terminator Plug

CAN Cable

Use CAN cables to daisy-chain the network between Jaguar modules. Standard off-the-shelf

modular 6P6C cables can be used. Cables must be “straight-pinned,” which means

Pin 1 > 1, Pin 2 > 2, and so on. This is also referred to as a reverse-cable because the tabs on the

connectors are on the opposite sides of the cable. The CAN cable needs only 4 conductors, but it

is acceptable to use a 6-conductor cable and plugs. A suitable 6-ft off-the-shelf 6P4C cable is

Digikey Stock No. A2662R-07-ND.

Figure A-2 shows the materials needed to build custom-length CAN cables. Apart from a modular

plug crimp tool, no special tools are required.

Figure A-2. Materials Needed to Assemble Custom-Length 6P4C Cable

January 5, 2011 29

Page 30

RS232 Cable

Modular Plug

4or 6 conductor cable

Modular adapter

6P6C to DB- 9 Female

CUI P/No AMK-0003

Digikey Stock No . 046-0003-ND

Modular cord

6 contact 6 conductor, reversed

Assmann Elect. AT-S-26-6/6/B-7/R-R

Digikey Stock No. 046-0003-ND

Resistor 100Ω 1%

Panasonic ERO-S2PHF1200

Digikey Stock N o. P100CACT-ND

Heatshrink tubing 1/8" diameter

Digikey Stock No . Q2F018B-ND

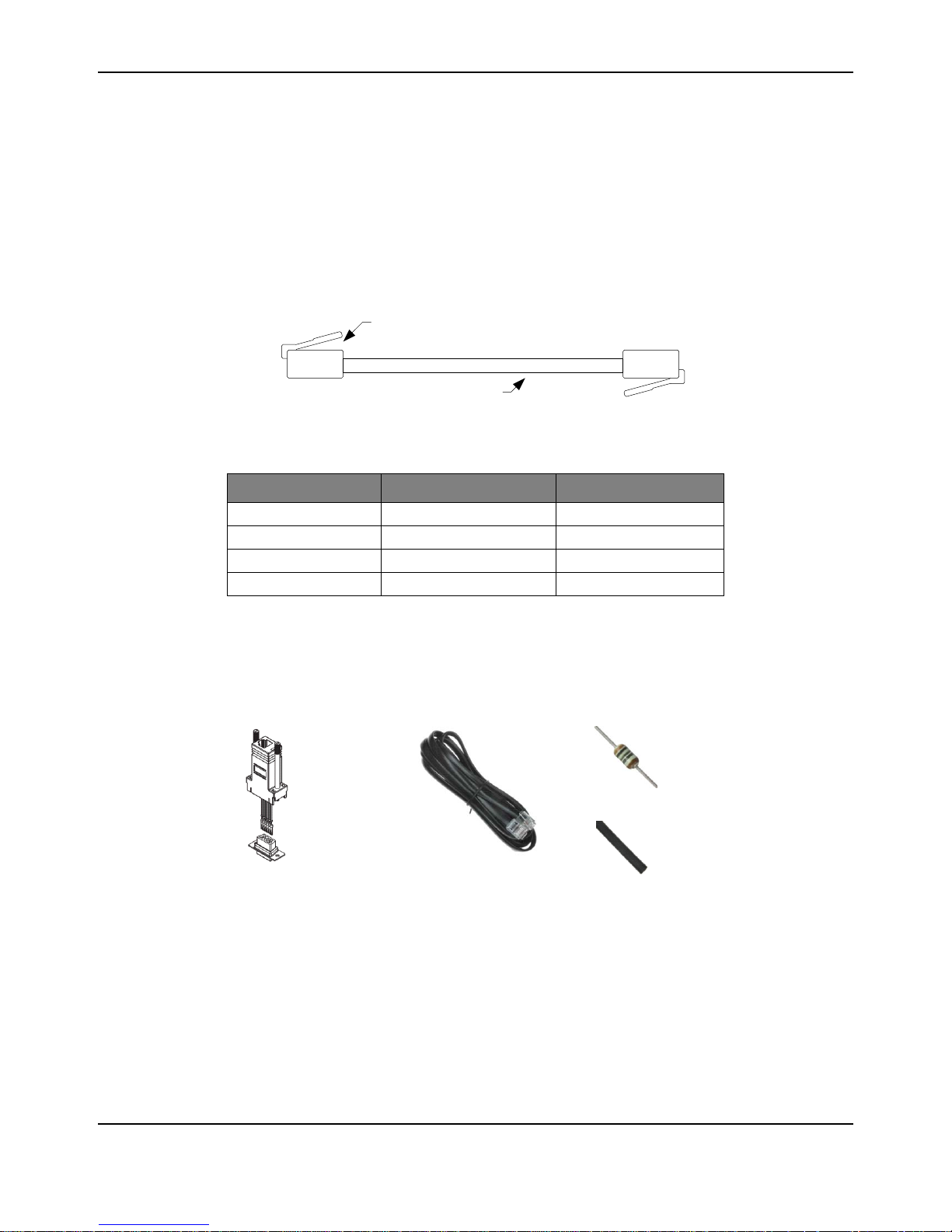

CAN Cable Assembly

Follow these steps to complete cable assembly (shown in Figure A-3):

1. Cut modular cable to length

2. Use the crimp to strip the outer jacket from each end of the cable.

3. Insert wires into the modular plug and load into crimper.

4. Close crimper to complete the connections and secure the cable.

Figure A-3. Completed Cable Assembly

CAN Cable Pin Assignments

Plug Wire Color Jaguar Use

1 Black -

2 Red CAN H

3 Green CAN L

4 Yellow GND

RS232 Cable

Figure A-4 shows the materials needed to build the RS232 cable. Apart from a soldering-iron, no

special tools are required.

Figure A-4. Materials Needed to Assemble RS232 Cable Components

RS232 Cable Assembly

Follow these steps to complete cable assembly (shown in Figure A-4):

1. Take the Modular Adapter and cut the black wire as short as possible. This wire is unused.

2. Cut off the terminals on the Red and Green wires. Strip then solder the Red and Green wires

to the 100 resistor. Use a section of heat shrink to protect the resistor and solder connections.

30 January 5, 2011

Page 31

3. Insert remaining terminals into the DB9 receptacle. Pin numbers are indicated on the plastic

connector body.

– White/Pin 3

– Blue/Pin 2

– Yellow/Pin 5

4. Slide the back-shell over the connector, then insert the modular cable to complete the

assembly.

RS232 Cable Pin Assignments

6P6C Wire Color Jaguar Use PC Use DB9 Pin

1WhiteRXDTXD 3

2 Black - - -

3 Red CAN H - -

4 Green CAN L - -

5 Yellow GND GND 5

6BlueTXDRXD2

Getting Started Guide

External References

The following references are also useful for working with MDL-BDC24 module:

The MDL-BDC24 Data Sheet contains detailed electrical specifications and connector details.

The BDC-COMM User’s Guide provides instructions on how to use the BDC-COMM GUI and

command line applications to control Jaguar networks.

MDL-BDC24 FAQ

January 5, 2011 31

Page 32

External References

32 January 5, 2011

Page 33

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Audio www.ti.com/audio Communications and Telecom www.ti.com/communications

Amplifiers amplifier.ti.com Computers and Peripherals www.ti.com/computers

Data Converters dataconverter.ti.com Consumer Electronics www.ti.com/consumer-apps

DLP® Products www.dlp.com Energy and Lighting www.ti.com/energy

DSP dsp.ti.com Industrial www.ti.com/industrial

Clocks and Timers www.ti.com/clocks Medical www.ti.com/medical

Interface interface.ti.com Security www.ti.com/security

Logic logic.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Power Mgmt power.ti.com Transportation and www.ti.com/automotive

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com Wireless www.ti.com/wireless-apps

RF/IF and ZigBee® Solutions www.ti.com/lprf

TI E2E Community Home Page e2e.ti.com

Automotive

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2011, Texas Instruments Incorporated

Loading...

Loading...