TEXAS INSTRUMENTS-PRODUCTION DATA

Stellaris® LM3S1439 Microcontroller

DATA SHEET

DS-LM3S1439-7393

Copyright © 2007-2010 Texas Instruments

Incorporated

Copyright

Copyright ©2007-2010 Texas Instruments Incorporated All rights reserved. Stellaris and StellarisWare are registered trademarks of Texas Instruments

Incorporated. ARM and Thumb are registered trademarks and Cortex is a trademark of ARM Limited. Other names and brands may be claimed as the

property of others.

PRODUCTION DATA information is current as of publication date. Products conform to specications per the terms of Texas Instruments standard

warranty. Production processing does not necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments semiconductor

products and disclaimers thereto appears at the end of this data sheet.

Texas Instruments Incorporated

108 Wild Basin, Suite 350

Austin, TX 78746

http://www.ti.com/stellaris

http://www-k.ext.ti.com/sc/technical-support/product-information-centers.htm

Texas Instruments-Production Data

June 23, 20102

Stellaris® LM3S1439 Microcontroller

Table of Contents

Revision History ............................................................................................................................. 20

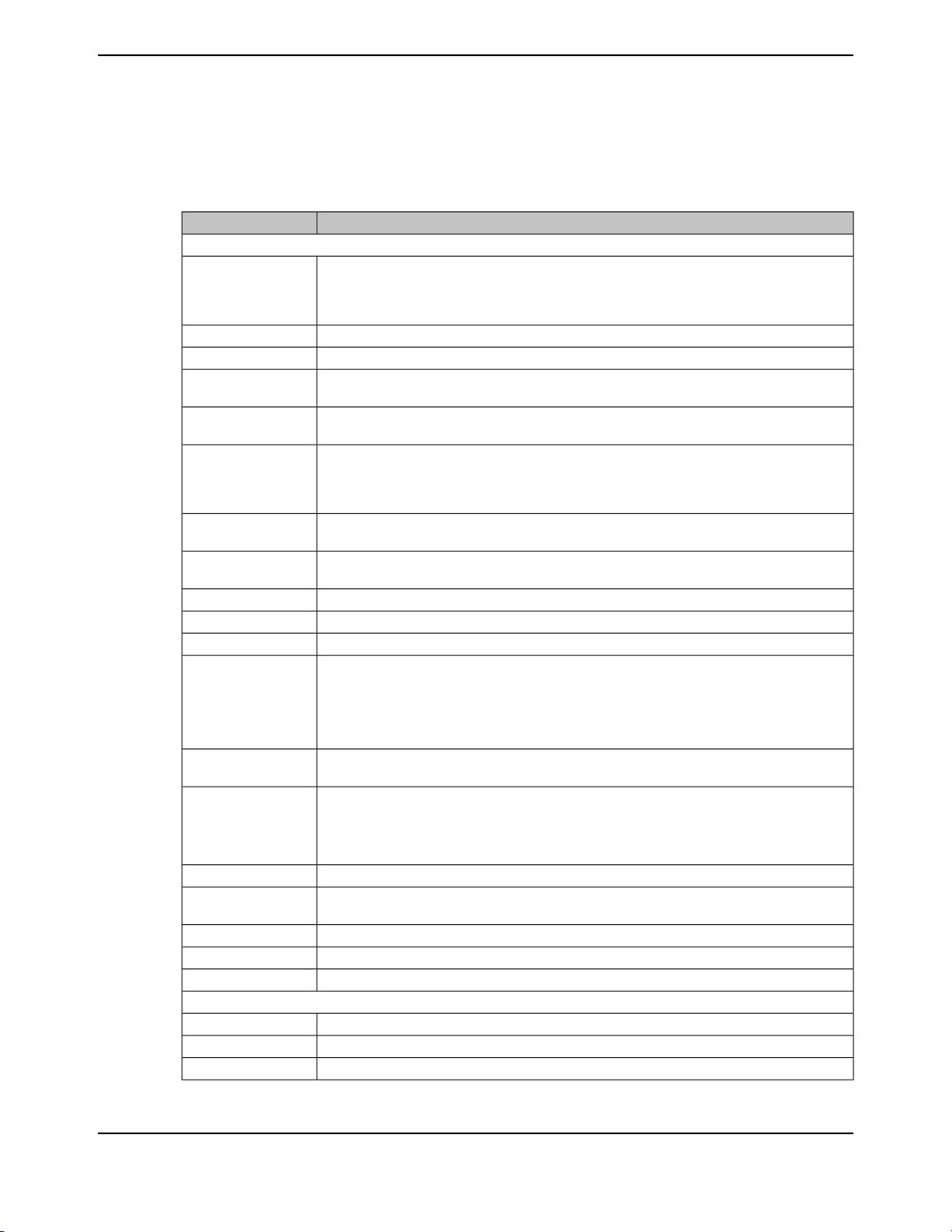

About This Document .................................................................................................................... 24

Audience .............................................................................................................................................. 24

About This Manual ................................................................................................................................ 24

Related Documents ............................................................................................................................... 24

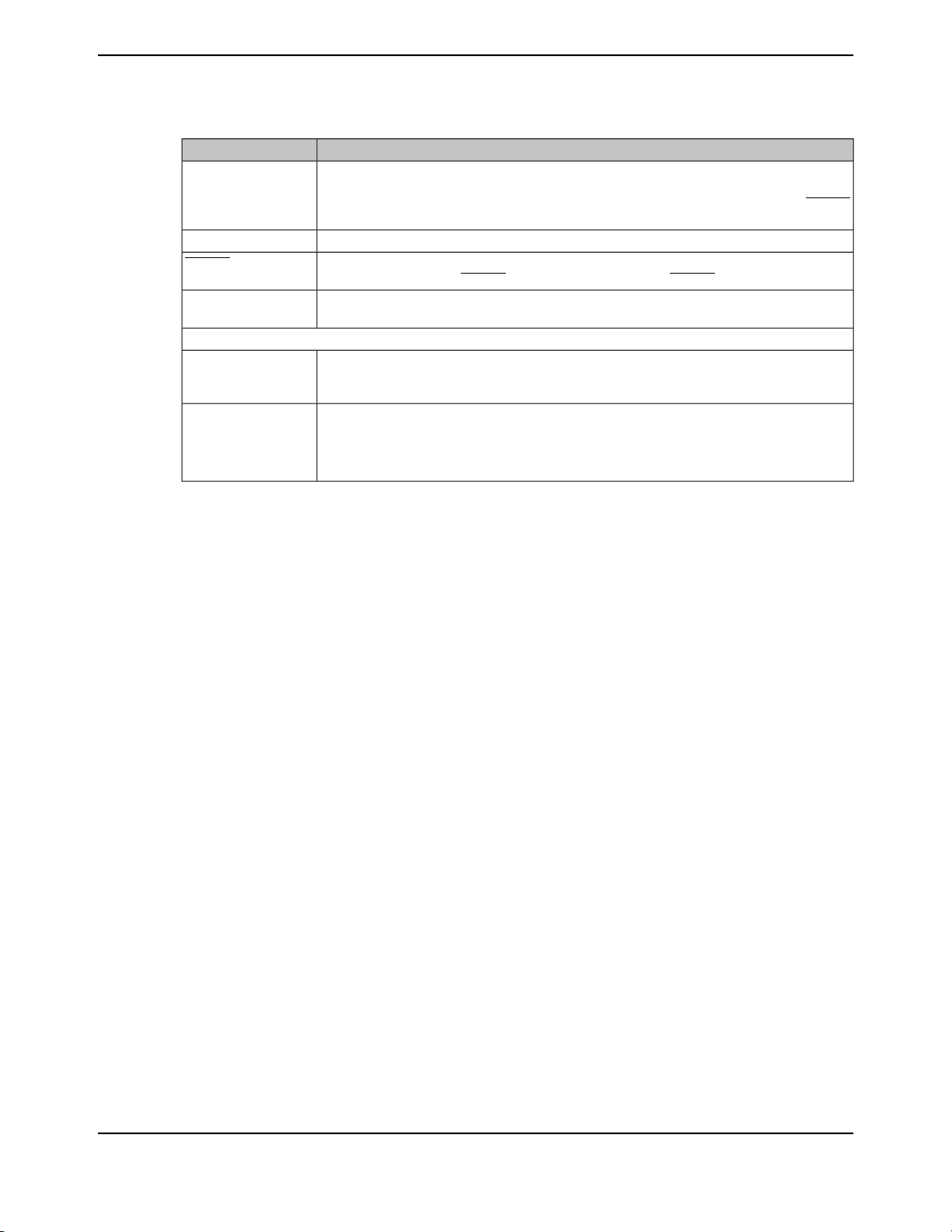

Documentation Conventions .................................................................................................................. 25

1 Architectural Overview .......................................................................................... 27

1.1 Product Features .......................................................................................................... 27

1.2 Target Applications ........................................................................................................ 35

1.3 High-Level Block Diagram ............................................................................................. 36

1.4 Functional Overview ...................................................................................................... 38

1.4.1 ARM Cortex™-M3 ......................................................................................................... 38

1.4.2 Motor Control Peripherals .............................................................................................. 39

1.4.3 Analog Peripherals ........................................................................................................ 39

1.4.4 Serial Communications Peripherals ................................................................................ 40

1.4.5 System Peripherals ....................................................................................................... 41

1.4.6 Memory Peripherals ...................................................................................................... 42

1.4.7 Additional Features ....................................................................................................... 43

1.4.8 Hardware Details .......................................................................................................... 43

2 ARM Cortex-M3 Processor Core ........................................................................... 45

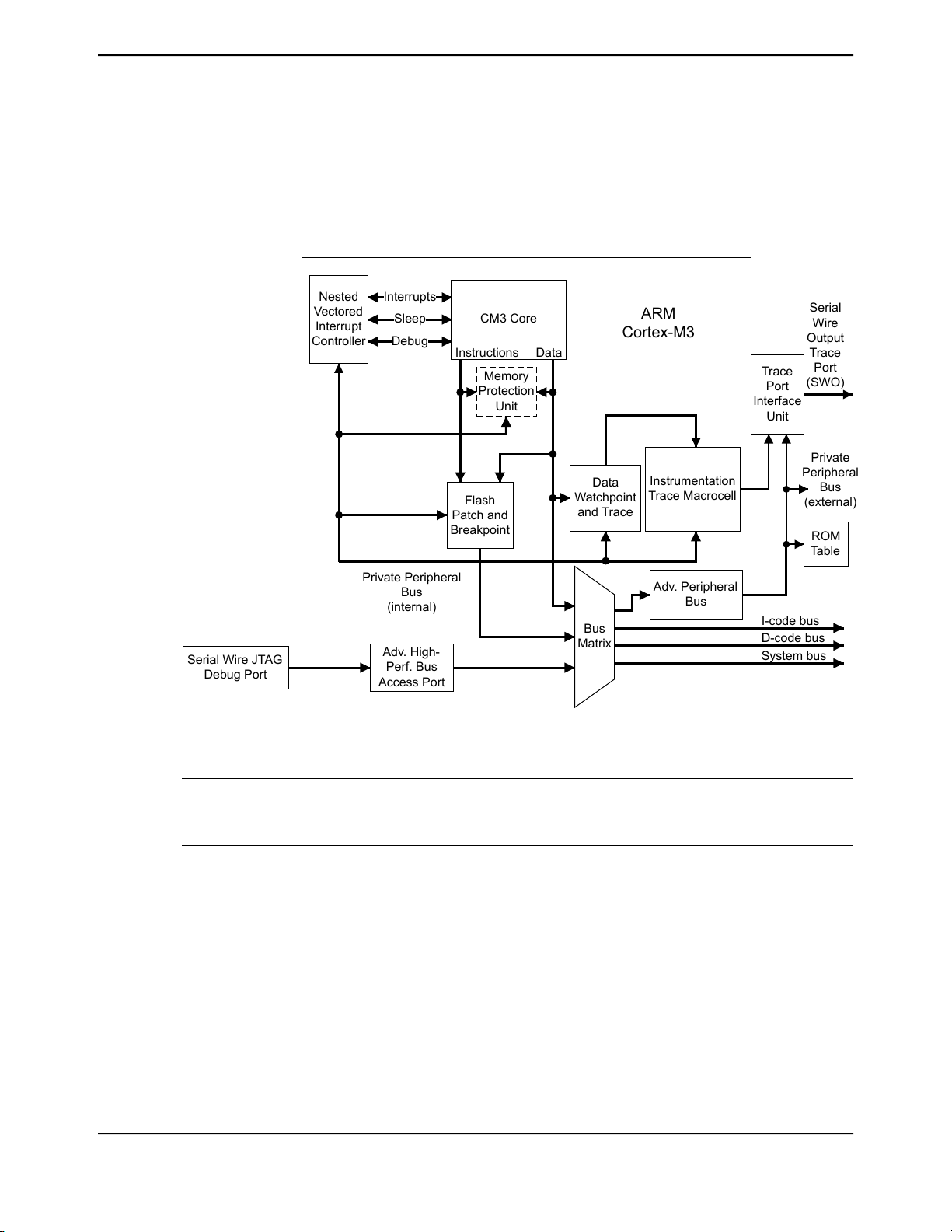

2.1 Block Diagram .............................................................................................................. 46

2.2 Functional Description ................................................................................................... 46

2.2.1 Serial Wire and JTAG Debug ......................................................................................... 46

2.2.2 Embedded Trace Macrocell (ETM) ................................................................................. 47

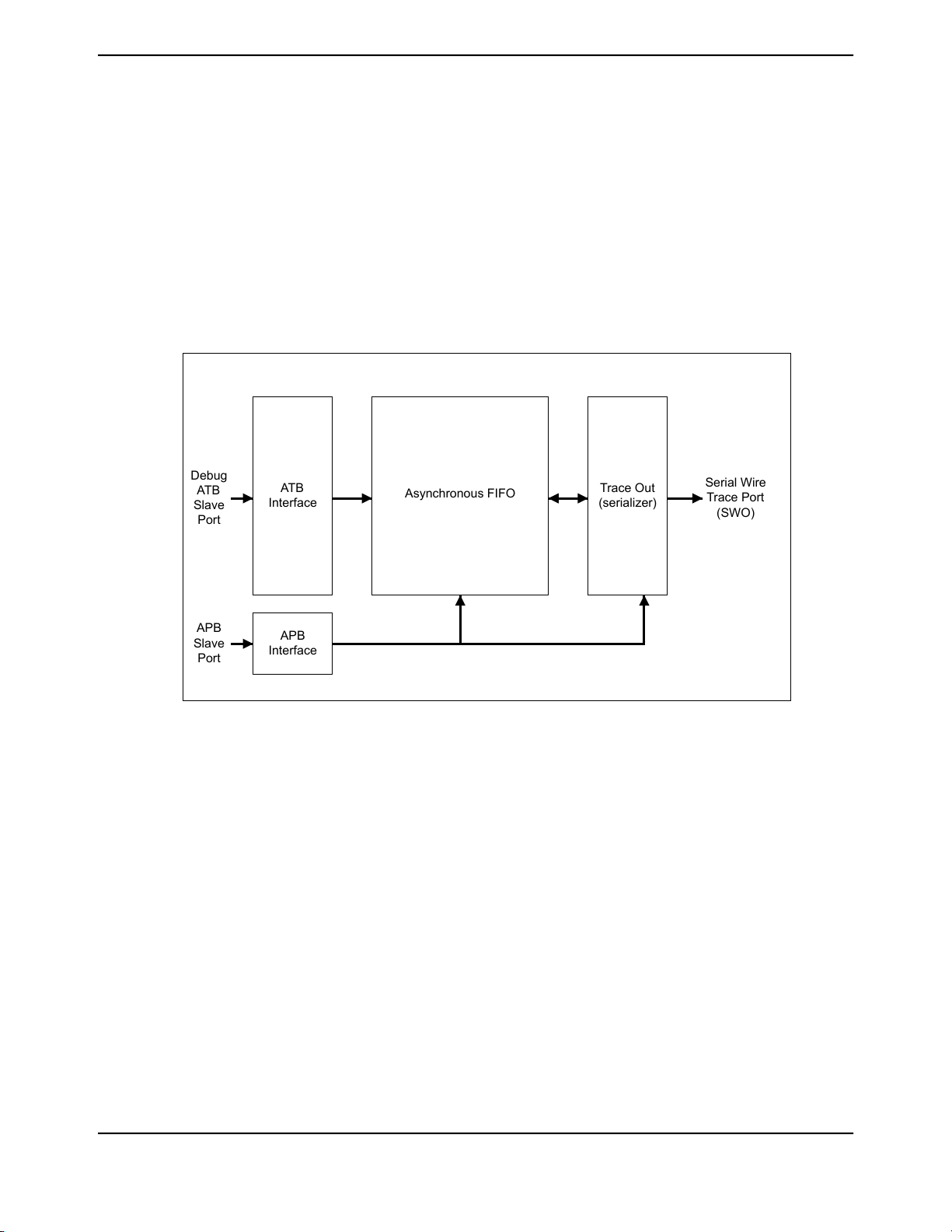

2.2.3 Trace Port Interface Unit (TPIU) ..................................................................................... 47

2.2.4 ROM Table ................................................................................................................... 47

2.2.5 Memory Protection Unit (MPU) ....................................................................................... 47

2.2.6 Nested Vectored Interrupt Controller (NVIC) .................................................................... 47

3 Memory Map ........................................................................................................... 51

4 Interrupts ................................................................................................................. 53

5 JTAG Interface ........................................................................................................ 56

5.1 Block Diagram .............................................................................................................. 57

5.2 Functional Description ................................................................................................... 57

5.2.1 JTAG Interface Pins ...................................................................................................... 57

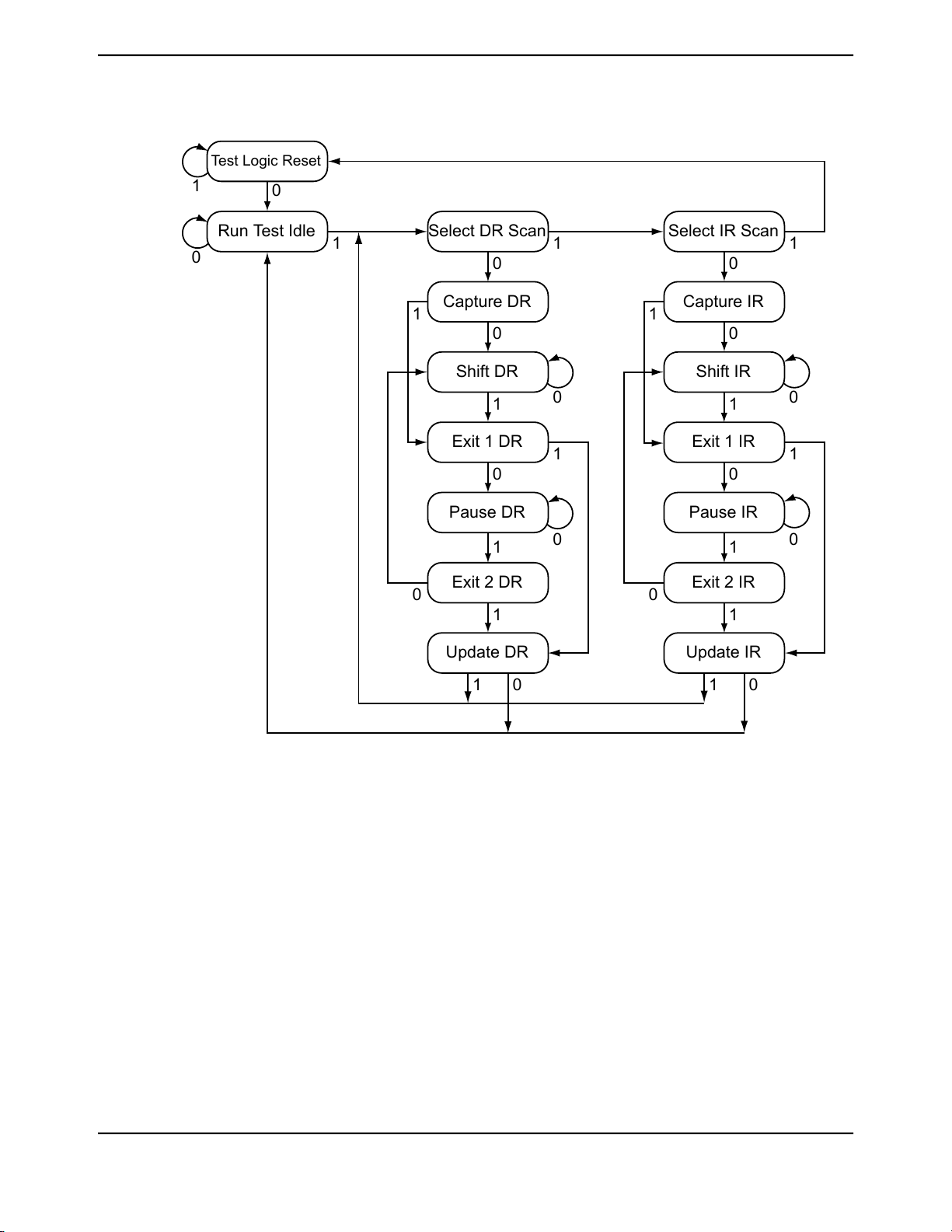

5.2.2 JTAG TAP Controller ..................................................................................................... 59

5.2.3 Shift Registers .............................................................................................................. 60

5.2.4 Operational Considerations ............................................................................................ 60

5.3 Initialization and Configuration ....................................................................................... 63

5.4 Register Descriptions .................................................................................................... 63

5.4.1 Instruction Register (IR) ................................................................................................. 63

5.4.2 Data Registers .............................................................................................................. 65

6 System Control ....................................................................................................... 68

6.1 Functional Description ................................................................................................... 68

6.1.1 Device Identification ...................................................................................................... 68

Texas Instruments-Production Data

3June 23, 2010

Table of Contents

6.1.2 Reset Control ................................................................................................................ 68

6.1.3 Power Control ............................................................................................................... 71

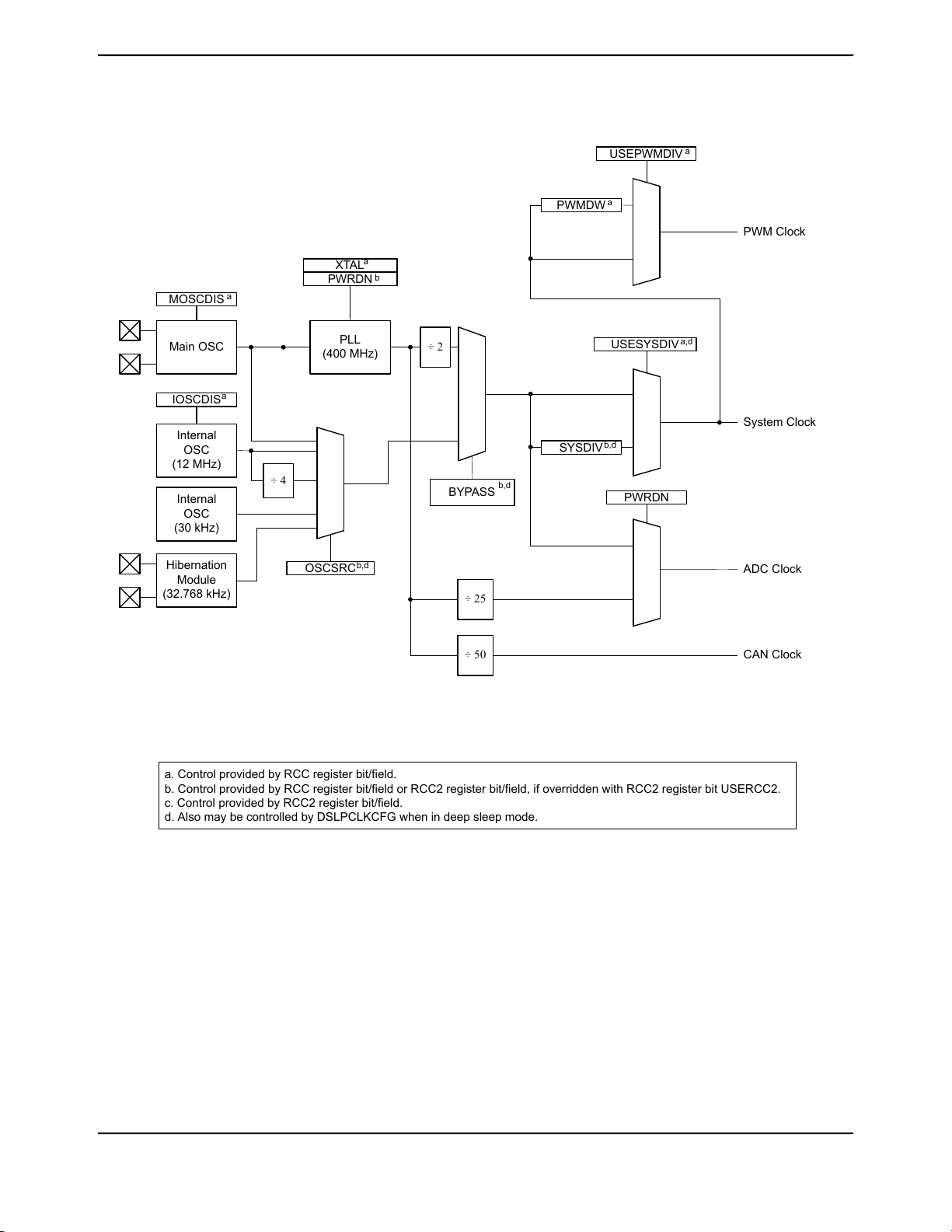

6.1.4 Clock Control ................................................................................................................ 72

6.1.5 System Control ............................................................................................................. 78

6.2 Initialization and Configuration ....................................................................................... 79

6.3 Register Map ................................................................................................................ 80

6.4 Register Descriptions .................................................................................................... 81

7 Hibernation Module .............................................................................................. 130

7.1 Block Diagram ............................................................................................................ 131

7.2 Functional Description ................................................................................................. 131

7.2.1 Register Access Timing ............................................................................................... 131

7.2.2 Clock Source .............................................................................................................. 132

7.2.3 Battery Management ................................................................................................... 133

7.2.4 Real-Time Clock .......................................................................................................... 133

7.2.5 Non-Volatile Memory ................................................................................................... 134

7.2.6 Power Control ............................................................................................................. 134

7.2.7 Initiating Hibernate ...................................................................................................... 134

7.2.8 Interrupts and Status ................................................................................................... 135

7.3 Initialization and Configuration ..................................................................................... 135

7.3.1 Initialization ................................................................................................................. 135

7.3.2 RTC Match Functionality (No Hibernation) .................................................................... 135

7.3.3 RTC Match/Wake-Up from Hibernation ......................................................................... 136

7.3.4 External Wake-Up from Hibernation .............................................................................. 136

7.3.5 RTC/External Wake-Up from Hibernation ...................................................................... 136

7.4 Register Map .............................................................................................................. 136

7.5 Register Descriptions .................................................................................................. 137

8 Internal Memory ................................................................................................... 150

8.1 Block Diagram ............................................................................................................ 150

8.2 Functional Description ................................................................................................. 150

8.2.1 SRAM Memory ............................................................................................................ 150

8.2.2 Flash Memory ............................................................................................................. 151

8.3 Flash Memory Initialization and Configuration ............................................................... 152

8.3.1 Flash Programming ..................................................................................................... 152

8.3.2 Nonvolatile Register Programming ............................................................................... 153

8.4 Register Map .............................................................................................................. 154

8.5 Flash Register Descriptions (Flash Control Offset) ......................................................... 154

8.6 Flash Register Descriptions (System Control Offset) ...................................................... 162

9 General-Purpose Input/Outputs (GPIOs) ........................................................... 175

9.1 Functional Description ................................................................................................. 175

9.1.1 Data Control ............................................................................................................... 176

9.1.2 Interrupt Control .......................................................................................................... 177

9.1.3 Mode Control .............................................................................................................. 178

9.1.4 Commit Control ........................................................................................................... 178

9.1.5 Pad Control ................................................................................................................. 178

9.1.6 Identification ............................................................................................................... 179

9.2 Initialization and Configuration ..................................................................................... 179

9.3 Register Map .............................................................................................................. 180

9.4 Register Descriptions .................................................................................................. 182

Texas Instruments-Production Data

June 23, 20104

Stellaris® LM3S1439 Microcontroller

10 General-Purpose Timers ...................................................................................... 217

10.1 Block Diagram ............................................................................................................ 218

10.2 Functional Description ................................................................................................. 218

10.2.1 GPTM Reset Conditions .............................................................................................. 219

10.2.2 32-Bit Timer Operating Modes ...................................................................................... 219

10.2.3 16-Bit Timer Operating Modes ...................................................................................... 220

10.3 Initialization and Configuration ..................................................................................... 224

10.3.1 32-Bit One-Shot/Periodic Timer Mode ........................................................................... 224

10.3.2 32-Bit Real-Time Clock (RTC) Mode ............................................................................. 225

10.3.3 16-Bit One-Shot/Periodic Timer Mode ........................................................................... 225

10.3.4 16-Bit Input Edge Count Mode ..................................................................................... 226

10.3.5 16-Bit Input Edge Timing Mode .................................................................................... 226

10.3.6 16-Bit PWM Mode ....................................................................................................... 227

10.4 Register Map .............................................................................................................. 227

10.5 Register Descriptions .................................................................................................. 228

11 Watchdog Timer ................................................................................................... 253

11.1 Block Diagram ............................................................................................................ 254

11.2 Functional Description ................................................................................................. 254

11.3 Initialization and Configuration ..................................................................................... 255

11.4 Register Map .............................................................................................................. 255

11.5 Register Descriptions .................................................................................................. 256

12 Analog-to-Digital Converter (ADC) ..................................................................... 277

12.1 Block Diagram ............................................................................................................ 277

12.2 Functional Description ................................................................................................. 278

12.2.1 Sample Sequencers .................................................................................................... 278

12.2.2 Module Control ............................................................................................................ 279

12.2.3 Hardware Sample Averaging Circuit ............................................................................. 280

12.2.4 Analog-to-Digital Converter .......................................................................................... 280

12.2.5 Differential Sampling ................................................................................................... 280

12.2.6 Test Modes ................................................................................................................. 282

12.2.7 Internal Temperature Sensor ........................................................................................ 283

12.3 Initialization and Configuration ..................................................................................... 283

12.3.1 Module Initialization ..................................................................................................... 283

12.3.2 Sample Sequencer Configuration ................................................................................. 284

12.4 Register Map .............................................................................................................. 284

12.5 Register Descriptions .................................................................................................. 285

13 Universal Asynchronous Receivers/Transmitters (UARTs) ............................. 314

13.1 Block Diagram ............................................................................................................ 315

13.2 Functional Description ................................................................................................. 315

13.2.1 Transmit/Receive Logic ............................................................................................... 315

13.2.2 Baud-Rate Generation ................................................................................................. 316

13.2.3 Data Transmission ...................................................................................................... 317

13.2.4 Serial IR (SIR) ............................................................................................................. 317

13.2.5 FIFO Operation ........................................................................................................... 318

13.2.6 Interrupts .................................................................................................................... 318

13.2.7 Loopback Operation .................................................................................................... 319

13.2.8 IrDA SIR block ............................................................................................................ 319

13.3 Initialization and Configuration ..................................................................................... 319

Texas Instruments-Production Data

5June 23, 2010

Table of Contents

13.4 Register Map .............................................................................................................. 320

13.5 Register Descriptions .................................................................................................. 321

14 Synchronous Serial Interface (SSI) .................................................................... 355

14.1 Block Diagram ............................................................................................................ 355

14.2 Functional Description ................................................................................................. 356

14.2.1 Bit Rate Generation ..................................................................................................... 356

14.2.2 FIFO Operation ........................................................................................................... 356

14.2.3 Interrupts .................................................................................................................... 356

14.2.4 Frame Formats ........................................................................................................... 357

14.3 Initialization and Configuration ..................................................................................... 364

14.4 Register Map .............................................................................................................. 365

14.5 Register Descriptions .................................................................................................. 366

15 Inter-Integrated Circuit (I2C) Interface ................................................................ 392

15.1 Block Diagram ............................................................................................................ 393

15.2 Functional Description ................................................................................................. 393

15.2.1 I2C Bus Functional Overview ........................................................................................ 393

15.2.2 Available Speed Modes ............................................................................................... 395

15.2.3 Interrupts .................................................................................................................... 396

15.2.4 Loopback Operation .................................................................................................... 397

15.2.5 Command Sequence Flow Charts ................................................................................ 397

15.3 Initialization and Configuration ..................................................................................... 404

15.4 Register Map .............................................................................................................. 405

15.5 Register Descriptions (I2C Master) ............................................................................... 406

15.6 Register Descriptions (I2C Slave) ................................................................................. 419

16 Analog Comparator .............................................................................................. 428

16.1 Block Diagram ............................................................................................................ 428

16.2 Functional Description ................................................................................................. 428

16.2.1 Internal Reference Programming .................................................................................. 429

16.3 Initialization and Configuration ..................................................................................... 430

16.4 Register Map .............................................................................................................. 430

16.5 Register Descriptions .................................................................................................. 431

17 Pulse Width Modulator (PWM) ............................................................................ 439

17.1 Block Diagram ............................................................................................................ 440

17.2 Functional Description ................................................................................................. 441

17.2.1 PWM Timer ................................................................................................................. 441

17.2.2 PWM Comparators ...................................................................................................... 441

17.2.3 PWM Signal Generator ................................................................................................ 442

17.2.4 Dead-Band Generator ................................................................................................. 443

17.2.5 Interrupt/ADC-Trigger Selector ..................................................................................... 443

17.2.6 Synchronization Methods ............................................................................................ 444

17.2.7 Fault Conditions .......................................................................................................... 444

17.2.8 Output Control Block ................................................................................................... 444

17.3 Initialization and Configuration ..................................................................................... 444

17.4 Register Map .............................................................................................................. 445

17.5 Register Descriptions .................................................................................................. 447

18 Quadrature Encoder Interface (QEI) ................................................................... 477

18.1 Block Diagram ............................................................................................................ 477

Texas Instruments-Production Data

June 23, 20106

Stellaris® LM3S1439 Microcontroller

18.2 Functional Description ................................................................................................. 478

18.3 Initialization and Configuration ..................................................................................... 480

18.4 Register Map .............................................................................................................. 481

18.5 Register Descriptions .................................................................................................. 481

19 Pin Diagram .......................................................................................................... 494

20 Signal Tables ........................................................................................................ 496

20.1 100-Pin LQFP Package Pin Tables ............................................................................... 496

20.2 108-Pin BGA Package Pin Tables ................................................................................ 508

20.3 Connections for Unused Signals ................................................................................... 521

21 Operating Characteristics ................................................................................... 523

22 Electrical Characteristics .................................................................................... 524

22.1 DC Characteristics ...................................................................................................... 524

22.1.1 Maximum Ratings ....................................................................................................... 524

22.1.2 Recommended DC Operating Conditions ...................................................................... 524

22.1.3 On-Chip Low Drop-Out (LDO) Regulator Characteristics ................................................ 525

22.1.4 GPIO Module Characteristics ....................................................................................... 525

22.1.5 Power Specifications ................................................................................................... 525

22.1.6 Flash Memory Characteristics ...................................................................................... 527

22.1.7 Hibernation ................................................................................................................. 527

22.2 AC Characteristics ....................................................................................................... 527

22.2.1 Load Conditions .......................................................................................................... 527

22.2.2 Clocks ........................................................................................................................ 528

22.2.3 JTAG and Boundary Scan ............................................................................................ 529

22.2.4 Reset ......................................................................................................................... 531

22.2.5 Sleep Modes ............................................................................................................... 533

22.2.6 Hibernation Module ..................................................................................................... 533

22.2.7 General-Purpose I/O (GPIO) ........................................................................................ 534

22.2.8 Analog-to-Digital Converter .......................................................................................... 534

22.2.9 Synchronous Serial Interface (SSI) ............................................................................... 535

22.2.10 Inter-Integrated Circuit (I2C) Interface ........................................................................... 537

22.2.11 Analog Comparator ..................................................................................................... 538

A Serial Flash Loader .............................................................................................. 539

A.1 Serial Flash Loader ..................................................................................................... 539

A.2 Interfaces ................................................................................................................... 539

A.2.1 UART ......................................................................................................................... 539

A.2.2 SSI ............................................................................................................................. 539

A.3 Packet Handling .......................................................................................................... 540

A.3.1 Packet Format ............................................................................................................ 540

A.3.2 Sending Packets ......................................................................................................... 540

A.3.3 Receiving Packets ....................................................................................................... 540

A.4 Commands ................................................................................................................. 541

A.4.1 COMMAND_PING (0X20) ............................................................................................ 541

A.4.2 COMMAND_GET_STATUS (0x23) ............................................................................... 541

A.4.3 COMMAND_DOWNLOAD (0x21) ................................................................................. 541

A.4.4 COMMAND_SEND_DATA (0x24) ................................................................................. 542

A.4.5 COMMAND_RUN (0x22) ............................................................................................. 542

A.4.6 COMMAND_RESET (0x25) ......................................................................................... 542

Texas Instruments-Production Data

7June 23, 2010

Table of Contents

B Register Quick Reference ................................................................................... 544

C Ordering and Contact Information ..................................................................... 562

C.1 Ordering Information .................................................................................................... 562

C.2 Part Markings .............................................................................................................. 562

C.3 Kits ............................................................................................................................. 563

C.4 Support Information ..................................................................................................... 563

D Package Information ............................................................................................ 564

Texas Instruments-Production Data

June 23, 20108

List of Figures

Figure 1-1. Stellaris®LM3S1439 Microcontroller High-Level Block Diagram ............................. 37

Figure 2-1. CPU Block Diagram ............................................................................................. 46

Figure 2-2. TPIU Block Diagram ............................................................................................ 47

Figure 5-1. JTAG Module Block Diagram ................................................................................ 57

Figure 5-2. Test Access Port State Machine ........................................................................... 60

Figure 5-3. IDCODE Register Format ..................................................................................... 66

Figure 5-4. BYPASS Register Format .................................................................................... 66

Figure 5-5. Boundary Scan Register Format ........................................................................... 67

Figure 6-1. Basic RST Configuration ...................................................................................... 69

Figure 6-2. External Circuitry to Extend Power-On Reset ........................................................ 70

Figure 6-3. Reset Circuit Controlled by Switch ........................................................................ 70

Figure 6-4. Power Architecture .............................................................................................. 72

Figure 6-5. Main Clock Tree .................................................................................................. 75

Figure 7-1. Hibernation Module Block Diagram ..................................................................... 131

Figure 7-2. Clock Source Using Crystal ................................................................................ 132

Figure 7-3. Clock Source Using Dedicated Oscillator ............................................................. 133

Figure 8-1. Flash Block Diagram .......................................................................................... 150

Figure 9-1. GPIO Port Block Diagram ................................................................................... 176

Figure 9-2. GPIODATA Write Example ................................................................................. 177

Figure 9-3. GPIODATA Read Example ................................................................................. 177

Figure 10-1. GPTM Module Block Diagram ............................................................................ 218

Figure 10-2. 16-Bit Input Edge Count Mode Example .............................................................. 222

Figure 10-3. 16-Bit Input Edge Time Mode Example ............................................................... 223

Figure 10-4. 16-Bit PWM Mode Example ................................................................................ 224

Figure 11-1. WDT Module Block Diagram .............................................................................. 254

Figure 12-1. ADC Module Block Diagram ............................................................................... 278

Figure 12-2. Differential Sampling Range, V

Figure 12-3. Differential Sampling Range, V

Figure 12-4. Differential Sampling Range, V

Figure 12-5. Internal Temperature Sensor Characteristic ......................................................... 283

Figure 13-1. UART Module Block Diagram ............................................................................. 315

Figure 13-2. UART Character Frame ..................................................................................... 316

Figure 13-3. IrDA Data Modulation ......................................................................................... 318

Figure 14-1. SSI Module Block Diagram ................................................................................. 355

Figure 14-2. TI Synchronous Serial Frame Format (Single Transfer) ........................................ 358

Figure 14-3. TI Synchronous Serial Frame Format (Continuous Transfer) ................................ 358

Figure 14-4. Freescale SPI Format (Single Transfer) with SPO=0 and SPH=0 .......................... 359

Figure 14-5. Freescale SPI Format (Continuous Transfer) with SPO=0 and SPH=0 .................. 359

Figure 14-6. Freescale SPI Frame Format with SPO=0 and SPH=1 ......................................... 360

Figure 14-7. Freescale SPI Frame Format (Single Transfer) with SPO=1 and SPH=0 ............... 361

Figure 14-8. Freescale SPI Frame Format (Continuous Transfer) with SPO=1 and SPH=0 ........ 361

Figure 14-9. Freescale SPI Frame Format with SPO=1 and SPH=1 ......................................... 362

Figure 14-10. MICROWIRE Frame Format (Single Frame) ........................................................ 363

Figure 14-11. MICROWIRE Frame Format (Continuous Transfer) ............................................. 364

Figure 14-12. MICROWIRE Frame Format, SSIFss Input Setup and Hold Requirements ............ 364

IN_ODD

IN_ODD

IN_ODD

Stellaris® LM3S1439 Microcontroller

= 1.5 V ...................................................... 281

= 0.75 V .................................................... 282

= 2.25 V .................................................... 282

Texas Instruments-Production Data

9June 23, 2010

Table of Contents

Figure 15-1. I2C Block Diagram ............................................................................................. 393

Figure 15-2. I2C Bus Configuration ........................................................................................ 393

Figure 15-3. START and STOP Conditions ............................................................................. 394

Figure 15-4. Complete Data Transfer with a 7-Bit Address ....................................................... 394

Figure 15-5. R/S Bit in First Byte ............................................................................................ 394

Figure 15-6. Data Validity During Bit Transfer on the I2C Bus ................................................... 395

Figure 15-7. Master Single SEND .......................................................................................... 398

Figure 15-8. Master Single RECEIVE ..................................................................................... 399

Figure 15-9. Master Burst SEND ........................................................................................... 400

Figure 15-10. Master Burst RECEIVE ...................................................................................... 401

Figure 15-11. Master Burst RECEIVE after Burst SEND ............................................................ 402

Figure 15-12. Master Burst SEND after Burst RECEIVE ............................................................ 403

Figure 15-13. Slave Command Sequence ................................................................................ 404

Figure 16-1. Analog Comparator Module Block Diagram ......................................................... 428

Figure 16-2. Structure of Comparator Unit .............................................................................. 429

Figure 16-3. Comparator Internal Reference Structure ............................................................ 429

Figure 17-1. PWM Unit Diagram ............................................................................................ 440

Figure 17-2. PWM Module Block Diagram .............................................................................. 441

Figure 17-3. PWM Count-Down Mode .................................................................................... 442

Figure 17-4. PWM Count-Up/Down Mode .............................................................................. 442

Figure 17-5. PWM Generation Example In Count-Up/Down Mode ........................................... 443

Figure 17-6. PWM Dead-Band Generator ............................................................................... 443

Figure 18-1. QEI Block Diagram ............................................................................................ 478

Figure 18-2. Quadrature Encoder and Velocity Predivider Operation ........................................ 479

Figure 19-1. 100-Pin LQFP Package Pin Diagram .................................................................. 494

Figure 19-2. 108-Ball BGA Package Pin Diagram (Top View) ................................................... 495

Figure 22-1. Load Conditions ................................................................................................ 528

Figure 22-2. JTAG Test Clock Input Timing ............................................................................. 530

Figure 22-3. JTAG Test Access Port (TAP) Timing .................................................................. 531

Figure 22-4. JTAG TRST Timing ............................................................................................ 531

Figure 22-5. External Reset Timing (RST) .............................................................................. 532

Figure 22-6. Power-On Reset Timing ..................................................................................... 532

Figure 22-7. Brown-Out Reset Timing .................................................................................... 532

Figure 22-8. Software Reset Timing ....................................................................................... 532

Figure 22-9. Watchdog Reset Timing ..................................................................................... 533

Figure 22-10. Hibernation Module Timing ................................................................................. 534

Figure 22-11. ADC Input Equivalency Diagram ......................................................................... 535

Figure 22-12. SSI Timing for TI Frame Format (FRF=01), Single Transfer Timing

Figure 22-13. SSI Timing for MICROWIRE Frame Format (FRF=10), Single Transfer ................. 536

Figure 22-14. SSI Timing for SPI Frame Format (FRF=00), with SPH=1 ..................................... 537

Figure 22-15. I2C Timing ......................................................................................................... 538

Figure D-1. 100-Pin LQFP Package ...................................................................................... 564

Figure D-2. 108-Ball BGA Package ...................................................................................... 566

Measurement .................................................................................................... 536

Texas Instruments-Production Data

June 23, 201010

List of Tables

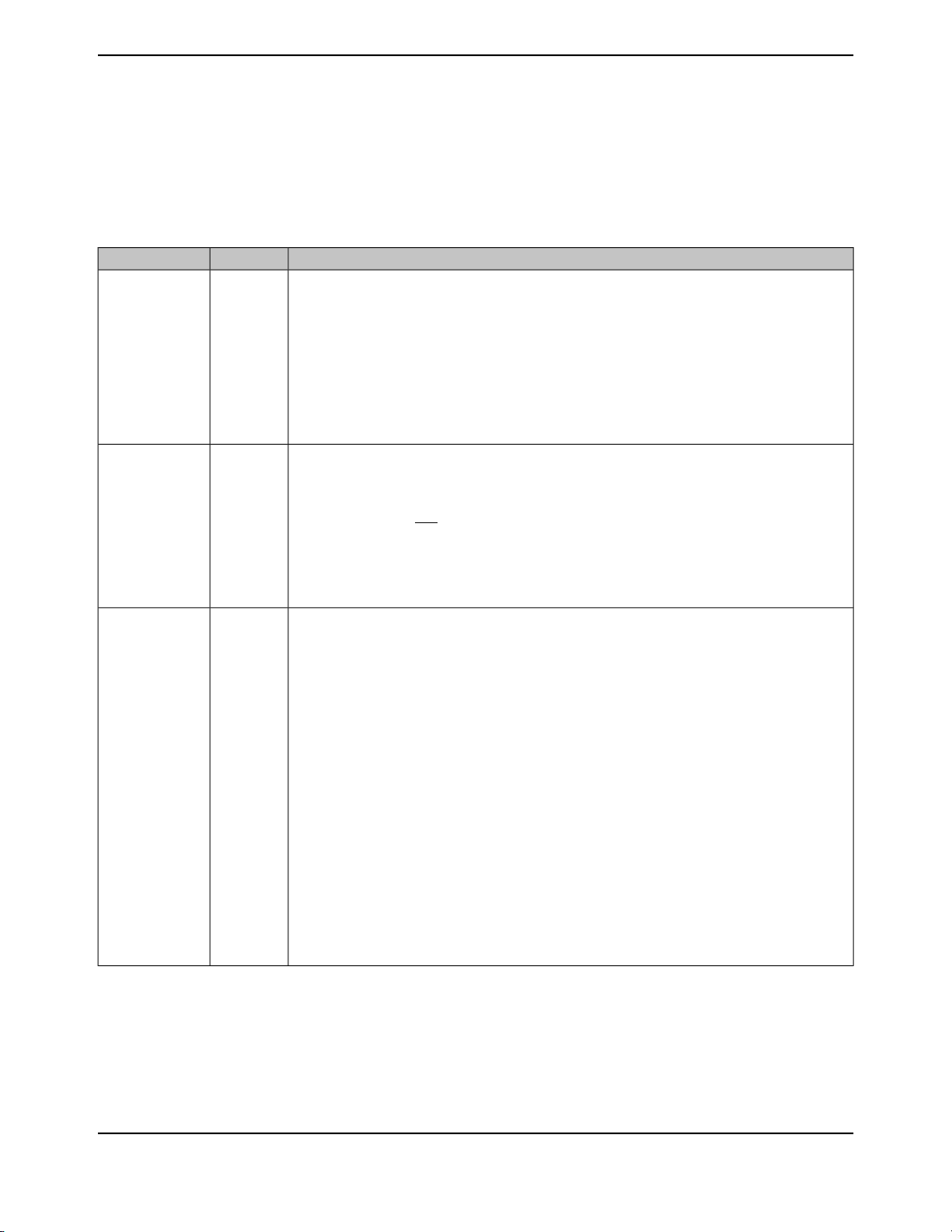

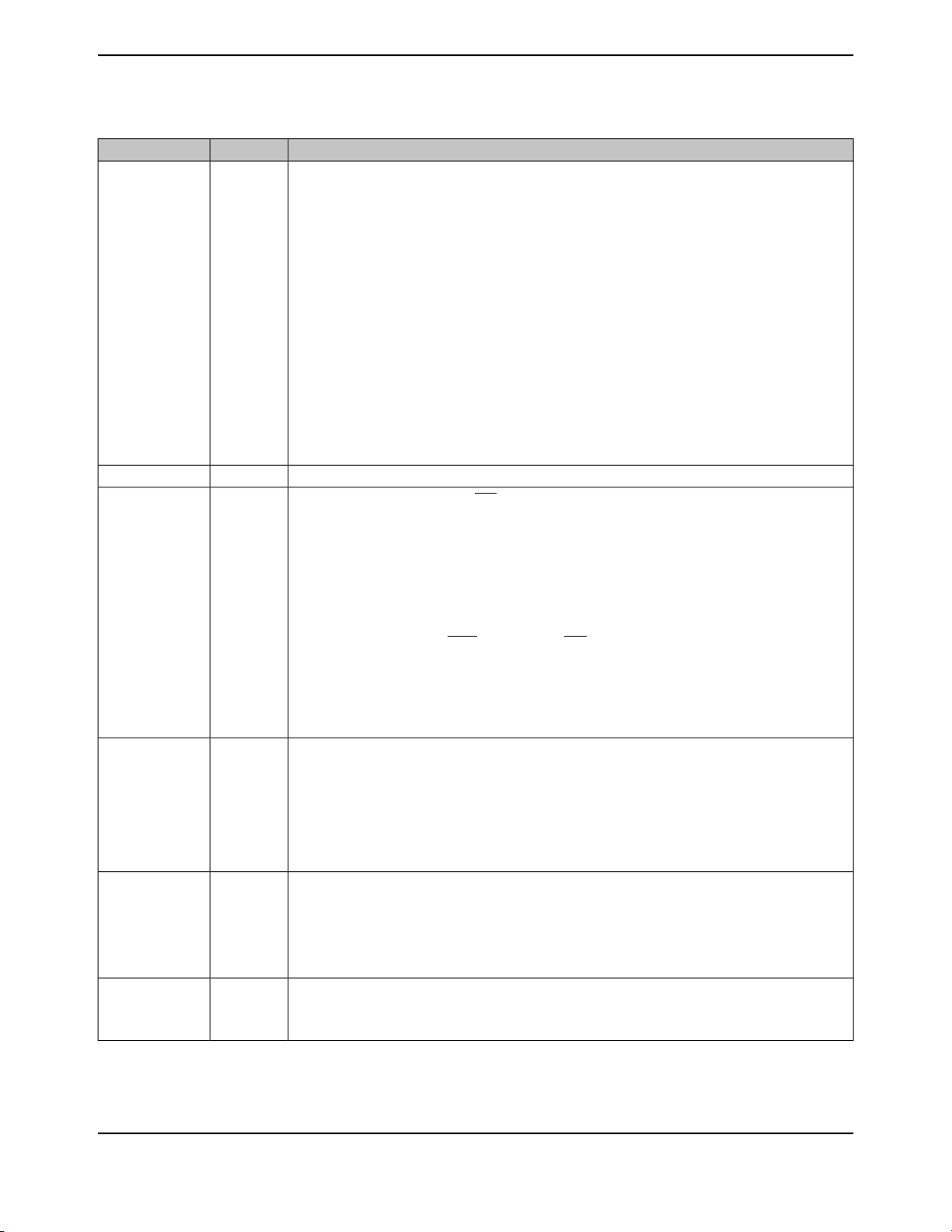

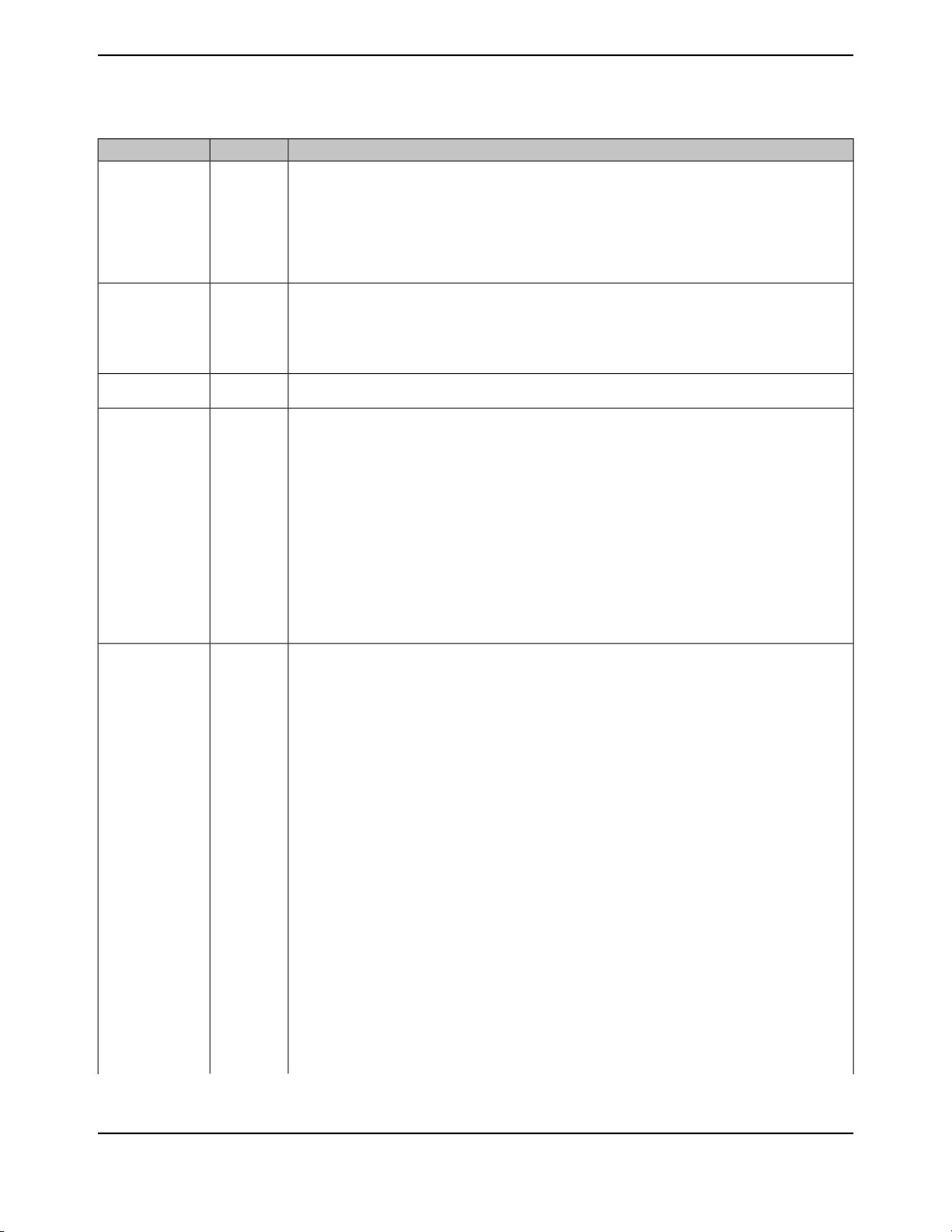

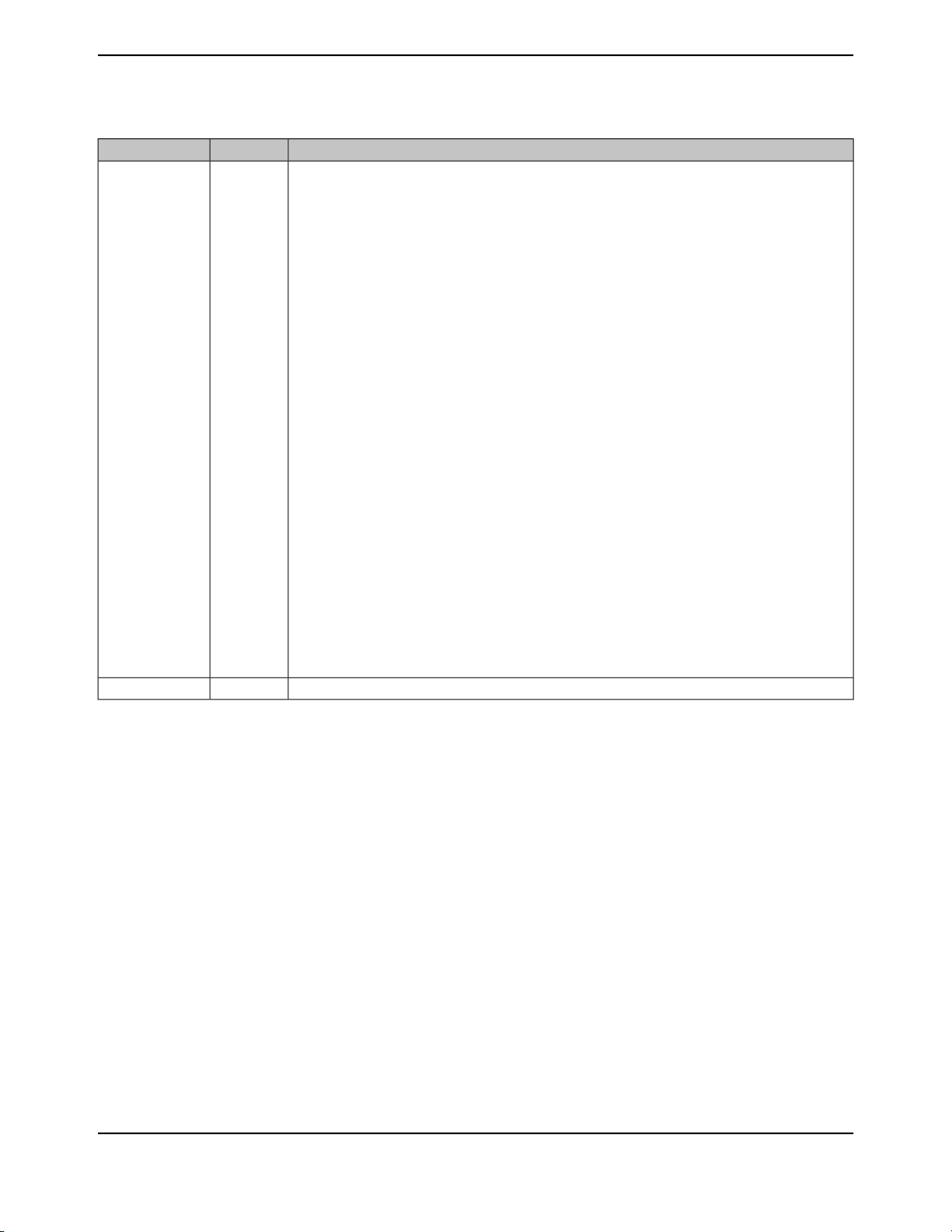

Table 1. Revision History .................................................................................................. 20

Table 2. Documentation Conventions ................................................................................ 25

Table 3-1. Memory Map ....................................................................................................... 51

Table 4-1. Exception Types .................................................................................................. 53

Table 4-2. Interrupts ............................................................................................................ 54

Table 5-1. JTAG Port Pins Reset State ................................................................................. 58

Table 5-2. JTAG Instruction Register Commands ................................................................... 63

Table 6-1. Clock Source Options .......................................................................................... 73

Table 6-2. Possible System Clock Frequencies Using the SYSDIV Field ................................. 76

Table 6-3. Examples of Possible System Clock Frequencies Using the SYSDIV2 Field ............ 76

Table 6-4. System Control Register Map ............................................................................... 80

Table 6-5. RCC2 Fields that Override RCC fields .................................................................. 95

Table 7-1. Hibernation Module Register Map ....................................................................... 136

Table 8-1. Flash Protection Policy Combinations ................................................................. 151

Table 8-2. User-Programmable Flash Memory Resident Registers ....................................... 153

Table 8-3. Flash Register Map ............................................................................................ 154

Table 9-1. GPIO Pad Configuration Examples ..................................................................... 179

Table 9-2. GPIO Interrupt Configuration Example ................................................................ 179

Table 9-3. GPIO Register Map ........................................................................................... 181

Table 10-1. Available CCP Pins ............................................................................................ 218

Table 10-2. 16-Bit Timer With Prescaler Configurations ......................................................... 221

Table 10-3. Timers Register Map .......................................................................................... 227

Table 11-1. Watchdog Timer Register Map ............................................................................ 255

Table 12-1. Samples and FIFO Depth of Sequencers ............................................................ 278

Table 12-2. Differential Sampling Pairs ................................................................................. 280

Table 12-3. ADC Register Map ............................................................................................. 284

Table 13-1. UART Register Map ........................................................................................... 320

Table 14-1. SSI Register Map .............................................................................................. 365

Table 15-1. Examples of I2C Master Timer Period versus Speed Mode ................................... 396

Table 15-2. Inter-Integrated Circuit (I2C) Interface Register Map ............................................. 405

Table 15-3. Write Field Decoding for I2CMCS[3:0] Field (Sheet 1 of 3) .................................... 410

Table 16-1. Internal Reference Voltage and ACREFCTL Field Values ..................................... 430

Table 16-2. Analog Comparators Register Map ..................................................................... 431

Table 17-1. PWM Register Map ............................................................................................ 445

Table 18-1. QEI Register Map .............................................................................................. 481

Table 20-1. Signals by Pin Number ....................................................................................... 496

Table 20-2. Signals by Signal Name ..................................................................................... 500

Table 20-3. Signals by Function, Except for GPIO ................................................................. 504

Table 20-4. GPIO Pins and Alternate Functions ..................................................................... 507

Table 20-5. Signals by Pin Number ....................................................................................... 508

Table 20-6. Signals by Signal Name ..................................................................................... 513

Table 20-7. Signals by Function, Except for GPIO ................................................................. 517

Table 20-8. GPIO Pins and Alternate Functions ..................................................................... 519

Table 20-9. Connections for Unused Signals (100-pin LQFP) ................................................. 521

Table 20-10. Connections for Unused Signals, 108-pin BGA .................................................... 521

Table 21-1. Temperature Characteristics ............................................................................... 523

Stellaris® LM3S1439 Microcontroller

Texas Instruments-Production Data

11June 23, 2010

Table of Contents

Table 21-2. Thermal Characteristics ..................................................................................... 523

Table 21-3. ESD Absolute Maximum Ratings ........................................................................ 523

Table 22-1. Maximum Ratings .............................................................................................. 524

Table 22-2. Recommended DC Operating Conditions ............................................................ 524

Table 22-3. LDO Regulator Characteristics ........................................................................... 525

Table 22-4. GPIO Module DC Characteristics ........................................................................ 525

Table 22-5. Detailed Power Specifications ............................................................................ 526

Table 22-6. Flash Memory Characteristics ............................................................................ 527

Table 22-7. Hibernation Module DC Characteristics ............................................................... 527

Table 22-8. Phase Locked Loop (PLL) Characteristics ........................................................... 528

Table 22-9. Actual PLL Frequency ........................................................................................ 528

Table 22-10. Clock Characteristics ......................................................................................... 528

Table 22-11. Crystal Characteristics ....................................................................................... 529

Table 22-12. System Clock Characteristics with ADC Operation ............................................... 529

Table 22-13. JTAG Characteristics ......................................................................................... 529

Table 22-14. Reset Characteristics ......................................................................................... 531

Table 22-15. Sleep Modes AC Characteristics ......................................................................... 533

Table 22-16. Hibernation Module AC Characteristics ............................................................... 533

Table 22-17. GPIO Characteristics ......................................................................................... 534

Table 22-18. ADC Characteristics ........................................................................................... 534

Table 22-19. ADC Module Internal Reference Characteristics .................................................. 535

Table 22-20. SSI Characteristics ............................................................................................ 535

Table 22-21. I2C Characteristics ............................................................................................. 537

Table 22-22. Analog Comparator Characteristics ..................................................................... 538

Table 22-23. Analog Comparator Voltage Reference Characteristics ........................................ 538

Table C-1. Part Ordering Information ................................................................................... 562

Texas Instruments-Production Data

June 23, 201012

Stellaris® LM3S1439 Microcontroller

List of Registers

System Control .............................................................................................................................. 68

Register 1: Device Identification 0 (DID0), offset 0x000 ....................................................................... 82

Register 2: Brown-Out Reset Control (PBORCTL), offset 0x030 .......................................................... 84

Register 3: LDO Power Control (LDOPCTL), offset 0x034 ................................................................... 85

Register 4: Raw Interrupt Status (RIS), offset 0x050 ........................................................................... 86

Register 5: Interrupt Mask Control (IMC), offset 0x054 ........................................................................ 87

Register 6: Masked Interrupt Status and Clear (MISC), offset 0x058 .................................................... 88

Register 7: Reset Cause (RESC), offset 0x05C .................................................................................. 89

Register 8: Run-Mode Clock Configuration (RCC), offset 0x060 .......................................................... 90

Register 9: XTAL to PLL Translation (PLLCFG), offset 0x064 .............................................................. 94

Register 10: Run-Mode Clock Configuration 2 (RCC2), offset 0x070 ...................................................... 95

Register 11: Deep Sleep Clock Configuration (DSLPCLKCFG), offset 0x144 .......................................... 97

Register 12: Device Identification 1 (DID1), offset 0x004 ....................................................................... 98

Register 13: Device Capabilities 0 (DC0), offset 0x008 ........................................................................ 100

Register 14: Device Capabilities 1 (DC1), offset 0x010 ........................................................................ 101

Register 15: Device Capabilities 2 (DC2), offset 0x014 ........................................................................ 103

Register 16: Device Capabilities 3 (DC3), offset 0x018 ........................................................................ 105

Register 17: Device Capabilities 4 (DC4), offset 0x01C ....................................................................... 107

Register 18: Run Mode Clock Gating Control Register 0 (RCGC0), offset 0x100 ................................... 108

Register 19: Sleep Mode Clock Gating Control Register 0 (SCGC0), offset 0x110 ................................. 110

Register 20: Deep Sleep Mode Clock Gating Control Register 0 (DCGC0), offset 0x120 ....................... 112

Register 21: Run Mode Clock Gating Control Register 1 (RCGC1), offset 0x104 ................................... 114

Register 22: Sleep Mode Clock Gating Control Register 1 (SCGC1), offset 0x114 ................................. 116

Register 23: Deep Sleep Mode Clock Gating Control Register 1 (DCGC1), offset 0x124 ....................... 118

Register 24: Run Mode Clock Gating Control Register 2 (RCGC2), offset 0x108 ................................... 120

Register 25: Sleep Mode Clock Gating Control Register 2 (SCGC2), offset 0x118 ................................. 122

Register 26: Deep Sleep Mode Clock Gating Control Register 2 (DCGC2), offset 0x128 ....................... 124

Register 27: Software Reset Control 0 (SRCR0), offset 0x040 ............................................................. 126

Register 28: Software Reset Control 1 (SRCR1), offset 0x044 ............................................................. 127

Register 29: Software Reset Control 2 (SRCR2), offset 0x048 ............................................................. 129

Hibernation Module ..................................................................................................................... 130

Register 1: Hibernation RTC Counter (HIBRTCC), offset 0x000 ......................................................... 138

Register 2: Hibernation RTC Match 0 (HIBRTCM0), offset 0x004 ....................................................... 139

Register 3: Hibernation RTC Match 1 (HIBRTCM1), offset 0x008 ....................................................... 140

Register 4: Hibernation RTC Load (HIBRTCLD), offset 0x00C ........................................................... 141

Register 5: Hibernation Control (HIBCTL), offset 0x010 ..................................................................... 142

Register 6: Hibernation Interrupt Mask (HIBIM), offset 0x014 ............................................................. 144

Register 7: Hibernation Raw Interrupt Status (HIBRIS), offset 0x018 .................................................. 145

Register 8: Hibernation Masked Interrupt Status (HIBMIS), offset 0x01C ............................................ 146

Register 9: Hibernation Interrupt Clear (HIBIC), offset 0x020 ............................................................. 147

Register 10: Hibernation RTC Trim (HIBRTCT), offset 0x024 ............................................................... 148

Register 11: Hibernation Data (HIBDATA), offset 0x030-0x12C ............................................................ 149

Internal Memory ........................................................................................................................... 150

Register 1: Flash Memory Address (FMA), offset 0x000 .................................................................... 155

Register 2: Flash Memory Data (FMD), offset 0x004 ......................................................................... 156

Texas Instruments-Production Data

13June 23, 2010

Table of Contents

Register 3: Flash Memory Control (FMC), offset 0x008 ..................................................................... 157

Register 4: Flash Controller Raw Interrupt Status (FCRIS), offset 0x00C ............................................ 159

Register 5: Flash Controller Interrupt Mask (FCIM), offset 0x010 ........................................................ 160

Register 6: Flash Controller Masked Interrupt Status and Clear (FCMISC), offset 0x014 ..................... 161

Register 7: USec Reload (USECRL), offset 0x140 ............................................................................ 163

Register 8: Flash Memory Protection Read Enable 0 (FMPRE0), offset 0x130 and 0x200 ................... 164

Register 9: Flash Memory Protection Program Enable 0 (FMPPE0), offset 0x134 and 0x400 ............... 165

Register 10: User Debug (USER_DBG), offset 0x1D0 ......................................................................... 166

Register 11: User Register 0 (USER_REG0), offset 0x1E0 .................................................................. 167

Register 12: User Register 1 (USER_REG1), offset 0x1E4 .................................................................. 168

Register 13: Flash Memory Protection Read Enable 1 (FMPRE1), offset 0x204 .................................... 169

Register 14: Flash Memory Protection Read Enable 2 (FMPRE2), offset 0x208 .................................... 170

Register 15: Flash Memory Protection Read Enable 3 (FMPRE3), offset 0x20C ................................... 171

Register 16: Flash Memory Protection Program Enable 1 (FMPPE1), offset 0x404 ............................... 172

Register 17: Flash Memory Protection Program Enable 2 (FMPPE2), offset 0x408 ............................... 173

Register 18: Flash Memory Protection Program Enable 3 (FMPPE3), offset 0x40C ............................... 174

General-Purpose Input/Outputs (GPIOs) ................................................................................... 175

Register 1: GPIO Data (GPIODATA), offset 0x000 ............................................................................ 183

Register 2: GPIO Direction (GPIODIR), offset 0x400 ......................................................................... 184

Register 3: GPIO Interrupt Sense (GPIOIS), offset 0x404 .................................................................. 185

Register 4: GPIO Interrupt Both Edges (GPIOIBE), offset 0x408 ........................................................ 186

Register 5: GPIO Interrupt Event (GPIOIEV), offset 0x40C ................................................................ 187

Register 6: GPIO Interrupt Mask (GPIOIM), offset 0x410 ................................................................... 188

Register 7: GPIO Raw Interrupt Status (GPIORIS), offset 0x414 ........................................................ 189

Register 8: GPIO Masked Interrupt Status (GPIOMIS), offset 0x418 ................................................... 190

Register 9: GPIO Interrupt Clear (GPIOICR), offset 0x41C ................................................................ 191

Register 10: GPIO Alternate Function Select (GPIOAFSEL), offset 0x420 ............................................ 192

Register 11: GPIO 2-mA Drive Select (GPIODR2R), offset 0x500 ........................................................ 194

Register 12: GPIO 4-mA Drive Select (GPIODR4R), offset 0x504 ........................................................ 195

Register 13: GPIO 8-mA Drive Select (GPIODR8R), offset 0x508 ........................................................ 196

Register 14: GPIO Open Drain Select (GPIOODR), offset 0x50C ......................................................... 197

Register 15: GPIO Pull-Up Select (GPIOPUR), offset 0x510 ................................................................ 198

Register 16: GPIO Pull-Down Select (GPIOPDR), offset 0x514 ........................................................... 199

Register 17: GPIO Slew Rate Control Select (GPIOSLR), offset 0x518 ................................................ 200

Register 18: GPIO Digital Enable (GPIODEN), offset 0x51C ................................................................ 201

Register 19: GPIO Lock (GPIOLOCK), offset 0x520 ............................................................................ 202

Register 20: GPIO Commit (GPIOCR), offset 0x524 ............................................................................ 203

Register 21: GPIO Peripheral Identification 4 (GPIOPeriphID4), offset 0xFD0 ....................................... 205

Register 22: GPIO Peripheral Identification 5 (GPIOPeriphID5), offset 0xFD4 ....................................... 206

Register 23: GPIO Peripheral Identification 6 (GPIOPeriphID6), offset 0xFD8 ....................................... 207

Register 24: GPIO Peripheral Identification 7 (GPIOPeriphID7), offset 0xFDC ...................................... 208

Register 25: GPIO Peripheral Identification 0 (GPIOPeriphID0), offset 0xFE0 ....................................... 209

Register 26: GPIO Peripheral Identification 1 (GPIOPeriphID1), offset 0xFE4 ....................................... 210

Register 27: GPIO Peripheral Identification 2 (GPIOPeriphID2), offset 0xFE8 ....................................... 211

Register 28: GPIO Peripheral Identification 3 (GPIOPeriphID3), offset 0xFEC ...................................... 212

Register 29: GPIO PrimeCell Identification 0 (GPIOPCellID0), offset 0xFF0 .......................................... 213

Register 30: GPIO PrimeCell Identification 1 (GPIOPCellID1), offset 0xFF4 .......................................... 214

Register 31: GPIO PrimeCell Identification 2 (GPIOPCellID2), offset 0xFF8 .......................................... 215

Texas Instruments-Production Data

June 23, 201014

Stellaris® LM3S1439 Microcontroller

Register 32: GPIO PrimeCell Identification 3 (GPIOPCellID3), offset 0xFFC ......................................... 216

General-Purpose Timers ............................................................................................................. 217

Register 1: GPTM Configuration (GPTMCFG), offset 0x000 .............................................................. 229

Register 2: GPTM TimerA Mode (GPTMTAMR), offset 0x004 ............................................................ 230

Register 3: GPTM TimerB Mode (GPTMTBMR), offset 0x008 ............................................................ 232

Register 4: GPTM Control (GPTMCTL), offset 0x00C ........................................................................ 234

Register 5: GPTM Interrupt Mask (GPTMIMR), offset 0x018 .............................................................. 237

Register 6: GPTM Raw Interrupt Status (GPTMRIS), offset 0x01C ..................................................... 239

Register 7: GPTM Masked Interrupt Status (GPTMMIS), offset 0x020 ................................................ 240

Register 8: GPTM Interrupt Clear (GPTMICR), offset 0x024 .............................................................. 241

Register 9: GPTM TimerA Interval Load (GPTMTAILR), offset 0x028 ................................................. 243

Register 10: GPTM TimerB Interval Load (GPTMTBILR), offset 0x02C ................................................ 244

Register 11: GPTM TimerA Match (GPTMTAMATCHR), offset 0x030 ................................................... 245

Register 12: GPTM TimerB Match (GPTMTBMATCHR), offset 0x034 .................................................. 246

Register 13: GPTM TimerA Prescale (GPTMTAPR), offset 0x038 ........................................................ 247

Register 14: GPTM TimerB Prescale (GPTMTBPR), offset 0x03C ....................................................... 248

Register 15: GPTM TimerA Prescale Match (GPTMTAPMR), offset 0x040 ........................................... 249

Register 16: GPTM TimerB Prescale Match (GPTMTBPMR), offset 0x044 ........................................... 250

Register 17: GPTM TimerA (GPTMTAR), offset 0x048 ........................................................................ 251

Register 18: GPTM TimerB (GPTMTBR), offset 0x04C ....................................................................... 252

Watchdog Timer ........................................................................................................................... 253

Register 1: Watchdog Load (WDTLOAD), offset 0x000 ...................................................................... 257

Register 2: Watchdog Value (WDTVALUE), offset 0x004 ................................................................... 258

Register 3: Watchdog Control (WDTCTL), offset 0x008 ..................................................................... 259

Register 4: Watchdog Interrupt Clear (WDTICR), offset 0x00C .......................................................... 260

Register 5: Watchdog Raw Interrupt Status (WDTRIS), offset 0x010 .................................................. 261

Register 6: Watchdog Masked Interrupt Status (WDTMIS), offset 0x014 ............................................. 262

Register 7: Watchdog Test (WDTTEST), offset 0x418 ....................................................................... 263

Register 8: Watchdog Lock (WDTLOCK), offset 0xC00 ..................................................................... 264

Register 9: Watchdog Peripheral Identification 4 (WDTPeriphID4), offset 0xFD0 ................................. 265

Register 10: Watchdog Peripheral Identification 5 (WDTPeriphID5), offset 0xFD4 ................................. 266

Register 11: Watchdog Peripheral Identification 6 (WDTPeriphID6), offset 0xFD8 ................................. 267

Register 12: Watchdog Peripheral Identification 7 (WDTPeriphID7), offset 0xFDC ................................ 268

Register 13: Watchdog Peripheral Identification 0 (WDTPeriphID0), offset 0xFE0 ................................. 269

Register 14: Watchdog Peripheral Identification 1 (WDTPeriphID1), offset 0xFE4 ................................. 270

Register 15: Watchdog Peripheral Identification 2 (WDTPeriphID2), offset 0xFE8 ................................. 271

Register 16: Watchdog Peripheral Identification 3 (WDTPeriphID3), offset 0xFEC ................................. 272

Register 17: Watchdog PrimeCell Identification 0 (WDTPCellID0), offset 0xFF0 .................................... 273

Register 18: Watchdog PrimeCell Identification 1 (WDTPCellID1), offset 0xFF4 .................................... 274

Register 19: Watchdog PrimeCell Identification 2 (WDTPCellID2), offset 0xFF8 .................................... 275

Register 20: Watchdog PrimeCell Identification 3 (WDTPCellID3 ), offset 0xFFC .................................. 276

Analog-to-Digital Converter (ADC) ............................................................................................. 277

Register 1: ADC Active Sample Sequencer (ADCACTSS), offset 0x000 ............................................. 286

Register 2: ADC Raw Interrupt Status (ADCRIS), offset 0x004 ........................................................... 287

Register 3: ADC Interrupt Mask (ADCIM), offset 0x008 ..................................................................... 288

Register 4: ADC Interrupt Status and Clear (ADCISC), offset 0x00C .................................................. 289

Register 5: ADC Overflow Status (ADCOSTAT), offset 0x010 ............................................................ 291

Register 6: ADC Event Multiplexer Select (ADCEMUX), offset 0x014 ................................................. 292

Texas Instruments-Production Data

15June 23, 2010

Table of Contents

Register 7: ADC Underflow Status (ADCUSTAT), offset 0x018 ........................................................... 296

Register 8: ADC Sample Sequencer Priority (ADCSSPRI), offset 0x020 ............................................. 297

Register 9: ADC Processor Sample Sequence Initiate (ADCPSSI), offset 0x028 ................................. 299

Register 10: ADC Sample Averaging Control (ADCSAC), offset 0x030 ................................................. 300

Register 11: ADC Sample Sequence Input Multiplexer Select 0 (ADCSSMUX0), offset 0x040 ............... 301

Register 12: ADC Sample Sequence Control 0 (ADCSSCTL0), offset 0x044 ........................................ 303

Register 13: ADC Sample Sequence Result FIFO 0 (ADCSSFIFO0), offset 0x048 ................................ 306

Register 14: ADC Sample Sequence Result FIFO 1 (ADCSSFIFO1), offset 0x068 ................................ 306

Register 15: ADC Sample Sequence Result FIFO 2 (ADCSSFIFO2), offset 0x088 ................................ 306

Register 16: ADC Sample Sequence Result FIFO 3 (ADCSSFIFO3), offset 0x0A8 ............................... 306

Register 17: ADC Sample Sequence FIFO 0 Status (ADCSSFSTAT0), offset 0x04C ............................. 307

Register 18: ADC Sample Sequence FIFO 1 Status (ADCSSFSTAT1), offset 0x06C ............................. 307

Register 19: ADC Sample Sequence FIFO 2 Status (ADCSSFSTAT2), offset 0x08C ............................ 307

Register 20: ADC Sample Sequence FIFO 3 Status (ADCSSFSTAT3), offset 0x0AC ............................ 307

Register 21: ADC Sample Sequence Input Multiplexer Select 1 (ADCSSMUX1), offset 0x060 ............... 308

Register 22: ADC Sample Sequence Input Multiplexer Select 2 (ADCSSMUX2), offset 0x080 ............... 308

Register 23: ADC Sample Sequence Control 1 (ADCSSCTL1), offset 0x064 ........................................ 309

Register 24: ADC Sample Sequence Control 2 (ADCSSCTL2), offset 0x084 ........................................ 309

Register 25: ADC Sample Sequence Input Multiplexer Select 3 (ADCSSMUX3), offset 0x0A0 ............... 311

Register 26: ADC Sample Sequence Control 3 (ADCSSCTL3), offset 0x0A4 ........................................ 312

Register 27: ADC Test Mode Loopback (ADCTMLB), offset 0x100 ....................................................... 313

Universal Asynchronous Receivers/Transmitters (UARTs) ..................................................... 314

Register 1: UART Data (UARTDR), offset 0x000 ............................................................................... 322

Register 2: UART Receive Status/Error Clear (UARTRSR/UARTECR), offset 0x004 ........................... 324

Register 3: UART Flag (UARTFR), offset 0x018 ................................................................................ 326

Register 4: UART IrDA Low-Power Register (UARTILPR), offset 0x020 ............................................. 328

Register 5: UART Integer Baud-Rate Divisor (UARTIBRD), offset 0x024 ............................................ 329

Register 6: UART Fractional Baud-Rate Divisor (UARTFBRD), offset 0x028 ....................................... 330

Register 7: UART Line Control (UARTLCRH), offset 0x02C ............................................................... 331

Register 8: UART Control (UARTCTL), offset 0x030 ......................................................................... 333

Register 9: UART Interrupt FIFO Level Select (UARTIFLS), offset 0x034 ........................................... 335

Register 10: UART Interrupt Mask (UARTIM), offset 0x038 ................................................................. 337

Register 11: UART Raw Interrupt Status (UARTRIS), offset 0x03C ...................................................... 339

Register 12: UART Masked Interrupt Status (UARTMIS), offset 0x040 ................................................. 340

Register 13: UART Interrupt Clear (UARTICR), offset 0x044 ............................................................... 341

Register 14: UART Peripheral Identification 4 (UARTPeriphID4), offset 0xFD0 ..................................... 343

Register 15: UART Peripheral Identification 5 (UARTPeriphID5), offset 0xFD4 ..................................... 344

Register 16: UART Peripheral Identification 6 (UARTPeriphID6), offset 0xFD8 ..................................... 345

Register 17: UART Peripheral Identification 7 (UARTPeriphID7), offset 0xFDC ..................................... 346

Register 18: UART Peripheral Identification 0 (UARTPeriphID0), offset 0xFE0 ...................................... 347

Register 19: UART Peripheral Identification 1 (UARTPeriphID1), offset 0xFE4 ...................................... 348

Register 20: UART Peripheral Identification 2 (UARTPeriphID2), offset 0xFE8 ...................................... 349

Register 21: UART Peripheral Identification 3 (UARTPeriphID3), offset 0xFEC ..................................... 350

Register 22: UART PrimeCell Identification 0 (UARTPCellID0), offset 0xFF0 ........................................ 351

Register 23: UART PrimeCell Identification 1 (UARTPCellID1), offset 0xFF4 ........................................ 352

Register 24: UART PrimeCell Identification 2 (UARTPCellID2), offset 0xFF8 ........................................ 353

Register 25: UART PrimeCell Identification 3 (UARTPCellID3), offset 0xFFC ........................................ 354

Texas Instruments-Production Data

June 23, 201016

Stellaris® LM3S1439 Microcontroller

Synchronous Serial Interface (SSI) ............................................................................................ 355

Register 1: SSI Control 0 (SSICR0), offset 0x000 .............................................................................. 367

Register 2: SSI Control 1 (SSICR1), offset 0x004 .............................................................................. 369

Register 3: SSI Data (SSIDR), offset 0x008 ...................................................................................... 371

Register 4: SSI Status (SSISR), offset 0x00C ................................................................................... 372