swivel

SN75LVDS83B

FlatLink Transmitter

TM

PackageOptions

TSSOP:8x14mmDGG

BGA:4.5x7mm

Application

processor

(e.g.OMAP )

TM

SN75LVDS83B

www.ti.com

FLATLINK™ TRANSMITTER

Check for Samples: SN75LVDS83B

1

FEATURES

2

• LVDS Display Serdes Interfaces Directly to

LCD Display Panels with Integrated LVDS

• Package Options: 4.5mm x 7mm BGA, and

8.1mm x 14mm TSSOP

• 1.8V up to 3.3V Tolerant Data Inputs to

Connect Directly to Low-Power, Low-Voltage

Application and Graphic Processors

• Transfer Rate up to 135Mpps (Mega Pixel Per

Second); Pixel Clock Frequency Range 10MHz

to 135MHz

• Suited for Display Resolutions Ranging From

HVGA up to HD With Low EMI

• Operates From a Single 3.3V Supply and

170mW (typ.) at 75MHz

• 28 Data Channels Plus Clock In Low-Voltage

TTL to 4 Data Channels Plus Clock Out Low-

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

Voltage Differential

• Consumes Less Than 1mW When Disabled

• Selectable Rising or Falling Clock Edge

Triggered Inputs

• ESD: 5kV HBM

• Support Spread Spectrum Clocking (SSC)

• Compatible with all OMAP™2x, OMAP™3x,

and DaVinci™ Application Processors

APPLICATIONS

• LCD Display Panel Driver

• UMPC and Netbook PC

• Digital Picture Frame

DESCRIPTION

The SN75LVDS83B FlatLink™ transmitter contains four 7-bit parallel-load serial-out shift registers, a 7X clock

synthesizer, and five Low-Voltage Differential Signaling (LVDS) line drivers in a single integrated circuit. These

functions allow 28 bits of single-ended LVTTL data to be synchronously transmitted over five balanced-pair

conductors for receipt by a compatible receiver, such as the SN75LVDS82 and LCD panels with integrated LVDS

receiver.

When transmitting, data bits D0 through D27 are each loaded into registers upon the edge of the input clock

signal (CLKIN). The rising or falling edge of the clock can be selected via the clock select (CLKSEL) pin. The

frequency of CLKIN is multiplied seven times, and then used to unload the data registers in 7-bit slices and

serially. The four serial streams and a phase-locked clock (CLKOUT) are then output to LVDS output drivers.

The frequency of CLKOUT is the same as the input clock, CLKIN.

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2OMAP, DaVinci, FlatLink are trademarks of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2009–2011, Texas Instruments Incorporated

SN75LVDS83B

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

www.ti.com

DESCRIPTION (CONTINUED)

The SN75LVDS83B requires no external components and little or no control. The data bus appears the same at

the input to the transmitter and output of the receiver with the data transmission transparent to the user(s). The

only user intervention is selecting a clock rising edge by inputting a high level to CLKSEL or a falling edge with a

low-level input, and the possible use of the Shutdown/Clear (SHTDN). SHTDN is an active-low input to inhibit the

clock, and shut off the LVDS output drivers for lower power consumption. A low-level on this signal clears all

internal registers to a low-level.

The SN75LVDS83B is characterized for operation over ambient air temperatures of -10°C to 70°C.

Alternative device option: The SN75LVDS83A (SLLS980) is an alternative to the SN75LVDS83B for clock

frequency range of 10MHz-100MHz only. The SN75LVDS83A is available in the TSSOP package option only.

ORDERING INFORMATION

PART NUMBER PART MARKING PACKAGE

SN75LVDS83BZQLR LVDS83B in BGA package 56-pin ZQL LARGE T&R

SN75LVDS83BDGG LVDS83B in TSSOP package 56-pin DGG TUBE

SN75LVDS83BDGGR LVDS83B in TSSOP package 56-pin DGG LARGE T&R

(1) For the most current package and ordering information, see the Package Option Addendum located at the end of this data sheet, or

refer to our web site at www.ti.com.

(1)

ABSOLUTE MAXIMUM RATINGS

Supply voltage range, VCC, IOVCC, LVDSVCC, PLLVCC

Voltage range at any output terminal -0.5 to VCC + 0.5 V

Voltage range at any input terminal -0.5 to IOVCC + 0.5 V

Continuous power dissipation See the dissipation rating table

Storage temperature, T

ESD rating Charged Device Model (CDM)

(1) Stresses above these ratings may cause permanent damage. Exposure to absolute maximum conditions for extended periods may

degrade device reliability. These are stress ratings only, and functional operation of the device at these or any other conditions beyond

those specified is not implied.

(2) All voltages are with respect to the GND terminals.

(3) In accordance with JEDEC Standard 22, Test Method A114-A.

(4) In accordance with JEDEC Standard 22, Test Method C101.

(5) In accordance with JEDEC Standard 22, Test Method A115-A.

s

Human Body Model (HBM)

Machine Model (MM)

(5)

(1)

VALUE UNIT

(2)

(3)

all pins 5 kV

(4)

all pins 500 V

all pins 150 V

-0.5 to 4 V

–65 to 150 °C

2 Copyright © 2009–2011, Texas Instruments Incorporated

SN75LVDS83B

www.ti.com

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

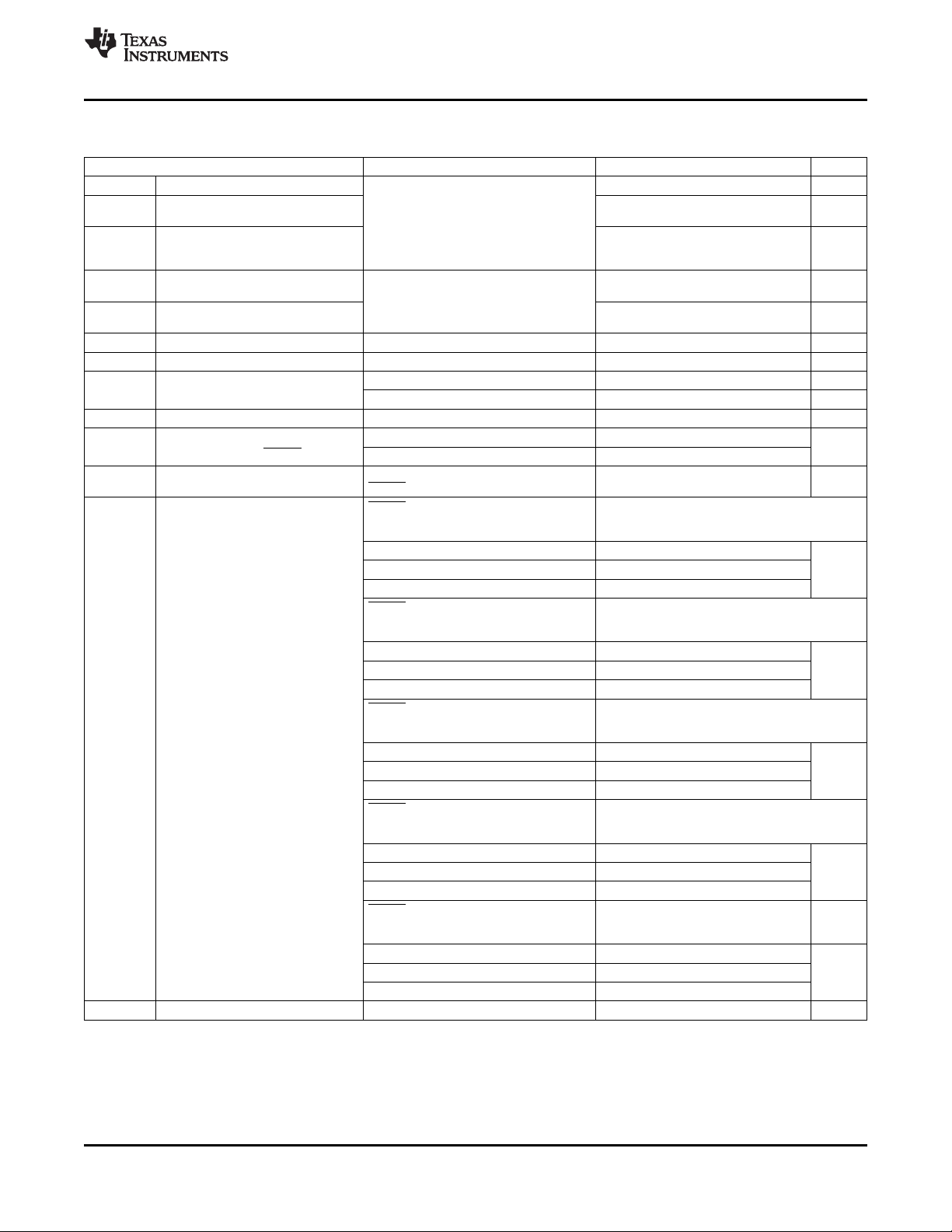

RECOMMENDED OPERATING CONDITIONS

over operating free-air temperature range (unless otherwise noted)

PARAMETER MIN NOM MAX UNIT

Supply voltage, VCC 3 3.3 3.6

LVDS output Supply voltage, LVDSVCC 3 3.3 3.6

PLL analog supply voltage, PLLVCC 3 3.3 3.6 V

IO input reference supply voltage, IOVCC 1.62 1.8 / 2.5 / 3.3 3.6

Power supply noise on any VCC terminal 0.1

IOVCC = 1.8V IOVCC/2 + 0.3V

High-level input voltage, V

Low-level input voltage, V

Differential load impedance, Z

IH

IL

L

Operating free-air temperature, T

A

IOVCC = 2.5V IOVCC/2 + 0.4V V

IOVCC = 3.3V IOVCC/2 + 0.5V

IOVCC = 1.8V IOVCC/2 - 0.3V

IOVCC = 2.5V IOVCC/2 - 0.4V V

IOVCC = 3.3V IOVCC/2 - 0.5V

90 132 Ω

-10 70 C

DISSIPATION RATINGS

PACKAGE CIRCUIT BOARD MODEL

DGG 1111mW 12.3mW/°C 555mW

ZQL 1034mW 11.5mW/°C 517mW

(3)

DGG

ZQL 2000mW 22mW/°C 1000mW

Low-K

High-K

(1)

TJA≤ 25°C

1730mW 19mW/°C 865mW

DERATING FACTOR

ABOVE TJA= 25°C POWER RATING

(1) In accordance with the High-K and Low-K thermal metric definitions of EIA/JESD51-2.

(2) This is the inverse of the junction-to-ambient thermal resistance when board-mounted and with no air flow.

(3) DGG junction to case thermal reistance (θJC) is 15.4°C/W.

(2)

TJA= 70°C

TIMING REQUIREMENTS

PARAMETER MIN MAX UNIT

Input clock period, t

Input clock modulation

High-level input clock pulse width duration, t

Input signal transition time, t

c

with modulation frequency 30kHz 8%

with modulation frequency 50kHz 6%

w

t

Data set up time, D0 through D27 before CLKIN (See Figure 3) 2 ns

Data hold time, D0 through D27 after CLKIN 0.8 ns

7.4 100 ns

0.4 t

c

0.6 t

c

3 ns

ns

Copyright © 2009–2011, Texas Instruments Incorporated 3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28 29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

IOVCC

VCC

LVDSVCC

GND

CLKSEL

D16

D15

D14

GND

CLKOUTM

D13

D17

D5

D6

D7

D8

D10

D11

D18

GND

D21

D23

D24

D2

D3

D4

GND

D1

D0

D27

GND

Y0M

GND

GND

PLLVCC

GND

SHTDN

CLKIN

D26

GND

GND

D9

D12

D19

D20

D22

IOVCC

D25

Y0P

Y1M

Y1P

Y2M

Y2P

Y3M

Y3P

CLKOUTP

SN75LVDS83B

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

www.ti.com

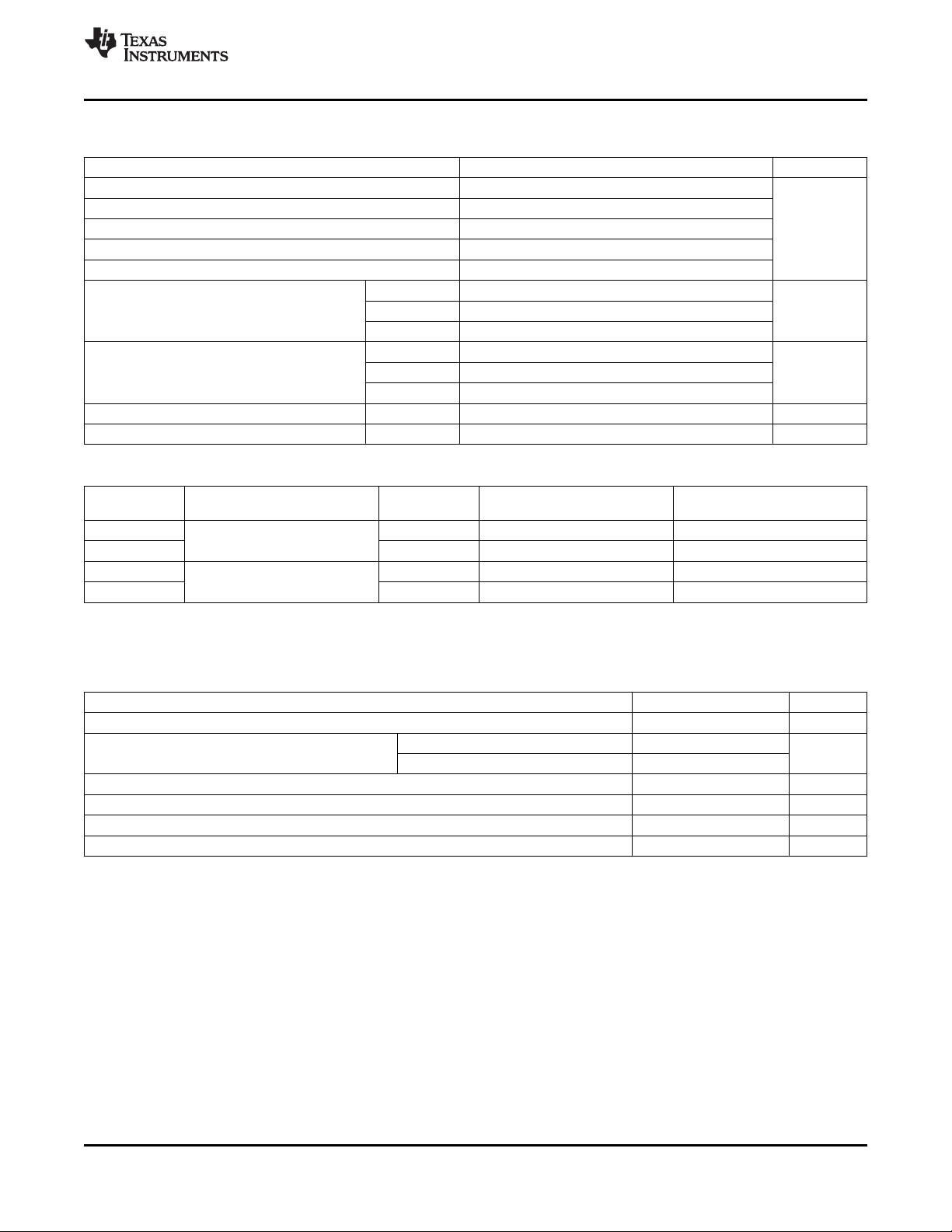

DGG PACKAGE

(TOP VIEW)

4 Copyright © 2009–2011, Texas Instruments Incorporated

Pin # Signal Pin # Signal Pin # Signal Pin # Signal

1 IOVCC 15 D15 29 GND 43 GND

2 D5 16 D16 30 D26 44 LVDSVCC

3 D6 17 CLKSEL 31 CLKIN 45 Y1P

4 D7 18 D17 32 SHTDN 46 Y1M

5 GND 19 D18 33 GND 47 Y0P

6 D8 20 D19 34 PLLVCC 48 Y0M

7 D9 21 GND 35 GND 49 GND

8 D10 22 D20 36 GND 50 D27

9 VCC 23 D21 37 Y3P 51 D0

10 D11 24 D22 38 Y3M 52 D1

11 D12 25 D23 39 CLKOUTP 53 GND

12 D13 26 IOVCC 40 CLKOUTM 54 D2

13 GND 27 D24 41 Y2P 55 D3

14 D14 28 D25 42 Y2M 56 D4

DGG PIN LIST

13 2456

K

G

H

J

D

E

F

C

D13

D14

D16

D17

GND Y3M

D15

GND

GND

GND

Y1P

Y2P

LVDSVCC

Y1M

Y2M

GND

Y0M

CLKM

CLKSEL

D8

CLKP

Y0P

D12

D11

D19

D3

D1

D27D6

D7

GND

D4D5

D0

D2

Y3P

D18

B

A

D22

D20

D26

GND

GNDD24

D21

D23

SHTDND25

CLKIN

PLLVCC

IOVCC

IOVCC

VCC

GND

GND

D10

D9

SN75LVDS83B

www.ti.com

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

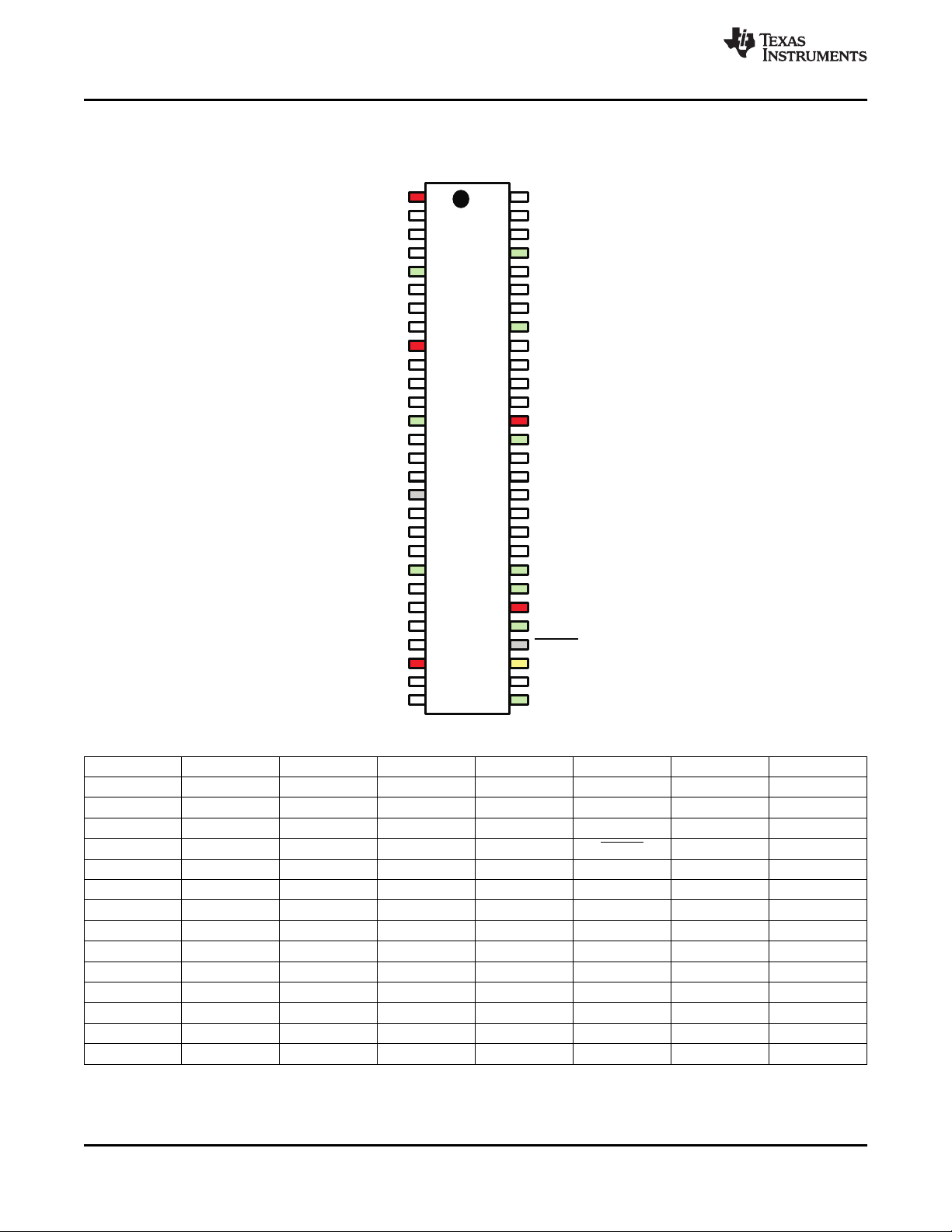

ZQL PACKAGE

(TOP VIEW)

ZQL PIN LIST

Copyright © 2009–2011, Texas Instruments Incorporated 5

Ball # Signal Ball # Signal Ball # Signal

A1 GND A2 CLKIN A3 D26

A4 D24 A5 D23 A6 D22

B1 GND B2 PLLVCC B3 SHTDN

B4 D25 B5 D21 B6 D20

C1 Y3M C2 Y3P C3 GND

C4 IOVCC C5 GND C6 D19

D1 CLKM D2 CLKP D3 GND

D4 CLKSEL D5 D18 D6 D17

E1 Y2M E2 Y2P E3 ball not populated

E4 ball not populated E5 D15 E6 D16

F1 LVDSVCC F2 GND F3 ball not populated

F4 ball not populated F5 GND F6 D14

G1 Y1M G2 Y1P G3 GND

G4 IOVCC G5 D12 G6 D13

H1 Y0M H2 Y0P H3 GND

H4 D10 H5 VCC H6 D11

J1 D27 J2 D0 J3 D3

J4 D6 J5 GND J6 D9

SN75LVDS83B

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

www.ti.com

ZQL PIN LIST (continued)

K1 D1 K2 D2 K3 D4

K4 D5 K5 D7 K6 D8

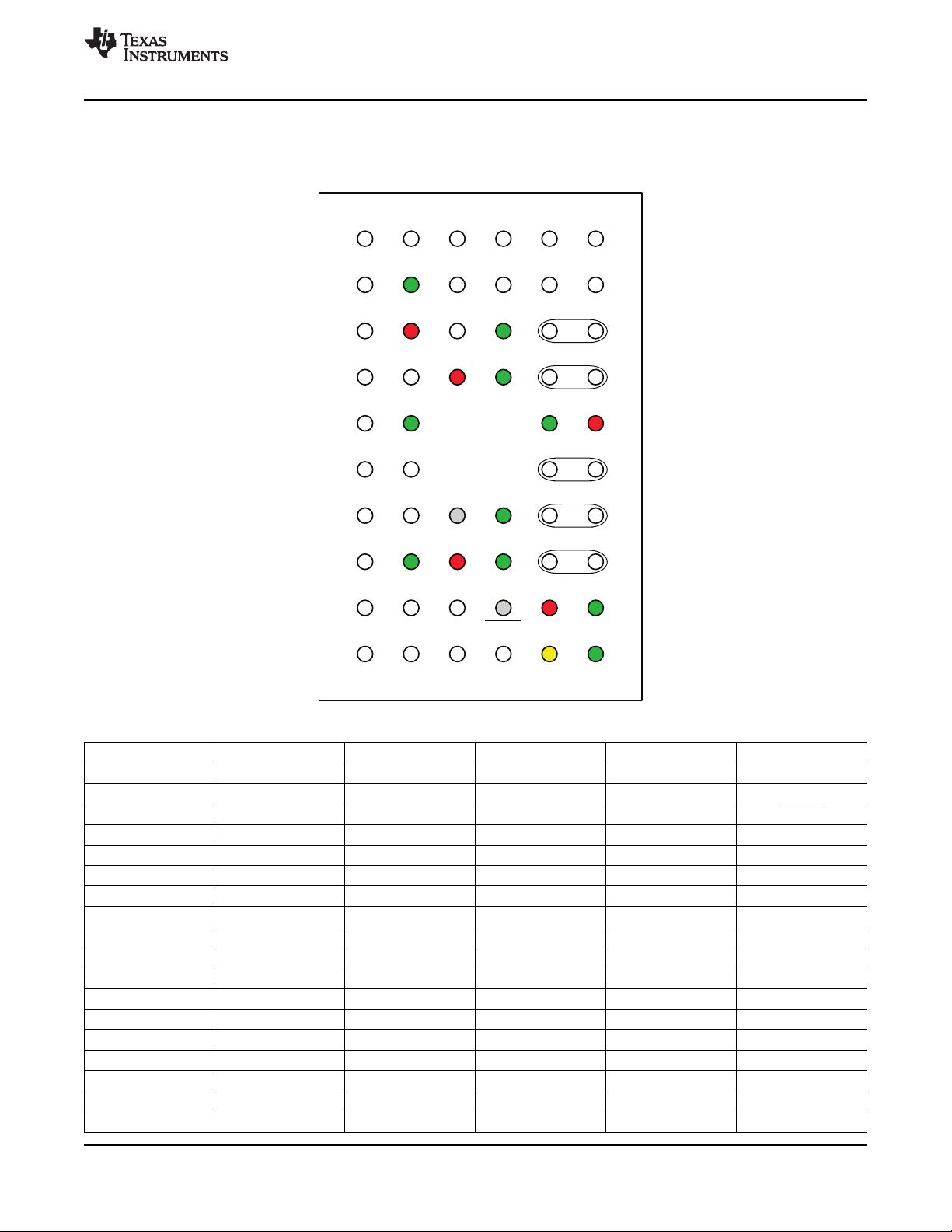

PIN FUNCTIONS

TERMINAL I/O DESCRIPTION

Y0P, Y0M, Y1P, Differential LVDS data outputs.

Y1M, Y2P, Y2M Outputs are high-impedance when SHTDN is pulled low (de-asserted)

Y3P, Y3M LVDS Out Output is high-impedance when SHTDN is pulled low (de-asserted).

CLKP, CLKM

D0 – D27

CMOS IN with

CLKIN Input pixel clock; rising or falling clock polarity is selectable by Control input CLKSEL.

SHTDN

CLKSEL

VCC 3.3V digital supply voltage

IOVCC I/O supply reference voltage (1.8V up to 3.3V matching the GPU data output signal swing)

PLLVCC Power Supply

LVDSVCC 3.3V LVDS output analog supply

GND Supply ground for VCC, IOVCC, LVDSVCC, and PLLVCC.

(1) For a multilayer pcb, it is recommended to keep one common GND layer underneath the device and connect all ground terminals

directly to this plane.

pulldn

Differential LVDS Data outputs.

Note: if the application only requires 18-bit color, this output can be left open.

Differential LVDS pixel clock output.

Output is high-impedance when SHTDN is pulled low (de-asserted).

Data inputs; supports 1.8V to 3.3V input voltage selectable by VDD supply. To connect a graphic

source successfully to a display, the bit assignment of D[27:0] is critical (and not necessarily

intuitive).

For input bit assignment see Figure 14 to Figure 17 for details.

Note: if application only requires 18-bit color, connect unused inputs D5, D10, D11, D16, D17, D23,

and D27 to GND.

Device shut down; pull low (de-assert) to shut down the device (low power, resets all registers) and

high (assert) for normal operation.

Selects between rising edge input clock trigger (CLKSEL = VIH) and falling edge input clock trigger

(CLKSEL = VIL).

(1)

3.3V PLL analog supply

6 Copyright © 2009–2011, Texas Instruments Incorporated

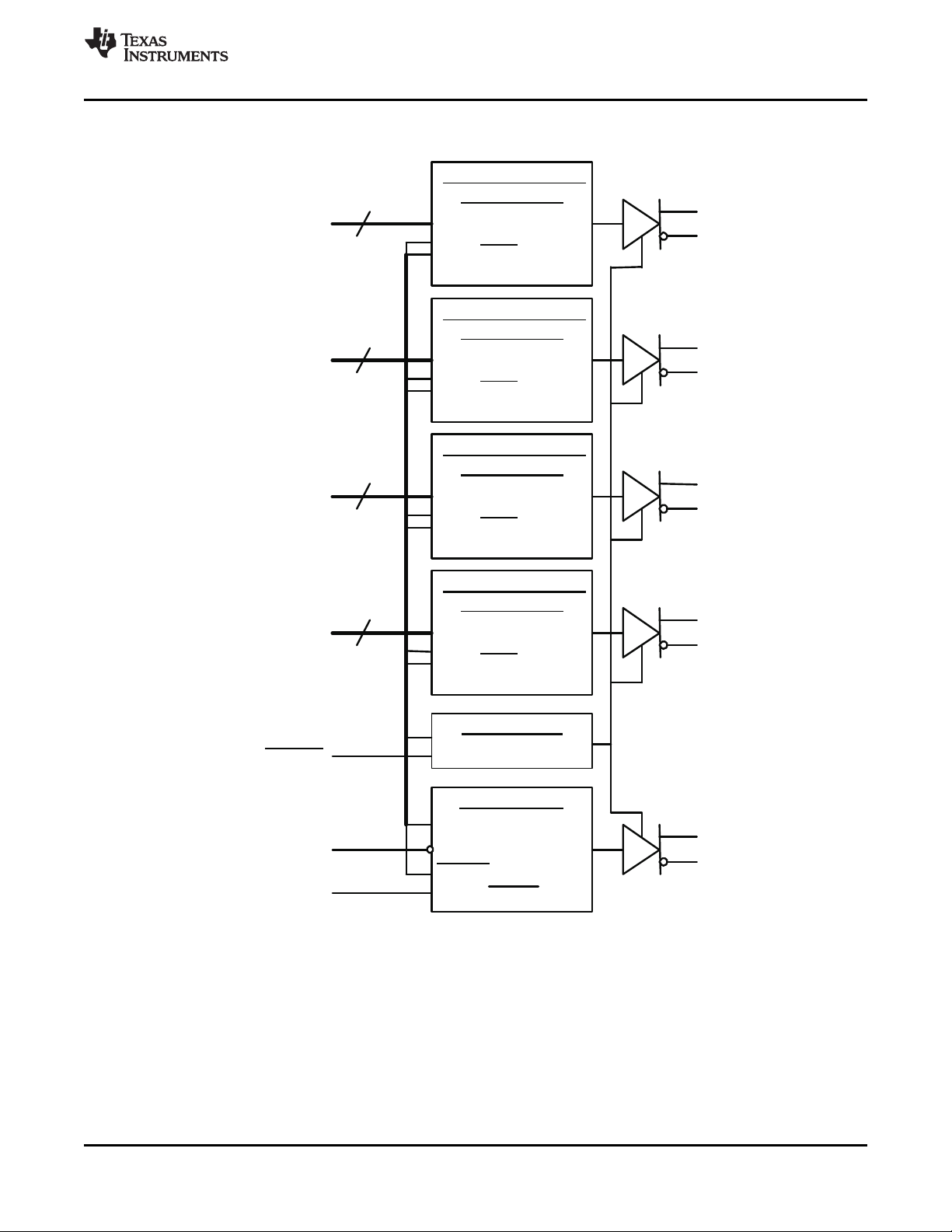

Parallel-Load7-bit

ShiftRegister

A,B,...G

SHIFT/LOAD

>CLK

7D0,D1,D2,D3,

D4,D6,D7

Y0P

Y0M

Parallel-Load7-bit

ShiftRegister

A,B,...G

SHIFT/LOAD

>CLK

7D8,D9,D12,D13,

D14,D15,D18

Y1P

Y1M

Parallel-Load7-bit

ShiftRegister

A,B,...G

SHIFT/LOAD

>CLK

7D19,D20,D21,D22,

D24,D25,D26

Y2P

Y2M

7XClock/PLL

7XCLK

>CLK

CLKINH

RISING/FALLINGEDGE

CLKIN

CLKOUTP

CLKOUTM

SHTDN

Parallel-Load7-bit

ShiftRegister

A,B,...G

SHIFT/LOAD

>CLK

7D27,D5,D10,D11,

D16, D17,D23

Y3P

Y3M

ControlLogic

CLKSEL

SN75LVDS83B

www.ti.com

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

FUNCTIONAL BLOCK DIAGRAM

Copyright © 2009–2011, Texas Instruments Incorporated 7

D0-1

D8-1

D19-1

D27-1

D7

D18

D26

D23 D17

D25

D15

D6

D16

D24

D14

D4

D11

D22

D13

D3

D10

D21

D12

D2

D5

D20

D9

D1

D27

D19

D8

D0

D23+1

D26+1

D18+1

D7+1

Dn

CLKIN

CLKOUT

Y0

Y1

Y2

Y3

Previouscycle

Currentcycle

Next

CLKIN

or

7V

Dor

IOVCC

LVDSVCC

SHTDN

50W

7V

5W

YnP or

YnM

10kW

300kW

SN75LVDS83B

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

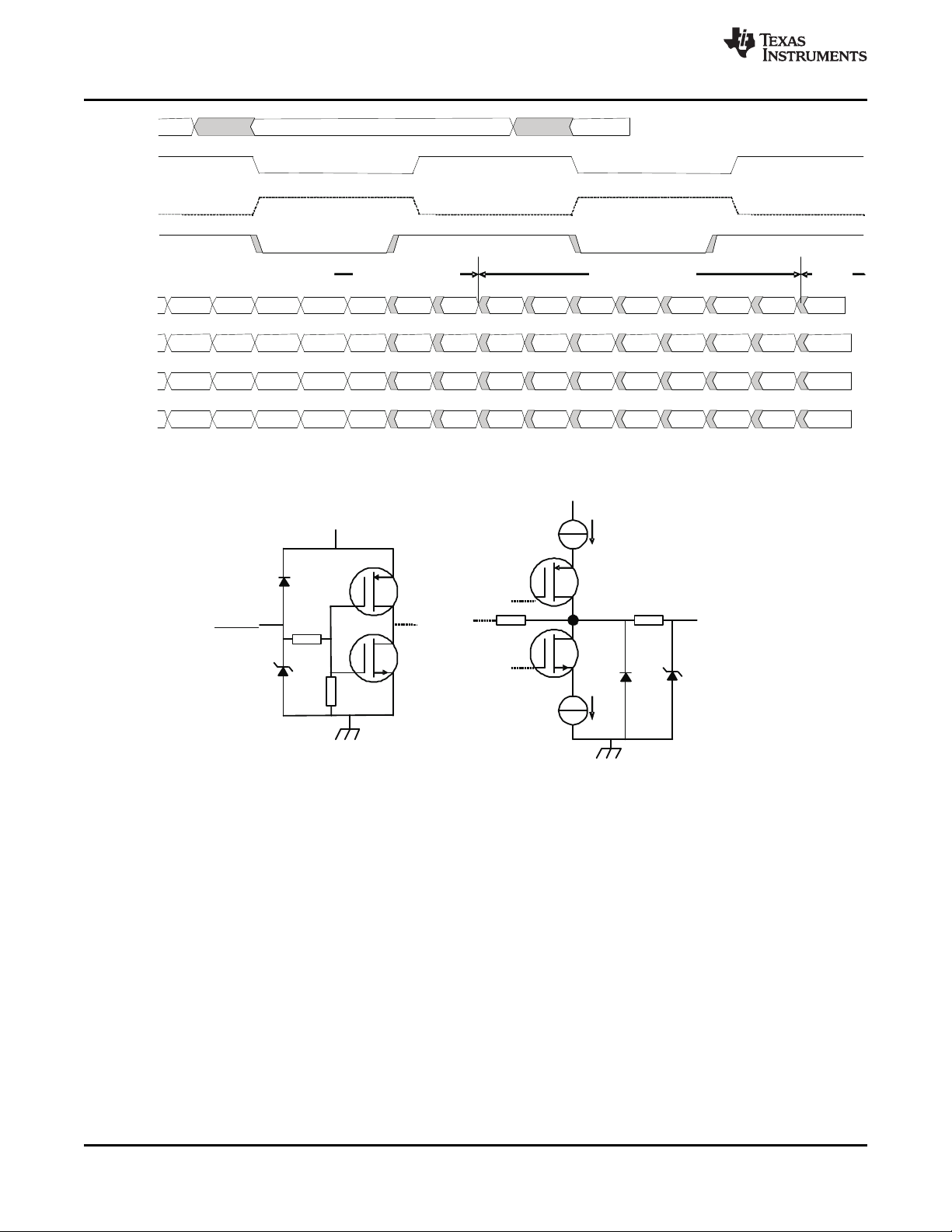

Figure 1. Typical SN75LVDS83B Load and Shift Sequences

www.ti.com

Figure 2. Equivalent Input and Output Schematic Diagrams

8 Copyright © 2009–2011, Texas Instruments Incorporated

SN75LVDS83B

www.ti.com

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

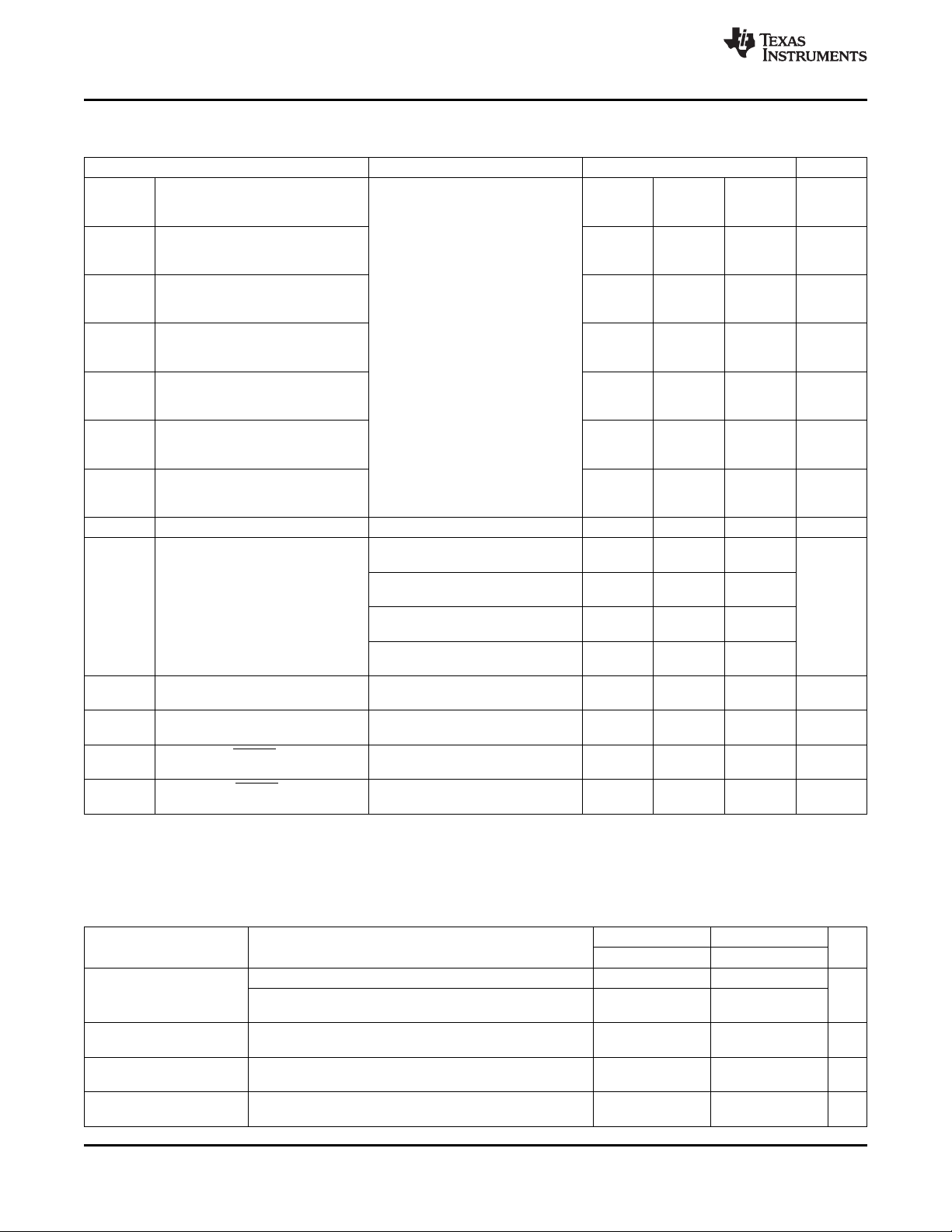

ELECTRICAL CHARACTERISTICS

over operating free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP

V

T

|VOD| 250 450

Δ|VOD| output voltage magnitude between 1 35 mV

V

OC(SS)

V

OC(PP)

I

IH

I

IL

I

OS

I

OZ

R

pdn

I

Q

I

CC

C

I

(1) All typical values are at VCC = 3.3V, TA= 25°C.

Input voltage threshold IOVCC/2 V

Differential steady-state output voltage mV

magnitude

RL= 100Ω, See Figure 4

Change in the steady-state differential

opposite binary states

Steady-state common-mode output

voltage

Peak-to-peak common-mode output

See Figure 4

t

(Dx, CLKin) = 1ns

R/F

1.125 1.375 V

voltage

High-level input current VIH= IOVCC 25 μA

Low-level input current VIL= 0 V ±10 μA

Short-circuit output current

VOY= 0 V ±24 mA

VOD= 0 V ±12 mA

High-impedance state output current VO= 0 V to VCC ±20 μA

Input pull-down integrated resistor on all

inputs (Dx, CLKSEL, SHTDN, CLKIN)

Quiescent current (average) 2 100 μA

IOVCC = 1.8V 200

IOVCC = 3.3V 100

disabled, all inputs at GND;

SHTDN = V

IL

SHTDN = VIH, RL= 100Ω (5 places),

grayscale pattern (Figure 5)

VCC = 3.3V, f

CLK

= 75MHz

I

(VCC)

I

(IOVCC)

I

(IOVCC)

+ I

+ I

(PLLVCC)

(LVDSVCC)

with IOVCC = 3.3V 0.4 mA

with IOVCC = 1.8V 0.1

SHTDN = VIH, RL= 100Ω (5 places), 50%

transition density pattern (Figure 5),

VCC = 3.3V, f

CLK

= 75MHz

I

(VCC)

I

(IOVCC)

I

(IOVCC)

+ I

+ I

(PLLVCC)

(LVDSVCC)

with IOVCC = 3.3V 0.6 mA

with IOVCC = 1.8V 0.2

SHTDN = VIH, RL= 100Ω (5 places), worstcase pattern (Figure 6),

VCC = 3.6V, f

Supply current (average)

CLK

= 75MHz

I

(VCC)

I

(IOVCC)

I

(IOVCC)

+ I

+ I

(PLLVCC)

(LVDSVCC)

with IOVCC = 3.3V 1.3 mA

with IOVCC = 1.8V 0.5

SHTDN = VIH, RL= 100Ω (5 places), worstcase pattern (Figure 6),

f

= 100MHz

CLK

I

(VCC)

I

(IOVCC)

I

(IOVCC)

+ I

+ I

(PLLVCC)

(LVDSVCC)

with IOVCC = 3.6V 1.6 mA

with IOVCC = 1.8V 0.6

SHTDN = VIH, RL= 100Ω (5 places), worstcase pattern (Figure 6),

f

= 135MHz

CLK

I

(VCC)

I

(IOVCC)

I

(IOVCC)

+ I

+ I

(PLLVCC)

(LVDSVCC)

with IOVCC = 3.6V 2.1 mA

with IOVCC = 1.8V 0.8

Input capacitance 2 pF

51.9

53.3

63.7

81.6

102.2

(1)

MAX UNIT

35 mV

kΩ

Copyright © 2009–2011, Texas Instruments Incorporated 9

SN75LVDS83B

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

www.ti.com

SWITCHING CHARACTERISTICS

over operating free-air temperature range (unless otherwise noted)

4

±26

±44

±35

±42

/7t

(1)

1

2

3

4

5

6

c

c

MAX UNIT

/7tc+ 0.1 ns

/7tc+ 0.1 ns

/7tc+ 0.1 ns

/7tc+ 0.1 ns

/7tc+ 0.1 ns

/7tc+ 0.1 ns

ns

ps

ns

PARAMETER TEST CONDITIONS MIN TYP

Delay time, CLKOUT↑ after Yn valid

t

t

t

t

t

t

t

t

0

1

2

3

4

5

6

c(o)

(serial bit position 0, equal D1, D9, -0.1 0 0.1 ns

D20, D5)

Delay time, CLKOUT↑ after Yn valid

(serial bit position 1, equal D0, D8,

1

/7tc- 0.1

D19, D27)

Delay time, CLKOUT↑ after Yn valid

(serial bit position 2, equal D7, D18,

2

/7tc- 0.1

D26. D23)

Delay time, CLKOUT↑ after Yn valid

(serial bit position 3; equal D6, D15,

D25, D17)

Delay time, CLKOUT↑ after Yn valid

(serial bit position 4, equal D4, D14,

See Figure 7, tC= 10ns,

|Input clock jitter| < 25ps

3

(2)

/7tc- 0.1

4

/7tc- 0.1

D24, D16)

Delay time, CLKOUT↑ after Yn valid

(serial bit position 5, equal D3, D13,

5

/7tc- 0.1

D22, D11)

Delay time, CLKOUT↑ after Yn valid

(serial bit position 6, equal D2, D12,

6

/7tc- 0.1

D21, D10)

Output clock period t

tC= 10ns; clean reference clock, see

Figure 8

tC= 10ns with 0.05UI added noise

modulated at 3MHz, see Figure 8

Δt

c(o)

Output clock cycle-to-cycle jitter

(3)

tC= 7.4ns; clean reference clock,

see Figure 8

tC= 7.4ns with 0.05UI added noise

modulated at 3MHz, see Figure 8

t

w

t

r/f

t

en

t

dis

High-level output clock pulse

duration

Differential output voltage transition

time (tror tf)

Enable time, SHTDN↑ to phase lock

(Yn valid)

Disable time, SHTDN↓ to off-state

(CLKOUT high-impedance)

See Figure 4 225 500 ps

f

= 135MHz, See Figure 9 6 µs

(clk)

f

= 135MHz, See Figure 10 7 ns

(clk)

(1) All typical values are at VCC= 3.3 V, TA= 25°C.

(2) |Input clock jitter| is the magnitude of the change in the input clock period.

(3) The output clock cycle-to-cycle jitter is the largest recorded change in the output clock period from one cycle to the next cycle observed

over 15,000 cycles.Tektronix TDSJIT3 Jitter Analysis software was used to derive the maximum and minimum jitter value.

THERMAL CHARACTERISTICS

PARAMETER TEST CONDITIONS UNIT

Junction-to-free-air

θ

JA

thermal resistance

Junction-to-case

θ

JC

thermal resistance

Junction-to-board

θ

JB

thermal resistance

Junction-to-top of

ψ

JT

package

Low-K JEDEC test board, 1s (single signal layer), no air flow 85

High-K JEDEC test board, 2s2p (double signal layer, double

buried power plane), no air flow

Cu cold plate measurement process 25.2 15.9 °C/W

EIA/JESD 51-8 31.0 32.5 °C/W

EIA/JESD 51-2 0.8 0.4 °C/W

10 Copyright © 2009–2011, Texas Instruments Incorporated

ZQL DGG

MIN TYP MAX MIN TYP MAX

67.1 63.4

°C/W

tsu

thold

Dn

CLKIN

V

OD

49.9 ±1%(2PLCS)W

YP

YM

t

f

t

r

0%

20%

80%

100%

0V

0V

V

OC

V

OD(H)

V

OC(SS)

V

OD(L)

V

OC(SS)

V

OC(PP)

SN75LVDS83B

www.ti.com

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

THERMAL CHARACTERISTICS (continued)

PARAMETER TEST CONDITIONS UNIT

ψ

Junction-to-board EIA/JESD 51-6 30.3 32.2 °C/W

JB

Operating ambient

T

A

temperature range

Virtual junction

T

J

temperature

ZQL DGG

MIN TYP MAX MIN TYP MAX

–10 70 -10 70 °C

0 105 0 105 °C

PARAMETER MEASUREMENT INFORMATION

All input timing is defined at IOVDD / 2 on an input signal with a 10% to 90% rise or fall time of less than 3 ns.

CLKSEL = 0V.

Figure 3. Set Up and Hold Time Definition

Copyright © 2009–2011, Texas Instruments Incorporated 11

Figure 4. Test Load and Voltage Definitions for LVDS Outputs.

CLKIN

D0,8,16

D1,9,17

D2,10,18

D3,11,19

D4-7,12-15,20-23

D24-27

T

CLKIN

EVENDn

ODDDn

t

7

t

0

t

1

t

2

t

3

t

4

t

5

t

6

CLKIN

CLKOUT

Yn

V

OD(L)

0.00V

t

0-6

t

7

1.40V

~2.5V

~0.5V

CLKIN

CLKOUT

or Yn

V

OD(H)

SN75LVDS83B

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

PARAMETER MEASUREMENT INFORMATION (continued)

The 16 grayscale test pattern test device power consumption for a typical display pattern.

www.ti.com

Figure 5. 16 Grayscale Test Pattern

12 Copyright © 2009–2011, Texas Instruments Incorporated

The worst-case test pattern produces nearly the maximum switching frequency for all of the LVDS outputs.

Figure 6. Worst-Case Power Test Pattern

CLKOUT is shown with CLKSEL at high-level.

CLKIN polarity depends on CLKSEL input level.

Figure 7. SN75LVDS83B Timing Definitions

VCO

Device

Under

Test

Reference

Modulation

v(t)= A sin(2 pf t)

mod

+

+

HP8656BSignal

Generator,

0.1MHz-990MHz

RFOutput

HP8665A Synthesized

SignalGenerator,

0.1MHz-4200MHz

RFOutput

ModulationInput

DeviceUnder

Test

CLKIN CLKOUT

DTS2070C

Digital

TimeScope

Input

ten

Invalid

Valid

CLKIN

Dn

SHTDN

Yn

tdis

CLKIN

SHTDN

CLKOUT

SN75LVDS83B

www.ti.com

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

PARAMETER MEASUREMENT INFORMATION (continued)

Figure 8. Output Clock Jitter Test Set Up

Figure 9. Enable Time Waveforms

Figure 10. Disable Time Waveforms

Copyright © 2009–2011, Texas Instruments Incorporated 13

f - Clock Frequency - MHz

clk

50

10 30 50 70 90 110 130

I - Average Supply Current - mA

CC

20

30

70

40

90

60

80

V = 3.6V

CC

V = 3.3V

CC

V = 3V

CC

100

Total Device Current (Using Grayscale

pattern) Over Pixel Clock Frequency

300

0.01 0.10 10

PeriodClockJitter-ps-pp

f -InputModularFrequency-MHz

(mod)

0

100

500

200

600

400

800

700

1

OutputJitter

InputJitter

CLKFrequencyDuringTest=100MHz

ClockSignal:135MHz

CLKL Signal

PRBSDataSignal

t -Time-1ns/div

k

V-Voltage-80mV/div

SN75LVDS83B

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

AVERAGE GRAYSCALE ICC OUTPUT CLOCK JITTER

vs vs

CLOCK FREQUENCY INPUT CLOCK JITTER

www.ti.com

TYPICAL CHARACTERISTICS

Figure 11. Figure 12.

TYPICAL PRBS OUTPUT SIGNAL

OVER ONE CLOCK PERIOD

Figure 13.

14 Copyright © 2009–2011, Texas Instruments Incorporated

SN75LVDS83B

www.ti.com

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

APPLICATION INFORMATION

This section describes the power up sequence, provides information on device connectivity to various GPU and

LCD display panels, and offers a pcb routing example.

Power Up Sequence

The SN75LVDS83B does not require a specific power up sequence.

It is permitted to power up IOVCC while VCC, VCCPLL, and VCCLVDS remain powered down and connected to

GND. The input level of the SHTDN during this time does not matter as only the input stage is powered up while

all other device blocks are still powered down.

It is also permitted to power up all 3.3V power domains while IOVCC is still powered down to GND. The device

will not suffer damage. However, in this case, all the I/Os are detected as logic HIGH, regardless of their true

input voltage level. Hence, connecting SHTDN to GND will still be interpreted as a logic HIGH; the LVDS output

stage will turn on. The power consumption in this condition is significantly higher than standby mode, but still

lower than normal mode.

The user experience can be impacted by the way a system powers up and powers down an LCD screen. The

following sequence is recommended:

Power up sequence (SN75LVDS83B SHTDN input initially low):

1. Ramp up LCD power (maybe 0.5ms to 10ms) but keep backlight turned off.

2. Wait for additional 0-200ms to ensure display noise won’t occur.

3. Enable video source output; start sending black video data.

4. Toggle LVDS83B shutdown to SHTDN = VIH.

5. Send >1ms of black video data; this allows the LVDS83B to be phase locked, and the display to show black

data first.

6. Start sending true image data.

7. Enable backlight.

Power Down sequence (SN75LVDS83B SHTDN input initially high):

1. Disable LCD backlight; wait for the minimum time specified in the LCD data sheet for the backlight to go low.

2. Video source output data switch from active video data to black image data (all visible pixel turn black); drive

this for >2 frame times.

3. Set SN75LVDS83B input SHTDN = GND; wait for 250ns.

4. Disable the video output of the video source.

5. Remove power from the LCD panel for lowest system power.

Signal Connectivity

While there is no formal industry standardized specification for the input interface of LVDS LCD panels, the

industry has aligned over the years on a certain data format (bit order). Figure 14 through Figure 17 show how

each signal should be connected from the graphic source through the SN75LVDS83B input, output and LVDS

LCD panel input. Detailed notes are provided with each figure.

Copyright © 2009–2011, Texas Instruments Incorporated 15

SN75LVDS83B24-bpc GPU

R0(LSB)

R1

R2

R3

R4

R5

R6

R7(MSB)

G0(LSB)

G1

G2

G3

G4

G5

G6

G7(MSB)

B0(LSB)

B1

B2

B3

B4

B5

B6

B7(MSB)

HSYNC

VSYNC

ENABLE

RSVD (Note C)

CLK

FORMAT1

D0

D1

D2

D3

D4

D6

D27

D5

D7

D8

D9

D12

D13

D14

D10

D11

D15

D18

D19

D20

D21

D22

D16

D17

D24

D25

D26

D23

CLKIN

Y0M

Y0P

Y1M

Y1P

Y2M

Y2P

Y3M

Y3P

CLKOUTM

CLKOUTP

FPC

Cable

VDD

GPU

IO

1.8V or 2.5V

or 3.3V

GND

C1

100

LVDS

timing

Controller

(8bpc, 24bpp)

100

100

100

100

to column

driver

to row driver

Main Board

IOVCC

CLKSEL

Rpullup

Rpulldown

(See Note B)

VCC

LVDSVCC

PLLVCC

GND

3.3V

C2 C3

3.3V

SHTDN

4.8k

24-bpp LCD Display

FORMAT2 (See Note A)

D27

D5

D0

D1

D2

D3

D4

D6

D10

D11

D7

D8

D9

D12

D13

D14

D16

D17

D15

D18

D19

D20

D21

D22

D24

D25

D26

D23

CLKIN

Panel connector

Main board connector

SN75LVDS83B

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

www.ti.com

16 Copyright © 2009–2011, Texas Instruments Incorporated

Note A. FORMAT: The majority of 24-bit LCD display panels require the two most significant bits (2 MSB ) of each

color to be transferred over the 4th serial data output Y3. A few 24-bit LCD display panels require the two LSBs of

each color to be transmitted over the Y3 output. The system designer needs to verify which format is expected by

checking the LCD display data sheet.

• Format 1: use with displays expecting the 2 MSB to be transmitted over the 4th data channel Y3. This is the

dominate data format for LCD panels.

• Format 2: use with displays expecting the 2 LSB to be transmitted over the 4th data channel.

Note B. Rpullup: install only to use rising edge triggered clocking.

Rpulldown: install only to use falling edge triggered clocking.

• C1: decoupling cap for the VDDIO supply; install at least 1x0.01µF.

• C2: decoupling cap for the VDD supply; install at least 1x0.1µF and 1x0.01µF.

• C3: decoupling cap for the VDDPLL and VDDLVDS supply; install at least 1x0.1µF and 1x0.01µF.

Note C. If RSVD is not driven to a valid logic level, then an external connection to GND is recommended.

Note D. RSVD must be driven to a valid logic level. All unused SN75LVDS83B inputs must be tied to a valid logic

level.

Figure 14. 24-Bit Color Host to 24-bit LCD Panel Application

SN75LVDS83B18-bpp GPU

R0(LSB)

R1

R2

R3

R4

R5(MSB)

G0(LSB)

G1

G2

G3

G4

G5(MSB)

B0(LSB)

B1

B2

B3

B4

B5(MSB)

HSYNC

VSYNC

ENABLE

RSVD

CLK

D0

D1

D2

D3

D4

D6

D27

D5

D7

D8

D9

D12

D13

D14

D10

D11

D15

D18

D19

D20

D21

D22

D16

D17

D24

D25

D26

D23

CLKIN

Y0M

Y0P

Y1M

Y1P

Y2M

Y2P

CLKOUTM

CLKOUTP

(See Note A)

(See Note B)

Y3M

Y3P

FPC

Cable

VDD

GPU

IO

1.8V or 2.5V

or 3.3V

GND

IOVCC

CLKSEL

Rpullup

Rpulldown

VCC

LVDSVCC

PLLVCC

GND

3.3V

C2C1 C3

3.3V

100

LVDS

timing

Controller

(6-bpc, 18-bpp)

100

100

100

to column

driver

to row driver

Main Board

SHTDN

4.8k

18-bpp LCD Display

Panel connector

Main board connector

SN75LVDS83B

www.ti.com

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

Note A. Leave output Y3 NC.

Note B.Rpullup: install only to use rising edge triggered clocking.

Rpulldown: install only to use falling edge triggered clocking.

• C1: decoupling cap for the VDDIO supply; install at least 1x0.01µF.

• C2: decoupling cap for the VDD supply; install at least 1x0.1µF and 1x0.01µF.

• C3: decoupling cap for the VDDPLL and VDDLVDS supply; install at least 1x0.1µF and 1x0.01µF.

Figure 15. 18-Bit Color Host to 18-Bit Color LCD Panel Display Application

Copyright © 2009–2011, Texas Instruments Incorporated 17

SN75LVDS83B

12-bpp GPU

R2

or VCC

R3 or GND

R0

R1

R2

R3

(MSB)

G2 or VCC

G3 or GND

G0

G1

G2

G3

(MSB)

B2 or VCC

B3 or GND

B0

B1

B2

B3

(MSB)

HSYNC

VSYNC

ENABLE

RSVD

CLK

D0

D1

D2

D3

D4

D6

D27

D5

D7

D8

D9

D12

D13

D14

D10

D11

D15

D18

D19

D20

D21

D22

D16

D17

D24

D25

D26

D23

CLKIN

Y0M

Y0P

Y1M

Y1P

Y2M

Y2P

CLKOUTM

CLKOUTP

Y3M

Y3P

FPC

Cable

VDD

GPU

IO

1.8V or 2.5V

or 3.3V

GND

IOVCC

CLKSEL

Rpullup

Rpulldown

(See Note C)

(See Note A)

VCC

LVDSVCC

PLLVCC

GND

3.3V

C2C1 C3

3.3V

100

LVDS

timing

Controller

(6-bpc, 18-bpp)

l

t

100

100

100

to column

driver

to row driver

Main Board

18-bpp LCD Display

SHTDN

4.8k

Panel connector

Main board connector

(See Note B)

(See Note B)

(See Note B)

SN75LVDS83B

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

www.ti.com

Note A. Leave output Y3 N.C.

Note B. R3, G3, B3: this MSB of each color also connects to the 5th bit of each color for increased dynamic range of

the entire color space at the expense of none-linear step sizes between each step. For linear steps with less dynamic

range, connect D1, D8, and D18 to GND.

R2, G2, B2: these outputs also connects to the LSB of each color for increased, dynamic range of the entire color

space at the expense of none-linear step sizes between each step. For linear steps with less dynamic range, connect

D0, D7, and D15 to VCC.

Note C.Rpullup: install only to use rising edge triggered clocking.

Rpulldown: install only to use falling edge triggered clocking.

• C1: decoupling cap for the VDDIO supply; install at least 1x0.01µF.

• C2: decoupling cap for the VDD supply; install at least 1x0.1µF and 1x0.01µF.

• C3: decoupling cap for the VDDPLL and VDDLVDS supply; install at least 1x0.1µF and 1x0.01µF.

Figure 16. 12-Bit Color Host to 18-Bit Color LCD Panel Display Application

18 Copyright © 2009–2011, Texas Instruments Incorporated

SN75LVDS83B24-bpp GPU

R2

R3

R4

R5

R6

R7

(MSB)

G2

G3

G4

G5

G6

G7

(MSB)

B2

B3

B4

B5

B6

B7

(MSB)

HSYNC

VSYNC

ENABLE

RSVD

CLK

D0

D1

D2

D3

D4

D6

D27

D5

D7

D8

D9

D12

D13

D14

D10

D11

D15

D18

D19

D20

D21

D22

D16

D17

D24

D25

D26

D23

CLKIN

Y0M

Y0P

Y1M

Y1P

Y2M

Y2P

CLKOUTM

CLKOUTP

Y3M

Y3P

FPC

Cable

VDD

GPU

IO

1.8V or 2.5V

or 3.3V

GND

IOVCC

CLKSEL

Rpullup

Rpulldown

(See Note C)

(See Note A)

VCC

LVDSVCC

PLLVCC

GND

3.3V

C2C1 C3

3.3V

100

LVDS

timing

Controller

(6-bpc, 18-bpp)

l

t

100

100

100

to column

driver

to row driver

Main Board

18-bpp LCD Display

SHTDN

4.8k

Panel connector

Main board connector

R0 and R1: NC

(See Note B)

B0 and B1: NC

(See Note B)

G0 and G1: NC

(See Note B)

B0 and B1: NC

(See Note B)

SN75LVDS83B

www.ti.com

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

Note A. Leave output Y3 NC.

Note B. R0, R1, G0, G1, B0, B1: For improved image quality, the GPU should dither the 24-bit output pixel down

to18-bit per pixel.

NoteC.Rpullup: install only to use rising edge triggered clocking.

Rpulldown: install only to use falling edge triggered clocking.

• C1: decoupling cap for the VDDIO supply; install at least 1x0.01µF.

• C2: decoupling cap for the VDD supply; install at least 1x0.1µF and 1x0.01µF.

• C3: decoupling cap for the VDDPLL and VDDLVDS supply; install at least 1x0.1µF and 1x0.01µF.

Figure 17. 24-Bit Color Host to 18-Bit Color LCD Panel Display Application

Copyright © 2009–2011, Texas Instruments Incorporated 19

J2

J8

J9

J7

J10

sma_surface

sma_surface

J6

J5

J1

SN65LVDS83BZQL

U1A

Y3M

C1

Y3P

C2

CLKM

D1

CLKP

D2

Y2P

E1

Y2M

E2

Y1M

G1

Y1P

G2

Y0M

H1

Y0P

H2

J4

J3

R5

4.7k

SN65LVDS83BZQL

U1B

D0

J2

D3

J3

D6

J4

D1

K1

D2

K2

D4

K3

D7

K5

R21

4.7k

R8

4.7k

R6

4.7k

JMP1

Header 7x2

1 2

14

R26

4.7k

R16

4.7k

R22

4.7k

R9

4.7k

R7

4.7k

R27

4.7k

SN65LVDS83BZQL

U1C

D18

D5

D15

E5

D14

F6

D12

G5

D13

G6

D9

J6

D8

K6

R17

4.7k

R23

4.7k

R10

4.7k

R11

4.7k

JMP4

Header 7x2

1 2

14

R28

4.7k

R24

4.7k

R12

4.7k

SN65LVDS83BZQL

U1D

D26

A3

D24

A4

D22

A6

D25

B4

D21

B5

D20

B6

D19

C6

R18

4.7k

JMP2

Header 7x2

1 2

14

R29

4.7k

R13

4.7k

R19

4.7k

R30

4.7k

SN65LVDS83BZQL

U1E

D23

A5

D17

D6

D16

E6

D10

H4

D11

H6

D27

J1

D5

K4

R14

4.7k

JMP3

Header 7x2

1 2

14

R20

4.7k

R31

4.7k

R25

4.7k

R4

4.7k

R15

4.7k

D2

D1

D6

D0

D7

D3

D4

D8

D9

D14

D13

D12

D18

D19

D22

D26

D21

D24

D25

D20

D5

D11

D27

D10

D23

D17

D16

D15

IOVCC

IOVCC

IOVCC

IOVCC

SN65LVDS83BZQL

U1I

PLLVCC

B2

IOVCC2

C4

LVDSVCC

F1

VCC

G4

IOVCC1

H5

VCC IOVCC

SN65LVDS83BZQL

U1H

PLLGND

A1

LVDSGND1

B1

GND1

C3

GND2

C5

GND3

D3

LVDSGND2

F2

GND4

F5

GND5

G3

GND6

H3

GND7

J5

U1J

SN65LVDS83BZQL

NC1

E3

NC2

E4

NC3

F3

NC4

F4

R2

SN65LVDS83BZQL

U1G

SHTDN

B3

CLKSEL

D4

JMP6

Header 2x2

1 2

3 4

R1

4.7k

SHTDN

CLKSEL

IOVCC IOVCC

C36

0.01uF

C39

0.01uF

C40

1uF

C33

0.01uF

C41

0.1uF

C32

0.1uF

C31

1uF

C42

0.01uF

C34

1uF

C37

1uF

C35

0.1uF

C38

0.1uF

VCC VCC

VCC IOVCC

PLACEUNDERLVDS83B

(bottompcbside)

sma_surface

sma_surface

sma_surface

sma_surface

sma_surface

sma_surface

sma_surface

sma_surface

SN75LVDS83B

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

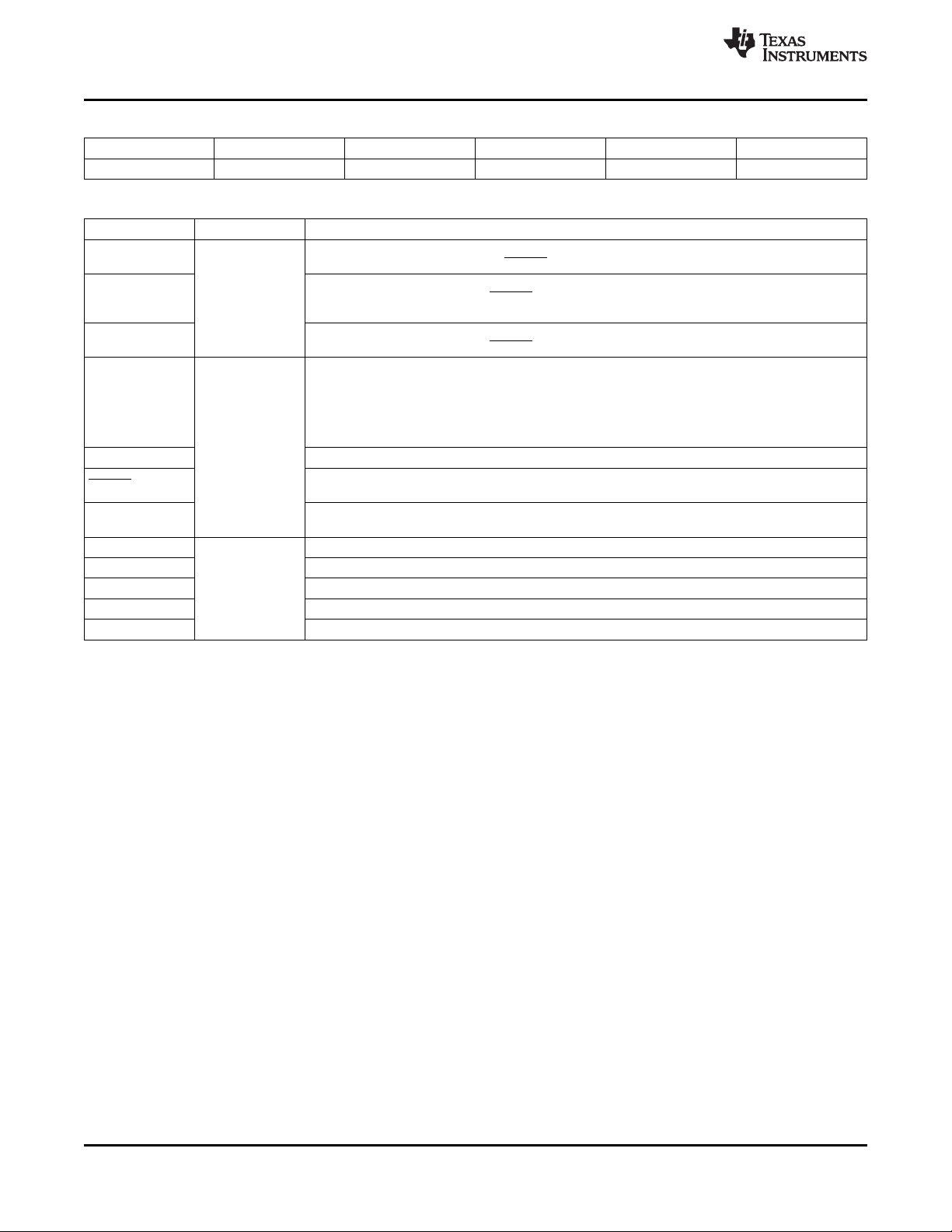

Typical Application Schematic

Figure 18 represents the schematic drawing of the SN75LVDS83B evaluation module.

20 Copyright © 2009–2011, Texas Instruments Incorporated

www.ti.com

Figure 18. Schematic Example (SN75LVDS83B Evaluation Board)

D13

D14

D16

D17

D9

GND Y3M

D15

GND

GND

D10 GND

Y1P

Y2P

LVDS

VCC

Y1M

Y2M

LVDS

GND

Y0M

IOVCC

CLKM

CLKSEL

D8

CLKP

Y0P

D12

D11

D19

VCC

D3

D1

D27D6

D7

GND

D4D5

D0

D2

Y3P

D18

D22

D20

D26

LVDS

GND

+PLL

GND

PLL

GND

D24

D21

D23

SHTDND25

CLKIN

PLLVCC

IOVCC

GND

GND

R1

R2

R3

R4

R5

R6

G0

G1

R7

R8

G2

G3

G4

G5

B0

B1

B2

B3

B4

B5

G6

G7

B6

B7

HS

VS

EN

CLK

SN75LVDS83B

www.ti.com

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

PCB Routing

Figure 19 and Figure 20 show a possible breakout of the data input and output signals from the BGA package.

Figure 19. 24-Bit Color Routing (See Figure 14 for the Schematic)

Copyright © 2009–2011, Texas Instruments Incorporated 21

D13

D14

D16

D17

GND Y3M

D15

GND

GND

GND

Y1P

Y2P

LVDS

VCC

Y1M

Y2M

LVDS

GND

Y0M

ToGND

ToGND

IOVCC

CLKM

CLKSEL

D8

CLKP

Y0P

D12

D11

D19

D3

D1

D27D6

D7

GND

D4D5

D0

D2

Y3P

D18

D22

D20

D26

LVDS

GND

+PLL

GND

PLL

GND

D24

D21

D23

SHTDN

D25

CLKIN

PLLVCC

IOVCC

GND

GND

D10VCC

D9

R0R1R2R3R4R5G0G1

G2

G3

G4

G5

B0

B1

B2

B3

B4

B5

HS VS EN CLK

remains

unconnected

SN75LVDS83B

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

www.ti.com

Figure 20. 18-Bit Color Routing (See Figure 15, Figure 16, and Figure 17 for the Schematic)

22 Copyright © 2009–2011, Texas Instruments Incorporated

SN75LVDS83B

www.ti.com

SLLS846B –MAY 2009–REVISED SEPTEMBER 2011

REVISION HISTORY

Changes from Original (May 2009) to Revision A Page

• Changed text and replaced TBDs in Note A and Note B of Figure 14 ............................................................................... 16

• Changed Note B of Figure 15 - Replaced TBDs. ............................................................................................................... 17

• Changed Note B of Figure 16 - Replaced TBDs. ............................................................................................................... 18

• Changed Note C of Figure 17 - Replaced TBDs. ............................................................................................................... 19

• Changed Figure 19 - removed 3 GND pin locations. ......................................................................................................... 21

• Changed Figure 20 - removed 3 GND pin locations. ......................................................................................................... 22

Changes from Revision A (October 2009) to Revision B Page

• Added Storage temperature, Tsto ABSOLUTE MAXIMUM RATINGS ................................................................................ 2

• Added Note 3 to DISSIPATION RATINGS ........................................................................................................................... 3

• Deleted max values for Supply current (average) ................................................................................................................ 9

• Changed Enable time units from ns to µs .......................................................................................................................... 10

• Added Thermal Characteristics table .................................................................................................................................. 10

• Changed G7(LSB) to G7(MSB) in Figure 14 ...................................................................................................................... 16

• Added Note C to Figure 14 ................................................................................................................................................. 16

• Added Note D to Figure 14 ................................................................................................................................................. 16

• Added connection between GND and D23 to Figure 19 .................................................................................................... 21

Copyright © 2009–2011, Texas Instruments Incorporated 23

PACKAGE OPTION ADDENDUM

www.ti.com

27-Feb-2014

PACKAGING INFORMATION

Orderable Device Status

SN75LVDS83BDGG ACTIVE TSSOP DGG 56 35 Green (RoHS

SN75LVDS83BDGGR ACTIVE TSSOP DGG 56 2000 Green (RoHS

SN75LVDS83BZQLR ACTIVE BGA

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

MICROSTAR

JUNIOR

Drawing

Pins Package

Qty

ZQL 56 1000 Green (RoHS

Eco Plan

(2)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

Lead/Ball Finish

(6)

CU NIPDAU Level-2-260C-1 YEAR -10 to 70 LVDS83B

CU NIPDAU Level-2-260C-1 YEAR -10 to 70 LVDS83B

SNAGCU Level-2-260C-1 YEAR -10 to 70 LVDS83B

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead/Ball Finish - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead/Ball Finish values may wrap to two lines if the finish

value exceeds the maximum column width.

Samples

Addendum-Page 1

PACKAGE OPTION ADDENDUM

www.ti.com

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

27-Feb-2014

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

Addendum-Page 2

PACKAGE MATERIALS INFORMATION

www.ti.com 26-Mar-2014

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

Type

SN75LVDS83BDGGR TSSOP DGG 56 2000 330.0 24.4 8.6 15.6 1.8 12.0 24.0 Q1

SN75LVDS83BZQLR BGA MI

CROSTA

R JUNI

OR

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

ZQL 56 1000 330.0 16.4 4.8 7.3 1.5 8.0 16.0 Q1

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com 26-Mar-2014

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

SN75LVDS83BDGGR TSSOP DGG 56 2000 367.0 367.0 45.0

SN75LVDS83BZQLR BGA MICROSTAR

JUNIOR

ZQL 56 1000 336.6 336.6 28.6

Pack Materials-Page 2

MECHANICAL DATA

MTSS003D – JANUARY 1995 – REVISED JANUARY 1998

DGG (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

48 PINS SHOWN

0,50

48

1

1,20 MAX

0,27

0,17

25

24

A

0,15

0,05

0,08

M

6,20

8,30

6,00

7,90

Seating Plane

0,10

0,15 NOM

Gage Plane

0,25

0°–8°

0,75

0,50

DIM

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold protrusion not to exceed 0,15.

D. Falls within JEDEC MO-153

PINS **

A MAX

A MIN

48

12,60

12,40

56

14,10

13,90

64

17,10

16,90

4040078/F 12/97

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2014, Texas Instruments Incorporated

Loading...

Loading...