Page 1

SN75LVCP601

www.ti.com

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

Two-Channel SATA 6-Gb/s Redriver

Check for Samples: SN75LVCP601

1

FEATURES

• 1.5/3/6-Gbps Two-Channel Redriver • 20-Pin 4-mm × 4-mm QFN Package

• Integrated Output Squelch • High Protection Against ESD Transient

• Programmable Rx/Tx Equalization and – HBM: 10,000 V

De-Emphasis Width Control

• Power-Save Feature Lowers Power by >80% in

Auto Low-Power Mode

• Low Power – <220 mW Typ. APPLICATIONS – <50 mW (in Auto Low-Power Mode) – <5m W (in Standby Mode)

• Excellent Jitter and Loss Compensation

Capability to Over 24-Inch (61-cm) FR4 Trace

DESCRIPTION

The SN75LVCP601 is a dual-channel, single-lane SATA redriver and signal conditioner supporting data rates up

to 6 Gbps. The device complies with SATA physical link 2m and 3i specifications. The SN75LVCP601 operates

from a single 3.3-V supply and has 100-Ω line termination with a self-biasing feature, making the device suitable

for ac coupling. The inputs incorporate an out-of-band (OOB) detector, which automatically squelches the output

while maintaining a stable common-mode voltage compliant to the SATA link. The device is also designed to

handle spread-spectrum clocking (SSC) transmission per the SATA specification.

The SN75LVCP601 handles interconnect losses at both its input and output. The input stage of each channel

offers selectable equalization settings that can be programmed to match the loss in the channel. The differential

outputs provide selectable de-emphasis to compensate for the distortion that the SATA signal is expected to

experience. The level of equalization and de-emphasis settings depends on the length of interconnect and its

characteristics. Both equalization and de-emphasis levels are controlled by the setting of signal control pins EQ1,

EQ2, DE1, and DE2.

The device is hot-plug capable (requires the use of ac-coupling capacitors at differential inputs and outputs),

preventing device damage under device hot-insertion, such as async signal plug/removal, unpowered

plug/removal, powered plug/removal, or surprise plug/removal.

– CDM: 1,500 V

– MM: 200 V

• Pin-Compatible to LVCP412A/MAX4951

• Notebooks, Desktops, Docking Stations,

Servers, and Workstations

ORDERING INFORMATION

PART NUMBER PART MARKING PACKAGE

SN75LVCP601RTJR LVC601 20-pin RTJ, reel (large)

SN75LVCP601RTJT LVC601 20-pin RTJ, reel (small)

(1) For the most-current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

Web site at www.ti.com.

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

(1)

Copyright © 2010–2012, Texas Instruments Incorporated

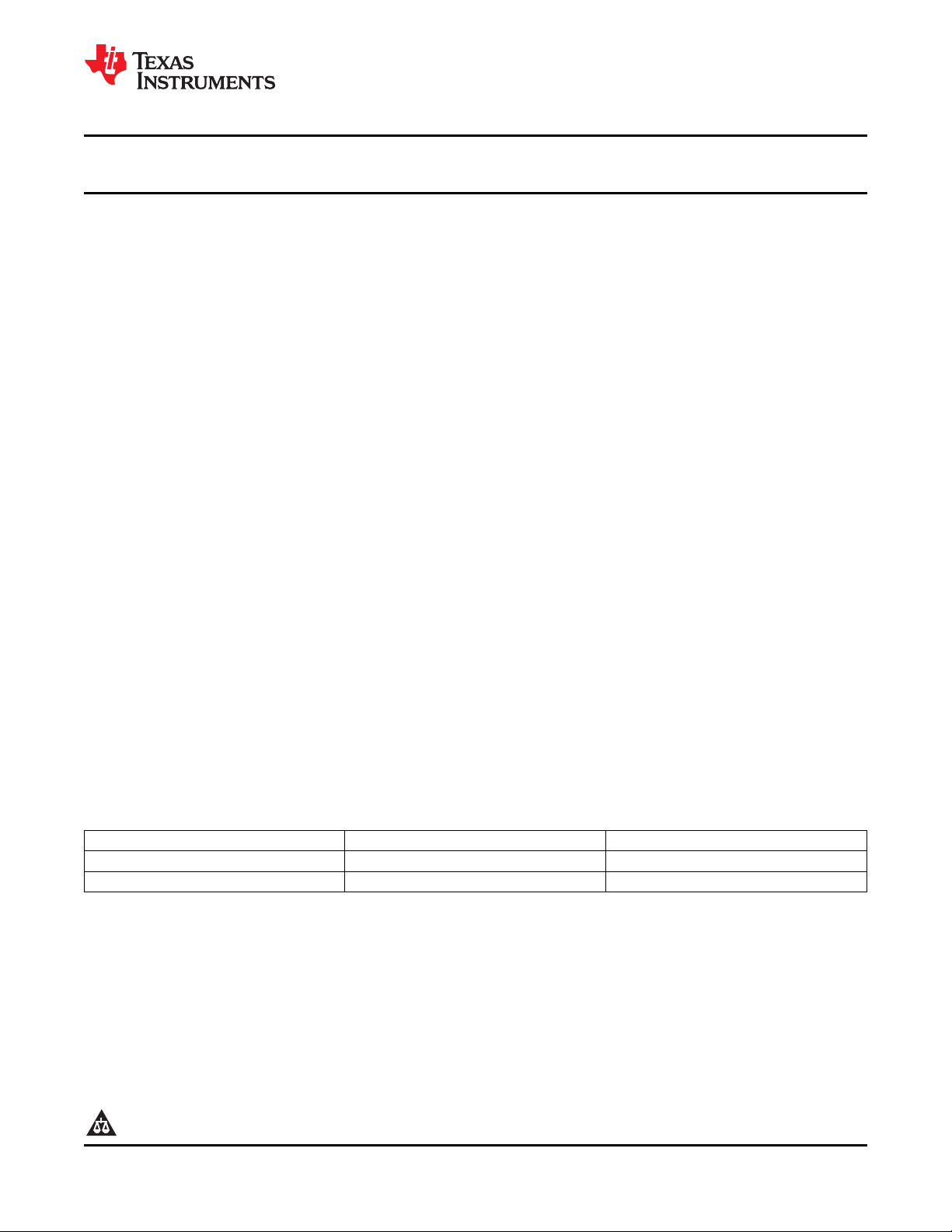

Page 2

ICH

R

HDD

eSATA

Cable

eSATA

connector

PC/WSMB

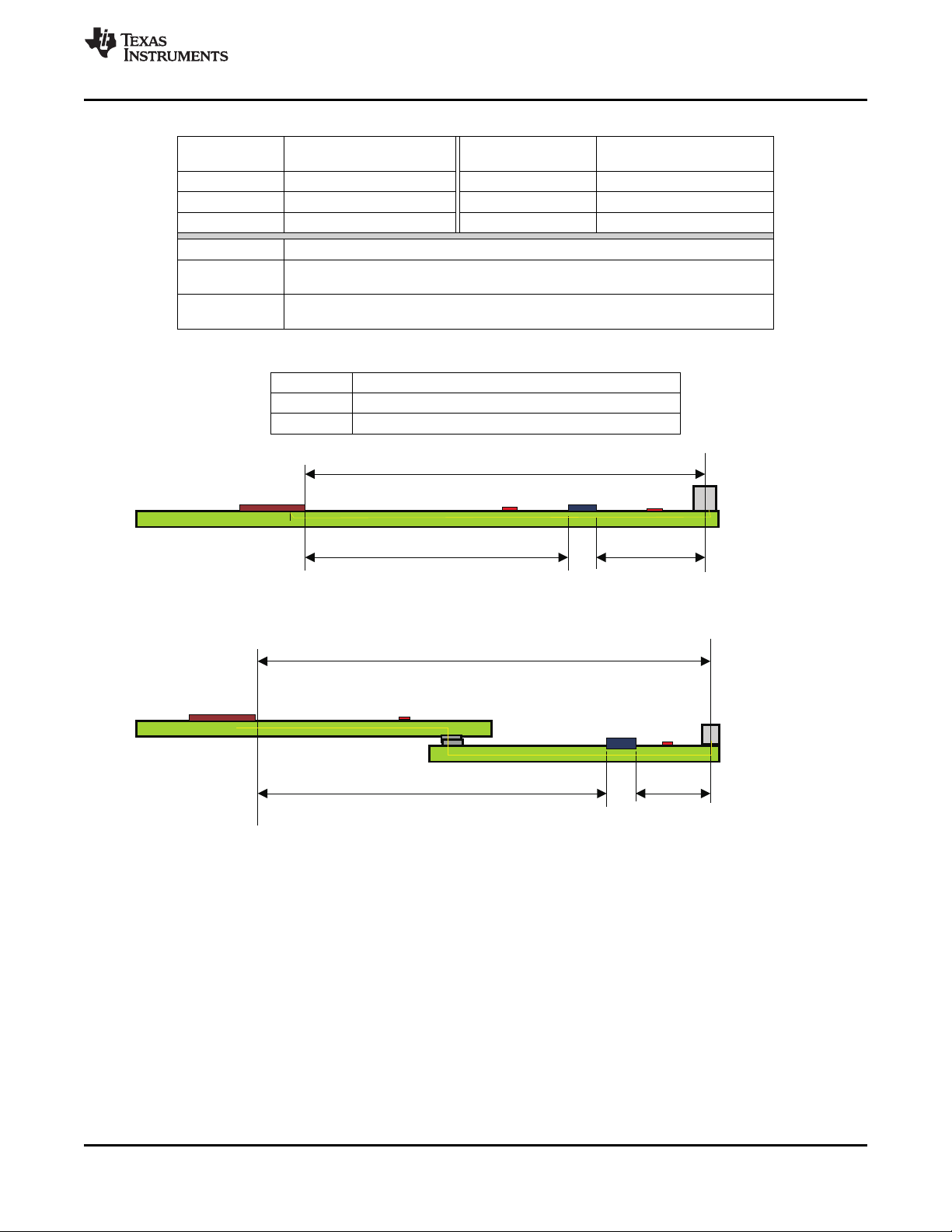

R = SN75LVCP601

ICH

R

Notebook

Dock

Dock Connector

PC/Workstation

Motherboard

NotebookDock

HDD

eSATA Cable

(2m)

eSATA

connector

SATA 6GHost

HDD

DTMB

DesktopMainBoard

iSATA

connector

R

SN75LVCP601

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

www.ti.com

Figure 1. Typical Application

2 Copyright © 2010–2012, Texas Instruments Incorporated

Page 3

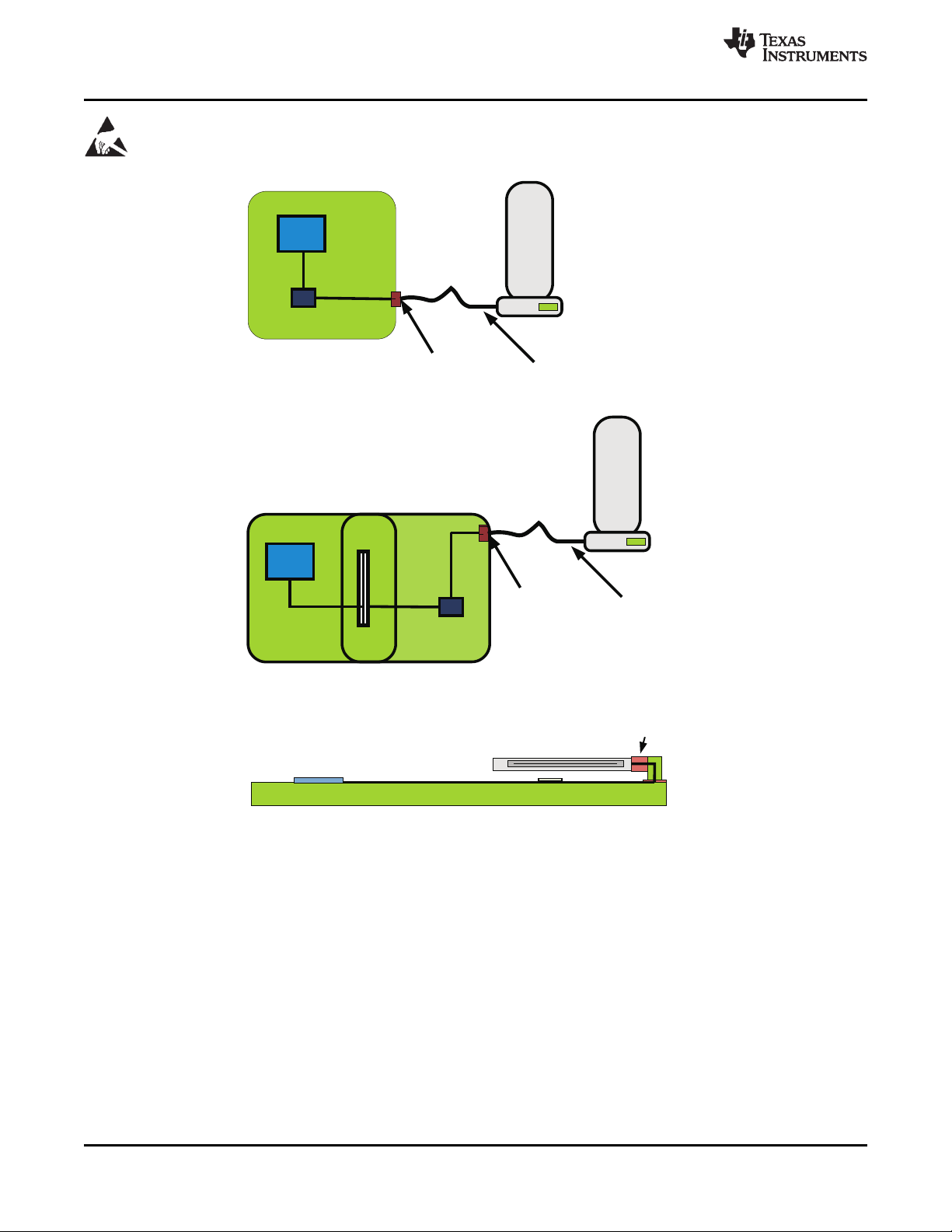

RX1P [1]

CTRL

RT

RT

VBB= 1.7 V TYP

V

BB

RT

RT

Equalizer

Equalizer

Driver

Driver

OOB

Detect

OOB

Detect

SN75LVCP601

TX1P [15]

RX1N [2]

TX1N [14]

RX2N [12]

RX2P [11]

TX2N [4]

TX2P [5]

EN[7]

DE2[8]

DE1[9]

VCC[10,20]

GND[3,13,18]

EQ1[17]

EQ2[19]

DEW1 [16]

DEW2 [6]

SN75LVCP601

www.ti.com

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

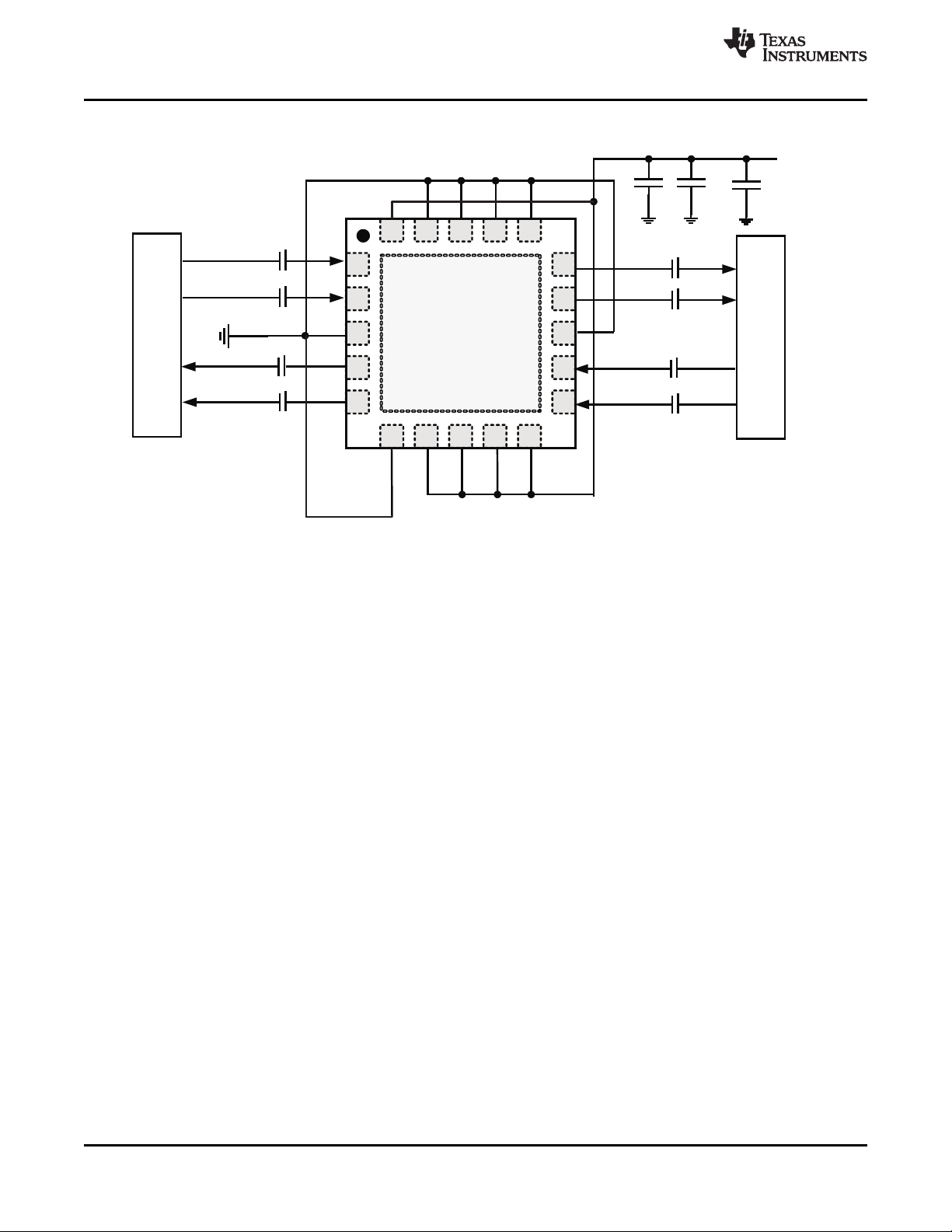

Figure 2. Data Flow Block Diagram

NAME PIN DESCRIPTION NAME PIN DESCRIPTION

RX1P 1 Input 1, non-inverting RX2P 11 Input 2, non-inverting

RX1N 2 Input 1, inverting RX2N 12 Input 2, inverting

GND 3 Ground GND 13 Ground

TX2N 4 Output 2, inverting TX1N 14 Output 1, inverting

TX2P 5 Output 2, non-inverting TX1P 15 Output 1, non-inverting

(1)

DEW2

(1)

EN

(2)

DE2

(2)

DE1

Vcc 10 3.3-V supply Vcc 20 3.3-V supply

(1) DEW1/2, EN tied to Vcc via internal PU resistor

(2) DE1, DE2, EQ1, EQ2 are tied to Vcc/2 via internal resistor

6 De-emphasis width cntrl.-CH 2 DEW1

7 Enable EQ1

8 De-emphasis CH2 GND 18 Ground

9 De-emphasis CH1 EQ2

PIN TABLE

(1)

(2)

(2)

16 De-emphasis width cntrl.-CH 1

17 EQ control CH 1

19 EQ control CH 2

Copyright © 2010–2012, Texas Instruments Incorporated 3

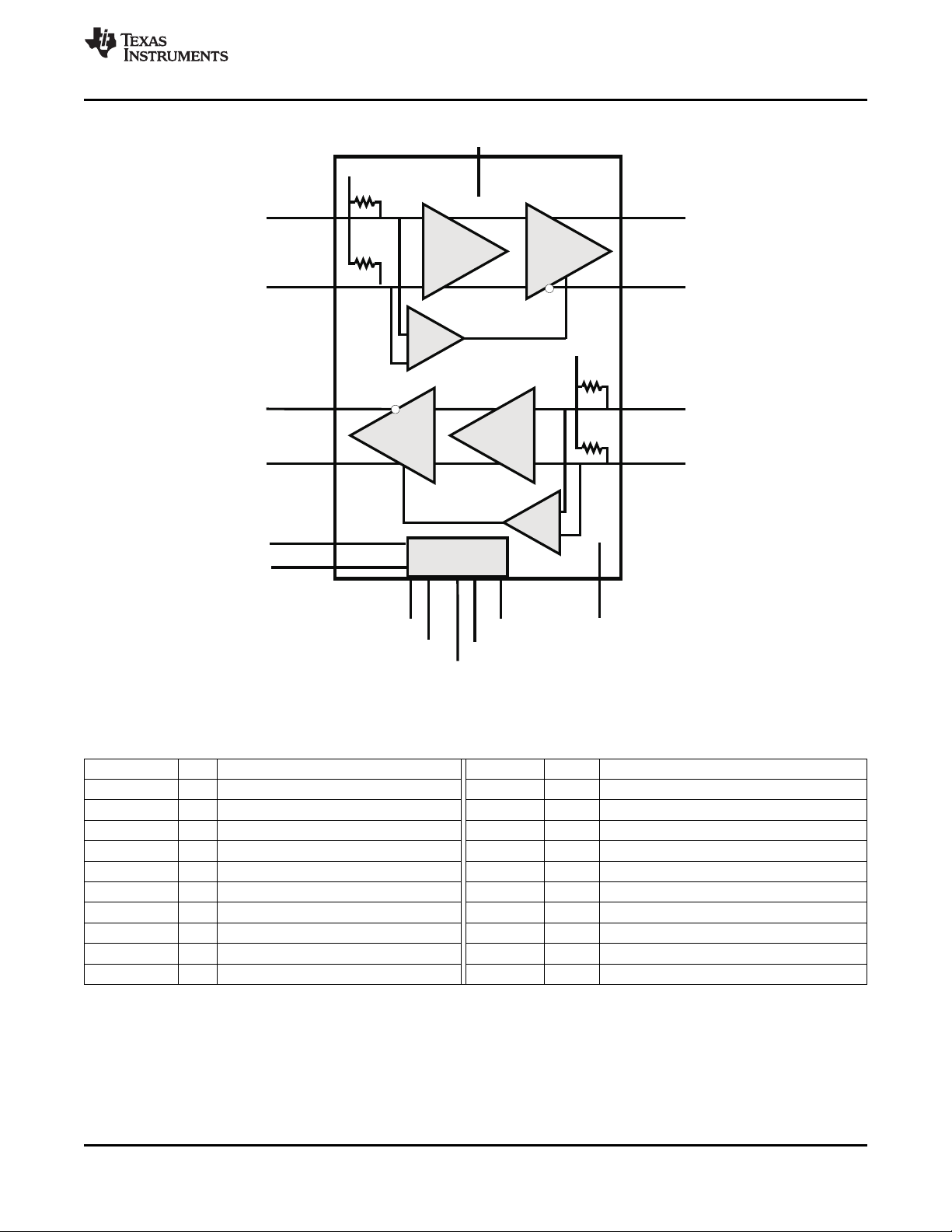

Page 4

20

19

18

17

16

6

7

8

9

10

15

14

13

12

11

1

2

3

4

5

RX1P

RX1N

GND

TX2 N

TX2 P

VCC

EN

DE 2

DE 1

DEW 2

RX2P

RX2N

GND

TX1 N

TX1 P

EQ 2

EQ 1

VCC

DEW 1

GND

LVCP601RTJ

Thermal Pad must

be soldered to PCB

GND plane for

efficient thermal

performance

Bottom View

1

1

1

2

1

RX1P

RX1N

GND

TX2 N

TX2 P

DEW 2

DE 1

DE 2

EN

VCC

RX2P

RX2N

GND

TX1 N

TX1 P

VCC

DEW 1

EQ 2

EQ 1

GND

LVCP601RTJ

Top View

18

19

20

10

9

8

7

6

1

2

3

4

5

16

17

11

12

13

14

15

SN75LVCP601

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

www.ti.com

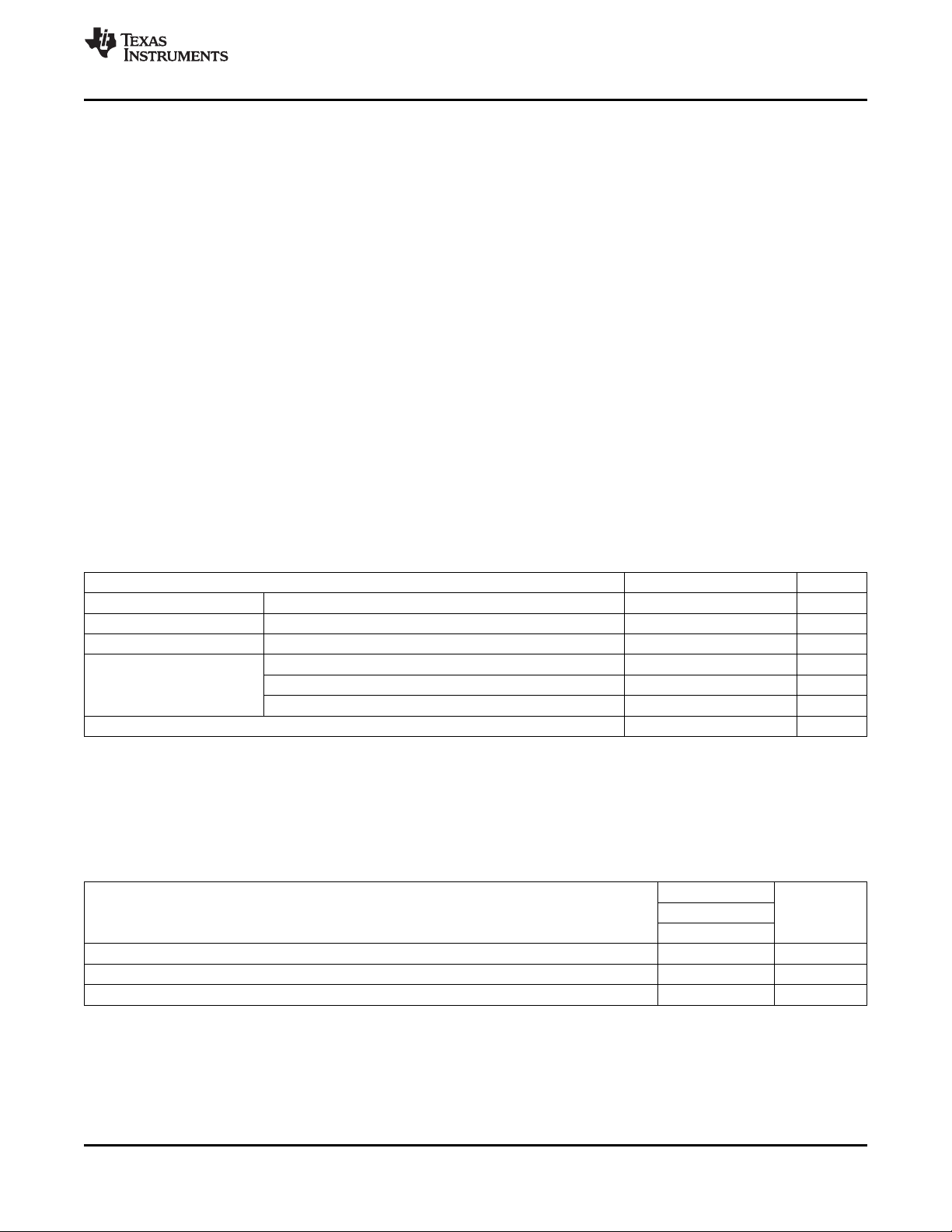

PACKAGE PINOUT

PIN FUNCTIONS

PIN

NO. NAME

HIGH-SPEED DIFFERENTIAL I/O

2 RX1N I, CML

1 RX1P I, CML

12 RX2N I, CML

11 RX2P I, CML

14 TX1N O, VML

15 TX1P O, VML

4 TX2N O, VML

5 TX2P O, VML

CONTROL PINS

7 EN I, LVCMOS Device enable/disable pin, internally pulled to VCC. See Table 2.

8, 9 DE1, DE2

17, 19 EQ1, EQ2

16, 6 DEW1, DEW2 I, LVCMOS De-emphasis width control for CH 1 and CH 2. See Table 2.

POWER

10, 20 Vcc Power Positive supply should be 3.3 V ± 10%.

3, 13, 18 GND Power Supply ground

(1) Internally biased to Vcc/2 with >200-kΩ pullup/pulldown. When 3-state pins are left as NC, board leakage at the pin pad must be <1 µA;

otherwise, drive to Vcc/2 to assert mid-level state.

(1)

(1)

PIN TYPE DESCRIPTION

Non-inverting and inverting CML differential input for CH 1 and CH 2. These pins are

tied to an internal voltage bias by a dual-termination resistor circuit.

Non-inverting and inverting VML differential output for CH 1 and CH 2. These pins are

internally tied to voltage bias by termination resistors.

I, LVCMOS Selects de-emphasis settings for CH 1 and CH 2 per Table 1. Internally tied to VCC/2

I, LVCMOS Selects equalization settings for CH 1 and CH 2 per Table 1. Internally tied to VCC/2

4 Copyright © 2010–2012, Texas Instruments Incorporated

Page 5

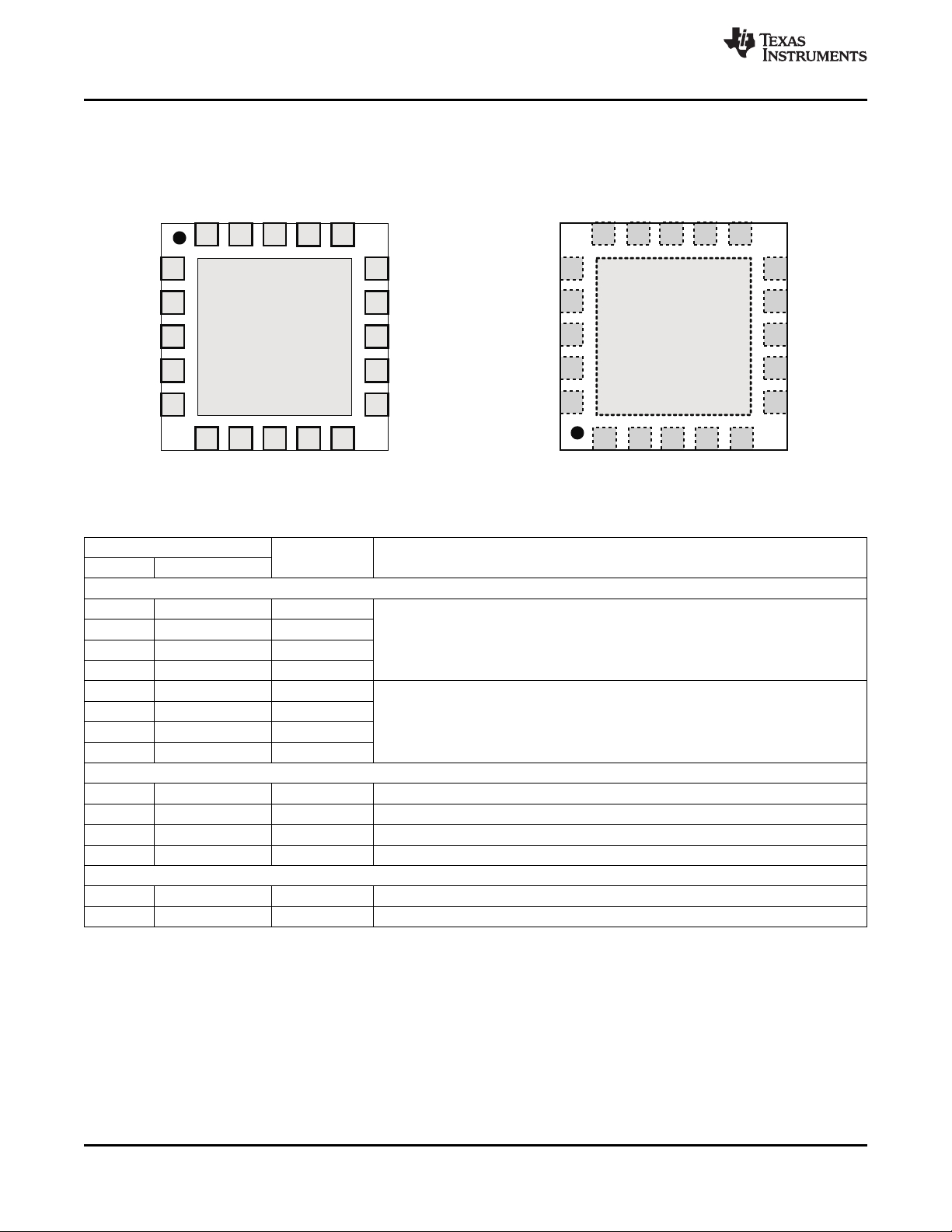

16 in. (40.6 cm)

24 in. (61 cm)

SATA Host

Redriver

Redriver on Motherboard

Main Board

SATA Host

Redriver

Dock Board

Redriver on Dock Board

SATA

Connector

SATA

Connector

16 in. (40.6 cm)

8 in.

(20.3 cm)

8 in.

(20.3 cm)

24 in. (61 cm)

SN75LVCP601

www.ti.com

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

Table 1. Tx/Rx EQ and DE Pulse-Duration Settings

DE1/DE2 EQ1/EQ2

NC (default) –4 NC (default) 0

0 0 0 7

1 –2 1 14

DEW1/DEW2 Device Function → DE Width for CH1/CH2

0 De-emphasis pulse duration, short (recommended setting when link operates at SATA

1 (default) De-emphasis pulse duration, long (recommended setting when link operates at SATA

CH1/CH2De-Emphasis CH1/CH2Equalization

dB (at 6Gbps) dB (at 6Gbps)

1.5/3/6 Gbps)

1.5/3 Gbps speed only)

Table 2. Control Pin Settings

EN Device Function → Standby Mode

0 Device in standby mode

1 (default) Device enabled

NOTE: *Trace lengths are suggested values based on TI spice simulations (done over programmable limits of input EQ and

Copyright © 2010–2012, Texas Instruments Incorporated 5

output de-emphasis) to meet SATA loss and jitter spec.

Actual trace length supported by the LVCP601 may be more or less than suggested values and depends on board

layout, trace widths, and number of connectors used in the SATA signal path.

Figure 3. Trace Length Example* for LVCP601

Page 6

15

14

13

12

11

1

2

3

4

5

3.3 V

LVCP601 RTJ

RX1P

RX1N

TX2N

TX2P

TX1P

TX1N

RX2N

RX2P

10 nF

10 nF

10 nF

10 nF

10 nF

10 nF

10 nF

10 nF

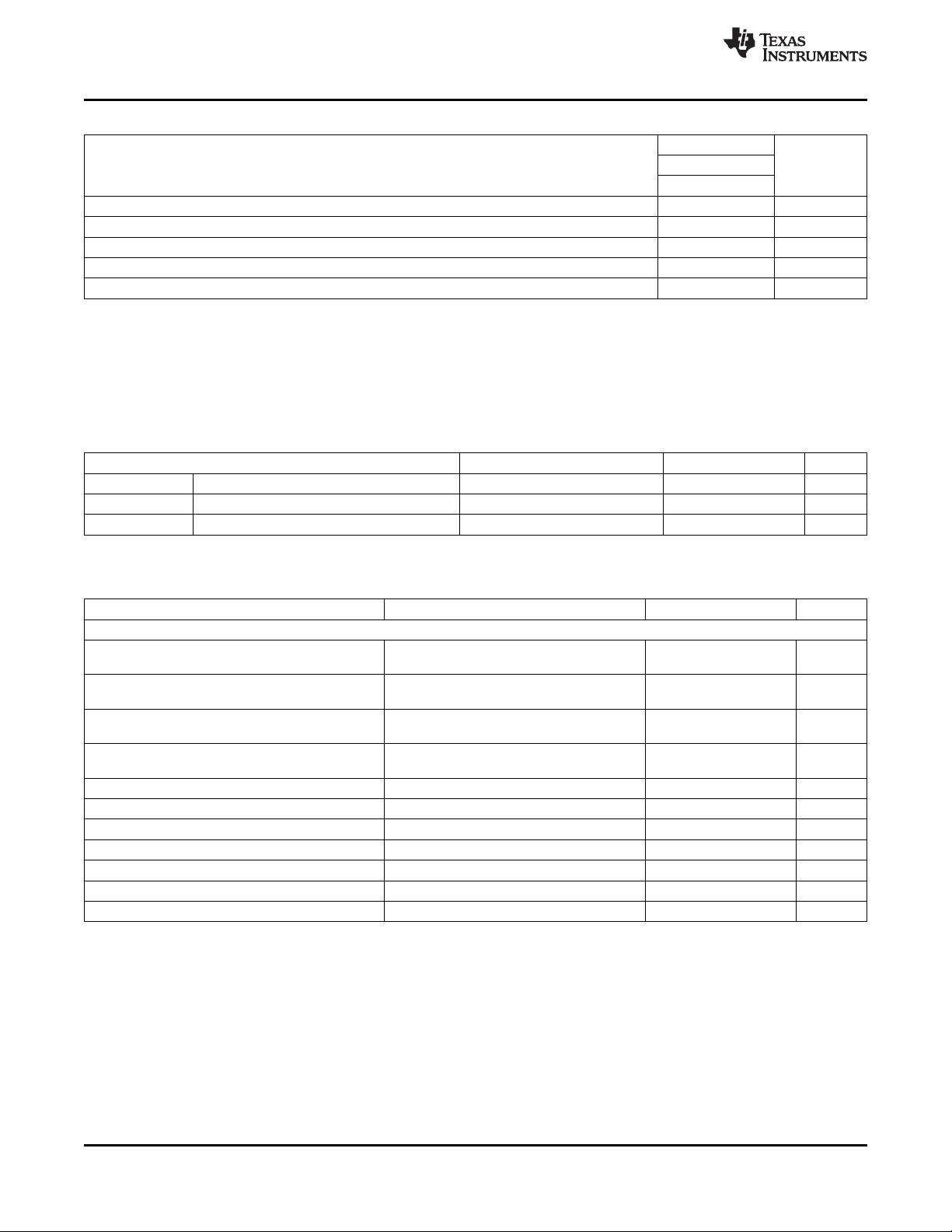

EQ2

EQ1

DEW1

20

19

18

17

16

6

7

8

9

10

1.0 Fm

1.0 Fm

1.0 Fm

SATA Host

SATA

Connector

DEW2

EN

DE1

DE2

Vcc

Vcc

SN75LVCP601

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

(1) Place supply capacitors close to device pin.

(2) EN can be left open or tied to supply when no external control is implemented.

(3) Output de-emphasis selection is set at –2 dB, EQ at 7 dB, and DE duration for SATA I/II/III operation for both

channels.

(4) Actual EQ/DE duration settings depend on device placement relative to host and SATA connector.

Figure 4. Typical Device Implementation

www.ti.com

OPERATION DESCRIPTION

INPUT EQUALIZATION

Each differential input of the SN75LVCP601 has programmable equalization in its front stage. The equalization

setting is shown in Table 1. The input equalizer is designed to recover a signal even when no eye is present at

the receiver, and effectively supports FR4 trace at the input anywhere from 4 in. (10.2 cm) to 20 in. (50.8 cm) at

SATA 6G speed.

OUTPUT DE-EMPHASIS

The SN75LVCP601 provides the de-emphasis settings shown in Table 1. De-emphasis is controlled

independently for each channel, and is set by the control pins DE1 and DE2 as shown in Table 1. There are two

de-emphasis duration settings available in the device. DEW1 and DEW2 control the DE durations for channels

one and two, respectively. The recommended settings for these control pins are listed Table 1. Output

de-emphasis is capable of supporting FR4 trace at the output anywhere from 2 in. (5.1 cm) to 12 in. (30.5 cm) at

SATA 3G/6G speed.

LOW-POWER MODE

Two low-power modes are supported by the SN75LVCP601, listed as follows:

1. Standby mode (triggered by the EN pin, EN = 0 V)

– Low-power mode is controlled by the enable (EN) pin. In its default state, this pin is internally pulled high.

Pulling this pin LOW puts the device in standby mode within 2 µs (max). In this mode, all active

components of the device are driven to their quiescent level, and differential outputs are driven to Hi-Z

(open). Maximum power dissipation in this mode is 5 mW. Exiting from this mode to normal operation

requires a maximum latency of 5 µs.

6 Copyright © 2010–2012, Texas Instruments Incorporated

Page 7

SN75LVCP601

www.ti.com

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

2. Auto low-power mode (triggered when a given channel is in the electrically idle state for more than 100 µs

and EN = Vcc)

– The device enters and exits low-power mode by actively monitoring the input signal (VIDp-p) level on

each of its channels independently. When the input signal on either or both channels is in the electrically

idle state, that is, VIDp-p < 50 mV and stays in this state for >100 µs, the associated channel(s) enters

into the low-power state. In this state, output of the associated channel(s) is driven to VCM and the

device selectively shuts off some circuitry to lower power by >80% of its normal operating power. Exit

time from the auto low-power mode is <50 ns.

Out-of-Band (OOB) SUPPORT

The squelch detector circuit within the device enables full detection of OOB signaling as specified in the SATA

specification. Differential signal amplitude at the receiver input of 50 mVpp or less is not detected as an activity

and hence not passed to the output. Differential signal amplitude of 150 mVp-p or more is detected as an activity

and therefore passed to the output, indicating activity. Squelch circuit ON/OFF time is 5 ns, maximum. While in

squelch mode, outputs are held to VCM.

DEVICE POWER

The SN75LVCP601 is designed to operate from a single 3.3 V supply. Always practice proper power-supply

sequencing procedure. Apply Vcc first, before any input signals are applied to the device. The power-down

sequence is in reverse order.

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

Supply voltage range

Voltage range Differential I/O –0.5 to 4 V

Electrostatic discharge Charged-device model

Continuous power dissipation See Thermal Table

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any conditions beyond those indicated under Recommended Operating

Conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltage values, except differential voltages, are with respect to the network ground terminal.

(3) Tested in accordance with JEDEC Standard 22, Test Method A114-B.

(4) Tested in accordance with JEDEC Standard 22, Test Method C101-A.

(5) Tested in accordance with JEDEC Standard 22, Test Method A115-A.

(2)

V

CC

Control I/O –0.5 to Vcc + 0.5 V

Human-body model

Machine model

(3)

(4)

(5)

(1)

VALUE UNIT

–0.5 to 4 V

±10,000 V

±1500 V

±200 V

THERMAL INFORMATION

SN75LVCP601

THERMAL METRIC

θ

JA

θ

JCtop

θ

JB

(1) For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

(2) The junction-to-ambient thermal resistance under natural convection is obtained in a simulation on a JEDEC-standard, high-K board, as

specified in JESD51-7, in an environment described in JESD51-2a.

(3) The junction-to-case (top) thermal resistance is obtained by simulating a cold plate test on the package top. No specific

JEDEC-standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

(4) The junction-to-board thermal resistance is obtained by simulating in an environment with a ring cold plate fixture to control the PCB

temperature, as described in JESD51-8.

Copyright © 2010–2012, Texas Instruments Incorporated Submit Documentation Feedback 7

Junction-to-ambient thermal resistance

Junction-to-case (top) thermal resistance

Junction-to-board thermal resistance

Product Folder Link(s): SN75LVCP601

(1)

(2)

(3)

(4)

QFN UNITS

20 PINS

38 °C/W

40 °C/W

10 °C/W

Page 8

SN75LVCP601

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

www.ti.com

THERMAL INFORMATION (continued)

SN75LVCP601

THERMAL METRIC

(1)

QFN UNITS

20 PINS

ψ

ψ

θ

P

P

JT

JB

JCbot

D

SD

Junction-to-top characterization parameter

Junction-to-board characterization parameter

Junction-to-case (bottom) thermal resistance

Device power dissipation in active mode 215 to 288 mW

Device power dissipation under standby mode 5 mW

(5)

(6)

(7)

0.5 °C/W

0.9 °C/W

15.2 °C/W

(5) The junction-to-top characterization parameter, ψJT, estimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining θJA, using a procedure described in JESD51-2a (sections 6 and 7).

(6) The junction-to-board characterization parameter, ψJB, estimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining θJA, using a procedure described in JESD51-2a (sections 6 and 7).

(7) The junction-to-case (bottom) thermal resistance is obtained by simulating a cold plate test on the exposed (power) pad. No specific

JEDEC standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

RECOMMENDED OPERATING CONDITIONS

(Typical values for all parameters are at VCC= 3.3V and TA= 25°C. All temp limits are specified by design)

PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

C

COUPLING

Supply voltage 3 3.3 3.6 V

Coupling capacitor 12 nF

Operating free-air temperature 0 85 °C

ELECTRICAL CHARACTERISTICS

over operating free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

DEVICE PARAMETERS

P

D

P

SD

I

CC

I

CC_ALP

I

CC_STDBY

t

PDelay

AutoLP

AutoLP

t

ENB

t

DIS

ENTRY

EXIT

Power dissipation in active mode 215 288 mW

Power dissipation in standby EN = 0 V, DEWx = EQx = DEx = NC, K28.5

mode pattern at 6 Gbps, VID= 700 mV

Active-mode supply current 65 80 mA

Acive power-save mode I

CC

Standby mode supply current EN = 0 V 1 mA

Maximum data rate 1 6 Gbps

Propagation delay Measured using K28.5 pattern. See Figure 8. 323 400 ps

Auto low-power entry time Electrical idle at input; see Figure 9. 80 105 130 µs

Auto low-power exit time After first signal activity; see Figure 9. 42 50 ns

Device enable time EN 0→1 5 µs

Device disable time EN 1→0 2 µs

DEWx = EN = Vcc, EQx = DEx = NC, K28.5

pattern at 6 Gbps, VID= 700 mV

EN = 3.3 V, DEWx= 0 V, EQx/DEx = NC,

K28.5 pattern at 6 Gbps, VID= 700 mV

When device is enabled and auto low-power

conditions are met

p-p

p-p

5 mW

p-p

6.5 10 mA

8 Submit Documentation Feedback Copyright © 2010–2012, Texas Instruments Incorporated

Product Folder Link(s): SN75LVCP601

Page 9

SN75LVCP601

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

over operating free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

OUT-OF-BAND (OOB)

V

OOB

D

VdiffOOB

D

VCMOOB

t

OOB1

t

OOB2

CONTROL LOGIC

V

IH

V

IL

VIN

HYS

I

IH

I

IL

RECEIVER AC/DC

Z

DIFFRX

Z

SERX

VCM

RX

RL

DiffRX

RX

DiffRLSlope

RL

CMRX

V

diffRX

IB

RX

t

20-80RX

t

skewRX

Input OOB threshold f = 750 MHz 50 78 150 mVpp

OOB differential delta 25 mV

OOB common-mode delta 50 mV

OOB mode enter See Figure 9. 3 5 ns

OOB mode exit 3 5 ns

Input high voltage For all control pins 1.4 V

Input low voltage 0.5 V

Input hysteresis 115 mV

High-level input current µA

Low-level input current µA

EQx, DEx = Vcc 30

EN, DEWx = Vcc 1

EQx, DEx = GND –30

EN, DEWx = GND –10

Differential-input impedance 85 100 115 Ω

Single-ended input impedance 40 Ω

Common-mode voltage 1.8 V

f = 150 MHz–300 MHz 18 28

f = 300 MHz–600 MHz 14 17

Differential-mode return loss (RL) f = 600 MHz–1.2 GHz 10 12 dB

f = 1.2 GHz–2.4 GHz 8 9

f = 2.4 GHz–3 GHz 3 9

Differential-mode RL slope f = 300 MHz–6 GHz (See Figure 5.) –13 dB/dec

f = 150 MHz–300 MHz 5 10

f = 300 MHz–600 MHz 5 17

Common-mode return loss f = 600 MHz–1.2 GHz 2 23 dB

f = 1.2 GHz–2.4 GHz 1 16

f = 2.4 GHz–3 GHz 1 12

Differential input voltage PP f = 1.5 GHz and 3 GHz 120 1600 mVppd

f = 150 MHz–300 MHz 30 41

f = 300 MHz–600 MHz 30 38

f = 600 MHz–1.2 GHz 20 32

Impedance balance f = 1.2 GHz–2.4 GHz 10 26 dB

f = 2.4 GHz–3 GHz 10 25

f = 3 GHz–5 GHz 4 20

f = 5 GHz–6.5 GHz 4 17

Rise times and fall times measured between

Rise/fall time 62 75 ps

20% and 80% of the signal. SATA 6-Gbps

speed measured 1 in, (2.5 cm) from device

pin

Difference between the single-ended

Differential skew 30 ps

midpoint of the RX+ signal rising/falling edge,

and the single-ended midpoint of the RX–

signal falling/rising edge

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

Copyright © 2010–2012, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): SN75LVCP601

Page 10

SN75LVCP601

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

over operating free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

TRANSMITTER AC/DC

Z

diffTX

Z

SETX

V

TXtrans

RL

DiffTX

TX

DiffRLSlope

RL

CMTX

IB

TX

Diff

VppTX

DE Output de-emphasis f = 3 GHz, DE1/DE2 = 1 –2 dB

t

DE

VCM

AC_TX

VCM

TX

t

20-80TX

t

skewTX

TxR/F

Imb

TxAmp

Imb

Pair differential impedance 85 100 122 Ω

Single-ended impedance 40 Ω

Sequencing transient voltage –1.2 1.2 V

Transient voltages on the serial data bus

during power sequencing (lab load)

f = 150 MHz–300 MHz 14 24

f = 300 MHz–600 MHz 8 19

Differential-mode return loss f = 600 MHz–1.2 GHz 6 14 dB

f = 1.2 GHz–2.4 GHz 6 10

f = 2.4 GHz–3 GHz 3 10

Differential-mode RL slope f = 300 MHz–3 GHz (SeeFigure 5.) –13 dB/dec

f = 150 MHz–300 MHz 5 20

f = 300 MHz–600 MHz 5 19

Common-mode return loss f = 600 MHz–1.2 GHz 2 17 dB

f = 1.2 GHz–2.4 GHz 1 12

f = 2.4 GHz–3.0 GHz 1 11

f = 150 MHz–300 MHz 30 41

f = 300 MHz–600 MHz 30 38

f = 600 MHz–1.2 GHz 20 33

Impedance balance f = 1.2 GHz–2.4 GHz 10 24 dB

f = 2.4 GHz–3 GHz 10 26

f = 3 GHz–5 GHz 4 22

f = 5 GHz–6.5 GHz 4 21

Differential output-voltage swing 550 mVppd

f = 3 GHz, DE1/DE2 = 0, DEWx = NC,

(under no interconnect loss)

f = 3 GHz, DE1/DE2 = 0 0

f = 3 GHz, DE1/DE2 = NC –4

De-emphasis duration ps

DEWx = 0 94

DEWx = 1 215

At 1.5 GHz 20 50 mVppd

TX AC CM voltage At 3 GHz 12 26

dBmV

At 6 GHz 13 30

Common-mode voltage 1.8 V

Rise times and fall times measured between

Rise/fall time 20% and 80% of the signal. At 6Gbps under 42 55 75 ps

no load conditions

Difference between the single-ended

Differential skew 6 20 ps

mid-point of the TX+ signal rising/falling

edge, and the single-ended mid-point of the

TX- signal falling/rising edge.

TX rise-fall imbalance At 3 Gbps 6% 20%

TX amplitude imbalance 2% 10%

(rms)

10 Submit Documentation Feedback Copyright © 2010–2012, Texas Instruments Incorporated

Product Folder Link(s): SN75LVCP601

Page 11

12" 6mil

Stripline

Jitter

Measurement

1

2

8" 6 milStripline

AWG*

AWG*

Jitter

Measurement

CP

CP = Compliancepoint

CP

SN75LVCP601

www.ti.com

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

ELECTRICAL CHARACTERISTICS (continued)

over operating free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

TRANSMITTER JITTER

DJ

TX

RJ

TX

DJ

TX

RJ

TX

(1) TJ = (14.1 × RJSD+ DJ), where RJSDis one standard deviation value of RJ Gaussian distribution. Jitter measurement is at the SATA

connector and includes jitter generated at the package connection on the printed circuit board, and at the board interconnect as shown

in Figure 6.

Deterministic jitter

Figure 6

Residual random jitter

Deterministic jitter

Figure 6

Residual random jitter

(1)

at CP in

(1)

at CP in

(1)

(1)

VID = 500 mVpp, UI = 333 ps,

K28.5 control character

VID = 500 mVpp, UI = 333 ps,

K28.7 control character

VID = 500 mVpp, UI = 167 ps,

K28.5 control character

VID = 500 mVpp, UI = 167 ps,

K28.7 control character

0.06 0.19 UIp-p

0.01 2 ps-rms

0.08 0.34 UIp-p

0.09 2 ps-rms

Figure 5. TX, RX Differential Return Loss Limits

Figure 6. Jitter Measurement Test Condition

Copyright © 2010–2012, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Link(s): SN75LVCP601

Page 12

t

PDelay

t

PDelay

IN

OUT

t

OOB2

t

OOB1

Vcm

IN+

IN-

OUT+

OUT-

Vcm

50 mV

t

OOB1

VCM

RX

VCM

TX

AutoLP

ENTRY

AutoLP

EXIT

RX1,2P

RX1,2N

TX1,2P

TX1,2N

PowerSaving

Mode

SN75LVCP601

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

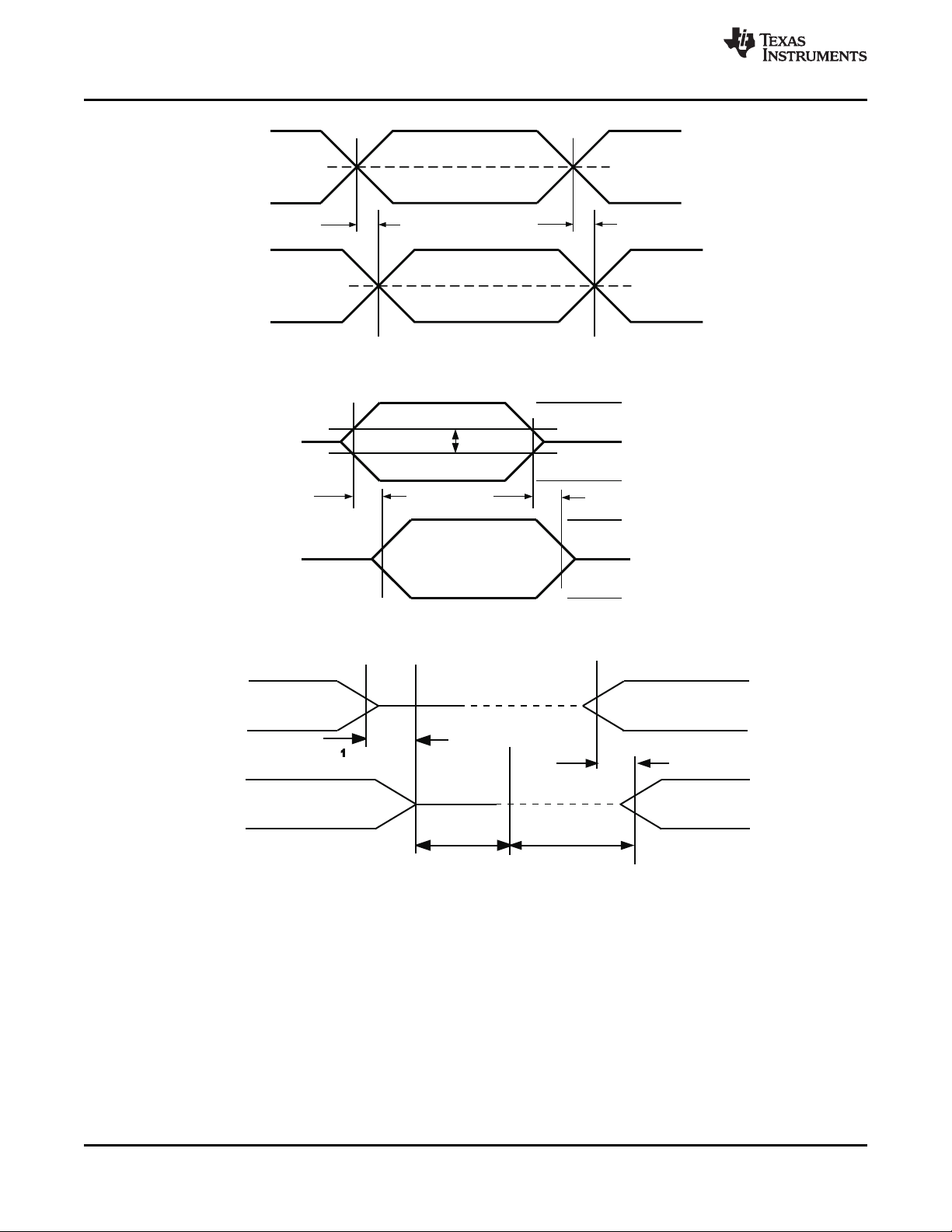

Figure 7. Propagation Delay Timing Diagram

www.ti.com

Figure 8. OOB Enter and Exit Timing

Figure 9. Auto Low-Power Mode Enter and Exit Timing

12 Submit Documentation Feedback Copyright © 2010–2012, Texas Instruments Incorporated

Product Folder Link(s): SN75LVCP601

Page 13

1-bit 1 toNbits

1-bit

1 toNbits

Diff

VppTX

Diff

VppTX_DE

t

DE

t

DE

0 dB

-2 dB

-4 dB

LVCP601

Agilent

DCA -J

Agilent

ParBERT

With LVCP601

Without LVCP601

TP1

TP2

TP3

TP4

TP1 TP4

EQ = 14 dB

DE = –2 dB

Agilent

ParBERT

Agilent

DCA -J

16-in., 4-mil (40.6-cm, 0.101-mm)

FR4 Trace +

2-in., 9.5-mil (5.05-cm, 0.241-mm)

FR4 Trace

8-in., 4-mil (20.3-cm, 0.101-mm)

FR4 Trace +

2-in., 9.5-mil (5.05-cm, 0.241-mm)

FR4 Trace

16-in., 4-mil (40.6-cm, 0.101-mm) FR4 Trace +

8-in., 4-mil (20.3-cm, 0.101-mm) FR4 Trace

4-in., 9.5-mil (10.1-cm, 0.241-mm) FR4 Trace +

SN75LVCP601

www.ti.com

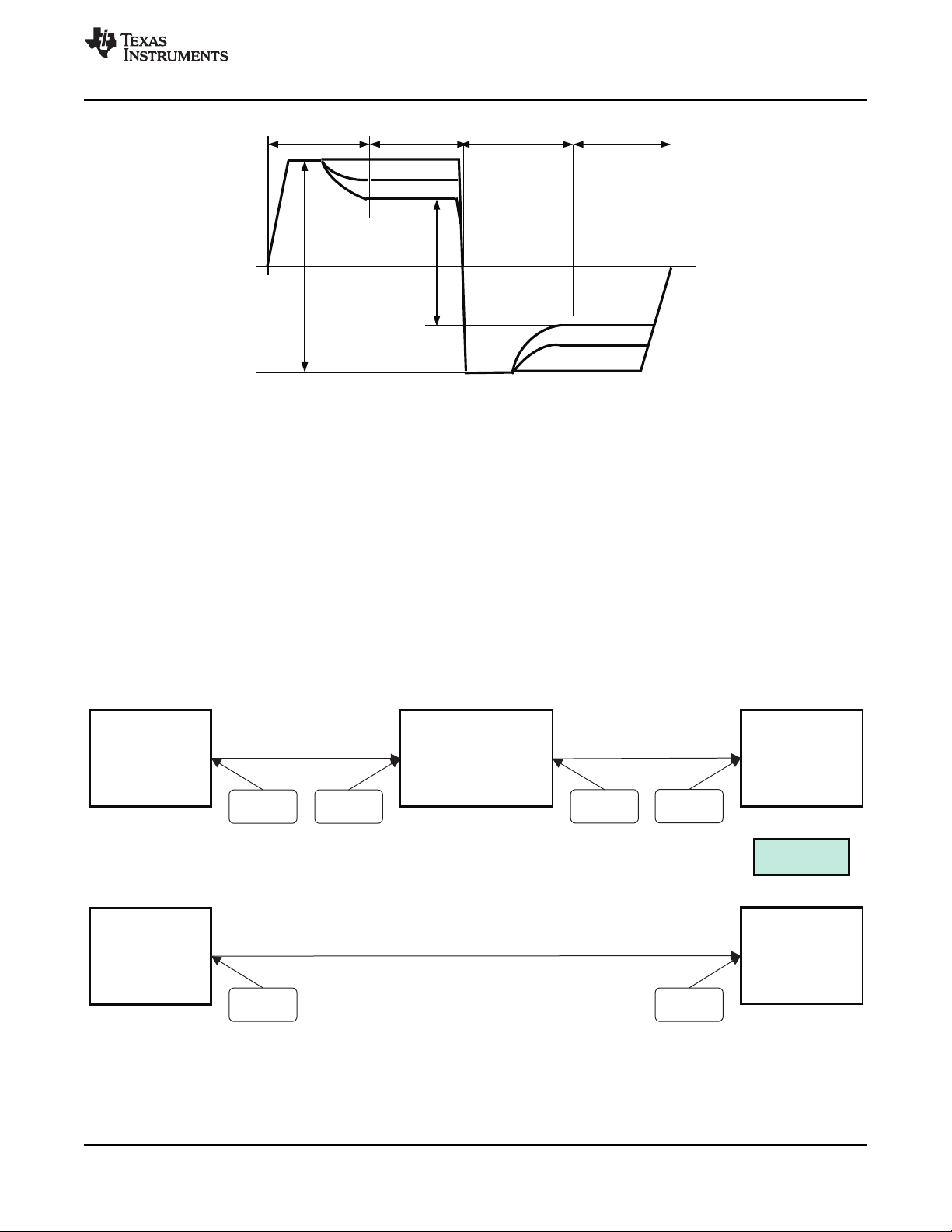

Figure 10. TX Differential Output De-Emphasis

SN75LVCP601 TYPICAL PERFORMANCE CURVE

• Input signal characteristics

– Data rate = 6 Gbps, 3 Gbps, 1.5 Gbps

– Amplitude = 500 mVp-p

– Data pattern = K28.5

• SN75LVCP601 device setup

– Temperature = 25°C

– Voltage = 3.3 V

– De-emphasis duration = 117 ps (short)

– Equalization and de-emphasis set to optimize performance at 6 Gbps

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

Copyright © 2010–2012, Texas Instruments Incorporated Submit Documentation Feedback 13

Figure 11. Performance Curve Measurement Setup

Product Folder Link(s): SN75LVCP601

Page 14

13.24101165.42.0029.856.7TP4

Without

LVCP601

459.62149.7557.11.9212.739.0TP4

With

LVCP601

623.02141.3788.81.9115.942.0TP3

81.2428.92401.9365.491.8TP2

350.52159.2412.41.883.329.0TP1

Eye

Diagram

Eye

Opening

mV

Eye

Width

ps

Eye

Amplitude

mV

RJ

(rms)

ps

DJ

(δ-δ)

ps

TJ

(1e-12)

ps

TestPoint

122.26118258.81.96101.8128.6TP4

Without

LVCP601

463.42305.0615.31.9920.347.9TP4

With

LVCP601

611.62321714.51.9612.839.6TP3

222.36237314.91.8946.872.7TP2

392.84326430.91.893.829.7TP1

Eye

Diagram

Eye

Opening

mV

Eye

Width

ps

Eye

Amplitude

mV

RJ

(rms)

ps

DJ

(δ-δ)

ps

TJ

(1e-12)

ps

TestPoint

SN75LVCP601

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

SN75LVCP601 TYPICAL PERFORMANCE CURVE (continued)

www.ti.com

Figure 12. Jitter and VOD Results: Case 1 at 6 Gbps

Figure 13. Jitter and VOD Results: Case 2 at 3 Gbps

14 Submit Documentation Feedback Copyright © 2010–2012, Texas Instruments Incorporated

Product Folder Link(s): SN75LVCP601

Page 15

217.46493322.82.3081.9113.3TP4

Without

LVCP601

442.42632.0672.82.6221.557.3TP4

With

LVCP601

604.02649753.12.3113.244.9TP3

318.48589363.42.1138.667.5TP2

417.286594482.263.434.3TP1

Eye

Diagram

Eye

Opening

mV

Eye

Width

ps

Eye

Amplitude

mV

RJ

(rms)

ps

DJ

(δ-δ)

ps

TJ

(1e-12)

ps

TestPoint

Input Trace Length (in)

Residual DJ (ps)

Eye Opening (V)

2 4 6 8 10 12 14 16 18 20 22

0 0.1

2 0.2

4 0.3

6 0.4

8 0.5

10 0.6

12 0.7

14 0.8

G001

Residual DJ 3Gbps

Residual DJ 6Gbps

Eye Opening 3Gbps

Eye Opening 6Gbps

SN75LVCP601

www.ti.com

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

SN75LVCP601 TYPICAL PERFORMANCE CURVE (continued)

Figure 14. Jitter and VOD Results: Case 3 at 1.5 Gbps

TYPICAL CHARACTERISTICS

RESIDUAL DJ AND EYE OPENING

vs

INPUT TRACE LENGTH

Copyright © 2010–2012, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Link(s): SN75LVCP601

Figure 15.

Page 16

Output Trace Length (in)

Residual DJ (ps)

Eye Opening (V)

2 4 6 8 10 12 14 16 18 20 22

0 0

5 0.1

10 0.2

15 0.3

20 0.4

25 0.5

30 0.6

35 0.7

40 0.8

G002

Residual DJ 3Gbps

Residual DJ 6Gbps

Eye Opening 3Gbps

Eye Opening 6Gbps

SN75LVCP601

SLLSE41B –JUNE 2010– REVISED FEBRUARY 2012

TYPICAL CHARACTERISTICS (continued)

www.ti.com

RESIDUAL DJ AND EYE OPENING

vs

OUTPUT TRACE LENGTH

Figure 16.

SPACER

REVISION HISTORY

Changes from Revision A (October 2011) to Revision B Page

• Changed pin type from CML to VML for pins 4, 5, 14, 15 .................................................................................................... 4

Changes from Original (June 2010) to Revision A Page

• Changed pin EN number From: 4 To: 7 ............................................................................................................................... 4

16 Submit Documentation Feedback Copyright © 2010–2012, Texas Instruments Incorporated

Product Folder Link(s): SN75LVCP601

Page 17

PACKAGE OPTION ADDENDUM

www.ti.com

30-Dec-2015

PACKAGING INFORMATION

Orderable Device Status

SN75LVCP601RTJR ACTIVE QFN RTJ 20 Green (RoHS

SN75LVCP601RTJT ACTIVE QFN RTJ 20 250 Green (RoHS

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

& no Sb/Br)

& no Sb/Br)

Lead/Ball Finish

(6)

CU NIPDAU | Call TI Level-2-260C-1 YEAR 0 to 85 LVC601

CU NIPDAU | Call TI Level-2-260C-1 YEAR 0 to 85 LVC601

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead/Ball Finish - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead/Ball Finish values may wrap to two lines if the finish

value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

Samples

Addendum-Page 1

Page 18

PACKAGE OPTION ADDENDUM

www.ti.com

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

30-Dec-2015

Addendum-Page 2

Page 19

PACKAGE MATERIALS INFORMATION

www.ti.com 14-Jul-2012

TAPE AND REEL INFORMATION

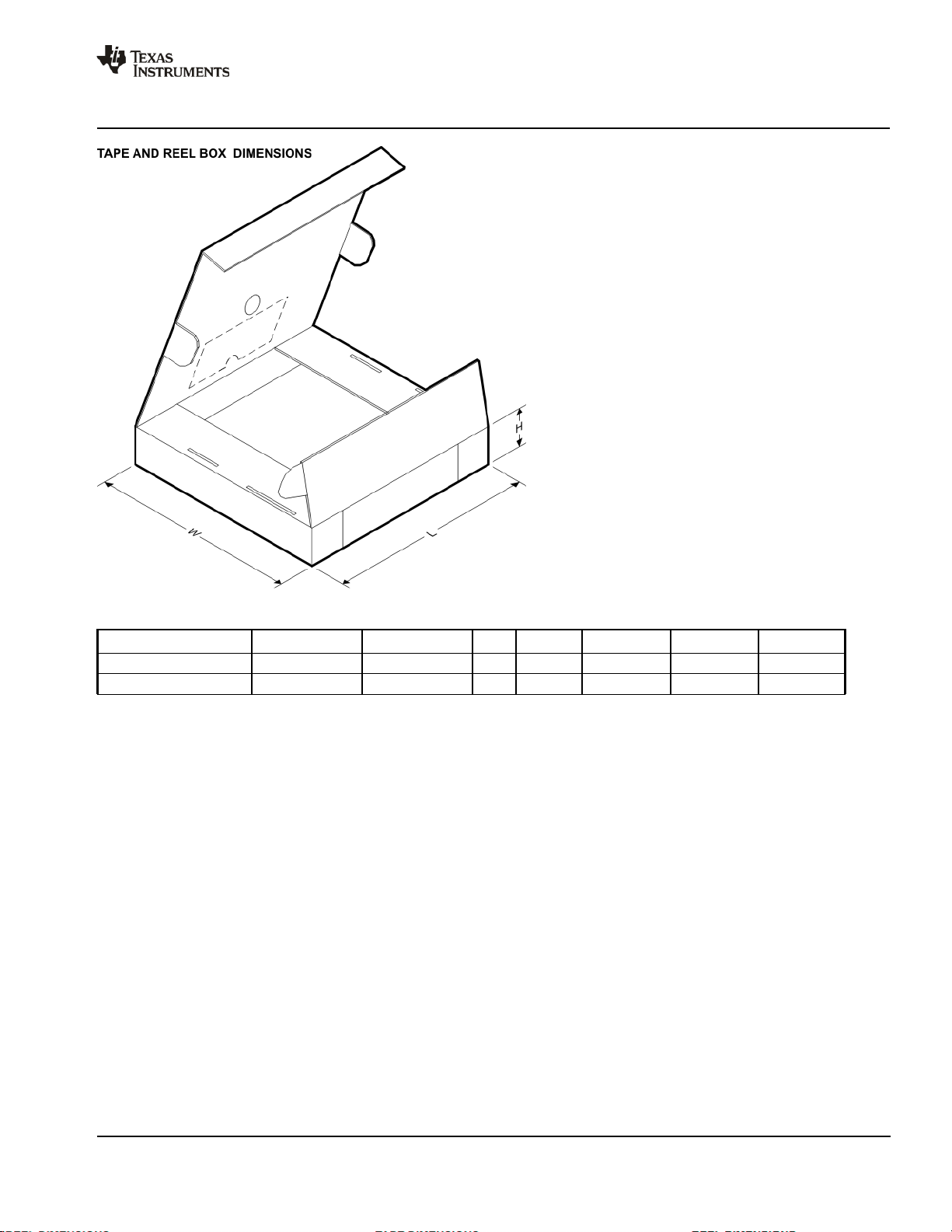

*All dimensions are nominal

Device Package

SN75LVCP601RTJR QFN RTJ 20 3000 330.0 12.4 4.25 4.25 1.15 8.0 12.0 Q2

SN75LVCP601RTJT QFN RTJ 20 250 180.0 12.4 4.25 4.25 1.15 8.0 12.0 Q2

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 20

PACKAGE MATERIALS INFORMATION

www.ti.com 14-Jul-2012

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

SN75LVCP601RTJR QFN RTJ 20 3000 367.0 367.0 35.0

SN75LVCP601RTJT QFN RTJ 20 250 210.0 185.0 35.0

Pack Materials-Page 2

Page 21

Page 22

Page 23

Page 24

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2015, Texas Instruments Incorporated

Page 25

Loading...

Loading...