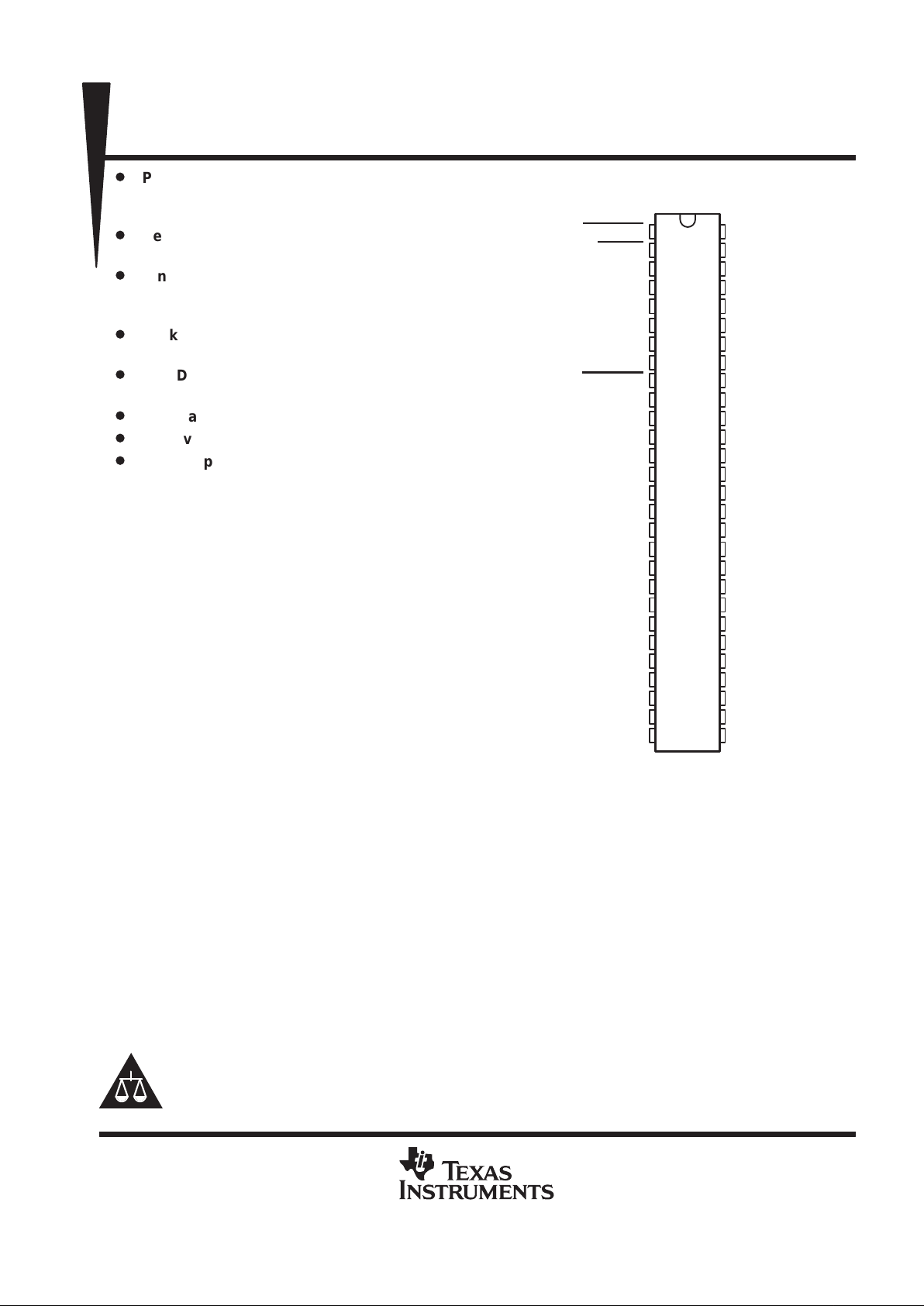

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

Provides Differential SCSI from SingleEnded Controller When Used With the

SN75LBC971A Data Transceiver

D

Designed to Operate at Fast-SCSI Speeds

of 10 Million Data Transfers per Second

D

Nine Transceivers Meet or Exceed the

Requirements of ANSI Standard EIA-485

and ISO-8482 Standards

D

Packaged in Shrink Small-Outline Package

with 25 mil Terminal Pitch

D

Low Disabled Supply Current

22 mA Typ

D

Thermal Shutdown Protection

D

Positive- and Negative-Current Limiting

D

Power-Up/-Down Glitch Protection

description

The SN75LBC970A SCSI differential convertercontrol is an adaptation of the industry’s first

9-channel RS-485 transceiver, the SN75LBC976.

When used in conjunction with one or more of its

companion data transceiver(s), SN75LBC971A,

the chip set provides the superior electrical

performance of differential SCSI from a single-ended SCSI bus controller. A 16-bit, Fast-SCSI bus

can be implemented with just three devices (two

for data and one for control) in the space-efficient,

56-pin, shrink small-outline package (SSOP) and

a few external components.

In a typical differential SCSI node, the SCSI

controller provides the enables for each external

RS-485 transceiver. This could require as many

as 27 additional terminals for a 16-bit differential

bus controller or relegate a 16-bit single-ended

controller to only an 8-bit differential bus. Using the standard nine SCSI control signals, the SN75LBC970A

control transceiver decodes the state of the bus and enables the SN75LBC971A data transceiver(s) to transmit

the single-ended SCSI input signals differentially to the cable or receive the differential cable signals and drive

the single-ended outputs to the controller.

The single-ended SCSI bus interface consists of CMOS bidirectional inputs and outputs. The drivers are rated

at ±16 mA of output current. The receiver inputs are pulled high with approximately 4 mA to eliminate the need

for external pullup resistors for the open-drain outputs of most single-ended SCSI controllers. The single-ended

side of the device is not intended to drive the SCSI bus directly.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright 1999, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

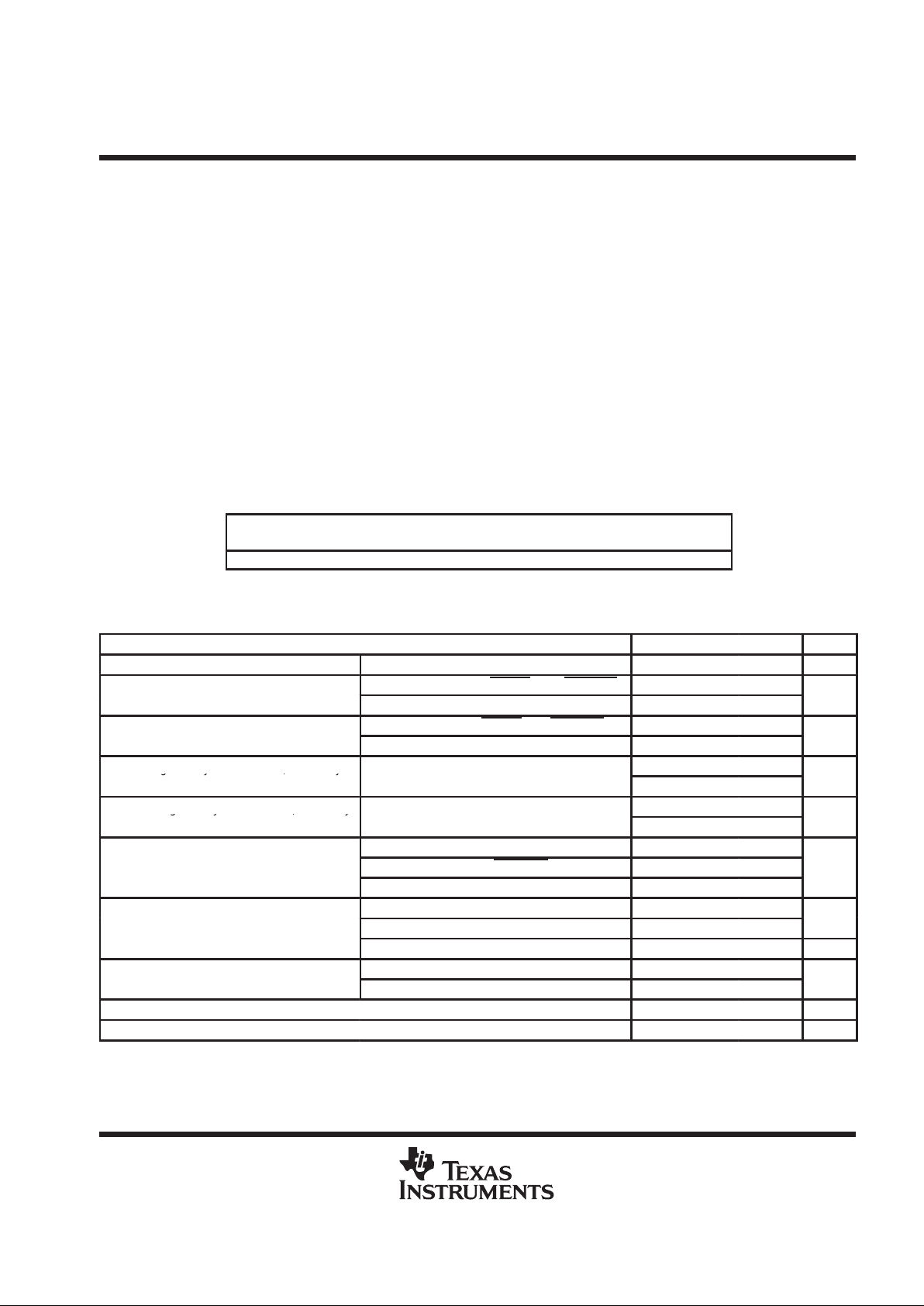

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

RSTFLTR

RESET

DSENS

CLK40

GND

AATN–

TEST

AACK–

TIMEOUT

AREQ–

AC/D–

V

CC

GND

GND

GND

GND

GND

V

CC

DRVBUS

SDB

AMSG–

AI/O–

ASEL–

NC

ABSY–

NC

ARST–

NC

X2

X1/CLK20

NC

BATN–

BATN+

BACK–

BACK+

BREQ–

BREQ+

BC/D–

BC/D+

V

CC

GND

GND

GND

GND

GND

V

CC

BMSG–

BMSG+

BI/O–

BI/O+

BSEL+

BSEL–

BBSY+

BBSY–

BRST+

BRST–

DL PACKAGE

(TOP VIEW)

NC – no internal connection

Terminals 13 through 17 and 40 through 44 are

connected together to the package lead frame and

signal ground.

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

description (continued)

The differential SCSI bus interface consists of

bipolar bidirectional inputs and outputs that meet

or exceed the requirements of EIA-485 and ISO

8482-1982/TIA TR30.2 referenced by the American National Standard of Information Systems

(ANSI) X3.131-1994 Small Computer System

Interface-2 (SCSI-2).

The SN75LBC970A is characterized for operation

over the temperature range of 0°C to 70°C.

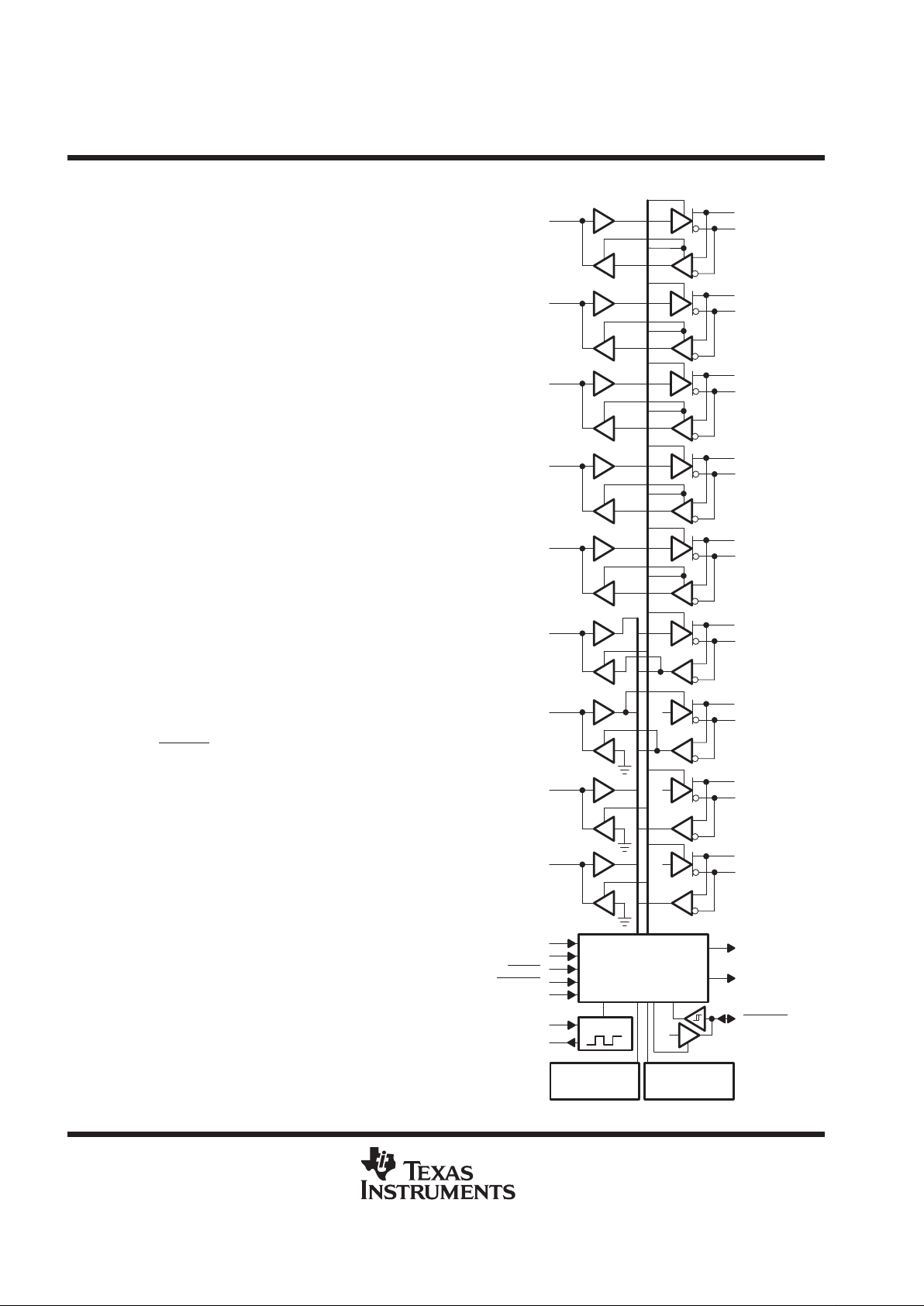

The SN75LBC970A consists of nine RS-485

differential transceivers, nine TTL- or CMOS-level

compatible transceivers, a state machine and

control logic block, a 20-MHz crystal-controlled

oscillator, a timer, a power-up/-down glitch

protection circuit, and a thermal-shutdown

protection circuit.

The single-ended or controller interface is

designated as the A side and the differential port

is the B side. Since the device uses the SCSI

control signals to decode the state of the bus and

data flow direction, the terminal assignments must

be matched to the corresponding signal on the

SCSI bus. The signal name followed by a minus

sign (–) indicates an active-low signal while a plus

sign (+) indicates an active-high signal.

A reset function, which disables all outputs and

clears internal latches, can be accomplished from

two external inputs and two internally-generated

signals. RESET

(Reset) and DSENS (differential

sense) are available to external circuits for a bus

reset or to disable all outputs should a

single-ended cable be inadvertently connected to

a differential connector. The power-up and

thermal-shutdown are internally generated signals that have the same effect when the supply

voltage is below 3.5 V or the junction temperature

exceeds approximately 175°C.

This data sheet contains descriptions of the

SN75LBC970A input and output signals followed

by the electrical characteristics. The parameter

measurement information is followed by the

theory of operation, a state flow chart, and a

typical circuit in the application information

section.

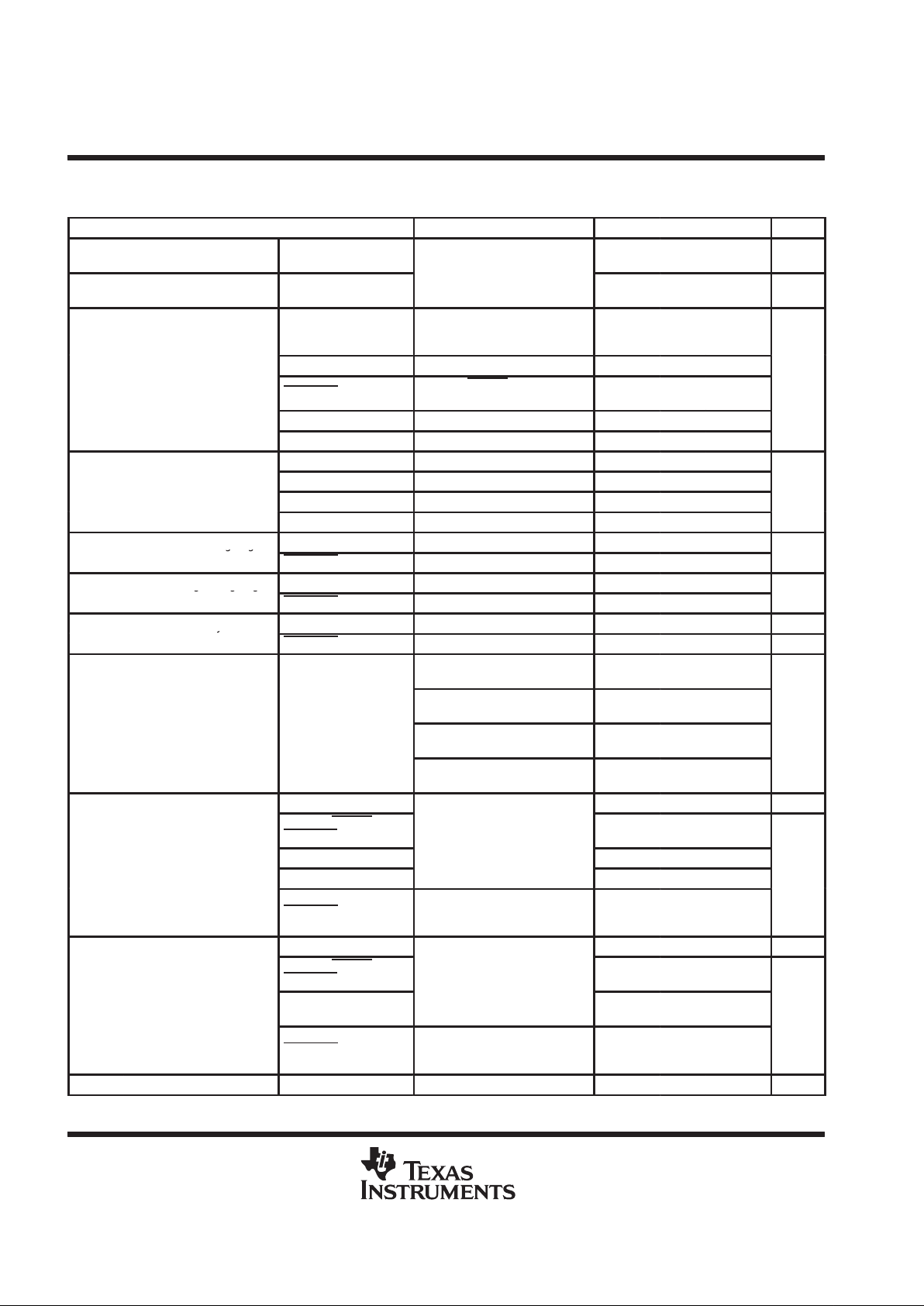

53

52

BATN–

BATN+

6

51

50

BACK–

BACK+

8

38

37

BMSG–

BMSG+

21

47

46

BC/D–

BC/D+

11

36

35

BI/O–

BI/O+

22

30

29

BRST+

BRST–

27

H

32

31

BBSY+

BBSY–

25

H

34

33

BSEL+

BSEL–

23

H

State Machine and

Control Logic

Oscillator

H

Thermal

Shutdown

Power-Up

and Reset Logic

3

7

2

1

4

55

56

19

DRVBUS

20

SDB

TIMEOUT

AATN–

AACK–

AMSG–

AC/D–

AI/O–

ARST–

ABSY–

ASEL–

49

48

BREQ–

BREQ+

10

AREQ–

9

DSENS

TEST

RESET

RSTFLTR

CLK40

X1/CLK20

X2

logic diagram (positive logic)

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

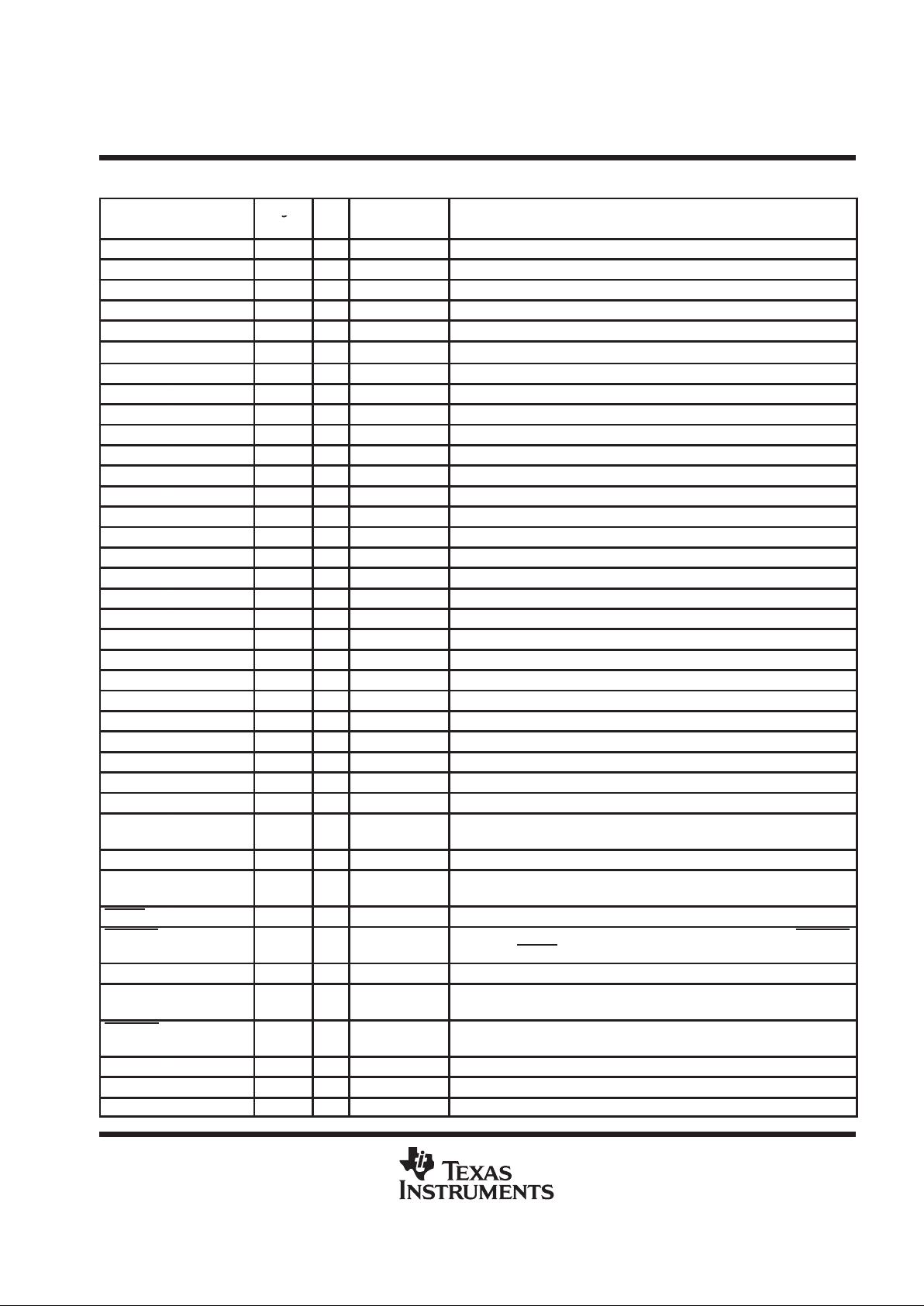

Terminal Functions

TERMINAL

Logic

NAME NO.

g

Level

I/O

Termination

DESCRIPTION

AACK– 8 TTL I/O Strong pullup SCSI acknowledge (–ACK) signal to/from controller

AATN– 6 TTL I/O Strong pullup SCSI attention (–ATN) signal to/from controller

ABSY– 25 TTL I/O Strong pullup SCSI busy (–BSY) signal to/from the controller

AC/D– 11 TTL I/O Strong pullup SCSI control/data (–C/D) signal to/from the controller

AI/O– 22 TTL I/O Strong pullup SCSI input/output (–I/O) signal to/from the controller

AMSG– 21 TTL I/O Strong pullup SCSI message (–MSG) signal to/from the controller

AREQ– 10 TTL I/O Strong pullup SCSI request (–REQ) signal to/from controller

ARST– 27 TTL I/O Strong pullup SCSI reset (–RST) signal to/from the controller

ASEL– 23 TTL I/O Strong pullup SCSI select (–SEL) signal to/from the controller

BACK– 51 RS-485 I/O Weak pullup SCSI acknowledge (–ACK) signal to/from the bus

BACK+ 50 RS-485 I/O Weak pulldown SCSI acknowledge (+ACK) signal to/from the bus

BATN– 53 RS-485 I/O Weak pullup SCSI attention (–ATN) signal to/from the bus

BATN+ 52 RS-485 I/O Weak pulldown SCSI attention (+ATN) signal to/from the bus

BBSY– 31 RS-485 I/O Weak pulldown SCSI busy (–BSY) signal to/from the bus

BBSY+ 32 RS-485 I/O Weak pullup SCSI busy (+BSY) signal to/from the bus

BC/D– 47 RS-485 I/O Weak pullup SCSI control/data (–C/D) signal to/from the bus

BC/D+ 46 RS-485 I/O Weak pulldown SCSI control/data (+C/D) signal to/from the bus

BI/O– 36 RS-485 I/O Weak pullup SCSI input/output (–I/O) signal to/from the bus

BI/O+ 35 RS-485 I/O Weak pulldown SCSI input/output (+I/O) signal to/from the bus

BMSG– 38 RS-485 I/O Weak pullup SCSI message (–MSG) signal to/from the bus

BMSG+ 37 RS-485 I/O Weak pulldown SCSI message (+MSG) signal to/from the bus

BREQ– 49 RS-485 I/O Weak pullup SCSI request (–REQ) signal to/from the bus

BREQ+ 48 RS-485 I/O Weak pulldown SCSI request (+REQ) signal to/from the bus

BRST– 29 RS-485 I/O Weak pulldown SCSI reset (–RST) signal to/from the bus

BRST+ 30 RS-485 I/O Weak pullup SCSI reset (+RST) signal to/from the bus

BSEL– 33 RS-485 I/O Weak pulldown SCSI select (–SEL) signal to/from the bus

BSEL+ 34 RS-485 I/O Weak pullup SCSI select (+SEL) signal to/from the bus

CLK40 4 CMOS I Strong pulldown 40-MHz clock input

DRVBUS 19 TTL O N/A Driver bus. A high-level logic signal that indicates the SCSI bus is in one of

the information transfer phases.

DSENS 3 TTL I Weak pullup A low-level input initializes the internal latches and disables all drivers.

GND 5, 13–17,

40–44

N/A N/A N/A Supply common

RESET 2 TTL I Weak pullup Reset. A low-level input initializes the internal latches and disables all drivers.

RSTFLTR 1 TTL I Weak pullup Reset filter. Filtered input from the SCSI bus for a system reset. RSTFLTR

differs from RESET by keeping the ARST and BRST drivers enabled.

SDB 20 TTL O N/A A high-level logic signal that indicates a differential to single-ended data flow.

TEST 7 TTL I Weak pulldown Test. A high-level input that places the device in a test mode (see Table 1).

It is grounded during normal operation.

TIMEOUT 9 Analog I/O N/A Time out. This signal connects to an external RC time constant for a time out

during bus arbitration.

V

CC

12, 18, 39, 45 N/A N/A N/A 5-V supply voltage

X1/CLK20 55 CMOS I None 20-MHz crystal oscillator or clock input

X2 56 Analog O None 20-MHz crystal oscillator feedback

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

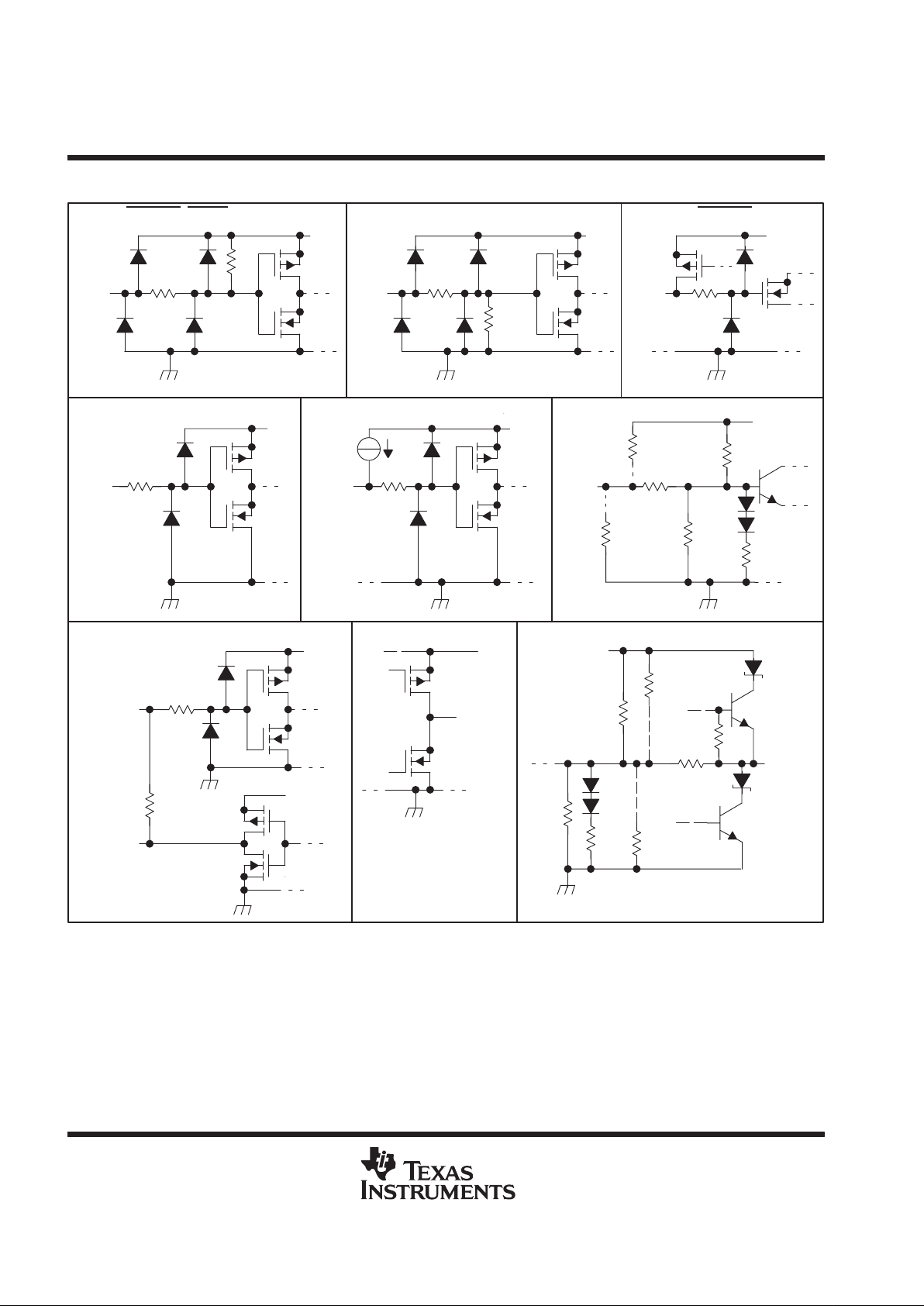

schematics of inputs and outputs

22 k

200 Ω

Input

V

CC

RSTFLTR

, RESET, AND DSENS

50 kΩ

200 Ω

Input

V

CC

TEST

200 Ω

Input

V

CC

TIMEOUT

200 Ω

Input

V

CC

CLK40

200 Ω

Input

V

CC

A

3 kΩ

12 kΩ

1 kΩ

100 kΩ

B– Pin Only

100 kΩ

B+ Pin Only

18 kΩ

V

CC

Input

B+ AND B–

200 Ω

100 kΩ

X1/CLK20

V

CC

V

CC

X2

X1/CLK20, X2

V

CC

Output

100 kΩ

B– Pin Only

100 kΩ

B+ Pin Only

3 kΩ

12 kΩ

V

CC

Output

A, SDB, DRVBUS B+ AND B–

4 mA

1 kΩ

18 kΩ

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

†

Supply voltage range, V

CC

(see Note 1) –0.3 V to 7V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential bus voltage range (B side) –15 V to 15 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal-ended bus voltage range (A side and control) –0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrostatic discharge: B side (see Note 2):Class 2, A: 2 kV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Class 2, B: 200 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

All terminals: Class 1, A: 500 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Class 1, B: 200 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

A

0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltage values are with respect to the GND terminals.

2. This absolute maximum rating is tested in accordance with MIL-STD-883C, Method 3015.7.

DISSIPATION RATING TABLE

PACKAGE

TA ≤ 25°C

POWER RATING

OPERATING FACTOR

‡

ABOVE TA = 25°C

TA = 70°C

POWER RATING

DL 2500 mW 20 mW/°C 1600 mW

‡

This is the inverse of the traditional junction-to-case thermal resistance (R

θJA

).

recommended operating conditions

MIN NOM MAX UNIT

Supply voltage, V

CC

4.75 5 5.25 V

p

A side, DSENS, TEST, RESET, AND RSTFLTR 2

High-level input voltage, V

IH

CLK40 AND X1/CLK20 0.7 V

CC

V

p

A side, DENS, TEST, RESET, and RSTFLTR 0.8

Low-level input voltage, V

IL

CLK40 AND X1/CLK20 0.2 V

CC

V

Input voltage at any bus terminal (separately

12

gy ( y

or common-mode), V

I

B side–7V

Output voltage at any bus terminal (separately

12

gy ( y

or common-mode), V

O

B side–7V

B side –60

High-level output current, I

OH

A side, DRVBUS, SDB, TIMEOUT –16

mA

X2 –4

B side 60

Low-level output current, I

OL

A side, DRVBUS, and SDB 16

mA

X2 4 mA

CLK20 20

Clock frequenc

y,

f

CLK

CLK40 40

MH

z

Operating case temperature, T

C

0 125 °C

Operating free-air temperature, T

A

0 70 °C

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating free-air temperature range (unless

otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP

†

MAX UNIT

V

OD(H)

Driver differential

high-level output voltage

B side except BBSY,

BRST, and BSEL

1 1.8 V

V

OD(L)

Driver differential low-level

output voltage

B side

See Figure 1

–1 – 2.2 V

AACK–, AATN–,

AC/D–, AI/O–,

AMSG–, AREQ–

VID = –200 mA,

IOH = –16 mA

2.5 4.3

DRVBUS, SDB IOH = –16 mA 2.5 4.4

V

OH

High-level output voltage

TIMEOUT

Test and RESET at 0.8 V, All

others open, IOH = –16 mA

2.5 4.5

V

B side 3.4

X2 IOH = - 4 mA 3.2

DRVBUS, SDB IOL = 16 mA 0.8

p

A side VID = 200 mV, IOL =16 mA 0.8

VOLLow-level output voltage

B side 1.6

V

X2 IOL = 4 mA 0.8

Receiver positive-going

B side IOH = –16 mA, See Figure 2 0.2

V

IT+

gg

input threshold voltage

TIMEOUT 2.6

V

Receiver negative-going

B side IOL = 16 mA, See Figure 2 –0.2

V

IT–

ggg

input threshold voltage

TIMEOUT

0.32 V

CC

0.4 V

CC

V

Receiver input hysteresis

B side 45 mV

V

hys

y

(V

IT+

– V

IT–

)

TIMEOUT 0.5 V

VI = 12 V, VCC = 5 V,

All other inputs at 0 V

0.6 1

p

VI = 12 V, VCC = 0,

All other inputs at 0 V

0.7 1

IIBus input current

B side

VI = –7 V, VCC = 5 V,

All other inputs at 0 V

–0.5 –0.8

mA

VI = –7 V, VCC = 0,

All other inputs at 0 V

–0.4 –0.8

A side –2.9 –6 –8 mA

DSENS, RESET,

RSTFLTR

V

= 2 V

–60 –100

-

p

CLK40, X1/CLK20

IH

±20

IIHHigh-level in ut current

TEST 100

µA

TIMEOUT

TEST at 2 V, A side and other

control inputs at 0.8 V ,

B side open, VIH = 2 V

±1

A side –6 –8 mA

DSENS, RESET,

RSTFLTR

VIH = 0.8 V

–100

I

IL

Low-level input current

CLK40, TEST,

X1/CLK20

±20

µA

TIMEOUT

TEST at 0.8 V, A side and

other control inputs at 0.8 V ,

B side open, VIH = 2 V

±1

I

OS

Short circuit output current B side VO = 5 V and 0 V ±250 mA

†

All typical values are at VCC = 5 V, TA = 25 °C.

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating free-air temperature range (unless

otherwise noted) (Continued)

PARAMETER TEST CONDITIONS MIN TYP†MAX UNIT

Disabled

RESET at 0.8 V,

All others open

27 36

I

CC

Supply current

All A-side to B-side

channels enabled

TEST and RSTFLTR at 2 V

RESET

at 0.8 V,

All other inputs open, no load

72 94

mA

All B-side to A-side

channels enabled

TEST at 2 V, RESET and

RSTFLTR

at 0.8 V,

All other inputs open,

No load

38 50

C

o

Bus output capacitance

B side to GND,

VI = 0.6 sin(2π 106 t)+ 1.5 V

19 21 pF

p

p

B side to A side, one channel 100 pF

CpdPower dissipation capacitance (see Note 3)

A side to B side, one channel 450 pF

†

All typical values are at VCC = 5 V, TA = 25 °C.

NOTE 3: Cpd determines the no-load dynamic current consumption, IS = Cpd × VCC × f + ICC (ICC depends upon the output states and load circuits

and is not necessarily the same ICC as specified in the electrical tables).

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

switching characteristics over recommended operating free-air temperature range (unless

otherwise noted)

PARAMETER

FROM

(INPUT)TO(OUTPUT)

TEST CONDITIONS MIN TYP†MAX UNIT

AATN–

AC/D–

BATN±

BC/D±

Delay time, A to B,

-

-

AI/O–

AMSG–

BI/O±

BMSG±

See Figure 3

7.6

26.6

t

d1

,

t

d2

high- to low-level or

low- to high-level output

8.5 25.3

ns

g

AACK–

–

BACK±

VCC = 5 V, TA = 25°C 10 18

AREQ

–

BREQ±

VCC = 5 V, TA = 70°C 12.5 20.5

t

sk(lim)

Skew limit

AACK– BACK±

See Note 4 8 ns

t

sk(p)

Pulse skew

AREQ– BREQ±

See Note 5 6 ns

Delay time, B to A,

-

-

BATN±

BC/D±

BI/O±

BMSG±

AATN–

AC/D–

AI/O–

AMSG–

See Figure 4 21.5 36.2

t

d3

,

t

d4

high- to low-level or

low- to high-level output

21.5 36.2

ns

g

BACK±

AACK–

–

VCC = 5 V, TA = 25°C 23.6 32.6

BREQ±

AREQ

–

VCC = 5 V, TA = 70°C 24.4 33.4

t

sk(lim)

Skew limit

BACK± AACK–

See Note 4 9 ns

t

sk(p)

Pulse skew

BREQ± AREQ–

See Note 5 6 ns

t

PHL

Delay time, high- to low-level

200 ns

t

PLH

Delay time, low- to high-level

TIMEOUT

DRVBUS

See Figure 5

200 ns

ABSY– BBSY± 200

t

dis

Disable time

ARST–

BRST±

See Figure 6

200

ns

ASEL– BSEL± 200

ABSY– BBSY± 40

t

en

Enable time

ARST–

BRST±

See Figure 6

55

ns

ASEL– BSEL± 39

t

dis1

Disable time BRST± ARST– 93 ns

t

dis2

Disable time BSEL± ASEL– 55 ns

t

dis3

Disable time BBSY± ABSY– 60 ns

t

en1

Enable time BRST± ARST–

See Figure 7

63 ns

t

en2

Enable time BSEL± ASEL– 45 ns

t

en3

Enable time BBSY± ABSY– 45 ns

t

en4

Enable time BSEL± ASEL– 92 ns

†

All typical values are at VCC = 5 V, TA = 25 °C.

NOTES: 4. This parameter is applicable at one VCC and operating temperature within the recommended operating conditions and to any two

devices.

5. Pulse skew is the difference between the high-to-low and low-to-high propagation delay times of any single channel.

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

5 V

V

OD

VOH, V

OL

VOH, V

OL

165 Ω

165 Ω

75 Ω

VIH, V

IL

BDBn–

BDBn+

A–

2 V

or

0.8 V

NOTES: A. The input pulse is supplied by a generator having the following characteristics: tr ≤ 6 ns, tf ≤ 6 ns PRR ≤1 MHz, 45% < duty cycle

< 50%, ZO = 50 Ω.

B. Resistance values are with a tolerance of 5%.

C. All input voltage levels are held to within 0.01 V.

Figure 1. Differential Driver VOD, VOH, and V

OL

T est Circuit

VID or V

IT

V

I

VOH, V

OL

ADBn–

IOH, I

OL

I

I

BDBn–

BDBn+

Figure 2. Single-Ended Driver VOD, VOH, and V

OL

T est Circuit

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

5 V

Output

165 Ω

165 Ω

75 Ω

Input

(see Note A)

A–

50 pF

50 pF

(see Note B)

B–

B+

t

d1

t

d2

Input Output

0 V

1.5 V

3 V

t0 t0or delay delay

V

OD

A–

RESET

TEST

DSENS

RSTFLTR

V

OD(L)

0 V

V

OD(H)

NOTES: A. The input pulse is supplied by a generator having the following characteristics: tr ≤ 6 ns, tf ≤ 6 ns PRR ≤ 1 MHz,

45% < duty cycle < 50%, ZO = 50 Ω.

B. Resistance values are with a tolerance of ±5%.

C. All input voltage levels are held to within 0.01 V.

Figure 3. A-Side to B-Side Propagation Delay Time Test Circuit and Timing Definitions

Output

1.5 V

Input

(see Note A)

B–

15 pF

(see Note B)

t

d3

t

d4

Input Output

0 V

1.5 V

3 V

t0 t0or delay delay

A–

RESET

TEST

DSENS

RSTFLTR

V

OL

1.5 V

V

OH

B+

A–

B–

NOTES: A. The input pulse is supplied by a generator having the following characteristics: tr ≤ 6 ns, tf ≤ 6 ns PRR ≤1 MHz, 45% < duty cycle

< 50%, ZO = 50 Ω.

B. Resistance values are with a tolerance of ±5%.

C. All input voltage levels are held to within 0.01 V.

Figure 4. B-Side to A-Side Propagation Delay Time Test Circuit and Timing Definitions

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

Table 1. Output Test Enabling (No Clock Input)

SIGNAL BUS CONTROL INPUT(s)

INPUT(s) OUTPUT TEST RSTFLTR RESET BBSY– BBSY+ ABSY– DSENS

ATN, ACK, MSG, C/D, REQ, I/O A B H H L

ATN, ACK, MSG, C/D, REQ, I/O B A H L L

RST A B L—>H H L H H

RST B A L—>H H L H H

SEL, BSY B A L H L—>H H

SEL, BSY B H H L

TIMEOUT N/A H L L

DRVBUS

†

BBSY–/ BBSY+,

BSEL–/BSEL+,

TIMEOUT

DRVBUS H L L

TIMEOUT N/A Z H L

†

For these conditions, DRVBUS = BSEL or BBSY and TIMEOUT together.

Output

Input

TIMEOUT

15 pF

Input Output

0 V

1.5 V

V

CC

t0 t0or t

P

t

P

V

OL

1.5 V

V

OH

DRVBUS

t

PHL

t

PLH

RESET

TEST

DSENS,

BSEL, BBSY

RSTFLTR

TIMEOUT

DRVBUS

Figure 5. TIMEOUT to DRVBUS Delay Time Test Circuit and Timing Definitions

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

Input

Output

5 V

50 pF

50 pF

165 Ω

165 Ω

75 Ω

A–

B–

B+

Input Output

0 V

1.5 V

3 V

t0 t0or enable disable

≈ –0.925 V

0.5 V

V

OD(H)

t

en

t

dis

RESET

TEST

DSENS

RSTFLTR

ARST–

ABSY– or ASEL–

CLK20

(see Note A)

t

en

t

dis

BRST

BBSY or BSEL

NOTE A: These are asynchronous events and do not necessarily align with clock edges.

Figure 6. A-Side to B-Side Enable and Disable Delay Time Test Circuit and Timing Definitions

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

t

en1

t

dis1

RESET

TEST

DSENS

RSTFLTR

Output

1.5 V

Input

B–

15 pF

Input Output

0 V

1.5 V

3 V

t0 t0or delay delay

V

OL

1.5 V

V

OH

B+

A–

t

en3

t

dis3

ООООООООО

t

en2

t

dis2

t

en4

Reset Bus Free

Arbitration

to Select 1

CLK40

(See Note A)

BRST–

BBSY–

BSEL–

ARST–

ABSY–

ASEL–

ООООООООО

ООООООООО

ООООООООО

ООООООООО

ООООООООО

NOTE A: These are asynchronous events and do not necessarily align with clock edges.

Figure 7. B-Side to A-Side Enable and Disable Delay Time Test Circuit and Timing Definitions

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

To correctly set the direction of the SCSI bus signals, the SN75LBC970A must follow the activity on the bus. An

asynchronous, 5-state controller watches the state of all the bus control signals, sets the direction of each control

signal as needed, and generates the DRVBUS and SDB outputs to control one or two external SN75LBC971A SCSI

differential converter-data devices. The controller never generates the data driven on a bus signal; it only enables

the drivers. The clock input implements a 400-ns timer that is not part of the controller itself. Controller-state

transitions occur immediately when all the transition conditions are met. Note that the frequency of the supplied clock,

either 20 MHz or 40 MHz, must be correct in order to meet the SCSI specifications.

As shown in Figure 8, after reset, the controller begins in the bus free state. In case the controller was attached to

an active differential bus, it waits for the SCSI bus free condition, defined as when BBSY and BSEL are deasserted

for 400 ns. While waiting for the SCSI bus free condition, the state of BBSY and BSEL passes through to the A side.

The A side bus device cannot take part in bus activity during this condition before the SCSI bus free condition. Once

SCSI bus free is detected, the SCSI arbitration state is entered. Both ABSY and BBSY are enabled; thus when either

signal asserts, both drivers turn on and both signals remain asserted until this state is left. Normally the SCSI

arbitration state ends after the winner of arbitration asserts BSEL. This would cause the controller to go to the select

1 state. However, when BSEL is not asserted, a timeout would eventually be detected and cause a reset of the

controller. In the select 1 state, two latches are open, DSEL_LATCH and RESEL_LATCH. The first latch captures

the state of BSEL so that following states can determine whether the arbitration winner was on the A side or B side.

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

Enable ABSY and ASEL

400 ns of

BBSY = BSEL = 0?

RESET

Enable ABSY and BBSY

Set DSEL_LATCH to BSEL

Set RESEL_LATCH to AI/O

NO

YES

TIMEOUT?

YES

NO

ASEL or

(DSEL_LATCH and

BSEL)?

BBSY?

NO

NO YES

YES

Set RESEL_LATCH to AI/O DSEL_LATCH = 1?

NO

Enable A Side

400 ns of

BBSY = 0?

ABSY = 1 And

BBSY = 0?

NO

NO

ASEL = 1?

Enable B Side

400 ns of

ABSY = 0?

YES

YES

NO

YES

NO

YES

A

RESET

Bus Free

State

SCSI

Arbitration

State

Select 1

State

YES

Continued on Figure 9

SCSI Bus Free Condition

Select 2 State

Figure 8. Bus Free, SCSI Arbitration, and Select 1 State Flow Chart

The second latch captures the state of AI/O. This is true during a reselection phase but not during the selection phase.

When the bus is in the selection or reselection phase, the controller enters the select 1 state. There are three possible

flows depending on bus events. The first flow is that the SCSI controller on the A side won the arbitration and asserted

ASEL. In this event DSEL_LA TCH would not be set. The controller passes all signals to the B side and waits for ABSY

to deassert for 400 ns, indicating that the A side controller is selecting or reselecting a device on the B side. The object

of the A side controller must be on the B side since only one device is allowed on the A side.

The second possible flow is that DSEL_LA TCH is set, indicating that the arbitration winner is on the B side, and the

winner is selecting or reselecting the device on the A side. The controller passes all signals to the A side and waits

for BBSY to deassert for 400 ns. When the A side controller responds by asserting ABSY , the controller detects ABSY

asserted and BBSY deasserts and goes to the select 2 state.

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

The third possible flow is that a device on the B side won the arbitration and is selecting or reselecting another device

on the B side. DSEL_LA TCH is set, and 400 ns of BBSY is asserted first by the object of the selection or reselection.

Since ASEL is still asserted, the controller remains in the select 1 state throughout the selection or reselection. If the

BBSY deassertion is missed by the timer , again the controller remains in the select 1 state. Once the transfer state

is entered, BBSY is asserted and BSEL is dropped. This again returns the controller to a select 1 state. At the end

of the transfer both BBSY and BSEL are deasserted. After the timer limit is reached, the controller goes to the

arbitration state for the next bus arbitration.

The controller enters the select 2 state (see Figure 9) during the selection or reselection phases when the initiator

and terminator are on the opposite side of SDCC. In this state the RESEL_LA TCH is closed, capturing the value of

the I/O. When RESEL_LATCH is one, reselection is indicated. When RESEL_LATCH equals zero, a selection is

indicated. RESEL_LA TCH, along with the DSEL_LATCH, now defines which side the initiator is on and therefore what

direction to establish for all the bus signals. The target must be on the other side; if both target and initiator were on

the B side, the select 2 state would never be entered.

When the RESEL_LATCH is zero, indicating a selection, the connection is not made. When DSEL_LATCH is one,

the initiator is on the B side and the control lines it drives have their A side drivers enabled. These terminals are the

initiator group of ACK and A TN along with SEL. The other terminals are driven by the target and have the B side drivers

enabled. They are the target group of REQ, MSG, C/D, and I/O, along with BSY. When DSEL_LATCH is zero the

connection is reversed. Since transfer states are not started, DRVBUS is set to 1, indicating that the data transceiver

chips should not take their direction control from SDB and should be actively negated. SDB is generated from I/O

and is the bus signal that determines data transfer direction. In this case it indicates the selection phase, the controller

immediately transfers to the transfer state, where exactly the same actions are done.

When the RESEL_LATCH is 1 indicating a reselection, there is one or more actions before information states can

be entered. When the target reselects the initiator, the initiator responds by asserting BSY. Once the connection is

made, the assertion of BSY must be changed over to the target, and the controller must reverse the BSY driver

direction. It does this when SEL deasserts by transferring to the transfer state where the BSY direction is reversed.

In the select 2 state all the control line directions are set as appropriate, except that DRVBUS is not yet asserted. In

the transfer state DRBVUS is set as well.

The controller remains in the transfer state during all other SCSI states. When a bus free state is detected, it goes

back to the arbitration state to wait for the next activity. Note that after BBSY and BSEL deassert, the controller

continues to actively drive the control lines and the data lines through DRVBUS until 400 ns of continuous deassertion

is detected. The drivers are turned off only when the state change occurs.

Figure 10 shows a typical system configuration. The timeout function used in the arbitration state is implemented with

a resistor and capacitor connected to the TIMEOUT

terminal. During reset and whenever the timer is not in use, the

terminal is driven to V

CC

. The timer starts when the driver turns off, allowing the capacitor to charge and the TIMEOUT

terminal to drop to ground. When V

IT-

is reached, the driver turns on, discharging the capacitor and returning

TIMEOUT

to VCC. A timeout event is declared after the driver turns back on and TIMEOUT exceeds V

IT+

.

RST can be asserted on either the A or B side, and is driven to the other side. The drive to the other side is controlled

by a bidirectional latch. When one side asserts, the other side is asserted and a latch is set to that direction. When

the first side deasserts, the driver turns off, but the direction is held until both sides are deasserted. Only then can

the direction change.

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

400 ns of

BBSY = BSEL = 0?

Enable ABSY , AINIT,

BSEL, And BTARG

YES

RESEL_LATCH = 1?

NO

NO

NO

BSEL = 1?

YES

NO

YES

A

YES

Continued From Figure 8

DSEL_LATCH = 1?

YES

Enable BBSY , BINIT,

ASEL, And ATARG

ASEL = 1?

YES

NO

DSEL_LATCH = 1?

DRVBUS = 1

SDB = BI/O

Enable ABSY , A TARG,

BSEL, And BINIT

DRVBUS = 1

SDB = AI/O

Enable BBSY , BT ARG,

ASEL, And AINIT

DSEL_LATCH = 1?

NO

RESEL_LATCH = 1?RESEL_LATCH = 1?

YES

NO

DRVBUS = 1, SDB = BI/O

Enable ABSY , A TARG,

BSEL, And BINIT

DRVBUS = 1, SDB = AI/O

Enable BBSY , BT ARG,

ASEL, And AINIT

YES

YES

Select 2

State

Transfer

State

NO

NO

(On Figure 8)

Select 1 State

Figure 9. SCSI Select 1, Select 2, and Transfer State Flow Chart

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

The SCSI bus signal RST does not directly clear SDCC internal logic. Instead, the RSTFLTR terminal can be

connected as ARST– so that a bus reset clears SDCC. RSTFL TR clears the internal controller but does not clear the

RST bidirectional latch. By connecting these terminals externally through a RC filter as shown in Figure 8, noise

pulses on the bus may be filtered as recommended by the SCSI-2 specification.

SN75LBC970A

3

DSENS

6

±BSY

±SEL

±RST

8

±I/O

±MSG

±C/D

±REQ

4

±ATN

±ACK

7

4

Test

CLK40

(see Note A)

SCSI Controller

–BSY

–SEL

–I/O

–MSG

–C/D

–REQ

–ATN

–ACK

8

–RST

1

2

RESET

(From System)

V

CC

TIMEOUT

55

0.022 µF

205 kΩ

RSTFLTR

RESET

X1/CLK20

X2

DRVBUS SDB

SN75LBC971A

16

2

8

–DB(7–0)

–DBP(0)

RESET

±DB(7–0)

±DBP(0)

DIFFSENS

SN75LBC971A

16

2

8

–DB(15–8)

–DBP(1)

RESET

±DB(15–8)

±DBP(1)

DIFFSENS

20 kΩ

0.1 pF

BBSY±

BSEL±

RST±

DIFFSENS

BI/O±

BMSG±

BC/D±

BREQ±

BATN±

BACK±

ABSY–

ASEL–

AI/O–

AMSG–

AC/D–

AREQ–

AATN–

AACK–

ARST–

20 MHz

(See Note A)

Optional

(See Note B)

DRVBUS

SDB

NOTES: A. When using the 40 MHz clock input, X1 must be connected to VCC.

B. The oscillator cell of the SN75LBC970A is for a series-resonant crystal and needs approximately

10 pF (including fixture capacitance) from X1 and X2 to ground in order to function.

Figure 10. Typical Application of the SN75LBC970A and SN75LBC971A

SN75LBC970A

SCSI DIFFERENTIAL CONVERTER-CONTROL

SLLS215B – MAY 1995 – REVISED JANUAR Y 1999

19

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL INFORMATION

DL (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

4040048/D 08/97

48-PIN SHOWN

56

0.730

(18,54)

0.720

(18,29)

4828

0.370

(9,40)

(9,65)

0.380

Gage Plane

DIM

0.420 (10,67)

0.395 (10,03)

A MIN

A MAX

0.006 (0,15) NOM

PINS **

0.630

(16,00)

(15,75)

0.620

0.010 (0,25)

Seating Plane

0.020 (0,51)

0.040 (1,02)

25

24

0.008 (0,203)

0.012 (0,305)

48

1

0.008 (0,20) MIN

A

0.110 (2,79) MAX

0.299 (7,59)

0.291 (7,39)

0.004 (0,10)

M

0.005 (0,13)

0.025 (0,635)

0°–8°

NOTES: D. All linear dimensions are in inches (millimeters).

E. This drawing is subject to change without notice.

F. Body dimensions do not include mold flash or protrusion not to exceed 0.006 (0,15).

G. Falls within JEDEC MO-118

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...