SN54ABT18502, SN74ABT18502

SCAN TEST DEVICES WITH

18-BIT REGISTERED BUS TRANSCEIVERS

SCBS109B – AUGUST 1992 – REVISED JUNE 1993

• Members of the Texas Instruments

SCOPE

Family of Testability Products

• Members of the Texas Instruments

Widebus

Family

• Compatible With the IEEE Standard

1149.1-1990 (JTAG) Test Access Port and

Boundary-Scan Architecture

•

UBT

(Universal Bus Transceiver)

Combines D-Type Latches and D-Type

Flip-Flops for Operation in Transparent,

Latched, or Clocked Mode

• Two Boundary-Scan Cells per I/O for

Greater Flexibility

• State-of-the-Art

Significantly Reduces Power Dissipation

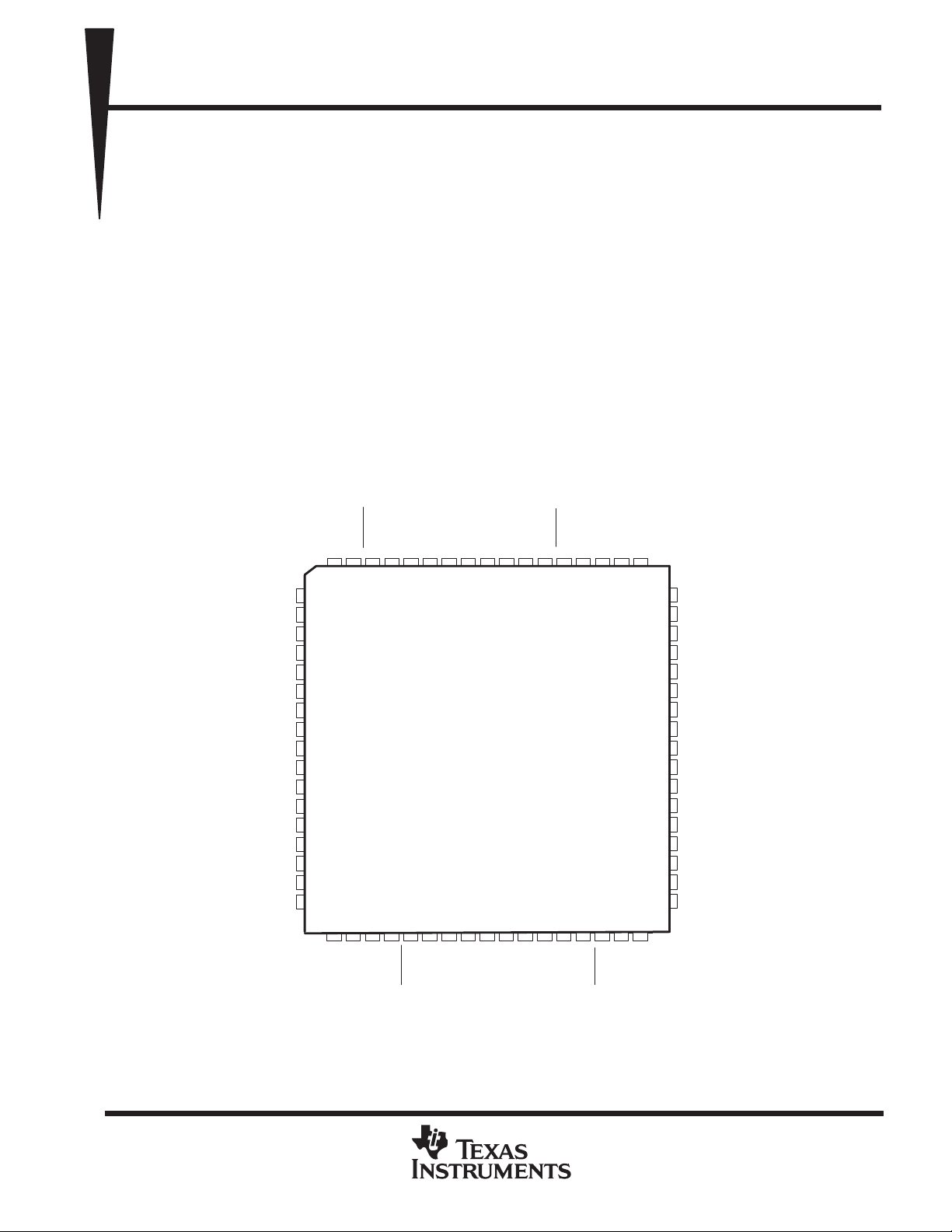

EPIC-ΙΙB

1A3

1A4

1A5

GND

1A6

1A7

1A8

1A9

NC

V

CC

2A1

2A2

2A3

GND

2A4

2A5

2A6

BiCMOS Design

1A2

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

28 29 30 31 32 33 34

SN54ABT18502 . . . HV PACKAGE

1A1

1OEAB

GND

87 65493168672

1LEAB

1CLKAB

(TOP VIEW)

CC

VNCTMS

TDO

35 36 37 38 39

•

SCOPE

Instruction Set

– IEEE Standard 1149.1-1990 Required

Instructions, Optional INTEST, and

P1149.1A CLAMP and HIGHZ

– Parallel Signature Analysis at Inputs With

Masking Option

– Pseudo-Random Pattern Generation

From Outputs

– Sample Inputs/Toggle Outputs

– Binary Count From Outputs

– Device Identification

– Even-Parity Opcodes

• Packaged in 64-Pin Plastic Thin Quad Flat

Pack Using 0.5-mm Center-to-Center

Spacings and 68-Pin Ceramic Quad Flat

Pack Using 25-mil Center-to-Center

Spacings

1CLKBA

1LEBA

1OEBA

GND

1B1

1B2

1B3

66 652764 63 62 61

1B4

60

1B5

59

1B6

58

GND

57

1B7

56

1B8

55

1B9

54

V

53

CC

NC

52

2B1

51

2B2

50

2B3

49

2B4

48

GND

47

2B5

46

2B6

45

2B7

44

40 41 42 43

CC

NC

2LEAB

2CLKAB

TDI

V

TCK

2LEBA

2CLKBA

2A9

2A7

2A8

GND

2OEAB

NC – No internal connection

SCOPE, Widebus, UBT, and EPIC-IIB are trademarks of T exas Instruments Incorporated.

UNLESS OTHERWISE NOTED this document contains PRODUCTION

DATA information current as of publication date. Products conform to

specifications per the terms of Texas Instruments standard warranty.

Production processing does not necessarily include testing of all

parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

GND

2B9

2B8

2OEBA

Copyright 1993, Texas Instruments Incorporated

1

SN54ABT18502, SN74ABT18502

SCAN TEST DEVICES WITH

18-BIT REGISTERED BUS TRANSCEIVERS

SCBS109B – AUGUST 1992 – REVISED JUNE 1993

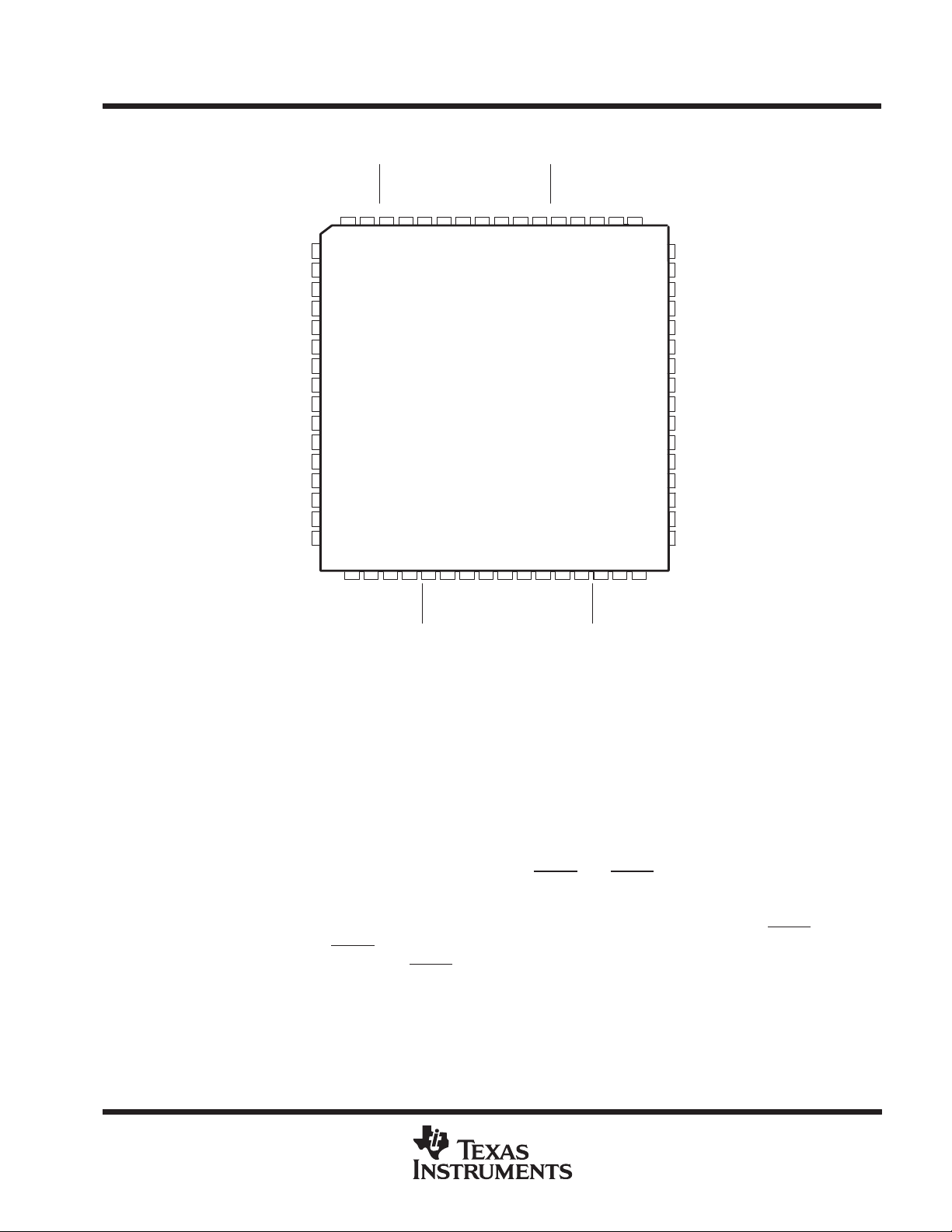

1A3

1A4

1A5

GND

1A6

1A7

1A8

1A9

V

CC

2A1

2A2

2A3

GND

2A4

2A5

2A6

SN74ABT18502 ...PM PACKAGE

1OEAB

1A2

1A1

63 62 61 60 5964 58 56 55 5457

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18 19

20

GND

1CLKAB

1LEAB

21 22 23 24

(TOP VIEW)

CC

TDO

V

TMS

25 26 27 28 29

1LEBA

1OEBA

1CLKBA

53 521751 50 49

1B1

GND

30 31 32

1B2

1B3

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

1B4

1B5

1B6

GND

1B7

1B8

1B9

V

CC

2B1

2B2

2B3

2B4

GND

2B5

2B6

2B7

CC

2LEAB

2CLKAB

TDI

V

TCK

2CLKBA

GND

2LEBA

2B9

2OEBA

2B8

2A7

2A8

2A9

GND

2OEAB

description

The SN54ABT18502 and SN74ABT18502 scan test devices with 18-bit universal bus transceivers are

members of the T exas Instruments SCOPE testability IC family . This family of devices supports IEEE Standard

1149.1-1990 boundary scan to facilitate testing of complex circuit board assemblies. Scan access to the test

circuitry is accomplished via the 4-wire test access port (TAP) interface.

In the normal mode, these devices are 18-bit universal bus transceivers that combine D-type latches and D-type

flip-flops to allow data flow in transparent, latched, or clocked modes. They can be used either as two 9-bit

transceivers or one 18-bit transceiver. The test circuitry can be activated by the TAP to take snapshot samples

of the data appearing at the device pins or to perform a self test on the boundary test cells. Activating the T AP

in the normal mode does not affect the functional operation of the SCOPE universal bus transceivers.

Data flow in each direction is controlled by output-enable (OEAB

and clock (CLKAB and CLKBA) inputs. For A-to-B data flow, the device operates in the transparent mode when

LEAB is high. When LEAB is low , the A-bus data is latched while CLKAB is held at a static low or high logic level.

Otherwise, if LEAB is low, A-bus data is stored on a low-to-high transition of CLKAB. When OEAB is low, the

B outputs are active. When OEAB

is high, the B outputs are in the high-impedance state. B-to-A data flow is

similar to A-to-B data flow but uses the OEBA, LEBA, and CLKBA inputs.

In the test mode, the normal operation of the SCOPE universal bus transceivers is inhibited, and the test

circuitry is enabled to observe and control the I/O boundary of the device. When enabled, the test circuitry

performs boundary scan test operations according to the protocol described in IEEE Standard 1149.1-1990.

and OEBA), latch-enable (LEAB and LEBA),

2 2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

SN54ABT18502, SN74ABT18502

SCAN TEST DEVICES WITH

18-BIT REGISTERED BUS TRANSCEIVERS

SCBS109B – AUGUST 1992 – REVISED JUNE 1993

description (continued)

Four dedicated test pins are used to observe and control the operation of the test circuitry: test data input (TDI),

test data output (TDO), test mode select (TMS), and test clock (TCK). Additionally , the test circuitry can perform

other testing functions such as parallel signature analysis on data inputs and pseudo-random pattern generation

from data outputs. All testing and scan operations are synchronized to the TAP interface.

Additional flexibility is provided in the test mode through the use of two boundary scan cells (BSCs) for each

I/O pin. This allows independent test data to be captured and forced at either bus (A or B). A PSA/COUNT

instruction is also included to ease the testing of memories and other circuits where a binary count addressing

scheme is useful.

The SN54ABT18502 is characterized for operation over the full military temperature range of –55°C to 125°C.

The SN74ABT18502 is characterized for operation from –40°C to 85°C.

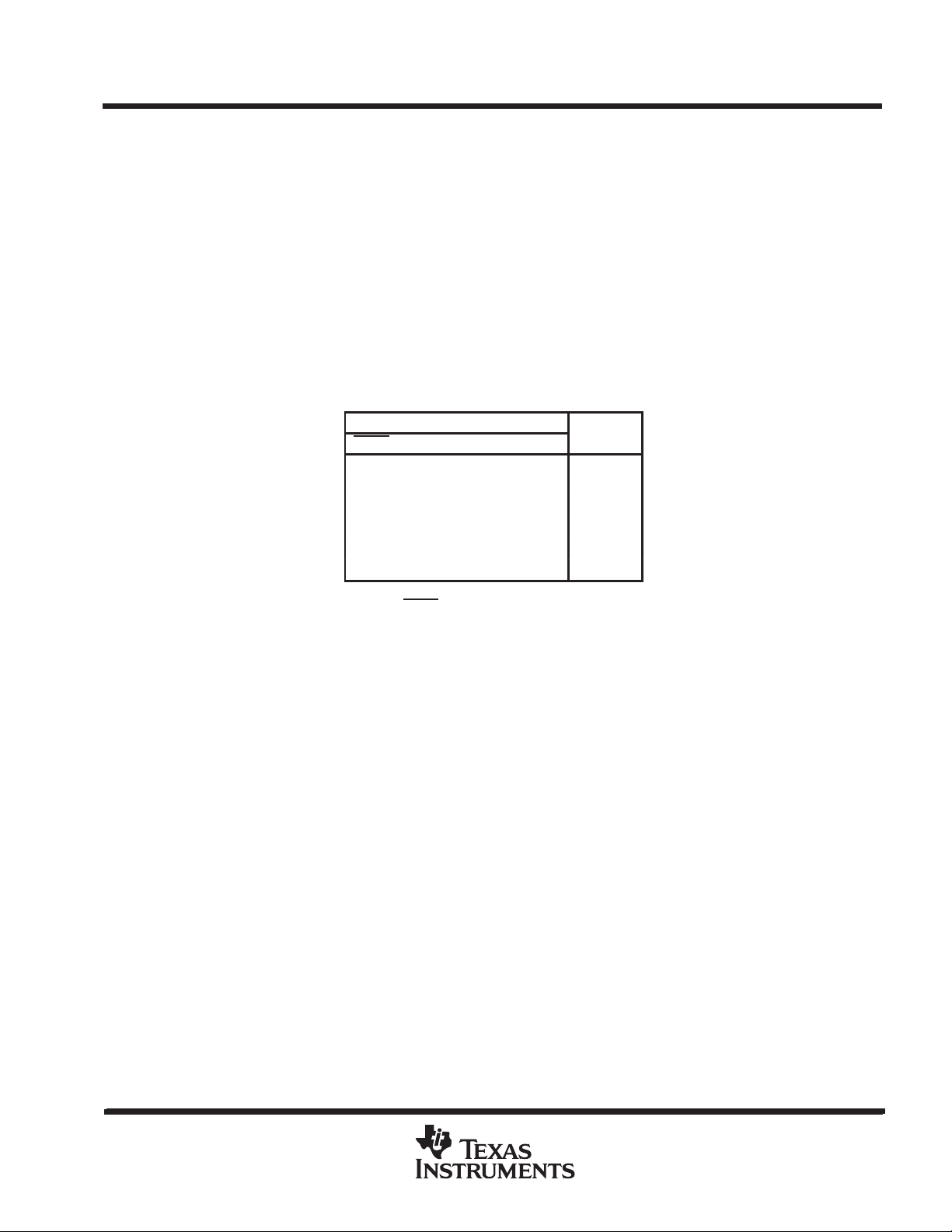

FUNCTION TABLE

(normal mode, each register)

INPUTS

OEAB LEAB CLKAB A

L L L X B

L L ↑ LL

L L ↑ HH

L HXLL

L HXHH

H X X X Z

†

A-to-B data flow is shown. B-to-A data flow is similar

but uses OEBA

‡

Output level before the indicated steady-state input

conditions were established.

, LEBA, and CLKBA.

†

OUTPUT

B

‡

0

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

SN54ABT18502, SN74ABT18502

SCAN TEST DEVICES WITH

18-BIT REGISTERED BUS TRANSCEIVERS

SCBS109B – AUGUST 1992 – REVISED JUNE 1993

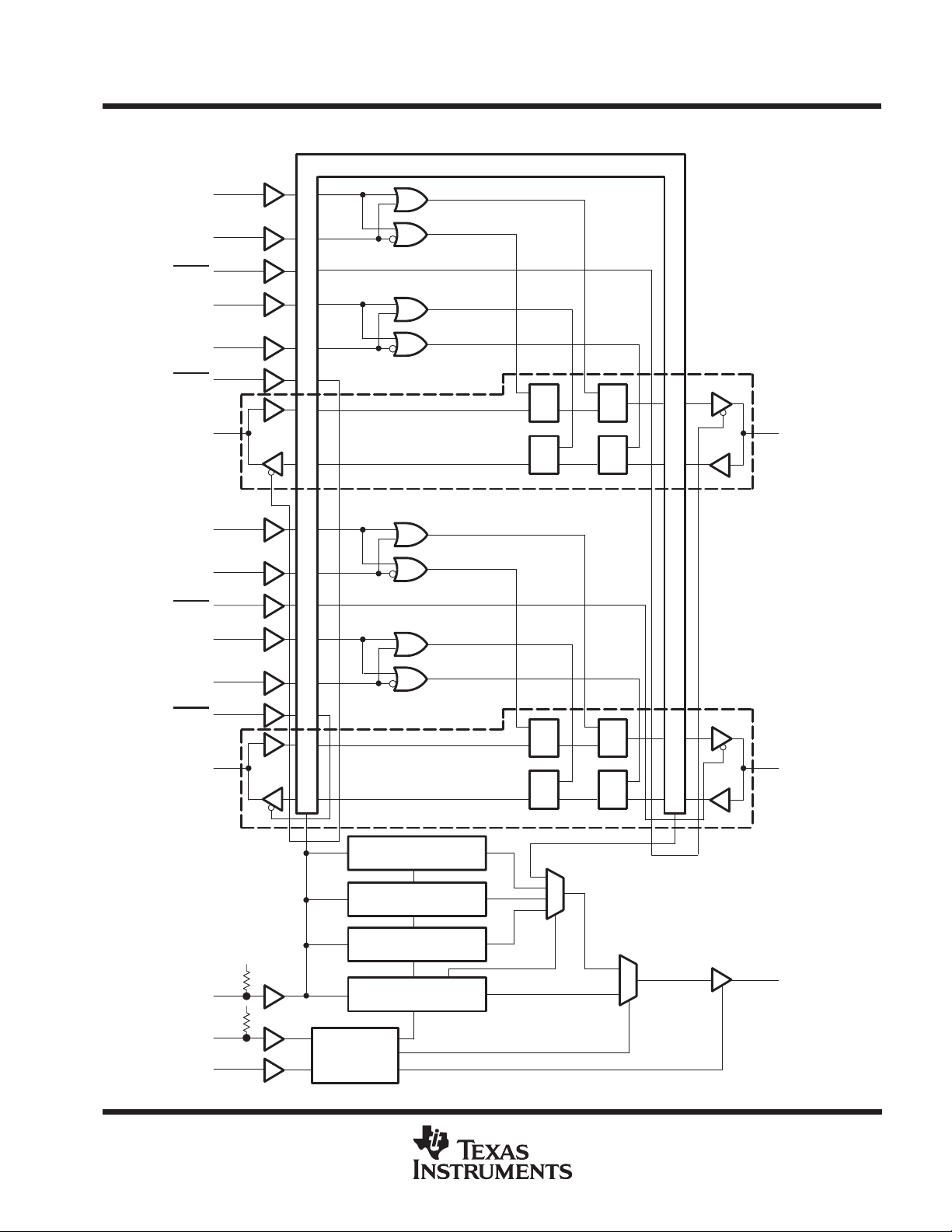

functional block diagram

Boundary-Scan Register

1LEAB

60

1CLKAB

1OEAB

1LEBA

1CLKBA

1OEBA

1A1

2LEAB

2CLKAB

2OEAB

2LEBA

2CLKBA

2OEBA

2A1

59

62

54

55

53

63

22

23

21

28

27

30

10

One of Nine Channels

One of Nine Channels

C1

1D

C1

1D

1D

1D

C1

C1

C1

1D

C1

1D

C1

1D

C1

1D

51

40

1B1

2B1

V

CC

24

TDI

V

CC

56

TMS

26

TCK

Pin numbers shown are for the PM package.

4 4

Controller

Bypass Register

Boundary-Control

Register

Identification

Register

Instruction

Register

TAP

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

58

TDO

18-BIT REGISTERED BUS TRANSCEIVERS

Terminal Functions

PIN NAME DESCRIPTION

GND Ground

TCK

TDI

TDO

TMS

V

CC

1A1–1A9,

2A1–2A9

1B1–1B9,

2B1–2B9

1CLKAB, 1CLKBA,

2CLKAB, 2CLKBA

1LEAB, 1LEBA,

2LEAB, 2LEBA

1OEAB, 1OEBA,

, 2OEBA

2OEAB

Test clock. One of four pins required by IEEE Standard 1149.1-1990. Test operations of the device are synchronous to

the test clock. Data is captured on the rising edge of TCK and outputs change on the falling edge of TCK.

T est data input. One of four pins required by IEEE Standard 1 149.1-1990. The test data input is the serial input for shifting

data through the instruction register or selected data register. An internal pullup forces TDI to a high level if left

unconnected.

Test data output. One of four pins required by IEEE Standard 1149.1-1990. The test data output is the serial output for

shifting data through the instruction register or selected data register.

T est mode select. One of four pins required by IEEE Standard 1 149.1-1990. The test mode select input directs the device

through its test access port (TAP) controller states. An internal pullup forces TMS to a high level if left unconnected.

Supply voltage

Normal-function A-bus I/O ports. See function table for normal-mode logic.

Normal-function B-bus I/O ports. See function table for normal-mode logic.

Normal-function clock inputs. See function table for normal-mode logic.

Normal-function latch enables. See function table for normal-mode logic.

Normal-function output enables. See function table for normal-mode logic.

SN54ABT18502, SN74ABT18502

SCAN TEST DEVICES WITH

SCBS109B – AUGUST 1992 – REVISED JUNE 1993

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

SN54ABT18502, SN74ABT18502

SCAN TEST DEVICES WITH

18-BIT REGISTERED BUS TRANSCEIVERS

SCBS109B – AUGUST 1992 – REVISED JUNE 1993

test architecture

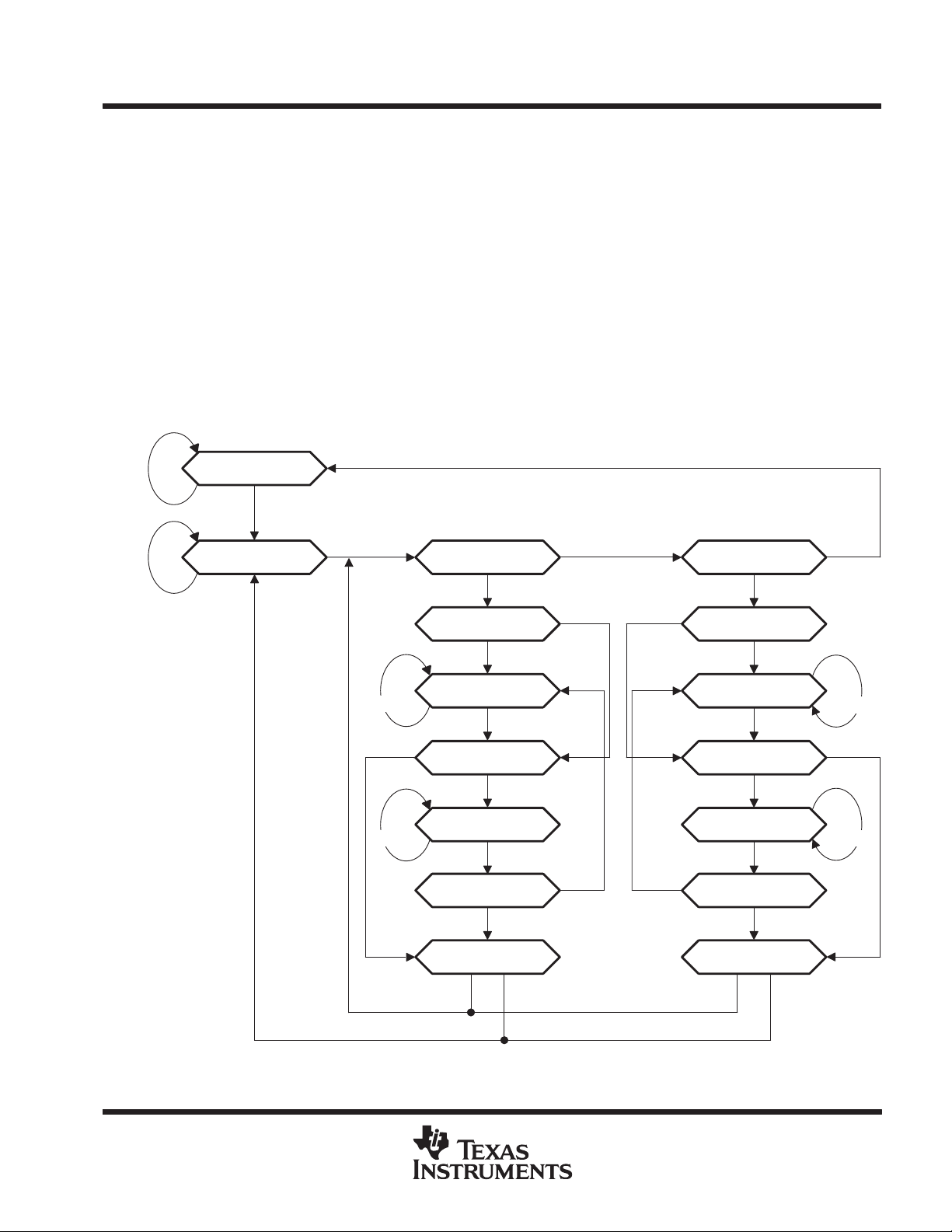

Serial test information is conveyed by means of a 4-wire test bus or test access port (T AP), that conforms to IEEE

Standard 1 149.1-1990. Test instructions, test data, and test control signals are all passed along this serial test

bus. The T AP controller monitors two signals from the test bus, namely TCK and TMS. The function of the T AP

controller is to extract the synchronization (TCK) and state control (TMS) signals from the test bus and generate

the appropriate on-chip control signals for the test structures in the device. Figure 1 shows the T AP controller

state diagram.

The T AP controller is fully synchronous to the TCK signal. Input data is captured on the rising edge of TCK and

output data changes on the falling edge of TCK. This scheme ensures that data to be captured is valid for fully

one-half of the TCK cycle.

The functional block diagram illustrates the IEEE Standard 1149.1-1990 4-wire test bus and boundary-scan

architecture and the relationship between the test bus, the T AP controller , and the test registers. As illustrated,

the device contains an 8-bit instruction register and four test data registers: an 84-bit boundary-scan register,

a 21-bit boundary-control register, a 1-bit bypass register, and a 32-bit device identification register.

Test-Logic-Reset

TMS = H

TMS = L

TMS = L

Run-Test/Idle Select-DR-Scan

TMS = L

Capture-DR

TMS = L

Shift-DR

TMS = L

TMS = H

TMS = H

Exit1-DR

TMS = L

Pause-DR

TMS = L

TMS = H

Exit2-DR

TMS = H

TMS = HTMS = H

TMS = H TMS = H

TMS = L

TMS = L

Select-IR-Scan

TMS = H

TMS = L

Capture-IR

TMS = L

Shift-IR

TMS = L

TMS = H

TMS = H

Exit1-IR

TMS = L

Pause-IR

TMS = L

TMS = H

Exit2-IR

TMS = H

Update-DR

TMS = LTMS = H

Update-IR

TMS = LTMS = H

Figure 1. TAP Controller State Diagram

6 6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

SN54ABT18502, SN74ABT18502

SCAN TEST DEVICES WITH

18-BIT REGISTERED BUS TRANSCEIVERS

SCBS109B – AUGUST 1992 – REVISED JUNE 1993

state diagram description

The test access port (TAP) controller is a synchronous finite state machine that provides test control signals

throughout the device. The state diagram is illustrated in Figure 1 and is in accordance with IEEE Standard

1149.1-1990. The TAP controller proceeds through its states based on the level of TMS at the rising edge of

TCK.

As illustrated, the T AP controller consists of sixteen states. There are six stable states (indicated by a looping

arrow in the state diagram) and ten unstable states. A stable state is defined as a state the T AP controller can

retain for consecutive TCK cycles. Any state that does not meet this criterion is an unstable state.

There are two main paths though the state diagram: one to access and control the selected data register and

one to access and control the instruction register. Only one register can be accessed at a time.

Test-Logic-Reset

The device powers up in the Test-Logic-Reset state. In the stable Test-Logic-Reset state, the test logic is reset

and is disabled so that the normal logic function of the device is performed. The instruction register is reset to

an opcode that selects the optional IDCODE instruction, if supported, or the BYP ASS instruction. Certain data

registers may also be reset to their power-up values.

The state machine is constructed such that the T AP controller returns to the Test-Logic-Reset state in no more

than five TCK cycles if TMS is left high. The TMS pin has an internal pullup resistor that forces it high if left

unconnected or if a board defect causes it to be open circuited.

For the ′ABT18502, the instruction register is reset to the binary value 10000001, which selects the IDCODE

instruction. Each bit in the boundary-scan register is reset to logic 0 except bits 83–80, which are reset to logic 1.

The boundary-control register is reset to the binary value 000000000000000000010, which selects the PSA test

operation with no input masking.

Run-Test/Idle

The T AP controller must pass through the Run-T est/Idle state (from T est-Logic-Reset) before executing any test

operations. The Run-Test/Idle state can also be entered following data register or instruction register scans.

Run-Test/Idle is provided as a stable state in which the test logic may be actively running a test or can be idle.

The test operations selected by the boundary-control register are performed while the T AP controller is in the

Run-Test/Idle state.

Select-DR-Scan, Select-lR-Scan

No specific function is performed in the Select-DR-Scan and Select-lR-Scan states, and the T AP controller exits

either of these states on the next TCK cycle. These states are provided to allow the selection of either data

register scan or instruction register scan.

Capture-DR

When a data register scan is selected, the TAP controller must pass through the Capture-DR state. In the

Capture-DR state, the selected data register can capture a data value as specified by the current instruction.

Such capture operations occur on the rising edge of TCK upon which the T AP controller exits the Capture-DR

state.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

SN54ABT18502, SN74ABT18502

SCAN TEST DEVICES WITH

18-BIT REGISTERED BUS TRANSCEIVERS

SCBS109B – AUGUST 1992 – REVISED JUNE 1993

state diagram description (continued)

Shift-DR

Upon entry to the Shift-DR state, the data register is placed in the scan path between TDI and TDO and, on the

first falling edge of TCK, TDO goes from the high-impedance state to an active state. TDO enables to the logic

level present in the least significant bit of the selected data register.

While in the stable Shift-DR state, data is serially shifted through the selected data register on each TCK cycle.

The first shift occurs on the first rising edge of TCK after entry to the Shift-DR state (i.e., no shifting occurs during

the TCK cycle in which the T AP controller changes from Capture-DR to Shift-DR or from Exit2-DR to Shift-DR).

The last shift occurs on the rising edge of TCK upon which the TAP controller exits the Shift-DR state.

Exit1-DR, Exit2-DR

The Exit1-DR and Exit2-DR states are temporary states used to end a data register scan. It is possible to return

to the Shift-DR state from either Exit1-DR or Exit2-DR without recapturing the data register.

On the first falling edge of TCK after entry to Exit1-DR, TDO goes from the active state to the high-impedance

state.

Pause-DR

No specific function is performed in the stable Pause-DR state, in which the TAP controller can remain

indefinitely. The Pause-DR state provides the capability of suspending and resuming data register scan

operations without loss of data.

Update-DR

If the current instruction calls for the selected data register to be updated with current data, such update occurs

on the falling edge of TCK following entry to the Update-DR state.

Capture-IR

When an instruction register scan is selected, the T AP controller must pass through the Capture-IR state. In the

Capture-IR state, the instruction register captures its current status value. This capture operation occurs on the

rising edge of TCK upon which the TAP controller exits the Capture-IR state.

For the ′ABT18502, the status value loaded in the Capture-IR state is the fixed binary value 10000001.

Shift-IR

Upon entry to the Shift-IR state, the instruction register is placed in the scan path between TDI and TDO and,

on the first falling edge of TCK, TDO goes from the high-impedance state to an active state. TDO enables to

the logic level present in the least significant bit of the instruction register.

While in the stable Shift-IR state, instruction data is serially shifted through the instruction register on each TCK

cycle. The first shift occurs on the first rising edge of TCK after entry to the Shift-IR state (i.e., no shifting occurs

during the TCK cycle in which the TAP controller changes from Capture-IR to Shift-IR or from Exit2-IR to

Shift-IR). The last shift occurs on the rising edge of TCK upon which the T AP controller exits the Shift-IR state.

Exit1-IR, Exit2-IR

The Exit1-IR and Exit2-IR states are temporary states used to end an instruction register scan. It is possible to

return to the Shift-IR state from either Exit1-IR or Exit2-IR without recapturing the instruction register.

On the first falling edge of TCK after entry to Exit1-IR, TDO goes from the active state to the high-impedance

state.

8 8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

SN54ABT18502, SN74ABT18502

SCAN TEST DEVICES WITH

18-BIT REGISTERED BUS TRANSCEIVERS

SCBS109B – AUGUST 1992 – REVISED JUNE 1993

state diagram description (continued)

Pause-IR

No specific function is performed in the stable Pause-IR state, in which the T AP controller can remain indefinitely.

The Pause-IR state provides the capability of suspending and resuming instruction register scan operations

without loss of data.

Update-IR

The current instruction is updated and takes effect on the falling edge of TCK following entry to the Update-IR

state.

register overview

With the exception of the bypass and device identification registers, any test register can be thought of as a serial

shift register with a shadow latch on each bit. The bypass and device identification registers differ in that they

contain only a shift register. During the appropriate capture state (Capture-IR for instruction register,

Capture-DR for data registers), the shift register may be parallel loaded from a source specified by the current

instruction. During the appropriate shift state (Shift-IR or Shift-DR), the contents of the shift register are shifted

out from TDO while new contents are shifted in at TDI. During the appropriate update state (Update-IR or

Update-DR), the shadow latches are updated from the shift register.

instruction register description

The instruction register (IR) is eight bits long and is used to tell the device what instruction is to be executed.

Information contained in the instruction includes the mode of operation (either normal mode, in which the device

performs its normal logic function, or test mode, in which the normal logic function is inhibited or altered), the

test operation to be performed, which of the four data registers is to be selected for inclusion in the scan path

during data register scans, and the source of data to be captured into the selected data register during

Capture-DR.

Table 4 lists the instructions supported by the ′ABT18502. The even-parity feature specified for SCOPE

devices is supported in this device. Bit 7 of the instruction opcode is the parity bit. Any instructions that are

defined for SCOPE devices but are not supported by this device default to BYPASS.

During Capture-IR, the IR captures the binary value 10000001. As an instruction is shifted in, this value will be

shifted out via TDO and can be inspected as verification that the IR is in the scan path. During Update-IR, the

value that has been shifted into the IR is loaded into shadow latches. At this time, the current instruction is

updated and any specified mode change takes effect. At power up or in the Test-Logic-Reset state, the IR is

reset to the binary value 10000001, which selects the IDCODE instruction.

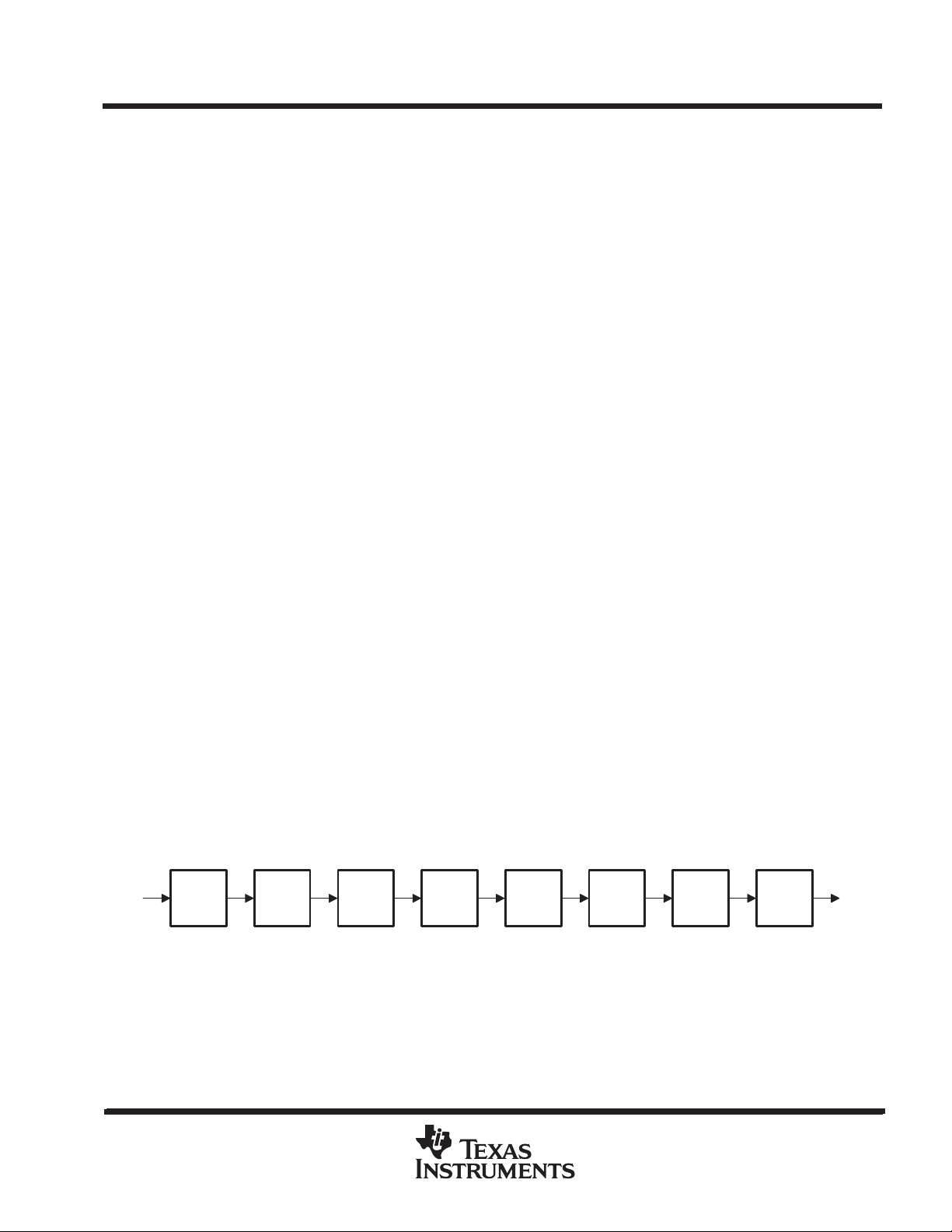

The instruction register order of scan is illustrated in Figure 2.

Bit 7

Parity

(MSB)

Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1

Figure 2. Instruction Register Order of Scan

Bit 0

(LSB)

TDOTDI

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

9

Loading...

Loading...