Page 1

SM320F28335-HT

Digital Signal Controller (DSC)

Data Manual

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Literature Number: SPRS682

December 2010

Page 2

SM320F28335-HT

SPRS682–DECEMBER 2010

www.ti.com

Contents

1 SM320F28335 DSC ............................................................................................................. 10

1.1 Features .................................................................................................................... 10

1.2 SUPPORTS EXTREME TEMPERATURE APPLICATIONS ......................................................... 11

2 Introduction ...................................................................................................................... 12

2.1 Pin Assignments ........................................................................................................... 13

2.2 Signal Descriptions ........................................................................................................ 18

3 Functional Overview .......................................................................................................... 26

3.1 Memory Maps .............................................................................................................. 27

3.2 Brief Descriptions .......................................................................................................... 31

3.2.1 C28x CPU ....................................................................................................... 31

3.2.2 Memory Bus (Harvard Bus Architecture) .................................................................... 31

3.2.3 Peripheral Bus .................................................................................................. 31

3.2.4 Real-Time JTAG and Analysis ................................................................................ 32

3.2.5 External Interface (XINTF) .................................................................................... 32

3.2.6 Flash ............................................................................................................. 32

3.2.7 M0, M1 SARAMs ............................................................................................... 32

3.2.8 L0, L1, L2, L3, L4, L5, L6, L7 SARAMs ..................................................................... 32

3.2.9 Boot ROM ....................................................................................................... 33

3.2.10 Security .......................................................................................................... 33

3.2.11 Peripheral Interrupt Expansion (PIE) Block ................................................................. 34

3.2.12 External Interrupts (XINT1-XINT7, XNMI) ................................................................... 35

3.2.13 Oscillator and PLL .............................................................................................. 35

3.2.14 Watchdog ........................................................................................................ 35

3.2.15 Peripheral Clocking ............................................................................................. 35

3.2.16 Low-Power Modes .............................................................................................. 35

3.2.17 Peripheral Frames 0, 1, 2, 3 (PFn) ........................................................................... 36

3.2.18 General-Purpose Input/Output (GPIO) Multiplexer ......................................................... 36

3.2.19 32-Bit CPU-Timers (0, 1, 2) ................................................................................... 36

3.2.20 Control Peripherals ............................................................................................. 37

3.2.21 Serial Port Peripherals ......................................................................................... 37

3.3 Register Map ............................................................................................................... 38

3.4 Device Emulation Registers .............................................................................................. 39

3.5 Interrupts .................................................................................................................... 40

3.5.1 External Interrupts .............................................................................................. 44

3.6 System Control ............................................................................................................ 44

3.6.1 OSC and PLL Block ............................................................................................ 46

3.6.1.1 External Reference Oscillator Clock Option .................................................... 47

3.6.1.2 PLL-Based Clock Module ......................................................................... 47

3.6.1.3 Loss of Input Clock ................................................................................ 49

3.6.2 Watchdog Block ................................................................................................. 49

3.7 Low-Power Modes Block ................................................................................................. 50

4 Peripherals ....................................................................................................................... 51

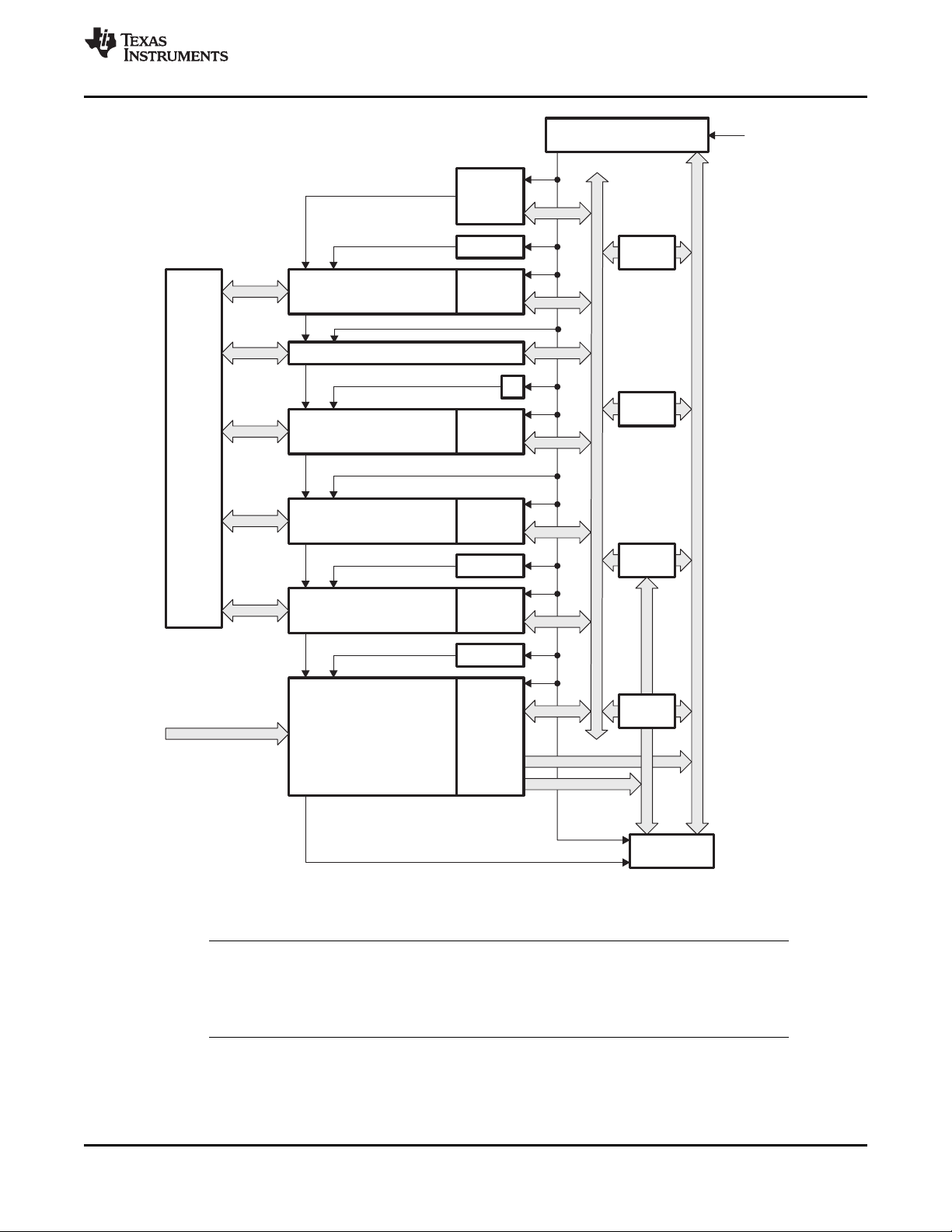

4.1 DMA Overview ............................................................................................................. 51

4.2 32-Bit CPU-Timers 0/1/2 ................................................................................................. 53

4.3 Enhanced PWM Modules (ePWM1/2/3/4/5/6) ......................................................................... 55

2 Contents Copyright © 2010, Texas Instruments Incorporated

Page 3

SM320F28335-HT

www.ti.com

4.4 High-Resolution PWM (HRPWM) ....................................................................................... 59

4.5 Enhanced CAP Modules (eCAP1/2/3/4/5/6) ........................................................................... 59

4.6 Enhanced QEP Modules (eQEP1/2) .................................................................................... 62

4.7 Analog-to-Digital Converter (ADC) Module ............................................................................ 64

4.7.1 ADC Connections if the ADC Is Not Used .................................................................. 67

4.7.2 ADC Registers .................................................................................................. 67

4.7.3 ADC Calibration ................................................................................................. 68

4.8 Multichannel Buffered Serial Port (McBSP) Module .................................................................. 69

4.9 Enhanced Controller Area Network (eCAN) Modules (eCAN-A and eCAN-B) .................................... 72

4.10 Serial Communications Interface (SCI) Modules (SCI-A, SCI-B, SCI-C) .......................................... 77

4.11 Serial Peripheral Interface (SPI) Module (SPI-A) ..................................................................... 80

4.12 Inter-Integrated Circuit (I2C) ............................................................................................. 83

4.13 GPIO MUX ................................................................................................................. 84

4.14 External Interface (XINTF) ............................................................................................... 91

SPRS682–DECEMBER 2010

5 Device Support ................................................................................................................. 93

6 Electrical Specifications ..................................................................................................... 93

6.1 Absolute Maximum Ratings .............................................................................................. 93

6.2 Recommended Operating Conditions .................................................................................. 95

6.3 Electrical Characteristics ................................................................................................. 95

6.4 Current Consumption ..................................................................................................... 96

6.4.1 Reducing Current Consumption .............................................................................. 98

6.4.2 Current Consumption Graphs ................................................................................. 99

6.4.3 Thermal Design Considerations ............................................................................. 100

6.5 Emulator Connection Without Signal Buffering for the DSP ....................................................... 100

6.6 Timing Parameter Symbology .......................................................................................... 102

6.6.1 General Notes on Timing Parameters ...................................................................... 102

6.6.2 Test Load Circuit .............................................................................................. 102

6.6.3 Device Clock Table ........................................................................................... 102

6.7 Clock Requirements and Characteristics ............................................................................. 104

6.8 Power Sequencing ....................................................................................................... 105

6.8.1 Power Management and Supervisory Circuit Solutions .................................................. 105

6.9 General-Purpose Input/Output (GPIO) ................................................................................ 108

6.9.1 GPIO - Output Timing ........................................................................................ 108

6.9.2 GPIO - Input Timing .......................................................................................... 109

6.9.3 Sampling Window Width for Input Signals ................................................................. 110

6.9.4 Low-Power Mode Wakeup Timing .......................................................................... 111

6.10 Enhanced Control Peripherals ......................................................................................... 115

6.10.1 Enhanced Pulse Width Modulator (ePWM) Timing ....................................................... 115

6.10.2 Trip-Zone Input Timing ....................................................................................... 115

6.11 External Interrupt Timing ................................................................................................ 117

6.12 I2C Electrical Specification and Timing ............................................................................... 118

6.13 Serial Peripheral Interface (SPI) Timing .............................................................................. 118

6.13.1 Master Mode Timing .......................................................................................... 118

6.13.2 SPI Slave Mode Timing ...................................................................................... 122

6.14 External Interface (XINTF) Timing ..................................................................................... 125

6.14.1 USEREADY = 0 ............................................................................................... 125

6.14.2 Synchronous Mode (USEREADY = 1, READYMODE = 0) ............................................. 126

Copyright © 2010, Texas Instruments Incorporated Contents 3

Page 4

SM320F28335-HT

SPRS682–DECEMBER 2010

6.14.3 Asynchronous Mode (USEREADY = 1, READYMODE = 1) ............................................ 126

6.14.4 XINTF Signal Alignment to XCLKOUT ..................................................................... 128

6.14.5 External Interface Read Timing ............................................................................. 129

6.14.6 External Interface Write Timing ............................................................................. 130

6.14.7 External Interface Ready-on-Read Timing With One External Wait State ............................ 132

6.14.8 External Interface Ready-on-Write Timing With One External Wait State ............................. 135

6.14.9 XHOLD and XHOLDA Timing ............................................................................... 138

6.15 On-Chip Analog-to-Digital Converter .................................................................................. 141

6.15.1 ADC Power-Up Control Bit Timing .......................................................................... 142

6.15.2 Definitions ...................................................................................................... 143

6.15.3 Sequential Sampling Mode (Single-Channel) (SMODE = 0) ............................................ 144

6.15.4 Simultaneous Sampling Mode (Dual-Channel) (SMODE = 1) .......................................... 145

6.15.5 Detailed Descriptions ......................................................................................... 146

6.16 Multichannel Buffered Serial Port (McBSP) Timing ................................................................. 147

6.16.1 McBSP Transmit and Receive Timing ...................................................................... 147

6.16.2 McBSP as SPI Master or Slave Timing .................................................................... 149

6.17 Flash Timing .............................................................................................................. 153

www.ti.com

7 Thermal/Mechanical Data .................................................................................................. 155

4 Contents Copyright © 2010, Texas Instruments Incorporated

Page 5

SM320F28335-HT

www.ti.com

SPRS682–DECEMBER 2010

List of Figures

2-1 181-Pin GB........................................................................................................................ 13

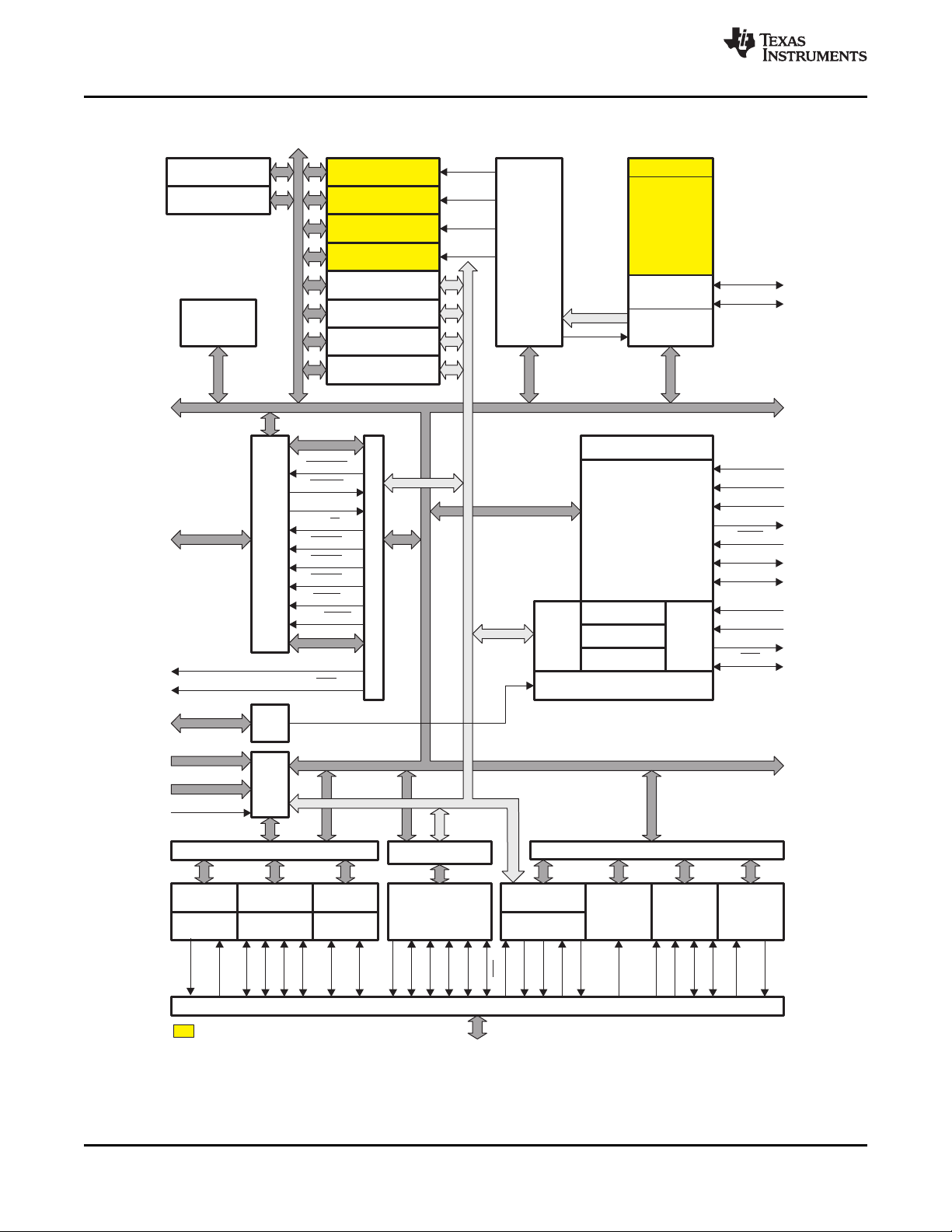

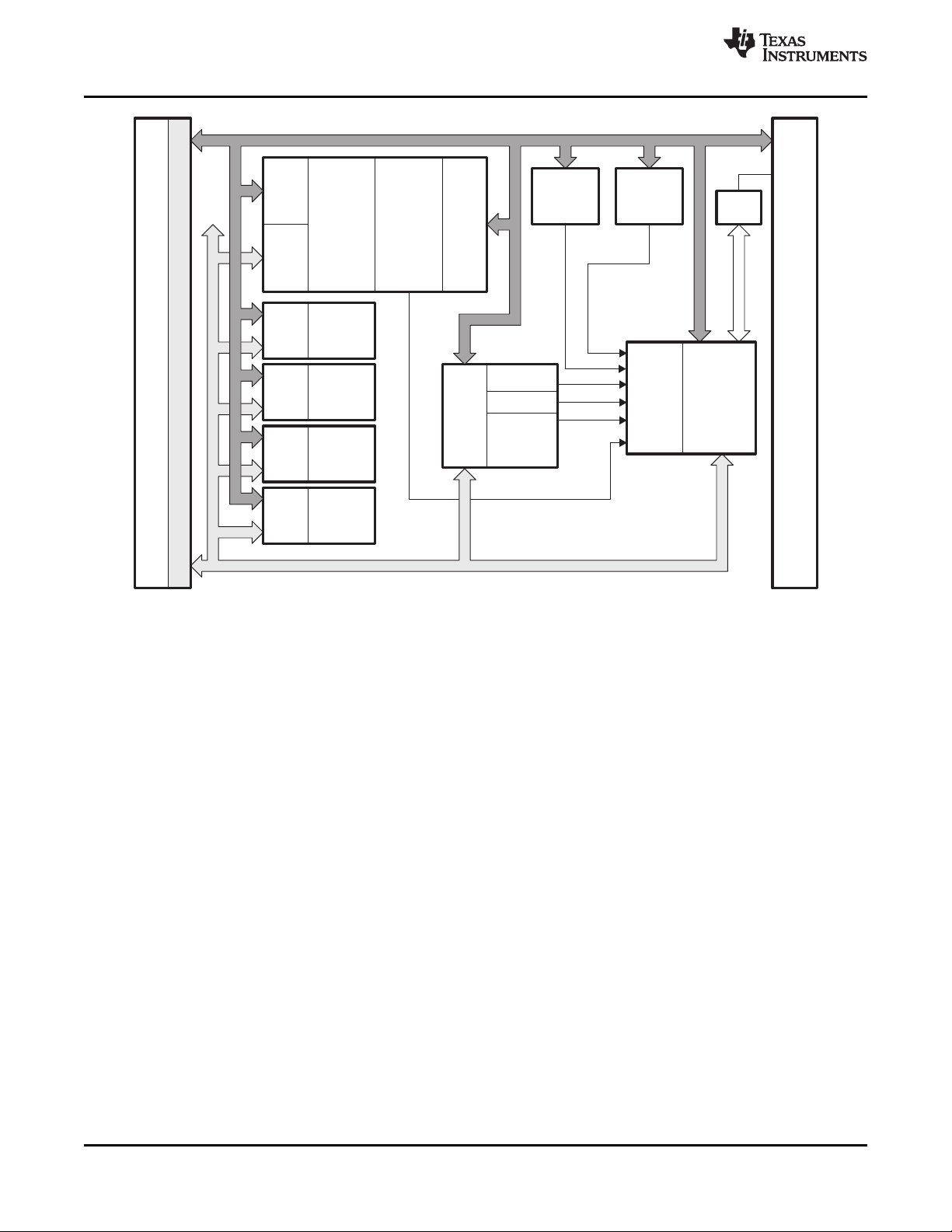

3-1 Functional Block Diagram ...................................................................................................... 26

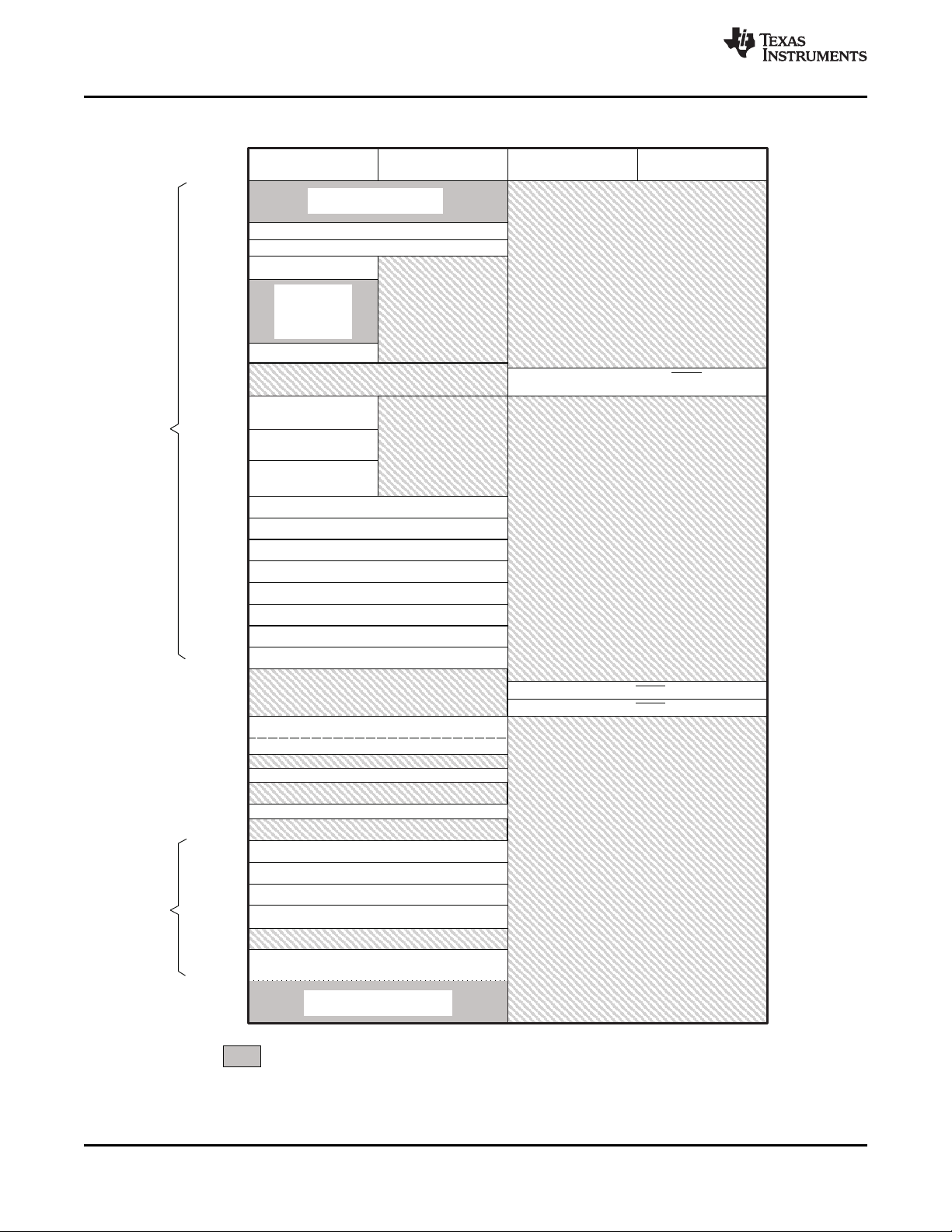

3-2 Memory Map ...................................................................................................................... 28

3-3 External and PIE Interrupt Sources............................................................................................ 41

3-4 External Interrupts................................................................................................................ 41

3-5 Multiplexing of Interrupts Using the PIE Block ............................................................................... 42

3-6 Clock and Reset Domains ...................................................................................................... 45

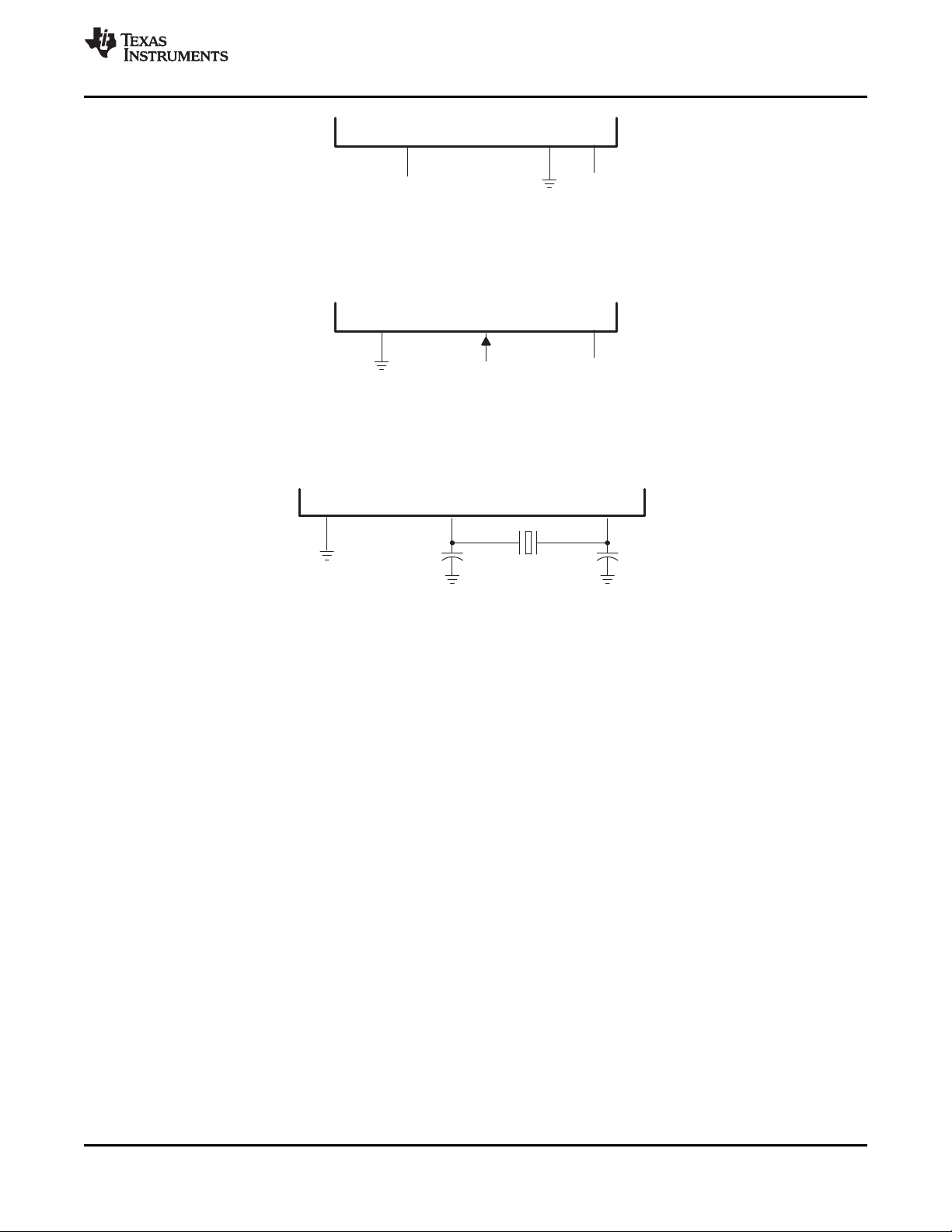

3-7 OSC and PLL Block Diagram................................................................................................... 46

3-8 Using a 3.3-V External Oscillator............................................................................................... 47

3-9 Using a 1.9-V External Oscillator............................................................................................... 47

3-10 Using the Internal Oscillator .................................................................................................... 47

3-11 Watchdog Module................................................................................................................ 49

4-1 DMA Functional Block Diagram ................................................................................................ 52

4-2 CPU-Timers....................................................................................................................... 53

4-3 CPU-Timer Interrupt Signals and Output Signal ............................................................................. 53

4-4 Multiple PWM Modules .......................................................................................................... 55

4-5 ePWM Submodules Showing Critical Internal Signal Interconnections................................................... 58

4-6 eCAP Functional Block Diagram ............................................................................................... 61

4-7 eQEP Functional Block Diagram............................................................................................... 62

4-8 Block Diagram of the ADC Module ............................................................................................ 65

4-9 ADC Pin Connections With Internal Reference .............................................................................. 66

4-10 ADC Pin Connections With External Reference ............................................................................. 67

4-11 McBSP Module .................................................................................................................. 70

4-12 eCAN Block Diagram and Interface Circuit ................................................................................... 73

4-13 eCAN-A Memory Map ........................................................................................................... 74

4-14 eCAN-B Memory Map ........................................................................................................... 75

4-15 Serial Communications Interface (SCI) Module Block Diagram............................................................ 79

4-16 SPI Module Block Diagram (Slave Mode) .................................................................................... 82

4-17 I2C Peripheral Module Interfaces .............................................................................................. 83

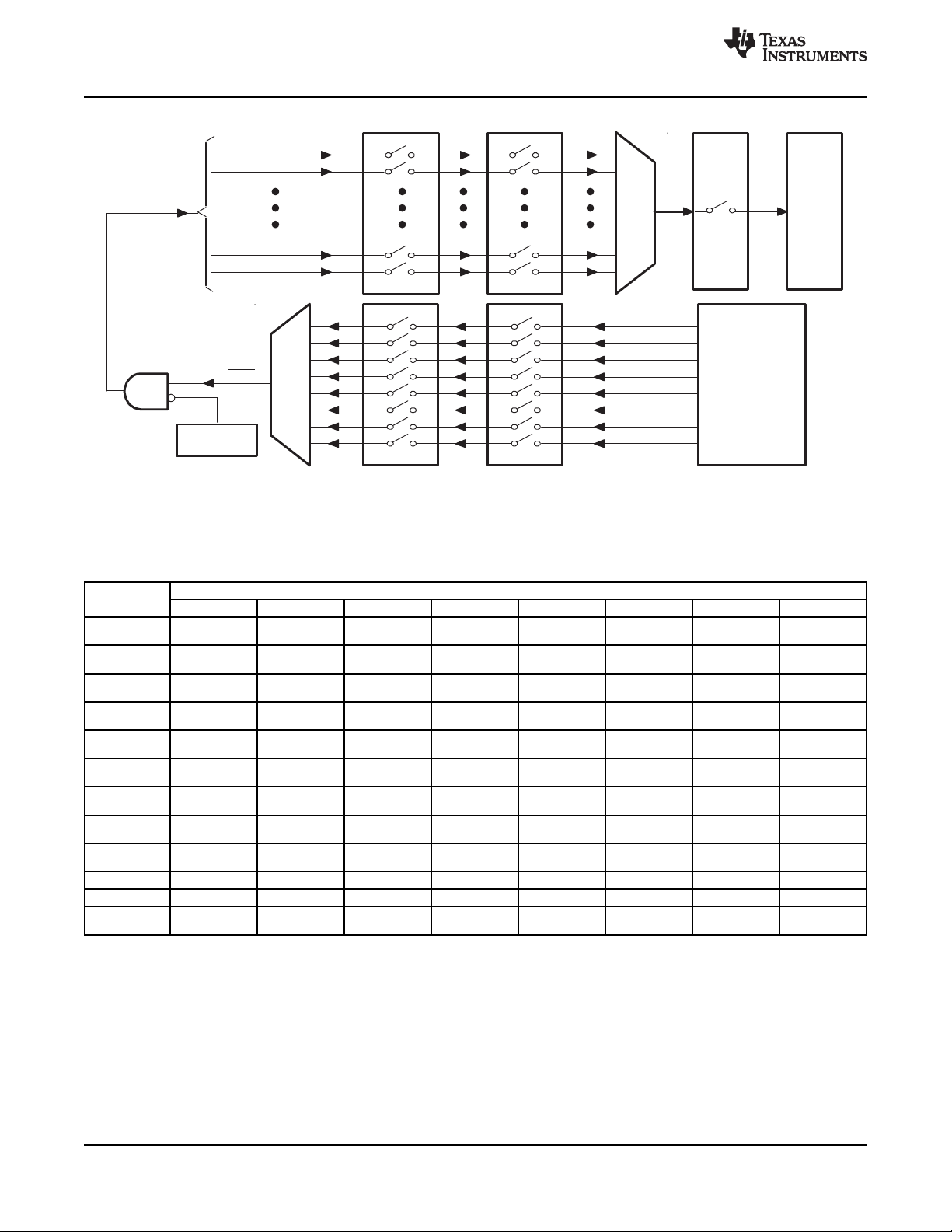

4-18 GPIO MUX Block Diagram...................................................................................................... 85

4-19 Qualification Using Sampling Window......................................................................................... 90

4-20 External Interface Block Diagram .............................................................................................. 91

4-21 Typical 16-bit Data Bus XINTF Connections ................................................................................. 92

4-22 Typical 32-bit Data Bus XINTF Connections ................................................................................. 92

6-1 SM320F28335 Operating Life Derating Chart................................................................................ 94

6-2 Typical Operational Current Versus Frequency for T

6-3 Typical Operational Current Versus Frequency for T

6-4 Emulator Connection Without Signal Buffering for the DSP .............................................................. 101

6-5 3.3-V Test Load Circuit......................................................................................................... 102

6-6 Clock Timing..................................................................................................................... 105

6-7 Power-on Reset................................................................................................................. 106

6-8 Warm Reset ..................................................................................................................... 107

6-9 Example of Effect of Writing Into PLLCR Register ......................................................................... 108

6-10 General-Purpose Output Timing.............................................................................................. 109

6-11 Sampling Mode ................................................................................................................. 109

6-12 General-Purpose Input Timing................................................................................................ 110

6-13 IDLE Entry and Exit Timing.................................................................................................... 111

Copyright © 2010, Texas Instruments Incorporated List of Figures 5

= 25°C ........................................................... 100

A

= 210°C.......................................................... 100

A

Page 6

SM320F28335-HT

SPRS682–DECEMBER 2010

6-14 STANDBY Entry and Exit Timing Diagram.................................................................................. 112

6-15 HALT Wake-Up Using GPIOn................................................................................................. 114

6-16 PWM Hi-Z Characteristics..................................................................................................... 115

6-17 ADCSOCAO or ADCSOCBO Timing ........................................................................................ 117

6-18 External Interrupt Timing....................................................................................................... 117

6-19 SPI Master Mode External Timing (Clock Phase = 0) ..................................................................... 120

6-20 SPI Master Mode External Timing (Clock Phase = 1) ..................................................................... 122

6-21 SPI Slave Mode External Timing (Clock Phase = 0)....................................................................... 124

6-22 SPI Slave Mode External Timing (Clock Phase = 1)....................................................................... 125

6-23 Relationship Between XTIMCLK and SYSCLKOUT ....................................................................... 128

6-24 Example Read Access......................................................................................................... 130

6-25 Example Write Access......................................................................................................... 131

6-26 Example Read With Synchronous XREADY Access ...................................................................... 133

6-27 Example Read With Asynchronous XREADY Access..................................................................... 134

6-28 Write With Synchronous XREADY Access.................................................................................. 136

6-29 Write With Asynchronous XREADY Access ................................................................................ 137

6-30 External Interface Hold Waveform............................................................................................ 139

6-31 XHOLD/XHOLDA Timing Requirements (XCLKOUT = 1/2 XTIMCLK).................................................. 140

6-32 ADC Power-Up Control Bit Timing ........................................................................................... 142

6-33 ADC Analog Input Impedance Model ........................................................................................ 143

6-34 Sequential Sampling Mode (Single-Channel) Timing...................................................................... 144

6-35 Simultaneous Sampling Mode Timing ....................................................................................... 145

6-36 McBSP Receive Timing........................................................................................................ 149

6-37 McBSP Transmit Timing....................................................................................................... 149

6-38 McBSP Timing as SPI Master or Slave: CLKSTP = 10b, CLKXP = 0................................................... 150

6-39 McBSP Timing as SPI Master or Slave: CLKSTP = 11b, CLKXP = 0................................................... 151

6-40 McBSP Timing as SPI Master or Slave: CLKSTP = 10b, CLKXP = 1................................................... 152

6-41 McBSP Timing as SPI Master or Slave: CLKSTP = 11b, CLKXP = 1................................................... 153

www.ti.com

6 List of Figures Copyright © 2010, Texas Instruments Incorporated

Page 7

SM320F28335-HT

www.ti.com

SPRS682–DECEMBER 2010

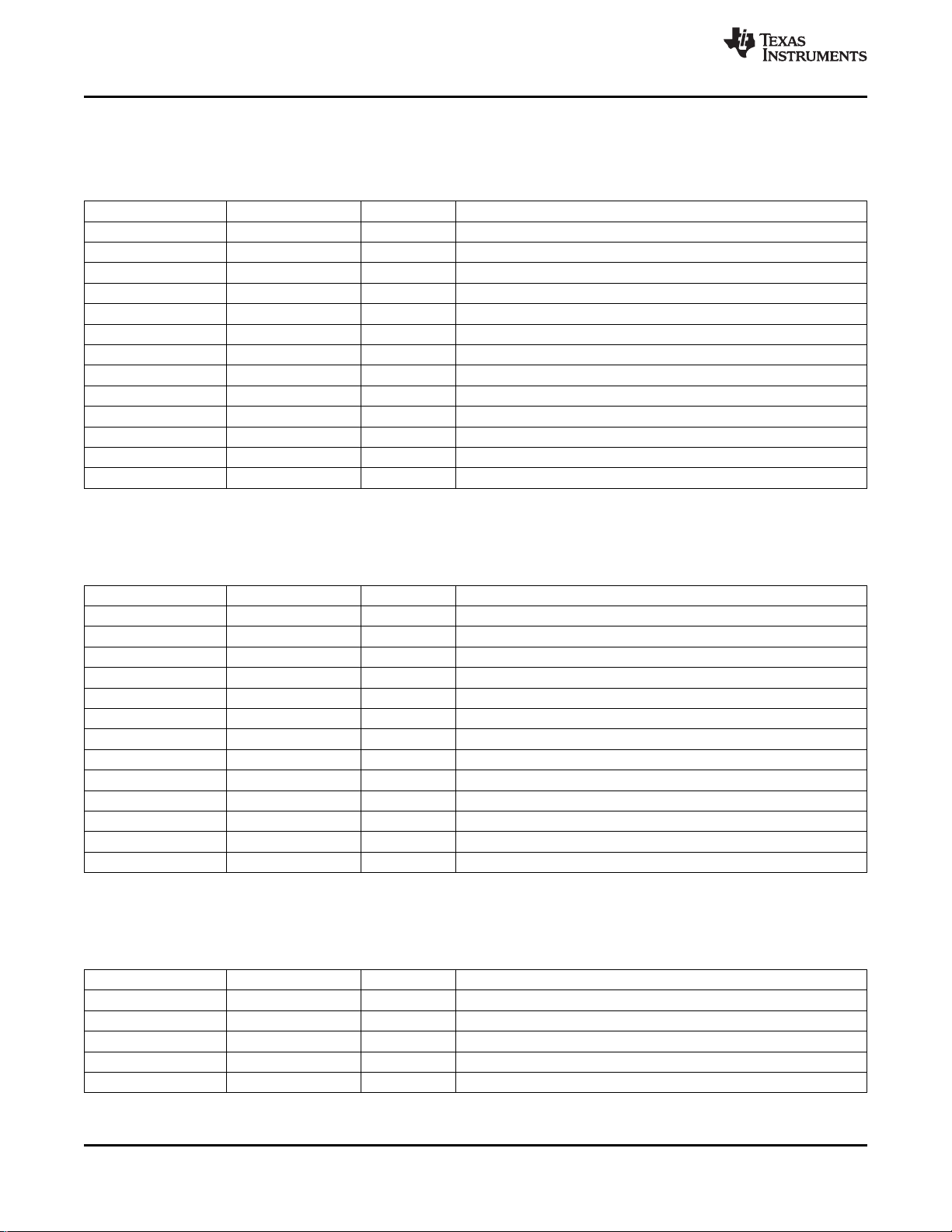

List of Tables

2-1 Hardware Features .............................................................................................................. 12

2-2 Pin Out Information .............................................................................................................. 13

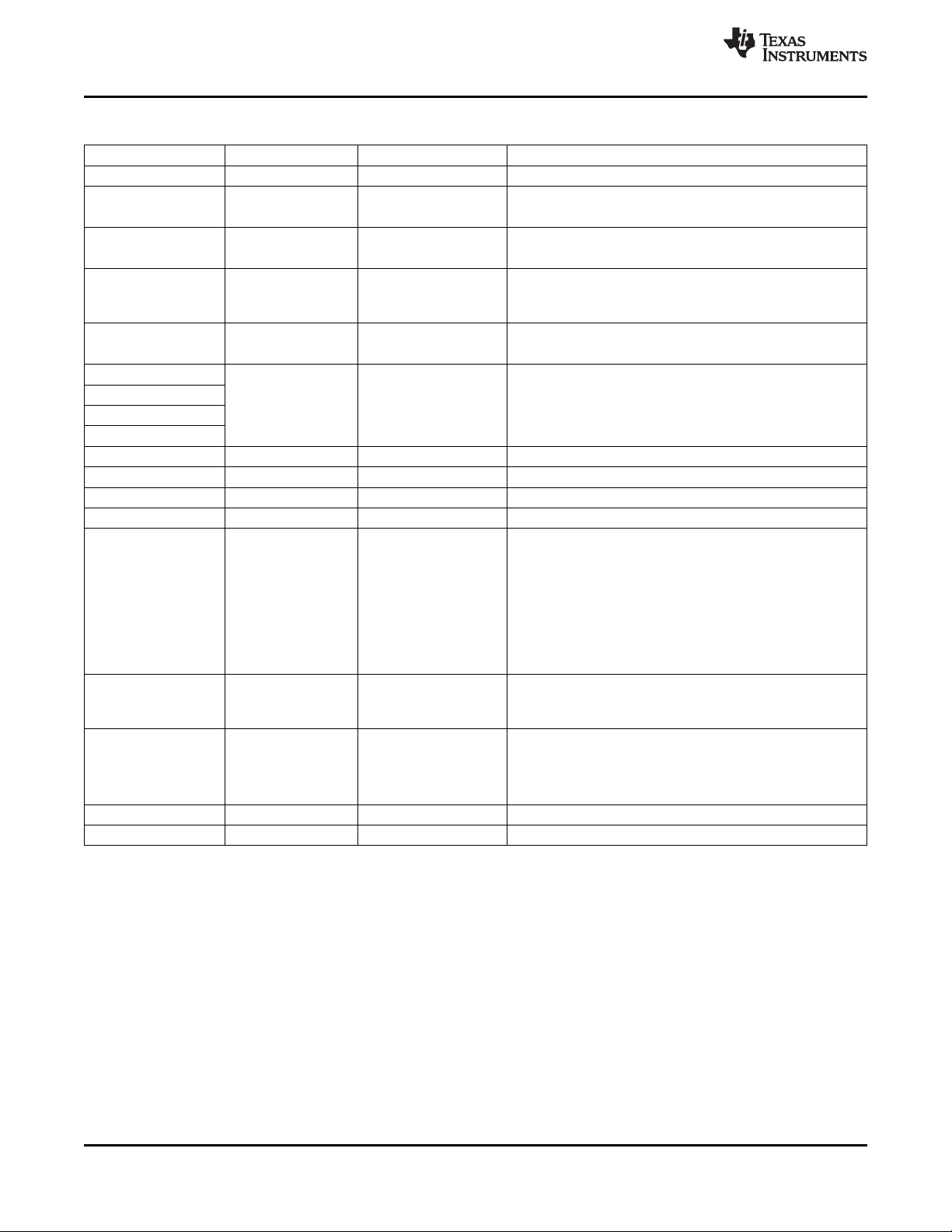

2-3 Signal Descriptions............................................................................................................... 18

3-1 Addresses of Flash Sectors .................................................................................................... 29

3-2 Handling Security Code Locations............................................................................................. 29

3-3 Wait-states ........................................................................................................................ 30

3-4 Boot Mode Selection............................................................................................................. 33

3-5 Peripheral Frame 0 Registers .................................................................................................. 38

3-6 Peripheral Frame 1 Registers .................................................................................................. 38

3-7 Peripheral Frame 2 Registers .................................................................................................. 39

3-8 Peripheral Frame 3 Registers .................................................................................................. 39

3-9 Device Emulation Registers..................................................................................................... 39

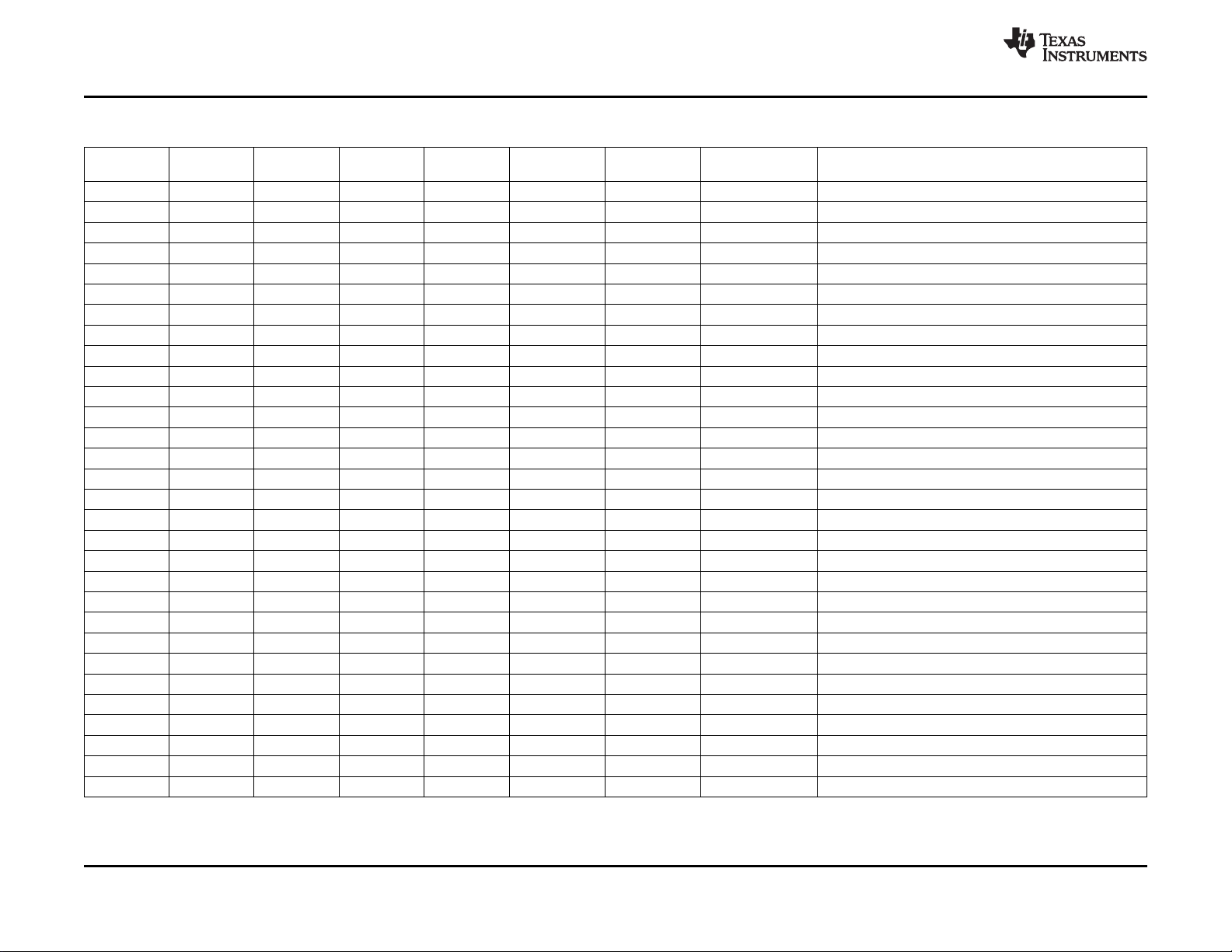

3-10 PIE Peripheral Interrupts ....................................................................................................... 42

3-11 PIE Configuration and Control Registers...................................................................................... 43

3-12 External Interrupt Registers..................................................................................................... 44

3-13 PLL, Clocking, Watchdog, and Low-Power Mode Registers ............................................................... 46

3-14 PLLCR Bit Descriptions ......................................................................................................... 48

3-15 CLKIN Divide Options ........................................................................................................... 48

3-16 Possible PLL Configuration Modes ............................................................................................ 48

3-17 Low-Power Modes ............................................................................................................... 50

4-1 CPU-Timers 0, 1, 2 Configuration and Control Registers................................................................... 54

4-2 ePWM Control and Status Registers (default configuration in PF1)....................................................... 56

4-3 ePWM Control and Status Registers (remapped configuration in PF3 - DMA accessible)............................. 57

4-4 eCAP Control and Status Registers ........................................................................................... 61

4-5 eQEP Control and Status Registers ........................................................................................... 63

4-6 ADC Registers ................................................................................................................... 67

4-7 McBSP Register Summary...................................................................................................... 71

4-8 3.3-V eCAN Transceivers ...................................................................................................... 73

4-9 CAN Register Map .............................................................................................................. 76

4-10 SCI-A Registers .................................................................................................................. 78

4-11 SCI-B Registers .................................................................................................................. 78

4-12 SCI-C Registers ................................................................................................................. 78

4-13 SPI-A Registers................................................................................................................... 81

4-14 I2C-A Registers................................................................................................................... 84

4-15 GPIO Registers .................................................................................................................. 86

4-16 GPIO-A Mux Peripheral Selection Matrix .................................................................................... 87

4-17 GPIO-B Mux Peripheral Selection Matrix .................................................................................... 88

4-18 GPIO-C Mux Peripheral Selection Matrix .................................................................................... 89

4-19 XINTF Configuration and Control Register Mapping ........................................................................ 92

6-1 Current Consumption by Power Supply Pins................................................................................. 96

6-2 Typical Current Consumption by Various Peripherals (at 150 MHz) ..................................................... 98

6-3 Clocking Nomenclature for T

6-4 Clocking Nomenclature for T

6-5 Input Clock Frequency ......................................................................................................... 104

6-6 XCLKIN Timing Requirements - PLL Enabled ............................................................................. 104

6-7 XCLKIN Timing Requirements - PLL Disabled ............................................................................. 104

6-8 XCLKOUT Switching Characteristics (PLL Bypassed or Enabled) ...................................................... 104

Copyright © 2010, Texas Instruments Incorporated List of Tables 7

= -55°C to 125°C (150-MHz Devices) ................................................... 103

C

= 210°C (100-MHz Devices) .............................................................. 103

C

Page 8

SM320F28335-HT

SPRS682–DECEMBER 2010

6-9 Power Management and Supervisory Circuit Solutions ................................................................... 105

6-10 Reset (XRS) Timing Requirements .......................................................................................... 107

6-11 General-Purpose Output Switching Characteristics........................................................................ 108

6-12 General-Purpose Input Timing Requirements .............................................................................. 109

6-13 IDLE Mode Timing Requirements ........................................................................................... 111

6-14 IDLE Mode Switching Characteristics ....................................................................................... 111

6-15 STANDBY Mode Timing Requirements ..................................................................................... 111

6-16 STANDBY Mode Switching Characteristics ................................................................................ 112

6-17 HALT Mode Timing Requirements ........................................................................................... 113

6-18 HALT Mode Switching Characteristics ...................................................................................... 113

6-19 ePWM Timing Requirements ................................................................................................. 115

6-20 ePWM Switching Characteristics ............................................................................................ 115

6-21 Trip-Zone input Timing Requirements ....................................................................................... 115

6-22 High Resolution PWM Characteristics at SYSCLKOUT = (60 - 120 MHz).............................................. 116

6-23 Enhanced Capture (eCAP) Timing Requirement .......................................................................... 116

6-24 eCAP Switching Characteristics ............................................................................................. 116

6-25 Enhanced Quadrature Encoder Pulse (eQEP) Timing Requirements .................................................. 116

6-26 eQEP Switching Characteristics ............................................................................................. 116

6-27 External ADC Start-of-Conversion Switching Characteristics............................................................. 117

6-28 External Interrupt Timing Requirements .................................................................................... 117

6-29 External Interrupt Switching Characteristics ................................................................................ 117

6-30 I2C Timing ...................................................................................................................... 118

6-31 SPI Master Mode External Timing (Clock Phase = 0) .................................................................... 119

6-32 SPI Master Mode External Timing (Clock Phase = 1) .................................................................... 121

6-33 SPI Slave Mode External Timing (Clock Phase = 0) ...................................................................... 122

6-34 SPI Slave Mode External Timing (Clock Phase = 1) ...................................................................... 124

6-35 Relationship Between Parameters Configured in XTIMING and Duration of Pulse ................................... 125

6-36 XINTF Clock Configurations................................................................................................... 128

6-37 External Interface Read Timing Requirements ............................................................................. 129

6-38 External Interface Read Switching Characteristics......................................................................... 129

6-39 External Interface Write Switching Characteristics......................................................................... 130

6-40 External Interface Read Switching Characteristics (Ready-on-Read, 1 Wait State)................................... 132

6-41 External Interface Read Timing Requirements (Ready-on-Read, 1 Wait State) ....................................... 132

6-42 Synchronous XREADY Timing Requirements (Ready-on-Read, 1 Wait State) ....................................... 132

6-43 Asynchronous XREADY Timing Requirements (Ready-on-Read, 1 Wait State)....................................... 132

6-44 External Interface Write Switching Characteristics (Ready-on-Write, 1 Wait State) ................................... 135

6-45 Synchronous XREADY Timing Requirements (Ready-on-Write, 1 Wait State) ....................................... 135

6-46 Asynchronous XREADY Timing Requirements (Ready-on-Write, 1 Wait State) ...................................... 135

6-47 XHOLD/XHOLDA Timing Requirements (XCLKOUT = XTIMCLK) ...................................................... 138

6-48 XHOLD/XHOLDA Timing Requirements (XCLKOUT = 1/2 XTIMCLK) ................................................. 139

6-49 ADC Electrical Characteristics (over recommended operating conditions) ............................................ 141

6-50 ADC Power-Up Delays......................................................................................................... 142

6-51 Typical Current Consumption for Different ADC Configurations (at 25-MHz ADCCLK) .............................. 142

6-52 Sequential Sampling Mode Timing ........................................................................................... 144

6-53 Simultaneous Sampling Mode Timing ....................................................................................... 145

6-54 McBSP Timing Requirements ................................................................................................ 147

6-55 McBSP Switching Characteristics ........................................................................................... 147

6-56 McBSP as SPI Master or Slave Timing Requirements (CLKSTP = 10b, CLKXP = 0) ................................ 149

www.ti.com

8 List of Tables Copyright © 2010, Texas Instruments Incorporated

Page 9

SM320F28335-HT

www.ti.com

SPRS682–DECEMBER 2010

6-57 McBSP as SPI Master or Slave Switching Characteristics (CLKSTP = 10b, CLKXP = 0)............................ 149

6-58 McBSP as SPI Master or Slave Timing Requirements (CLKSTP = 11b, CLKXP = 0) ................................ 150

6-59 McBSP as SPI Master or Slave Switching Characteristics (CLKSTP = 11b, CLKXP = 0)............................ 150

6-60 McBSP as SPI Master or Slave Timing Requirements (CLKSTP = 10b, CLKXP = 1) ................................ 151

6-61 McBSP as SPI Master or Slave Switching Characteristics (CLKSTP = 10b, CLKXP = 1)............................ 151

6-62 McBSP as SPI Master or Slave Timing Requirements (CLKSTP = 11b, CLKXP = 1) ................................ 152

6-63 McBSP as SPI Master or Slave Switching Characteristics (CLKSTP = 11b, CLKXP = 1) ........................... 152

6-64 Flash Endurance for A and S Temperature Material ...................................................................... 153

6-65 Flash Endurance for Q Temperature Material .............................................................................. 153

6-66 Flash Parameters at 150-MHz SYSCLKOUT............................................................................... 153

6-67 Flash/OTP Access Timing..................................................................................................... 153

6-68 Minimum Required Flash/OTP Wait-States at Different Frequencies ................................................... 154

7-1 Thermal Model of 181-Pin GB ................................................................................................ 155

Copyright © 2010, Texas Instruments Incorporated List of Tables 9

Page 10

SM320F28335-HT

www.ti.com

Digital Signal Controller (DSC)

1 SM320F28335 DSC

1.1 Features

12

• High-Performance Static CMOS Technology

– Up to 150 MHz for TC= -55°C to 125°C

and Up to 100 MHZ for TC= 210°C

– 1.9-V Core, 3.3-V I/O Design

• High-Performance 32-Bit CPU

– IEEE-754 Single-Precision Floating-Point

Unit (FPU) )

– 16 x 16 and 32 x 32 MAC Operations

– 16 x 16 Dual MAC

– Harvard Bus Architecture

– Fast Interrupt Response and Processing

– Unified Memory Programming Model

– Code-Efficient (in C/C++ and Assembly)

• Six Channel DMA Controller (for ADC, McBSP,

ePWM, XINTF, and SARAM)

• 16-bit or 32-bit External Interface (XINTF)

– Over 2M x 16 Address Reach

• On-Chip Memory

– 256K x 16 Flash, 34K x 16 SARAM

– 1K x 16 OTP ROM

• Boot ROM (8K x 16)

– With Software Boot Modes (via SCI, SPI,

CAN, I2C, McBSP, XINTF, and Parallel I/O)

– Standard Math Tables

• Clock and System Control

– Dynamic PLL Ratio Changes Supported

– On-Chip Oscillator

– Watchdog Timer Module

• GPIO0 to GPIO63 Pins Can Be Connected to

One of the Eight External Core Interrupts

• Peripheral Interrupt Expansion (PIE) Block That

Supports All 58 Peripheral Interrupts

• 128-Bit Security Key/Lock

– Protects Flash/OTP/RAM Blocks

– Prevents Firmware Reverse Engineering

• Enhanced Control Peripherals

– Up to 18 PWM Outputs

– Up to 6 HRPWM Outputs With 150 ps MEP Boundary Scan Architecture

Resolution

– Up to 6 Event Capture Inputs

– Up to 2 Quadrature Encoder Interfaces

– Up to 8 32-bit/Nine 16-bit Timers

• Three 32-Bit CPU Timers

• Serial Port Peripherals

– Up to 2 CAN Modules

– Up to 3 SCI (UART) Modules

– Up to 2 McBSP Modules (Configurable as

SPI)

– One SPI Module

– One Inter-Integrated-Circuit (I2C) Bus

• 12-Bit ADC, 16 Channels

– 80-ns Conversion Rate

– 2 x 8 Channel Input Multiplexer

– Two Sample-and-Hold

– Single/Simultaneous Conversions

– Internal or External Reference

• Up to 88 Individually Programmable,

Multiplexed GPIO Pins With Input Filtering

• JTAG Boundary Scan Support

• Advanced Emulation Features

– Analysis and Breakpoint Functions

– Real-Time Debug via Hardware

• Development Support Includes

– ANSI C/C++ Compiler/Assembler/Linker

– Code Composer Studio™ IDE

– DSP/BIOS™

– Digital Motor Control and Digital Power

Software Libraries

• Low-Power Modes and Power Savings

– IDLE, STANDBY, HALT Modes Supported

– Disable Individual Peripheral Clocks

• Package Option

– Ceramic Pin Grid Array (GB)

• Temperature Range:

– –55°C to 210°C

(1) IEEE Standard 1149.1-1990 Standard Test Access Port and

SPRS682–DECEMBER 2010

(1)

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2Code Composer Studio, DSP/BIOS are trademarks of Texas Instruments.

Copyright © 2010, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Page 11

SM320F28335-HT

www.ti.com

SPRS682–DECEMBER 2010

1.2 SUPPORTS EXTREME TEMPERATURE APPLICATIONS

• Controlled Baseline

• One Assembly/Test Site

• One Fabrication Site

• Available in Extreme (–55°C/210°C)

Temperature Range

• Extended Product Life Cycle

• Extended Product-Change Notification

• Product Traceability

• Texas Instruments high temperature products utilize highly optimized silicon (die) solutions with

design and process enhancements to maximize performance over extended temperatures.

(2) Custom temperature ranges available

(2)

Copyright © 2010, Texas Instruments Incorporated SM320F28335 DSC 11

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 12

SM320F28335-HT

SPRS682–DECEMBER 2010

www.ti.com

2 Introduction

The SM320F28335 is a highly integrated, high-performance solution for demanding control applications.

Throughout this document, the device is abbreviated as F28335. Table 2-1 provides a summary of

features.

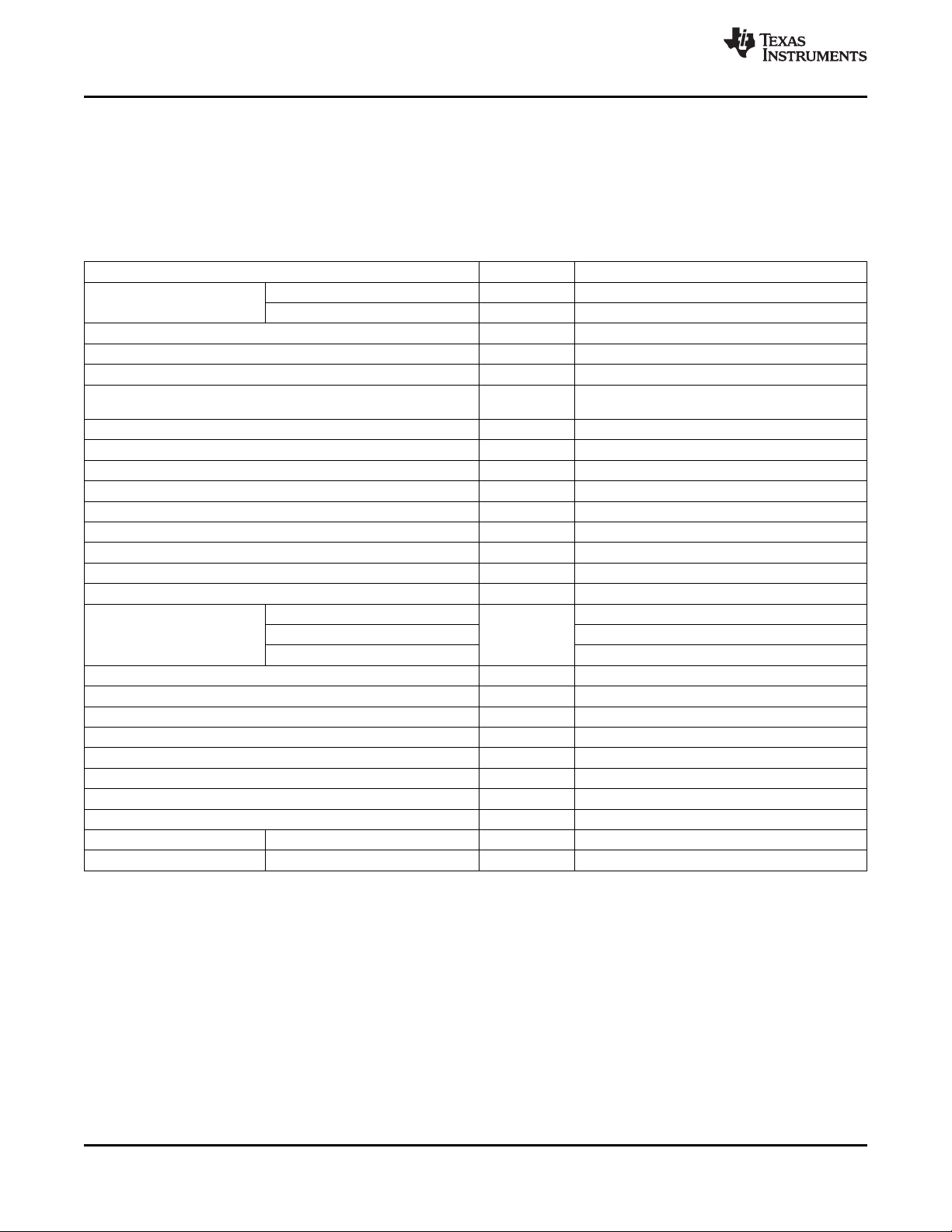

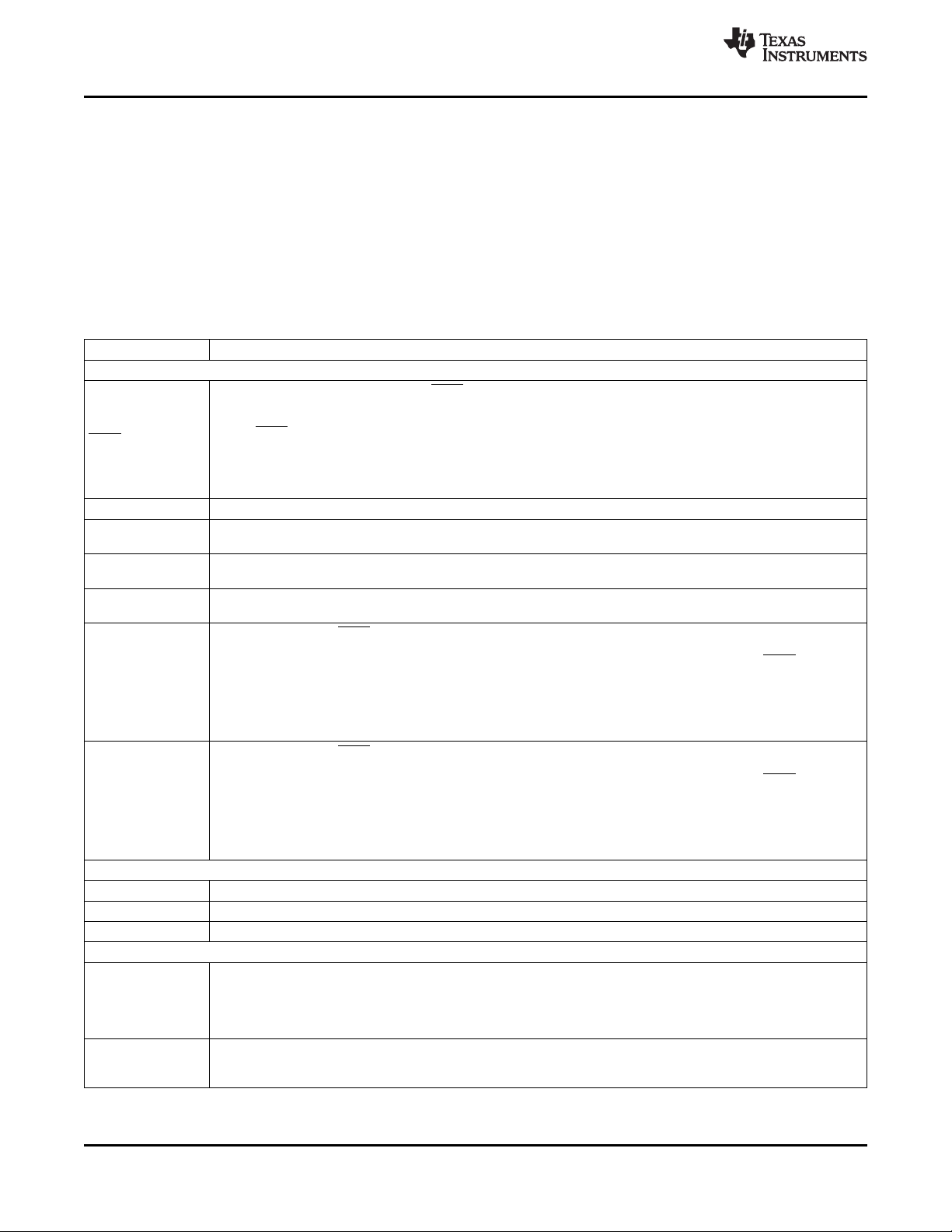

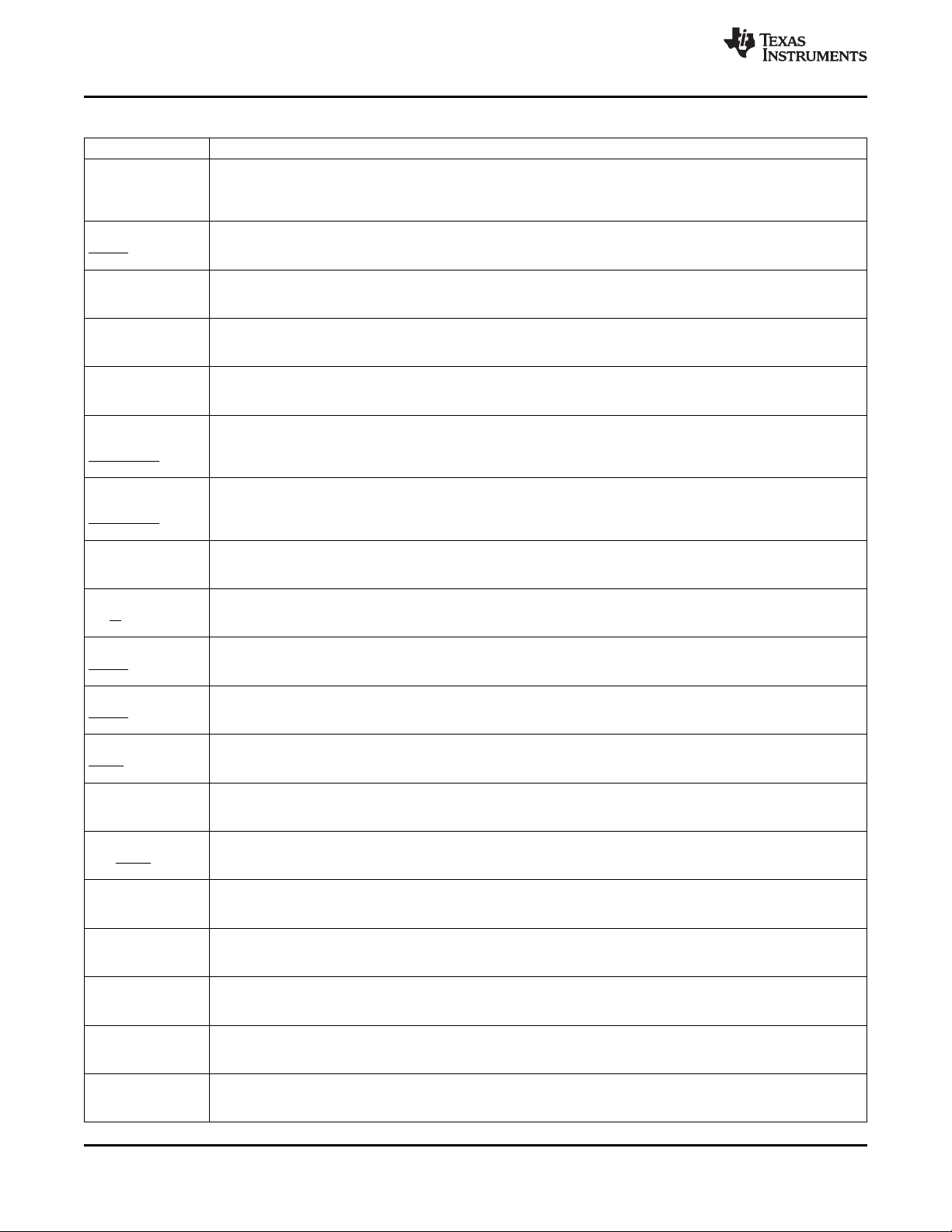

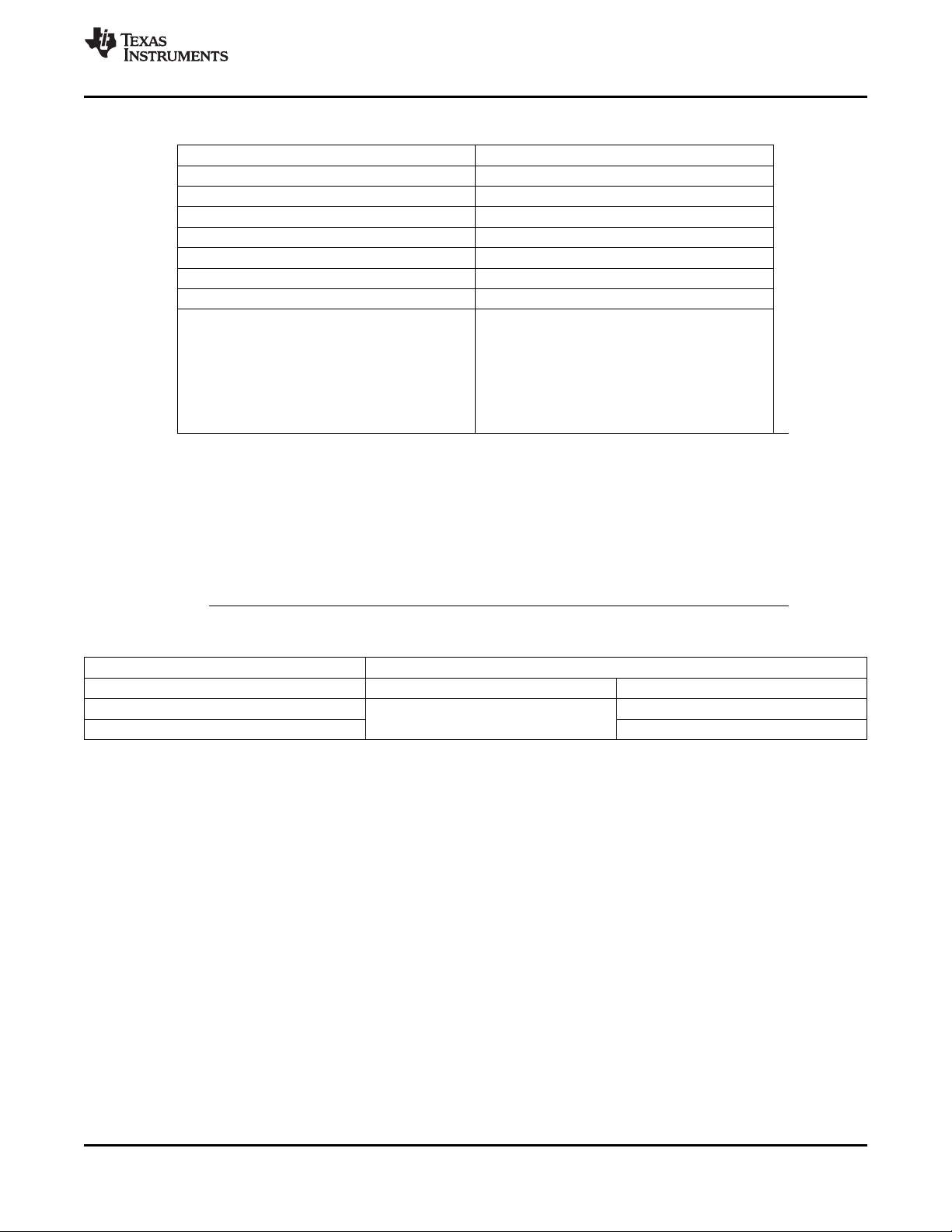

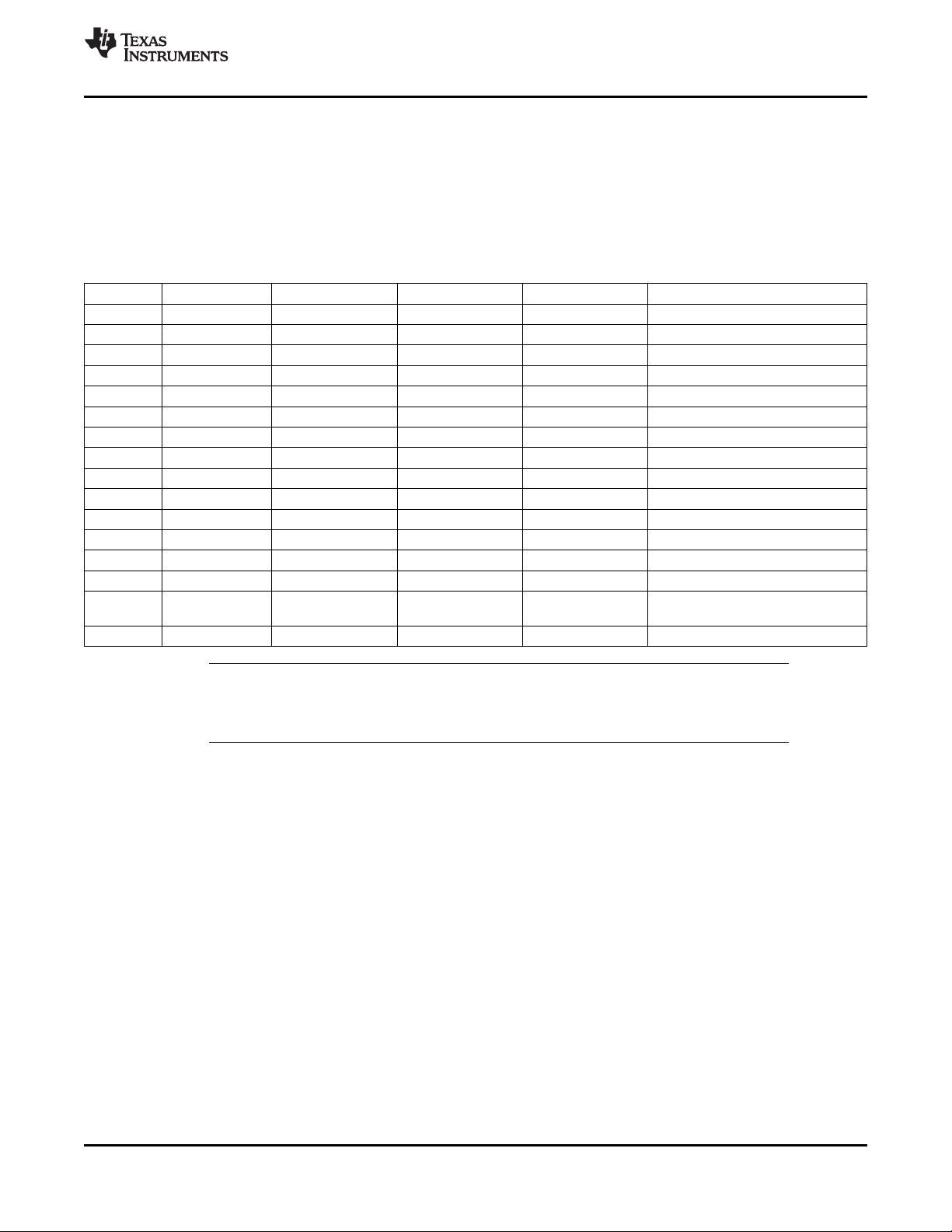

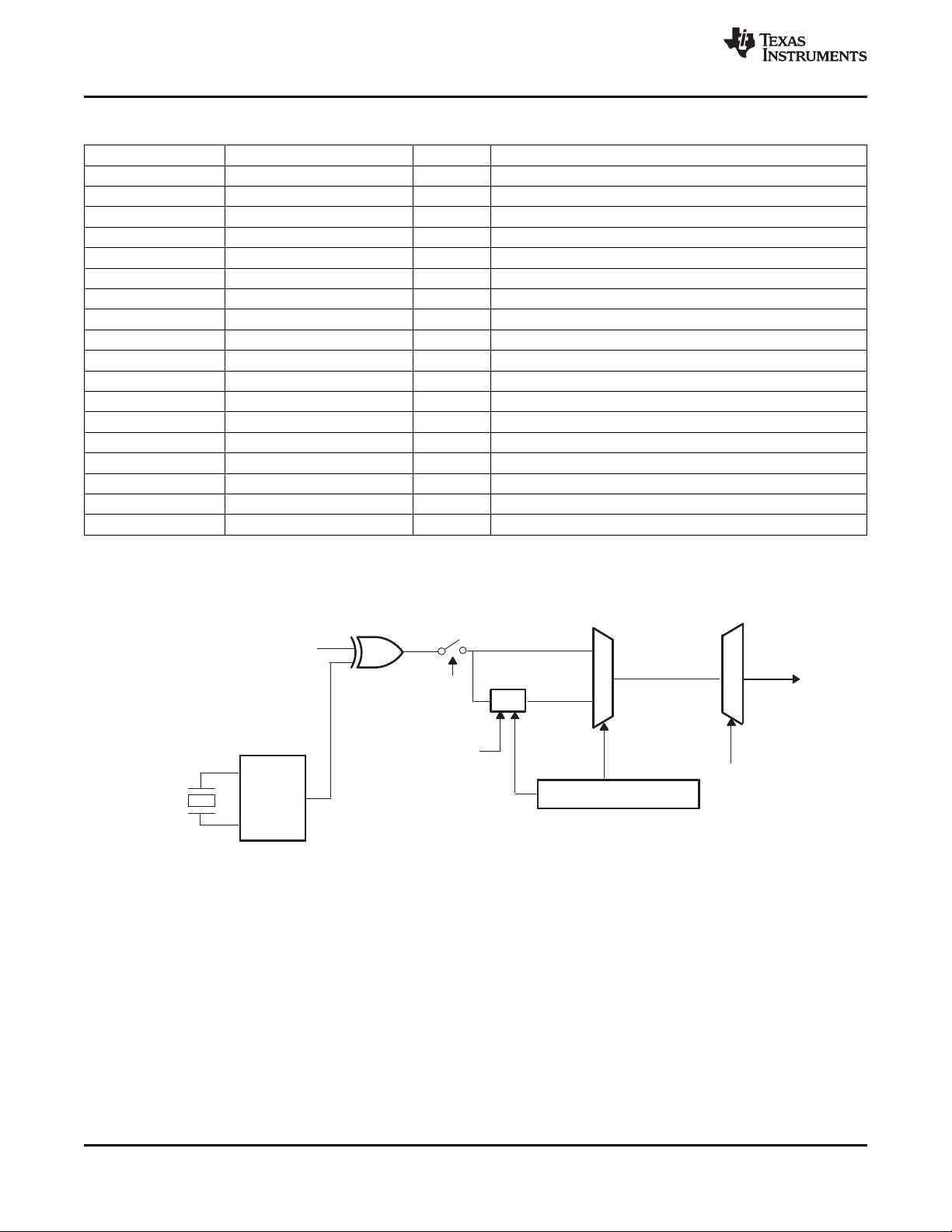

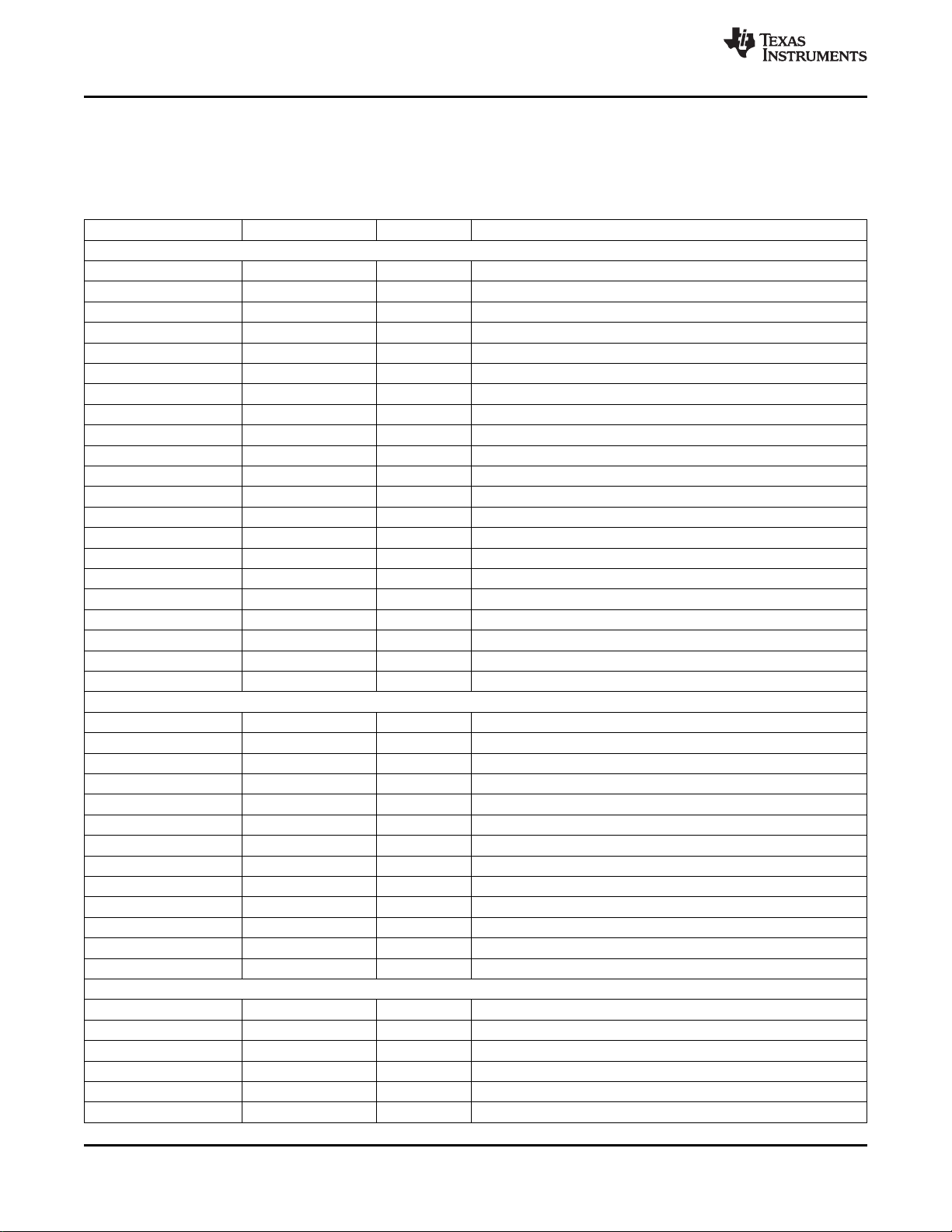

Table 2-1. Hardware Features

FEATURE TYPE

Instruction cycle

Floating-point Unit – Yes

3.3-V on-chip flash (16-bit word) – 256K

Single-access RAM (SARAM) (16-bit word) – 34K

One-time programmable (OTP) ROM

(16-bit word)

Code security for on-chip flash/SARAM/OTP blocks – Yes

Boot ROM (8K X16) – Yes

16/32-bit External Interface (XINTF) 1 Yes

6-channel Direct Memory Access (DMA) 0 Yes

PWM outputs 0 ePWM1/2/3/4/5/6

HRPWM channels 0 ePWM1A/2A/3A/4A/5A/6A

32-bit Capture inputs or auxiliary PWM outputs 0 6

32-bit QEP channels (four inputs/channel) 0 2

Watchdog timer – Yes

12-Bit ADC MSPS 2 12.5

32-Bit CPU timers – 3

Multichannel Buffered Serial Port (McBSP)/SPI 1 2

Serial Peripheral Interface (SPI) 0 1

Serial Communications Interface (SCI) 0 3

Enhanced Controller Area Network (eCAN) 0 2

Inter-Integrated Circuit (I2C) 0 1

General Purpose I/O pins (shared) – 88

External interrupts – 8

Packaging 181-pin GB – Yes

Temperature range –55°C to 210°C – Yes

(1) A type change represents a major functional feature difference in a peripheral module. Within a peripheral type, there may be minor

differences between devices that do not affect the basic functionality of the module.

TC= -55°C to 125°C – 6.66 ns

TC= 210°C – 10 ns

No. of channels 16

Conversion time 80 ns

(1)

– 1K

F28335 (150 MHz)

12 Introduction Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 13

15141311 128 96 7 10

P

R

N

L

M

K

J

542 3

G

F

D

C

E

A

1

B

H

0.100 (2,54) TYP

1.400 (35,56) TYP

Bottom View

SM320F28335-HT

www.ti.com

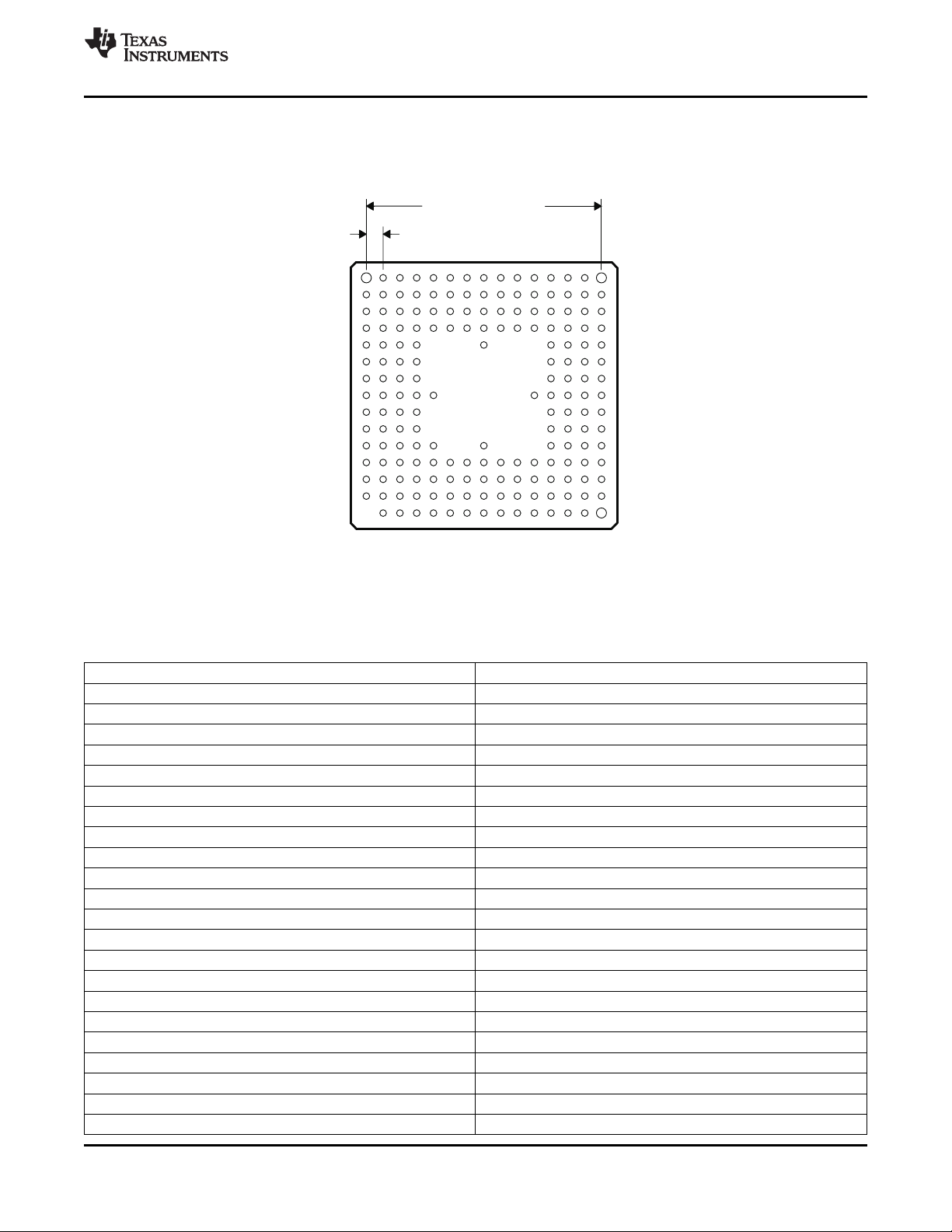

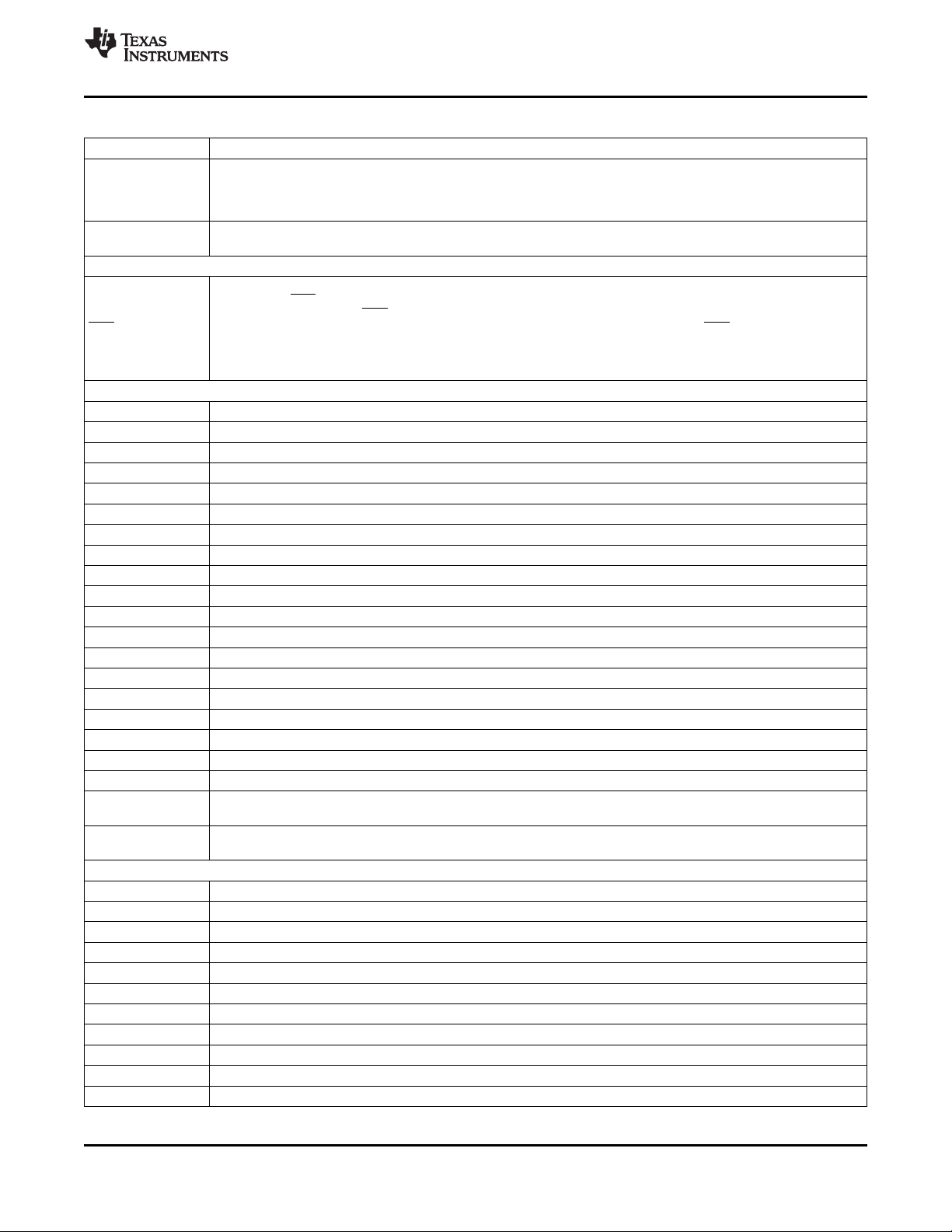

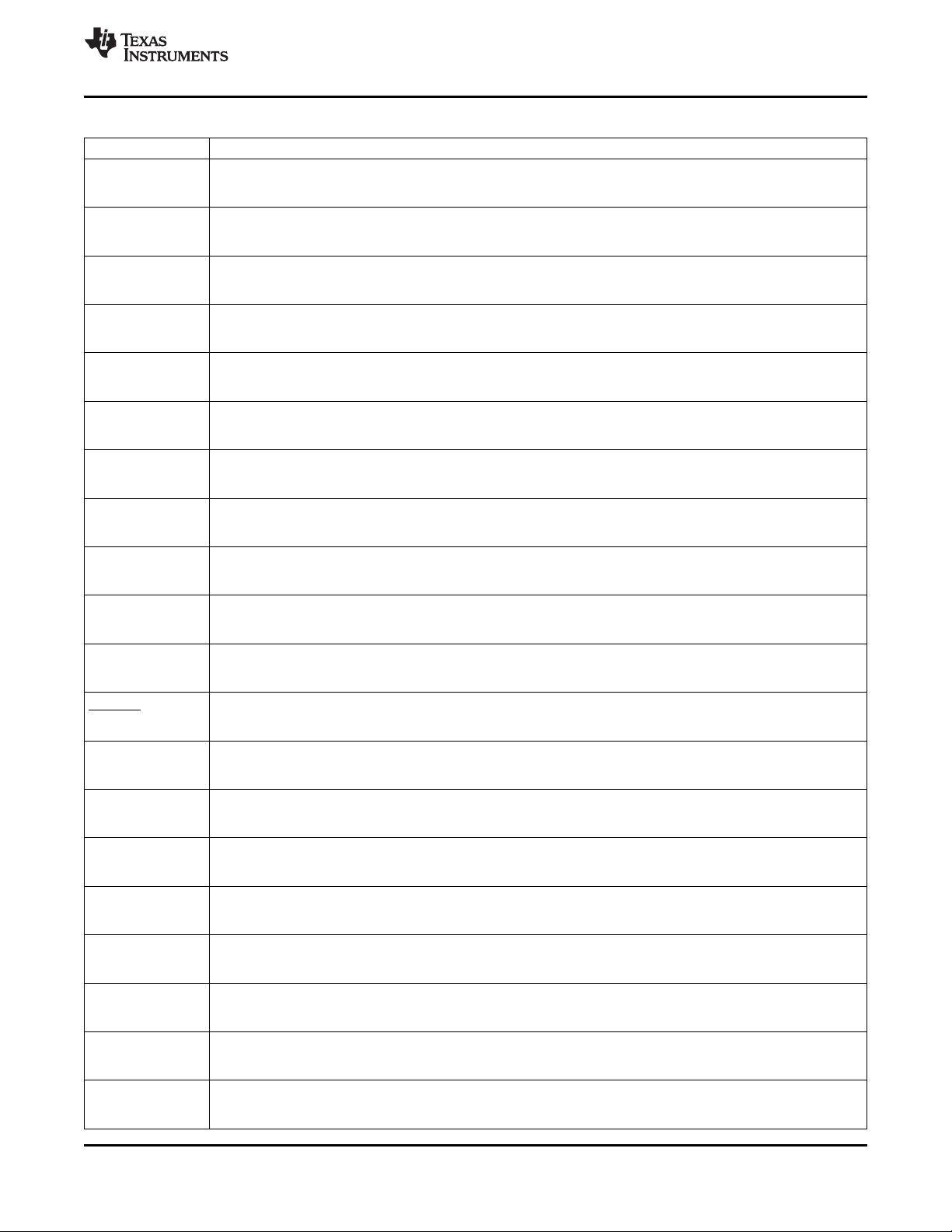

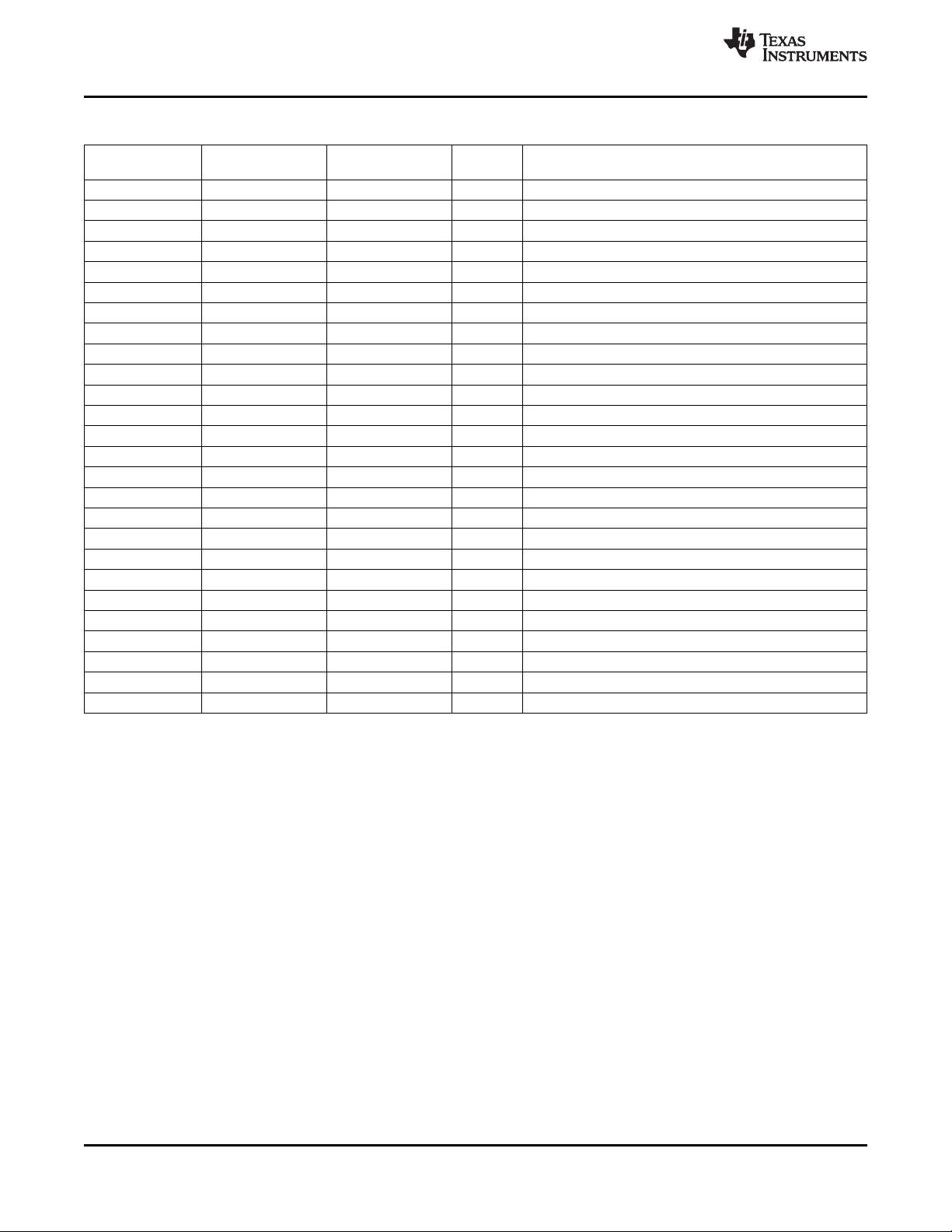

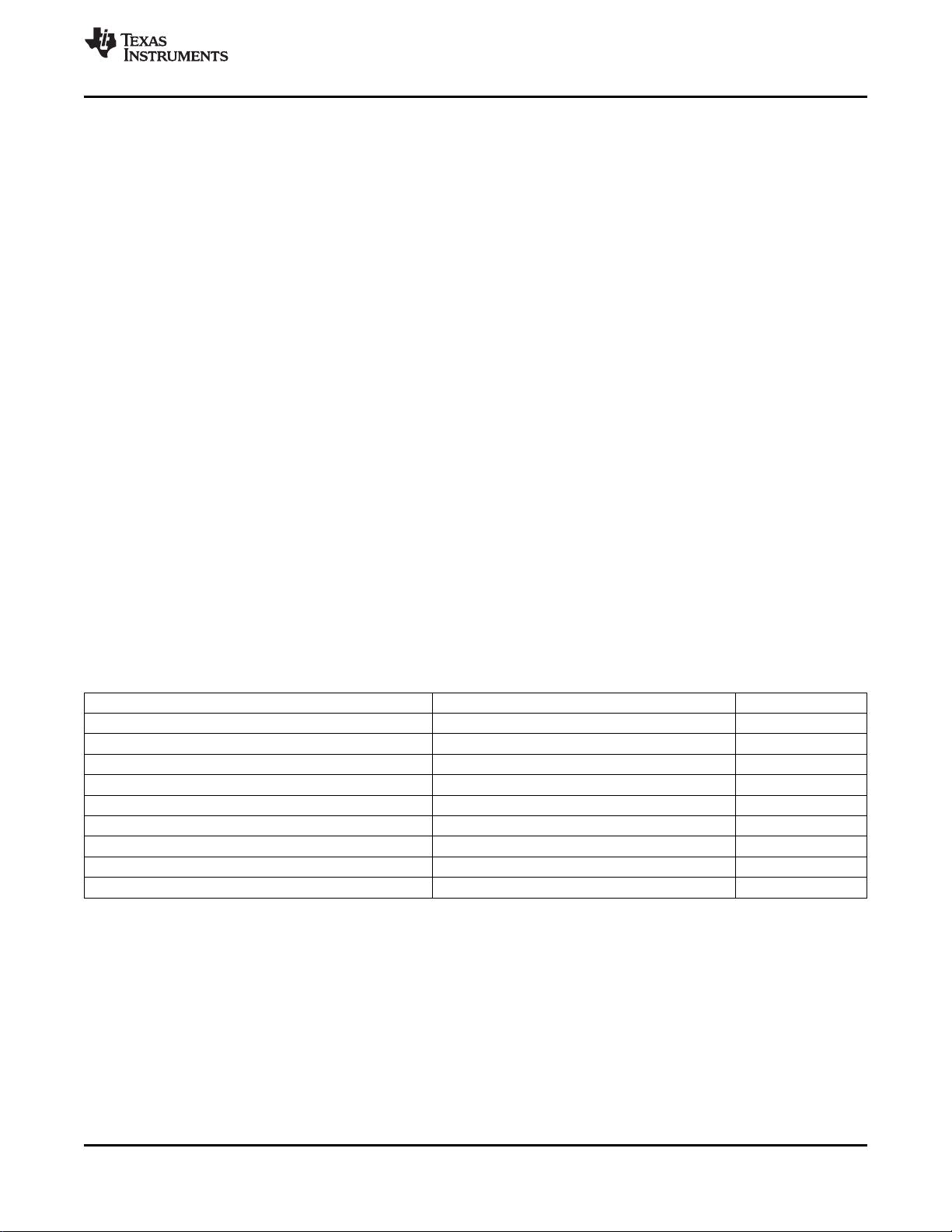

2.1 Pin Assignments

The 181-pin ceramic pin grid array (CPGA) terminal assignments are shown in Figure 2-1. Table 2-2 gives

the pin out information and Table 2-3 describes the function(s) of each pin.

SPRS682–DECEMBER 2010

Figure 2-1. 181-Pin GB

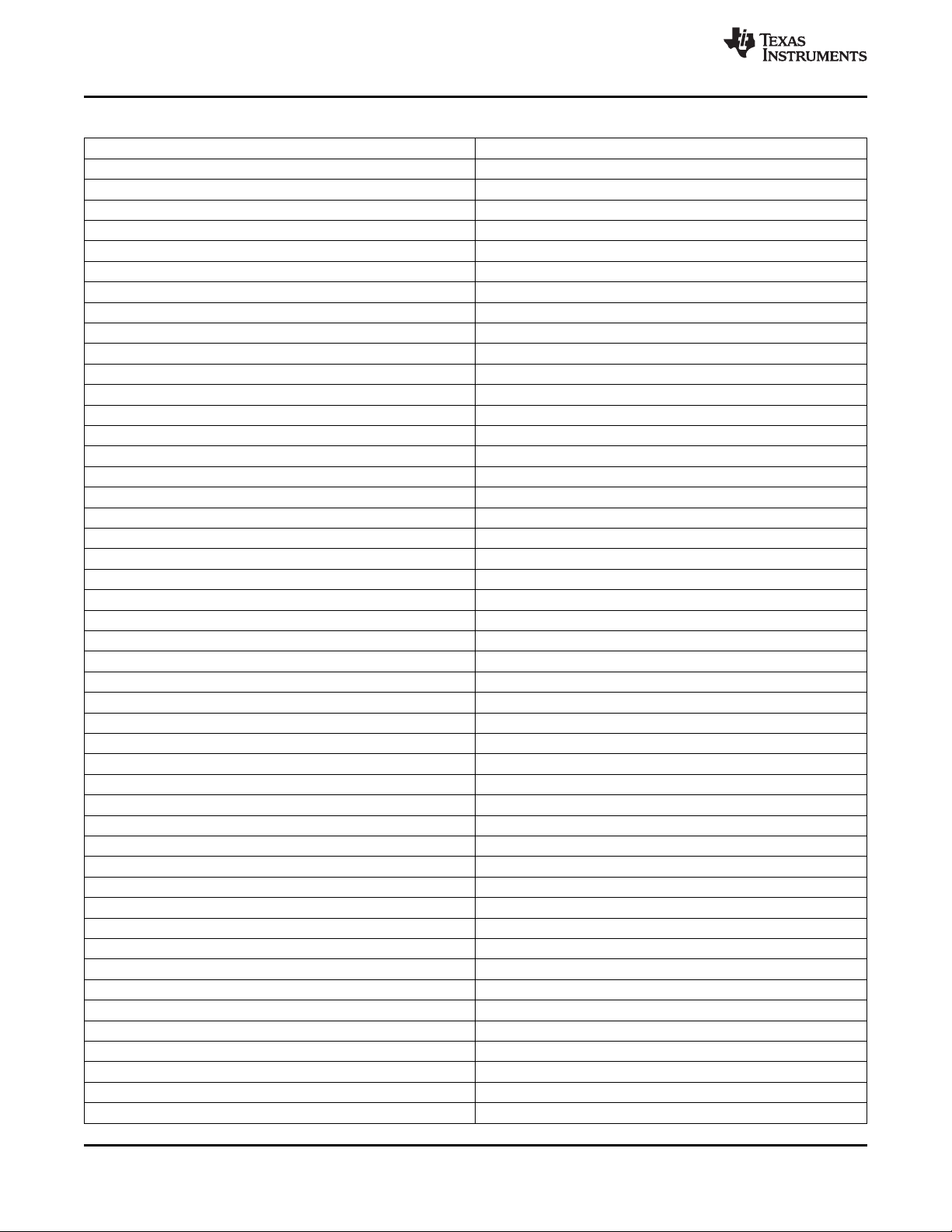

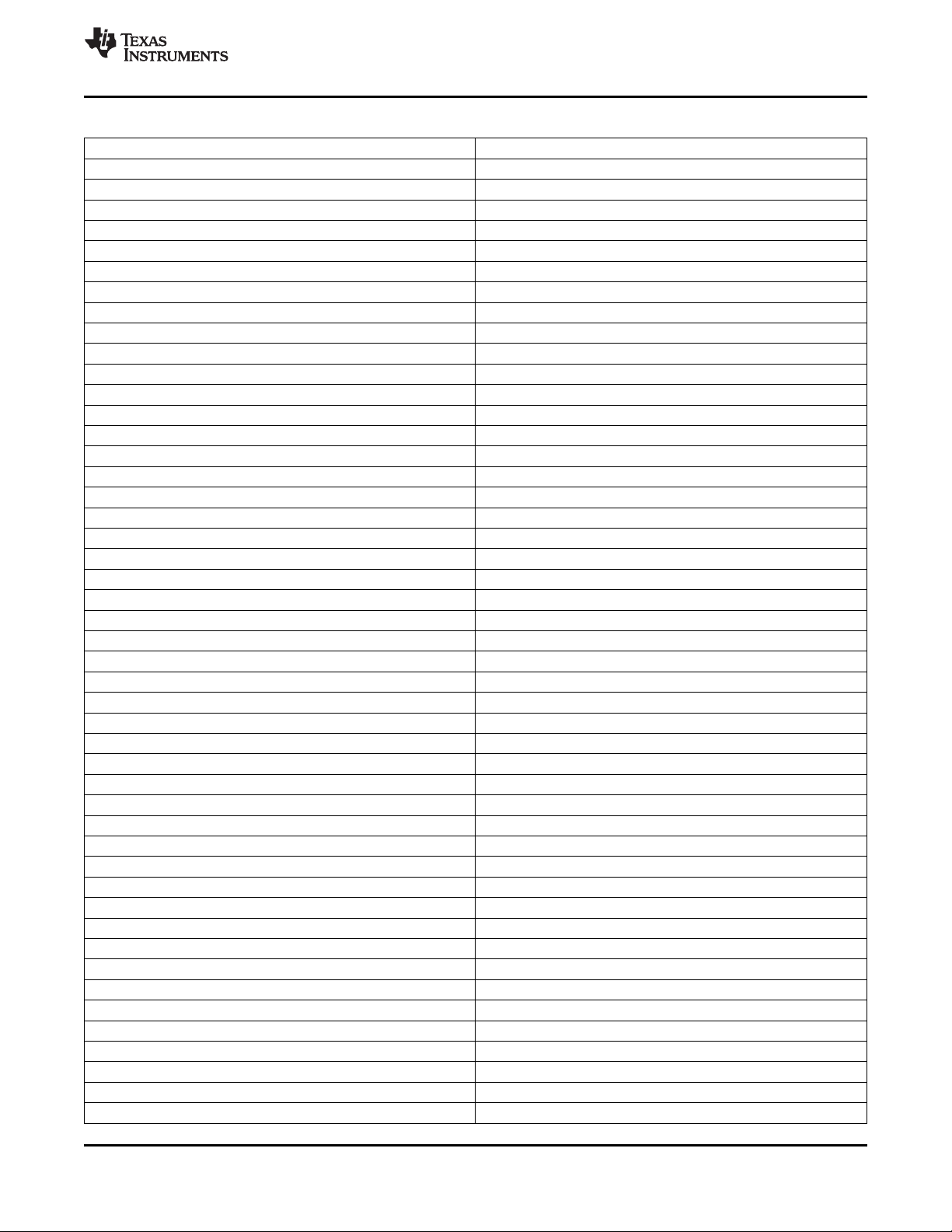

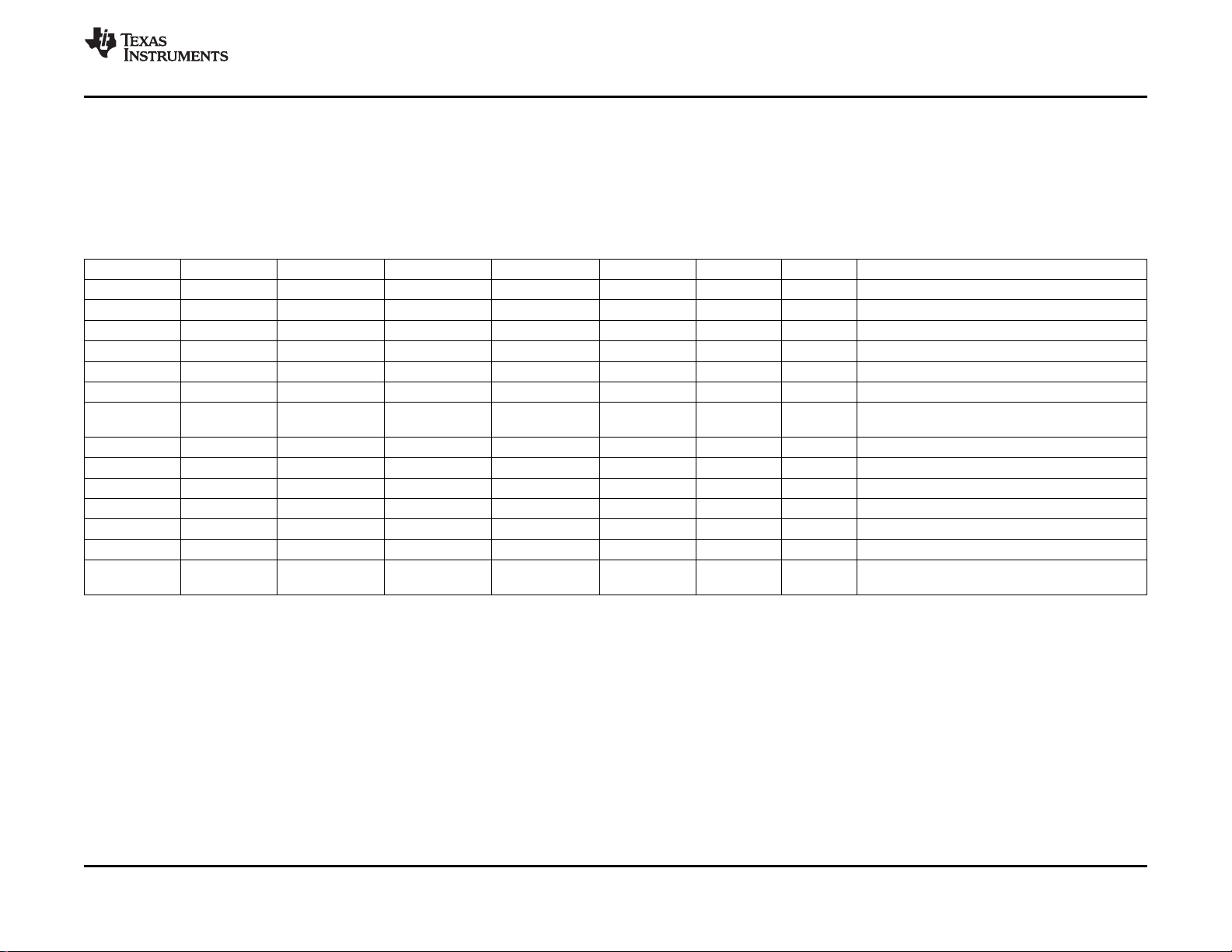

Table 2-2. Pin Out Information

PIN FUNCTION

A1 NC

M1 ADCINA0

L1 ADCINA1

K1 ADCINA2

J1 ADCINA3

P2 ADCINA4

N2 ADCINA5

M2 ADCINA6

Copyright © 2010, Texas Instruments Incorporated Introduction 13

L2 ADCINA7

M6 ADCINB0

M7 ADCINB1

R2 ADCINB2

R3 ADCINB3

R4 ADCINB4

R5 ADCINB5

R6 ADCINB6

R7 ADCINB7

N1 ADCLO

P3 ADCREFIN

P4 ADCREFM

P5 ADCREFP

P6 ADCRESEXT

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 14

SM320F28335-HT

SPRS682–DECEMBER 2010

www.ti.com

Table 2-2. Pin Out Information (continued)

R11 EMU0

R12 EMU1

F1 GPIO0/EPWM1A

G1 GPIO1/EPWM1B/ECAP6/MFSRB

E4 GPIO10/EPWM6A/CANRXB/ADCSOCBO

F4 GPIO11/EPWM6B/SCIRXDB/ECAP4

G4 GPIO12/TZ1/CANTXB/MDXB

J4 GPIO13/TZ2/CANRXB/MDRB

K4 GPIO14/TX3/XHOLD/SCITXDB/MCLKXB

L4 GPIO15/TZ4/XHOLDA/SCIRXDB/MFSXB

M4 GPIO16//SPISIMOA/CANTXB/TZ5

J3 GPIO17/SPIOMIA/CANRXB/TZ6

N7 GPIO18/SPICLKA/SCITXDB/CANRXA

M8 GPIO19/SPISTEA/SCIRXDB/CANTXA

H1 GPIO2/EPWM2A

M9 GPIO20/EQEP1A/MDXA/CANTXB

M10 GPIO21/EQEP1B/MDRA/CANRXB

M11 GPIO22/EQEP1S/MCLKXA/SCITXDB

L8 GPIO23/EQEP1I/MFSXA/SCIRXDB

M12 GPIO24/ECAP1/EQEP2A.MDXB

N8 GPIO25/ECAP2/EQEP2B/MDRB

N11 GPIO26/ECAP3/EQEP2I/MCLKXB

N12 GPIO27/ECAP4/EQEP2S/MFSX

A9 GPIO28/SCIRXDA/XZCS6

C1 GPIO29/SCITXDA/XA19

E2 GPIO3/EPWM2B/ECAP5/MCLKRB

B1 GPIO30/CANRXA/XA18

A2 GPIO31/CANTXA/XA17

N13 GPIO32/SDAA/EPWMSYNCI/ADCSOCAO

P8 GPIO33/SCLA/EPWMSYNCO/ADCSOCBO

B13 GPIO34/ECAP1/XREADY

C11 GPIO35/SCITXDA/XR/1

B10 GPIO36/SCIRXDA/XZCS0

C9 GPIO37/ECAP2/XZCS7

A13 GPIO38/nXWEO

A3 GPIO39/XA16

F2 GPIO4/EPWM3A

D8 GPIO40/XA0/XWE1

D7 GPIO41/XA1

D6 GPIO42/XA2

D4 GPIO43/XA3

C8 GPIO44/XA4

C7 GPIO45/XA5

C4 GPIO46/XA6

C3 GPIO47/XA7

R14 GPIO48/ECAP5/XD31

P15 GPIO49/ECAP6/XD30

G2 GPIO5/EPWM3B/MFSRA/ECAP1

14 Introduction Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 15

SM320F28335-HT

www.ti.com

SPRS682–DECEMBER 2010

Table 2-2. Pin Out Information (continued)

N15 GPIO50/EQEP1A/XD29

M15 GPIO51/EQEP1B/XD28

J15 GPIO52/EQEP1S/XD27

H15 GPIO53/EQEP1I/XD26

N14 GPIO54/SPISIMOA/XD25

M14 GPIO55/SPISOMIA/XD24

L14 GPIO56/SPICLKA/XD23

K14 GPIO57/SPISTEA/XD22

J14 GPIO58/MCLKRA/XD21

H12 GPIO59/MFSRA/XD20

H2 GPIO6/EPWM4A/EPWMSYNCI/EPWMSYNCO

H11 GPIO60/MCLKRB/XD19

G12 GPIO61/MFSRB/XD18

F12 GPIO62/SCIRXDC/XD17

E12 GPIO63/SCITXDC/XD16

D12 GPIO64/XD15

G13 GPIO65/XD14

D13 GPIO66/XD13

F14 GPIO67/XD12

E14 GPIO68/XD11

D14 GPIO69/XD10

F3 GPIO7/EPWM4B/MCLKRA/ECAP2

G15 GPIO70/XD9

F15 GPIO71/XD8

E15 GPIO72/XD7

D15 GPIO73/XD6

C15 GPIO74/XD5

B15 GPIO75/XD4

D11 GPIO76/XD3

D10 GPIO77/XD2

D9 GPIO78/XD1

A14 GPIO79/XD0

G3 GPIO8/EPWM5A/CANTXB/ADCSOCAO

B8 GPIO80/XA8

B7 GPIO81/XA9

B6 GPIO82/XA10

B3 GPIO83/XA11

B2 GPIO84/XA12

A6 GPIO85/XA13

A5 GPIO86/XA14

A4 GPIO87/XA15

H3 GPIO9/EPWM5B/SCITXDB/ECAP3

R13 TCK

P9 TDI

P10 TDO

P14 TEST1

R8 TEST2

P12 TMS

Copyright © 2010, Texas Instruments Incorporated Introduction 15

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 16

SM320F28335-HT

SPRS682–DECEMBER 2010

www.ti.com

Table 2-2. Pin Out Information (continued)

P11 TRSTn

A11 VDD

B14 VDD

B4 VDD

B9 VDD

D5 VDD

E1 VDD

E3 VDD

F13 VDD

H14 VDD

H5 VDD

J12 VDD

K3 VDD

N6 VDD

M3 VDD1A18

N4 VDD2A18

R10 VDD3VFL

K2 VDDA2

M5 VDDAIO

A8 VDDIO

B12 VDDIO

C6 VDDIO

D2 VDDIO

G14 VDDIO

K15 VDDIO

L12 VDDIO

N10 VDDIO

A10 VSS

A7 VSS

B11 VSS

B5 VSS

C12 VSS

C13 VSS

C14 VSS

C2 VSS

C5 VSS

D1 VSS

D3 VSS

E13 VSS

E8 VSS

H13 VSS

H4 VSS

K12 VSS

L13 VSS

L15 VSS

L3 VSS

N5 VSS

N9 VSS

16 Introduction Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 17

SM320F28335-HT

www.ti.com

SPRS682–DECEMBER 2010

Table 2-2. Pin Out Information (continued)

R9 VSS

N3 VSS1AGND

P7 VSS2AGND

J2 VSSA2

P1 VSSAIO

K13 X1

M13 X2

J13 XCLKIN

A12 XCLKOUT

C10 XRD

P13 XRSn

A15 NC

R1 NC

R15 NC

Copyright © 2010, Texas Instruments Incorporated Introduction 17

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 18

SM320F28335-HT

SPRS682–DECEMBER 2010

www.ti.com

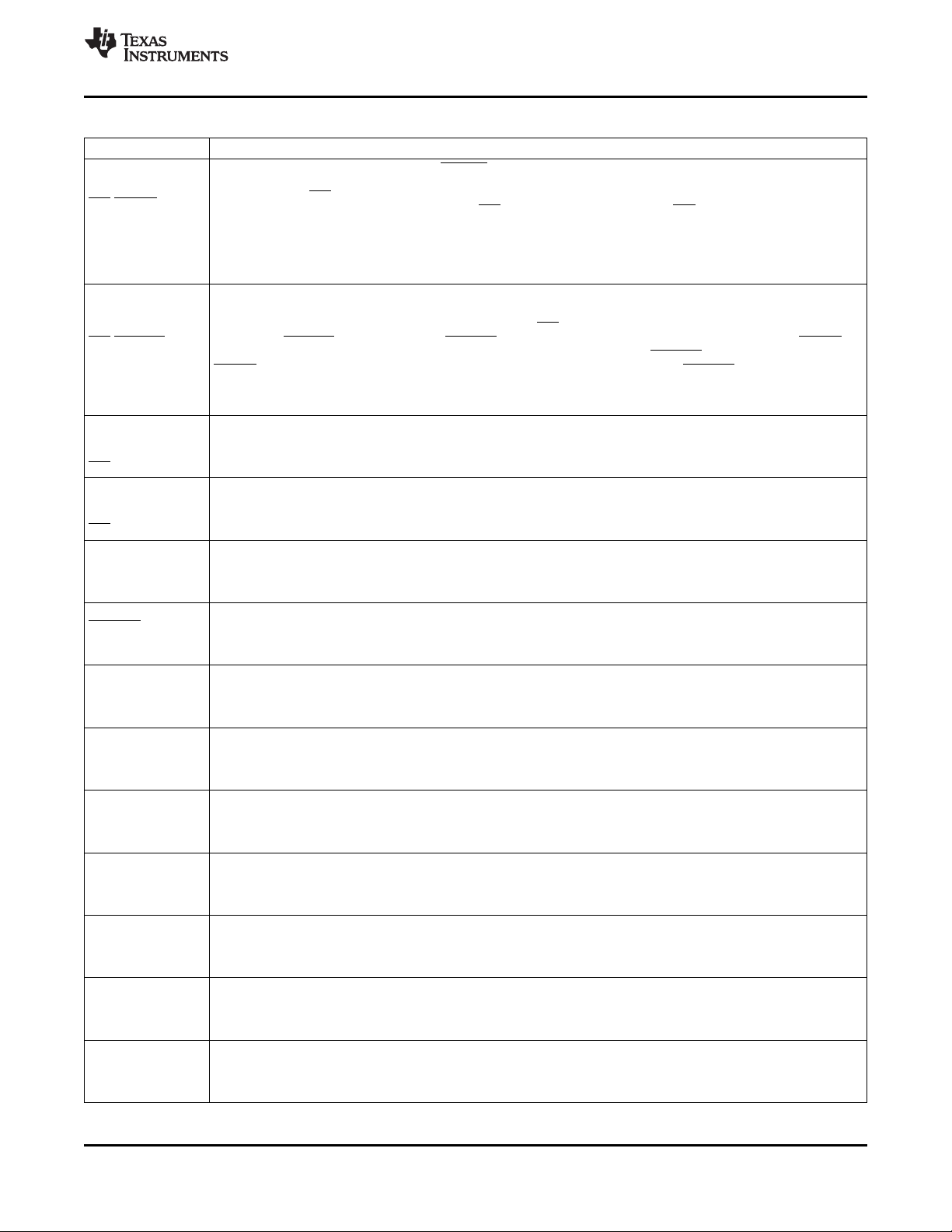

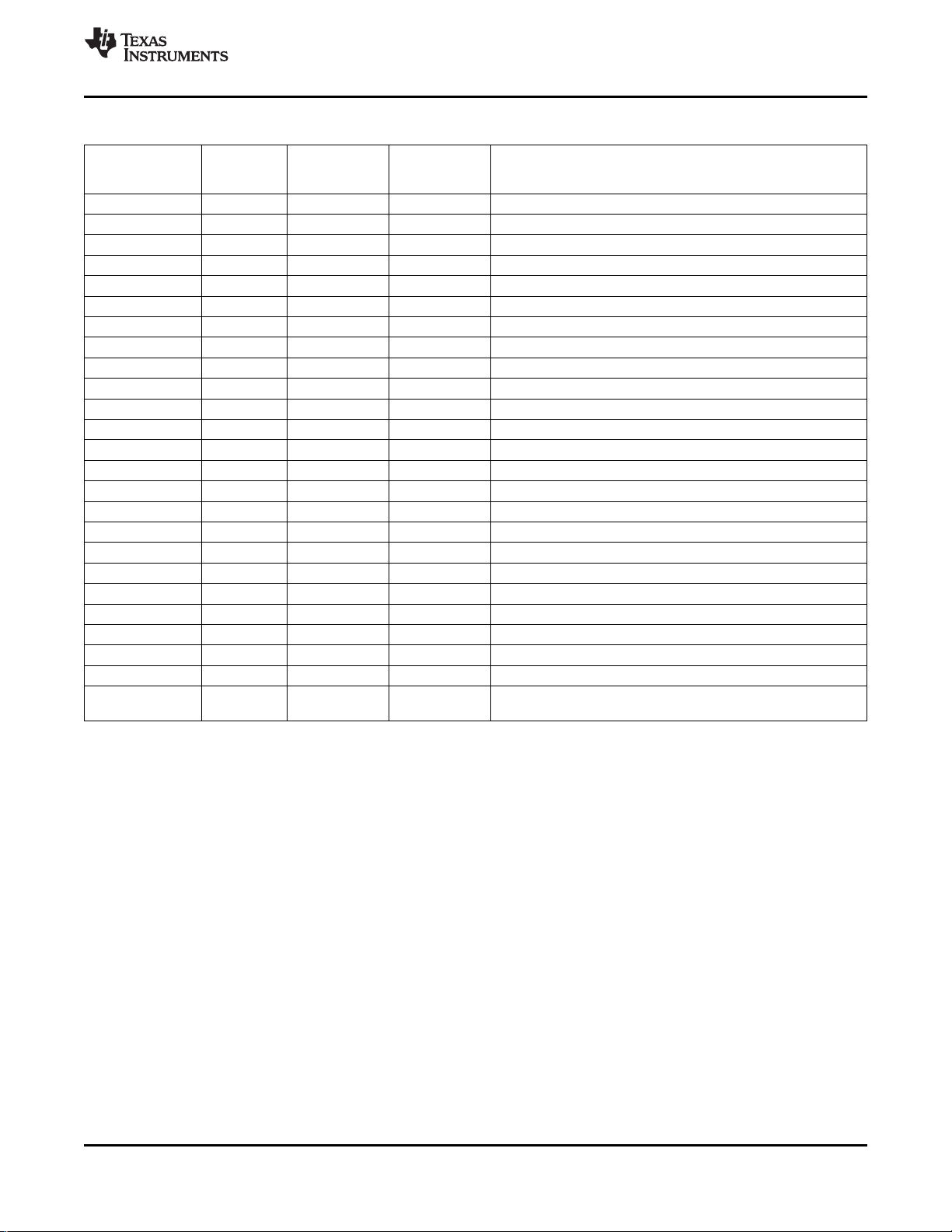

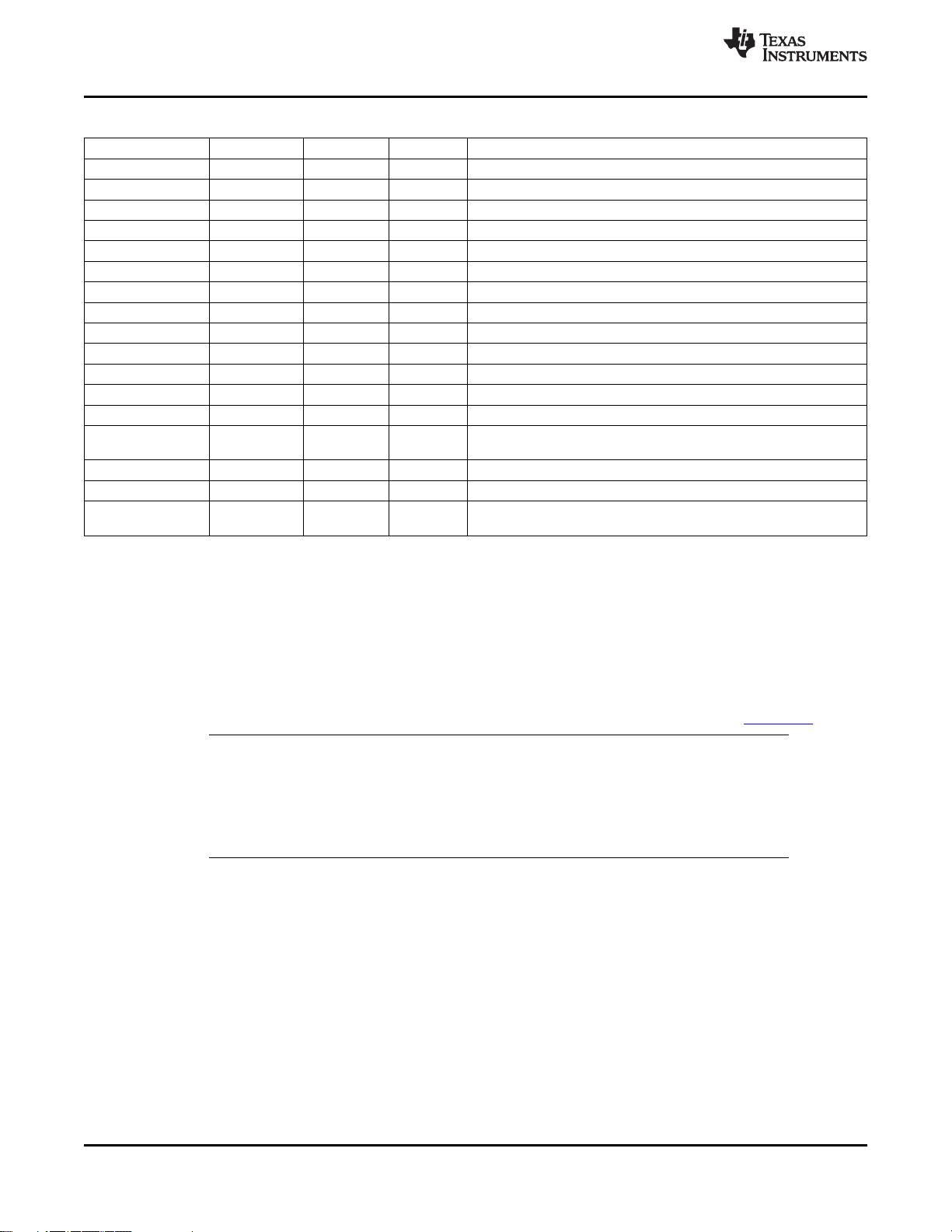

2.2 Signal Descriptions

Table 2-3 describes the signals. The GPIO function (shown in Italics) is the default at reset. The peripheral

signals that are listed under them are alternate functions. Some peripheral functions may not be available

in all devices. See Table 2-1 for details. Inputs are not 5-V tolerant. All pins capable of producing an

XINTF output function have a drive strength of 8 mA (typical). This is true even if the pin is not configured

for XINTF functionality. All other pins have a drive strength of 4-mA drive typical (unless otherwise

indicated). All GPIO pins are I/O/Z and have an internal pullup, which can be selectively enabled/disabled

on a per-pin basis. This feature only applies to the GPIO pins. The pullups on GPIO0-GPIO11 pins are not

enabled at reset. The pullups on GPIO12-GPIO34 are enabled upon reset.

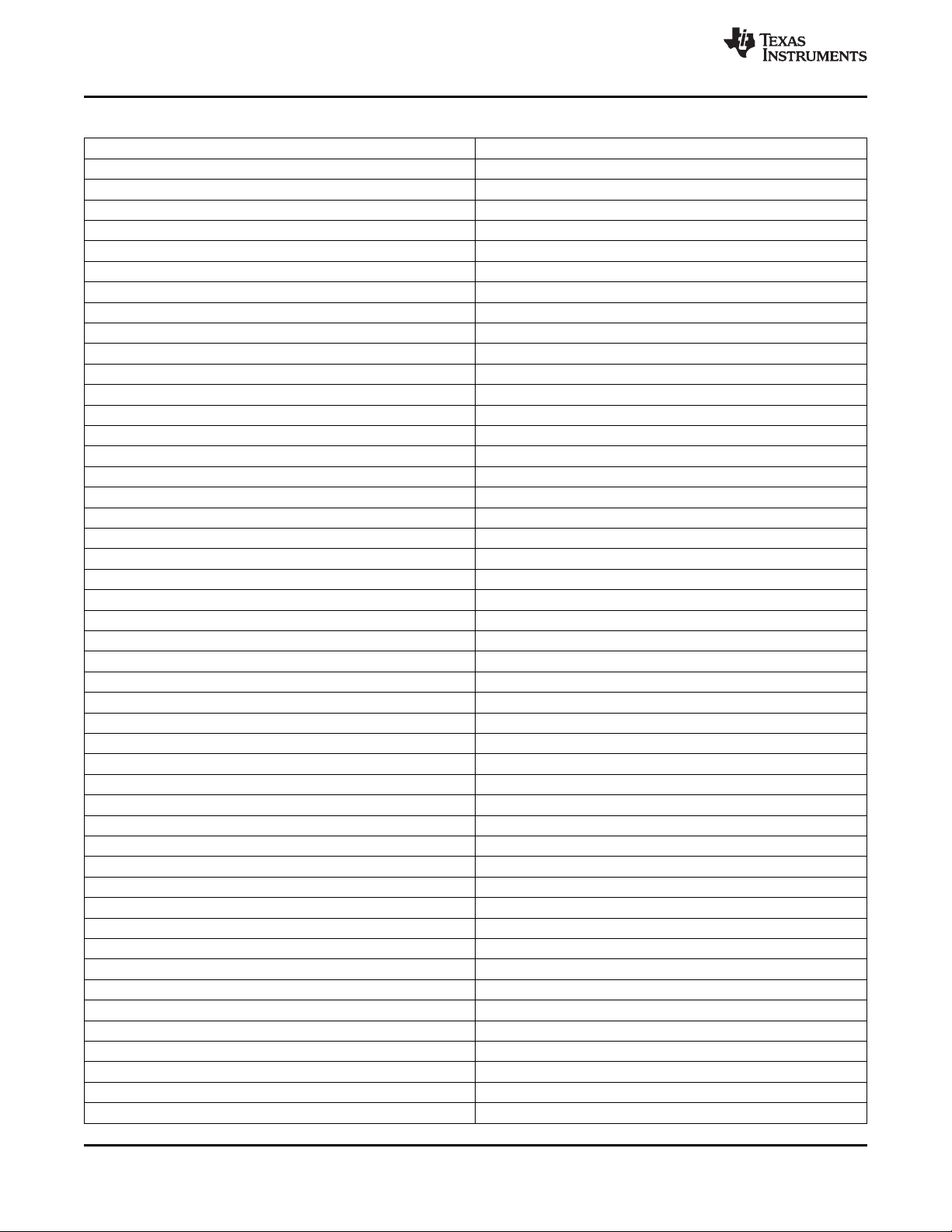

Table 2-3. Signal Descriptions

NAME DESCRIPTION

JTAG

JTAG test reset with internal pulldown. TRST, when driven high, gives the scan system control of the operations of

the device. If this signal is not connected or driven low, the device operates in its functional mode, and the test reset

signals are ignored.

TRST

TCK JTAG test clock with internal pullup (I, ↑)

TMS

TDI

TDO

EMU0

EMU1

V

DD3VFL

TEST1 Test Pin. Reserved for TI. Must be left unconnected. (I/O)

TEST2 Test Pin. Reserved for TI. Must be left unconnected. (I/O)

XCLKOUT XINTCNF2 register. At reset, XCLKOUT = SYSCLKOUT/4. The XCLKOUT signal can be turned off by setting

XCLKIN tied to GND. If a crystal/resonator is used (or if an external 1.9-V oscillator is used to feed clock to X1 pin), this pin

NOTE: TRST is an active high test pin and must be maintained low at all times during normal device operation. An

external pulldown resistor is recommended on this pin. The value of this resistor should be based on drive strength of

the debugger pods applicable to the design. A 2.2-kΩ resistor generally offers adequate protection. Since this is

application-specific, it is recommended that each target board be validated for proper operation of the debugger and

the application. (I, ↓)

JTAG test-mode select (TMS) with internal pullup. This serial control input is clocked into the TAP controller on the

rising edge of TCK. (I, ↑)

JTAG test data input (TDI) with internal pullup. TDI is clocked into the selected register (instruction or data) on a

rising edge of TCK. (I, ↑)

JTAG scan out, test data output (TDO). The contents of the selected register (instruction or data) are shifted out of

TDO on the falling edge of TCK. (O/Z 8 mA drive)

Emulator pin 0. When TRST is driven high, this pin is used as an interrupt to or from the emulator system and is

defined as input/output through the JTAG scan. This pin is also used to put the device into boundary-scan mode.

With the EMU0 pin at a logic-high state and the EMU1 pin at a logic-low state, a rising edge on the TRST pin would

latch the device into boundary-scan mode. (I/O/Z, 8 mA drive ↑)

NOTE: An external pullup resistor is recommended on this pin. The value of this resistor should be based on the

drive strength of the debugger pods applicable to the design. A 2.2-kΩ to 4.7-kΩ resistor is generally adequate.

Since this is application-specific, it is recommended that each target board be validated for proper operation of the

debugger and the application.

Emulator pin 1. When TRST is driven high, this pin is used as an interrupt to or from the emulator system and is

defined as input/output through the JTAG scan. This pin is also used to put the device into boundary-scan mode.

With the EMU0 pin at a logic-high state and the EMU1 pin at a logic-low state, a rising edge on the TRST pin would

latch the device into boundary-scan mode. (I/O/Z, 8 mA drive ↑)

NOTE: An external pullup resistor is recommended on this pin. The value of this resistor should be based on the

drive strength of the debugger pods applicable to the design. A 2.2-kΩ to 4.7-kΩ resistor is generally adequate.

Since this is application-specific, it is recommended that each target board be validated for proper operation of the

debugger and the application.

FLASH

3.3-V Flash Core Power Pin. This pin should be connected to 3.3 V at all times.

CLOCK

Output clock derived from SYSCLKOUT. XCLKOUT is either the same frequency, one-half the frequency, or onefourth the frequency of SYSCLKOUT. This is controlled by bits 18:16 (XTIMCLK) and bit 2 (CLKMODE) in the

XINTCNF2[CLKOFF] to 1. Unlike other GPIO pins, the XCLKOUT pin is not placed in high-impedance state during a

reset. (O/Z, 8 mA drive).

External Oscillator Input. This pin is to feed a clock from an external 3.3-V oscillator. In this case, the X1 pin must be

must be tied to GND. (I)

(1)

(1) I = Input, O = Output, Z = High impedance, OD = Open drain, ↑ = Pullup, ↓ = Pulldown

18 Introduction Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 19

SM320F28335-HT

www.ti.com

SPRS682–DECEMBER 2010

Table 2-3. Signal Descriptions (continued)

NAME DESCRIPTION

Internal/External Oscillator Input. To use the internal oscillator, a quartz crystal or a ceramic resonator may be

X1

connected across X1 and X2. The X1 pin is referenced to the 1.9-V core digital power supply. A 1.9-V external

oscillator may be connected to the X1 pin. In this case, the XCLKIN pin must be connected to ground. If a 3.3-V

external oscillator is used with the XCLKIN pin, X1 must be tied to GND. (I)

X2

Internal Oscillator Output. A quartz crystal or a ceramic resonator may be connected across X1 and X2. If X2 is not

used it must be left unconnected. (O)

RESET

Device Reset (in) and Watchdog Reset (out).

Device reset. XRS causes the device to terminate execution. The PC will point to the address contained at the

location 0x3FFFC0. When XRS is brought to a high level, execution begins at the location pointed to by the PC. This

XRS pin is driven low by the DSC when a watchdog reset occurs. During watchdog reset, the XRS pin is driven low for the

watchdog reset duration of 512 OSCCLK cycles. (I/OD, ↑)

The output buffer of this pin is an open-drain with an internal pullup. It is recommended that this pin be driven by an

open-drain device.

ADC SIGNALS

ADCINA7 ADC Group A, Channel 7 input (I)

ADCINA6 ADC Group A, Channel 6 input (I)

ADCINA5 ADC Group A, Channel 5 input (I)

ADCINA4 ADC Group A, Channel 4 input (I)

ADCINA3 ADC Group A, Channel 3 input (I)

ADCINA2 ADC Group A, Channel 2 input (I)

ADCINA1 ADC Group A, Channel 1 input (I)

ADCINA0 ADC Group A, Channel 0 input (I)

ADCINB7 ADC Group B, Channel 7 input (I)

ADCINB6 ADC Group B, Channel 6 input (I)

ADCINB5 ADC Group B, Channel 5 input (I)

ADCINB4 ADC Group B, Channel 4 input (I)

ADCINB3 ADC Group B, Channel 3 input (I)

ADCINB2 ADC Group B, Channel 2 input (I)

ADCINB1 ADC Group B, Channel 1 input (I)

ADCINB0 ADC Group B, Channel 0 input (I)

ADCLO Low Reference (connect to analog ground) (I)

ADCRESEXT ADC External Current Bias Resistor. Connect a 22-kΩ resistor to analog ground.

ADCREFIN External reference input (I)

ADCREFP

ADCREFM

Internal Reference Positive Output. Requires a low ESR (50 mΩ - 1.5 Ω) ceramic bypass capacitor of 2.2 mF to

analog ground. (O)

Internal Reference Medium Output. Requires a low ESR (50 mΩ - 1.5 Ω) ceramic bypass capacitor of 2.2 mF to

analog ground. (O)

CPU AND I/O POWER PINS

V

DDA2

V

SSA2

V

DDAIO

V

SSAIO

V

DD1A18

V

SS1AGND

V

DD2A18

V

SS2AGND

V

DD

V

DDIO

V

SS

ADC Analog Power Pin

ADC Analog Ground Pin

ADC Analog I/O Power Pin

ADC Analog I/O Ground Pin

ADC Analog Power Pin

ADC Analog Ground Pin

ADC Analog Power Pin

ADC Analog Ground Pin

CPU and Logic Digital Power Pin

Digital I/O Power Pin

Digital Ground Pin

(1)

Copyright © 2010, Texas Instruments Incorporated Introduction 19

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 20

SM320F28335-HT

SPRS682–DECEMBER 2010

Table 2-3. Signal Descriptions (continued)

NAME DESCRIPTION

GPIOA AND PERIPHERAL SIGNALS

GPIO0 General purpose input/output 0 (I/O/Z)

EPWM1A Enhanced PWM1 Output A and HRPWM channel (O)

- -

- GPIO1 General purpose input/output 1 (I/O/Z)

EPWM1B Enhanced PWM1 Output B (O)

ECAP6 Enhanced Capture 6 input/output (I/O)

MFSRB McBSP-B receive frame synch (I/O)

GPIO2 General purpose input/output 2 (I/O/Z)

EPWM2A Enhanced PWM2 Output A and HRPWM channel (O)

- -

- GPIO3 General purpose input/output 3 (I/O/Z)

EPWM2B Enhanced PWM2 Output B (O)

ECAP5 Enhanced Capture 5 input/output (I/O)

MCLKRB McBSP-B receive clock (I/O)

GPIO4 General purpose input/output 4 (I/O/Z)

EPWM3A Enhanced PWM3 output A and HRPWM channel (O)

- -

- GPIO5 General purpose input/output 5 (I/O/Z)

EPWM3B Enhanced PWM3 output B (O)

MFSRA McBSP-A receive frame synch (I/O)

ECAP1 Enhanced Capture input/output 1 (I/O)

GPIO6 General purpose input/output 6 (I/O/Z)

EPWM4A Enhanced PWM4 output A and HRPWM channel (O)

EPWMSYNCI External ePWM sync pulse input (I)

EPWMSYNCO External ePWM sync pulse output (O)

GPIO7 General purpose input/output 7 (I/O/Z)

EPWM4B Enhanced PWM4 output B (O)

MCLKRA McBSP-A receive clock (I/O)

ECAP2 Enhanced capture input/output 2 (I/O)

GPIO8 General Purpose Input/Output 8 (I/O/Z)

EPWM5A Enhanced PWM5 output A and HRPWM channel (O)

CANTXB Enhanced CAN-B transmit (O)

ADCSOCAO ADC start-of-conversion A (O)

GPIO9 General purpose input/output 9 (I/O/Z)

EPWM5B Enhanced PWM5 output B (O)

SCITXDB SCI-B transmit data(O)

ECAP3 Enhanced capture input/output 3 (I/O)

GPIO10 General purpose input/output 10 (I/O/Z)

EPWM6A Enhanced PWM6 output A and HRPWM channel (O)

CANRXB Enhanced CAN-B receive (I)

ADCSOCBO ADC start-of-conversion B (O)

GPIO11 General purpose input/output 11 (I/O/Z)

EPWM6B Enhanced PWM6 output B (O)

SCIRXDB SCI-B receive data (I)

ECAP4 Enhanced CAP Input/Output 4 (I/O)

GPIO12 General purpose input/output 12 (I/O/Z)

TZ1 Trip Zone input 1 (I)

CANTXB Enhanced CAN-B transmit (O)

MDXB McBSP-B transmit serial data (O)

GPIO13 General purpose input/output 13 (I/O/Z)

TZ2 Trip Zone input 2 (I)

CANRXB Enhanced CAN-B receive (I)

MDRB McBSP-B receive serial data (I)

GPIO14 General purpose input/output 14 (I/O/Z)

www.ti.com

(1)

20 Introduction Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 21

SM320F28335-HT

www.ti.com

SPRS682–DECEMBER 2010

Table 2-3. Signal Descriptions (continued)

NAME DESCRIPTION

Trip Zone input 3/External Hold Request. XHOLD, when active (low), requests the external interface (XINTF) to

release the external bus and place all buses and strobes into a high-impedance state. To prevent this from

TZ3/XHOLD

SCITXDB SCI-B Transmit (I)

MCLKXB McBSP-B transmit clock (I/O)

GPIO15 General purpose input/output 15 (I/O/Z)

TZ4/XHOLDA output, then XHOLDA function is chosen. XHOLDA is driven active (low) when the XINTF has granted an XHOLD

SCIRXDB SCI-B receive (I)

MFSXB McBSP-B transmit frame synch (I/O)

GPIO16 General purpose input/output 16 (I/O/Z)

SPISIMOA SPI slave in, master out (I/O)

CANTXB Enhanced CAN-B transmit (O)

TZ5 Trip Zone input 5 (I)

GPIO17 General purpose input/output 17 (I/O/Z)

SPISOMIA SPI-A slave out, master in (I/O)

CANRXB Enhanced CAN-B receive (I)

TZ6 Trip zone input 6 (I)

GPIO18 General purpose input/output 18 (I/O/Z)

SPICLKA SPI-A clock input/output (I/O)

SCITXDB SCI-B transmit (O)

CANRXA Enhanced CAN-A receive (I)

GPIO19 General purpose input/output 19 (I/O/Z)

SPISTEA SPI-A slave transmit enable input/output (I/O)

SCIRXDB SCI-B receive (I)

CANTXA Enhanced CAN-A transmit (O)

GPIO20 General purpose input/output 20 (I/O/Z)

EQEP1A Enhanced QEP1 input A (I)

MDXA McBSP-A transmit serial data (O)

CANTXB Enhanced CAN-B transmit (O)

GPIO21 General purpose input/output 21 (I/O/Z)

EQEP1B Enhanced QEP1 input B (I)

MDRA McBSP-A receive serial data (I)

CANRXB Enhanced CAN-B receive (I)

GPIO22 General purpose input/output 22 (I/O/Z)

EQEP1S Enhanced QEP1 strobe (I/O)

MCLKXA McBSP-A transmit clock (I/O)

SCITXDB SCI-B transmit (O)

GPIO23 General purpose input/output 23 (I/O/Z)

EQEP1I Enhanced QEP1 index (I/O)

MFSXA McBSP-A transmit frame synch (I/O)

SCIRXDB SCI-B receive (I)

GPIO24 General purpose input/output 24 (I/O/Z)

ECAP1 Enhanced capture 1 (I/O)

EQEP2A Enhanced QEP2 input A (I)

MDXB McBSP-B transmit serial data (O)

GPIO25 General purpose input/output 25 (I/O/Z)

ECAP2 Enhanced capture 2 (I/O)

EQEP2B Enhanced QEP2 input B (I)

MDRB McBSP-B receive serial data (I)

GPIO26 General purpose input/output 26 (I/O/Z)

ECAP3 Enhanced capture 3 (I/O)

EQEP2I Enhanced QEP2 index (I/O)

MCLKXB McBSP-B transmit clock (I/O)

happening when TZ3 signal goes active, disable this function by writing XINTCNF2[HOLD] = 1. If this is not done, the

XINTF bus will go into high impedance anytime TZ3 goes low. On the ePWM side, TZn signals are ignored by

default, unless they are enabled by the code. The XINTF will release the bus when any current access is complete

and there are no pending accesses on the XINTF. (I)

Trip Zone input 4/External Hold Acknowledge. The pin function for this option is based on the direction chosen in the

GPADIR register. If the pin is configured as an input, then TZ4 function is chosen. If the pin is configured as an

request. All XINTF buses and strobe signals will be in a high-impedance state. XHOLDA is released when the

XHOLD signal is released. External devices should only drive the external bus when XHOLDA is active (low). (I/0)

(1)

Copyright © 2010, Texas Instruments Incorporated Introduction 21

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 22

SM320F28335-HT

SPRS682–DECEMBER 2010

Table 2-3. Signal Descriptions (continued)

NAME DESCRIPTION

GPIO27 General purpose input/output 27 (I/O/Z)

ECAP4 Enhanced capture 4 (I/O)

EQEP2S Enhanced QEP2 strobe (I/O)

MFSXB McBSP-B transmit frame synch (I/O)

GPIO28 General purpose input/output 28 (I/O/Z)

SCIRXDA SCI receive data (I)

XZCS6 External Interface zone 6 chip select (O)

GPIO29 General purpose input/output 29. (I/O/Z)

SCITXDA SCI transmit data (O)

XA19 External Interface Address Line 19 (O)

GPIO30 General purpose input/output 30 (I/O/Z)

CANRXA Enhanced CAN-A receive (I)

XA18 External Interface Address Line 18 (O)

GPIO31 General purpose input/output 31 (I/O/Z)

CANTXA Enhanced CAN-A transmit (O)

XA17 External Interface Address Line 17 (O)

GPIO32 General purpose input/output 32 (I/O/Z)

SDAA I2C data open-drain bidirectional port (I/OD)

EPWMSYNCI Enhanced PWM external sync pulse input (I)

ADCSOCAO ADC start-of-conversion A (O)

GPIO33 General-Purpose Input/Output 33 (I/O/Z)

SCLA I2C clock open-drain bidirectional port (I/OD)

EPWMSYNCO Enhanced PWM external synch pulse output (O)

ADCSOCBO ADC start-of-conversion B (O)

GPIO34 General-Purpose Input/Output 34 (I/O/Z)

ECAP1 Enhanced Capture input/output 1 (I/O)

XREADY External Interface Ready signal

GPIO35 General-Purpose Input/Output 35 (I/O/Z)

SCITXDA SCI-A transmit data (O)

XR/W External Interface read, not write strobe

GPIO36 General-Purpose Input/Output 36 (I/O/Z)

SCIRXDA SCI receive data (I)

XZCS0 External Interface zone 0 chip select (O)

GPIO37 General-Purpose Input/Output 37 (I/O/Z)

ECAP2 Enhanced Capture input/output 2 (I/O)

XZCS7 External Interface zone 7 chip select (O)

GPIO38 General-Purpose Input/Output 38 (I/O/Z)

- XWE0 External Interface Write Enable 0 (O)

GPIO39 General-Purpose Input/Output 39 (I/O/Z)

- XA16 External Interface Address Line 16 (O)

GPIO40 General-Purpose Input/Output 40 (I/O/Z)

- XA0/XWE1 External Interface Address Line 0/External Interface Write Enable 1 (O)

GPIO41 General-Purpose Input/Output 41 (I/O/Z)

- XA1 External Interface Address Line 1 (O)

GPIO42 General-Purpose Input/Output 42 (I/O/Z)

- XA2 External Interface Address Line 2 (O)

GPIO43 General-Purpose Input/Output 43 (I/O/Z)

- XA3 External Interface Address Line 3 (O)

GPIO44 General-Purpose Input/Output 44 (I/O/Z)

- XA4 External Interface Address Line 4 (O)

GPIO45 General-Purpose Input/Output 45 (I/O/Z)

- XA5 External Interface Address Line 5 (O)

(1)

www.ti.com

22 Introduction Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 23

SM320F28335-HT

www.ti.com

Table 2-3. Signal Descriptions (continued)

NAME DESCRIPTION

GPIO46 General-Purpose Input/Output 46 (I/O/Z)

- XA6 External Interface Address Line 6 (O)

GPIO47 General-Purpose Input/Output 47 (I/O/Z)

- XA7 External Interface Address Line 7 (O)

GPIO48 General-Purpose Input/Output 48 (I/O/Z)

ECAP5 Enhanced Capture input/output 5 (I/O)

XD31 External Interface Data Line 31 (O)

GPIO49 General-Purpose Input/Output 49 (I/O/Z)

ECAP6 Enhanced Capture input/output 6 (I/O)

XD30 External Interface Data Line 30 (O)

GPIO50 General-Purpose Input/Output 50 (I/O/Z)

EQEP1A Enhanced QEP 1input A (I)

XD29 External Interface Data Line 29 (O)

GPIO51 General-Purpose Input/Output 51 (I/O/Z)

EQEP1B Enhanced QEP 1input B (I)

XD28 External Interface Data Line 28 (O)

GPIO52 General-Purpose Input/Output 52 (I/O/Z)

EQEP1S Enhanced QEP 1Strobe (I/O)

XD27 External Interface Data Line 27 (O)

GPIO53 General-Purpose Input/Output 53 (I/O/Z)

EQEP1I Enhanced CAP1 lndex (I/O)

XD26 External Interface Data Line 26 (O)

GPIO54 General-Purpose Input/Output 54 (I/O/Z)

SPISIMOA SPI-A slave in, master out (I/O)

XD25 External Interface Data Line 25 (O)

GPIO55 General-Purpose Input/Output 55 (I/O/Z)

SPISOMIA SPI-A slave out, master in (I/O)

XD24 External Interface Data Line 24 (O)

GPIO56 General-Purpose Input/Output 56 (I/O/Z)

SPICLKA SPI-A clock (I/O)

XD23 External Interface Data Line 23 (O)

GPIO57 General-Purpose Input/Output 57 (I/O/Z)

SPISTEA SPI-A slave transmit enable (I/O)

XD22 External Interface Data Line 22 (O)

GPIO58 General-Purpose Input/Output 58 (I/O/Z)

MCLKRA McBSP-A receive clock (I/O)

XD21 External Interface Data Line 21 (O)

GPIO59 General-Purpose Input/Output 59 (I/O/Z)

MFSRA McBSP-A receive frame synch (I/O)

XD20 External Interface Data Line 20 (O)

GPIO60 General-Purpose Input/Output 60 (I/O/Z)

MCLKRB McBSP-B receive clock (I/O)

XD19 External Interface Data Line 19 (O)

GPIO61 General-Purpose Input/Output 61 (I/O/Z)

MFSRB McBSP-B receive frame synch (I/O)

XD18 External Interface Data Line 18 (O)

GPIO62 General-Purpose Input/Output 62 (I/O/Z)

SCIRXDC SCI-C receive data (I)

XD17 External Interface Data Line 17 (O)

GPIO63 General-Purpose Input/Output 63 (I/O/Z)

SCITXDC SCI-C transmit data (O)

XD16 External Interface Data Line 16 (O)

GPIO64 General-Purpose Input/Output 64 (I/O/Z)

- XD15 External Interface Data Line 15 (O)

GPIO65 General-Purpose Input/Output 65 (I/O/Z)

- XD14 External Interface Data Line 14 (O)

SPRS682–DECEMBER 2010

(1)

Copyright © 2010, Texas Instruments Incorporated Introduction 23

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 24

SM320F28335-HT

SPRS682–DECEMBER 2010

Table 2-3. Signal Descriptions (continued)

NAME DESCRIPTION

GPIO66 General-Purpose Input/Output 66 (I/O/Z)

- XD13 External Interface Data Line 13 (O)

GPIO67 General-Purpose Input/Output 67 (I/O/Z)

- XD12 External Interface Data Line 12 (O)

GPIO68 General-Purpose Input/Output 68 (I/O/Z)

- XD11 External Interface Data Line 11 (O)

GPIO69 General-Purpose Input/Output 69 (I/O/Z)

- XD10 External Interface Data Line 10 (O)

GPIO70 General-Purpose Input/Output 70 (I/O/Z)

- XD9 External Interface Data Line 9 (O)

GPIO71 General-Purpose Input/Output 71 (I/O/Z)

- XD8 External Interface Data Line 8 (O)

GPIO72 General-Purpose Input/Output 72 (I/O/Z)

- XD7 External Interface Data Line 7 (O)

GPIO73 General-Purpose Input/Output 73 (I/O/Z)

- XD6 External Interface Data Line 6 (O)

GPIO74 General-Purpose Input/Output 74 (I/O/Z)

- XD5 External Interface Data Line 5 (O)

GPIO75 General-Purpose Input/Output 75 (I/O/Z)

- XD4 External Interface Data Line 4 (O)

GPIO76 General-Purpose Input/Output 76 (I/O/Z)

- XD3 External Interface Data Line 3 (O)

GPIO77 General-Purpose Input/Output 77 (I/O/Z)

- XD2 External Interface Data Line 2 (O)

GPIO78 General-Purpose Input/Output 78 (I/O/Z)

- XD1 External Interface Data Line 1 (O)

GPIO79 General-Purpose Input/Output 79 (I/O/Z)

- XD0 External Interface Data Line 0 (O)

GPIO80 General-Purpose Input/Output 80 (I/O/Z)

- XA8 External Interface Address Line 8 (O)

GPIO81 General-Purpose Input/Output 81 (I/O/Z)

- XA9 External Interface Address Line 9 (O)

GPIO82 General-Purpose Input/Output 82 (I/O/Z)

- XA10 External Interface Address Line 10 (O)

GPIO83 General-Purpose Input/Output 83 (I/O/Z)

- XA11 External Interface Address Line 11 (O)

GPIO84

XA12

GPIO85 General-Purpose Input/Output 85 (I/O/Z)

- XA13 External Interface Address Line 13 (O)

General-Purpose Input/Output 84 (I/O/Z)

External Interface Address Line 12 (O)

www.ti.com

(1)

24 Introduction Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 25

SM320F28335-HT

www.ti.com

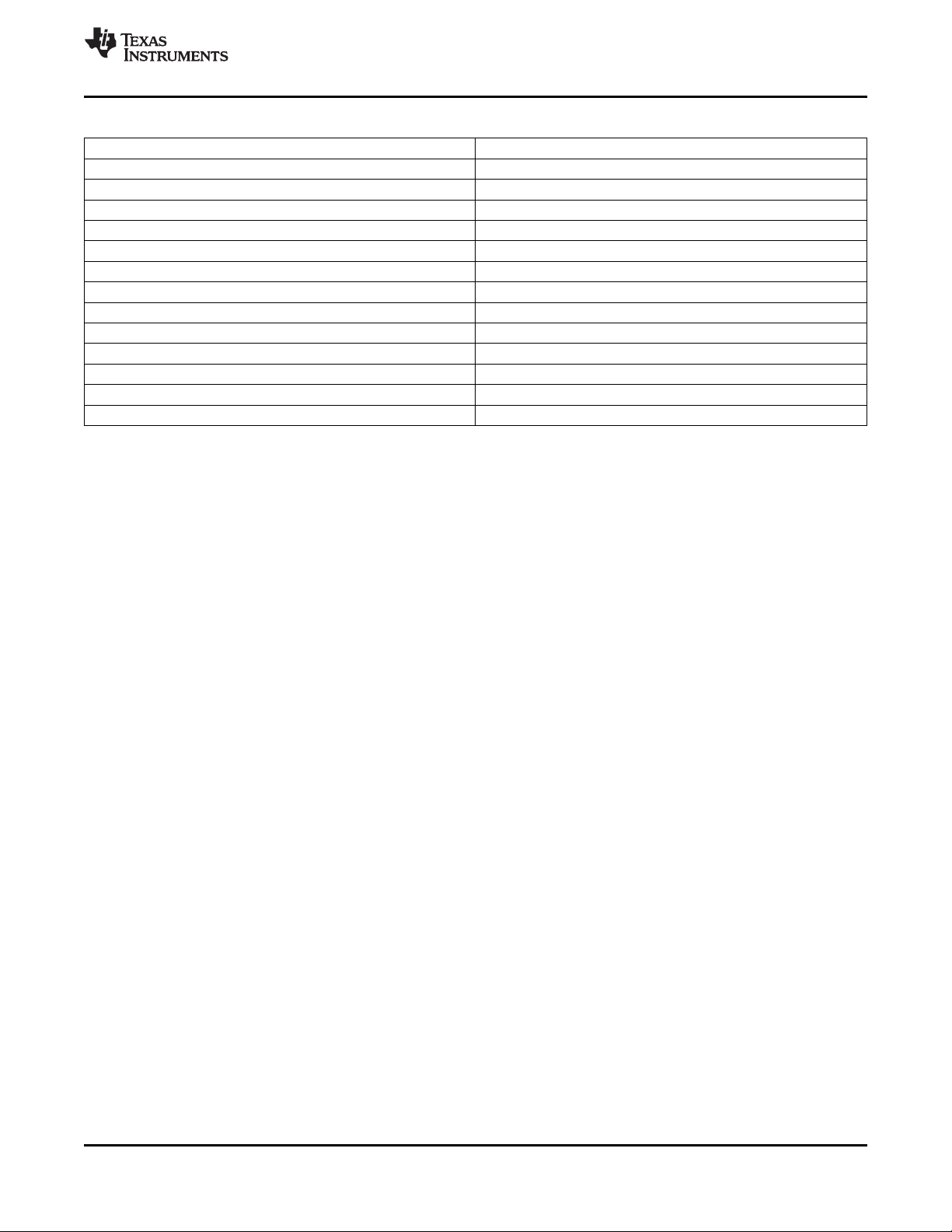

Table 2-3. Signal Descriptions (continued)

NAME DESCRIPTION

GPIO86 General-Purpose Input/Output 86 (I/O/Z)

- XA14 External Interface Address Line 14 (O)

GPIO87 General-Purpose Input/Output 87 (I/O/Z)

- XA15 External Interface Address Line 15 (O)

XRD External Interface Read Enable

SPRS682–DECEMBER 2010

(1)

Copyright © 2010, Texas Instruments Incorporated Introduction 25

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 26

L0SARAM4Kx16

(0-Wait,DualMap)

L1SARAM4Kx16

(0-Wait,DualMap)

L2SARAM4Kx16

(0-Wait,DualMap)

L3SARAM4Kx16

(0-Wait,DualMap)

M0SARAM1Kx16

(0-Wait)

M1SARAM1Kx16

(0-Wait)

L4SARAM4Kx16

(0-WData,1-WProg)

L5SARAM4Kx16

(0-WData,1-WProg)

L6SARAM4Kx16

(0-WData,1-WProg)

L7SARAM4Kx16

(0-WData,1-WProg)

MemoryBus

BootROM

8Kx16

Code

Security

Module

DMA Bus

PSWD

OTP 1Kx16

Flash

256Kx16

8Sectors

Pump

Flash

Wrapper

TEST1

TEST2

XINTF

XA0/XWE1

XWE0

XZCS6

XZCS7

XZCS0

XR/W

XREADY

XHOLD

XHOLDA

XD31:0

XA19:1

GPIO

MUX

MemoryBus

MemoryBus

XCLKOUT

XRD

GPIO

MUX

88GPIOs

8ExternalInterrupts

88GPIOs

12-Bit

ADC

2-S/H

A7:0

B7:0

CPUTimer0

CPUTimer1

CPUTimer2

OSC,

PLL,

LPM,

WD

DMA

6Ch

PIE

(Interrupts)

32-bitCPU

(150MHZ@1.9V)

(100MHz@1.8V)

EMU1

EMU0

TRST

TDO

TMS

TDI

TCK

XRS

X2

X1

XCLKIN

FPU

REFIN

DMA Bus

MemoryBus

FIFO

(16Levels)

SCI-A/B/C

FIFO

(16Levels)

SPI-A

FIFO

(16Levels)

I2C

16-bitperipheralbus

SPISOMIx

SPISIMOx

SPICLKx

SPISTEx

SCIRXDx

SCITXDx

SDAx

SCLx

McBSP-A/B

MRXx

MDXx

MCLKXx

MCLKRx

MFSXx

MFSRx

32-bitperipheralbus

(DMA accessible)

EPWM-1/../6

HRPWM-1/../6

ECAP-1/../6

EQEP-1/2

EPWMxA

EPWMxB

ESYNCI

ESYNCO

TZx

ECAPx

EQEPxA

EQEPxB

EQEPxI

EQEPxS

CAN-A/B

(32-mbox)

CANRXx

CANTXx

32-bitperipheralbus

GPIOMUX

88GPIOs

XINTF

Securezone

SM320F28335-HT

SPRS682–DECEMBER 2010

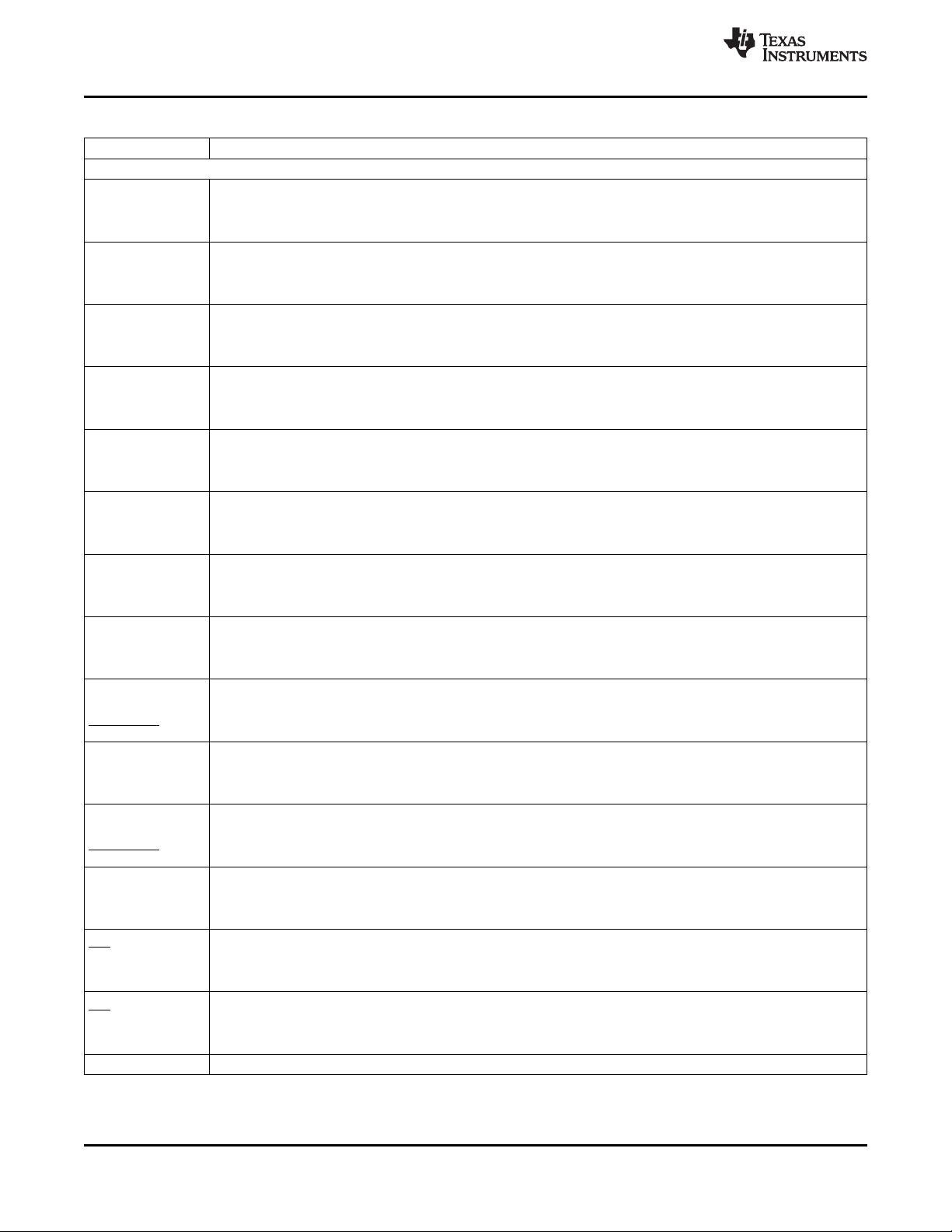

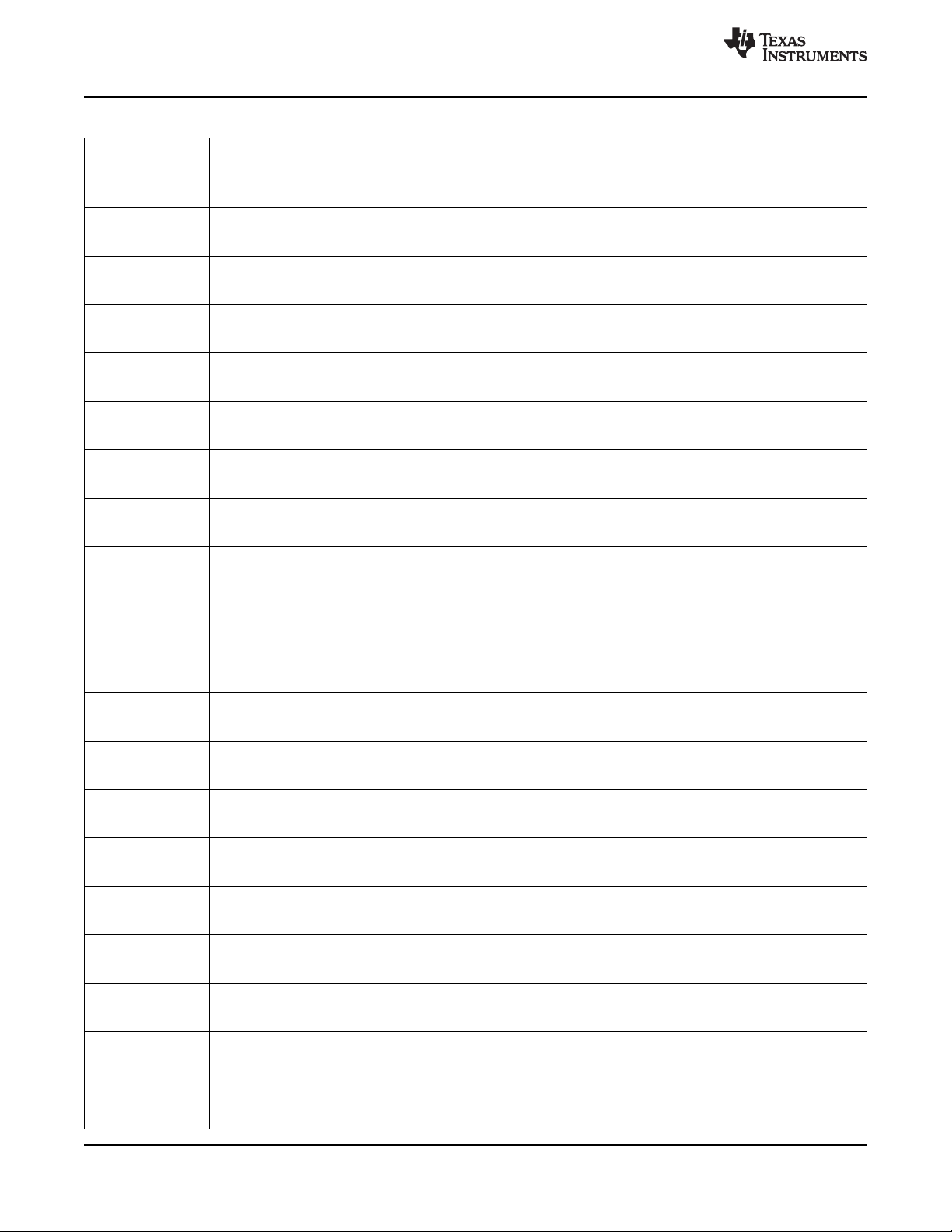

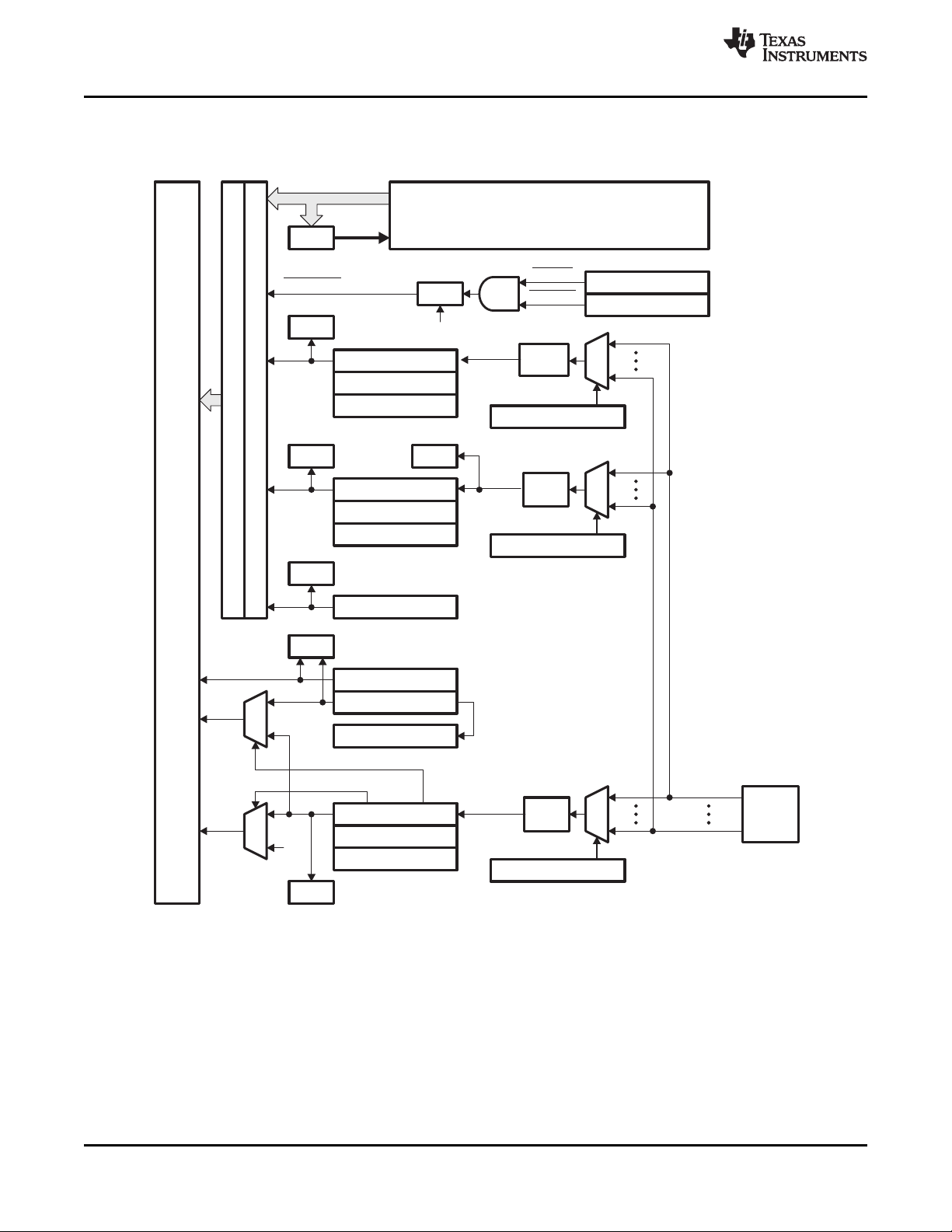

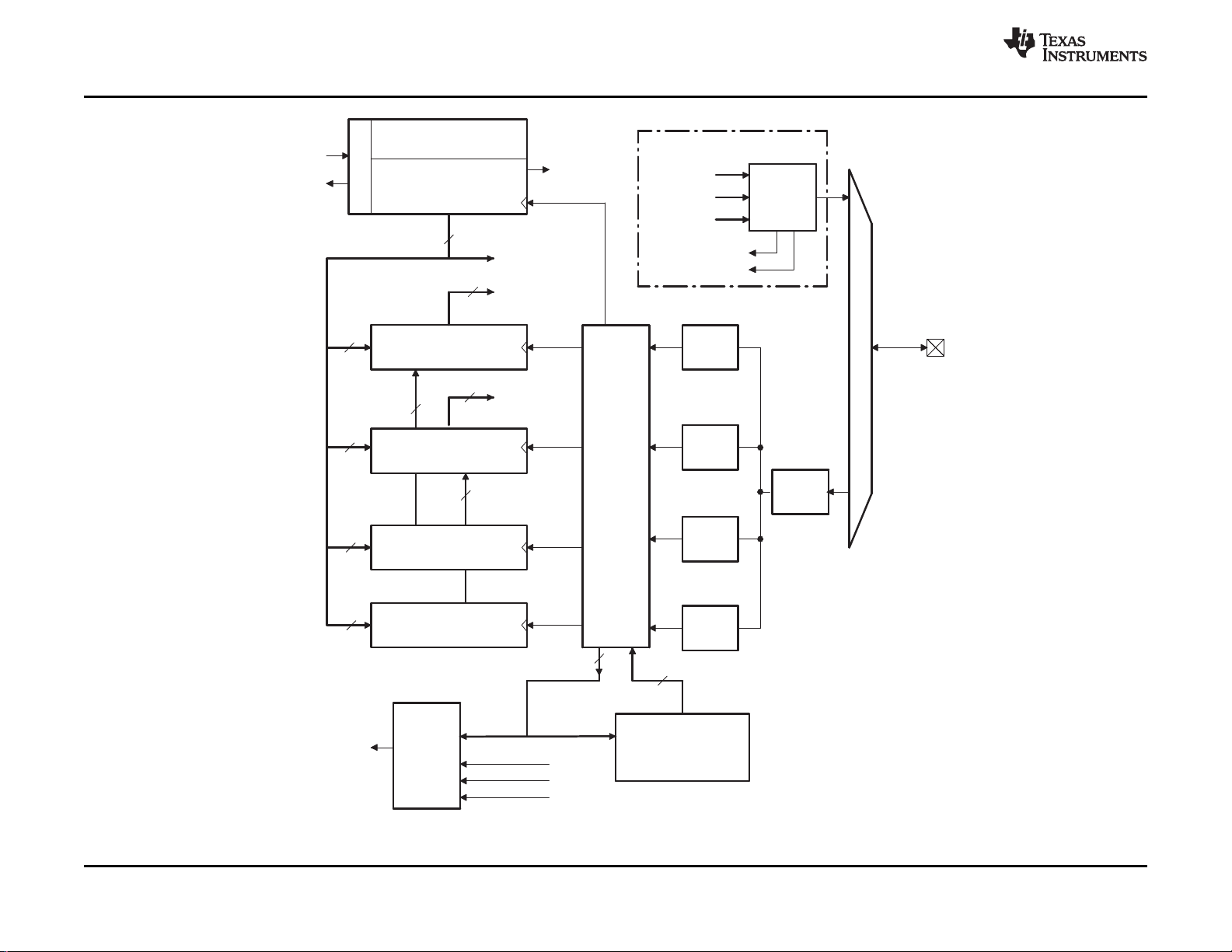

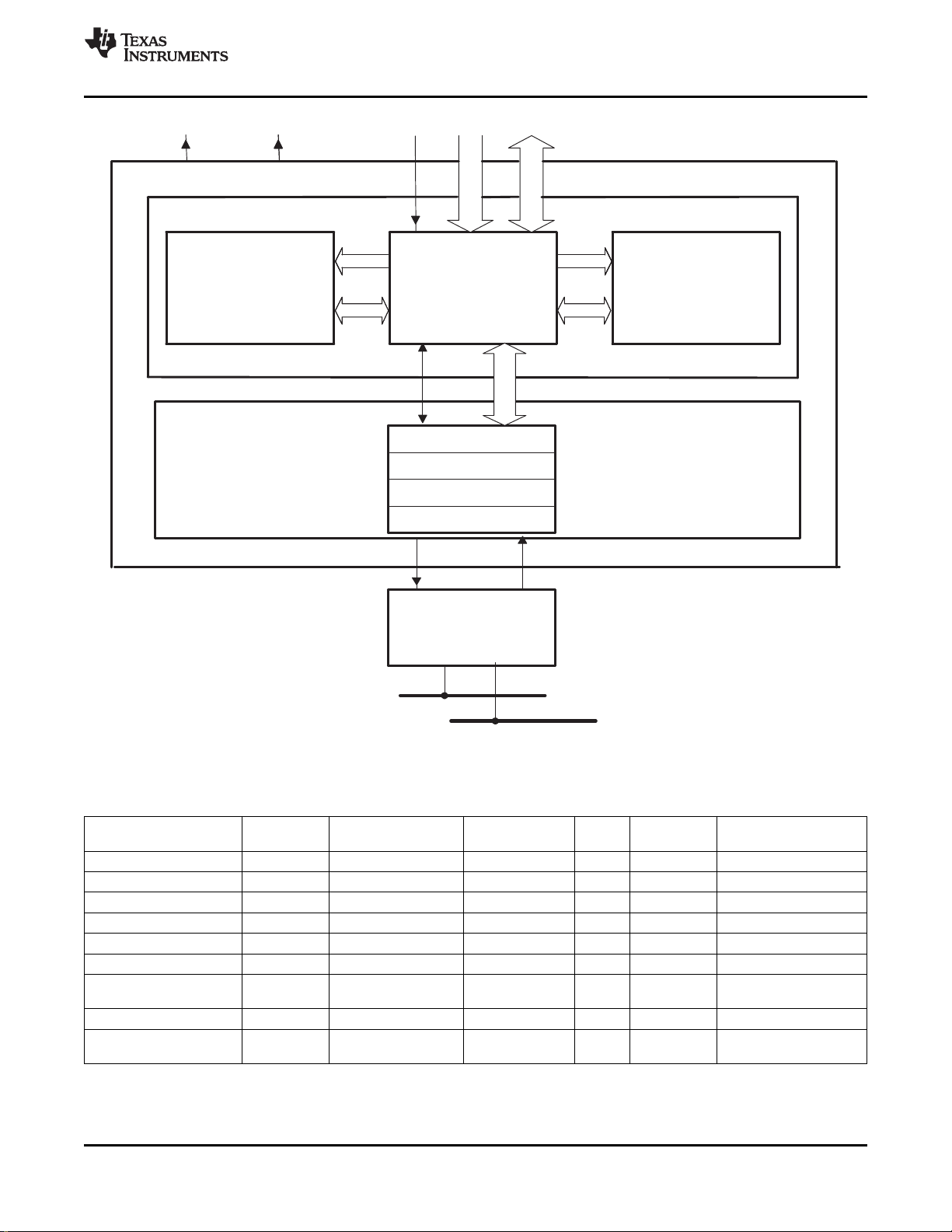

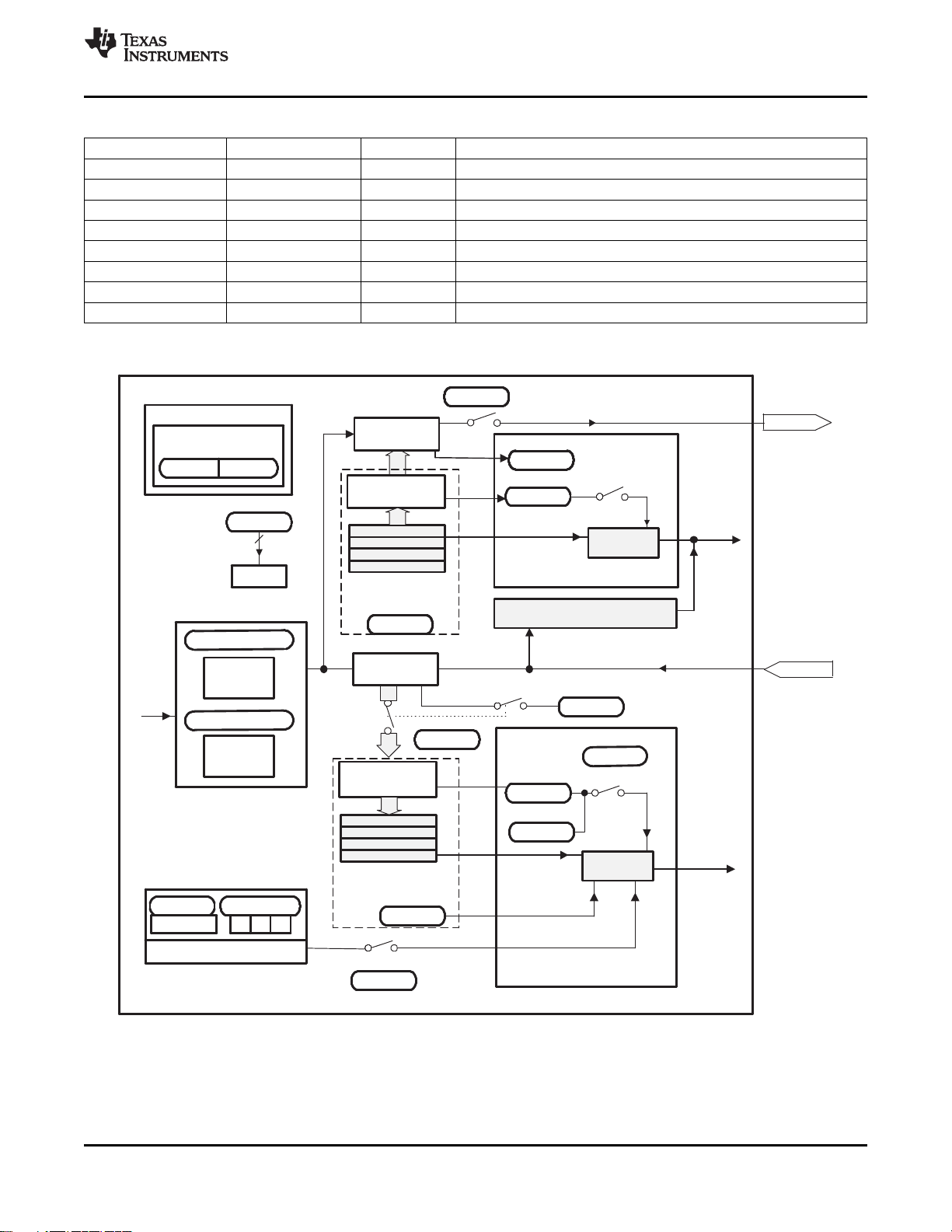

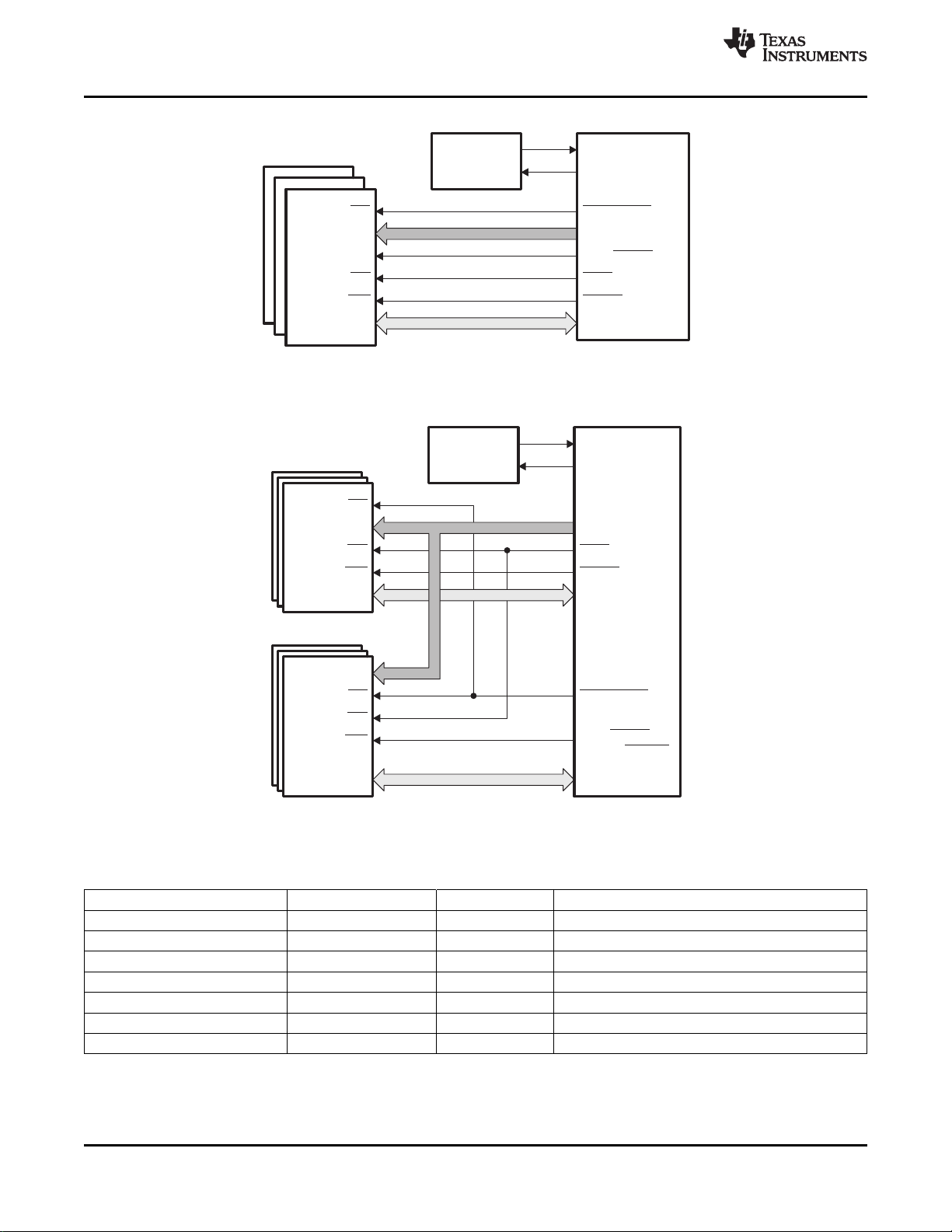

3 Functional Overview

www.ti.com

Figure 3-1. Functional Block Diagram

26 Functional Overview Copyright © 2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F28335-HT

Page 27

SM320F28335-HT

www.ti.com

3.1 Memory Maps