Page 1

SM320F2812-HT

Digital Signal Processor

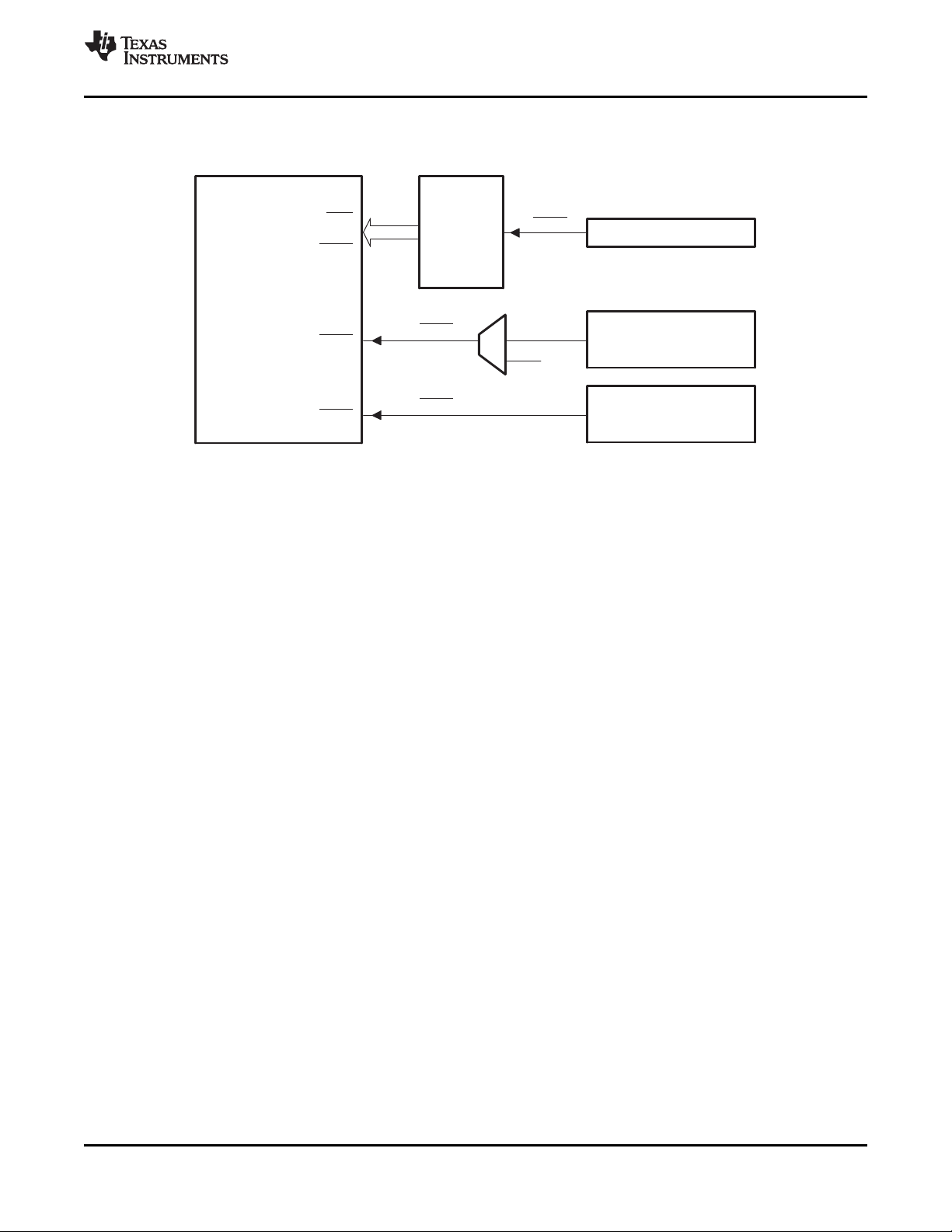

Data Manual

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Literature Number: SGUS062A

June 2009–Revised April 2010

Page 2

SM320F2812-HT

SGUS062A–JUNE 2009–REVISED APRIL 2010

www.ti.com

Contents

1 Features ........................................................................................................................... 11

1.1 SUPPORTS EXTREME TEMPERATURE APPLICATIONS ......................................................... 12

2 Introduction ...................................................................................................................... 13

2.1 Description ................................................................................................................. 13

2.2 Device Summary .......................................................................................................... 14

2.3 Die Layout .................................................................................................................. 15

2.4 Pin Assignments ........................................................................................................... 16

2.5 Signal Descriptions ........................................................................................................ 17

3 Functional Overview .......................................................................................................... 27

3.1 Memory Map ............................................................................................................... 28

3.2 Brief Descriptions .......................................................................................................... 31

3.2.1 C28x CPU ....................................................................................................... 31

3.2.2 Memory Bus (Harvard Bus Architecture) .................................................................... 31

3.2.3 Peripheral Bus .................................................................................................. 31

3.2.4 Real-Time JTAG and Analysis ................................................................................ 31

3.2.5 External Interface (XINTF) .................................................................................... 32

3.2.6 Flash ............................................................................................................. 32

3.2.7 L0, L1, H0 SARAMs ............................................................................................ 32

3.2.8 Boot ROM ....................................................................................................... 32

3.2.9 Security .......................................................................................................... 33

3.2.10 Peripheral Interrupt Expansion (PIE) Block ................................................................. 34

3.2.11 External Interrupts (XINT1, XINT2, XINT13, XNMI) ........................................................ 34

3.2.12 Oscillator and PLL .............................................................................................. 34

3.2.13 Watchdog ........................................................................................................ 34

3.2.14 Peripheral Clocking ............................................................................................. 34

3.2.15 Low-Power Modes .............................................................................................. 34

3.2.16 Peripheral Frames 0, 1, 2 (PFn) .............................................................................. 35

3.2.17 General-Purpose Input/Output (GPIO) Multiplexer ......................................................... 35

3.2.18 32-Bit CPU Timers (0, 1, 2) ................................................................................... 35

3.2.19 Control Peripherals ............................................................................................. 35

3.2.20 Serial Port Peripherals ......................................................................................... 36

3.3 Register Map ............................................................................................................... 36

3.4 Device Emulation Registers .............................................................................................. 39

3.5 External Interface, XINTF ................................................................................................ 39

3.5.1 Timing Registers ................................................................................................ 41

3.5.2 XREVISION Register ........................................................................................... 41

3.6 Interrupts .................................................................................................................... 42

3.6.1 External Interrupts .............................................................................................. 45

3.7 System Control ............................................................................................................ 46

3.8 OSC and PLL Block ....................................................................................................... 48

3.8.1 Loss of Input Clock ............................................................................................. 49

3.9 PLL-Based Clock Module ................................................................................................ 49

3.10 External Reference Oscillator Clock Option ........................................................................... 49

3.11 Watchdog Block ........................................................................................................... 50

3.12 Low-Power Modes Block ................................................................................................. 51

2 Contents Copyright © 2009–2010, Texas Instruments Incorporated

Page 3

SM320F2812-HT

www.ti.com

SGUS062A–JUNE 2009–REVISED APRIL 2010

4 Peripherals ....................................................................................................................... 52

4.1 32-Bit CPU-Timers 0/1/2 ................................................................................................. 52

4.2 Event Manager Modules (EVA, EVB) ................................................................................... 55

4.2.1 General-Purpose (GP) Timers ................................................................................ 58

4.2.2 Full-Compare Units ............................................................................................. 58

4.2.3 Programmable Deadband Generator ........................................................................ 58

4.2.4 PWM Waveform Generation .................................................................................. 58

4.2.5 Double Update PWM Mode ................................................................................... 58

4.2.6 PWM Characteristics ........................................................................................... 59

4.2.7 Capture Unit ..................................................................................................... 59

4.2.8 Quadrature-Encoder Pulse (QEP) Circuit ................................................................... 59

4.2.9 External ADC Start-of-Conversion ........................................................................... 59

4.3 Enhanced Analog-to-Digital Converter (ADC) Module ............................................................... 60

4.4 Enhanced Controller Area Network (eCAN) Module .................................................................. 65

4.5 Multichannel Buffered Serial Port (McBSP) Module .................................................................. 69

4.6 Serial Communications Interface (SCI) Module ....................................................................... 73

4.7 Serial Peripheral Interface (SPI) Module ............................................................................... 76

4.8 GPIO MUX ................................................................................................................. 79

5 Development Support ........................................................................................................ 82

5.1 Device and Development Support Tool Nomenclature ............................................................... 82

5.2 Documentation Support ................................................................................................... 83

6 Electrical Specifications ..................................................................................................... 85

6.1 Absolute Maximum Ratings .............................................................................................. 85

6.2 Recommended Operating Conditions .................................................................................. 86

6.3 Electrical Characteristics ................................................................................................. 86

6.4 Current Consumption by Power-Supply Pins Over Recommended Operating Conditions During

Low-Power Modes at 150-MHz SYSCLKOUT ......................................................................... 88

6.5 Current Consumption Graphs ............................................................................................ 89

6.6 Reducing Current Consumption ......................................................................................... 90

6.7 Power Sequencing Requirements ....................................................................................... 90

6.8 Signal Transition Levels .................................................................................................. 91

6.9 Timing Parameter Symbology ........................................................................................... 92

6.10 General Notes on Timing Parameters .................................................................................. 93

6.11 Test Load Circuit .......................................................................................................... 93

6.12 Device Clock Table ........................................................................................................ 94

6.13 Clock Requirements and Characteristics ............................................................................... 94

6.13.1 Input Clock Requirements ..................................................................................... 94

6.13.2 Output Clock Characteristics .................................................................................. 95

6.14 Reset Timing ............................................................................................................... 96

6.15 Low-Power Mode Wakeup Timing ..................................................................................... 100

6.16 Event Manager Interface ................................................................................................ 104

6.16.1 PWM Timing ................................................................................................... 104

6.16.2 Interrupt Timing ................................................................................................ 106

6.17 General-Purpose Input/Output (GPIO) – Output Timing ............................................................ 107

6.18 General-Purpose Input/Output (GPIO) – Input Timing .............................................................. 108

6.19 SPI Master Mode Timing ................................................................................................ 109

Copyright © 2009–2010, Texas Instruments Incorporated Contents 3

Page 4

SM320F2812-HT

SGUS062A–JUNE 2009–REVISED APRIL 2010

6.20 SPI Slave Mode Timing ................................................................................................. 113

6.21 External Interface (XINTF) Timing ..................................................................................... 117

6.22 XINTF Signal Alignment to XCLKOUT ................................................................................ 121

6.23 External Interface Read Timing ........................................................................................ 122

6.24 External Interface Write Timing ........................................................................................ 123

6.25 External Interface Ready-on-Read Timing With One External Wait State ....................................... 125

6.26 External Interface Ready-on-Write Timing With One External Wait State ........................................ 128

6.27 XHOLD and XHOLDA ................................................................................................... 131

6.28 XHOLD/XHOLDA Timing ............................................................................................... 132

6.29 On-Chip Analog-to-Digital Converter .................................................................................. 134

6.29.1 ADC Absolute Maximum Ratings ........................................................................... 134

6.29.2 ADC Electrical Characteristics Over Recommended Operating Conditions ........................... 135

6.29.3 Current Consumption for Different ADC Configurations (at 25-MHz ADCCLK) ...................... 136

6.29.4 ADC Power-Up Control Bit Timing .......................................................................... 137

6.29.5 Detailed Description .......................................................................................... 138

6.29.5.1 Reference Voltage ................................................................................ 138

6.29.5.2 Analog Inputs ..................................................................................... 138

6.29.5.3 Converter .......................................................................................... 138

6.29.5.4 Conversion Modes ............................................................................... 138

6.29.6 Sequential Sampling Mode (Single Channel) (SMODE = 0) ............................................ 138

6.29.7 Simultaneous Sampling Mode (Dual-Channel) (SMODE = 1) .......................................... 140

6.29.8 Definitions of Specifications and Terminology ............................................................. 141

6.29.8.1 Integral Nonlinearity .............................................................................. 141

6.29.8.2 Differential Nonlinearity .......................................................................... 141

6.29.8.3 Zero Offset ........................................................................................ 141

6.29.8.4 Gain Error ......................................................................................... 141

6.29.8.5 Signal-to-Noise Ratio + Distortion (SINAD) ................................................... 141

6.29.8.6 Effective Number of Bits (ENOB) ............................................................... 141

6.29.8.7 Total Harmonic Distortion (THD) ............................................................... 141

6.29.8.8 Spurious Free Dynamic Range (SFDR) ....................................................... 141

6.30 Multichannel Buffered Serial Port (McBSP) Timing ................................................................. 142

6.30.1 McBSP Transmit and Receive Timing ...................................................................... 142

6.30.2 McBSP as SPI Master or Slave Timing .................................................................... 145

6.31 Flash Timing .............................................................................................................. 149

6.31.1 Recommended Operating Conditions ...................................................................... 149

www.ti.com

7 Mechanical Data .............................................................................................................. 151

4 Contents Copyright © 2009–2010, Texas Instruments Incorporated

Page 5

SM320F2812-HT

www.ti.com

SGUS062A–JUNE 2009–REVISED APRIL 2010

List of Figures

2-1 SM320F2812 Die Layout........................................................................................................ 15

2-2 SM320F2812 172-Pin HFG CQFP (Top View)............................................................................... 16

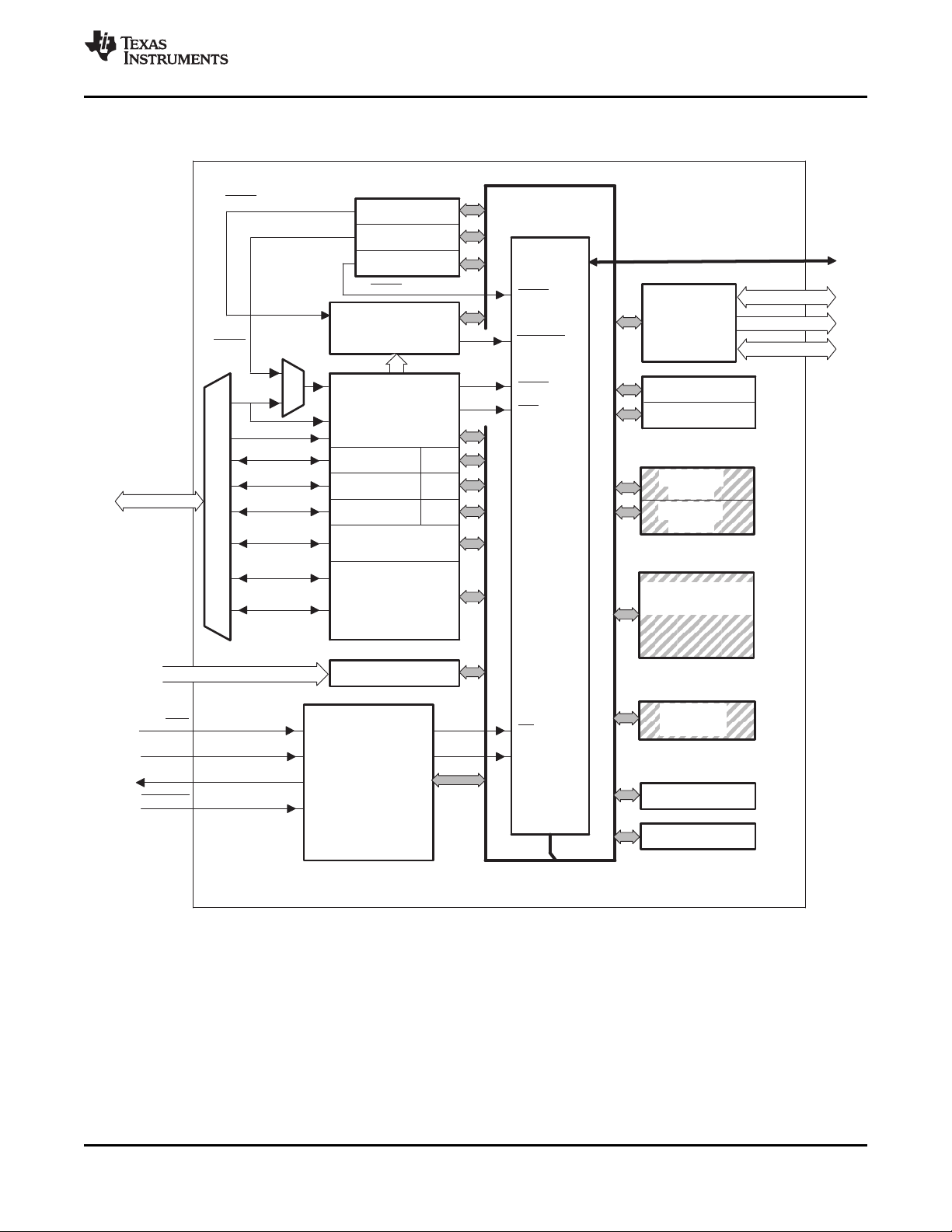

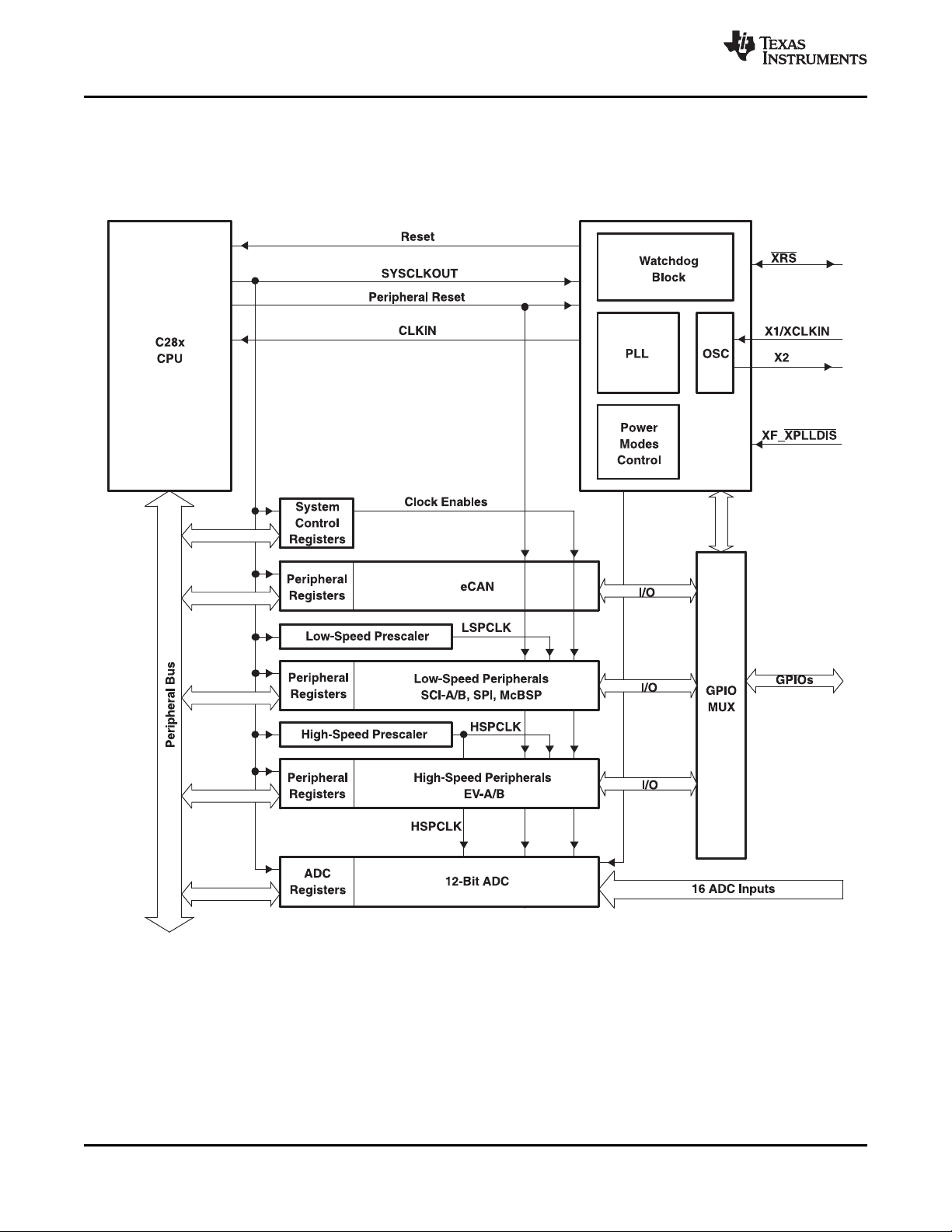

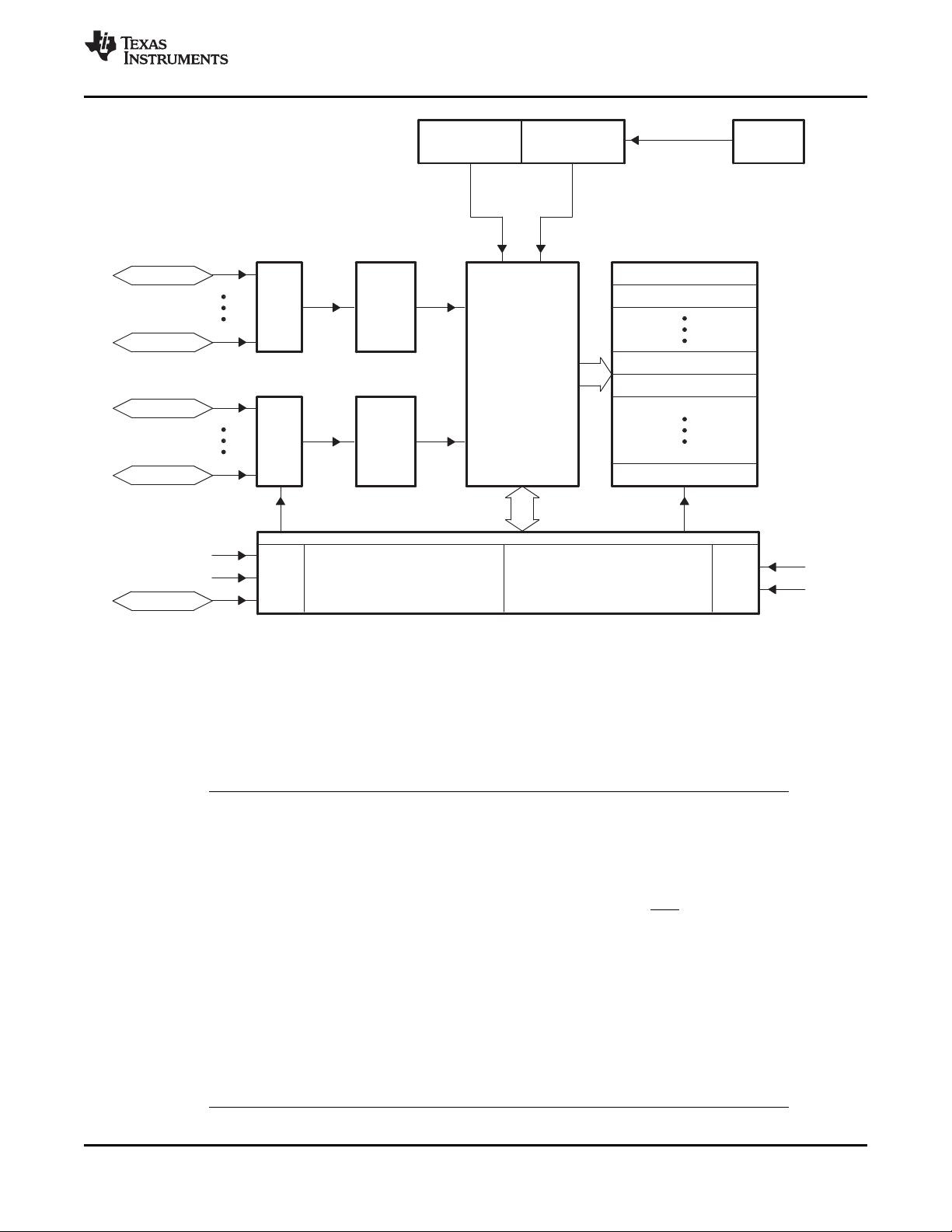

3-1 Functional Block Diagram....................................................................................................... 28

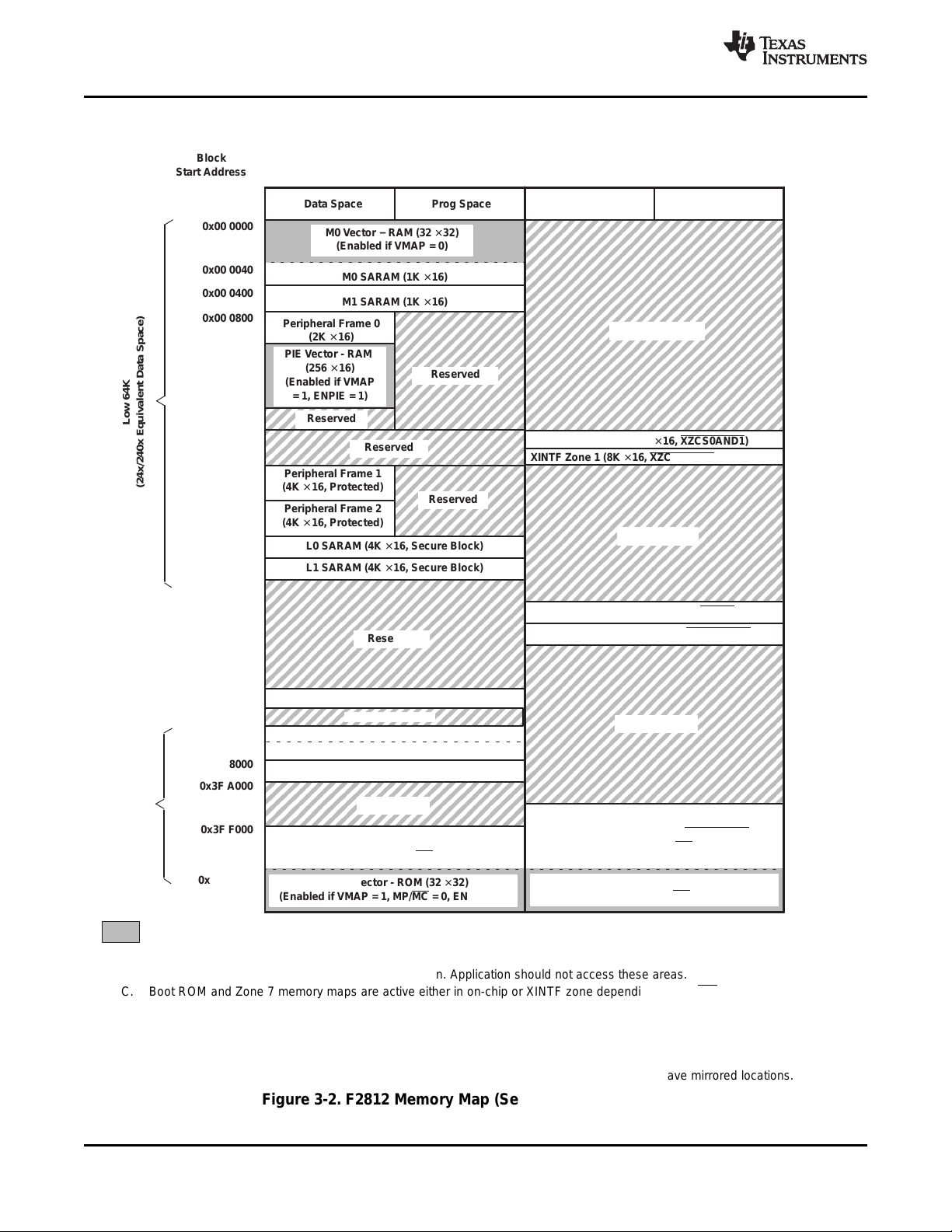

3-2 F2812 Memory Map (See Notes A. Through G.) ............................................................................ 28

3-3 External Interface Block Diagram .............................................................................................. 40

3-4 Interrupt Sources ................................................................................................................. 42

3-5 Multiplexing of Interrupts Using the PIE Block ............................................................................... 43

3-6 Clock and Reset Domains ...................................................................................................... 46

3-7 OSC and PLL Block.............................................................................................................. 48

3-8 Recommended Crystal/Clock Connection .................................................................................... 49

3-9 Watchdog Module ................................................................................................................ 50

4-1 CPU-Timers....................................................................................................................... 52

4-2 CPU-Timer Interrupts Signals and Output Signal (See Notes A. and B.)................................................. 53

4-3 Event Manager A Functional Block Diagram (See Note A.)................................................................ 58

4-4 Block Diagram of the F2812 ADC Module.................................................................................... 61

4-5 ADC Pin Connections With Internal Reference (See Notes A and B)..................................................... 62

4-6 ADC Pin Connections With External Reference ............................................................................. 63

4-7 eCAN Block Diagram and Interface Circuit................................................................................... 66

4-8 eCAN Memory Map .............................................................................................................. 67

4-9 McBSP Module With FIFO...................................................................................................... 70

4-10 Serial Communications Interface (SCI) Module Block Diagram............................................................ 75

4-11 Serial Peripheral Interface Module Block Diagram (Slave Mode).......................................................... 78

4-12 GPIO/Peripheral Pin Multiplexing .............................................................................................. 81

5-1 28x Device Nomenclature....................................................................................................... 83

6-1 SM320F2812-HT Life Expectancy Curve ..................................................................................... 87

6-2 Typical Current Consumption Over Frequency............................................................................... 89

6-3 Typical Power Consumption Over Frequency................................................................................ 90

6-4 F2812 Typical Power-Up and Power-Down Sequence – Option 2 ........................................................ 91

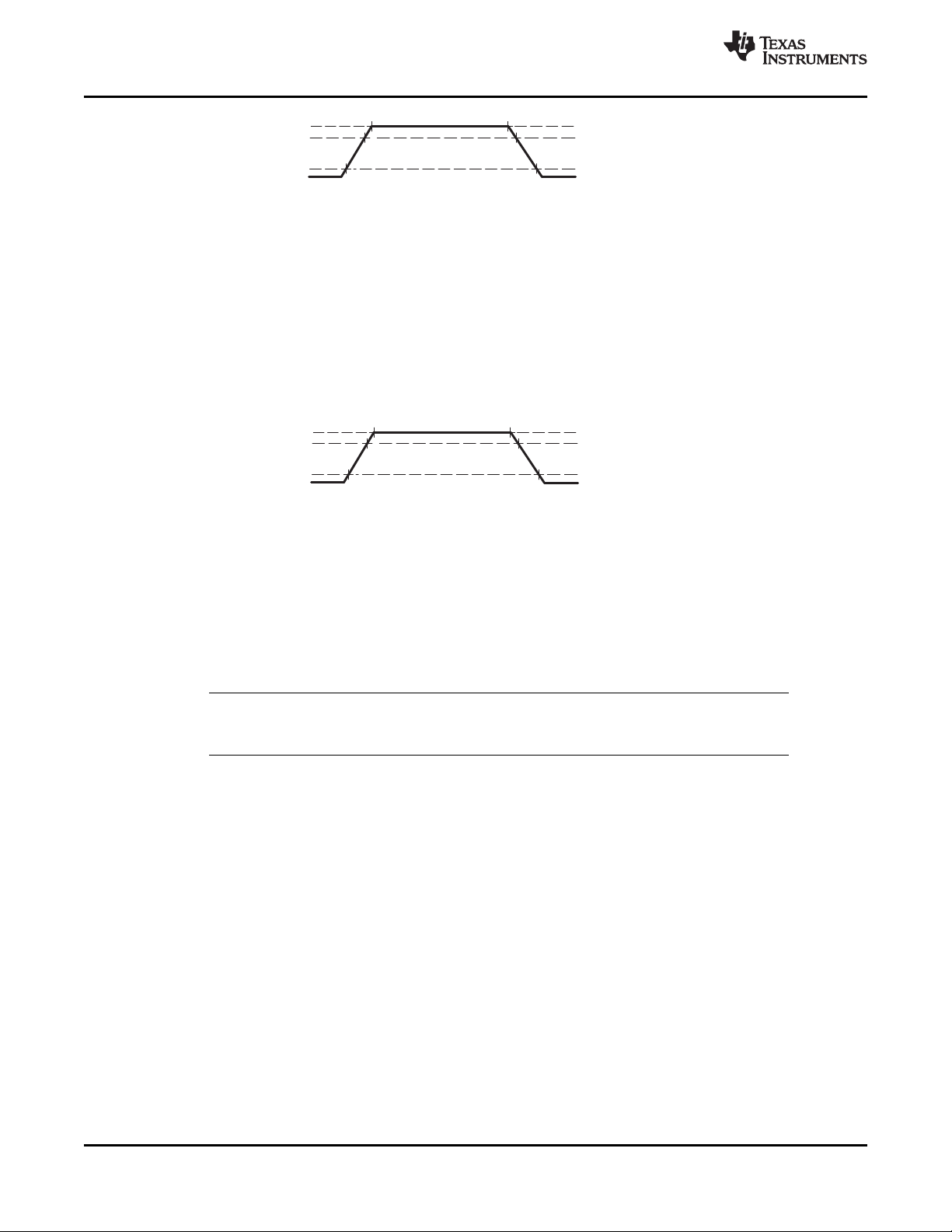

6-5 Output Levels ..................................................................................................................... 92

6-6 Input Levels ....................................................................................................................... 92

6-7 3.3-V Test Load Circuit.......................................................................................................... 93

6-8 Clock Timing ...................................................................................................................... 96

6-9 Power-on Reset in Microcomputer Mode (XMP/MC = 0) (See Note A)................................................... 98

6-10 Power-on Reset in Microprocessor Mode (XMP/MC = 1)................................................................... 99

6-11 Warm Reset in Microcomputer Mode.......................................................................................... 99

6-12 Effect of Writing Into PLLCR Register......................................................................................... 99

6-13 IDLE Entry and Exit Timing.................................................................................................... 100

6-14 STANDBY Entry and Exit Timing............................................................................................. 102

6-15 HALT Wakeup Using XNMI ................................................................................................... 104

6-16 PWM Output Timing............................................................................................................ 105

6-17 TDIRx Timing.................................................................................................................... 106

6-18 EVASOC Timing................................................................................................................ 106

6-19 EVBSOC Timing................................................................................................................ 106

6-20 External Interrupt Timing....................................................................................................... 107

6-21 General-Purpose Output Timing.............................................................................................. 108

6-22 GPIO Input Qualifier – Example Diagram for QUALPRD = 1............................................................. 108

Copyright © 2009–2010, Texas Instruments Incorporated List of Figures 5

Page 6

SM320F2812-HT

SGUS062A–JUNE 2009–REVISED APRIL 2010

6-23 General-Purpose Input Timing................................................................................................ 109

6-24 SPI Master Mode External Timing (Clock Phase = 0) ..................................................................... 110

6-25 SPI Master External Timing (Clock Phase = 1)............................................................................. 112

6-26 SPI Slave Mode External Timing (Clock Phase = 0)....................................................................... 114

6-27 SPI Slave Mode External Timing (Clock Phase = 1)....................................................................... 116

6-28 Relationship Between XTIMCLK and SYSCLKOUT ....................................................................... 120

6-29 Example Read Access......................................................................................................... 122

6-30 Example Write Access......................................................................................................... 124

6-31 Example Read With Synchronous XREADY Access ...................................................................... 126

6-32 Example Read With Asynchronous XREADY Access..................................................................... 127

6-33 Write With Synchronous XREADY Access.................................................................................. 129

6-34 Write With Asynchronous XREADY Access ................................................................................ 130

6-35 External Interface Hold Waveform............................................................................................ 132

6-36 XHOLD/XHOLDA Timing Requirements (XCLKOUT = 1/2 XTIMCLK).................................................. 133

6-37 ADC Analog Input Impedance Model ........................................................................................ 137

6-38 ADC Power-Up Control Bit Timing ........................................................................................... 137

6-39 Sequential Sampling Mode (Single-Channel) Timing...................................................................... 139

6-40 Simultaneous Sampling Mode Timing ....................................................................................... 140

6-41 McBSP Receive Timing........................................................................................................ 144

6-42 McBSP Transmit Timing....................................................................................................... 144

6-43 McBSP Timing as SPI Master or Slave: CLKSTP = 10b, CLKXP = 0................................................... 145

6-44 McBSP Timing as SPI Master or Slave: CLKSTP = 11b, CLKXP = 0................................................... 146

6-45 McBSP Timing as SPI Master or Slave: CLKSTP = 10b, CLKXP = 1................................................... 147

6-46 McBSP Timing as SPI Master or Slave: CLKSTP = 11b, CLKXP = 1................................................... 148

www.ti.com

6 List of Figures Copyright © 2009–2010, Texas Instruments Incorporated

Page 7

SM320F2812-HT

www.ti.com

SGUS062A–JUNE 2009–REVISED APRIL 2010

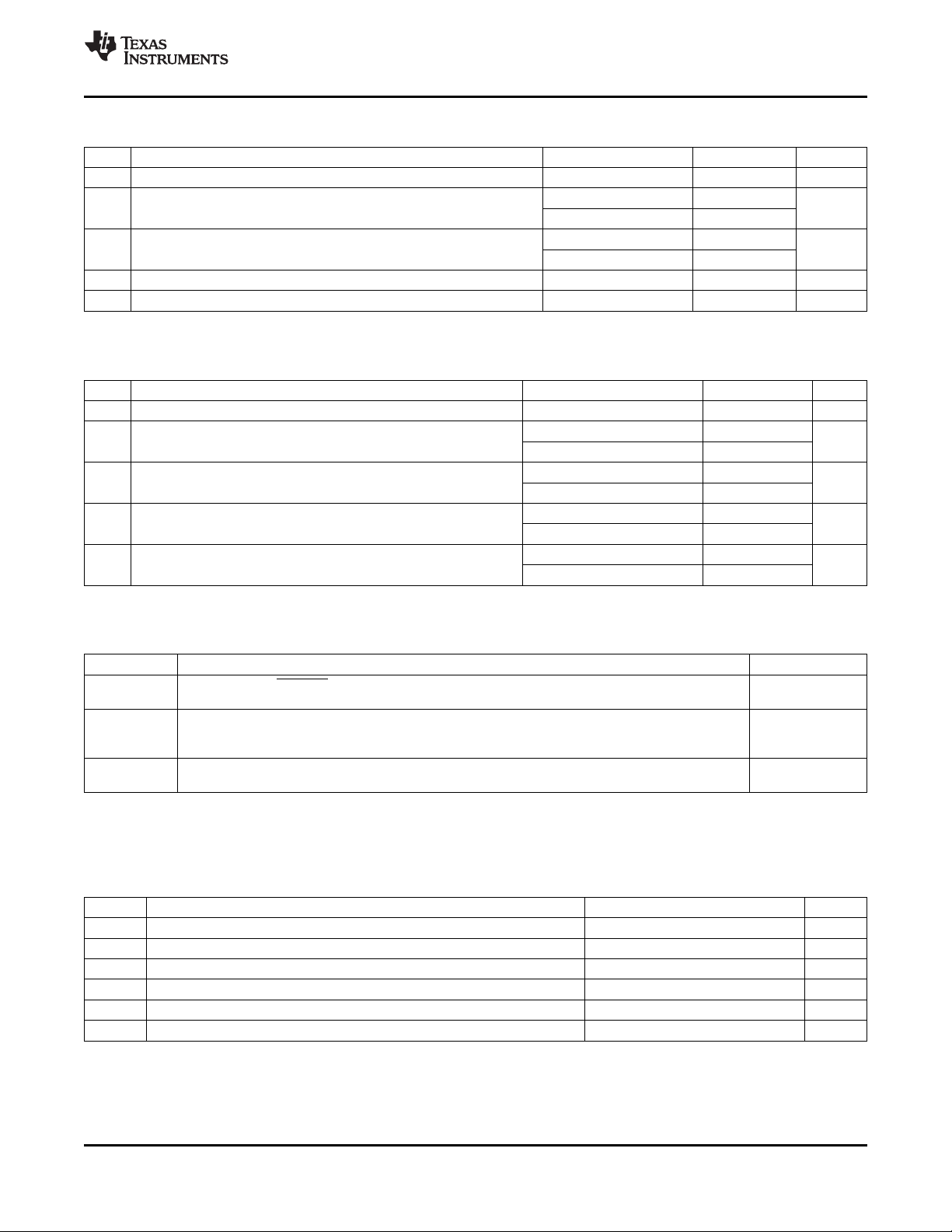

List of Tables

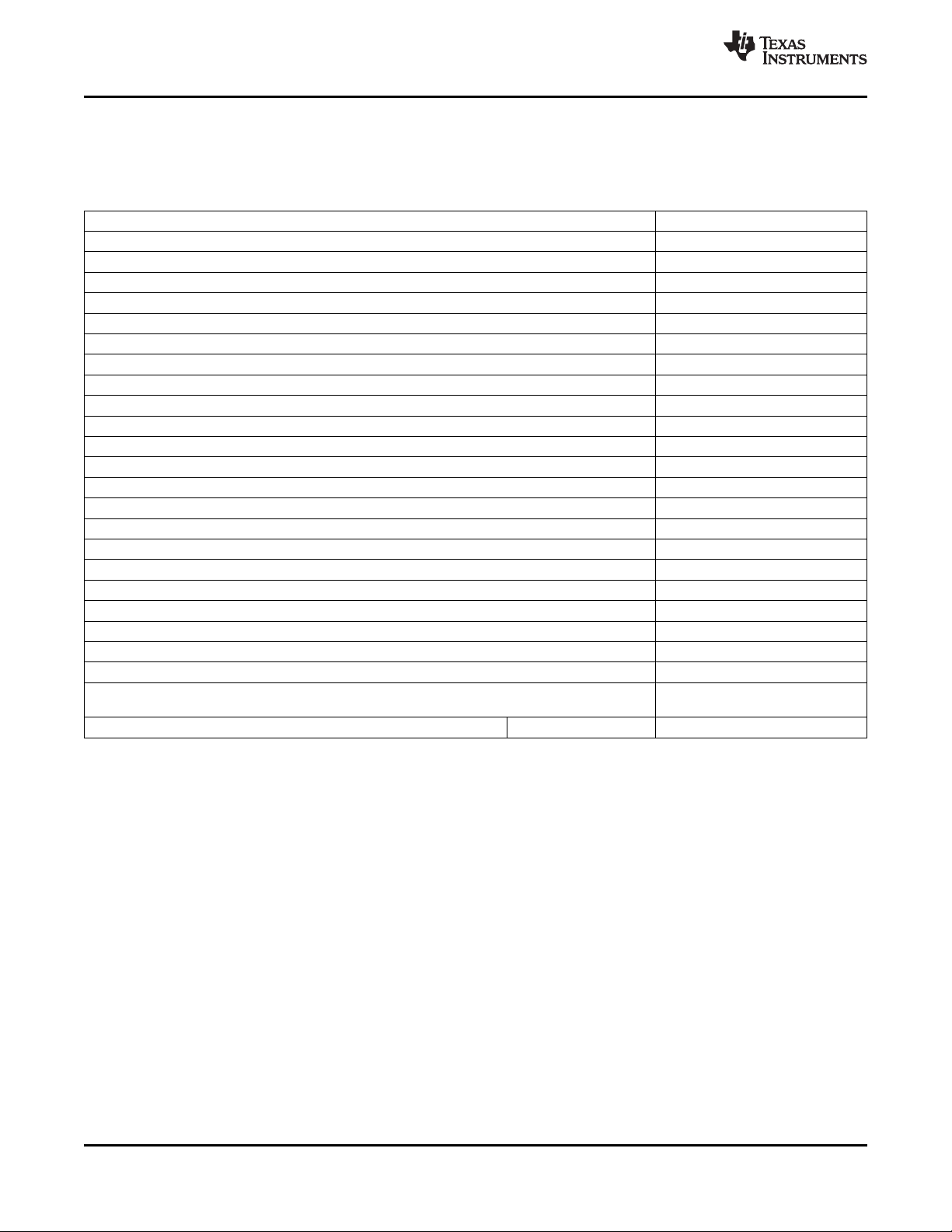

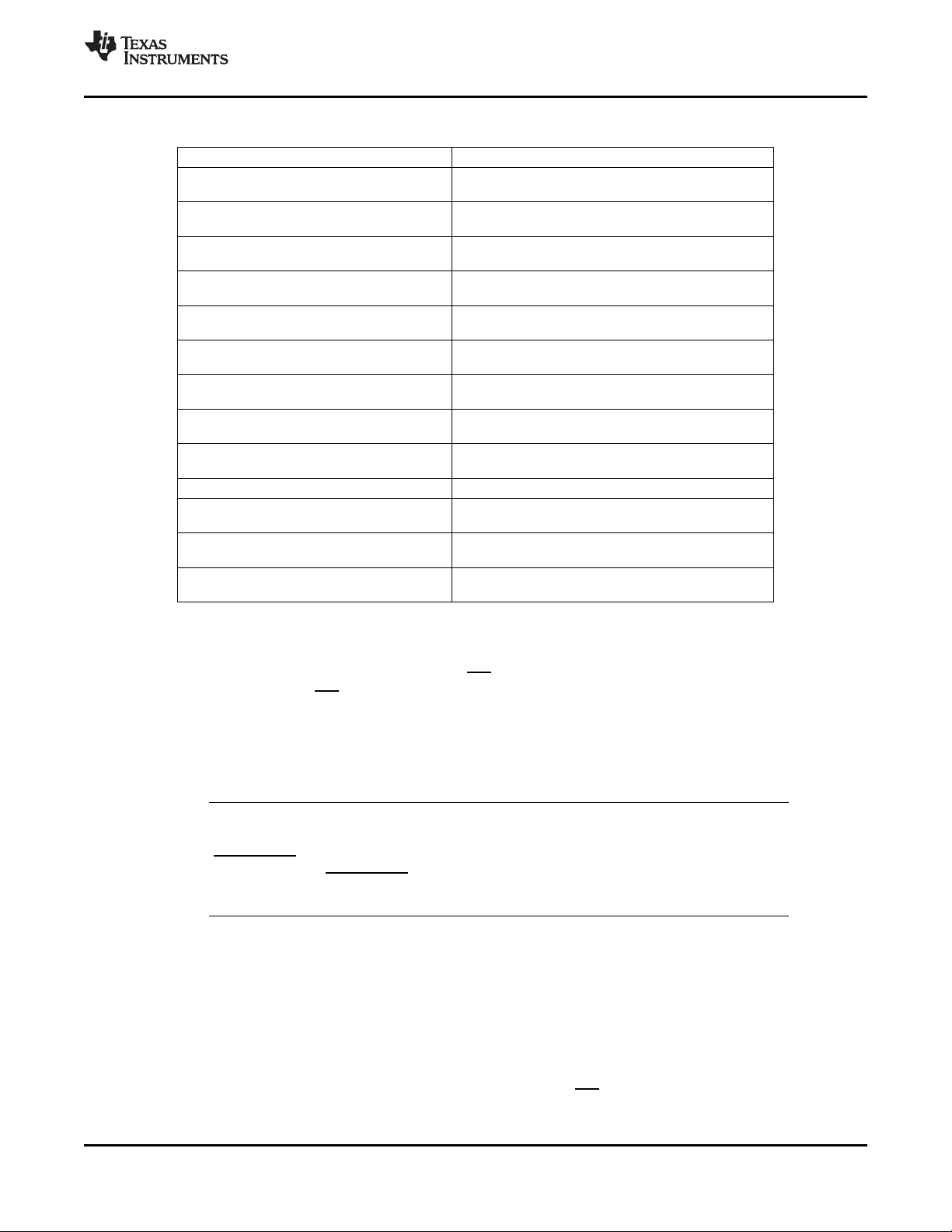

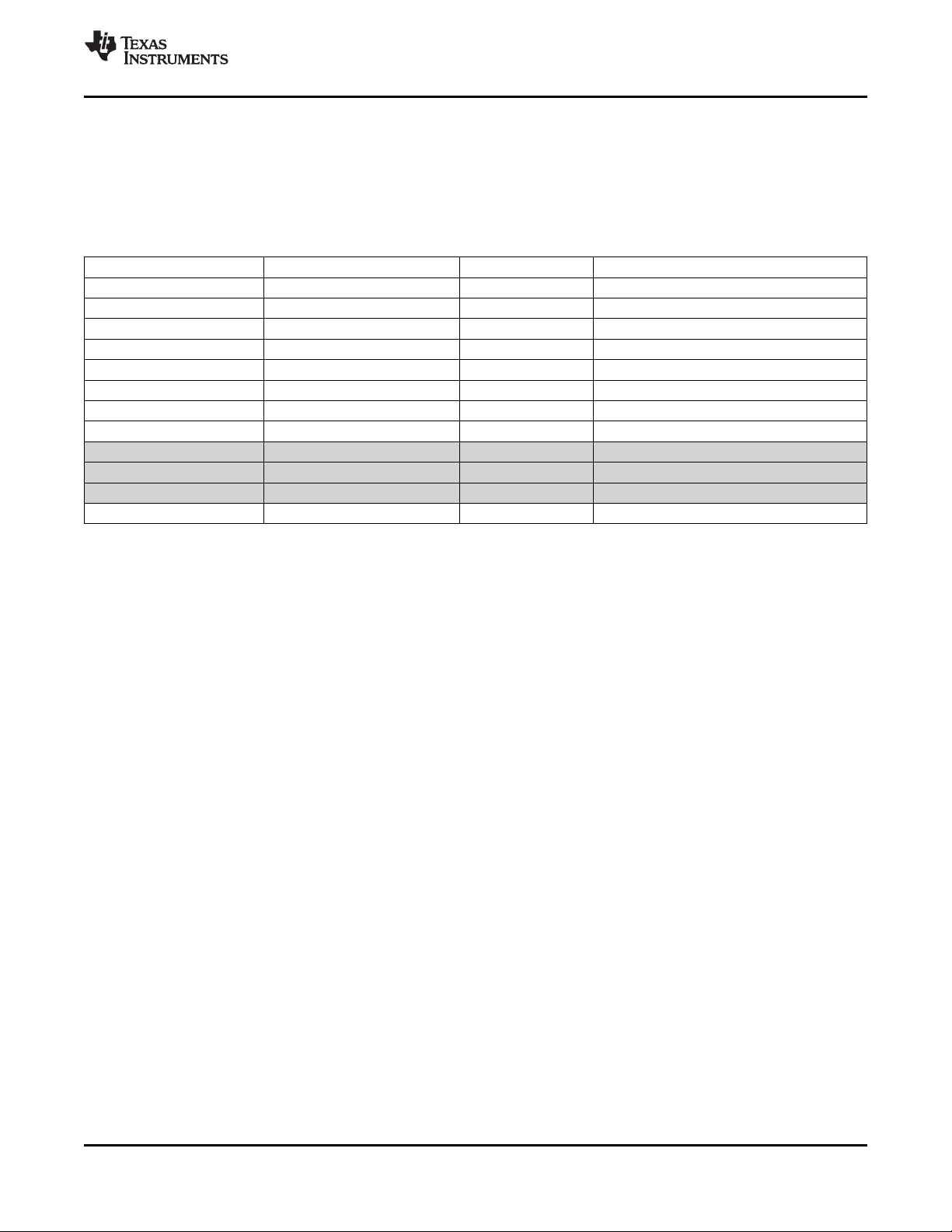

2-1 Hardware Features............................................................................................................... 14

2-2 Bare Die Information............................................................................................................. 15

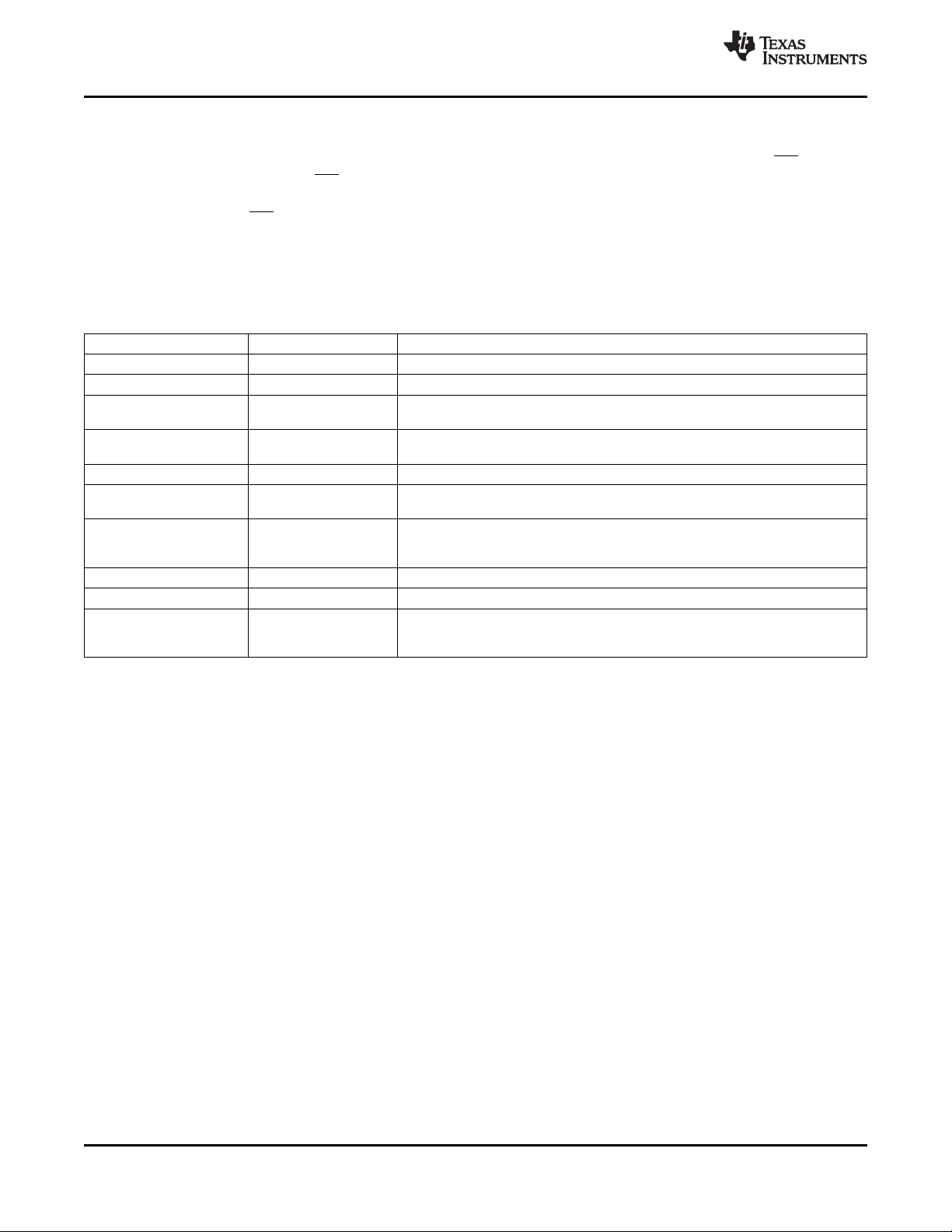

2-3 Signal Descriptions .............................................................................................................. 17

3-1 Addresses of Flash Sectors in F2812 ......................................................................................... 29

3-2 Wait States ........................................................................................................................ 30

3-3 Boot Mode Selection............................................................................................................. 33

3-4 Peripheral Frame 0 Registers .................................................................................................. 37

3-5 Peripheral Frame 1 Registers .................................................................................................. 37

3-6 Peripheral Frame 2 Registers .................................................................................................. 38

3-7 Device Emulation Registers..................................................................................................... 39

3-8 XINTF Configuration and Control Register Mappings....................................................................... 41

3-9 XREVISION Register Bit Definitions........................................................................................... 41

3-10 PIE Peripheral Interrupts ....................................................................................................... 43

3-11 PIE Configuration and Control Registers ..................................................................................... 44

3-12 External Interrupts Registers ................................................................................................... 45

3-13 PLL, Clocking, Watchdog, and Low-Power Mode Registers .............................................................. 47

3-14 PLLCR Register Bit Definitions................................................................................................. 48

3-15 Possible PLL Configuration Modes ............................................................................................ 49

3-16 F2812 Low-Power Modes....................................................................................................... 51

4-1 CPU-Timers 0, 1, 2 Configuration and Control Registers................................................................... 54

4-2 Module and Signal Names for EVA and EVB ................................................................................ 55

4-3 EVA Registers ................................................................................................................... 56

4-4 ADC Registers ................................................................................................................... 64

4-5 3.3-V eCAN Transceivers for the SM320F2812 DSP....................................................................... 66

4-6 CAN Registers Map ............................................................................................................. 68

4-7 McBSP Register Summary...................................................................................................... 71

4-8 SCI-A Registers .................................................................................................................. 74

4-9 SCI-B Registers .................................................................................................................. 74

4-10 SPI Registers .................................................................................................................... 77

4-11 GPIO Mux Registers ............................................................................................................ 79

4-12 GPIO Data Registers ............................................................................................................ 80

6-1 Typical Current Consumption by Various Peripherals (at 150 MHz) ..................................................... 90

6-2 Recommended Low-Dropout Regulators ..................................................................................... 91

6-3 Clock Table and Nomenclature................................................................................................. 94

6-4 Input Clock Frequency .......................................................................................................... 94

6-5 XCLKIN Timing Requirements – PLL Bypassed or Enabled .............................................................. 95

6-6 XCLKIN Timing Requirements – PLL Disabled .............................................................................. 95

6-7 Possible PLL Configuration Modes ........................................................................................... 95

6-8 XCLKOUT Switching Characteristics (PLL Bypassed or Enabled) ....................................................... 95

6-9 Reset (XRS) Timing Requirements ........................................................................................... 96

6-10 IDLE Mode Switching Characteristics ....................................................................................... 100

6-11 STANDBY Mode Switching Characteristics ................................................................................ 101

6-12 HALT Mode Switching Characteristics ...................................................................................... 103

6-13 PWM Switching Characteristics .............................................................................................. 105

6-14 Timer and Capture Unit Timing Requirements ............................................................................. 105

6-15 External ADC Start-of-Conversion – EVA – Switching Characteristics ................................................. 106

Copyright © 2009–2010, Texas Instruments Incorporated List of Tables 7

Page 8

SM320F2812-HT

SGUS062A–JUNE 2009–REVISED APRIL 2010

6-16 External ADC Start-of-Conversion – EVB – Switching Characteristics ................................................. 106

6-17 Interrupt Switching Characteristics ........................................................................................... 106

6-18 Interrupt Timing Requirements................................................................................................ 107

6-19 General-Purpose Output Switching Characteristics........................................................................ 107

6-20 General-Purpose Input Timing Requirements .............................................................................. 108

6-21 SPI Master Mode External Timing (Clock Phase = 0) .................................................................... 109

6-22 SPI Master Mode External Timing (Clock Phase = 1) .................................................................... 111

6-23 SPI Slave Mode External Timing (Clock Phase = 0) ...................................................................... 113

6-24 SPI Slave Mode External Timing (Clock Phase = 1) ...................................................................... 115

6-25 Relationship Between Parameters Configured in XTIMING and Duration of Pulse ................................... 117

6-26 XTIMING Register Configuration Restrictions .............................................................................. 117

6-27 Valid and Invalid Timing ....................................................................................................... 117

6-28 XTIMING Register Configuration Restrictions .............................................................................. 118

6-29 Valid and Invalid Timing when using Synchronous XREADY ............................................................ 118

6-30 XTIMING Register Configuration Restrictions .............................................................................. 118

6-31 XTIMING Register Configuration Restrictions .............................................................................. 119

6-32 Asynchronous XREADY ...................................................................................................... 119

6-33 XINTF Clock Configurations................................................................................................... 119

6-34 External Memory Interface Read Switching Characteristics ............................................................. 122

6-35 External Memory Interface Read Timing Requirements .................................................................. 122

6-36 External Memory Interface Write Switching Characteristics .............................................................. 123

6-37 External Memory Interface Read Switching Characteristics (Ready-on-Read, 1 Wait State) ....................... 125

6-38 External Memory Interface Read Timing Requirements (Ready-on-Read, 1 Wait State) ............................ 125

6-39 Synchronous XREADY Timing Requirements (Ready-on-Read, 1 Wait State) ....................................... 125

6-40 Asynchronous XREADY Timing Requirements (Ready-on-Read, 1 Wait State) ...................................... 125

6-41 External Memory Interface Write Switching Characteristics (Ready-on-Write, 1 Wait State) ........................ 128

6-42 Synchronous XREADY Timing Requirements (Ready-on-Write, 1 Wait State) ....................................... 128

6-43 Asynchronous XREADY Timing Requirements (Ready-on-Write, 1 Wait State) ...................................... 128

6-44 XHOLD/XHOLDA Timing Requirements (XCLKOUT = XTIMCLK) ...................................................... 132

6-45 XHOLD/XHOLDA Timing Requirements (XCLKOUT = 1/2 XTIMCLK) ................................................. 133

6-46 DC Specifications .............................................................................................................. 135

6-47 AC Specifications .............................................................................................................. 136

6-48 Current Consumption .......................................................................................................... 136

6-49 ADC Power-Up Delays ........................................................................................................ 137

6-50 Sequential Sampling Mode Timing .......................................................................................... 139

6-51 Simultaneous Sampling Mode Timing ....................................................................................... 140

6-52 McBSP Timing Requirements ................................................................................................ 142

6-53 McBSP Switching Characteristics ........................................................................................... 143

6-54 McBSP as SPI Master or Slave Timing Requirements (CLKSTP = 10b, CLKXP = 0) ............................... 145

6-55 McBSP as SPI Master or Slave Switching Characteristics (CLKSTP = 10b, CLKXP = 0) ........................... 145

6-56 McBSP as SPI Master or Slave Timing Requirements (CLKSTP = 11b, CLKXP = 0) ............................... 146

6-57 McBSP as SPI Master or Slave Switching Characteristics (CLKSTP = 11b, CLKXP = 0) ........................... 146

6-58 McBSP as SPI Master or Slave Timing Requirements (CLKSTP = 10b, CLKXP = 1) ............................... 147

6-59 McBSP as SPI Master or Slave Switching Characteristics (CLKSTP = 10b, CLKXP = 1) ........................... 147

6-60 McBSP as SPI Master or Slave Timing Requirements (CLKSTP = 11b, CLKXP = 1) ............................... 148

6-61 McBSP as SPI Master or Slave Switching Characteristics (CLKSTP = 11b, CLKXP = 1) ........................... 148

6-62 Flash Parameters at 150-MHz SYSCLKOUT .............................................................................. 149

6-63 Flash/OTP Access Timing .................................................................................................... 149

www.ti.com

8 List of Tables Copyright © 2009–2010, Texas Instruments Incorporated

Page 9

SM320F2812-HT

www.ti.com

SGUS062A–JUNE 2009–REVISED APRIL 2010

6-64 Minimum Required Wait-States at Different Frequencies ................................................................ 149

Copyright © 2009–2010, Texas Instruments Incorporated List of Tables 9

Page 10

SM320F2812-HT

SGUS062A–JUNE 2009–REVISED APRIL 2010

www.ti.com

10 List of Tables Copyright © 2009–2010, Texas Instruments Incorporated

Page 11

SM320F2812-HT

www.ti.com

SGUS062A–JUNE 2009–REVISED APRIL 2010

Digital Signal Processor

Check for Samples: SM320F2812-HT

1 Features

12

• High-Performance Static CMOS Technology • 128 Bit Security Key/Lock

– 150 MHz (6.67 ns Cycle Time) – Protects Flash/ROM/OTP and L0/L1 SARAM

– Low Power (1.8 V Core at 135 MHz, 1.9 V, – Prevents Firmware Reverse Engineering

Core at 150 MHz, 3.3 V I/O) Design

– 3.3 V Flash Voltage

• JTAG Boundary Scan Support

(1)

• High-Performance 32 Bit CPU (TMS320C28x)

– 16 × 16 and 32 x 32 MAC Operations

– 16 × 16 Dual MAC

– Harvard Bus Architecture

– Atomic Operations (SCIs), Standard UART

– Fast Interrupt Response and Processing – Enhanced Controller Area Network (eCAN)

– Unified Memory Programming Model – Multichannel Buffered Serial Port (McBSP)

– 4M Linear Program Address Reach

– 4M Linear Data Address Reach

– Code-Efficient (in C/C++ and Assembly)

– TMS320F24x/LF240x Processor Source Code

Compatible – Single/Simultaneous Conversions

• On-Chip Memory – Fast Conversion Rate: 80 ns/12.5 MSPS

– Flash Devices: Up to 128K × 16 Flash (Four • Up to 56 Individually Programmable,

8K × 16 and Six 16K × 16 Sectors) Multiplexed General-Purpose Input / Output

– ROM Devices: Up to 128K × 16 ROM

– 1K × 16 OTP ROM

– L0 and L1: 2 Blocks of 4K × 16 Each

Single-Access RAM (SARAM) – Real-Time Debug via Hardware

– H0: 1 Block of 8K × 16 SARAM • Development Tools Include

– M0 and M1: 2 Blocks of 1K × 16 Each – ANSI C/C++ Compiler/Assembler/Linker

SARAM

• Boot ROM (4K × 16)

– With Software Boot Modes

– Standard Math Tables

• External Interface (TI) or Third-Party]

– Up to 1M Total Memory – Evaluation Modules

– Programmable Wait States – Broad Third-Party Digital Motor Control

– Programmable Read/Write Strobe Timing

– Three Individual Chip Selects

• Clock and System Control

– Dynamic PLL Ratio Changes Supported

– On-Chip Oscillator

– Watchdog Timer Module

• Three External Interrupts xxx

• Peripheral Interrupt Expansion (PIE) Block That

Supports 45 Peripheral Interrupts

(1) IEEE Standard 1149.1-1990, IEEE Standard Test-Access Port

1TMS320C24x, Code Composer Studio, DSP/BIOS, C28x, TMS320C2000, TMS320C54x, TMS320C55x, TMS320C28x are trademarks of

Texas Instruments.

2eZdsp is a trademark of Spectrum Digital Incorporated.

• Three 32 Bit CPU Timers

• Motor Control Peripherals

– Two Event Managers (EVA, EVB)

– Compatible to 240xA Devices

• Serial Port Peripherals

– Serial Peripheral Interface (SPI)

– Two Serial Communications Interfaces

With SPI Mode

• 12 Bit ADC, 16 Channels

– 2 × 8 Channel Input Multiplexer

– Two Sample-and-Hold

(GPIO) Pins

• Advanced Emulation Features

– Analysis and Breakpoint Functions

– Supports TMS320C24x™/240x Instructions

– Code Composer Studio™ IDE

– DSP/BIOS™

– JTAG Scan Controllers [Texas Instruments

Support

• Low-Power Modes and Power Savings

– IDLE, STANDBY, HALT Modes Supported

– Disable Individual Peripheral Clocks

xxx

xxx

xxx

xxx

Copyright © 2009–2010, Texas Instruments Incorporated Features 11

Page 12

SM320F2812-HT

SGUS062A–JUNE 2009–REVISED APRIL 2010

xxx

www.ti.com

1.1 SUPPORTS EXTREME TEMPERATURE APPLICATIONS

• Controlled Baseline

• One Assembly/Test Site

• One Fabrication Site

• Available in Extreme (–55°C/220°C) Temperature Range

• Extended Product Life Cycle

• Extended Product-Change Notification

• Product Traceability

• Texas Instruments high temperature products utilize highly optimized silicon (die) solutions with

design and process enhancements to maximize performance over extended temperatures.

(2) Custom temperature ranges available

(2)

12 Features Copyright © 2009–2010, Texas Instruments Incorporated

Page 13

SM320F2812-HT

www.ti.com

2 Introduction

This section provides a summary of the device features, lists the pin assignments, and describes the

function of each pin. This document also provides detailed descriptions of peripherals, electrical

specifications, parameter measurement information, and mechanical data about the available packaging.

3

2.1 Description

The SM320F2812 device, member of the C28xE DSP generation, is a highly integrated, high-performance

solution for demanding control applications. The functional blocks and the memory maps are described in

Section 3, Functional Overview.

Throughout this document SM320F2812 is abbreviated as F2812.

SGUS062A–JUNE 2009–REVISED APRIL 2010

3

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2009–2010, Texas Instruments Incorporated

Page 14

SM320F2812-HT

SGUS062A–JUNE 2009–REVISED APRIL 2010

www.ti.com

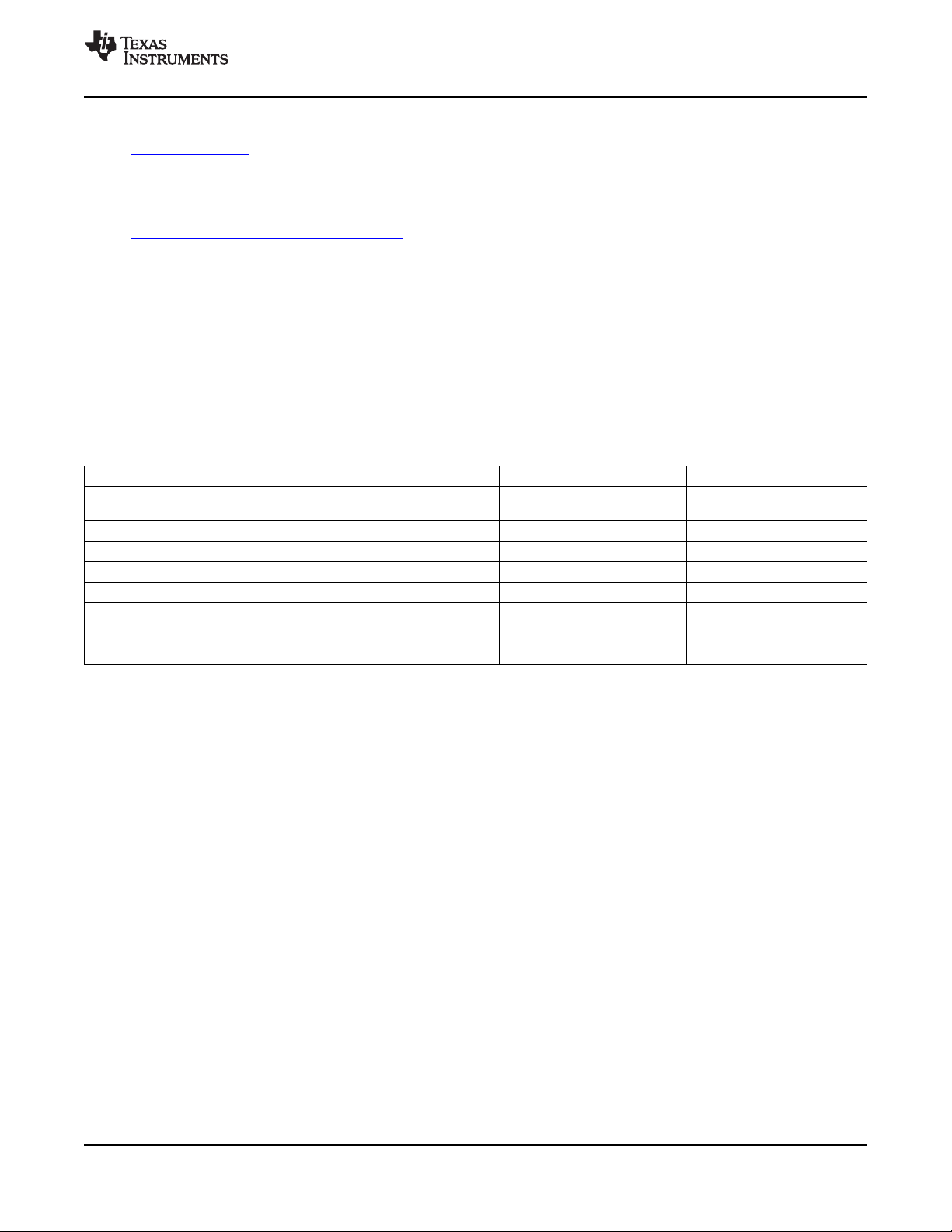

2.2 Device Summary

Table 2-1 provides a summary of the device features.

Table 2-1. Hardware Features

FEATURE F2812

Instruction Cycle (at 150 MHz) 6.67 ns

Single-Access RAM (SARAM) (16 bit word) 18K

3.3 V On-Chip Flash (16 bit word) 128K

On-Chip ROM (16-bit word) —

Code Security for On-Chip Flash/SARAM/OTP/ROM Yes

Boot ROM Yes

OTP ROM (1K × 16) Yes

External Memory Interface Yes

Event Managers A and B (EVA and EVB) EVA, EVB

• General-Purpose (GP) Timers 4

• Compare (CMP)/PWM 16

• Capture (CAP)/QEP Channels 6/2

Watchdog Timer Yes

12 Bit ADC Yes

• Channels 16

32 Bit CPU Timers 3

SPI Yes

SCIA, SCIB SCIA, SCIB

CAN Yes

McBSP Yes

Digital I/O Pins (Shared) 56

External Interrupts 3

Supply Voltage 1.8-V Core, (135 MHz) 1.9-V Core

Temperature Options S: –55°C to 220°C Yes

(150 MHz), 3.3-V I/O

14 Introduction Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F2812-HT

Page 15

SM320F2812-HT

www.ti.com

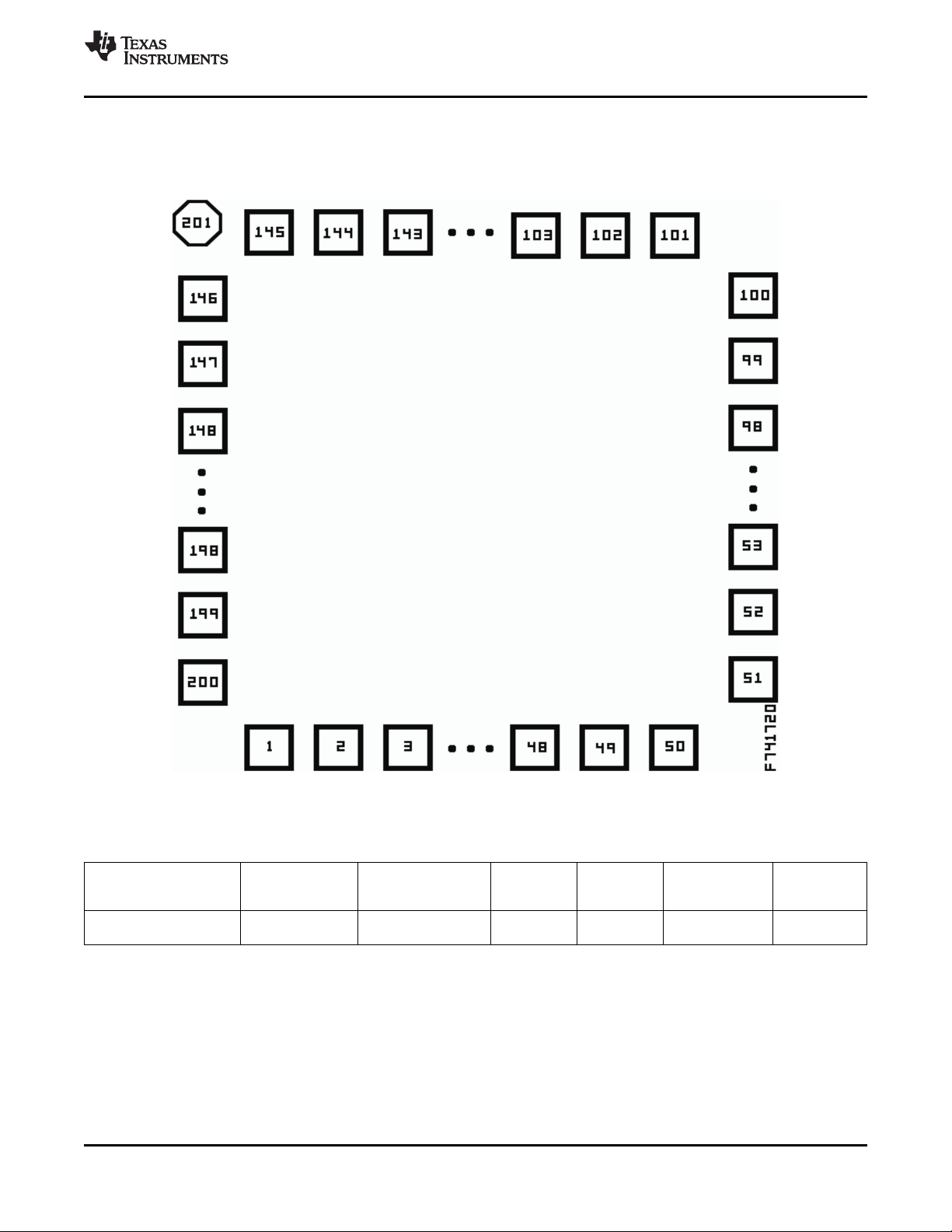

2.3 Die Layout

The SM320F2812 die layout is shown in Figure 2-1. See Table 2-3 for a description of each pad's

function.

SGUS062A–JUNE 2009–REVISED APRIL 2010

Figure 2-1. SM320F2812 Die Layout

Table 2-2. Bare Die Information

DIE SIZE DIE PAD SIZE COMPOSITI

219.4 x 207.0 (mils); Silicon with

5572.0 x 5258.0 (mm) backgrind

Copyright © 2009–2010, Texas Instruments Incorporated Introduction 15

55.0 x 64.0 (mm) See Table 2-3 11.0 mils AlCu/TiN Ground

DIE PAD DIE BACKSIDE BACKSIDE

COORDINATES THICKNESS FINISH POTENTIAL

Submit Documentation Feedback

Product Folder Link(s): SM320F2812-HT

DIE PAD

ON

Page 16

V

DDAIO

1

130

172

ADCINB0

ADCINB1

ADCINB2

ADCINB3

ADCINB4

ADCINB5

ADCINB6

ADCINB7

ADCREFM

ADCREFP

AVSSREFBG

AVDDREFBG

V

DDA1

V

SSA1

ADCRESEXT

MC

XMP/

XA[0]

MDRA

XD[0]

MDXA

V

DD

XD[1]

MCLKRA

MFSXA

XD[2]

MCLKXA

MFSRA

XD[3]

V

DDIO

V

SS

XD[4]

SPICLKA

SPISTEA

XD[5]

V

DD

V

SS

XD[6]

SPISIMOA

SPISOMIA

XRD

XA[1]

XZCS0AND1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

XA[11]

TDI

XA[10]

TDO

TMS

XA[9]

XA[8]

XCLKOUT

XA[7]

TCLKINA

TDIRA

XA[6]

CAP3_QEPI1

XA[5]

CAP2_QEP2

CAP1_QEP1

T2PWM_T2CMP

XA[4]

T1PWM_T1CMP

PWM6

PWM5

XD[13]

XD[12]

PWM4

PWM3

PWM2

PWM1

SCIRXDB

SCITXDB

CANRXA

V

SS

V

DD

V

SS

T1CTRIP_PDPINTA

V

DD

V

SS

V

DDIO

T2CTRIP / EVASOC

C1TRIP

C2TRIP

C3TRIP

V

DD

V

PWM8

PWM9

PWM10

PWM11

PWM12

XR/W

V

SS

T3PWM_T3CMP

XD[7]

T4PWM_T4CMP

V

DD

CAP4_QEP3

V

SS

CAP5_QEP4

CAP6_QEPI2

C4TRIP

C5TRIP

C6TRIP

V

DDIO

XD[8]

TEST2

TEST1

XD[9]

V

DD3VFL

TDIRB

TCLKINB

XD[10]

XD[11]

V

DD

X2

X1/XCLKIN

V

SS

T3CTRIP_PDPINTB

XA[2]

V

DDIO

XHOLDA

T4CTRIP/EVBSOC

XWE

XA[3]

V

SS

CANTXA

XZCS2

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

86

44

129 87

43

TESTSEL

TRST

TCK

EMU0

XA[12]

XD[14]

XA[13]

V

SS

V

DD

XA[14]

V

DDIO

EMU1

XD[15]

XA[15]

XINT1_XBIO

XA[16]

V

DD

SCITXDA

XA[17]

SCIRXDA

XA[18]

XHOLD

XRS

XREADY

V

DD1

V

SS1

V

SSA2

V

DDA2

ADCINA7

ADCINA6

ADCINA5

ADCINA4

ADCINA3

ADCINA2

ADCINA1

ADCINA0

ADCLO

V

SSAIO

45

89

88

132

133

XZCS6AND7

XF_XPLLDIS

XNMI_XINT13

XINT2_ADCSOC

ADCBGREFIN

PWM7

131

SM320F2812-HT

SGUS062A–JUNE 2009–REVISED APRIL 2010

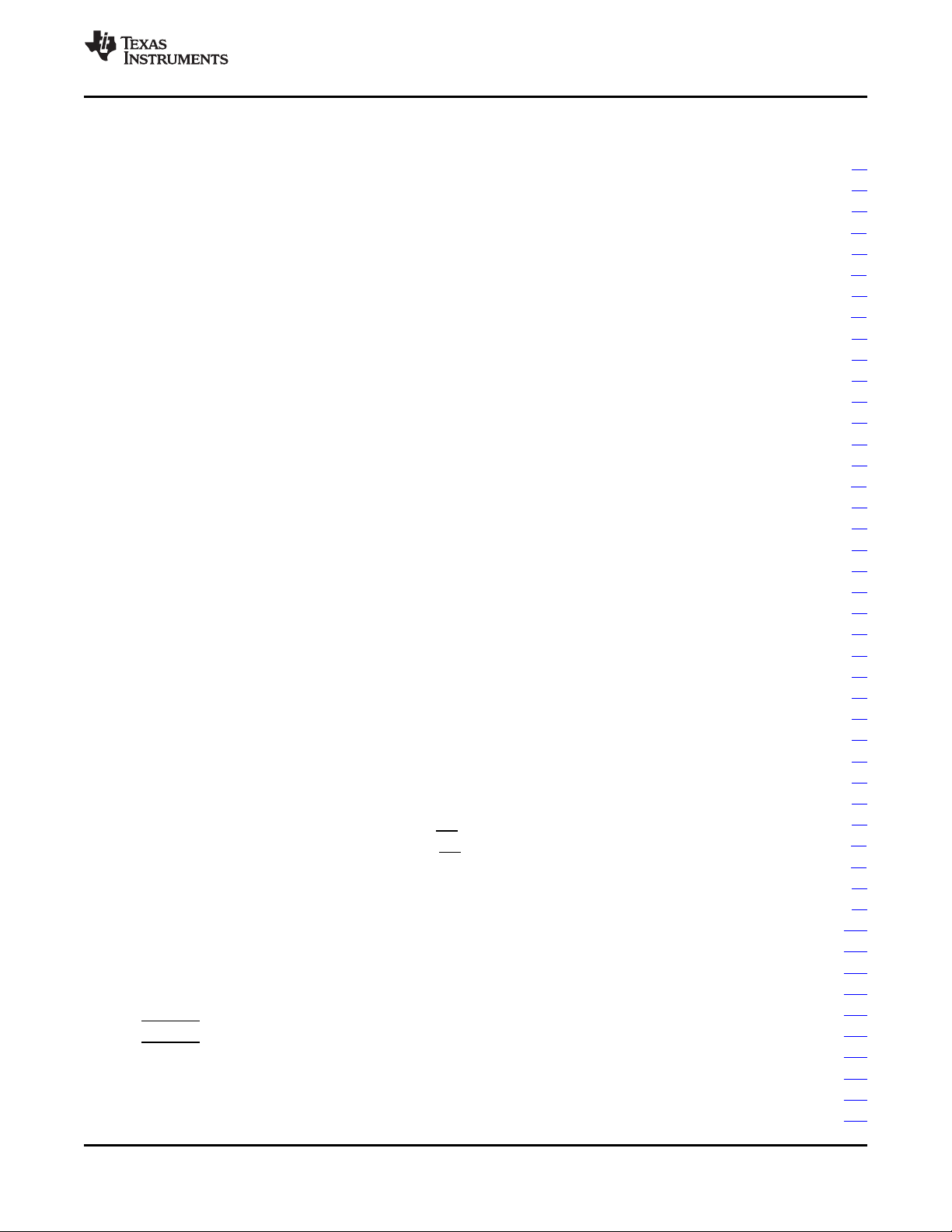

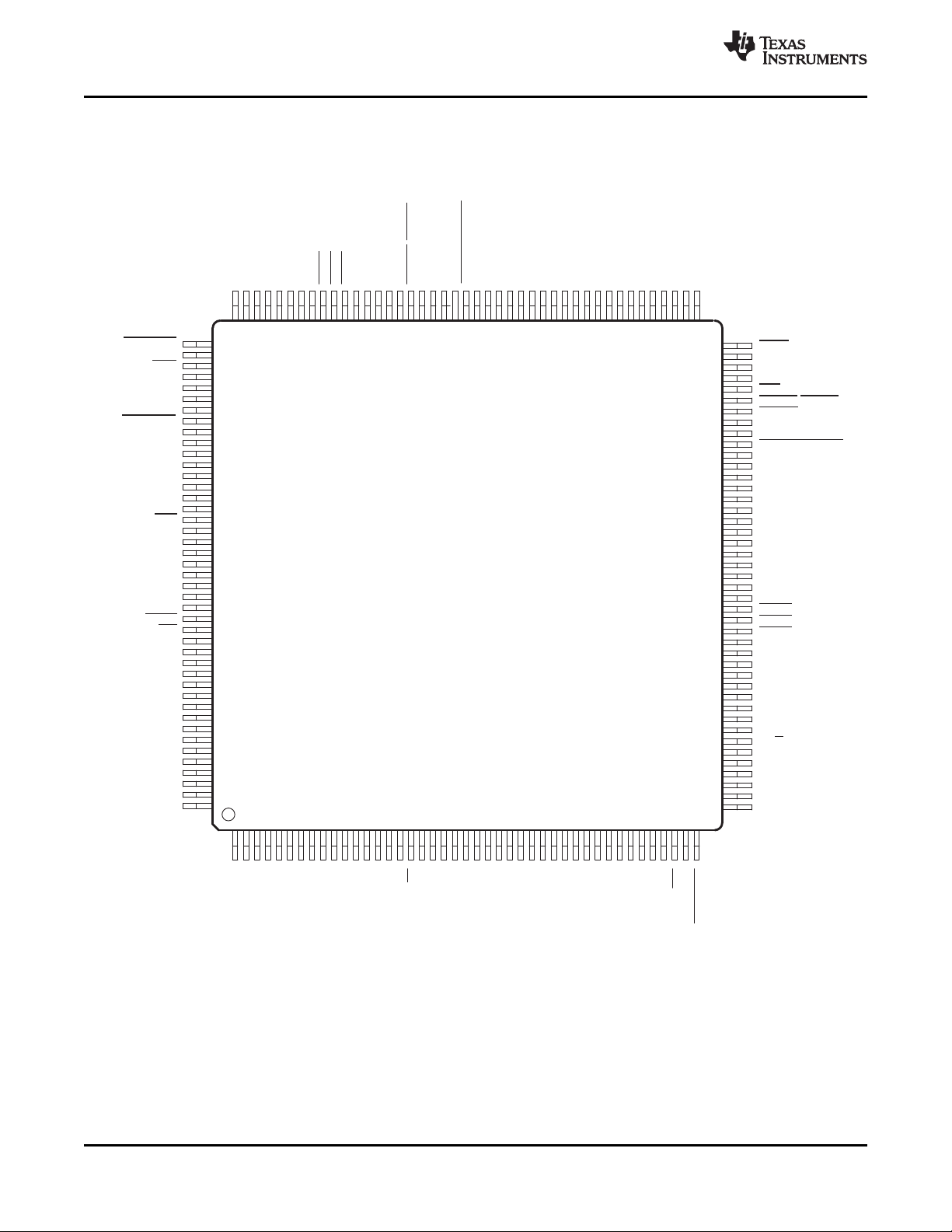

2.4 Pin Assignments

The SM320F2812 172-pin HFG ceramic quad flatpack (CQFP) pin assignments are shown in Figure 2-2.

See Table 2-3 for a description of each pin’s function(s).

www.ti.com

Figure 2-2. SM320F2812 172-Pin HFG CQFP (Top View)

16 Introduction Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F2812-HT

Page 17

SM320F2812-HT

www.ti.com

SGUS062A–JUNE 2009–REVISED APRIL 2010

2.5 Signal Descriptions

Table 2-3 specifies the signals on the F2812 device. All digital inputs are TTL-compatible. All outputs are

3.3 V with CMOS levels. Inputs are not 5 V tolerant. A 100 mA (or 20 mA) pullup/pulldown is used.

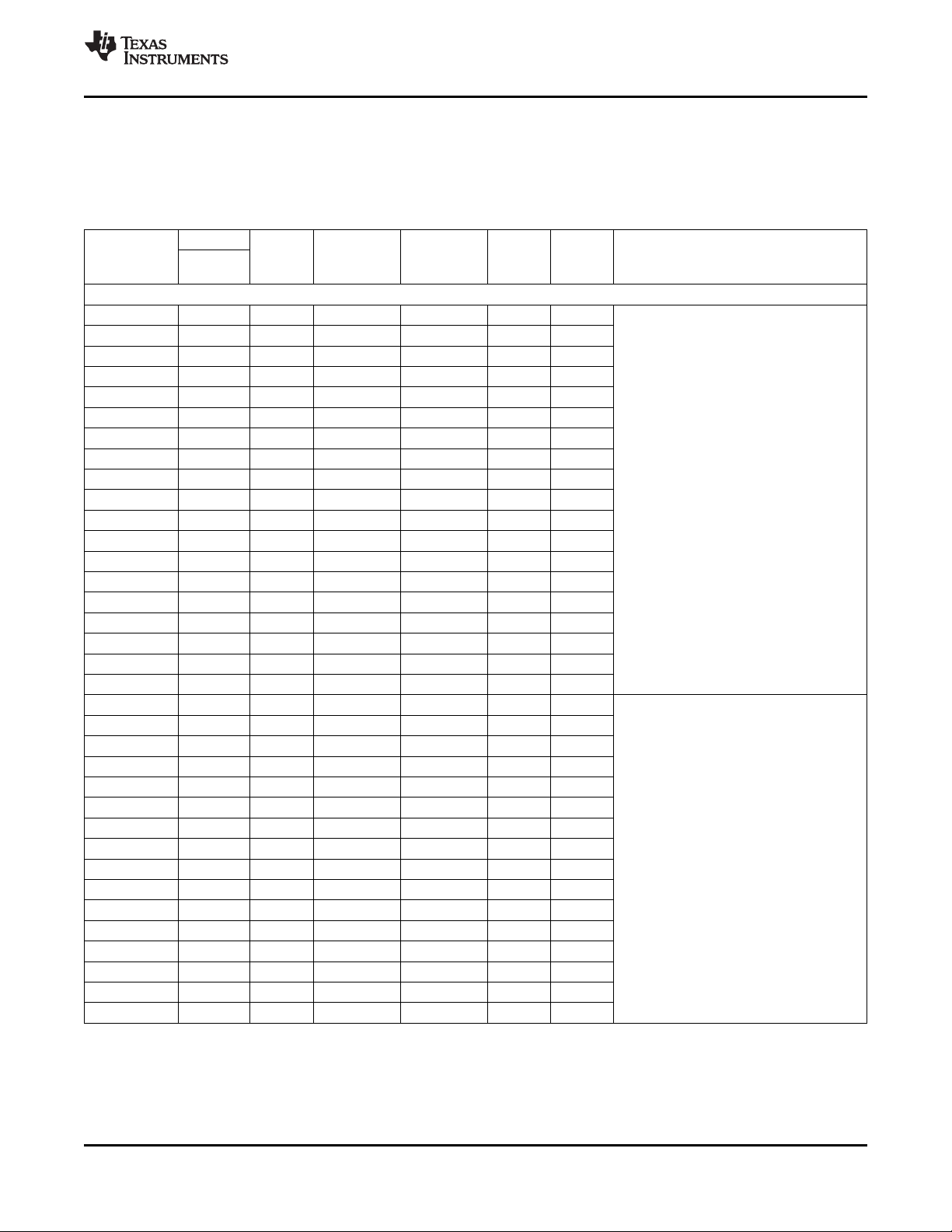

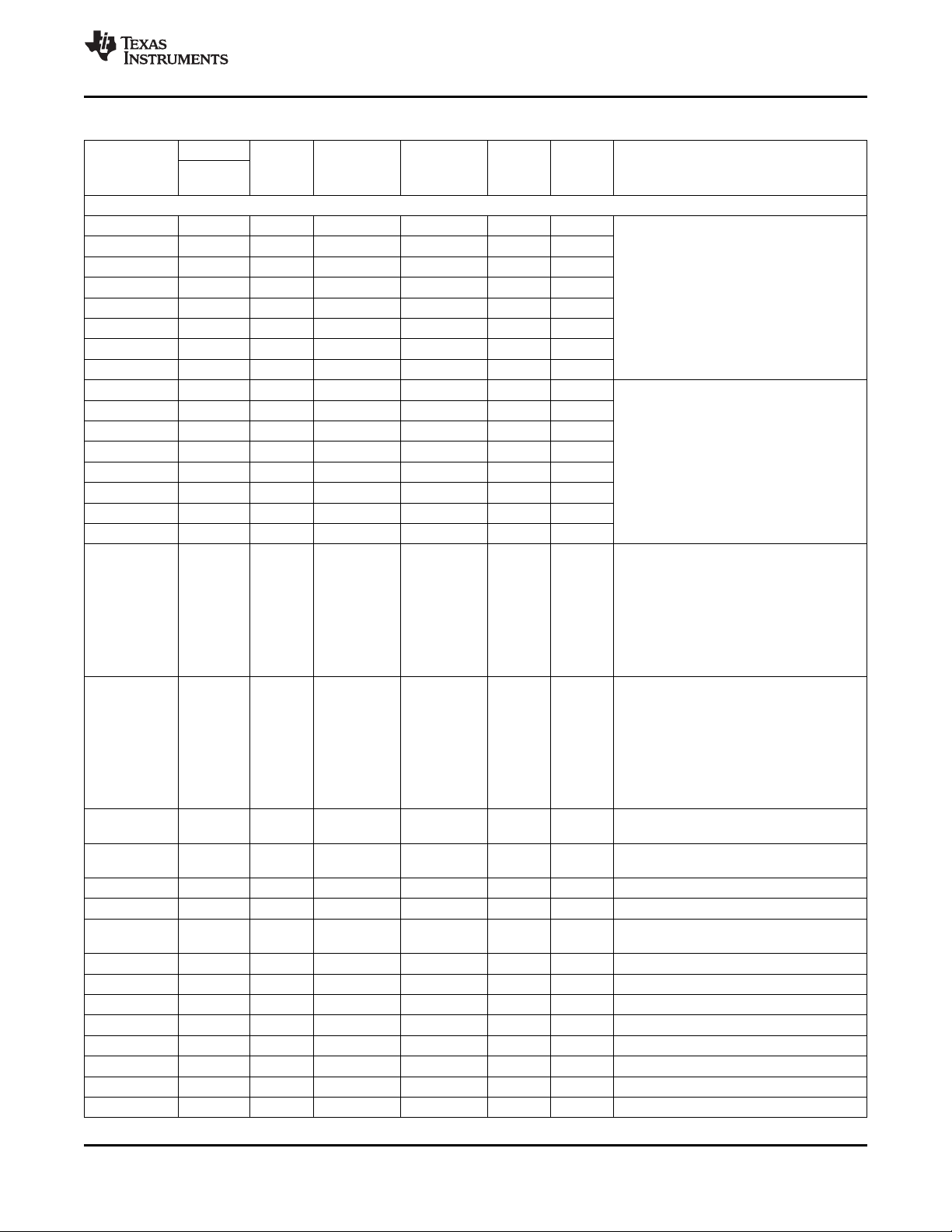

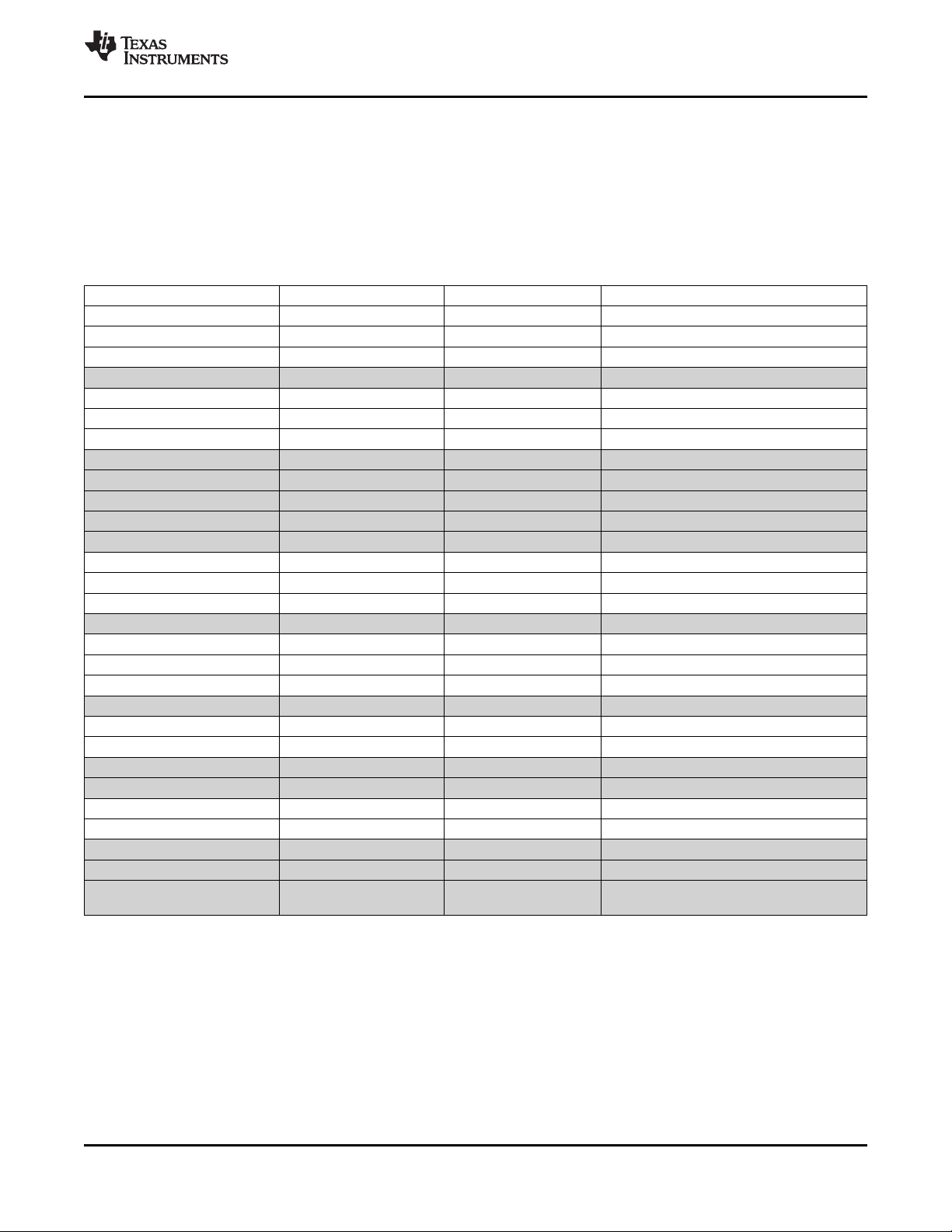

Table 2-3. Signal Descriptions

PIN NO.

NAME X-CENTER Y-CENTER I/O/Z

XA[18] 154 173 42.6 2281.5 O/Z –

XA[17] 152 171 42.6 2485.3 O/Z –

XA[16] 149 167 42.6 2819.6 O/Z –

XA[15] 145 163 42.6 3182.9 O/Z –

XA[14] 141 157 42.6 3774.9 O/Z –

XA[13] 138 154 42.6 4029.4 O/Z –

XA[12] 135 151 42.6 4401.3 O/Z –

XA[11] 129 145 255.7 5057.5 O/Z

XA[10] 127 143 474.4 5057.5 O/Z –

XA[9] 122 138 996.5 5057.5 O/Z – 19-bit XINTF Address Bus

XA[8] 118 134 1492.4 5057.5 O/Z –

XA[7] 116 131 1825.2 5057.5 O/Z –

XA[6] 109 124 2566.0 5057.5 O/Z –

XA[5] 106 121 2937.9 5057.5 O/Z –

XA[4] 101 116 3518.7 5057.5 O/Z –

XA[3] 83 96 5361.5 4471.5 O/Z –

XA[2] 78 91 5361.5 3927.2 O/Z –

XA[1] 42 49 5024.5 42.6 O/Z –

XA[0] 18 24 2403.5 42.6 O/Z

XD[15] 144 162 42.6 3306.9 I/O/Z PU

XD[14] 136 152 42.6 4277.3 I/O/Z PU

XD[13] 95 110 4194.1 5057.5 I/O/Z PU

XD[12] 94 109 4318.1 5057.5 I/O/Z PU

XD[11] 72 85 5361.5 3382.2 I/O/Z PU

XD[10] 71 84 5361.5 3258.3 I/O/Z PU

XD[9] 67 77 5361.5 2608.4 I/O/Z PU

XD[8] 64 74 5361.5 2312.1 I/O/Z PU

XD[7] 53 60 5361.5 1045.9 I/O/Z PU

XD[6] 38 45 4586.0 42.6 I/O/Z PU

XD[5] 35 42 4281.2 42.6 I/O/Z PU

XD[4] 32 39 3966.6 42.6 I/O/Z PU

XD[3] 29 36 3652.0 42.6 I/O/Z PU

XD[2] 26 33 3337.5 42.6 I/O/Z PU

XD[1] 23 30 3022.9 42.6 I/O/Z PU

XD[0] 20 27 2708.3 42.6 I/O/Z PU

172-PIN

HFG

DIE PAD

NO.

DIE PAD DIE PAD

(mm) (mm)

XINTF SIGNALS

(2)

(1)

PU/PD

(3)

16-bit XINTF Data Bus

DESCRIPTION

(1) Typical drive strength of the output buffer for all pins is 4 mA except for TDO, XCLKOUT, XF, XINTF, EMU0, and EMU1 pins, which are

8 mA.

(2) I = Input, O = Output, Z = High impedance

(3) PU = pin has internal pullup; PD = pin has internal pulldown

Copyright © 2009–2010, Texas Instruments Incorporated Introduction 17

Submit Documentation Feedback

Product Folder Link(s): SM320F2812-HT

Page 18

SM320F2812-HT

SGUS062A–JUNE 2009–REVISED APRIL 2010

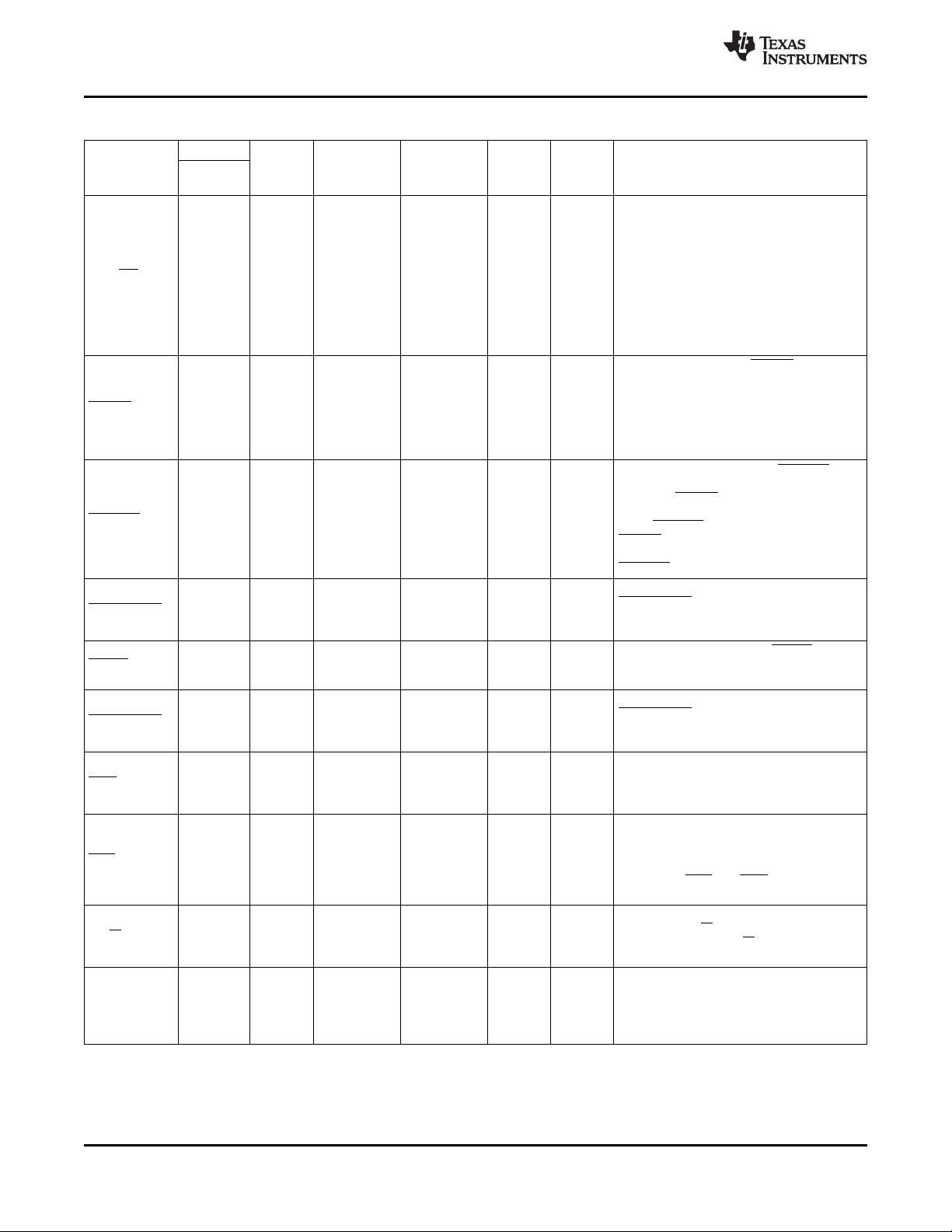

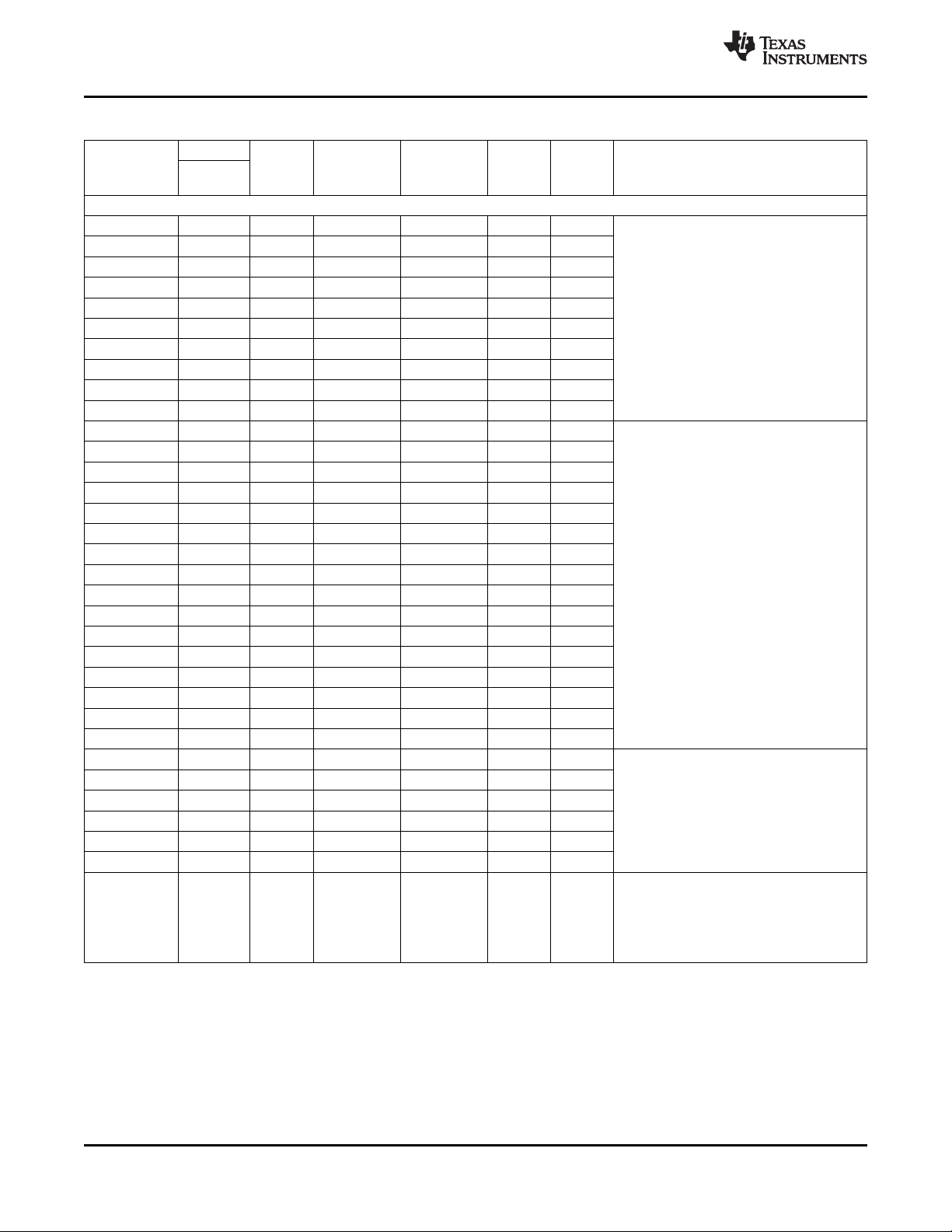

Table 2-3. Signal Descriptions

PIN NO.

NAME X-CENTER Y-CENTER I/O/Z

XMP/MC 17 23 2308.2 42.6 I PD external interface and on-chip boot ROM

XHOLD 155 174 42.6 2157.6 I PU strobes into a high-impedance state. The

XHOLDA 80 93 5361.5 4137.4 O/Z –

XZCS0AND1 43 50 5148.5 42.6 O/Z –

XZCS2 86 100 5361.5 4844.2 O/Z – (low) when an access to the XINTF Zone 2

XZCS6AND7 130 146 42.6 4888.6 O/Z –

XWE 82 95 5361.5 4347.5 O/Z –

XRD 41 48 4900.6 42.6 O/Z –

XR/W 50 57 5361.5 755.0 O/Z –

XREADY 157 176 42.6 1972.4 I PU XREADY can be configured to be a

172-PIN

HFG

DIE PAD

NO.

DIE PAD DIE PAD

(mm) (mm)

(1)

(continued)

(2)

PU/PD

(3)

Microprocessor/Microcomputer Mode

Select. Switches between microprocessor

and microcomputer mode. When high,

Zone 7 is enabled on the external interface.

When low, Zone 7 is disabled from the

may be accessed instead. This signal is

latched into the XINTCNF2 register on a

reset and the user can modify this bit in

software. The state of the XMP/MC pin is

ignored after reset.

External Hold Request. XHOLD, when

active (low), requests the XINTF to release

the external bus and place all buses and

XINTF releases the bus when any current

access is complete and there are no

pending accesses on the XINTF.

External Hold Acknowledge. XHOLDA is

driven active (low) when the XINTF has

granted a XHOLD request. All XINTF buses

and strobe signals are in a high-impedance

state. XHOLDA is released when the

XHOLD signal is released. External devices

should only drive the external bus when

XHOLDA is active (low).

XINTF Zone 0 and Zone 1 Chip Select.

XZCS0AND1 is active (low) when an

access to the XINTF Zone 0 or Zone 1 is

performed.

XINTF Zone 2 Chip Select. XZCS2 is active

is performed.

XINTF Zone 6 and Zone 7 Chip Select.

XZCS6AND7 is active (low) when an

access to the XINTF Zone 6 or Zone 7 is

performed.

Write Enable. Active-low write strobe. The

write strobe waveform is specified, per zone

basis, by the Lead, Active, and Trail periods

in the XTIMINGx registers.

Read Enable. Active-low read strobe. The

read strobe waveform is specified, per zone

basis, by the Lead, Active, and Trail periods

in the XTIMINGx registers.

NOTE: The XRD and XWE signals are

mutually exclusive.

Read Not Write Strobe. Normally held high.

When low, XR/W indicates write cycle is

active; when high, XR/W indicates read

cycle is active.

Ready Signal. Indicates peripheral is ready

to complete the access when asserted to 1.

synchronous or an asynchronous input.

See the timing diagrams for more details.

DESCRIPTION

www.ti.com

18 Introduction Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F2812-HT

Page 19

SM320F2812-HT

www.ti.com

Table 2-3. Signal Descriptions

PIN NO.

NAME X-CENTER Y-CENTER I/O/Z

172-PIN

HFG

DIE PAD

NO.

DIE PAD DIE PAD

(mm) (mm)

(1)

(continued)

(2)

PU/PD

SGUS062A–JUNE 2009–REVISED APRIL 2010

(3)

DESCRIPTION

JTAG AND MISCELLANEOUS SIGNALS

Oscillator Input – input to the internal

oscillator. This pin is also used to feed an

external clock. The 28× can be operated

with an external clock source, provided that

the proper voltage levels be driven on the

X1/XCLKIN pin. It should be noted that the

X1/XCLKIN 75 88 5361.5 3668.7 I

X1/XCLKIN pin is referenced to the 1.8-V

(or 1.9-V) core digital power supply (VDD),

rather than the 3.3-V I/O supply (V

clamping diode may be used to clamp a

DDIO

buffered clock signal to ensure that the

logic-high level does not exceed V

(1.8 V or 1.9 V) or a 1.8-V oscillator may be

DD

used.

X2 74 87 5361.5 3582.6 O Oscillator Output

Output clock derived from SYSCLKOUT to

be used for external wait-state generation

and as a general-purpose clock source.

XCLKOUT is either the same frequency,

XCLKOUT 117 132 1701.2 5057.5 O – 1/2 the frequency, or 1/4 the frequency of

SYSCLKOUT. At reset, XCLKOUT =

SYSCLKOUT/4. The XCLKOUT signal can

be turned off by setting bit 3 (CLKOFF) of

the XINTCNF2 register to 1.

TESTSEL 131 147 42.6 4764.6 I PD

Test Pin. Reserved for TI. Must be

connected to ground.

Device Reset (in) and Watchdog Reset

(out).

Device reset. XRS causes the device to

terminate execution. The PC points to the

address contained at the location

0x3FFFC0. When XRS is brought to a high

level, execution begins at the location

XRS 156 175 42.6 2077.8 I/O PU

pointed to by the PC. This pin is driven low

by the DSP when a watchdog reset occurs.

During watchdog reset, the XRS pin is

driven low for the watchdog reset duration

of 512 XCLKIN cycles.

The output buffer of this pin is an

open-drain with an internal pullup (100 mA,

typical). It is recommended that this pin be

driven by an open-drain device.

TEST1 66 76 5361.5 2522.3 I/O –

TEST2 65 75 5361.5 2436.1 I/O –

Test Pin. Reserved for TI. On F281x

devices, TEST1 must be left unconnected.

Test Pin. Reserved for TI. On F281x

devices, TEST2 must be left unconnected.

). A

Copyright © 2009–2010, Texas Instruments Incorporated Introduction 19

Submit Documentation Feedback

Product Folder Link(s): SM320F2812-HT

Page 20

SM320F2812-HT

SGUS062A–JUNE 2009–REVISED APRIL 2010

Table 2-3. Signal Descriptions

PIN NO.

NAME X-CENTER Y-CENTER I/O/Z

TRST 132 148 42.6 4684.8 I PD

TCK 133 149 42.6 4605.1 I PU JTAG test clock with internal pullup

TMS 123 139 872.5 5057.5 I PU

TDI 128 144 350.4 5057.5 I PU

TDO 124 140 777.9 5057.5 O/Z –

EMU0 133 150 42.6 4525.3 I/O/Z PU

EMU1 143 161 42.6 3430.9 I/O/Z PU

172-PIN

HFG

DIE PAD

NO.

DIE PAD DIE PAD

(mm) (mm)

(1)

(continued)

(2)

PU/PD

(3)

JTAG test reset with internal pulldown.

TRST, when driven high, gives the scan

system control of the operations of the

device. If this signal is not connected or

driven low, the device operates in its

functional mode, and the test reset signals

are ignored.

NOTE: Do not use pullup resistors on

TRST; it has an internal pulldown device. In

a low-noise environment, TRST can be left

floating. In a high-noise environment, an

additional pulldown resistor may be

needed. The value of this resistor should be

based on drive strength of the debugger

pods applicable to the design. A 2.2-kΩ

resistor generally offers adequate

protection. Since this is application specific,

it is recommended that each target board is

validated for proper operation of the

debugger and the application.

JTAG test-mode select (TMS) with internal

pullup. This serial control input is clocked

into the TAP controller on the rising edge of

TCK.

JTAG test data input (TDI) with internal

pullup. TDI is clocked into the selected

register (instruction or data) on a rising

edge of TCK.

JTAG scan out, test data output (TDO). The

contents of the selected register (instruction

or data) is shifted out of TDO on the falling

edge of TCK.

Emulator pin 0. When TRST is driven high,

this pin is used as an interrupt to or from

the emulator system and is defined as

input/output through the JTAG scan.

Emulator pin 1. When TRST is driven high,

this pin is used as an interrupt to or from

the emulator system and is defined as

input/output through the JTAG scan.

DESCRIPTION

www.ti.com

20 Introduction Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F2812-HT

Page 21

SM320F2812-HT

www.ti.com

Table 2-3. Signal Descriptions

PIN NO.

NAME X-CENTER Y-CENTER I/O/Z

172-PIN

HFG

DIE PAD

NO.

DIE PAD DIE PAD

(mm) (mm)

(1)

(continued)

(2)

PU/PD

SGUS062A–JUNE 2009–REVISED APRIL 2010

(3)

DESCRIPTION

ADC ANALOG INPUT SIGNALS

ADCINA7 163 186 42.6 1253.9 I

ADCINA6 164 188 42.6 1094.3 I

ADCINA5 165 190 42.6 954.0 I

ADCINA4 166 192 42.6 794.4 I

ADCINA3 167 194 42.6 654.1 I

ADCINA2 168 196 42.6 513.9 I

Eight-channel analog inputs for

Sample-and-Hold A. The ADC pins should

not be driven before V

V

pins have been fully powered up.

DDAIO

DDA1

ADCINA1 169 197 42.6 434.1 I

ADCINA0 170 198 42.6 354.3 I

ADCINB7 9 13 1355.2 42.6 I

ADCINB6 8 11 1164.6 42.6 I

ADCINB5 7 10 1069.2 42.6 I

ADCINB4 6 8 878.6 42.6 I

ADCINB3 5 6 688.0 42.6 I

ADCINB2 4 4 497.4 42.6 I

Eight-channel analog inputs for

Sample-and-Hold B. The ADC pins should

not be driven before the V

V

pins have been fully powered up.

DDAIO

ADCINB1 3 3 402.1 42.6 I

ADCINB0 2 2 306.8 42.6 I

ADC Voltage Reference Output (2 V).

Requires a low ESR (50 mΩ – 1.5 Ω)

ceramic bypass capacitor of 10 mF to

analog ground. (Can accept external

ADCREFP 11 15 1545.8 42.6 O reference input

(2 V) if the software bit is enabled for this

mode. 1-mF to 10-mF low ESR capacitor

can be used in the external reference

mode.)

ADC Voltage Reference Output (1 V).

Requires a low ESR (50 mΩ – 1.5 Ω)

ceramic bypass capacitor of 10 mF to

analog ground. (Can accept external

ADCREFM 10 14 1450.5 42.6 O reference input

(1 V) if the software bit is enabled for this

mode. 1-mF to 10-mF low ESR capacitor

can be used in the external reference

mode.)

ADCRESEXT 16 22 2212.9 42.63 O

ADCBGREFIN 160 180 42.6 1680.9 I

ADC External Current Bias Resistor

(24.9 kΩ ±5%)

Test Pin. Reserved for TI. Must be left

unconnected.

AVSSREFBG 12 17 1831.7 42.6 I ADC Analog GND

AVDDREFBG 13 18 1736.4 42.6 I ADC Analog Power (3.3 V)

ADCLO 171 199 42.6 274.5 I

V

SSA1

V

SSA2

V

DDA1

V

DDA2

V

SS1

V

DD1

V

DDAIO

V

SSAIO

15 21 2117.6 42.6 I ADC Analog GND

161 182 42.6 1550.7 I ADC Analog GND

14 19 1927.0 42.6 I ADC Analog 3.3-V Supply

162 184 42.6 1394.2 I ADC Analog 3.3-V Supply

159 178 42.6 1830.8 I ADC Digital GND

158 177 42.6 1901.0 I ADC Digital 1.8-V (or 1.9-V) Supply

1 1 211.5 42.6 3.3-V Analog I/O Power Pin

172 200 42.6 204.3 Analog I/O Ground Pin

Common Low Side Analog Input. Connect

to analog ground.

, V

DDA1

DDA2

, V

, and

DDA2

, and

Copyright © 2009–2010, Texas Instruments Incorporated Introduction 21

Submit Documentation Feedback

Product Folder Link(s): SM320F2812-HT

Page 22

SM320F2812-HT

SGUS062A–JUNE 2009–REVISED APRIL 2010

Table 2-3. Signal Descriptions

PIN NO.

NAME X-CENTER Y-CENTER I/O/Z

172-PIN

HFG

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

DDIO

V

DDIO

V

DDIO

V

DDIO

V

DDIO

V

DDIO

V

DD3VFL

22 29 2927.6 42.6

36 43 4395.4 42.6

55 62 5361.5 1256.0

73 86 5361.5 3496.4

98 113 3861.3 5057.5

110 125 2451.9 5057.5

125 141 663.7 5057.5

140 156 42.6 3845.1

150 169 42.6 2635.3

31 38 3871.3 42.6

37 44 4490.7 42.6

51 58 5361.5 869.2

57 65 5361.5 1514.6

76 89 5361.5 3754.9

84 97 5361.5 4585.7

97 112 3956.0 5057.5

103 118 3280.5 5057.5

111 126 2357.2 5057.5

126 142 569.0 5057.5

139 155 42.6 3915.2

30 37 3776.0 42.6

63 73 5361.5 2226.0

79 92 5361.5 4051.2

112 127 2262.5 5057.5

142 160 42.6 3510.7

68 78 5361.5 2732.4

DIE PAD

NO.

- 98 5361.5 4671.835

- 25 2517.7 42.6

- 79 5361.5 2818.6

- 133 1587.1 5057.5

- 159 42.6 3580.8

- 168 42.6 2705.4

- 105 4784.7 5057.5

DIE PAD DIE PAD

(mm) (mm)

POWER SIGNALS

(1)

(continued)

(2)

PU/PD

www.ti.com

(3)

DESCRIPTION

1.8-V or 1.9-V Core Digital Power Pins. See

Section 6.2, Recommended Operating

Conditions, for voltage requirements.

Core and Digital I/O Ground Pins

3.3–V I/O Digital Power Pins

3.3–V Flash Core Power Pin. This pin

should be connected to 3.3 V at all times

after power-up sequence requirements

have been met. This pin is used as VDDIO

in ROM parts and must be connected to

3.3 V in ROM parts as well.

22 Introduction Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F2812-HT

Page 23

SM320F2812-HT

www.ti.com

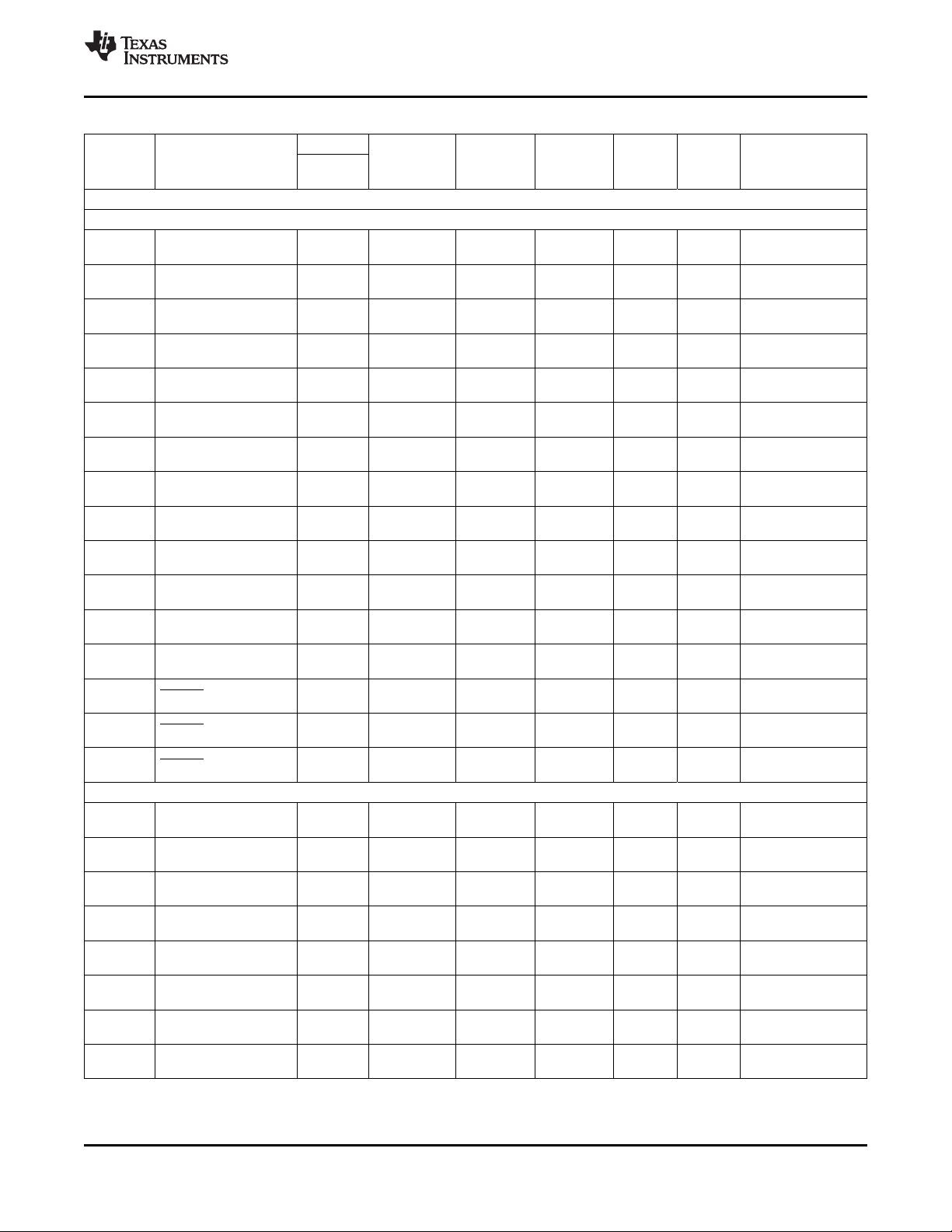

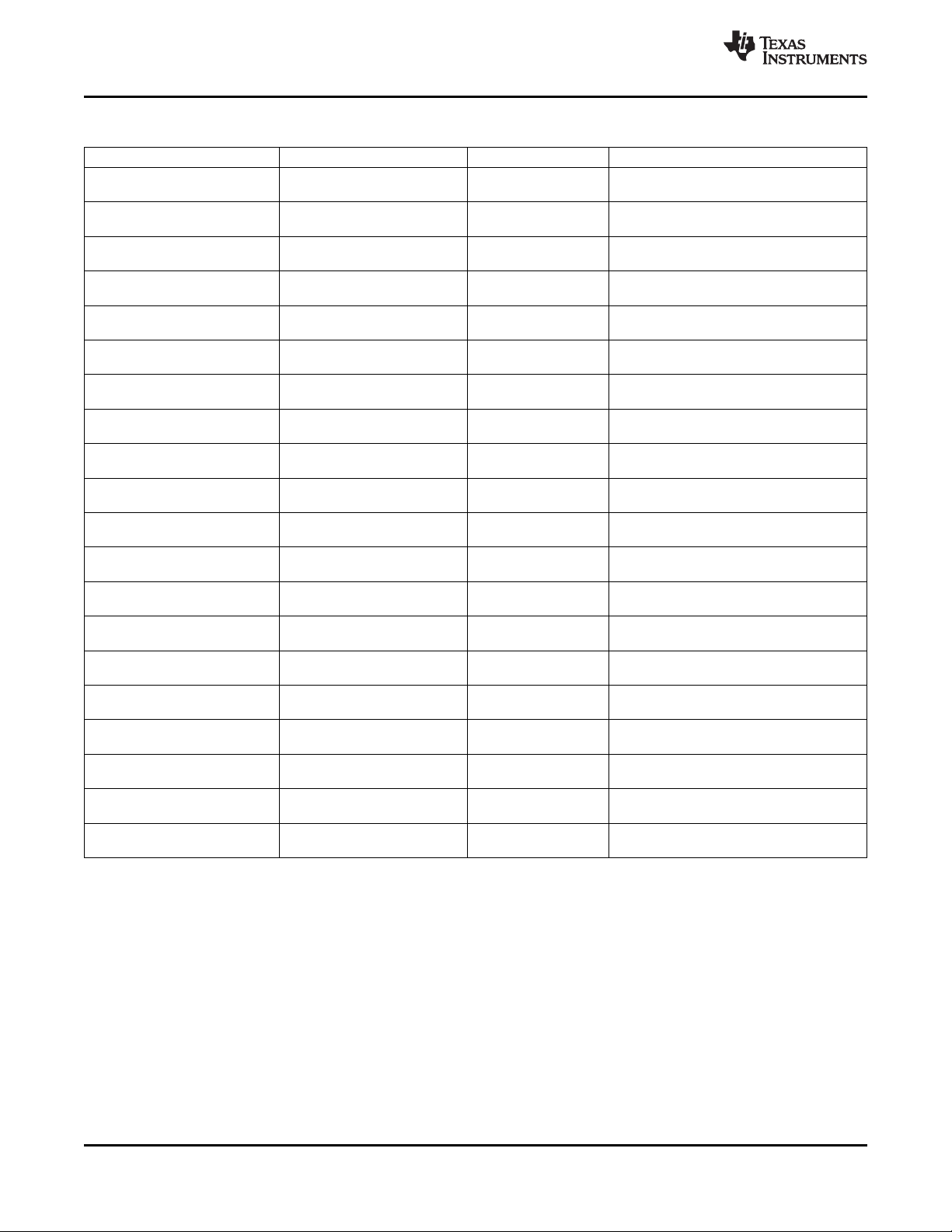

Signal Descriptions (Continued)

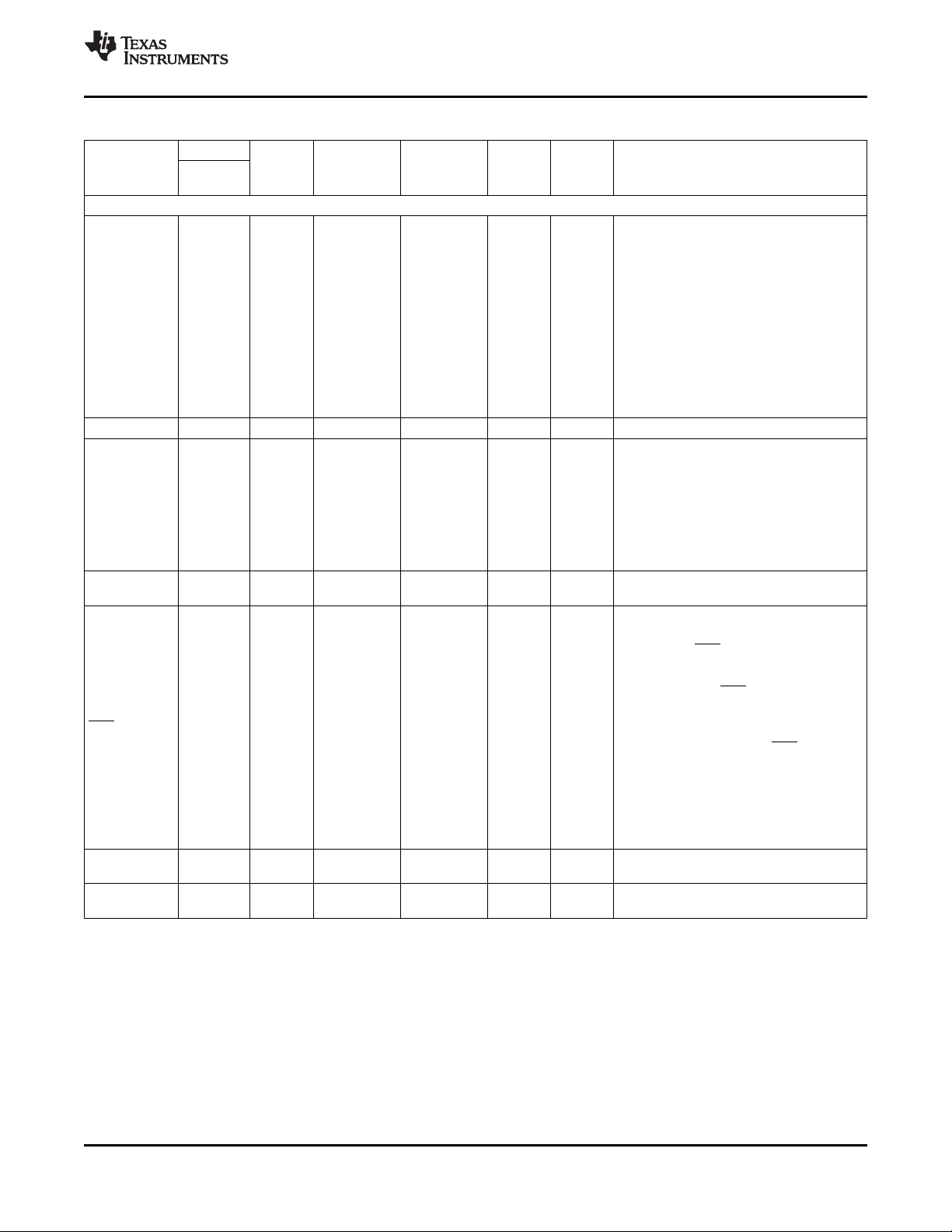

GPIO DIE PAD NO. I/O/Z

GPIOA0 PWM1 (O) 90 104 4908.6 5057.5 I/O/Z PU

GPIOA1 PWM2 (O) 91 106 4690.0 5057.5 I/O/Z PU

GPIOA2 PWM3 (O) 92 107 4566.0 5057.5 I/O/Z PU

GPIOA3 PWM4 (O) 93 108 4442.1 5057.5 I/O/Z PU

GPIOA4 PWM5 (O) 96 111 4070.1 5057.5 I/O/Z PU

GPIOA5 PWM6 (O) 99 114 3766.6 5057.5 I/O/Z PU

GPIOA6 T1PWM_T1CMP (I) 100 115 3642.7 5057.5 I/O/Z PU

GPIOA7 T2PWM_T2CMP (I) 102 117 3394.7 5057.5 I/O/Z PU

GPIOA8 CAP1_QEP1 (I) 104 119 3185.9 5057.5 I/O/Z PU

GPIOA9 CAP2_QEP2 (I) 105 120 3061.9 5057.5 I/O/Z PU

GPIOA10 CAP3_QEPI1 (I) 107 122 2814.0 5057.5 I/O/Z PU

GPIOA11 TDIRA (I) 114 129 2073.2 5057.5 I/O/Z PU

GPIOA12 TCLKINA (I) 115 130 1949.2 5057.5 I/O/Z PU

GPIOA13 C1TRIP (I) 119 135 1368.4 5057.5 I/O/Z PU

GPIOA14 C2TRIP (I) 120 136 1244.5 5057.5 I/O/Z PU

GPIOA15 C3TRIP (I) 121 137 1120.5 5057.5 I/O/Z PU

GPIOB0 PWM7 (O) 44 51 5361.5 211.5 I/O/Z PU

GPIOB1 PWM8 (O) 45 52 5361.5 302.1 I/O/Z PU

GPIOB2 PWM9 (O) 46 53 5361.5 392.7 I/O/Z PU

GPIOB3 PWM10 (O) 47 54 5361.5 483.2 I/O/Z PU

GPIOB4 PWM11 (O) 48 55 5361.5 573.8 I/O/Z PU

GPIOB5 PWM12 (O) 49 56 5361.5 664.4 I/O/Z PU

GPIOB6 T3PWM_T3CMP (I) 52 59 5361.5 955.3 I/O/Z PU

GPIOB7 T4PWM_T4CMP (I) 54 61 5361.5 1169.9 I/O/Z PU

PERIPHERAL DIE PAD DIE PAD

SIGNAL X-CENTER Y-CENTER

PIN NO.

172-PIN

HFG

GPIO OR PERIPHERAL SIGNALS

GPIOA OR EVA SIGNALS

GPIOB OR EVB SIGNALS

SGUS062A–JUNE 2009–REVISED APRIL 2010

(1)

(2)

PU/PD

(3)

DESCRIPTION

GPIO or PWM

Output Pin #1

GPIO or PWM

Output Pin #2

GPIO or PWM

Output Pin #3

GPIO or PWM

Output Pin #4

GPIO or PWM

Output Pin #5

GPIO or PWM

Output Pin #6

GPIO or Timer 1

Output

GPIO or Timer 2

Output

GPIO or Capture

Input #1

GPIO or Capture

Input #2

GPIO or Capture

Input #3

GPIO or Timer

Direction

GPIO or Timer Clock

Input

GPIO or Compare 1

Output Trip

GPIO or Compare 2

Output Trip

GPIO or Compare 3

Output Trip

GPIO or PWM

Output Pin #7

GPIO or PWM

Output Pin #8

GPIO or PWM

Output Pin #9

GPIO or PWM

Output Pin #10

GPIO or PWM

Output Pin #11

GPIO or PWM

Output Pin #12

GPIO or Timer 3

Output

GPIO or Timer 4

Output

(1) Typical drive strength of the output buffer for all pins [except TDO, XCLKOUT, XF, XINTF, EMU0, and EMU1 pins] is 4 mA typical.

(2) I = Input, O = Output, Z = High impedance

(3) PU = pin has internal pullup; PD = pin has internal pulldown

Copyright © 2009–2010, Texas Instruments Incorporated Introduction 23

Submit Documentation Feedback

Product Folder Link(s): SM320F2812-HT

Page 24

SM320F2812-HT

SGUS062A–JUNE 2009–REVISED APRIL 2010

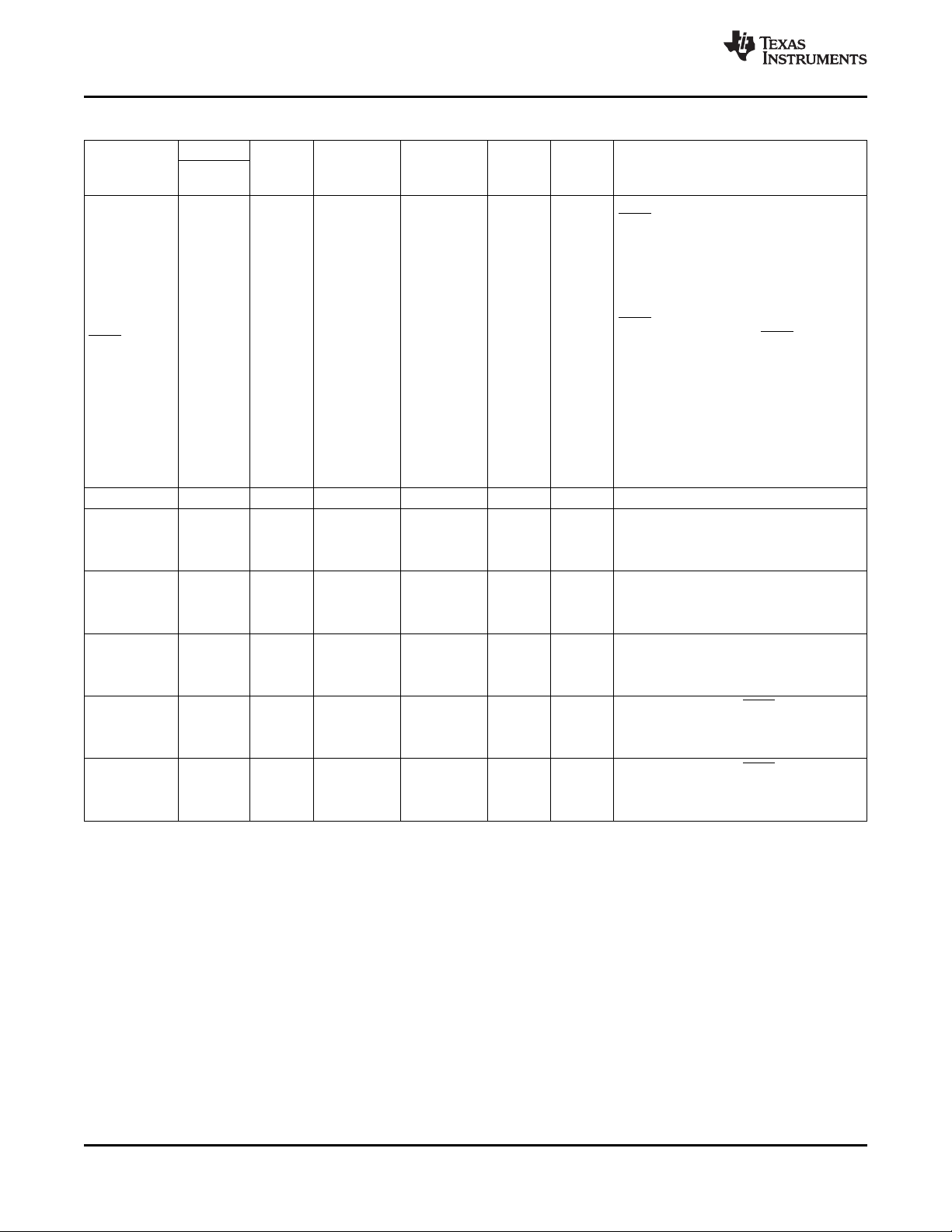

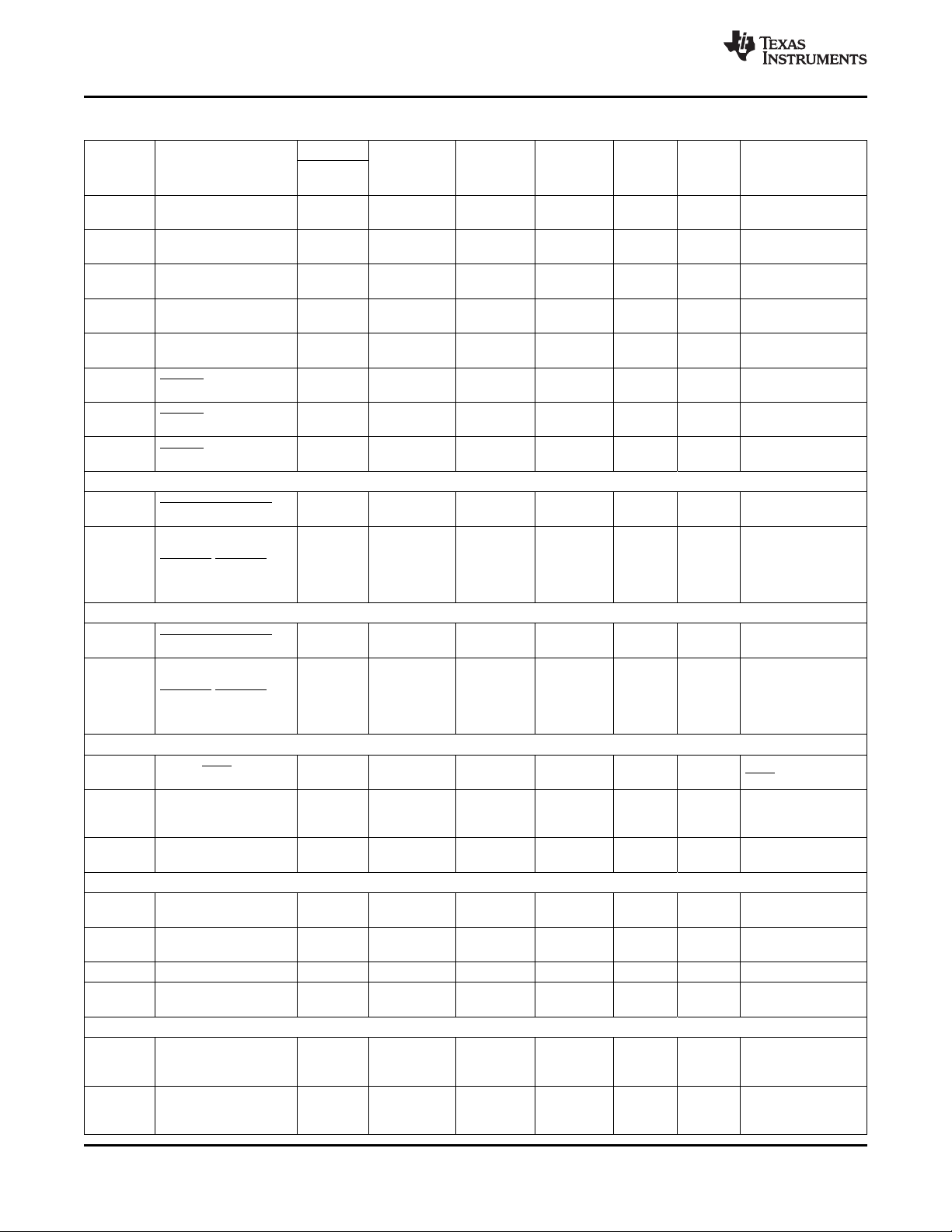

Signal Descriptions (Continued)

GPIO DIE PAD NO. I/O/Z

GPIOB8 CAP4_QEP3 (I) 56 64 5361.5 1428.4 I/O/Z PU

GPIOB9 CAP5_QEP4 (I) 58 66 5361.5 1600.7 I/O/Z PU

GPIOB10 CAP6_QEPI2 (I) 59 67 5361.5 1691.3 I/O/Z PU

GPIOB11 TDIRB (I) 69 81 5361.5 2990.9 I/O/Z PU

GPIOB12 TCLKINB (I) 70 82 5361.5 3081.5 I/O/Z PU

GPIOB13 C4TRIP (I) 60 69 5361.5 1868.1 I/O/Z PU

GPIOB14 C5TRIP (I) 61 71 5361.5 2044.8 I/O/Z PU

GPIOB15 C6TRIP (I) 62 72 5361.5 2135.4 I/O/Z PU

GPIOD0 T1CTRIP_PDPINTA (I) 108 123 2690.0 5057.5 I/O/Z PU

GPIOD1 T2CTRIP/EVASOC (I) 113 128 2167.8 5057.5 I/O/Z PU External ADC

GPIOD5 T3CTRIP_PDPINTB (I) 77 90 5361.5 3841.1 I/O/Z PU

GPIOD6 T4CTRIP/EVBSOC (I) 81 94 5361.5 4261.4 I/O/Z PU External ADC

GPIOE0 XINT1_XBIO (I) 146 164 42.6 3059.0 I/O/Z –

GPIOE1 XINT2_ADCSOC (I) 148 166 42.6 2899.4 I/O/Z – ADC start of

GPIOE2 XNMI_XINT13 (I) 147 165 42.6 2979.2 I/O/Z PU

GPIOF0 SPISIMOA (O) 39 46 4709.9 42.6 I/O/Z –

GPIOF1 SPISOMIA (I) 40 47 4805.3 42.6 I/O/Z –GPIOF2 SPICLKA (I/O) 33 40 4090.6 42.6 I/O/Z – GPIO or SPI clock

GPIOF3 SPISTEA (I/O) 34 41 4185.9 42.6 I/O/Z –

GPIOF4 SCITXDA (O) 151 170 42.6 2565.1 I/O/Z PU asynchronous serial

GPIOF5 SCIRXDA (I) 153 172 42.6 2361.3 I/O/Z PU asynchronous serial

PERIPHERAL DIE PAD DIE PAD

SIGNAL X-CENTER Y-CENTER

PIN NO.

172-PIN

HFG

GPIOD OR EVA SIGNALS

GPIOD OR EVB SIGNALS

GPIOE OR INTERRUPT SIGNALS

GPIOF OR SPI SIGNALS

GPIOF OR SCI-A SIGNALS

(1)

(continued)

(2)

PU/PD

(3)

GPIO or Capture

Input #4

GPIO or Capture

Input #5

GPIO or Capture

Input #6

GPIO or Timer

Direction

GPIO or Timer Clock

Input

GPIO or Compare 4

Output Trip

GPIO or Compare 5

Output Trip

GPIO or Compare 6

Output Trip

Timer 1 Compare

Output Trip

Timer 2 Compare

Output Trip or

Start-of-Conversion

EV-A

Timer 3 Compare

Output Trip

Timer 4 Compare

Output Trip or

Start-of-Conversion

EV-B

GPIO or XINT1 or

XBIO input

GPIO or XINT2 or

conversion

GPIO or XNMI or

XINT13

GPIO or SPI slave

in, master out

GPIO or SPI slave

out, master in

GPIO or SPI slave

transmit enable

GPIO or SCI

port TX data

GPIO or SCI

port RX data

www.ti.com

DESCRIPTION

24 Introduction Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F2812-HT

Page 25

SM320F2812-HT

www.ti.com

Signal Descriptions (Continued)

GPIO DIE PAD NO. I/O/Z

GPIOF6 CANTXA (O) 85 99 5361.5 4758.0 I/O/Z PU

GPIOF7 CANRXA (I) 87 101 5192.7 5057.5 I/O/Z PU

GPIOF8 MCLKXA (I/O) 27 34 3461.4 42.6 I/O/Z PU

GPIOF9 MCLKRA (I/O) 24 31 3146.8 42.6 I/O/Z PU

GPIOF10 MFSXA (I/O) 25 32 3242.2 42.6 I/O/Z PU

GPIOF11 MFSRA (I/O) 28 35 3556.7 42.6 I/O/Z PU

GPIOF12 MDXA (O) 21 28 2832.3 42.6 I/O/Z –

GPIOF13 MDRA (I) 19 26 2613.0 42.6 I/O/Z PU

GPIOF14 XF_XPLLDIS (O) 137 153 42.6 4153.3 I/O/Z PU

PERIPHERAL DIE PAD DIE PAD

SIGNAL X-CENTER Y-CENTER

PIN NO.

172-PIN

HFG

GPIOF OR CAN SIGNALS

GPIOF OR McBSP SIGNALS

GPIOF OR XF CPU OUTPUT SIGNAL

(1)

(continued)

SGUS062A–JUNE 2009–REVISED APRIL 2010

(2)

PU/PD

(3)

DESCRIPTION

GPIO or eCAN

transmit data

GPIO or eCAN

receive data

GPIO or transmit

clock

GPIO or receive

clock

GPIO or transmit

frame synch

GPIO or receive

frame synch

GPIO or transmitted

serial data

GPIO or received

serial data

This pin has three

functions:

1. XF –

General-purpose

output pin.

2. XPLLDIS – This

pin is sampled

during reset to check

if the PLL needs to

be disabled. The

PLL will be disabled

if this pin is sensed

low. HALT and

STANDBY modes

cannot be used

when the PLL is

disabled.

3. GPIO – GPIO

function

Copyright © 2009–2010, Texas Instruments Incorporated Introduction 25

Submit Documentation Feedback

Product Folder Link(s): SM320F2812-HT

Page 26

SM320F2812-HT

SGUS062A–JUNE 2009–REVISED APRIL 2010

Signal Descriptions (Continued)

GPIO DIE PAD NO. I/O/Z

GPIOG4 SCITXDB (O) 88 102 5098.0 5057.5 I/O/Z – asynchronous serial

GPIOG5 SCIRXDB (I) 89 103 5003.3 5057.5 I/O/Z – asynchronous serial

PERIPHERAL DIE PAD DIE PAD

SIGNAL X-CENTER Y-CENTER

PIN NO.

172-PIN

HFG

GPIOG OR SCI-B SIGNALS

(1)

(continued)

(2)

PU/PD

(3)

GPIO or SCI

port transmit data

GPIO or SCI

port receive data

www.ti.com

DESCRIPTION

NOTE

Other than the power supply pins, no pin should be driven before the 3.3-V rail has reached

recommended operating conditions.

26 Introduction Copyright © 2009–2010, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Link(s): SM320F2812-HT

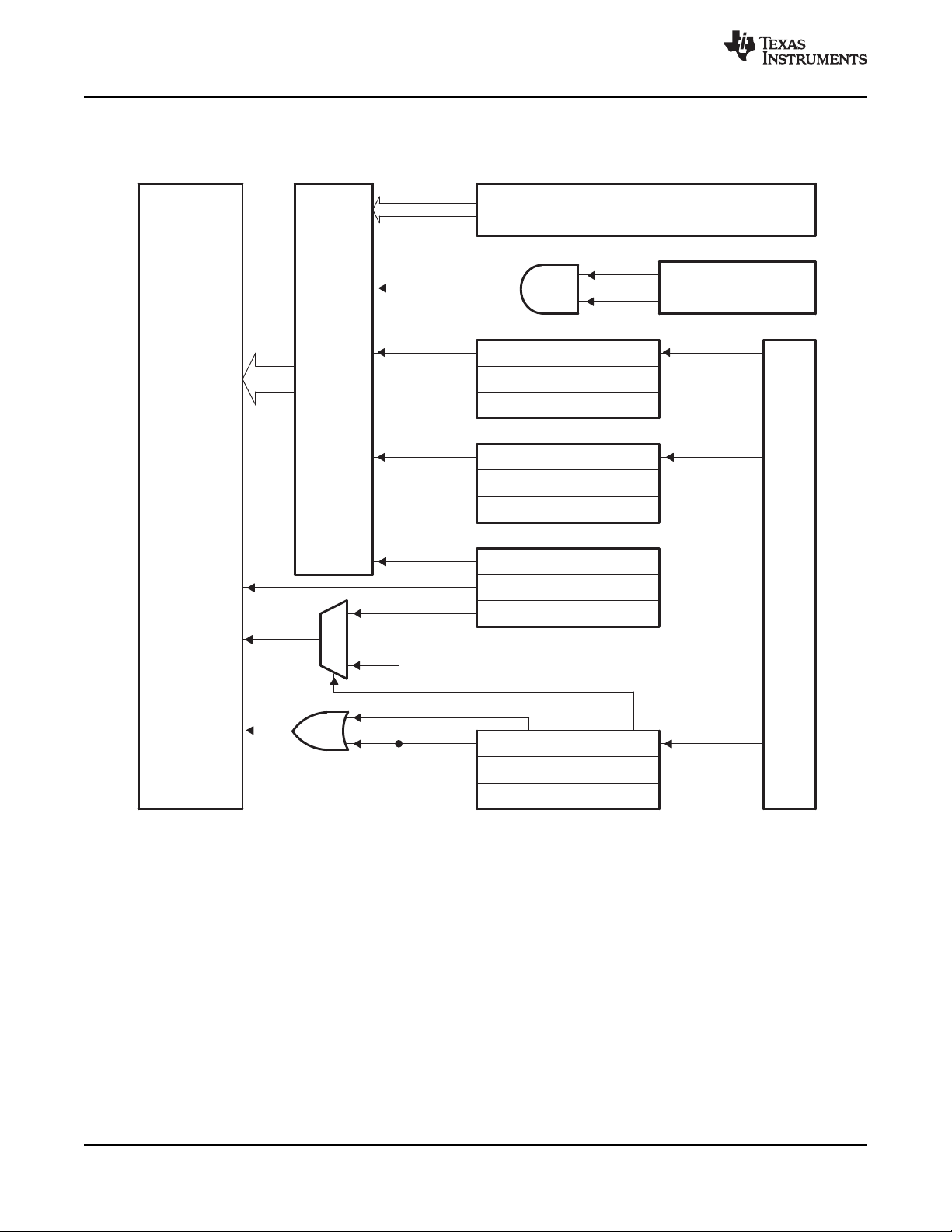

Page 27

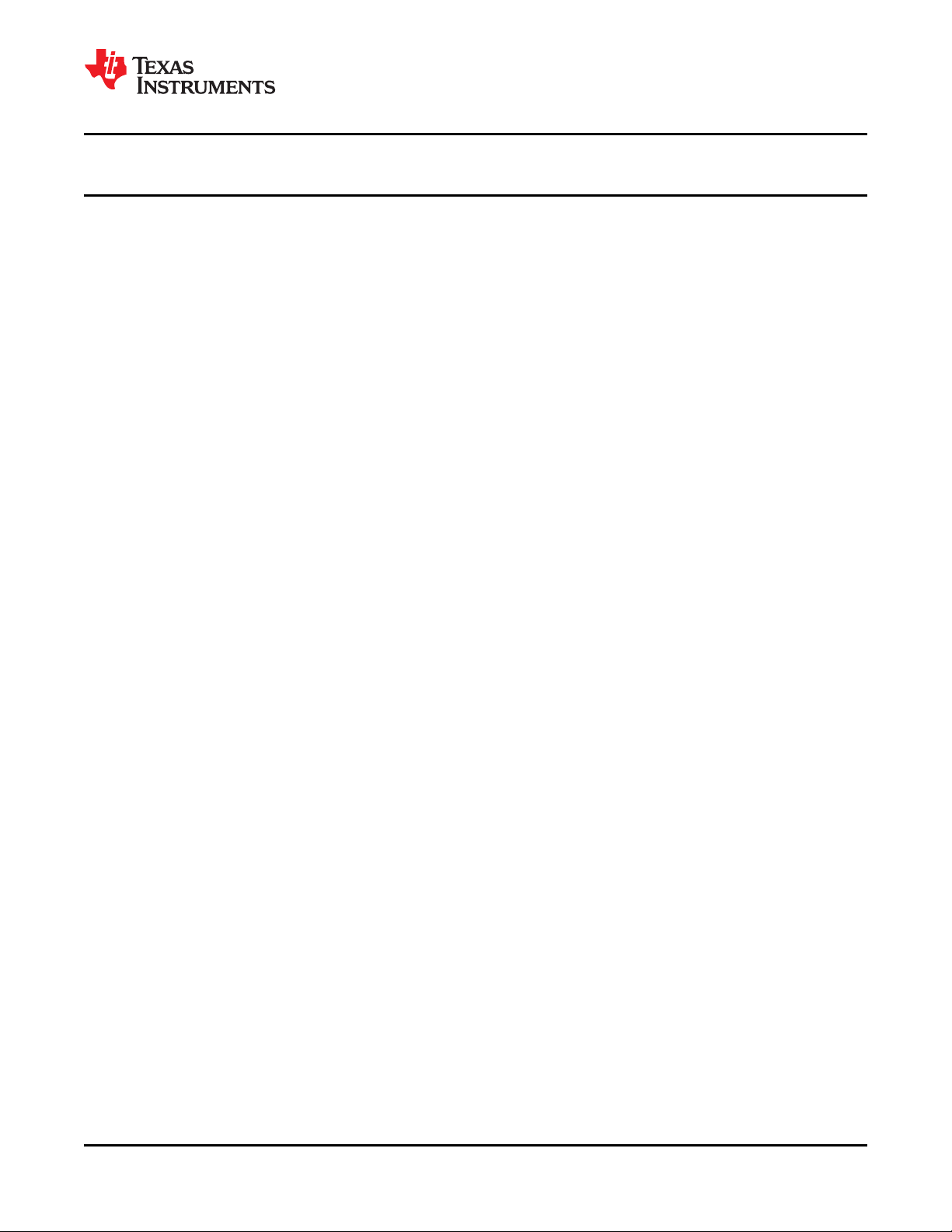

M0 SARAM

1K x 16

CPU-Timer 0

CPU-Timer 1

INT[12:1]

CLKIN

Real-Time JTAG

CPU-Timer 2

Peripheral Bus

C28x CPU

H0 SARAM

8K ⋅ 16

INT14

NMI

INT13

Memory Bus

M1 SARAM

1K x 16

Flash

128K x 16

Boot ROM

4K ⋅ 16

eCAN

SCIA/SCIB

12-Bit ADC

External Interrupt

Control

(XINT1/2/13, XNMI)

EVA/EVB

Memory Bus

OTP

1K x 16

McBSP

System Control

(Oscillator and PLL

+

Peripheral Clocking

+

Low-Power

Modes

+

WatchDog)

FIFO

FIFO

PIE

(96 interrupts)

†

RS

SPI FIFO

TINT0

TINT1

TINT2

Control

Address(19)

Data(16)

External

Interface

(XINTF)

16 Channels

†

45 of the possible 96 interrupts are used on the device.

GPIO Pins

XRS

X1/XCLKIN

X2

XF_XPLLDIS

Protected by the code-security module.

XINT13

G

P

I

O

M

U

X

L1 SARAM

4K x 16

XNMI