Page 1

User’s Guide

July 2002 Advanced Analog Products

SLUU083A

Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty . Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. T o minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third–party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party , or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2002, Texas Instruments Incorporated

Page 3

About This Manual

Trademarks

Preface

Read This First

This user’s guide describes the bq2400x evaluation module. The EVM conve-

niently evaluates a linear Li-ion bq2400x charge-management solution for

one- and two-cell battery-pack applications. This guide describes a complete

designed-and-tested charger, which delivers up to 1.2 A of continuous-charge

current for one- or two-cell applications

How to Use This Manual

This document contains the following chapters:

- Chapter 1—Introduction

- Chapter 2—Test Summary

- Chapter 3—Physical Layouts

- Chapter 4—Bill of Materials

- Appendix A—Schematic

Related Documentation From Texas Instruments

- bq24001, bq24002, bq24003 data sheet, literature number

SLUS462A

- bq24004, bq24005, bq24006 data sheet, literature number

SLUS476

Trademarks

PowerPAD is a trademark of Texas Instruments.

Read This First

iii

Page 4

Running Title—Attribute Reference

Contents

1 Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Background 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Performance Specification Summary 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 T est Summary 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Setup 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 I/O Connections 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Jumper-Selectable Configuration 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Test Procedures 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 For Single-Cell Applications 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 For Two-Cell Applications 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Physical Layouts 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Board Layout 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Bill of Materials 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Bill of Materials 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 bq2400x Charge Status Configurations 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

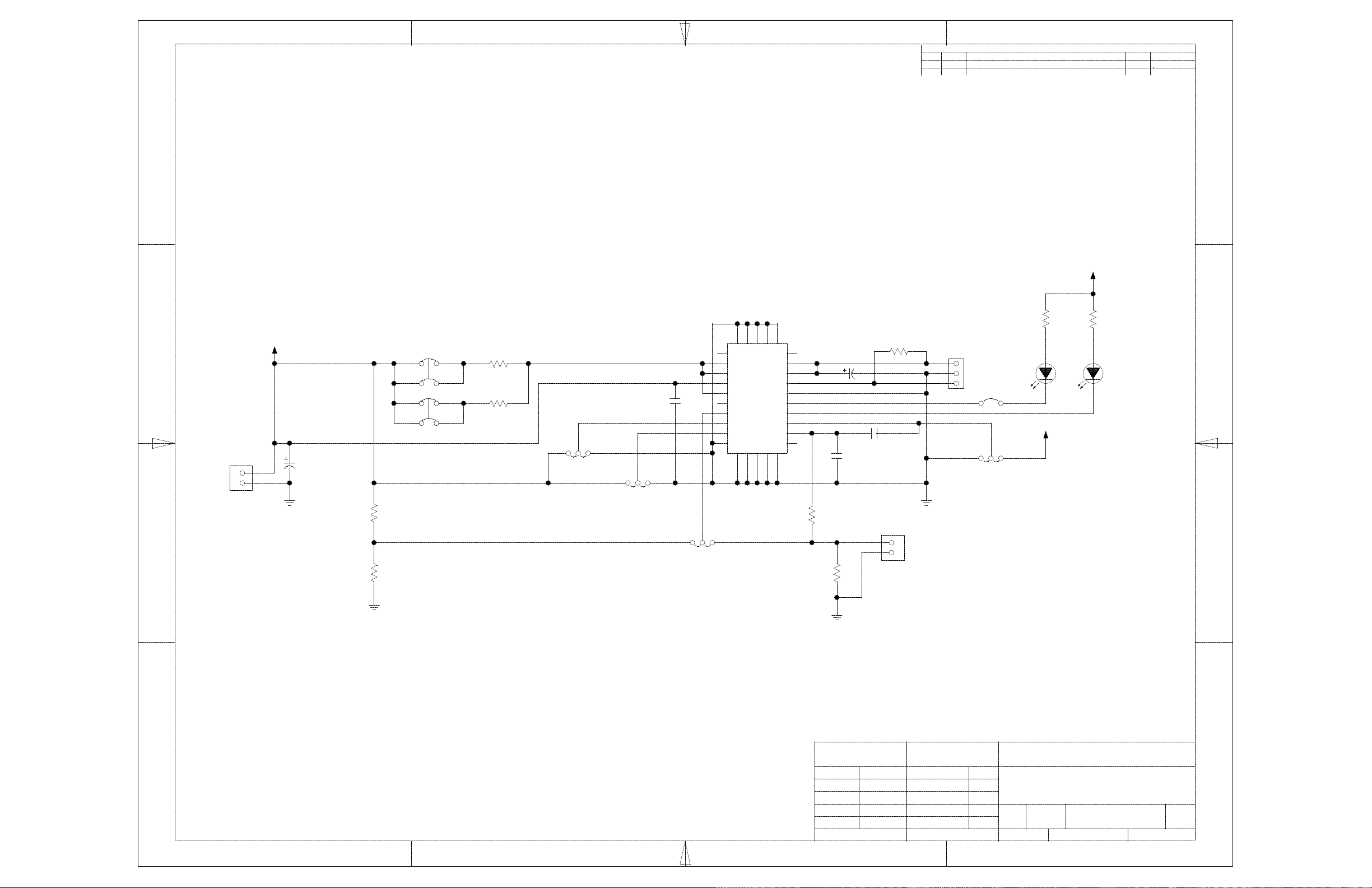

A Schematic A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figures

3–1 SLUP051 Board Layout Top Layer 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2 SLUP051 Board Layout Bottom Layer 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3 SLUP051 Top Assembly View 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Schematic A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tables

1–1 Performance Specification Summary (One Cell) 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2 Performance Specification Summary (Two Cell) 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–2 SLUP051 Bill of Materials 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

v

Page 5

Chapter 1

Introduction

This user’s guide describes the bq2400x Evaluation Module (SLUP051). The

EVM conveniently evaluates a linear Li-ion bq2400x charge-management

solution for one- and two-cell battery-pack applications. This guide describes

a complete designed-and-tested charger, which delivers up to 1.0 A of continuous-charge current for one- or two-cell applications.

Topic Page

1.1 Background 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Performance Specification Summary 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

Page 6

Background

B

I

A

B

V

V

Th

C

1.1 Background

The bq2400x series ICs are advanced Li-Ion linear charge management

devices for highly integrated and space-limited applications. They combine

high-accuracy current and voltage regulation; FET pass-transistor and

reverse-blocking Schottky; battery conditioning, temperature, or input-power

monitoring; charge termination; charge-status indication; and charge timer in

a small, 20-lead TSSOP PowerPAD package.

The bq2400x continuously measures battery temperature using an external

thermistor. For safety reasons, the bq2400x inhibits charge until the battery

temperature is within the user-defined thresholds. Alternatively , the user can

monitor the input voltage to qualify charge. The bq2400x series then charge

the battery in three phases: preconditioning, constant current and constant

voltage. If the battery voltage is below the internal low-voltage threshold, the

bq2400x uses trickle-charge to condition the battery . A preconditioning timer

is provided for additional safety. Following preconditioning, the bq2400x

applies a constant-charge current to the battery. An external sense-resistor

sets the magnitude of the current. The constant-current phase is maintained

until the battery reaches the charge-regulation voltage. The bq2400x then

transitions to the constant voltage phase. The user can configure the device

for cells with either coke or graphite anodes.

Charge is terminated by either of the following methods:

- Maximum time

- Minimum current detection

1.2 Performance Specification Summary

This section summarizes the performance specifications of the SLUP051

EVM. Table 1–1 gives the performance specifications of the hubs.

The bq2400x automatically restarts the charge if the battery voltage falls below

an internal recharge threshold.

Table 1–1.Performance Specification Summary (One Cell)

Specification Test Conditions Min Typ Max Units

Input dc voltage, V

attery charge current,

attery voltage regulation,

erm fault

APG (user defined, see data sheet) J2 set to APG ‡

Power dissipation, P

†

VI, for a single-cell, should not exceed 5.3 VDC for the 1-A charge rate and 7.6 V for the 0.5-A charge rate. (VI is the input voltage

to the bq2400x IC, pins 2 and 3. The power supply source voltage, at J1, is 0.1 V larger than VI because of the regulated voltage

drop across the current sense resistor, during constant current regulation.)

‡

If J2 is set to APG, then the chip will be disabled when the input is outside of this range: 4.02 V±0.07 V and 10.76 V ±0.09 V.

DC

J4 shorted, J3 open 0.4 0.5 0.6

CHG

REG

High, T

BATMAX

Low, T

BATMIN

D

J3 shorted, J4 open 0.9 1 1.1

J6 set to V

J6 set to GND 4.05 4.1 4.15

J2 set to Therm 43 48 53

J2 set to Therm 0 5 10

(VI-VO) × I

CC

load

4.9 5.0 † V

4.15 4.20 4.25

2.3 W

°

°

1-2

Page 7

Performance Specification Summary

B

I

A

B

V

V

Th

C

Table 1–2.Performance Specification Summary (Two Cell)

Specification Test Conditions Min Typ Max Units

Input dc voltage, V

DC

J4 shorted, J3 open 0.4 0.5 0.6

attery charge current,

attery voltage regulation,

erm fault

CHG

REG

High, T

Low, T

BATMAX

BATMIN

J3 shorted, J4 open 0.9 1 1.1

J6 set to V

CC

J6 set to GND 8.15 8.20 8.25

J2 set to Therm 43 48 53

J2 set to Therm 0 5 10

APG (user defined, see data sheet) J2 set to APG ‡

Power dissipation, P

†

VI, for a 2-cell, should not exceed 9.1 VDC for the 1-A charge rate and 10.6 V for the 0.5-A charge rate. (VI is the input voltage

to the bq2400x IC, pins 2 and 3. The power supply source voltage, at J1, is 0.1 V larger than VI because of the regulated voltage

drop across the current sense resistor, during constant current regulation.)

‡

If J2 is set to APG, then the chip will be disabled when the input is outside of this range: 4.02 V±0.07 V and 10.76 V ±0.09 V.

D

(VI-VO) × I

load

9.1 9.5 † V

8.35 8.40 8.45

2.3 W

°

°

Introduction

1-3

Page 8

Chapter 2

Test Summary

This chapter shows the test setups used, and the tests performed, in designing

the bq2400xEVM.

Topic Page

2.1 Setup 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 T est Procedures 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Summary

2-1

Page 9

Setup

2.1 Setup

The bq2400X EVM board requires a DC power source to provide input power

and a single-cell lithium-ion or lithium-polymer battery to charge.

Note:

Other versions of the bq2400x IC can charge two-cell battery packs.

The test setup connections and jumper setting selections are listed below.

2.1.1 I/O Connections

Jack Connect to:

J1–VCC Power source positive output

J1–GND Power source negative output

J9–+ Positive lead of single lithium cell

J9– – Negative lead of single lithium cell

J9 – VSENSE Tie to battery’s positive terminal

J10 – THERM Tie to thermistor lead in battery pack

J10 – GND

Tie to other thermistor lead (may be GND)

2.1.2 Jumper-Selectable Configuration

Jumper Selection

J3 1-A charge, use two jumpers placed horizontally; no jumpers on J4

J4 0.5-A charge, use two jumpers placed horizontally , no jumpers on J3

J2 Adapter power good (APD) or battery’s thermistor

†

J5

J6 Regulation voltage, 4.2 V or 4.1 V (single cell), 8.4 V or 8.2 V (double cell)

J7 Timer, 3-hour (float, no jumper), 4.5-hour, or 6-hour

J8

†

This jumper enables/disables the IC for bq24001/2/3/4/5/6. For bq24007/8, this jumper enables/

disables the change timer.

‡

For bq24003/6/8 the evaluation board used two LED (red and green) in place of a single

dull-color LED. Therefore, when both LEDs are lit a yellow status is indicated.

Enable, on or off

Stat2 green diode, connect for bq24002/3/5/6/8

2.2 Test Procedures

2.2.1 For Single-Cell Applications

Set up the evaluation board as described above, by making the necessary I/O

connections and jumper selections.

‡

2-2

Note:

Before test and evaluation, it is important to verify that the maximum power

dissipation on the IC is not exceeded. Pmax = 2.3 W.

P

diss, single cell

= (VI – 3 V) × I

where VI = VCC –0.1 V

CHG

Page 10

Test Procedures

Note:

for a single cell should not exceed 5.3 VDC for the 1-A charge rate and

V

I

7.6 V for the .5-A charge rate.

Adjust the input power supply for 5 V . The red LED should illuminate to indicate

charging, unless there is a fault or the battery is fully charged.

The bq2400x enters preconditioning mode if the battery is below the LowV

threshold. In this mode, the bq2400x trickle-charges with approximately

65 mA for approximately 23 minutes. If the battery does not reach the LowV

threshold after this period, then the charge current is terminated and the

bq2400x enters fault mode. The red LED flashes when in fault mode. This

feature may be tested in the .5-A charge mode by using a 5-Ω, 3-W resistor

in place of the battery. Fault mode is reset by toggling input power or enable

pin.

Once the battery charges to the LowV-stop threshold, the battery enters fast

charge mode and charges at the selected I

level (0.5-1 A).

CHG

The battery remains at the fast-charge mode until either the selected time

expires or the battery charges to the selected regulation voltage.

The time-out feature may be tested in the 0.5-A charge mode by using a 7 Ω,

3-W resistor in place of the battery . Apply the resistor after the unit is powered.

If the battery discharges down to the HighV threshold, the charger starts fast

charging. The refresh feature may be tested in the 0.5-A charge mode by using

a 7-Ω, 3-W resistor in parallel with a fully charged battery.

The circuit has an overvoltage comparator for added protection. If the battery

voltage exceeds this threshold for 330 ms, then the charger goes into fault

mode. This may be tested by connecting an external power supply in place of

the battery and adjusting the voltage above the threshold.

2.2.2 For Two-Cell Applications

Set up the evaluation board as described above, by making the necessary I/O

connections and jumper selections.

Note:

Before test and evaluation, it is important to verify that the maximum power

dissipation on the IC is not exceeded. P

P

diss, 2 cell

Note:

= (VI – 6.8 V) × I

= 2.3 W.

max

where VI = VCC –0.1 V

CHG

With a two-cell battery pack at 6 V , charging at 1 A, the IC power dissipation

is temporarily as high as 3.1 W until the pack charges to 6.8 V . This condition

is acceptable for the short time before the pack reaches 6.8 V.

Adjust the input power supply for 9.1 V. The red LED should illuminate to

indicate charging, unless there is a fault or the battery is fully charged.

Test Summary

2-3

Page 11

Test Procedures

The bq2400x enters preconditioning mode if the battery is below the LowV

threshold. In this mode, the bq2400x trickle-charges with approximately

65 mA for approximately 23 minutes. If the battery does not reach the LowV

threshold after this period, then the charge current is terminated and the

bq2400x enters fault mode. The red LED flashes in fault mode. This feature

is tested in the 0.5-A charge mode by using a 10-Ω, 5-W resistor in place of

the battery. Fault mode is reset by toggling input power or enable pin.

Once the battery charges to the LowV-stop threshold, the battery enters fast

charge mode and charges at the selected Ichg level (0.5 A/1 A).

The battery remains at the fast charge mode until either the selected time

expires or the battery charges to the selected regulation voltage.

The timeout feature is tested in the 0.5-A charge mode by using a 14-Ω, 5-W

resistor in place of the battery . Apply the resistor after the unit is powered up.

Once the battery voltage reaches voltage regulation (8.2 or 8.4 VDC), the

charge current tapers off as the battery charges.

If the battery discharges down to the HighV threshold, the charger starts fast

charging. The refresh feature is tested, in the 0.5-A charge mode, by using a

14-Ω 5-W resistor in parallel with a fully charged battery.

The circuit has an overvoltage comparator for added protection. If the battery

voltage exceeds this threshold for 330 ms, then the charger goes into fault

mode. This process may be tested by connecting an external power supply in

place of the battery and adjusting the voltage above the threshold.

2-4

Page 12

Chapter 3

Physical Layouts

This chapter contains the board layout and assembly drawings for the

SLUP051 EVM.

Topic Page

3.1 Board Layout 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Layouts

3-1

Page 13

Board Layout

3.1 Board Layout

Figure 3-1 shows the top layer of the SLUP051. Figure 3-2 shows the bottom

layer. Figure 3-3 shows the SLUP051 top assembly view.

Figure 3–1.SLUP051 Board Layout Top Layer

3-2

Page 14

Figure 3–2.SLUP051 Board Layout Bottom Layer

Board Layout

Figure 3–3.SLUP051 Top Assembly View

Physical Layouts

3-3

Page 15

Chapter 4

Bill of Materials

This chapter contains the bill of materials required for the SLUP051 EVM. It

also specifies the charge status configurations for the bq2400x.

Topic Page

4.1 Bill of Materials 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 bq2400x Charge Status Configurations 4-3. . . . . . . . . . . . . . . . . . . . . . . . .

Bill of Materials

4-1

Page 16

Bill of Materials

4.1 Bill of Materials

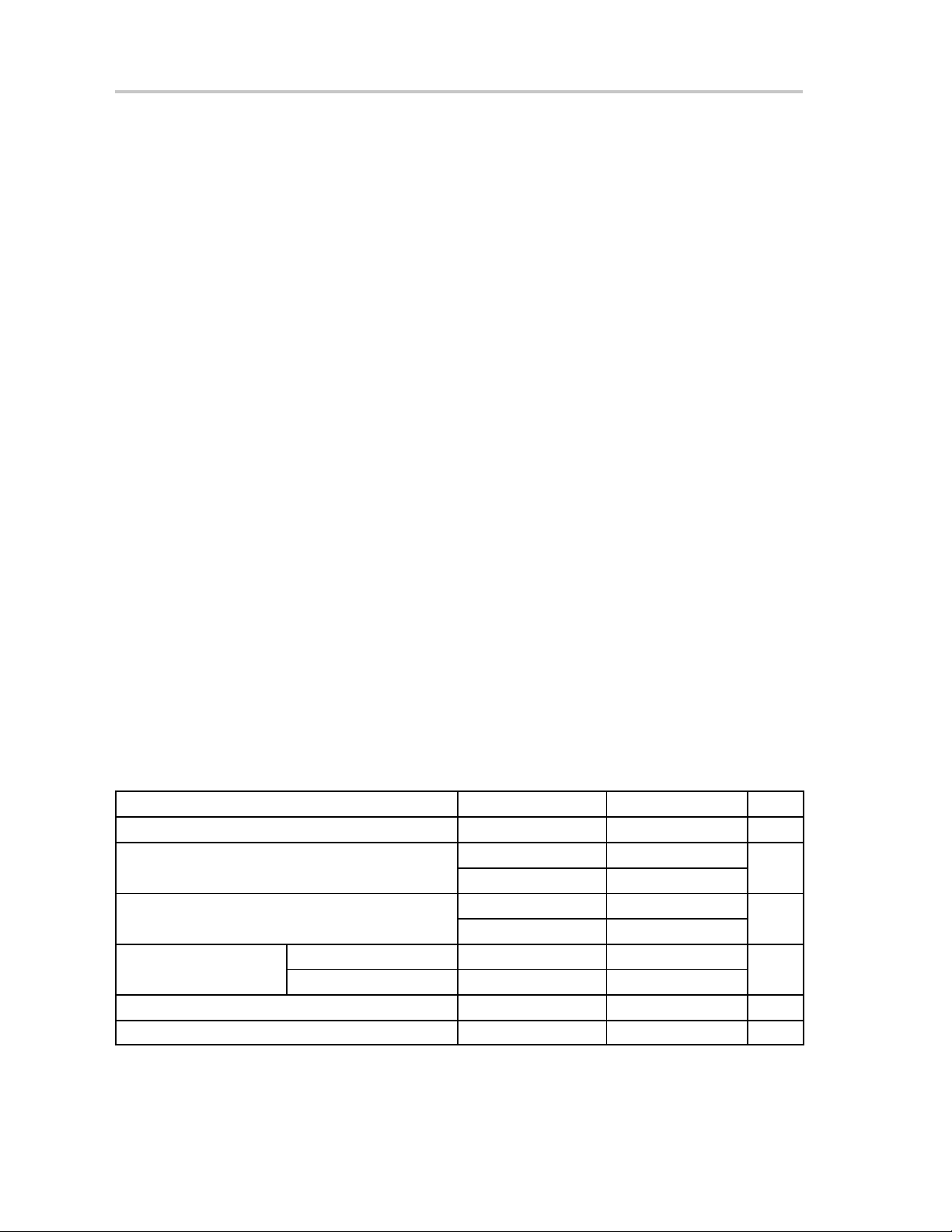

Table 4-1 lists materials required for the SLUP051 EVM.

Table 4–1.SLUP051 Bill of Materials

Reference

Designator

Qty

2 C1, C4 TAJC106M016R Capacitor, 10 µF tantalum, 16 V, ±20%,

1 C2 C0805X7R250-104KNE Capacitor, 0.1 µF ceramic, X7R, 25 V,

1 C3 ECJ-2YB1E224K Capacitor, 0.22 µF ceramic, X7R, 25 V,

1 C5 ECJ-2VCH100F Capacitor, 10 pF ceramic, NPO, 50 V,

1 D1 LN1361C(UY)-(TR) LED, green, GW type Panasonic

D2 LN1261CAL-(TR) LED, red, GW type Panasonic

2 J1, J10 AKZ500/2WP Terminal block, 2 pin Altech

4 J2, J5-J7 2340-6111TG Pin strip header, 3 pin 3M

5 J3a/b,

J4a/b,J8

1 J9 ED350/3 (ED1610-ND) Terminal block, 3-pin On shore

1 R1 CR0805-105113F Resistor, 51.1 kΩ, 1%, 1/10W, see Note 1 Venkel 805

1 R2 CR0805-10W3163JT Resistor, 316 Ω, 1%, 1/10W, see Note 1 Venkel 805

1 R3 LR2512-01-R100-G Resistor, 0.10 Ω, 2%, 1W IRC 2512

1 R4 LR2512-01-R200-G Resistor, 0.20 Ω, 2%, 1W IRC 2512

1 R5 CR0805-10W1872F Resistor , 18.7 kΩ, 1%, 1/10W, see Note 1 Venkel 805

2 R6, R8

(see Note 3)

1 R7 CR0805-10W9532F Resistor , 95.3 kΩ, 1%, 1/10W, see Note 1 Venkel 805

1 R9 CR0805-10W1000F Resistor , 100 Ω, 1%, 1/10W, see Note 1 Venkel 805

1 U1 bq2400x (see Note 2) Battery charger, linear, lithium-ion TI HTSSOP-20

1 PWB bq2400x EVM REV B PWB, bq2400x EVM REV B TI

Part Number Description MFG Size

AVX-Future 1210

6032

Venkel 805

±10%, 805

Panasonic 805

±10%, 0805

Panasonic 805

±10%, 0805

2380-6221TG Pin strip header, 2 pin 3M

CR0805-10W5110F Resistor, 511 Ω, 1%, 1/10W, see Note 1 Venkel 805

Notes: 1) 5% tolerance rsistors may be used in place of 1% resistors if the application allows for it.

2) See Table 4.2 for 2400x charge stuatus configuration.

3) For bq24004/5/6 resistor value should be 1K.

4-2

Page 17

4.2 bq2400x Charge Status Configurations

Table 4–2 lists the charge status configurations for the bq2400x.

Table 4–2.Charge Status Configurations

Part Number Number of Cells Charge Status Configuration

bq24001 Single cell Single LED

bq24002 Single cell 2 LED

bq24003 Single cell Bicolor LED

bq24004 Two cell Single LED

bq24005 Two cell 2 LED

bq24006 Two cell Bicolor LED

bq24007 Single cell Single LED

bq24008 Single cell Bicolor LED

bq2400x Charge Status Configurations

Bill of Materials

4-3

Page 18

Appendix A

Schematic

This chapter contains the schematic diagram for the EVM.

Topic Page

A.1 Schematic A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Schematic

A-1

Page 19

ZONE APPROVEDDATELTR DESCRIPTION

B

1234

REVISIONS

X X

D

D

VCC

R8

511

C

B

VCC

J3

1 3

B1A1

A2 B2

42

J4

1 3

B1A1

42

A2 B2

J1

1

C1

10UF

2

R2

316K

1%

R1

51.1K

1%

R3

0.1

R4

0.2

2

ON OFF

1

J5

EN JUMPER

3

1

CHG VOLTAGE

C2

0.1UF

2

4.1V4.2V

3

J6

JUMPER

APG MODE THERMISTOR MODE

2

1

J2

APG/THM JUMPER

30

1

N/C

2

IN

3

IN

4

VCC

5

ISNS

6

N/C

7

APG/THM

8

EN

9

VSEL

10

PBKG

2524232221

3

N/C

OUT

OUT

VSENS

AGND

STAT2

STAT1

TMR_SEL

N/C

10PF

1

2

J10

1

2

100

R9

J9

1

2

3

STAT 2 JUMPER

6 Hr 4.5 Hr

3

TMR JUMPER

J8

21

(NO JUMPER)

3 Hr

2

1

J7

20

19

18

17

16

15

14

13

12

CR

11

R5

18.7K

1%

C4

C3

0.22UF

R7

95.3K

1%

16V10UF

C5

U1

BQ24000

26

27

28

29

5%

A

GRN

D2 D1

C

VCC

R6

511

5%

C

A

RED

C

B

A

A

TEXAS INSTRUMENTS

TITLE

DRAWN

S. MCGEE

ENGR

CHK

NEXT ASSY

USED ON

APPLICATION

$1I217

RELEASE

FILE NAME:

DATE

05/23/2000

SCHEMATIC

BQ2400X EVM

SIZE

C

SCALE: NONE

DRAWING DATE

DRAWING NO:CODE REV:

BQ2400X

01/11/2001

1 1

SHEET OF

1234

D

Loading...

Loading...