Page 1

S6500 Long Range Reader Module - Reference Guide May ’01

HF Reader System Series 6000

S6500 Long Range Reader Module RI-STU-650A

Reference Guide

11-06-21-059 May 2001

1

Page 2

S6500 Long Range Reader Module - Reference Guide May ’01

Edition One - May 2001

This is the first edition of this manual. It describes the following equipment:

S6500 Long Range Reader Module RI-STU-650A

Texas Instruments (TI) reserves the right to make changes to its products or services

or to discontinue any product or service at any time without notice. TI provides customer assistance in various technical areas, but does not have full access to data

concerning the use and applications of customer's products.

Therefore, TI assumes no liability and is not responsible for customer applications or

product or software design or performance relating to systems or applications incorporating TI products. In addition, TI assumes no liability and is not responsible for

infringement of patents and/or any other intellectual or industrial property rights of

third parties, which may result from assistance provided by TI.

TI products are not designed, intended, authorized or warranted to be suitable for life

support applications or any other life critical applications which could involve potential risk of death, personal injury or severe property or environmental damage.

The

or registered trademarks of Texas Instruments Incorporated.

Copyright 2001 Texas Instruments Incorporated (TI)

This document may be downloaded onto a computer, stored and duplicated as necessary to support the use of the related TI products. Any other type of duplication,

circulation or storage on data carriers in any manner not authorised by TI represents

a violation of the applicable copyright laws and shall be prosecuted.

TIRIS

and

TI*RFID

logos, the words

TIRIS, TI*RFID

and

Tag-it

are trademarks

2

Page 3

About This Manual

Conventions

PREFACE

Read This First

This reference guide for the S6500 Long Range Reader Module is designed for use

by TI partners who are engineers experienced with Radio Frequency Identification

Devices (RFID).

Regulatory, safety and warranty notices that must be followed are given in

Chapter 5.

WARNING:

WARNING IS USED WHERE CARE MUST BE TAKEN, OR A

A

CERTAIN

VENT INJURY OR HARM TO YOUR HEALTH

PROCEDURE MUST BE FOLLOWED IN ORDER TO PRE

.

-

If You Need Assistance

For more information, please contact the sales office or distributor nearest you. This

contact information can be found on our web site at:

CAUTION:

This indicates information on conditions which must be

met, or a procedure which must be followed, which if not

heeded could cause permanent damage to the equipment

or software.

Note:

Indicates conditions which must be met, or procedures which must be

followed, to ensure proper functioning of the equipment or software.

Information:

Indicates information which makes usage of the equipment or software easier

http://www.ti-rfid.com

3

Page 4

S6500 Long Range Reader Module - Reference Guide May ’01

Document Overview

Page

Chapter 1: Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 General .................................................................................................................... 7

1.2 System Description .................................................................................................. 7

1.3 Product Description .................................................................................................. 7

1.4 Communications Protocols....................................................................................... 8

1.5 Delivery .................................................................................................................... 8

Chapter 2: Reader Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 General .................................................................................................................. 10

2.2 Mechanical Information .......................................................................................... 10

2.3 Connectors ............................................................................................................. 11

2.4 Reader Module LEDs ............................................................................................. 15

2.5 Switches ................................................................................................................. 16

Chapter 3: Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Introduction ............................................................................................................ 18

3.2 General .................................................................................................................. 18

3.3 Mechanical Mounting ............................................................................................. 18

3.4 Connectors ............................................................................................................. 20

3.5 Interface Configuration Jumper Settings ................................................................ 24

3.6 Setting Bus Addresses ........................................................................................... 25

Chapter 4: Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.1 Specification Summary........................................................................................... 27

4.2 Mechanical Information .......................................................................................... 28

Chapter 5: Regulatory, Safety and Warranty Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1 Regulatory Notes ................................................................................................... 30

5.2 Safety Precautions ................................................................................................. 31

5.3 Warranty and Liability............................................................................................. 31

List of Figures

Page

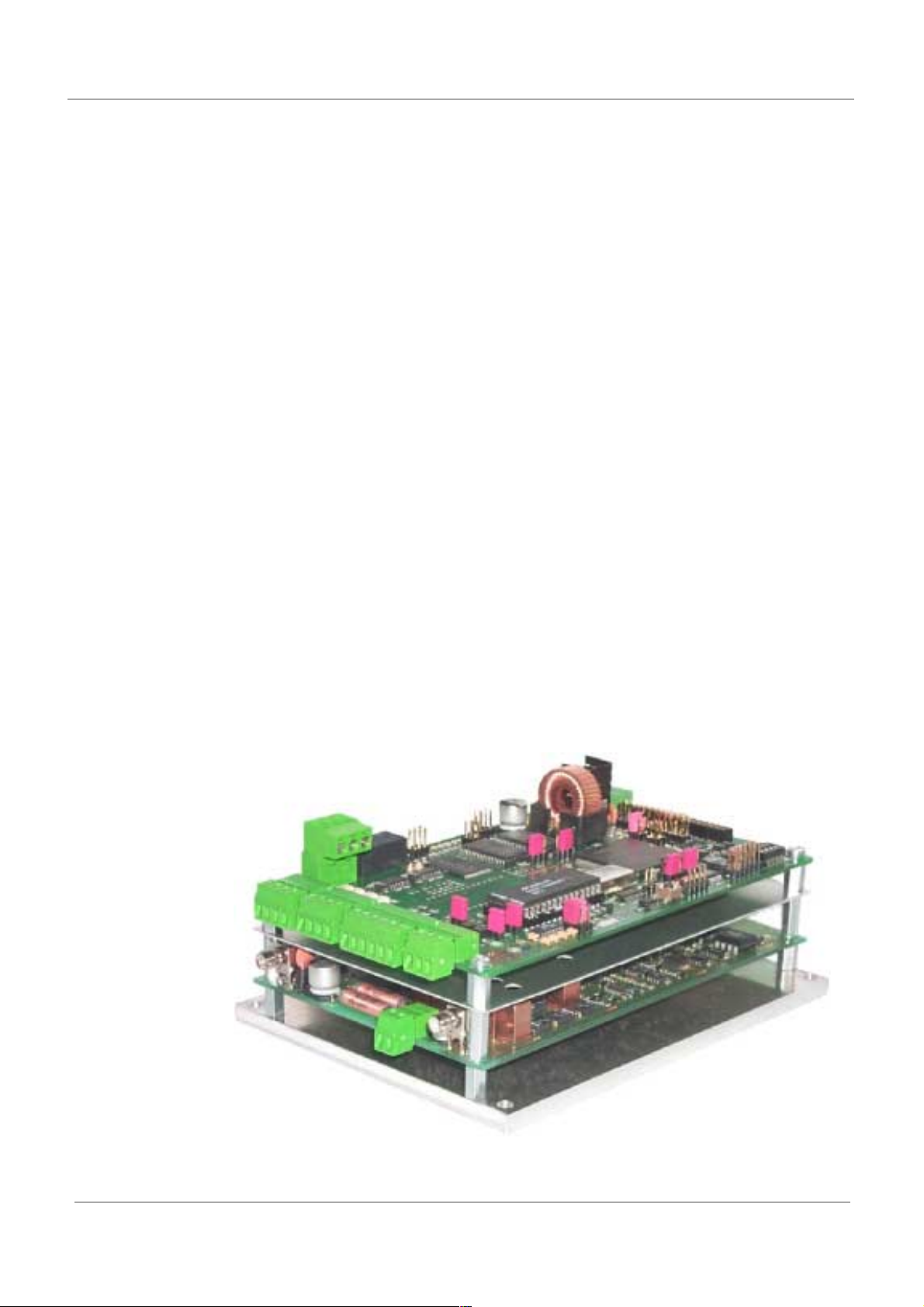

Figure 1: S6500 Long Range Reader Module (RI-STU-650A)........................................... 7

Figure 2: Top View Upper and (part of) Lower pcb .......................................................... 10

Figure 3: Reader Mounting Holes..................................................................................... 19

Figure 4: Supply Voltage Connector X3 ........................................................................... 20

Figure 5: Antenna Line on a Ring Core ............................................................................ 21

Figure 6: Optocoupler Input - Internal and External Wiring .............................................. 21

Figure 7: Optocoupler Outputs ......................................................................................... 22

Figure 8: Relay Connector................................................................................................ 23

Figure 9: RS485 Interface ................................................................................................ 23

Figure 10: RS232 Interface .............................................................................................. 23

Figure 11: RS232 Interface Line on a Ring Core ............................................................. 24

Figure 12: Jumper Settings for RS232 ............................................................................. 24

Figure 13: Jumper Settings for RS485 ............................................................................. 24

Figure 14: Jumper Settings for RS485 Line Termination ................................................. 25

4

Page 5

May ‘01 Preface

List of Tables

Page

Table 1: List of Connectors............................................................................................... 11

Table 2: Antenna Connectors........................................................................................... 11

Table 3: Antenna - Specifications..................................................................................... 11

Table 4: Supply Connector ............................................................................................... 12

Table 5: Supply Connector - Specifications...................................................................... 12

Table 6: Optocoupler Inputs Connector............................................................................ 12

Table 7: Optocoupler Inputs Connector - Specifications .................................................. 12

Table 8: Optocoupler Outputs Connector......................................................................... 13

Table 9: Optocoupler Outputs Connector - Specifications ............................................... 13

Table 10: Relay Outputs Connector ................................................................................. 13

Table 11: Relay Outputs Connector - Specifications........................................................ 13

Table 12: RS485 Interface Connector .............................................................................. 14

Table 13: RS232 Interface Connector .............................................................................. 14

Table 14: Description of LEDs.......................................................................................... 15

Table 15: Description of Switches .................................................................................... 16

Table 16: Required External Dropping Resistor ............................................................... 21

Table 17: Jumper Setting - J400 and J401....................................................................... 24

Table 18: Jumper Setting - J403, J405 and J407............................................................. 24

Table 19: Ambient Conditions .......................................................................................... 27

Table 20: Electrical Data .................................................................................................. 27

5

Page 6

Chapter 1:Introduction

This chapter introduces you to the S6500 Long Range Reader Module.

Topic Page

1.1 General........................................................................................................ 7

1.2 System Description.................................................................................... 7

1.3 Product Description...................................................................................7

1.4 Communications Protocols ......................................................................8

CHAPTER 1

Introduction

1.5 Delivery ....................................................................................................... 8

6

Page 7

May ’01 Chapter 1. Introduction

1.1 General

This document provides information about the S6500 Long Range Reader Module.

It describes the reader and how to install it.

1.2 System Description

The HF Reader System Series 6000 works at a frequency of 13.56 MHz. It comprises

a reader, antenna and transponder (for example: smart label) and is used for wireless identification of a variety of objects.

The system works according the “reader talks first” principle which means that the

transponder keeps quiet until the reader sends a request to it. The reader can rapidly

and simultaneously identify numerous transponders in the antenna’s field. It can

write data to and read data from the transponders; either in addressed mode by using

the factory programmed read only number, or in general mode to all of the transponders in its field. The read/write capability of the transponder allows users to update the

data stored in the transponders memory anywhere along its movements.

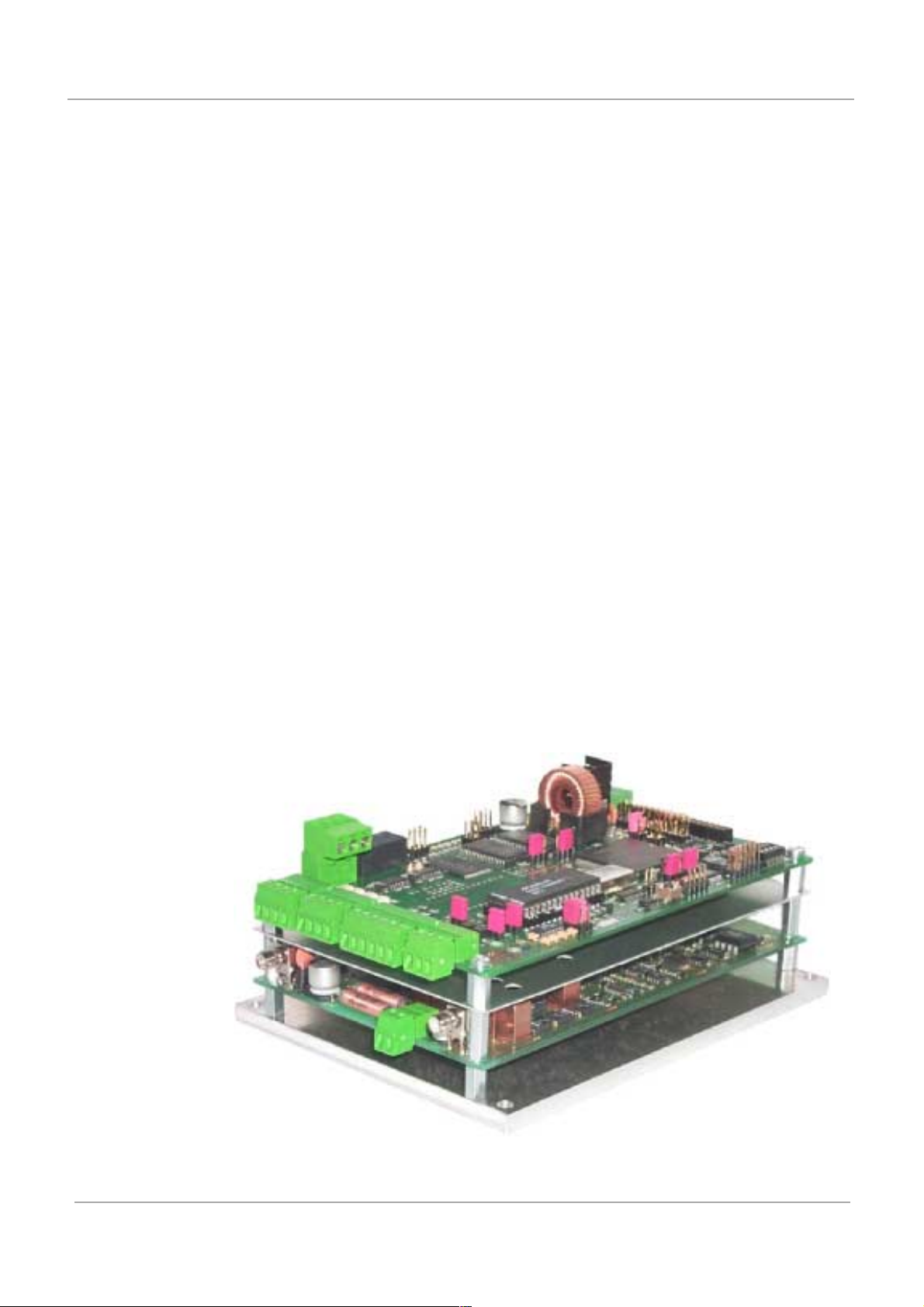

1.3 Product Description

The S6500 Long Range Reader Module handles all RF and digital functions required

in order to communicate with Tag-it HF, Tag-it HF-I (ISO 15693 compliant) and all

other ISO 15693 compliant transponder from various suppliers.

The Reader Module is mounted onto a rigid, 6 mm thick aluminium base plate. The

module has two digital inputs, two digital outputs, a relay output and an asynchronous interface which can be configured as RS232 or RS485.

The configurability of the interfaces also allows the module to be operated on an

RS485 data bus. The address can be assigned either through software or hardware

(3 DIP switches).

Figure 1: S6500 Long Range Reader Module (RI-STU-650A)

7

Page 8

Page 9

May ’01 Chapter 1. Introduction

1.1 General

This document provides information about the S6500 Long Range Reader Module.

It describes the reader and how to install it.

1.2 System Description

The HF Reader System Series 6000 works at a frequency of 13.56 MHz. It comprises

a reader, antenna and transponder (for example: smart label) and is used for wireless identification of a variety of objects.

The system works according the “reader talks first” principle which means that the

transponder keeps quiet until the reader sends a request to it. The reader can rapidly

and simultaneously identify numerous transponders in the antenna’s field. It can

write data to and read data from the transponders; either in addressed mode by using

the factory programmed read only number, or in general mode to all of the transponders in its field. The read/write capability of the transponder allows users to update the

data stored in the transponders memory anywhere along its movements.

1.3 Product Description

The S6500 Long Range Reader Module handles all RF and digital functions required

in order to communicate with Tag-it HF, Tag-it HF-I (ISO 15693 compliant) and all

other ISO 15693 compliant transponder from various suppliers.

The Reader Module is mounted onto a rigid, 6 mm thick aluminium base plate. The

module has two digital inputs, two digital outputs, a relay output and an asynchronous interface which can be configured as RS232 or RS485.

The configurability of the interfaces also allows the module to be operated on an

RS485 data bus. The address can be assigned either through software or hardware

(3 DIP switches).

Figure 1: S6500 Long Range Reader Module (RI-STU-650A)

7

Page 10

S6500 Long Range Reader Module - Reference Guide May ’01

2.1 General

This chapter provides a description of the S6500 Long Range Reader Module hardware. It also provides the electrical specifications of the inputs and outputs.

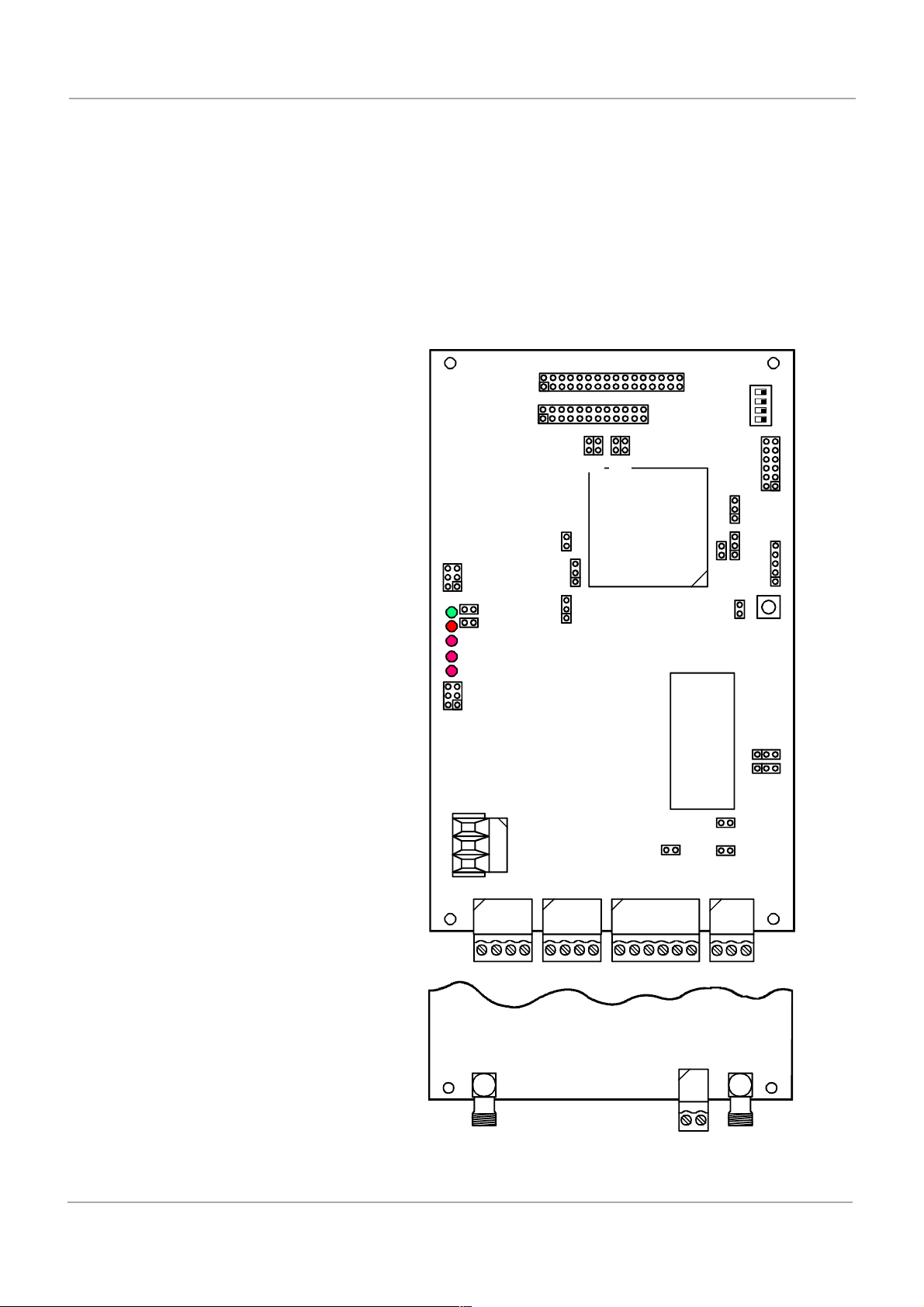

2.2 Mechanical Information

Figure 2 shows the location of the connectors, jumpers and LEDs on the S6500

Reader.

Figure 2: Top View Upper and (part of) Lower pcb

X13

X14

J2

J3

X15

X16

J6

X21

V1

V2

V3

V4

V5

J5

J4

Upper Circuit Board

X18

X11

J51

J50

ON

OFF

1 2 3 4

S2

X20

J1

J8

X19

J350

S1

J402

J401

J400

J403

J405

X6 X7 X9 X10

Lower Circuit Board

X2 X1

10

X3

J407

Page 11

May ’01 Chapter 2. Reader Hardware

2.3 Connectors

Three connectors are located on the lower pcb and 5 connectors are on the upper

pcb. The connectors are all shown on Figure 2. Table 1 provides an overview of all

the connectors and lists the section that describes them.

Table 1: List of Connectors

Identifying Letter Function Section

X1 Rx Only Antenna Connection 2.3.1

X2 Tx/Rx Antenna Connection 2.3.1

X3 Voltage Supply 2.3.2

X6 Isolated Optocoupler Outputs 2.3.4

X7 Isolated Optocoupler Inputs 2.3.3

X9 RS485 Interface 2.3.6

X10 RS232 Interface 2.3.7

X11 Relay Outputs 2.3.5

2.3.1 Antenna Connectors

There are two antenna connectors on the reader module. They are listed in Table 2.

Table 2: Antenna Connectors

Table 3: Antenna - Specifications

Pin Signal Description

X1 ANT Receive Only Antenna

X2 ANT Transmit/Receive Antenna

Parameter Minimum Maximum

Antenna Q-factor 10 30

Antenna Impedance

Tightening Torque - 0.45 Nm

50 Ω ± (3 Ω ∠ 3º)

11

Page 12

S6500 Long Range Reader Module - Reference Guide May ’01

2.3.2 Supply Connector (X3)

The supply voltage is connected to connector X3 on the lower circuit board.

Table 4: Supply Connector

Pin Name Description

1 + 24 V Positive supply

2 GND Ground

Table 5: Supply Connector - Specifications

Parameter Minimum Maximum

Logic Supply Voltage VSL 23.75 V 25.2 V

Logic Supply current ISL - 2.5 A

Connecting Cable Length - 3 m

Ripple (acceptable level) - 20 mV

2.3.3 Isolated Optocoupler Inputs (X7)

The optocoupler inputs on Terminal X7 are galvanically isolated from the reader electronics and must therefore be powered by a separate external DC supply. For supply

voltages above 10 V, the input current must be limited to a maximum of 20 mA by an

additional external dropping resistor (see section 3.4.3).

Table 6: Optocoupler Inputs Connector

Pin Name Description

1 IN1+ + Input 1

2 IN1- - Input 1

3 IN2+ + Input 2

4 IN2- - Input 2

Table 7: Optocoupler Inputs Connector - Specifications

External Supply Voltage 5 VDC 24 VDC

External Supply Current - 20 mA

Parameter Minimum Maximum

12

Page 13

Page 14

S6500 Long Range Reader Module - Reference Guide May ’01

2.3.6 RS485 Interface (X9)

Depending on the configuration, the reader module will communicate either via the

RS232 or RS485 interface (see Section 3.5).

The RS485 interface is connected to X9.

The transmission parameters can be software configured.

Table 12: RS485 Interface Connector

Pin Name Description Direction

1 Rx+/Tx+ RS485 Non-inverted data Input/Output

2 Rx+/Tx+ RS485 Inverted data Input/Output

3 GND Signal ground -

4- n.c.

5- n.c.

6- n.c.

All interface parameters are according to RS485 specifications and are not given in

detail in this manual.

2.3.7 RS232 Interface (X10)

Depending on the configuration, the reader module will communicate either via the

RS232 or RS485 interface (see Section 3.5).

The RS232 interface is connected to X10.

The transmission parameters can be software configured.

Table 13: RS232 Interface Connector

All interface parameters are according to RS232 specifications and are not given in

detail in this manual.

Pin Name Description Direction

1 GND Signal ground -

2 RxD Receive data Input

3 TxD Transmit data Output

14

Page 15

May ’01 Chapter 2. Reader Hardware

2.4 Reader Module LEDs

There are five (one green and four red) LEDs on the reader. Their location is shown

in Figure 2 and their function is described in Table 14.

Table 14: Description of LEDs

Name Description

“RUN-LED”

- If all checks are OK this LED comes on (flashes) when V5

goes out. It indicates that the reader’s internal software is

LED V1 (green)

LED V2 (red)

running properly.

- Flashing rate approximately 1 Hz.

- After a firmware change this LED flashes alternately with V5

until a second reset is performed.

Diagnostic 1: RF communication / EEPROM status

- Short flashing indicates error-free communication with a

transponder on the RF interface.

- Flashes alternating with V1 after a Reset following a software

update.

- Flashes alternating with V1 in case a data error while reading

the parameters occurred following a Reset.

Diagnostic 2: Host communication

LED V3 (red)

LED V4 (red) Diagnostic 3: Reserved

LED V5 (red)

- Short flashing indicates a protocol is being sent to the host on

the RS232/RS485 interface.

Diagnostic 4: Reader initialization / RF error

- Comes on during Reader initialization after power-up or after a

reset, and goes out if everything is OK.

- Comes on to indicate an error in the RF section of the Reader.

The error type can be read out via software on the RS232/

RS485 interface.

- After a firmware change this LED flashes alternately with V1

until a second reset is performed.

15

Page 16

S6500 Long Range Reader Module - Reference Guide May ’01

2.5 Switches

There are two switches on the reader. Their location is shown in Figure 2 and their

function is described in Table 15.

Table 15: Description of Switches

Name Description

S1 Reset button

1 - Setting data bus addresses (0 ... 7)

S2

Note:

In order to set the bus address using S2, the reader must be set to

software address “0" (default factory setting).

2 - Setting data bus addresses (0 ... 7)

3 - Setting data bus addresses (0 ... 7)

4 - not used

16

Page 17

Page 18

S6500 Long Range Reader Module - Reference Guide May ’01

3.1 Introduction

Note:

Always ensure that the reader is switched off when making or breaking connections to it.

3.2 General

The S6500 Reader Module has been designed with easy installation in mind. The following information provides you with any details that you will need to know.

3.2.1 Default Configuration

The S6500 Reader is delivered with the default configuration as follows:

- Communication Interface: 38400 Baud,

8 data bits,

1 stop bit, even parity

- Antenna Connection: Only TX/RX Antenna active

- Anticollision procedure: active

- Supported Transponder Types: Tag-it HF,

Tag-it HF-I (and other ISO 15693 compliant

transponders)

However, if your system requires that you use the reader with a different configuration, you can use the S6 Reader Utility program which is available at our internet site

http://www.ti-rfid.com (S/W Tools & Download) to re-configure the reader to your sys-

tem’s requirements.

3.3 Mechanical Mounting

Mounting is accomplished using the 4.5 mm diameter holes located in each corner

of the base plate (see Figure 3). If the antenna is properly tuned and there is sufficient

air convection along the mounting plate, the reader can be operated without an additional heat sink at up to 4 W of RF power.

If you are going to operate the reader module above 4 W (to fully exploit the reader’s

performance) it must be mounted on an additional heat sink. The heat sink should

have a thermal resistance R

Module to the heat sink you should strive for as little heat transfer resistance between

the base plate and the heat sink as possible. We recommend that you use a heat

sink compound.

Note:

If you are only using one transponder Type in the application, the

reaction time of the reader for transponder read/write operations can

be optimized as long as only one transponder driver (not both of

them) is activated.

of maximum 0.8 K/W. When attaching the Reader

ThK

18

Page 19

May ’01 Chapter 3. Installation

Note:

Detuning of the antenna can result in additional heat being generated

in the reader. If this happens the reader regulates its output power

down until the final stage is once again within its upper temperature

limit.

Figure 3: Reader Mounting Holes

120 mm

110 mm

100 mm

ø 4,5 mmø 4,5 mm

ø 4,5 mm ø 4,5 mm

The tolerances for the position of the mounting holes is ± 0.5 mm.

150,00 mm

160,00 mm

19

Page 20

S6500 Long Range Reader Module - Reference Guide May ’01

3.4 Connectors

3.4.1 Power Supply Connector

The supply voltage is connected to connector X3 on the lower circuit board.

CAUTIONS:

1. Reversing the power supply wires may destroy the

device.

2. If you are using a switched power supply you must

ensure that the switching frequency is below 300 kHz.

Figure 4: Supply Voltage Connector X3

X3

+24 V DC

1

2

GND

X1

!

Notes:

1. In order to conform to national requirements for radio devices, the

power supply line must incorporate one of the ∅ 28 mm x 20 mm

ring cores mentioned in section 1.5. The cable must be wound

around the core at least eight times (as shown in Figure 11). The

distance between the ring core and the reader connection must

not be more than 10 cm.

2. In order to avoid interference, the length of the cable between the

power supply and the reader must not exceed 3 m.

3.4.2 Antenna Connectors (X1 & X2)

The transmit/receive antenna must be connected to the reader via the antenna SMA

socket (X2). The maximum tightening torque for the SMA socket is 0.45 Nm.

If you are using a receive only antenna (together with the read write antenna) it must

be connected to the reader via the antenna SMA socket (X1). The maximum tightening torque for the SMA socket is 0.45 Nm.

Notes:

1. In order to conform to national requirements for radio devices,

each antenna line must incorporate one of the ∅ 28 mm x 20 mm

ring cores mentioned in section 1.5. The cable must be wound

around the core at least four times (as shown in Figure 5). The

distance between the ring core and the reader connection must

not be more than 10 cm.

2. When connecting an antenna, ensure that it does not exceed the

permissible limits as prescribed by the national regulations for

radio frequency devices.

20

Page 21

May ’01 Chapter 3. Installation

Figure 5: Antenna Line on a Ring Core

3.4.3 Isolated Optocouplers Input Connector

The input LED's on the optocouplers have an internal input series resistor of 500 Ω.

For supply voltages above 10V the input current must be limited to a maximum of 20

mA by an additional external dropping resistor (see Figure 6 and Table 16).

CAUTION:

Reversing the polarity or overloading the inputs will

destroy the reader.

Notes:

1. If the connecting cable is longer than 3 m you must use a shielded

cable.

2. You must NOT use the reader’s supply voltage to drive these

inputs as the added noise may reduce the effective reading range.

Figure 6: Optocoupler Input - Internal and External Wiring

X7

R

U

ext

U

ext

ext

R

ext

Table 16: Required External Dropping Resistor

External voltage V

IN1 +

R

R

ext

int

int

Required External

Dropping Resistor R

ext

1

IN1 -

2

IN2 +

3

IN2 -

4

21

5 V ... 10 V ---

11 V ... 15 V 270

16 V ... 20 V 560

21 V ... 24 V 820

Ω

Ω

Ω

Page 22

S6500 Long Range Reader Module - Reference Guide May ’01

3.4.4 Isolated Optocoupler Outputs Connector

The transistor connections, collector and emitter, of the two optocoupler outputs are

galvanically isolated from the reader electronics and brought out on connector X6

without any additional circuitry. The outputs must therefore be powered by external

supplies.

The outputs are designed to switch resistive loads only.

Note:

If the connecting cable is longer than 3 m you must use shielded

cable.

CAUTIONS:

Reversing the power supply wires may destroy the device.

Figure 7: Optocoupler Outputs

U

ext.

U

ext.

X6

X6

ID ISC.LRM200

O1-C

1

O1-E

2

O2-C

3

O2-E

4

22

Page 23

May ’01 Chapter 3. Installation

3.4.5 Relay Connector

CAUTIONS:

The two relay change-over contacts are designed to switch

resistive loads only. If you are using an inductive load, the

relay contacts must be protected by means of an external

protection circuit.

Figure 8: Relay Connector

X11

common

normally closed

normally open

1

2

3

3.4.6 RS485 Connection

Figure 9: RS485 Interface

3.4.7 RS232 Connection

Figure 10: RS232 Interface

X9

5

3

2

GND

RXD

TXD

X10

Tx+/Rx+

1

Tx-/Rx -

2

GND

3

n.c.

4

n.c.

5

n.c.

6

1

2

3

9-pin sub-D female

In order to conform to national requirements for radio devices, the interface connector line must incorporate one of the ring cores mention in section 1.5. The cable must

be wound around the core at least eight times as shown in Figure 11. The distance

between the ring core and the reader connection must not be more than 10 cm.

23

Page 24

S6500 Long Range Reader Module - Reference Guide May ’01

J401

J400

1

1

Figure 11: RS232 Interface Line on a Ring Core

3.5 Interface Configuration Jumper Settings

There are five jumpers used on the reader. They are Jumpers J400 - J401 which are

used to configure the asynchronous interface for RS232 or RS485 described in Table

17, and Jumpers J403, J405 and J407 are used to insert the termination resistors

which may be required for the RS485 interface, described in Table 18 and shown in

Figure 14.

Table 17: Jumper Setting - J400 and J401

Jumper RS232 RS485

400 1 - 2 connected 2 - 3 connected

401 1 - 2 connected 2 - 3 connected

Figure 12: Jumper Settings for RS232

Figure 13: Jumper Settings for RS485

J401

1

1

J400

Table 18: Jumper Setting - J403, J405 and J407

Jumper In Out

403

405 Pull-Up on RS485 - B No Pull-Up on RS485 - B

407 Pull-Down on RS485 - A No Pull-Down on RS485 - A

Termination resistor between

RS485 - A and RS485 - B

No termination resistor between

RS485 - A and RS485 - B

24

Page 25

May ’01 Chapter 3. Installation

Figure 14: Jumper Settings for RS485 Line Termination

3.6 Setting Bus Addresses

If you are going to use the reader connected to a bus you will have to give each reader an individual address. You can do that either by setting switch S2 on the reader or

by software from the controlling computer.

3.6.1 Using S2 to Set the Address

You can use switch S2 to set the reader address between “0" and “7".

To set the bus address using S2, the Reader must be set to software address “0"

(factory setting).

J405

RS485 - B+

J403

RS485 - A-

J407

Address S2-1 S2-2 S2-3

0 OFF OFF OFF

1OFFOFF

2OFF

3OFF

4

5

6

7

Note:

When you are using the reader modules in a multi-drop configuration

you must power the readers up one-by-one, giving each reader its

unique address before progressing to the next reader.

3.6.2 Setting the Reader’s Bus Address through Software

Addresses “0” to 253” can be set by the host computer software, using the S6 Reader

Utility program.

ON

ON

ON ON

ON

ON

ON ON

ON ON ON

OFF OFF

OFF

OFF

ON

OFF

25

Page 26

Chapter 4:Technical Data

This chapter provides the technical specifications of the S6500 Reader Module. It

also provides information about packing and storage.

Topic Page

4.1 Specification Summary ........................................................................... 27

4.2 Mechanical Information ...........................................................................28

CHAPTER 4

Technical Data

26

Page 27

May ’01 Chapter 4. Technical Data

4.1 Specification Summary

Table 19: Ambient Conditions

Operating Temperature

Storage Temperature

Vibration

Shock

Table 20: Electrical Data

Supply Voltage

Power Consumption

Operating Frequency

Transmitter Power

Transmitter Modulation

Antenna Connection

- Tx/Rx Antenna

- Rx Only Antenna

Optocoupler Outputs

-20°C to +65°C

-40°C to +85°C

According to EN60068-2-6, 10 Hz to 200 Hz: 0.15 mm / 2 g

According to EN60068-2-27, acceleration 30 g

24 VDC +5%/-1%

Ripple: maximum 20 mV

maximum 60 W

13.56 MHz ± 7 kHz

0.5 to 10 W*

(set by software in steps of 0.25W)

(10% to 30%) ± 6% and 100% (adjustable by software)

1 x SMA socket (50W)

1 x SMA socket (50W)

24 V DC / 30 mA (galvanically isolated)

Relay (1 x change-over)

Outputs

Optocoupler Inputs

Interfaces

Memory

24 V DC / 60 W

maximum 24 V DC/ 20 mA

RS232 and RS485 (internally selectable)

EEPROM 1 kByte (for parameters; up to 10,000 write

cycles)

RAM 256 kByte (for data)

Flash 512 kByte (for firmware; update via

communication interface)

* If the configured output power is above 4 W, an additional 0.8 K/W heat sink is

necessary

27

Page 28

S6500 Long Range Reader Module - Reference Guide May ’01

4.2 Mechanical Information

• Dimensions (W x L x H)

•

Weight

120 x 160 x 69 mm

650 g

Figure 15 shows the dimensions of the S6500 Reader. The tolerances are:

Length and Width: ± 0.5 mm

Height: ± 2.0 mm

Figure 15: Reader Dimensions and Mounting Holes

69 mm

43 mm

6 mm

120 mm

110 mm

100 mm

ø 4,5 mmø 4,5 mm

ø 4,5 mm ø 4,5 mm

150,00 mm

160,00 mm

28

Page 29

Regulatory, Safety and Warranty Notices

Chapter 5:Regulatory, Safety and Warranty Notices

This chapter provides important information about regulatory constraints and safety

precautions.

Topic Page

5.1 Regulatory Notes ..................................................................................... 30

5.1.1 FCC Notices (U.S.A.) ...........................................................................30

5.1.2 R&TTE Conformity (Europe) ................................................................ 30

5.2 Safety Precautions...................................................................................31

5.2.1 Human Safety ...................................................................................... 31

5.2.2 Application Restrictions........................................................................31

5.2.3 ESD Safety Information........................................................................31

CHAPTER 5

5.3 Warranty and Liability..............................................................................31

29

Page 30

S6500 Long Range Reader Module - Reference Guide May ’01

5.1 Regulatory Notes

An RFID system comprises an RF transmission device, and is therefore subject to

national and international regulations.

Prior to operating the S6500 Long Range Reader Module together with antenna(s)

and power supply, the required FCC, PTT or relevant government agency approval

must be obtained. Sale, lease or operation in some countries may be subject to prior

approval by the government or other organization.

5.1.1 FCC Notices (U.S.A.)

A typical system configuration containing the S6500 Long Range Reader Module has

been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. It is the responsibility of the system integrators to get

their complete system tested and to obtain approvals from the appropriate local authorities before operating or selling this system.

5.1.2 R&TTE Conformity (Europe)

A R&TTE Declaration of Conformity is available for the S6500 Long Range Reader

Module at TI*RFID Sales Offices.

The equipment complies with the essential requirements of the Telecommunication

Terminal Equipment Act (FTEG) and the R&TTE Directive 1999/5/EC when used for

its intended purpose.

Any device or system incorporating the S6500 Long Range Reader Module in any

other than the originally tested configuration needs to be verified against the requirements of the Telecommunication Terminal Equipment Act (FTEG) and the R&TTE

Directive 1999/5/EC. A separate Declaration of Conformity must be issued by the

System Integrator or user of such a system prior to marketing and operating it in European Community.

It is the responsibility of the system integrators to get their complete system tested

and to obtain approvals from the appropriate local authorities before operating or

selling the system.

30

Page 31

May ’01 Chapter 5. Regulatory, Safety and Warranty Notices

5.2 Safety Precautions

5.2.1 Human Safety

WARNING:

C

RESPONSIBLE

MENTED POWER LEVELS AND ANTENNA CONFIGURATIONS

AGAINST

ELECTRONIC

5.2.2 Application Restrictions

CAUTIONS:

When integrating these boards into housings appropriate

means of cooling may be necessary in order to prevent

that the combination of environmental temperature and

heat generated by the reader board will not exceed the

specified operating temperature.

5.2.3 ESD Safety Information

The Reader Module is packed in special anti-static envelopes, which protect against

electrostatic charge that could cause damage.

• Handle the Reader Module carefully and keep it in the protective envelope until

you are ready to install it.

• Whenever possible, handle the Reader Module by its edges or frame.

USTOMERS USING THE

FOR OPERATING THEIR SYSTEM UNDER IMPLE

RELEVANT STANDARDS FOR HUMAN SAFETY IN

FIELDS

.

S6500 R

EADER

ODULE ARE

M

-

5.3 Warranty and Liability

The “General Conditions of Sale and Delivery” of Texas Instruments Incorporated or

a TI subsidiary apply. Warranty and liability claims for defect products, injuries to persons and property damages are void if they are the result of one or more of the following causes:

• improper use of the Reader Modules

• unauthorized assembly, operation and maintenance of the Reader Modules

• operation of the Reader Modules with defective and/or non-functioning safety

and protective equipment

• failure to observe the instructions during transport, storage, assembly, operation,

maintenance and setting up of the Reader Modules

• unauthorized changes to the Reader Modules

• insufficient monitoring of the Reader Modules' operation or environmental conditions

• improperly conducted repairs

• catastrophes caused by foreign bodies and acts of God.

31

Page 32

APPENDIX A

Terms & Abbreviations

The terms and abbreviations used in this manual can be found in the TIRIS Terms

and Abbreviations Manual - document number 11-03-21-002. This manual can be

found in the document center on our home page:

http://www.ti-rfid.com

32

Loading...

Loading...