Page 1

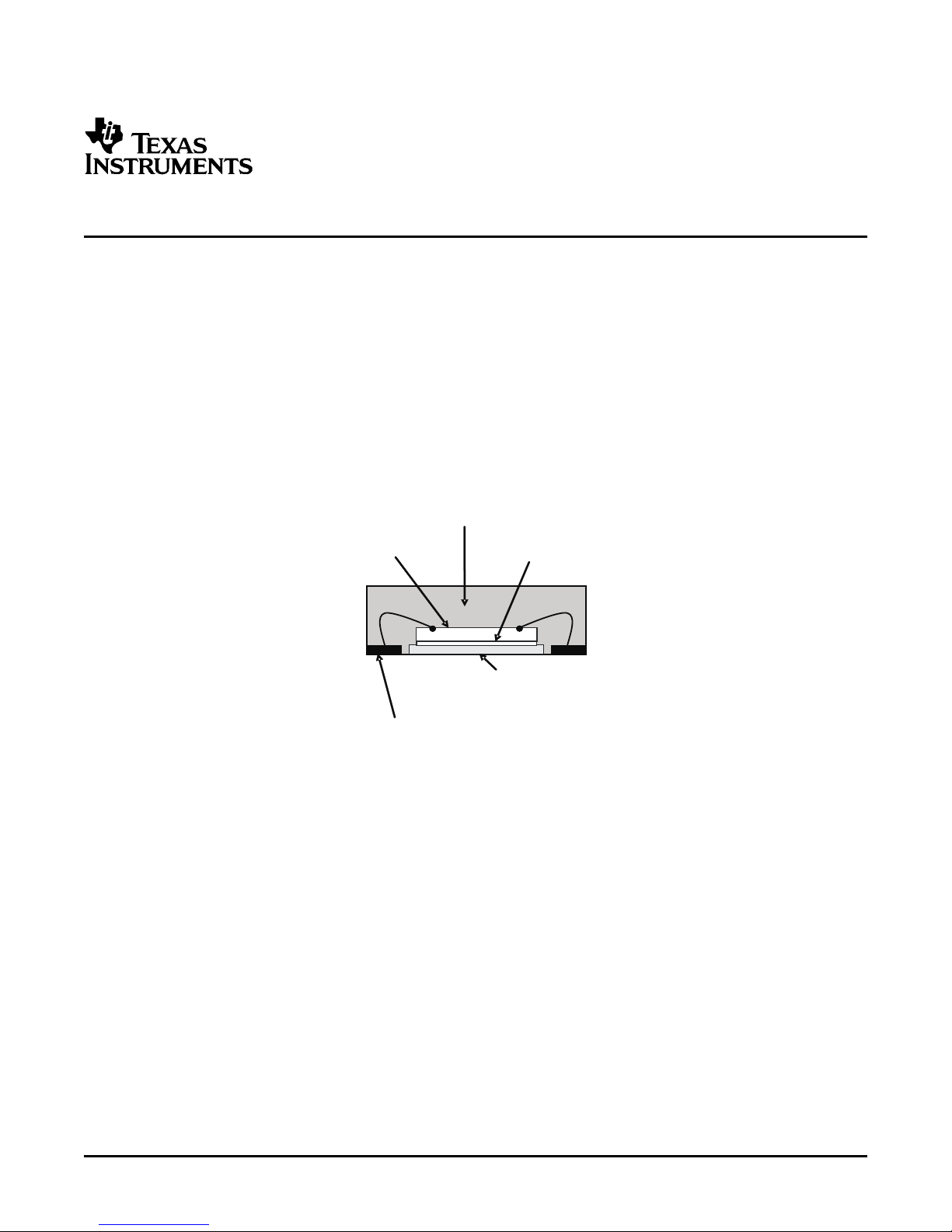

PlasticMold Compound

ExposedThermalPadLocated

UnderneaththePackage

Die Attach(Epoxy)

IC(Silicon)

Leadframe(Copper Alloy)

Application Report

QFN Layout Guidelines

Yang Boon Quek ........................................................................................ HPL Audio Power Amplifiers

1 Introduction

Board layout and stencil information for most Texas Instruments (TI) Quad Flat No-Lead (QFN) devices is

provided in their data sheets. This document helps printed-circuit board (PCB) designers understand and

better use this information for optimal designs.

The QFN package is a thermally enhanced standard size IC package designed to eliminate the use of

bulky heat sinks and slugs. This package can be easily mounted using standard PCB assembly

techniques and can be removed and replaced using standard repair procedures.

The QFN package is designed so that the lead frame die pad (or thermal pad) is exposed on the bottom

of the IC (see Figure 1 ). This provides an extremely low thermal resistance ( θJC) path between the die and

the exterior of the package.

SLOA122 – July 2006

SLOA122 – July 2006 QFN Layout Guidelines 1

Submit Documentation Feedback

Figure 1. Section View of a QFN Package

Page 2

www.ti.com

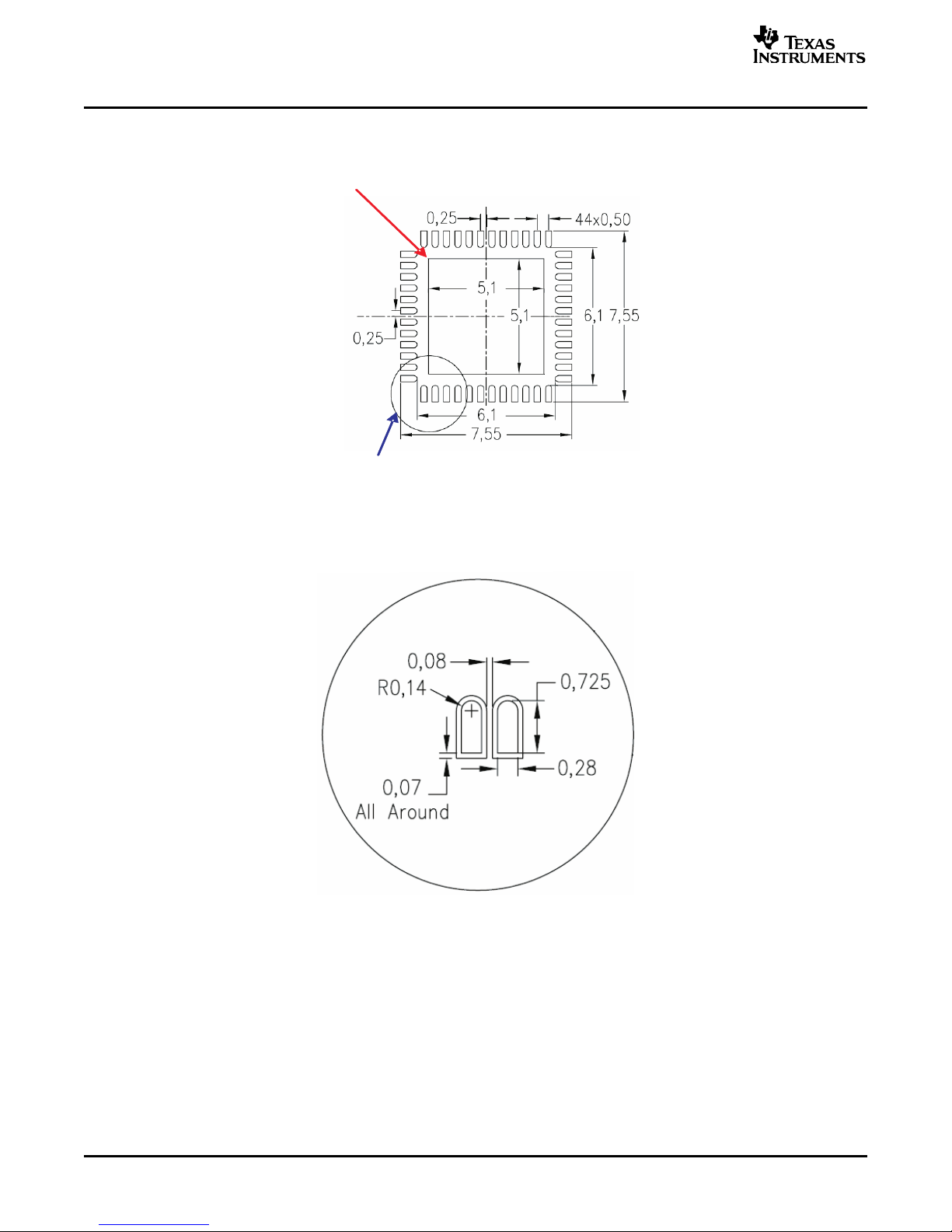

SolderMaskDefinedThermalPad,seeFigure4

FingerPads,seeFigure3

Board Layout

2 Board Layout

Figure 2 shows an example of the recommended board layout for an RGZ package.

Figure 2. Board Layout for an RGZ Package Finger Pads

TI recommends the use of rounded finger pads to prevent solder bridging. Surround each pad with a

0,07-mm wide solder mask. The recommended dimensions are shown in Figure 3 .

2.1 Solder Mask Defined Thermal Pad

The solder mask defined thermal pad is the exposed copper area not covered by solder mask. It must be

soldered directly to the thermal pad on the bottom of the IC. Figure 2 shows an example of the

recommended dimensions.

2.1.1 Copper Areas

Copper areas on and in a PCB act as heat sinks for the QFN device. Top copper areas should be covered

with solder mask leaving only the solder mask defined thermal pad exposed. The top copper areas should

be made as large as possible.

2 QFN Layout Guidelines SLOA122 – July 2006

Figure 3. Finger Pads Layout

Submit Documentation Feedback

Page 3

www.ti.com

ThermalVia

WeborSpokeVia

NOTRecommended

Solid Via

Recommended

Exposed Copper–

0,05mm AroundVia

Inner or bottom layer copper planes also can be connected to thermal pad using vias and should be made

as large as possible. The thermal pad is usually tied to ground, and designers should verify the electrical

correctness when connecting the copper planes to the thermal pad.

Designers may leave the bottom copper plane exposed. However, studies have shown that this has

minimal impact on thermal performance.

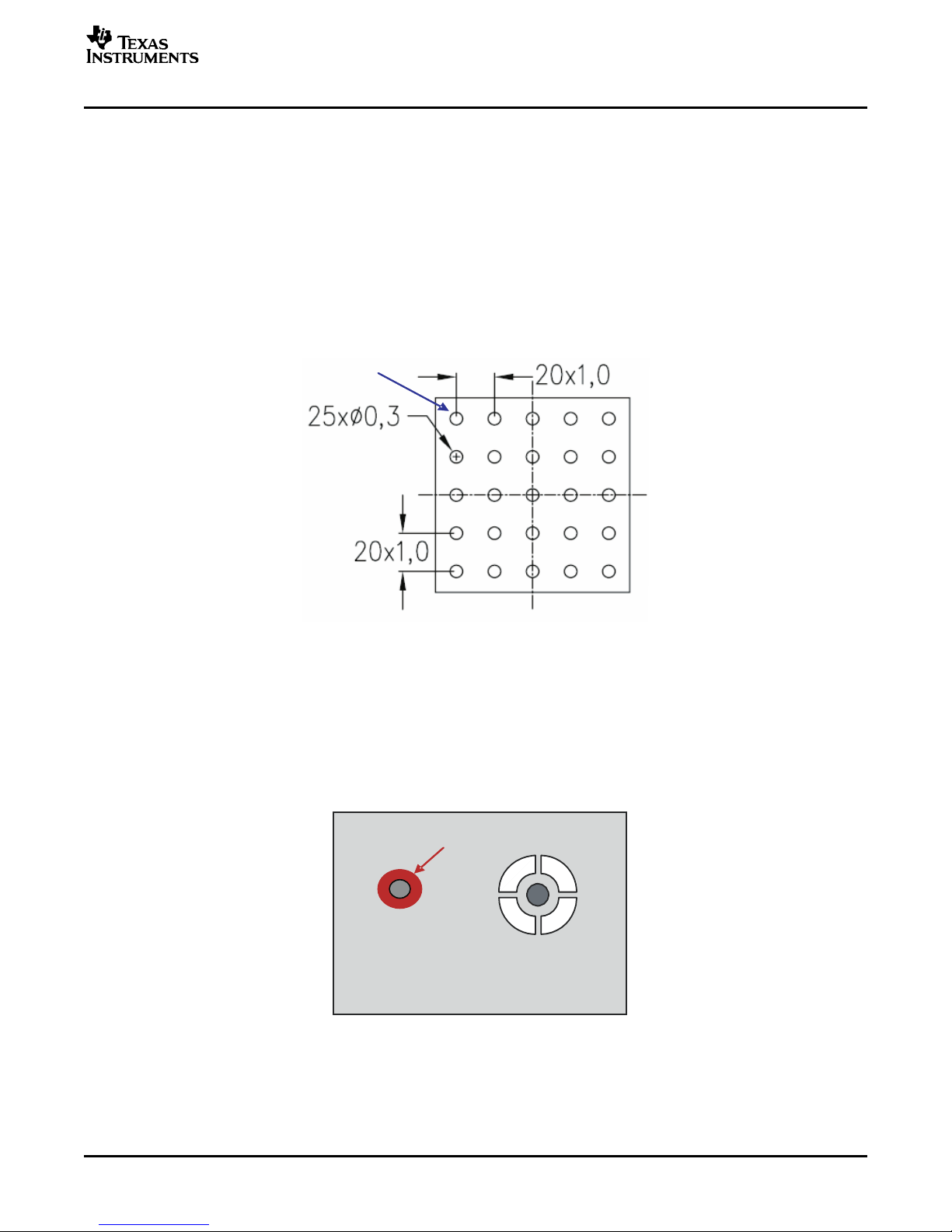

2.1.2 Thermal Vias

TI recommends placing thermal vias in the solder mask defined thermal pad to transfer effectively the heat

from the top copper layer of the PCB to the inner or bottom copper layers.

TI provides the recommended layout of the thermal vias in most data sheets. The recommended via

diameter is 0,3 mm or less, and the recommended via spacing is 1 mm (see Figure 4 ).

Board Layout

Figure 4. Solder Mask Defined Thermal Pad

The thermal vias should make their connection to the internal ground plane with a complete connection

around the entire circumference of the plated through hole. Place a ring of exposed copper (0,05 mm

wide) around the vias at the bottom of the copper plane.

Do not cover the vias with solder mask which causes excessive voiding.

Do not use a thermal relief web or spoke connection which impedes the conduction path into the inner

copper layer(s) (see Figure 5 ).

Figure 5. Via Connection at the Bottom of the Copper Plane

SLOA122 – July 2006 QFN Layout Guidelines 3

Submit Documentation Feedback

Page 4

www.ti.com

Copper Areas – makeaslargeaspossible

SolderMask

Defined

ThermalPad –

follow

dimensions

given

Thermal Via – follow spacing givenandkeepdiameters less

than orequalto 0.3mm

External Via

Rounded

Finger Pads

Voiding – keep

lessthan 50%

Onlyexternal

viasareused

Topcopper

areacovered

withsolder

mask

SolderMaskDefined

ThermalPad-exposed

copperarea

Board Layout

Figure 6. X-Ray – DRB Device

Vias may be plugged to prevent solder loss and protrusions. This often produces the best thermal

performances but is not necessary or recommended because of the increased cost of PCBs and because

solder tends to wet the upper surface first before filling the vias.

Vias also can be used in the copper area outside the solder mask defined thermal pad to help dissipate

heat through bottom or inner planes.

If thin PCBs or vias larger than 0,3 mm are used, designers may use only external vias to prevent solder

loss and protrusions (see Figure 7 ). Designers should note that this might reduce thermal performance

significantly and should be evaluated on their PCBs.

2.1.3 Solder Loss and Protrusions

Solder loss and protrusions result when excessive solder flowed through internal vias during reflow. These

usually happen when incorrect internal vias sizes and stencil openings are used.

Solder loss results in voiding and severely affects thermal conductivity. Designers are encouraged to x-ray

their reflowed boards to verify that at least 50% of thermal pad area is soldered (less than 50% voiding)

when using 0,127-mm thick stencils.

Figure 7. Example of Using Only External Vias in a DRB Package

Protrusions might cause misalignment in stencil on the reverse side of the PCB (see Figure 8 ).

4 QFN Layout Guidelines SLOA122 – July 2006

Submit Documentation Feedback

Page 5

www.ti.com

Protrusion

2.1.4 Stencil

Board Layout

Figure 8. Protrusion at the Other Side of Board

Figure 9 shows an example of the recommended stencil openings and thickness. Follow stencil openings

and thickness recommended to ensure that the right amount of solder paste is used.

Figure 9. Recommended Stencil Openings and Thickness for RGZ Package

Use cross-hatching in the thermal pad stencil opening of a QFN device. This prevents excessive amount

of solder paste applied thus prevents solder bridging (see Figure 10 ).

SLOA122 – July 2006 QFN Layout Guidelines 5

Submit Documentation Feedback

Page 6

www.ti.com

SolderpasteappliedNosolderpasteapplied

Cross-Hatching – Recommended

NoCross-Hatching – NotRecommended

Board Layout

2.1.5 Recommended Solder Paste

TI recommends the use of type 3 or finer solder paste when mounting a QFN.

2.2 Additional Information

For detailed information on the QFN package including thermal modeling considerations and repair

procedures, see (SLUA271 ) QFN/SON PCB attachment.

Figure 10. Thermal Pad Stencil Opening

6 QFN Layout Guidelines SLOA122 – July 2006

Submit Documentation Feedback

Page 7

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Low Power Wireless www.ti.com/lpw Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2006, Texas Instruments Incorporated

Loading...

Loading...