Page 1

查询PT78ST100供应商

PT78ST100 Series

1.5 Amp Positive Step-Down

Integrated Switching Regulator

SLTS059A

(Revised 6/30/2000)

• Very Small Footprint

• High Efficiency > 85%

• Self-Contained Inductor

• Internal Short-Circuit Protection

• Over-Temperature Protection

• Fast Transient Response

• Wide Input Range

These ISRs have a maximum output current

of 1.5 Amps and an output voltage that is laser

trimmed to a variety of industry standard voltages.

These 78 series regulators have excellent line and load regulation with internal

short- circuit and over-temperature protection, and are offered in a variety of standard

The PT78ST100 is a series of wide-

input range, 3-terminal regulators.

output voltages. These ISRs are very flexible and may be used in a wide variety of

applications.

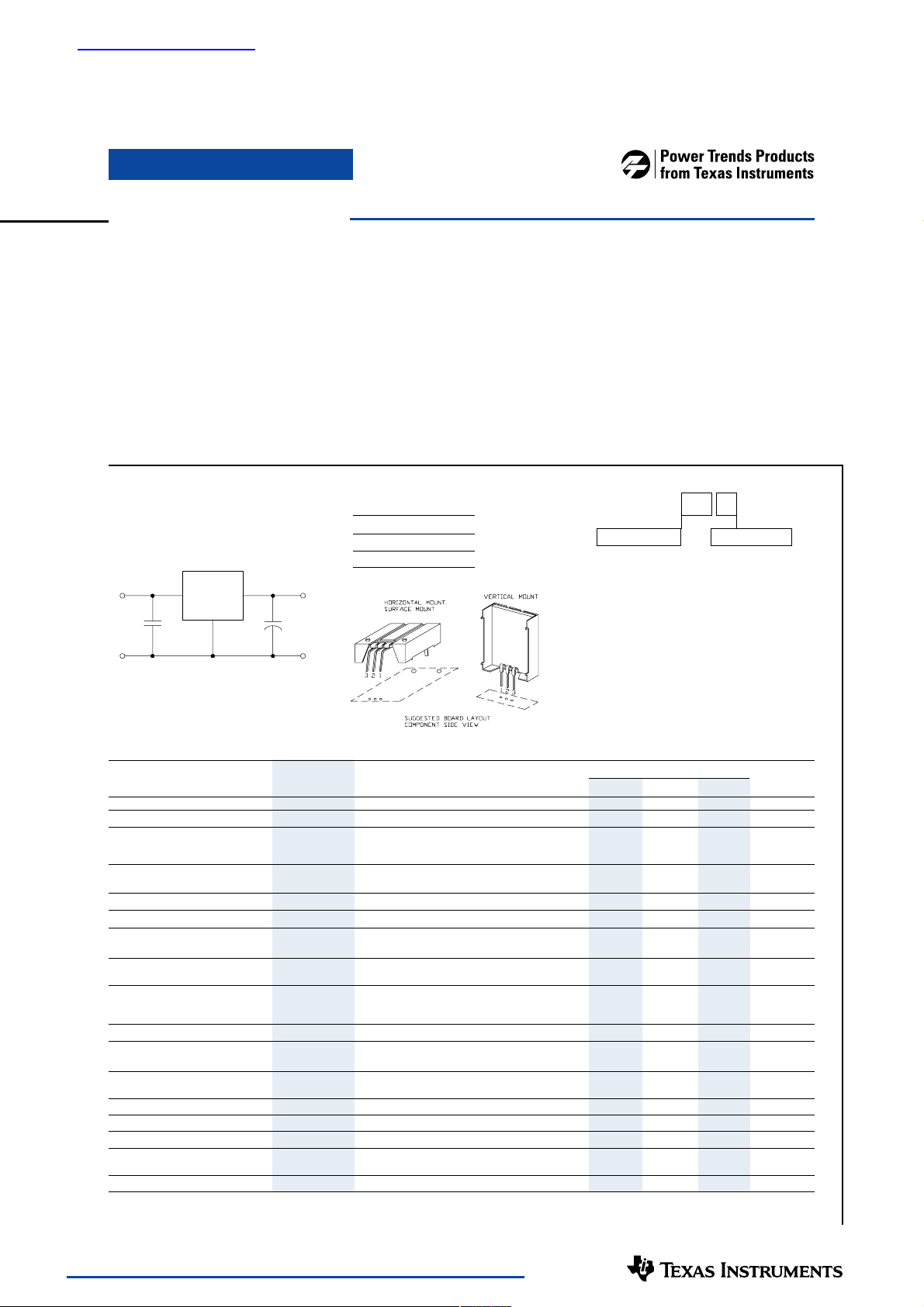

Pin-Out Information

Pin Function

1V

in

Standard Application

C2

Vout

+

COMCOM

Vin

C1

1

C1 = Optional 1µF ceramic

C2

= Required 100µF electrolytic

PT78ST100

2

3

Specifications

Characteristics

(Ta = 25°C unless noted) Symbols Conditions Min Typ Max Units

Output Current I

Short Circuit Current I

Input Voltage Range V

Output Voltage Tolerance ∆V

Line Regulation Reg

Load Regulation Reg

Ripple/Noise V

V

o

Transient Response t

(with 100µF output cap) Vo over/undershoot — 5 — %V

Efficiency η V

Switching Frequency ƒ

Absolute Maximum T

Operating Temperature Range

Recommended Operating T

Temperature Range At Vin= 24V, Io=1.0A

Thermal Resistance θ

Storage Temperature T

Mechanical Shock — Per Mil-STD-883D, Method 2002.3 — 500 — G’s

Mechanical Vibration — Per Mil-STD-883D, Method 2007.2,

Weight — — — 6.5 — grams

*ISR will operate down to no load with reduced specifications. **See Thermal Derating chart.

Note:

The PT78ST100 Series requires a 100µF electrolytic or tantalum output capacitor for proper operation in all applications.

o

sc

in

o

line

load

n

tr

o

a

a

ja

s

2 GND

3V

out

Pkg Style 500

Over Vin range 0.1* — 1.5 A

Vin = V

min — 3.5 — Apk

in

0.1 ≤ Io ≤ 1.5A V

Over Vin range, Io=1.5A

Ta = 0°C to +60°C

Over Vin range — ±0.2 ±0.4 %V

0.1 ≤ Io ≤ 1.5A — ±0.1 ±0.2 %V

Vin= 9V, Io= 1.5A Vo= 5V — 65 — mV

Vin= 16V, Io= 1.5A Vo= 12V 90 mV

50% load change — 100 — µSec

= 10V, Io= 1A Vo= 3.3V — 80 — %

in

= 10V, Io= 1A Vo= 5V — 85 — %

V

in

Vin= 17V, Io= 1A Vo= 12V — 90 — %

Over Vin range, Io=1.5A 600 650 700 kHz

—

Free Air Convection, (40-60LFM)

Free Air Convection, (40-60LFM) — 45 — °C/W

— -40 — +125 °C

20-2000 Hz, soldered in a PC board

= 3.3V 9 — 26 V

o

V

= 5V 9 — 38 V

o

Vo= 12V 16 — 38 V

Ordering Information

PT78ST1

Output Voltage

33 = 3.3 Volts

36 = 3.6 Volts

05 = 5.0 Volts

51 = 5.1 Volts

53 = 5.25 Volts

06 = 6.0 Volts

65 = 6.5 Volts

07 = 7.0 Volts

08 = 8.0 Volts

09 = 9.0 Volts

10 = 10.0 Volts

12 = 12.0 Volts

14 = 13.9 Volts

15 = 15.0 Volts

PT78ST100 SERIES

— ±1.0 ±2.0 %V

-40 — +85 °C

-40 — +80** °C

—5

XX Y

Package Suffix

V = Vertical Mount

S = Surface Mount

H = Horizontal

Mount

—

G’s

o

o

o

pp

pp

o

For technical support and more information, see inside back cover or visit www.ti.com/powertrends

Page 2

PT78ST100 Series

Typical Characteristics

1.5 Amp Positive Step-Down

Integrated Switching Regulator

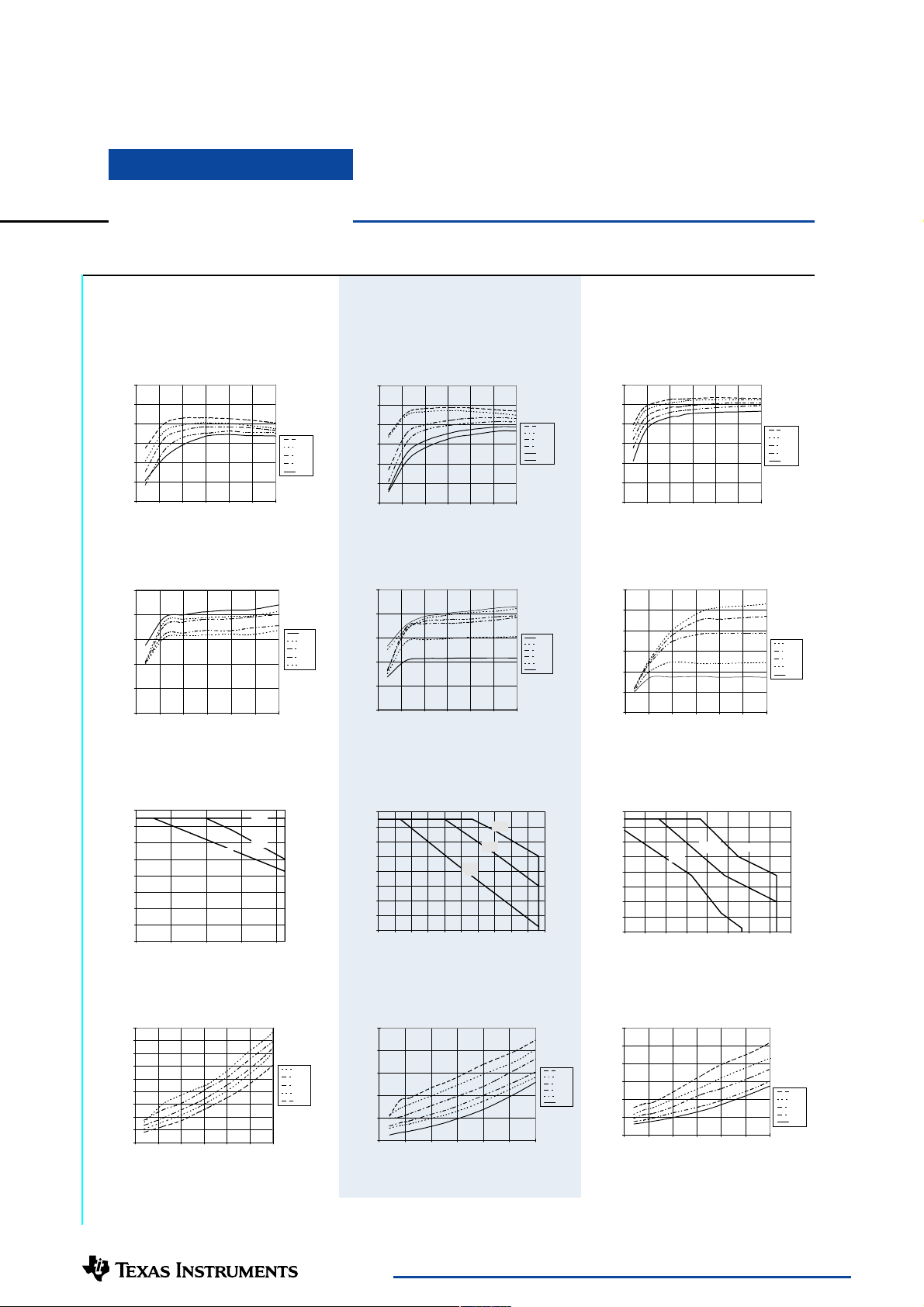

PT78ST133, 3.3 VDC (See Note 1) PT78ST105, 5.0 VDC (See Note 1) PT78ST112, 12.0 VDC (See Note 1)

Efficiency vs Output Current Efficiency vs Output Current

100

90

80

70

60

Efficiency - %Ripple-(mV)Iout-(Amps)PD-(Watts)

50

40

0 0.25 0.5 0.75 1 1.25 1.5

Iout-(Amps)

Vin

9.0V

12.0V

15.0V

20.0V

26.0V

100

90

80

70

Efficiency - %

60

50

40

0 0.25 0.5 0.75 1 1.25 1.5

Iout-(Amps)

Ripple vs Output Current Ripple vs Output Current

100

80

60

40

20

0

00.250.50.7511.251.5

Iout-(Amps)

Thermal Derating (T

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

913172125

) (See Note 2) Thermal Derating (Ta) (See Note 2)

a

60°C

70°C

85°C

Vin-(Volts) Vin-(Volts)Vin-(Volts)

Vin

26.0V

20.0V

15.0V

12.0V

9.0V

150

120

90

60

Ripple-(mV)

30

0

0 0.25 0.5 0.75 1 1.25 1.5

Iout-(Amps)

1.6

1.4

1.2

1

0.8

0.6

Iout-(Amps)

0.4

0.2

0

9 12151821242730333639

85°C

70°C

60°C

Efficiency vs Output Current

100

Vin

9.0V

12.0V

18.0V

24.0V

30.0V

38.0V

90

80

70

Efficiency - %

60

50

40

0 0.25 0.5 0.75 1 1.25 1.5

Vin

16.0V

18.0V

24.0V

30.0V

38.0V

Iout-(Amps)

Ripple vs Output Current

300

250

Vin

38.0V

30.0V

24.0V

18.0V

12.0V

9.0V

200

150

100

50

Ripple-(mV)Iout-(Amps)

0

0 0.25 0.5 0.75 1 1.25 1.5

Iout-(Amps)

Thermal Derating (T

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

16 19 22 25 28 31 34 37 40

85°C

) (See Note 2)

a

70°C

60°C

Vin

38.0V

30.0V

24.0V

18.0V

16.0V

Power Dissipation vs Output Current Power Dissipation vs Output Current

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

00.250.50.7511.251.5

Vin

26.0V

20.0V

15.0V

12.0V

9.0V

2.5

2

1.5

1

PD-(Watts)

0.5

0

0 0.25 0.5 0.75 1 1.25 1.5

Vin

38.0V

30.0V

24.0V

18.0V

12.0V

9.0V

Power Dissipation vs Output Current

3

2.5

2

1.5

1

PD-(Watts)

0.5

0

0 0.25 0.5 0.75 1 1.25 1.5

Iout-(Amps) Iout-(Amps) Iout-(Amps)

Note 1: All data listed in the above graphs, except for derating data, has been developed from actual products tested at 25°C. This data is considered typical data for the ISR.

Note 2: Thermal derating graphs are developed in free air convection cooling of 40-60 LFM. (See Thermal Application Notes.)

For technical support and more information, see inside back cover or visit www.ti.com/powertrends

Vin

38.0V

30.0V

24.0V

18.0V

16.0V

Page 3

I MPORTANT NOTI CE

T e xas Instrume nts and its subsidiarie s (TI) re se rve the right to make change s to the ir products or to discontinue

any product or se rvice without notice , and advise custome rs to obtain the late st ve rsion of re le vant information

to ve rify, be fore placing orde rs, that information be ing re lie d on is curre nt and comple te . All products are sold

subje ct to the te rms and conditions of sale supplie d at the time of orde r acknowle dgme nt, including those

pe rtaining to warranty, pate nt infringe me nt, and limitation of liability.

TI warrants pe rformance of its se miconductor products to the spe cifications applicable at the time of sale in

accordance with TI’s standard warranty. Te sting and othe r quality control te chnique s are utilize d to the e xte nt

TI de e ms ne ce ssary to support this warranty. Spe cific te sting of all parame te rs of e ach de vice is not ne ce ssarily

pe rforme d, e xce pt those mandate d by gove rnme nt re quire me nts.

Custome rs are re sponsible for the ir applications using TI compone nts.

In orde r to minimize risks associate d with the custome r’s applications, ade quate de sign and ope rating

safe guards must be provide d by the custome r to minimize inhe re nt or proce dural hazards.

TI assume s no liability for applications assistance or custome r product de sign. TI doe s not warrant or re pre se nt

that any lice nse , e ithe r e xpre ss or implie d, is grante d unde r any pate nt right, copyright, mask work right, or othe r

inte lle ctual prope rty right of TI cove ring or re lating to any combination, machine , or proce ss in which such

se miconductor products or se rvice s might be or are use d. TI’s publication of information re garding any third

party’s products or se rvice s doe s not constitute TI’s approval, warranty or e ndorse me nt the re of.

Copyright 2000, Te xas Instrume nts Incorporate d

Page 4

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish MSL Peak Temp

(3)

PT78ST105H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST105S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST105ST ACTIVE SIP MOD

ULE

EFC 3 200 TBD Call TI Level-1-215C-UNLIM

PT78ST105U NRND SIP MOD

ULE

EFU 3 TBD Call TI Call TI

PT78ST105V ACTIVE SIP MOD

ULE

EFD 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST106H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST106S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST106ST ACTIVE SIP MOD

ULE

EFC 3 200 TBD Call TI Level-1-215C-UNLIM

PT78ST106V ACTIVE SIP MOD

ULE

EFD 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST107H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST107S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST107ST ACTIVE SIP MOD

ULE

EFC 3 200 TBD Call TI Level-1-215C-UNLIM

PT78ST108H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST108S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST108V ACTIVE SIP MOD

ULE

EFD 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST109H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST109S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST109V ACTIVE SIP MOD

ULE

EFD 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST110H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST110S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST110V ACTIVE SIP MOD

ULE

EFD 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST112H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST112S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST112ST ACTIVE SIP MOD

ULE

EFC 3 200 TBD Call TI Level-1-215C-UNLIM

PT78ST112T ACTIVE SIP MOD

ULE

EFT 3 25 TBD Call TI Level-1-215C-UNLIM

PACKAGE OPTION ADDENDUM

www.ti.com

13-Oct-2005

Addendum-Page 1

Page 5

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish MSL Peak Temp

(3)

PT78ST112V ACTIVE SIP MOD

ULE

EFD 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST114H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST114S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST114V ACTIVE SIP MOD

ULE

EFD 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST115H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST115S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST115ST ACTIVE SIP MOD

ULE

EFC 3 200 TBD Call TI Level-1-215C-UNLIM

PT78ST115V ACTIVE SIP MOD

ULE

EFD 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST133H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST133S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST133ST ACTIVE SIP MOD

ULE

EFC 3 200 TBD Call TI Level-1-215C-UNLIM

PT78ST133V ACTIVE SIP MOD

ULE

EFD 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST136H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST136S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST151H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST151S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST151V ACTIVE SIP MOD

ULE

EFD 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST153H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST153S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST153V ACTIVE SIP MOD

ULE

EFD 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST165H ACTIVE SIP MOD

ULE

EFA 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST165S ACTIVE SIP MOD

ULE

EFC 3 25 TBD Call TI Level-1-215C-UNLIM

PT78ST165V ACTIVE SIP MOD

ULE

EFD 3 25 TBD Call TI Level-1-215C-UNLIM

(1)

The marketing statusvalues are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

PACKAGE OPTION ADDENDUM

www.ti.com

13-Oct-2005

Addendum-Page 2

Page 6

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS) or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

PACKAGE OPTION ADDENDUM

www.ti.com

13-Oct-2005

Addendum-Page 3

Page 7

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Page 8

WWW.ALLDATASHEET.COM

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...