MOC3020 THRU MOC3023

OPTOCOUPLERS/OPTOISOLATORS

SOES025 – OCTOBER 1986 – REVISED OCTOBER 1995

• 250 V Phototriac Driver Output

• Gallium-Arsenide-Diode Infrared Source and

Optically-Coupled Silicon Traic Driver

(Bilateral Switch)

• UL Recognized File Number E65085. . .

MOC3020 – MOC3023 ...PACKAGE

ANODE

CATHODE

NC

(TOP VIEW)

1

2

3

6

5

4

MAIN TERM

TRIAC SUB

MAIN TERM

†

• High Isolation 7500 V Peak. . .

• Output Driver Designed for 220 V ac

• Standard 6-Terminal Plastic DIP

†

Do not connect this terminal

NC – No internal connection

• Directly Interchangeable with

Motorola MOC3020, MOC3021, MOC3022,

and MOC3023

logic diagram

• Direct Replacements for:

– TRW Optron OPI3020, OPI3021,

OPI3022, and OPI3023;

1

– General Instrument MCP3020,

MCP3021, and MCP3022;

2

– General Electric GE3020,

GE3021, GE3022, and GE3023

absolute maximum ratings at 25°C free-air temperature (unless otherwise noted)

Input-to-output peak voltage, 5 s maximum duration, 60 Hz (see Note 1) 7.5 kV. . . . . . . . . . . . . . . . . . . . . . . .

Input diode reverse voltage 3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input diode forward current, continuous 50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output repetitive peak off-state voltage 400 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output on-state current, total rms value (50-60 Hz, full sine wave):T

Output driver nonrepetitive peak on-state current (t

= 10 ms, duty cycle = 10%, see Figure 7) 1.2 A. . . . . .

w

Continuous power dissipation at (or below) 25°C free-air temperature:

Infrared-emitting diode (see Note 2) 100 mW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phototriac (see Note 3) 300 mW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Total device (see Note 4) 330 mW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating junction temperature range, T

Storage temperature range, T

–40°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

–40°C to 100°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

J

Lead temperature 1,6 (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. Input-to-output peak voltage is the internal device dielectric breakdown rating.

2. Derate linearly to 100°C free-air temperature at the rate of 1.33 mW/°C.

3. Derate linearly to 100°C free-air temperature at the rate of 4 mW/°C.

4. Derate linearly to 100°C free-air temperature at the rate of 4.4 mW/°C.

= 25°C 100 mA. . . . . . . . . . . . . . . . . . .

A

T

= 70°C 50 mA. . . . . . . . . . . . . . . . . . . .

A

6

4

†

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Copyright 1995, Texas Instruments Incorporated

7–1

MOC3020 THRU MOC3023

I

Input trigger current,

Output

V

A

OPTOCOUPLERS/OPTOISOLATORS

SOES025 – OCTOBER 1986 – REVISED OCTOBER 1995

electrical characteristics at 25°C free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

R

V

F

I

(DRM)

dv/dt Critical rate of rise of off-state voltage See Figure 1 100 V/µs

dv/dt(c) Critical rate of rise of commutating voltage IO = 15 mA, See Figure 1 0.15 V/µs

FT

V

TM

I

H

NOTE 5: Test voltage must be applied at a rate no higher than 12 V/µs.

Static reverse current VR = 3 V 0.05 100 µA

Static forward voltage IF = 10 mA 1.2 1.5 V

Repetitive off-state current, either direction V

MOC3020

Input trigger current,

either direction

Peak on-state voltage, either direction ITM = 100 mA 1.4 3 V

Holding current, either direction 100 µA

MOC3021

MOC3022

MOC3023 3 5

= 400 V, See Note 5 10 100 nA

(DRM)

15 30

supply voltage = 3

8 15

5 10

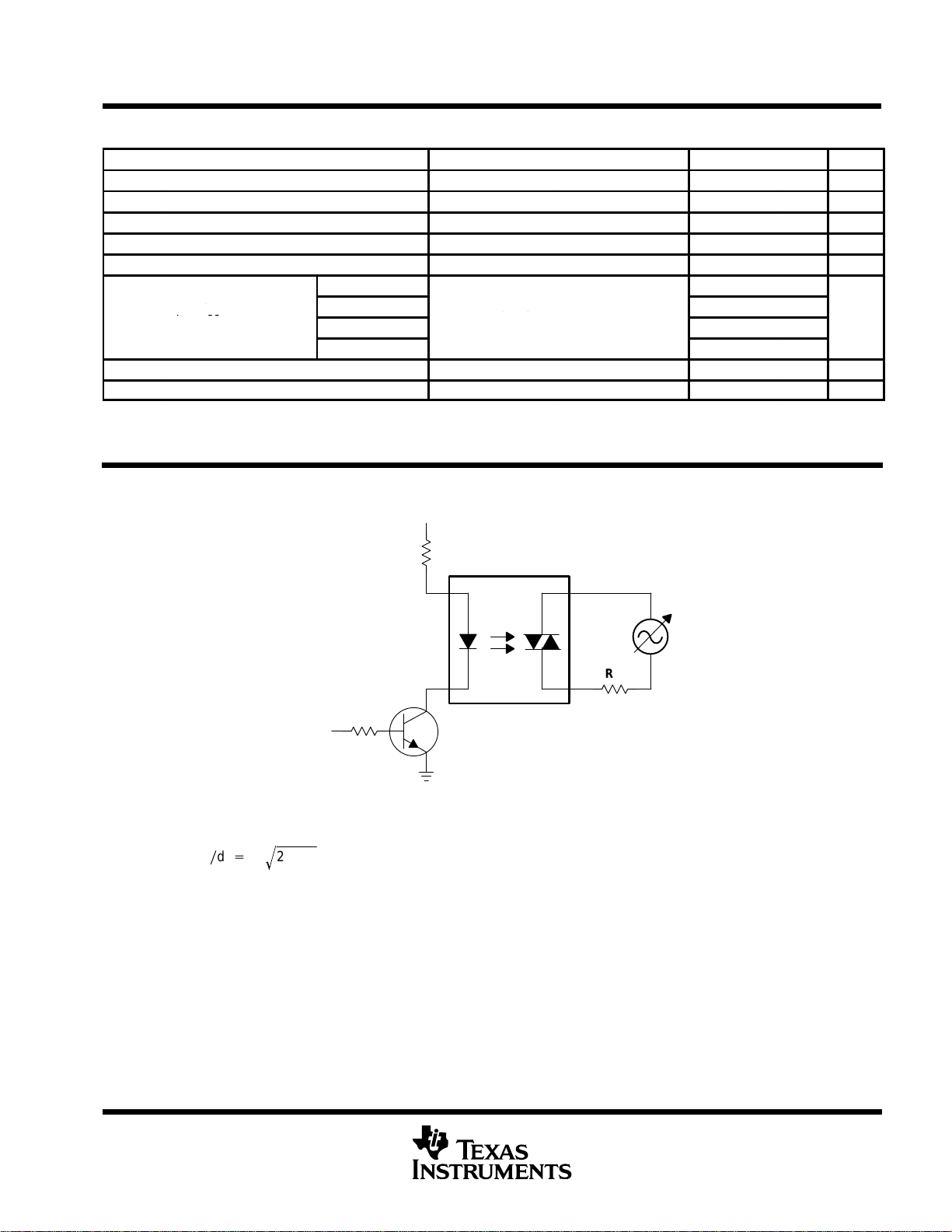

PARAMETER MEASUREMENT INFORMATION

m

V

CC

1

2

Input

(see Note A)

NOTE A. The critical rate of rise of off-state voltage, dv/dt, is measured with the input at 0 V. The frequency of Vin is increased until the

phototriac turns on. This frequency is then used to calculate the dv/dt according to the formula:

dvńdt+22πfV

The critical rate of rise of commutating voltage, dv/dt(c), is measured by applying occasional 5-V pulses to the input and increasing

the frequency of Vin until the phototriac stays on (latches) after the input pulse has ceased. With no further input pulses, the

frequency of Vin is then gradually decreased until the phototriac turns off. The frequency at which turn-off occurs may then be used

to calculate the dv/dt(c) according to the formula shown above.

Ǹ

10 kΩ

2N3904

in

6

VI = 30 V rms

R

L

4

7–2

Figure 1. Critical Rate of Rise Test Circuit

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

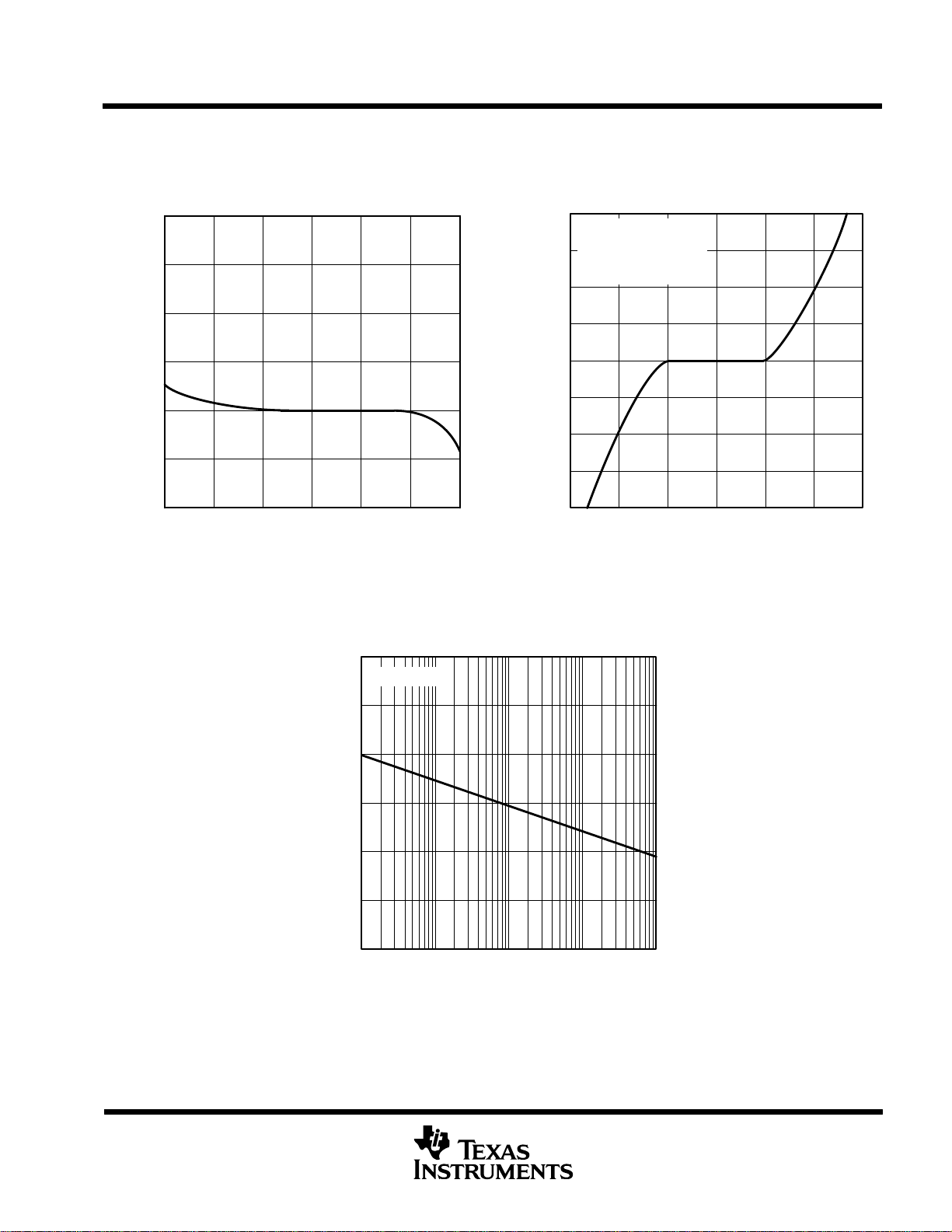

TYPICAL CHARACTERISTICS

EMITTING-DIODE TRIGGER CURRENT (NORMALIZED)

vs

FREE-AIR TEMPERATURE

1.4

1.3

1.2

MOC3020 THRU MOC3023

OPTOCOUPLERS/OPTOISOLATORS

SOES025 – OCTOBER 1986 – REVISED OCTOBER 1995

ON-STATE CHARACTERISTICS

800

Output tw = 800 µs

IF = 20 mA

600

f = 60 Hz

TA = 25°C

400

200

1.1

1

0.9

Emitting-Diode Trigger Current (Normalized)

0.8

–50 –25 0 25 50 75 100

TA – Free-Air Temperature – ° C

Figure 2 Figure 3

NONREPETITIVE PEAK ON-STATE CURRENT

3

TA = 25°C

2

0

–200

– Peak On-State Current – mA

–400

TM

I

–600

–800

vs

PULSE DURATION

–3 –2 –1 0 1 2 3

VTM – Peak On-State Voltage – V

1

– Nonrepetitive Peak On-State Current – mA

TSM

I

0

0.01 0.1 1

tw – Pulse Duration – ms

Figure 4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

10 100

7–3

MOC3020 THRU MOC3023

OPTOCOUPLERS/OPTOISOLATORS

SOES025 – OCTOBER 1986 – REVISED OCTOBER 1995

APPLICATIONS INFORMATION

R

in

V

CC

R

in

V

CC

MOC3020, MOC3023

1

2

6

4

Figure 5. Resistive Load

MOC3020, MOC3023

1

6

180 Ω

R

L

180 Ω

R

L

2.4 kΩ

220 V, 60 Hz

Z

L

0.1 µF

2

IGT ≤ 15 mA

4

Figure 6. Inductive Load With Sensitive-Gate Triac

R

in

V

CC

MOC3020, MOC3023

1

2

180 Ω

6

0.2 µF

4

15 mA < IGT < 50 mA

1.2 kΩ

Figure 7. Inductive Load With Nonsensitive-Gate Triac

220 V, 60 Hz

Z

L

220 V, 60 Hz

7–4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MOC3020 THRU MOC3023

OPTOCOUPLERS/OPTOISOLATORS

SOES025 – OCTOBER 1986 – REVISED OCTOBER 1995

MECHANICAL INFORMATION

Each device consists of a gallium-arsenide infrared-emitting diode optically coupled to a silicon phototriac

mounted on a 6-terminal lead frame encapsulated within an electrically nonconductive plastic compound. The

case can withstand soldering temperature with no deformation and device performance characteristics remain

stable when operated in high-humidity conditions.

9,40 (0.370)

8,38 (0.330)

Index Dot

(see Note B)

6 5 4

C

105°

90

0,305 (0.012)

0,203 (0.008)

NOTES: A. Leads are within 0,13 (0.005) radius of true position (T.P.) with maximum material condition and unit installed.

B. Pin 1 identified by index dot.

C. T erminal connections:

1. Anode (part of the infrared-emitting diode)

2. Cathode (part of the infrared-emitting diode)

3. No internal connection

4. Main terminal (part of the phototransistor)

5. Triac Substrate (DO NOT connect) (part of the phototransistor)

6. Main terminal (part of the phototransistor)

D. The dimensions given fall within JEDEC MO-001 AM dimensions.

E. All linear dimensions are given in millimeters and parenthetically given in inches.

C

LL

7,62 (0.300) T.P.

(see Note A)

6,61 (0.260)

6,09 (0.240)

Seating Plane

°

3,81 (0.150)

3,17 (0.125)

5,46 (0.215)

2,95 (0.116)

2,03 (0.080)

1,52 (0.060)

1,78 (0.070)

0,51 (0.020)

4 Places

2,54 (0.100) T.P.

(see Note A)

1 2 3

(see Note C)

1,78 (0.070) MAX

6 Places

1,01 (0.040) MIN

0,534 (0.021)

0,381 (0.015)

6 Places

Figure 8. Mechanical Information

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7–5

7–6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

IMPORTANT NOTICE

T exas Instruments (TI) reserves the right to make changes to its products or to discontinue any semiconductor

product or service without notice, and advises its customers to obtain the latest version of relevant information

to verify, before placing orders, that the information being relied on is current.

TI warrants performance of its semiconductor products and related software to the specifications applicable at

the time of sale in accordance with TI’s standard warranty. Testing and other quality control techniques are

utilized to the extent TI deems necessary to support this warranty. Specific testing of all parameters of each

device is not necessarily performed, except those mandated by government requirements.

Certain applications using semiconductor products may involve potential risks of death, personal injury, or

severe property or environmental damage (“Critical Applications”).

TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, INTENDED, AUTHORIZED, OR WARRANTED

TO BE SUITABLE FOR USE IN LIFE-SUPPORT APPLICATIONS, DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS.

Inclusion of TI products in such applications is understood to be fully at the risk of the customer. Use of TI

products in such applications requires the written approval of an appropriate TI officer . Questions concerning

potential risk applications should be directed to TI through a local SC sales office.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards should be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance, customer product design, software performance, or

infringement of patents or services described herein. Nor does TI warrant or represent that any license, either

express or implied, is granted under any patent right, copyright, mask work right, or other intellectual property

right of TI covering or relating to any combination, machine, or process in which such semiconductor products

or services might be or are used.

Copyright 1995, Texas Instruments Incorporated

Loading...

Loading...