Page 1

User's Guide

SNVU698–March 2020

LMQ61460EVM-400K User's Guide

The LMQ61460-Q1 evaluation module (EVM) is designed to help customers evaluate the performance of

the LMQ61460-Q1 synchronous step-down voltage converter. This EVM implements the LMQ61460-Q1 in

a 14-pin wettable flanks Hotrod™ package, as shown in Table 1. It is capable of delivering 5-V output

voltage and up to 6-A load current switching at 400 kHz with exceptional efficiency and output accuracy in

a very small solution size. The EVM provides multiple power connectors and test points. In addition to an

optimized EMI board layout, the LMQ61460-Q1 uses integrated bypass capacitors which results in great

EMI performance.

Table 1. Device and Package Configurations

CONVERTER IC PACKAGE

U1 LMQ61460-Q1 14-pin wettable flanks Hotrod package 4.0 mm × 3.5 mm × 1.0 mm

SNVU698–March 2020

Submit Documentation Feedback

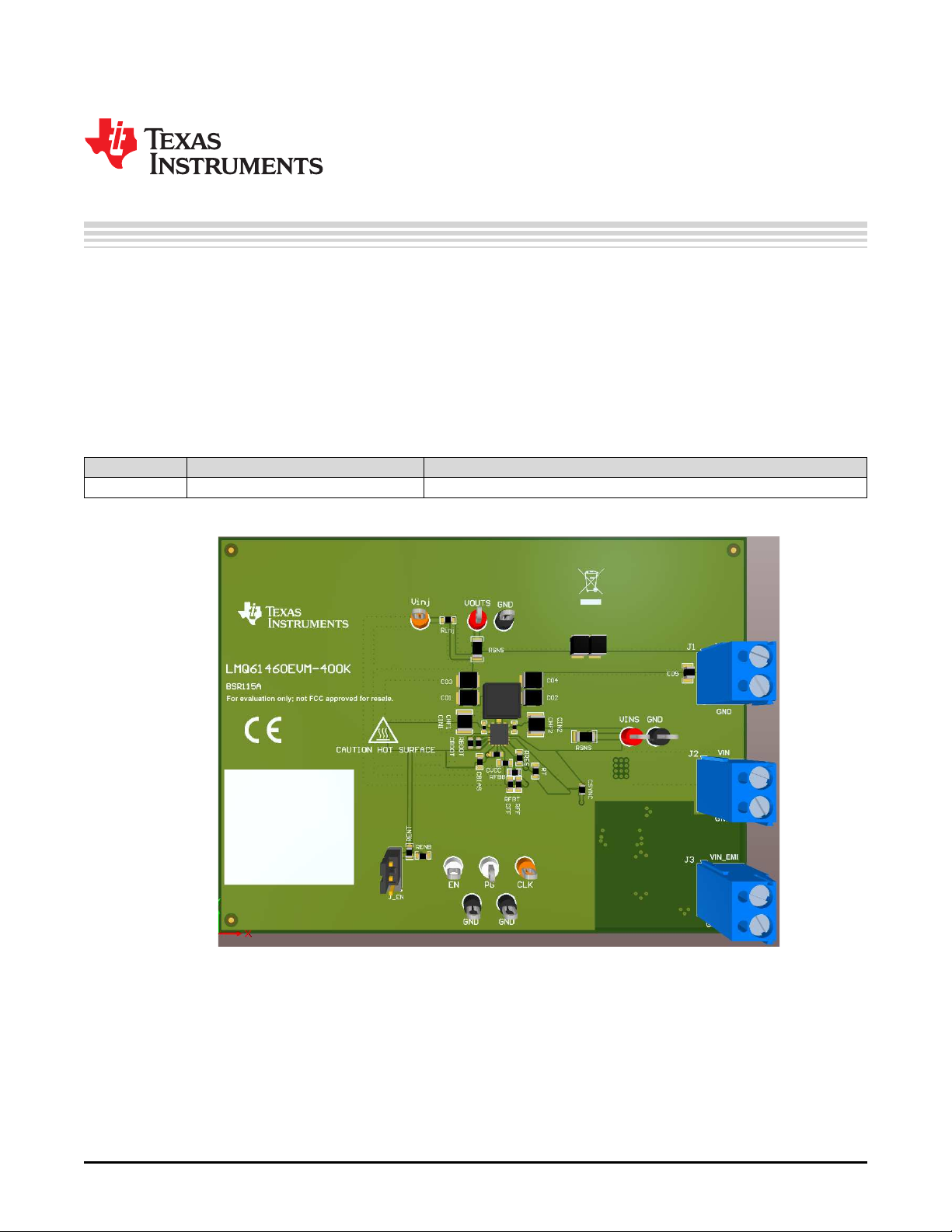

Figure 1. LMQ61460EVM-400K Top View

Copyright © 2020, Texas Instruments Incorporated

LMQ61460EVM-400K User's Guide

1

Page 2

Introduction

Contents

1 Introduction ................................................................................................................... 2

2 Quick Start Guide............................................................................................................ 3

3 Detailed Descriptions........................................................................................................ 4

4 Schematic..................................................................................................................... 5

5 Board Layout ................................................................................................................. 8

6 LMQ61460EVM-400K Board Test Results.............................................................................. 11

7 Bill of Materials ............................................................................................................. 13

Trademarks

Hotrod is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

1 Introduction

1.1 LMQ61460-Q1 Synchronous Step-Down Voltage Converter

The LMQ61460-Q1 is an easy-to-use synchronous step-down DC/DC converter capable of delivering up

to 6 A of load current from a supply voltage ranging from 3 V to 36 V. The LMQ61460-Q1 provides

exceptional efficiency and output accuracy in a very small solution size. The LMQ61460-Q1 is capable of

delivering 6 A of load current and implements peak current mode control. The following are additional

features that provide both flexible and easy-to-use solutions for a wide range of applications:

• Adjustable switching frequency (RT)

• Synchronization to an external clock (CLK jumper)

• FPWM variant (LMQ61460AFS) (IC swap)

• Power-good flag (PG jumper)

• Precision enable (EN jumper with RENT and RENB resistors)

Automatic frequency foldback at light load and optional external bias improve efficiency over the entire

load range. The device requires few external components and has a pinout designed for optimal EMI and

thermal performance. Protection features include the following:

• Thermal shutdown

• Input undervoltage lockout

• Cycle-by-cycle current limiting

• Hiccup short-circuit protection

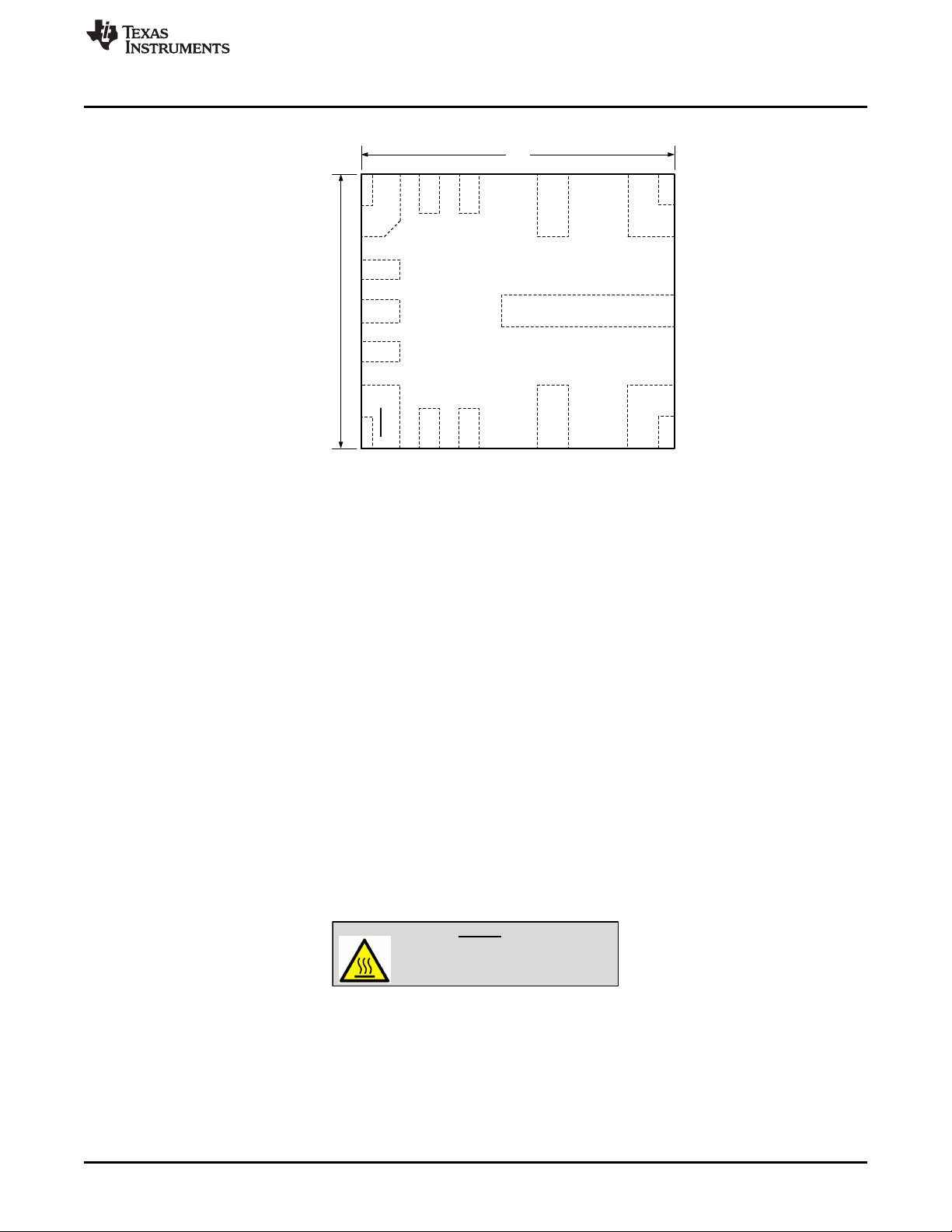

For a quick reference, Figure 2 shows the pin configuration of the LMQ61460-Q1.

www.ti.com

2

LMQ61460EVM-400K User's Guide

Copyright © 2020, Texas Instruments Incorporated

Submit Documentation Feedback

SNVU698–March 2020

Page 3

CAUTION

Caution Hot surface.

Contact may cause burns.

Do not touch.

3.5 mm

4 mm

BIAS

CBOOT

RBOOT

EN/

SYNC

RESET

VIN1

VIN2

PGND1

PGND2

SW

FB

AGND

VCC

RT

www.ti.com

Figure 2. LMQ61460-Q1 Pin Configuration (Top View)

1.2 LMQ61460-Q1 Evaluation Module

The LMQ61460EVM-400K is populated with the LMQ61460AASQRJRRQ1 which automatically reduces

frequency at light loads (PFM - pulse frequency modulation). This IC can be replaced with the

LMQ61460AFSQRJRRQ1 for a constant switching frequency across load (FPWM - forced pulse width

modulation).

Introduction

2 Quick Start Guide

1. Connect the voltage supply between the VIN and GND connectors or between VIN_EMI and

GND_EMI to include the on-board input filter in the input path. Use short and thick gauge wires to

minimize inductance and IR drop. Note that sense points for VINand V

2. Connect the load of the converter between VOUT and GND connectors using short and thick wires.

3. Set the supply voltage at an appropriate level between 6 V to 36 V. The 6 V minimum input voltage

ensures enough head room for V

supply to an appropriate level to supply needed current and protection.

4. Turn on the power supply. With the default configuration, the EVM powers up and provides V

to 5 V.

5. Monitor the output voltage with sense points. The maximum load current is 6 A with the LMQ61460Q1. Note that the maximum output current may need to derate if ambient temperature is high,

especially if device is operated at higher frequency, that is 2.2 MHz.

See Figure 4 for connector locations.

are provided.

OUT

to equal 5 V at a 6 A load current. Set the current limit of the

OUT

equal

OUT

SNVU698–March 2020

Submit Documentation Feedback

LMQ61460EVM-400K User's Guide

Copyright © 2020, Texas Instruments Incorporated

3

Page 4

Detailed Descriptions

3 Detailed Descriptions

This section describes the connectors on the EVM and how to properly connect, set up, and use the EVM.

See Figure 1 for a top view of the EVM.

VOUT —Output voltage of the converter

VOUT connectors connect to the power inductor and output capacitors. Connect the load between

the VOUT connector and the GND connector to provide load current. Connect the loading device to

the board with short and thick wires to handle the large DC output current.

GND —Ground of the converter

The GND is connected to the PGND and AGND pins of the device as well as the ground of the

input and output capacitors. The GND connections next to VIN, VIN_EMI, and VOUT connectors

are meant for current return path for the supply voltage and load, respectively. Connectors are

provided in pairs to allow easy and accurate sensing of voltages. Connect to supply and load

grounds with short and thick wires. Other GND connectors are for signal measurement and probing.

VIN— Input voltage to the converter

The VINconnector connects to the input capacitors and the VIN pins of the LMQ61460-Q1. Connect

the supply voltage from a power supply or a battery between VIN and GND connectors as power

input to the device. The input voltage (VIN) range must be higher than 3.9 V for the device to start

up and above 3 V to maintain operation. A VINhigher than 6 V provides a regulated 5-V output

voltage. Maximum VINis limited to 36 V to avoid damaging the device. The current limit on the

supply must be high enough to provide the needed supply current. The supply voltage must be

connected to the board with short and thick wires to handle the required input current at maximum

load current. If long cables are used to power up the board, damping must be provided by adding

CFLT3 and RFLT3 to avoid oscillation between the cable parasitic inductance and the existing lowESR ceramic capacitors.

www.ti.com

VIN_EMI —Low EMI option

If the input filter is required, connect the supply voltage between VIN_EMI and GND_EMI. The

supply voltage must be connected to the board with short and thick wires.

The input filter consists of the following: CF1, CF2, CF3, CF4, CF5, CF6, and L2. CD1, CD2, RD1,

and RD2 are provided to allow more options for filter optimization. To include the input filter in the

power path, connect the supply voltage between the VIN_EMI and GND_EMI connectors. The

output of the filter is connected to VIN, which is connected to the VINpins of the LMQ61460-Q1.

Conducted EMI arises from the operation of switching circuits.

GND_EMI —Ground return for the input filter

This is the current return path for the supply connected to VIN_EMI. It provides a short-loop

connection to the input filter capacitors to best filter the conducted noise generated from the PCB.

Use VIN_EMI and GND_EMI connection if input filter is used and conducted EMI test is desired.

CLK —For synchronization clock input

The CLK input connector is designed for external clock input to the EN/SYNC pin. Switching action

of the buck is synchronized to the external clock when it is present. The operation mode

automatically changes to forced PWM mode, maintaining a constant switching frequency over the

entire load range while the clock signal is present.

EN — To monitor the EN pin or control EN signal

This test point is used to monitor the voltage on the device EN pin. By default, the EN pin is

connected to the mid-point of an enable divider. Note that the lower resistor in this divider, RENB, is

not populated so the IC turns on by default. Populate RENB to adjust UVLO. Apply a voltage to EN

to externally enable or disable the device.

PG — To monitor the PGOOD/RESET pin

The PGOOD flag indicates whether the output voltage is within the regulation band. The RESET

pin (synonymous with PGOOD pin) of the device is an open-drain output and is pulled up to V

OUT

through a 100 k resistor. This pin pulls to GND when the output voltage is out of regulation.

4

LMQ61460EVM-400K User's Guide

Copyright © 2020, Texas Instruments Incorporated

Submit Documentation Feedback

SNVU698–March 2020

Page 5

www.ti.com

Vinj —For measuring AC response

A low value resistor, Rinj, is placed between VOUT and this node. The feedback divider of the

board is connected to this node. An AC signal is applied across Rinj when taking measurements for

bode plots.

VOUTS —VOUT sense

This connector is provided for measuring the output voltage accurately.

VINS —VIN sense

This connector is provided for measuring the input voltage accurately.

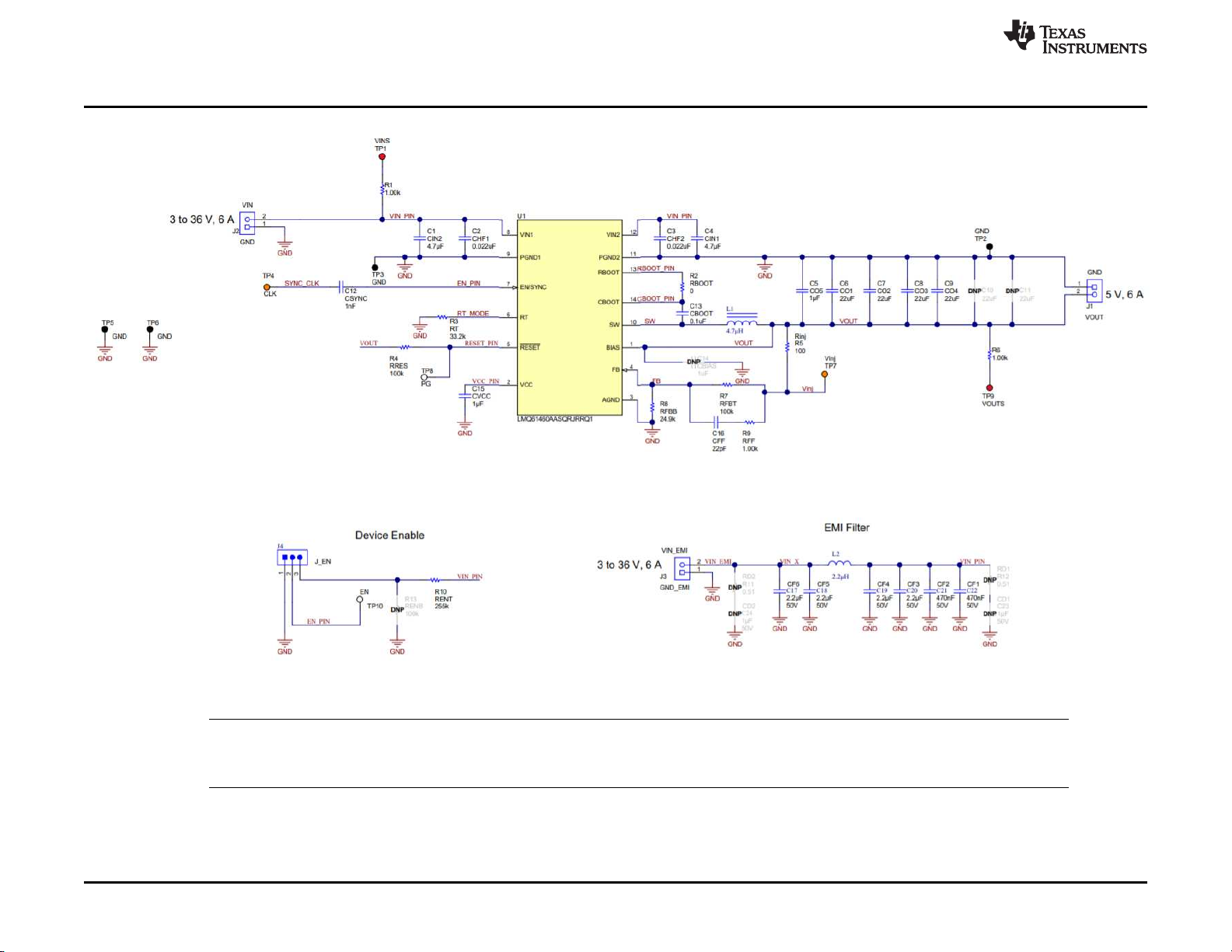

4 Schematic

The bill of materials is tabulated in Section 7. In addition, Figure 3 shows the corresponding schematic.

Schematic

SNVU698–March 2020

Submit Documentation Feedback

Copyright © 2020, Texas Instruments Incorporated

LMQ61460EVM-400K User's Guide

5

Page 6

Schematic

www.ti.com

NOTE: Long leads and additional inductance in used to power the DC/DC may cause issues for ideal device operation. RD2, CD2, RD1, and

CD1 are placeholders for damping networks to be populated. For more information regarding this topic, reference the EMI Filter

Components and Their Nonidealities for Automotive DC/DC Regulators Technical Brief.

6

LMQ61460EVM-400K User's Guide

Figure 3. LMQ61460EVM-400K Schematic

SNVU698–March 2020

Submit Documentation Feedback

Copyright © 2020, Texas Instruments Incorporated

Page 7

www.ti.com

4.1 Alternative BOM Configurations

VOUT FREQUENCY RFBB RT COUT CIN + CHF L1

3.3 V 400 kHz 43.2 kΩ 33.2 kΩ 6 x 22 µF 2 x 4.7 µF + 2 x

3.3 V 2100 kHz 43.2 kΩ 6.04 kΩ 3 x 22 µF 2 x 4.7 µF + 2 x

5 V 400 kHz 24.9 kΩ 33.2 kΩ 4 x 22 µF 2 x 4.7 µF + 2 x

5 V 2100 kHz 24.9 kΩ 6.04 kΩ 3 x 22 µF 2 x 4.7 µF + 2 x

Table 2. BOM Configurations

100 nF

100 nF

100 nF

100 nF

Schematic

4.7 µH

(XHMI6060)

1 µH (XEL5030)

4.7 µH

(XHMI6060)

1 µH (XEL5030)

SNVU698–March 2020

Submit Documentation Feedback

Copyright © 2020, Texas Instruments Incorporated

LMQ61460EVM-400K User's Guide

7

Page 8

Board Layout

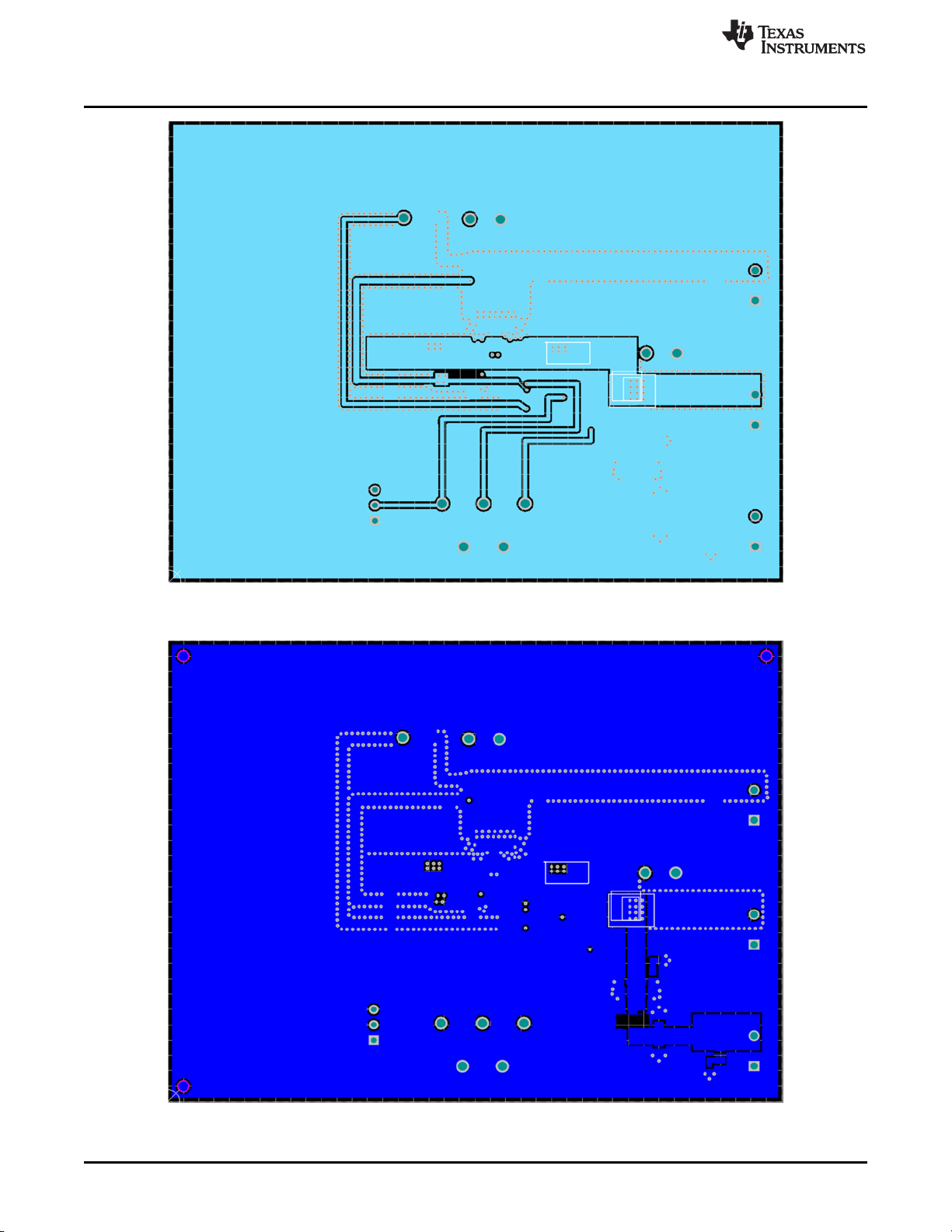

5 Board Layout

Figure 4 through Figure 8 show the board layout for the LMQ61460-Q1 EVM. The EVM offers resistors,

capacitors, and test points to configure the following:

• Output voltage (RFBT and RFBB)

• Precision enable pin (RENT and RENB)

• Set frequency (RT)

• External clock synchronization (CLK jumper)

The 14-pin Hotrod package with integrated capacitors offers a very small size and low-noise solution. The

PCB consists of a 4-layer design. There are 2-oz copper planes on the top and bottom and 1-oz copper

mid-layer planes to route signals and dissipate heat with an array of thermal vias to connect to all four

layers.

Test points have been provided for ease of use to connect the power supply and required load, and to

monitor critical signals.

The board measures 3.00" x 4.00" (76mm x 101mm).

www.ti.com

Figure 4. Top View with Silkscreen

8

LMQ61460EVM-400K User's Guide

Copyright © 2020, Texas Instruments Incorporated

Submit Documentation Feedback

SNVU698–March 2020

Page 9

www.ti.com

Board Layout

Figure 5. Top Layer

SNVU698–March 2020

Submit Documentation Feedback

Figure 6. Signal Layer 1 - Ground Plane

Copyright © 2020, Texas Instruments Incorporated

LMQ61460EVM-400K User's Guide

9

Page 10

Board Layout

www.ti.com

Figure 7. Signal Layer 2 - Routing

10

LMQ61460EVM-400K User's Guide

Figure 8. Bottom Layer

Copyright © 2020, Texas Instruments Incorporated

Submit Documentation Feedback

SNVU698–March 2020

Page 11

www.ti.com

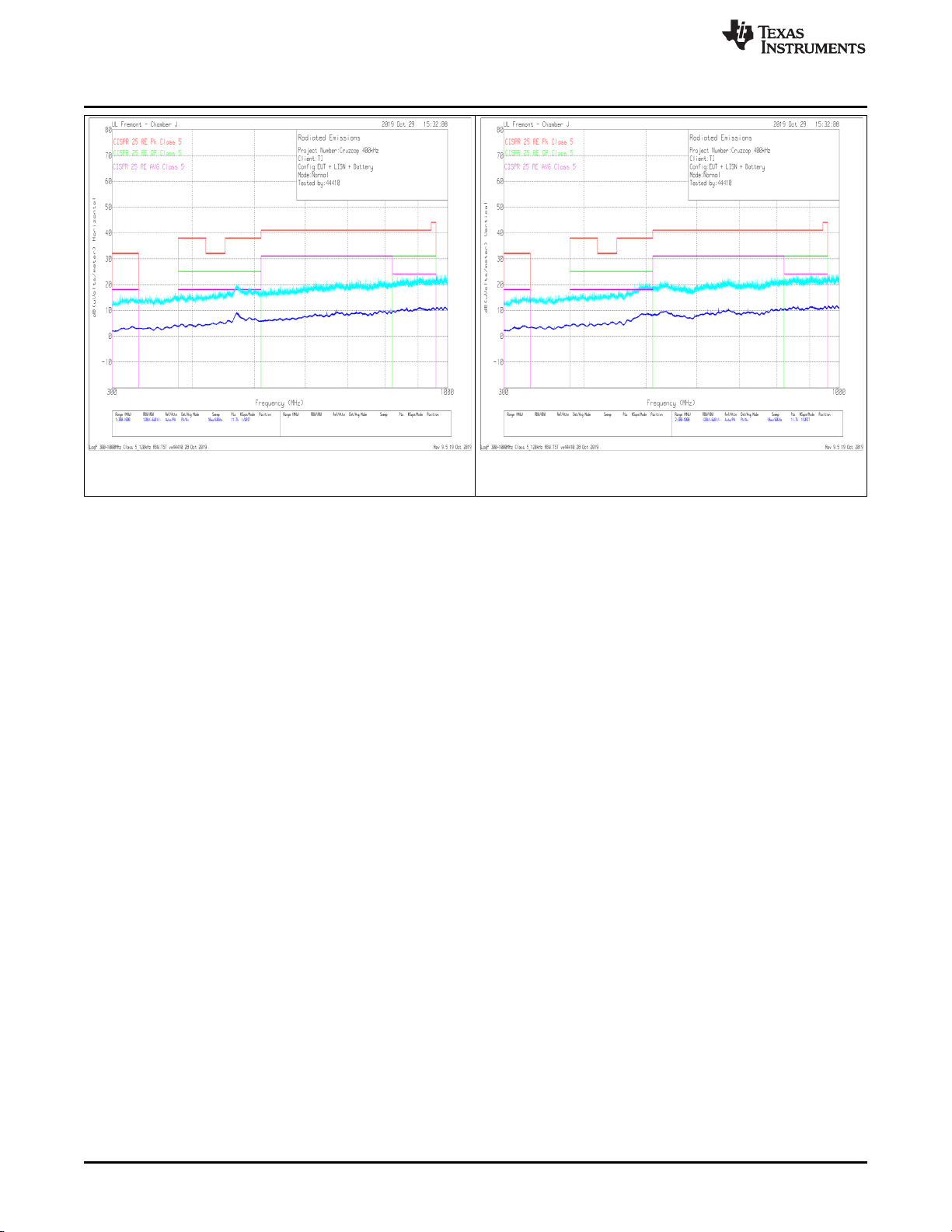

6 LMQ61460EVM-400K Board Test Results

6.1 EMI

The EMI measurements were taken following CISPR 25, Class 5 standards. The measurements were

taken at 13.5 VIN, 5 VOUT with a 6 A load switching at 400kHz.

LMQ61460EVM-400K Board Test Results

Figure 9. Conducted EMI Measurement with CISPR 25

Class 5 Limit Lines (150 kHz to 30 MHz)

Figure 11. Radiated EMI Measurement with Horizontal

Bicon Antenna Under CISPR 25 Class 5 Limits

Figure 10. Conducted EMI Measurement with CISPR 25

Class 5 Limit Lines (30 MHz to 108 MHz)

Figure 12. Radiated EMI Measurement with Vertical Bicon

Antenna Under CISPR 25 Class 5 Limits

SNVU698–March 2020

Submit Documentation Feedback

Copyright © 2020, Texas Instruments Incorporated

LMQ61460EVM-400K User's Guide

11

Page 12

LMQ61460EVM-400K Board Test Results

www.ti.com

Figure 13. Radiated EMI Measurement with Horizontal Log

Antenna Under CISPR 25 Class 5 Limits

Figure 14. Radiated EMI Measurement with Vertical Log

Antenna Under CISPR 25 Class 5 Limits

12

LMQ61460EVM-400K User's Guide

Copyright © 2020, Texas Instruments Incorporated

Submit Documentation Feedback

SNVU698–March 2020

Page 13

www.ti.com

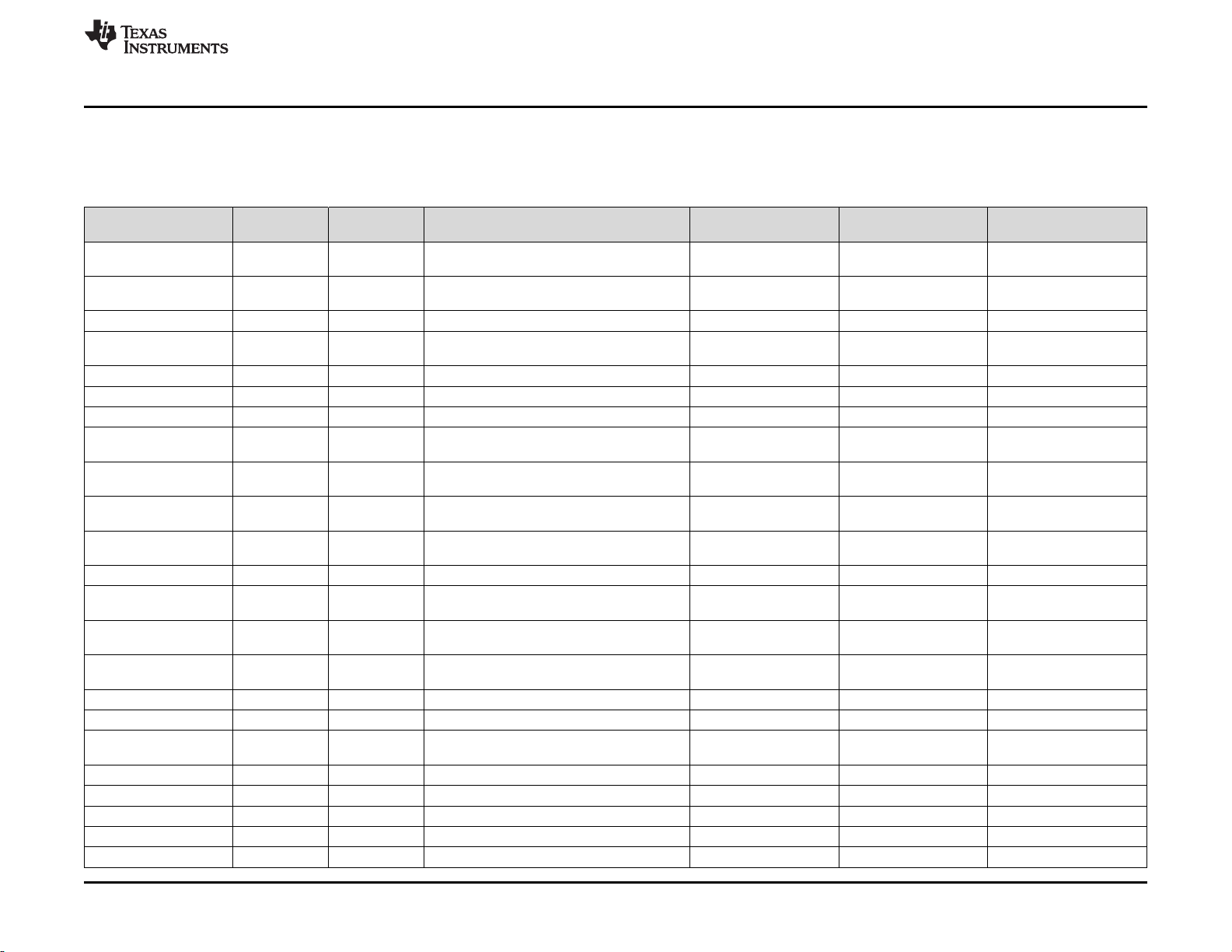

7 Bill of Materials

The bill of materials is shown Table 3 for the LMQ61460EVM-400K.

Bill of Materials

Table 3. LMQ61460EVM-400K EVM Bill of Materials

DESIGNATOR QUANTITY VALUE DESCRIPTION

C1, C4 2 4.7 µF CAP, CERM, 4.7 µF, 50 V, ±20%, X7R, AEC-

Q200 Grade 1, 1210

C2, C3 2 0.022 µF CAP, CERM, 0.022 µF, 50 V, ±10%, X7R,

0402

C5 1 1 µF CAP, CERM, 1 µF, 25 V, ±10%, X7R, 0805 0805 C0805C105K3RACTU Kemet

C6, C7, C8, C9 4 22 µF CAP, CERM, 22 µF, 16 V, ±20%, X7R, AEC-

Q200 Grade 1, 1210

C12 1 1000 pF CAP, CERM, 1000 pF, 50 V, ±0%, X7R, 0603 0603 C0603C102K5RACTU Kemet

C13 1 0.1 µF CAP, CERM, 0.1 µF, 10 V, ±10%, X7R, 0603 0603 C0603X104K8RACTU Kemet

C15 1 1 µF CAP, CERM, 1 µF, 16 V, ±10%, X7R, 0603 0603 885012206052 Wurth Elektronik

C16 1 22 pF CAP, CERM, 22 pF, 50 V, ±5%, C0G/NP0,

AEC-Q200 Grade 1, 0603

C17, C18, C19, C20 4 2.2 µF CAP, CERM, 2.2 µF, 50 V, ±10%, X7R, AEC-

Q200 Grade 1, 0805

C21, C22 2 0.47 µF CAP, CERM, 0.47 µF, 50 V, ±10%, X7R,

AEC-Q200 Grade 1, 0603

J1, J2, J3 3 Terminal Block, 5 mm, 2x1, Tin, TH Terminal Block, 5 mm,

J4 1 Header, 100 mil, 3x1, Gold, TH Header, 100 mil, 3x1, TH HTSW-103-07-G-S Samtec

L1 1 4.7 µH Inductor, Shielded, Hyperflux, 4.7 µH, 7.4 A,

0.0143 Ω , SMD

L2 1 1.2 µH Shielded Molded Inductor 7.5 A, 11.3

mΩ Max 2-SMD

LBL1 1 PCB Label 0.650 x 0.200

R1, R6 2 1.00 k RES, 1.00 k, 1%, 0.25 W, 1206 1206 RC1206FR-071KL Yageo America

R2 1 0 RES, 0, 5%, 0.1 W, 0603 0603 RC0603JR-070RL Yageo

R3 1 33.2 k RES, 33.2 k, 1%, 0.1 W, AEC-Q200 Grade 0,

0603

R4, R7 2 100 k RES, 100 k, 1%, 0.1 W, 0603 0603 RC0603FR-07100KL Yageo

R5 1 100 RES, 100, 1%, 0.1 W, 0603 0603 RC0603FR-07100RL Yageo

R8 1 24.9 k RES, 24.9 k, 1%, 0.1 W, 0603 0603 RC0603FR-0724K9L Yageo

R9 1 1.00 k RES, 1.00 k, 1%, 0.1 W, 0603 0603 ERJ-3EKF1001V Panasonic

R10 1 255 k RES, 255 k, 1%, 0.1 W, 0603 0603 RC0603FR-07255KL Yageo

PACKAGE

REFERENCE

1210 UMK325B7475MMHT Taiyo Yuden

0402 GRM155R71H223KA12DMuRata

1210 CGA6P1X7R1C226M25

0603 CGA3E2C0G1H220J080AATDK

0805 CGA4J3X7R1H225K125ABTDK

0603 CGA3E3X7R1H474K080AETDK

2x1, TH

6.65x6.45 mm 74439346047 Wurth Elektronik

SMD2 744316220 Wurth Electronics

inch

0603 CRCW060333K2FKEA Vishay-Dale

PART NUMBER MANUFACTURER

TDK

0AC

691 101 710 002 Wurth Elektronik

THT-14-423-10 Brady

SNVU698–March 2020

Submit Documentation Feedback

Copyright © 2020, Texas Instruments Incorporated

LMQ61460EVM-400K User's Guide

13

Page 14

Bill of Materials

Table 3. LMQ61460EVM-400K EVM Bill of Materials (continued)

DESIGNATOR QUANTITY VALUE DESCRIPTION

SH-J1 1 Shunt, 100 mil, Gold plated, Black Shunt 2 pos. 100 mil 881545-2 TE Connectivity

TP1, TP9 2 Test Point, Multipurpose, Red, TH Red Multipurpose

TP2, TP3, TP5, TP6 4 Test Point, Multipurpose, Black, TH Black Multipurpose

TP4, TP7 2 Test Point, Multipurpose, Orange, TH Orange Multipurpose

TP8, TP10 2 Test Point, Multipurpose, White, TH White Multipurpose

U1 1 Automotive 6-A Low Noise Synchronous Buck

C10, C11 0 22 µF CAP, CERM, 22 µF, 16 V, ±20%, X7R, AEC-

C14 0 1 µF CAP, CERM, 1 µF, 10 V, ±10%, X7R, 0603 0603 GRM188R71A105KA61DMuRata

C23, C24 0 1 µF CAP, CERM, 1 µF, 50 V, ±10%, X7R, 0603 0603 UMK107AB7105KA-T Taiyo Yuden

FID1, FID2, FID3, FID4,

FID5, FID6

R12 0 0.51 RES, 0.51, 1%, 0.25 W, 0805 0805 CRM0805-FX-R510ELF Bourns

R13 0 100 k RES, 100 k, 1%, 0.1 W, 0603 0603 RC0603FR-07100KL Yageo

0 Fiducial mark. There is nothing to buy or

Regulators, RJR0014A (VQFN-HR-14)

Q200 Grade 1, 1210

mount.

PACKAGE

REFERENCE

Testpoint

Testpoint

Testpoint

Testpoint

RJR0014A LMQ61460AASQRJRRQ1Texas Instruments

1210 CGA6P1X7R1C226M25

N/A N/A N/A

PART NUMBER MANUFACTURER

5010 Keystone

5011 Keystone

5013 Keystone

5012 Keystone

TDK

0AC

www.ti.com

14

LMQ61460EVM-400K User's Guide

Submit Documentation Feedback

SNVU698–March 2020

Copyright © 2020, Texas Instruments Incorporated

Page 15

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2020, Texas Instruments Incorporated

Loading...

Loading...