Page 1

GTLP Evaluation Module

(EVM)

User’s Guide

June 2001 Standard Linear & Logic

Page 2

Printed in U.S.A.

0601

SCEA023

Page 3

GTLP Evaluation Module (EVM)

User’s Guide

SCEA023

June 2001

Printed on Recycled Paper

Page 4

IMPORTANT NOTICE

Texas Instruments and its subsidiaries (TI) reserve the right to make changes to their products

or to discontinue any product or service without notice, and advise customers to obtain the latest

version of relevant information to verify , before placing orders, that information being relied on

is current and complete. All products are sold subject to the terms and conditions of sale supplied

at the time of order acknowledgment, including those pertaining to warranty , patent infringement,

and limitation of liability .

TI warrants performance of its products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty . T esting and other quality control techniques are utilized

to the extent TI deems necessary to support this warranty . Specific testing of all parameters of

each device is not necessarily performed, except those mandated by government requirements.

Customers are responsible for their applications using TI components.

In order to minimize risks associated with the customer’s applications, adequate design and

operating safeguards must be provided by the customer to minimize inherent or procedural

hazards.

TI assumes no liability for applications assistance or customer product design. TI does not

warrant or represent that any license, either express or implied, is granted under any patent right,

copyright, mask work right, or other intellectual property right of TI covering or relating to any

combination, machine, or process in which such products or services might be or are used. TI’s

publication of information regarding any third party’ s products or services does not constitute TI’s

approval, license, warranty or endorsement thereof.

Reproduction of information in TI data books or data sheets is permissible only if reproduction

is without alteration and is accompanied by all associated warranties, conditions, limitations and

notices. Representation or reproduction of this information with alteration voids all warranties

provided for an associated TI product or service, is an unfair and deceptive business practice,

and TI is not responsible nor liable for any such use.

Resale of TI’s products or services with statements different from or beyond the parameters

stated by TI for that product or service voids all express and any implied warranties for the

associated TI product or service, is an unfair and deceptive business practice, and TI is not

responsible nor liable for any such use.

Also see: Standard Terms and Conditions of Sale for Semiconductor Products.

www.ti.com/sc/docs/stdterms.htm

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2001, Texas Instruments Incorporated

Page 5

About This Manual

Use this manual to set up and use the GTLP evaluation module (EVM) for the

SN74GTLPH1655 and other GTLP devices.

How to Use This Manual

This document contains the following chapters:

-

-

-

-

Preface

Read This First

Chapter 1 – Introduction

Chapter 2 – GTLP EVM Board Typical Test and Setup Configuration

Chapter 3 – Oscilloscope Operation

Chapter 4 – Waveform Measurement and Interpretation

-

Chapter 5 – Troubleshooting

-

Appendix A – Bill of Materials, Schematics, Board Layouts, and

Suggested Specifications

iii

Page 6

Information About Cautions and Warnings

Information About Cautions and Warnings

This book may contain cautions and warnings.

This is an example of a caution statement.

A caution statement describes a situation that could potentially

damage your software or equipment.

This is an example of a warning statement.

A warning statement describes a situation that could potentially

cause harm to you

The information in a caution or a warning is provided for your protection.

Please read each caution and warning carefully.

.

FCC Warning

Trademarks

iv

This equipment is intended for use in a laboratory test environment only. It

generates, uses, and can radiate radio frequency energy and has not been

tested for compliance with the limits of computing devices pursuant to subpart

J of part 15 of FCC rules, which are designed to provide reasonable protection

against radio frequency interference. Operation of this equipment in other

environments may cause interference with radio communications, in which

case, users, at their own expense, will be required to take whatever measures

may be required to correct this interference.

TI-OPC is a trademark of Texas Instruments.

Trademarks are the property of their respective owners.

Page 7

Contents

Contents

1 Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 GTLP EVM Overview 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 GTLP EVM Kit Contents 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 GTLP EVM Kit Availability 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 GTLP EVM Board Typical Test and Setup Configuration 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 GTLP EVM Case 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Top Tray 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Backplane Board 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Connectors 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Power Supply 2-1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Clock Crystals 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Termination Cards 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Bottom Compartment 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 Measurement Equipment 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 Clock Cards 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 Driver Cards 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 1.1 Single-Bit Selection 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.2 Edge-Rate Control 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 1.3 Source-Synchronous Clock/System-Clock Selection 2-25. . . . . . . . . . . . . . . . . . . .

2.12 Receiver Cards 2-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13 Backplane Setup 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13.1 Insertion of Clock Cards 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13.2 Insertion of Clock Crystals 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13.3 Insertion of Termination Cards 2-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13.4 Insertion of Driver and Receiver Cards 2-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Oscilloscope Operation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Oscilloscope Setup 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Measurements 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vContents

Page 8

Contents

4 Waveform Measurement and Interpretation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and

Driver Card (D1) Latch Clock (Ch2) 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and

Driver Card (D1) Group 1 GTLP Data Out (Ch2) 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and

Receiver Card (R2) Group 1 GTLP Data In (Ch2) 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and

Receiver Card (R2) Group 1 LVTTL Data Out (Ch2) 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Timing Relationship of Receiver Card (R2) Group 1 GTLP Data In (Ch1) and

Receiver Card (R20) Group 1 GTLP Data In (Ch2) 4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Monitored Waveforms 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Troubleshooting 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Spare Parts 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Replacing 5-A Fuse F2 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Replacing 2.5-A Fuse F1 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Damage to the Daughter Cards 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Bill of Materials, Schematics, Board Layouts, and Suggested Specifications A-1. . . . . . . . .

A.1 GTLP EVM Bill of Materials A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Board Layouts and Schematics A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Page 9

Figures

Figures

2–1 GTLP EVM Case 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2 GTLP EVM Top Tray 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3 GTLP EVM Backplane Board 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–4 GTLP EVM Backplane Block Diagram 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–5 AMP Z-PACK 2-mm, 110-Pin, Hard-Metric (HM) Male Connector 2-8. . . . . . . . . . . . . . . . . .

2–6 AMP Pin Lengths 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–7 AMP Single-Line-Model Data Sheet 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–8 Power Supply (Left) and Backplane Connection (Right) 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . .

2–9 1.5-V V

2–10 Power-Supply LED Indicators 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–11 Clock Crystal on Card (Left) and Stored in Tube (Right) 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . .

2–12 Clock Crystal With Leads in Position for Storage 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–13 Termination Card Location (Left) and Close-Up View (Right) 2-15. . . . . . . . . . . . . . . . . . . . . . .

2–14 Termination-Card Storage 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–15 Oscilloscope and Backplane Daughter-Card Storage Area 2-17. . . . . . . . . . . . . . . . . . . . . . . .

2–16 Tektronix THS730A O-Scope 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–17 GTLP EVM Clock Card 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–18 GTLP EVM Driver Daughter Card 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–19 Bit Selection for Normal Data Pattern (Left), Signal Held Low (Center), or

Signal Held High (Right) 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–20 ERC Bit-Selection Jumper Set for Slow (Left) or Fast (Right) Rate 2-24. . . . . . . . . . . . . . . . . .

2–21 JB2 Set to Source-Synchronous Clock (Left) or System-Clock (Right) Operation 2-25. . . . .

2–22 GTLP EVM Monitored Receiver Card 2-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–23 AMP Z-PACK, 2-mm, 55-Pin, HM Male (Left) and

Female (Right) Clock-Card Connectors 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–24 Connector Premate (Left), Mating (Center), and Mated (Right) 2-30. . . . . . . . . . . . . . . . . . . . .

2–25 Clock Card Properly (Left) and Improperly (Right) Inserted 2-30. . . . . . . . . . . . . . . . . . . . . . . .

2–26 Clock Crystal Removal (Left) and Insertion (Right) 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–27 Termination-Card Keying 2-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–28 Slot 1 (Left) and Slot 20 (Right) Termination Cards on the Backplane 2-32. . . . . . . . . . . . . . .

2–29 Driver and Receiver Connector Keying 2-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–30 Close-up View of Connector Keying 2-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–31 Proper Connector Mating Sequence (Left to Right) 2-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–32 Connectors Properly Mated 2-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linear Regulator 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TT

viiContents

Page 10

Figures

3–1 Tektronix O-Scope Front (Left) and Top (Right) 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2 O-Scope Probe Monitor-Point Adapters 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3 Simple Test-Measurement 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4 Turn on O-Scope (Left) and Select Channel (Right) 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–5 O-Scope Display 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–6 Timing Adjustment 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–7 Voltage Adjustment 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–8 Trigger Adjustment 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–1 Case 1: D1 Data Pattern (Ch1) and D1 Latch Clock (Ch2) 4-2. . . . . . . . . . . . . . . . . . . . . . . . . .

4–2 Case 2: D1 Data Pattern (Ch1) and D1 Group 1 GTLP Data Out (Ch2) 4-3. . . . . . . . . . . . . . .

4–3 Case 3: D1 Data Pattern (Ch1) and R2 Group 1 GTLP Data In (Ch2) 4-4. . . . . . . . . . . . . . . .

4–4 Case 4: D1 Data Pattern (Ch1) and R2 Group 1 LVTTL Data Out (Ch2) 4-5. . . . . . . . . . . . . .

4–5 Case 5: R2 Group 1 GTLP Data In (Ch1) and R20 Group 1 GTLP Data In (Ch2) 4-6. . . . . .

4–6 GTLP Backplane Waveforms at 23-MHz Clock Frequency 4-7. . . . . . . . . . . . . . . . . . . . . . . . . .

4–7 GTLP Monitor Test-Point Waveforms at 23-MHz Clock Frequency 4-7. . . . . . . . . . . . . . . . . . .

5–1 Spare Fuses and Jumpers 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–2 Fuse F2 (Left) and Removal Procedure (Right) 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–3 Fuse F1 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–1 Backplane Layout, Front Side A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–2 Backplane Layout, Back Side A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–3 Driver-Card and Receiver-Card Connector Pinout A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–4 Backplane Schematic A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–5 Driver-Card Layout A-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–6 Driver-Card Schematic A-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–7 Unmonitored-Receiver Card Layout A-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–8 Monitored-Receiver Card Layout A-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–9 Receiver-Card Schematic A-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–10 Clock-Card Layout A-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–11 Clock-Card Schematic A-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–12 Resistor-Termination-Card Layout A-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–13 Standard-Termination-Card Schematic A-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

Page 11

Tables

Tables

2–1 GTLP EVM Group Assignment 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–2 GTLP EVM Backplane Eight-Layer Stackup 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–3 GTLP EVM Group 1, Bits 1 Through 8 Trace Impedance 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . .

2–4 Termination-Card Stackup 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–5 Clock-Card Stackup 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–6 Driver-Card Stackup 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–7 Receiver-Card Stackup 2-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ixContents

Page 12

Tables

x

Page 13

Chapter 1

Introduction

The Texas Instruments (TI) GTLP evaluation module (EVM) board is used to

evaluate the SN74GTLPH1655 in multipoint data-transmission applications in

a heavily loaded backplane.

The GTLP EVM is a 17.9-in., 20-slot, 0.94-in.-pitch, 8-layer PC backplane

board that provides a total of 48 parallel data lines divided into 6 groups of 8

bits staggered into various lengths. The EVM also includes a 1-bit clock along

the length of the backplane showing source-synchronous transfer mode. This

board allows the designer to connect 50-Ω unloaded parallel buses to the

transmitter and receiver connectors in a backplane configuration.

New-design backplane-driver selection criteria are based on drive capability ,

live-insertion capability, data throughput, noise margin, backward

compatibility, and bus configuration. The purpose of the GTLP EVM is to

demonstrate the performance of the TI GTLP product portfolio in a

best-in-class high-performance backplane. The backplane enables users to

observe the effects of different kinds of terminations, changing load conditions

due to different spacing and count of daughter cards, and various frequencies,

as well as the benefit of source-synchronous clock over system-synchronous

clock operations. The backplane also can be used to observe the advantages

of edge-rate control and TI-OPC overshoot-protection circuitry, and show

the performance of TI GTLP devices vs alternate-source devices under

different loading conditions.

Topic Page

1.1 GTLP EVM Overview 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 GTLP EVM Kit Contents 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 GTLP EVM Kit Availability 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

Page 14

GTLP EVM Overview

1.1 GTLP EVM Overview

The EVM can be used to evaluate device parameters, while acting as a guide

for high-speed board layout. Because GTLP operates over a wide range of

frequencies, designers must optimize their designs for the frequency of

interest. Additionally , designers can use buried transmission lines and provide

additional noise attenuation and EMI suppression to optimize their

end product.

The board layout is designed and optimized to support high-speed operation

up to 100 MHz. Thus, understanding impedance control and transmission-line

effects are crucial when designing high-speed boards.

Some of the advanced features offered by this board include:

-

The backplane printed circuit board (PCB) is designed for high-speed

signal integrity, while the daughter card is designed with integral

measurement points for easily measuring signal integrity.

-

Subminiature A connectors (SMA) as specified by MIL-C-39012 coaxial

connector specification and parallel fixtures easily are connected to test

equipment.

-

The first bit of each group of input/output signals is accessible for rapid

prototyping.

1-2

Page 15

1.2 GTLP EVM Kit Contents

This EVM kit comprises the following major parts, components of which are

listed in Appendix A.1, GTLP EVM Bill of Materials:

-

GTLP EVM kit documentation (this document, SCEA023)

-

Backplane

-

Clock driver card

-

Termination card

-

Monitored receiver card

-

Monitored driver card

-

Unmonitored receiver card

GTLP EVM Kit Contents

1-3Introduction

Page 16

GTLP EVM Kit Availability

1.3 GTLP EVM Kit Availability

The GTLP EVM kit is not available for resale, but can be obtained and used

for short periods of time by contacting the GTLP team at GTLP@list.ti.com.

There are six locations worldwide where GTLP EVMs can be obtained:

Europe, China, Korea, Japan, and the Americas (2).

1-4

Page 17

Chapter 2

GTLP EVM Board

Typical Test and Setup Configuration

This chapter describes the GTLP EVM setup and the configurations used to

evaluate the SN74GTLPH1655 transceiver . These configurations can be used

to evaluate different transceivers that will be available in the future.

Topic Page

2.1 GTLP EVM Case 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Top Tray 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Backplane Board 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Connectors 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Power Supply 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Clock Crystals 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Termination Cards 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Bottom Compartment 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 Measurement Equipment 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 Clock Cards 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 Driver Cards 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12 Receiver Cards 2-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13 Backplane Setup 2-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

Page 18

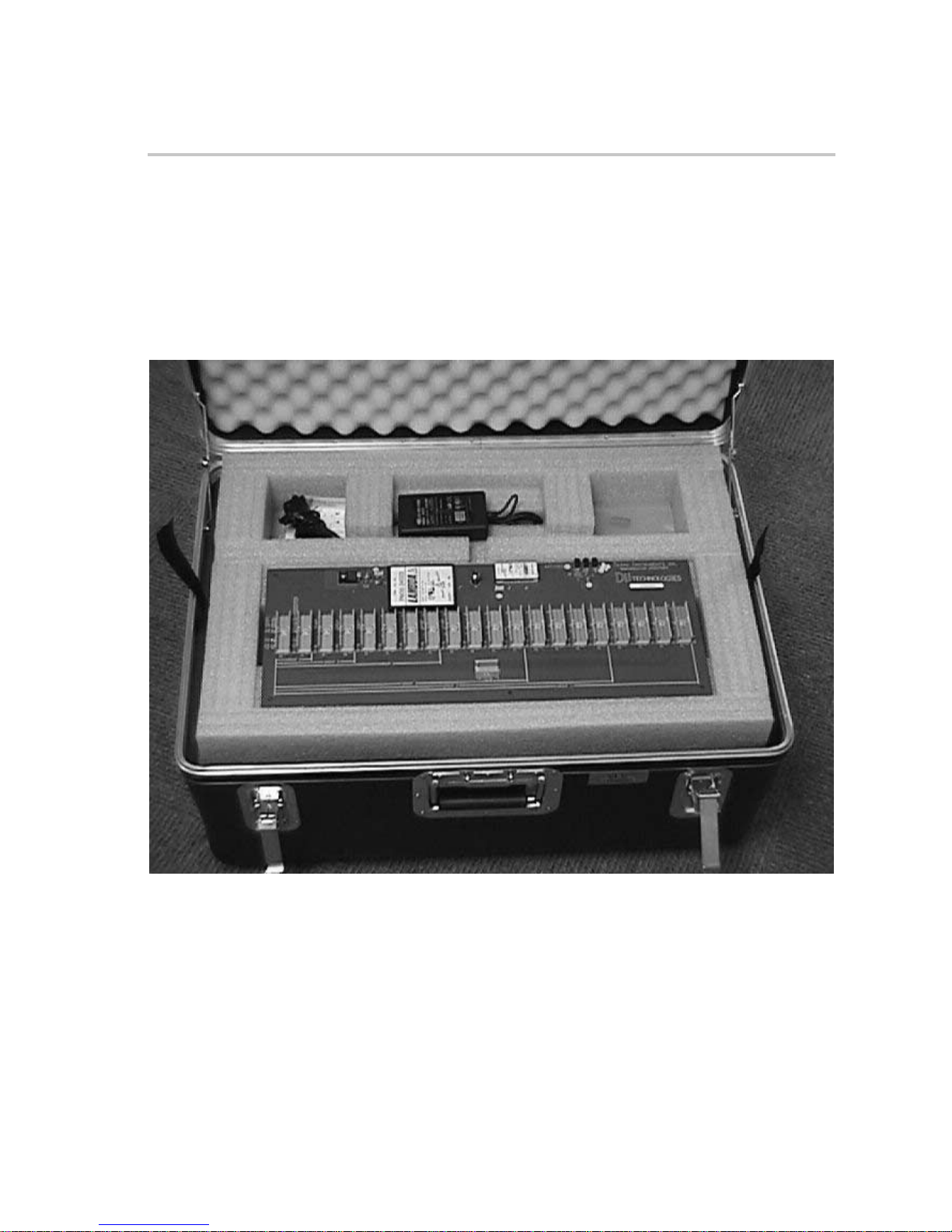

GTLP EVM Case

2.1 GTLP EVM Case

The EVM is stored and transported in a sturdy plastic case with rollers and

extensible handle (see Figure 2–1). The handle locks in position and can be

extended or retracted by pressing the release on the underside of the handle.

Figure 2–1. GTLP EVM Case

The case is suitable for air transportation and has the combination lock set at

394. To lock the case, rotate one or more of the dials from the opening

combination.

2-2

Page 19

2.2 Top Tray

The top tray fits snuggly in the GTLP EVM case (see Figure 2–2) and holds

the backplane board, power supply , extra clock crystals, and extra termination

cards in place. The tray is electrostatic protective foam that holds the

backplane board during demonstrations.

Figure 2–2. GTLP EVM Top Tray

Top Tray

2-3 GTLP EVM Board Typical Test and Setup Configuration

Page 20

Backplane Board

2.3 Backplane Board

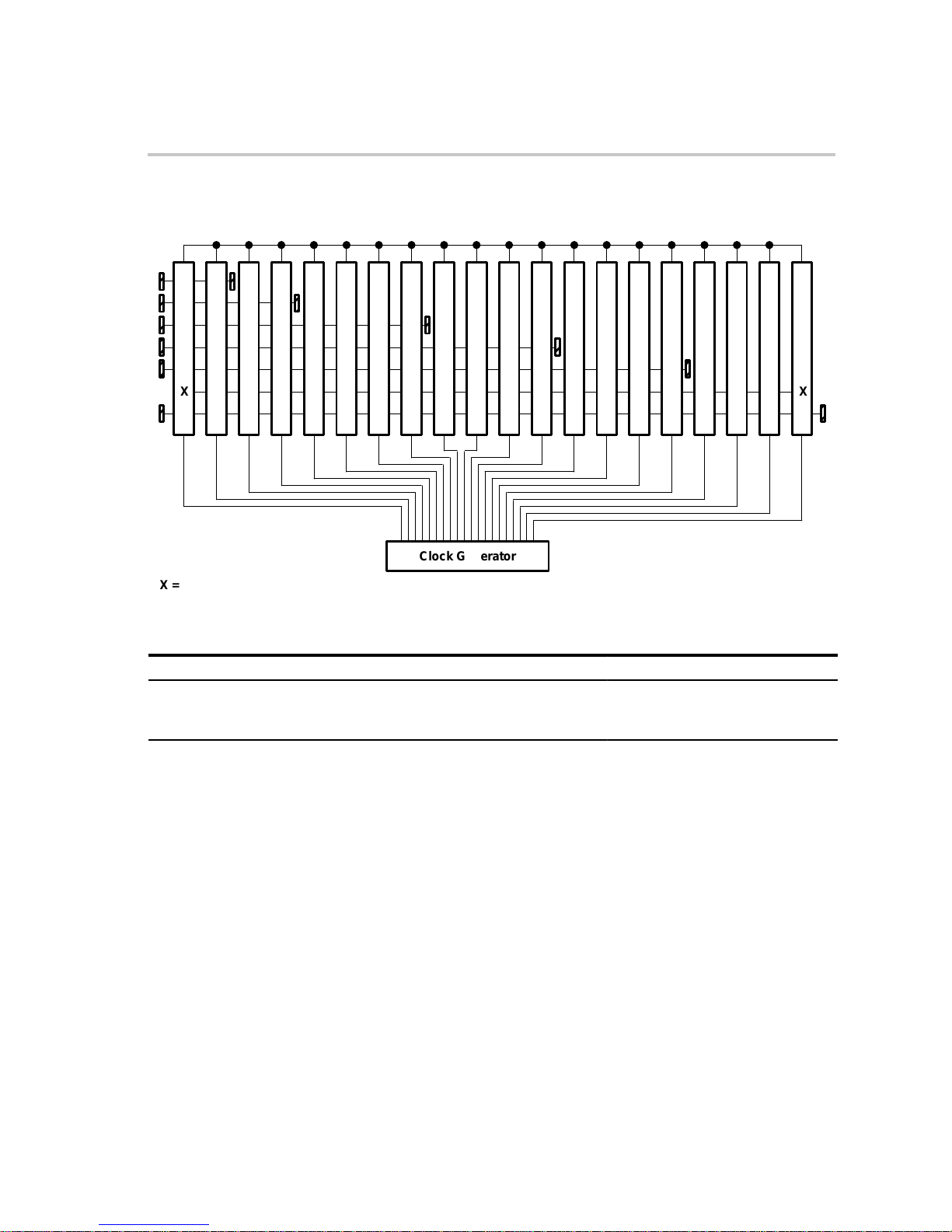

The backplane board (see Figure 2–3) is typical of backplanes used in

commercial applications, and consists of 20 slots with 0.94-in. pitch and

48 data bits, and 1 clock bit on stripline transmission lines.

Figure 2–3. GTLP EVM Backplane Board

This backplane board is constructed uniquely of six groups of eight data bits

each to study the effect of different backplane lengths and driver/receiver

placements. Group 1 consists of all 20 slots, but subsequent groups move to

the left (see Figure 2–4) and have a reduced number of slots, as listed in

Table 2–1.

2-4

Page 21

Backplane Board

Figure 2–4. GTLP EVM Backplane Block Diagram

Backplane Overview

Slot 1

Slot 2

Slot 3

Slot 4

Slot 5

Slot 6

Slot 7

Slot 8

Slot 9

X X

Clock Generator

X = Termination Card on Back of Connector

Slot 10

Slot 11

Slot 12

Slot 13

Slot 14

Slot 15

Slot 16

Slot 17

Slot 18

Slot 19

Slot 20

Table 2–1. GTLP EVM Group Assignment

Group 6 Group 5 Group 4 Group 3 Group 2 Group 1

2 slots 4 slots 8 slots 12 slots 16 slots 20 slots

P1-1 to P1-2 P1-1 to P1-4 P1-1 to P1-8 P1-1 to P1-12 P1-1 to P1-16 P1-1 to P1-20

A single GTLP clock line that runs from P1-1 to P1-20 is used in the

source-synchronous transfer mode.

The GTLP clock and the data lines from groups 2 through 6 have fixed,

on-board, 25-Ω termination resistors. Group 1 data lines terminate on plug-in

cards on the back of the backplane board at P1-1B and P1-20B. This provides

a way to vary the termination resistance or demonstrate other termination

techniques.

The design also uses a system clock that is generated on the clock-driver

board plugged into P3. This system clock is distributed to all 20 slots

simultaneously and is used as the system master timing in the system-clock

mode. Using a separate card for clock generation and distribution is not an

industry standard, but it provides flexibility in using this demonstration board.

2-5 GTLP EVM Board Typical Test and Setup Configuration

Page 22

Backplane Board

A logic selection line (MODESEL) connects P1-1 through P1-20. The driver

card uses this line to select between source-synchronous and system-clock

operation. The demonstration board is an eight-layer board with separate V

and ground planes. The backplane board stackup is shown in Table 2–2.

Embedded microstrip nominal line width is 0.006 in., dielectric material is

Nelco N4000-13 with a dielectric constant (50% resin contents) of

3.80 @ 100 MHz.

Table 2–2. GTLP EVM Backplane Eight-Layer Stackup

CC

Trace Name Use Layer

Top Regulator power/

bypass capacitor/

termination

Internal signal 2 Clock distribution/

signal

Ground plane Ground plane 3 1

Internal signal 3 Data signal 4 1

Internal signal 4 Data signal 5 1

V

CC

V

CC

1 0.5

2 1

6 1

Copper

Weight

(oz)

Physical

Representation

Dielectric

Height

(in.)

0.004 B stage

0.004 Core

0.004 B stage

0.058 Core

0.004 B stage

0.004 Core

Dielectric

Name

Internal signal 5 Data signal 7 1

Bottom Termination 8 0.5

2-6

0.004 B stage

Page 23

Backplane Board

Targeted, nominal, unloaded line impedance was 50 Ω, but, based on

post-manufacturing testing, was not consistent. Results for Group 1, bits 1

through 8 are shown in T able 2–3. The backplane natural trace impedance (Z

is calculated and is a best estimate. The backplane trace impedance with only

the connector pins attached (i.e., all cards removed) (Z

′) and the backplane

o

trace impedance in a fully loaded backplane (i.e., 20 cards inserted) (Z

measured.

Table 2–3. GTLP EVM Group 1, Bits 1 Through 8 Trace Impedance

Group 1 Trace D1 D2 D3 D4 D5 D6 D7 D8

Natural Trace Impedance

Zo (Ω) 91 47.5 47 47 48 47.5 83 47.5

tpd (ps/in.) 165 140 138 139 141 148 147 142

C

(pF/in.) 1.81 2.95 2.94 2.96 2.94 3.12 1.77 2.99

o

Trace Impedance With Only Connectors

Zo′ (Ω) 62.7 37.5 37 36.3 37.1 37.9 58.5 36.8

′′) are

o

)

o

tpd′ (ps/in.) 240 177 175 180 183 185 208 183

Trace Impedance Under Full Load

Zo′′ (Ω) 26.6 17.7 17.9 17.5 17.9 18 24.8 17.7

tpd′′ (ps/in.) 564 377 362 373 377 390 493 382

Note the difference in fully loaded trace impedance between trace bit 1 and

bit 7 (D1 and D7) and the other traces. Using the lower natural trace

impedance offers the advantage of a smaller t

and shorter flight time, but at

pd

the expense of terminating with a lower-value termination resistor and the

subsequent increase in power consumption. TI offers both medium-drive

(50 mA) and high-drive (100 mA) GTLP devices that allow designers to match

the device with backplane loading. The termination resistor (R

) should

TT

match the fully loaded trace impedance (i.e., Zo′′) of the backplane for optimal

signal integrity.

2-7 GTLP EVM Board Typical Test and Setup Configuration

Page 24

Connectors

2.4 Connectors

An AMP Z-P ACK 2-mm, 110-pin, hard-metric (HM) male connector is used

in slots 1 through 20 (see Figure 2–5) .

Figure 2–5. AMP Z-PACK 2-mm, 110-Pin, Hard-Metric (HM) Male Connector

Five pins are used on the backplane, with three different lengths on the

backplane daughter-card side. Pins A, B, and C are used for data/VCC,

BIAS V

, and GND, respectively. C-length pins are in the center, and

CC

A-length pins are in two rows on either side. The daughter-card connectors

P1-1 through P1-20 use these three levels of pin height for power sequencing.

The ground pins make contact first, followed by a pin for BIAS V

other connections are made. There is only one B-length pin because BIAS V

, then all

CC

CC

can be distributed to all four GTLP devices on the board. The pin lengths of

pins K and T are identical to those of pins A and C on the card side, but they

protrude through the backplane board, providing connection to the termination

cards that are on the reverse side.

Initial testing revealed that this pin configuration was unacceptable for actual

operation because the BIAS V

circuitry was disabled before all I/O pins were

CC

connected. Any tilt on the card caused VCC to be connected first. Some slots

in selected EVMs have been modified, so that BIAS V

and GND are

CC

C length, data signal is B length, and VCC is A length, to allow proper operation

of the BIAS V

precharge circuitry.

CC

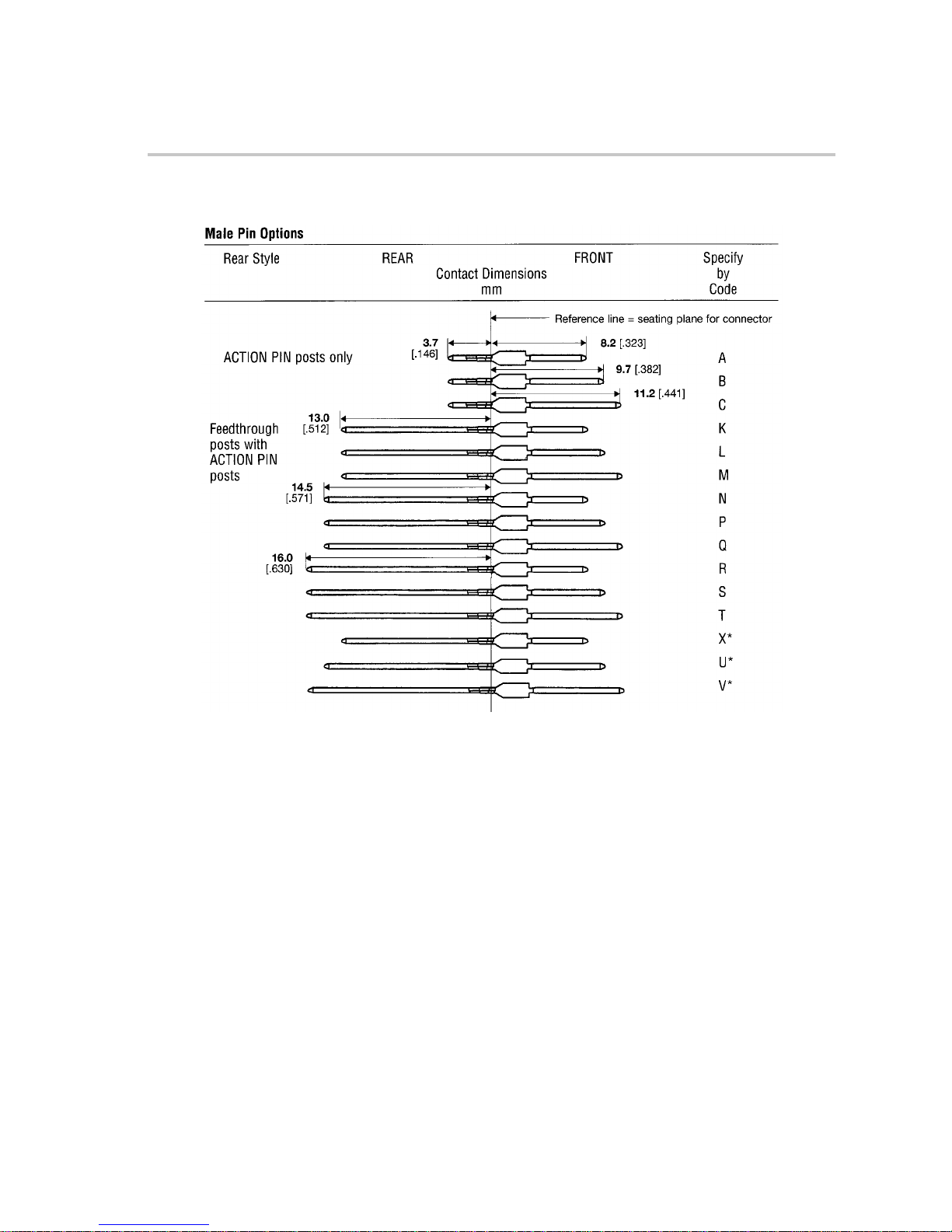

Various AMP pin lengths, including pins A, B, C, K, and T, are shown in

Figure 2–6, and the single-line-model data sheet is shown in Figure 2–7.

2-8

Page 25

Figure 2–6. AMP Pin Lengths

Connectors

* X, U, V are used only for cross-connect applications. Not all versions are tooled.

2-9 GTLP EVM Board Typical Test and Setup Configuration

Page 26

Connectors

Figure 2–7. AMP Single-Line-Model Data Sheet

2-10

Page 27

2.5 Power Supply

The power supply (see Figure 2–8) is a universal power supply that accepts

100 V to 240 V , 50/60-Hz ac and uses any wall plug that connects to the IEC

320 two-connector universal socket with the US/Canada Edison plug. An

alternate supply cord with a different wall plug must be procured locally, if

required.

The power-supply output is 24-Vdc at 2.1 A, which is fed to the backplane

board using the 5.5-mm plug to J5 (see Figure 2–8), and connects through a

2.5-A slow-blow fuse (F1). Power should not be applied to the backplane board

until the cards have been inserted during the initial setup because the clock

card is not hot insertable. The termination, daughter cards, and clock crystals

are live insertable and can be inserted and removed to change position/values

during testing without disconnecting the power supply.

Figure 2–8. Power Supply (Left) and Backplane Connection (Right)

Power Supply

The 24-Vdc is reduced to 5 V, 1 A by the Lambda PM10-24S05 switching

regulator (Figure 2–8 background) and to 3.3 V, 7.5 A by the Lambda

PM30-24503 switching regulator (Figure 2–8 foreground) for V

and the linear regulator. The 3.3 V is supplied to all connectors through a 5-A

fuse (F2). The 5 V also is applied to all connectors. Originally , F2 was specified

as a 3.5-A fuse, but, at 100-MHz operation, current exceeds this value, so 5-A

fuses are necessary.

, BIAS VCC,

CC

2-11 GTLP EVM Board Typical Test and Setup Configuration

Page 28

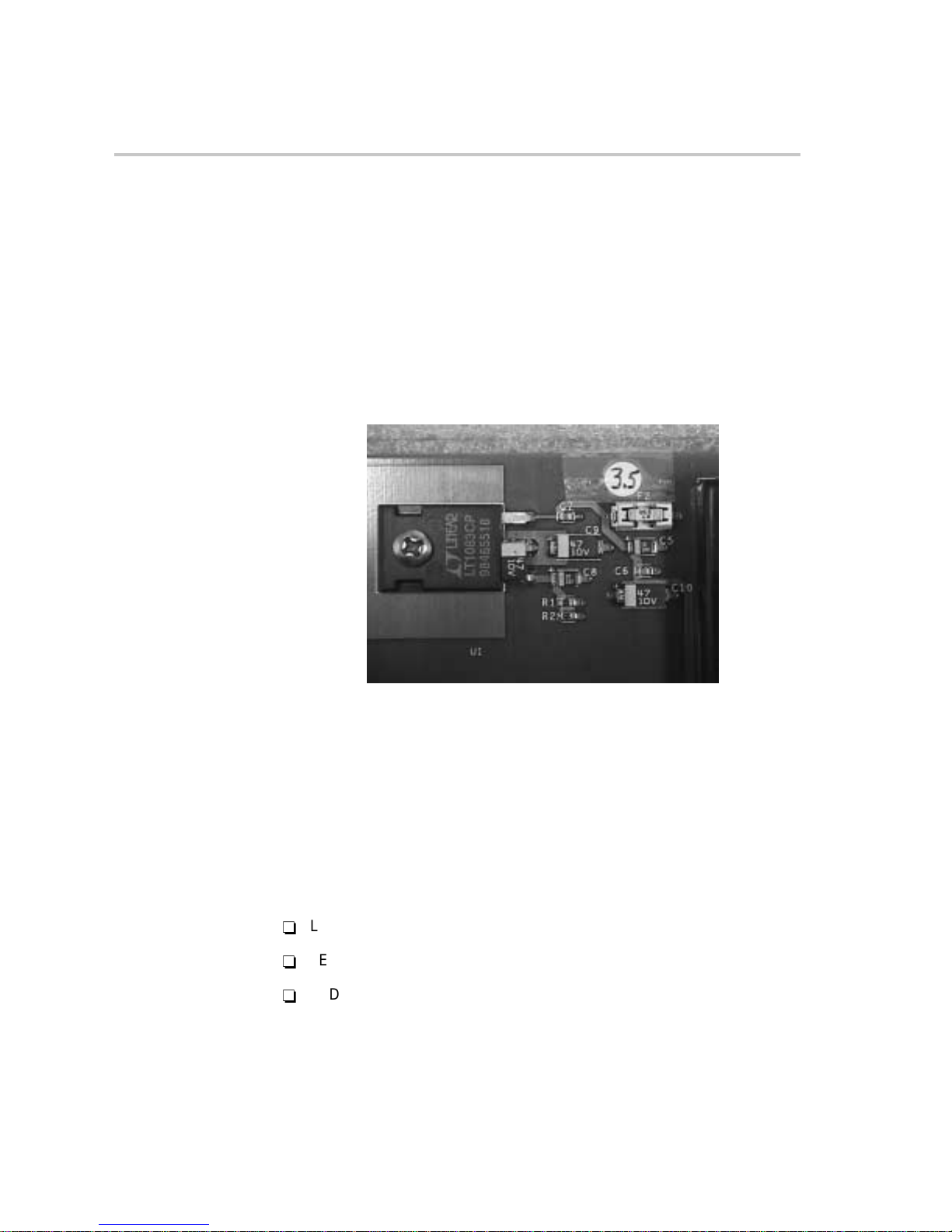

Power Supply

The 3.3 V is further reduced to 1.5 V , 7.5 A by the LT1083CP linear regulator

(see Figure 2–9) for the termination voltage (VTT). VTT is set by the

combination of R1 and R2 and can be varied in the factory between 0.8 V to

1.8 V, but is set at 1.0 V for field use at GTLP levels. The 5-V power supply is

required for driver cards that use both 5-V and 3.3-V V

SN74GTLPH16612. There is an option to change the 5-V power supply to

2.5 V for future devices at that voltage node. This is accomplished by removing

JP1 (near the dc converter) and installing an LM317M regulator (U2), R5, and

R6. The two resistors set the output voltage of the regulator.

Figure 2–9. 1.5-V VTT Linear Regulator

, such as the

CC

Unitrode offers two devices (UC382 and UC385) that can be used in place of

the LT1083CP. They offer low dropout at a given current (500-mV dropout

maximum at 5 A), the ability to handle transients with tight regulation,

high-current capability, fast transient response, separate bias and V

pins,

in

and 5-pin TO220 and TO263 packages with Kelvin sensing. UC382 provides

3-A capacity and UC385 provides 5-A capacity with fixed (1.5 V, 2.1 V, or

2.5 V) or adjustable-output-voltage capability.

Power-supply operation indication is provided by three LEDs (see

Figure 2–10) on the upper edge of the backplane opposite slot 16:

-

LED 1 – 24-V green LED shows there is power coming to the board.

-

LED 2 – 5-V green LED shows the 5-V power supply is operational.

-

LED 3 – 3.3-V red LED shows the 3.3-V power supply is supplying power

to the devices, BIAS VCC, and linear regulator.

2-12

Page 29

Figure 2–10. Power-Supply LED Indicators

Power Supply

2-13 GTLP EVM Board Typical Test and Setup Configuration

Page 30

Clock Crystals

2.6 Clock Crystals

Clock frequency is controlled by the clock-driver card and is limited by

clock-control components to 100 MHz. The GTLP receiver device is used in

a latched mode of operation, so GTLP data frequency is equal to one-half the

clock frequency . Clock crystals and spares, in frequencies of 66 MHz, 75 MHz,

87 MHz, and 100 MHz, are included with the kit. One crystal can be installed

on each clock card, with the others stored in the clock-crystal tube (see

Figure 2–11).

Figure 2–11.Clock Crystal on Card (Left) and Stored in Tube (Right)

If you plan to store the clock-driver card with the crystal installed, insert the

crystal far enough so that the leads barely protrude on the opposite side (see

Figure 2–12). This prevents bending the leads if they catch on the foam when

the card is placed in the case.

Figure 2–12. Clock Crystal With Leads in Position for Storage

2-14

Page 31

2.7 Termination Cards

Because proper backplane termination has a large effect on signal integrity

and is investigated easily, Group 1 has removable termination cards on the

back of the backplane (see Figure 2–13). The termination cards are identical,

except for the resistor values that are 25 Ω, 33 Ω, 38 Ω, or 50 Ω. One bypass

capacitor is mounted with every other termination resistor to limit voltage

fluctuations. The termination cards provide a method of varying the

termination resistance to only Group 1 data lines. These termination resistors

connect to the V

Figure 2–13. Termination Card Location (Left) and Close-Up View (Right)

supply (1.5 V because GTLP levels are used).

TT

Match Dots

Termination Cards

Connector Key.

Can be reversed, so

ensure that dots are

on the same side.

The termination cards have a four-layer stackup. The stackup is signal layer,

VCC plane, ground plane, and signal layer (see Table 2–4).

2-15 GTLP EVM Board Typical Test and Setup Configuration

Page 32

Termination Cards

Table 2–4. Termination-Card Stackup

Trace Name Use Layer

Top Data signal 1 0.5

V

plane VCC plane 2 1

CC

Ground plane Ground plane 3 1

Bottom

Data signal 4 0.5

Groups 2 through 6 have 25-Ω fixed termination resistors due to space

limitations, and have one bypass capacitor for every four termination resistors.

The 25-Ω termination is optimized for estimated 25-Ω loaded-line impedance.

The termination cards can remain installed on the backplane board or be

removed during storage and transit. Both termination cards can be stored in

the same slot in the tray (see Figure 2–14) or stored separately. If stored

together, the resistor/capacitor sides must face each other.

Figure 2–14. Termination-Card Storage

Copper

Weight (oz)

Physical

Representation

Dielectric

Height (in.)

0.004 B stage

0.004 Core

0.004 B stage

Dielectric

Name

2-16

Page 33

2.8 Bottom Compartment

The portable oscilloscope and backplane daughter cards are stored under the

top tray of the GTLP EVM case (see Figure 2–15).

Figure 2–15. Oscilloscope and Backplane Daughter-Card Storage Area

Clock

Cards

Bottom Compartment

Monitored

Receiver

Cards

Oscilloscope

Storage

Driver

Cards

Unmonitored

Receiver

Cards

Empty

Slots

There are 2 clock cards, 19 unmonitored receiver cards, 3 monitored receiver

cards, and 2 driver cards in every GTLP EVM kit. Store the cards as shown

in Figure 2–15, with the 2 clock cards (top left) followed by 10 unmonitored

receiver cards, 3 monitored receiver cards (middle left) followed by

9 unmonitored receiver cards, 2 driver cards (bottom left) followed by

10 empty slots.

2-17 GTLP EVM Board Typical Test and Setup Configuration

Page 34

Measurement Equipment

2.9 Measurement Equipment

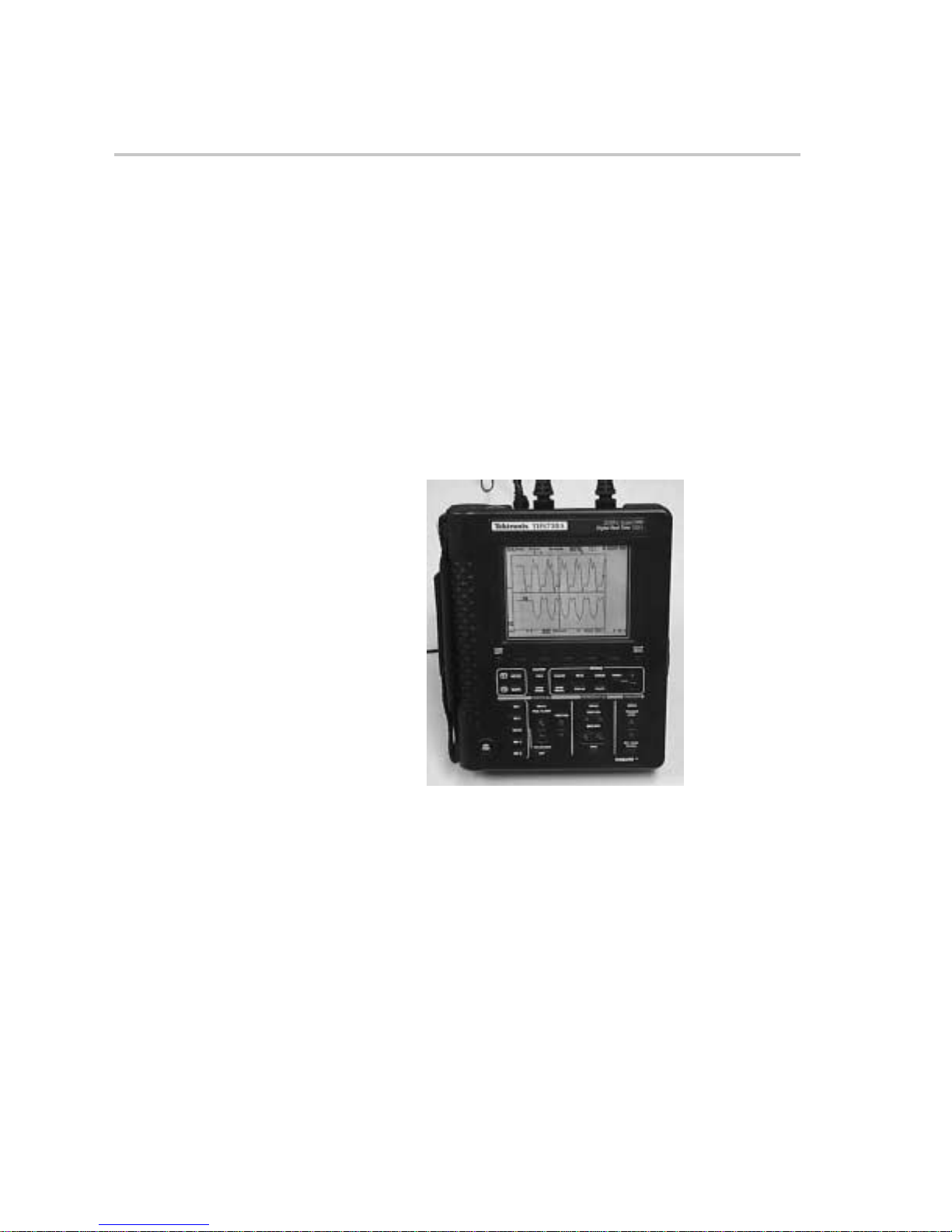

The T ektronix THS730A Oscilloscope/DMM (O-Scope) (see Figure 2–16) can

be stored in the bottom of the case (see Figure 2–15). It is easy to operate and

is portable. The O-Scope can monitor two channels simultaneously . Store the

O-Scope face down to prevent damage to the buttons during transit. The

probes can be stored on top of the O-Scope, as shown, or alongside,

depending on the amount of space in either location. The O-Scope is not

included with the loaned EVM kits. Chapter 3, Oscilloscope Operation,

discusses O-Scope setup and operation and is included to provide assistance

to TI product marketing engineers and technical sales representatives when

demonstrating the GTLP EVM to customers in the field.

Figure 2–16. Tektronix THS730A O-Scope

2-18

Page 35

2.10 Clock Cards

Two clock cards (see Figure 2–17) are included with the EVM, one primary and

one spare. The clock cards generate the clock signal that is sent to every slot

via mitered lines, so that the clock arrives at exactly the same time at each

card. The clock card uses a plug-in half-can oscillator for a reference to two

CDC2586 phase-locked-loop clock drivers. These two drivers provide the

20 system clocks used on the backplane. The CDC2586 supports a maximum

frequency of 100 MHz. The clock card has one subminiature B connector

(SMB) as specified by MIL-C-39012 coaxial connector specification test point

to monitor the oscillator output.

Figure 2–17. GTLP EVM Clock Card

Clock Cards

The clock-card board is a four-layer printed circuit board (PCB). The stackup

is signal layer, VCC plane, ground plane, and signal layer (see Table 2–5).

2-19 GTLP EVM Board Typical Test and Setup Configuration

Page 36

Clock Cards

Table 2–5. Clock-Card Stackup

Copper

Trace Name Use Layer

Top Data signal 1 0.5

V

plane VCC plane 2 1

CC

Ground plane Ground plane 3 1

Bottom

Data signal 4 0.5

Weight (oz)

Physical

Representation

Dielectric

Height (in.)

0.004 B stage

0.004 Core

0.004 B stage

Dielectric

Name

2-20

Page 37

2.11 Driver Cards

Separate driver and receiver daughter cards were manufactured for use on the

backplane because, even though the bidirectional SN74GTLPH1655 device

is used, each type of card is hardwired to operate in a certain direction. The

driver card generates a data pattern from the system clock and drives the

GTLP lines on the backplane. The GTLP devices are hardwired for clocked

storage in the A-to-B direction. Data is transmitted on the rising edge of the

system clock. The driver card is a six-layer PCB with two signal layers, a

plane, a ground plane, then two signal layers. Stackup is shown in

V

CC

Table 2–6.

Table 2–6. Driver-Card Stackup

Driver Cards

Copper

Trace Name Use Layer

Top Data signal 1 0.5

Internal signal 2 Data signal 2 1

V

plane VCC plane 3 1

CC

Ground plane Ground plane 4 1

Internal signal 3 Data signal 5 1

Bottom

Data signal 6 1

Weight (oz)

Physical

Representation

Dielectric

Height (in.)

0.004 B stage

0.004 Core

0.004 B stage

0.004 Core

0.004 B stage

Dielectric

Name

2-21 GTLP EVM Board Typical Test and Setup Configuration

Page 38

Driver Cards

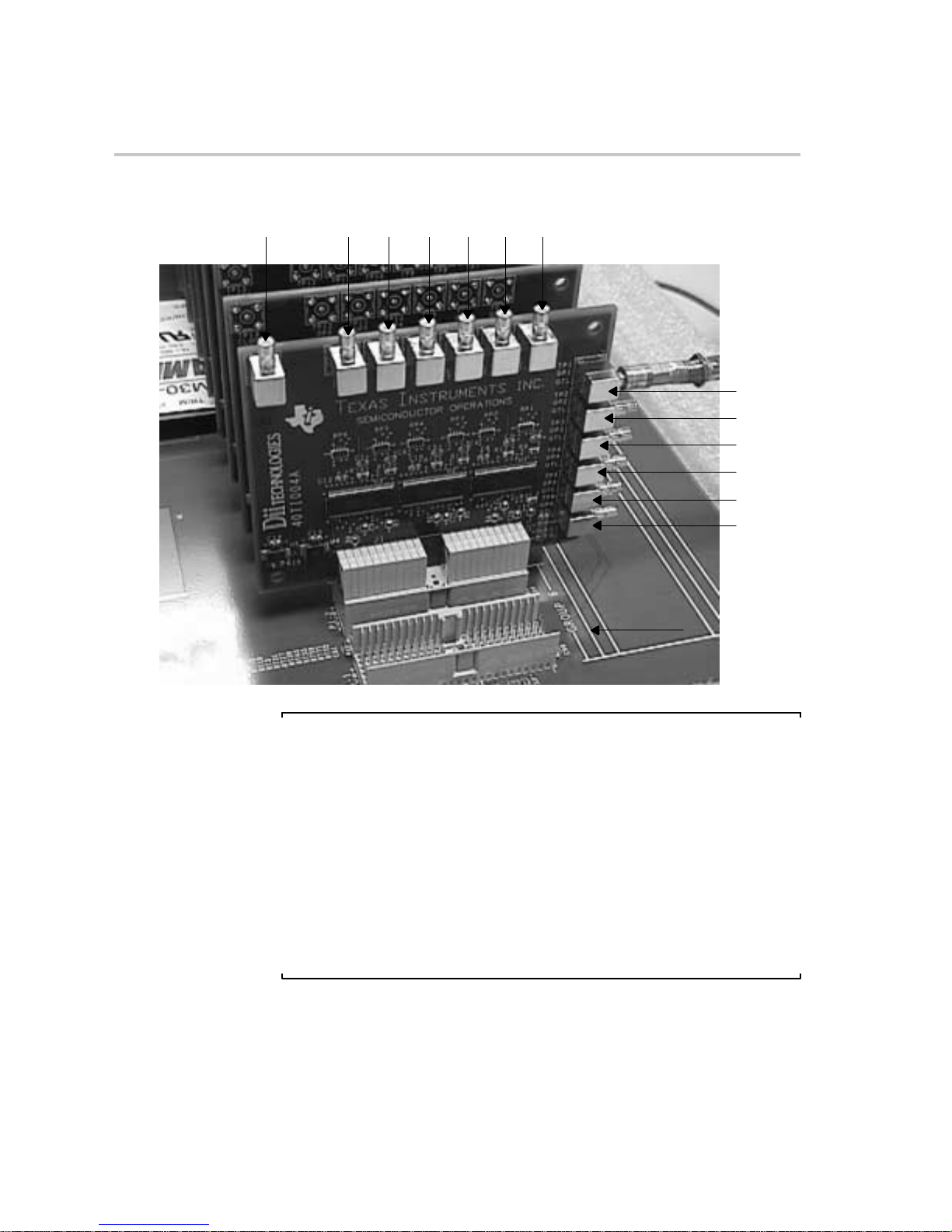

The driver daughter card (see Figure 2–18) has SMB monitor points for

selected LVTTL and GTLP signals, in addition to jumpers for Group 1, bit 1

switching (JB1), system or SN74GTLP1394 source-synchronous clock

selection (JB2), and selection of the SN74GTLPH1655 slow or fast edge rate

(JB3). The monitor points along the top edge are the latch clock and the master

data pattern sent to all SN74GTLPH1655 L VTTL A-port inputs. There are no

LVTTL group-bit monitor points because the card always is driven. Monitor

points along the right edge are GTLP Group 1, 2, 3, 4, 5, and 6. The following

signals are monitored:

-

TP1 GTLP level Group 1, bit 1

-

TP2 GTLP level Group 2, bit 1

-

TP3 GTLP level Group 3, bit 1

-

TP4 GTLP level Group 4, bit 1

-

TP5 GTLP level Group 5, bit 1

-

TP6 GTLP level Group 6, bit 1

-

TP7 LVTTL level Group 1, bit 1, and master data pattern

-

TP8 LVTTL level GTLP latch clock

Figure 2–18. GTLP EVM Driver Daughter Card

TP7

JB1

TP8

GTLPH1655

GTLP1394

JB2

2-22

JB2

TP1

TP2

TP3

TP4

TP5

TP6

Page 39

Driver Cards

r

2.11.1 Single-Bit Selection

JB1 three-position jumper is used to set Group 1, bit 1 to pass the normal data

pattern, set the signal low, or set the signal high (see Figure 2–19). The JB1

jumper is stored on the lowest pin (see Figure 2–19) when set high, to prevent

losing it. The following options are available:

-

JB1 1-2 shorted Group 1, bit 1 normal data pattern

-

JB1 2-3 shorted Group 1, bit 1 held low

-

JB1 open Group 1, bit 1 held high

Figure 2–19. Bit Selection for Normal Data Pattern (Left), Signal Held Low (Center), or

Signal Held High (Right)

JB1 Jumpe

2-23 GTLP EVM Board Typical Test and Setup Configuration

Page 40

Driver Cards

2.11.2 Edge-Rate Control

The device used as the backplane driver, SN74GTLPH1655, has a feature by

which the backplane slew rate is adjustable via an external edge-rate-control

(ERC) pin held at 3.3 V (slow) or GND (fast). The ERC is set by the JB3 jumper

located below the bit-selection jumper and has two positions: not connected

is slow, and shorted is fast (see Figure 2–20). The following ERC options are

available:

-

JB3 open Slow edge rate

-

JB3 shorted Fast edge rate

Figure 2–20. ERC Bit-Selection Jumper Set for Slow (Left) or Fast (Right) Rate

JB3 Jumper

2-24

Page 41

2.11.3 Source-Synchronous Clock/System-Clock Selection

Backplanes usually have a system-wide synchronous clock. A system clock

provides an absolute reference time signal from the clock card to every

daughter card at exactly the same time. Source-synchronous clock operation

is different because it allows the absolute system clock to be sent by the

backplane driver along with the data. In the EVM, this is implemented with the

SN74GTLP1394 transceiver on all daughter cards. This transceiver acts as

the driver on the driver cards and as the receiver on the receiver cards. The

SN74GTLP1394 has ERC that is set to the fast edge rate in conjunction with

the JB3 selection.

Source-synchronous clock operation provides a relative clock to all receiver

cards, which removes the flight-time delay restrictions required when an

absolute system clock is used. The flight-time delay depends primarily on bus

length and bus loading.

The driver card uses JB2 to select the transfer mode of operation and to drive

the MODESEL line. Source-synchronous clock operation is selected when the

JB2 jumper shorts the pins, and system-clock operation is selected when the

pins are open (see Figure 2–21). When JB2 is shorted, the SN74GTLP1394

drives the GTLP clock line with a phased system clock. When JB2 is open,

there is no activity on the GTLP clock line. The following options are available:

Driver Cards

-

JB2 shorted Source-synchronous clock transfer

-

JB2 open System-clock transfer

Figure 2–21. JB2 Set to Source-Synchronous Clock (Left) or System-Clock (Right)

Operation

2-25 GTLP EVM Board Typical Test and Setup Configuration

Page 42

Receiver Cards

2.12 Receiver Cards

Receiver cards place a load on the backplane and provide a point to monitor

the signals. There are two types of receiver cards: one that has built-in monitor

points, and one with no monitor points. Either type can be placed in any slot

in the backplane, typically with the monitored receiver card placed in the slots

under observation. There is a monitor point for only one bit per group. Only a

few receiver cards have monitor points because the capacitance added by the

monitor point affects backplane signal integrity . Minimal use of the monitored

receiver card is encouraged because of the increased loading this card

causes.

Receiver cards have GTLP devices hardwired for clocked storage in the

B-to-A direction. Data is latched on the rising edge of the GTLP latch clock. The

latch clock comes from the system clock when the MODESEL line is high, and

from the GTLP clock when the MODESEL line is low. The receiver card is a

six-layer PCB with two signal layers, a V

signal layers. The GTLP data and clock stub lines are approximately 1 in. in

length. Stackup is shown in Table 2–7.

Table 2–7. Receiver-Card Stackup

plane, a ground plane, then two

CC

Copper

Trace Name Use Layer

Top Data signal 1 0.5

Internal signal 2 Data signal 2 1

V

plane VCC plane 3 1

CC

Ground plane Ground plane 4 1

Internal signal 3 Data signal 5 1

Bottom

Data signal 6 1

Weight (oz)

Physical

Representation

Dielectric

Height (in.)

0.004 B stage

0.004 Core

0.004 B stage

0.004 Core

0.004 B stage

Dielectric

Name

2-26

Page 43

Receiver Cards

Figure 2–22 shows a monitored receiver card. Monitor points on the right side

are for GTLP Groups 1, 2, 3, 4, 5, and 6. Monitor points on the top are for L VTTL

latch clock, Groups 6, 5, 4, 3, 2, and 1. The L VTTL latch-clock source is either

the system clock or source-synchronous clock. The source-synchronous

clock is the system clock sent via the SN74GTLP1394 driver card along the

1-bit clock trace on the backplane to the SN74GTLP1394 receiver card that

converts it back to LVTTL logic levels.

The monitored receiver card has SMB jacks to monitor selected signals:

-

TP1 GTLP level Group 1, bit 1

-

TP2 GTLP level Group 2, bit 1

-

TP3 GTLP level Group 3, bit 1

-

TP4 GTLP level Group 4, bit 1

-

TP5 GTLP level Group 5, bit 1

-

TP6 GTLP level Group 6, bit 1

-

TP7 LVTTL level Group 1, bit 1

-

TP8 LVTTL level Group 2, bit 1

-

TP9 LVTTL level Group 3, bit 1

-

TP10 LVTTL level Group 4, bit 1

-

TP11 LVTTL level Group 5, bit 1

-

TP12 LVTTL level Group 6, bit 1

-

TP13 LVTTL level GTLP latch clock

2-27 GTLP EVM Board Typical Test and Setup Configuration

Page 44

Receiver Cards

Figure 2–22. GTLP EVM Monitored Receiver Card

TP13 TP12 TP11 TP10 TP9 TP8 TP7

TP1

TP2

TP3

TP4

TP5

TP6

Note:

SN74GTL1655 devices were used on the receiver cards. The

SN74GTLPH1655 was in development and initial preproduction samples

were used for the driver cards, but insufficient quantities were available for

the receiver cards. The SN74GTL1655 and SN74GTLPH1655 are identical,

except for the B-port output edge rate (slew) and B-port C

. Because the

io

GTLP signals only are received by the receiver cards, it is essentially

immaterial which devices are used on the receiver cards, because both have

the same differential input (except for the difference in B-port C

, which is

io

6 pF typical and 8 pF maximum for the SN74GTL1655, and 8.5 pF typical and

10.5 pF maximum for the SN74GTLPH1655). GTLP devices have a larger

B-port C

, because a larger transistor and ESD cell is required by the newer

io

CMOS process.

2-28

Page 45

Backplane Setup

2.13 Backplane Setup

2.13.1 Insertion of Clock Cards

The clock-card connectors (see Figure 2–23) use AMP 55-pin, 2-mm, HM

connectors and are identical to the backplane termination-card connectors.

They can be mated improperly because they are keyed only on one side,

whereas the backplane connectors are keyed in the center and do not allow

improper insertion.

The clock card should be inserted or removed from the backplane

only after power has been disconnected, to prevent damage to the

CDC components.

Figure 2–23. AMP Z-PACK, 2-mm, 55-Pin, HM Male (Left) and Female (Right)

Clock-Card Connectors

Connector Key

Figure 2–24 shows the mating sequence. When mated, the connectors should

be firm with no lines showing. Some rocking action might be required to seat

or remove the connectors, but should be minimal to prevent bending the pins.

Connector Key

2-29 GTLP EVM Board Typical Test and Setup Configuration

Page 46

Backplane Setup

Figure 2–24. Connector Premate (Left), Mating (Center), and Mated (Right)

Key

Figure 2–25 (left) shows the clock card properly inserted, with the CDC

components and the clock crystal facing away from the backplane connectors

and daughter cards. Y ellow dots are located on the connector and the card to

help ensure proper orientation. Figure 2–25 (right) shows the card

improperly inserted.

Figure 2–25. Clock Card Properly (Left) and Improperly (Right) Inserted

Match

Dots

2-30

Page 47

2.13.2 Insertion of Clock Crystals

Clock crystals are live insertable, unlike the clock card, which is not live

insertable. Clock crystals are inserted easily on the clock card by pulling off

one crystal and inserting the new crystal (see Figure 2–26). The leads can be

bent gently to ease insertion. The clock crystal need not be inserted fully flush

with the card for proper operation. In fact, this condition is preferred if the clock

card is stored with the crystal inserted, otherwise, the foam liner can bend the

exposed leads.

Figure 2–26. Clock Crystal Removal (Left) and Insertion (Right)

Backplane Setup

2-31 GTLP EVM Board Typical Test and Setup Configuration

Page 48

Backplane Setup

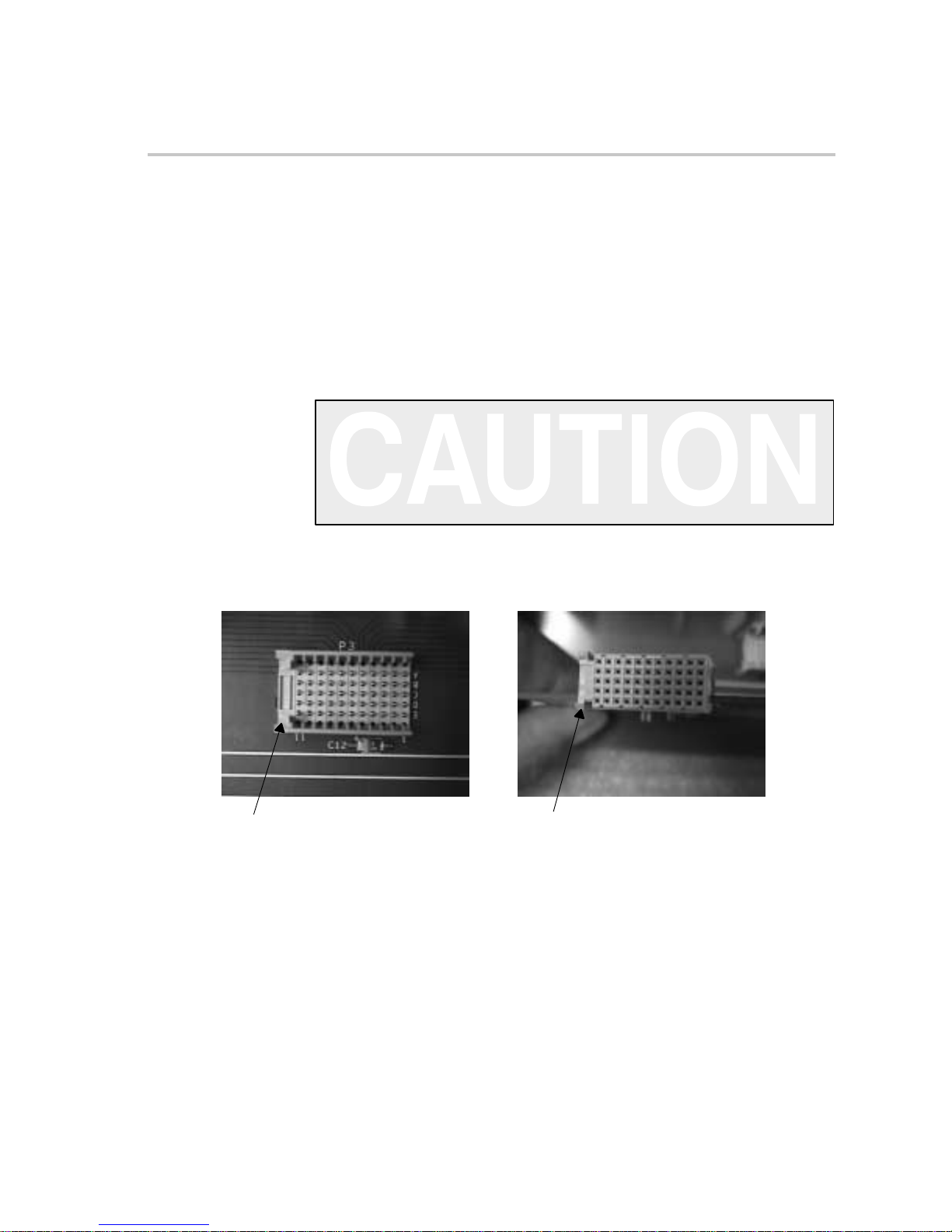

2.13.3 Insertion of Termination Cards

Termination-card, AMP Z-PACK, 2-mm, 55-pin, HM male and female

connectors are identical to the clock-card connectors, and are inserted directly

onto the K and T pins used for slots 1 and 20, V

termination card connectors are keyed on the top (see Figure 2–27), they can

be inserted backward because they are keyed on only one side.

Figure 2–27. Termination-Card Keying

Be sure that the red dot on the male connector and the card are facing each

other, to prevent improper operation. Both termination-card components face

the same direction, toward slot 20, so the key to proper operation is to inspect

for the keying and line up the red dots (see Figure 2–28). If the backplane is

not working, the proper orientation of the termination cards should be the first

thing you check. The cards can be rocked slightly side to side to seat and

remove them, but avoid bending the pins.

, and data bits. Although the

CC

Keying

Figure 2–28. Slot 1 (Left) and Slot 20 (Right) Termination Cards on the Backplane

2-32

Page 49

2.13.4 Insertion of Driver and Receiver Cards

The driver and receiver cards are live insertable and are easy to insert and

remove, although some slight side-to-side rocking action might be required.

The cards can be inserted into any slot in any order, but only one driver card

should be used at any one time. There is no bus contention damage if multiple

driver cards are in operation at the same time, this is one key benefit from using

the GTLP open-drain technology. Figure 2–29 shows the connector keying

that allows the cards to be placed on the connector in only one direction. When

inserted properly, the component side of the card faces slot 1.

Figure 2–29. Driver and Receiver Connector Keying

Backplane Setup

Keying

Figure 2–30 shows the keying in more detail. The upper key is wider than the

lower key, preventing improper insertion.

2-33 GTLP EVM Board Typical Test and Setup Configuration

Page 50

Backplane Setup

Figure 2–30. Close-up View of Connector Keying

Wide Key

Narrow Key

The card should be placed squarely on the connector and pressed down (see

Figure 2–31), with very little side-to-side motion. The components are facing

left towards slot 1, the power supplies are on the top/right, and the Group 1–6

markings are on the bottom/left. The card in Figure 2–31 is being inserted into

slot 20.

Figure 2–31. Proper Connector Mating Sequence (Left to Right)

Figure 2–32 shows the connectors properly mated.

2-34

Page 51

Figure 2–32. Connectors Properly Mated

Backplane Setup

2-35 GTLP EVM Board Typical Test and Setup Configuration

Page 52

Chapter 3

Oscilloscope Operation

Topic Page

3.1 Oscilloscope Setup 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Measurements 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

Page 53

Oscilloscope Setup

3.1 Oscilloscope Setup

The recommended oscilloscope (O-Scope) for the GTLP EVM is the T ektronix

THS730A (see Figure 3–1). It allows only two-channel operation, which should

be sufficient for most investigations done with the demonstration backplane.

Figure 3–1. Tektronix O-Scope Front (Left) and Top (Right)

SMB adapters (see Figure 3–2) are needed to properly mate T ektronix probes

with the test points. These adapters are custom built for the T ektronix O-Scope

probes and are not normally included in the GTLP EVM.

Figure 3–2. O-Scope Probe Monitor-Point Adapters

3-2

Page 54

3.2 Measurements

The first step in taking measurements is to plug one probe into channel 1

(CH 1) of the O-Scope and connect the opposite end to the desired monitor

point. Plug the other probe into channel 2 (CH 2) of the O-Scope and connect

the opposite end to the desired monitor point (see Figures 3–1 and 3–3).

Chapter 4, Waveform Measurement and Interpretation, discusses which

monitor points should be used and why.

Figure 3–3. Simple Test-Measurement Connection

Measurements

Press the ON/STBY button on the O-Scope (see Figure 3–4), and press the

CH 1 or CH 2 button.

Figure 3–4. Turn On O-Scope (Left) and Select Channel (Right)

3-3Oscilloscope Operation

Page 55

Measurements

Waveforms similar to those in Figure 3–5, depending on how the O-Scope

presets were set, are displayed. In Figure 3–5, CH 2 is selected.

Figure 3–5. O-Scope Display

3-4

Page 56

To adjust the timing (x or horizontal axis), press the appropriate side of the

SEC/DIV button (see Figure 3–6). An example of the results is shown for

50 ns/division and 100 ns/division. Timing is the same for both channels and

is independent of channel selection.

Figure 3–6. Timing Adjustment

To adjust the voltage (y or vertical axis), press the top or bottom of the

VOLTS/DIV button (see Figure 3–7). An example of the results is shown for

Ch2 at 1 V (center) and Ch2 at 2 V (right). Voltage adjustment is independent

of channels, which are selected by pressing either the CH 1 or the CH 2 button.

Measurements

Figure 3–7. Voltage Adjustment

3-5Oscilloscope Operation

Page 57

Measurements

To adjust the trigger, press the MENU button (see Figure 3–8), then press

Trigger Source to display a submenu. In the submenu, select Ch1, Ch2, or Ext

[DMM] by repeatedly pressing the same Trigger Source button. After the

appropriate trigger is selected, press the CLEAR MENU button to restore the

O-Scope to operation.

Figure 3–8. Trigger Adjustment

3-6

Page 58

Chapter 4

Waveform Measurement and Interpretation

In this chapter, five dif ferent measurement cases are discussed in detail, and

several more measurement combinations are outlined. Many other

combinations are possible.

Topic Page

4.1 Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and

Driver Card (D1) Latch Clock (Ch2) 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and

Driver Card (D1) Group 1 GTLP Data Out (Ch2) 4-3. . . . . . . . . . . . . . . . . .

4.3 Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and

Receiver Card (R2) Group 1 GTLP Data In (Ch2) 4-4. . . . . . . . . . . . . . . . .

4.4 Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and

Receiver Card (R2) Group 1 LVTTL Data Out (Ch2) 4-5. . . . . . . . . . . . . . .

4.5 Timing Relationship of Receiver Card (R2) Group 1 GTLP Data In

(Ch1) and Receiver Card (R20) Group 1 GTLP Data In (Ch2) 4-6. . . . . .

4.6 Monitored Waveforms 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

Page 59

Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and Driver Card (D1) Latch Clock (Ch2)

4.1 Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and

Driver Card (D1) Latch Clock (Ch2)

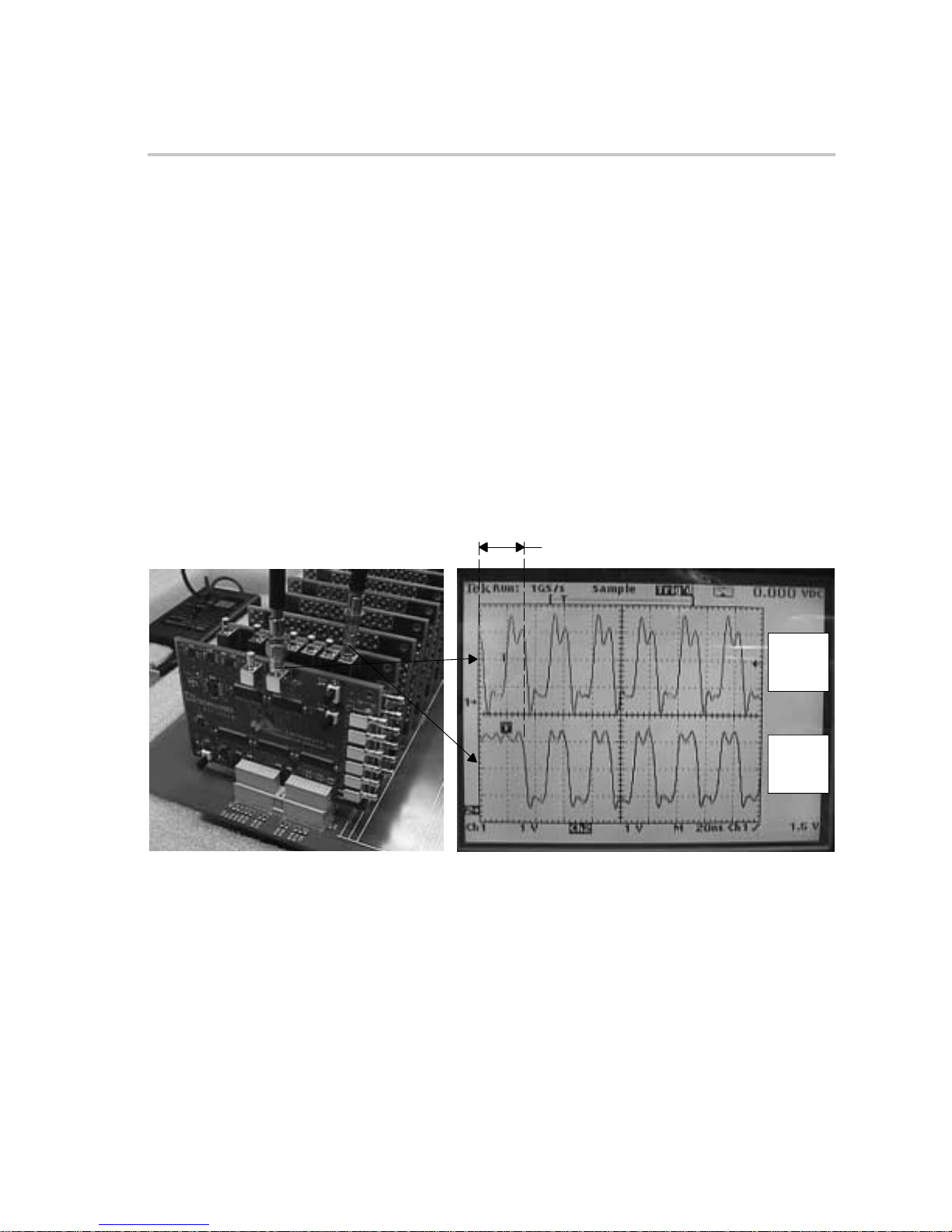

Figure 4–1 shows the probe hookup and related O-Scope output for Case 1.

The LVTTL latch clock signal goes to the SN74GTLPH1655 driving device

CLK pin, and the LVTTL data signal goes to the A-port input pin, specifically

the Group 1, bit 1 data signal.

Figure 4–1. Case 1: D1 Data Pattern (Ch1) and D1 Latch Clock (Ch2)

LVTTL

Data

Input

LVTTL

Latch-Clock

Input

4-2

Page 60

Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and Driver Card (D1) Group 1 GTLP Data Out (Ch2)

4.2 Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and

Driver Card (D1) Group 1 GTLP Data Out (Ch2)

Figure 4–2 shows the probe hookup and O-Scope output for Case 2. The

LVTTL data goes into the SN74GTLPH1655 driving device A-port input, and

the GTLP data comes out of the B-port output. The driver-card GTLP data

output comes out after the rising edge of the clock, in addition to the CLK-to-B

propagation delay. This is why the signals look 180 degrees out of phase.

Figure 4–2. Case 2: D1 Data Pattern (Ch1) and D1 Group 1 GTLP Data Out (Ch2)

LVTTL

Data

Input

GTLP

Data

Output

4-3Waveform Measurement and Interpretation

Page 61

Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and Receiver Card (R2) Group 1 GTLP Data In (Ch2)

4.3 Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and

Receiver Card (R2) Group 1 GTLP Data In (Ch2)

Figure 4–3 shows the probe hookup and O-Scope output for Case 3. The

LVTTL data input goes to the SN74GTLPH1655 driving device A-port input,

and the GTLP data input goes to the SN74GTL1655 receiving device B-port

in slot 2. These waveforms look similar to those in Figure 4–2, but with slightly

more delay caused by the flight time between slots 1 and 2.

Figure 4–3. Case 3: D1 Data Pattern (Ch1) and R2 Group 1 GTLP Data In (Ch2)

LVTTL

Data

Input

GTLP

Data

Input

4-4

Page 62

Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and Receiver Card (R2) Group 1 LVTTL Data Out (Ch2)

4.4 Timing Relationship of Driver Card (D1) Data Pattern (Ch1) and

Receiver Card (R2) Group 1 LVTTL Data Out (Ch2)

Figure 4–4 shows the probe hookup and O-Scope output for Case 4. The

LVTTL data input goes to the SN74GTLPH1655 driving device A-port input,

and the LVTTL data output of the SN74GTL1655 receiving device goes to

A port in slot 2. Because the GTLP EVM is clocked using the central system

clock (i.e., clock arrives at all daughter cards at the same time) the total delay

from the LVTTL data input on slot 1 to the LVTTL data output on slot 2 is the

sum of one clock cycle (20 ns), the setup time on the driver card (∼9 ns), and

the propagation delay of the GTLPH1655 CLK to A of about 3 ns. The GTLP

EVM driver card is set up to transmit sixteen bits of data and then wait eight

cycles before transmitting again. This allows the technician to determine the

total delay. In this case, assuming the waveform in Ch1 had just started, the

total delay is about 32 ns.

Figure 4–4. Case 4: D1 Data Pattern (Ch1) and R2 Group 1 LVTTL Data Out (Ch2)

Total Propagation Delay

LVTTL

Data

Input

LVTTL

Data

Output

4-5Waveform Measurement and Interpretation

Page 63

Timing Relationship of Receiver Card (R2) Group 1 GTLP Data In (Ch1)

4.5 Timing Relationship of Receiver Card (R2) Group 1 GTLP Data In (Ch1)

and Receiver Card (R20) Group 1 GTLP Data In (Ch2)

Figure 4–5 shows the probe hookup and O-Scope output for Case 5. Y ou can

see the flight-time delay between the output of the SN74GTLPH1655 driving

device B port in slot 1 and the SN74GTL1655 receiving device B port in

slot 20. Total flight time is about 9 ns.

Figure 4–5. Case 5: R2 Group 1 GTLP Data In (Ch1) and R20 Group 1 GTLP Data In

(Ch2)

Flight-Time Delay

GTLP

Data

Input

GTLP

Data

Input

4-6

Page 64

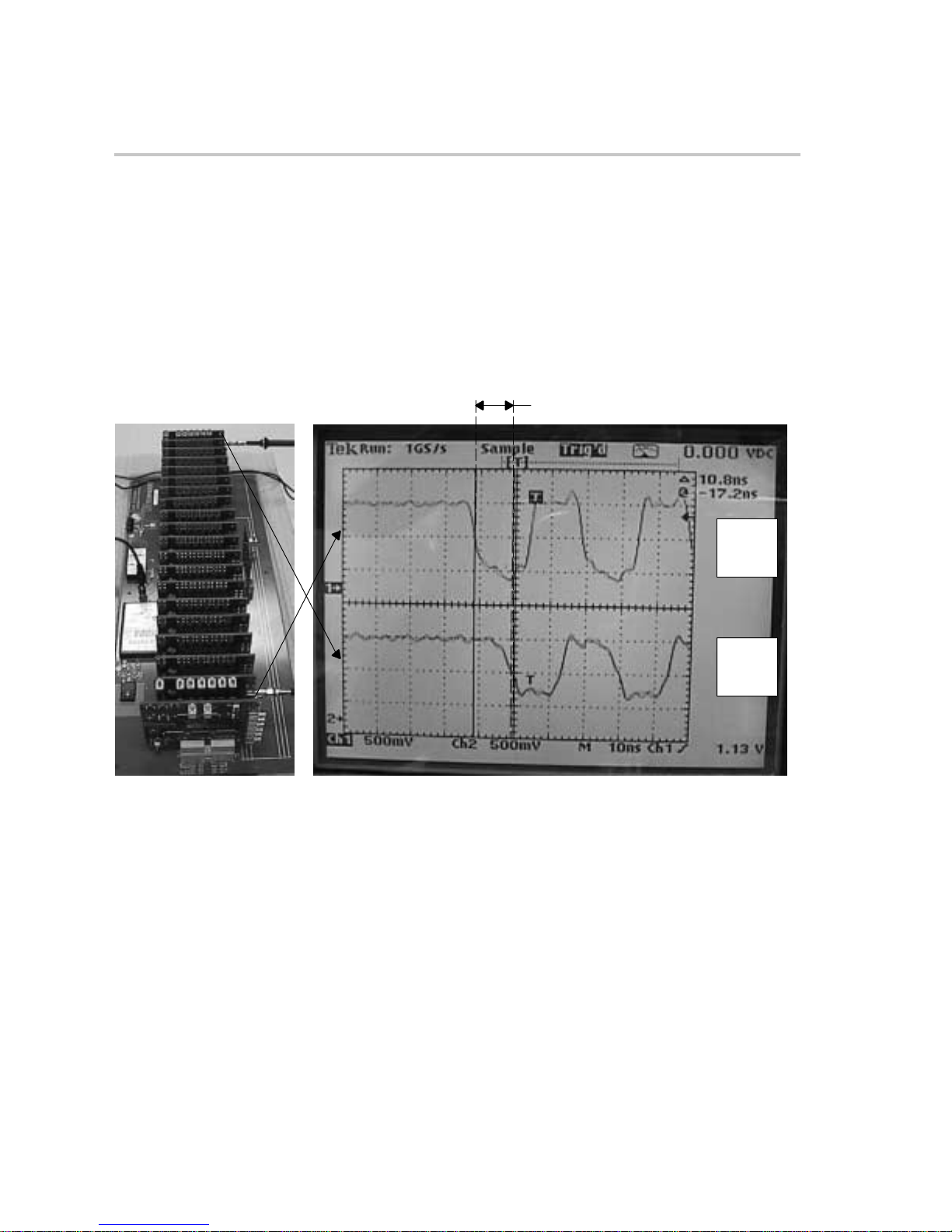

4.6 Monitored Waveforms

There are differences in waveforms between GTLP monitor test points and

measurements taken at the backplane connector pins, due to interference

from LVTTL data and clock signals not shielded adequately on the daughter

cards. This concern is only for this demonstration backplane because there is

no reason to extend the GTLP signals past the GTLP device B-port output pins

on operational daughter cards. Figures 4–6 and 4–7 show the difference

between waveforms taken directly on the backplane and those taken from the

monitor test points under fully loaded conditions at a clock frequency of

23 MHz. Waveforms shown in Figures 4–6 and 4–7 are at one-half clock

frequency, or 11.5 MHz, and are taken with various termination cards.

Figure 4–6. GTLP Backplane Waveforms at 23-MHz Clock Frequency

Monitored Waveforms

Figure 4–7. GTLP Monitor Test-Point Waveforms at 23-MHz Clock Frequency

4-7Waveform Measurement and Interpretation

Page 65

Monitored Waveforms

4-8

Page 66

Chapter 5

Troubleshooting

Topic Page

5.1 Spare Parts 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Replacing 5-A Fuse F2 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Replacing 2.5-A Fuse F1 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Damage to the Daughter Cards 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1

Page 67

Spare Parts

5.1 Spare Parts

Each EVM is equipped with spare fuses and jumpers (see Figure 5–1).

Figure 5–1. Spare Fuses and Jumpers

5-2

Page 68

5.2 Replacing 5-A Fuse F2

Fuse F2 (see Figure 5–2) provides power from the 3.3-V switching regulator

to the 3.3-V power plane and blows if V

occur if a connector pin is bent during insertion or if measurements are taken

directly from the backplane.

F2 can be replaced easily with one of the spare fuses. Simply disconnect

power from the board, and pull out the fuse with pliers (see Figure 5–2). Push

in the new fuse, and reconnect the power supply.

Figure 5–2. Fuse F2 (Left) and Removal Procedure (Right)

Replacing 5-A Fuse F2

is shorted to GND. Shorting can

CC

5-3Troubleshooting

Page 69

Replacing 2.5-A Fuse F1

5.3 Replacing 2.5-A Fuse F1

Fuse F1 (see Figure 5–3) provides power from the power supply to the 3.3-V

and 5-V switching regulators and blows if the switching regulators fail. It is

replaced as easily as fuse F2. Disconnect the power from the board, pull out

the fuse with pliers, push in the new fuse, then reconnect the power supply.

Figure 5–3. Fuse F1

5-4

Page 70

5.4 Damage to the Daughter Cards

The daughter cards are not field repairable and must be returned to the factory

for repair.

Damage to the Daughter Cards

5-5Troubleshooting

Page 71

Damage to the Daughter Cards

5-6

Page 72

Appendix A

Appendix A

Bill of Materials, Schematics, Board Layouts,

and Suggested Specifications

Topic Page

A.1 GTLP EVM Bill of Materials A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 Board Layouts and Schematics A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-1

Page 73

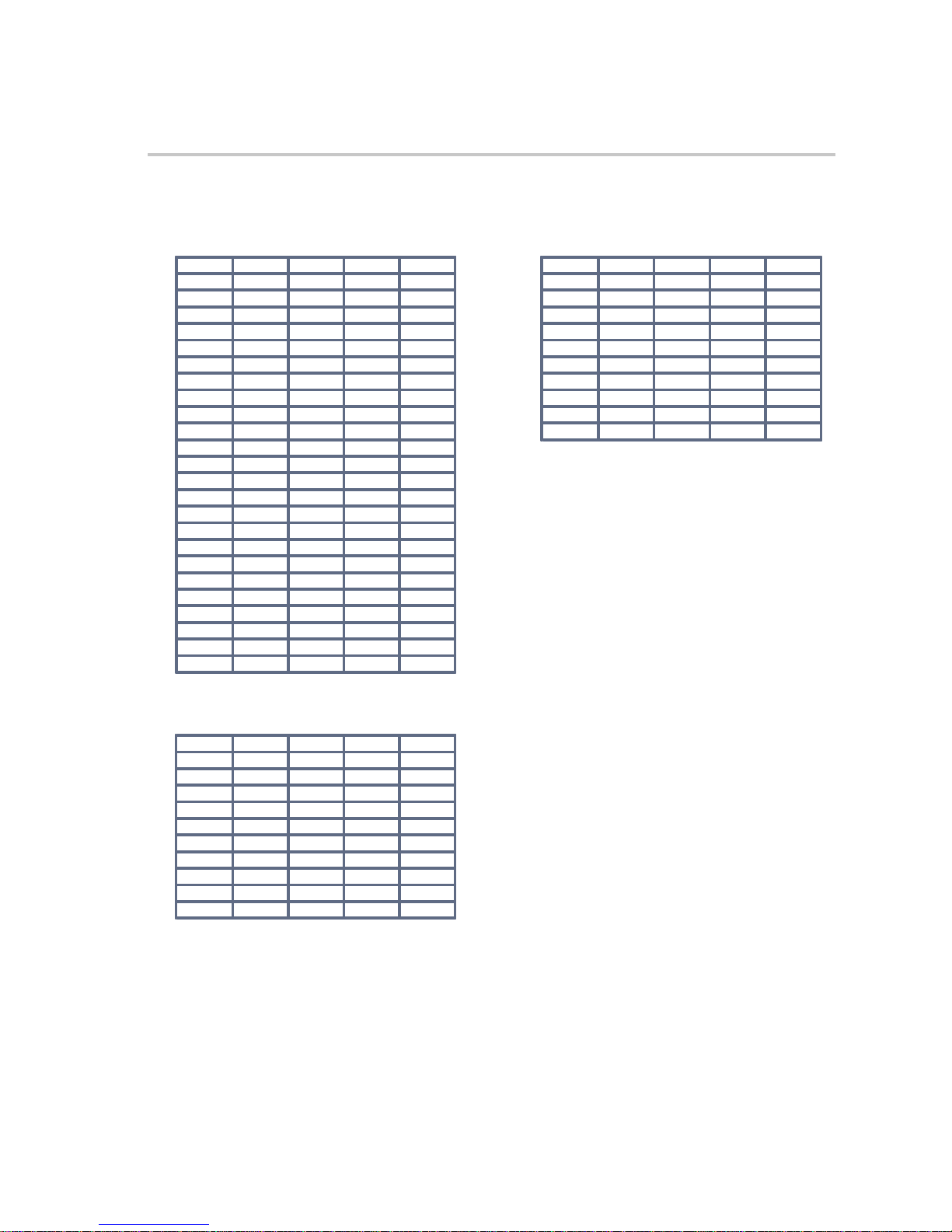

GTLP EVM Bill of Materials

A.1 GTLP EVM Bill of Materials

-

Backplane

Device Type Quantity

Z-PAK 110-Pin Male Connector 20

Z-PAK 55-Pin Male Connector 1

2.5 AMP Fuseholder 1

5 AMP Fuseholder 1

Surface Mount 0.01uF Cap 3

Surface Mount 0.1uF Cap 75

Surface Mount Tantalum 10uF/10V Cap 4

Surface Mount Tantalum 1uF/35V Cap 2

Surface Mount Tantalum 47uF/10V Cap 2

Surface Mount 100 ohm Resistor 1

Surface Mount 120 ohm Resistor 1

Surface Mount 1.5K ohm Resistor 1

Surface Mount 20 ohm Resistor 1

Surface Mount 240 ohm Resistor 1

Surface Mount 25 ohm Resistor 1

Green LED 2

Red LED 1

L T1083CP Voltage Regulator 1

Powerjack 1

24V-to-5V DC-to-DC Converter 1

24V-to-3.3V DC-to-DC Converter 1

A-2

Page 74

GTLP EVM Bill of Materials

Clock Driver Card

-

Device Type Quantity

Z-PAK 55-Pin Female Connector 1

CDC2586 TQFP Clock Driver 2

Surface Mount 0.1uF Cap 10

Surface Mount 453 ohm Resistor 1

Oscillator Mount 1

SMB Coax Connector 1

-

Termination Card

Device Type Quantity

Z-PAK 55-Pin Female Connector 1

Surface Mount 0.1uF Cap 4

Surface Mount 25 ohm Resistor 8

-

Monitored Receiver Card

Device Type Quantity

Z-PAK 55-Pin Female Connector 1

10K ohm Resistor Network 6

SN74ALVC126 TVSOP Buffer 1

SN74GTLP1394 TVSOP Transceiver 1

SN74GTL1655 TSSOP UBT 3

Surface Mount 0.1uF Cap 12

Surface Mount 47pF Cap 6

Surface Mount 1K ohm Resistor 1

Surface Mount 2K ohm Resistor 1

Surface Mount 453 ohm Resistor 7

Surface Mount 51.1 ohm Resistor 13

SMB Coax Connector 13

A-3Bill of Materials, Schematics, Board Layouts, and Suggested Specifications

Page 75

GTLP EVM Bill of Materials

Monitored Driver Card

-

Device Type Quantity

Z-PAK 55-Pin Female Connector 1

SN74ALVC126 TVSOP Buffer 1

SN74GTLP1394 TVSOP Transceiver 1

SN74GTLPH1655 TSSOP UBT 3

SN74ALVCH16344 TSSOP Buffer 2

CDC351 Clock Buffer 1

SN74LVC112A JK Flip-Flop 3

SN74LVC04 Inverter 1

Surface Mount 0.1uF Cap 23

Surface Mount 47pF Cap 1

Surface Mount 1K ohm Resistor 3

Surface Mount 2K ohm Resistor 1

Surface Mount 500 ohm Resistor 2

Surface Mount 243 ohm Resistor 1

Surface Mount 51.1 ohm Resistor 6

SMB Coax Connector 8

-

Unmonitored Receiver Card

Device Type Quantity

Z-PAK 55-Pin Female Connector 1

10K ohm Resistor Network 6

SN74ALVC126 TVSOP Buffer 1

SN74GTLP1394 TVSOP Transceiver 1

SN74GTL1655 TSSOP UBT 3

Surface Mount 0.1uF Cap 12

Surface Mount 47pF Cap 6

Surface Mount 1K ohm Resistor 1

Surface Mount 2K ohm Resistor 1

A-4

Page 76

A.2 Board Layouts and Schematics

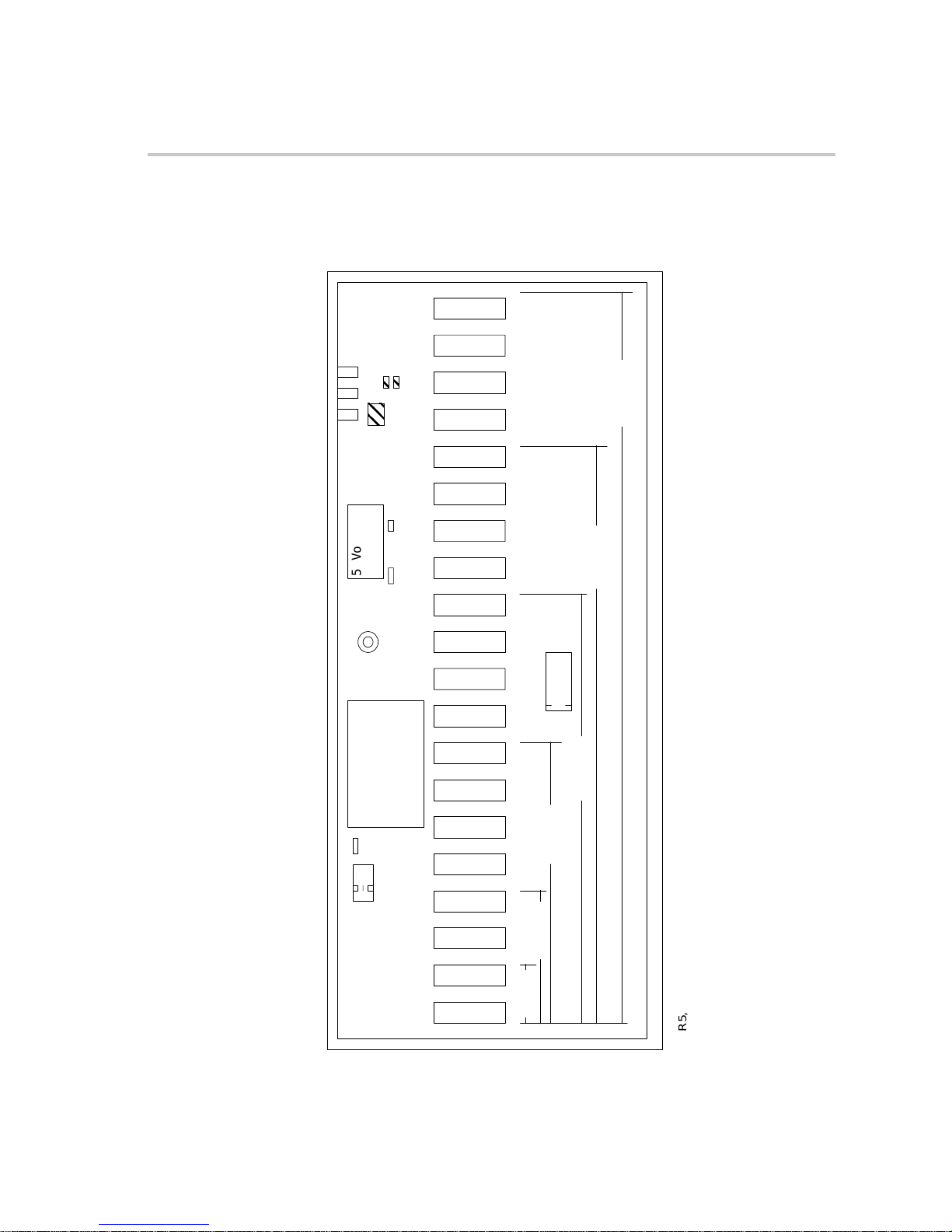

Figure A–1. Backplane Layout, Front Side

LED 3

R6

R5

LED 2

LED 1

P1–20

P1–19

P1–18

P1–17

Board Layouts and Schematics

Group 1

U2

JP1

5 Volts @

1 Amp.

F1

J5

3.3 Volts @ 7.5

Amps.

F2

U1

P1–16

P1–15

P1–14

P1–13

P1–12

P1–11

P1–10

P1–9

P1–8

P1–7

P1–6

P1–5

P1–4

Group 2

P3

Group 3

Group 4

P1–3

P1–2

P1–1

Group 5

Group 6

U2, R5, and R6 are not installed at this time.

A-5Bill of Materials, Schematics, Board Layouts, and Suggested Specifications

Page 77

Board Layouts and Schematics

Figure A–2. Backplane Layout, Back Side

P1–1B

A-6

P1–20B

Page 78

Board Layouts and Schematics

Figure A–3. Driver-Card and Receiver-Card Connector Pinout

P1-X P1-1B and P1-20B

ABCDE EDCBA

1

Sys. Clk.

2 3.3V 3.3V GND 3.3V 3.3V 2 3.3V 3.3V 3.3V

3

G1D3 G1D1

4

G1D7 G1D5

5 1.5V 1.5V GND 1.5V 1.5V 5 1.5V 1.5V 1.5V 1.5V

6

G2D3 G2D1

7

G2D7 G2D5

8 GND GND GND GND GND 8 GND GND GND GND

9

G3D3 G3D1

10

G3D7 G3D5

11 GND GND GND GND GND 11 GND GND GND GND

15 GND GND GND GND GND

16

G4D3 G4D1

17

G4D7 G4D5

18 GND GND GND GND GND

19

G5D3 G5D1

20

G5D7 G5D5

21 GND GND GND GND GND

22

G6D3 G6D1

23

G6D7 G6D5

24 GND GND GND GND GND

25

MODESEL

GND GND 5V 5V 1 GND 5V

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND GND GND

G1D4 G1D2

G1D8 G1D6

G2D4 G2D2

G2D8 G2D6

G3D4 G3D2

G3D8 G3D6

G4D4 G4D2

G4D8 G4D6

G5D4 G5D2

G5D8 G5D6

G6D4 G6D2

G6D8 G6D6

GTL Clk.

3

G1D3 G1D1 G1D4 G1D2

4

G1D7 G1D5 G1D8 G1D6

6

7

9

10

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

P3

ABCDE

1

Clk.Out 20

2