Page 1

DRV603

LEFT

RIGHT

-

+

-

+

DAC

DAC

DRV603

www.ti.com

DirectPath™, 3-VRMS Line Driver With Adjustable Gain

1

FEATURES

234

• DirectPath™

– Eliminates Pop/Clicks

– Eliminates Output DC-Blocking Capacitors

– Provides Flat Frequency Response 20

Hz–20 kHz

• Low Noise and THD

– SNR > 109 dB

– Typical Vn < 7 μVms

– THD+N < 0.002%

• Output Voltage Into 2.5-kΩ Load

– 2 Vrms With 3.3-V Supply Voltage

– 3 Vrms With 5-V Supply Voltage

• Differential Input

• External Undervoltage Mute

APPLICATIONS

• PDP / LCD TV

• Blu-ray Disc™, DVD Players

• Home Theater in a Box

• Set-Top Boxes

Check for Samples: DRV603

DESCRIPTION

The DRV603PW is a 3-V

driver designed to allow the removal of the output

dc-blocking capacitors for reduced component count

and cost. The device is ideal for single-supply

electronics where size and cost are critical design

parameters.

Designed using TI’s patented DirectPath™

technology, The DRV603 is capable of driving 3 V

into a 2.5-kΩ load with 5-V supply voltage. The

device has differential inputs and uses external

gain-setting resistors to support a gain range of ±1

V/V to ±10 V/V, and line outputs that have ±8 kV IEC

ESD protection. The DRV603 (occasionally referred

to as the ‘603) has built-in shutdown control for

pop-free on/off control. The DRV603 has an external

and internal undervoltage detector that mutes the

output.

Using the DRV603 in audio products can reduce

component count considerably compared to

traditional methods of generating a 3-V

DRV603 does not require a power supply greater

than 5 V to generate its 8.5-Vppoutput, nor does it

require a split-rail power supply. The DRV603

integrates its own charge pump to generate a

negative supply rail that provides a clean, pop-free

ground biased 3-V

The DRV603 is available in a 14-pin TSSOP.

If the low noise and trimmed dc-offset and external

undervoltage mute function are not beneficial in the

application, TI recommends the footprint compatible

DRV602.

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

pop-free stereo line

RMS

rms

output. The

rms

output.

rms

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2DirectPath is a trademark of Texas Instruments.

3Blu-ray Disc is a trademark of Blu-ray Disc Association.

4All other trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2009, Texas Instruments Incorporated

Page 2

DRV603

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

www.ti.com

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

(1)

Tape and reel, 2000

T

A

–40°C to 85°C

ORDERING INFORMATION

PACKAGE TRANSPORT MEDIA, QUANTITY

DRV603PW RAIL, 90

DRV603PWR

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

Web site at www.ti.com.

ABSOLUTE MAXIMUM RATINGS

(1)

over operating free-air temperature range

VALUE UNIT

Supply voltage, VDDto GND –0.3 to 5.5 V

V

R

T

T

ESD Electrostatic discharge, IEC ESD OUTL, OUTR ±8 kV

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

Input voltage VSS– 0.3 to VDD+ 0.3 V

I

Minimum load impedance > 600 Ω

L

EN to GND –0.3 to VDD+0.3 V

Maximum operating junction temperature range –40 to 150 °C

J

Storage temperature range –40 to 150 °C

stg

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

DISSIPATION RATINGS

PACKAGE R

(°C/W) R

θJC

θJA

TSSOP-14 (PW) 35 115

(°C/W)

(2)

POWER RATING

AT TA≤ 25°C AT TA≤ 70°C

870 mW 348 mW

(1)

POWER RATING

(1) Power rating is determined with a junction temperature of 125°C. This is the point where performance starts to degrade and long-term

reliability starts to be reduced. Thermal management of the final PCB should strive to keep the junction temperature at or below 125°C

for best performance and reliability.

(2) These data were taken with the JEDEC high-K test printed circuit board (PCB). For the JEDEC low-K test PCB, the R

θJA

(1)

is 185°C/W.

RECOMMENDED OPERATING CONDITIONS

MIN NOM MAX UNIT

V

V

V

T

Supply voltage DC supply voltage 3 3.3 5.5 V

DD

High-level input voltage EN 60 % of V

IH

Low-level input voltage EN 40 % of V

IL

Operating free-air temperature 0 70 °C

A

DD

DD

2 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DRV603

Page 3

DRV603

www.ti.com

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

ELECTRICAL CHARACTERISTICS

TA= 25°C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

|VOS| Output offset voltage VDD= 3 V to 5 V, input grounded, unity gain 1 mV

PSRR Power-supply rejection ratio VDD= 3 V to 5 V 88 dB

V

V

|IIH| High-level input current (EN) VDD= 5 V, VI= V

|IIL| Low-level input current (EN) VDD= 5 V, VI= 0 V 1 µA

I

High-level output voltage VDD= 3.3 V, RL= 2.5 kΩ 3.1 V

OH

Low-level output voltage VDD= 3.3 V, RL= 2.5 kΩ –3.05 V

OL

DD

VDD= 3.3 V, no load, EN = V

Supply current VDD= 5 V, no load, EN = V

DD

DD

DD

12.5 mA

Shutdown mode, VDD= 3 V to 5 V 1

1 µA

11

OPERATING CHARACTERISTICS

VDD= 3.3 V , TA= 25°C, RL= 2.5 kΩ, C

noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

O

THD+N Total harmonic distortion plus noise VO= 2 V

I

O

R

IN

R

fb

V

N

SNR Signal-to-noise ratio 112 dB

G

BW

A

VO

V

uvp

I

Hys

f

cp

Output voltage (outputs in phase) THD = 1%, VDD= 5 V, f = 1 kHz 3.01 V

Crosstalk VO= 2 V

Maximum output current VDD= 3.3 V 20 mA

Input resistor range 1 10 47 kΩ

Feedback resistor range 4.7 20 100 kΩ

Slew rate 4.5 V/μs

Maximum capacitive load 220 pF

Noise output voltage BW = 20 Hz to 22 kHz, A-weighted 6 μV

Unity-gain bandwidth 8 MHz

Open-loop voltage gain 150 dB

External undervoltage detection 1.25 V

External undervoltage detection

hysteresis current

Charge pump frequency 225 450 675 kHz

(PUMP)

= C

= 1 µF , CIN= 10 µF, RIN= 10 kΩ, Rfb= 20 kΩ (unless otherwise

(PVSS)

THD = 1%, VDD= 3.3 V, f = 1 kHz 2.05

THD = 1%, VDD= 5 V, f = 1 kHz, RL= 100 kΩ 3.1

, f = 1 kHz 0.001%

rms

, f = 1 kHz –100 dB

rms

VO= 3 Vrms, THD+N = 0.1%, BW = 22 kHz,

A-weighted

5 μA

rms

rms

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): DRV603

Page 4

1

+INR

2

3

4

-INR

OUTR

SGND

5

6

7 8

EN

PVSS

CN

9

10

11

12

13

14

CP

PVDD

PGND

OUTL

-INL

+IN

ChargePump

UVP

External

Under

Voltage

Detector

DRV603

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

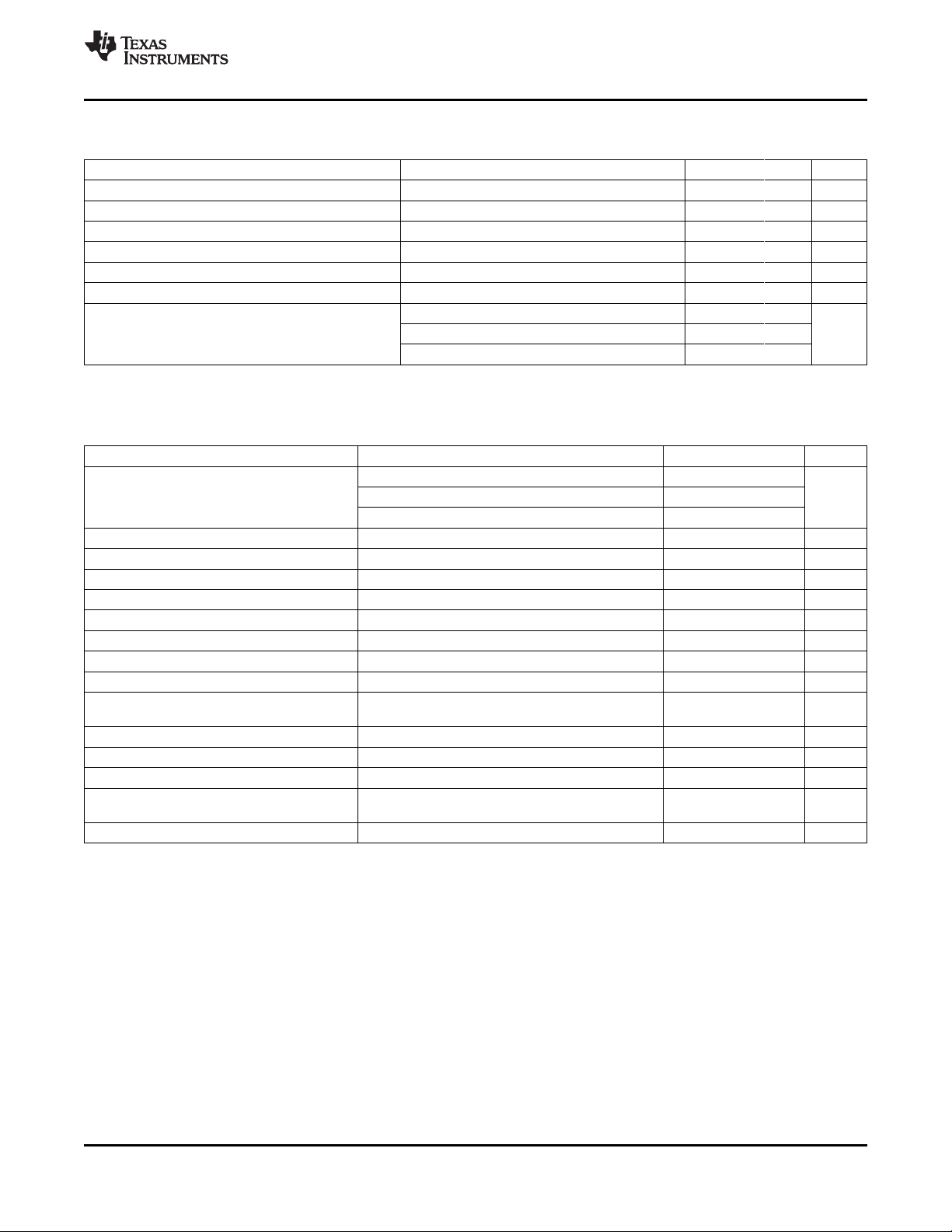

PW PACKAGE

(TOP VIEW)

PIN FUNCTIONS

PIN

NAME NO.

+INR 1 I Right-channel OPAMP positive input

–INR 2 I Right-channel OPAMP negative input

OUTR 3 O Right-channel OPAMP output

SGND 4 P Signal ground

EN 5 I Enable input, active-high

PVSS 6 P Supply voltage

CN 7 I/O Charge-pump flying capacitor negative terminal

CP 8 I/O Charge-pump flying capacitor positive terminal

PVDD 9 P Positive supply

PGND 10 P Power ground

UVP 11 I Undervoltage protection input

OUTL 12 O Left-channel OPAMP output

–INL 13 I Left-channel OPAMP negative input

+INL 14 I Left-channel OPAMP positive input

(1) I = input, O = output, P = power

I/O

(1)

DESCRIPTION

www.ti.com

4 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DRV603

Page 5

Click& Pop

Suppression

ShortCircuit

Protection

SGND

Bias

Circuitry

PVSS

CN CP

PVDD

-INR

+INR

OUTL

-INL

OUTR

+INL

EN PGND

UVP

Line

Driver

Line

Driver

DRV603

www.ti.com

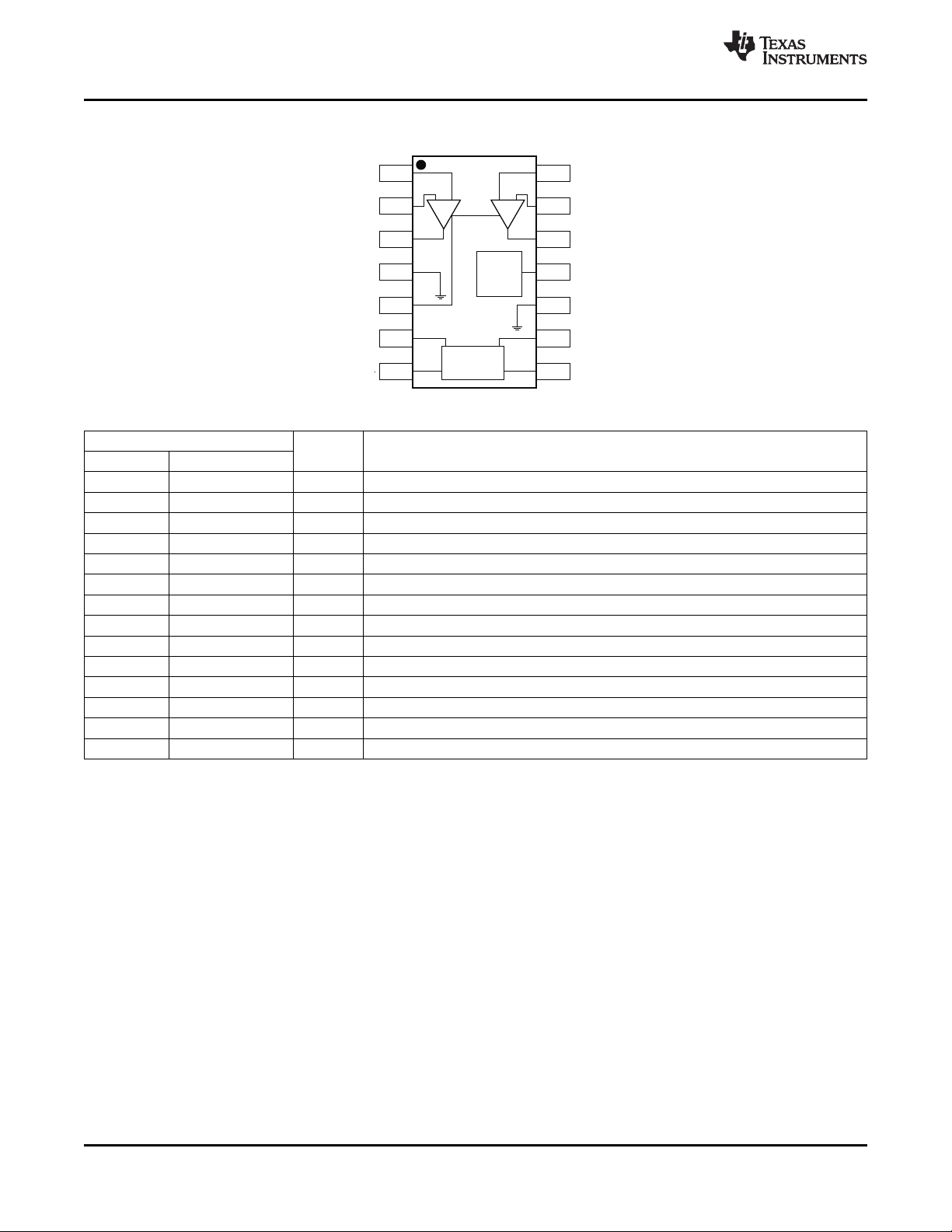

FUNCTIONAL BLOCK DIAGRAM

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): DRV603

Page 6

100m 5200m 300m 500m 800m 2 3 4

V -OutputVoltage-V

O

0.0001

10

0.001

0.01

0.1

1

THD+N-TotalHarmonicDistortion+Noise-%

0.0001

10

0.001

0.01

0.1

1

THD+N-TotalHarmonicDistortion+Noise-%

100m 5200m 500m 800m 2 3 4

V -OutputVoltage-V

O

0.0001

10

0.001

0.01

0.1

1

THD+N-TotalHarmonicDistortion+Noise-%

100m 5200m 500m 800m 2 3 4

V -OutputVoltage-V

O

0.0001

10

0.001

0.01

0.1

1

THD+N-TotalHarmonicDistortion+Noise-%

100m 5200m 500m 800m 2 3 4

V -OutputVoltage-V

O

DRV603

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

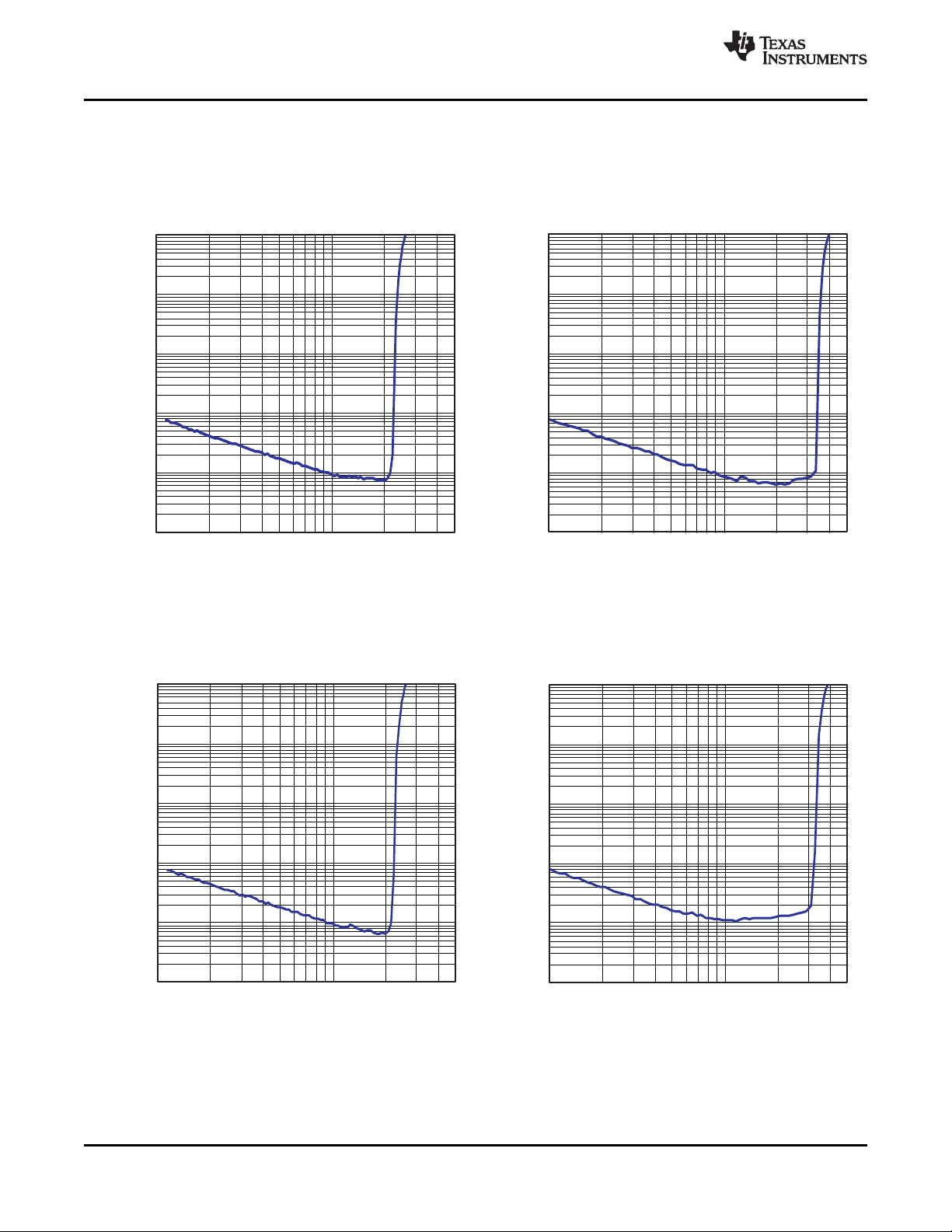

TYPICAL CHARACTERISTICS

VDD= 3.3 V , TA= 25°C, RL= 2.5 kΩ, C

TOTAL HARMONIC DISTORTION + NOISE TOTAL HARMONIC DISTORTION + NOISE

vs vs

OUTPUT VOLTAGE OUTPUT VOLTAGE

VDD= 3.3 V, RL= 100 kΩ, f = 1 kHz VDD= 5 V, RL= 100 kΩ, f = 1 kHz

(PUMP)

= C

= 1 µF , CIN= 10 µF, RIN= 10 kΩ, Rfb= 20 kΩ (unless otherwise noted)

(VSS)

www.ti.com

Figure 1. Figure 2.

TOTAL HARMONIC DISTORTION + NOISE TOTAL HARMONIC DISTORTION + NOISE

OUTPUT VOLTAGE OUTPUT VOLTAGE

VDD= 3.3 V, RL= 2.5 kΩ, f = 1 kHz VDD= 5 V, RL= 600 Ω, f = 1 kHz

vs vs

Figure 3. Figure 4.

6 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DRV603

Page 7

20 20k50 100 200 500 1k 2k 5k 10k

f-Frequency-Hz

0.0001

10

0.001

0.01

0.1

1

THD+N-TotalHarmonicDistortion+Noise-%

0.0001

10

0.001

0.01

0.1

1

THD+N-TotalHarmonicDistortion+Noise-%

20 20k50 100 200 500 1k 2k 5k 10k

f-Frequency-Hz

-150

+150

-100

-50

+0

+50

+100

20 200k50 100 500 1k 2k 5k 10k 50k

f-Frequency-Hz

Phase-deg

0

+10

+1

+2

+3

+4

+5

+6

+7

+8

+9

20

200k

50 100 500 1k 2k 5k 10k 50k

f-Frequency-Hz

Gain-dBV

DRV603

www.ti.com

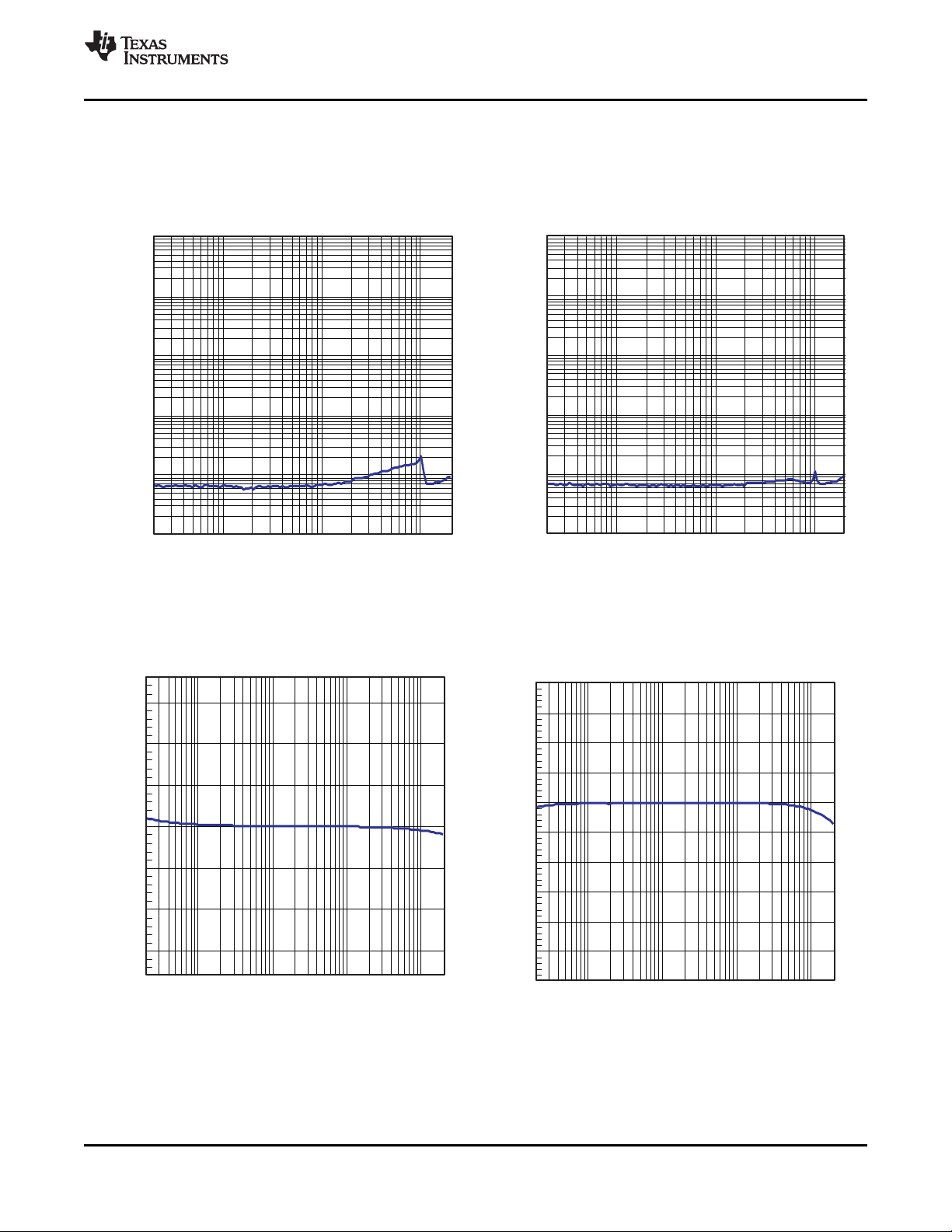

TYPICAL CHARACTERISTICS (continued)

VDD= 3.3 V , TA= 25°C, RL= 2.5 kΩ, C

TOTAL HARMONIC DISTORTION+NOISE TOTAL HARMONIC DISTORTION+NOISE

vs vs

FREQUENCY FREQUENCY

VDD= 3.3 V, RL= 2.5 kΩ, VO= 2 V

(PUMP)

= C

rms

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

= 1 µF , CIN= 10 µF, RIN= 10 kΩ, Rfb= 20 kΩ (unless otherwise noted)

(VSS)

VDD= 5 V, RL= 100 kΩ, VO= 2 V

rms

VDD= 5 V, RL= 100 kΩ, VO= 2 V

FREQUENCY FREQUENCY

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 7

Figure 5. Figure 6.

PHASE GAIN

vs vs

rms

VDD= 5 V, RL= 100 kΩ, VO= 2 V

Figure 7. Figure 8.

Product Folder Link(s): DRV603

rms

Page 8

14m

12m

10m

8m

6m

4m

2m

0

-0 +1

+2 +3

+4

+5

QuiescentCurrent- A

V -SupplyVoltage-V

DD

NoLoad,

V =0V

I

-140

+0

-120

-100

-80

-60

-40

-20

0 20k5k 10k 15k

f-Frequency-Hz

FFT-dBr

DRV603

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

TYPICAL CHARACTERISTICS (continued)

VDD= 3.3 V , TA= 25°C, RL= 2.5 kΩ, C

FFT

vs QUIESCENT CURRENT

FREQUENCY vs

VDD= 5 V, RL= 100 kΩ, VO= 3 V

(PUMP)

(-60 dB) SUPPLY VOLTAGE

rms

= C

= 1 µF , CIN= 10 µF, RIN= 10 kΩ, Rfb= 20 kΩ (unless otherwise noted)

(VSS)

www.ti.com

8 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Figure 9. Figure 10.

Product Folder Link(s): DRV603

Page 9

OPAMP

Co

MuteCircuit

Output

Enable

+

+

+

-

ConventionalSolution

DRV603

MuteCircuit

Output

Enable

5 V

+

-

DRV603Solution

VDD

VSS

GND

VDD

VDD/2

GND

DirectPath

9-12V

DRV603

www.ti.com

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

APPLICATION INFORMATION

LINE DRIVER AMPLIFIERS

Single-supply line-driver amplifiers typically require dc-blocking capacitors. The top drawing in Figure 11

illustrates the conventional line-driver amplifier connection to the load and output signal.

DC blocking capacitors are often large in value, and a mute circuit is needed during power up to minimize click

and pop. The output capacitor and mute circuit consume PCB area and increase cost of assembly, and can

reduce the fidelity of the audio output signal.

Figure 11. Conventional and DirectPath Line Driver

The DirectPath™ amplifier architecture operates from a single supply but makes use of an internal charge pump

to provide a negative voltage rail.

Combining the user-provided positive rail and the negative rail generated by the IC, the device operates in what

is effectively a split supply mode.

The output voltages are now centered at zero volts with the capability to swing to the positive rail or negative rail.

Combining this with the built-in click and pop reduction circuit, the DirectPath™ amplifier requires no output dc

blocking capacitors.

The bottom block diagram and waveform of Figure 11 illustrate the ground-referenced line-driver architecture.

This is the architecture of the DRV603.

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): DRV603

Page 10

+

-

Inverting

R

IN

R

FB

+

-

C

IN

-IN

Differential

Input

+IN

C

IN

R

IN

R

FB

-IN

R

IN

C

IN

R

FB

Rx

+

-

Cx

Non

Inverting

R

IN

R

FB

C

IN

+IN

DRV603

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

www.ti.com

CHARGE PUMP FLYING CAPACITOR AND PVSS CAPACITOR

The charge pump flying capacitor serves to transfer charge during the generation of the negative supply voltage.

The PVSS capacitor must be at least equal to the charge pump capacitor in order to allow maximum charge

transfer. Low-ESR capacitors are an ideal selection, and a value of 1 μF is typical. Capacitor values that are

smaller than 1 μF can be used, but the maximum output voltage may be reduced and the device may not

operate to specifications.

DECOUPLING CAPACITORS

The DRV603 is a DirectPath™ line-driver amplifier that requires adequate power supply decoupling to ensure

that the noise and total harmonic distortion (THD) are low. A good low equivalent-series-resistance (ESR)

ceramic capacitor, typically 1 μF, placed as close as possible to the device VDDlead works best. Placing this

decoupling capacitor close to the DRV603 is important for the performance of the amplifier. For filtering

lower-frequency noise signals, a 10-μF or greater capacitor placed near the audio power amplifier would also

help, but it is not required in most applications because of the high PSRR of this device.

GAIN-SETTING RESISTOR RANGES

The gain-setting resistors, RINand Rfb, must be chosen so that noise, stability, and input capacitor size of the

DRV603 are kept within acceptable limits. Voltage gain is defined as Rfbdivided by RIN.

Selecting values that are too low demands a large input ac-coupling capacitor, CIN. Selecting values that are too

high increases the noise of the amplifier. Table 1 lists the recommended resistor values for different gain

settings.

Table 1. Recommended Resistor Values

INPUT RESISTOR FEEDBACK RESISTOR DIFFERENTIAL INPUT NONINVERTING INPUT

VALUE, R

IN

22 kΩ 22 kΩ 1 V/V –1 V/V 2 V/V

15 kΩ 30 kΩ 1.5 V/V –1.5 V/V 2.5 V/V

33 kΩ 68 kΩ 2.1 V/V –2.1 V/V 3.1 V/V

10 kΩ 100 kΩ 10 V/V –10 V/V 11 V/V

VALUE, R

fb

GAIN GAIN

INVERTING INPUT GAIN

10 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Figure 12. Differential, Inverting and Non-Inverting Gain Configurations

Product Folder Link(s): DRV603

Page 11

fc

IN

+

1

2p RINC

IN

C

IN

+

1

2p fcINR

IN

or

--IN

DifferentialInput

InvertingInput

DRV603

R1

R1

R2

R2

+

-

C3

C3

R3

R3

C1

C1

C2

R1

R2

+

-

C3

R3

C1

C2

+IN

-IN

DRV603

DRV603

www.ti.com

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

INPUT-BLOCKING CAPACITORS

DC input-blocking capacitors are required to be added in series with the audio signal into the input pins of the

DRV603. These capacitors block the dc portion of the audio source and allow the DRV603 inputs to be properly

biased to provide maximum performance.

These capacitors form a high-pass filter with the input resistor, RIN. The cutoff frequency is calculated using

Equation 1. For this calculation, the capacitance used is the input-blocking capacitor and the resistance is the

input resistor chosen from Table 1. Then the frequency and/or capacitance can be determined when one of the

two values is given.

(1)

USING THE DRV603 AS A SECOND-ORDER FILTER

Several audio DACs used today require an external low-pass filter to remove out-of-band noise. This is possible

with the DRV603, as it can be used like a standard OPAMP. Several filter topologies can be implemented, both

single-ended and differential. In Figure 13 , a multi-feedback (MFB) with differential input and single-ended input

is shown.

An ac-coupling capacitor to remove dc content from the source is shown; it serves to block any dc content from

the source and lowers the dc-gain to 1, helping reducing the output dc-offset to minimum.

The component values can be calculated with the help of the TI FilterPro™ program available on the TI website

at:

http://focus.ti.com/docs/toolsw/folders/print/filterpro.html

Figure 13. Second-Order Active Low-Pass Filter

The resistor values should have a low value for obtaining low noise, but should also have a high enough value to

get a small size ac-coupling capacitor. Using 5.6 kΩ for the resistors, C1 = 220 pF, and C2 = 470 pF, a DNR of

112 dB can be achieved with a 10-μF input ac-coupling capacitor.

Product Folder Link(s): DRV603

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 11

Page 12

SupplyRamp

Supply

Enable

Timeforac-coupling

capacitorstocharge

R11

R12

R13

Cy

VSUP_MO

UVP pin11

DRV603

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

www.ti.com

POP-FREE POWER UP

Pop-free power up is ensured by keeping the SD (shutdown pin) low during power-supply ramp up and ramp

down. The SD pin should be kept low until the input ac-coupling capacitors are fully charged before asserting the

SD pin high to achieve pop-less power up. Figure 14 illustrates the preferred sequence.

Figure 14. Power-Up Sequence

EXTERNAL UNDERVOLTAGE DETECTION

External undervoltage detection can be used to

mute/shut down the DRV603 before an input device

can generate a pop.

The shutdown threshold at the UVP pin is 1.25 V.

The user selects a resistor divider to obtain the

shutdown threshold and hysteresis for the specific

application. The thresholds can be determined as

follows:

V

= 1.25 V × (R11 + R12) / R12

UVP

Hysteresis = 5 μA × R13 × (R11 + R12) / R12

with the condition R13 >> R11//R12.

For example, to obtain V

hysteresis, R11 = 3 kΩ, R12 = 1 kΩ and R13 = 50

kΩ.

= 5 V and 1-V

UVP

CAPACITIVE LOAD

The DRV603 has the ability to drive a high capacitive load up to 220 pF directly. Higher capacitive loads can be

accepted by adding a series resistor of 47 Ω or larger.

LAYOUT RECOMMENDATIONS

A proposed layout for the DRV603 can be seen in the DRV603EVM User's Guide (SLOU248), and the Gerber

files can be downloaded from http://focus.ti.com/docs/toolsw/folders/print/drv603evm.html. To access this

information, open the DRV603 product folder and look in the Tools and Software folder.

GAIN-SETTING RESISTORS

The gain-setting resistors, RINand Rfb, must be placed close to the input pins to minimize capacitive loading on

these input pins and to ensure maximum stability of the DRV603. For the recommended PCB layout, see the

DRV603EVM user's guide (SLOU248).

Product Folder Link(s): DRV603

12 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Page 13

R3

+

C1

RIGHT

INPUT

+

-

LEFT

INPUT

LEFT

OUTPUT

RIGHT

OUTPUT

5 VSupply

C2

C1

R3

R2

R2

R1

R1

R3

+

-

C2

R3R1

R1

1mF

R2 C1

R2

C1

1mF

1mF

LinearLowDrop

Regulator

R11

R12

10mF

SystemSupply

C3

C3

C3

C3

+INL

-INL

OUTL

UVP

PGND

PVDD

CP

Line

Driver

Line

Driver

ShortCircuit

Protection

ClickandPop

Suppression

Bias

Circuitry

+INR

-INR

OUTR

SGND

EN

PVSS

CN

DRV603

DRV603

www.ti.com

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

APPLICATION CIRCUIT

R1 = 5.6 kΩ, R2 = 5.6 kΩ, R3 = 5.6 kΩ, C1 = 220 pF, C2 = 470 pF

Differential-input, single-ended output, second-order filter

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Link(s): DRV603

Page 14

DRV603

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

www.ti.com

REVISION HISTORY

NOTE: Page numbers of current version may differ from previous versions.

Changes from Revision A (February 2009) to Revision B Page

• Changed Crosstalk spec from –80dB to –100dB ................................................................................................................. 3

• Added missing voltage value (1.25V) to External Undervoltage Detection threshold equation. ........................................ 12

14 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DRV603

Page 15

DRV603

www.ti.com

SLOS617C –JANUARY 2009–REVISED NOVEMBER 2009

Changes from Revision B (October 2009) to Revision C Page

• Changed maximum operating junction temperature ............................................................................................................. 2

• In Dissipation Ratings section, changed θJxto R

in three places and 185°C to 185°C/W ............................................... 2

θJx

• Corrected reference to Figure 11 .......................................................................................................................................... 9

• Added cross-reference to Figure 13 ................................................................................................................................... 11

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Link(s): DRV603

Page 16

PACKAGE OPTION ADDENDUM

www.ti.com 18-Nov-2009

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

DRV603PW ACTIVE TSSOP PW 14 90 Green(RoHS &

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-1-260C-UNLIM

(3)

no Sb/Br)

DRV603PWR ACTIVE TSSOP PW 14 2000 Green (RoHS &

CU NIPDAU Level-1-260C-UNLIM

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 17

PACKAGE MATERIALS INFORMATION

www.ti.com 20-Jul-2010

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

DRV603PWR TSSOP PW 14 2000 330.0 12.4 6.9 5.6 1.6 8.0 12.0 Q1

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 18

PACKAGE MATERIALS INFORMATION

www.ti.com 20-Jul-2010

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

DRV603PWR TSSOP PW 14 2000 346.0 346.0 29.0

Pack Materials-Page 2

Page 19

Page 20

Page 21

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Audio www.ti.com/audio Communications and Telecom www.ti.com/communications

Amplifiers amplifier.ti.com Computers and Peripherals www.ti.com/computers

Data Converters dataconverter.ti.com Consumer Electronics www.ti.com/consumer-apps

DLP® Products www.dlp.com Energy and Lighting www.ti.com/energy

DSP dsp.ti.com Industrial www.ti.com/industrial

Clocks and Timers www.ti.com/clocks Medical www.ti.com/medical

Interface interface.ti.com Security www.ti.com/security

Logic logic.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Power Mgmt power.ti.com Transportation and www.ti.com/automotive

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com Wireless www.ti.com/wireless-apps

RF/IF and ZigBee® Solutions www.ti.com/lprf

TI E2E Community Home Page e2e.ti.com

Automotive

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2011, Texas Instruments Incorporated

Loading...

Loading...