Page 1

DAC8718

DAC8718

ControlLogic

An ogal Monit ro

ToDAC-0,DAC-1,

DAC-2,DAC-3

ToDAC-0,DAC-1,

DAC-2,DAC-3

ToDAC-4,DAC-5,DAC-6,DAC-7

DAC8718

OFFSET-B

AGND-B

V -7

OUT

V

MON

OFFSET-A

AGND-A

REF-B

Reference

BufferB

InternalTrimming

Zero/Gain;INL

Reference

BufferA

OFFSET

DACA

OFFSET

DACB

DAC-0

Latch-0

Power-Up/

Power-Down

Control

(SameFunctionBlocks

forAllChannels)

REF-A

LDAC

RST

RSTSEL

LDAC

CLR

USB/BTC

AIN-0

AIN-1

GPIO-0

GPIO-1

GPIO-2

SDO

SDI

CS

SCLK

WAKEUP

SPIShiftRegister

IOVDDDGND DVDDAVDDAV

SS

DGND DVDDAVDDAV

SS

V -0

OUT

V -7

OUT

AIN-0

AIN-1

RefBufferA

RefBufferB

OFFSET-B

Mux

Command

Registers

InputData

Register0

Correction

Engine

(WhenCorrectionEngineDisabled)

DAC-0

Data

UserCalibration:

ZeroRegister0

GainRegsiter0

V -0

OUT

DAC8718

www.ti.com

SBAS467A –MAY 2009–REVISED DECEMBER 2009

Octal, 16-Bit, Low-Power, High-Voltage Output, Serial Input

DIGITAL-TO-ANALOG CONVERTER

Check for Samples: DAC8718

1

FEATURES

2345

• Bipolar Output: ±2V to ±16.5V

• Unipolar Output: 0V to +33V

• 16-Bit Resolution

• Low Power: 14.4mW/Ch (Bipolar Supply)

• Relative Accuracy: 4 LSB Max when operating from a +30.5V (or higher) power

• Low Zero/Full-Scale Error

– Before User Calibration: ±10 LSB Max

– After User Calibration: ±1 LSB

• Flexible System Calibration

• Low Glitch: 4nV-s

• Settling Time: 15μs

• Channel Monitor Output

• Programmable Gain: x4/x6

• Programmable Offset

• SPI™: Up to 50MHz, 1.8V/3V/5V Logic

• Schmitt Trigger Inputs

• Daisy-Chain with Sleep Mode Enhancement

• Packages: QFN-48 (7x7mm), TQFP-64

(10x10mm)

APPLICATIONS

• Automatic Test Equipment

• PLC and Industrial Process Control

• Communications

DESCRIPTION

The DAC8718 is a low-power, octal, 16-bit

digital-to-analog converter (DAC). With a 5V

reference, the output can either be a bipolar ±15V

voltage when operating from dual ±15.5V (or higher)

power supplies, or a unipolar 0V to +30V voltage

supply. With a 5.5V reference, the output can either

be a bipolar ±16.5V voltage when operating from dual

±17V (or higher) power supplies, or a unipolar 0V to

+33V voltage when operating from a +33.5V (or

higher) power supply. This DAC provides low-power

operation, good linearity, and low glitch over the

specified temperature range of –40°C to +105°C. This

device is trimmed in manufacturing and has very low

zero-code and gain error. In addition, system level

calibration can be performed to achieve ±1 LSB

bipolar zero/full-scale error with bipolar supplies, or

±1 LSB zero code/full-scale error with a unipolar

supply, over the entire signal chain. The output range

can be offset by using the DAC offset register.

The DAC8718 features a standard, high-speed serial

peripheral interface (SPI) that operates at up to

50MHz and is 1.8V, 3V, and 5V logic compatible, to

communicate with a DSP or microprocessor. The

input data of the device are double-buffered. An

asynchronous load input (LDAC) transfers data from

the DAC data register to the DAC latch. The

asynchronous CLR input sets the output of all eight

DACs to AGND. The V

that connects to the individual analog outputs, the

offset DAC, the reference buffer outputs, and two

external inputs through a multiplexer (mux).

The DAC8718 is pin-to-pin and function-compatible

with the DAC8218 (14-bit) and the DAC7718 (12-bit).

pin is a monitor output

MON

1

2DSP is a trademark of Texas Instruments.

3SPI, QSPI are trademarks of Motorola Inc.

4Microwire is a trademark of National Semiconductor.

5All other trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of allparameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2009, Texas Instruments Incorporated

Page 2

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

www.ti.com

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

ORDERING INFORMATION

(1)

RELATIVE DIFFERENTIAL SPECIFIED

ACCURACY LINEARITY PACKAGE- PACKAGE TEMPERATURE PACKAGE

PRODUCT (LSB) (LSB) LEAD DESIGNATOR RANGE MARKING

DAC8718

±4 ±1 QFN-48 RGZ –40°C to +105°C DAC8718

±4 ±1 TQFP-64 PAG –40°C to +105°C DAC8718

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this data sheet, or see the TI

web site at www.ti.com.

ABSOLUTE MAXIMUM RATINGS

(1)

Over operating free-air temperature range (unless otherwise noted).

DAC8718 UNIT

AVDDto AV

SS

AVDDto AGND –0.3 to 38 V

AVSSto AGND, DGND –19 to 0.3 V

DVDDto DGND –0.3 to 6 V

IOVDDto DGND –0.3 to min of (6 or DVDD+ 0.3) V

AGND-x to DGND –0.3 to 0.3 V

Digital input voltage to DGND –0.3 to IOVDD+ 0.3 V

SDO to DGND –0.3 to IOVDD+ 0.3 V

V

OUT

-x, V

, AIN-x to AV

MON

SS

REF-A, REF-B to AGND –0.3 to DV

GPIO-n to DGND –0.3 to IOVDD+ 0.3 V

GPIO-n input current 5 mA

Maximum current from V

MON

Operating temperature range –40 to +105 °C

Storage temperature range –65 to +150 °C

Maximum junction temperature (TJmax) +150 °C

Human body model (HBM) 2.5 kV

ESD ratings Charged device model (CDM) 1000 V

Machine model (MM) 200 V

TQFP 55 °C/W

QFN 27.5 °C/W

TQFP 21 °C/W

QFN 10.8 °C/W

Thermal impedance

Junction-to-ambient, θ

Junction-to-case, θ

JC

JA

Power dissipation (TJmax – TA) / θ

(1) Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. Exposure to absolute

maximum conditions for extended periods may affect device reliability.

–0.3 to 38 V

–0.3 to AVDD+ 0.3 V

DD

3 mA

JA

V

W

2 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DAC8718

Page 3

DAC8718

www.ti.com

SBAS467A –MAY 2009–REVISED DECEMBER 2009

ELECTRICAL CHARACTERISTICS: Dual-Supply

All specifications at TA= T

gain = 6, AGND-x = DGND = 0V, data format = straight binary, and Offset DAC A and Offset DAC B are at default values

unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNIT

STATIC PERFORMANCE

Resolution 16 Bits

Linearity error Measured by line passing through codes 0000h and FFFFh ±4 LSB

Differential linearity error Measured by line passing through codes 0000h and FFFFh ±1 LSB

Bipolar zero error TA= +25°C, before user calibration, gain = 4, code = 8000h ±15 LSB

Bipolar zero error TC Gain = 4 or 6, code = 8000h ±0.5 ±2 ppm FSR/°C

Zero-code error

Zero-code error TC Gain = 4 or 6, code = 0000h ±0.5 ±3 ppm FSR/°C

Gain error

Gain error TC Gain = 4 or 6 ±1 ±3 ppm FSR/°C

Full-scale error TA= +25°C, before user calibration, gain = 4, code = FFFFh ±15 LSB

Full-scale error TC Gain = 4 or 6, code = FFFFh ±0.5 ±3 ppm FSR/°C

DC crosstalk

(3)

(1) Offset DAC A and Offset DAC B are trimmed in manufacturing to minimize the error for symmetrical output. The default value may vary

no more than ±10 LSB from the nominal number listed in Table 7. The Offset DAC pins are not intended to drive an external load, and

must not be connected during dual-supply operation.

(2) Gain = 4 and TC specified by design and characterization.

(3) The DAC outputs are buffered by op amps that share common AVDDand AVSSpower supplies. DC crosstalk indicates how much dc

change in one or more channel outputs may occur when the dc load current changes in one channel (because of an update). With

high-impedance loads, the effect is virtually immeasurable. Multiple AVDDand AVSSterminals are provided to minimize dc crosstalk.

(2)

to T

MIN

TA= +25°C, before user calibration, gain = 6, code = 8000h ±10 LSB

TA= +25°C, after user calib., gain = 4 or 6, code = 8000h ±1 LSB

TA= +25°C, gain = 6, code = 0000h ±10 LSB

TA= +25°C, gain = 4, code = 0000h ±15 LSB

TA= +25°C, gain = 6 ±10 LSB

TA= +25°C, gain = 4 ±15 LSB

TA= +25°C, before user calibration, gain = 6, code = FFFFh ±10 LSB

TA= +25°C, after user calib., gain = 4 or 6, code = FFFFh ±1 LSB

Measured channel at code = 8000h, full-scale change on any

other channel

, AVDD= +16.5V, AVSS= –16.5V, IOVDD= DVDD= +5V, REF-A and REF-B = +5V,

MAX

DAC8718

0.2 LSB

(1)

,

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): DAC8718

Page 4

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

www.ti.com

ELECTRICAL CHARACTERISTICS: Dual-Supply (continued)

All specifications at TA= T

gain = 6, AGND-x = DGND = 0V, data format = straight binary, and Offset DAC A and Offset DAC B are at default values

unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNIT

ANALOG OUTPUT (V

Voltage output

Output impedance Code = 8000h 0.5 Ω

Short-circuit current

Load current See Figure 37 ±3 mA

Output drift vs time

Capacitive load stability 500 pF

Settling time 15 μs

Slew rate

Power-on delay

Power-down recovery time 60 μs

Digital-to-analog glitch

Glitch impulse peak amplitude Code from 7FFFh to 8000h and 8000h to 7FFFh 5 mV

Channel-to-channel isolation

DAC-to-DAC crosstalk

Digital crosstalk

Digital feedthrough

Output noise TA= +25°C at 10kHz, gain = 4 130 nV/√Hz

Power-supply rejection

(5)

(7)

(8)

(12)

(4) Specified by design.

(5) The analog output range of V

the analog output must not be greater than (AVDD– 0.5V), and the minimum value must not be less than (AVSS+ 0.5V). All

specifications are for a ±16.5V power supply and a ±15V output, unless otherwise noted.

(6) When the output current is greater than the specification, the current is clamped at the specified maximum value.

(7) Slew rate is measured from 10% to 90% of the transition when the output changes from 0 to full-scale.

(8) Power-on delay is defined as the time from when the supply voltages reach the specified conditions to when CS goes low, for valid

digital communication.

(9) Digital-to-analog glitch is defined as the amount of energy injected into the analog output at the major code transition. It is specified as

the area of the glitch in nV-s. It is measured by toggling the DAC register data between 7FFFh and 8000h in straight binary format.

(10) Channel-to-channel isolation refers to the ratio of the signal amplitude at the output of one DAC channel to the amplitude of the

sinusoidal signal on the reference input of another DAC channel. It is expressed in dB and measured at midscale.

(11) DAC-to-DAC crosstalk is the glitch impulse that appears at the output of one DAC as a result of both the full-scale digital code and

subsequent analog output change at another DAC. It is measured with LDAC tied low and expressed in nV-s.

(12) Digital crosstalk is the glitch impulse transferred to the output of one converter as a result of a full-scale code change in the DAC input

register of another converter. It is measured when the DAC output is not updated, and is expressed in nV-s.

(13) Digital feedthrough is the glitch impulse injected to the output of a DAC as a result of a digital code change in the DAC input register of

the same DAC. It is measured with the full-scale digital code change without updating the DAC output, and is expressed in nV-s.

(14) The output must not be greater than (AVDD– 0.5V) and not less than (AVSS+ 0.5V).

(13)

-0 to V

OUT

(6)

(9)

(11)

(14)

to T

MIN

-7)

OUT

V

V

TA= +25°C, device operating for 500 hours, full-scale output 3.4 ppm of FSR

TA= +25°C, device operating for 1000 hours, full-scale output 4.3 ppm of FSR

To 0.03% of FSR, CL= 200pF, RL= 10kΩ, code from 0000h

to FFFFh and FFFFh to 0000h

To 1 LSB, CL= 200pF, RL= 10kΩ, code from 0000h to

FFFFh and FFFFh to 0000h

To 1 LSB, CL= 200pF, RL= 10kΩ, code from 7F00h to

8100h and 8100h to 7F00h

From IOVDD≥ +1.8V and DVDD≥ +2.7V to CS low 200 μs

Code from 7FFFh to 8000h and 8000h to 7FFFh 4 nV-s

(10)

V

DACs in the same group 7.5 nV-s

DACs among different groups 1 nV-s

TA= +25°C at 10kHz, gain = 6 200 nV/√Hz

0.1Hz to 10Hz, gain = 6 20 μV

AVDD= ±15.5V to ±16.5V 0.05 LSB

, AVDD= +16.5V, AVSS= –16.5V, IOVDD= DVDD= +5V, REF-A and REF-B = +5V,

MAX

DAC8718

(4)

= +5V –15 +15 V

REF

= +1.5V –4.5 +4.5 V

REF

±8 mA

10 μs

6 μs

6 V/μs

= 4VPP, f = 1kHz 88 dB

REF

1 nV-s

1 nV-s

OUT

-0 to V

-7 is equal to (6 × V

OUT

– 5 × OUTPUT_OFFSET_DAC) for gain = 6. The maximum value of

REF

(1)

PP

,

4 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DAC8718

Page 5

DAC8718

www.ti.com

SBAS467A –MAY 2009–REVISED DECEMBER 2009

ELECTRICAL CHARACTERISTICS: Dual-Supply (continued)

All specifications at TA= T

gain = 6, AGND-x = DGND = 0V, data format = straight binary, and Offset DAC A and Offset DAC B are at default values

unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNIT

OFFSET DAC OUTPUT

Voltage output V

Full-scale error TA= +25°C ±4 LSB

Zero-code error TA= +25°C ±2 LSB

Linearity error ±6 LSB

Differential linearity error ±1 LSB

ANALOG MONITOR PIN (V

Output impedance

Three-state leakage current 100 nA

AUXILIARY ANALOG INPUT

Input range AV

Input impedance

(AIN-x to V

MON

)

Input capacitance

Input leakage current 30 nA

REFERENCE INPUT

Reference input voltage range

Reference input dc impedance 10 MΩ

Reference input capacitance

DIGITAL INPUT

High-level input voltage, V

Low-level input voltage, V

Input current

Input capacitance USB/BTC and RSTSEL 12 pF

DIGITAL OUTPUT

High-level output voltage, V

(SDO)

Low-level output voltage, V

(SDO)

GPIO-n output voltage low, V

GPIO-n output voltage high, VOH10kΩ pull-up resistor to IOV

High-impedance leakage current SDO and GPIO-n ±5 μA

High-impedance output

capacitance

(15) Specified by design.

(16) Offset DAC A and Offset DAC B are trimmed in manufacturing to minimize the error for symmetrical output. The default value may vary

no more than ±10 LSB from the nominal number listed in Table 7. The Offset DAC pins are not intended to drive an external load, and

must not be connected during dual-supply operation.

(17) 8kΩ when V

(18) Reference input voltage ≤ DVDD.

(15) (16)

(17)

(15)

(15)

IH

IL

(15)

OH

OL

is connected to Reference Buffer A or B, and 4kΩ when V

MON

to T

MIN

, AVDD= +16.5V, AVSS= –16.5V, IOVDD= DVDD= +5V, REF-A and REF-B = +5V,

MAX

DAC8718

= +5V 0 5 V

REF

)

MON

TA= +25°C 2 kΩ

SS

TA= +25°C 2 kΩ

4 pF

(18)

(15)

1.0 5.5 V

10 pF

IOVDD= +4.5V to +5.5V 3.8 0.3 + IOV

IOVDD= +2.7V to +3.3V 2.3 0.3 + IOV

IOVDD= +1.7V to 2.0V 1.5 0.3 + IOV

IOVDD= +4.5V to +5.5V –0.3 0.8 V

IOVDD= +2.7V to +3.3V –0.3 0.6 V

IOVDD= +1.7V to 2.0V –0.3 0.3 V

CLR, LDAC, RST, CS, and SDI ±1 μA

USB/BTC, RSTSEL, and GPIO-n ±5 μA

CLR, LDAC, RST, CS, and SDI 5 pF

GPIO-n 14 pF

IOVDD= +2.7V to +5.5V, sourcing 1mA IOVDD– 0.4 IOV

IOVDD= +1.8V, sourcing 200μA 1.6 IOV

IOVDD= +2.7V to +5.5V, sinking 1mA 0 0.4 V

IOVDD= +1.8V, sinking 200μA 0 0.2 V

1mA sink from IOV

OL

DD

DD

0.99 × IOV

DD

0.15 V

SDO 5 pF

GPIO-n 14 pF

is connected to Offset DAC-A or -B.

MON

AV

(1)

DD

DD

DD

DD

DD

DD

V

V

V

V

V

V

V

,

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): DAC8718

Page 6

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

www.ti.com

ELECTRICAL CHARACTERISTICS: Dual-Supply (continued)

All specifications at TA= T

gain = 6, AGND-x = DGND = 0V, data format = straight binary, and Offset DAC A and Offset DAC B are at default values

unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNIT

POWER SUPPLY

AV

DD

AV

SS

DV

DD

(19)

IOV

DD

AI

DD

AI

SS

DI

DD

IOI

DD

Power dissipation Normal operation, ±16.5V supplies, midscale code 115 165 mW

TEMPERATURE RANGE

Specified performance –40 +105 °C

(19) IOVDD≤ DVDD.

to T

MIN

Normal operation, midscale code, output unloaded 4.3 6 mA

Power down, output unloaded 35 μA

Normal operation, midscale code, output unloaded –4 –2.7 mA

Power down, output unloaded 35 μA

Normal operation 78 μA

Power down 36 μA

Normal operation, VIH= IOVDD, VIL= DGND 5 μA

Power down, VIH= IOVDD, VIL= DGND 5 μA

, AVDD= +16.5V, AVSS= –16.5V, IOVDD= DVDD= +5V, REF-A and REF-B = +5V,

MAX

DAC8718

+4.5 +18 V

–18 –4.5 V

+2.7 +5.5 V

+1.8 +5.5 V

(1)

,

6 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DAC8718

Page 7

DAC8718

www.ti.com

SBAS467A –MAY 2009–REVISED DECEMBER 2009

ELECTRICAL CHARACTERISTICS: Single-Supply

All specifications at TA= T

AGND-x = DGND = 0V, data format = straight binary, and OFFSET-A = OFFSET-B = AGND, unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNIT

STATIC PERFORMANCE

Resolution 16 Bits

Linearity error Measured by line passing through codes 0100h and FFFFh ±4 LSB

Differential linearity error Measured by line passing through codes 0100h and FFFFh ±1 LSB

Unipolar zero error TA= +25°C, before user calibration, gain = 4, code = 0100h ±15 LSB

Unipolar zero error TC Gain = 4 or 6, code = 0100h ±0.5 ±3 ppm FSR/°C

Gain error

Gain error TC Gain = 4 or 6 ±1 ±3 ppm FSR/°C

Full-scale error TA= +25°C, before user calibration, gain = 4, code = FFFFh ±15 LSB

Full-scale error TC Gain = 4 or 6, code = FFFFh ±0.5 ±3 ppm FSR/°C

DC crosstalk

ANALOG OUTPUT (V

Voltage output

Output impedance Code = 8000h 0.5 Ω

Short-circuit current

Load current SeeFigure 84 and Figure 85 ±3 mA

Output drift vs time

Capacitive load stability 500 pF

Settling time 15 μs

Slew rate

Power-on delay

Power-down recovery time 90 μs

Digital-to-analog glitch

Glitch impulse peak amplitude Code from 7FFFh to 8000h and 8000h to 7FFFh 5 mV

Channel-to-channel isolation

(2)

(4)

(6)

(7)

(1) Gain = 4 and TC specified by design and characterization.

(2) The DAC outputs are buffered by op amps that share common AVDDand AVSSpower supplies. DC crosstalk indicates how much dc

change in one or more channel outputs may occur when the dc load current changes in one channel (because of an update). With

high-impedance loads, the effect is virtually immeasurable. Multiple AVDDand AVSSterminals are provided to minimize dc crosstalk.

(3) Specified by design.

(4) The analog output range of V

greater than (AVDD– 0.5V). All specifications are for a +32V power supply and a 0V to +30V output, unless otherwise noted.

(5) When the output current is greater than the specification, the current is clamped at the specified maximum value.

(6) Slew rate is measured from 10% to 90% of the transition when the output changes from 0 to full-scale.

(7) Power-on delay is defined as the time from when the supply voltages reach the specified conditions to when CS goes low, for valid

digital communication.

(8) Digital-to-analog glitch is defined as the amount of energy injected into the analog output at the major code transition. It is specified as

the area of the glitch in nV-s. It is measured by toggling the DAC register data between 7FFFh and 8000h in straight binary format.

(9) Channel-to-channel isolation refers to the ratio of the signal amplitude at the output of one DAC channel to the amplitude of the

sinusoidal signal on the reference input of another DAC channel. It is expressed in dB and measured at midscale.

(1)

-0 to V

OUT

(5)

(8)

to T

MIN

TA= +25°C, before user calibration, gain = 6, code = 0100h ±10 LSB

TA= +25°C, after user calib., gain = 4 or 6, code = 0100h ±1 LSB

TA= +25°C, gain = 6 ±10 LSB

TA= +25°C, gain = 4 ±15 LSB

TA= +25°C, before user calibration, gain = 6, code = FFFFh ±10 LSB

TA= +25°C, after user calib., gain = 4 or 6, code = FFFFh ±1 LSB

Measured channel at code = 8000h, full-scale change on any

other channel

-7)

OUT

V

REF

V

REF

TA= +25°C, device operating for 500 hours, full-scale output 3.4 ppm of FSR

TA= +25°C, device operating for 1000 hours, full-scale output 4.3 ppm of FSR

To 0.03% of FSR, CL= 200pF, RL= 10kΩ, code from 0100h to

FFFFh and FFFFh to 0100h

To 1 LSB, CL= 200pF, RL= 10kΩ, code from 0100h to FFFFh

and FFFFh to 0100h

To 1 LSB, CL= 200pF, RL= 10kΩ, code from 7F00h to 8100h

and 8100h to 7F00h

From IOVDD≥ +1.8V and DVDD≥ +2.7V to CS low 200 μs

Code from 7FFFh to 8000h and 8000h to 7FFFh 4 nV-s

(9)

V

REF

, AVDD= +32V, AVSS= 0V, IOVDD= DVDD= +5V, REF-A and REF-B = +5V, gain = 6,

MAX

DAC8718

0.2 LSB

(3)

= +5V 0 +30 V

= +1.5V 0 +9 V

±8 mA

10 μs

6 μs

6 V/μs

= 4VPP, f = 1kHz 88 dB

OUT

-0 to V

-7 is equal to (6 × V

OUT

) for gain = 6. The maximum value of the analog output must not be

REF

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Link(s): DAC8718

Page 8

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

www.ti.com

ELECTRICAL CHARACTERISTICS: Single-Supply (continued)

All specifications at TA= T

AGND-x = DGND = 0V, data format = straight binary, and OFFSET-A = OFFSET-B = AGND, unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNIT

DAC-to-DAC crosstalk

Digital crosstalk

Digital feedthrough

Output noise TA= +25°C at 10kHz, gain = 4 130 nV/√Hz

Power-supply rejection

ANALOG MONITOR PIN (V

Output impedance

Three-state leakage current 100 nA

AUXILIARY ANALOG INPUT

Input range AV

Input impedance

(AIN-x to V

MON

Input capacitance

Input leakage current 30 nA

REFERENCE INPUT

Reference input voltage

(16)

range

Reference input dc impedance 10 MΩ

Reference input capacitance

DIGITAL INPUT

High-level input voltage, V

Low-level input voltage, V

Input current

Input capacitance USB/BTC and RSTSEL 12 pF

(10) DAC-to-DAC crosstalk is the glitch impulse that appears at the output of one DAC as a result of both the full-scale digital code and

subsequent analog output change at another DAC. It is measured with LDAC tied low and expressed in nV-s.

(11) Digital crosstalk is the glitch impulse transferred to the output of one converter as a result of a full-scale code change in the DAC input

register of another converter. It is measured when the DAC output is not updated, and is expressed in nV-s.

(12) Digital feedthrough is the glitch impulse injected to the output of a DAC as a result of a digital code change in the DAC input register of

the same DAC. It is measured with the full-scale digital code change without updating the DAC output, and is expressed in nV-s.

(13) The analog output must not be greater than (AVDD– 0.5V).

(14) 8kΩ when V

(15) Specified by design.

(16) Reference input voltage ≤ DVDD.

(10)

(11)

(12)

(13)

(14)

)

(15)

(15)

IH

IL

is connected to Reference Buffer A or B, and 4kΩ when V

MON

to T

MIN

, AVDD= +32V, AVSS= 0V, IOVDD= DVDD= +5V, REF-A and REF-B = +5V, gain = 6,

MAX

DAC8718

DACs in the same group 10 nV-s

DACs among different groups 1 nV-s

1 nV-s

1 nV-s

TA= +25°C at 10kHz, gain = 6 200 nV/√Hz

0.1Hz to 10Hz, gain = 6 20 μV

AVDD= +33V to +36V 0.05 LSB

)

MON

TA= +25°C 2 kΩ

SS

AV

DD

TA= +25°C 2 kΩ

4 pF

1.0 5.5 V

(15)

IOVDD= +4.5V to +5.5V 3.8 0.3 + IOV

IOVDD= +2.7V to +3.3V 2.3 0.3 + IOV

IOVDD= +1.7V to 2.0V 1.5 0.3 + IOV

10 pF

DD

DD

DD

IOVDD= +4.5V to +5.5V –0.3 0.8 V

IOVDD= +2.7V to +3.3V –0.3 0.6 V

IOVDD= +1.7V to 2.0V –0.3 0.3 V

CLR, LDAC, RST, CS, and SDI ±1 μA

USB/BTC, RSTSEL, and GPIO-n ±5 μA

CLR, LDAC, RST, CS, and SDI 5 pF

GPIO-n 14 pF

is connected to Offset DAC-A or -B.

MON

PP

V

V

V

V

8 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DAC8718

Page 9

DAC8718

www.ti.com

SBAS467A –MAY 2009–REVISED DECEMBER 2009

ELECTRICAL CHARACTERISTICS: Single-Supply (continued)

All specifications at TA= T

AGND-x = DGND = 0V, data format = straight binary, and OFFSET-A = OFFSET-B = AGND, unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNIT

DIGITAL OUTPUT

High-level output voltage, V

(SDO)

Low-level output voltage, V

(SDO)

GPIO-n output voltage low, VOL1mA sink from IOV

GPIO-n output voltage high, VOH10kΩ pull-up resistor to IOV

High-impedance leakage current SDO and GPIO-n ±5 μA

High-impedance output

capacitance

POWER SUPPLY

AV

DD

DV

DD

(18)

IOV

DD

AI

DD

DI

DD

IOI

DD

Power dissipation Normal operation 140 225 mW

TEMPERATURE RANGE

Specified performance –40 +105 °C

(17) Specified by design.

(18) IOVDD≤ DVDD.

(17)

OH

OL

to T

MIN

, AVDD= +32V, AVSS= 0V, IOVDD= DVDD= +5V, REF-A and REF-B = +5V, gain = 6,

MAX

DAC8718

IOVDD= +2.7V to +5.5V, sourcing 1mA IOVDD– 0.4 IOV

IOVDD= +1.8V, sourcing 200μA 1.6 IOV

DD

DD

IOVDD= +2.7V to +5.5V, sinking 1mA 0 0.4 V

IOVDD= +1.8V, sinking 200μA 0 0.2 V

DD

DD

0.99 × IOV

DD

0.15 V

SDO 5 pF

GPIO-n 14 pF

+9 +36 V

+2.7 +5.5 V

+1.8 +5.5 V

Normal operation, midscale code, output unloaded 4.5 7 mA

Power down, output unloaded 35 µA

Normal operation 70 μA

Power down 36 μA

Normal operation, VIH= IOVDD, VIL= DGND 5 μA

Power down, VIH= IOVDD, VIL= DGND 5 μA

V

V

V

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): DAC8718

Page 10

ControlLogic

An ogal Monit ro

ToDAC-0,DAC-1,

DAC-2,DAC-3

ToDAC-0,DAC-1,

DAC-2,DAC-3

ToDAC-4,DAC-5,DAC-6,DAC-7

DAC8718

OFFSET-B

AGND-B

V -7

OUT

V

MON

OFFSET-A

AGND-A

REF-B

Reference

BufferB

InternalTrimming

Zero/Gain;INL

Reference

BufferA

OFFSET

DACA

OFFSET

DACB

DAC-0

Latch-0

Power-Up/

Power-Down

Control

(SameFunctionBlocks

forAllChannels)

REF-A

LDAC

RST

RSTSEL

LDAC

CLR

USB/BTC

AIN-0

AIN-1

GPIO-0

GPIO-1

GPIO-2

SDO

SDI

CS

SCLK

WAKEUP

SPIShiftRegister

IOVDDDGND DV

DD

AV

DD

AV

SS

DGND DV

DD

AV

DD

AV

SS

V -0

OUT

V -7

OUT

AIN-0

AIN-1

RefBufferA

RefBufferB

OFFSET-B

Mux

Command

Registers

InputData

Register0

Correction

Engine

(WhenCorrectionEngineDisabled)

DAC-0

Data

UserCalibration:

ZeroRegister0

GainRegsiter0

V -0

OUT

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

www.ti.com

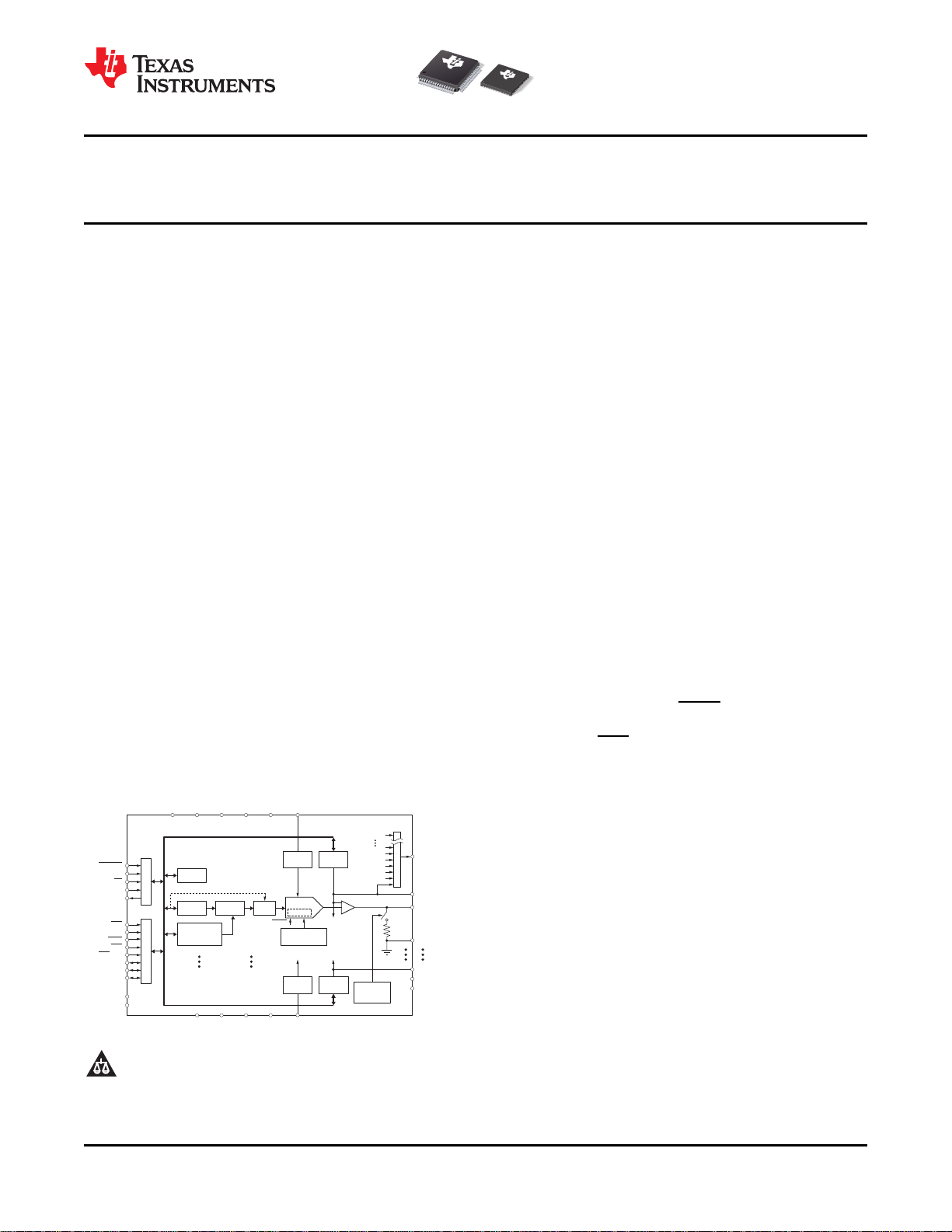

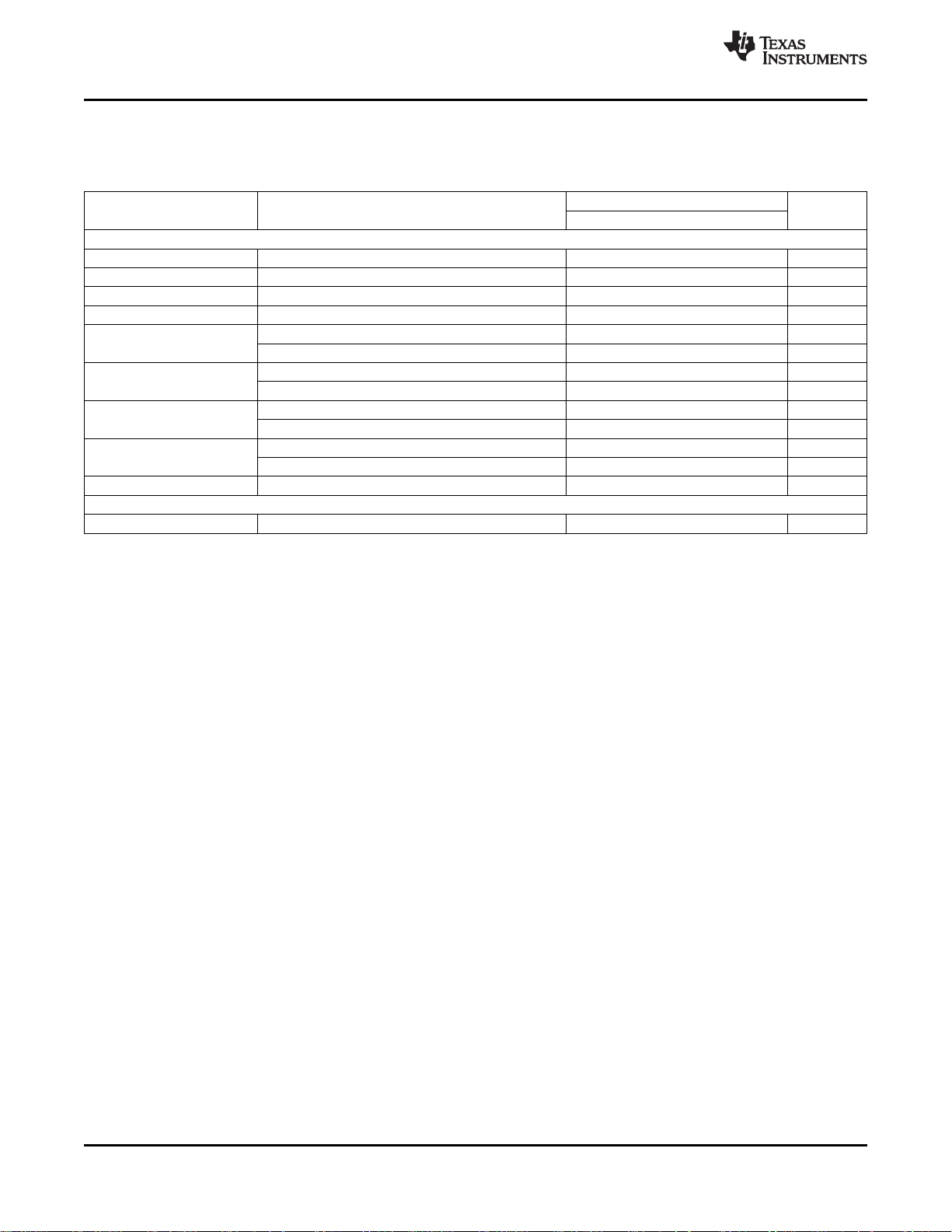

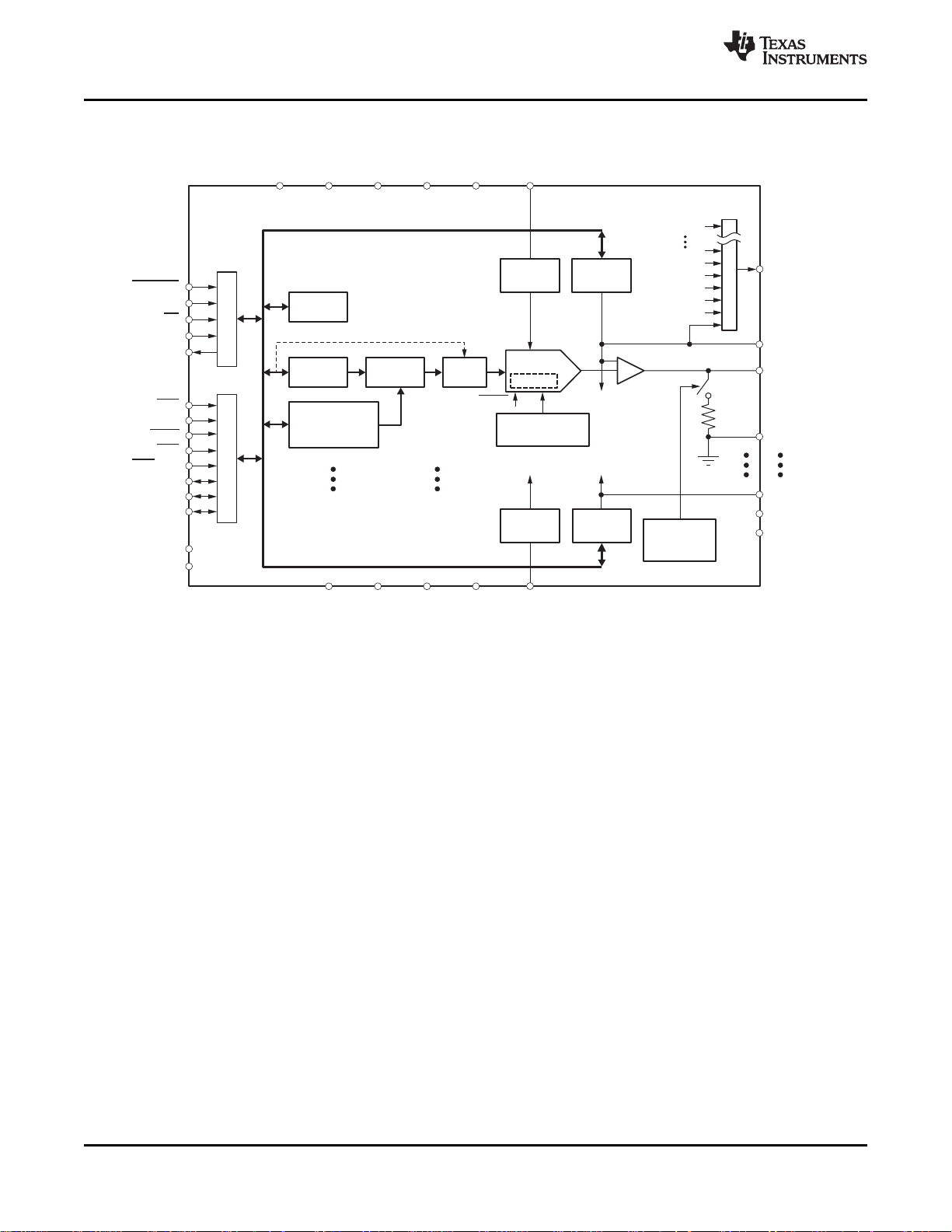

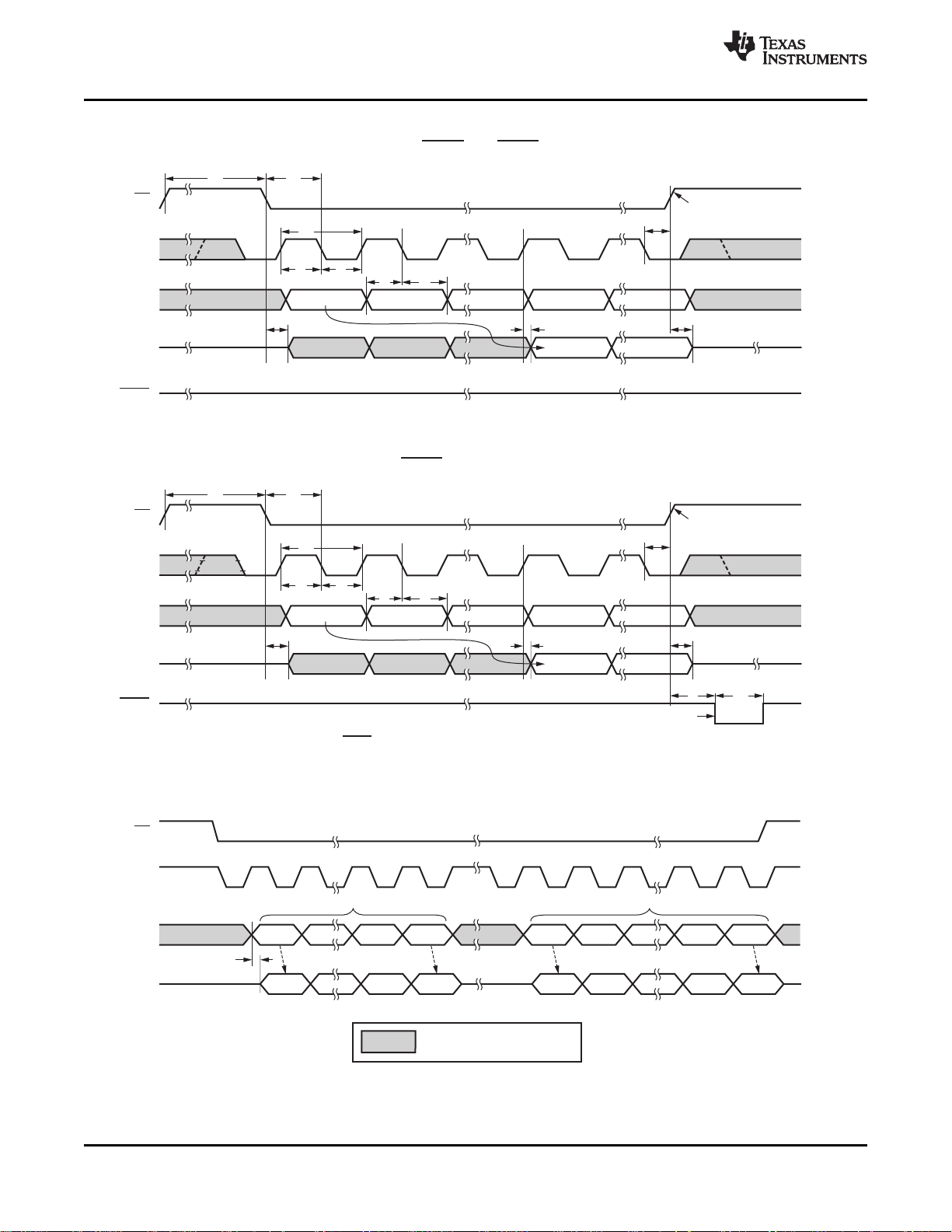

FUNCTIONAL BLOCK DIAGRAM

Figure 1. Functional Block Diagram

10 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DAC8718

Page 11

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

AV

DD

NC

AIN-1

V -4

OUT

REF-B

V -5

OUT

V -6

OUT

AGND-B

AGND-B

OFFSET-B

V -7

OUT

AV

SS

NC

NC

NC

NC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

AV

DD

NC

AIN-0

V -3

OUT

REF-A

V -2

OUT

V -1

OUT

AGND-A

AGND-A

OFFSET-A

V -0

OUT

AV

SS

NC

V

MON

NC

NC

NC

WAKEUP

LDAC

SDONCSDICSSCLK

DV

DD

IOV

DD

DGNDNCNC

RSTSEL

USB/BTC

NC

NC

NC

GPIO-2

CLR

RST

NC

NC

DV

DD

DGND

NC

NC

DGND

GPIO-1

GPIO-0

NC

NC

64 63 62 61 60 59 58 57 56 55 54

17

18 19 20

21 222324

25 26

27

53 52 51 50 49

28 29 30 31 32

DAC8718

AV

DD

AIN-0

V -3

OUT

REF-A

V -2

OUT

V -1

OUT

AGND-A

AGND-A

OFFSET-A

V -0

OUT

AV

SS

V

MON

AV

DD

AIN-1

V -4

OUT

REF-B

V -5

OUT

V -6

OUT

AGND-B

AGND-B

OFFSET-B

V -7

OUT

AV

SS

NC

1

2

3

4

5

6

7

8

9

10

11

12

36

35

34

33

32

31

30

29

28

27

26

25

DAC8718

WAKEUP

LDAC

SDO

SDICSSCLK

DV

DD

IOV

DD

DGNDNCRSTSEL

USB/BTC

4847464544434241403938

37

GPIO-2

CLR

RST

NC

DV

DD

NC

NC

DGND

NC

DGND

GPIO-1

GPIO-0

1314151617181920212223

24

DAC8718

www.ti.com

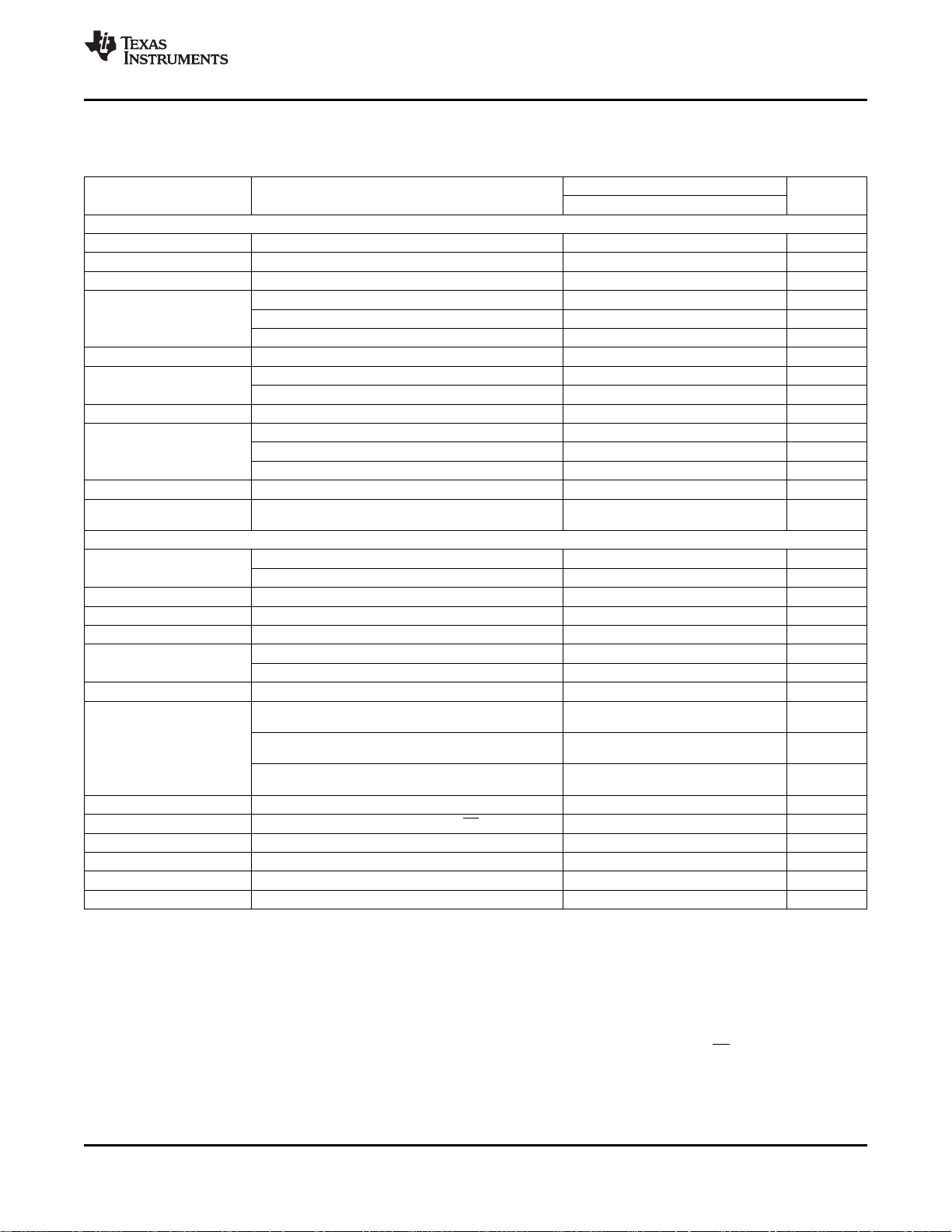

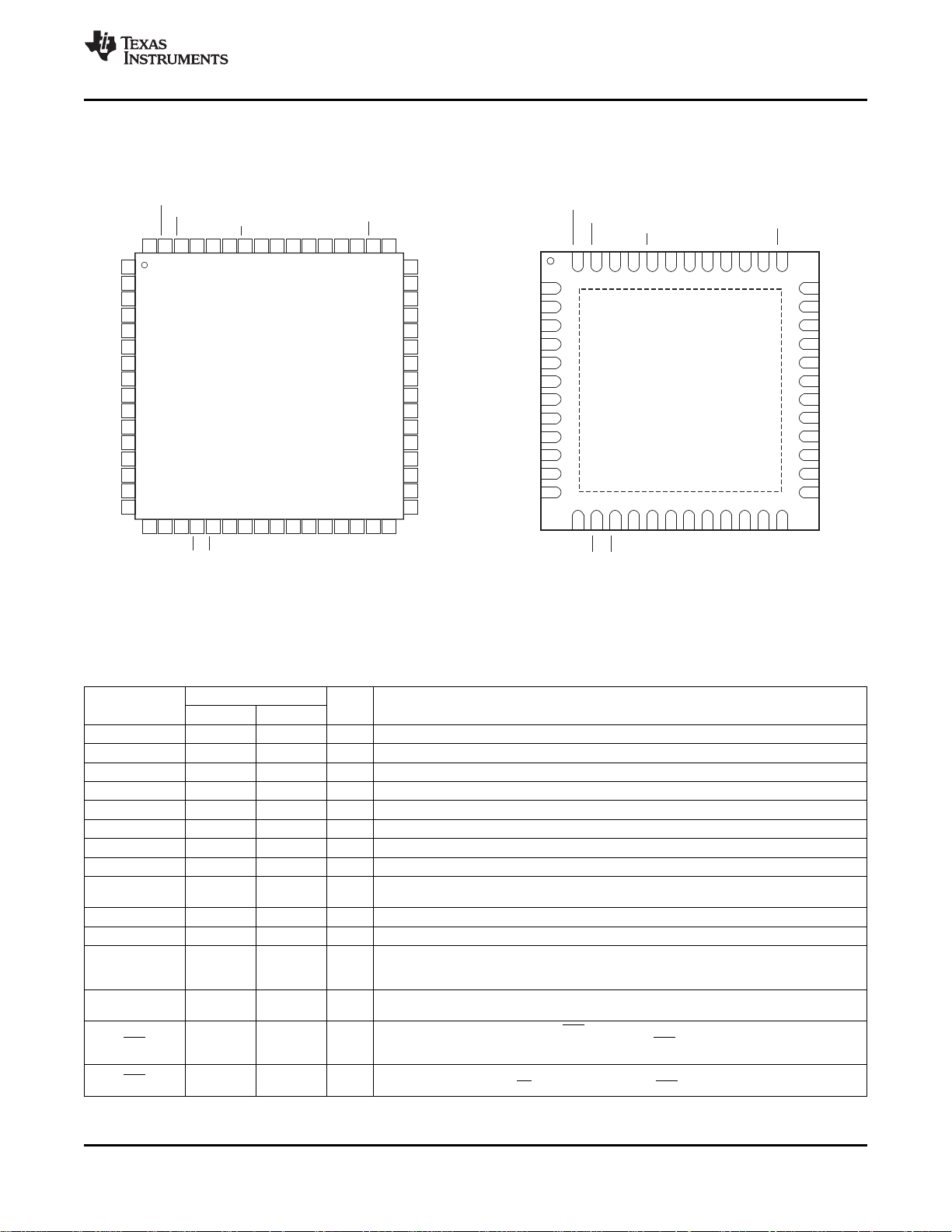

PAG PACKAGE

TQFP-64

(TOP VIEW)

SBAS467A –MAY 2009–REVISED DECEMBER 2009

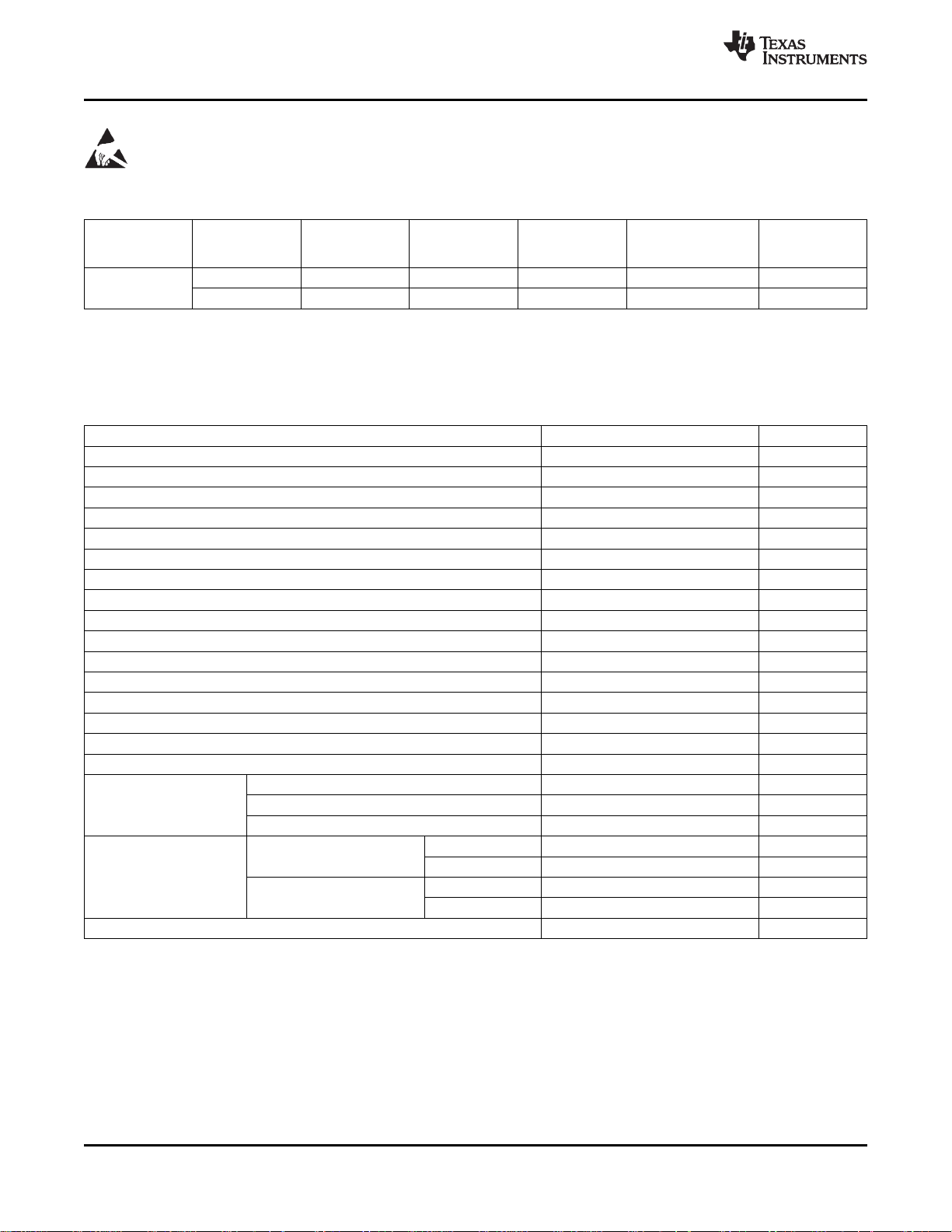

PIN CONFIGURATIONS

RGZ PACKAGE

QFN-48

(TOP VIEW)

PIN

NAME

AV

DD

AIN-0 2 3 I Auxiliary analog input 0, directly routed to the analog mux

V

-3 3 4 O DAC-3 output

OUT

REF-A 4 5 I Group A

V

-2 5 6 O DAC-2 output

OUT

V

-1 6 7 O DAC-1 output

OUT

AGND-A 7 8 I Group A analog ground and the ground of REF-A. This pin must be tied to AGND-B and DGND.

AGND-A 8 9 I Group A analog ground and the ground of REF-A. This pin must be tied to AGND-B and DGND.

OFFSET-A 9 10 O

(1) Group A consists of DAC-0, DAC-1, DAC-2, and DAC-3. Group B consists of DAC-4, DAC-5, DAC-6, and DAC-7.

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 11

V

-0 10 11 O DAC-0 output

OUT

AV

SS

V

MON

GPIO-2 13 19 I/O

CLR 14 20 I through switches and internal low-impedance. When the CLR pin is logic '1', all V

RST 15 21 I

(1) The thermal pad is internally connected to

the substrate. This pad can be connected

to AVSSor left floating. Keep the thermal

pad separate from the digital ground, if

possible.

PIN DESCRIPTIONS

PIN NO.

QFN-48 TQFP-64 I/O DESCRIPTION

1 1 I Positive analog power supply

(1)

reference input

11 12 I Negative analog power supply

12 14 O reference buffer outputs, offset DAC outputs, or one of the auxiliary analog inputs, depending on

OFFSET DAC-A analog output. Must be connected to AGND-A during single power-supply

operation (AVSS= 0V). This pin is not intended to drive an external load.

Analog monitor output. This pin is either in Hi-Z status, connected to one of the eight DAC outputs,

the content of the Monitor Register. See the Monitor Register, Table 12, for details.

General-purpose digital input/output 2. This pin is a bidirectional digital input/output, open-drain and

requires an external pull-up resistor. See the GPIO Pins section for details.

Clear input, level triggered. When the CLR pin is logic '0', all V

connect to the amplifier outputs.

Reset input (active low). Logic low on this pin resets the DAC registers and DACs to the values

defined by the RSTSEL pin. CS must be logic high when RST is active.

Product Folder Link(s): DAC8718

-X pins connect to AGND-x

OUT

OUT

-X pins

Page 12

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

PIN DESCRIPTIONS (continued)

PIN

NAME

DV

DD

DGND 20 25 I Digital ground

DGND 22 28 I Digital ground

GPIO-1 23 29 I/O

GPIO-0 24 30 I/O

AV

SS

V

-7 27 38 O DAC-7 output

OUT

OFFSET-B 28 39 O

AGND-B 29 40 I Group B

AGND-B 30 41 I Group B analog ground and the ground of REF-B. This pin must be tied to AGND-A and DGND.

V

-6 31 42 O DAC-6 output

OUT

V

-5 32 43 O DAC-5 output

OUT

REF-B 33 44 I Group B reference input

V

-4 34 45 O DAC-4 output

OUT

AIN-1 35 46 I Auxiliary analog input 1, directly routed to the analog mux

AV

DD

USB/BTC 37 50 I when connected to DGND or in twos complement format when connected to IOVDD. The command

RSTSEL 38 51 I

DGND 40 54 I Digital ground

IOV

DD

DV

DD

SCLK 43 57 I SPI bus serial clock input

CS 44 58 I

SDI 45 59 I SPI bus serial data input

SDO 46 61 O

LDAC 47 62 I

WAKEUP 48 63 I

NC — Not connected

PIN NO.

QFN-48 TQFP-64 I/O DESCRIPTION

17 24 I Digital power supply

General-purpose digital input/output 1. This pin is a bidirectional digital input/output, open-drain and

requires an external resistor. See the GPIO Pins section for details.

General-purpose digital input/output 0. This pin is a bidirectional digital input/output, open-drain and

requires an external resistor. See the GPIO Pins section for details.

26 37 I Negative analog power supply

OFFSET DAC-B analog output. Must be connected to AGND-B during single-supply operation

(AVSS= 0V).

(1)

analog ground and the ground of REF-B. This pin must be tied to AGND-A and DGND.

36 48 I Positive analog power supply

Data format selection of Input DAC data and Offset DAC data. Data are in straight binary format

data are always in straight binary format. Refer to Input Data Format section for details.

Output reset selection. Selects the output voltage on the V

Refer to the Power-On Reset section for details.

41 55 I Interface power

42 56 I Digital power supply

SPI bus chip select input (active low). Data are not clocked into SDI unless CS is low. When CS is

high, SDO is in a high-impedance state and the SCLK and SDI signals are blocked from the device.

SPI bus serial data output.

When the DSDO bit = '0', the SDO pin works as an output in normal operation.

When the DSDO bit = '1', SDO is always in a Hi-Z state, regardless of the CS pin status. Refer to

the Timing Diagrams section for details.

Load DAC latch control input (active low). When LDAC is low, the DAC latch is transparent and the

contents of the DAC Data Register are transferred to it. The DAC output changes to the

corresponding level simultaneously when the DAC latch is updated. See the Updating the DAC

Outputs section for details. If asynchronous mode is desired, LDAC must be permanently tied low

before power is applied to the device. If synchronous mode is desired, LDAC must be logic high

during power-on.

Wake-up input (active low). Restores the SPI from sleep to normal operation. See the Daisy-Chain

Operation section for details.

2, 13,

15-18, 22,

16, 18, 19, 23, 26, 27,

21, 25, 39 31-36, 47,

49, 52, 53,

60, 64

pin after power-on or hardware reset.

OUT

www.ti.com

12 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DAC8718

Page 13

t

8

CS

SCLK

InputDataRegisterand

DACLatchUpdated

WhenCorrectionCompletes

(1)

DACLatchUpdated

(2)

SDI

BIT23(MSB)

BIT23(MSB)

BIT22 BIT1

Low

BIT0

LDAC

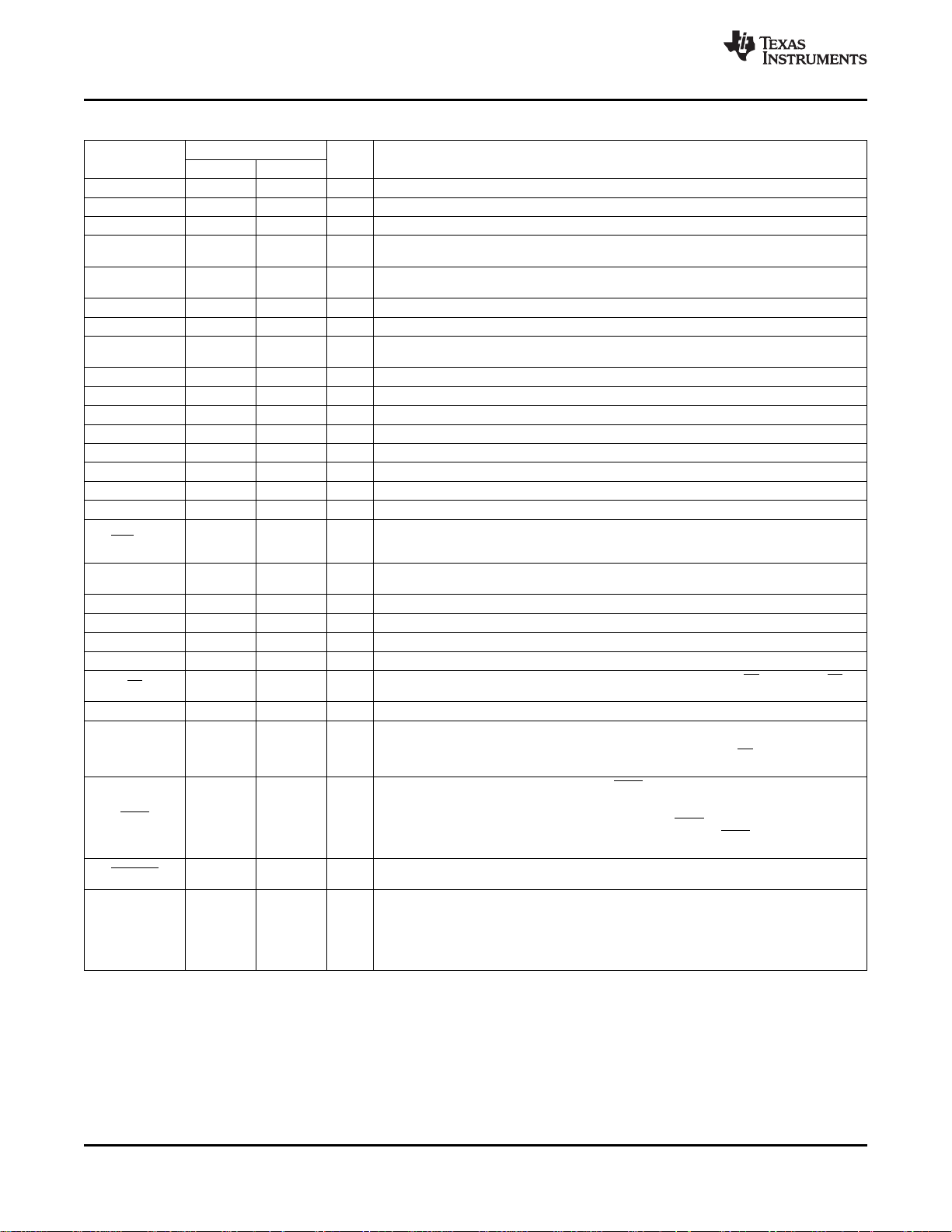

Ifthecorrectionengineisoff,theDAClatchisreloadedimmediatelyaftertheDACDataRegisterisupdated.NOTE:(1)

TheDAClatchisupdatedwhen goeslow,aslongasthetimingrequirementoft issatisfied.

9

LDAC

NOTE:(2)

t

4

t

1

t

2

t

5

t

6

t

7

Case1:Standalonemode:Updatewithout pin; tiedtologiclowLDAC LDAC pin .

t

8

CS

SCLK

InputDataRegisterUpdated,

butDACLatchisNot Updated

SDI

BIT22 BIT1

High

BIT0

LDAC

t

4

t

1

t

2

t

5

t

6

t

7

t

9

Case2:Standalonemode:Updatewith pin.LDAC

t

10

=Don’tCare

Bit23=MSB

Bit0=LSB

t

3

t

3

DAC8718

www.ti.com

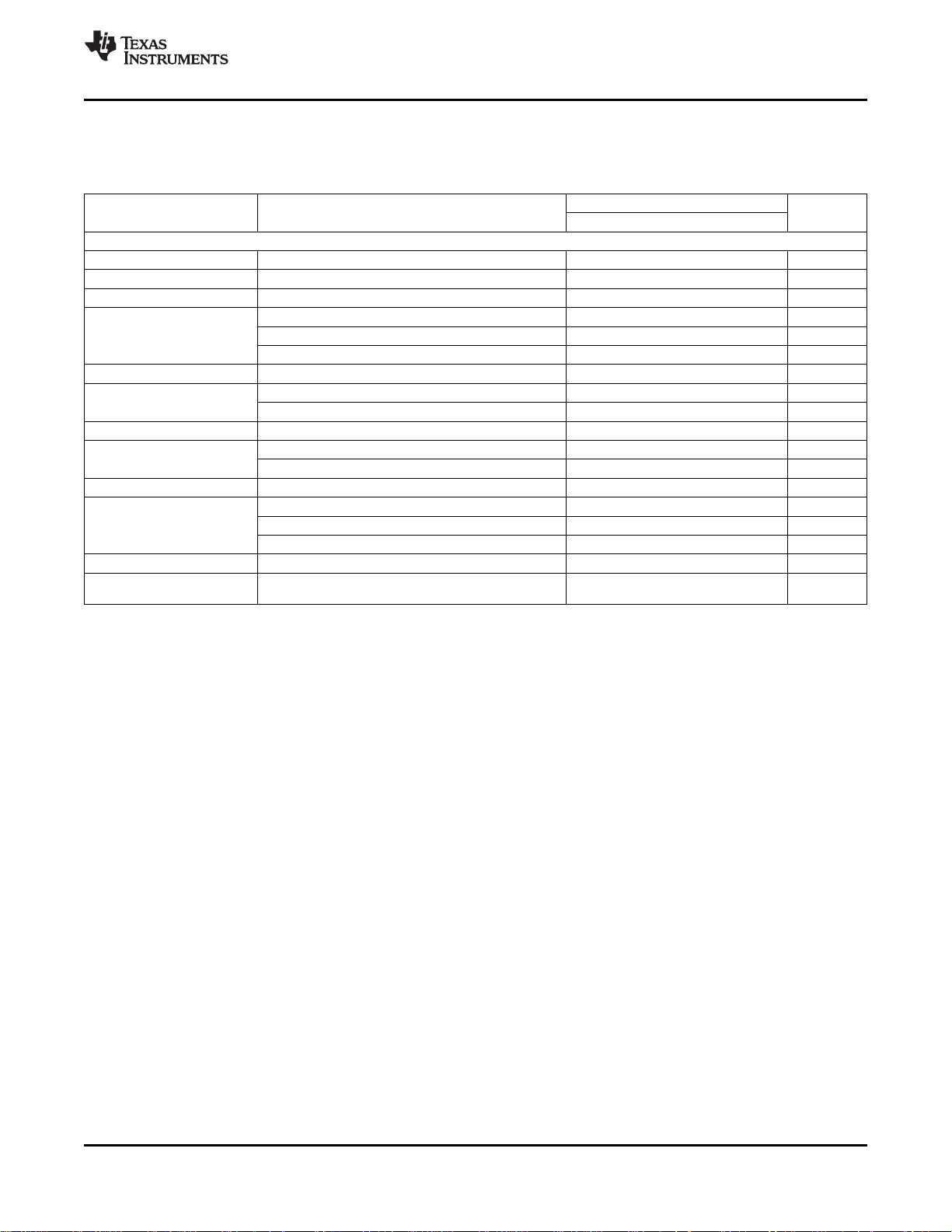

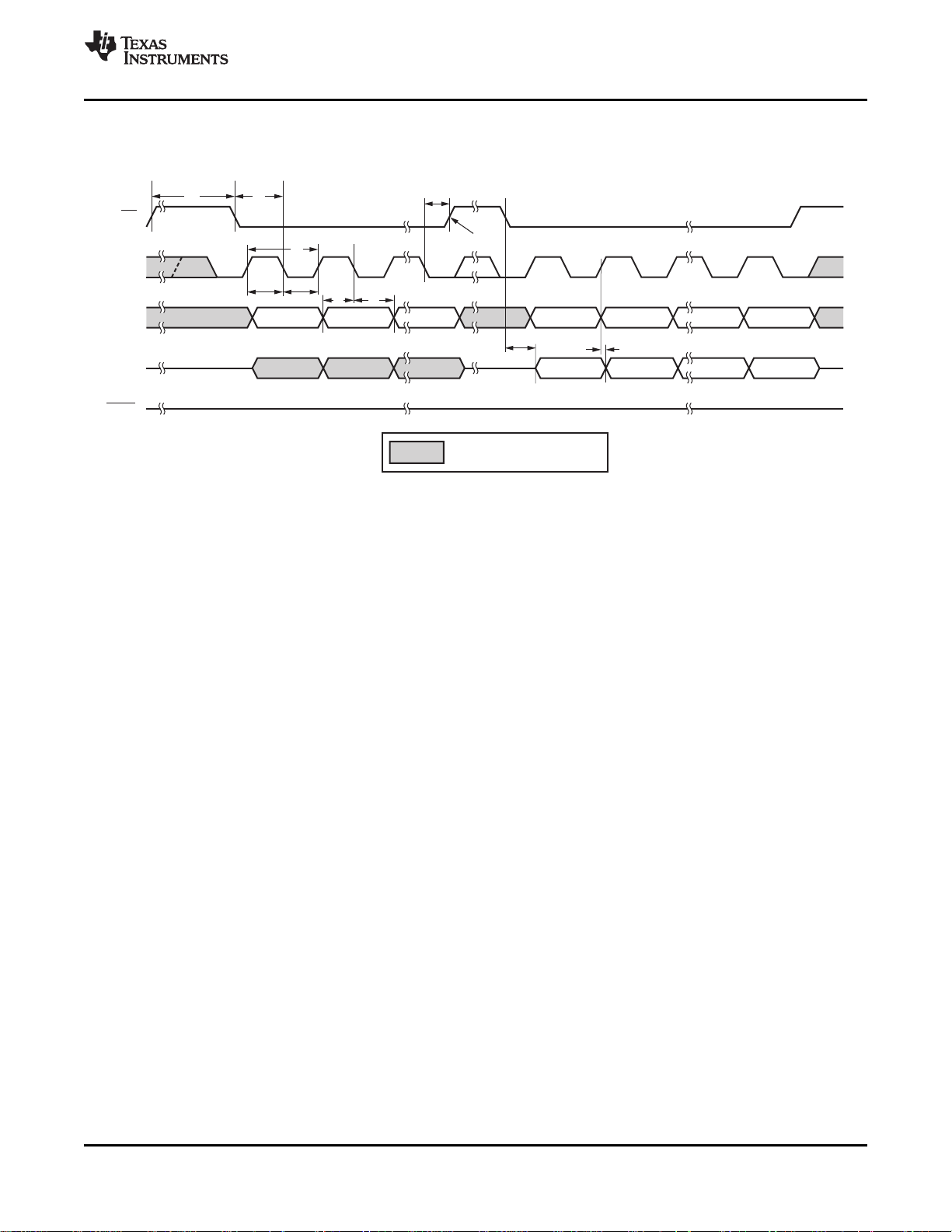

TIMING DIAGRAMS

SBAS467A –MAY 2009–REVISED DECEMBER 2009

Figure 2. SPI Timing for Standalone Mode

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Link(s): DAC8718

Page 14

t

8

CS

SCLK

SDI

BIT23(N)

BIT22(N) BIT0(N) BIT23(N+1)

BIT23(N) BIT0(N)

Low

BIT0(N+1)

SDO

LDAC

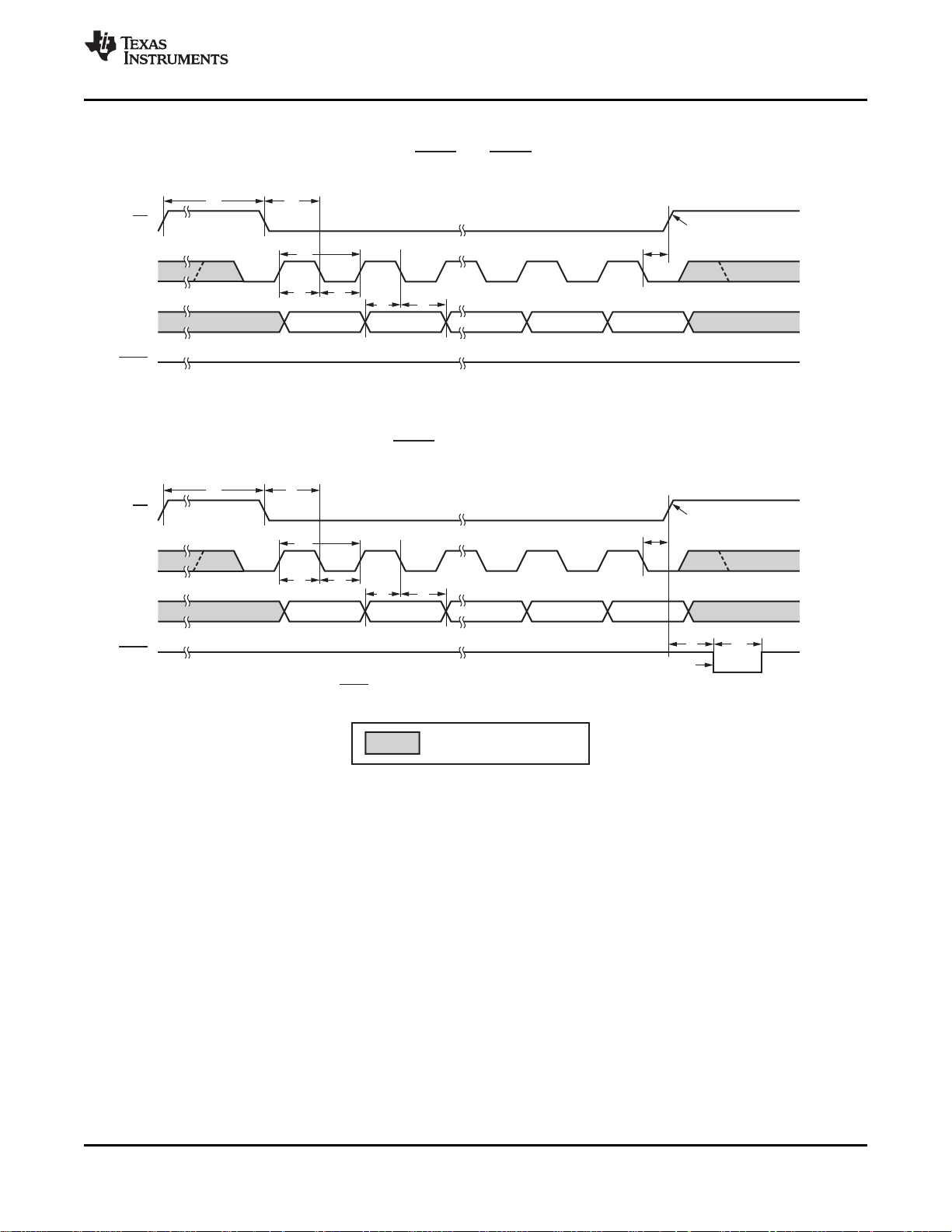

Ifthecorrectionengineisoff,theDAClatchisreloadedimmediatelyaftertheDACDataRegisterisupdated.NOTE:(1)

TheDAClatchisupdatedwhen goeslow.Theproperdataareloadedifthet timingrequirementissatisfied.

Otherwise,invaliddataareloaded.

9

LDAC

NOTE:(2)

t

4

t

1

t

2

t

5

t

6

t

7

Case3:Daisy-ChainMode:Updatewithout pin; pintiedtologiclow.LDAC LDAC

High

LDAC

t

9

t

10

=Don’tCare

Bit23=MSB

Bit0=LSB

t

11

t

8

CS

SCLK

InputDataRegisterUpdated,

butDACLatchisNotUpdated

SDI

BIT23(N)

BIT22(N) BIT0(N) BIT23(N+1)

BIT23(N) BIT0(N)

BIT0(N+1)

SDO

t

4

t

1

t

2

t

5

t

6

t

7

Case4:Daisy-ChainMode:Updatewith pin.LDAC

t

11

t

14

DACLatchUpdated

(2)

InputDataRegisterand

DACLatchUpdated

WhenCorrectionCompletes

(1)

DB23 DB0

Case5:Daisy-ChainMode:Sleeping.

CS

SCLK

SDI

FirstWord LastWord

DB23 DB0

DB23 DB0

SDO

DB23 DB0

t

12

t

12

Hi-Z

Hi-Z Hi-Z Hi-Z

Hi-Z Hi-Z

t

13

t

13

t

3

t

3

Hi-Z

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

TIMING DIAGRAMS (continued)

www.ti.com

Figure 3. SPI Timing for Daisy-Chain Mode

14 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DAC8718

Page 15

Case6:ReadbackforStandalonemode.

t

8

t

4

t

1

t

2

t

7

t

6

BIT23(=1) BIT22

InputWordSpecifiesRegistertobeRead

NOPCommand(write ‘1’ toNOPbit)

DatafromtheSelectedRegister

BIT0

BIT23

BIT23(=1)

BIT22

BIT22

BIT1

BIT1

BIT0

BIT0

InternalRegisterUpdated

CS

SCLK

SDI

SDO

LDAC

Low

t

13

t

11

=Don’tCare

Bit23=MSB

Bit0=LSB

Hi-Z Hi-Z Hi-Z

t

3

t

5

DAC8718

www.ti.com

TIMING DIAGRAMS (continued)

Figure 4. SPI Timing for Readback Operation in Standalone Mode

SBAS467A –MAY 2009–REVISED DECEMBER 2009

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Link(s): DAC8718

Page 16

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

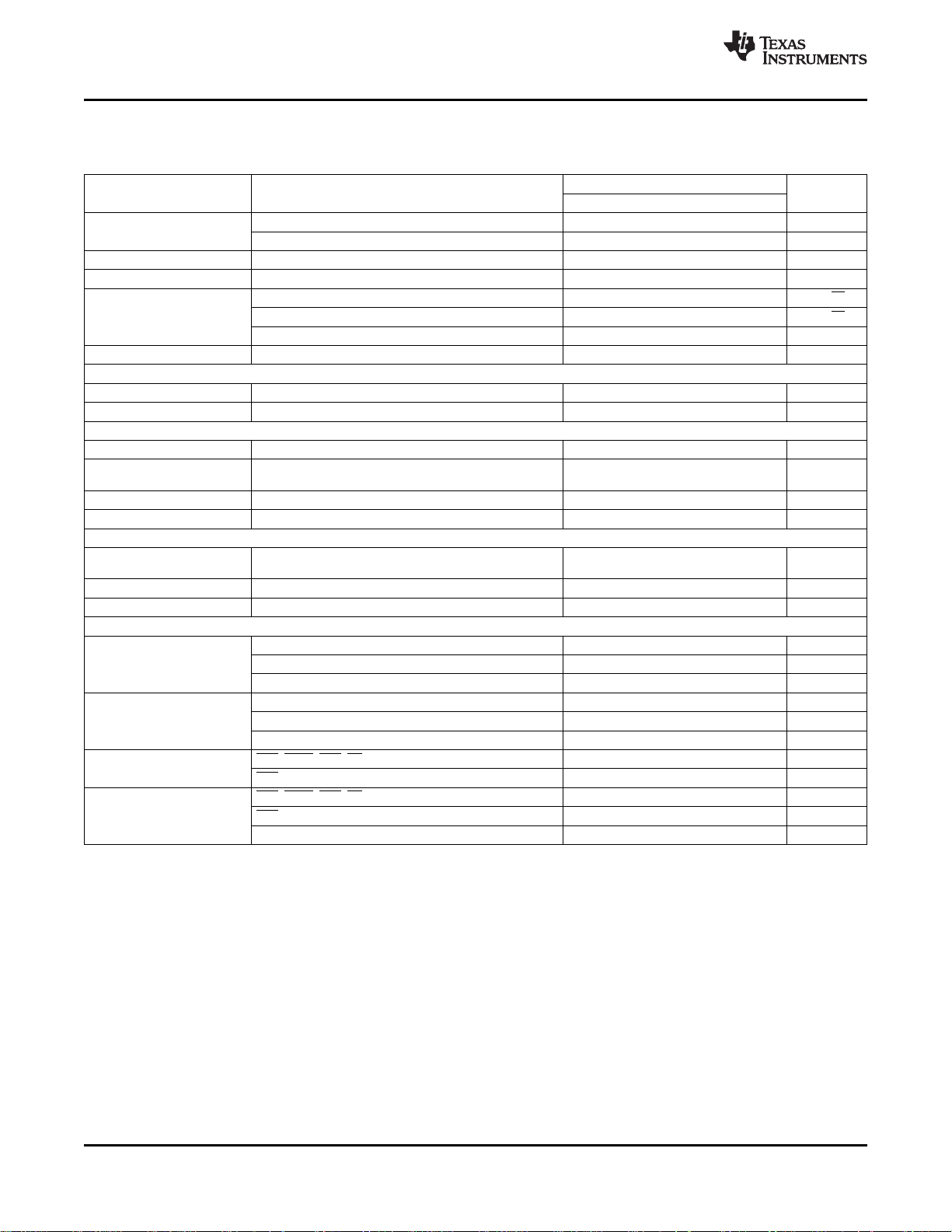

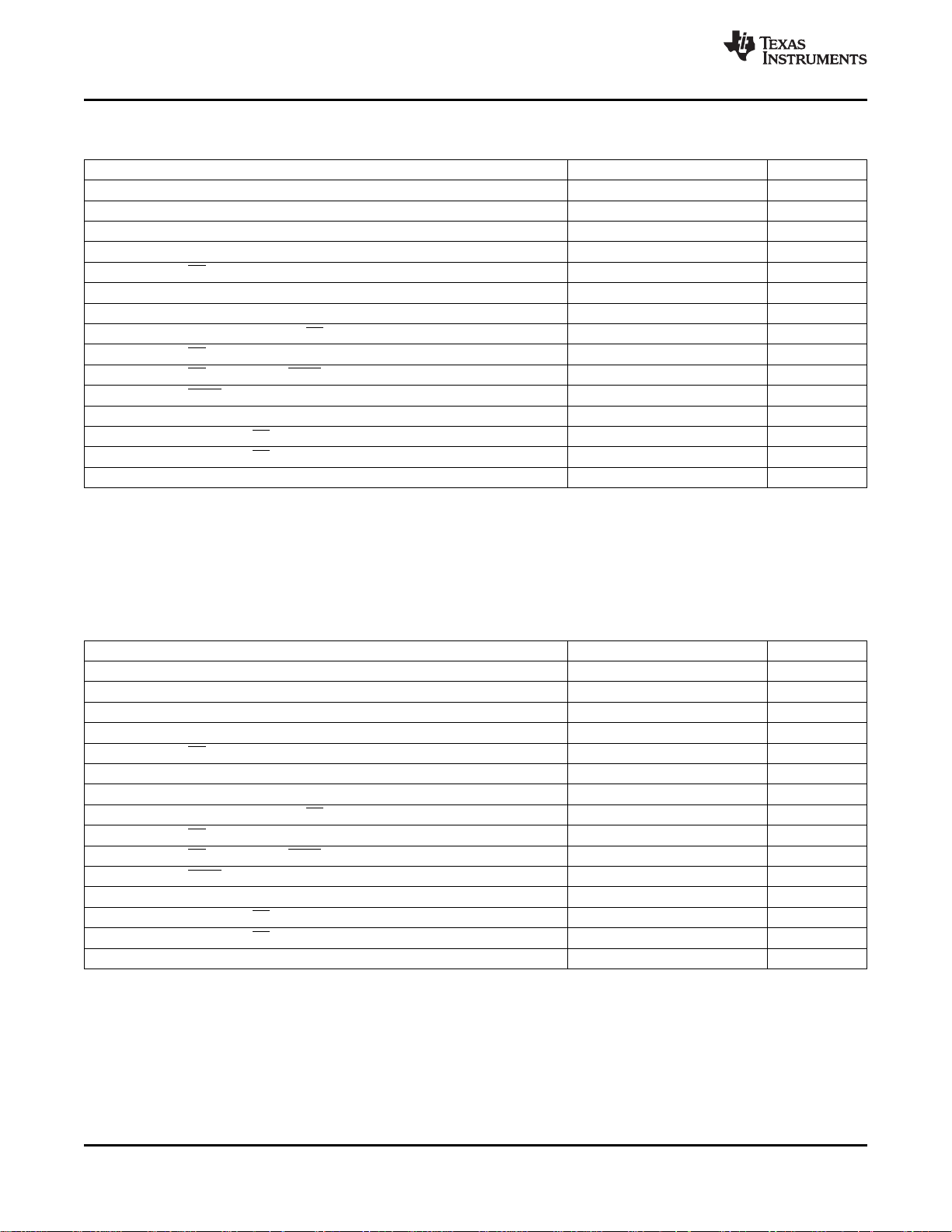

TIMING CHARACTERISTICS: IOVDD= +5V

(1)(2)(3)(4)

At –40°C to +105°C, DVDD= +5V, and IOVDD= +5V, unless otherwise noted.

PARAMETER MIN MAX UNIT

f

SCLK

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

11

t

12

t

13

t

14

Clock frequency 50 MHz

SCLK cycle time 20 ns

SCLK high time 10 ns

SCLK low time 7 ns

CS falling edge to SCLK falling edge setup time 8 ns

SDI setup time before falling edge of SCLK 5 ns

SDI hold time after falling edge of SCLK 5 ns

SCLK falling edge to CS rising edge 5 ns

CS high time 10 ns

CS rising edge to LDAC falling edge 5 ns

LDAC pulse duration 10 ns

Delay from SCLK rising edge to SDO valid 3 8 ns

Delay from CS rising edge to SDO Hi-Z 5 ns

Delay from CS falling edge to SDO valid 6 ns

SDI to SDO delay during sleep mode 2 5 ns

(1) Specified by design. Not production tested.

(2) Sample tested during the initial release and after any redesign or process changes that may affect these parameters.

(3) All input signals are specified with tR= tF= 2ns (10% to 90% of IOVDD) and timed from a voltage level of IOVDD/2.

(4) SDO loaded with 10Ω series resistance and 10pF load capacitance for SDO timing specifications, with tR= tF≤ 5ns.

BLANKSPACE

www.ti.com

TIMING CHARACTERISTICS: IOVDD= +3V

(1)(2)(3)(4)

At –40°C to +105°C, DVDD= +3V/+5V, and IOVDD= +3V, unless otherwise noted.

PARAMETER MIN MAX UNIT

f

SCLK

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

11

t

12

t

13

t

14

(1) Specified by design. Not production tested.

(2) Sample tested during the initial release and after any redesign or process changes that may affect these parameters.

(3) All input signals are specified with tR= tF= 3ns (10% to 90% of IOVDD) and timed from a voltage level of IOVDD/2.

(4) SDO loaded with 10Ω series resistance and 10pF load capacitance for SDO timing specifications, with tR= tF≤ 5ns.

Clock frequency 25 MHz

SCLK cycle time 40 ns

SCLK high time 19 ns

SCLK low time 7 ns

CS falling edge to SCLK falling edge setup time 15 ns

SDI setup time before falling edge of SCLK 5 ns

SDI hold time after falling edge of SCLK 5 ns

SCLK falling edge to CS rising edge 10 ns

CS high time 19 ns

CS rising edge to LDAC falling edge 5 ns

LDAC pulse duration 10 ns

Delay from SCLK rising edge to SDO valid 3 15 ns

Delay from CS rising edge to SDO Hi-Z 7 ns

Delay from CS falling edge to SDO valid 10 ns

SDI to SDO delay during sleep mode 2 10 ns

16 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DAC8718

Page 17

DAC8718

www.ti.com

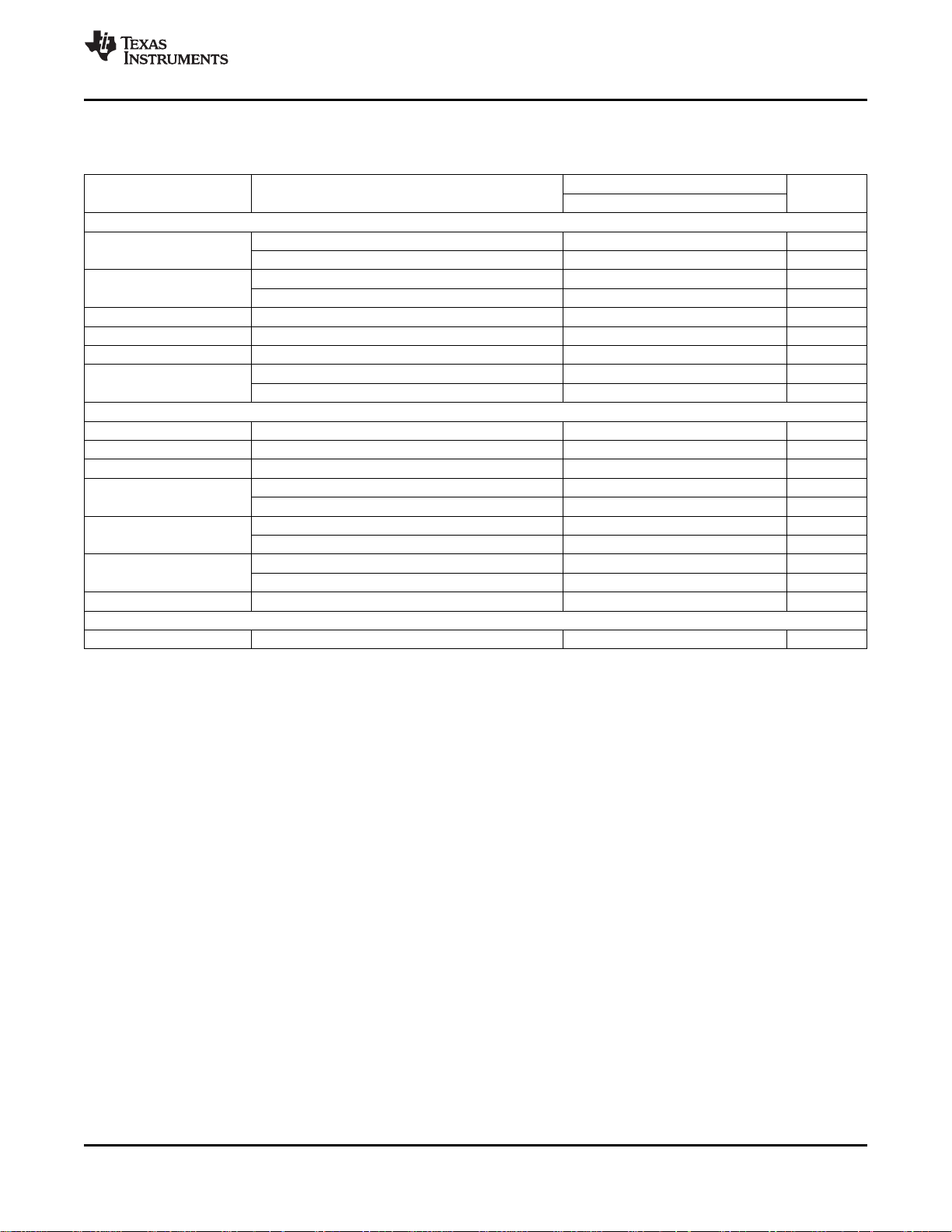

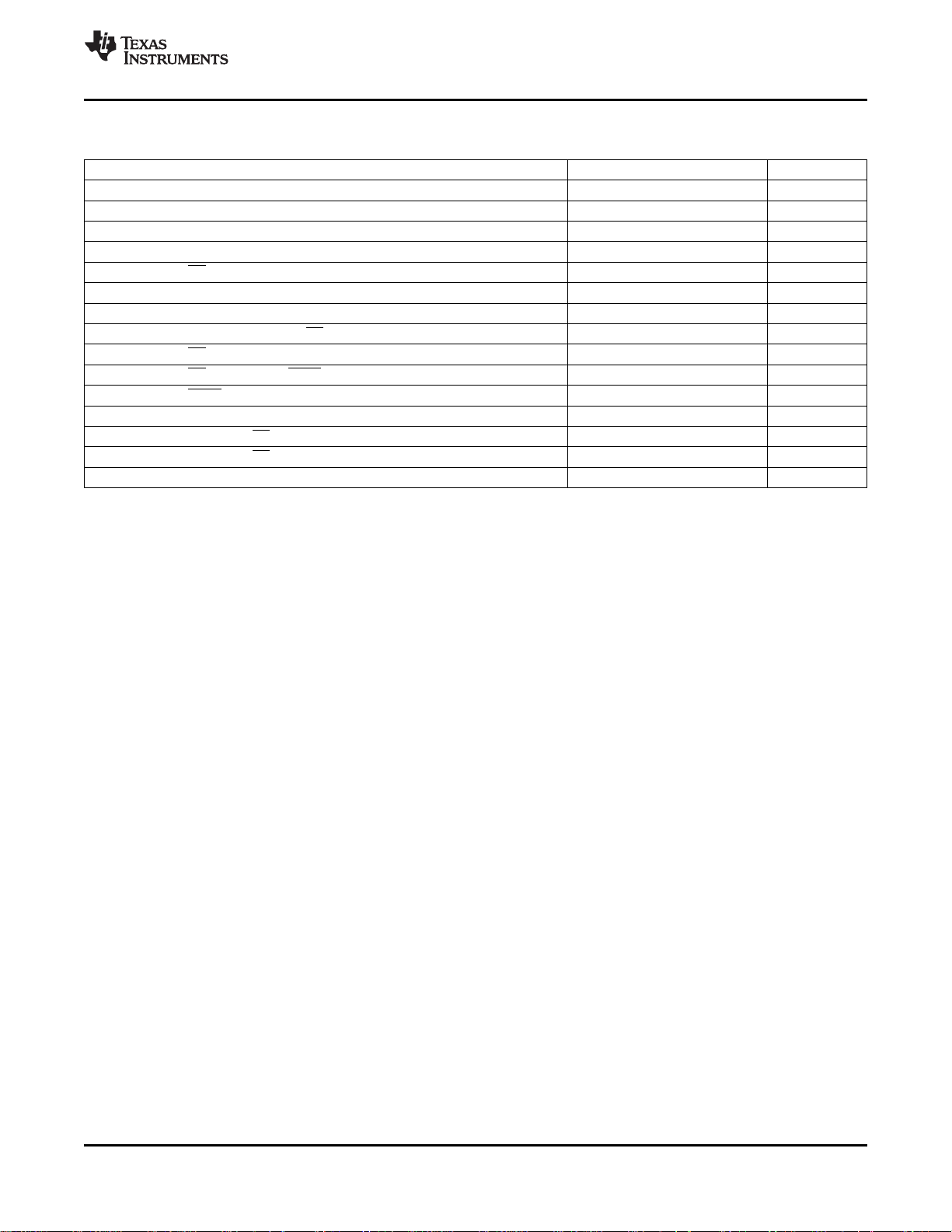

TIMING CHARACTERISTICS: IOVDD= +1.8V

(1)(2)(3)(4)

SBAS467A –MAY 2009–REVISED DECEMBER 2009

At –40°C to +105°C, DVDD= +3V/+5V, and IOVDD= +1.8V, unless otherwise noted.

PARAMETER MIN MAX UNIT

f

SCLK

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

11

t

12

t

13

t

14

(1) Specified by design. Not production tested.

(2) Sample tested during the initial release and after any redesign or process changes that may affect these parameters.

(3) All input signals are specified with tR= tF= 6ns (10% to 90% of IOVDD) and timed from a voltage level of IOVDD/2.

(4) SDO loaded with 10Ω series resistance and 10pF load capacitance for SDO timing specifications, with tR= tF≤ 15ns.

Clock frequency 16.6 MHz

SCLK cycle time 60 ns

SCLK high time 28 ns

SCLK low time 7 ns

CS falling edge to SCLK falling edge setup time 28 ns

SDI setup time before falling edge of SCLK 10 ns

SDI hold time after falling edge of SCLK 5 ns

SCLK falling edge to CS rising edge 10 ns

CS high time 28 ns

CS rising edge to LDAC falling edge 5 ns

LDAC pulse duration 10 ns

Delay from SCLK rising edge to SDO valid 3 25 ns

Delay from CS rising edge to SDO Hi-Z 15 ns

Delay from CS falling edge to SDO valid 23 ns

SDI to SDO delay during sleep mode 2 25 ns

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Link(s): DAC8718

Page 18

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

AllEightChannelsShown

8192

0

65536573444915240960327682457616384

DigitalInputCode

AllEightChannelsShown

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

Gain=4

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

Gain=4

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

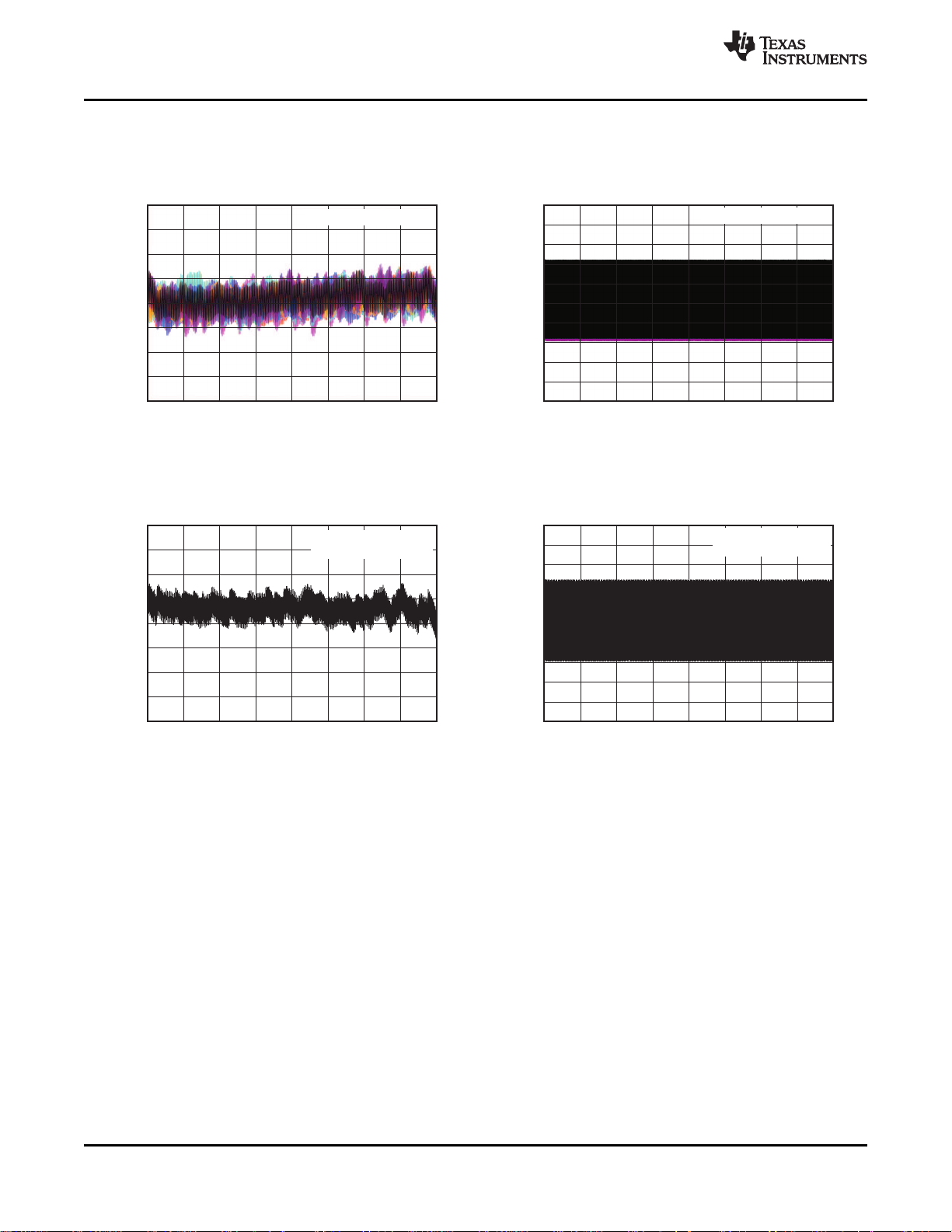

TYPICAL CHARACTERISTICS: Bipolar

At TA= 25°C, AVDD= 16.5V, AVSS= –16.5V, V

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (All 8 Channels) vs DIGITAL INPUT CODE (All 8 Channels)

Figure 5. Figure 6.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (+25°C) vs DIGITAL INPUT CODE (+25°C)

www.ti.com

= IOVDD= DVDD= 5V, gain = 6, data format=USB, unless otherwise noted.

REF

Figure 7. Figure 8.

18 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DAC8718

Page 19

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

DAC8718

www.ti.com

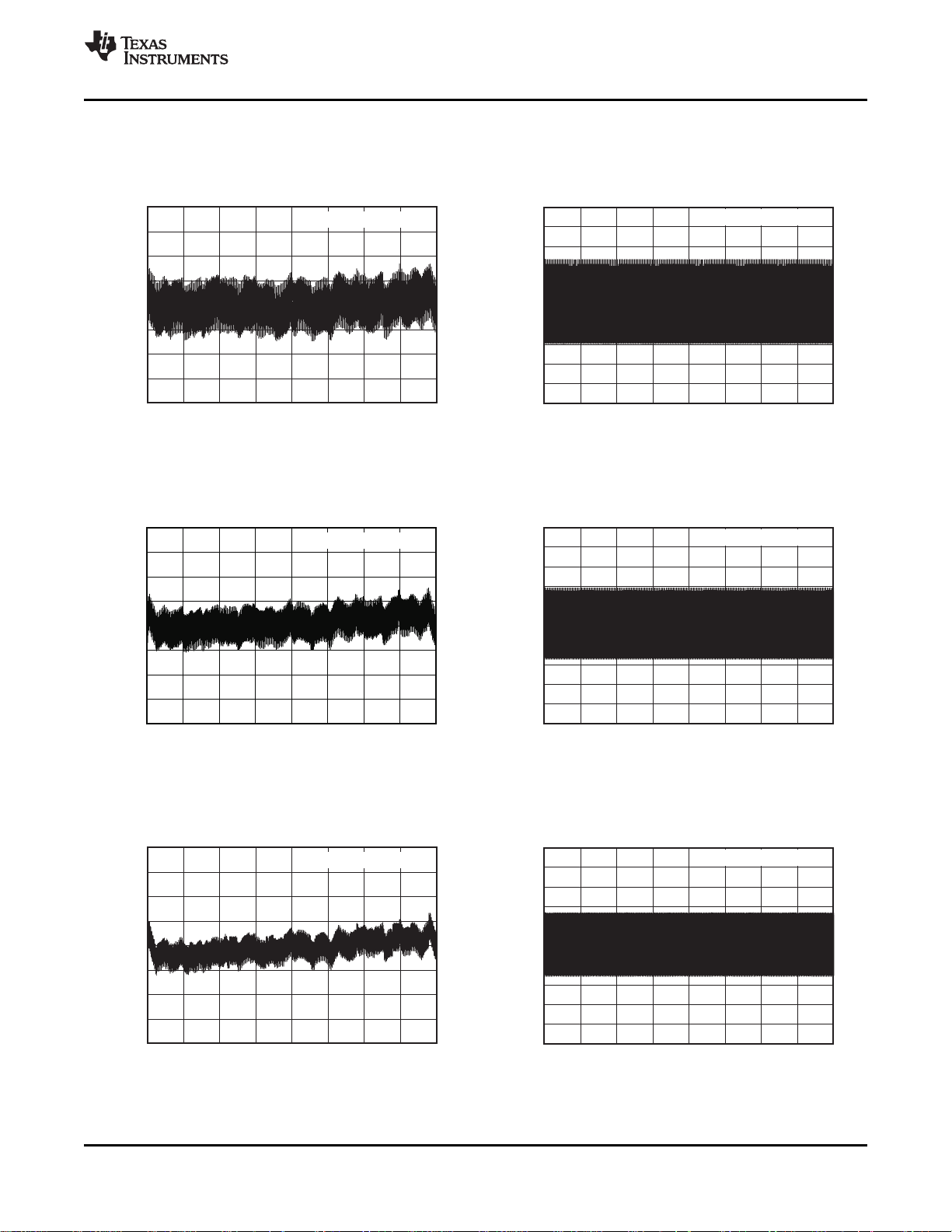

TYPICAL CHARACTERISTICS: Bipolar (continued)

At TA= 25°C, AVDD= 16.5V, AVSS= –16.5V, V

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (–40°C) vs DIGITAL INPUT CODE (–40°C)

Figure 9. Figure 10.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (+25°C) vs DIGITAL INPUT CODE (+25°C)

SBAS467A –MAY 2009–REVISED DECEMBER 2009

= IOVDD= DVDD= 5V, gain = 6, data format=USB, unless otherwise noted.

REF

Figure 11. Figure 12.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (+105°C) vs DIGITAL INPUT CODE (+105°C)

Figure 13. Figure 14.

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Link(s): DAC8718

Page 20

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature( C)°

INLMax

INLMin

1.0

0.8

0.6

0.4

0.2

0

0.2

0.4

0.6

0.8

1.0

-

-

-

-

-

DNLError(LSB)

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature(°C)

DNLMin

DNLMax

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature( C)°

Gain=4

INLMax

INLMin

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature(°C)

Gain=4

1.0

0.8

0.6

0.4

0.2

0

0.2

0.4

0.6

0.8

1.0

-

-

-

-

-

DNLError(LSB)

DNLMax

DNLMin

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

1.0 5.55.04.54.03.53.01.5 2.0

V (V)

REF

INLMax

AVDD=+18V

AV = -SS18V

INLMin

2.5

1.0 5.55.04.54.03.53.01.5 2.0

V (V)

REF

2.5

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

AVDD=+18V

AV = -SS18V

DNLMax

DNLMin

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

TYPICAL CHARACTERISTICS: Bipolar (continued)

At TA= 25°C, AVDD= 16.5V, AVSS= –16.5V, V

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs TEMPERATURE vs TEMPERATURE

Figure 15. Figure 16.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs TEMPERATURE vs TEMPERATURE

www.ti.com

= IOVDD= DVDD= 5V, gain = 6, data format=USB, unless otherwise noted.

REF

Figure 17. Figure 18.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs REFERENCE VOLTAGE vs REFERENCE VOLTAGE

20 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Figure 19. Figure 20.

Product Folder Link(s): DAC8718

Page 21

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

4.5 6.0 7.5 9.0 10.5 12.0 13.5 15.0 16.5 18.0

AV = AV (V)-

DD S S

INLMax

DVDD=IOVDD=4.5V

V =2.048V

REF

Gain=4

INLMin

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

4.5 6.0 7.5 9.0 10.5 12.0 13.5 15.0 16.5 18.0

AV =

DD S S

-AV (V)

DNLMax

DV

DD DD

=IOV =4.5V

V =2.048V

REF

Gain=4

DNLMin

5

4

3

2

1

0

-1

-2

-3

-4

-5

BipolarZeroError(mV)

4.5 6.0 7.5 9.0 10.5 12.0 13.5 15.0 16.5 18.0

A VV = A (V)-

DD S S

DV =IOV =4.5V

DD DD

V =2.048V

REF

Gain=4

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

5

4

3

2

1

0

-1

-2

-3

-4

-5

BipolarGainError(mV)

4.5 6.0 7.5 9.0 10.5 12.0 13.5 15.0 16.5 18.0

AV = AV (V)

DD S S

-

DVDD=IOVDD=4.5V

V =2.048V

REF

Gain=4

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

5

4

3

2

1

0

-1

-2

-3

-4

-5

BipolarZeroError(mV)

1.51.0 5.55.04.54.03.53.02.52.0

V (V)

REF

AVDD=+18V

AV = -SS18V

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

5

4

3

2

1

0

-1

-2

-3

-4

-5

BipolarZeroError(mV)

1.51.0 5.55.04.54.03.53.02.52.0

V (V)

REF

AVDD=+18V

AV = -SS18V

Gain=4

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

DAC8718

www.ti.com

TYPICAL CHARACTERISTICS: Bipolar (continued)

At TA= 25°C, AVDD= 16.5V, AVSS= –16.5V, V

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs AVDDAND AV

Figure 21. Figure 22.

BIPOLAR ZERO ERROR BIPOLAR GAIN ERROR

vs AVDDAND AV

SS

SS

SBAS467A –MAY 2009–REVISED DECEMBER 2009

= IOVDD= DVDD= 5V, gain = 6, data format=USB, unless otherwise noted.

REF

vs AVDDAND AV

vs AVDDAND AV

SS

SS

Figure 23. Figure 24.

BIPOLAR ZERO ERROR BIPOLAR ZERO ERROR

vs REFERENCE VOLTAGE vs REFERENCE VOLTAGE

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 21

Figure 25. Figure 26.

Product Folder Link(s): DAC8718

Page 22

5

4

3

2

1

0

-1

-2

-3

-4

-5

BipolarGainError(mV)

1.51.0 5.55.04.54.03.53.02.52.0

V (V)

REF

AVDD=+18V

AV = -SS18V

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

5

4

3

2

1

0

-1

-2

-3

-4

-5

BipolarGainError(mV)

1.51.0 5.55.04.54.03.53.02.52.0

V (V)

REF

AVDD=+18V

AV = -SS18V

Gain=4

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

BipolarZeroError(mV)

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature(°C)

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

5

4

3

2

1

0

1

2

3

4

5

-

-

-

-

-

BipolarZeroError(mV)

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature(°C)

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

5

4

3

2

1

0

1

2

3

4

5

-

-

-

-

-

Gain=4

BipolarGainError(mV)

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature(°C)

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

5

4

3

2

1

0

1

2

3

4

5

-

-

-

-

-

BipolarGainError(mV)

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature(°C)

5

4

3

2

1

0

1

2

3

4

5

-

-

-

-

-

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

Gain=4

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

TYPICAL CHARACTERISTICS: Bipolar (continued)

At TA= 25°C, AVDD= 16.5V, AVSS= –16.5V, V

BIPOLAR GAIN ERROR BIPOLAR GAIN ERROR

vs REFERENCE VOLTAGE vs REFERENCE VOLTAGE

Figure 27. Figure 28.

BIPOLAR ZERO ERROR BIPOLAR ZERO ERROR

vs TEMPERATURE vs TEMPERATURE

www.ti.com

= IOVDD= DVDD= 5V, gain = 6, data format=USB, unless otherwise noted.

REF

Figure 29. Figure 30.

BIPOLAR GAIN ERROR BIPOLAR GAIN ERROR

vs TEMPERATURE vs TEMPERATURE

22 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Figure 31. Figure 32.

Product Folder Link(s): DAC8718

Page 23

8

7

6

5

4

3

2

1

0

AnalogPower-SupplyCurrent(mA)

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature(°C)

I

AVDD

-I

AVSS

8

7

6

5

4

3

2

1

0

AnalogPower-SupplyCurrent(mA)

-I

AVSS

I

AVDD

1.0 5.55.04.54.03.53.01.5 2.0

V (V)

REF

2.5

AllDACsLoadedwithMidscaleCode

AVDD=+18V

A =VSS-18V

8

7

6

5

4

3

2

1

0

AnalogPower-SupplyCurrent(mA)

8192

0

65536573444915240960327682457616384

DigitalInputCode

AllDACsLoadedwithSameCode

I

AVDD

-I

AVSS

250

200

150

100

50

0

DigitalPower-SupplyCurrent( A)m

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5

LogicInputVoltage(V)

SweepFrom

5.5Vto0V

SweepFrom

0Vto5.5V

OneDigitalInputSwept,AllOthersatGNDorIOV

DD

DV (mV)

OUT

-15 -9 -3 3 9-12 -6 0 6 12 15

CurrentOutputI (mA)

OUT

6

5

4

3

2

1

0

1

2

3

4

5

-

-

-

-

--6

FFFFh

C000h

8000h

4000h

0000h

2000

1800

1600

1400

1200

1000

800

600

400

200

0

Noise(nV/ )ÖHz

1 100k10k1k10010

Frequency(Hz)

DACLoadedwithMidscaleCode

Gain=6

Gain=4

DAC8718

www.ti.com

TYPICAL CHARACTERISTICS: Bipolar (continued)

At TA= 25°C, AVDD= 16.5V, AVSS= –16.5V, V

ANALOG POWER-SUPPLY CURRENT ANALOG POWER-SUPPLY CURRENT

vs TEMPERATURE vs REFERENCE VOLTAGE

Figure 33. Figure 34.

ANALOG POWER-SUPPLY CURRENT DIGITAL POWER-SUPPLY CURRENT

vs DIGITAL INPUT CODE vs LOGIC INPUT VOLTAGE

SBAS467A –MAY 2009–REVISED DECEMBER 2009

= IOVDD= DVDD= 5V, gain = 6, data format=USB, unless otherwise noted.

REF

Figure 35. Figure 36.

DELTA OUTPUT VOLTAGE DAC OUTPUT NOISE DENSITY

vs SOURCE AND SINK CURRENTS vs FREQUENCY

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 23

Figure 37. Figure 38.

Product Folder Link(s): DAC8718

Page 24

Time(10 s/div)m

1LSB/div

5V/div

5V/div

TriggerPulse: LDAC

FromCode:0000h

ToCode:

Load:10k ||240pF

FFFFh

W

Small-SignalError

Large-SignalV

OUT

Time(10 s/div)m

1LSB/div

5V/div

TriggerPulse: LDAC

FromCode:FFFFh

ToCode:

Load:10k ||240pF

0000h

W

5V/div

Large-SignalV

OUT

Small-SignalError

Time(10 s/div)m

1LSB/div

5V/div

FromCode:4000h

ToCode:

Load:10k ||240pF

C000h

W

5V/div

Large-SignalV

OUT

Small-SignalError

TriggerPulse: LDAC

Time(10 s/div)m

1LSB/div

5V/div

FromCode:C000h

ToCode:

Load:10k ||240pF

4000h

W

5V/div

TriggerPulse: LDAC

Large-SignalV

OUT

Small-SignalError

Time(2 s/div)m

V (1mV/div)

OUT

GlitchImpulse

TriggerPulse5V/div

FromCode:7FFFh

ToCode:

Channel0asExample

8000h

Load:10k ||200pFW

Time(2 s/div)m

V (1mV/div)

OUT

FromCode:8000h

ToCode:

Channel0asExample

Load:10k ||200pF

7FFFh

W

TriggerPulse5V/div

GlitchImpulse

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

TYPICAL CHARACTERISTICS: Bipolar (continued)

At TA= 25°C, AVDD= 16.5V, AVSS= –16.5V, V

SETTLING TIME SETTLING TIME

–15V TO +15V TRANSITION +15V TO –15V TRANSITION

Figure 39. Figure 40.

SETTLING TIME SETTLING TIME

1/4 TO 3/4 FULL-SCALE TRANSITION 3/4 TO 1/4 FULL-SCALE TRANSITION

www.ti.com

= IOVDD= DVDD= 5V, gain = 6, data format=USB, unless otherwise noted.

REF

Figure 41. Figure 42.

GLITCH ENERGY GLITCH ENERGY

1 LSB STEP, RISING EDGE 1 LSB STEP, FALLING EDGE

24 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Figure 43. Figure 44.

Product Folder Link(s): DAC8718

Page 25

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

2

3

4

5

6

7

8

9

10

BipolarZeroError(LSB)

40

35

30

25

20

15

10

5

0

Population(%)

-15

-13

-11

-9

-7

-5

-3

-1

1

3

5

7

9

11

13

15

BipolarZeroError(LSB)

Gain=4

60

55

50

45

40

35

30

25

20

15

10

5

0

Population(%)

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

2

3

4

5

6

7

8

9

10

BipolarGainError(LSB)

25

20

15

10

5

0

Population(%)

-15

-13

-11

-9

-7

-5

-3

-1

1

3

5

7

9

11

13

15

BipolarGainError(LSB)

Gain=4

25

20

15

10

5

0

Population(%)

2.6

2.8

3.0

3.2

3.4

3.6

3.8

4.0

4.2

4.4

4.6

4.8

5.0

5.2

5.4

5.6

5.8

6.0

AI (mA)

DD

30

25

20

15

10

5

0

Population(%)

-4.0

-3.6

-3.2

-2.8

-2.4

-2.0

-1.6

-1.2

-0.8

AI (mA)

SS

45

40

35

30

25

20

15

10

5

0

Population(%)

DAC8718

www.ti.com

TYPICAL CHARACTERISTICS: Bipolar (continued)

At TA= 25°C, AVDD= 16.5V, AVSS= –16.5V, V

BIPOLAR ZERO ERROR BIPOLAR ZERO ERROR

HISTOGRAM HISTOGRAM

Figure 45. Figure 46.

BIPOLAR GAIN ERROR BIPOLAR GAIN ERROR

HISTOGRAM HISTOGRAM

SBAS467A –MAY 2009–REVISED DECEMBER 2009

= IOVDD= DVDD= 5V, gain = 6, data format=USB, unless otherwise noted.

REF

Figure 47. Figure 48.

NEGATIVE ANALOG POWER SUPPLY POSITIVE ANALOG POWER SUPPLY

HISTOGRAM HISTOGRAM

Figure 49. Figure 50.

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Link(s): DAC8718

Page 26

Time(2 s/div)m

DACCode=8000h

NoLoad

Gain=6

Channel0asExample

V (5 V/div)m

OUT

Time(2 s/div)m

DACCode=8000h

NoLoad

Gain=4

Channel0asExample

V (5 V/div)m

OUT

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

TYPICAL CHARACTERISTICS: Bipolar (continued)

At TA= 25°C, AVDD= 16.5V, AVSS= –16.5V, V

DAC OUTPUT NOISE DAC OUTPUT NOISE

0.1Hz TO 10Hz 0.1Hz TO 10Hz

Figure 51. Figure 52.

www.ti.com

= IOVDD= DVDD= 5V, gain = 6, data format=USB, unless otherwise noted.

REF

26 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DAC8718

Page 27

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

AllEightChannelsShown

8192

0

65536573444915240960327682457616384

DigitalInputCode

AllEightChannelsShown

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

Gain=4

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

Gain=4

DAC8718

www.ti.com

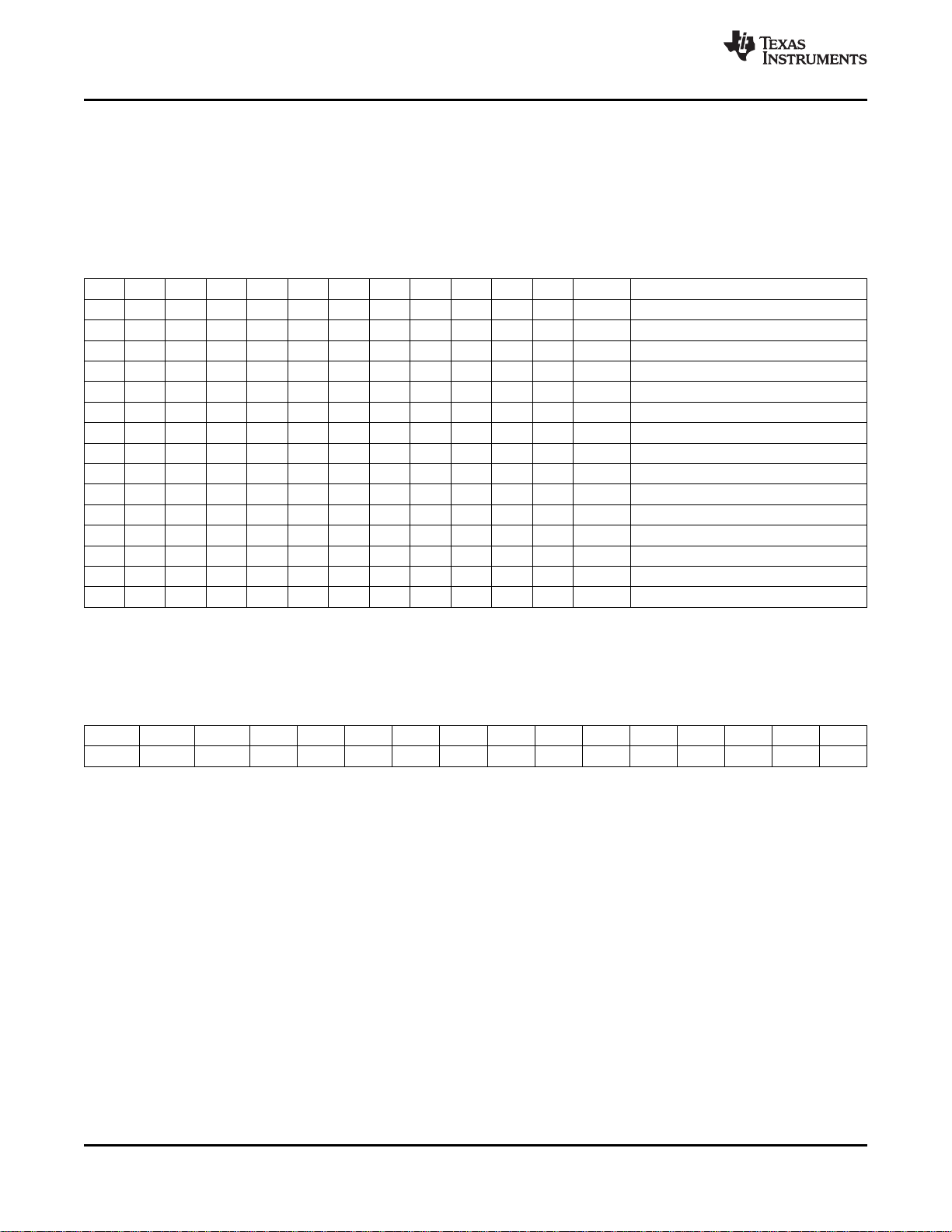

TYPICAL CHARACTERISTICS: Unipolar

At TA= 25°C, AVDD= 32V, AVSS= 0V, V

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (All 8 Channels) vs DIGITAL INPUT CODE (All 8 Channels)

Figure 53. Figure 54.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (+25°C) vs DIGITAL INPUT CODE (+25°C)

SBAS467A –MAY 2009–REVISED DECEMBER 2009

= 5V, IOVDD= DVDD= 5V, gain=6, and data format=USB, unless otherwise noted.

REF

Figure 55. Figure 56.

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Link(s): DAC8718

Page 28

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

8192

0

65536573444915240960327682457616384

DigitalInputCode

TypicalChannelShown

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

TYPICAL CHARACTERISTICS: Unipolar (continued)

At TA= 25°C, AVDD= 32V, AVSS= 0V, V

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (–40°C) vs DIGITAL INPUT CODE (–40°C)

Figure 57. Figure 58.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (+25°C) vs DIGITAL INPUT CODE (+25°C)

www.ti.com

= 5V, IOVDD= DVDD= 5V, gain=6, and data format=USB, unless otherwise noted.

REF

Figure 59. Figure 60.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs DIGITAL INPUT CODE (+105°C) vs DIGITAL INPUT CODE (+105°C)

Figure 61. Figure 62.

28 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Product Folder Link(s): DAC8718

Page 29

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature( C)°

INLMax

INLMin

DNLError(LSB)

-55

-40 -25 -10

5

20 35 50 65 80 95 110 125

Temperature(°C)

DNLMin

DNLMax

1.0

0.8

0.6

0.4

0.2

0

0.2

0.4

0.6

0.8

1.0

-

-

-

-

-

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature(°C)

INLMax

Gain=4

INLMin

DNLError(LSB)

-55

-40 -25 -10

5

20 35 50 65 80 95 110 125

Temperature(°C)

1.0

0.8

0.6

0.4

0.2

0

0.2

0.4

0.6

0.8

1.0

-

-

-

-

-

DNLMin

DNLMax

Gain=4

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

1.0 5.55.04.54.03.53.01.5 2.0

V (V)

REF

2.5

AVDD=+36V

DNLMax

DNLMin

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

1.0 5.55.04.54.03.53.01.5 2.0

V (V)

REF

2.5

INLMax

INLMin

AVDD=+36V

DAC8718

www.ti.com

TYPICAL CHARACTERISTICS: Unipolar (continued)

At TA= 25°C, AVDD= 32V, AVSS= 0V, V

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs TEMPERATURE vs TEMPERATURE

Figure 63. Figure 64.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs TEMPERATURE vs TEMPERATURE

SBAS467A –MAY 2009–REVISED DECEMBER 2009

= 5V, IOVDD= DVDD= 5V, gain=6, and data format=USB, unless otherwise noted.

REF

Figure 65. Figure 66.

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs REFERENCE VOLTAGE vs REFERENCE VOLTAGE

Copyright © 2009, Texas Instruments Incorporated Submit Documentation Feedback 29

Figure 67. Figure 68.

Product Folder Link(s): DAC8718

Page 30

4

3

2

1

0

-1

-2

-3

-4

INLError(LSB)

9 12 15 18 21 24 27 30 33 36

AV (V)

DD

INLMax

INLMin

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-0.6

-0.8

-1.0

DNLError(LSB)

9 12 15 18 21 24 27 30 33 36

AV (V)

DD

DNLMax

DNLMin

5

4

3

2

1

0

-1

-2

-3

-4

-5

Zero-ScaleError(mV)

9 12 15 18 21 24 27 30 33 36

+AV (V)

DD

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

AllDACSLoadedwith0100h

Gain=4

V =2.048V

REF

5

4

3

2

1

0

-1

-2

-3

-4

-5

UnipolarGainError(mV)

9 12 15 18 21 24 27 30 33 36

+AV (V)

DD

DVDD=IOVDD=4.5V

V =2.048V

REF

Gain=4

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

5

4

3

2

1

0

-1

-2

-3

-4

-5

Zero-ScaleError(mV)

1.51.0 5.55.04.54.03.53.02.52.0

V (V)

REF

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

AllDACSLoadedwith0100h

AV =+36V

DD

5

4

3

2

1

0

-1

-2

-3

-4

-5

Zero-ScaleError(mV)

1.51.0 5.55.04.54.03.53.02.52.0

V (V)

REF

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

AllDACSLoadedwith0100h

Gain=4

AV =+36V

DD

DAC8718

SBAS467A –MAY 2009–REVISED DECEMBER 2009

TYPICAL CHARACTERISTICS: Unipolar (continued)

At TA= 25°C, AVDD= 32V, AVSS= 0V, V

LINEARITY ERROR DIFFERENTIAL LINEARITY ERROR

vs ANALOG SUPPLY VOLTAGE vs ANALOG SUPPLY VOLTAGE

Figure 69. Figure 70.

ZERO-SCALE ERROR UNIPOLAR GAIN ERROR

vs ANALOG SUPPLY VOLTAGE vs ANALOG SUPPLY VOLTAGE

www.ti.com

= 5V, IOVDD= DVDD= 5V, gain=6, and data format=USB, unless otherwise noted.

REF

Figure 71. Figure 72.

ZERO-SCALE ERROR ZERO-SCALE ERROR

vs REFERENCE VOLTAGE vs REFERENCE VOLTAGE

30 Submit Documentation Feedback Copyright © 2009, Texas Instruments Incorporated

Figure 73. Figure 74.

Product Folder Link(s): DAC8718

Page 31

5

4

3

2

1

0

-1

-2

-3

-4

-5

UnipolarGainError(mV)

1.51.0 5.55.04.54.03.53.02.52.0

V (V)

REF

AVDD=+36V

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

5

4

3

2

1

0

-1

-2

-3

-4

-5

UnipolarGainError(mV)

1.51.0 5.55.04.54.03.53.02.52.0

V (V)

REF

AVDD=+36V

Gain=4

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

Zero-ScaleError(mV)

-55

-40 -25 -10

5

20 35 50 65 80 95 110 125

Temperature(°C)

5

4

3

2

1

0

1

2

3

4

5

-

-

-

-

-

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

AllDACSLoadedwith0100h

Zero-ScaleError(mV)

-55

-40 -25 -10

5

20 35 50 65 80 95 110 125

Temperature(°C)

5

4

3

2

1

0

1

2

3

4

5

-

-

-

-

-

Ch0

Ch1

Ch2

Ch3

Ch4

Ch5

Ch6

Ch7

AllDACSLoadedwith0100h

Gain=4

UnipolarGainError(mV)

-55 -40 -25 -10 5 20 35 50 65 80 95 110 125

Temperature(°C)

5

4

3

2

1

0

1

2

3

4

5