Page 1

DAC1006,DAC1007,DAC1008

DAC1006/DAC1007/DAC1008 P Compatible, Double-Buffered D to A Converters

Literature Number: SNAS540

Page 2

DAC1006/DAC1007/DAC1008

µP Compatible, Double-Buffered D to A Converters

General Description

The DAC1006/7/8 are advanced CMOS/Si-Cr 10-, 9- and

8-bit accurate multiplying DACs which are designed to interface directly with the 8080, 8048, 8085, Z-80 and other

popular microprocessors. These DACs appear asamemory

location or an I/O port to the µP and no interfacing logic is

needed.

These devices, combinedwith an external amplifier and voltage reference, can be used as standard D/A converters; and

they are very attractive for multiplying applications (such as

digitally controlled gain blocks) since their linearity error is

essentially independent of the voltage reference. They become equally attractive in audio signal processing equipment as audio gain controls or as programmable attenuators

which marry high quality audio signal processing to digitally

based systems under microprocessor control.

All of these DACs are double buffered. They can load all 10

bits or two 8-bit bytes and the data format is left justified. The

analog section of these DACs is essentially the same as that

of the DAC1020.

The DAC1006 series are the 10-bit members of a family of

microprocessor-compatible DAC’s (MICRO-DAC’s

applications requiring other resolutions, the DAC0830 series

(8 bits) and the DAC1208 and DAC1230 (12 bits) are available alternatives.

#

Part

DAC1006 10 For leftDAC1007 9 20 justified

DAC1008 8 data

Accuracy Pin Description

(bits)

™

). For

Features

n Uses easy to adjust END POINT specs, NOT BEST

STRAIGHT LINE FIT

n Low power consumption

n Direct interface to all popular microprocessors

n Integrated thin film on CMOS structure

n Double-buffered, single-buffered or flow through digital

data inputs

n Loads two 8-bit bytes or a single 10-bit word

n Logic inputs which meet TTL voltage level specs (1.4V

logic threshold)

n Works with

multiplication

n Operates STAND ALONE (without µP) if desired

n Available in 0.3" standard 20-pin package

n Differential non-linearity selection available as special

order

±

10V reference— full 4-quadrant

Key Specifications

n Output Current Settling Time: 500 ns

n Resolution: 10 bits

n Linearity: 10, 9, and 8 bits (guaranteed over temp.)

n Gain Tempco: −0.0003%of FS/˚C

n Low Power Dissipation: 20 mW (including ladder)

n Single Power Supply: 5 to 15 V

DC

April 1998

DAC1006/DAC1007/DAC1008 µP Compatible, Double-Buffered D to A Converters

DAC1006/DAC1007/DAC1008

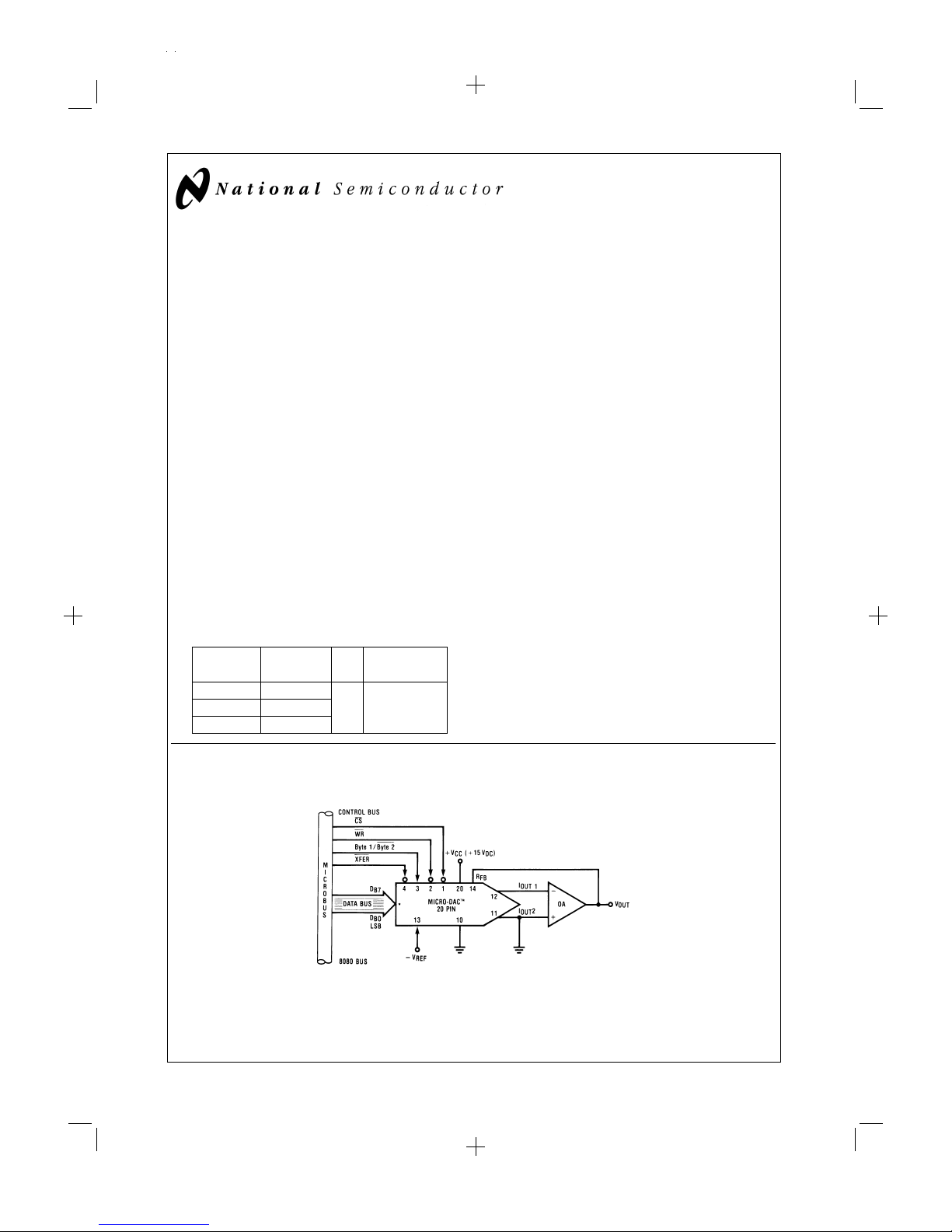

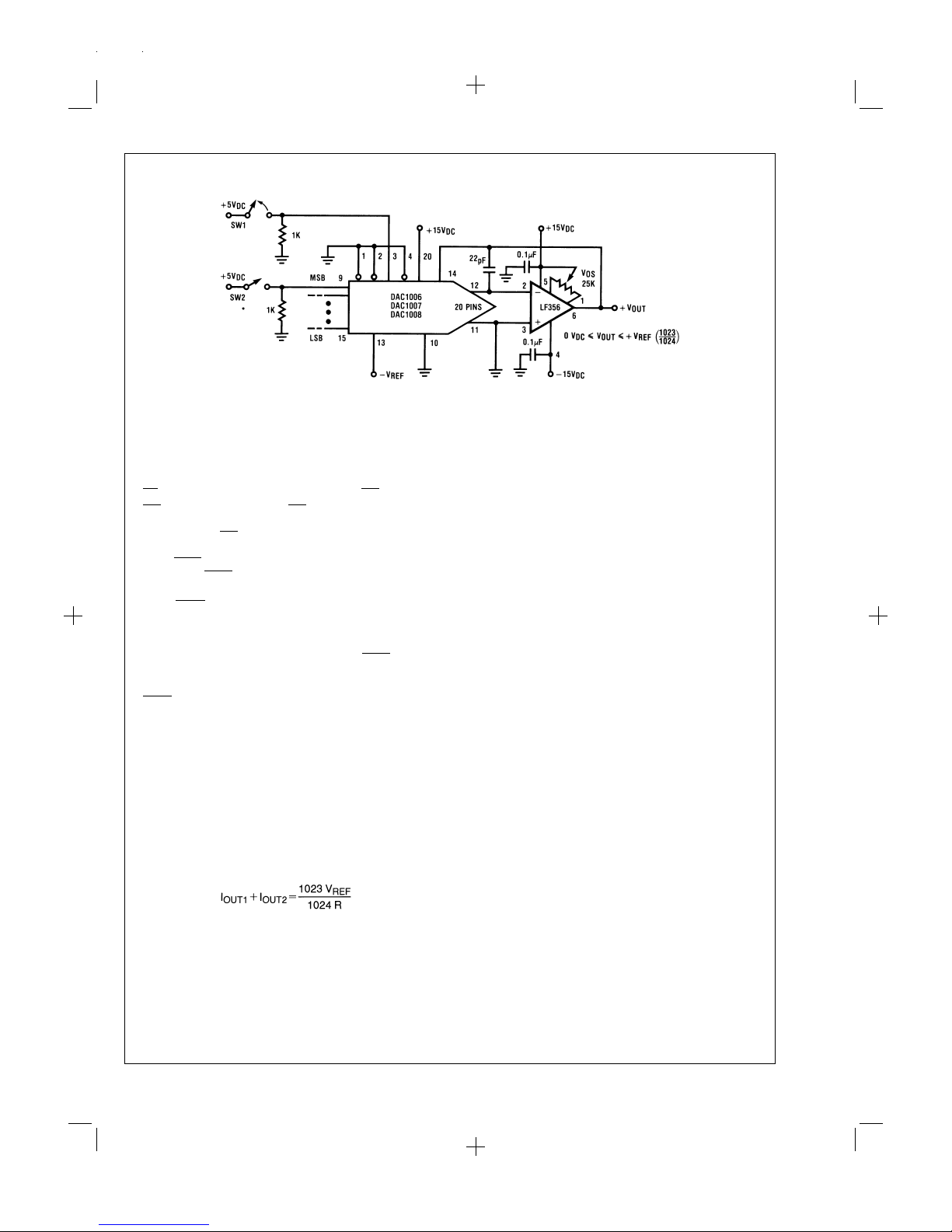

Typical Application

DAC1006/1007/1008

*

NOTE: FOR DETAILS OF BUS CONNECTION SEE SECTION 6.0

MICRO-DAC™and BI-FET™are trademarks of National Semiconductor Corp.

© 1998 National Semiconductor Corporation DS005688 www.national.com

PrintDate=1998/11/17 PrintTime=11:38:07 46711 ds005688 Rev. No. 4 cmserv

DS005688-1

Proof 1

1

Page 3

Absolute Maximum Ratings (Notes 1, 2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (V

Voltage at Any Digital Input VCCto GND

Voltage at V

Storage Temperature Range −65˚C to +150˚C

Package Dissipation at T

(Note 3) 500 mW

DC Voltage Applied to I

(Note 4) −100 mV to V

)17V

CC

REF

Input

OUT1

=

25˚C

A

or I

OUT2

±

25V

ESD Susceptibility (Note 11) 800V

Lead Temp. (Soldering, 10 seconds)

Dual-In-Line Package (plastic) 260˚C

Dual-In-Line Package (ceramic) 300˚C

DC

Operating Ratings (Note 1)

Temperature Range T

Part numbers with

“LCN” and “LCWN” suffix 0˚C to 70˚C

Voltage at Any Digital Input V

CC

MIN

≤ TA≤ T

to GND

CC

MAX

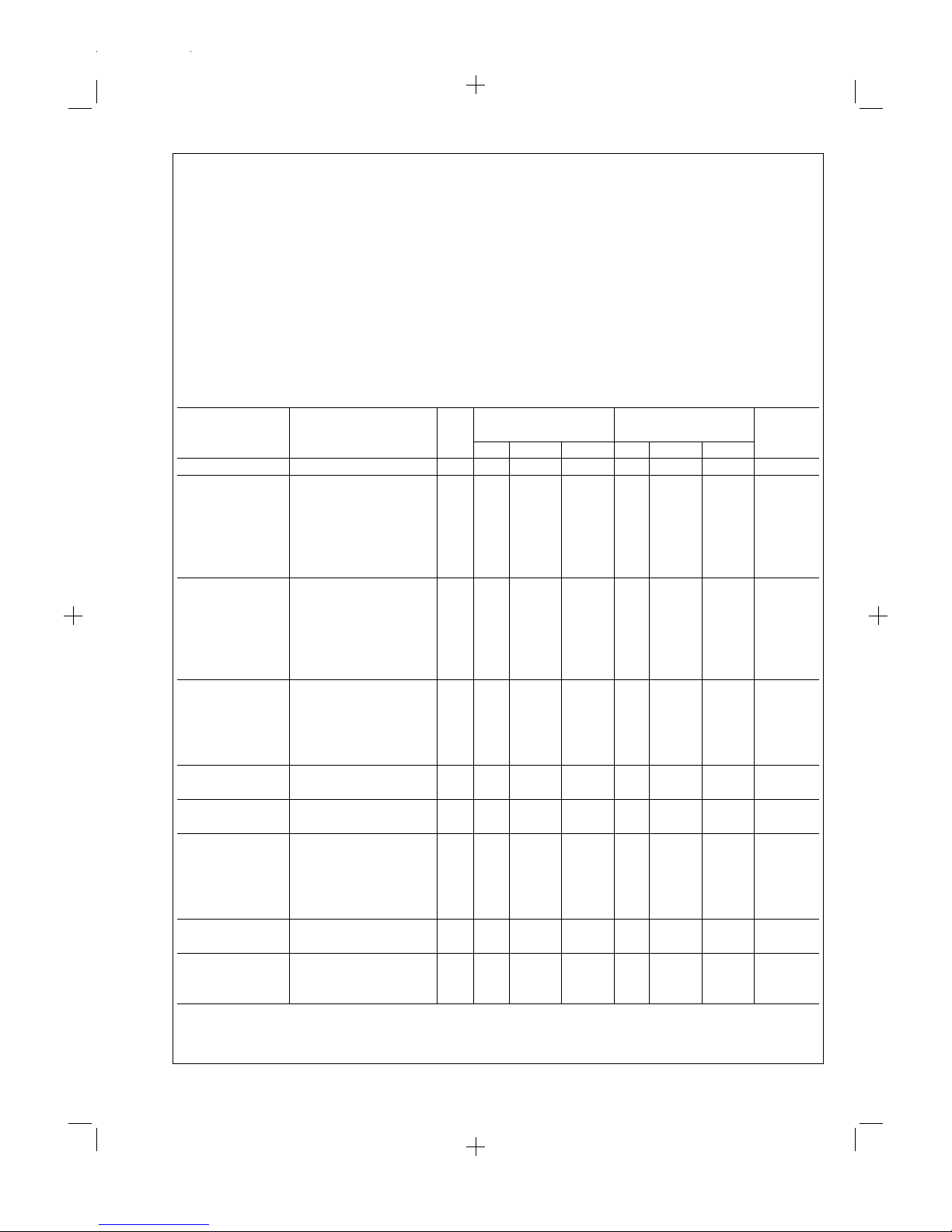

Electrical Characteristics

Tested at V

=

4.75 V

CC

and 15.75 VDC,T

DC

Parameter Conditions

Resolution 10 10 bits

Linearity Error Endpoint adjust only 4,7

<

<

T

T

T

MIN

A

−10V≤V

MAX

≤+10V 5

REF

DAC1006 0.05 0.05

DAC1007 0.1 0.1

DAC1008 0.2 0.2

Differential Endpoint adjust only 4,7

<

Nonlinearity T

MIN

−10V≤V

<

T

T

A

MAX

≤+10V 5

REF

DAC1006 0.1 0.1

DAC1007 0.2 0.2

DAC1008 0.4 0.4

<

Monotonicity T

MIN

−10V≤V

<

T

T

A

MAX

≤+10V 5

REF

DAC1006 10 10 bits

DAC1007 9 9 bits

DAC1008 8 8 bits

Gain Error Using internal R

Gain Error Tempco T

−10V≤V

MIN

≤+10V 5 −1.0±0.3 1.0 −1.0±0.3 1.0

REF

<

<

T

T

A

MAX

Using internal R

Power Supply All digital inputs

Rejection latched high

=

V

14.5V to 15.5V 0.003 0.008

CC

11.5V to 12.5V 0.004 0.010

4.75V to 5.25V 0.033 0.10

Reference Input

Resistance 10 15 20 10 15 20 kΩ

Output Feedthrough V

REF

=

20V

p-p

Error All data inputs 90 90 mV

latched low

=

A

fb

fb

,f=100 kHz

25˚C, V

=

10.000 V

REF

See

Note

Min. Typ. Max. Min. Typ. Max.

unless otherwise noted

DC

=

12V

±

DC

±

5

DC

V

CC

to 15V

=

%

5

V

±

%

5

5V

CC

DC

%

6

6

4,6

6

9 −0.0003 −0.001 −0.0006 −0.002%of FS/˚C

%

%

%

%

%

%

%

%

%

%

Units

of FSR

of FSR

of FSR

of FSR

of FSR

of FSR

of FS

FSR/V

FSR/V

FSR/V

p-p

www.national.com 2

PrintDate=1998/11/17 PrintTime=11:38:07 46711 ds005688 Rev. No. 4 cmserv Proof 2

Page 4

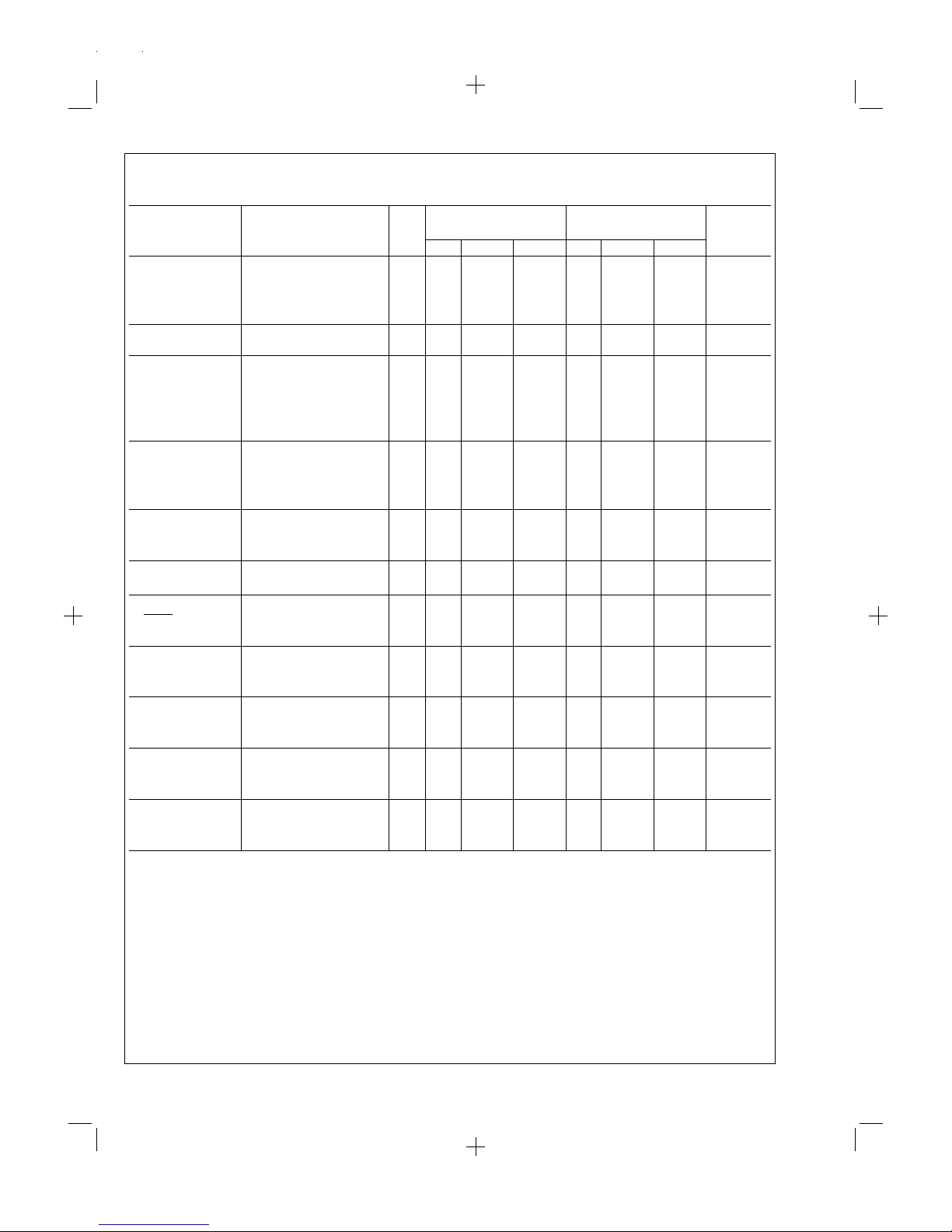

Electrical Characteristics (Continued)

Tested at V

=

4.75 V

CC

and 15.75 VDC,T

DC

Parameter Conditions

Output I

Capacitance I

Supply Current

Drain

Output Leakage T

Current I

All data inputs 60 60 pF

OUT1

OUT2

I

OUT1

I

OUT2

OUT1

latched low 250 250 pF

All data inputs 250 250 pF

latched high 60 60 pF

T

MIN≤TA≤TMAX

MIN≤TA≤TMAX

All data inputs

latched low 10 200 200 nA

I

All data inputs

OUT2

latched high 200 200 nA

Digital Input T

MIN≤TA≤TMAX

Voltages Low level

LCN and LCWM suffix 0.8, 0.8 0.7, 0.8 V

High level (all parts) 2.0 2.0 V

Digital Input T

Currents Digital inputs

MIN≤TA≤TMAX

<

Digital inputs>2.0V 1.0 +10 1.0 +10 µA

=

Current tSV

IL

0V, V

=

IH

Settling Time

=

Write and t

XFER Pulse

Width T

Data Set Up t

Time T

Data Hold t

Time T

Control Set t

Up Time T

Control Hold t

Time T

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. DC and AC electrical specifications do not apply when operating

the device beyond its specified operating conditions.

Note 2: All voltages are measured with respect to GND, unless otherwise specified.

Note 3: This 500 mW specification applies for all packages. The low intrinsic power dissipation of this part (and the fact that there is no way to significantly modify

the power dissipation) removes concern for heat sinking.

Note 4: For current switching applications, both I

by approximately V

Note 5: Guaranteed at V

Note 6: T

Note 7: The unit “FSR” stands for “Full Scale Range.” “Linearity Error” and “Power Supply Rejection” specs are based on this unit to eliminate dependence on a par-

ticular V

REF

after performing a zero and full scale adjustment (See Sections 2.5 and 2.6), the plot of the 1024 analog voltage outputs will each be within 0.05%xV

line which passes through zero and full scale.

Note 8: This specification implies that all parts are guaranteed to operate with a write pulse or transfer pulse width (t

of only 100 ns. The entire write pulse must occur within the valid data interval for the specified tW,tDS,tDH, and tSto apply.

Note 9: Guaranteed by design but not tested.

WVIL

T

A

MIN≤TA≤TMAX

DSVIL

A

T

MIN≤TA≤TMAX

DHVIL

A

T

MIN≤TA≤TMAX

CSVIL

A

T

MIN≤TA≤TMAX

CHVIL

A

T

MIN≤TA≤TMAX

÷

V

. For example, if V

OS

REF

=

±

REF

=

0˚C and T

MIN

value and to indicate the true performance of the part. The “Linearity Error” specification of the DAC1006 is “0.05%of FSR (MAX).” This guarantees that

=

70˚C for “LCN” and “LCWM” suffix parts.

MAX

=

0V, V

5V,

IH

=

25˚C 8 150 60 320 200 ns

=

0V, V

IH

=

25˚C 9 150 80 320 170 ns

=

=

OV, V

5V

IH

=

25˚C 9 200 100 320 220 ns

=

=

0V, V

5V,

IL

=

25˚C 9 150 60 320 180 ns

=

=

0V, V

5V,

IH

=

25˚C 9 10 0 10 0 ns

10 VDCand V

=

A

25˚C, V

=

10.000 V

REF

See

Note

Min. Typ. Max. Min. Typ. Max.

unless otherwise noted

DC

=

12V

±

DC

±

5

DC

V

CC

to 15V

%

5

V

%

=

±

%

5

5V

CC

DC

6 0.5 3.5 0.5 3.5 mA

6

6

6

0.8V −40 −150 −40 −150 µA

5V 500 500 ns

9 320 100 500 250 ns

=

5V,

320 120 500 250 ns

250 120 500 320 ns

320 100 500 260 ns

10 0 10 0 ns

and I

OUT1

=

10Vthena1mVoffset, V

REF

=

±

REF

must go to ground or the “Virtual Ground” of an operational amplifier.Thelinearity error is degraded

OUT2

1VDC.

OS

,onI

OUT1

or I

will introduce an additional 0.01%linearity error.

OUT2

) of 320 ns. A typical part will operate with t

W

of a straight

REF

Units

DC

DC

DC

DC

W

PrintDate=1998/11/17 PrintTime=11:38:08 46711 ds005688 Rev. No. 4 cmserv Proof 3

www.national.com3

Page 5

Electrical Characteristics (Continued)

Note 10: A 200 nA leakage current with R

Note 11: Human body model, 100 pF discharged through a 1.5 kΩ resistor.

=

20K and V

fb

=

10V corresponds to a zero error of (200x10

REF

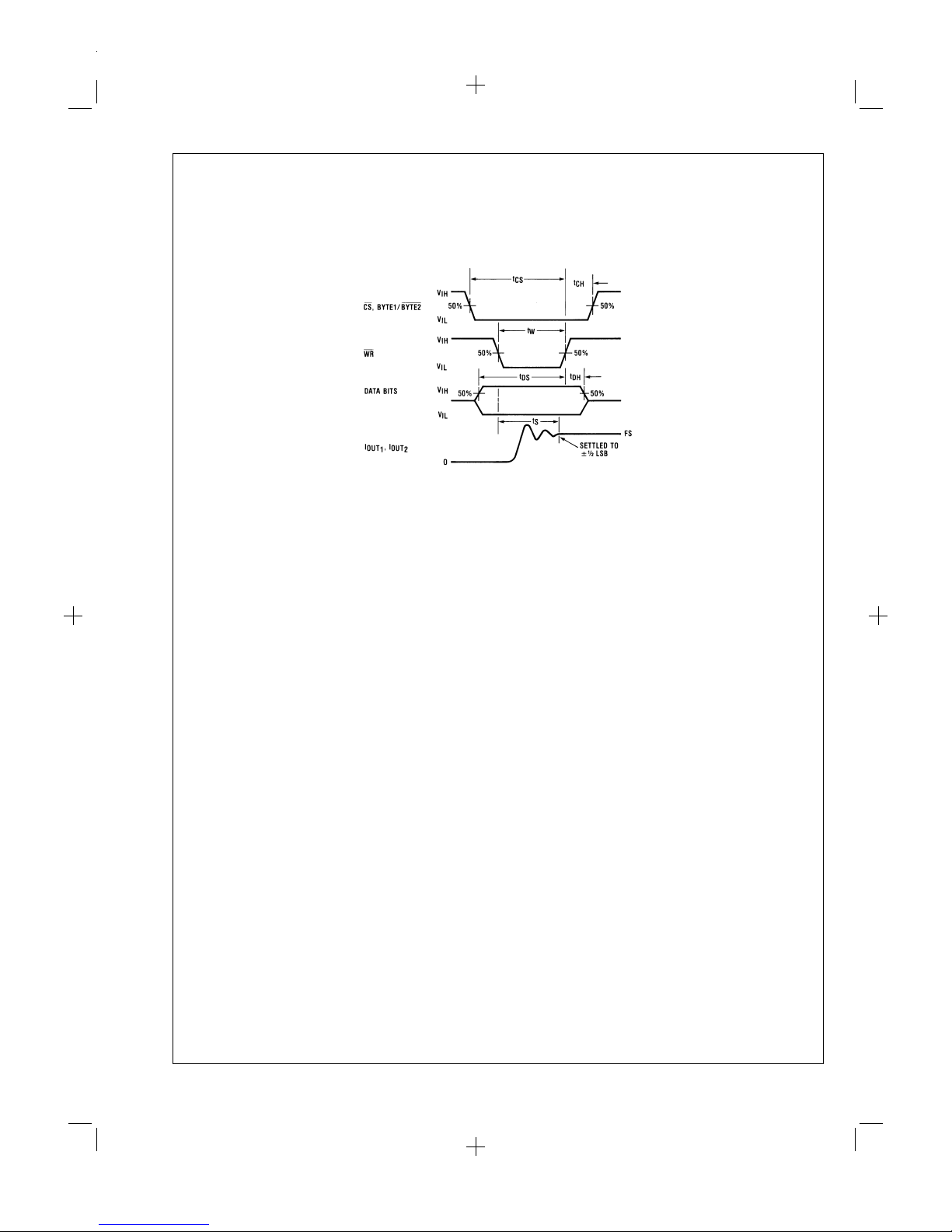

Switching Waveforms

−9

x20x103)x100÷10 which is 0.04%of FS.

DS005688-2

www.national.com 4

PrintDate=1998/11/17 PrintTime=11:38:08 46711 ds005688 Rev. No. 4 cmserv Proof 4

Page 6

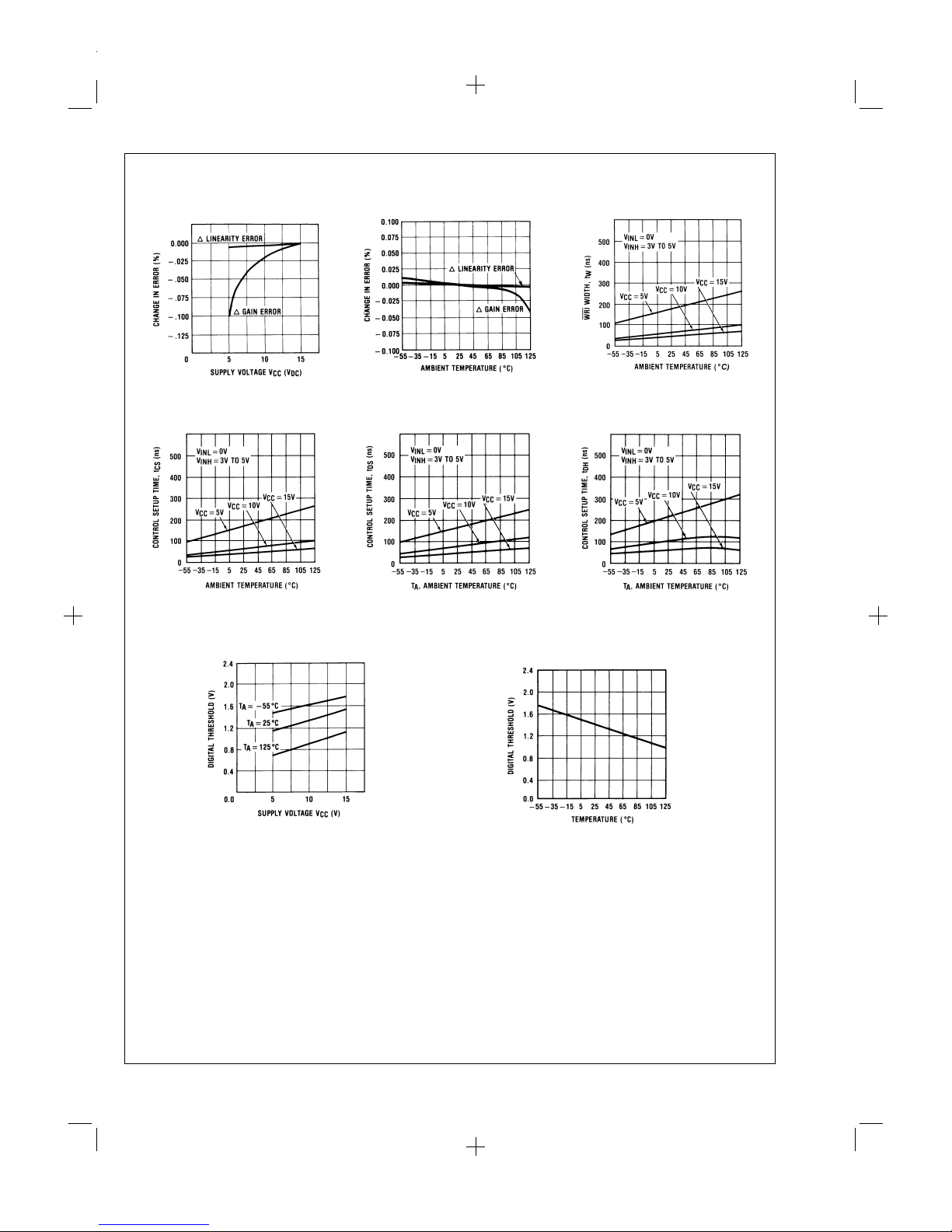

Typical Performance Characteristics

Errors vs. Supply Voltage

Control Setup Time, t

CS

Digital Threshold

vs. Supply Voltage

DS005688-29

DS005688-32

Errors vs. Temperature

Data Setup Time, t

DS

Digital Input Threshold

vs. Temperature

DS005688-30

DS005688-33

Write Width, t

w

Data Hold Time, t

DS005688-31

DH

DS005688-34

PrintDate=1998/11/17 PrintTime=11:38:08 46711 ds005688 Rev. No. 4 cmserv Proof 5

DS005688-35

DS005688-36

www.national.com5

Page 7

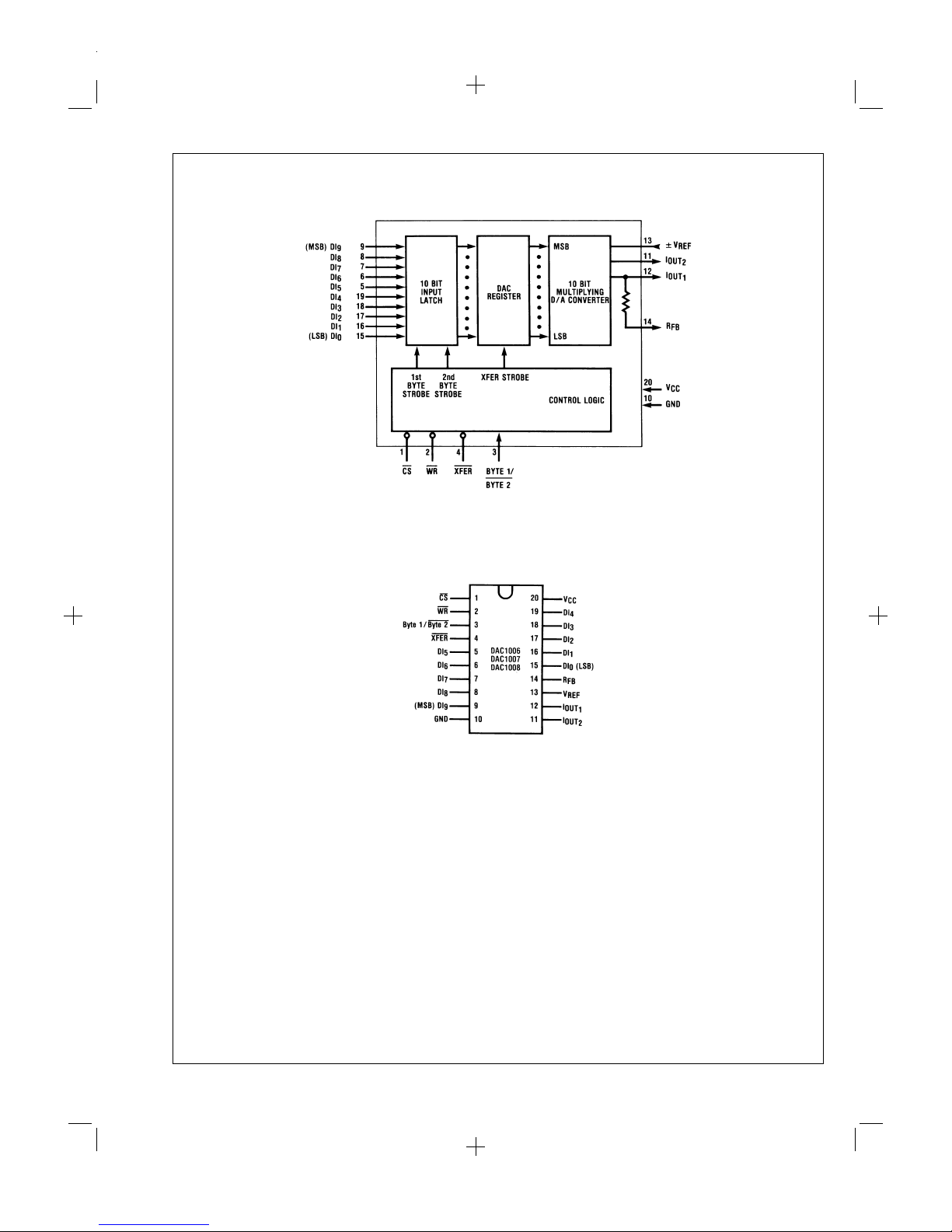

Block and Connection Diagrams

DAC1006/1007/1008 (20-Pin Parts)

Use DAC1006/1007/1008 for left justified data.

DS005688-5

DAC1006/1007/1008

(20-Pin Parts)

Dual-In-Line Package

DS005688-28

Top View

See Ordering Information

www.national.com 6

PrintDate=1998/11/17 PrintTime=11:38:08 46711 ds005688 Rev. No. 4 cmserv Proof 6

Page 8

DAC1006/1007/1008—Simple Hookup for a “Quick Look”

*

A TOTAL OF 10 INPUT SWITCHES & 1K RESISTORS

Notes:

=

REF

−10.240 V

1. For V

2. SW1 is a normally closed switch. While SW1 is closed, the DAC register is latched and new data can be loaded into the input latch via the 10 SW2 switches.

When SW1 is momentarily opened the new data is transferred from the input latch to the DAC register and is latched when SW1 again closes.

1.0 DEFINITION OF PACKAGE PINOUTS

1.1 Control Signals (All control signals are level actuated.)

CS: Chip Select — active low, it will enable WR.

WR: Write — The active low WR is used to load the digital

data bits (DI) into the input latch. The data in the input latch

is latched when WR is high. The 10-bit input latch is split into

two latches; one holds 8 bits and the other holds 2 bits. The

Byte1/Byte2 control pin is used to select both input latches

when Byte1/Byte2=1 or to overwrite the 2-bit input latch

when in the low state.

Byte1/Byte2: Byte Sequence Control — When this control

is high, all ten locations of the input latch are enabled. When

low, only two locations of the input latch are enabled and

these two locations are overwritten on the second byte write.

On the DAC1006, 1007, and 1008, the Byte1/Byte2 must be

low to transfer the 10-bit data in the input latch to the DAC

register.

XFER: Transfer Control Signal, active low — This signal, in

combination with others, is used to transfer the 10-bit data

which is available in the input latch to the DAC register —

see timing diagrams.

1.2 Other Pin Functions

DI

(i=0to9):Digital Inputs — DI0is the least significant bit

i

(LSB) and DI

: DAC Current Output 1 — I

I

OUT1

digital input code of all 1s and is zero for a digital input code

of all 0s.

I

: DAC Current Output 2 — I

OUT2

I

,or

OUT1

the output voltage steps are approximately 10 mV each.

DC

is the most significant bit (MSB).

g

is a maximum for a

OUT1

is a constant minus

OUT2

amp is used to provide an output voltage for the DAC. This

on-chip resistor should always be used (not an external resistor) because it matches the resistors used in the on-chip

R-2R ladder and tracks these resistors over temperature.

V

: Reference Voltage Input — This is the connection for

REF

the external precision voltage source which drives the R-2R

ladder.V

analog voltage input for a 4-quadrant multiplying DAC appli-

can range from −10 to +10 volts. This is also the

REF

cation.

V

: Digital Supply Voltage — This is the power supply pin

CC

for the part. V

timum for +15V. The input threshold voltages are nearly independent of V

and Description in Section 3.0, T

can be from +5 to +15 VDC. Operation is op-

CC

. (See Typical Performance Characteristics

CC

GND: Ground — the ground pin for the part.

1.3 Definition of Terms

Resolution: Resolution is directly related to the number of

switches or bits within the DAC. For example, the DAC1006

10

has 2

or 1024 steps and therefore has 10-bit resolution.

Linearity Error: Linearity error is the maximum deviation

from a

straight line passing through the endpoints of the

DAC transfer characteristic.

zero and full-scale. Linearity error is a parameter intrinsic to

the device and cannot be externally adjusted.

National’s linearity test (a) and the “best straight line” test (b)

used by other suppliers are illustrated below. The “best

straight line” requires a special zero and FS adjustment for

each part, which is almost impossible for user to determine.

The “end point test” uses a standard zero and FS adjustment

procedure and is a much more stringent test for DAC linear-

DS005688-7

2

L compatible logic inputs.)

It is measured after adjusting for

ity.

Power Supply Sensitivity: Power supply sensitivity is a

measure of the effect of power supply changes on the DAC

where R≅15 kΩ.

: Feedback Resistor — This is provided on the IC chip

R

FB

for use as the shunt feedback resistor when an external op

full-scale output (which is the worst case).

PrintDate=1998/11/17 PrintTime=11:38:08 46711 ds005688 Rev. No. 4 cmserv Proof 7

www.national.com7

Page 9

DAC1006/1007/1008—Simple Hookup for a “Quick Look” (Continued)

a. End Point Test After Zero and FS Adj.

DS005688-37

Settling Time: Settling time is the time required from a code

transition until the DAC output reaches within

1

±

⁄2LSB of the

final output value. Full-scale settling time requires a zero to

full-scale or full-scale to zero output change.

Full-Scale Error: Full scale error is a measure of the output

error between an ideal DAC and the actual device output.

Ideally, for the DAC1006 series, full-scale is V

For V

V

FULL-SCALE

adjustable to zero.

=

−10V and unipolar operation,

REF

=

10.0000V −9.8mV=9.9902V.Full-scale error is

REF

−1 LSB.

Monotonicity: If the output of a DAC increases for increasing digital input code, then the DAC is monotonic. A 10-bit

DAC with 10-bit monotonicity will produce an increasing analog output when all 10 digital inputs are exercised. A 10-bit

DAC with 9-bit monotonicity will be monotonic when only the

most significant 9 bits are exercised. Similarly, 8-bit monotonicity is guaranteed when only the most significant 8 bits are

exercised.

2.0 DOUBLE BUFFERING

These DACs are double-buffered, microprocessor compatible versions of the DAC1020 10-bit multiplying DAC. The

addition of the buffers for the digital input data not only allows for storage of this data, but also provides a way to assemble the 10-bit input data word from two write cycles when

using an 8-bit data bus. Thus, the next data update for the

DAC output can be made with the complete new set of 10-bit

data. Further, the double buffering allows many DACs in a

system to store current data and also the next data. The updating of the new data for each DAC is also not time critical.

When all DACs are updated, a common strobe signal can

then be used to cause all DACs to switch to their new analog

output levels.

b. Best Straight Line

DS005688-38

3.0 TTL COMPATIBLE LOGIC INPUTS

To guarantee TTL voltage compatibility of the logic inputs, a

novel bipolar (NPN) regulator circuit is used. This makes the

input logic thresholds equal to the forward drop of two diodes

(and also matches the temperature variation) as occurs

naturally in TTL. The basic circuit is shown in

Figure 1

.A

curve of digital input threshold as a function of power supply

voltage is shown in the Typical Performance Characteristics

section.

4.0 APPLICATION HINTS

The DC stability of the V

factor to maintain accuracy of the DAC over time and tem-

source is the most important

REF

perature changes. A good single point ground for the analog

signals is next in importance.

These MICRO-DAC converters are CMOS products and reasonable care should be exercised in handling them prior to final mounting on a PC board. The digital inputs are protected,

but permanent damage may occur if the part is subjected to

high electrostatic fields. Store unused parts in conductive

foam or anti-static rails.

4.1 Power Supply Sequencing & Decoupling

Some IC amplifiers draw excessive current from the Analog

inputs to V− when the supplies are first turned on. To prevent

damage to the DAC — an external Schottky diode connected from I

vent destructive currents in I

LF356 is used — these diodes are not required.

OUT1

or I

to ground may be required to pre-

OUT2

OUT1

or I

OUT2

. If an LM741 or

The standard power supply decoupling capacitors which are

used for the op amp are adequate for the DAC.

www.national.com 8

PrintDate=1998/11/17 PrintTime=11:38:08 46711 ds005688 Rev. No. 4 cmserv Proof 8

Page 10

DAC1006/1007/1008—Simple Hookup for a “Quick Look” (Continued)

DS005688-9

FIGURE 1. Basic Logic Threshold Loop

4.2 Op Amp Bias Current & Input Leads

The op amp bias current (I

™

BI-FET

op amps have very low bias current, and therefore

) CAN CAUSE DC ERRORS.

B

the error introduced is negligible. BI-FET op amps are

strongly recommended for these DACs.

The distance from the I

input of the op amp should be kept as short as possible to

pin of the DAC to the inverting

OUT1

prevent inadvertent noise pickup.

5.0 ANALOG APPLICATIONS

The analog section of these DACs uses an R-2R ladder

which can be operated both in the current switching mode

and in the voltage switching mode.

The major product changes (compared with the DAC1020)

have been made in the digital functioning of the DAC. The

analog functioning is reviewed here for completeness. For

additional analog applications, such as multipliers, attenuators, digitally controlled amplifiers and low frequency sine

wave oscillators, refer to the DAC1020 data sheet. Some basic circuit ideas are presented in this section in addition to

complete applications circuits.

5.1 Operation in Current Switching Mode

The analog circuitry,

Figure 2

, consists of a silicon-chromium

(Si-Cr) thin film R-2R ladder which is deposited on the surface oxide of the monolithic chip. As a result, there is no

parasitic diode connected to the V

diffused resistors were used. The reference voltage input

(V

) can therefore range from −10V to +10V.

REF

pin as would exist if

REF

The digital input code to the DAC simply controls the position

of the SPDT current switches, SW0 to SW9. A logical 1 digital input causes the current switch to steer the available lad-

der current to the I

erate in the current mode with a small voltage drop across

them and can therefore switch currents of either polarity.

This is the basis for the 4-quadrant multiplying feature of this

DAC.

5.1.1 Providing a Unipolar Output Voltage with the

DAC in the Current Switching Mode

Avoltage output is provided by making use of an external op

amp as a current-to-voltage converter.The idea is to use the

internal feedback resistor, R

amp to the inverting (−) input. Now, when current is entered

at this inverting input, the feedback action of the op amp

keeps that input at ground potential. This causes the applied

input current to be diverted to the feedback resistor. The output voltage of the op amp is forced to a voltage given by:

Notice that the sign of the output voltage depends on the direction of current flow through the feedback resistor.

In current switching mode applications, both current output

pins (I

accomplished as shown in

OUT1

and I

used to compensate for the output capacitance of the DAC

and the input capacitance of the op amp. The required feedback resistor, R

nally tied to I

tor will not provide the needed matching and temperature

OUT1

tracking. This circuit can therefore be simplified as shown in

Figure 4

, where the sign of the reference voltage has been

changed to provide a positive output voltage. Note that the

output current, I

output pin. These MOS switches op-

OUT1

, from the output of the op

FB

=

V

−(I

OUT

OUT1xRFB

) should be operated at 0 VDC. This is

OUT2

, is available on the chip (one end is inter-

FB

) and must be used since an external resis-

OUT1

Figure 3

. The capacitor, CC,is

, now flows through the RFBpin.

)

PrintDate=1998/11/17 PrintTime=11:38:09 46711 ds005688 Rev. No. 4 cmserv Proof 9

www.national.com9

Page 11

DAC1006/1007/1008—Simple Hookup for a “Quick Look” (Continued)

DIGITAL INPUT CODE

DS005688-39

FIGURE 2. Current Mode Switching

DS005688-40

C

pF

R

C

ts µS

j

∞

3

∞

4

to V

OUT

OUT

OP

AMP

LF356 22

LF351 24

LF357 10 2.4k 1.5

FIGURE 3. Converting I

5.1.2 Providing a Bipolar Output Voltage with the DAC

in the Current Switching Mode

The addition of a second op amp to the circuit of

Figure 4

(−512≤D≤+511 or 1000000000≤D≤0111111111). If the applied digital input is interpreted as the decimal equivalent of

a true binary word, V

can be found by:

OUT

can be used to generate a bipolar output voltage from a fixed

reference voltage

Figure 5

. This, in effect, gives sign significance to the MSB of the digital input word to allow two quadrant multiplication of the reference voltage. The polarity of

the reference can also be reversed to realize the full

four-quadrant multiplication.

The applied digital word is offset binary which includes a

code to output zero volts without the need of a large valued

resistor common to existing bipolar multiplying DAC circuits.

Offset binary code can be derived from 2’s complement data

(most common for signed processor arithmetic) by inverting

the state of the MSB in either software or hardware. After doing this the output then responds in accordance to the following expression:

With this configuration, only the offset voltage of amplifier 1

need be nulled to preserve linearity of the DAC. The offset

voltage error of the second op amp has no effect on linearity.

It presents a constant output voltage error and should be

nulled only if absolute accuracy is needed. Another advantage of this configuration is that the values of the external resistors required do not have to match the value of the internal DAC resistors; they need only to match and temperature

track each other.

A thin film 4 resistor network available from Beckman Instruments, Inc. (part no. 694-3-R10K-D) is ideally suited for this

application. Two of the four available 10 kΩ resistor can be

paralleled to form R in

Figure 5

and the other two can be

used separately as the resistors labeled 2R.

where V

decimal equivalent of the 2’s complement processor data.

www.national.com 10

can be positive or negative and D is the signed

REF

PrintDate=1998/11/17 PrintTime=11:38:09 46711 ds005688 Rev. No. 4 cmserv Proof 10

Page 12

DAC1006/1007/1008—Simple Hookup for a “Quick Look” (Continued)

Operation is summarized in the table below:

Applied

2’s Comp. 2’s Comp. Applied True Binary V

(Decimal) (Binary) Digital Input (Decimal) +V

+511 0111111111 1111111111 1023 V

+256 0100000000 1100000000 768 V

REF

−1 LSB −|V

REF

REF

0 0000000000 1000000000 512 0 0

−1 1111111111 0111111111 511 −1 LSB +1 LSB

−256 1100000000 0100000000 256 −V

−512 1000000000 0000000000 0 −V

REF

REF

DS005688-41

FIGURE 4. Providing a Unipolar Output Voltage

OUT

REF

/2 −|V

/2 +|V

−V

REF

REF

+|V

REF

|+1 LSB

REF

|/2

|/2

|

DS005688-42

FIGURE 5. Providing a Bipolar Output Voltage with the DAC in the Current Switching Mode

5.2 Analog Operation in the Voltage Switching Mode

Some useful application circuits result if the R-2R ladder is

operated in the voltage switching mode. There are two very

important things to remember when using the DAC in the

voltage mode. The reference voltage (+V) must always be

positive since there are parasitic diodes to ground on the

I

pin which would turn on if the reference voltage went

OUT1

negative. To maintain a degradation of linearity less than

±

0.005%, keep +V ≤ 3VDCand VCCat least 10V more posi-

tive than +V.

Figures 6, 7

show these errors for the voltage

switching mode. This operation appears unusual, since a reference voltage (+V) is applied to the I

age output is the V

8

.

This V

gain stage as shown in

range can be scaled by use of a non-inverting

OUT

pin. This basic idea is shown in

REF

Figure 9

.

pin and the volt-

OUT1

Figure

single op amp as shown in

of all zeros, the output voltage from the V

volts. The external op amp now has a single input of +V and

Figure 10

. For a digital input code

REF

pin is zero

is operating with a gain of −1 to this input. The output of the

op amp therefore will be at −V for a digital input of all zeros.

As the digital code increases, the output voltage at the V

pin increases.

REF

Notice that the gain of the op amp to voltages which are applied to the (+) input is +2 and the gain to voltages which are

applied to the input resistor, R, is −1. The output voltage of

the op amp depends on both of these inputs and is given by:

=

V

OUT

(+V) (−1)+V

REF

(+2)

Notice that this is unipolar operation since all voltages are

positive. A bipolar output voltage can be obtained by using a

www.national.com11

PrintDate=1998/11/17 PrintTime=11:38:09 46711 ds005688 Rev. No. 4 cmserv Proof 11

Page 13

DAC1006/1007/1008—Simple Hookup for a “Quick Look” (Continued)

DS005688-43

FIGURE 6.

FIGURE 7.

DIGITAL INPUT CODE

DS005688-45

FIGURE 8. Voltage Mode Switching

DS005688-46

FIGURE 9. Amplifying the Voltage Mode Output (Single Supply Operation)

DS005688-44

FIGURE 10. Providing a Bipolar Output Voltage with a Single Op Amp

www.national.com 12

PrintDate=1998/11/17 PrintTime=11:38:09 46711 ds005688 Rev. No. 4 cmserv Proof 12

DS005688-47

Page 14

DAC1006/1007/1008—Simple Hookup for a “Quick Look” (Continued)

DS005688-48

FIGURE 11. Increasing the Output Voltage Swing

The output voltage swing can be expanded by adding 2 resistors to

Figure 10

as shown in

Figure 11

. These added resistors are used to attenuate the +V voltage. The overall

gain, A

(−), from the +V terminal to the output of the op amp

V

determines the most negative output voltage, −4(+V) (when

the V

voltage at the + input of the op amp is zero) with the

REF

component values shown. The complete dynamic range of

V

is provided by the gain from the (+) input of the op

OUT

amp. As the voltage at the V

+V(1023/1024) the output of the op amp will range from −10

V

to +10V (1023/1024) when using a +V voltage of +2.500

DC

V

. The 2.5 VDCreference voltage can be easily developed

DC

by using the LM336 zener which can be biased through the

R

internal resistor, connected to VCC.

FB

5.3 Op Amp V

Switching Mode

Adjust (Zero Adjust) for Current

OS

pin ranges from 0V to

REF

Proper operation of the ladder requires that all of the 2R legs

always go to exactly 0 V

age, V

, of the external op amp cannot be tolerated as ev-

OS

ery millivolt of V

ror. At first this seems unusually sensitive, until it becomes

will introduce 0.01%of added linearity er-

OS

(ground). Therefore offset volt-

DC

clear the 1 mV is 0.01%of the 10V reference! High resolution converters of high accuracy require attention to every

detail in an application to achieve the available performance

which is inherent in the part. To prevent this source of error,

the V

of the op amp has to be initially zeroed. This is the

OS

“zero adjust” of the DAC calibration sequence and should be

done first.

If the V

Note that no “dc balancing” resistance should be used in the

is to be adjusted there are a few points to consider.

OS

grounded positive input lead of the op amp. This resistance

and the input current of the op amp can also create errors.

The low input biasing current of the BI-FET op amps makes

them ideal for use in DAC current to voltage applications.

The V

of the op amp should be adjusted with a digital input

OS

of all zeros to force I

porarily connected from the inverting input to ground to provide a dc gain of approximately 15 to the V

and make the zeroing easier to sense.

=

0mA.A1kΩresistor can be tem-

OUT

of the op amp

OS

5.4 Full-Scale Adjust

The full-scale adjust procedure depends on the application

circuit and whether the DAC is operated in the current

switching mode or in the voltage switching mode. Techniques are given below for all of the possible application circuits.

5.4.1 Current Switching with Unipolar Output Voltage

After doing a “zero adjust,” set all of the digital input levels

HIGH and adjust the magnitude of V

REF

This completes the DAC calibration.

5.4.2 Current Switching with Bipolar Output Voltage

The circuit of

Figure 12

shows the 3 adjustments needed.

The first step is to set all of the digital inputs LOW (to force

I

to 0) and then trim “zero adj.” for zero volts at the in-

OUT1

verting input (pin 2) of 0A1. Next, with a code of all zeros still

applied, adjust “−FS adj.”, the reference voltage, for

=

±

V

|(ideal V

OUT

opposite that of the applied reference.

Finally,set all of the digital inputs HIGH and adjust “+FS adj.”

=

for V

will be the same as that of the reference voltage. The addi-

OUT

V

)|. The sign of the output voltage will be

REF

(511/512).The sign of the output at this time

REF

tion of the 200Ω resistor in series with the V

DAC is to force the circuit gain error from the DAC to be

negative. This insures that adding resistance to R

500Ω pot, will always compensate the gain error of the DAC.

5.4.3 Voltage Switching with a Unipolar Output Voltage

Refer to the circuit of

LOW. Trim the “zero adj.” for V

all digital inputs HIGH and trim the “FS Adj.” for:

Figure 13

and set all digital inputs

=

0V

OUT

5.4.4 Voltage Switching with a Bipolar Output Voltage

Figure 14

Refer to

“−FS Adj.” for V

HIGH and trim the “+FS Adj.” for V

Test the zero by setting the MS digital input HIGH and all the

rest LOW. Adjust V

the full-scale values.

and set all digital inputs LOW. Trim the

OUT

=

OS

. Then set all digital inputs

−2.5 V

DC

=

OUT

of amp#3, if necessary, and recheck

for

pin of the

REF

, with the

fb

±

1 mV. Then set

DC

+2.5 (511/512) V

.

DC

PrintDate=1998/11/17 PrintTime=11:38:09 46711 ds005688 Rev. No. 4 cmserv Proof 13

www.national.com13

Page 15

DAC1006/1007/1008—Simple Hookup for a “Quick Look” (Continued)

DS005688-49

FIGURE 12. Full Scale Adjust — Current Switching with Bipolar Output Voltage

FIGURE 13. Full Scale Adjust — Voltage Switching with a Unipolar Output Voltage

FIGURE 14. Voltage Switching with a Bipolar Output Voltage

6.0 DIGITAL CONTROL DESCRIPTION

The DAC1006 series of products can be used in a wide variety of operating modes. Most of the options are shown in

Table1

. Also shown in this table are the section numbers of

this data sheet where each of the operating modes is dis-

www.national.com 14

DS005688-50

DS005688-15

cussed. For example, if your main interest in interfacing to a

µP with an 8-bit data bus you will be directed to Section

6.1.0.

The first consideration is “will the DAC be interfaced to a µP

with an 8-bit or a 16-bit data bus or used in the stand-alone

mode?” For the 8-bit data bus, a second selection is made

PrintDate=1998/11/17 PrintTime=11:38:09 46711 ds005688 Rev. No. 4 cmserv Proof 14

Page 16

DAC1006/1007/1008—Simple

Hookup for a “Quick Look”

on how the 2nd digital data buffer (the DAC Latch) is updated by a transfer from the 1st digital data buffer (the Input

Latch). Three options are provided: 1) an automatic transfer

when the 2nd data byte is written to the DAC, 2) a transfer

which is under the control of the µP and can include more

than one DAC in a simultaneous transfer, or 3) a transfer

which is under the control of external logic. Further, the data

format can be either left justified or right justified.

When interfacing to a µP with a 16-bit data bus only two selections are available: 1) operating the DAC with a single

digital data buffer (the transfer of one DAC does not have to

be synchronized with any other DACs in the system), or 2)

operating with a double digital data buffer for simultaneous

transfer, or updating, of more than one DAC.

For operating without a µP in the stand alone mode, three

options are provided: 1) using only a single digital data

Operating Mode Automatic Transfer µP Control Transfer External Transfer

Section Figure No. Section Figure No. Section Figure No.

Data Bus

8-Bit Data Bus (6.1.0)

Left Justified (6.1.1) 6.2.1 16 6.2.2 16 6.2.3 16

16-Bit Data Bus (6.3.0) Single Buffered Double Buffered Flow Through

6.3.1 17 6.3.2 17 Not Applicable

Stand Alone (6.4.0) Single Buffered Double Buffered Flow Through

6.4.1 17 6.4.2 17 NA

(Continued)

buffer, 2) using both digital data buffers — “double buffered,” or 3) allowing the input digital data to “flow through” to

provide the analog output without the use of any data

latches.

To reduce the required reading, only the applicable sections

of 6.1 through 6.4 need be considered.

6.1 Interfacing to an 8-Bit Data Bus

Transferring 10 bits of data over an 8-bit bus requires two

write cycles and provides four possible combinations which

depend upon two basic data format and protocol decisions:

1. Is the data to be left justified (considered as fractional bi-

nary data with the binary point to the left) or right justified

(considered as binary weighted data with the binary

point to the right)?

2. Which byte will be transfered first, the most significant

byte (MS byte) or the least significant byte (LS byte)?

TABLE 1.

These data possibilities are shown in

the justification of data depends on how the 10-bit data word

is located within the 16-bit data source (CPU) register. In either case, there is a surplus of 6 bits and these are shown as

“don’t care” terms (“x”) in this figure.

All of these DACs load 10 bits on the 1st write cycle. A particular set of 2 bits is then overwritten on the 2nd write cycle,

depending on the justification of the data. For all left justified

data options, the 1st write cycle must contain the MS or Hi

Byte data group.

6.1.1 For Left Justified Data

For applications which require left justified data,

DAC1006–1008 can be used. A simplified logic diagram

which shows the external connections to the data bus and

the internal functions of both of the data buffer registers (Input Latch and DAC Register) is shown in

parts require the MS or Hi Byte data group to be transferred

on the 1st write cycle.

Figure 15

Figure 16

. Note that

. These

6.2 Controlling Data Transfer for an 8-Bit Data Bus

Three operating modes are possible for controlling the transfer of data from the Input Latch to the DAC Register, where

it will update the analog output voltage. The simplest is the

automatic transfer mode, which causes the data transfer to

occur at the time of the 2nd write cycle. This is recommended when the exact timing of the changes of the DAC

analog output are not critical. This typically happens where

each DAC is operating individually in a system and the analog updating of one DAC is not required to be synchronized

to any other DAC. For synchronized DAC updating, two options are provided: µP control via a common XFER strobe or

external update timing control via an external strobe. The details of these options are now shown.

www.national.com15

PrintDate=1998/11/17 PrintTime=11:38:10 46711 ds005688 Rev. No. 4 cmserv Proof 15

Page 17

DAC1006/1007/1008—Simple Hookup for a “Quick Look” (Continued)

DAC1006/1007/1008 (20-Pin Parts for Left Justified Data)

DS005688-16

FIGURE 15. Fitting a 10-Bit Data Word into 16 Available Bit Locations

FIGURE 16. Input Connections and Controls for DAC1006/1007/1008 Left Justified Data

www.national.com 16

DS005688-17

PrintDate=1998/11/17 PrintTime=11:38:10 46711 ds005688 Rev. No. 4 cmserv Proof 16

Page 18

DAC1006/1007/1008—Simple

Hookup for a “Quick Look”

6.2.1 Automatic Transfer

This makes use of a double byte (double precision) write.

The first byte (8 bits) is strobed into the input latch and the

second byte causes a simultaneous strobe of the two remaining bits into the input latch and also the transfer of the

complete 10-bit word from the input latch to the DAC register.This is shown in the following timing diagram; the point in

time where the analog output is updated is also indicated on

this diagram.

DAC1006/1007/1008 (20-Pin Parts)

*

SIGNIFIES CONTROL INPUTS WHICH ARE DRIVEN IN PARALLEL

6.2.2 Transfer Using µP Write Stroke

The input latch is loaded with the first two write strobes. The

XFER signal is provided by external logic, as shown below,

to cause the transfer to be accomplished on a third write

strobe. This is shown in the following diagram:

(Continued)

DS005688-18

DAC1006/1007/1008 (20–Pin Parts)

DS005688-19

6.2.3 Transfer Using an External Strobe

This is similar to the previous operation except the XFER

signal is not provided by the µP. The timing diagram for this

is:

DAC1006/1007/1008 (20–Pin Parts)

6.3 Interfacing to a 16-Bit Data Bus

DS005688-20

The interface to a 16-bit data bus is easily handled by connecting to 10 of the available bus lines. This allows a wiring

selected right justified or left justified data format. This is

shown in the connection diagram of

Figure 17

, where the

use of DB6 to DB15 gives left justified data operation. Note

that any part number can be used and the Byte1/Byte2 control should be wired Hi.

www.national.com17

PrintDate=1998/11/17 PrintTime=11:38:10 46711 ds005688 Rev. No. 4 cmserv Proof 17

Page 19

DAC1006/1007/1008—Simple Hookup for a “Quick Look” (Continued)

DS005688-21

FIGURE 17. Input Connections and Logic for DAC1006/1007/1008 with 16-Bit Data Bus

Three operating modes are possible: flow through, single

buffered, or double buffered. The timing diagrams for these

are shown below:

6.3.1 Single Buffered

DAC1006/1007/1008 (20-Pin Parts)

6.4.1 Single Buffered

DAC1006/1007/1008 (20-Pin Parts)

6.4.2 Double Buffered

DS005688-53

DS005688-51

6.3.2 Double Buffered

DAC1006/1007/1008 (20-Pin Parts)

DS005688-52

6.4 Stand Alone Operation

For applications for a DAC which are not under µP control

(stand alone) there are two basic operating modes, single

buffered and double buffered. The timing diagrams for these

are shown below:

www.national.com 18

DAC1006/1007/1008 (20-Pin Parts) (Note 12)

Note 12: For a connection diagram of this operating mode use

the Logic and

Figure 17

for the Data Input connections.

DS005688-54

Figure 16

7.0 MICROPROCESSOR INTERFACE

The logic functions of the DAC1006 family have been oriented towards an ease of interface with all popular µPs. The

following sections discuss in detail a few useful interface

schemes.

7.1 DAC1001/1/2 to INS8080A Interface

Figure 18

illustrates the simplicity of interfacing the

DAC1006 to an INS8080A based microprocessor system.

The circuit will perform an automatic transfer of the 10 bits of

output data from the CPU to the DAC register as outlined in

Section 6.2.1, “Controlling Data Transfer for an 8-Bit Data

Bus.”

Since a double byte write is necessary to control the DAC

with the INS8080A, a possible instruction to achieve this is a

PUSH of a register pair onto a “stack” in memory. The 16-bit

register pair word will contain the 10 bits of the eventual DAC

input data in the proper sequence to conform to both the requirements of the DAC (with regard to left justified data) and

for

PrintDate=1998/11/17 PrintTime=11:38:10 46711 ds005688 Rev. No. 4 cmserv Proof 18

Page 20

DAC1006/1007/1008—Simple

Hookup for a “Quick Look”

the implementation of the PUSH instruction which will output

the higher order byte of the register pair (i.e., register B of the

BC pair) first. The DAC will actually appear as a two-byte

“stack” in memory to the CPU. The auto-decrementing of the

(Continued)

stack pointer during a PUSH allows using address bit 0 of

the stack pointer as the Byte1/Byte2 and XFER strobes if bit

0 of the stack pointer address −1, (SP−1), is a “1” as presented to the DAC. Additional address decoding by the

DM8131 will generate a unique DAC chip select (CS) and

synchronize this CS to the two memory write strobes of the

PUSH instruction.

NOTE: DOUBLE BYTE STORES CAN BE USED.

e.g. THE INSTRUCTION SHLD F001 STORES THE L REG INTO B1 AND THE H REG INTO B2 AND TRANSFERS THE RESULT TO THE DAC REGISTER.

THE OPERAND OF THE SHLD INSTRUCTION MUST BE AN ODD ADDRESS FOR PROPER TRANSFER.

DS005688-24

FIGURE 18. Interfacing the DAC1000 to the INS8080A CPU Group

To reset the stack pointer so new data may be output to the

same DAC, a POP instruction followed by instructions to insure that proper data is in the DAC data register pair before

it is “PUSHED” to the DAC should be executed, as the POP

instruction will arbitrarily alter the contents of a register pair.

Another double byte write instruction is Store H and L Direct

(SHLD), where the HL register pair would temporarily contain the DAC data and the two sequential addresses for the

DAC are specified by the instruction op code. The auto incrementing of the DAC address by the SHLD instruction permits

the same simple scheme of using address bit 0 to generate

the byte number and transfer strobes.

7.2 DAC1006 to MC6820/1 PIA Interface

In

Figure 19

the DAC1006 is interfaced to an M6800 system

through an MC6820/1 Peripheral Interface Adapter (PIA). In

this case the CS pin of the DAC is grounded since the PIA is

already mapped in the 6800 system memory space and no

decoding is necessary. Furthermore, by using both Ports A

and B of the PIA the 10-bit data transfer, assumed left justified again in two 8-bit bytes, is greatly simplified. The HIGH

byte is loaded into Output Register A (ORA) of the PIA, and

the LOW byte is loaded into ORB. The 10-bit data transfer to

the DAC and the corresponding analog output change occur

simultaneously upon CB2 going LOW under program con-

trol. The 10-bit data word in the DAC register will be latched

(and hence V

HIGH.

will be fixed) when CB2 is brought back

OUT

If both output ports of the PIA are not available, it is possible

to interface the DAC1006 through a single port without much

effort. However, additional logic at the CB2(or CA2) lines or

access to some of the 6800 system control lines will be required.

7.3 Noise Considerations

A typical digital/microprocessor bus environment is a tremendous potential source of high frequency noise which can

be coupled to sensitive analog circuitry.The fast edges of the

data and address bus signals generate frequency components of 10’s of megahertz and can cause noise spikes to

appear at the DAC output. These noise spikes occur when

the data bus changes state or when data is transferred between the latches of the device.

In low frequency or DC applications, low pass filtering can

reduce these noise spikes. This is accomplished by

over-compensating the DAC output amplifier by increasing

the value of the feedback capacitor (C

C

in

Figure 3

).

In applications requiring a fast transient response from the

DAC and op amp, filtering may not be feasible. Adding a

latch, DM74LS374, as shown in

Figure 20

isolates the de-

vice from the data bus, thus eliminating noise spikes that oc-

PrintDate=1998/11/17 PrintTime=11:38:10 46711 ds005688 Rev. No. 4 cmserv Proof 19

www.national.com19

Page 21

DAC1006/1007/1008—Simple

Hookup for a “Quick Look”

cur every time the data bus changes state. Another method

FIGURE 19. DAC1000 to MC6820/1 PIA Interface

(Continued)

for eliminating noise spikes is to add a sample and hold after

the DAC op amp. This also has the advantage of eliminating

noise spikes when changing digital codes.

DS005688-25

NOTE: DATA HOLD TIME REDUCED TO THAT OF DM74LS374 (≈10 ns)

FIGURE 20. Isolating Data Bus from DAC Circuitry to Eliminate Digital Noise Coupling

www.national.com 20

PrintDate=1998/11/17 PrintTime=11:38:10 46711 ds005688 Rev. No. 4 cmserv Proof 20

DS005688-55

Page 22

DAC1006/1007/1008—Simple Hookup for a “Quick Look” (Continued)

DS005688-56

FIGURE 21. Digitally Controlled Amplifier/Attenuator

7.4 Digitally Controlled Amplifier/Attenuator

Figure 21

An unusual application of the DAC,

, applies the input voltage via the on-chip feedback resistor. The lower op

amp automatically adjusts the V

I

is equal to the input current (VIN/RfB). The magnitude

OUT1

of this V

in the DAC register. I

nitude of V

verts I

voltage depends on the digital word which is

REF IN

and the digital word. The second op amp con-

IN

to a voltage, V

OUT2

then depends upon both the mag-

OUT2

, which is given by:

OUT

REF IN

voltage such that

To provide a digitally controlled divider, the output op amp

can be eliminated. Ground the I

V

is now taken from the lower op amp (which also drives

OUT

the V

input of the DAC). The expression for V

REF

given by

pin of the DAC and

OUT2

OUT

is now

Note that N=0 (or a digital code of all zeros) is not allowed or

this will cause the output amplifier to saturate at either

±

V

, depending on the sign of VIN.

MAX

FIGURE 22. Digital to Synchro Converter

DS005688-27

www.national.com21

Book

Extract

End

PrintDate=1998/11/17 PrintTime=11:38:10 46711 ds005688 Rev. No. 4 cmserv Proof 21

Page 23

THIS PAGE IS IGNORED IN THE DATABOOK

PrintDate=1998/11/17 PrintTime=11:38:11 46711 ds005688 Rev. No. 4 cmserv Proof 22

22

Page 24

Ordering Information

For Left Justified Data

— 20-pin package.

Accuracy Temperature Range

0˚ to +70˚C

0.05%(10-bit) DAC1006LCN DAC1006LCWM

0.10%(9-bit) DAC1007LCN

0.20%(8-bit) DAC1008LCN

Package Outline N20A M20B

Physical Dimensions inches (millimeters) unless otherwise noted

PrintDate=1998/11/17 PrintTime=11:38:11 46711 ds005688 Rev. No. 4 cmserv

Order Number DAC1006LCWM

NS Package Number M20B

www.national.com23

Proof 23

23

Page 25

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

Order Number DAC1006LCN, DAC1007LCN or DAC1008LCN

NS Package Number N20A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant into

DAC1006/DAC1007/DAC1008 µP Compatible, Double-Buffered D to A Converters

the body, or (b) support or sustain life, and whose failure to perform when properly used in accordance

2. A critical component in any component of a life support

device or system whose failure to perform can be reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

with instructions for use provided in the labeling, can

be reasonably expected to result in a significant injury

to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5620-6175

Fax: 81-3-5620-6179

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

PrintDate=1998/11/17 PrintTime=11:38:11 46711 ds005688 Rev. No. 4 cmserv Proof 24

Page 26

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Audio www.ti.com/audio Communications and Telecom www.ti.com/communications

Amplifiers amplifier.ti.com Computers and Peripherals www.ti.com/computers

Data Converters dataconverter.ti.com Consumer Electronics www.ti.com/consumer-apps

DLP® Products www.dlp.com Energy and Lighting www.ti.com/energy

DSP dsp.ti.com Industrial www.ti.com/industrial

Clocks and Timers www.ti.com/clocks Medical www.ti.com/medical

Interface interface.ti.com Security www.ti.com/security

Logic logic.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Power Mgmt power.ti.com Transportation and Automotive www.ti.com/automotive

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Mobile Processors www.ti.com/omap

Wireless Connectivity www.ti.com/wirelessconnectivity

TI E2E Community Home Page e2e.ti.com

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2011, Texas Instruments Incorporated

Loading...

Loading...