Page 1

CLC520

CLC520 Amplifier with Voltage Controlled Gain, AGC +Amp

Literature Number: SNOS861C

Page 2

CLC520

Amplifier with Voltage Controlled Gain, AGC +Amp

CLC520 Amplifier with Voltage Controlled Gain, AGC +Amp

May 2001

General Description

The CLC520 is a wideband DC-coupled amplifier with voltage controlled gain (AGC). The amplifier has a high impedance, differential signal input; a high bandwidth, gain control

input; and a single-ended voltage output. Signal channel

performance is outstanding with 160MHz small signal bandwidth, 0.5 degree linear phase deviation (to 60MHz) and

0.04% signal nonlinearity at 4V

Gain control is very flexible and easy to use. Maximum gain

may be set over a nominal range of 2 to 100 with one

external resistor. In addition, the gain control input provides

more than 40dB of voltage controlled gain adjustment from

the maximum gain setting. For example, a CLC520 may be

set for a maximum gain of 2 (or 6dB) for a voltage controlled

gain range from 40dB to less than 34dB. Alternatively, the

CLC520 could be set for a maximum gain of 100 or (40dB)

for a voltage controlled gain range from 40dB to less than

0dB.

The gain control bandwidth of 100MHz is superb for AGC/

ALC loop stabilization. And since the gain is minimum with a

zero volt input and maximum with a +2 volt input, driving the

control input is easy.

Finally, the CLC520 differential inputs, and ground referenced voltage output take the trouble out of designing

DC-coupled AGC circuits for display normalizers; signal leveling automatic circuits; etc.

Enhanced Solutions (Military/Aerospace)

SMD Number: 5962-91694

Space level versions also available.

For more information, visit http://www.national.com/mil

PP

output.

Features

n 160MHz, −3dB bandwidth

n 2000V/µsec slew rate

n 0.04% signal nonlinearity at 4V

n −43dB feedthrough at 30MHz

n User adjustable gain range

n Differential voltage input and single-ended voltage

output

PP

output

Applications

n Wide bandwidth AGC systems

n Automatic signal leveling

n Video signal processing

n Voltage controlled filters

n Differential amplifier

n Amplitude modulation

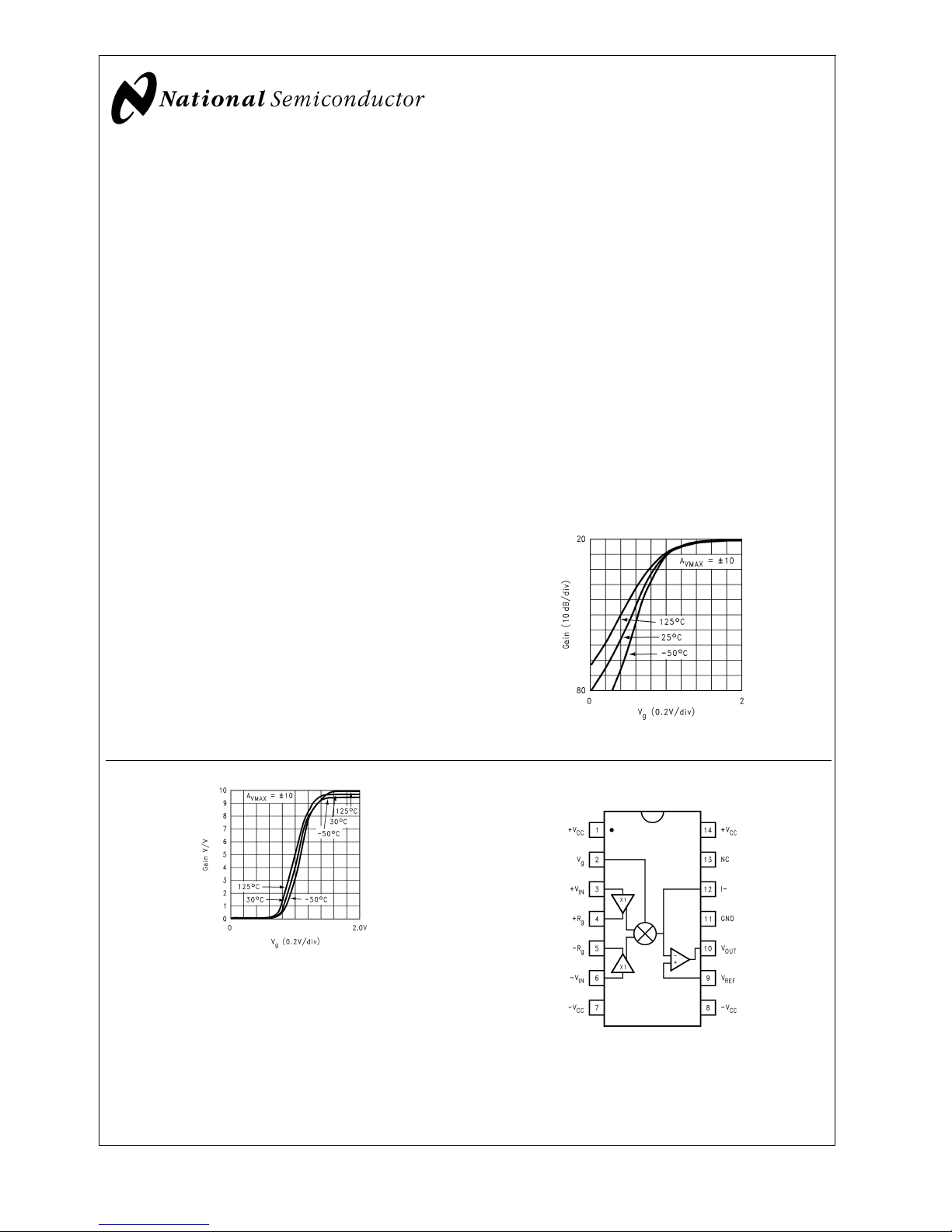

Gain vs. V

g

01275640

Gain vs. V

© 2001 National Semiconductor Corporation DS012756 www.national.com

g

Connection Diagram

01275639

01275629

Pinout

DIP & SOIC

Page 3

Ordering Information

CLC520

Package Temperature Range

Industrial

14-pin plastic DIP −40˚C to +85˚C CLC520AJP CLC520AJP N14A

14-pin plastic SOIC −40˚C to +85˚C CLC520AJE CLC520AJE M14A

Part Number Package

Marking

NSC

Drawing

www.national.com 2

Page 4

CLC520

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact theNationalSemiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (V

I

OUT

Output is short circuit protected to

ground, but maximum reliability will

be maintained if I

exceed... 60mA

Common Mode Input Voltage

VINDifferential Input Voltage 10V

V

Differential Input Voltage

g

V

Differential Input Voltage

ref

CC

OUT

)

does not

±

7V

±

V

CC

±

V

CC

±

V

CC

Junction Temperature +150˚C

Operating Temperature Range −40˚C to +85˚C

Storage Temperature Range −65˚C to +150˚C

Lead Solder Duration (+300˚C) 10 sec

ESD (human body model) 500V

Operating Ratings

Thermal Resistance

Package (θ

MDIP 55˚C/W 105˚C/W

SOIC 45˚C/W 120˚C/W

)(θ

JC

)

JA

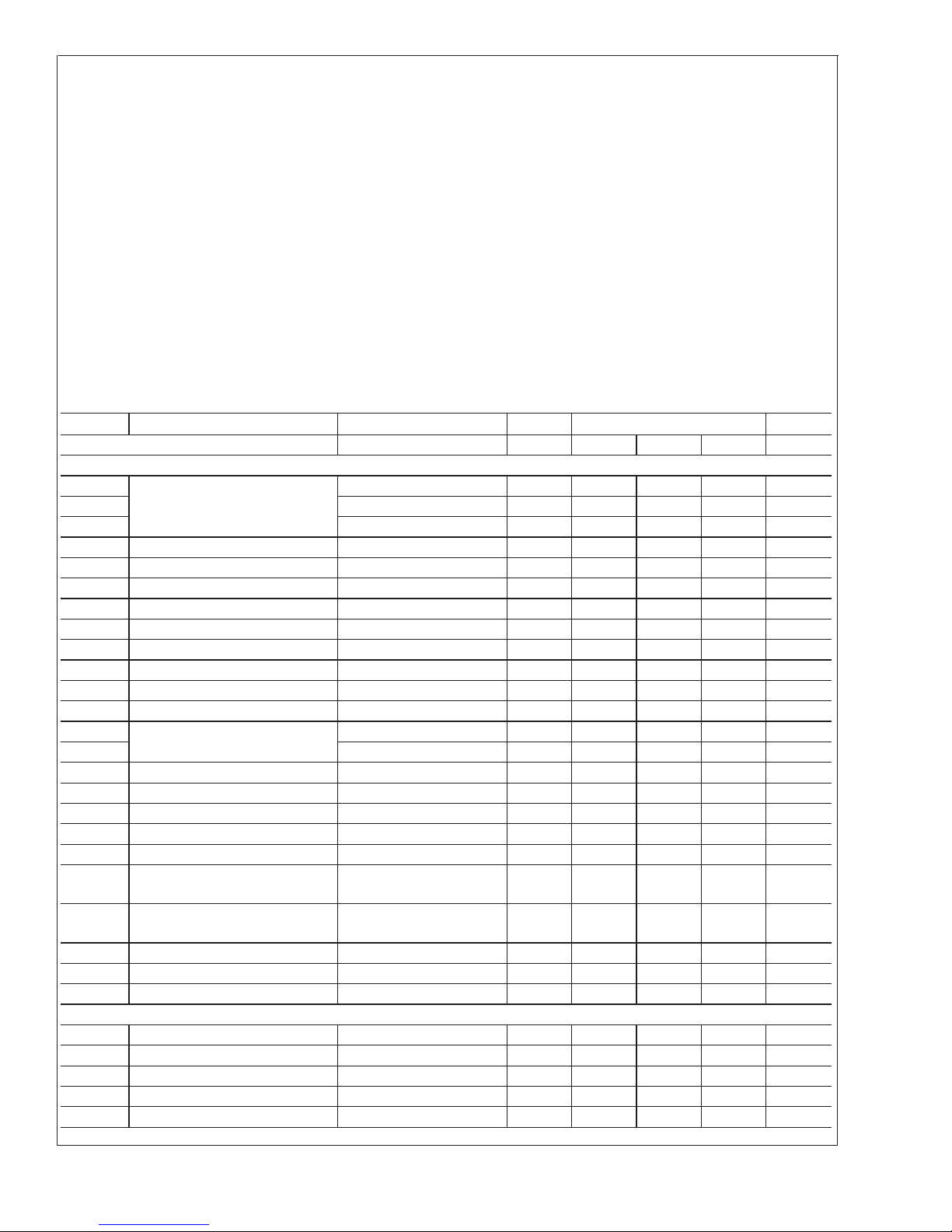

Electrical Characteristics

AV= +10, VCC=±5V, RL= 100Ω,Rf=1kΩ,Rg= 182Ω,Vg= +2V; unless specified

Symbol Parameter Conditions Typ Max/Min (Note 2) Units

Ambient Temperature CLC520AJ +25˚C −40˚C +25˚C +85˚C

Frequency Domain Response

SSBW -3dB Bandwidth V

SSBW V

LSBW V

-3dB Bandwidth V

SBWC Gain Control Channel VIN= +0.2V, Vg= +1VDC 100

Gain Flatness V

GFPL Peaking 0.1MHz to 30MHz 0

GFPH Peaking 0.1MHz to 20MHz 0

GFRL Rolloff 0.1MHz to 30MHz 0.1

GFRH Rolloff 0.1MHz to 60MHz 0.5

LPD Linear Phase Deviation 0.1MHz to 60MHz 0.5

FDTH Feedthrough V

TRS Rise and Fall Time 0.5V Step 2.5

TRL 4.0V Step 3.7

TS Settling Time to

OS Overshoot 0.5V Step 0

SR Slew Rate 4V Step 2000

HD2 2nd Harmonic Distortion 2V

HD3 3rd Harmonic Distortion 2V

Equivalent Output Noise (÷10 for input noise) (Note

SNF Noise floor 1MHz to 200MHz −132

INV Integrated noise 1MHz to 200MHz 800

DG Differential Gain (Note 4) at 3.58MHz 0.15 %

DP Differential PIase (Note 4) at 3.58MHz 0.15 deg

Static, DC Performance

SGNL Integral Signal Nonlinearity V

Gain Accuracy R

GACCU For Nominal Max Gain = 20dB

VOS Output Offset Voltage (Note 5) 40

DVOS Average Temperature Coefficient 100

±

0.1% 2.0V Step 12

<

0.5V

OUT

OUT

OUT

OUT

OUT

= 0V, VIN= -22dBm -38

g

PP

PP

3)

OUT

=1kΩ,Rg= 182Ω

f

PP

<

0.5VPP(AJE only) 140

<

4.0V

PP

<

0.5V

PP

<

0.5V

PP

, 20MHz −47

, 20MHz −60

=4V

PP

160

140

0.04

±

0

>

110

>

90

>

85

>

80

<

0.4

<

0.7

<

0.4

<

1.3

<

1.2

<

-31

<

3.7

<

5

<

18

<

15

>

1450

<

−40

<

−50

<

−130

<

1000

<

0.1

<

±

1.0

<

150

<

400 –

>

>

>

<

<

<

<

>

<

<

<

<

<

<

<

120

100

100

>

80

0.3

0.5

0.3

<

1

<

1

-31

<

3

<

5

<

18

<

15

1450

−40

−50

−130

1000

0.1

±

0.5

120

>

120 MHz

>

100 MHz

>

100 MHz

>

80 MHz

<

0.4 dB

<

0.7 dB

<

0.4 dB

<

1.3 dB

<

1.2 deg

<

-31 dB

<

3ns

<

5ns

<

18 ns

<

15 %

>

1450 V/µsec

<

−35 dBc

<

−45 dBc

<

−129 dBm

(1Hz)

<

1100 µV

<

0.2 %

<

±

0.5 dB

<

150 mV

<

300 µV/˚C

www.national.com3

Page 5

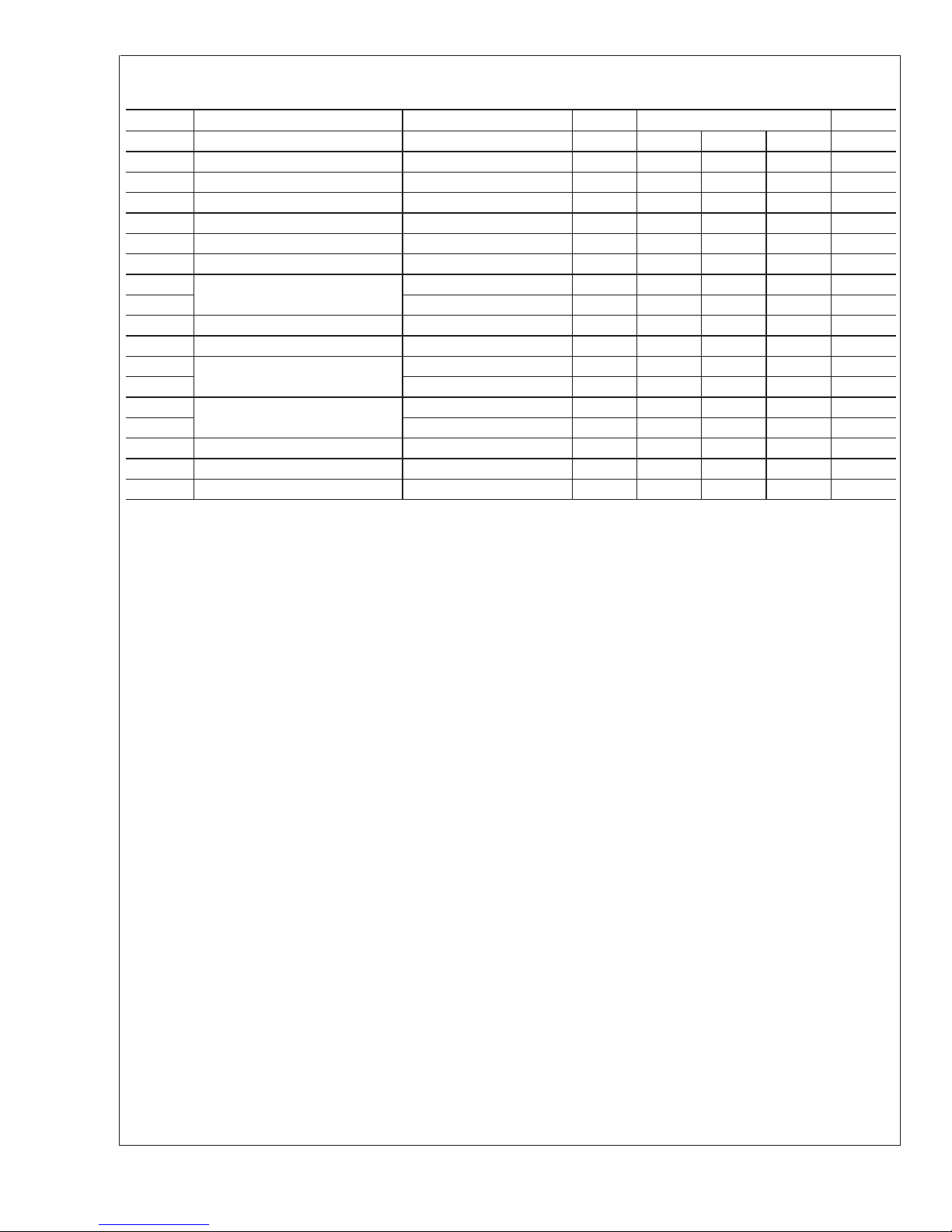

Electrical Characteristics (Continued)

AV= +10, VCC=±5V, RL= 100Ω,Rf=1kΩ,Rg= 182Ω,Vg= +2V; unless specified

CLC520

Symbol Parameter Conditions Typ Max/Min (Note 2) Units

IB Input Bias Current (Note 5) 12

DIB Average Temperature Doefficient 100

IOS Input Offset Current 0.5

DIOS Average Temperature Coefficient 5

PSS Power Supply Sensitivity Output Referred DC 10

CMRR Common Mode Rejection Ratio Input Referred 70

ICC Supply Current (Note 5) No Load 28

RIN V

CIN Capacitance 1

DMIR V

CMIR Common Mode Voltage Range

RINC V

CINC Capacitance 1

VGHI V

VGLO For Min Gain 0.4

RO Output Impedance At DC 0.1

VO Output Voltage Range No Load

IO Output Current

Note 1: “Absolute Maximum Ratings” are those values beyond which the safety of the device cannot be guaranteed. They are not meant to imply that the devices

should be operated at these limits. The table of “Electrical Characteristics” specifies conditions of device operation.

Note 2: Max/min ratings are based on product characterization and simulation. Individual parameters are tested as noted. Outgoing quality levels are determined

from tested parameters.

Note 3: Measured at A

Note 4: Differential gain and phase are measured at: A

at 3.58 MHz.

Note 5: AJ-level: spec. is 100% tested at +25˚C.

Signal Input Resistance 200

IN

Differential Voltage Range Rg= 182Ω only

IN

Control Input Resistance 750

g

Input Voltage For Max Gain 1.6

g

= 10, Vg= +2V

VMAX

= +20, Vg= +2V, RL= 150Ω,Rf=2kΩ,Rg= 182Ω, equivalent video signal of 0-100 IRE with 40 IRE

V

±

280

±

2.2

±

3.5

±

60

<

61

<

415 -

<

4

<

40 -

<

28

>

59

<

38

>

50

<

2

±

250

>

±

1.4

>

535

<

2

<

2

>

0

<

0.3

>

±

3

>

±

35

<

28

<

2

<

28

>

59

<

38

>

100

<

2

±

250

>

±

2

>

600

<

2

<

2

>

0

<

0.2

>

±

3.2

>

±

50

<

28 µA

<

165 nA/˚C

<

2µA

<

20 nA/˚C

<

28 mV/V

>

59 dB

<

38 mA

>

100 kΩ

<

2pF

±

210 mV

>

±

2V

>

600 Ω

<

2pF

<

2kΩ

>

0V

<

0.2 Ω

>

±

3.2 V

>

±

50 mA

PP

www.national.com 4

Page 6

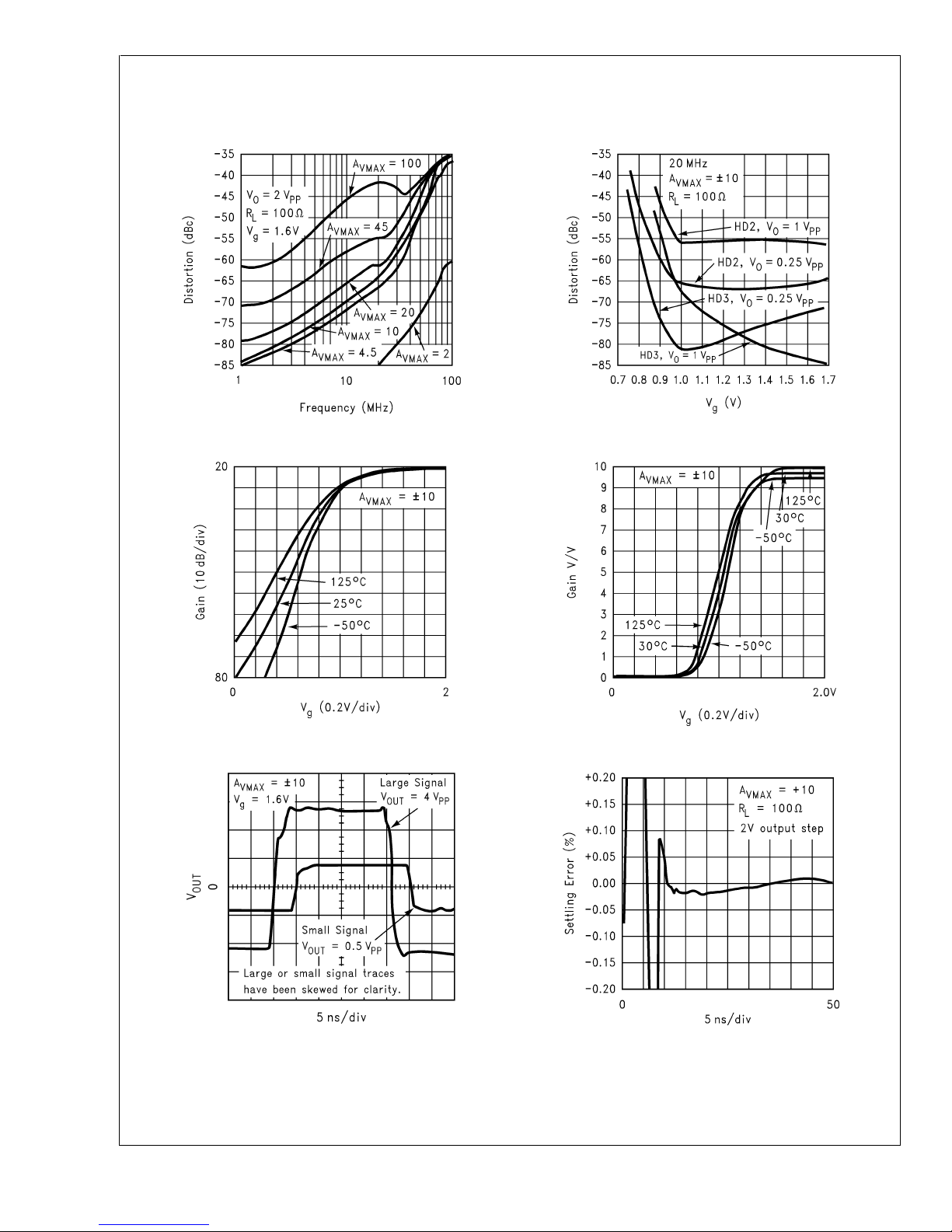

Typical Performance Characteristics

(TA= 25˚C, AV= +10, VCC=±5V, RL= 100Ω,Rf=

1kΩ,R

= 182Ω,Vg= +2V)

g

CLC520

Frequency Response, A

Frequency Response, A

=±2 Frequency Response, A

VMAX

01275630 01275616

=±100 Large Signal Frequency Response

VMAX

VMAX

=±10

Small Signal Gain vs. R

01275619 01275621

f

01275641

2nd Harmonic Distortion

01275601

www.national.com5

Page 7

Typical Performance Characteristics (T

= 182Ω,Vg= +2V) (Continued)

CLC520

3rd Harmonic Distortion 2nd and 3rd Harmonic Distortion vs. V

= 25˚C, AV= +10, VCC=±5V, RL= 100Ω,Rf=1kΩ,R

A

g

g

01275602

Gain vs. V

g

01275640

Gain vs. V

g

Large and Small Signal Pulse Response Settling Time, Vg=2V

01275603

01275639

www.national.com 6

01275642

01275613

Page 8

CLC520

Typical Performance Characteristics (T

= 182Ω,Vg= +2V) (Continued)

Settling Time, V

Settling Time vs. Capacitive Load, A

= 1.2V Long-Term Settling Time

g

01275614

=±10 Gain Control Settling Time

VMAX

= 25˚C, AV= +10, VCC=±5V, RL= 100Ω,Rf=1kΩ,R

A

01275615

g

01275604

Gain Control Channel Feedthrough CMRR

01275618

01275617

01275605

www.national.com7

Page 9

Typical Performance Characteristics (T

= 182Ω,Vg= +2V) (Continued)

CLC520

Differential Gain and Phase PSRR

= 25˚C, AV= +10, VCC=±5V, RL= 100Ω,Rf=1kΩ,R

A

g

01275643

Output Noise vs. V

g

01275622

Linearity, Vg= 0.6V to 1.6V

Linearity, Vg= 0.75V to 1.4V Linearity, Vg= 0.9V to 1.2V

01275606

01275644

www.national.com 8

01275645 01275646

Page 10

Application Information

01275607

FIGURE 1. CLC520 Simplified Schematic

Simplified Circuit Description

A simplified schematic for the CLC520 is given in

+V

and −VINare buffered with closed-loop voltage follow-

IN

ers inducing a signal current in R

(+V

)−(−VIN), the differential input voltage. This current con-

IN

g

trols a current source which supplies two well matched transistors, Q1 and Q2.

The current flowing through Q2 is converted to the final

output voltage using R

and output amplifier, U1. By chang-

f

ing the fraction of the signal current I which flows through Q2

the gain is changed. This is done by changing the voltage

applied differentially to the bases of Q1 and Q2. For example, with V

current of flowing through Q2 into R

minimum gain. Conversely, with V

the signal current I flows through Q2 to R

mum gain. With V

= 0, Q1 is on and Q2 is off. With zero signal

g

set to 1.1V, the bases of Q1 and Q2 are

g

, the CLC520 is set to

f

= 2V, Q1 is off and all of

g

f

set to approximately the same voltage, causing their collector currents to equally divide the signal current I, and establish the gain at one half the maximum gain.

Typical application circuit

Figure 2

illustrates a voltage-controlled gain block offering

broadband performance in a 50Ω system environment. The

input signal is applied to pin 3 of the CLC520 and terminating

resistor R2. Gain control signals are applied to pin 2. The net

gain control port input impedance is 50Ω, set by the parallel

combination of R1 and the 750Ω input impedance of pin 2 of

the CLC520. R

is set to the standard value, 1kΩ, and R

f

sets the maximum voltage gain to 10V/V. Output impedance

is set by R

to 50Ω so with 50Ω source and load termina-

o

tions, the gain is approximately 14dB.

Figure 1

proportional to

producing maxi-

CLC520

.

01275608

FIGURE 2. CLC520 Typical Application Circuit

Capacitors C1-C6 provide broadband power supply bypassing. C2 and C5 should be tantalum capacitors. All other

capacitors should be high quality ceramic capacitors (CK-05

or equivalent).

Adjusting offset

Offset can be broken into two parts; an input-referred term

and an output-referred term. The input-referred offset shows

up as a variation in output voltage as V

be trimmed using the circuit in

frequency square wave (V

the input referred V

os

riding a DC value.Adjust R

= 0 to 2V, into Vgwith VIN=0V,

IN

term shows up as a small square wave

to null the Vossquare wave term

1

to zero. After adjusting the input-referred offset, adjust R2

(with V

applications V

=0,Vg= 0) until V

IN

may be applied to pin 6 and the offset

IN

OUT

adjustment to pin 3. This offset trim does not improve output

offset temperature coefficient.

g

is changed. This can

g

Figure 3

by placing a low

is zero. Finally, for inverting

01275628

FIGURE 3. CLC520 Offset Adjustment Circuitry

(other external elements not shown)

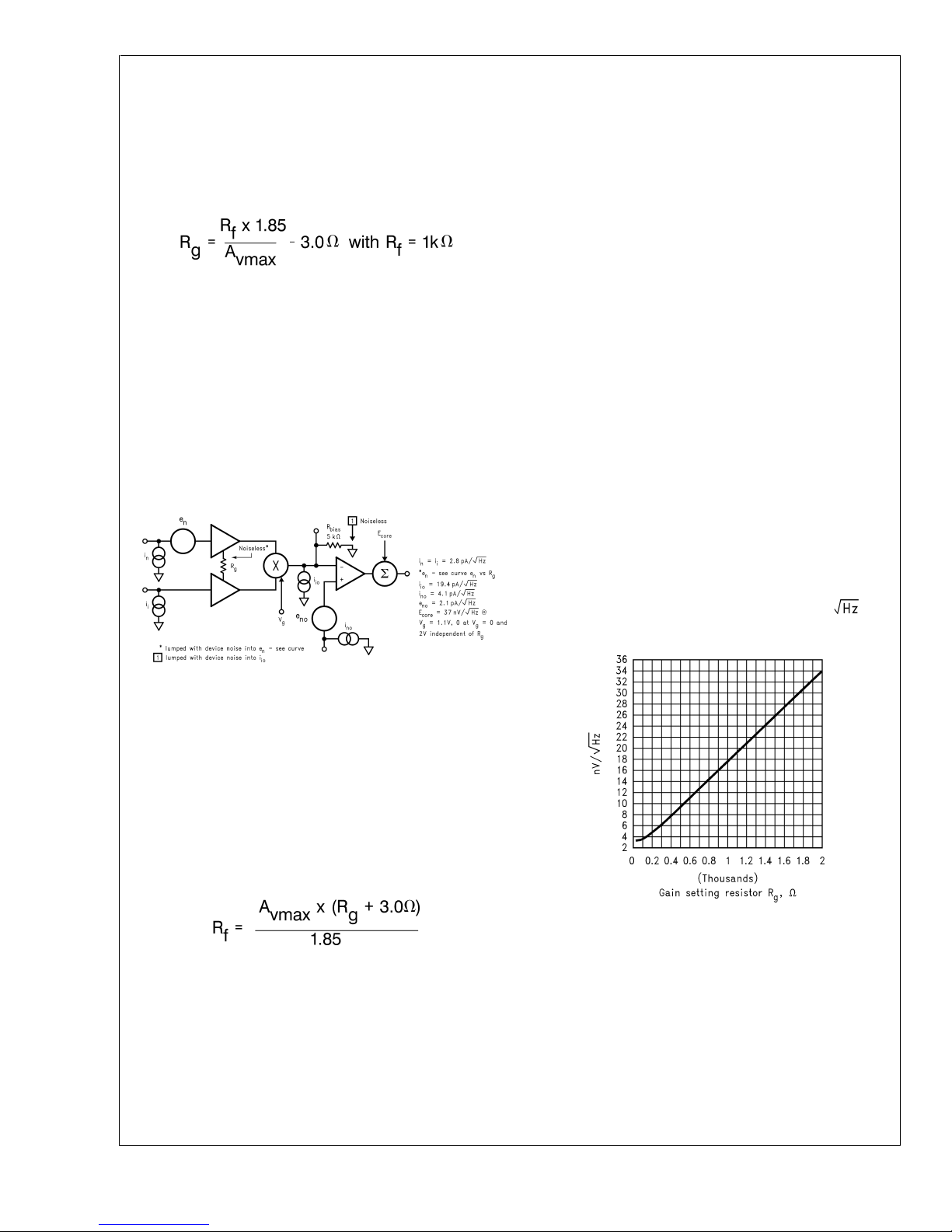

Selecting component values

Most applications of the CLC520 adjust the gain to maximize

the V

signal. When referred back to the input, this means

OUT

www.national.com9

Page 11

Application Information (Continued)

the input signal, signal-to-noise ratio is maximized. The

CLC520

maximum allowed input amplitude and from system specifications, using maximum required gain R

calculated.

The output stage op amp is a current-feedback type amplifier

optimized for R

=1kΩ.Rgcan then be computed as:

f

To determine whether the maximum input amplitude will

overdrive the CLC520, compute:

V

=(Rg+3.0Ω) · 0.00135

dmax

the maximum differential input voltage for linear operation. If

the maximum input amplitude exceeds the above V

then CLC520 should either be moved to a location in the

signal chain where input amplitudes are reduced, or the

CLC520 gain A

should be reduced or the values for R

VMAX

and Rfshould be increased. The overall system performance

impact is different based on the choice made.

If the input amplitude is reduced, recompute the impact on

signal-to-noise ratio. If A

VMAX

is reduced,

and Rgcan be

f

dmax

limit,

capacitance across the feedback resistor should not be used

to compensate for this effect.

<

For best performance at low maximum gains (A

R

+ and Rgconnections should be treated in a similar fash-

g

VMAX

10)

ion. Capacitance to ground should be minimized by removing the ground plane from under the resistor of R

.

g

Parasitic or load capacitance directly on the output (pin 10)

degrades phase margin leading to frequency response

peaking. A small series resistor before this capacitance,

effectively reduces this effect (see Settling Time vs. Capacitive Load).

Precision buffed resistors (PRP8351 series from Precision

Resistive Products) must be used for R

mance. Precision buffed resistors are suggested for R

low gain settings (A

<

10). Carbon composition resis-

VMAX

for rated perfor-

f

for

g

tors and RN55D metal-film resistors may be used with reduced performance.

Evaluation PC boards (part no. 730021) for the CLC520 are

available.

Predicting the output noise

g

Seven noise sources (e

model the CLC520 noise performance (

i

model the equivalent input noise terms for the input buffer

i

while i

, and enomodel the noise terms for the output

io,ino

buffer.To simplify the model e

R

(see

Figure 5

g

R

is assumed noiseless and its noise contribution is

bias

included in i

.

io

An additional term E

n,in,ii,iio,ino,eno,Ecore

includes the effect of resistor

n

for envs. Rg). To simplify the model further,

mimics the active device noise

core

Figure 4

) are used to

). en,in, and

contribution from the Gilbert multiplier core. Core noise is

theoretically zero when the multiplier is set to maximum gain

or zero gain (V

>

1.6V or V

g

temperature) and reaches a maximum of 37nV/

A

/2.

VMAX

<

0.63V respectively at room

g

at

01275647

FIGURE 4. CLC520 Noise Model

Post CLC520 amplifier gain, should be increased, or another

gain stage added to make up for reduced system gain..

To increase R

and Rf, where V

g

= (+VIN)−(−VIN) the

dmax

largest expected peak differential input voltage. Compute the

lowest acceptable value for R

>

R

740˚V

g

Operating with R

−3Ω

dmax

larger than this value insures linear op-

g

:

g

eration of the input buffers.

R

may be computed from selected Rgand A

f

VMAX

:

Rfshould be>=1kΩfor overall best performance, however

<

R

1kΩ can be implemented if necessary using a loop gain

f

reducing resistor to ground on the inverting summing node of

the output amplifier (see application note QA-13 for details).

Printed Circuit Layout

A good high frequency PCB layout including ground plane

construction and power supply bypassing close to the package are critical to achieving full performance. The amplifier is

sensitive to stray capacitance to ground at the

Inverting-input (pin12); keep node trace area small. Shunt

01275648

FIGURE 5. Equivalent Input Noise Voltage (en) vs. R

g

Several points should be made concerning this model. First,

external component noise contributions need to be factored

in when computing total output referred noise. The only

exception is R

, where its noise contribution is already fac-

g

tored in. Second, the model ignores flicker noise contributions.Applications where noise below approximately 100kHz

must be considered should use this model with caution.

Third, this model very accurately predicts output noise voltage for the typical application circuit (see above) but accuracy will degrade the component values deviate further from

those in the typical application circuit. In general, however,

www.national.com 10

Page 12

Application Information (Continued)

the model should predict the equivalent output noise above

the flicker noise region to within a few dB of actual performance over the normal range of A

values.

and component

VMAX

01275610

inodoes not contribute to the output buffer noise because the

output buffer non-inverting input is grounded.

The core noise is already output referred and is 37nV/

at Vg=1.1 (A

A

Summing the noise power for each term gives the

VMAX

/2) and approaches zero as A goes to 0 or

VMAX

total output noise power.

The total output noise voltage is given by:

CLC520

FIGURE 6. Typical Circuit

01275611

FIGURE 7. Noise Model for Typical Circuit

Calculating CLC520 output noise in a typical circuit

To calculate the noise in a CLC520 application, the noise

terms given for the amplifier as well as the noise terms of the

external components must be included. To clarify the techniques used, output noise in a typical circuit will be calculated. (

Figure 6

The noise model is depicted in

sumes spot noise source with V

)

Figure 7

rms

. The diagram as-

/ and Amps

rms

/

units. The Thevenin equivalent of the source and input termination is used; 25Ω in series with a noise voltage source.

R

is assumed noiseless since its effect is included in en.

g

The internal 5kΩ resistor at the CLC520 core output is also

assumed noiseless since its effect is included in i

noise contribution from R

is modeled as a noise source.

f

, The

io

The easiest way to analyze the output noise of this circuit is

to divide the noise power into three pieces; −input buffer

noise calculation, output buffer noise and core noise. The

input buffer varies with the gain. The output buffer term is

constant. The core noise term is zero at both maximum and

minimum gain and reaches peak at A

VMAX

/2.

Since we assume all noise terms are uncorrelated, the

equivalent input noise voltage squared is given by:

iidoes not contribute to the output buffer noise because the

input buffer inverting input is grounded. e

Figure 5

.

is taken from

n

The equivalent output buffer noise is given by:

Where AVis the input to output voltage gain, which varies

with V

.

g

C accounts for the variation in core noise contribution as V

is adjusted. C=1 when gain AVis A

A

and AV= 0 and varies between 0 and 1 for all other

VMAX

/2. C is zero at

VMAX

values.

Using these equations, total calculated output noise for the

circuit was 20nV/

mid-gain, and 53nV/

at minimum gain, 49nV/ at

at maximum gain.

01275612

FIGURE 8. Automatic Gain Control (AGC) Loop

AGC circuits

Figure 8

shows a typical AGC circuit. The CLC520 is followed up with a CLC401 for higher overall gain. The output

of the CLC401 is rectified and fed to an inverting integrator

using a CLC420 (wideband voltage feedback op amp).

When the output voltage, V

, is too large the integrator

OUT

output voltage ramps down reducing the net gain of the

CLC520 and V

. If the output voltage is too small, the

OUT

integrator ramps up increasing the net gain and the output

voltage.Actual output level is set with R1. To prevent shifts in

DC output voltage with DC changes in input signal level, trim

pot R2 is provided. AGC circuits are always limited in the

range of input signals over which constant output level can

be maintained. In this circuit, we would expect that reasonable AGC action could be maintained over the gain adjustment range of the CLC520 (at least 40dB). In practice,

rectifier dynamic range limits reduce this slightly.

Evaluation Board

Evaluation PC boards (part number 730029 for through-hole

and 730023 for SOIC) for the CLC520 are available.

g

www.national.com11

Page 13

Physical Dimensions inches (millimeters)

unless otherwise noted

CLC520

14-Pin MDIP

NS Package Number N14A

www.national.com 12

14-Pin SOIC

NS Package Number M14A

Page 14

Notes

CLC520 Amplifier with Voltage Controlled Gain, AGC +Amp

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +44 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

Fax: +49 (0) 180-530 85 86

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: ap.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Page 15

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Audio www.ti.com/audio Communications and Telecom www.ti.com/communications

Amplifiers amplifier.ti.com Computers and Peripherals www.ti.com/computers

Data Converters dataconverter.ti.com Consumer Electronics www.ti.com/consumer-apps

DLP® Products www.dlp.com Energy and Lighting www.ti.com/energy

DSP dsp.ti.com Industrial www.ti.com/industrial

Clocks and Timers www.ti.com/clocks Medical www.ti.com/medical

Interface interface.ti.com Security www.ti.com/security

Logic logic.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Power Mgmt power.ti.com Transportation and Automotive www.ti.com/automotive

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Mobile Processors www.ti.com/omap

Wireless Connectivity www.ti.com/wirelessconnectivity

TI E2E Community Home Page e2e.ti.com

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2011, Texas Instruments Incorporated

Loading...

Loading...