Page 1

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

S0/A0/CLK_SEL

S1/A1

V

CC

GND

CLK_IN0

CLK_IN1

V

CC

GND

SDATA

SCLOCK

Y5

Y4

V

CCOUT2

GND

Y3

Y2

V

CCOUT1

GND

Y1

Y0

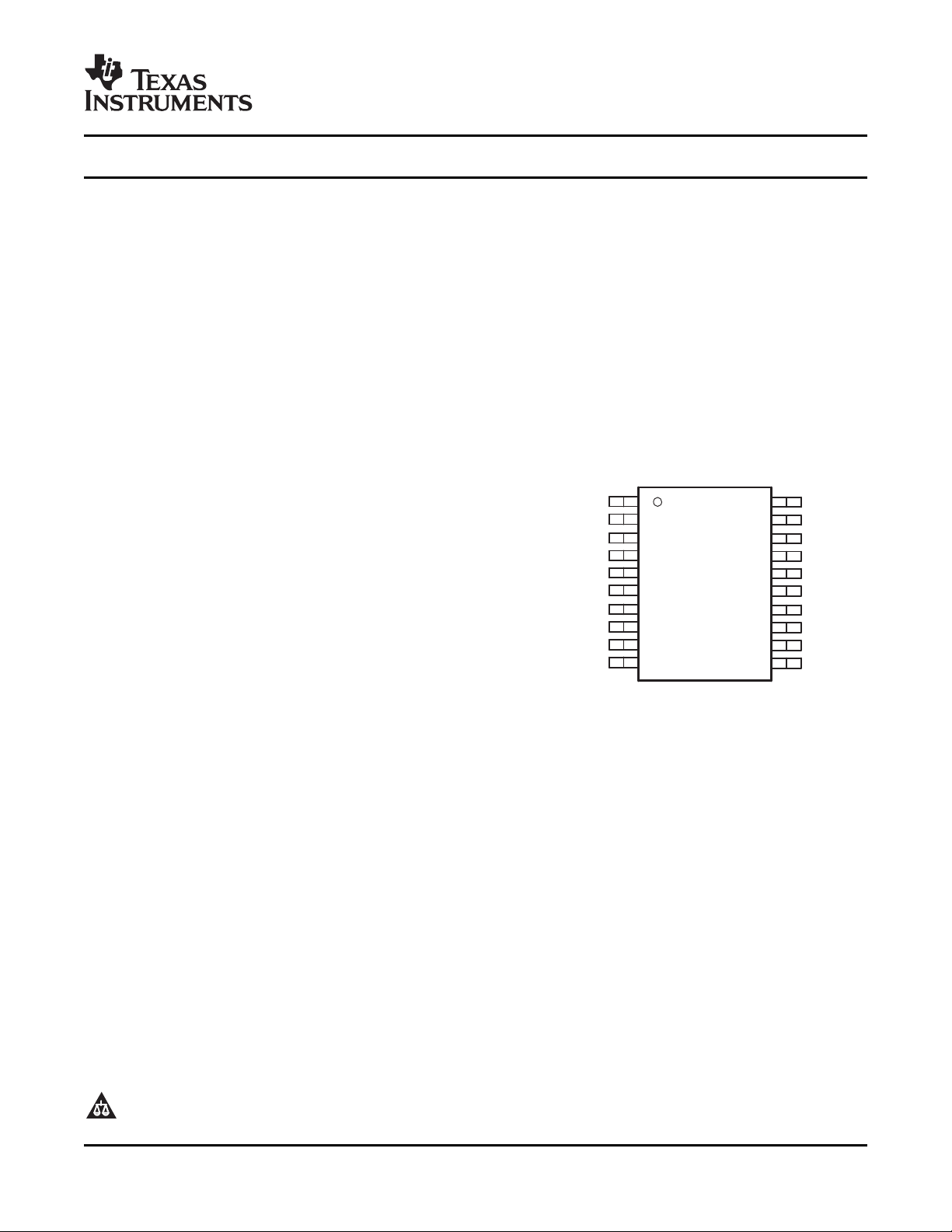

PW PACKAGE

(TOP VIEW)

TSSOP 20

Pitch 0,65 mm

6.6 x 6.6

CDCE906

www.ti.com

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

PROGRAMMABLE 3-PLL CLOCK SYNTHESIZER / MULTIPLIER / DIVIDER

1

FEATURES

2

• High Performance 3:6 PLL based Clock

Synthesizer / Multiplier / Divider • Programmable Output Slew-Rate Control

• User Programmable PLL Frequencies

• EEPROM Programming Without the Need to

Apply High Programming Voltage • Commercial Temperature Range 0 ° C to 70 ° C

• Easy In-Circuit Programming via SMBus Data • Development and Programming Kit for Easy

Interface PLL Design and Programming

• Wide PLL Divider Ratio Allows 0-ppm Output

Clock Error • Packaged in 20-Pin TSSOP

• Generates Precise Video (27 MHz or 54 MHz)

and Audio System Clocks from Multiple

Sampling Frequencies (f

44.1, 48, 96 kHz)

• Clock Inputs Accept a Crystal or a

Single-Ended LVCMOS or a Differential Input

Signal

• Accepts Crystal Frequencies from 8 MHz up to

54 MHz

• Accepts LVCMOS or Differential Input

Frequencies up to 167 MHz

• Two Programmable Control Inputs [S0/S1,

A0/A1] for User Defined Control Signals

• Six LVCMOS Outputs with Output Frequencies

up to 167 MHz

• LVCMOS Outputs can be Programmed for

Complementary Signals

• Free Selectable Output Frequency via

Programmable Output Switching Matrix [6x6]

Including 7-Bit Post-Divider for Each Output

• PLL Loop Filter Components Integrated

• Low Period Jitter (Typ 60 ps)

• Features Spread Spectrum Clocking (SSC) for

Lowering System EMI

• Programmable Center Spread SSC Modulation

( ± 0.1%, ± 0.25%, and ± 0.4%) with a Mean Phase

Equal to the Phase of the Non-Modulated

Frequency

= 16, 22.05, 24, 32,

S

• Programmable Down Spread SSC Modulation

(1%, 1.5%, 2%, and 3%)

(SRC) for Lowering System EMI

• 3.3-V Device Power Supply

(TI Pro-Clock™)

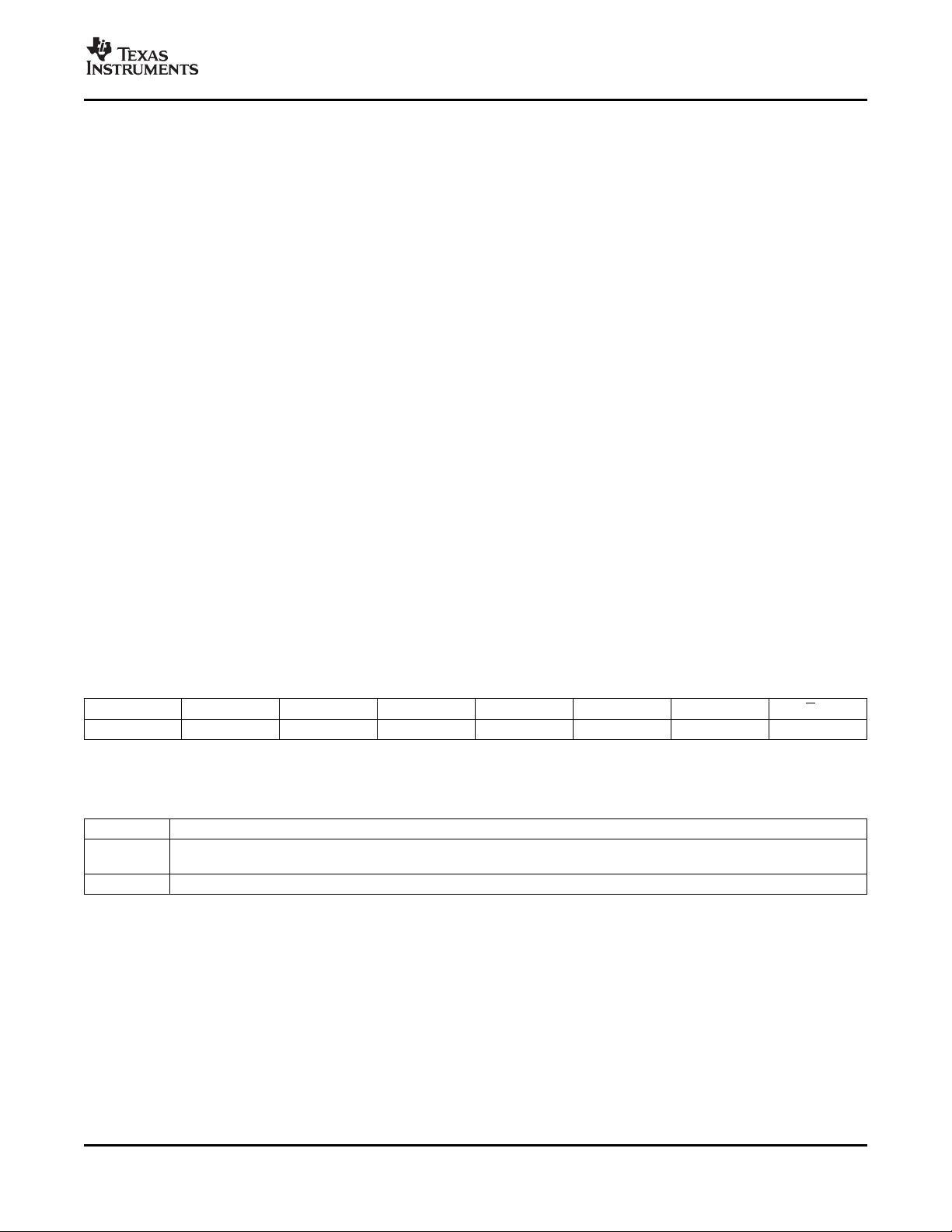

TERMINAL ASSIGNMENT

DESCRIPTION

The CDCE906 is one of the smallest and powerful

PLL synthesizer / multiplier / divider available today.

Despite its small physical outlines, the CDCE906 is

flexible. It has the capability to produce an almost

independent output frequency from a given input

frequency.

The input frequency can be derived from a LVCMOS,

differential input clock, or a single crystal. The

appropriate input waveform can be selected via the

SMBus data interface controller.

1

2 Pro-Clock is a trademark of Texas Instruments.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2005 – 2007, Texas Instruments Incorporated

Page 2

www.ti.com

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

DESCRIPTION (CONTINUED)

To achieve an independent output frequency the reference divider M and the feedback divider N for each PLL

can be set to values from 1 up to 511 for the M-Divider and from 1 up to 4095 for the N-Divider. The PLL-VCO

(voltage controlled oscillator) frequency than is routed to the free programmable output switching matrix to any of

the six outputs. The switching matrix includes an additional 7-bit post-divider (1-to-127) and an inverting logic for

each output.

The deep M/N divider ratio allows the generation of zero ppm clocks from any reference input frequency (e.g., a

27 MHz).

The CDCE906 includes three PLLs of those one supports SSC (spread-spectrum clocking). PLL1, PLL2, and

PLL3 are designed for frequencies up to 167 MHz and optimized for zero-ppm applications with wide divider

factors.

PLL2 also supports center-spread and down-spread spectrum clocking (SSC). This is a common technique to

reduce electro-magnetic interference. Also, the slew-rate controllable (SRC) output edges minimize EMI noise.

Based on the PLL frequency and the divider settings, the internal loop filter components will be automatically

adjusted to achieve high stability and optimized jitter transfer characteristic of the PLL.

The device supports non-volatile EEPROM programming for easy-customized application. It is preprogrammed

with a factory default configuration (see Figure 13 ) and can be reprogrammed to a different application

configuration before it goes onto the PCB or reprogrammed by in-system programming. A different device setting

is programmed via the serial SMBus interface.

Two free programmable inputs, S0 and S1, can be used to control for each application the most demanding logic

control settings (outputs disable to low, outputs 3-state, power down, PLL bypass, etc).

The CDCE906 has three power supply pins, V

operates from a single 3.3-V supply voltage. V

V

CCOUT1

supplies the outputs Y0 and Y1 and V

supplies can be 2.3 V to 3.6 V. At output voltages lower than 3.3 V, the output drive current is limited.

The CDCE906 is characterized for operation from 0 ° C to 70 ° C.

, V

CC

CCOUT1

CCOUT1

CCOUT2

and V

and V

CCOUT2

. V

CCOUT2

is the power supply for the device. It

CC

are the power supply pins for the outputs.

supplies the outputs Y2, Y3, Y4, and Y5. Both outputs

2 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Product Folder Link(s): CDCE906

Page 3

www.ti.com

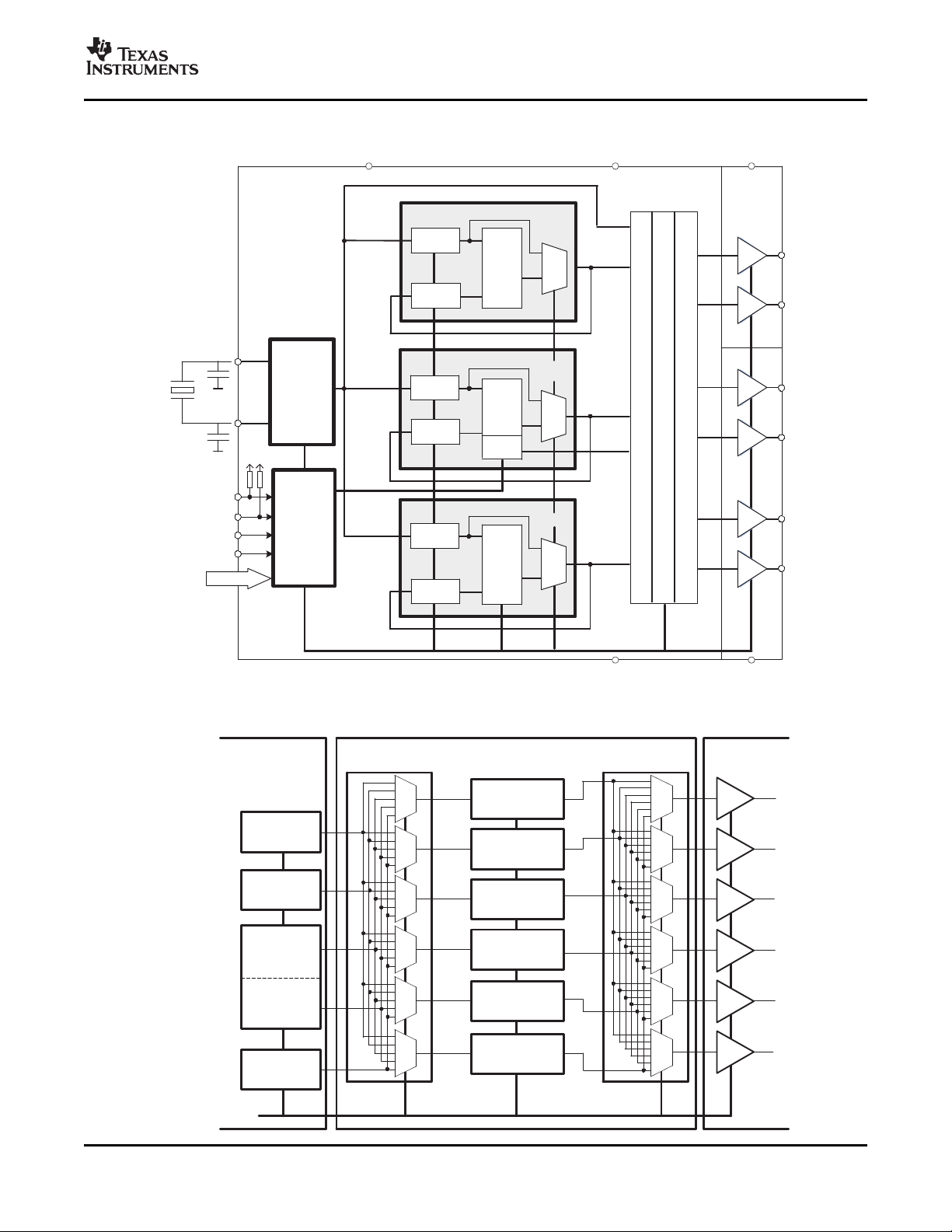

PLL1

XO

or

2LVCMOS

or

Differential

Input

MUX

MUX

PLL3

PFD

Filter

VCO

PLL2

w/SSC

PFD

Filter

VCO

SO/AO/CLK_SEL

S1/A1

SCLOCK

OutputSwitchMatrix

LV

CMOS

LV

CMOS

LV

CMOS

LV

CMOS

LV

CMOS

LV

CMOS

EEPROM

LOGIC

SMBUS

LOGIC

PFD

Filter

VCO

SDATA

Y5

Y4

Y3

Y2

Y1

Y0

VCO1Bypass

VCO2Bypass

VCO3Bypass

MUX

6xProgrammable7-BitDividerP0,P1,P2,P3,P4,P5,andInversionLogic

5x6ProgrammableSwitch A

PLL Bypass

V

CC

GND V

CCOUT1

GND V

CCOUT2

prg. 9Bit

DividerM

prg.12Bit

DividerN

prg.9Bit

DividerM

prg.12Bit

DividerN

prg.9Bit

DividerM

prg.12Bit

DividerN

Crystalor

ClockInput

CLK_IN1

FactoryPrg.

CLK_IN0

SSC

On/Off

6x6ProgrammableSwitchB

5x6 − Switch A

Input CLK

(PLL Bypass)

PLL 1

PLL 2

non SSC

PLL 2

w/ SSC

PLL 3

6x6 − Switch B7-Bit Divider

Y0

Y1

Y2

Y3

Y4

Y5

P0

P1

P2

P3

P4

P5

Programming

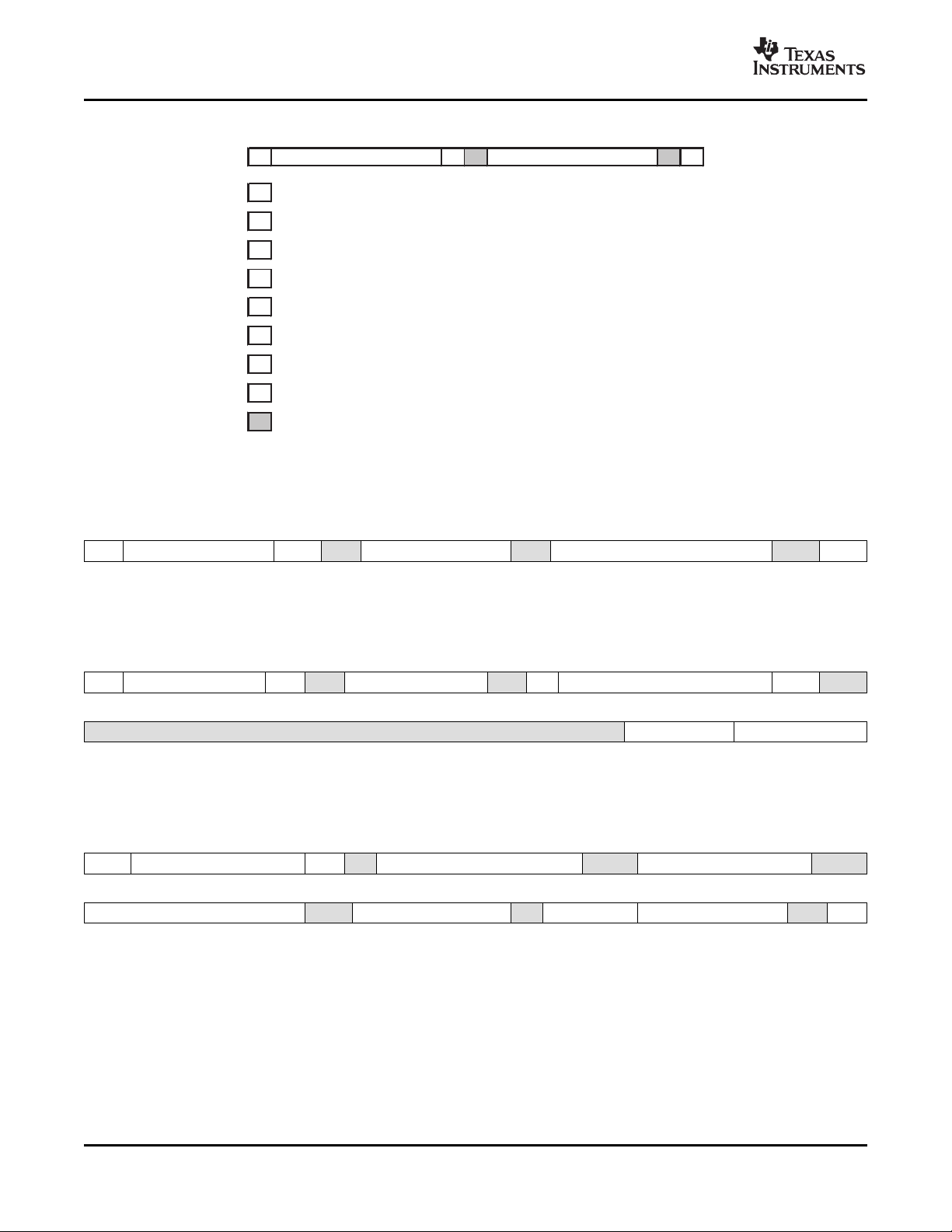

FUNCTIONAL BLOCK DIAGRAM

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

OUTPUT SWITCH MATRIX

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): CDCE906

Page 4

www.ti.com

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

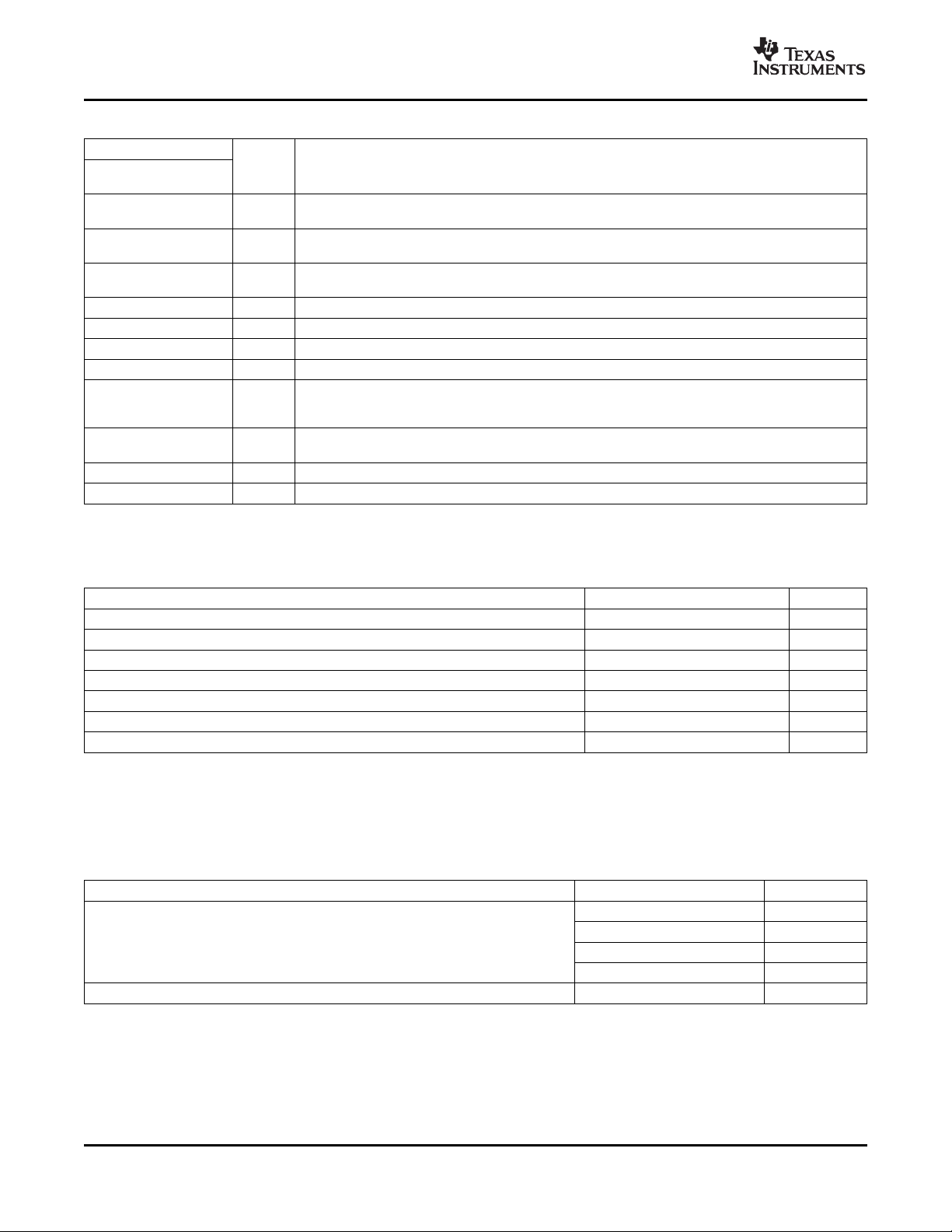

TERMINAL FUNCTIONS

TERMINAL

NAME

Y0 to Y5 O LVCMOS outputs

TSSOP20

NO.

11, 12, 15,

16, 19, 20

CLK_IN0 5 I

CLK_IN1 6 I/O

V

CC

V

CCOUT1

V

CCOUT2

3, 7 Power 3.3-V power supply for the device.

14 Power Power supply for outputs Y0, Y1.

18 Power Power supply for outputs Y2, Y3, Y4, Y5.

GND 4, 8, 13, 17 Ground Ground

S0, A0,

CLK_SEL

1 I CLK_SEL (selects one of two LVCMOS clock inputs), dependent on the SMBus settings; LVCMOS

S1, A1 2 I

SDATA 9 I/O Serial control data input/output for SMBus controller; LVCMOS input

SCLOCK 10 I Serial control clock input for SMBus controller; LVCMOS input

I/O DESCRIPTION

Dependent on SMBus settings, CLK_IN0 is the crystal oscillator input and can also be used as

LVCMOS input or as positive differential signal inputs.

Dependent on SMBus settings, CLK_IN1 is serving as the crystal oscillator output or can be the

second LVCMOS input or the negative differential signal input.

User programmable control input S0 (PLL bypass or power-down mode) or AO (address bit 0), or

inputs; internal pullup 150 k Ω .

User programmable control input S1 (output enable/disable or all output low), A1 (address bit 1),

dependent on the SMBus settings; LVCMOS inputs; internal pullup 150 k Ω

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

V

V

V

I

I

I

O

T

stg

T

J

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

(2) The input and output negative voltage ratings may be exceeded if the input and output clamp-current ratings are observed.

Supply voltage range – 0.5 to 4.6 V

CC

Input voltage range

I

Output voltage range

O

(2)

(2)

Input current (VI< 0, VI> VCC) ± 20 mA

Continuous output current ± 50 mA

Storage temperature range – 65 to 150 ° C

Maximum junction temperature 125 ° C

only and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute maximum rated conditions for extended periods may affect device reliability.

(1)

VALUE UNIT

– 0.5 to V

– 0.5 to V

+ 0.5 V

CC

+ 0.5 V

CC

PACKAGE THERMAL RESISTANCE

for TSSOP20 (PW) Package

θ

JA

θ

JC

(1) The package thermal impedance is calculated in accordance with JESD 51 and JEDEC2S2P (high-k board).

Thermal resistance junction-to-ambient

Thermal resistance junction-to-case 19.7

(1)

PARAMETER AIRFLOW (LFM) ° C/W

0 66.3

150 59.3

250 56.3

500 51.9

4 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Product Folder Link(s): CDCE906

Page 5

www.ti.com

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

RECOMMENDED OPERATING CONDITIONS

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

V

CC

V

CCOUT1

V

CCOUT2

V

IL

V

IH

V

Ithresh

V

I

|V

| Differential input voltage 0.1 V

ID

V

IC

IOH/ I

IOH/ I

C

L

T

A

(1) The minimum output voltage can be down to 1.8 V. See the application note for more information.

Device supply voltage 3 3.3 3.6 V

(1)

Output Y0,Y1 supply voltage 2.3 3.6 V

(1)

Output Y2, Y3, Y4, Y5 supply voltage 2.3 3.6 V

Low level input voltage LVCMOS 0.3 V

High level input voltage LVCMOS 0.7 V

Input voltage threshold LVCMOS 0.5 V

CC

CC

Input voltage range LVCMOS 0 3.6 V

Common-mode for differential input voltage 0.2 Vcc- 0.6 V

Output current (3.3 V) ± 6 mA

OL

Output current (2.5 V) ± 4 mA

OL

Output load LVCMOS 25 pF

Operating free-air temperature 0 70 ° C

RECOMMENDED CRYSTAL SPECIFICATIONS

MIN NOM MAX UNIT

f

Xtal

ESR Effective series resistance

C

(1) For crystal frequencies above 50 MHz the effective series resistor should not exceed 50 Ω to assure stable start-up condition.

(2) Maximum Power Handling (Drive Level) see Figure 16 .

Crystal input frequency range (fundamental mode) 8 27 54 MHz

(1) (2)

Input capacitance CLK_IN0 and CLK_IN1 3 pF

IN

15 60 Ω

CDCE906

CC

V

V

V

EEPROM SPECIFICATION

MIN TYP MAX UNIT

EEcyc Programming cycles of EEPROM 100 1000 Cycles

EEret Data retention 10 Years

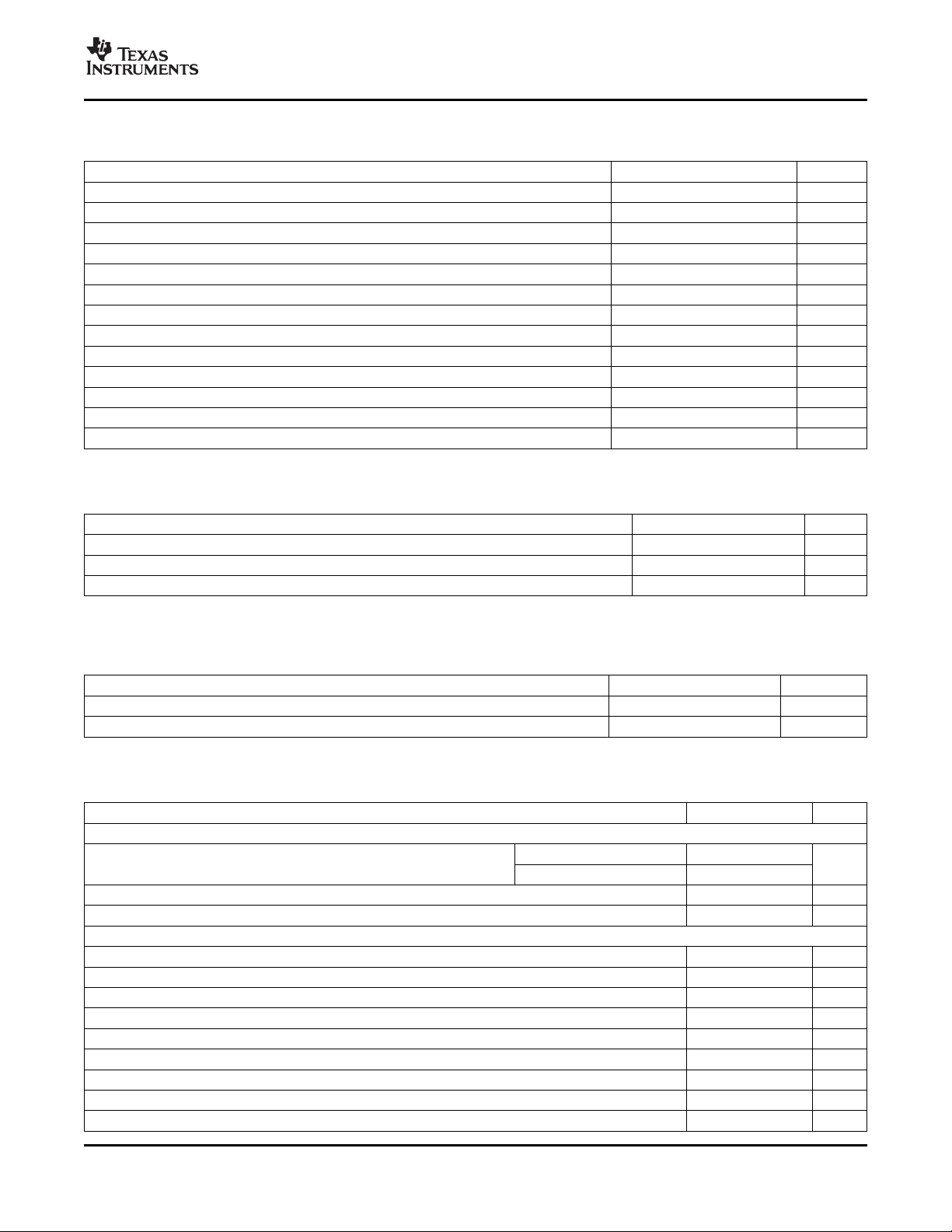

TIMING REQUIREMENTS

over recommended ranges of supply voltage, load, and operating-free air temperature

MIN NOM MAX UNIT

CLK_IN REQUIREMENTS

f

CLK_IN

tr/ t

f

duty

REF

CLK_IN clock input frequency (LVCMOS or Differential) MHz

Rise and fall time CLK_IN signal (20% to 80%) 4 ns

Duty cycle CLK_IN at V

/ 2 40% 60%

CC

SMBus TIMING REQUIREMENTS (see Figure 11 )

f

SCLK

t

h(START)

t

w(SCLL)

t

w(SCLH)

t

su(START)

t

h(SDATA)

t

su(SDATA)

t

r

t

f

SCLK frequency 100 kHz

START hold time 4 µ s

SCLK low-pulse duration 4.7 µ s

SCLK high-pulse duration 4 50 µ s

START setup time 0.6 µ s

SDATA hold time 0.3 µ s

SDATA setup time 0.25 µ s

SCLK / SDATA input rise time 1000 ns

SCLK / SDATA input fall time 300 ns

PLL mode 1 167

PLL bypass mode 0 167

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): CDCE906

Page 6

www.ti.com

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

TIMING REQUIREMENTS (continued)

over recommended ranges of supply voltage, load, and operating-free air temperature

MIN NOM MAX UNIT

t

su(STOP)

t

BUS

t

POR

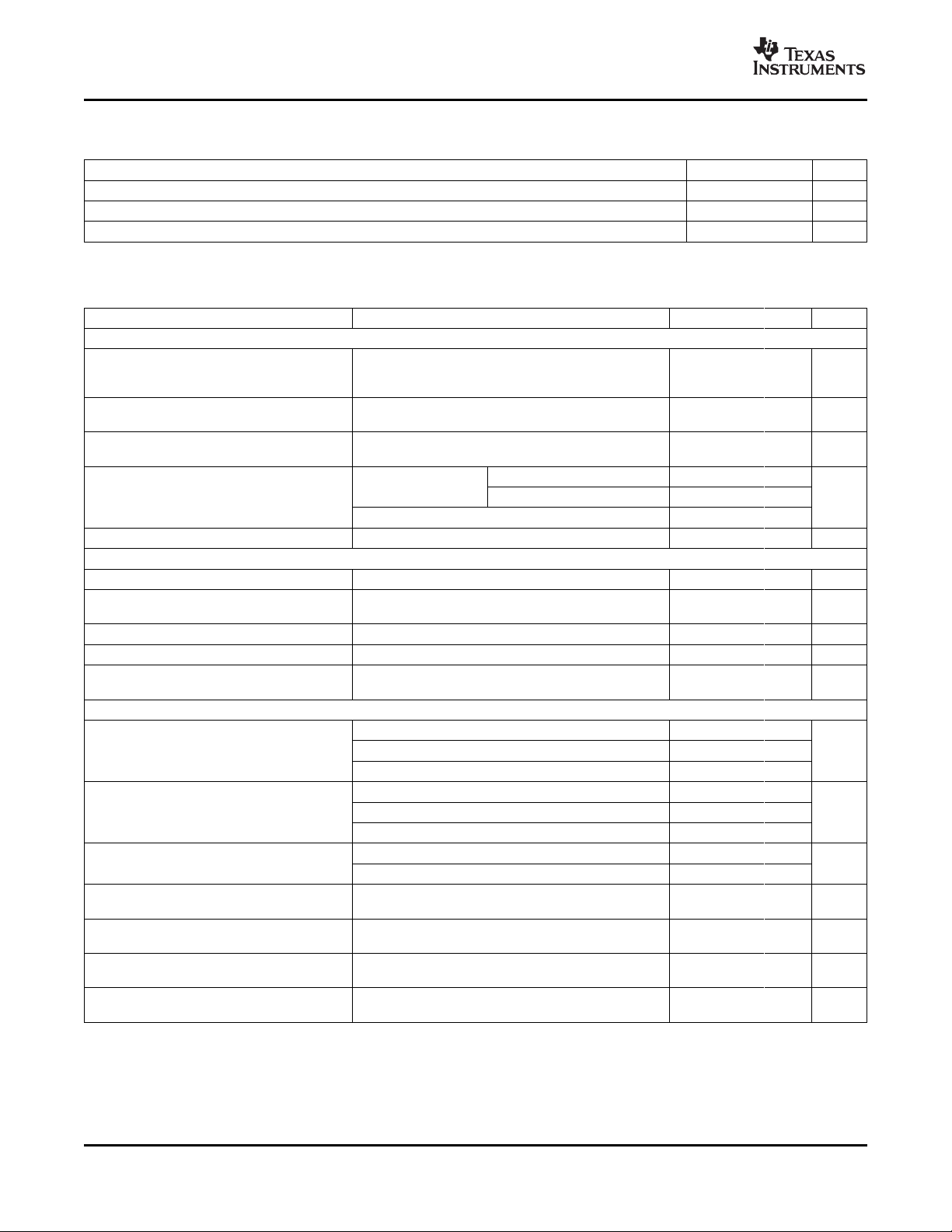

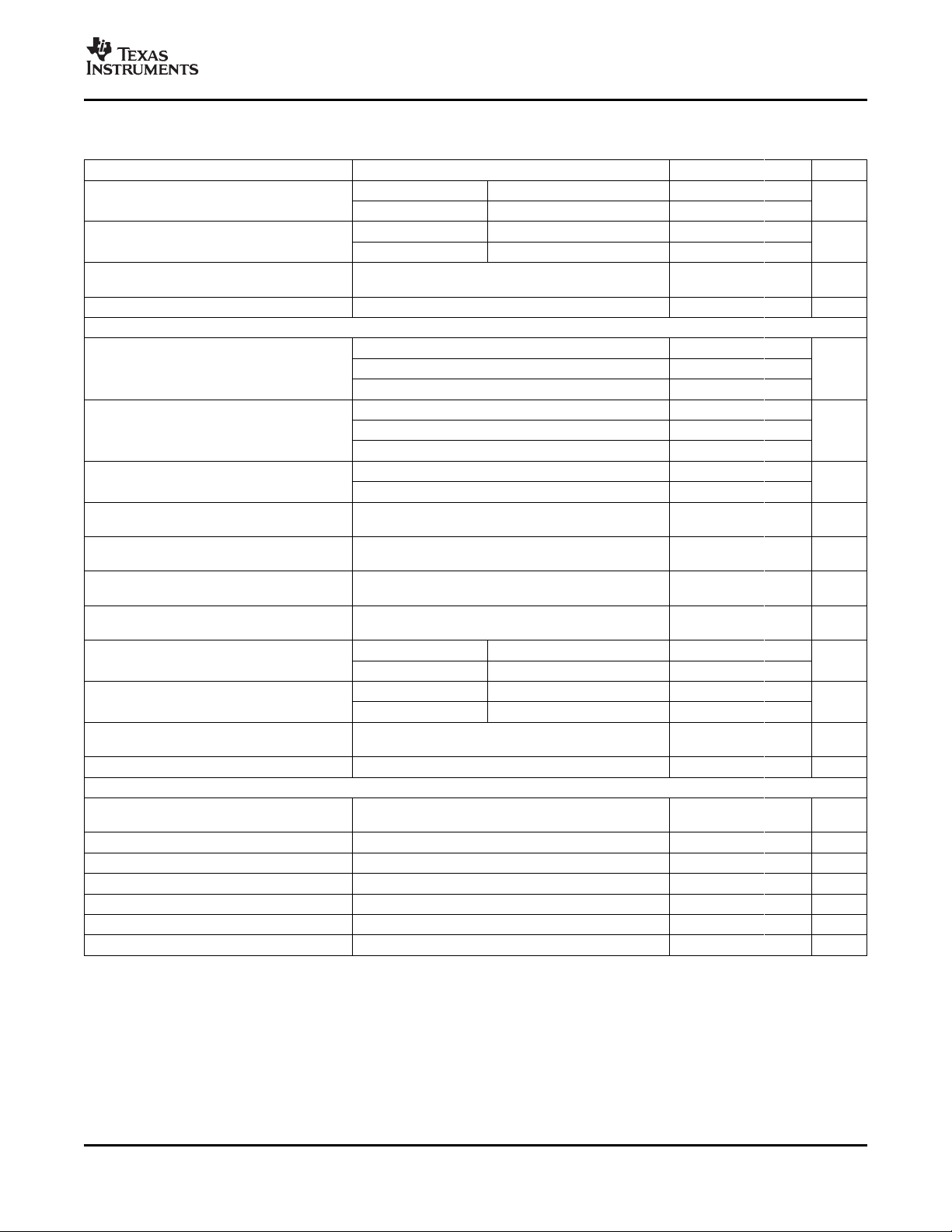

DEVICE CHARACTERISTICS

over recommended operating free-air temperature range and test load (unless otherwise noted), see Figure 1

OVERALL PARAMETER

I

CC

I

CCPD

V

PUC

f

VCO

f

OUT

LVCMOS PARAMETER

V

IK

I

I

I

IH

I

IL

C

I

LVCMOS PARAMETER FOR V

V

OH

V

OL

t

,

PLH

t

PHL

tr0/t

f0

tr1/t

f1

tr2/t

f2

tr3/t

f3

STOP setup time 4 µ s

Bus free time 4.7 µ s

Time in which the device must be operational after power-on reset 500 ms

PARAMETER TEST CONDITIONS MIN TYP

Supply current

(2)

Power down current. Every circuit

powered down except SMBus

All PLLs on, all outputs on,

f

= 80 MHz, f

out

f

= 160 MHz

vco

fIN= 0 MHz, V

CLK_IN

= 3.6 V 50 µ A

CC

= 27 MHz, 90 115 mA

Supply voltage Vccthreshold for

power up control circuit

VCO frequency of internal PLL (any

of three PLLs)

Normal

speed-mode

(3)

High-speed mode

LVCMOS output frequency range

LVCMOS input voltage V

LVCMOS input current (CLK_IN0 /

CLK_IN1)

LVCMOS input current (For S1/S0) VI= VCC, V

LVCMOS input current (For S1/S0) VI= 0 V, V

Input capacitance at CLK_IN0 and VI= 0 V or V

CLK_IN1

ccout

LVCMOS high-level output voltage V

LVCMOS low-level output voltage V

Propagation delay ns

Rise and fall time for output slew

rate 0

Rise and fall time for output slew

rate 1

Rise and fall time for output slew

rate 2

Rise and fall time for output slew

rate 3 (Default Configuration)

(4)

V

= 2.5 V or 3.3 V 167 MHz

CC

= 3 V, II= – 18 mA – 1.2 V

CC

VI= 0 V or VCC, V

= 3.6 V 5 µ A

CC

= 3.6 V -35 -10 µ A

CC

CC

= 3.3-V Mode

V

= 3 V, IOH= – 0.1 mA 2.9

ccout

= 3 V, IOH= – 4 mA 2.4 V

ccout

V

= 3 V, IOH= – 6 mA 2.1

ccout

V

= 3 V, IOL= 0.1 mA 0.1

ccout

= 3 V, IOL= 4 mA 0.5 V

ccout

V

= 3 V, IOL= 6 mA 0.85

ccout

All PLL bypass 9

VCO bypass 11

V

= 3.3 V (20% – 80%) 1.7 3.3 4.8 ns

ccout

V

= 3.3 V (20% – 80%) 1.5 2.5 3.2 ns

ccout

V

= 3.3 V (20% – 80%) 1.2 1.6 2.1 ns

ccout

V

= 3.3 V (20% – 80%) 0.4 0.6 1 ns

ccout

All PLLs 80 200

PLL2 with SSC 80 167 MHz

(3)

= 3.6 V ± 5 µ A

CC

180 300

(1)

MAX UNIT

2.1 V

3 pF

(1) All typical values are at respective nominal VCC.

(2) For calculating total supply current, add the current from Figure 2 , Figure 3 , and Figure 4 . Using high-speed mode of the VCO reduces

the current consumption significantly. See Figure 3

(3) Normal-speed mode or high-speed mode must be selected by the VCO frequency selection bit in Byte 6, Bit [7:5]. The min f

lower but impacts jitter-performance.

(4) The maximum output frequency may be exceeded, but specifications under the Recommended Operating Condition may change and

are no longer assured. Do not exceed the maximum power dissipation of the 20-pin TSSOP package (600 mW at no air flow).

6 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Product Folder Link(s): CDCE906

can be

VCO

Page 7

www.ti.com

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

DEVICE CHARACTERISTICS (continued)

over recommended operating free-air temperature range and test load (unless otherwise noted), see Figure 1

PARAMETER TEST CONDITIONS MIN TYP

t

jit(cc)

t

jit(per)

t

sk(o)

Cycle-to-cycle jitter

Peak-to-peak period jitter

Output skew (see

odc Output duty cycle

LVCMOS PARAMETER FOR V

V

OH

V

OL

t

PLH

t

PHL

tr0/t

tr1/t

tr2/t

tr3/t

t

jit(cc)

t

jit(per)

t

sk(o)

LVCMOS high-level output voltage V

LVCMOS low-level output voltage V

,

Propagation delay ns

Rise and fall time for output

f0

slew rate 0

Rise and fall time for output

f1

slew rate 1

Rise and fall time for output

f2

slew rate 2

Rise and fall time for output

f3

slew rate 3 (Default Configuration)

Cycle-to-cycle jitter

Peak-to-peak period jitter

Output skew (see

odc Output duty cycle

(5) (6)

1 PLL, 1 Output f

3 PLLs, 3 Outputs f

(5) (6)

1 PLL, 1 Output f

3 PLLs, 3 Outputs f

(7)

and Table 5 ) 1.6-ns rise/fall time at

(8)

= 2.5-V Mode

ccout

f

= 150 MHz, Pdiv = 3

vco

f

= 100 MHz, Pdiv = 1 45% 55%

vco

(9)

V

= 2.3 V, IOH= 0.1 mA 2.2

ccout

= 2.3 V, IOH= – 3 mA 1.7 V

ccout

V

= 2.3 V, IOH= – 4 mA 1.5

ccout

V

= 2.3 V, IOL= 0.1 mA 0.1

ccout

= 2.3 V, IOL= 3 mA 0.5 V

ccout

V

= 2.3 V, IOL= 4 mA 0.85

ccout

All PLL bypass 9

VCO bypass 11

V

= 2.5 V (20% – 80%) 2 3.9 5.6 ns

ccout

V

= 2.5 V (20% – 80%) 1.8 2.9 4.4 ns

ccout

V

= 2.5 V (20% – 80%) 1.3 2 3.2 ns

ccout

V

= 2.5 V (20% – 80%) 0.4 0.8 1.1 ns

ccout

(10) (11)

1 PLL, 1 Output f

3 PLLs, 3 Outputs f

(10) (11)

1 PLL, 1 Output f

3 PLLs, 3 Outputs f

(12)

and Table 5 ) 250 ps

(13)

2-ns rise/fall time at

f

= 150 MHz, Pdiv = 3

VCO

f

= 100 MHz, Pdiv = 1 45% 55%

VCO

= 24.576 MHz 65 95

OUT

= 24.576 MHz 85 135

OUT

= 24.576 MHz 90 115

OUT

= 24.576 MHz 100 150

OUT

= 24.576 MHz 85 120

OUT

= 24.576 MHz 95 155

OUT

= 24.576 MHz 110 135

OUT

= 24.576 MHz 110 175

OUT

SMBus PARAMETER

V

IK

I

I

V

IH

V

IL

V

OL

C

C

SCLK and SDATA input clamp

voltage

SCLK and SDATA input current VI= 0 V or VCC, V

V

= 3 V, II= – 18 mA – 1.2 V

CC

= 3.6 V ± 5 µ A

CC

SCLK input high voltage 2.1 V

SCLK input low voltage 0.8 V

SDATA low-level output voltage IOL= 4 mA, V

Input capacitance at SCLK VI= 0 V or V

ISCLK

Input capacitance at SDATA VI= 0 V or V

ISDATA

= 3 V 0.4 V

CC

CC

CC

(5) 50000 cycles.

(6) Jitter depends on configuration. Jitter data is for normal tr/tf, input frequency = 27 MHz, f

(7) The t

(8) odc depends on output rise and fall time (tr/tf); above limits are for normal tr/tf.

specification is only valid for equal loading of all outputs.

sk(o)

= 147 MHz output.

VCO

(9) There is a limited drive capability at output supply voltage of 2.5 V. For proper termination, see application report SCAA080 .

(10) 50000 cycles.

(11) Jitter depends on configuration. Jitter data is for normal tr/tf, input frequency = 27 MHz, f

(12) The t

(13) odc depends on output rise and fall time (tr/tf); above limits are for normal tr/tf.

specification is only valid for equal loading of all outputs.

sk(o)

= 147 MHz output.

VCO

(1)

3 10 pF

3 10 pF

CDCE906

MAX UNIT

ps

ps

200 ps

ps

ps

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Link(s): CDCE906

Page 8

www.ti.com

Yn

1 kW

1 kW

10 pF

LVCMOS

CDCE906

PLL 1+PLL 2SSC+PLL3

V =3.3V,

Mdiv=1,

Ndiv=2,

P div=1,

VCOnormal-speedmode

CC

PLL 1+PLL 2+PLL3

PLL 1+PLL 2

f -[MHz]

VCO

210

I -[mA]

CC

PLL 1

20017016015090

90

80

80

0

0

70

70

60

60

50

50

40

40

30

30

20

20

10

10

140130120

120

110

110

100

100

190180

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

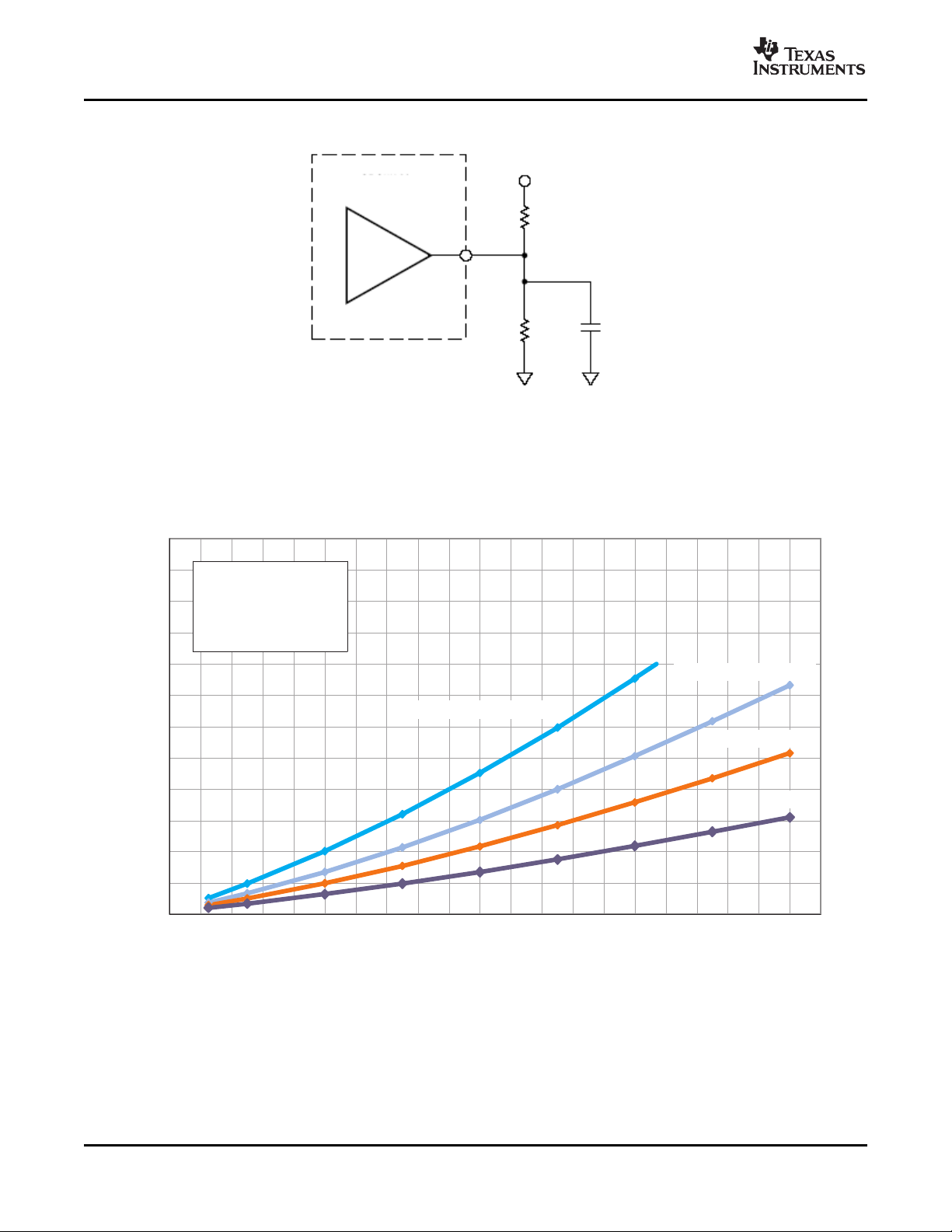

PARAMETER MEASUREMENT INFORMATION

Figure 1. Test Load

Figure 2. ICCvs Number of PLLs and VCO Frequency (VCO at Normal-Speed Mode, Byte 6 Bit [7:5])

TYPICAL CHARACTERISTICS

8 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Product Folder Link(s): CDCE906

Page 9

www.ti.com

PLL 1+PLL 2SSC+PLL3

V =3.3V,

Mdiv=1,

Ndiv=2,

P div=1,

VCOhigh-speedmode

CC

PLL 1+PLL 2+PLL3

PLL 1+PLL 2

f -[MHz]

VCO

310

I

-[mA]

CC

PLL 1

300250190180

90

80

0

70

60

50

40

30

20

10

170160150

120

140

110

130

100

270260240230200 220210 290280

0

5

10

15

20

25

30

35

40

45

50

55

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

6Outputs

5Outputs

4Outputs

3Outputs

2Outputs

1Outputs

V =3.3V,

Mdiv=1,

Ndiv=2,

P div=1

CC

f -[MHz]

VCO

I -[mA]

CC

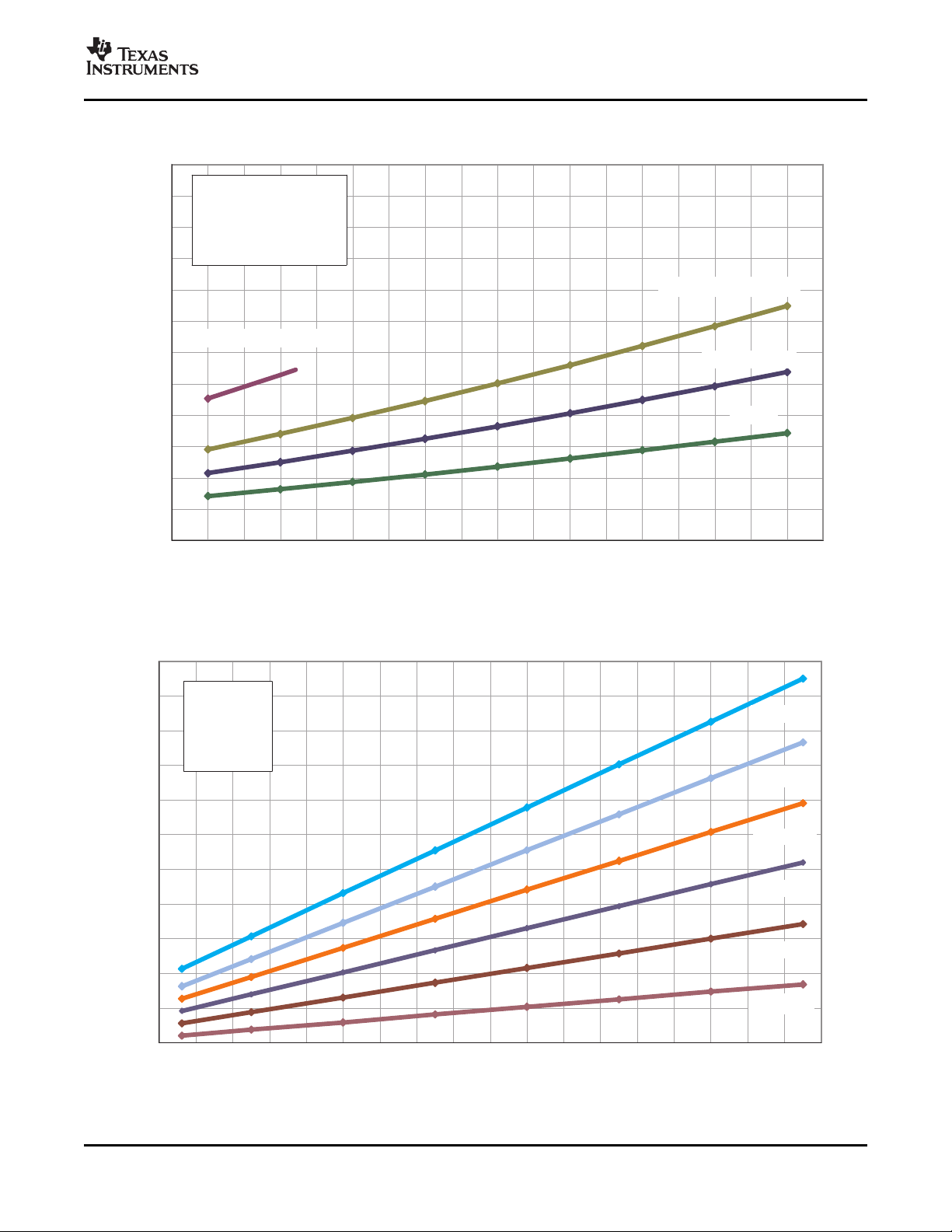

TYPICAL CHARACTERISTICS (continued)

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Figure 3. ICCvs Number of PLLs and VCO Frequency (VCO at High-Speed Mode, Byte 6 Bit [7:5])

Figure 4. I

vs Number of Outputs and VCO Frequency

CCOUT

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): CDCE906

Page 10

www.ti.com

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

3.2

3.4

3.6

90 100 110 120 130 140 150 160 170 180 190 200 210 220

VOHatV =3.6V

CCOUT

VOHatV =2.3V

CCOUT

VOLatV =3.6V

CCOUT

VOLatV =2.3V

CCOUT

f -[MHz]

OUT

VOUT-[V]

V =3.3V,

Mdiv=4,

Ndiv=15,

P div=1

CC

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

TYPICAL CHARACTERISTICS (continued)

Figure 5. Output Swing vs Output Frequency

10 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Product Folder Link(s): CDCE906

Page 11

www.ti.com

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

APPLICATION INFORMATION

SMBus Data Interface

To enhance the flexibility and function of the clock synthesizer, a two-signal serial interface is provided. It follows

the SMBus specification Version 2.0, which is based upon the principals of operation of I2C. More details of the

SMBus specification can be found at http://www.smbus.org .

Through the SMBus, various device functions, such as individual clock output buffers, can be individually

enabled or disabled. The registers associated with the SMBus data interface initialize to their default setting upon

power-up, and therefore using this interface is optional. The clock device register changes are normally made

upon system initialization, if any are required.

Data Protocol

The clock driver serial protocol accepts Byte Write, Byte Read, Block Write, and Block Read operations from the

controller.

For Block Write/Read operations, the bytes must be accessed in sequential order from lowest to highest byte

(most significant bit first) with the ability to stop after any complete byte has been transferred. For Byte Write and

Byte Read operations, the system controller can access individually addressed bytes.

Once a byte has been sent, it will be written into the internal register and effective immediately. With the rising

edge of the ACK bit, this applies to each transferred byte, independent of whether this is a Byte Write or a Block

Write sequence.

If the EEPROM write cycle is initiated, the data of the internal SMBus register is written into the EEPROM.

During EEPROM write, no data is allowed to be sent to the device via the SMBus until the programming

sequence is completed. Data, however, can be readout during the programming sequence (byte read or block

read). The programming status can be monitored by EEPIP, byte 24 bit 7.

The offset of the indexed byte is encoded in the command code, as described in Table 1 .

The Block Write and Block Read protocol is outlined in Figure 9 and Figure 10 , while Figure 7 and Figure 8

outlines the corresponding Byte Write and Byte Read protocol.

Slave Receiver Address (7 bits)

A6 A5 A4 A3 A2 A1* A0* R/W

1 1 0 1 0 0 1 0

* Address bits A0 and A1 are programmable by the Configuration Inputs S0 and S1 (Byte 10 Bit [1:0] and Bit [3:2]. This allows addressing up

to four devices connected to the same SMBus.

Table 1. Command Code Definition

Bit Description

7

(6:0) Byte Offset for Read and Write operation.

0 = Block Read or Block Write operation

1 = Byte Read or Byte Write operation

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Link(s): CDCE906

Page 12

www.ti.com

1 7 1 1 8 1 1

S Slave Address Wr A Data Byte A P

S Start Condition

Sr

Reapeated Start Condition

Rd

Read (Bit Value = 1)

Wr

Write (Bit Value = 0)

A Acknowledge (ACK = 0 and NACK = 1)

P Stop Condition

PE Packet Error

Master to Slave Transmission

Slave to Master Transmission

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Figure 6. Generic Programming Sequence

Byte Write Programming Sequence

1 7 1 1 8 1 8 1 1

S Slave Address Wr A CommandCode A Data Byte A P

Figure 7. Byte Write Protocol

Byte Read Programming Sequence

1 7 1 1 8 1 1 7 1 1

S Slave Address Wr A CommandCode A S Slave Address Rd A

8 1 1

Data Byte A P

Figure 8. Byte Read Protocol

Block Write Programming Sequence

1 7 1 1 8 1 8 1

S Slave Address Wr A CommandCode A Byte Count N A

8 1 8 1 8 1 1

Data Byte 0 A Data Byte 1 A - - - - - Data Byte N – 1 A P

(1)

Data Byte 0 is reserved for revision code and vendor identification. However, this byte is used for internal test. Do not write into it other

than 0000 0001.

(1)

Figure 9. Block Write Protocol

12 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Product Folder Link(s): CDCE906

Page 13

www.ti.com

P S P

SCLK

SDATA

A

Bit 7 (MSB)

Bit 6 Bit 0 (LSB)

t

h(SDATA)

t

su(SDATA)

t

su(START)

t

(BUS)

t

h(START)

t

r(SM)

t

r(SM)

t

f(SM)

t

f(SM)

t

W(SCLH)

t

W(SCLL)

t

su(STOP)

V

IH(SM)

V

IL(SM)

V

IH(SM)

V

IL(SM)

9

10

SDATA

SCLK

SMB Host

CDCE906

C

BUS

C

BUS

R

P

R

P

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Block Read Programming Sequence

1 7 1 1 8 1 1 7 1 1

S Slave Address Wr A CommandCode A Sr Slave Address Rd A

8 1 8 1 8 1 1

Byte Count N A Data Byte 0 A - - - - - Data Byte N – 1 A P

Figure 10. Block Read Protocol

CDCE906

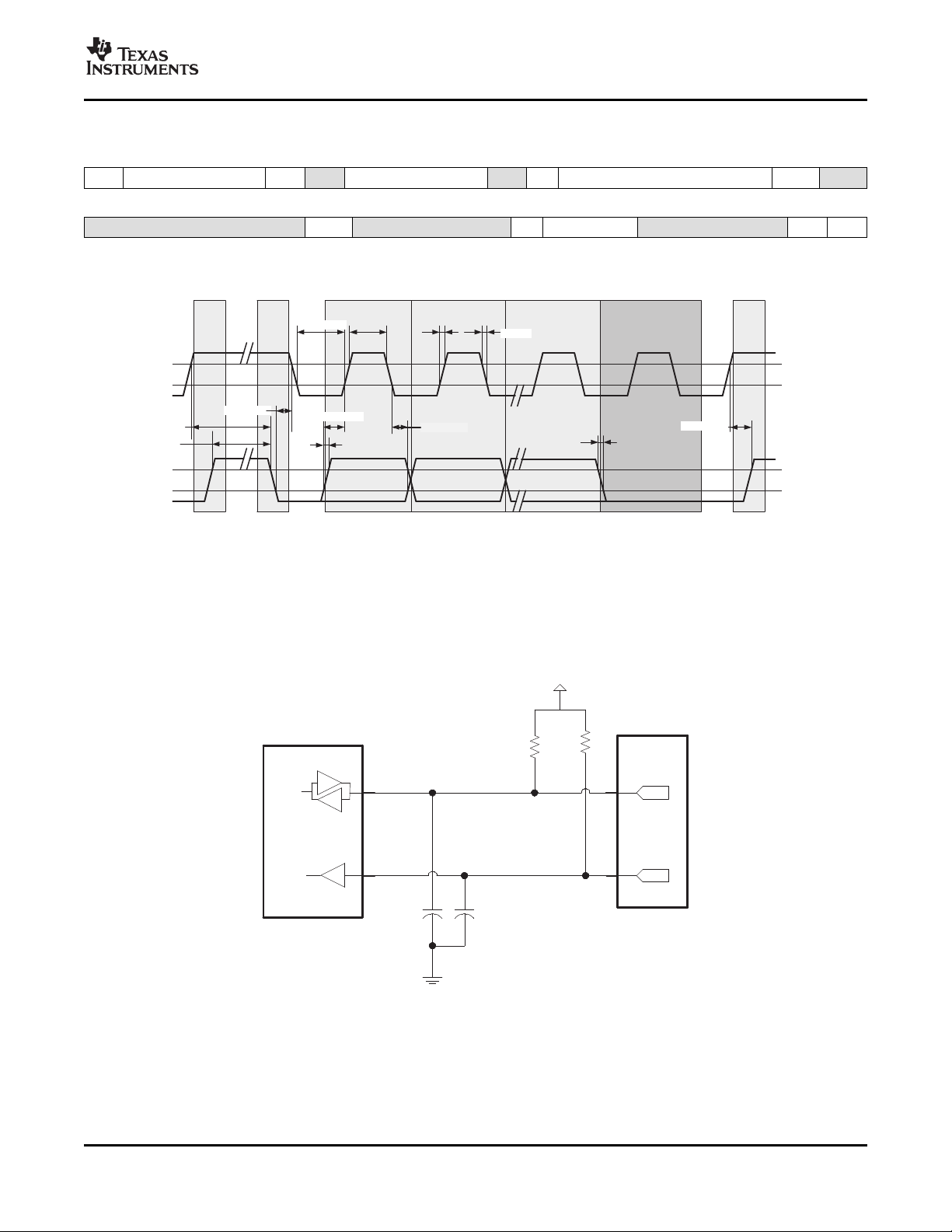

Figure 11. Timing Diagram Serial Control Interface

SMBus Hardware Interface

The following diagram shows how the CDCE906 clock synthesizer is connected to the SMBus. Note that the

current through the pullup resistors (R

CDCE906 is not connected to the SMBus, then SDATA and SCLK inputs have to be connected with 10-k Ω

pullup resistors to V

to avoid floating input conditions.

CC

) must meet the SMBus specifications (min 100 µ A, max 350 µ A). If the

p

Figure 12. SMBus Hardware Interface

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Link(s): CDCE906

Page 14

www.ti.com

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

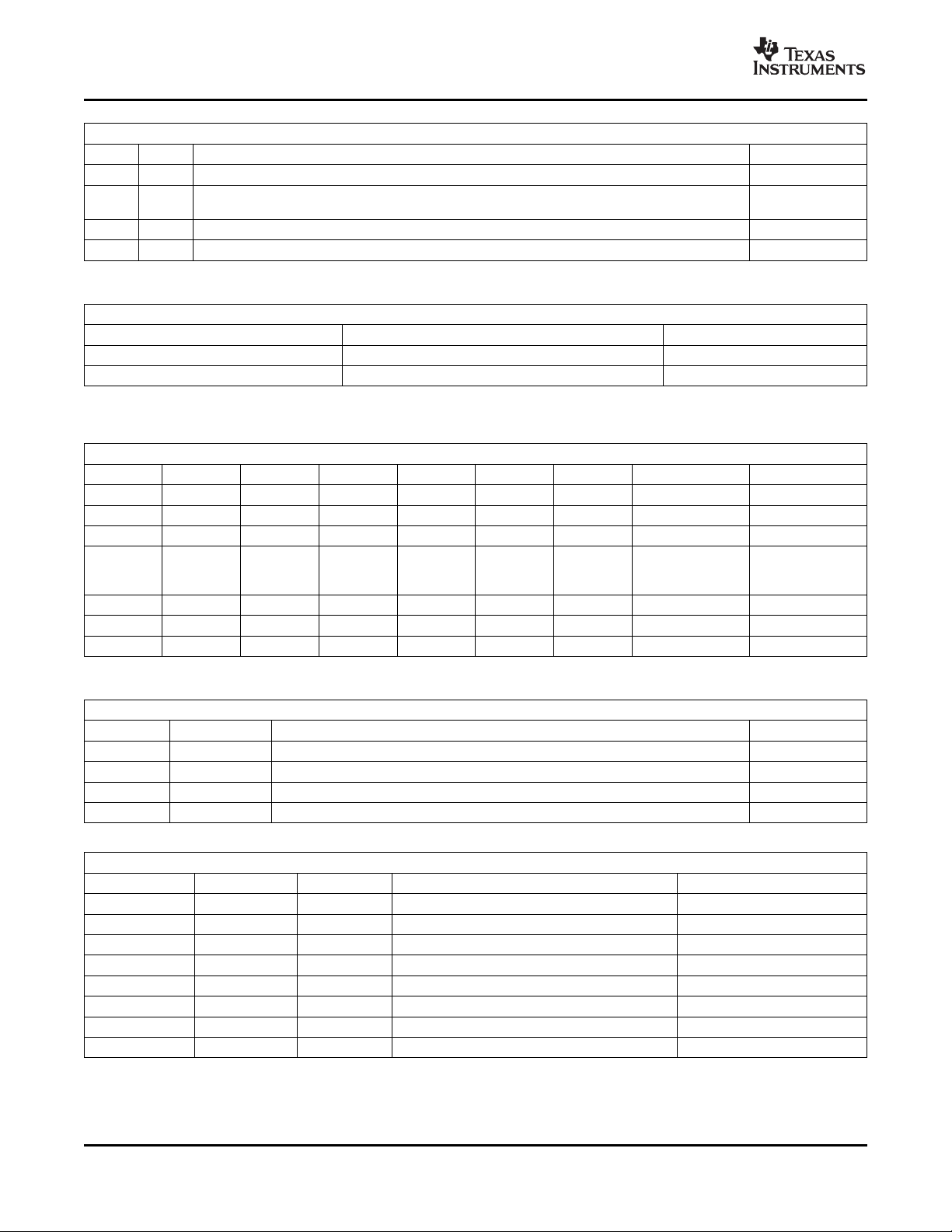

Table 2. Register Configuration Command Bitmap

Adr Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0 Revision Code Vendor Identification

Byte 1 PLL1 Reference Divider M 9-Bit [7:0]

Byte 2 PLL1 Feedback Divider N 12-Bit [7:0]

Byte 3 PLL1 Mux PLL2 Mux PLL3 Mux PLL1 Feedback Divider N 12-Bit [11:8] PLL1 Ref

Byte 4 PLL2 Reference Divider M 9-Bit [7:0]

Byte 5 PLL2 Feedback Divider N 12-Bit [7:0]

Byte 6 PLL1 fvco PLL2 fvco PLL3 fvco PLL2 Feedback Divider N 12-Bit [11:8] PLL2 Ref

Selection Selection Selection Dev M [8]

Byte 7 PLL3 Reference Divider 9-Bit M [7:0]

Byte 8 PLL3 Feedback Divider N [12-Bit 7:0]

Byte 9 PLL Selection for P0 (Switch A) PLL3 Feedback Divider N 12-Bit [11:8] PLL3 Ref

Byte 10 PLL Selection for P1 (Switch A) Inp. Clock Configuration Inputs S1 Configuration Inputs S0

Selection

Byte 11 Input Signal Source PLL Selection for P3 (Switch A) PLL Selection for P2 (Switch A)

Byte 12 Reserved Power Down PLL Selection for P5 (Switch A) PLL Selection for P4 (Switch A)

Byte 13 Reserved 7-Bit Divider P0 [6:0]

Byte 14 Reserved 7-Bit Divider P1 [6:0]

Byte 15 Reserved 7-Bit Divider P2 [6:0]

Byte 16 Reserved 7-Bit Divider P3 [6:0]

Byte 17 Reserved 7-Bit Divider P4 [6:0]

Byte 18 Reserved 7-Bit Divider P5 [6:0]

Byte 19 Reserved Y0 Inv. or Y0 Slew-Rate Control Y0 Enable or Y0 Divider Selection (Switch B)

Non-Inv Low

Byte 20 Reserved Y1 Inv. or Y1 Slew-Rate Control Y1 Enable or Y1 Divider Selection (Switch B)

Non-Inv Low

Byte 21 Reserved Y2 Inv. or Y2 Slew-Rate Control Y2 Enable or Y2 Divider Selection (Switch B)

Non-Inv Low

Byte 22 Reserved Y3 Inv. or Y3 Slew-Rate Control Y3 Enable or Y3 Divider Selection (Switch B)

Non-Inv Low

Byte 23 Reserved Y4 Inv. or Y4 Slew-Rate Control Y4 Enable or Y4 Divider Selection (Switch B)

Non-Inv Low

Byte 24 EEPIP [read Y5 Inv or Y5 Slew-Rate Control Y5 Enable or Y5 Divider Selection (Switch B)

only] Non-Inv Low

Byte 25 EELOCK Spread Spectrum (SSC) Modulation Frequency Selection for SSC

Selection

Byte 26 EEWRITE 7-Bit Byte Count

Dev M [8]

Dev M [8]

Default Device Setting

The internal EEPROM of CDCE906 is pre-programmed with a factory default configuration as shown below. This

puts the device in an operating mode without the need to program it first. The default setting appears after power

is switched on or after a power-down/up sequence until it is re-programmed by the user to a different application

configuration. A new register setting is programmed via the serial SMBUS Interface.

A different default setting can be programmed upon customer request. Contact a Texas Instruments sales or

marketing representative for more information.

14 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Product Folder Link(s): CDCE906

Page 15

www.ti.com

PLL1

XO

or

2LVCMOS

or

Differential

Input

MUX

MUX

DividerM

1

MUX

DividerM

375

PLL3

PFD

Filter

VCO

PLL2

w/SSC

PFD

Filter

VCO

DividerN

8

DividerN

250

DividerN

3136

SO/CLK_SEL

S1

SCLOCK

OutputSwitchMatrix

27MHz

PROGRAMMING

LOGIC

SMBUS

LOGIC

PFD

Filter

VCO

SDATA

P0-Div

10

P1-Div

20

P2-Div

8

P3-Div

9

P4-Div

32

P5-Div

4

f

VCO3

=225.792MHz

CLK_IN0

CLK_IN1

27MHz

Crystal

1

4pF

1

4pF

SSC-OFF

Y5

Y4

Y3

Y2

Y1

Y0

27MHz

27MHz

27MHz

27MHz

LV

CMOS

LV

CMOS

LV

CMOS

LV

CMOS

LV

CMOS

LV

CMOS

27MHz

DividerM

27

f

VCO1

=216MHz

f

VCO2

=250MHz

fout=

finxN

MxP

, i.e.fout=

27MHzx8

(1x8)

=27MHz

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

NOTE: All outputs are enabled and in non-inverting mode. S0, S1, and SSC comply according the default setting described in

The output frequency can be calculated:

Byte 10 and Byte 25 respectively.

Figure 13. Default Device Setting

(1)

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Link(s): CDCE906

Page 16

www.ti.com

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Functional Description of the Logic

All Bytes are read-/write-able, unless otherwise expressly mentioned.

Byte 0 (read only): Vendor Identification Bits [3:0]; Revision Code Bit [7:4]

Revision Code

X X X X 0 0 0 1

(1) Byte 0 is readable by "Byte Read sequency" only.

Byte 1 to 9: Reference Divider M of PLL1, PLL2, PLL3

M8 M7 M6 M5 M4 M3 M2 M1 M0 Div by Default

0 0 0 0 0 0 0 0 0 Not allowed

0 0 0 0 0 0 0 0 1 1

0 0 0 0 0 0 0 1 0 2

0 0 0 0 0 0 0 1 1 3

1 1 1 1 1 1 1 0 1 509

1 1 1 1 1 1 1 1 0 510

1 1 1 1 1 1 1 1 1 511

(1) By selecting the PLL divider factors, M ≤ N and 80 MHz ≤ fvco ≤ 300 MHz.

(2) Unless customer specific setting.

(3) Default setting of divider M for PLL1 = 1, for PLL2 = 27 and for PLL3 = 375.

Byte 1 to 9: Feedback Divider N of PLL1, PLL2, PLL3

N11 N10 N9 N8 N7 N6 N5 N4 N3 N2 N1 N0 Div by Default

0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 1 1

0 0 0 0 0 0 0 0 0 0 1 0 2

0 0 0 0 0 0 0 0 0 0 1 1 3

1 1 1 1 1 1 1 1 1 1 0 1 4093

1 1 1 1 1 1 1 1 1 1 1 0 4094

1 1 1 1 1 1 1 1 1 1 1 1 4095

(1) By selecting the PLL divider factors, M ≤ N and 80 MHz ≤ fvco ≤ 300 MHz.

(2) Unless customer specific setting.

(3) Default setting of divider N for PLL1 = 8, for PLL2 = 250 and for PLL3 = 3136.

Byte 3 Bit [7:5]: PLL (VCO) Bypass Multiplexer

PLLxMUX PLL (VCO) MUX Output Default

0 PLLx Yes

1 VCO bypass

(1) Unless customer specific setting.

Byte 6 Bit [7:5]: VCO Frequency Selection Mode for each PLL

PLLxFVCO VCO Frequency Range Default

0 80-200 MHz

1 180-300 MHz Yes

(1) This bit selects the normal-speed mode or the high-speed mode for the dedicated VCO in PLL1, PLL2 or PLL3. At power-up, the

high-speed mode is selected, f

(2) Unless customer specific setting.

(1)

(1)

•

•

•

(1)

is 180-300 MHz. In case of higher f

VCO

Vendor Identification

Not

allowed

•

•

•

(1)

(1)

(2)

, this bit has to be set to [1].

VCO

(2) (3)

(2) (3)

16 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Product Folder Link(s): CDCE906

Page 17

www.ti.com

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Byte 9 to 12: Outputs Switch Matrix (5x6 Switch A) PLL Selection for P-Divider P0-P5

SWAPx2 SWAPx1 SWAPx0 Any Output Px Default

0 0 0 PLL bypass (input clock)

0 0 1 PLL1 P2, P3, P4, P5

0 1 0 PLL2 non-SSC P0

0 1 1 PLL2 w/ SSC

1 0 0 PLL3 P1

1 0 1 Reserved

1 1 0 Reserved

1 1 1 Reserved

(1) Unless customer specific setting.

(2) PLL2 has a SSC output and non-SSC output. If SSC bypass is selected (see Byte 25, Bit [6:4]), the SSC circuitry of PLL2 is

powered-down and the SSC output is reset to logic low. The non-SSC output of PLL2 is not affected by this mode and can still be used.

Byte 10, Bit [1:0]: Configuration Settings of Input S0/A0/CLK_SEL

S01 S00 Function Default

0 0

If S0 is low, the PLLs and the clock-input stage are going into power-down mode, outputs are in Yes

3-state, all actual register settings will be maintained, SMBus stays active

If S0 is low, the PLL and all dividers (M-Div and P-Div) are bypassed and PLL is in power-down,

0 1 all outputs are active (inv. or non-inv.), actual register settings will be maintained, SMBus stays

active; this mode is useful for production test;

CLK_SEL (input clock selection — overwrites the CLK_SEL setting in Byte 10, Bit [4])

1 0 — CLK_SEL is set low selects CLK_IN_IN0

— CLK_SEL is set high selects CLK_IN_IN1

1 1

In this mode, the control input S0 is interpreted as address bit A0 of the slave receiver address

(4)

byte

(1) Unless customer specific setting.

(2) Power-down mode overwrites 3-state or low-state of S1 setting in Byte 10, Bit [3:2].

(3) If the clock input (CLK_IN0/CLK_IN1) is selected as crystal input or differential clock input (Byte 11, Bit [7:6]) then this setting is not

relevant.

(4) To use this pin as Slave Receiver Address Bit A0, an Initialization pattern needs to be sent to CDCE906. When S00/S01 is set to be 1,

the S0 input pin will be interpreted in the next read or write cycle as the Address Bit A0 of the Slave Receiver Address Byte. Note that

right after the Byte 10 (S00/S01) has been written, A0 (via S0-pin) will immediately be active (also when Byte 10 is sent within a block

write sequence). After the Initialization each CDCE906 has its own S0 dependent Slave Receiver Address and can be addressed

accordingly to their new valid address.

Byte 10, Bit [3:2]: Configuration Settings of Input S1/A1

S11 S10 Function Default

0 0 If S1 is set low, all outputs are switched to a low-state (non-inv.) or high-state (inv.); Yes

0 1 If S1 is set low, all outputs are switched to a 3-state

1 0 Reserved

1 1

In this mode, the control input S1 is interpreted as Address Bit A1 of the Slave Receiver Address

(2)

Byte

(1) Unless customer specific setting.

(2) To use this pin as Slave Receiver Address Bit A1, an Initialization pattern needs to be sent to CDCE906. When S10/S11 is set to be 1,

the S1 input pin will be interpreted in the next read or write cycle as the Address Bit A1 of the Slave Receiver Address Byte. Note that

right after the Byte 10 (S10/S11) has been written, A1 (via S1-pin) will immediately be active (also when Byte 10 is sent within a block

write sequence). After the Initialization each CDCE906 has its own S1 dependent Slave Receiver Address and can be addressed

accordingly to their new valid address.

Byte 10, Bit [4]: Input Clock Selection

(1)

CLKSEL Input Clock Default

0 CLK_IN0 Yes

1 CLK_IN1

(1) This bit is not relevant, if crystal input or differential clock input is selected, Byte 11, Bit [7:6].

(2) Unless customer specific setting.

(2)

(2)

(3)

(2)

(1)

(1)

(1)

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Link(s): CDCE906

Page 18

www.ti.com

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Byte 11, Bit [7:6]: Input Signal Source

(1)

IS1 IS0 Function Default

0 0 CLK_IN0 is Crystal Oscillator Input and CLK_IN1 is serving as Crystal Oscillator Output. Yes

0 1

CLK_IN0 and CLK_IN1 are two LVCMOS Inputs. CLK_IN0 or CLK_IN1 are selectable via

CLK_SEL control pin.

1 0 CLK_IN0 and CLK_IN1 serve as differential signal inputs.

1 1 Reserved

(1) In case the crystal input or differential clock input is selected, the input clock selection, Byte 10, Bit [4], is not relevant.

(2) Unless customer specific setting.

Byte 12, Bit [6]: Power-Down Mode (except SMBus)

PD Power-Down Mode Default

0 Normal Device Operation Yes

1 Power Down

(2)

(1) Unless customer specific setting.

(2) In power down, all PLLs and the Clock-Input-Stage are going into power-down mode, all outputs are in 3-State, all actual register

settings will be maintained and SMBus stays active. Power-Down Mode overwrites 3-State or Low-State of S0 and S1 setting in Byte 10.

Byte 13 to 18, Bit [6:0]: Outputs Switch Matrix - 6x7-Bit Divider P0-P5

DIVYx6 DIVYx5 DIVYx4 DIVYx3 DIVYx2 DIVYx1 DIVYx0 Div by Default

0 0 0 0 0 0 0 Not allowed

0 0 0 0 0 0 1 1

0 0 0 0 0 1 0 2

•

•

•

1 1 1 1 1 0 1 125

1 1 1 1 1 1 0 126

1 1 1 1 1 1 1 127

(1) Unless customer specific setting.

(2) Default setting of divider P0 = 10, P1 = 20, P2 = 8, P3 = 9, P4 = 32, and P5 = 4

Byte 19 to 24, Bit [5:4]: LVCMOS Output Rise/Fall Time Setting at Y0-Y5

SRCYx1 SRCYx0 Yx Default

0 0 Nominal +3 ns (tr0/tf0)

0 1 Nominal +2 ns (tr1/tf1)

1 0 Nominal +1 ns (tr2/tf2)

1 1 Nominal (tr3/tf3) Yes

(1) Unless customer specific setting.

Byte 19 to 24, Bit [2:0]: Outputs Switch Matrix (6 x 6 Switch B) Divider (P0-P5) Selection for Outputs Y0-Y5

SWBYx2 SWBYx1 SWBYx0 Any Output Yx Default

0 0 0 Divider P0

0 0 1 Divider P1

0 1 0 Divider P2 Y0, Y1, Y2, Y3, Y4, Y5

0 1 1 Divider P3

1 0 0 Divider P4

1 0 1 Divider P5

1 1 0 Reserved

1 1 1 Reserved

(1) Unless customer specific setting.

(2)

(1)

(1) (2)

(1)

(1)

18 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Product Folder Link(s): CDCE906

Page 19

www.ti.com

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Byte 19 to 24, Bit [3]: Output Y0-Y5 Enable or Low-State

ENDISYx Output Yx Default

0 Disable to low

1 Enable Yes

(1) Unless customer specific setting.

Byte 19 to 24, Bit [6]: Output Y0-Y5 Non-Inverting/Inverting

INVYx Output Yx Status Default

0 Non-inverting Yes

1 Inverting

(1) Unless customer specific setting.

Byte 24, Bit [7] (read only): EEPROM Programming In Process Status

(1)

EEPIP Indicate EEPROM Write Process Default

0 No programming

1 Programming in process

(1) This read only Bit indicates an EEPROM write process. It is set to high if programming starts and resets to low if programming is

completed. Any data written to the EEPIP-Bit will be ignored. During programming, no data are allowed to be sent to the device via the

SMBus until the programming sequence is completed. Data, however, can be readout during the programming sequence (Byte Read or

Block Read).

Byte 25, Bit [3:0]: SSC Modulation Frequency Selection in the Range of 30 kHz 60 kHz

FSSC3 FSSC2 FSSC1 FSSC0 Modulation f

0 0 0 0 5680 f

0 0 0 1 5412 18.5 20.3 22.2 24.0 25.9 27.7 29.6 30.9

0 0 1 0 5144 19.4 21.4 23.3 25.3 27.2 29.2 31.1 32.5

0 0 1 1 4876 20.5 22.6 24.6 26.7 28.7 30.8 32.8 34.2

0 1 0 0 4608 21.7 23.9 26.0 28.2 30.4 32.6 34.7 36.2

0 1 0 1 4340 23.0 25.3 27.6 30.0 32.3 34.6 36.9 38.5

0 1 1 0 4072 24.6 27.0 29.5 31.9 34.4 36.8 39.3 41.0

0 1 1 1 3804 26.3 28.9 31.5 34.2 36.8 39.4 42.1 43.9

1 0 0 0 3536 28.3 31.1 33.9 36.8 39.6 42.4 45.2 47.2

1 0 0 1 3286 30.4 33.5 36.5 39.6 42.6 45.6 48.7 50.8 Yes

1 0 1 0 3000 33.3 36.7 40.0 43.3 46.7 50.0 53.3 55.7

1 0 1 1 2732 36.6 40.3 43.9 47.6 51.2 54.9 58.6 61.1

1 1 0 0 2464 40.6 44.6 48.7 52.8 56.8 60.9 64.9 67.8

1 1 0 1 2196 45.5 50.1 54.6 59.2 63.8 68.3 72.9 76.0

1 1 1 0 1928 51.9 57.1 62.2 67.4 72.6 77.8 83.0 86.6

1 1 1 1 1660 60.2 66.3 72.3 78.3 84.3 90.4 96.4 100.6

Factor

mod

[kHz]

100 110 120 130 140 150 160 167

17.6 19.4 21.1 22.9 24.6 26.4 28.2 29.4

(1)

[MHz] Default

vco

(1) The PLL has to be bypassed (turned off) when changing SSC Modulation Frequency Factor on-the-fly. This can be done by following

programming sequence: bypass PLL2 (Byte 3, Bit 6 = 1); write new Modulation Factor (Byte 25); re-activate PLL2 (Byte 3, Bit 6 = 0).

(2) Unless customer specific setting.

(1)

(1)

(2)

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Link(s): CDCE906

Page 20

www.ti.com

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Byte 25, Bit [6:4]: SSC Modulation Amount

(1)

SSC2 SSC1 SSC0 Function Default

0 0 0 SSC Modulation Amount 0% = SSC bypass for PLL

(3)

Yes

0 0 1 SSC Modulation Amount ± 0.1% (center spread)

0 1 0 SSC Modulation Amount ± 0.25% (center spread)

0 1 1 SSC Modulation Amount ± 0.4% (center spread)

1 0 0 SSC Modulation Amount 1% (down spread)

1 0 1 SSC Modulation Amount 1.5% (down spread)

1 1 0 SSC Modulation Amount 2% (down spread)

1 1 1 SSC Modulation Amount 3% (down spread)

(1) The PLL has to be bypassed (turned off) when changing SSC Modulation Amount on-the-fly. This can be done by following

programming sequence: bypass PLL2 (Byte 3, Bit 6 = 1); write new Modulation Amount (Byte 25); re-activate PLL2 (Byte 3, Bit 6 = 0).

(2) Unless customer specific setting.

(3) If SSC bypass is selected, SSC circuitry of PLL2 is powered-down and the SSC output is reset to logic low. The non-SSC output of

PLL2 is not affected by this mode and can still be used.

Byte 25, Bit [7]: Permanently Lock EEPROM-Data

EELOCK Permanently Lock EEPROM

(1)

(2)

Default

0 No Yes

1 Yes

(1) If this bit is set, the actual data in the EEPROM will be permanently locked. There is no further programming possible, even this bit is set

low. Data, however can still be written via SMBUS to the internal register to change device function on the fly. But new data no longer

can be stored into the EEPROM.

(2) Unless customer specific setting.

Byte 26, Bit [6:0]: Byte Count

(1)

BC6 BC5 BC4 BC3 BC2 BC1 BC0 No. of Bytes Default

0 0 0 0 0 0 0 Not allowed

0 0 0 0 0 0 1 1

0 0 0 0 0 1 0 2

0 0 0 0 0 1 1 3

•

•

•

0 0 1 1 0 1 1 27 Yes

•

•

•

1 1 1 1 1 0 1 125

1 1 1 1 1 1 0 126

1 1 1 1 1 1 1 127

(1) Defines the number of Bytes, which will be sent from this device at the next Block Read protocol.

(2) Unless customer specific setting.

Byte 26, Bit [7]: Initiate EEPROM Write Cycle

EEWRITE Starts EEPROM Write Cycle Default

(1)

(2)

0 No Yes

1 Yes

(1) The EEPROM WRITE cycle is initiated with the rising edge of the EEWRITE-Bit. A static level high does not trigger an EEPROM WRITE

cycle. This bit stays high until the user reset it to low (it will not automatically be reset after the programming has been completed).

Therefore, to initiate an EEPROM WRITE cycle, it is recommended to send a zero-one sequence to the EEWRITE bit in Byte 26.

During EEPROM programming, no data are allowed to be sent to the device via the SMBus until the programming sequence has been

completed. Data, however, can be readout during the programming sequence (Byte Read or Block Read). The programming status can

be monitored by readout EEPIP, Byte 24 – Bit 7. If EELOCK is set, no EEPROM programming will be possible.

(2) Unless customer specific setting.

(2)

(2)

20 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Product Folder Link(s): CDCE906

Page 21

www.ti.com

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

FUNCTIONAL DESCRIPTION

Zero ppm Audio and Video System Clock Generation and Divider Setting

The CDCE906 is ideally suited for audio and video applications. It consists of a triple PLL clock generator which

generates up to six audio, video and system clocks from i.e. a 27-MHz master clock. The output frequencies are

programmable to meet different application requirements. The master clock can be either a crystal oscillator or

an external input clock signal. The CDCE906 provides a very low jitter, high accuracy clock with zero ppm for the

common audio and video clocks. The following table shows the system clocks versus the standard sampling

frequency and the corresponding divider settings.

Audio Rate fs x 256 fs x 384

[kHz] [MHz] [MHz]

16 4.096 375 2048 36 0 6.144 125 768 27 0

22.05 5.6448 75 392 25 0 8.4672 125 588 15 0

24 6.144 125 768 27 0 9.216 125 768 18 0

32 8.192 375 2048 18 0 12.288 375 2048 12 0

44.1 11.2896 375 1568 10 0 16.9344 125 784 10 0

48 12.288 375 2048 12 0 18.432 125 768 9 0

96 24.576 375 2048 6 0 36.864 375 2048 4 0

Divider Divider

M N P M N P

Error ppm Error ppm

Audio Rate fs x 512 fs x 768

[kHz] [MHz] [MHz]

16 8.192 375 2048 18 0 12.288 375 2048 12 0

22.05 11.2896 375 1568 10 0 16.9344 125 784 10 0

24 12.288 375 2048 12 0 18.432 125 768 9 0

32 16.384 375 2048 9 0 24.576 375 2048 6 0

44.1 22.5792 375 1568 5 0 33.8688 125 784 5 0

48 24.576 375 2048 6 0 36.864 375 2048 4 0

96 49.152 375 2048 3 0 73.728 375 2048 2 0

Divider Divider

M N P M N P

Error ppm Error ppm

NOTE: Input frequency is 27 MHz.

Video Divider Divider Divider

Rate

[MHz]

27 54 1 8 4 0 27 - - 1 0 13.5 - - 2 0

2 Error 1 Error 0.5 Error

[MHz] ppm [MHz] ppm [MHz] ppm

M N P M N P M N P

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Link(s): CDCE906

Page 22

www.ti.com

27 MHz

Crystal

CDCE906

16.9344 MHz (384fs)

33.8688 MHz (768fs)

11.2896 MHz (256fs)

27 MHz

DVD−DSP

MPEG/AC−3

Audio Dec

Karaoke

DSP

PCM1716

Front

Surround

Center

Subwoofer

CPU Clock

64 MHz

i.e. audio rate: 44.1 kHz

XO

or

2LVCMOS

or

Differential

Input

CLK_IN0

CLK_IN1

Input source select

(from EEPROM)

C

X0

C

X1

crystal

unit

C

ICB

C

ICB

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Typical applications for the CDCE906 are digital HDTV systems, gaming consoles, DVD players, DVD add-on

cards for multimedia PCs, and step-top boxes.

Figure 14. CDCE906 System Application Block Diagram

Clock Inputs (CLK_IN0 and CLK_IN1)

The CDCE906 features two clock inputs which can be used as:

• Crystal oscillator input (default setting)

• Two independent single-ended LVCMOS inputs

• Differential signal input

The dedicated clock input can be selected by the input signal source Bit [7:6] of Byte 11.

Crystal Oscillator Inputs

The input frequency range in crystal mode is 8 MHz to 54 MHz. The CDCE906 uses a Pierce-type oscillator

circuitry with included feedback resistance for the inverting amplifier. The user, however, has to add external

capacitors C

, C

X0

) to match the input load capacitor from the crystal (see Figure 15 ). The required values can

X1

be calculated:

C

= C

where C

X0

= 2 × CL– C

X1

is the crystal load capacitor as specified for the crystal unit and C

L

,

ICB

is the input capacitance of the

ICB

device including the board capacitance (stray capacitance of PCB).

For example, for a fundamental 27-MHz crystal with C

C

= C

X0

= (2 × 9 pF) – 3 pF = 15 pF.

X1

of 9 pF and C

L

of 4 pF,

ICB

It is important to use a short PCB trace from the device to the crystal unit to keep the stray capacitance of the

oscillator loop to a minimum.

22 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Figure 15. Crystal Input Circuitry

Product Folder Link(s): CDCE906

Page 23

www.ti.com

0

10

20

30

40

50

60

70

80

90

100

5 10 15 20 25 30 35 40 45 50 55

C=18pF

Upk=300mV

Frequency − MHz

P

drive

− W

21 W

ESR=60

ESR=50

ESR=40

ESR=30

ESR=25

ESR=15

XO

or

2LVCMOS

or

Differential

input

CLK_IN0

CLK_IN1

CLK_SEL

(A)

Input Source Select

(From EEPROM)

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

In order to ensure a stable oscillating, a certain drive power must be applied. The CDCE906 features an input

oscillator with adaptive gain control which relieves the user to manually program the gain. The drive level is the

amount of power dissipated by the oscillating crystal unit and is usually specified in terms of power dissipated by

the resonator (equivalent series resistance (ESR)). Figure 16 gives the resulting drive level vs crystal frequency

and ESR.

Figure 16. Crystal Drive Power

For example, if a 27-MHz crystal with ESR of 50 Ω is used and 2 × C

is 18 pF, the drive power is 21 µ W. Drive

L

level should be held to a minimum to avoid over driving the crystal. The maximum power dissipation is specified

for each type of crystal in the oscillator specifications, i.e., 100 µ W for the example above.

Single-Ended LVCMOS Clock Inputs

When selecting the LVCMOS clock mode, CLK_IN0 and CLK_IN1 act as regular clock inputs pins and can be

driven up to 167 MHz. Both clock inputs circuitry are equal in design and can be used independently to each

other (see Figure 17 ). The internal clock select bit, Byte 10, Bit [4], selects one of the two input clocks. CLK_IN0

is the default selection. There is also the option to program the external control pin S0/A0/CLK_SEL as clock

select pin, Byte 10, Bit [1:0].

The two clock inputs can be used for redundancy switching, i.e. to switch between a primary clock and

secondary clock. Note a phase difference between the clock inputs may require PLL correction. Also in case of

different frequencies between the primary and secondary clock, the PLL has to re-lock to the new frequency.

A. CLK_SEL is optional and can be configured by EEPROM setting.

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 23

Figure 17. LVCMOS Clock Input Circuitry

Product Folder Link(s): CDCE906

Page 24

www.ti.com

XO

or

2LVCMOS

or

Differential

input

CLK_IN0

CLK_IN1

Input source select

(from EEPROM)

MUX

9−Bit Divider M

1 .. 511

PLLx

12−Bit Divider N

1 .. 4095

PFD

Filter

VCO

SSC

(PLL2 only)

Input Clock

Programming

PLL output

SSC output

(PLL2 Only)

VCO Bypass

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Differential Clock Inputs

The CDCE906 supports differential signaling as well. In this mode, CLK_IN0 and CLK_IN1 pin serve as

differential signal inputs and can be driven up to 167 MHz.

The minimum magnitude of the differential input voltage is 100 mV over a differential common-mode input

voltage range of 200 mV to V

structure is recommended to adjust the different physical layers (see Figure 18 ). The capacitor removes the dc

component of the signal (common-mode voltage), while the ac component (voltage swing) is passed on. A

resistor pull-up and/or pull-down network represents the biasing structure used to set the common-mode voltage

on the receiver side of the ac-coupling capacitor. DC coupling is also possible.

– 0.6. If LVDS or LVPECL signal levels are applied, ac-coupling and a biasing

CC

Figure 18. Differential Clock Input Circuitry

PLL Configuration and Setting

The CDCE906 includes three PLLs which are equal in function and performance. Except PLL2 which in addition

supports spread spectrum clocking (SSC) generation. Figure 19 shows the block diagram of the PLL.

Figure 19. PLL Architecture

All three PLLs are designed for easiest configuration. The user just has to define the input and output

frequencies or the divider (M, N, P) setting respectively. All other parameters, such as charge-pump current, filter

components, phase margin, or loop bandwidth are controlled and set by the device itself. This assures optimized

jitter attenuation and loop stability.

The PLL support normal-speed mode (80 MHz ≤ f

MHz) which can be selected by PLLxFVCO (Bit [7:5] of Byte 6). The respective speed option assures stable

operation and lowest jitter.

The divider M and divider N operates internally as fractional divider for f

divider ratio for zero ppm output clock error.

In case of f

For optimized jitter performance, keep divider M as small as possible. Also, the fractional divider concept

requires a PLL divider configuration, M ≤ N (or N/M ≥ 1).

24 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

VCO

> 250 MHz, it is recommended that integer factors of N/M are used only.

Product Folder Link(s): CDCE906

≤ 200 MHz) and high-speed mode (180 MHz ≤ f

VCO

up to 250 MHz. This allows fractional

VCO

≤ 300

VCO

Page 25

www.ti.com

Down Spread 3%

9thHarmonic, fm = 60 kHz

11.3dB

7dB

Center Spread+0.4%

9thHarmonic, fm = 60 kHz

Down Spread 3%

9thHarmonic, fm = 60

11.3dB11.3 dB

7dB7 dB

Center Spread+0.4%

9thHarmonic, fm = 60

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Additionally, each PLL supports two bypass options:

• PLL Bypass and

• VCO Bypass

In PLL bypass mode, the PLL completely is bypassed, so that the input clock is switched directly to the

Output-Switch-A (SWAPxx of Byte 9 to12). In the VCO bypass mode, only the VCO of the respective PLL is

bypassed by setting PLLxMUX to 1 (Bit [7:5] of Byte 3). But the divider M still is useable and expands the output

divider by additional 9-bits. This gives a total divider range of M x P = 511 × 127 = 64897. In VCO bypass mode

the respective PLL block is powered down and minimizes current consumption.

Table 3. Example for Divide, Multiplication, and Bypass Operation

Function Equation

Fractional

Integer Factor

VCO bypass f

(1) P-divider of Output-Switch-Matrix is included in the calculation.

(2) Fractional operation for f

(3) Integer operation for f

(2)

(3)

f

= fINx (N/M)/P 30.72 155.52 155.52 16 81 1 5.0625 155.52

OUT

f

= fINx (N/M)/P 27 162 162 1 6 1 6 162

OUT

OUT

VCO

Spread Spectrum Clocking and EMI Reduction

In addition to the basic PLL function, PLL2 supports spread spectrum clocking (SSC) as well. Thus, PLL 2

features two outputs, a SSC output and a non-SSC output. Both outputs can be used in parallel. The mean

phase of the Center Spread SSC modulated signal is equal to the phase of the non-modulated input frequency.

SSC is selected by Output-Switch-A (SWAPxx of Byte 9 to 12).

SSC also is bypass-able (Byte 25, Bit [6:4]), which powers-down the SSC output and set it to logic low state. The

non-SSC output of PLL2 is not affected by this mode and can still be used.

SSC is an effective method to reduce electro-magnetic interference (EMI) noise in high-speed applications. It

reduces the RF energy peak of the clock signal by modulating the frequency and spread the energy of the signal

to a broader frequency range. Because the energy of the clock signal remains constant, a varying frequency that

broadens the overtones necessarily lowers their amplitudes. Figure 20 shows the effect of SSC on a 54-MHz

clock signal for DSP

(1)

= fIN/(M x P) 30.72 0.06 0.06 8 — 64 — —

≤ 250 MHz.

VCO

> 250 MHz.

f

IN

[MHz] [MHz] [MHz]

f

OUT-desired

f

OUT-actual

M N P N/M

Divider f

[MHz]

VCO

The peak amplitude of the modulated clock is 11.3 dB lower than the non-modulated carrier frequency for down

spread and radiated less electro-magnetic energy.

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 25

Figure 20. Spread Spectrum Clocking With Center Spread and Down Spread

Product Folder Link(s): CDCE906

Page 26

www.ti.com

3

4

5

6

7

8

9

10

11

12

30 40 50 60

3% Down Spread

2% Down Spread

fmodulation − kHz

EMI Reduction− dB

+0.4 Center Spread

+0.25 Center Spread

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

In SSC mode, the user can select the SSC modulation amount and SSC modulation frequency. The modulation

amount is the frequency deviation based to the carrier (min/max frequency), whereas the modulation frequency

determines the speed of the frequency variation. In SSC mode, the maximum VCO frequency is limited to 167

MHz.

SSC Modulation Amount

The CDCE906 supports center spread modulation and down spread modulation. In center spread, the clock is

symmetrically shifted around the carrier frequency and can be ± 0.1%, ± 0.25%, and ± 0.4%. At down spread, the

clock frequency is always lower than the carrier frequency and can be 1%, 1.5%, 2%, and 3%. The down spread

is preferred if a system can not tolerate an operating frequency higher than the nominal frequency (over-clocking

problem).

Example:

Modulation Type Minimum Center Maximum

A ± 0.25% center spread 53.865 MHz 54 MHz 54.135 MHz

B 1% down spread 53.46 MHz — 54 MHz

C 0.5% down spread

(1) A down spread of 0.5% of a 54-MHz carrier is equivalent to 59.865 MHz at a center spread of ± 0.25%.

(1)

SSC Modulation Frequency

The modulation frequency (sweep rate) can be selected between 30 kHz and 60 kHz. It is also based on the

VCO frequency as shown in the SSC Modulation Frequency Selection as shown on page 19. As shown in

Figure 21 , the damping increases with higher modulation frequencies. It may be limited by the tracking skew of a

downstream PLL. The CDCE906 uses a triangle modulation profile which is one of the common profiles for SSC.

Frequency Frequency Frequency

53.73 MHz 53.865 MHz 54 MHz

Further EMI Reduction

The optimum damping is a combination of modulation amount, modulation frequency and the harmonics which

are considered. Note that higher order harmonic frequencies results in stronger EMI reduction because of

respective higher frequency deviation.

As seen in Figure 22 and Figure 23 , a slower output slew rate and/or smaller output signal amplitude helps to

reduce EMI emission even more. Both measures reduce the RF energy of clock harmonics. The CDCE906

allows slew rate control in four steps between 0.6 ns and 3.3 ns (Byte 19-24, Bit [5:4]). The output amplitude is

set by the two independent output supply voltage pins, V

Even a lower output supply voltage down to 1.8 V works, but the maximum frequency has to be considered.

26 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Figure 21. EMI Reduction vs f

Product Folder Link(s): CDCE906

and V

and f

Amount

, and can vary from 2.3 V to 3.6 V.

CCOUT2

Modulation

CCOUT1

Page 27

www.ti.com

11.3dB

7dB

11.3dB11.3dB

7dB7dB

nom−1

nom

nom+2

−3dB

6.4dB

nom−1

nom

nom+2

−2.5dB

5.6dB

Slew-Rate for V

CCOUT

= 2.5 V Slew-Rate for V

CCOUT

= 3.3 V

−1

0

1

2

3

4

5

3.6 V3 V2.5 V

V

CCOUT

EMI Reduction − dB

(Relative to Nom)

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Figure 22. EMI Reduction vs Slew-Rate and V

Figure 23. EMI Reduction vs V

ccout

ccout

Multi-Function Control Inputs S0 and S1

The CDCE906 features two user definable inputs pins which can be used as external control pins or address

pins. When programmed as control pins, they can function as clock select pin, enable/disable pin or device

power-down pin. If both pins used as address-bits, up to four devices can be connected to the same SMBus. The

respective function is set in Byte 10; Bit [3:0]. Table 4 shows the possible setting for the different output

conditions, clock select and device addresses.

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Link(s): CDCE906

Page 28

www.ti.com

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Table 4. Configuration Setting of Control Inputs

Configuration Bits

Byte 10, Byte 10,

Bit [3:2] Bit [1:0]

S11 S10 S01 S00 S1 S0 Yx Outputs Power Pin 2 Pin 1

0 X 0 X 1 1 Active No Output ctrl Output ctrl

0 0 0 X 0 1 Low/High

0 1 0 X 0 1 3-State Outputs only Output ctrl Output ctrl

0 X 0 0 X 0 3-State PLL, inputs and outputs Output ctrl Output ctrl and pd

0 X 0 1 0 0 S10=0: low/high

0 X 0 1 1 0 Active PLL only Output ctrl PLL and Div bypass

0 X 1 0 0 0/1

0 X 1 0 1 0/1

1 1 1 1 X X Active No A1

(1) A non-inverting output will be set to low and an inverting output will be set to high.

(2) If S0 is 0, CLK_IN0 is selected; if S0 is 1, CLK_IN1 is selected.

(3) S0 and S1 are interpreted as Address Bit A0 and A1 of the Slave Receiver Address Byte.

External Control Pins Device Function

(Pin 2) (Pin 1) Down

(1)

(1)

S10=1: 3-State

(2)

(2)

S10=0: Low/High

S10=1: 3-State

Active No Output ctrl CLK_SEL

(1)

No Output ctrl Output ctrl

PLL only Output ctrl PLL and Div bypass

No Output ctrl CLK_SEL

(3)

(3)

A0

As shown in Table 4 , there is a specific order of the different output condition: Power-down mode overwrites

3-state, 3-state overwrites low-state, and low-state overwrites active-state.

Output Switching Matrix

The flexible architecture of the output switch matrix allows the user to switch any of the internal clock signal

sources via a free-selectable post-divider to any of the six outputs.

As shown in Figure 24 , the CDCE906 is based on two banks of switches and six post-dividers. Switch A

comprises six 5-Input-Muxes which selects one of the four PLL clock outputs or directly selects the input clock

and feed it to one of the 7-bit post-divider (P-Divider). Switch B is made up of six 6-Input-Muxes which takes any

post-divider and feeds it to one of the six outputs, Yx.

Switch B was added to the output switch matrix to ensure that outputs frequencies derive from one P-divider are

100% phase aligned. Also, the P-divider is built in a way that every divide factor is automatically duty-cycle

corrected. Changing the divider value on the fly may cause a glitch on the output.

28 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Product Folder Link(s): CDCE906

Page 29

www.ti.com

5x6 − Switch A

Input CLK

(PLL Bypass)

PLL 1

PLL 2

non SSC

PLL 2

w/ SSC

PLL 3

6x6 − Switch B

7-Bit Divider

Y0

Y1

Y2

Y3

Y4

Y5

Output Switch Matrix

P0

(1..127)

P2

(1..127)

P3

(1..127)

P4

(1..127)

P5

(1..127)

Programming

OutputsInternal Clock Sources

PLL/Input_Clk

Selection

P-Divider

Selection

Output Selection:

Active/Low/3-State/

Inverting/Non-Inverting

P-Divider

Setting

P1

(1..127)

Slew Rate/V

CCOUT

Inverting

Slew Rate

Low Select

Enable/Disable

Clock

div by 3

Buffer

Sel

M

U

X

P−div(0) output

P−div(1) output

P−div(2) output

P−div(3) output

P−div(4) output

P−div(5) output

Yx

S1

Inversion Select

Slew-Rate Control

Low Select

Enable/Disable

P−Divider Select

(Optional all

outputs low

or 3−State)

V

CCOUT1/VCCOUT2

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Figure 24. CDCE906 Output Switch Matrix

In addition, the outputs can be switched active, low or 3-state and/or 180 degree phase shifted. Also the outputs

slew-rate and the output-voltage is user selectable.

LVCMOS Output Configuration

The output stage of the CDCE906 supports all common output setting, such as enable, disable, low-state and

signal inversion (180 degree phase shift). It further features slew-rate control (0.6 ns to 3.3 ns) and variable

output supply voltage (2.3 V to 3.6 V).

Figure 25. Block Diagram of Output Architecture Figure 26. Example for Output Waveforms

All output settings are programmable via SMBus:

• enable, disable, low-state via external control pins S0 and S1 → Byte 10, Bit[3:0]

• enable or disable-to-low → Byte 19 to 24, Bit[3]

• inverting/non-inverting → Byte 19 to 24, Bit[6]

• slew-rate control → Byte 19 to 24, Bit[5:4]

• output swing → external pins V

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 29

CCOUT1

(Pin 14) and V

Product Folder Link(s): CDCE906

CCOUT2

(Pin 18)

Page 30

www.ti.com

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Performance Data: Output Skew, Jitter, Cross Coupling, Noise Rejection (Spur-Suppression), and Phase Noise

Output Skew

Skew is an important parameter for clock distribution circuits. It is defined as the time difference between outputs

that are driven by the same input clock. Table 5 shows the output skew (t

and low-to-high transitions over the entire range of supply voltages, operating temperature and output voltage

swing.

Table 5. Output Skew

PARAMETER V

t

sk(o)

ccout

2.5 V 130 250 ps

3.3 V 130 200 ps

TYP MAX UNIT

Jitter Performance

Jitter is a major parameter for PLL-based clock driver circuits. This becomes important as speed increases and

timing budget decreases. The PLL and internal circuits of CDCE906 are designed for lowest jitter. The

peak-to-peak period jitter is only 60 ps (typical). Table 6 gives the peak-to-peak and rms deviation of

cycle-to-cycle jitter, period jitter and phase jitter as taken during characterization.

) of the CDCE906 for high-to-low

sk(o)

Table 6. Jitter Performance of CDCE906

PARAMETER f

t

jit(cc)

t

jit(per)

t

jit(phase)

(1) All typical and maximum values are at V

10000 cycles.

50 MHz 55 – 75 – ps

133 MHz 50 – 85 –

50 MHz 60 4 76 7 ps

133 MHz 55 5 84 11

50 MHz 730 90 840 115 ps

133 MHz 930 130 1310 175

out

= 3.3 V, temperature = 25 ° C, V

CC

(1)

TYP

Peak-Peak rms Peak-Peak rms

(one sigma) (one sigma)

= 3.3 V; one output is switching, data taken over several

ccout

(1)

MAX

UNIT

Figure 27 , Figure 28 , and Figure 29 show the relationship between cycle-to-cycle jitter, period jitter, and phase

jitter over 10000 samples. The jitter varies with a smaller or wider sample window. The cycle-to-cycle jitter and

period jitter show the measured value whereas the phase jitter is the accumulated period jitter.

Cycle-to-Cycle jitter (t

) is the variation in cycle time of a clock signal between adjacent cycles, over a random

jit(cc)

sample of adjacent cycle pairs. Cycle-to-cycle jitter will never be greater than the period jitter. It is also known as

adjacent cycle jitter.

30 Submit Documentation Feedback Copyright © 2005 – 2007, Texas Instruments Incorporated

Product Folder Link(s): CDCE906

Page 31

www.ti.com

−40

−30

−20

−10

0

10

20

30

40

1 1001 2001 3001 4001 5001 6001 7001 8001 9001 10001

Cycle

tjit(cc) [ps]

−25

−20

−15

−10

−5

0

5

10

15

20

25

1 1001 2001 3001 4001 5001 6001 7001 8001 9001 10001

Cycle

tjit(per) [ps]

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Figure 27. Snapshot of Cycle-to-Cycle Jitter

Period jitter (t

) is the deviation in cycle time of a clock signal with respect to the ideal period (1/fo) over a

jit(per)

random sample of cycles. In reference to a PLL, period jitter is the worst-case period deviation from the ideal that

would ever occur on the PLLs outputs. This is also referred to as short-term jitter.

Copyright © 2005 – 2007, Texas Instruments Incorporated Submit Documentation Feedback 31

Figure 28. Snapshot of Period Jitter

Product Folder Link(s): CDCE906

Page 32

www.ti.com

−300

−250

−200

−150

−100

−50

0

50

100

150

200

250

300

1 1001 2001 3001 4001 5001 6001 7001 8001 9001 10001

Cycle

tjit(phase) [ps]

CDCE906

SCAS814H – NOVEMBER 2005 – REVISED DECEMBER 2007

Phase jitter (t