www.DataSheet4U.com

www.ti.com

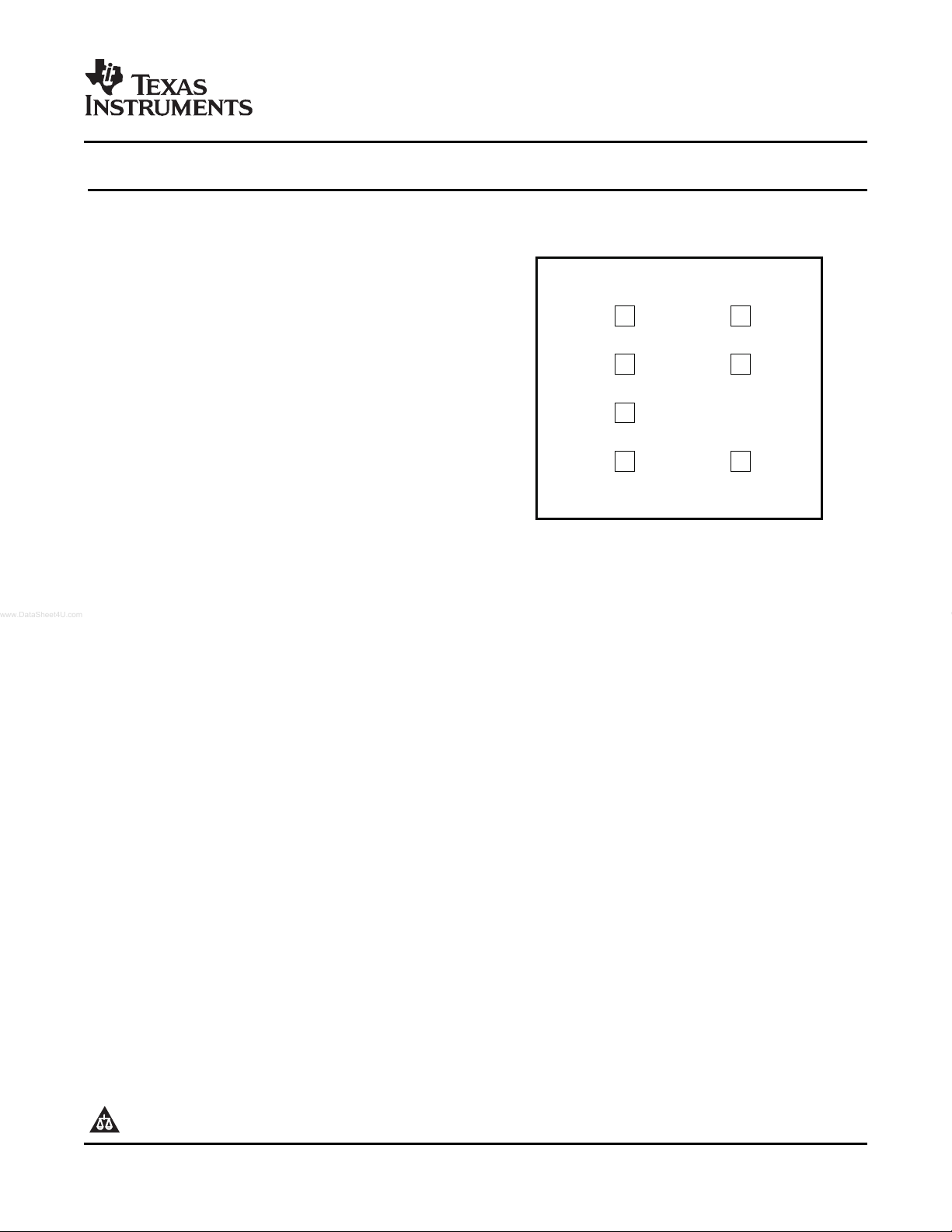

EN

XIN

XOUT

VSS

VDD

FOUT

SDATA

1

2

3

4

5

6

8

» ´1mm 1mm

M0018-03

OSCILLATOR IC WITH ELECTRONIC CALIBRATION

CDCE401

SCAS820 – JUNE 2006

FEATURES

• Oscillator Gain Stage Implemented

• One LVCMOS Frequency Output

• Frequency Range of Oscillator Gain Stage =

20 MHz–100 MHz

• Frequency Range of LVCMOS Output = 0.625

MHz–100 MHz

• Electronic Trimming of Oscillator Using

Capacitance Arrays

• Programmable Post Dividers x, x/2, x/4, x/8,

x/16, x/32

• Nonvolatile Storage of Settings Using

EEPROM Technology

• Easy One-Wire In-Circuit Programming Allows

Programming and Trimming of Oscillator After

Manufacturing

• EEPROM Programming Without the Need to

Apply High Voltage to the Device

• Available as Die

• Small Form Factor From Less Than 1 mm × 1

mm, Allowing the Smallest Form Factor

Available for Today’s and Next-Generation

Oscillators

• Industrial Temperature Range –40°C to 85°C

• Wide VDD Range: 2.25 V up to 3.3 V

• ESD Protection Exceeds JESD22

– >2000-V Human-Body Model (A114-B)

– >200-V Machine Model (A115_A)

– >500-V Charged-Device Model (C101-B.01)

Die Terminal Assignment

(Top View = Bond Pad View)

DESCRIPTION

The CDCE401 is designed to achieve today’s demanding challenges for crystal oscillator modules. The small

form factor of the unpackaged die or the QFN package reduces the space consumption of the device to the

technical minimum level of today’s silicon technology.

The on-die trimming capacitance allows frequency trimming of the oscillator module after the manufacturing

process. Therefore, by doing a post-manufacturing programming, crystal manufacturing tolerances can be

trimmed out.

During power up or with each enabling, the CDCE401 oscillator start-up circuit switches off all oscillator

capacitors (CXI, CXO, CBASE) to maximize negative impedance during start-up. After a certain time

(1/XTAL-frequency × 2

frequency range.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

17

~ 1.311 ms–6.554 ms), the capacitances are connected to tune to the trimmed

Copyright © 2006, Texas Instruments Incorporated

www.ti.com

EN VDD1

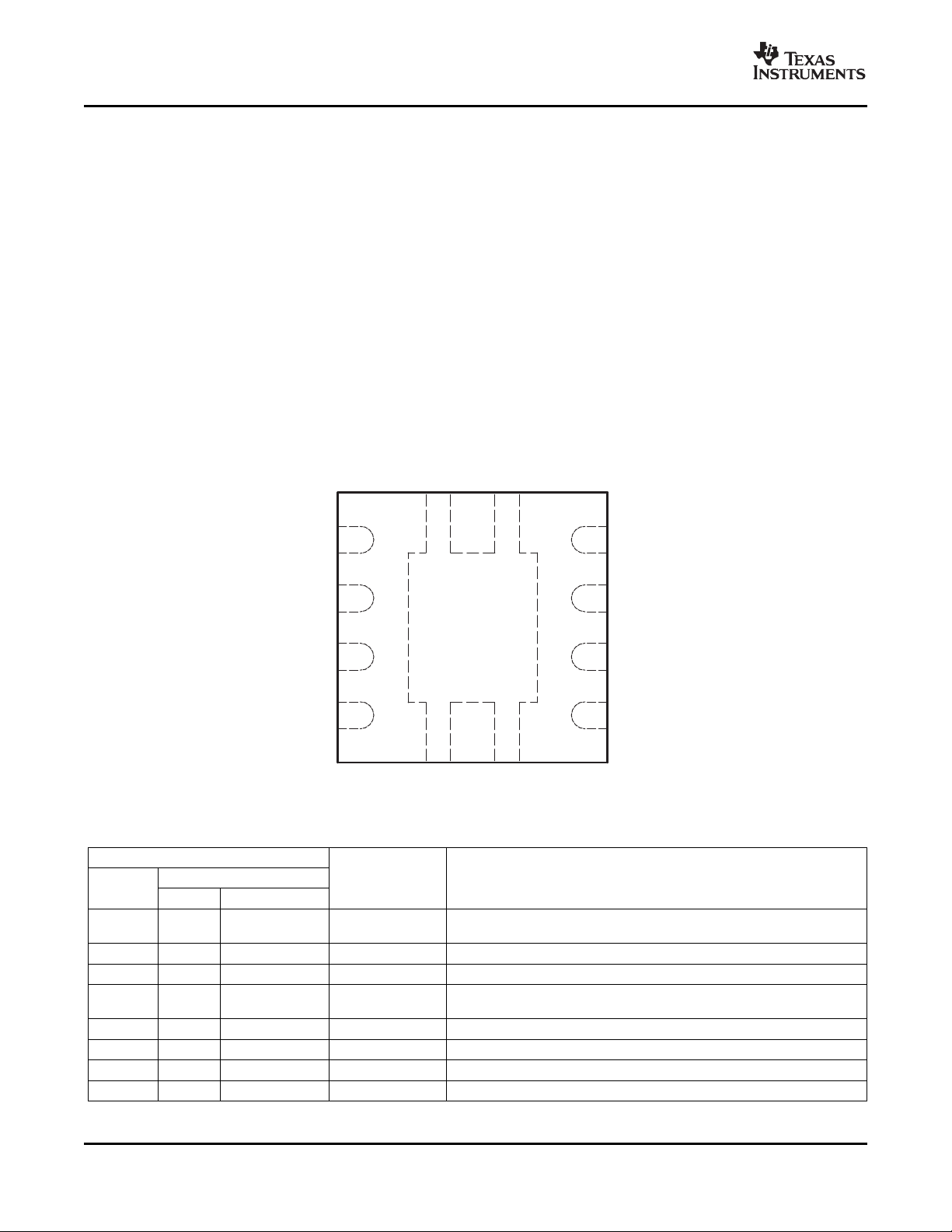

DRB PACKAGE

(TOP VIEW)

NC − No internal connection

2

3

4

8

7

6

5

XIN NC

XOUT SDATA

VSS FOUT

P0012-01

CDCE401

SCAS820 – JUNE 2006

An on-die EEPROM enables nonvolatile storage of the frequency setting. For the transfer of the programming

into the EEPROM, the CDCE401 takes advantage of the SDATA input. In-circuit programming of the device is

possible.

Unlike other EEPROM-based devices, it is not necessary to apply a high supply voltage to the device in order to

program it.

The CDCE401 accepts crystals from 20 MHz up to 100 MHz. For lower frequencies, the CDCE401 provides a

programmable post-divider.

The CDCE401 features a wide supply-voltage range. This makes the device ideal to use at today’s most

commonly used supply voltage of 2.5 V, and operation at supply voltages of 2.8 V, 2.85 V, and 3 V for cellular

applications can be addressed with a single device. Therefore, use of the device in multiple different application

spaces is possible, reducing inventory costs.

The CDCE401 is characterized to work in the industrial temperature range from –40°C to 85°C.

Optional: QFN Package Terminal Assignment

For evaluation purposes, the CDCE401 is also available in a QFN package. The packaged device can be

obtained together with an EVM.

Table 1. TERMINAL FUNCTIONS

TERMINAL

NAME

EN 1 1 Input LVCMOS

FOUT 5 5 Output LVCMOS Frequency output

NC 7 N/A Not connected

SDATA 6 7 Input LVCMOS

VDD 8 8 Power Voltage supply

VSS 4 4 Ground Ground

XIN 2 2 Input oscillator Crystal oscillator input

XOUT 3 3 Output oscillator Crystal oscillator output

2

NUMBER TYPE DESCRIPTION

QFN BOND PAD

Logic select pin. Enables/disables device. Has a hysteresis of 300 mV. A

2-M Ω pullup resistor is built in.

Logic select pin. This input serves as programming input. Has a

hysteresis of 300 mV. A 2-M Ω pullup resistor is built in.

Submit Documentation Feedback

www.ti.com

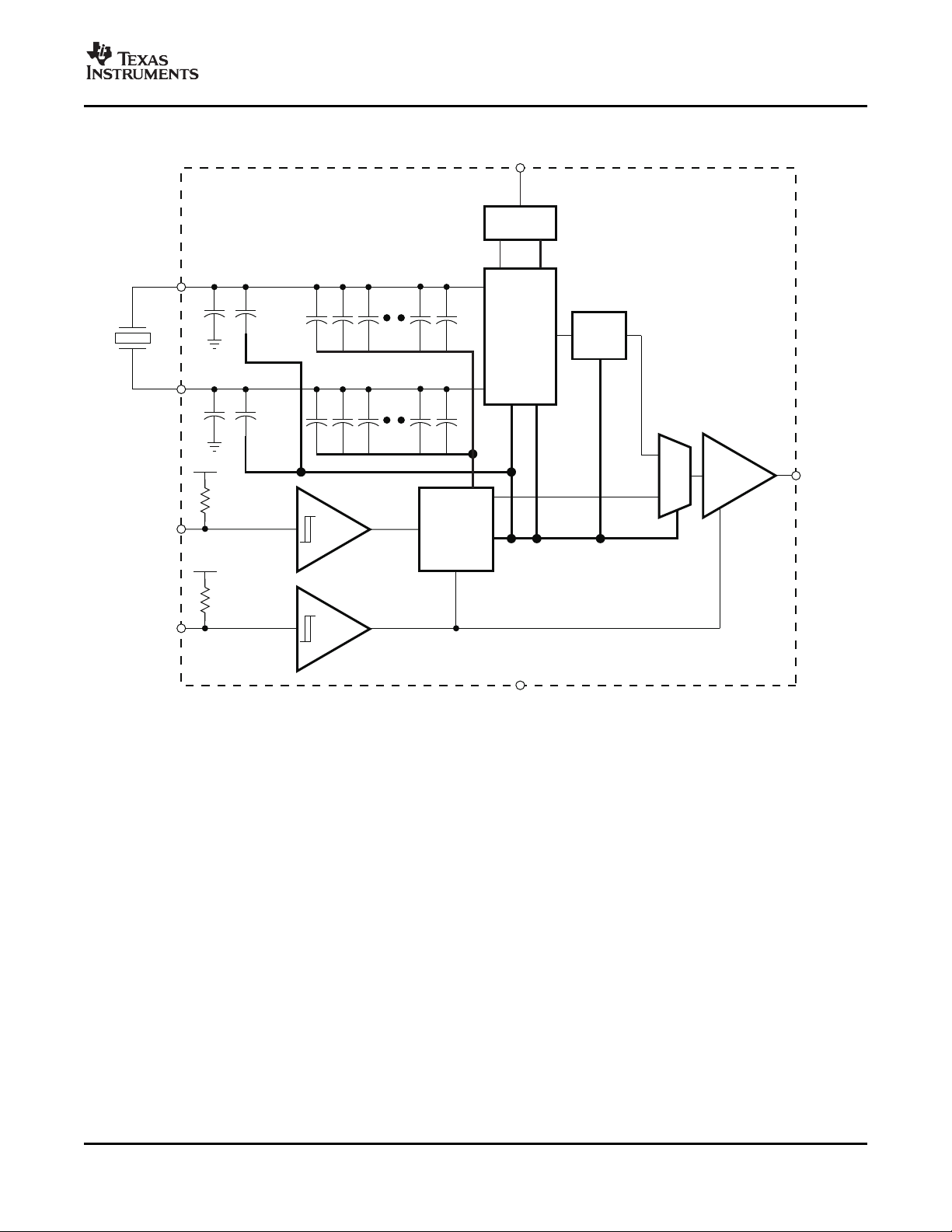

XIN

OG[1:0]

OG[1:0]

OP[2:0]

OG[1:0]

PD[2:0]

EN

FOUT

XOUT

VSS

CXOUT

C

BASE

CXOUT

C

BASE

Var

C

BASE

Var

C

BASE

C

L

C

L

CXO[7:0]

Read-Back

Mode

CXI[7:0]

Oscillator

Gain

Stage

EEPROM

and

Control

Logic

SDATA

2MW

VDD

Divider

P

Bias

M

U

X

2MW

B0027-03

LVCMOS

LVCMOS

LVCMOS

FUNCTIONAL BLOCK DIAGRAM

CDCE401

SCAS820 – JUNE 2006

Submit Documentation Feedback

3

www.ti.com

T0130-01

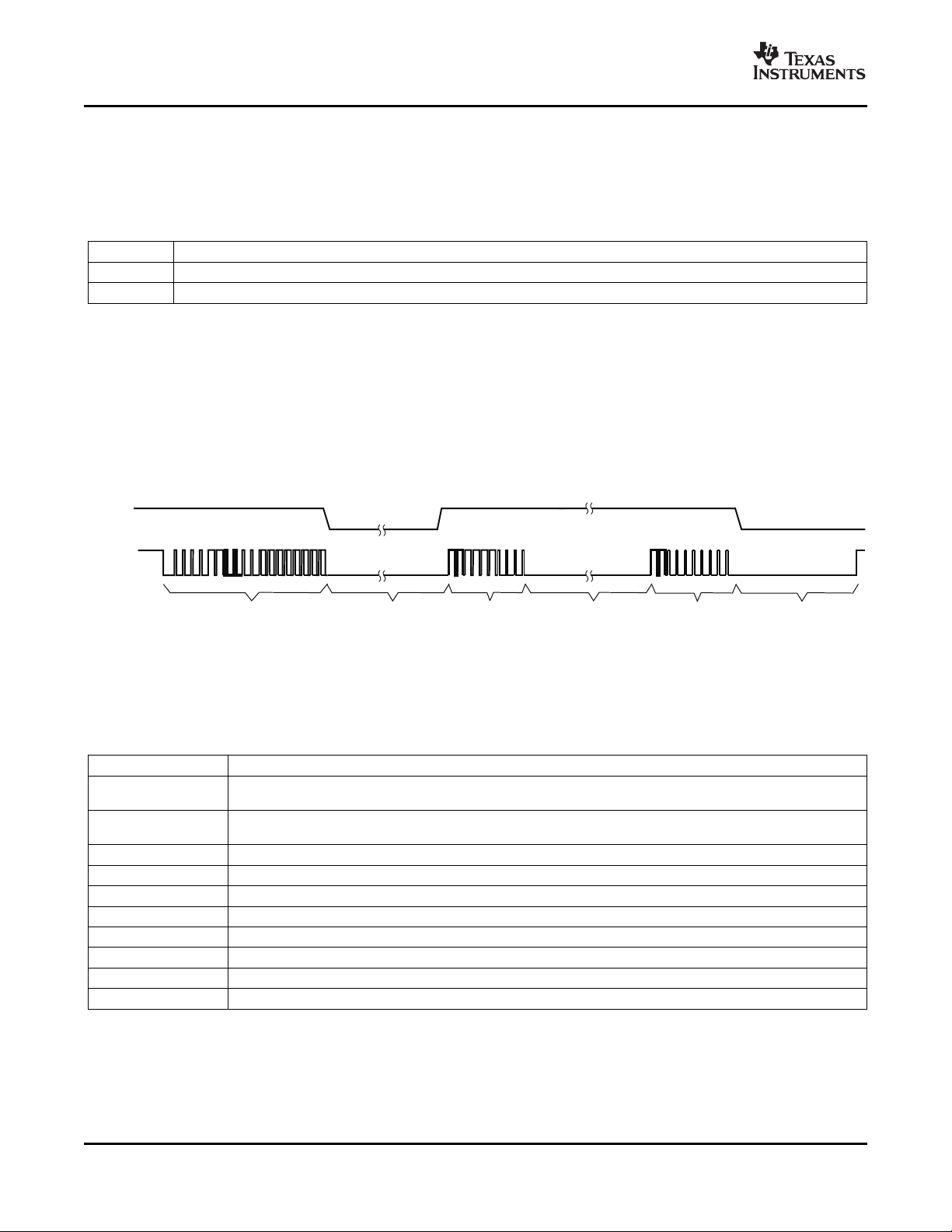

VDD

EnterProgramming

SequenceandWrite

Word0(TrimPPM)

EN/SDATA

Apply Application

VDDandVerify

Settings(Measure)

Perform

StateJump

Into

Program

EEPROM

HoldforMinimum

10msto Achieve

SafeProgramming

JumpFrom

State3 State1®

BackIntoNormal

Application After

200- sLowm

2.25V VDD 3.3V£ £

3.1V VDD 3.3V£ £3.1V VDD 3.3V£ £

2.25V VDD 3.3V£ £

CDCE401

SCAS820 – JUNE 2006

DETAILED DESCRIPTION

CONTROL PIN EN: Enable

The functions of the EN control pin are listed and explained in Table 2 .

Table 2. EN Control Pin Functions

EN FUNCTION

0 Disabled: all current sources are switched off, output is in the high-impedance state.

1 Enabled: output follows the XIN/XOUT oscillation.

SINGLE-PIN INTERFACE CONTROL COMMANDS

The CDCE401 can be configured and programmed via the SDATA input pin. For this purpose, a

pulse-code-shaped signal must be applied to the device as shown in the waveforms of Figure 1 to select one of

the operation modes described in the State Flow-Diagram of the Single-Pin Interface section. During the

EEPROM programming phase, the device requires a stable VDD of 3.2 V ±100 mV for secure writing of the

EEPROM cells. After each Write-to-WordX, the written data is latched, made effective, and offers look-ahead

before the actual data is stored into the EEPROM.

Table 3 summarizes all valid programming commands.

Figure 1. Typical Programming Cycle

Table 3. Single-Pin Interface Control Commands

SDATA FUNCTION

00 1100 Enter register programming mode (state 1 → state 2); bits must be sent in the specified order with the specified

11 1011 Enter register read-back mode; bits must be sent in the specified order with the specified timing. Otherwise a

00 xxxx xxxx Write-to-word0 (state 2)

10 xxxx xxxx Write-to-word1 (state 2)

01 xxxx xxxx Write-to-word2 (state 2)

11 xxxx xxxx State-machine jump: All other patterns not defined as follows cause exit to normal mode.

11 1111 1111 Jump: Exit write-to-RAM (state 2 → state 1)

11 1111 0000 Jump: Enter EEPROM programming without an EEPROM lock (state 2 → state 3)

11 0101 0101 Jump: Enter EEPROM programming with EEPROM lock (state 2 → state 4)

11 0000 0000 Jump: Exit EEPROM programming (state 3 or state 4 → state 1)

(1) Each rising edge causes a bit to be latched.

(2) Between the bits, some longer time delays can occur, but this has no effect on the data.

(3) A Write-to-WordX is expected to be 10 bits long. After the 10

look-ahead function.

timing. Otherwise, a time-out occurs.

time-out occurs.

(1) (2) (3)

(1) (2) (3)

(1) (2) (3)

th

bit, the respective word is latched, and its effect can be observed as

4

Submit Documentation Feedback

www.ti.com

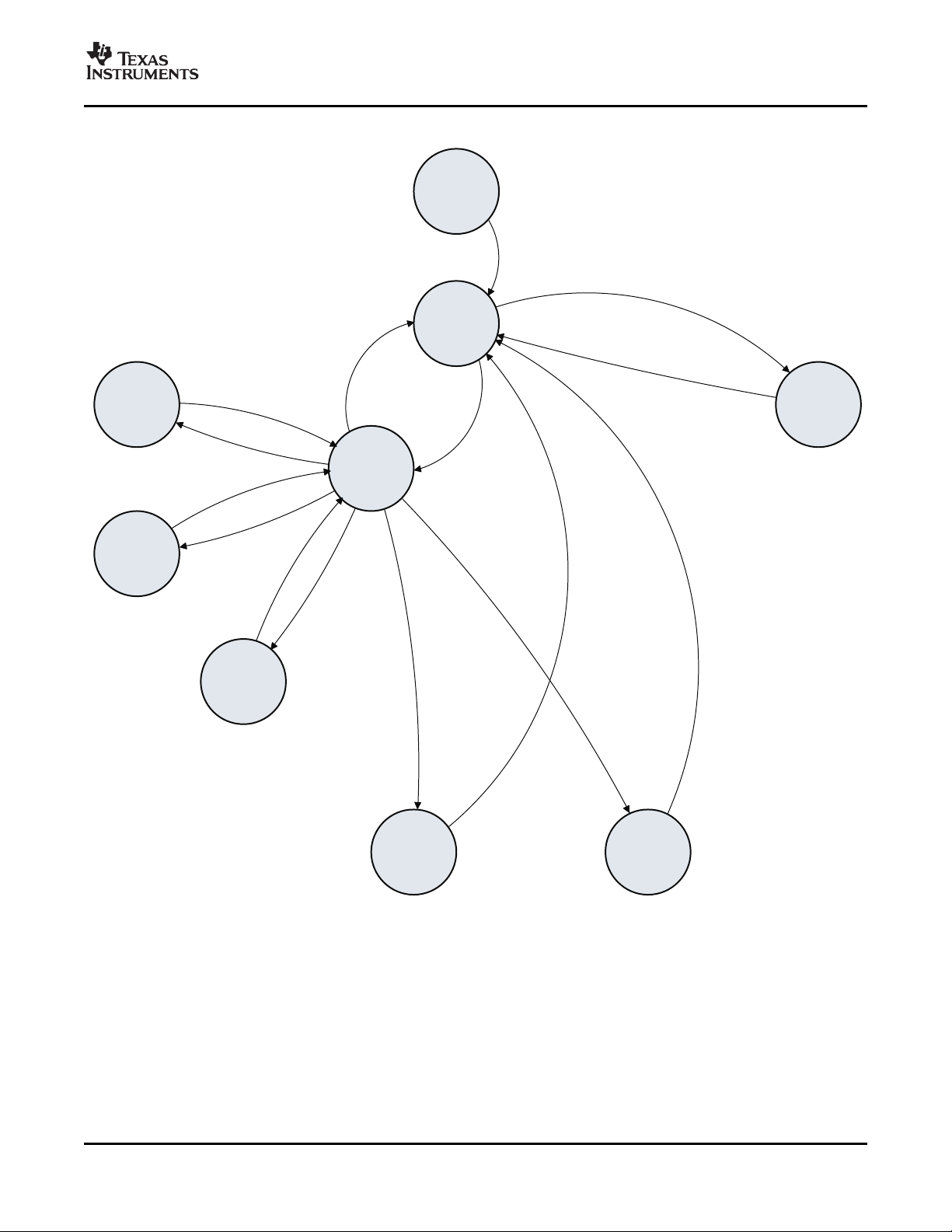

STATE FLOW-DIAGRAM OF THE SINGLE-PIN INTERFACE

F0016-01

PowerUp:

Read

EEPROM

and

Configure

State1: IDLE

Normal

Operation

State2:

Register

Programming

Mode

State3:

Program

EEPROM

NoLocking

State4:

Program

EEPROM

WithLocking

Write

Word2

Write

Word1

Write

Word0

State5:

Register

Read-Back

Mode

Power-UpReset

Completed

SDATA =

1111111111

SDATA =

0000000011

SDATA =

0101010111

SDATA =

1111000011

SDATA =

xxxxxxxx01

SDATA =

xxxxxxxx00

SDATA =

xxxxxxxx10

SDATA =

0000000011

SDATA =

001100

SDATA =

111011

30 Clock

Applied

th

10 Bit

Written

th

10 Bit

Written

th

10 Bit

Written

th

CDCE401

SCAS820 – JUNE 2006

NOTE: In states 2, 3, 4, and 5, the signal pin EN is disregarded and has no influence on power down.

Submit Documentation Feedback

5

www.ti.com

SDATA

EN

0

t

2

DATA

0 1 1 0 0

SDATA

DELAYED

t

1

t

6

t

f

t

5

t

4

t

8

t

r

T0042-03

t

3

t

7

CDCE401

SCAS820 – JUNE 2006

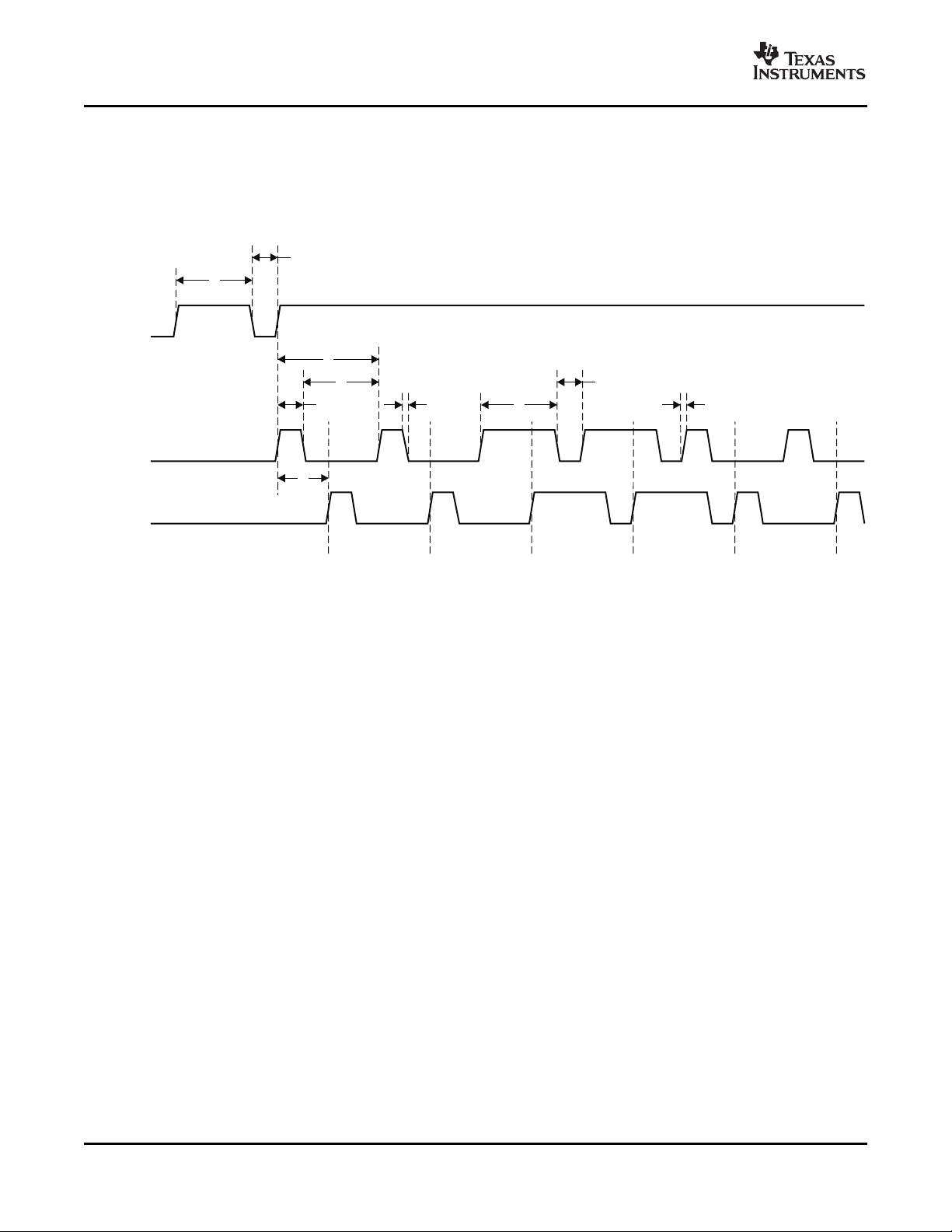

ENTER REGISTER PROGRAMMING MODE

Figure 2 shows the timing behavior of data to be written into SDATA. The sequence shown is 00 1100. If the

high period is as short as t1, this is interpreted as a 0. If the high period is as long as t3, this is interpreted as

a 1. This behavior is achieved by shifting the incoming signal SDATA by time t5into signal SDATA_DELAYED.

As can be seen in Figure 2 , SDATA_DELAYED can be used to latch (or strobe) SDATA. The specification for

the timings t1– t8, tr, and tfare given in the Timing Requirements section of this document.

Figure 2. Timing Diagram for SDATA Programming

6

Submit Documentation Feedback

www.ti.com

EnterProgramming Sequence

Word0

After8bits,thepayload

dataistransferredto

theRAMandisactive.

Waitforatleast

10msbefore

exitingEEPROM

writephase,for

safeoperation.

Payload

Word1

Payload

Word2

Payload

State

Machine

Jump

State

Machine

Jump

State2 ® State3

State3 ® State1

T0043-02

CDCE401

SCAS820 – JUNE 2006

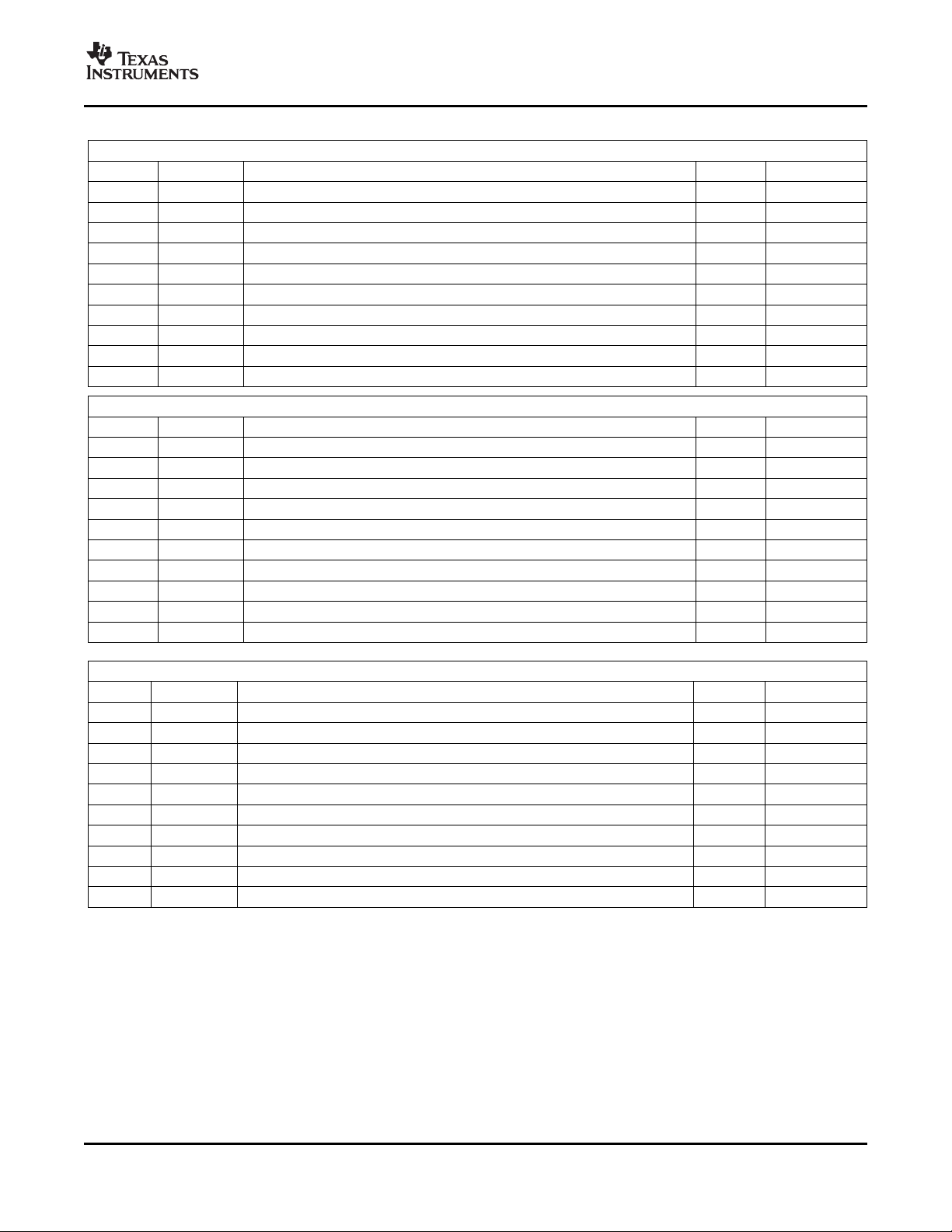

TYPICAL CYCLE, PROGRAMMING THREE WORDS INTO EEPROM

Figure 3 shows an enter register programming mode and how the different words can be written. Bold highlights

the addressing of word0–word2. After that, the payload for the respective word is clocked in. In this example,

this is followed by a jump from state 2 → state 3 into enter EEPROM programming with EEPROM lock. In the

EEPROM-programming state, it is necessary to wait at least 10 ms for safe programming. The last command is

a jump from state 3 into state 1 (normal operation).

TYPICAL WRITE/VERIFY/PROGRAM CYCLE

As stated previously in this document, for safe writing and programming, the supply voltage must be held within

a narrow window of 3.2 V ±100 mV. Figure 1 illustrates writing to the device and verifying the settings, followed

by a safe programming into EEPROM.

Figure 3. EEPROM Programming Example

Submit Documentation Feedback

7

www.ti.com

T0044-02

0

0

1 1 1 1 1

1 2

26

27

28

SDATA

FOUT

EnterRegister

Read-BackMode

Fetch

EEPROM

ContentWith

1 CLK

st

EEPROMContent

1 Bit Available After

1 FallingEdge

st

st

30 FallingEdge

SwitchesBackInto

NormalOperation

th

OutputOscillation

OutputOscillation

CDCE401

SCAS820 – JUNE 2006

ENTER REGISTER READ-BACK MODE

Similar to the enter registerprogramming mode sequence, the enter register read-back mode is written into

SDATA. Before the enter register read-back mode is written, the device must be disabled via EN for 100 µ s to

ensure that the EEPROM content is read out correctly with enter register read-back mode. After the command

has been issued, the SDATA input is reconfigured as a clock input. By applying one clock, the EEPROM content

is read into shift registers. Now, by further applying clocks at SDATA, the EEPROM content can be clocked out

and observed at FOUT. Also, FOUT is reconfigured during that operation, as can be seen in the following figure.

There are 29 bits to be clocked out. With the 30

normal operation.

Figure 4. Typical Register Read-Back Cycle

th

falling clock edge, the FOUT pin is reconfigured back to

In Table 4 , the content of the bits in the output stream is summarized. Note that the MSB is clocked out first.

Table 4. Read-Back Cycle Bit Stream

OUTPUT-STREAM BITS FUNCTION

Bits[0:2] Revision identifier (MSB first)

Bit[3] EEPROM status:

Bit[4] EEPROM lock:

Bits[5:12] Storage value, word2 (MSB first)

Bits[13:20] Storage value, word1 (MSB first)

Bits[21:28] Storage value, word0 (MSB first)

0 = EEPROM has never been written.

1 = EEPROM has been programmed before.

0 = EEPROM can be rewritten.

1 = EEPROM is locked; rewriting to the EEPROM is not possible.

8

Submit Documentation Feedback

www.ti.com

REGISTER DESCRIPTION

WORD 0:

BIT NAME DESCRIPTION/FUNCTION TYPE DEFAULT

0 C0 Register selection W 0

1 C1 Register selection W 0

2 CXI0 Load capacitance XIN, bit 0 W 0

3 CXI1 Load capacitance XIN, bit 1 W 0

4 CXI2 Load capacitance XIN, bit 2 W 0

5 CXI3 Load capacitance XIN, bit 3 W 0

6 CXI4 Load capacitance XIN, bit 4 W 0

7 CXI5 Load capacitance XIN, bit 5 W 1

8 CXI6 Load capacitance XIN, bit 6 W 1

9 CXI7 Load capacitance XIN, bit 7 W 0

WORD 1:

BIT NAME DESCRIPTION/FUNCTION TYPE DEFAULT

0 C0 Register selection W 1

1 C1 Register selection W 0

2 CXO0 Load capacitance XOUT, bit 0 W 0

3 CXO1 Load capacitance XOUT, bit 1 W 0

4 CXO2 Load capacitance XOUT, bit 2 W 0

5 CXO3 Load capacitance XOUT, bit 3 W 0

6 CXO4 Load capacitance XOUT, bit 4 W 0

7 CXO5 Load capacitance XOUT, bit 5 W 1

8 CXO6 Load capacitance XOUT, bit 6 W 1

9 CXO7 Load capacitance XOUT, bit 7 W 0

CDCE401

SCAS820 – JUNE 2006

WORD 2:

BIT NAME DESCRIPTION/FUNCTION TYPE DEFAULT

0 C0 Register selection W 0

1 C1 Register selection W 1

2 PD0 Post-divider selection, bit 0 W 0

3 PD1 Post-divider selection, bit 1 W 0

4 PD2 Post-divider selection, bit 2 W 0

5 OG0 Oscillator gain definition, bit 0

6 OG1 Oscillator gain definition, bit 1

7 OP0 Oscillator operating-point adjustment, bit 0

8 OP1 Oscillator operating-point adjustment, bit 1

9 OP2 Oscillator operating-point adjustment, bit 2

(1) The oscillator gain bits have impact on the capacitance C

bits OP[2:0] are used to set the bias point of the oscillator core stage. In combination with setting the post-divider ratio PD[2:0] = 111,

(1)

(1)

(1)

(1)

(1)

. See the table for input capacitance values. The oscillator operating-point

BASE

W 1

W 1

W 0

W 0

W 0

the current consumption can be optimized to set oscillator core current consumption for lower frequencies and higher frequencies. This

ensures that the oscillator core is in operating optimally for phase noise and low XTAL-drive power. Setting core power too high impacts

XTAL-drive power, which affects the lifetime of the crystal.

Submit Documentation Feedback

9

www.ti.com

CDCE401

SCAS820 – JUNE 2006

POST-DIVIDER SETTINGS

PD2 PD1 PD0 POST-DIVIDER SETTINGS COMMENT

0 0 0 Post-divider × 1 Default

0 0 1 Post-divider × 1/2

0 1 0 Post-divider × 1/4

0 1 1 Post-divider × 1/8

1 0 0 Post-divider × 1/16

1 0 1 Post-divider × 1/32

1 1 0 Test mode: turns off CXI, CXO, and C

Post-divider × 1 (like in default).

1 1 1 No division: The post-divider setting PD[2:0] = 111 is used to turn off the amplifier after the

oscillator core. This offers the capability to disable effectively all blocks except the oscillator

core (current consumption of core only can be measured and adjusted)

(1) Setting core current consumption too high impacts the crystal drive power, which affects crystal performance and lifetime.

.

BASE

(1)

.

RECOMMENDATIONS FOR OSCILLATOR GAIN

OG[1:0] OP[2:0] OSCILLATOR OSCILLATOR OPERATING FREQUENCY COMMENT

11 000 Oscillator gain for 20 MHz ≤ frequency < 40 MHz Default

10 000 Oscillator gain for 40 MHz ≤ frequency < 60 MHz

01 000 Oscillator gain for 60 MHz ≤ frequency < 80 MHz

00 000 Oscillator gain for 80 MHz ≤ frequency ≤ 100 MHz

(2) The oscillator gain bits have an impact on the capacitance C

whole supply voltage range. Depending on the crystal series equivalent resistance, the OP[2:0] bits might require different settings.

Contact TI for assistance.

(2)

AND OPERATING POINT DEFINITIONS

. See the table for input capacitance values. This table is valid for the

BASE

10

Submit Documentation Feedback

www.ti.com

CDCE401

SCAS820 – JUNE 2006

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

VDD Supply voltage range –0.5 to 8 V

V

V

Input voltage range

I

Output voltage range

O

Input current (V

I

O

θ

JA

T

stg

Continuous output current ±50 mA

Package thermal impedance:

Storage temperature range –65 to 150 °C

(2)

(2)

< 0, VI> VDD) ±20 mA

I

(3)

QFN8 package TBD K/W

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) The input and output negative voltage ratings may be exceeded if the input and output clamp-current ratings are observed.

(3) The package thermal impedance is calculated in accordance with JESD 51 (no-airflow condition) and JEDEC2S2P (high-k board).

RECOMMENDED OPERATING CONDITIONS

over operating free-air temperature range (unless otherwise noted)

SUPPLY VOLTAGES, CURRENTS AND TEMPERATURE RANGE

Supply voltage: the four target supply-voltage ranges are:

VDD b) 2.8 V ±10% = 2.52 V–3.08 V 2.25 3 3.3 V

VDD Supply voltage during configuration of the device and EEPROM writing 3.1 3.2 3.3 V

I

DD

I

DD(DIS)

T

A

LVCMOS INPUT PARAMETER (SDATA, EN)

V

IH

V

IL

R

PULLUP

LVCMOS OUTPUT PARAMETER (FOUT)

V

OH

V

OL

V

OH_12mA

V

OL_12mA

I

/I

OZH

a) 2.5 V ±10% = 2.25 V–2.75 V

c) 2.85 V ±10%= =2.56 V–3.14 V

d) 3 V ±10% = 2.7 V–3.30 V

Supply current f

CLOCK-max

3.3 V, C

L-max

Disable current fIN= 0 MHz, V

Operating free-air temperature –40 85 °C

High-level input voltage VDD = 3.3 V VDD – 0.5 VDD + 0.3 V

Low-level input voltage VDD = 3.3 V V

Pullup resistor (EN and SDATA) 1.4 2 3.5 M Ω

High-level output voltage IOH= –6 mA VDD – 0.3 V

Low-level output voltage IOL= 6 mA V

High-level output voltage IOH= –12 mA VDD – 0.6 V

Low-level output voltage IOL= 12 mA V

Output current in high-impedance state V

OZL

OUT

= VDD and V

(1)

= 100 MHz, V

= 15 pF

DD-max

OUT

VALUE UNIT

–0.5 to VDD + 0.5 V

–0.5 to VDD + 0.5 V

MIN NOM MAX UNIT

= 20 mA

DD-max

– 0.3 V

SS

= V

SS

+ 0.5 V

SS

+ 0.3 V

SS

+ 0.6 V

SS

10 µ A

±10 µ A

TIMING REQUIREMENTS

over recommended ranges of supply voltage, load, and operating free-air temperature

PARAMETER MIN NOM MAX UNIT

XIN/XOUT REQUIREMENTS

f

CLK_IN

f

Range

C

BASE_XIN

Crystal frequency 20 100 MHz

Trimming range (range is dependent on connected crystal) ±20 ppm

OG0 = 1 OG1 = 1 33

Base input capacitance into XIN, measured

single-ended with all CXx turned off

OG0 = 1 OG1 = 0 30

OG0 = 0 OG1 = 1 27

OG0 = 0 OG1 = 0 25

Submit Documentation Feedback

pF

11

www.ti.com

CDCE401

SCAS820 – JUNE 2006

TIMING REQUIREMENTS (continued)

over recommended ranges of supply voltage, load, and operating free-air temperature

PARAMETER MIN NOM MAX UNIT

OG0 = 1 OG1 = 1 25

C

BASE_XOUT

measured single-ended with all CXx turned pF

off

Crystal tune capacitance, measured single-ended against

CXI[7:0] VSS (subtracted from C

Base input capacitance into XOUT,

CXO[7:0] CXI[0:7] = C

CXO[0:7] = C

– C

XIN

XOUT

FOUT OUTPUT PARAMETER

f

CLK_OUT

tr/t

f

f

max

C

Load

Crystal frequency 20 100 MHz

Rise and fall time 10% to 90% VDD and 2 3 ns

Highest output frequency C

Load capacitance 15 pF

odc Output duty cycle

SDATA/EN TIMING

f

SDATACLK

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

tr/t

f

Repeat frequency of programming 200 kHz

LOW signal: high-pulse duration 0.5 1 1.2 µ s

LOW signal: low-pulse duration while entering programming sequence 3.8 4 4.2

LOW signal: low-pulse duration while programming bits 3.8

HIGH signal: high-pulse duration 3.8 4 4.5 µ s

HIGH signal: low-pulse duration while entering programming sequence 0.5 1 1.2

HIGH signal: low-pulse duration while programming bits 0.5

Time delay between SDATA signal and SDATA_Delayed signal at VDD = 3.3 V 1.5 2.5 3.5 µ s

Time between bits during enter programming mode and enter read-back mode 10 30 µ s

beyond which a time-out must occur

EN high time before first SDATA can be clocked in 60 µ s

EN low time before first SDATA bit is clocked in 2 10 µ s

Rise and fall time from 20% to 80% of VDD 1 15 ns

), i.e.:

BASE

(OGx) or

BASE

– C

(OGx)

BASE

OG0 = 1 OG1 = 0 17

OG0 = 0 OG1 = 1 16

OG0 = 0 OG1 = 0 11

C

Load,max

Load,max

At VDD/2, 20 MHz ≤ freq ≤ 80 45% 50% 55%

MHz

At VDD/2, 80 MHz < freq ≤ 40% 50% 60%

100MHz

CXx7 6

CXx6 3

CXx5 1.5

CXx4 0.75

CXx3 375

CXx2 187

CXx1 94

CXx0 47

= 15 pF

= 15 pF 100 MHz

pF

fF

µ s

µ s

12

Submit Documentation Feedback

www.ti.com

DEVICE CHARACTERISTICS

over recommended ranges of supply voltage, load, and operating free-air temperature (unless otherwise noted)

PARAMETER

Phase noise specifications under following assumptions for 20-MHz and 40-MHz crystals:

f = 20 MHz (L

f = 40 MHz (L

phn

10

phn

100

phn

1k

phn

10k

phn

100k

phn

1M

= 22.79 mH, CS= 2.78 fF, CP= 0.77 pF) and post-divider × 1

S

= 6.231 mH, CS= 2.541 fF, CP= 0.628 pF) and post-divider × 1

S

Phase noise at 10 Hz –65 dBc/Hz

Phase noise at 100 Hz –95 dBc/Hz

Phase noise at 1 kHz –125 dBc/Hz

Phase noise at 10 kHz –140 dBc/Hz

Phase noise at 100 kHz –145 dBc/Hz

Phase noise at 1 MHz –145 dBc/Hz

Phase noise specifications under following assumptions for 60-MHz and 80-MHz crystals:

f = 60 MHz (L

f = 80 MHz (L

phn

10

phn

100

phn

1k

phn

10k

phn

100k

phn

1M

= 2.015 mH, CS= 3.493 fF, CP= 0.876 pF) and post-divider × 1

S

= 0.907 mH, CS= 4.376 fF, CP= 1.156 pF) and post-divider × 1

S

Phase noise at 10 Hz –65 dBc/Hz

Phase noise at 100 Hz –95 dBc/Hz

Phase noise at 1 kHz –125 dBc/Hz

Phase noise at 10 kHz –133 dBc/Hz

Phase noise at 100 kHz –140 dBc/Hz

Phase noise at 1 MHz –145 dBc/Hz

Phase noise specifications under following assumptions for 100-MHz crystals:

f = 100 MHz (L

phn

10

phn

100

phn

1k

phn

10k

phn

100k

phn

1M

= 0.515 mH, CS= 4.923 fF, CP= 1.468 pF) and post-divider × 1

S

Phase noise at 10 Hz –65 dBc/Hz

Phase noise at 100 Hz –90 dBc/Hz

Phase noise at 1 kHz –120 dBc/Hz

Phase noise at 10 kHz –130 dBc/Hz

Phase noise at 100 kHz –135 dBc/Hz

Phase noise at 1 MHz –145 dBc/Hz

(1)

TEST CONDITIONS MIN TYP MAX UNIT

CDCE401

SCAS820 – JUNE 2006

(1) All parameters are defined for the test load given in SubSec1 5.1 .

Submit Documentation Feedback

13

www.ti.com

VDD

R=1kW

FromOutputofDUT

Out

LVCMOS

Output

R=1kW C =15pF

LOAD

S0034-02

FromOutputofDUT

LVCMOS

Output

R=50 W

C =100nF

C

S0199-01

CDCE401

SCAS820 – JUNE 2006

TEST LOAD CONDITION

Figure 5. LVCMOS Output Test Load for All Specifications Except Phase Noise Values

Figure 6. LVCMOS Output Test Load for Phase Noise Values

14

Submit Documentation Feedback

www.ti.com

CRYSTAL OSCILLATOR LEVEL CONVERSION

XIN

OG[1:0]

OG[1:0]

OP[2:0]

OG[1:0]

PD[2:0]

EN

FOUT

XOUT

VSS

OscillatorCaseWith4Pins

CXOUT

C

BASE

CXOUT

C

BASE

Var

C

BASE

Var

C

BASE

C

L

C

L

CXO[7:0]

Read-Back

Mode

CXI[7:0]

Oscillator

Gain

Stage

EEPROM

and

Control

Logic

SDATA

ENand

SDATA

2MW

VDD

Divider

P

Bias

+

–

M

U

X

2MW

B0027-04

LVCMOS

LVCMOS

LVCMOS

C =

15pF

LOAD

C =100nF

Filter

VSUPPLY

2.25V – 3.3V

CDCE401

SCAS820 – JUNE 2006

APPLICATION INFORMATION

Phase noise specifications under following assumptions:

Crystal with f = 40 MHz (L

phn

10

phn

100

phn

1k

phn

10k

phn

100k

phn

1M

Phase noise at 10 Hz VDD = 2.5 V –70 dBc/Hz

Phase noise at 100 Hz VDD = 2.5 V –100 dBc/Hz

Phase noise at 1 kHz VDD = 2.5 V –130 dBc/Hz

Phase noise at 10 kHz VDD = 2.5 V –145 dBc/Hz

Phase noise at 100 kHz VDD = 2.5 V –150 dBc/Hz

Phase noise at 1 MHz VDD = 2.5 V –150 dBc/Hz

Figure 7. Crystal Oscillator Application at 40 MHz in a 4-Pin Oscillator Case

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

= 10.534 mH, CS= 2.208 pF, CP= 0.551 pF) and post-divider × 1

S

Submit Documentation Feedback

15

www.ti.com

206

90

Note: AllUnits mm

964 – (WidthofSawBlade)

EN

XIN

XOUT

VSS

VDD

FOUT

SDATA

178

231

231

77

77

482 – (Widthof

SawBlade)/2

435

– (Widthof

SawBlade)/2

90

M0018-04

870 – (WidthofSawBlade)

CDCE401

SCAS820 – JUNE 2006

Figure 8. Die Dimensions (Top View – Bond Pad Locations)

16

Submit Documentation Feedback

PACKAGE OPTION ADDENDUM

www.ti.com

16-Apr-2007

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

CDCE401YS PREVIEW XCEPT YS 0 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(2)

Lead/Ball Finish MSL Peak Temp

Call TI N / A for Pkg Type

(3)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements,

improvements, and other changes to its products and services at any time and to discontinue any product or service without notice.

Customers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All products are sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s

standard warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this

warranty. Except where mandated by government requirements, testing of all parameters of each product is not necessarily

performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should

provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask

work right, or other TI intellectual property right relating to any combination, machine, or process in which TI products or services

are used. Information published by TI regarding third-party products or services does not constitute a license from TI to use such

products or services or a warranty or endorsement thereof. Use of such information may require a license from a third party under

the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without alteration and is

accompanied by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an

unfair and deceptive business practice. TI is not responsible or liable for such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service

voids all express and any implied warranties for the associated TI product or service and is an unfair and deceptive business

practice. TI is not responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would

reasonably be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement

specifically governing such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications

of their applications, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related

requirements concerning their products and any use of TI products in such safety-critical applications, notwithstanding any

applications-related information or support that may be provided by TI. Further, Buyers must fully indemnify TI and its

representatives against any damages arising out of the use of TI products in such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is

solely at the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in

connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products

are designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any

non-designated products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Low Power www.ti.com/lpw Telephony www.ti.com/telephony

Wireless

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2007, Texas Instruments Incorporated

Loading...

Loading...