查询CDC509供应商

CDC509

3.3-V PHASE-LOCK LOOP CLOCK DRIVER

SCAS576B – JULY 1996 – REVISED JANUAR Y 1998

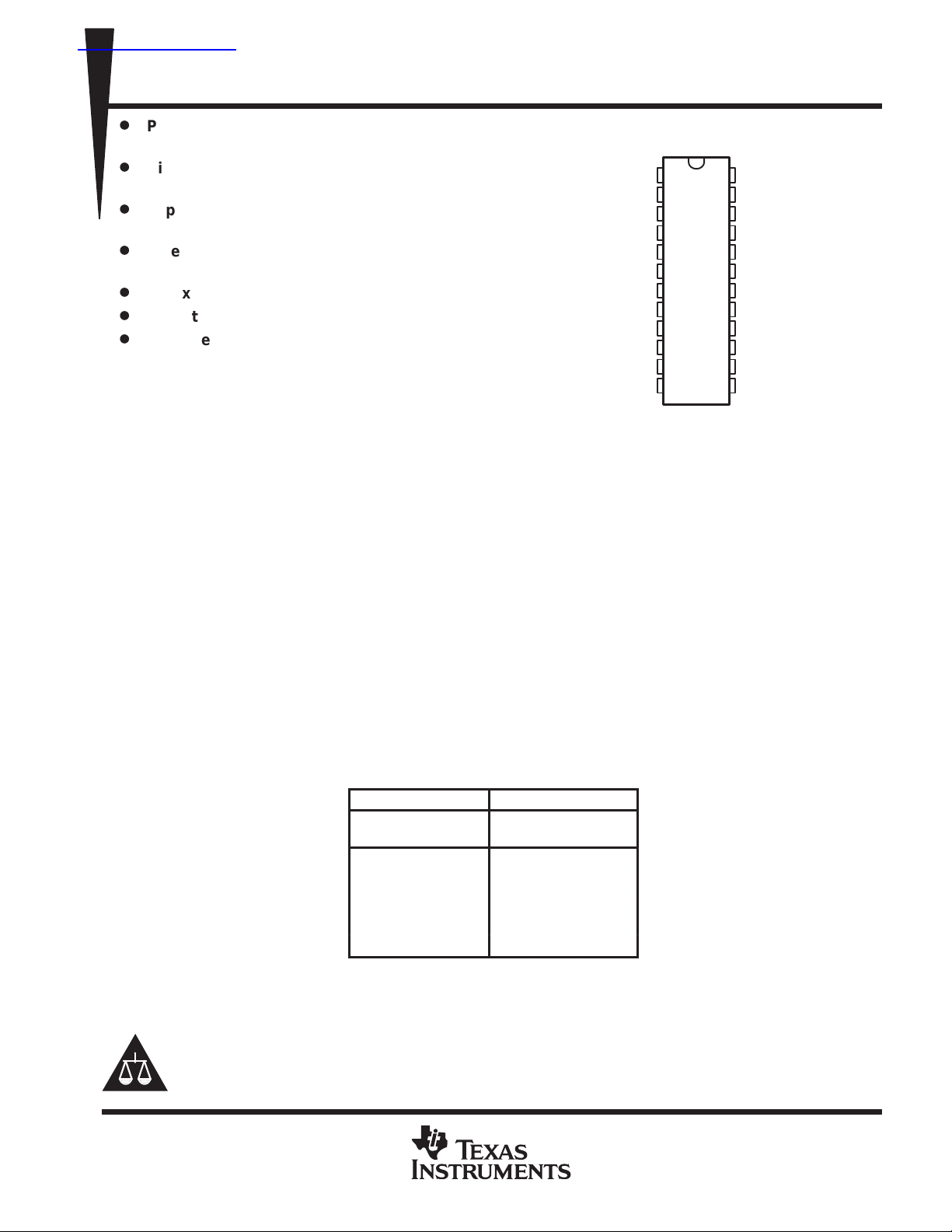

AGND

V

CC

1Y0

1Y1

1Y2

GND

GND

1Y3

1Y4

V

CC

1G

PW PACKAGE

(TOP VIEW)

1

24

2

23

3

22

4

21

5

20

6

19

7

18

8

17

9

16

10

15

11

14

12

13

CLK

AV

CC

V

CC

2Y0

2Y1

GND

GND

2Y2

2Y3

V

CC

2G

FBIN

D

Phase-Lock Loop Clock Distribution for

Synchronous DRAM Applications

D

Distributes One Clock Input to One Bank of

Five and One Bank of Four Outputs

D

Separate Output Enable for Each Output

Bank

D

External Feedback (FBIN) Pin Is Used to

Synchronize the Outputs to the Clock Input

D

No External RC Network Required

D

Operates at 3.3-V V

D

Packaged in Plastic 24-Pin Thin Shrink

CC

Small-Outline Package

description

FBOUT

The CDC509 is a high-performance, low-skew, low-jitter, phase-lock loop (PLL) clock driver. It uses a PLL to

precisely align, in both frequency and phase, the feedback (FBOUT) output to the clock (CLK) input signal. It

is specifically designed for use with synchronous DRAMs. The CDC509 operates at 3.3-V VCC and is designed

to drive up to five clock loads per output.

One bank of five outputs and one bank of four outputs provide nine low-skew , low-jitter copies of CLK. Output

signal duty cycles are adjusted to 50 percent, independent of the duty cycle at CLK. Each bank of outputs can

be enabled or disabled separately via the control (1G and 2G) inputs. When the G inputs are high, the outputs

switch in phase and frequency with CLK; when the G inputs are low, the outputs are disabled to the logic-low

state.

Unlike many products containing PLLs, the CDC509 does not require external RC networks. The loop filter for

the PLL is included on-chip, minimizing component count, board space, and cost.

Because it is based on PLL circuitry, the CDC509 requires a stabilization time to achieve phase lock of the

feedback signal to the reference signal. This stabilization time is required, following power up and application

of a fixed-frequency, fixed-phase signal at CLK, as well as following any changes to the PLL reference or

feedback signals. The PLL can be bypassed for test purposes by strapping AV

to ground.

CC

The CDC509 is characterized for operation from 0°C to 70°C.

FUNCTION TABLE

INPUTS

1G 2G CLK

X X L L L L

L LHLLH

L HHLHH

H LHHLH

H H H H H H

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

OUTPUTS

1Y

(0:4)2Y(0:3)

FBOUT

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Copyright 1998, Texas Instruments Incorporated

1

CDC509

3.3-V PHASE-LOCK LOOP CLOCK DRIVER

SCAS576B – JULY 1996 – REVISED JANUAR Y 1998

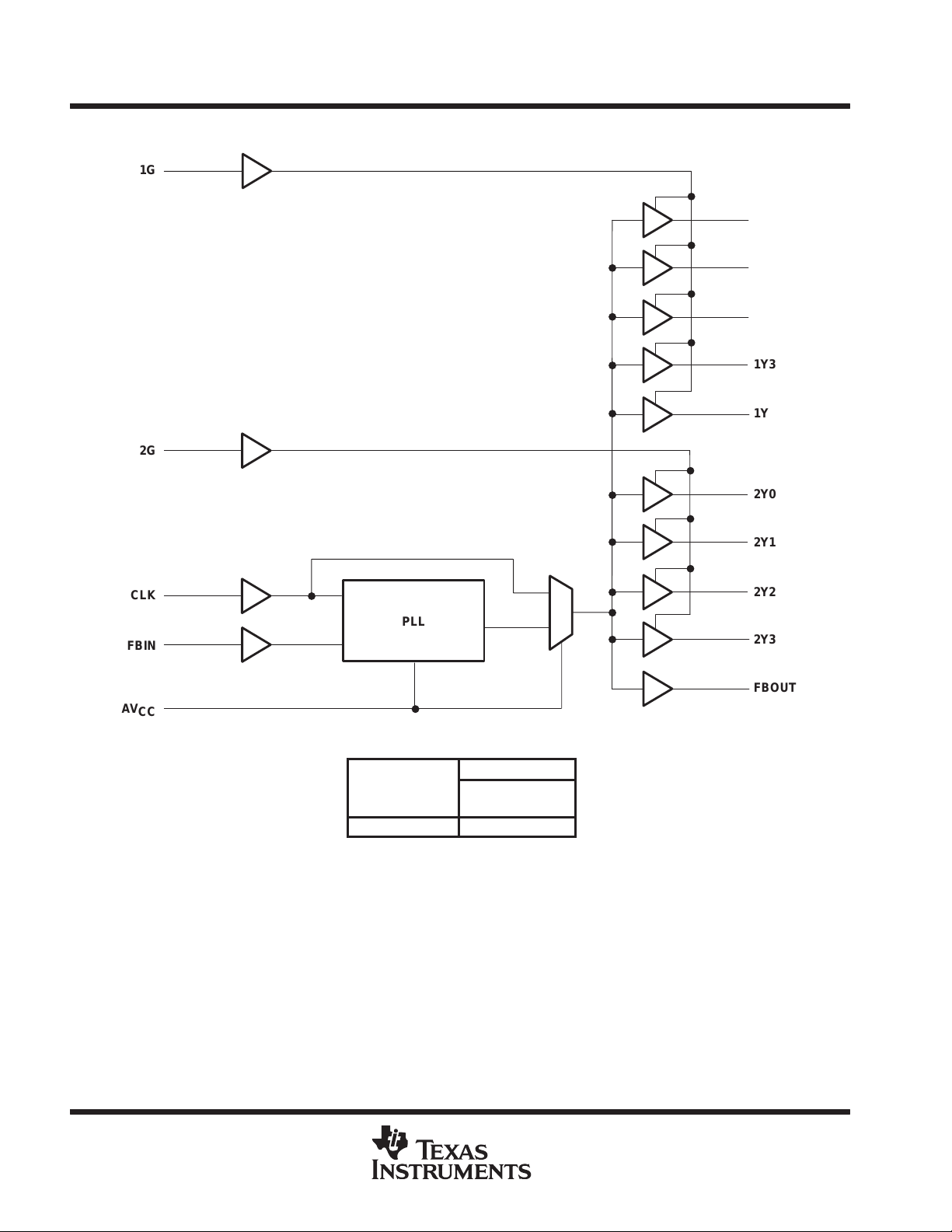

functional block diagram

11

1G

14

2G

21

3

1Y0

4

1Y1

5

1Y2

8

1Y3

9

1Y4

2Y0

CLK

FBIN

AV

CC

24

13

23

PLL

AVAILABLE OPTIONS

PACKAGE

T

A

0°C to 70°C CDC509PWR

SMALL OUTLINE

(PW)

20

17

16

12

2Y1

2Y2

2Y3

FBOUT

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPE

DESCRIPTION

3.3-V PHASE-LOCK LOOP CLOCK DRIVER

SCAS576B – JULY 1996 – REVISED JANUAR Y 1998

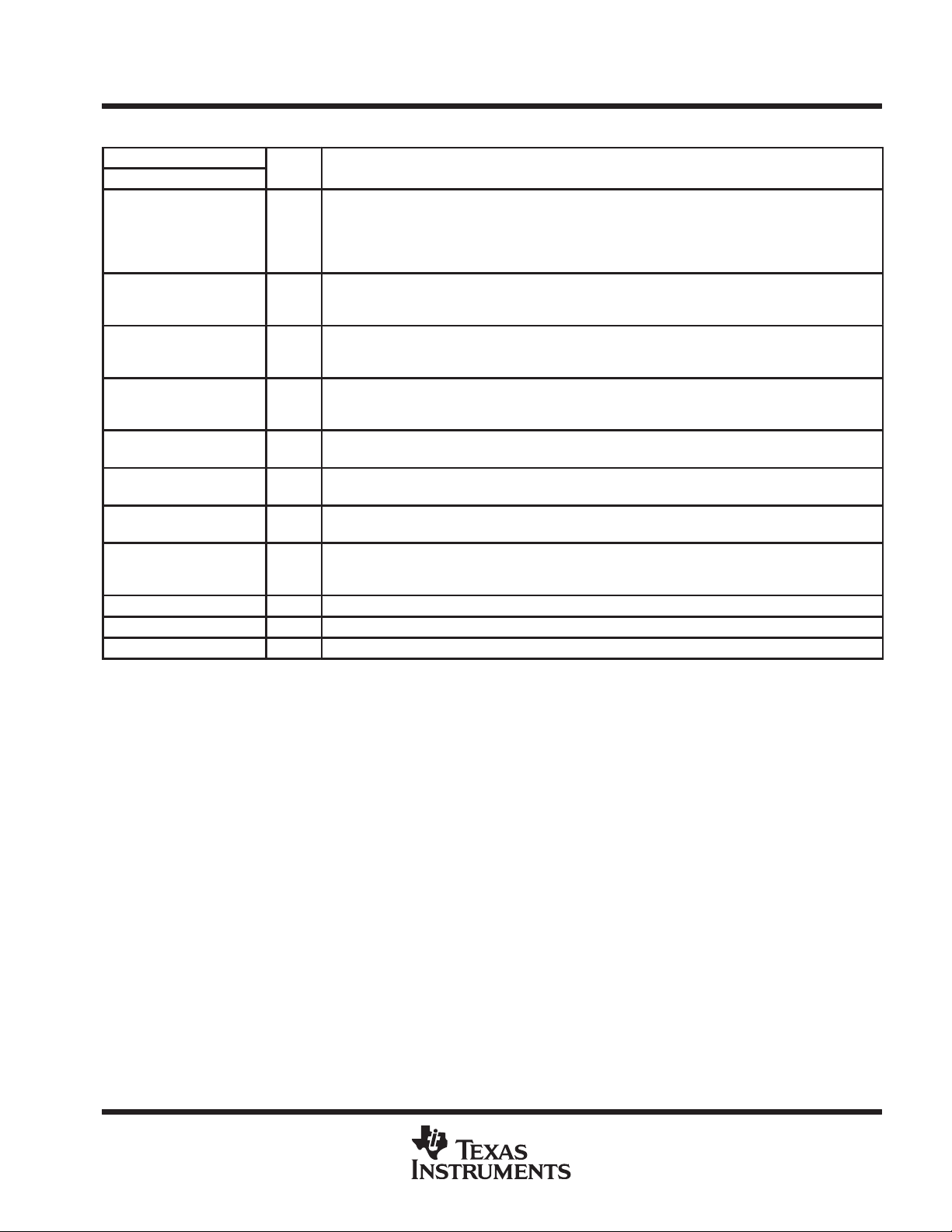

Terminal Functions

TERMINAL

NAME NO.

Clock input. CLK provides the clock signal to be distributed by the CDC509 clock driver. CLK is used

to provide the reference signal to the integrated PLL that generates the clock output signals. CLK must

CLK 24 I

FBIN 13 I

1G 11 I

2G 14 I

FBOUT 12 O

1Y(0:4) 3, 4, 5, 8, 9 O

2Y(0:3) 16, 17, 20 21 O

AV

CC

AGND 1 Ground Analog ground. AGND provides the ground reference for the analog circuitry.

V

CC

GND 6, 7, 18, 19 Ground Ground

23 Power

2, 10, 15, 22 Power Power supply

have a fixed frequency and fixed phase for the PLL to obtain phase lock. Once the circuit is powered

up and a valid CLK signal is applied, a stabilization time is required for the PLL to phase lock the

feedback signal to its reference signal.

Feedback input. FBIN provides the feedback signal to the internal PLL. FBIN must be hard-wired to

FBOUT to complete the PLL. The integrated PLL synchronizes CLK and FBIN so that there is

nominally zero phase error between CLK and FBIN.

Output bank enable. 1G is the output enable for outputs 1Y(0:4). When 1G is low, outputs 1Y(0:4) are

disabled to a logic-low state. When 1G is high, all outputs 1Y(0:4) are enabled and switch at the same

frequency as CLK.

Output bank enable. 2G is the output enable for outputs 2Y(0:3). When 2G is low, outputs 2Y(0:3) are

disabled to a logic low state. When 2G is high, all outputs 2Y(0:3) are enabled and switch at the same

frequency as CLK.

Feedback output. FBOUT is dedicated for external feedback. It switches at the same frequency as

CLK. When externally wired to FBIN, FBOUT completes the feedback loop of the PLL.

Clock outputs. These outputs provide low-skew copies of CLK. Output bank 1Y(0:4) is enabled via

the 1G input. These outputs can be disabled to a logic-low state by deasserting the 1G control input.

Clock outputs. These outputs provide low-skew copies of CLK. Output bank 2Y(0:3) is enabled via

the 2G input. These outputs can be disabled to a logic-low state by deasserting the 2G control input.

Analog power supply. A VCC provides the power reference for the analog circuitry. In addition, A V

can be used to bypass the PLL for test purposes. When AVCC is strapped to ground, PLL is bypassed

and CLK is buffered directly to the device outputs.

CDC509

CC

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

Supply voltage range, V

Input voltage range, V

Voltage range applied to any output in the high

or low state, VO (see Notes 1 and 2) –0.5 V to VCC + 0.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input clamp current, I

Output clamp current, I

Continuous output current, I

Continuous current through each VCC or GND ±100 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum power dissipation at TA = 55°C (in still air) (see Note 3) 0.7 W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. The input and output negative-voltage ratings may be exceeded if the input and output clamp-current ratings are observed.

2. This value is limited to 4.6 V maximum.

3. The maximum package power dissipation is calculated using a junction temperature of 150°C and a board trace length of 750 mils.

For more information, refer to the

Book

, literature number SCBD002.

–0.5 V to 4.6 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CC

(see Note 1) –0.5 V to 6.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

(V

< 0) –50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IK

I

(V

< 0 or VO > VCC) ±50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OK

O

(V

= 0 to VCC) ±50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O

O

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

Package Thermal Considerations

application note in the

ABT Advanced BiCMOS T echnology Data

†

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

3

CDC509

V

V

V

V

3.3-V PHASE-LOCK LOOP CLOCK DRIVER

SCAS576B – JULY 1996 – REVISED JANUAR Y 1998

recommended operating conditions (see Note 4)

MIN MAX UNIT

V

V

V

V

I

OH

I

OL

T

NOTE 4: Unused inputs must be held high or low to prevent them from floating.

electrical characteristics over recommended operating free-air temperature range (unless

otherwise noted)

†

For conditions shown as MIN or MAX, use the appropriate value specified under recommended operating conditions.

‡

For ICC of AVCC, see Figure 5.

Supply voltage 3 3.6 V

CC

High-level input voltage 2 V

IH

Low-level input voltage 0.8 V

IL

Input voltage 0 V

I

High-level output current –20 mA

Low-level output current 20 mA

Operating free-air temperature 0 70 °C

A

PARAMETER TEST CONDITIONS V

V

I

I

∆I

C

C

IK

OH

OL

I

CC

i

o

‡

CC

II = –18 mA 3 V –1.2 V

IOH = –100 µA MIN to MAX VCC–0.2

IOH = –20 mA 3 V 2.4

IOL = 100 µA MIN to MAX 0.2

IOL = 20 mA 3 V 0.55

VI = VCC or GND 3.6 V ±5 µA

VI = VCC or GND, IO = 0, Outptus high or low 3.6 V 10 µA

One input at VCC – 0.6 V, Other inputs at VCC or GND 3.3 V to 3.6 V 500 µA

VI = VCC or GND 3.3 V 4 pF

VO = VCC or GND 3.3 V 6 pF

CC

MIN TYP†MAX UNIT

CC

V

timing requirements over recommended ranges of supply voltage and operating free-air

temperature

MIN MAX UNIT

f

clock

§

Time required for the integrated PLL circuit to obtain phase lock of its feedback signal to its reference signal. For phase lock to be obtained, a

fixed-frequency , fixed-phase reference signal must be present at CLK. Until phase lock is obtained, the specifications for propagation delay, skew ,

and jitter parameters given in the switching characteristics table are not applicable.

Clock frequency 25 125 MHz

Input clock duty cycle 40% 60%

Stabilization time

§

1 ms

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

(INPUT)

(OUTPUT)

yy ,

CDC509

3.3-V PHASE-LOCK LOOP CLOCK DRIVER

SCAS576B – JULY 1996 – REVISED JANUAR Y 1998

switching characteristics over recommended ranges of supply voltage and operating free-air

temperature, C

PARAMETER

t

phase error

t

phase error

Duty cycle, reference

†

This parameters are not production tested.

‡

The t

NOTES: 5. The specifications for parameters in this table are applicable only after any appropriate stabilization time has elapsed.

, reference

(see Figure 3)

(see Note 6)

t

sk(o)

Jitter

(pk-pk)

(see Figure 4)

t

r

t

f

specification is only valid for equal loading of all outputs.

sk(o)

6. Phase error does not include jitter. The total phase error is 120 ps to 580 ps for the 5% VCC range.

= 30 pF (see Note 5 and Figures 1 and 2)

L

, – jitter,

‡

FROM

66 MHz < CLKIN↑ < 100

MHz

CLKIN↑ = 100 MHz FBIN↑ 220 480 340 ps

Any Y or FBOUT Any Y or FBOUT 200 ps

F(clkin > 66 MHz) Any Y or FBOUT –100 100 ps

F(clkin ≤ 66 MHz) Any Y or FBOUT 45% 55%

F(clkin > 66 MHz) Any Y or FBOUT 43% 57%

TO

FBIN↑ 100...480 ps

Any Y or FBOUT 1.1 1.5 0.7 1.6 ns

Any Y or FBOUT 0.8 1.3 0.5 1.5 ns

†

VCC = 3.3 V

± 0.165 V

MIN TYP MAX MIN TYP MAX

VCC = 3.3 V

± 0.3 V

UNIT

PARAMETER MEASUREMENT INFORMATION

From Output

Under Test

500

30 pF

LOAD CIRCUIT FOR OUTPUTS

NOTES: A. CL includes probe and jig capacitance.

B. All input pulses are supplied by generators having the following characteristics: PRR ≤ 100 MHz, ZO = 50 Ω, tr ≤ 1.2 ns, tf≤ 1.2 ns.

C. The outputs are measured one at a time with one transition per measurement.

Figure 1. Load Circuit and Voltage Waveforms

3 V

Input

t

W

Output

50% V

CC

pd

2 V

0.4 V

t

r

VOLTAGE WAVEFORMS

PROPAGATION DELAY TIMES

50% V

CC

0 V

V

2 V

0.4 V

t

f

OH

V

OL

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

5

CDC509

3.3-V PHASE-LOCK LOOP CLOCK DRIVER

SCAS576B – JULY 1996 – REVISED JANUAR Y 1998

PARAMETER MEASUREMENT INFORMATION

CLKIN

FBIN

t

phase error

FBOUT

Any Y

Any Y

Any Y

t

sk(o)

t

sk(o)

Figure 2. Phase Error and Skew Calculations

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

CDC509

3.3-V PHASE-LOCK LOOP CLOCK DRIVER

SCAS576B – JULY 1996 – REVISED JANUAR Y 1998

TYPICAL CHARACTERISTICS

1.2

VDD = 3.3 V

TA = 25°C

1

0.8

0.6

0.4

Phase Error – ns

0.2

0

–0.2

35

45 55 65 95 105

PHASE ERROR

vs

CLOCK FREQUENCY

85

75 115 125 135

f

– Clock Frequency – MHz

clk

Figure 3

9

8

Output Duty Cycle

ANALOG SUPPLY CURRENT

vs

CLOCK FREQUENCY

VDD = 3.3 V

TA = 25°C

OUTPUT DUTY CYCLE

vs

CLOCK FREQUENCY

57%

VDD = 3.3 V

55%

53%

51%

49%

47%

45%

43%

CL = 30 pF

30 50 70 90 130110

f

– Clock Frequency – MHz

clk

Figure 4

7

6

5

4

3

2

Analog Supply Current – mA

1

0

35

25

45 55 65 95 105

f

– Clock Frequency – MHz

clk

Figure 5

85

75 115 125

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

7

CDC509

3.3-V PHASE-LOCK LOOP CLOCK DRIVER

SCAS576B – JULY 1996 – REVISED JANUAR Y 1998

MECHANICAL INFORMATION

PW (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PIN SHOWN

0,65

14

1

1,20 MAX

A

7

0,05 MIN

0,30

0,19

8

6,60

4,50

4,30

6,20

M

0,10

Seating Plane

0,10

0,15 NOM

Gage Plane

0,25

0°–8°

0,75

0,50

PINS **

DIM

A MAX

A MIN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. Falls within JEDEC MO-153

8

3,10

2,90

14

5,10

4,90

16

5,10

20

6,60

6,404,90

24

7,90

7,70

28

9,80

9,60

4040064/E 08/96

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOL VE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...