Data sheet acquired from Harris Semiconductor

SCHS206

February 1998

CD74HC4059

High-Speed CMOS Logic

CMOS Programmable Divide-by-N Counter

[ /Title

(CD74

HC4059

)

/Subject

(HighSpeed

CMOS

Logic

CMOS

Pro-

Features

• Synchronous Programmable ÷N Counter N = 3 to 9999

or 15999

• Presettable Down-Counter

• Fully Static Operation

• Mode-Select Control of Initial Decade Counting

Function (÷10, 8, 5, 4, 2)

• Master Preset Initialization

• Latchable ÷N Output

• Fanout (Over Temperature Range)

- Standard Outputs. . . . . . . . . . . . . . . 10 LSTTL Loads

- Bus Driver Outputs . . . . . . . . . . . . . 15 LSTTL Loads

• Wide Operating Temperature Range . . . -55

• Balanced Propagation Delay and Transition Times

• Significant Power Reduction Compared to LSTTL

Logic ICs

• HC Types

- 2V to 6V Operation

- High Noise Immunity: N

at VCC = 5V

= 30%, NIH = 30% of V

IL

o

C to 125oC

CC

Description

The Harris CD74HC4059 are high-speed silicon-gate

devices that are pin-compatible with the CD4059A devices of

the CD4000B series. These devices are divide-by-N downcounters that can be programmed to divide an input

frequency by any number “N” from 3 to 15,999. The output

signal is a pulse one clock cycle wide occurring at a rate

equal to the input frequency divide by N. The down-counter

is preset by means of 16 jam inputs.

The three Mode-Select Inputs K

modulus (“divide-by” number) of the first and last counting

sections in accordance with the truth table shown on Tab le 1.

Every time the first (fastest) counting section goes through one

cycle, it reduces by 1 the number that has been preset

(jammed) into the three decades of the intermediate counting

section an the last counting section, which consists of flip-flops

that are not needed for opening the first counting section. For

example, in the ÷2 mode, only one flip-flop is needed in the first

counting section. Therefore the last counting section has three

flip-flops that can be preset to a maximum count of seven with a

place value of thousands. If ÷10 is desired for the first section,

K

is set “high”, Kb“high” and Kc“low”. Jam inputs J1, J2, J3,

a

and J4 are used to preset the first counting section and there is

no last counting section. The intermediate counting section

consists of three cascaded BCD decade (÷10) counters

presettable by means of Jam Inputs J5 through J16.

and Kcdetermine the

a,Kb

Applications

• Communications Digital Frequency Synthesizers;

VHF, UHF, FM, AM, etc.

• Fixed or Programmable Frequency Division

• “Time Out” Timer for Consumer-Application Industrial

Controls

• AN6374 “Application of the CMOS CD4059A Programmable Divide-by-N Counter in FM and Citizens Band

Transceiver Digital Tuners”

Ordering Information

TEMP. RANGE

PART NUMBER

CD74HC4059E -55 to 125 24 Ld PDIP E24.3

NOTE:

1. Wafer and die is available which meets all electrical

specifications. Please contact your local sales office or Harris

customer service for ordering information.

(oC) PACKAGE

PKG.

NO.

The Mode-Select Inputs permit frequency-synthesizer

channel separations of 10, 12.5, 20, 25 or 50 parts. These

inputs set the maximum value of N at 9999 (when the first

counting section divides by 5 or 10) or 15,999 (when the first

counting section divides by 8, 4, or 2).

The three decades of the intermediate counter can be preset

to a binary 15 instead of a binary 9, while their place values

are still 1, 10, and 100, multiplied by the number of the ÷N

mode. For example, in the ÷8 mode, the number from which

counting down begins can be preset to:

3rd Decade 1500

2nd Decade 150

1st Decade 15

Last Counting Section 1000

The total of these numbers (2665) times 8 equals 12,320.

The first counting section can be preset to 7. Therefore,

21,327 is the maximum possible count in the ÷8 mode.

The highest count of the various is shown in the column entitled

Extended Counter Range of Table 1. Control inputs K

can be used to initiate and lock the counter in the “master

preset” state. In this condition the flip-flops in the counter are

preset in accordance with the jam inputs and the counter

remains in that state as long as K

counter begins to count down from the preset state when a

counting mode other than the master preset mode is selected.

and Kcboth remain low.The

b

and K

b

c

CAUTION: These devices are sensitive to electrostatic discharge. Users should follow proper IC Handling Procedures.

Copyright

© Harris Corporation 1998

1

File Number 1853.2

CD74HC4059CD74HC4059

The counter should always be put in the master preset mode

before the ÷5 mode is selected. Whenever the master preset

mode is used, control signals K

= “low” and Kc= “low” must

b

be applied for at least 3 full clock pulses.

After Preset Mode inputs have been changed to one of the ÷

modes, the next positive-going clock transition changes an

internal flip-flop so that the countdown can begin at the

second positive-going clock transition. Thus, after an MP

(Master Preset) mode, there is always one extra count

before the output goes high. Figure 1 illustrates a total count

of 3 (÷8 mode). If the Master Preset mode is started two

clock cycles or less before an output pules, the output pulse

will appear at the time due. If the Master Preset Mode is not

used, the counter jumps back to the “Jam” count when the

output pulse appears.

A “high” on the Latch Enable input will cause the counter

output to remain high once an output pulse occurs, and to

remain in the high state until the latch input returns to “low”.

If the Latch Enable is “low”, the output pulse will remain high

for only one cycle of the clock-input signal.

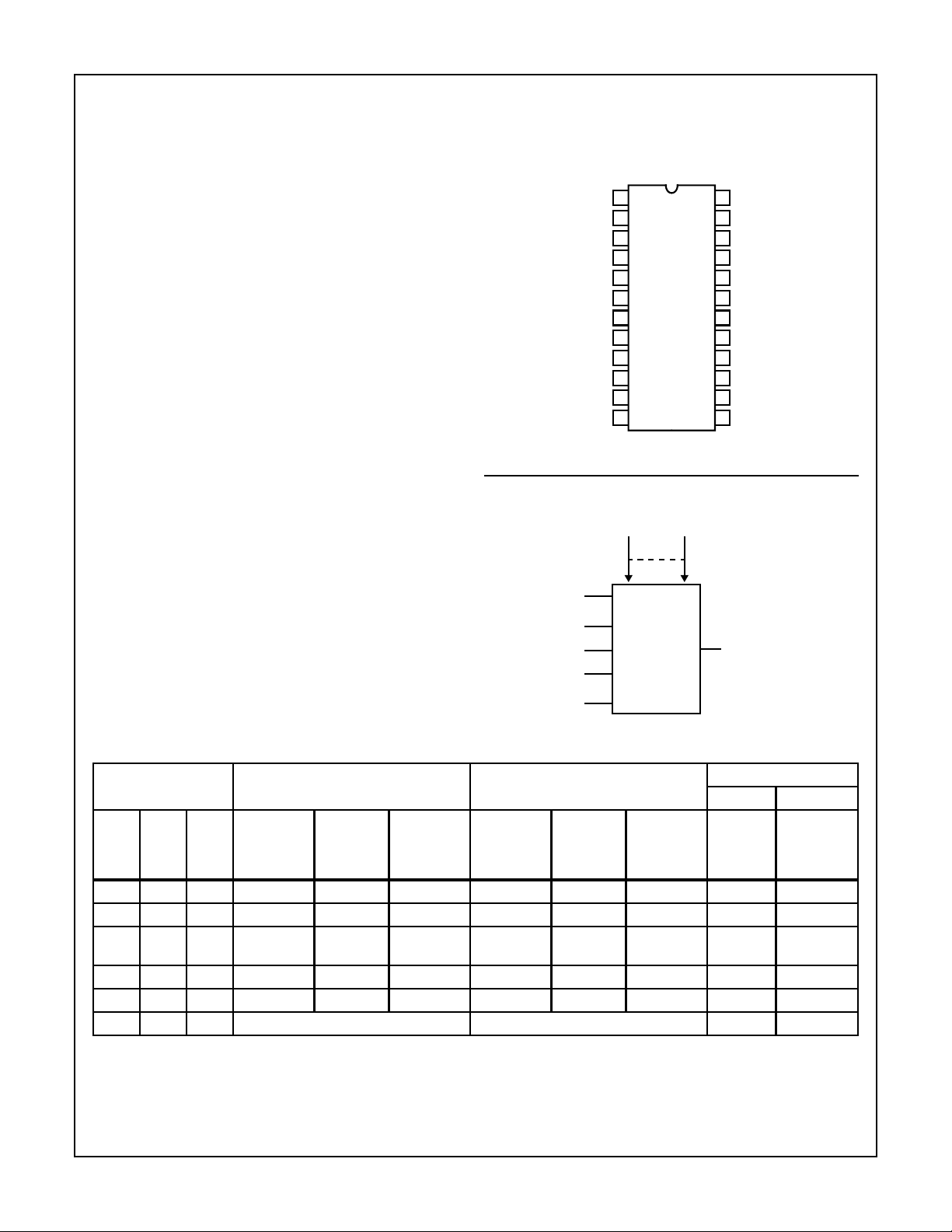

Pinout

CD74HC4059

TOP VIEW

CP

1

2

LE

J1

3

J2

4

J3

5

6

J4

J16

7

8

J15

J14

9

10

J13

K

11

c

12

GND

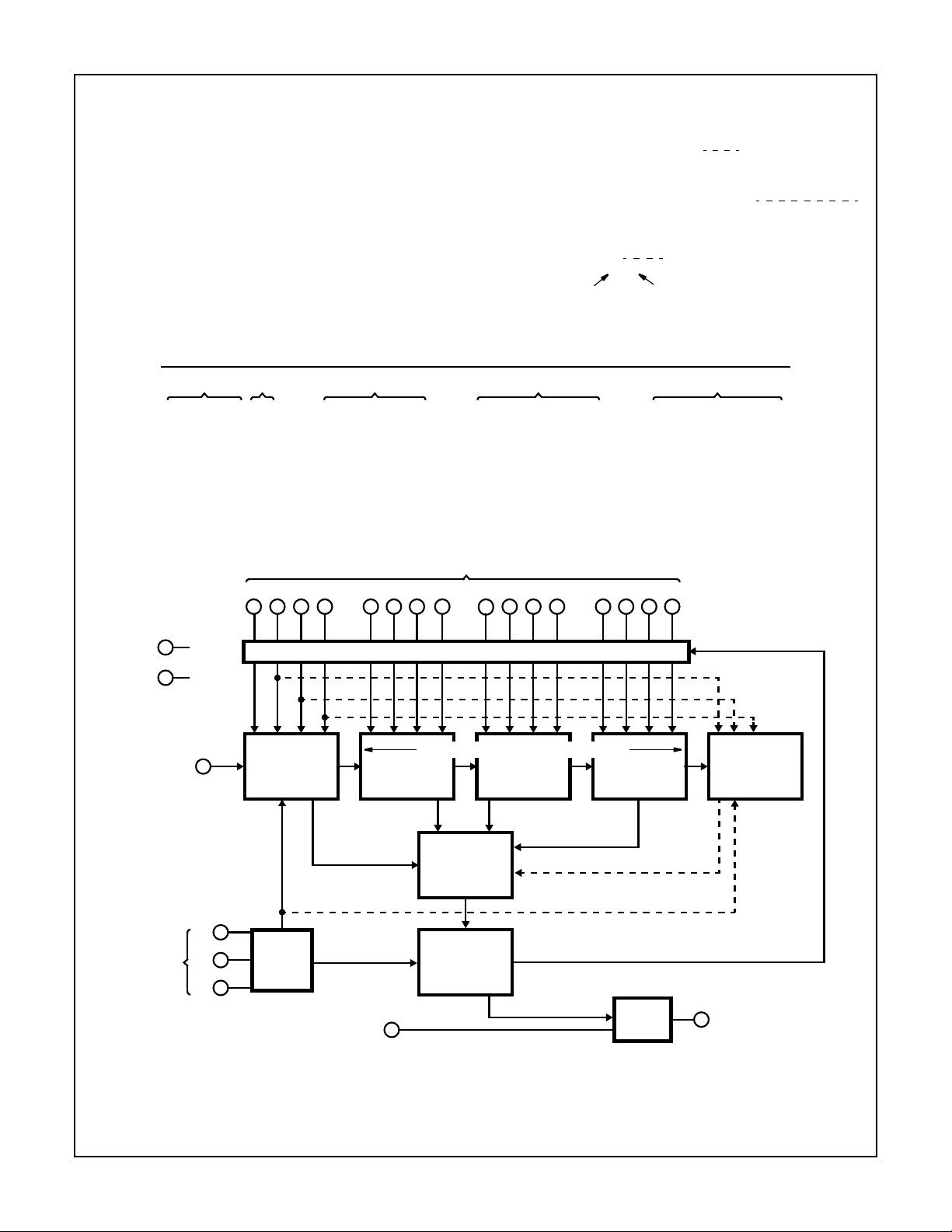

Functional Diagram

J1 - J16

(PDIP)

24

V

CC

23

Q

22

J5

21

J6

20

J7

19

J8

J9

18

17

J10

16

J11

15

J12

14

K

a

13

K

b

CP

K

K

K

LE

a

b

c

Q =

f

IN

-------

N

TRUTH TABLE

COUNTER RANGE

MODE SELECT INPUT FIRST COUNTING SECTION LAST COUNTING SECTION

CAN BE

PRESET

MODE

K

K

a

K

b

DIVIDES-BY

c

TO A MAX

OF:

(NOTE 3)

JAM

INPUTS

USED:

MODE

DIVIDES-BY

CAN BE

PRESET

TO A MAX

OF:

(NOTE 3)

JAM

INPUTS

USED: MAX MAX

DESIGN EXTENDED

H H H 2 1 J1 8 7 J2, J3, J4 15,999 17,331

L H H 4 3 J1, J2 4 3 J3, J4 15,999 18,663

HLH 5

4 J1, J2, J3 2 1 J4 9,999 13,329

(Note 4)

L L H 8 7 J1, J2, J3 2 1 J4 15,999 21,327

H H L 10 9 J1, J2, J3, J4 1 0 - 9,999 16,659

X L L Master Preset Master Preset - -

NOTES:

2. X = Don’t Care

3. J1 = Least Significant Bit. J4 = Most Significant Bit.

4. Operation in the ÷5 mode (1stcounting section) requires going through theMaster Preset mode prior to going into the ÷5 mode. At power

turn-on, Kc must be “low” for a period of 3 input clock pulses after VCC reaches a minimum of 3V.

2

CD74HC4059CD74HC4059

How to Preset the CD74HC/HCT4059 to Desired ÷N

The value N is determined as follows:

(EQ. 1)

N = (MODE†) (1000 x Decade 5 Preset + 100 x Decade 4

Preset + 10 x Decade 3 Preset + 1 x Decade 2 Preset) +

Decade 1 Preset

† MODE = First counting section divider (10, 8, 5, 4 or 2)

To calculate preset values for any N count, divide the N

count by the Mode. The resultant is the corresponding

preset values of the 5th through 2nd decade with the

remainder being equal to the 1st decade value.

Program Jam Inputs (BCD)

Example:

N = 8479, Mode = 5

Mode N

Preset Value =

N

Mode

1695 + 4 (Preset Values)

| 8479

5

(EQ. 2)

Mode Select = 5

K

aKbKc

HLH

41

J1 J2 J3 J4

L LH H

NOTE:

To verify the results, use Equation 1:

N = 5 (1000 x 1 + 100 x 6 + 10 x 9 + 1 x 5) + 4

N = 8479

J13J24J35J4

12

GND

24

V

CC

CLOCK

INPUT

1

FIRST

COUNTING

SECTION

÷10, 8, 5, 4, 2

J5 J6 J7 J8

H LHL

6

5

9

J9 J10 J11 J12

HLLH

PROGRAM JAM INPUTS (BCD)

J522J621J720J8

PRESETTABLE LOGIC

INTERMEDIATE COUNTING SECTION

÷10 ÷10 ÷10

J918J1017J1116J1215J1310J149J158J16

19

6

J13 J14 J15 J16

LHHL

7

P.E.

LAST

COUNTING

SECTION

÷1, 2, 2, 4, 8

MODE

SELECT

INPUTS

RECOGNITION

GATING

14

K

a

13

K

b

11

K

c

MODE

CONTROL

LATCH

ENABLE

PRESET

ENABLE

2

OUTPUT

STAGE

23

DIVIDE-BY-N

OUTPUT

FIGURE 1. FUNCTIONAL BLOCK DIAGRAM

3

CD74HC4059CD74HC4059

Absolute Maximum Ratings Thermal Information

DC Supply Voltage, VCC. . . . . . . . . . . . . . . . . . . . . . . . -0.5V to 7V

DC Input Diode Current, I

IK

For VI < -0.5V or VI > VCC + 0.5V. . . . . . . . . . . . . . . . . . . . . .±20mA

DC Output Diode Current, I

OK

For VO < -0.5V or VO > VCC + 0.5V . . . . . . . . . . . . . . . . . . . .±20mA

DC Output Source or Sink Current per Output Pin, I

O

For VO > -0.5V or VO < VCC + 0.5V . . . . . . . . . . . . . . . . . . . .±25mA

DC VCC or Ground Current, ICC . . . . . . . . . . . . . . . . . . . . . . . . .±50mA

Operating Conditions

Temperature Range, TA . . . . . . . . . . . . . . . . . . . . . . -55oC to 125oC

Supply Voltage Range, VCC. . . . . . . . . . . . . . . . . . . . . . . . .2V to 6V

DC Input or Output Voltage, VI, VO . . . . . . . . . . . . . . . . . 0V to V

Input Rise and Fall Time

2V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1000ns (Max)

4.5V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500ns (Max)

6V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400ns (Max)

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

5. θJA is measured with the component mounted on an evaluation PC board in free air.

DC Electrical Specifications

Thermal Resistance (Typical, Note 5) θJA (oC/W)

PDIP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Maximum Junction Temperature (Hermetic P ac kage or Die) . . . 175oC

Maximum Junction Temperature (Plastic Package) . . . . . . . . 150oC

Maximum Storage Temperature Range . . . . . . . . . .-65oC to 150oC

Maximum Lead Temperature (Soldering 10s). . . . . . . . . . . . . 300oC

CC

PARAMETER SYMBOL

High Level Input

Voltage

Low Level Input

Voltage

High Level Output

Voltage

CMOS Loads

High Level Output

Voltage

TTL Loads

Low Level Output

Voltage

CMOS Loads

Low Level Output

Voltage

TTL Loads

Input Leakage

Current

Quiescent Device

Current

TEST

CONDITIONS

V

CC

(V)

V

IH

- - 2 1.5 - - 1.5 - 1.5 - V

25oC -40oC TO 85oC -55oC TO 125oC

UNITSVI(V) IO(mA) MIN TYP MAX MIN MAX MIN MAX

4.5 3.15 - - 3.15 - 3.15 - V

6 4.2 - - 4.2 - 4.2 - V

V

IL

- - 2 - - 0.5 - 0.5 - 0.5 V

4.5 - - 1.35 - 1.35 - 1.35 V

6 - - 1.8 - 1.8 - 1.8 V

V

OH

VIH or

V

IL

-0.02 2 1.9 - - 1.9 - 1.9 - V

-0.02 4.5 4.4 - - 4.4 - 4.4 - V

-0.02 6 5.9 - - 5.9 - 5.9 - V

---------V

-4 4.5 3.98 - - 3.84 - 3.7 - V

-5.2 6 5.48 - - 5.34 - 5.2 - V

V

OL

VIH or

V

IL

0.02 2 - - 0.1 - 0.1 - 0.1 V

0.02 4.5 - - 0.1 - 0.1 - 0.1 V

0.02 6 - - 0.1 - 0.1 - 0.1 V

---------V

4 4.5 - - 0.26 - 0.33 - 0.4 V

5.2 6 - - 0.26 - 0.33 - 0.4 V

I

VCC or

I

-6--±0.1 - ±1-±1 µA

GND

I

CC

VCC or

0 6 - - 8 - 80 - 160 µA

GND

4

Prerequisite for Switching Specifications

CD74HC4059CD74HC4059

25oC -40oC TO 85oC -55oC TO 125oC

PARAMETER SYMBOL VCC(V)

Pulse Width CP t

W

2 90 - - 115 - - 135 - - ns

4.5 18 - - 23 - - 27 - - ns

615- -20- -23--ns

Setup Time

t

SU

2 75 - - 95 - - 110 - - ns

Kb, Kc to CP

4.5 15 - - 19 - - 22 - - ns

613- -16- -19--ns

CP Frequency f

MAX

2 5 - - 4 - - 4 - - MHz

4.5 27 - - 22 - - 18 - - MHz

6 32 - - 26 - - 21 - - MHz

Switching Specifications Input t

PARAMETER SYMBOL

Propagation Delay,

CP to Q

t

PLH

, tf = 6ns

r

, t

PHL

TEST

CONDITIONS

V

CC

(V)

CL= 50pF 2 - - 200 - 250 - 300 ns

4.5 - - 40 - 50 - 60 ns

6 - - 34 - 43 - 51 ns

CL= 15pF 5 - 17 - ----ns

Propagation Delay,

LE to Q

t

PLH

, t

CL= 50pF 2 - - 175 - 220 - 265 ns

PHL

4.5 - - 35 - 44 - 53 ns

6 - - 30 - 37 - 45 ns

CL= 15pF 5 - 14 - ----ns

Output Transition Time t

THL

, t

CL= 50pF 2 - - 75 - 95 - 110 ns

TLH

4.5 - - 15 - 19 - 22 ns

6 - - 13 - 16 - 19 ns

CP Frequency f

MAX

Input Capacitance C

Power Dissipation Capacitance

C

I

PD

CL= 15pF 5 - 54 - ----MHz

- - - - 10 - 10 - 10 pF

- 5-36-----pF

(Notes 6, 7)

NOTES:

6. CPD is used to determine the dynamic power consumption, per package.

7. PD=CPDV

CC

2

fi+ Σ CLV

2

fowhere fi= input frequency, fo= output frequency, CL= output load capacitance, VCC= supply voltage.

CC

UNITSMIN TYP MAX MIN TYP MAX MIN TYP MAX

25oC -40oC TO 85oC -55oC TO 125oC

UNITSMIN TYP MAX MIN MAX MIN MAX

5

CD74HC4059CD74HC4059

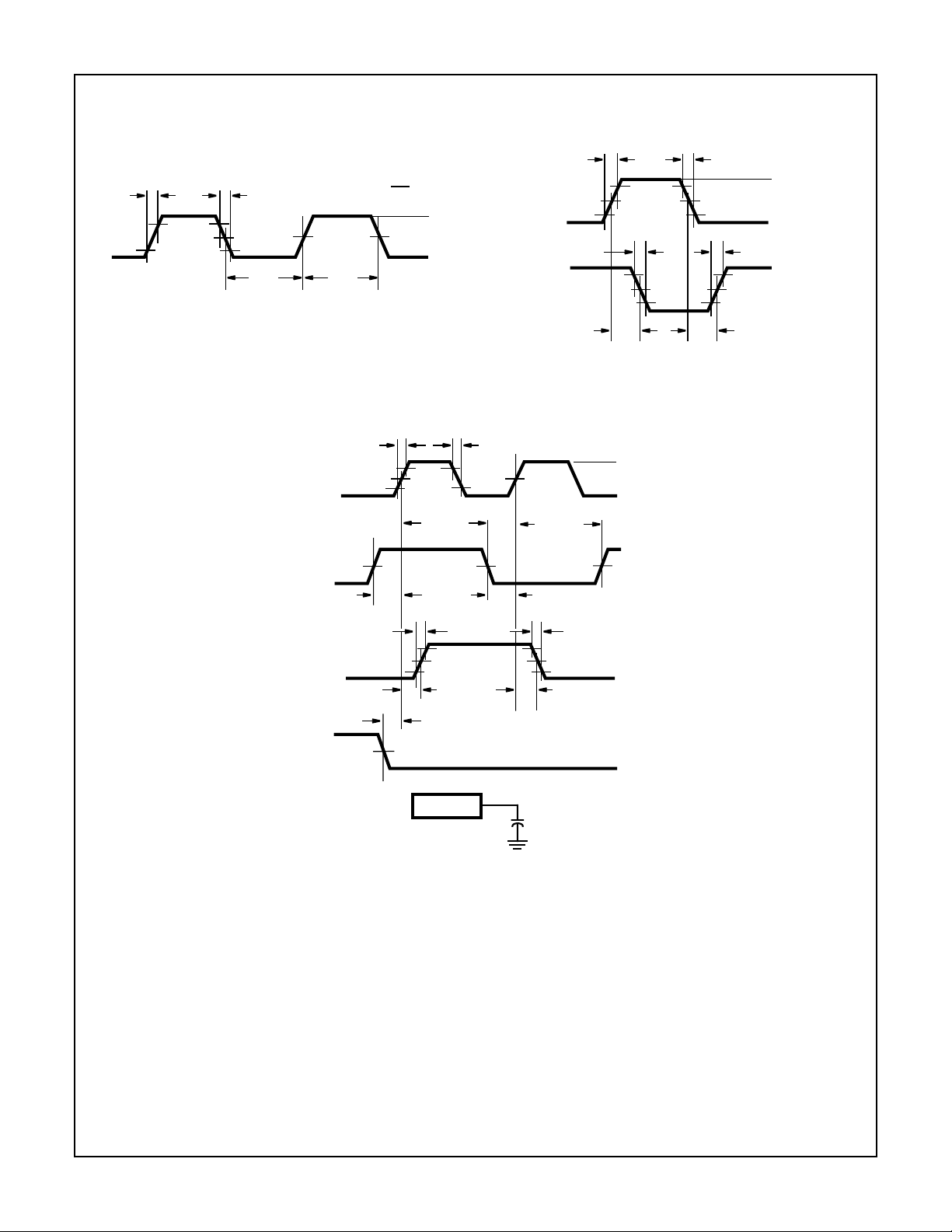

Test Circuits and Waveforms

trC

L

CLOCK

10%

90%

50%

10%

tfC

t

L

WL

tWL+ tWH=

50%

t

WH

NOTE: Outputs should be switching from 10% VCC to 90% VCC in

accordance with devicetruth table. For f

, input duty cycle = 50%.

MAX

FIGURE 2. HC CLOCK PULSE RISE AND FALLTIMES AND

PULSE WIDTH

fC

50%

I

L

V

CC

GND

tr = 6ns tf = 6ns

V

t

TLH

CC

GND

INPUT

INVERTING

OUTPUT

t

THL

t

PHL

90%

50%

10%

t

90%

50%

10%

PLH

FIGURE 3. HC TRANSITION TIMES AND PROPAGATION

DELAY TIMES, COMBINATION LOGIC

90%

t

PLH

IC

t

TLH

tfC

L

50%

t

H(L)

t

SU(L)

t

THL

90%

50%

10%

t

PHL

C

L

50pF

CLOCK

INPUT

DAT A

INPUT

t

SU(H)

OUTPUT

t

REM

V

CC

SET, RESET

OR PRESET

trC

L

90%

10%

t

H(H)

50%

FIGURE 4. HC SETUP TIMES, HOLD TIMES, REMOVAL

TIME, AND PROPAGATION DELAY TIMES FOR EDGE

TRIGGERED SEQUENTIAL LOGIC CIRCUITS

V

CC

GND

V

CC

50%

GND

GND

6

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...