Data sheet acquired from Harris Semiconductor

/

j

/

SCHS165

September 1997

CD74HC195

High Speed CMOS Logic

4-Bit Parallel Access Register

[ /Title

(CD74

HC195

)

Sub-

ect

(High

Speed

CMOS

Logic

4-Bit

Parallel

Access

Register)

Autho

Features

• Asynchronous Master Reset

K, (D) Inputs to First Stage

•J,

• Fully Synchronous Serial or Parallel Data Transfer

• Shift Right and Parallel Load Capability

• Complementary Output From Last Stage

• Buffered Inputs

• Typical f

C

= 15pF, TA = 25oC

L

• Fanout (Over Temperature Range)

- Standard Outputs. . . . . . . . . . . . . . . 10 LSTTL Loads

- Bus Driver Outputs . . . . . . . . . . . . . 15 LSTTL Loads

• Wide Operating Temperature Range . . . -55

• Balanced Propagation Delay and Transition Times

• Significant Power Reduction Compared to LSTTL

Logic ICs

• HC Types

- 2V to 6V Operation

- High NoiseImmunity: N

V

CC

= 50MHz at VCC = 5V,

MAX

= 5V

o

C to 125oC

= 30%, NIH= 30%of VCCat

IL

Description

The device is useful in a wide variety of shifting, counting

and storage applications. It performs serial, parallel, serial to

parallel, or parallel to serial data transfers at very high

speeds.

The two modes of operation, shift right (Q

load, are controlled by the state of the Parallel Enable (

input. Serial data enters the first flip-flop (Q

inputs when the

direction Q

transition. The J and K inputs provide the flexibility of the JKtype input for special applications and by tying the two pins

together, the simple D-type input for general applications.

The device appears as four common-clocked D flip-flops

when the

tion, data on the parallel inputs (D0-D3) is transferred to the

respective Q

be achieved by tying the Q

holding the

All parallel and serial data transfers are synchronous, occurring

after each Low to High clock transition. The CD74HC195 series

utilizes edge triggering; therefore, there is no restriction on the

activity of the J,

than set-up and hold time requirements. A Low on the

asynchronous Master Reset (

independent of any other input condition.

PE input is high, and is shifted one bit in the

0-Q1-Q2-Q3

PE input is Low. After the Low to High clock transi-

0-Q3

PE input low.

K, Pn and PE inputs for logic operations, other

following each Low to High clock

outputs. Shift left operation (Q3-Q2) can

outputs to the Dn-1 inputs and

n

MR) input sets all Q outputs Low,

) and parallel

0-Q1

) via the J and K

0

PE)

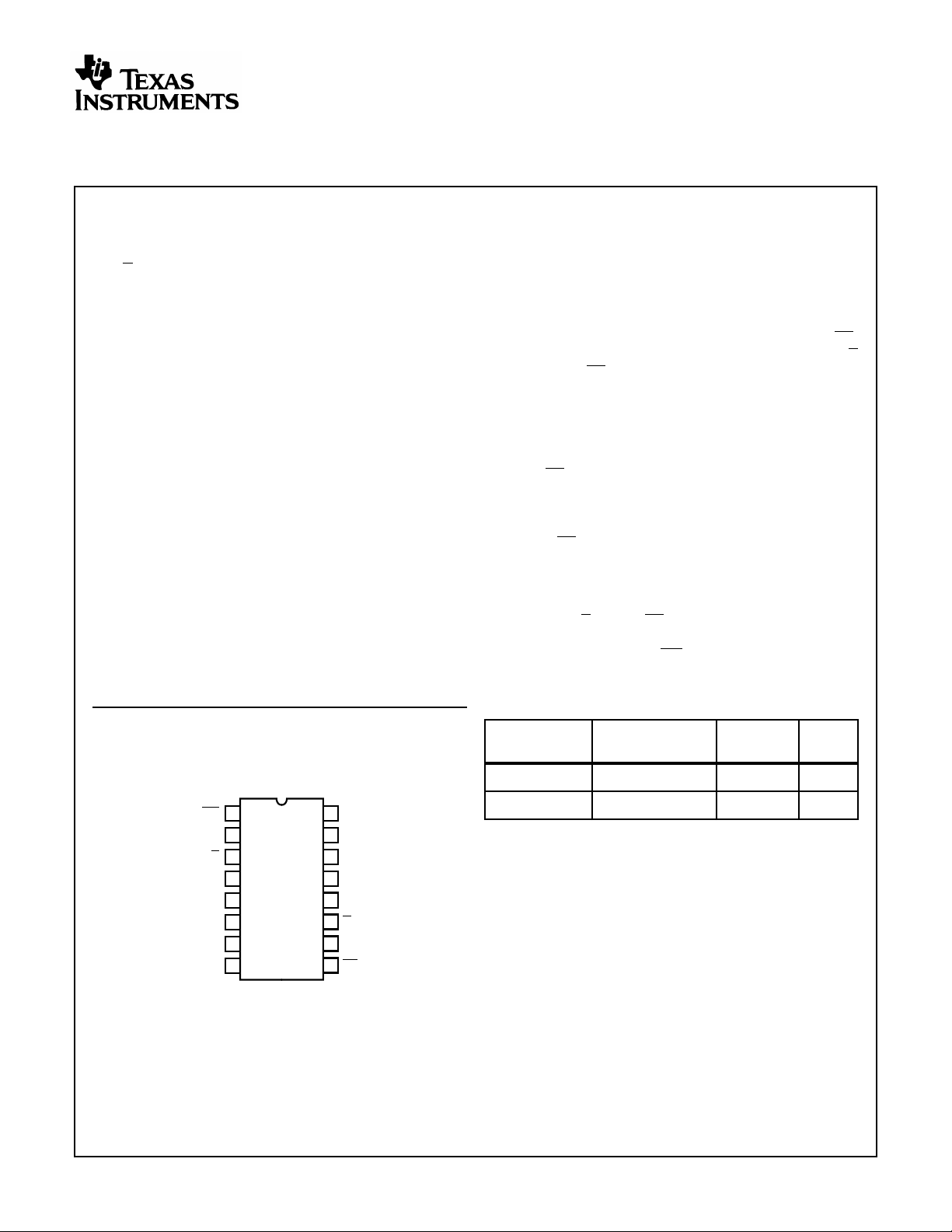

PInout

MR

D0

D1

D2

D3

GND

1

2

J

3

K

4

5

6

7

8

CD74HC195

(PDIP, SOIC)

TOP VIEW

Ordering Information

PKG.

PART NUMBER TEMP. RANGE (oC) PACKAGE

CD74HC195E -55 to 125 16 Ld PDIP E16.3

16

V

CC

15

Q

0

14

Q

1

13

Q

2

12

Q

3

11

Q

3

10

CP

9

PE

CD74HC195M -55 to 125 16 Ld SOIC M16.15

NOTES:

1. When ordering, use the entire part number.

2. Die for this part number is available which meets all electrical

specifications. Please contact your local sales office or Harris

customer service for ordering information.

NO.

CAUTION: These devices are sensitive to electrostatic discharge. Users should follow proper IC Handling Procedures.

Copyright

© Harris Corporation 1997

1

File Number 1482.1

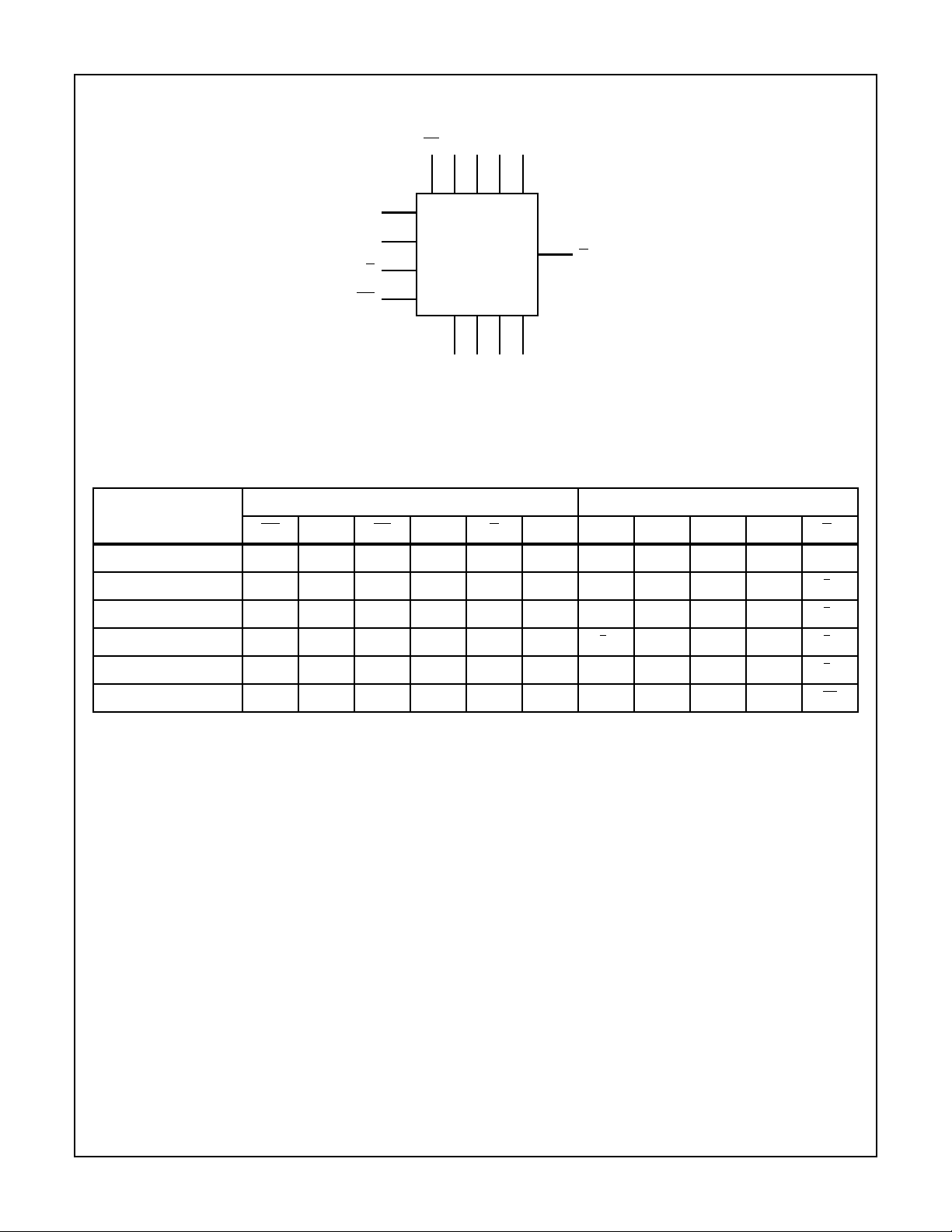

Functional Diagram

CP

MR

CD74HC195

D0D1D2D

PE

94567

2

J

10

3

K

1

15 14 13 12

3

11

Q

3

Q0Q1Q2Q

3

TRUTH TABLE

INPUTS OUTPUT

OPERATING MODES

MR CP PE J KDnQ0Q

Q

1

Q

2

Q

3

3

Asynchronous Reset L XXXXXLLLLH

Shift, Set First Stage H ↑ hhhX

H

Shift, Reset First Stage H ↑ hllXLq0q

Shift, Toggle First Stage H ↑ hhlXq

0

Shift, Retain First Stage H ↑ hlhXq0q

Parallel Load H ↑ lXXdnd0d

q

0

q

0

0

1

q

1

1

q

1

q

1

d

2

q

2

q

2

q

2

q

2

q

q

q

q

d3 d2

2

2

2

2

NOTE: H = High Voltage Level

L = Low Voltage Level,

X = Don’t Care

↑ = Transition from Low to High Level

l = Low Voltage Level One Set-up Time Prior to the Low to High Clock Transition

h = Low Voltage Level One Set-up Time prior to the High to Low Clock Transition,

dn (qn) = Lower Case Letters Indicate the State of the Referenced Input (or output) One Set-up Time Prior to the Low to High Clock

Transition.

2

CD74HC195

Absolute Maximum Ratings Thermal Information

DC Supply Voltage, VCC. . . . . . . . . . . . . . . . . . . . . . . . -0.5V to 7V

DC Input Diode Current, I

IK

For VI < -0.5V or VI > VCC + 0.5V. . . . . . . . . . . . . . . . . . . . . .±20mA

DC Output Diode Current, I

OK

For VO < -0.5V or VO > VCC + 0.5V . . . . . . . . . . . . . . . . . . . .±20mA

DC Output Source or Sink Current per Output Pin, I

O

For VO > -0.5V or VO < VCC + 0.5V . . . . . . . . . . . . . . . . . . . .±25mA

DC VCC or Ground Current, I

CC orIGND

. . . . . . . . . . . . . . . . . .±50mA

Operating Conditions

Temperature Range (TA) . . . . . . . . . . . . . . . . . . . . . -55oC to 125oC

Supply Voltage Range, V

HC Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2V to 6V

HCT Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.5V to 5.5V

DC Input or Output Voltage, VI, VO . . . . . . . . . . . . . . . . . 0V to V

Input Rise and Fall Time

2V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1000ns (Max)

4.5V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500ns (Max)

6V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400ns (Max)

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

3. θJA is measured with the component mounted on an evaluation PC board in free air.

CC

Thermal Resistance (Typical, Note 3) θJA (oC/W)

PDIP Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

SOIC Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Maximum Junction Temperature. . . . . . . . . . . . . . . . . . . . . . .150oC

Maximum Storage Temperature Range . . . . . . . . . .-65oC to 150oC

Maximum Lead Temperature (Soldering 10s). . . . . . . . . . . . .300oC

(SOIC - Lead Tips Only)

CC

DC Electrical Specifications

TEST

CONDITIONS

PARAMETER SYMBOL

High Level Input

Voltage

Low Level Input

Voltage

High Level Output

Voltage

V

IH

V

IL

V

OH

CMOS Loads

High Level Output

Voltage

TTL Loads

Low Level Output

Voltage

V

OL

CMOS Loads

Low Level Output

Voltage

TTL Loads

Input Leakage

Current

Quiescent Device

I

CC

I

I

Current (Note)

NOTE: For dual-supply systems theorectical worst case (V

(V) IO(mA) MIN TYP MAX MIN MAX MIN MAX

I

- - 2 1.5 - - 1.5 - 1.5 - V

- - 2 - - 0.5 - 0.5 - 0.5 V

VIHor VIL-0.02 2 1.9 - - 1.9 - 1.9 - V

-0.02 4.5 4.4 - - 4.4 - 4.4 - V

-0.02 6 5.9 - - 5.9 - 5.9 - V

- - ---- - - - V

-4 4.5 3.98 - - 3.84 - 3.7 - V

-5.2 6 5.48 - - 5.34 - 5.2 - V

VIHor VIL0.02 2 - - 0.1 - 0.1 - 0.1 V

0.02 4.5 - - 0.1 - 0.1 - 0.1 V

0.02 6 - - 0.1 - 0.1 - 0.1 V

- - ---- - - - V

4 4.5 - - 0.26 - 0.33 - 0.4 V

5.2 6 - - 0.26 - 0.33 - 0.4 V

VCC or

-6--±0.1 - ±1-±1 µA

GND

VCC or

0 6 - - 8 - 80 - 160 µA

GND

o

25

C -40oC TO 85oC -55oC TO 125oC

(V)

V

CC

4.5 3.15 - - 3.15 - 3.15 - V

6 4.2 - - 4.2 - 4.2 - V

4.5 - - 1.35 - 1.35 - 1.35 V

6 - - 1.8 - 1.8 - 1.8 V

= 2.4V, VCC = 5.5V) specification is 1.8mA.

I

UNITSV

3

Prerequisite For Switching Function

PARAMETER SYMBOL

Clock Frequency f

MR Pulse Width t

Clock Pulse Width t

Set-up Time

J, K, PE to Clock

Hold Time

J, K, PE to Clock

Removal Time,

MR to Clock

MAX

t

t

REM

SU

t

w

w

H

CD74HC195

TEST

CONDITIONS VCC (V)

- 26-5-4-MHz

4.5 30 - 25 - 20 - MHz

6 35 - 29 - 23 - MHz

- 2 80 - 100 - 120 - ns

4.5 16 - 20 - 24 - ns

614-17-20-ns

- 2 80 - 100 - 120 - ns

4.5 16 - 20 - 24 - ns

614-17-20-ns

- 2 100 - 125 - 150 - ns

4.5 20 - 25 - 30 - ns

617-21-26-ns

- 23-3-3-ns

4.53-3-3-ns

65-3-3-ns

- 2 80 - 100 - 120 - ns

4.5 16 - 20 - 24 - ns

614-17-20-ns

25oC -40oC TO 85oC -55oC TO 125oC

UNITSMIN MAX MIN MAX MIN MAX

Switching Specifications Input t

, tf = 6ns

r

TEST

PARAMETER SYMBOL

CONDITIONS VCC (V)

HC TYPES

Propagation Delay, CP to

Output

t

PLH

, t

PHLCL

= 50pF 2 - 175 220 265 ns

4.5 - 35 44 53 ns

6 - 30 37 45 ns

Propagation Delay,

MR toOutput

t

PLH

, t

PHLCL

= 50pF 2 - 150 190 225 ns

4.5 - 30 38 45 ns

6 - 26 33 38 ns

Output Transition Times

(Figure 1)

t

TLH

, t

THLCL

= 50pF 2 - 75 95 110 ns

4.5 - 15 19 22 ns

6 - 13 16 19 ns

Input Capacitance C

CP to Qn Propagation Delay t

MR to Q

n

PLH

Maximum Clock Frequency f

Power Dissipation

IN

, t

PHLCL

t

PHL

MAX

C

PD

---1010 10pF

= 15pF 5 14 - - - ns

CL= 15pF 5 13 - - - ns

CL= 15pF 5 50 - - - MHz

CL= 15pF 45 - - - pF

Capacitance (Notes 4, 5)

NOTES:

4. CPD is used to determine the dynamic power consumption, per flip-flop.

5. PD=V

CC

2

fi+∑ (CLV

2

+fO) where fi= Input Frequency, fO= Output Frequency, CL= Output Load Capacitance, VCC= Supply Voltage.

CC

25oC -40oC TO 85oC -55oC TO 125oC

UNITSTYP MAX MAX MAX

4

Test Circuit and Waveforms

CLOCK

Q OR

t

r

90%

V

S

10%

t

W

t

PLHtPHL

Q

90%

10%

l/f

t

TLH

MAX

t

t

f

THL

0.5 V

V

CC

GND

CC

CD74HC195

RESET

CLOCK

Q

t

PHL

Q

t

W

V

S

t

PLH

0.5 V

CC

V

S

t

REM

0.5 V

CC

V

CC

GND

V

CC

GND

FIGURE 1. CLOCK PRE-REQUISITE AND PROPAGATION

DELAYS AND OUTPUT TRANSITION TIMES

PE, K

J

t

SU

CLOCK

FIGURE 3. J, K OR PARALLEL ENABLE PRE-REQUISITE TIMES

FIGURE 2. MASTER RESET PRE-REQUISITE AND

PROPAGATION DELAYS

VALID

V

V

S

t

h

0.5 V

CC

CC

GND

GND

5

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...