Datasheet CD4541BPWR, CD4541BM96, CD4541BM, CD4541BF3A, CD4541BF Datasheet (Texas Instruments)

...

CD4541B

/

j

/

/

[ /Title

(CD45

41B)

Sub-

ect

(CMO

S Programmable

Timer

High

Voltage

Types

(20V

Rating))

Autho

r ()

Keywords

(Harris

Semiconductor,

CD400

0,

metal

gate,

CMOS

, pdip,

cerdip,

mil,

military,

mil

Data sheet acquired from Harris Semiconductor

SCHS085

Features

• Low Symmetrical Output Resistance, Typically 100Ω

at V

= 15V

DD

• Built-In Low-Power RC Oscillator

• Oscillator Frequency Range. . . . . . . . . . DC to 100kHz

• External Clock (Applied to Pin 3) can be Used Instead

of Oscillator

N

• Operates as 2

Transition Timer

Q Select Provides Output Logic Level Flexibility

•Q/

• AUTO or MASTER RESET Disables Oscillator During

Reset to Reduce Power Dissipation

• Operates With Very Slow Clock Rise and Fall Times

• Capable of Driving Six Low Power TTL Loads, Three

Low-Power Schottky Loads, or Six HTL Loads Over

the Rated Temperature Range

• Symmetrical Output Characteristics

• 100% Tested for Quiescent Current at 20V

• 5V, 10V, and 15V Parametric Ratings

• Meets All Requirements of JEDEC Standard No. 13B,

“Standard Specifications for Description of ‘B’ Series

CMOS Devices”

Frequency Divider or as a Single-

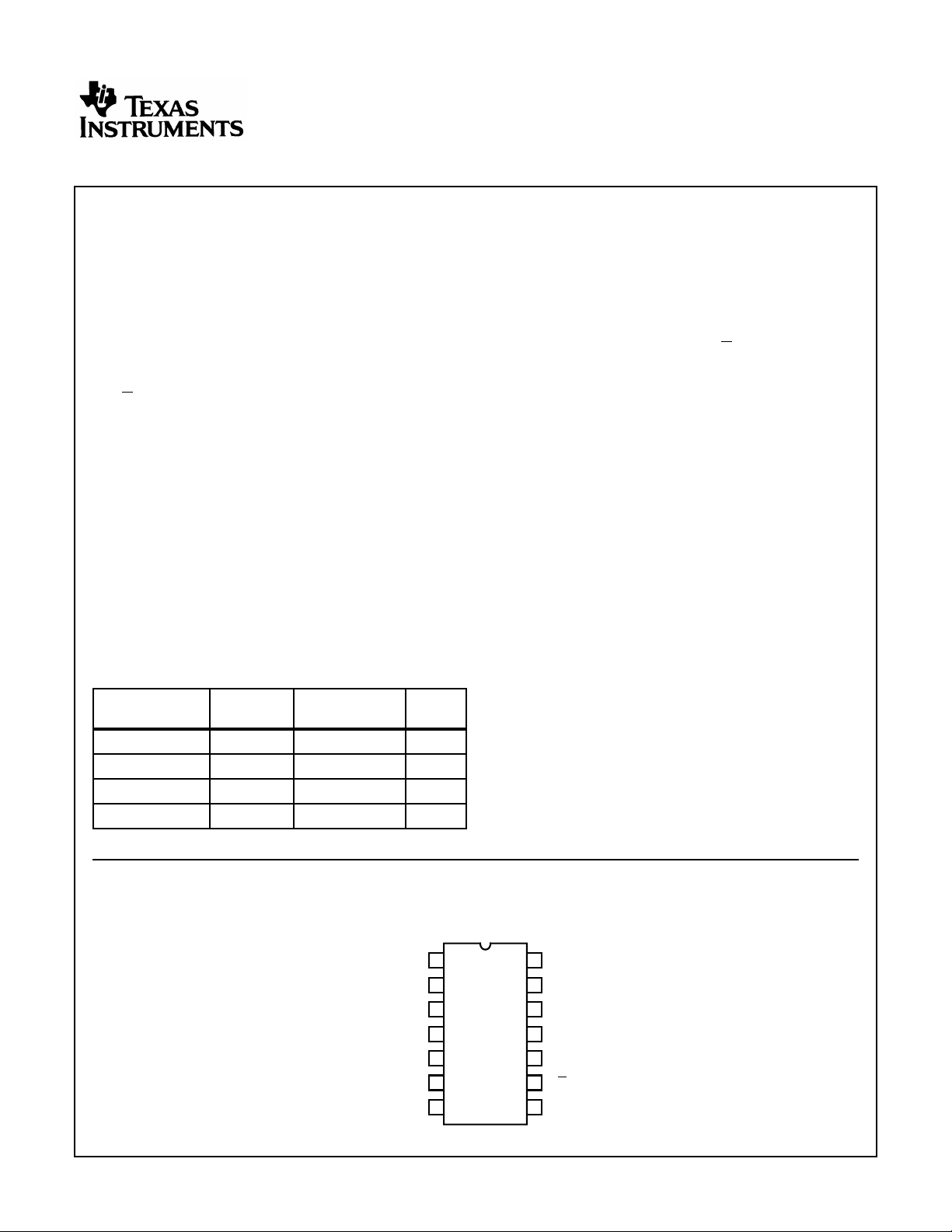

Ordering Information

TEMP.

PART NUMBER

CD4541BF -55 to 125 14 Ld CERDIP F14.3

CD4541BE -55 to 125 14 Ld PDIP E14.3

CD4541BH -55 to 125 Chip CD4541BM -55 to 125 14 Ld SOIC M14.15

RANGE (oC) PACKAGE

Pinout

CD4541B (CERDIP, PDIP, SOIC)

R

TC

C

TC

R

NC

AUTO RESET

MASTER RESET

V

SS

PKG.

NO.

S

1

2

3

4

5

6

7

CMOS Programmable Timer

High Voltage Types (20V Rating)

Description

CD4541B programmable timer consists of a 16-stage binary

counter, an oscillator that is controlled by external R-C components (2 resistors and a capacitor), an automatic power-on

reset circuit, and output control logic. The counter increments

on positive-edge clock transitions and can also be reset via the

MASTER RESET input.

The output from this timer is the Q or

10th, 13th, or 16th counter stage. The desired stage is chosen

using time-select inputs A and B (see Frequency Select Table).

The output is available in either of two modes selectable via the

MODE input, pin 10 (see TruthTable). When this MODE input is

a logic “1”, the output will be a continuous square wave having

a frequency equal to the oscillator frequency divided by 2

With the MODE input set to logic “0” and after a MASTER

RESET is initiated, the output (assuming Q output has been

selected) changes from a low to a high state after 2

and remains in that state until another MASTER RESET pulse

is applied or the MODE input is set to a logic “1”.

Timing is initialized by setting the AUTO RESET input (pin 5) to

logic “0” and turning power on. If pin 5 is set to logic “1”, the

AUT ORESET circuit is disabled and counting will not start until

after a positive MASTER RESET pulse is applied and returns

to a low level. The AUTO RESET consumes an appreciable

amount of power and should not be used if low-power operation

is desired. For reliable automatic power-on reset, V

be greater than 5V.

The RC oscillator, shown in Figure 2, oscillates with a

frequency determined by the RC network and is calculated

using:

f =

TOP VIEW

1

---------------------------------- -

2.3 R

TCCTC

V

14

DD

B

13

12

A

11

NC

10

MODE

9

Q/

8

OUTPUT

Where f is between 1kHz

and 100kHz

and R

S

Q SELECT

10k≥Ωand 2RTC≈

Q output from the 8th,

N-1

DD

N

counts

should

.

CAUTION: These devices are sensitive to electrostatic discharge. Users should follow proper IC Handling Procedures.

Copyright

© Harris Corporation 1998

1

File Number 1378.1

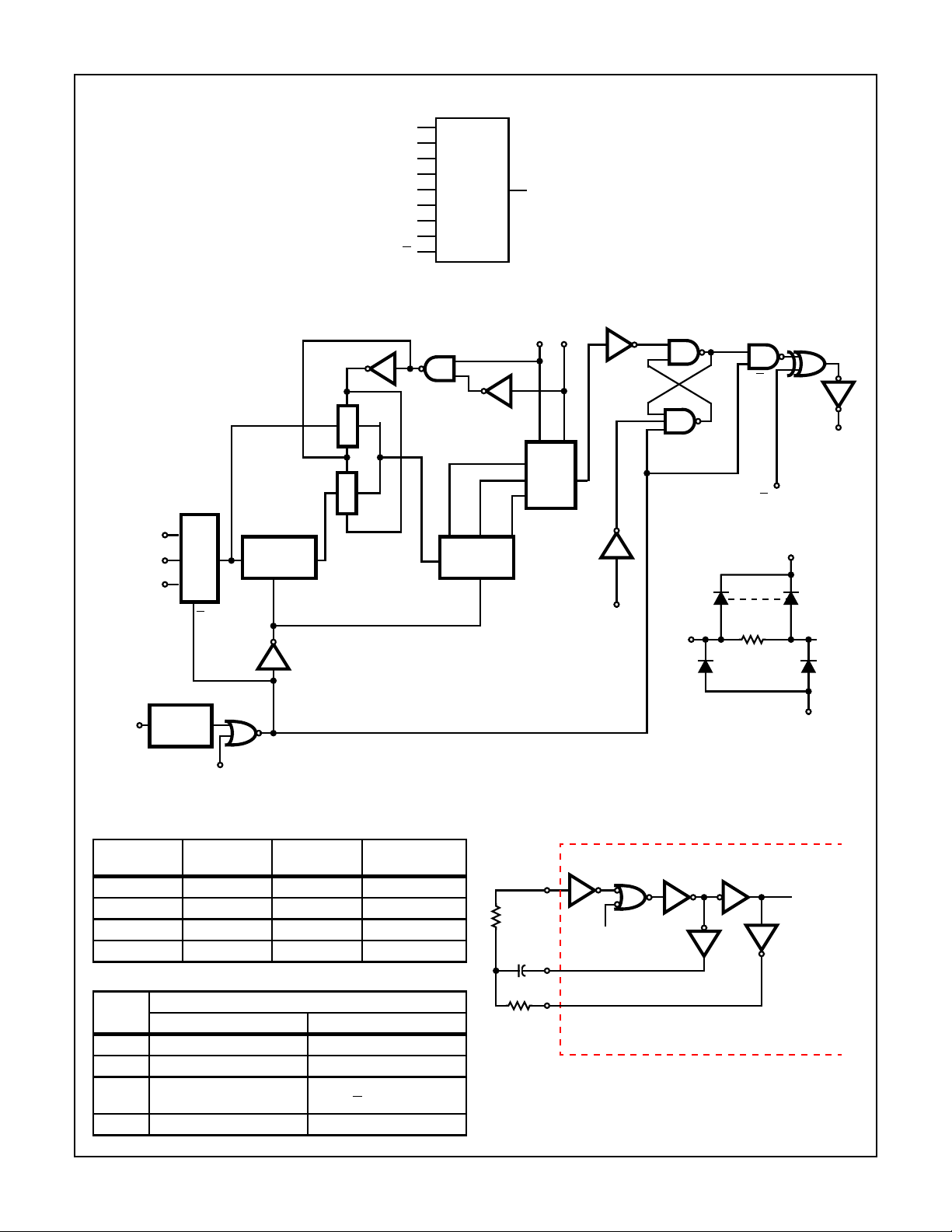

Functional Diagram

R

TC

C

TC

R

AR

MR

MODE

Q/

SELECT

CD4541B

12

A

13

B

1

2

3

S

5

6

10

9

Q

8

V

DD

V

SS

Q

= PIN 14

= PIN 7

Functional Block Diagram

3

†R

S

2

†C

TC

1

†R

TC

5

PWR ON

RESET

AUTO

RESET†

MANUAL RESET†

OSC

R

8-STAGE

COUNTER

R

6

N

P

N

P

V

= 14

DD

V

= 7 NC = 4, 11

SS

2102

8-STAGE

COUNTER

FIGURE 1.

12 13

†A †B

R

8

Q

1 OF 3

MUX

16

2

OR

13

8

2

R

10

†Q/Q SELECT

9

V

DD

†MODE

V

SS

† All inputs are protected by CMOS Protection Network.

FREQUENCY SELECTION TABLE

NO. OF

AB

STAGES N COUNT 2

N

0 0 13 8192

0 1 10 1024

108256

1 1 16 65536

TRUTH TABLE

STATE

PIN

01

5 Auto Reset On Auto Reset Disable

6 Master Reset Off Master Reset On

9 Output Initially Low After

Reset (Q)

Output Initially High After

Q)

Reset (

10 Single Transition Mode Recycle Mode

3

R

S

C

TC

R

TC

2

1

INTERNAL

RESET

TO CLOCK

CKT

FIGURE 2. RC OSCILLATOR CIRCUIT

2

CD4541B

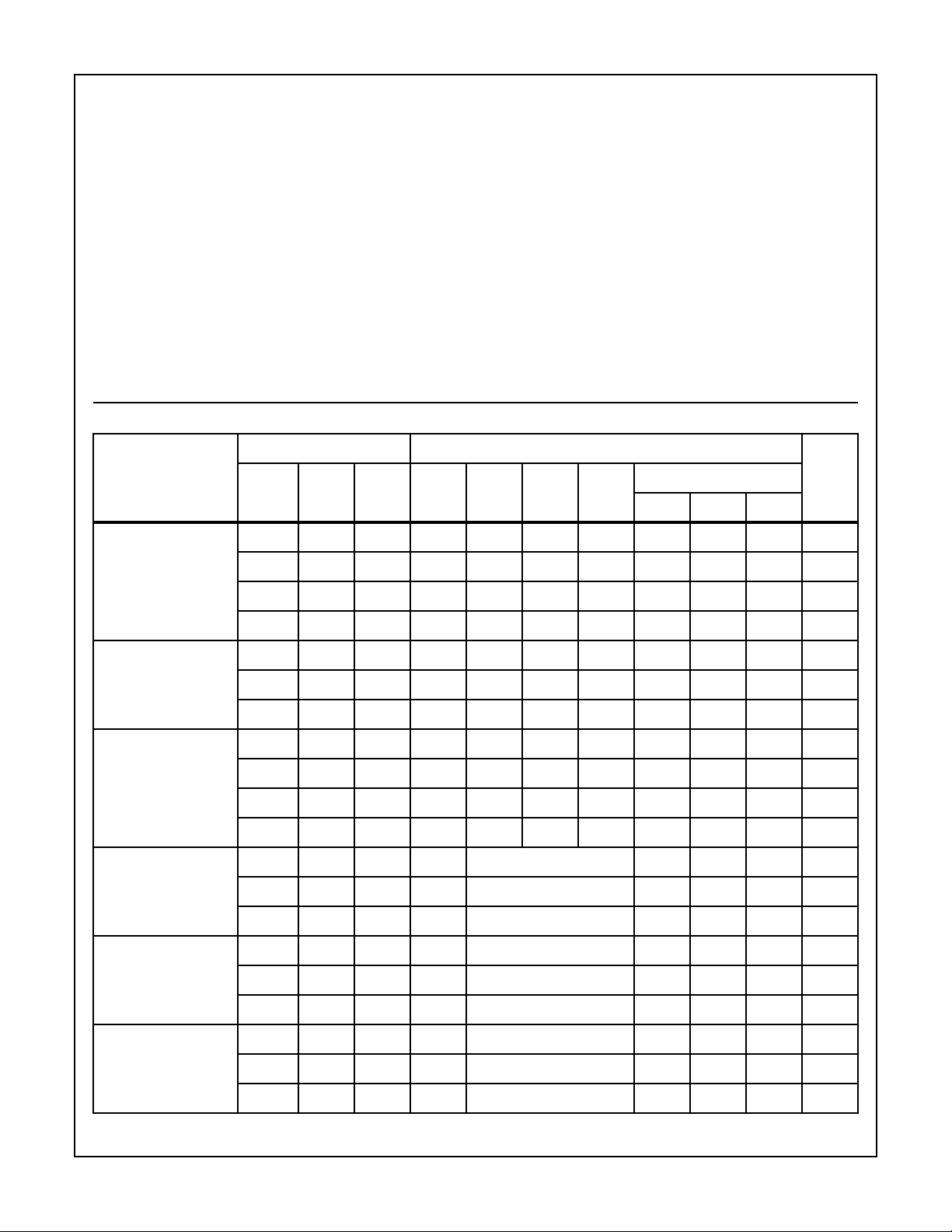

Absolute Maximum Ratings Thermal Information

DC Supply - Voltage Range, V

Voltages Referenced to VSSTerminal . . . . . . . . . . -0.5V to +20V

Input Voltage Range, All Inputs . . . . . . . . . . . . . -0.5V to VDD+0.5V

DC Input Current, Any One Input . . . . . . . . . . . . . . . . . . . . . ±10mA

Device Dissipation Per Output Transistor

For TA = Full Package Temperature Range

(All Package Types) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100mW

DD

Operating Conditions

Temperature Range TA. . . . . . . . . . . . . . . . . . . . . . . -55oC to 125oC

Supply Voltage Range

For TA = Full Package Temperature Range . . . . .3V (Min), 18V (Typ)

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

Electrical Specifications

CONDITIONS LIMITS AT INDICATED TEMPERATURES (oC)

Thermal Resistance (Typical, Note 1) θJA (oC/W) θJC (oC/W)

PDIP Package. . . . . . . . . . . . . . . . . . . 90 N/A

CERDIP Package . . . . . . . . . . . . . . . . 90 36

SOIC Package. . . . . . . . . . . . . . . . . . . 120 N/A

Maximum Junction Temperature (Plastic Package) . . . . . . . . 150oC

Maximum Storage Temperature Range (T

Maximum Lead Temperature (Soldering 10s)

At Distance 1/16in ± 1/32in (1.59mm ±0.79mm)

from case for 10s Maximum . . . . . . . . . . . . . . . . . . . . . . . . 265oC

(SOIC - Lead Tips Only)

) . . . -65oC to 150oC

STG

PARAMETER

Quiescent Device

Current,

(Note 2) IDD (Max)

Output Low (Sink)

Current lOL(Min)

Output High (Source)

Current, IOH (Min)

Output Voltage:

Low-Level, VOL (Max)

V

O

(V)

- 0, 5 5 5 5 150 150 - 0.04 5 µA

- 0, 10 10 10 10 300 300 - 0.04 10 µA

- 0, 15 15 20 20 600 600 - 0.04 20 µA

- 0, 20 20 100 100 3000 3000 - 0.08 100 µA

0.4 0, 5 5 1.9 1.85 1.26 1.08 1.55 3.1 - µA

0.5 0, 10 10 5 4.8 3.3 2.8 4 8 - µA

1.5 0, 15 15 12.6 12 8.4 7.2 10 20 - µA

4.6 0, 5 5 -1.9 -1.85 -1.26 -1.08 -1.55 -3.1 - mA

2.5 0, 5 5 -6.2 -6 -4.1 -3 -5 -10 - mA

9.5 0, 10 10 -5 -4.8 -3.3 -2.8 -4 -8 - mA

13.5 0, 15 15 -12.6 -12 -8.4 -7.2 -10 -20 - mA

- 0, 5 5 - 0.05 - 0 0.05 mA

- 0, 10 10 - 0.05 - 0 0.05 mA

- 0, 15 15 - 0.05 - 0 0.05 mA

V

(V)

V

IN

DD

(V) -55 -40 85 125

MIN TYP MAX

25

UNITS

Output Voltage:

High-Level, VOH (Min)

Input Low Voltage,

VIL (Max)

- 0, 5 5 - 4.95 4.95 5 - mA

- 0, 10 10 - 9.95 9.95 10 - mA

- 0, 15 15 - 14.95 14.95 15 - mA

0.5, 4.5 - 5 - 1.5 - - 1.5 V

1, 9 - 10 - 3 - - 3 V

1.5, 13.5 - 15 - 4 - - 4 V

3

Electrical Specifications (Continued)

CONDITIONS LIMITS AT INDICATED TEMPERATURES (oC)

CD4541B

PARAMETER

Input High Voltage,

V

O

(V)

0.5, 4.5 - 5 - 3.5 3.5 - - V

V

(V)

V

IN

DD

(V) -55 -40 85 125

MIN TYP MAX

VIH(Min)

1, 9 - 10 - 7 7 - - V

1.5, 13.5 - 15 - 11 11 - - V

Input Current, lIN (Max) - 0, 18 18 ±0.1 ±0.1 ±1 ±1-±10

NOTE:

2. With AUTO RESET enabled, additional current drain at 25oC is:

7µA (Typ), 200µA (Max) at 5V;

30µA (Typ), 350µA (Max) at 10V;

80µA (Typ), 500µA (Max) at 15V

Dynamic Electrical Specifications T

= 25oC, Input tr, tf = 20ns, CL = 50pF, RL = 200kΩ

A

PARAMETER SYMBOL VDD (V) MIN TYP MAX UNITS

Propagation Delay Times

(28) t

PHL

, t

PLH

5 - 3.5 10.5 µs

Clock to Q

10 - 1.25 3.8 µs

15 - 0.9 2.9 µs

(216) t

PHL

, t

PLH

5 - 6.0 18 µs

10 - 3.5 10 µs

25

-5

UNITS

±0.1 µA

Transition Time t

MASTER RESET, CLOCK

Pulse Width

Maximum Clock Pulse Input

Frequency

Maximum Clock Pulse Input

Rise or Fall time

THL

t

THL

f

tr,t

CL

15 - 2.5 7.5 µs

5 - 100 200 ns

10 - 50 100 ns

15 - 40 80 ns

5 - 180 360 ns

10 - 90 180 ns

15 - 65 130 ns

5 900 300 - ns

10 300 100 - ns

15 225 85 - ns

5 - 1.5 - MHz

10 - 4 - MHz

15 - 6 - MHz

f

5, 10, 15 Unlimited µs

4

CD4541B

Digital Timer Application

A positive pulse on MASTER RESET resets the counters

and latch. The output goes high and remains high until the

number of pulses, selected by A and B, are counted. This

circuit is retriggerable and is as accurate as the input frequency. If additional accuracy is desired, an external clock

can be used on pin 3. A setup time equal to the width of the

one-shot output is required immediately following initial

power up, during which time the output will be high.

V

R

INPUT

TC

C

TC

RSAR

MR

1

2

3

4

5

6

7

14

13

12

11

10

9

8

OUTPUT

FIGURE 3. DIGITAL TIMER APPLICATION CIRCUIT

DD

B

A

t

0102030405060708088

82

80

70

60

50

79 - 87

40

30

20

10

0

4 - 10

(0.102 - 0.254)

85 - 93

(2.159 - 2.362)

(2.007 - 2.210)

NOTE: Dimensions in parentheses are in millimeters and are derived from the basic inch dimensions as indicated. Grid graduations

are in mils (10-3 inch).

FIGURE 4. DIMENSIONS AND PAD LAYOUT FOR CD4541B

5

Dual-In-Line Plastic Packages (PDIP)

CD4541B

N

D1

-C-

E1

-B-

A1

A2

E

A

L

e

C

C

L

e

A

C

e

B

INDEX

AREA

BASE

PLANE

SEATING

PLANE

D1

B1

1 2 3 N/2

-AD

e

B

0.010 (0.25) C AM BS

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between English

and Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO SeriesSymbolList”in Section 2.2 of

Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated in

JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions.

Mold flash or protrusions shall not exceed 0.010 inch (0.25mm).

6. E and are measured with the leads constrained to be perpen-

e

dicular to datum .

A

-C-

7. eB and eC are measured at the lead tips with the leads unconstrained. eC must be zero or greater.

8. B1maximum dimensionsdonotincludedambar protrusions.Dambar

protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3, E28.3,

E42.6 will have a B1 dimension of 0.030 - 0.045 inch (0.76 -

1.14mm).

E14.3 (JEDEC MS-001-AA ISSUE D)

14 LEAD DUAL-IN-LINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A - 0.210 - 5.33 4

A1 0.015 - 0.39 - 4

A2 0.115 0.195 2.93 4.95 -

B 0.014 0.022 0.356 0.558 B1 0.045 0.070 1.15 1.77 8

C 0.008 0.014 0.204 0.355 -

D 0.735 0.775 18.66 19.68 5

D1 0.005 - 0.13 - 5

E 0.300 0.325 7.62 8.25 6

E1 0.240 0.280 6.10 7.11 5

e 0.100 BSC 2.54 BSC -

e

A

e

B

0.300 BSC 7.62 BSC 6

- 0.430 - 10.92 7

L 0.115 0.150 2.93 3.81 4

N14 149

NOTESMIN MAX MIN MAX

Rev. 0 12/93

6

CD4541B

Ceramic Dual-In-Line Frit Seal Packages (CERDIP)

LEAD FINISH

c1

-DBASE

M

SECTION A-A

METAL

b1

M

(b)

α

E

D

S

S

Q

A

-CL

eA

eA/2

aaa C A - B

M

c

D

S S

bbb C A - B

BASE

PLANE

SEATING

PLANE

S1

b2

b

ccc C A - BMD

-A-

-B-

S

D

A

A

e

S

S

NOTES:

1. Index area: A notch orapinoneidentificationmarkshallbelocated adjacent to pin one and shall be located within the shaded

area shown. The manufacturer’s identification shall not be used

as a pin one identification mark.

2. The maximum limits of lead dimensions b and c or M shall be

measured at the centroid of the finished lead surfaces, when

solder dip or tin plate lead finish is applied.

3. Dimensions b1 and c1 apply to lead base metal only. Dimension

M applies to lead plating and finish thickness.

4. Corner leads (1, N, N/2, and N/2+1) may be configured with a

partial lead paddle. For this configuration dimension b3 replaces

dimension b2.

5. This dimension allows for off-center lid, meniscus, and glass

overrun.

6. Dimension Q shall be measured from the seating plane to the

base plane.

7. Measure dimension S1 at all four corners.

8. N is the maximum number of terminal positions.

9. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

10. Controlling dimension: INCH.

F14.3 MIL-STD-1835 GDIP1-T14 (D-1, CONFIGURATION A)

14 LEAD CERAMIC DUAL-IN-LINE FRIT SEAL PACKAGE

(c)

SYMBOL

A - 0.200 - 5.08 -

b 0.014 0.026 0.36 0.66 2

b1 0.014 0.023 0.36 0.58 3

b2 0.045 0.065 1.14 1.65 b3 0.023 0.045 0.58 1.14 4

c 0.008 0.018 0.20 0.46 2

c1 0.008 0.015 0.20 0.38 3

D - 0.785 - 19.94 5

E 0.220 0.310 5.59 7.87 5

e 0.100 BSC 2.54 BSC eA 0.300 BSC 7.62 BSC -

eA/2 0.150 BSC 3.81 BSC -

L 0.125 0.200 3.18 5.08 -

Q 0.015 0.060 0.38 1.52 6

S1 0.005 - 0.13 - 7

α

aaa - 0.015 - 0.38 bbb - 0.030 - 0.76 ccc - 0.010 - 0.25 -

M - 0.0015 - 0.038 2, 3

N14 148

INCHES MILLIMETERS

90

o

105

o

90

o

105

NOTESMIN MAX MIN MAX

o

Rev. 0 4/94

-

7

Small Outline Plastic Packages (SOIC)

CD4541B

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45

o

α

e

B

0.25(0.010) C AM BS

M

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed0.15mm (0.006

inch) per side.

4. Dimension“E” doesnotinclude interleadflashor protrusions.Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

5. The chamfer on the body is optional. If it is not present, avisual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch).

10. Controlling dimension: MILLIMETER. Converted inchdimensions

are not necessarily exact.

A1

C

0.10(0.004)

M14.15 (JEDEC MS-012-AB ISSUE C)

14 LEAD NARROW BODY SMALL OUTLINE PLASTIC

PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0532 0.0688 1.35 1.75 -

A1 0.0040 0.0098 0.10 0.25 -

B 0.013 0.020 0.33 0.51 9

C 0.0075 0.0098 0.19 0.25 D 0.3367 0.3444 8.55 8.75 3

E 0.1497 0.1574 3.80 4.00 4

e 0.050 BSC 1.27 BSC -

H 0.2284 0.2440 5.80 6.20 -

h 0.0099 0.0196 0.25 0.50 5

L 0.016 0.050 0.40 1.27 6

N14 147

o

α

0

o

8

o

0

o

8

Rev. 0 12/93

NOTESMIN MAX MIN MAX

-

8

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...