Page 1

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

Reference

Design

CC2640 SimpleLink™ Bluetooth®Wireless MCU

1 Device Overview

1.1 Features

1

• Microcontroller

– Powerful ARM®Cortex®-M3

– EEMBC CoreMark®Score: 142

– Up to 48-MHz Clock Speed

– 128KB of In-System Programmable Flash

– 8KB of SRAM for Cache

– 20KB of Ultralow-Leakage SRAM

– 2-Pin cJTAG and JTAG Debugging

– Supports Over-The-Air Upgrade (OTA)

• Ultralow-Power Sensor Controller

– Can Run Autonomous From the Rest of the

System

– 16-Bit Architecture

– 2KB of Ultralow-Leakage SRAM for Code and

Data

• Efficient Code Size Architecture, Placing Drivers,

Bluetooth®Low Energy Controller, and Bootloader

in ROM

• RoHS-Compliant Packages

– 4-mm × 4-mm RSM VQFN32 (10 GPIOs)

– 5-mm × 5-mm RHB VQFN32 (15 GPIOs)

– 7-mm × 7-mm RGZ VQFN48 (31 GPIOs)

• Peripherals

– All Digital Peripheral Pins Can Be Routed to

Any GPIO

– Four General-Purpose Timer Modules

(Eight 16-Bit or Four 32-Bit Timers, PWM Each)

– 12-Bit ADC, 200-ksamples/s, 8-Channel Analog

MUX

– Continuous Time Comparator

– Ultralow-Power Analog Comparator

– Programmable Current Source

– UART

– 2× SSI (SPI, MICROWIRE, TI)

– I2C

– I2S

– Real-Time Clock (RTC)

– AES-128 Security Module

– True Random Number Generator (TRNG)

– 10, 15, or 31 GPIOs, Depending on Package

Option

– Support for Eight Capacitive-Sensing Buttons

– Integrated Temperature Sensor

• External System

– On-Chip internal DC-DC Converter

1

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

– Very Few External Components

– Seamless Integration With the SimpleLink™

CC2590 and CC2592 Range Extenders

– Pin Compatible With the SimpleLink CC13xx in

4-mm × 4-mm and 5-mm × 5-mm VQFN

Packages

• Low Power

– Wide Supply Voltage Range

• Normal Operation: 1.8 to 3.8 V

• External Regulator Mode: 1.7 to 1.95 V

– Active-Mode RX: 5.9 mA

– Active-Mode TX at 0 dBm: 6.1 mA

– Active-Mode TX at +5 dBm: 9.1 mA

– Active-Mode MCU: 61 µA/MHz

– Active-Mode MCU: 48.5 CoreMark/mA

– Active-Mode Sensor Controller: 8.2 µA/MHz

– Standby: 1 µA (RTC Running and RAM/CPU

Retention)

– Shutdown: 100 nA (Wake Up on External

Events)

• RF Section

– 2.4-GHz RF Transceiver Compatible With

Bluetooth Low Energy (BLE) 4.2 Specification

– Excellent Receiver Sensitivity (–97 dBm for

BLE), Selectivity, and Blocking Performance

– Link budget of 102 dB for BLE

– Programmable Output Power up to +5 dBm

– Single-Ended or Differential RF Interface

– Suitable for Systems Targeting Compliance With

Worldwide Radio Frequency Regulations

• ETSI EN 300 328 (Europe)

• EN 300 440 Class 2 (Europe)

• FCC CFR47 Part 15 (US)

• ARIB STD-T66 (Japan)

• Tools and Development Environment

– Full-Feature and Low-Cost Development Kits

– Multiple Reference Designs for Different RF

Configurations

– Packet Sniffer PC Software

– Sensor Controller Studio

– SmartRF™ Studio

– SmartRF Flash Programmer 2

– IAR Embedded Workbench®for ARM

– Code Composer Studio™

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Page 2

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

1.2 Applications

• Home and Building Automation

– Connected Appliances

– Lighting

– Locks

– Gateways

– Security Systems

• Industrial

– Logistics

– Production and Manufacturing

– Automation

– Asset Tracking and Management

– Remote Display

– Cable Replacement

– HMI

– Access Control

• Retail

– Beacons

– Advertising

– ESL and Price Tags

– Point of Sales and Payment Systems

www.ti.com

• Health and Medical

– Thermometers

– SpO2

– Blood Glucose and Pressure Meters

– Weight Scales

– Vitals Monitoring

– Hearing Aids

• Sports and Fitness

– Activity Monitors and Fitness Trackers

– Heart Rate Monitors

– Running Sensors

– Biking Sensors

– Sports Watches

– Gym Equipment

– Team Sports Equipment

• HID

– Remote Controls

– Keyboards and Mice

– Gaming

• Accessories

– Toys

– Trackers

– Luggage Tags

– Wearables

1.3 Description

The CC2640 device is a wireless MCU targeting Bluetooth applications.

The device is a member of the CC26xx family of cost-effective, ultralow power, 2.4-GHz RF devices. Very

low active RF and MCU current and low-power mode current consumption provide excellent battery

lifetime and allow for operation on small coin cell batteries and in energy-harvesting applications.

The CC2640 device contains a 32-bit ARM Cortex-M3 processor that runs at 48 MHz as the main

processor and a rich peripheral feature set that includes a unique ultralow power sensor controller. This

sensor controller is ideal for interfacing external sensors and for collecting analog and digital data

autonomously while the rest of the system is in sleep mode. Thus, the CC2640 device is ideal for a wide

range of applications where long battery lifetime, small form factor, and ease of use is important.

The Bluetooth Low Energy controller is embedded into ROM and runs partly on an ARM Cortex-M0

processor. This architecture improves overall system performance and power consumption and frees up

flash memory for the application.

The Bluetooth stack is available free of charge from www.ti.com.

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

CC2640F128RGZ VQFN (48) 7.00 mm × 7.00 mm

CC2640F128RHB VQFN (32) 5.00 mm × 5.00 mm

CC2640F128RSM VQFN (32) 4.00 mm × 4.00 mm

(1) For more information, see Section 9, Mechanical Packaging and Orderable Information.

(1)

2

Device Overview Copyright © 2015–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: CC2640

Page 3

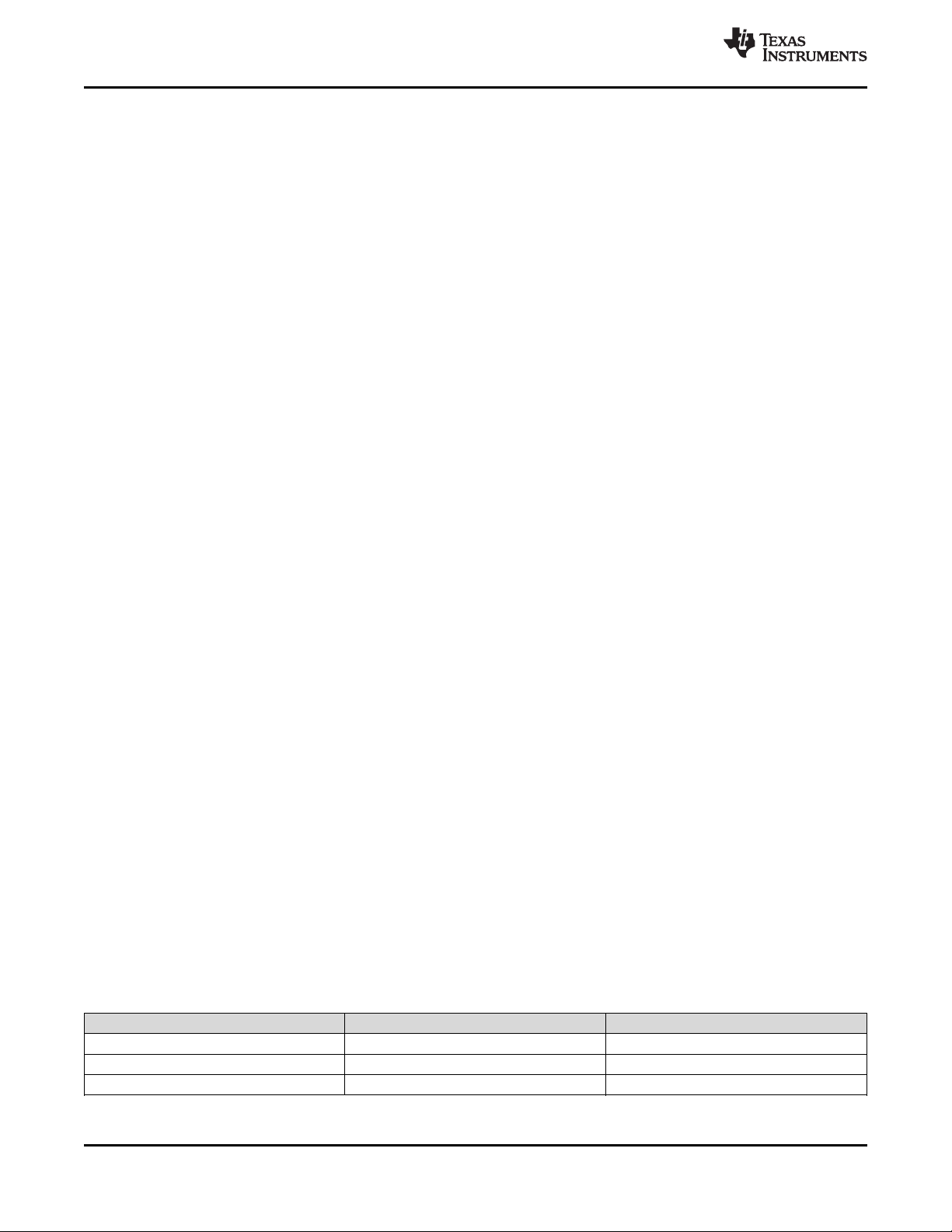

SimpleLinkTM CC26xx wireless MCU

Main CPU

128KB

Flash

Sensor controller

cJTAG

20KB

SRAM

ROM

ARM

®

Cortex®-M3

DC-DC converter

RF core

ARM

®

Cortex®-M0

DSP modem

4KB

SRAM

ROM

Sensor controller

engine

2x comparator

12-bit ADC, 200 ks/s

Constant current source

SPI-I2C digital sensor IF

2KB SRAM

Time-to-digital converter

General peripherals / modules

4× 32-bit Timers

2× SSI (SPI, µW, TI)

Watchdog timer

Temp. / batt. monitor

RTC

I2C

UART

I2S

10 / 15 / 31 GPIOs

AES

32 ch. µDMA

ADC

Digital PLL

TRNG

ADC

8KB

cache

Copyright © 2016, Texas Instruments Incorporated

www.ti.com

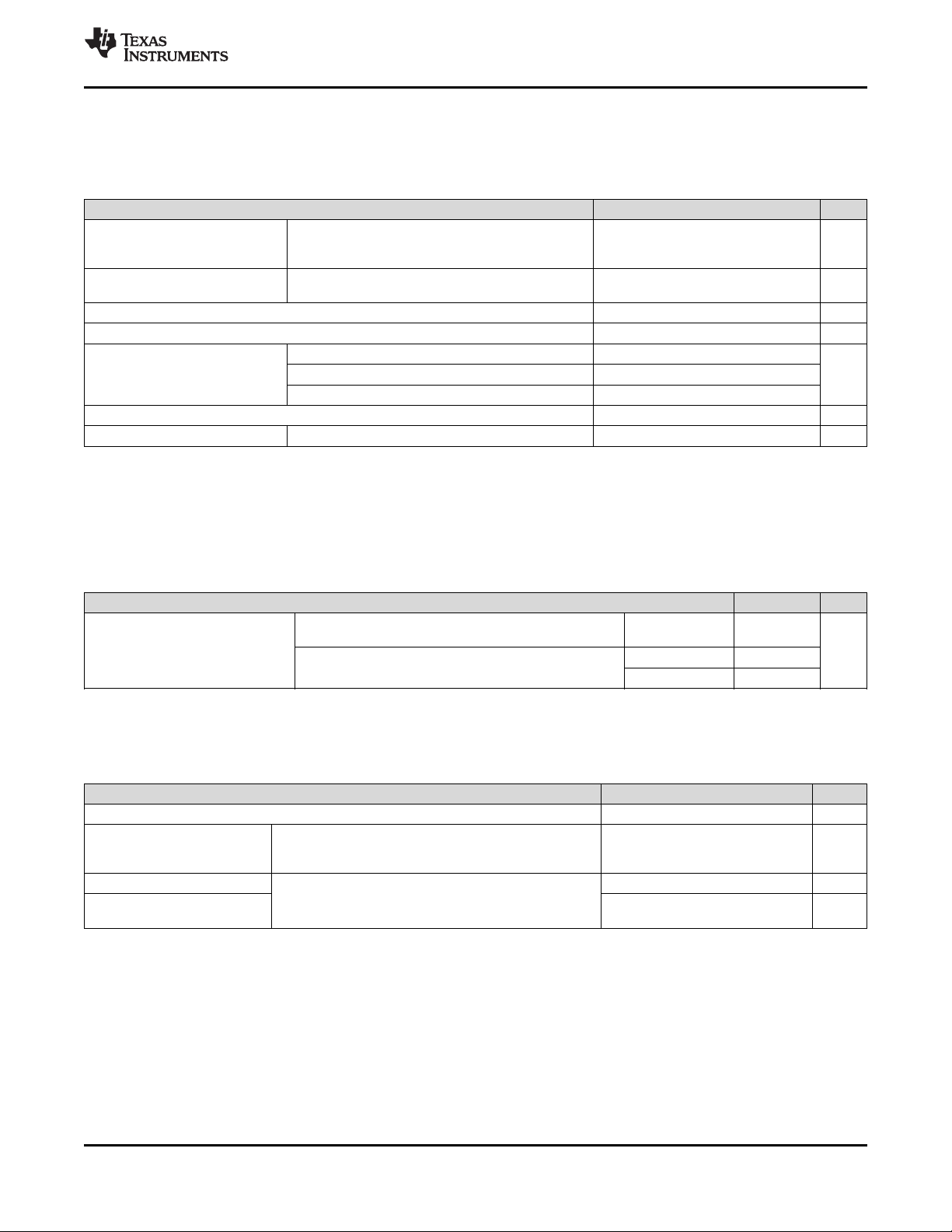

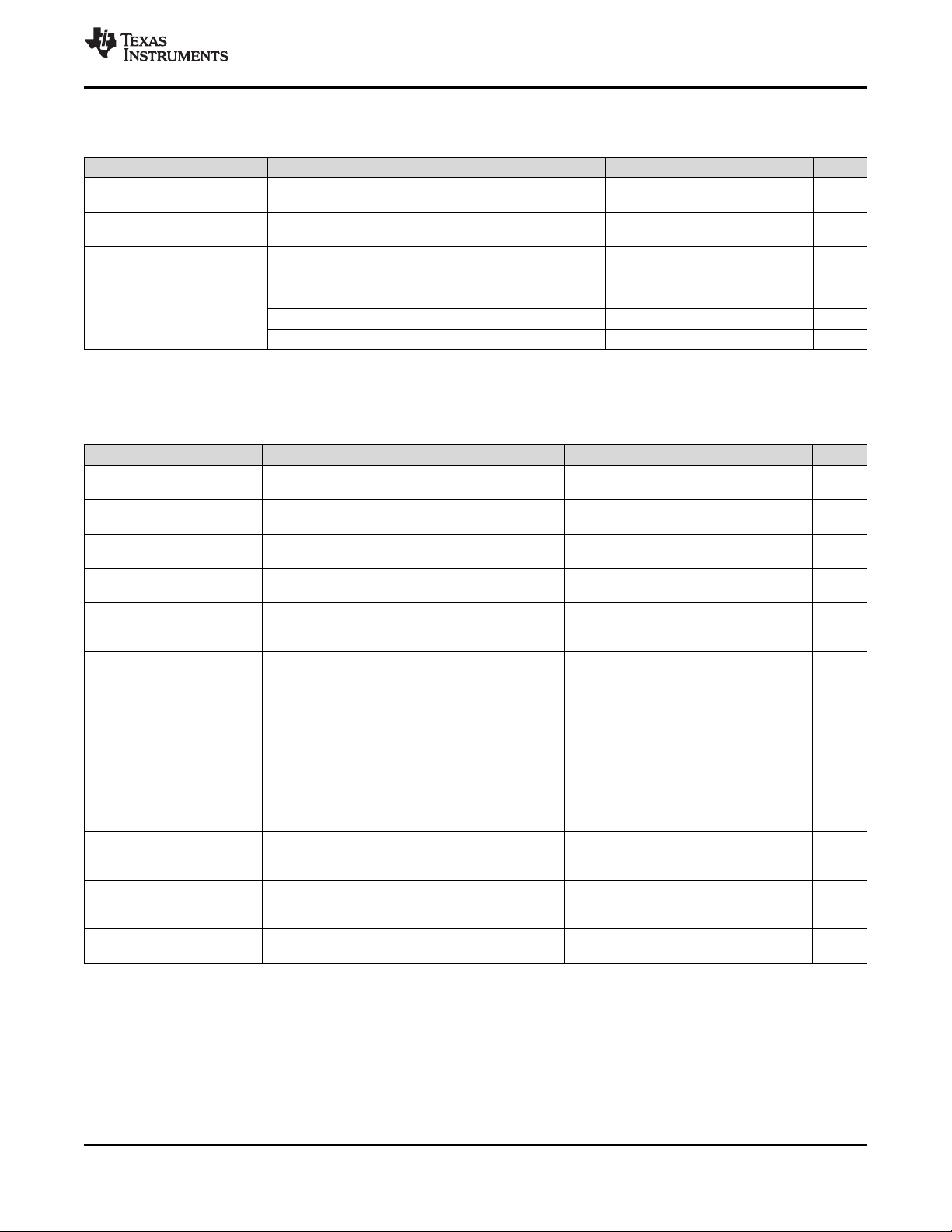

1.4 Functional Block Diagram

Figure 1-1 shows a block diagram for the CC2640.

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

Figure 1-1. Block Diagram

Submit Documentation Feedback

Product Folder Links: CC2640

Device OverviewCopyright © 2015–2016, Texas Instruments Incorporated

3

Page 4

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

www.ti.com

Table of Contents

1 Device Overview ......................................... 1

1.1 Features .............................................. 1

1.2 Applications........................................... 2

1.3 Description............................................ 2

1.4 Functional Block Diagram ............................ 3

2 Revision History ......................................... 5

3 Device Comparison ..................................... 6

3.1 Related Products ..................................... 6

4 Terminal Configuration and Functions.............. 7

4.1 Pin Diagram – RGZ Package ........................ 7

4.2 Signal Descriptions – RGZ Package ................. 7

4.3 Pin Diagram – RHB Package ........................ 9

4.4 Signal Descriptions – RHB Package ................. 9

4.5 Pin Diagram – RSM Package....................... 11

4.6 Signal Descriptions – RSM Package ............... 11

5 Specifications........................................... 13

5.1 Absolute Maximum Ratings......................... 13

5.2 ESD Ratings ........................................ 13

5.3 Recommended Operating Conditions............... 13

5.4 Power Consumption Summary...................... 14

5.5 General Characteristics ............................. 14

5.6 1-Mbps GFSK (Bluetooth low energy Technology) –

RX ................................................... 15

5.7 1-Mbps GFSK (Bluetooth low energy Technology) –

TX ................................................... 16

5.8 2-Mbps GFSK (Bluetooth 5) – RX .................. 16

5.9 2-Mbps GFSK (Bluetooth 5) – TX................... 17

5.10 5-Mbps (Proprietary) – RX .......................... 17

5.11 5-Mbps (Proprietary) – TX .......................... 18

5.12 24-MHz Crystal Oscillator (XOSC_HF) ............. 18

5.13 32.768-kHz Crystal Oscillator (XOSC_LF).......... 18

5.14 48-MHz RC Oscillator (RCOSC_HF) ............... 19

5.15 32-kHz RC Oscillator (RCOSC_LF)................. 19

5.16 ADC Characteristics................................. 19

5.17 Temperature Sensor ................................ 21

5.18 Battery Monitor...................................... 21

5.19 Continuous Time Comparator....................... 21

5.20 Low-Power Clocked Comparator ................... 22

5.21 Programmable Current Source ..................... 22

5.22 Synchronous Serial Interface (SSI) ................ 22

5.23 DC Characteristics .................................. 24

5.24 Thermal Resistance Characteristics ................ 25

5.25 Timing Requirements ............................... 26

5.26 Switching Characteristics ........................... 26

5.27 Typical Characteristics .............................. 27

6 Detailed Description ................................... 31

6.1 Overview ............................................ 31

6.2 Functional Block Diagram........................... 31

6.3 Main CPU ........................................... 32

6.4 RF Core ............................................. 32

6.5 Sensor Controller ................................... 33

6.6 Memory.............................................. 34

6.7 Debug ............................................... 34

6.8 Power Management................................. 35

6.9 Clock Systems ...................................... 36

6.10 General Peripherals and Modules .................. 36

6.11 Voltage Supply Domains............................ 37

6.12 System Architecture................................. 37

7 Application, Implementation, and Layout ......... 38

7.1 Application Information.............................. 38

7.2 5 × 5 External Differential (5XD) Application Circuit

...................................................... 40

7.3 4 × 4 External Single-ended (4XS) Application

Circuit ............................................... 42

8 Device and Documentation Support ............... 44

8.1 Device Nomenclature ............................... 44

8.2 Tools and Software ................................. 45

8.3 Documentation Support ............................. 46

8.4 Texas Instruments Low-Power RF Website ........ 46

8.5 Low-Power RF eNewsletter ......................... 46

8.6 Community Resources .............................. 46

8.7 Additional Information ............................... 47

8.8 Trademarks.......................................... 47

8.9 Electrostatic Discharge Caution..................... 47

8.10 Export Control Notice ............................... 47

8.11 Glossary............................................. 47

9 Mechanical Packaging and Orderable

Information .............................................. 47

9.1 Packaging Information .............................. 47

4

Table of Contents Copyright © 2015–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: CC2640

Page 5

CC2640

www.ti.com

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

2 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from October 23, 2015 to July 5, 2016 Page

• Added split VDDS supply rail feature .............................................................................................. 1

• Added 5-Mbps proprietary mode ................................................................................................... 1

• Added option for up to 80-Ω ESR when C

• Added tolerance for RCOSC_LF and RTC accuracy content ................................................................ 19

• Updated the Soc ADC internal voltage reference specification in Section 5.16 ........................................... 19

• Moved all SSI parameters to Section 5.22 ...................................................................................... 22

• Added 0-dBm setting to the TX Current Consumption vs Supply Voltage (VDDS) graph ................................ 27

• Changed Figure 5-11, Receive Mode Current vs Supply Voltage (VDDS) ................................................. 27

• Added Figure 5-21, Supply Current vs Temperature .......................................................................... 28

Changes from February 15, 2015 to October 22, 2015 Page

• Removed RHB package option from CC2620 .................................................................................... 6

• Added motional inductance recommendation to the 24-MHz XOSC table ................................................. 18

• Added SPI timing parameters ..................................................................................................... 22

• Added VOH and VOL min and max values for 4-mA and 8-mA load ....................................................... 24

• Added min and max values for VIH and VIL .................................................................................... 25

• Added BLE Sensitivity vs Channel Frequency .................................................................................. 27

• Added RF Output Power vs Channel Frequency ............................................................................... 27

• Added Figure 5-11, Receive Mode Current vs Supply Voltage (VDDS)..................................................... 27

• Changed Figure 5-20, SoC ADC ENOB vs Sampling Frequency (Input Frequency = FS / 10).......................... 28

• Clarified Brown Out Detector status and functionality in the Power Modes table. ......................................... 35

• Added application circuit schematics and layout for 5XD and 4XS .......................................................... 38

is 6 pF or lower .................................................................. 18

L

Submit Documentation Feedback

Product Folder Links: CC2640

Revision HistoryCopyright © 2015–2016, Texas Instruments Incorporated

5

Page 6

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

3 Device Comparison

www.ti.com

Table 3-1. Device Family Overview

DEVICE PHY SUPPORT

CC2650F128xxx Multi-Protocol

CC2640F128xxx Bluetooth low energy (Normal) 128 20 31, 15, 10 RGZ, RHB, RSM

CC2630F128xxx IEEE 802.15.4 ( ZigBee®/6LoWPAN) 128 20 31, 15, 10 RGZ, RHB, RSM

CC2620F128xxx IEEE 802.15.4 (RF4CE) 128 20 31, 10 RGZ, RSM

(1) Package designator replaces the xxx in device name to form a complete device name, RGZ is 7-mm × 7-mm VQFN48, RHB is

5-mm × 5-mm VQFN32, and RSM is 4-mm × 4-mm VQFN32.

(2) The CC2650 device supports all PHYs and can be reflashed to run all the supported standards.

(2)

FLASH

(KB)

128 20 31, 15, 10 RGZ, RHB, RSM

RAM (KB) GPIO PACKAGE

3.1 Related Products

Wireless Connectivity The wireless connectivity portfolio offers a wide selection of low power RF

solutions suitable for a broad range of application. The offerings range from fully customized

solutions to turn key offerings with pre-certified hardware and software (protocol).

Sub-1 GHz Long-range, low power wireless connectivity solutions are offered in a wide range of Sub-1

GHz ISM bands.

Companion Products Review products that are frequently purchased or used in conjunction with this

product.

SimpleLink™ CC2650 Wireless MCU LaunchPad™ Kit The CC2650 LaunchPad kit brings easy

Bluetooth® Smart connectivity to the LaunchPad kit ecosystem with the SimpleLink ultra-low

power CC26xx family of devices. This LaunchPad kit also supports development for multiprotocol support for the SimpleLink multi-standard CC2650 wireless MCU and the rest of

CC26xx family of products: CC2630 wireless MCU for ZigBee®/6LoWPAN and CC2640

wireless MCU for Bluetooth®Smart.

Reference Designs for CC2640 TI Designs Reference Design Library is a robust reference design library

spanning analog, embedded processor and connectivity. Created by TI experts to help you

jump-start your system design, all TI Designs include schematic or block diagrams, BOMs

and design files to speed your time to market. Search and download designs at

ti.com/tidesigns.

(1)

6

Device Comparison Copyright © 2015–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: CC2640

Page 7

40

39

DIO_25 38

DIO_24 37

21

22

23

24

DCDC_SW33

DIO_18

34

RESET_N35

DIO_2336

X32K_Q2 4

X32K_Q1 3

RF_N 2

RF_P 1

DIO_2232

DIO_2131

DIO_2030

DIO_1929

DIO_0 5

DIO_1 6

DIO_2 7

8

28

27

26

JTAG_TCKC25

9

10

11

12

41

42

43

44

20

DIO_15

19

DIO_14

18

17

VDDR 45

46

47

VDDR_RF 48

16

15

14

13

DIO_17

DIO_16

VDDS_DCDC

DIO_26

DIO_12

DIO_13

VDDS2

DIO_11

DIO_10

DIO_5

DIO_6

DIO_7

DIO_3

DIO_4

X24M_P

X24M_N

DIO_8

DIO_9

DIO_28

VDDS3

DCOUPL

JTAG_TMSC

DIO_29

DIO_30

DIO_27

VDDS

www.ti.com

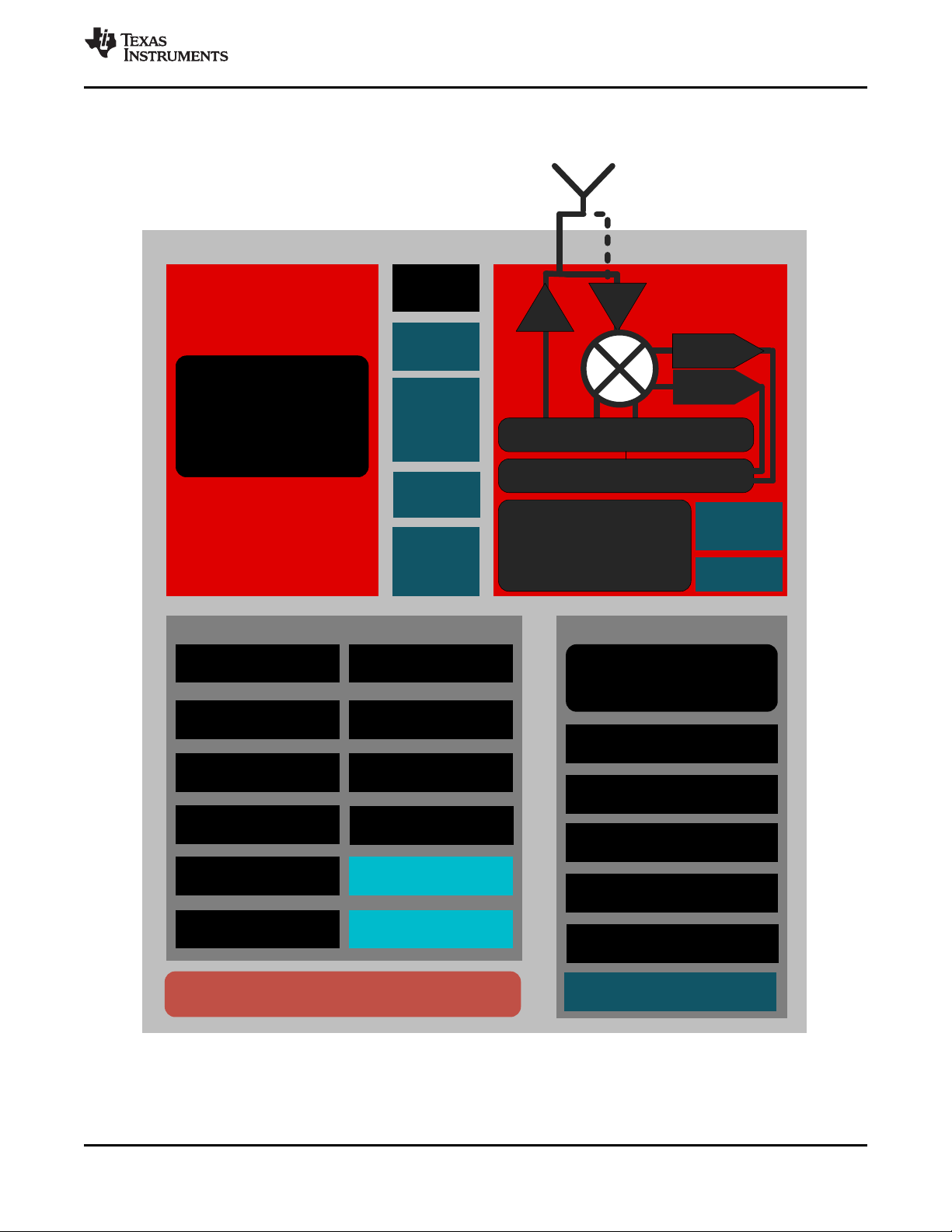

4 Terminal Configuration and Functions

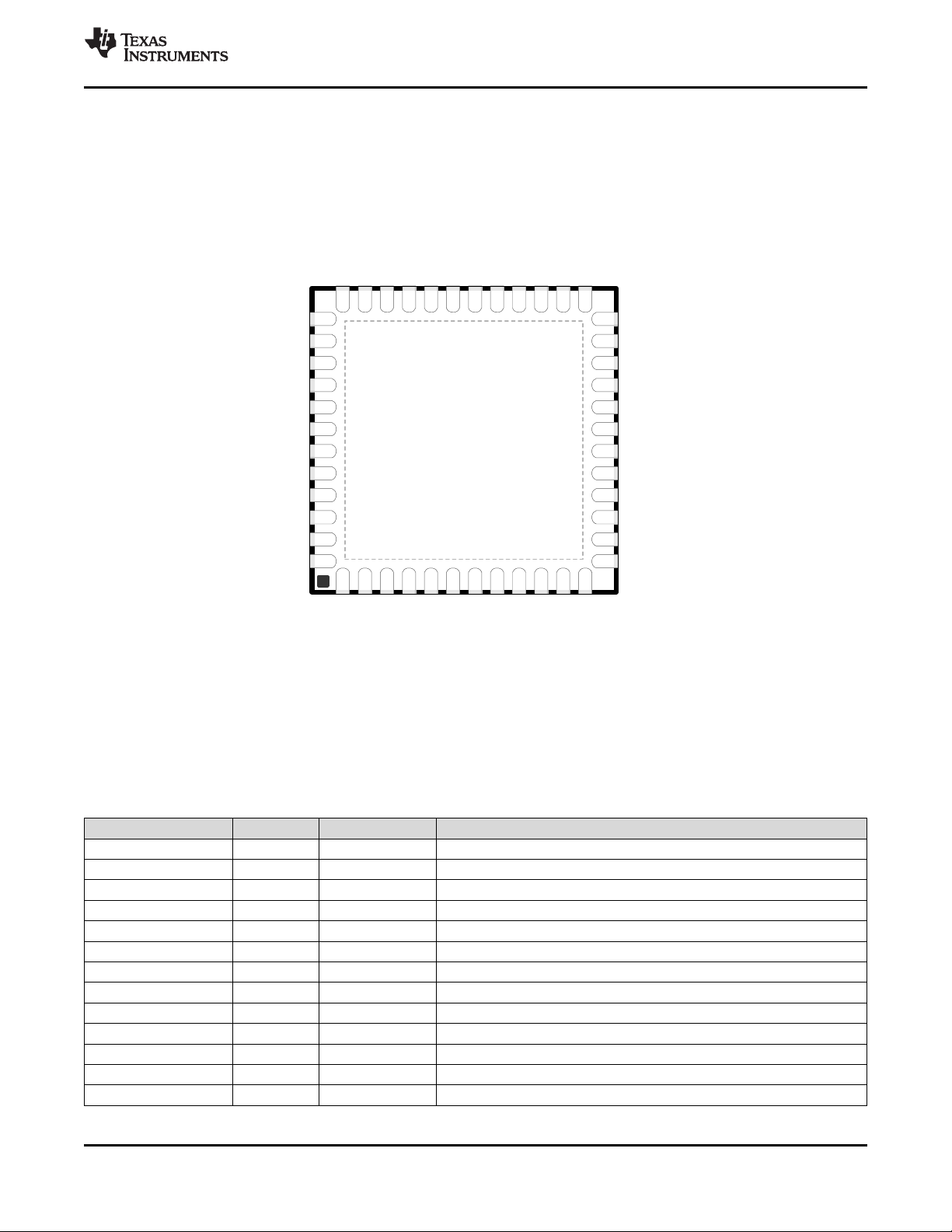

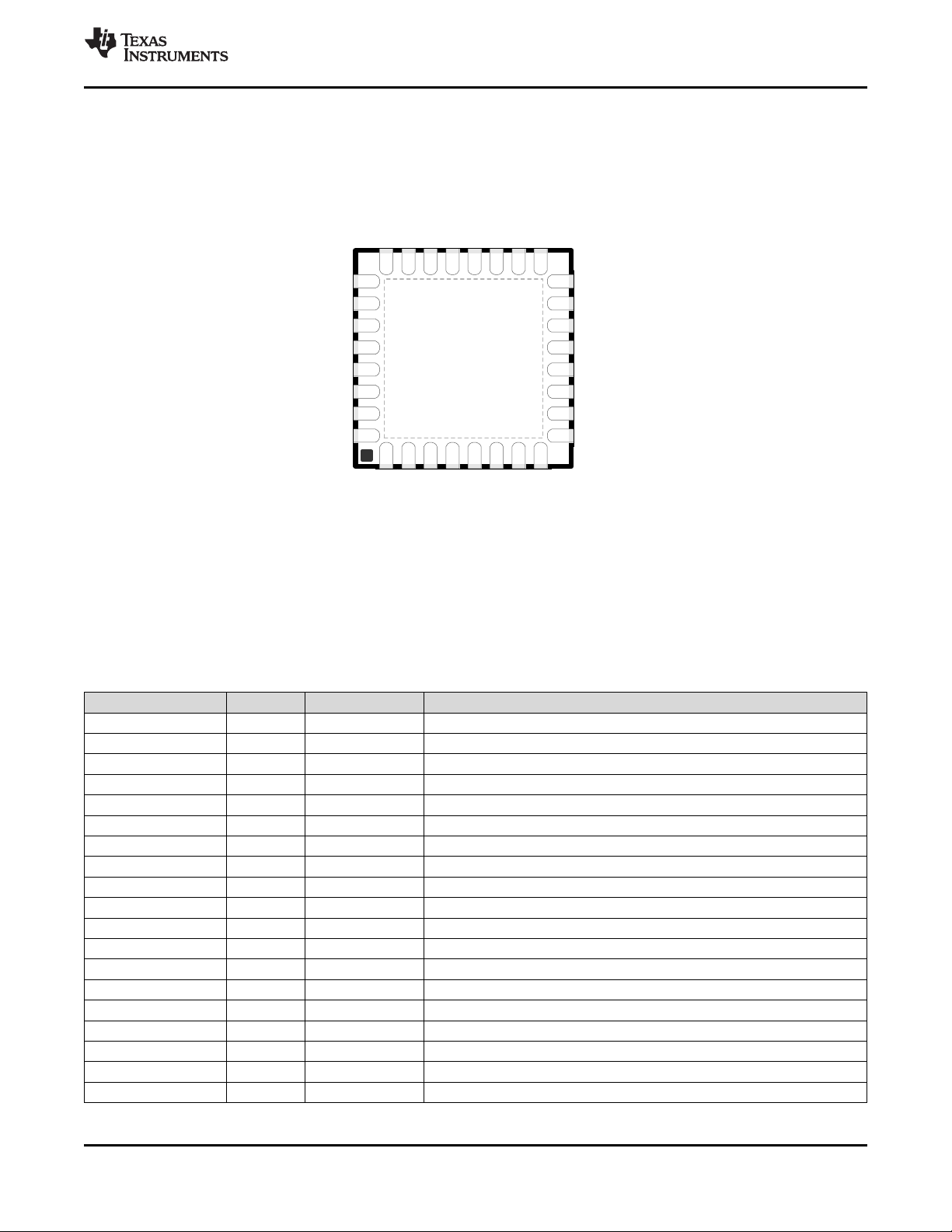

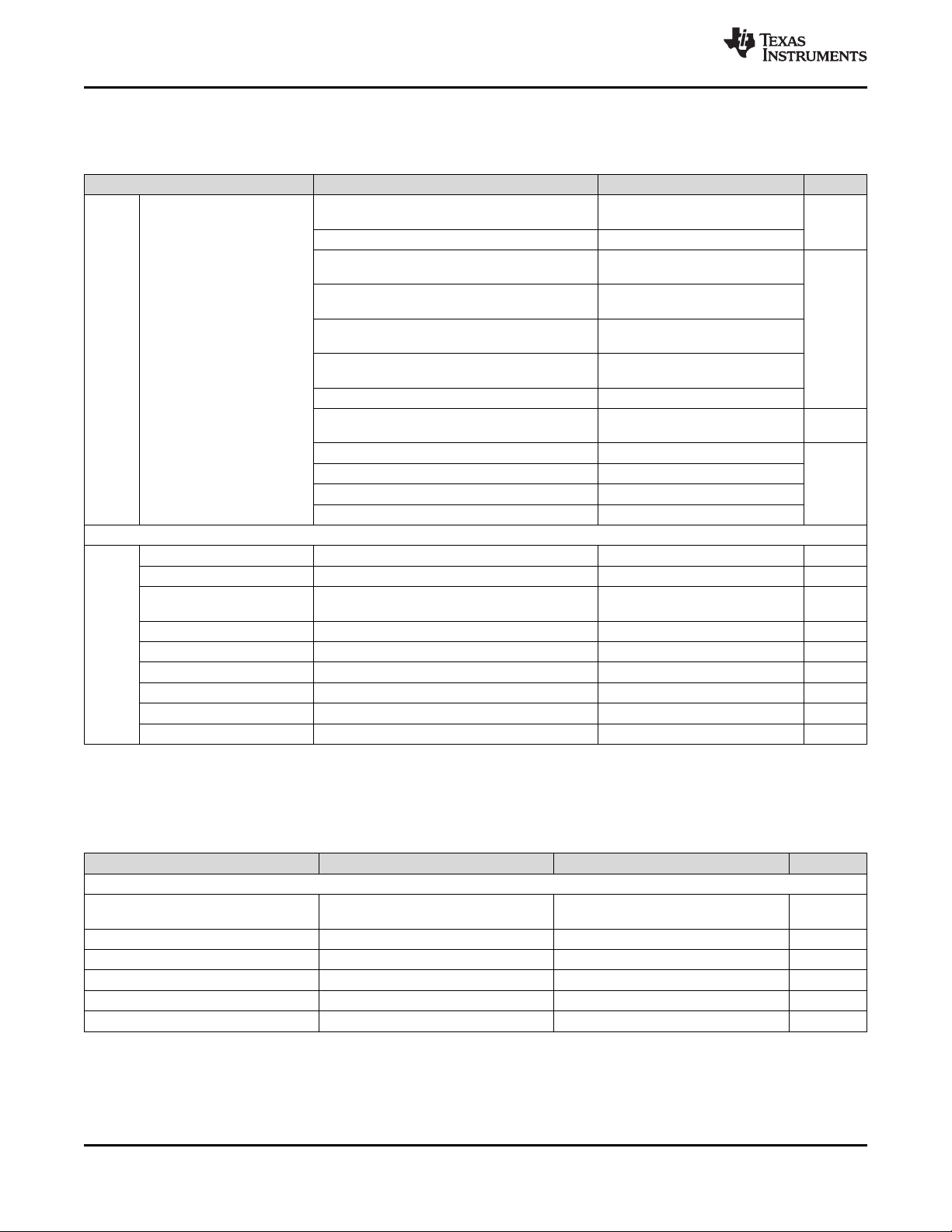

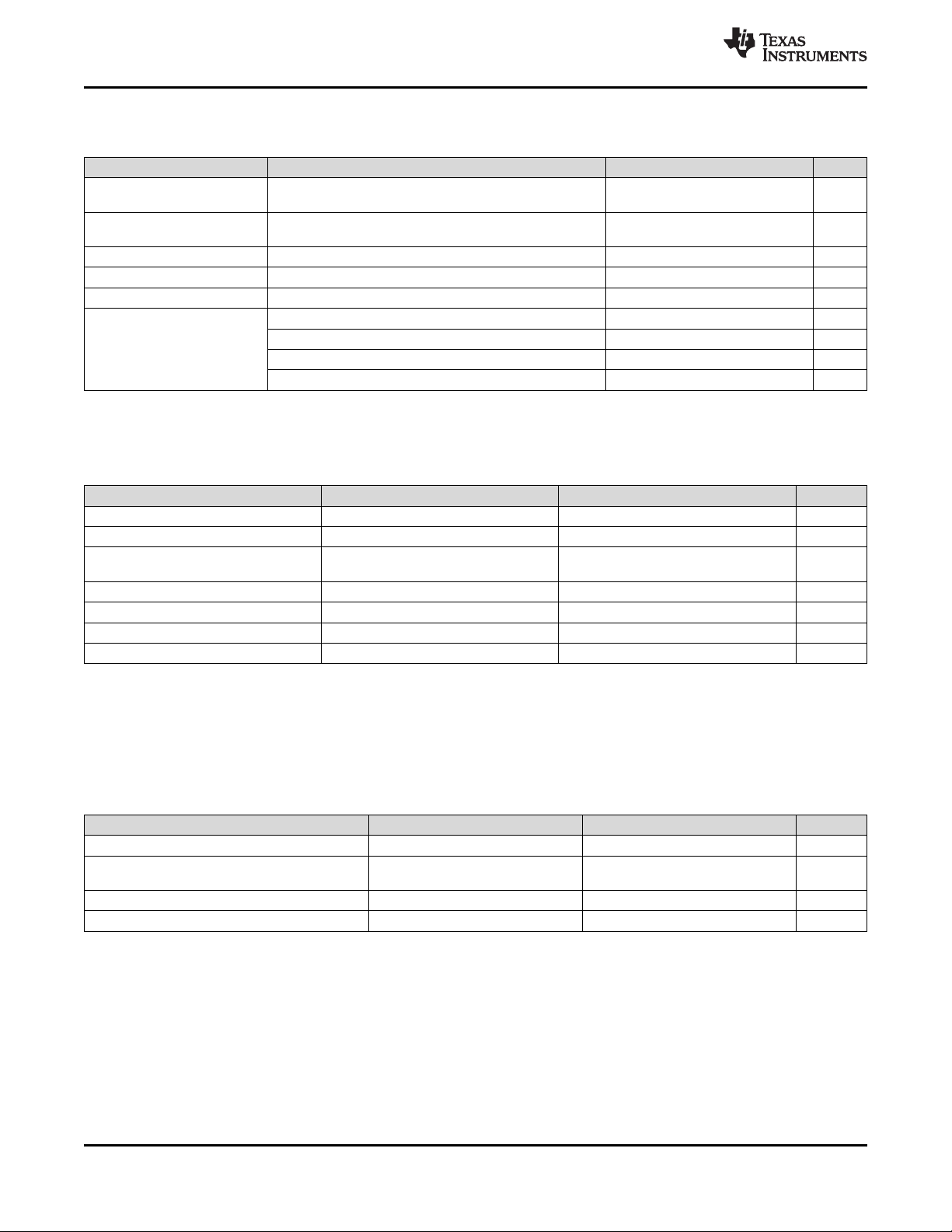

4.1 Pin Diagram – RGZ Package

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

Note: I/O pins marked in bold have high drive capabilities. I/O pins marked in italics have analog capabilities.

Figure 4-1. RGZ Package

48-Pin VQFN

(7-mm × 7-mm) Pinout, 0.5-mm Pitch

4.2 Signal Descriptions – RGZ Package

Table 4-1. Signal Descriptions – RGZ Package

NAME NO. TYPE DESCRIPTION

DCDC_SW 33 Power Output from internal DC-DC

DCOUPL 23 Power 1.27-V regulated digital-supply decoupling capacitor

DIO_0 5 Digital I/O GPIO, Sensor Controller

DIO_1 6 Digital I/O GPIO, Sensor Controller

DIO_2 7 Digital I/O GPIO, Sensor Controller

DIO_3 8 Digital I/O GPIO, Sensor Controller

DIO_4 9 Digital I/O GPIO, Sensor Controller

DIO_5 10 Digital I/O GPIO, Sensor Controller, high-drive capability

DIO_6 11 Digital I/O GPIO, Sensor Controller, high-drive capability

DIO_7 12 Digital I/O GPIO, Sensor Controller, high-drive capability

DIO_8 14 Digital I/O GPIO

DIO_9 15 Digital I/O GPIO

DIO_10 16 Digital I/O GPIO

(1) See technical reference manual (listed in Section 8.3) for more details.

(2) Do not supply external circuitry from this pin.

Submit Documentation Feedback

Product Folder Links: CC2640

(1)

Terminal Configuration and FunctionsCopyright © 2015–2016, Texas Instruments Incorporated

(2)

7

Page 8

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

Table 4-1. Signal Descriptions – RGZ Package (continued)

NAME NO. TYPE DESCRIPTION

DIO_11 17 Digital I/O GPIO

DIO_12 18 Digital I/O GPIO

DIO_13 19 Digital I/O GPIO

DIO_14 20 Digital I/O GPIO

DIO_15 21 Digital I/O GPIO

DIO_16 26 Digital I/O GPIO, JTAG_TDO, high-drive capability

DIO_17 27 Digital I/O GPIO, JTAG_TDI, high-drive capability

DIO_18 28 Digital I/O GPIO

DIO_19 29 Digital I/O GPIO

DIO_20 30 Digital I/O GPIO

DIO_21 31 Digital I/O GPIO

DIO_22 32 Digital I/O GPIO

DIO_23 36 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_24 37 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_25 38 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_26 39 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_27 40 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_28 41 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_29 42 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_30 43 Digital/Analog I/O GPIO, Sensor Controller, Analog

JTAG_TMSC 24 Digital I/O JTAG TMSC, high-drive capability

JTAG_TCKC 25 Digital I/O JTAG TCKC

RESET_N 35 Digital input Reset, active-low. No internal pullup.

RF_P 1 RF I/O

RF_N 2 RF I/O

VDDR 45 Power 1.7-V to 1.95-V supply, typically connect to output of internal DC-DC

VDDR_RF 48 Power 1.7-V to 1.95-V supply, typically connect to output of internal DC-DC

VDDS 44 Power 1.8-V to 3.8-V main chip supply

VDDS2 13 Power 1.8-V to 3.8-V DIO supply

VDDS3 22 Power 1.8-V to 3.8-V DIO supply

VDDS_DCDC 34 Power 1.8-V to 3.8-V DC-DC supply

X32K_Q1 3 Analog I/O 32-kHz crystal oscillator pin 1

X32K_Q2 4 Analog I/O 32-kHz crystal oscillator pin 2

X24M_N 46 Analog I/O 24-MHz crystal oscillator pin 1

X24M_P 47 Analog I/O 24-MHz crystal oscillator pin 2

EGP Power Ground – Exposed Ground Pad

(3) If internal DC-DC is not used, this pin is supplied internally from the main LDO.

(4) If internal DC-DC is not used, this pin must be connected to VDDR for supply from the main LDO.

Positive RF input signal to LNA during RX

Positive RF output signal to PA during TX

Negative RF input signal to LNA during RX

Negative RF output signal to PA during TX

(1)

(1)

(1)

www.ti.com

(2)(3)

(2)(4)

8

Terminal Configuration and Functions Copyright © 2015–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: CC2640

Page 9

28

29

27

30

212022

19

18

13

12

14

11

453

6

7

26 15

25 16

31 10

32 9

232

241

178

DIO_10

DIO_7

DIO_9

DIO_8

DCDC_SW

RESET_N

VDDS_DCDC

DIO_11

VDDR_RF

X24M_N

X24M_P

VDDR

VDDS

DIO_13

DIO_14

DIO_12

DIO_3

JTAG_TMSC

DIO_4

DCOUPL

VDDS2

JTAG_TCKC

DIO_5

DIO_6

RF_P

RF_N

RX_TX

DIO_0

DIO_1

DIO_2

X32K_Q1

X32K_Q2

www.ti.com

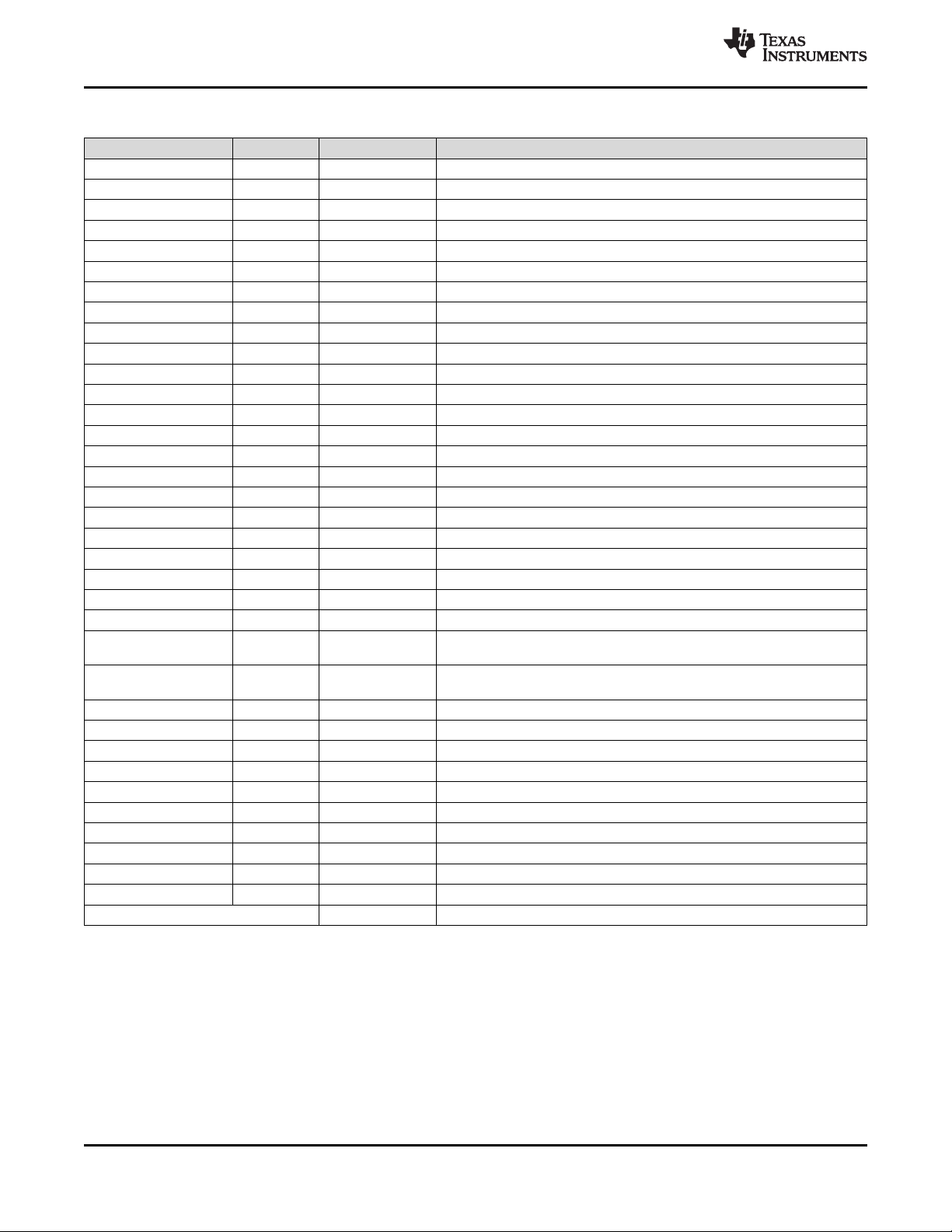

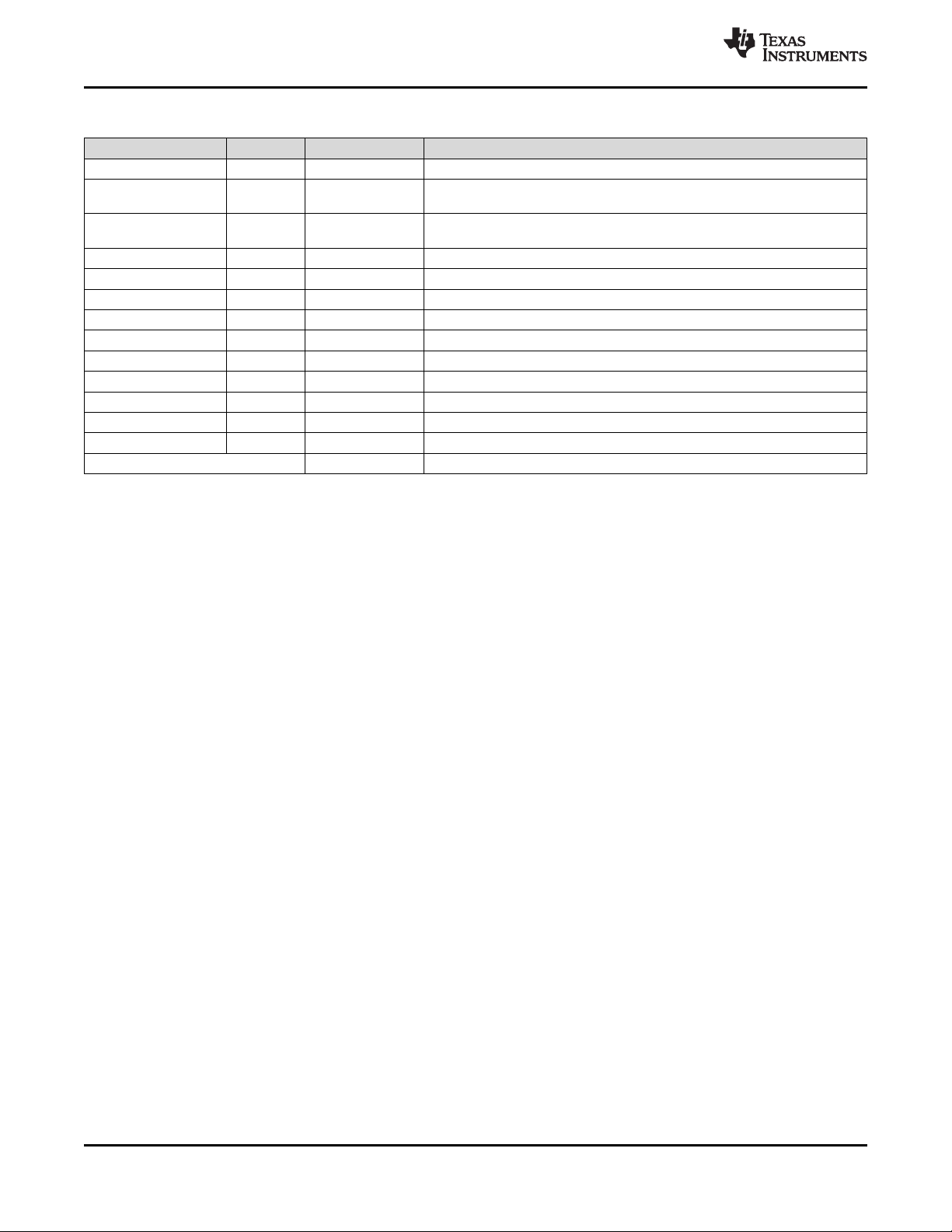

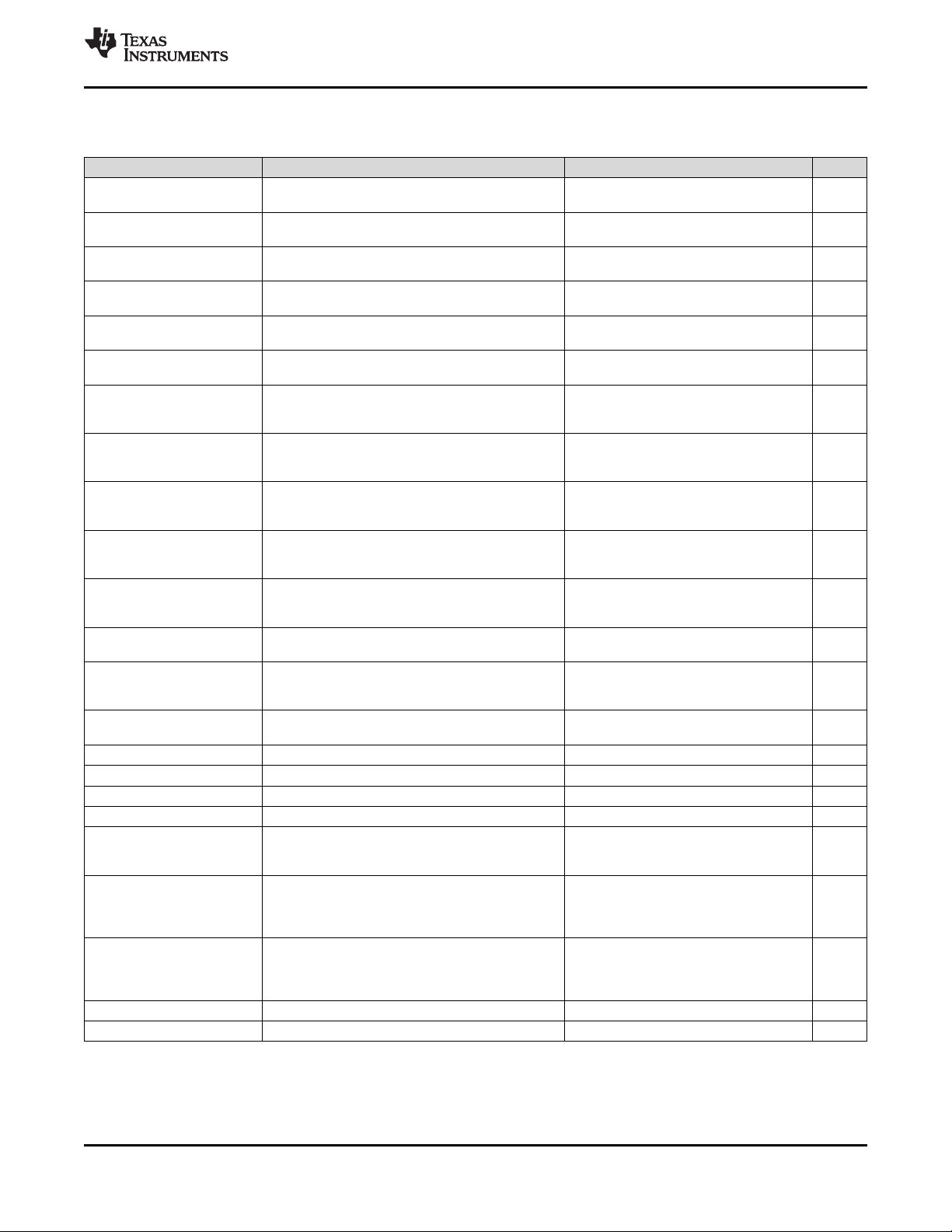

4.3 Pin Diagram – RHB Package

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

Note: I/O pins marked in bold have high drive capabilities. I/O pins marked in italics have analog capabilities.

Figure 4-2. RHB Package

32-Pin VQFN

(5-mm × 5-mm) Pinout, 0.5-mm Pitch

4.4 Signal Descriptions – RHB Package

Table 4-2. Signal Descriptions – RHB Package

NAME NO. TYPE DESCRIPTION

DCDC_SW 17 Power Output from internal DC-DC

DCOUPL 12 Power 1.27-V regulated digital-supply decoupling

DIO_0 6 Digital I/O GPIO, Sensor Controller

DIO_1 7 Digital I/O GPIO, Sensor Controller

DIO_2 8 Digital I/O GPIO, Sensor Controller, high-drive capability

DIO_3 9 Digital I/O GPIO, Sensor Controller, high-drive capability

DIO_4 10 Digital I/O GPIO, Sensor Controller, high-drive capability

DIO_5 15 Digital I/O GPIO, High drive capability, JTAG_TDO

DIO_6 16 Digital I/O GPIO, High drive capability, JTAG_TDI

DIO_7 20 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_8 21 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_9 22 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_10 23 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_11 24 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_12 25 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_13 26 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_14 27 Digital/Analog I/O GPIO, Sensor Controller, Analog

JTAG_TMSC 13 Digital I/O JTAG TMSC, high-drive capability

JTAG_TCKC 14 Digital I/O JTAG TCKC

(1) See technical reference manual (listed in Section 8.3) for more details.

(2) Do not supply external circuitry from this pin.

Submit Documentation Feedback

Product Folder Links: CC2640

(1)

Terminal Configuration and FunctionsCopyright © 2015–2016, Texas Instruments Incorporated

(2)

9

Page 10

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

Table 4-2. Signal Descriptions – RHB Package (continued)

NAME NO. TYPE DESCRIPTION

RESET_N 19 Digital input Reset, active-low. No internal pullup.

RF_N 2 RF I/O

RF_P 1 RF I/O

RX_TX 3 RF I/O Optional bias pin for the RF LNA

VDDR 29 Power 1.7-V to 1.95-V supply, typically connect to output of internal DC-DC

VDDR_RF 32 Power 1.7-V to 1.95-V supply, typically connect to output of internal DC-DC

VDDS 28 Power 1.8-V to 3.8-V main chip supply

VDDS2 11 Power 1.8-V to 3.8-V GPIO supply

VDDS_DCDC 18 Power 1.8-V to 3.8-V DC-DC supply

X32K_Q1 4 Analog I/O 32-kHz crystal oscillator pin 1

X32K_Q2 5 Analog I/O 32-kHz crystal oscillator pin 2

X24M_N 30 Analog I/O 24-MHz crystal oscillator pin 1

X24M_P 31 Analog I/O 24-MHz crystal oscillator pin 2

EGP Power Ground – Exposed Ground Pad

(3) If internal DC-DC is not used, this pin is supplied internally from the main LDO.

(4) If internal DC-DC is not used, this pin must be connected to VDDR for supply from the main LDO.

Negative RF input signal to LNA during RX

Negative RF output signal to PA during TX

Positive RF input signal to LNA during RX

Positive RF output signal to PA during TX

(1)

(1)

www.ti.com

(3)(2)

(2)(4)

10

Terminal Configuration and Functions Copyright © 2015–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: CC2640

Page 11

28

29

27

30

212022

19

18

13

12

14

11

453

6

7

26 15

25 16

31 10

32 9

232

241

178

DIO_6

VSS

DIO_5

RESET_N

VSS

VDDS_DCDC

DCDC_SW

DIO_7

VDDR_RF

X24M_N

X24M_P

VSS

VDDR

DIO_9

VDDS

DIO_8

DIO_1

JTAG_TMSC

DIO_2

DCOUPL

VDDS2

JTAG_TCKC

DIO_3

DIO_4

RF_P

RF_N

VSS

X32K_Q2

VSS

DIO_0

RX_TX

X32K_Q1

www.ti.com

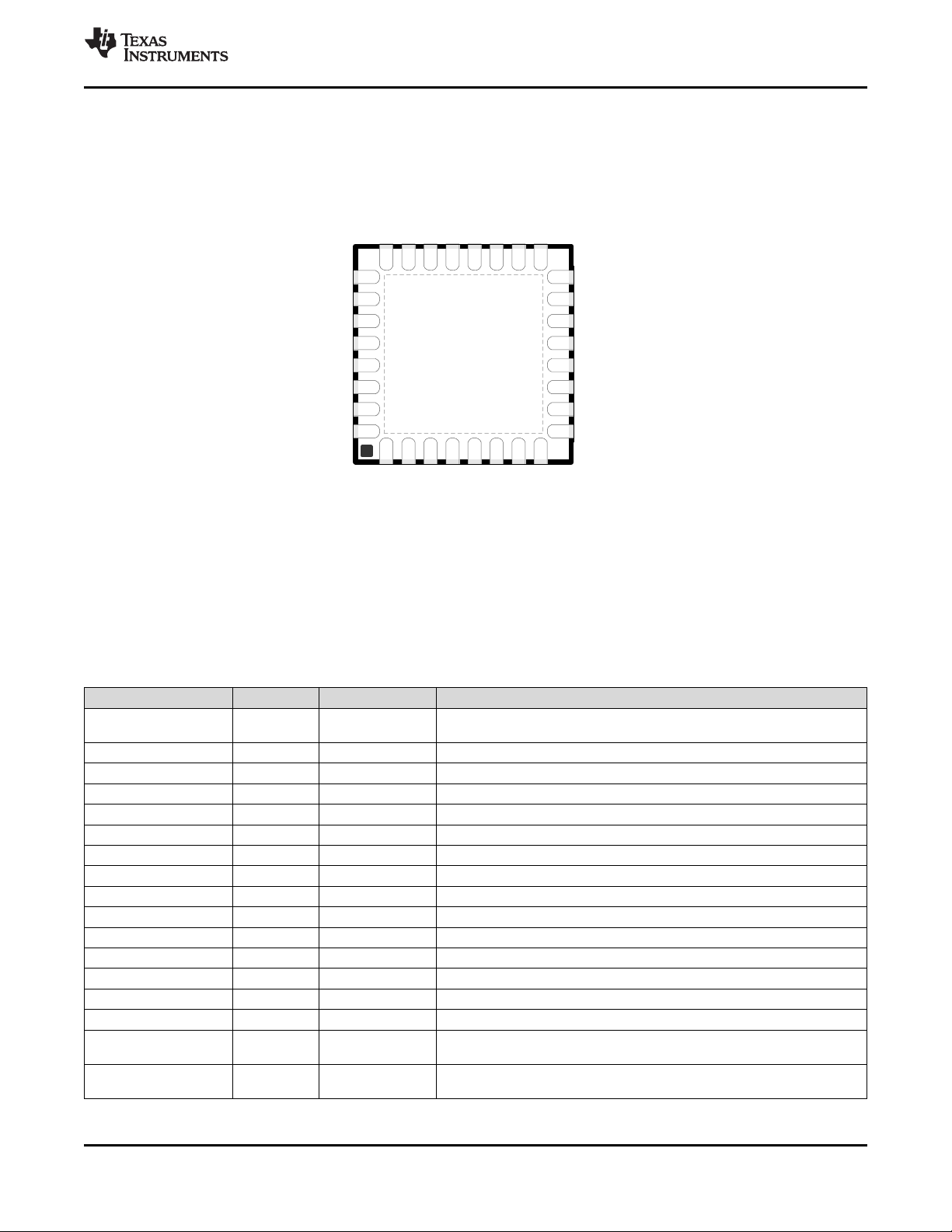

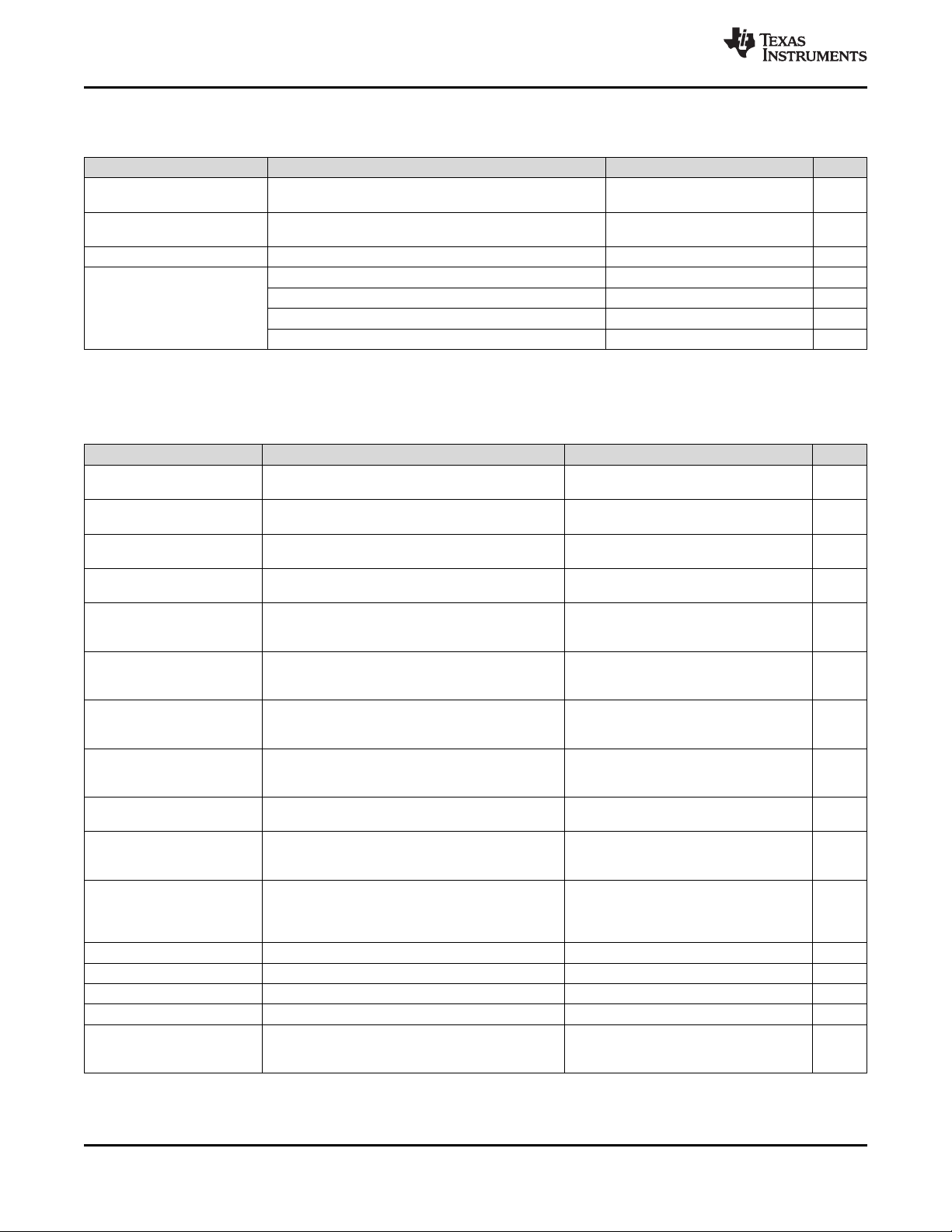

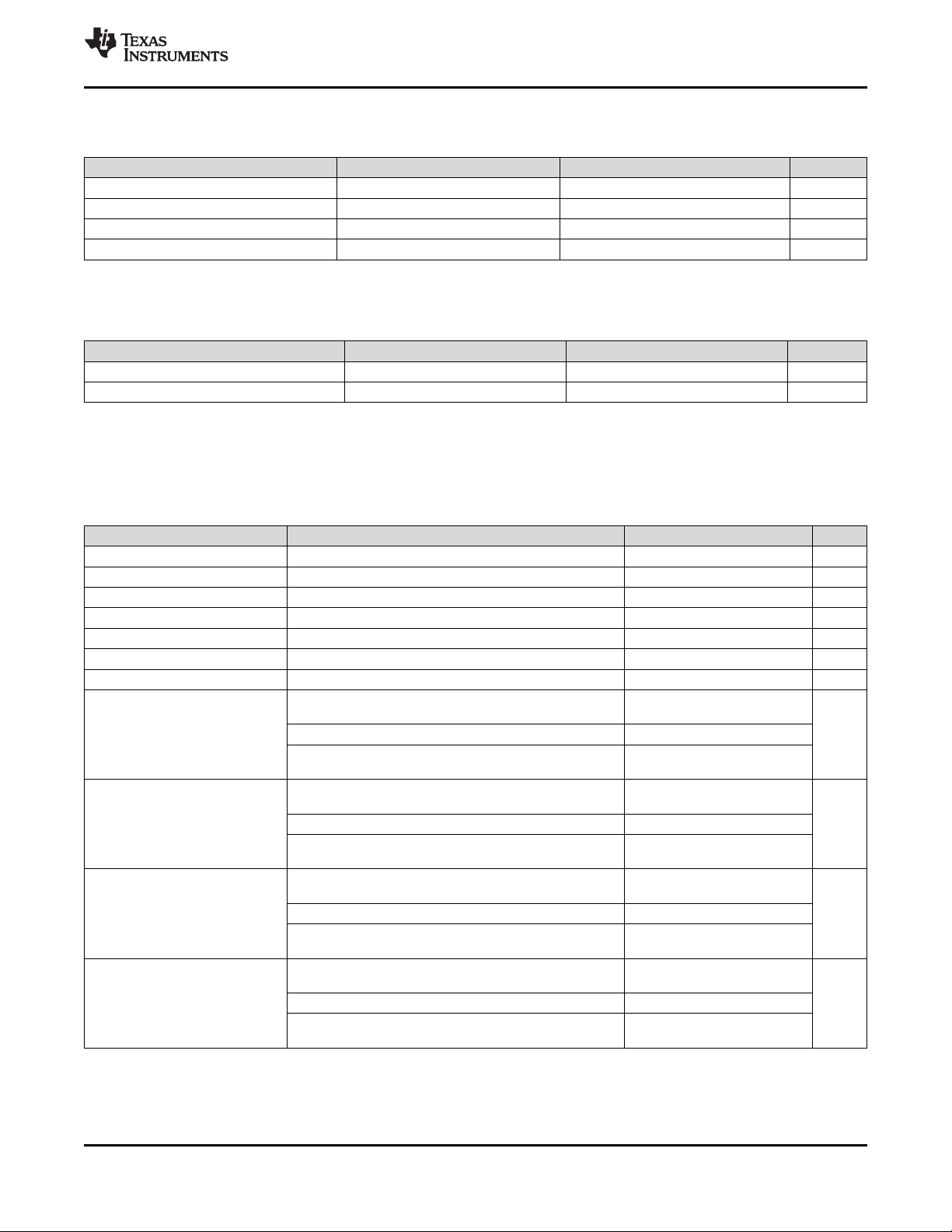

4.5 Pin Diagram – RSM Package

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

Note: I/O pins marked in bold have high drive capabilities. I/O pins marked in italics have analog capabilities.

Figure 4-3. RSM Package

32-Pin VQFN

(4-mm × 4-mm) Pinout, 0.4-mm Pitch

4.6 Signal Descriptions – RSM Package

Table 4-3. Signal Descriptions – RSM Package

NAME NO. TYPE DESCRIPTION

DCDC_SW 18 Power

DCOUPL 12 Power 1.27-V regulated digital-supply decoupling capacitor

DIO_0 8 Digital I/O GPIO, Sensor Controller, high-drive capability

DIO_1 9 Digital I/O GPIO, Sensor Controller, high-drive capability

DIO_2 10 Digital I/O GPIO, Sensor Controller, high-drive capability

DIO_3 15 Digital I/O GPIO, High drive capability, JTAG_TDO

DIO_4 16 Digital I/O GPIO, High drive capability, JTAG_TDI

DIO_5 22 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_6 23 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_7 24 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_8 25 Digital/Analog I/O GPIO, Sensor Controller, Analog

DIO_9 26 Digital/Analog I/O GPIO, Sensor Controller, Analog

JTAG_TMSC 13 Digital I/O JTAG TMSC

JTAG_TCKC 14 Digital I/O JTAG TCKC

RESET_N 21 Digital Input Reset, active-low. No internal pullup.

RF_N 2 RF I/O

RF_P 1 RF I/O

(1) See technical reference manual (listed in Section 8.3) for more details.

(2) Do not supply external circuitry from this pin.

Submit Documentation Feedback

Product Folder Links: CC2640

Output from internal DC-DC.

(1.7-V to 1.95-V operation)

Negative RF input signal to LNA during RX

Negative RF output signal to PA during TX

Positive RF input signal to LNA during RX

Positive RF output signal to PA during TX

(1)

. Tie to ground for external regulator mode

Terminal Configuration and FunctionsCopyright © 2015–2016, Texas Instruments Incorporated

(2)

11

Page 12

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

Table 4-3. Signal Descriptions – RSM Package (continued)

NAME NO. TYPE DESCRIPTION

RX_TX 4 RF I/O Optional bias pin for the RF LNA

VDDR 28 Power 1.7-V to 1.95-V supply, typically connect to output of internal DC-DC.

VDDR_RF 32 Power 1.7-V to 1.95-V supply, typically connect to output of internal DC-DC

VDDS 27 Power 1.8-V to 3.8-V main chip supply

VDDS2 11 Power 1.8-V to 3.8-V GPIO supply

VDDS_DCDC 19 Power

VSS

3, 7, 17, 20,

29

Power

1.8-V to 3.8-V DC-DC supply. Tie to ground for external regulator mode

(1.7-V to 1.95-V operation).

Ground

X32K_Q1 5 Analog I/O 32-kHz crystal oscillator pin 1

X32K_Q2 6 Analog I/O 32-kHz crystal oscillator pin 2

X24M_N 30 Analog I/O 24-MHz crystal oscillator pin 1

X24M_P 31 Analog I/O 24-MHz crystal oscillator pin 2

EGP Power Ground – Exposed Ground Pad

(3) If internal DC-DC is not used, this pin is supplied internally from the main LDO.

(4) If internal DC-DC is not used, this pin must be connected to VDDR for supply from the main LDO.

(1)

(1)

www.ti.com

(2)(3)

(2)(4)

12

Terminal Configuration and Functions Copyright © 2015–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: CC2640

Page 13

CC2640

www.ti.com

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

5 Specifications

5.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

Supply voltage (VDDS, VDDS2,

and VDDS3)

Supply voltage (VDDS

VDDR)

Voltage on any digital pin

Voltage on crystal oscillator pins, X32K_Q1, X32K_Q2, X24M_N and X24M_P –0.3 VDDR + 0.3, max 2.25 V

Voltage on ADC input (Vin)

Input RF level 5 dBm

T

stg

(1) All voltage values are with respect to ground, unless otherwise noted.

(2) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating

Conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(3) In external regulator mode, VDDS2 and VDDS3 must be at the same potential as VDDS.

(4) Including analog-capable DIO.

(5) Each pin is referenced to a specific VDDSx (VDDS, VDDS2 or VDDS3). For a pin-to-VDDS mapping table, see Table 6-3.

(3)

and

(4)(5)

VDDR supplied by internal DC-DC regulator or

internal GLDO. VDDS_DCDC connected to VDDS on

PCB.

External regulator mode (VDDS and VDDR pins

connected on PCB)

Voltage scaling enabled –0.3 VDDS

Voltage scaling disabled, VDDS as reference –0.3 VDDS / 2.9

Storage temperature –40 150 °C

(1)(2)

MIN MAX UNIT

–0.3 4.1 V

–0.3 2.25 V

–0.3 VDDSx + 0.3, max 4.1 V

VVoltage scaling disabled, internal reference –0.3 1.49

5.2 ESD Ratings

VALUE UNIT

Human body model (HBM), per ANSI/ESDA/JEDEC

(1)

V

ESD

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

Electrostatic discharge

(ESD) performance

JS001

Charged device model (CDM), per JESD22-C101

(2)

All pins ±2500

RF pins ±750

Non-RF pins ±750

5.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN MAX UNIT

Ambient temperature range –40 85 °C

Operating supply voltage

(VDDS and VDDR), external

regulator mode

Operating supply voltage VDDS

Operating supply voltages

VDDS2 and VDDS3

For operation in 1.8-V systems

(VDDS and VDDR pins connected on PCB, internal DCDC cannot be used)

For operation in battery-powered and 3.3-V systems

(internal DC-DC can be used to minimize power

consumption)

1.7 1.95 V

1.8 3.8 V

0.7 × VDDS, min 1.8 3.8 V

V

Submit Documentation Feedback

Product Folder Links: CC2640

SpecificationsCopyright © 2015–2016, Texas Instruments Incorporated

13

Page 14

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

5.4 Power Consumption Summary

Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

otherwise noted.

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Reset. RESET_N pin asserted or VDDS below

Power-on-Reset threshold

Shutdown. No clocks running, no retention 150

Standby. With RTC, CPU, RAM and (partial)

register retention. RCOSC_LF

Standby. With RTC, CPU, RAM and (partial)

register retention. XOSC_LF

Standby. With Cache, RTC, CPU, RAM and

(partial) register retention. RCOSC_LF

I

core

Peripheral Current Consumption (Adds to core current I

I

peri

(1) Single-ended RF mode is optimized for size and power consumption. Measured on CC2650EM-4XS.

(2) Differential RF mode is optimized for RF performance. Measured on CC2650EM-5XD.

(3) I

Core current consumption

Standby. With Cache, RTC, CPU, RAM and

(partial) register retention. XOSC_LF

Idle. Supply Systems and RAM powered. 550

Active. Core running CoreMark

Radio RX

Radio RX

Radio TX, 0-dBm output power

Radio TX, 5-dBm output power

(1)

(2)

(1)

(2)

for each peripheral unit activated)

core

Peripheral power domain Delta current with domain enabled 20 µA

Serial power domain Delta current with domain enabled 13 µA

RF Core

Delta current with power domain enabled, clock

enabled, RF core idle

µDMA Delta current with clock enabled, module idle 130 µA

Timers Delta current with clock enabled, module idle 113 µA

I2C Delta current with clock enabled, module idle 12 µA

I2S Delta current with clock enabled, module idle 36 µA

SSI Delta current with clock enabled, module idle 93 µA

UART Delta current with clock enabled, module idle 164 µA

is not supported in Standby or Shutdown.

peri

= 3.0 V with internal DC-DC converter, unless

DDS

(3)

100

1

1.2

2.5

2.7

1.45 mA +

31 µA/MHz

5.9

6.1

6.1

9.1

237 µA

www.ti.com

nA

µA

mA

5.5 General Characteristics

Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

FLASH MEMORY

Supported flash erase cycles before

failure

Flash page/sector erase current Average delta current 12.6 mA

Flash page/sector size 4 KB

Flash write current Average delta current, 4 bytes at a time 8.15 mA

Flash page/sector erase time

Flash write time

(1)

(1) This number is dependent on Flash aging and will increase over time and erase cycles.

14

Specifications Copyright © 2015–2016, Texas Instruments Incorporated

(1)

4 bytes at a time 8 µs

Submit Documentation Feedback

Product Folder Links: CC2640

= 3.0 V, unless otherwise noted.

DDS

100 k Cycles

8 ms

Page 15

CC2640

www.ti.com

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

5.6 1-Mbps GFSK (Bluetooth low energy Technology) – RX

Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Receiver sensitivity

Receiver sensitivity

Receiver saturation

Receiver saturation

Frequency error tolerance

Data rate error tolerance

Co-channel rejection

Selectivity, ±1 MHz

Selectivity, ±2 MHz

Selectivity, ±3 MHz

Selectivity, ±4 MHz

(1)

(1)

(1)

(1)

(1)

Selectivity, ±5 MHz or more

Selectivity, Image frequency

Selectivity, Image frequency

(1)

±1 MHz

Out-of-band blocking

(3)

Out-of-band blocking 2003 MHz to 2399 MHz –5 dBm

Out-of-band blocking 2484 MHz to 2997 MHz –8 dBm

Out-of-band blocking 3000 MHz to 12.75 GHz –8 dBm

Intermodulation

Spurious emissions,

30 to 1000 MHz

Spurious emissions,

1 to 12.75 GHz

RSSI dynamic range 70 dB

RSSI accuracy ±4 dB

(1) Numbers given as I/C dB.

(2) X / Y, where X is +N MHz and Y is –N MHz.

(3) Excluding one exception at F

Differential mode. Measured at the CC2650EM-5XD

SMA connector, BER = 10

Single-ended mode. Measured on CC2650EM-4XS,

at the SMA connector, BER = 10

Differential mode. Measured at the CC2650EM-5XD

SMA connector, BER = 10

Single-ended mode. Measured on CC2650EM-4XS,

at the SMA connector, BER = 10

–3

–3

–3

–3

Difference between the incoming carrier frequency

and the internally generated carrier frequency

Difference between incoming data rate and the

internally generated data rate

Wanted signal at –67 dBm, modulated interferer in

channel,

BER = 10

–3

Wanted signal at –67 dBm, modulated interferer at

±1 MHz,

BER = 10

–3

Wanted signal at –67 dBm, modulated interferer at

±2 MHz,

BER = 10

–3

Wanted signal at –67 dBm, modulated interferer at

±3 MHz,

BER = 10

–3

Wanted signal at –67 dBm, modulated interferer at

±4 MHz,

BER = 10

Wanted signal at –67 dBm, modulated interferer at ≥

(1)

±5 MHz, BER = 10

Wanted signal at –67 dBm, modulated interferer at

(1)

image frequency,

BER = 10

Wanted signal at –67 dBm, modulated interferer at

±1 MHz from image frequency, BER = 10

–3

–3

–3

–3

30 MHz to 2000 MHz –20 dBm

Wanted signal at 2402 MHz, –64 dBm. Two

interferers at 2405 and 2408 MHz respectively, at

the given power level

Conducted measurement in a 50-Ω single-ended

load. Suitable for systems targeting compliance with

EN 300 328, EN 300 440 class 2, FCC CFR47, Part

15 and ARIB STD-T-66

Conducted measurement in a 50 Ω single-ended

load. Suitable for systems targeting compliance with

EN 300 328, EN 300 440 class 2, FCC CFR47, Part

15 and ARIB STD-T-66

/ 2, per Bluetooth Specification.

wanted

= 3.0 V, fRF= 2440 MHz, unless otherwise noted.

DDS

–97 dBm

–96 dBm

4 dBm

0 dBm

–350 350 kHz

–750 750 ppm

–6 dB

(2)

7 / 3

(2)

34 / 25

(2)

38 / 26

(2)

42 / 29

32 dB

25 dB

(2)

3 / 26

–34 dBm

–71 dBm

–62 dBm

dB

dB

dB

dB

dB

Submit Documentation Feedback

Product Folder Links: CC2640

SpecificationsCopyright © 2015–2016, Texas Instruments Incorporated

15

Page 16

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

www.ti.com

5.7 1-Mbps GFSK (Bluetooth low energy Technology) – TX

Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output power, highest setting

Output power, highest setting

Output power, lowest setting Delivered to a single-ended 50-Ω load through a balun –21 dBm

Spurious emission conducted

measurement

(1)

(1) Suitable for systems targeting compliance with worldwide radio-frequency regulations ETSI EN 300 328 and EN 300 440 Class 2

(Europe), FCC CFR47 Part 15 (US), and ARIB STD-T66 (Japan).

Differential mode, delivered to a single-ended 50-Ω load

through a balun

Measured on CC2650EM-4XS, delivered to a single-ended

50-Ω load

f < 1 GHz, outside restricted bands –43 dBm

f < 1 GHz, restricted bands ETSI –65 dBm

f < 1 GHz, restricted bands FCC –76 dBm

f > 1 GHz, including harmonics –46 dBm

= 3.0 V, fRF= 2440 MHz, unless otherwise noted.

DDS

5 dBm

2 dBm

5.8 2-Mbps GFSK (Bluetooth 5) – RX

Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Receiver sensitivity

Receiver saturation

Frequency error tolerance

Data rate error tolerance

Co-channel rejection

Selectivity, ±2 MHz

Selectivity, ±4 MHz

Selectivity, ±6 MHz

Alternate channel rejection, ±7

(1)

MHz

(1)

(1)

(1)

(1)

Selectivity, Image frequency

Selectivity, Image frequency

(1)

±2 MHz

Out-of-band blocking

(3)

Out-of-band blocking 2003 MHz to 2399 MHz –15 dBm

Out-of-band blocking 2484 MHz to 2997 MHz –12 dBm

Out-of-band blocking 3000 MHz to 12.75 GHz –10 dBm

Intermodulation

(1) Numbers given as I/C dB.

(2) X / Y, where X is +N MHz and Y is –N MHz.

(3) Excluding one exception at F

Differential mode. Measured at the CC2650EM-5XD

SMA connector, BER = 10

Differential mode. Measured at the CC2650EM-5XD

SMA connector, BER = 10

–3

–3

Difference between the incoming carrier frequency

and the internally generated carrier frequency

Difference between incoming data rate and the

internally generated data rate

Wanted signal at –67 dBm, modulated interferer in

channel,

BER = 10

–3

Wanted signal at –67 dBm, modulated interferer at

±2 MHz, Image frequency is at -2 MHz

BER = 10

–3

Wanted signal at –67 dBm, modulated interferer at

±4 MHz,

BER = 10

–3

Wanted signal at –67 dBm, modulated interferer at

±6 MHz,

BER = 10

Wanted signal at –67 dBm, modulated interferer at ≥

±7 MHz, BER = 10

Wanted signal at –67 dBm, modulated interferer at

(1)

image frequency,

BER = 10

–3

–3

–3

Note that Image frequency + 2 MHz is the Cochannel. Wanted signal at –67 dBm, modulated

interferer at ±2 MHz from image frequency, BER =

–3

10

30 MHz to 2000 MHz –33 dBm

Wanted signal at 2402 MHz, –64 dBm. Two

interferers at 2405 and 2408 MHz respectively, at

the given power level

/ 2, per Bluetooth Specification.

wanted

= 3.0 V, fRF= 2440 MHz, unless otherwise noted.

DDS

–92 dBm

4 dBm

–300 500 kHz

–1000 1000 ppm

–7 dB

(2)

8 / 4

(2)

31 / 26

(2)

37 / 38

(2)

37 / 36

4 dB

(2)

-7 / 26

–45 dBm

dB

dB

dB

dB

dB

16

Specifications Copyright © 2015–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: CC2640

Page 17

CC2640

www.ti.com

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

5.9 2-Mbps GFSK (Bluetooth 5) – TX

Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output power, highest setting

Output power, highest setting

Output power, lowest setting Delivered to a single-ended 50-Ω load through a balun –21 dBm

Spurious emission conducted

measurement

(1)

(1) Suitable for systems targeting compliance with worldwide radio-frequency regulations ETSI EN 300 328 and EN 300 440 Class 2

(Europe), FCC CFR47 Part 15 (US), and ARIB STD-T66 (Japan).

Differential mode, delivered to a single-ended 50-Ω load

through a balun

Measured on CC2650EM-4XS, delivered to a single-ended

50-Ω load

f < 1 GHz, outside restricted bands –43 dBm

f < 1 GHz, restricted bands ETSI –65 dBm

f < 1 GHz, restricted bands FCC –76 dBm

f > 1 GHz, including harmonics –46 dBm

= 3.0 V, fRF= 2440 MHz, unless otherwise noted.

DDS

5 dBm

2 dBm

5.10 5-Mbps (Proprietary) – RX

Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Receiver sensitivity

Receiver saturation

Frequency error tolerance

Data rate error tolerance

Co-channel rejection

Selectivity, ±4 MHz

Selectivity, ±5 MHz

Selectivity, ±8 MHz

Selectivity, ±10 MHz

Selectivity, ±12 MHz

Selectivity, ±15 MHz

Blocker rejection ±10 MHz

and above

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1) Numbers given as I/C dB.

(2) X / Y, where X is +N MHz and Y is –N MHz.

Differential mode. Measured at the CC2650EM-5XD

SMA connector, BER = 10

Differential mode. Measured at the CC2650EM-5XD

SMA connector, BER = 10

–3

–3

Difference between the incoming carrier frequency

and the internally generated carrier frequency

Difference between incoming data rate and the

internally generated data rate

Wanted signal 11 dB above sensitivity level,

modulated interferer in channel,

BER = 10

–3

Wanted signal 11 dB above sensitivity level,

modulated interferer at ±4 MHz

BER = 10

–3

Wanted signal 11 dB above sensitivity level,

modulated interferer at ±5 MHz,

BER = 10

–3

Wanted signal 11 dB above sensitivity level,

modulated interferer at ±8 MHz,

BER = 10

Wanted signal 11 dB above sensitivity level,

modulated interferer at ±10 MHz, BER = 10

–3

–3

Wanted signal 11 dB above sensitivity level,

modulated interferer at ±12 MHz,

BER = 10

–3

Wanted signal 11 dB above sensitivity level,

modulated interferer at ±15 MHz,

BER = 10

Wanted signal 3dB above sensitivity limit , CW

interferer at ±10 MHz and above, BER = 10

–3

–3

= 3.0 V, fRF= 2440 MHz, unless otherwise noted.

DDS

–81 dBm

-11 dBm

–300 300 kHz

–200 200 ppm

–19 dB

(2)

9 / 9

(2)

19 / 19

(2)

28 / 28

(2)

33 / 33

(2)

37/ 37

(2)

43/ 43

40 dB

dB

dB

dB

dB

dB

dB

Submit Documentation Feedback

Product Folder Links: CC2640

SpecificationsCopyright © 2015–2016, Texas Instruments Incorporated

17

Page 18

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

www.ti.com

5.11 5-Mbps (Proprietary) – TX

Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output power, highest setting

Output power, highest setting

Output power, lowest setting Delivered to a single-ended 50-Ω load through a balun –21 dBm

Occupied bandwidth 95% BW 2.4 MHz

Occupied bandwidth 99% BW 3.7 MHz

Spurious emission conducted

measurement

(1)

(1) Suitable for systems targeting compliance with worldwide radio-frequency regulations ETSI EN 300 328 and EN 300 440 Class 2

(Europe), FCC CFR47 Part 15 (US), and ARIB STD-T66 (Japan).

Differential mode, delivered to a single-ended 50-Ω load

through a balun

Measured on CC2650EM-4XS, delivered to a single-ended

50-Ω load

f < 1 GHz, outside restricted bands –43 dBm

f < 1 GHz, restricted bands ETSI –65 dBm

f < 1 GHz, restricted bands FCC –76 dBm

f > 1 GHz, including harmonics –46 dBm

= 3.0 V, fRF= 2440 MHz, unless otherwise noted.

DDS

5 dBm

2 dBm

5.12 24-MHz Crystal Oscillator (XOSC_HF)

Tc= 25°C, V

= 3.0 V, unless otherwise noted.

DDS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

ESR Equivalent series resistance

ESR Equivalent series resistance

LMMotional inductance

(2)

CLCrystal load capacitance

Crystal frequency

(2)(3)

Crystal frequency tolerance

Start-up time

(3)(5)

(2)

(2)

Relates to load capacitance

(CLin Farads)

(2)

(2)(4)

(1) Probing or otherwise stopping the XTAL while the DC-DC converter is enabled may cause permanent damage to the device.

(2) The crystal manufacturer's specification must satisfy this requirement

(3) Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

(4) Includes initial tolerance of the crystal, drift over temperature, ageing and frequency pulling due to incorrect load capacitance. As per

Bluetooth specification.

(5) Kick-started based on a temperature and aging compensated RCOSC_HF using precharge injection.

(1)

6 pF < CL≤ 9 pF 20 60 Ω

5 pF < CL≤ 6 pF 80 Ω

–24

< 1.6 × 10

/ C

2

L

5 9 pF

24 MHz

–40 40 ppm

150 µs

= 3.0 V

DDS

H

5.13 32.768-kHz Crystal Oscillator (XOSC_LF)

Tc= 25°C, V

Crystal frequency

Crystal frequency tolerance, Bluetooth low-

energy applications

ESR Equivalent series resistance

CLCrystal load capacitance

(1) The crystal manufacturer's specification must satisfy this requirement

(2) Includes initial tolerance of the crystal, drift over temperature, ageing and frequency pulling due to incorrect load capacitance. As per

Bluetooth specification.

18

Specifications Copyright © 2015–2016, Texas Instruments Incorporated

= 3.0 V, unless otherwise noted.

DDS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

(1)

(1)(2)

–500 500 ppm

(1)

(1)

32.768 kHz

30 100 kΩ

6 12 pF

Submit Documentation Feedback

Product Folder Links: CC2640

Page 19

CC2640

www.ti.com

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

5.14 48-MHz RC Oscillator (RCOSC_HF)

Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Frequency 48 MHz

Uncalibrated frequency accuracy ±1%

Calibrated frequency accuracy

Start-up time 5 µs

(1) Accuracy relative to the calibration source (XOSC_HF).

(1)

= 3.0 V, unless otherwise noted.

DDS

±0.25%

5.15 32-kHz RC Oscillator (RCOSC_LF)

Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Calibrated frequency

Temperature coefficient 50 ppm/°C

(1) The frequency accuracy of the Real Time Clock (RTC) is not directly dependent on the frequency accuracy of the 32-kHz RC Oscillator.

The RTC can be calibrated to an accuracy within ±500 ppm of 32.768 kHz by measuring the frequency error of RCOSC_LF relative to

XOSC_HF and compensating the RTC tick speed. The procedure is explained in Running Bluetooth®Low Energy on CC2640 Without

32 kHz Crystal.

(1)

= 3.0 V, unless otherwise noted.

DDS

32.8 kHz

5.16 ADC Characteristics

Tc= 25°C, V

= 3.0 V and voltage scaling enabled, unless otherwise noted.

DDS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Input voltage range 0 VDDS V

Resolution 12 Bits

Sample rate 200 ksps

Offset Internal 4.3-V equivalent reference

Gain error Internal 4.3-V equivalent reference

(3)

DNL

INL

Differential nonlinearity >–1 LSB

(4)

Integral nonlinearity ±3 LSB

ENOB Effective number of bits

THD Total harmonic distortion

SINAD,

SNDR

SFDR

Signal-to-noise

and

Distortion ratio

Spurious-free dynamic

range

(2)

(2)

Internal 4.3-V equivalent reference

(2)

, 200 ksps,

9.6-kHz input tone

Internal 1.44-V reference, voltage scaling disabled,

32 samples average, 200 ksps, 300-Hz input tone

Internal 4.3-V equivalent reference

(2)

, 200 ksps,

9.6-kHz input tone

Internal 1.44-V reference, voltage scaling disabled,

32 samples average, 200 ksps, 300-Hz input tone

Internal 4.3-V equivalent reference

(2)

, 200 ksps,

9.6-kHz input tone

Internal 1.44-V reference, voltage scaling disabled,

32 samples average, 200 ksps, 300-Hz input tone

Internal 4.3-V equivalent reference

(2)

, 200 ksps,

9.6-kHz input tone

Internal 1.44-V reference, voltage scaling disabled,

32 samples average, 200 ksps, 300-Hz input tone

(1)

2 LSB

2.4 LSB

9.8

BitsVDDS as reference, 200 ksps, 9.6-kHz input tone 10

11.1

–65

dBVDDS as reference, 200 ksps, 9.6-kHz input tone –69

–71

60

dBVDDS as reference, 200 ksps, 9.6-kHz input tone 63

69

67

dBVDDS as reference, 200 ksps, 9.6-kHz input tone 72

73

(1) Using IEEE Std 1241™-2010 for terminology and test methods.

(2) Input signal scaled down internally before conversion, as if voltage range was 0 to 4.3 V.

(3) No missing codes. Positive DNL typically varies from +0.3 to +3.5, depending on device (see Figure 5-22).

(4) For a typical example, see Figure 5-23.

Submit Documentation Feedback

Product Folder Links: CC2640

SpecificationsCopyright © 2015–2016, Texas Instruments Incorporated

19

Page 20

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

ADC Characteristics (continued)

Tc= 25°C, V

(5) Applied voltage must be within absolute maximum ratings (Section 5.1) at all times.

= 3.0 V and voltage scaling enabled, unless otherwise noted.

DDS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Conversion time Serial conversion, time-to-output, 24-MHz clock 50

Current consumption Internal 4.3-V equivalent reference

(2)

Current consumption VDDS as reference 0.75 mA

Equivalent fixed internal reference (input voltage scaling

Reference voltage

enabled). For best accuracy, the ADC conversion should

be initiated through the TIRTOS API in order to include the

gain/offset compensation factors stored in FCFG1.

Fixed internal reference (input voltage scaling disabled).

For best accuracy, the ADC conversion should be initiated

Reference voltage

through the TIRTOS API in order to include the gain/offset

compensation factors stored in FCFG1. This value is

derived from the scaled value (4.3V) as follows:

Vref=4.3V*1408/4095

Reference voltage

Reference voltage

VDDS as reference (Also known as RELATIVE) (input

voltage scaling enabled)

VDDS as reference (Also known as RELATIVE) (input

voltage scaling disabled)

200 ksps, voltage scaling enabled. Capacitive input, Input

Input Impedance

impedance depends on sampling frequency and sampling

time

www.ti.com

(1)

clockcycles

0.66 mA

(2)(5)

4.3

V

1.48 V

VDDS V

VDDS /

(5)

2.82

V

>1 MΩ

20

Specifications Copyright © 2015–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: CC2640

Page 21

CC2640

www.ti.com

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

5.17 Temperature Sensor

Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Resolution 4 °C

Range –40 85 °C

Accuracy ±5 °C

Supply voltage coefficient

(1) Automatically compensated when using supplied driver libraries.

(1)

= 3.0 V, unless otherwise noted.

DDS

3.2 °C/V

5.18 Battery Monitor

Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Resolution 50 mV

Range 1.8 3.8 V

Accuracy 13 mV

= 3.0 V, unless otherwise noted.

DDS

5.19 Continuous Time Comparator

Tc= 25°C, V

Input voltage range 0 VDDS V

External reference voltage 0 VDDS V

Internal reference voltage DCOUPL as reference 1.27 V

Offset 3 mV

Hysteresis <2 mV

Decision time Step from –10 mV to 10 mV 0.72 µs

Current consumption when enabled

(1) Additionally, the bias module must be enabled when running in standby mode.

= 3.0 V, unless otherwise noted.

DDS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

(1)

8.6 µA

Submit Documentation Feedback

Product Folder Links: CC2640

SpecificationsCopyright © 2015–2016, Texas Instruments Incorporated

21

Page 22

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

www.ti.com

5.20 Low-Power Clocked Comparator

Tc= 25°C, V

Input voltage range 0 VDDS V

Clock frequency 32 kHz

Internal reference voltage, VDDS / 2 1.49 – 1.51 V

Internal reference voltage, VDDS / 3 1.01 – 1.03 V

Internal reference voltage, VDDS / 4 0.78 – 0.79 V

Internal reference voltage, DCOUPL / 1 1.25 – 1.28 V

Internal reference voltage, DCOUPL / 2 0.63 – 0.65 V

Internal reference voltage, DCOUPL / 3 0.42 – 0.44 V

Internal reference voltage, DCOUPL / 4 0.33 – 0.34 V

Offset <2 mV

Hysteresis <5 mV

Decision time Step from –50 mV to 50 mV <1 clock-cycle

Current consumption when enabled 362 nA

= 3.0 V, unless otherwise noted.

DDS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

5.21 Programmable Current Source

Tc= 25°C, V

Current source programmable output range 0.25 – 20 µA

Resolution 0.25 µA

Current consumption

(1) Additionally, the bias module must be enabled when running in standby mode.

= 3.0 V, unless otherwise noted.

DDS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

(1)

Including current source at maximum

programmable output

23 µA

5.22 Synchronous Serial Interface (SSI)

Tc= 25°C, V

(1)

S1

t

clk_per

(1)

S2

t

clk_high

(1)

S3

t

clk_low

S1 (TX only)

S1 (TX and RX)

(1)

S2

t

clk_high

(1)

S3

t

clk_low

(1) Refer to SSI timing diagrams Figure 5-1, Figure 5-2, and Figure 5-3.

= 3.0 V, unless otherwise noted.

DDS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

(SSIClk period) Device operating as SLAVE 12 65024

(SSIClk high time) Device operating as SLAVE 0.5 t

(SSIClk low time) Device operating as SLAVE 0.5 t

(1)

t

(SSIClk period)

clk_per

(1)

t

(SSIClk period)

clk_per

One-way communication to SLAVE Device operating as MASTER

Normal duplex operation - Device

operating as MASTER

(SSIClk high time) Device operating as MASTER 0.5 t

(SSIClk low time) Device operating as MASTER 0.5 t

4 65024

8 65024

system

clocks

clk_per

clk_per

system

clocks

system

clocks

clk_per

clk_per

22

Specifications Copyright © 2015–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: CC2640

Page 23

0

SSIClk

SSIFss

SSITx

SSIRx

MSB LSB

MSB LSB

S2

S3

S1

8-bit control

4 to 16 bits output data

SSIClk

SSIFss

SSITx

SSIRx

MSB LSB

S2

S3

S1

4 to 16 bits

www.ti.com

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

Figure 5-1. SSI Timing for TI Frame Format (FRF = 01), Single Transfer Timing Measurement

Figure 5-2. SSI Timing for MICROWIRE Frame Format (FRF = 10), Single Transfer

Submit Documentation Feedback

Product Folder Links: CC2640

SpecificationsCopyright © 2015–2016, Texas Instruments Incorporated

23

Page 24

SSIClk

(SPO = 1)

SSITx

(Master)

SSIRx

(Slave)

LSB

SSIClk

(SPO = 0)

S2

S1

SSIFss

LSB

S3

MSB

MSB

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

www.ti.com

Figure 5-3. SSI Timing for SPI Frame Format (FRF = 00), With SPH = 1

5.23 DC Characteristics

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

TA= 25°C, V

GPIO VOH at 8-mA load IOCURR = 2, high-drive GPIOs only 1.32 1.54 V

GPIO VOL at 8-mA load IOCURR = 2, high-drive GPIOs only 0.26 0.32 V

GPIO VOH at 4-mA load IOCURR = 1 1.32 1.58 V

GPIO VOL at 4-mA load IOCURR = 1 0.21 0.32 V

GPIO pullup current Input mode, pullup enabled, Vpad = 0 V 71.7 µA

GPIO pulldown current Input mode, pulldown enabled, Vpad = VDDS 21.1 µA

GPIO high/low input transition,

no hysteresis

GPIO low-to-high input transition,

with hysteresis

GPIO high-to-low input transition,

with hysteresis

IH = 0, transition between reading 0 and reading 1 0.88 V

IH = 1, transition voltage for input read as 0 → 1 1.07 V

IH = 1, transition voltage for input read as 1 → 0 0.74 V

GPIO input hysteresis IH = 1, difference between 0 → 1 and 1 → 0 points 0.33 V

DDS

= 1.8 V

24

Specifications Copyright © 2015–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: CC2640

Page 25

CC2640

www.ti.com

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

DC Characteristics (continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

TA= 25°C, V

GPIO VOH at 8-mA load IOCURR = 2, high-drive GPIOs only 2.68 V

GPIO VOL at 8-mA load IOCURR = 2, high-drive GPIOs only 0.33 V

GPIO VOH at 4-mA load IOCURR = 1 2.72 V

GPIO VOL at 4-mA load IOCURR = 1 0.28 V

TA= 25°C, V

GPIO pullup current Input mode, pullup enabled, Vpad = 0 V 277 µA

GPIO pulldown current Input mode, pulldown enabled, Vpad = VDDS 113 µA

GPIO high/low input transition,

no hysteresis

GPIO low-to-high input transition,

with hysteresis

GPIO high-to-low input transition,

with hysteresis

IH = 0, transition between reading 0 and reading 1 1.67 V

IH = 1, transition voltage for input read as 0 → 1 1.94 V

IH = 1, transition voltage for input read as 1 → 0 1.54 V

GPIO input hysteresis IH = 1, difference between 0 → 1 and 1 → 0 points 0.4 V

TA= 25°C

VIH

VIL

Lowest GPIO input voltage reliably interpreted as a

«High»

Highest GPIO input voltage reliably interpreted as a

«Low»

(1) Each GPIO is referenced to a specific VDDS pin. See the technical reference manual listed in Section 8.3 for more details.

DDS

DDS

= 3.0 V

= 3.8 V

0.8 VDDS

0.2 VDDS

(1)

(1)

5.24 Thermal Resistance Characteristics

NAME DESCRIPTION RSM (°C/W)

Rθ

Rθ

Rθ

Psi

Psi

Rθ

JA

JC(top)

JB

JT

JB

JC(bot)

Junction-to-ambient thermal resistance 36.9 32.8 29.6

Junction-to-case (top) thermal resistance 30.3 24.0 15.7

Junction-to-board thermal resistance 7.6 6.8 6.2

Junction-to-top characterization parameter 0.4 0.3 0.3

Junction-to-board characterization parameter 7.4 6.8 6.2

Junction-to-case (bottom) thermal resistance 2.1 1.9 1.9

(1) (2)

RHB (°C/W)

(1) °C/W = degrees Celsius per watt.

(2) These values are based on a JEDEC-defined 2S2P system (with the exception of the Theta JC [RθJC] value, which is based on a

JEDEC-defined 1S0P system) and will change based on environment as well as application. For more information, see these

EIA/JEDEC standards:

• JESD51-2, Integrated Circuits Thermal Test Method Environmental Conditions - Natural Convection (Still Air).

• JESD51-3, Low Effective Thermal Conductivity Test Board for Leaded Surface Mount Packages.

• JESD51-7, High Effective Thermal Conductivity Test Board for Leaded Surface Mount Packages.

• JESD51-9, Test Boards for Area Array Surface Mount Package Thermal Measurements.

Power dissipation of 2 W and an ambient temperature of 70ºC is assumed.

(1) (2)

RGZ (°C/W)

(1) (2)

Submit Documentation Feedback

Product Folder Links: CC2640

SpecificationsCopyright © 2015–2016, Texas Instruments Incorporated

25

Page 26

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

www.ti.com

5.25 Timing Requirements

MIN NOM MAX UNIT

Rising supply-voltage slew rate 0 100 mV/µs

Falling supply-voltage slew rate 0 20 mV/µs

Falling supply-voltage slew rate, with low-power flash settings

Positive temperature gradient in standby

(2)

(1)

No limitation for negative

temperature gradient, or

3 mV/µs

5 °C/s

outside standby mode

CONTROL INPUT AC CHARACTERISTICS

(3)

RESET_N low duration 1 µs

(1) For smaller coin cell batteries, with high worst-case end-of-life equivalent source resistance, a 22-µF VDDS input capacitor (see

Figure 7-1) must be used to ensure compliance with this slew rate.

(2) Applications using RCOSC_LF as sleep timer must also consider the drift in frequency caused by a change in temperature (see

Section 5.15).

(3) TA= –40°C to 85°C, V

= 1.7 V to 3.8 V, unless otherwise noted.

DDS

5.26 Switching Characteristics

Measured on the TI CC2650EM-5XD reference design with Tc= 25°C, V

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

WAKEUP AND TIMING

Idle → Active 14 µs

Standby → Active 151 µs

Shutdown → Active 1015 µs

= 3.0 V, unless otherwise noted.

DDS

26

Specifications Copyright © 2015–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: CC2640

Page 27

VDDS (V)

Output power (dBm)

1.8 2.3 2.8 3.3 3.8

0

1

2

3

4

5

6

D003

5XD 5dBm Setting

4XS 2dBm Setting

Frequency (MHz)

Output Power (dBm)

2400 2410 2420 2430 2440 2450 2460 2470 2480

-1

0

1

2

3

4

5

6

7

8

D021

5-dBm setting (5XD)

0-dBm setting (4XS)

Frequency (MHz)

Sensitivity Level (dBm)

2400 2410 2420 2430 2440 2450 2460 2470 2480

-99

-98.5

-98

-97.5

-97

-96.5

-96

-95.5

-95

D020

Sensitivity 5XD

Sensitivity 4XS

Temperature (qC)

Output Power (dBm)

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

0

1

2

3

4

5

6

4XS 2-dBm Setting

5XD 5-dBm Setting

VDDS (V)

Sensitivity (dBm)

1.8 2.3 2.8 3.3 3.8

-101

-100

-99

-98

-97

-96

-95

D004

BLE 5XD Sensitivity

BLE 4XS Sensitivity

Temperature (qC)

Sensitivity (dBm)

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

-99

-98

-97

-96

-95

-94

Sensitivity 4XS

Sensitivity 5XD

www.ti.com

5.27 Typical Characteristics

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

Figure 5-4. BLE Sensitivity vs Temperature

Figure 5-6. BLE Sensitivity vs Channel Frequency

Figure 5-5. BLE Sensitivity vs Supply Voltage (VDDS)

Figure 5-7. TX Output Power vs Temperature

Figure 5-8. TX Output Power vs Supply Voltage (VDDS)

Submit Documentation Feedback

Product Folder Links: CC2640

Figure 5-9. TX Output Power

vs Channel Frequency

SpecificationsCopyright © 2015–2016, Texas Instruments Incorporated

27

Page 28

Temperature (qC)

Active Mode Current Consumpstion (mA)

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

2.85

2.9

2.95

3

3.05

3.1

D006

Active Mode Current

VDDS (V)

Current Consumption (mA)

1.8 2.3 2.8 3.3 3.8

2

2.5

3

3.5

4

4.5

5

D007

Active Mode Current

Temperature (qC)

TX Current (mA)

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

0

2

4

6

8

10

12

D002

5XD 5dBm Setting

4XS 2dBm Setting

Temperature (qC)

RX Current (mA)

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

5.6

5.8

6

6.2

6.4

6.6

6.8

7

D001

5XD RX Current

4XS RX Current

VDDS (V)

TX Current (mA)

1.8 2 2.2 2.4 2.6 2.8 3 3.2 3.4 3.6 3.8

4

5

6

7

8

9

10

11

12

13

14

15

16

D015

4XS 0-dBm Setting

4XS 2-dBm Setting

5XD 5-dBm Setting

Voltage (V)

Current Consumption (mA)

1.8 2.05 2.3 2.55 2.8 3.05 3.3 3.55 3.8

4

4.5

5

5.5

6

6.5

7

7.5

8

8.5

9

9.5

10

10.5

D016

4XS

5XD

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

Typical Characteristics (continued)

www.ti.com

Figure 5-10. TX Current Consumption

vs Supply Voltage (VDDS)

Figure 5-12. RX Mode Current Consumption vs Temperature

Figure 5-11. RX Mode Current vs Supply Voltage (VDDS)

Figure 5-13. TX Mode Current Consumption vs Temperature

Figure 5-14. Active Mode (MCU Running, No Peripherals)

28

Current Consumption vs Temperature

Specifications Copyright © 2015–2016, Texas Instruments Incorporated

Figure 5-15. Active Mode (MCU Running, No Peripherals) Current

Consumption vs Supply Voltage (VDDS)

Submit Documentation Feedback

Product Folder Links: CC2640

Page 29

Sampling Frequency (Hz)

ENOB

9.6

9.7

9.8

9.9

10

10.1

10.2

10.3

10.4

10.5

1k 10k 100k 200k

D009A

ENOB Internal Reference (No Averaging)

ENOB Internal Reference (32 Samples Averaging)

Temperature (qC)

Standby Current (PA)

-40 -20 0 20 40 60 80 100

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

D021

VDDS (V)

ADC Code

1.8 2.3 2.8 3.3 3.8

1004.8

1005

1005.2

1005.4

1005.6

1005.8

1006

1006.2

1006.4

D012

Temperature (qC)

ADC Code

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

1004.5

1005

1005.5

1006

1006.5

1007

1007.5

D013

Temperature (qC)

Current (uA)

-20 -10 0 10 20 30 40 50 60 70 80

0

0.5

1

1.5

2

2.5

3

3.5

4

D008

Standby Mode Current

Input Frequency (Hz)

Effective Number of Bits

200300 500 1000 2000 5000 10000 20000 100000

9.4

9.6

9.8

10

10.2

10.4

10.6

10.8

11

11.2

11.4

D009

Fs= 200 kHz, No Averaging

Fs= 200 kHz, 32 samples averaging

www.ti.com

Typical Characteristics (continued)

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

Figure 5-16. Standby Mode Current Consumption With RCOSC

Figure 5-18. SoC ADC Output vs Supply Voltage (Fixed Input,

RTC vs Temperature

Internal Reference, No Scaling)

Figure 5-17. SoC ADC Effective Number of Bits vs Input

Frequency (Internal Reference, No Scaling)

Figure 5-19. SoC ADC Output vs Temperature (Fixed Input,

Internal Reference, No Scaling)

Figure 5-20. SoC ADC ENOB vs Sampling Frequency

(Input Frequency = FS / 10)

Submit Documentation Feedback

Product Folder Links: CC2640

Figure 5-21. Standby Mode Supply Current vs Temperature

SpecificationsCopyright © 2015–2016, Texas Instruments Incorporated

29

Page 30

ADC Code

INL

0 200 400 600 800 1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 4000 4200

-4

-3

-2

-1

0

1

2

3

D011

ADC Code

DNL

0

200

400

600

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

3200

3400

3600

3800

4000

4200

-1.5

-1

-0.5

0

0.5

1

1.5

2

2.5

3

3.5

D010

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

Typical Characteristics (continued)

Figure 5-22. SoC ADC DNL vs ADC Code (Internal Reference, No Scaling)

www.ti.com

Figure 5-23. SoC ADC INL vs ADC Code (Internal Reference, No Scaling)

30

Specifications Copyright © 2015–2016, Texas Instruments Incorporated

Submit Documentation Feedback

Product Folder Links: CC2640

Page 31

SimpleLinkTM CC26xx wireless MCU

Main CPU

128KB

Flash

Sensor controller

cJTAG

20KB

SRAM

ROM

ARM

®

Cortex®-M3

DC-DC converter

RF core

ARM

®

Cortex®-M0

DSP modem

4KB

SRAM

ROM

Sensor controller

engine

2x comparator

12-bit ADC, 200 ks/s

Constant current source

SPI-I2C digital sensor IF

2KB SRAM

Time-to-digital converter

General peripherals / modules

4× 32-bit Timers

2× SSI (SPI, µW, TI)

Watchdog timer

Temp. / batt. monitor

RTC

I2C

UART

I2S

10 / 15 / 31 GPIOs

AES

32 ch. µDMA

ADC

Digital PLL

TRNG

ADC

8KB

cache

Copyright © 2016, Texas Instruments Incorporated

www.ti.com

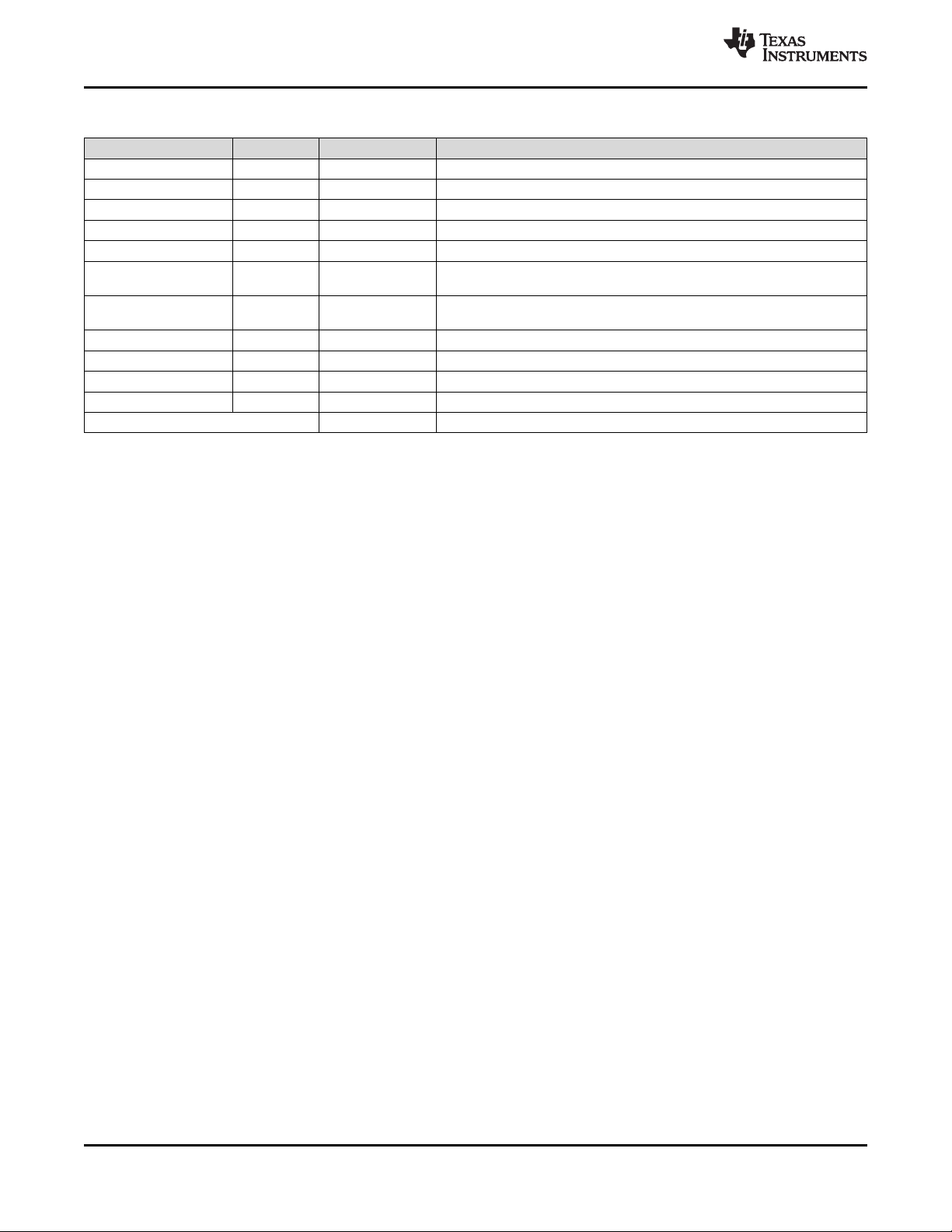

6 Detailed Description

6.1 Overview

The core modules of the CC26xx product family are shown in the Section 6.2.

6.2 Functional Block Diagram

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

Submit Documentation Feedback

Product Folder Links: CC2640

Detailed DescriptionCopyright © 2015–2016, Texas Instruments Incorporated

31

Page 32

CC2640

SWRS176B –FEBRUARY 2015–REVISED JULY 2016

6.3 Main CPU

The SimpleLink CC2640 Wireless MCU contains an ARM Cortex-M3 (CM3) 32-bit CPU, which runs the

application and the higher layers of the protocol stack.

The CM3 processor provides a high-performance, low-cost platform that meets the system requirements

of minimal memory implementation, and low-power consumption, while delivering outstanding

computational performance and exceptional system response to interrupts.

CM3 features include the following: