Page 1

Bluetooth® Low Energy

Sensor Tag Hands On

Page 2

for Sensor Tag

SWRU270C

1. Introduction

Thank you for purchasing a Texas Instruments (TI) Bluetooth® low energy (BLE) Sensor Tag Development

Kit. The purpose of this document is to give an overview of the hardware and software included in the kit

and to provide an introduction into BLE.

The information in this guide will get you up and running with the kit. For more detailed information on

BLE technology and the TI BLE protocol stack, please consult the Texas Instruments Bluetooth® Low

Energy Software Developer’s Guide.

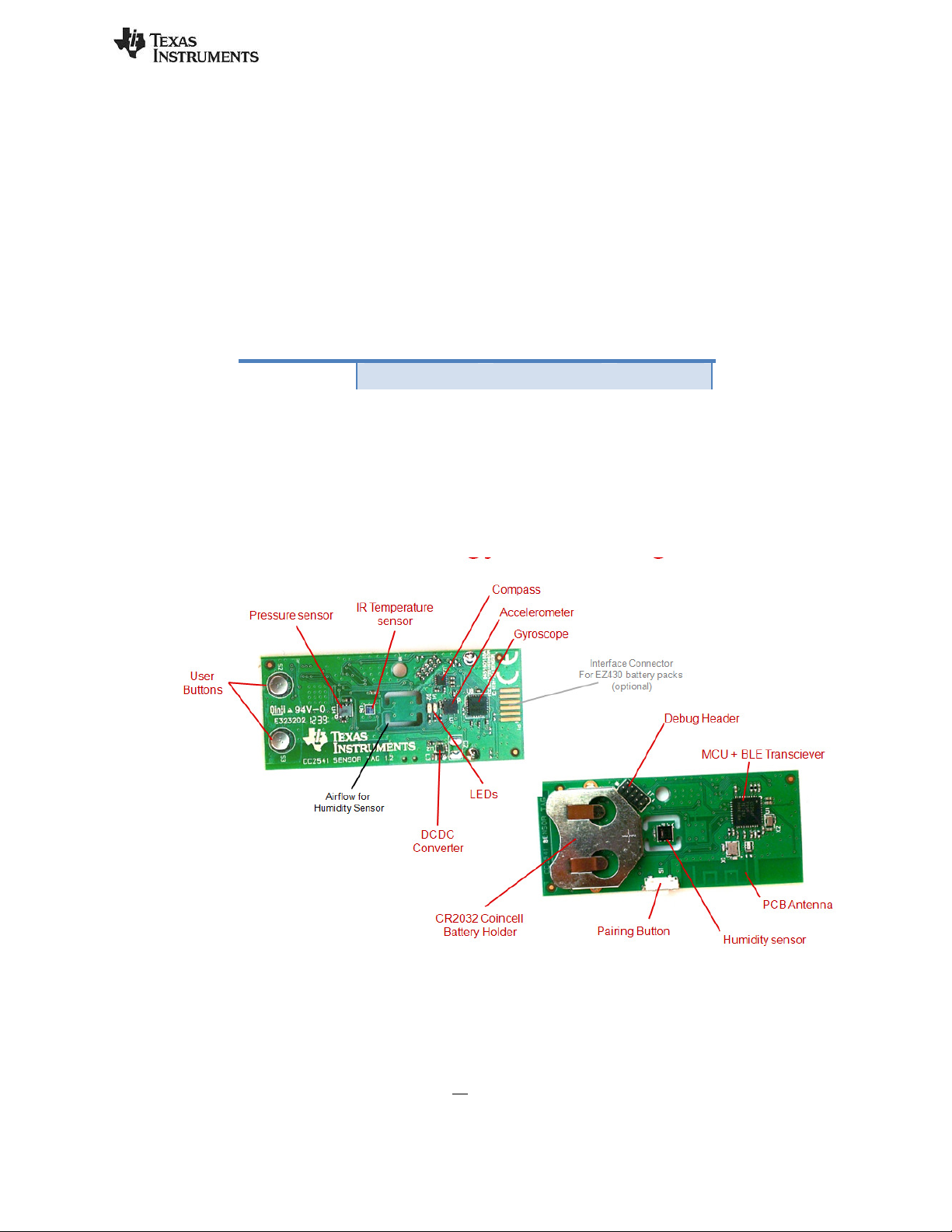

1.1 Kit Contents Overview

The kits contain the following hardware components including cables:

CC2541 Sensor Tag CC2540 Dongle Plastic Case

Sensor Tag Kit • • •

The CC2541 Sensor Tag is designed to act as a Peripheral Device (BLE Slave). Plastic casing for the sensor

tag is also included. The sensor tag operates on a single CR2032 coin cell battery and includes a twocolored LED and the following sensors: temperature, humidity, pressure, accelerometer, gyroscope, and

magnetometer.

The sensor tag uses I2C to interface to the different sensors. It is a FCC, IC, and ETSI certified solution. An

overview of the sensor tag is shown below:

The CC2540 USB Dongle can be used to emulate any type of Bluetooth low energy behavior but is usually

used as a Central Device (BLE Master). It connects to a Windows PC’s USB Port, and is pre-loaded with the

necessary software to receive commands from the PC tool BTool. That is, it acts as a network processor

by default.

Caution! The kits include a non-rechargeable lithium battery. Always make sure the battery is removed from the CC2540/41 Sensor

tag when it is connected to an external power source (Do not apply voltage > 3.6V). Dispose the battery properly and keep out of the

reach of children. If swallowed, contact a physician immediately.

Caution! The kits contain ESD sensitive components. Handle with care to prevent permanent damage.

Page 2 of 30

Page 3

SWRU270C

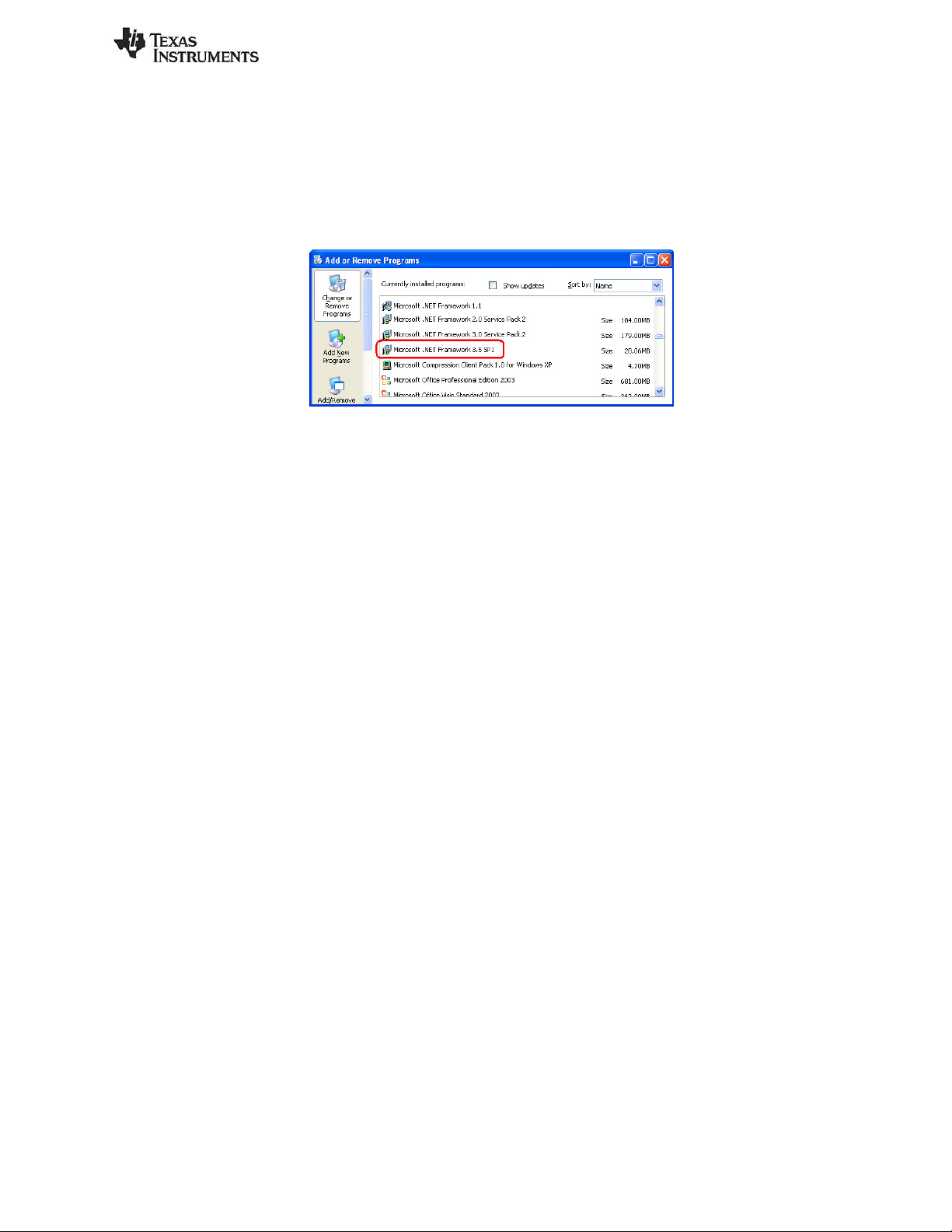

1.2 System Requirements

To use the TI BLE software, a PC running Microsoft Windows (XP or later) is required, as well as Microsoft

.NET Framework 3.5 Service Pack 1 (SP1) or greater.

In order to check whether your system has the appropriate .NET Framework, open up the Windows

Control Panel, and select “Add or Remove Programs”. Amongst the list of currently installed programs,

you should see “Microsoft .NET Framework 3.5 SP1”, as shown in Figure 1:

Figure 1 System Requirements, .NET Framework 3.5 SP1

If you do not see it in the list, you can download the framework from Microsoft.

From a hardware standpoint, the Windows PC must contain one free USB port. An additional free USB

port is required in order to use the CC Debugger and the USB Dongle simultaneously.

IAR Embedded Workbench for 8051 development environment is required in order to make changes to

the sensor tag software. More information on IAR can be found in the Texas Instruments Bluetooth® Low

Energy Software Developer’s Guide Error! Reference source not found..

Page 3 of 30

Page 4

SWRU270C

2. Getting Started

This section describes how to set up the software and get started with the Development Kit. It is assumed

that the Sensor tag comes pre-programmed out of the box. If not, please see Chapter 4 for details on how

to program the sensor tag with the latest firmware. In addition, this section assumes that the latest

version of the TI BLE software (v1.3.1 as of the release of this document) has been installed. The latest BLE

software can be downloaded at www.ti.com/ble-stack.

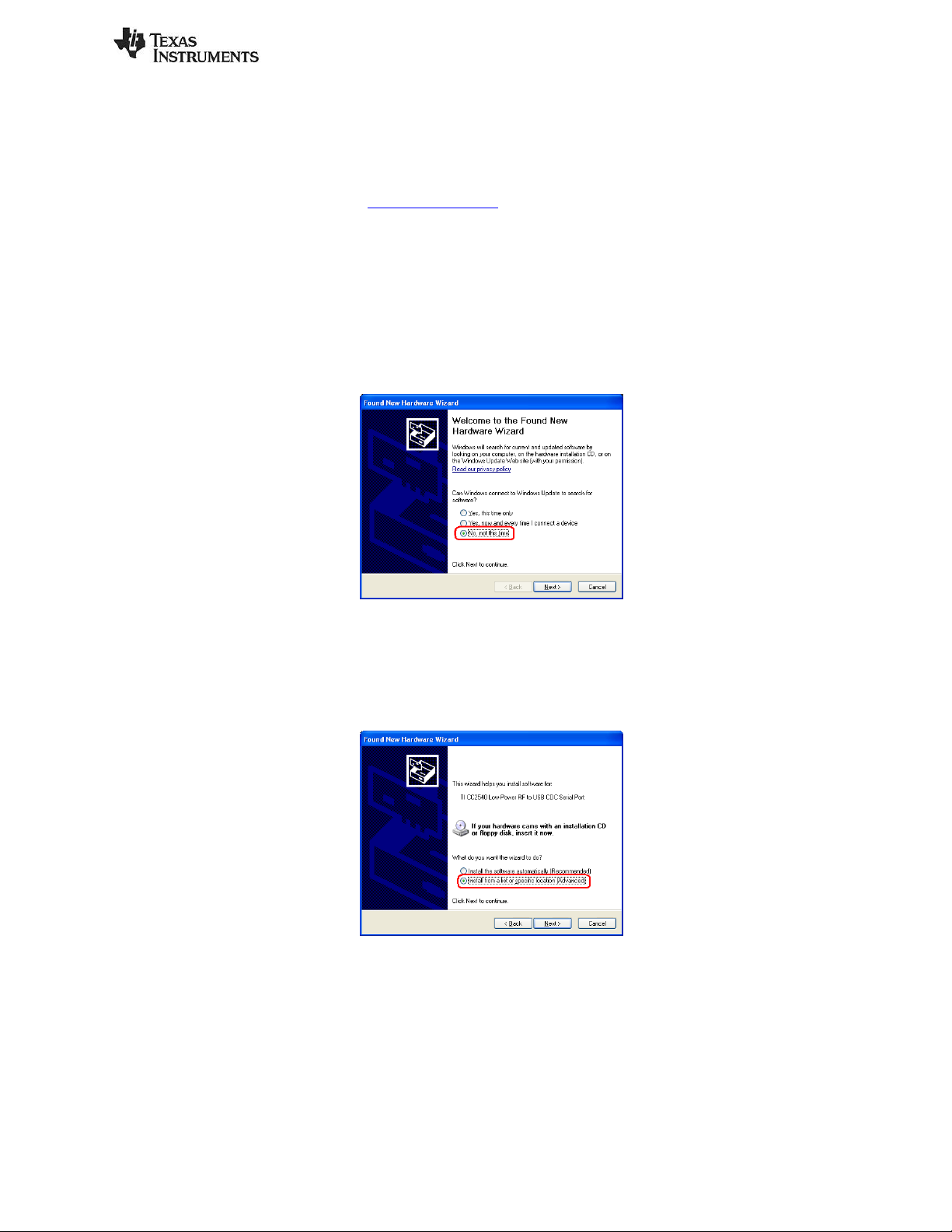

2.1 Associate Driver with USB Dongle

After the software installation is complete, the USB Dongle driver must be associated with the device in

order to use the demo application. To associate the USB Dongle driver, first you must connect the USB

Dongle to the PC’s USB port, or to a USB hub that connects to the PC.

The first time that the dongle is connected to the PC, a message will most probably pop-up, indicating

that Windows does not recognize the device.

Figure 2 PC, Found New Hardware

When prompted whether to use Windows Update search for software, select “No, not this time” and

press the “Next” button. On the next screen, select the option “Install from a list or specific location

(Advanced)”, and press the “Next” button:

Figure 3 PC, Install Driver

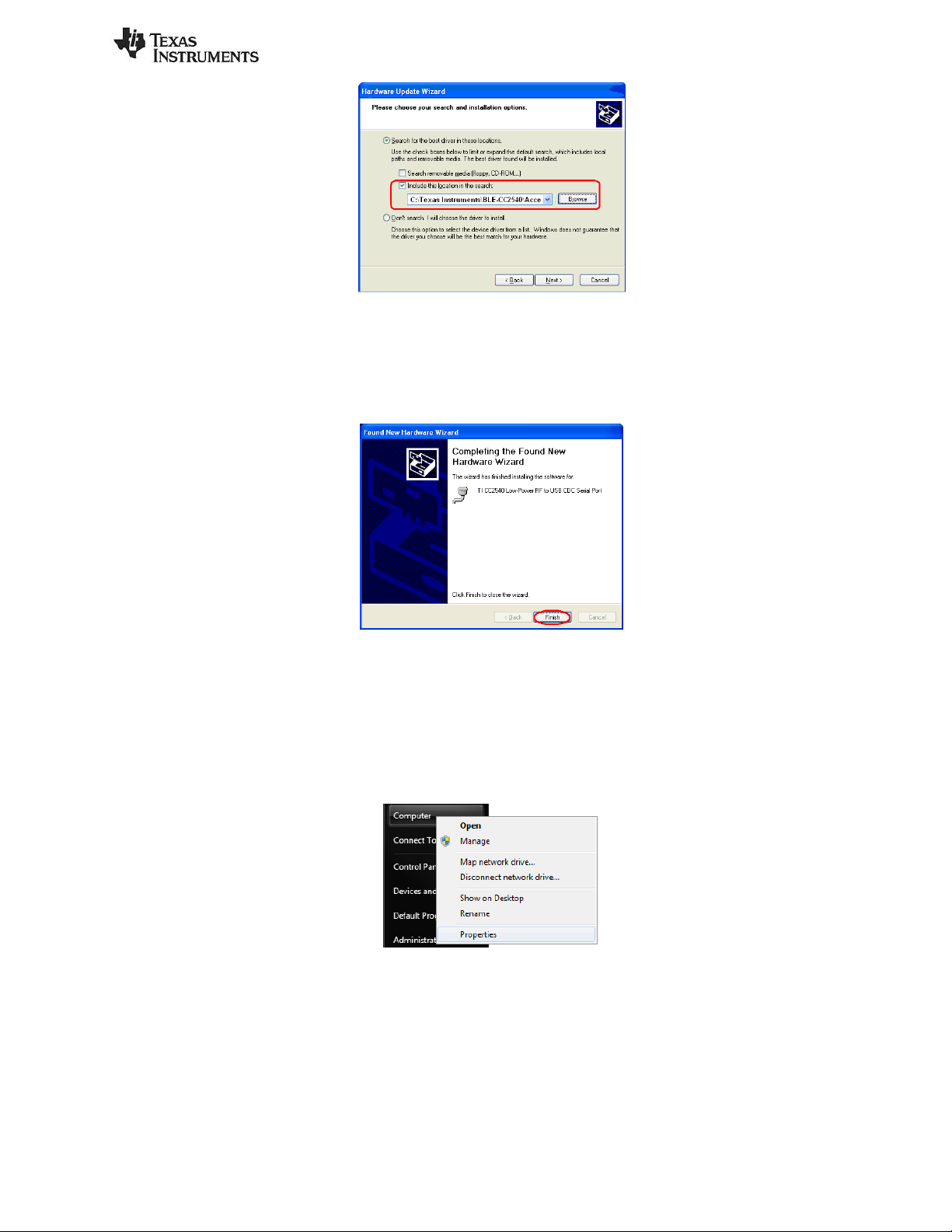

On the next screen, click the checkbox labeled “Include this location in the search:”, and click the

“Browse” button. Select the following directory (assuming the default installation path was used):

C:\Texas Instruments\BLE-CC254x-1.3.1\Accessories\Drivers

Page 4 of 30

Page 5

SWRU270C

Figure 4 PC, Select Driver

Click the “Next” button. This should install the driver. It will take a few seconds for the file to load. If the

installation was successful, you should see the screen to the below. Click the “Finish” button to complete

the installation.

Figure 5 PC, CDC Driver Installation Complete

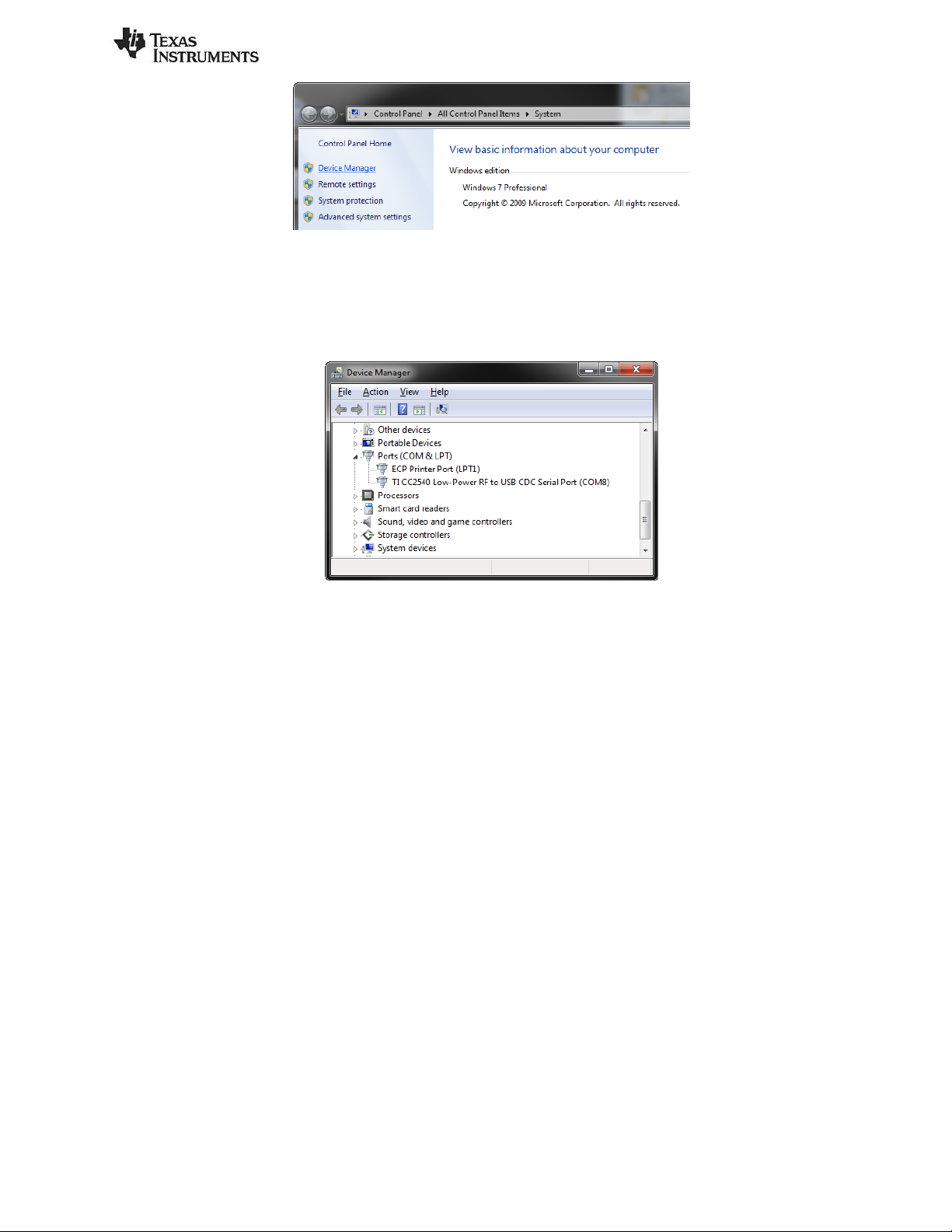

2.2 Determining the COM Port

Once the driver is installed, you need to determine which COM port Windows has assigned to the USB

Dongle. After you have completed the USB Dongle driver association in section 2.1, right-click on the

“Computer” icon on your Start and select “Properties”, as shown in Figure 5.

Figure 6 Win7 PC, Finding Computer Properties

The “System Properties” window should open up. Click “Device Manager as shown in Figure 7.

Page 5 of 30

Page 6

SWRU270C

Figure 7 Win7 PC, Finding Device Manager

A list of all hardware devices should appear. Under the section “Ports (COM & LPT)”, the device “TI

CC2540 Low-Power RF to USB CDC Serial Port” should appear. Next to the name should be the port

number (for example, the CC2540USB Dongle uses COM8 in Figure 8).

Figure 8 Win7 PC, Connected Ports List

Take note of this port number, as it will be needed in order to use BTool. You may close the device

manager at this point.

Page 6 of 30

Page 7

SWRU270C

3. Using BTool

BTool is a PC Application that allows a user to form a connection between two BLE devices. BTool works

by communicating with the CC2540 USB Dongle, acting as a network processor, by means of HCI vendor

specific commands. The USB Dongle software (when running the HostTestRelease project) and driver

create a virtual serial port over the USB interface. BTool, running on the PC, communicates with the USB

Dongle through this virtual serial port.

More information on the network processor configuration and the HostTestRelease project can be found

in the Texas Instruments Bluetooth® Low Energy Software Developer’s Guide. More information on the

HCI interface, as well as details on the HCI vendor specific commands that are used by the CC2540/41, can

be found in the TI BLE Vendor Specific HCI Reference Guide. These documents can be found in the

Documents folder of the stack install directory.

For this section, a PC running windows 7 has been used, but the procedures are essentially the same for

other windows version, such as XP.

3.1 Starting the Application

To start the application, go into your programs by choosing Start > Programs > Texas Instruments > BLECC254x-1.3.1 > BTool. On Start-up you should be able to set the Serial Port Settings. Set the “Port” value

to the COM port earlier noted in Section 3.2. For the other settings, use the default values as shown in

Figure 9. Press “OK” to connect to the CC2540 USB Dongle.

Figure 9 BTool, Serial Port settings

When connected you should see the screen presented in Figure 10. The screen indicates that you now

have a serial port connection to the CC2540 USB Dongle. The screen is divided up into a few sections: the

left sidebar contains information on the CC2540 USB Dongle status. The left side of the sub-window

contains a log of all messages sent from the PC to the CC2540 USB Dongle and received by the PC from

the CC2540 USB Dongle. The right side of the sub-window contains a GUI for control of the CC2540 USB

Dongle. The bottom pane is the attribute explorer which we will discuss later on.

Page 7 of 30

Page 8

Device Information

SWRU270C

Message Log

Device Control

Figure 10 BTool, Overview

3.2 Creating a BLE Connection between USB Dongle and Sensor tag

At this point the USB Dongle (central) is ready to discover other BLE devices that are advertising. The

sensor tag should be preloaded with the sensor tag application. The full project and application source

code files for the sensor tag are included in the BLE software development kit.

At this time you will want to insert the battery (or remove and re-insert the battery to reset the device)

into the sensor tag (peripheral). You should also assemble the plastic and rubber portions of the kit to

minimize ESD on the board.

In order to ensure that you are connecting to the correct device, you need to know your sensor tag’s

address. To save time for this tutorial, we have included your address on the bottom of the lid of your

development kit. Alternatively, you can refer to section 5.3.2 for instructions to read the sensor tag’s

primary address.

3.2.1 Making the Sensor tag Discoverable

When the sensor tag powers up, it will not immediately go into a discoverable state. To enable advertising

and make the sensor tag discoverable, press the “pairing button” on the side of the sensor tag once. This

will turn advertisements on; making the device discoverable for 30 seconds (this value is defined in the

Specification of the Bluetooth System). After that time, the device will return to standby mode. To make

the device discoverable again, simply press the button once again. During discoverable mode, the LED will

flash green.

Page 8 of 30

Page 9

Figure 11 Press Side Button to Turn On Advertisements

3.2.2 Scanning for Devices

In BTool, Press the “Scan” button under the “Discover / Connect” tab, as shown in Figure 12.

SWRU270C

Figure 12 BTool, Scan for Devices

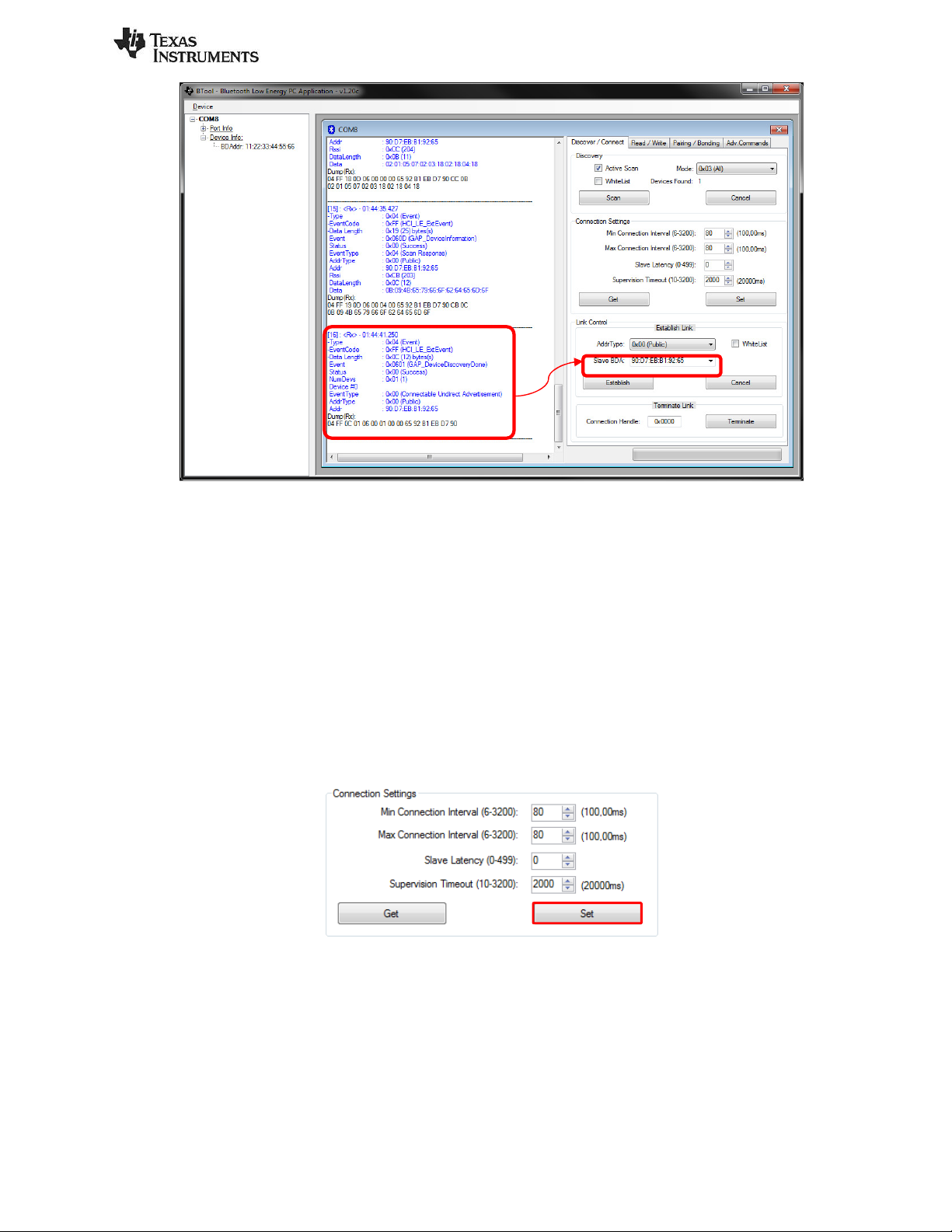

The USB Dongle will begin search for other BLE devices. As devices are found, the log on the left side of

the screen will display the devices discovered. After 10 seconds, the device discovery process will

complete, and the USB Dongle will stop scanning. A summary of all the scanned devices will be displayed

in the log window. In the example in Figure 13, one peripheral device was discovered while scanning. If

you do not want to wait through the full 10 seconds of scanning, the “Cancel” button can be pressed

alternatively, which will stop the device discovery process. The address of any scanned devices will appear

in the “Slave BDA” section of the “Link Control” section in the bottom right corner of the sub-window.

Page 9 of 30

Page 10

Figure 13 BTool, Slave Address

SWRU270C

3.2.3 Selecting Connection Parameters

Before establishing a connection, you can set up the desired connection parameters. The default values of

100ms connection interval, 0 slave latency, and 20s supervision timeout should serve as a good starting

point; however for different applications you may want to experiment with these values.

Once the desired values have been set, be sure to click the “Set” button; otherwise the settings will not be

saved. Note that the connection parameters must be set before a connection is established; changing the

values and clicking the “Set” button while a connection is active will not change the settings of an active

connection. The connection must be terminated and re-established to use the new parameters. (The

Bluetooth specification does support connection parameter updates while a connection is active; however

this must be done using either an L2CAP connection parameter update request, or using a direct HCI

command. More information can be found in the Specification of the Bluetooth System)

Figure 14 BTool, Connection Settings

3.2.4 Establishing a Connection

To establish a connection with the sensor tag, select the address of the device to connect with and click

the “Establish” button as shown in Figure 15.

Page 10 of 30

Page 11

SWRU270C

Figure 15 BTool, Establish Connection

If the sensor tag is still in discoverable mode, a connection should be established (if more than 30 seconds

have passed since the device was previously made discoverable, press the right button on the sensor tag

once again). Once a connection is established, the message window will return a “GAP_EstablishLink”

event message with a “Status” value of “0x00 (Success)” as shown in Figure 16.

Figure 16 BTool Log, Link Established

In BTool, you can see your connected peripheral device in the Device Information field, as shown in Figure

17.

Figure 17 BTool, Device Information

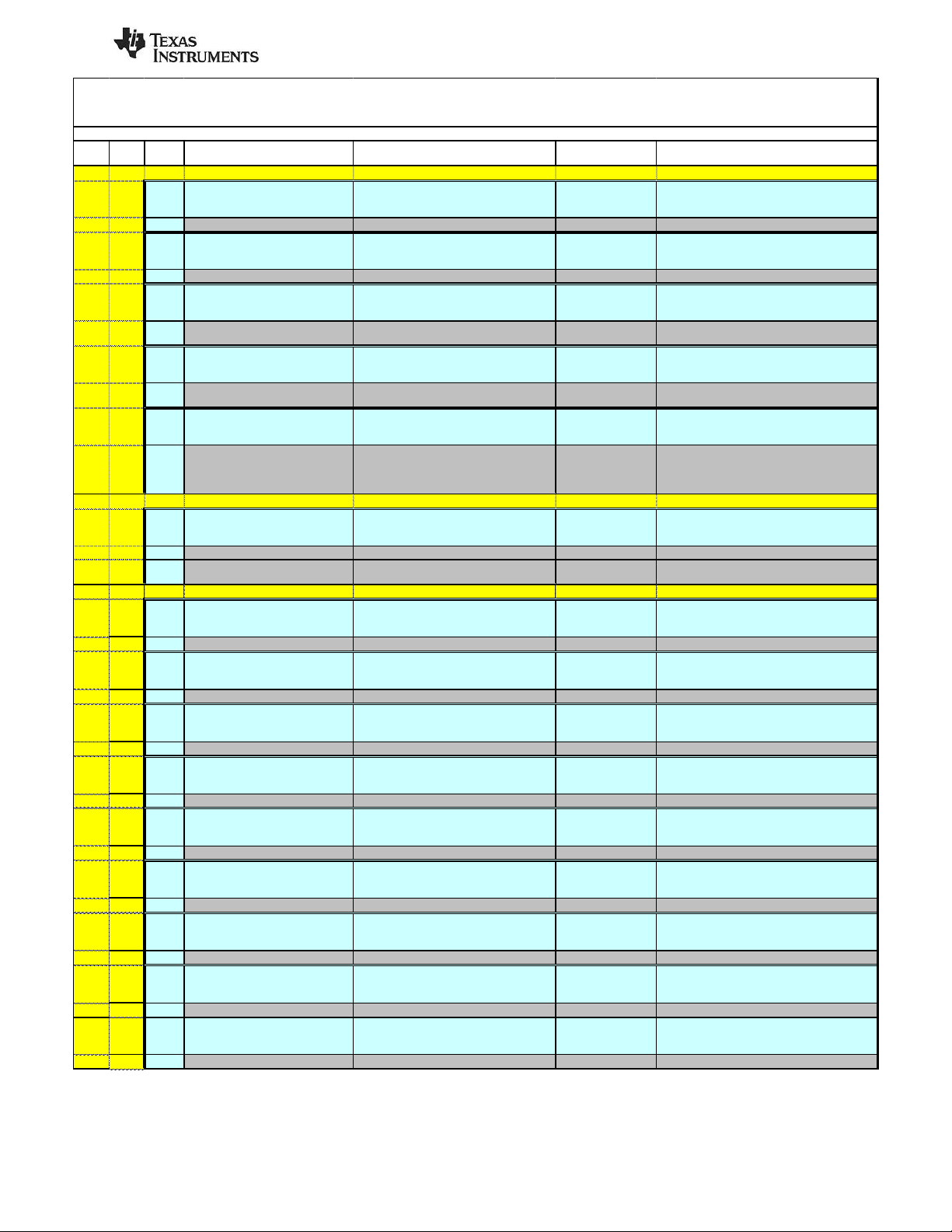

3.3 Using the Sensor Tag’s GATT Profiles

We will now begin investigating the sensor tag’s GATT profiles. Besides the standard GAP, GATT, and

device information services, the sensor tag contains the following GATT services: temperature,

accelerometer, humidity, magnetometer, barometer, gyroscope, simple keys, and test. You will find the

sensor tag complete attribute below and it can be used as a reference. Services are shown in yellow,

characteristics are shown in blue, and characteristic values / descriptors are shown in grey.

Services are constructed of characteristics, each of which have, at minimum, a declaration and a value,

and may have a client configuration and/or a user description. The actual payload data is stored with the

characteristic values. All application data that is being sent or received in Bluetooth low energy must be

contained within characteristic values. This section details a step-by-step process that demonstrates

several processes for reading, writing, discovering, and notifying GATT characteristic values using BTool.

In a Bluetooth low energy system, upon connection, the Central Device (GATT Client) performs a service

discovery on the Peripheral device (GATT server) to build up an attribute table. This attribute table will

provide handles (internal addresses of the characteristics) which can be used by the Client to access the

data located in the Server. The service discovery is typically an automated process that can be started

with a single command. In BTool however, the automated service discovery is not implemented (although

it’s still possible to perform it manually). To simplify the evaluation of the sensor tag, the attribute table

will be known and is shown below so it is possible to use handles directly to read out data.

Page 11 of 30

Page 12

handle

02 (read permis sions)

SWRU270C

Sensor Tag Application: Complete Attribute Table

TI Base UUID: F000XXXX-0451-4000-B000-000000000000. 128-but UUIDs are typed 'b old'

02 (properties: read only)

03 00 (handle: 0x0003)

00 2A (UUID: 0x2A 00)

02 (properties: read only)

05 00 (handle: 0x0005)

01 2A (UUID: 0x2A 01)

0A (properties: read/w rite)

07 00 (handle: 0x0007)

02 2A (UUID: 0x2A 02)

0A (properties: read/w rite)

09 00 (handle: 0x0009)

03 2A (UUID: 0x2A 03)

02 (properties: read only)

0B 00 (handle: 0x000B)

04 2A (UUID: 0x2A 04)

50 00 (100ms preferr ed min connection interval)

A0 00 (200ms preferred max connection interval)

00 00 (0 preferred slave latency)

E8 03 (10000ms preferred s upervision timeout)

20 (properties: indicate only)

0E 00 (handle: 0x000E)

05 2A (UUID: 0x2A 05)

0x180A (DEVINFO_SERV_UUID) GATT_PERMIT_READ Start of Device Information Service

02 (read permis sions)

11 00 (handle 0x0011)

23 2A (UUID 0x2A 23) GATT_PERMIT_READ

xx x x xx 00 00 xx xx x x (xx 's are IEEE address ) GATT_PERMIT_READ System ID

02 (read permis sions)

13 00 (handle 0x0013)

24 2A (UUID 0x2A 24) GATT_PERMIT_READ

"Model Number" GATT_PERMIT_READ Model Number String

02 (read permis sions)

15 00 (handle 0x0015)

25 2A (UUID 0x2A 25) GATT_PERMIT_READ

"Serial Number" GATT_PERMIT_REA D Serial Number String

02 (read permis sions)

17 00 (handle 0x0017)

26 2A (UUID 0x2A 26) GATT_PERMIT_READ

"Firmw are Revision" GATT_PERMIT_READ Firmwar e Revision String

02 (read permis sions)

19 00 (handle 0x0019)

27 2A (UUID 0x2A 27) GATT_PERMIT_READ

"Hardware Revision" GATT_PERMIT_READ Hardw are Rev ision String

02 (read permis sions)

1B 00 (handle 0x001B)

28 2A (UUID 0x2A 28) GATT_PERMIT_READ

"Softw are Revision" GATT_PERMIT_READ Softw are Rev ision String

02 (read permis sions)

1D 00 (handle 0x001D)

29 2A (UUID 0x2A 29) GATT_PERMIT_READ

"Manufactur er Name" GATT_PERMIT_READ Manufacturer Name Str ing

02 (read permis sions)

1F 00 (handle 0x001F)

2A 2A (UUID 0x2A2A ) GATT_PERMIT_READ

FE 00 65 78 70 65 72 69 6D 65 6E 74 61 6C GATT_PERMIT_READ IEEE 11073-20601 Regulatory Certification Data List

22 00 (handle 0x0022)

50 2A (UUID 0x2A 50) GATT_PERMIT_READ PnP ID characteristic declaration

FE 00 65 78 70 65 72 69 6D 65 6E 74 61 6C GATT_PERMIT_READ PnP ID

GATT Server

Per mis sio ns

GATT_PERMIT_READ Device Name characteristic declaration

GATT_PERMIT_READ Appearance charac teristic declaration

GATT_PERMIT_READ Peripheral Privacy Flag characteristic declaration

GATT_PERMIT_READ |

GATT_PERMIT_WRITE

GATT_PERMIT_READ Reconnection address characteristic declaration

GATT_PERMIT_READ |

GATT_PERMIT_WRITE

GATT_PERMIT_READ

GATT_PERMIT_READ

GATT_PERMIT_READ Service Changed characteristic declaration

GATT_PERMIT_READ |

GATT_PERMIT_WRITE

Notes

Peripheral Privacy Flag characteristic v alue

Reconnection address characteristic value

Peripheral Pref erred Connection Parameters

characteristic dec laration

Peripheral Pref erred Connection Parameters

characteristic dec laration

Write "01:00" to enable notifications, "00:00" to disable

System ID

characteristic dec laration

Model Number String

characteristic dec laration

Serial Number String

characteristic dec laration

Firmw are Revision String

characteristic dec laration

Hardware Revision String

characteristic dec laration

Softw are Revision String

characteristic dec laration

Manufacturer Name Str ing

characteristic dec laration

IEEE 11073-20601 Regulatory Certification Data List

characteristic dec laration

(de c)

Type

(he x)

Type (#DEFINE) Hex / Text V alue (d efault )

handle

(he x)

0x1 1 0x2800 GATT_PRIMARY_SERVICE_UUID 0x1800 (GAP_SERVICE_UUID) GATT_PERMIT_READ Start of GAP Service (Mandatory)

0x2 2 0x2803 GATT_CHA RACTER_UUID

0x3 3 0x2A00 GAP_DEVICE_NAME_UUID "Sensor Tag" GATT_PERMIT_READ Device Name characteristic value

0x4 4 0x2803 GATT_CHA RACTER_UUID

0x5 5 0x2A01 GAP_APPEARANCE_UUID 0x0000 GATT_PERMIT_READ Appearance charac teristic value

0x6 6 0x2803 GATT_CHA RACTER_UUID

0x7 7 0x2A02 GAP_PERI_PRIVA CY_FLA G_UUID 0x00 (GAP_PRIVACY_DISA BLED)

0x8 8 0x2803 GATT_CHA RACTER_UUID

0x9 9 0x2A03 GAP_RECONNECT_ADDR_UUID 00:00:00:00:00:00

0xA 10 0x2803 GATT_CHARACTER_UUID

0xB 11 0x2A04 GAP_PERI_CONN_PARAM_UUID

0xC 12 0x2800 GATT_PRIMA RY_SERVICE_UUID 0x1801 (GATT_SERVICE_UUID) GATT_PERMIT_READ Start of GATT Service (mandatory)

0xD 13 0x2803 GATT_CHARACTER_UUID

0xE 14 0x2A05 GATT_SERVICE_CHA NGED_UUID (null value) (none) Service Changed characteristic value

0xF 15 0x2902 GA TT_CLIENT_CHAR_CFG_UUID 00:00 (2 bytes)

0x10 16 0x2800 GATT_PRIMA RY_SERVICE_UUID

0x11 17 0x2803 GATT_CHARACTER_UUID

0x12 18 0x2A23 DEVINFO_SY STEM_ID_UUID

0x13 19 0x2803 GATT_CHARACTER_UUID

0x14 20 0x2A24 DEV INFO_MODEL_NUMBER_UUID

0x15 21 0x2803 GATT_CHARACTER_UUID

0x16 22 0x2A25 DEV INFO_SERIAL_NUMBER_UUID

0x17 23 0x2803 GATT_CHARACTER_UUID

0x18 24 0x2A26 DEVINFO_FIRMWA RE_REV _UUID

0x19 25 0x2803 GATT_CHARACTER_UUID

0x1A 26 0x2A27 DEVINFO_HARDWARE_REV_UUID

0x1B 27 0x2803 GATT_CHARACTER_UUID

0x1C 28 0x 2A28 DEVINFO_SOFTWA RE_REV_UUID

0x1D 29 0x2803 GATT_CHARACTER_UUID

0x1E 30 0x2A 29 DEVINFO_MA NUFACTURER_NAME_UUID

0x1F 31 0x2803 GATT_CHA RACTER_UUID

0x20 32 0x 2A2A DEV INFO_11073_CERT_DATA_UUID

0x21 33 0x2803 GATT_CHARACTER_UUID

0x22 34 0x 2A2A PNPID_DATA_UUID

Page 12 of 30

Page 13

0x23

0x24

0x25

0x26

0x27 39 0x2901 GATT_CHA R_USER_DESC_UUID "IR Temp. Data" (14 bytes) GATT_PERMIT_REA D

0x28

0x29

0x2A 42 0x2901 GATT_CHAR_USER_DESC_UUID "IR Temp. Conf." (15 bytes) GATT_PERMIT_REA D

0x2B

0x2C

0x2D 45

0x2E

0x2F 47 0x2901 GATT_CHAR_USER_DESC_UUID "A ccel. Data" (14 bytes) GATT_PERMIT_REA D

0x30

0x31

0x32 50 0x2901 GATT_CHA R_USER_DESC_UUID "A ccel. Conf." (15 bytes) GATT_PERMIT_REA D

0x33

0x34

0x35 53 0x2901 GATT_CHA R_USER_DESC_UUID "A cc. Period" (12 bytes) GATT_PERMIT_READ

0x36

0x37

0x38 56

0x39

0x3A 58 0x2901 GATT_CHAR_USER_DESC_UUID "Humid. Data" (14 by tes) GATT_PERMIT_READ

0x3B

0x3C

0x3D 61 0x2901 GATT_CHAR_USER_DESC_UUID "Humid. Conf ." (15 bytes) GATT_PERMIT_READ

0x3E

0x3F

0x40 64

0x41

0x42 66 0x2901 GATT_CHA R_USER_DESC_UUID "Mag. Data" ( 10 bytes) GATT_PERMIT_READ

0x43

0x44

0x45 69 0x2901 GATT_CHA R_USER_DESC_UUID "Mag. Conf ." (11 bytes) GATT_PERMIT_READ

0x46

0x47

0x48 72 0x2901 GATT_CHA R_USER_DESC_UUID "Mag. Period" (12 bytes) GATT_PERMIT_REA D

0x2800 GATT_PRIMA RY _SERVICE_UUID

35

0x2803 GATT_CHARACTER_UUID

36

0xAA01

37

0x2902 GATT_CLIENT_CHAR_CFG_UUID 00:00 (2 bytes)

38

IRTEMPERATURE_DA TA_UUID 00:00:00:00 (4 bytes) GATT_PERMIT_READ ObjectLSB:ObjectMSB:AmbientLSB:AmbientMSB

0x2803 GATT_CHARACTER_UUID

40

0xAA02

41

IRTEMPERATURE_CONF_UUID 1 ( 1 byte)

0x2800 GATT_PRIMA RY _SERVICE_UUID

43

0x2803 GATT_CHARACTER_UUID

44

0xAA11

0x2902 GATT_CLIENT_CHAR_CFG_UUID 00:00 (2 bytes)

46

0x2803 GATT_CHARACTER_UUID

48

0xAA12

49

ACCELEROMETER_DA TA_UUID 00:00:00 (3 bytes) GATT_PERMIT_REA D X : Y : Z Coordinates

ACCELEROMETER_CONF_UUID 1 (1 byte)

0x2803 GATT_CHARACTER_UUID

51

0xAA13

52

0x2800 GATT_PRIMA RY _SERVICE_UUID

54

0x2803 GATT_CHARACTER_UUID

55

0xAA21

0x2902 GATT_CLIENT_CHAR_CFG_UUID 00:00 (2 bytes)

57

ACCELEROMETER_PERI_UUID 1 (1 byte)

HUMIDITY_DATA_UUID 00:00:00:00 (4 bytes) GATT_PERMIT_READ TempLSB:TempMSB:HumidityLSB:HumidityMSB

0x2803 GATT_CHARACTER_UUID

59

0xAA22

60

0x2800 GATT_PRIMA RY _SERVICE_UUID

62

0x2803 GATT_CHARACTER_UUID

63

0xAA31

0x2902 GATT_CLIENT_CHAR_CFG_UUID 00:00 (2 bytes)

65

HUMIDITY_CONF_UUID 1 (1 byte)

MAGNETOMETER_DATA_UUID 00:00:00:00:00:00 (6 bytes) GATT_PERMIT_READ XLSB:XMSB:YLSB:YMSB: ZLSB:ZMSB Coordinates

0x2803 GATT_CHARACTER_UUID

67

0xAA32

68

0x2803 GATT_CHARACTER_UUID

70

0xAA33

71

MAGNETOMETER_CONF_UUID 1 (1 byte)

MAGNETOMETER_PERI_UUID 1 (1 byte)

(IRTEMPERATURE_SERV_UUID ) GATT_PERMIT_REA D Start of Sensor Pr ofile Temperature Service

0xAA00

12 (properties: read/notify)

25 00 (handle: 0x0025)

01 AA (UUID:

0A (properties: read/w rite)

29 00 (handle: 0x0029)

02AA ( UUID:

(ACCELEROMETER_SERV_UUID ) GATT_PERMIT_REA D Start of Sensor Pr ofile Acc elerometer Service

0xAA10

12 (properties: read/notify)

2D 00 (handle: 0x002D)

11 AA (UUID:

0A (properties: read/w rite)

31 00 (handle: 0x0031)

12 AA (UUID:

0A (properties: read/w rite)

34 00 (handle: 0x0034)

13 AA (UUID:

(HUMIDITY_SERV_UUID ) GATT_PERMIT_READ Start of Sensor Profile Humidity Service

0xAA20

12 (properties: read/notify)

38 00 (handle: 0x0038)

21 AA (UUID:

0A (properties: read/w rite)

3C 00 (handle: 0x003C)

22 AA (UUID:

(MAGNETOMETER_SERV_UUID ) GATT_PERMIT_REA D Start of Sensor Pr ofile Magnetometer Serv ice

0xAA30

12 (properties: read/notify)

40 00 (handle: 0x0040)

31 AA (UUID:

0A (properties: read/w rite)

44 00 (handle: 0x0044)

32 AA (UUID: 0xAA 32)

0A (properties: read/w rite)

47 00 (handle: 0x0047)

33 AA (UUID:

0xAA01

0xAA02

0xAA11

0xAA12

0xAA13

0xAA21

0xAA22

0xAA31

0xAA33

)

)

)

)

)

)

)

)

)

GATT_PERMIT_REA D

GATT_PERMIT_READ |

GATT_PERMIT_WRITE

GATT_PERMIT_REA D

GATT_PERMIT_READ |

GATT_PERMIT_WRITE

GATT_PERMIT_REA D

GATT_PERMIT_READ |

GATT_PERMIT_WRITE

GATT_PERMIT_REA D

GATT_PERMIT_READ |

GATT_PERMIT_WRITE

GATT_PERMIT_REA D

GATT_PERMIT_READ |

GATT_PERMIT_WRITE

GATT_PERMIT_REA D

GATT_PERMIT_READ |

GATT_PERMIT_WRITE

GATT_PERMIT_REA D

GATT_PERMIT_READ |

GATT_PERMIT_WRITE

GATT_PERMIT_REA D

GATT_PERMIT_READ |

GATT_PERMIT_WRITE

GATT_PERMIT_REA D

GATT_PERMIT_READ |

GATT_PERMIT_WRITE

GATT_PERMIT_REA D

GATT_PERMIT_READ |

GATT_PERMIT_WRITE

SWRU270C

Write "01:00" to enable notifications, "00:00" to disable

Write "01" to start Sensor and Measurements, "00" to

put to sleep

Write "01:00" to enable notifications, "00:00" to disable

Write "01" to start Sensor and Measurements, "00" to

put to sleep

Period = [Input*10] ms, default 1000 ms , low er limit 100

ms

Write "01:00" to enable notifications

Write "01" to start Sensor and Measurements, "00" to

put to sleep

Write "01:00" to enable notifications, "00:00" to disable

Write "01" to start Sensor and Measurements, "00" to

put to sleep

Period = [Input*10]ms, default 2000ms , low er limit 100

ms

Page 13 of 30

Page 14

to enable Y axis only, 3 = X and Y, 4 = Z only, 5 = X and

GATT_PERMIT_READ |

0x49

0x4A

0x4B 75 0xAA41 BAROMETER_DA TA_UUID 00:00:00:00 (4 bytes) GATT_PERMIT_READ TempLSB:TempMSB:PressureLSB:Pressure MSB

0x4C

0x4D 7 7 0x2901 GATT_CHAR_USER_DESC_UUID "Barometer Data" (15 bytes ) GATT_PERMIT_REA D

0x4E

0x4F

0x50 80 0x2901 GATT_CHAR_USER_DESC_UUID "Barometer Conf ." (16 bytes) GATT_PERMIT_REA D

0x51

0x52

0x53

0x54 84 0x2901 GATT_CHAR_USER_DESC_UUID "Barometer Cali." (16 bytes) GATT_PERMIT_REA D

0x55 85 0x2800 GATT_PRIMA RY_SERVICE_UUID 0xAA50 (GYROSCOPE_SERV_UUID ) GATT_PERMIT_REA D Start of Sensor Profile Gy roscope Service

0x56 86 0x2803 GATT_CHARACTER_UUID

0x57 87 0xAA51 GYROSCOPE_DATA_UUID 00:00:00:00:00:00 (6 bytes) GA TT_PERMIT_READ XLSB:XMSB:YLSB:YMSB: ZLSB:ZMSB

0x58 88 0x2902 GA TT_CLIENT_CHAR_CFG_UUID 00:00 (2 bytes)

0x59 89 0x2901 GATT_CHAR_USER_DESC_UUID "Gyro. Data" (11 bytes) GATT_PERMIT_READ

0x5A 90 0x2803 GATT_CHARACTER_UUID

0x5B 91 0xAA52 GYROSCOPE_CONF_UUID 1 (1 byte)

0x5C 9 2 0x2901 GATT_CHAR_USER_DESC_UUID "Gyro. Conf." (13 bytes) GATT_PERMIT_READ

0x5D

0x5E

0x5F

0x60

0x61 97 0x2901 GATT_CHAR_USER_DESC_UUID "Key Press State" GATT_PERMIT_READ Key s state characteris tic user description

0x62 98 0x2800 GATT_SERVICE_UUID 0xAA60 (TEST_SERVICE_UUID) GATT_PERMIT_READ Start of TestService

0x63

0x64 100 0xAA61 TEST_DATA_UUID 1 byte GATT_PERMIT_READ Test Data: 1 bit set of each test passed

0x65 101 0x2901 GATT_CHAR_USER_DESC_UUID "Test Data" (10 bytes) GATT_PERMIT_READ

0x66

0x67

0x68 104 0x2901 GATT_CHAR_USER_DESC_UUID "Test Config" (12 bytes) GATT_PERMIT_REA D

0x2800 GATT_PRIMA RY_SERVICE_UUID 0xAA40 (BAROMETER_SERV_UUID ) GATT_PERMIT_REA D Start of Sensor Profile Barometer Service

73

0x2803 GA TT_CHARACTER_UUID

74

0x2902 GATT_CLIENT_CHAR_CFG_UUID 00:00 (2 bytes)

76

0x2803 GA TT_CHARACTER_UUID

78

0xAA42 BA ROMETER_CONF_UUID 1 (1 byte)

79

0x2803 GA TT_CHARACTER_UUID

81

0xAA43 BAROMETER_CA LI_UUID 00:00:...:00:00 (16 bytes) GATT_PERMIT_READ

82

0x2902 GATT_CLIENT_CHAR_CFG_UUID 00:00 (2 bytes)

83

12 (properties: read/notify)

4B 00 (handle: 0x004B)

41 AA (UUID: 0xAA41)

0A (properties: read/w rite)

53 00 (handle: 0x0053)

42 AA (UUID: 0xAA42)

02 (properties: read only)

4F 00 (handle: 0x004F)

43 AA (UUID: 0xAA43)

GATT_PERMIT_REA D

GATT_PERMIT_REA D |

GATT_PERMIT_WRITE

GATT_PERMIT_REA D

GATT_PERMIT_REA D |

GATT_PERMIT_WRITE

GATT_PERMIT_REA D

GATT_PERMIT_REA D |

GATT_PERMIT_WRITE

Write "01" to start Sensor and Measur ements, "00" to

put to sleep, "02" to read calibration values fr om sensor

When wr ite 02 to Barometer Conf. has been issued, the

calibration values is found here

93

0x2800 GATT_SERVICE_UUID 0xFFE0 (SK_KEYPRESSED_UUID) GATT_PERMIT_READ Start of Simple Keys Service

94

0x2803 GATT_CHARACTER_UUID

95

0xFFE1 SK_KEY PRESSED_UUID 0 (none)

96

0x2902 GATT_CLIENT_CHAR_CFG_UUID 0x0000

99

0x2803 GATT_CHARACTER_UUID

12 (properties: read/notify)

57 00 (handle: 0x0057)

51 AA (UUID: 0xAA51)

0A (properties: read/w rite)

5B 00 (handle: 0x005B)

52 AA (UUID: 0xAA52)

10 (notify permission)

34 00 (handle 0x0034)

E1 FF (UUID 0xFFE1) GATT_PERMIT_REA D Keys state c haracteristic declaration

02 (read permis sion)

64 00 (handle 0x0064)

61 AA (UUID: 0xAA61) GATT_PERMIT_READ Test Data characteristic declaration

GATT_PERMIT_REA D

GATT_PERMIT_REA D |

GATT_PERMIT_WRITE

GATT_PERMIT_REA D

GATT_PERMIT_REA D |

GATT_PERMIT_WRITE

GATT_PERMIT_WRITE

Write 0 to turn off gyros cope, 1 to enable X axis only, 2

Z, 6 = Y and Z, 7 = X, Y and Z

Keys state charac teristic value (bit mas k of left / right

key presses ). Side key as bit 2 in test mode only.

102

0x2803 GATT_CHARACTER_UUID

103

0xAA62 TEST_CONFIG_UUID 1 byte GA TT_PERMIT_READ

0A (read/w rite permiss ion)

68 00 (handle 0x0068)

62 AA (UUID: 0xAA62) GATT_PERMIT_READ Test Config characteristic dec laration

Test Config: bit 7 - enable test mode, bit 1 - set LED2, bit

0 - set LED 1

SWRU270C

Page 14 of 30

Page 15

SWRU270C

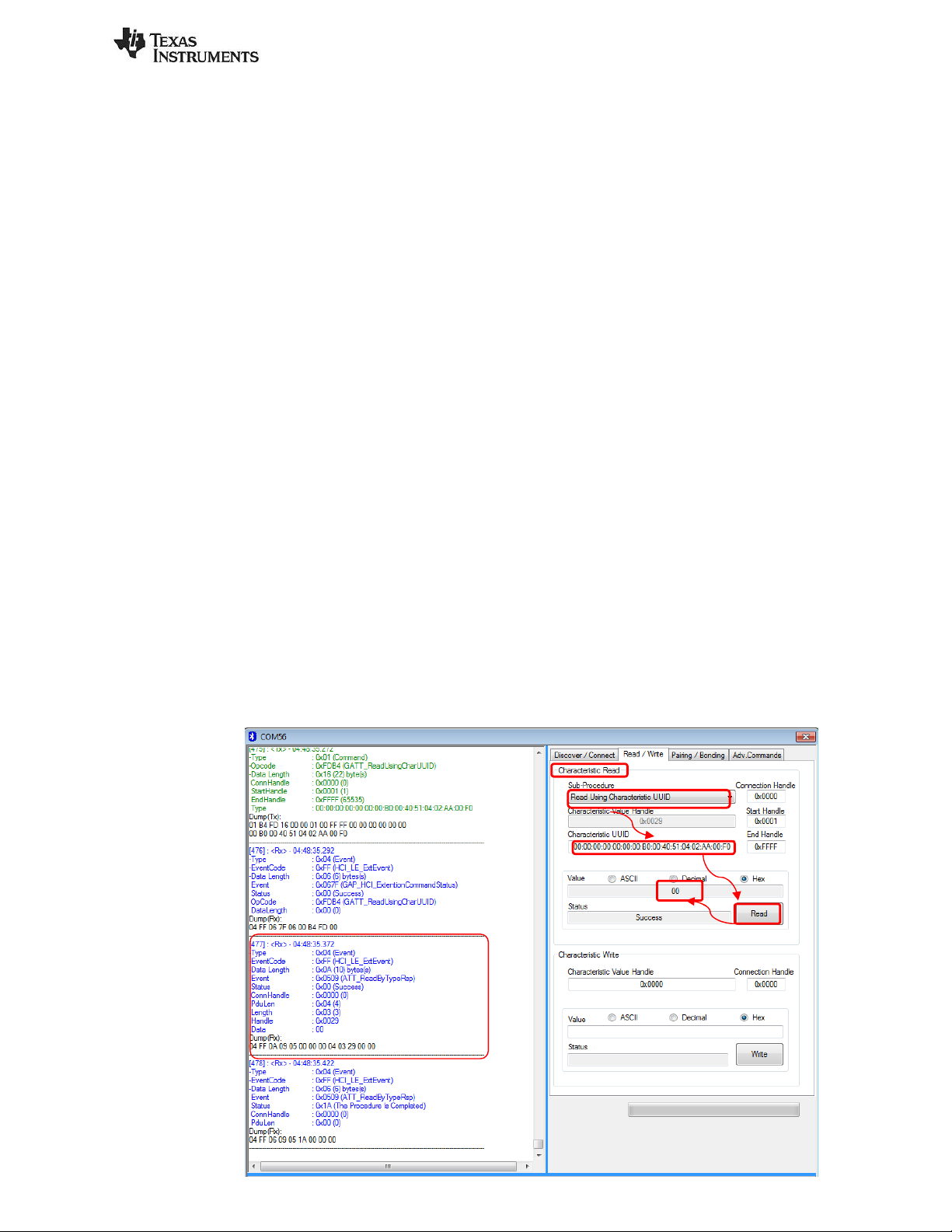

3.3.1 Reading a Characteristic Value by UUID

A characteristic value is essentially where the data payload is stored, which could be, for example,

temperature data or battery level. It is the stored data in a server that a client wants to access. A

characteristic is a discrete value that has, at minimum, the following three properties associated with it:

1. A handle (address)

2. A type (UUID)

3. A set of permissions

Let’s consider the IR Temperature service: handles 0x23 to 0x2A as seen above. This service has two

characteristics: IR temperature data and IR temperature config. We must first enable the IR sensor by

writing to the IR temperature config characteristic. We can then read the temperature by reading from

the IR temperature data characteristic. First, let’s read the IR temperature config characteristic to ensure

that isn’t already enabled (it won’t be). The simplest way to read its value is to use the “Read

Characteristic by UUID” sub-procedure. To do this, you will first need to click the “Read / Write” tab in

BTool. Select the option “Read Using Characteristic UUID” under the “Sub-Procedure” option in the

“Characteristic Read” section at the top of the screen. Enter the UUID we are looking for. The UUID from

the table above is 0xAA02. However, this is a 128-bit UUID so we must add the TI Base UUID. The

effective UUID we are looking for is F000AA02-0451-4000-B000-000000000000. Also, we must enter this

LSB to MSB in BTool with each byte separated by a colon. So enter

00:00:00:00:00:00:00:B0:00:40:51:04:02:AA:00:F0 in the “Characteristic UUID” box, and click the “Read”

button as shown below.

An attribute protocol Read by Type Request packet gets sent over the air from the central device to the

peripheral device, and an attribute protocol Read by Type Response packet gets sent back from the

peripheral device to the central device. The value “00” is displayed in the “Value” box, and “Success” is

displayed in the “Status” box. The “00” indicates that the temperature sensor is not enabled. In addition,

the message window will display information on the Read by Type Response packet that was received by

the central device. The message includes not only the characteristic’s data value, but also the handle of

the characteristic value (0x0029 in this case).

****Note that, as you read attributes from the peripheral, the attribute table in the bottom pane begins

to fill up. You can actually fill this entire table up initially by choosing ATT_FindInfoReq in the Adv.

Commands tab. You can then read and write to many characteristics by clicking on their respective

column in the table. However, it is recommended to go through these manual steps first to gain

understanding.

Page 15 of 30

Loading...

Loading...