Page 1

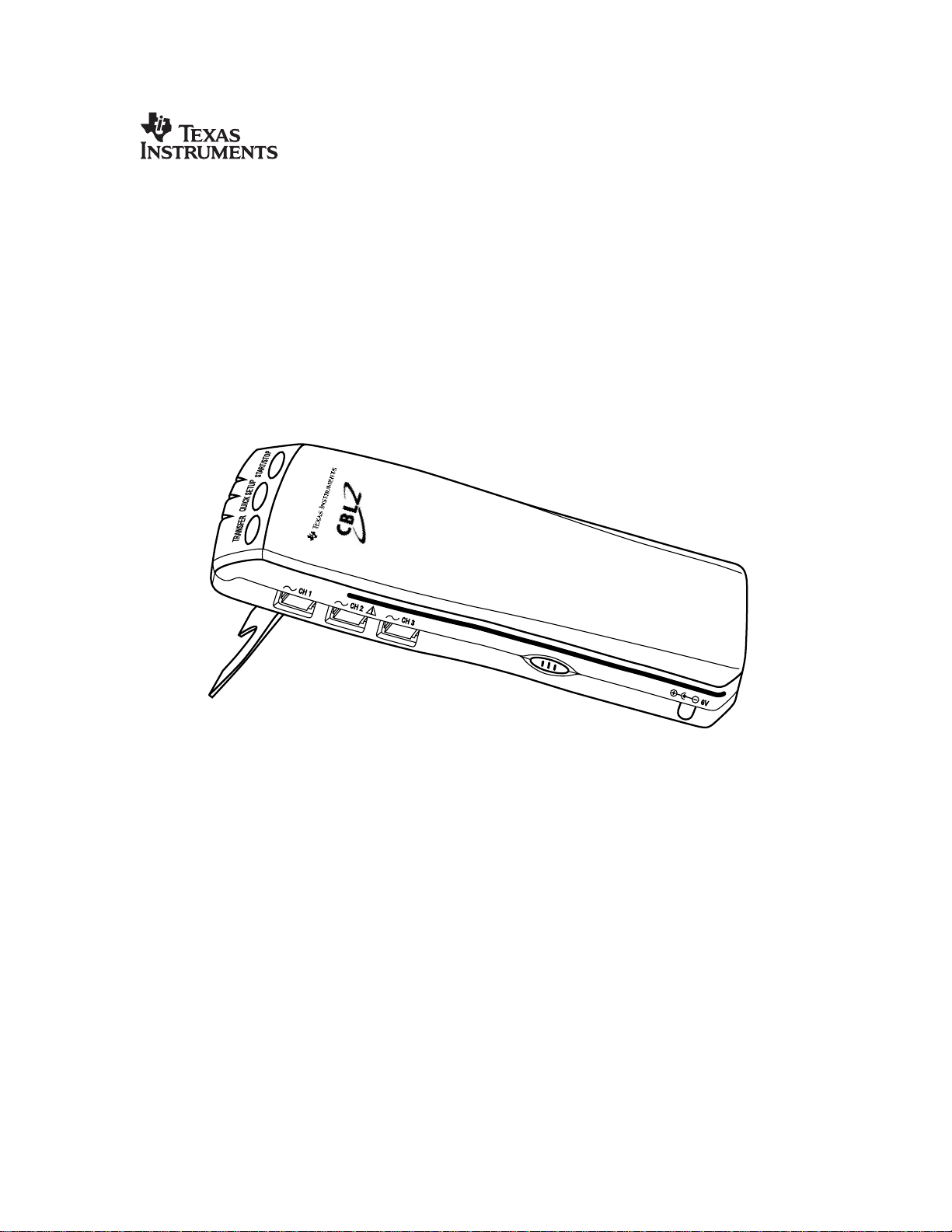

CBL 2™

Technical Reference

Calculator-Based Laboratory, CBL, and CBL 2 are trademarks of Texas Instruments Incorporated.

LabPro is a trademark of Vernier Software & Technology.

Santoprene is a registered trademark of Monsanto.

2000 Texas Instruments Incorporated. All rights are reserved.

Page 2

Contents

Introduction 5

Miscellaneous Reference Information 5

CBL 2 Software Upgrades 5

Data Collection Modes 5

Realtime Sampling 5

Non-Realtime Sampling 6

FastMode Sampling 6

Mode Comparison Table 7

Beep Sequences 8

Archiving in CBL 2’s

Memory 9

FLASH

Technical Specifications for Sensors 10

TI Light Sensor 10

TI Light Sensor Specifications 10

Stainless Steel Temperature Sensor 10

Stainless Steel Temperature Sensor Specifications 11

Temperature Accuracy 12

Stainless Steel Temperature Sensor Chemical Tolerance 12

TI Temperature Sensor Note 13

TI Voltage Sensor 13

Auto-ID Sensors 14

Custom Sensors 15

Connector Pinouts 16

Programming the CBL 2 17

Digital Output Buffer 17

Digital Output Buffer Example 17

Triggering and Thresholds 18

Measuring Period and Frequency 19

Example: Measuring Frequency 20

Asynchronous/ Synchronous Triggering versus Record Time 21

Example 21

CBL 2 Command Summary 22

Command 0 Reset CBL 2 RAM 23

Command 1 Channel Setup 23

Command 2 Data Type 26

Command 3 Trigger Setup 26

2 CBL 2 Technical Reference

Page 3

Command 4 Conversion Equation Setup (Analog) 28

Command 4 Sonic Temperature Compensation (Sonic) 30

Command 5 Data Control 30

Command 6 System Setup 31

Command 7 Request System Status 31

Command 8 Request Channel Status 33

Command 9 Request Channel Data 33

Command 10 Advanced Data Reduction 33

Command 12 Digital Data Capture 34

Command Sequence 34

General Information 36

Additional Notes on Command 12 41

Command 102 Power Control Command 41

Command 115 Check Set-up Information 41

Command 116 Check Long Sensor Name 42

Command 117 Check Short Sensor Name 43

Command 1998 Set LED Command 43

Command 1999 Sound Command 43

Command 2001 Direct Output to Digital-Out Port 43

Command 201 Archive Operations Command 44

Programming Examples 49

Example 1: Temperature Non-Realtime Data Collection 49

Example 2: Temperature Realtime Data Collection 49

Example 3: Distance and Velocity Non-Realtime

Data Collection 49

Example 4: Multiple Channels Non-Realtime Data Collection 50

Example 5: Conversion Equation Setup (Command 4) 50

Example 6: Data Control Setup (Command 5) 51

Example 7: Digital In Data Collection 51

Example 8: Digital Out 51

Example 9: CBL 2 LED Display 52

Example 10: Playing Music on the CBL 2 52

Example 11: Command 8 Program 52

Example 12: Command 9 Program 53

Example 13: Command 10 Program 53

Example 14: Archive Program (Command 201) 54

CBL 2 Technical Reference 3

Page 4

Appendix A: Glossary A-1

Appendix B: CBL 2 Error Messages B-1

Appendix C: DataMate Sensor Setup Default Settings C-1

4 CBL 2 Technical Reference

Page 5

Introduction

This technical reference is intended for CBL 2 users who want to write their own

programs for CBL 2 and Texas Instruments graphing calculators. This document includes

technical data such as specifications for sensors, syntax for CBL 2 commands, sample

programs, error codes, and miscellaneous other topics.

Instructions for using CBL 2 with the DataMate program or app are given in

Started with CBL 2

not addressed in this technical reference except for

Setup Default Settings

used by the DataMate program.

, which is included in the CBL 2 package. The DataMate program is

Appendix C: DataMate Sensor

. This table shows the default sensor settings and calibrations

Miscellaneous Reference Information

CBL 2 Software Upgrades

The CBL 2 uses

without buying a new CBL 2. As new functionality becomes available, you can

download the software from the TI web site to your PC and then use the TI-GRAPH

LINKé (sold separately) to upgrade your CBL 2.

Check the TI website (

compatibility statements. Directions for downloading upgrades will be given on the

web site.

FLASH

technology, which allows you to easily upgrade to new software

www.ti.com/calc

) for upgrades, paying special attention to

Getting

Data Collection Modes

On the CBL 2, data can be collected in one of three modes: realtime, non-realtime or

FastMode.

♦

In

realtime

after each point is taken.

♦

In

non-realtime

all of the data points are taken and then sends it to the calculator.

♦

In

FastMode

very fast sample rate, stores it internally until all of the data points are taken, and

then sends it to the calculator.

It is the default to return the time with the data collected.

CBL 2 Technical Reference 5

data collection, the CBL 2 collects data and sends it to the calculator

data collection, the CBL 2 collects data and stores it internally until

data collection, the CBL 2 collects data on a single analog channel at a

Page 6

Realtime Sampling

In realtime data collection, the CBL 2 sends each data point to the calculator as it is

taken, so some data can be lost if the calculator is not ready to accept the data. In

addition, the quantity of data that can be collected is limited by the size of the

calculator memory.

Realtime data collection is used for:

♦

Slower sampling where the user wants to see the data as it is being collected.

♦

Very long data collection times where the CBL 2 may run out of memory during

data collection.

♦

Situations where the host calculator must process the data as soon as it becomes

available (such as to control an output in response to a temperature input).

This data collection mode should not be used for data collection of more than a few

points each second because the host calculator will not be able to keep up. In addition,

because of the nature of realtime data collection, the period/frequency and Command

12 channels cannot be sampled in this mode.

Since the number of points to be collected may not be known at the start of sampling,

set the “number of samples” to M1 when sending Command 3. This tells the CBL 2 to

take data but not send it to the host calculator until the calculator requests data.

Non-Realtime Sampling

In non-realtime data collection, the samples are taken and stored in the CBL 2 memory

until all the data has been collected. Then the data is sent to the host calculator. The

quantity of data collected is not limited by the size of the calculator memory, but is

limited by the size of the CBL 2 memory. Up to 12,000 samples max (or less under some

conditions) can be collected in non-realtime.

Non-realtime data collection is used for fast sampling of multiple channels and when

triggering is required.

All of the channels can be used in this mode, and the Command 12 functions can be

used. The sample time is limited by the number and types of channels enabled. For a

E

single channel, the sampling can be as fast as 1

calculator communication is maintained during the sampling. This allows the host

calculator to issue a Command 7 or Command 8 to ascertain the progress of the

sampling without disturbing the sampling process.

-4 second. In addition, normal

FastMode Sampling

FastMode sampling is designed to be used where a single channel must be sampled at

very fast sample times. This mode is used primarily when sampling sound using the

microphone.

6 CBL 2 Technical Reference

Page 7

In general, FastMode is identical to non-realtime sampling with the following

exceptions:

♦

The sampling is limited to a single analog channel when doing FastMode sampling.

♦

The selected channel must not be in operation mode 5, 6, or 7.

♦

The communications with the host calculator are turned off during FastMode

sampling.

Note: In FastMode sampling, it is very important that the program not issue a GET command

until after sampling has been completed. If the CBL 2 receives a GET command it will abort

FastMode sampling with an error in order to respond to the GET command.

In FastMode, the sample times can be as fast as 20 msec (a sample frequency of 50KHz).

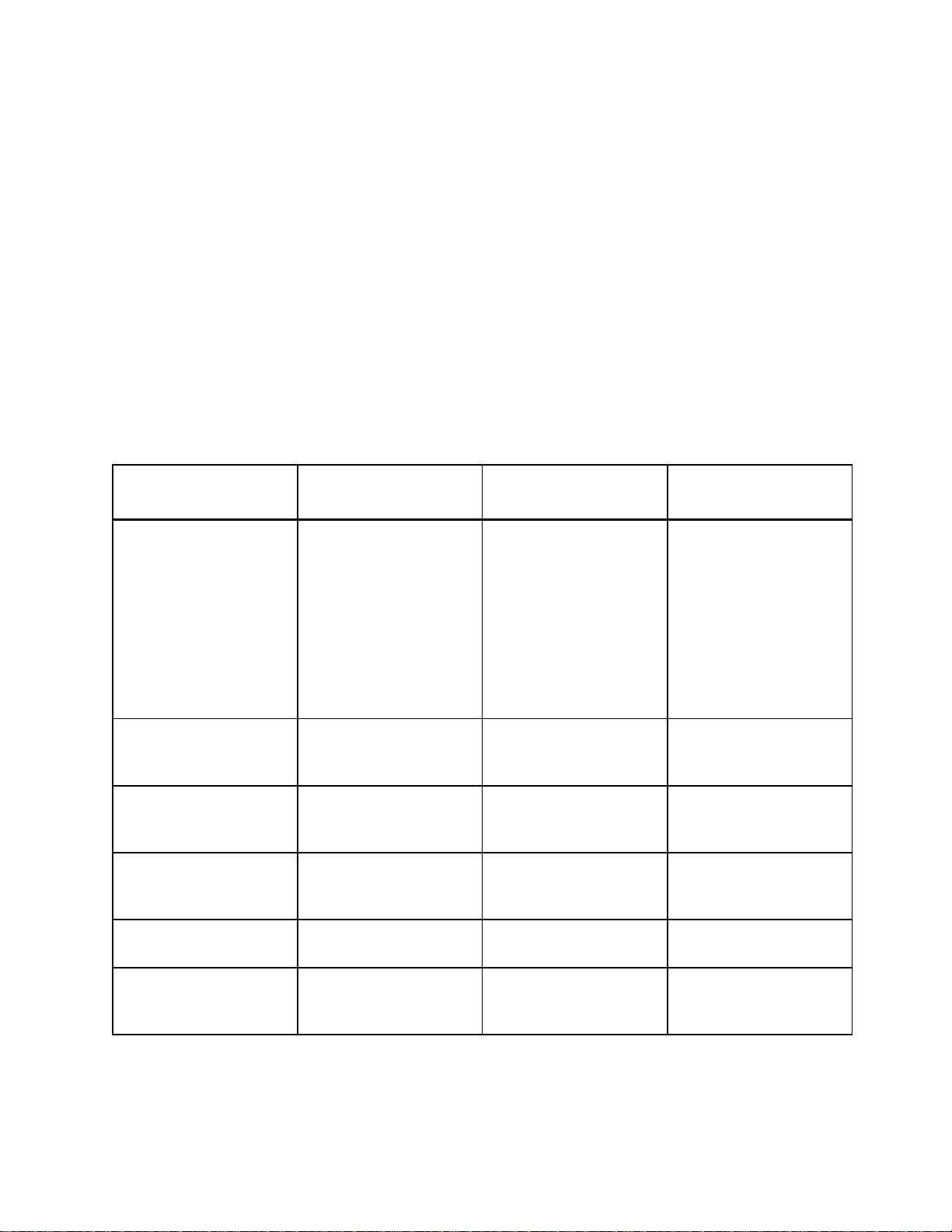

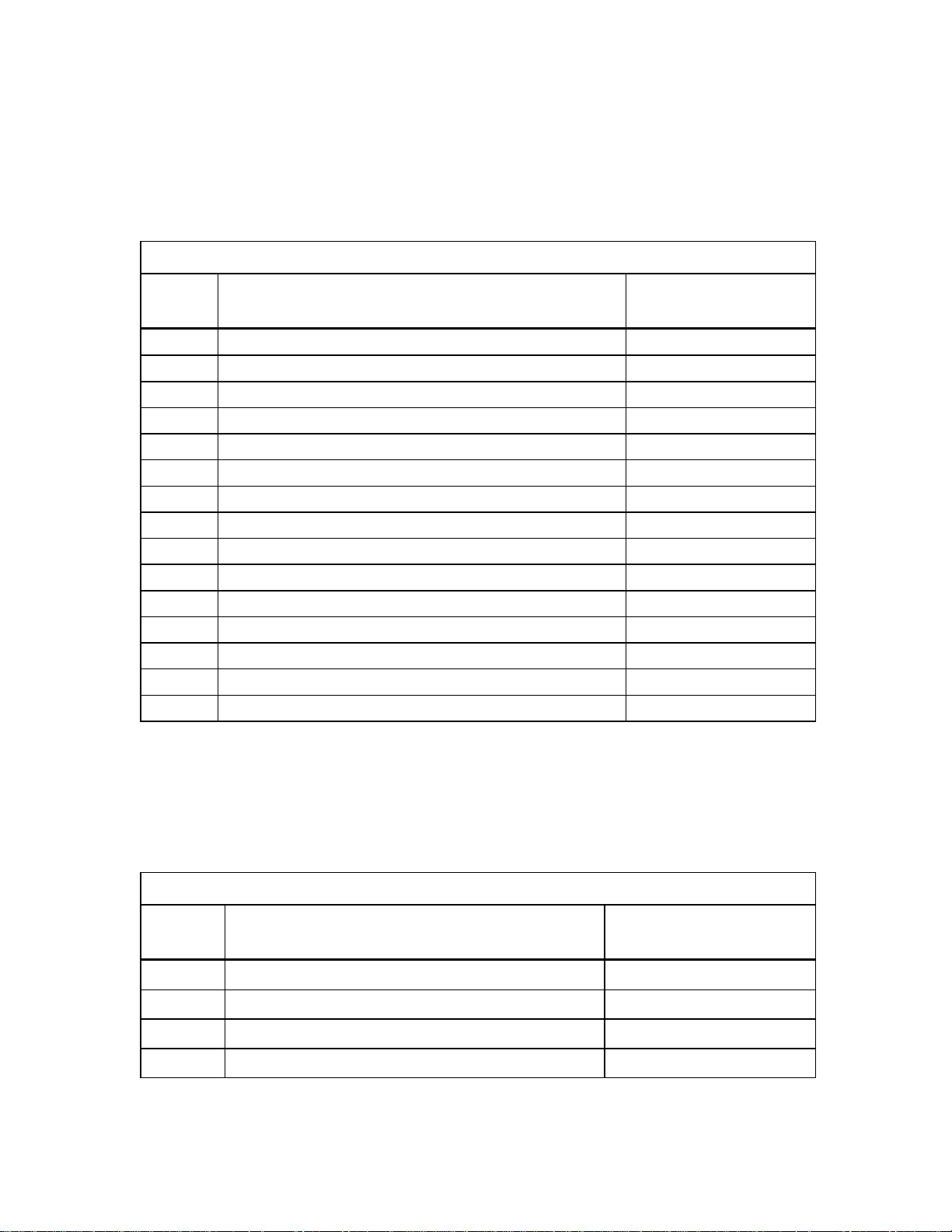

Mode Comparison Table

The table below shows some of the differences between the data collection modes.

Order of data

returned when

doing the GETs

from the host

calculator

Number of samples

limited?

Sample time limits

(approximate)

Number of

channels limited?

Realtime Mode

{ch1_1, ch2_1, …

deltatime_1}

{ch1_2, ch2_2, …

deltatime_2}

:

:

{ch1_n, ch2_n, …

deltatime_n}

Not by CBL 2, but

may be limited by

the host calculator

Sample Time > .25

second to 16000

seconds

Yes, only CH1-3

and 11

Non-Realtime

Mode

{ch1_1, ch1_2, …

ch1_n}

{ch2_1, ch2_2, …

ch2_n}

{ch3_1, ch3_2, …

ch3_n}

{time_1, time_2, …

time_n}

Yes, limited by

available memory

in CBL2

Sample Time ‚ 1e-4

seconds to 16000

seconds

No Yes, only a single

FastMode

Same as NonRealtime

Same as NonRealtime

Sample Time ‚ 2e-5

seconds to 1e-4

seconds

channel from CH1

to CH3

Can use

Triggering?

Communication

maintained during

sampling?

CBL 2 Technical Reference 7

No Yes Yes

Yes Yes No

Page 8

Beep Sequences

The CBL 2 makes four kinds of sounds:

♦

A low tone followed by a high tone (low-to-high beep).

♦

A medium tone followed by another medium tone (medium-medium beep).

♦

A high tone followed by another high tone (high-high beep).

♦

A “tick” sound when a key is pressed.

The following bullets explain when beep sequences normally occur and what the beep

sequences mean.

♦

When the CBL 2 completes initialization, you will hear the startup sequence: highhigh beep, medium-medium beep, low-to-high beep (6 total beeps, plus LEDs light

up in this order: red LED, yellow LED, and green LED)

♦

When you press the QUICK SETUP button:

the medium-medium beep sounds if a sensor is attached to the CBL 2.

−

the high-high beep sounds if no sensors are attached to the CBL 2.

−

♦

When the CBL 2 is connected to a calculator during sampling commands:

the medium-medium beep sounds when initializing data collection.

−

the medium-medium beep sounds when starting data collection (transition from

−

pre-store to store).

the medium-medium beep sounds when completing data collection.

−

Note: If the sampling timing causes the beeps to run together, the CBL 2 software may not

sound all the beeps.

Note 2: You will not get all the beeps when Fast Sampling is enabled.

Note 3: You will not get all the beeps when using triggering.

♦

When you set the CBL 2 for manual trigger and press the START button, a mediummedium beep sounds.

♦

When you press the TRANSFER BUTTON:

the low-to-high beep sounds when the transfer succeeds.

−

the high-high beep sounds if the transfer fails for any reason.

−

♦

When an overcurrent condition is detected, five high-high beeps sound. (This causes

an error, which causes even more beeps to sound.)

♦

When the CBL 2 begins a full self-test, three low-to-high beeps sound.

♦

When self-test completes:

the low-to-high beep sounds if self-test passes.

−

the high-high beep sounds if self-test fails.

−

8 CBL 2 Technical Reference

Page 9

When the CBL 2’s base code detects an error in the commands sent from the host, a

♦

high-high beep sounds twice.

When the CBL 2 powers up:

♦

two high-high beeps sound if the base code is not loaded.

−

three high-high beeps sound if the power-up self-test fails.

−

During base code download, three high-high beeps sound when any errors occur.

♦

(The unit resets and then the two high-high beeps mentioned in the previous bullet

sound.)

Archiving in CBL 2’s

The

FLASH

allowing updates to the operating system and storing the DataMate programs, the

FLASH

To preserve collected data so that it can be retrieved at a later time, data sets can be

stored in the

data set can be given a name.

You can write a program on the calculator to review the list of stored data sets and

♦

retrieve the desired one for further analysis. (See the sample archive program on

page 56.)

You can use the DATADIR program (available on the TI Resource CD or on the TI

♦

web site at

DATADIR program are given in

The

FLASH

convenient location for storing frequently used programs or as a temporary storage to

create more available memory on the calculator.

Command 201, in conjunction with the Link menu on the calculator, provides access to

these

memory in the CBL 2 can be used for several purposes. In addition to

memory serves as an archive space for other programs and data.

FLASH

archive can also store calculator programs and applications. This provides a

FLASH

archive operations. For details about Command 201, see page 44.

archive. To distinguish between different stored data sets, each

www.ti.com/calc

FLASH

) to manage

Memory

FLASH

Getting Started with CBL 2

memory. Directions for using the

.

CBL 2 Technical Reference 9

Page 10

Technical Specifications for Sensors

TI Light Sensor

The TI light sensor uses a phototransistor to measure relative irradiance. The units of

irradiance are milliwatts per square centimeter. The light sensor’s output is a voltage

that is linearly proportional to the amount of irradiance it senses. The range of light

2

over which the sensor is sensitive is 10µW/cm

to 1mW/cm2.

The

auto-ID

measured voltage to relative units. The sensor is direction dependent and achieves the

highest output when the end of the sensor is pointed directly at the light source.

The light sensor is sensitive in the visible and near-infrared (

you can use it with

is designed to work in air only—it is not waterproof.

The light sensor returns

vary from light sensor to light sensor. The light sensor readings are also sensitive to

temperature.

resistor in the sensor causes the CBL 2 software to automatically convert the

) light range. This means

IR

emitting diodes as well as all visible light sources. The light sensor

IR

relative

readings, not absolute irradiance readings. Values may

TI Light Sensor Specifications

Channels Connects to

channels)

Current drain 5 mA max.

Voltage range 0–5 Volts

Irradiance range 10µW/cm2 to 1mW/cm2 (approximately)

Spectral response range 300nm to 1100nm (nanometers) (non-flat

response)

CH1, CH2, CH3

(analog

Chemical tolerance None (air only)

Pins used 2 ground

4 auto-ID resistor

5 +5 Volts DC

6 Signal

Stainless Steel Temperature Sensor

The Stainless Steel Temperature Sensor is an auto-ID general-purpose laboratory

temperature sensor that comes with your CBL 2. The sensor is rugged and durable, and

is designed to be used as you would use a thermometer for experiments in chemistry,

physics, biology, earth science, and environmental science.

10 CBL 2 Technical Reference

Page 11

This probe uses the 20 kΩ NTC Thermistor. The thermistor is a variable resistor whose

resistance decreases nonlinearly with increasing temperature. The best-fit

approximation to this nonlinear characteristic is the Steinhart-Hart equation. The CBL 2

or CBL interface measures the resistance value, R, at a particular temperature, and

converts the resistance using the Steinhart-Hart equation:

T = [K

where T is temperature (°C), R is the measured resistance in kΩ, K

-

= 2.22468 X 10

K

1

4

, and K2 = 1.33342 X 10-7. Fortunately, CBL 2 and CBL take care of this

+ K1(ln 1000R) + K2(ln 1000R)3]-1 – 273.15

0

= 1.02119 X 10

0

conversion for you, and provide readings in °C (or other units, if you load a different

calibration).

Stainless Steel Temperature Sensor Specifications

Channels Connects to CH1, CH2, CH3 (analog channels)

Current drain 0.5 mA max.

Temperature range -25 to 125°C (-13 to 257°F)

Maximum temperature

sensor can tolerate

without damage

10-bit resolution 0.32°C (-25 to 0°C)

Temperature sensor 20 kΩ NTC Thermistor

150°C

0.12°C (0 to 40°C)

0.4°C (40 to 100°C)

1.0°C (100 to 125°C)

-

3

,

Accuracy ±0.2°C at 0°C, ±0.5°C at 100°C

Response time 95% of full reading: 11 seconds

98% of full reading: 18 seconds

100% of full reading: 30 seconds

Probe dimensions Probe length (handle plus body): 16 cm

Stainless steel body: length 11 cm,

diameter 4.0 mm

Probe handle: length 5.0 cm, diameter 1.25 cm

Pins used 2 Ground

3 Vres

4 auto-ID resistor

6 Signal

CBL 2 Technical Reference 11

Page 12

Temperature Accuracy

This probe provides very accurate temperature readings. Near 0°C, readings are

accurate to ±0.2°C; near 100°C, readings are accurate to 0.5°C.

Important:

you cannot re-calibrate this sensor. Probe-specific calibrations should not be necessary

when using this sensor.

Because of the non-linear nature of the Stainless Steel Temperature Probe,

Stainless Steel Temperature Sensor Chemical Tolerance

The body of this sensor is constructed from grade 316 stainless steel (0.08% carbon,

2.0% manganese, 0.75% silicon, 0.04% phosphorus, 0.03% sulfur, 16-18% chromium,

10-14% nickel, 2-3% molybdenum, and 0.1% nitrogen). This high-grade stainless steel

provides a high level of corrosion resistance for use in the science classroom.

Here are some general guidelines for using this probe:

1.

The probe handle is constructed of molded plasticized Santoprene®. While this

material is very chemical resistant, we recommend that you avoid submerging the

probe beyond the stainless steel portion.

2.

Always wash the probe thoroughly after use.

3.

The probe can be left continuously in water at temperatures within the range of

–25° to 125°C. Continuous usage in saltwater will cause only minor discoloration of

the probe, with no negative effect on performance.

4.

You can leave the probe continuously in most organic compounds, such as

methanol, ethanol, 1-propanol, 2-propanol, 1-butanol, n-hexane, lauric acid,

paradichlorobenzene, phenyl salicylate, and benzoic acid. The probe should not be

left in n-pentane for more than 1 hour.

5.

The probe can be left in strong basic solutions, such as NaOH, for up to 48 hours

with only minor discoloration. We do not recommend usage in basic solutions that

are greater than 3 M in concentration.

6.

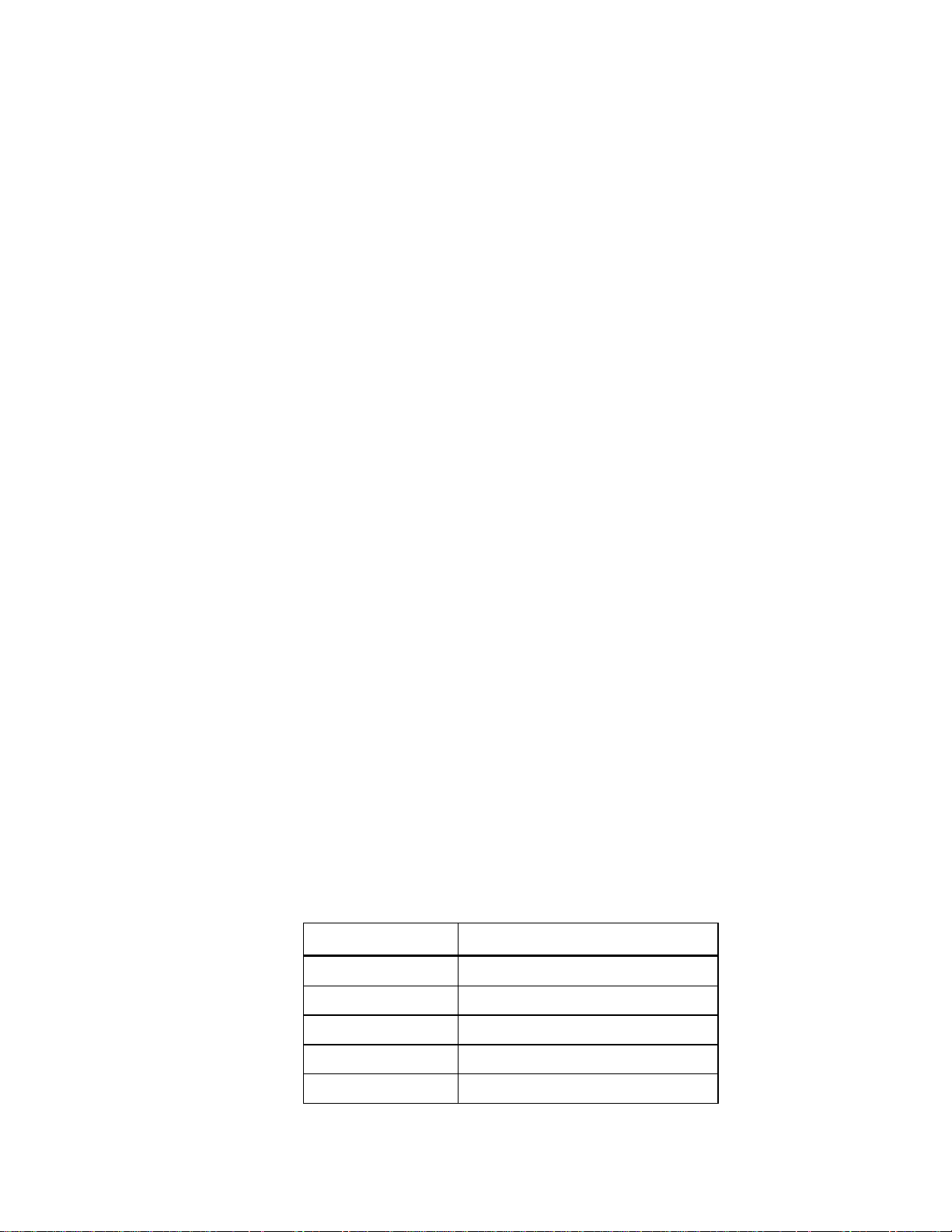

The following chart provides the maximum length of time we recommend for

probe exposure to some common acids. Probes left in an acid longer than these

times may bubble and/or discolor, but will still be functional. We do not

recommend probes be left in

Acid

1 M HCI 20 minutes

2 M HCI 10 minutes

3 M HCI 5 minutes

1 M H2SO

2 M H2SO

12 CBL 2 Technical Reference

4

4

acid longer than 48 hours.

any

Maximum Exposure Time

48 hours

20 minutes

Page 13

Acid

3 M H2SO

1 M HNO

2 M HNO

3 M HNO

1 M CH3CO OH 48 hours

2 M CH3CO OH 48 hours

3 M CH3CO OH 48 hours

1 M H3PO

2 M H3PO

3 M H3PO

7.

Cole Parmer has an extensive listing of chemical compatibility of grade 316 stainless

steel on their web site (

be used for general guidelines not covered in this summary.

4

3

3

3

4

4

4

www.coleparmer.com/techinfo

TI Temperature Sensor Note

Maximum Exposure Time

10 minutes

48 hours

48 hours

48 hours

48 hours

48 hours

48 hours

). This listing can

If a TI Temperature sensor (the flexible temperature sensor that came with the original

CBL) is used with CBL 2, it will auto-ID as the Stainless Steel Temperature sensor. Both

sensors use the same calibration that is built into the CBL 2.

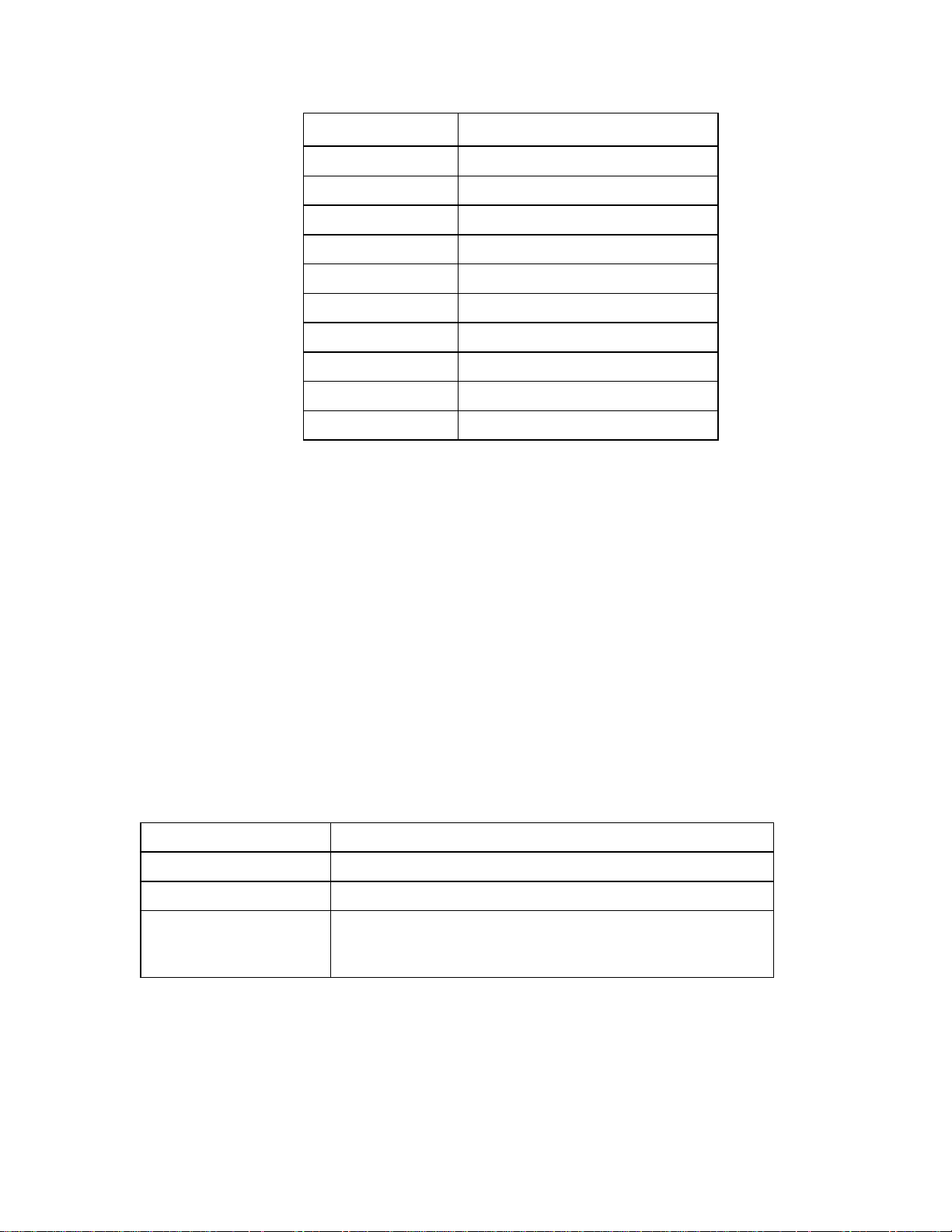

TI Voltage Sensor

The TI voltage sensor is a generic sensor that you can use to read any voltage between

±10 Volts. The auto-ID resistor contained in the sensor causes the CBL 2 software to

automatically measure voltage. No conversion equation is loaded. The black hook

should be connected to ground and the red hook to the signal voltage.

Channels Connects to CH1, CH2, CH3 (analog channels)

Voltage range ±10 Volts

Chemical tolerance None (air only)

Pins used 1 Signal

2 Ground

4 auto-ID resistor

Note: It is very important that the ground connections of the analog inputs are never connected

to different potentials. These ground connections are all in common. Connecting the grounds to

different potentials may damage the CBL 2.

CBL 2 Technical Reference 13

Page 14

1

1

Auto-ID Sensors

The CBL 2 contains provisions for the auto-ID sensor resistor values listed below. If

needed, a conversion equation is loaded automatically for some of the auto-ID values.

Channels 1, 2, and 3

IDENT

Valu e

2.2KThermocouple °CM200C to 1400¡C

33KTI Voltage sensorM10 to +10 Volts

6.8K Current sensor

3.3K Resistance sensor 1K to 100K

22K Extra long temperature sensor for °C

68K CO2 gas sensor (PPM) 0 to 5000 ppm

100K Oxygen gas sensor (PCT) 0 to 27%

150K C V voltage sensor (V)

220K C V current sensor (A)

10K Stainless steel or TI temperature sensor3 for °C

15K Stainless steel or TI temperature sensor for °F

4.7K TI Light sensor 0 to 1

1K Ex heart rate sensor (BPM) N/A

47K Voltage sensor 0 to 5 Volts

1.5K EKG N/A

Sensor Type

Range

2

M

10 to +10 Amps

J

L

50°C to 150°C

M

6 to +6 Volts

M

0.6 to +0.6 Amps

M25¡

C to 125¡C

M13¡

F to 257¡F

1

IDENT values are resistance values in ohms (tolerance ±5%).

2

Operation 3 is a mathematical conversion of voltage to a current reading (1V=1A).

There is no circuitry inside the CBL 2 unit to convert current to voltage; this must be

done in the external probe.

3

Default units for the Stainless Steel and TI Temperature sensors is °C.

Channel 11 (SONIC)

IDENT

Valu e

15K Motion detector, meters ½ meter to 6 meters

22K Motion detector, meters ½ meter to 6 meters

10K Motion detector, feet 1½ feet to 18 feet

33K Photogate sensor N/A

1

IDENT values are resistance values in ohms (tolerance ±5%).

14 CBL 2 Technical Reference

Sensor Type

Range

Page 15

Custom Sensors

To create custom-designed sensors or other circuits for the analog input channels, the

sonic input channel, the digital input channel, or the digital output channel on the

CBL 2, you can purchase sensor kits from TI (

♦

For a custom analog sensor, use the Analog Probe Kit (order entry no. CBL/CA/D).

1-800-TI-CARES

Each sensor kit includes a four-foot length of telephone cable with a connector

attached to one end. The other end of the cable is not terminated.

♦

For a custom digital sensor, cut a CBR-to-CBL cable (order entry no. CBR/CA/C) into

two pieces to get two lengths of cable with connectors. (The digital probe kit used

with the original CBL will not work with CBL 2.)

♦

For a custom digital ID probe, contact Vernier Software and Technology

(

www.vernier.com

) for more information.

Be very careful when designing a custom sensor or circuit. For more accurate operation,

do not connect pins 1 and 6 together on the analog input channels. Pin 1 on the British

Telecom-style connector is the pin farthest from the release lever as shown in the

pictures below.

If you design a resistance-type sensor, connect pin 3 (Vres) to pin 6 (Vin-low) (refer to

“Connector Pinouts” below). Connect the resistance to be measured from the junction

of these pins to pin 2 (Gnd). The resistance range for useful measurements is limited

from approximately 1 Kohms to 100 Kohms.

) or its Instructional Dealers.

When the Operation parameter in Command 1 (page 23) is set to 2, 3, 5, 6, or 7, the

data is measured on the Vin pin (pin 1). The data for all other operations is measured

on the Vin-low pin (pin 6).

Note: The most current that can be drained from all three analog channels is 160 mA. This is

limited by the hardware.

CBL 2 Technical Reference 15

Page 16

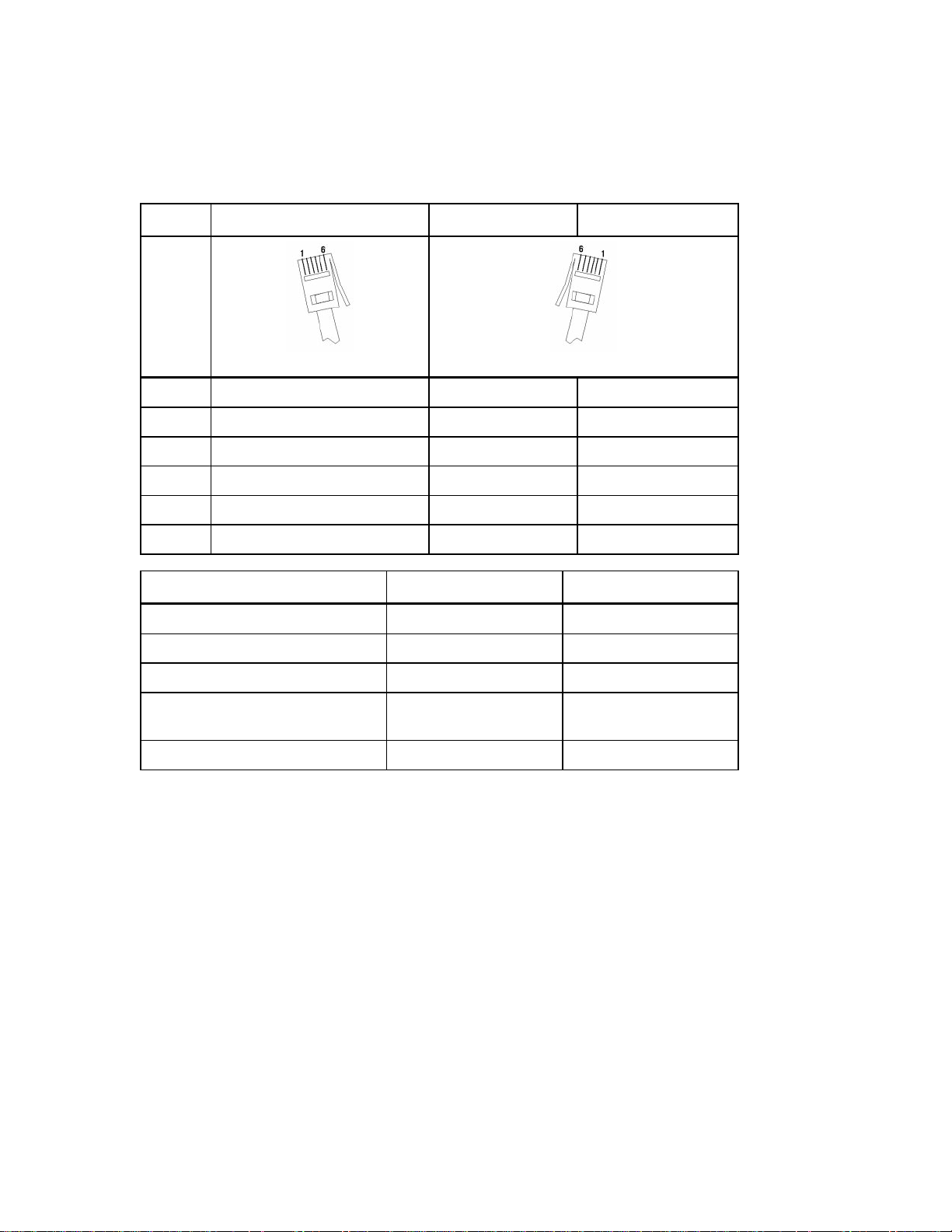

Connector Pinouts

The CBL 2 sensors use 6-pin British Telecom-style connectors.

Pin

1 Vin Echo DI0

2 Gnd Init DI1

3 Vres/Smart ID CLK Auto-ID DI2

4 Auto-ID +5 Volts DC +5 Volts DC

5 +5 Volts DC Gnd Gnd

6 Vin-low Not Applicable DI3

Channels: CH1, CH 2, CH 3 CH1, CH2, CH3

Input signal: Analog data Analog data

Analog CH1, CH2, CH3

(Right-hand Connector) (Left-hand Connector)

SONIC

Vin

DIG IN/OUT

Vin-low

Input range: ±10 Volts 0 to 5 Volts

Resolution (using CBL 2’s

10-bit A/D converter):

Input impedance: 1.046 M

Vres:

♦

♦

♦

♦

♦

♦

♦

Output reference voltage from the CBL 2 through a 15 Kohm resistor. When

using this feature, Vres should be tied to Vin-low and the value to be measured

should be connected between Vin-low and Gnd.

Gnd:

Ground (common for all channels).

Auto-ID: Auto-ID

pin 4 to ground.)

Echo:

Init:

Ultrasonic motion detector input.

Distance initialization signal

sensor detection data input. (

D0 In/Out to D3 In/Out:

Smart ID Clk:

Clock to synchronize data transfer from smart probes.

19.6 mV 5.6 mV

J

>10 M

Auto-ID

Input or output pins for digital pulses.

J

resistor connected from

16 CBL 2 Technical Reference

Page 17

Programming the CBL 2

Digital Output Buffer

The digital output buffer (DOB) is a circular buffer that contains up to 32 elements. The

output from the buffer is 4-bits wide, and the outputs are CMOS (0-5V) compatible.

The data in Command 1 is entered as decimal representation of the digital value that is

output. For example, 0=0000, 5=0101, and 15=1111. At the beginning of each sample, a

pointer into the digital output buffer is incremented and the next available data is sent

to the output lines.

The electrical characteristics of the digital outputs are:

♦

Voutput-high ‚ 3.7V @ M400uA

♦

Voutput-low 0.65V @ 1.6mA

The number of times that the DOB outputs the contents of the buffer depends on the

number of data elements defined in Command 1 and the number of samples defined

in Command 3.

Digital Output Buffer Example

Command 1 list is {1,31,5,1,2,3,4,5}

where:

1=Channel Setup.

31=DIG OUT.

5=Five data elements.

1=0001 (digital nibble).

2=0010 (digital nibble).

3=0011 (digital nibble).

4=0100 (digital nibble).

5=0101 (digital nibble).

Command 3 list is {3,1,100}

where:

3=Sample and Trigger Setup.

1=One second sample time.

100=One hundred samples.

(Trigger Type defaults to manual

triggering.)

CBL 2 Technical Reference 17

Page 18

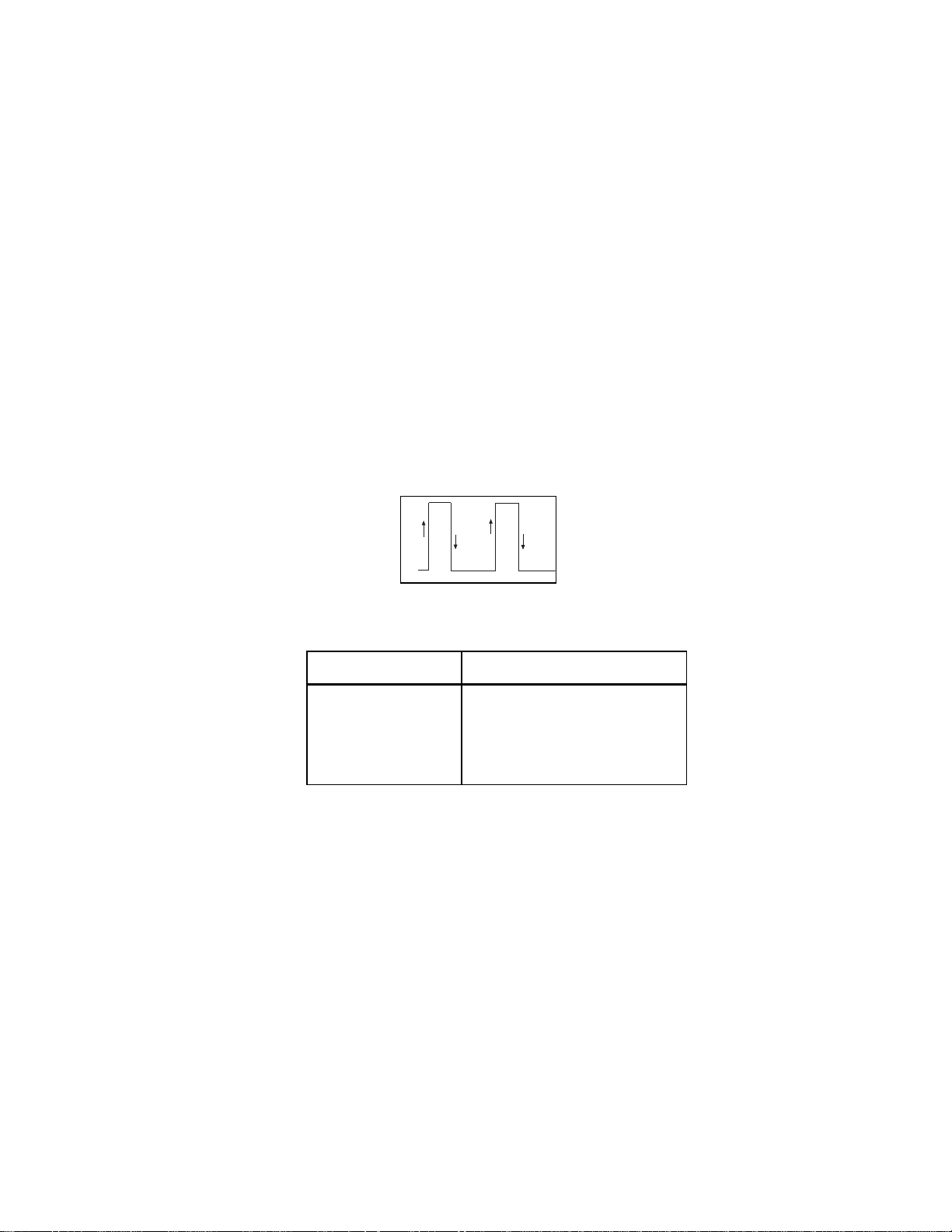

The DOB outputs pulses that correspond to the five digital nibbles (1234512345...12345

etc.). This sequence is repeated 20 times (100 samples/5 data elements) to the DIG OUT

channel. The diagram below shows a portion of this output for the first five data

elements.

Sample

Clock

D3

D2

D1

D0

1234

1

5

Figure 1. Digital Output Example

Triggering and Thresholds

Two types of triggering thresholds can be set in the CBL 2:

♦

Hardware triggering

is set to trigger on a specific voltage level established by the

trigger threshold parameter.

♦

Software triggering

is set to begin data collection on either the rising edge or

falling edge of the signal, depending on the trigger type and trigger threshold

selected.

The THRESHOLD parameter specified in Command 3 can be used for two purposes:

♦

If the operation in Command 1 is frequency, period, or count (operation = 5, 6, or 7

on Channel 1 only), then the threshold parameter in Command 3 sets a voltage

level in the CBL 2 hardware. The signal on the Vin pin of CH 1 must pass through

this voltage for the CBL 2 to see the signal change states.

♦

If the operation in Command 1 is anything other than 5, 6, or 7, then the threshold

parameter in Command 3 specifies a trigger level and is measured in the units of

the sensor selected.

When triggering, sampling does not start until the signal on the trigger channel (also

specified in Command 3) passes through this level once in the direction specified. This

comparison of trigger level and signal level occurs in software, so any level in the

proper range can be selected. Also, either the Vin or VinLow pin (on any of the analog

channels or the sonic channel) can be used as the trigger channel. CBL 2 knows

whether to use the Vin or VinLow pin by looking at which operation was set up in

Command 1.

18 CBL 2 Technical Reference

Page 19

0

1

2

3

T=

+

-

+

-

If a conversion equation is enabled for the trigger channel, then the threshold

specified in Command 3 should be a converted level. For example, if a pH probe is

plugged into CH 2 with a conversion equation loaded into CBL 2 and the trigger

channel specified as CH 2, the threshold level should be entered as a pH level in the

range 0-14, not as a voltage in the range 0-5V.

Measuring Period and Frequency

Period and frequency apply only to CH1 and only CH1 can be active if the operation is

set to 5 (Period) or 6 (Frequency). Period and frequency are measured on Vin pin (pin 1)

of CH1. Period and frequency measurements always use the hardware threshold.

The CBL 2 measures period and frequency by counting edges for 0.25 seconds, or by

measuring the time between the selected edges for one period—whichever is larger

(see figure below). If a significant number of edges are counted during the 0.25-second

period, the count is used to compute both period and frequency; otherwise, the period

and frequency are computed from the time interval for one period.

Figure 2. Period and Frequency Measurement

Trigger Type

2

3

4

5

Measuring Points

+ + (T=0 to 2)

N N

N + N

N N

(T=1 to 3)

(T=0 to 1)

+ (T=1 to 2)

The crossover point between the two computations is about 600 Hz. Because there can

be a one-count uncertainty during the 0.25-second period, the accuracy around 600 Hz

is approximately ±4 Hz (about 0.7%). The resolution of the timer measuring the time

between edges is 6.4 microseconds; therefore, the percentage accuracy improves for

frequencies above and below 600 Hz.

If the CBL 2 is set up using Command 3 to make multiple measurements at a particular

sample time, the CBL 2 waits for the sample time that you specified after it completes

the current measurement. It then initiates the next cycle of period/frequency

measurement. The minimum sampling time for period and frequency is 0.25 seconds.

Note: Period and frequency measurements using Trigger Type 4 or 5 are only possible on nonrepetitive signals or on repetitive signals that are less then 600 Hz. This is because at 600 Hz, the

edge counts will prevail.

CBL 2 Technical Reference 19

Page 20

The parameters shown in this table are used when measuring period or frequency.

Trigger Type

0 Rising (+) Trigger Threshold parameter

2–5 Specified by trigger type Trigger Threshold parameter

6 Not allowed (E.34 error).

Edge Polarity Used

Hardware Threshold Used

Example: Measuring Frequency

Assume a frequency measurement is requested on CH 1, and 20 measurements are

desired at a .5 second sample time. The following commands would set up the CBL 2

for this example:

{1,1,6}

{3,.5,20,2,0,1}

3 = Sample and Trigger setup command

.5 = Sample time of 0.5 seconds

20 = Number of samples to take

2 = Trigger from rising edge to rising edge for frequency

0 = Trigger channel not applicable

1 = Trigger at 1 Volt

Assume a ±10 Volt, 20 Hz sine wave is the input signal on pin 1. The CBL 2 follows the

sequence of steps indicated below when the first trigger occurs (a trigger occurs every

0.05 seconds).

1. Trigger occurs on the rising edge.

2. Start counter and timer.

3. Stop timer at next rising edge.

4. Wait until 0.25 seconds has elapsed.

5. Stop counter (count should be about 5).

6. Count is less than 150 (or 600 Hz); therefore, frequency is computed from the

time interval for one period.

7. Wait for 0.5 seconds specified in Sample Time.

8. Wait for additional processing time to complete. (This time depends on what

processing is currently being performed and is typically about 0.25 additional

seconds.)

9. Repeat steps 1 through 8 for nineteen more samples.

In this example, the CBL 2 takes approximately 15 seconds to complete all the sampling

and turn on the DONE indicator in the display.

20 CBL 2 Technical Reference

Page 21

Asynchronous/ Synchronous Triggering versus Record Time

Actual triggering is asynchronous from the internal sampling clock when Trigger Type

in Command 3 is set to 1 or 6 (manual triggering). If sampling at very fast rates, the

actual trigger may be slightly different from the commanded trigger. The user should

take this into account when calculating prestore and trigger levels.

The actual sample time for the trigger point depends on whether or not prestore is

selected in Command 3.

When prestore and relative record time are selected, the sample time for the trigger

point will generally not be identical to times around it. The time recorded for the

trigger point will be the actual time between the previous sampled point on the

internal sampling clock interval and the asynchronous trigger event. The sample taken

after the trigger point will be at the specified sample time since the clock is reset each

time the trigger event occurs (pressing START/STOP or the hardware threshold trigger

event).

When Trigger Type is set to 6 (Manual and Sample Trigger) in Command 3, the

recorded sample times are the actual relative times when START/STOP is pressed.

When no prestore is selected, the first sample time will be the trigger point. Its

recorded time will not be the internal sample clock time because the CBL 2 is always

sampling on the internal clock interval that you selected and is storing points (if you

selected prestore) until the trigger event occurs.

Example

Assume the following:

♦

Input to CH1, set to measure ±10 Volts, is a 0.01 Hz sine wave.

♦

Sample Time is set to 10 seconds and Number of Samples is set to collect 30 points.

♦

Trigger Channel is set to 1.

♦

Trigger Threshold is set to 1.0 and Trigger Type is set to 2 (trigger on rising edge).

The CBL 2 will collect and store a sample every 10 seconds. The recorded time for each

sample will be 10 seconds. The trigger event (signal rising through 1.0 Volts) occurs 1.5

seconds after the previous sample, so a sample collected at the trigger point is taken

and stored with a recorded time of 1.5. The next sample is taken 10 seconds after the

trigger sample, not 8.5 seconds later as would have happened if the internal sample

clock had not been reset.

The Record Time returned (around the trigger point) will be the list:

{...10,10,10,1.5,10,10,...}.

CBL 2 Technical Reference 21

Page 22

CBL 2 Command Summary

The table below lists the commands you can use in writing programs for CBL 2.

Detailed explanations of each command and its syntax can be found beginning on the

page number shown in the third column.

Command

Number

0 Reset:

1 Channel Setup:

2 Data Type:

sent. It is included only for compatibility with older CBL

programs.

3 Trigger Setup:

experiment.

4 Conversion Equation Setup (Analog Channels):

parameters to convert physical units measured by CBL 2 into

a more useful measurement unit such as Newtons or ¡C.

Sonic Temperature Compensation (Sonic Channel):

Sets the unit of measurement for sonic data.

5 Data Control:

well as the starting and ending data points to be retrieved

by a TI calculator.

6 System Setup:

for the CBL 2; selects a filter to be applied to data.

Resets all channels to default conditions. 23

This command is not used and should not be

Command Description

sets up a channel for data collection. 23

Sets up the trigger parameters for an

Selects the type of data to be retrieved, as

Turns sound on or off; sets an ID number

Sets up

See

Page

26

26

28

30

30

30

7 Request System Status:

status information.

8 Request Channel Status:

return sensor type, last valid data, and last valid data

position for the requested channel.

9 Request Channel Data:

one data point before sampling starts. Used to verify that

setup is correct.

10 Advanced Data Reduction:

certain time-intensive algorithms instead of processing them

in the calculator.

12 Digital Data Capture:

of motion data from the digital input channel.

102 Power Control Command:

power-saving; or designated power up.

22 CBL 2 Technical Reference

Generates and prepares to return

Generates and prepares to

Generates and prepares to return

Sets up CBL 2 to process

Sets up the capture or measurement

Sets the power to always on;

31

32

33

33

34

41

Page 23

Command

Number

115 Check Set-up Information:

the designated channel.

116 Check Long Sensor Name:

117 Check Short Sensor Name:

1998 Set LED Command:

1999 Sound Command:

sounds.

2001 Direct Output to Digital-Out Port:

digital output port during a sampling run.

201 Archive Operations Command:

determine the contents of the CBL 2’s

Detailed information about each command is given below. The table following each

syntax lists valid values. Default values appear in

Command Description

Returns status information for

Returns long sensor name. 42

Returns short sensor name. 43

Turns LEDs on and off on command. 43

Specifies length and frequency of CBL 2

Outputs data to the

Allows the calculator to

FLASH

boldface

memory.

type.

Command 0 Reset CBL 2 RAM

See

Page

41

43

43

44

Syntax:

This command has no parameters or options. Clears data memory back to power-up

state. Clears error information. Resets only the RAM; does not clear

This command should be sent at the beginning of each program.

{0}

FLASH

memory.

Command 1 Channel Setup

This command sets up a channel for data collection. It has six syntaxes, as shown below.

Syntax:

Clears all channels.

Syntax: {1,channel,

Turns off the selected channel.

Channel

1-3 = Analog

11 = Sonic

21 = Digital Input

{1,0}

0}

31 = Digital Output

CBL 2 Technical Reference 23

Page 24

Syntax:

{1,

channel,operation,post-processing,(delta) 1,equ

Use this syntax to set up analog channels.

Operation/

Channel

1-3 = Analog

Sensor Type

0 = Turn channel off

1 = Auto-ID this sensor

(default is 0-5V sensor)

2 = TI Voltage „10V

3 = Current „10A

4 = Resistance

4

= Measure period on

5

„

10V input line (CH 1

only)

4

= Frequency on „10V

6

input line (CH 1 only)

5

= Count transitions

7

on „10V input line

(CH 1 only)

Post-Processing

0 = None (RT

and NON-RT3)

1 = d/dt (NON-RT)

2 = d/dt and d

(NON-RT)

2

2

/dt

}

Conversion Equation

0 = Off

1 = On (must also

send Command 4)

2

10 = TI Temperature or

Stainless Steel

Temperature

(Centigrade)

11 = TI Temperature or

Stainless Steel

Temperature

(Fahrenheit)

12 = TI Light

14 = Low voltage (0-5V)

1

This parameter is ignored.

2

RT: REALTIME mode sampling.

3

NON-RT: NON-REALTIME mode sampling.

4

When using Command 1 operation 5 or 6, Trigger Type in Command 3 must be 2, 3, 4

or 5.

5

When using Command 1 operation 7, Trigger Type in Command 3 must be 0.

24 CBL 2 Technical Reference

Page 25

Syntax:

Use this syntax to set up the sonic channel.

{1,11,

operation,post-processing,(delta)1,equ

Operation

0 = Resets channel

1 = Meters – Returns distance and

@

time (RT and NON-RT)

2 = Meters – Returns distance and

@

time (RT and NON-RT)

3 = Feet – Returns distance and @time

(RT and NON-RT)

4 = Meters – Returns distance, velocity,

and @time (RT) or distance and @time

(NON-RT)

5 = Feet – Returns distance, velocity,

and @time (RT) or distance and @time

(NON-RT)

6 = Meters – Returns distance, velocity,

acceleration, @time (RT) or distance

and @time (NON-RT)

Post-Processing

0 = None (RT

and NON-RT3)

1 = d/dt (NON-RT)

2 = d/dt and d

(NON-RT)

2

2

/dt

}

Conversion Equation

0 = Off

1 = On (must also send

Command 4 for

temperature

2

compensation)

7 = Feet – Returns distance, velocity,

acceleration, @time (RT) or distance

and @time (NON-RT)

1

This parameter is ignored.

2

RT: REALTIME mode sampling.

3

NON-RT: NON-REALTIME mode sampling.

Note: When post-processing is enabled in non-realtime sampling mode, all operations will

return the first derivative and the second derivative.

Syntax:

Use this syntax to set up the digital input channel.

Channel

21 = Digital Input

{1,

channel,operation

Operation

0 = Off

1 = On

}

CBL 2 Technical Reference 25

Page 26

Syntax:

Use this syntax to set up the digital output channel.

Channel

31 = Digital

Output

The CBL 2 outputs one element for each sample. Between samples, the output returns

to 0 unless the user has commanded the power to remain on (using Command 102, M1).

Caution: Using Command 102, M1 can drain the CBL 2 batteries.

{1,

channel,operation,list of values

Operation

0 = Clears the channel

1-32 = Count (number

of data elements in list)

List of Values

Lists values output

to digital output

port

}

Note: the list of values

must have one value

for each count.

Command 2 Data Type

This command is not used and should not be sent. However, it is included for

compatibility with older CBL 2 programs.

Command 3 Trigger Setup

This command sets up the trigger parameters for an experiment. It has three syntaxes.

Syntax: {3, .1}

Repeats last Command 3 (used to quickly collect new data).

Syntax:

Use this syntax for realtime data collection.

Sample Time Number of Points

>0 to 16000

Default = 0.5

{3,

samptime,numpoints,

.

1 = REALTIME mode

0 = Invalid

0,0,0,0,0,0,

Filter

0 = None

7 = Light Realtime tracking filter

8 = Medium Realtime tracking filter

9 = Uses Heavy Realtime tracking filter

filter

}

26 CBL 2 Technical Reference

Page 27

Syntax:

{3,

samptime,numpoints,trigtype,trigchan,trigthresh,

pre-store,(extclock)1,rectime,filter,fastmode

Use this syntax for non-realtime data collection.

Sample

Time

>0 to

16000

Default

= 0.5

Number of

Points

0 = Invalid

1 to 12,000 =

NON-REALTIME

mode and

number of

points to collect

Trigger Type

0 = Immediate

1 = Manual

2 = Rising edge/

rising edge

3 = Falling

edge/ falling

edge

4 = Rising edge/

falling edge

5 = Falling

edge/ rising

edge

6 = Single

sample

Trigger Channel

0 = Disables

trigger

1 = CH1 (channel

must be active)

2 = CH2 (channel

must be active)

3 = CH3 (channel

must be active)

11 = CH11 (channel

must be active)

}

Trigger

Threshold

-

channel

limit to +

channel

2

3

3

3

limit

(channel

limit is

determined

by sensor

attached to

the channel)

Default =

1V

Pre-store

Data

% to 100%

0

1

This parameter is ignored.

2

Hardware trigger only for Command 1 operation 5, 6, or 7; software trigger for all others.

3

Software trigger only.

4

Prestore is not valid for manual trigger or immediate trigger. Due to the delay in

determining the start of sample, the actual amount of prestore may be smaller than

the selected amount.

5

FASTMODE does not apply to the Sonic/Digital channels.

Record Time Filter

4

0 = None

1 =

Absolute

2 = Relative

Note: This is

different

from the

original CBL.

Default on

CBL was 0.

0 = None

1 = Savitzsky-Golay 5-point filter

2 = Savitzsky-Golay 9-point filter

3 = Savitzsky-Golay 17-point filter

4 = Savitzsky-Golay 29-point filter

5 = Uses Median Pruning 3-point

filter

6 = Uses Median Pruning 5-point

filter

FastMode

0 = OFF

(normal

operation)

1 = ON

(FASTMODE

sampling)

5

6

CBL 2 Technical Reference 27

Page 28

N

6

In FASTMODE, only one channel can be active, and it must be an analog channel.

Sampling can be as fast as 20ms/sample in this mode. FASTMODE is operational only for

sample rates from 50,000 sample/second to 5,000 samples/second.

Each probe has a minimum sample time, which is listed in the table below:

Probe Type

Analog probes 100msec/per probe

Sonic probes 8 milliseconds

Digital In/Out 100msec/per probe

Note: TrigTypes 0, 1, and 6 cannot be used with frequency measurements (operation 6) or with

period measurements (operation 5).

Note 2: TrigTypes 2, 3, 4, 5, and 6 cannot be used with count transition (operation 7).

Note 3: TrigTypes 1 and 6 cannot be used with FASTMODE sampling.

Note 4: While CBL 2 is waiting for TrigThresh, you can press the START/STOP to start sampling

immediately.

Minimum Sample Time

Command 4 Conversion Equation Setup (Analog)

This command sets up parameters to convert physical units measured by CBL 2 into a

more useful measurement unit such as Newtons or ¡C. It has six syntaxes.

Syntax: {4,

Clears the equation for all channels.

0}

Syntax: {4,channel,

M

1}

Channel

1, 2, or 3

Sets unary equation; returns raw data for the channel.

Syntax: {4,channel,1,N,K0, . . .K

Channel

1 = Sets CH 1

2 = Sets CH 2

3 = Sets CH 3

Sets up polynomial equation:

+ K1X + K2X2 + ... + KnX

K

0

N = 1 through 9 No restrictions

n

}

n

K

except overflow.

28 CBL 2 Technical Reference

Page 29

M N

Syntax: {4,channel,2,M,N, Km, K

m-1

Channel

1 = Sets CH 1

2 = Sets CH 2

3 = Sets CH 3

Sets up mixed polynomial equation:

m

.

X

m

.

+ ... + K

K

M = 0 through 4 N = 0 through 4 M + N > 0 X ƒ 0

1

.

X

+ K0 + K1X + ... + KnX

1

.

Syntax: {4,channel,equtype, K0,K

Channel

1 = Sets CH 1

2 = Sets CH 2

3 = Sets CH 3

Equation Type

3 = Power

4 = Modified power

5 = Logarithmic

6 = Modified logarithmic

7 = Exponential

,. . .K0, . . .K

n

}

1

}

n

M +N

X

8 = Modified exponential

9 = Geometric

10 = Modified geometric

11 = Reciprocal logarithmic

12 = Steinhart-Hart Model

Equation Type

3 Power K0X

4 Modified Power K0K

5 Logarithmic K

6 Modified Logarithmic K

7 Exponential K

8 Modified Exponential K

9 Geometric K

10 Modified Geometric K

11 Reciprocal Logarithmic [K

12 Steinhart-Hart Model [K

0

0

0

0

0

0

(K1)

(X)

1

Equation

Restrictions

X>0

K1>0

+ K1ln(X) X>0

+ K1ln(1/X) X>0

(K1X)

e

No restrictions other

than overflow.

(K1/X)

e

(K1X)

X

(K1/X)

X

+ K1ln(K2X)]

0

+ K1 (ln 1000X) + K2(ln 1000X)3]

0

-1

1

.

Xƒ0

X‚0

X>0

K2X>0

X>0

CBL 2 Technical Reference 29

Page 30

Command 4 Sonic Temperature Compensation (Sonic)

This command sets the unit of measurement for sonic data.

Syntax: {4,channel,equtype,temperature,units

Channel

4 = Sets SONIC

if

equtype

11 = Sets SONIC

=13

Equation Type

0 = Clears the

equation for

the selected

channel

13 = Sonic

temperature

compensation

Temperature

Temperature

value for

which you

want to

compensate

}

Units

0 = temperature in ¡Celsius

1 = temperature in ¡Fahrenheit

2 = temperature in ¡Celsius

3 = temperature in Kelvin

4 = temperature in Rankin

Command 5 Data Control

This command selects the type of data to be retrieved, as well as the starting and

ending data points to be retrieved by a TI calculator.

Syntax:

Channel

.

1 = Sets recorded

time

{5,

channel,dataselect,databegin,dataend

Data Select

0 = raw collected data

(filtered)

Data Begin

0 = first point

collected

}

Data End

0 = last point

collected

0 = Lowest

active channel

1-3 = Analog

11 = Sonic

21 = Digital input

Note: If Data Select = 0, 1, or 2 and Command 3 Filter = 1-6, data will be filtered according to

the filter selected in Command 3. If Data Select = 3, 4,or 5; the filter setting in Command 3 will

be ignored.

Note 2: Data End must be greater than or equal to Data Begin (unless Data End = 0). Both

DataBegin and DataEnd must be less than or equal to the number of samples sent to the CBL 2

in the last Command 3.

Note 3: Each Command 5 must be followed by a Get statement.

Note 4: Sampling must be completed before sending Command 5 to control the data. Before

sending Command 5, do a Get statement to ensure that sampling is completed or send

Command 7 to check the status and verify that sampling is completed.

1 = d/dt (filtered)

2

/dt2 (filtered)

2 = d

3 = raw collected data

(unfiltered)

4 = d/dt (unfiltered)

2

/dt2 (unfiltered)

5 = d

1 through n =

point selected

1 through n =

point selected

30 CBL 2 Technical Reference

Page 31

Command 6 System Setup

This command has three syntaxes. The first turns sound on or off, the second sets an ID

number for the CBL 2, and the third selects a filter to be applied to data.

Syntax:

{6,

command

}

Command

0 = Abort sampling

2 = Abort sampling

3 = Turns sound off

4 = Turns sound on

Syntax:

Command

5 number you specify (any floating point number

Syntax:

Command

{6,

command,parm

}

Parameter

38

between M10

CBL 2 that is used to identify a specific CBL 2 when

multiple units are linked together

{6,

command,filter

to + 1038) = Sets an ID number for

}

Filter

6 0-6 = number of new filter to be applied

Default = 0

Command 7 Request System Status

Syntax: {7}

This command generates and prepares to return the following status information:

softwareID

error

battery

Current software ID in format: X.MMmms where X=product code

number, MM=major ID number, mm=minor ID number, and s=step ID

number.

If non-zero, CBL 2 should be reset and the cause of the error corrected

Battery status. Can return the following values:

0 Battery is OK for use

1 Battery is low during sampling

2 Battery is low all the time

CBL 2 Technical Reference 31

Page 32

8888

Constant value. If the correct list location is set to zero prior to

requesting and getting the list, this value can be used to ensure that

the status message was received correctly.

Sample time

trigger

condition

channel

function

channel post

channel filter

num samples

record time

temperature

piezo flag

Sample time that was commanded by the host during the last sample

run

Triggering condition that was commanded by the host during the last

sample run

Triggering channel that was commanded by the host during the last

sample run

Post-processing setting that was commanded by the host during the last

sample run

Filter that was commanded by the host during the last sample run

Number of samples that was commanded by the host during the last

sample run. (If sampling was aborted, this parameter reflects the actual

number of samples taken.)

This can have the following values:

0 No time was recorded in the last run

1 Absolute time was recorded in the last run

2 Relative time was recorded in the last run

Temperature used for the temperature correction of the sonic data

during the last run if a sonic sensor was selected

This is the buzz/no-buzz value that was last commanded. Values are:

0 Sound is disabled (OFF)

1 Sound is enabled (ON)

system state

data start

data end

systemID

The following values are used for the system state:

1 Idle

2 Armed

3 Busy

4 Done

5 Self-test

99 Initializing code

First point of data available for transmission to the host unless the host

has sent Command 5 to override this value

Last point of data available for transmission to the host unless the host

has sent Command 5 to override this value

The System ID that was set using Command 6

32 CBL 2 Technical Reference

Page 33

P1 P2

Command 8 Request Channel Status

Syntax:

Channel

1, 2, 3, or 11 0 = returns current sampled data

This command generates and prepares to return a list with three elements: E1, E2, E3:

E

E

applicable to CH1 ops 5, 6, 7 or CH21 Digital In or CH31 Digital Out)

E

valid when sampling is active]

Note: Each Command 8 must be followed by a Get statement.

{8,

channel,request type

}

Request Type

1 = returns data stored when channel was last set up

= sensor type (one of the

1

= last valid data read from sensor, if any [only valid when sampling is active] (not

2

= last valid data position (sample number where stored in the resulting list) [only

3

operation

options shown under Command 1)

Command 9 Request Channel Data

Syntax:

Channel

1, 2, 3, or 11 0 = Re-test input auto-ID value

{9,

channel,mode

Mode

1 = Return stored auto-ID value

}

This command generates and prepares to return one data point before sampling starts.

Used to verify that setup is correct.

Note: Each Command 9 must be followed by a Get statement.

Command 10 Advanced Data Reduction

This command sets up CBL 2 to process certain time-intensive algorithms instead of

processing them in the calculator.

Syntax:

Channel

1, 2, 3, 11 1 = HeartBeat algorithm 0% to 100%

P1 value determines when data transitions from “high” to “low.”

P2 value determines when data transitions from “low” to “high.”

P3 value determines the minimum difference in data between UpperThld and LowerThld.

Note: P1 must be less than P2.

{10,

channel,alg,P1,P2,P3

Algorithm

}

Lower

Thld

0% to 100%

Upper

Thld

P3

RejectThld in

the units of

the channel

selected

CBL 2 Technical Reference 33

Page 34

Notes on Operation

Certain algorithms are very time intensive to run in the calculator, and the CBL 2

product team has made an effort to include those algorithms in the CBL 2’s optimized

code. This allows large data sets to be processed much more quickly.

Currently only one algorithm has been defined. This algorithm determines the number

of cycles of a repetitive waveform in the sampling buffer. (This routine is known as the

heartbeat algorithm

This algorithm works as follows:

1.

First, the normal data collection (using commands {1, …} and {3, …}) must be

completed.

2.

Next, the algorithm must be started using the command {10,

3.

The CBL 2 starts by finding the maximum and minimum points of the data set. The

lower threshold is set at P1 percent of the maximum point, and the upper threshold

is set at P2 percent of the minimum point.

4.

The CBL 2 checks the difference between the maximum point and minimum point

against P3. If the difference is less than P3, the algorithm is aborted and a 0.0 is

returned. (This is the case where the user expected the input data to have a certain

variation but, for some reason, the variation was not found.)

5.

The CBL 2 then finds the number of “rising edges” where the data in the data set is

increasing from below the upper threshold and the number of “falling edges”

where the data is decreasing to below the lower threshold. The total number of

rising edges and falling edges is stored.

for its frequent use in measuring the heart rate.)

channel

,1,P1,P2,P3}.

6.

Next the CBL 2 determines how many samples are between the first edge and the

last edge. The frequency is then determined as the number of edges divided by the

number of samples and is returned to the host calculator or computer.

7.

The user program is responsible for taking the result from the CBL 2 and dividing it

by the sample time to get the true frequency in Hz.

Command 12 Digital Data Capture

This command sets up the capture or measurement of motion data from the digital

input channel. It has seven syntaxes.

Command Sequence

In general, when you want to sample data, you should send commands in this

sequence: Reset the unit, setup the channels, start sampling, retrieve the data.

The commands used to do this are shown below:

♦

Command 6,0 to force the CBL 2 to stop executing any prior commands (This

command may not be needed.)

♦

Command 0 to reset CBL 2 to a known state

♦

Command(s) 1 to set up any channels needed for sampling

34 CBL 2 Technical Reference

Page 35

♦

Command(s) 4 to send the equations for any sensors that need special equations

(use only if needed)

♦

Command 3 to start the sampling process

♦

GET commands (one or more) to retrieve data from the CBL2.

It is important to notice that the channels get setup before sampling starts and that the

Command 3 starts the actual sampling. The GET command forces the host calculator to

wait until the data is ready and then transfer the data from the CBL 2 into the

calculator.

Only a few of the commands that can be sent during sampling are useful; many of

these commands will abort the sampling. For example, if you send a Command 1

during sampling, the sampling aborts, your data is lost, and the new channel is set up

according to the new command.

A more useful command to send during sampling is Command 7. If you send this

command, you can then do a GET and see the status of the CBL 2. The status will show

the sampling (ARMED – meaning that the unit has not gotten to the trigger condition

yet, or BUSY – meaning that sampling is in progress).

Another useful command to send while sampling is the Command 8, which reads back

the most recent data sample collected for a single channel. This allows a sophisticated

program to monitor data collection while the CBL 2 is collecting the data.

One of the new features of the CBL 2 is its ability to automatically work with many

digital sensors such as photogates. With a photogate, the timing of the data transitions

is the parameter of interest. Using the standard command order defined above, the

user would:

♦

Send {1, 21, …} to command a digital input channel

♦

Send a command 3 to start sampling

♦

Send a GET to retrieve the data.

In order to find the transition times, the data collection program must scan the data

looking for each transition and then subtract the time of the start and end points to

get the transition time. Using Command 12 automates this process (and makes it more

accurate).

There are a few things to be aware of, though. When using Command 12, the number

of samples collected is not the same as the number of samples taken. If the photogate

only transitions 12 times, there will be 12 transitions recorded. Even if there are 1000

analog data samples taken, there will still only be 12 transitions of the photogate data.

Therefore, you should command a SEND {12, 41, 0} to find out how many transitions

were recorded before requesting photogate data from the CBL 2. After getting the

number of transitions, you can retrieve the actual transition timing.

CBL 2 Technical Reference 35

Page 36

When using a photogate, or other digital sensor, your command sequence should be as

follows:

♦

Command 6,0 to force the CBL 2 to stop executing any prior commands (may not be

needed)

♦

Command 0 to reset CBL 2 to a known state

♦

Command(s) 1 to setup any channels needed for sampling (you must setup at least 1

analog channel)

♦

Command 12, 41,3 to enable the photogate mode for digital CH 41 (Digital Input

Port 1)

♦

Command(s) 4 to send the equations for any sensors that need special equations

(only if needed)

♦

Command 3 to start sampling

♦

GET commands to retrieve the data from the CBL 2 (This forces the calculator to

wait for sampling to finish.)

♦

Command 12,41,0 to command the CBL 2 to return the number of transitions

recorded

♦

GET command to retrieve the number of transitions from the CBL 2

♦

Command 12, 41,M1 to command the CBL 2 to return the transitions recorded

♦

GET command to retrieve the number of transitions from the CBL 2

♦

Command 12, 41,M2 to command the CBL 2 to return the transition times recorded

♦

GET command to retrieve the number of transitions from the CBL 2

General Information

There are six types of motion capture commands. Each digital data capture command is

designed to support the capture or measurement of data from the digital input. Some

commands capture data at periodic intervals while others are triggered by changes in

the data.

Each of the digital data commands is designed for a specific sensor and/or experiment

as shown in the following table:

Send {12, 41, mode}

Mode = 1 Sample Mode. This mode is used when none of the other

Send {12, 41, mode}

Mode = 2 and Mode = 3 Measures pulse width of the data on the D0 line. This

Use

modes (below) are useful. In this mode, each time the

data changes, it is recorded in the CBL 2. This allows for

any new digital probes to be used if the user is willing to

write the program to process the data.

Use

mode is used with a photogate to get very accurate

measurement of the time the photogate is blocked.

Generally, this measurement is used to determine the

speed of an object (must know object’s length).

36 CBL 2 Technical Reference

Page 37

Send {12, 41, mode}

Mode = 4 Measures period of the data on the D0 line. This mode is

Mode = 5 Counts the transitions on the D0 input line of the Digital

Mode = 6 Measures the outputs of a Vernier Rotary Motion sensor.

The sections that follow explain more fully how to use the digital data capture

commands.

Note: Command 12 is valid only in non-realtime mode; it is not valid in realtime mode.

Digital Input Syntax:

At each transition of the digital inputs, the absolute time and state of the inputs is

reported. See Fig 1.

Use,

continuedcontinued

used with a photogate to get very accurate measurement

of the times between when the photogate becomes

blocked. Generally, this measurement is used to

determine the speed of a wheel or a picket fence.

input port. This mode is used when the frequency of a

source with a TTL (or CMOS compatible) output must be

measured.

Generally this indicates the position of a wheel on the

sensor.

{12,41,1}

Digital/Sonic

(D 1 , D 2 )

Figure 3. Digital Input Measurement

Inputs will be value 0-3 corresponding to 00, 01,10, or 11. Each transition stored takes

three data point locations.

This command can be run at the same time as analog sampling.

After “getting” the analog channels, send the following commands to return the data

from the CBL 2 to the host:

Command Syntax: Comment:

{12,41,1} collect digital input data;

{12,41,0} return number of points collected on next get

{12,41,.1,

{12,41,.2,

Start,Stop

Start,Stop

statement;

} return state list on next get statement

} return time list on next get statement

send after “getting” the analog channels

send before Command 3

CBL 2 Technical Reference 37

Page 38

Notes on Operation

The digital inputs are sampled 10,000 times/second in the main timer ISR. (Transitions

that are so short that they are not seen in the ISR will be lost.) Each time a change in

the input bits is found, the time and the new value are written to a data buffer area.

When the data buffer area overflows, data collection is halted and an error message is

sent.

Pulse Width – Continuous Pulse Mode Syntax:

{12,41

,2 or 3,direction

Direction

0 = low active pulse

1 = high active pulse

This mode is designed to measure the widths of pulses in a continuous stream of

pulses. Each pulse is measured. See Figure 3.

Digital/Sonic (D0)

T

∆

Figure 4. Continuous Pulse Period Measurement

After “getting” the analog channels, send the following commands to return the data

from the CBL 2 to the host:

T

∆

Command Syntax: Comment:

{12,41,3} collect pulse width data in continuous pulse mode;

before Command 3

send

}

{12,41,0} return number of points collected on next get

{12,41,.1,

{12,41,.2,

Start,Stop

Start,Stop

statement;

} return @time list on next get statement

} return time list on next get statement

send after “getting” the analog channels

Notes on Operation

The Sonic Timer is used to record the time of the rising and falling edges. The

resolution is 1.6msec. At the start of the pulse the time is recorded and again at the end

of the pulses. The difference (properly scaled) is returned to the host.

38 CBL 2 Technical Reference

Page 39

Period – Continuous Pulse Mode Syntax:

{12,41

,4,direction

}

Direction

0 = low active pulse

1 = high active pulse

This mode is designed to measure the periods of pulses in a continuous stream of

pulses. Each pulse is measured. See Figure 4.

Digital/Sonic (D 0)

T

∆

Figure 5. Continuous Pulse Period Measurement

After “getting” the analog channels, send the following commands to return the data

from the CBL 2 to the host:

T

∆

T

∆

Command Syntax: Comment:

{12,41,4} collect period data in continuous pulse mode;

before Command 3

send

{12,41,0} return number of points collected on next get

{12,41,.1,

{12,41,.2,

Start,Stop

Start,Stop

statement;

} return @time list on next get statement

} return time list on next get statement

send after “getting” the analog channels

Notes on Operation

The Sonic Timer is used to record the time of the rising and falling edges. The

resolution is 1.6msec. At the start of the pulse the time is recorded and again at the end

of the pulses. The difference (properly scaled) is returned to the host.

Counter Mode Syntax:

This mode is designed to count the transitions on the DIGITAL input line. (Use

Command 1,1,7 to count the transitions on the ANALOG Channel 1 Hi input line.) The

ECHO pin (D0) must be used for the input.

{12,41,5}

CBL 2 Technical Reference 39

Page 40

After “getting” the analog channels, send the following commands to return the data

from the CBL 2 to the host:

Command Syntax: Comment:

{12,41,5} collect data in counter mode;

{12,41,0} return number of points collected on next get

{12,41,.1,

Start,Stop

statement;

} return count list on next get statement

send after “getting” the analog channels

send before Command 3

Notes on Operation

The Sonic Timer is re-configured as a counter and will count the input transitions. The

transitions count is limited to 65535 transitions per cycle. The cycle time is the same as

the sample time. In other words, one count will be returned for each analog sample

returned.

Rotary Motion Mode Syntax:

Scale Factor

Number of user units to

increment/decrement

for each count change

This mode is designed to measure the position of a rotary motion sensor. Rotational

motion information is determined by counting clockwise and counterclockwise signals

from the Vernier Rotary Motion Sensor. See Figure 5.

Start Position

Initial position

(in user units)

{12,41,6

,scalefactor,startpos

}

CWCNT (DI)

CCWCNT (D0)

Figure 6. Rotary Motion Mode

Each rising edge of the CWCNT (D1) line will cause the position to be incremented by 1.

Each rising edge of the CCWCNT (D0) line will cause the position to be decremented

by 1. The position will start at StartPos. Only a 16-bit counter will be used, giving a

count range from .32K to +32K.

One data point will be saved for each sample. Sampling will be commanded by the

normal Command 3.

40 CBL 2 Technical Reference

Page 41

After “getting” the Analog channels, send the following commands to return the data

from the CBL 2 to the host:

Command Syntax: Comment:

{12,41,6} collect data in rotary motion mode;

Command 3

{12,41,0} return number of points collected on next get

{12,41,.1,

Start,Stop

statement;

} return position list on next get statement

send after “getting” the analog channels

Additional Notes on Command 12

A few additional things to be aware of when using Command 12:

♦

When Command 12 is used, the power generally stays on all during sampling. (This

is because the processor must look for the data at all times during the sample

interval and not just at the sample times.) As a result, this mode tends to deplete

the batteries very quickly.

♦

The number of data samples taken is limited only by the available memory after

memory is reserved for the Command 1 channels that are set up. The CBL 2 has about

12,000 available memory locations. If X channels are setup and Y samples are selected

using Command 3, the number of samples on CH 41 is limited to (12,000 – X…Y)/3.

♦

You absolutely must have at least one analog channel activated before sending the

Command 3 to start sampling. You must do a GET of the analog data (to force the

calculator to wait for the end of sampling) before retrieving the Command 12

CH 41 data.

send before

Command 102 Power Control Command

Syntax:

Power Control

.

1 = Always ON; will automatically power down (APD) if running on batteries.

0 = Normal mode

1-1000 = Powers up this many seconds before data taken

CBL 2 Technical Reference 41

{102,

pwrctl

}

Page 42

Command 115 Check Set-up Information

Syntax:

{115,

channel

}

Channel

1, 2, 3, 11

This command returns the following status information:

CBL 2 sig

LabPro™ sig

Y-min

Y-max

Y-scale

sample rate

number of samples

operation command

calculation equation

sensor warm-up time

first coefficient

CBL 2 significant figures

LabPro significant figures

Suggested Y-min for graphing

Suggested Y-max for graphing

Suggested Y-scale for graphing

Typical sample rate

Typical number of samples to collect

Typical operation command

Suggested calculation equation for Command 4

Sensor warm-up time (in seconds)

Suggested first coefficient for Command 4

second coefficient

third coefficient

number of pages

active page

Suggested second coefficient for Command 4

Suggested third coefficient for Command 4

Sensor’s number of calculation pages (usually 0)

Sensor’s active calculation page (usually 0)

Command 116 Check Long Sensor Name

Syntax:

Channel

1, 2, 3, 11

This command returns the following information:

long sensor name

{116,